Page 1

Installation Instructions

AC (120/220V) 16A

Power Supply

(Cat. No. 1771-P7 Series C)

To the Installer

Compliance to European Union Directives

This document provides you with the following information:

For this information See page

compliance European Union Directive

preparing to install the power supply 2

installing the power supply 3

connecting ac power to the power supply 7

troubleshooting 8

specifications 9

power ratings 9

The series C version of this product is marked with the

indicating that this version complies with the European Union

Directives noted below.

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

1

logo,

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2

EMC – Generic Emission Standard, Part 2 – Industrial

Environment

• EN 50082-2

EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

This product is intended for use in an industrial environment.

Publication

17715.39 December 1995

Page 2

AC (120/220V) 16A Power Supply2

Low Voltage Directive

This product is also tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements

and Tests.

For specific information that the above EN requires, see the

appropriate sections in this publication, as well as the following

Allen-Bradley publications:

• Industrial Automation Wiring and Grounding Guidelines

(for noise immunity), publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

Prepare for Installation

The 1771-P7 power supply can power one 1771-A1B, -A2B, -A3B,

-A3B1, or -A4B I/O chassis when used with any adapter module or

programmable controller (Mini-PLC-2/02

Mini-PLC-2/16

that does not have an internal power supply.

Important: The power supply is not compatible with the 1771-A1,

!

!

, Mini-PLC-2/17, or PLC-5 family processor)

-A2, or -A4 I/O chassis.

ATTENTION: The 1771-P7 is a stand-alone

power supply. Do not connect it in parallel with any

other power supply. Connecting it in parallel could

result in processor memory loss or injury due to

unexpected machine operation.

ATTENTION: Under some conditions, electrostatic

discharge can degrade performance or damage system

components. Observe the following precautions to

guard against electrostatic damage:

, Mini-PLC-2/05,

• Touch a grounded object to rid yourself of charge

before handling a module.

• Do not touch the backplane connector or

connector pins.

• When not in use, keep modules in their

static-shield bags.

Publication

17715.39 December 1995

Page 3

AC (120/220V) 16A Power Supply 3

Before installing the power supply, you should:

• mount the I/O chassis that the power supply will be connected to.

See the Universal I/O Chassis Installation Data (1771-2.210) for

information on mounting the I/O chassis.

