Page 1

1771-QRD Pulse Flowmeter Module

Installation and User’s Manual

Page 2

Important

This module is designed for use ONLY as an operating control. Where an

operating control failure would result in personal injury and/or loss of

property, it is the responsibility of the system designer or end user to add

devices (safety, limit controls) or other systems (alarm, supervisory

systems) that protect against or warn of control failure.

Solid state equipment has operational characteristics differing from those

of electromechanical equipment. ‘Application Considerations for Solid

State Controls’ (publication SGI–1.1) describes some important differences

between solid state equipment and hard wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application is acceptable.

In no event will Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Allen-Bradley Company cannot

assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to

use of information, circuits, equipment or software described in this

manual.

Reproduction of the contents of this manual, in whole or part, without

written permission of the Allen-Bradley Company is prohibited.

copyright 1990 Allen-Bradley Company

1–1

Page 3

Table of Contents

Before You Begin 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual's Purpose 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audience 1

Vocabulary 1

Overview

Warnings and Cautions 2

Explosion Hazard 2

Related Products 2

Product

Related

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of the Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility

Publications

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Module Description and General Features 1

How the 1771-QRD Works 2

How the 1771-QRD Communicates With Programmable Controllers 3

Chapter Summary 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objectives

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Installing the 1771-QRD Module 1

Power Requirements 1

Module

Module Keying 2

Wiring 2

Electrostatic Discharge 3

Module

Indicators 7

Chapter Summary 7

Module

Objective

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location in the I/O Chassis

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. . . . . . . . . . . . . . . . . . . . . . .

2

3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Reading Data From The Module 1

Overrange and Overflow 2

Block Transfer Programming 2

Example #1: PLC-5/15 Processor in a Local 1771 Backplane 3

Example

Example

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

#2: PLC-5/15 with Remote I/O

#3: PLC-3/10 with Remote I/O

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

8. . . . . . . . . . . . . . . . . . . .

12. . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contentsii

More on Overrange and Overflow 1. . . . . . . . . . . . . . . . . . .

Chapter

Frequency Overrange Flags 1

Totalizer Overflow Flags 2

Using A Block Transfer W

Chapter Summary 5

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rite to Reset the T

and/or Overflow Flags 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

otalizer(s)

Troubleshooting 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Objectives

Data Formats 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer Write Format From PLC to QRD 1. . . . . . . . . . . . . .

Response from QRD to PLC Block Transfer 1

. . . . . . . . . . . . . . . . .

Specifications 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment 1

Agency Approval 1

Packaging 1

Weight 1

Capacity 1

Performance 1

Operational

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limits

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Before You Begin

Chapter 1

Manual's

Purpose

Audience

Vocabulary

This manual shows you how to apply the 1771–QRD Pulse Flowmeter

Module to an Allen-Bradley PLC system. It describes methods for

installation, programming, and troubleshooting the module. It also

provides examples of how to use the module.

You must be able to program and operate an Allen-Bradley programmable

controller to make efficient use of this module. In particular, you must

know how to program Block Transfer instructions. If you do not, refer to

the appropriate programming and operations manual for the processor you

are using.

We refer to the:

Pulse Flowmeter Module (Catalog No. 1771–QRD) as “the module”, or

“the QRD”.

Programmable Controller as “the processor”.

