Page 1

Allen-Bradley

Plastic Molding

Module

(Cat. No. 1771-QI)

Reference

Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those

of electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication

SGI-1.1) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this

difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is

acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application

of this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect

to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

!

property damage, or economic loss.

Attentions help you

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for

successful application and understanding of the product.

PLC and Pro-Set are trademarks of Allen-Bradley Company, Inc.

Page 3

Preface

Preface

Read this preface to familiarize yourself with the manual.

This preface covers the following topics:

• the purpose of this manual

• Related Publications

• Terms

• Allen-Bradley support

Purpose of this Manual

Related Publications

This manual provides reference information for the 1771-QI Plastic

Molding Module. It provides lists of words, bits, addresses, and

error codes needed for all applications. It also describes procedures

you use to calibrate the module. The contents include:

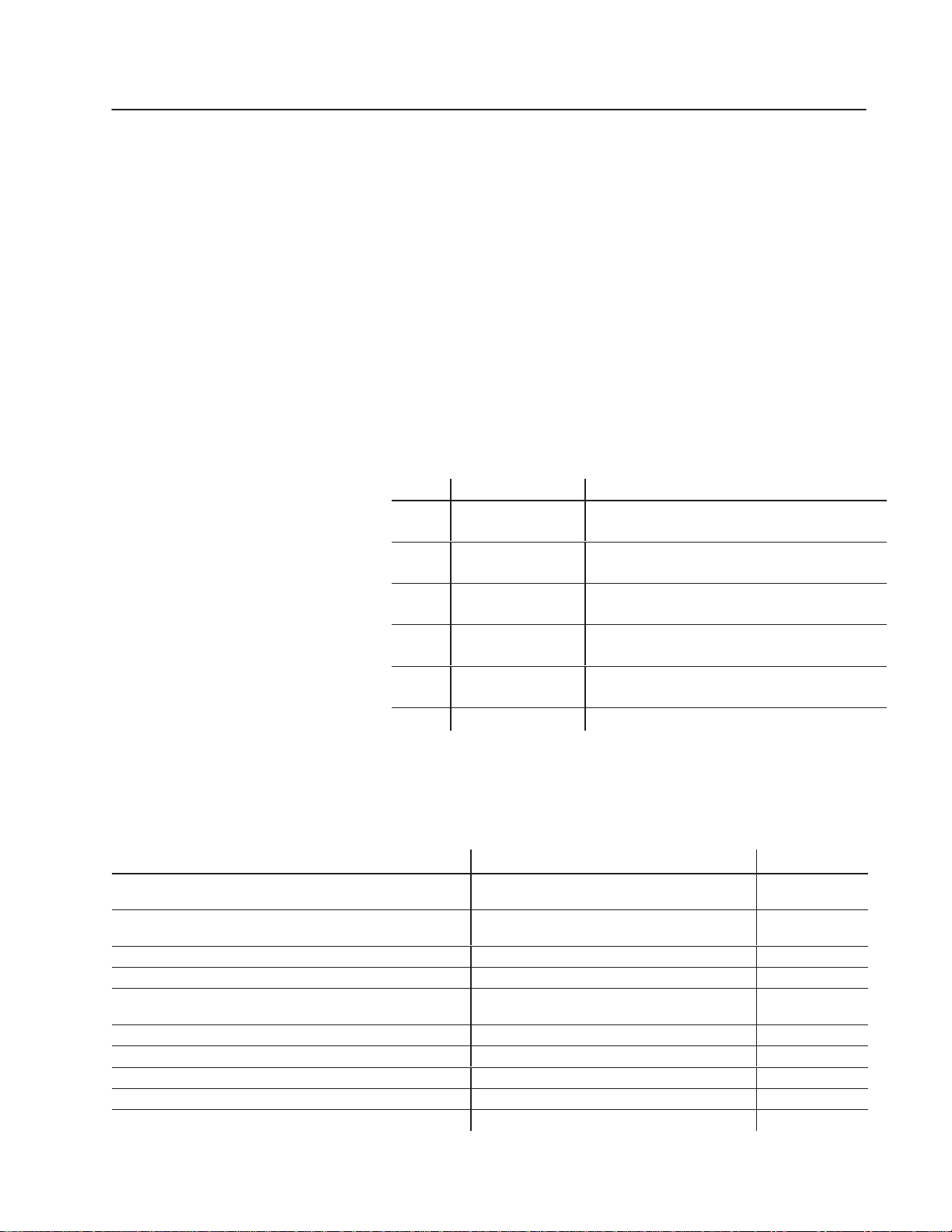

Chapter Title Contents

Abbreviated Command

1

and Status Blocks

Word/Bit Descriptions

2

for Command Blocks

Word/Bit Descriptions

3

for Status Blocks

Programming

4

Error Codes

Specifications Provides physical, electrical, environmental, and

5

6 Calibration Instructions Provides procedures for calibrating the QDC module.

A summary list of command and status block words with

Pro-Set addresses used by the QDC module.

A detailed list of command block words with word/bit

descriptions.

A detailed list of status block words with word/bit

descriptions.

A list of all possible error codes that could be presented

when you enter invalid data in command blocks.

functional specifications for the QDC module.

The 1771-QI module is similar the 1771-QDC module configured

for Inject Mode, but with additional co-injection capabilities.

We recommend that you use the following publications:

For Read This Document Pub Number

Installing your QI module to control inject operations

Selecting instructions and organizing memory when writing ladder

logic to run your machine

Installing Pro-Set 700 injection molding software Pro-Set 700 Installation Instructions 6500-5.4

Installing your Pro-Set 700 operator interface Pro-Set 700 Operator Interface Installation Manual 6500-6.2.1

Customizing Pro-Set 700 software for your application

Setting up your molding machine for use with Pro-Set 700 software Pro-Set 700 Software Release 2.1 User Manual 6500-6.5.18

Using co-injection software Pro-Set 700 Co-injection Software User Manual 6500-6.5.19

Inputting injection molding system setpoints and actuals Pro-Set 700 Systems Jobsetting Guide 6500-6.9.3

Installing modules for co–injection applications Installing Co-injection and Plastic Molding Modules 6500-10.1

A complete listing of current Allen-Bradley documentation Allen-Bradley Publication Index SD499

Plastic Molding Module User Manual 1771-QDC

Inject Mode Operation

1785 PLC-5 Programmable Controller

Instruction Set Reference

Pro-Set 700 Software Release 2.1 Reference Mnl

Publication

1771-6.5.85

1785-6.1

6500-6.4.3

1771-6.5.126 – March 1998

Page 4

PrefaceP–2

Terms

The following terms are specific to this product or commonly used:

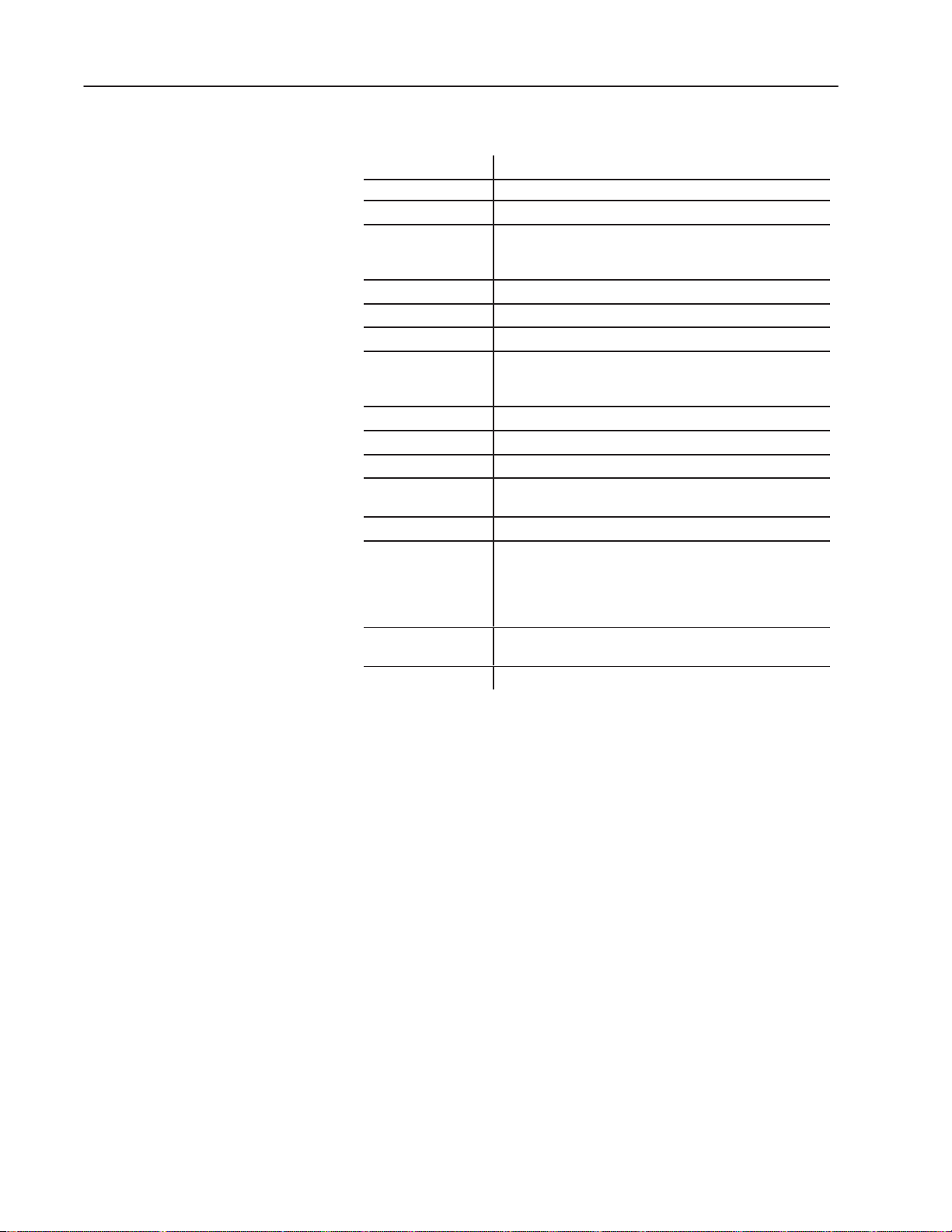

Term: Definition:

BTR Block-transfer Read

BTW Block-transfer Write

Command Block

(MCC)

Configuration Blocks Data blocks containing machine-specific setpoints.

Profile Blocks Data blocks with setpoints used to control profiles.

Status Blocks Module status returned by the QI module to the PLC data table.

Direct Acting

and

Reverse Acting Valves

FF Feed Forward

in.(mm)/s inches (millimeters) per second

PID Proportional-Integral-Derivative

Profile A group of mold/part setpoints which define a given machine

RFU Reserved for future use

Selected and

Unselected Valves

Unselected Valves When executing a profile in a multi-valve system, the QI

SWTL Software travel limit

Downloaded from the PLC data table to the QI module to

initiate or change machine operation. It must accompany every

configuration or profile block transferred to the QI module.

An analog control valve that delivers increasing velocity or

pressure with increasing signal input. A reverse acting valve

delivers increasing velocity or pressure with decreasing signal.

operation to the QI module

When executing a profile in a multi-valve system, the QI

module controls one valve and presets the remaining valves.

We call the valve being controlled by the QI module’s

algorithms the selected valve, and the valves that are preset

with an open loop percentage setpoint the unselected valves.

module controls one valve and presets the remaining valves.

Allen-Bradley Support

Publication

1771-6.5.126 – March 1998

Allen-Bradley offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the Troubleshooting chapter of User Manual

1771-6.85 before calling your local Allen-Bradley representative.

Page 5

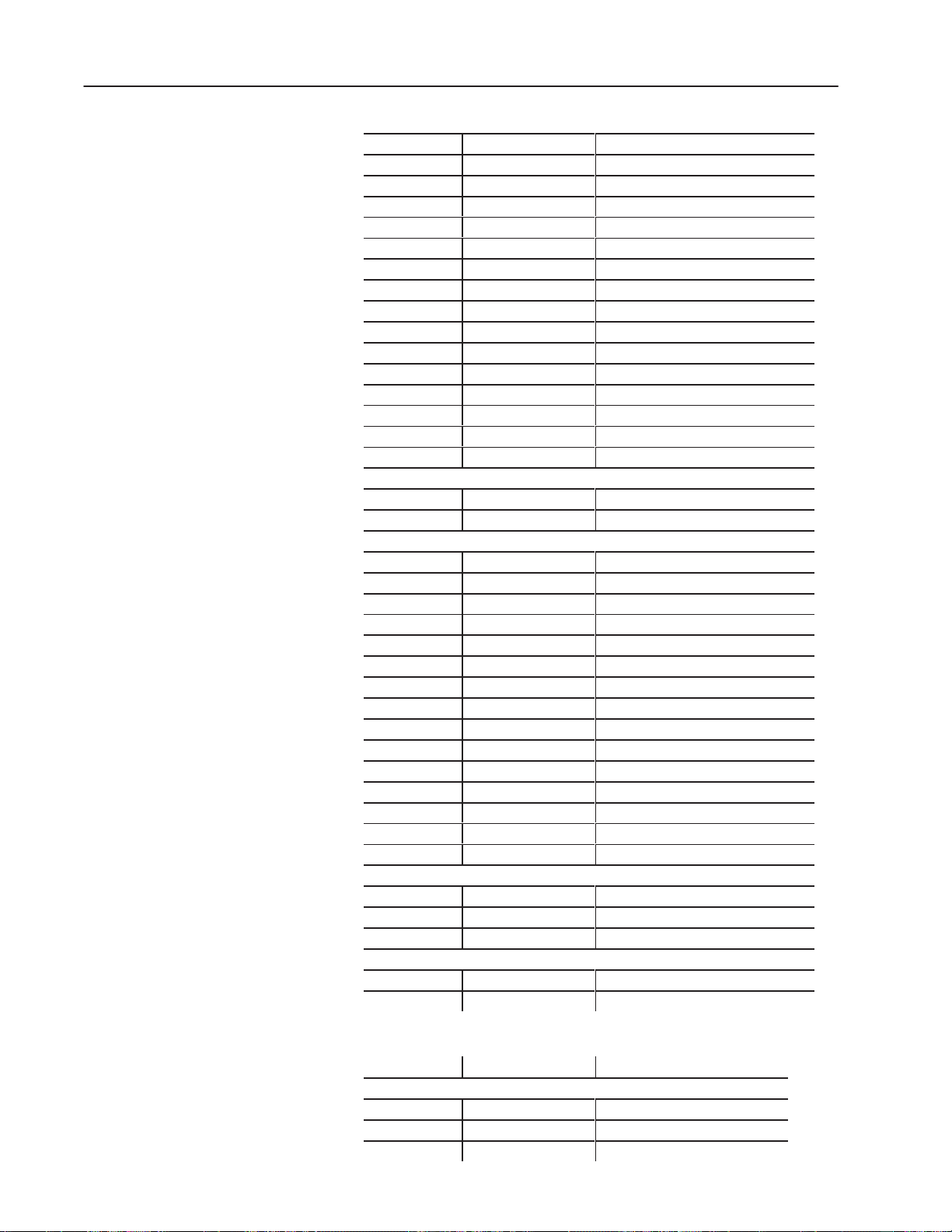

Table of Contents

Abbreviated Command and Status Block

Chapter 1

Chapter

DYC – Dynamic Command Block 1–2. . . . . . . . . . . . . . . . . . . . . . . . .

HDC

HPC

INC

IPC

JGC

MCC

PKC

PLC

PPC

PRC

PSC

PTC – Process T

RLC

HPS

IPS

PPS

PTS – Process Trace Status Block 1–19. . . . . . . . . . . . . . . . . . . . . . . .

RLS

SYS – System Status Block 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

– Hold Configuration Block

– Pack/Hold Profile Block

– Injection Configuration Block

– Injection Profile Block

– Jog Configuration Block

– Module Configuration Command Block

– Pack Configuration Block

– Plastication Configuration Block

– Plastication Profile Block

– Pre-decompression Configuration Block

– Post-decompression Configuration Block

race Configuration Block

– Inject ERC V

– Pack/Hold Profile Status Block

– Injection Profile Status Block

– Plastication Profile Status Block

– Inject ERC V

alues Block 1–14. . . . . . . . . . . . . . . . . . . . . . . . . .

alues Status Block 1–20. . . . . . . . . . . . . . . . . . . . .

1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2. . . . . . . . . . . . . . . . . . . . . . . . .

1–3. . . . . . . . . . . . . . . . . . . . . . . . . .

1–4. . . . . . . . . . . . . . . . . . . . . . .

1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–7. . . . . . . . . . . . . . . . . . . . . . . . . .

1–8. . . . . . . . . . . . . . . .

1–19. . . . . . . . . . . . . . . . . . . . . . . . .

1–10. . . . . . . . . . . . . . . . . . . . .

1–11. . . . . . . . . . . . . . . . . . . . . . . . . .

1–12. . . . . . . . . . . . . . .

1–13. . . . . . . . . . . . . .

1–14. . . . . . . . . . . . . . . . . . .

1–15. . . . . . . . . . . . . . . . . . . . .

1–16. . . . . . . . . . . . . . . . . . . . . . . .

1–18. . . . . . . . . . . . . . . . . . . . .

Command Word/Bit Descriptions

Chapter 2

List of Command Blocks and Block ID codes 2–1. . . . . . . . . . . . . . . . .

of Data W

List

Engineering Units 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

Blocks Require I/O Configuration

Data Blocks for System Control 2–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Data Blocks for Controlling Ram (Screw) Position 2–3. . . . . . . . . . . . . .

DYC – Dynamic Command Block 3–4. . . . . . . . . . . . . . . . . . . . . . . . .

Bit-mapped

Direct

Direct

ords 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control W

Set-output V

Set-output Ramp Rates

ords 2–4. . . . . . . . . . . . . . . . . . . . . . . . . .

alues 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication

1771-6.5.126– March 1998

2–2. . . . . . . . . . . . . . . . . . . . . .

2–9. . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contentstoc–ii

HDC

– Hold Configuration Block

Bit-mapped

Control W

ords 2–10. . . . . . . . . . . . . . . . . . . . . . . . . .

2–10. . . . . . . . . . . . . . . . . . . . . . . . .

Expert Response Compensation (ERC) Percentage 2–10. . . . . . . .

Unselected V

alve Set-output V

alues 2–11. . . . . . . . . . . . . . . . . . .

Output Ramp Rates 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End

of Profile Set-output V

alues 2–11. . . . . . . . . . . . . . . . . . . . . .

Ram (Screw) Pressure Control Limits 2–12. . . . . . . . . . . . . . . . . .

Cavity Pressure Control Limits 2–12. . . . . . . . . . . . . . . . . . . . . . .

Profile

T

uning Constants

Profile

Pressure Alarm Setpoint

– Pack/Hold Profile Block

HPC

Bit-mapped

Pack

Pack

Hold

Hold

Control W

Profile Setpoints

Profile Of

Profile Setpoints

Profile Of

ords 2–13. . . . . . . . . . . . . . . . . . . . . . . . . .

fsets 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

fsets 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–12. . . . . . . . . . . . . . . . . . . . . . . . . . .

2–12. . . . . . . . . . . . . . . . . . . . . .

2–13. . . . . . . . . . . . . . . . . . . . . . . . . .

