Page 1

SoftLogix

TM

Motion

Card

(Cat.No. 1784-PM02AE, -PM16SE)

Setup and Configuration

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include intellectual

property liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation

and Maintenance of Solid-State Control (available from your local Allen-Bradley

office), describes some important differences between solid-state equipment

and electromechanical devices that should be taken into consideration when

applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

WARNING

Identifies information about practices or circumstances that

can lead to personal injury or death, property damage or

economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

RSLogix, SoftLogix, Ultra3000, Ultra5000, and Kinetix 6000 are all trademarks of Rockwell Automation

SERCOS interface is a trademark of the Interests group SERCOS interface e.V. of Stuttgart, Germany

Identifies information that is critical for successful

application and understanding of the product.

Page 3

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following standards, in

whole or in part, documented in a technical construction file:

This product is intended for use in an industrial environment.

Low Voltage Directive

• EN 50081-2 EMC — Generic Emission Standard, Part 2 — Industrial

Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 — Industrial

Environment

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests. For specific

information required by EN 61131-2, see the appropriate sections in this

publication, as well as the Allen-Bradley publication Industrial Automation

Wiring and Grounding Guidelines For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Page 4

Page 5

Preface

Table of Contents

Using This Manual

The SoftLogix Motion Control

System

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

On the Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 1

SoftLogix Motion Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Components of the SoftLogix Motion System. . . . . . . . . . . . . . . . . . . . 6

SoftLogix Chassis Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

The SoftLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

The Analog/Encoder Servo Module (1784-PMO2AE) . . . . . . . . . 9

The 16 Axis SERCOS interface Module (1784-PM16SE). . . . . . . . 9

RSLogix 5000 Programming Software . . . . . . . . . . . . . . . . . . . . . . . 9

Developing a Motion Control Application Program . . . . . . . . . . . . . . 10

Application Program Development . . . . . . . . . . . . . . . . . . . . . . . . 10

The MOTION_INSTRUCTION Tag. . . . . . . . . . . . . . . . . . . . . . 10

Motion Status and Configuration Parameters . . . . . . . . . . . . . . . . 11

Modifying Motion Configuration Parameters . . . . . . . . . . . . . . . . 11

Handling Motion Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2

SoftLogix Controller

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Accessing the New Controller Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . 14

Editing Controller Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3

Adding and Configuring Your

1784-PM02AE Motion Module

i Publication 1784-UM003A-EN-P – June 2003

Adding the 1784-PM02AE Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Editing Your Motion Module Settings . . . . . . . . . . . . . . . . . . . . . . . . . 51

Assigning Additional Motion Modules . . . . . . . . . . . . . . . . . . . . . . . . . 60

Page 6

ii

Chapter 4

Configuring the1784-PM16SE Card

The Motion Group

Naming & Configuring Your

Motion Axis

Creating & Configuring Your

Coordinate System Tag

Adding the 1784-PM16SE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

SERCOS interface Motion Card Overview . . . . . . . . . . . . . . . . . . . . . 66

Editing 1784-PM16SE Card Properties . . . . . . . . . . . . . . . . . . . . . . . . 67

Chapter 5

Creating A Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Editing the Motion Group Properties. . . . . . . . . . . . . . . . . . . . . . . . . . 82

Chapter 6

Naming an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Editing Motion Axis Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Assigning Additional Motion Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Creating a Coordinate System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Editing Coordinate System Properties . . . . . . . . . . . . . . . . . . . . . . . . 179

Right Mouse Click Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Configuring a 1394x-SJTxx-D

Digital Servo Drive

Configuring an Ultra 3000 Drive

Configuring a Kinetix 6000 Drive

Configuring an 8720MC Drive

Chapter 8

1394x-SJTxx-D Digital Servo Drive Overview . . . . . . . . . . . . . . . . . 193

Chapter 9

Editing the Ultra Drive Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Chapter 10

Editing the Kinetix Drive Properties . . . . . . . . . . . . . . . . . . . . . . . . . 225

Chapter 11

Editing the 8720MC Drive Properties . . . . . . . . . . . . . . . . . . . . . . . . 240

Publication 1784-UM003A-EN-P – June 2003

Page 7

Chapter 12

iii

Motion Instructions

Motion Object Attributes

Motion State Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Motion Move Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Motion Group Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Motion Event Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Motion Configuration Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Motion Coordinated Move Instructions . . . . . . . . . . . . . . . . . . . . . . . 256

Motion Direct Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Accessing Direct Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Supported Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Motion Direct Command Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Chapter 13

Object Support Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Motion Object Status Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Motion Status Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Motion Status Bit Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Motion Object Configuration Attributes . . . . . . . . . . . . . . . . . . . . . . 287

Motion Unit Configuration Attributes . . . . . . . . . . . . . . . . . . . . . . . . 287

Motion Conversion Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Motion Homing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Motion Dynamics Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Servo Status Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Servo Status Bit Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Commissioning Status Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Servo Configuration Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Servo Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Servo Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Servo Fault Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Commissioning Configuration Attributes. . . . . . . . . . . . . . . . . . . . . . 343

Servo Drive Status Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Commissioning Status Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Servo Drive Configuration Attributes. . . . . . . . . . . . . . . . . . . . . . . . . 372

Motor and Feedback Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Servo Loop Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Drive Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

Drive Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Drive Fault Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

Drive Power Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Commissioning Configuration Attributes. . . . . . . . . . . . . . . . . . . . . . 405

Publication 1784-UM003A-EN -P – June 2003

Page 8

iv

Chapter 14

Troubleshooting

Specifications and Performance

Wiring Diagrams

1784-PM02AE LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

SERCOS interface LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Appendix A

1784-PM02AE Motion Card Specifications . . . . . . . . . . . . . . . . . . . . 417

1784-M16SE Motion Card Specifications. . . . . . . . . . . . . . . . . . . . . . 418

Appendix B

About Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

Using a 1784-PM02AE Module With a Torque Servo Drive . . . 422

Using a 1784-PM02AE Module With a Velocity Servo Drive . . 423

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

1784-PM02AE Termination Panel . . . . . . . . . . . . . . . . . . . . . . . . 423

Pinouts for Cable 1784-PM02AE-TP0x . . . . . . . . . . . . . . . . . . 426

1398 to Termination Panel Wiring Diagram . . . . . . . . . . . . . . . . 428

Publication 1784-UM003A-EN-P – June 2003

Page 9

Using This Manual

Preface

Who Should Use This

To use this manual, you should be able to program and operate the

Allen-Bradley SoftLogix5800™ controllers to efficiently use your motion

Manual

control modules. The manual’s focus is from the RSLogix 5000 software.

If you need more information about programming and operating the

SoftLogix5800 controllers, refer to the SoftLogix5800 System User Manual,

publication number 1789-UM002.

The Purpose of This Manual

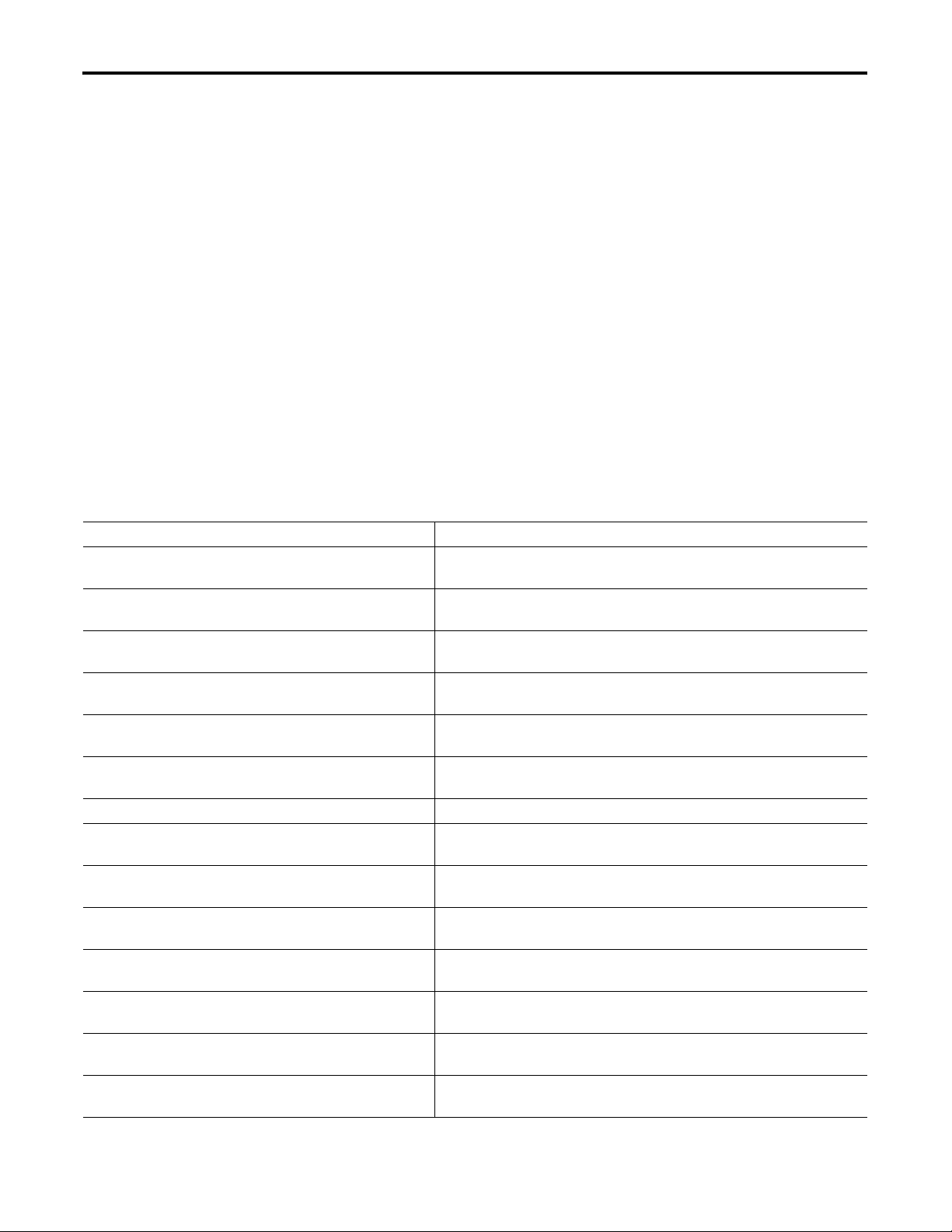

This manual describes how to setup and configure and troubleshoot your

SoftLogix motion cards using the RSLogix 5000 software. The following table

shows the contents of each section in this manual:

Section Contains

Chapter 1

The ControlLogix Motion Control System

Chapter 2

Controller Properties

Chapter 3

Adding and Configuring Your 1784-PM02AE Motion Card

Chapter 4

Adding and Configuring Your 17846-PM16SE Motion Card

Chapter 5

The Motion Group

Chapter 6

Adding and Configuring Motion Axes

Chapter 7 Creating and Configuring a Coordinate System How to create and configure a Coordinated System.

Chapter 8

Configuring a 1394C-SJT05/10/22-D Digital Servo Drive

Chapter 9

Configuring an Ultra3000

Chapter 10

Configuring the Kinetix 6000

Chapter 11

Configuring the 8720MC High Performance Drive

Chapter 12

The Motion Instructions

Chapter 13

Motion Object Attributes

Chapter 14

Troubleshooting

TM

Drive

TM

Drive

Information about the SoftLogix motion control system.

Explains how to create and edit your controller.

How to add and configure your 1784-PM02AE motion module using the

RSLogix™ 5000 programming software.

How to add and configure your 1784-PM16SE motion card using the

RSLogix 5000 programming software

How to create and edit your Motion Group.

How to name and configure a motion axis using the RSLogix 5000

programming software.

How to add and configure a 1394C Digital Servo Drive.

How to add and configure an Ultra3000 drive

How to add and configure a Kinetix 6000 drive

How to add and configure an 8720MC High Performance Drive

Information about the motion instructions provided in the RSLogix 5000

programming software.

Information about the Motion Object attributes.

Information about troubleshooting your SoftLogix motion control system.

