Page 1

Installation Instructions

Device N et Sc an ne r Mo du le

Catalog Number 1771-SDN/C

Contents

Use this document as a guide to install your 1771-SDN/C Scanner

Module.

To: See page:

understand important user information below

prevent Electrostatic Discharge 3

identify related publications 3

understand module compatibili ty and main tenance 4

understand module enhancement s and features 4

identify external sc anner module features 6

understand soft ware and hardware requirements 8

set data rate switches for channels 1 and 2 10

set I/O chassis addressing mo de switches 11

set node address switches for channels 1 and 2 11

install your module into the chassis 13

connect to the DeviceNet network 14

understand how your module communi cates with the PLC

program your PL C-5 processor 16

configure your module for the DeviceNet™ network 25

use the Explicit Message Program Control feature 26

troubleshoot your module 35

For this reference information: See page:

Specifications 39

®

processor

16

Before you install your module you must know how to:

• program and operate an Allen-Bradley PLC processor

• install and configure devices on your DeviceNet network

1 Publication 1771- IN014B-EN-P - September 2001

Page 2

2 DeviceNet Scanner Module Catalog Number 1771-SDN/C

Important User Information

Because of the variety of uses for the products described in

this publication, those responsible for the application and use

of these products must satisfy themselves that all necessary

steps have been taken to assure that each application and use

meets all performance and safety requirements, including any

applicable laws, regulations, codes and standards.

In no event will Allen-Bradley be responsible or liable for

indirect or consequential damage resulting from the use or

application of these products.

Any illustrations, charts, sample programs, and layout

examples shown in this publication are intended solely for

purposes of example. Since there are many variables and

requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to

include intellectual property liability) for actual use based

upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State

Control (available from your local Allen-Bradley office),

describes some important differences between solid-state

equipment and electromechanical devices that should be taken

into consideration when applying products such as those

described in this publication.

Reproduction of the contents of this copyrighted publication,

in whole or part, without written permission of Rockwell

Automation, is prohibited.

ATTENTION

ATTENTION

!

!

IMPORTANT

Identifies information about practices or

circumstances that can lead to personal

injury or death, property damage, or

economic loss.

Identifies information that is critical for

successful application and understanding of

the product.

Environment and Enclosure

ATTENTION

ATTENTION

!

!

This equipment is intended for use in a

Pollution Degree 2 industrial environment,

in overvoltage Category II applications (as

defined in IEC publication 60664-1), at

altitudes up to 2000 meters without

derating.

This equipment is considered Group 1,

Class A industrial equipment according to

IEC/CISPR Publication 11. Without

appropriate precautions, there may be

potential difficulties ensuring

electromagnetic compatibility in other

environments due to conducted as well as

radiated disturbance.

Throughout this publication, notes may be used to make you

aware of safety considerations. The following annotations and

their accompanying statements help you to i dentif y a potential

hazard, avoid a potential hazard, and recognize the

consequences of a potential hazard:

Identifies information about practices or

WARNING

circumstances that can cause an explosion

in a hazardous environment, which may

lead to personal injury or death, property

damage, or economic loss.

!

This equipment is supplied as "open type"

equipment. It must be mounted within an

enclosure that is suitably designed for those

specific environmental conditions that will

be present and appropriately designed to

prevent personal injury resulting from

accessibility to live par ts. The inter ior of the

enclosure must be accessible only by the

use of a tool. Subsequent sections of this

publication may contain additional

information regarding specific enclosure

type ratings that are required to comply

with certain product safety certifications.

See NEMA Standards publication 250 and

IEC publication 60529, as applicable, for

explanations of the degrees of protection

provided by different types of enclosure.

Also, see the appropriate sections in this

publication, as well as the Allen-Bradley

publication 1770-4.1 ("Industr ial Automation

Wiring and Grounding Guidelines"), for

additional installation requirements

pertaining to this equipment.

Publication 1771-IN014B-E N-P - September 2001

Page 3

DeviceNet Scanner Module Catalog Num ber 1771-SDN/C 3

Prevent Electrostatic Discharge

Where to Find More Information

.

ATTENTION

ATTENTION

!

!

The following table describes related documentation. To order a copy

or to view or download an online version, visit The Automation

Bookstore at:

This equipment is sensitive to electrostatic discharge

which can cause internal damage and affect normal

operation. Follow these gui delin es when you handle

this equipment:

• touc h a gro unded object to di scharge potentia l

static

• wear an approved grounding wrist strap

• do not to uc h c onnectors or pins on component

boards

• do not to uc h c i rcuit compo nents inside t he

equipment

• if available, use a static-safe workstation

• when not in use, store the equipment in

appropriate static-safe packaging

www.theautomationbookstore.com

For information about: See this document: Publication number:

Configuring the scanner

module and associated

hardware in an exa m ple

application

Performing the ControlFlash

Update

RSLogix 5™ software Getting Results with RSLogix 5 9399-RL53GR

RSLinx™ software Getting Results with RSLinx 9399-WAB32GR

RSNetWorx for DeviceNet™

software

Connecting the DeviceNet

network

1771-SDN DeviceNet Scanner

Module User Manual

ControlFlash Firmware Upgrade

Kit User Manual

RSNetWorx for DeviceNet Demo

CD

DeviceNet Cable Planning and

Installation Manual

1771-6.5.132

1756-6.5.6

9398-DNETDEMO

DN-6.7.2

Publication 1771- IN014B-EN-P - September 2001

Page 4

4 DeviceNet Scanner Module Catalog Number 1771-SDN/C

Module Compatibility and Maintenance Requirements

Series C label

NOTE: Default scanner setting is Series C operation.

When replacing an older scanner , se t

configuration Switch 5 to the OFF position.

See Installation Instructions for details.

The 1771-SDN/C DeviceNet Scanner Module is fully compatible with

the Series A and Series B vers ions . You can use the Ser ies C vers ion as

a spare or replacement module with one requirement: you must

change the postion of Switch 5 to the off or “0” position in the

Configuration switchbank as show n bel ow :

Configuration

Chassis Address

The scanner revision is identified by RSNetWorx. In Series B mode,

the scanner is identified as Series B with major number as 4 and minor

number as 50. In Series C mode, the scanner is identified as Series C

with major number as 6 and minor number as 2 or higher.

To use the Series C module enhancements listed below, the scanner

module Configuration Switch 5 must be set in the on or “1” position.

Module Enhancements

Updated DeviceNet Master Library

Electronic Keying - added to include Major and Minor revision

checking.

Shared Inputs - multiple scanner modules can acquire the inputs

from a specific input device without using separate connections.

Auto Device Replacement (ADR) - consists of No de Recovery and

Configuration Recovery:

• Node Recovery - this feature causes the node number of the

replacement device to be automatically changed to the node

number of the original device. The replacement device’s node

number must be writable over the DeviceNet network and must

initially be set to 63.

• Configuration Recovery - this feature causes the replacement

device’s configuration to be made identical to the original device.

The replacement device’s configuration must be writable over the

DeviceNet network. Configuration Recovery files are stored in the

master scanner that is communicating with the original device

through RSNetWorx for DeviceNet.

Publication 1771-IN014B-E N-P - September 2001

Page 5

DeviceNet Scanner Module Catalog Num ber 1771-SDN/C 5

Other Features

Change of State

Change of state enables the scanner module to perform a scan:

• whenever a network data change occurs, or

• at a user-configurable heartbeat rate

Because data is only sent on an as-needed basis, this feature increases

system performance by reducing network traffic.

Cyclic I/O

Cyclic I/O allows you to instruct the scanner module to perform a

scan at a spe c ific se nd rate.

Because data is only sent at a periodic rate, this feature increases

system performance by reducing network traffic.

Pass-Through

The 1771-SDN “pass-through” feature allows communication with the

DeviceNet network from another network. This feature can be used to

adjus t an d f i ne t une the nodes on your network.

For more information on how to use the pas s-throu gh feature, refer to

Chapter 5 of the PLC-5 DeviceNet Scanner Module User Manual,

publication 1771-6.5.132.

Publication 1771- IN014B-EN-P - September 2001

Page 6

6 DeviceNet Scanner Module Catalog Number 1771-SDN/C

External Module Features

Module Status Indicator - indicates

MODULE

STATUS

CHANNEL 1

NETWORK

STATUS

NODE/

ERROR CODE

DeviceNet

RESET

whether the device has power and

is functioning properly

Reset Button - resets your module.

Channel 1 Status Indicator - gives

diagnostic indications for Channel 1.

Node Address and Status Display displays numeric codes that indicate

scanner node address, status and/or

errors for Channel 1.

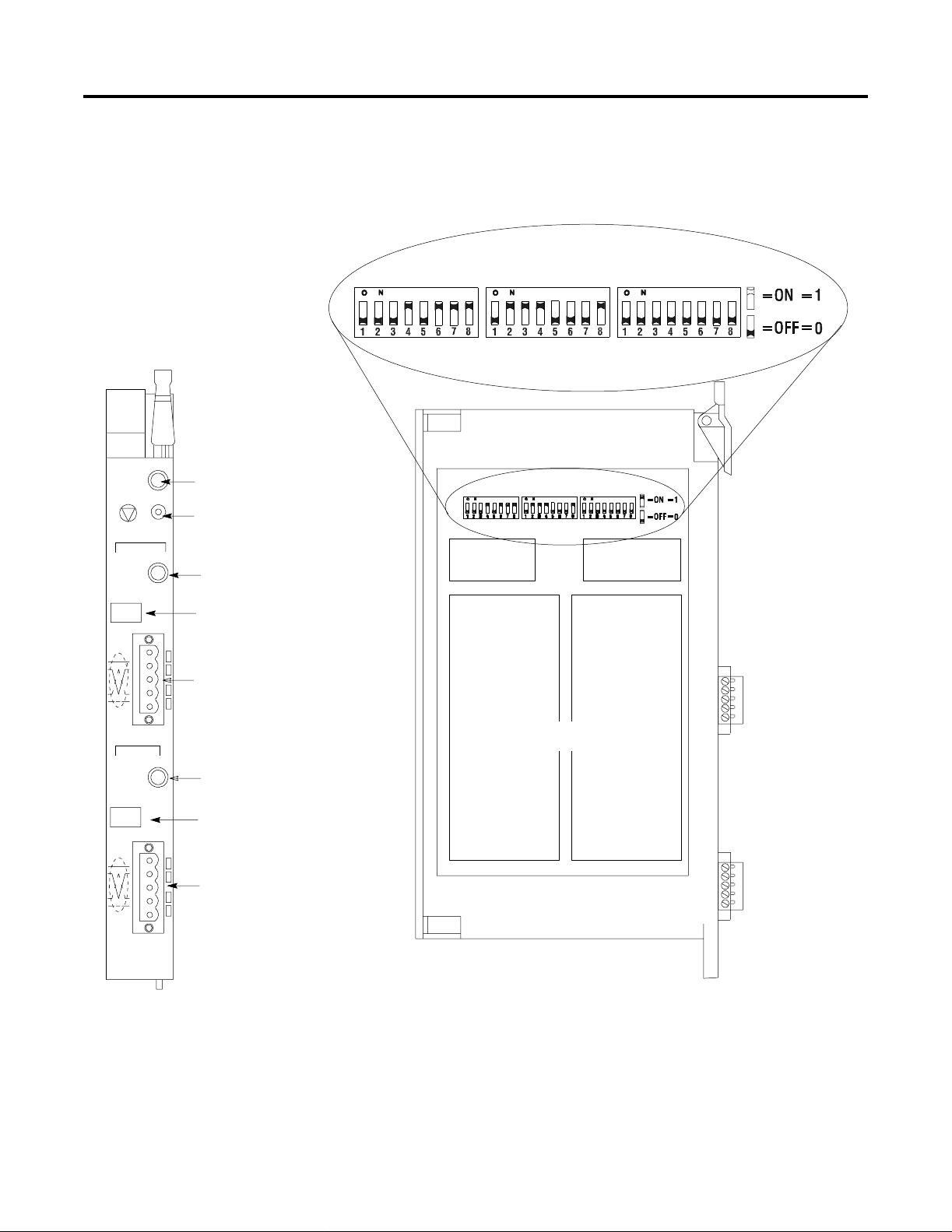

Use the drawing below to identify the featu res of t he 1771-SDN/C and

B versions of the Scanner Module.