2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Critical Process Setpoints 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

INC

– Injection Configuration Block

Bit-mapped

Control W

ords 2–16. . . . . . . . . . . . . . . . . . . . . . . . . .

2–16. . . . . . . . . . . . . . . . . . . . . . .

Expert Response Compensation (ERC) Percentage 2–16. . . . . . . .

Unselected V

alve Set-output V

alues 2–16. . . . . . . . . . . . . . . . . . .

Output Ramp Rates 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure

Velocity

Profile

Profile

Set-outputs

IPC

– Injection Profile Block

Bit-mapped

Control Limits

Control Limits

T

uning Constants

Pressure Alarm Setpoint

During Suspended Injection

Control W

ords 2–19. . . . . . . . . . . . . . . . . . . . . . . . . .

2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

2–18. . . . . . . . . . . . . . . . . . . . . .

2–18. . . . . . . . . . . . . . . .

2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Co-injection Parameters 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Injection

Injection

Pressure

Injection

Pressure

JGC

– Jog Configuration Block

Bit-mapped

Jog

Screw

Ram

Profile Setpoints

Profile Of

fsets 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Injection Parameters

T

ransition Parameters

T

ransition Inhibit

Control W

ords 2–25. . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Setpoints

Rotate Jog Set-output V

alues 2–26. . . . . . . . . . . . . . . . . . .

(Screw) Forward Jog Set-output V

2–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

2–24. . . . . . . . . . . . . . . . . .

2–25. . . . . . . . . . . . . . . . . . . . . . .

2–25. . . . . . . . . . . . . . . . . . . . . . . . . .

2–25. . . . . . . . . . . . . . . . . . . . . . . . . .

2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alues 2–26. . . . . . . . . . . . .

Ram (Screw) Reverse Jog Set-output Values 2–26. . . . . . . . . . . . .

Publication

1771-6.5.126– March 1998

Page 7

Table of Contents toc–iii

MCC

– Module Configuration Command Block

Bit-mapped

Control W

Ram (Screw) Position T

Ram (Screw) Pressure T

Ram (Screw) Position T

Screw RPM T

ransducer Configuration

Cavity Pressure T

ords 2–27. . . . . . . . . . . . . . . . . . . . . . . . . .

ransducer Configuration

ransducer Configuration

ransducer Configuration (other injector)

ransducer Configuration

Other 2–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PKC

– Pack Configuration Block

Bit-mapped

Control W

ords 2–30. . . . . . . . . . . . . . . . . . . . . . . . . .

Expert Response Compensation (ERC) Percentage 2–30. . . . . . . .

Unselected V

alve Set-output V

alues 2–30. . . . . . . . . . . . . . . . . . .

Output Ramp Rates 2–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ram (Screw) Pressure Control Limits 2–31. . . . . . . . . . . . . . . . . .

Cavity Pressure Control Limits 2–31. . . . . . . . . . . . . . . . . . . . . . .

Profile

T

uning Constants

Profile

Pressure Alarm Setpoint

PLC

– Plastication Configuration Block

Bit-mapped

Control W

ords 2–32. . . . . . . . . . . . . . . . . . . . . . . . . .

Expert Response Compensation (ERC) Percentage 2–33. . . . . . . .

Watchdog

Unselected V

T

imer 2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alve Set-output V

alues 2–33. . . . . . . . . . . . . . . . . . .

Output Ramp Rates 2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End

of Profile Set-output V

Pressure

RPM

Profile

Profile

PPC

– Plastication Profile Block

Bit-mapped

Plastication

Plastication

Control Limits

Control Limits

T

uning Constants

Pressure Alarm Setpoint

Control W

Profile Setpoints

Profile Of

alues 2–34. . . . . . . . . . . . . . . . . . . . . .

ords 2–35. . . . . . . . . . . . . . . . . . . . . . . . . .

fsets 2–38. . . . . . . . . . . . . . . . . . . . . . . . . .

Critical Process Setpoints 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . .

PRC

– Pre-decompression Configuration Block

Bit-mapped

Movement

Watchdog

Movement

Control W

Length

T

imer 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set-output V

ords 2–38. . . . . . . . . . . . . . . . . . . . . . . . . .

alues 2–39. . . . . . . . . . . . . . . . . . . . . . . .

Output Ramp Rates 2–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End

of Movement Set-output V

Movement

Pressure Alarm Setpoint

alues 2–39. . . . . . . . . . . . . . . . . . .

2–27. . . . . . . . . . . . . . .

2–28. . . . . . . . . . .

2–28. . . . . . . . . .

2–29

2–29. . . . . . . . . . . . . . . . . .

2–29. . . . . . . . . . . . . . .

2–30. . . . . . . . . . . . . . . . . . . . . . . . .

2–32. . . . . . . . . . . . . . . . . . . . . . . . . . .

2–32. . . . . . . . . . . . . . . . . . . . . .

2–32. . . . . . . . . . . . . . . . . . . . .

2–34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–34. . . . . . . . . . . . . . . . . . . . . . . . . . .

2–35. . . . . . . . . . . . . . . . . . . . . .

2–35. . . . . . . . . . . . . . . . . . . . . . . . . .

2–36. . . . . . . . . . . . . . . . . . . . . . . . .

2–38. . . . . . . . . . . . . . .

2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–39. . . . . . . . . . . . . . . . . . .

Publication

1771-6.5.126– March 1998

Page 8

Table of Contentstoc–iv

PSC

– Post-decompression Configuration Block

Bit-mapped

Movement

Watchdog

Movement

Output Ramp Rates 2–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End

Movement

PTC – Process T

Bit-mapped

– Inject ERC V

RLC

Bit-mapped

Injection

Pack

Hold

Plastication

Control W

Length

T

imer 2–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set-output V

of Movement Set-output V

Pressure Alarm Setpoint

race Configuration Block

Control W

alues Block 2–42. . . . . . . . . . . . . . . . . . . . . . . . . .

Control W

Profile ERC V

Profile ERC V

Profile ERC V

Profile ERC V

ords 2–40. . . . . . . . . . . . . . . . . . . . . . . . . .

alues 2–40. . . . . . . . . . . . . . . . . . . . . . . .

alues 2–41. . . . . . . . . . . . . . . . . . .

ords 2–41. . . . . . . . . . . . . . . . . . . . . . . . . .

ords 2–42. . . . . . . . . . . . . . . . . . . . . . . . . .

alues 2–42. . . . . . . . . . . . . . . . . . . . . . . . .

alues 2–43. . . . . . . . . . . . . . . . . . . . . . . . . . .

alues 2–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

alues 2–43. . . . . . . . . . . . . . . . . . . . . . .

2–40. . . . . . . . . . . . . .

2–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–41. . . . . . . . . . . . . . . . . . .

2–41. . . . . . . . . . . . . . . . . . .

Status Word/Bit Descriptions

Chapter 3

List of Status Blocks and Block ID codes 3–1. . . . . . . . . . . . . . . . . . . .

List

of Data W

Blocks Require I/O Configuration

Data

Engineering Units 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Blocks for Reporting System and Ram (Screw) Position 3–2. . . .

HPS

– Pack/Hold Profile Status Block

Bit-mapped

Pack

Hold

Pack Maximum Pressures 3–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Hold Maximum Pressures 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-decompression Maximum Pressure 3–5. . . . . . . . . . . . . . . . .

Execution

Pre-decompression Movement Actuals 3–5. . . . . . . . . . . . . . . . .

End of Hold Ram (Screw) Position 3–5. . . . . . . . . . . . . . . . . . . .

IPS

– Injection Profile Status Block

Bit-mapped

Injection

Injection Maximum Pressures 3–7. . . . . . . . . . . . . . . . . . . . . . . .

Injection

ords 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status W

Profile Actuals

Profile Actuals

T

imes 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status W

Profile Actuals

T

ransition Actuals

ords 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

ords 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2. . . . . . . . . . . . . . . . . . . . . .

3–3. . . . . . . . . . . . . . . . . . . . .

3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5. . . . . . . . . . . . . . . . . . . . . . . .

3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Publication

1771-6.5.126– March 1998

Page 9

Table of Contents toc–v

PPS

– Plastication Profile Status Block

Bit-mapped

Plastication

Plastication Maximum Pressure 3–10. . . . . . . . . . . . . . . . . . . . . .

Post-decompression Maximum Pressure 3–10. . . . . . . . . . . . . . . .

Execution

Post-decompression Movement Actuals 3–11. . . . . . . . . . . . . . . .

Shot

PTS – Process Trace Status Block 3–11. . . . . . . . . . . . . . . . . . . . . . . .

Bit-mapped

– Inject ERC V

RLS

Bit-mapped

Injection Profile ERC Actuals 3–13. . . . . . . . . . . . . . . . . . . . . . . .

Pack Profile ERC Actuals 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Hold Profile ERC Actuals 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Plastication Profile ERC Actuals 3–13. . . . . . . . . . . . . . . . . . . . . .

SYS – System Status Block 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit-mapped

Input

Input

Output

Cycle Maximum Pressures 3–25. . . . . . . . . . . . . . . . . . . . . . . . . .

Process

Process

Diagnostics 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New

Status W

Profile Actuals

T

imes 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Size Actual

Status W

Status W

Status W

Level In Engineering Units

Level, Raw Signal

Level in Percentage

T

race Data Collection Status

T

imes 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Confirmation

ords 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

ords 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

alues Status Block 3–13. . . . . . . . . . . . . . . . . . . . .

ords 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

ords 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

3–8. . . . . . . . . . . . . . . . . . . . .

3–9. . . . . . . . . . . . . . . . . . . . . . . . . .

3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–24. . . . . . . . . . . . . . . . . . . . . .

3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–24. . . . . . . . . . . . . . . . . . . . . . . . . .

3–25. . . . . . . . . . . . . . . . . .

3–26. . . . . . . . . . . . . . . . . . . . . . . . . . .

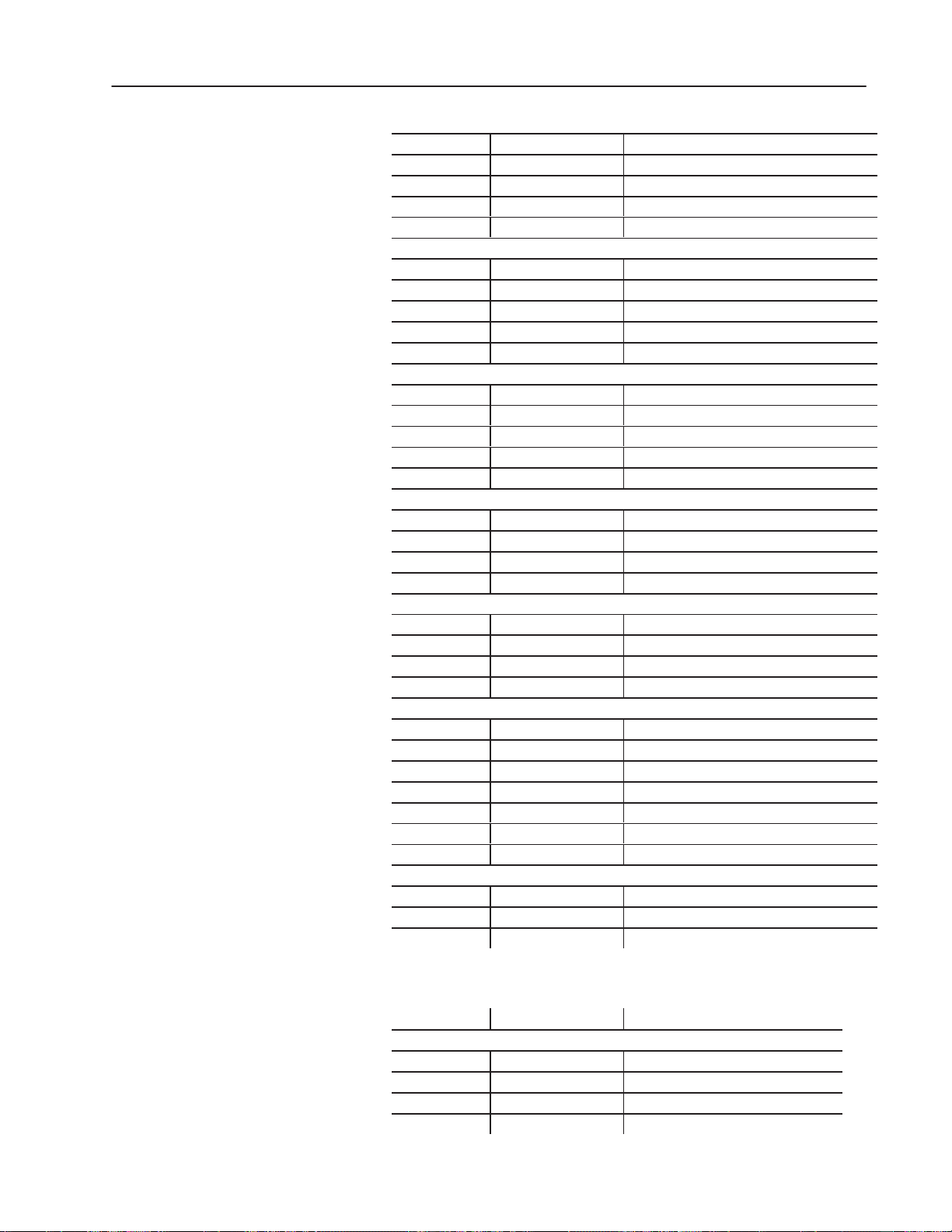

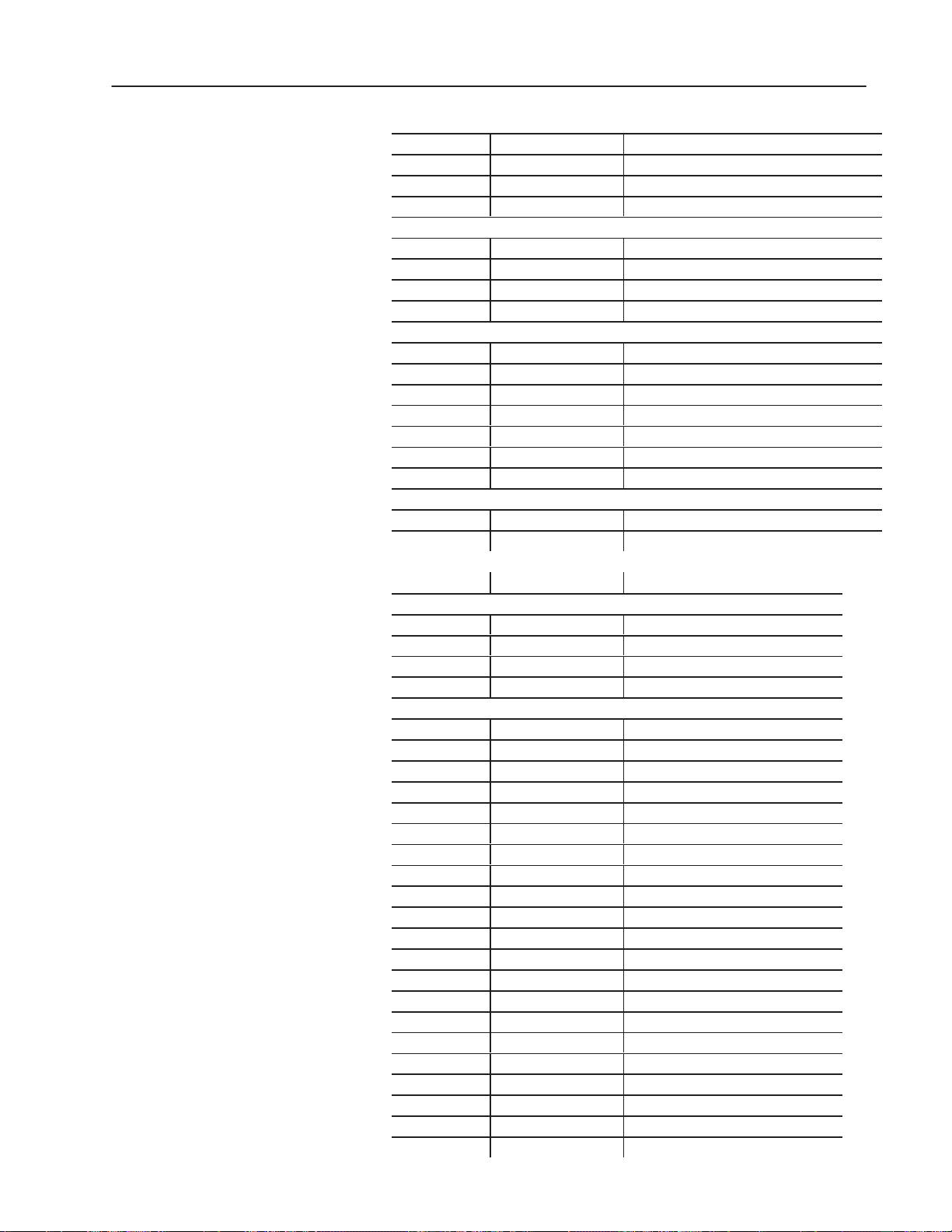

Programming Error Codes

Chapter 4

How

to Read Error Codes

= 1 MCC – Module Configuration Command Block

ID

ID

= 2 JGC – Jog Configuration Block

ID

= 8 INC – Injection Configuration Block

= 9 IPC – Injection Profile Block

ID

= 10 PKC – Pack Configuration Block

ID

ID

= 1

1 HDC – Hold Configuration Block

ID = 12 HPC – Pack/Hold Profile Block 4–17. . . . . . . . . . . . . . . . .

ID = 13 PRC – Pre-Decompression Configuration Block

ID

= 14 PLC – Plastication Configuration Block

= 15 PPC – Plastication Profile Block

ID

ID = 16 PSC – Post-Decompression Configuration Block

ID = 25 DYC – Dynamic Command Block 4–29. . . . . . . . . . . . . . .

ID

= 26 RLC – Inject ERC V

ID = 28 PTC – Process T

alues Block 4–29. . . . . . . . . . . . . . . . .

race Configuration Block

Publication

1771-6.5.126– March 1998

4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3. . . . . .

4–6. . . . . . . . . . . . . . . . . .

4–7. . . . . . . . . . . . . . .

4–9. . . . . . . . . . . . . . . . . . . .

4–15. . . . . . . . . . . . . . . .

4–16. . . . . . . . . . . . . . . .

.

4–20. . . .

4–21. . . . . . . . . . . .

4–22. . . . . . . . . . . . . . . .

.

4–28. . . .

4–30. . . . . . . . .

