Page 1

AllenBradley

Proportional/Inte

gral/Derivative

User

Control (2-Loop)

Module

(Cat.

No. 1771-PD)

Manual

Page 2

Table of Contents

Introduction 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly and Installation 21. . . . . . . . . . . . . . . . . . . . . . . . .

General 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Description 21

Internal Selections 22

Manual

Control Station Interface

Input Power Supply Requirements 219

Installation Practices 222

Chassis Considerations 223

Internal Fusing 224

Recommendations for Installing or Removing Modules 224

Keying 225

Power Supply Specifications 227

Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

217. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Overview 32

Word

and Bit Definitions

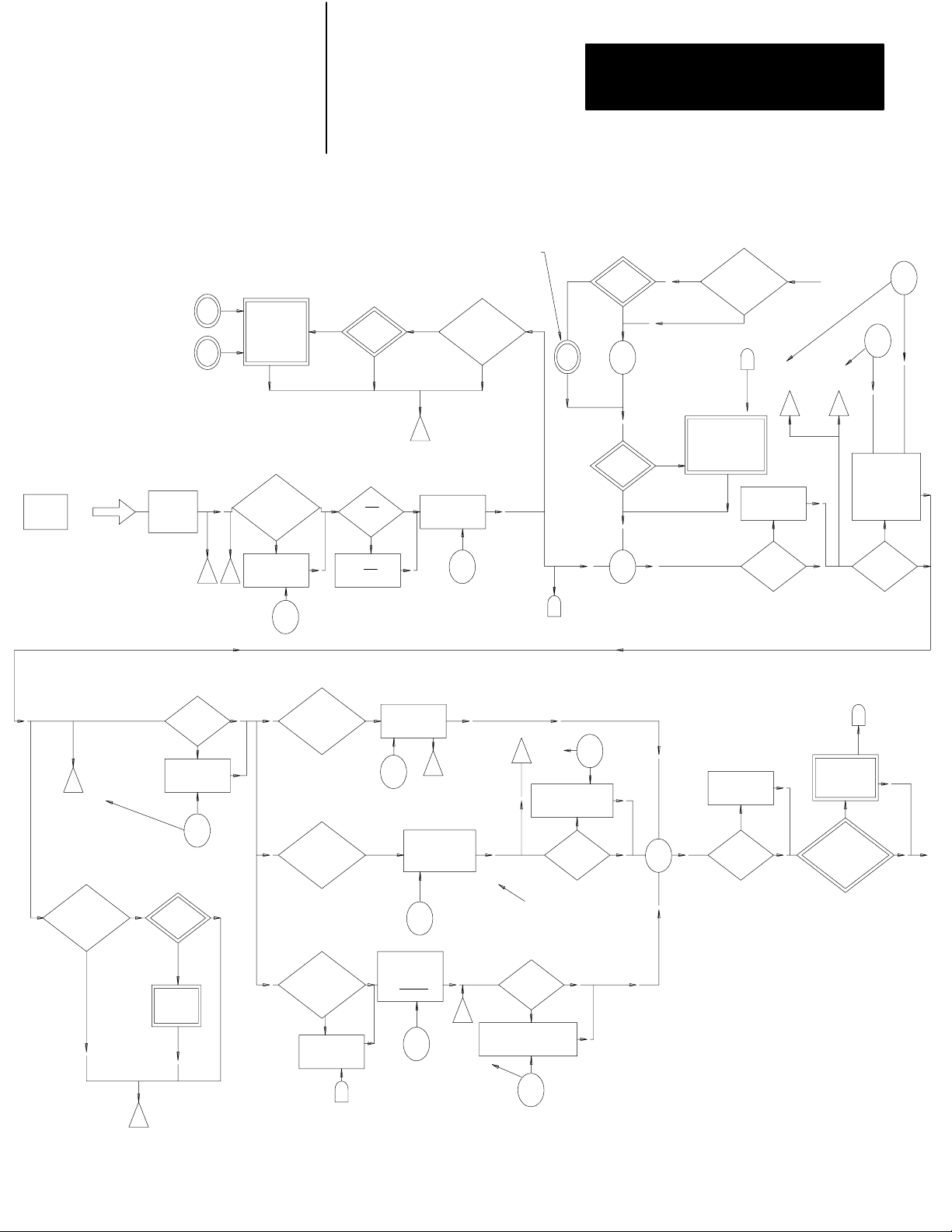

Algorithm Flow Chart 351

Block Transfer Programming 351

Programming Considerations 370

Expanded Features 377

Programming Recommendations for Startup 388

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

Troubleshooting 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Troubleshooting Guide 41

Program Troubleshooting Guide 41

Calibration 51

General 51

Test

Preparation 52

Calibration Program 55

Calibration Procedures 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contentsii

Worksheets A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Example 1, Continuous Block Transfer B1. . . . . .

General B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example

Application

B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Example 2, Periodic Block Transfer C1. . . . . . . . .

General C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example

Application

C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary Word and Bit Tables D1. . . . . . . . . . . . . . . . . . . . . .

Comparing ISA 1771PD Algorithms E1. . . . . . . . . . . . . . . . .

Algorithm Flow Chart F1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Introduction

Chapter

1

General

The Proportional/Integral/Derivation Control (2-loop) Module Assembly

(cat.no.1771-PD) is an intelligent I/O module that performs closed loop

PID control. The PID module is a process controller. The PID module

monitors the analog input process variable, compares the input to the

desired set point, and calculates the analog output control variable based

on the control algorithm programmed in the module. The PID module has

the hardware inputs and outputs and microprocessor to perform PID

control.

The PID module assembly consists of:

1 Proportional/Integral/Derivation Control (2-loop) Module (cat. No.

1771-PD)

1 Field Wiring Arm (cat. No. 1771-WF)

The PID module can control up to two closed loops such as flow,

temperature, pH, and level. Advanced control features include cascade,

feedforward, scaling, square root, error squared, digital and led/lag

filtering. The PID module can directly interface with an optional user

supplied manual control station. Transition from manual to automatic

control can be performed with bumpless transfer.

ranges can be selected for each loop to either +1 to +5V DC or +4 to

+20mA.

[1]

Input and output

The PC processor uses block transfer programming to communicate with

the module. The PC processor writes loop configuration parameters such

as gain constants, set points, digital filter values, limits, alarm points to

the PID module and reads status information such as analog input values,

analog output values, limit alarms and diagnostics from the PID module.

The PID module can be used with any Allen-Bradley PC processor that

has block transfer capability and uses the 1771 I/O structure.

When using the Mini-PLC-2 and PLC-2/20 processors, programming will

be more lengthy because these processors do not have the block format

instructions which permit shorter programs and easier data monitoring.

[1]

Bumpless

means a smooth transition from manual to automatic control.

transfer

, as defined in Fundamentals of Process Control Theory by Paul W

. Murril,

11

Page 5

Chapter 1

Introduction

Capabilities

The PID module can control one or two PID closed loops. The two loops

can be independent or linked together by and advanced control function

such as cascade or decoupling. Expanded loop features can be chosen in

addition to standard features to suite the application. All features are

software selectable with the exception of the I/O range, the source of +5V

DC, and the fault response to a hardware failure (which are selected using

internal programming plugs). Write block transfers to the module allow

program logic to enable the following features:

Standard features for input conditioning

detect the loss of process variable input

read the process variable at the PC processor

substitute a value from the PC processor for the process variable

take the square root of the process variable

\\digitally filter the process variable

Standard control features

select direct or reverse acting control

download a set point from the PC processor

limit and/or set an alarm on the error signal

download a dead band value from the PC processor

perform error dead band (zero crossing)

set an alarm when the error exceeds the dead band

select the control mode: proportional only, integral only, proportional

and integral, proportional and derivative, or all three

select error or error squared conditioning of the proportional and/or

integral error

select whether the derivative function operates on the error or the

process variable

set an alarm on the proportional term

limit and/or set an alarm on the integral term

limit and/or set an alarm on the derivative term

Standard features for output conditioning

limit and/or set an alarm on the PID algorithm output

read the PID algorithm output at the PC processor

download an output value from the PC processor

interface directly with a manual control station (bumpless transfer)

hold the PID algorithm output for independent loop tuning

hold the bias/feed forward term for independent loop tuning

12

Page 6

Chapter 1

Introduction

download an output bias from the PC processor

Expanded control features

perform scaling on the process variable, set point and/or error

set minimum and maximum scaling values

use the tieback as the feedforward input

take the square root of the feedforward input

add a feedforward offset

multiply the feedforward term by a constant

perform lead/lag filtering on the feedforward term

download a feedforward value from the PC processor

cascade the output of loop 1 into the set point of loop 2

decouple the VPID output of loop 1 into the feedforward input of loop

2

These features including integral term anti-reset wind-up are described in

chapter 3.

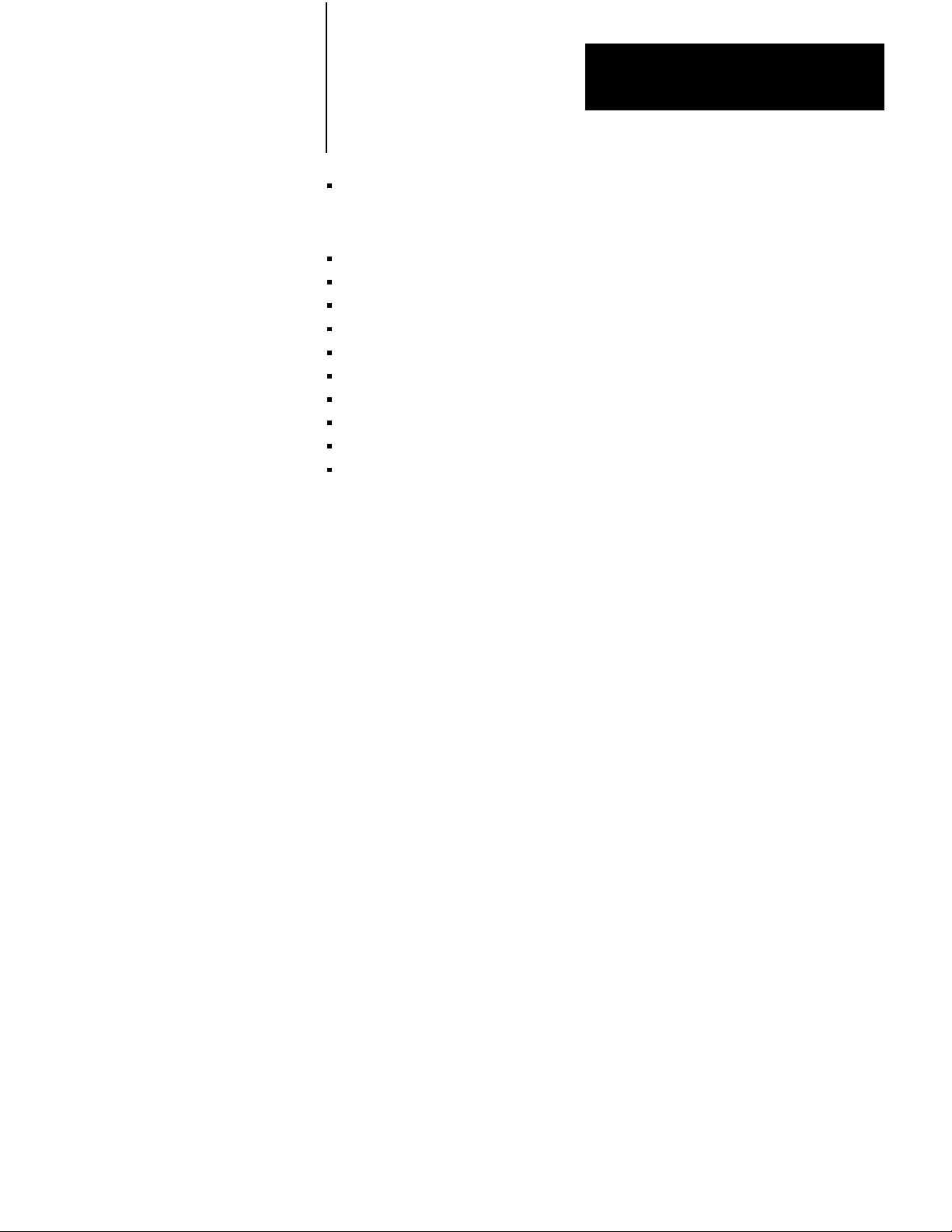

PID Algorithm

An algorithm is a step-by-step procedure. The purpose of the PID

algorithm is to maintain the process at the desired setpoint. A diagram of

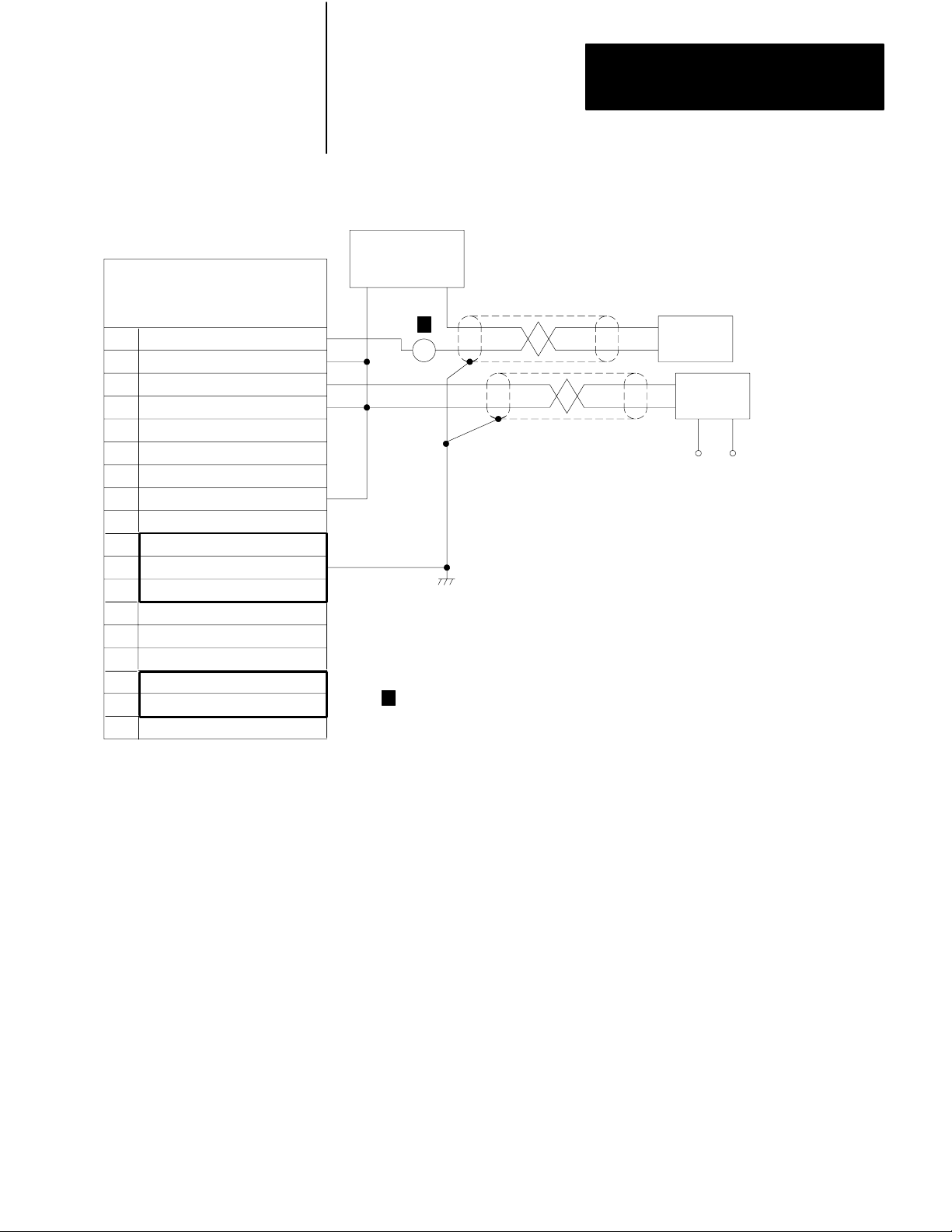

PID closed loop control is shown in Figure 1.1a.

The PID module has many features. Select only those features that are

required for the particular application. Major control functions are shown

in Figure 1.1b. Refer to figure 3.15 for a detailed algorithm flow chart.

This flow chart shows the relationship of the user-selectable features.

PID modules (rev C or later) let you select the ISA or Allen-Bradley

algorithm. Refer to appendix E for a comparison of algorithm values.