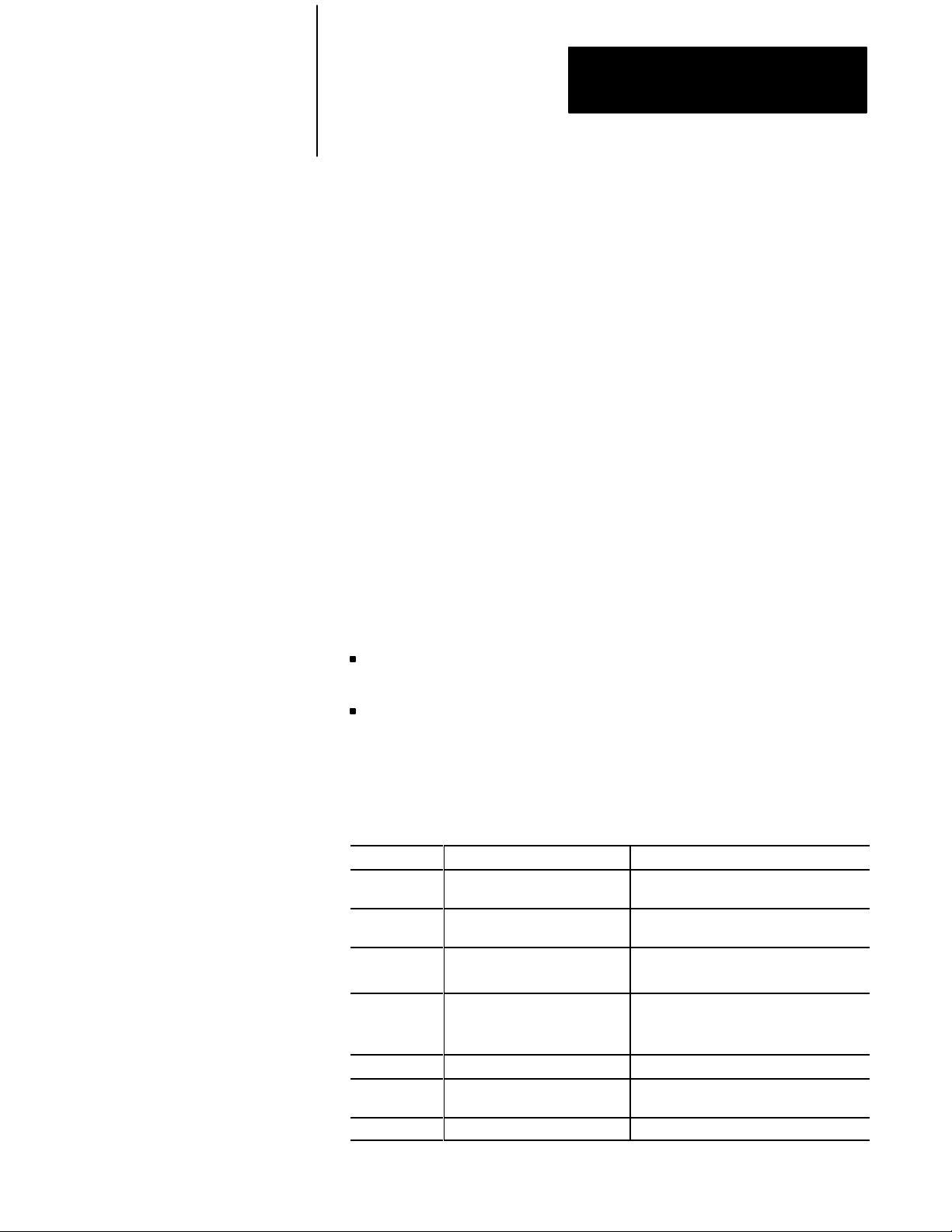

Overview of the Manual

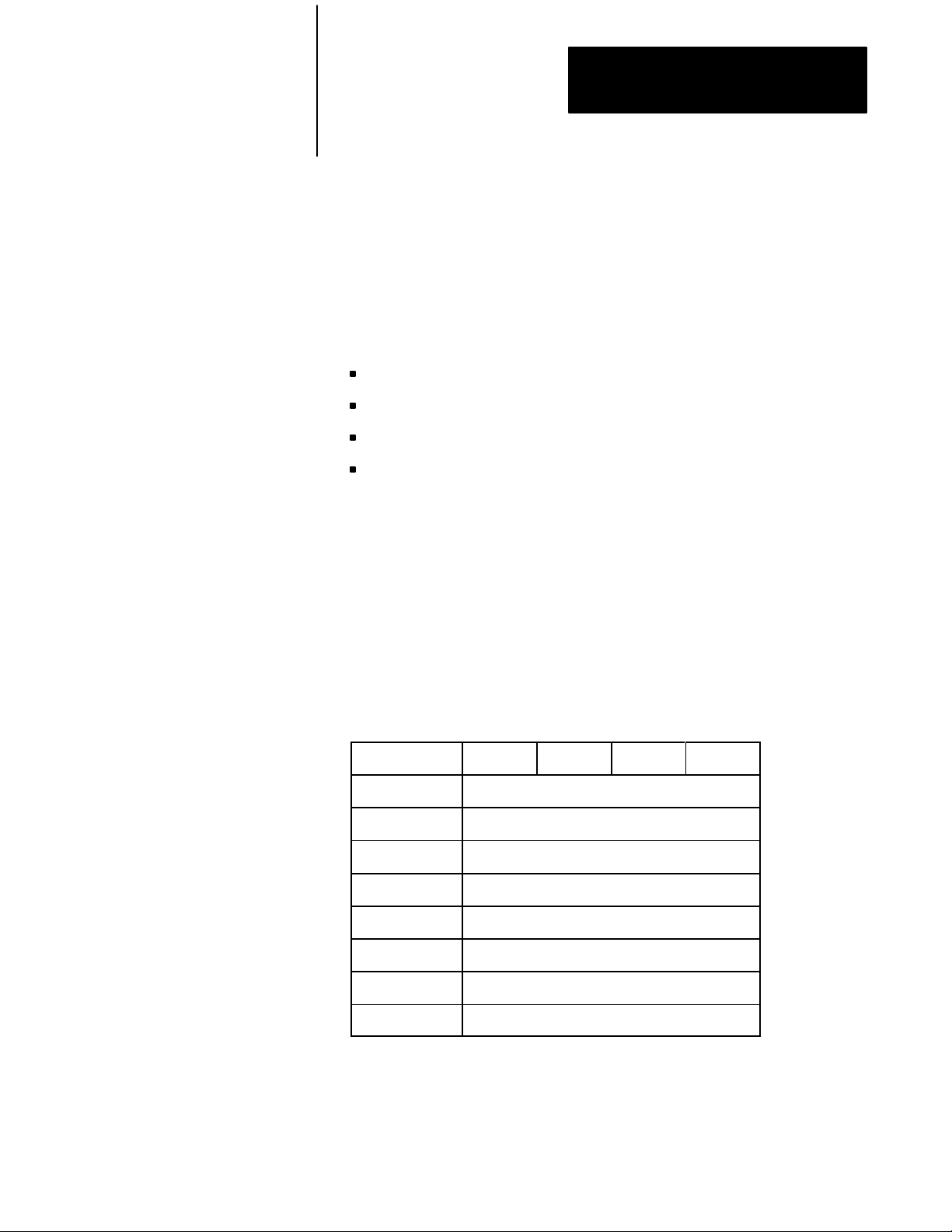

This manual is divided into 6 chapters. The following table provides a brief

overview of the topics covered in each chapter.

Chapter Title Topics Covered

2 Introduction Description of module including

programmable features

3 Installation Module power requirements, keying chassis

location, field wiring

4 Programming Reading data from the module

Sample programs for various processors

5 More on Overrange and Overflow Error codes

Block transfer write rung for resetting

totalizers and/or overflow flags

6 Troubleshooting Symptom/solution guide

Appendix A Data Formats Data formats fore Blcok Transfer Write and

Block Transfer Read

Appendix B Specifications

1–1

Page 6

Chapter 1

Before You Begin

Warnings and Cautions

Explosion Hazard

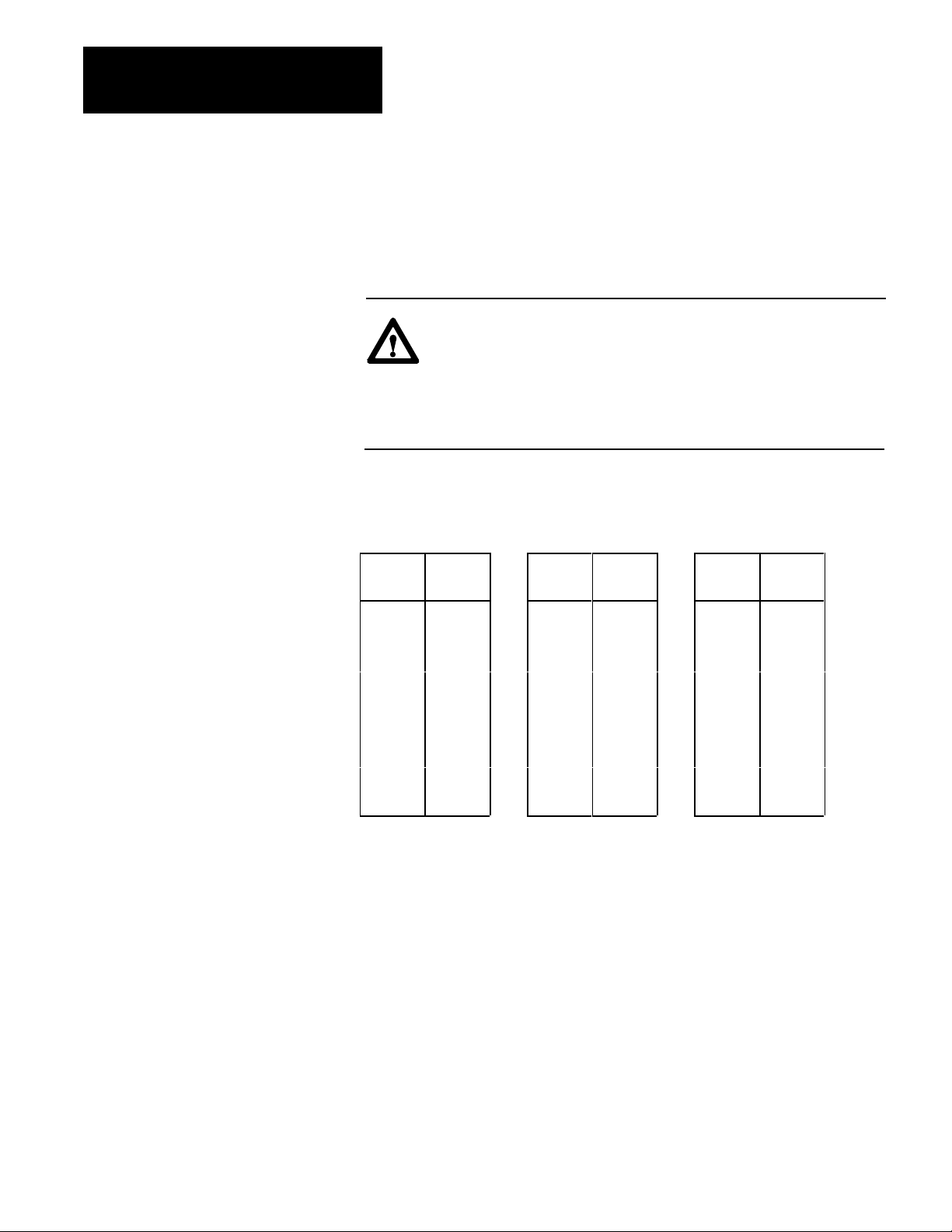

Warnings are found in this manual and on the equipment. The following

symbols are used:

WARNING: A warning symbol means people might be injured

if the the procedures are not followed.

CAUTION: A caution symbol is used when machinery could

be damaged if the procedures are not followed. Explosion

Hazard

WARNING: Explosion hazard — substitution of components

may impair suitability for Class 1. Division 2

AVERTISSEMENT: Risque d’explosion — la substitution de

composants peut rendre ce matériel inacceptable pour les

emplacements de Classe 1, Division 2.

Related Products

WARNING: Explosion hazard — do not disconnect equipment

unless power has been switched off or the area is known to be

non-hazardous.

AVERTISSEMENT: Risque d’explosion — avant de

déconnecter l’équipement, couper le courant ou s’assurer que

l’emplacement est designe non dangereux.

The 1771–QRD Module can be installed in any system that uses

Allen-Bradley PLC–2, PLC–3 or PLC–5 Programmable Controllers with

Block Transfer capability and 1771 I/O structure.

Contact your nearest Allen-Bradley office for more information about

programmable controllers.

1–2

Page 7

Product Compatibility

Chapter 1

Before You Begin

Do not put the module Do not put the module in the same module group

as a discrete high-density module with 2 slot addressing.

Avoid placing the module adjacent to AC modules or high voltage DC

modules.

Related Publications

Consult the Allen-Bradley Industrial Computer Group Publications Index

(SD 499) for more information about programmable controllers.

1–3

Page 8

Chapter 1

Before You Begin

1–4

Page 9

Introduction

Chapter 2

Chapter

Objectives

Module Description and General Features

In this chapter you will read about:

1771–QRD Pulse Flowmeter Module features

How the 1771–QRD Module communicates with programmable

controllers

The Catalog No. 1771–QRD Pulse Flowmeter Module is an intelligent

block transfer module that interfaces Programmable Controllers with

magnetic pickups, single channel shaft encoders, and turbine flowmeters,

or with any source of TTL pulses. The module is generally compatible

with, but does not require the use of, turbine flowmeter signal

preconditioning modules. It provides rate and count data in 2’s

complement binary format to the processor data table through block data

transfers.

