Page 1

Installation Instructions

1747-SDN DeviceNet Scanner Module

Catalog Number 1747-SDN, Series D

Topic Page

Important User Information 2

Safety Guidelines 2

About the 1747-SDN, Series D DeviceNet Scanner Module 4

Before You Begin 7

Install DeviceNet Scanner Module 9

Interpret the LED Indicators 12

Numeric Codes and Descriptions 14

Specifications 16

Additional Resources 18

Publication 1747-IN058F-EN-P - December 2010

Page 2

2 1747-SDN DeviceNet Scanner Module

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

) describes some important differences between solid state

Safety Guidelines

Publication 1747-IN058F-EN-P - December 2010

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you to identify a hazard,

avoid a hazard, and recognize the consequences.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

Page 3

1747-SDN DeviceNet Scanner Module 3

ATTENTION

ATTENTION

Follow these guidelines for environment and enclosure information for this equipment.

This equipment is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in IEC

publication 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according

to IEC/CISPR Publication 11. Without appropriate precautions, there may be

potential difficulties ensuring electromagnetic compatibility in other

environments due to conducted as well as radiated disturbance.

This equipment is supplied as open type equipment. It must be mounted within

an enclosure that is suitably designed for those specific environmental

conditions that will be present and appropriately designed to prevent personal

injury resulting from accessibility to live parts. The enclosure must have

suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA, V2, V1, V0 (or equivalent) if

non-metallic. The interior of the enclosure must be accessible only by the use

of a tool. Subsequent sections of this publication may contain additional

information regarding specific enclosure type ratings that are required to

comply with certain product safety certifications.

In addition to this publication, see:

Follow these guidelines when you handle this equipment.

• Industrial Automation Wiring and Grounding Guidelines, Rockwell

Automation publication 1770-4.1

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the

degrees of protection provided by different types of enclosure.

This equipment is sensitive to electrostatic discharge that can cause internal

damage and affect normal operation. Follow these guidelines when you handle

this equipment.

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wrist strap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation if available.

• Store the equipment in appropriate static-safe packaging when not in use.

, for additional installation requirements.

Publication 1747-IN058F-EN-P - December 2010

Page 4

4 1747-SDN DeviceNet Scanner Module

ATTENTION

To comply with UL restrictions, this equipment must be powered from a source

compliant with the following:

Class 2 or Limited Voltage/Current.

About the 1747-SDN, Series D DeviceNet Scanner Module

The 1747-SDN, Series D module includes these firmware enhancements.

• ADR user memory space increased from 64K to 256K

• Support added for Online Scanlist Changes in Run Mode. This feature allows scanlist

changes to be downloaded to the scanner when the both the SLC processor and the

scanner are in RUN mode.

• Scanner CCV attribute supported, provides optimization for RSNetWorx.

Refer to the SLC 500 DeviceNet Scanner Module User Manual, publication

1747-UM655

The 1747-SDN Series D module includes all features provided in the Series C module. The

module has the following software and hardware features.

, for additional information on these new enhancements.

Software Features

The module has these software features.

Slave Mode

Slave mode allows processor-to-processor communication and enables the scanner to

perform as a slave device to another master on the network.

When the scanner module is in slave mode, it exchanges data with only one master. You

control what information is exchanged through scan list configuration and associated

mapping functions of RSNetWorx for DeviceNet software.

