Page 1

Installation Instructions

MicroLogix™ 1762-IA8 120V ac Input Module

Inside

Description.......................................................3

Installation........................................................4

Mounting..........................................................5

System Assembly .............................................7

Field Wiring Connections...................................7

I/O Memory Ma pping......................................10

Specifications.................................................11

Hazardous Location Considerations ................13

Environnements dang ereux.............................14

1762-IN002A-US-P

Page 2

2 MicroLogix™ 1762-IA8 120V ac Input Module

For More Information

For Refer to this Document Pub. No.

Information on installing, wiring, and

operating a MicroLogix 1200

Programmable Controller

Installation guide for the MicroLogix

1200 Programmable Controller.

Installation guide for the MicroLogix

1200 Memory Module and Real Time

Clock.

Installation guide for the 1762-OW8

Discrete Output Module

Installation guide for the 1762-IQ8

Discrete Input Module

Installation guide for the 1762-IF2OF2

Analog I/O Module

More information on proper wiring and

grounding techniques.

If you would like a manual, you can:

MicroLogix 1200 Programmable

Controllers User Manual

MicroLogix 1200 Programmable

Controllers Inst al lation

Instructions

MicroLogix 1200 Memory

Module and/or Real Time Clock

Installation Instructions

1762-OW8 Relay Outpu t Module

Installation Instructions

1762-IQ8 DC Input Module

Installation Instructions

1762-IF2OF2 Analog Input/

Outp ut Module Installation

Inst ructions

Industrial Automation Wirin g

and Grounding Guidelines

1762-UM001A-US-P

1762-IN006A-ML-P

1762-IN001A-US-P

1762-IN003A-US-P

1762-IN004A-US-P

1762-IN005A-US-P

1770-4.1

• downlo ad a fre e el ec tr o n ic ver s i on fro m the inter n et :

www.ab .c om /micrologix

or

www.theautomationbookstore.com

• purchase a printed manual by:

– conta cting your local distributor or Rockwell Automation representative

– visiting

– calling

1762-IN002A-US-P

1.800.963.9548

or

001.330.725.1574

www.theautomationbookstore.com

(USA/Canada)

(Outside USA/Canada)