Rates as high as 10.0 kHz and counts as large as 32,767 are supported. At

overflow, the count continues from zero and an overflow flag is set. The

overflow flag can be reset by the ladder logic. In addition, the PLC can

reset any or all counts directly.

The module functions with reduced performance in PLC–2 systems due to

their three digit BCD operation. Rates as high as 0.999 kHz are permitted

as are total counts of any size, provided that the PLC ladder polls the

module at intervals faster than it can acquire 999 counts.

The 1771–QRD module receives +5 Vdc operating voltage through the I/O

chassis backplane. It draws a maximum of 0.50 A from this supply.

The module is implemented in a 1771 single-density module form factor.

2–1

Page 10

Chapter 2

Introduction

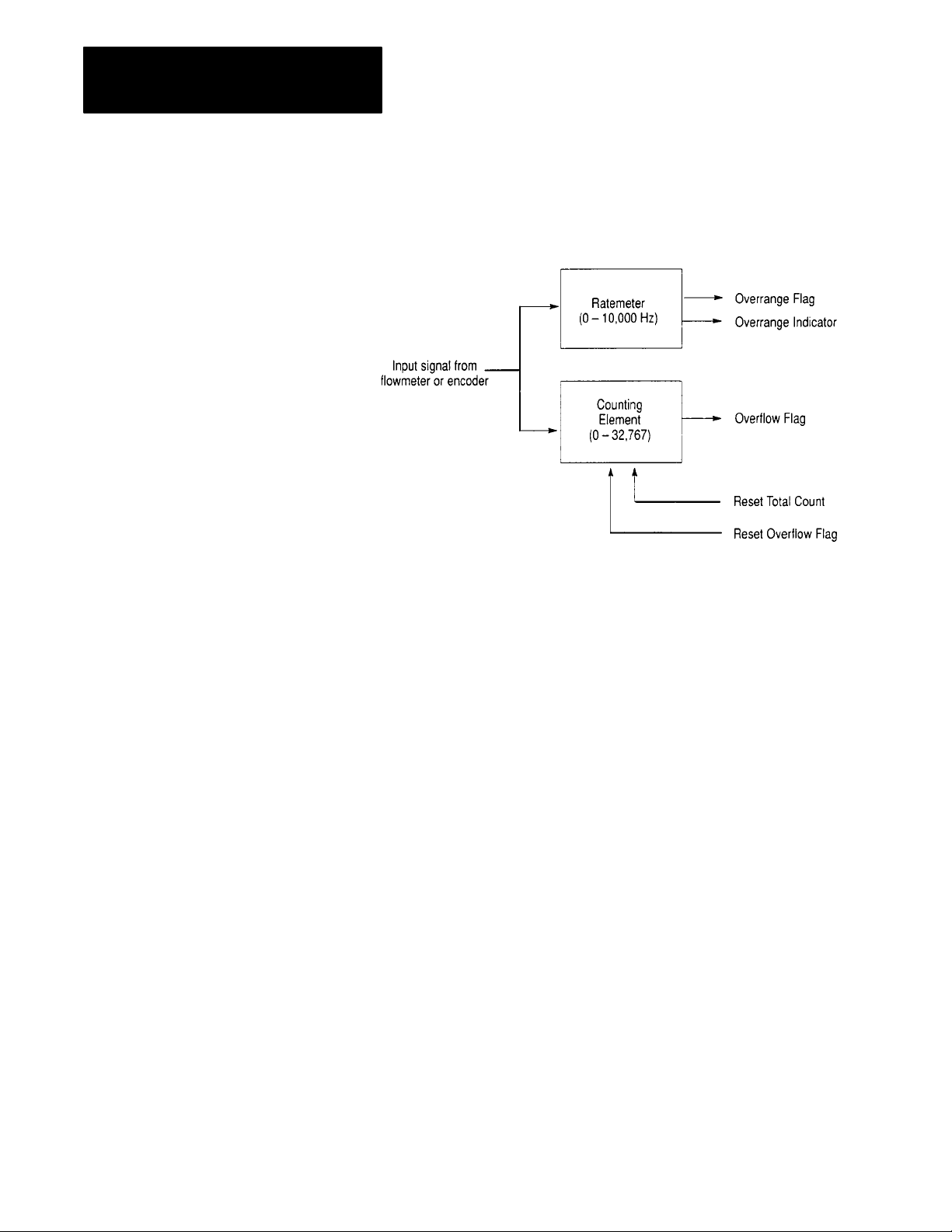

How

the 1771-QRD W

orks

Figure

2.1

A T

ypical Channel

The QRD is operated with block transfers. Block Transfer Reads report the

count values, rates, and both overrange and overflow flags to the PLC.

Block Transfer Writes are used by the PLC to reset the total count or to

reset the overflow flags.

2–2

Page 11

Chapter 2

Introduction

How

the 1771-QRD

Communicates With

Programmable Controllers

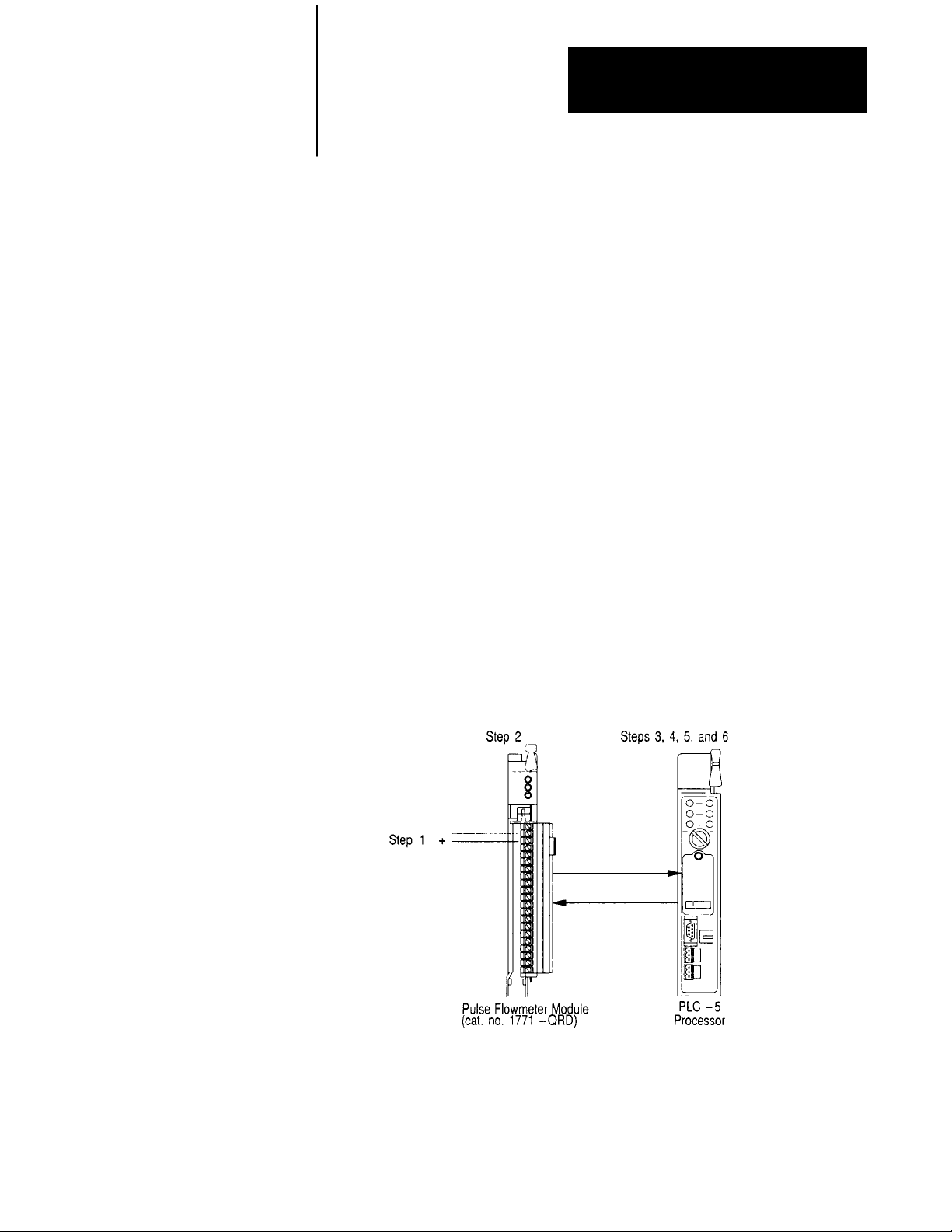

The following is a step-by-step example of the information flow to and

from a 1771–QRD Module (Figure 2.2):

1. External devices (magnetic pickups, single channel encoders)

generate signals that are conducted to the 1771–QRD module.