Page 10

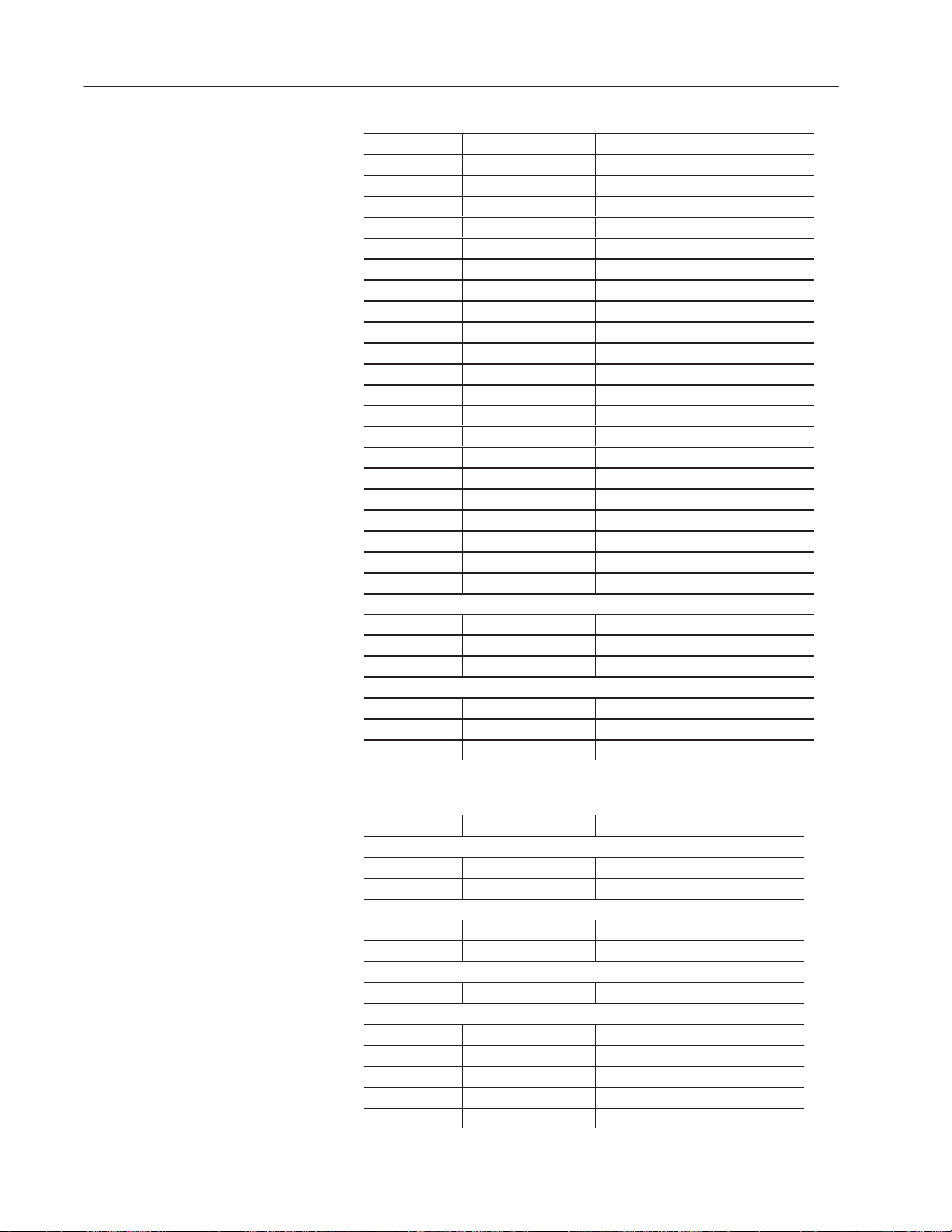

Table of Contentstoc–vi

Sequencing Co-injection

Module Specifications

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A, Only or B, Only 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

and B

then B

A

Standard Programming 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Co-injection Programming 5–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Suspended

Suspended Outputs Are Programmed 5–4. . . . . . . . . . . . . . . . . .

During

Flow

Chart for Co-injection Programming

Co-injection Diagram for ABA 5–6. . . . . . . . . . . . . . . . . . . . . . . .

List

of Co-injection Parameters for ABA

Flow

Flow

Outputs Are T

B, A Maintains Low Pressure or Flow (plateau)

Chart for A in Sequence ABA

Chart for Sequence ABA

urned Of

f 5–3. . . . . . . . . . . . . . . . . . . .

Chapter 6

I/O

Specifications

Environmental

Hardware Requirements 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Process

Conditions

Control Options

5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–5. . . . . .

5–6. . . . . . . . . . . . . . . . . . . .

5–6. . . . . . . . . . . . . . . . .

5–7. . . . . . . . . . . . . . . . . . . .

5–8. . . . . . . . . . . . . . . . . . . . . . .

6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Instructions

Chapter 7

Calibration

Map Your BTW and BTR Data Blocks 7–2. . . . . . . . . . . . . . . . . . . . . .

Write Y

Set

Wire the Wiring Arms 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration

Calibration

Calibration

Calibration

Equipment Required

our Calibration Logic

Internal Jumpers

Setup Using Optional Equipment

Setup at the Machine Location

Procedure for Inputs

Procedure for Outputs

7–1. . . . . . . . . . . . . . . . . . . . . . . . . .

7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7–6. . . . . . . . . . . . . . . . .

7–6. . . . . . . . . . . . . . . . . . .

7–7. . . . . . . . . . . . . . . . . . . . . . . . . .

7–8. . . . . . . . . . . . . . . . . . . . . . . . .

Publication

1771-6.5.126– March 1998

Page 11

Chapter 1

Abbreviated Command and Status Blocks

Chapter Contents

Use this chapter as a quick reference to word descriptions and

Pro-Set addresses of all data blocks used by the QI module.

For complete word and bit descriptions of these data blocks,

see Chapter 2 (command) and Chapter 3 (status).

The following tables list command and status blocks in this chapter

by page number. Blocks are presented in abbreviated format.

