Page 1

Analog Input Module

Cat. No. 1771IFE

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes

and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for example. Since there are many variables

and requirements associated with any particular installation, Allen-Bradley

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI–1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some important

differences between solid-state equipment and electromechanical devices

which should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen–Bradley Company, Inc.

is prohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

Identify a hazard.

Avoid the hazard.

Recognize the consequences.

Important: Identifies information that is especially important for

successful application and understanding of the product.

Important: We recommend you frequently backup your application

programs on appropriate storage medium to avoid possible data loss.

Page 3

Summary of Changes

Summary of Changes

Summary of Changes

This release of the publication contains updated information from the last

release.

Updated Information

This release includes information previously included in a documentation

update (publication 1771-6.5.90–RN1 dated March 1993).

In addition, many areas in this publication have been restructured or

rewritten.

To help you find new and updated information in this release of the

publication, we have included change bars as shown to the right of this

paragraph.

SI

Page 4

Table of Contents

Summary of Changes

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SI

Using This Manual P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose

Audience P1

Vocabulary P1

Manual Organization P1

Related Products P2

Product

Related

of Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility

Publications

P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of the Analog Input Module 11. . . . . . . . . . . . . . . .

Chapter

Module Description 11

Features 11

How Analog Modules Communicate with Programmable Controllers 12

Accuracy 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Summary 13

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Input Module 21. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Before Y

Electrostatic Damage 21

Power Requirements 22

Module

Module Keying 22

Wiring Your Input Module 23

Grounding 28

Changing

Module

Indicator Lights 212

Chapter Summary 212

Module

Chapter

Block Transfer Programming 31

PLC2 Programming 32

PLC3 Programming 33

PLC5 Programming 34

Module Scan Time 35

Objectives

ou Install Y

Location in the I/O Chassis

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Module'

Installation

our Input Module 21. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

s Configuration 29. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22. . . . . . . . . . . . . . . . . . . . . . .

212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contentsii

Chapter Summary 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Your Module 41. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Configuring Your Input Module 41

Input Range Selection 42

Input Type 43

Data Format 43

Digital

Real T

Scaling 46

Default

Chapter Summary 49

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filtering

ime Sampling

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Status and Input Data 51. . . . . . . . . . . . . . . . . . . . . .

Chapter

Reading Data From Your Module 51

Block Transfer Read Format 52

Chapter Summary 52

Objectives

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating Your Module 61. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Tools and Equipment 61

Calibration Procedure 61

Chapter Summary 63

Objectives

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Your Input Module 71. . . . . . . . . . . . . . . . . .

Chapter

Diagnostics Reported by the Module 71

Chapter Summary 73

Objective

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Examples B1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sample Programs for the Analog Input Module B1. . . . . . . . . . . . . . .

PLC2 Family Processors B1

PLC3 Family Processor B2

PLC5 Family Processors B4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table Formats C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4Digit Binary Coded Decimal (BCD) C1. . . . . . . . . . . . . . . . . . . . . .

Signedmagnitude Binary C2

Two's Complement Binary C3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contents iii

Block Transfer (MiniPLC2 and PLC2/20 Processors) D1. . .

Multiple GET Instructions MiniPLC2 and PLC2/20 Processors D1.

Setting the Block Length (Multiple GET Instructions only) D3

. . . . . . . .

Forms E1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Block Transfer Read E2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Block Transfer Write E3

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Using This Manual

Preface

Purpose

of Manual

Audience

Vocabulary

Manual Organization

This manual shows you how to use your Analog Input module with an

Allen-Bradley programmable controller. It helps you install, program,

calibrate, and troubleshoot your module.

You must be able to program and operate an Allen-Bradley

programmable controller to make efficient use of your input module. In

particular, you must know how to program block transfers.

We assume that you know how to do this in this manual. If you do not,

refer to the appropriate programming and operations manual before you

attempt to program this module.

In this manual, we refer to:

- Each individual analog input module as the “input module”

- The Programmable Controller as the “controller”

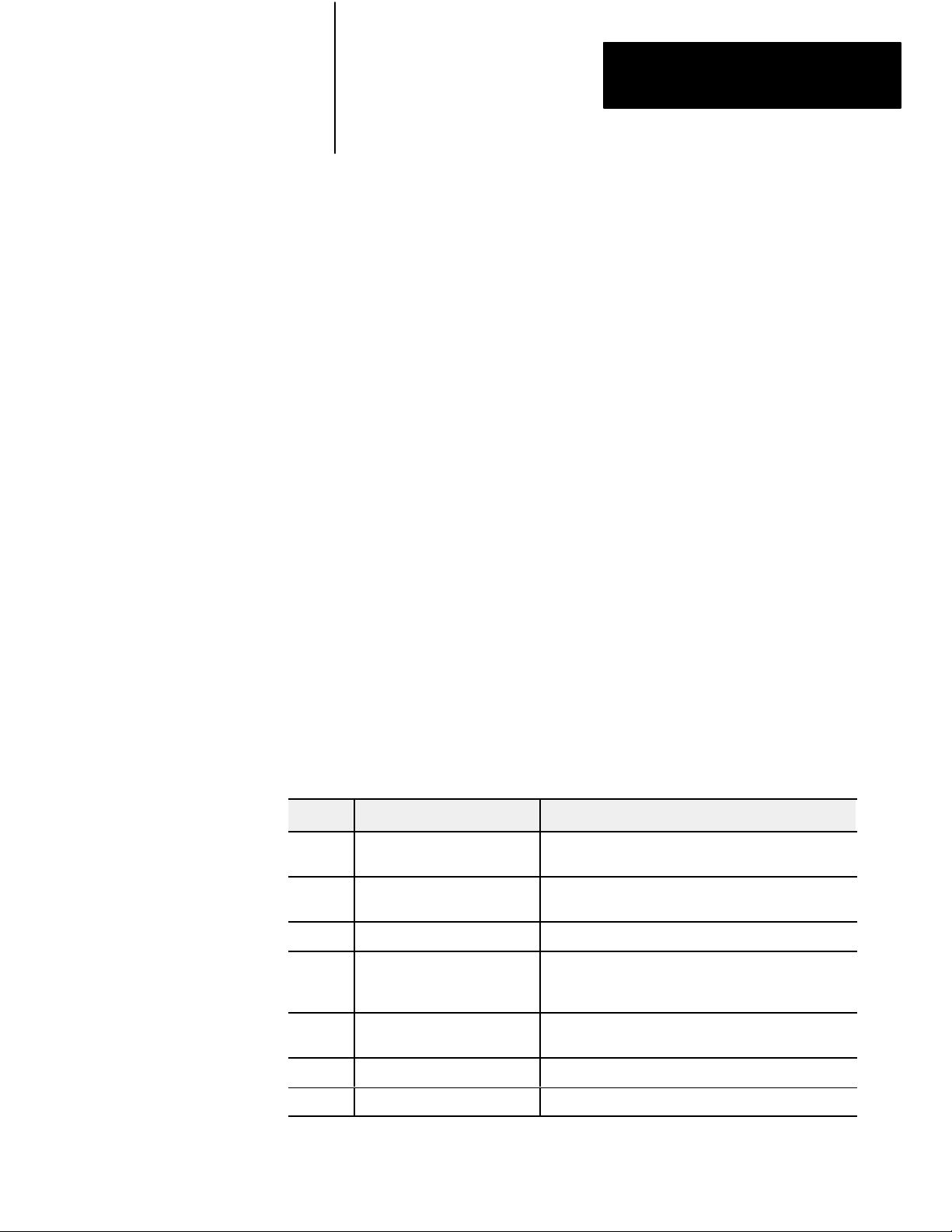

This manual is divided into seven chapters. The following chart shows

each chapter with its corresponding title and a brief overview of the topics

covered in that chapter.

Chapter Title Topics Covered

1 Overview of the input modules

2 Installing the module

3 Module programming Sample programs

4 Module configuration

5 Module status and input data

6 Calibration Information on calibrating your module

7 Troubleshooting your module Troubleshooting guide for problem diagnosis

Description of the module including general and hardware

features

Module power requirements, keying, chassis location

Wiring of the field wiring arm

Hardware and software configuration

Input range selection

Data format

Reading data from the module

Read block format

P-1

Page 8

Preface

ube

Image

Image

Block

Block

Using This Manual

Topics CoveredTitleChapter

Appendix Title Topics Covered

A Specifications

B Programming Examples

Related Products

Product Compatibility

C Data Formats

Block transfer with MiniPLC2

D

and PLC2/20 processors

E Forms Useful forms for identifying your data table

Information on BCD, 2s complement binary, signed

magnitude (12bit) binary

How to use GETGET instructions

You can install your input module in any system that uses Allen-Bradley

programmable controllers with block transfer capability and the 1771 I/O

structure.

Contact your nearest Allen-Bradley office for more information about your

programmable controllers.

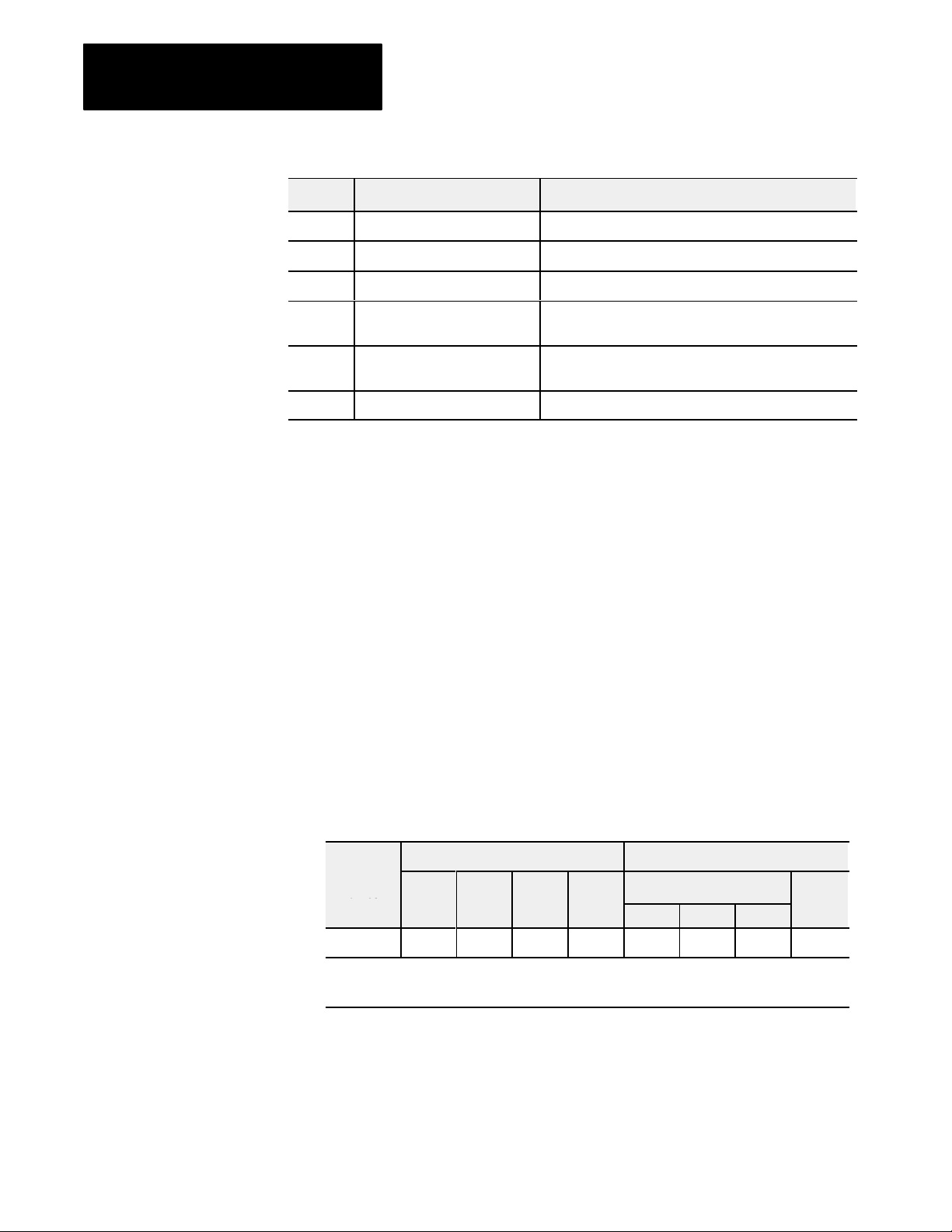

The 1771-IFE module can be used with any 1771 I/O chassis.

