Page 1

AllenBradley

Clutch/Brake

Module

User

(Cat. No. 1771-PM)

Manual

Page 2

Table of Contents

Introduction 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Objectives

How To Use This Manual 11

Terminology 12

Firmware Revision Record 12

Objectives

Of This Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Press System Description 21. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

System Components 21

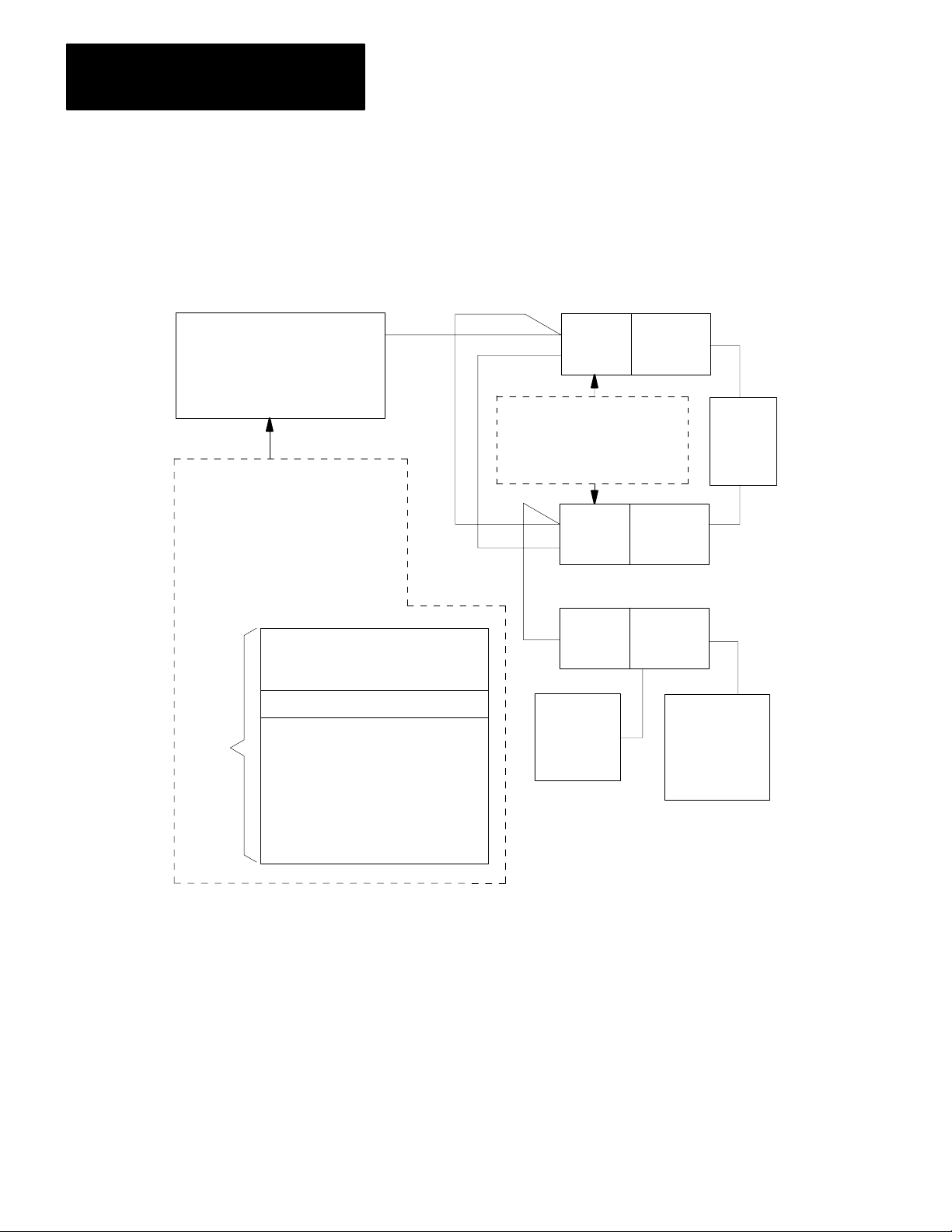

Figure 2.1

Related

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Block Diagram 22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Documentation

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23. . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch/Brake Controller Hardware 31. . . . . . . . . . . . . . . . . . .

Chapter

General Hardware Considerations 31

Description of your Clutch/Brake Controller 31

Twinaxial Cable Connections 34

Multiple Clutch/Brake Controllers 36

Panel Switches and Operator Stations 36

Interlock Switches 37

Configuring Your Clutch/Brake Controller 37

Rack Address of Chassis A and B 39

Setting

Response Time 311

Module

Keying 314

Objectives

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

the Communication Rate

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Placement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

311. . . . . . . . . . . . . . . . . . . . . . . . .

312. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC

Ladder Programming

Chapter

Programming Fundamentals 41

Configuration Rungs 43

Matching Configuration Bits and Backplane Switches 47

PLC Command Rungs 48

Summary of PLC Configuration and Command Rungs 412

Module Group 5, Slot 0 Reserved for MicroInch 413

Module Groups 6 and 7 Reserved for Data Storage 413

Monitoring Clutch/Brake Controller Inputs and Outputs 413

Report Generation 414

Summary of Clutch/Brake Controller Functions 415

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contentsii

Voting Processor Firmware 51. . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Operation

Emergency Shut Down 51

Fault

Operation

Clutch/Brake Operating Modes 55

Objectives

of V

oting Processors 51. . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring

of Cam Limit Switches

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Connections to Field Wiring Arms 61. . . . . . . . . . . . . . . . . . .

Chapter

Installation Considerations 61

Electrical Connections and Safety Requirements 61

Control Power 63

EStop Switches, Seal Relays, and Crowbar Relays 63

Crowbar T

Optional Hardwire Inputs 65

Internal/External

Optional

Main Valve Solenoids A and B 68

Optional Auxiliary Valve Solenoids 69

Optional Dump Valve Solenoids 69

Optional Microinch Valve Solenoids 610

Electrical Noise Suppression 611

Cam

Required Hardwire Inputs 622

Inch Buttons and PlugIn Operator Stations 624

Optional Binary Display 627

Optional Indicators 627

Lamp Test 631

Inputs to Chassis C 631

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

est Inputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Detection

Valve

Stem Switches,

Motion Detectors, and

Air Pressure Switches 67

Limit Switches

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66. . . . . . . . . . . . . . . . . . . . . . . . .

620. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Troubleshooting Considerations and Requirements 71

Troubleshooting

General Troubleshooting Procedure 74

Troubleshooting

Troubleshooting Example 76

Display of Diagnostic Message Codes 78

Types of Diagnostic Message Codes 79

Messagecode Priority 712

Processing Diagnostic Message Codes 713

Objectives

with LED'

Hints

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

s 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contents iii

Diagnostic Message Codes (Table 7.C) 713. . . . . . . . . . . . . . . . . . . .

Complete Listing of diagnostic message codes 723

Summary 737

Diagnostic diagnostic message codes in T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

able 7.C

737. . . . . . . . . . . .

Bit Monitoring Addresses A1. . . . . . . . . . . . . . . . . . . . . . . . .

I/O FROM /T

O LISTS

B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Introduction

Chapter

1

Chapter Objectives

Objectives Of This Manual

How To Use This Manual

This chapter will help you become familiar with the:

objectives of this manual

procedure for using this manual

We have written this manual to help an electrical engineering technician,

or any person with a similar background:

design a clutch/brake controller for a mechanical power press using the

1771-PM clutch/brake module.

install the clutch/brake controller

troubleshoot the clutch/brake controller

The overall safety of your mechanical power press rests upon your

knowledge of this manual and other referenced documents. Moreover, the

ease with which you can understand each chapter rests upon your

knowledge of previous chapters.

To simplify your installation and maintenance tasks, we recommend that

you become familiar with this entire manual before installing your

clutch/brake controller. The following suggestions should help you use

this manual:

Before reading this manual, scan through it. This will help you

understand its organization.

Before installing your clutch/brake controller, read this manual

thoroughly. You should also read other publications that we refer.

While installing or troubleshooting your clutch/brake controller, use

this manual as a reference.

11

Page 6

Chapter 1

Introduction

Terminology

Firmware Revision Record

We define new terms where they first appear in this manual. You should

be familiar with the following terms because we use them throughout this

manual.

a press is a mechanical (part revolution) power press that is actuated by

a clutch and stopped by a brake

a clutch/brake controller is an Allen-Bradley controller, which

includes chassis A and B, two Clutch/Brake Modules (cat. no.

1771-PM), and associated I/O modules.

a press system includes your mechanical power press, clutch/brake

controller, and all associated wiring and components.

a PLC is any Allen-Bradley programmable controller that has 1771

remote I/O operation.

TCAM is the acronym for Top-Stop-Check Cam switch

ACAM is the acronym for Anti-repeat Cam switch

RCAM is the acronym for Run-on Cam switch

The firmware has been revised as follows:

Firmware

Revision Change in operation

A/B Micro-inch added

A/C None

(corrected intermittent stoppage in continuous mode)

A/D Motion detector time-out increased to 4 sec

A/E None

(corrected intermittent communications problem)

12

Page 7

Chapter

Press System Description

2

Chapter Objectives

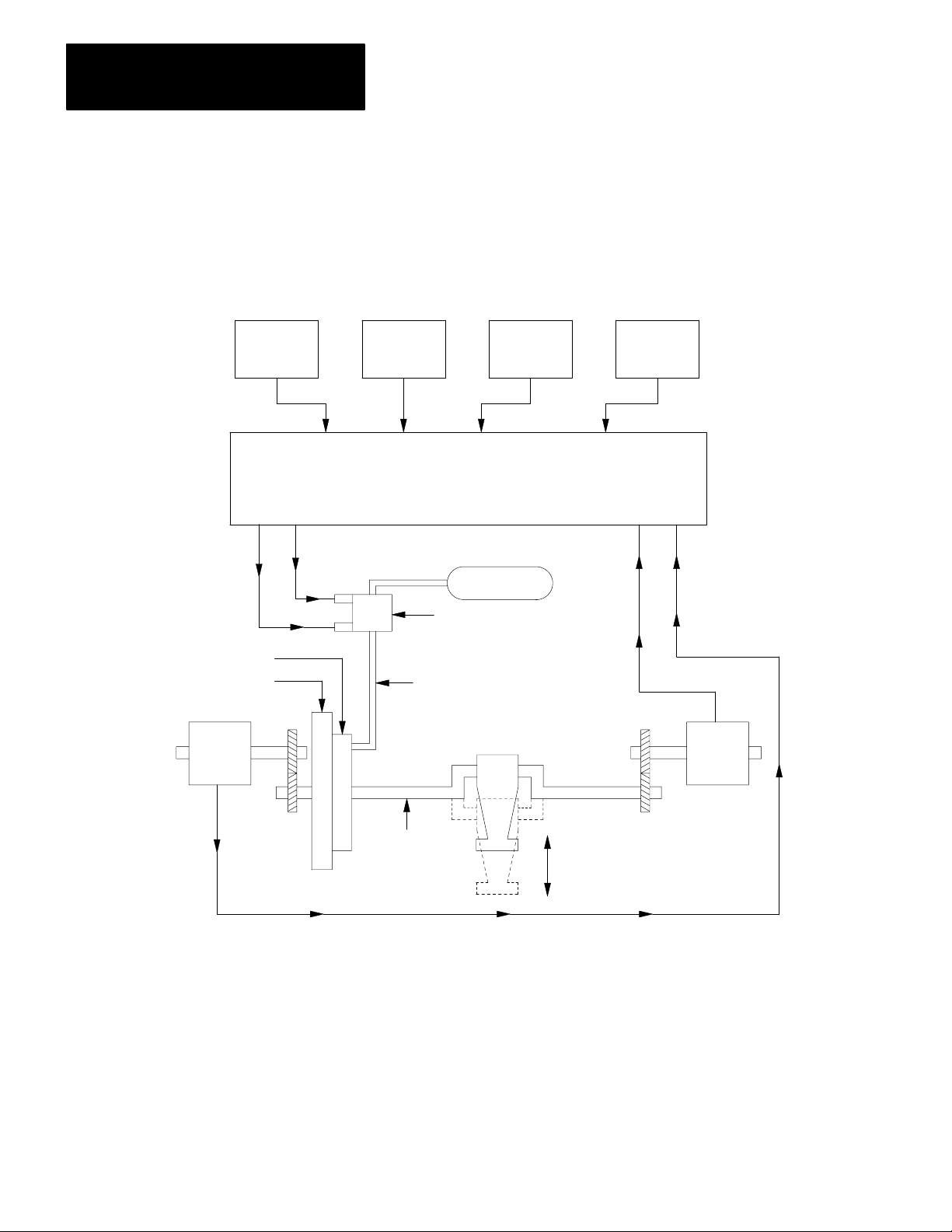

System Components

This chapter will help you become familiar with:

major components of a typical press system

safety requirements for a press system

A press system, as referred to in this manual, includes:

a mechanical power press

an Allen-Bradley clutch/brake controller

all associated control panels and operator stations

all associated output and feedback devices

all wires and cables that interconnect system components

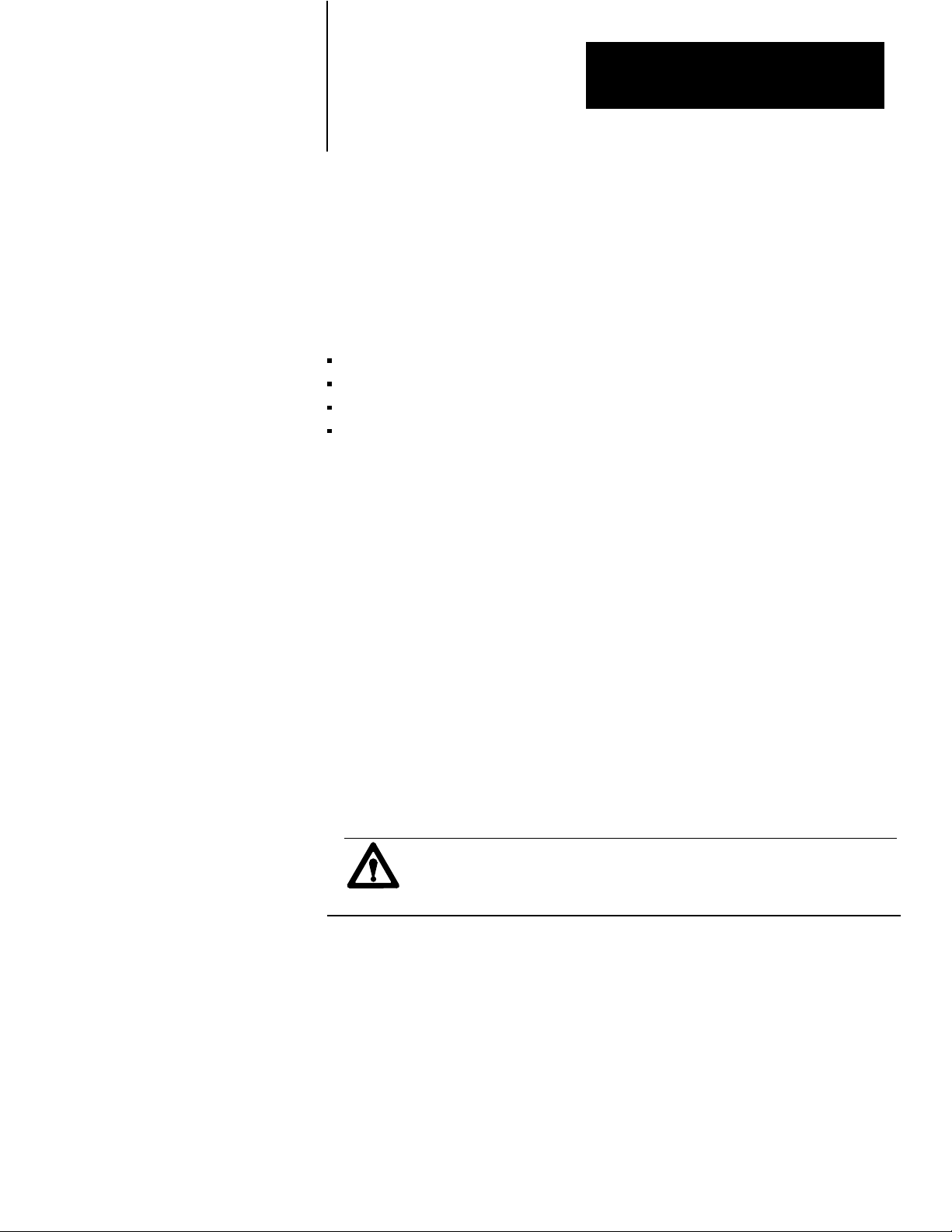

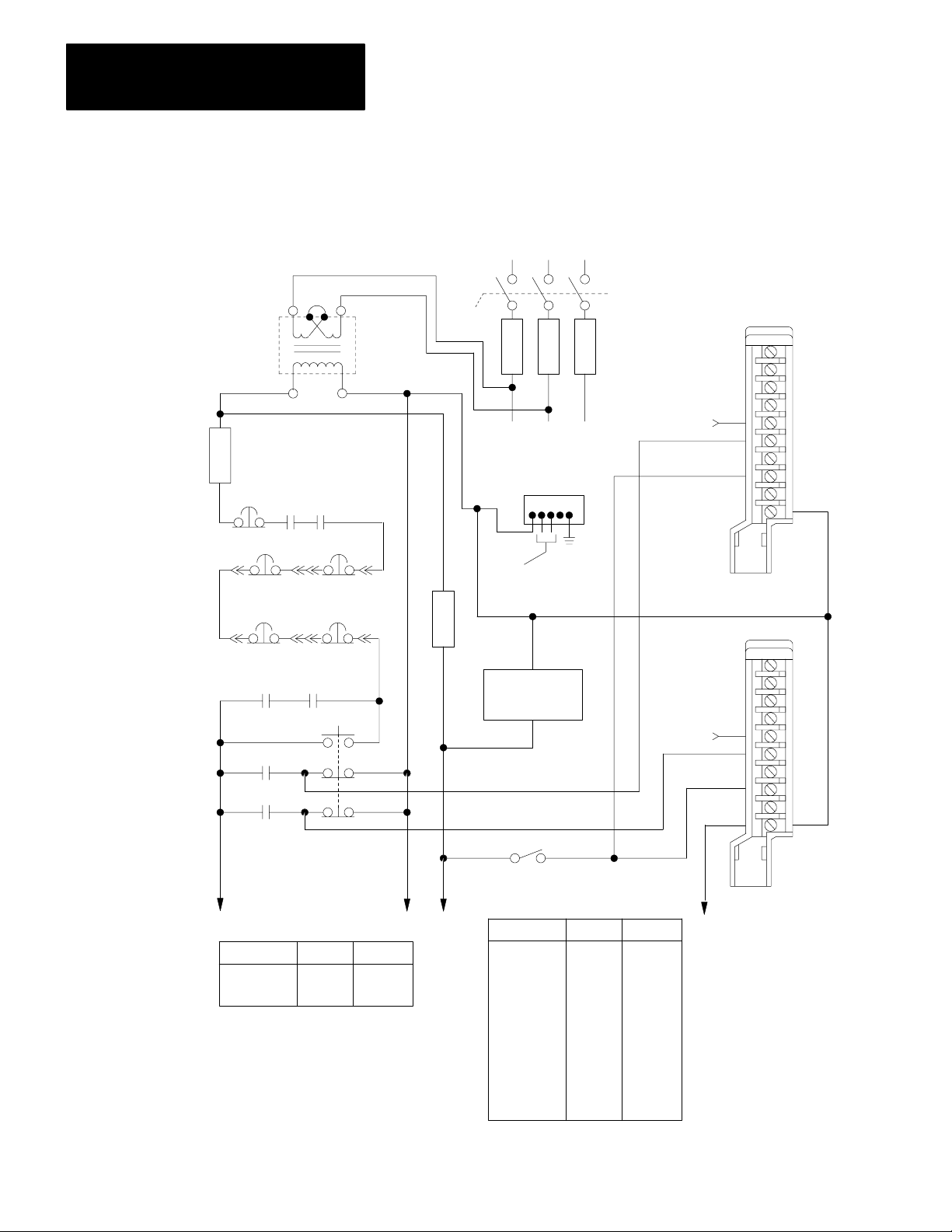

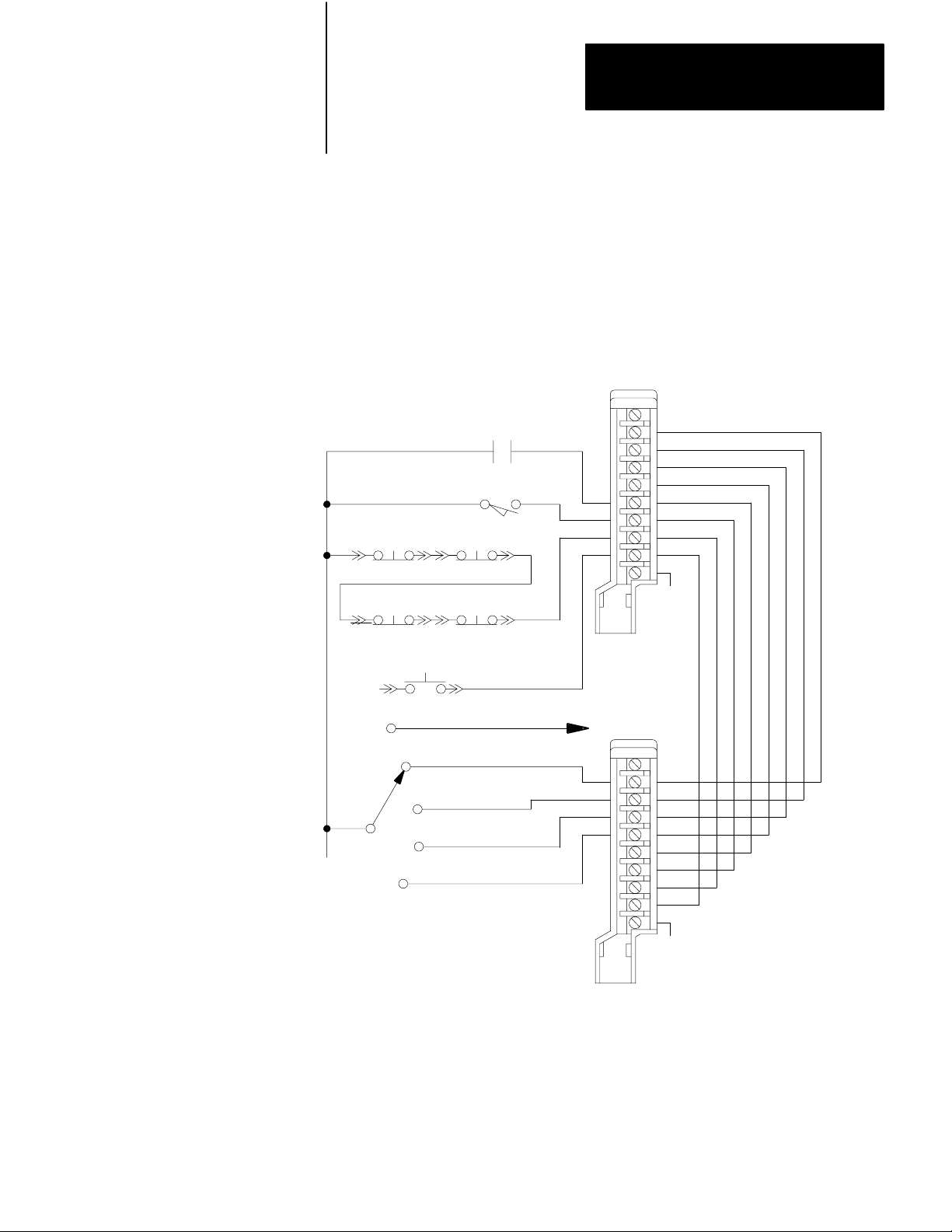

A functional block diagram of a typical press system is shown in

Figure 2.1. This figure shows general relationships between major

components. Specific functional relationships vary according to the

requirements of your particular press system. For details, refer to;

chapters 3 thru 7 of this manual

technical documentation provided by your press manufacturer

ANSI B11.1, American National Standard for Machine Tools,

Mechanical Power Presses, Construction, Care, and Use

Important: Use an Allen-Bradley clutch/brake controller only with a

mechanical power press that has a part-revolution clutch. A

part-revolution clutch can be disengaged at any position of the shaft. This

allows your clutch/brake controller to stop the press at any position. In

contrast, a full-revolution clutch can be disengaged and stop the press

only at the top position of the stroke.

21

Page 8

Chapter 2

Press System Description

Figure 2.1

Functional Block Diagram

Triac

Outputs

to Main

Solenoids

Clutch/Brake Assembly

Flywheel

Cam

Switch

Assembly

Operator

Station

No. 1

Operator

Station

No. 2

Allen - Bradley Clutch/Brake Controller

- Monitors operator inputs

- Monitors shaft position using cam limit switch feedback

- Controls the press using solenoid triac outputs

Main Solenoid Valves

Air to Clutch

Operator

Station

No. 3

Air Supply

Press

Operator

Station

No. 4

Cam Switch

Feedback

Inputs

Cam

Switch

Assembly

22

Crankshaft

Shaft at Top Position

Shaft at Bottom Position

12245

Page 9

Chapter 2

Press System Description

Related Safety Documentation

This manual concentrates on safety considerations relative to the

clutch/brake controller. Study this entire manual and all technical

documentation provided by the press manufacturer before you install your

press system. In addition to local codes and laws, follow the safety

requirements detailed in the following publications:

OSHA Regulations, Title 29-Labor, Chapter XVII, Section 1910.217,

Mechanical Power Presses

ANSI B11.1, American National Standard for Machine Tools,

Mechanical Power Presses, Construction, Care, and Use

NFPA No. 79, Electrical Standard for Metalworking Machine Tools

23

Page 10

Chapter

3

Clutch/Brake Controller Hardware

Chapter Objectives

General Hardware Considerations

This chapter will help you become familiar with the:

hardware components of your Allen-Bradley clutch/brake controller

functional relationships between your PLC and clutch/brake controller

interconnections between your PLC and clutch/brake controller

switch settings that configure your clutch/brake controller and establish

its rack addresses

For details on how to install the I/O chassis and modules, refer to the

installation publications that apply to your particular PLC. These

publications, listed in our Publications Index (publication SD-499),

discuss general layout rules, mounting dimensions, enclosure

considerations, module keying, and field wiring arm connection

technique.

Important: If you are using a large mechanical power press that

generates high levels of shock and vibration, we recommend that you

shock-mount each I/O chassis of your clutch/brake controller.

Important: Electrostatic discharge can damage integrated circuits or semi

conductors in the PM Module if you touch backplane connector pins or

internal components.

Description of your Clutch/Brake Controller

CAUTION: Rid yourself of charge before handling the module

by touching a grounded object.

