Page 1

Installation Instructions

AC/DC (220V) Input Module

Cat. No. 1771IMD Series B

To The Installer

Preinstallation

Considerations

This document provides information on:

• important pre-installation considerations

• power supply requirements

• initial handling

• installing the module

• using the indicators for troubleshooting

• module specifications

This module must be used with a 1771 B Series I/O chassis. If you

are using a 1771-ASB remote I/O adapter you may use any

combination of I/O modules. Otherwise, make sure no other input

module or single card block transfer module is placed in the same

I/O group.

This module contains input filtering to limit the effects of voltage

transients caused by contact bounce and/or radiated electrical noise.

The delay due to filtering is listed in the Specifications section.

European Union Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard, Part 2 –

Industrial Environment

• EN 50082-2EMC – Generic Immunity Standard, Part 2 –

Industrial Environment

This product is intended for use in an industrial environment.

Publication

17715.27

Page 2

2

AC/DC (220V) Input Module Cat. No. 1771-IMD Series B

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For

Noise Immunity, publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

Power Requirements

Initial Handling

Your module receives its power through the 1771 I/O chassis

backplane from the chassis power supply. The module requires

250mA from the output of this supply. Add this to the requirements

of all other modules in the I/O chassis to prevent overloading the

chassis backplane and/or chassis power supply.

The ac input module is shipped in a static-shielded bag to guard

against electrostatic discharge damage. Observe the following

precautions when handling the module.

ATTENTION: This module is equipped with a

plastic cover that is unique to assembly numbers

!

960378-02 through 960378-09. (This part number is

located near the backplane edge connector pins on the

component-side of the circuit board.) Do not use this

plastic cover on any other module.

Electrostatic Discharge Damage

ATTENTION: Under some conditions, electrostatic

discharge can degrade performance or damage the

!

module. Observe the following precautions to guard

against electrostatic damage.

Publication

• Wear an approved wrist strap grounding device, or touch a

grounded object to discharge yourself before handling the

module.

• Do not touch the backplane connector or connector pins.

• If you configure or replace internal components, do not touch

other circuit components inside the module. If available, use a

static-free work station.

• When not in use, keep the module in a static-shielded bag.

17715.27

Page 3

AC/DC (220V) Input Module Cat. No. 1771-IMD Series B

3

Installing Your Module

In this section we tell you how to set the fault mode selection plug,

key your I/O chassis, install your module and make your wiring

connections.

Fault Mode Selection

You may select one of two input-failure configurations (last state or

reset) by positioning a configuration plug on the top edge of the

printed circuit board. This configuration plug is independent of the

last state switch on the I/O chassis backplane during a module fault.

During a chassis fault, the I/O chassis backplane last state switch

setting overrides the module fault mode selection plug.

To set the fault mode selection, proceed as follows:

1. Locate the fault mode selection plug at the top edge of the

module circuit board.

Top edge of circuit board

Fault Mode Selection Plug

(shown in last state position)

RESET LS

10548I

2. Using your finger, slide the plug off the 2 posts.

3. Carefully position the plug on 2 of the 3 posts that correspond to

your requirement.

Keying Your I/O Chassis

Use the plastic keying bands, shipped with each I/O chassis, to key

the I/O slots to accept only this type of module.

The module circuit board is slotted in two places on the rear edge.

The position of the keying bands on the backplane connector must

correspond to these slots to allow insertion of the module. You can

key any connector in an I/O chassis to receive this module except for

the left-most connector reserved for adapter or processor modules.

Place keying bands between the following numbers labeled on the

backplane connector:

• Between 2 and 4

• Between 12 and 14

You can change the position of these keys if system redesign and

rewiring makes insertion of a different module necessary.

Publication

17715.27

Page 4

4

AC/DC (220V) Input Module Cat. No. 1771-IMD Series B

Installing the Input Module

To install the ac/dc input module in your 1771 I/O chassis, follow the

steps listed below.

ATTENTION: Remove power from the 1771 I/O

chassis backplane and field wiring arm before

!

removing or installing an I/O module.