and placing your order

Page 3

MicroLogix™ 1762-IA8 120V ac Input Module 3

Description

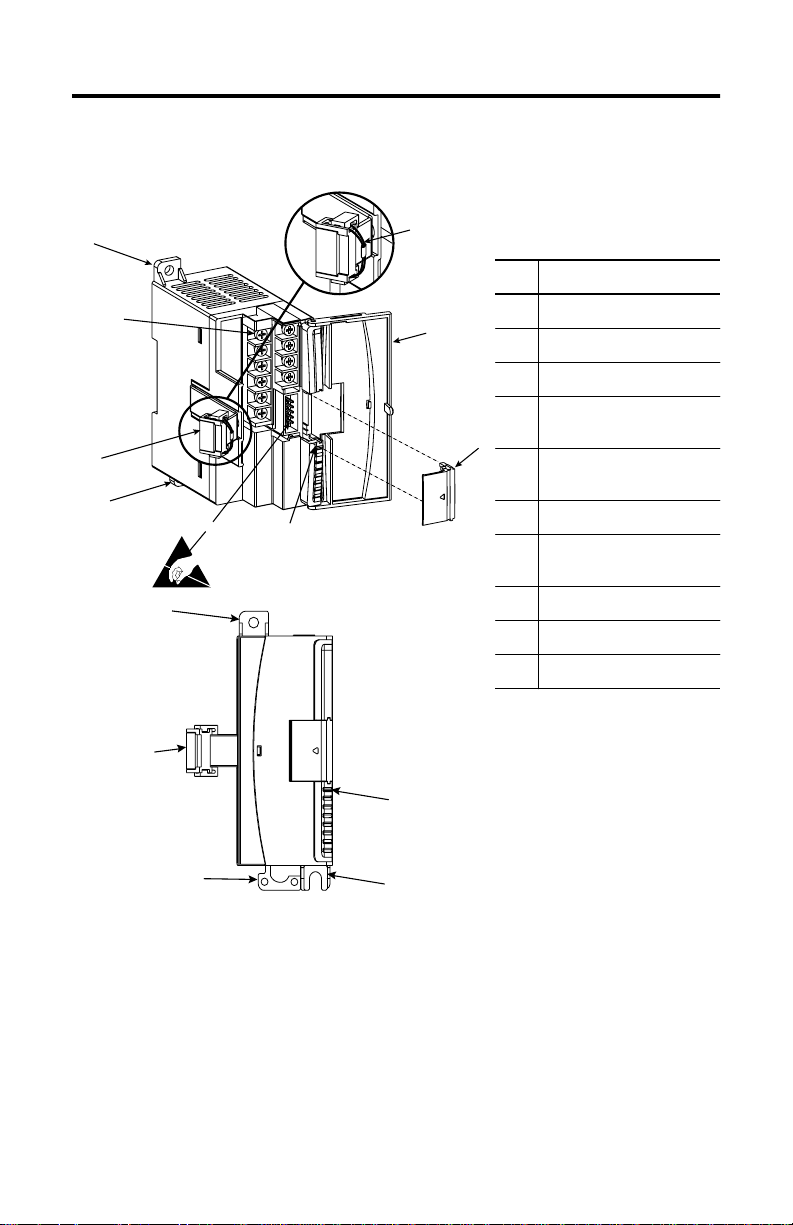

1a

9

Item Description

7

3

1a upper panel mounting tab

1b lower panel mounting tab

2 I/O diagno stic LEDs

3 module door with terminal

identification label

6

5

4 bus connecto r

with male pins

1b

4

2

5 bus connector cover

6 flat ribbon c able with bus

connector (female pins)

1a

7 terminal block

8 DIN rail latch

9 pull loop

6

2

8

1b

1762-IN002A-US-P

Page 4

4 MicroLogix™ 1762-IA8 120V ac Input Module

Installation

1762 I/O is suitable for use in an industrial environment whe n installed in

accord an ce with thes e in struction s . Sp e ci fic ally, this equipm en t is in tended for

use in clean, dry environmen ts (Pollution degree 2

exceeding Over Vo ltage Category II

(2)

(IEC 60664-1).

Prevent Electrostatic Discharge

(1)

) and to circuits not

(3)

!

Remove Power

!

ATTENTION:

circuits or semiconductors if you touch bus connector pins.

Follow these guidelines when you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding de vice.

• Do not touch the bus connector or connector pins.

• Do not touch circuit components insid e the module.

• If av ailable, use a static-safe work s tation.

• When not in use, keep the module in its static-shield box.

ATTENTION:

this module. When you remov e or install a module with power

applied, an electrical arc may occur. An electrical arc can cause

personal injury or property damage by:

• sending an erroneous signal to your system’s field devices ,

causing unintended machine motion

• causing an explosion in a hazardous environment

• causing permanent damage to the module’s circuitry

Electrical arcing causes excessive wear to contacts on both the

module and its mati ng connector. Worn contacts may create

electri cal resistan c e.

Electrostati c discharge can damage integrated

Remove po wer before removing or installing

(1)

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that

occasionally a temporary conductivity caused by condensation shall be expected.

(2)

Over Voltage C ateg ory II i s the l oad leve l se ction of t he elec tri c al dist ribution system. A t this lev el tr ans ient

voltages are controlled and do not exceed the impulse voltage capability of the product’s insulation.

(3)

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC)

designations.