Multi-position Switchesuse to set the data rate, chassis addressing mode

and scanner node address for each channel.

CHANNEL 1 CHANNEL 2 CONFIGURATION

Data Rate

Switch Settings

Chassis Address

Switch Settings

CHANNEL 2

NETWORK

STATUS

NODE/

ERROR CODE

DeviceNet

Allen-Bradley

1771-SDN

Front of Module

DeviceNet Port 1 - use the color-coded

header to wire your module.

Channel 2 Status Indicator - gives

diagnostic indications for Channel 2.

Node Address and Status Display displays numeric codes that indicate

scanner node address, status and/or

errors for Channel 2.

DeviceNet Port 2 - use the

color-coded header to wire your

module.

20274

Channel 1 & 2

Node Address Switch Settings

Left Side of Module

20275

Publication 1771-IN014B-E N-P - September 2001

Page 7

DeviceNet Scanner Module Catalog Num ber 1771-SDN/C 7

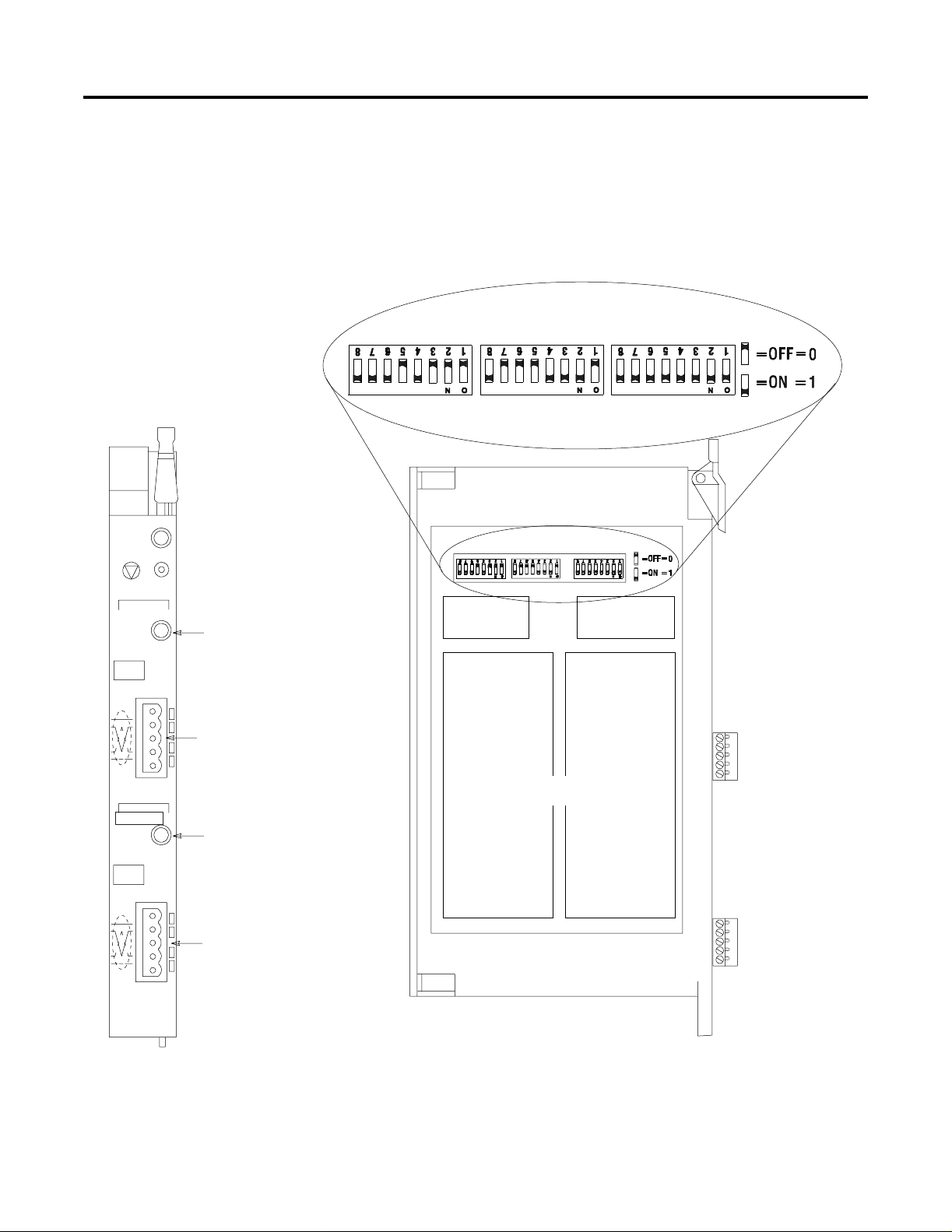

Series A Channel, Port and Switch Identification

The Series A version of this module (1771-SDN) uses different

channel, port and switch identification as shown in the following

figure:

Multi-position Switchesuse to set the data rate, chassis addressing mode

and scanner node address for each channel.

Channel A

Channel B

Channel A Status Indicator gives diagnostic indications for

Channel A.

DeviceNet Port A - use the

color-coded header

to wire your module.

Channel B Status Indicator gives diagnostic indications for

Channel B.

DeviceNet Port B - use the

color-coded header to wire your

module.

CHANNEL A CHANNEL B CONFIGURATION

Data Rate

Settings

Channel A & B

Node Address Settings

AddressChassis

Settings

Front of Module

20274

Left Side of Module

20275

Publication 1771- IN014B-EN-P - September 2001

Page 8

8 DeviceNet Scanner Module Catalog Number 1771-SDN/C

Software and Hardware Requirements

Software Requirements

Before you intall the scanner module, make sure you have the

followi ng software:

• personal computer with Microsoft Windows™ 95 or later

operating system

• RSNetWorx for DeviceNet software, version 2.22 or later

• RSLogix 5 software

Electronic Data Sheet Requirement

To use the new features of this release, the scanner module requires

the latest EDS file for RSNetWorx for DeviceNet software. If the

software displays the device as an “unknown device”, you must

download the current EDS file.

You can get the latest EDS file online at:

http://www.ab.com/networks/eds

Once you are at this location:

1. Select

2. Enter the catalog number: 1771-SDN

3. Select Search

DeviceNet

Hardware Requirements

The 1771-SDN Scanner Module is compatible only with the 1771-A1B

through 1771-A4B or later I/O chassis in any configuration supported

by the 1771 family.

Y ou can use the following chassis with the 17 71-SDN Scanner Module:

• Local I/O Chassis with only the PLC processor running in the

leftmost slo t

• Extended Local I/O Chassis with any 1771-ALX Adapter Module

running in the leftmost slot

• Remote I/O Chassi s with a 1 771-ASB Adapter Module ru nning i n

the leftmost slot or a PLC processor running in the leftmost slot

Publication 1771-IN014B-E N-P - September 2001

Page 9

DeviceNet Scanner Module Catalog Num ber 1771-SDN/C 9

• Remote I/O Chassis linked to ControlNet with a 1771-ACN(R)

running in the leftmost slot

Do not use the 1771-SDN Scanner Module with the following:

• Chassis configured for complementary I/O

• Remote I/O chassis connected to a preceding chassis using a

1771-SN Sub I/O Scanner Module

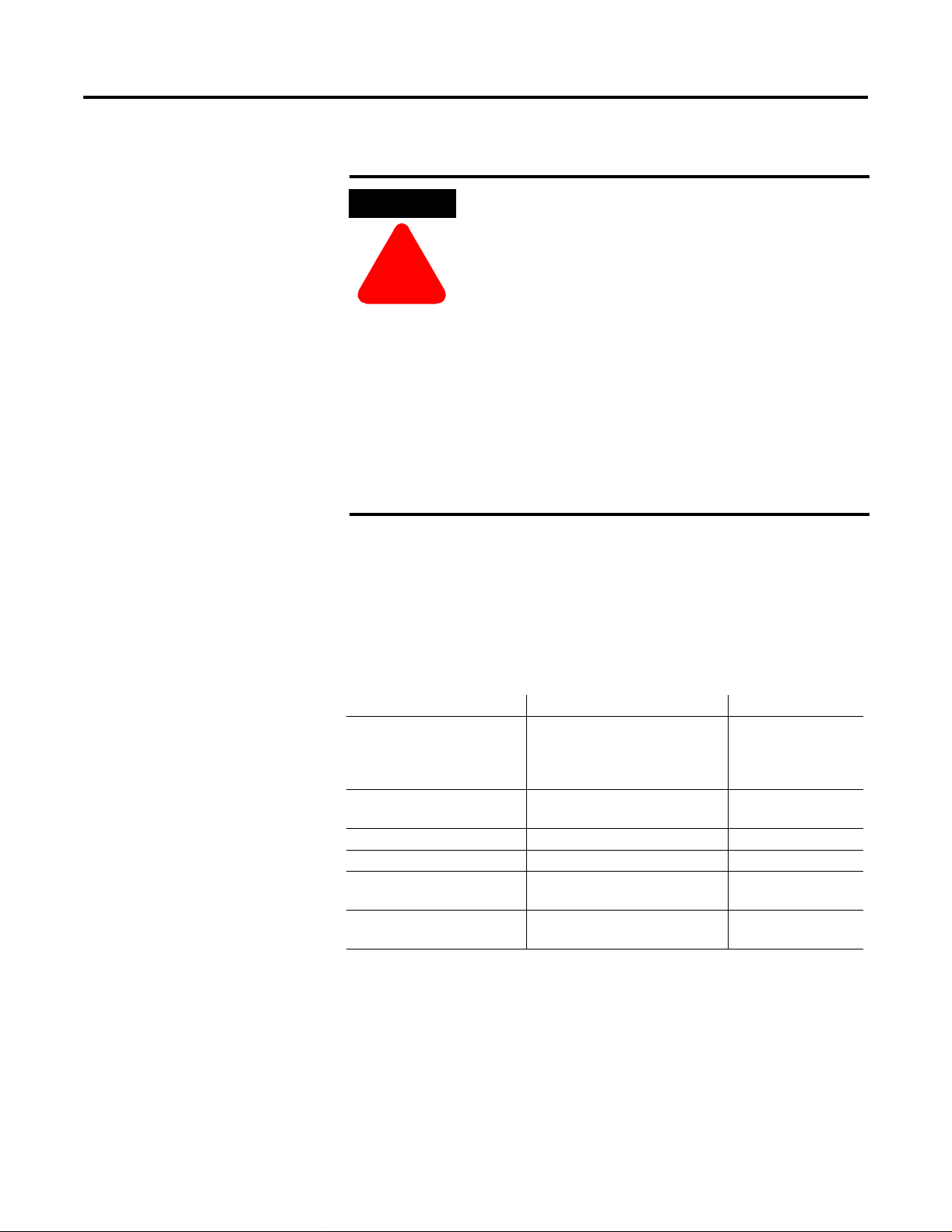

IMPORTANT

The 1771-SDN Scanner Module fits in any slot of the

chassis except for the leftmost slo t, which is reserv ed

for the PLC processor. The scanner module will not

conflict with other 1771 I/O devices in the chassis.