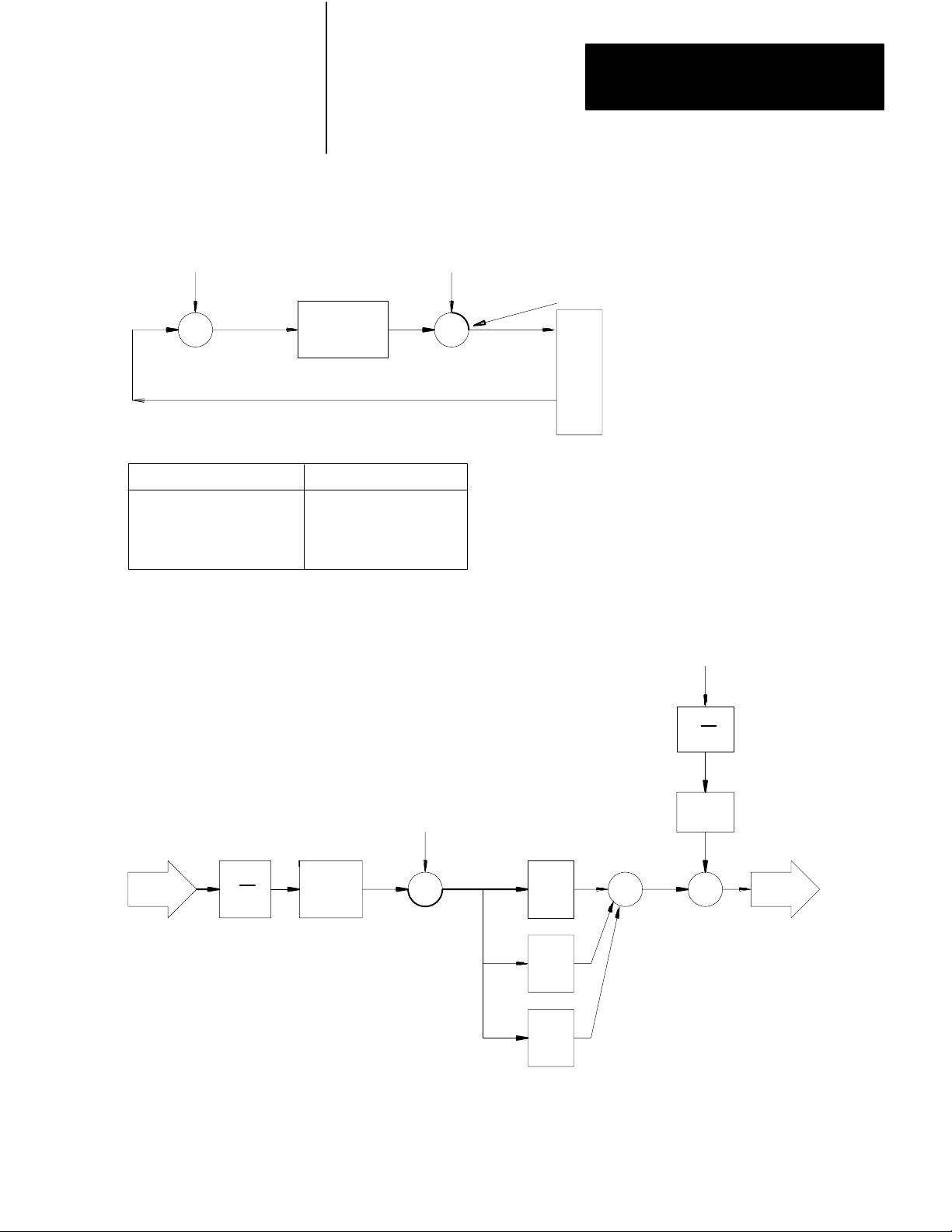

Hardware Description

The PID module has four analog inputs and two analog outputs each with

12-bit binary resolution. Each input and output can be individually

selected to either the +4 to +20mA or +1 to +5V DC range without

recalibration. The selection is made with internal programming plugs.

Each loop has one process variable input, one tieback input and one

analog output associated with it. The tieback analog input is used to track

the analog output of the manual control station to permit bumpless

transfer. Each loop uses one discrete input to track the status of the

optional manual control station. A contact output is used to switch the

13

Page 7

Chapter 1

Introduction

manual control station of both loops to manual control. The module’s

analog inputs can be read and outputs can be set by the PC processor.

The PID module can draw its +5V DC operating power from either the

chassis backplane power supply or from a user-supplied +5V DC power

supply through the field wiring arm. The external power supply option

permits a more fault tolerant system by allowing the PID module to be

powered independently. The PID module also requires +15V DC power

for the analog circuitry.

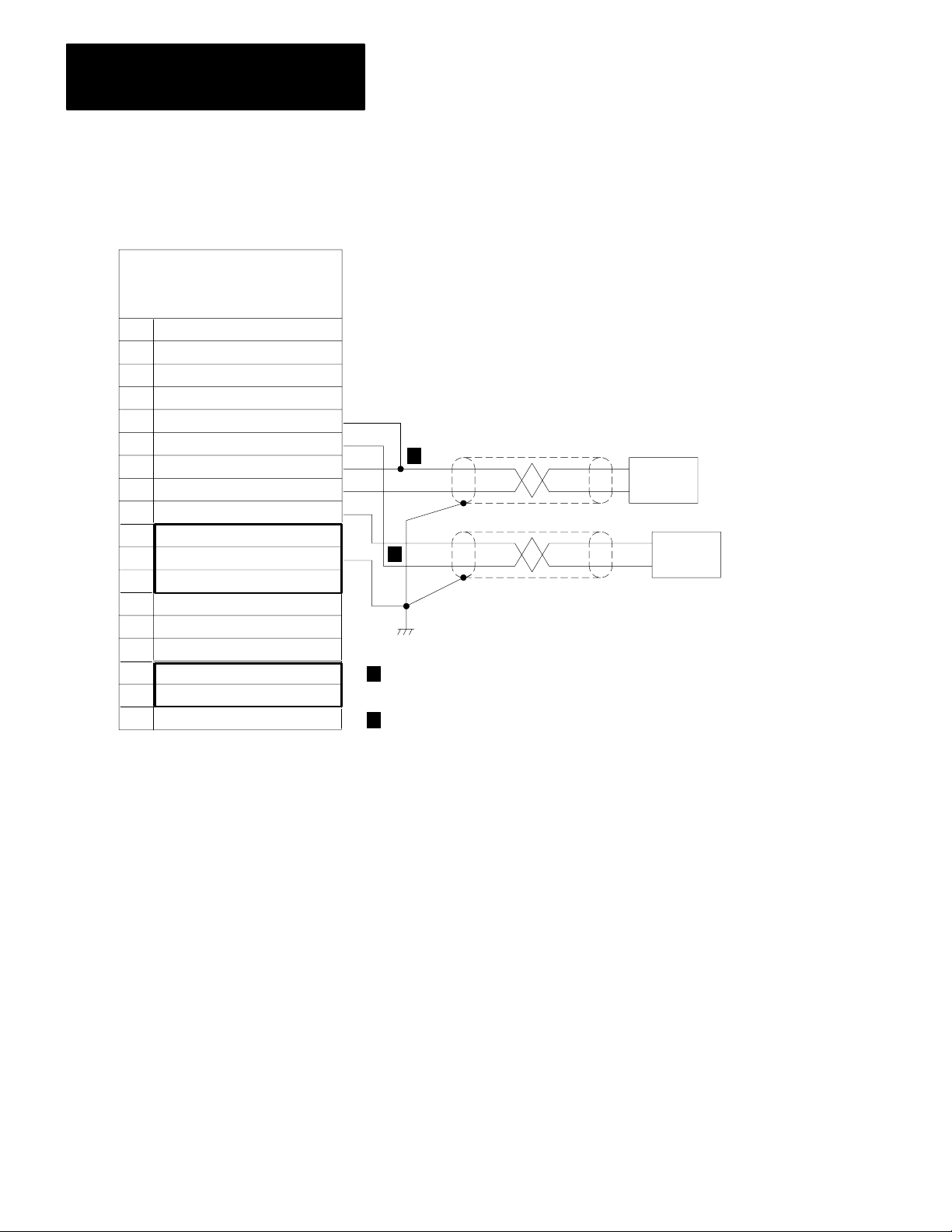

Typical PID hardware and signal paths are shown in Figure 1.2.

14

Page 8

Chapter 1

Introduction

SP

+

-

PV

S

Error=SP-PV

PV = Process Variable

SP = Set Point

AB ISA

V = Control Variable

= Proportional Term K

V

P

VI = Integral Term K

VD = Derivative term K

Figure 1.1

Simplified

VP + VI + V

Control Variable

P

I

D

Controller Gain K

Reset Term 1/

Rate Term T

PID Algorithm

D

C

Ti

d

BIAS

+ VI + V

V = V

+

P

D +

BIAS

+

S

P

r

o

c

e

s

s

a) PID Closed Loop Control

Process

Variable

A/D

/

Hardware

Analog

Input

b) Major Control Functions

Digital

Filter

PV

SP

+

Error=SP-PV

S P

Feedforward Input

/

Lead

Lag

BIAS

V

PID

SS

V

I

D

(FFV)

Control Variable

D/A

Hardware

Analog

Output

11099

15

Page 9

Chapter 1

Introduction

Figure 1.2

Overview

System

1771 –P1

Supply

PC Processor

or Adapter

Block Transfer

1770 –P1 supply

+

15V DC

–

100mA

1771 –PD

Module

+5V DC

1.2A

Optional

Supply

Manual Request

Man/Auto Status

Analog Output (V)

Analog Input (PV)

Optional

User Supplied

Manual Control Station

Tieback Input

X

P

r

o

c

e

s

s

11092

16

Programming Description

The PID algorithm can be adapted to the particular control application by

selecting desired features. The features and parameter values are chosen

and stored in the PC processor data table. The PC processor transfers to

the PID module data table blocks which contain the feature selections and

parameter values. The module uses the values to establish its operational

characteristics. The PC processor can read the module status by

transferring information from the module into the data table.

Communication between PC processor and PID module is performed by

block transfer programming.

Levels of Fault Tolerance

The module has five levels of fault tolerance.

The first level occurs when the PID module is operating properly but a

loss of communication with the active PC processor occurs. The module

enters a mode of operation defined as soft fault. A soft fault occurs when:

Page 10

Chapter 1

Introduction

PC processor operation is changed from run mode to program or

test mode

a PC processor fault occurs

a communications cable break occurs between the PC processor

and the I/O chassis

Each loop can be programmed independently to one of the following

responses when a soft fault occurs:

set the analog output to minimum value (+4mA or +1V DC)

holds the analog output to the last value before the soft fault occurre

performs PID control based on the last values transferred to the module

before the soft fault occurred.

sets the analog output to maximum value (+20MA or +5V DC)

The second level of fault tolerance is how the module sets its outputs in

response to a hard fault. A hard fault occurs when the module detects a

failure of its microprocessor or its self-diagnostics. Internal programming

plugs are used to select the manner in which the PID module can respond

if a hard fault should occur:

sets analog output to minimum value (+4MA or +1V DC)

holds analog outputs at the last value before the fault occurred

sets analog outputs to maximum value (+20mA or +5V DC)

Note: These hard fault responses cannot be ensured if a component in the

analog output circuit should fail.

A manual control station can be connected between the PID module

analog output and the controlled element of the process. Control of the

output can be switched manually to the manual control station by a switch

at the station. Manual control at the station overrides the PID module’s

output.

The third level of fault tolerance is automatic switching of control to the

manual control station when a hard fault occurs. A relay contact in the

PID module closes automatically (manual request), putting the station in

control. The module’s output is overridden by the station output.

The fourth level of fault tolerance is the module’s response to loss of +5V

DC. Outputs respond as if a hard fault occurred (a or C above, but not b).

The same programming plug configuration selects the module’s response.

If +15V DC is lost, analog outputs go to minimum value, regardless.

17

Page 11

Chapter 1

Introduction

The last level of fault tolerance results from powering the module from

external +5V DC and +

l5V DC power supplies, independent of I/O

chassis backplane power, through the field wiring arm.

Application in Control Systems

The PID module performs closed loop control. Once programmed, it can

operate independently of the PC processor. System status and alarm

information can be reported to the PC processor to ensure safe system

performance.

Redundant control is another alternative. PID modules could serve as

back-up to a PC processor performing the PID loop algorithms. The PC

processor can control many complex and interaction loops using PID

modules for analog inputs and outputs. The complex algorithm could be

subdivided into individual loop algorithms stored in the PID modules

operating as analog I/O modules. In the event of a PC processor failure or

loss of communication between PC processor and a PID module, the soft

fault mode of the PID module would allow it to automatically control its

loops according to the PID loop algorithms stored in its memory if the

appropriate soft fault response had been selected.

18

Page 12

Figure 1.3

of Distributed Control

Levels

Chapter 1

Introduction

Data Highway

1771 - PD

1771 - PD

P

r

o

c

e

s

s

P

r

o

c

e

s

s

1771 - PD

1771 - PD

P

r

o

c

e

s

s

Manual Control

Station

P

r

o

c

e

s

s

1771 - PD

1771 - PD

P

r

o

c

e

s

s

P

r

o

c

e

s

s

P

r

o

c

e

s

s

11100

The PID module can also be used in a system with adaptive control based

on the PC processor’s ability to constantly adjust the control algorithm in

the module.

