Page 1

Installation Instructions

Cat. No. 1771-IBD Series B

Contents

Prevent Electrostatic Discharge

Use this document as a guide when installing the catalog number

1771-IBD series B input module.

To See page

Prevent Electrostatic Discharge Below

Important Preinstallation Considerations 2

Understand Compliance to European Union Directives 2

Calculate Power Requirements 3

Set the Filter Off Delay 3

Key the Backplane Connector 3

Install the Module and Field Wiring Arm 4

Connect Wiring to the Field Wiring Arm 5

For this reference information See page

Status Indicators 6

Troubleshooting 6

CSA Hazardous Location 7

Specifications 8

This input module is sensitive to electrostatic discharge. This module

is shipped in static-shielded packaging to guard against electrostatic

discharge damage. Observe the following precautions when handling

this module.

Electrostatic Discharge Damage

ATTENTION: Electrostatic discharge can damage

integrated circuits or semiconductors if you touch

!

backplane connector pins. Follow these guidelines

when you handle the module:

• Touch a grounded object to discharge static potential

• Wear an approved wrist-strap grounding device

• Do not touch the backplane connector or

connector pins

• Do not touch circuit components inside the module

• If available, use a static-safe work station

• When not in use, keep the module in its original

static-shielded packaging

Publication 1771-5.53 – April 1999

Page 2

DC (10-30V) Input Module2

ATTENTION: This module is equipped with a plastic

cover that is unique to assembly numbers 960364-05

!

and 961344-01. (This part number is located near the

backplane edge connector pins on the component-side

of the circuit board.) Do not use this plastic cover on

any other module.

Pre-installation Considerations

Understand Compliance to European Union Directives

The 1771-IBD Series B module is compatible with all chassis except

1771-A1, 1771-A2, 1771-A4 chassis. Make sure no other input

module or single card block transfer module is placed in the same

module group when using 2-slot addressing. Any discrete output

module may be used within the same module group.

The 1771-IBD Series B module has a selectable off-delay filter time

of either 1ms or 6ms. To select the off-delay filter time, use the

procedure on page 3.

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard,

Part 2 – Industrial Environment

• EN 50082-2EMC – Generic Immunity Standard,

Part 2 – Industrial Environment

Publication

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as these Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For

Noise Immunity, publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

This equipment is classified as open equipment and must be mounted

in an enclosure during operation to provide safety protection.

1771-5.53 – April 1999

Page 3

DC (10-30V) Input Module 3

Key

Power Requirements

Set the Filter Off Delay

Your module receives its power through the 1771 I/O chassis

backplane from the chassis power supply. The module requires

130mA from the output of this supply. To calculate the requirements

for the backplane power supply, add 130mA to the power

requirements of all other modules in the I/O chassis. Calculating the

requirements will prevent an overload to the chassis backplane

and/or backplane power supply.

The off delay filter time is preset to 1ms. To change the filter time to

6ms, do the following:

1. Turn off power to the I/O chassis.

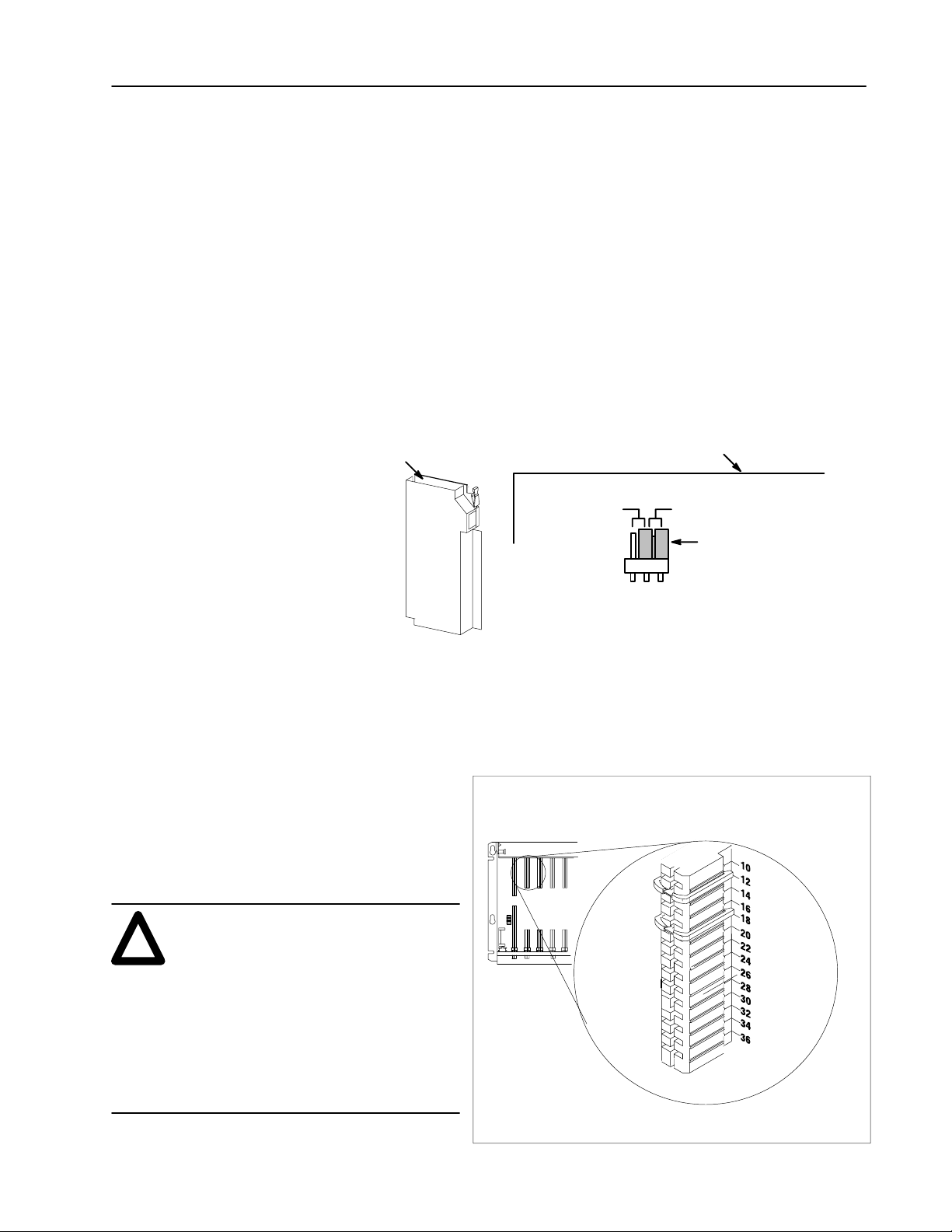

2. Locate the off-delay filter time configuration plug on the top-left

edge of the printed circuit board as shown below.

Filter Delay Configuration Plug

6ms OFF

Top edge of circuit board

1ms OFF

Off-Delay Filter Time Jumper

(shown in 1ms off position)

3. Use your finger to slide the jumper off the 1ms position (the

4. Carefully reposition the jumper by sliding it onto the 6ms

the Backplane Connector

Place your module in any slot in the chassis

except the leftmost slot which is reserved for

processors or adapters.

ATTENTION: Observe the following

precautions when inserting or removing

!

keys:

• insert or remove keys with your fingers

• make sure that key placement is correct

Incorrect keying or the use of a tool can

result in damage to the backplane

connector and possible system faults.

module

middle post and the right post).

position (the middle post and the left post).

Position the keying bands in the backplane connectors to correspond to

the key slots on the module.

I/O chassis

Upper Connector

12636-I

Place the keying bands:

between 10 and 12

between 16 and 18

You can change the position of these bands if subsequent system design

and rewiring makes insertion of a different type of module necessary.