You can install multiple scanners in the same chassis.

The 1771-SDN Scanner Module is compatible wit h any PLC-2

or PLC-5

processor that supports block transfer read and write

, PLC-3

instructions. The example configurations in these installation

instructions use a PLC-5 processor.

Perform the ControlFLASH Update

If you have the previous releas e of fi rmware and you want to up grade

it to this release, you must perform the ControlFLASH update. To get

the kit, contact Rockwell Automation Technical Support at

440.646.5800. To install the kit, refer to the ControlFLASH Firmware

Upgrade Kit User Manual, publication 1756-6.5.6.

Before you install your module you must set the following switches:

• data rate for each DeviceNet channel

• I/O cha ssi s a d dressing mode (1 /2, 1 or 2-sl o t ad dressing )

• scanner node address for each channel

Publication 1771- IN014B-EN-P - September 2001

Page 10

10 DeviceNet Scanner Module Catalog Number 1771-SDN/C

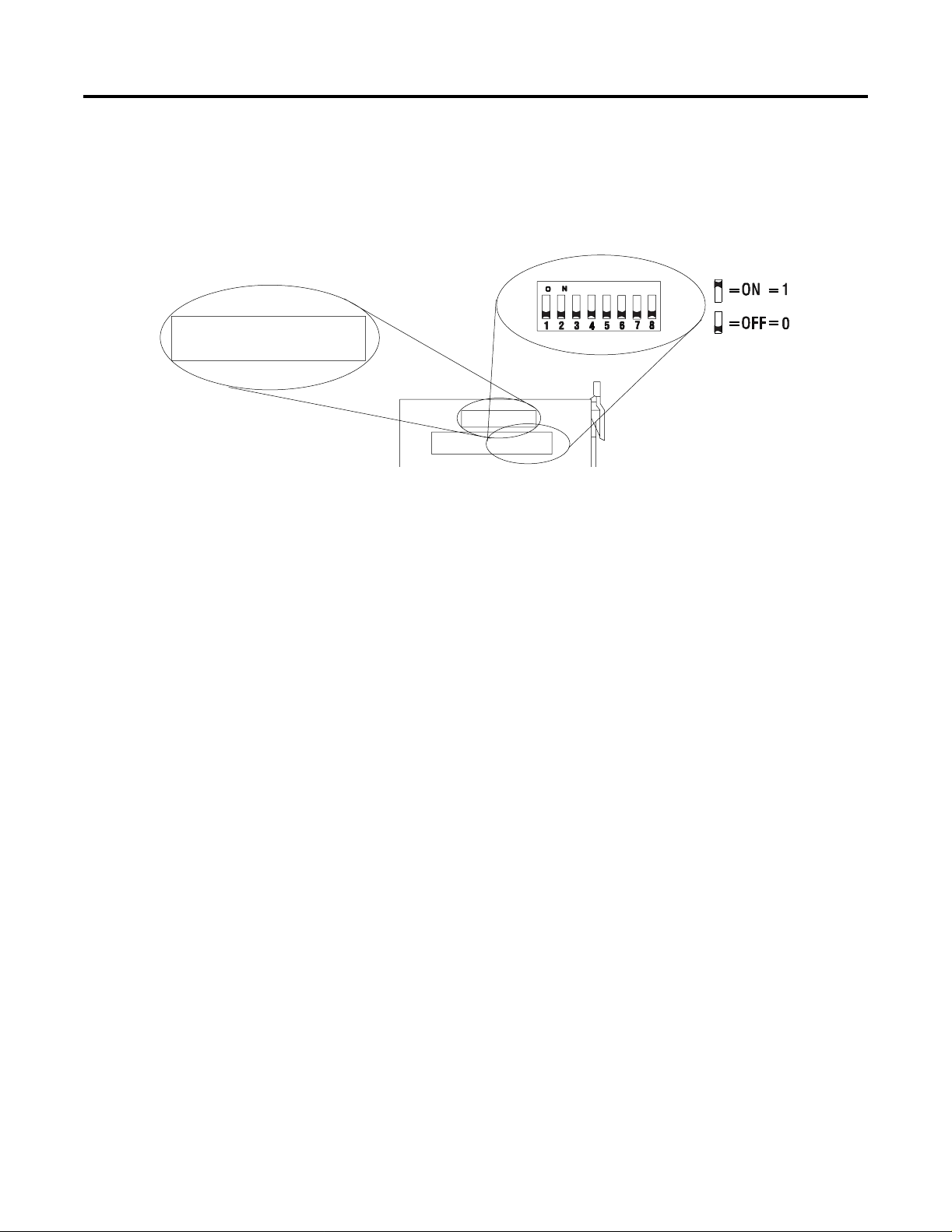

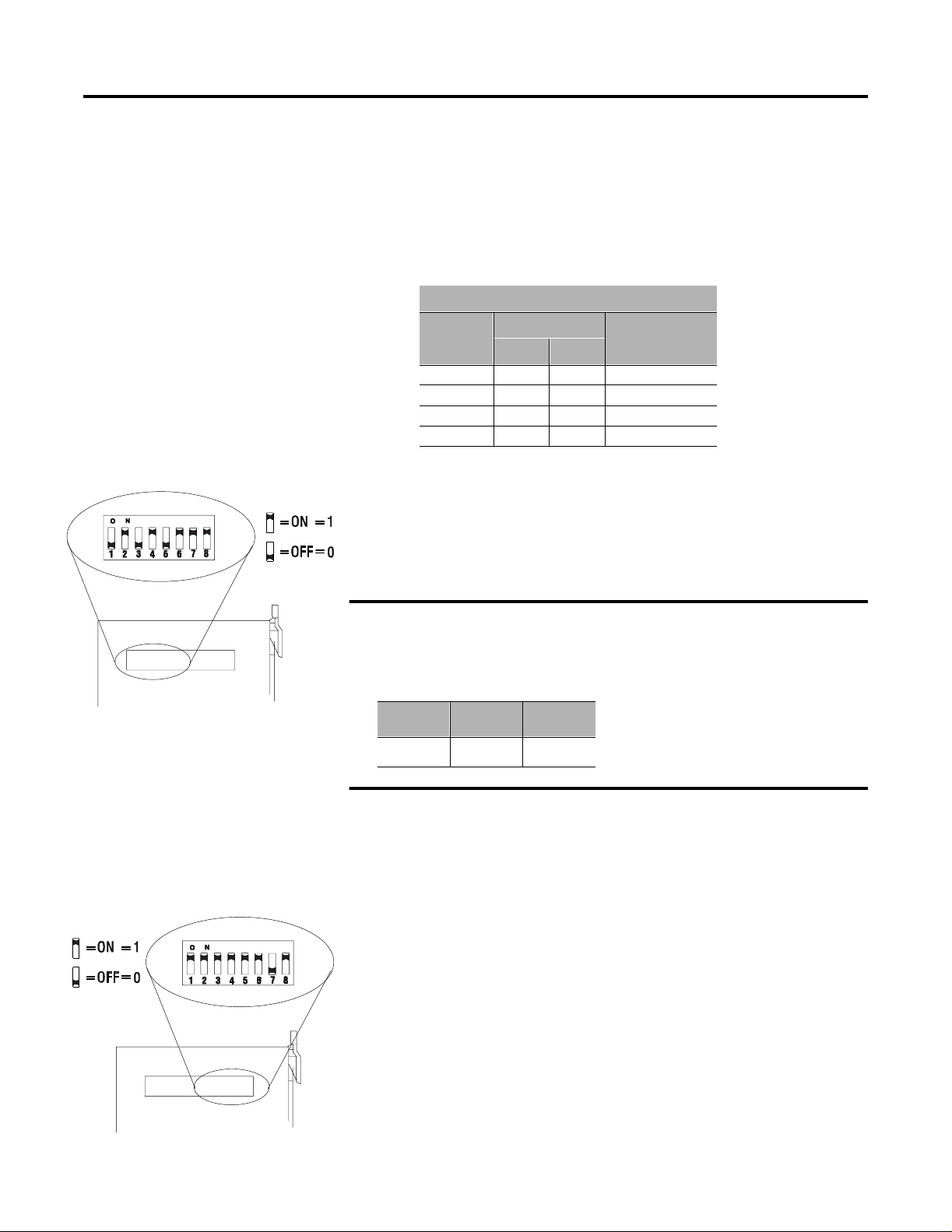

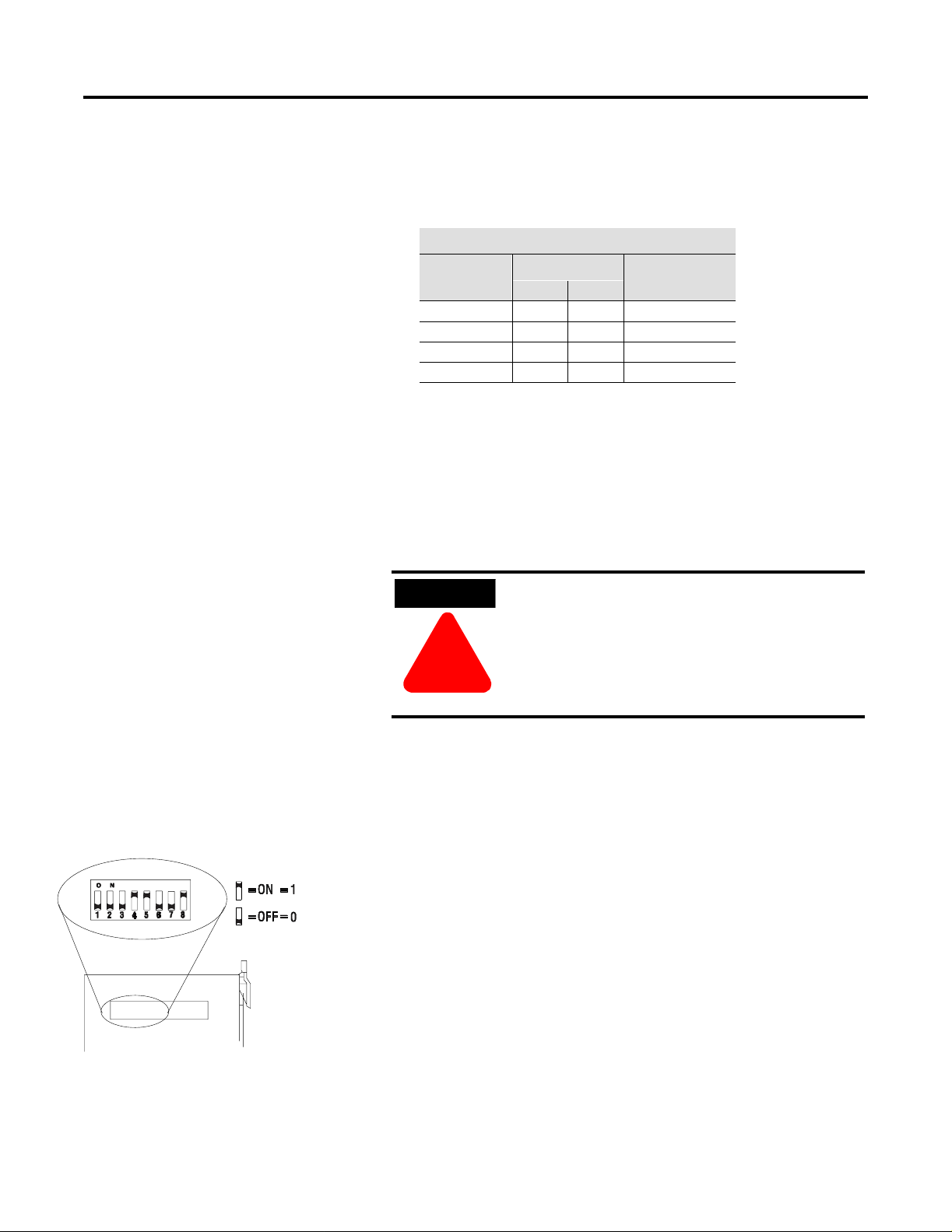

Set the Data Rate Switches for Channels 1 and 2

Channel 1

Data Rate

To set the DeviceNet data rate switches for Channels 1 and 2:

1. Locate the swit chbank label ed “Cha nnel 1” on t he lef t side of the

module.

2. Use the table below to determine the data rate you want to set

for “Channel 1.” Record your choice in the fourth column.

Channel 1 and 2

Data Rate

Switch Position

1 2

125K baud 0 0

250K baud 0 1

500K baud 1 0

Not allowed 1 1

Note Your

Data Rate

3. Using a ball point pen or similar object, adjust switches 2 and 1

to your desired data rate setting. (NOTE: Do not use a pencil

to adjust switches. The lead may break off in the

switchbank.) Slide the switches up to denote an on or “1”

position. Slide the switches down to denote an off or “0”

position.

20276

Configuration

Set the I/O Chassis Addressing Mode Switches

Chassis Address

For example, if you want to set DeviceNet data rate of 500K baud for

Channel 1, then you set switch 2 to an off or “0” position and switch 1

to an on or “1” position.

Data Rate Sw.1 Sw.2

500K 1 0

4. Repeat steps 1-3 to set the DeviceNet data rate for Channel 2,

using the switchbank labeled “Channel 2’. Adjust the switches to

your desired data rate setting.

To set the I/O chassis addressing mode switches:

1. Locate the switchbank labeled “Configuration” on the left side of

the module.

2. Use the following table to determine the chassis addressing

mode you want to set. Record your choice in the fourth column.

20277

Publication 1771-IN014B-E N-P - September 2001

Page 11

DeviceNet Scanner Module Catalog Number 1771-SDN/C 11

Note: The scanner module consumes/produces 8 bits of discrete

output/input for t he processo r co nnection . The re fore, the scanner

module cannot be placed next to a 16-point module when using

1-slot ad dr e ssi n g.

I/O Chassis Addressing Mode

Mode

2-slot 0 0

1-slot 0 1

1/2-slot 1 0

Not allowed 1 1

3. Using a ball point pen or similar pointed object, adjust switches

7 and 8 to your desired chassis addressing mode. Slide the

switches up to denote an on or “1” position. Slide the switches

down to denote an off or “0” position. Make sure switches 1

through 4 and 6 in the switc hbank l abeled “ Config uratio n”

