Page 1

Installation Instructions

ControlNet IP67 Tap and Cable Assembly Kit

Installation Instructions

Cat. No.1786-TCT2BD1, -TPST2T, -TPRT2T

What’s in This Document

This document describes how to install the ControlNet IP67 Tap and Cable Assembly Kit.

The kit is available in three versions, as shown in the table below. All kits are identical, except

for the 1-meter drop cable.

for this version of the drop able order this kit

TNC to Straight BNC (TNC at tap body; BNC at node

end)

TNC to Straight TNC (TNC at tap body; TNC at node

end)

TNC to Right-angle TNC (TNC at tap body; TNC at node

end)

1786-TCT2BD1

1786-TPST2T

1786-TPRT2T

The kit is made up of a tap body and a 1-meter drop cable with overmolded connectors. The

drop cable has a TNC connector at the tap body end and either a BNC or TNC connector at

the ControlNet node end (depending on the version of the kit you order). The tap and cable

are rated to IP67 when mated to a sealed connector, which means they are water-tight.

Publication 1786-IN017B-EN-P - May 2004

Page 2

2 ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions

Topic Page

Why Use Sealed Media Components? 5

Select a Location to Install Sealed Components 7

Install the Components 8

Terminate the Cable 9

Apply Heat-shrink Tubing 12

Connect ControlNet Segments in a Network Topology 14

Specifications 15

The modular design of the kit lets you disconnect the devices at either the end of the drop

cable, or at the tap port located on the tap body, without disrupting communications to the

rest of the network. You can permanently disconnect a tap from a device by installing a tap

dummy load (1786-TCAP) at the tap end of the drop cable.

TIP

IMPORTANT

The 1786-TCAP is compatible only with the 1786-TCT2BD1 drop

cable. You can use the 1786-TCT2BD1 drop cable with the

1786-TPRT2T tap body.

No more than one tap should be disconnected at the body at a time and

no more than 10% of the taps in a network may be terminated with tap

dummy loads (1786-TCAP). Failure to adhere to these rules may cause

excessive network errors and/or loss of network communications.

Publication 1786-IN017B-EN-P - May 2004

Page 3

ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions 3

The kit also includes other items, such as a DIN rail mounting bracket and screws. See Table

1 below for a complete listing of the kit’s contents.