Publication 1747-IN058F-EN-P - December 2010

Page 5

1747-SDN DeviceNet Scanner Module 5

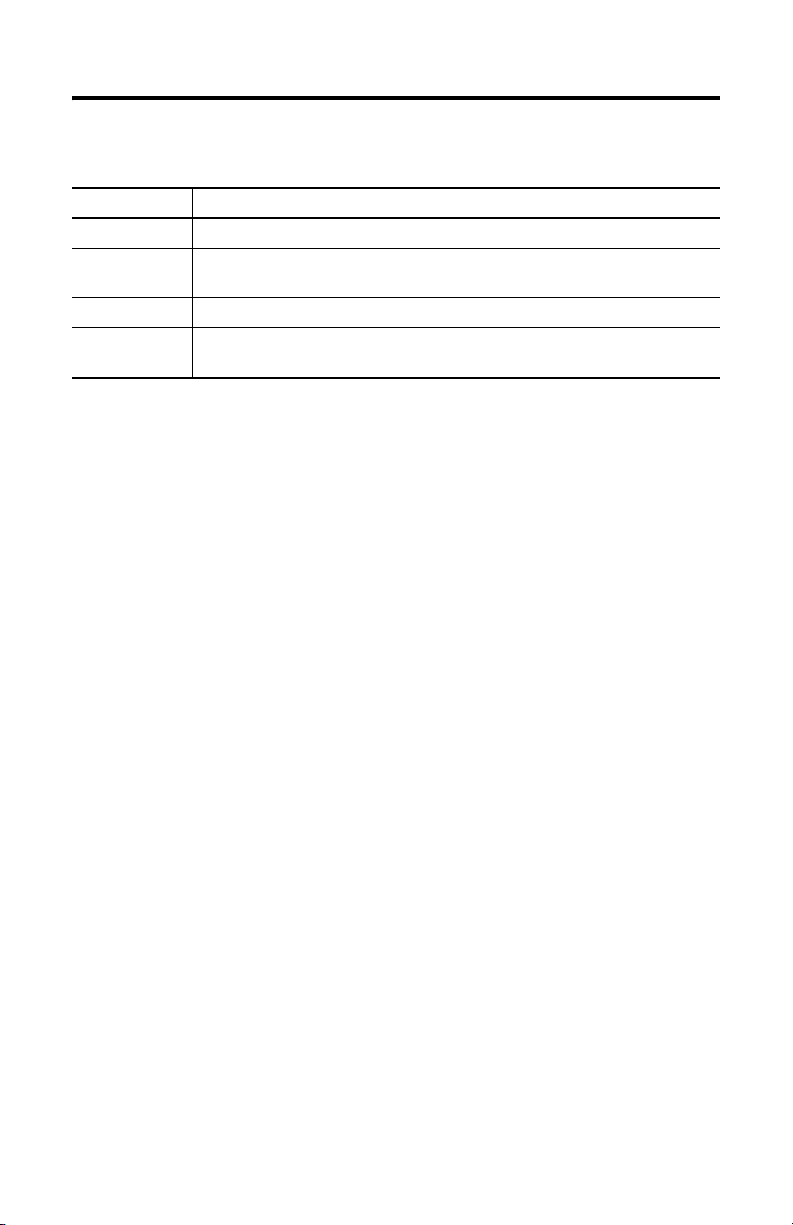

This feature has the following variations.

Module Mode Description

Null Contains an empty or disabled scan list (default)

Master Serves as a master to one or more slaves but is not simultaneously serving as a slave to

another master

Slave Serves as a slave to another master

Dual Serves as both a master to one or more slaves and as a slave to another master

simultaneously

Poll

A poll message is a point-to-point transfer of data (0…255 bytes) sent by the scanner module

that solicits a response from a single device. The device responds with its input data

(0…255 bytes).

Strobe

A strobe message is a multicast transfer of data (64 bits in length) sent by the scanner module

that solicits a response from each strobed slave device. There is one bit for each of the

possible 64 node addresses. The devices respond with their data, which can be as much as

8bytes.

Change of State

Change of state enables the scanner module to perform a scan:

• whenever a network data change occurs.

• at a user-configurable heartbeat rate.

Because data is only sent on an as-needed basis, this feature increases system performance by

reducing network traffic.

Cyclic I/O

Cyclic I/O allows you to instruct the scanner module to perform a scan at a specific send rate.

Because data is only sent at a periodic rate, this feature increases system performance by

reducing network traffic.

Publication 1747-IN058F-EN-P - December 2010

Page 6

6 1747-SDN DeviceNet Scanner Module

Pass-through

The SLC 500 pass-through feature allows communication with the DeviceNet network from

another network. This feature can be used to adjust and fine tune the nodes on your network.