1 Publication 1784-UM003A-EN-P – June 2003

Page 10

2 Using This Manual

Appendix A

Specifications

Appendix B

Loop and Interconnect Diagrams

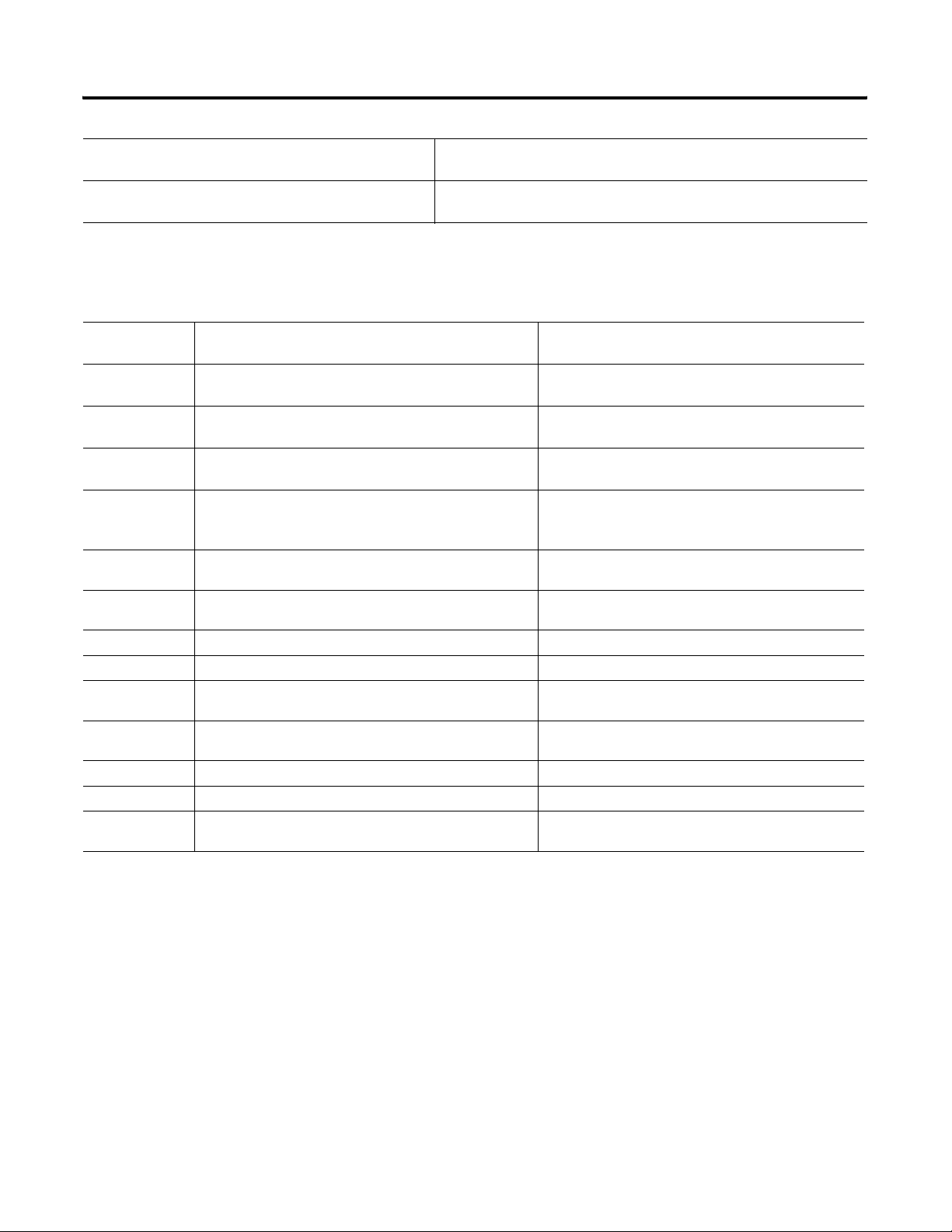

Related Documentation

Publication

Number

1784-IN047 Analog Encoder (AE) Servo Module Installation

1789-UM002 SoftLogix5800 System User Manual Provides information for using your SoftLogix5800

1756-RM007 Motion Instructions Set Reference Manual Provides descriptions of all of the motion instructions

1784-IN041 16 Axis SERCOS interface Card Installation Instructions Provides instructions for installing, wiring, and

1394C-5.20 1394 SERCOS Interface Multi Axis Motion Control System Information on installation, wiring, and setup for the

1394-IN024 1394 SERCOS Integration Manual Information on integrating the 1394 drive with the

2098-IN003 Ultra3000 Hardware Installation Manual Information on Ultra3000 installation

2098-IN001 Ultra5000 Hardware Installation Manual Information on Ultra5000 installation

2098-IN005 Ultra3000 SERCOS Integration Manual Information on integrating the Ultra3000 with the

8720MC-UM001 8720MC High Performance Drive User Manual Information on use of the 8720MC High Performance

2094-IN004 Kinetix 6000 Module Installation Manual Information on installing the Kinetix 6000 Module

2094-IN001 Kinetix 6000 Installation Manual Information on installing Kinetix 6000

2094-IN002 Kinetix 6000 Integration Manual Information on integrating the Kinetix 6000 with

Publication Description

Instructions

The following table lists related ControlLogix documentation:

Specifications and performance guidelines for the motion card.

Loop diagrams and wiring diagrams for your SoftLogix motion control

system.

Provides instructions for installing, wiring, and

troubleshooting your 1784-PM02AE servo card.

controller and its components.

used in the RSLogix 5000 software.

troubleshooting your 1784-PM16SE SERCOS

interface

1394C-SJTxx-D

1784-PM16SE

1784-PM16SE SERCOS interface modules

Drive

SERCOS

TM

card.

Rockwell Automation Support

Publication 1784-UM003A-EN-P – June 2003

For more information on the documentation, refer to the Allen-Bradley

Publication Index, publication number SD499.

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors, and 260 authorized systems

integrators located throughout the United States. In addition, Rockwell

Automation representatives are located in every major country in the world.

Page 11

Using This Manual 3

Technical Product Assistance

On the Web

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

If you need to contact Rockwell Automation for technical assistance, please

review the information in this manual. If the problem persists, call your local

Rockwell Automation representative.

The Rockwell Automation Technical Support number is:

1-440-646-5800

For information about Rockwell Automation, visit the following World Wide

Web site:

http://www.ab.com/support

Publication 1784-UM003A-EN-P – June 2003

Page 12

4 Using This Manual

Publication 1784-UM003A-EN-P – June 2003

Page 13

Chapter

The SoftLogix Motion Control System

This chapter describes the SoftLogix motion control system and its

components.

1

SoftLogix Motion Control

The Virtual Chassis, SoftLogix controller, 1784-PM02AE servo card,

1784-PM16SE SERCOS interface card, and RSLogix 5000 programming

software provide integrated motion control support.

• The Chassis Monitor lets you create, delete, monitor, and configure

controllers and communication interface cards such as ControlNet,

DeviceNet, 1784-PM02AE and 1784-PM16SE motion cards in the

SoftLogix Virtual Chassis.

• The SoftLogix5860 controller contains a high-speed motion task, which

executes ladder motion commands and generates position and velocity

profile information. The controller sends this profile information to one

or more 1784-PM02AE servo modules. You can use several Logix

controllers in each chassis. Each controller can control up to 32 axes of

motion.

• The 1784-PM02AE servo module connects to a servo drive and closes a

high-speed position and velocity loop. Each SoftLogix controller can

support up to 16 1784-PM02AE servo modules. Each 1784-PM02AE

module can control up to two axes.

• The 1784-PM16SE SERCOS interface module serves as the interface

between one SoftLogix processor and 1 to 16 axes operating in either

position or velocity mode. The module has a programmable ring Cycle

Period of 0.5 ms, 1 ms, or 2 ms depending on the number of axes and a

ring Data Rate of 4 or 8 Mbaud.

• RSLogix 5000 programming software provides complete axis

configuration and motion programming support.