19

Page 13

Chapter 1

Introduction

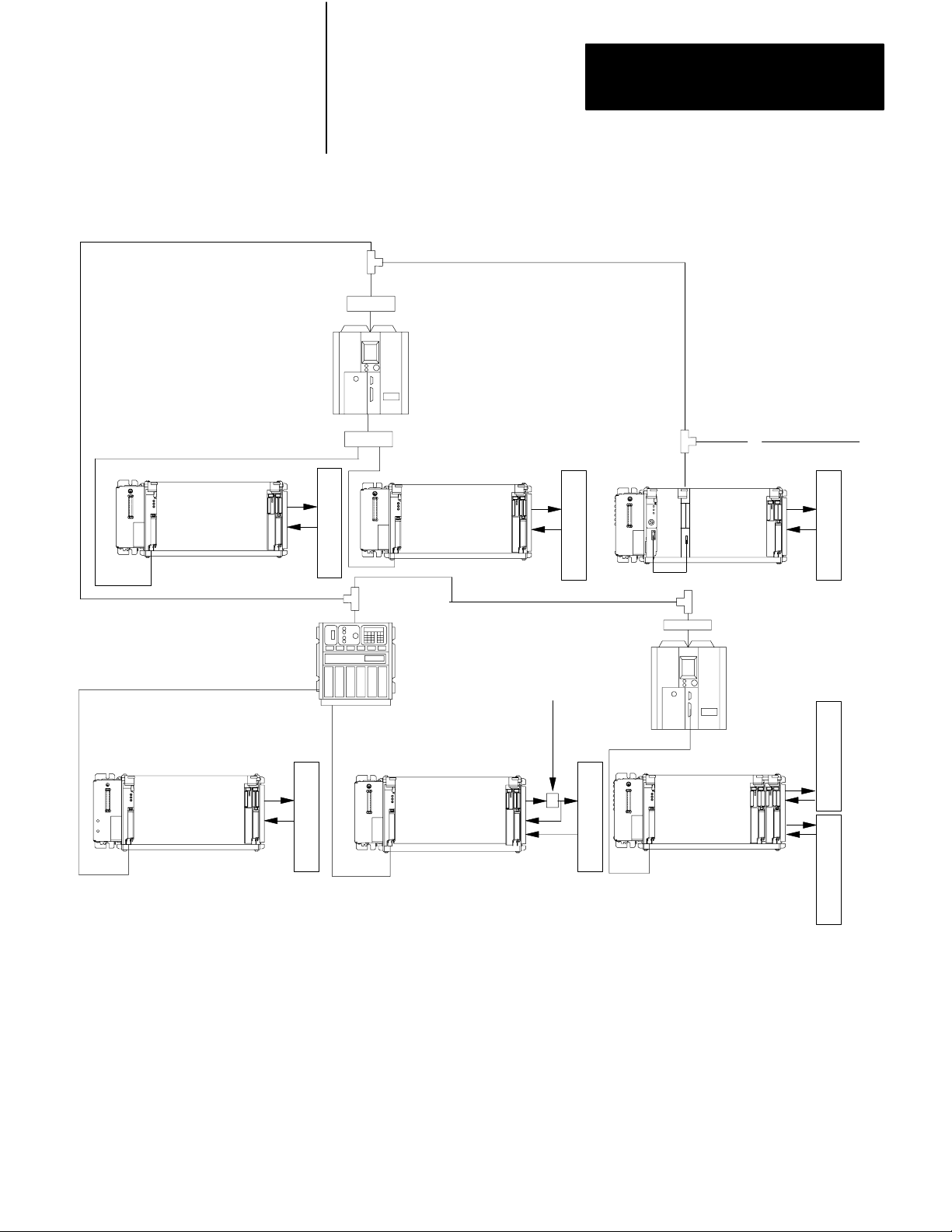

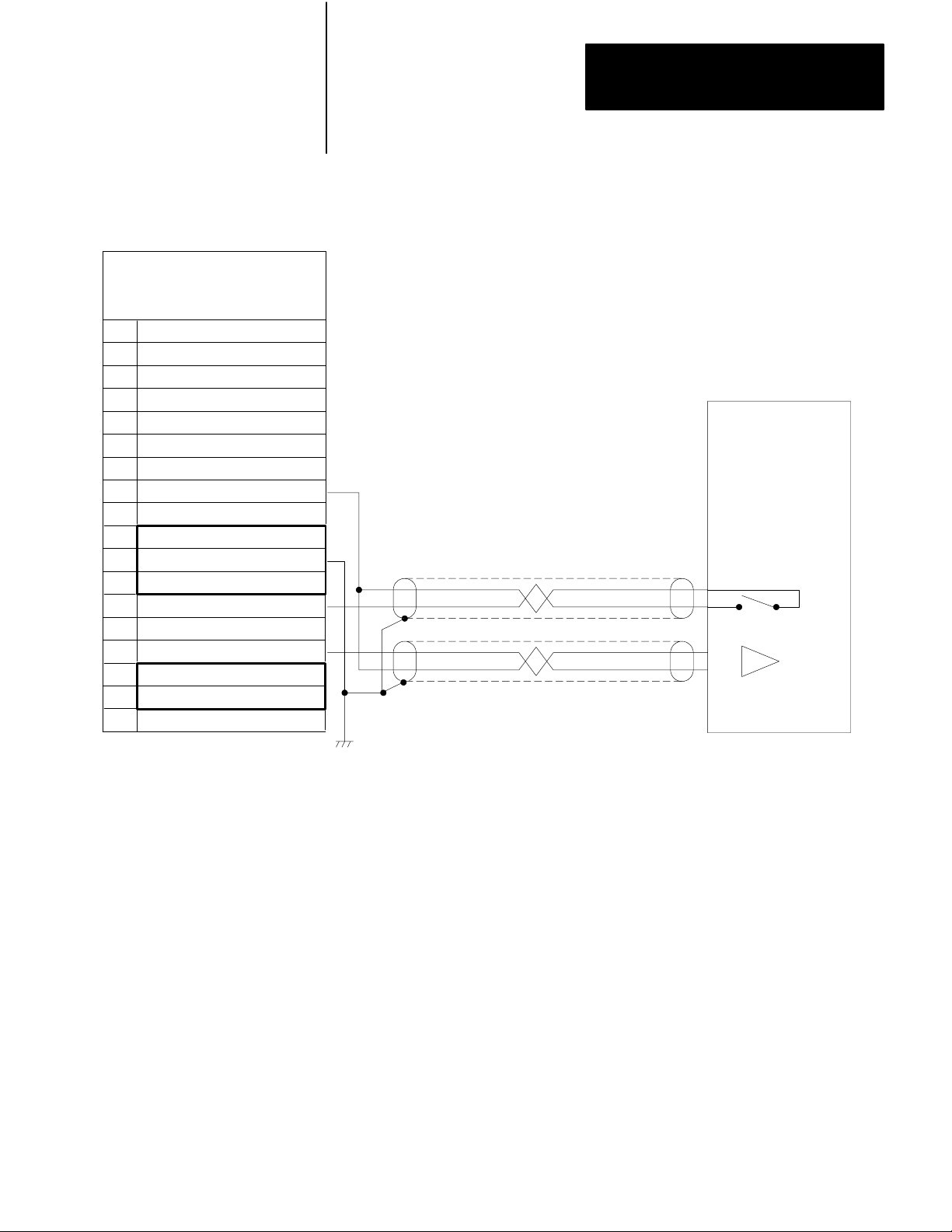

Finally, PID modules can be used in distributed control schemes. The

data highway can be used to link PC processors which are controlling PID

modules. Figure 1.3 shows the various levels of distributed control.

Manual Overview

The remainder of the manual explains different aspects of PID module

operation.

Chapter 2 - Assembly and Installation contains hardware information

including wiring diagrams, programming plug selection of I/O ranges

and compliance, installation and keying, wiring diagrams and

specifications of the PID module and power supplies.

Chapter 3 - Programming contains detailed explanations of all the

software selectable features.

Chapter 4 - Troubleshooting contains helpful troubleshooting

information.

Chapter 5 - Calibration presents the procedure for recalibrating the PID

module.

Appendix A contains recots which are helpful when selecting features

and programming the module.

Appendices B and C provide sample ladder diagram programs based on

sample applications.

Appendix D contains summaries of value words and control bits used

when programming.

Appendix E shows how to convert ISA standard values to 1771-PD

gain values.

Appendix F is an enlarged algorithm flow chart for your convenience.

110

Page 14

Chapter

Assembly and Installation

2

General

Hardware Description

The PID module must be configured internally and wired externally to

suite the conditions under which the module will be used. Module and

power supply specifications are listed at the end of this chapter.

The PID module is a dual-slot module. The left front panel contains three

LED indicators, the right front panel contains a write-on label that can be

used to record the voltage or current range and the most recent date of

calibration. An 18 terminal field wiring arm is connected to the lower

right front of the module for I/O and power connections. The label on the

right cover plate identifies the terminals of the field wiring arm.

Diagnostic Indicators

Front panel indicators (Figure 2.1) allow an operator to observe the

operating condition of the module. The indicators will be on, off or

flashing (Table 2.A).

Figure 2.1

Diagnostic

Indicators

FAULT

RUN

STAND

ALONE

21

Page 15

Chapter 2

Assembly and Installation

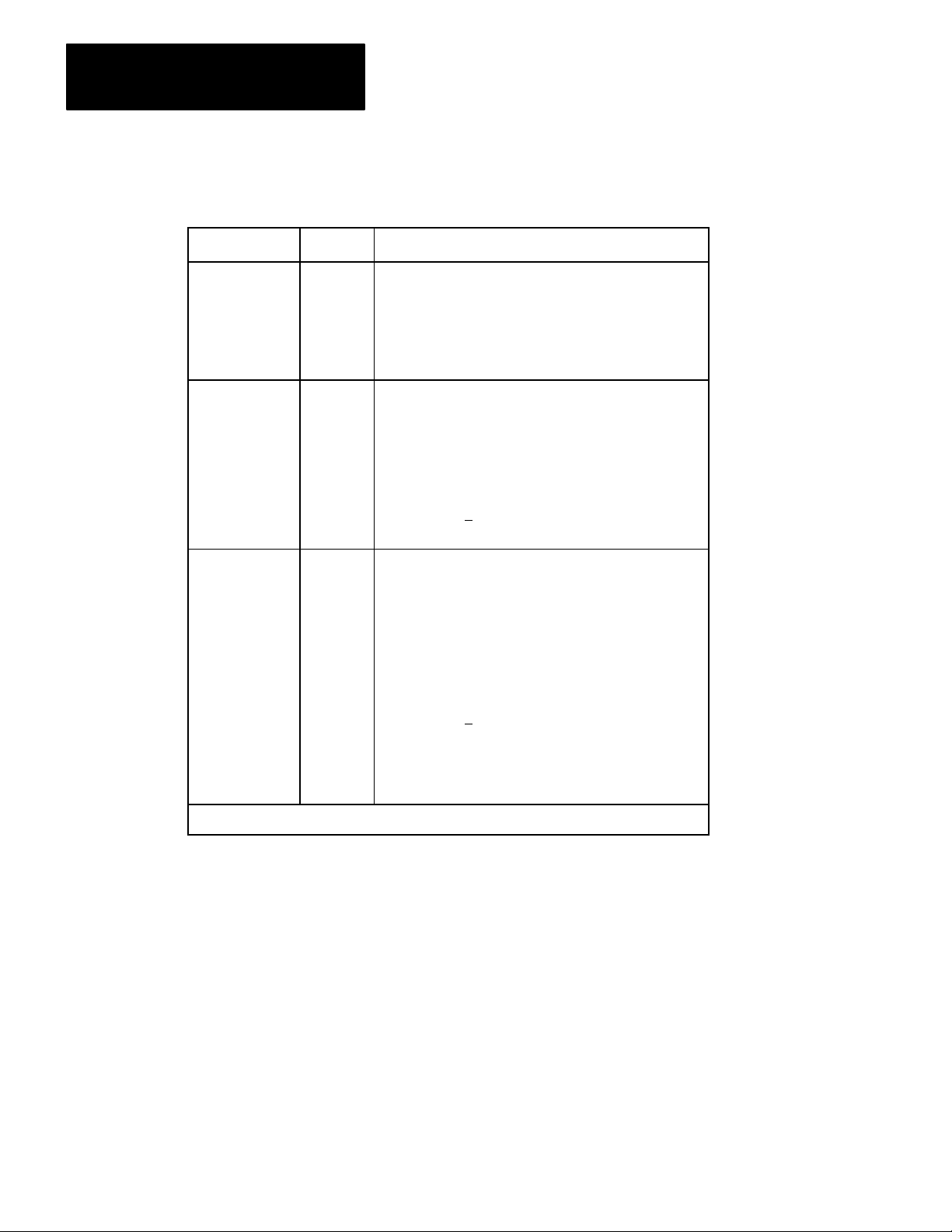

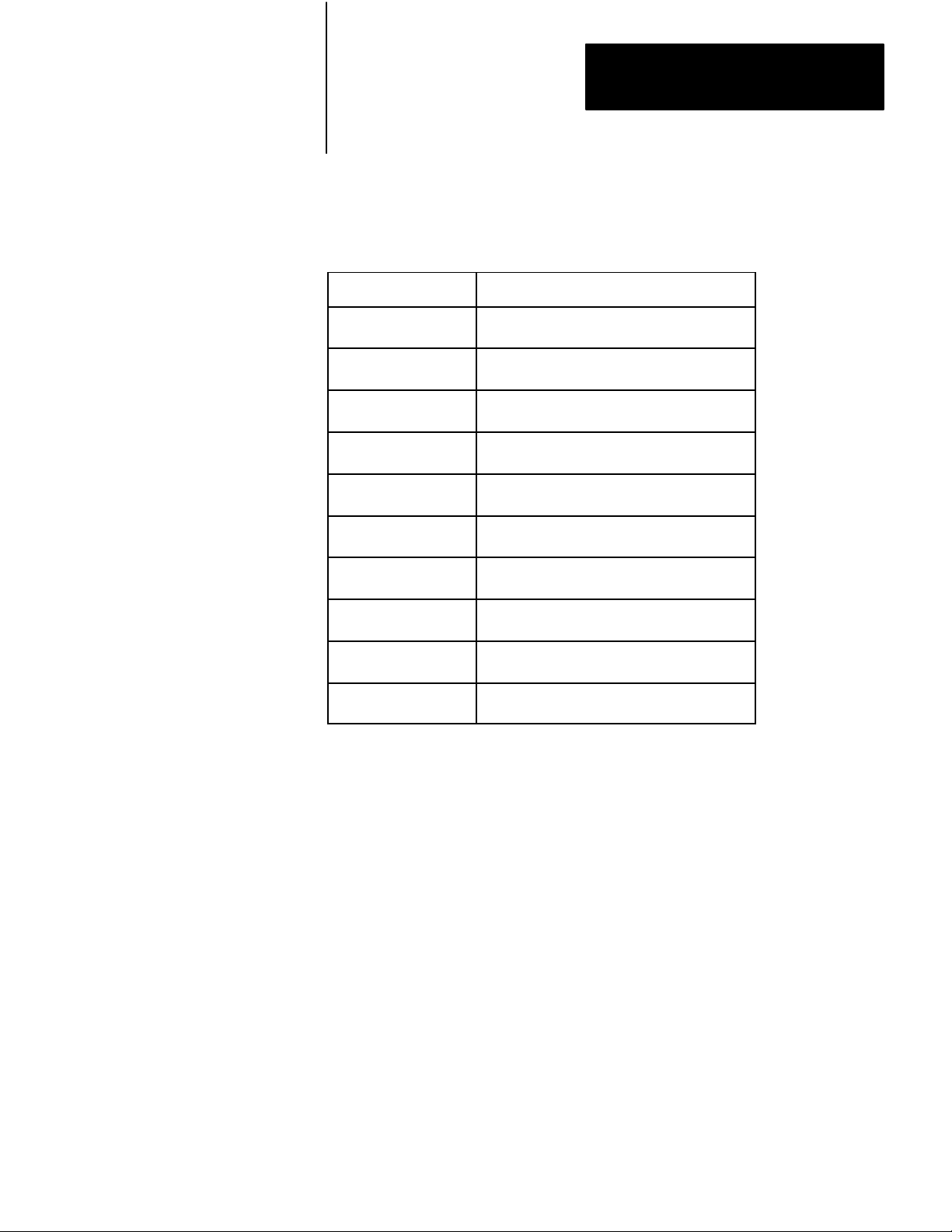

Table 2.A

Indicator

Indicator State Condition

FAULT

(red)

RUN

(green)

STAND

ALONE

(yellow)

OFFONNormal operation.

ON

Flashing

OFF

Toggle

OFF

Flashing

Diagnostics

Hardware fault. Analog outputs are held at either last

state, minimum or maximum value as determined by the

userselected programming plugs. If this indicator is on,

the other indicators are not valid

Normal operation

PID module is initially powered (unprogrammed and is

waiting for data from the PC processor

PID module is not in the normal run mode.

Analog power (+

and RUN indicators are alternately toggling on and of

Normal operation

The module is in soft mode and is controlling PID loops

independently

Processor.

15V dc) is lost when ST

. It is not communicating with an active PC

.

AND ALONE

f.

NOTE: All indicators are of

Internal Selections

NOTE: Disconnecting the field wiring arm will interrupt

PID control.

Toggle

ON

Analog power (+

and RUN indicators are alternately toggling on and of

A programming error is causing a block transfer

communication error

f when in calibration mode.

15V dc) is lost when ST

.

AND ALONE

f.

In order to accommodate a wide variety of applications, a number of

programming (jumper) plugs must be correctly positioned inside the PID

module. The following functions are user-selectable using the

programming plugs:

output range: +4 to +20mA or +1 to +5V dc

input range: +4 to +20mA or +1 to +5V dc

tieback input range: +4 to +20mA or +1 to +5V dc, if used current

output compliance: standard or additional hard fault output: hold last

value or max/min value output for loss of +5V dc: max or min value

+5V dc source: backplane or external

22

Page 16

Chapter 2

Aseembly and Installation

Calibration of the I/O ranges should be checked yearly to maintain

specified accuracy.

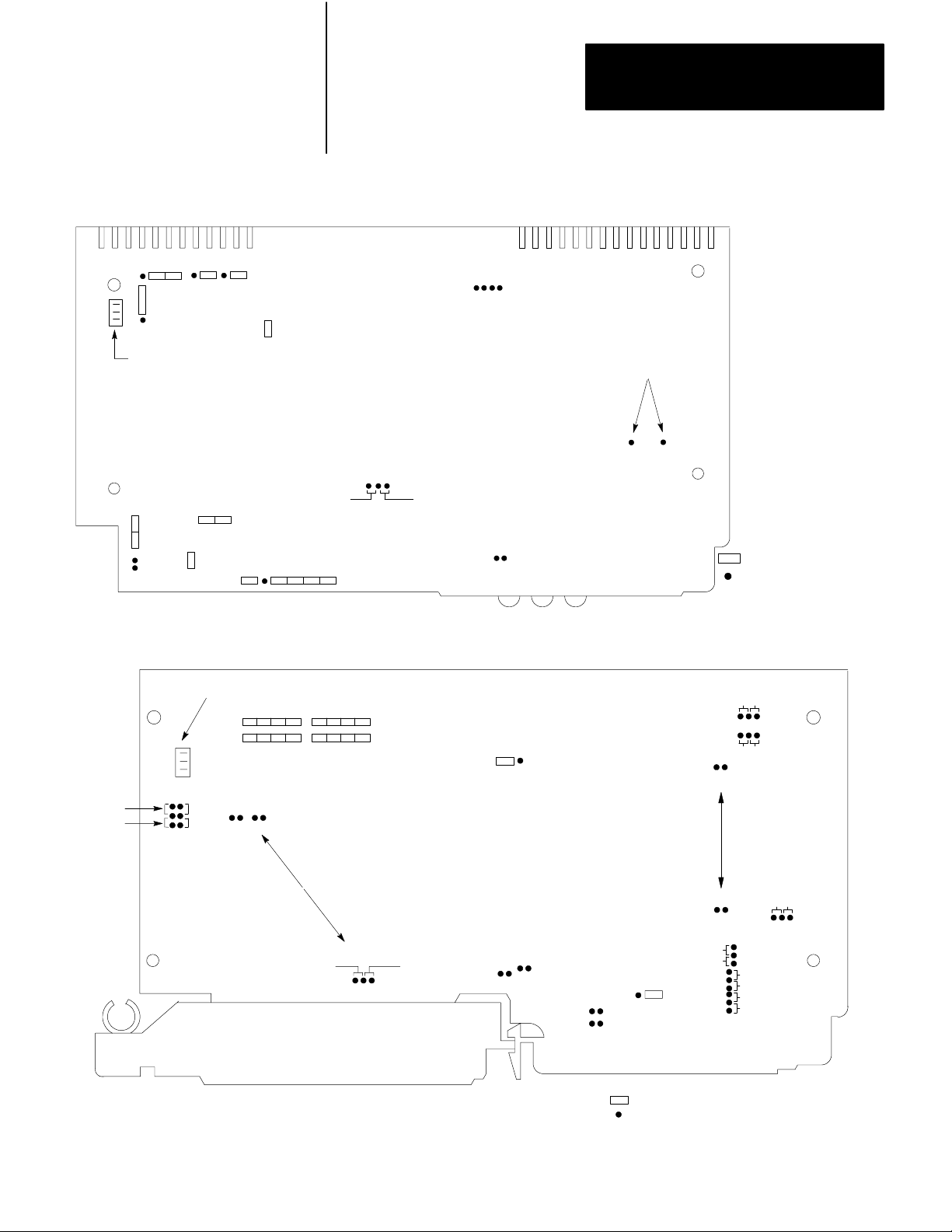

Programming Plugs and Locations

The PID module contains two printed circuit boards. The left-hand board

is the digital board, the right-hand board is the analog board.