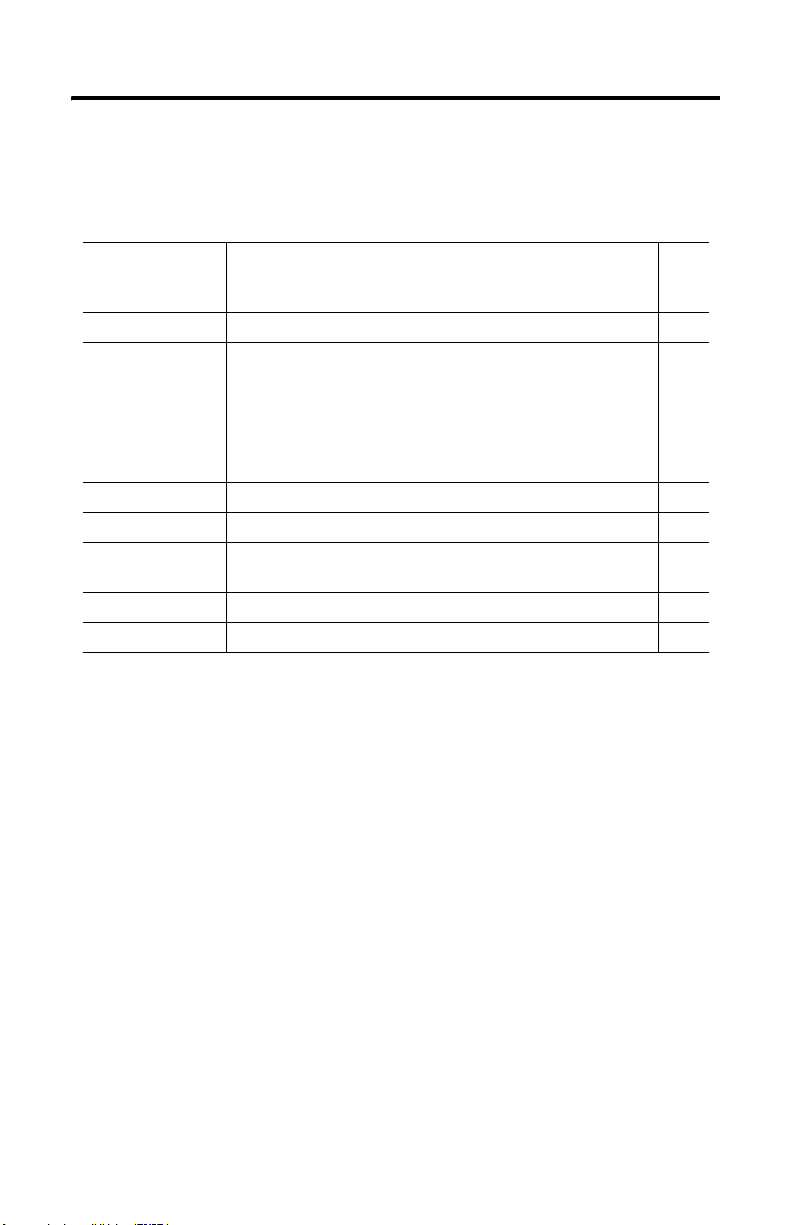

Table 1 ControlNet IP67 Tap and Cable Assembly Kit Contents

Catalog/

Publication

Number

1786-TPIP67 IP67 Tap Body (not sold separately) 1

1786-TPSDT2B TNC to Straight BNC Drop Cable

1786-TPRDT2T TNC to Right-angle TNC Drop Cable

1786-TPSDT2T TNC to Straight TNC Drop Cable

1786-TNCL10 TNC Plugs (bagged) 2

1799-BRKD DIN Rail Mounting Bracket 1

1786-IN017B-EN-P ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions 1

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

Description Qty.

One of the following 1-meter drop cables, depending on the version of

the kit you order (not sold separately):

DIN Rail Mounting Screws, #4-40 x .375

Pan Head, Cross Recess, Stainless Steel

Gray dust cap (for the drop cable) 1

1

2

Publication 1786-IN017B-EN-P - May 2004

Page 4

4 ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions

Important User Information

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage,

or economic loss.

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment to alert people that dangerous

voltage may be present.

Labels may be located on or inside the equipment to alert people that surfaces may be

dangerous temperatures.

Publication 1786-IN017B-EN-P - May 2004

Page 5

ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions 5

Why Use Sealed Media Components?

Sealed media components are ControlNet taps and TNC connectors, rated to IP67, that are

suitable for use in harsh environments. IP67 is an industry-standard protection rating that

describes the degree of protection provided to the components within the IP67-rated device.

The IP67 rating means that the components are dust- and water-tight and water-immersible.

While the tap bodies and TNC connectors in all three versions of the kit are water-tight, the

BNC connector in the 1786-TCT2BD1 kit is not. Use the BNC version of the kit

(1786-TCT2BD1) in applications in which you can mount the BNC connector inside a

cabinet, or in another non-harsh environment. The sealed tap body contained in all versions

of the kit can be mounted in any environment requiring an IP67 rating.

ATTENTION

Be sure to mate or terminate all connections. The taps and drop

cables are rated to IP67 only when properly mated. Unterminated

connections could be a source of contamination. Use the gray dust

caps supplied in this kit to terminate unused connections. Never

install extra taps in IP67 environments because there is no way to seal

and protect the tap connections.

The IP67 rating is guaranteed only when you use Rockwell

Automation-supplied connectors and heat-shrink tubing.

Publication 1786-IN017B-EN-P - May 2004

Page 6

6 ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions

Here are some example applications in which you would use the dust- and water-tight

ControlNet IP67 Tap and Cable Assembly kit:

ATTENTION

TIP

• robotic welding

• bottling

• automotive paint spray booth

• food processing (with washdown)

• metal processing

• wastewater treatment facility

• automotive manufacturing

• paper/pulp processing

IMPORTANT

Contact your Rockwell Automation representative for information on

chemical environments in which the taps are suited for use. Cutting

fluids and oils are not recommended for use with the taps.

Because TNC connectors have a greater operational vibration

tolerance than BNC connectors (10g vs. 2.5g), TNC connectors are

recommended for applications with a great deal of vibration, such as

stamping or automotive presses.

For information on how to plan and install your ControlNet cable

System, see the ControlNet Coax Media Planning and Installation Guide,

publication CNET-IN002.

Publication 1786-IN017B-EN-P - May 2004

Page 7

ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions 7

Select a Location to Install Sealed Components

Use these guidelines to select where to install the components.

IMPORTANT

ATTENTION

IMPORTANT

• Be certain that the installation location is convenient for routing your cable and meets

the bend radius of the coax trunk line.

• Do not install sealed components so that the dropline cable is routed over any ac

power terminals on nearby modules.

ControlNet is an isolated system. Connectors and the shield must not

come in direct contact with a metal enclosure or other grounded

equipment. The 1786-BNC2TNC and 1786-TNCJI4 isolated bulkhead

connectors (available from Rockwell Automation) provide an isolation

from ground when properly installed.

Do not allow any metal portions of the tap, such as the universal

mounting bracket screws or connectors to contact any conductive

material. This contact could cause noise on the network.

Do not cut, lengthen, or substitute the drop cable supplied in this kit.