5 Publication 1784-UM003A-EN-P – June 2003

Page 14

6 The SoftLogix Motion Control System

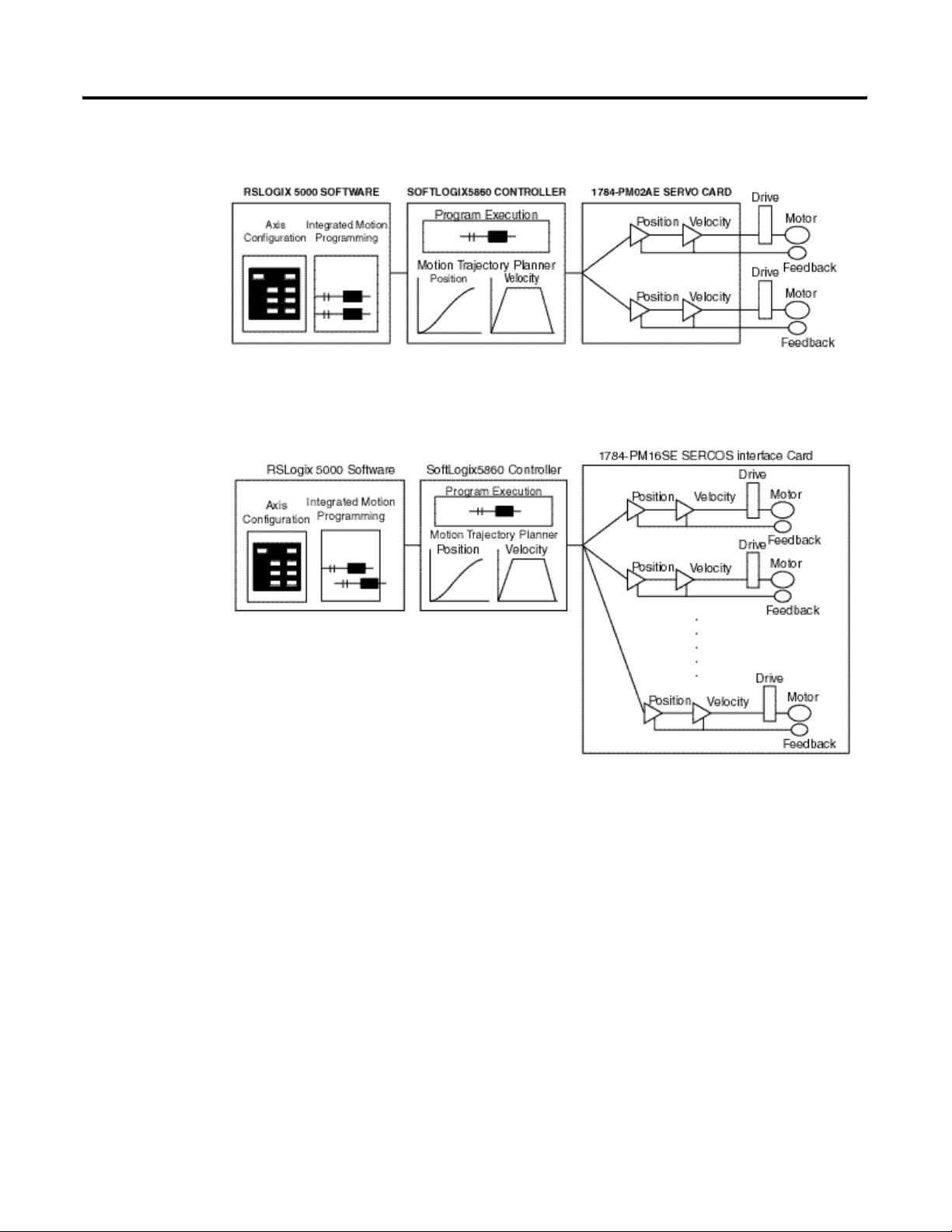

Figure 1.1 SoftLogix System with 1784-PM02AE

Components of the SoftLogix Motion System

Publication 1784-UM003A-EN-P – June 2003

Figure 1.2 SoftLogix System with 1784-PM16SE

Page 15

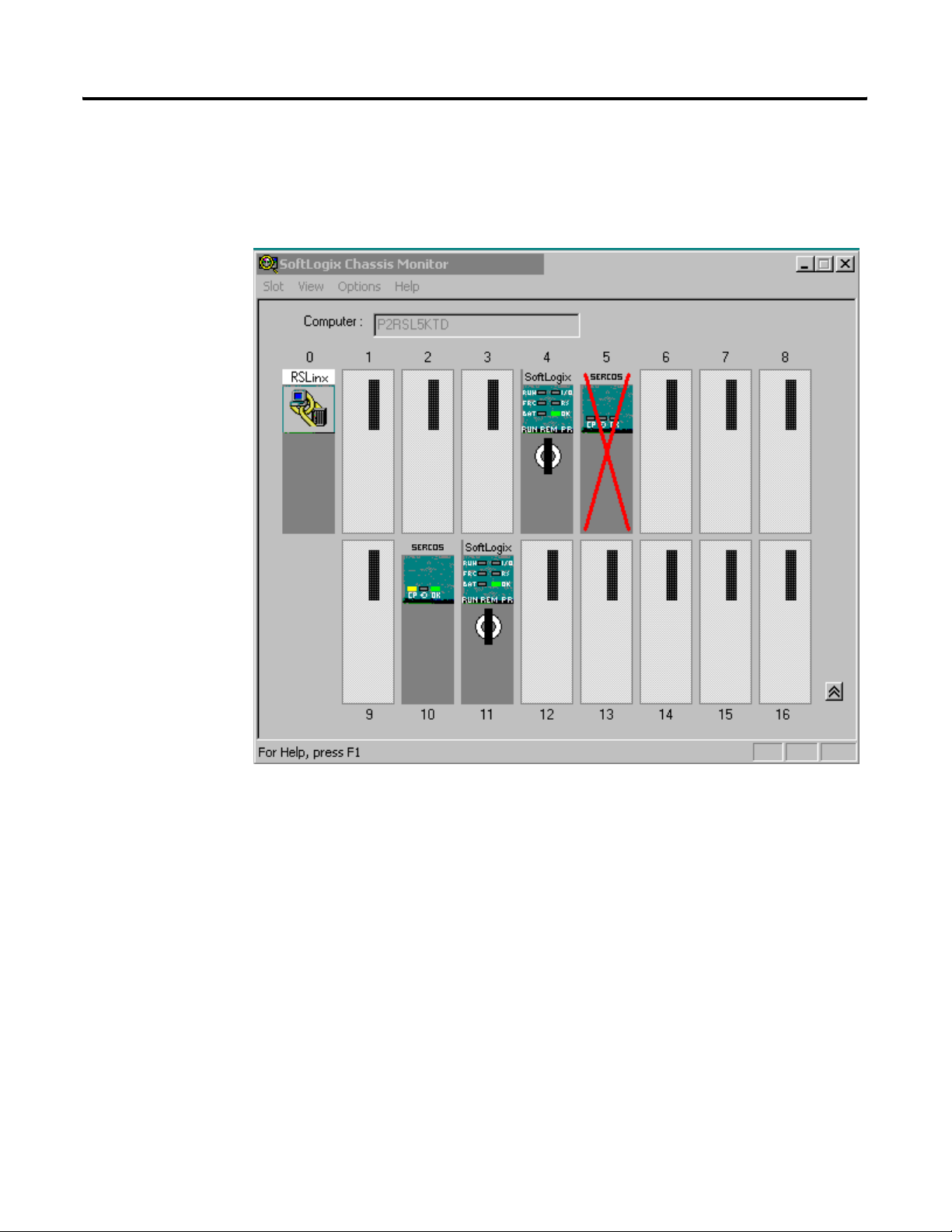

The SoftLogix Motion Control System 7

SoftLogix Chassis Monitor

It is at the Chassis Monitor where you can change the processor mode, and

view system status. After you have created and configured the various modules

of your SoftLogix system you can use the Chassis Monitor to display the

virtual chassis where you can monitor the simulated LEDs to view status

information for your modules.

Figure 1.3 SoftLogix Chassis Monitor

Publication 1784-UM003A-EN-P – June 2003

Page 16

8 The SoftLogix Motion Control System

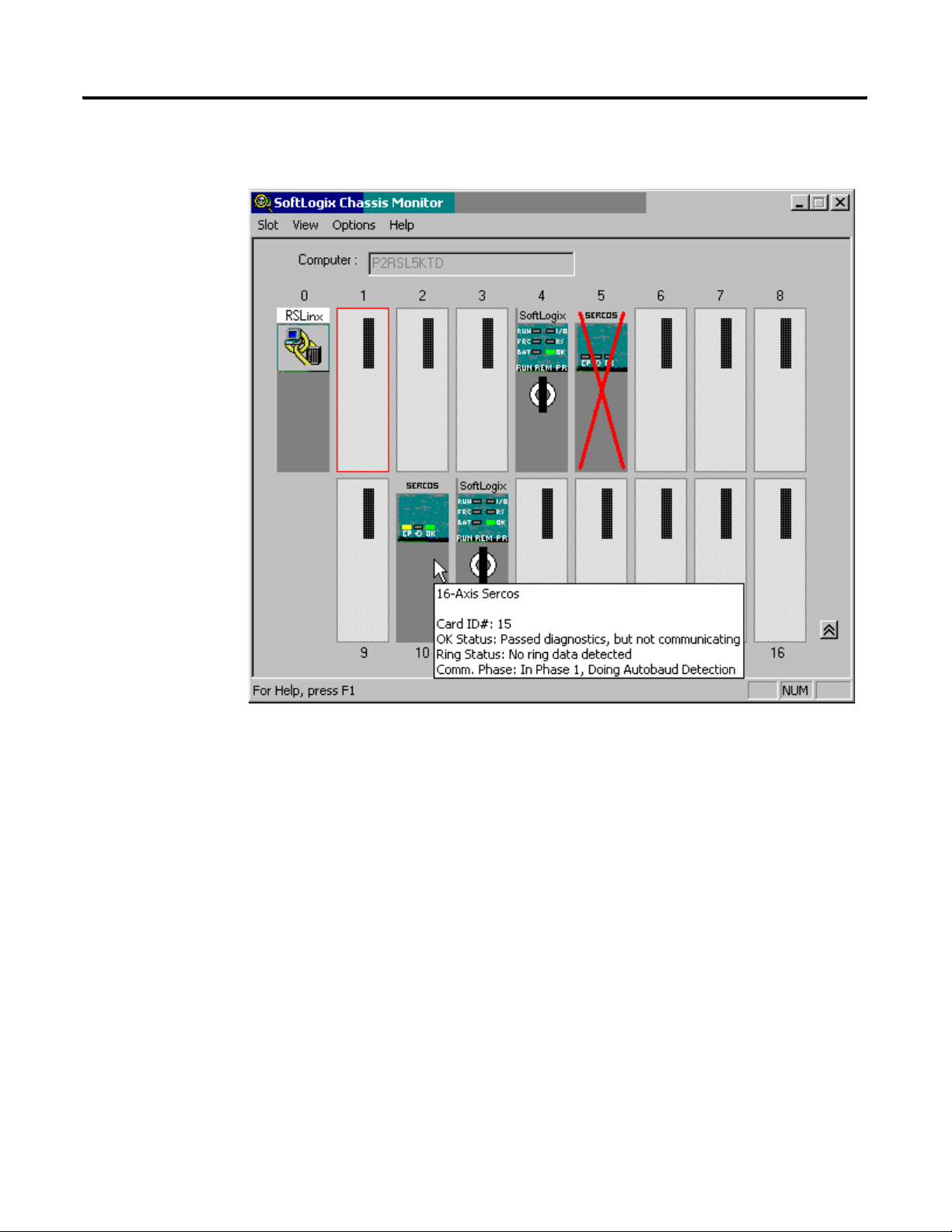

Additional information in the form of a tooltip about the modules can be

ascertained by placing the mouse over a specific module.

The SoftLogix Controller

Figure 1.4 Additional Information for the PM16SE Card

The SoftLogix controller is the main component in the SoftLogix system. It

supports sequential and motion functions, and it performs all of the motion

command execution and motion trajectory planner functions. You can use one

or more SoftLogix controllers in each chassis, and each controller can control

up to 32 axes of motion.

The SoftLogix controller provides the following motion support:

• A high-speed motion task, which manages motion functions and

generates move profiles

• The ability to control up to 16 Analog/Encoder servo modules for a

total of 32 axes

• SERCOS support

Publication 1784-UM003A-EN-P – June 2003

Page 17

The SoftLogix Motion Control System 9

The Analog/Encoder Servo Module

(1784-PMO2AE)

The 16 Axis SERCOS interface

Module (1784-PM16SE)

The Analog/Encoder servo module provides an analog/quadrature encoder

servo drive interface. The servo module receives configuration and move

information from the SoftLogix controller and manages motor position and

velocity.

The servo module supports:

• Connection capability for up to two drives

• ±10V analog outputs

• Quadrature encoder inputs

• Home limit switch inputs

• Drive fault inputs

• Drive enable outputs

• 5V or 24V position registration inputs

• 250 μs position and velocity loop updates

The 16 Axis SERCOS interface modules (1784-PM16SE) serves as a link

between the SoftLogix platform and intelligent drives. The communication

link between the module and the drive(s) is via IEC 1491 SErial Real-time

COmmunication System (SERCOS) using fiber optic medium.

RSLogix 5000 Programming Software

The SERCOS interface module supports:

• reliable high speed data transmission

• excellent noise immunity

• elimination of interconnect wiring

• ASA messages converted to SERCOS formatted messages

The RSLogix 5000 programming software provides complete programming

and commissioning support for the SoftLogix system. RSLogix 5000 is the

only programming software needed to fully configure and program SoftLogix

motion control systems.

RSLogix 5000 software provides the following motion support:

• Wizards for servo axis configuration including drive hookup diagnostics

and auto tuning

• Ladder-based application programming including support for 31

motion commands

Publication 1784-UM003A-EN-P – June 2003

Page 18

10 The SoftLogix Motion Control System

Developing a Motion Control Application Program

Application Program Development

This section provides an introduction to concepts used in developing

application programs for motion control. These concepts include:

• Application program development

• The MOTION_INSTRUCTION tag

• Motion status and configuration parameters

• Modifying motion configuration parameters

• Handling motion faults

Developing a motion control application program involves the following:

Task Description

Select the master coordinated system

time

Name and Configure an axis Adds an axis to your application

Develop a motion application program Create a program for your motion

Add a motion module Adds a motion module to your

Assign additional servo modules and

axes

Run hookup diagnostics and auto

tuning

Sets one controller as the master

controller. Once you complete this

step, you can synchronize all the

motion modules and SoftLogix

controllers in your chassis

program

control application

application program

Adds additional modules and axes to

your application program

Completes hookup diagnostics and

auto tuning for each axis

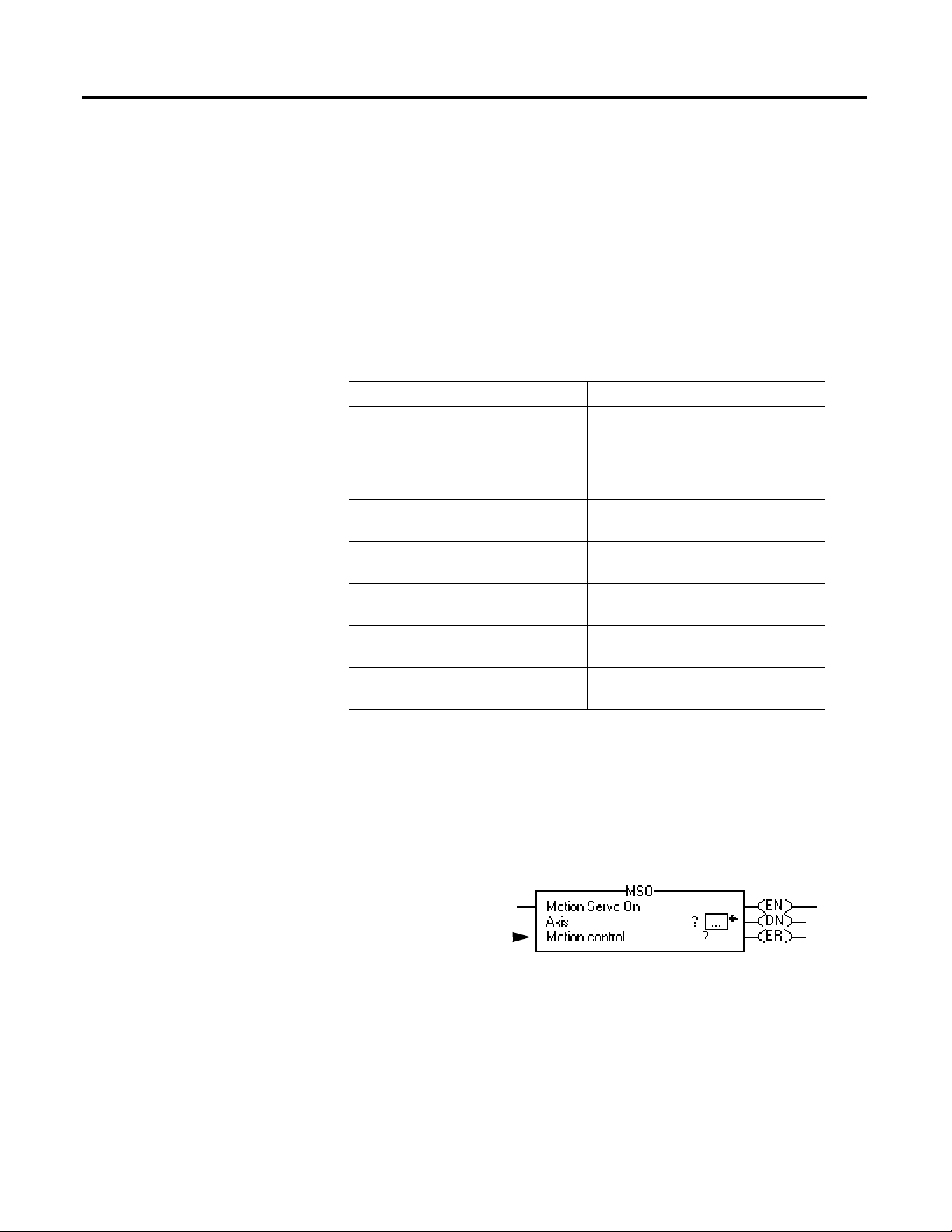

The MOTION_INSTRUCTION Tag

Publication 1784-UM003A-EN-P – June 2003

The controller uses the MOTION_INSTRUCTION tag (structure) to store

status information during the execution of motion instructions. Every motion

instruction has a motion control parameter that requires a

MOTION_INSTRUCTION tag to store status information.