The pass-through feature is not intended to replace a 1770-KFD, 1784-PCD, 1784-PCID, or

1784-PCIDS connection to the network.

To use the pass-through feature you must meet the following hardware, software and

firmware requirements.

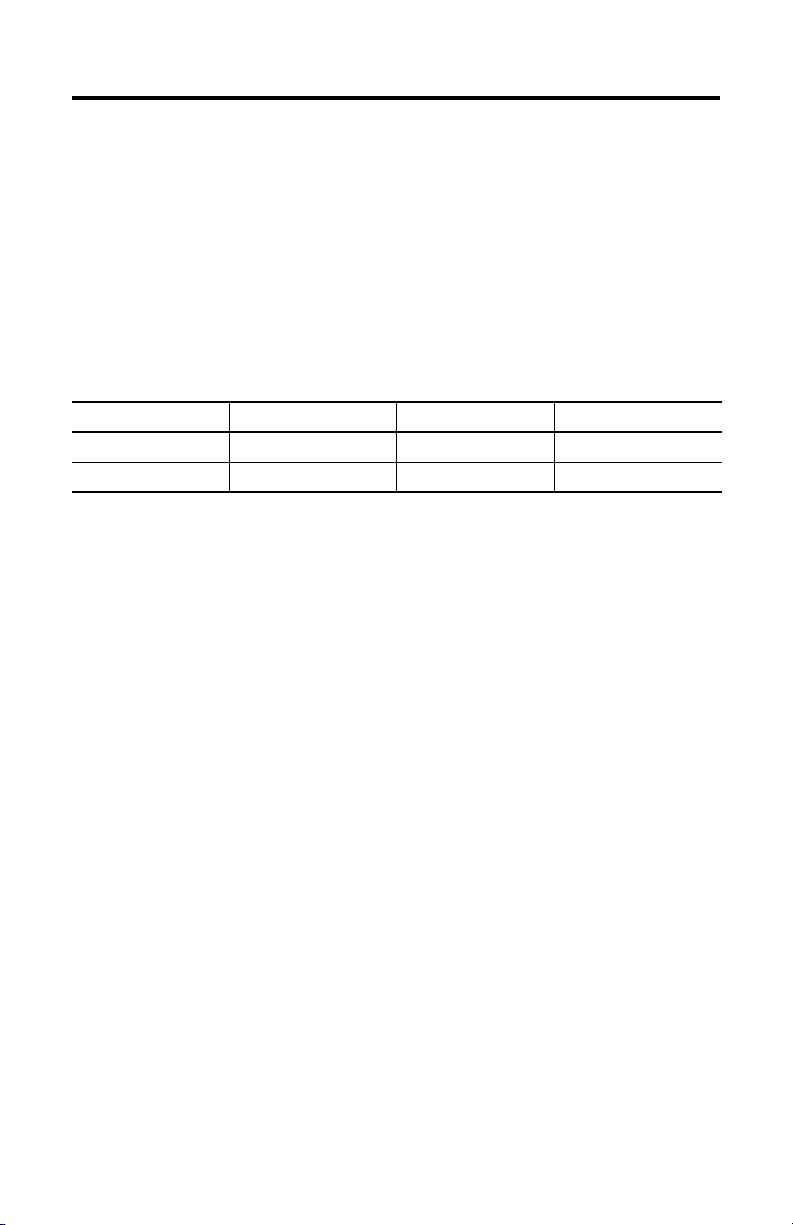

Pass-through Requirements

SLC 500 Processor 1747-SDN Firmware RSLinx Software M0 and M1 Files

SLC 5/03 or later 4.015…5.001 2.10 or later Configured for 361 words

SLC 5/03 or later 6.001 or later 2.31 or later Configured for 395 words

U2DN module

The pass-through feature is not intended to replace a 1784-U2DN, 1770-KFD, 1784-PCD,

1784-PCID, or 1784-PCIDS connection to the network.