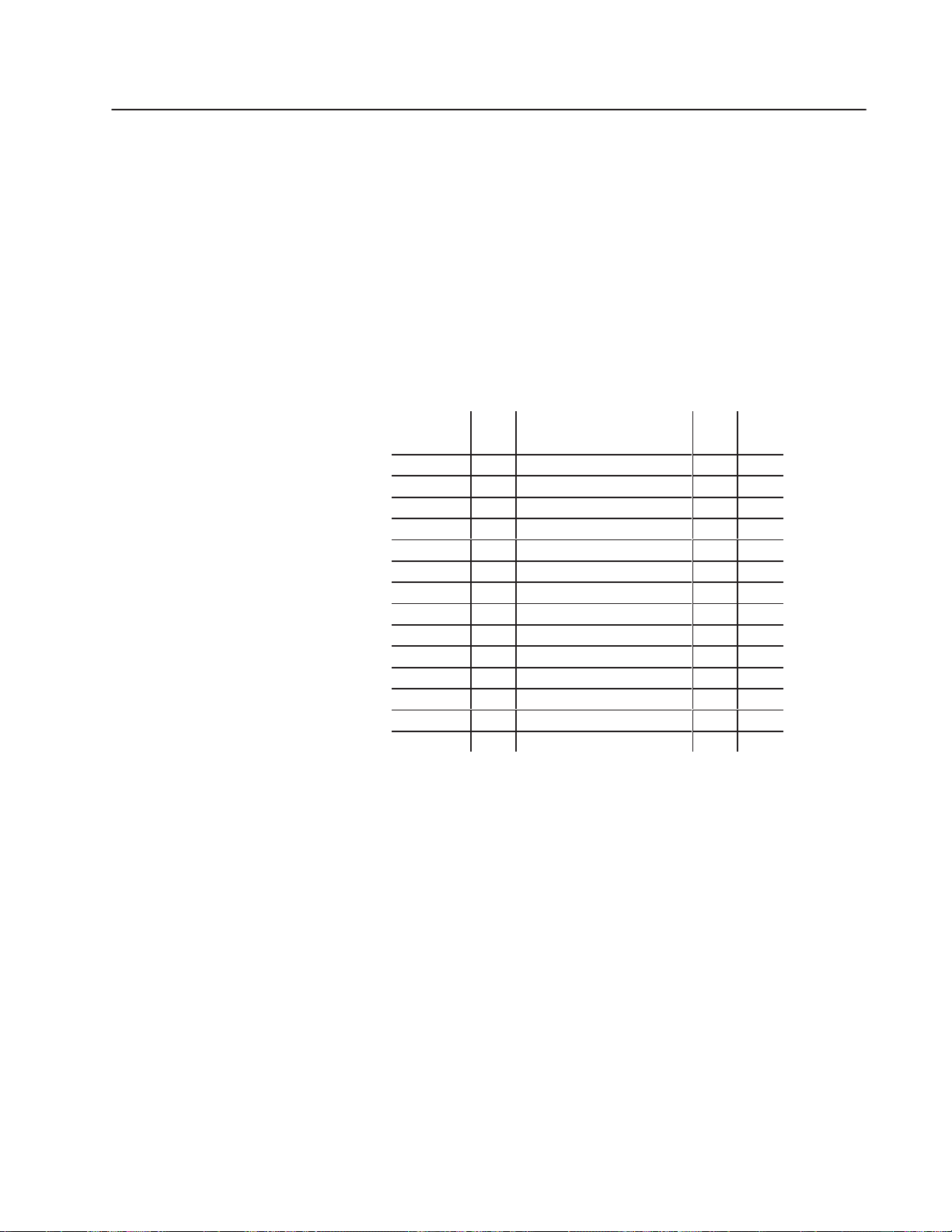

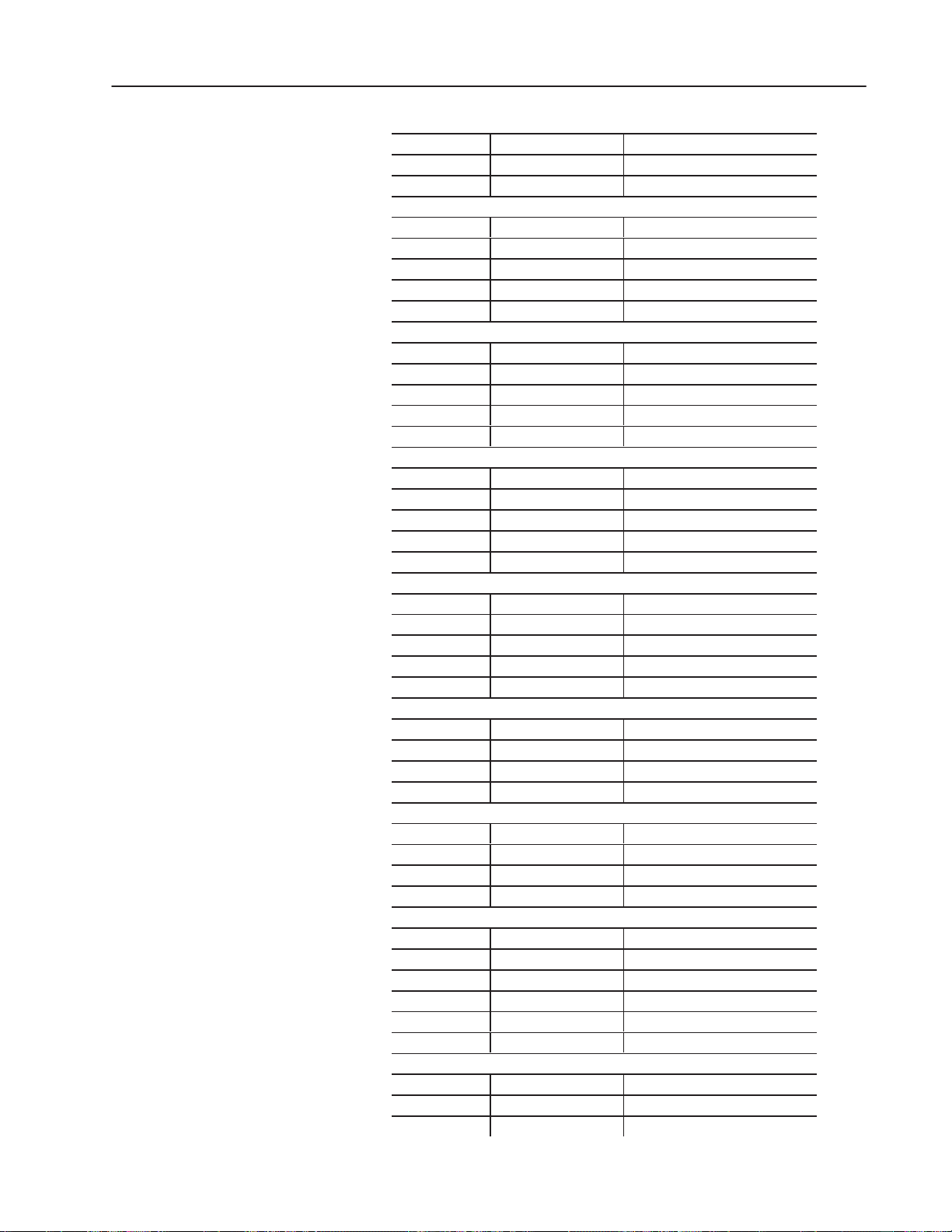

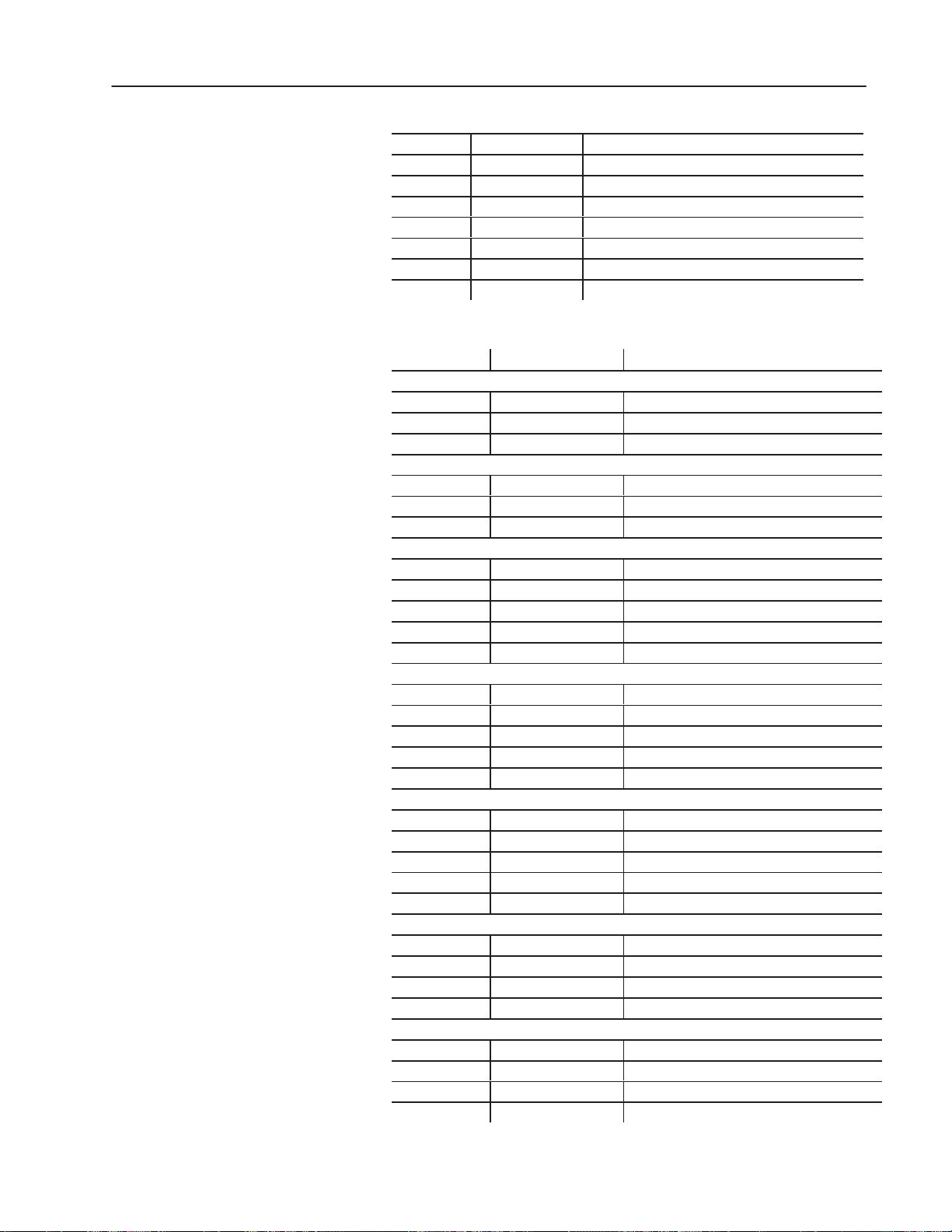

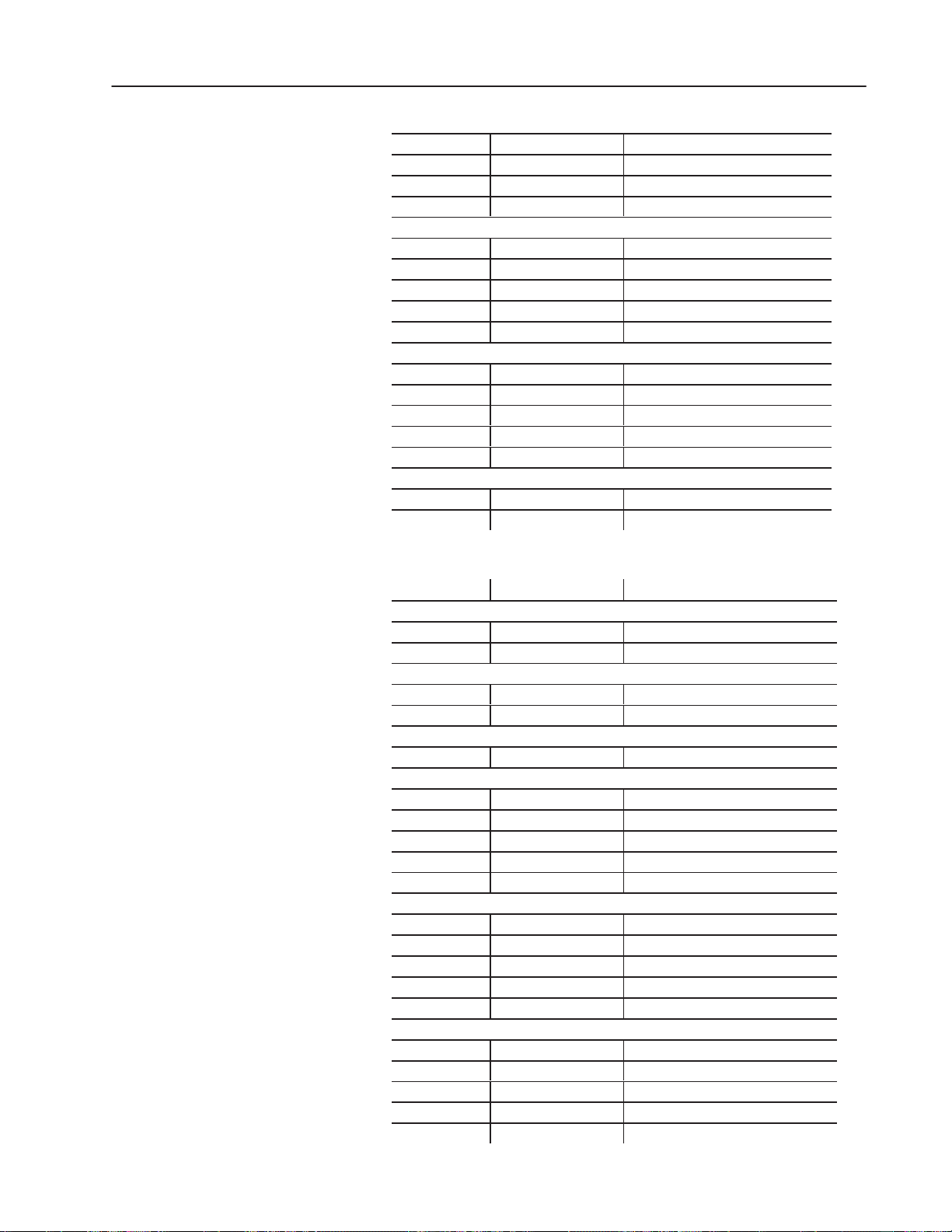

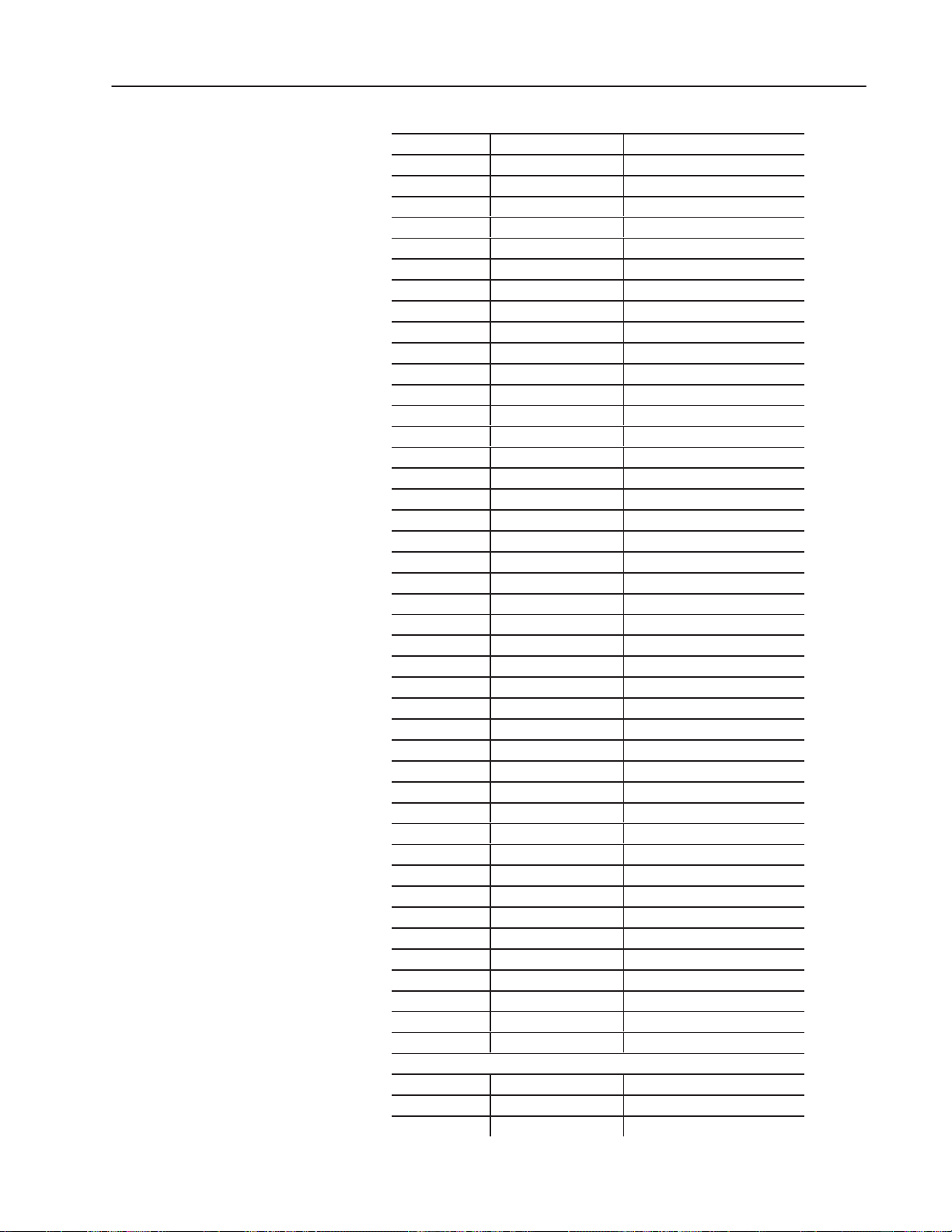

Command

Block:

DYC 25 1-2

HDC 11 1-2

HPC 12 1-3 HPS 12 1-15

INC 8 1-4

IPC 9 1-6 IPS 9 1-16

JGC 2 1-7

MCC 1 1-8 SYS 1 1-21

PKC 10 1-9

PLC 14 1-10

PPC 15 1-11 PPS 15 1-18

PRC 13 1-12

PSC 16 1-13

PTC 28 1-14 PTS 28 1-19

RLC 26 1-14 RLS 26 1-20

Block

ID: Page:

Status

Block:

Block

ID:

Page:

Important: Addresses are identical for both Pro-Set 600

(1771-QDC) and Pro-Set 700 except where noted for the following:

MCC05-08 and SYS23, 24

Important: In the listings that follow, we use the term RFU for

reserved for future use. Do not program the use of these words.

Publication

1771-6.5.126 – March 1998

Page 12

1–2 Abbreviated Command and Status Blocks

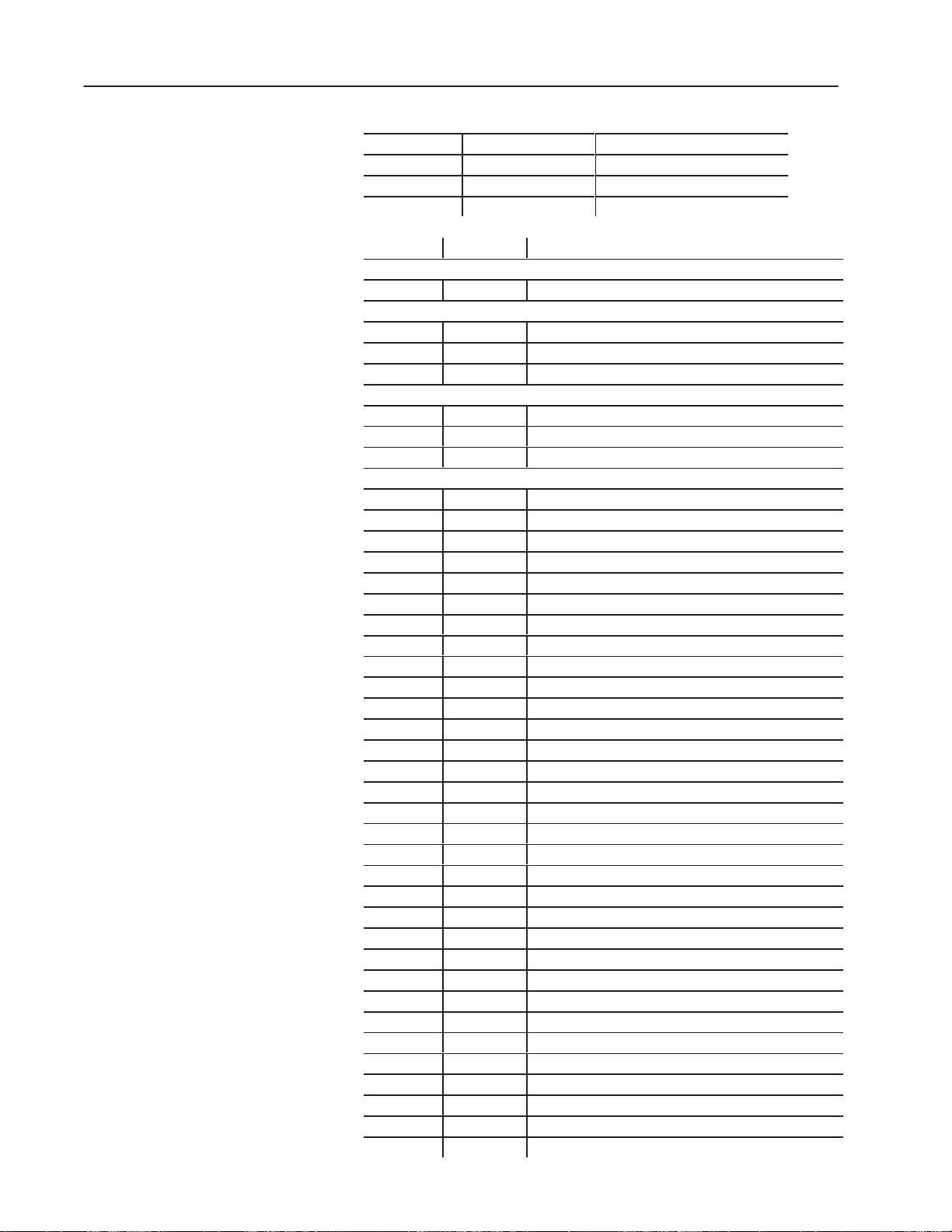

DYC – Dynamic

Command Block

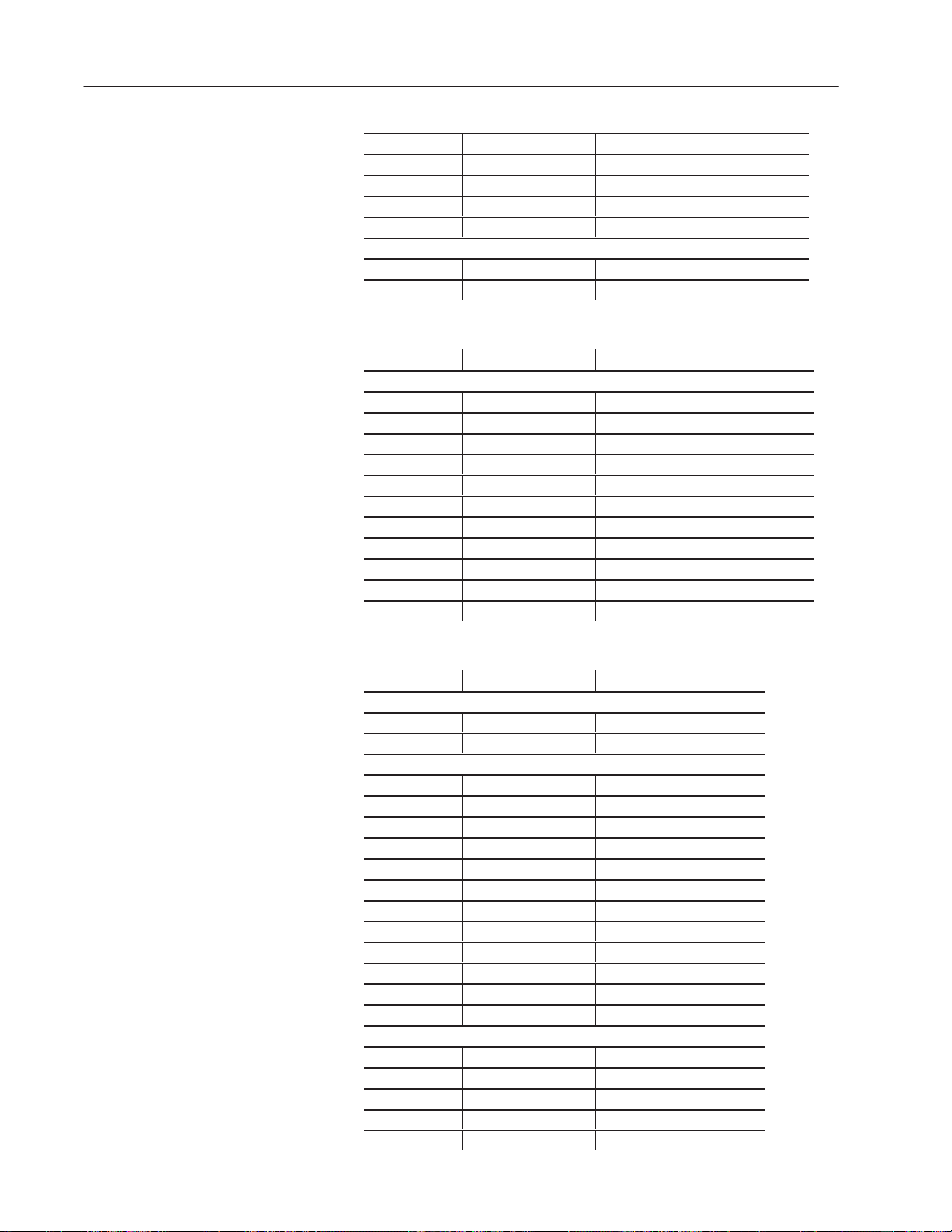

Word Pro-Set Address Description

Bit-mapped Control Words

DYC01 B34:24 Block ID 00011001 and jog commands

DYC02 B34:25 Action-execution commands

DYC03 B34:26 Miscellaneous commands

DYC04 B34:27 Status request and status clear commands

DYC05-06 B34:28-29 RFU

DYC07 B34:30 Process trace commands

DYC08 B34:31 Process trace data block request

Direct Set-output Values

DYC09 N40:121 Output #1

DYC10 N40:122 Output #2

DYC11 N40:123 Output #3

DYC12 N40:124 Output #4

DYC131-16 N40:125-128 RFU

Acceleration Ramp Rates

DYC17 N40:129 Output #1

DYC18 N40:130 Output #2

DYC19 N40:131 Output #3

DYC20 N40:132 Output #4

DYC21-24 N40:133-136 RFU

Deceleration Ramp Rates

DYC25 N40:137 Output #1

DYC26 N40:138 Output #2

DYC27 N40:139 Output #3

DYC28 N40:140 Output #4

DYC29-32 N40:141-144 RFU

DYC33-60 N40:145-172 RFU

Request for Programming Error

DYC61 N40:173 Fetch SYS61 and SYS62

DYC62-64 N40:174-176 RFU

(Series D and newer only)

(Series D and newer only)

HDC – Hold

Configuration Block

Publication

1771-6.5.126 – March 1998

Word Pro-Set Address Description

Bit-mapped Control Words

HDC01 B38:12 Block ID 00000000 00001011

HDC02 B38:13 Selected valve configurations

HDC03-04 B38:14-15 RFU

Expert Response Compensation Percentage

HDC05 N44:181 ERC % minimum cavity pressure

HDC06 N44:182 ERC % minimum ram pressure

HDC07-08 N44:183-184 RFU

Set-output Values for Unselected Valves (During Profile)