always remain in the off or “0” position. For Series C

functionality, make sure switch 5 is in the on or “1”

position.

Switch Position

7 8

Note Your

Mode

Set Node Address Switches for Channels 1 and 2

Channel 1

Node Address

20276

ATTENTION

ATTENTION

!

!

For more information about addressing, refer to your PLC processor

system level installation manual and design manual.

To set the scanner DeviceNet node address:

1. Locate the switchbank labeled “Channel 1”, on the left side of

the m odule.

2. Use th e following tab le to determine the node add ress you want

to set for the module on Channel 1, and note your choice. The

address range is 0 to 63.

3. Using a ball point pen or similar object, adjust switches 3

through 8 to your desired node address settings. Slide the

switches up to denote an on or “1” position. Slide the switches

down to denote an off or “0” position.

4. Using a ball point pen or similar object, adjust switches 3

through 8 to your desired node address settings. Slide the

switches up to denote an on or “1” position. Slide the switches

down to denote an off or “0” position.

The I/O chassis addr e ss se t t ing must match

the chassis addressing mode setting for the

1771 chassis. If the switches do not match,

data will be lost in the data transfer between

the PLC-5 processor and the scanner module.

Publication 1771- IN014B-EN-P - September 2001

Page 12

12 DeviceNet Scanner Module Catalog Number 1771-SDN/C

5. Repeat steps 1–3 to set the scanner node addres s f or Channel 2,

using the switchbank labeled “Channel 2”. Adjust the switches to

your desired node address setting.

IMPORTANT

The node address setting for DeviceNet Channel 1 must

not conflict with the node address of any other device on

the network.

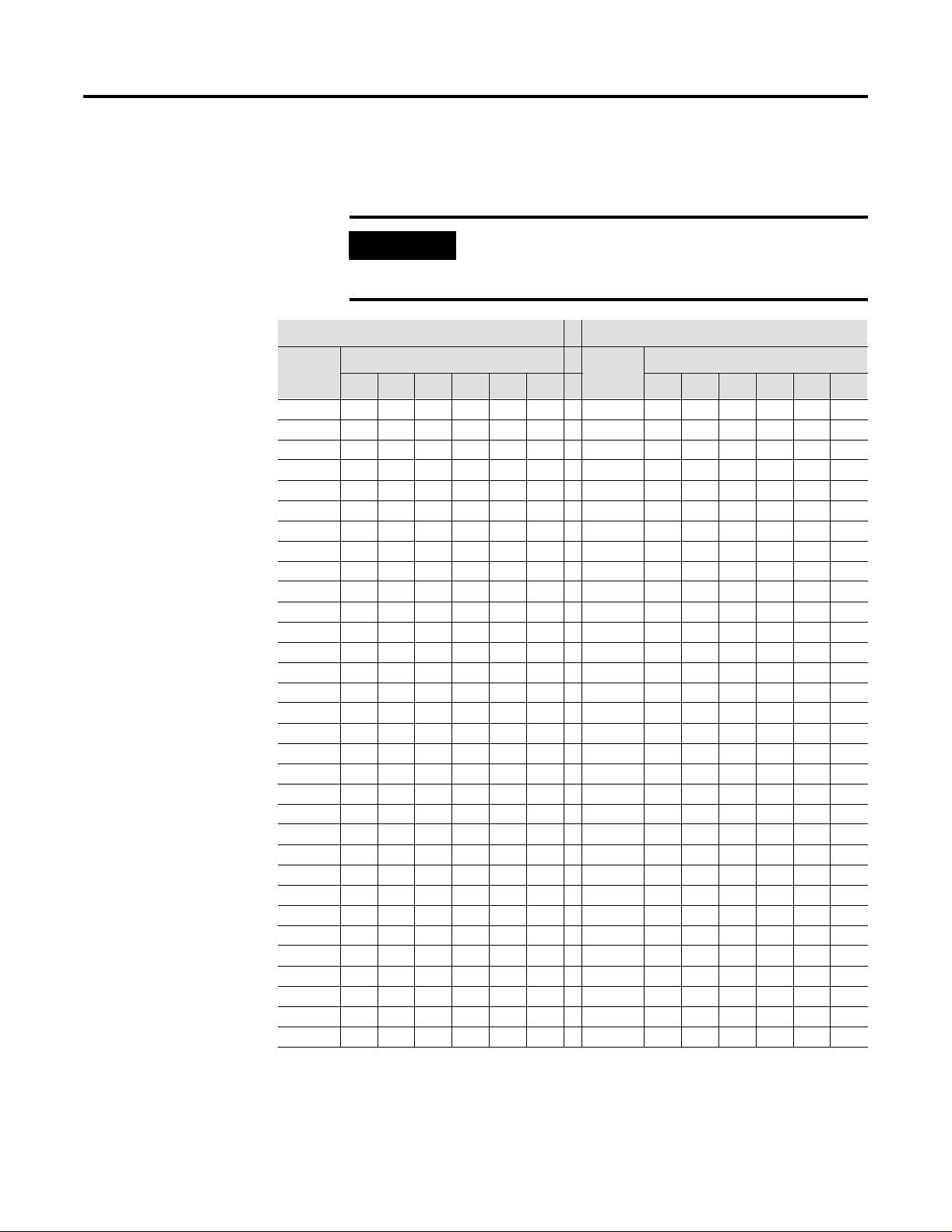

Channel 1 and 2 Node Address Channels 1 and 2 Node Address

Node

Address

0 0 0 0 0 0 0 32 1 0 0 0 0 0

1 0 0 0 0 0 1 33 1 0 0 0 0 1

2 0 0 0 0 1 0 34 1 0 0 0 1 0

3 0 0 0 0 1 1 35 1 0 0 0 1 1

4 0 0 0 1 0 0 36 1 0 0 1 0 0

5 0 0 0 1 0 1 37 1 0 0 1 0 1

6 0 0 0 1 1 0 38 1 0 0 1 1 0

7 0 0 0 1 1 1 39 1 0 0 1 1 1

8 0 0 1 0 0 0 40 1 0 1 0 0 0

9 0 0 1 0 0 1 41 1 0 1 0 0 1

10 0 0 1 0 1 0 42 1 0 1 0 1 0

11 0 0 1 0 1 1 43 1 0 1 0 1 1

12 0 0 1 1 0 0 44 1 0 1 1 0 0

13 0 0 1 1 0 1 45 1 0 1 1 0 1

14 0 0 1 1 1 0 46 1 0 1 1 1 0

15 0 0 1 1 1 1 47 1 0 1 1 1 1

16 0 1 0 0 0 0 48 1 1 0 0 0 0

17 0 1 0 0 0 1 49 1 1 0 0 0 1

18 0 1 0 0 1 0 50 1 1 0 0 1 0

19 0 1 0 0 1 1 51 1 1 0 0 1 1

20 0 1 0 1 0 0 52 1 1 0 1 0 0

21 0 1 0 1 0 1 53 1 1 0 1 0 1

22 0 1 0 1 1 0 54 1 1 0 1 1 0

23 0 1 0 1 1 1 55 1 1 0 1 1 1

24 0 1 1 0 0 0 56 1 1 1 0 0 0

25 0 1 1 0 0 1 57 1 1 1 0 0 1

26 0 1 1 0 1 0 58 1 1 1 0 1 0

27 0 1 1 0 1 1 59 1 1 1 0 1 1

28 0 1 1 1 0 0 60 1 1 1 1 0 0

29 0 1 1 1 0 1 61 1 1 1 1 0 1

30 0 1 1 1 1 0 62 1 1 1 1 1 0

31 0 1 1 1 1 1 63 1 1 1 1 1 1

3 4 5 6 7 8 3 4 5 6 7 8

Switch Position

Node

Address

Switch Position

Publication 1771-IN014B-E N-P - September 2001

Page 13

DeviceNet Scanner Module Catalog Number 1771-SDN/C 13

Install Your Module into the Chassis

Before you insert the module into the chassis, set all switches in

accordance with the requirements of your n etworks. Y ou must s et th e

switches before you install the the 1771-SDN Scanner Module or it will

not function properly.

