Page 1

AllenBradley

Configurable

Flowmeter

Module

(1771CFM/B)

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

death, property damage or economic loss.

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

ControlNet is a trademark; PLC is a registered trademark of Allen-Bradley Company, Inc.

Page 3

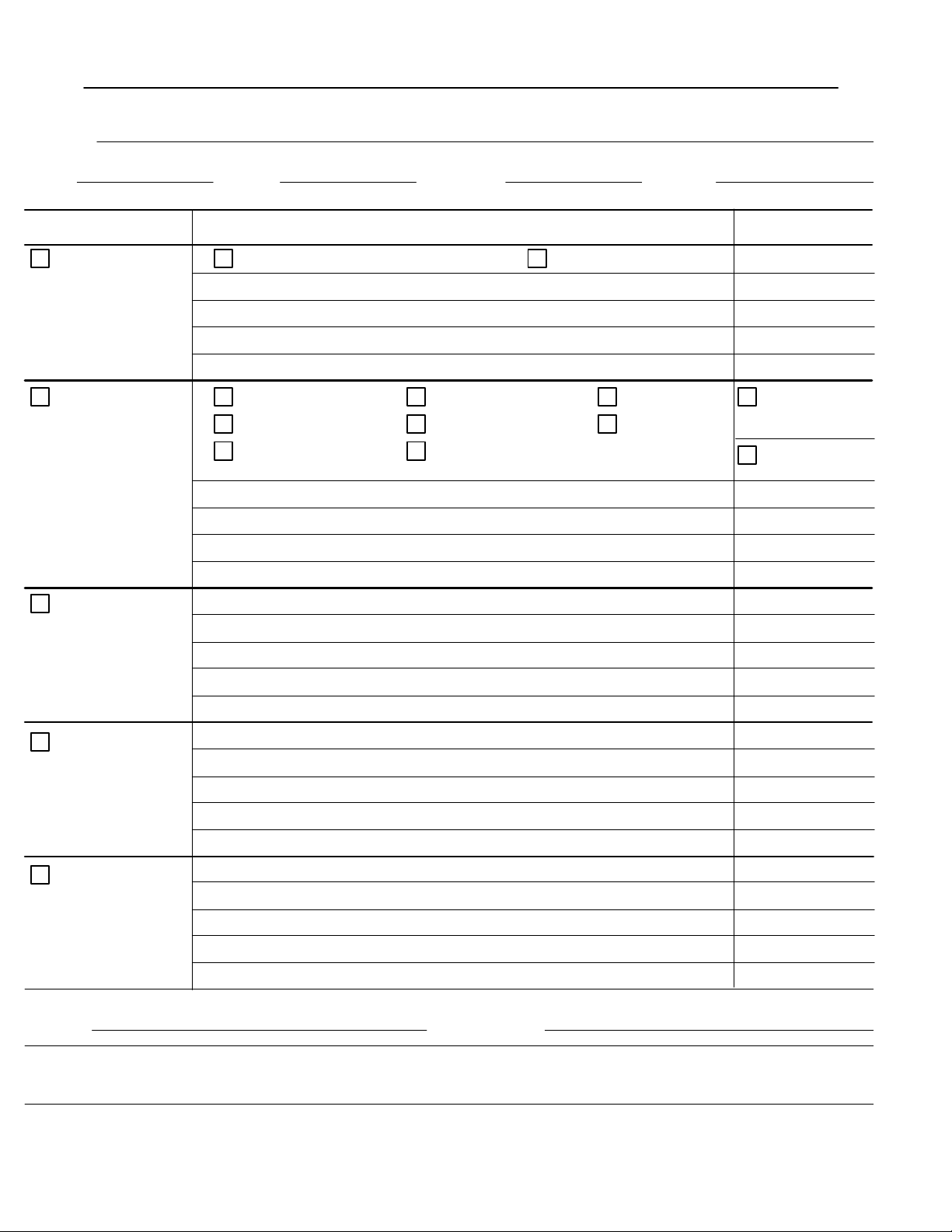

Table of Contents

Important User Information -1. . . . . . . . . . . . . . . . . . . . . . . .

Using This Manual P-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What's In This Manual P-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New/Updated

Abbreviations P-2

Related

Related Products P-3

Get Started P-4

Overview of the CFM Module 1-1. . . . . . . . . . . . . . . . . . . . . . .

What This Chapter Contains 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

How You Use the CFM Module 1-1

What's

What the CFM Module Does 1-2

Typical

Input

Capabilities

Selecting the Mode(s) of Operation 1-5

Using a Prover 1-6

Storing Current Count Values 1-6

Output

Implementing Application Features 1-8

What's

Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Documentation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Next

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applications

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

Capabilities

. . . . . . . . . . . . . . . . . . . . .

Next

P-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the CFM Module 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

What This Chapter Contains 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understand Compliance to European Union Directive 2-2

EMC Directive 2-2

Low V

oltage Directive

Calculate Power Requirements 2-3

Set the Configuration Jumpers 2-3

Check the Module Operation Jumper 2-3

Set the Input Channel Jumpers 2-4

Determine

Key the Backplane Connector 2-6

Install the CFM Module 2-7

Make Connections to the Field Wiring Arm 2-8

Wiring Examples 2-9

What's

CFM Module Placement

Next

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6. . . . . . . . . . . . . . . . . . . . . . .

2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contentsii

Edit Your Ladder Logic Program 3-1. . . . . . . . . . . . . . . . . . . .

What This Chapter Contains 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enter Block Transfer Instructions 3-1

PLC2 Family Processor 3-2

PLC3 Family Processor 3-3

PLC5 Family Processor 3-4

PLC5/250 Processor 3-5

What's

Next

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the CFM Module 4-1. . . . . . . . . . . . . . . . . . . . . . . .

What This Chapter Contains 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understand

BTW Configuration Block 4-2

Select the Mode(s) of Operation 4-8

Totalizer and Nonresettable Totalizer Modes 4-8

Highresolution Frequency Mode 4-11

Direction Sensor Mode 4-14

Configure the Module 4-16

Using

Setting Bits in the BTW Configuration Block 4-16

What's

the CFM Module'

BTW Word Description Key 4-2

BTW Word Descriptions 4-3

Counting 4-8

Frequency

Storing Count Value 4-10

Frequency

Frequency

Next

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sampling

Sampling

Sampling

I/O Configuration Software

s BTW Structure 4-1. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-16. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interpret Module Status and Input Data 5-1. . . . . . . . . . . . . . .

What This Chapter Contains 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understand

BTR Word Description Key 5-2

BTR Word Descriptions 5-3

What's

the CFM Module'

Next

s BTR Structure 5-1. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshoot the CFM Module 6-1. . . . . . . . . . . . . . . . . . . . . .

What This Chapter Contains 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Indicators 6-1

Diagnostics 6-2

Diagnostic Words in the BTR File 6-2

What's

Next

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents iii

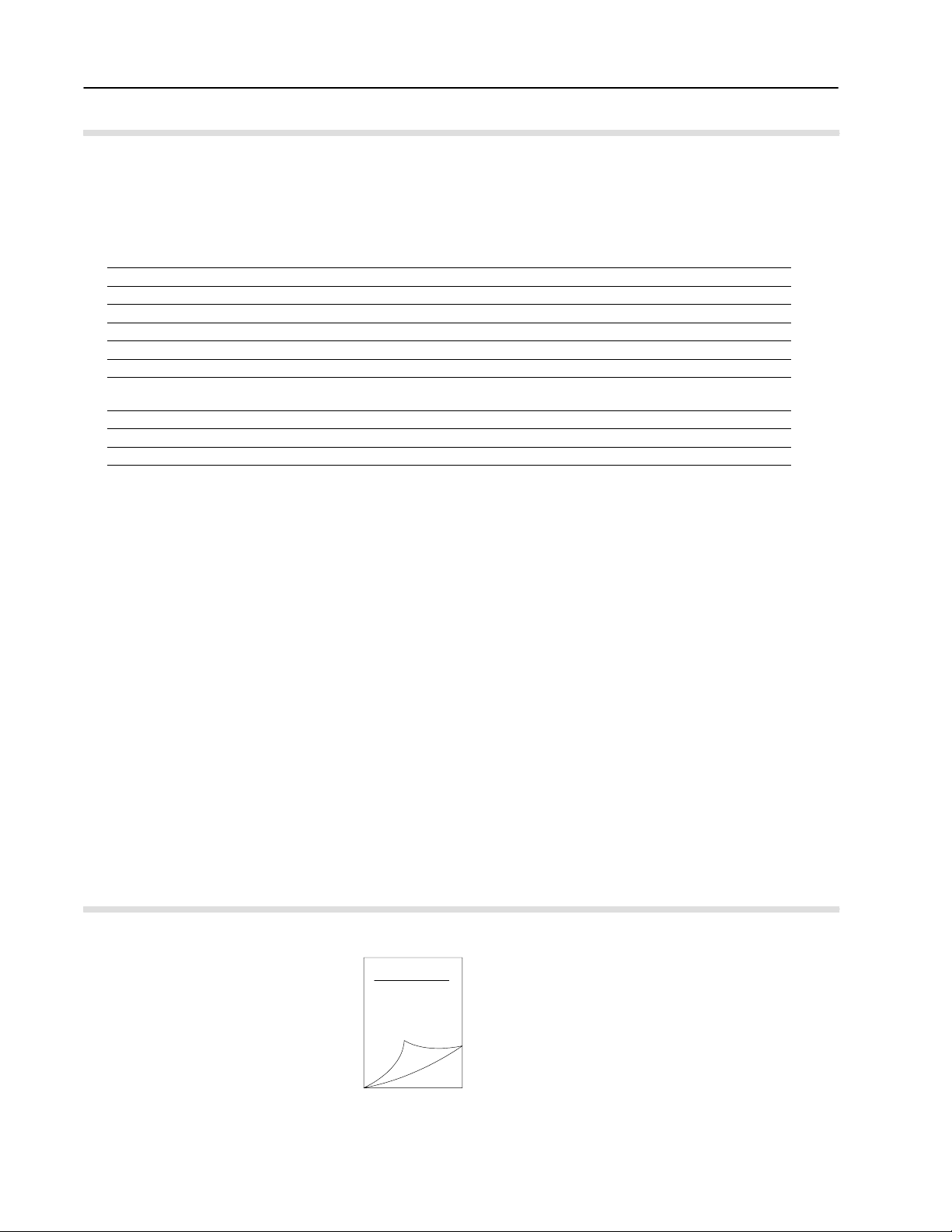

Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What This Appendix Contains A-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency Accuracy A-1

General

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematics B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What This Appendix Contains B-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Input

Circuits

Flowmeter

Gate

Output

Discrete

DC to DC Converters (24V dc power supplies) B-4

Inputs

Inputs

Circuits

Outputs

. . . . . . . . . . . . .

B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replace Your QRC Module C-1. . . . . . . . . . . . . . . . . . . . . . . . .

What This Appendix Contains C-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

What the CFM Module Does C-1

Check Power Requirements C-1

Remove Your QRC Module C-2

Set the Configuration Jumpers C-3

Set the Module Operation Jumper C-3

Check the Input Channel Jumpers C-4

Install

the CFM Module

Make Connections to the New Wiring Arm C-6

Wiring Example C-7

Resume Normal Operation C-8

Edit Your Ladder Logic Program C-8

Read Data From the CFM Module C-9

BTR Word Descriptions C-9

Interpret Status Indicators C-10

Additional Feature C-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

C-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replace Your QRD Module D-1. . . . . . . . . . . . . . . . . . . . . . . . .

What This Appendix Contains D-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

What the CFM Module Does D-1

Check Power Requirements D-2

Remove Your QRD Module D-2

Set the Configuration Jumpers D-3

Set the Module Operation Jumper D-3

Check the Input Channel Jumpers D-4

Install

the CFM Module

Make Connections to the New Wiring Arm D-6

Wiring Examples D-7

Resume Normal Operation D-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

D-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contentsiv

Edit Your Ladder Logic Program D-8. . . . . . . . . . . . . . . . . . . . . . .

Read Data From the CFM Module D-9

BTR Word Description Key D-9

BTR Word Descriptions D-10

Reset Total and Overflow Flags D-10

BTW Word Description D-10

Interpret Status Indicators D-11

Additional Feature D-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

Using I/O Configuration Software E-1. . . . . . . . . . . . . . . . . . .

What This Appendix Contains E-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure

the CFM Module

Block Transfer Data Screen E-1

Channel Setup Screen E-2

Output Setup Screen E-5

Monitor Screen E-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Using This Manual

Preface

What's In This Manual

Use this manual to install, program and troubleshoot your

Configurable Flowmeter module (1771-CFM/B).

Important: We assume that you know how to program and operate

an Allen-Bradley PLC

processor. If you do not, see

the appropriate programming and operations manual for

the PLC processor you are using, before you attempt to

use this manual.

To Read chapter

Understand the CFM module

Install the CFM module

Edit your ladder logic to contain block transfer instructions

for the CFM module

Configure the CFM module

Read data from your module

Interpret status indicators and diagnostic codes

1

2

3

4

5

6

Specifications

Schematics

Using the CFM module as a replacement for the QRC module

Using the CFM module as a replacement for the QRD module

Using I/O Configuration software

See appendixFor reference on

A

B

C

D

E

Publication 17716.5.99 December 1995

Page 8

Using This ManualP–2

New/Updated Information

Abbreviations

The1771-CFM/B is marked with the

logo, indicating that this

version complies with the European Union Directives. Technical

additions and corrections are marked with change bars.

To comply with the European Union Directives, this information in

the manual has been updated:

Updated information On page(s)

European Union Directives compliance

CFM module field wiring arm connections 2-8

CFM module wiring examples 2-9

General specifications A-1

CFM (QRC) module wiring arm connections C-6

CFM (QRD) module wiring arm connections D-6, D-7

We refer to As

Configurable Flowmeter module (1771CFM/B)

Configurable Flowmeter module emulating a 1771QRC module CFM (QRC) module

Configurable Flowmeter module emulating a 1771QRD module CFM (QRD) module

AllenBradley programmable logic controllers PLC processors

1771QRD Pulse Flowmeter module QRD module

Bulletin 1771 Dual Ratemeter module (1771QRC) QRC module

2-2

CFM module

Publication

17716.5.99 December 1995

Page 9

Using This Manual P–3

Related Documentation

Related Products

Document Publication number

Configurable Flowmeter Module Product Data 17712.226

PLC2 Programming Software Documentation Set (D6200L06)

PLC2 Programming Software Programming Manual

PLC3 Programming Software Documentation Set (D6200L07)

PLC3 Programming Software Programming Manual

PLC5 Programming Software Documentation Set

(6200N8.001)

PLC5 Programming Software I/O Configuration Manual

PLC5/250 Programming Software Documentation Set

(6200N8.002)

PLC5/250 Programming Software Programming Manual

SCADA Custom Application Routines (CARs) for Gas and Liquid

Petroleum Flow Calculations Product Profile

PLC5 Volume Flow CARs for Orifice Metering User Manual 62006.5.17

PLC5 Volumetric Flow CARs for Turbine and Displacement

Metering User Manual

62006.4.14

62006.4.17

62006.4.12

50006.4.8

62001.22

62006.5.18

See the Automation Group Publication Index (publication SD499)

for additional publications with information on PLC processors.

You can install the CFM module in any system that uses

PLC processors with block-transfer capability and the

1771 I/O structure. Contact your local Allen-Bradley representative

for more information about our PLC processors.