Communication between the discrete analog module and the processor is

bidirectional; the processor block-transfers output data through the output

image table to the module and block-transfers input data from the module

through the input image table. The module also requires an area in the data

table to store the read block transfer data and write block transfer data. I/O

image table use is an important factor in module placement and addressing

selection. Compatibility and data table use is listed in Table P.A.

P-2

Table P.A

Compatibility

Catalog

Number

1771IFE 8 8 20 37 Y Y Y A, B

A

= Compatible with 1771A1, A2, A4

B = Compatible with 1771A1B, A2B, A3B, A3B1, A4B

Y = Compatible without restriction.

and Use of Data T

Use of Data Table Compatibility

Input

Ima

Bits

Output

e

Ima

Bits

able

Read

e

Block

Words

Write

Block

Words

Addressing

1/2Slot 1Slot 2Slot

Chassis

Series

You can place your input module in any I/O module slot of the I/O chassis.

You can put two input modules in the same module group. You can put an

input and an output module in the same module group.

Page 9

Preface

Using This Manual

Do not put the module in the same module group as a discrete high density

module. Avoid placing analog input modules close to ac modules or high

voltage dc modules.

Related

Publications

For a list of publications with information on Allen-Bradley programmable

controller products, consult our publication index (SD499).

P-3

Page 10

Chapter

1

Overview of the Analog Input Module

Chapter

Objectives

Module Description

Features

This chapter gives you information on:

features of the module

how the input module communicates with programmable

controllers

The Analog input module is an intelligent block transfer module that

interfaces analog input signals with any Allen-Bradley programmable

controllers that have block transfer capability. Block transfer programming

moves input data words from the module’s memory to a designated area in

the processor data table in a single scan. It also moves configuration words

from the processor data table to module memory.

The input module is a single-slot module and requires no external power

supply. (If using passive transducers for input, the user must supply loop

power.) After scanning the analog inputs, the input data is converted to a

specified data type in a digital format to be transferred to the processor’s

data table on request. The block transfer mode is disabled until this input

scan is complete. Consequently, the minimum interval between block

transfer reads is the same as the total input update time for each analog

input module.

The Analog input module senses up to 16 single-ended or 8 differential

analog inputs and converts them to a proportional four-digit BCD or

twelve-bit binary value. You can select from five voltage or three current

input ranges. Each input can be configured as a current or voltage input

with internal jumpers.

This module’s features include:

16 single-ended or 8 differential inputs on one card

User program selectable input ranges on a per channel basis (Table 1.A)

Selectable real-time sampling

Selectable scaling to engineering units

Selectable digital filtering

Selectable data format

1-1

Page 11

Chapter 1

Overview of the Analog Input Module

How Analog Modules

Communicate with

Programmable Controllers

Table 1.A

Program

Selectable Input Ranges

Voltage Current

1 to 5V dc 4 to 20mA

0 to 5V dc 0 to 20mA

5 to +5V dc 20 to +20mA

10 to +10V dc

0 to 10V dc

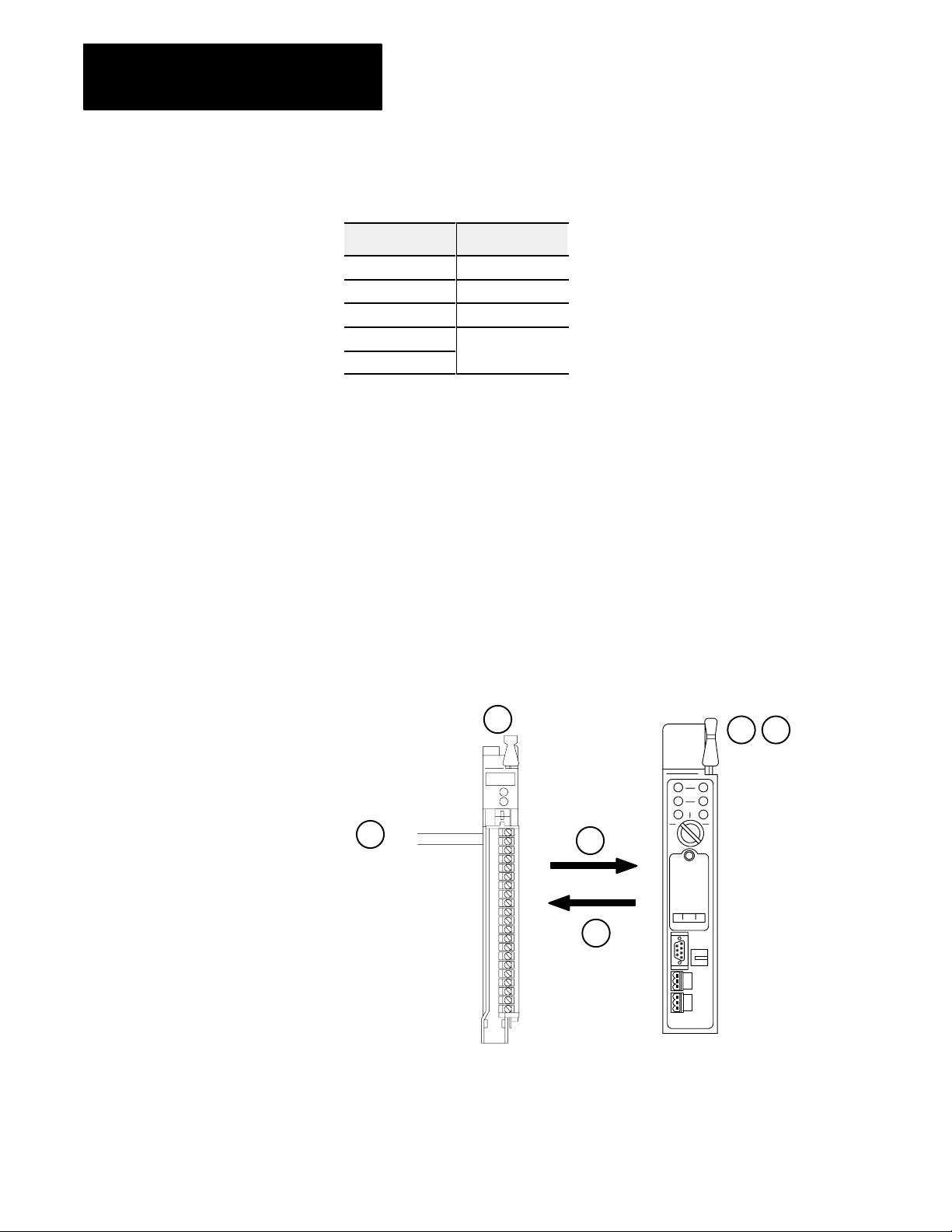

The processor transfers data to the module (block transfer write) and from

the module (block transfer read) using BTW and BTR instructions in your

ladder diagram program. These instructions let the processor obtain input

values and status from the module, and let you establish the module’s

mode of operation (Figure 1.1).

1. The processor transfers your configuration data to the module via a

block transfer write instruction.

2. External devices generate analog signals that are transmitted to the

module.

Figure 1.1

Communication

+

2

Between Processor and Module

3

I/O Chassis

Backplane

4

1

Input Module

Cat. No. 1771IFE

56

PC Processor

10947I

1-2

Page 12

Chapter 1

Overview of the Analog Input Module

3. The module converts analog signals into binary or BCD format, and

stores theses values until the processor requests their transfer.

4. When instructed by your ladder program, the processor performs a

read block transfer of the values and stores them in a data table.

5. The processor and module determine that the transfer was made

without error, and that input values are within specified range.

6. Your ladder program can use and/or move the data (if valid) before it

is written over by the transfer of new data in a subsequent transfer.

7. Your ladder program should allow write block transfers to the module

only when enabled by operator intervention or at power-up.

Accuracy

Chapter Summary

The accuracy of your input module is described in Appendix A.

In this chapter you read about the functional aspects of the input module

and how the module communicates with the programmable controller.

1-3

Page 13

Chapter

Installing the Input Module

2

Chapter

Objectives

Before You Install Your Input

Module

This chapter gives you information on:

calculating the chassis power requirement

choosing the module’s location in the I/O chassis

keying a chassis slot for your module

wiring the input module’s field wiring arm

configuring your module configuration plugs

installing the input module

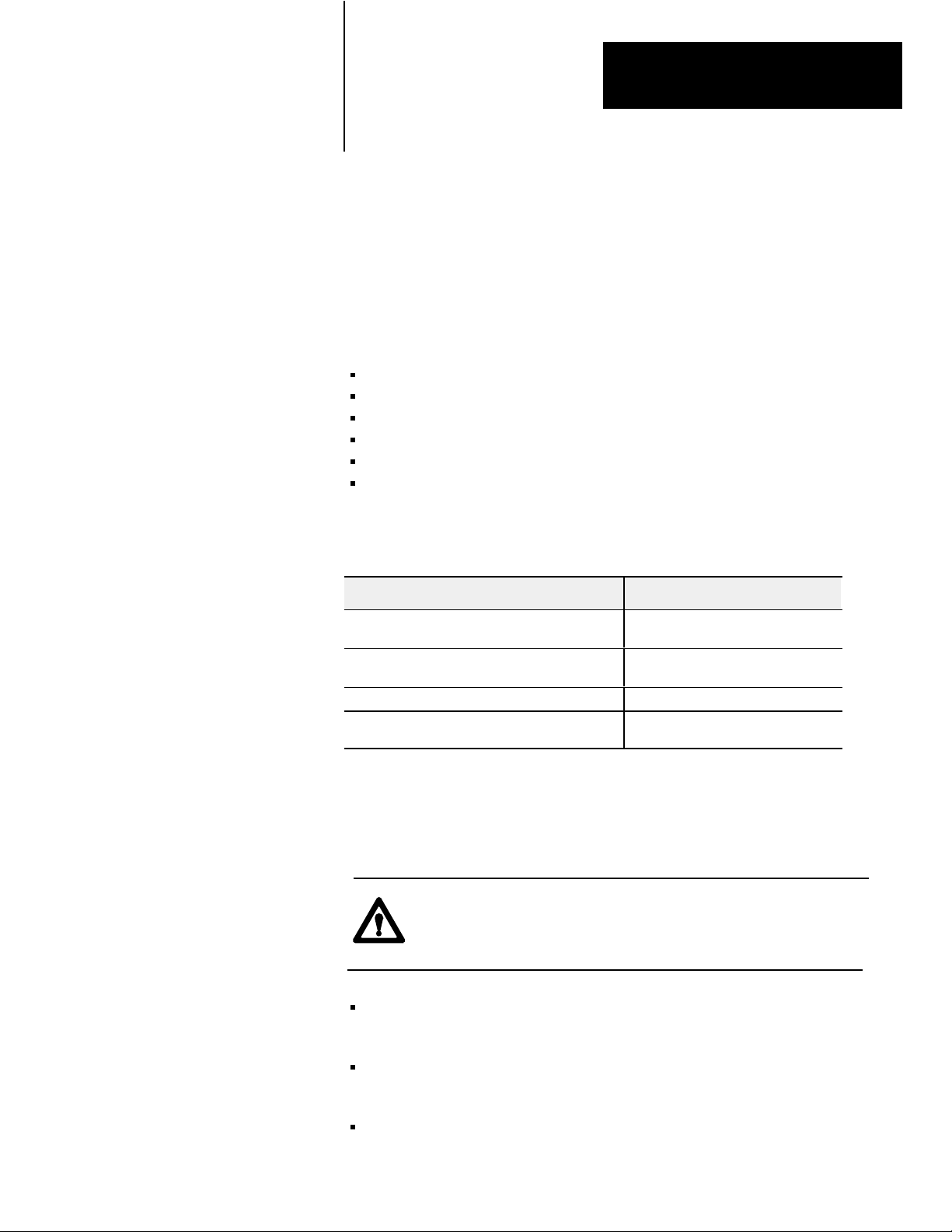

Before installing your input module in the I/O chassis:

You need to: As described under:

Calculate the power requirements of all modules in

each chassis.

Determine where to place the module in the I/O

chassis.

Key the backplane connector in the I/O chassis. Module Keying, page 22.

Make connections to the wiring arm.

Power Requirements, page 22.

Module Location in the I/O Chassis,

page 22.

Wiring Your Input Module, page 23

and Grounding, page 28.

Electrostatic Damage

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins. Guard against electrostatic

damage by observing the following precautions:

ATTENTION: Electrostatic discharge can degrade

performance or cause permanent damage. Handle the module as

stated below.

Wear an approved wrist strap grounding device, or touch a grounded

object to rid yourself of electrostatic charge before handling the module.

Handle the module from the front, away from the backplane connector.

Do not touch backplane connector pins.

Keep the module in its static-shield bag when not in use.

2-1

Page 14

Chapter 2

Installing the Input Module

Power Requirements

Module Location in the I/O

Chassis

Your module receives its power through the 1771 I/O power supply. The

module requires 750mA from the backplane.

Add this current to the requirements of all other modules in the I/O chassis

to prevent overloading the chassis backplane and/or backplane power

supply.

Place your module in any I/O module slot of the I/O chassis except for the

extreme left slot. This slot is reserved for PC processors or adapter

modules.

Group your modules to minimize adverse affects from radiated electrical

noise and heat. We recommend the following.

Group analog input and low voltage dc modules away from ac modules

or high voltage dc modules to minimize electrical noise interference.

Do not place this module in the same I/O group with a discrete

high-density I/O module when using 2-slot addressing. This module

uses a byte in both the input and output image tables for block transfer.

After determining the module’s location in the I/O chassis, connect the

wiring arm to the pivot bar at the module’s location.

Module Keying

2-2

Use the plastic keying bands, shipped with each I/O chassis, for keying I/O

slots to accept only one type of module.

The module is slotted in two places on the edge of the rear circuit board.

The position of the keying bands on the backplane connector must

correspond to these slots to allow insertion of the module. You can key

any connector in an I/O chassis to receive this module except for the

leftmost connector reserved for adapter or processor modules. Place

keying bands between the following numbers labeled on the backplane

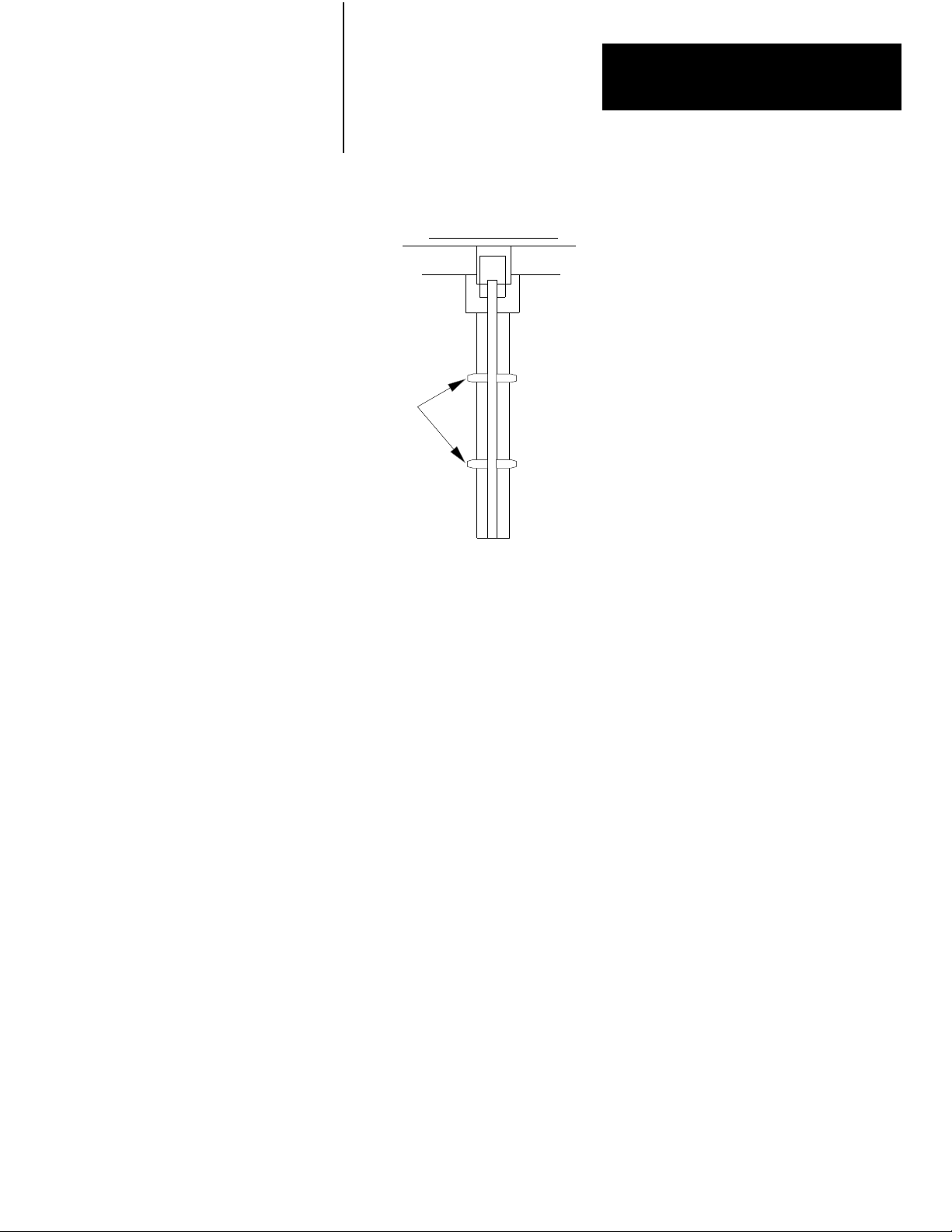

connector (Figure 2.1):

between 10 and 12

between 24 and 26

Page 15

Figure 2.1

Positions

Keying

Keying

Bands

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Chapter 2

Installing the Input Module

Wiring Your Input Module

1771IFE

12676

Connect your I/O devices to the cat. no. 1771-WG wiring arm shipped

with the module. Attach the wiring arm to the pivot bar at the bottom of

the I/O chassis. It pivots upward and connects with the module so you can

install or remove the module without disconnecting the wires.

Input connections for the 1771-IFE with single-ended inputs are shown in

Figure 2.2 and Figure 2.3. Input connections for the 1771-IFE with

differential inputs are shown in Figure 2.4 and Figure 2.5.

Recommended maximum cable length for voltage-mode input devices is

50 feet. This recommendation is based on considerations of signal

degradation and electrical noise immunity in typical industrial

environments. Cable length for current-mode input devices need not be as

restrictive because analog signals from these devices are less sensitive to

electrical noise interference.

The 1771-IFE module is shipped from the factory set for a 1 to 5V DC

voltage input. Refer to “Changing Your Module’s Configuration”on page

2-9 for other combinations of current and voltage inputs.

