Page 1

AllenBradley

Direct

Communication

User

Module

(Cat. No. 1771-DCM)

Manual

Page 2

Table of Contents

To Our Customers 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Our Customers 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual's Purpose 11

Intended Audience 11

Terminology 11

Related

Publications

Overview of Direct Communication Module 21. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview

Describing the 1771DCM 21

Choosing 1771DCM or Data Highway 22

Selecting

Example

Compatible Processors 23

Keying 23

of Direct Communication Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Options

Applications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . .

22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Options 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting

Switch Bank 0 32

Switch Bank 1 34

Options

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Cables 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Cables 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Connector 41

Daisy Chain Hookup 42

Trunkline/Dropline Hookup 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Status Word 51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Status Word 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Examining

Status Bits Read by the Local Processor 52

Status Bits Read by the Supervisory Processor 53

Status Bits

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

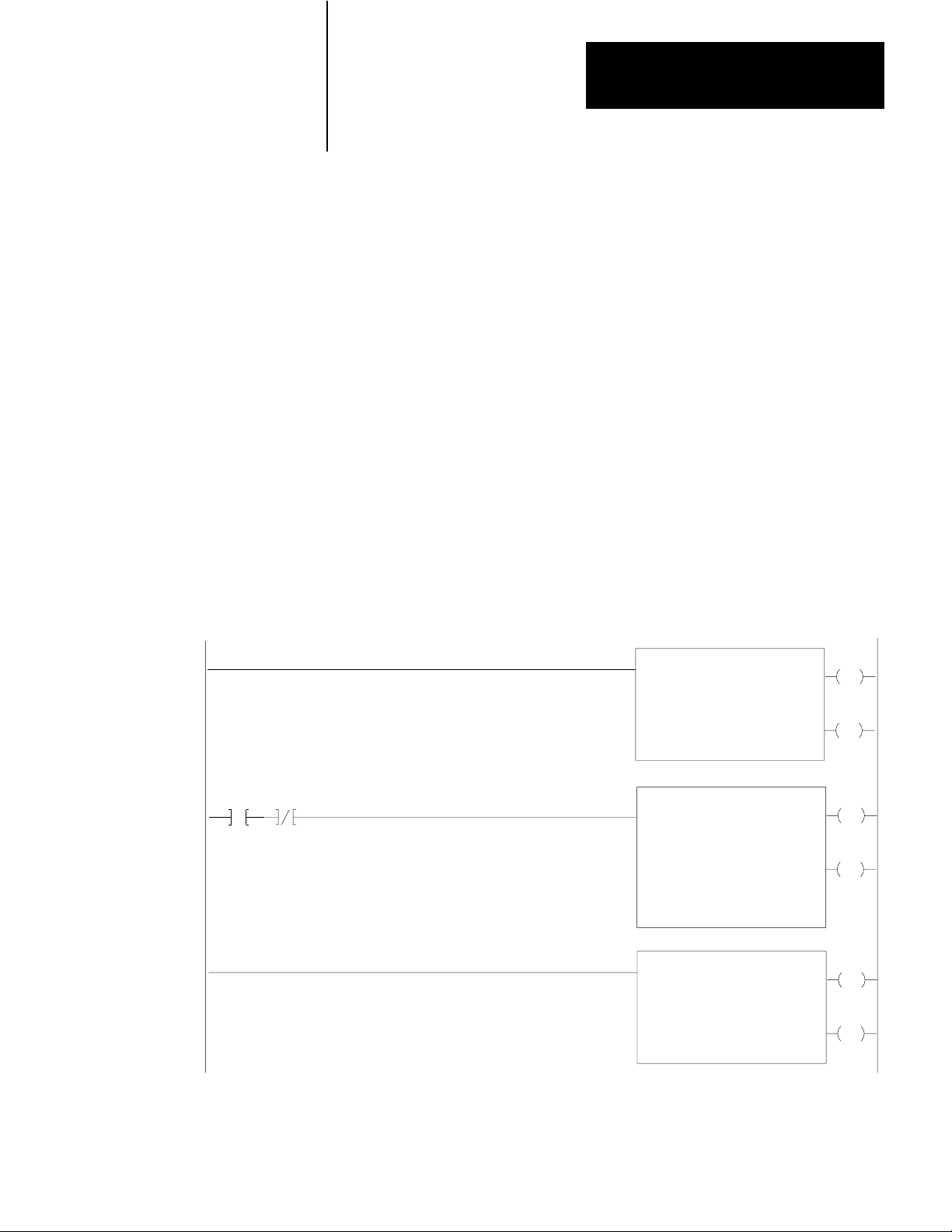

Programming the 1771-DCM 61. . . . . . . . . . . . . . . . . . . . . . .

Programming the 1771-DCM 61. . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Processor Logic 61

1771-DCM

Supervisory Processor Logic 63

Processor/Module

Switch Settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility

63. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

613. . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contentsii

Calculating Transfer Time 71. . . . . . . . . . . . . . . . . . . . . . . . .

Calculating Transfer Time 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete Transfer Time 71

Block Transfer Time 74

Block Transfer with a PLC3 Supervisory Processor 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

Troubleshooting Your 1771-DCM 81. . . . . . . . . . . . . . . . . . . .

Troubleshooting Your 1771-DCM 81. . . . . . . . . . . . . . . . . . . . . . . .

LED Display for Normal Operation 81

LED

Display for Fault Conditions

Causes of Block Transfer Errors 82

Errors

Indicated by Status Bits

Specifications 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

81. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

83. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

To Our Customers

Chapter

1

To Our Customers

Manual's Purpose

Intended Audience

The following information may be helpful when using this manual:

The purpose of this manual is to help you understand the intended

application of your Direct Communication Module (cat. no.

1771-DCM) and operate your 1771-DCM correctly in the shortest

possible time. We show you how to:

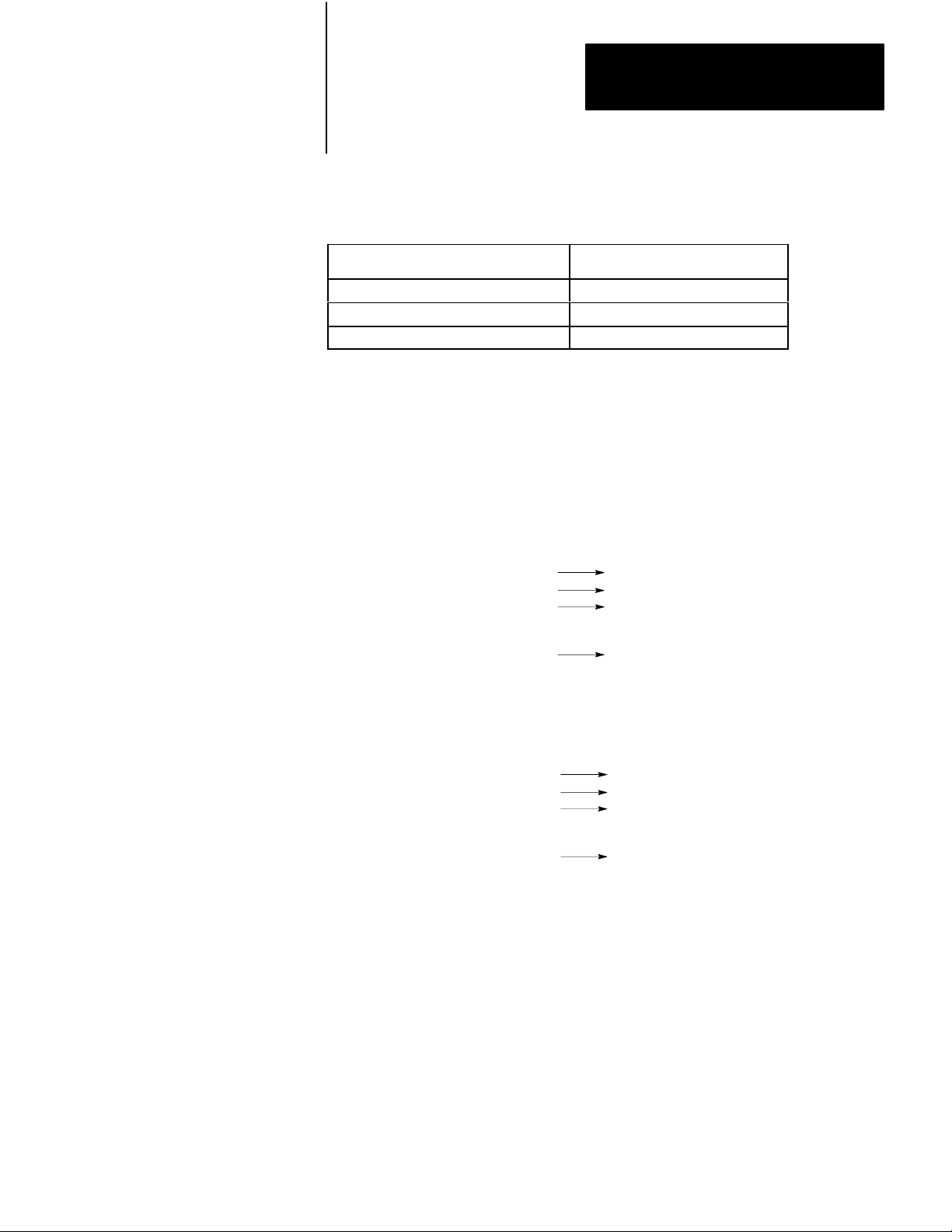

Select Module Options to Fit your Application Chapter 3

Install and Connect Your 1771-DCM Chapter 4

Use Status Bits to Detect Faults Chapter 5

Program the Transfer of Data between Processors Chapter 6

Compute the Transfer Time between Processors Chapter 7

Troubleshoot Module or System Malfunctions Chapter 8

We assume you are familiar with installing and using Allen-Bradley

programmable controllers and that you have written ladder diagram

programs. If not, we suggest that you study the Programming and

Operations Manual of your processor(s) listed below under Related

Publications.

Terminology

Related Publications

We have written this manual using current programmable controller

terminology and have attempted to keep it free of jargon. If you

encounter terms that you do not understand, we suggest that you obtain

the current booklet, Programmable Controller Terms, listed below under

Related Publications.

You should be able to install and operate your 1771-DCM without the

need for additional publications. If not, the following publications may be

of interest to you:

11

Page 5

Chapter 1

To Our Customers

Title Publication

1771ASB

Programmable Controller T

PLC2/05 Programming Manual

PLC2/15 Programming Manual

PLC2/02, 2/16, 2/17 User's Manual

PLC2/30 Programming Manual

PLC3 Programming Manual

PLC5 Family Processor Manual

PLC5/250 Programmer's Manual

Remote I/O Adapter

erms PCGI7.2

17716.5.37

17726.8.6

17726.8.2

17726.5.8

17726.8.3

17756.4.1

17856.8.2

50006.4.1

12

Page 6

Chapter

2

Overview of Direct Communication Module

Overview of Direct

Communication Module

Describing the 1771DCM

Local

Proc.

PLC-2

PLC-5

Allen-Bradley has introduced the Direct Communication Module (cat. no.

1771-DCM) to meet the growing need for communication between PC

processors.

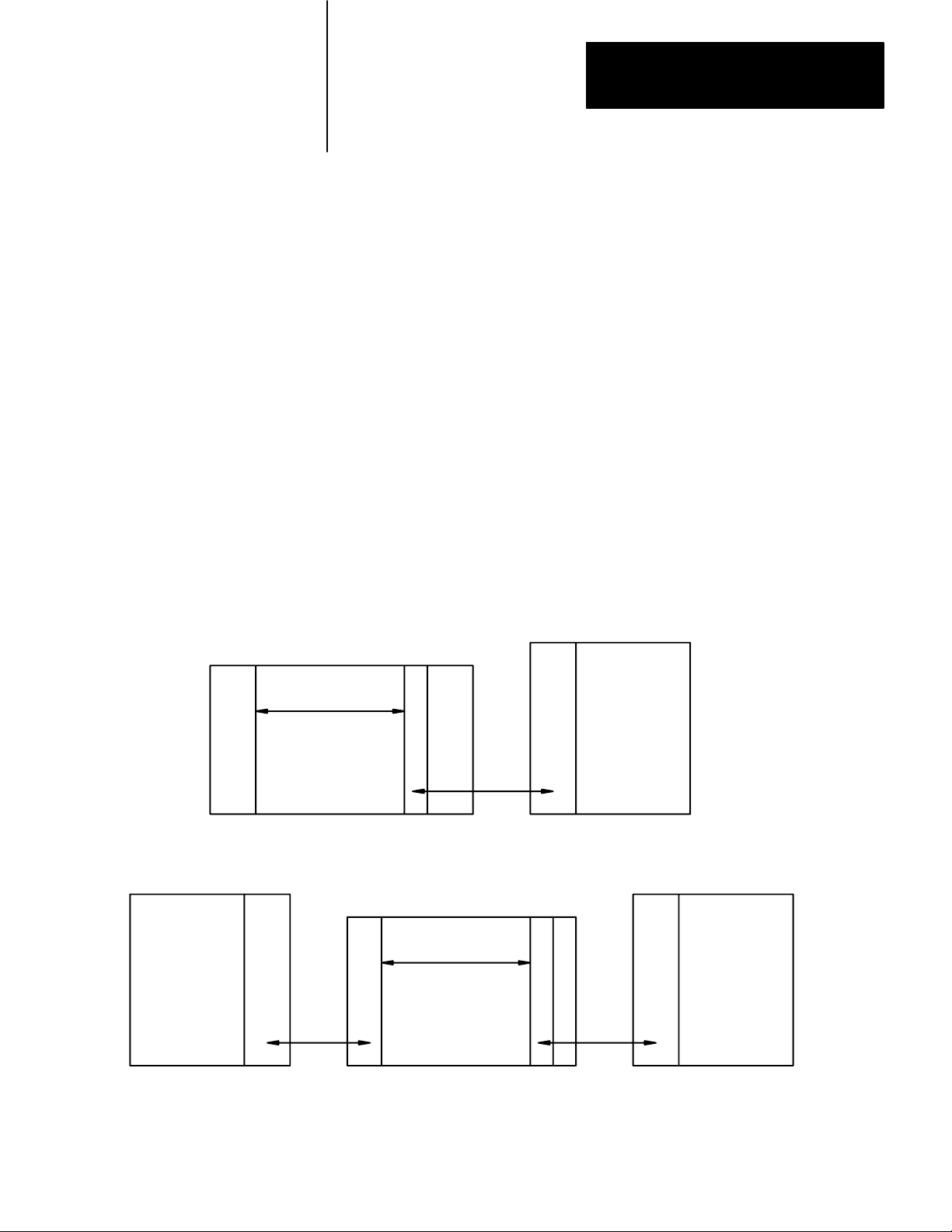

The 1771-DCM is a chassis-mounted single-slot I/O module that allows

communication between a supervisory processor and local processors

(Figure 2.1). The local processor can be chassis-mounted or configured

as a local or remote system.

Figure 2.1

and Remote Configurations

Local

Local Configuration

Bidirectional

Block Transfer

S

C

D

C

M

A

N

N

E

R

Supervisory

Processor

PLC–2/30

PLC–3 Family

PLC–5/15

PLC–5/25

PLC–5/250

Local

Processor

PLC–2/30

PLC–3 Family

PLC–5/250

S

C

A

N

N

E

R

Remote I/O Link

1771–ASB Protocol

1

7

7

1

A

S

Remote I/O Link

1771–ASB Protocol

Remote Configuration

Bidirectional

Block Transfer

D

C

M

Remote I/O Link

1771–ASB Protocol

S

C

A

N

N

E

R

Supervisory

Processor

PLC–2/30

PLC–3 Family

PLC–5/15

PLC–5/25

PLC–5/250

12825

21

Page 7

Chapter 2

Overview of Direct

Communication Module

The 1771-DCM passes data table values such as command bits, status

bits, and data blocks between supervisory and local processors. The

supervisory processor typically writes commands and/or data table values

to the local processor, and reads resulting status, diagnostic data, and data

values from the local processor (or vice versa).

The supervisory processor communicates serially with the 1771-DCM as

though it were a 1771-ASB Adapter Module, and addresses the

1771-DCM as though it were addressing a separate I/O chassis. You

select the mode of transfer between the supervisory processor and

1771-DCM: discrete transfer (up to eight words) or block transfer (up to

64 words). Either mode includes one status word.

The local processor communicates with the 1771-DCM over the

backplane using block transfers and addresses the 1771-DCM as an

intelligent I/O module. When the local processor is remotely configured,

it communicates with the 1771-DCM via block transfer through its

scanner-adapter link.

Choosing 1771DCM or Data

Highway

Selecting Options

The 1771-DCM and data highway allow communication between PC

processors. Consider the following factors when determining the

appropriate choice. Use the 1771-DCM to:

Transfer data table words

Obtain predictable transfer times

Transfer up to eight words when transfer time over a remote I/O

channel is adequate, in addition to the transfer time of the local

processor and 1771-DCM

Transfer up to 64 words when transfer time for block transfers over a

remote I/O channel is adequate, in addition to the transfer time of the

local processor and 1771-DCM

Decrease data highway traffic

At least one processor must have a remote I/O scanner.

You cannot transfer ladder diagram programs nor messages stored in the

message area of memory using the 1771-DCM.