Publication 1747-IN058F-EN-P - December 2010

Page 7

1747-SDN DeviceNet Scanner Module 7

DeviceNet

STATUS

MODULE

NET

ADDRESS/ERROR

Module Status indicator

indicates module status

Node address and status

displays numeric codes

and indicates scanner

node address or error

Network Status indicator indicates status

of DeviceNet channel communication link

Access door

Wiring color codes

10-pin linear plug inserted

into DeviceNet port

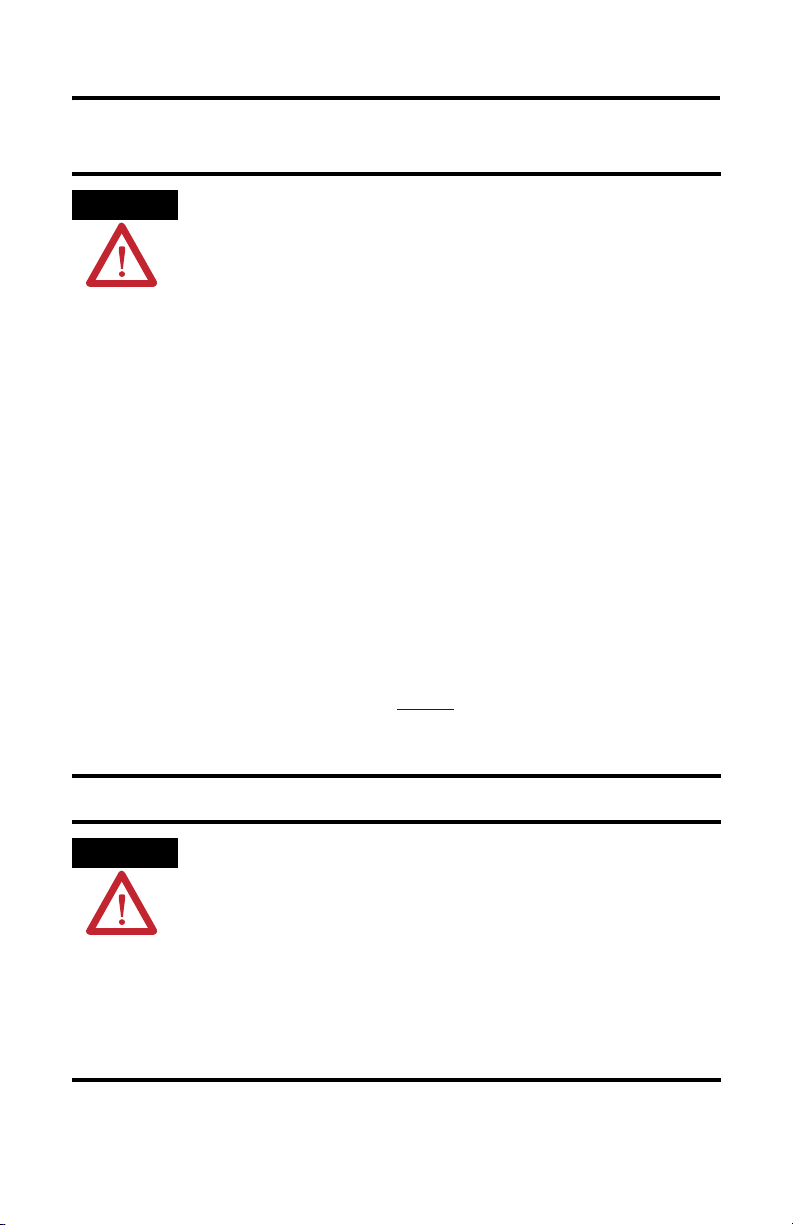

Hardware Features

Use this illustration to identify the external features of the scanner module.

Before You Begin

Before you install your module you need the following items.

• Personal computer with Microsoft Windows 2000 or later operating system

• RSNetWorx for DeviceNet software, version 2.22 or later

• RSLogix 500 software

• SLC 1746 chassis with SLC 5/02, SLC 5/03, SLC 5/04, or SLC 5/05 processor

Publication 1747-IN058F-EN-P - December 2010

Page 8

8 1747-SDN DeviceNet Scanner Module

For network communication, you have three options.