2. The 1771–QRD module converts the incoming signals into counts

and rates, then stores these values until the PLC requests a transfer of

data.

3. When instructed by the ladder program, the processor performs a

Block Transfer Read of the values and stores them in the processor’s

data table.

4. In the case of a count overflow, the ladder program can sense the

overflow and reset the overflow flag, if desired, using data from

within a Block Transfer Write command. Any or all of the totalizers

can also be reset. (Note that when the totalizers are reset the overflow

flags are also reset.)

5. In the case of a rate overrange, the ladder program can sense the

overrange condition and act upon it accordingly.

6. The ladder program can use and/or move the data before it is written

over by the transfer of new data in a subsequent block transfer.

Chapter Summary

Figure

2.2

Information flow through a programmable controller/1771-QRD System

In this chapter you read about the functional aspects of the 1771–QRD

Module and how it communicates with a Programmable Controller.

2–3

Page 12

Installation

Chapter 3

Chapter

Objective

Installing the 1771-QRD Module

In this chapter you will read how to install the 1771–QRD module in the

I/O chassis.

Read this installation section completely before installing the module.

Double check all connections before you begin programming.

WARNING: Disconnect and lock out all power from the

controller and system power supplies before installing and

wiring modules to avoid injury to personnel and damage to

equipment.

Before installing the 1771–QRD Module in the I/O chassis:

1. Calculate the power requirements of all the modules in the chassis.

See the section below titled “Power Requirements”.

2. Determine the location of the module in the I/O chassis. See the

section titled “Module Location in the I/O chassis”.

3. Key the backplane connectors in the I/O chassis. See the sect ion

titled “Module Keying”.

Power Requirements

4. Connect the field wiring. See the section titled “Wiring”.

The1771–QRD Module receives its power through the 1771 I/O chassis

backplane from the chassis power supply. It does not require any other

external power supply to function. When planning the system, consider the

power usage of all modules in the I/O chassis to prevent overloading the

chassis backplane or power supply. Each 1771–QRD Module requires 0.50

A at +5VDC. Add this to the requirements of all other modules in the I/O

chassis.

CAUTION: Do not insert or remove modules from the I/O

chassis while system power is on. Failure to observe this rule

may result in damage to the module circuitry.

3–1

Page 13

Chapter 3

Installation

Module

Location in the I/O

Chassis

Module Keying

Place the module in any I/O module slot of the I/O chassis except for the

extreme left slot. This slot is reserved for the programmable controllers or

adapter modules. In addition:

1. Do not put the module in the same module group as a discrete

high-density module with 2-slot addressing. However, other

single-slot modules may be placed in the same module group.

2. Do not put the module adjacent to AC or high voltage DC I/O

modules, to minimize electrical noise and temperature effects. Noise

can be minimized by grouping input and output modules together

within an I/O chassis.

See the user’s manual of any other intelligent I/O modules involved for

possible grouping limitations.

Module Keying Plastic keying bands, shipped with each I/O chassis

provide an easy method for keying I/O slots to accept only one type of

module. The module is slotted in two places on the edge of the rear circuit

board. The position of the keying bands on the backplane connector must

correspond to these slots to allow insertion of the module. You can key any

connector in an I/O chassis to receive this module except for the leftmost

connector reserved for processor or adapter modules. Place the keying

band between the following numbers labeled on the backplane connector:

Wiring

between pins 2 and 4

between pins 6 and 8

You may change the positions of the bands if subsequent system design

and rewiring makes insertion of a different type of module necessary. Use

needle-nose pliers to insert or remove a keying band.

WARNING: To avoid injury to personnel and damage to

equipment, disconnect and lock out power from the processor

and system power supplies before wiring the m module.

Connections to/from I/O devices are made to the field wiring arm (catalog

no. 1771–WG shipped with the module. Attach the wiring arm to the pivot

bar at the bottom of the I/O chassis. It pivots upward and connects with the

module so you can install or remove the module without disconnecting the

wires.

3–2

Page 14

Chapter 3

Installation

The sensor cable must be shielded. The shield must extend the length of

the cable, but be connected only at the 1771–QRD end. The recommended

sensor wiring cable type is Belden 8761 or similar. The functions of the

individual terminals of the field wiring arm are shown in Figure 3.1.

The wiring diagrams for both magnetic pickups and TTL are shown in

Figures 3.2 and 3.3, respectively.

Electrostatic

Discharge

Module Installation

Electrostatic Discharge Electrostatic discharge can damage the integrated

circuits in this module, if you touch the backplane connector pins. Avoid

electrostatic damage by observing the following precautions:

Touch a grounded object to rid yourself of charge before handling the

module.

Do not touch the backplane connector or connector pins.

When not in use, keep module in its static-shield bag.

CAUTION: Electrostatic discharge can degrade performance

or damage the module. Handle as stated above.

Now that you have determined the power requirements, location, keying

and wiring for the 1771–QRD Module, you are ready to install it in the I/O

chassis.

1. Turn off power to the chassis.

2. Place the module in the plastic tracks on the top and bottom of the

slot to guide the module into position.

3. Seat the module into the connector by applying firm, even pressure.

Do not force the module into its backplane connector.

4. Snap the chassis latch over the top of the module to secure its

position.

5. Connect the wiring arm to the module.

6. Turn on power to the chassis. The green “ACTIVE” light should be

illuminated. If it is not lit, there is no power being applied to the

module. Turn the power off, re-insert the module and try again.

Connect one or more signal sources to the 1771–QRD. The signal source

can be a magnetic pickup/turbine flowmeter or TTL pulses.

3–3

Page 15

Chapter 3

Installation

Figure

Field W

3.1

iring Arm

3–4

WARNING: Explosion hazard. Do not disconnect equipment

unless power has been switched off or the area is known to be

nonhazardous.

AVERTISSEMENT: Risque d’explosion. Avant de

déconnecter l’équipment, couper le courant ou s’assurer que

l’emplacement est designe non dangereux.

Page 16

Figure

3.2

W

iring for Pickups or Flowmeters

Chapter 3

Installation

3–5

Page 17

Chapter 3

Installation

Figure 3.3

W

iring for Active TTL Drivers

Note: The jumper between terminals 17 and 19 changes the sensitivity of

channels 3 and 4 so that they are compatible with TTL pulses.

The jumper between terminals 17 and 20 changes the sensitivity of

channels 1 and 2 so that they are compatible with TTL pulses.

Signal types may not be mixed within a channel pair.

For use with magnetic pickups or turbine flowmeters, do not connect a

jumper to these terminals.

WARNING: Remove power from the 1771 I/O chassis

backplane and from the wiring arm before removing or

installing the module.

Failure to remove power from the backplane or the wiring arm could

cause module damage, degradation of performance or injury.

Failure to remove power from the backplane could cause injury or

equipment damage due to possible unexpected operation.

3–6

Page 18

Chapter 3

Installation

Indicators

Chapter

Summary

There are three indicator LEDs on the front panel. The indicator LED

functions are listed in Table 3.A.

Table

3.A

Indicators

Legend Color Type Function

FAULT Red Solid One or more inputs are above 10.0 kHZ

FAULT Red Flashing Internal hardware failure, or input rates drifiting above

and below 10.0 kHz

PROG Yellow Flashing Block transfer in process

ACTIVE Green Solid Module active

In this chapter you read how to install the 1771–QRD Module in a

Programmable Controller system, as well as how to wire the field wiring

arm.