WARNING

WARNING

If you ins e rt or re move the scan ne r module with

power applied to this module or any device on the

network, an electrical arc can occur. This could

cause an explosion in hazardous location

!

!

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

1. Se lect a s lot for the module in the chassis. You may use any sl ot

except the leftmost slo t, w hich i s r ese rved for the PLC processor.

2. Adjust the chassis’ keying bands (see figures below).

The 1771-SDN Scanner Module uses keying bands to prevent

placi ng modul es into t he wrong sl ot. You c an key any c onnect or

in an I/O chassis to receive the module except for the leftmost

connector, which is reserved for adapter or processor modules.

The 1771-SDN Scanner Module is slotted in two places on the

rear edge of the circuit board. These slots are intended to

mate with the plastic keying bands supplied with the I/O

chassis.

I/O chassis

backplane connector

Scanner module

Position the keying bands in the backplane connectors to

correspond to the key slots on the module.

I/O chassis

2

4

6

8

10

Place the keying bands:

between 2 and 4

between 22 and

You can change the position of these bands if subsequent system design and

rewiring makes insertion of a different type of module necessary.

24

keying bands

2

4

6

8

10

12

14

16

18

20

22

24

26

28

19808

Publication 1771- IN014B-EN-P - September 2001

Page 14

14 DeviceNet Scanner Module Catalog Number 1771-SDN/C

3. Insert the 1771-SDN Scanner Module into the slot you have

selected.

4. Apply firm, even pressure to seat the module in the I/O chassis

backplane connectors.

5. Swing the locking bar down until locked in place to make sure

that you have secured t h e module in the slot.

Locking Bar

20278

Connect to the DeviceNet Network

To connect to the DeviceNet network:

WARNING

WARNING

!

!

If you ins e rt or re move the scan ne r module with

power applied to this module or any device on the

network, an electrical arc can occur. This could

cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

Locking Bar

20279

Publication 1771-IN014B-E N-P - September 2001

Page 15

DeviceNet Scanner Module Catalog Number 1771-SDN/C 15

1. Connect th e DeviceNet drop line to the li near plug, by matching

the wire insulation colors to the colors shown on the label:

Module label shows

wiring color scheme:

+24V RED

Can_H WHITE

Drain/Shield

Can_L BLUE

+24V Return BLACK

Ten-pin

Linear

Plug

Red

White

Bare (shield)

Blue

Black

DeviceNet

Drop Line

Front of Scanner Module

2. Locate the DeviceNet

Port 1 connector for Channel 1 on the

front of the module.

3. Insert the linear plug into the five-pin header for

Channel 1.

DeviceNet Port 1

for Channel 1

Red

White

Bare (shield)

Blue

Black

Five-Pin

Header

DeviceNet

Drop Line

4. Repeat steps 1–3 for Channel 2, if necessary.

20298

20298

Module installation is complete. To operate the module,

you must program the PLC processor to communicate with it. In the

following two sections, we describe how your module communicates

with the PLC-5 processor and how to program your processor.

WARNING

WARNING

If you connect or disconnect the DeviceNet cable

with power applied to this module or any device on

the network, an electrical arc can occur. This could

cause an explosion in hazardous location

!

!

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

Publication 1771- IN014B-EN-P - September 2001

Page 16

16 DeviceNet Scanner Module Catalog Number 1771-SDN/C

How Your Module Communicates with the PLC-5 Processor

The 1771-SDN scanner module uses four methods to transfer data,

status and command information between the scanner and the PLC-5:

• DIO points for high-speed discrete outputs

• DIO points for high-speed discrete inputs

• BTW to send output data to the scanner

• BTR to upload input data from the scanner

Using DIO Points for High-Speed Discrete Inputs and Outputs

The foll owing table describes chassis addressin g modes and the

number of discrete inputs and outputs assigned to the 1771-SDN

Scanne r Module slot .

Addressing Mode Discrete Inputs Discrete Outputs

1/2-slot 24 24

1-slot 8 8

2-slot 0 0

Program Your PLC-5 Processor

These inputs and outputs will appear in the PLC I/O image table in

the location corresponding to the rack, group and slot the module is

plugged into. Since the bits are in the I/O table, they can be forced.

For more information about chassis addressing modes, refer to your

PLC-5 processor system level installation manual.

You must pr ogram your PLC -5 processor so it commun i c a t e s with the

1771-SDN Scanner Module. Communication is possible when you

program your processor through multiple block transfer instructions.

The scanner uses the size of the block transfer to map the block

transfer data words into the scanner’s internal data table. The scanner

module accepts blocks of different sizes and knows that each block

has a different meaning.

PLC-5 block transfer instructions use one integer file in the data table

section for module location and other data to execute the instruction.

This is the control block file. The block transfer data file stores data

that you want to transfer to your mod ule (wh en pr ogra mmin g a bl ock

transfer write (BTW)) or from your module (when programming a

block transfer read (BTR)). The address of the block transfer data file

is stored in the control block file.

Publication 1771-IN014B-E N-P - September 2001

Y ou must select a separate data file for each of the block transfer

instructions. You must also use separate 5-word block transfer

Page 17

DeviceNet Scanner Module Catalog Number 1771-SDN/C 17

control files for each of the block transfer in structio ns when an

integer file is used. This is not necessary when a control block file is

a BT data type.

To make sure the ins truction is reset af ter the block tr ansfer completes

and recyc les , y ou mus t use enab le bits as th e cond i tio ns on e ach r ung

with the PLC-5. The following figure shows a PLC-5 sample program

.

IMPORTANT

The module does not support continuo us mode block

transfer. Set Continuous to NO for eac h BTW or BTR .

Precondition

Precondition

Block-transfer rungs must be scanned for the transfers to occur. The

preconditions allow time-driven or event-driven transfers.

BT10:0

BTR

enable bit

BTW

enable bit

BT10:5.EN

BT10:5.EN

EN

EN EN

EN

BTW

enable bit

BTR

enable bit

BT10:0

BTR

BLOCK TRANSFER READ

Rack

Group

Module

Control Block

Data file

Length

Continuous NO

BTW

Rack

Group

Module

Control Block

Data file

Length

Continuous

BT10:0

N11:0

62

BT10:5

N11:62

62

NO

EN

3

2

DN

0

ER

ENBLOCK TRANSFER WRITE

3

2

DN

0

ER

Publication 1771- IN014B-EN-P - September 2001

Page 18

18 DeviceNet Scanner Module Catalog Number 1771-SDN/C

When using rungs like those in the preceding figure, the processor

alternates between the BTR and the BTW , waiting to request the next

block transfer until the previous block transfer is completed. When

only one block transfer is active at a time, it is considered a

single- thr eaded bloc k t ransf er. Sing l e-th reade d blo ck t ran sf ers op erat e

in an orderly sequence of read and write, however, they are slower

than the asy nc hronous method, shown bel ow:

Precondition

Precondition

Block-transfer rungs must be scanned for the transfers to occur. The

preconditions allow time-driven or event-driven transfers.

BT10:0

EN

BTR

enable bit

BTW

enable bit

BT10:5.EN

EN

BTR

BLOCK TRANSFER READ

Rack

Group

Module

Control Block

Data file

Length

Continuous NO

BTW

Rack

Group

Module

Control Block

Data file

Length

Continuous

BT10:0

N11:0

62

BT10:5

N11:62

62

NO

EN

3

2

DN

0

ER

ENBLOCK TRANSFER WRITE

3

2

DN

0

ER

As soon as an asynchronous block transfer completes, it is requested

again, independent of other block transfers going to th e same module.

If you have programmed many block tran sfers to the same logical rack

(especially a remote rack), you will fill the processor’s queue. In this

situation, the asynchronous method can result in irregular timing

between successive executions of the same block transfer.

For more information on programming and block transfers, refer to

your PLC-5 Programming Software Instruction Set Reference Manual,

publication 1785-6.1.

Using BTW to Send Outputs to the Scanner

The PLC-5 downloads output data to the scanner using block

transfer write instructi ons over the 1771 backplane. The scanner

module can update a maximum of 357 output words by internally

linking together six different sized block transfers as shown in the

following table.

Publication 1771-IN014B-E N-P - September 2001

Page 19

DeviceNet Scanner Module Catalog Number 1771-SDN/C 19

Block

Transf er Size

62 words Block 62

61 words Block 61 Words 62–122

60 words Block 60 Words 123–182

59 words Block 59 Words 183–241

58 words Block 58 Words 242–299

57 words Block 57 Words 300–356

1-50 words Block 1-50 Words 0-49

Accessed

Scanner Output

Block

Scanner Output Data Table

Word 0 – Module Command Register Word

Words 1–61

Each indi vidual bl ock transfer is independent, but alwa y s updates t he

same output bytes in the scanner’s memory table. Of the scanner

output words 0 through 61, the word 0 is reserved for the Module

Command Register. Block transfer sizes 1 through 50 update scanner

output words 0 through 49, thus reducing the required BTW time

when 50 or fewer output words are needed. Sizes 51 thru 56 are

illegal and size 64 is used for Explicit Message Program Control. For

more details on Explicit Message Program Control, refer to page 26.

If the scanner receives a BTW of 62 words, then it knows that it

contains the first block of the table. A BTW of 61 words, if necessary,

contains the second block of the table and so on for 60, 59, 58 and 57

words.

DeviceNet Messages

You determine the data that is exchanged with a given node on

channel 1 or 2 by creating custom configurations using RSNetworx

software version 2.22 or later. Refer to you r RSNetworx documentation

or online help and your 1771-SDN Scanner Configuration Manual

(publication number 1771-6.5.132) for more information on custom

configurations.