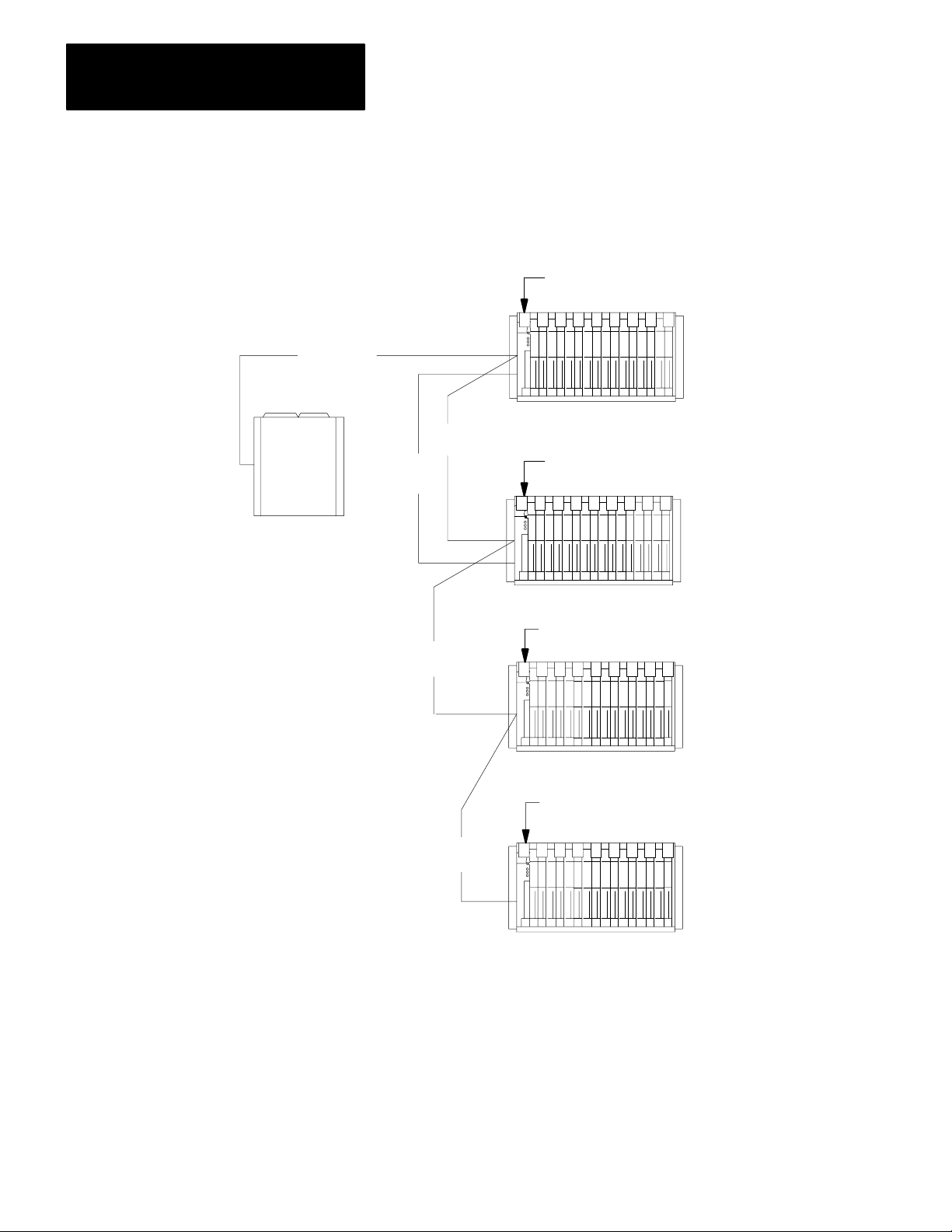

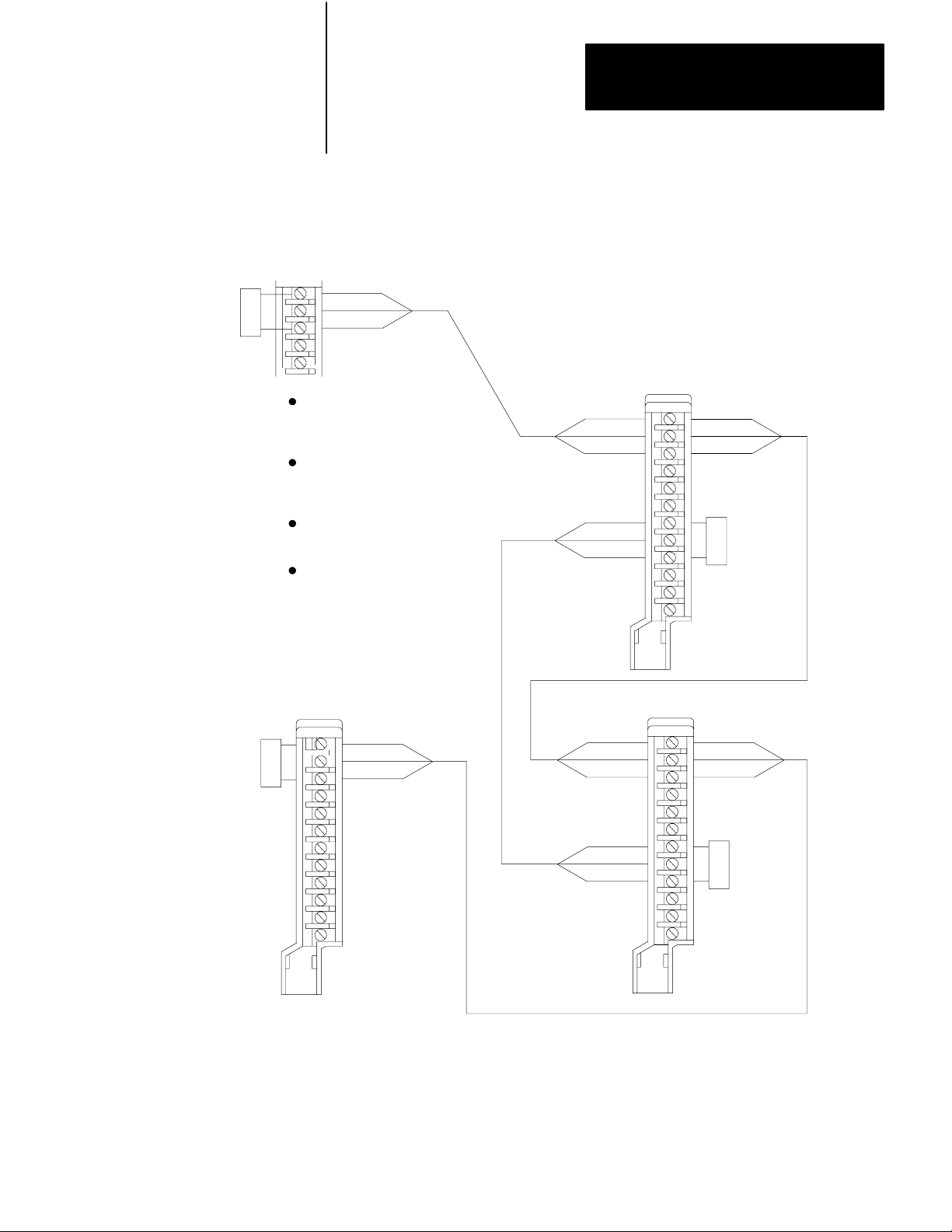

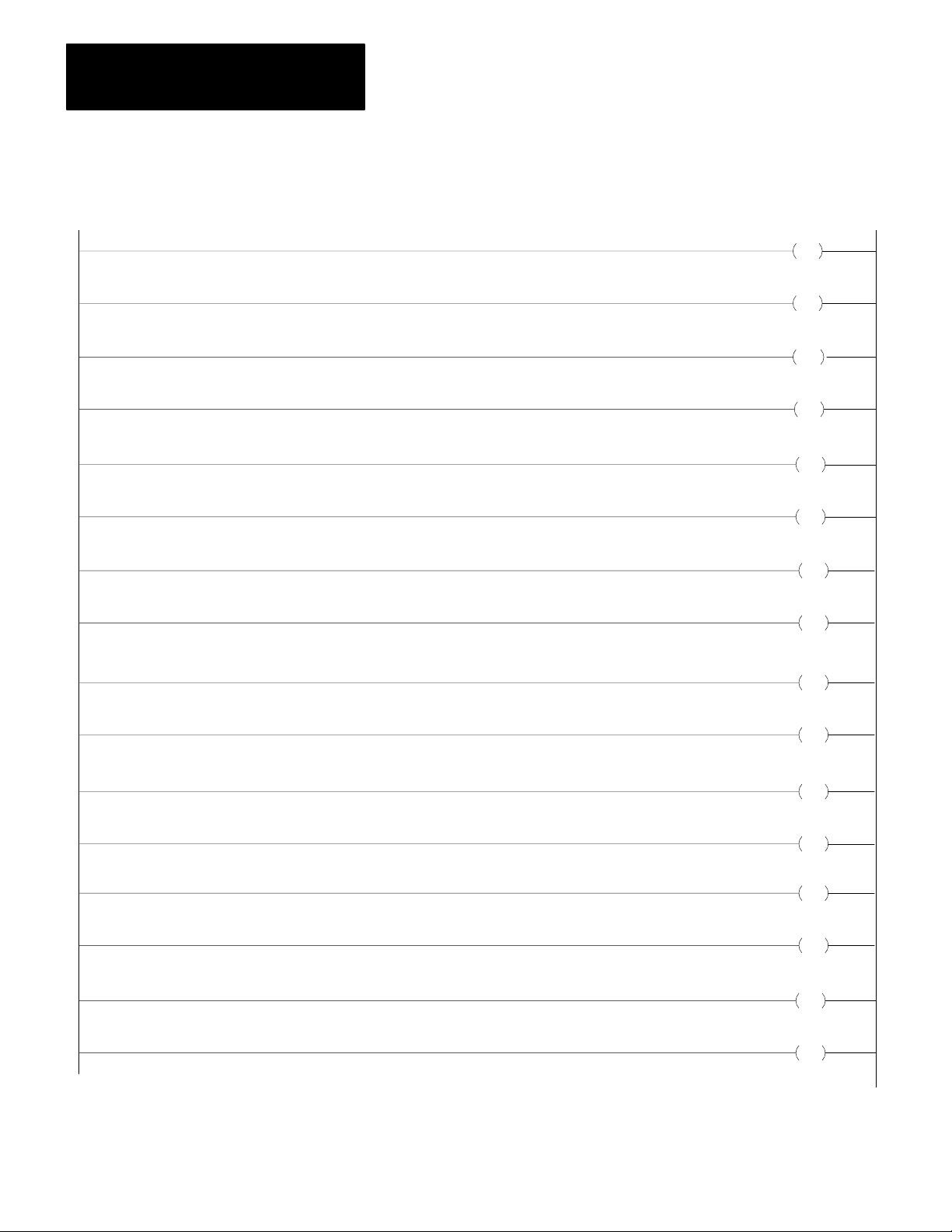

Your clutch/brake controller consists of chassis A and B connected to

your PLC in a serial chain with remote I/O chassis, as shown in

Figure 3.1. Table 3.A. lists required and optional clutch/brake controller

hardware.

Chassis A and B are similar to remote I/O chassis. The major difference

is that the left-most slot of chassis A and B contains a clutch/brake

module. In contrast, the left-most slot of an I/O chassis contains an I/O

adapter module.