3–7

Page 19

Module Programming

Chapter 4

Chapter

Objectives

Reading Data From The Module

In this chapter you will learn about:

Reading data from the 1771–QRD module

Writing data to the 1771–QRD module

Black transfer programming format

Programming techniques

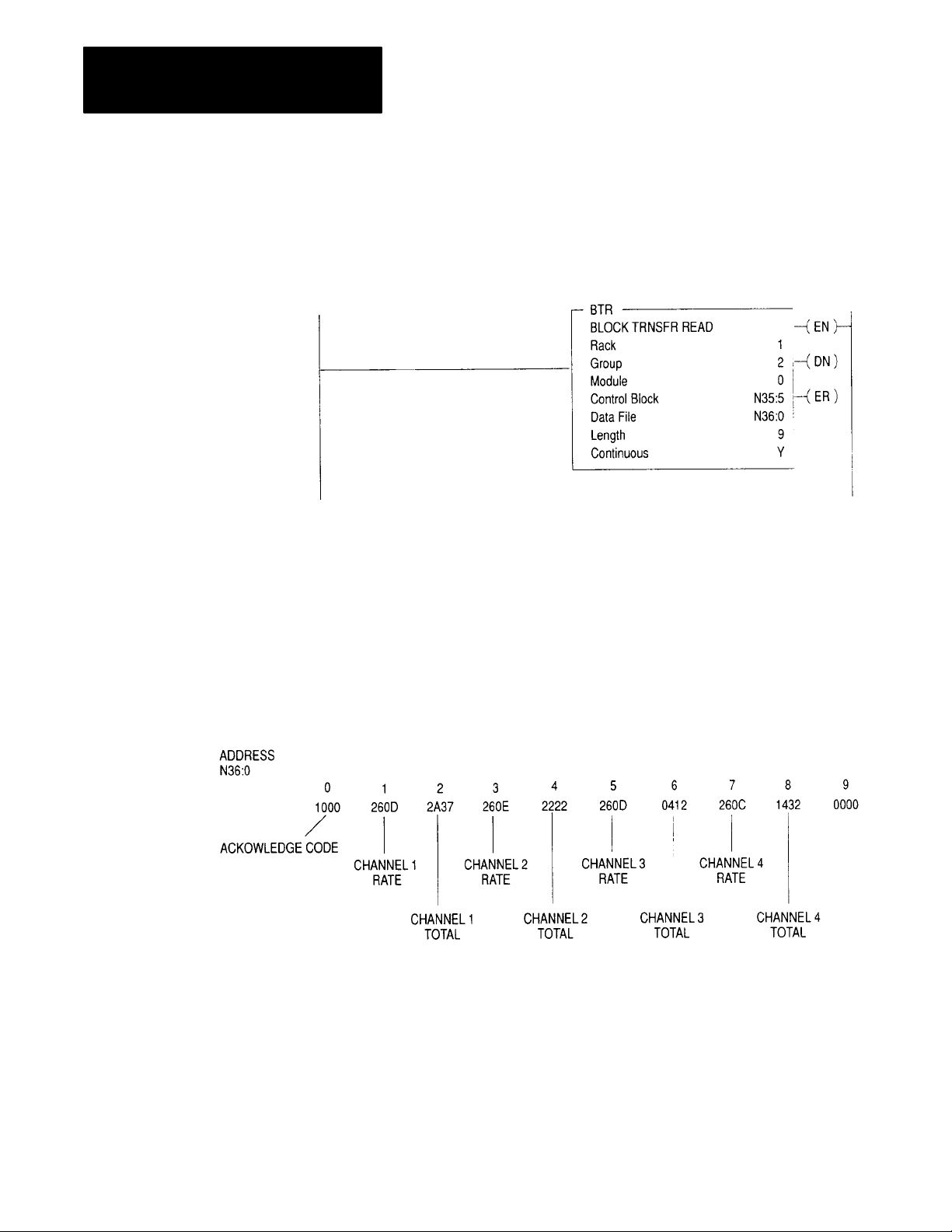

Block Transfer Read programming moves 9 words from the 1771–QRD

Module to the processor’s data table. The ladder program initiates the

request to transfer data from the QRD to the processor.

Figure 4.1 illustrates the module’s response after the PLC processor’s

block transfer request for counts and rates.

Figure

4.1

Module'

s Response to Block T

Word 0 1 0 0 0

Word 1 Channel 1 Rate

ransfer Read Request

Word 2 Channel 1 Total

Word 3 Channel 2 Rate

Word 4 Channel 2 Total

Word 5 Channel 3 Rate

Word 6 Channel 3 Total

Word 7 Channel 4 Rate

Word 8 Channel 4 Total

4–1

Page 20

Chapter 4

Module Programming

Word 0 (1000) is the header code that identifies the data source as a

1771–QRD module. When the module is active, it also contains the status

of the overrange and overflow flags. Overrange and overflow are discussed

in more detail in the next section of this chapter. Word #1 contains the rate

of the signal on channel 1; word #2 contains the total number of pulses

received on channel 1. Word #3 contains the rate of the signal on channel

2; word #4 contains the total number of pulses received on channel 2.

Word #5 contains the rate of the signal on channel 3; word #6 contains the

total number of pulses received on channel 3. And finally, words #7 and #8

contain the rate and total number of pulses received on channel 4,

respectively.

Overrange

and Overflow

Block Transfer Programming

The 1771–QRD processes input signals at a maximum rate of 10.0kHz. If

the rate of the incoming signal on any channel is greater than 10.0 kHz, the

red FAULT indicator will illuminate, revealing an overrange. At the same

time, a bit will be set in the acknowledge word (word 0), showing the

channel(s) whose rate is in an overrange condition. The red FAULT light

will extinguish only when the frequency of the input that is causing the

overrange is reduced to less than 10.0 kHz. At that time, the FAULT light

will go out, and the overrange flag for that channel will automatically be

reset. Overrange rates are reported as zero values, and cause their totalizers

to reset to zero.

The 1771–QRD also acts as a totalizer for each of the channels. Each of

the totalizers is capable of counting up to 32,767. When this number is

reached by any of the totalizers, an overflow flag for that channel is set in

the acknowledge word. The counter will again start from zero and continue

to count, with the overflow flag set. These flags can be detected by the

processor, and any or all of them can be reset using a Block Transfer Write

command. Examples of the detection and handling of overflow conditions

with a BTW command are discussed further in Chapter 5.

The following sections show how to program and set up typical

programmable controllers for use with the 1771–QRD Module. In each

example, the switch settings for all of the processors and adapters used are

given, as well as the backplane settings for the I/O chassis. Note that 2-slot

addressing is used in all of these examples, but the 1771–QRD will

function with any type of addressing (2-slot, 1-slot, 1/2-slot).

4–2

Page 21

Chapter 4

Module Programming

The following table outlines the examples that are contained in this

chapter:

Table

4.A

Examples Contained in This Section

Example Number System Type Page

1 PLC-5/15 in a local 1771 backplane 4-3

2 PLC-5/15 with Remote I/O 4-8

3 PLC-3/10 with Remote I/O 4-12

These examples represent the most common configurations for a controller

system. One of them should be close enough to your application to be used

as a guide.

Example

#1: PLC-5/15

Processor in a Local 1771

Backplane

1. Install the 1771–QRD module in a 1771 backplane. Figure 4.2

illustrates a PLC–5/15 configured for 2-slot addressing.

Figure

4.2

2Slot Addressing Configuration Example

4–3

Page 22

Chapter 4

Module Programming

The eight physical slots labeled with Rack/Group/Slot (RGS) addresses in

Figure 4.2 would have different RGS addresses if single or 1/2 slot

addressing were chosen.

Please refer to Figure 4.3 for dual, single, or 1/2 slot addressing RGS

numbers.

WARNING: Remove system power and power to all devices

connected to the swing arm terminals before removing or

installing your module into the 1771 I/O chassis. Failure to

observe this warning could result in damage to the module

circuitry and/or undesired operation with possible injury to

personnel.

Figure

4.3

Dual, Single and Half Slot Addressing for Rack 0

DualSlot SingleSlot HalfSlot

Slot

Number

1 000 1 000 1 000

2 001 2 010 2 020

3 010 3 020 3 040

4 011 4 030 4 060

5 020 5 040 5 100

6 021 6 050 6 120

7 030 7 060 7 140

8 031 8 070 8 160

RGS Slot

Number

RGS Slot

Number

RGS

4–4

Page 23

Chapter 4

Module Programming

2. Set the PLC–5/15 configuration switches as shown in Figure 4.4.

Figure

4.4

PLC-5/15 Configuration Dip Switches

NOTE: The black area indicates the selected switch position (up or down).

3. Set the 1771 backplane dip switch as shown in Figure 4.5.

Figure

4.5

1771 Backplane Dip Switch.

NOTE: The black area indicates where the switch should be pressed with

a pencil or other sharp instrument.

The backplane is now set up for 2 (dual) slot addressing.