HDC09 N44:185 Output #1

HDC10 N44:186 Output #2

HDC11 N44:187 Output #3

HDC12 N44:188 Output #4

HDC13-16 N44:189-192 RFU

Page 13

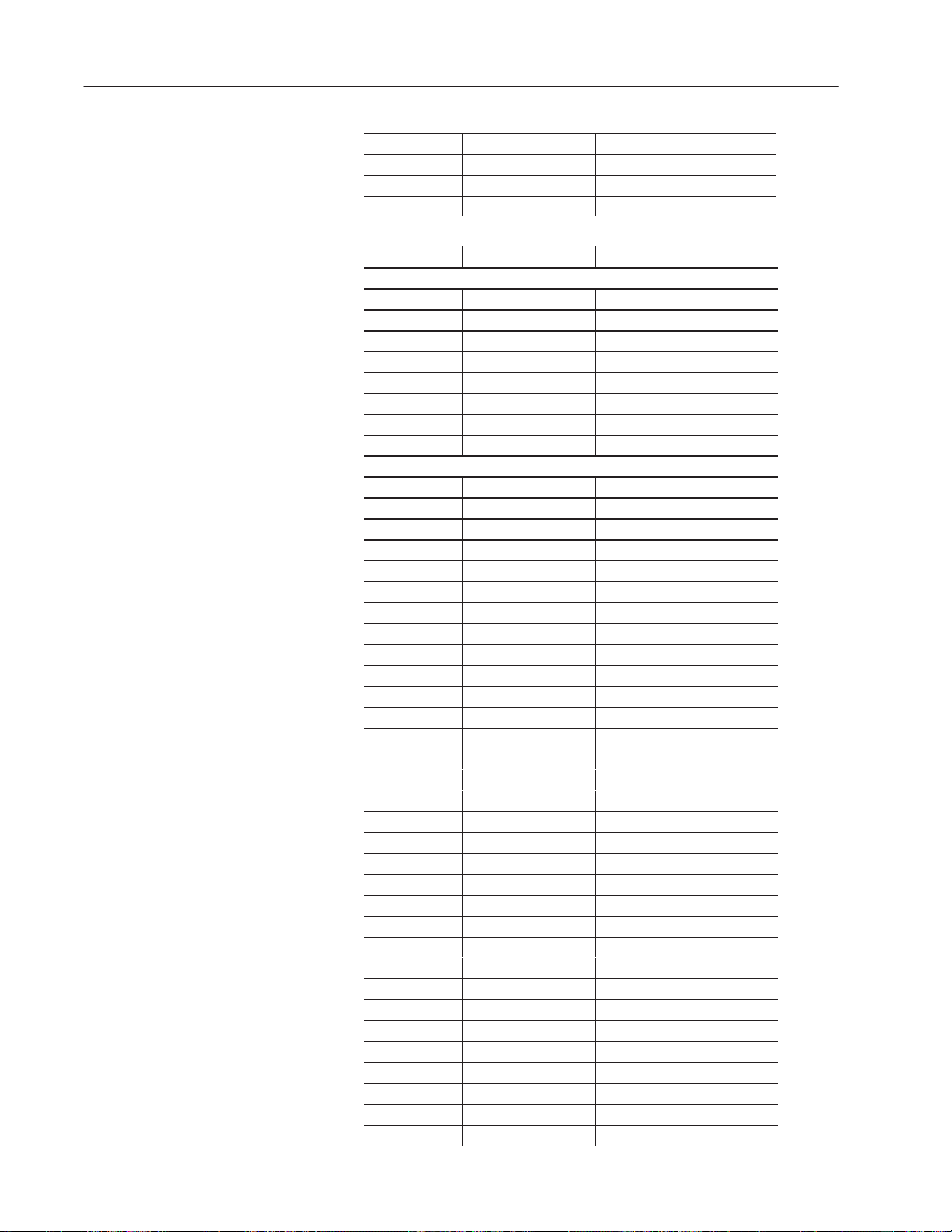

1–3Abbreviated Command and Status Blocks

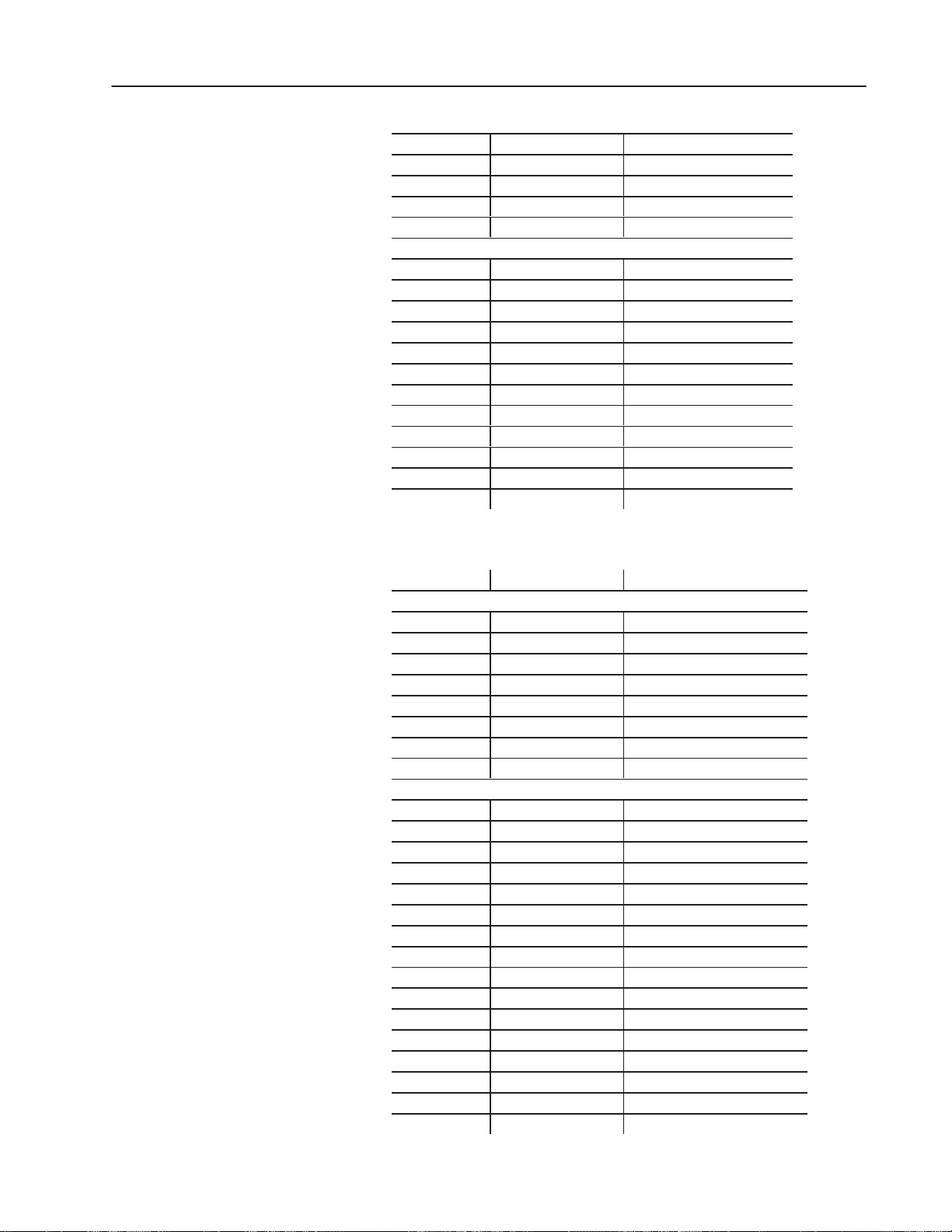

Acceleration Ramp Rates

HDC17

HDC18 N44:194 Output #2

HDC19 N44:195 Output #3

HDC20 N44:196 Output #4

HDC21-24 N44:197-200 RFU

Deceleration Ramp Rates

HDC25 N44:201 Output #1

HDC26 N44:202 Output #2

HDC27 N44:203 Output #3

HDC28 N44:204 Output #4

HDC29-32 N44:205-208 RFU

End of Profile Set-output Values

HDC33 N44:209 Output #1

HDC34 N44:210 Output #2

HDC35 N44:211 Output #3

HDC36 N44:212 Output #4

HDC37-40 N44:213-216 RFU

Ram (Screw) Pressure Control Limits

HDC41 N44:217 Minimum limit

HDC42 N44:218 Maximum limit

HDC43 N44:219 % output for minimum

HDC44 N44:220 % output for maximum

Cavity Pressure Control Limits

HDC45 N44:221 Minimum limit

HDC46 N44:222 Maximum limit

HDC47 N44:223 % output for minimum

HDC48 N44:224 % output for maximum

Profile Tuning Constants

HDC49 N44:225 Proportional gain, ram (screw) pressure control

HDC50 N44:226 Integral gain, ram (screw) pressure control

HDC51 N44:227 Derivative gain, ram (screw) pressure control

HDC52 N44:228 Proportional gain, cavity pressure control

HDC53 N44:229 Integral gain, cavity pressure control

HDC54 N44:230 Derivative gain, cavity pressure control

HDC55-56 N44:231-232 RFU

Setpoints for Profile Pressure Alarms

HDC57 N44:233 High ram (screw) pressure alarm

HDC58 N44:234 High cavity pressure alarm

HDC59-64 N44:235-240 RFU

N44:193 Output #1

HPC – Pack/Hold

Profile Block

Word Pro-Set Address Description

Bit-mapped Control Words

HPC01 B38:16 Block ID 00000000 00001100

HPC02 B38:17 RFU

HPC03 B38:18 Algorithm and logical bridging selections

HPC04 B38:19 Open/closed loop and ERC selections

Publication

1771-6.5.126 – March 1998

Page 14

1–4 Abbreviated Command and Status Blocks

Setpoints for Pack Profile

HPC05-08

HPC09 N44:245 Segment 1 cavity pressure

HPC10 N44:246 Segment 1 ram (screw) pressure

HPC11 N44:247 Segment 1 time

HPC12 N44:248 Segment 2 cavity pressure

HPC13 N44:249 Segment 2 ram (screw) pressure

HPC14 N44:250 Segment 2 time

HPC15 N44:251 Segment 3 cavity pressure

HPC16 N44:252 Segment 3 ram (screw) pressure

HPC17 N44:253 Segment 3 time

HPC18 N44:254 Segment 4 cavity pressure

HPC19 N44:255 Segment 4 ram (screw) pressure

HPC20 N44:256 Segment 4 time

HPC21 N44:257 Segment 5 cavity pressure

HPC22 N44:258 Segment 5 ram (screw) pressure

HPC23 N44:259 Segment 5 time

Pack Profile Offsets

HPC24 N44:260 Cavity pressure

HPC25 N44:261 Ram (screw) pressure

Setpoints for Hold Profile

HPC26 N44:262 Segment 1 cavity pressure

HPC27 N44:263 Segment 1 ram (screw) pressure

HPC28 N44:264 Segment 1 time

HPC29 N44:265 Segment 2 cavity pressure

HPC30 N44:266 Segment 2 ram (screw) pressure

HPC31 N44:267 Segment 2 time

HPC32 N44:268 Segment 3 cavity pressure

HPC33 N44:269 Segment 3 ram (screw) pressure

HPC34 N44:270 Segment 3 time

HPC35 N44:271 Segment 4 cavity pressure

HPC36 N44:272 Segment 4 ram (screw) pressure

HPC37 N44:273 Segment 4 time

HPC38 N44:274 Segment 5 cavity pressure

HPC39 N44:275 Segment 5 ram (screw) pressure

HPC40 N44:276 Segment 5 time

Hold Profile Offsets

HPC41 N44:277 Cavity pressure

HPC42 N44:278 Ram (screw) pressure

HPC43-60 N44:279-296 RFU

Critical Process Setpoints

HPC61 N44:297 Cure timer preset

HPC62-64 N44:298-300 RFU

N44:241-244 RFU

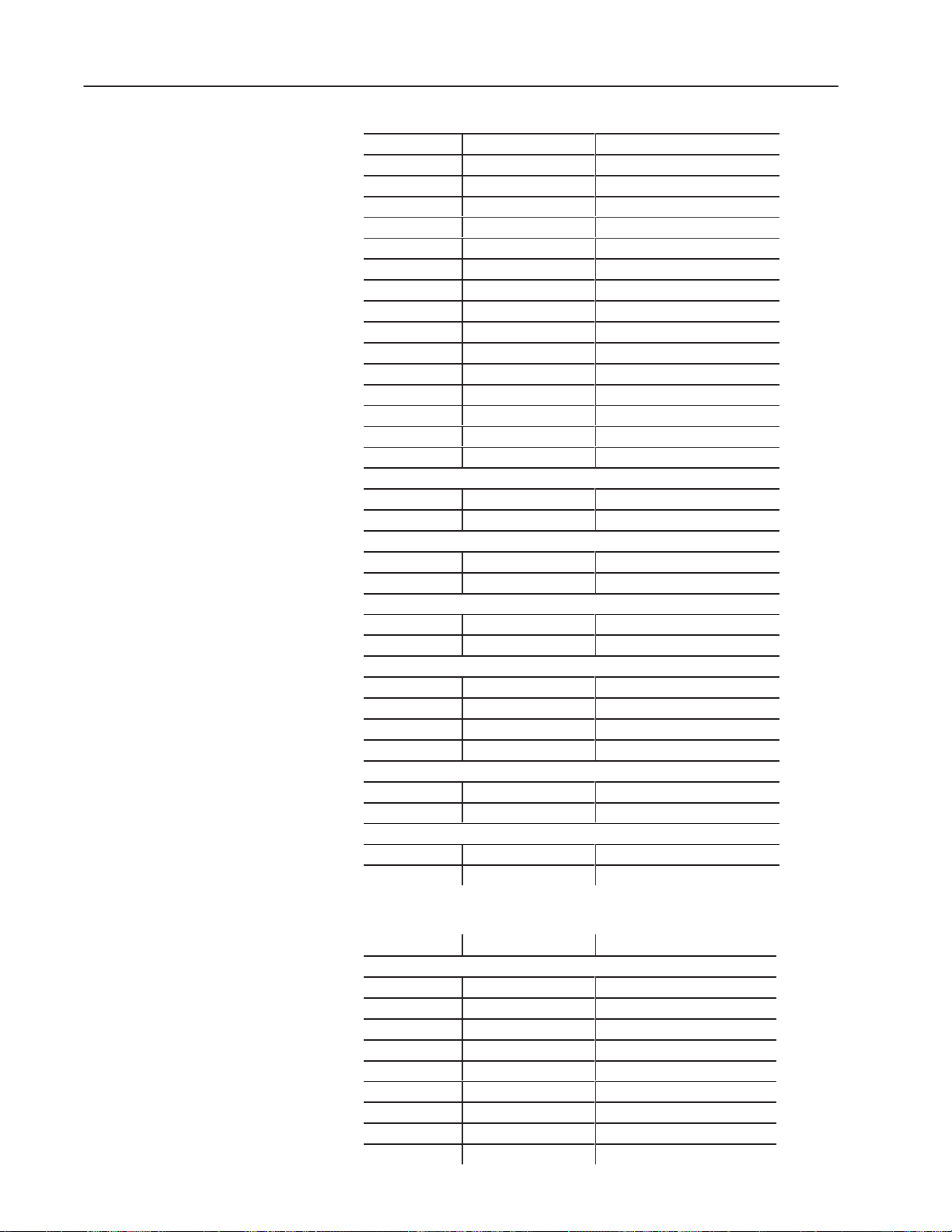

INC – Injection

Configuration Block

Publication

1771-6.5.126 – March 1998

Word Pro-Set Address Description

Bit-mapped Control Words

INC01 B38:0 Block ID 00000000 00001000

INC02 B38:1 Selected valve configurations

INC03-04 B38:2-3 RFU

Page 15

Expert Response Compensation Percentage

INC05

N44:1 ERC % minimum velocity

INC06 N44:2 ERC % minimum pressure

INC07, 08 N44:3, 4 RFU

Set-output Values for Unselected Valves (During Profile)

INC09 N44:5 Output #1

INC10 N44:6 Output #2

INC11 N44:7 Output #3

INC12 N44:8 Output #4

INC13-16 N44:9-12 RFU

Acceleration Ramp Rates

INC17 N44:13 Output #1

INC18 N44:14 Output #2

INC19 N44:15 Output #3

INC20 N44:16 Output #4

INC21-24 N44:17-20 RFU

Deceleration Ramp Rates

INC25 N44:21 Output #1

INC26 N44:22 Output #2

INC27 N44:23 Output #3

INC28 N44:24 Output #4

INC29-32 N44:25-28 RFU

End of Profile Set-output Values

INC33 N44:29 Output #1

INC34 N44:30 Output #2

INC35 N44:31 Output #3

INC36 N44:32 Output #4

INC37-40 N44:32-36 RFU

Pressure Control Limits

INC41 N44:37 Minimum limit

INC42 N44:38 Maximum limit

INC43 N44:39 % output for minimum

INC44 N44:40 % output for maximum

Velocity Control Limits

INC45 N44:41 Minimum limit

INC46 N44:42 Maximum limit

INC47 N44:43 % output for minimum

INC48 N44:44 % output for maximum

Profile Tuning Constants

INC49 N44:45 Proportional gain, pressure control

INC50 N44:46 Integral gain, pressure control

INC51 N44:47 Derivative gain, pressure control

INC52 N44:48 Proportional gain, velocity control

INC53 N44:49 Feedforward gain, velocity control

INC54-56 N44:50-52 RFU

Setpoints for Profile Pressure Alarms

INC57 N44:53 High ram (screw) pressure alarm

INC58 N44:54 High cavity pressure alarm

INC59-60 N44:55-56 RFU

1–5Abbreviated Command and Status Blocks

Publication

1771-6.5.126 – March 1998

Page 16

1–6 Abbreviated Command and Status Blocks

Set-outputs During Suspended Injection

INC:61

INC:62 N44:58 Output #2

INC:63 N44:59 Output #3

INC:64 N44:60 Output #4

IPC – Injection

Profile Block

Word Pro-Set Addr Description

Bit-mapped Control Words

IPC01 B38:4 Block ID 00000000 00001001

Bit-mapped Control Words

IPC02 B38:5 RFU

IPC03 B38:6 Algorithm and offset polarity selections

IPC04 B38:7 Open/closed loop and ERC selections

Co-injection Parameters

IPC05-06 N44:61-62 RFU

IPC07 N44:63 Time delay after reaching opposite screw position, co-inject

IPC08 N44:64 Screw position to exit injection suspension, co-injection

Injection Profile Setpoints

IPC09 N44:65 Segment 1 velocity

IPC10 N44:66 Segment 1 pressure

IPC11 N44:67 End of Segment 1 position

IPC12 N44:68 Segment 1 time

IPC13 N44:69 Segment 2 velocity

IPC14 N44:70 Segment 2 pressure

IPC15 N44:71 End of Segment 2 position

IPC16 N44:72 Segment 2 time

IPC17 N44:73 Segment 3 velocity

IPC18 N44:74 Segment 3 pressure

IPC19 N44:75 End of Segment 3 position

IPC20 N44:76 Segment 3 time

IPC21 N44:77 Segment 4 velocity

IPC22 N44:78 Segment 4 pressure

IPC23 N44:79 End of Segment 4 position

IPC24 N44:80 Segment 4 time

IPC25 N44:81 Segment 5 velocity

IPC26 N44:82 Segment 5 pressure

IPC27 N44:83 End of Segment 5 position

IPC28 N44:84 Segment 5 time

IPC29 N44:85 Segment 6 velocity

IPC30 N44:86 Segment 6 pressure

IPC31 N44:87 End of Segment 6 position

IPC32 N44:88 Segment 6 time

IPC33 N44:89 Segment 7 velocity

IPC34 N44:90 Segment 7 pressure

IPC35 N44:91 End of Segment 7 position

IPC36 N44:92 Segment 7 time

IPC37 N44:93 Segment 8 velocity

IPC38 N44:94 Segment 8 pressure

IPC39 N44:95 End of Segment 8 position

IPC40 N44:96 Segment 8 time

N44:57 Output #1

Publication

1771-6.5.126 – March 1998

Page 17

1–7Abbreviated Command and Status Blocks

Setpoints for Injection Profile (continued)

IPC41

IPC42 N44:98 Segment 9 pressure

IPC43 N44:99 End of Segment 9 position

IPC44 N44:100 Segment 9 time

IPC45 N44:101 Segment 10 velocity

IPC46 N44:102 Segment 10 pressure

IPC47 N44:103 End of Segment 10 position

IPC48 N44:104 Segment 10 time

IPC49 N44:105 Segment 11 velocity

IPC50 N44:106 Segment 11 pressure

Profile Offsets

IPC51 N44:107 Velocity Profile

IPC52 N44:108 Pressure Profile

IPC53 N44:109 RFU

Setpoints for Suspended Injection

IPC54 N44:110 Closed-loop velocity setpoint during suspended injection

IPC55 N44:111 Closed-loop pressure setpoint during suspended injection

IPC56 N44:112 Screw position (of own) to start suspension

Pressure Limiting Values

IPC57 N44:113 Ram (Screw) pressure, LimVel/Pos profile

IPC58 N44:114 Ram (Screw) position to begin pressure limiting

IPC59 N44:115 Time delay for change in algorithm

Transition (Transfer) Values

IPC60 N44:116 Time

IPC61 N44:117 Ram (Screw) position

IPC62 N44:118 Ram (Screw) pressure

IPC63 N44:119 Cavity pressure

Transition (Transfer) Pressure Inhibit

IPC64 N44:120 Ram (Screw) position

N44:97 Segment 9 velocity

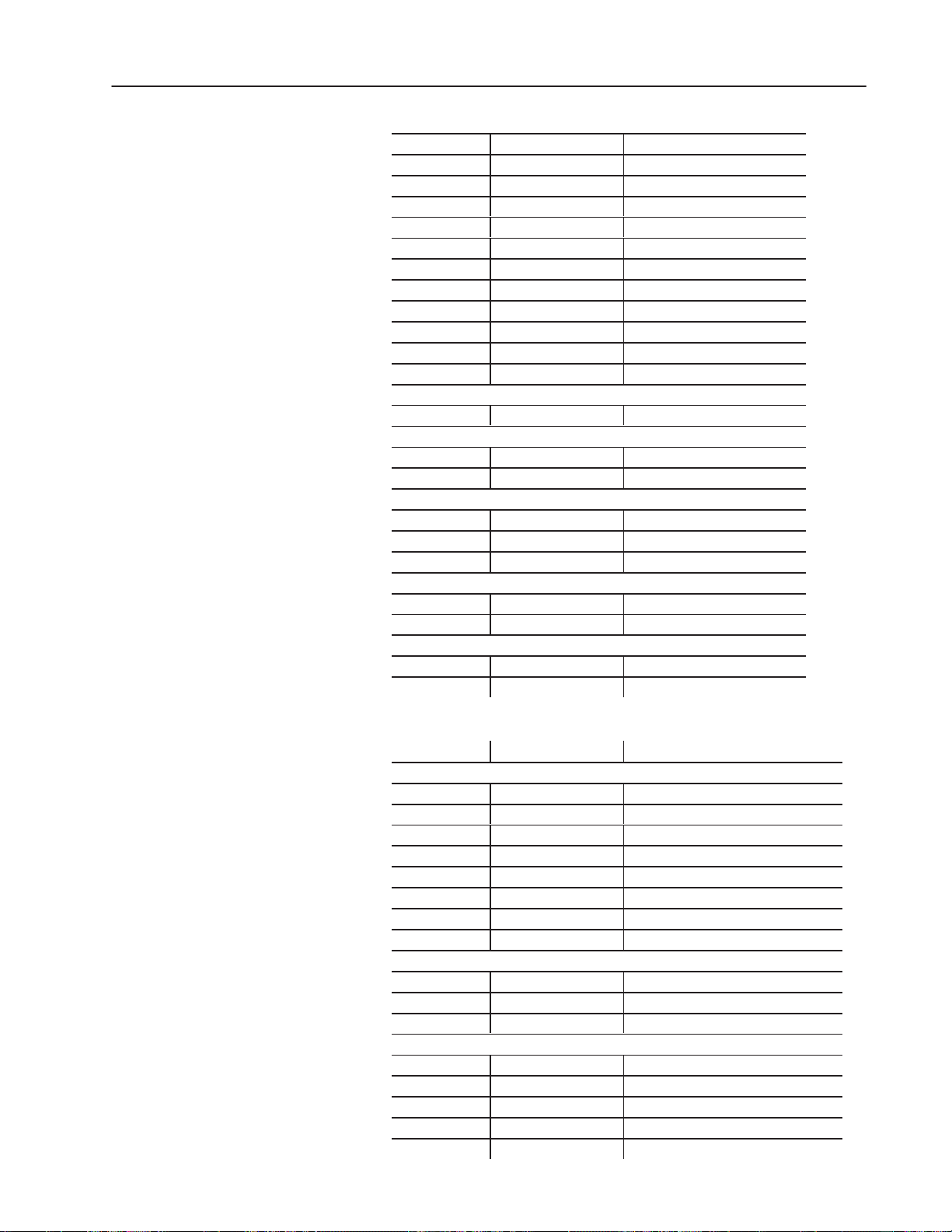

JGC – Jog

Configuration Block

Word Pro-Set Address Description

Bit-mapped Control Words

JGC01 B34:36 Block ID 00000000 00000010

JGC02-04 B34:37-39 RFU

Jog Alarm Setpoints

JGC05 N40:61 Screw jog RPM alarm

JGC06 N40:62 Ram jog pressure alarm

JGC07 N40:63 RFU

JGC08 N40:64 RFU

Screw-rotate Jog Set-output Values

JGC09 N40:65 Output #1

JGC10 N40:66 Output #2

JGC11 N40:67 Output #3

JGC12 N40:68 Output #4

JGC13-16 N40:69-72 RFU

Publication

1771-6.5.126 – March 1998

Page 18

1–8 Abbreviated Command and Status Blocks

Ram(Screw) Forward-jog Set-output Values

JGC17

JGC18 N40:74 Output #2

JGC19 N40:75 Output #3

JGC20 N40:76 Output #4

JGC21-24 N40:77-80 RFU

Ram(Screw) Reverse-jog Set-output Values

JGC25 N40:81 Output #1

JGC26 N40:82 Output #2

JGC27 N40:83 Output #3

JGC28 N40:84 Output #4

JGC29-64 N40:85-120 RFU

MCC – Module

Configuration Command

Block

Word Pro-Set Address Description

Bit-mapped Control Words

MCC01 B34:32 Block ID 00000000 00000001

MCC02 B34:33 Module density and operating modes

MCC03 B34:34 Input range selection

MCC04 B34:35 Output range selection

Output Stop-position Adjustment

MCC05*_0** N40:1* N24:72** Output #1 stop position adjustment

MCC06*_0** N40:2 N24:73** Output #2 stop position adjustment

MCC07*_0** N40:3 N24:74** Output #3 stop position adjustment

MCC08*_0** N40:4 N24:75** Output #4 stop position adjustment

*Pro-set

600 **Pro-Set 700

Ram (Screw) Position Sensor Configuration

MCC09 N40:5 Minimum position

MCC10 N40:6 Maximum position

MCC11 N40:7 Analog signal @ min position

MCC12 N40:8 Analog signal @ max position

MCC13 N40:9 Minimum SWTL (software travel limit)