31

Page 11

Chapter 3

Clutch/Brake Controller Hardware

Figure 3.1

Overview

Remote I/O

Communications

A-B Programmable Controller

with Remote I/O

of a Clutch/Brake Controller

Remote

I/O

Clutch/Brake

Remote

I/O

Voting Processor A

Clutch/Brake Module

Chassis A

Voting Processor B

Clutch/Brake Module

Chassis B

Remote I/O

Adapter Module

Remote

I/O

Chassis C

Remote I/O

Adapter Module

Remote I/O Chassis

other I/O chassis

independent of the

Clutch/Brake Controller

12246

32

Page 12

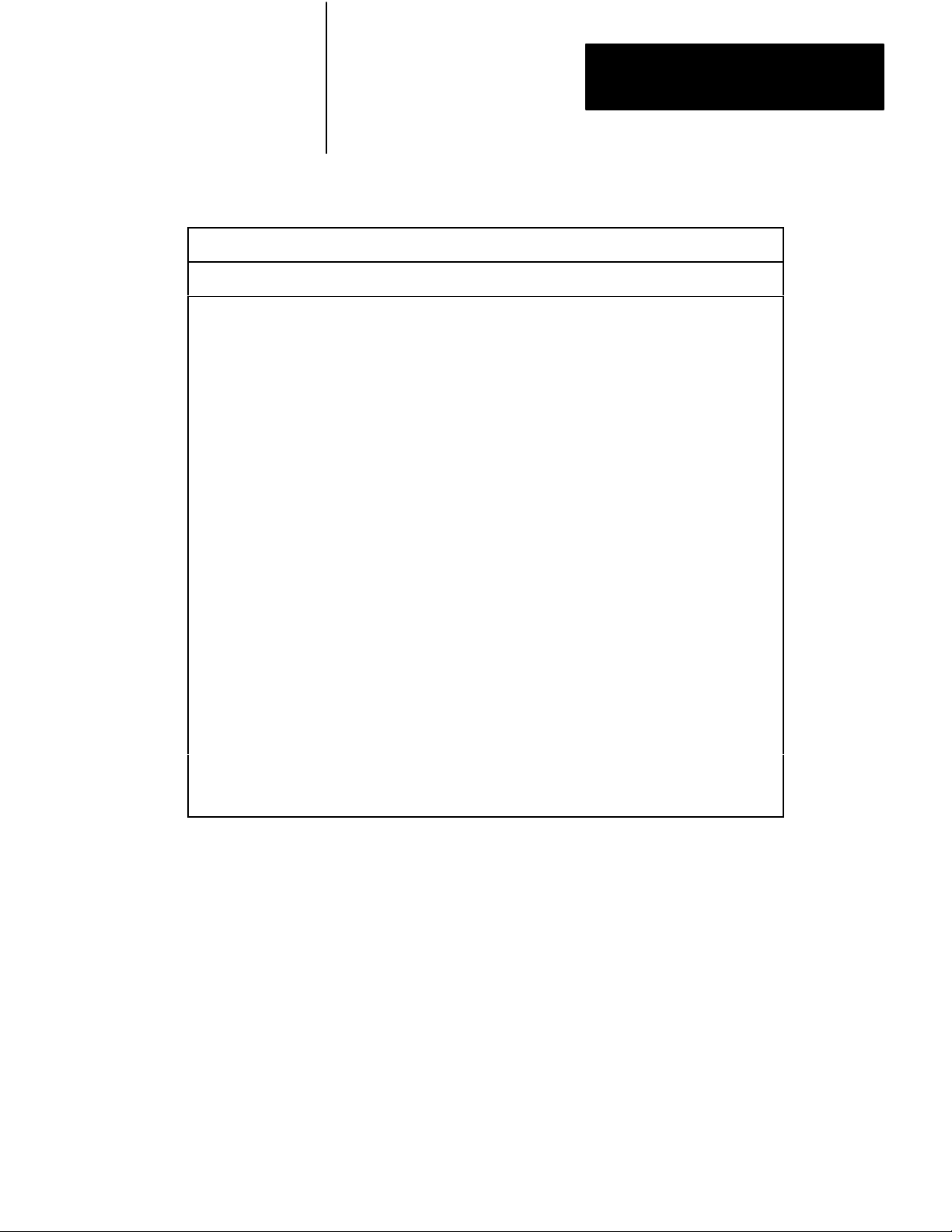

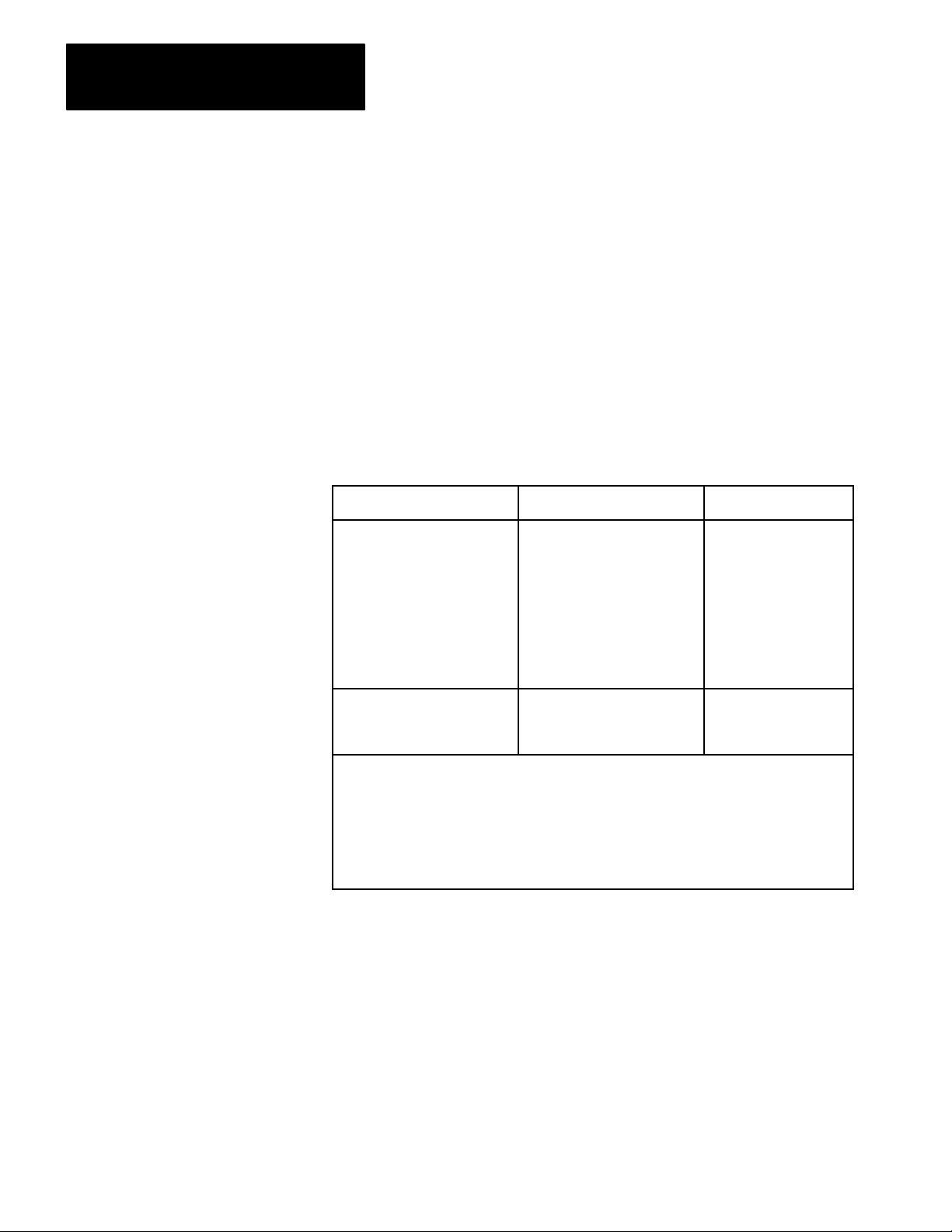

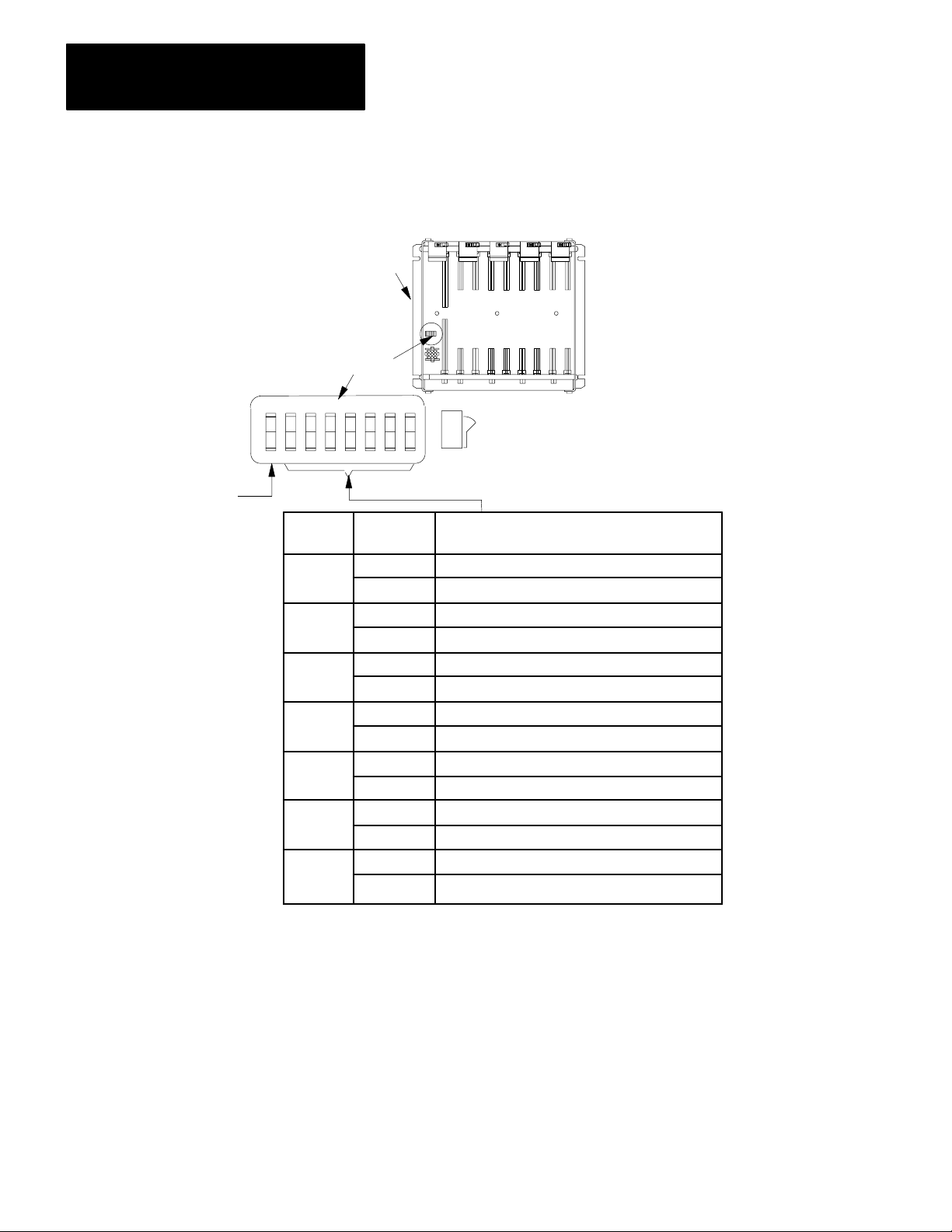

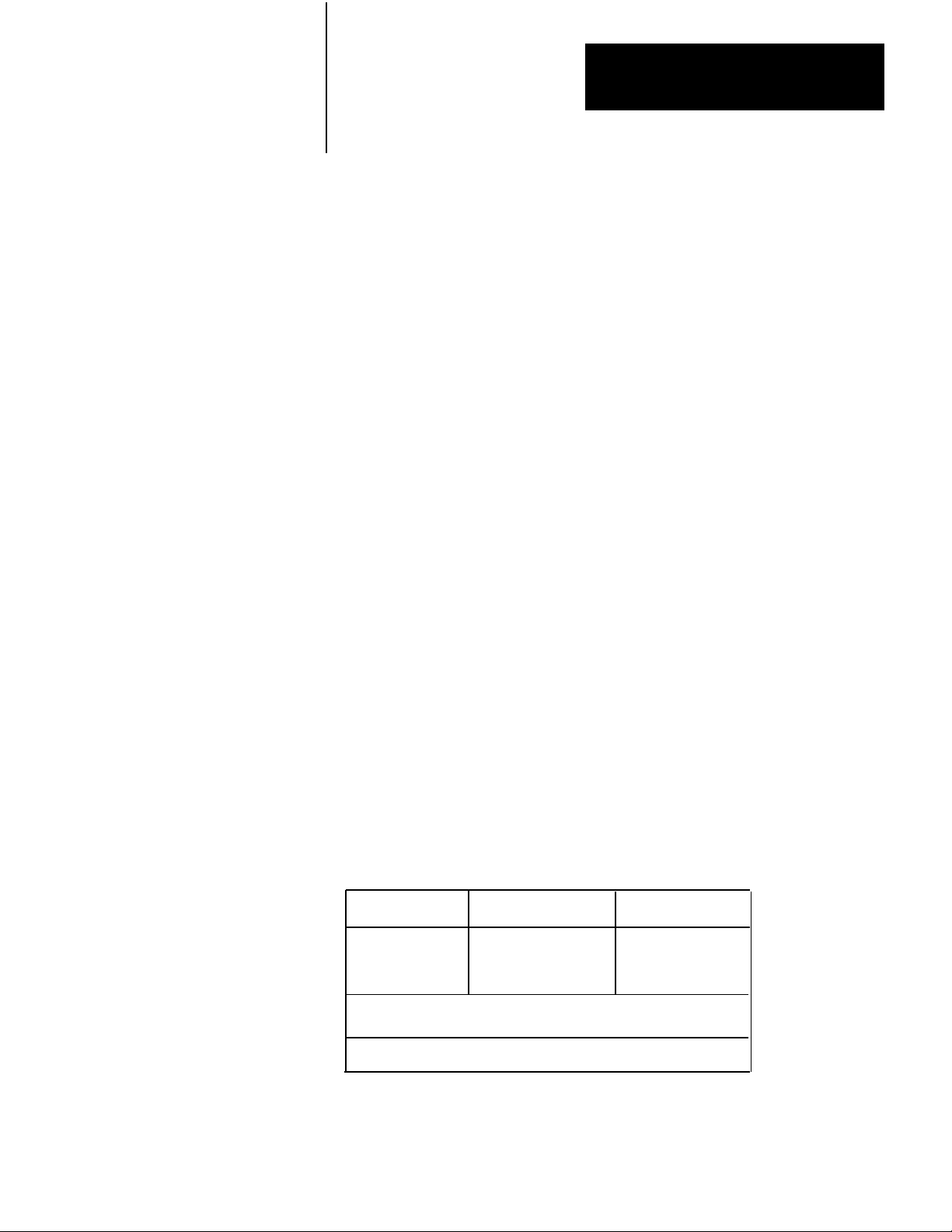

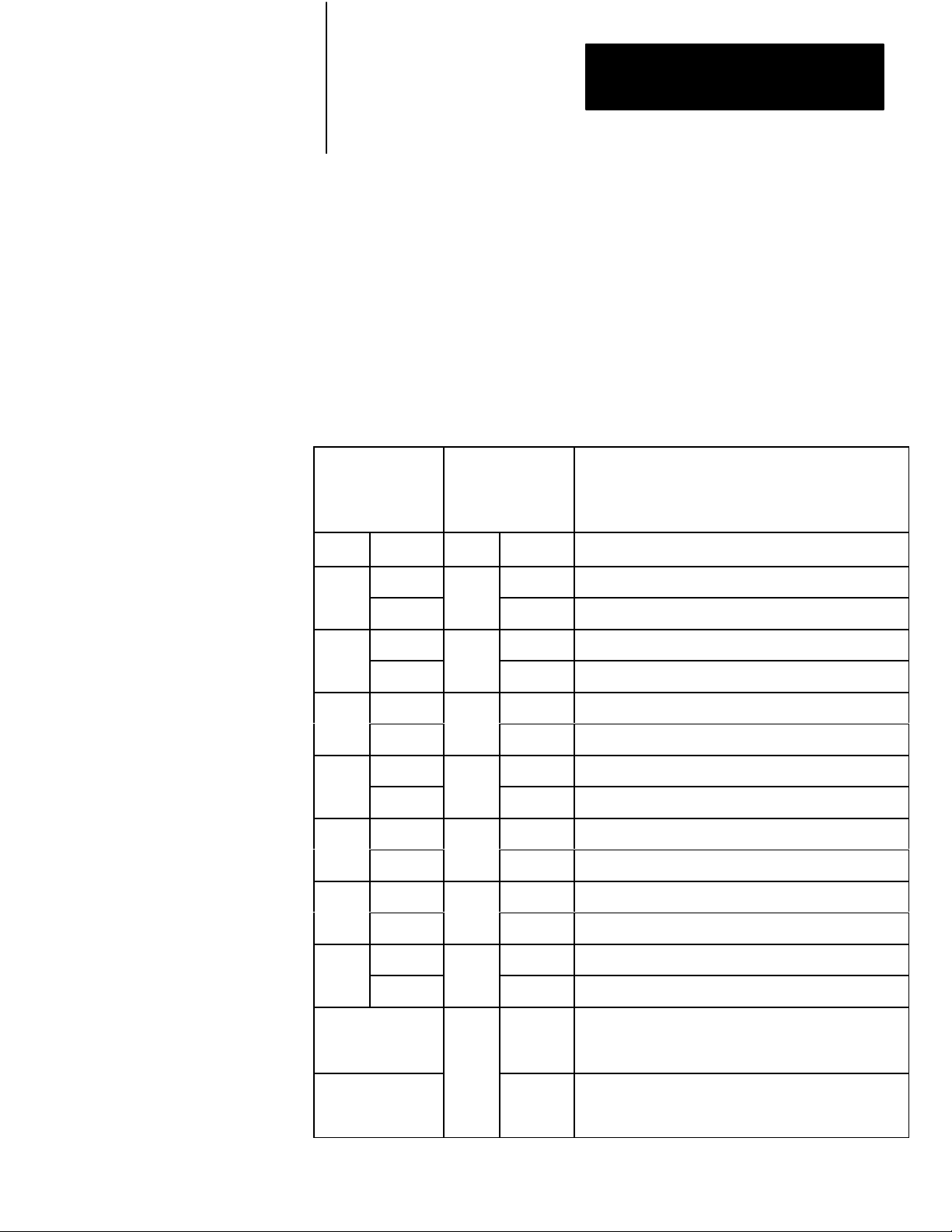

Table 3.A

Required and Optional Hardware

Chapter 3

Clutch/Brake Controller Hardware

Quantity Item

Important: (Y

2

2

2

10

2

2

1

2

2

2

ou must use 8point modules with 2slot addressing)

Clutch/Brake Module

Wiring Arm

I/O Chassis

120V AC Input Modules

120V AC Isolated Output Modules

(Series C)

120V AC Output Modules

120AC Output Module

120V AC Input Modules

120V AC Isolated Output Modules

(Series C)

I/O chassis

Cat. No.

Required Hardware

1771PM

1771WB

1771A2B

1771IA

1771OD

Optional Hardware

1771OA

1771OA

1771IA

1771OD

1771A4B

Function

Monitors and controls the press

Connections to 1771PM

Contains the modules

Monitors press inputs

Controls press outputs

Display of diagnostic messages

Controls optional indicators

Dump valve circuit

Dump valve and/or microinch circuit

Substitute chassis when using the

optional dump valve circuit.

1

2

2

120V AC Output Module

120V AC Input Modules

120V AC Input Modules

1771OA

1771IA

1771IA

Microinch indicator

Microinch circuit

Additional operator stations

Clutch/brake modules operate in parallel to monitor and control your

press. Clutch/brake modules are also called “voting processors” because

they must always have a consensus. Unless both voting processors

constantly agree that they sense identical conditions in your clutch/brake

press system, either or both voting processors stop press motion or

prevent it from starting.

Your clutch/brake controller monitors and controls your press. Although

your PLC does not control your press, it does configure and enable the

clutch/brake controller. Your PLC ladder program can monitor inputs to,

and the status of, your clutch/brake controller. This allows your PLC to

control other indicators, machines, or processes related to your press

system.

33

Page 13

Chapter 3

Clutch/Brake Controller Hardware

In addition to chassis A and B, you must connect your PLC to at least one

local or remote I/O chassis, chassis C. You need two, three, or four inputs

at a local or remote I/O chassis.

Important: You must use 2-slot addressing and 8-point (single-density)

I/O modules.

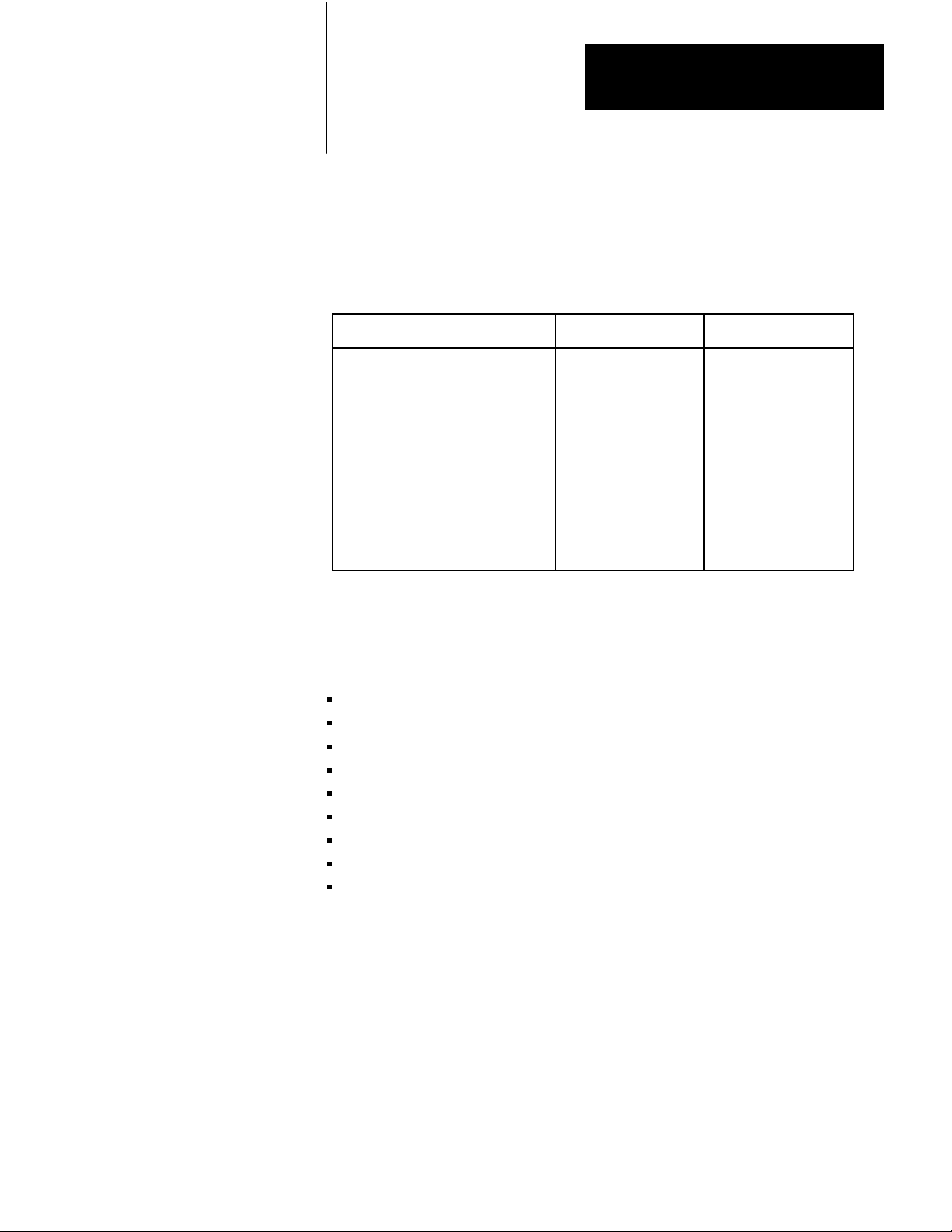

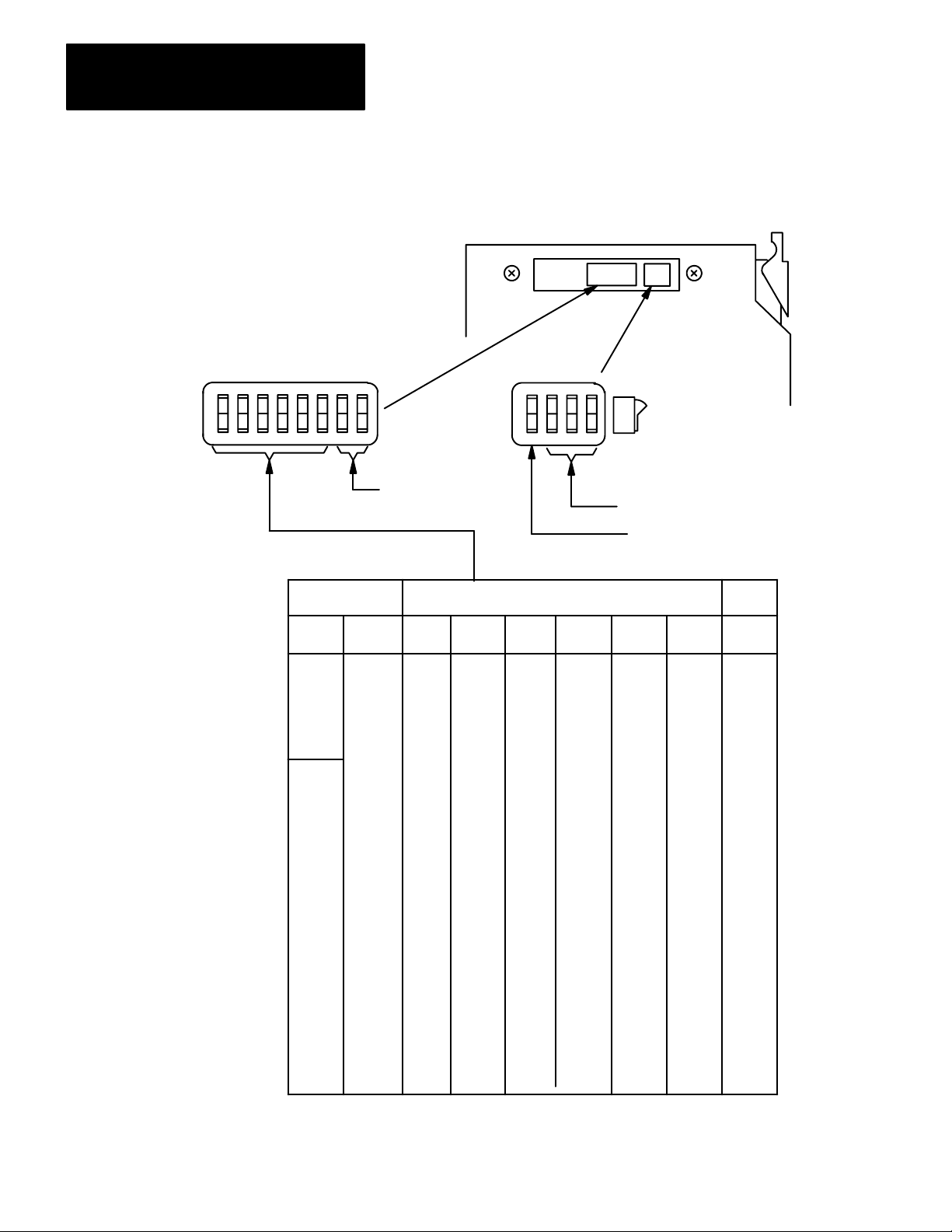

Twinaxial Cable Connections

Typical twinaxial cable connections of your clutch/brake controller are

shown in Figure 3.2. Connect your clutch/brake controller to your PLC as

part of its remote I/O distribution network. Use Twinaxial Cable (cat.no.