4–5

Page 24

Chapter 4

Module Programming

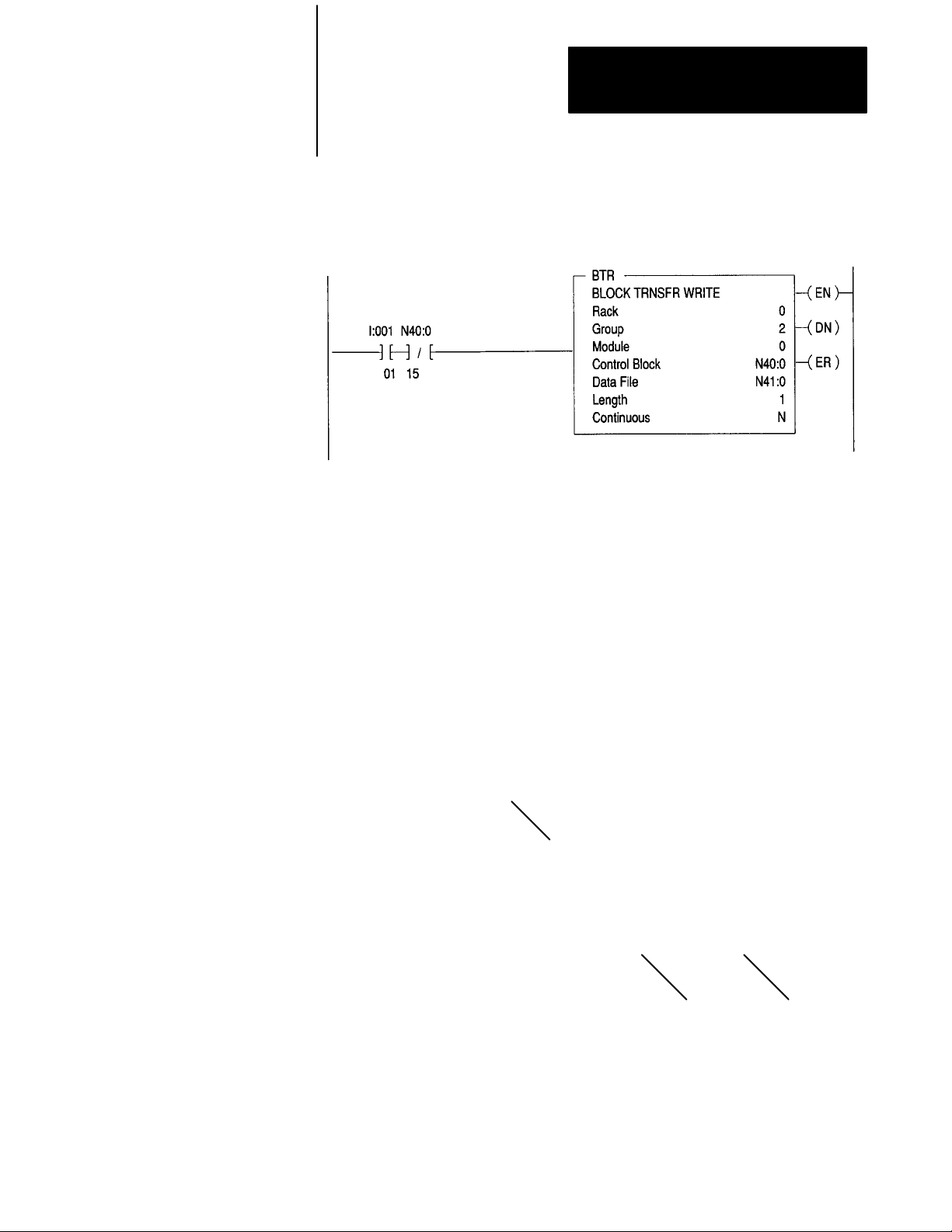

4. Apply power to the I/O chassis. Enter the Block Transfer rung shown

in Figure 4.6 into the PLC–5/15 processor.

Figure

4.6

Block T

ransfer Rung for a PLC-5/15 Processor

NOTE: If the module is installed in a physical slot other than the fifth slot

to the right of the PLC processor, the BTR block will have to be set up

with a Rack/Group/Slot address other than 020. Refer to Figure 4.3 for the

correct address settings.

5. Place the PLC–5/15 processor into RUN mode.

Use the Data Monitor in the 6200 Series Software to examine data table

address N36:0. This is where the processor has stored the rates and total

counts received from the 1771–QRD.

Only the channels which are actually driven will be active.

4–6

Page 25

Chapter 4

Module Programming

If all four input channels are being driven, we see that the value that

appears at address #1 is the rate of the signal that appears at swingarm

terminals 3 and 4. Note that the value that appears at address #3 is the rate

of the signal that appears at swingarm terminals 6 and 7; the value

appearing at address #5 is the rate of the signal that appears at swingarm

terminals 9 and 10; and finally, the value that appears at address #7 is the

rate of the signal that appears at swingarm terminals 12 and 13. The totals

for each of the channels appear to the right of their respective rates; i.e.

channel 1 rate (word #1) is accompanied by channel 1 total (word #2);

Channel 2 rate (word #3) is accompanied by channel 2 total (word #4);

Channel 3 rate (word #5) is accompanied by channel 3 total (word #6); and

channel 4 rate (word #7) is accompanied by channel 4 total (word #8). The

acknowledgement code of 1000 (in word 0) identifies the module as

1771–QRD Pulse Flowmeter Module.

4–7

Page 26

Chapter 4

Module Programming

Example

#2: PLC-5/15 with

Remote I/O

1. Install the module in the remote 1771 backplane,as shown in Figure

4.7.

Figure

4.7

PLC-5/15 in a Local Backplane With an ASB in a Remote Backplane

4–8

Page 27

Chapter 4

Module Programming

2. Set the PLC–5/15 configuration dip switches, as shown in Figure 4.8.

Figure

4.8

PLC-5/15 Configuration Dip Switches

NOTE: The black area indicates the selected switch position (up or down).

3. Set the 1771 Backplane dip switch, as shown in Figure 4.9.

Figure

4.9

Backplane Dip Switches

NOTE: The black area indicates where the switch should be pressed with

a pencil or other sharp instrument.

The local chassis is now configured for 2-slot addressing.

4–9

Page 28

Chapter 4

Module Programming

4. Set the 1771–ASB configuration switches, as shown Figure 4.10.

Figure

4.10

1771-ASB Configuration Dip Switches

NOTE: The black area indicates where the switch should be pressed with

a pencil or other sharp instrument.

5. Set the remote 1771 backplane dip switch, as shown in Figure 4.11.

Figure

4.1

1771 Remote Backplane Dip Switch

1

NOTE: The black area indicates where the switch should be pressed with

a pencil or other sharp instrument.

The remote chassis is now configured for 2-slot addressing.

4–10

Page 29

Chapter 4

Module Programming

6. Enter the Block Transfer Rung found in Figure 4.12 into the

PLC–5/15.

Figure

4.12

Block T

ransfer Rung for a PLC-5/15 W

ith Remote I/O

7. Place the PLC–5/15 Processor in RUN mode.

Use the DATA MONITOR to examine data table address N36:0. This is

where the QRD has stored the data from the four channels. They will

appear as:

Only the channels which are actually driven will be active.

4–11

Page 30

Chapter 4

Module Programming

Example

#3: PLC-3/10 with

Remote I/O

1. Install the module in the remote 1771 backplane, as shown in Figure

4.13.

Figure

4.13

PLC-3/10 with an ASB in a Remote Backplane

4–12

Page 31

Chapter 4

Module Programming

2. Set the 1771–ASB configuration switches, as shown in Figure 4.14.

Figure

4.14

1771-ASB Configuration Dip Switches

NOTE: The black area indicates where the switch should be pressed with

a pencil or other sharp instrument.

3. Set the 1771 Remote Backplane dip switch, as shown in Figure 4.15.

Figure

4.15

1771 Remote Backplane Dip Switch

NOTE: The black area indicates where the switch should be pressed with

a pencil or other sharp instrument.

The remote chassis is now configured for 2-slot addressing.