You can select one or more of the following options depending on your

application requirements using switches on the module:

22

Page 8

Chapter 2

Overview of Direct

Communication Module

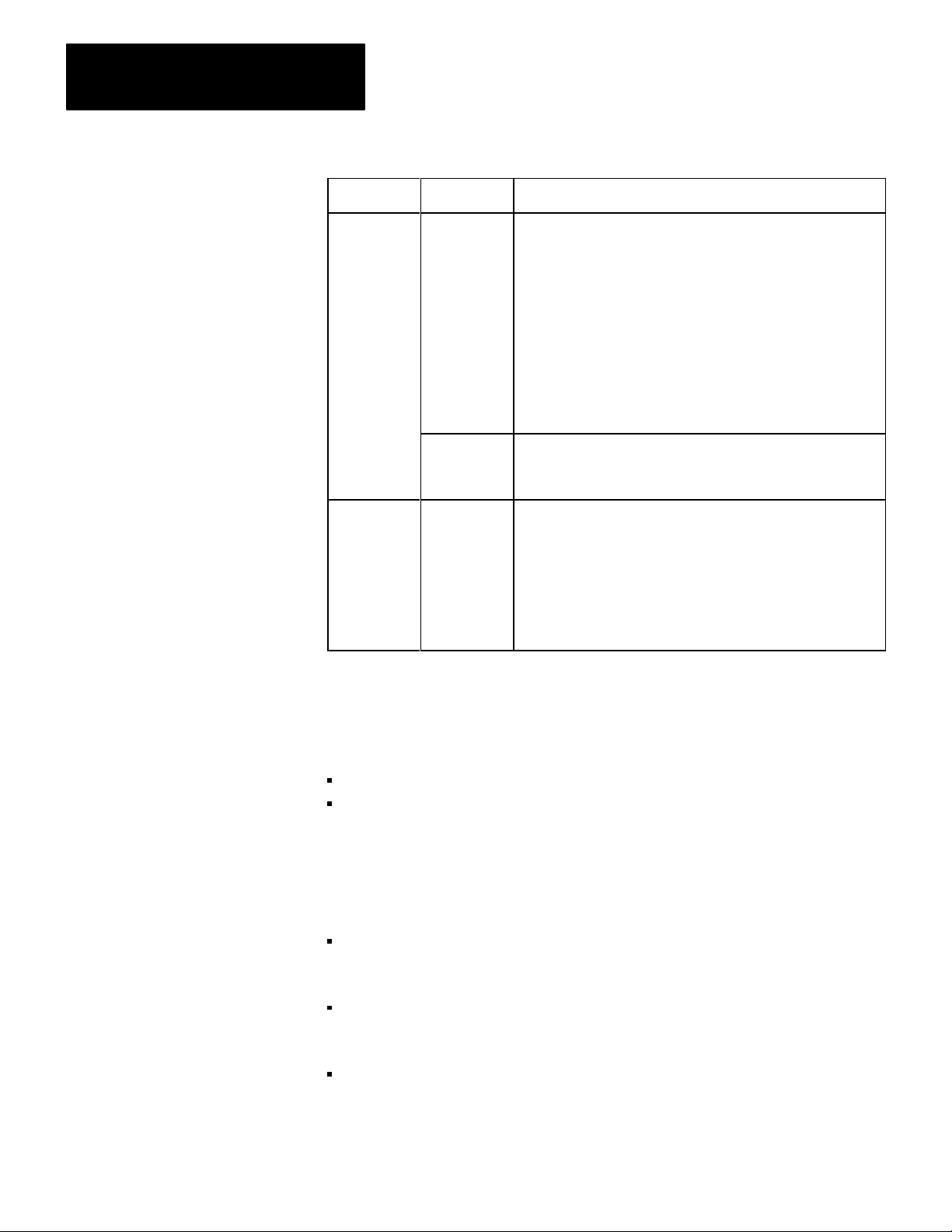

Baud

Rate/Distance

T

ransfer Method

Rack Size

Protected Data

I/O Rack Address Designate the I/O rack number, the number of the first module group

Select the communication rate and distance to the supervisory proces

sor as either 57.6K baud to a distance of 10,000 feet, or 1

to a distance of 5,000 feet.

Select block transfer or discrete data transfer between the 1771DCM

and the supervisory processor

When using discrete data transfer

termines how the 1771DCM appears to the scanner of the superviso

ry processor (the size of the I/O chassis simulated by the 1771DCM).

This also determines the number of words transferred.

Select protected data to prevent block transfers from the local proces

sor until the supervisory processor has received the previous block

transfer.

of the I/O chassis simulated by the 1771DCM, and whether it has the

highest starting module group address of two or more chassis as

signed to the same rack address.

.

, select the number of slots that de

15.2K baud

Example Applications

Compatible Processors

Keying

These options are described in Chapter 3.

You can use the 1771-DCM in a variety of applications where the transfer

of data table values is required. For example, consider using it to:

Call messages stored in the data table of the supervisory processor and

outputted through an ASCII I/O module (cat. no. 1771-DA) or BASIC

module (cat. no. 1771-DB)

Download recipe data table values from supervisory to local

processor(s) where you want local processor(s) to execute different

versions of the same program

Download commands from the supervisory processor to execute

different sections of a ladder diagram program at the local processor

Use the 1771-DCM with any Allen-Bradley programmable controller that

uses block transfer and the 1771 I/O structure.

Reserve an I/O slot for this module by placing keying bands on the

backplane connector. Position keying bands between the following

numbers labeled on the backplane adjacent to the upper backplane

connector. The keying bands mate with corresponding slots in the module

connector:

Between 2 and 4

Between 16 and 18

23

Page 9

Selecting Options

Chapter

3

Selecting Options

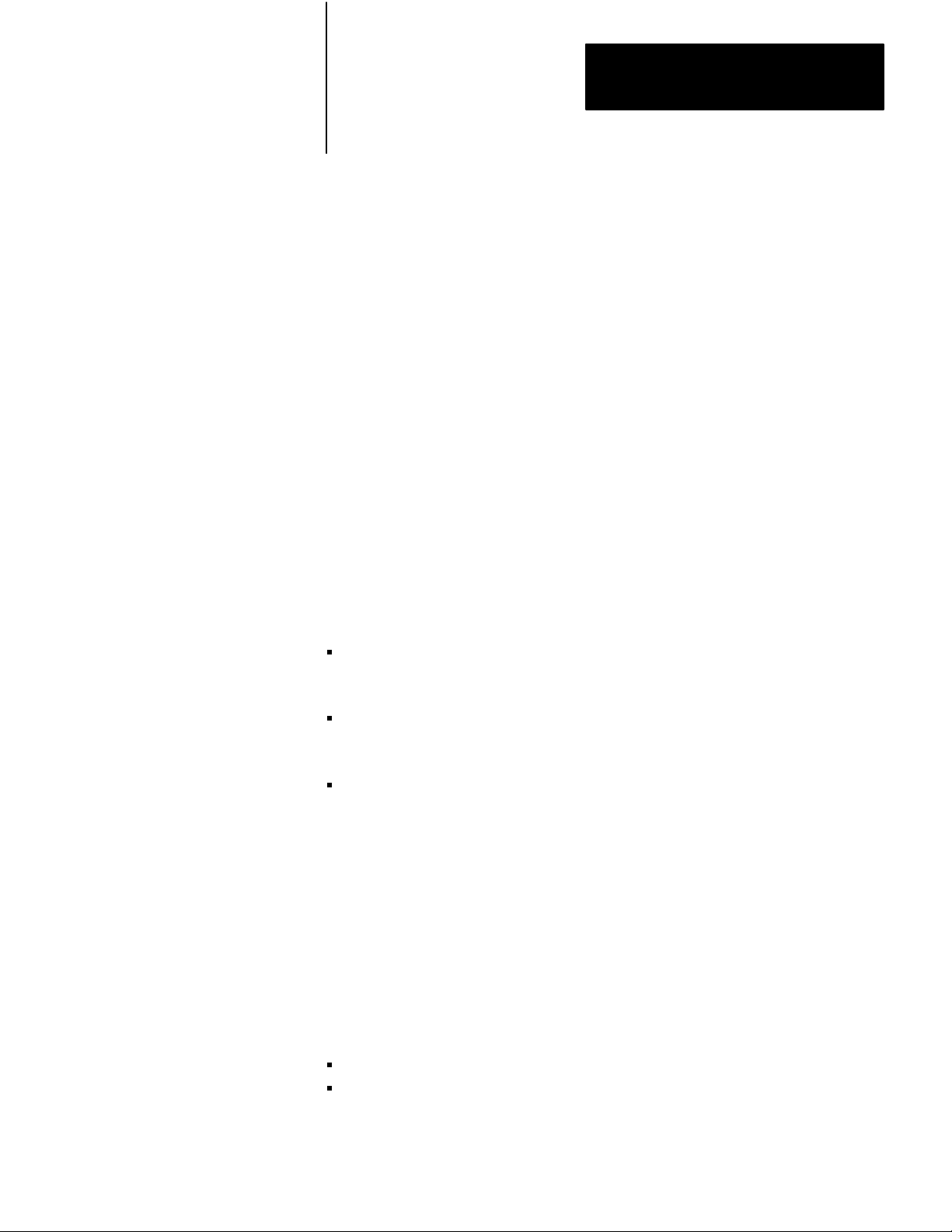

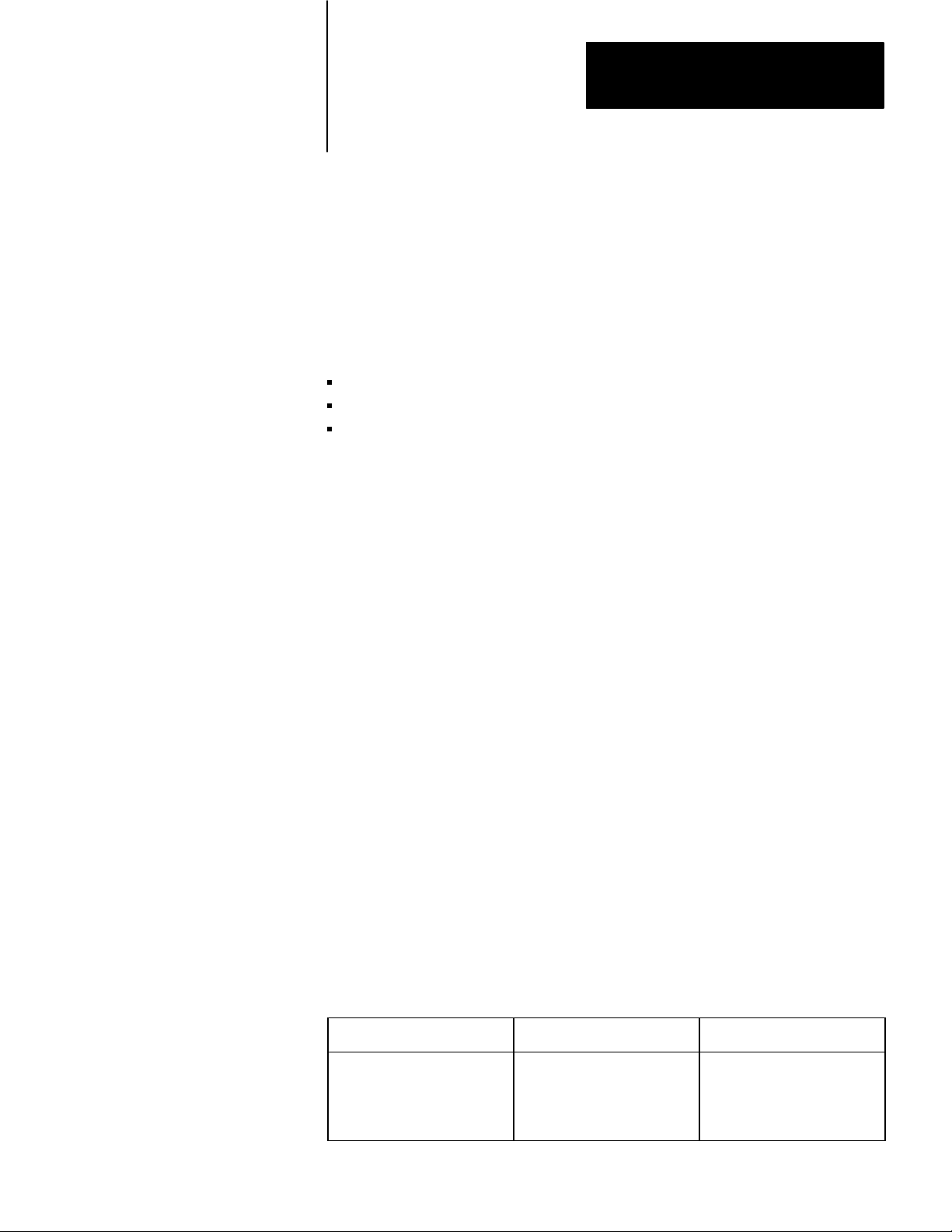

Select one or more of the following options depending on your

application requirements. Do this by setting switches in Switch Banks 0

and 1 on the left (metal cover) side of the 1771-DCM. To assist you, we

have printed a table of switch settings for each switch bank on the

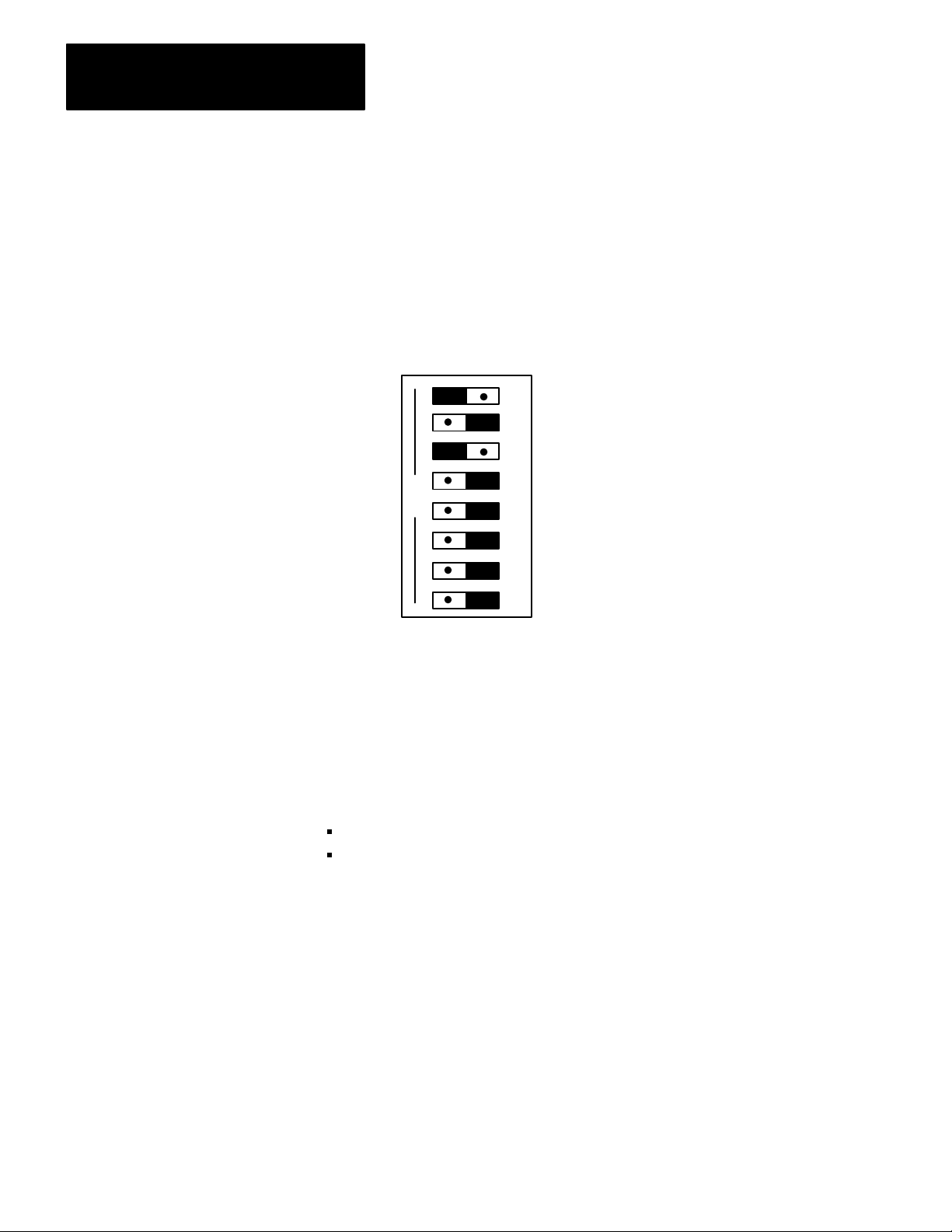

module’s cover next to the switches (Figure 3.1).