1770-CD) and Terminators (cat. no. 1770-XT).

Connect chassis A next to chassis B in the serial chain as shown in

Figure 3.2. You may connect one or more remote I/O chassis in the same

serial chain. Also, you may connect remote I/O chassis to other

distribution channels at the I/O scanner module of your PLC.

Connect four Terminator Resistors (cat. No. 1770-XT) as shown in

Figure 3.2. Connect one at:

the scanner module

the last chassis, whether it is a clutch/brake chassis or a remote I/O

chassis

each end of the cable that connects chassis A and B at terminals 7, 8

and 9 of the 1771-PM module field wiring arms

For more information on how to connect remote I/O channels, refer to the

installation publications that apply to your particular PLC. Also refer to

Product Data of the Remote I/O Adapter Module. These publications are

listed in our Publications Index (publication SD499)

34

Page 14

Terminator

(cat. no.

1770 -XT)

Figure 3.2

Typical

Processor/Scanner

Shield

Clear

T

winaxial Cable Connections

Blue

Chapter 3

Clutch/Brake Controller Hardware

Use Twinaxial Cable

(cat. no. 1770 -CD)

for all cable connections.

Chassis A

Terminator

(cat. no.

1770-XT)

Terminal Strip on 1772 - SD,

SD2 Remote I/O Scanner/

Distribution Module (PLC - 2)

or

Terminal Block on

1775 - S4A, - S4B, -S5,

I/O Scanner Module (PLC -2)

or

Connector on PLC - 5

Processor

or

Connector on 5/50 - RS2

Remote I/O Scanner (PLC -5/250)

Chassis C

Blue

Shield

Clear

Remote

I/O Chassis

1771 -ASB

Adapter

Module

Blue

Shield

Clear

Blue

Shield

Clear

1771 - PM

Module

Shield

Clear

Shield

Clear

Blue

Blue

Blue

Shield

Clear

Terminator

(cat. no.

1770 -XT)

1771 - WB

Wiring Arm

Chassis B

Blue

Shield

Clear

Terminator

(cat. no.

1770 -XT)

1771 - WB

Wiring Arm

1771 - PM

Module

12248

35

Page 15

Chapter 3

Clutch/Brake Controller Hardware

Multiple Clutch/Brake Controllers

Panel Switches and Operator Stations

Although this manual describes a single clutch/brake controller, you may

connect your PLC to multiple controllers, each controlling a separate

press. Each clutch/brake controller uses two remote I/O racks for chassis

A and B. For example, since a PLC-3 controller can support as many as

32 I/O racks, you may connect it to as many as 15 clutch/brake controllers

with two additional I/O racks for modules in chassis C.

You can operate your press using up to four operator stations and an

optional control panel. Installations vary according to the type of

mechanical press and its application requirements. The number of

stations, control switches contained in each, and the control panel could

be as follows:

Assembly Control

Control Panel and/or Station 1

Mode select

Arm continuous

Stopontop

L/R Inch

Press enable

Reset latched messages

Lamp test

L/R Run

EStop

Switches

Notes

1

1

1 and/or 3

2

3

3

3

2

2

Stations 2 thru 4

1 Connect these switches to input modules in chassis A and B (Figure 6.10).

2 Connect these switches to input modules in chassis A and B (Figures 6.11 thru

6.12).

3 These switches are inputs for command rungs (Figures 4.6 thru 4.8). Connect

these

switches to input modules in remote I/O chassis C (Figure 6.15).

L/R Run

Stop On T

EStop

op

2

2 and/or 3

2

36

Page 16

Chapter 3

Clutch/Brake Controller Hardware

Interlock Switches

Configuring Your Clutch/Brake Controller

Various interlock switches are required for safety as specified in ANSI

B11.1. The locations, types, and quantities vary with the type of

mechanical press and its application requirements. Use these interlock

switches to prevent the press from starting or to stop the press when

operation could cause injury to personnel or damage to the press.

Interlock

Barrier guard

Press interlock

Motion detector

Main motor forward

Cam limit switch assembly

topstopcheck (TCAM)

runon (RCAM)

antirepeat (ACAM)

Switch

Quantity Reference

1 or more

1

1

1

2

Figures 6.10 and 6.15

Figures 6.1 and 6.5

Figure 6.2 and 6.6

Figure 6.10

Figure 6.9

You have flexibility in selecting clutch/brake controller functions. You

may select any of the following functions according to your application

requirements by setting switches on the I/O chassis.

Operator station 3 and 4

Motion detector feedback

Valve stem feedback

Air pressure feedback

Ungrounded or grounded AC power

On-the-hop

Half stroke, or Stroke-and-a-half

Dump valve circuit

Micro-inch

37

Page 17

Chapter 3

Clutch/Brake Controller Hardware

Always OFF

1234

O

N

O

F

F

Switch

No:

IMPORTANT:

Figure 3.3

Backplane

Backplane

Assembly

2

3

4

5

6

7

8

Switch Settings

Chassis

A and B

Switches

5678

Position:

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Make backplane switch settings in chassis A and B identical.

ON

OFF

OFF

Function:

Use Stations 3 and 4

Stations 3 and 4 not used

Use Motion Detector Feedbck

Motion Detector Feedback not used

Use Valve Stem Feedback

Valve Stem Feedback not used

Use Air Pressure Feedback

Air Pressure Feedback not used

Ungrounded AC Power

Grounded AC Power

Use On-The-Hop

On-The-Hop not used

Use HalfStoke

Use StrokeAndAHalf

12249

38

Page 18

Chapter 3

Clutch/Brake Controller Hardware

Important: There is no backplane switch setting to configure the optional

dump valve circuit. You configure the optional dump valve circuit by

inserting dump valve modules (cat. no. 1771-OD and 1771-IA) into

module group 4, slots 0 and 1, respectively of chassis A and B. You must

also set bit 14 unconditionally in your configuration rungs.

Important: To configure your clutch/brake controller for Micro-inch, see

chapter 4 “Module Group 5, Slot 0 Reserved for Micro-inch”.

Important: Your PLC ladder program must include unconditioned

configuration rungs that set or reset configuration bits to match the

settings of backplane switches. Refer to chapter 4.

Rack Address of Chassis A and B

Establish the address of chassis A and B in each clutch/brake module so

the PLC can communicate with it. Use valid rack addresses as

determined by your PLC.

Switch assembly SW-1 determines the rack address. It is located under a

sliding cover plate on the left side of the clutch/brake module near the top.

Loosen the two screws holding the cover plate and slide it open. Locate

switch assembly SW-1 at the top of the printed circuit board as shown in

Figure 3.4.

Using switch assembly SW-1, designate chassis A and B as follows:

Chassis A - any rack address having position 6 OFF

Chassis B - next consecutive upper or lower rack address

Important: If your ladder program monitors rack adapter fault bits for

each chassis containing a clutch/brake module, the fault bits will indicate

a faulted rack whenever the module trips power to I/O swingarms. This is

because clutch/brake modules stop all communciation with the PLC until

they verify that swingarm power has been disconnected.

Important: Always configure I/O racks assigned to clutch/brake

controllers as full

racks, so the PLC can write configuration bits to each

PM chassis in Module Group 7.

39

Page 19

Chapter 3

Clutch/Brake Controller Hardware

Figure 3.4

Address Switch Setting on 1771PM Module

Rack

1234

O

N

O

F

F

SW-1

5678

Rack Addresses

PLC-2/30

PLC-5/25

1

2

3

4

5

6

7

SW-2

1234

O

Always ON (star

Module Group 0)

ting

N

O

F

F

ON

OFF

OFF

Always OFF

Always ON(57.6K baud)

Switch Assembly SW-1 Position

PLC-3

PLC-5/250

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

20

21

22

23

24

25

26

27

30

31

32

33

34

35

36

37

NOTE: Chassis A and B must have consecutive rack address

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

1

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

on

off

off

off

off

off

off

off

off

off

off

off

off

off

off

off

off

2

on

on

on

on

on

on

on

on

off

off

off

off

off

off

off

off

on

on

on

on

on

on

on

on

off

off

off

off

off

off

off

off

3

4

on

on

on

on

off

off

off

off

on

on

on

on

off

off

off

off

on

on

on

on

off

off

off

off

on

on

on

on

off

off

off

off

5

on

on

off

off

on

on

off

off

on

on

off

off

on

on

off

off

on

on

off

off

on

on

off

off

on

on

off

off

on

on

off

off

es.

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

on

off

Chassis

6

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

12250

310

Page 20

Chapter 3

Clutch/Brake Controller Hardware

For example, if you choose rack address 2 for chassis A, you must choose

rack address 1 or 3 for chassis B.

Set the rack address in each clutch/brake module. Place a label on each

clutch/brake module to identify in which chassis, A or B, it belongs.

Important: Chassis A and B rack addresses must be unique. No I/O

chassis can have the same rack address as either chassis A or B. This

restriction prohibits using the rack address of either chassis A or B for any

complementary I/O chassis (a chassis with the same module addresses but

having input modules where chassis A and B have output modules, and

output modules where chassis A and B have input modules). This

restriction also prohibits using the rack address of either chassis A or B

for any partial remote I/O chassis (a chassis that starts with module group

2, 4, or 6). (Refer to chapter 4, Module Group 7, PLC Command Rungs,

for reasons why you must restrict the use of this address.)

Setting the Communication Rate

Response Time

Triacs of your clutch/brake controller turn on in sequential order. Triacs

connected to the high AC power line (L1) turn on before those in the

triac-solenoid string connected to the low AC power line (L2). If the

addresses are reversed, the triacs will turn on out of sequence, and the

clutch/brake controller will not operate.

Set switch 1 on switch assembly SW-2 to the ON position. This sets the

module’s communication rate at 57.6K baud. Be sure that you set the

communication rate of both 1771-PM modules and the processor’s

scanner to 57.6K baud, as well.

The worst case time required for the clutch/brake controller to respond to

a change of input depends on Module-response and triac-switching times:

Delay

Characteristic

1771IA

module

response time

1771PM module

response time

T

riac switching time

T

otal response time

(ms)