The

motion control

parameter

Figure 1.5 Motion Control Parameter

Page 19

The SoftLogix Motion Control System 11

Motion Status and Configuration

Parameters

ATTENTION

Tags used for the motion control parameter of instructions

should only be used once. Re-use of the motion control

parameter in other instructions can cause unintended

operation of the control variables.

!

For more information about the MOTION_INSTRUCTION tag, refer to the

Logix5000 Controller Motion Instruction Set Reference Manual (1756-RM007).

You can read motion status and configuration parameters in your ladder logic

program using two methods.

Method Example For more information

Directly accessing

the AXIS and

MOTION_GROUP

structures

Using the GSV

instruction

• Axis faults

• Motion status

• Servo status

• Actual

position

• Command

position

• Actual

velocity

Refer to

Motion Instruction Set Reference

Manual (1756-RM007).

Refer to the Input/Output

Instructions chapter of the Logix

Controller Instruction Set Reference

Manual, publication 1756-RM003.

the Logix5000 Controller

Modifying Motion Configuration

Parameters

In your ladder logic program, you can modify motion configuration

parameters using the SSV instruction. For example, you can change position

loop gain, velocity loop gain, and current limits within your program.

For more information about the SSV instruction, refer to the Logix Controller

Instruction Set Reference Manual, publication 1756-RM003.

Publication 1784-UM003A-EN-P – June 2003

Page 20

12 The SoftLogix Motion Control System

Handling Motion Faults

Two types of motion faults exist.

Type Description Example

Motion

Instruction

Errors

Minor/Maj or Faults

• Do not impact controller

operation

• Should be corrected to

optimize execution time and

ensure program accuracy

• Caused by a problem with

the servo loop

• Can shutdown the controller

if you do not correct the fault

condition

A Motion Axis Move (MAM)

instruction with a parameter out

of range

The application exceeded the

PositionErrorTolerance value

Errors

Executing a motion instruction within an application program can generate

errors. The MOTION_INSTRUCTION tag has a field that contains the error

code. For more information on error codes for individual instructions, refer to

the motion instruction chapters in the Logix5550 Controller Instruction Set

Reference Manual.

Minor/Major Faults

Several faults can occur that are not caused by motion instructions. For

example, a loss of encoder feedback or actual position exceeding an overtravel

limit cause faults. The motion faults are considered Type 11 faults with error

codes from 1 to 32. For more information about motion error codes, refer to

Handling Controller Faults in the Logix Controller User Manual.

TIP

You can configure a fault as either minor (non major) or

major by using the Axis Wizard-Group window.

For more information about handling faults, see Handling Controller Faults in the

Logix 5000 Controller User Manual.

Publication 1784-UM003A-EN-P – June 2003

Page 21

SoftLogix Controller

Chapter

2

Introduction

Before you can begin programming or configuring your controller, you must

create a project file in which to store it.

To create a Project:

1. From the Type pull-down menu, choose the controller type that you

wish to use for this project.

2. Enter the name you wish to use for the controller.

The same name is used for the project file with the .acd extension.

3. Enter a description of the controller.

4. Choose the appropriate chassis type in which the controller resides.

5. Enter the slot number for the controller.

In SoftLogix, controllers occupy a numbered slot in the chassis and can be

placed in any slot. It is also possible to place multiple controllers in the same

chassis.

6. Verify the appropriate revision information for your controller. This

field defaults to the latest revision for the given controller type.

7. Enter the directory in which you want to store the project file.

The directory defaults to the one you configured in the Workstation Options

dialog. If you want to use a different directory, type its path or click on the

Browse button to find the directory.

The project file is created in this directory with the same name as the

controller with a .ACD file extension. For example, if your controller name is

Oven1, the project file name becomes Oven1.ACD.

8. Click on OK to create the project.

Once the project file is created, you can see the Controller Organizer, which

shows everything in the controller. The default configuration contains a

continuous task, called Main Task. The Main Task contains a program called

Main Program. The Main Program contains a routine called Main Routine,

which is configured as the main routinedef_main_routine@gloss.hlp.

13 Publication 1784-UM003A-EN-P – June 2003

Page 22

14 SoftLogix Controller

In addition, if you have chosen a FlexLogix controller, 2 FlexBus adapters are

created in slots 3 and 4 under the I/O Configuration folder. These 2 folders

contain all local I/O for FlexLogix, other than the 2 local slots for

communication. The first folder contains all I/O configured on the local Flex

rail housing the Flex controller; the second folder contains all I/O configured

for the local non-controller rail.

Note: You cannot delete, copy, cut, paste, or drag and drop the FlexBus

adapters. Once you create a FlexLogix controller, the adapters appear

under the I/O Configuration folder and cannot be altered unless you

delete the FlexLogix controller.

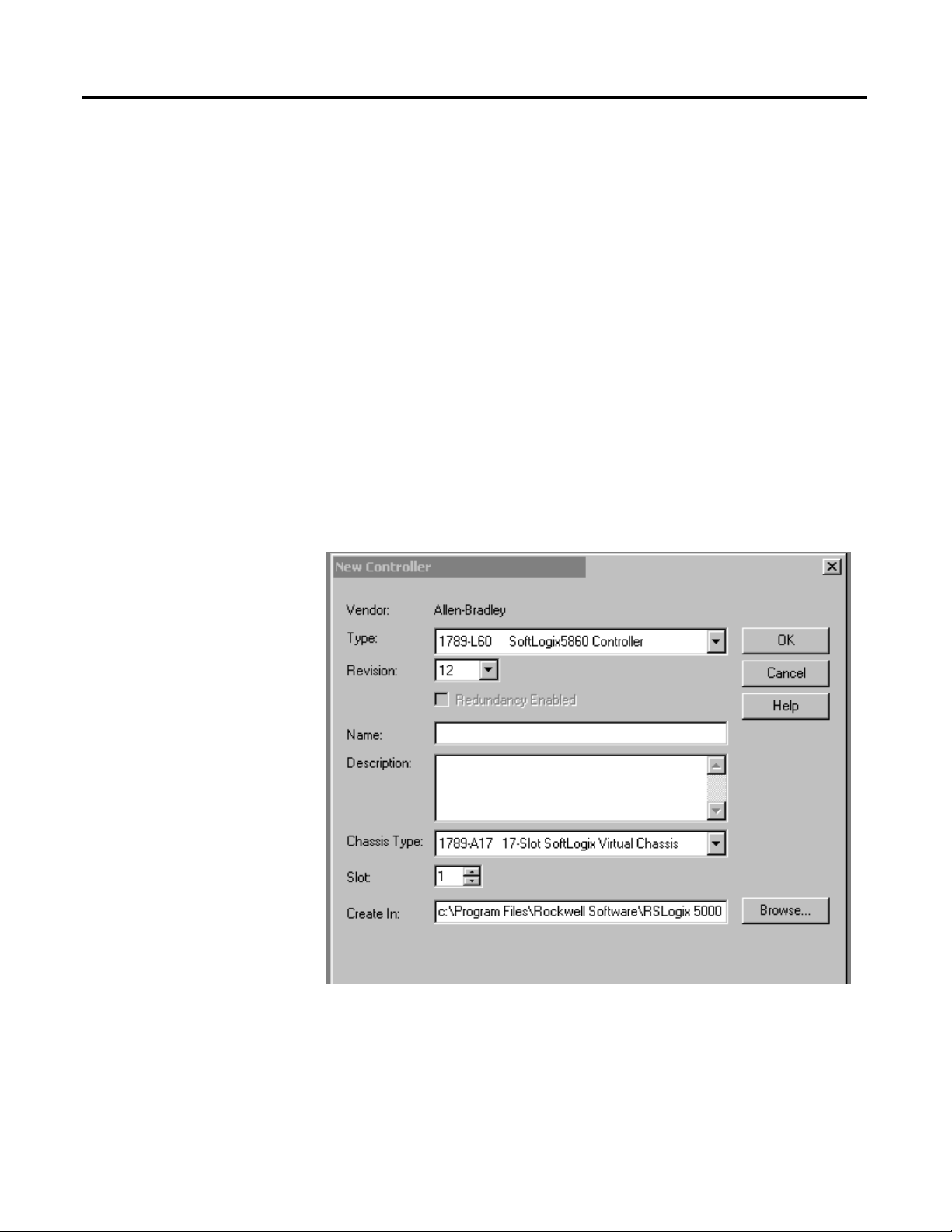

Accessing the New Controller Dialog

New Controller Dialog

From the File menu, choose New to access the New Controller dialog.

Create a new controller (i.e., project) from this dialog.

Publication 1784-UM003A-EN-P – June 2003

Figure 2.1 New Controller Dialog

Page 23

SoftLogix Controller 15

Vendor

Displays the name of the controller’s manufacturer.

Ty pe

Select the controller type from the pull-down menu, shown here by catalog

number, platform, and processor.

Choose from:

• 1756-L1 ControlLogix5550 Controller

• 1756-L55 ControlLogix5555 Controller

• 1756-L61 ControlLogix5561 Controller

• 1756-L62 ControlLogix5562 Controller

• 1756-L63 ControlLogix5563 Controller

• 1756-LCE ControlLogixCE Controller

• 1769-L20 CompactLogix5320 Controller

• 1769-L30 CompactLogix5330 Controller

• 1769-L35E CompactLogix5335E Controller

• 1789-L60 SoftLogix5860 Controller

• 1794-L33 FlexLogix5433 Controller

• 1794-L34 FlexLogix5434 Controller

• 618x-LCE PanelViewLogix Controller

• Emulator RSLogix Emulate 5000 Controller

• PowerFlex700S DriveLogix5720 Controller

Redundancy Enabled

Check this box if you wish to enable redundancy for this controller. Note that

this option is disabled if you have chosen a controller that does not support

redundancy.

Name

Enter the name you wish to use for the new controller. This name is also used

for the project file, with a .acd extension.

Description

Enter a description of the controller.