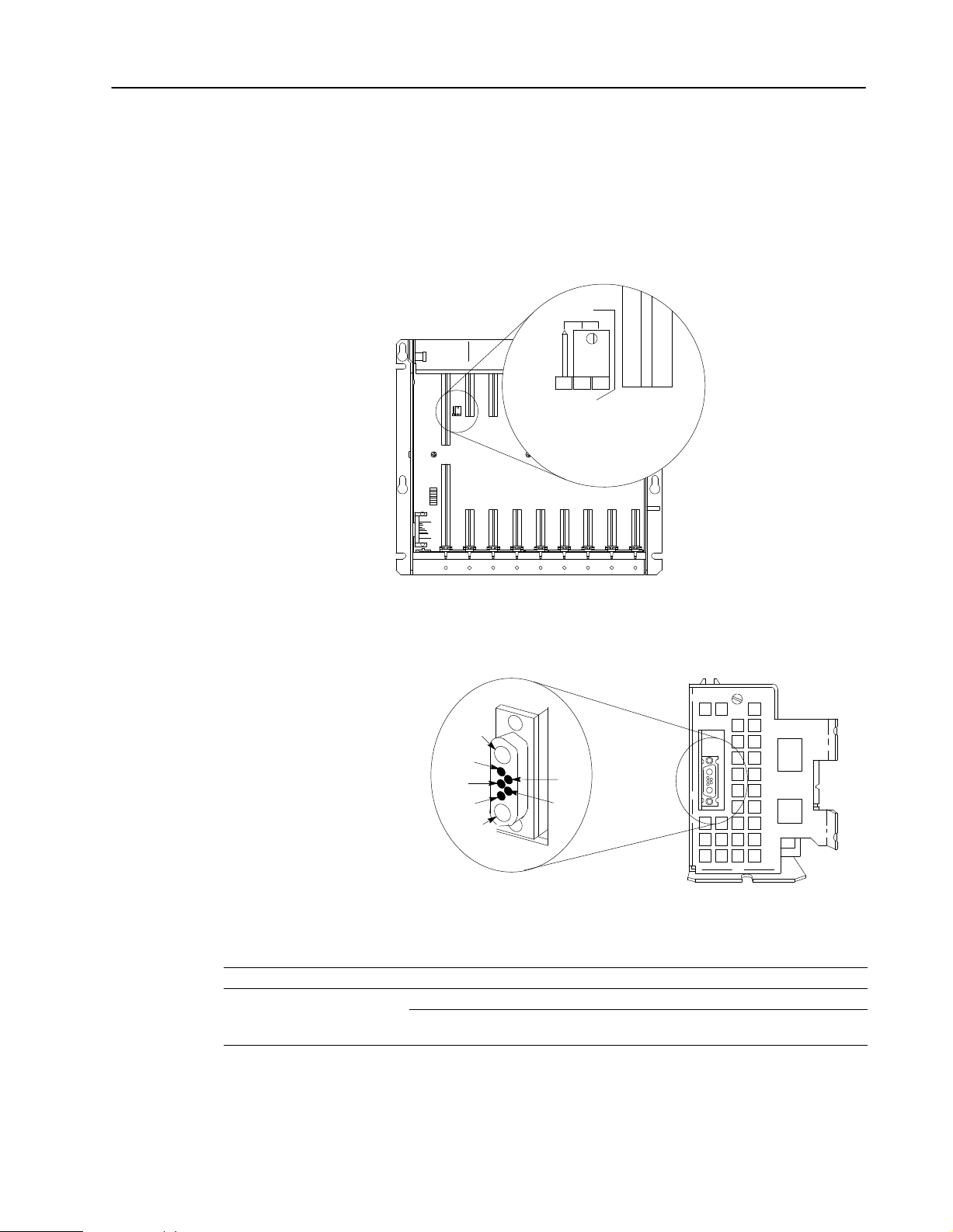

• set the power supply configuration jumper on the I/O chassis.

The 1771-P7 is an external power supply. Set the configuration

jumper to the N position.

NY

Using

Power

Supply

Module in

the Chassis?

Install the 1771P7 and

Connect Backplane Power

A1 backplane common

A2 backplane +5V dc

1 no connection

2 backplane processor enable

3 backplane +5V dc sense

4 backplane signal ground sense

5 no connection

If you have this I/O chassis Use this power cable To connect a 1771P7 mounted

1771A3B

1771A1B, A2B, A3B1, or A4B

The power supply has a D-shell power connector that provides

power to the I/O chassis backplane.

A1

3

4

5

A2

1771CP2 within 1.52m (5ft) of the I/O chassis

1771CP1 within 0.32m (1.04ft) on the leftside of the I/O chassis

1771CP3

(right angle connector)

1

2

bottom view of power supply

within 1.68m (5.5ft) of the I/O chassis

12620I

13445

Publication

17715.39 December 1995

Page 4

AC (120/220V) 16A Power Supply4

If you are mounting the power supply Go to

on the left side of a panelmounted I/O chassis next section

separately from an I/O chassis page 6

Attaching to a Panelmounted I/O Chassis

1. Attach the mounting screws to the side of the I/O chassis

as shown:

ATTENTION: Use the mounting screws provided

with the 1771-P7. Longer screws may intrude into

!

the I/O chassis and interfere with module insertion.

shoulder washer

large screw

Tighten this screw.

lockwasher

two small screws

and lockwashers

leftside of I/O chassis

Loosely attach these screws.

2. Connect the power cable (ordered separately) to the D-shell

connector on the I/O chassis and tighten the connector screws.

13446

Publication

17715.39 December 1995

Dshell connector

connector screws

1771CP1 cable

leftside of I/O chassis

13447

Page 5

AC (120/220V) 16A Power Supply 5

3. Slide the power supply onto the left side of the chassis, as shown:

Place keyhole slot over

1771P7

Make sure mounting brackets

are behind the small screws.

large screw on I/O chassis.

Slide power supply down.

left side I/O chassis

13448

4. Tighten the small screws to secure the power supply to the

I/O chassis.

1771P7

left side I/O chassis

small

screws

12629I

5. Attach the other end of the power cable to the D-shell connector

on the bottom of the power supply and tighten the

connector screws.

1771P7

Dshell connector

connector screws

left side I/O chassis

1771CP1 cable

Publication

13449

17715.39 December 1995

Page 6

AC (120/220V) 16A Power Supply6

Mounting the Power Supply Separately

When mounted separately, the power supply may be mounted above

or next to the I/O chassis. It may not be mounted below, since it is

necessary to allow convection cooling of both the power supply and

the I/O chassis. A minimum vertical distance of 6 inches should be

maintained.

1. Mount the power supply vertically, above and within the

specified cable-feet (for your cable) of the D-shell connector on

the I/O chassis.

1771P7

Use the rear mounting flanges on the

power supply to mount it to a panel.

Allow for a generous bend of the

1771CP2 or 1771CP3 cable to reduce

stress on the connectors mounted on

the chassis and the power supply.

2. Connect one end of the power cable (ordered separately) to the

D-shell connector located on the bottom of the power supply and

tighten the connector screws.

1771P7

15.2cm

(6")

12621I

Publication

17715.39 December 1995

connector screws

1771-CP2 or 1771CP3 cable

12622I

Page 7

AC (120/220V) 16A Power Supply 7

3. Connect the other end of the power cable to the D-shell connector

on the I/O chassis and tighten the connector screws.

1771A1B, A2B, A3B1, A4B I/O chassis 1771A3B I/O chassis

1771-CP3

1771-CP2

Connect ac Power Source to the Power Supply

ON

POWER

OFF

115V

12625I

12623I

The power supply operates on nominal120V ac or 220V ac

input source.

1. Make sure the power switch is set to OFF.

2. Use a 1/8” slotted screwdriver to set the input-voltage

selector switch.