MCC14 N40:10 Maximum SWTL

MCC15 N40:11 SWTL alarm deadband

MCC16 N40:12 Digital filter

MCC17 N40:13 Minimum pressure

MCC18 N40:14 Maximum pressure

MCC19 N40:15 Analog signal @ min pressure

MCC20 N40:16 Analog signal @ max pressure

MCC21 N40:17 High pressure alarm setpoint

MCC22 N40:18 Time delay for pressure alarms

MCC43 N40:39 SWTL alarm deadband

MCC44 N40:40 Digital filter

MCC50 N40:46 Time delay for pressure alarms

Screw RPM Sensor Configuration

MCC51 N40:47 Minimum RPM

MCC52 N40:48 Maximum RPM

MCC53 N40:49 Analog signal @ min RPM

MCC54 N40:50 Analog signal @ max RPM

MCC55 N40:51 High RPM alarm setpoint

MCC56 N40:52 Time delay for RPM alarms

N40:73 Output #1

For example, MCC05_0 is correct for Pro-Set 700.

Publication

1771-6.5.126 – March 1998

Page 19

PKC – Pack

Configuration Block

1–9Abbreviated Command and Status Blocks

Cavity Pressure Sensor Configuration

MCC57

MCC58 N40:54 Maximum pressure

MCC59 N40:55 Analog signal @ min pressure

MCC60 N40:56 Analog signal @ max pressure

MCC61 N40:57 High pressure alarm setpoint

MCC62 N40:58 Time delay for pressure alarms

MCC63 N40:59 Switchover time delay, input 3: cavity pressure/RPM

MCC64 N40:60 Number of input samples for loss-of-sensor alarms

Word Pro-Set Address Description

Bit-mapped Control Words

PKC01 B38:8 Block ID 00000000 00001010

PKC02 B38:9 Selected valve configurations

PKC03-04 B38:10-11 RFU

Expert Response Compensation Percentage

PKC05 N44:121 ERC % minimum cavity pressure

PKC06 N44:122 ERC % minimum ram pressure

PKC07-08 N44:123-124 RFU

Set-output Values for Unselected Valves (During Profile)

PKC09 N44:125 Output #1

PKC10 N44:126 Output #2

PKC11 N44:127 Output #3

PKC12 N44:128 Output #4

PKC13-16 N44:129-132 RFU

Acceleration Ramp Rates

PKC17 N44:133 Output #1

PKC18 N44:134 Output #2

PKC19 N44:135 Output #3

PKC20 N44:136 Output #4

PKC21-24 N44:137-140 RFU

Deceleration Ramp Rates

PKC25 N44:141 Output #1

PKC26 N44:142 Output #2

PKC27 N44:143 Output #3

PKC28 N44:144 Output #4

PKC29-40 N44:145-156 RFU

Ram (Screw) Pressure Control Limits

PKC41 N44:157 Minimum limit

PKC42 N44:158 Maximum limit

PKC43 N44:159 % output for minimum

PKC44 N44:160 % output for maximum

Cavity Pressure Control Limits

PKC45 N44:161 Minimum limit

PKC46 N44:162 Maximum limit

PKC47 N44:163 % output for minimum

PKC48 N44:164 % output for maximum

N40:53 Minimum pressure

Publication

1771-6.5.126 – March 1998

Page 20

1–10 Abbreviated Command and Status Blocks

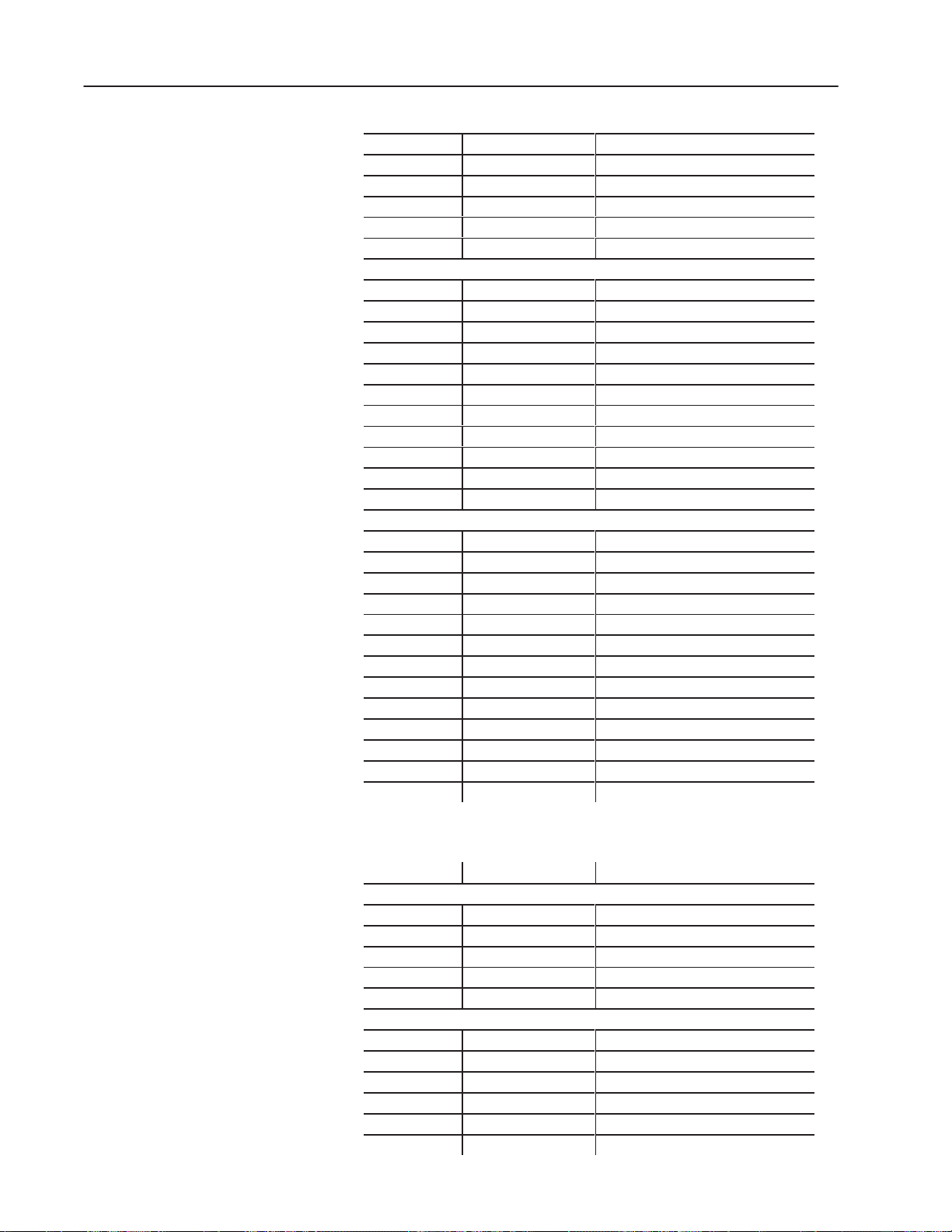

Profile Tuning Constants

PKC49

PKC50 N44:166 Integral gain, ram (screw) pressure control

PKC51 N44:167 Derivative gain, ram (screw) pressure control

PKC52 N44:168 Proportional gain, cavity pressure control

PKC53 N44:169 Integral gain, cavity pressure control

PKC54 N44:170 Derivative gain, cavity pressure control

Setpoints for Profile Pressure Alarms

PKC55-56 N44:171-172 RFU

PKC57 N44:173 High ram (screw) pressure alarm

PKC58 N44:174 High cavity pressure alarm

PKC59-64 N44:175-180 RFU

PLC – Plastication

Configuration Block

Word Pro-Set Address Description

Bit-mapped Control Words

PLC01 B38:24 Block ID 00000000 00001110

PLC02 B38:25 Selected valve configurations

PLC03-04 B38:26-27 RFU

Expert Response Compensation Percentage

PLC05 N44:361 ERC % minimum RPM

PLC06 N44:362 ERC % minimum pressure

PLC07 N44:363 RFU

Watchdog Timer

PLC08 N44:364 Profile timer preset

Set-output Values for Unselected Valves (During Profile)

PLC09 N44:365 Output #1

PLC10 N44:366 Output #2

PLC11 N44:367 Output #3

PLC12 N44:368 Output #4

PLC13-16 N44:369-372 RFU

Acceleration Ramp Rates

PLC17 N44:373 Output #1

PLC18 N44:374 Output #2

PLC19 N44:375 Output #3

PLC20 N44:376 Output #4

PLC21-24 N44:377-380 RFU

Deceleration Ramp Rates

PLC25 N44:381 Output #1

PLC26 N44:382 Output #2

PLC27 N44:383 Output #3

PLC28 N44:384 Output #4

PLC29-32 N44:385-388 RFU

End of Profile Set-output Values

PLC33 N44:389 Output #1

PLC34 N44:390 Output #2

PLC35 N44:391 Output #3

PLC36 N44:392 Output #4

PLC37-40 N44:393-396 RFU

N44:165 Proportional gain, ram (screw) pressure control

Publication

1771-6.5.126 – March 1998

Page 21

PPC – Plastication

Profile Block

Pressure Control Limits

PLC41

PLC42 N44:398 Maximum limit

PLC43 N44:399 % output for minimum

PLC44 N44:400 % output for maximum

RPM Control Limits

PLC45 N44:401 Minimum limit

PLC46 N44:402 Maximum limit

PLC47 N44:403 % output for minimum

PLC48 N44:404 % output for maximum

Profile Tuning Constants

PLC49 N44:405 Proportional gain, pressure control

PLC50 N44:406 Integral gain, pressure control

PLC51 N44:407 Derivative gain, pressure control

PLC52 N44:408 Proportional gain, RPM control

PLC53 N44:409 Integral gain, RPM control

PLC54 N44:410 Derivative gain, RPM control

PLC55-56 N44:411-412 Open

Setpoint for Profile Pressure Alarm

PLC57 N44:413 High pressure alarm

PLC58-64 N44:414-420 RFU

Word Pro-Set Address Description

Bit-mapped Control Words

PPC01 B38:28 Block ID 00000000 00001111

PPC02 B38:29 RFU

PPC03 B38:30 Algorithm and logical bridging selections

PPC04 B38:31 Open/closed loop and ERC selections

Setpoints for Plastication Profile

PPC05-08 N44:421-424 RFU

PPC09 N44:425 Segment 1 RPM

PPC10 N44:426 Segment 1 pressure

PPC11 N44:427 End of Segment 1 position

PPC12 N44:428 Segment 1 time

PPC13 N44:429 Segment 2 RPM

PPC14 N44:430 Segment 2 pressure

PPC15 N44:431 End of Segment 2 position

PPC16 N44:432 Segment 2 time

PPC17 N44:433 Segment 3 RPM

PPC18 N44:434 Segment 3 pressure

PPC19 N44:435 End of Segment 3 position

PPC20 N44:436 Segment 3 time

PPC21 N44:437 Segment 4 RPM

PPC22 N44:438 Segment 4 pressure

PPC23 N44:439 End of Segment 4 position

PPC24 N44:440 Segment 4 time

PPC25 N44:441 Segment 5 RPM

PPC26 N44:442 Segment 5 pressure

PPC27 N44:443 End of Segment 5 position

PPC28 N44:444 Segment 5 time

N44:397 Minimum limit

1–11Abbreviated Command and Status Blocks

Publication

1771-6.5.126 – March 1998

Page 22

1–12 Abbreviated Command and Status Blocks

Setpoints for Plastication Profile (continued)

PPC29

PPC30 N44:446 Segment 6 pressure

PPC31 N44:447 End of Segment 6 position

PPC32 N44:448 Segment 6 time

PPC33 N44:449 Segment 7 RPM

PPC34 N44:450 Segment 7 pressure

PPC35 N44:451 End of Segment 7 position

PPC36 N44:452 Segment 7 time

PPC37 N44:453 Segment 8 RPM

PPC38 N44:454 Segment 8 pressure

PPC39 N44:455 End of Segment 8 position

PPC40 N44:456 Segment 8 time

PPC41 N44:457 Segment 9 RPM

PPC42 N44:458 Segment 9 pressure

PPC43 N44:459 End of Segment 9 position

PPC44 N44:460 Segment 9 time

PPC45 N44:461 Segment 10 RPM

PPC46 N44:462 Segment 10 pressure

PPC47 N44:463 End of Segment 10 position

PPC48 N44:464 Segment 10 time

PPC49 N44:465 Segment 11 RPM

PPC50 N44:466 Segment 11 pressure

Profile Offsets

PPC51 N44:467 RPM

PPC52 N44:468 Pressure

PPC53-60 N44:469-476 RFU

Critical Process Setpoints

PPC61 N44:477 Cushion

PPC62 N44:478 Shot size

PPC63-64 N44:479-480 RFU

N044:445 Segment 6 RPM

PRC – Pre-decompression

Configuration Block

Publication

1771-6.5.126 – March 1998

Word Pro-Set Address Description

Bit-mapped Control Words

PRC01 B38:20 Block ID 00000000 00001101

PRC02-04 B38:21-23 RFU

Movement Length

PRC05 N44:301 Length of pre-decompress movement

PRC06-07 N44:302-303 RFU

Watchdog Timer

PRC08 N44:304 Movement timer preset

Set-output Values During Movement

PRC09 N44:305 Output #1

PRC10 N44:306 Output #2

PRC11 N44:307 Output #3

PRC12 N44:308 Output #4

PRC13-16 N44:309-312 RFU

Page 23

Acceleration Ramp Rates

PRC17

PRC18 N44:314 Output #2

PRC19 N44:315 Output #3

PRC20 N44:316 Output #4

Deceleration Ramp Rates

PRC25 N44:321 Output #1

PRC26 N44:322 Output #2

PRC27 N44:323 Output #3

PRC28 N44:324 Output #4

PRC29-32 N44:325-328 RFU

End of Movement Set-output Values

PRC33 N44:329 Output #1

PRC34 N44:330 Output #2

PRC35 N44:331 Output #3

PRC36 N44:332 Output #4

PRC37-56 N44:333-352 RFU

Setpoint for Movement Pressure Alarm

PRC57 N44:353 High pressure alarm

PRC58-64 N44:354-360 RFU

N44:313 Output #1

1–13Abbreviated Command and Status Blocks

PSC –

Post-decompression

Configuration Block

Word Pro-Set Address Description

Bit-mapped Control Words

PSC01 B38:32 Block ID 00000000 00010000

PSC02-04 B38:33-35 RFU

Movement Length

PSC05 N44:481 Length of post-decompress movement

PSC06-07 N44:482-483 RFU

Watchdog Timer

PSC08 N44:484 Movement timer preset

Set-output Values During Movement

PSC09 N44:485 Output #1

PSC10 N44:486 Output #2

PSC11 N44:487 Output #3

PSC12 N44:488 Output #4

PSC13-16 N44:489-492 RFU

Acceleration Ramp Rates

PSC17 N44:493 Output #1

PSC18 N44:494 Output #2

PSC19 N44:495 Output #3

PSC20 N44:496 Output #4

PSC21-24 N44:497-500 RFU

Deceleration Ramp Rates

PSC25 N44:501 Output #1

PSC26 N44:502 Output #2

PSC27 N44:503 Output #3

PSC28 N44:504 Output #4

PSC29-32 N44:505-508 RFU

Publication

1771-6.5.126 – March 1998

Page 24

1–14 Abbreviated Command and Status Blocks

End of Movement Set-output Values

PSC33

PSC34 N44:510 Output #2

PSC35 N44:511 Output #3

PSC36 N44:512 Output #4

PSC37-56 N44:513-532 RFU

Setpoint for Movement Pressure Alarm

PSC57 N44:533 High pressure alarm

PSC58-64 N44:534-40 RFU

PTC – Process Trace

Configuration Block

Word Pro-Set Address Description

Bit-mapped Control Words

PTC01 B131:9 Block ID 00000000 00011100

PTC02 B131:10 Process trace and trigger control

PTC03-04 B131:11-12 Open

PTC05 N132:0 Trigger delay

PTC06 N132:1 Trigger position

PTC07 N132:2 Trace data collection sample rate

PTC08 N132:3 Trace 1 selection

PTC09 N132:4 Trace 2 selection

PTC10 N132:5 Trace 3 selection

PTC11 N132:6 Trace 4 selection

PTC12-64 N132:7-59 RFU

N44:509 Output #1

RLC – Inject ERC Values

Block

Word Pro-Set Address Description

Bit-mapped Control Words

RLC01 B38:36 Block ID 00000000 00011010

RLC02-04 B38:37-39 RFU

ERC Values for Injection Profile

RLC05-08 N44:541-544 RFU

RLC09 N44:545 Injection segment 1

RLC10 N44:546 Injection segment 2

RLC11 N44:547 Injection segment 3

RLC12 N44:548 Injection segment 4

RLC13 N44:549 Injection segment 5

RLC14 N44:550 Injection segment 6

RLC15 N44:551 Injection segment 7

RLC16 N44:552 Injection segment 8

RLC17 N44:553 Injection segment 9

RLC18 N44:554 Injection segment 10

RLC19 N44:555 Injection segment 11

ERC Values for Pack Profile

RLC20 N44:556 Pack segment 1

RLC21 N44:557 Pack segment 2

RLC22 N44:558 Pack segment 3

RLC23 N44:559 Pack segment 4

RLC24 N44:560 Pack segment 5

Publication

1771-6.5.126 – March 1998

Page 25

ERC Values for Hold Profile

RLC25

RLC26 N44:562 Hold segment 2

RLC27 N44:563 Hold segment 3

RLC28 N44:564 Hold segment 4

RLC29 N44:565 Hold segment 5

ERC Values for Plastication Profile

RLC30 N44:566 Plastication segment 1

RLC31 N44:567 Plastication segment 2

RLC32 N44:568 Plastication segment 3

RLC33 N44:569 Plastication segment 4

RLC34 N44:570 Plastication segment 5

RLC35 N44:571 Plastication segment 6

RLC36 N44:572 Plastication segment 7

RLC37 N44:573 Plastication segment 8

RLC38 N44:574 Plastication segment 9

RLC39 N44:575 Plastication segment 10

RLC40 N44:576 Plastication segment 11

RLC41-64 N44:577-600 RFU

N44:561 Hold segment 1

1–15Abbreviated Command and Status Blocks

HPS – Pack/Hold Profile

Status Block

Word Pro-Set Address Description

Bit-mapped Status Words

HPS01 B34:0 Block ID 00000100 (lower byte)