Publication 1784-UM003A-EN-P – June 2003

Page 24

16 SoftLogix Controller

Chassis Type

Select the appropriate chassis type from the pull-down menu, shown here by

catalog number. The software uses this information to determine the number

of slots in the chassis. Depending on the controller type you chose, the

available options in this menu vary:

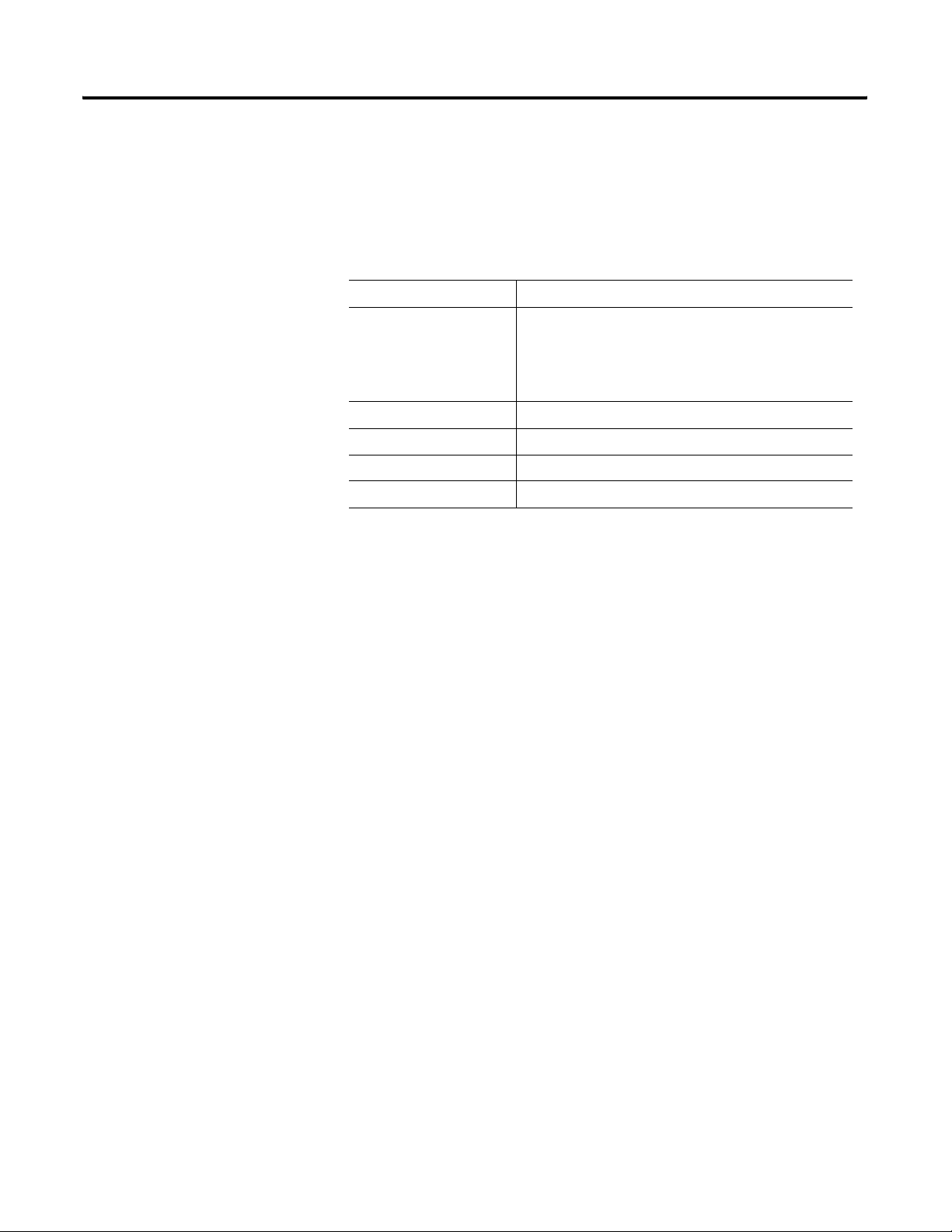

For this platform: Choose from these chassis types:

ControlLogix 1756-A4, 4-slot ControlLogix chassis

1756-A7, 7-slot ControlLogix chassis

1756-A10, 10-slot ControlLogix chassis

1756-A13, 13-slot ControlLogix chassis

1756-A17, 17-slot ControlLogix chassis

CompactLogix Not applicable

SoftLogix 1789-17, 17-slot SoftLogix virtual chassis

FlexLogix Not applicable

DriveLogix Not applicable

Slot Number

Choose the slot number where the controller resides on the backplane.

For ControlLogix controllers, the default value is 0. If the slot number exceeds

the chassis size, an error message appears, prompting you to enter a number

within the valid range.

For SoftLogix controllers, the default value is 1.

For CompactLogix, FlexLogix, and DriveLogix controllers, the value in this

field is always 0 and cannot be edited.

Revision

Enter the controller revision.

For this release of RSLogix 5000, this field is not editable. The revision

defaults to the latest revision for the given controller type.

Create In:

Publication 1784-UM003A-EN-P – June 2003

Enter the directory in which you want the project file to be created. The file

name is the same as the controller name, with a .acd extension.

Browse

Click on this button to bring up the Choose Directory dialog from which you

can browse for the appropriate directory.

Page 25

SoftLogix Controller 17

Editing Controller Properties

The Controller Properties dialog displays controller configuration information

for the open project and, when online, for the attached controller. The Tabs

that appear are governed by the type of the selected controller. This section

describes the fields on each of the dialogs for the Controller Properties.

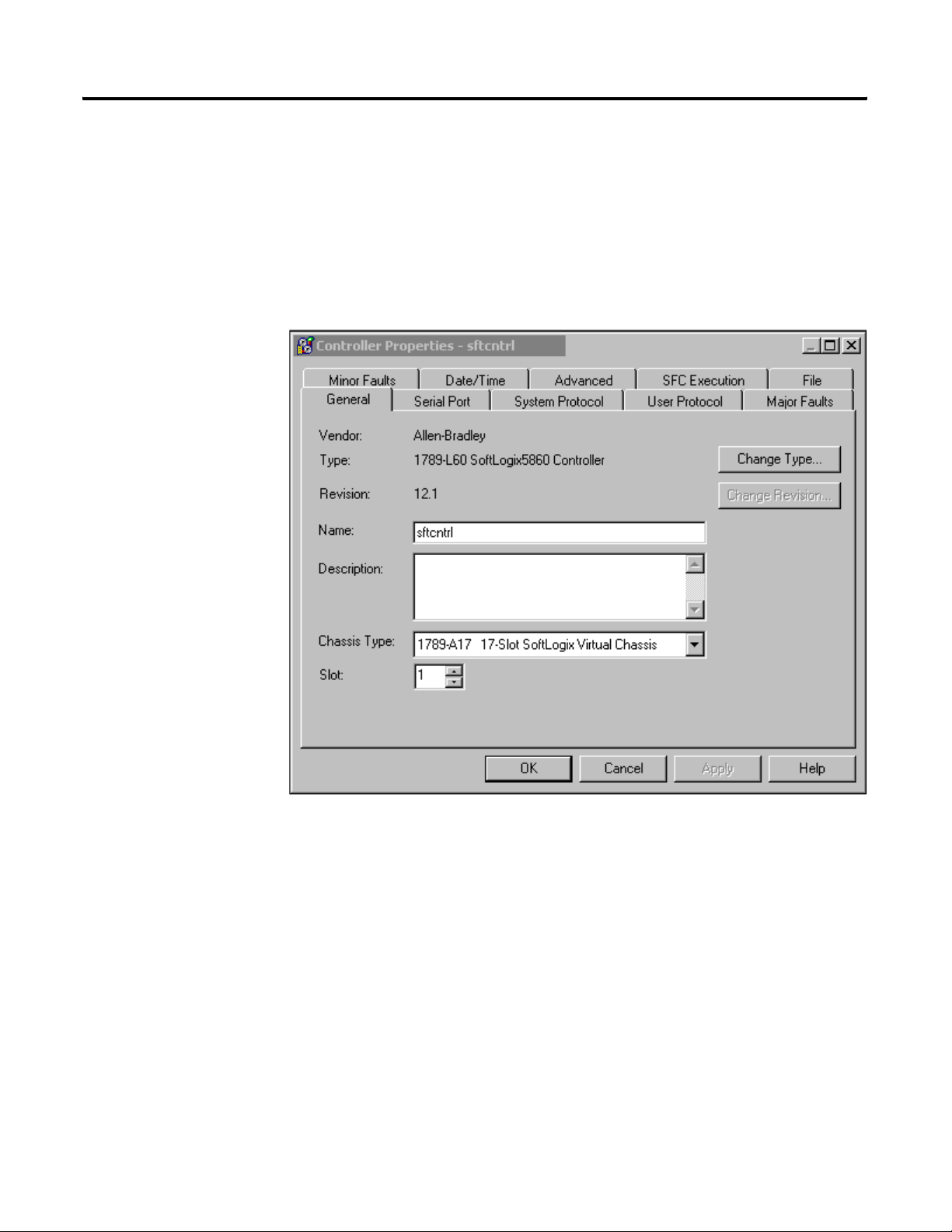

General Tab

The General tab displays the controller name and description, as well as the

physical properties of the controller.

Figure 2.2 Controller Properties General Tab

Vendor

Displays the name of the controller’s manufacturer.

Ty pe

The catalog number and description of the controller. When online, this field

includes the catalog number of the memory card (if any).

Publication 1784-UM003A-EN-P – June 2003

Page 26

18 SoftLogix Controller

Name

The name of the controller. When you create a project, this is the same as the

name of the project file. When you change the name of the controller,

however, the name of the project file does not change. If you want to keep the

two the same, then you must rename the file using Windows Explorer or a

similar file management tool.

IMPORTANT

You cannot change the name when online.

This name must be IEC_1131 compliant. If you enter an

invalid character in this field, or if the name you enter

exceeds 40 characters, the software ignores the character.

Description

Enter a description for the controller here, up to 128 characters. You can use

any printable character in this field. If you exceed the maximum length, the

software ignores any extra characters.

Chassis Type

Select a supported chassis type from the pull-down list. Each entry in the list

consists of the catalog number of the chassis, as well as a brief description.

The chassis type cannot be changed when online.

Slot

Publication 1784-UM003A-EN-P – June 2003

Enter the chassis slot number in which the controller resides. The spin button

contains values that range from 0 to 1 less than the chassis size (e.g., if you

have a 4-slot chassis, the spin button spins from 0 to 3). If you enter a slot

number that is out of this range, you receive an error message when you go to

apply your changes.

The slot number cannot be changed when online.

Revision

Displays the major and minor firmware revision of the controller. The minor

revision is available only when you are online.

Change Type

Click on this button to access the Change Processor Type dialog. This dialog

lets you change your controller to another controller within the same platform.

Page 27

SoftLogix Controller 19

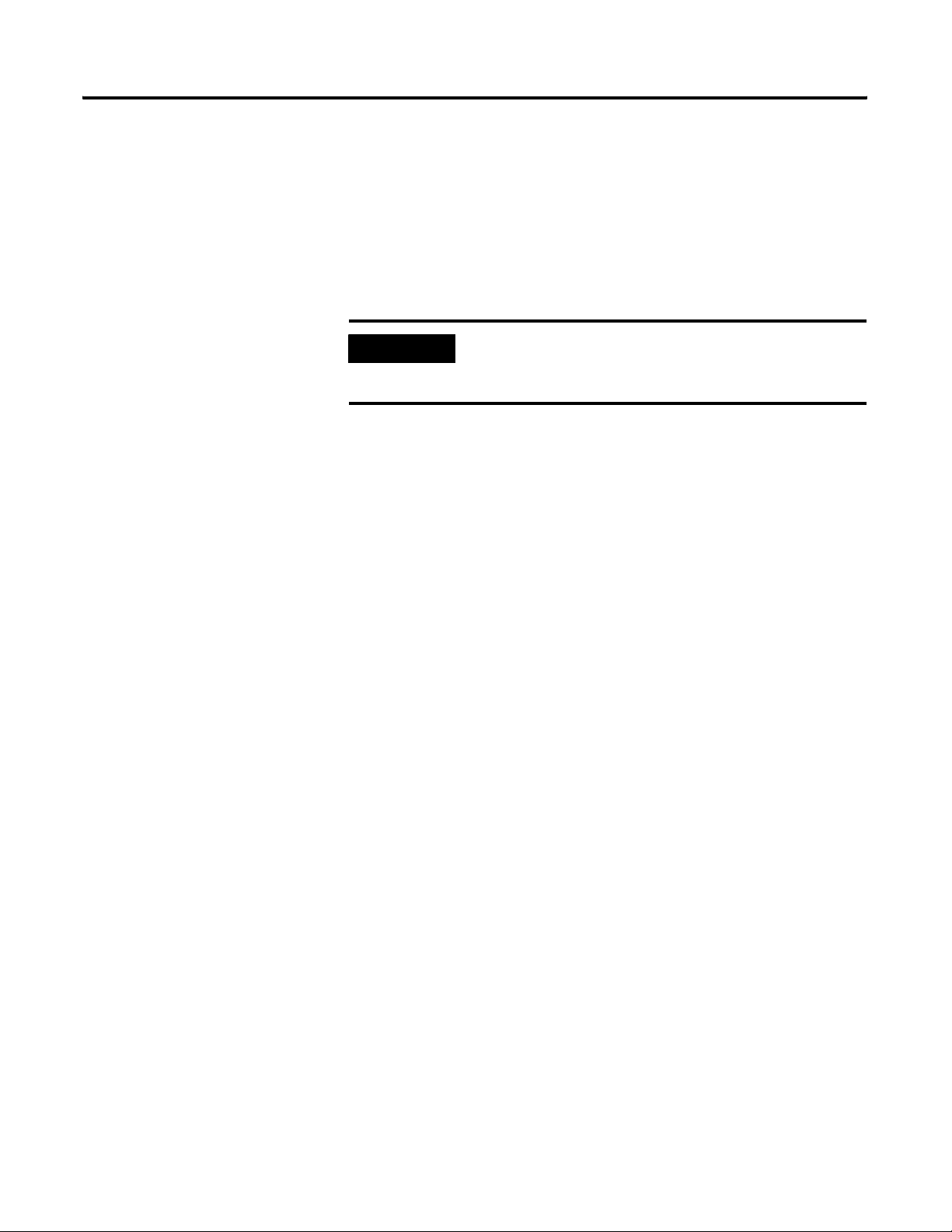

Change Controller Type Dialog Box

Overview

Use this dialog to change your controller to another controller within the same

platform (e.g. changing from a 1756-L1 ControlLogix 5550 Controller to a

1756-L53/A ControlLogix 5553 controller).