Publication

17716.5.99 December 1995

Page 10

Using This ManualP–4

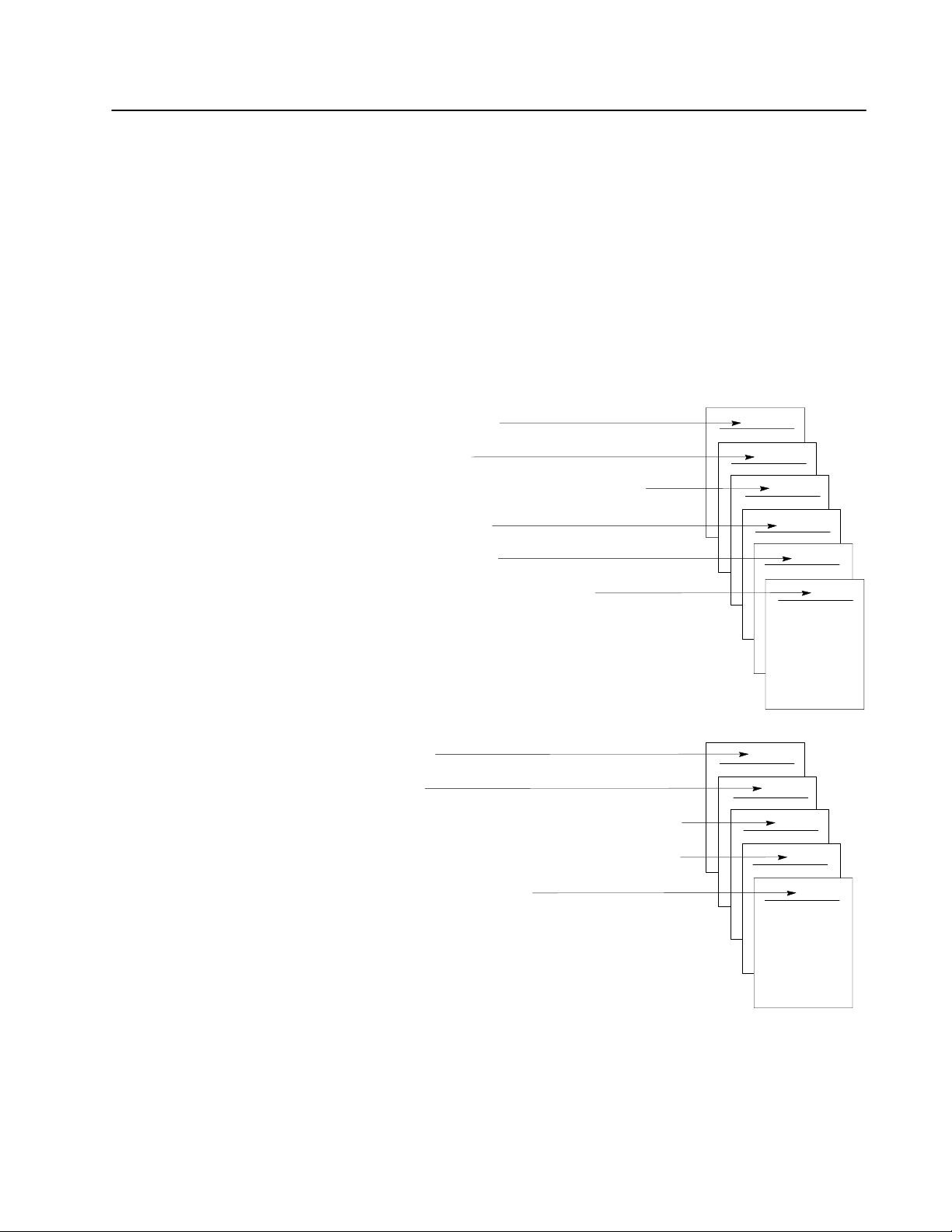

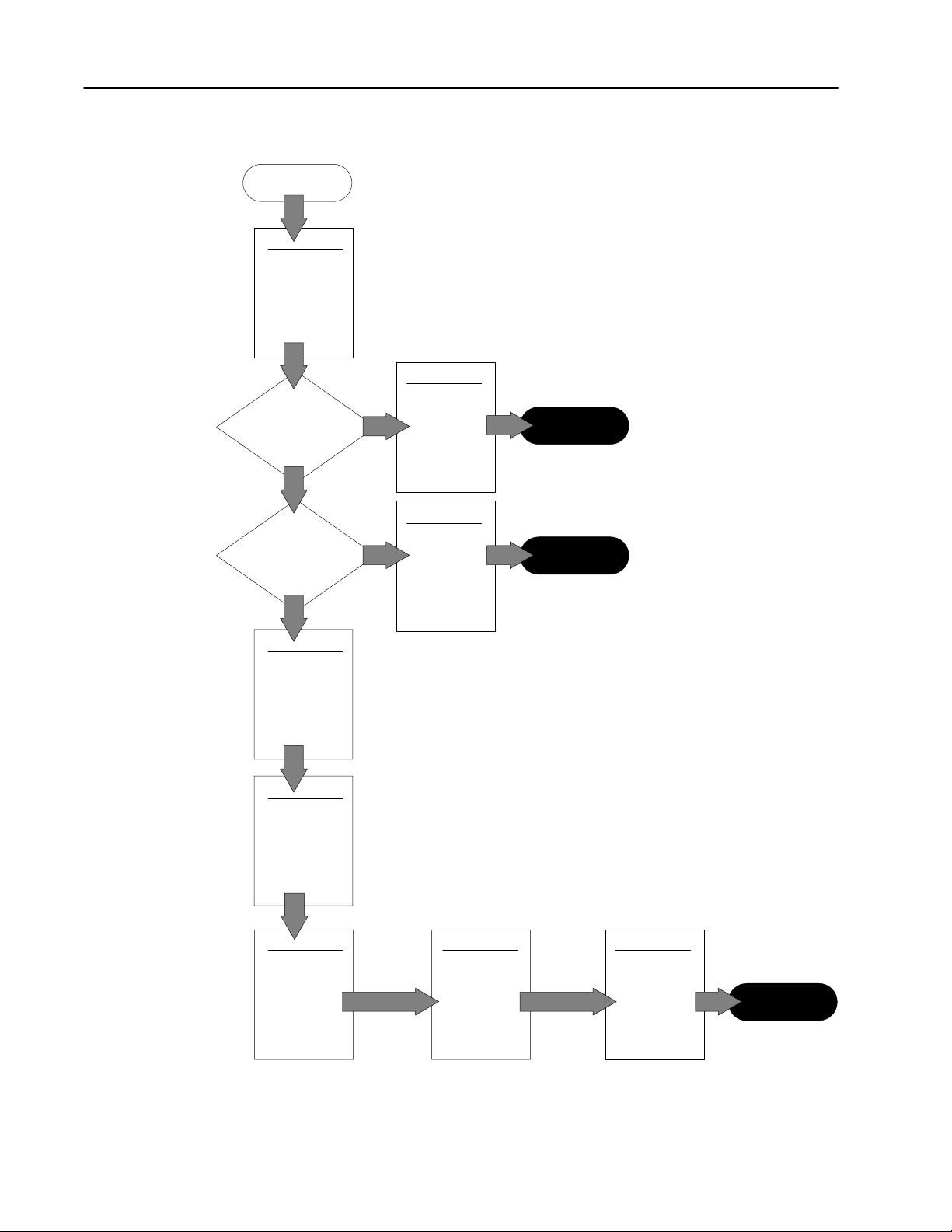

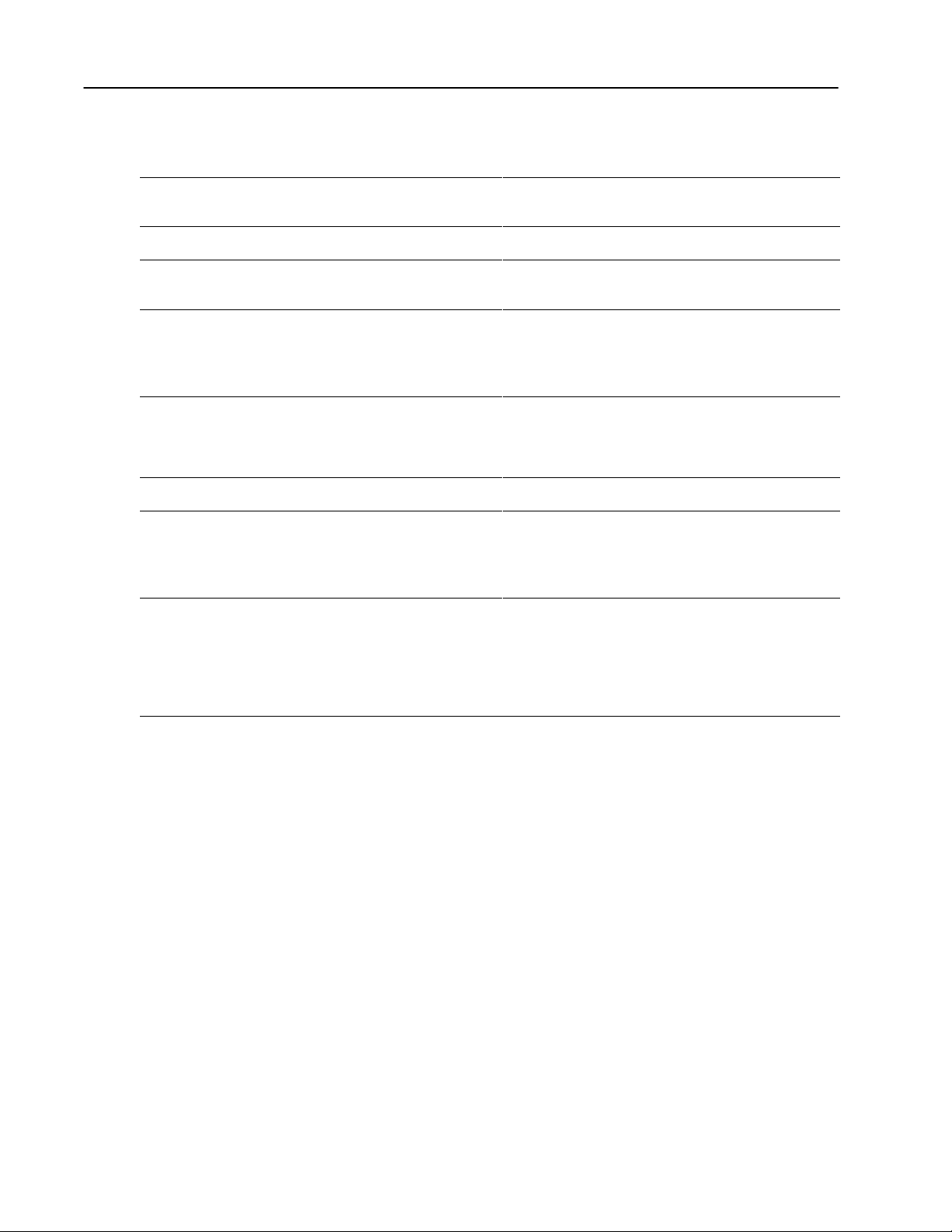

Get Started

Start

Overview of the

CFM Module

Using

CFM module

as replacement for

QRC module?

N

Using CFM module

as replacement for

QRD module?

Use this diagram to help you get started.

1

A

Y

Replace Y

our

Y

QRC Module

Replace Y

our

QRD Module

B

Complete

Complete

N

Install the

CFM Module

Edit Y

our

Ladder Logic

Program

Configure the

CFM Module

2

3

4 5 6

Interpret

Module

Status and

Input Data

T

roubleshoot

the CFM Module

Complete

Publication

17716.5.99 December 1995

Page 11

Chapter

Overview of the CFM Module

1

What This Chapter Contains

How You Use the CFM Module

1

Make sure the module operation

jumper is set in the CFM position.

Read this chapter to familiarize yourself with the CFM module.

For information on See page

How You Use the CFM Module . . . . . . . . . . . . . . . . . . . . . . . 1-1

What's Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What the CFM Module Does . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Input Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Selecting the Mode(s) of Operation . . . . . . . . . . . . . . . . . 1-5

Using a Prover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Storing Current Count Values . . . . . . . . . . . . . . . . . . . . . 1-6

Output Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Implementing Application Features . . . . . . . . . . . . . . . . .

1-8

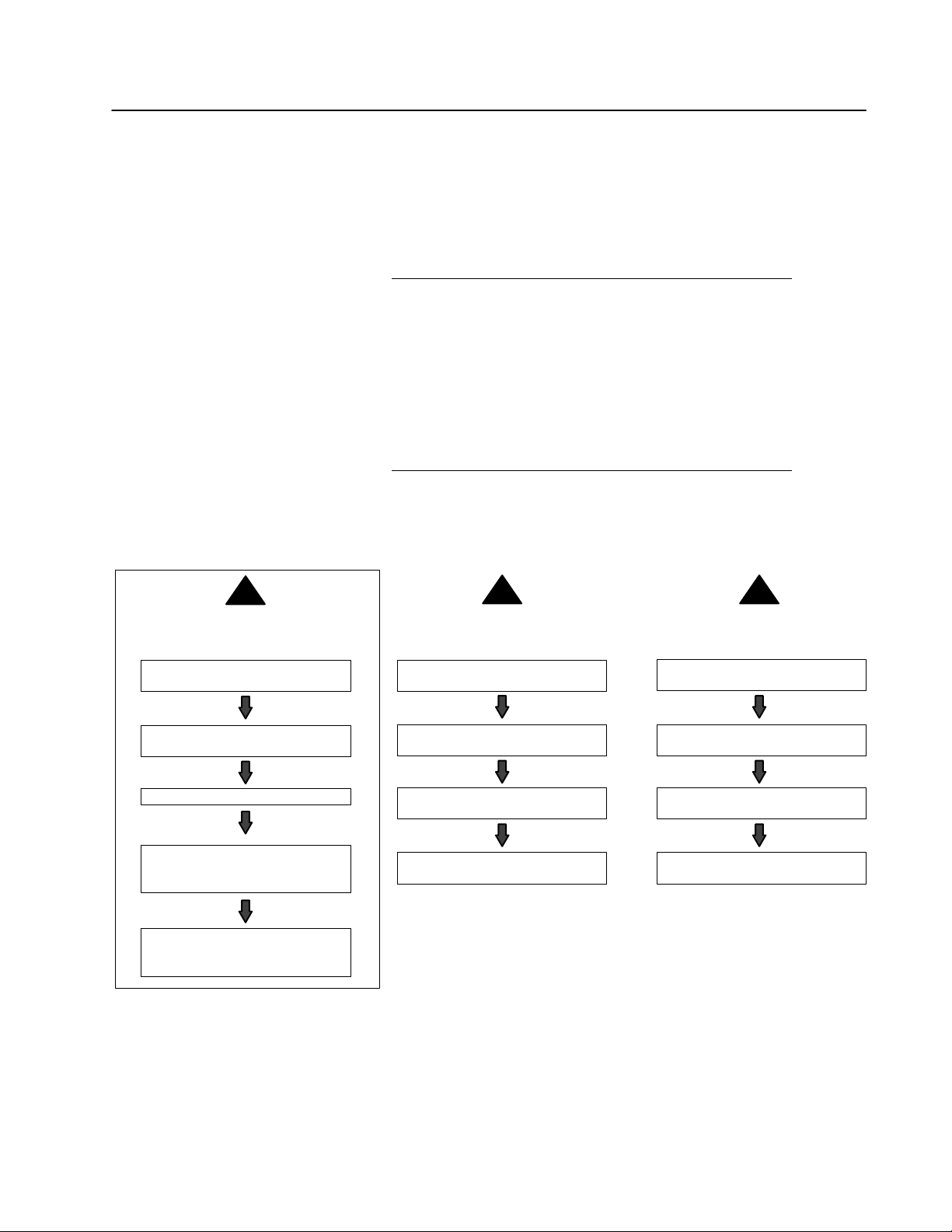

The CFM module is designed to operate in one of three ways:

2

as a replacement for a QRC module

Set the module operation jumper in

the QRC position.

as a replacement for a QRD moduleas a CFM module

Set the module operation jumper in

the QRD position.

3

Wire input and outputs to swing arm

(1771WN).

Install the CFM module.

Edit your ladder logic to contain

BTW and BTR instructions for the

CFM module.

Edit CFM module's BTW configuration

block and send configuration BTW to

the CFM module.

Wire inputs to the new swing arm

(1771WN).

Replace the QRC module with the

CFM module.

Continue to program BTRs as before

(no changes to ladder logic).

Important: If you use the CFM module as a replacement for a QRC or QRD module,

the CFM module operates like a QRC or QRD module. You do not use

any of the CFM module's features; therefore, you cannot configure outputs

to any of the four input channels.

Wire inputs to the new swing arm

(1771WN).

Replace the QRD module with the

CFM module.

Continue to program BTWs and BTRs

as before (no changes to ladder logic).

Publication

17716.5.99 - December 1995

Page 12

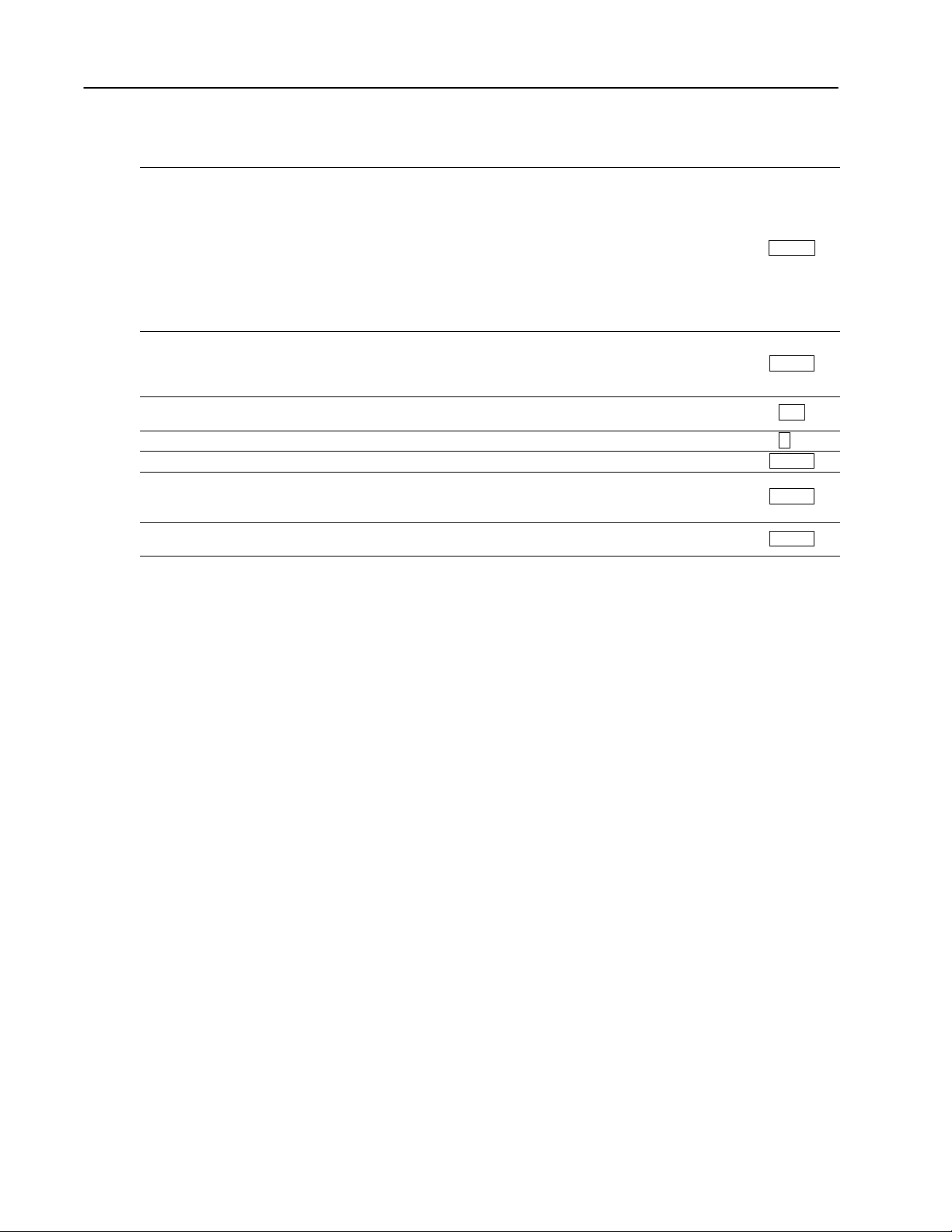

1–2 Overview of the CFM Module

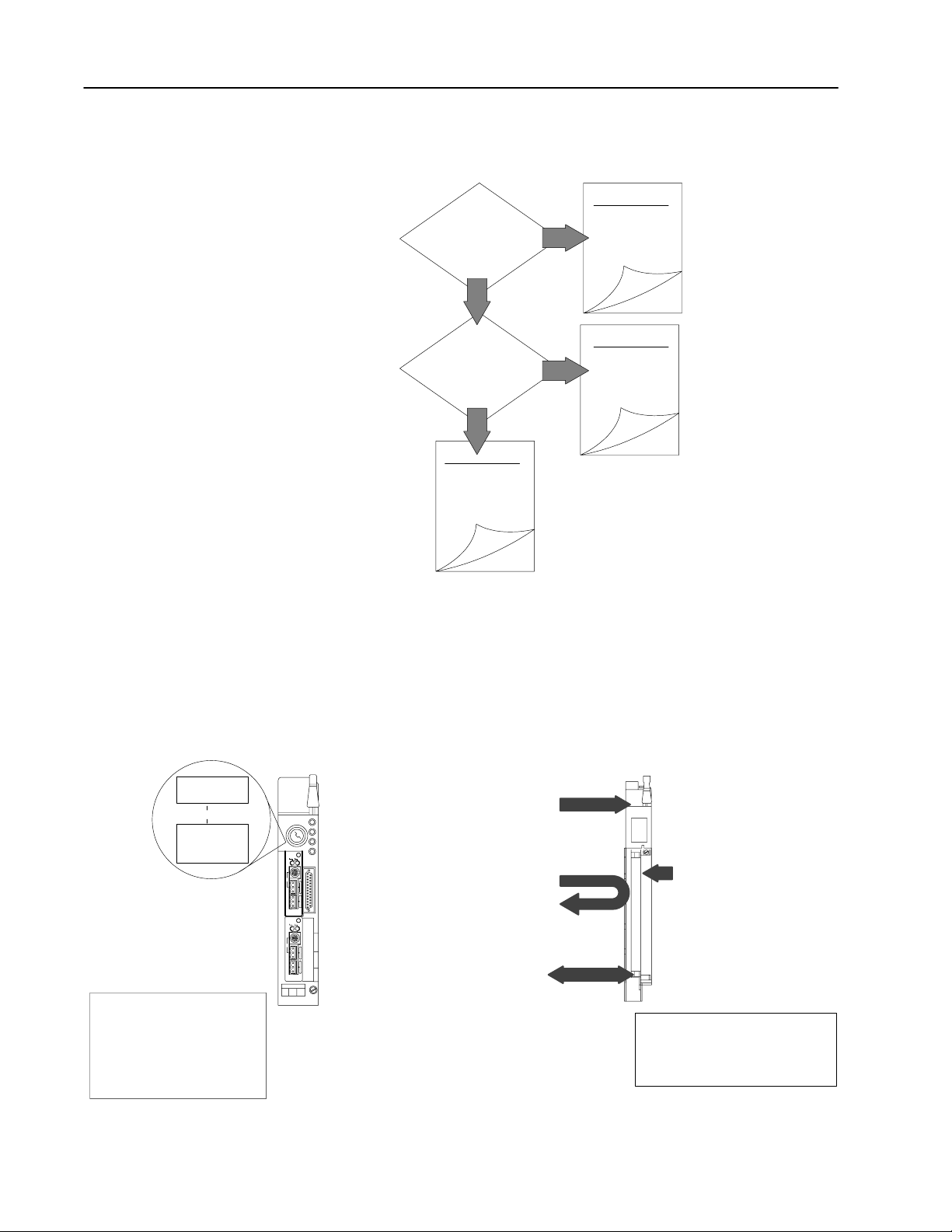

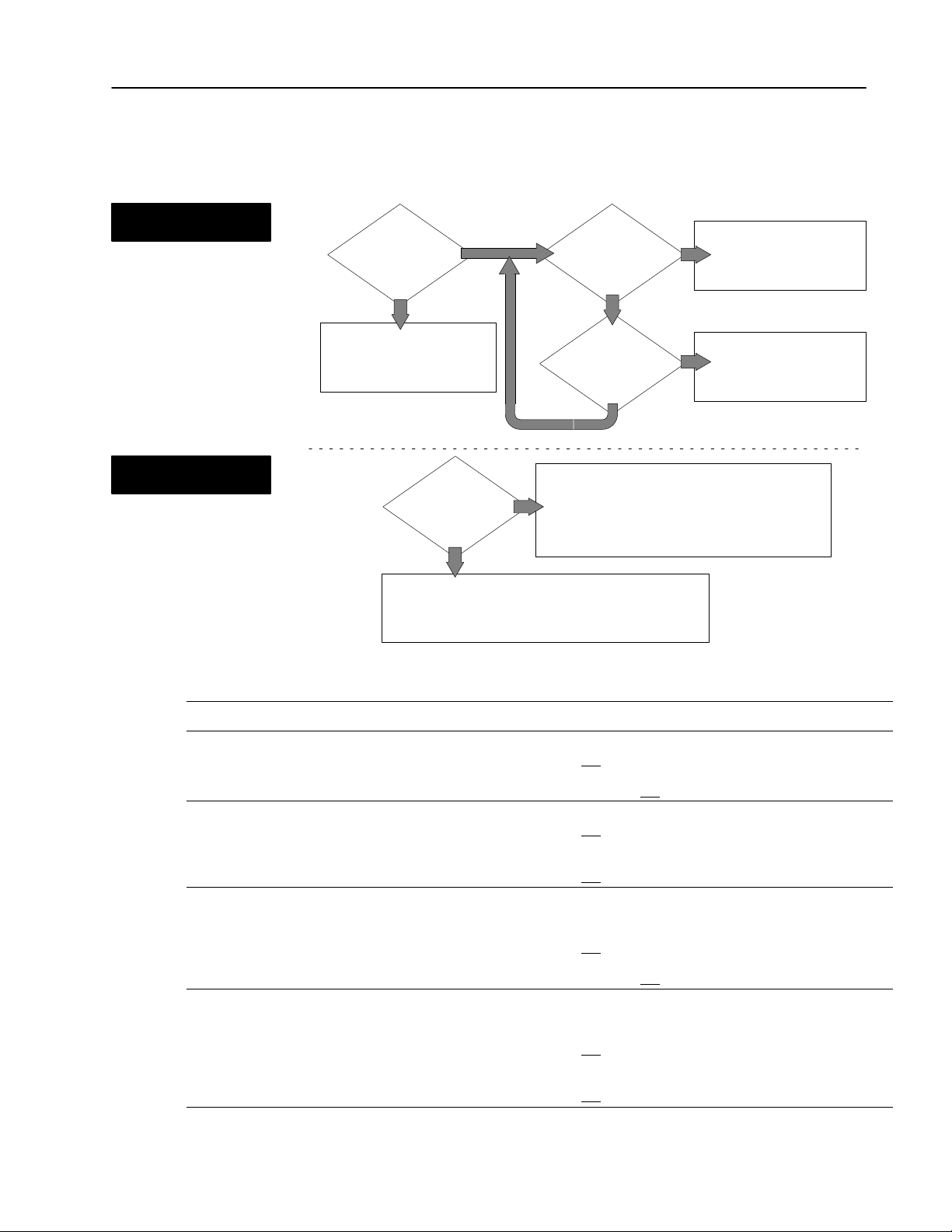

What's Next

The rest of this chapter contains information on

CFM module operation.

