Page 1

Installation Instructions

ControlNet-to-Foundation Fieldbus H1 Linking

Device

Catalog 1788-CN2FF

Product Overview

ATTENTION

The ControlNet-to-Foundation Fieldbus H1 linking device (1788-CN2FF) connects a

ControlNet™ network with one or two F

Each H1 network consists of multiple Fieldbus devices. Each field device has one or more

function blocks. Each function block performs an elementary control function such as analog

input, analog output, discrete input, or discrete output. The ControlNet network consists of

controllers, such as PLC

1788-CN2FF has three broad functions, supporting the following:

• closed-loop control

• configuration

• a redundant ControlNet network design

The 1788-CN2FF module ships from the factory with

configuration switches set to “ON (RESET)”. With switches

“ON”, any configuration data would be reset on Power

interruption. Set the switches to “OFF (NORMAL)” after initial

power-up (to clean any Factory test configurations) but before you

configure the module with your application.

Remove power to the module before resetting configuration

switches. For more information on configuration

to Configuring the 1788-CN2FF Linking Device on page 9.

OUNDATION Fieldbus H1 (Fieldbus) networks.

®

processors, HMIs, drives, I/O devices, and so on. The

refer

Publication 1788-IN051D-EN-P - February 2004

Page 2

2 ControlNet-to-Foundation Fieldbus H1 Linking Device

Use this document as a guide when you install the 1788-CN2FF module.

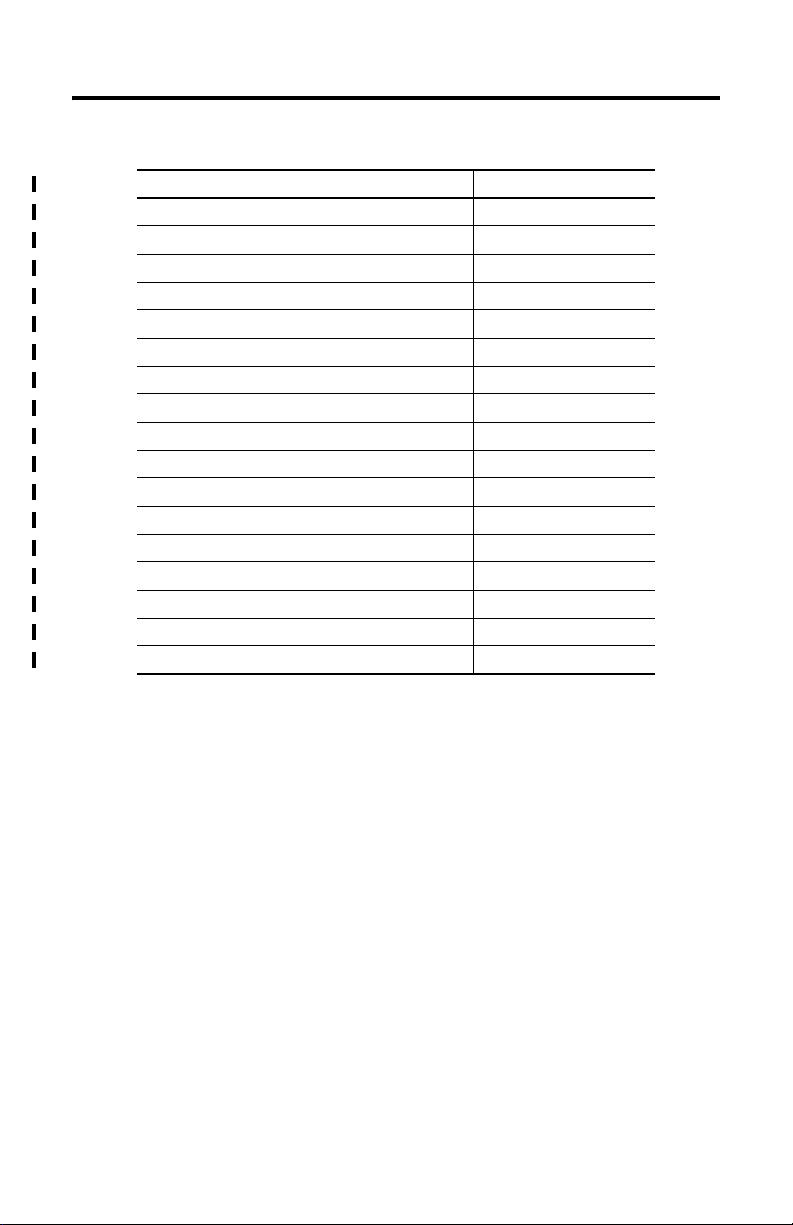

For information about: Refer to page:

Important User Information 4

Handling the 1788-CN2FF Module 6

System Requirements 6

1788-CN2FF Hardware Description 7

Installation Considerations 7

Power Conditioning 8

Configuring the 1788-CN2FF Linking Device 9

Installing the 1788-CN2FF 10

Removing the 1788-CN2FF 11

Connecting Power 12

Connecting to the ControlNet Network 13

Interpreting the LEDs: ControlNet Network Status 15

Interpreting the LEDs: Module Status 16

Connecting to the Fieldbus Network 17

Device vs. Connection Clarifications 18

Specifications 22

Rockwell Automation Support 24

Publication 1788-IN051D-EN-P - February 2004

Page 3

ControlNet-to-Foundation Fieldbus H1 Linking Device 3

Additional Information

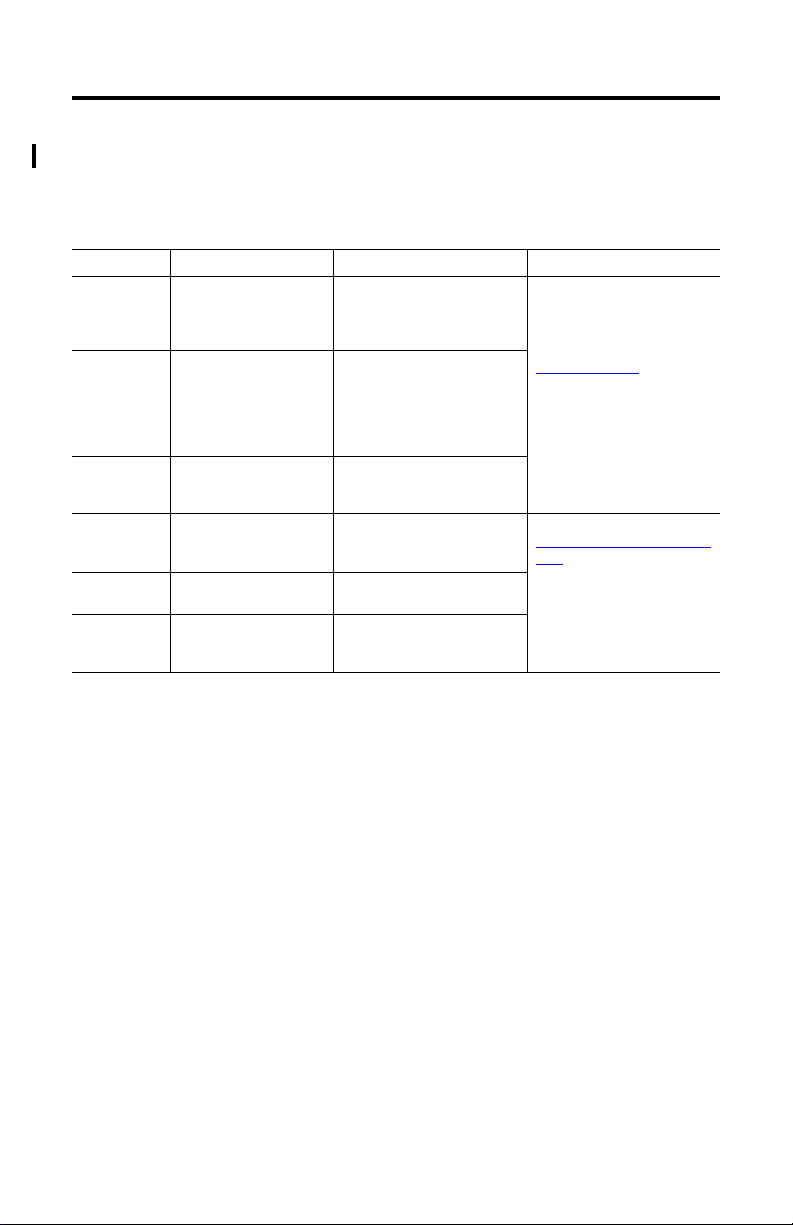

Refer to the following publications for additional information on the NI-FBUS Configurator,

the 1788-CN2FF Linking Device, and general fieldbus solutions information.

Pub Number Publication Title Scope Source

AG-140 Wiring and Installation

AG-163 31.25 kbit/s Intrinsically

AG-165 Fieldbus Installation and

1788-UM052 NI-FBUS Configurator

1788-6.5.1 ControlNet to Foundation

1757UM006

31.25 kbit/s, Voltage

Mode, Wire Medium

Application Guide

Safe Systems

Planning Guide

User Manual

Fieldbus User Manual

Fieldbus Solutions for

Rockwell Automation’s

Integrated Architecture

Overview of what you need to

know to wire, power, and

layout network components

Complements the previous

document, introduces you to

the principles of intrinsic

safety, and outlines how to

apply approved devices in a

hazardous area.

Outlines things to consider

before installing a Fieldbus

network

Provides the information you

need to use the NI-FBUS

Configurator software.

Provides the information about

the 1788-CN2FF module.

Overview of integrating

fieldbus into ProcessLogix,

ControlLogix and PLC5.

Fieldbus Foundation

9005 Mountain Ridge Dr.,

Bowie - Suite 190

Austin, TX 78759 USA

512.794.8890

www.fieldbus.org

Rockwell Automation

www.theautomationbookstore

.com

Publication 1788-IN051D-EN-P - February 2004

Page 4

4 ControlNet-to-Foundation Fieldbus H1 Linking Device

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc. is prohibited.