4–13

Page 32

Chapter 4

Module Programming

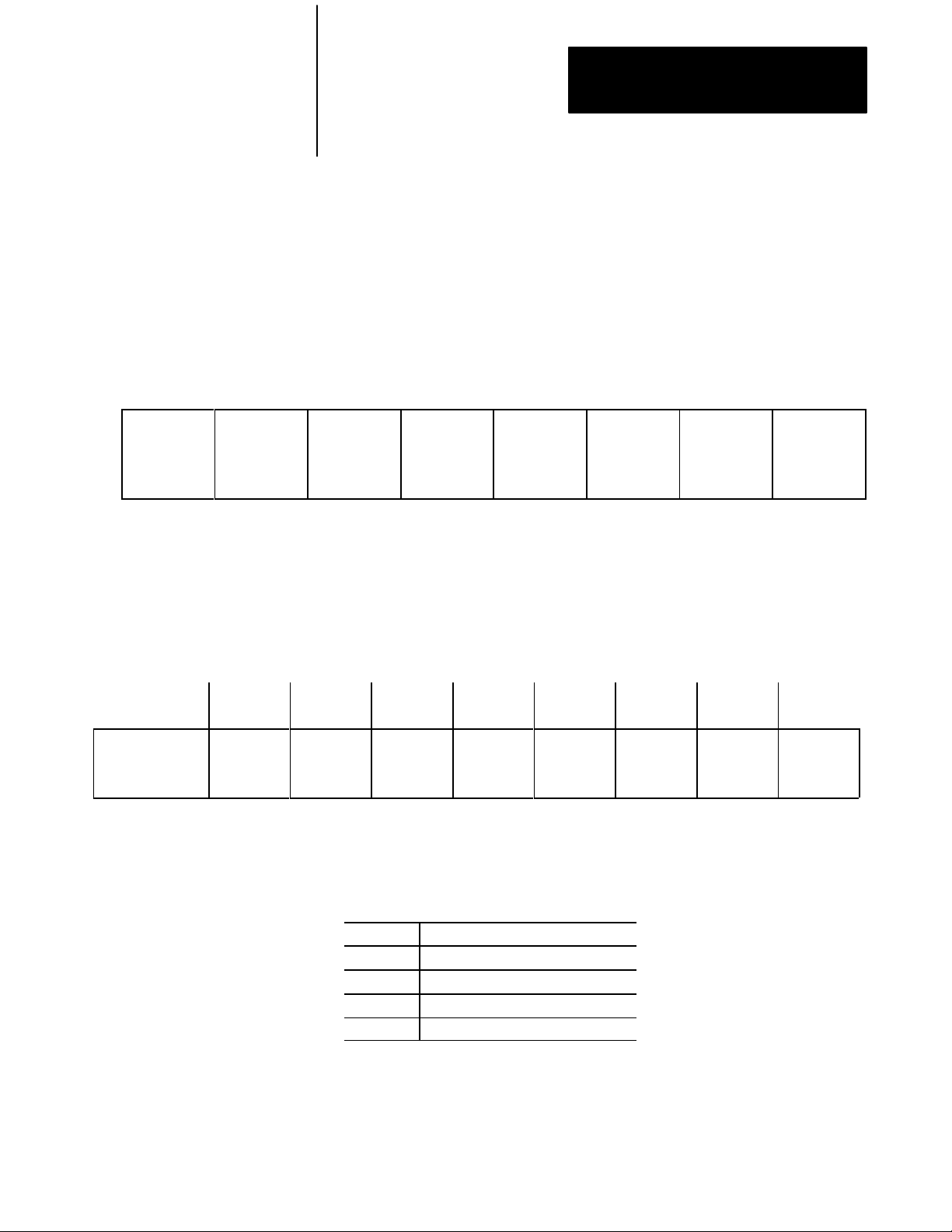

4. Enter the Block Transfer Rung found in Figure 4.16 into the

PLC–3/10 processor.

Figure

4.16

Block T

ransfer Rung for a PLC-3/10 with Remote I/O

5. Place the PLC–3/10 Processor in RUN mode.

Use the DATA MONITOR to examine data table address #N40:0. This is

where the QRD has stored the rates from the four channels.

Only the channels which are actually driven will be active.

4–14

Page 33

Chapter 5

More on Overrange and Overflow

Chapter

Objectives

Frequency Overrange Flags

In this chapter you will learn more about the overrange and overflow status

flags sent from the QRD to the PLC. You will also learn how to use a

Block Transfer Write to clear the overflow bits, the totalizers or any

combination of both.

As discussed in Chapter 4, an overflow occurs when the value of any of the

four totalizers exceeds the maximum value of 32,767. At that time, an

overflow flag for that channel is set and can be seen in the first word of the

Block Transfer data table. These overflow flags can be reset by the ladder

logic. Any or all of the totalizers can also be reset either independently of

each other, or they can all be reset simultaneously.

When it detects an overflow, the 1771–Q RD sets an overflow flag in the

acknowledge word (word 000) of the Block Transfer Read response. The

best way to understand this concept is to break down the acknowledge

word into bit format. The 16 bits are grouped by function into four

categories (Figure 5.1):

Figure

5.1

Acknowledge W

ord (From 1771-QRD Module)

T

able 5.A

Error Codes from Acknowledge W

Code Meaning

0 Valid Data

1 Channel Pair Fault

2 BLOCK TRANSFER Syntax Error

4 Channel Pair Fault and Syntax Error

ord

5–1

Page 34

Chapter 5

More on Overrange and Overflow

Each time an input for one (or more) of the channels is greater than 10.0

kHz, the overrange flag for that channel is set; for example, if the input

frequency for channel 1 is greater than 10.0 kHz, bit #4 is set. (This is the

first bit of the overrange group.)

Acknowledge Word = 1010 = 0001 XXXX XXX1 0000

Overrange, Channel 1

If the input frequency for any other channel is greater than 10.0 kHz, the

QRD sets the appropriate bit in the acknowledge code. It is possible for all

channels to be in an overrange condition; in such a case, the acknowledge

code would be:

Acknowledge Word = 10F0 = 0001 XXXX 1111 00000

Totalizer

Overflow Flags

All inputs are overrange (u10.0 kHz)

The overflow flags work in the same manner as the overrange flags. As an

example, when totalizer #1 has reached its maximum (32,767), an

overflow flag (bit #8) is set in the acknowledge code. If the acknowledge

code is put in binary format, it looks like this:

Acknowledge Code = 1100 = 0001 XXX1 XXXX 0000

Overflow, Channel 1

Any or all of the four channels can overflow, and any or all of the overflow

flags can be reset using a Block Transfer Write command. If all of the

channels overflow, the acknowledge code will look like:

Acknowledge Code = 1F00 = 0001 1111 XXXX 0000

All inputs are overflowed (u32,767)

5–2

Page 35

Chapter 5

More on Overrange and Overflow

Using

A Block T

to Reset the T

ransfer W

otalizer(s)

and/or Overflow Flags

rite

Any or all of the totalizers and overflow flags can be reset using a Block

Transfer Write command sent to the 1771–QRD from the PLC. For a

PLC–5 processor, the rung might look like this:

The Block Transfer Write sends the 1771–QRD one word that contains the

correct bit pattern to reset the totalizer(s) and/or overflow flags. The BTW

data word can be changed through the ladder logic, or by editing the data

table.

Note that the Block Transfer Write is switch selectable, and its length is

one word. The block transfer should only be sent once unless the ladder

intelligently sets and clears the reset bits within the Block Transfer data. As

an example, the ladder might set the reset bit at the time of overflow. If the

Block Transfer is sent continuously and the reset bits contained within the

Block Transfer data are simply left set to “1”, the transfers will constantly

be resetting the totalizer(s) and/or overflow flags of the specified channels.

The word from the block transfer data table would appear in the DATA

MONITOR as:

N41:0 00XX

Where: “XX” are the 8 bits used to reset the totalizer(s) and/or overflow bits.

Breaking down the word in the data table into binary format:

N41:0 0000 0000 XXXX XXXX

4 3 2 1 4 3 2 1

To reset overflow flags To reset totalizers

The numbers underneath the “X” ’s are the channel numbers that are

affected when the corresponding bit is a “1”. Note that a “1” resets the

totalizer(s) and/or overflow bits, and a “0” leaves them unchanged.

NOTE: Resetting the totalizer(s) will automatically reset its respective

overflow flag(s).

5–3

Page 36

Chapter 5

More on Overrange and Overflow

Figure

5.2

Example of Detecting and Resetting an Overflow Flag on Channel 1

5–4

Page 37

Chapter 5

More on Overrange and Overflow

The example in Figure 5.2 detects a count overflow on Channel 1, and

resets the overflow bit for that channel with a Block Transfer Write

command. The ladder logic also keeps track of the total number of counts

received at the channel 1 inputs.

A similar ladder could reset the overflow bits for channels 2, 3, and 4 by

setting bits 165, 166, and 167 of data table B3. The actual totals for the

four channels could be reset by setting bits 160, 161, 162, and 163 of data

table B3.

Although not shown in the previous examples, it is good PLC–5

programming procedure to include a rung to reset the EN bit of a block

transfer control file when the ER bit is set, when continuous transfers are

used.

Chapter

Summary

In this chapter, you learned the structure of the acknowledge code sent

from the QRD and how to reset the totalizer(s) and/or the overflow flags.

You also learned about the overrange condition, and how to detect it.

Finally, you learned the structure of the Block Transfer Write command

that is sent to the QRD Module for resetting overflow flags and/or

totalizer(s).