C

Using the

CFM module

as a replacement for

a QRC module?

N

Using the

CFM module

as replacement for

a QRD module?

N

Y

Y

1

D

What the CFM Module Does

Data T

able

User Program

❻ Your ladder program can use or

move the data before it is

written over by the transfer of

new data in a subsequent

transfer.

The CFM module interfaces

with these PLC processors:

• PLC2 processor family

• PLC3 processor family

• PLC5

• PLC5/250

processor family

processors

PLC5/40

processor

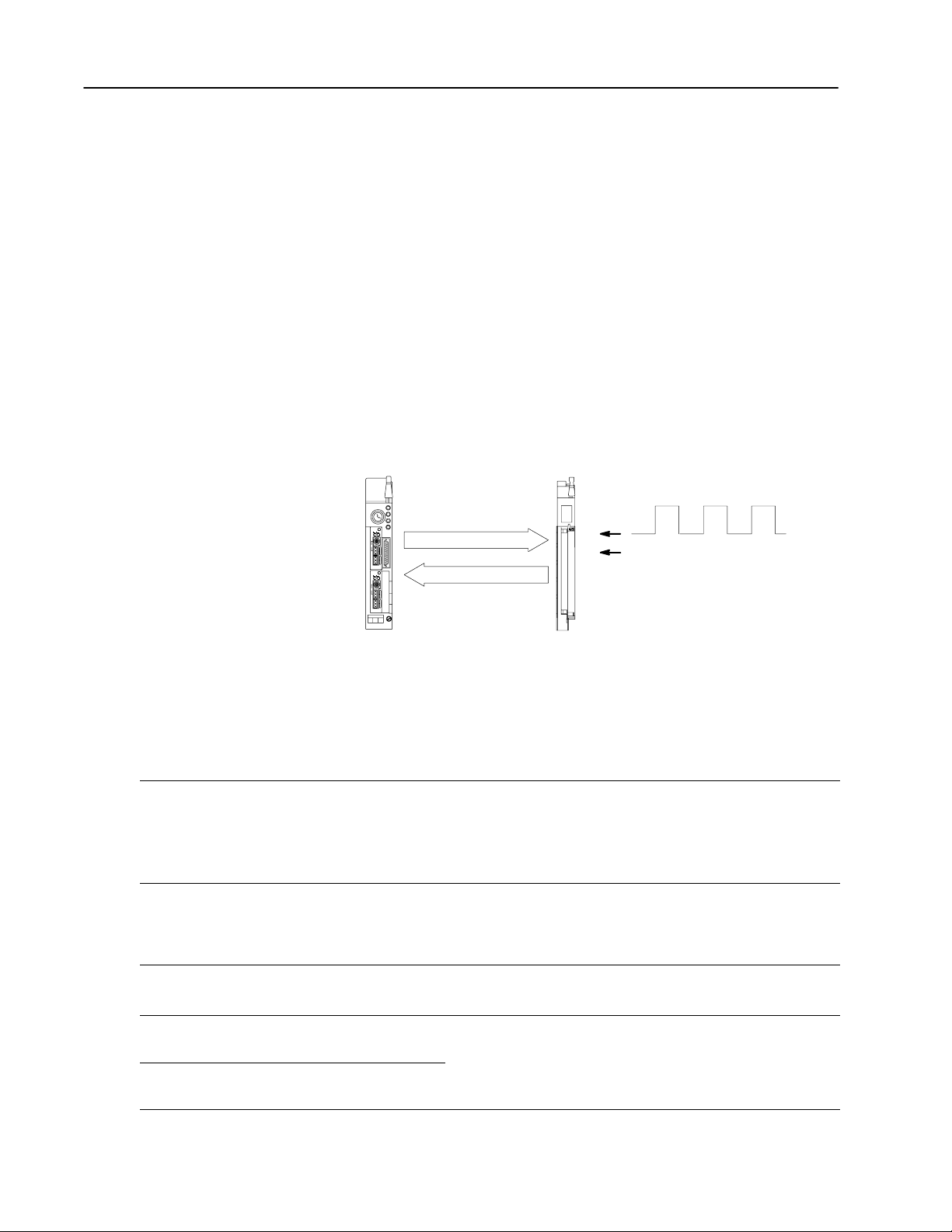

The CFM module performs high-speed totalizing and/or rate

calculation operations for various industrial applications. The CFM

module is a single-slot I/O module that interfaces between an

Allen-Bradley PLC processor that has block-transfer capability and

external I/O devices.

1771CFM

❶

The PLC processor transfers your

configuration data and output channel

data to the CFM module using a block

transfer write (BTW) instruction.

❹ When instructed by your ladder program,

the PLC processor performs a block

transfer read (BTR) of the values

(count and/or frequency in binary format)

and stores them in a data table.

BTW

BTR

External devices generate

❷

input signals that are

transmitted to the

CFM module.

❸ The CFM module performs

❺ The PLC processor and CFM module

determine that the transfer was made

without error.

The CFM module interfaces with:

• magnetic pickup flowmeters

• 440V dc pulses (TTL compatible)

• proximity probes

calculations on

accumulated pulse

counts.

1

Publication

17716.5.99 - December 1995

Page 13

1–3Overview of the CFM Module

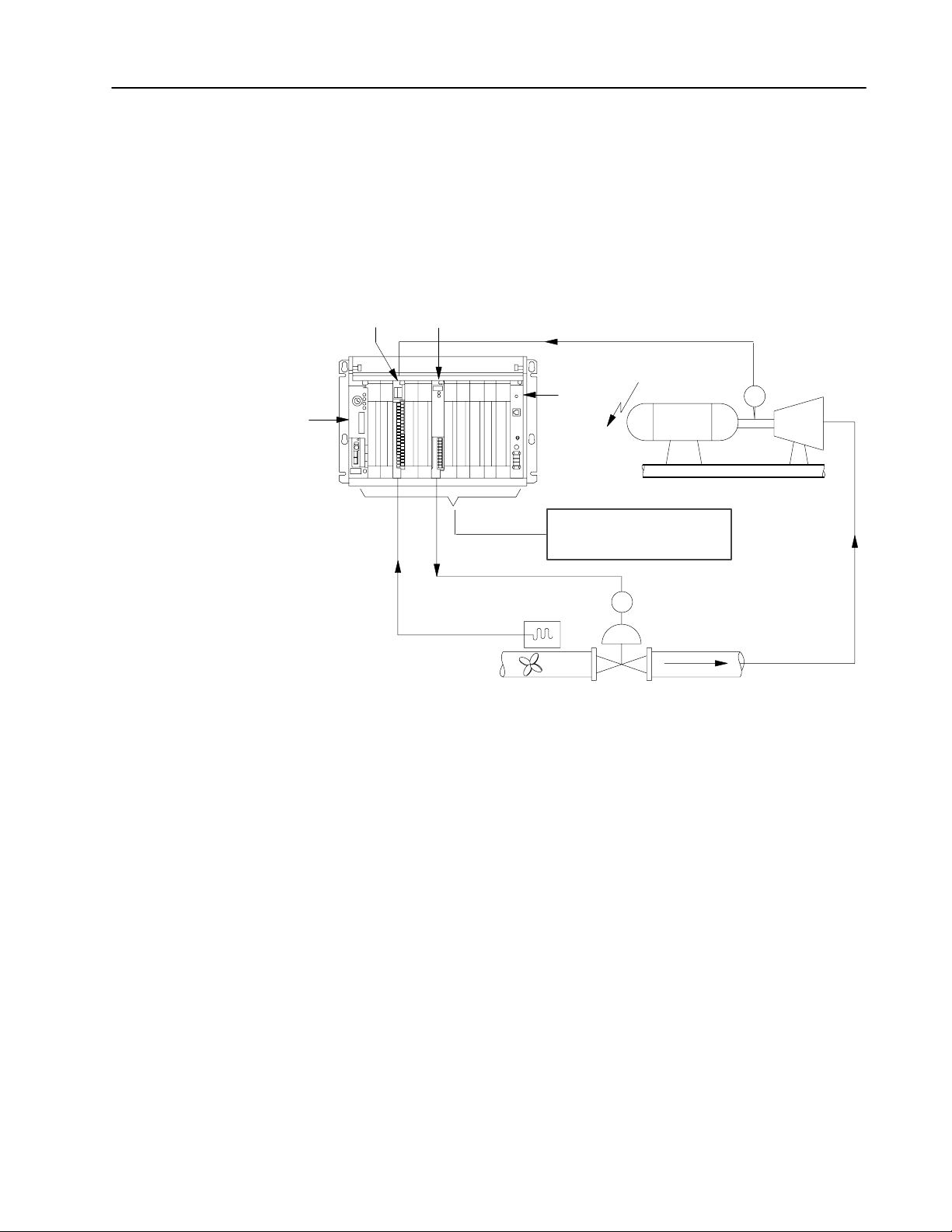

Typical Applications

PLC5/30

processor

You can use the CFM module in the power management, automotive,

food and beverage, and oil and gas industries for various flow and/or

turbine metering applications. Some sample applications include:

• turbine shaft speed monitoring

• automotive paint booths

• brewery flow monitoring

• petrochemical flow and custody transfer

1771CFM

1771OFE

shaft speed

power

supply

generator

electricity

PLC controller monitors shaft

speed, performs PID calculations

and adjusts valve.

shaft

encoder

turbine

monitors fuel flow

and total gallons

pulse output

fuel

CV

19885

Publication

17716.5.99 - December 1995

Page 14

1–4 Overview of the CFM Module

Input Capabilities

The CFM module accepts input for up to four channels

(mode dependent). Each of the four input channels may accept these

input signals:

•magnetic pickup — 50mV to 200V ac peak (optional 500mV to

200V ac peak for improved noise immunity)

•4-40V dc pulses with open collector (TTL compatible)

•proximity probe inputs

–compatible with Bently Nevada 3300 (5mm and 8mm)

proximity transducer systems

–provides two isolated 24V dc power supplies (rated at 12mA)

to power external devices

You configure the CFM module’s four input channels for your

specific application(s). Each input channel has two input selections:

flowmeter input (F0F3) you connect

your input device to this input (ac, TTL)

gate input (G0G3) accepts 440V dc

input pulse from open collector or external

contact closure. Used in Totalizer and

Nonresettable Totalizer modes to:

•store the current count of an input channel

upon impulse on gate

•interface to a prover when a prover is

enabled used to store the count as the

spheroid is sensed in the prover tube

four input channels

flowmeter input (F0)

gate input (G0)

flowmeter input (F1)

gate input (G1)

flowmeter input (F2)

gate input (G2)

flowmeter input (F3)

gate input (G3)

➀

Channel 0

Channel 1

Channel 2

Channel 3

➀

See

pages

2-9

and

2-10 for wiring diagrams.

Publication

17716.5.99 - December 1995

Page 15

Selecting the Mode(s) of Operation

You configure the CFM module for these modes of operation:

1–5Overview of the CFM Module

Use this mode To

• accurately measure counts using a flowmeter

or positive displacement meter

• trigger outputs directly from the CFM module

trigger on total, frequency, acceleration

Totalizer

Nonresettable Totalizer

Highresolution Frequency

(channels 0&1 or channels 2&3)

Direction Sensor

(channels 0&1 or channels 2&3)

➀

This mode uses two channels for one input (your input device is connected to F0 or F2, while F1 or F3 is unused).

➀

➀

• monitor flow total, rate, and rate of change

independent of your PLC processor scan times

• store counts based on external input

• scale the frequency and count to

engineering units

• interface to a prover

operate in the Totalizer mode with the count

reset function disabled to prevent loss of

accumulated value

• monitor the frequency of an input with high

accuracy (e.g. shaft)

• monitor the rate of speed change

• operate outputs based on speed or

rate of change

• scale the frequency to engineering units

• monitor the direction of shaft rotation

• monitor rate of change and frequency

• trigger outputs based on direction, frequency,

rate of change

• scale the frequency and count to

engineering units

Indicators/

Alarms

overrange

overflow

overspeed

acceleration

overrange

overflow

overspeed

acceleration

overspeed

overrange

acceleration

overspeed

acceleration

overrange

Prover

√ √ √ √

√ √ √

Total

reset

Scaler

values

√

√

Rollover

value

Publication

17716.5.99 - December 1995

Page 16

1–6 Overview of the CFM Module

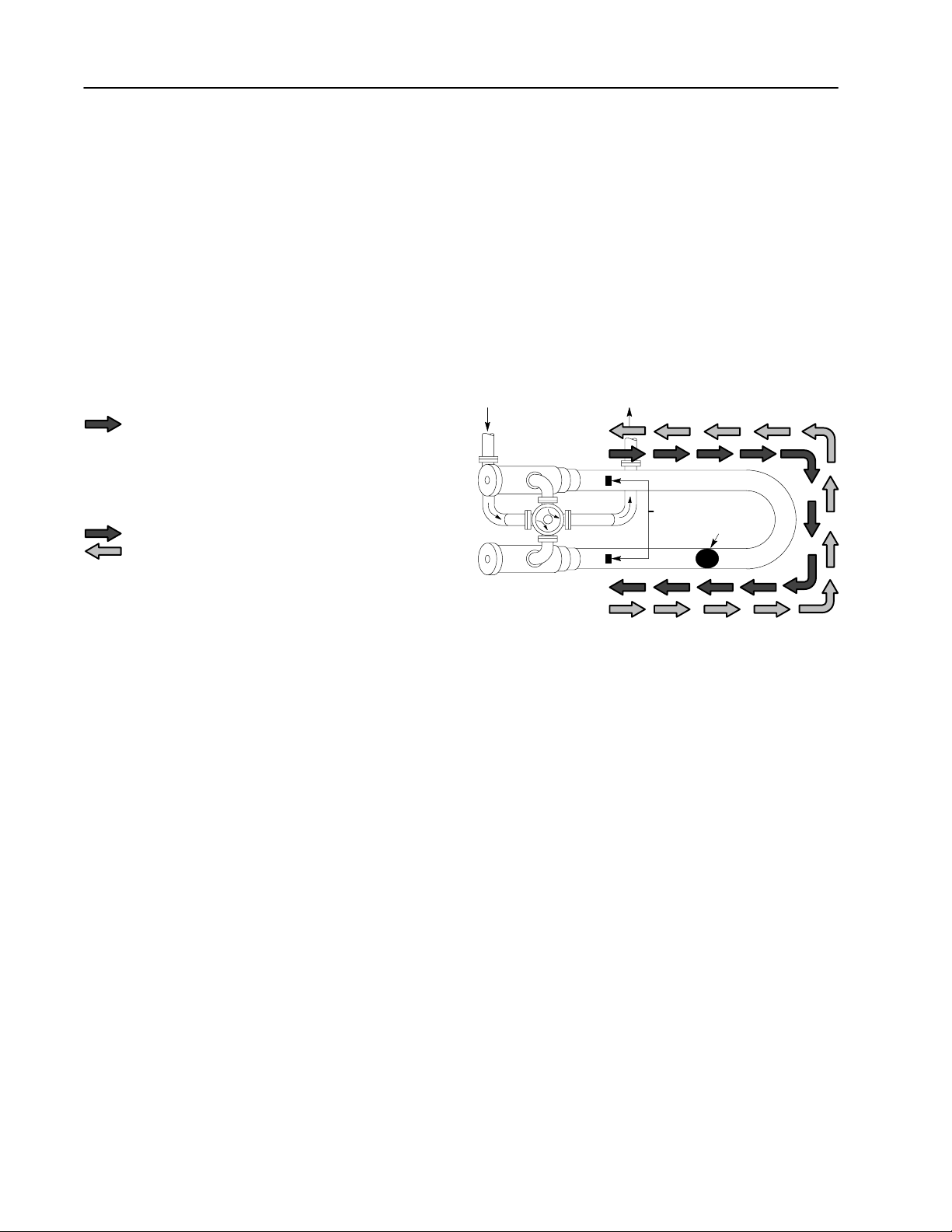

Using a Prover

A prover is used for the calibration of liquid meters in custody

transfer applications. This calibration is done by comparing a

metered throughput to a known volume in the prover. The number

of pulses accumulated (Prover Total Count Value), while the

spheroid moves between two detectors, is then compared to the

predetermined volume of the prover section to ascertain the

meter factor.

If you are using the Totalizer or Nonresettable Totalizer mode for

capturing meter counts during a prover calibration, you have the

option of selecting either of these types of provers:

unidirectional the CFM module:

• begins counting when the spheroid passes the

first detector

• stops counting when the spheroid passes the second

detector (Prover Total Count Value is updated at

this time)

bidirectional the CFM module:

• begins counting when the spheroid passes the first detector

• stops counting when the spheroid passes the second

detector (Prover Total Count Value is updated at this time -

intermediate value returned)

• continues counting when the spheroid returns past the

second detector

• stops counting when the spheroid returns past the first

detector (Prover Total Count Value is updated at this time)

detectors

spheroid

19884

Storing Current Count Values

If you are using the Totalizer or Nonresettable Totalizer mode and

you are not using a prover, you can use the gate input to store the

current count value of any (or all) of the four input channels.

The current count value of each channel is placed in a separate word

in the BTR file (Store Count Value). The Store Count Value will

remain in the BTR file until a new trigger pulse is received at the

gate input. The Store Count Value is then updated to reflect the

new value.

Publication

17716.5.99 - December 1995

Page 17

1–7Overview of the CFM Module

Output Capabilities

The CFM module has four assignable outputs. These outputs are

designed for applications that require fast response. The outputs:

• are electrically fused/current limited to 3A (output combinations

are limited to 7A)

• can be assigned to any input channel with user-selectable turn-on

and turn-off values

• are current sourcing at 5-40V dc (1A maximum per output)

• must be connected to an external power supply

• are in groups of two — this lets you use two separate external

power supplies if desired (one for outputs 0&1 and one for

outputs 2&3)

Outputs may be forced on or off independent of count or

frequency value. They may be forced on and off by setting bits in the

BTW configuration block.

Important: You can assign as many as four outputs to a given

channel; however, you can not use the same output with

two different channels.

In this mode

of operation

Totalizer

Nonresettable Totalizer

Highresolution

Frequency

Direction Sensor

You can assign outputs that are programmable to trigger

on total, rate, rate change (acceleration), total overflow or

prover status

on total, rate, rate change (acceleration), total overflow or

prover status

on frequency or frequency rate of change (acceleration)

on either CLOCKWISE or COUNTERCLOCKWISE direction,

acceleration or frequency (outputs are triggered ON only)

Publication

17716.5.99 - December 1995

Page 18

1–8 Overview of the CFM Module

Totalizer

(programmable rollover)

This bit will toggle

count rollover

tivat

overrange alarm

all

frequency > 100kHz

Implementing Application Features

You can use the CFM module to implement programmable

application features that are usually initiated by your PLC processor.

This frees the PLC processor to do other tasks and helps increase the

overall throughput of your PLC system.

This feature Is used in these modes To Alarm is ON when

overflow indication

overrange alarm all

overspeed alarm all

acceleration alarm all

Totalizer

Nonresettable Totalizer

set an overflow flag when the count is greater

than the highest allowable count

(programmable rollover). This bit will toggle

with each successive rollover (010101).

The count continues from zero. This bit can be

reset in the BTW configuration block.

tivt vrrn lrm wh

e overrange alarm when rate is greater

ac

than allowable Hertz (fixed at 100kHz).

activate overspeed alarm when frequency is

higher than userspecified frequency value.

activate acceleration alarm when acceleration is

greater than userspecified acceleration value.

.

n rt i rtr

count = rollover

(default 10,000,000)

frequency > 100kHz

frequency > userspecified value

|acceleration| >

userspecified value

What's Next

2

Install the

CFM Module

Publication

17716.5.99 - December 1995

Page 19

Chapter

Install the CFM Module

2

What This Chapter Contains

Follow the instructions in this chapter to install the CFM module.