• Failure to remove power from the backplane or wir-

ing arm could cause module damage, degradation of

performance, or injury.

• Failure to remove power from the backplane could

cause injury or equipment damage due to possible

unexpected operation.

1. Turn off power to the I/O chassis.

2. Place the module in the plastic tracks on the top and bottom of the

slot that guides the module into position.

3. Do not force the module into its backplane connector. Apply firm,

even pressure on the module to seat it properly.

4. Snap the chassis latch over the top of the module to secure its

position.

5. Connect the wiring arm to the module.

6. Make wiring connections to the field wiring arm as indicated in

“Connecting Wiring to the Input Module.”

Publication

17715.27

Page 5

AC/DC (220V) Input Module Cat. No. 1771-IMD Series B

5

Connecting Wiring to the Input Module

Connections to the input module are made to the 21 terminal field

wiring arm (cat. no. 1771-WH) shipped with the module. Attach the

wiring arm to the pivot bar on the bottom of the I/O chassis. The

wiring arm pivots upward and connects with the module so you can

install or remove the module without disconnecting the wires.

Connect one terminal of your 2-wire input devices to terminals 00

through 17.

Connection Diagram for the 1771-IMD Module

L1

Terminal A

Terminal B

Terminal C

Terminal D

Input 00

Input 01

Input 02

Input 03

Input 04

Input 05

Input 06

Input 07

Input 10

Input 11

Input 12

Input 13

Input 14

Input 15

Input 16

Input 17

Terminal E

A

B

C

D

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

E

ac/dc High

L2

ac/dc Low

(Actual wiring runs in this direction.)

10549I

Connect terminal E to the L2 (low) ac/dc return. Terminals A

through D are not used. Connect the L1 (high) ac/dc line to the other

terminal of your input devices. Use stranded 14 or 16 gauge wire to

minimize the voltage drop over long cable distances.