• Use the pass-through feature to communicate with the DeviceNet network from

another network. This method is intended for fine tuning and adjustment of network

devices.

• Use a 1770-KFD RS-232 DeviceNet adapter or 1784-PCD, 1784-PCID, or

1784-PCIDS DeviceNet PC card. This method is necessary for a complete network

configuration and real time monitoring of your network devices.

• Use a 1784-U2DN USB adapter, a 1770-KFD RS-232 DeviceNet adapter or

1784-PCD, 1784-PCID, or 1784-PCIDS DeviceNet PC card. This method is

necessary for a complete network configuration and real time monitoring of your

network devices.

Before you install your module you must know how to:

• program and operate an Allen-Bradley SLC 500 programmable controller.

• install and configure the devices on your DeviceNet network.

Electronic Data Sheet Requirement

This release of the scanner module requires the latest EDS file for RSLinx Classic and

RSNetWorx for DeviceNet software. If the software displays the device as an

Unrecognized Device, the EDS file must be installed.

You can download the latest EDS file online at:

http://www.ab.com/networks/eds

For FRN 8.002 and later, you can upload the embedded EDS file from the scanner module

itself.

1. Open RSLinx Classic or RSNetWorx for DeviceNet software and right click on the

Unrecognized Device.

2. Select Upload EDS file from device for RSLinx Classic software or Register

Device for RSNetWorx for DeviceNet software.

3. Follow the instructions in the EDS wizard to complete the installation.

Perform a ControlFLASH Update

If you want to upgrade the scanner module to a newer firmware release, you must perform a

ControlFLASH update. To get the kit, contact Rockwell Automation Technical Support at

Publication 1747-IN058F-EN-P - December 2010

Page 9

1747-SDN DeviceNet Scanner Module 9

IMPORTANT

IMPORTANT

WARNING

440.646.5800. To install the kit, refer to the ControlFLASH Firmware Upgrade Kit User

Manual, publication 1756-QS105.

You can update Series A and B scanner modules up to FRN 7.006. Series C

scanner modules support only FRN 8.001 to 8.006. Series D scanner modules

support FRN 9.001 and later.

Confirm Processor and Adapter Compatibility

Make sure that your processor and adapter are compatible. You can use the 1747-SDN

scanner module in any slot in an I/O chassis except for the leftmost, which is reserved for the

SLC 500 processor.

You cannot use the scanner module in a remote I/O chassis with a 1747-ASB

adapter module. The adapter module does not support M-file transfer.

Install DeviceNet Scanner Module

Follow these steps to install the module.

1. Turn off the chassis power supply.

If you insert or remove the module while backplane power is on, an electrical

arc can occur. This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

2. Select a slot for the module in the chassis.

You may use any slot except the leftmost slot, which is reserved for the SLC 500

processor.

Publication 1747-IN058F-EN-P - December 2010

Page 10

10 1747-SDN DeviceNet Scanner Module

ATTENTION

3. Insert the module into the slot you have selected.

4. Apply firm, even pressure to seat the module in the I/O chassis backplane

connectors.

Connect the Module to the DeviceNet Network

Follow these steps to connect the module to the DeviceNet network.

Publication 1747-IN058F-EN-P - December 2010

To comply with the CE Low Voltage Directive (LVD), DeviceNet must be

powered from a source compliant with the following:

• Safety Extra Low Voltage (SELV)

• Protected Extra Low Voltage (PELV).

To comply with UL restrictions, DeviceNet must be powered from a source

compliant with the following:

• Class 2

• Limited Voltage/Current.

1. Turn off the network power supply.

Page 11

1747-SDN DeviceNet Scanner Module 11

WARNING

+24V Red

Can_H White

Drain/Shield

Can_L Blue

+24V Return Black

Front of Module

10-pin linear

plug

Red

White

Shield

Blue

Black

10-pin Linear plug

DeviceNet drop line

DeviceNet port

connector

If you connect or disconnect the communications cable with power applied to

this module or any device on the network, an electrical arc can occur. This could

cause an explosion in hazardous location installations.