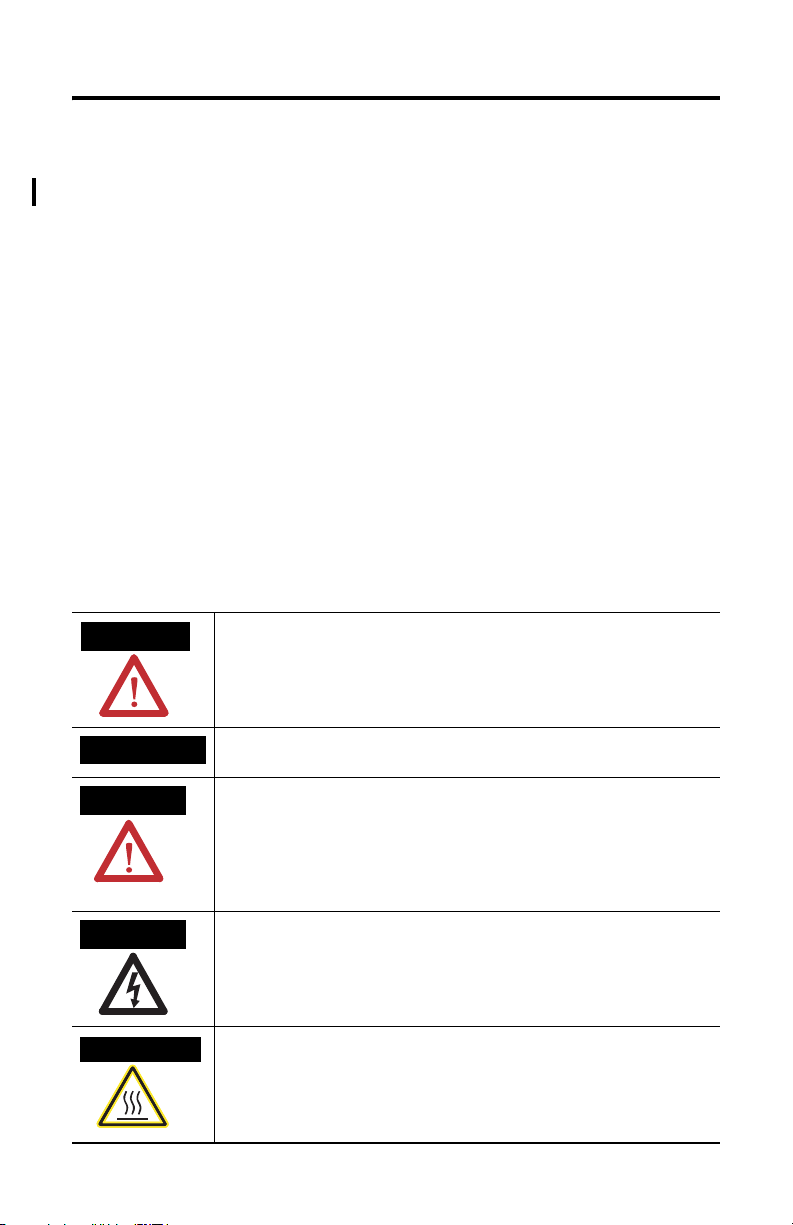

Throughout this manual we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion

in a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the drive to alert people that dangerous voltage

may be present.

Labels may be located on or inside the drive to alert people that surfaces may be

dangerous temperatures.

Publication 1788-IN051D-EN-P - February 2004

Page 5

ControlNet-to-Foundation Fieldbus H1 Linking Device 5

ATTENTION

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in

IEC publication 60664-1), at altitudes up to 2000 meters without

derating.

This equipment is considered Group 1, Class A industrial equipment

according to IEC/CISPR Publication 11. Without appropriate

precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to conducted

as well as radiated disturbance.

This equipment is supplied as “open type” equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product

safety certifications.

See NEMA Standards publication 250 and IEC publication 60529, as

applicable, for explanations of the degrees of protection provided by

different types of enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication 1770-4.1

(“Industrial Automation Wiring and Grounding Guidelines”), for

additional installation requirements pertaining to this equipment.

Publication 1788-IN051D-EN-P - February 2004

Page 6

6 ControlNet-to-Foundation Fieldbus H1 Linking Device

Handling the 1788-CN2FF Module

ATTENTION

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause

internal damage and affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in appropriate static-safe

packaging.

System Requirements

This section describes the required hardware and software components you need before you

can use the 1788-CN2FF. You should also review the README.TXT file on the setup disk

for the latest information.

Hardware

• ControlNet-to-Foundation Fieldbus H1 linking device, 1788-CN2FF module

• PC ControlNet interface: 1784-KTCX15, 1784-PCC, 1784-PCIC

• ControlNet and Fieldbus cabling

Software

The following software is necessary to configure the Fieldbus devices and the 1788-CN2FF

using ControlNet.

• Windows NT 4.0, service pack 6 or Windows 2000, service pack 3 or higher

• NI-FBUS Configurator, 1788-FFCT version 2.6.0 or higher

• RSLinx OEM 2.40.00 (build 16) or later, RSLinx Lite is not sufficient.

Other Software

To use the 1788-CN2FF module with RSLogix 5000 and a ControlLogix controller you will

need:

• RSLogix 5000 version 11.11 or later

• RSNetWorx for ControlNet version 4.01.00 (build 04) or later

To use the 1788-CN2FF module with ProcessLogix, refer to:

• The ProcessLogix Installation and Upgrade Guide.

