Page 1

Page 2

T

able of Contents

Introduction 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 1-1

Typical

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

Module Preparation, Wiring and Installation 2-1 . . . . . . . . . . . . . .

General 2-1

Switch

Wiring 2-4

Additional

Keying 2-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selection of Operating Modes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Considerations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-10

Programming and Operation 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . .

General 3-1

Module Scan of Switch Contacts

Storage

Block

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of Switch Contact Data

T

ransfer of Switch Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3-1

3-14

Specifications A-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 3

T

able of Contents

ii

Page 4

Introduction

Chapter

1

General

The 1771-IS DC (5V) Multiplexer Input Module, Figure 1.1 reads the

status of up to 72 hard contact switch devices through one I/O slot. This

information is transferred to the PC processor by block transfer

programming. The module can be used with any Allen-Bradley

programmable controller that has block transfer capability, an expandable

data table, and uses the 1771-I/O structure.

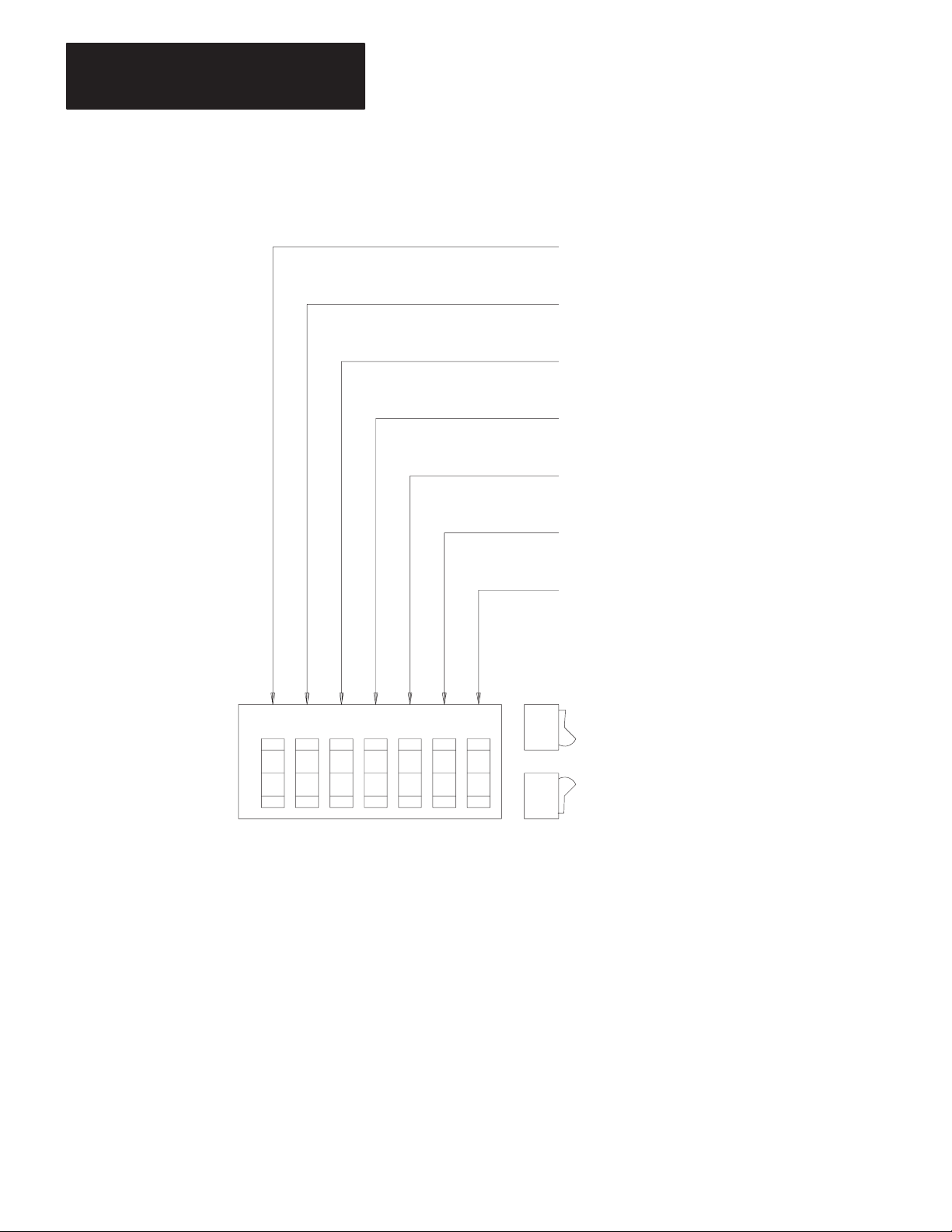

Figure 1.1

DC

(5V) Multiplexer Input Module

17929

When thumbwheel switches are used with the module, user-selectable

operating modes can be selected for convenient storage of 3-digit and

4-digit BCD thumbwheel data. An additional mode is provided that

latches the input of momentary contact devices such as pushbutton or

keyboard switches.

The module performs self diagnostics during its initial power-up

sequence. If a memory failure is detected at any time, the fault LED on

the front panel will illuminate and the module will not operate.

i

Page 5

T

able of Contents

The module reads the status of switch contacts by enabling and reading a

“bank” of 8 contacts at a time. This requires that the contacts be grouped

and that diode decoupling be used to prevent the appearance of a

“phantom” contact closure. Up to 9 banks of 8 contacts per bank can be

handled by the module. Power to the switch banks is provided by the

module.

Contact scanning occurs until the module is interrupted by a read

instruction from the PC processor. Contact status is stored in on-board

RAM memory until the module outputs the contact status to the

processor. Therefore switch scanning by the module is totally

independent of I/O scanning by the processor. Module scanning is

user-selectable at a normal or fast rate with contact de-bouncing.

Typical Applications

In many applications, it is necessary to set or change the preset values of

timers or counters or the values of process variables. It is convenient to

do this using BCD thumbwheel switches (Figure 1.2). Applications that

require the use of multiple thumbwheel switches include, but are not

limited, to the following:

control of chemical processes

production-part adjustments used in the automatic balancing of tires

control of pallets in materials handling

cycle time adjusments in production machines and processes

Figure 1.2

Typical

3-digit Thumbwheel Switch

6

–

–

9

–

2

+

The DC (5V) Multiplexer Input Module saves I/O space and user

program. It can handle the switch input from up to six 3-digit or four

4-digit BCD thumbwheel switches. It can also handle up to 72 discrete

contact switches.

ii

+

+

17928

Page 6

T

able of Contents

WARNING: Outputs of any output module may temporarily

change operating state at power-up if placed in the same I/O

chassis with a multiplexer module, cat. no. 1771-IS, earlier

than hardware revision D, and a power supply (or processor

with self-contained power supply) other than 1771-P1 or

1771-P2. To avoid damage to equipment and/or injury to

personnel use only multiplexer modules, cat. no. 1771-IS,

hardware revision D or later.

Important: Hardware revision D is designated by part no.

XXXXXX-XX/D on the module nameplate. Earlier modules (cat. no

1771-ISC) do not have this part no./D designation.

iii

Page 7

T

able of Contents

iv

Page 8

Chapter

2

Module Preparation, Wiring and Installation

General

Switch Selection of Operating

Modes

The modes of operation must be set internally to suit the conditions under

which the module will be used. In addition, switch contacts and

decoupling diodes must be wired to the module.

The module is capable of operating in a variety of modes depending on

the kinds of switches connected to it, whether the module is placed in a

local or remote I/O rack, and/or whether latched data in module memory

will be reset automatically or by program logic after the transfer of data.

The mode selection switch is mounted near the lower rear corner of the

printed circuit board under the left side cover of the module. It is

accessible by removing the four slotted cover screws on the right side of

the module.