2-3

Page 16

Chapter 2

Installing the Input Module

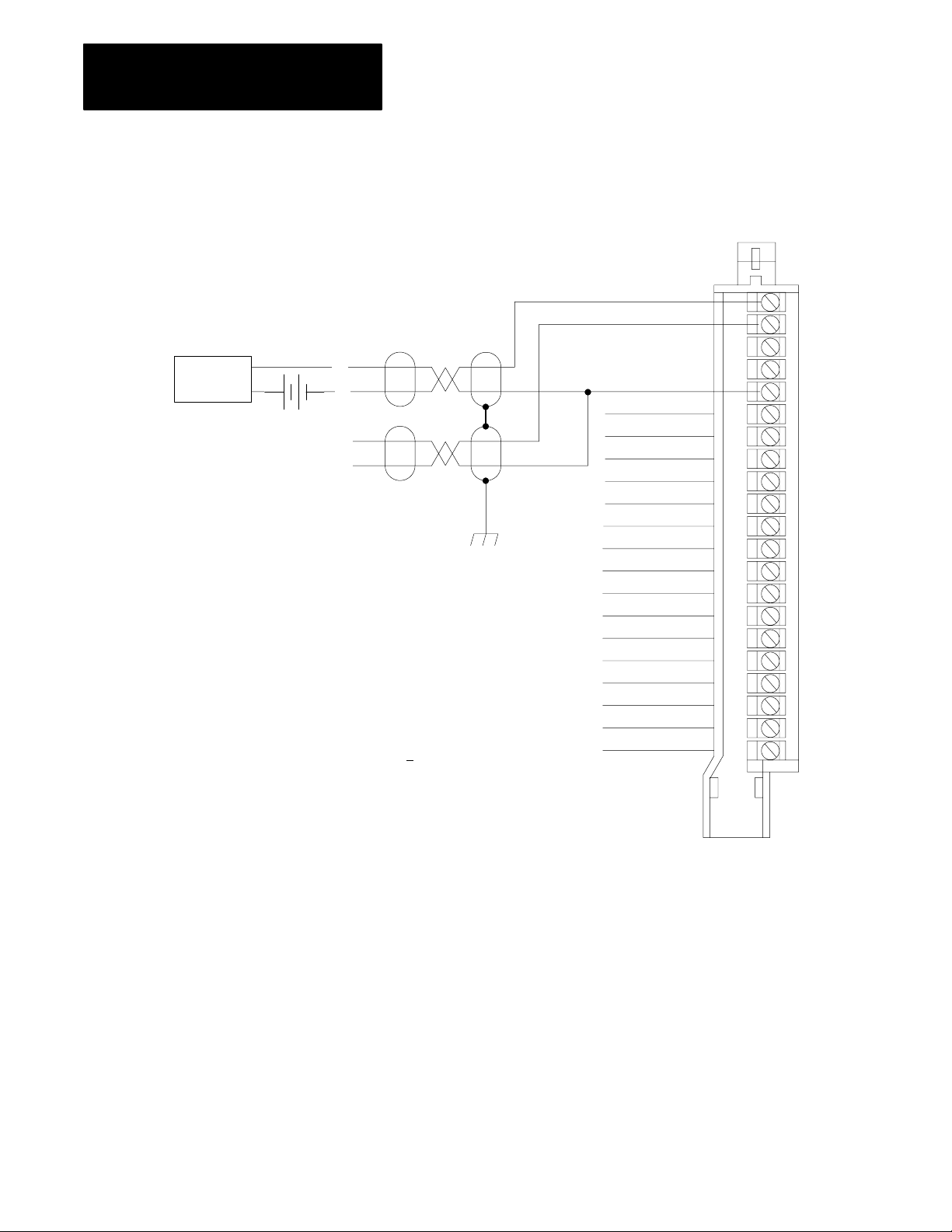

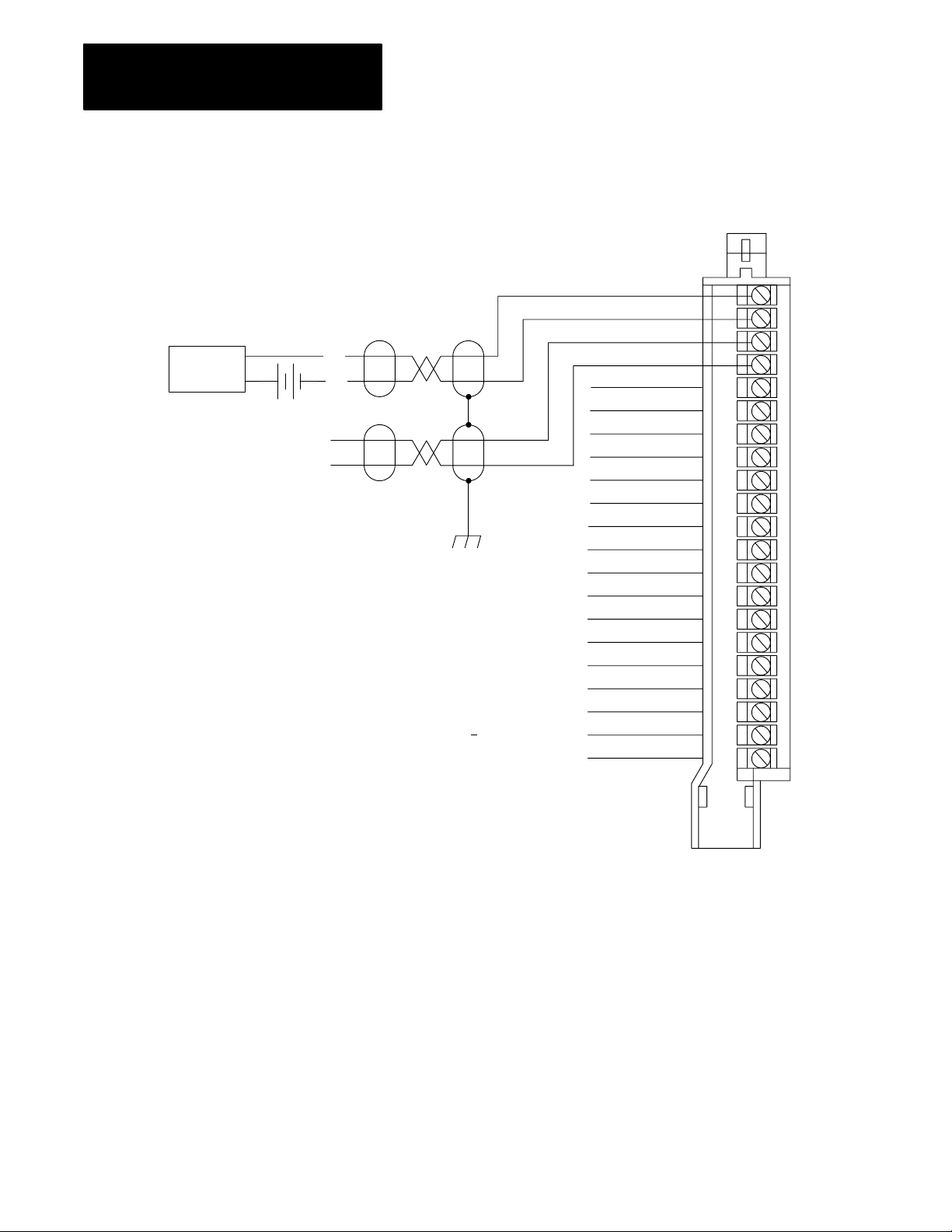

Figure 2.2

Connection

Diagram for 16 Singleended Inputs and T

Transmitters

2Wire

Transmitter

+

–

+

–

Source

1

All commons are electrically tied

together inside the module.

2

Jumper all unused channels to

module common to reduce noise.

Attention: Analog input signals must be within +14.25V

referenced

common

and module common. If an input terminal

channeltochannel crosstalk can cause invalid input

readings and invalid underrange or overrange bits.

The 1771IFE module does not supply loop power for the input

device. The user must supply loop power for looppowered

input devices.

to module common.