Programming plugs are located on both the analog and digital circuit

boards inside the PID module. Typically they stand higher than the

surrounding components on the circuit board. The programming plug

locations are labeled E1 through E24 on the analog board. The only

user-selectable programming plugs on the digital board are E2 and E10.

Some of the programming plug locations are factory configured and must

remain in the configuration except during calibration. They are called out

as factory configured in the programming plug position tables and in the

figures which show their locations.

User-selectable plug locations have either two or three pins per plug.

Programming plugs electrically connect two pins. The plug can be placed

over the required pins or stored by placing the plug over a single pin,

electrically floating.

Programming Plug Selection

Programming plugs should be set with care after decisions are made

which govern their placement. The following procedure will be helpful to

ensure that all the programming plugs are properly set. The procedure

consists of 5 parts.

a. Select digital board features. Record features on Table 2.B

b. Select analog board features. Record features on Table 2.C.

c. Record the position on analog plugs by completing Table 2.D.

d. Set programming plugs on the digital board using Table 2.B.

e. Set programming plugs on the analog board using Table 2.D.

23

Page 17

Chapter 2

Assembly and Installation

Selection Procedure (Part A)

Begin with digital board features using Table 2.B.

1. The hard fault response of the module is selected first. A hard fault

occurs when a module failure is detected in the event of a failure, the

analog output will either maintain the last value or will be set to the

minimum or maximum value. A single choice is made for both

outputs as to whether they hold last value or go to

minimum/maximum.

Select hold last value or go to minimum/maximum for the hard fault

response. Record your selection on Table 2.B by circling RIGHT for hold

last value or LEFT for minimum/maximum.

NOTE: If hold last value is selected for hard fault, output 1 and output 2

must still be selected for minimum or maximum. The selection

determines the state of outputs at module power-up (green LED flashing)

until the load/enter sequence is complete, or power-down of +5V dc. See

Table 2.C.

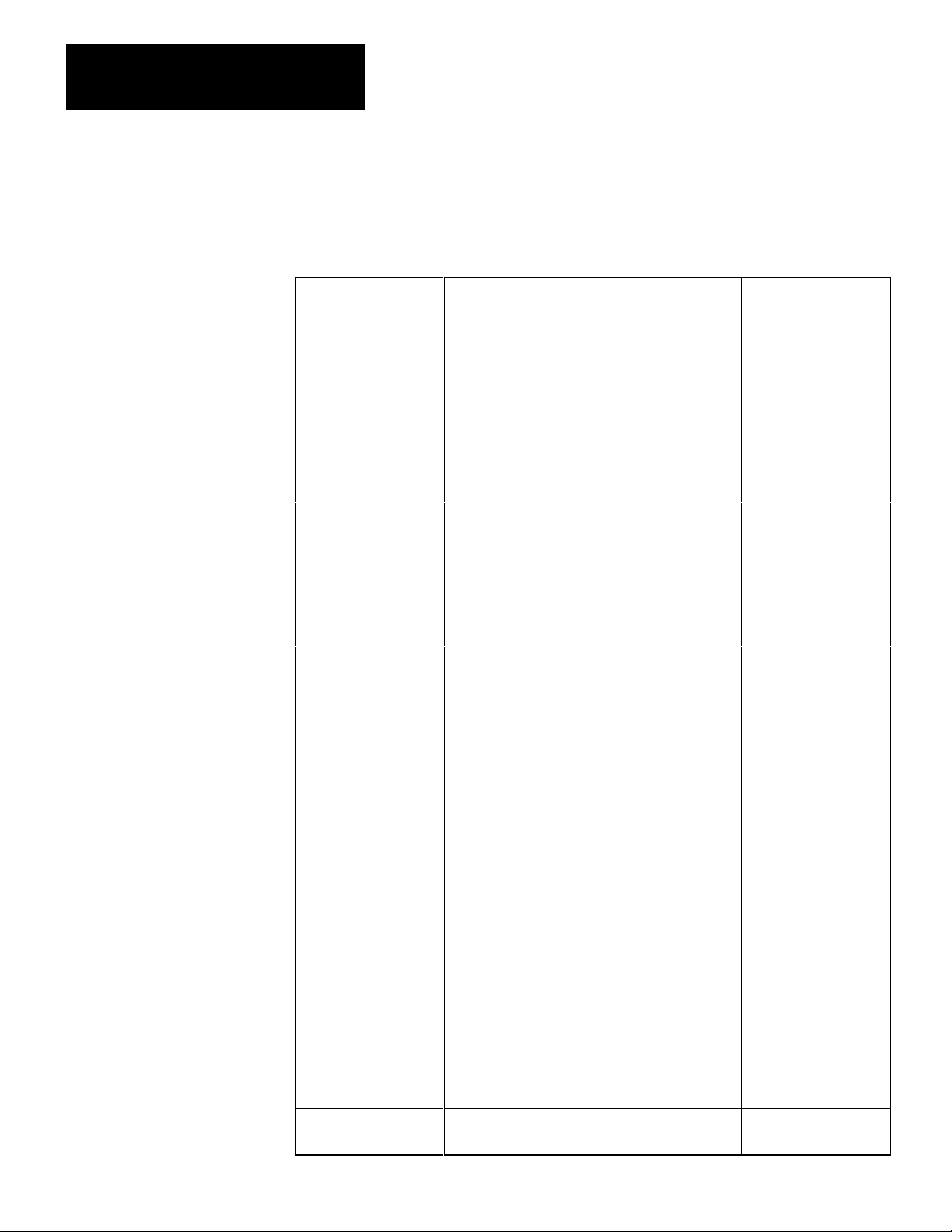

Table 2.B

Programming

E1

E2

[1]

E3 through E9

E10

[1]

The selection for E2 affects both outputs the same. The choice of minimum value or maximum

value for the hard fault output must be made on the analog board regardless of the choice of

E2. (see text and analog board plugs E4 and/or E5).

Plug Selections: Digital (lefthand) Board

Location Function Position

Factory Configured

Hard fault response:

Hold last value

Minimum/maximum value

Factory Configured

Source of +5V dc

Backplane

External supply

OUT

RIGHT

LEFT

See figure 22

IN

OUT

24

Page 18

Chapter 2

Aseembly and Installation

Table 2.C

Programming Plug Selections: Analog (righthand) Board

Choose and record the required conditions for each function below.

Function Condition

Output

1: Hard Fault

or Loss of +5V dc

Output 2: Hard Fault

or Loss of +5V dc

Analog Input 1

Analog Output 1

T

ieback Input 1

Analog Input 2

Analog Output 2

T

ieback Input 2

Compliance

Source of +5V dc

Minimum V

Maximum V

Minimum V

Maximum V

Voltage

Current

Voltage

Current

Voltage

Current

Voltage

Current

Voltage

Current

Voltage

Current

Standard (500 ohms: COMMON @ OV)

Additional (1250 ohms: COMMON @ 15V)

Backplane

External Supply

alue

alue

alue

alue

25

Page 19

Chapter 2

Assembly and Installation

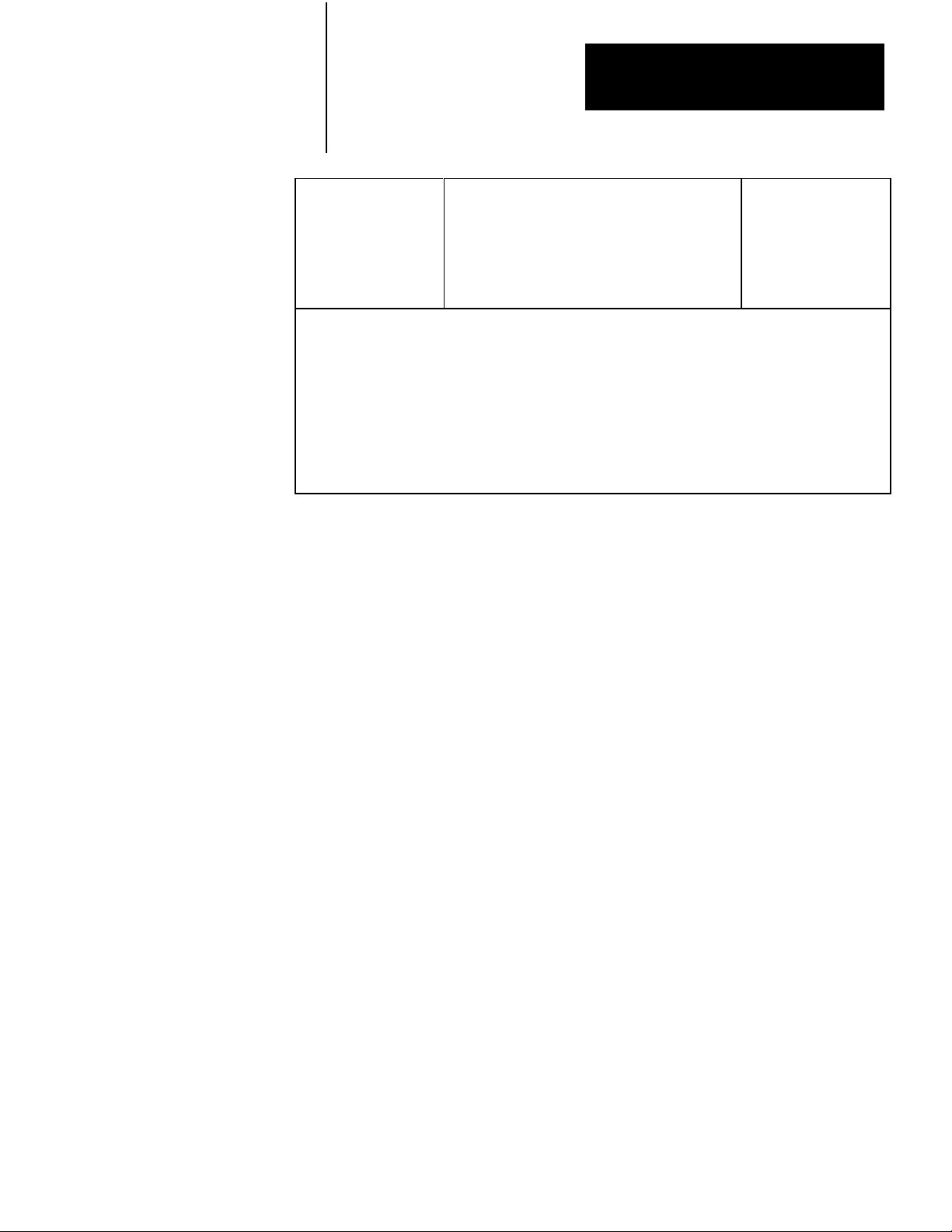

Table 2.D

Programming Plug Positions: Analog (righthand) Board

Mark the programming plug position for each function below.

Location Function Position

E1 Output

Output 2, voltage mode

E2

E3

E4

E5

E6

E7

E8

E9

E11 T

Output 2, current mode

Output 2, voltage mode

Output 1, current mode

Output 1, voltage mode

Hard fault* output 2, minimum

Hard fault* output 2, maximum

Hard fault* output 1, to minimum

Hard fault* output 1, to maximum

Output 1, voltage mode

Output 1, current mode

Output 2, voltage mode

Output 2, current mode

Output 1, voltage mode

Output 2, current mode

Factory configured

ieback 1, current mode

T

ieback 1, voltage mode

2, current mode

LEFT

RIGHT

LEFT

RIGHT

LEFT

RIGHT

IN

OUT

IN

OUT

TOP

BOTTOM

TOP

BOTTOM

TOP

BOTTOM

RIGHT

IN

OUT 1

26

E12 T

E13

E14

E15

E16,17

E18

[2]

E19, 20 Factory configured

E21

[2]

E22[ 2 ]

ieback 2, current mode

T

ieback 2, voltage mode

Factory configured

Input 2, current mode

Input 2, voltage mode

Input 1, current mode

Input 1, voltage mode

Factory configured

Additional compliance (15V dc)

Standard compliance (OV dc)

Additional compliance

Standard compliance

Additional compliance

Standard compliance

IN

OUT 1

LEFT

IN

OUT 1

IN

OUT 1

BOTH IN

LEFT

RIGHT

BOTH IN

OUT 1

IN

OUT [1]

IN

Page 20

Chapter 2

Aseembly and Installation

Location PositionFunction

E23

[3]

E24

[3]

*or loss of +5V dc

[1]

IN refers to connecting the two pins together. OUT refers to storing the programming plug by

placing it over a single pin, electrically floating.

[2]

The positions of programming plugs E18, E21 and E22 must be the same.

[3]

The positions of programming plugs E23 and E24 must be the same.

NOTE

: Use figure 2.3 to locate the programming plugs.

+5V dc from backplane

+5V dc from external source

+5V dc from backplane

+5V dc from external source

TOP

BOTTOM

TOP

BOTTOM

2. Select source of +5V dc as the backplane or external supply. Record

your selection on Table 2.B by circling IN for backplane or OUT for

external.

Part B)

Select and record the analog board features on Table 2.C using the

following procedure.

Select the modules’ response to a hard fault or loss of +5V dc. Choose

maximum or minimum value for either output 1 or 2. Make these

selections regardless of how you set E2 in Table 2.B. If you selected hold

last value, you still must select maximum or minimum value for each

output. Outputs go to the selected value at module power-up (green LED

flashing) until the load/enter sequence is complete, or when powering

down +5V dc.

1. Choose minimum or maximum response of output 1 for hard fault or

power-down of +5V dc.

2. Choose minimum or maximum response of output 2 for hard fault or

power-down of +5V dc.

3. Choose analog input 1 as either voltage mode (+1 to 5V dc) or

current mode (+4 to +20mA).

4. Choose analog output 1 as voltage or current.

27

Page 21

Chapter 2

Assembly and Installation

5. Choose the tieback input 1 as voltage or current.

If tieback input 1 is wired to track the manual control station associated

with analog output 1, then both tieback input 1 and analog output 1 must

be selected to the same mode of either current or voltage.

6. Choose analog input 2 as voltage or current.

7. Choose analog output 2 as voltage or current.

8. Choose tieback input 2 as voltage or current.

If tieback input 2 is wired to track the manual control station associated

with analog output 2, then both tieback input 2 and analog output 2 must

be selected to the same mode of current or voltage.

9. Choose compliance as standard or additional.

Compliance is defined as the maximum allowable load impedance in the

current mode. The standard compliance for the PID module is 500 ohms.

Additional compliance can be established for one or two loops, only if

analog outputs 1 and 2 and tieback inputs 1 and 2 are all selected for the

current mode.

(The condition on tieback inputs is required only when they are tracking

outputs.) Additional compliance allows a maximum load impedance of

1250 ohms. Additional compliance is obtained by internally referencing

the MODULE COMMON terminal to the -15V dc terminal. Choose

standard or additional compliance and record in Table 2.C. The choice

may affect the power supply requirement for input devices as described in

section titled External Connections.

10.Choose the source of +5V dc as either the backplane or external

supply.

11.Review all the choices made in table 2.C before continuing.

28

Page 22

Chapter 2

Aseembly and Installation

Part C)

Record the required programming plug positions on table 2.D using your

selections on table 2.C for reference. Select LEFT/RIGHT, IN/OUT or

TOP/BOTTOM so that Table 2.D has a position defined for every E

location.