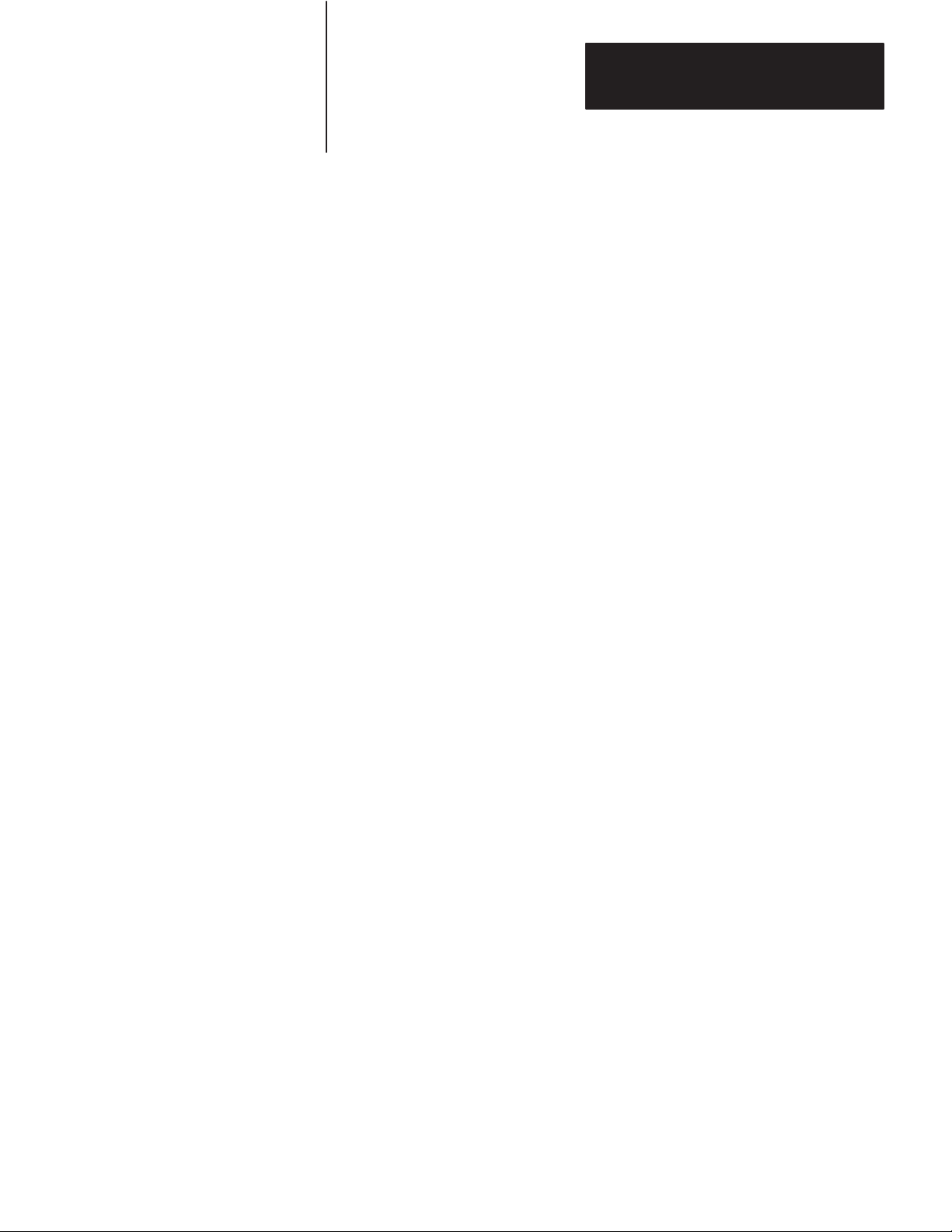

The modes are selected by setting the mode selection switches ON or OFF

according to the positions defined in Figure 2.1.

2-1

Page 9

Chapter 2

Module Preparation, Wiring, and

Installation

Figure 2.1

Mode

Selection Dip Switch

ON

1

OFF

ON

2

OFF

ON

3

OFF

ON Momentary (Latched) Contact Mode

4

OFF

ON

5

OFF

ON

6

OFF

ON

7

OFF

Always OFF

16–Bit Data

12–Bit Data

Fast

Normal

Maintained Contact Mode

Always OFF

Always OFF

Program Initiated Reset

Automatic Reset

1234567

O

N

O

F

F

Switch #1 - Always OFF.

Switch #2 - 16 Bit Storage/12 Bit Storage, Select 12-bit storage when

using 3-digit BCD thumbwheel switches. Select 16-bit storage when

using 4-digit BCD thumbwheel switches, discrete momentary contact

switches, or discrete maintained contact switches. (ON for 16-bit storage,

OFF for 12-bit storage.)

Switch #3 - Normal Scan/Fast Scan. The module scan is independent of

the processor scan and is generally set at the normal (15.3 msec) position.

The fast scan (5.1 msec) can be used when operating in either the

ON

OFF

ON

OFF

ON

OFF

10362

2-2

Page 10

Chapter 2

Module Preparation, Wiring and

Installation

momentary (latched) contact mode or maintained contact mode. (ON for

fast scan, OFF for normal scan.)

Switch #4 - Maintained Contact Mode/Momentary (latched) Contact

Mode. Select the maintained contact mode when storing the status, ON or

OFF, of maintained switch contacts. Their status is updated in every scan.

Select the momentary (latched) contact mode when storing momentary

OFF-ON switch contact transitions. Subsequent scans will not reset

latched bits even if the corresponding switches are reopened. The

transition is latched ON in module memory and must be reset after the

latched data is transferred to the processor. [ON for momentary (latched)

contacts, OFF for maintained contacts.] The position of SW #4 will also

affect data byte storage. See the diagrams in chapter 3 for further detail.

Switch #5 - Always OFF.

Switch # 6 - Always OFF.

Switch # 7 - Program Reset/Automatic Reset. Select program reset when

momentary (latched) switch status data is to be reset by setting a bit in a

user program instruction. Refer to section titled “Other Programming

Considerations, PLC-2 Family and PLC-3.” Select automatic reset when

momentary (latched) switch data is to be reset automatically. This switch

is not functional when the module is operating in the maintained contact

mode. (ON for program reset, OFF for automatic reset).

Important: When using momentary contact mode in remote applications,

only the program reset mode should be selected. Use program reset to

guard against loss of data during transfer to the processor. When using

momentary contact mode in local I/O applications, either the program

reset or automatic reset can be selected.

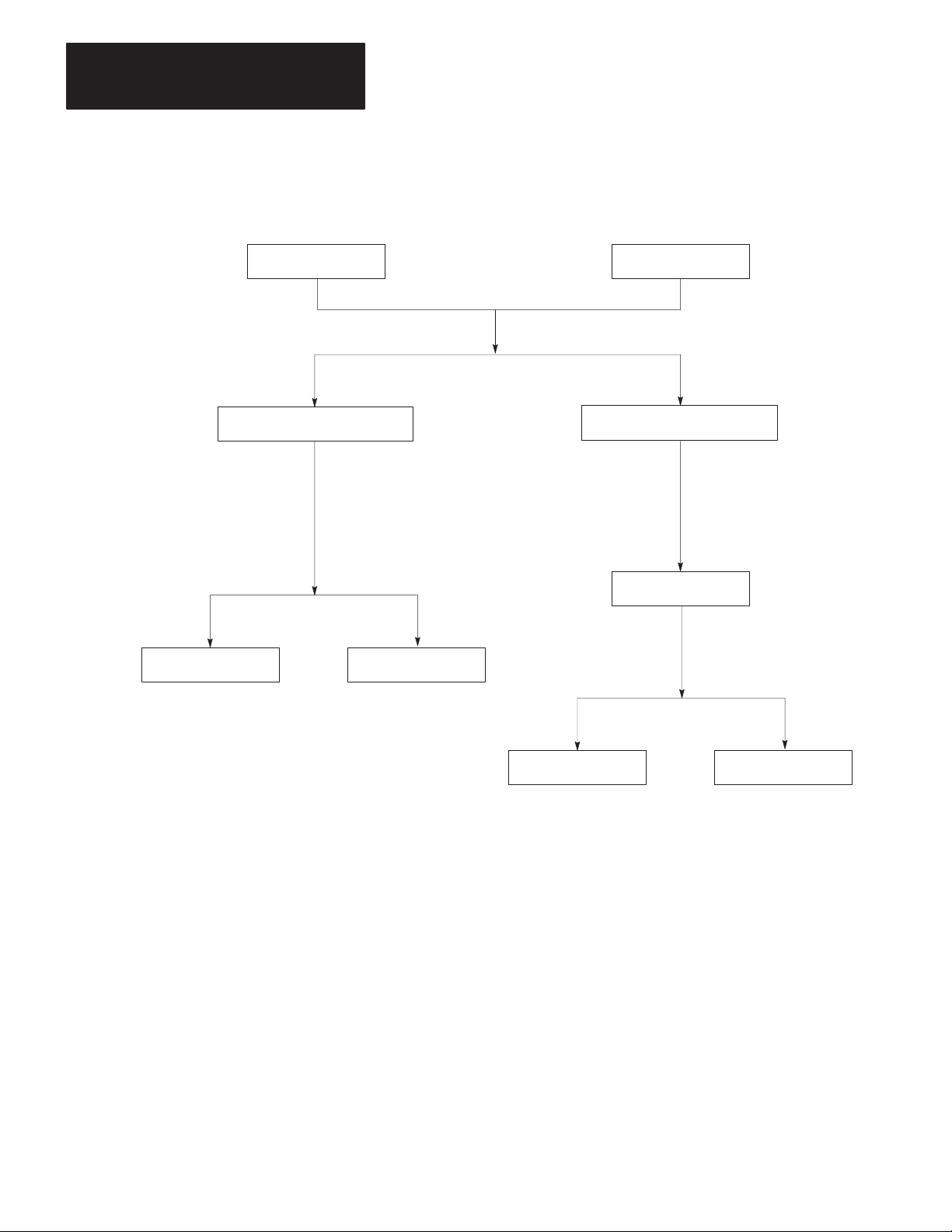

The allowable combinations of module operating modes are summarized

in Figure 2.2.