• Knowledge Builder

Publication 1788-IN051D-EN-P - February 2004

Page 7

ControlNet-to-Foundation Fieldbus H1 Linking Device 7

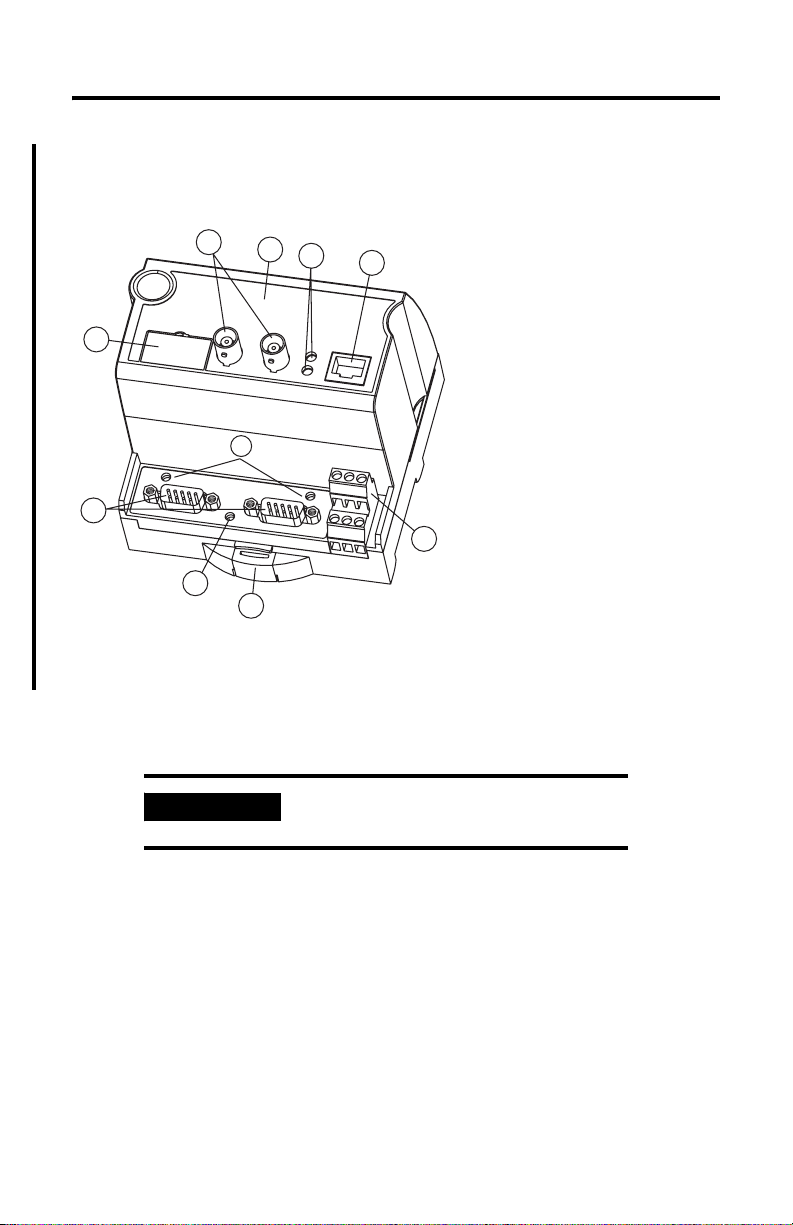

1788-CN2FF Hardware Description

Figure 1 ControlNet-to-Foundation Fieldbus Linking Device

1

9

8

7

2

3

10

6

4

1

5

43163

1. ControlNet A and B BNC

Connectors, to support single or

redundant network topologies.

2. Case/Enclosure

3. ControlNet Network Status LEDs

4. Non-isolated ControlNet Network

Access Port (NAP)

5. Power Supply Connector

6. DIN Rail Clip

7. ControlNet Module STATUS LED

8. Fieldbus Connectors

9. Network Address Switches

(under cover)

10. Not Used

Installation Considerations

The 1788-CN2FF is designed to be mounted on a 35 mm DIN rail. The device dimensions

are 4.375 x 4.375 and is 4.5 inches high. ControlNet connectors are on top of the unit, allow

1.5 inches for the connectors.

IMPORTANT

Make sure that the power to the network is off

when connecting the module.

The CN2FF supports redundant media and a ControlNet network access port (NAP). There

are 2 (A, B) BNC ControlNet connectors. We recommend using the “A” BNC connector

when setting up a single network and then using the “B” connector for the second

(redundant) network. It does not matter, but when you are working with redundant networks,

the industry tends to refer to the primary network as A and the secondary network as B.

The ControlNet status LEDs on the front of the module display the current status of each of

the redundant media channels. The rotary switches are used to set the ControlNet network

address. You can write the network address in the space provided on front of the device.

The module has two separate Fieldbus ports which supports 2 Fieldbus networks. The power

connections are used to supply power to the CN2FF.

Publication 1788-IN051D-EN-P - February 2004

Page 8

8 ControlNet-to-Foundation Fieldbus H1 Linking Device

Power Conditioning

You must use a power conditioner between your Fieldbus power supply and the Fieldbus

network. You can use a power supply designed for Foundation Fieldbus operation which has

the proper power conditioning elements. If you are using an ordinary power supply, a separate

power conditioner must also be used. If an ordinary power supply is connected directly to the

Fieldbus, the power supply would absorb signals on the cable because it would try to maintain

a constant voltage level. The power conditioner puts an inductor between the power supply

and the Fieldbus wiring. The inductor connects the DC power to the Fieldbus wiring but

prevents signals from going into the power supply.

In practice, a real inductor is not used in the power conditioner but an electronic equivalent.

The electronic inductor circuit has the added advantage of limiting the current provided to

the network segment if the cable is shorted.