This input signal includes any

mode voltage present between either input

exceeds this range,

terminal

Ground

woWire

Channel 1

Channel 2

2

Channel 3

Channel 4

1

Module Common

Channel 5

Channel 6

Channel 7

Channel 8

1

Module Common

Channel 9

Channel 10

Channel 11

Channel 12

1

Module Common

Channel 13

Channel 14

Channel 15

Channel 16

1

Module Common

1

Module Common

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1771WG

Field Wiring Arm

10948I

2-4

Page 17

Chapter 2

Installing the Input Module

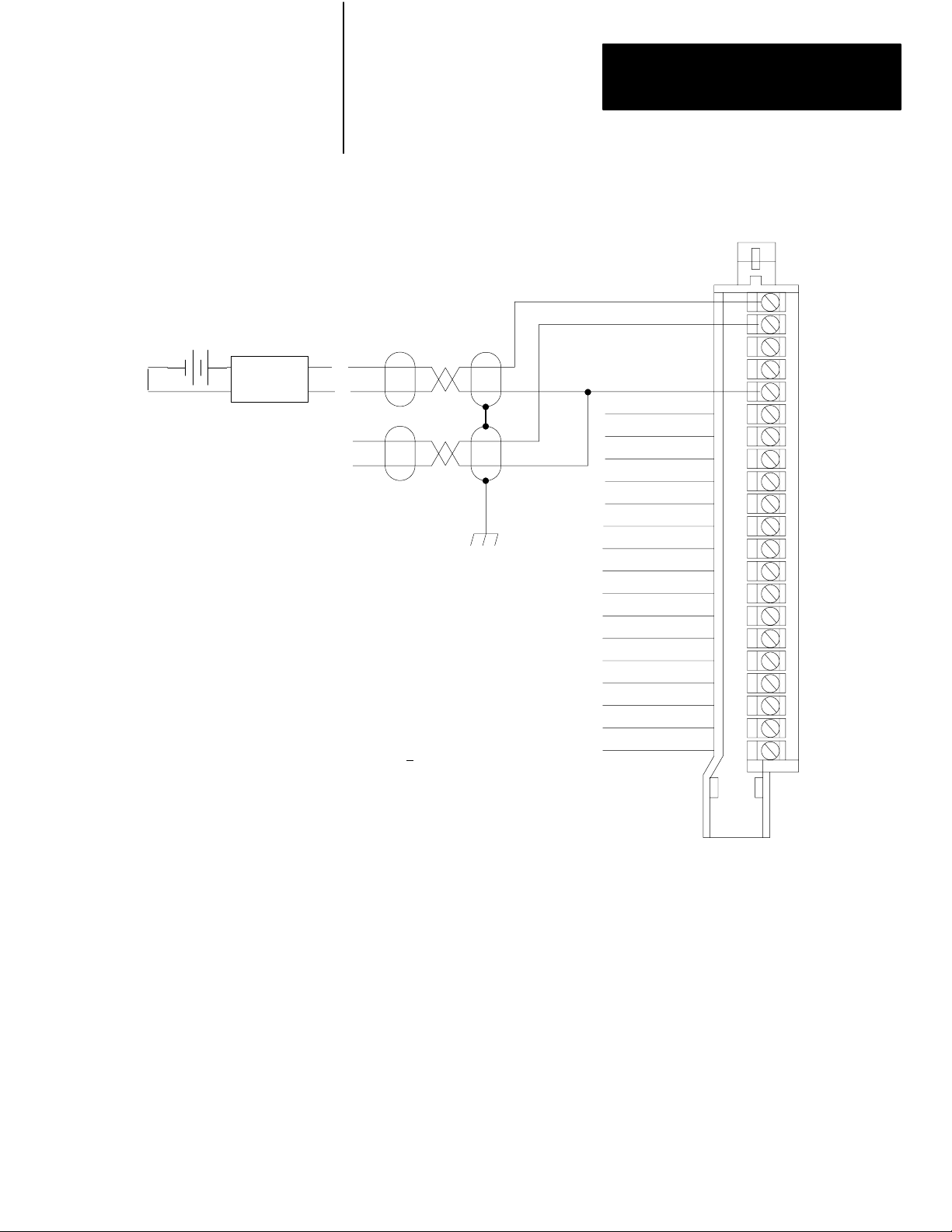

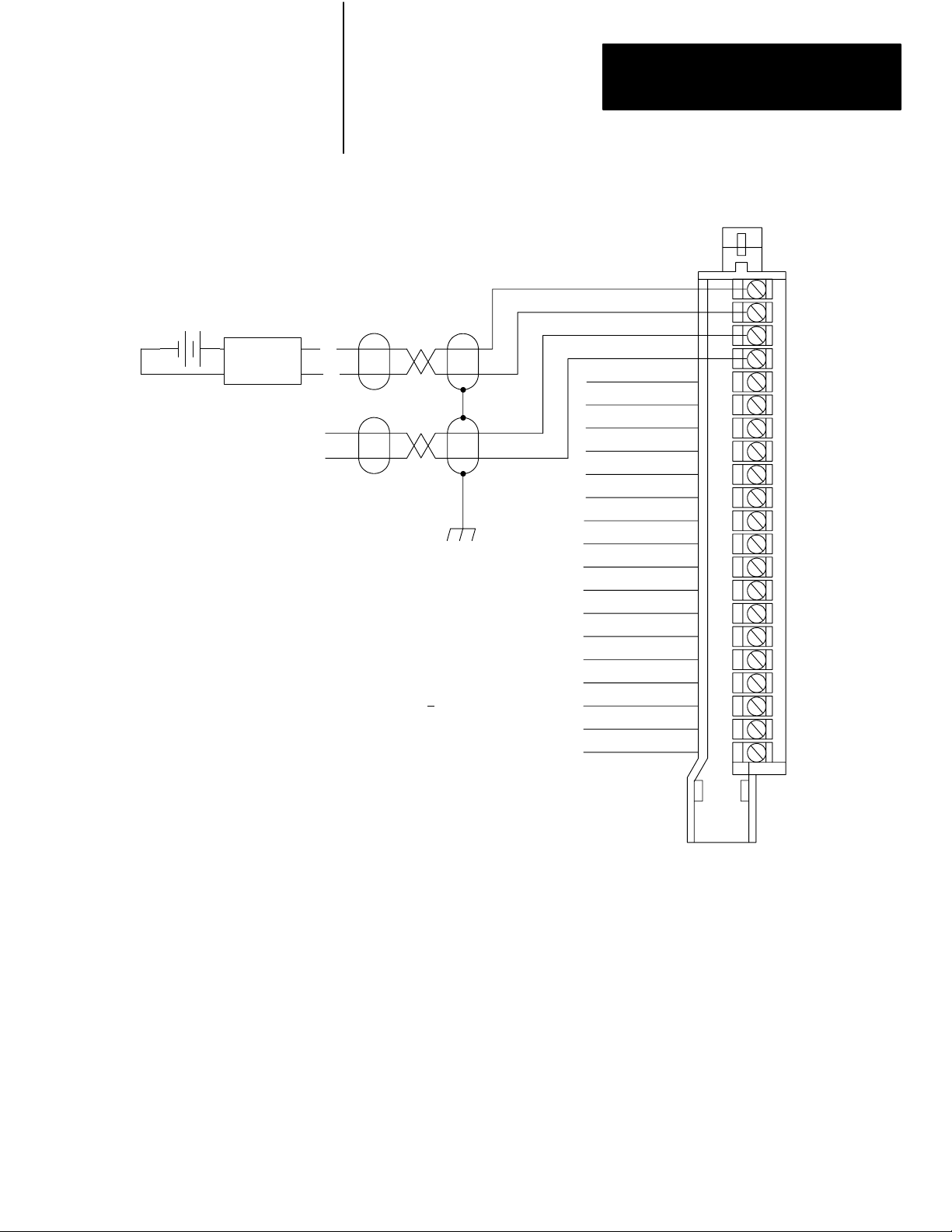

Figure 2.3

Connection

Diagram for 16 Singleended Inputs and FourW

Transmitters

+

–

4Wire

Transmitter

+

–

+

–

Source

1

All commons are electrically tied

together inside the module.

2

Jumper all unused channels to

module common to reduce noise.

Attention: Analog input signals must be within +14.25V

referenced

common

and module common. If an input terminal

channeltochannel crosstalk can cause invalid input

readings and invalid underrange or overrange bits.

The 1771IFE module does not supply loop power for the input

device. The user must supply loop power for looppowered

input devices.

to module common.

This input signal includes any

mode voltage present between either input

exceeds this range,

terminal

Ground

Channel 1

Channel 2

2

Channel 3

Channel 4

1

Module Common

Channel 5

Channel 6

Channel 7

Channel 8

1

Module Common

Channel 9

Channel 10

Channel 11

Channel 12

1

Module Common

Channel 13

Channel 14

Channel 15

Channel 16

1

Module Common

1

Module Common

ire

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1771WG

Field Wiring Arm

10948I

2-5

Page 18

Chapter 2

Installing the Input Module

2Wire

Transmitter

Figure 2.4

Connection

+

–

+

–

Diagram for 8 Differential Inputs and T

Source Ground

NOTE:

1. Unused channels must have their + and inputs jumpered

together and tied to module common to reduce noise.

Attention: Analog input signals must be within +14.25V

referenced

to module

range, channeltochannel crosstalk can cause invalid input

readings and invalid underrange or overrange bits.

common. If an input channel exceeds this

woW

Channel 1+

Channel 1

Channel 2+

Channel 2

Not used

Channel 3+

Channel 3

Channel 4+

Channel 4

Not used

Channel 5+

Channel 5

Channel 6+

Channel 6

Not used

Channel 7+

Channel 7

Channel 8+

Channel 8

Module Common

Module Common

ire T

ransmitters

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

2-6

The 1771IFE module does not supply loop power for the input

device. The user must supply loop power for looppowered

input devices.

Configuring the module for differential inputs does not provide isolation.

1771WG

Field Wiring Arm

10949I

Page 19

Chapter 2

Installing the Input Module

Figure 2.5

Connection

+

–

4Wire

Transmitter

+

–

+

–

Diagram for 8 Differential Inputs and FourW

Source

NOTE:

1. Unused channels must have their + and inputs jumpered

together and tied to module common to reduce noise.

Attention: Analog input signals must be within +14.25V

referenced

range, channeltochannel crosstalk can cause invalid input

readings and invalid underrange or overrange bits.

The 1771IFE module does not supply loop power for the input

device. The user must supply loop power for looppowered

input devices.

to module

common. If an input channel exceeds this

Ground

Channel 1+

Channel 1

Channel 2+

Channel 2

Not used

Channel 3+

Channel 3

Channel 4+

Channel 4

Not used

Channel 5+

Channel 5

Channel 6+

Channel 6

Not used

Channel 7+

Channel 7

Channel 8+

Channel 8

Module Common

Module Common

ire T

ransmitters

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Configuring the module for differential inputs does not provide isolation.

1771WG

Field Wiring Arm

10949-I

2-7

Page 20

Chapter 2

Installing the Input Module

Grounding

When using shielded cable wire, ground the foil shield and drain wire only

at one end of the cable. We recommend that you wrap the foil shield and

drain wire together and connect them to a chassis mounting bolt

(Figure 2.6). At the opposite end of the cable, tape exposed shield and

drain wire with electrical tape to insulate it from electrical contact.

Figure 2.6

Cable

Remove a length of cable

jacket from the Belden 8761

cable.

Belden

8761 Cable

When you connect grounding conductors to the I/O chassis

grounding stud, place a star washer under the first lug, then

place a nut with captive lock washer on top of each ground lug.

Pull the foil shield and bare

drain wire from the insulated

wires.

Foil

shield

Chassis Ground Singlepoint Grounding

Grounding

Bare

drain

wire

Insulated

wires

Twist the foil shield and drain

wire together to form a single

strand.

Attach a ground lug.

20104

Grounding Stud

I/O Chassis Side Plate

2-8

Star

Washer

1

Use

the cup washer if crimpon lugs are not used.

Ground Lug

Nut

Nut and Captive

Washer

Ground Lug

Shield and Drain

twisted together

1

19480

Shield and Drain

twisted together

#10 Threadforming screw

Externaltooth Washers

Refer

to Wiring and Grounding Guidelines, publication 17704.1 for additional information.

19923

Page 21

Chapter 2

Installing the Input Module

Changing the Module's

Configuration

The analog input module (1771-IFE) has configuration plugs for

determining the input type (voltage or current) desired for each input. The

module comes from the factory with the plugs positioned for

voltage inputs.

To set the configuration plugs for your desired inputs, proceed as follows:

1. Remove the module’s covers by removing the four screws securing

the covers to the module.

2. Locate the selection plugs (Figure 2.7).

Figure 2.7

Configuration

Plug Locations

Selection Plugs

(refer to Figures 2.8, 2.9 and 2.10)

10950I

3. Position the plugs as shown in the Figures for your particular module

(Figures 2.8, 2.9 and 2.10).

4. Reassemble the module after you have finished checking and/or

setting the selection plugs.

2-9

Page 22

Chapter 2

Installing the Input Module

Figure 2.8

Selection

Plug Settings for Differential or Singleended V

Differential or Singleended Current Inputs

Voltage

Differential or Singleended

storage positions

[1] [1] [1]

1

5

9

Differential Current

storage positions storage positions

1

5

9

Current

channel 1

channel 2

13

17

21

13

17

21

channel 3

channel 4

25

25

oltage or

Singleended Current

1

5

9

13

17

21

25

channel 1

channel 2

channel 3

channel 4

channel 5

channel 6

channel 7

channel 8

29

33

37

41

45

49

12677 12678

[1]

Positions 1 and 2 are not used.

Note:

Plugs are not needed for operation in the voltage mode.

29

33

37

41

45

49

channel 5

channel 6

channel 7

channel 8

29

33

37

41

45

49

channel 9

channel 10

channel 11

channel 12

channel 13

channel 14

channel 15

channel 16

10951I

2-10

Page 23

Chapter 2

Installing the Input Module

Figure 2.9

Configuration Plug Settings for Singleended Voltage and Current Inputs

on Adjacent Channels

[1]

1

channel 1 (single-ended voltage)

5

channel 2 (single-ended current)

9

channel 3 (single-ended current)

channel 4 (single-ended voltage)

13

positions 1 and 2 are not used[1]

Figure 2.10

Configuration Plug Settings for Differential Voltage and Current Inputs

on Adjacent Channels

[1]

1

5

channel 1 (differential current)

9

channel 2 (differential voltage)

13

10952I

Note: Either dif

positions 1 and 2 are not used[1]

10953I

ferential and singleended configurations must be selected for the entire module.

2-11

Page 24

Chapter 2

Installing the Input Module

Module Installation

When installing your module in an I/O chassis:

1. First, turn off power to the I/O chassis.

ATTENTION: Remove power from the 1771 I/O chassis

backplane and wiring arm before removing or installing an I/O

module.

Failure to remove power from the backplane could cause injury or

equipment damage due to possible unexpected operation.

Failure to remove power from the backplane or wiring arm could

cause module damage, degradation of performance, or injury.

2. Place the module in the plastic tracks on the top and bottom of the

slot that guides the module into position.

3. Do not force the module into its backplane connector. Apply firm

even pressure on the module to seat it properly.

4. Snap the chassis latch over the top of the module to secure it.

5. Connect the wiring arm to the module.

Indicator Lights

Chapter Summary

The front panel of the input module contains a green RUN and a red FLT

(fault) indicator (Figure 2.11). At power-up an initial module self-check

occurs. If there is no fault, the red indicator turns off. The green indicator

will be on when the module is powered. If a fault is found initially or

occurs later, the red FLT indicator lights. Possible module fault causes and

corrective action is discussed in Chapter 7, Troubleshooting.

Figure 2.11

Diagnostic

ANALOG

(12

RUN

FLT

Indicators

IN

BIT)

Green RUN indicator

Red FLT indicator

10528I

In this chapter you learned how to install your input module in an existing

programmable controller system and how to wire to the field wiring arm.

2-12

Page 25

Module Programming

Chapter

3

Chapter

Objectives

Block Transfer

Programming

In this chapter we describe:

block transfer programming

sample programs in the PLC-2, PLC-3 and PLC-5

processors

module scan time issues

Your module communicates with your processor through bidirectional

block transfers. This is the sequential operation of both read and write

block transfer instructions.