HPS01 B34:0 Jog status (upper byte)

HPS02 B34:1 Status of profile execution

HPS03 B34:2 Miscellaneous status

HPS04 B34:3 Status of watchdog timers

HPS05-06 B38:44-45 RFU

HPS07 B38:46 CV high limit alarms

HPS08 B38:47 CV low limit alarms

Actuals from Pack Profile

HPS09 N44:657 Segment 1 cavity pressure

HPS10 N44:658 Segment 1 ram (screw) pressure

HPS11 N44:659 End of Segment 1 position

HPS12 N44:660 Segment 2 cavity pressure

HPS13 N44:661 Segment 2 ram (screw) pressure

HPS14 N44:662 End of Segment 2 position

HPS15 N44:663 Segment 3 cavity pressure

HPS16 N44:664 Segment 3 ram (screw) pressure

HPS17 N44:665 End of Segment 3 position

HPS18 N44:666 Segment 4 cavity pressure

HPS19 N44:667 Segment 4 ram (screw) pressure

HPS20 N44:668 End of Segment 4 position

HPS21 N44:669 Segment 5 cavity pressure

HPS22 N44:670 Segment 5 ram (screw) pressure

HPS23 N44:671 End of Segment 5 position

HPS24-25 N44:672 RFU

Publication

1771-6.5.126 – March 1998

Page 26

1–16 Abbreviated Command and Status Blocks

Actuals from Hold Profile

HPS26

HPS27 N44:675 Segment 1 ram (screw) pressure

HPS28 N44:676 End of Segment 1 position

HPS29 N44:677 Segment 2 cavity pressure

HPS30 N44:678 Segment 2 ram (screw) pressure

HPS31 N44:679 End of Segment 2 position

HPS32 N44:680 Segment 3 cavity pressure

HPS33 N44:681 Segment 3 ram (screw) pressure

HPS34 N44:682 End of Segment 3 position

HPS35 N44:6834 Segment 4 cavity pressure

HPS36 N44:684 Segment 4 ram (screw) pressure

HPS37 N44:685 End of Segment 4 position

HPS38 N44:686 Segment 5 cavity pressure

HPS39 N44:687 Segment 5 ram (screw) pressure

HPS40 N44:688 End of Segment 5 position

HPS41-50 N44:689-698 RFU

Maximum Pressures During Pack

HPS51 N44:699 Ram (screw)

HPS52 N44:700 Cavity

Maximum Pressures During Hold

HPS53 N44:701 Ram (screw)

HPS54 N44:702 Cavity

Maximum Pressure During Pre-decompression

HPS55 N44:703 Ram (screw)

HPS56 N44:704 RFU

Profile Execution Times

HPS57 N44:705 During pack

HPS58 N44:706 During hold

HPS59 N44:707 During pre-decompression

HPS60 N44:708 RFU

Actuals from Pre-decompression Movement

HPS61 N44:709 Velocity

HPS62 N44:710 Pressure

End of Hold Ram (Screw) Position

HPS63 N44:711 Position at End of-hold

HPS64 N44:712 RFU

N44:674 Segment 1 cavity pressure

IPS – Injection Profile

Status Block

Publication

1771-6.5.126 – March 1998

Word Pro-Set Address Description

Bit-mapped Status Words

IPS01 B34:0 Block ID 00000011 (lower byte)

IPS01 B34:0 Jog status (upper byte)

IPS02 B34:1 Status of profile execution

IPS03 B34:2 Miscellaneous status

IPS04 B34:3 Status of watchdog timers

IPS05 B38:40 Status of pressure limit alarms

IPS06 B38:41 Status of injection transitions

IPS07 B38:42 CV high limit alarms

IPS08 B38:43 CV low limit alarms

Page 27

Injection Profile Actuals

IPS09

N44:601 Segment 1 velocity

IPS10 N44:602 Segment 1 pressure

IPS11 N44:603 Segment 1 execution time

IPS12 N44:604 End of Segment 1 position

IPS13 N44:605 Segment 2 velocity

IPS14 N44:606 Segment 2 pressure

IPS15 N44:607 Segment 2 execution time

IPS16 N44:608 End of Segment 2 position

IPS17 N44:609 Segment 3 velocity

IPS18 N44:610 Segment 3 pressure

IPS19 N44:611 Segment 3 execution time

IPS20 N44:612 End of Segment 3 position

IPS21 N44:613 Segment 4 velocity

IPS22 N44:614 Segment 4 pressure

IPS23 N44:615 Segment 4 execution time

IPS24 N44:616 End of Segment 4 position

IPS25 N44:617 Segment 5 velocity

IPS26 N44:618 Segment 5 pressure

IPS27 N44:619 Segment 5 execution time

IPS28 N44:620 End of Segment 5 position

IPS29 N44:621 Segment 6 velocity

IPS30 N44:622 Segment 6 pressure

IPS31 N44:623 Segment 6 execution time

IPS32 N44:624 End of Segment 6 position

IPS33 N44:625 Segment 7 velocity

IPS34 N44:626 Segment 7 pressure

IPS35 N44:627 Segment 7 execution time

IPS36 N44:628 End of Segment 7 position

IPS37 N44:629 Segment 8 velocity

IPS38 N44:630 Segment 8 pressure

IPS39 N44:631 Segment 8 execution time

IPS40 N44:632 End of Segment 8 position

IPS41 N44:633 Segment 9 velocity

IPS42 N44:634 Segment 9 pressure

IPS43 N44:635 Segment 9 execution time

IPS44 N44:636 End of Segment 9 position

IPS45 N44:637 Segment 10 velocity

IPS46 N44:638 Segment 10 pressure

IPS47 N44:639 Segment 10 execution time

IPS48 N44:640 End of Segment 10 position

IPS49 N44:641 Segment 11 velocity

IPS50 N44:642 Segment 11 pressure

IPS51 N44:643 Segment 11 execution time

IPS52 N44:644 RFU

Maximum Pressures During Injection

IPS53 N44:645 Ram (screw)

IPS54 N44:646 Cavity

IPS55-60 N44:647-652 RFU

1–17Abbreviated Command and Status Blocks

Publication

1771-6.5.126 – March 1998

Page 28

1–18 Abbreviated Command and Status Blocks

Transition (Transfer) Actuals

IPS61

IPS62 N44:654 Position

IPS63 N44:655 Ram (screw) pressure

IPS64 N44:656 Cavity pressure

PPS – Plastication Profile

Status Block

Word Pro-Set Address Description

Bit-mapped Status Words

PPS01 B34:0 Block ID 00000101 (lower byte)

PPS01 B34:0 Jog status (upper byte)

PPS02 B34:1 Status of profile execution

PPS03 B34:2 Miscellaneous status

PPS04 B34:3 Status of watchdog timers

PPS05-06 B38:48-49 RFU

PPS07 B38:50 CV high limit alarms

PPS08 B38:51 CV low limit alarms

Plastication Profile Actuals

PPS09 N44:713 Segment 1 RPM

PPS10 N44:714 Segment 1 pressure

PPS11 N44:715 Segment 1 execution time

PPS12 N44:716 End of Segment 1 position

PPS13 N44:717 Segment 2 RPM

PPS14 N44:718 Segment 2 pressure

PPS15 N44:719 Segment 2 execution time

PPS16 N44:720 End of Segment 2 position

PPS17 N44:721 Segment 3 RPM

PPS18 N44:722 Segment 3 pressure

PPS19 N44:723 Segment 3 execution time

PPS20 N44:724 End of Segment 3 position

PPS21 N44:725 Segment 4 RPM

PPS22 N44:726 Segment 4 pressure

PPS23 N44:727 Segment 4 execution time

PPS24 N44:728 End of Segment 4 position

PPS25 N44:729 Segment 5 RPM

PPS26 N44:730 Segment 5 pressure

PPS27 N44:731 Segment 5 execution time

PPS28 N44:732 End of Segment 5 position

PPS29 N44:733 Segment 6 RPM

PPS30 N44:734 Segment 6 pressure

PPS31 N44:735 Segment 6 execution time

PPS32 N44:736 End of Segment 6 position

PPS33 N44:737 Segment 7 RPM

PPS34 N44:738 Segment 7 pressure

PPS35 N44:739 Segment 7 execution time

PPS36 N44:740 End of Segment 7 position

PPS37 N44:741 Segment 8 RPM

PPS38 N44:742 Segment 8 pressure

PPS39 N44:743 Segment 8 execution time

PPS40 N44:744 End of Segment 8 position

N44:653 Time

Publication

1771-6.5.126 – March 1998

Page 29

Plastication Profile Actuals (continued)

PPS41

PPS42 N44:746 Segment 9 pressure

PPS43 N44:747 Segment 9 execution time

PPS44 N44:748 End of Segment 9 position

PPS45 N44:749 Segment 10 RPM

PPS46 N44:750 Segment 10 pressure

PPS47 N44:751 Segment 10 execution time

PPS48 N44:752 End of Segment 10 position

PPS49 N44:753 Segment 11 RPM

PPS50 N44:754 Segment 11 pressure

PPS51 N44:755 Segment 11 execution time

PPS52 N44:756 RFU

Maximum Plastication Pressure

PPS53 N44:757 Ram (screw)

Maximum Post-decompression Pressure

PPS54 N44:758 Ram (screw)

PPS55-56 N44:759-760 RFU

Profile Execution Times

PPS57 N44:761 During plastication

PPS58 N44:762 During post-decompression

PPS59-60 N44:763-764 RFU

Actuals from Post-decompression Movement

PPS61 N44:765 Velocity

PPS62 N44:766 Pressure

Actual Shot Size

PPS63 N44:767 Total length

PPS64 N44:768 RFU

N44:745 Segment 9 RPM

1–19Abbreviated Command and Status Blocks

PTS – Process Trace

Status Block

Word Pro-Set Address Description

Bit-mapped Status Words

PTS01 B131:0 Block ID 00001010 (lower byte)

PTS01 B131:1 Power up, jog execution status (hi byte)

PTS02 B131:2 Status of profile execution

PTS03 B131:3 Miscellaneous status

PTS04 B131:4 Status of watchdog timers

PTS05 B131:5 Trace selection

PTS06 B131:6 Trace data block number

PTS07-08 B131:7-8 RFU

Data Point Time/Count

PTS09 N132:60 Time to first trace data point

PTS10 N132:61 Trace data point count

PTS11-14 N132:62-65 RFU

Starting Data Points from Injection Profile

PTS15 N132:66 Inject segment 1 start data point

PTS16 N132:67 Inject segment 2 start data point

PTS17 N132:68 Inject segment 3 start data point

PTS18 N132:69 Inject segment 4 start data point

PTS19 N132:70 Inject segment 5 start data point

Publication

1771-6.5.126 – March 1998

Page 30

1–20 Abbreviated Command and Status Blocks

Starting Data Points from Injection Profile (continued)

PTS20

PTS21 N132:72 Inject segment 7 start data point

PTS22 N132:73 Inject segment 8 start data point

PTS23 N132:74 Inject segment 9 start data point

PTS24 N132:75 Inject segment 10 start data point

PTS25 N132:76 Inject segment 11 start data point

Starting Data Points from Pack/Hold Profiles

PTS26 N132:77 Pack segment 1 start data point

PTS27 N132:78 Pack segment 2 start data point

PTS28 N132:79 Pack segment 3 start data point

PTS29 N132:80 Pack segment 4 start data point

PTS30 N132:81 Pack segment 5 start data point

PTS31 N132:82 Hold segment 1 start data point

PTS32 N132:83 Hold segment 2 start data point

PTS33 N132:84 Hold segment 3 start data point

PTS34 N132:85 Hold segment 4 start data point

PTS35 N132:86 Hold segment 5 start data point

PTS36 N132:87 Pre-decompress start data point

Starting Data Points from Plastication Profile

PTS37 N132:88 Plastication segment 1 start data point

PTS38 N132:89 Plastication segment 2 start data point

PTS39 N132:90 Plastication segment 3 start data point

PTS40 N132:91 Plastication segment 4 start data point

PTS41 N132:92 Plastication segment 5 start data point

PTS42 N132:93 Plastication segment 6 start data point

PTS43 N132:94 Plastication segment 7 start data point

PTS44 N132:95 Plastication segment 8 start data point

PTS45 N132:96 Plastication segment 9 start data point

PTS46 N132:97 Plastication segment 10 start data point

PTS47 N132:98 Plastication segment 11 start data point

PTS48 N132:99 Post-decompress start data point

PTS49 - 64 N132:100-115 RFU

N132:71 Inject segment 6 start data point

RLS – Inject ERC Values

Status Block

Publication

1771-6.5.126 – March 1998

Word Pro-Set Address Description

Bit-mapped Status Words

RLS01 B34:0 Block ID 00001000 (lower byte)

RLS01 B34:0 Jog status (upper byte)

RLS02 B34:1 Status of profile execution

RLS03 B34:2 Miscellaneous status

RLS04 B34:3 Status of watchdog timers

ERC Actuals from Injection Profile

RLS05-08 N44:541-544 RFU

RLS09 N44:545 Injection segment 1

RLS10 N44:546 Injection segment 2

RLS11 N44:547 Injection segment 3

RLS12 N44:548 Injection segment 4

RLS13 N44:549 Injection segment 5

Page 31

ERC Actuals from Injection Profile (continued)

RLS14

RLS15 N44:551 Injection segment 7

RLS16 N44:552 Injection segment 8

RLS17 N44:553 Injection segment 9

RLS18 N44:554 Injection segment 10

RLS19 N44:555 Injection segment 11

ERC Actuals from Pack Profile

RLS20 N44:556 Pack segment 1

RLS21 N44:557 Pack segment 2

RLS22 N44:558 Pack segment 3

RLS23 N44:559 Pack segment 4

RLS24 N44:560 Pack segment 5

ERC Actuals from Hold Profile

RLS25 N44:561 Hold segment 1

RLS26 N44:562 Hold segment 2

RLS27 N44:563 Hold segment 3

RLS28 N44:564 Hold segment 4

RLS29 N44:565 Hold segment 5

ERC Actuals from Plastication Profile

RLS30 N44:566 Plastication segment 1

RLS31 N44:567 Plastication segment 2

RLS32 N44:568 Plastication segment 3

RLS33 N44:569 Plastication segment 4

RLS34 N44:570 Plastication segment 5

RLS35 N44:571 Plastication segment 6

RLS36 N44:572 Plastication segment 7

RLS37 N44:573 Plastication segment 8

RLS38 N44:574 Plastication segment 9

RLS39 N44:575 Plastication segment 10

RLS40 N44:576 Plastication segment 11

RLS41-64 N44:577-600 RFU

N44:550 Injection segment 6

1–21Abbreviated Command and Status Blocks

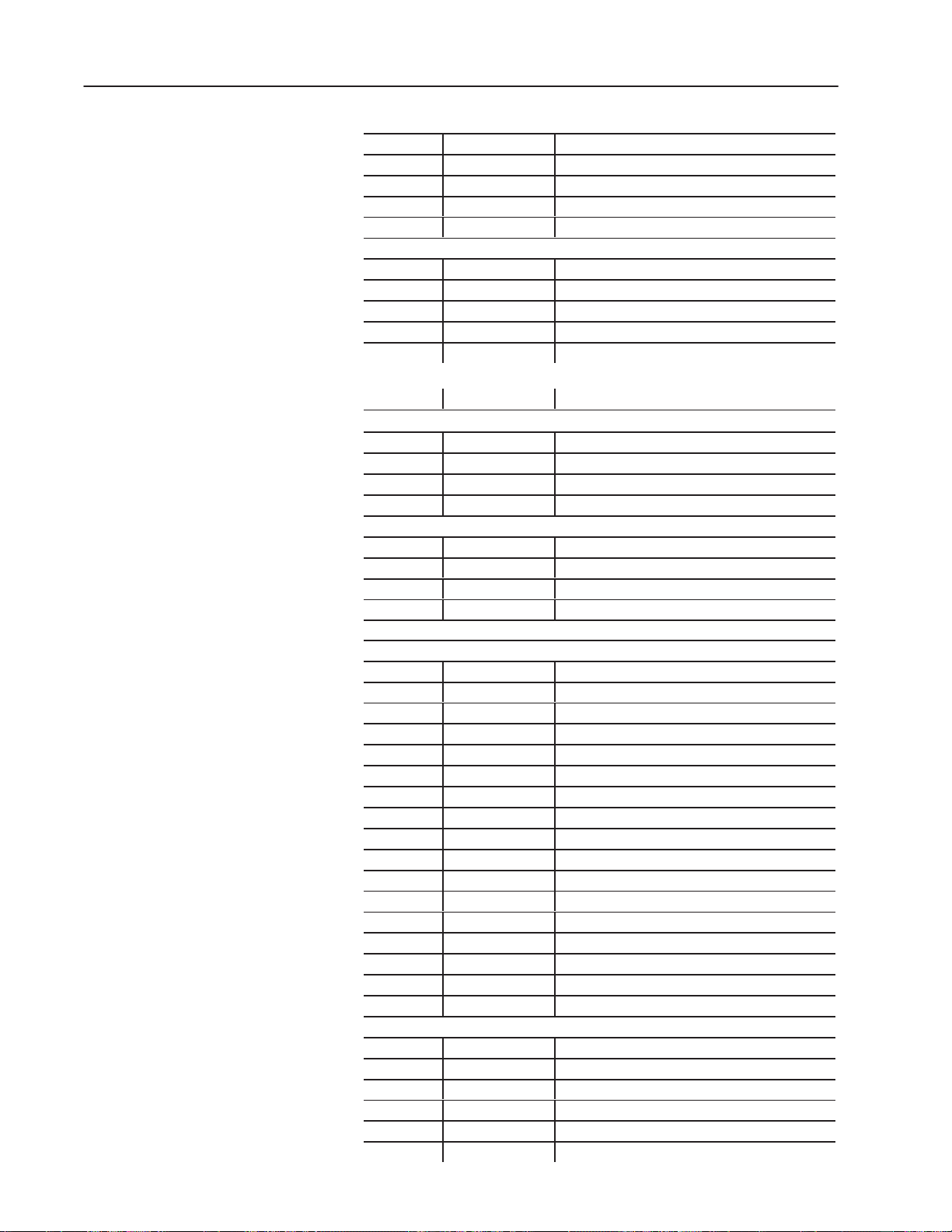

SYS - System Status Block

Word Pro-Set Address Description

Bit-Mapped Status Words

SYS01 B34:0 Block ID 00000001 (lower byte)