To install the CFM module See page

Understand Compliance to European Union Directive . . . . . .

Calculate Power Requirements . . . . . . . . . . . . . . . . . . . . . . 2-3

Set the Configuration Jumpers . . . . . . . . . . . . . . . . . . . . . . . 2-3

Check the Module Operation Jumper . . . . . . . . . . . . . . . . 2-3

Set the Input Channel Jumpers . . . . . . . . . . . . . . . . . . . . 2-4

Determine CFM Module Placement . . . . . . . . . . . . . . . . . . . 2-6

Key the Backplane Connector . . . . . . . . . . . . . . . . . . . . . . . 2-6

Install the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Make Connections to the Field Wiring Arm . . . . . . . . . . . . . .

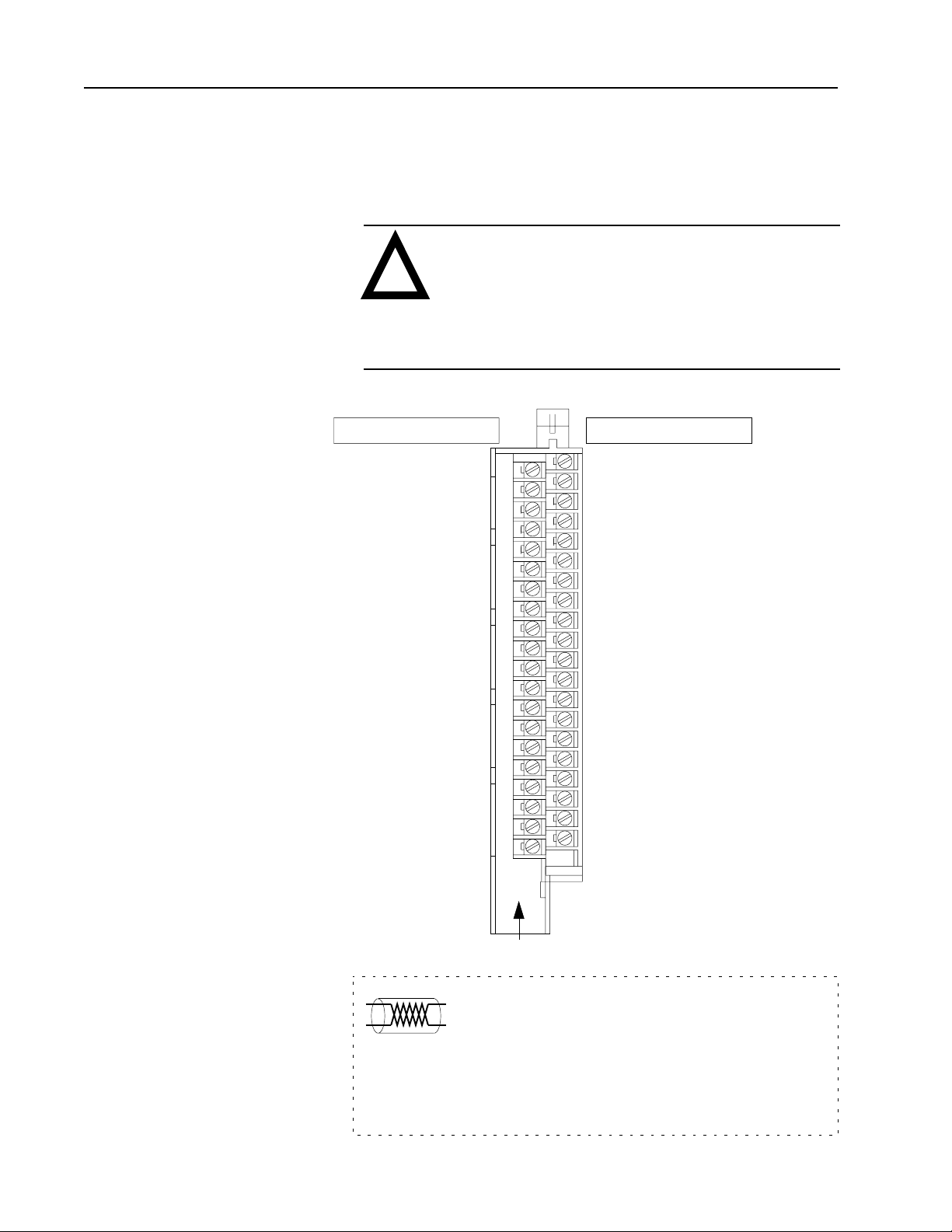

ATTENTION: Electrostatic discharge can damage

integrated circuits or semiconductors if you touch

!

backplane connector pins. Follow these guidelines

when you handle the CFM module.

2-2

2-8

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the backplane connector or

connector pins.

• Do not touch circuit components inside the module.

• If available, use a static-safe work station.

• When not in use, keep the CFM module in its

static-shield bag.

Publication

17716.5.99 - December 1995

Page 20

2–2 Install the CFM Module

Understand Compliance to European Union Directive

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2

EMC – Generic Emission Standard, Part 2 – Industrial

Environment

• EN 50082-2

EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements

and Tests.

For specific information that this EN requires, see the appropriate

sections in this publication, as well as the following

Allen-Bradley publications:

• Industrial Automation Wiring and Grounding Guidelines

(for noise immunity), publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

Publication

17716.5.99 - December 1995

Page 21

2–3Install the CFM Module

Calculate Power Requirements

Set the Configuration Jumpers

Your CFM module receives its power through the 1771 I/O chassis

backplane from the chassis power supply. The maximum current

drawn by the CFM module is 1.0A.

Add this value to the requirements of all other modules in the I/O

chassis to prevent overloading the chassis backplane and/or

backplane power supply.

ATTENTION: When using a 1771-P7 or 1771-PS7

power supply to power an I/O chassis, you cannot

!

place more than four CFM modules in this chassis.

The interaction between the four CFM modules and the

1771-P7 or 1771-PS7 power supply (not 16A limit)

prevents the power supply from powering up.

You check or set these jumpers:

• module operation jumper

• input channel jumpers

Check the Module Operation Jumper

Important: Make sure the module operation jumper is in the

CFM position (default setting).

CFM

QRD

QRC

If The Jumper Is

Set In This Position

QRC

QRD a QRD module (1 word BTW / 9 word BTR)

The CFM Module

Will Operate As

a QRC module (no BTW / 3 word BTR)

19807

Publication

17716.5.99 - December 1995

Page 22

2–4 Install the CFM Module

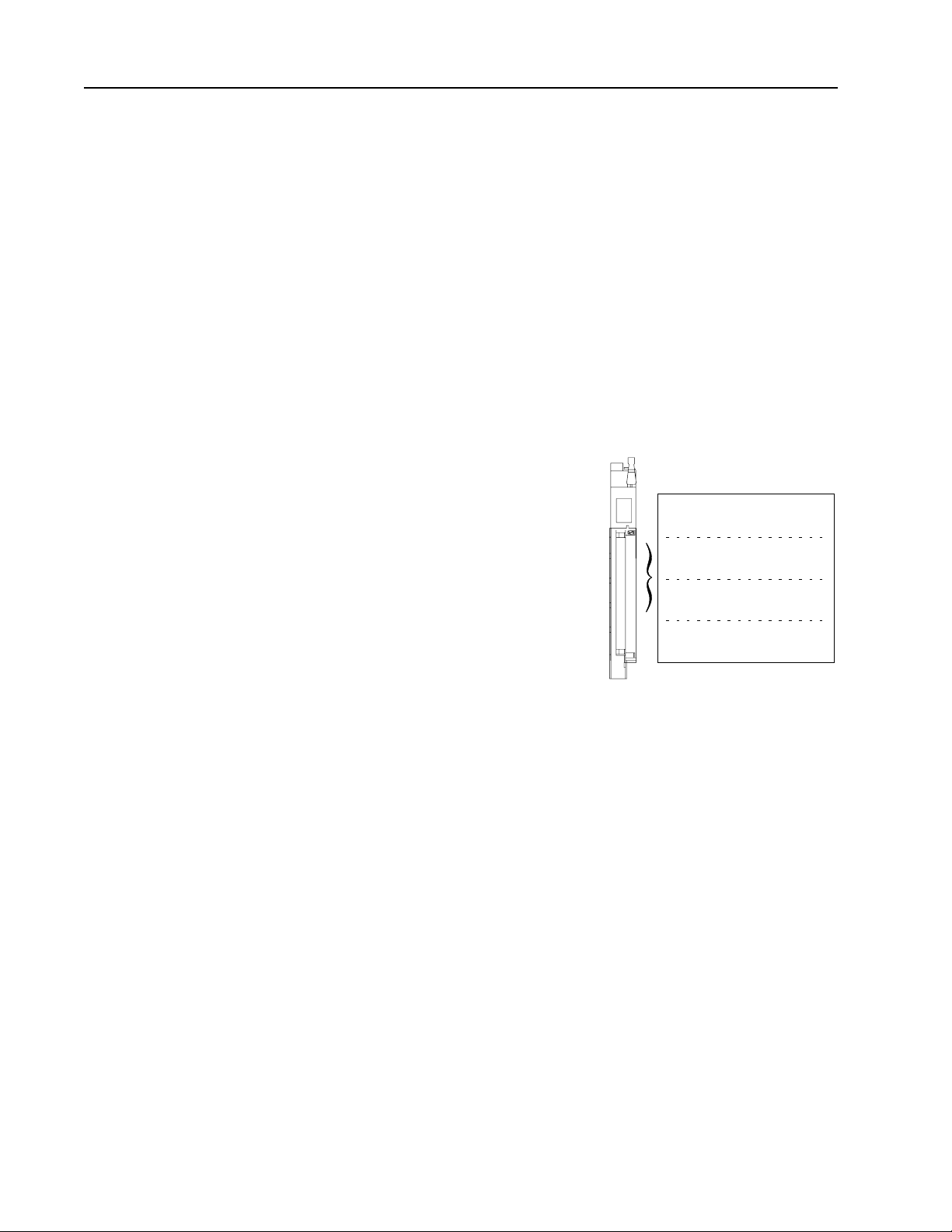

Set the Input Channel Jumpers

The CFM module has user-selectable jumpers for each flowmeter

and gate input:

• flowmeter jumpers (F0-F3) — set jumper for low-pass filter

(70Hz) or high-speed operation

• gate jumpers (G0-G3) — set jumper for +5-12V or

+12-40V operation

The CFM module is configured for high-speed operation. If any

input channel will be accepting input from a mechanical switch, you

need to set the flowmeter jumper for that input channel to filter

operation. The filter provides debouncing for the mechanical switch.

ATTENTION: The frequency of counting must be

less than 70Hz when the filter mode is selected. If the

!

frequency exceeds 70Hz, the CFM module will not

read the incoming pulse.

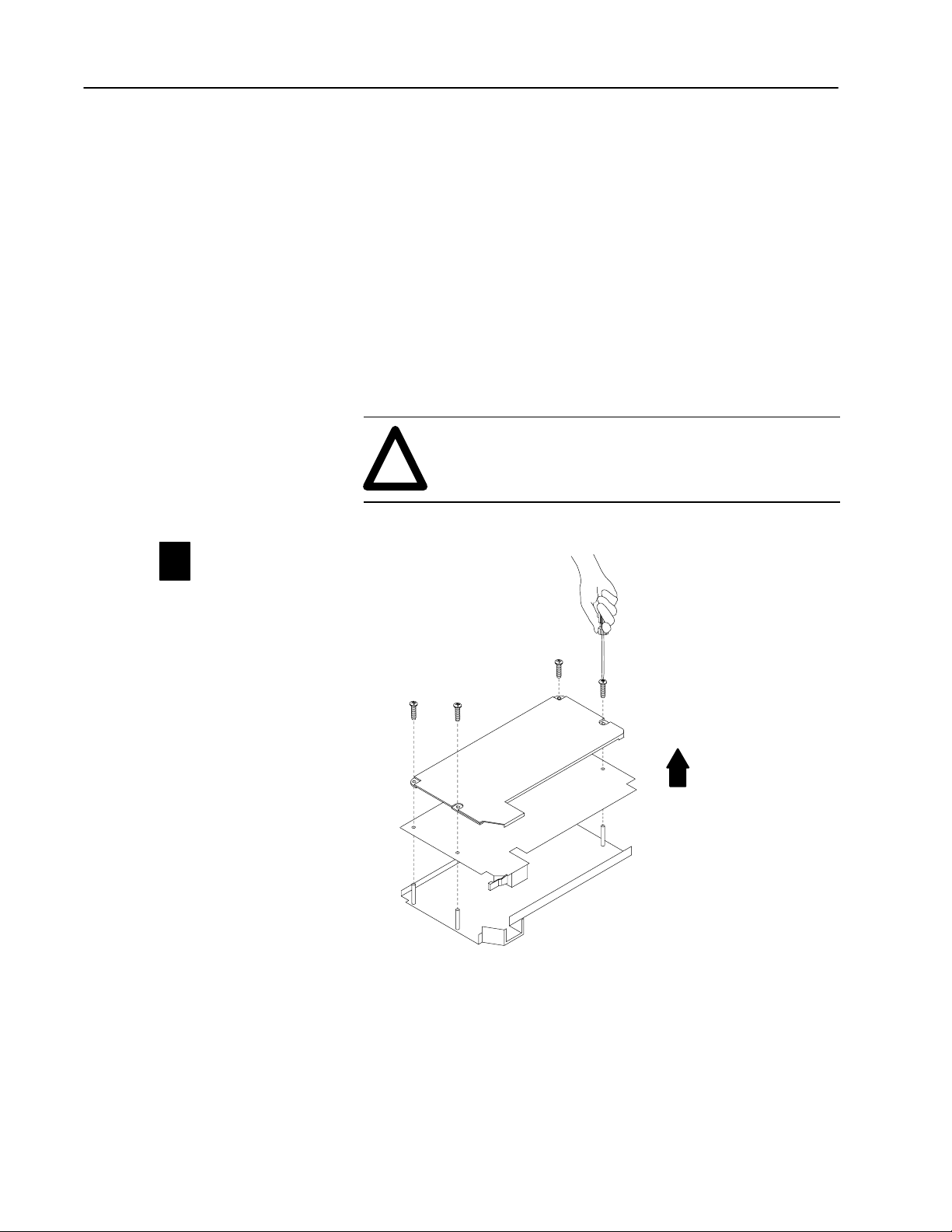

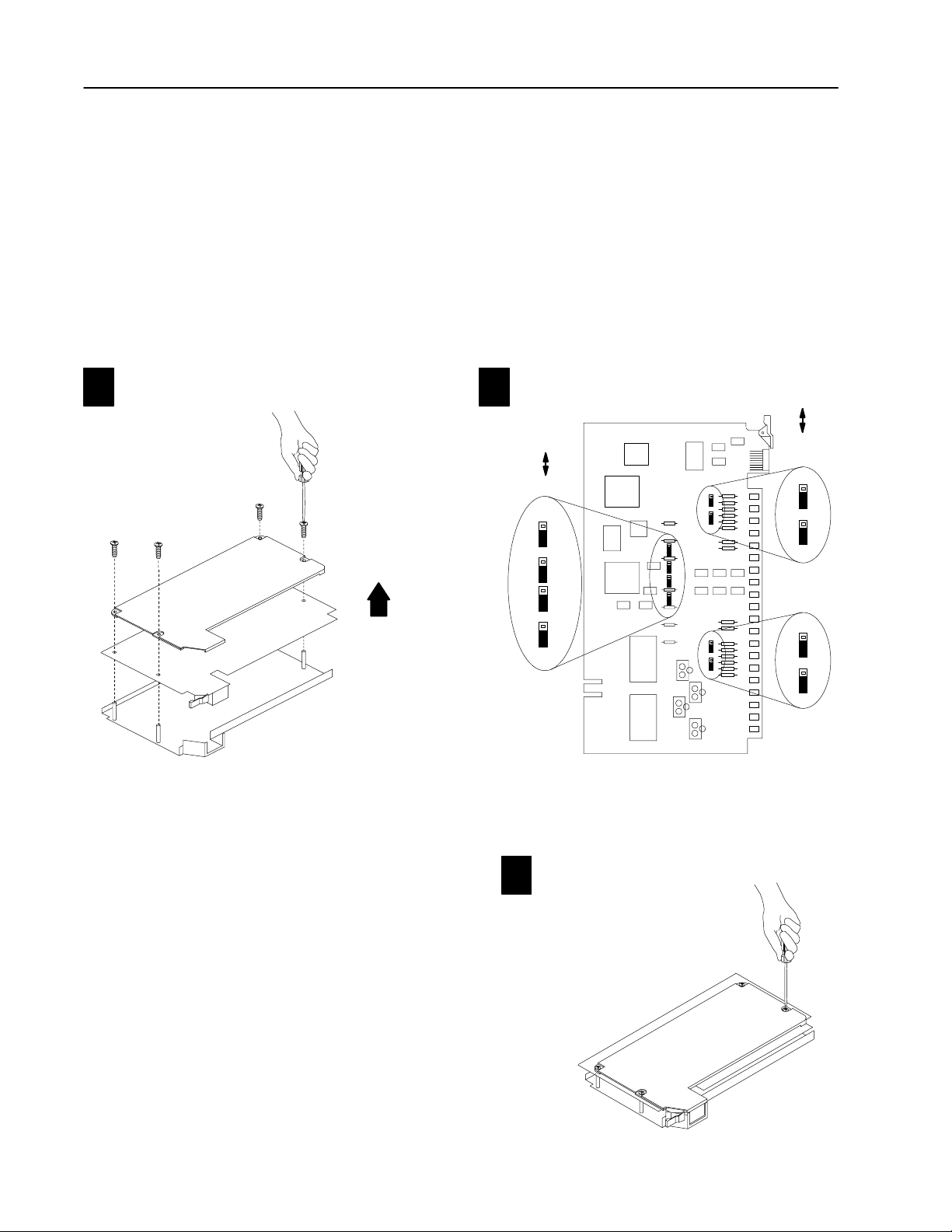

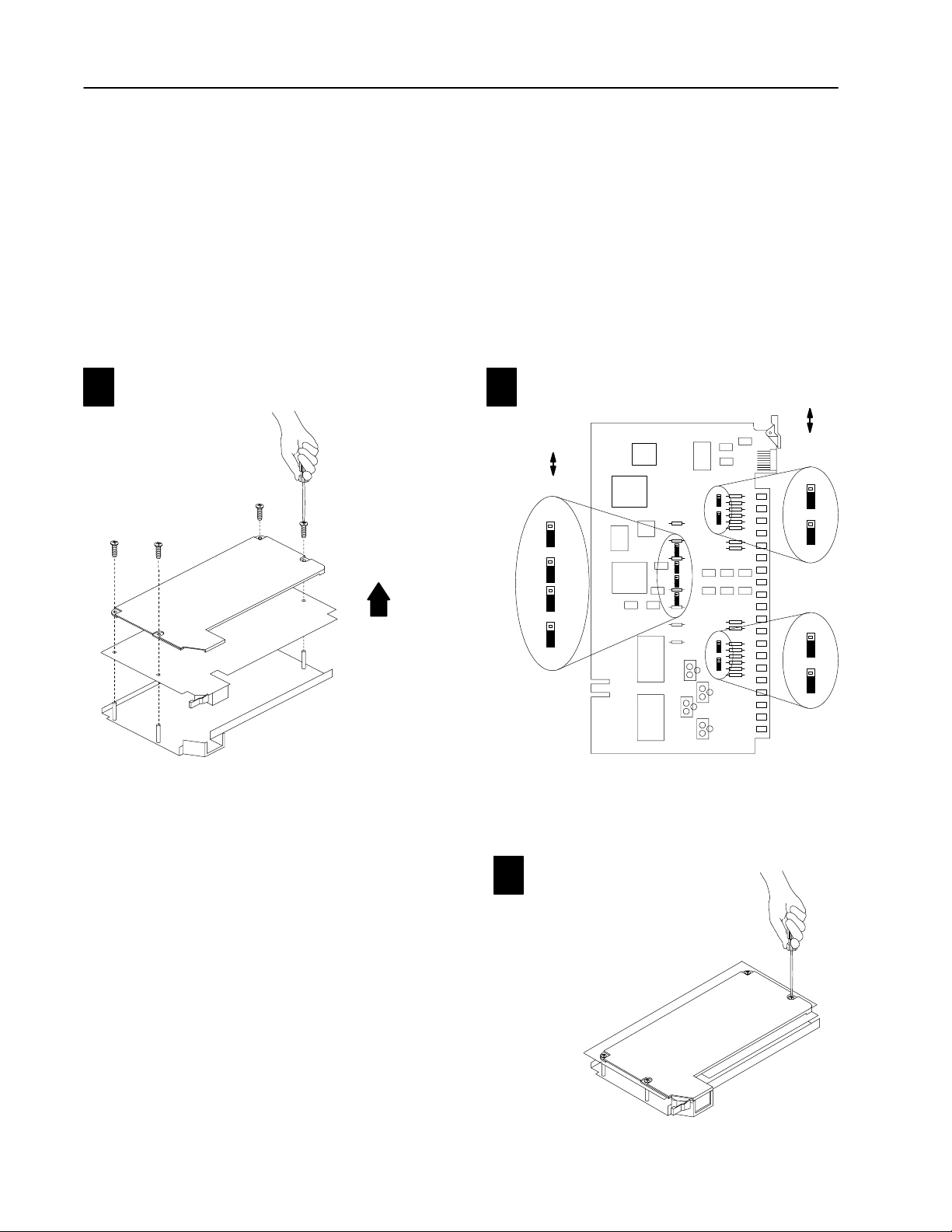

Remove the four screws securing the side cover

11

to the module and remove the covers.