Publication

1771-5.53 – April 1999

11022-I

Page 4

DC (10-30V) Input Module4

Install the Module and Field Wiring Arm

ATTENTION: Remove power from the 1771 I/O

chassis backplane and field wiring arm before

!

removing or installing an I/O module.

• Failure to remove power from the backplane or wir-

ing arm could cause module damage, degradation of

performance, or injury.

• Failure to remove power from the backplane could

cause injury or equipment damage due to possible

unexpected operation.

1

2

1771-A1B, -A2B, -A3B, -A3B1, -A4B I/O chassis

locking

card guides

Snap the chassis latch over

the top of the module to secure it.

Attach the wiring arm (1771-WH) to the horizontal

bar at the bottom of the I/O chassis.

The wiring arm pivots upward and connects with

the module so you can install or remove the

module without disconnecting the wires.

tab

module

1771-A1B, -A2B, -A3B1, -A4B Series B I/O chassis

locking bar pin

Swing the chassis locking bar down into place to secure

the modules. Make sure the locking pins engage.

wiring arm

locking bar

card guides

module

1771-WH

19809

Publication

1771-5.53 – April 1999

horizontal bar

remove

install

17643

Page 5

DC (10-30V) Input Module 5

Connect Wiring to the Field Wiring Arm

Connection

Terminal A

Terminal B

Terminal C

Terminal D

Input 00

Input 01

Input 02

Input 03

Input 04

Input 05

Input 06

Input 07

Input 10

Input 11

Input 12

Input 13

Input 14

Input 15

Input 16

Input 17

Terminal E

Diagram (2-W

(See

A

B

C

D

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

E

Make wiring connections to the field wiring arm (cat. no. 1771-WH)

shipped with the module.

1. Connect one terminal of your two or three-wire input device to

terminals 00 through 17.

2. Connect the +dc line to the other terminal of your input devices.

Connect three-wire input devices, such as Allen-Bradley

proximity switches (Bulletin 871), to operate in a current source

mode.

3. Connect terminal E to the dc common. Terminals A thru D are

not used. Use stranded 14 or 16 gauge wire to minimize the

voltage drop over long cable distances.

!

ire Devices)

applicable codes and laws.)

+

dc

Power Supply

-

ATTENTION: Observe proper polarity with dc power

connections. Reverse polarity, or application of ac

voltage could damage the module.

Connection Diagram (3-W

Terminal A

Terminal B

Terminal C

Terminal D

Input 00

Input 01

Input 02

Input 03

Input 04

Input 05

Input 06

Input 07

Input 10

Input 11

Input 12

Input 13

Input 14

Input 15

Input 16

Input 17

Terminal E

A

B

C

D

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

E

ire Devices)

(See applicable codes and laws.)

The switch is sourcing current

to the input module.

+

+

+

dc

Power Supply

-

Sinking Configuration

(Actual wiring runs in this direction.)

10597-I

(Actual wiring runs in this direction.)

Publication

10598-I

1771-5.53 – April 1999

Page 6

DC (10-30V) Input Module6

Important: You can directly drive terminals on a DC (10-30V)

Input Module (cat. no. 1771-IBD Series B) from

terminals on the following modules:

• DC (10-30V) Output module (cat. no. 1771-OBN)

• DC (10-60V) Output module (cat. no. 1771-OBD)

• DC (12-24V) Output module (cat. no. 1771-OB)

• DC (24V) Output module (cat. no. 1771-OQ)

• DC (24V) Output module (cat. no. 1771-OQ16)

Important: Use the same dc power source to power both modules

to ensure that ground is at the same potential.

Interpreting the Status Indicators

The front panel of your module contains one green module active

indicator, and 16 red status indicators.

The green active indicator turns on when the module is powered. The

red status indicators are provided for system logic side indication of

individual inputs. When a red status indicator lights, voltage is

present on the terminal. The module transfers this information to the

ACTIVE

10

00

11

01

12

02

13

03

14

04

15

05

16

06

17

07

Module Active

Indicator

(green)

00 to 17

Status

Indicators

(red)

10599-I

backplane for the processor to read. See ‘‘Troubleshooting” for a

description, probable causes, and recommended actions to take for

common faults based on indicator responses.