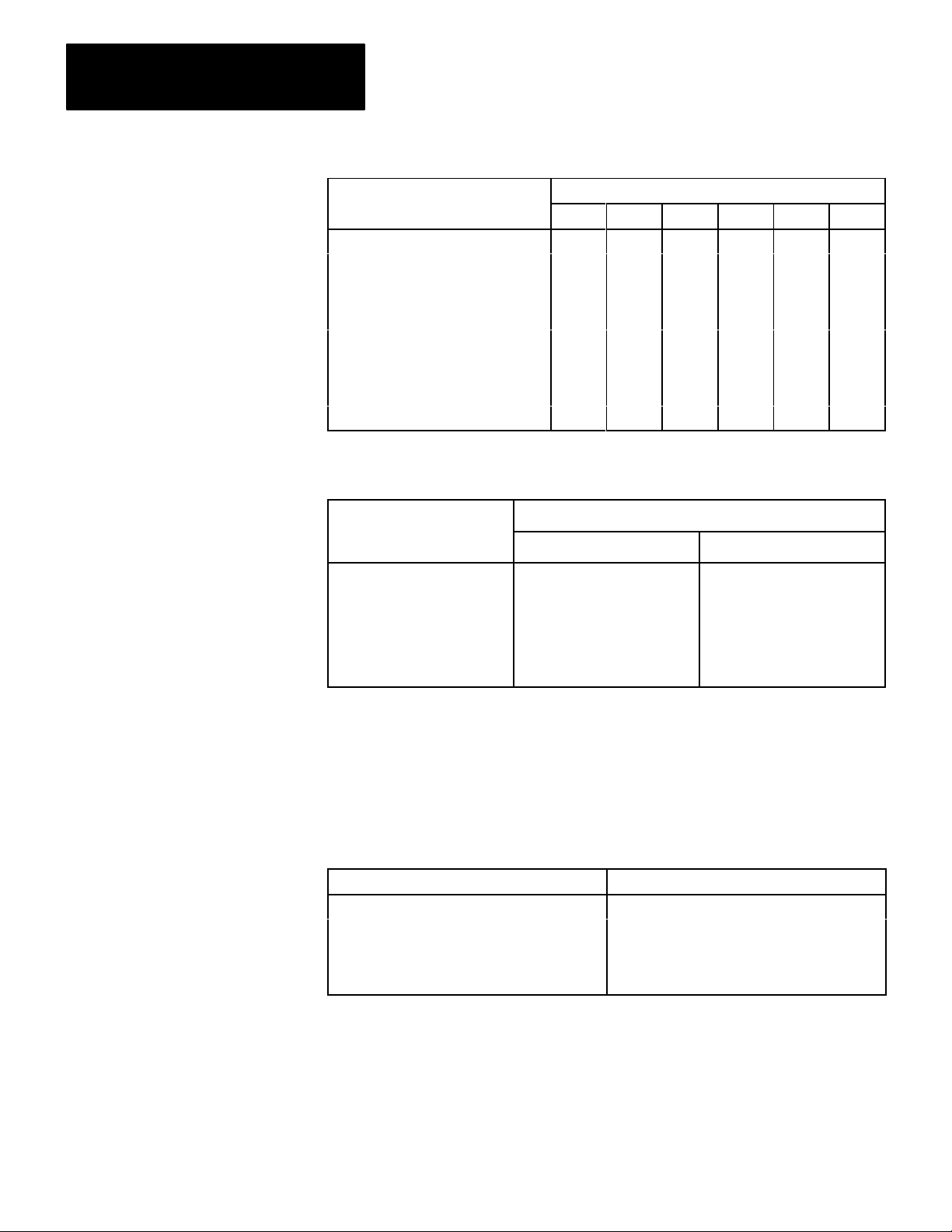

Figure 3.1

Tables

for Switch Settings

BANK 0

SW SW SW SW SW SW SWITCH

BAUD

RATE

57.6

115.2

I/O RACK

NUMBER

1

P

P

2

L

L

3

C

C

4

-

_

5

5

6

2

7

&

5

/

2

5

0

P

L

C

_

3

NOTE: DO NOT USE OTHER SWITCH POSITIONS

LAST

RACK

12 3 45 6 78

Not

NO

Used

YES

12 34 5 6

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

20

21

22

23

24

25

26

27

30

31

32

33

34

35

36

37

TRAN S

MTHD

BLOCK

DSCRT

BANK 1

SWITCH SWITCH

DATA

PTCT

Not

NO

Used

YES

FIRST

MODULE

GROUP NO.

0

2

4

6

ON

CLOSED

OFF

OPEN

RACK

SIZE

1/4

1/2

3/4

FULL

78

1

B

2

A

3

N

4

K

5

6

0

7

8

1

B

2

A

3

N

4

K

5

6

1

7

8

17906

31

Page 10

Chapter 3

Selecting Options

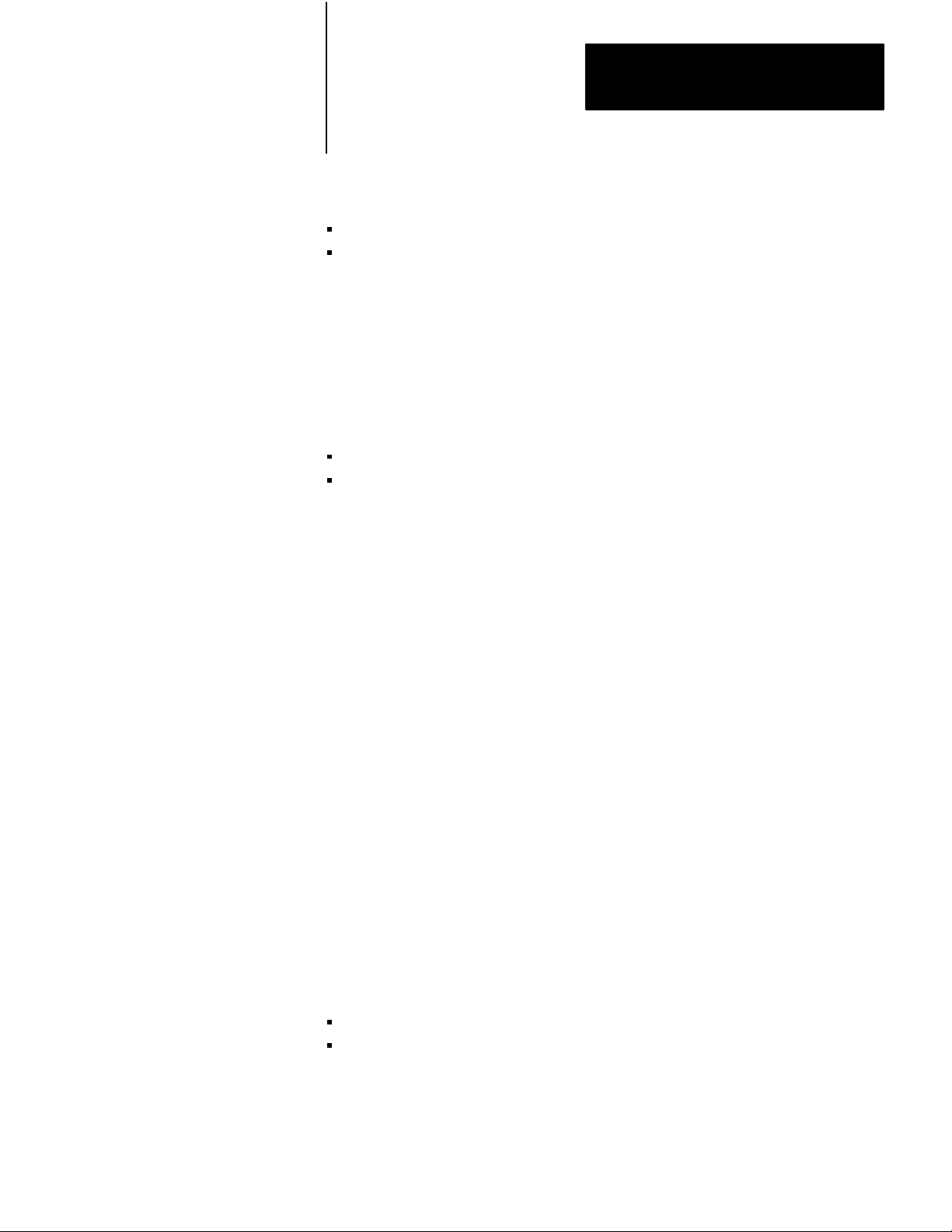

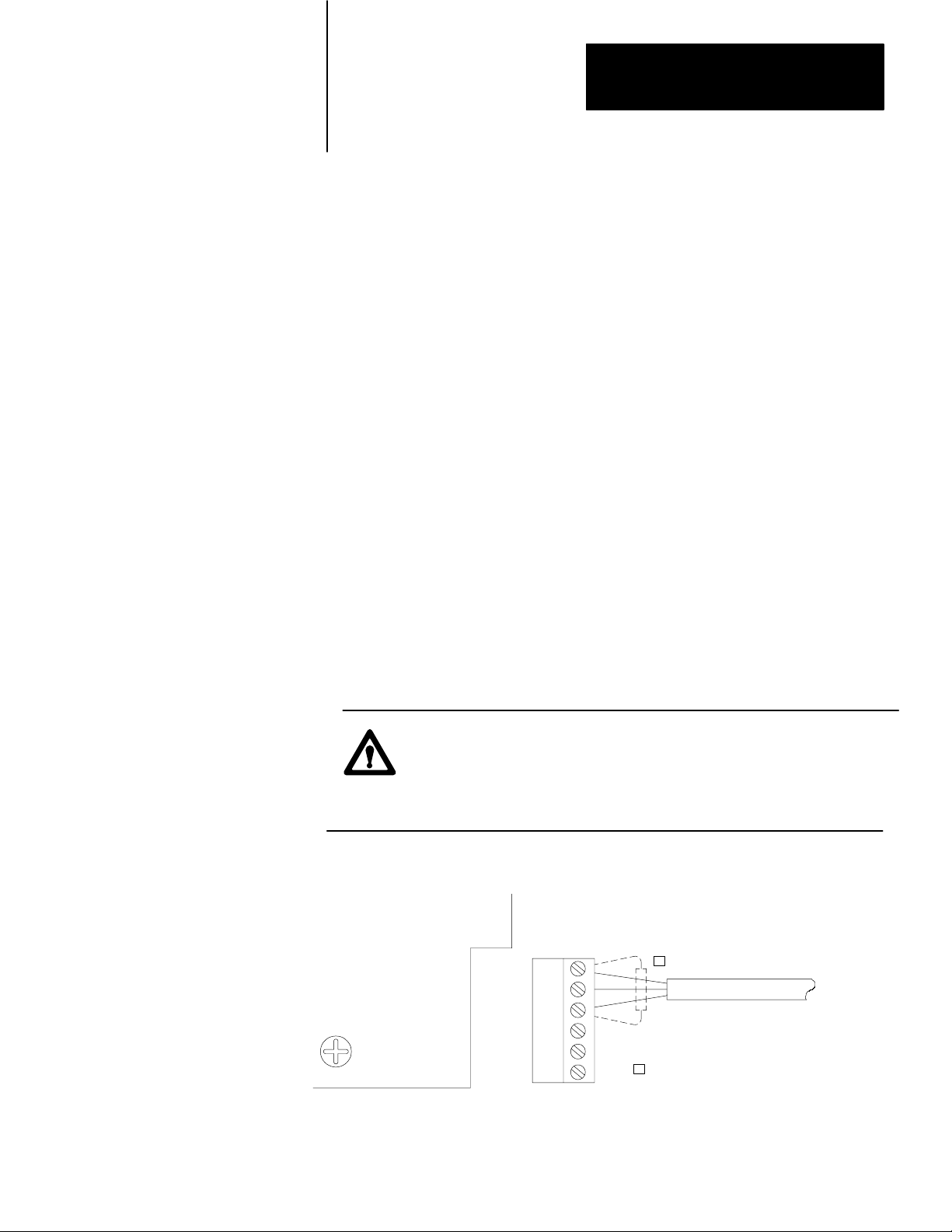

Each switch bank has eight switches. Set each switch to the ON (closed)

position by depressing the right-hand side of the switch or to the OFF

(open) position by depressing the left-hand side of the switch (Figure 3.2).

Figure 3.2

Example

Switch Bank

OPEN

1

2 3 4 5 6 7 8

Switches 1 and 3 are OFF (open)

Shading represents the switch position

Switch Bank 0

12826

The options that you select with Switch Bank 0 are as follows:

Switch 1 Baud Rate

ON (Closed) for 57.6K Baud

OFF (Open) for 115.2K Baud

Set the baud rate equal to that of the scanner of your supervisory

processor. You can transmit data up to 10,000 feet at a data rate of

57.6K baud or up to 5,000 feet at a data rate of 115.2K baud.

Switch 2 Not Used

32

Page 11

Chapter 3

Selecting Options

Switch 3 Last Rack

ON (Closed) Not Last Rack

OFF (Open) Last Rack

If the 1771-DCM is assigned the same I/O rack number as other I/O

chassis, designate whether this I/O chassis is the last chassis (has the

highest starting module group number) of those assigned the same rack

number. (Refer to I/O Rack Number below.)

Switch 4 Transfer Method

ON (Closed) for Block Transfer

OFF (Open) for Discrete Data Transfer

Choose either discrete data transfer or block transfer between the

supervisory processor and 1771-DCM. With discrete transfer, the rack

size you select determines the number of words transferred as either 2, 4,

6, or 8 words including a status word. Data is transferred between the

1771-DCM and the supervisory processor as serial remote I/O data for

each slot of the simulated I/O chassis. The supervisory processor updates

the 1771-DCM as if it were an I/O chassis on a remote I/O link.

With block transfer, you can transfer up to 64 words including a status

word. The 1771-DCM appears to the supervisory processor as a remote

1/4 rack. Data is transferred between the first I/O slot simulated by the

1771-DCM and the supervisory processor when the supervisory

processor’s ladder program executes block transfers.

Communication between the 1771-DCM and local processor is always

block transfer regardless of the mode of communication between

1771-DCM and supervisory processor.

Switch 5 Not Used

Switch 6 Protected Data

ON (Closed) for Unprotected Data

OFF (Open) for Protected Data

This option maintains data integrity and maintains the order of data blocks

sent from the local processor to the supervisory processor only when you

select block transfer. The 1771-DCM does not recognize the start of a

33

Page 12

Chapter 3

Selecting Options

new write block transfer from the local processor until the supervisory

processor has read the previous data from the 1771-DCM.

When you select unprotected data, the local processor updates the

1771-DCM continually, regardless of whether the supervisory processor

has read the data from the 1771-DCM.

Switches 7 and 8 Rack Size

Switch

7

ON ON 1/4

ON OFF 1/2

OFF ON 3/4

Switch 8

Rack Size

Switch Bank 1

OFF OFF Full

When your application requires the transmission of discrete data words,

the 1771-DCM appears to the scanner of the supervisory processor as a

4-, 8-, 12-, or 16-slot remote I/O chassis for the transfer of either 2, 4, 6,

or 8 words respectively. Select the equivalent rack size depending on the

number of words of discrete data you want to write or read. One slot is

equivalent to eight discrete data bits. One module group is equivalent to a

word. A full rack is equivalent to eight data words. The 1771-DCM

inserts one status word in the transfer regardless of the equivalent rack

size you select.

When you set the 1771-DCM for block transfer, the 1771-DCM appears

to the scanner of the supervisory processor as a block transfer module in

the first module group of a four-slot chassis (1/4 rack). You can read and

write up to 64 words including one status word. Slots 1 through 3 are not

used.

The options that you select with Switch Bank 1 are as follows:

34

Switches 1 through 6 I/O Rack Number

PLC2

Family

1 7

PLC3 and PLC5/250

0 thru 37 octal

PLC5/15 PLC5/25

1 3 1 7

Page 13

Chapter 3

Selecting Options

Designate the I/O rack number that you assign to the 1771-DCM with

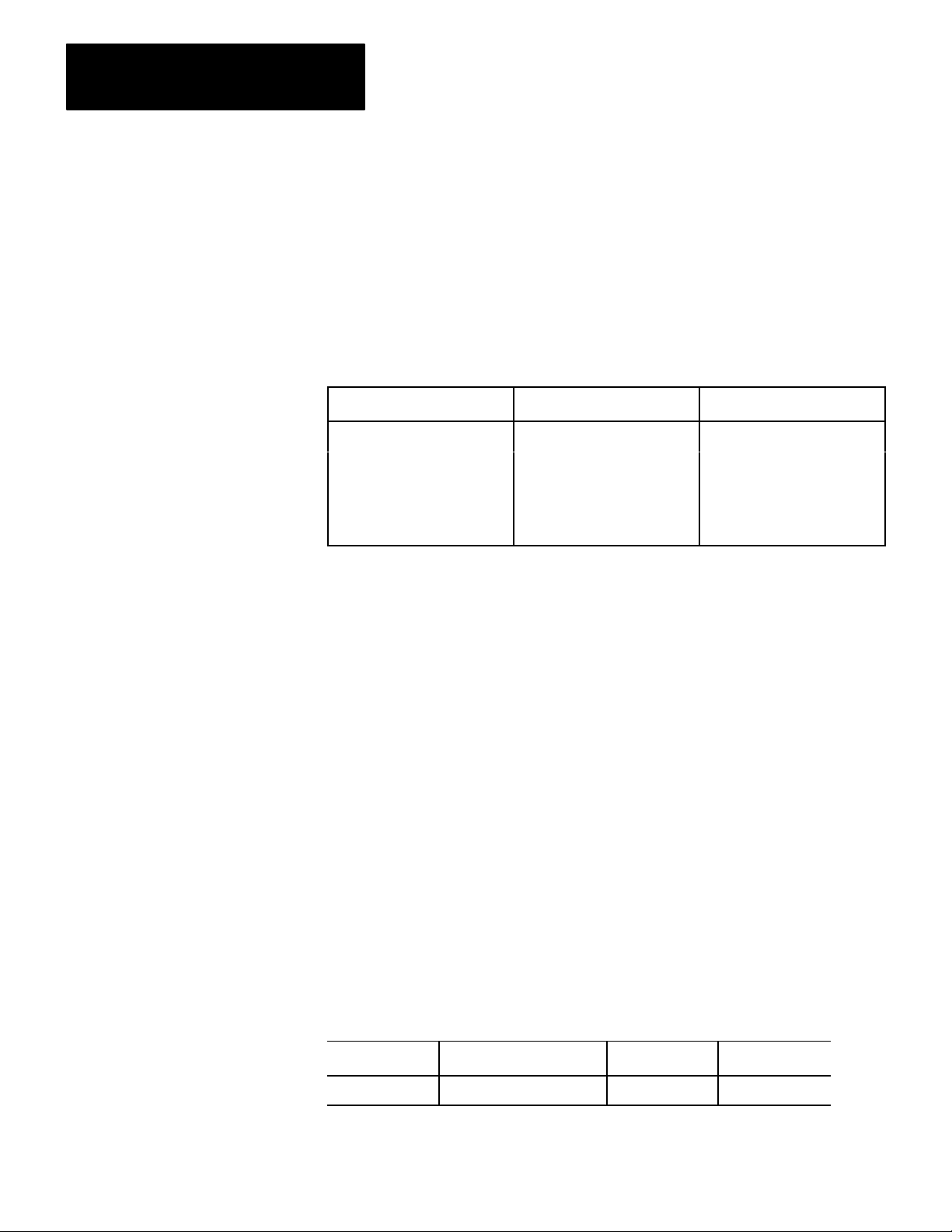

Switches 1 - 6 of Switch Bank 1 (Table 3.A).