1762-IN002A-US-P

Page 5

MicroLogix™ 1762-IA8 120V ac Input Module 5

Mounting

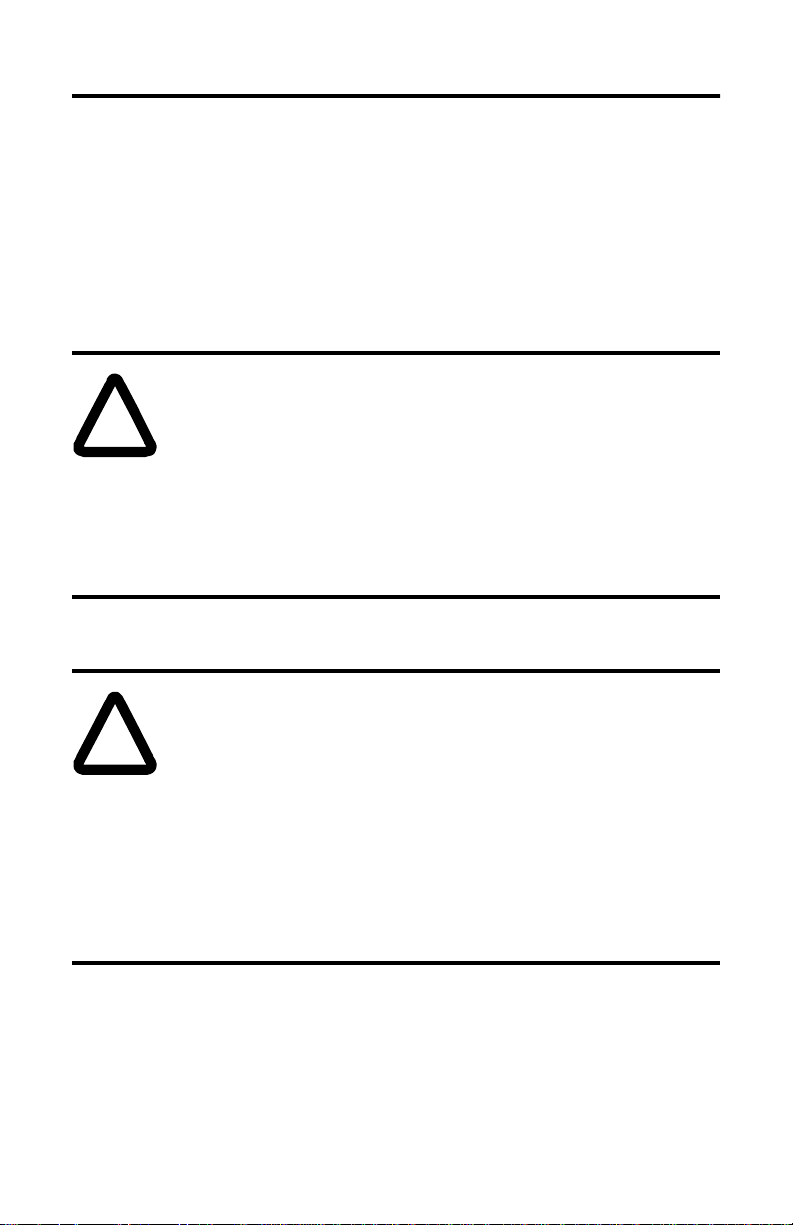

ATTENTION:

the module and a ll other e qui pment near t he module is mounte d a nd

!

wiring is complete. Once wiring is complete and the module is free

of debris, carefully remove protective debris strip. Failure to

remove strip before operating can cause overheating.

Minimum Spacing

Main ta in s p acing from

enclosure walls,

wireways, adjacent

equipment, et c. Allow

50.8 mm (2 in.) of space

on all side s for ad eq u at e

ventilation, as sho wn:

Note:

1762 expansion I/O ma y be mounted horizontally only.

ATTENTION:

be sure that all debris (metal chips, wire strands, etc.) is kept from

!

falling into the module. Debris that falls into the module could

cause damage when power is applied to the module.