1. Using your selections inTable 2.C for reference, mark the

corresponding plug positions in the right-hand column of Table 2.D

Table 2.D. For example, if the required condition for output is

minimum value due to hard fault or loss of +5V dc, mark the IN

position in Table 2.D for E5.

Part D)

Set programming plugs E2 and E10 on the digital board using Table 2.B

and the following procedure:

1. Remove the unmarked left cover plate to gain access to the digital

circuit board.

2. Refer to Figure 2.2 to identify the location of the user-selectable and

factory configured programming plugs.

3. Set programming plugs E2 and E10 according to the functions

circled in Table 2.B.

4. Verify that the factory configured programming plugs are installed as

shown in Figure 2.2

5. Set the completed digital board, cover, and screws to one side.

Part E)

Set the programming plugs on the analog board usingTable 2.D and the

following procedure:

1. Remove the right cover (with the terminal identification label) to

gain access to the analog circuit board.

29

Page 23

Chapter 2

Assembly and Installation

2. Refer to Figure 2.3 to identify the locations of the user-selectable and

factory configured programming plugs.

3. Starting at E1, read down table 2.D and set each programming plug

on the analog board.

CAUTION: The programming plugs at location E11 and E12

could interfere with the front cover flange when the analog

board is re-assembled to the rest of the module. This could

happen when either the E11 or E12 programming plug is placed

in the OUT (floating) position. When either is required to be in

the OUT position, place the floating side of the E11 plug toward

the center of the board and the floating side of the E12 plug

toward the top of the board.

4. Verify that factory configured programming plugs are in their correct

positions.

5. Re-assemble the PID module. Typically it is easier to re-assemble

the digital board and cover before the analog board and cover.

Observe caution when re-assembling the analog circuit board. Be

certain that the three stake pins located on the lower corner of the

board mate with their respective sockets on the digital board.

Carefully align these connections before aligning and tightening the

screws on the module cover.

Record the I/O range selections on the module’s write-on label.

210

Page 24

Chapter 2

Aseembly and Installation

Backplane Connector

*

E6

StakePin

Connector

*

E8

E9

Figure 2.2

Programming

*

E5

E4

Hold

Max

*

E7

*

Min

E3

*

Plug Locations (Digital Board)

Backplane Connector

*

E1

No

Plug

Hold

Last

State

E10

Diagnostic Indicators

Jumper

Test

Pins

Programming Plug

Pin

*

Factory Configured Plug

11101

Backplane

External

E24E

Stake Pins

E19

E

20

23

*

*

E22E

IN or Out

21

Figure 2.3

Programming Plug Locations (Analog Board)

*

E1

6

*

E

7

Additional

(-15V dc)

Compliance

E18

1

Standard

(0V dc)

E

13

IN or OUT

E14

*

E15

IN or OUT

E11

E12

E9

VI

E1

E2

I

V

E4

IN or OUT

IN or OUT

E5

*

E8

E6

V

V

I

V

E3

I

I

Plug

n

Pi

Factory Configured

*

11096

211

Page 25

Chapter 2

Assembly and Installation

External Connections

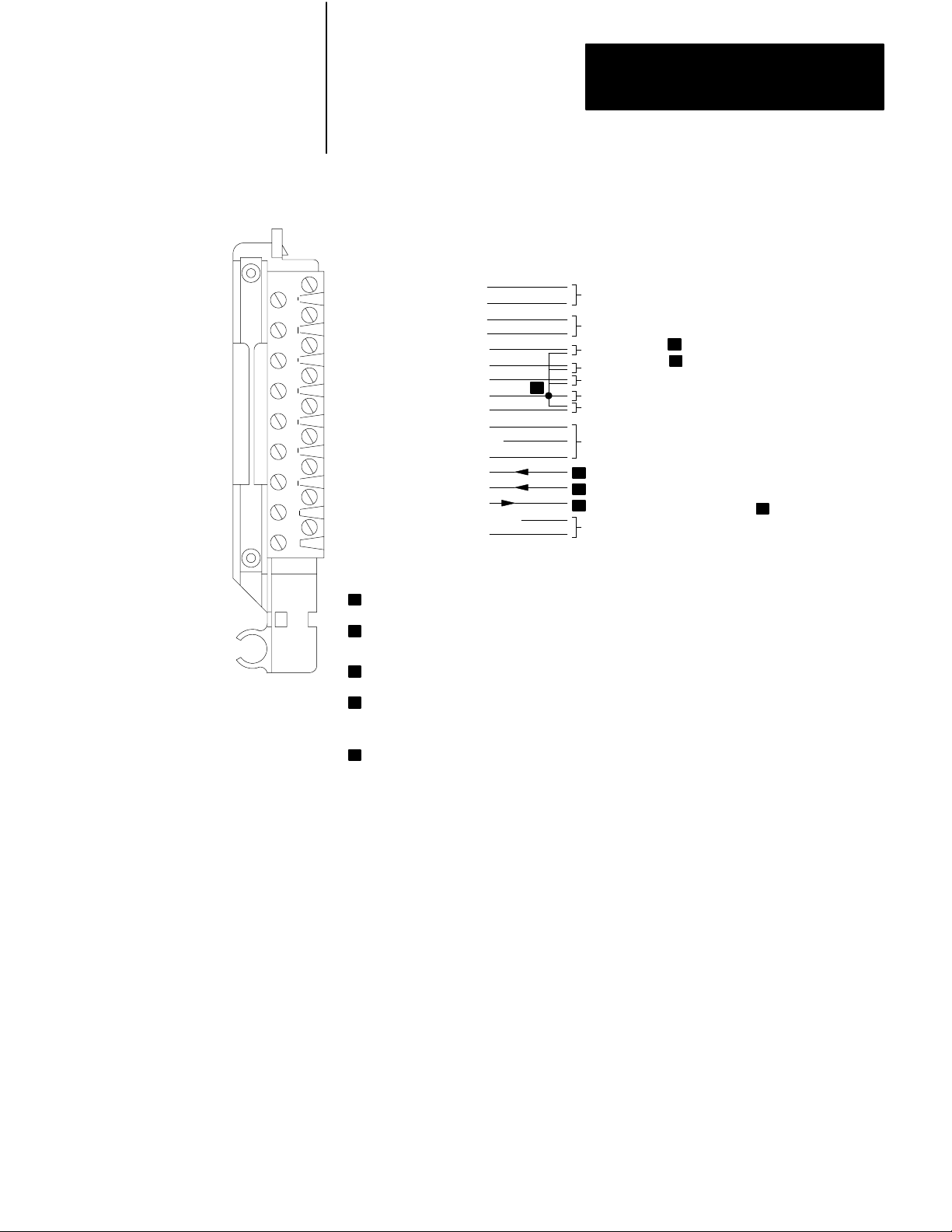

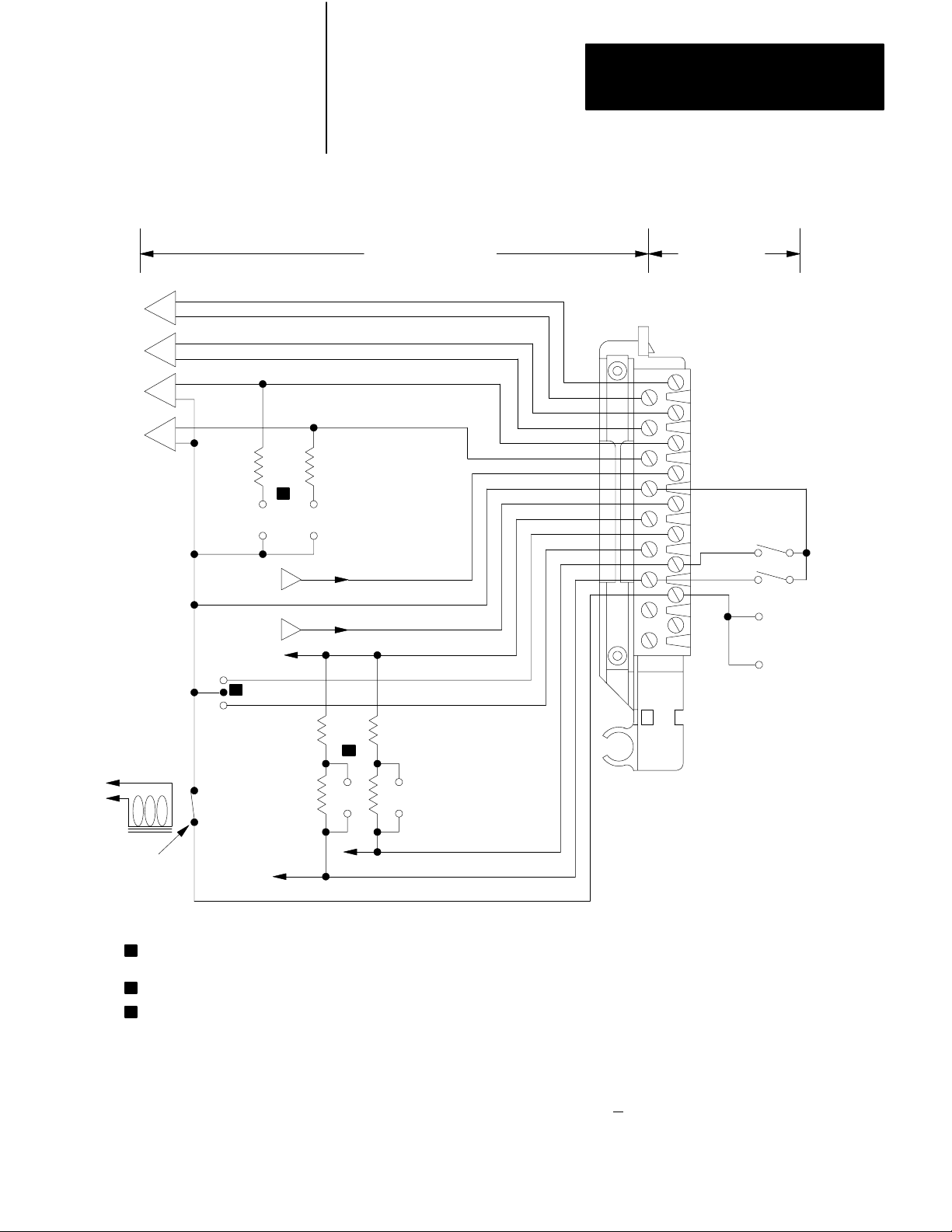

Terminal identification of the PID module’s field wiring arm and general

connections are shown in Figure 2.4. Typical I/O connections for a single

closed loop configured in current mode are shown in Figure 2.5. The

remaining three figures show typical connections to input and output

devices and control mode connections to a manual control station.

Figure 2.6 shows typical connections to input devices without a manual

control station. When an input loop is configured in current mode, the

input impedance of all devices connected in series must be considered

when selecting the input power supply. the input loop could contain one

or more recording devices (250 ohms) and/or a manual control station

(100 ohms) in addition to the PID module (250 ohms) and the current

transmitter. Current transmitters typically require at least 18V dc.

Voltage transmitters, if used, draw their power from a supply independent

of the input circuit.

Figure 2.7 shows typical connections to actuators when the output is

monitored by the tieback input. Note that when a tieback input is not used

to monitor a voltage output, the jumper to the TIEBACK INPUT terminal

is not connected. When the tieback input is not used to monitor a current

output, the return from the actuator is connected to MODULE

COMMON, not to the TIEBACK INPUT terminal. The module monitors

tieback inputs only when you enable manual mode of the manual control

station described below.

Figure 2.8 shows the connections from the PID module to a manual

control station required for switching control automatically to the station

or manually at the station. The wiring is the same for PID module outputs

configured in current or voltage mode.

The MANUAL REQUEST terminal permits the PID module, upon

detecting a hard fault or when under PC processor control, to switch the

manual control station from automatic to manual mode. The MANUAL

MODE terminal is used to inform the PID module when the station is in

manual mode. The TIEBACK INPUT terminal monitors the station

output and allows a bumpless transfer of control from the manual control

station to the PID module.

212

Page 26

Chapter 2

Aseembly and Installation

Figure 2.4

Terminal

Terminal Identification

Terminal Function

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

18 Input 1 (+ Lead)

17 Input 1 (- Lead)

16 Input 2 (+ Lead)

15 Input 2 (- Lead)

14 Tieback Input 1

13 Tieback Input 2

12 Analog Output 1

11 Module Common

10 Analog Output 2

9 +15V DC

8 15V DC Common

7 -15V DC

6 Manual Mode 1

5 Manual Mode 2

4 Manual Request

3OPT.+5VDCCommon

2 Optional +5V DC

1 Not Used

1

The tieback inputs can be used to track manual control station output to provide bumpless

transfer, or can be used as feedforward inputs.

2

Module common signal level can be selected to either 15V DC COMMON (system

common) for standard compliance, or -15V DC for additional compliance depending

on the application.

3

When the manual control station is in manual, the station switches these line to the

MODULE COMMON terminal.

4

When a request for manual is made from the PID module or when this relay contact output

is used for alarm annunciation, the line is switched to the module common signal level for

50 msec. For hardware failure or loss of analog power ( 15V DC), this relay output is held

at module common until the fault is corrected.

5

Programming plugs must be positioned for optional + 5V DC supply.

Identification and Connections

Cat. No. 1771-PDC

2

+

-

Process Variable 1

Process Variable 2

Process Variable 2Process Variable 2

Tieback Input 1

Tieback Input 2

1

1

Control Element 1

Module Common

Control Element 2

Required +15V DC Power Supply

(cat. no. 1770-P1, 1778-P2, or equivalent)

3

3

4

Optional +5V DC Power Supply

5

(cat. no. 1771-P2 or equivalent)

+

-

+

-

11097

213

Page 27

Chapter 2

Assembly and Installation

PID Module

TERMINAL IDENTIFICATION

CAT. NO. 1771-PDC

TERMINAL FUNCTION

INPUT 1 (+LEAD)

18

INPUT 1 (-LEAD)

17

INPUT 2 (+LEAD)

16

INPUT 2 (-LEAD)

15

14

TIEBACK INPUT 1

13

TIEBACK INPUT 2

ANALOG OUTPUT 1

12

MODULE COMMON

11

ANALOG OUTPUT 2

10

9

+ 15V DC

+

8

15V DC COMMON

-

- 15V DC

7

MANUAL MODE 1

6

MANUAL MODE 2

5

4

MANUAL REQUEST

OPT. +5V DC COMMON

3

OPTIONAL +5V DC

2

1

NOT USED

Figure 2.5

ypical Connections for 1Loop Control

T

Power

Supply

+

-

+

-

Belden 8761

General

Manual Control

Station

Two-Wire Transmitter

+4 to 20mA

PV Input

Control

Signal

Input

Control

Signal

Output

-

+

Actuator

+4 to 20mA

Auto/

Manual

Switch

214

Manual

Request

Input

11098

Page 28

Figure 2.6

Connections to Input Devices

Chapter 2

Aseembly and Installation

PID Module

TERMINAL IDENTIFICATION

CAT. NO. 1771-PDC

TERMINAL FUNCTION

INPUT 1 (+LEAD)

18

INPUT 1 (-LEAD)

17

INPUT 2 (+LEAD)

16

INPUT 2 (-LEAD)

15

TIEBACK INPUT 1

14

TIEBACK INPUT 2

13

ANALOG OUTPUT 1

12

MODULE COMMON

11

ANALOG OUTPUT 2

10

+ 15V DC

9

+

15V DC COMMON

8

-

- 15V DC

7

MANUAL MODE 1

6

MANUAL MODE 2

5

4

MANUAL REQUEST

OPT. +5V DC COMMON

3

2

OPTIONAL +5V DC

NOT USED

1

POWER

SUPPLY

-

1

+

1

R

If used connect a recorder or other monitoring instrument in series with

the transmitter on the transmitter return lead.