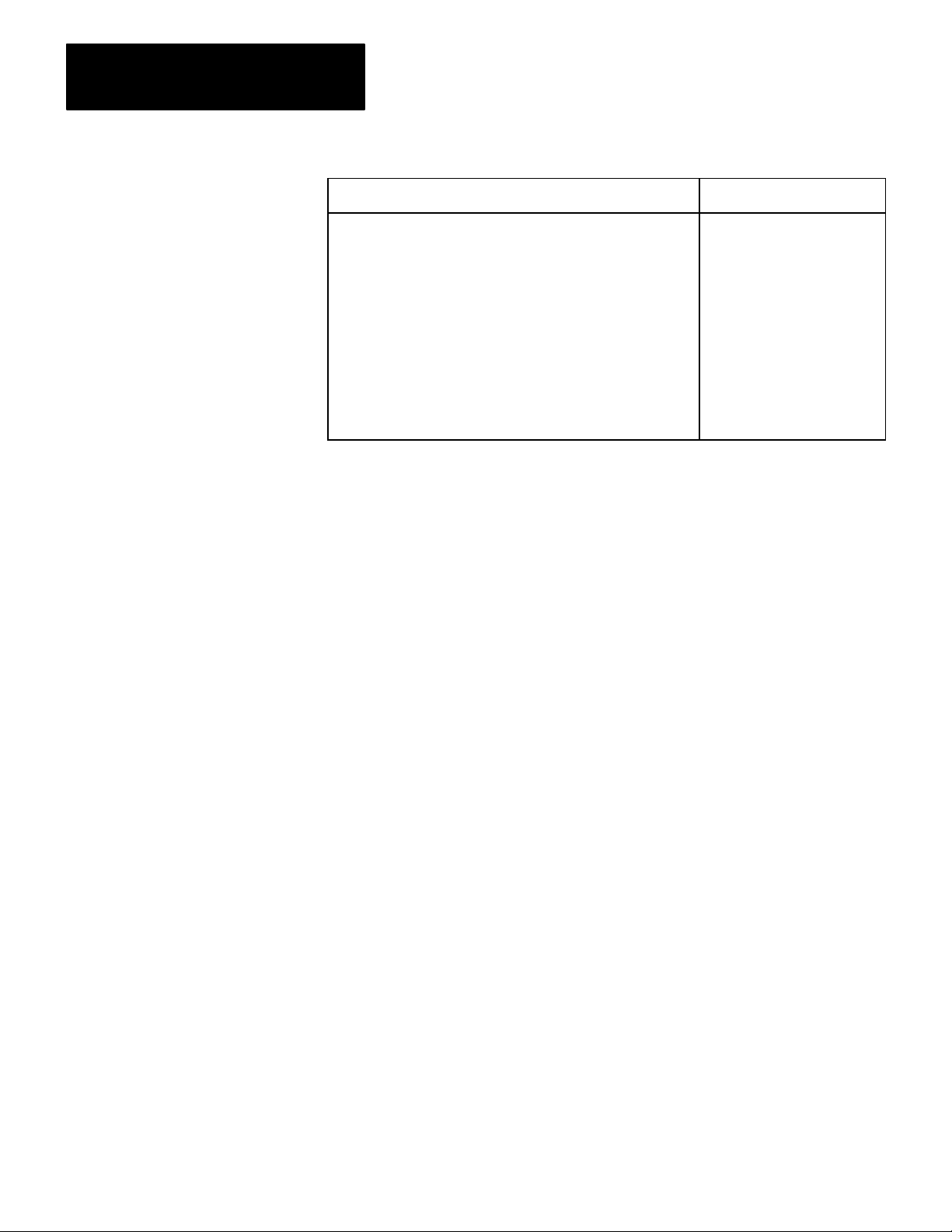

Table 3.A

Rack Number Selection for PLC2, PLC3, and PLC5 Family Processors

I/O

Switch

I/O Rack Number (Octal)

1 0 ON ON ON ON ON ON

P 2 1 ONON ON ON ON OFF

L 3 2 ONON ON ON OFF ON

C 4 3 ONON ON ON OFF OFF

5 4 ONON ON OFF ON ON

2 6 5 ONON ON OFF ON OFF

7 6 ONON ON OFF OFF ON

PLC-3

&

PLC5/250

PLC5/15

7 ON ON ON OFF OFF OFF

10 ON ON OFF ON ON ON

11 ON ON OFF ON ON OFF

12 ON ON OFF ON OFF ON

13 ON ON OFF ON OFF OFF

14 ON ON OFF OFF ON ON

15 ON ON OFF OFF ON OFF

16 ON ON OFF OFF OFF ON

17 ON ON OFF OFF OFF OFF

20 ON OFF ON ON ON ON

21 ON OFF ON ON ON OFF

22 ON OFF ON ON OFF ON

23 ON OFF ON ON OFF OFF

24 ON OFF ON OFF ON ON

25 ON OFF ON OFF ON OFF

26 ON OFF ON OFF OFF ON

27 ON OFF ON OFF OFF OFF

1 2 3 4 5 6

PLC5/25

35

Page 14

Chapter 3

Selecting Options

Switch

I/O Rack Number (Octal)

30 ON OFF OFF ON ON ON

31 ON OFF OFF ON ON OFF

32 ON OFF OFF ON OFF ON

33 ON OFF OFF ON OFF OFF

34 ON OFF OFF OFF ON ON

35 ON OFF OFF OFF ON OFF

36 ON OFF OFF OFF OFF ON

37 ON OFF OFF OFF OFF OFF

1 2 3 4 5 6

Switches 7 and 8 First (Starting) Module Group Number

First

Module

Group Number

0 ON ON

2 ON OFF

4 ON ON

6 OFF OFF

7 8

Switch

Assign a unique stating module group number--such as 0, 2, 4, or 6--in

accordance with the number of chassis you assigned to the same I/O rack

number. You can assign from one to four 1771-DCMs and I/O adapters to

the same I/O rack number, provided that the combination does not exceed

a full rack. For example, assign starting module group numbers to each

I/O chassis or 1771-DCM in the following combinations:

Rack

Configuration

•

Four 1/4 Racks

• T

wo 1/2 Racks

•

One 1/4 and One 3/4 Rack

•

One 3/4 and One 1/4 Rack

Assign Module Group Numbers

0, 2, 4, and 6

0 and 4

0 and 2

0 and 6

36

You selected the equivalent rack size of your 1771-DCM with Switch

Bank 0, Switches 7 and 8, above.

Page 15

Connecting Cables

Chapter

4

Connecting Cables

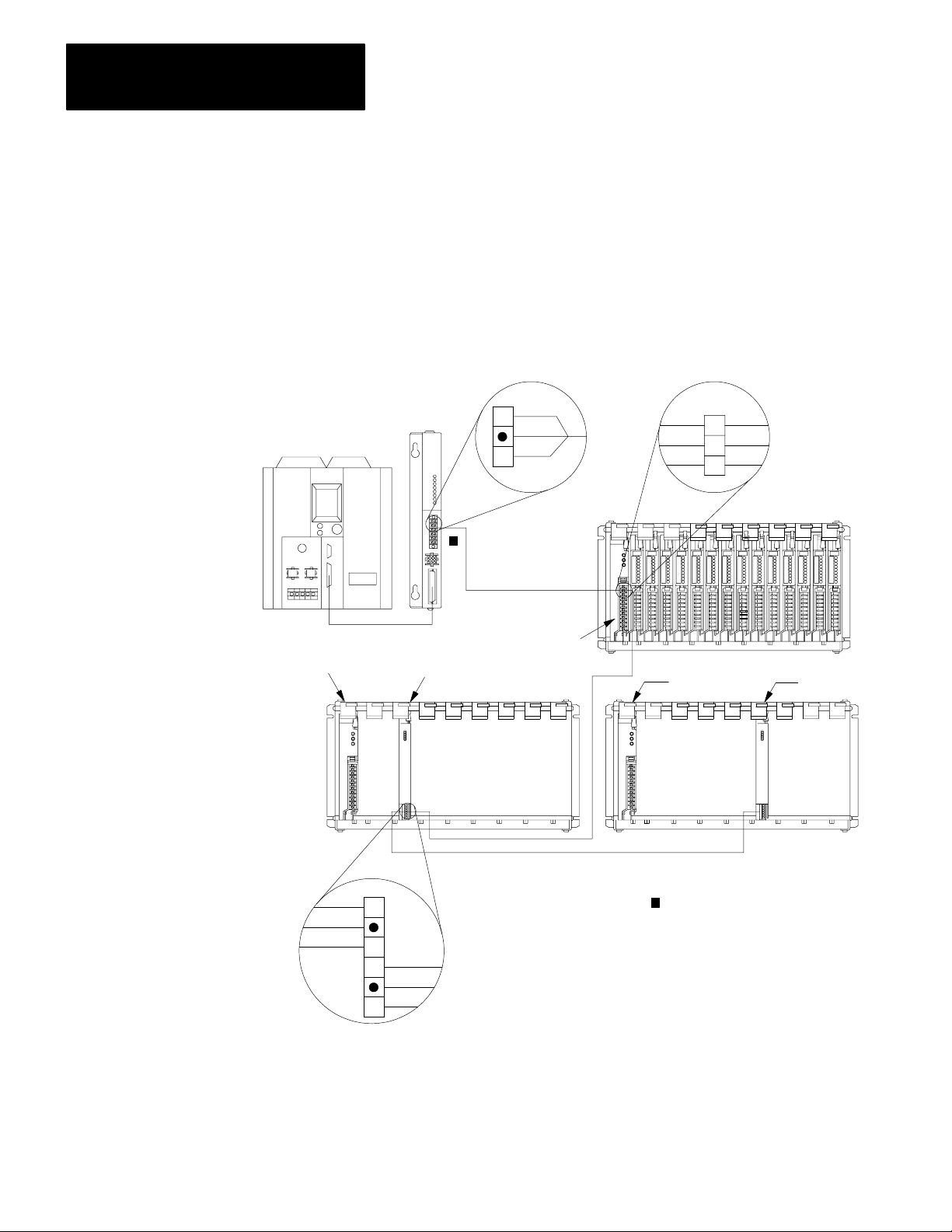

Module Connector

The communications channel between the 1771–DCM and a supervisory

processor is the same serial communications channel as used between the

1771–ASB Remote I/O Adapter (Series A) and the scanner of a

supervisory processor. You insert the 1771–DCM in a local or remote I/O

chassis and configure the 1771–DCM as an I/O chassis unique to the

supervisory processor. You can connect the 1771–DCM in a daisy chain

or trunkline/dropline hookup with other remote I/O chassis.

Make your connections to the connector at the bottom of the module

(Figure 4.1). Connector terminals are labeled at the bottom of the left

cover plate. Connector terminals accommodate two cables––one for the

incoming line of a daisy chain hookup, the other for the outgoing line.

Use either set of connector terminals for the dropline in the

trunkline/dropline hookup. Terminal 1 is connected to Terminal 4,

Terminal 2 to Terminal 5, and Terminal 3 to Terminal 6 inside the

1771–DCM.

WARNING: Do not disconnect this connector in a daisy chain

hookup when the system is operating because you disconnect

the remaining I/O chassis in the daisy chain. The connection

between terminals is inside the 1771–DCM.

Figure 4.1

Cable

Connections

Line 2

Shield

Line 1

Line 2

Shield

Line 1

Connector on 1771-DCM

(Clear)

(Blue)

(Clear)

(Blue)

Mating Connector

1

I/O Cable

Install a 150 ohm 1/2 watt resistor when the 1771-DCM

1

is simulating the last I/O chassis in the daisy chain.

12827

41

Page 16

Chapter 4

Connecting Cables

Daisy Chain Hookup

When using the daisy chain hookup (Figure 4.2), splice each I/O chassis

into the main communication line (serial I/O channel). Install a 150 ohm

terminator resistor between the terminals of Lines 1 and 2 at the scanner

and at the last hookup on the main communications line to terminate both

ends of the line.

Figure 4.2

Example

PLC -2/ 30

Daisy Chain Hookup

1772 - SD2

1

Blue

1

Shield

Clear

2

Blue

Shield

Clear

Blue

1

Shie ld

2

Clear

3

1771 - ASB

Clear

Shie ld

Blue

2

1

2

1

1771 - DCM

Cle ar

Shield

Blue

1771 - ASB

Remote I/O Chassis

1771 - ASB

1

Install Terminator Resistor:

150oh m 1/2 watt

1771 - DCM

12661

42

Page 17

Chapter 4

Connecting Cables

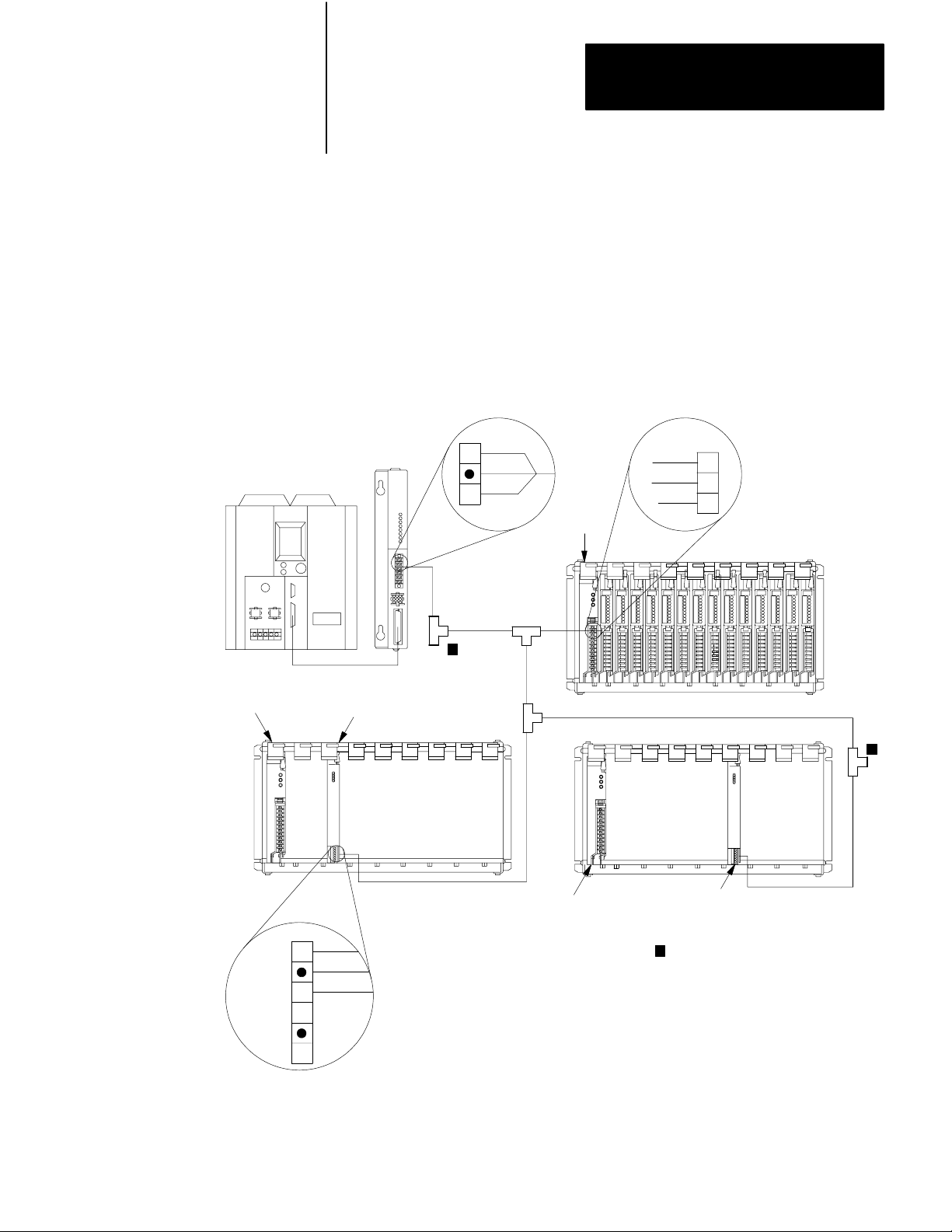

Trunkline/Dropline Hookup

PLC -2/30

When using the trunkline/dropline hookup, connect the 1771–DCM to the

serial I/O channel trunkline using a dropline that does not exceed 100 feet

in length (Figure 4.3). Connect the dropline to the trunkline using a T

connector (cat. no. 1770–XG) or a station connector (cat. no. 1770–SC).

There are no restrictions as to the spacing between station connectors or T

connectors if you do not exceed the maximum cable distance. Terminate

the open port at the first and last T connector or station connector using a

Terminator Set (cat. no. 1770–XF).

Figure 4.3

Example

Trunkline/Dropline Hookup with T Connectors

Blue

1772 - SD2

1

2

Shie l d

Clear

1771 - ASB

Bl ue

Shield

Clear

1

2

3

1771 - ASB

2

1

2

1

1771 - DCM

Cle ar

Shield

Blue

1

Remote I/O Chassis

1

1771 - ASB

1771 - DCM

1

Install Terminator Resistor

(cat. no. 1770XF)

12662

43

Page 18

Using the Status Word

Chapter

5

Using the Status Word

The 1771-DCM sets status/alarm bits in the upper byte of the first word

transferred to either processor, regardless of whether you select block

transfer or discrete data transfer. In block transfer operation, the status

word is the first word of the read data block. In discrete data transfer, the

status word is found in the equivalent of the first module group of the I/O

chassis simulated by the 1771-DCM.