Do not remove protective debris strip until after

Top

Side Side

During panel or DIN rail mounting of all device s,

MicroLogix

1200

1762 I/O

1762 I/O

Bottom

1762 I/O

1762-IN002A-US-P

Page 6

6 MicroLogix™ 1762-IA8 120V ac Input Module

DIN Rail Mounting

The module can be mounted us ing the following DIN rails: 35 x 7.5 mm

(EN 50 022 - 35 x 7.5) or 35 x 15 mm (EN 50 022 - 35 x 15).

Before mounting the module on a DIN rail, close the DIN rail lat ch. Press the

DIN rail mounting area of the module against the DIN rail. T he latch will

momentarily open and lock into place .

Use DIN rail end anchors (Allen-Bradley part number 1492-EA35 or

1492-EAH35) for vibrati on or shock environ ments .

End Anchor

End Anchor

Note:

For environ ments with greater vi bration and shock concerns , use the

panel mounting method des cribed below, instead of DIN rail

mounting.

Panel Mounting

Use the dimensiona l template shown bel ow to mount the module. Th e preferred

mounting method is to use two M4 or #8 pa nhe ad scre ws per modul e. M3.5 or #6

panhead screws may also be used, but a washer may be needed to ensure a good

ground current. Mounting screws are required on every module.

For more than 2 modules: (number of modules - 1) x 40 mm (1.58 in.)

100

90

(3.94)

(3.54)

1762-IN002A-US-P

14.5

(0.57)

Controller

MicroLogix 1200

40.4

(1.59)

Expansion I/O

MicroLogix 1200

MicroLogix 1200

40.4

(1.59)

Expansion I/O

Expansion I/O

MicroLogix 1200

NOTE: All

dimensions are in

mm (inches). Hole

spacing tolerance:

±0.4 mm

(0.016 in.).

Page 7

MicroLogix™ 1762-IA8 120V ac Input Module 7

System Assembly

The expansi on I/O module is attache d to the controller or another I/O module by

means of a fl a t rib b on ca bl e after mounting as shown below.

Note:

Use the pull loop on the connector to disconnect modules. Do not pull

on the ribbon cable.

ATTENTION: EXPLOSION HAZARD

!

• In Class I, Division 2 applications, the bus connector m ust be

fully seated and the bus connector cover must be snapped in

place.

• In Class I, Division 2 appli cations, al l modules must be mounted

in direct contact with each other as shown on page 6. If DIN rail

mounting is used, an end stop must be installed ahead of the

controller and after the last 1762 I/O module.

Field Wiring Connections

Grounding the Module

This product is intended to be mounted to a well-grounded mounting surface

such as a metal panel. Additional grounding connections from the module’s

mounting tabs or DIN rail (if used) are not required unless the mounting surface

cannot be grounde d. Re fer to Industrial Automation Wiri ng and Grounding

Guidelines, All en-Bradley publication 1770-4.1, for additional information.

1762-IN002A-US-P

Page 8

8 MicroLogix™ 1762-IA8 120V ac Input Module

Input Wiring

Basic wiring

A write-on label is provided with the module. Mark the identification of ea ch

terminal with permanent ink, and slide the label back into the door.

(1)

of input devices to the 1762-IA8 is shown below.

L1

IN 0

IN 1

IN 2

100/120V ac

L2

IN 3

IN 5

IN 7

AC

COM

AC

COM

IN 4

IN 6

Commons are

connected

internally.

ATTENTION:

Be careful when stripping wires. W ire fragments

that fall into a mo dule could cause damage when power is ap plied.

!

(1)

A current limit ing res is tor can b e used t o limi t inru sh c urr ent; h owev er, the op erati ng c har acteri sti cs of th e

ac input circuit will be affec ted. If a 6.8K Ω resistor is placed in series w ith the input , the inru sh curren t is

reduced to 35 mA. In this configuration the minimum on-state voltage increases to 92V ac.

Before adding the resistor in a hazardous environment, be sure to consider the operating temperature of

the resistor and the temperature limits of the environment. The operating temperature of the resistor

must remain below the temperature limit of the environment.