2. Connect the DeviceNet drop line to the 10-pin linear plug by matching the wire

insulation colors to the colors shown on the label.

3. Locate the DeviceNet port connector on the front of the module.

4. Insert the 10-pin linear plug into the DeviceNet port connector.

You have installed and wired your module. To operate the module you must apply power and

then configure and program the SLC processor to communicate with it.

Publication 1747-IN058F-EN-P - December 2010

Page 12

12 1747-SDN DeviceNet Scanner Module

DeviceNet

STATUS

MODULE NET

ADDRESS/ERROR

Module

Numeric

Indicators

Apply Chassis Power

When you apply chassis power, the module numeric indicators cycle through the following

displays.

• Seven-segment lamp test (88)

• Firmware major revision (01…7F hexadecimal)

• Firmware minor revision (01…FF hexadecimal)

• Communication rate (indicates 00 for the default of 125, 01 for 250, or 02 for

500 Kbps)

• Node address (00…63 with 63 as the default)

Use the RSNetWorx for DeviceNet software to change the communication rate and node

address.

Refer to the Numeric Code Display Summary table on page 14 for a complete listing of

numeric displays.

Interpret the LED Indicators

The bicolor (green/red) module status indicator (MODULE) on the front of your module

displays module status. It indicates whether the module has power and is functioning

properly.

Module Status LED Indicator

Indicator Color Description Corrective Action

Off There is no power applied to the

Green The module is operating normally. No action required.

Flashing Green The module is not configured. Configure the module.

Flashing Red There is an invalid configuration. Check configuration setup.

Red The module has an unrecoverable

Publication 1747-IN058F-EN-P - December 2010

module.

fault.

Verify power connections and apply

power.

Replace the module.

Page 13

1747-SDN DeviceNet Scanner Module 13

The DeviceNet channel has a bicolor (green/red) network status indicator (NET). The

following table provides troubleshooting information about the DeviceNet channel

communication link.

DeviceNet Channel Communication

Indicator

Color

Off The channel is disabled for

Green All slave devices in the scan

Flashing

Green

Flashing

Red

Red The module may be

Description Device Operation Corrective Action

DeviceNet communication.

list table are communicating

normally with the module.

The channel is enabled but

no communication is

occurring.

At least one of the slave

devices in the module’s scan

list table has failed to

communicate with the

module.

defective.

The device has no power or

the channel is disabled for

communication due to bus off

condition, loss of network

power, or has been

intentionally disabled.

Normal operation. None.

The two-digit numeric display

for the channel indicates an

error code that provides more

information about the

condition of the channel.

The two-digit numeric display

for the channel displays an

error code that provides more

information about the

condition of the channel.

The communications channel

has failed. The two-digit

numeric display for the

channel displays an error code

that provides more information

about the condition of the

channel.

Power-up the module, provide

network power to the channel,

and be sure the channel is

enabled in both the module

configuration table and the

module command word.

Configure the scan list table

for the channel to add devices.

Examine the failed device and

the scan list table for accuracy.

Reset module. If failures

persist, replace module.

Publication 1747-IN058F-EN-P - December 2010

Page 14

14 1747-SDN DeviceNet Scanner Module

Numeric Codes and Descriptions

Your module uses numeric displays to indicate diagnostic information about the status of

your module. The display flashes at 1-second intervals. The following table summarizes the

meanings of the numeric codes.

Numeric

Code

0…63 Normal operation. The numeric display

70 Module failed Duplicate Node Address check. Change the module channel address to another

71 Illegal data in scan list table (node number

72 Slave device stopped communicating (node

73 Identity information for the device does not

74 Data overrun on port detected. Modify your configuration and check for invalid

75 No traffic from other modules detected on the

76 No direct network traffic for module detected. None. The module detects other network

77 Data size expected by the device does not

78 Slave device in scan list table does not exist. Add the device to the network, or delete the

79 Module has failed to transmit a message. Make sure that your module is connected to a

80 Module is in Idle mode. Put controller in Run mode. Enable Run bit in

81 Module is in Fault mode. Check Module Command Register for fault bit

Description Corrective Action

None.

indicates the 1747-SDN node address on the

DeviceNet network.

available one. The node address you selected

is already in use on that channel.