26

10

8

44

311

Page 21

Chapter 3

Clutch/Brake Controller Hardware

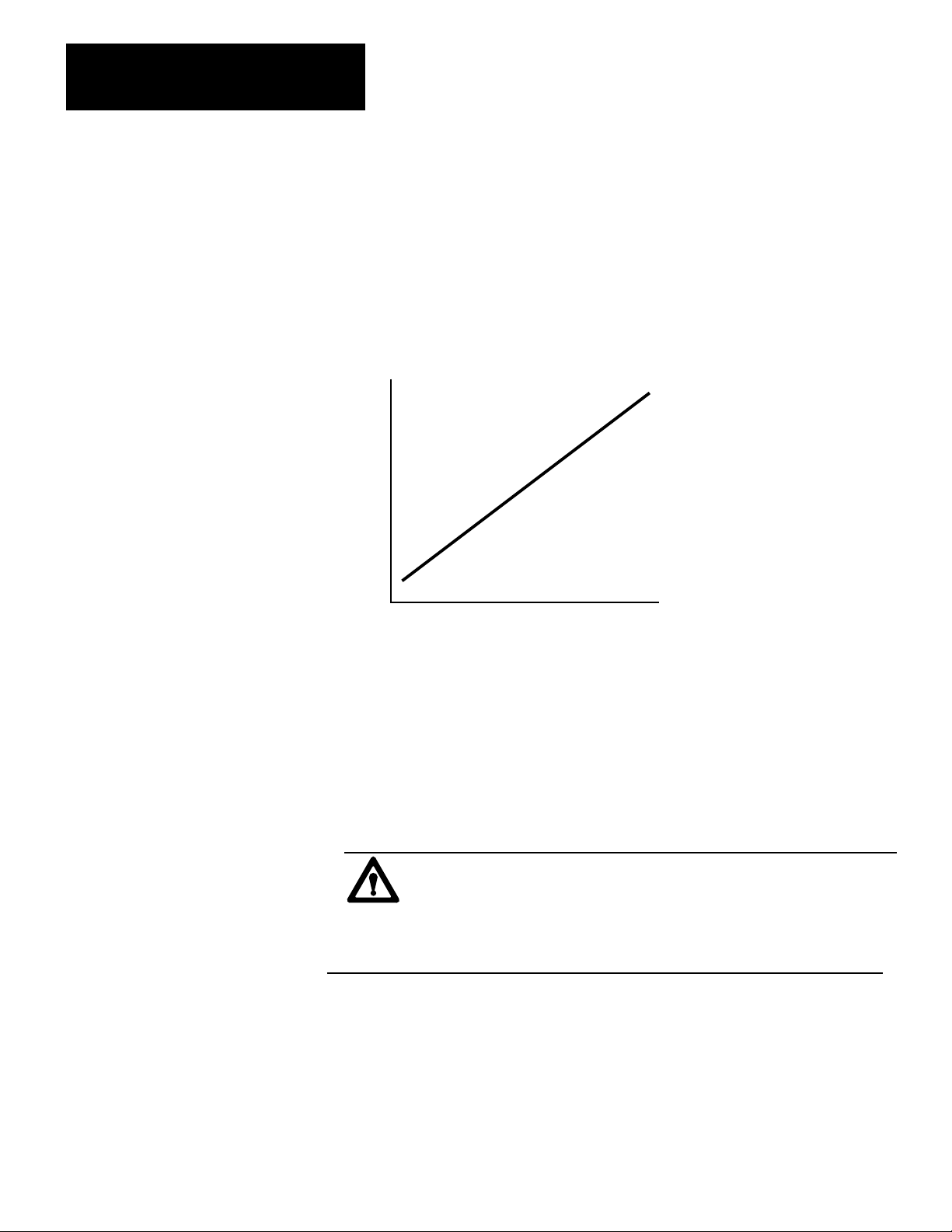

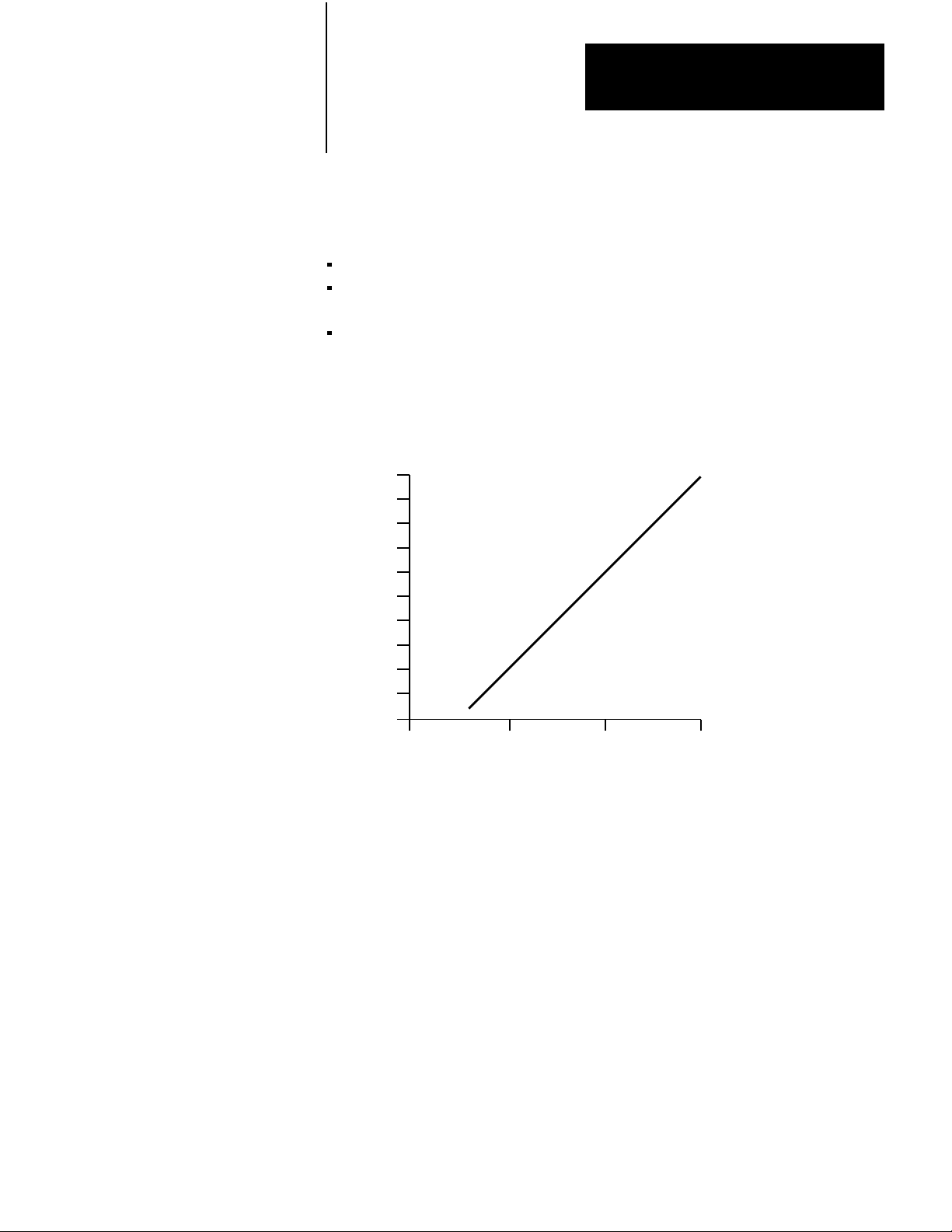

The number of degrees that the shaft continues to rotate, beyond the

moment in time when the input changes, depends on the speed of rotation.

The greater the number of strokes per minute (SPM), the further the shaft

rotates before a command from the clutch/brake controller is applied. The

response time of 44ms is represented in degrees of shaft rotation that

increases as the rate of press operation increases (Figure 3.5).

Figure 3.5

Response

Time of Clutch Brake Controller

SPM

100

90

80

70

60

50

40

30

20

10

0

0 5 10 15 20 25

DegreesofShaftRotation

12251

Important: When estimating the braking distance in degrees of rotation,

add the response time of the controller (Figure 3.5) to the specified

downstroke or upstroke braking distance of your press.

Module Placement

312

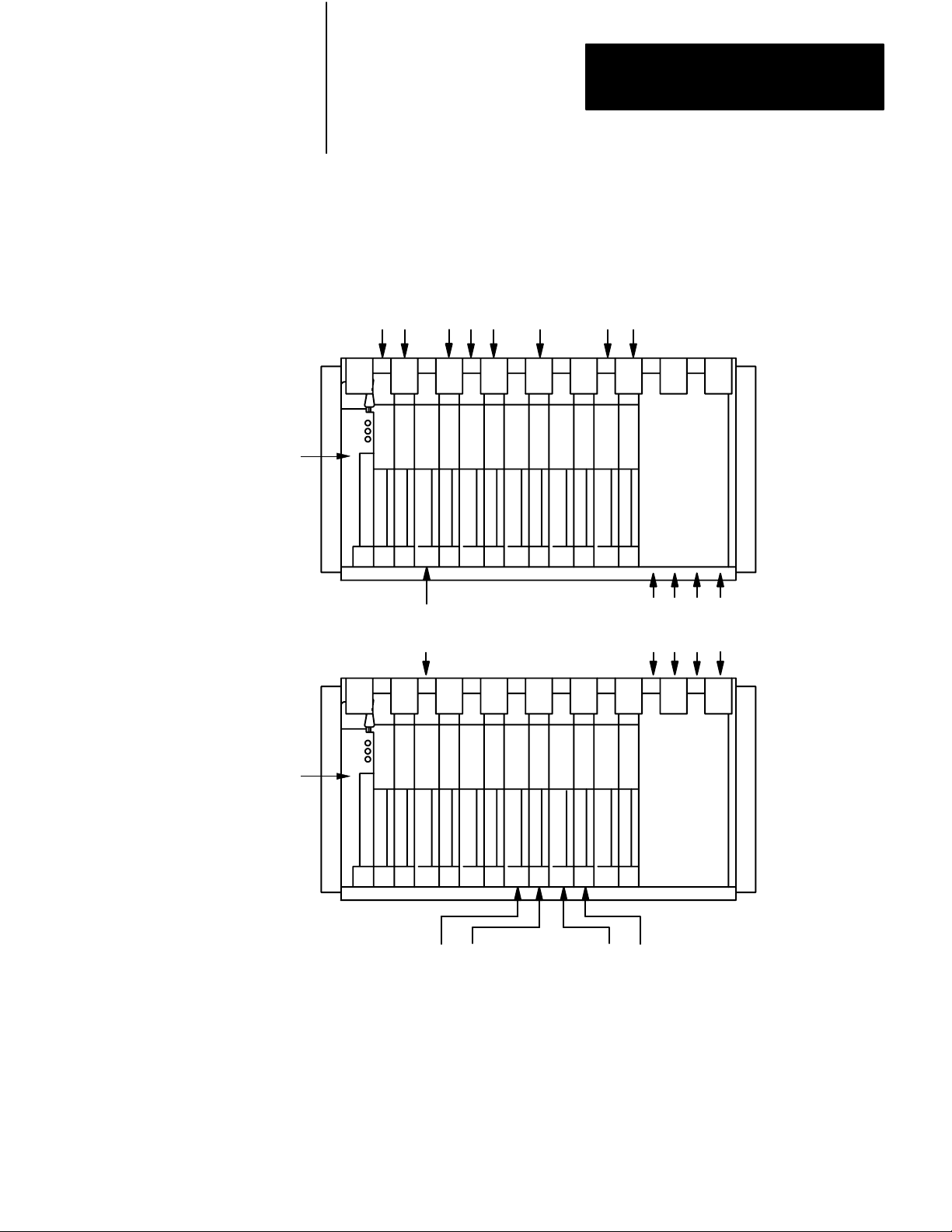

Locations of all clutch/brake controller modules are shown in Figure 3.6.

Note that some of these modules are optional.

CAUTION: Do not place any I/O module in module groups

6 or 7 of chassis A or B. These module group locations are

non-functional and reserved for future use. If you use a slot

power supply, install it in module group 7.

Important: Use series C or later 1771-OD modules because they have

improved electrical noise immunity. Refer to Electrical Noise

Suppression, in chapter 6, for a method of suppressing surge transient

noise.

Page 22

1771 -PM

module

Figure 3.6

Locations

Module

Required 1771 -IA modules for

press inputs chassis A & B

module group 0, slots 0 & 1

module group 1, slot 1

module group 2, slots 0 & 1

01234567

Chapter 3

Clutch/Brake Controller Hardware

Optional 1771 -OA modules for display of

message codes, brake fault, run window and micro inch.

module group 3, slot 1 chassis A

module group 5, slot 1, chassis A & B

Optional 1771 -IA modules for micro-inch inputs, chassis A & B

mdoule group 5, slot 0

Chassis A

1771 -A4, -A4B

Optional 1771 -IA modules for station 3 & 4

inputs chassis A & B (remove them if you do

not configure for stations 3 & 4

module group 1, slot 0

01234567

1771 -PM

module

Chassis A

1771 -A4, -A4B

Required 1771 -OD modules for outputs

to solenoid valves, Chassis A & B

module group 3, slot 0

Optional micro -inch indicator, chassis B

1771 -OA, module group 3, slot 1

Important: Use 1771A2, A2B chassis when not using optional dump valves,

display of diagnostic message codes, nor microinch inputs.

These slots must remain empty in chassis A & B

module group 6, slots 0 & 1

module group 7, slots 0 & 1

Optional modules for dump

valve in chassis A & B

1771 -OD, module group 4, slot 0

1771 -IA, module group 4, slot 1

12247

313

Page 23

Chapter 3

Clutch/Brake Controller Hardware

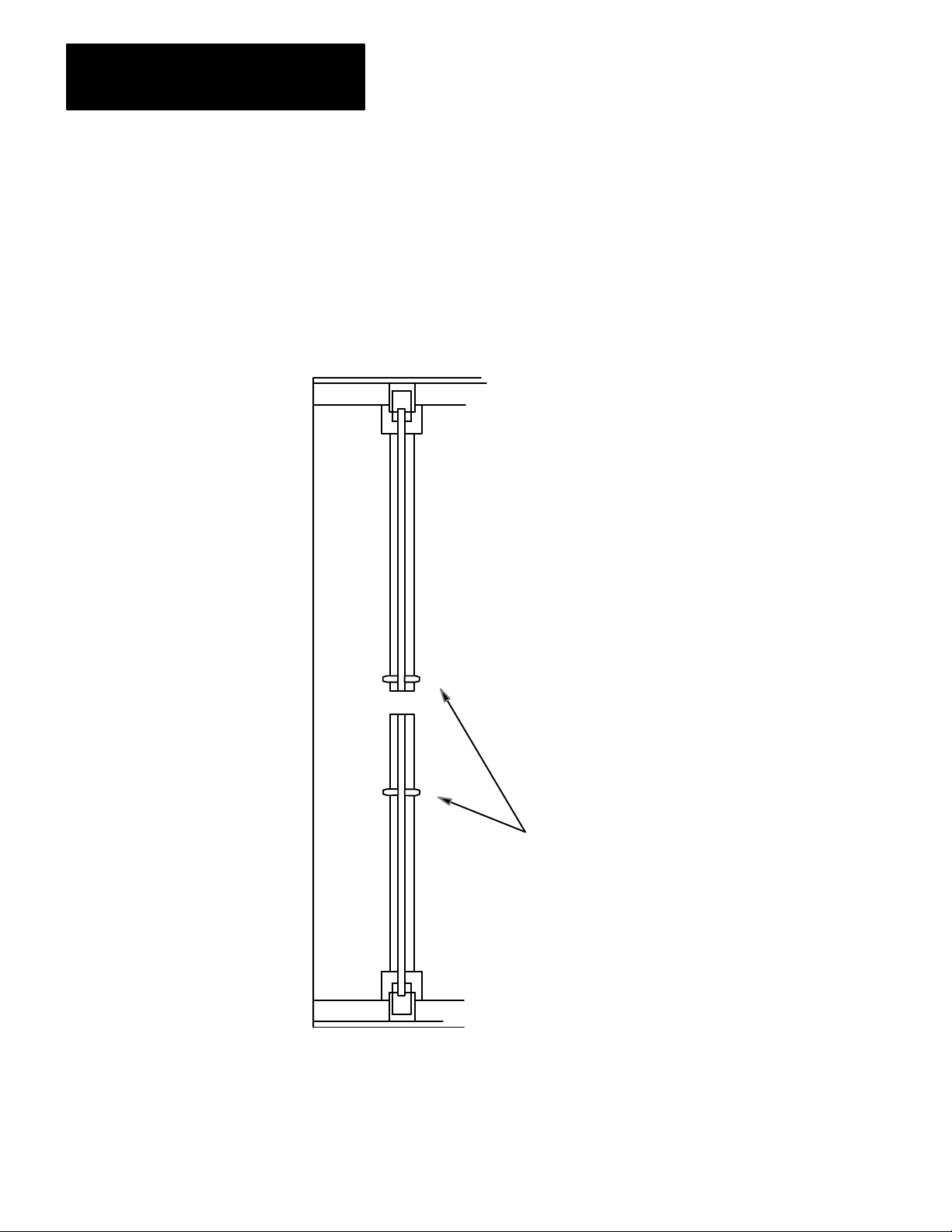

Keying

Install the keying bands on the I/O chassis backplane connector as shown

in Figure 3.7. After you install keying bands in chassis A and B, you can

insert only a clutch/brake module in the left-most slot of chassis A and B.

Figure 3.7

Keying

Chassis A and B

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

Insert keying bands so that you

can install only a 1771-PM

module in this slot.

12252

314

Page 24

Chapter

PLC Ladder Programming

4

Chapter Objectives

Programming Fundamentals

This chapter will help you become familiar with:

programming fundamentals as they relate to your clutch/brake

controller

the need for press configuration rungs

relationships between your press configuration rungs and backplane

switch settings

relationships between configuration rungs and voting processor

firmware

the option of monitoring the press through your PLC ladder program

the option of using PLC report generation to display messages that you

have stored.

Your PLC ladder program is composed of instructions that you enter into

PLC memory. These instructions are organized into rungs. They

typically monitor inputs and control outputs.

Your PLC ladder program does not control your clutch/brake controller,

but it does configure and enable it. Although your ladder program cannot

control any clutch/brake controller outputs, it controls output image table

bits to configure and enable the voting processors. Your ladder program

may examine input image table bits to monitor clutch/brake controller

functions as we will explain later.

This chapter concentrates on PLC ladder programming that relates to your

clutch/brake controller. For more details on ladder programming, refer to

the programming manual that applies to your PLC processor. These

publications are listed in our Systems Division Publication Index

(publication SD499).

PLC ladder programming is described in this chapter as it relates to

clutch/brake controller hardware and voting processor firmware

(Figure 4.1).