2-3

Page 11

Chapter 2

Module Preparation, Wiring, and

Installation

Figure 2.2

Allowable

Normal Scan Fast Scan

Operating Modes

1771-IS Multiplexer Module

12–Bit

Maintained Contacts

Momentary (latched) Contacts

16–Bit

16–Bit

Program Reset Automatic Reset

10363

Wiring

2-4

The wiring and programming of the module are dependent on each other.

Switch assemblies should be wired according to the wiring schematics

presented in this chapter. If wired differently, the transfer of data may not

take place or may become scrambled.

Module Wiring

Connections to the module are made through a removable field wiring

arm connector (cat. no. 1771-WF) which allows the module to be

Page 12

Chapter 2

Module Preparation, Wiring and

Installation

removed or installed in the I/O rack without disconnecting the wiring.)

The swingarm can be removed from the I/O rack at the pivot bar.

Thumbwheel Switch Wiring

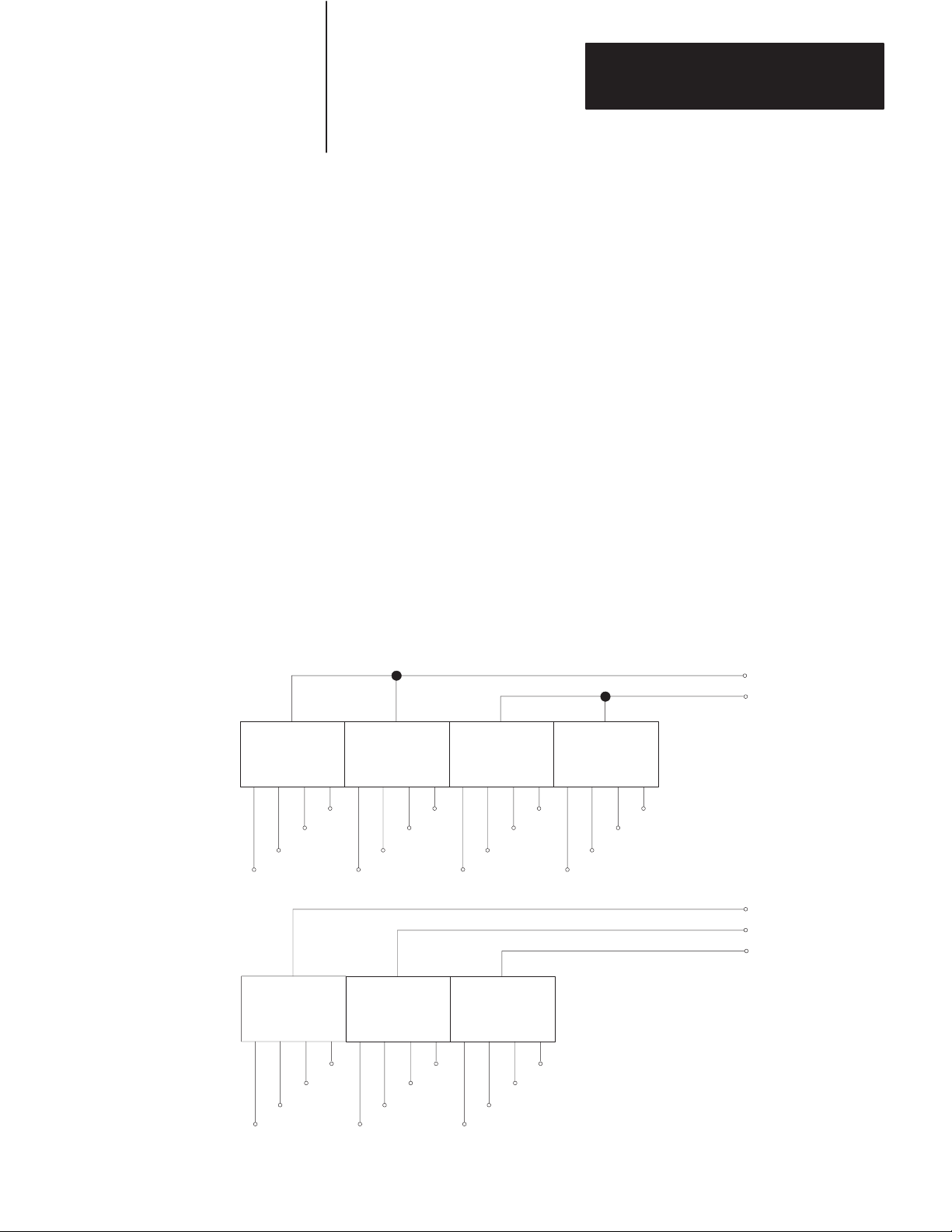

Thumbwheel switch terminations are illustrated in Figure 2.3. Digit place

labels refer to the position of each digit in a 3-digit or 4-digit thumbwheel

switch as follows:

MSD and LSD - Most and Least Significant Digit; MD Middle Digit;

UMD and LMD - Upper and Lower Middle Digit, respectively.

Thumbwheel switches are wired in parallel as shown in Figure 2.4 for

4-digit switches, and in Figure 2.5 for 3-digit switches. The four switch

terminals numbered 8, 4, 2, 1 for each thumbwheel digit are wired

respectively to field wiring arm terminals 2, 3, 4, 5 or 6, 7, 8, 9. Field

wiring arm terminal 1 is not used.