Module Command Register

The firs t word of the BTW downl oaded from th e PL C-5 to block 62 is

reserved as the module command register. The r egister is downloaded

with every 1 through 50 and 62 word block transfer write. This

modifies the scanner’s operation.

To execute a command, you set the appropriate bits in the module

command word, then perform a block transfer write to the first block

(the 62 word block) of the scanner output table. When the scanner

receives the command it immediately executes it. You latch bits 0

through 5 in your program to maintain the scanner’s desired state.

Publication 1771- IN014B-EN-P - September 2001

Page 20

20 DeviceNet Scanner Module Catalog Number 1771-SDN/C

The following table outlines the module command register’s bit

numbers and descriptions.

Module Command Register - Word 0, Block 62

Bit

Number

00 – 01

02 - 03

04

05

06

07

08 – 15

Bits

01 00

0 0 DeviceNet Channel 1

in idle mode

0 1 DeviceNet Channel 1

in run mode

1 0 DeviceNet Channel 1

in fault mode

11Reserved

0 0 DeviceNet Channel 2

in idle mode

0 1 DeviceNet Channel 2

in run mode

1 0 DeviceNet Channel 2

in fault mode

11Reserved

0 Enable DeviceNet

Channel 1

1 Disable DeviceNet

Channel 1

0 Enable DeviceNet

Channel 2

1 Disable DeviceNet

Channel 2

0 Scanner run

1 Scanner halt

0 Scanner Active

1 Sc anner reboot

0 Reserved for future use

Operating Mode Operating Mode Description

Idle

The scanner does not map output dat a to the devices, but keeps network

connections to devices open so device failures can be detected. Input data

is returned from devices, and mapped into the scanner input table and the

discrete inputs. Outputs on the network are not under program control and

will be in their configured ‘idl e st ate.’ The scanner must be put into this

mode to perform configuration of the scanner database tables.

Run

The scanner module maps output data from its scanner output table and

discrete outp uts to each device on the network. Inputs are received and

mapped into the scanner input table and discrete inputs. Outputs on the

network are un der program co ntrol.

Placing the PLC-5 into PROG or REM_PROG mode places the scanner into

idle mode regardless of the state of the bits in the module command

register. Placing the PLC-5 into RUN or REM_RUN mode causes the state

of the bits in th e modu le comma nd r egis te r to de termi ne the scanne r state.

Fault Network

The scanner stops communicating with devices on the network. No

outputs or inputs are mapped. O utputs on the network are not under

program control. If the scanner was in run, devices will go to their

configu red ‘fau lt st ate.’

Enable

The DeviceNet channel is enabled for communication. This is the normal

opera ting state of the channel.

Disable

The DeviceNet channel is disabled for communication. No communication

may occur over this channel. Outputs on the network are not under

program control. If the scanner was in run, devices will go to their

configured ‘fault state.’ Numeric error code 90 will occur when channel is

disabled.

Scanner Active

This is the normal operating mode of the scanner.

Scanner Halt

All scanner operations stop when this command is issued. No

communications occur over either DeviceNet port. No b lock transfer or

discrete I/O mapping occurs. Outputs on the network are not under

program control. If the scanner was in run, devices will go to their

configured ‘fault state.’ Numeric error code 97 will occur - you must reset

the scanner or cycle power to the scanner to recover from this state.

Scanner Reboot

This comman d ca uses th e s can ner to res et as th ou gh th e res et b utton ha d

been pressed. When this command is issued, all scanner communication

stops for the duration of the scanner’s initialization sequence. Outputs on

the network are no longer under program control. If the scanner was in

run, devices will go to their configured ‘fault state.’

Publication 1771-IN014B-E N-P - September 2001

Page 21

DeviceNet Scanner Module Catalog Number 1771-SDN/C 21

Use BTR to Upload Input Data from the Scanner

The PLC-5 uploads input data from the scanner using block transfer

read instructions over the 1771 backplane. The scanner interprets

BTRs of length 1 through 50 and 62 words as being from the first

block of the scanner input table. The scanner module can update a

maximum of 357 input words by internally linking together six

different sized block transfers. See the table below.

Block

Transf er Size

62 words Block 62

61 words Block 61 Words 62–122

60 words Block 60 Words 123–182

59 words Block 59 Words 183–241

58 words Block 58 Words 242–299

57 words Block 57 Words 300–356

52 words Block 52 Device Failure Table

51 words Block 51 Device Active Table

1-50 words Block 1-50 Words 0–49

Accessed

Scanner

Input Block

Scanner Input Data Table

Word 0 – Module Status Register Word

Words 1–61

Each ind i vidu al blo ck tr a nsf er is inde pend ent , but alwa ys re tri ev es the

same input bytes from the scanner’s input data table. The types of

information that a PLC-5 program will upload from the scanner via the

BTR are the:

• Device Input Data Table (6 blocks, 62 through 57 words)

• Device Failure Table (1 block, 52 words)

DeviceNet Messages

• Device Active Table (1 block, 51 words)

When the scanner receives a BTR, it automatically knows which block

of data is desired by the size specified.

Y ou may upload portions of the scanner input table rather than the

entire table, to support higher-speed operations. The scanner will

interpret any BTR of length 1 through 50 with the words 0 thru 49 of

block 62 of the scanner in put table. BTR s of sizes 57 through 61

represent full blocks of the table. A BTR of 52 words contains the

Device Failure Table . Sizes 53 through 56 are res erved. Size 64 is used

for Explicit Message Program Control. For more details on Explicit

Message Program Control, refer to page 26.

Publication 1771- IN014B-EN-P - September 2001

Page 22

22 DeviceNet Scanner Module Catalog Number 1771-SDN/C

To reduce block transfer time a nd i nc rease syst em performance, use

only the words you need.

Use the RSNetWorx for DeviceNet software to map data from a

DeviceNet node into the scanner input table. Data from a DeviceNet

node can be split and put into as many as four different locations in

the scanner input table.

Module Status Register

In the Module Status Register (word 0, block 62), bits 0 through 5

indicate to the PLC-5 the current state of the scanner module. When

a Module Comman d R egis ter c omm and is s ent t o the sc an ner mod ule ,

the respective bits are set in the Module Status Register when the

command executes. Depending on network load, the scanner may

take several moments to detect network status changes. The bits latch

on in the “on” state until the command clears.

Bits 6 and 7 indicate that you should read the device failure table for

more specific information about which devices failed. Bits 8 and 9

indicate that you should read the device autoverify table to determine

which device has incorrect device keying or a misconfigured data size

in the scanner configuration tables. Use the DeviceNetManager

software to correct this error.

You can use bits 6 and 7 of the Module Status Register to enable

the scanner module’s Module Command Register to react to certain

conditions. An example reaction to a condition is to keep the

communication ports in the “idle” mode until the bits clear.

When the bits clear, this indicates that all dev ices on the networks are

operational. When the devices are operational, you can put the ports

in the “run” mode, so that output data goes to the devices.

If a device failure is detected, you can put the communication into the

“idle” mode, so that all devices would go into t heir idl e state. You may

tie these inputs to the Module Command Register, so that you may use

them to adjust the operating mode of t he scanner when devices fail or

go online at startup.

You can also modify your control logic to run differently to

compensate for the loss of communication with a certain node.

An alarm message to alert an operator of the problem is also possible.

Publication 1771-IN014B-E N-P - September 2001

The following table lists Module Status Register bit numbers and their

descriptions.

Page 23

Bit

Number

00 - 01

02 - 03

04

05

06

07

08

09

10

11

12

13

14

15

Module Status Register - Word 0, Block 62

Bits

01 00

0 0 DeviceNet Channel 1 in idle mode Idle

0 1 DeviceNet Channel 1 in run mode

1 0 DeviceNet Channel 1 in fault mode

11Reserved

0 0 DeviceNet Channel 2 in idle mode

0 1 DeviceNet Channel 2 in run mode

1 0 DeviceNet Channel 2 in fault mode

11Reserved

0 Enable DeviceNet Channel 1

1 Disable DeviceNet Channel 1

0 Enable DeviceNet Channel 2

1 Disable DeviceNet Channel 2

0 No failures detected

1 DeviceNet C hannel 1 device failure detec ted

0 No failures detected

1 DeviceNet C hannel 2 device failure detec ted

0 No failures detected

1 DeviceNet C hannel 1 autoverify failure detected

0 No failures detected

1 DeviceNet C hannel 2 autoverify failure detected

0 No failures detected

DeviceNet Channel 1 communications failure

1

detected

0 No failures detected

DeviceNet Channel 2 communications failure

1

detected

0 No failures detected

DeviceNet Channel 1 duplicate node address

1

failure

0 No failures detected

DeviceNet Channel 2 duplicate node address

1

failure

0 No failures detected

1 Scanner configuration missing or corrupted

0 No failures detected

Client/server transaction response queued

1

Operating Mode Operating Mode Description

The scanner does not map output data to the devices, but keeps networ k

connections to devices open so device failures can be detected. Input data

is returned from devices, and mapped into the scanner input table and the

discrete inputs. Outputs on the network are not under program control and

will be in their configured ‘safe state.’ The scanner must be in this mode to

perform configuration of the scanner database tables.

Run

The scanner module maps output data from it s scanner output table and

discrete outputs to each device on the network. Inputs are received and

mapped into the scanner input tabl e and discrete inputs. Outputs on the

network are under program control.

Placing the PLC-5 into the PROG or REM_PROG mode places the scanner

into IDLE MODE regard le ss of th e st ate of the bi ts in the mod ul e comman d

register. Placing the PLC-5 into RUN or REM_RUN mode causes the state

of the bits in th e mod ule c omma nd r eg iste r to deter mi ne th e scan ne r stat e.

Fault

The scanner has stopped communicating with devices on the network.

No outputs or inputs are mapped. Outputs on the network are not

under program control. If the scanner was in run, devices will go to their

fault state.

Device Failure

One or more of the devices in the scan ner’s scan list has failed to

communicate with the scanner.

Autoverify Failure

One or more of the devices in the scanner’s scan list is returning an

incorrect num ber of bytes of data in res p onse to a s trobe/poll, acco r di ng t o

the information stored in the scanner’s scan list.

Communications Failure

There is no communication on the port.

Duplicate Node Address Failure

There is another node with the same address on the network.

Scanner Configuration Missing or Corrupted

Either the I/O chassis addressing mode is set to an illegal position or, the

chassis addressing mode switch does not match the value stored in the

scanner’s scan list.

Client /server transactio n response queued

The client/server response is loaded and available with a 64-word Block

Transfer Read.

DeviceNet Scanner Module Catalog Number 1771-SDN/C 23

Publication 1771- IN014B-EN-P - September 2001

Page 24

24 DeviceNet Scanner Module Catalog Number 1771-SDN/C

Device Active Table

The Device Active Table is located in words 0–7 of a 51 word BTR.

The scanner assigns one bit of the first 128 bits to each device on the

networks. The scanner assigns one bit to consecutive Device

Addresses.

Devices on Channel 1 are indicated by a single bit in consecutive

order in words 0–3. Devices on Channel 2 are indi cated by a single bit

in consecutive order in words 4–7.