41

Page 25

Chapter 4

PC Ladder Programming

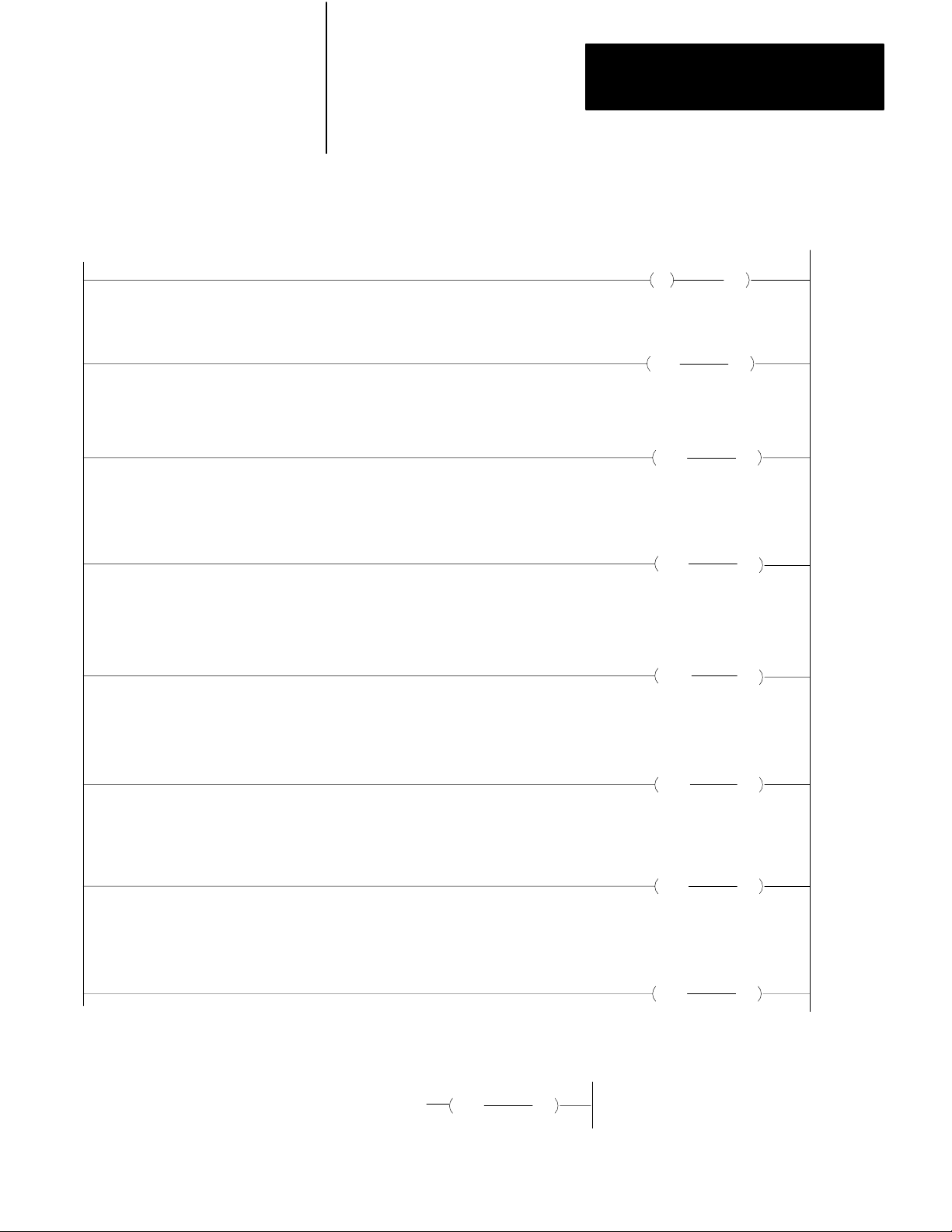

Figure 4.1

Overview

A-B Programmable Controller

with Remote I/O

Your ladder diagram

program configures and

enables voting processors

A and B, while it monitors

and controls I/O through

remote I/O adapters.

I/O Control Rungs

of Clutch/Brake Controller

Thefirmwareinvoting

processors A and B

monitors and controls the press.

1771 - PM

Voting

Processor

1771 - PM

Voting

Processor

1771 - ASB

Remote I/O

Adapter

Chassis

A

Chassis

B

Chassis

C

(optional)

C/B

Press

PLC

Ladder

Program

Configuration Rungs

I/O Control Rungs

Configuration

Switch

Inputs

Other inputs

that are

independent

of the

Clutch/brake

controller

12253

42

Page 26

Chapter 4

PC Ladder Programming

Configuration Rungs

You have flexibility in selecting clutch/brake controller functions by

setting/resetting configuration bits. Use any of the following functions

according to your application requirements:

Functions Bit

3 and 4

Stations

Motion detector feedback

alve stem feedback

V

Air pressure feedback

Ungrounded or grounded AC power

Onthehop 06

Halfstroke or Strokeandahalf

Dump valve circuit

01

02

03

04

05

07

14

You enable various functions by programming configuration rungs to set

(turn on) or reset (turn off) configuration bits 01 thru 07 and 14 in the

output image table word for module group 7, chassis A and chassis B.

Bit addresses are shown in Figure 4.2. Example configuration rungs are

shown in Figure 4.3 through Figure 4.5. Program your configuration

rungs according to the requirements of your press system.

Be sure to set or reset each configuration bit 01 thru 07 and 14 with

unconditioned rungs. They contain only output instructions, such as latch,

unlatch, or output energize. Bits set by these rungs do not change during

press operation. The latching or unlatching of these bits must correspond

with backplane switch settings covered in chapter 3.

Figure 4.2

addresses of Output Image T

Bit

PLC-2/20 PLC-3

PLC-2/30 PLC-5/250

0y7/xx Oyy7/xx O:y7/xx

where yy = rack address per Figure 3.4

xx = bit number 00 - 17

Important: Do not use bits 00 and 15-17 for any purpose.

able W

ord for Module Group 7 of Chassis A & B

PLC-5

43

Page 27

Chapter 4

PC Ladder Programming

Figure 4.3

Example

Stations 3 and 4 not used

Motion detector feedback used

Valve stem switch feedback used

Air pressure switch feedback not used

PLC Configuration Rungs for Bits 01 thru 07 and 14 (PLC2 Family)

057

U

01

067

U

01

057

L

02

067

L

02

057

L

03

067

L

03

057

U

04

067

U

04

Ungrounded AC power

On-the-hop not used

Strokeandahalf used

Optional dump valve triacs used

057

L

05

067

L

05

057

U

06

067

U

06

057

U

07

067

U

07

057

L

14

067

L

14

44

Page 28

Chapter 4

PC Ladder Programming

Figure 4.4

Example PLC Configuration Rungs for Bits 01 thru 07 and 14

(PLC3 and PLC5/250)

Stations 3 and 4 not used

Motion detector feedback used

Valve stem switch feedback used

Air pressure switch feedback not used

Ungrounded AC power

O0057

U

01

O0057

L

02

O0057

L

03

O0057

U

04

O0057

L

05

O0067

(

U

01

O0067

)

(

L

02

)

)

)

O0067

(

L

O0067

(

U

O0067

(

L

03

04

05

On-the-hop not used

Half-stroke or Stroke-and-a-half used

Optional dump valve triacs used

NOTE: Unconditionally latch or unlatch bits 0 through 7 and 14 for chassis A and B as shown to use these functions.

Use this address format for PLC-5/250 processors

O:057

U

01

)

O:067

(

U

01

O0057

U

06

O0057

U

07

O0057

L

14

)

)

)

O0067

(

U

O0067

(

U

O0067

(

L

06

07

14

45

Page 29

Chapter 4

PC Ladder Programming

Figure 4.5

Example PLC Configuration Rungs for Bits 01thru 07 and 14

(PLC5 family)

Stations 3 and 4 not used

Motion detector feedback used

Valve stem switch feedback used

Air pressure switch feedback not used

Ungrounded AC power

On-the-hop not used

Stroke-and-a-half or Half-stroke used

Optional dump valve triacs used

NOTE: Unconditionally latch or unlatch bits 0 through 7 and 14 for chassis A and B as shown to use these functions.

(

O:57

(

(

(

(

(

(

(

O:67

O:57

U

01

O:67

U

01

L

02

O:67

L

02

O:57

L

03

O:67

L

03

O:57

U

04

O:67

U

04

O:57

L

05

O:67

L

05

O:57

U

06

O:67

U

06

O:57

U

07

O:67

U

07

O:57

L

14

L

14

)

)

)

46

Page 30

Chapter 4

PC Ladder Programming

Matching Configuration Bits and Backplane Switches

As listed in Table 4.A, backplane switch positions 2 thru 8 correspond

with configuration bits 01 thru 07. The voting processors in your

clutch/brake modules allow press operation only if the set (on) and reset

(off) states of configuration bits in your program correctly match the ON

and OFF settings of corresponding backplane switches. The voting

processors check for correct configuration when you apply power to your

clutch/brake controller or change its mode of operation using the mode

select switch.

Table 4.A

Corresponding

Backplane

Switch

Settings

(figure 3.3)

Pos. Setting Bit: Status: Function:

2 ON 01 Set

Backplane Switch Settings and Configuration Bits

Configuration

Bits

OFF reset

Backplane switch settings and configuration bits

must be identical

Use Stations 3 and 4

Stations 3 and 4 not used

3 ON 02 set

OFF reset

4 ON 03 set

OFF reset V

5 ON 04 set

OFF reset

6 ON 05 set

OFF reset

7 ON 06 set

OFF reset

8 ON 07 set

OFF reset

Module Group 4

Slot 1, Chassis A&B

1771IA

Module Group 4

Slot 1, Chassis A&B

is EMPTY

14

Set

reset

Use Motion Detector Feedback

Motion Detector Feedback not used

Use V

alve Stem Feedback

alve Stem Feedback not used

Use Air Pressure Feedback

Air Pressure Feedback not used

Ungrounded AC Power

Grounded AC Power

Use OnTheHop

OnTheHop not used

Use Halfstroke

Use StrokeAndAHalf

Use Dump V

alve Outputs

Dump V

alve Outputs not used

47

Page 31

Chapter 4

PC Ladder Programming

PLC Command Rungs

Your ladder diagram program can send four commands to the clutch/brake

controller by setting command bits 10-13 in the output image word for

module group (MG) 7, Slot 1 for I/O chassis A and B:

Command Bit

enable

Press

Stopontop

Reset latched messages

Lamp test

10

11

12

13

These commands can be issued manually by an operator pushing a switch,

or automatically by a switch closure in your machinery. They function as

follows:

Output Status Condition

Press Enable

Bit 10

Stopontop

(Continuous mode, only)

Bit 1

1

must be ON

OFF

offtoon

transition

must be OFF

T

o enable motion in any mode

Immediately turns OFF triac outputs

T

urns OFF solenoid outputs the next time the

runon cam switches open

T

o start or maintain continuous stroking

Controlled by PM Module

Reset Latched Message

Bit 12

Lamp T

est

Bit 13

1

Holding this bit ON may inhibit the capture of subsequent L or t messages.

offtoon

transition

ON

OFF

Clears any latched or tripped message code

1

shown in MG 5, Slot 1, as long as the condition

that caused the message no longer exists.

T

urns ON all these outputs

Brake Fault , Run Window

and other diagnostic message lamps

T

urns OFF these outputs

Bit addresses for these command bits are shown in Figure 4.2. Example

PLC command rungs are shown in Figure 4.6 through Figure 4.8.

To enable these commands, write ladder program rungs that are

conditioned with examine-on/examine-off instructions to monitor

corresponding switch inputs wired to I/O chassis C. You can use any

available discrete module terminals (excluding those in chassis A or B)

for these inputs (Figure 6.15). For additional information refer to chapter

6, Inputs to Chassis C .

, Microinch Message,

48

Page 32

Chapter 4

PC Ladder Programming

132

13

132

13

132

15

132

15

132

132

PRESS ENABLE Switch

STOP-ON-TOP Switch

RESET Switch

14

Figure 4.6

Example

Optional conditions

Enable Press Operation

Command Stop-on-top

Reset latched messages

PLC Command Rungs for Bits 10 thru 13 (PLC2 Family)

057

10

067

10

057

11

067

11

057

12

067

14

132

16

132

16

NOTE:

12

LAMP TEST Switch

Test optional indicators

PLC command bits 10 through 13 use conditioned logic. Do not latch or unlatch instructions. Corresponding

switch input wiring is shown in Figure 6.15.

057

13

067

13

49

Page 33

Chapter 4

PC Ladder Programming

PRESS ENABLE Switch

Figure 4.7

Example PLC Command Rungs for Bits 10 thru 13

(PLC3 and PLC5/250)

Optional conditions

I0032

13

I0032

15

I0032

14

I0032

Enable Press Operation

STOP-ON-TOP Switch

Command Stop-on-top

RESET Switch

Reset latched messages

LAMP TEST Switch

O0057

10

O0057

11

O0057

O0057

12

O0067

10

O0067

11

O0067

12

O0067

410

16

NOTE:

13

Test optional indicators

PLC command bits 10 through 13 use conditioned logic. Do not latch or unlatch instructions. Corresponding

switch input wiring is shown in Figure 6.15.

Use this address format for PLC-5/250 processors

O:057

U

01

)

O:067

(

U

01

13

Page 34

PRESS ENABLE Switch

Optional conditions

Chapter 4

PC Ladder Programming

Figure 4.8

Example PLC Command Rungs for Bits 10 thru 13 (PLC5)

I032

13

I032

15

I032

14

I032

Enable Press Operation

STOP-ON-TOP Switch

Command Stop-on-top

RESET Switch

Reset latched messages

LAMP TEST Switch

O:57

10

O:67

10

O:57

11

O:67

11

O:57

12

O:67

12

O:57

16

NOTE:

13

Test optional indicators

PLC command bits 10 through 13 use conditioned logic. Do not latch or unlatch instructions. Corresponding

switch input wiring is shown in Figure 6.15.

O:67

13

411

Page 35

Chapter 4

PC Ladder Programming

Summary of PLC Configuration and Command Rungs

Output image table word,

Module Group 7, Chassis

A & B

Bit Bit

No: Function: Set Reset Rung:

01

02

03 V

Stations 3 and 4

Motion Detector Feedback

alve Stem Feedback

We summarize the bits in module group 7 used for determining

configuration requirements and enabling operator commands (Figure 4.9).

Figure 4.9

Functions

17161514131211100706050403020100

of PLC Configuration and Command Bits

PLC Configuration Bits

PLC Command Bits

Status

Used

Used

Used

Not Used

Not Used

Not Used

T

Unconditioned

Unconditioned

Unconditioned

ype of

04

05

06 OnTheHop Used

07

10

11 StopOnT

12

13

14

NOTES: Do not use bits 00 and 15 17 for any purpose.

See Figure 4.2

See Figure 4.3

Air Pressure Feedback

AC Power Configuration

Strokeandahalf or Halfstroke

Press Enable (PLC Command)

op (PLC Command)

Latched Messages (PLC Command)

Lamp T

est (PLC Command)

Dump V

alve T

riacs Used

for bit addresses

through 4.8 for programming

Ungrounded Grounded Unconditioned

Used

Not Used

Enabled Disabled Conditioned

Enabled Disabled Conditioned

Enabled Disabled Conditioned

Enabled Disabled Conditioned

Not Used

Not Used

Used Unconditioned

Not used

Unconditioned

Unconditioned

Unconditioned

12254

412

Page 36

Chapter 4

PC Ladder Programming

Module Group 5, Slot 0

Reserved for MicroInch

Module Groups 6 and 7 Reserved for Data Storage

Important: Use module group 5, slot 0 only if your mechanical power

press is equipped for micro-inch.

When you insert an input module (1771-IA) into this slot of chassis A and

B, the processor recognizes micro-inch inputs at terminals 0, 1, 2. For the

wiring of these terminals refer to chapter 6, Figure 6.4 or

Figure 6.8.

Module group 6 is non-functional and reserved for future use.

Your program must use the output image table word associated with

module group 7 as a storage word for configuring your clutch/brake

modules (Figure 4.9). The processor transmits configuration data to the

clutch/brake modules in each I/O scan.

CAUTION: Do not assign any I/O module to module group 7

of the rack address assigned to chassis A and B. Unexpected

press operation will occur with possible damage to equipment

and/or injury to personnel. However, you may install a slot

power supply in module group 7, if needed.

Monitoring Clutch/Brake Controller Inputs and Outputs

Important: Be sure to assign full rack addresses for chassis A and B,

regardless of whether you are using the optional dump valve and/or

micro-inch circuit. This guards against assigning an I/O module to

module group 7.

Refer to Rack Address of Chassis A and B, in chapter 3, for instructions

on assigning rack addresses.

Your PLC ladder program cannot control outputs of your clutch/brake

controller. However, your PLC ladder program can monitor any

clutch/brake controller input or output because the I/O image table of

chassis A and B is in the PLC data table.

Input image table bit addresses for chassis A and B are listed in tables A

thru F in appendix 1. You may monitor these addresses. However, do not

examine them as conditions for configuration rungs shown in Figures 4.3

through Figure 4.5. If you do, PM modules may stop the press. Then

you must cycle power to restart.

413

Page 37

Chapter 4

PC Ladder Programming

For an example of monitoring a clutch/brake controller function, assume

that you wish to turn on a indicator while your clutch/brake controller is

in continuous mode. You would wire your CONTINUOUS indicator to a

terminal of an output module in any I/O chassis. You would also program

a rung with one examine-on instruction and one output-energize

instruction:

the examine-on instruction monitors input image bit 03 for module

group 0 chassis A or B.

the output energize instruction controls the CONTINUOUS indicator.