4–Digit

Thumbwheel

3–Digit

Thumbwheel

Figure 2.3

Thumbwheel Terminations

Enable Lines

MSD

1

2

4

8

MSD

UMD

1

2

4

8

MD

LMD

1

2

4

8

LSD

LSD

2

4

8

Enable Lines

Digit Place Labels

Digit Place Labels

1

Switch Terminal

Numbers

1

2

4

8

4

8

1

2

4

8

1

2

Switch Terminal

Numbers

10364

2-5

Page 13

Chapter 2

Module Preparation, Wiring, and

Installation

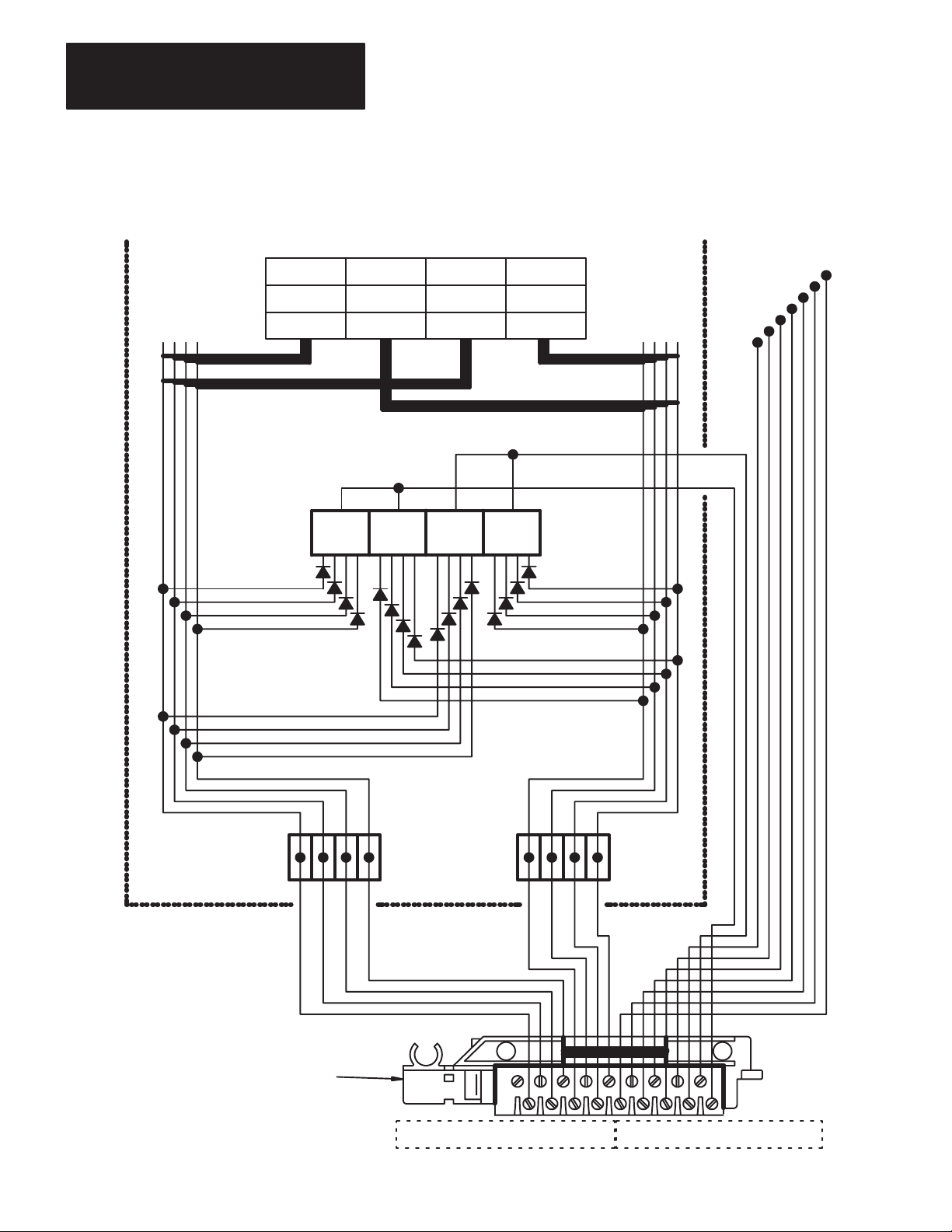

Figure 2.4

T

ypical Point-to-point W

Switch Contact Mode)

iring for Up to Four 4-digit Thumbwheel Switches (Maintained

Enable

SW4

SW3

8421 8421

SW2

MSD UMD LMD LSD

MSD

MSD

UMD

UMD

LMD

LMD

LMD

AABB

SW1

8

421 8421 8421 8421

LSDLMDUMDMSD

LSD

LSD

4–Digit

Thumbwheel

Switch

(User Supplied)

Lines

G & H

E & F

C & D

I

H

G

F

E

D

C

B

A

2-6

8421

Field Wiring Arm

1771–WF

Digit Junction

Terminal Strip

(User Supplied)

8421

2346578

1

Module Inputs 7 6 5 4 3 2 1 0 ABCDEFGHI

9

10111213141516

18

17

Enable Lines

10365

Page 14

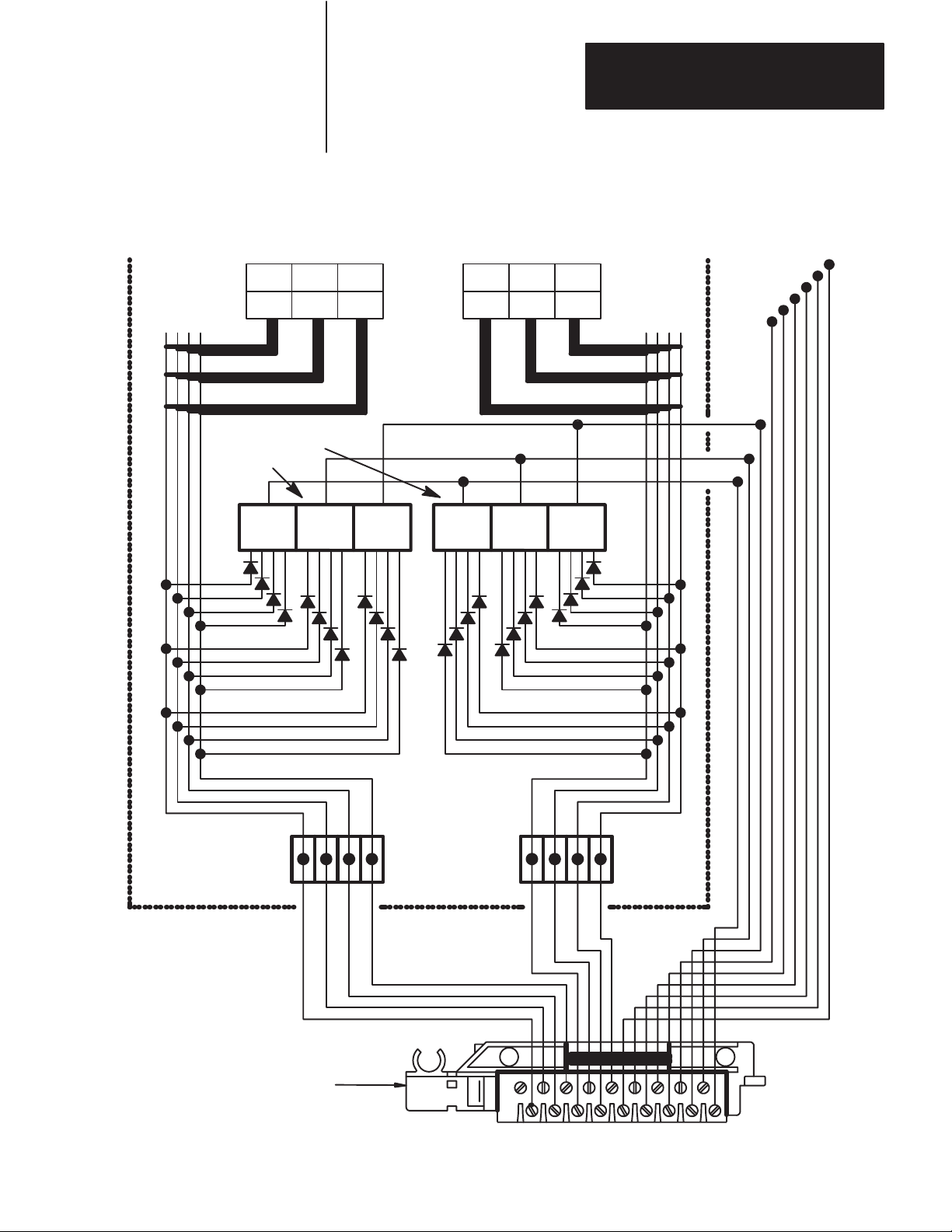

Figure 2.5

T

ypical Point-to-point W

Contact Mode)

Chapter 2

Module Preparation, Wiring and

Installation

iring for Up to Six 3-digit Thumbwheel Switches (Maintained Switch

Enable

Lines

SW6

MSD MD LSD MSD

MSD MD LSD MSD

G, H, I

D, E, F

MD LSD

MD LSD

SW3

SW2SW5

8421 8421

3–Digit

Thumbwheel Switch

(User Supplied)

SW4

ABC

MSD MD

LSD

A

MSD MD LSD

BC

SW1

8421 8421 8421 8421 8421 8421

I

H

G

F

E

D

C

B

A

8421

Field Wiring Arm

1771–WF

Digit Junction

Terminal Strip

(User Supplied)

8421

1

2345678

9

10

1112131415

Module Inputs 7 6 5 4 3 2 1 0 I H G F E D C B A

17

18

16

Enable Lines

10366

2-7

Page 15

Chapter 2

Module Preparation, Wiring, and

Installation

Important: The selection of the four field wiring arm terminals, either 2,

3, 4, 5 or 6, 7, 8, 9 is critical for correct transfer of switch status data.

The point-to-point wiring schematics show all electrical connections for

the first of several parallel switch assemblies. The wiring of additional

assemblies is shown conceptually (in the upper portion of each

schematic). Switch lines 8, 4, 2, 1 are wired to each additional switch

assembly using decoupling diodes identically to the first switch assembly.

Enable line(s) for each additional switch assembly are specified in the

conceptual part of the drawing.

The enable lines, A through I, are wired to field wiring arm terminals 18

through 10, respectively. Note that enable line A is connected to field

wiring arm terminal 18, etc. It may be desirable to terminate thumbwheel

switch lines 8, 4, 2, 1 at a terminal block on the switch panel. A single set

of switch lines 8, 4, 2, 1 and enable lines should be contained in a shielded

cable connecting the switch panel to the field wiring arm to minimize

connections at the field wiring arm terminals.