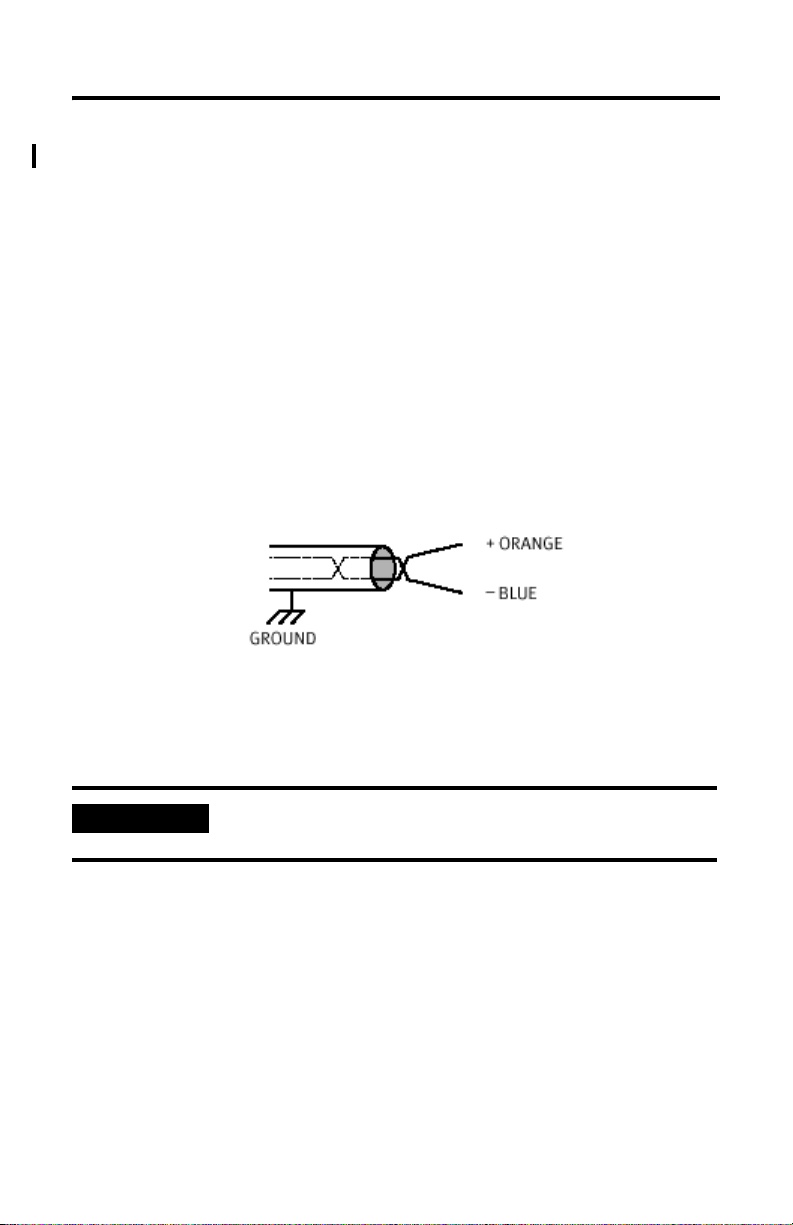

The voltage supplied to the Fieldbus cable can be as high as 32 V. The voltage at any device

can be as low as 9 V for the device to operate correctly. A typical Fieldbus device takes about

20 mA of current from the cable. The Fieldbus is configured so that one of the wires has a

(+) voltage, the other wire has a (-) voltage and the shield is grounded.

A cable with the orange wire as plus and the blue wire as minus is shown above. This type of

cable is available from Fieldbus cable manufacturers. Other cables or existing plant wiring

conventions may be different. Regardless of the color convention, keep the sense of Fieldbus

(1)

polarity consistent throughout the plant.

IMPORTANT

We suggest that you not use White/Black or White/Red pairs since

they may be mistaken for 115 volt power wiring.

Be sure to follow the wiring and installation requirements in the Foundation Fieldbus

publications listed in the section

(1)

RELCOM inc., Fieldbus Wiring Design and Installation Guide (2221 Yew Street, Forest Grove, OR 97116) p. 5. Reprinted by

permission.

Additional Information on page 3.

Publication 1788-IN051D-EN-P - February 2004

Page 9

ControlNet-to-Foundation Fieldbus H1 Linking Device 9

Configuring the 1788-CN2FF Linking Device

ATTENTION

The 1788-CN2FF module ships from the factory with

configuration switches set to “ON (RESET)”. With switches

“ON”, any configuration data would be reset on Power

interruption. Set the switches to “OFF (NORMAL)” after initial

power-up (to clean any Factory test configurations) but before you

configure the module with your application.

Remove power to the module before resetting configuration

switches.

The CN2FF has three configuration switches accessible from an opening in the bottom of

the module. These switches are illustrated in Figure 2.

Figure 2 The 1788-CN2FF Configuration Switches

ON (RESET)*

OFF (NORMAL)

(UNUSED)

OFF

top of module

(UNUSED)

OFF

* When set to ON (RESET), this switch causes

the device to reset all configuration

information to factory defaults at a power

back of module

cycle. To resume normal operation, this

switch must be set to OFF.

Publication 1788-IN051D-EN-P - February 2004

Page 10

10 ControlNet-to-Foundation Fieldbus H1 Linking Device

Installing the 1788-CN2FF

The CN2FF has a rugged, simple clip for mounting reliably on a standard

35mm DIN rail. Follow these steps to mount the module onto a DIN rail.

1. Use a flat-bladed screwdriver to open the DIN Rail Clip to the unlocked position.

Rail Clip Locked

Rail Clip Unlocked

43167

2. Hook the lip on the rear of the module onto the top of a 35mm DIN rail and press

the module down onto the DIN rail.

DIN Rail

Cover

Press

43168

3. Slide the module to the desired position on the DIN rail. After it is in position, push

the rail clip into the locked position to lock it in place on the DIN rail.

Publication 1788-IN051D-EN-P - February 2004

Page 11

ControlNet-to-Foundation Fieldbus H1 Linking Device 11

Figure 3 Install the 1788-CN2FF on to the DIN Rail

DIN Rail

Rail Clip Unlocked

Position Device Along DIN Rail

Rail Clip Locked

43169

Removing the 1788-CN2FF

To remove a module, unlock it from the DIN rail by placing a screwdriver in the slot on the

rail clip and opening the rail clip to the unlocked position as shown in step 1 on page 10.

Then lift the device off of the rail.

Publication 1788-IN051D-EN-P - February 2004

Page 12

12 ControlNet-to-Foundation Fieldbus H1 Linking Device

Connecting Power

The 1788-CN2FF requires 15-30V dc power and the cable is limited to a maximum of 3m in

length. One power supply can support several CN2FFs. The power connector is a 6-pin

screw terminal connector. The pinout for the power connector is shown in

Figure 4.

IMPORTANT

Make sure that the power to the network is off when

connecting the module.

Figure 4 Power Connector Pinout

v

v

15-30 V dc Backup

Power Supply

(optional)

43170

15-30 V dc

Primary Power

Supply

+

–

+

–

c

Connect the primary power supply to the center V and C pair. An optional backup power

supply may be connected to the left V and C pair. The right V and C pair may be used to

chain the primary power supply to other devices. All three terminals labeled C are connected

in the CN2FF. The right two V terminals are connected in the CN2FF. These connections are

indicated on the power connector by the lines over the V and C terminals.

v

To adjacent device

V

(optional connection)

c

c

C

Publication 1788-IN051D-EN-P - February 2004

Page 13

ControlNet-to-Foundation Fieldbus H1 Linking Device 13

Connecting to the ControlNet Network

There are two types of ControlNet connectors on the CN2FF, the BNC and the RJ-45.