1762-IN002A-US-P

Once wiring is complete, ensure the module is free of all meta l

fragments.

Page 9

MicroLogix™ 1762-IA8 120V ac Input Module 9

Note: Fi nger-safe cover not shown.

Wiring the Finger-Safe Terminal Block

When wiring the terminal block, keep the finger-safe cover in place.

1. Rou te the wire unde r the te rmina l pressure pla te. You can use the strippe d end

of the wire or a spade lug. The termi nals will accept a 6.35 mm (0.25 in. )

spade lug.

2. Tighten the termi n al sc r ew mak i n g s u re th e pr essure plat e secures the wir e.

Recommended torque when tigh tening terminal screws is 0.904 Nm

(8 in-lbs).

Note:

If you need to remove the finger-safe cover, insert a screw driver into

one of the square wiring holes and gently pry the cover off. If you wire

the terminal block with the finger-s afe cover remov ed, you will not be

able to put it back on the t erminal block beca use the wires will be in the

way.

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions:

Wire Type Wire Size Terminal Screw Torque

Solid Cu-90°C (194°F) #14 to #22 AWG 0.904 Nm (8 in-lbs)

Stranded Cu-90°C (194°F) #16 to #22 AWG 0.904 Nm (8 in-lbs)

1762-IN002A-US-P

Page 10

10 MicroLogix™ 1762-IA8 120V ac Input Module

I/O Memory Mapping

Input Data File

For each input module, the input data file contains the curre nt state of the field

input points. Bit positions 0 through 7 correspond to input terminals 0 through 7.

Bit Position

1514131211109876543210

Word

000000000r rrrrrrr

r = read only, 0 = always at a 0 or OFF state

Addressing

The addressing scheme for 1762 Expansion I/O is shown below.

(1)

Word (always zero for this module)

Data File

Slot Number

Input

Bit (0 - 7)

I1:x.0/0

Slot Delimiter

(1) I/O locate d on the controller (embedded I/O) is slot 0. I/O added to the controller (expansion I/O) begins

with slot 1.

1762-IN002A-US-P

Word Delimiter

Bit Delimiter

Page 11

MicroLogix™ 1762-IA8 120V ac Input Module 11

Specifications

General Specifications

Specification Value

Dimensions 90 mm (height) x 87 mm (depth) x 40 mm (width)

Approximate Shipping Weight

(with carton)

Storage Temperature -40°C to +85°C (-40°F to +185°F)

Operating Temperature 0°C to +55°C (-32°F to +131°F)

Operating Humidity 5% to 95% non-condensing

Operating Altitude 2000 meters (6561 feet)

Vibration Operating: 10 to 500 Hz, 5G, 0.030 in. max. peak-to-peak

Shock Operating: 30G panel mounted

Agency Certification C-UL certified (under CSA C22.2 No. 142)

Hazardous Environment Class Class I, Division 2, Hazardous Location, Groups A, B, C, D

Noise Imm unity NEMA standard ICS 2-230

Radiated and Conducted Emissions EN50081-2 Class A

Electrica l /EMC: The module has passed testing at the following levels:

ESD Immunity (IEC1000-4-2) 4 kV contact, 8 kV air, 4 kV indirect

Radiated Immunity (IEC1000-4-3) 10 V/m, 80 to 1000 MHz, 80% amplitude modulation,

Fast Transient Burst (IEC1000-4-4) 2 kV, 5 kHz

Surge Immunity (IEC1000-4-5) 2 kV common mode, 1 kV differential mode

Conducted Immunity (IEC1000-4-6)

(1)

Conducted Immunity frequency range may be 150 kHz to 30 MHz if the Radiated Immunity frequency

range is 30 MHz to 1000 MHz.

height including mounting tabs is 110 mm

3.543 in. (height) x 3.425 in. (depth) x 1.575 in. (width)

height including mounting tabs is 4.33 in.

209 g (0.46 lbs.)