19805

Publication

17716.5.99 - December 1995

Page 23

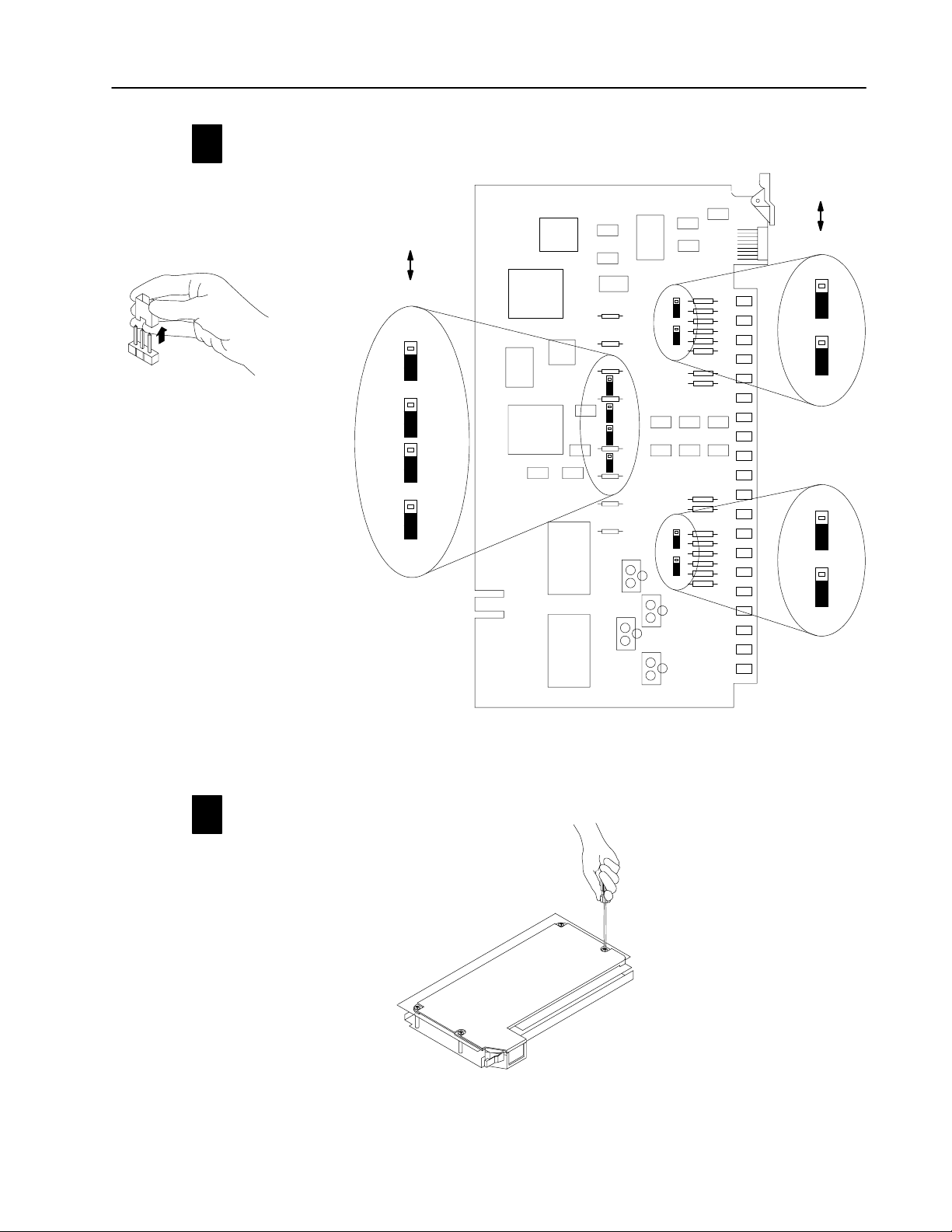

Reposition the flowmeter and gate jumpers associated

2

with each input channel according to your requirements.

The flowmeter and gate jumpers

➁

can be

set independent of each other (you can

select the filter action for each flowmeter

input and a voltage for each and gate

input independently).

➀

FILTER

HIGH SPEED

F1

F0

F3

2–5Install the CFM Module

5-12V

12-40V

G0

G1

gate jumpers

G2

Reposition the cover and secure with

13

the fours screws removed in step 1.

F2

flowmeter jumpers

➀

In

the filter position, the module will not read frequencies above 70Hz.

➁

Jumpers are shown in default settings.

G3

19806

19813

Publication

17716.5.99 - December 1995

Page 24

2–6 Install the CFM Module

ith

bit

ith

bit

icti

block transfer module

16bit or block transfer module

Determine CFM Module Placement

Place your module in any slot of the I/O chassis except for the

extreme left slot. This slot is reserved for processors or adapter

modules.

Use of data table 2slot addressing 1slot addressing 1/2slot addressing

Input Image Bits 8

Output Image Bits 8

Read Block Words 41 max

Write Block Words

60 max

Place the CFM module in any

module group w

block transfer module.

Key the Backplane Connector

The CFM module is slotted in two places on the rear edge of

the circuit board. These slots are intended to mate with the

plastic keying bands supplied with the I/O chassis.

any 8

.

or

Place the CFM module in any

module group w

16bit or block transfer module.

any 8

,

.

no restr

ons

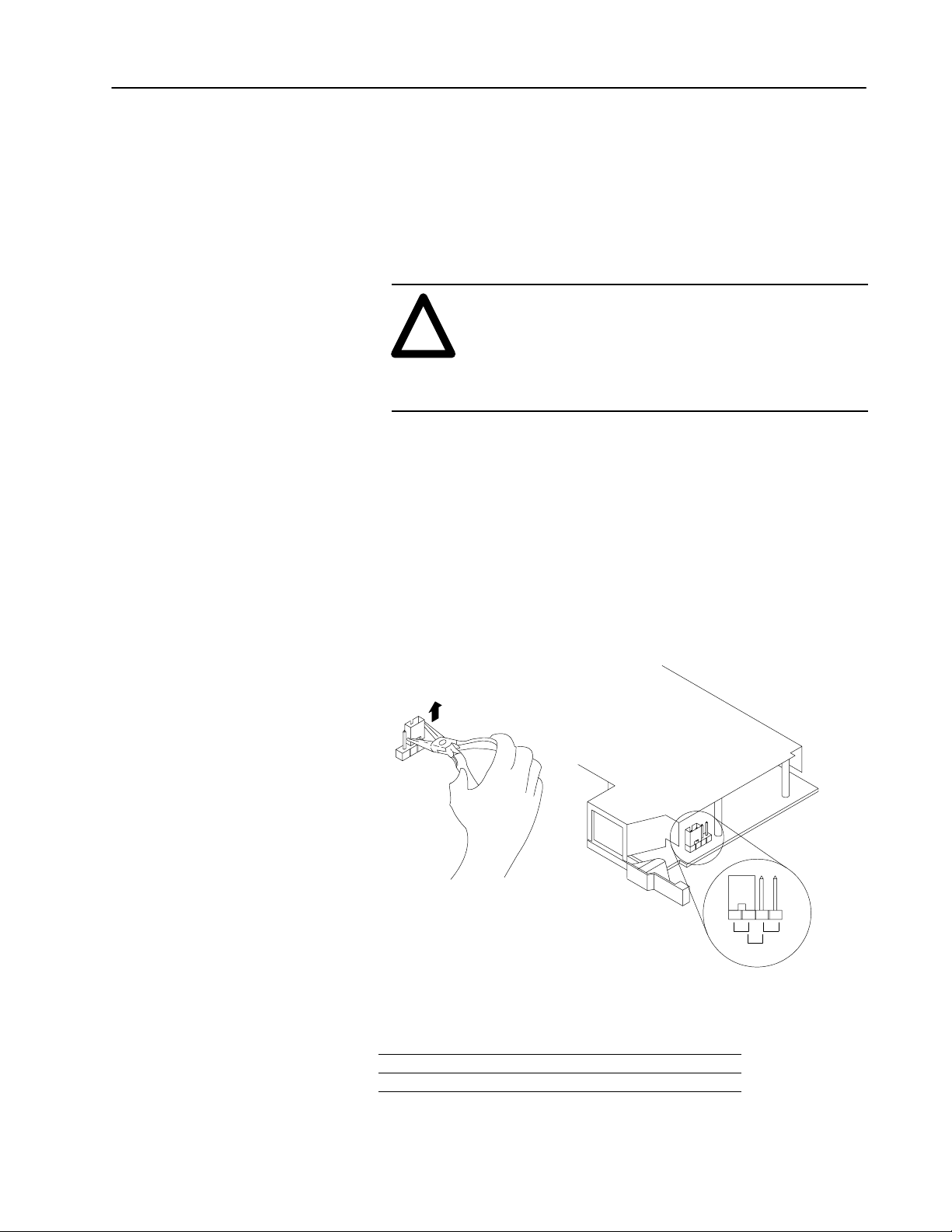

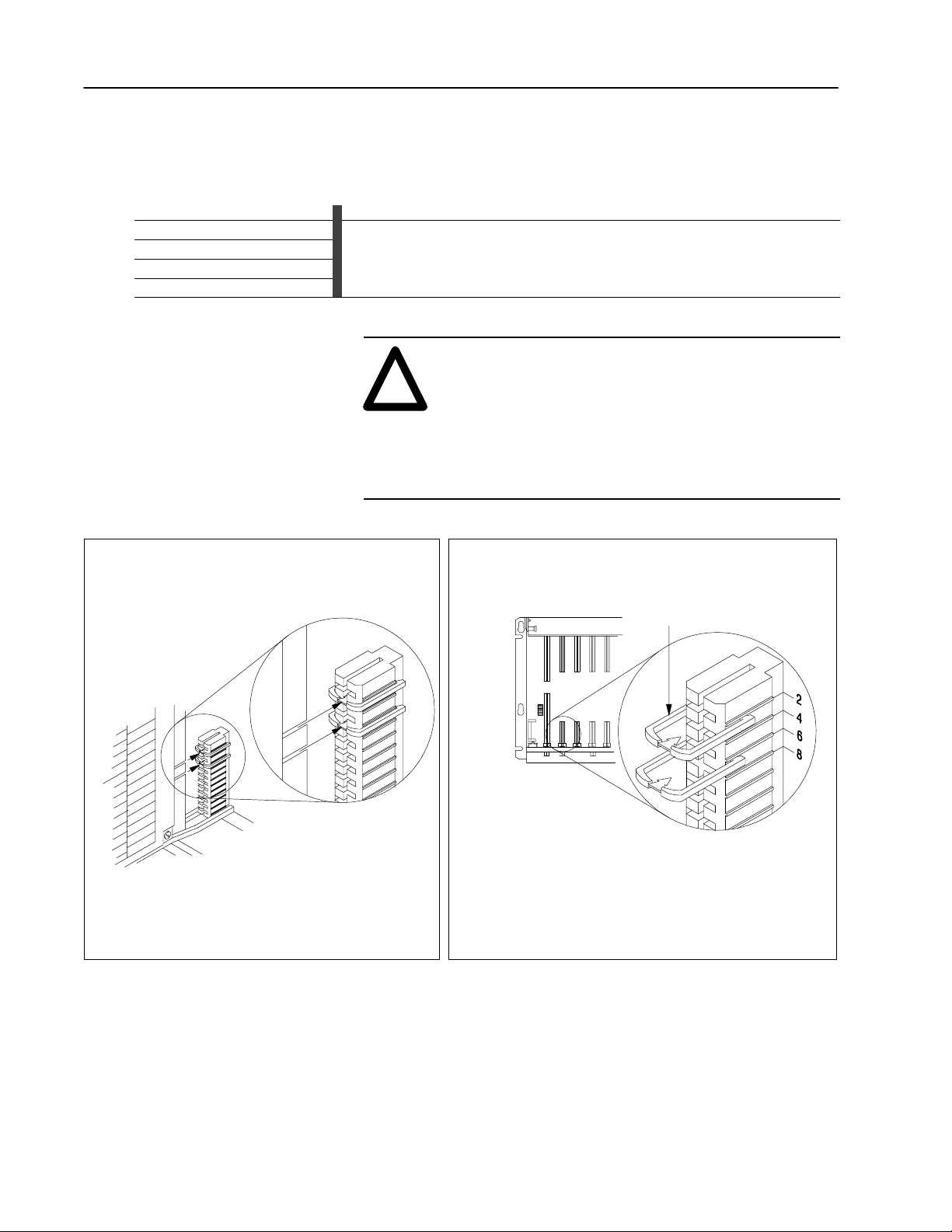

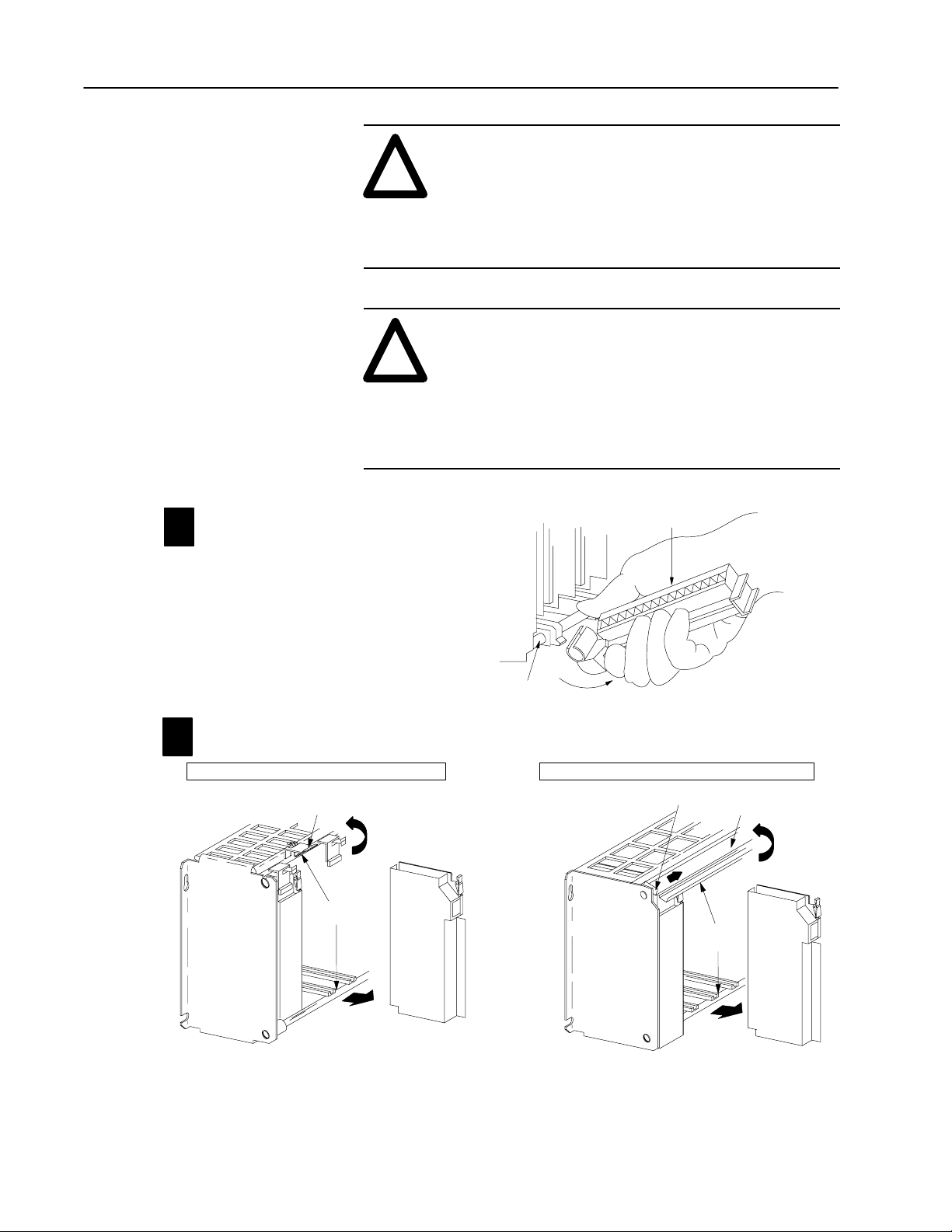

ATTENTION: Observe the following precautions

when inserting or removing keys:

!

• insert or remove keys with your fingers

• make sure that key placement is correct

Incorrect keying or the use of a tool can result in

damage to the backplane connector and possible

system faults.

Position the keying bands in the backplane connectors to

correspond to the key slots on the CFM module.

I/O chassis

keying bands

CFM module

Publication

I/O chassis

backplane connector

17716.5.99 - December 1995

Place the keying bands:

between 2 and 4

between 6 and 8

You can change the position of these bands if subsequent system design

and rewiring makes insertion of a different type of module necessary.