Publication

17715.27

Page 6

6

AC/DC (220V) Input Module Cat. No. 1771-IMD Series B

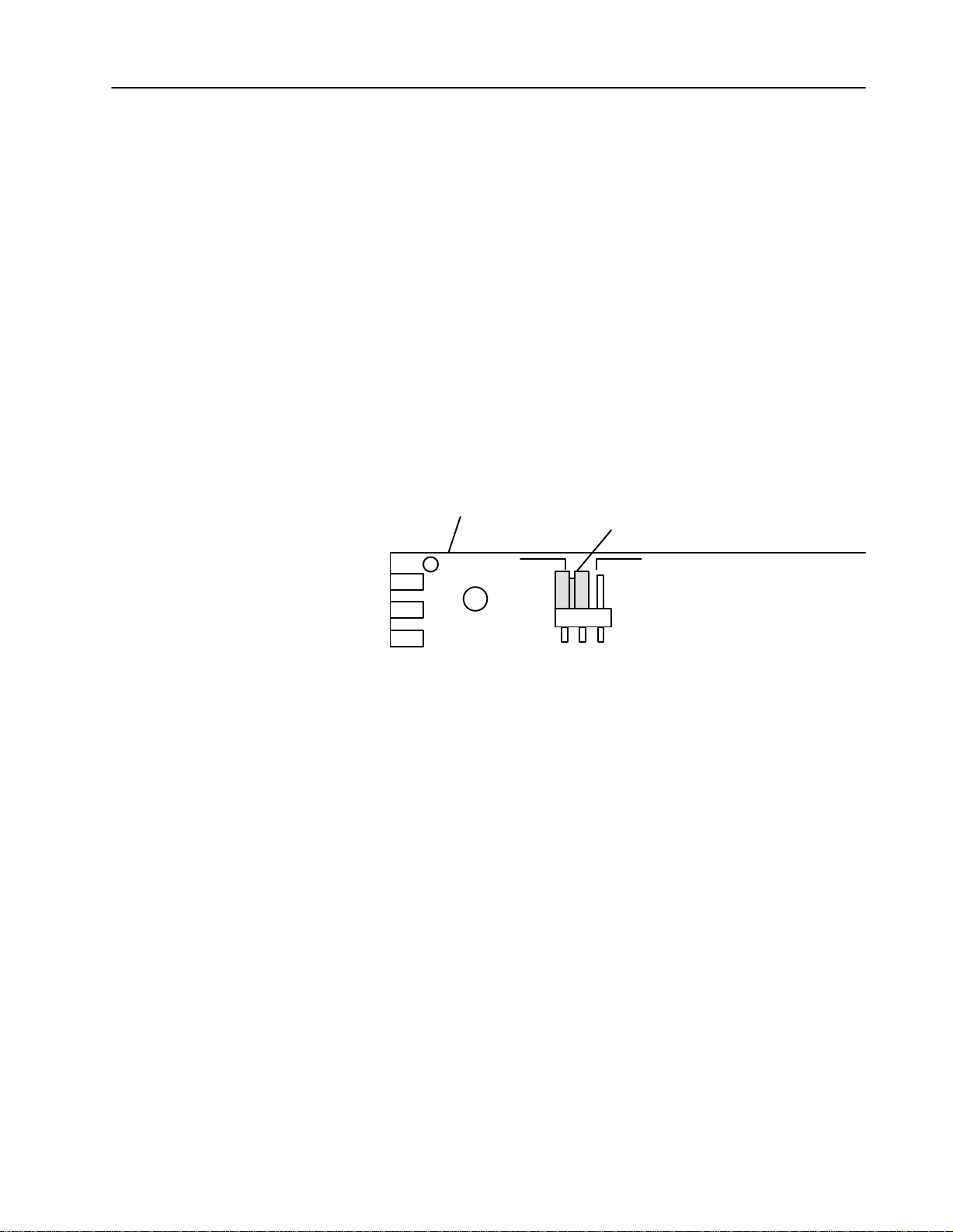

Important: You can use an AC (220V) Output Module (cat. no.

1771-OMD) to directly drive terminals on an AC/DC

(220V) Input Module (cat. no. 1771-IMD) as shown

below.

You can also use a 1771-OM Output module to drive an AC/DC

(220V) Input Module (cat. no. 1771-IMD) but you must connect a

10K ohm, 10W resistor between the output terminal and L2

(common) as shown below. Use the same ac power source to

power both modules to ensure proper phasing and prevent

module damage.

Driving

a 1771IMD Module with a 1771OMD Module

AC (220V)

Output Module

(Cat. No. 1771OMD)

L1

220V ac High

AC/DC (220V)

Input Module

(Cat. No. 1771IMD)

Driving an Input with an Output

AC (220V)

Output Module

(Cat. No. 1771OM)

AC/DC (220V)

Input Module

(Cat. No. 1771IMD)

220V ac High

L1

Publication

17715.27

L2

ac Low

10550I

10K ohm 10W

resistor

L2

ac Low

10551I

Page 7

AC/DC (220V) Input Module Cat. No. 1771-IMD Series B

7

Interpreting the Status Indicators

The front panel of your module contains one green, module active

LED, and 16 red status LED indicators. The 1771-IMD performs

diagnostics in a handshaking mode when first powered up. Upon

successful completion of the diagnostics, the green module active

indicator lights. It turns off if a fault occurs in the data paths or the

opto-isolators.

Module Active Indicator (green)

ACTIVE

00

10

01

11

02

12

03

13

04

14

05

15

06

16

07

17

00 to 17 Status Indicators (red)

10552I

If a module fault occurs, the module resets its inputs or sets them to

last state, depending on the fault mode selection. The module active

indicator must be on to properly interpret the red status indicators.

The red status indicators are provided for system logic side

indication of individual inputs. When a red indicator lights, voltage

is present on the terminal. The module transfers this information to

the backplane for the processor to read. See ”Troubleshooting” for a

description, probable cause, and recommended action to take for

common faults based on indicator responses.

Troubleshooting

Use this table to help you interpret the 1771-IMD status indicators

and to troubleshoot module and system faults.