(+)

(-)

(+)

(-)

2-Wire

Transmitter

+4 to 20mA

4-Wire

Transmitter

+1 to 5V DC

-

+

V

11102

215

Page 29

Chapter 2

Assembly and Installation

PID Module

TERMINAL IDENTIFICATION

CAT. NO. 1771-PDC

TERMINAL FUNCTION

INPUT 1 (+LEAD)

18

INPUT 1 (-LEAD)

17

INPUT 2 (+LEAD)

16

INPUT 2 (-LEAD)

15

TIEBACK INPUT 1

14

TIEBACK INPUT 2

13

ANALOG OUTPUT 1

12

MODULE COMMON

11

ANALOG OUTPUT 2

10

+ 15V DC

9

+

15V DC COMMON

8

-

- 15V DC

7

MANUAL MODE 1

6

MANUAL MODE 2

5

4

MANUAL REQUEST

OPT. +5V DC COMMON

3

2

OPTIONAL +5V DC

NOT USED

1

Figure 2.7

Connections

1

2

to MODULE COMMON terminal 11.

to Output Actuators

1

2

If tieback is not used to monitor a voltage output, do not make this

connection.

if tieback is not used to monitor a current output, connect the return lead

(+)

(-)

(+)

(-)

Actuator

+1 to +5V DC

+4 to +20mA

Actuator

11103

216

Page 30

PID Module

TERMINAL IDENTIFICATION

CAT. NO. 1771-PDC

TERMINAL FUNCTION

INPUT 1 (+LEAD)

18

INPUT 1 (-LEAD)

17

INPUT 2 (+LEAD)

16

INPUT 2 (-LEAD)

15

TIEBACK INPUT 1

14

TIEBACK INPUT 2

13

ANALOG OUTPUT 1

12

MODULE COMMON

11

ANALOG OUTPUT 2

10

+ 15V DC

9

+

15V DC COMMON

8

-

- 15V DC

7

MANUAL MODE 1

6

MANUAL MODE 2

5

4

MANUAL REQUEST

OPT. +5V DC COMMON

3

2

OPTIONAL +5V DC

NOT USED

1

Figure 2.8

Mode Connections to Manual Control Station

Control

Chapter 2

Aseembly and Installation

General

Manual Control

Station

Auto/Manual

Switch

Manual

Request

Input

Manual Control Station Interface

11104

The PID module is designed for use with commercially available manual

control stations, one per loop. The station is connected between the

analog output and the controlled element of the process. The station

provides manual override control and automatic backup to the PID

module. Manual control stations can be used for start-ups, on-line process

adjustments, and routine maintenance. The station can be used in either

of two ways, manual override control or module back-up.

Manual Override Control

An operator can override automatic control by switching to manual

control and adjusting the output at the manual control station. When the

manual control station is switched to manual mode, a connection is closed

between the MANUAL MODE terminal (referenced to +15V dc) and the

MODULE COMMON terminal on the PID module (Figure 2.8). This

217

Page 31

Chapter 2

Assembly and Installation

allows the PID output to be switched open at the manual control station

and a manually controlled output to be switched into the system.

When in manual mode, care should be taken not to return to automatic

control when the output is below +1V dc or +4mA. If attempted, an

output surge could occur. The PID module performs a bumpless transfer

when the tieback input is tracking a signal at or above the minimum level

of +1V dc or +4mA. Also, the PID module’s operating mode must

include integral control and the manual mode status line must be closed at

the manual control station. The module monitors tieback inputs only

when you enable manual control.

Module Backup

The manual control station can be used to automatically backup the PID

module in the event of module failure. A module failure would

de-energize the PID module’s contact output and generate a manual

request to the manual control station causing control to be transferred in

the following manner.

The contact output (Figure 2.9) is a normally closed contact. When the

PID module is in normal operation, the contact will be held open. A

manual request is generated by contact closure. The contact will close

and remain closed in the event of module failure or loss of +

15V dc

analog power. Contact closure internally switches the signal at terminal 4

MANUAL REQUEST to terminal 11 MODULE COMMON. There is

only one contact output. If two manual control stations are used, both will

be switched simultaneously.

If a manual request is generated by program logic, contact closure is a

one-shot 50 millesecond closure. The closure can be used to activate an

alarm device by connecting a latching relay to terminal 4 MANUAL

REQUEST and terminal 11 MODULE COMMON on the PID module.

Once the PID module relinquishes control to the manual control station,

the plant operator must physically reset the operation to automatic mode

using a switch on the manual control station.

When control is returned from manual to automatic at the manual control

station, the PID module performs a bumpless transfer if the tieback analog

input is used to track the output from the manual control station and the

PID module’s operating mode includes integral control.

218

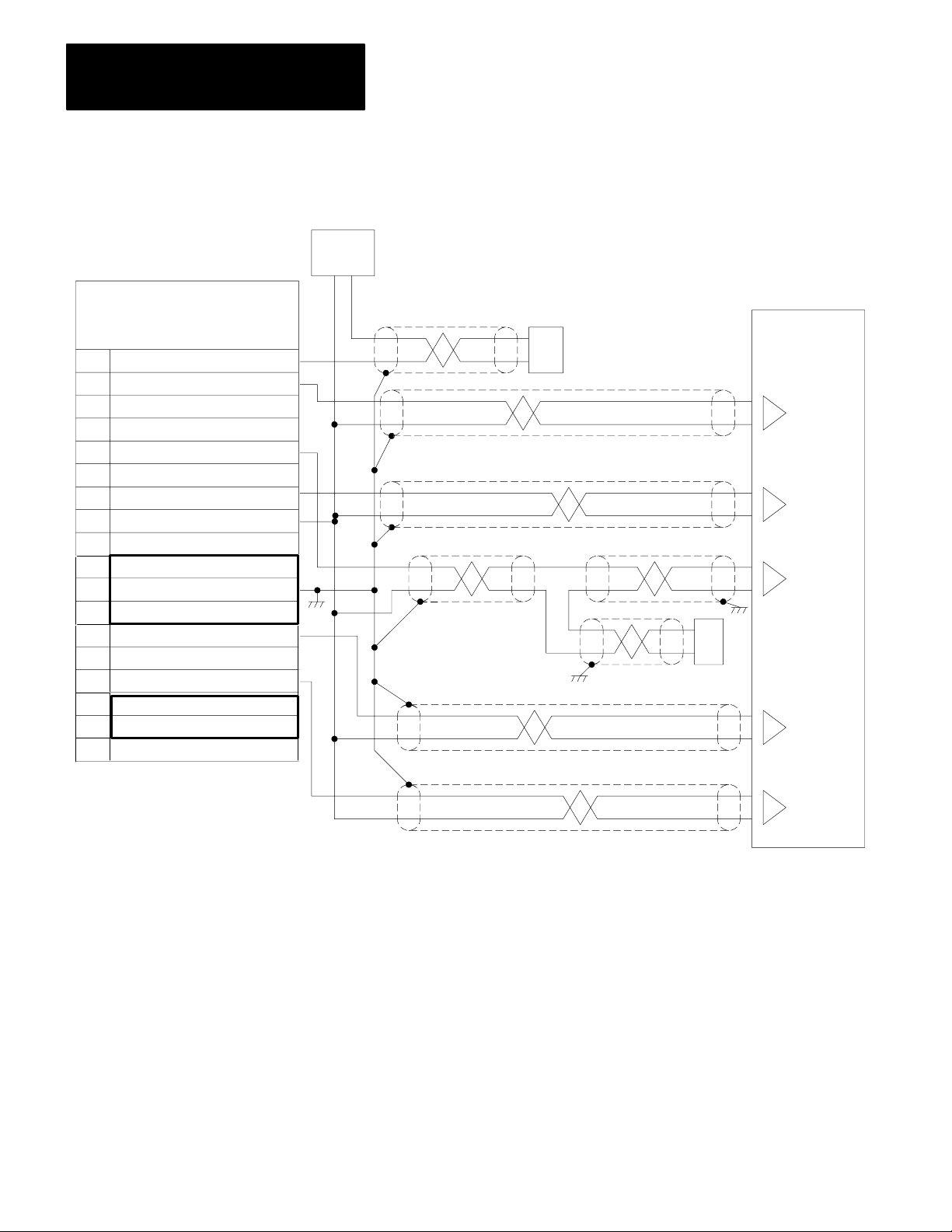

Page 32

Figure 2.9

Connections to the Field Wiring Arm

Internal

Chapter 2

Aseembly and Installation

1771 - PID Module

Ω

250

2

E11 E12

Standard

1

Compliance

Additional

250

Internal Connections

Input 1 (+ Lead)

Input 2 (+ Lead)

Tieback Input 1

Tieback Input 2

Ω

Analog Output 1

Module Common

Analog Output 2

+15V DC

+

-

-15V DC

15V DC Common

1771 - WF

Wiring Arm

External

Connections

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Station 1

Station 2

Manual

Request

Station 1

Manual

Request

Station 2

3

Contact Output

(normally closed)

E22 E21

30V peak

1/4 AMP Max.

Max. 3VA

OptoIso

NOTE: Optional +5V DC power supply wiring is not shown.

1

Standard compliance selects module common as 15V DC Common (500 max for current outputs.)

Additional compliance selects module common as -15V DC Common (1250 max for current outputs.)

2

Programming plugs inserted for current mode.

Programming pl ugs inserted for standard compliance.

3

Input Power Supply Requirements

The source of power for the input loop when the input is configured for

current mode can be either the analog +

supply. The choice depends on the selected output compliance and the

number of devices in the loop.

Manual Mode 1

Manual Mode 2

Manual Request

+

-

Ω

Ω

11105

15V dc supply or a separate

219

Page 33

Chapter 2

Assembly and Installation

+15V dc Analog Supply

When both the module outputs and tieback inputs (if used) are configured

in current mode, additional compliance can be selected. As such, module

common is internally connected to -15V dc. The +

15V dc analog power

supply can provide a 30 V dc source to the input current loop by

jumpering the +15V Dc terminal of the PID module to the positive lead of

the current transmitter (Figure 2.10). The potential of 30 V dc is enough

to provide the required voltage drops for the transmitter, PID module, and

manual control station.

220

Page 34

Figure 2.10

Mode Input Using External +

Current

Chapter 2

Aseembly and Installation

15V dc Supply

PID Module

1771-PD

TERMINAL IDENTIFICATION

CAT. NO. 1771-PDC

TERMINAL FUNCTION

INPUT 1 (+LEAD)

18

INPUT 1 (-LEAD)

17

INPUT 2 (+LEAD)

16

INPUT 2 (-LEAD)

15

14

TIEBACK INPUT 1

13

TIEBACK INPUT 2

ANALOG OUTPUT 1

12

MODULE COMMON

11

ANALOG OUTPUT 2

10

9

+ 15V DC

+

8

15V DC COMMON

-

- 15V DC

7

MANUAL MODE 1

6

MANUAL MODE 2

5

4

MANUAL REQUEST

OPT. +5V DC COMMON

3

OPTIONAL +5V DC

2

1

NOT USED

Two-Wire

Transmitter

+4 to +20mA

(+)

(-)

R

General

Manual Control

Station

PV

Input

R

Recorder or indicating instrument if used

10997

Separate Supply

If additional compliance is not selected (as when one of the module

outputs is configured in voltage mode), a separate DC power supply must

be used to power the input current loop.

Power Supply Voltage

When selecting the power supply to operate the input current loop, the

required voltage must be equal to the voltage drop across all impedances

at the maximum current of 20mA. Current transmitters typically require a

voltage drop of 18V dc or more. The process variable input impedance of

the PID module (250 ohms), manual control station (100 ohms), recording

221

Page 35

Chapter 2

Assembly and Installation

or indicating instrument if used (typically 250 ohms) must be considered

when calculating the voltage drop in the loop.

For example, the required voltage for an input loop that contained the PID

module, manual control station, and current transmitter that requires at

least 18V dc would be 18V +2 (250 ohms) (.020 amps)= 18V +10V =

28V dc. Up to 2 V dc could be allowed for voltage drops in the cables

when using a 30 V dc source such as the +

15V dc analog power supply

with the module output configured for current operation and additional

compliance.

If the input loop were to contain a chart recorder and an indicating

instrument (250 ohms each) in addition to the basic loop in the previous

example, the power supply would have to provide a least 38V dc plus an

amount equal to the voltage drop of the cables. A separate power supply

would have to be used.

Installation Practices

Power Supply Current

The +

15V dc analog power supply must provide 100mA to the PID

module’s analog circuits. This includes 20mA that the module provides to

each output current loop. If the +

15V dc supply is providing 20mA to

each input current loop, a 2-loop control system will require 140mA. This

is within the specification for the Allen-Bradley 1770-P1 power supply

rated at 150mA at +

15V dc.

To minimize the effects of electromagnetic interference (EMI), group

analog modules together in the I/O chassis whenever possible. Avoid

placing PID modules close to AC modules or high voltage DC modules.

It is important to use shielded cable when wiring analog signals. Belden

8761 or equivalent cable has an insulated twisted pair of conductors

covered by a foil shield. To reduce the effect of EMI induced noise along

the cable, the shield must be properly grounded at one end, only. The

recommended grounding point for each cable is identified in the wiring

diagram (Figure 2.5-Figure 2.8 and Figure 2.10). One end of the shield

should be cut short and taped to insulate it from any electrical contact.

The other end should be tied to a common point at earth ground.

222

Optional Instrument Grounding Bus

An alternate grounding system can be used to separate analog signal

ground from the grounding of equipment such as motor starters and are

Page 36

Chapter 2

Aseembly and Installation

welders which generate high electrical noise. Equipment grounding can

carry electrical noise when ground loops exists.

The alternate grounding method is for instruments, only. A instrument

ground bus is located inside the enclosure containing the I/O chassis,

manual control station, and PC processor. The instrument bus is

electrically isolated from the I/O chassis and enclosure. The bus is

connected to earth ground by a direct path, independent of other

equipment ground connections.

When using instrument grounding, the only change to the connection

drawings (Figure 2.5 through Figure 2.8 and Figure 2.10) is that the

chassis ground symbol would be redefined as instrument ground. All

cable shields and the +

15V dc COMMON terminal of the PID module

would be connected to the instrument ground bus.

Chassis Considerations

When multiple PID modules are placed in the same chassis, the +

15V dc

commons and +5V dc commons, if used, should be connected to the

ground bus at one point. Do not daisy-chain the commons.

The PID dual-slot module must be placed with single module group when

placed in a I/O chassis. Up to eight PID modules can be placed in a single

128 I/O chassis. Up to four of the PID modules can be powered from the

+5V I/O chassis power supply. The remaining PID modules, if installed,

must be powered by a separate +5V dc supply through the field wiring

arm +5V dc and 5V dc COMMON terminals. Be sure that the total

current requirement for all modules in the I/O chassis using the I/Ochassis

power supply does not exceed the rating of the I/O chassis and the I/O

chassis power supply.

Avoid placing the PID module close to AC I/O modules or high voltage

DC I/O modules. It cannot be inserted in the left-most slot reserved for the

processor module in a single I/O chassis system or for the I/O adapter

module in a multi-chassis system.

Set switch 1 of the I/O chassis last state switch assembly to the off

position to allow PID module operation in soft fault mode. Refer to

section titled Loop Control Word B for additional information on soft

fault mode selection.

Other intelligent I/O modules can operate without interference in the same

I/O chassis with PID modules.

223

Page 37

Chapter 2

Assembly and Installation

Internal Fusing

The PID module has internal pico fuses to protect circuitry from surges in

the optional +5V dc supply., A blown fuse condition is indicated when

none of the front panel LED indicators turn on after you turn on this

supply. If the LEDs do not turn on, check programming plugs E23 and

E24. These plugs allow you to select the source of +5V dc from the

backplane or from an external supply. Incorrect positioning of these plugs

can prevent the LEDs from turning on even when pico fuses are OK.

Check that E23 and E24 are in the correct position for using the external

+5V dc supply (Table 2.D and Figure 2.3).

If the fuses are blown, we recommend that you return the module for

factory repair through your nearest field service or sales office.

Unauthorized repair of these fuses could result in damage to other circuit

components and void your warrantee.

Precautions

Take the following precautions to avoid blowing these fuses:

Be sure that the optional +5V dc supply is connected correctly to field

wiring arm terminals (Figure 2.4).

Be sure that the optional +5V dc supply meets specifications

(Table 2.G), especially for surge voltage at turn on.

Supply +5V dc to each PID module using one or more optional external

power supplies.

Place an on/off switch in the +5V dc lead to each PID module. This

allows you to remove power and replace a PID module without turning

off power to other PID modules in the chassis.

Remove power from the PID Module’s field wiring arm before

connecting or disconnecting the arm.

Recommendations for Installing

or Removing Modules

224

We make the following recommendations for removing one of several

PID modules from an I/O chassis.

WARNING: Remove power from a field wiring arm before

connecting or disconnecting it. Turn off power to the I/O

chassis before inserting or removing any of its modules. Failure

to observe this warning can result in damage to module circuitry

and/or unpredictable operation of other modules in the chassis

with possible damage to equipment and/or injury to personnel.

Page 38

Chapter 2

Aseembly and Installation

Place PID modules in one or more chassis containing only PID

modules.

Supply +5V dc to each PIC module using one or more optional external

power supplies.

Place an on/off switch in the +5V dc lead to each PID module. This

allows you to remove power and replace a PID module without turning

off power to other PID modules in the chassis.

Removal of a Faulted PID Module

You can replace a faulted PID module in an I/O chassis using the

following procedure if each PID module is supplied with +5V dc from a

separate power supply or from a common supply with a switch in each

+5V dc lead.

1. Select the soft fault mode that allows PID modules to continue

operation when they lose communication with the PC processor. Do

this by means of your ladder program.