19808

Page 25

2–7Install the CFM Module

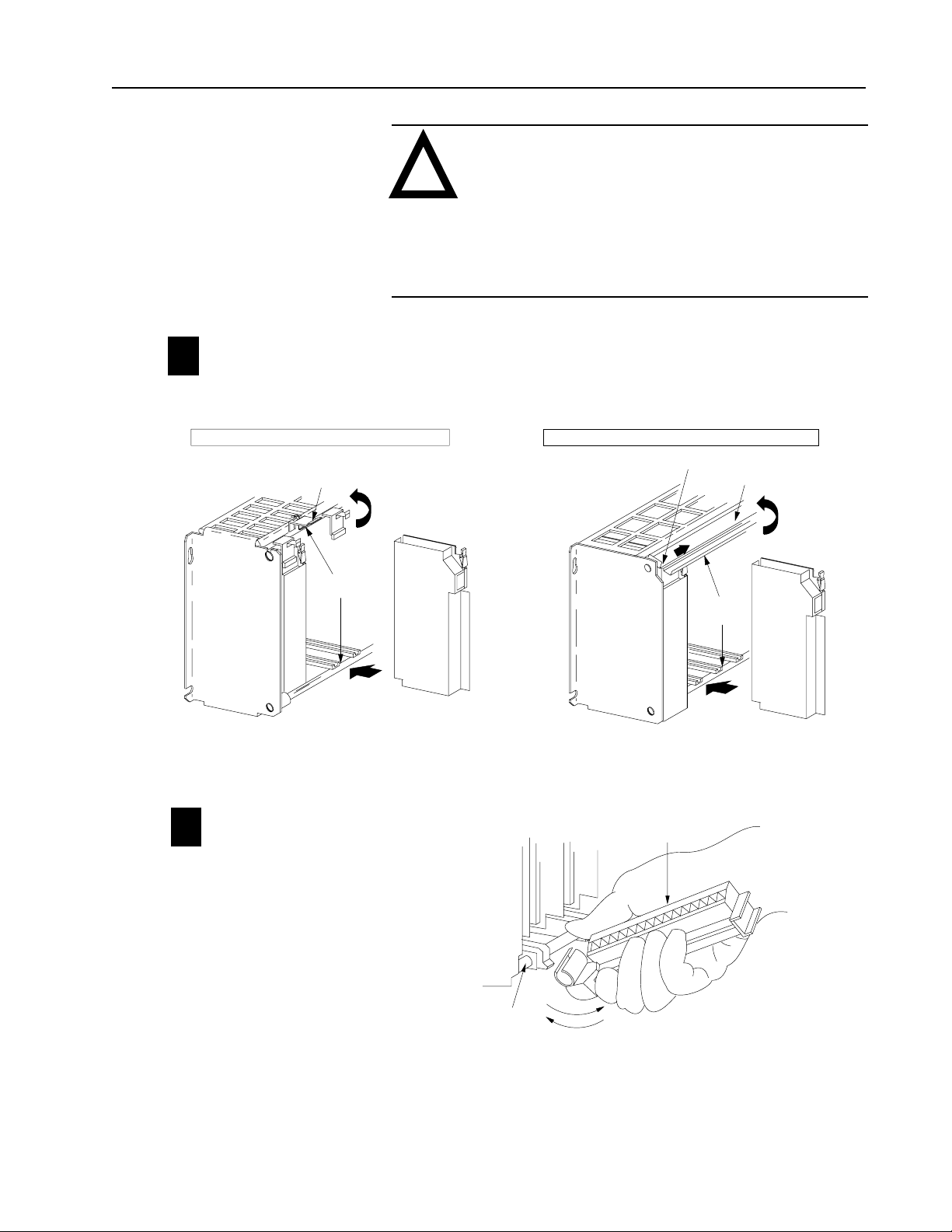

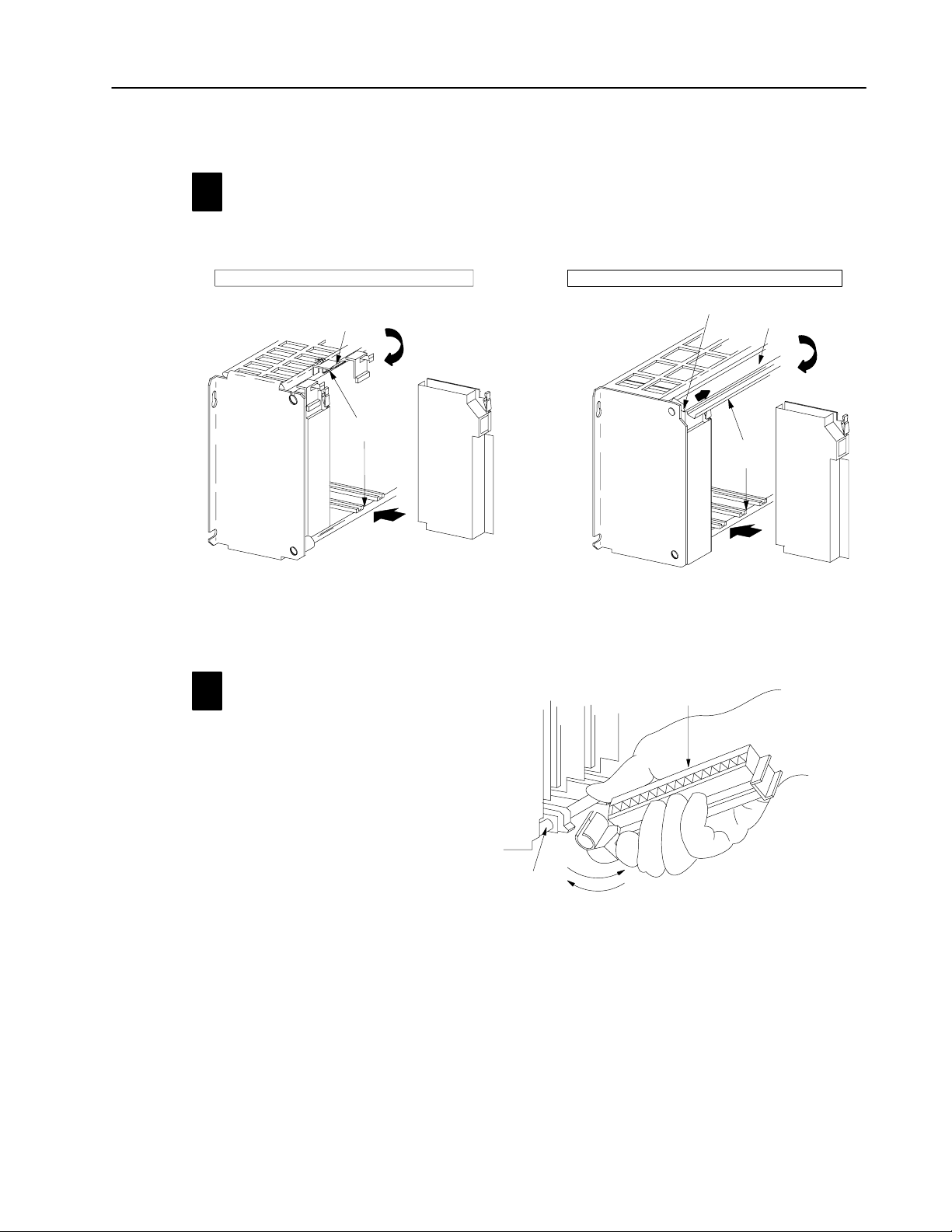

Install the CFM Module

Place the module in the card guides on the top and bottom of the slot

11

that guide the CFM module into position.

Important: Apply firm even pressure on the module to seat it into

its backplane connector.

1771A1B, A2B, A3B, A3B1, A4B I/O chassis 1771A1B, A2B, A3B1, A4B Series B I/O chassis

locking

card guides

tab

ATTENTION:Remove power from the 1771 I/O

chassis backplane before you install the CFM module.

!

Failure to remove power from the backplane

could cause:

•injury

•equipment damage due to unexpected operation

•degradation of performance

locking bar pin

locking bar

card guides

Snap the chassis latch over

the top of the module to secure it.

Attach the wiring arm (1771WN) to the horizontal

12

bar at the bottom of the I/O chassis.

The wiring arm pivots upward and connects with

the module so you can install or remove the

module without disconnecting the wires.

CFM module

CFM module

Swing the chassis locking bar down into place to secure

the modules. Make sure the locking pins engage.

wiring arm

1771WN

remove

horizontal bar

install

At power-up, the active and fault indicators are on. An initial

module self-check occurs. If there is no fault, the fault indicator

turns off. See page6–1 for information on interpreting the status

indicators.

19809

17643

Publication

17716.5.99 - December 1995

Page 26

2–8 Install the CFM Module

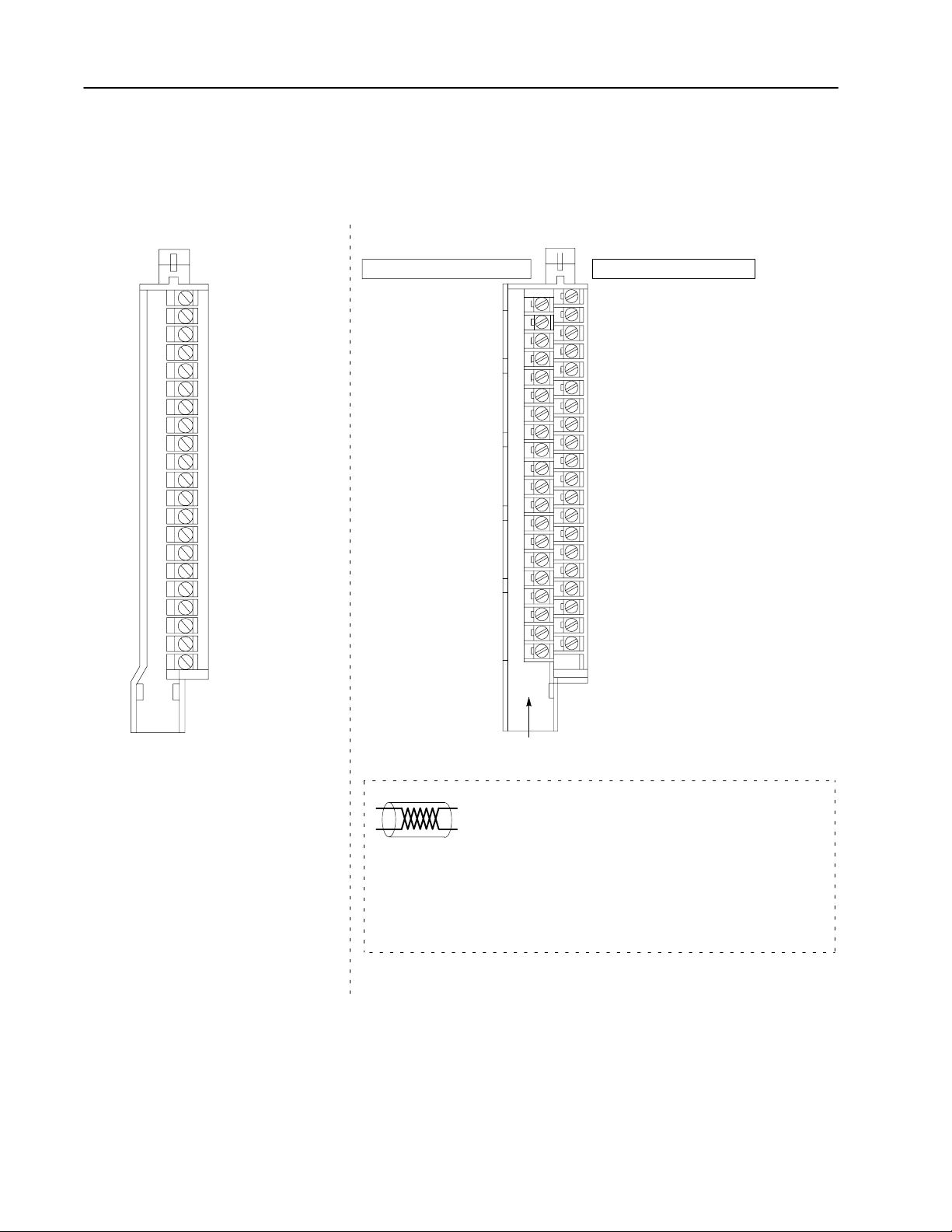

Make Connections to the Field Wiring Arm

DC source #1 @ 12mA RET (- proximity pickup)

DC source #2 @ 12mA RET (- proximity pickup)

Customer V DC #1 RET (Outputs 0 & 1 RET)

Customer V DC #2 RET (Outputs 2 & 3 RET)

Connect your I/O devices to the 40-terminal field wiring arm

(cat. no. 1771-WN) shipped with the CFM module. Use the wiring

examples on pages 2–9 and 2–10 for additional assistance on

connecting your devices.

ATTENTION:Remove power to all I/O devices

before you connect them to the wiring arm. Failure to

!

remove power from your I/O devices could cause:

•injury

•damage to module circuitry

•equipment damage due to unexpected operation

Even Numbered T

erminals 240

not used

not used

G0 RET

G1 RET

F0 (500mV)

F0 Input

F1 (500mV)

F1 Input

F2 (500mV)

F2 Input

F3 (500mV)

F3 Input

G2 RET

G3 RET

Output 0

Output 2

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

Odd Numbered T

1

Chassis GND

3

+5V dc RET

5

G0

7

G1

9

F0 (TTL)

11

F0 RET

13

F1 (TTL)

15

F1 RET

17

+24V DC source #1 @ 12mA

19

+24V DC source #2 @ 12mA

21

F2 (TTL)

23

F2 RET

25

F3 (TTL)

27

F3 RET

29

G2

31

G3

33

Customer V DC #1 (5 to 40V)

35

Output 1

37

Customer V DC #2 (5 to 40V)

39

Output 3

erminals 139

Publication

17716.5.99 - December 1995

1771WN

(See applicable codes and laws.)

actual wiring runs in this direction

The sensor cable must be shielded. The shield:

•must extend the length of the cable, but be connected only at the

1771 I/O chassis

•must extend up to the point of termination

Important:The shield should extend to the termination point,

exposing just enough cable to adequately terminate the

inner conductors. Use heat shrink or another suitable

insulation where the wire exits the cable jacket.

10689I

Page 27

2–9Install the CFM Module

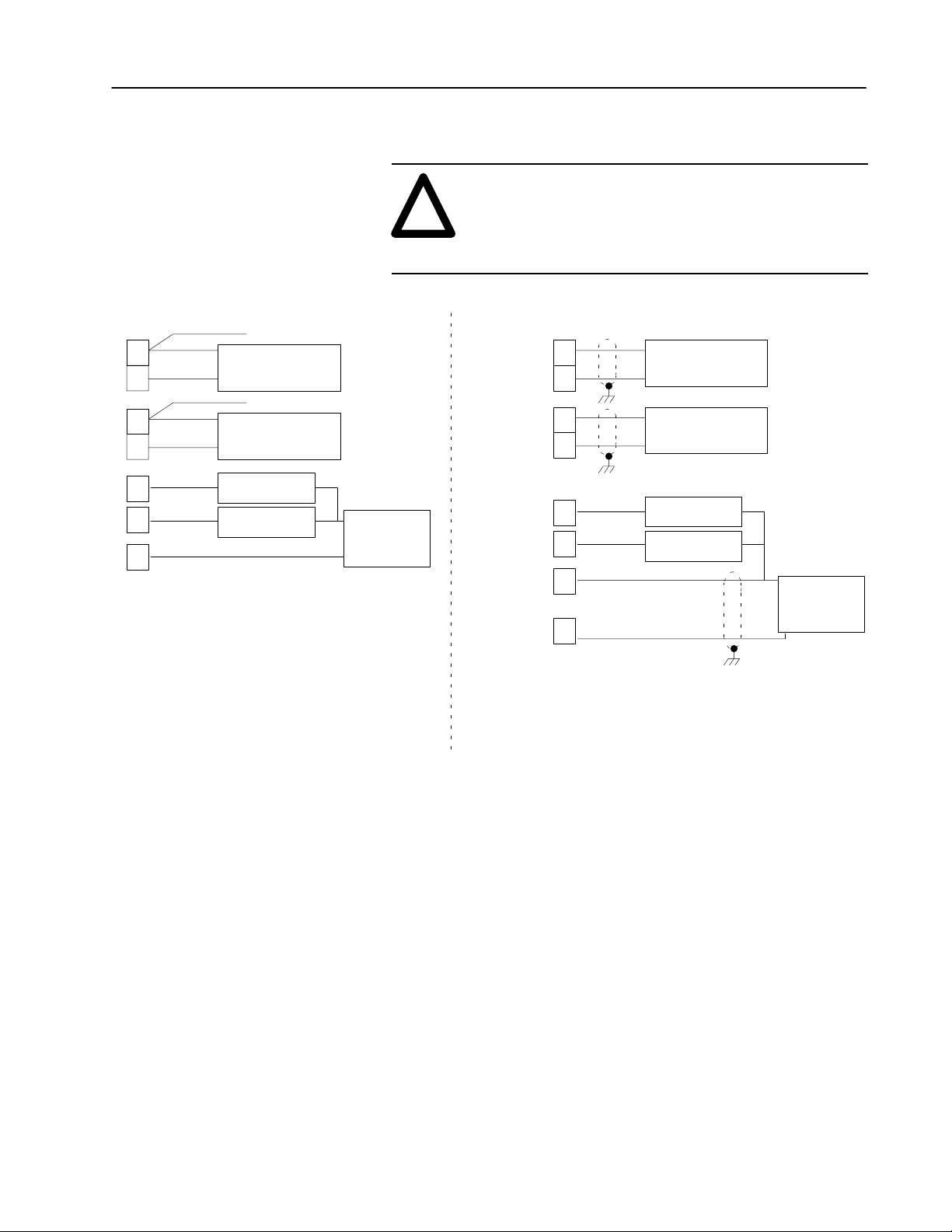

Wiring Examples

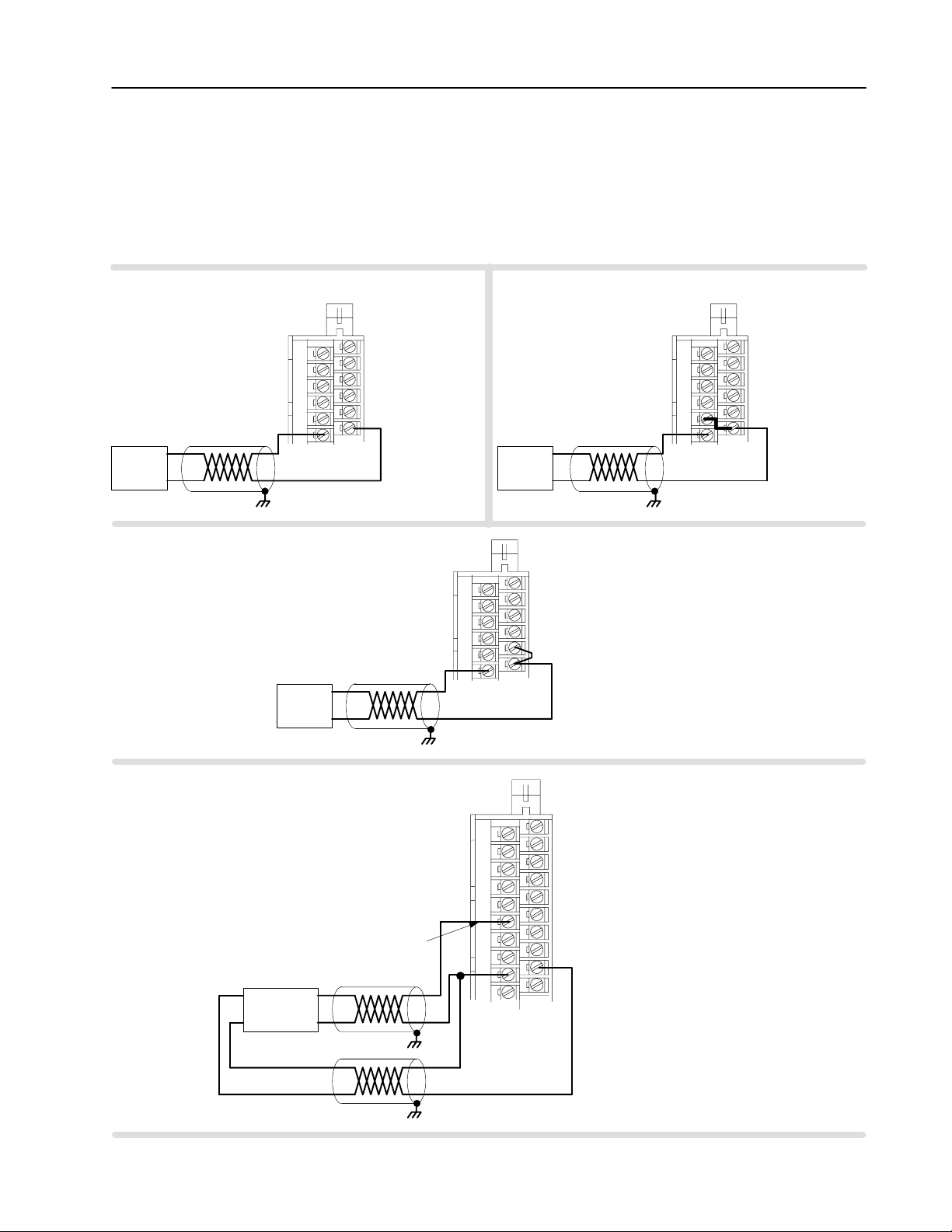

These wiring diagrams represent wiring for a flowmeter input (F0),

a gate input (G0) and an output (O0). See the wiring arm diagram

on page2–8 for the terminals used in wiring F1-F3, G1-G3

and O1-O3.

Standard Magnetic Pickup

50mV threshold (F0)

2

4

6

8

not used F0 (500mV)

+

Input

Device

-

F0 Input

10

12

➀ ➀

Standard TTL or Open Collector

1.3V threshold (F0)

Important: To use a channel in TTL, jumper

the appropriate TTL pin to the appropriate RET

To use Channel 0 in TTL, jumper pin 9 to pin 11.

Input

Device

1771WN

1

3

5

7

9

11

.

not

used F0 (500mV)

+

-

F0 (TTL)

F0 RET

F0 Input

not used

2

4

6

8

10

12

➀

Standard Magnetic Pickup

500mV threshold (F0)

Important: T

500mV sensor

pin to the appropriate RET. For

Channel 0, jumper pin 10 to pin 1

Input

Device

o use a channel for

+

-

1771WN

1

3

5

7

9

F0 (TTL)

11

F0 RET

, jumper the 500mV

F0 (500mV)

F0 Input

1771WN

2

1.

4

6

8

10

12

1

3

5

7

9

F0 (TTL)

11

F0 RET

not used

Standard Proximity

using CFM Module Source (F0)

+24V

DC source #1 @ 12mA RET (- proximity pickup)

+

-

Input

Device

1771WN

2

4

6

8

not used F0 (500mV)

F0 Input

+

10

12

14

16

18

20

1

3

5

7

9

F0 (TTL)

11

F0 RET not used

13

15

+24V DC source #1 @ 12mA to power a proximity transducer

17

19

not used

-

➀

➀

➀

For new installations, terminate the shields at

the chassis. While not recommended,

existing installations can continue to terminate

the shields at the return (RET) terminal.