5–5

Page 38

Troubleshooting

Chapter 6

Chapter

Objectives

Symptom Probable Causes Possible Solutions

No indicators lit Power not applied Check that power supply is turned on

Green light off Power not applied Firmly reseat module in backplane

Red, green indicators solid,

yellow indicator flashing

Yellow light off Wrong rack, group, slot address used in block

No block transfer writes

done

No block transfer reads

done

All zeros in data table, red,

green indicators solid,

yellow indicator flashing

Data table values not being

incremented; no rate

The following table may be used to identify the probable cause of

difficulties with the 1771–QRD Module during initial installation.

Rate overrange Decrease input frequencies

Check connection of cable shield(s)

Move signal cable away from

electrical noise sources

Verify correct address in ladder rung

transfer rung

Processor in Program Mode

Wrong address setting on chassis switches

Wrong rack, group, slot address

Wrong address setting on chassis switches

Wrong rack, group, slot address

Wrong address setting on chassis switches

Frequency overrange Decrease input frequencies

Wrong signal type or low signal voltage Verify jumpers between terminals 17

for block transfer (See table 4.3)

Set to run mode

Verify chassis switch settings

Verify correct address in ladder rung

for block transfer (See table 4.3)

Verify chassis switch settings

Verify correct address in ladder rung

for block transfer (See table 4.3)

Verify chassis switch settings

Check connection of cable shield(s)

Move signal cable away from

electrical noise sources

and 19, and/or terminals 17 and 20

on the swingarm.

Jumper is ONLY used for TTL

signals.

Verify input voltage levels

6–1

Page 39

Chapter 6

Troubleshooting

Symptom

Data counts to small value,

then jumps to zero

Rates and counts from one

input appear in more than

one channel position in the

data table

Probable Causes Possible Solutions

Continuous BTW Reset Check ladder program to be sure that

the block transfer write is not causing

continuous resets of the totalizer(s)

Wiring reversal of + and - inputs Refer to wiring diagrams

6–2

Page 40

Data Formats

Appendix A

Block Transfer W

From PLC to QRD

b7

RESET

CH 4

Overflow Flag

rite Format

b6

RESET

CH 3

Overflow Flag

Use this block format to reset totalizer(s) and/or overflow flag(s).

Note: b8 through b15 are unused.

b5

RESET

CH 2

Overflow Flag

b4

RESET

CH 1

Overflow Flag

b3

RESET

CH4

TOTAL

b2

RESET

CH3

TOTAL

b1

RESET

CH2

TOTAL

Where: “1”=reset

“0” = not reset

Response from QRD to PLC Block Transfer

first

word

RESPONSE CODE

AND ERROR

CODE (1XYZ)

second

word

CH 1

RATE

third

word

CH 1

TOTAL

fourth

word

CH 2

RATE

fifth

word

CH 3

TOTAL

sixth

word

CH 3

RATE

seventh

word

CH 4

TOTAL

eighth

word

CH 4

RATE

b0

RESET

CH1

TOTAL

ninth

word

CH 4

TOTAL

Notes:

The digit in the response/error code labeled “Z” will adhere to the

following definitions:

Code Meaning

0 Valid data

1 Channel pair default

2 BLOCK TRANSFER syntax error

3 Channel pair fault and syntax error

A–1

Page 41

Appendix A

Data Formats

The digit in the response/error code labeled “Y” will adhere to the

following definitions:

b7 b6 b5 b4

channel

4 rate

overrange

channel

3 rate

overrange

channel

2 rate

overrange

channel

1 rate

overrange

“1” indicates overrange

“0” indicates not overrange

Note that the overrange condition causes both the rate and total to be

zeroed

The digit in the response/error code labeled “X” will adhere to the

following definitions:

b11 b10 b9 b8

channel

4 total

overflow

flag

channel

3 total

overflow

flag

channel

2 total

overflow

flag

channel

1 total

overflow

flag

“1” indicates totalizer has overflowed

“0” indicates totalizer has not overflowed

Important: When the totalizer overflows, it continues to count unless

manually reset.

A–2

Page 42

Specifications

Appendix B

Power Requirements

Environment

Agency Approval

Packaging

DC Supply Voltage from Backplane: 5 Volts " 5% @ 0.50 A Maximum

Note: This supply must meet the Allen–Bradley series B power bus

specification. Typical supplies are 1771–P3, –P4, –P5, and –P7.

Isolated Field Supply Required: none

Operating Temperature: 0 degrees C to 60 degrees C

Storage Temperature: minus 40 degrees C to 85 degrees C

Operating Humidity: 5% – 95 % relative (non–condensing)

UL (Pending), CSA Class I, Division 2, Group D

Single slot 1771 I/O module, 21 terminals, swing arm connector

Weight

Capacity

Performance

1.0 lb (approximately)

Hardware channels per module: 4

Independent ratemeters per module: 4

Independent totalizers per module: 4

Ratemeter update time: 1.0 Second

Block transfer time: Less than 10 mS

Note: Ladders longer than 10 mS or STI files with repeat intervals longer

than 10 mS will receive updated totals once per scan or STI.

B–1

Page 43

Appendix B

Specifications

Operational

Limits

Signal Characteristics, Turbine Flowmeter or Magnetic Pickup: 50 mV

to 142 VAC RMS

The signal should be approximately sinusoidal and must be AC. The signal

must be greater than 50 mV peak to peak, and must be smaller than 400 V

peak to peak.

Signal Characteristics, TTL: 1.3 V threshold

The signal should be DC pulses with width greater than 20 uS. The logic

“1” level must be greater than + 1.3 V and smaller than +200 V while the

logic “0” level must be larger than –.7V and smaller than +1.3V.

The TTL mode is compatible with TTL, 4,000 series CMOS, and most

0–24 V systems. The TTL mode is not compatible with any signal format

with DC pulses riding on a fixed DC level greater than + 1.3 V.

Note: Signal type is selectable by swing arm jumper. Channel thresholds

are jumpered in pairs.

Input Impedance: 5 kOhm " 30% resistive, minimum

Isolation: 1000 V minimum between channels and microcontroller, and

between channel pairs

Accuracy: 0.1% "1 Hz for frequency t 3.0 kHz 0.2% "1 Hz for

frequency u 3.0 kHz

Overrange Indication: Individual bit for each channel set to indicate rate

above 10 kHz

Overflow Indication: Individual bit for each channel set to indicate total

above 32, 767

Overrange Response: When a channel signal exceeds 10 kHz the rate

overrange bit will be set, the total reset to zero, and the rate for that

channel reported as zero

Maximum Operating Frequency: 10.0 kHz for PLC–3 and PLC–5, 0.999

kHz for PLC–2 (New Use)

Total Control: Overflow bit and total can be cleared by ladder logic.

Clearing total also clears overflow bit

B–2

Page 44

Appendix B

Specifications

With offices in major cities worldwide

WORLD

HEADQUARTERS

Allen-Bradley

1201 South Second Street

Milwaukee, WI 53204 USA

Tel: (1) 414 382-2000

Telex: 43 11 016

FAX: (1) 414 382-4444

Publication 1771–6.5.73 — November 1990

B–4

EUROPE/MIDDLE

EAST/AFRICA

HEADQUARTERS

Allen-Bradley Europe B.V.

Amsterdamseweg 15

1422 AC Uithoorn

The Netherlands

Tel: (31) 2975/43500

Telex: (844) 18042

FAX: (31) 2975/60222

As a subsidiary of Rockwell International, one of the world’s largest technology

companies — Allen-Bradley meets today’s challenges of industrial automation with over

85 years of practical plant-floor experience. More than 11,000 employees throughout the

world design, manufacture and apply a wide range of control and automation products

and supporting services to help our customers continuously improve quality, productivity

and time to market. These products and services not only control individual machines but

integrate the manufacturing process, while providing access to vital plant floor data that

can be used to support decision-making throughout the enterprise.

ASIA/PACIFIC

HEADQUARTERS

Allen-Bradley (Hong Kong)

Limited

Room 1006, Block B, Sea

View Estate

28 Watson Road

Hong Kong

Tel: (852) 887-4788

Telex: (780) 64347

FAX: (852) 510-9436

CANADA

HEADQUARTERS

Allen-Bradley Canada

Limited

135 Dundas Street

Cambridge, Ontario N1R

5X1

Canada

Tel: (1) 519 623-1810

FAX: (1) 519 623-8930

LATIN AMERICA

HEADQUARTERS

Allen-Bradley

1201 South Second Street

Milwaukee, WI 53204 USA

Tel: (1) 414 382-2000

Telex: 43 11 016

FAX: (1) 414 382-2400

Printed in USA

Loading...

Loading...