Important: Do not store data in unused data table addresses for chassis A

and B. These are reserved for future enhancements for the clutch/brake

controller.

Report Generation

Your PLC ladder program can monitor clutch/brake controller functions

for report generation. This allows you to display, through an RS-232-C

peripheral device, any of the following:

operator instructions fault correction procedures

status reports diagnostic message codes

The clutch/brake module generates diagnostic message codes presented in

table 7.C. Use them to generate messages that you have stored in PLC

memory. These messages can be troubleshooting instructions to your

press operators. For detailed descriptions of report generation, see the

following publications:

For PLC-2 family processors:

PLC-2 Family Report Generation Module (cat. no. 1770-RG) User’s

Manual (publication 170-815)

For PLC-3 processors:

I/O Scanner-Message Handling Module (cat. no. 1775-S4B) User’s

Manual (publication 1775-6.5.3)

Peripheral Communications Module (cat. no. 1775-GA) User’s Manual

(publication 1775-6.5.4)

414

For PLC-5 family processors:

BASIC Module (cat. no. 1771-DB) User’s Manual (publication

1771-6.5.34)

Page 38

Chapter 4

PC Ladder Programming

Summary of Clutch/Brake Controller Functions

Function or Command

You should now be familiar with required and optional PLC ladder

programming needed to configure and monitor your clutch/brake

controller. Complete your ladder diagram programming addresses after

you have wired your press system as described in chapter 6. Clutch/brake

controller functions (Table 4.B) are summarized on the next page.

Table 4.B

Summary

Off

Inch

Microinch

Singlestroke

of Clutch/Brake Controller Functions

Operating Mode

[ 1 ]

Description

Clutch/brake controller locks out press motion

The operator can jog the press through a complete cycle by

pressing and releasing the pair of INCH buttons. If INCH

buttons are held, the press will stop at the top of its stroke.

This mode of operation lets you run your press at low speeds

(1 to 5spm) for setting up dies and making trial runs. Y

supply a separate drive and clutch/brake assembly to drive the

shaft with full tonnage capacity at low press speeds, bypassing

the flywheel.

The press completes one cycle and then stops on top, provided

the operator holds both RUN buttons until completion of the

down stroke.

ou must

Continuous

[ 1 ]

Stopontop

(cycle stop)

Onthehop Singlestroke

Halfstroke or

Strokeandahalf

[ 1 ] Cam limit switches must indicate that the press is in the neartop position before motion can start in

single or continuous mode.

Continuous

Continuous

Operators must assert the ARM CONTINUOUS switch and all

station RUN buttons within five seconds, and then hold the RUN

buttons for half a stroke (or 1 1/2 strokes) if so configured to

start the press in continuous mode. Thereafter

until stopped by a stopontop command, or when a fault is

detected.

This command, from a switch wired to the clutch/brake

controller or from the PLC, stops the press at a predetermined

point.

Releasing and pressing both RUN buttons during a specific

portion of the upstroke causes the press to continue running

onto the next stroke without stopping. This is a configurable

option.

The operator must press both RUN buttons for 1/2 or 1 1/2

press cycles before the press can run on its own. This is a

configurable option. Run buttons must be held until Runon

(takeover) Cams are made.

, the press runs

415

Page 39

Chapter 4

PC Ladder Programming

Function

or Command

Interrupted stroke

Interrupted stroke

Antitiedown All

Antirepeat Singlestroke

Operating Mode

Continuous

Singlestroke

Inch

Description

If an operator releases a RUN button during a down stroke, the

press stops immediately

operator releases both RUN buttons and presses them again,

the press continues the downstroke. If more than five seconds

elapses, the operator must inch the press to top, select

continuous mode, and follow the first Continuous procedure

above..

Same as Continuous mode except there is no time limit on

reapplying the RUN button.

The press will not start if you tie down one or more RUN

buttons. After all RUN buttons are released, the operator must

press both RUN buttons at a station simultaneously

operators at active stations must press all RUN buttons within

five seconds of each other to start the press.

The same applies to the pair of INCH buttons.

The press is limited to a single stroke, even if the operator

continues to press both RUN buttons. The operator must

release both RUN buttons and press them again to start press

motion.

The same applies to a pair of INCH buttons as described for

Singlestroke.

. If within five seconds of stopping, an

, and/or

Motion detector

TopstopCheck All

Singlestroke

Continuous

The clutch/brake controller detects press motion using your

motion detector which provides a 120AC input signal. This is a

configurable option.

The clutch/brake controller signals a worn or faulty brake by

monitoring the T

T

opstopcheck cam closed after a normal cycle stop has been

initiated and before the press comes to a top stop, it prevents

the press from restarting and energizes the brakefault output.

opstopcheck cam inputs. Should it see the

416

Page 40

Chapter

Voting Processor Firmware

5

Chapter Objectives

Operation of Voting Processors

This chapter will help you become familiar with:

operation of your voting processor firmware

operational sequences for controlling your press

A clutch/brake controller has two clutch/brake modules, one in chassis A

and the other in chassis B. Each clutch/brake module contains firmware

that makes it function as a voting processor. Both voting processors

contain identical firmware programs that independently monitor your

clutch/brake controller I/O while controlling the press.

While running their firmware programs, both voting processors constantly

“vote” on the status of your press. Both voting processors must always

have a consensus. If they find that they don’t agree on their perceived

conditions of your press, they either stop the press or prevent it from

starting.

Also, both voting processors constantly check their communication

channels. Press motion is stopped or inhibited if either voting processor

detects a loss of communications with the PLC or the other voting

processor. A failure in one voting processor is immediately seen as a

communication loss by the other voting processor.

Emergency Shut Down

Finally, voting processors control the operational sequences that your

operators must perform in inch, single, and continuous modes.

Each voting processor (PM module) controls one seal relay and one

crowbar relay. All E-STOP switches are connected in series with seal

relay contacts. If any of these contacts opens or if the PM module detects

a trip condition, solenoid power is disconnected. If a PM module detects

that solenoid power should be off when on, it turns on the crowbar relay

to blow the solenoid power line fuses. At clutch/brake start, both PM

modules test their crowbar relays without blowing the line fuses. Wiring

diagrams in chapter 6 show these connections.

51

Page 41

Chapter 5

Voting Processor Firmware

Fault Monitoring

PM modules continuously monitor your clutch/brake system for a trip or

stop condition. Either condition halts and/or prevents press operation.

For

this condition

Trip

Stop T

PM modules remove solenoid power by

Removing power from field wiring arms

urning of

controlling the solenoids

f outputs from the output module

Trip condition - A PM module turns off swing arm output power by

de-energizing its seal relay output when it detects these trip conditions:

lost communications with the other PM module for 100ms

a change in wiring of operator stations 1 thru 4

a short or open solenoid triac

short or open solenoid

feedback [1] connections are wired but not configured

feedback connections are configured but not wired

feedback signals are not working correctly

[1]

feedback from valve stem switches, air pressure sensors, and motion detector contacts

Whenever a PM module detects a trip condition, it:

trips power to the wiring arms of the I/O chassis

sets rack fault bits

stops communication with the PLC

If programmed to monitor rack fault bits, the PLC sees the clutch/brake

I/O chassis as faulted until both PM modules verify that power to wiring

arms has been removed. Then they resume communications

automatically.

Stop condition - A PM module stops the press or prevents it from starting

by turning off output triacs to solenoid valves when it detects stop

conditions such as:

lost communications with the other PM module for 50ms

lost communications with the PLC for one second

cam limit switch signals out of sequence

barrier guard opened during continuous mode

This is described further in Chapter 7, Diagnostic Message Codes.

52

Page 42

Chapter 5

Voting Processor Firmware

Operation of Cam Limit Switches

The PM Module uses cam limit switches to determine press slide position.

(Figure 5.1 and Table 5.A). You set two independent cam limit switch

assemblies to the same settings so that:

run-on contacts are closed in the near bottom and upstroke zones

top-stop-check contacts are closed in the downstroke and near-bottom

zones

anti-repeat contacts open during mid-upstroke for at least 70ms. Set the

open span to the approximate number of rotational degrees (10

0 -

450)

according to the speed of the press (1spm - 100spm).

UpStroke

Press

Speed

Span vs. Press Speed for AntiRepeat Contacts

SPM

100

90

80

70

60

50

40

30

20

10

0

15

OpenSpanDuringUp-Stroke

00

30

45

12971

The anti-repeat cam is not required while operating in inch or micro-inch

mode. However, before entering any operating mode, the PM module

checks that at least one cam limit switch is closed at any point in the

cycle.

53

Page 43

Chapter 5

Voting Processor Firmware

Figure 5.1

Limit Switch Settings

Cam

Run - On

Upstroke

Anti - Repeat

Near Top

Position

70 ms

Near Bottom

Zone

Top-stopcheck

Downstroke

Table 5.A

Operation

NOTE:

Install two mechanically independent cam limit switch assemblies each with three cams and three

limit switches. Set the assemblies to similar settings according to the requirements of your press.

You can set cam limit switches to other configurations provided they meet the make/break conditions

listed below:

Cam Linit Switch Settings

Top-Stop

Zone

-Check

MAKE

Downstroke

MAKE

Near

Bottom

BREAK

Upstroke

BREAK

BREAK

BREAK

Near

Top

Refer to Diagnostic Messages, table 7.C. Hex codes 80 thru AA, for descriptions of faults caused

by cam limit switches.

Run-On

BREAK

MAKE

MAKE

MAKE

MAKE

BREAK

AntiRepeat

MAKE

MAKE

MAKE

BREAK

MAKE

MAKE

Topstopcheck

before run-on contacts make, or the controller faults.

Run-on contacts must make (not necessarily at the same time)

before

T

opstopcheck contacts must break (not necessarily at the same time)

before antirepeat contacts break or the controller faults.

Anti-repeat contacts must break for at least 70ms during

upstroke, then make before run-on contacts break, or the controller faults.

Anti-repeat contacts must make (not necessarily at the same time)

before run-on contacts break, or the controller faults.

Run-on contracts must break (not necessarily at the same time)

before T

contacts must make (not necessarily at the same time)

T

opstopcheck contacts break, or the controller faults.

opstopcheck contacts make or the controller faults.

Comments

of Cam Limit Switches

12970

54

This

Cam

Anti

Repeat

Runon

TopStop

Check

In this

Mode

Onthehop single

stroke

Inch and Microinch

(forward) and Single

stroke

Continuous

Single stroke and

Continuous

any

Inch and

Microinch

(reverse)

W

ith these

Conditions

Run buttons released

past bottom

Cam opens at neartop

position T

Cam opens at neartop

position after

stopontop command

Cam closes at

nearbottom position

Cam closes during

stopontop

Cam opens in neartop

position

Provides the PM Module a Signal:

T

o allow a second stroke when run buttons

are pressed a second time

o turn OFF triac output for

stopontop (cycle stop)

T

o let operator release any depressed run

buttons without interrupting a single stroke

or continuous stroking

T

o energize a Brake Fault output to warn

that the brake is faulty (Hazardous

Condition)

T

o turn OFF solenoid outputs to stop the

cycle

Page 44

Chapter 5

Voting Processor Firmware

Clutch/Brake Operating Modes

Select inch or microinch

No

Has an operator released

both INCH buttons?

Has an operator pressed

both INCH buttons

Inch and Microinch Modes

Use inch or micro-inch mode before entering single or continuous mode

to position the shaft near the top, or for machine tool set-up. You may jog

the shaft either forward or in reverse. The shaft stops when it moves into

the near top position or when you release an INCH button.

Figure 5.2

Operational

mode

Yes

simultaneously?

Yes

Sequence for Inch or MicroInch Mode

WARNING: To guard against the

possibility of personal injury, install a

keylock mode select switch so that only

supervisory personnel can select inch

mode.

No

Both voting processors

energize their solenoid triacs

to actuate the clutch

Has the shaft moved into its

neartop position?

deenergize their solenoid

triacs to stop the shaft in its

NOTE: Use inch or microinch mode to position the shaft near the top. Operators may

jog the shaft in either direction. The shaft stops when it moves near top position or

when an operator released an INCH button.

No

Yes

Both voting processors

neartop position

Has an operator released

either INCH button?

Yes

WARNING: If the shaft

coasted past its neartop

position while braking, the

brake is faulty and

hazardous. Repair it

immediately.

No

12261

55

Page 45

Chapter 5

Voting Processor Firmware

Single Stroke Mode

Use single-stroke mode to actuate the press through a single cycle.

During the downstroke (Figure 5.3)

releasing a RUN button stops the press

if the shaft did not enter the near bottom zone, you may resume the

downstroke

if the shaft entered the near bottom zone, you must inch the press back

to the near top position before restarting

During the upstroke (Figure 5.4)

the shaft continues automatically through the upstroke

If you enabled on-the-hop , you can start another cycle without stopping

the press if you

release all RUN buttons after the near bottom position

press all RUN buttons after the anti-repeat contacts open during the

upstroke

56

Page 46

Chapter 5

Voting Processor Firmware

Start onthehop

downstroke.

From figure 5.4

Figure 5.3

Operational

Select single mode

Main Motor Forward

Yes

Is the shaft near the top?

Yes

Have all operators released all

RUN buttons?

Yes

Has each operator pressed his

RUN buttons simultaneously,

and within 5 seconds for all

stations?

Yes

Both voting processors

energize their solenoid triacs to

actuate the clutch for the

downstroke

Sequence for Downstroke in Single Mode

No

No

No

Select inch mode and position the

shaft near the top.

No

Has an operator released a

RUN button?

Is the shaft past the near

bottom zone?

Yes

Start upstroke.

Go to figure 5.4

NOTE: Releasing a RUN button during the downstroke stops the press. If the shaft does

not reach the nearbottom zone, operators may resume the downstroke. If the shaft

reaches the nearbottom zone, an operator must inch the press back to the neartop

position.

No

Both voting processors

deenergize their solenoid

triacs to stop the shaft. A stop

condition message is

Did the shaft coast into the

near bottom zone while

No

Have all operators released all

Has each operator pressed his

Yes

RUN buttons simultaneously,

and within 5 seconds for all

Yes

displayed.

breaking?

No

RUN buttons?

Yes

stations?

Yes

CAUTION: Releasing a RUN

button late in the downstroke

can damage the press

No

12262

57

Page 47

Chapter 5

Voting Processor Firmware

Both voting processors

deenergize their solenoid triacs

to stop the shaft. A stop condition

mesage is displayed.

Yes

Has the shaft moved into its

neartop position?

No

No

Figure 5.4

Operational

Start upstroke.

From figure 5.3

Upstroke continues regardless of

releasing RUN buttons

Have both voting processors

detected that antirepeat cams

have opened?

Yes

Has onthehop been enabled?

Sequence for Upstroke in Single Mode

Yes

Have all operators released all RUN

buttons?

Yes

Yes

Has each operator pressed his RUN

buttons simultaneously, and within 5

seconds for all stations?

Yes

Has the shaft moved into its neartop

position?

No

Has the shaft moved into its neartop

position?

No

Yes

No

Has the shaft moved into its

neartop position?

No

NOTE: The shaft continues automatically through its upstroke, then stops. If onthehop has

been enabled, operators can start another downstroke without stopping at the top. Do this by

releasing all RUN buttons after the downstroke. Then, press all RUN buttons after the antirepeat

contacts open on the upstroke.

Yes

Both voting processors

deenergize their solenoid triacs

to stop the shaft in its neartop

position

WARNING: If the shaft coasted

past its neartop position while

braking, the brake is faulty and

hazardous. Repair it immediately.

No

No

Has an operator released a RUN

button?

Yes

Start onthehop downstroke.

Go to figure 5.3

12263

58

Page 48

Chapter 5

Voting Processor Firmware

Continuous Mode

Select continuous mode when you want to run your press continuously.

Do this as follows:

inch the press to the near top position

close the barrier guard(s)

select continuous mode, and

press the ARM CONTINUOUS button (Figure 5.5)

During the first downstroke (Figure 5.6).

releasing a RUN button or opening a barrier guard stops the press

if the shaft did not enter the near bottom zone, you may resume the

downstroke within five seconds after a stop

if the shaft entered the near bottom zone and is stopped, you must inch

the press to the near top position and press the ARM CONTINUOUS

button in order to restart press operation.