ATTENTION: To avoid damaging the power

supply, do not place the screwdriver blade more

!

For an input voltage of Set the voltage selector switch to

97 to 132V ac

195 to 264V ac

than 3/8” into the switch slot.

115 position

230 position

115V

230V

12624I

Publication

17715.39 December 1995

Page 8

AC (120/220V) 16A Power Supply8

3. Connect the ac power line to the terminal strip on the

power supply.

ATTENTION: You must connect a 14 AWG wire

from the GND terminal to the ground bus to provide

!

an adequate safety ground.

ac power connectors

Troubleshooting

P/S

Active

Connect

high side of the line power

low side of the line power

central ground bus (earth ground)

➀

A

3A 250V normalblow fuse protects the input line L1 from drawing more than 3 amperes.

➀

L1

L2/N

GND

Line 1

Line 2 or

neutral

14 AWG

Ground

Bus

Grounding electrode

conductor

The power supply has a green P/S ACTIVE LED that provides status

indication during power supply operation.

Normal operation If indicator is Then

on

off it may be due to:

• input voltage not within specified range

• blown fuse

• overcurrent

ac power

(customer

supplied)

12626I

Publication

12627I

17715.39 December 1995

Important: If a shutdown condition occurs, wait 15 seconds before

attempting to apply power.

For additional assistance, contact your local Allen-Bradley

representative.

Page 9

AC (120/220V) 16A Power Supply 9

Specifications

45mm

1.77"

315mm

(12.40")

293mm

(11.53")

Depth is 159mm (6.25")

115mm

(4.53")

12628I

Nominal Input Voltage/Current

Input Voltage Range

Input Power (Real/Apparent) 108 Watts/176VA

External Transformer 270VA at full load

Frequency Range 4763Hz

Isolation Voltage

Output Voltage

Output Current 16A max @ 5V dc

Power Loss Time Delay

Input Power to Processor Disable

Fuse

Screw Torque 12 poundinch

Weight 1.95kg (4.3 lbs.)

Dimensions (H x W x D)

Environmental Conditions

Operating Temperature

Storage Temperature

Relative Humidity

1771CP1

Cables 1771CP2

1771CP3

Agency Certification

(when product or packaging

is marked)

120V ac @ 2.0A

220V ac @ 1.0A

120V ac: 97132V ac

220V ac: 195264V ac

2500V dc for 1s

1800V ac (rms) for 1s

5.06V dc ±3.8%

13.6msec ±2.9ms

3A, 250V 3AG normal blow

(Bussmann AGC 3 Littelfuse 312003)

315mm x 115mm x 159mm

(12.40" x 4.53" x 6.25" )

32 to 140° F (0 to 60° C)

-40 to 185° F (-40 to 85° C)

5 to 95%, noncondensing

0.32m (1.04ft) connects panel mounted I/O chassis

to chassis mounted 1771P7

1.52m (5ft) connects rackmounted I/O chassis

to remote 1771P7

1.68m (5.5ft) connects panelmounted I/O chassis

to remote 1771P7

marked for all applicable directives

input power to chassis ground

Power Ratings

16

Backplane

Load Current

(Amps)

12

8

4

0

20 60 100 140 180

Apparent Power (VA)

Use these graphs to determine your:

• cooling requirements

• power cost

• transformer size (unless the transformer manufacturer has a

recommended multiplier for sizing a transformer for an ac-to-dc

power supply)

16

12

8

4

0

0 306090120

Real Power (Watts)

PLC-2/02, PLC-2/05, PLC-2/16, and PLC-2/17 are trademarks of Allen-Bradley Company, Inc.

16

12

8

4

0

0 75 150 225 300

Transformer Sizing (VA) =

Real Power (Watts) x 2.5

Publication

17715.39 December 1995

Page 10

AC (120/220V) 16A Power Supply10

AllenBradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

worlds leading technology companies.

Worldwide representation.

Argentina •

Denmark • Ecuador

Ireland

Philippines •

Sweden

AllenBradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 3822000 Fax: (1) 414 3824444

Publication

Australia • Austria • Bahrain

• Israel • Italy • Jamaica •

• Switzerland • T

17715.39 December 1995

Publication

• Egypt • El Salvador • Finland • France •

Poland • Portugal • Puerto Rico • Qatar • Romania • Russia-CIS • Saudi Arabia • Singapore

aiwan

17715.39 December 1995

• Belgium • Brazil •

Japan • Jordan • Korea • Kuwait • Lebanon

• Thailand • T

urkey • United Arab Emirates • United Kingdom • United States • Uruguay

Bulgaria • Canada

Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary

• Chile •

China, PRC • Colombia

• Malaysia • Mexico •

• Costa Rica •

Netherlands

• New Zealand •

• Slovakia • Slovenia •

Croatia • Cyprus

Norway

South Africa, Republic

• V

enezuela

Copyright

• Iceland •

• Yugoslavia

1995 AllenBradley Company

• Czech Republic •

India • Indonesia

• Pakistan •

Peru

•

• Spain •

PN 95512301

, Inc. Printed in USA

•

Loading...

Loading...