The block transfer write (BTW) instruction is initiated when the analog

module is first powered up, and subsequently only when the programmer

wants to write a new configuration to the module. At all other times the

module is basically in a repetitive block transfer read (BTR) mode.

The application programs for the three processor families were written to

accomplish this handshaking in the described manner. They are minimum

programs; all the rungs and conditioning must be included in your

application program. If you wish to disable BTRs for any reason, or add

interlocks to the BTW rung to prevent writes from happening at certain

times, you are allowed to do it. You may not eliminate any storage bits or

interlocks that are included in our examples. If interlocks are removed, the

program may not work properly.

The analog input module will work with a default configuration of

zeroes entered in all five words of a five word BTW configuration

block. See the configuration default section to understand what this

configuration will look like. Also, refer to Appendix B for example

configuration blocks and instruction addresses to get started.

ATTENTION: In PLC-2 family processors you must not

enable both the read and write instructions at the same time.

Undesirable data could transfer, resulting in unpredictable

machine operation. Using the prescribed programs will prevent

this situation.

3-1

Page 26

Chapter 3

Module Programming

PLC2 Programming

Rung 1

Block transfer read buffer: the

filetofile move instruction holds the

block transfer read (BTR) data (file A)

until the processor checks the data

integrity. If the data was successfully

transferred, the processor energizes

the BTR done bit, initiating a data

transfer to the buffer (file R) for use in

the program.

If the data is corrupted during the BTR

operation, the BTR done bit is not

energized and data is not transferred to

the buffer file. In this case, the data in

the BTR file will be overwritten by data

from the next BTR.

Rungs 2 and 3

These rungs provide for a userinitiated

block transfer write (BTW) after the

module is initialized at powerup.

Pressing the pushbutton locks out BTR

operation and initiates a BTW that

reconfigures the module. Block transfer

writes will continue for as long as the

pushbutton remains closed.

Rungs 4 and 5

These rungs provide a readwriteread"

sequence to the module at powerup.

They also make sure that only one

block transfer (read or write) is enabled

during a particular program scan.

Rungs 6 and 7

These rungs are the conditioning block

transfer rungs. Include all the input

conditioning shown in the example

program.

The PLC-2 program example regulates when each block transfer will be

initiated to eliminate problems caused by limited regulation of

bidirectional block transfers. Both storage bits are needed, as shown in the

example, to accomplish this task in all PLC-2 systems, local or remote,

with long or short program scans. Therefore, the program as shown is the

minimum required. Note that PLC-2 processors that do not have the block

transfer instruction must use the GET-GET block transfer format which is

outlined in Appendix E.

Figure 3.1

PLC2

Block Transfer Read

Done Bit

1

Pushbutton [1]

2

Block Transfer Write

Done Bit Pushbutton [1]

3

Block Transfer Write

Done Bit

4

Block Transfer Read

Done Bit

5

Power-up

6

7

Bit

Storage

Bit B

Power-up

Bit

Storage

Bit A

Family Sample Program Structure

FILE TO FILE MOVE

COUNTER ADDR:

POSITION:

FILE LENGTH:

FILE A:

FILE R:

RATE PER SCAN

Power-up

Bit

Storage

Bit A

[1] You can replace the pushbutton with a timer done" bit to initiate the block transfer

write on a timed basis. You can also use any storage bit in memory.

BTR Done

Bit

Storage

Bit B

BTR

BLOCK XFER READ

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

BTW

BLOCK XFER WRITE

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

YYYY - XXXX

YYYY - XXX

XXXX - XXXX

XXX

XXX

XXX

XXX - XXX

XXX

XXX

RGS

XX

XXX

RGS

XX

ENABLE

DONE

ENABLE

EN

17

DONE

DN

15

Storage

Bit A

L

Storage

Bit A

U

Storage

Bit B

L

Storage

Bit B

U

ENABLE

EN

X7

DONE

DN

X7

EN

X6

DN

X6

10954I

3-2

Page 27

Chapter 3

Module Programming

PLC3 Programming

Program Action

At powerup, the user program examines, the

BTR done bit in the block transfer read file,

initiates a block transfer write to configure the

module, and then does consecutive block

transfer reads continuously. The powerup bit

can be examined and used anywhere in the

program.

Rungs 1 and 2

Rungs 1 and 2 are the block transfer read and

write instructions. The BTR done bit in rung 1,

being false, initiates the first read block transfer.

After the first read block transfer, the module

performs a block transfer write and then does

continuous block transfer reads until the

pushbutton is used to request another block

transfer write. After this single block transfer

write is performed, the module returns to

continuous block transfer reads automatically.

Block transfer instructions with the PLC-3 processor use one binary file in

a data table section for module location and other related data. This is the

block transfer control file. The block transfer data file stores data that you

want transferred to your module (when programming a block transfer

write) or from your module (when programming a block transfer read).

The address of the block transfer data files are stored in the block transfer

control file.

The industrial terminal prompts you to create a control file when a block

transfer instruction is being programmed. The same block transfer

control file is used for both the read and write instructions for your

module. A different block transfer control file is required for every

module.

A sample program segment with block transfer instructions is shown in

Figure 3.2, and described below.

Figure 3.2

Family Sample Program Structure

PLC3

Block Transfer

1

2

Read

Done Bit

Pushbutton

Power-up

Bit

Block Transfer

Write

Done Bit

BTR

BLOCK XFER READ

RACK:

GROUP:

MODULE:

DATA:

LENGTH =

CNTL:

XXXXX=XXXX

XXXXX:XXXX

BTW

BLOCK XFER WRITE

RACK :

GROUP :

MODULE:

DATA:

LENGTH =

CNTL:

XXXXX = XXXX

XXXXX:XXXX

X=XXXX

X = XXXX

XXX

XXX

X

X

X

X

ENABLE

EN

12

DONE

DN

15

ERROR

ER

13

ENABLE

EN

02

DONE

DN

05

ERROR

ER

03

3-3

Page 28

Chapter 3

Module Programming

PLC5 Programming

Program Action

Rungs 1 and 2

At powerup, the program enables a block

transfer read and examines the powerup bit

in the BTR file (rung 1). Then, it initiates one

block transfer write to configure the module

(rung 2). Thereafter, the program continuously

reads data from the module (rung 1).

A subsequent BTW operation is enabled by a

pushbutton switch (rung 2). Changing

processor mode will not initiate a block

transfer write.

The PLC-5 program is very similar to the PLC-3 program with the

following exceptions:

1. You must use enable bits instead of done bits as the conditions on

each rung.

2. A separate control file must be selected for each of the block transfer

instructions. Refer to Appendix B.

Figure 3.3

Family Sample Program Structure

PLC5

BTR Enable

1

2

Bit

Pushbutton

Power-up Bit

BTW Enable

BTR

BLOCK TRANSFER READ

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

BTW

BLOCK TRANSFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

XX:XX

XX:XX

XX:XX

XX:XX

EN

X

X

DN

X

ER

X

N

EN

X

X

DN

X

ER

X

N

3-4

10956I

Page 29

Chapter 3

Module Programming

Module

Scan T

ime

Scan time is defined as the amount of time it takes for the input module to

read the input channels and place new data into the data buffer. Scan time

for your module is shown in Appendix A.

The following description references the sequence numbers in Figure 3.4.

Following a block transfer write “1” the module inhibits communication

until after it has configured the data “2,” performed self-calibration “3,”

scanned the inputs “4,” and filled the data buffer “5.” Write block transfers,

therefore, should only be performed when the module is being configured

or calibrated.

Any time after the second scan begins “6,” a BTR request “7” can be

acknowledged. This interrupts the scan and the BTR empties the buffer.

Following the BTR, the input module inhibits block transfer

communications with the programmable controller until it has scanned its

inputs “8” and new data is ready ”9.” The input module repeats the scan

sequence “10,” updating the input values until another block transfer

request is received. Therefore, BTRs will only be completed as frequently

as the total scan time of the input module.

Figure 3.4

T

Block

ransfer T

ime

Chapter Summary

End of block

transfer write

Block

Transfer

Write

time

1 2 3 4 56789

Note: Configure/Calibration time:

Configure

time

Singleended mode = 100ms without filter, 102ms with filter

Differential mode = 56ms without filter, 58ms with filter

Scan time:

= 12.5 ms for 8 differential inputs (no scaling or digital filter);

= 25 ms for 16 singleended inputs (no scaling or digital filter)

Calibration

time

See note

Module available to

perform block transfer

1st

Scan

2nd

Scan

3rd

Scan

In this chapter, you learned how to program your programmable controller.

You were given sample programs for your PLC-2, PLC-3 and PLC-5

family processors.

You also read about module scan time.

10

12689

3-5

Page 30

Configuring Your Module

Chapter

4

Chapter

Objectives

Configuring Your Input

Module

In this chapter you will read how to configure your module’s features,

condition your inputs and enter your data.

Because of the many analog devices available and the wide variety of

possible configurations, you must configure your module to conform to the

analog device and specific application that you have chosen. Data is

conditioned through a group of data table words that are transferred to the

module using a block transfer write instruction. Before continuing, make

sure you read “Setting Module Selection Plugs” in chapter 2.

The software configurable features available with the Analog Input

Module (cat. no. 1771-IFE) are:

input range selection

input type

data format

digital filtering

real time sampling

scaling to engineering units

Note that digital filtering and scaling values must be entered in BCD

format only. Change your display format to BCD in the PLC-5 and

PLC-3 to accomplish this.

Note: Programmable controllers that use 6200 software programming tools

can take advantage of the IOCONFIG utility to configure this module.

IOCONFIG uses menu-based screens for configuration without having to

set individual bits in particular locations. Refer to your 6200 software

literature for details.

Note: Programmable controllers that use process configuration and

operation software (cat. no. 6190–PCO) can take advantage of those

development and runtime tools used for the application of programmable

controllers in process control. The PCO worksheets and the menu-driven

configuration screens and faceplates let you configure, test/debug and

operate the I/O module. Refer to your 6190-PCO software literature for

details.

4-1

Page 31

Chapter 4

Module Configuration

Input Range Selection

You can configure the module to operate with any of five voltage or three

current ranges. You can select individual channel ranges using the

designated words of the write block transfer instruction (Table 4.A). Use

BTW word 1 for range selection of channels 1 through 8, and BTW word 2

for channels 9 through 16. Two bits are allocated for each channel. For

example, for channel 1, set word 1 bits 00-01 as shown in Table 4.A.

Table 4.A

Range Selection Bits

Input

Bit 01 Bit 00 Voltage or current input

0 0 1 to 5 V DC, 4 to 20 mA

0 1 0 to 5 V DC, 0 to 20 mA

1 0 5 to +5 V DC, 20 to +20 mA

1 1 10 to +10 V DC2, 0 to 10 V DC

1

Current input mode selected by configuration plug.

2

Configurable

using bipolar scaling.

1

1

1,2

Table 4.B shows the incremented voltage or current assigned to each bit for

the seven different input ranges. For example, if the channel 1 input range

is 0 to +5V and the actual incoming signal is at mid-range (+2.5V) the

value in the module’s data word would be 0000 1000 0000 0000 (binary)

or 2048 (decimal). The input is 2048/4096, or 1/2 of full scale.