2. Turn off power to the I/O chassis. Block transfers cease but PID

modules continue to operate.

3. Turn off the +5V and +

15V dc power to the faulted module.

4. Replace the faulted PID module.

5. Turn on power to the module and I/O chassis.

6. Restore the original soft fault mode to the PID modules.

If there are other modules and/or other PID modules without an external

+5V dc supply, they cease to operate when you turn off power to the

chassis. After restoring power, you must download PID control

parameters to PID modules through a load/enter sequence.

Keying

PID modules (rev C or later) have the option for you to select how outputs

respond when +5V dc is removed from the module. You select either

maximum or minimum, output using programming plus (refer to titled

Programming Plug Selection).

The backplane connector should be keyed to accept only this module after

its position in the I/O chassis has been determined.

225

Page 39

Chapter 2

Assembly and Installation

Plastic keying bands shipped with the I/O chassis should be used. The

position of the keying bands on the upper backplane connector must

correspond to the mating slots on the module connector.

Refer to Figure 2.11. Using needle-nose pliers, place the keying bands on

the backplane connector between these numbers:

Slot 0 (left)

8 and 10

18 and 20

slot 1 (right)

2 and 4

28 and 30

The position of the keying bands can be changed if subsequent system

design requires the module to be moved to a different location.

226

Page 40

Figure 2.11

Diagram

Keying

Chapter 2

Aseembly and Installation

Single Module Group

0PID Module 1

Upper Backplane Connectors

Power Supply Specifications

Keying

Bands

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Left

Connector

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Right

Connector

11106

Isolation must be maintained between the analog and digital circuits of the

PID module to minimize electrical noise interference. Therefore, separate

power supplies must be used for the analog +

15V dc supply and for the

digital +5V dc supply.

The requirements for the customer +

15V dc power supply and for the

optional +5V dc power supply are listed in Table 2.E and Table 2.F,

respectively.

227

Page 41

Chapter 2

Assembly and Installation

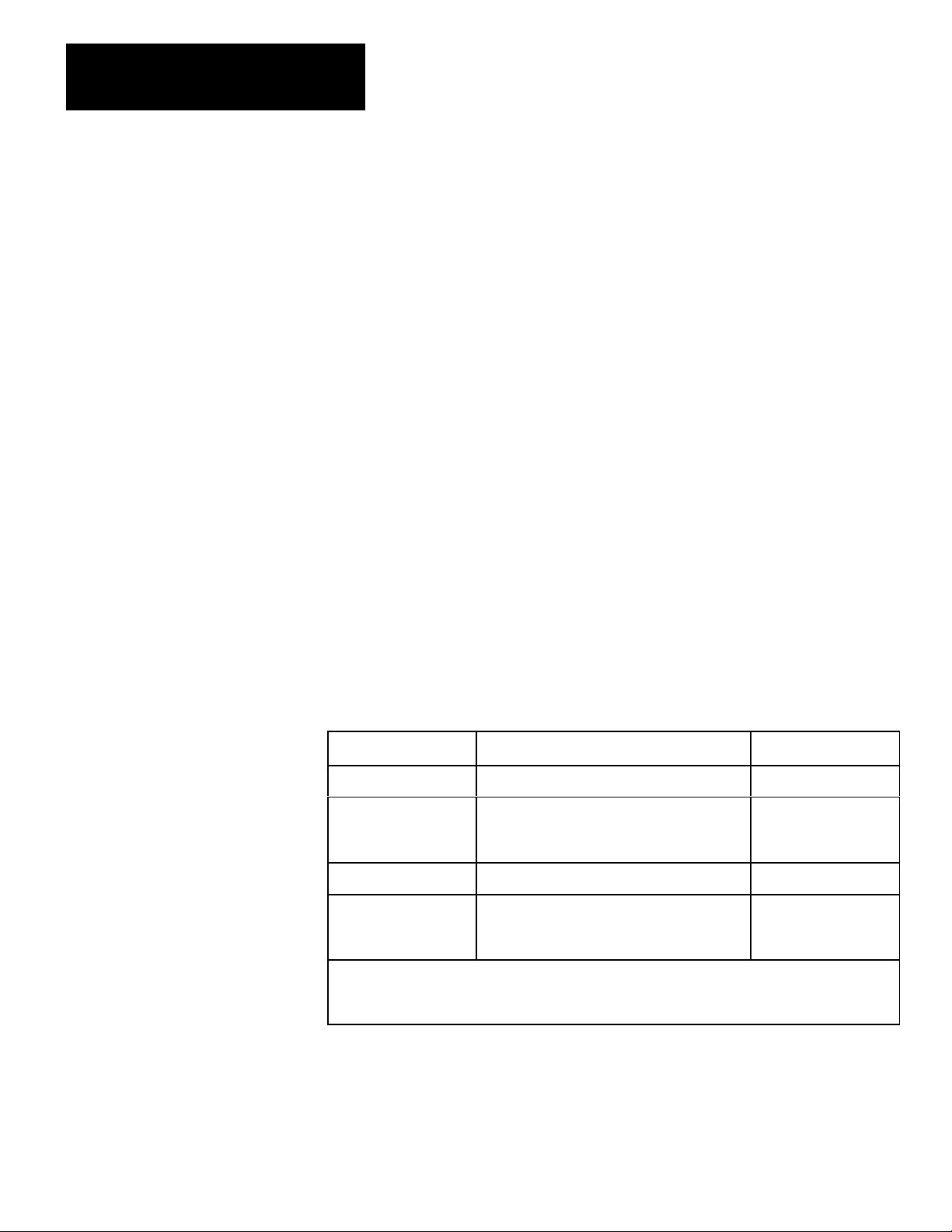

Table 2.E

Customer

Output Current

Output V

Regulation (type)

Line Regulation (for 10V AC input change)

Load Regulation (no load to full load)

Ripple 10mVpp 10mVpp

Overvoltage Protection

Current Limit (percent of full load)

[1] The module is not protected from overvoltages from the customer power supply

Table 2.F

+5V dc Power Supply (Optional) Requirements

+

15V dc Power Supply Requirements

Specifications

oltage T

olerance 1% 1%

[1]

+15 V

100mA 100mA

Series Series

+0.2% +0.2%

+1.0% +1.0%

+18V dc 18V dc

125% 125%

olts

15 V

.

olts

Specifications +5Volts

V

oltage (at wiring arm)

Current

V

oltage Regulation

Rise T

ime (to 4.75V dc) Less than 10msec

5.05V dc

1.2A per PID module

Sum of all deviations due to line,

load, and ripple should not exceed

+

0.15V dc

228

Page 42

Chapter 2

Aseembly and Installation

Module Specifications

V

Process

Number 12binary

Configuration

Range (userselectable)

Digital Resolution

ariable Inputs

process variable input 1

process variable input 2

Differential

+4 to +20mA

+1 to +5V dc

12bit binary

, 1 part in 4095

The PID module specifications are listed in Table 2.G.

Table 2.G

Specifications

Digital Resolution Maximum Current

Accuracy

+

0.1% of range at 250C3VA

Input Impedance

250 ohms (current)

4.7 megohms (voltage)

Maximum Allowable Input

+

30mA (current)

25V rms (voltage) Backplane or External (Digital Circuits)

T

emperature Coefficient

, 1 part in 4095

250mA

Maximum Power

Digital Inputs (from manual

manual control station)

T

wo independent inputs for moni

toring

Power Requirements

1.2A at +5V dc

Accuracy +

+

0.1% of range at 250C

Input Impedance

250 ohms (current) analog output 1

10 megohms (voltage)

Common Mode Rejection Ratio

70dB DC

Common Mode V

+

common

Common Mode Input Resistance referenced to power supply Relative Humidity Rating

2.5 megohms

Input Frequency Respnse

3dB at 1kHz

Maximum Allowable Input

oltage Range

200V with respect to module +4 to +20mA

Number

Configuration

Range (userselectable)

50 ppm/0C

Analog Outputs 100mA A

analog output 2 100msec, typical

Single ended

(With output common internally

common

the output will drive up to a 500 ohm

load over the full current range.

+1 to +5V dc

External (Analog Circuits)

100mA at 15V dc

Loop Update T

Ambient T

Operation 00C to 600C (320F to

1400F

Storage 400C to 850C (400F to

1850F)

5% to 95% (without condensation)

Electrical Isolation

[1]

1500V rms (transient

(Isolation is achieved by

T +15V dc

ime

emperature Ratings

+

30mA (current)

(500 ohms minimum load resistance

optoelectronic coupling between I/O

229

Page 43

Chapter 2

Assembly and Installation

dc (voltage) 10mA maximum load current.)

125V

T

emperature Coeffeicient

+

50 ppm/0C

T

ieback Inputs

Number +

tieback input 1

tieback input 2

Configuration

Single ended

Range (userselectable)

+4 to +20mA

+1 to +5V dc

Digital Resolution

Accuracy

T

emperature Coefficient

Number

Peak V

oltage

analog circuit and control logic)

Keying

12bit binary

0.1% of range at 250C

+

50 ppm/0C

one normally closed contact,held extended from 500ohms (standard compli

open

30V

, 1 part in 4095

Contact Output

Left connector (slot 0) between 8

and 10, 18 and 20

Right connector (slot 1) between 2

and 4, 28 and 30

[1]

If all analog outputs and tieback inputs

used are selected to current mode, the

compliance of the analog outpus can be

ance to 1250 ohms(additional compliance).

This is achieved by internally referencing the

outputs to 15V dc.

230

Page 44

Programming

Chapter

3

General

Before starting to program the PID module, read this entire chapter

thoroughly. Be sure that the programming plug functions have been

selected as described in section titled Programming Plug Selection.

The PID module can be programmed in four general steps:

1. Choose the PID module features required for the application. These

are listed in section titled Capabilities (chapter 1) and are presented

in the algorithm flow chart (Figure 3.15).

2. Identify the control bits and loop storage words which must be

programmed to implement the features. These are defined in section

titled Word and Bit Definitions. Record the values of the storage

words and the logic state of the control bits on the worksheets found

in appendix A.

3. Write the ladder diagram program and assign data table addresses to

the data blocks used to store loop values. The examples presented in

appendix B or C should be used as guides.

4. Using a industrial terminal, enter the program into memory and the

block data into the data table. Refer to the worksheets on which the

values of the loop storage words have been recorded. Set the

appropriate control bits.

Sections listed below provide information for selecting PID module

features and programming the module.

Section titled Operational Overview provides an overview of the

programming concepts which are used to program and monitor the PID

module.

Section titled Word and Bit Definitions defines the words and bits

which can be used to program the module.

Section titled Algorithm Flow Chart contains the algorithm flow chart

and explains it use.

Section titled Block Transfer Programming explains how the module is

programmed using block transfer instructions.

31

Page 45

Chapter 3

Programming

Section titled Programming Consideration explains the application of

block transfer instructions.

Section titled Expanded Features describes the expanded features of the

PID module and how they can be applied.

Additionally, four appendices contain helpful programming information:

Appendix A contains the worksheets which are used to record data that

is entered into the PC processor and transferred to the PID module.

Appendix B describes a program that performs continuous block

transfers to the PID module. This program may be used when

continuous parameter adjustment or continuous reporting of module

status is required for a critical application.

Appendix C describes a program that performs periodic block transfers

to the PID module. This program may be used when less frequent

parameter adjustment is required.

Appendix D contains summary word and bit tables and a word/bit

reference.

Operational Overview

The PID module is a closed loop process controller with proportional,

integral, and derivative control action. Control algorithm features are user

determined and loaded in the PID module by block transfer from the PC

processor. The PID module is equipped to control up to two process

control loops using its internal microprocessor. Because the features of

the two loops are similar, the description will be general to both loops

except where otherwise stated. Each loop is individually configured with

its own parameter values.

PID Algorithm

The PID module contains features which are user-selected to perform the

desired control. Figure 3.1 is a simplified diagram of the PID module

features. Basically, the PID module reads the process variable, compares

it to the set point, and adjusts the analog output to make the process

variable equal the set point. The process variable PV is the analog input

from the process. The setpoint SP is the equilibrium value of the process,

and the analog output is the control variable to the process. The

difference between the set point and the process variable is the error

signal, E=SP-PV.

32

The PID module can perform a combination of proportional, integral and

derivative control. Integral control is also known as reset action.

Derivative control is also known as rate action. The PID module can

perform relatively simple or very complex control based on selected

Page 46

Chapter 3

Programming

features. The full algorithm flow chart is presented in section titled

Algorithm Flow Chart.

The PID module (rev C or later) uses the ISA algorithm (P, I and D

dependent gains) or the Allen-Bradley algorithm (P, I and D independent

gains). Refer to appendix E for algorithm comparison and selection.

Earlier revision modules use only the Allen-Bradley algorithm.

Figure 3.1

Simplified

PID Algorithm

Feedforward Input

Process

Variable

A/D

Hardware

Analog

Input

/

SP

+

-

/

Digital

Filter

PV

S

Error=SPPV

P

I

D

SS

Lead

Lag

BIAS

V

PID

V

(FFV)