Figure 2.3 Change Controller Type Dialog

Select a processor to change to

Choose the controller you wish to change to from the pull-down menu. The

list of available controllers includes all controller types except the current

processor itself. Once a new controller is selected and the OK button is

clicked, a warning message displays. There are two different warning screens

depending upon whether the change is within the same platform or to another

platform. These warnings inform you that certain settings and properties are

changed or deleted based upn the type of controller selected.

Figure 2.4 Warning Message for Change to a Different Platform

Publication 1784-UM003A-EN-P – June 2003

Page 28

20 SoftLogix Controller

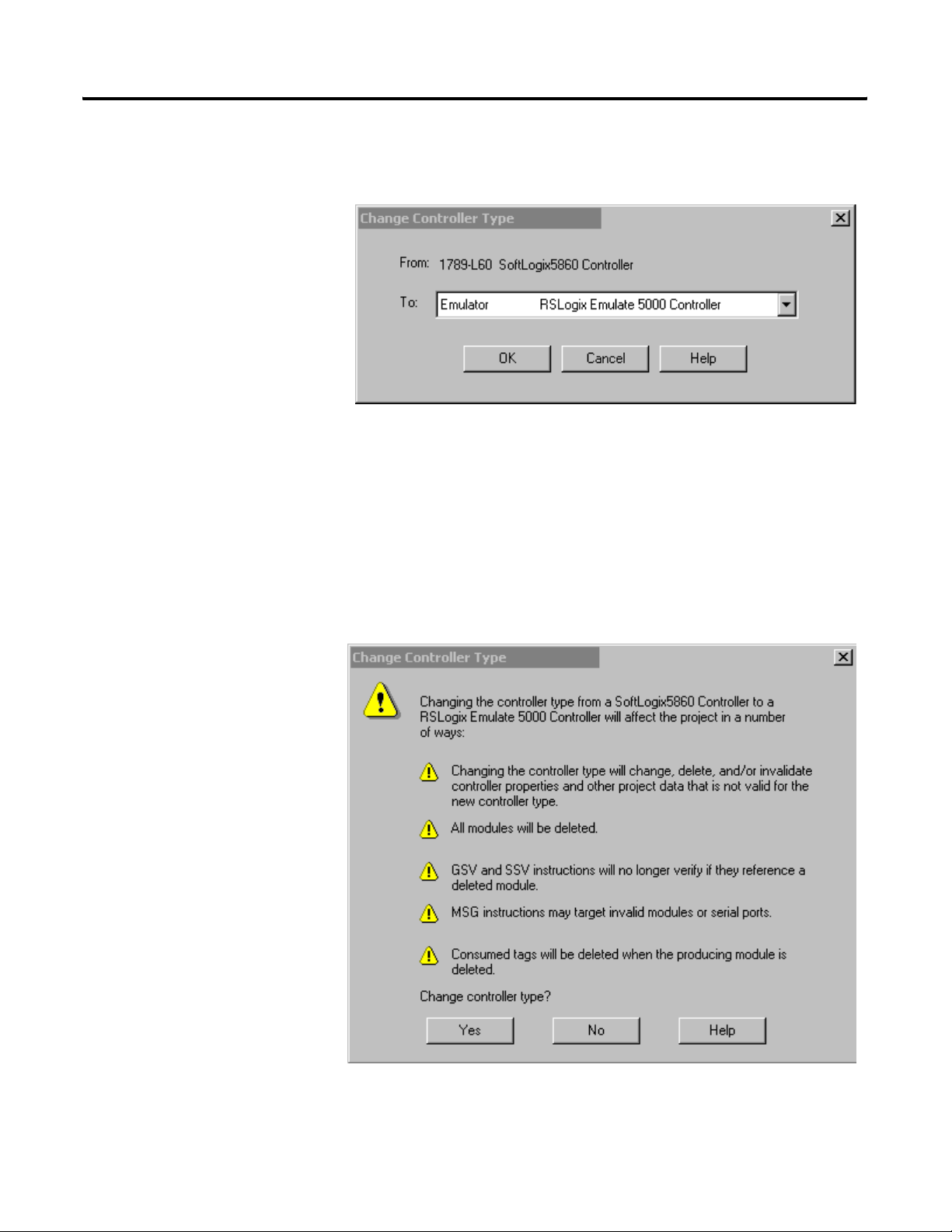

Serial Port Tab

The Serial Port tab allows you to view and configure the controller’s serial port.

Figure 2.5 Controller Properties Serial Port Tab

Mode

The type of protocol you want to use. Choose from System or User (default).

Baud Rate

The baud rate assigned to the serial port on the Logix5550. Choose from 110,

300, 600, 1200, 2400, 4800, 9600, 19200 (default), and 38,400.

Data Bits

The actual number of bits of data per character. Choose from 7 (ASCII only)

or 8 (default).

Parity

The parity for the link. Choose from Even, Odd (ASCII only) or No Parity

(default).

Publication 1784-UM003A-EN-P – June 2003

Page 29

SoftLogix Controller 21

Stop Bits

The actual number of stop bits per character. Choose from 2 (ASCII only) or 1

(default).

Control Line

Choose the type of handshaking you wish to use during communications. The

choices available to you vary, depending on the protocol you have selected:

For this mode: And this protocol: Choose from:

User ASCII No Handshake (default)

Full Duplex

Half Duplex

System Point-to-Point No Handshake (default)

Full Duplex

Slave No Handshake (default)

Half Duplex

Master No Handshake (default)

Full Duplex

Half Duplex

Continuous Carrier

Check this box if you wish to use Half Duplex communication with

continuous carrier. This checkbox is disabled if you have chosen something

other than Half Duplex communication, or if you have chosen Master as your

protocol. By default, this option is unchecked when enabled.

RTS Send Delay

Enter the time (in ms) to delay transmitting the first character of a message

after turning on the RTS line. The default value is 0.

RTS Off Delay

Enter the time (in ms) to delay turning off the RTS line after the last character

has been transmitted. The default value is 0.

Publication 1784-UM003A-EN-P – June 2003

Page 30

22 SoftLogix Controller

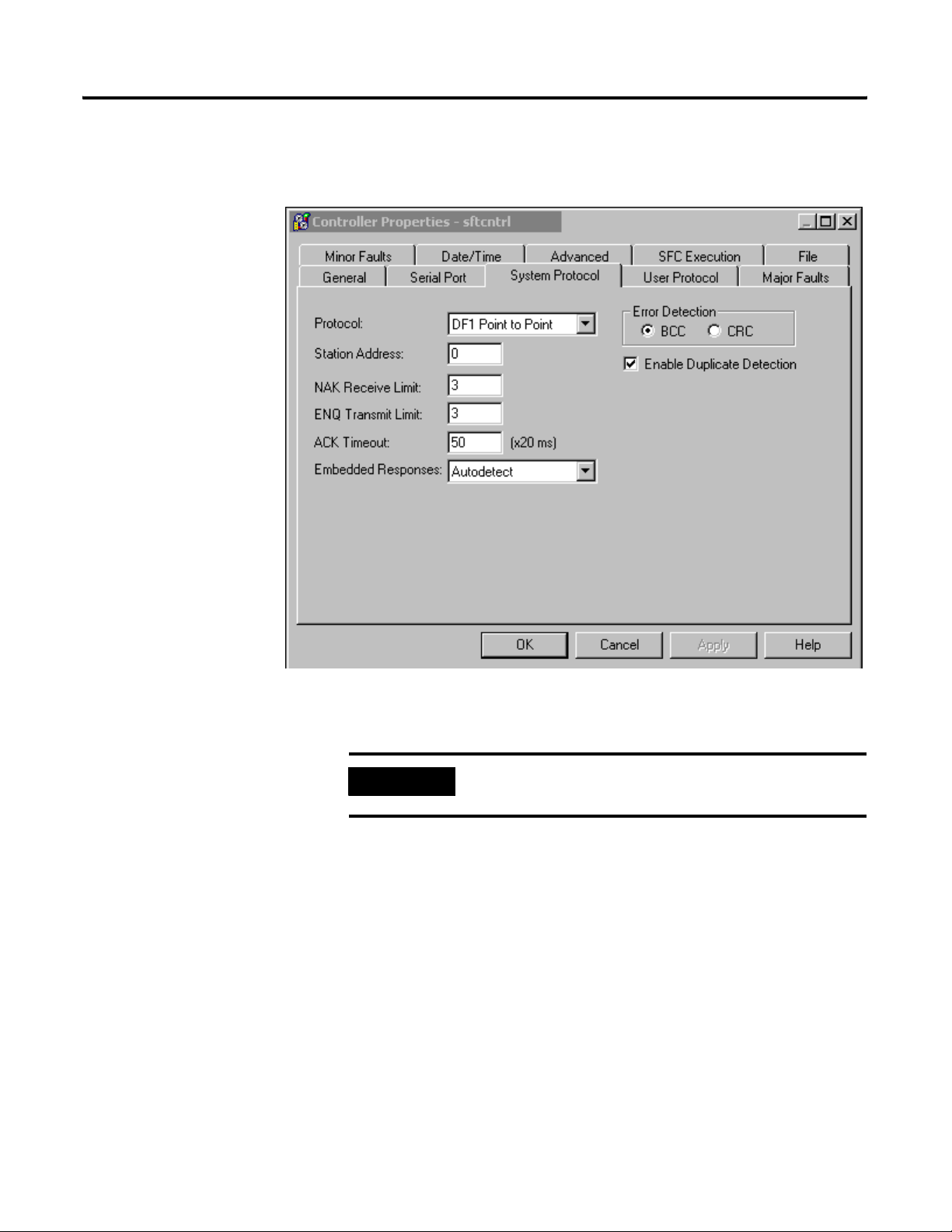

System Protocol Tab

The System Protocol tab allows you to configure the controller’s serial port for

DF1 Point to Point, DF1 Master, DF1 Slave or DH485. The parameters

present on this tab are dependent upon the protocol you select.

Figure 2.6 Controller Properties System Protocol Tab

IMPORTANT

If you wish to configure your system for ASCII, click on

the User Protocol tab.

The parameters present on this tab are dependent upon the protocol you

select.

Common Parameters

Protocol

Choose the protocol from the pull-down menu. Choose from DF1 Point to

Point (default), DF1 Slave, DF1 Master or DH485.

Station Address

Enter the current station link address of the com port to which the DF1 object

is now associated. Valid values are from 0 to 254; the default value is 0.

Publication 1784-UM003A-EN-P – June 2003

Page 31

SoftLogix Controller 23

Error Detection

Click on one of the radio buttons to specify the error detection scheme used

for all messages.

• BCC - the processor sends and accepts messages that end with a BCC

byte.

• CRC - the processor sends and accepts messages with a 2-byte CRC.

Enable Duplicate Detection

Check this box to enable duplicate message detection, which causes the object

to ignore all duplicate messages. This option is disabled by default.

ACK Timeout

Enter the time the object waits for an acknowledgment to a message

transmission. Valid values are from 0 to 65535, in 20 ms increments; the

default value is 50 ms.

DF1 Point to Point Parameters

ENQ Transmit Limit

Enter the number of inquiries you want the processor to send after an ACK

Timeout. Valid values are from 0 to 255; the default value is 3.

NAK Receive Limit

Enter the number of NAKs the processor can receive in response to a

message before stopping the transmission. Valid values are from 0 to 255; the

default value is 3.

Embedded Responses

This parameter sets the flag that enables the embedded response functionality.

Your options are:

• Autodetect – embedded responses are initiated only after one is

received.

• Enabled – embedded responses are enabled unconditionally.

Publication 1784-UM003A-EN-P – June 2003

Page 32

24 SoftLogix Controller

DF1 Slave Parameters

Transmit Retries

Enter the number of attempted transmits without getting an acknowledgment

before a message is deemed undeliverable. Valid values are from 0 to 255; the

default value is 3.

Slave Poll Timeout

Enter the amount of time that the master waits for an acknowledgment to a

message sent to the slave.