Important: Reserve the first transferred word for status data inserted by

the 1771-DCM. Be sure this word contains zeros when you initialize the

ladder program for either processor. The upper byte contains status data.

The lower byte is not available for transferring data under any

circumstances.

When you select discrete data transfer and set your rack size for the

number of words required for your application, keep in mind that the

number of words available for your data is one less than the number of

words transferred.

Rack

Size

Number of

T

ransfer W

ords

W

ords A

vailable

For Your Data

Examining Status Bits

1/4 2 1

1/2 4 3

3/4 6 5

Full 8 7

Examine bits in the upper byte of the status word using your ladder

program so it can take appropriate action when the 1771-DCM detects an

error or change in status. Upon detecting an error or change in status, the

1771-DCM sets an invalid data bit along with one or more bits that

indicate the nature of the error or change in status. These bits are

non-retentive.

51

Page 19

Chapter 5

Using the Status Word

Bits in the status word read by the supervisory processor differ from those

read by the local processor. Some bits apply only when the 1771-DCM is

communicating with the supervisory processor by block transfer.

Status Bits Read by the Local

Processor

When the 1771-DCM detects an error in its communication with the

supervisory processor, it indicates this condition in the status word read by

the local processor as follows:

17 16 15 14 13 12 11 10

Insuf Excess Scanner No Inhibit Invalid

Data Data Comm 0 Data 0 Outputs Data

Error

Bit 17 Insufficient Data Available

Set by the 1771-DCM when data received from the supervisory processor

is less than that requested by the local processor. It appends zeroed data

words to provide the requested number of words.

Bit 16 Excessive Data Available

Set by the 1771-DCM when the data received from the supervisory

processor is more than that requested by the local processor. It truncates

the data and returns only the number of words requested.

52

Important: In block transfer mode, the 1771-DCM sets Bit 17 or 16

(defined above) when it detects that the length of a read block transfer

request from one processor differs from the number of words previously

written by the other processor. In discrete data transfer, the 1771-DCM

sets Bit 17 or 16 when it detects that the number of words read by one

processor differs from the number of words that the 1771-DCM

temporarily stored. This depends on the equivalent rack size that you set,

such as eight slots for four words.

Bit 15 Scanner Communications Error

Set by the 1771-DCM when it detects a loss in communications with the

scanner of the supervisory processor followed by a request for a read

block transfer from the local processor. The 1771-DCM returns the last

data received from the scanner, or zeroed data words if communications

had not been established. The 1771-DCM turns off the serial

communications LED until communications are restored.

Page 20

Chapter 5

Using the Status Word

Bit 14 Not Used

Bit 13 No Data Available

Set by the 1771-DCM at power-up. The 1771-DCM rests this bit when it

receives data from the supervisory processor.

Bit 12 Not Used

Bit 11 Inhibit Outputs

Set by the 1771-DCM to inform the local processor that the supervisory

processor has been switched to program or test mode, has switched itself

to program mode because of a dependent I/O fault (PLC-2 family), or that

the 1771-DCM has lost communication with the supervisory processor.

Status Bits Read by the

Supervisory Processor

Bit 10 Invalid Data

Set by the 1771-DCM whenever it sets any other status bit. As long as

this bit is reset, the 1771-DCM has detected no error condition or change

in status.

When the 1771-DCM detects an error in its communication with the local

processor, it indicates this condition in the status word read by the

supervisory processor as follows:

17 16 15 14 13 12 11 10

Insuf Excess Backplane Backplane No Old 0 Invalid

Data Data Reset Error Data Data Data

Bits 17, 16, 13, and 10 Same as Local Processor

Bit 15 Backplane Reset

Set by the 1771-DCM to inform the supervisory processor that the local

processor has reset the backplane. The local processor typically resets the

backplane when switched to program/test mode, or when it detects a fault

condition and turns off outputs. The 1771-DCM cannot detect a

backplane reset due to a fault condition resulting in outputs remaining in

last state. You determine the last state condition (hold last state or turn

off) by a DIP switch on the I/O chassis.

53

Page 21

Chapter 5

Using the Status Word

Bit 14 Backplane Error

Set by the 1771-DCM whenever it detects that a block transfer operation

by the local processor was not completed on time, was out of sequence, or

contained a checksum error. The 1771-DCM returns the last valid data

received from the local processor. It returns zeroed data words if

communications had not been established. It inhibits block transfers to

the local processor until it detects a backplane reset or a scan from the

local processor.

Bit 12 Old Data

Set by the 1771-DCM whenever it detects that it has not received data

from the local processor after a delay of 14 read scans by the supervisory

processor (discrete data transfer), or since the last read block transfer by

the supervisory processor. The 1771-DCM passes old data to the

supervisory processor until it detects new data, passes it, and resets this

bit.

Bit 11 Not Used

54

Page 22

Chapter

Programming the 1771-DCM

6

Programming the 1771-DCM

Local Processor Logic

We assume that you are familiar with block transfer programming, that

you can allocate data table areas for read and write data blocks, and that

you can manipulate data to and from these data blocks. We will confine

this discussion to programming characteristics unique to the 1771–DCM.

The local processor, typically a PLC–2 family mini–processor or PLC–5

family processor, reads and writes data to the 1771–DCM using block

transfers. Programming examples (Figure 6.1, Figure 6.2) assume that the

1771–DCM is set for six–word block transfers.

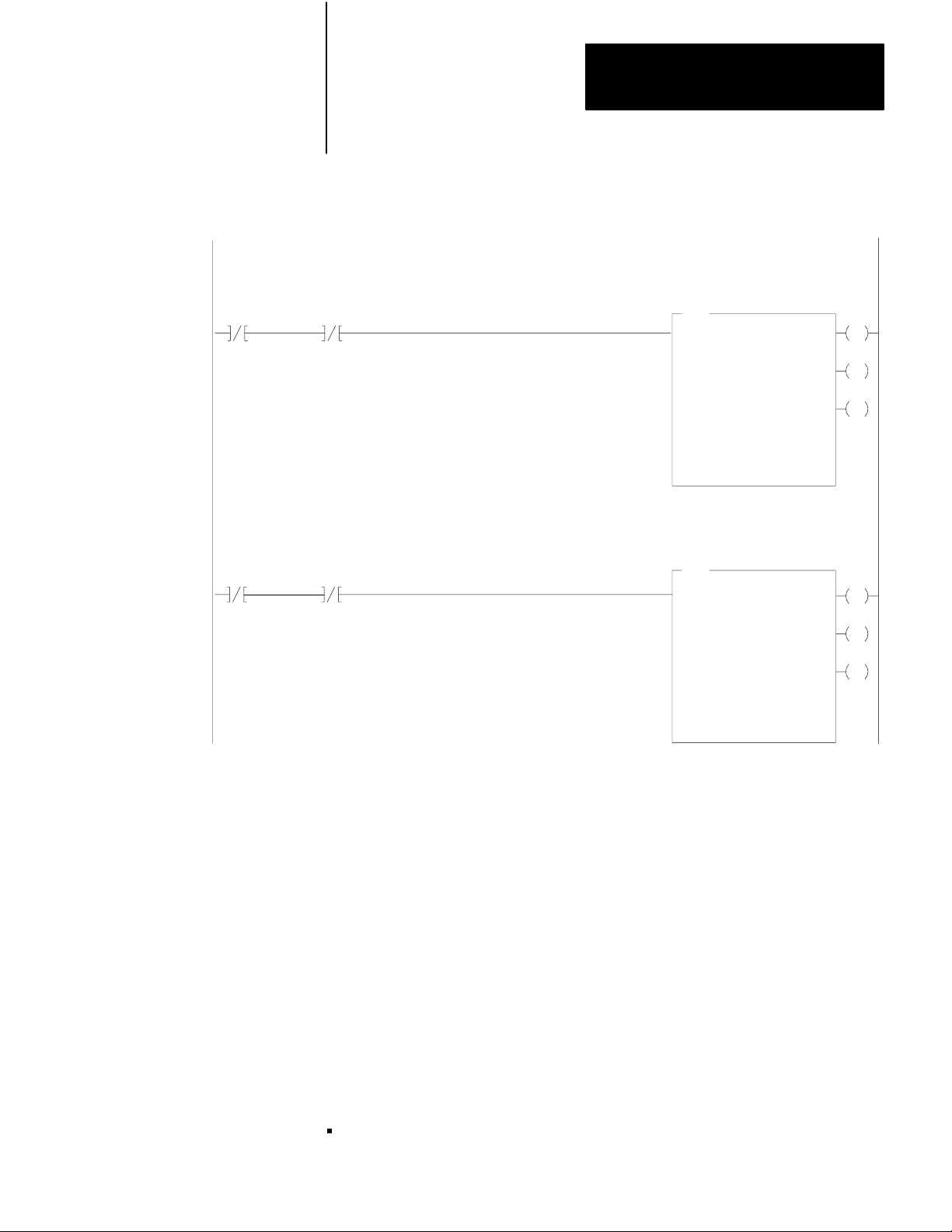

Figure 6.1

Local

Processor Programming Example (PLC-2)

013

131

06

EN

17

113

DN

17

BLOCK XFER READ

Data Address:

Module Address:

Block Length:

File:

0030

0300-0305

BTR Done Bit

11310300

17

Data Valid Bit

Buffer File

FILE TO FILE MOVE

Counter Address:

Position:

File Length:

File A:

File R: 0400-0405

Rate per Scan: 006

BLOCK XFER WRITE

Data Address:

Module Address:

Block Length:

File:

0040

001

006

0300-0305

0031

131

06

0200-0205

0040

EN

17

0040

DN

15

013

EN

16

113

DN

16

61

Page 23

Chapter 6

Programming the 1771-DCM

Block Transfer and File Move Instructions

Enter these instructions using the following information:

BTR/BTW Module Address

The module address of BTR and BTW instructions in the local

processor’s program is the physical location of the 1771–DCM. It is the

I/O rack, module group, and slot number (RGS) of the 1771–DCM:

In the same I/O chassis with the local processor

In an I/O chassis connected to a processor configured for local or

remote I/O operation

Block Length/File Length

Generally, set them to the number of words that you set for the

1771–DCM. If you have reason to set the read block length different

from the write block length (PLC–2 family processors), be sure that both

the BTR and BTW instructions cannot be enabled in the same scan.

When moving or transferring words into the BTW file for transfer to the

1771–DCM, be sure to avoid placing data in the first word because the

1771–DCM inserts status in this word.

File–to–File Move (FFM)

Use this instruction to store data received from the 1771–DCM. File A

address of the FFM is the same as the BTR file address. File R address is

a storage file for data received from the 1771–DCM.

Your ladder program must place data into the BTW file for transfer to the

1771–DCM. We leave this ladder logic to you because your application

and processor’s set of instructions determine how you would do this.

Examine the status word received from the 1771–DCM as a condition for

using the read block transfer data. Zero the status word at power–up and

be sure that your program does not use this word for any other purpose.

62

Page 24

Chapter 6

Programming the 1771-DCM

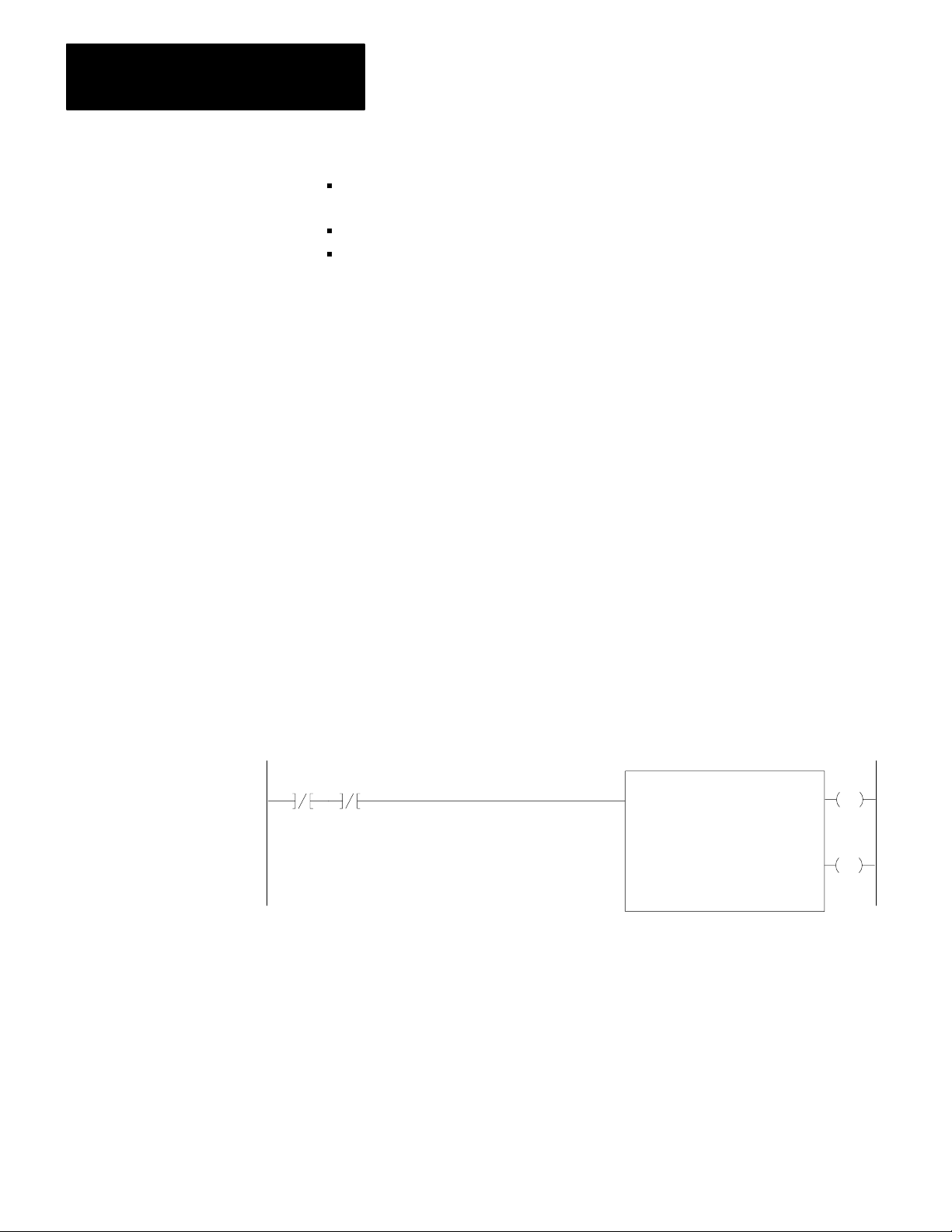

Figure 6.2

Processor Programming Example (PLC-5)

Local

Rung 2:0

PLC5 local write rung. The DCM is located in the same I/O chassis as the PLC5, and is set for block transfer. The local proces

sor's write length must match the supervisory processor's read length.

BTR

ENABLE BIT

N12:0

15

Rung 2:1

PLC5 local read rung. The DCM is located in the same I/O chassis as the PLC5, and is set for block transfer. The local proces

sor's read length must match the supervisory processor's write length.

BTR

ENABLE BIT

N12:0

15

BTW

ENABLE BIT

N12:5

15

BTW

ENABLE BIT

N12:5

15

BTW

BLOCK TRNSFR WRITE

Rack

Group

Module

Control Block

Data file

Length

Continuous

BTR

BLOCK TRNSFR READ

Rack

Group

Module

Control Block

Data file

Length

Continuous

N12:5

N13:30

N12:0

N13:30

17

21

EN

0

DN

3

1

ER

N

EN

0

3

DN

1

ER

N

1771-DCM Switch Settings

Supervisory Processor Logic

Select module operating conditions by setting switches on the module for

discrete data transfer or block transfer as follows:

Discrete Data Transfer Block Transfer

• Transfer Method • Transfer Method

• Rack Size • Data Protect (If Applicable)

Set other switches as required by your application.

The addresses that you use for the 1771–DCM in the supervisory

processor’s ladder program are the addresses (RGS) to which you

configure your 1771–DCM using Switch Banks 0 and 1:

I/O Rack Number (Switch Bank 1, Switches 1 through 6).

63

Page 25

Chapter 6

Programming the 1771-DCM

First (Starting) Module Group Number (Switch Bank 1, Switches 7 and

8)

The slot number will always be zero for block transfer only.

Equivalent rack size for discrete data transfer only (Switch Bank 0,

Switches 7 and 8). The equivalent rack size for block transfer mode is

fixed at 1/4 rack.

Discrete Data Transfer

The supervisory processor transfers discrete data to and from the

1771–DCM automatically via its I/O scan. You do not program these

transfers.

To transfer discrete data words to and from the 1771–DCM, you must use

I/O image table addresses in the supervisory processor’s ladder program

starting with the addresses (RGS) to which you configured your

1771–DCM. Use the number of image table words equal to the

equivalent I/O rack size that you set for the 1771–DCM.

The ladder program of your supervisory processor must move discrete

data, read from the 1771–DCM, from input image table words to a storage

location (Figure 6.3).

Figure 6.3

Supervisory

FFM Done Bit

04110120

15

Processor Programming Example for Discrete Data T

Data Valid Bit

Buffer File

FILE TO FILE MOVE

Counter Address:

Position:

File Length:

File A:

File R: 0700-0707

Rate per Scan: 008

ransfer (PLC-2/30)

0120-0127

Your ladder program must place data into output image table words for

transfer to the 1771–DCM. Avoid placing data in the first word because

the 1771–DCM inserts status in this word. We leave this ladder logic to

you because your application and processor’s set of instructions determine

how you would do this.