Use this table to help you interpret the 1771-IBD Series B status

Troubleshooting

Indicator Status (color) Description of Fault or System Status Action to Take

Module active ON (green) Normal Indication None

Module active ON (green) and

Input status ON (red)

indicators and to troubleshoot module and system faults.

Check for voltage on terminal. If voltage is present, take no action. If no

voltage is present, replace the module.

Module active ON (green) and

Input status OFF

Module active OFF and

Output status ON (red) or OFF

Publication

1771-5.53 – April 1999

Input devices not functioning properly or faulty

input circuitry on module.

No voltage on terminal. None

Module not functioning properly. Check chassis power supply and

1. Check input devices.

2. If input devices are OK, replace the

module.

processor. If they are OK, replace the

module.

Page 7

DC (10-30V) Input Module 7

’étiquette de certification d’un produit par la CSA

Tempe

ode

Taux du code de températur

CSA

Hazardous Location Approval Approbation d’utilisation dans des emplacements dangereux

par la CSA

CSA certifies products for general use as well as for use in hazardous locations.

Actual CSA certification is indicated by the product label

not by statements in any user documentation.

as shown below

, and

Example of the CSA certification product

label

To

comply with CSA certification for use in hazardous locations, the following

information becomes a part of the product literature for CSA-certified Allen-Bradley

industrial control products.

• This equipment is suitable for use in Class I, Division 2,

Groups A, B, C, D, or non-hazardous locations only

The products having the appropriate CSA markings (that is, Class I Division 2,

•

Groups A, B, C, D), are certified for use in other equipment where the suitability

of combination (that is, application or use) is determined by the CSA or the local

inspection of

Important:

the highest temperature rating determines the overall temperature code rating of a

PLC control system in a Class I, Division 2 location. The temperature code rating is

marked on the product label

as shown.

Due to the modular nature of a PLC control system, the product with

rature c

I

.

fice having jurisdiction.

rating

I

La CSA certifie les produits d’utilisation générale aussi bien que ceux qui

s’utilisent dans des emplacements dangereux.

est indiquée par l’étiquette du produit

documentation à l’usage des utilisateurs.

La certification CSA en vigueur

et non par des af

firmations dans la

Exemple d

I

Pour satisfaire à la certification de la CSA dans des endroits dangereux, les

informations suivantes font partie intégrante de la documentation des produits

industriels de contrôle Allen

•

Cet équipement convient à l’utilisation dans des emplacements de Classe 1,

Division 2, Groupes A, B, C, D, ou ne convient qu’à l’utilisation dans des

endroits non dangereux.

•

Les produits portant le marquage approprié de la CSA (c’est à dire, Classe 1,

Division 2, Groupes A, B, C, D) sont certifiés à l’utilisation pour d’autres

équipements où la convenance de combinaison (application ou utilisation) est

déterminée par la CSA ou le bureau local d’inspection qualifié.

Important:

produit ayant le taux le plus élevé de température détermine le taux d’ensemble

du code de température du système de contrôle d’un PLC dans un emplacement

de Classe 1, Division 2. Le taux du code de température est indiqué sur l’étiquette

du produit.

Par suite de la nature modulaire du système de contrôle PLC, le

-Bradley certifiés par la CSA.

e

I

Look for temperature code

rating here

The

following warnings apply to products having CSA certification for use in

hazardous locations.

ATTENTION: Explosion hazard —

Substitution of components may impair suitability for Class I,

•

!

Le

sigle CSA est la marque déposée de l’Association des Standards pour le Canada.

PLC est une marque déposée de Allen-Bradley Company

CSA logo is a registered trademark of the Canadian Standards Association

PLC is a registered trademark of Allen-Bradley Company

Division 2.

Do not replace components unless power has been switched

•

of

f or the area is known to be non-hazardous.

•

Do not disconnect equipment unless power has been switched

of

f or the area is known to be non-hazardous.