SYS01 B34:0 Jog status (upper byte)

SYS02 B34:1 Status of profile execution

SYS03 B34:2 Miscellaneous status

SYS04 B34:3 Status of watchdog timers

SYS05-08 B34:4-7 Status of real-time alarms

SYS09-12 B34:8-11 Status of latched alarms

SYS13-14 B34:12-13 Command errors

SYS15-16 B34:14-15 Status of transferred command blocks

SYS17-18 B34:16-17 Status of last block decoding

SYS19-20 B34:18-19 Programming error alarms

SYS21 B34:20 Status of profile execution

SYS22 B34:21 Status of End of Profile action

Publication

1771-6.5.126 – March 1998

Page 32

1–22 Abbreviated Command and Status Blocks

Bit-Mapped Status Words (continued)

SYS23*_0**

SYS24*_0** B34:23* B21:19** Status of process trace data collected

*Pro-set

600 **Pro-Set 700

Input Level in Engineering Units

SYS25 N40:177 Input #1

SYS26 N40:178 Input #2

SYS27 N40:179 Input #3

SYS28 N40:180 Input #4

SYS29-32 N40:181-184 RFU

Input Level, Raw Signal Level at A/D Converter

SYS33 N40:185 Input #1

SYS34 N40:186 Input #2

SYS35 N40:187 Input #3

SYS36 N40:188 Input #4

SYS37-40 N40:189-192 RFU

Output Level in Percent

SYS41 N40:193 Output #1

SYS42 N40:194 Output #2

SYS43 N40:195 Output #3

SYS44 N40:196 Output #4

SYS45-48 N40:197-200 RFU

Maximum Pressures of Each Cycle

SYS49 N40:201 Maximum ram (screw) pressure, last cycle

SYS50, 51 N40:202, 203 RFU

SYS52 N40:204 Maximum cavity pressure, last cycle

SYS53 N40:205 RFU

Process Trace

SYS54 N40:206 Process trace data collection in progress

SYS55 N40:207 Process trace data collection done

SYS56 N40:208 RFU

Accumulated Process Times

SYS57 N40:209 Tonnage

SYS58 N40:210 Cure

SYS59 N40:211 Mold open dwell

SYS60 N40:212 Cycle

Programming Error Codes

SYS61 N40:213 ID of data block with error

SYS62 N40:214 Programming error code

Firmware ID

SYS63 N40:215 Module Series/Revision

Confirmation of New Status

SYS64 N40:216 Counter accumulated value, each new SYS

B34:22* B21:18** Status of trace data collection in progress

For example, MCC05_0 is correct for Pro-Set 700.

Publication

1771-6.5.126 – March 1998

Page 33

Command Word/Bit

Descriptions

Chapter 2

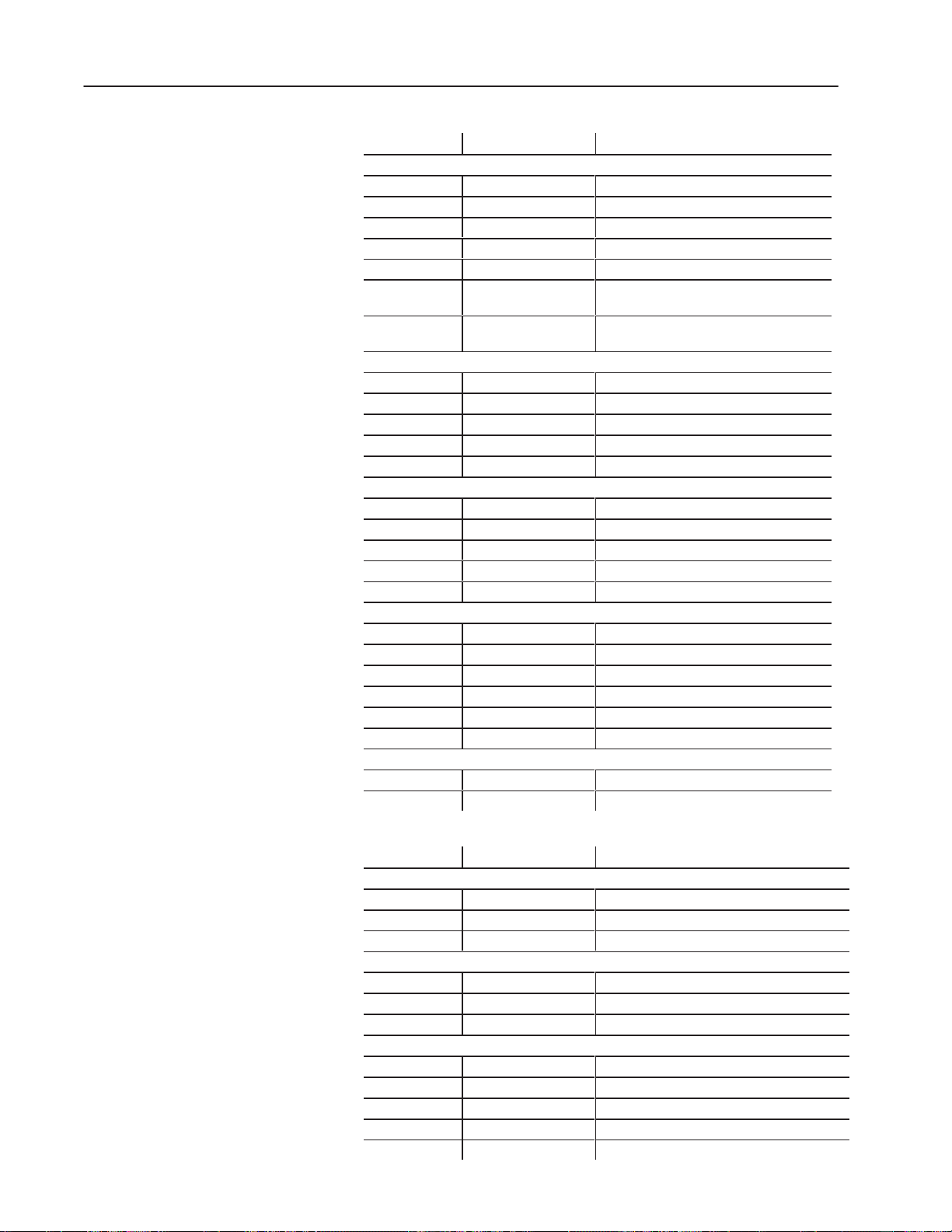

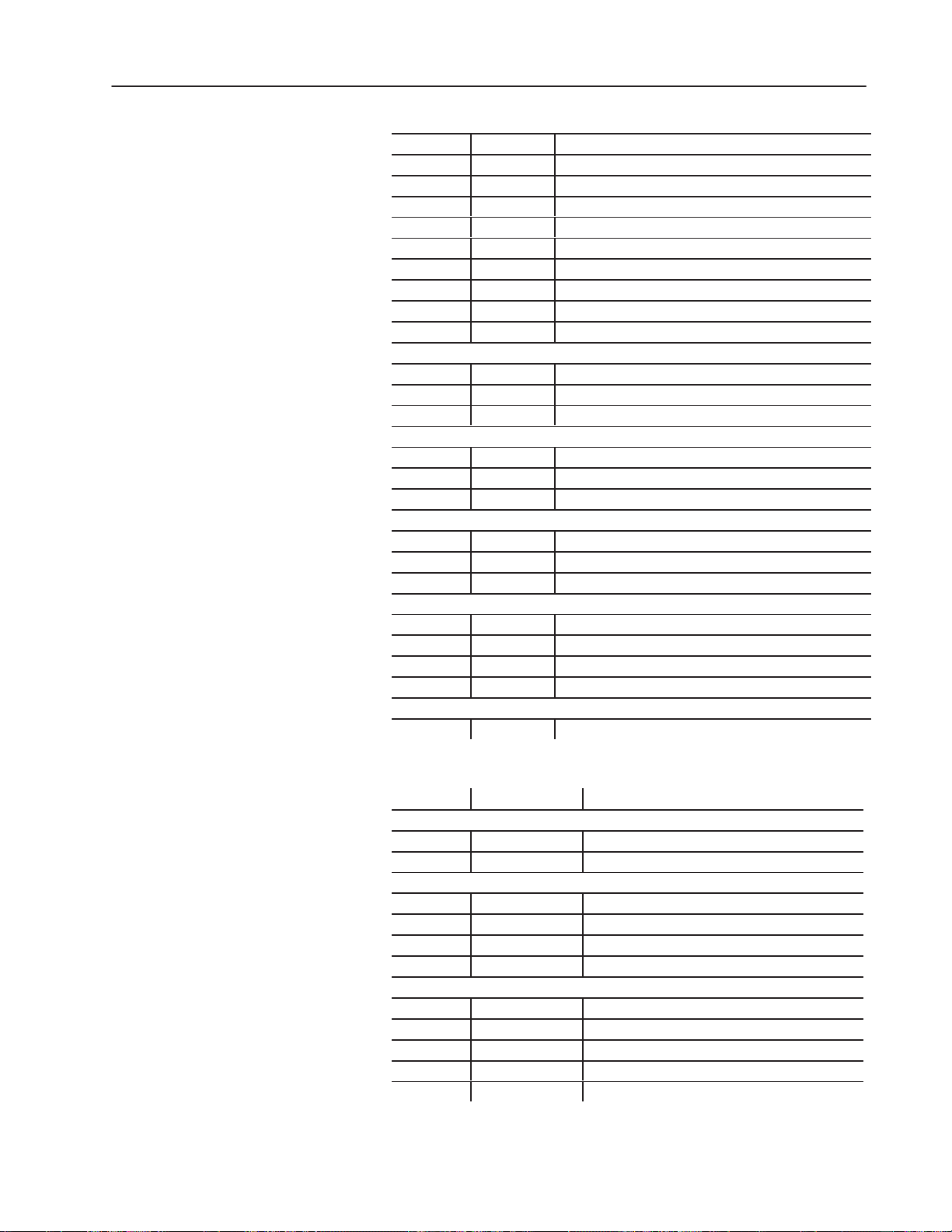

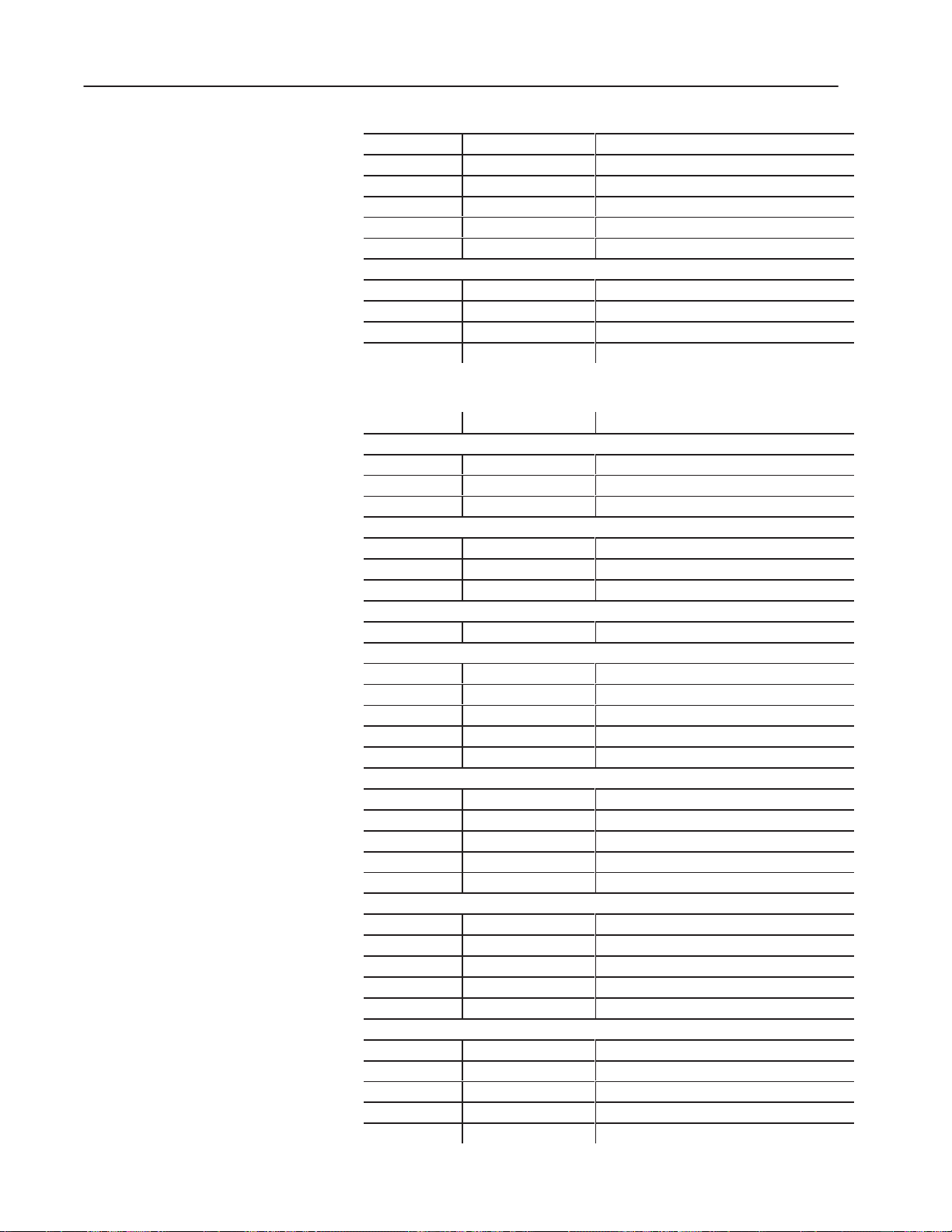

Alphabetical List of Command Blocks and Block ID Codes

Command blocks provide the parameters that control machine

operation. Command blocks are transferred from the PLC processor

to the QI module by block transfer write (BTW) instructions in

software ladder logic.

Acronym:

DYC 00011001 25 Dynamic Command Block 2-4

HDC 00001011 11 Hold Configuration Block 2-10

HPC 00001100 12 Pack/Hold Profile Block 2-13

INC 00001000 8 Injection Configuration Block 2-16

IPC 00001001 9 Injection Profile Block 2-19

JGC 00000010 2 Jog Configuration Block 2-25

MCC 00000001 1 Module Configuration Command Block 2-26

PKC 00001010 10 Pack Configuration Block 2-30

PLC 00001110 14 Plastication Configuration Block 2-32

PPC 00001111 15 Plastication Profile Block 2-35

PRC 00001101 13 Pre-Decompression Configuration Block 2-38

PSC 00010000 16 Post-Decompression Configuration Block 2-40

PTC 00011100 28 Process Trace Configuration Block 2-41

RLC 00011010 26 Inject ERC Values Block 2-42

Block ID

Binary: Decimal: Description: Page:

List of Data Words

Refer to chapter 3 for the word/bit descriptions of status blocks.

The listings of command blocks use five types of data words:

• Block ID

• Bit-mapped

• Stored-value

• Reserved (RFU)

Block ID Word

The first word in each command block contains a binary number

code in the low byte that identifies the block. The QI module uses

block IDs to identify command blocks sent from the PLC processor,

while the PLC processor uses them to identify status blocks received

from the QI module.

Publication

1771-6.5.126 – March 1998

Page 34

2–2 Command Word/Bit Descriptions

Bit-mapped Words

The first several words in any data block are bit-mapped. For

bit-mapped command words, you must set/reset or latch/ unlatch

command bits to set QI module operating configurations.

Stored-value Words

These words establish operating conditions for the QI module, such as:

• output values for certain conditions

• minimum and maximum pressures, positions, and velocities

• alarm setpoints

Reserved Words (RFU)

These words are Reserved for Future Use. Do not use them.

Engineering Units

#Code Type of Block Units and Range

01 Ram (Screw) Pressure (0000.0 to 9999.0 PSI or 000.0 to 999.9 Bar)

04 Cavity Pressure (00000.0 to 20000.0 PSI or 0000.0 to 2000.0 Bar)

05 Ram (Screw) Percent of maximum velocity (00.00 to 99.99%)

06 Ram (Screw) Velocity along axis (00.00 to 99.99 in. per sec. or 000.0 to 999.9 mm per sec.)

11 Ram (Screw) Measured from zero Incremental distance (00.00 to 99.99 in. or 000.0 to 999.9 mm.)

12 Ram (Screw) Measured from MCC13 Incremental distance (00.00 to 99.99 in. or 000.0 to 999.9 mm.)

17 Measured as noted in text Incremental distance (00.00 to 99.99 in. or 000.0 to 999.9 mm.)

18 Measured as noted in text Incremental distance (00.00 to 00.99 in. or 000.0 to 009.9 mm.)

19 Percent signal output (00.00 to 99.99%)

20 Percent signal output per second (0000. To 9999.)

21 Time measured in seconds (00.00 to 99.99)

22 Time measured in seconds (000.0 to 999.9)

23 Time measured in seconds (00.00 to 00.99)

24 Input signal range (00.00 to 10.00 or 01.00 to 05.00 or 04.00 to 20.00)

25 Screw rotational speed (000.0 to 999.9 RPM)

26 Time (algorithm) (00.00 to 9.99 minutes)

27 Inverse time (algorithm) (00.00 to 99.99 inverse minutes)

28 Inverse time (algorithm) (00.00 to 99.99 inverse seconds)

29 Unit-less

30 Binary Bit Map: bit value of 0 or 1; range of 00-15

31 Percent (00.00 to 99.99%)

In the listings of command blocks, each stored-value word is followed

by a bracketed [ ] 2-digit number code denoting the engineering units

and range associated with the value as shown in the following table:

Data Blocks Require I/O Configuration

Notes: For [ ] engineering units, see page 2.

Publication

1771-6.5.126 – March 1998

The QI module decodes its own I/O configuration based on parameters

that you provide in the Module Configuration Command Block (MCC).

I/O configuration determines which of the command and status blocks

the module supports. For the module to support command and status

blocks, you must establish the following position input:

• Connect a ram (screw) position sensor to input 1.

Page 35

2–3Command Word/Bit Descriptions

Data Blocks for System Control

Command Blocks for system level control are:

Block Description

MCC Module Configuration Command Block

JGC Jog Configuration Command Block

DYC Dynamic Command Block

You must establish the QI module’s I/O configuration before it can

decide which command blocks to support. Although the module always

accepts the Module Configuration Command Block (MCC), the module

considers all other command blocks unrecognizable until it has received,

processed, and successfully error checked an MCC download from the

host processor. After you configure the QI module with a valid MCC,

the module always accepts and processes (considers them recognizable)

either of the two basic command blocks JGC and DYC when received.

The module reports system status in the system status block (SYS). The