0041

001

008

0041

EN

17

0041

DN

15

64

Page 26

Chapter 6

Programming the 1771-DCM

Example 1:

Suppose you want to transfer six words, and you have configured the

1771–DCM to simulate a 3/4 I/O rack with the following address:

Rack Number = 2, First Module Group = 0. Also, suppose that the

1771–DCM is located in the same chassis with the local processor,

that the 1771–DCM’s actual location (RGS) is 131, that the local

processor’s block transfer read block is 300 through 305, and that the

block transfer write block is 200 through 205.

Data transfers would occur as follows:

Supervisory

Output Image Table Words Match the I/O

Chassis Slots Simulated by the

1771-DCM

020 Status Word (Zeroed)

021 First Data Word

022 Second Data Word

:

:

025 Fifth Data Word

Local

BTW Instruction Writes Data to the

1771-DCM from Words 200 through

205

200 Status Word (Zeroed)

201 First Data Word

202 Second Data Word

:

:

205 Fifth Data Word

Processor

Processor

To

BTR Instruction Reads Data from the 1771-DCM

into Words 300 through 305

300 Status Word (Inserted by DCM)

301 First Data Word

302 Second Data Word

:

:

305 Fifth Data Word

To

Input Image Table Words Match the I/O Chassis

Slots Simulated by the 1771-DCM

120 Status Word (Inserted by DCM)

121 First Data Word

122 Second Data Word

:

:

125 Fifth Data Word

Local Processor

Supervisory Processor

65

Page 27

Chapter 6

Programming the 1771-DCM

Your ladder program for the supervisory processor must place data in

output image table word addresses for transfer to the 1771–DCM and

move data from input image table word addresses as needed by your

application. We leave this ladder logic to you because your application

and processor’s set of instructions determine how you would do this.

Block Transfer

We present block transfer rungs for the supervisory processor when the

1771–DCM is operating in block transfer mode (Figure 6.4 for a

PLC–2/30 supervisory processor, Figure 6.5 for PLC–3, and Figure 6.6

for a PLC–5 family processor).

66

Page 28

LOCAL PROCESSOR

Chapter 6

Programming the 1771-DCM

Figure 6.4

T

ransfer Programming Example for PLC-2 Family Local and Supervisory Processor

Block

BTR Done Bit

11310300

17

Data Valid Bit

SUPERVISORY PROCESSOR

BTR Done Bit

12010600

07

Data Valid Bit

Buffer File

Buffer File

BLOCK XFER READ

Data Address:

Module Address:

Block Length:

File:

FILE TO FILE MOVE

Counter Address:

Position:

File Length:

File A:

File R: 0400-0477

Rate per Scan: 064

BLOCK XFER WRITE

Data Address:

Module Address:

Block Length:

File:

BLOCK XFER READ

Data Address:

Module Address:

Block Length:

File:

FILE TO FILE MOVE

Counter Address:

Position:

File Length:

File A:

File R: 0700-0777

Rate per Scan: 064

0030

131

0300-0377

0040

001

064

0300-0377

0031

131

0200-0277

0032

200

00

0600-0677

0042

001

064

0600-0677

00

00

013

EN

17

113

DN

17

0040

EN

17

0040

DN

15

013

EN

16

113

DN

16

020

EN

07

120

DN

07

0042

EN

17

0042

DN

15

BLOCK XFER WRITE

Data Address:

Module Address:

Block Length:

File:

0500-0577

0033

200

00

020

EN

06

120

DN

06

67

Page 29

Chapter 6

Programming the 1771-DCM

Figure 6.5

T

ransfer Programming Example for PLC-3 Supervisory Processor

Block

BTR Done Bit

WB001:0000

15

BTR Done Bit

WB001:000010WB002:0000

15

Data Valid Bit

Read Request

WB001:0000

17

Buffer File

BTR

BLOCK XFER READ

Rack:

Group:

Module:

Data:

Length: 064

CNTL: FB001:0000

MVF

BTW

BLOCK XFER WRITE

Rack:

Group:

Module:

Data:

Length: 064

CNTL: FB001:0000

MVF

FILES FROM A TO R

File A:

File R:

Counter:

Pos/Len: 0/ 64

Mode: ALL/SCAN

002

0 = Low

FB002:0000

002

0 = Low

FB003:0000

FB002:0000

FB004:0000

C0005

CNTL

LE

12

CNTL

0

DN

15

CNTL

ER

13

CNTL

LE

02

CNTL

0

DN

05

CNTL

ER

03

C0005

EN

12

C0005

DN

15

C0005

ER

13

68

Page 30

Chapter 6

Programming the 1771-DCM

Figure 6.6

Block T

ransfer Programming Example for PLC-5 Family Supervisory Processor

Rung 2:2

PLC5 supervisory write rung. The DCM is connected via remote I/O to the PLC5, and is set for 57.6K baud, block

transfer, and rack 3. The supervisory processor's write length must match the local processor's read length.

BTR

ENABLE BIT

N22:0

15

Rung 2:3

PLC5 supervisory read rung. The DCM is connected via remote I/O to the PLC5, and is set for 57.6K baud, block

transfer, and rack 3. The supervisory processor's read length must match the local processor's write length.

BTR

ENABLE BIT

N22:0

15

BTW

ENABLE BIT

N22:5

15

BTW

ENABLE BIT

N22:5

15

BTW

BLOCK TRNSFR WRITE

Rack

Group

Module

Control Block

Data file

Length

Continuous

BTR

BLOCK TRNSFR READ

Rack

Group

Module

Control Block

Data file

Length

Continuous

N22:0

N19:0

31

N22:5

N19:40

27

EN

3

0

DN

0

ER

N

EN

3

0

DN

0

ER

N

69

Page 31

Chapter 6

Programming the 1771-DCM

Rung 1STEP0:0

PLC5/250 supervisory write rung. The DCM is connected via remote I/O to the PLC5/250. The DCM baud rate switch

setting must match that of its scanner channel. The DCM rack switches are set for rack 7. The local processor's read

length must match the supervisory processor's write length.

Figure 6.7

T

ransfer Programming Example for PLC-5/250 Supervisory Processor

Block

BTW

ENABLE BIT

BW070:0

EN

Rung 1STEP0:1

PLC5/250 supervisory read rung. The DCM is connected via remote I/O to the PLC5/250. The DCM baud-rate switch

setting must match that of its scanner channel. The DCM rack switches are set for rack 7. The local processor's write

length must match the supervisory processor's read length.

BTW

ENABLE BIT

BW070:0

EN

BTR

ENABLE BIT

BR070:0

EN

BTR

ENABLE BIT

BR070:0

EN

BTW

BLOCK TRNSFR WRITE

Rack

Group

Module

Control Block

Data file

Length

Continuous

BT Timeout 4

BTR

BLOCK TRNSFR READ

Rack

Group

Module

Control Block

Data file

Length

Continuous

BT Timeout 4

BW070:0

1BTD2:1

BR070:0

1BTD3:1

007

NO

007

NO

17

15

EN

0

DN

0

ER

EN

0

DN

0

ER

610

Page 32

Chapter 6

Programming the 1771-DCM

BTR/BTW Module Address

The module address of BTR and BTW instructions in the supervisory

processor’s program is the configured address of the 1771–DCM. It is the

I/O rack number and starting module group number (its slot number is

always zero for block transfer) that you set using Switch Banks 0 and 1).

Block Length/File Length

Generally, set them to the number of words that you set for the

1771–DCM. If you have reason to set the read block length different

from the write block length (PLC–2 family processors), be sure that both

the BTR and BTW instructions cannot be enabled in the same scan.

When moving or transferring words into the BTW file for transfer to the

1771–DCM, be sure to avoid placing data in the first word because the

1771–DCM inserts status in this word.

File–to–File Move (FFM) or (MVF)

Use this instruction to store data received from the 1771–DCM. File A

address of the FFM or MVF is the same as the BTR file address. File R

address of the FFM or MVF is a storage file for data from the

1771–DCM.

Your ladder program for the supervisory processor must place data into

the BTW file for transfer to the 1771–DCM. We leave this ladder logic to

you because your application and processor’s set of instructions determine

how you would do this.

Examine the status word received from the 1771–DCM as a condition for

using the read block transfer data. Zero the status word at power–up and

be sure that your ladder program does not use this word for any other

purpose.

611

Page 33

Chapter 6

Programming the 1771-DCM

Example 2:

Suppose you want to transfer 64 words, and you have configured the

1771–DCM to simulate a block transfer module in Rack 2, First

Module Group = 0. Also suppose that the 1771–DCM is located in

the same chassis with the local processor, and that the 1771–DCM’s

actual location (RGS) is 131. In this example, you allocated data

blocks for block transfer as follows: (Refer to Figure 6.4 for

PLC–2/30, or Figure 6.5 for PLC–3 Programming)

Data

Block Supervisory Processor Local Processor

Read

Write

600 through 677 300 through 377

500 through 577 200 through 277

Data transfers would occur as follows for PLC–2 family processors:

Supervisory

BTW Instruction W

1771-DCM from W

577

500 Status W

501 First Data W

502 Second Data Word

:

:

577 Last Data W

Local Processor

BTW Instruction W

1771-DCM from W

277

Processor

rites Data to the

ords 500 through

ord (Zeroed)

ord

ord

rites Data to the

ords 200 through

To

BTR Instruction Reads Data from the

1771-DCM into W

300 Status Word (Inserted by DCM)

301 First Data W

302 Second Data W

377 Last Data W

To

BTR Instruction Reads Data from the

1771-DCM into W

Local Processor

ords 300 through 377

ord

:

:

ord

Supervisory Processor

ords 600 through 677

ord

612

200 Status W

201 First Data W

202 Second Data W

277 Last Data W

ord (Zeroed)

ord

:

:

ord

ord

600 Status Word (Inserted by DCM)

601 First Data W

602 Second Data W

677 Last Data W

ord

ord

:

:

ord

Page 34

Chapter 6

Programming the 1771-DCM

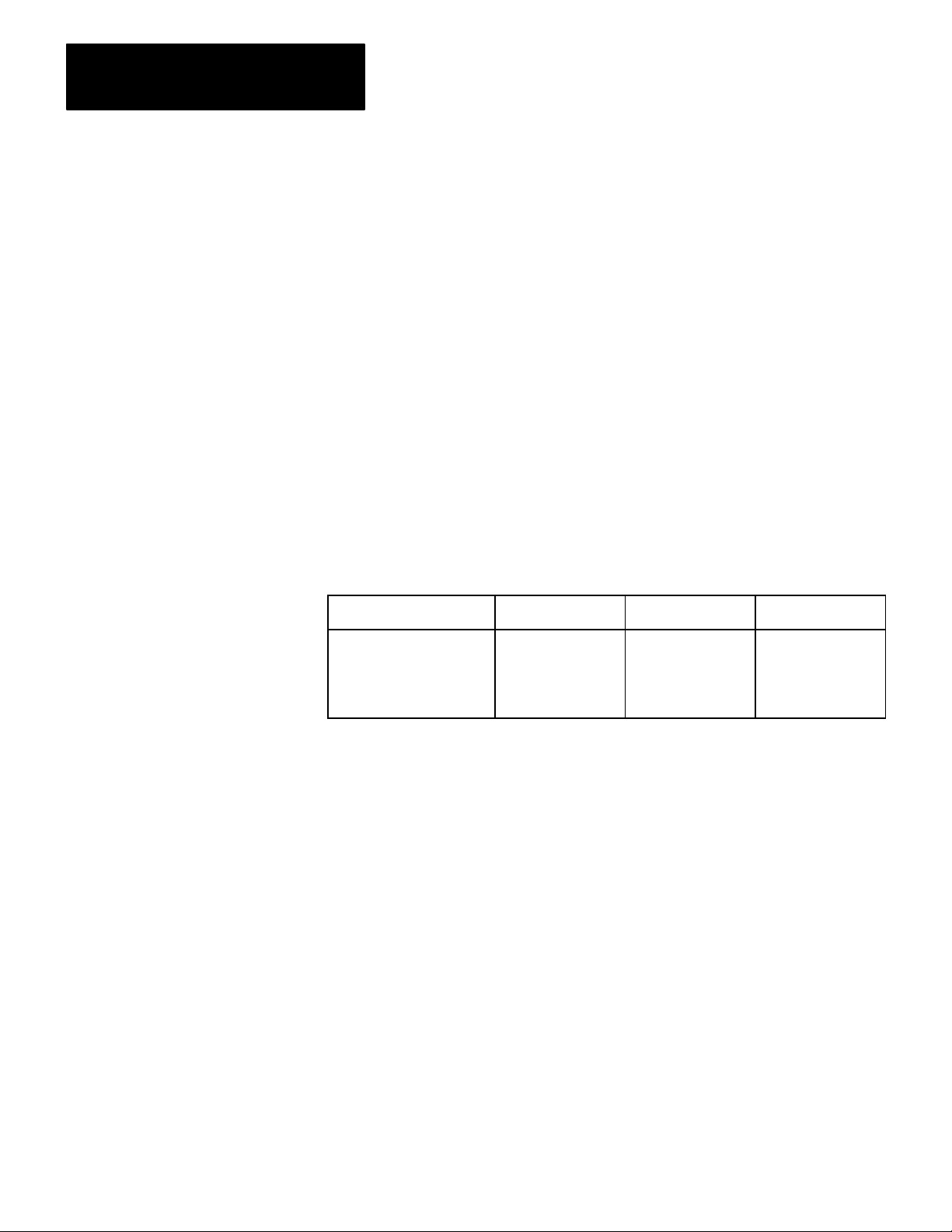

Processor/Module Compatibility

Your 1771–DCM must have the following revision (or later) for

compatible block transfer operation with your processor.

Processor

Family

PLC-3 F

PLC-5 E

PLC-5/250 E

1771-DCM Revision

Data transfers would occur as follows when the supervisory processor is a

PLC–3:

Supervisory

BTW Instruction Writes Data to the

1771-DCM from Binary File 3, Words

0 through 63

FB003:0000 Status Word (Zeroed)

FB003:0001 First Data Word

FB003:0002 Second Data Word

:

:

FB003:0063 Last Data Word

Processor

To

BTR Instruction Reads Data from the 1771-DCM

into Words 300 through 377

300 Status Word (Inserted by DCM)

301 First Data Word

302 Second Data Word

:

:

377 Last Data Word

Local Processor

Local

Processor

BTW Instruction Writes Data to the

1771-DCM from Words

200 through 277

200 Status Word (Zeroed)

201 First Data Word

202 Second Data Word

:

:

277 Last Data Word

To

BTR Instruction Reads Data from the 1771-DCM

FB002:0000 Status Word (Inserted by DCM)

Supervisory Processor

into Binary File 2, Words 0 through 63

FB002:0001 First Data Word

FB002:0002 Second Data Word

:

:

FB002:0063 Last Data Word

613

Page 35

Calculating Transfer Time

Chapter

7

Calculating Transfer Time

Discrete Transfer Time

The time required for the transfer of data from supervisory to local

processor (and vice versa) is the sum of three events:

Supervisory Processor and Remote I/O Scan Time

Transfer Time through the 1771-DCM

Local Processor Scan Time

The time required for the supervisory processor to communicate with the

1771-DCM depends on whether you select discrete data transfer (up to

eight words) or block transfer (up to 64 words), the number of other

remote I/O chassis, and the number of block transfer modules in the local

and remote I/O systems.

You select the mode of transfer between the supervisory processor and the

1771-DCM as either discrete data transfer or block transfer. Discrete data

transfer is faster than block transfer.

Calculate the transfer time between processors when the 1771-DCM is

transferring discrete data by calculating the times associated with the

supervisory processor, 1771-DCM, and the local processor. Assume the

supervisory and local processor systems contain no other block transfer

modules.

Supervisory Processor

The supervisory processor reads discrete input data or writes discrete

output data to/from its I/O through its remote I/O scanner. Calculate the

total scan time of the supervisory processor as the sum of the program

scan, processor I/O scan if applicable, and the remote I/O scan using

values in the table as follows:

Scan PLC2/30 PLC3

Program 5 ms/K Words 2.5 ms/K Words

Processor I/O 0.5 ms/Rack N/A

Remote I/O 7 ms/Chassis 6 ms/Chassis

71

Page 36

Chapter 7

Calculating Transfer Time

Total Scan (PLC-2) = Program + Processor I/O + Remote I/O

Total Scan (PLC-3) = Program + Remote I/O

1771DCM

The delay from the time the 1771-DCM receives data until it is ready for

data transfer is 15 ms. During this time, it detects errors and changes in

status and formats data.

Local Processor

The local processor reads data from or writes data to the 1771-DCM using

block transfer instructions, regardless of how data is transferred between

1771-DCM and supervisory processor. The time required is equal to the

program scan plus block transfer time which depends on the number of

words transferred.

Time

for

Program Scan 15 ms/K 18 ms/K 5 ms/K

I/O Scan 1 ms 4 ms 0.7 ms

Block Transfer 0.08 ms/W 0.08 ms/W 0.08 ms/W

PLC2/05 PLC2/15

PLC2/30 (Local)

W = Number of Words Transferred

Total Scan = Program and I/O Scan + (Multiplier) x (Number of Words

Transferred)

See the appropriate processor manual for times for other processors.

Addition of Block Transfer Modules

Block transfer modules in the local I/O chassis can lengthen the I/O scan

time by the time required for each to perform a block transfer (worst

case). The delay depends on the number of block transfer modules

waiting to transfer and the number of words each will transfer. Calculate

the additional block transfer time for your processor as follows for each

block transfer module:

72

Time (Local) = Multiplier x (Number of Words Transferred)

Page 37

Chapter 7

Calculating Transfer Time

Processor Multiplier

PLC2/05, 2/15 0.08

PLC2/30 (Local) 0.08

PLC2 Family Example Computation

Suppose that a PLC-2/30 supervisory processor has a 6K program and

seven assigned rack numbers and the PLC-2/05 local processor has a 2K

program. There are no other block transfer modules in either the

supervisory or local systems.