•

Do not disconnect connectors unless power has been switched

of

f or the area is known to be non-hazardous. Secure any

user-supplied connectors that mate to external circuits on an

Allen-Bradley product using screws, sliding latches, threaded

connectors, or other means such that any connection can

withstand a 15 Newton (3.4 lb.) separating force applied for a

minimum of one minute.

, Inc.

, Inc.

Le taux du code de

température est indiqué ici

Les avertissements suivants s’appliquent aux produits ayant la certification CSA

pour leur utilisation dans des emplacements dangereux.

AVERTISSEMENT: Risque d’explosion —

La substitution de composants peut rendre ce matériel

•

!

inacceptable pour lesemplacements de Classe I, Division 2.

•

Couper le courant ou s’assurer quel’emplacement est désigné

non dangereux avant de remplacer lescomposants.

• A

vant de débrancher l’équipement, couper le courant ou

s’assurer que l’emplacement est désigné non dangereux.

• A

vant de débrancher les connecteurs, couper le courant ou

s’assurer que l’emplacement est reconnu non dangereux.

Attacher tous connecteurs fournis par l’utilisateur et reliés aux

circuits externes d’un appareil Allen-Bradley à l ’aide de vis,

loquets coulissants, connecteurs filetés ou autres moyens

permettant aux connexions de résister à une force de

séparation de 15 newtons (3,4 lb. - 1,5 kg) appliquée pendant

au moins une minute.

Publication

1771-5.53 – April 1999

Page 8

DC (10-30V) Input Module8

Specifications

Inputs per Module 16

Module Location All 1771 I/O chassis except 1771-A1, -A2, and -A4

Input Voltage Range 10 to 30V dc

Minimum Input Current 4.5mA at 10V dc

15mA at 30V dc

Minimum Off-state Current 2.0mA @ 5V dc

Maximum Off-state Voltage 5V dc

Minimum On-state Voltage 10V dc

Input Impedance 2.2K ohms maximum

Input Signal Delay Low to High propagation delay - 1ms

High to Low propagation delay selectable - 1ms or 6ms

Power Dissipation 7.3 Watts (max.), 1.0 Watts (min.)

Thermal Dissipation 24.7 BTU/hr (max.), 3.4 BTU/hr (min.)

Backplane Current 130mA @ 5V dc +5%

Isolation Voltage This isolation meets or exceeds the requirements of

UL Standard 508, and CSA Standard C22.2 No. 142.

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

Conductors Wire Size

Category

0o to 60oC (32o to 140oF)

-40o to 85oC (-40o to 185oF)

5 to 95% (without condensation)

14 gauge (2mm2) stranded maximum

3/64 inch (1.2mm) insulation maximum

1

2

Keying Between 10 and 12

Between 16 and 18

Field Wiring Arm Standard Cat. No. 1771-WH

Wiring Arm Screw Torque 7-9 inch-pounds

Agency Certification

(when product is marked)

• CSA certified

• CSA Class 1, Division 2, Groups A, B, C, D certified

• UL listed

• CE marked for all applicable directives

1

Refer

to publication 1770-4.1, Programmable Controller Wiring and Grounding Guidelines.

Allen-Bradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

world’s leading technology companies.

Worldwide representation.

Argentina •

Ecuador

Jamaica

Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain • Sweden

United

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication

Supersedes

Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech Republic • Denmark

• Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia •

• Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands

Arab Emirates • United Kingdom • United States • Uruguay • V

1771-5.53 – April 1999

Publication 1771–2.75 – June 1993

Publication

1771-5.53 – April 1999

enezuela • Y

•New

Zealand • Norway • Pakistan • Peru • Philippines • Poland • Portugal • Puerto

ugoslavia

•Switzerland • Taiwan •

Copyright

1999 Allen-Bradley Company

Ireland •

Thailand • T

, Inc. Printed in USA

Israel • Italy •

urkey

PN955126–24

•

•

Loading...

Loading...