If a bit is set, it in dicates that the node is in the scanner’s scan list an d

has successfully communicated with the scanner. These bits are not

cleared if the slave node goes off-line. The bits are cleared by

resetting the scanner.

Device Failure T able

The scanner maintains one Device Failure Table accessed with a

52-wo rd B TR. The table con si st s of:

• Communications Failure Bitmap – the scanner tracks device

failures in its scan list b y as sig ning one bit of the first 128 bits in

the table to each device on the networks. The scanner assigns

one bit to consecutive Device Addresses. Devices on Channel 1

are indicated by a single bit in consecutive order in words 0–3.

Devices on Channel 2 are indicated by the bits in words 4–7.

If a bit is set, it indicates that the node is in the scanner’s scan

list and is either not present, not communicating or failed

autoverify.

• Autoverify Failure Bitmap – the scanner tracks auto verify failures

by assigning one bit of the second 128 bits in the table to each

device on the networks. A value o f 1 in t he bit position in dicates

a fail ure is det ec ted a nd a value of 0 indi cate s no rmal opera t ion.

The scanner assigns one bit to consecutive Device Addresses.

Devices on Channel 1 are indicated by a single bit in

consecutive order in words 8–11. Devices on Channel 2 are

indicated by the bits in words 12–15. If a bit is set, it indicates

that the device is returning device keying or a data size that

does not match the keying or data size in the scanner

configuration ta ble.

Publication 1771-IN014B-E N-P - September 2001

• DeviceNet 1 Scan C ounter (word 16) – th e s c ann er increments a

one-word counter whenever a scan of the DeviceNet 1 devices

is completed. The counter rolls over when it reaches its

maximum value.

Page 25

DeviceNet Scanner Module Catalog Number 1771-SDN/C 25

• DeviceNet 2 Scan Counter (word 17) – the scanner increments

a one-word counter w henever a scan of th e DeviceNet 2 devices

is completed. The counter rolls over when it reaches its

maximum value.

• Device Idle State Bitmap (words 18–25, 4 words for Channel 1,

four words for Channel 2) – the scanner assigns one bit to

consecutive Device Addresses. Devices on Channel 1 are

indicated by a single bit in consecutive order in words 18–21.

Devices on Channel 2 are indicated by the bits in words 22–25.

If a bit is set, it indicates that the scanner received a valid

DeviceNet idle indication from this node. A device in i dle mode

does not return updated I/O data to the scanner because the

device is not in its run mode.

• Node Address/Status Indicator (word 26) –- Channel 1 and

Channel 2 node a ddress and sca nner diagnostic info rmat i on is

copied to the low and high bytes of Word 26, respectively.

The descriptions of these codes are listed on page 36.

Configure Your Module for the DeviceNet Network

• 25 words of pad data (zeroes, words 27–51), to complete the

table for a total of 52 words.

To operate your 1771-SDN Scanner Module, you must configure the

two tables listed b elow, us ing RS Networx for DeviceNet software. For

additional information, refer to your RSNetworx documentation or

online help and your 1771-SDN Scanner Configuration Manual

(publication number 1771-UM118C-EN-P).

Configure this table: To:

Control ho w the scanner gathers DeviceNet messag es.

The information you configure for this table includes:

Scanner Configuration Table

Scan List Table

• frequency of background poll messages on each

DeviceNet channel

• DeviceNet port disable/enable

Use the informat ion gathere d from the scan lis t table to

map the I/O data between the scanner’s I/O data table

and DeviceNet nodes. A device must have a

configuration table entry in the s canner’s database

before its I/O messages are mapped to the PLC. The

information you configure for this table includes:

• the size of data in each node’s DeviceNet messages

• location of a d ev ice ’s data in the data tab les th at a re

transferred to and from the PLC

Publication 1771- IN014B-EN-P - September 2001

Page 26

26 DeviceNet Scanner Module Catalog Number 1771-SDN/C

Clear the Scanner Module’ s Scan List

To clear the scanner module’s scan list, follow these procedures:

1. Remove power from the I/O chassis.

WARNING

WARNING

!

!

2. Remove the scanner module from the I/O chassis

3. In the Configur a t i on switchbank , se t sw i t c h 6 to the on or “1 ”

position .

4. Reinstall the scanner module and apply chassis power.

5. Wait for the Module Status indicator to flash red.

6. Remove power from the I/O chassis.

WARNING

WARNING

!

!

If you ins e rt or re move the scan ne r module with

power applied to this module or any device on the

network, an electrical arc can occur. This could

cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

If you ins e rt or re move the scan ne r module with

power applied to this module or any device on the

network, an electrical arc can occur. This could

cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

Use the Explicit Message Program Control Feature

Publication 1771-IN014B-E N-P - September 2001

7. Remove the scanner module from the I/O chassis.

8. In the Configur a t i on switchbank , se t sw i t c h 6 to the off or “0”

position .

9. Insert scanner module into the I/O chassis and apply power.

Use the Explicit Message Program Control feature to configure device

parameters on your DeviceNet network via the ladder logic program

in the PLC-5 processor that is controlling these devices.

Page 27

DeviceNet Scanner Module Catalog Number 1771-SDN/C 27

Use the Explicit Message Program Control feature to:

• transmit configuration data from your scanner module to its

slave devices on your DeviceNet network

• receive status and diagnostics from these devices on your

DeviceNet network

• make runtime adjustments to device parameters according to

chang ing cond i tions det e c t e d by y our proc e ssor

How the Explicit Message Program Control Feature Works

Block Transfer Read file (64 words)

(sent from scanner module to processor)

5

Block Transfer Read file

is completed. TXID’s

are deleted and can be

reused.

DeviceNet trunk line

Block Transfer Write file (64 words)

(sent from processor to scanner module)

4

Master’s Explicit

Request

DeviceNet

drop line

Explicit Message - A message used to transmit

commands, data, requests for data or responses.

The message is sent from a client on the Device

Net network to a server on that

network.

Request - An explicit message sent by a client

to a server requesting the server to perform

a function.

Response - An explicit message sent by a server

to a client in response to the client’s request. For

every request issued, there is a response.

Slave’s Explicit

Response

1203-GK5

Communication

Adapter

1305 AC

drive

1. Format a Block Transfer Write file in the processor to send an

Explicit Message Request to the scanner module (download).

Publication 1771- IN014B-EN-P - Septem ber 2001

Page 28

28 DeviceNet Scanner Module Catalog Number 1771-SDN/C

2. The scanner module transmits the Explicit Message Request to

the slave device over the DeviceNet network.

3. The slave device transmits the Explicit Message Response back

to the scanner and is queued int o a block trans f e r buffer .

4. The processor uses a Block Transfer Read file to retrieve the

Explicit Message Response from the scanner’s buffer (upload).

5. The Block Transfer Read file is completed. The transaction IDs

are deleted and can be reused.

The scanner module requires a precisely-formatted block transfer read

and write size of 64 words. The Explicit Message Control table in the

scanner module is 64 words. The scanner module uses the block

transfer size as an indicator that the content is a client/server request.

How to Format the Explicit Message T ransaction Block

Ten 32-word transaction blocks within the scanner module are

reserved for Explicit Message Program Control. The transaction blocks

accommodate both the download of Explicit Message Requests and

the upload of Explicit Message Responses.

The sca n ne r modu l e c a n a cc ommod a t e one reque st or respon se f or

each transaction block and can transfer two blocks for each upload

and download. You must format each transaction block as shown in

the f ollo wing fi gure :

15 0

Transaction

Header

(3 words)

TXID cmd/status

port

service

Transaction Body

(29 words)

One word = two bytes = 16 bits

size

MAC ID

word 0

word 1

word 2

word 31

Publication 1771-IN014B-E N-P - September 2001

Page 29

DeviceNet Scanner Module Catalog Number 1771-SDN/C 29

The transaction block is divided into two parts:

• transaction header – contains information that identifies the

transaction to the scanner and processor

• transaction body – in a request, this contains the DeviceNet

Class, Instance, Attribute and Service Data portion of the

transaction. In a response, this contains only the response

message.

Each of the data attributes in the transaction header are one byte in

length:

• command/status – for each download, you assign a command

code to instruct the scanner how to administer the request:

Command Code Description

0 Ignore transaction block (block empty)

1 Execute this transaction block

2 Get status of transaction TXID

3 Reset all client/server transactions

4–255 Reserved

For each upload, the status code provides the processor with status on

the device and its response:

Status Code Description

0 Ignore transaction block (block empty)

1 Transaction completed successfully

2 Transaction in progress (not ready)

3 Error – slave not in scan list

4 Error – slave offli ne

5 Error – DeviceNet port disabled/offline

6 Error – transaction TXID unknown

7 Error – slave not responding to request

8 Error – Invalid command code

9 Error – Scann er out of buffers

10 Error – Other Client/server transaction in

progress

11 Error – could not connect to slave device

12 Error– response data too large for block

13 Error – invalid port

14 Error – invalid size specified

15 Error – connection busy

16-255 Reserved

Publication 1771- IN014B-EN-P - Septem ber 2001

Page 30

30 DeviceNet Scanner Module Catalog Number 1771-SDN/C

Transaction

Header

(3 words)

15 0

TXID cmd/status

port

service

Transaction Body

(29 words)

One word = two bytes = 16 bits

size

MAC ID

word 0

word 1

word 2

word 31

• TXID (transaction ID) – when you create and download a

request t o t he sc a nner, the pro c e ssor’s ladd e r logic progr a m

assigns a TXID to the transaction. This is a one-byte integer in

the range of 1 to 255. The scanner uses this value to track the

transaction to completion, and returns the value with the

response that matches the request downloaded by the

processor. The ladder logic program monitors rollover and

usage of TXID values.

• size – the size of the transaction body in bytes. The transaction

body can be as many as 29 words ( 58 bytes) in len gth. If the s ize

exceeds 29 words, an error code will be returned.

• port – the DeviceNet port where the transaction is routed. The

port can be z ero (Channel 1) or one (Channel 2).

• MAC ID (node address) – the DeviceNet network address of

the slave device where the transaction is sent. This value can

range from 0 to 63. The port and MAC ID attributes coupled

together identify the target slave device.

• service – for each Explicit Message Request and Response, the

service attribute contains the service request and response codes

that match the corresponding request for the TXID.

Publication 1771-IN014B-E N-P - September 2001

Page 31

DeviceNet Scanner Module Catalog Number 1771-SDN/C 31

The following figure describes the fo rmat and mapping of transact ion

blocks for request and response messages in the scanner module:

Transaction

Header

(3 words)

Transaction

Header

(3 words)

Format of 64-word Block Transfer Write

for Explicit Message Request

15 0

TXID command

port

service

Instance

Attribute (optional)

Service Data

TXID command

port

service

Instance

Attribute (optional)

size

MAC ID

Class

size

MAC ID

Class

word 0

Transaction #1

word 31

word 32

Transaction #2

Transaction

Header

(3 words)

Transaction

Header

(3 words)

Format of 64-word Block Transfer Read

for Explicit Message Response

15 0

TXID status

port

service

Service Response Data

TXID status

port

service

Service Response Data

size

MAC ID

size

MAC ID

word 0

word 31

word 32

Transaction #1

Transaction #2

Service Data

word 63

word 63

How the Processor and Scanner Module Manage Messages

Block transfer operations between the processor and the scanner

always originate in the processor. The scanner module can only wait

for the processor to download a transaction block to the module or

request an upload of a transaction block from the module.