1. Calculate the time required to transfer eight words from supervisory

to local processor.

2. Calculate the total time required if there are two additional block

transfer modules in the local chassis, transferring 64 words each.

Assume worst case.

Solution Part 1:

PLC-2/30 Supervisory Processor Scan Time:

Scan PLC2/30

Program 5 ms/K Words

Processor I/O 0.5 ms/Rack

Remote I/O 7 ms/Chassis

Time (PLC-2/30) = Program + Processor I/O + Remote I/O

= (5 ms)(6) + (0.5 ms)(7) + (7 ms)(7)

= 30 ms + 3.5 ms + 49 ms

= 82.5 ms

1771-DCM Delay: 15 ms

Local Processor Scan Time:

Time

for

I/O Scan 1 ms

Program Scan 15 ms/K

Block Transfer 0.08 ms/W

PLC2/05

73

Page 38

Chapter 7

Calculating Transfer Time

W = Number of Words Transferred

Scan = Program Scan + I/O Scan + (Multiplier) x (Number of Words

Transferred)

= (15 ms)(2) + 1 ms + (0.08)(8) ms

= 30 ms + 1 ms + 0.64 ms

= 31.6 ms

Transfer Time = Supervisory + 1771-DCM + Local

= 82.5 ms + 15 ms + 31.6 ms

= 129 ms

Solution Part 2:

Block Transfer Time

Additional time for two block transfer modules in the local chassis:

Time (PLC-2/05) = 2(0.08 ms) x (Number of Words Transferred)

= 2(0.08 ms)(64) 1

= 10.2 ms

Total Transfer Time = Discrete Transfer + Block Transfer

= 129 ms + 10.2 ms

= 139 ms (Worst Case)

When you select block transfer as the mode of transfer between the

supervisory processor and 1771-DCM, you can transfer up to 64 words

but the transfer time increases.

The time required for the transfer of data from supervisory to local

processor (and vice versa) is the sum of three events:

Supervisory Processor and Remote I/O Scan Time

Transfer Time through the 1771-DCM

Local Processor Scan Time

74

1771DCM and Local Processor

Refer to Discrete Data Transfer, above, for the time required by the

1771-DCM and the local processor. These times are the same for either

method of transfer between the supervisory processor and the 1771-DCM.

Page 39

Chapter 7

Calculating Transfer Time

PLC2 Family Supervisory Processor

The time required by the supervisory processor is the sum of the program

scan, processor I/O scan, and remote I/O scan. The time is lengthened by

the number of enabled block transfer modules transferring data, one

module after the other, and on the number of words that each module

transfers. Calculate the time for a read or write operation for each enabled

block transfer module as follows:

Scan PLC2/30

Program 5 ms/K Words

Processor I/O 0.5 ms/Rack

Remote I/O 7 ms/Chassis

Time (1 Module) = Program + Processor I/O + 2(Remote I/O) + 0.5W +

10

Where W = number of words transferred and 10 is an average constant

(typically, this constant is 4 for a read and 13 for a write).

If it is possible that all block transfer modules in the supervisory system

could be enabled at the same time, the worst case time for any one

transfer would include the waiting time for all other other block transfers.

PLC2 Family Example Computation

Suppose there are four block transfer modules in addition to the

1771-DCM that could be enabled simultaneously in a PLC-2/30

supervisory system. The local system has no additional block transfer

modules. Assume that the program has 4.8K words, there are six assigned

rack numbers in the remote I/O link, and that each block transfer is 64

words.

1. Calculate the worst case time for the five modules to block transfer

their data.

2. Calculate the worst case time for a block transfer from the

supervisory to the local processor.

75

Page 40

Chapter 7

Calculating Transfer Time

Solution Part 1:

Time (1 Module) = (5 ms)(4.8) + (0.5 ms)(6) + 2(7 ms)(6) + (0.5)(64) +

10

= 24 ms + 3 ms + 84 ms + 32 ms + 10 ms

= 153 ms

Total Time (All Five Modules) = 5(153)

= 765 ms (Worst Case)

Solution Part 2:

To calculate the worst case time for block transfer from supervisory to

local processor via the 1771-DCM, add times for the 1771-DCM and local

processor: 15 ms and 31.6 ms, respectively, assuming no other block

transfer modules in the local chassis.

Block Transfer with a PLC3

Supervisory Processor

Total Time = 765 ms + 15 ms + 31 ms

= 811 ms

The time required to complete a read or write block transfer depends on

factors that include the number of:

Words of user program

Active I/O channels on the scanner

I/O chassis entries in the rack list for the channel

I/O channels on the scanner that contain block transfer modules

Block transfer modules on the channel (if the I/O chassis containing a

block transfer module appears more than once in the I/O chassis rack

list, count the module once each time the chassis appears in the rack

list)

Typical time required to complete a read or write block transfer depends

on the program scan and the scanner scan as follows:

Time (Read or Write) = Program Scan + 2(Scanner Scan)

76

Program Scan

The program scan is approximately 2.5 ms per 1K words of user program

when using a mix of examine ON/OFF and block instructions.

Page 41

Chapter 7

Calculating Transfer Time

Scanner Scan

The time required for the scanner to complete a read or write block

transfer depends on the number of other block transfer modules on the

same scanner channel that are enabled simultaneously. Use the following

procedure to calculate the time required for the PLC-3 processor to

perform all block transfers on the channel.

1. Determine the number of active I/O channels on the scanner.

2. Determine the number of I/O channels with block transfer modules.

3. Use these tables to determine the nominal block transfer time using

the numbers from Steps 1 and 2.

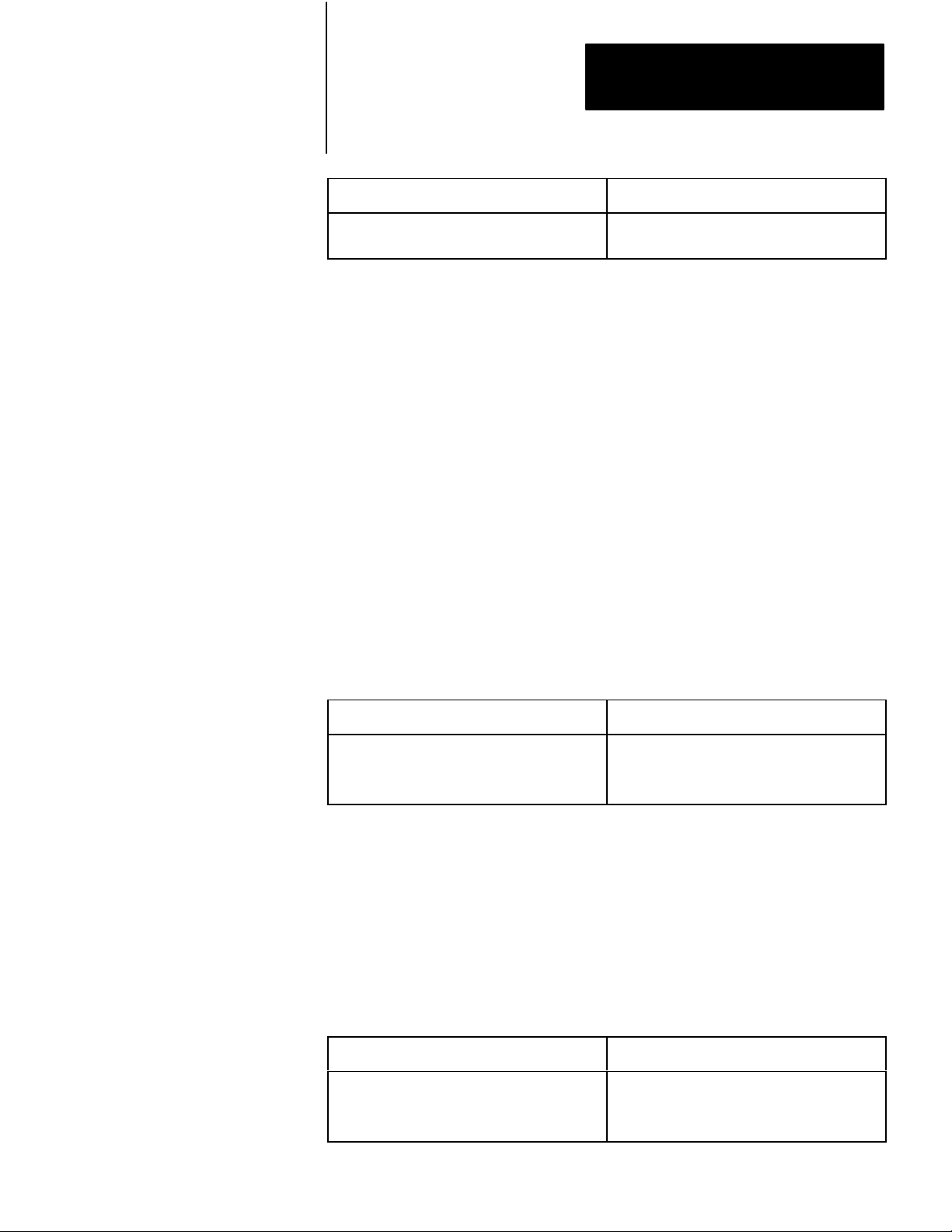

Nominal Block Transfer Times (ms) for a BTW

Channels

Block Transfer Modules

with

1 45 50 60 65

2 70 70 75

3 85 95

4 100

1 Active

Channel

2 Active

Channels

Nominal Block Transfer Times (ms) for a BTR

Channels

Block Transfer Modules

with

1 35 50 50 60

2 60 60 65

3 70 80

1 Active

Channel

2 Active

Channels

3 Active

Channels

3 Active

Channels

4 Active

Channels

4 Active

Channels

4 90

Block transfer times typically are similar regardless of the type of block

transfer module or the number of words transferred. Nominal read block

transfer times typically are faster than nominal write block transfer times

by approximately 10 ms. In this example, consider them the same.

77

Page 42

Chapter 7

Calculating Transfer Time

4. Count the number of block transfer modules on the channel. If a

chassis containing block transfer modules is repeated in the rack list,

count chassis and modules as often as listed.

5. Count the number of I/O chassis entries in the rack list for the

channel.

6. Calculate the block transfer time for the scanner as follows:

Scanner

Time

=

Nominal

Time

BT Modules

#

x

on the Channel

# I/O Chassis1

+

in Rack List

x

9 ms

PLC3 Example Computation

As an example, we will compute the read or write block transfer time

between the supervisory processor and a 1771-DCM in an I/O channel

with no other block transfer modules and in an I/O channel with two other

block transfer modules in the following system:

User program contains 20K words.

Channel 1 contains four I/O chassis, with a total of three block transfer

modules including one 1771-DCM.

Channel 2 contains two I/O chassis with no block transfer modules.

Channel 3 contains two I/O chassis with one 1771-DCM.

Channel 4 is made inactive through processor LIST.

You can compute the read or write block transfer times for the supervisory

processor in this example in four steps. Each of the following steps is

explained by an accompanying figure:

78

1. Diagram the I/O channels of your PLC system (Figure 7.1), showing

the number of:

Block transfer modules in each I/O chassis

Block transfer I/O channels

I/O chassis entries in the rack list for each block transfer I/O

channel

Active I/O channels per scanner

A block transfer I/O channel is a channel that contains one or more

block transfer modules located in any chassis connected to the

channel.

Page 43

An I/O chassis can appear more than once in a rack list of I/O

chassis. Count it and the block transfer module(s) that it contains as

often as it is listed.

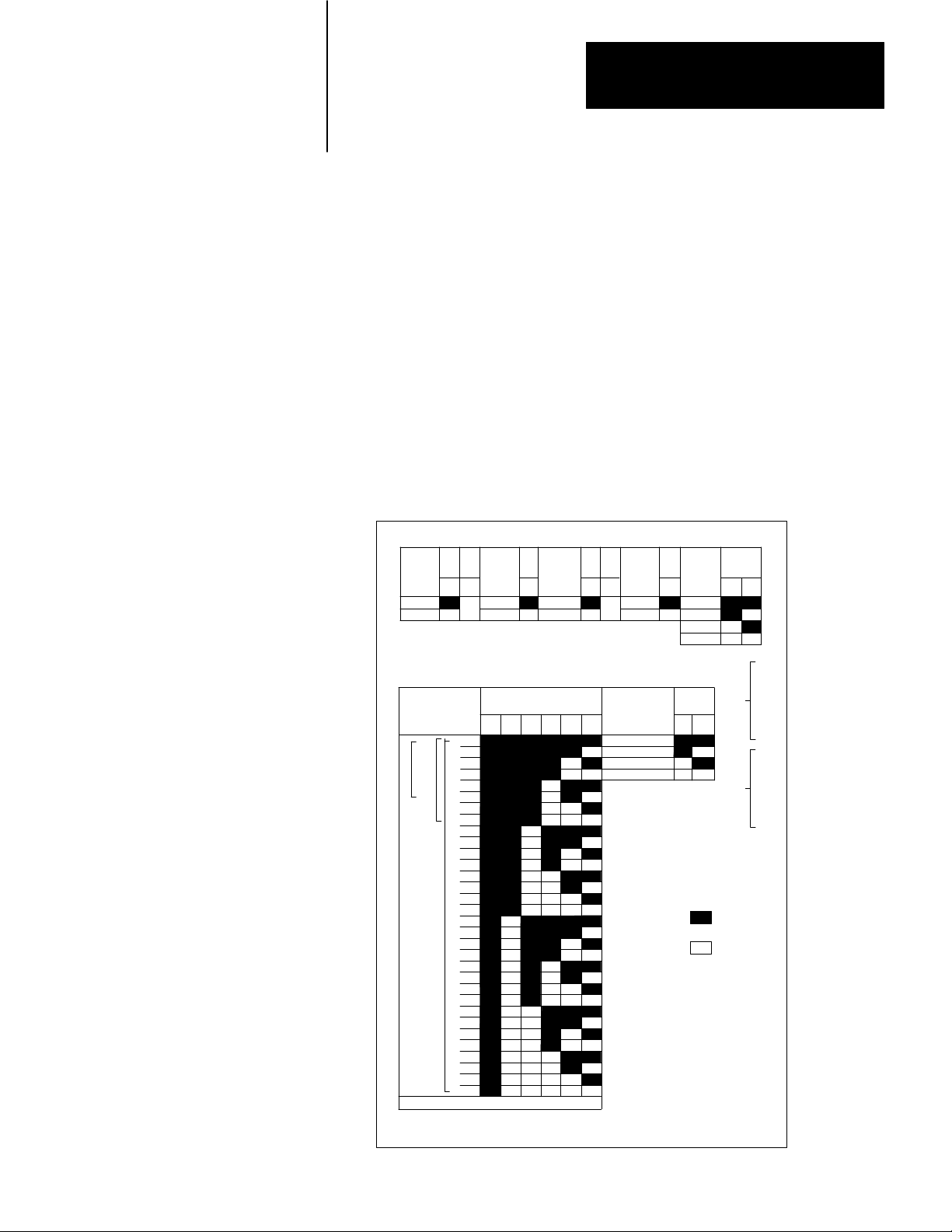

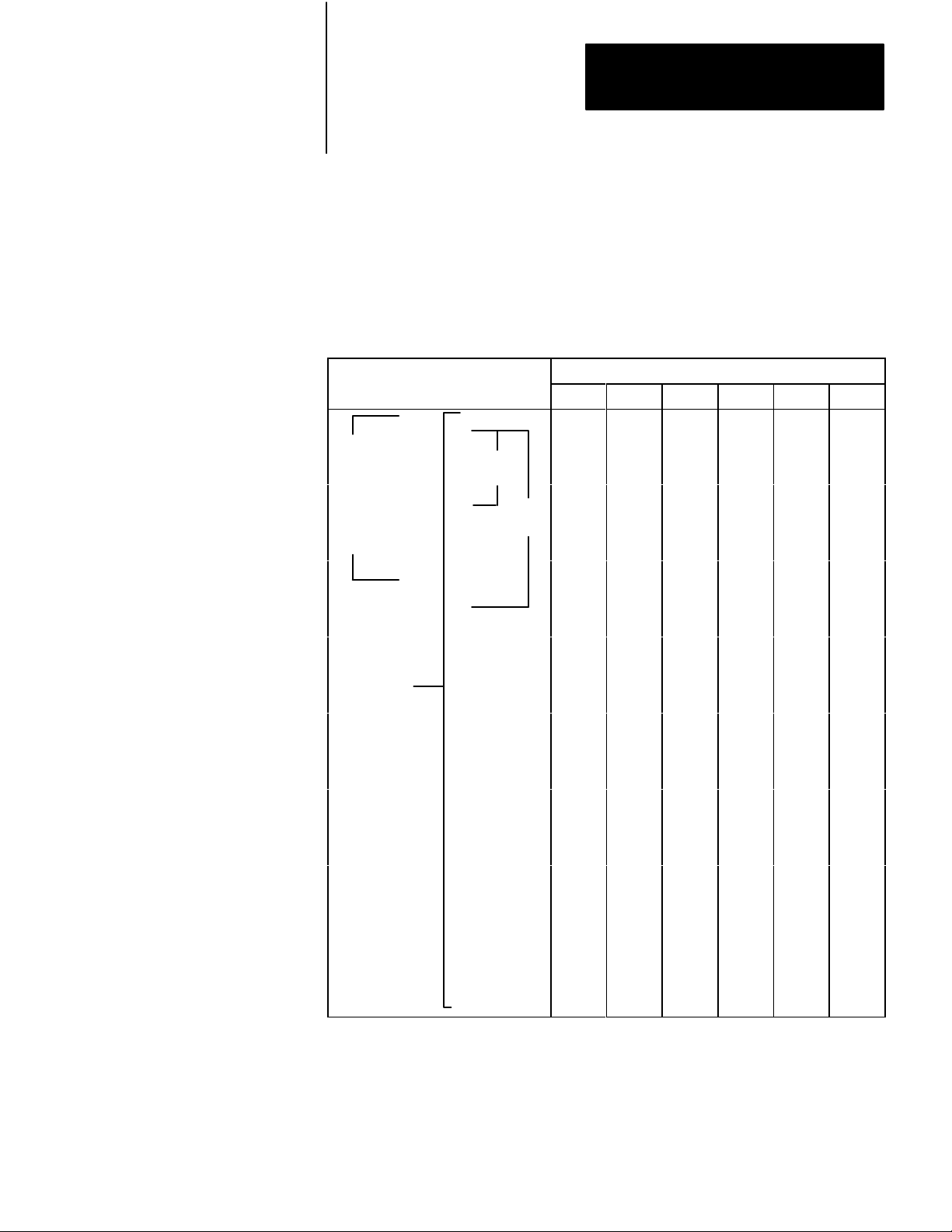

Figure 7.1

Diagramming

Step 1 Diagram the chassis connected in series to each channel

(up to 4) of your scanner module. Then, fill in the information called fo below.