Doing so may diminish the integrity of your ControlNet network

connection.

Publication 1786-IN017B-EN-P - May 2004

Page 8

8 ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions

Install the Components

1. Determine an adequate mounting location for the tap. Refer to the dimension

drawing shown below.

2.30 in. (5.8 cm)

1.42 in.

(3.6 cm)

1.21 in.

1.65 in.

(4.2 cm)

Front View

(3.1 cm)

2. To mount the tap to the DIN rail, use the hardware provided in the kit and attach as

shown in the following illustration.

Universal mounting bracket

.90 in.

(2.3 cm)

Side View

.49 in.

(1.2 cm)

.45 in.

(1.1 cm)

1 in.

(2.5 cm)

.60 in.

(1.5 cm)

Back View

.49 in.

(1.2 cm)

312889-M

Mount the universal

mounting bracket on the DIN

rails supplied in the kit.

DIN rail

31287-M

ATTENTION

Do not over-tighten the screws. Over-tightening the screws can

damage the tap. The applied torque should be 0.2-0.4 N-m (1-2

ft.-lbs).

3. To mount the tap through an enclosure wall, drill a hole of approximately 17.2 mm

for the 1786-TNCJI4 isolated bulkhead connector.

Publication 1786-IN017B-EN-P - May 2004

Page 9

ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions 9

4. Attach the tap body to the isolated bulkhead connector using the 1786-TNCLP4

plug-to-plug adapter.

5. Attach the drop cable to the bulkhead connector. Attach the other end to the

ControlNet node.

1786-TCT2BD1

TNC tap

1786-TNCJI4 jack-to-jack isolated bulkhead

1 meter drop cable to device

1786-TNCLP4 plug-to-plug adapter

Terminate the Cable

IMPORTANT

IMPORTANT

To make IP67-approved crimps when installing connectors onto a cable,

order the ControlNet Coax Tool Kit, catalog number 1786-CTK). You

can also use this tool kit to make standard coax cables.

For more information on the ControlNet Coax Tool Kit, contact your

Rockwell Automation representative or refer to the ControlNet Coax

Media Planning and Installation Guide, publication CNET-IN002. You

can order a paper copy or view an electronic copy of this manual at

www.theautomationbookstore.com, or call 1-800-963-9548.

For more information on how to properly terminate cables, refer to the

ControlNet BNC installation training video on compact disk, publication

CNET-DM001. This CD is available from

www.theautomationbookstore.com or by calling 1-800-963-9548.

Do not cut, lengthen, or substitute the drop cable supplied in this kit.

Doing so may diminish the integrity of your ControlNet network

connection.

Publication 1786-IN017B-EN-P - May 2004

Page 10

10 ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions

1. If your installation requires IP67-rated connectors, slide the heat-shrink tubing onto

the cable.

2. Place the crimp ferrule on to the cable.

3. Strip the cable using the 1786-CTK stripper tool.

4. Trim the center conductor to the required length as directed on the connector bag.

5. Push the flare tool onto the cable with a slight twisting motion (with sufficient inward

pressure to expand the braid).

41888

Push the flare/calibration tool gently and rotate

slightly onto the connector while applying pressure.

This will work the base of the connector underneath

the wire braid slowly.

6. Place the center pin over the center conductor.

IMPORTANT

Be certain that the center pin slips onto the center conductor completely.

The back shoulder of the center pin should be up against the white

insulation. If it is not, recheck the length of the center conductor.

Publication 1786-IN017B-EN-P - May 2004

41890

Page 11

ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions 11

7. With the center pin in place, use the crimp tool to crimp the pin into place.

The smaller hexagonal crimping notch is for crimping

the center pin onto the center connector.

41903

Check for braid strands that could

cause a short to center conductor.

8. Slide the ControlNet connector onto the cable. Push the connector body on tight

until the center pin tip is flush with the inner ground ring.

9. Slide the crimp ferrule over the three outer shields and connector base until it meets

the shoulder on the connector.

10. Using the crimp tool, crimp the ferrule. Position the crimp tool on the ferrule as close

as possible to the connector base and ferrule meeting line. Press the tool tightly

around the ferrule until the crimp tool allows release.

TIP

TIP

The larger hexagonal crimping notch is for crimping the ferrule which

holds the connector to the cable.

Many network problems are due to improperly installed connectors.

You should have tight-fitting connectors on the ends of all your

cables. Pull the connector to verify that it is attached. If it is loose or

comes off, snip off the connector and install a new one. The

connector should withstand a minimum 60lbs pull force if properly

installed.

Publication 1786-IN017B-EN-P - May 2004

Page 12

12 ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions

11. Inspect the cable at the TNC connector end for any loose cable braids. Loose braids may

cause voids in the heat-shrink tubing.