Once an Explicit Message Request transaction block is downloaded to

the scanner module, a ladder logic progr am i n t he pro cessor p olls th e

scanner module for the transaction block containing the Explicit

Message Response for that req uest. This is do ne by the proces sor with

a Block Transfer Read on the scanner module.

Publication 1771- IN014B-EN-P - Septem ber 2001

Page 32

32 DeviceNet Scanner Module Catalog Number 1771-SDN/C

Depending on the network load, the scanner could take a few

seconds to complete the request. When a response is loaded, bit 15 of

the module status register is set to 1. The program may have to poll

the scanner module a number of times before the scanner returns

a Response Transact i on Block.

The scanner module recognizes I/O data and control as higher

priorities over explicit messaging on DeviceNet.

Message lengths and slave device types impact transaction message

completion times. If the processor has queued multiple Explicit

Message Transactions to the scanner module for multiple slave

devices, the transactions with the slaves may not complete in the

order in which the requests were received. The slave responses are

queued to the 64 word Bl ock T ransf er Read in the or der in which th ey

are received. As response transaction blocks are uploaded, the

processor’s program matches the responses to the requests using

the TXID field.

Processor Scanner Module

BTW

Request

Transaction

Block

Ladder Scans

Response

Transaction

Block

BTR

Request

Transaction

Blocks

Execute

Process Requests

and Responses

Done or

Error-detected

Response

Transaction

Blocks

Scanner

Request

Queue

Scanner

Response

Queue

DeviceNet

Explicit Message

Requests and

Responses

DeviceNet Network

Slave

Device

Publication 1771-IN014B-E N-P - September 2001

Page 33

DeviceNet Scanner Module Catalog Number 1771-SDN/C 33

Explicit Message Program Control Limitations

• The processor is always the DeviceNet client and the slave is

always the DeviceNet server.

• A max imum of te n Explicit Mes sage R equest Transaction Blocks

with the execute command can be queued to the scanner

module at any time. For example, five Block Transfer W ri te files

contai ni ng tw o tran sac ti ons e ach, can be pe rformed a t any time .

The scanner module receives and deletes any additional

client/server requests with the execute command over the

maximum of ten.

As transactions are removed from the queue and response transaction

blocks are returned to the processor , additio nal transaction blocks can

be issued in their place, as long as the total does not exceed ten.

• The scanner module supports two transact ion bloc ks per uplo ad

and download.

• If a slave device is not communicating at the time the scanner

module processes its Request Transaction Block, the scanner

module will return an error status for that transaction.

• At a minimum, the scanner module supports the following

DeviceNet services in Request Transaction Blocks:

Service Name: Service Code: Example:

Get_Attribute_Single 0E

Set_Attribute_Single 10

Get_Attribute_All 01

Set_Attribute_All 02

hex

hex

hex

hex

Upload a single parameter value

from a device

Download a single parameter

value to a device

Upload all parameter values from

a device

Download all parameter values to

a device

• Continuous Block Transfers of 64 words are not supported.

• All transaction blocks are processed, therefore, any unused

transaction blocks must be left blank.

• Client/Server commands and requests with transaction IDs that

are in use are deleted by the scanner module.

Publication 1771- IN014B-EN-P - Septem ber 2001

Page 34

34 DeviceNet Scanner Module Catalog Number 1771-SDN/C

• If a slave device returns a DeviceNet error in response to the

request downloaded fro m the processor, the scanner recognize s

the error as a successful transaction (status code =1).

A failure to respond to the request within the number of retries or

timeout period specified for the Explicit Message Connection is

recognized by the scanner module as an error. The error code is

returned in the status attribute of the transaction header.

Explicit Messaging Error Codes

Error codes have two bytes of data. The first byte is a General Error

Code and the second is an optional Additional Code Field that may

contain additional information about the error. If this field is unused,

the value 0FFH is shown.

messagi ng error co de s.

The following table describes explicit

Numer i c

Code:

02H Resource unavailable A needed reso ur c e wa s not av ail ab le

08H Servi c e un sup ported Service is not defined or implemented for

09H Invalid attribute value Data is invalid for the specified attribute

0BH Already in requested state Object is in the requested state - redundant

0CH Object state conflict Not allowed with object in present state

0EH Attribute cannot be set Read-only at tr ib ut e

0FH Privilege violation A permission/privilege check failed

10H Device sta te conflict Not allowed with device in present state

11H Reply too big Reply larger t han buffer allocated when

13H Too little data Request included insufficient data

14H Attrib ute not suppo rted Attribute number is incorrect

15H Too much data Reques t included extra data

16H Object does not exist Class/instance numbers are incorrect

18H No stored attribute data Attribute data was not saved prior to this

19H Store operation failure Attribute data was not successfully saved

1FH Vendor-specific error Second byte may offer details - refer to

20H Invalid parameter Parameter associated with request is invalid

D0H Reserved and service-specific

FFH

Name: Description:

this class/instance

request

connection was established

request

vendor documentation

Used only when none of the standard error

errors

codes supplemented by the second byte

accurately describes the problem.

Publication 1771-IN014B-E N-P - September 2001

Page 35

DeviceNet Scanner Module Catalog Number 1771-SDN/C 35

Troubleshoot Your Module

The bicolor (green/red) module status indicator displays device status.

It indic a tes whether the de vice has power a nd i s functioning properly.

If your indicator is: Then: Take this action:

Channel 1

Module Status

Indicator

Network Status

Indicator

Off There is no power applied to

the module.

Green The module is operating

normally.

Flashing Gr een The module is not configured. Configure the module.

Flashing Red There is an invalid

configuration.

Red The m odule has an

unrecoverable fault.

Verify power connections and

apply power.

Do nothing.

Verify module switch settings.

Check configuration setup.

Replace the module.

Channels 1 and 2 each have a bicolor (green/red) network status

indicator. The following table provides troubleshooting information

Top part of module

If the indicator is Then Which indicates Take this action

Off The device has no power or the

channe l is disabled for

comm un ic a tio n du e to a bus of f

condition, loss of network power, or

it has been intentionally disabled.

Green Normal operation. All slave devices in the scanlist table

Flashing Green The two-digit numeric display for the

channel indicates an error code that

provide s mor e i nfor m ati on ab ou t t he

condition of the channel.

Flashing Red The two-digit numeric display for the

channel displays an error code that

provide s mor e i nfor m ati on ab ou t t he

condition of the channel.

Red The communications channel has

failed. The two digit numeric display

for the channel displays an error

code that p ro vi des mor e i nfo rm at ion

about th e condition of the channel.

about the Channel 1 and 2 communication links.

The channel is disabled for DeviceNet

communication.

are communicating normally with the

module.

The channel is enabled but no

communication is occurring.

At leas t one of the slav e devic es in th e

module’s scanlist table has failed to

communicate with the module.

The network has faulted.

The module may be defective. Reset the module. If failures continue,

Power-up the module, provide network

power to the channel, and be sure the

channel is enabled in both the module

configuration table and the module

command word.

None.

Configure the scanlist table for the

channel to add devices.

Examine the failed device and the

scanlist table for accuracy.

replace module.

Your 1771-SDN Scanner Module has a node address/status indicator

that uses numeric displays to indicate diagnostic information about

your module. The display flashes at approximately 1 second

intervals, depending on network traffic. The following table

summarizes the meanings of the numeric codes.

Publication 1771- IN014B-EN-P - Septem ber 2001

Page 36

36 DeviceNet Scanner Module Catalog Number 1771-SDN/C

Top part of module

Channel 1

Node Address /

Status Indicator

Numeric

Description Take this action

Code

0 - 63 Normal operation. The numeric display

None.

indicates the 1771-SDN’s node

address on the DeviceNet network.

70 Module f ai l ed Du pl i cate Node Addr es s

check.

71 Illegal data in scan list table (node

number alternately flashes).

72 Slave device stopped communicating

(node number alternately flashes).

73 Device’s identity information does not

match electronic key in scan list table

entry.

Change the module channel address to

another available one. The node address

you selected

channel.

is already in use on that

Reconfigure the scan list table and

remove any illegal data.

Inspect the field devices and verify

connections.

Verify that the correct device is at this

node number. Make sure that the device

at the scrolling node address matches

the desired electronic key (vendor,

product code, product type, etc.).

74 Data overrun on port detected. Modify your configuration and check for

invalid data. Check network

communication traffic.

75 No traffic from ot her modu les detec ted

on the network.

76 No direct network traffic for modu le

detected.

77 Data size expected by the device does

not match scan list entry.

78 Slave device in scan list table does not

exist.

79 Module has failed to transmit a

message.

Check the network configuration.

(Scanlist may be empty.)

None. The module hears other network

communication.

Reconf igure your module for the correct

transm it and receive data sizes.

Add the device to the network, or delete

the scan list entry for that device.

Make sure that your module is

connected to a valid network.

Check fo r disconne c te d cab l e s.

80 Module is in IDLE mode. Put controller in RUN mode. Enable RUN

bit in module command register.

81 Module is in FAULT mode. Check Module Command Register for

fault bit set.

82 Error detected in sequence of

fragmented I/O messages from device.

Check scan list table entry for slave

device to make sure that input and

output data lengths are correct. C heck

slave device co nfiguration.

83 Slave device is returning error

responses when module attempts to

communicate with it.

Check accuracy of scan list table entry.

Check slave device configuration. Slave

device may be in another maste r’s scan

list. R eboot slave de vice.

84 Module is initializing the DeviceNet

network.

None. This code clears itself once

module attempts to initialize all slave

devices on the network.

Publication 1771-IN014B-E N-P - September 2001

Page 37

DeviceNet Scanner Module Catalog Number 1771-SDN/C 37

Numeric

Description Take this action

Code

85 Data size was incorrect for this device

at runtime.

• Slave device is transmitting

incorrect length data.

• Verify device is not configured

for variable poll connection size.

• Try replacing the device.

86 Device is producing zero length data

(idle state) while module is in Run

Check device configuration and slave

node status.

Mode.

87 The primary owner has not alloc ated

Put the p rimary owner on line.

the slave.

88 The connection choices (polled,

stro bed, etc.) between the primary

connection and the shared input only

connection do not match.

89 Slave device initialization using Auto

Device Replace m ent param e te rs

failed.

Reconfigure the shared input only

connection’s choice(s) to be the same

as, or a subset of, the primary

connection’s choice(s).

• Put the slave device into

configurab le mode.

• Check the slave’s EDS file, if the

slave is configured offline.

• Check to see if the slave device

has been replaced with an

incompatible device.

90 User has disabled communication port. Check Module Command Register for

DISABLE bit set.

91 Bus-off conditio n de te cte d on co mm

port. Module is detecting

communication errors.

Check DeviceNet connections and

physical media integrity. Check system

for faile d s lav e devi c es or other possible

sources of network interference.