Example values have been added.

I/O Channels

Chapter 7

Calculating Transfer Time

1

2

3

4

1 0 2 0

0 0

1 0

Make interactive thru processor LIST

Description Number Ch 1 Ch 2 Ch 3 Ch 4

Active I/O channels

Block-transfer I/O channels

Block-transfer modules on each

I/O block transfer channel

I/O chassis on each block transfer

I/O channel

(I/O chassis in rack list)

3

2

3

4

= I/O chassis

n = number of block tranfer

modules in chassis

0

0

1

2

0

0

12828

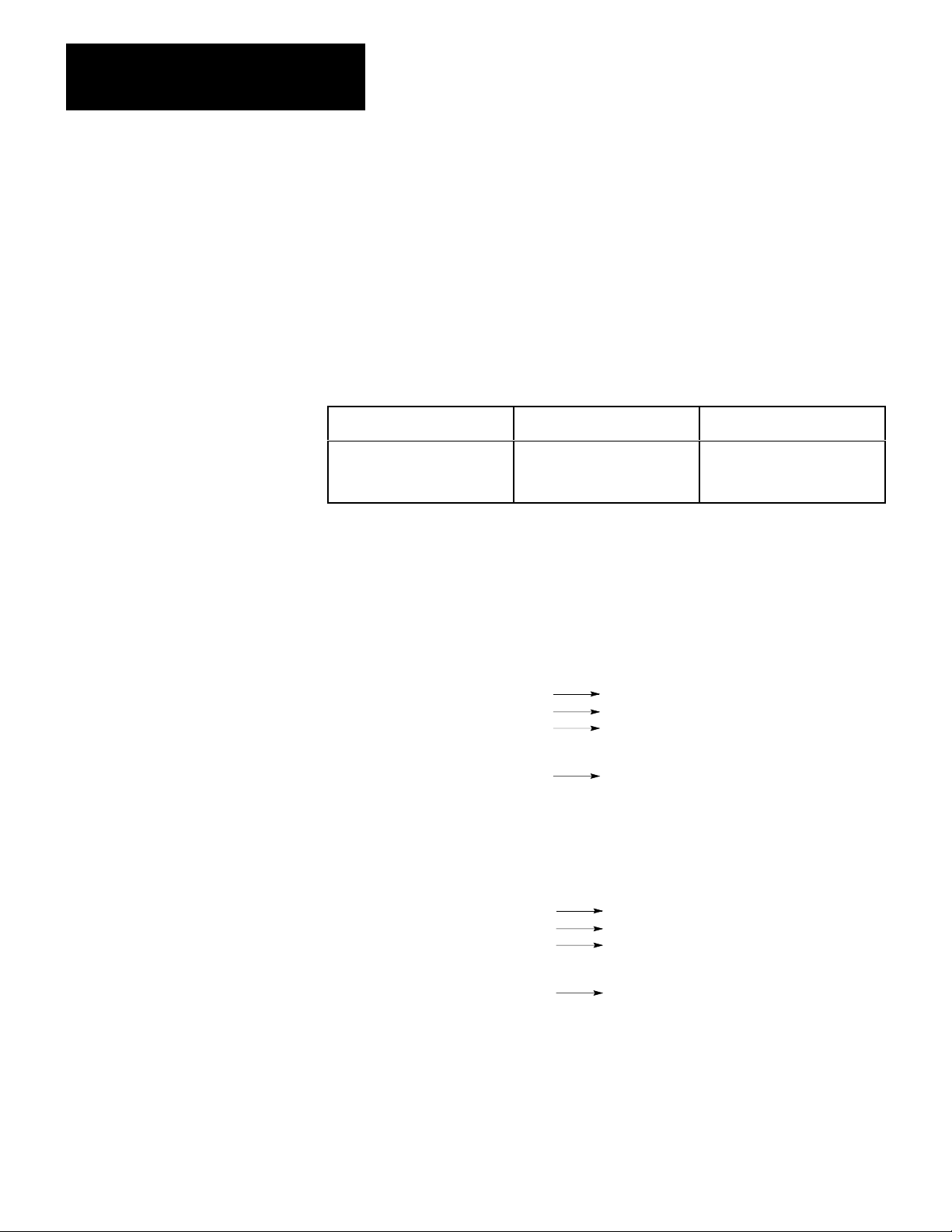

2. Using information from the diagram of I/O channels (Figure 7.1),

look up the nominal time from the table in Figure 7.2.

79

Page 44

Chapter 7

Calculating Transfer Time

Figure 7.2

T

ime T

Nominal

Step 2 Determine a time from the table. Example values have been added for a BTW instruction.

Number of Active I/O Channels

1 2 3 4

1

Active I/O channels

containing one or more

blocktransfer modules

45 50 60 65

2

3

4

Time (ms)

able

70 70 75

85 95

100

Number of active I/O channels: 3

Number of active I/O channels containing one or

more blocktransfer module: 2

Time from table: 70 ms

3. Compute the approximate transfer time for each block transfer I/O

channel. Use values from your channel diagram (Figure 7.1), a value

from the table (Figure 7.2), and the formula from Step 6 above. We

make these calculations for you in Figure 7.3.

12829

Figure 7.3

Computing

STEP 3

CT =

CT =

CT1

CT2

CT3

CT4 =

Channel T

:

imes

Compute the scanner time for each block transfer channel.

Example values have been added.

Channel T

Nominal

Time

=

[ 70 ms ] x [ 3 ] + [ 41 ] x 9 ms

ime

x

210 ms + 3 x 9 ms

237 ms

=

Not a Block T

=

[ 70 ms ] x [ 1 ] + [ 21 ] x 9 ms

ransfer Channel

70 ms + 9 ms

79 ms

Not an Active Channel

# BT Modules

on BT Channel

I/O Chassis

+

on BT Channel

-1

x

9 ms

710

Page 45

Chapter 7

Calculating Transfer Time

4. Compute the approximate read or write block transfer time for

Channel 1 and Channel 3 (Figure 7.4).

Figure 7.4

Computing

Block T

STEP 4

:

Program Scan Time (Program)

Scanner Scan Time (Read or W

Block T

ransfer

T

ime Per Channel

ransfer for Each Channel

Compute the read or write block transfer time.

Example values have been added.

Channel 1

Channel 3

rite) =

=

2.5 ms/K Words x 20K W

2.5 ms x 20

=

50 ms

=

237 ms for Channel 1 and 79 ms

for Channel 3 (from Step 3)

Program Scan + 2 [Scanner Scan]

=

50 ms + 2 [ 237 ms ]

50 ms + 474 ms

524 ms

=

Program Scan + 2 [Scanner Scan]

50 ms + 2 [ 79 ms ]

50 ms + 158 ms

208 ms

ords

Reducing PLC3 Scan Time

Due to the asynchronous scan relationship between program and scanner

and the serial operation of each channel in the scanner, we suggest that

you optimize the overall scan time. Although recommendations are

application dependent, we make the following recommendations as

general guidelines:

Whenever possible, control the manner in which block transfer

instructions are enabled. For example, if only a few block transfer

modules require frequent transfer of data, program them to run

continually. Inhibit block transfer instructions of those modules that

require less frequent transfer until enabled by a timer and/or some

application dependent condition.

Program the read and write block transfer instructions of your

1771-DCM in the same rung (Figure 6.5).

Distribute your block transfer modules equally between all four scanner

channels.

711

Page 46

Chapter 7

Calculating Transfer Time

Distribute block transfer instructions equally throughout your program.

Place an equal number of non-block transfer rungs between block

transfer rungs.

For large numbers of block transfer instructions, distribute groups of

block transfer rungs equally throughout your program. Place no more

than four block transfer rungs consecutively in one group. Within each

group, condition the next rung using the done bit of the previous block

transfer instruction.

Consider an additional I/O scanner module (cat. no. 1775-S4A) if you

cannot otherwise reduce the block transfer times to meet your timing

requirements.

Special Timing Considerations

When using one 1775-S4A I/O scanner with thumbwheel switch set to 1,

only part of its data handling capacity is available for handling block

transfers. This scanner can store and transfer a maximum of 72 words at

any one time. This scanner can do four block transfer modules across any

of the active channels.

If a block transfer read instruction is enabled but the scanner’s buffer

cannot accept the instruction’s block length (the scanner is processing

other blocks of data), the block transfer instruction must wait for a

subsequent scan when the scanner’s buffer can accept all the words that

the module has to transfer. The same applies for a write block transfer

instruction. We suggest that you add an additional scanner if necessary.

Block Transfer Errors

Once enabled, a block transfer instruction in a PLC-3 ladder program will

set either a done bit or an error bit. The instruction indicates an error

when it illuminates the -(ER)- symbol. Typical block transfer errors occur

when:

You do not correctly enter the instruction:

- The rack, group, and module numbers do not match the location of

the installed module.

- You entered a file length greater than 64.

- You did not create the data file or the address that you entered does

not match the file you created.

712

Read and write error bits illuminate at the same time when the error

source is the module address entry or the file length entry in the

instruction block.

Page 47

Chapter 7

Calculating Transfer Time

You have a communications problem.

You did not correctly connect the twin-axial cable to the scanner.

You did not connect a terminator resistor to each end of the twin-axial

cable.

When the scanner encounters a communication fault, it tries twice to

complete the transfer. It sets the error bit after the second unsuccessful

try.

When the scanner and/or processor detects a block transfer error, the

transfer is halted. Transfers from that module are prevented until:

Your program clears the instruction’s control word (clears the error,

Figure 7.5).

You locate and correct the error.

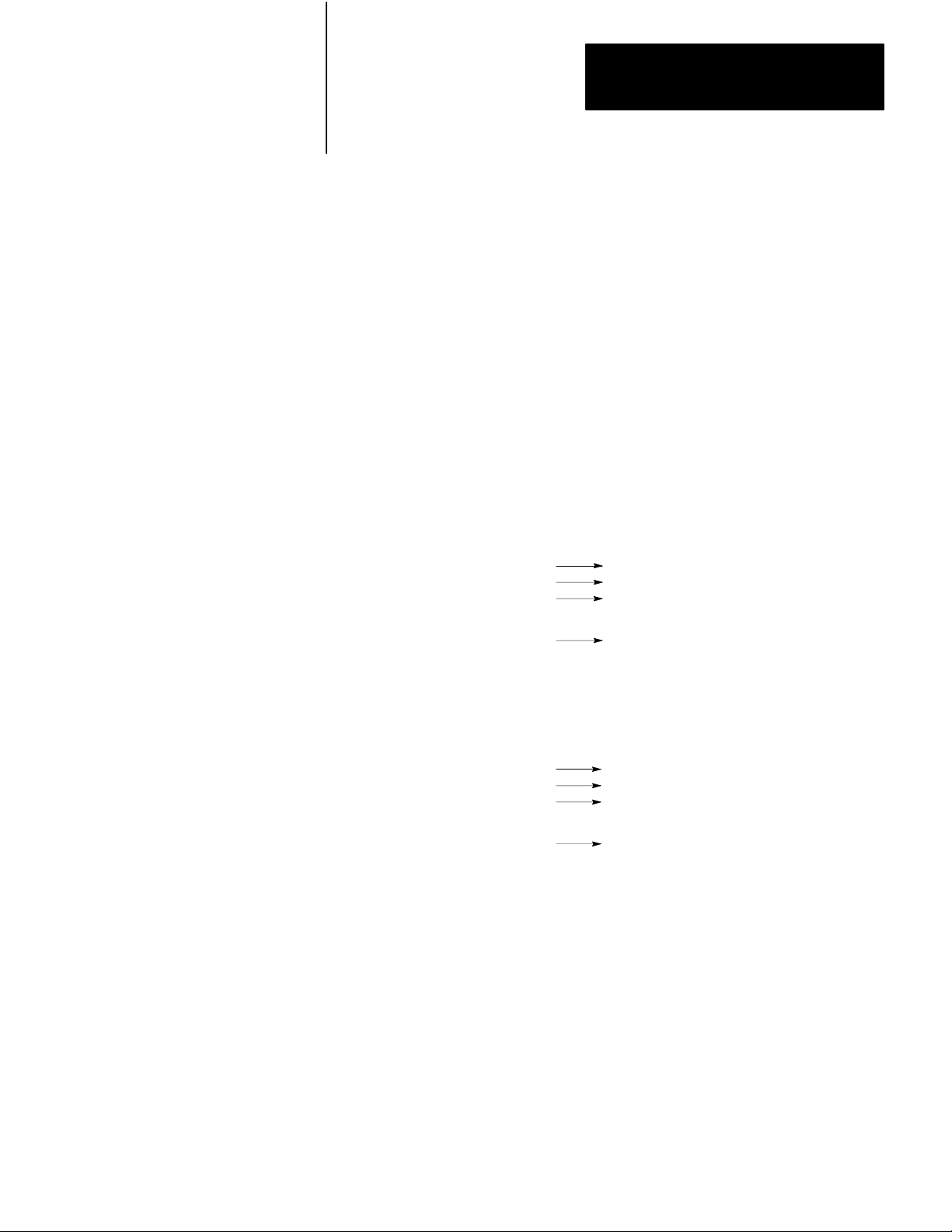

Figure 7.5

Resetting

Control Word

the Control W

03

13

ord after a Block T

ransfer Error

MOV

Move from A to R

A : Storage Word

0000000000000000

R : Control Word

0000000000000000

713

Page 48

Chapter

8

Troubleshooting Your 1771-DCM

Troubleshooting Your 1771-DCM

LED Display for Normal

Operation

LED Display for Fault Conditions

When troubleshooting your 1771–DCM, check each of the following

sources in the order given for the cause of the fault:

LEDs on the 1771–DCM

Block transfer rungs in the ladder program of your local or supervisory

processor

Status bits in the status word read by the local or supervisory processor

Under normal operating conditions, the LEDs are lit as follows:

Power

(PWR)

Serial Communication (SER COM)

Backplane Communications

(BCKPLN COM)

Module Fault (DCM FL

T) OFF

ON

ON

ON

If a fault should occur, the LED display changes to indicate the source of

the fault which you diagnose as follows:

LED Status Diagnosis

PWR OFF The

SER COM

Blinking

OFF

1771-DCM is not getting +5V DC. Check the backplane

power supply

Supervisory processor is in program or test mode. Check mode

selection.

Supervisory processor is not connected to the scanner

the cable between processor and scanner (PLC-2/30 proces

sor).

Supervisory processor detected a fault and turned off outputs.

Check processor LEDs and status of outputs.

The supervisory processor is not communicating with the

1771-DCM. Check cable connections in the remote I/O link to

the 1771-DCM.

.

. Check

81

Page 49

Chapter 8

Troubleshooting Your 1771-DCM

LED Status Diagnosis

BCKPLN

COM

DCM FL

Blinking The

OFF

T ON

1771-DCM turns on this LED for half a second at the com

pletion of a read or write block transfer

•

The local processor performs block transfers at a

rate slower than once every 1/2 second.

•

With the 1771-DCM in protected data mode, the

supervisory processor performs block transfers

at a rate slower than once every 1/2 second.

Reduce program scan and/or I/O scan time if possible in either

processor.

No block transfers are occurring across the backplane between

the local processor and 1771-DCM. Refer to Block T

Errors for the local processor

The 1771-DCM has detected an internal fault and is not operat

ing. Cycle power to the I/O chassis containing the 1771-DCM.

Replace it if the LED remains lit when you restore power

If the 1771-DCM is the only thing connected to a supervisory

PLC-3, and the scanner baud is 115.2K, the DCM will stop

communicating and turn on the red fault light after approximate

ly 20 minutes of communication.

, below

. This LED blinks when:

ransfer

.

.

Causes of Block Transfer Errors

Observe block transfer rungs in the ladder diagram program of the

processor not performing block transfers. You have a block transfer error

when you observe one or both of the following:

The block transfer error bit is intensified (PLC–3 processor).

Enable and done bits of block transfer instructions either do not

intensify or remain intensified. They should alternately turn ON

(intensify) and turn OFF.

Block transfer errors are caused if one more more of the following are

incorrect:

The 1771–DCM’s location (RGS) in the local I/O chassis must match

the RGS of block transfer instructions in the local processor’s ladder

program.

The address of the I/O chassis simulated by the 1771–DCM (RGS)

must match the module address (RGS) of block transfer instructions in

the supervisory processor’s ladder program.

The block lengths of read and write block transfer instructions should

be equal (PLC–2 family processors); or if different, do not enable BTR

and BTW instructions in the same scan.

82

Page 50

Chapter 8

Troubleshooting Your 1771-DCM

You assigned valid areas of data table for read and write blocks. For

example, if operating in discrete data transfer mode, I/O image table

addresses of the supervisory processor’s ladder program match the RGS

to which you configured the 1771–DCM.

Your conditioning instructions in block transfer rungs allow the rungs

to turn ON and OFF.