EOT Suppression

Check this box if you want to suppress "End of Text" transmissions at the end

of a slave message.

DF1 Master Parameters

Transmit Retries

Enter the number of attempted transmits without getting an acknowledgment

before a message is deemed undeliverable. Valid values are from 0 to 255; the

default value is 3.

Reply Message Wait

Enter the time (in ms) that the master waits after receiving an acknowledgment

to a master-initiated message before polling the slave for a reply. Specify this

time in 20 ms increments; the default value is 50 (i.e., 50*20 ms, or 1000 ms, or

1 second).

Polling Mode

Choose a polling mode from the pull-down menu. Choose from:

• Message Based - slave can initiate messages.

• Message Based - slave cannot initiate messages.

• Standard - Multiple message transfers per node scan.

Publication 1784-UM003A-EN-P – June 2003

• Standard - Single message transfer per node scan.

The default mode is Message Based, allowing a slave to initiate messages.

Page 33

SoftLogix Controller 25

Master Transmit

Choose the master message transmit that designates when to send any DF1

master message. Choose from:

• Between Station Polls - The master transmits a message before the next

station.

• In Poll Sequence - The master transmits messages only when the station

number is encountered in the poll list.

The default is Between Station Polls.

Normal Poll Node Tag

Choose the tag name of the structure that contains the normal poll node list.

Use the Tag Browser to select the appropriate tag name.

The default tag is <none>.

Normal Poll Group Size

Enter the total number of active stations polled from the poll node list. Valid

values are 0 to 255; the default value is 0.

Priority Poll Node Tag

Choose the tag name of the structure to store the priority poll node list. Use

the Tag Browser to select the appropriate tag name.

The default tag is <none>.

Active Station Tag

Choose the tag name of the structure to store the status (active/non-active) of

each node. Use the Tag Browser to select the appropriate tag name.

The default tag is <none>.

DH485 Parameters

Max Station Address

This field is available when you choose DH485 as the protocol. It sets the

maximum value allowable for the Station Address. The range is from 0 to 31.

Publication 1784-UM003A-EN-P – June 2003

Page 34

26 SoftLogix Controller

Token Hold Factor

A value between 1 and 4.

User Protocol Tab

The User Protocol tab allows you to configure the controller’s serial port for

the ASCII protocol.

Publication 1784-UM003A-EN-P – June 2003

Figure 2.7 Controller Properties User Protocol

Protocol

Choose the ASCII protocol.

Buffer Size

Enter the maximum size (in bytes) of the data array that you are planning on

sending and receiving. Valid values are from 1 to 65536; the default size is 82.

When the controller sends out the data, if it detects an array that is larger than

this buffer size, a minor fault occurs and the extra data is truncated. When the

controller receives data, if it detects data that is larger than the size of the

buffer, the extra characters are dropped.

Page 35

SoftLogix Controller 27

Termination Character 1 and 2

Enter the characters that be used to define the end of a line. Valid hex range

values are from 0 to 255. The default value for Termination Character 1 is $0D,

and the default value for Termination Character 2 is $FF.

The ARL and ABL instructions use these characters to signal the end of a line.

If you do not wish to use these characters, you can either avoid the use of these

instructions, or you can define Termination Character 1 as $FF, where $FF

tells the controller not to use any definable termination characters when using

the ARL or ABL instructions.

If you want to use only one character to signal the end of a line, use

Termination Character 1, and define Termination Character 2 as $FF.

Append Character 1 and 2

Enter the characters that are appended to the end of a line. Valid hex range

values are from 0 to 255. The default value for Append Character 1 is $0D, and

the default value for Append Character 2 is $0A.

The AWA instruction appends the specified characters to the end of the

messages it sends out. If you do not wish to use these characters, you can

either avoid the use of the AWA instruction, or you can define Append

Character 1 as $FF, where $FF tells the controller not to append characters

when using the AWA instruction.

If you want to append only one character, define Termination Character 1 as

the desired character, and define Termination Character 2 as 0xFF.

XON/OFF

Check this option to regulate the flow of incoming data.

For example, when this option is checked and the receive buffer gets to be

80% full, an XOFF (0x13) character is transmitted to tell the sending device to

stop sending. When the buffer has been processed so that it is less than 80%

full, the XON (0x11) character is sent to tell the device to resume sending.

This option is disabled when the Control Line option is configured for Half

Duplex.

Echo Mode

Check this option to cause any data received in the ASCII port to be sent right

back out to the device that sent it. For example, you could use this option with

a dumb terminal that is unable to display what it sends, but can display what is

echoed to it.

Publication 1784-UM003A-EN-P – June 2003

Page 36

28 SoftLogix Controller

This option is disabled when the Control Line option is configured for Half

Duplex.

Delete Mode

The character received just before the delete character sequence (0x7F) is

removed by the serial port driver before it is given to the ladder logic. Choose

from:

• Ignore - The delete character sequence is treated the same as any other

character that is read in.

• CRT or Printer - The preceding character in the string buffer is removed

before being given to the ladder logic. The only difference between CRT

and Printer modes is the type of device sending the string to the

controller. If Echo mode is disabled, CRT and Printer do exactly the

same thing.

Major Faults Tab

The Major Faults tab displays information on the major faults that have

occurred in the controller.

Publication 1784-UM003A-EN-P – June 2003

Figure 2.8 Controller Properties Major Faults Tab

Page 37

SoftLogix Controller 29

Number of Major Faults Since Last Cleared

Displays the number of major fault events that have been reported since the

log was last cleared.

Recent Faults

Displays a description of the last three major faults that have occurred. These

faults are stored in reverse chronological order. When offline, this field

contains the stored contents of the last online session.

Clear Majors

Click on this button to clear the Major Fault log.

Minor Faults Tab

The Minor Faults tab displays information on the minor faults that have

occurred in the controller.

Figure 2.9 Controller Properties Minor Fault Tab

Number of Minor Faults Since Last Cleared

Displays the number of minor fault events that have been reported since the

log was last cleared.

Publication 1784-UM003A-EN-P – June 2003

Page 38

30 SoftLogix Controller

Recent Faults

Displays a description of the last eight minor faults that have occurred. These

faults are stored in reverse chronological order. When offline, this field

contains the stored contents of the last online session.

Clear Minors

Click on this button to clear the Minor Fault log.

Fault Bits

Lists the minor fault bits that have a specific fault type assigned to them. If the

bit is set, the checkbox is set.

When offline, these checkboxes are disabled, but display the contents of the

last online session.

Date/Time Tab

The Date/Time tab allows you to view and edit the controller’s wall clock time

and the coordinated system time status.

Publication 1784-UM003A-EN-P – June 2003

Figure 2.10 Controller Properties Date/Time Tab

Page 39

SoftLogix Controller 31

Date

The wall clock date, in the format currently selected in the Regional Settings

application in your Windows NT Control Panel.

This parameter is read-only. When offline, this parameter is empty.

Time

The wall clock time, in the format currently selected in the Regional Settings

application in your Windows NT Control Panel.

This parameter is read-only. When offline, this parameter is empty.

Set

Click on this button to bring up the Set Date/Time dialog, from which you

can set the date and/or time.

This button is disabled when offline.

Make this controller the Coordinated System Time master

Click on this checkbox to select this controller as the CST master. This does

not mean that this controller IS the master, it means that you intend for this

controller to be the master. If another controller is already the CST master,

“duplicate master detected” appears in the status field.

If you are using a Servo card on this controller, set the CST Master.

Status

Indicates the state of the coordinated system time. There are four status fields,

with a circular indicator to the left of each. This indicator is blue if the

corresponding status condition is true; otherwise, it is clear. The status

conditions are:

• Is the master - you checked the “Make this controller the master” box,

and this controller is the CST master.

• Synchronized with a master - this controller is not the master; its time is

being synchronized by a master.

• Duplicate master detected - you checked the “Make this controller the

master” box, but there is already a CST master.

• Timer hardware faulted - there is a hardware fault.

Publication 1784-UM003A-EN-P – June 2003

Page 40

32 SoftLogix Controller

All of the circular indicators are clear when you are offline.

Advanced Tab

The Advanced tab allows you to view and edit advanced controller properties.

Figure 2.11 Controller Properties Advanced Tab

Memory Used

The amount of memory used in the controller. When offline, this parameter is

empty.

Memory Unused

The amount of memory available in the controller. When offline, this

parameter is empty.

Memory Total

The total amount of memory in the controller (used plus unused). If a memory

daughter card is present, this total includes that memory. When offline, this

parameter is empty.

Publication 1784-UM003A-EN-P – June 2003

Page 41

SoftLogix Controller 33

Controller Fault Handler

Choose the program that runs as the result of a system fault from the

pull-down menu. The list contains all of the unscheduled programs.

Power-Up Handler

Choose the program the processor executes when it powers up in Run mode

after a power-down in Run mode. The list contains all of the unscheduled

programs.

System Overhead Time Slice

Enter or select the percentage of time the controller spends running its system

task, relative to running user tasks.

SFC Execution Tab

The SFC Execution tab sets the configuration that affects the execution of the

SFC (Sequential Function Chart). These settings apply to the entire Controller

and therefore affect all SFCs within the Controller.

Figure 2.12 Controller Properties SFC Execution Tab

Publication 1784-UM003A-EN-P – June 2003

Page 42

34 SoftLogix Controller

Execution Control

This determines the execution model for the SFC. Your options are:

• Execute current active steps only – Execution control is returned to

the controller after processing the active steps, even if the Transitions

following the active steps are True.

• Execute until False transition – The controller continually processes

Steps and Transitions, in a single scan, until a False Transition is found.

It then returns to the Controller operating system.

Restart Position

Your selection here indicates at what point the SFC starts after it has

completed executing and been restarted.

• Restart at most recently executed step – Restarts at the step where it

left off.

• Restart at initial step – The SFC re-initializes and starts at the Initial

Step.

Last Scan of Active Steps

This determines how the controller performs a final scan of Action logic when

the associated Step is deactivated.

• Automatic reset – All non-retentive timers and outputs associated with

the Step’s non-stored Actions are reset when the step is deactivated.

• Programmatic reset – All non-retentive timers and outputs associated

with the Step’s non-stored Actions must be reset manually.

• Don’t scan – No scan is done on the Action logic when the associated

Step is deactivated.

Publication 1784-UM003A-EN-P – June 2003

Page 43

SoftLogix Controller 35

File Tab

The File tab displays information about the project file.

The fields on this tab cannot be edited. To change the file name or path, you

must use the Save As command.

Figure 2.13 Controller Properties File Tab

Name

The name of the project file

Path

The drive and directory of the project file.

Created

The creation date and time of the project file, in the format currently selected

in the Regional Settings application in your Windows NT Control Panel.

Edited

The date and time that the project file was last edited, in the format currently

selected in the Regional Settings application in your Windows NT Control

Panel.

Publication 1784-UM003A-EN-P – June 2003

Page 44

36 SoftLogix Controller

Redundancy Tab

The Redundancy Tab is only present if the specified processor type and

version supports the Redundancy feature. This tab supports the configuration

for redundancy.

Figure 2.14 Controller Properties Redundancy Tab

Redundancy Enabled

This checkbox lets you select whether to enable the redundancy feature or not.

It can only be selected when the Controller is offline. When it is on-line it

provides a valid indication of the redundancy enabled selection.

Redundancy Status

This section shows the redundancy states.

Chassis ID – Displays the chassis identification.

Chassis State – This shows the redundancy state of the entire chassis. The

possible states include:

0 – Unsupported – also displays when the system is offline.

1 – Undetermined

2 – Primary with Synchronized Secondary

3 – Primary with Disqualified Secondary

Publication 1784-UM003A-EN-P – June 2003

Page 45

SoftLogix Controller 37

4 – Primary with no partner

8 – Synchronized Secondary

9 – Disqualified Secondary with partner

10 – Disqualified Secondary with no partner

Module State – Indicates the redundancy state of the controller. If the

controller does not have the redundancy feature or if it is offline, this field is

empty and the controls are disabled. The possible states include:

0 – Unsupported – also displays when the system is offline.

1 – Undetermined

2 – Primary with Synchronized Secondary

3 – Primary with Disqualified Secondary

4 – Primary with no partner

6 – Synchronizing Primary

7 – Synchronizing Secondary

8 – Synchronized Secondary

9 – Disqualified Secondary with partner

10 – Disqualified Secondary with no partner

Module Compatibility – Shows the modules compatibility with its

corresponding module in the partner chassis. If the controller does not have

the redundancy feature or if it is offline, this field is empty and the controls are

disabled. The possible states include:

0 – Unsupported – also displays when the system is offline.