Using the BNC:

• BNC connectors are for direct connection to a ControlNet network through a tap.

• BNC connectors must be used to connect the CN2FF to the ControlNet network.

Using the RJ-45:

• The RJ-45 connector is a network access port (NAP).

• This port is provided for configuration and development use only and it is not

intended for long term use.

• Maximum length of the cable connecting the NAP to the CN2FF is limited to 30m.

• When not in use remove the NAP port connection.

IMPORTANT

Figure 5 Typical 1788-CN2FF Connections to a Redundant ControlNet Network

Redundant

ControlNet

Networks

A is typically used

for single

networks and add

B for redundancy.

Do not connect the 1788-CN2FF to more than one ControlNet

network at a time. Attempting to connect to a second network will cause

the CN2FF to operate erratically.

Linking Device

Warning

The RJ-45 connector, NAP

AB

port is for temporary use

only, not for production

monitoring. This port is not

intended for long term use.

When not in use remove the

NAP port connection.

ControlNet

Device

ControlNet

Device

Publication 1788-IN051D-EN-P - February 2004

Page 14

14 ControlNet-to-Foundation Fieldbus H1 Linking Device

Setting the ControlNet Network Address

Valid ControlNet network addresses are 1-99. Network address zero is reserved. Switch 1

controls the most significant decimal digit (the tens). Switch 2 controls the least significant

decimal digit (the ones).

example of switch settings for a network address of 15.

Figure 6 ControlNet Network Address Switches Set to 15

Figure 6 shows the location of the network address switches and an

3

3

2

2

4

4

1

1

5

5

0

0

6

6

9

9

7

7

8

8

43164

Switch Cover

(Removed)

SW 1

1

0

SW 2

3

2

4

9

7

8

3

2

4

1

5

6

5

0

6

9

7

8

Follow these steps to set the ControlNet network address for the 1788-CN2FF.

1. Choose and set a network address.

2. Write the network address setting in the space provided on the CN2FF label.

3. Apply (or cycle) power to the CN2FF to enable the new network address.

4. Make the same address changes in your NI-FBUS configuration software.

Publication 1788-IN051D-EN-P - February 2004

Page 15

ControlNet-to-Foundation Fieldbus H1 Linking Device 15

Interpreting the LEDs: ControlNet Network Status

The ControlNet network status LEDs are located on the front of the 1788-CN2FF, beside

the ControlNet BNC connectors, as shown in Figure 1, Item 3. They indicate the state of the

ControlNet connected to the BNC connectors. These LEDs do not reflect anything about

the status of the network access port (NAP). If more than one state is present, the LEDs

always reflect the highest priority status present on the network. Table 7 describes the LED

states and the priority of each status.

Table 7 ControlNet Network LED Status Descriptions

LED State Priority How to View Cause

Both steady off 1 (highest) View together Reset or no power

Both steady red 2 Failed to link interface to ControlNet

Alternating red & green 3 Self testing

Alternating red 4 Bad node configuration (such as duplicate

Steady off 5 View

Flashing red & green 6 Invalid link configuration

Flashing red 7 Link fault or no frames received

Flashing green 8 Temporary channel error or listen only

Steady green 9 (lowest) Normal operation

independently

ControlNet network address)

Channel disabled or not supported

Publication 1788-IN051D-EN-P - February 2004

Page 16

16 ControlNet-to-Foundation Fieldbus H1 Linking Device

Interpreting the LEDs: Module Status

The STATUS LED is located on the front of the 1788-CN2FF, between the two Fieldbus

connectors, as shown in Figure 1, Item 7. It indicates whether the CN2FF is powered,

configured, and operating properly. Table 8 shows how to interpret the STATUS LED states.

Table 8 Module Status LED State Descriptions

LED State Description

Off No power to the CN2FF

Flashing red and green CN2FF self testing

Flashing green

Solid green

Flashing red Major recoverable fault

Solid red Major unrecoverable fault

(1)

Standby state indicates the CN2FF has passed all self tests and is ready to operate.

Yet, it is not functioning because it is not been configured.

(2)

Operational state indicates the CN2FF has left standby state because the necessary

network configuration (if any) has occurred.

Standby state

Operational state

(1)

(2)

Publication 1788-IN051D-EN-P - February 2004

Page 17

ControlNet-to-Foundation Fieldbus H1 Linking Device 17

N

N

N

N

Connecting to the Fieldbus Network

Figure 9 Fieldbus Connector Locations on the 1788-CN2FF

43171

Fieldbus Connections

Use pins 6 and 7 for the Fieldbus signals, as specified in the Fieldbus Standard for Use in

Industrial Control Systems, Part 2, ISA-S50.02.1992. Refer to

of the 1788-CN2FF.

Figure 10 for the connector pinout

IMPORTANT

Make sure that the power to the network is off when

connecting the module.

Figure 10 Fieldbus Connector Pinout for the 1788-CN2FF

C

C

C

CNC

1 2345

6

789

Data +

Data –

NC

NC

43172

Publication 1788-IN051D-EN-P - February 2004

Page 18

18 ControlNet-to-Foundation Fieldbus H1 Linking Device

Device vs. Connection Clarifications

This section describes the functional relationship and differences between 1788-CN2FF

Connections and Foundation FieldbusΤΜ Devices. A connection does not always equal a

device.

ATTENTION

The maximum number of “connections” is 30 per CN2FF. The

recommended number of “devices” is 8 per H1 port on the

CN2FF. If you exceed the maximum number of connections or

the recommended number of devices, system performance could

be compromised.