Observe the following practices when wiring thumbwheel switches:

Bundle thumbwheel switch wiring separately from other wiring.

Shielded cable is recommended.

Ground the shielded cable only at the I/O rack. The shield must remain

ungrounded at the other end.

Discrete Switch Bank Wiring

Up to 72 discrete contact switches can be wired to the module as shown in

Figure 2.6. These switches can be momentary contact or maintained

contact switches. Refer to section titled “Thumbwheel Switch Wiring”

for wiring guidelines and practices.

2-8

Page 16

Figure 2.6

Typical

Point-to-point W

Contact Mode)

Chapter 2

Module Preparation, Wiring and

Installation

iring for up to 72 Discrete Contact Switches (Maintained Switch

7 6 5 4

Bank 9

Bank 8

Bank 7

Bank 6

Bank 5

Bank 4

Bank 3

Bank 2

S7 S6 S5 S4 S3 S2 S1 S0

Discrete

Switches

(User

Supplied)

S7 S6 S5 S4 S3

S2 S1 S0Bank 1

Enable

I

H

G

F

E

D

C

B

A

Lines

3 2 1 0

I

H

G

F

E

D

C

B

A

7654

Field Wiring Arm

1771–WF

Digit Junction

Terminal Strip

(User Supplied)

Module Inputs

32 10

1

2345678

65432 0

17 I H G F E D C B A

9

10

11121314151617

18

Enable Lines

10367

2-9

Page 17

Chapter 2

Module Preparation, Wiring, and

Installation

Diode Decoupling

Decoupling diodes prevent unwanted currents from circulating through

the switch circuits and causing the false appearance of switch closures.

Use decoupling diodes when the application calls for more than 8 switch

contacts. Some thumbwheel switches have provision at the switch

terminals for wiring the diodes. Otherwise, a separate terminal strip

should be used for wiring a diode to each switch terminal. Be sure that all

diodes are wired with the same polarity as shown in Figure 2.4, Figure 2.5

or Figure 2.6.

Additional Considerations

The following information will be helpful when selecting the cable and

components, and when wiring the switches and decoupling diodes to the

module.

Low - TRUE Logic

Module operation is based on a low = TRUE logic. Enable lines, A

through I, ground the inputs connected to them through the switch

contacts. This low = TRUE condition is interpreted as a logic “1” (or

contact closed) by the module.

No External Power

The switches connected to the module are powered by the module enable

lines. Any additional power source must NOT be used.

CAUTION: Damage to the module will result if any external

power source is connected to the module field wiring arm

terminals.

2-10

Switch Selection

Any contact closure switch than can successfully handle 8 to 14mA of

current at 5V DC can be used. The minimum OFF resistance can be 10 K

ohms. The maximum ON resistance can be 10 ohms including the cable

resistance.

Page 18

Chapter 2

Module Preparation, Wiring and

Installation

CAUTION: This module is not compatible with TTL

switching. The external power source will damage the module.

When selecting BCD thumbwheel switches, be sure that they are equipped

with decoupling diodes or that terminals are available on the thumbwheel

switch so that the diodes can be wired directly to the switch assembly.

The diode polarity must be set for low = TRUE operation. Cathodes must

be connected to the switch contacts and anodes to the module inputs (lines

8, 4, 2, 1).

When selection thumbwheel switches, be sure to select a BCD type.

Decimal thumbwheel switches should be avoided because the 10 discrete

connections for each digit would not be compatible with the 4 BCD coded

input terminals for each digit on the module swingarm.

Keying

Diode Selection

Any diode can be used for diode decoupling that has a forward voltage

drop of approximately 0.7 volts at 14 mA forward current. A 1N914 is a

typical diode that can be used.

Cable Selection

The maximum cable capacitance can be .039 microfarad. The wire size

can be 20 gauge or larger for cables shorter than 100 feet; and 18 gauge

for up to 400 feet. The cable should be shielded and should not exceed

400 feet in length.

The backplane connector should be keyed to accept only this module after

its position in the I/O rack has been determined. The module can be

placed in any I/O slot except for the left-most slot. Th slot is reserved for

the processor module in a single rack system or the I/O adapter module in

a multi-rack system.

Plastic keying bands shipped with the I/O chassis should be used. The

position of the keying bands on the upper backplane connector must

correspond to the mating slots on the module connector.

2-11

Page 19

Chapter 2

Module Preparation, Wiring, and

Installation

Refer to Figure 2.7. Using needle-nose pliers, place the keying bands

between these numbers on the backplane:

Between 8 and 10

Between 26 and 28

Figure 2.7

Keying

Diagram

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Keying

Bands

Backplane

Connector

17871

The position of the keying bands can be changed if subsequent system

design requires the module to be moved to a different location.

2-12

Page 20

Chapter

Programming and Operation

3

General

Module Scan of Switch Contacts

Storage of Switch Contact Data

Switch status data is stored in the module, transferred to the data table

upon request by block transfer instructions, then stored in a data table file

until operated upon by user program instructions.

The user-selectable scan rates are 15.3 msec (normal) and 5.1 msec (fast).

The nine enable lines, A through I, are sequentially and repeatedly

enabled, one line at a time. The enable lines operate in a low = TRUE

logic. Each enable line can enable a bank of 8 switches simultaneously.

The module allows for contact debouncing before the module’s

microprocessor reads the status of the switch bank. Scanning is

continuous unless interrupted by a user program instruction to transfer the

status of the switch contacts to the data table. Scanning resumes at the

same point where it was interrupted after the data is transferred.

BCD thumbwheel switches convert selected decimal numbers to a switch

status setting. Four switch contacts are required to encode each decimal

digit of a thumbwheel switch in BCD. Switch status can be transferred to

the processor data table and stored in word format by user program

instructions (Figure 3.1).

Figure 3.1

Bit

Pattern of a Thumbwheel Setting

2951

MSD UMD LMD LSD

8421842184218421

17 10 07 00

00101001

01010001

Thumbwheel settings

Digit place labels

Switch status setting

Switch terminal numbers

Bit numbers

Equivalent bit pattern

(1 data table word)

10369

3-1

Page 21

Chapter 3

Programming and Operation

4-digit Thumbwheel Switch Data (16-bit storage)

Data is loaded into memory based on whether you have selected the

maintained or momentary switch contact mode (SWITCH #4).

Maintained Contact Mode

When 4-digit BCD thumbwheel switches are wired according to the block

diagram in Figure 3.2a, the switch settings will be stored automatically in

the data table after a block transfer as shown in Figure 3.2b. The first

word is reserved for diagnostic data. Each remaining word stores the four

digits of the thumbwheel setting. The digits MSD, UMD, LMD and LSD

have been loaded, respectively, from left to right, in the same order that

they are normally read (left to right). For example, observe how the

4-digit switch setting 9753 of thumbwheel switch #2 is loaded into the

data table.

3-2

Page 22

Chapter 3

Programming and Operation

Figure 3.2

4-digit

Thumbwheel Switch Data Storage, Maintained Contacct mode ( SWITCH #4 OFF)

A

MSD UMD

LMD LSD

B

C

9 7

35

D

E

MSD UMD

LMD LSD

F

G

MSD UMD

LMD LSD

H

I

Switch 1

a) Block Diagram

User Thumbwheel

Switch 2

9 7 5 3

Switch 3

Switch 4

Switch

Terminals

Field Wiring Arm

Terminals

Data

Table

Word

XX0

1

2

3

4

5

Extra Byte

2 8

3 4

4 2

5 1

Switch Status Data

17

Diagnostics - - -

MSD UMD LMD LSD 1

97532

MSD UMD LMD LSD 3

MSD UMD LMD LSD 4

--

10 07

1/2 Switch 5

8 6

4 7

2 8

1 9

Extra Byte

Switch

Terminals

Field Wiring Arm

Switch

Number

00

5

Terminals

b) Data Table Map

10370

3-3

Page 23

Chapter 3

Programming and Operation

Momentary Contact Mode

When 4-digit BCD thumbwheel switches are wired according to the block

diagram in Figure 3.3a, the switch settings will be stored automatically in

the data table after a block transfer as shown in Figure 3.3b. The first

word is reserved for diagnostic data. Each remaining word stores the 4

digits of the thumbwheel setting. The digits MSD, UMD, LMD and LSD

have been loaded, respectively, from left to right, in the opposite byte

order from which they normally read (left to right). For example, observe

how the 4-digit switch setting 9753 of thumbwheel switch #2 is loaded

into the data table.