Sometimes strands will be too long and

protrude out of the ferrule. Using the

Exacto blade, trim the excess length off

flush with the connector body.

12. Place the heat-shrink tubing with heat-active glue (provided in the IP67 Tap and Cable

Assembly Kit) over the TNC connector body and cable.

IMPORTANT

Use only the ACUM heat-shrink tubing provided in the kit. Do not

substitute other types of heat-shrink tubing. Substitutions may cause a

loss of the IP67 rating.

Apply Heat-shrink Tubing

1. Follow these guidelines when heating the tubing:

ATTENTION

a. Place the tubing against the shoulder of the TNC connector.

b. Allow the heat gun to come to a temperature of between 110 and 160 degrees Celsius.

c. Hold the cable assembly approximately 2 inches away from the heat exhaust area of

the heat gun while shrinking the tubing.

d. Continuously rotate the cable assembly around the heat exhaust area of the heat gun.

The entire process should take about 4 minutes.

Be careful when using heat guns. High temperatures can lead to burns,

risk of fire, or other property damage.

Publication 1786-IN017B-EN-P - May 2004

Page 13

ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions 13

e. Inspect the heat-shrink tubing to ensure that there are no voids where the glue has

incompletely melted. Voids could cause a loss of the IP67 rating.

Place the tubing against

the shoulder of the TNC

connector

Ensure that there are no

voids where glue has

incompletely melted

31297-M

2. Attach the trunk line to the tap. Tighten the trunk-line connector to 1 N-m (0.74

ft.-lbs.).

IMPORTANT

Be sure to install the dust cap on any unused connectors. Doing so will:

• prohibit the center conductor or the outer conductor from

inadvertently shorting to ground during installation

• provide partial environmental protection if a tap is left disconnected

for a prolonged time

Publication 1786-IN017B-EN-P - May 2004

Page 14

14 ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions

Connect ControlNet Segments in a Network Topology

See the following illustration for a sample network topology installation.

1786-RG6

1786-BNC2TNC

1786-TNCL10

1786-TNCL10

1786-RG6

IP67-compliant

ControlNet device

1786-BNC/B

1786-BNC/B

1786-TNCL10

1786-TPST2T,

-TPRT2T

1786-TPS

1786-BNC/B

1786-RG6

1

TNC to BNC

drop cable

1786-BNC2TNC

1786-BNC/B

1786-RG6

1786-TNCL10

1786-TNCLP4

1786-TCT2BD1

TNC to BNC

drop cable

1786-TCT2BD1

1

TNC to BNC

drop cable

1786-TCT2BD1

1786-TNCLXTL4

1

1

1786-TNCLP4

1786-TNCJI4

TNC to BNC

drop cable

Wire Gland

(not supplied by

Rockwell Automation)

31290-M

1 Although the arrow in this illustration points to the tap body, the catalog number called out corresponds to the appropriate

ControlNet Tap and Cable Assembly Kit.

TIP

Except where indicated in the illustration above, use only the

hardware that we provide with the connector. Other hardware can

diminish the integrity of your connection. For catalog numbers shown

in the illustration above but not supplied in the kit, contact your local

Rockwell Automation distributor.

Publication 1786-IN017B-EN-P - May 2004

Page 15

Specifications

ControlNet IP67 Tap and Cable Assembly Kit Installation Instructions 15

operational temperature IEC 60068-2-1 (Test Ad, Operating Cold),

storage temperature IEC 60068-2-2 (Test Ab, Un-packaged Non-operating Cold),

relative humidity IEC 60068-2-30 (Test Db, Un-packaged Non-operating Damp Heat):

vibration IEC 60068-2-6 (Test Fc, Operating):

operating shock IEC 60068-2-27 (Test Ea, Unpackaged Shock):

non-operating shock IEC 60068-2-27 (Test Ea, Unpackaged Shock):

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20 to 70 °C (-4 to 158 °F)

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating Thermal Shock):

-40 to 85 °C (-40 to 185 °F)

5 to 95% non-condensing

10g @ 10-500Hz

30g

50g

Publication 1786-IN017B-EN-P - May 2004

Page 16

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using our

products. At http://support.rockwellautomation.com, you can find technical manuals, a

knowledge base of FAQs, technical and application notes, sample code and links to software

service packs, and a MySupport feature that you can customize to make the best use of these

tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect Support programs. For more information, contact

your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation,

please review the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your module up and running:

United States 1.440.646.3223

Outside United

States

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of our products to ensure that they are fully operational when shipped from

the manufacturing facility. However, if your product is not functioning and needs to be

returned:

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Publication 1786-IN017B-EN-P - May 2004 PN 957899-44

Supersedes Publica tion 1786-IN017A-EN-P - Ma rch 2002 Copyright © 2004 Rockwell Automation, Inc. A ll rights reserved. Printed in the U.S.A.

Loading...

Loading...