Table 4.B

V

oltage and Current Ranges for the Analog Input Module

Input

Nominal Voltage or

Current Range

+1 to +5V 0000 to +4095 0000 to + 4095 0.98mV

0 to 5V 0000 to +4095 0000 to +4095 1.22 mV

5 to +5V 4095 to +4095 4095 to +4095 1.22mV

10 to +10V 4095 to +4095 4095 to +4095 2.44mV

0 to +20mA 0000 to +4095 0000 to +4095 .0049mA

+4 to +20mA 0000 to +4095 0000 to +4095 .0039mA

20 to +20mA 4095 to +4095 4095 to +4095 .0049 mA

Note: Voltage

and current input ranges are selectable on a per channel basis.

Corresponding 4Digit

BCD Output Range

Corresponding 12Bit

Binary Output Range

Current Per Bit

Voltage or

4-2

Page 32

Chapter 4

Module Configuration

Input Type

Data Format

You can select single-ended or differential inputs using the designated bit

in the configuration file. Inputs to a particular module must be all

single-ended or all differential. Set BTW word 3, bit 08 (bit 10 octal) as

shown in Table 4.C.

Table 4.C

Selecting

Decimal Bit 8

(Octal Bit 10)

Singleended or Differential Inputs

Input type

1 differential inputs

0 singleended inputs

You must also indicate what format will be used to read data from your

module. Typically, you select BCD with PLC-2 processors, and 2’s

complement binary with PLC-3 and PLC-5 processors. See Appendix C

for details on data format. You use BTW word 3 bits 09-10 (11-12 octal) to

set the data format (Table 4.D).

Table 4.D

Selecting

the Data Format

Decimal Bit 10

(Octal Bit 12)

0 0 BCD

0 1 not used

1 0 two's complement binary

1 1 signed magnitude binary

Decimal Bit 09

(Octal Bit 11)

Data Format

4-3

Page 33

Chapter 4

Module Configuration

Digital Filtering

The module has hardware-based high frequency filters on all channels to

reduce the effect of electrical noise on the input signal. Software digital

filtering is meant to reduce the effect of process noise on the input signal.

Digital filtering is selected using BTW word 3, bits 00-07.

The digital filter equation is a classic first order lag equation (Figure 4.1).

Using a step input change to illustrate the filter response (Figure 4.2), you

can see that when the digital filter constant time elapses, 63.2% of the total

response is reached. Each additional time constant achieves 63.2% of the

remaining response.

Figure 4.1

Filter Equation

Digital

t

(X

Yn = Y

Where:

- Y

+

n-1

t + TA

Y

n = present output, filtered peak voltage (PV)

Y

n -1 = previous output, filtered PV

t = module channel update time (seconds)

TA

= digital filter time constant (seconds)

X

n = present input, unfiltered PV

n

n-1

)

Figure 4.2

Digital Filter Lag Equation Illustration

100%

63%

Amplitude

0

0 0.01 0.5 0.99 Time in Seconds

Unfiltered Input

TA = 0.01 sec

TA = 0.5 sec

TA = 0.99 sec

16723

Digital filter time constant values of 0.00 BCD to 0.99 BCD (0.00 BCD =

no filter; 0.99 BCD = maximum filter) are set in bits 00 through 07 of

word 3 of the block transfer write instruction. If an invalid digital filter

value is entered (i.e., 0.1F), bit 02, word 1 of the block transfer read

instruction will be set. If an invalid digital filter value is entered, the

module will not perform digital filtering. If you use the digital filtering

feature, the filter time constant value chosen will apply to all input signals.

4-4

Page 34

Chapter 4

S

d

S

d

Module Configuration

Real Time Sampling

The real time sampling (RTS) mode of operation provides data gathered at

precisely timed intervals for use by the processor. BTW word 3 bits 11–15

(13–17 octal) are used to set the real time sampling interval.

RTS is invaluable for time based functions (such as PID and totalization) in

the PLC. It allows accurate time based calculations in local or remote I/O

racks. In the RTS mode the module scans and updates its inputs at a user

defined time interval (T) instead of the default interval. The module

ignores block transfer read (BTR) requests for data until the sample time

period elapses. The BTR of a particular data set occurs only once at the

end of the sample period and subsequent requests for transferred data are

ignored by the module until a new data set is available. If a BTR does not

occur before the the end of the next RTS period, a time-out bit is set in the

BTR status area. When set, this bit indicates that at least one data set was

not transferred to the processor. (The actual number of data sets missed is

unknown.) The time-out bit is reset at the completion of the BTR.

Set appropriate bits in the BTW data file to enable the RTS mode. You can

select RTS periods ranging from 100 milliseconds (ms) to 3.1 seconds.

Refer to Table 4.E below for actual bit settings. Note that the default mode

of operation is implemented by placing all zeroes in bits 11–15

(13–17 octal).

Decimal Bits 15 14 13 12 11

Octal Bits 17 16 15 14 13

0 0 0 0 0 No RTS, Default settings 1 0 0 0 0 1.6s

0 0 0 0 1 100ms 1 0 0 0 1 1.7s

0 0 0 1 0 200ms 1 0 0 1 0 1.8s

0 0 0 1 1 300ms 1 0 0 1 1 1.9s

0 0 1 0 0 400ms 1 0 1 0 0 2.0s

0 0 1 0 1 500ms 1 0 1 0 1 2.1s

0 0 1 1 0 600ms 1 0 1 1 0 2.2s

0 0 1 1 1 700ms 1 0 1 1 1 2.3s

0 1 0 0 0 800ms 1 1 0 0 0 2.4s

0 1 0 0 1 900ms 1 1 0 0 1 2.5s

0 1 0 1 0 1.0s 1 1 0 1 0 2.6s

0 1 0 1 1 1.1s 1 1 0 1 1 2.7s

0 1 1 0 0 1.2s 1 1 1 0 0 2.8s

0 1 1 0 1 1.3s 1 1 1 0 1 2.9s

0 1 1 1 0 1.4s 1 1 1 1 0 3.0s

0 1 1 1 1 1.5s 1 1 1 1 1 3.1s

Default

Settings =

Singleended inputs 25 ms

Dif

ferential inputs 12.5 ms

Table 4.E

Settings for the Real T

Bit

ample Time Perio

ime Sample Mode

15 14 13 12 11

ample Time Perio

17 16 15 14 13

4-5

Page 35

Chapter 4

Module Configuration

Scaling

Your module can perform linear conversion of unscaled data to

engineering units, (for example; gallons/minute, degrees C/degrees F and

pounds/square inch). Unscaled data in the module has a range of : 0

through 4095 for the polar ranges (0 to 5V DC/0 to 20mA and 1 to 5V

DC/4 to 20mA); and -4095 to +4095 (8190) for the bipolar ranges

(+

5V/+20mA and +10V). BTW words 6 through 37 are the scaling words

for channels 1 through 16. Channel 1 minimum scaling values are set in

word 6, and maximum scaling values are set in word 7. Channel 2

minimum scaling values are set in word 8, and maximum scaling values

are set in word 9, and so on for the other channels.

The format of this data is 4-digit BCD or 12-bit binary. The resolution at

the module of scaled values is the same as for unscaled data: one part in

4095 for 0 to 5V DC/0 to 20mA and 1 to 5V DC/4 to 20mA ranges; and

one part in 8190 for the +

processor, however, is determined by the scaled ranges (i.e., if 0 =

minimum and 500 = maximum, resolution is now 1 part in 500). Each

input channel can be scaled independently of the other channels.

Note: To achieve the 0 to +10V range you must use bipolar scaling. Select

the +

10V range and scale for + the actual intended range. If you need 0 to

100 gpm, set scaling values at -100 and +100. You will effectively be

creating a 0 to 10V range that is scaled from 0 to 100.

5V/+20mA and +10V ranges. Resolution at the

Implementing the Scaling Feature

You implement the scaling feature by:

1. Inserting minimum and maximum scaled values in the appropriate

configuration words

2. If any of the minimum or maximum values are negative, set the

appropriate sign bits in the minimum or maximum sign bit word

3. If a single channel is scaled, all channels must be scaled, and all 37

configuration words must be written to the module.

Scaling Ranges

The maximum range of the scaling values is +9999 BCD. These values

must be entered in BCD.

Typically, invalid values are “minimum greater than maximum,” or

“minimum equal to maximum.” If invalid values are entered into the

scaling words, the corresponding input in the BTR data will be zero

and the invalid scaling bit will be set.

4-6

Page 36

Chapter 4

Module Configuration

Important: Scaling values must always be entered in BCD format,

even if the data format chosen is binary. If scaling is selected for any

channel, all channels must be scaled. If scaling is not required on certain

channels, set those to the default input range: 0 to 4095 for 0 to + voltage

or current ranges, and -4095 to +4095 for - to + voltage or current ranges.

If scaling is not selected, the module requires specific minimum BTR

file lengths for the number of channels used. The BTW file length can

be set to 3 words. Table 4.F shows the required BTW and BTR file lengths.

Table 4.F

Block

T

ransfer Read and W

rite File Lengths

Channels

Used

1 5 7

2 6 9

3 7 11

4 8 13

5 9 15

6 10 17

7 11 19

8 12 21

9 13 23

10 14 25

11 15 27

12 16 29

13 17 31

14 18 33

15 19 35

16 20 37

BTR File

Length

BTW File

Length

Important: Use decimally addressed bit locations for PLC-5 processors.

4-7

Page 37

Chapter 4

Module Configuration

Default Configuration

If a write block of five words, with all zeroes, is sent to the Analog Input

Module (cat. no. 1771-IFE), default selections will be:

1 to 5V DC or 4 to 20mA (dependent on configuration jumper setting)

BCD data format

no real time sampling (RTS)

no filtering

no scaling

single-ended inputs

Figure 4.3

Input Module (1771IFE) Block T

Analog

Block

Decimal Bits 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bits 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Word 1 8 7 6 5 4 3 2 1 Range Selection Channels 1 thru 8

2 16 15 14 13 12 11 10 9 Range Selection Channels 9 thru 16

3 Real Time Sampling

Data

Format

Input

Type

Digital Filter

ransfer W

rite Configuration

Description

Real time sampling, data format, input

type and digital filter

4 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 Sign Bits, minimum scaling values

5 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 Sign Bits, maximum scaling values

6 Channel 1 minimum scaling

7 Channel 1 maximum scaling

8 Channel 2 minimum scaling

9 Channel 2 maximum scaling

10 Channel 3 minimum scaling

⇓⇓⇓⇓

37 Channel 16 maximum scaling

4-8

Page 38

Word

Chapter 4

Module Configuration

Bit/Word Descriptions for the Analog Input Module Block Transfer

Write Configuration Block

Note that decimal bits are shown, with octal bits in parentheses.

Decimal

Bit

(Octal Bit)

Description

Word 1 and 2

Word 3

Word 4

Word 5

Words 637

Bits 0015

(0017)

Bits 0007

(0007)

Bit 08

(10)

Bits 0910

(0710)

Bits 1115

(1317)

Bits 0015

(0017)

Bits 0015

(0017)

Bits 0015

(0017)

Input range selections allow the user to configure the inputs for any of 7 input

voltage or current ranges. Two bits are required for each channel. See Table 4.A.