3-4

Page 24

Chapter 3

Programming and Operation

Figure 3.3

4-digit

Thumbwheel Switch Data Storage, Momentary Contact Mode ( SWITCH #4 ON)

A

MSD UMD

LMD LSD

B

C

9 7

35

D

E

MSD UMD

LMD LSD

F

G

MSD UMD

LMD LSD

H

I

Switch 1

a) Block Diagram

User Thumbwheel

Switch 2

9 7 5 3

Switch 3

Switch 4

Switch

Terminals

Field Wiring Arm

Terminals

Data

Table

Word

XX0

1

2

3

4

5

Extra Byte

2 8

3 4

4 2

5 1

Switch Status Data

17

Diagnostics - - -

MSD UMD LMD LSD 1

53972

MSD UMD LMD LSD 3

MSD UMD LMD LSD 4

--

10 07

1/2 Switch 5

8 6

4 7

2 8

1 9

Extra Byte

Switch

Terminals

Field Wiring Arm

Switch

Number

00

5

Terminals

b) Data Table Map

10370

3-5

Page 25

Chapter 3

Programming and Operation

Important: The 16-bit data position (switch #2 ON) should be selected

when 4-digit thumbwheel switches or discrete contact switches are used.

Otherwise switch status data from these devices can become scrambled

when transferred to the data table.

Discrete Contact Switch Data (16-Bit storage)

Data is loaded into memory on the basis of whether you have selected the

maintained or momentary switch contact mode (switch #4).

Momentary Contact Mode

When up to 72 discrete contact switches are wired as switch banks,

Figure 3.4a, the settings are stored automatically in the data table after a

block transfer as shown in Figure 3.4b. The first word is reserved for

diagnostic data. Each remaining word stores the status of two switch

banks. The settings of a switch bank are represented by S7, S6, S5, S4,

S3, S2, S1, S0.

Data of odd-numbered switch banks appears in the lower byte, and data of

even-numbered switch banks appears in the upper byte, of their respective

data table words. For example, observe how the ON/OFF settings of

switch banks 5 and 6 are loaded into the data table in Figure 3.4b.

3-6

Page 26

Figure 3.4

Discrete-Contact

Chapter 3

Programming and Operation

Switch Bank Data Storage (SW #4 ON (Momentary) Mode)

A

S7 S6 S5 S4 S3 S2 S1 S0

Bank 1

B

Same

Bank 2

C

Same

Bank 3

D

Same

E

1

0 1101010

F

2

1 1100001

Bank 4

Bank 5

Bank 6

a) Block Diagram

G

S7 S6 S5 S4 S3 S2 S1 S0

Bank 7

H

Same

Bank 8

Switch

Terminals

Field Wiring Arm

Terminals

2

3

4

5

Data

Table

Word

XX0

1

4

I

Same

Bank 9

Switch

Terminals

7

6

5

4

Switch Status Data

Bit Number

17

10 07

Diagnostics

Bank 2

2

3

Bank 4

1110 0001

2

Bank 8

5

-

3

2

1

0

- -

Bank 1

Bank 3

0110 1010

Bank 7

Bank 9

6

7

8

9

Field Wiring Arm Terminals

00

1

2

1

10371

b) Data Table Map

0110

1010 shows the settings, ON or OFF

S7, S6, S5, S4, S3, S2, S1, S0 of switch bank 5.

11

10 0001 shows the settings, ON or OFF

S7, S6, S5, S4, S3, S2, S1, S0 of switch bank 6.

, of Switches

, of Switches

3-7

Page 27

Chapter 3

Programming and Operation

Maintained Control Mode

When up to 72 discrete contact switches are wired as switch banks,

Figure 3.5a, the settings are stored automatically in the data table after a

block transfer as shown in Figure 3.5b. The first word is reserved for

diagnostic data. Each remaining word stores the status of two switch

banks. The settings of a switch bank are represented by S7, S6, S5, S4,

S3, S2, S1, S0.

Data of odd-numbered switch banks appears in the upper byte, and data of

even-numbered switch banks appears in the lower byte of their respective

data table words. For example, observe how the ON/OFF settings of

switch banks 5 and 6 are loaded into the data table in Figure 3.5b.

3-8

Page 28

Figure 3.5

Discrete-Contact

Chapter 3

Programming and Operation

Switch Bank Data Storage (SW #4 OFF (Maintained) (Mode)

A

S7 S6 S5 S4 S3 S2 S1 S0

Bank 1

B

Same

Bank 2

C

Same

Bank 3

D

Same

E

1

0 1101010

F

2

1 1100001

Bank 4

Bank 5

Bank 6

a) Block Diagram

G

S7 S6 S5 S4 S3 S2 S1 S0

Bank 7

H

Same

Bank 8

Switch

Terminals

Field Wiring Arm

Terminals

2

3

4

5

Data

Table

Word

XX0

1

4

I

Same

Bank 9

Switch

Terminals

7

6

5

4

Switch Status Data

Bit Number

17

10 07

Diagnostics

Bank 2

2

3

Bank 4

0110 1010

1

Bank 8

5

-

3

2

1

0

- -

Bank 1

Bank 3

1110 0001

Bank 7

Bank 9

6

7

8

9

Field Wiring Arm Terminals

00

1

2

2

10371

b) Data Table Map

0110

1010 shows the settings, ON or OFF

S7, S6, S5, S4, S3, S2, S1, S0 of switch bank 5.

11

10 0001 shows the settings, ON or OFF

S7, S6, S5, S4, S3, S2, S1, S0 of switch bank 6.

, of Switches

, of Switches

3-9

Page 29

Chapter 3

Programming and Operation

Important: When momentary switch contacts are used, the momentary

(latched) contact position (switch #4, ON) should be selected. Otherwise,

bits will be reset when the momentary contact switches open and data

representing OFF-to-ON transitions can be lost.

The maintained contact position (switch #4 OFF) should be selected if the

application calls for the use of up to 72 maintained contact switches.

3-digit Thumbwheel Switch Data (12-bit storage)

Data is loaded into memory on the basis of whether you have selected the

maintained or momentary switch contact mode (switch #4).

Maintained Contact Mode

When 3-digit BCD thumbwheel switches are wired according to the block

diagram in Figure 3.6a, the switch settings are stored automatically in the

data table after a block transfer as shown in Figure 3.6b. The first word is

reserved for diagnostic data. Each remaining word stores the three digits

of the thumbwheel setting. The digits MSD, MD and LSD have been

loaded, respectively, from left to right, in bits 13-00 in the same order that

they are normally read. For example, observe how the 3-digit switch

setting 642 of switch #3 is loaded into the data table (Figure 3.6b).

3-10

Page 30

Chapter 3

Programming and Operation

Figure 3.6

3-digit

Thumbwheel Switch Data Storage, Maintained Contact Mode ( SWITCH #4 OFF)

Switch 4

Switch 5

Switch 6

A

B

C

D

E

F

G

H

I

MSD

MD

LSD

MSD

MD

LSD

MSD

MD

LSD

MSD

MD

LSD

MSD

MD

LSD

6

4

2

A

B

Switch 1

C

D

E

F

G

H

I

Switch 2

User Thumbwheel

Switch 3

6 4 2

a) Block Diagram

Switch

Terminals

Field Wiring Arm

Terminals

Data

Table

Word

XX0

1

2

3

4

5

6

17

2

8

3

4

4

2

1

5

Diagnostics

-

-

-

-

-

-

Switch Status Data

10 07

MSD

MSD

6

MSD

MSD

MSD

MD

MD

MD

MD

MD

Switch

Field Wiring Arm

Terminals

00

-

Terminals

Switch

Number

1

2

3

4

5

6

b) Data Table Map

10372

8

6

4

7

2

8

1

9

LSD

LSD

4

2

LSD

LSD

LSD

3-11

Page 31

Chapter 3

Programming and Operation

Momentary Contact Mode

When 3-digit BCD thumbwheel switches are wired according to the block

diagram in Figure 3.7a, the switch settings are stored automatically in the

data table after a block transfer, as shown in Figure 3.7b. The first word

is reserved for diagnostic data. The remaining words store the three digits

of the thumbwheel setting. The digits MSD, MD and LSD have been

loaded in the order are shown in Figure 3.7. For example, observe how

the 3-digit switch setting 642 of switch #3 is loaded into the data table

(Figure 3.7b).