Publication

17716.5.99 - December 1995

Page 28

2–10 Install the CFM Module

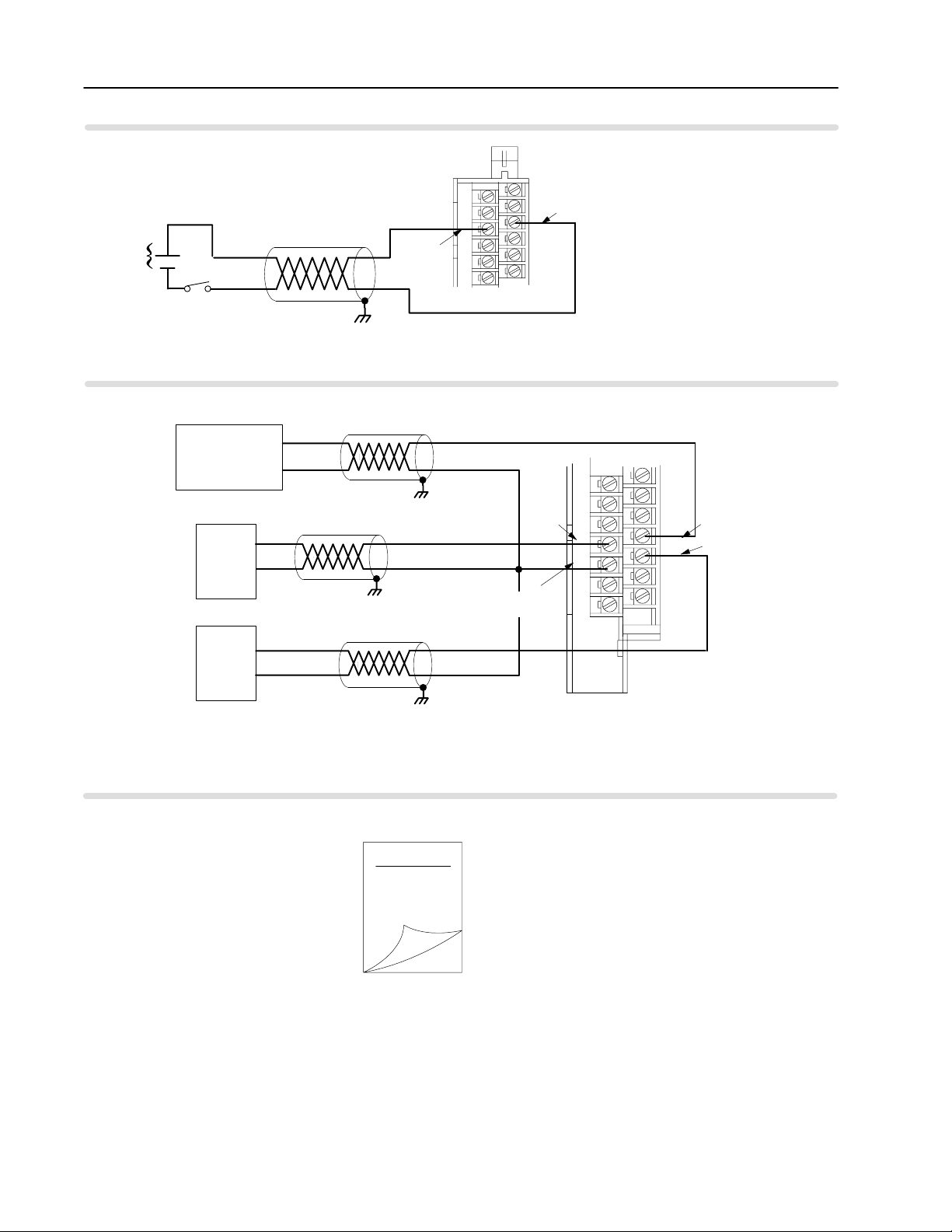

Standard Prover/Store Count (G0)

5-12V dc

OR

12-40V dc

-

+

S

1

Standard Output (O0)

External

Power Supply #1

540V dc @ 2A

+

LOAD 0

-

external device

➀

G0 RET

2

4

6

8

10

12

1771WN

1

3

5

7

9

11

G0

+

-

➀

Output 0

➀

Customer V DC #1 RET

(Outputs 0 & 1 RET)

28

30

32

34

36

38

40

27

29

31

Customer V DC #1 (5 to 40V)

33

Output 1

35

37

39

What's Next

LOAD 1

LOAD 1

+

-

➀

➀

For new installations, terminate the shields at

the chassis. While not recommended,

existing installations can continue to terminate

the shields at the return (RET) terminal.

3

Edit Your

Ladder Logic

Program

1771WN

Publication

17716.5.99 - December 1995

Page 29

Chapter

Edit Your Ladder Logic

Program

3

What This Chapter Contains

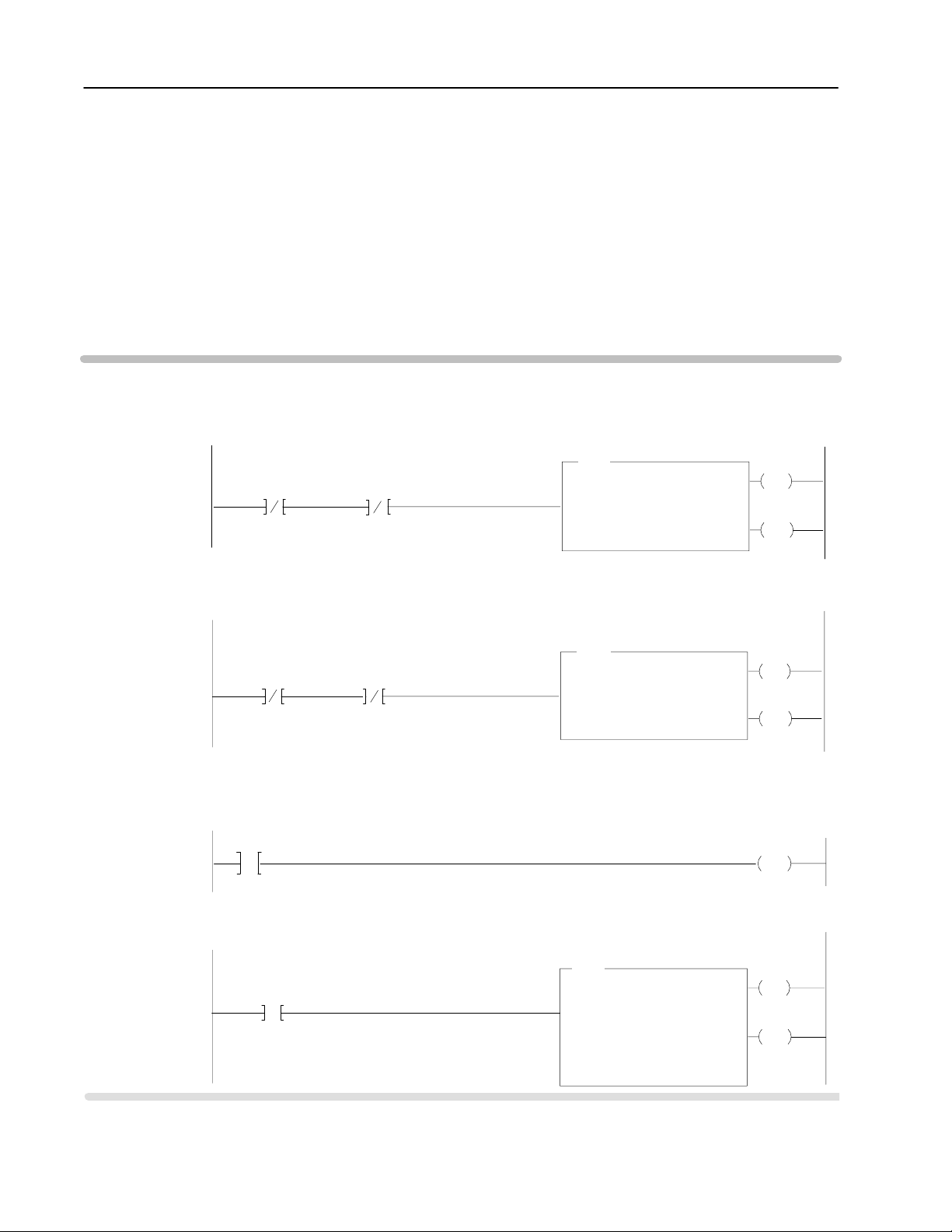

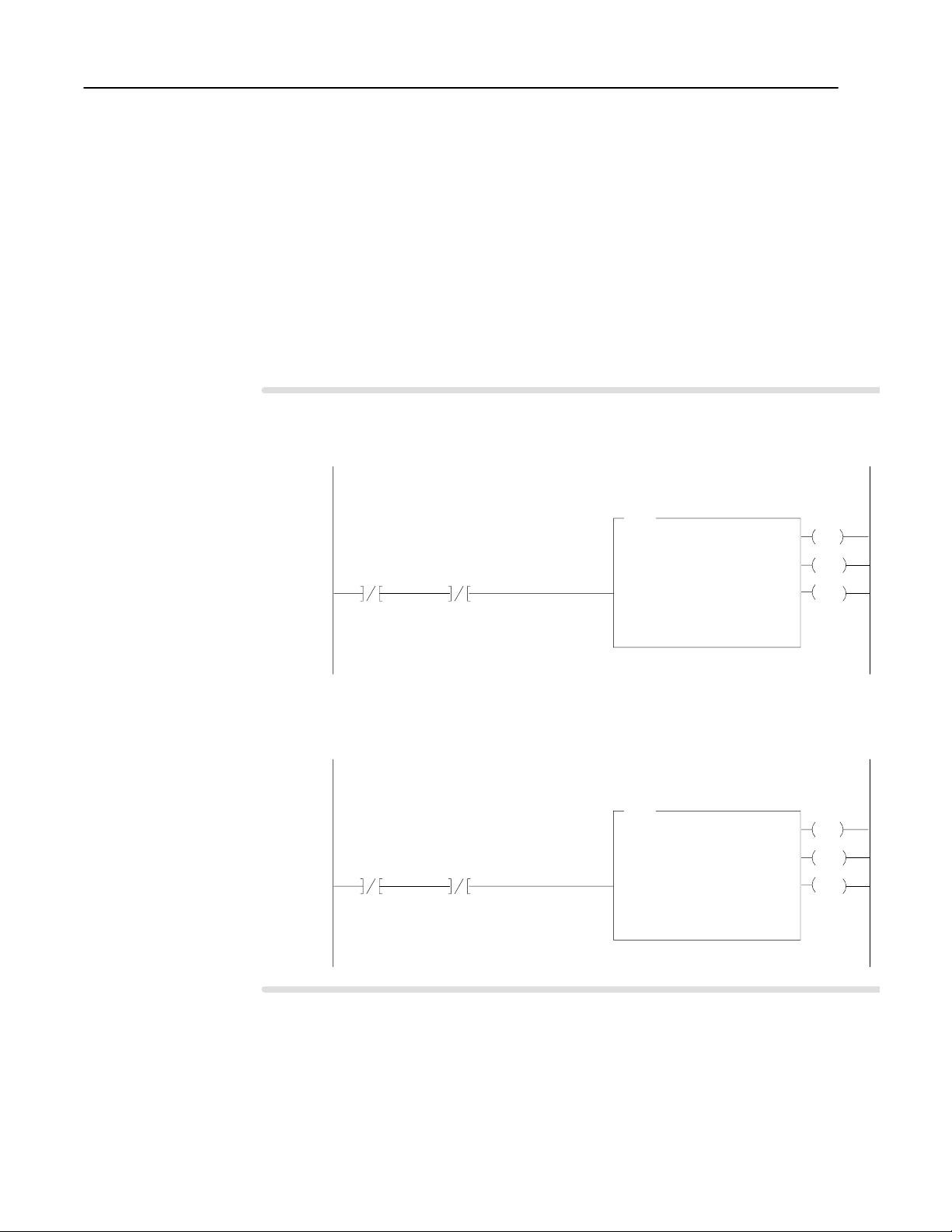

Enter Block Transfer Instructions

To initiate communication between the CFM module and your

PLC processor, you must enter block transfer instructions into your

ladder logic program. Use this chapter to enter the necessary block

transfer instructions into your ladder logic program.

To edit your ladder logic you See page

Enter Block Transfer Instructions. . . . . . . . . . . . . . . . . . . . .

PLC2 Family Processors. . . . . . . . . . . . . . . . . . . . . . . . 3-2

PLC3 Family Processors. . . . . . . . . . . . . . . . . . . . . . . . 3-3

PLC5 Family Processors. . . . . . . . . . . . . . . . . . . . . . . . 3-4

PLC5/250 Processors. . . . . . . . . . . . . . . . . . . . . . . . . .

The CFM module communicates with the PLC processor through

bidirectional block transfers. This is the sequential operation of both

read and write block transfer instructions.

Before you configure the CFM module, you need to enter block

transfer instructions into your ladder logic. The following example

programs illustrate the minimum programming required for

communication to take place between the CFM module and a PLC

processor. These programs can be modified to suit your application

requirements.

3-1

3-5

Publication

17716.5.99 - December 1995

Page 30

3–2 Edit Your Ladder Logic Program

PLC2 Family Processor

Important: The CFM module functions with reduced performance

Use the following rungs to establish communication between the

CFM module and a PLC-2 processor.

in PLC-2 systems. Because the CFM module does not

support BCD and the PLC-2 processor is limited to

values of 4095 (12 bit binary), many values returned in

the BTR file may not provide meaningful data to the

PLC-2 processor.

PLC2 Processor

Program Example

Rung M:1

The CFM module is located in rack 1, I/O group 1, slot 0. The data address 030 must be among the first available timer/

address used for block transfer

counter

length other than 0 is desired, the BTR and BTW must not both be enabled in the same scan.

CFM BTR

Done Bit

111

07

Rung M:2

The CFM module is located in rack 1, I/O group 1, slot 0. The data address 031 must be among the first available timer/

address used for block transfer

counter

other than 0 is desired, the BTR and BTW must not both be enabled in the same scan.

CFM BTW

Done Bit

111

06

Rung M:3

This rung is used to place a zero between the first available timer counters used for all block transfers and those used

throughout the rest of the program.

UNUSED

must be = 0

032

G

0

Rung M:4

This rung uses the BTR done bit to trigger a FFM that moves the CFM status to a buffered data file. The program should

access all CFM data from the file starting at 401.

CFM BTR

Done Bit

111

07

CFM BTW

Enable Bit

CFM BTR

Enable Bit

. The default block length of 0 will return 41 words starting at address 301. If a block

CFM BTR Data Address

BTR

011

06

. The default length of 0 will send 60 words

011

07

BLOCK TRANSFER READ

Data Addr:

Module Addr:

Block Length:

File: 301-400

starting at address 201. If a block length

BTW

BLOCK TRANSFER WRITE

Data Addr:

Module Addr:

Block Length:

File: 201-300

FFM

FILE TO FILE MOVE

Counter Addr:

Position:

File Length:

File A:

File R:

Rate per Scan:

030

110

031

110

033

41

41

301-351

401451

41

00

00

must be = 0

011

EN

07

111

DN

07

011

EN

06

111

DN

06

UNUSED

032

PUT

0

033

EN

17

033

DN

15

Publication

17716.5.99 - December 1995

Page 31

3–3Edit Your Ladder Logic Program

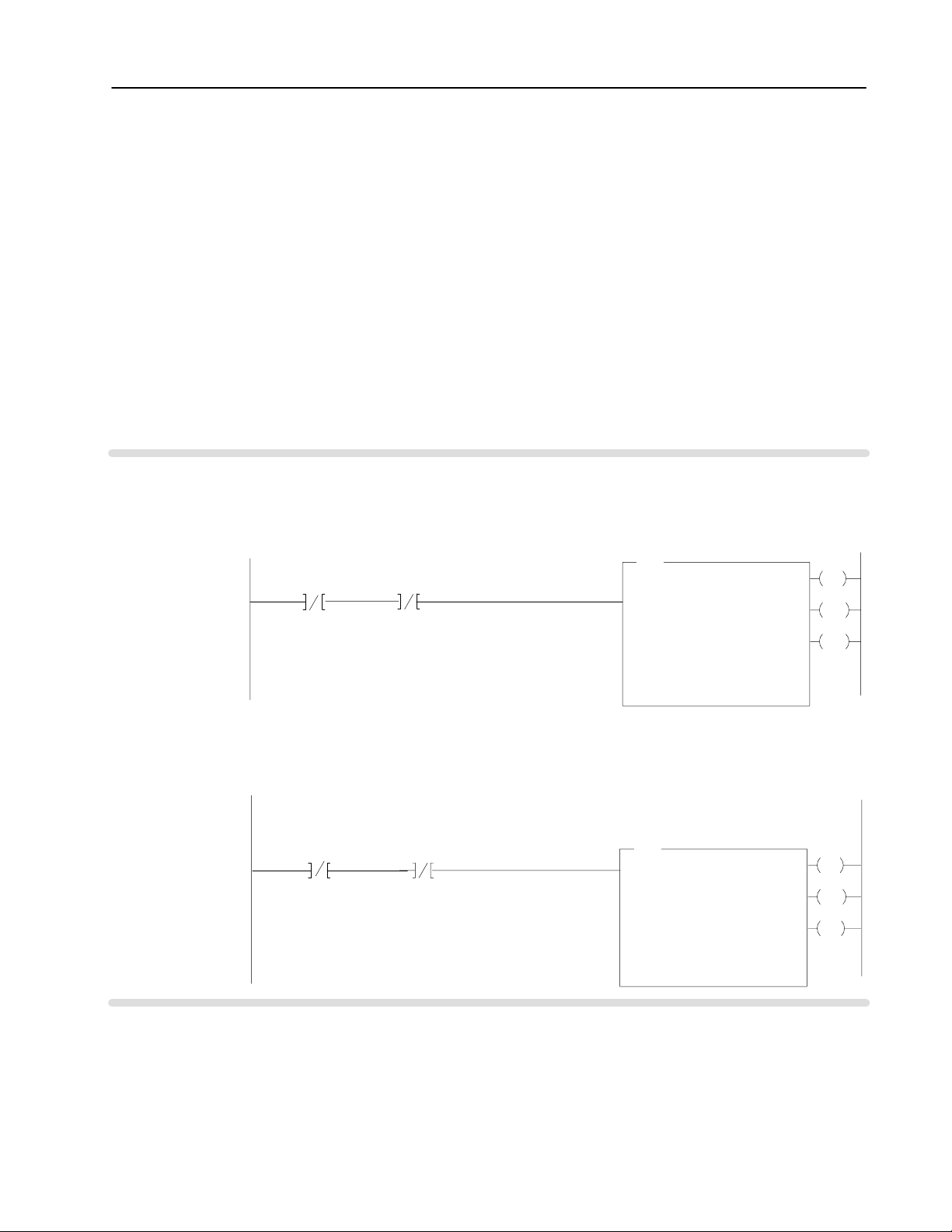

PLC3 Family Processor

Block transfer instructions with the PLC-3 processor use a control

file and a data file. The block transfer control file contains the data

table section for module location, the address of the block transfer

data file and other related data. The block transfer data file stores

data that you want transferred to the module (when programming a

BTW) or from the module (when programming a BTR).

The programming terminal prompts you to create a control file when

a block transfer instruction is being programmed. The same block

transfer control file is used for both the read and write

instructions for your module. A different block transfer control

file is required for every module.

PLC3 Processor

Program Example

Rung M:0

The

CFM module is located in rack 3, I/O group 2, slot 1. The control file is a 10 word file starting at B17:0

by the BTR/BTW. The data obtained by the PLC3 processor is placed in memory starting at location N18:101, and with

the default length of 0, is 41 words long.

CFM BTR/BTW

Control Block

BTR

CFM BTR

Done Bit

B17:0

15

CFM BTR

Error Bit

B17:0

13

The CFM module is located in rack 3, I/O group 2, slot 1. The control file is a 10 word file starting at B17:0 that is shared

by the BTR/BTW. The data sent by the PLC3 processor to the CFM module is from PLC memory starting at N18:1, and

with the default length of 0, is 60 words long.

CFM BTW

Done Bit

B17:0

5

BLOCK TRANSFER READ

Rack

Group

Slot

Control

Data File

Length

CFM BTR

Error Bit

B17:0

U

13

CFM BTR/BTW

Control Block

BTW

BLOCK TRANSFER WRITE

Rack

Group

Slot

Control

Data

Length

N18:101

B17:0

B17:0

N18:1

that is shared

EN

3

2

DN

1

ER

0

EN

3

2

DN

1

ER

0

CFM BTW

Error Bit

B17:0

3

CFM BTW

Error Bit

B17:0

U

3

Publication

17716.5.99 - December 1995

Page 32

3–4 Edit Your Ladder Logic Program

PLC5 Family Processor

Block transfer instructions with the PLC-5 processor use a control

file and a data file. The block transfer control file contains the data

table section for module location, the address of the block transfer

data file and other related data. The block transfer data file stores

data that you want transferred to the module (when programming a

BTW) or from the module (when programming a BTR).

The programming terminal prompts you to create a control file when

a block transfer instruction is being programmed. A different block

transfer control file is used for the read and write instructions

for your module.

PLC5 Processor

Program Example

Rung 2:0

The CFM module is located in rack 0, I/O group 2, slot 1. The integer

compatible with all PLC5 family members. The data obtained by the PLC5 processor from the CFM module is placed in

memory starting at N22:101, and with the default length of 0, is 41 words long. The length can be any number between 0

and 41. In enhanced PLC5 processors

CFM BTR

Enable Bit

N22:200

CFM BTW

Enable Bit

N22:205

15

Rung 2:1

CFM module is located in rack 0, group 2, slot 1. The integer control file starts at N22:205, is a 5 words long and is compat

The

ible will all PLC5 family members. The data sent by the PLC5 processor to the CFM module starts at N22:1, and with the

default length of 0, is 60 words long. Valid BTW lengths: 0, 1, 2, 3, 4, 14, 24, 34, 44, 48, 52, 56 and 60.