Control Variable

D/A

Hardware

Analog

Output

11093

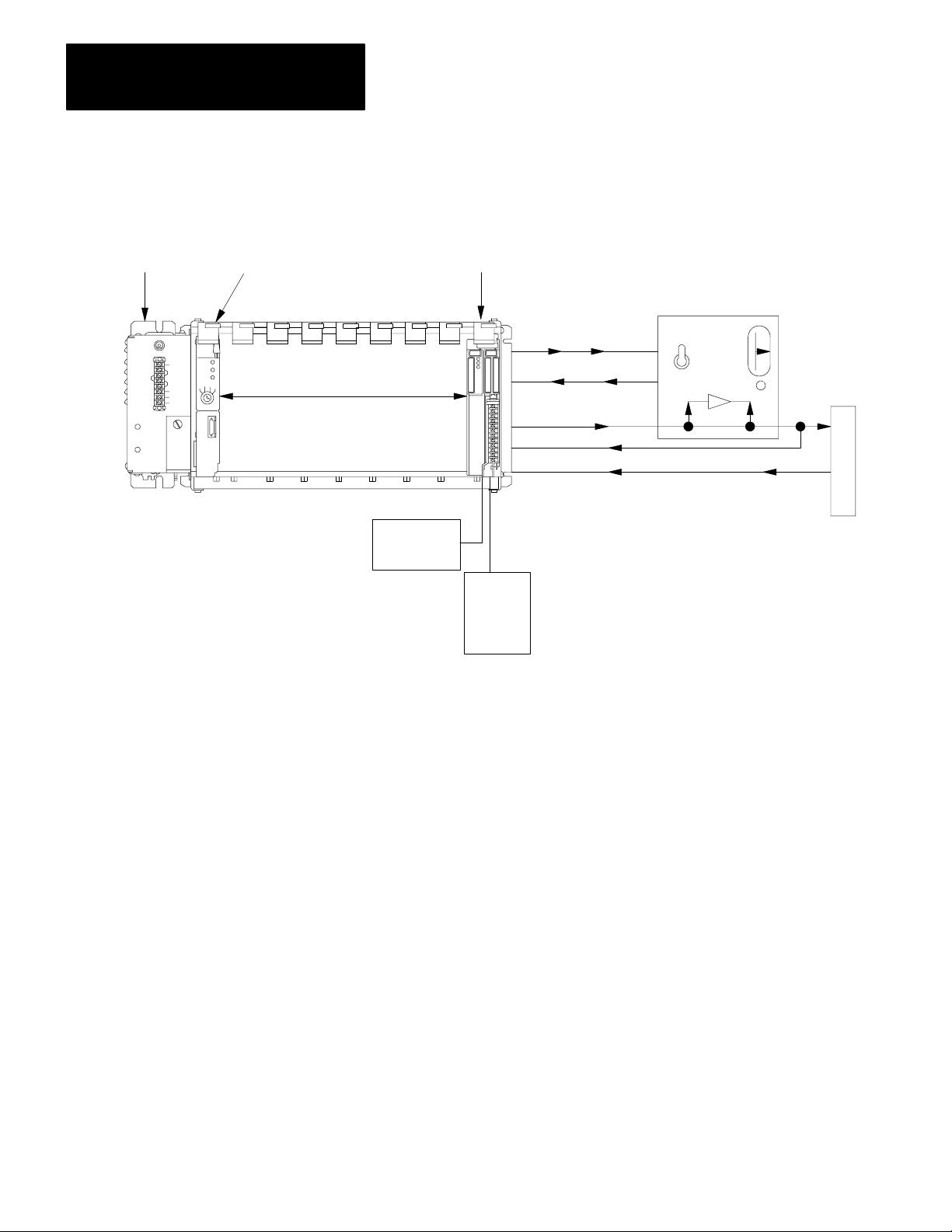

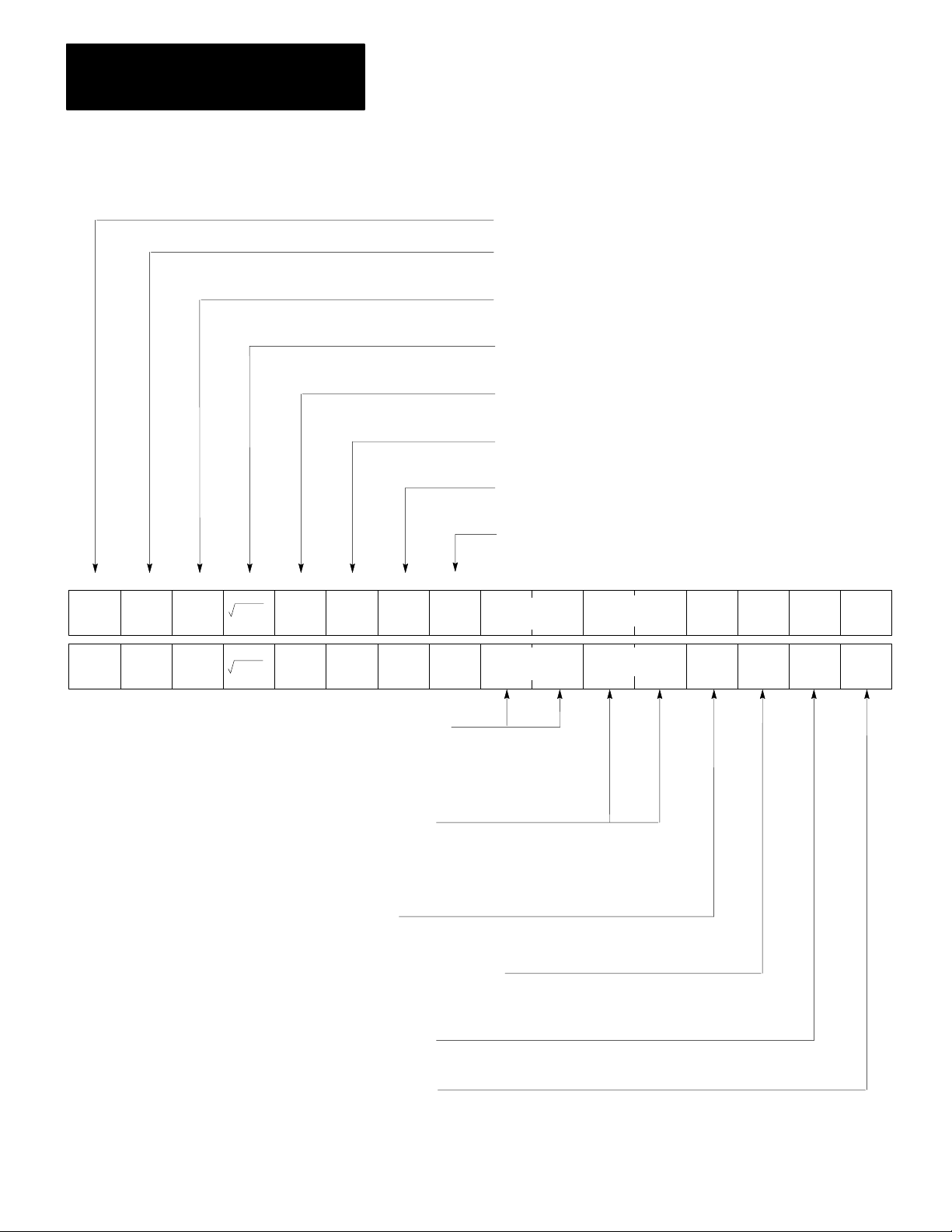

Block Transfer Data Blocks

Data block files are areas of the PC processor data table used to store loop

control words and loop values. The features of the module are selected by

setting word and bit values in data block files. The data block files are

transferred to the PID module by block transfer instructions.

Three write block transfers are required to load the PID module with data

from three data table block files. The dynamic block DB contains values

which are subject to change for both loops. The loop 1 block LP1 and

loop 2 block LP2 contain loop constants which seldom change.

33

Page 47

Chapter 3

Programming

The status block SB is a read block transfer file used to report the current

status of the PID module and any alarm condition detected by the module.

The transfer of the status block is also used to prompt the next write block

transfer.

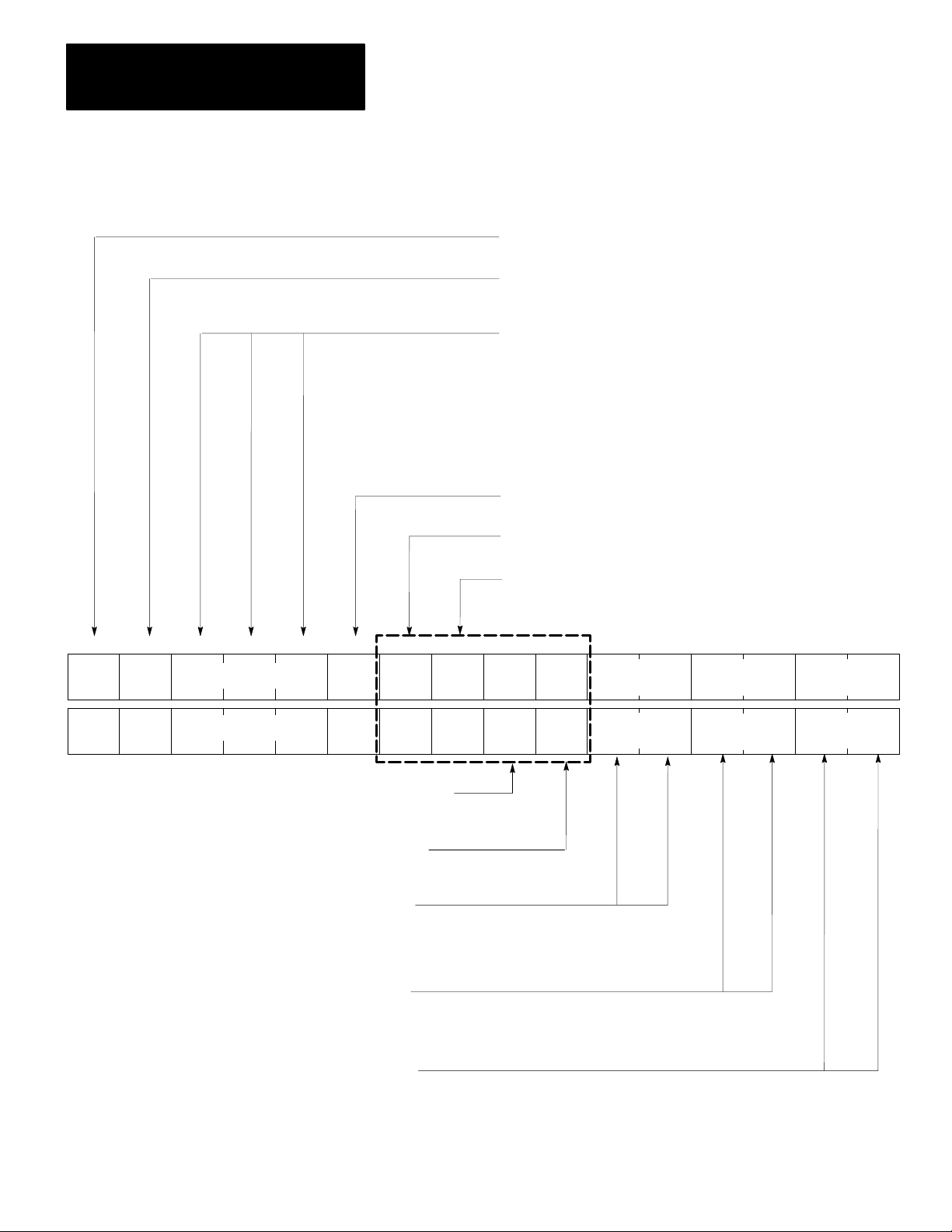

Figure 3.2 illustrates the multiple block concept.

Figure 3.2

Multiple

Block Concept

PCProcessor

DataTable

Dynamic

Block

Loop1

Constants

Block

Loop2

Constants

Block

Status

Block

PIDModule

WriteBlock

Transfer

WriteBlock

Transfer

WriteBlock

Transfer

ReadBlock

Transfer

11094

34

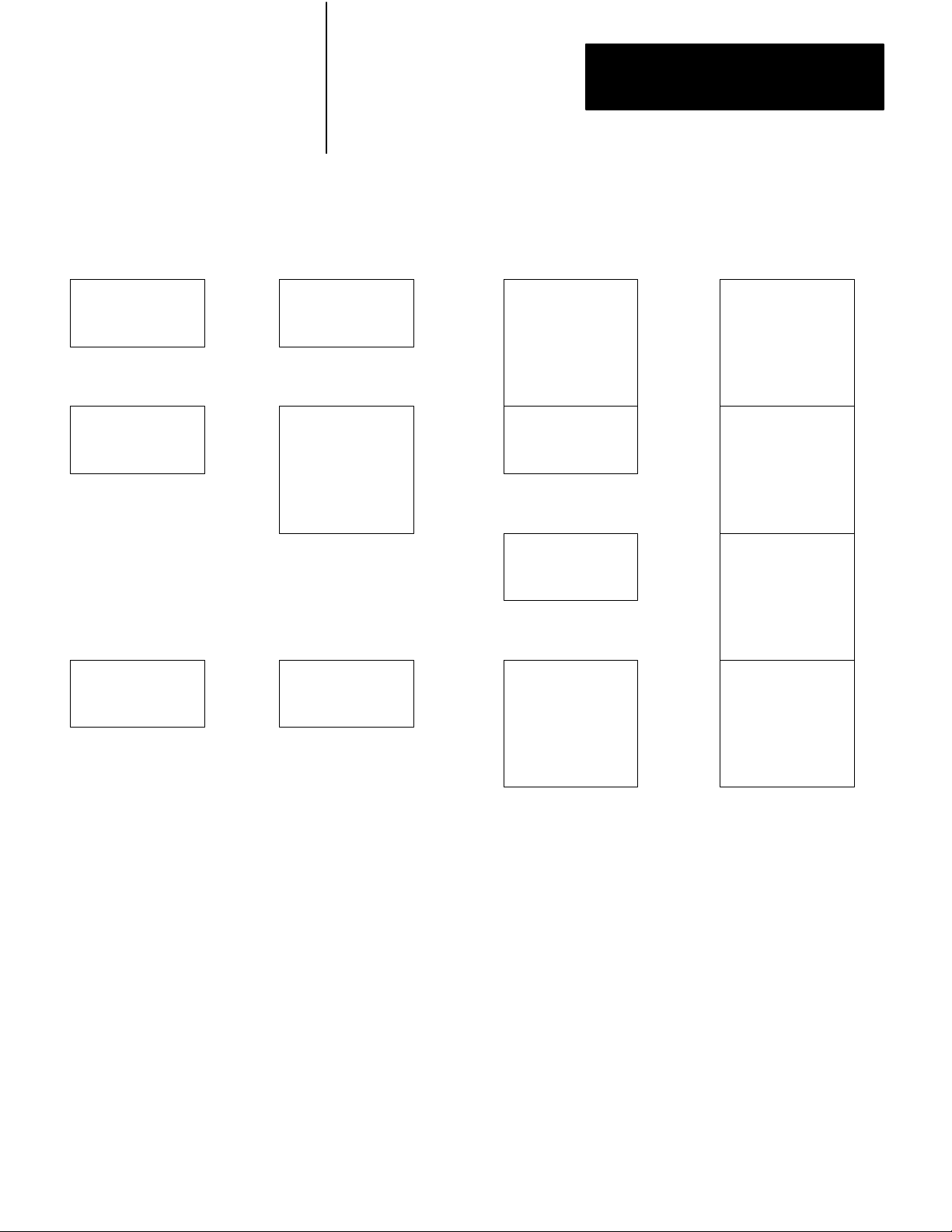

PC Processor Memory Requirements

The PID module requires multiple files in the C processor data table to

store the different blocks of data. Storage requirements are determined by

the features selected. The module can be configured for one or two loops

with either standard or expanded features. There are four different

memory requirements for storing block of data (Figure 3.3).

User program memory requirements will vary depending on the

application. Examples are shown in appendicies B and C.

Page 48

Chapter 3

Programming

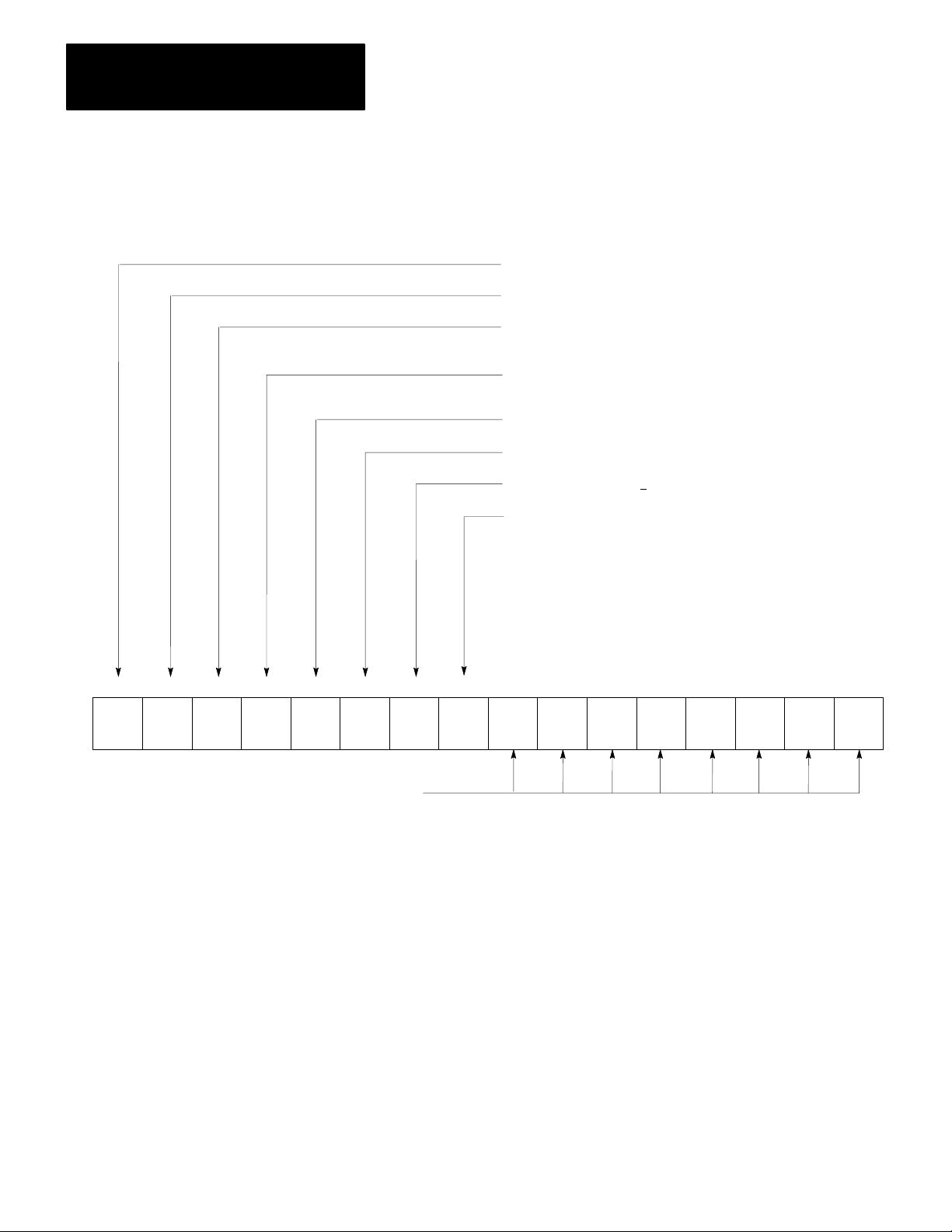

Figure 3.3

File Memory Requirements

Block

1 Standard Loop 1 Expanded Loop 2 Standard Loops 2 Expanded Loops

Dynamic

Block

10 Words

Loop 1 Constants

Block

12 Words

Status Block

11 Words

Dynamic

Block

10 Words

Loop 1

Constants

Block

19 Words

Status Block

11 Words

Dynamic

Block

17 Words

Loop 1 Constants

Block

12 Words

Loop 2 Constants

Block

12 Words

Status

Block

18 Words

Dynamic

Block

17 Words

Loop 1

Constants

Block

19 Words

Loop 2

Constants

Block

19 Words

Status

Block

18 Words

Load/Enter Sequence

The load/enter sequence is used when all PID control parameters

(dynamic block and loop block data) are transferred from the PC