3-12

Page 32

Chapter 3

Programming and Operation

Figure 3.7

3-digit

Thumbwheel Switch Data Storage,Momentary Contact Mode ( SWITCH #4 ON)

Switch 4

Switch 5

Switch 6

A-4

B-4

C-4

D-5

E-5

F-5

G-6

H-6

I-6

MSD

MD

LSD

MSD

MD

LSD

MSD

MD

LSD

MSD

MD

LSD

MSD

MD

LSD

6

4

2

A-1

B-1

Switch 1

C-1

D-2

E-2

Switch 2

F-2

G-3

User Thumbwheel

H-3

Switch 3

642

I-3

a) Block Diagram

Switch

Terminals

Field Wiring Arm

Terminals

Data

Table

Word

XX0

1

2

3

4

5

6

17

2

8

3

4

4

2

1

5

Diagnostics

B-4

D-5

F-5

H-6

-

-

Switch Status Data

10 07

MD

B-1

D-2

F-2

MD

4

-

-

A-4

C-4

E-5

G-6

-

Switch

8

4

2

1

6

7

8

9

Terminals

Field Wiring Arm

Terminals

00

A-1

C-1

-

MSD

LSD

b) Data Table Map

E-2

MSD

6

I-6

LSD

2

-

10372A

3-13

Page 33

Chapter 3

Programming and Operation

Important: The 12-bit data position (switch #2 OFF) should be selected

when 3-digit thumbwheel switches are used. Otherwise switch status data

from this device can become scrambled when transferred to the data table.

Block Transfer of Switch Data

Switch status data can be transferred to the PC processor data table by

using block transfer instructions.

The Mini-PLC-2/15, PLC-2/30 and PLC-3 programmable controllers use

block transfer instructions. The Mini-PLC-2 (1772-LN3 Processor) and

PLC-2/20 use multiple GET instructions for programming block transfer.

Block Transfer Programming, PLC-2 Family

The processor transfers switch status data from the module to the data

table by a block transfer read operation. The following information must

be specified in order to program block transfer, whether using block

transfer instructions or multiple GET instructions. Values entered in

parentheses correspond to the programming example in paragraph titled

“Programming Example, PLC-2 Family” and Figure 3.8.

a) block length: the number of words to be transferred can be 0-7

depending on the number of switch assemblies. (03)

b) module address: rack, module group and slot number. (121)

3-14

c) data address: contains the module address in binary coded decimal

and is the first available address in the timer/counter accumulated area

of the data table. (030)

d) file address: defines the first of a group of words in the data table to

receive the transferred data and is located 100

above the data address.

8

(060)

For additional information on programming block transfer instructions,

refer to paragraph titled “Programming Considerations, PLC-2 Family”

and the Programming and Operations manual for the processor being

used.

Page 34

Figure 3.8

Example

Chapter 3

Programming and Operation

Block Transfer Programming, PLC-2 Family

Output

Image

Table

Accumulated

Area

Input

Image

Table

Preset

Area

R

Block length code

1

Diagnostics

9

8

R

1

010

Data Table

012

017

027

121

–

7

6

060

5

4

1

2

030

060

062

110

112

117

130

Output Image Table

Byte, contains Read

Enable Bit and Block

Length in binary code.

Data Address, contains

Module Address in BCD

First address, destination of

Transferred Data

Input Image Table Byte,

contains Done Bit

Storage location, contains

file address in BCD

Block Transfer Instruction

113

Rung 1

Multiple Get Instructions

11302030

Rung 1

Rung 2

Rung 3

02

G

121

130

060

R = Bit 17 = READ

012

BLOCK XFER READ

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

G

030

121

060–062

03

EN

17

112

DN

17

012

17

012

10

012

11

10373

3-15

Page 35

Chapter 3

Programming and Operation

Programming Example, PLC-2 Family

Two methods of programming are described: one using block transfer

instructions, the other using multiple GET instructions. Refer to

Figure 3.8. The data table mapping is the same for both.

For this example, 3 words of data are used to transfer the settings of two

4-digit thumbwheel switches. The settings are 9751 and 8642 for

thumbwheel switch assembly 1 and 2, respectively. (The first word is

reserved for diagnostic data.) The module is located in the upper slot of

rack 1 module group 2. The module address is 121

lower slot, the module address would be 120

and output bits 10, 11, 12,

8

. If located in the

8

16 and 17 used in the example would become 00, 01, 02, 06 and 07,

respectively.

Block Transfer Instructions

Rung 1 - When this rung is enabled, the switch status data in module

memory is transferred to the data table. The 3 words specified by the

block length will contain diagnostic data and the data of thumbwheel

switch assemblies 1 and 2.

The block length is set to 1 plus the number of thumbwheel switch

assemblies, or 1 plus the number of pairs of switch banks required by the

application.

Multiple Get Instructions

Read the description for BLOCK TRANSFER INSTRUCTIONS first.

Rung 1 - This rung is used to identify the module (module address 121

8

in the first GET instruction) and the first address of the destination of the

transferred data (word address 060

in the second GET instruction). The

8

rung also sets the block transfer read bit (bit 17) in the module’s output

image table byte.

3-16

Rungs 2, 3 - These rungs set the number of words to be transferred by

setting a binary bit pattern in the module’s output image table byte. Bits

10 and 11 are set ON. the binary bit pattern 11 is equivalent to the

number 3.

Page 36

Chapter 3

Programming and Operation

Programming Considerations, PLC-2 Family

The block transfer data address is the address that identifies the block

transfer instruction. Care should be taken when assigning these addresses

in the data table.

Date Address (PLC-2 Family)

The data address for a block transfer instruction should be the first

available address in the timer/counter accumulated area of the data table.

This address is 030

for the Mini-PLC-2 or -2/15. For the PLC -2/20 or

8

-2/30, this address depends on the number of I/O racks connected to the

processor module, i.e. address 020

070

for 6 racks and 2008 for 7 racks. When more than one block transfer

8

for 1 I/O rack, 0308 for 2 racks, etc. to

8

module is used, the data addresses should be consecutive.

Data Address Boundary (PLC-2 Family)

A boundary word containing zeros should be entered in the data table

following the last block transfer data address. When the processor sees

the boundary word, it terminates the block transfer search routine so that

subsequent data table values are not interpreted as the rack, module group

and slot numbers associated with block transfer data addresses.

Block Transfer Programming, PLC-3

The processor transfers switch status data from the module to the data

table by a block transfer read operation. The following information must

be specified in order to program block transfer with the PLC-3 processor.

Values entered in parentheses correspond to the programming example in

paragraph titled “Programming Example PLC-3” and Figure 3.9.

3-17

Page 37

Chapter 3

ЙЙЙЙЙ

Programming and Operation

Data T

able Maps

a) Control File (FB001:0010)

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

RQ EN DN ER LE SD SE RQ EN DN ER LE SD SE

0010

0011

0012

0013

0014

Figure 3.9

Example

Read Bits Write Bits

Block Transfer Programming, PLC-3

Mod. GroupRack Number

Data Table Section

File Number

Word Number

Bit Control Word (WB001:0010)

I/O Module Address

SL

Data File Address (Write)

0015

0016

0017

0018

0019

b) Data File (FD002:0012)

Data File

Addr

(FD002:0012

Bit Legend

RQ = Request

EN = Enable

DN = Done

ER = Error

WB001:0010

15

Write Data File Length

Data Table Section

File Number

Word Number

Read Data File Length

17 10 07 00

Diagnostics

9

8

LE = Latched Enable

SD = Scanner Done

SE = Scanner Error

SL = Slot Number

7

6

5

4

(Decimal 7)

1

2

Prefix Legend

F = File Address

W = Word Address

B = Binary File

D = Decimal FIle

(002)

Data File Address (Read)

(0012)

(3)

0012

0013

0014

BTR

BLOCK XFER READ

RACK:

GROUP:

MODULE:

DATA:

LENGTH =

CNTL:

001

1=HIGH

FD002:0012

FB001:0010

CNTL

EN

12

CNTL

2

DN

15

CNTL

3

ER

13

3-18

10374

Page 38

Chapter 3

Programming and Operation

length: the number of words to be transferred can be 0-7 depending on

the number of switch assemblies. (03)

module address: rack, module group and slot number where 1 =

HIGH = upper slot, 0 = LOW = lower slot. (121)

control file address: location of a 10-word file necessary for block

transfer read and write operations, contains the module address in

binary, the address of the data file and the block transfer status/control

bits. (FB002:0010)

data file address: location of the source or destination of block

transfer data, generally equal in length to the maximum number of

transfer words. (FD002:0012)

For additional information on programming block transfer instructions,

refer to paragraph titled “Other Programming Considerations, PLC-2

Family and PLC-3” and the Programming and Operation Manual for the

PLC-3 processor.