Digital filter reduces effect of noise on input. See "Digital Filtering" on page 44.

Input type, set bit for differential mode on all channels.

Reset (0) = singleended. Refer to Table 4.C

Data format matches format of processor. See Table 4.D.

Real time sampling will default to 12.5ms for differential mode and 25ms for

singleended, greater with filtering selected. See appendix A for timing details.

See Table 4.E for other real time intervals.

Minimum sign bits, when set, designate negative minimum scaling values for the

corresponding input channels. Bit 00 corresponds to channel 1, bit 01

corresponds to channel 2, etc.

Maximum sign bits, when set, designate maximum scaling values that are

negative. Maximum scaling value must be greater than minimum on any

particular channel. Bit 00 corresponds to channel 1, bit 01 corresponds to

channel 2, etc.

Minimum and maximum scaling values for each channel. Enter in BCD format.

Chapter Summary

In this chapter you learned how to configure your module’s features,

condition your inputs and enter your data.

4-9

Page 39

Chapter

Module Status and Input Data

5

Chapter

Objectives

In this chapter you will read about:

reading data from your module

block transfer read block format

Reading Data From Your

Module

Block transfer read programming moves status and data from the input

module to the processor’s data table in one I/O scan (Figure 5.1). The

processor’s user program initiates the request to transfer data from the

input module to the processor.

Figure 5.1

Assignments for Analog Input Module (1771IFE)

Word

Block T

ransfer Read

Decimal Bits 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Description

Octal Bits 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Word 1 Not Used Diagnostic Bits Diagnostics

2 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 Data underrange for channels 1-16

3 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 Data overrange for channels 1-16

4 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 Data polarity for channels 1-16

Description

1

1

5 Channel 1 Input Channel 1 Input

6 Channel 2 Input Channel 2 Input

7 Channel 3 Input Channel 3 Input

8 Channel 4 Input Channel 4 Input

⇓⇓⇓⇓

20 Channel 16 Input Channel 16 Input

1

These

bits are set (1) at approximately the input range limits selected (

Table 5.B).

5-1

Page 40

Chapter 5

Module Status and Input Data

Block Transfer Read Format

Word 1

Word 2

Word 3

The bit/word description for the block transfer read of the Analog Input

Module is described below in Table 5.A.

Table 5.A

W

ord Format for the Analog Input Module

BTR

Decimal

Word

Bit

(Octal Bit)

Bit 00

Bit 01

Bit 02

Bit 03

Bits 00-15

(00-17)

Bits 00-15

(00-17)

Description

Power up bit is used by the module to tell the processor that it is alive

but not yet configured. It is a key element in the application program.

Out of range bit is sent to tell the processor that one or more

channels are either over or under range.

1

Invalid scaling bit reports that the scaling is somehow invalid.

Usually, both values are equal or minimum is greater than maximum

when this bit comes on. Can also be an invalid filter value.

Real time sample fault bit. This bit is set if the module is configured for

RTS and a block transfer read has not occurred within the

user-programmed period.

Individual underrange bits for each channel. Bit 00 for channel 1, bit

01 for channel 2, etc.

1

These bits are set (1) at approximately the input

range limits selected from Table 5.B.

Individual overrange bits for each channel. Bit 00 for channel 1, bit

01 for channel 2, etc.

1

These bits are set (1) at approximately the

input range limits selected from Table 5.B.

Chapter Summary

Word 4

Bits 00-15

(00-17)

Polarity bits are set when input is less than zero. Bit 00 for channel

1, bit 01 for channel 2, etc.

Word 5 thru 20 Input values. Word 5 for channel 1, word 6 for channel 2, etc.

1

Attention: If

invalid input readings and invalid underrange/overrange bits.

an input terminal'

s voltage exceeds +

14.25V as referenced to module common, channeltochannel crosstalk can cause

Table 5.B

Range Selection

Input

Voltage input Current input

1

1 to 5V dc 4 to 20mA

0 to 5V dc 0 to 20mA

-5 to +5V dc -20 to +20mA

-10 to +10V dc

2

1

2

0 to 10V dc

1

Current input mode selected by configuration plug.

2

Configurable

using bi-polar scaling.

In this chapter you learned the meaning of the status information that the

input module sends to the processor.

5-2

Page 41

Calibrating Your Module

Chapter

6

Chapter

Objectives

Tools and Equipment

Calibration Procedure

In this chapter we tell you what tools you need and how to calibrate your

module.

In order to calibrate your input module you will need the following tools

and equipment:

Equipment Description

Digital voltmeter

Alignment tool

Potentiometer sealant

Industrial terminal

Backplane extender card Cat. no. 1771EZ

The analog input module is shipped from the factory already calibrated.

If necessary to recalibrate the module, you must calibrate the module in an

I/O chassis. The module must communicate with the processor and

industrial terminal. Calibration consists of adjusting the 10V reference and

nulling the input offset.

51/2 digit, 0.01% accuracy minimum: Keithley191 or Fluke

8300A or equivalent

P/n 35F616, for pot adjustment: Newark Electronics,

500 N.Pulaski Rd., Chicago, IL

Torque Seal: Organic Products,

P.O. Box 928, Irving, TX

Cat. no. 1770T3 and program panel interconnect cable

(cat. no. 1772TC) for PLC2 family processors:

AllenBradley,Highland Hts., OH

Important: The module must be powered up for at least 30 minutes before

attempting to calibrate.

ATTENTION: Do not attempt to calibrate your module until

you have read and thoroughly understand this procedure. Also,

do not attempt to calibrate this module in an operating system.

Damage to the equipment or personal injury may result.

6-1

Page 42

Chapter 6

Calibrating Your Module

Adjusting the 10V Reference

1. Turn off power to your processor and I/O chassis.

2. Swing the field wiring arm out of the way.

3. Remove the module from the I/O chassis.

4. Plug the module into the extender card, and insert the extender card

into the I/O chassis.

5. Attach the negative lead to an analog common (pin 5, 10, 15, 20 or

21) of the wiring arm.

6. Attach the positive lead of your voltmeter to TP1.

7. To set the on-board +10V reference, adjust potentiometer R64

(Figure 6.1) until the value at TP1 = 10.0000V (+

.0002V maximum).

Figure 6.1

Test

E1 Jumper in calibration position

1

E1

3

Points and Potentiometers for Analog Input Module (1771IFE)

13

E1

Left

Side of Module

6-2

TP1TP2R64R63

10956I

Page 43

Chapter 6

Calibrating Your Module

Nulling the Input Offset

After completing the 10V reference adjustment, turn off power to your

processor and I/O chassis and complete the following steps.

1. Move jumper E1 (Figure 6.1) from the default position (connecting

the center and right posts) to the calibration position (connecting the

center and left posts).

2. Attach the negative lead of your voltmeter to an analog common (pin

5, 10, 15, 20 or 21) of the field wiring arm.

3. Attach the positive lead of your voltmeter to TP2.

4. Turn on power to your processor and I/O chassis. Check to make

sure the red FLT indicator is lit and the green RUN indicator is off. If

the red indicator is off, check the position of E1.

Chapter Summary

5. Adjust potentiometer R63 (Figure 6.1) until the value at

TP2 = 0.0000V (+

0.0002V maximum).

6. After completing the adjustment, remove power from the I/O chassis

and return jumper E1 to the default position.

In this chapter you learned how to calibrate your module. This included the

necessary tools, adjusting the 10V reference, and nulling the offset.

6-3

Page 44

Chapter

7

Troubleshooting Your Input Module

Chapter

Objective

Diagnostics Reported by the

Module

In this chapter, we describe how to troubleshoot your module by observing

the indicators and by monitoring status bits reported to the processor.

At power-up, the module momentarily turns on the red indicator as a lamp

test, then checks for:

correct RAM operation

firmware errors

Thereafter, the module lights the green RUN indicator when operating

without fault, or lights the red FAULT indicator when it detects fault

conditions. The module also reports status and specific faults (if they

occur) in every transfer of data (BTR) to the PC processor. Monitor the

green and red indicators and status bits in word 1 of the BTR file when

troubleshooting your module.

Figure 7.1

Diagnostic

Indicators

ANALOG

IN

BIT)

(12

RUN

FLT

10528I

Diagnostic Bits Reported By the Analog Input Module

Diagnostic bits in the read block transfer status words provide diagnostic

capabilities.

Word 1 provides power-up and valid data status. Words 2, 3 and 4

provide channel data status.

If a module on-board self test fault occurs, block transfers will be

inhibited, the red fault (FLT) will light, and the green run (RUN) light will

go out.

7-1

Page 45

Chapter 7

Troubleshooting Your Input Module

Word 1

Diagnostics word 1 is the first data word in the read block transfer file for

transfer to the central processor. It contains a power-up bit (bit 00) that is

set (1) when the module is first powered up. It is reset (0) after a write

block transfer. It also contains an under-range or over-range bit (bit 01)

that is set when any input is under or over-range.

An invalid scaling data bit (bit 02) will be set if invalid scaling data is

entered into any of the minimum/maximum scaling value words. Note that

minimum equal to maximum is an invalid value. If invalid values are

entered into the minimum or maximum scaling words the corresponding

read block transfer input channel word will be set to 0000.

Bit 02 will also be set if an invalid digital filter value is entered (e.g., 1F).

If an invalid digital filter value is entered, the module will not perform

digital filtering.

The real time sample (RTS) fault bit (bit 03) is set if the module is

configured for RTS and a block transfer read has not occurred within the

user-programmed period.

Word 2

Word 2 provides for under-range conditions. When a particular channel

input is under-range, the associated bit will be set. As long as inputs are

under range the associated bit will remain set. Bit 00 corresponds to

channel 1, bit 01 to channel 2, etc.

Word 3

Word 3 provides for over-range conditions. When a particular channel

input is over-range, the associated bit will be set. As long as inputs are in

range the associated bit will remain reset. Bit 00 corresponds to channel 1,

bit 01 to channel 2, etc.

Word 4

Word 4 provides an indication of a particular channel’s input polarity (set,

or 1 = negative; reset, or 0 = positive). Bit 00 corresponds to channel 1, bit

01 to channel 2, etc.

Table 7.A lists the probable cause and recommended actions for a number

of common trouble indications.

7-2

Page 46

Chapter 7

Troubleshooting Your Input Module

Legend

Off

On

Table 7.A

Troubleshooting

Indicators Probable Cause Recommended Action

RUN (green)

FLT (red)

RUN (green)

FLT (red)

Chart for Analog Input Module (1771IFE)

Normal operation None

If outofrange bit is set (BTR word 1, bit

02) and all 8 underrange bits are set

(BTR word 2, bits 00 through 07).

If incorrect data in final storage word

locations in processor's data table,

possible severed or disconnected input

cable associated with the affected

channels.

or

Input module is conditioned for BCD

instead of binary or the reverse, incorrect

scaling, sign bits missing, wrong range.

Hardware failure in module Return module for repair.

Return module for repair

Repair/replace cable.

Condition module for desired format

(BCD or binary), enter correct data and

initiate another write block transfer.

If module connections are intact and

configuration data is correct check

calibration procedure.