• A connection is considered any link (wire connection) to:

• CNAI, ControlNet ANALOG INPUT

• CNAO, ControlNet ANALOG OUTPUT

• CNDI, ControlNet DIGITAL INPUT

• CNDO, ControlNet DIGITAL OUTPUT

• A device is considered a specific Foundation Fieldbus device such as a

transmitter.

For each different network configuration, you must account for all connections and devices

toward the maximum recommendations.

Publication 1788-IN051D-EN-P - February 2004

Page 19

ControlNet-to-Foundation Fieldbus H1 Linking Device 19

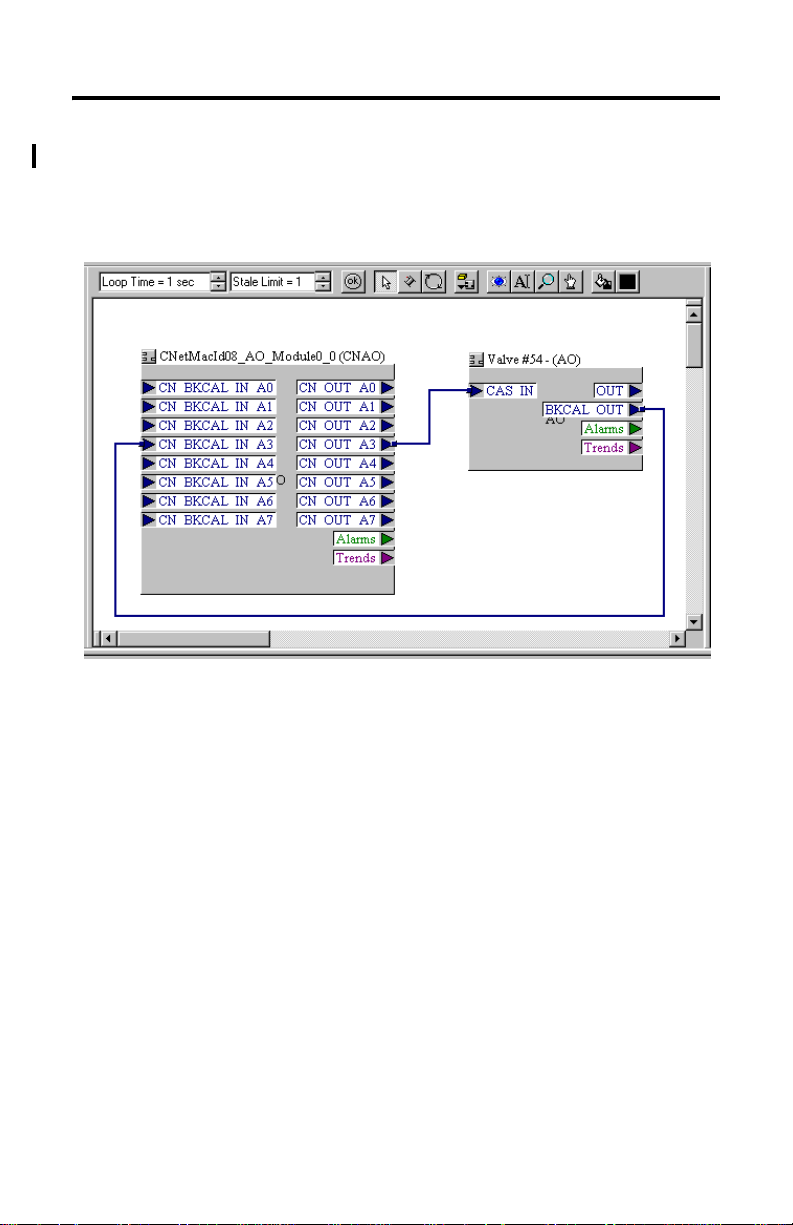

1788-CN2FF Connections

A connection is considered any link (wire connection) to a CNAI, CNAO, CNDI, and

CNDO. When using the CNAO, refer to the graphic below that illustrates there are two

connections for each CNAO.

For help in determining the number of connections on a port, refer to the Device Info screen

once you have downloaded the function block applications to the CN2FF.

Publication 1788-IN051D-EN-P - February 2004

Page 20

20 ControlNet-to-Foundation Fieldbus H1 Linking Device

To locate the Device Info, expand the CN2FF tree and double-click on Device Info.

When

accounting

for the

number of

connections,

you need to

count the

number of

Tags in the

FieldbusTag

column and

not the

number

identifying

the

Instances.

Even though

there is a

duplicate

Instance of 1, it

is still counted as

a separate

FieldbusTag that

counts against

the total 30

connections. This

example has 12

connections.

Each tag in the FieldbusTag column counts as a fieldbus connection. There can be duplicate

Instance numbers for different types of modules (e.g. DI vs. AI).

On any one port you can have up to a maximum of 18 connections. If you are using 18

connections on one port, the second port would only be allowed 12 connections for a total of

30 per CN2FF.

Publication 1788-IN051D-EN-P - February 2004

Page 21

ControlNet-to-Foundation Fieldbus H1 Linking Device 21

1788-CN2FF and Foundation Fieldbus Devices

Devices do not equate to connections. The current recommended number of devices per H1

port is 8 and the maximum number of devices per 1788-CN2FF module is 16 for any type of

bus power used.

ATTENTION

The maximum number of “connections” is 30 per CN2FF. The

recommended number of “devices” is 8 per H1 port on the

CN2FF. If you exceed the maximum number of connections or

the recommended number of devices, system performance could

be compromised.

These numbers are for Non-IS (Intrinsically Safe) class devices only. IS device maximums are

even lower, depending on all the configuration constraints of a particular application.