Programming Example, PLC-3

To program block transfer with a PLC-3 processor, you must create a

control file and a data file (Figure 3.9). The control file can be located

anywhere in the binary section of the processor data table. The data file

for thumbwheel switches should be entered in the decimal section of the

processor data table; the data file for discrete switches in the binary

section of the processor data table. Neither block transfer file should

overlap other assigned storage words.

This example is similar to the one described in paragraph titled

“Programming Example, PLC-2 Family,” except that the rung is

programmed for recurring block transfers. Three words of data are used

to transfer the settings of two 4-digit thumbwheel switches. The settings

are 9751 and 8642 for thumbwheel switch assemblies 1 and 2,

respectively. (The first word is reserved for diagnostic data.) The module

is located in the upper slot of module group 2 in I/O rack 1. The

explanation of the single programming rung is that described for block

format instructions in paragraph titled “Programming Example, PLC-2

Family.”

3-19

Page 39

Chapter 3

Programming and Operation

Other Programming Considerations, PLC-2 Family and PLC-3

When programming block transfer instructions the following should also

be considered.

Automatic/Program Reset, switch #7

When in momentary (latched) contact mode, latched data should be reset

after its image is transferred to the data table. It can be reset by program

logic (program reset mode) or automatically by the module (automatic

reset mode).

In program reset mode, module memory can be reset by user program

after a successful transfer has occurred by setting bit 6 or 16 in the

module’s output image table byte. (Bit 6 is set when the module is in the

lower slot, bit 16 when in the upper slot.) If bit 6 or 16 is set by mistake

during a request for block transfer, the module will respond that it is not

ready to transfer.

Important: Bit 6 or 16 should be programmed only when mode selection

switch #4 and #7 are both in the ON position. Refer to paragraph titled “

Switch Selection of Operating Modes” (Chapter 2).

Reset rungs are illustrated for the PLC-2 family and PLC-3 programmable

controllers in Figure 3.10. The reset condition can be conditioned upon

the completion of a successful block transfer. The output energize

instruction sets the reset bit of the module.

In program reset mode, if any bit in addition to bit 6 or 16 is on, the

module will not reset.

3-20

Page 40

Block Transfer, PLC-2 Family

Optional

Condition

Reset

Condition

Reset

Condition

Multiple GET, PLC–2 Family

Optional

Condition

Reset

Condition

Reset

Condition

Reset

Condition

Store

Word

G

000

Reset

Condition

Store

Word

G

000

030

G

121

Figure 3.10

Examples

030

G

060

of Program Reset

Chapter 3

Programming and Operation

BLOCK XFER READ

DATA

ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE

Use bit 6 if module is in the left slot of

module group.

060 – 062

030

121

03

012

EN

17

112

DN

17

012

PUT

012

16

012

17

012

10

012

11

012

PUT

012

PLC–3 Block Transfer

Optional

Condition

Reset

I0010

00

NOTES:

a) Module is located in rack 1, module group 2, slot 1

b) If any bit in addition to bit 6 or 16 is set in the store word, the module will not reset.

WB001:0010

15

Reset

I

0010

00

Use bit 6 if module is in the left slot of

module group.

BTR

BLOCK XFER READ

RACK :

GROUP

:

MODULE:

DATA:

LENGTH:

CNTL:

Use bit 6 if module is in the left slot of

module group.

1 = HIGH

FD002:0012

FB001:0010

001

16

CNTL

EN

12

CNTL

2

DN

15

3

CNTL

ER

13

O0012

16

3-21

Page 41

Chapter 3

Programming and Operation

In automatic reset mode, the module resets its data and stores new latched

data after each block transfer. Allow at least 20ms between block

transfers for the module to store new data. A method for doing this is

shown in Figure 3.11.

Figure 3.1

Example

Block Transfer in a Local AND a Remote System – PLC –2 Family

111

17

070

15

071

00

070

/

15

Multiple GET, PLC–2 Family

050

/

15

1

Logic for Automatic Reset, Latched Contacts Mode

BLOCK XFER READ

DATA

ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE

200 – 277

050

111

00

071

U

ON 00

071

L

ON 00

011

EN

17

111

DN

17

070

TON

.01

PR 002

AC 000

050

TON

.01

PR 002

AC 000

3-22

050

15

Optional

Condition

030

G

121

030

G

060

012

17

012

10

012

11

Page 42

PLC–3 Block Transfer

B001:0010

15

T0001

15

BLOCK XFER DONE

TIMER DONE

Chapter 3

Programming and Operation

B002:0000

U

00

B002:0000

L

00

B002:0000

00

T0001

/

NOTES:

a) Module located in rack 1, module group 2, slot 1.

b) Timer allows at least 20ms between block transfers.

Diagnostics

BTR

BLOCK XFER READ

RACK :

:

GROUP

MODULE:

DATA:

LENGTH:

CNTL:

TON

TIMER ON T0001

0.01 SECOND

TP = 2

TA = 0

1 = HIGH

FD002:0012

FB001:0010

001

CNTL

EN

12

CNTL

2

DN

15

3

CNTL

ER

13

T0001

TE

17

T0001

TD

15

Bit 12 of the block transfer diagnostic word is the communication fault

bit. A communication fault can be caused either by cycling power to the

processor, by a break in I/O communications or by excessive electrical

noise radiating into the I/O communication cable. This bit will go ON if

the transfer is aborted. The I/O communication cable and system

grounding should be checked thoroughly in accordance with grounding

and shielding recommendations presented in the processor Assembly and

Installation Manual. This bit can be reset only by cycling power to the

module.

Data Buffering

Data that is block transferred to the data table should be buffered before it

is used to guard against the manipulation of invalid data by subsequent

user program instructions.

3-23

Page 43

Chapter 3

Programming and Operation

This can be done by examining the block transfer done bit for an ON

condition. An EXAMINE ON instruction addressed to the done bit

should be a logic condition for any further manipulation of transferred

data. The done bit for the PLC-2 family and PLC-3 programming

example is 112/17 and WB001:0010/15, respectively.

WARNING: Program the examination of the block transfer

done bit as a condition for subsequent data manipulation

following each block transfer. Otherwise, invalid data could be

operated upon causing unexpected machine operation with

possible damage to equipment and/or injury to personnel.

The communication fault bit, bit 12 of the diagnostic word, can be

examined as an additional buffering condition. This can be done by using

an EXAMINE OFF instruction addressed to bit 12 of the diagnostic

word’s location in the data table (060/12 for PLC-2 family,

WD002:0012/12 for PLC-3 in this example). If transfer was aborted, the

next transfer of data would contain bit 12 ON, in the diagnostic word.

3-24

Page 44

Specifications

Module

Inputs

Up to four 4–digit BCD

Thumbwheel Switches or

Appendix

A

Module Current Requirement

800 mA max @ 5V DC from

the backplane

Up to six 3–digit BCD

Thumbwheel Switches or

Up to 72 Discrete Contact

Switches (Maintained or

Momentary contact)

Diode Decoupling is required

for more than 8 Switch

Contacts

Module Location

Any Bulletin 1771 I/O Rack

location except the left–most

slot

Switch Power Requirement

Supplied by the module

Nominal 13 mA @ 5V DC

per switch

Maximum Switch Cable Distance

400 feet

Ambient T

Humidity

Keying

emperature Rating

0–60 0C Operational

–20 to +850 C Storage

5% to 95%

(without condensation)

Keying positions are between

8 and 10 and between 26 and

28

i

Page 45

T

able of Contents

ii

Page 46

Index

I

Symbols

**Empty**, 2-1

1 , 3-19

Numbers

4–digit thumbwheel switch data, 3-2

A

automatic, 3-22

D

Data buf

data storage, 3-6

Decoupling, 2-10

fering, 3-23

Diagnostics, 3-23

Dip switch settings, 2-1

Discrete contact switch data, 3-6

Discrete switch bank wiring, 2-8

E

external power

, 2-10

K

Keying, 2-1

1

L

Low = TRUE, 2-10

I–1

Page 47

I

M

Mode selection dip switch, 2-1

Module scan of switch contacts, 3-1

Module wiring, 2-4

O

od switch data, 3-14

P

PLC–2 family

, 3-14

R

reset, 3-20

Index

S

selection, 2-1

Specifications, A-1

1

T

Thumbwheel switch wiring, 2-5

T

ypical Applications, 1-2

W

When to use 16–bit or 12–bit storage, 2-2

Wiring, 2-4

with 3–digit thumbwheel switch data, 3-10

–2 I–2

Page 48

Loading...

Loading...