UL 508 listed

CE compliant for all applicable directives

(UL 1604, C-UL under CSA C22.2 No. 213)

+900 MHz keyed carrier

10V, 0.15 to 80 MHz

(1)

1762-IN002A-US-P

Page 12

12 MicroLogix™ 1762-IA8 120V ac Input Module

Input Specifications

Specification 1762-IA8

Voltage Category 100/120V ac

Operating Voltage Range 79V ac to 132V ac at 47 Hz to 63 Hz

Number of Inputs 8

Bus Current Draw (max.) 50 mA at 5V dc (0.25W)

Heat Dissipation (max.) 2.0 Total Watts

Signal Delay (max.) On Delay: 20.0 ms

Off-State Voltage (max.) 20V ac

Off-State Current (max.) 2.5 mA

On-State Voltage (min.) 79V ac (min.) 132V ac (max.)

On-State Current 5.0 mA (min.) at 79V ac 47 Hz

Inrush Current (max.) 250 mA

Nominal Impedance 12K

IEC Input Compatibility Type 1+

Power Supply Distance Rating 6

Isolated Groups Group 1: inputs 0 to 7 (internally connected commons)

Input Group to Backplane

Isolation

Vendor I.D. Code 1

Product Type Code 7

Product Code 114

Off Delay: 20.0 ms

12.0 mA (nominal) at 120V ac 60 Hz

16.0 mA (max.) at 132V ac 63 Hz

Ω

at 50 Hz

10K Ω at 60 Hz

Verified by one of the following dielectric tests: 1517V ac for 1

sec. or 2145V dc for 1 sec.

132V ac working voltage (IEC Class 2 reinforced insulation)

1762-IN002A-US-P

Page 13

MicroLogix™ 1762-IA8 120V ac Input Module 13

Hazardous Location Considerations

This equipment is suitable for use in Clas s I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following ATTENTION statement applies to

use in hazardous locations.

ATTENTION:

!

• Substitution of components may impair suitability for Class I,

Division 2.

• Do not replace components or disconnect equip me nt unless

power has been switched off.

• Do not connect or disconnect components unless power has

been switched off.

• This product must be ins talled in an enclosure.

• In Class I, Division 2 applications, the bus connector m ust be

fully seated and the bus connector cover must be snapped in

place.

• In Class I, Division 2 applications, all modules must be

mounted in direct con tact with each other as sho w n on page 6.

If DIN rail mounting is used, an end stop must be installed

ahead of the controller and after the last 1762 I/O module.

EXPLOSION HAZARD

1762-IN002A-US-P

Page 14

14 MicroLogix™ 1762-IA8 120V ac Input Module

Environnements dangereux

Cet équipement est conçu pour être utilisé dans des environnements d e Classe I,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

s’applique à une utilisation dans des environnements dangereux.

ATTENTION:

!

• La substituti on de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe I,

Division 2.

• Ne pas remplacer de composants ou déconnecter l'équipement

sans s'être assu ré que l'alimentation est coupée.

• Ne pas connecter ou déconne cter des composants san s s'être

assuré que l'alimentation est coupée.

• Ce produit doit être installé dans une armoire .

• Pour les applications de Classe I, Division 2, le connecteur de

bus doi t être corr ectement installé et son co u vercle en clenché.

• Pour les applications de Classe I, Division 2, tous les modules

doivent être installés en contact direct les uns avec les autres,

comme indiqué page 6. Si on utilise le montage sur rail DIN,

une butée doit être placée à l'avant de l'automate et après la

dernière unité d'E/S 1762.

DANGER D’EXPLOSION

1762-IN002A-US-P

Page 15

MicroLogix™ 1762-IA8 120V ac Input Module 15

1762-IN002A-US-P

Page 16

MicroLogix is a trademark of Rockwell Automation.

Publication 1762-IN002A-US-P - September 1999 PN 40071-070-01(A)

© (1999) Rockwell International Corporation. Printed in the U.S.A.

´H'*f!¶Ae¨

Loading...

Loading...