1 – No compatible Partner

2 – Fully compatible Partner

Publication 1784-UM003A-EN-P – June 2003

Page 46

38 SoftLogix Controller

Partner Status

This section shows information on the status of the Partner module.

Mode – Shows the current state of the partner module’s mode. If the

controller does not have the redundancy feature or if it is offline, this field is

empty and the controls are disabled. Valid modes include:

• Faulted

• Run

• Program

• Test

• Unknown – Displayed for any mode that is not one of those listed

above. It also displays if the Module Compatibility is not "Fully

Compatible Partner" or "Standby Compatible Partner". Also displays

when the system is offline.

Key Switch Position – Shows the current status of the partner module’s

keyswitch position. If the controller does not have the redundancy feature or if

it is offline, this field is empty and the controls are disabled. Valid modes

include:

• Run

• Remote

• Program

• Unknown – Displays when the Module Compatibility is not "Fully

Compatible Partner" or "Standby Compatible Partner". Also displays

when the system is offline.

Publication 1784-UM003A-EN-P – June 2003

Key Switch Mismatch – Is activated when there is a mismatch between the

key switch position between the primary and partner modules.

Partner Minor Faults

This section shows the minor faults that are set in the partner controller. These

controls are read-only. If the controller does not have the redundancy feature

or if it is offline, the radio button is greyed and the text label is disabled. Minor

partner faults include:

• Powerup

• I/O

• Program

• Watchdog

• Serial Port

• Battery

Page 47

SoftLogix Controller 39

Advanced Button

The Advanced Button displays configuration parameters for retaining test

edits when switched to a secondary system and lets you set the percentage of

memory that is reserved for the data table.

Nonvolatile Memory Tab

Figure 2.15 Advanced Button from Redundancy Tab

Retain Test Edits on Switchover

Select the checkbox to allow temporary execution of online edits to be

maintained or canceled when a switchover to a secondary system occurs.

When enabled, this option prevents the Logix controller from automatically

switching back to the unedited version of your program if the primary chassis

fails while testing on-line edits.

Memory Usage

Lets you modify the percentage of memory that is to be reserved in the data

table area. This lets you create tags in RUN mode on a synchronized primary

system.

The Nonvolatile Memory tab of the Controller Properties dialog serves as the

starting point from which you can perform nonvolatile memory operations.

Publication 1784-UM003A-EN-P – June 2003

Page 48

40 SoftLogix Controller

Click on the Load/Store button to access the Nonvolatile Memory

Load/Store dialog, from which you can perform the actual operations.

The Nonvolatile Memory tab also provides you with status information that

indicates any conditions that might prevent you from loading or storing.

Possible status messages include:

• Nonvolatile memory not present.

• Nonvolatile memory not supported in redundant systems.

• Controller being edited by another user.

• No controller image or stored controller image.

• Controller not in Program mode.

• Stored image revision in nonvolatile memory does not match controller

revision.

The Controller Properties dialog displays controller configuration information

for the open project and, when online, for the attached controller.

The Nonvolatile Memory tab provides you with access to nonvolatile memory

operations.

Note: This tab is available only when the selected controller supports

nonvolatile memory.

Publication 1784-UM003A-EN-P – June 2003

Page 49

SoftLogix Controller 41

Figure 2.16 Controller Properties Nonvolatile Memory Tab

Name

The name of the stored controller image that resides in nonvolatile memory.

Ty pe

The controller type for the image stored in nonvolatile memory. This

controller type can be any type that supports nonvolatile memory.

Revision

The firmware revision of the controller when the image in nonvolatile memory

was stored. In order for the image in nonvolatile memory to be loaded back

into controller memory, the firmware revision of that image must match the

revision of the controller.

Publication 1784-UM003A-EN-P – June 2003

Page 50

42 SoftLogix Controller

Load Image

The condition under which the image stored in nonvolatile memory is loaded

back to controller memory. Available conditions include:

• On Corrupt Memory – this will cause a load whenever there is no

project in the controller and you turn on or cycle power on the chassis.

If you are using a battery the controller, selecting this option performs a

load only if the battery has failed to maintain the project during a loss of

power.

• On Power Up – this will cause a load whenever you turn on or cycle

power on the chassis. If you are using a battery on the controller,

selecting this option performs a load even if the battery has maintained

the project during loss of power.

• User Initiated – choose this option if you want to load only through

RSLogix 5000 software.

Regardless of the currently-selected load option, you can always manually

initiate a load as well.

Load Mode

The mode the controller enters upon loading from nonvolatile memory.

Choose from:

• Program (Remote Only)

• Run (Remote Only)

TIP

The Load Mode only applies if the Load Image selection is On Corrupt

Memory or On Power Up. If the Load Image is User Initiated, the Load Mode

is disabled.

The Load Mode only applies if the controller keyswitch is

in the remote position when loading. If the controller

keyswitch is in Run or Program the controller will be

returned to that mode once the load is complete. The

controller keyswitch always has priority over the Load

Mode.

Publication 1784-UM003A-EN-P – June 2003

Image Note

Descriptive information that you entered at the time the image was stored in

nonvolatile memory. You may enter up to 128 text characters.

Page 51

SoftLogix Controller 43

Stored

The workstation date and time when the image was stored in nonvolatile

memory.

Load/Store

Click on this button to access the Load/Store dialog.

This button is disabled when:

• Nonvolatile memory is not present in the controller.

• The controller is in Run mode.

• Another user has locked the controller.

• Redundancy is enabled for the controller.

• The controller is offline.

If the Load/Store button is disabled, the status bar indicates the reason. Note

that the status bar displays only one status at a time, and you must work

through each of them to enable the Load/Store button.

Publication 1784-UM003A-EN-P – June 2003

Page 52

44 SoftLogix Controller

Publication 1784-UM003A-EN-P – June 2003

Page 53

Chapter

3

Adding and Configuring Your 1784-PM02AE Motion Module

This chapter describes how to add, configure, and edit your 1784-PM02AE

motion module for use in your motion control application.

Adding the 1784-PM02AE Module

To use your motion module in a control system, you must add your motion

module to the application program. To add a motion module:

1. Right-click the I/O Configuration folder.

Figure 3.1 Selecting New Module from the Controller Organizer

45 Publication 1784-UM003A-EN-P – June 2003

Page 54

46 Adding and Configuring Your 1784-PM02AE Motion Module

2. Select New Module. The Select Module Type window appears.

Figure 3.2 Select Module Type Screen Fully Loaded

Publication 1784-UM003A-EN-P – June 2003

Page 55

Adding and Configuring Your 1784-PM02AE Motion Module 47

3. Click on the Clear All button to clear the dialog window then click on

Motion to list the available Motion Controllers.

New Module

Figure 3.3 Select Module Type Screen with Motion Options - M02AE Highlighted

Use this dialog to select and create a new module. Highlight the

1784-PM02AE The context sensitive menu appears, from which you can select

a New Module.

Ty pe

The Type field displays the catalog number of the module highlighted in the

Type list box. You can either type in a module catalog number in this field to

quickly select/find the module you want to create or you can scroll through

the list of modules in the Type list box.

Publication 1784-UM003A-EN-P – June 2003

Page 56

48 Adding and Configuring Your 1784-PM02AE Motion Module

Major Revision

Select the major revision number of the physical module that you want in the

chassis.

The major revision is used to indicate the revision of the interface to the

module.

Type (list box)

This box lists the installed module catalog numbers based on the selected

check boxes.

Description (list box)

This portion of the list box contains descriptions of the modules.

Show

Displays check boxes, which support filtering on particular types of modules.

Check this box: If you want to:

Digital display digital modules supported by the software

Analog display analog modules supported by the software

Communication display communication modules supported by the software

Motion display motion modules supported by the software

Controller display controller modules supported by the software

Vendor display a particular vendor's module profiles that are installed on the system.

Other display modules that do not fit under the rest of the check box categories.

Select All

Click on this button to display all modules in the list box; all the check boxes in

the Show field are checked.

Clear All

Publication 1784-UM003A-EN-P – June 2003

Click on this button to clear all check boxes in the Show field.

4. In the Type field, select 1784-PM02AE 2 Axis Analog/Encoder Servo.

Page 57

Adding and Configuring Your 1784-PM02AE Motion Module 49

5. Select OK. The Module Create Wizard displays.

Figure 3.4 Module Properties Dialog Wizard - Naming the Module

6. Make entries in the following fields.

Field Entry

Name Type a name for the servo module.

The name can:

• have a maximum of 40 characters

• contain letters, numbers and underscores (_).

Slot Enter the number of the chassis slot that contains your

module.

Description Type a description for your motion module.

This field is optional.

Electronic

keying

Select the electronic keying level.

To Select

Match the vendor, catalog

number, and major revision

attributes of the physical module

and the software configured

module

Disable the electronic keying

protection mode

Match the vendor, catalog

number, major revision, and

minor revision attributes of the

physical module and the

software configured module

Compatible module

Disable keying

Exact match

Publication 1784-UM003A-EN-P – June 2003

Page 58

50 Adding and Configuring Your 1784-PM02AE Motion Module

7. Press the Next button to proceed to the next Create Wizard screen.

Figure 3.5 Module Properties Wizard - Fault Handling

8. This screen is where you determine how faults are to be handled. The

choices are to inhibit module or to configure the module so that a loss

of connection to this module causes a major fault. Make your entries

and press the Next button to proceed to the next wizard screen.

Publication 1784-UM003A-EN-P – June 2003

Figure 3.6 Module Properties Wizard - Servo Update/Associated Axis

Page 59

Adding and Configuring Your 1784-PM02AE Motion Module 51

9. This screen lets you associate an axis with the module. Make the

appropriate choices for your application. At this point, the rest of the

screens are informational only and it would be best to press the Finish

button to create the module.

All of the above screens can be accessed and edited by going to the tabbed

Module Property screens. Further explanations of the fields in this dialog are

detailed below.

Editing Your Motion Module Settings

The following section provides explanations of the Motion Module Properties

screens. Use these screens to edit the properties of the module when changes

need to be made. You can access the Module Properties screen by highlighting

the motion module and right clicking the mouse.

Select Properties from the displayed pop-up menu screen as shown in the

following figure.

Figure 3.7 Controller Organizer - Module Properties Pop up

Publication 1784-UM003A-EN-P – June 2003

Page 60

52 Adding and Configuring Your 1784-PM02AE Motion Module

This accesses the Module Properties screen. The screen is tabbed to expedite

movement to the required dialog.

General Tab

Figure 3.8 Module Properties - General Tab

Use this tab to create/view module properties for 1784-PM02AE motion

module. This dialog provides you with the means to view the type, description,

vendor, and the name of the parent module. You can also enter the name and a

description for the module. Other fields and buttons on this dialog let you set

the slot location of the module, review information for both channels, go to

the New Tag dialog to create an axis to associate with one of the channels,

select the minor revision number and select an electronic keying option. You

can also view the status the controller has about the module but, only when

online.

Ty pe

Displays the type and description of the module being created (read only).

Vendor

Displays the vendor of the module being created (read only).

Name

Publication 1784-UM003A-EN-P – June 2003

Enter the name of the module.

Page 61

Adding and Configuring Your 1784-PM02AE Motion Module 53

The name must be IEC 1131-3 compliant. If you attempt to enter an invalid

character or exceed the maximum length, the software beeps and ignores the

character.

Description

Enter a description for the module here, up to 128 characters. You can use any

printable character in this field. If you exceed the maximum length, the

software beeps to warn you, and ignores any extra characters.

Slot

Enter the slot number where the module resides. The spin button contains

values that range from 0 to 1 less than the chassis size (e.g., if you have a 4-slot

chassis, the spin button will spin from 0 to 3). If you enter a slot number that

is out of this range, you will receive an error message when you go to apply

your changes.

The slot number cannot be changed when online.

Revision

Select the minor revision number of your module.

The revision is divided into the major revision and minor revision. The major

revision displayed statically is chosen on the Select Module Type dialog.

Electronic Keying

Select one of these keying options for your module during initial module

configuration:

• Exact Match - all of the parameters must match or RSLogix rejects the

inserted module.

• Vendor

• Product Type

• Catalog Number

• Major Revision

• Minor Revision

• Compatible Module

• the Module Types, Catalog Number, and Major Revision must match

• the Minor Revision of the physical module must be equal to or

greater than the one specified in the software or RSLogix 5000 will

reject the inserted module.

• Disable Keying - RSLogix 5000 will not employ keying at all.

Publication 1784-UM003A-EN-P – June 2003