In enhanced PLC5 processors

CFM BTR

Enable Bit

N22:200

CFM BTW

Enable Bit

N22:205

15

➀

, the block transfer data type may be used as a control file.

15

1

, the block transfer data type may be used as a control file.

15

control file starts at N22:200, is 5 words long and is

CFM BTR

BTR

BLOCK TRANSFER READ

Rack

Group

Slot

Control

Data File

Length

Continuous

BTW

BLOCK TRANSFER WRITE

Rack

Group

Slot

Control

Data File

Length

Continuous

Control File

CFM BTW

Control File

N22:200

N22:101

00

N22:205

N22:1

00

EN

2

DN

1

ER

0

N

EN

2

DN

1

ER

0

N

Publication

➀

Enhanced PLC5 processors include: PLC5/11, 5/20, 5/3x, 5/4x, and 5/6x.

17716.5.99 - December 1995

Page 33

3–5Edit Your Ladder Logic Program

PLC5/250 Processor

Block transfer instructions with the PLC-5/250 processor use a

control file and a data file. The block transfer control file contains

the data table section for module location, the address of the block

transfer data file and other related data. The block transfer data file

stores data that you want transferred to the module (when

programming a BTW) or from the module (when programming

a BTR).

The programming terminal will automatically select the control file

based on rack, group and module, and whether it is a read or write.

A different block transfer control file is used for the read and

write instructions for your module. A different block transfer

control file is required for every module.

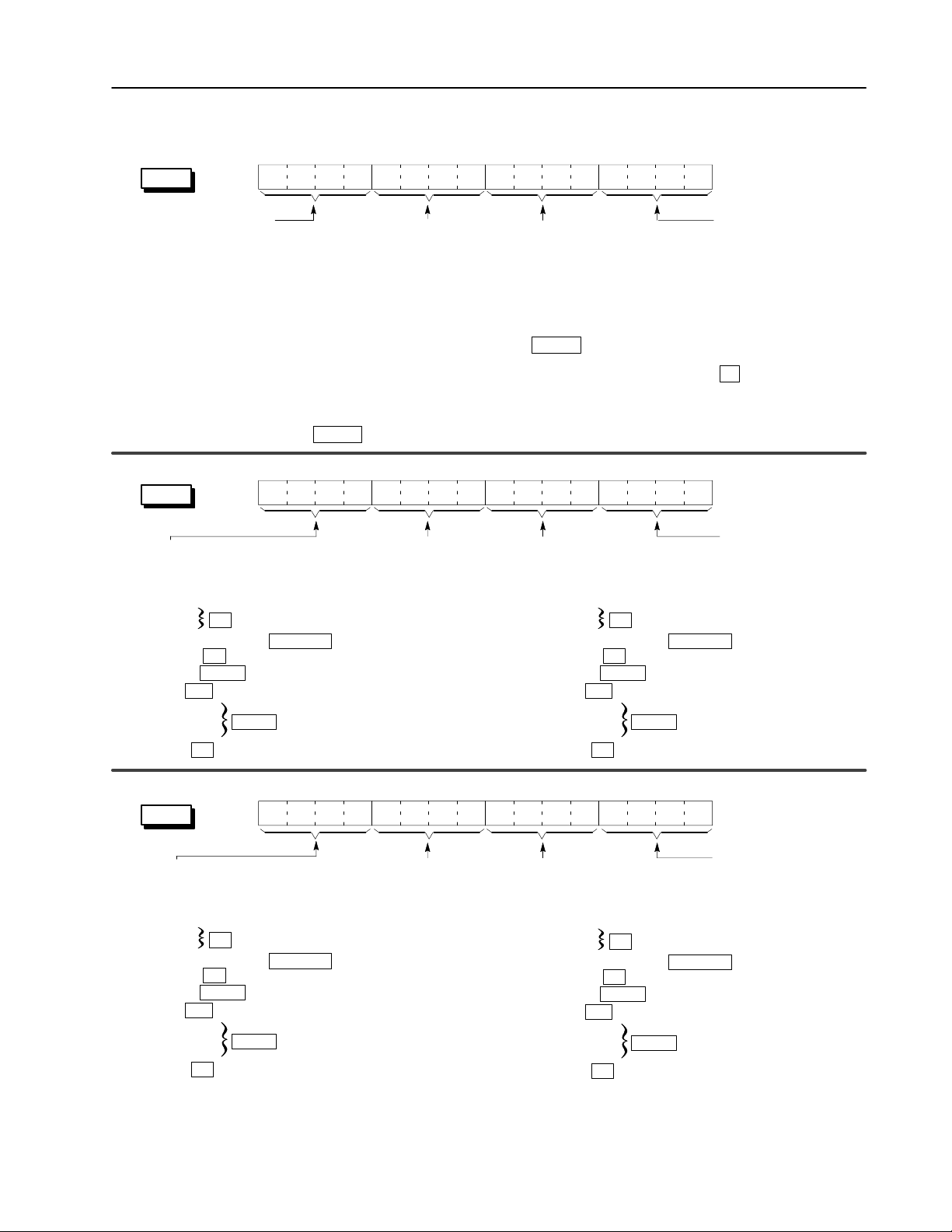

PLC5/250 Processor

Program Example

Rung 1STEPO:1

The

CFM module is located in rack 14, I/O group 1, slot 0. The data

CFM module is placed in the data table starting at 2BTD5:101, and with the default length of 0, is 41 words long.

The length can be any number between 0 and 41.

CFM BTR

Enable Bit

BR141:0

EN

Rung 1STEPO:1

CFM module is located in rack 14, I/O group 1, slot 0. The data sent to the CFM module from the PLC5/250 processor

The

is from the data table starting at 2BTD5:1, and with a default length of 0, is 60 words long.

Valid BTW lengths: 0, 1, 2, 3, 4, 14, 24, 34, 44, 48, 52, 56 and 60.

CFM BTR

Enable Bit

BR141:0

EN

CFM BTW

Enable Bit

BW141:0

EN

CFM BTW

Enable Bit

BW141:0

EN

obtained by the PLC5/250 processor from the

CFM BTR

BTR

BLOCK TRANSFER READ

Rack

Group

Slot

Control Block

Data File

BT Length

Continuous

BT Timeout 4

BTW

BLOCK TRANSFER WRITE

Rack

Group

Slot

Control Block

Data File

BT Length

Continuous

BT Timeout 4

Control File

14

1

0

BR141:0

2BTD5:101

0

NO

CFM BTW

Control File

14

1

0

BW141:0

2BTD5:1

0

NO

EN

DN

ER

EN

DN

ER

Publication

17716.5.99 - December 1995

Page 34

3–6 Edit Your Ladder Logic Program

What's Next

4

Configure the

CFM Module

Publication

17716.5.99 - December 1995

Page 35

Chapter

Configure the CFM Module

4

What This Chapter Contains

Understand the CFM

Module's BTW Structure

Use this chapter to configure the CFM module.

To configure the CFM module See page

Understand the CFM Module's BTW Structure . . . . . . . . . . . . 4-1

BTW Configuration Block . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Select the Mode(s) of Operation . . . . . . . . . . . . . . . . . . . . . . 4-8

Configure the CFM Module . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Using I/O Configuration Software . . . . . . . . . . . . . . . . . . . 4-16

Setting Bits in the BTW Configuration Block . . . . . . . . . . .

Important: You must edit your ladder logic as shown in chapter 3

before you can use this chapter to configure the BTW

configuration block.

Data is conditioned through a group of data table words that are

transferred from the PLC processor to the CFM module using a

BTW instruction. Now that you have entered BTW and BTR

instructions into your ladder logic, you are ready to enter data into

the BTW instruction. This data should conform to the input device

and specific application that you have chosen.

4-16

During normal operation, the processor transfers from 1 to 60 words

to the CFM module when you program a BTW instruction to the

CFM module’s address.

Important: You must program at least one BTW, with a word

length of 4, to get useful data back from the

CFM module.

For See page(s)

a general overview of the CFM module's BTW configuration block

detailed descriptions of each word in the BTW configuration block 4-3 through 4-7

4-2

Publication

17716.5.99 - December 1995

Page 36

4–2 Configure the CFM Module

É

BTW Configuration Block

➀

Word(s)

1 Header Prover

2 Output 1 Trigger T

3 Output 3 Trigger T

4 Channel

5,

15, 25, 35

6, 16, 26, 36

7, 17, 27, 37

8, 18, 28, 38

9, 19, 29, 39

10, 20, 30, 40

1

1, 21, 31, 41

12, 22, 32, 42

13, 23, 33, 43

14, 24, 34, 44

45,

49, 53, 57

46, 50, 54, 58

47, 51, 55, 59

48, 52, 56, 60

➀

Valid

BTW lengths are: 0, 1, 2, 3, 4, 14, 24, 34, 44, 48, 52, 56, 60.

➁

ALL

numeric values are in binary

➂

When scaling is used, all outputs are still controlled by the actual value not the scaled value.

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Block

Output

1 and Output 0 T

Output

3 and Output 2 T

Input

Channel Operating Mode

3

Input

Channel Configuration

Channel 0 (words 514) Channel 1 (words 1524) Channel 2 (words 2534) Channel 3 (words 3544)

Frequency

in

10ths

Bandwidth

Limit

Sampling

Termination

4 x

High Hz

Prover

Type

Acceleration Alarm V

Frequency Scaler Multiplier

Rollover Value Most Significant Digit (0999 x 10,000)

Rollover Value Least Significant Digit (09,999)

Number of Pulses to T

Output

Output 0 (words 4548) Output 1 (words 4952) Output 2 (words 5356) Output 3 (words 5760)

Output ON value Most Significant Digit (0999 x 10,000)

Output ON value Least Significant Digit (09,999)

Output OFF value Most Significant Digit (0999 x 10,000)

Output OFF value Least Significant Digit (09,999)

.

➁

Bit

ID & Resets

Run Initialize

rigger & Select

ie Output 1 to Channel

rigger & Select

ie Output 3 to Channel

Channel 2

Debounce

Filtering

ÉÉ

Minimum Frequency Sampling T

erminate Sampling

Highest Allowable Frequency

alue (what rate to trigger on)

➂

T

otal Scaler Multiplier

T

otal Scaler Divisor

➂

➂

Configuration

Overflow Reset

Output 0 T

Output 2 T

rigger T

rigger T

Channel 1

Acceleration Calculation Time

ime

Frequency Scaler Divisor

T

otal Reset

ie Output 0 to Channel

ie Output 2 to Channel

Channel 0

➂

word #

Publication

BTW Word Description Key

Bits

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Description of what these bits are used for.

Mode(s) that use these bits.

17716.5.99 - December 1995

Mode

abbreviations:

Totalizer = T

Nonresettable T

otalizer = NR

T

Highresolution Frequency = HR

Direction Sensor = DS

Page 37

word 1

4–3Configure the CFM Module

BTW Word Descriptions

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

0010

Header must be 0010.

Identifies the module as a

CFM module.

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

word 2

Output 1 Trigger selects what

channel characteristic output 1

is triggered ON or OFF by placing

the shown hex values in these bits:

0 = Force OFF

1 = Frequency

2 = % of Fullscale Frequency

3 = Acceleration

4 = Total Value

5 = Direction

DS

all

T,

all

T,

NR

T

NRT, HR

6 = Overflow

7 = Prover Running

T

, NR

T

8 = Prover Range

F = Force ON

all

Prover Run Initialize initializes the

channel for prover inputs on the Gate.

Also resets Store Count Value

(BTR words 13 & 14). Only occurs on a

change in bit state from a 0 to a 1.

This bit should remain ON (= 1) until the

prover is done or until the prover run is

aborted.

b08 = Counter 0 b10 = Counter 2

b09 = Counter 1 b11 = Counter 3

If this bit is OFF (= 0), a low to high transition

of the Gate will store the current count in

Store Count Value (BTR words 13 & 14).

T, NRT

Tie Output 1 to Channel ties

output 1 to operate according to

the state of a specific channel.

b08 = Counter 0 b10 = Counter 2

b09 = Counter 1 b11 = Counter 3

Output 0 Trigger selects what

channel characteristic output 0

is triggered ON or OFF by placing

the shown hex values in these bits:

0 = Force OFF

1 = Frequency

2 = % of Fullscale Frequency

3 = Acceleration

4 = Total Value

5 = Direction

6 = Overflow

7 = Prover Running

8 = Prover Range

F = Force ON

Overflow Reset resets the

overflow status of the module for

the appropriate counter on a 0 to 1

transition. Only occurs on a

change in bit state from a 0 to a 1.

b04 = Counter 0 b06 = Counter 2

b05 = Counter 1 b07 = Counter 3

T, NRT

all

T

T

, NR

, NRT, HR

T

DS

all

T

, NR

T

all

Total Reset resets the

total count for the

appropriate counter on a 0

to 1 transition.

Only occurs on a change

in bit state from a 0 to a 1.

b00 = Counter 0

b01 = Counter 1

b02 = Counter 2

b03 = Counter 3

T

Tie Output 0 to Channel

ties output 0 to operate

according to the state

of a specific channel.

b00 = Counter 0

b01 = Counter 1

b02 = Counter 2

b03 = Counter 3

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

word 3

Output 3 Trigger selects what

channel characteristic output 3

is triggered ON or OFF by placing

the shown hex values in these bits:

0 = Force OFF

1 = Frequency

2 = % of Fullscale Frequency

3 = Acceleration

4 = Total Value

5 = Direction

DS

all

T

all

, NR

T

, NRT, HR

T

6 = Overflow

7 = Prover Running

T

, NR

T

8 = Prover Range

F = Force ON

all

Tie Output 3 to Channel ties

output 3 to operate according to

the state of a specific channel.

b08 = Counter 0 b10 = Counter 2

b09 = Counter 1 b11 = Counter 3

Output 2 Trigger selects what

channel characteristic output 2

is triggered ON or OFF by placing

the shown hex values in these bits:

0 = Force OFF

1 = Frequency

2 = % of Fullscale Frequency

3 = Acceleration

4 = Total Value

5 = Direction

DS

T

all

all

, NR

T

, NRT, HR

T

6 = Overflow

7 = Prover Running

T

, NR

T

8 = Prover Range

F = Force ON

all

Publication

Tie Output 2 to Channel

ties output 2 to operate

according to the state of

a specific channel.

b00 = Counter 0

b01 = Counter 1

b02 = Counter 2

b03 = Counter 3

17716.5.99 - December 1995

Page 38

4–4 Configure the CFM Module

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

word 4

Operating Mode for Channel 3

Select a mode of operation on a per

channel basis by placing the shown

hex values in the proper bits:

word 5 (channel 0)

word 5 (channel 0)

word 15 (channel 1)

word 15 (channel 1)

word 25 (channel 2)

word 25 (channel 2)

word 35 (channel 3)

word 35 (channel 3)

Frequency in 10ths allows you

to select the precision of the

frequency returned in the BTR.

If set, the frequency is returned

with the LSD being in tenths,

while if 0, the LSD is in ones.

0

= frequency returned as 100, 123

1 = frequency returned as 100, 123.2

HR

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Operating Mode for Channel 2

0 = unused channel

1 = Totalizer 3 = Highresolution Frequency (channels 0 & 1 or 2 & 3)

2 = Nonresettable Totalizer 4 = Direction Sensor (channels 0 & 1 or 2 & 3)

➀

These modes are selected only via channel 0 or channel 2.

➁

If using both channels (0 & 1 and 2 & 3) for this mode, you cannot set sampling time for both = 4ms.

Sampling Termination

if set, enables the input

sampling to be terminated

on either a time base only

(BTW 6) or a set number

of input pulses (BTW 7)

depending on which

condition arises first.

HR

Bandwidth Limit if set, limits the minimum

frequency the CFM module is capable of reading

to 1/Minimum Frequency Sampling Time.

When 1: the worst case response time of the

module is decreased to approximately

2 x Minimum Frequency Sampling Time.

When 0: frequency range = 1Hz 100kHz

(worst case response time can be 2s at

extremely low frequencies)

0 = full frequency range (1Hz 100kHz)

1 = minimum frequency (1/Minimum Frequency Sampling Time)

all

Operating Mode for Channel 1

Debounce Filtering

debounces the Gate

input for a period of 1s.

The first low to high transition

of the gate will cause the

CFM module to take

appropriate action (no other

transitions will be seen for 1s).

0 = OFF / 1 = ON

T, NRT

Prover Type selects the type

of prover being used

(unidirectional or bidirectional):

0 = unidirectional (1 run, 2 switches)

1 = bidirectional (4 switch run)

T, NRT

4 x High Hertz if set, the Highest Allowable

Frequency entry is multiplied by 4 to enable

entries > 32,767.

For example, to get a 100,000 peak allowable

frequency, you set this bit and enter 25,000 in the

word containing the Highest Allowable Frequency

(BTW 8, 18, 28 or 38).

all

Operating Mode for Channel 0

➀

➀➁

Acceleration Calculation Time

calculates acceleration every Nth

frequency sample.

0 = acceleration rolling average over 5

samples

1750 = number of frequency samples

(BTW 9 Acceleration Alarm Value must

0 0).

For example, if you place a value of 7

here, the CFM module:

a. stores the 1st frequency calculation

b. subtracts this calculation from the

8th frequency sample

c. divides this remainder by the time

between samples and places the

result in BTR 11, 20, 29 or 38

d. stores the 8th frequency sample

and waits for the 15th sample

all

word 6 (channel 0)

word 16 (channel 1)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

word 26 (channel 2)

word 36 (channel 3)

Minimum Frequency Sampling Time specifies the minimum time the

CFM module spends to determine frequency (unless Number of Pulses to

Terminate Sampling is enabled in Highresolution Frequency mode, which may

allow the the input channel to end sampling earlier than the specified minimum).

Important: In Direction Sensor, this time is used to determine the maximum

sample time and the minimum frequency returned and does not

actually determine the time period for frequency sampling.

all

Publication

17716.5.99 - December 1995

RANGE: 4ms 1000ms (0 3 = DEFAULT)

DEFAULTS: HR, DS = 4ms / T, NRT = 100ms

The maximum sampling time is:

< 2s if the Bandwidth Limit is not enabled and

a signal < 1 Hz is applied (sample time [

Minimum Frequency Sampling Time + 1/frequency input)

< 2 x the Minimum Frequency Sampling Time

if

Bandwidth Limit is enabled and a very low input signal

frequency is applied (sample time [

Minimum Frequency Sampling Time + 1/frequency input)

Page 39

4–5Configure the CFM Module

word 7 (channel 0)

word 17 (channel 1)

word 27 (channel 2)

word 37 (channel 3)

word 8 (channel 0)

word 18 (channel 1)

word 28 (channel 2)

word 38 (channel 3)

word 9 (channel 0)

word 19 (channel 1)

word 29 (channel 2)

word 39 (channel 3)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Number of Pulses to Terminate Sampling applied when Sampling Termination (bit 13 of word 5, 15, 25 or 35)

is set. Causes the sampling to cease when the specified number of input pulses are received or the

Minimum Frequency Sampling Time is exceeded, which ever occurs first. RANGE: 032,767

Highresolution Frequency

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Highest Allowable Frequency the highest frequency allowed on the channel. When the specified frequency is

exceeded, the channel's overspeed alarm will activate. Also used to calculate Percent of Full Scale (BTR word 6,15,24,33).

RANGE: 0 32,767 DEFAULT: 0 (=120,000)

Used with the 4 x High Hertz (bit 12 of word 5, 15, 25, or 35) to have an effective range of 0120,000.

all

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

word 10 (channel 0)

word 20 (channel 1)

word 30 (channel 2)

word 40 (channel 3)

Acceleration Alarm Value determines at what acceleration values (Hz/s) the BTR alarm bits are activated.

The alarm bits occur when the absolute value of the acceleration exceeds the Acceleration Alarm Value.

This word also determines whether acceleration is calculated. A value of 0 deactivates all acceleration calculations.

RANGE: 0 32,767 (0 disables)

all

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Frequency Scaler➀ Multiplier the frequency value

returned in the BTR is multiplied by the specified value.

RANGE: 0255 DEFAULT: 1

all

Frequency Scaler Divisor the frequency value

returned in the BTR is divided by the specified value.

RANGE: 0255 DEFAULT: 1

all

Important: The Frequency Multiplier must be ≤ the Frequency Divisor.

Example:

If

Frequency Divisor = 50, Frequency Multiplier = 6 and frequency at the input = 75 Hz,

the scaled value returned will be 6/50(75) = 9

➀

When

scaling is used, all outputs are still controlled by the actual value (in example, 75Hz) not the scaled value (in example, 9).

Publication

17716.5.99 - December 1995

Page 40

4–6 Configure the CFM Module

word 11 (channel 0)

word 21 (channel 1)

word 31 (channel 2)

word 41 (channel 3)

word 12 (channel 0)

word 22 (channel 1)

word 32 (channel 2)

word 42 (channel 3)

word 13 (channel 0)

word 23 (channel 1)

word 33 (channel 2)

word 43 (channel 3)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Total Scaler➀ Multiplier the total

value returned in the BTR is multiplied by

the specified value.