Understanding the 1788-CN2FF Connection and Device Relationship

One connection does not equal one device. The maximum recommended number of devices

per each H1 port is 8 for a total 16. That maximum takes into account that you have an

optimal sized network, the correct number of connections, followed wiring guidelines and

you don’t have 16 devices that exceed the current limitation of your systems’ power supply.

Many devices require 2 connections (e.g. an AO) and some devices that can require 3 or more

connections (e.g. a PID). The number of connections needs be considered when counting

devices. You may have 8 devices that exceed the connection limits of the module. For

example: AIs take one connection, AOs will require two, and PIDs will need at least 2 but

could use more depending on how it is wired.

The maximum number of connections (30) is specified as a combination for BOTH channels.

In addition, you need to account for other process aspects such as loop time and stale limits

for your network segments. You need to take into account the length of your cables and spurs,

the number of devices per spur, power consumption of each device, etc.

ATTENTION

Be sure to follow the wiring and installation requirements in the

Foundation Fieldbus publications listed in the section Additional

Information on page

3.

Publication 1788-IN051D-EN-P - February 2004

Page 22

22 ControlNet-to-Foundation Fieldbus H1 Linking Device

Specifications

Ty pe Specifications

Operating Temperature 0 to 60°C (32 to 140°F)

Storage Temperature –40 to 85°C (–40 to 185°F)

Relative Humidity 5 to 95% non-condensing

Vibration IEC60068-2-6 (Test Fc, Operating): 2g @ 10-500Hz

Physical Dimensions 4.375 in. x 4.375 in x 4.5 in

Shock IEC60068-2-27 (Test Ea, Unpackaged shock):

Emissions CISPR 11: Group 1, Class A

ESD Immunity IEC 61000-4-2:

Radiated RF Immunity IEC 61000-4-3:

EFT/B Immunity IEC 61000-4-4: ±2kV at 5kHz on signal ports

Surge Transient Immunity IEC 61000-4-5: ±1kV line-line(DM) and ±2kV line-earth(CM) on signal ports

Conducted RF Immunity IEC 61000-4-6: 10Vrms with 1kHz sine-wave 80%AM from 150kHz to 80MHz

Magnetic Field Immunity IEC 61000-4-8: 30A/m at 50Hz

Enclosure Type Rating None (open-style)

Communication • ControlNet - redundant media

Mounting 35 mm DIN rail

Power Requirements Class 2 power supply 24V dc

IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock)

IEC 60068-2-1 (Test Ab, Un-packaged Non-operating Cold),

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating Thermal Shock)

IEC 60068-2-30 (Test Db, Un-packaged Non-operating Damp Heat)

• ControlNet connectors are on top of the unit

• Allow 1.5 inches for the connectors.

Operating 30g

Non-operating 50g

4kV contact discharges

8kV air discharges

10V/m with 1kHz sine-wave 80%AM from 30MHz to 1000MHz

10V/m with 200Hz 50% Pulse 100%AM at 900Mhz

• NAP, network access port

• FOUNDATION Fieldbus H1, 2 independent channels

• LAS on both channels

• Time Master on both channels

15-30V dc

270 mA @ 24V dc (typical)

Publication 1788-IN051D-EN-P - February 2004

Page 23

ControlNet-to-Foundation Fieldbus H1 Linking Device 23

Type Specifications

Indicators • Module Status

Connectors • ControlNet - BNC connectors, provides redundancy

Conductors Wire Size

Category

Certifications

(when product is marked)

(1)

Use this Conductor Category information for planning conductor routing. Refer to Publication 1770-4.1, “Industrial

Automation Wiring and Grounding Guidelines”.

(2)

Appropriate shielded cable is required for Electromagnetic compatibility (EMC) standards.

(3)

See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other certification details.

• ControlNet Status, 1 each connection

• two 10-position rotary switches

• Network Access Port - RJ45 (non-isolated)

• Fieldbus - 9-pin sub-D connectors

• Power Input Terminals:

-Torque 5-7 in-lb.

-Not to be used with combination of solid and stranded 16 GA wire

#22 AWG (0.355 SQmm) Copper Stranded wire to #14 AWG (2.08 SQmm)

Copper Stranded wire

60° C minimum

(1) (2)

2

c-UL-us UL Listed Industrial Control Equipment, certified for US and

Canada

FCC North American EMI Verification

Part 15-Class A-ICES003

(3)

C-Tick

CE

Australian EMC Compliance

AS/NZS CISPR 11; Industrial Emissions

(3)

European Union 89/336/EEC EMC Directive, compliant with:

EN 61000-6-4; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

Allen-Bradley and ProcessLogix are trademarks of Rockwell Automation.

RSLinx, RSLinx OEM, RSNetWorx are trademarks of Rockwell Software.

Foundation Fieldbus is a trademark of the Fieldbus Foundation.

Windows NT and 2000 are trademarks of the Microsoft Corporation.

Publication 1788-IN051D-EN-P - February 2004

Page 24

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using our

products. At http://support.rockwellautomation.com, you can find technical manuals, a

knowledge base of FAQs, technical and application notes, sample code and links to software

service packs, and a MySupport feature that you can customize to make the best use of these

tools.

For an additional level of technical phone support for installation, configuration and

roubleshooting, we offer TechConnect Support programs. For more information, contact

t

your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation,

please review the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your module up and running:

United States 1.440.646.3223

Outside United

t

ates

S

New Product Satisfaction Return

Rockwell tests all of our products to ensure that they are fully operational when shipped from

the manufacturing facility. However, if your product is not functioning and needs to be

returned:

United States Contact your distributor. You must provide a Customer Support case number

Outside United

ates

St

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

(see ph

one number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Publication 1788-IN051D-EN-P - February 2004 PN 957868-05

Supersedes Publication 1788-IN051C-EN-P - September 2003 Copyright © 2004 Rockwell Automation. All rights reserved. Printed in the U.S.A.

Loading...

Loading...