Indicator Status (color) Description of Fault or System Status Action to Take

Module active ON (green) Normal Indication None

Module active ON (green) and

Input status ON (red)

Module active ON (green) and

Input status OFF

Module active OFF Module is not powered or fault in optoisolators

Check for voltage on terminal If none, replace module

Input devices not functioning properly or faulty

input circuitry on module

1. Check input devices

2. If input devices are OK, replace module

No voltage on terminal None

1. Check chassis power supply and module

and/or data paths; module resets inputs or goes to

last state

input power

2. If power supplies are OK, replace module

Module active OFF and

Input status ON (red) or OFF

Not valid unless module active indicator is on;

when active is off, indicators do not represent

processor status

1. Check chassis power supply and module

input power

2. If power supplies are OK, replace module

Publication

17715.27

Page 8

8

AC/DC (220V) Input Module Cat. No. 1771-IMD Series B

Specifications

Inputs per Module 16

Module Location 1771A1B, A2B, A3B, A3B1, A4B or later I/O chassis

Nominal Input Voltage 220V ac @ 50/60Hz; 220V dc

Nominal Input Current 10.4mA @ 220V ac 60Hz; 9.9mA @ 220V ac 50Hz

0.6mA @ 220V dc

Onstate Voltage Range 184V to 250V ac

166V to 230V dc

Minimum Onstate Current 8.7mA at 184V ac, 50Hz

0.43mA at 166V dc

Maximum Offstate Voltage 92V ac or dc

Maximum Offstate Current 3mA at 92V ac, 60Hz

0.25mA at 92V dc

Input Impedance 0.15uF (21.2K at 50Hz) in parallel with 370K; in series with 1K ohm

Peak Inrush Current VPS/1K ohm, where VPS = customer supply peak voltage

Input Signal Delay Off to on:

On to off:

15+8ms for ac or dc

56ms for ac or dc

172+

Power Dissipation 5.8 Watts (max.), 1.3 Watts (min.)

Thermal Dissipation 19.8 BTU/hr (max.), 4.5 BTU/hr (min.)

Backplane Current 250mA @ 5V dc

Isolation Voltage Isolation meets or exceeds UL Standard 508, and CSA Standard

C22.2 No. 142.

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

Conductors Wire Size

Category

0o to 60oC (32o to 140oF)

o

40

to 85oC (40o to 185oF)

5 to 95% (without condensation)

14 gauge stranded maximum

3/64 inch insulation maximum

1

1

Keying Between 2 and 4

Between 12 and 14

Field Wiring Arm Catalog Number 1771WH

Wiring Arm Screw Torque 79 inchpounds

Agency Certification

(when product or packaging is

marked)

• CSA certified

• CSA Class I, Division 2, Groups A, B, C, D certified

• UL listed

• CE marked for all applicable directives

1

Refer

to publication 17704.1, Programmable Controller Wiring and Grounding Guidelines.

AllenBradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

world's leading technology companies.

Worldwide representation.

Argentina •

Denmark • Ecuador

Ireland

Philippines •

Sweden

AllenBradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 3822000 Fax: (1) 414 3824444

Publication

Australia • Austria • Bahrain

• Israel • Italy • Jamaica •

• Switzerland • T

17715.27 - November 1995

Publication

• Egypt • El Salvador • Finland • France •

Poland • Portugal • Puerto Rico • Qatar • Romania • Russia-CIS • Saudi Arabia • Singapore

aiwan

17715.27

• Belgium • Brazil •

Japan • Jordan • Korea • Kuwait • Lebanon

• Thailand • T

urkey • United Arab Emirates • United Kingdom • United States • Uruguay

Bulgaria • Canada

Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary

• Chile •

China, PRC • Colombia

• Malaysia • Mexico •

• Costa Rica •

Netherlands

• New Zealand •

• Slovakia • Slovenia •

Croatia • Cyprus

Norway

South Africa, Republic

• V

enezuela

Copyright

• Iceland •

• Yugoslavia

• Czech Republic •

India • Indonesia

• Pakistan •

1995 AllenBradley Company

•

Peru

•

• Spain •

PN955122-71

, Inc. Printed in USA

Loading...

Loading...