Reconfigure the scan list table and remove any

alternately flashes).

number alternately flashes).

match electronic key in scan list table entry.

network.

match scan list entry.

illegal data.

Inspect the field devices and verify

connections.

Verify that the correct device is at this node

number. Make sure that the device at the

scrolling node address matches the desired

electronic key (vendor, product code, product

type).

data. Check network communication traffic.

Check the network configuration. Scanlist may

be empty.

communication.

Reconfigure your module for the correct

transmit and receive data sizes.

scan list entry for that device.

valid network.

Check for disconnected cables.

module command register.

set.

Publication 1747-IN058F-EN-P - December 2010

Page 15

1747-SDN DeviceNet Scanner Module 15

Numeric

Code

82 Error detected in sequence of fragmented I/O

83 Slave device is returning error responses when

84 Module is initializing the DeviceNet network. None. This code clears itself once module

85 Data size was incorrect for this device at

86 Device is producing zero length data (idle

87 The primary owner has not allocated the slave. Put the primary owner online.

88 The connection choices (polled, strobed)

89 Slave device initialization using Auto Device

90 User has disabled communication port. Check Module Command Register for DISABLE

91 Bus-off condition detected on comm port.

92 No network power detected on communication

95 Application FLASH update in progress. None. Do not disconnect the module while

97 Module operation halted by user command. Check Module Command Register for HALT bit

Description Corrective Action

Check scan list table entry for slave device to

messages from device.

module attempts to communicate with it.

runtime.

state) while module is in Run mode.

between the primary connection and the

shared input only connection do not match.

Replacement parameters failed.

Module is detecting communication errors.

port.

make sure that input and output data lengths

are correct. Check slave device configuration.

Check accuracy of scan list table entry. Check

slave device configuration. Slave device may

be in another master’s scan list. Reboot slave

device.

attempts to initialize all slave devices on the

network.

Slave device is transmitting incorrect length

data.

Verify device is not configured for variable poll

connection size.

Try replacing the device.

Check device configuration and slave node

status.

Reconfigure the shared input-only connection

choices to be the same as, or a subset of, the

choices for the primary connection.

Put the slave device into configurable mode.

If the slave is configured offline, check its EDS

file.

Check to see if the slave device has been

replaced with an incompatible device.

bit set.

Check DeviceNet connections and physical

media integrity. Check system for failed slave

devices or other possible sources of network

interference.

Provide network power. Make sure that

module drop cable is providing network power

to module comm port.

application FLASH is in progress. You will lose

existing data in the module memory.

set.

Publication 1747-IN058F-EN-P - December 2010

Page 16

16 1747-SDN DeviceNet Scanner Module

Numeric

Code

98 Unrecoverable firmware failure. Service or replace your module.

99 Unrecoverable hardware failure. Service or replace your module.

E2 RAM Test Failure Service or replace your module.

E4 Lost power during FLASH upgrade Service or replace your module.

E5 No application code Service or replace your module.

E9 Module memory has been flushed for factory

Description Corrective Action

Cycle module power to recover.

default settings.

Specifications

SLC DeviceNet Scanner — 1747-SDN

Attribute Value

Module location SLC 5/02 or later chassis

Module defaults Node Address – 63

Power consumption

- Backplane current

- DeviceNet

Isolation voltage 30V (continuous), Basic Insulation Type

Temperature, operating IEC 60068-2-1 (Test Ad, Operating Cold),

Temperature, non-operating IEC 60068-2-1 (Test Ab, Unpackaged Nonoperating Cold),

Relative humidity IEC 60068-2-30 (Test Db, Unpackaged Damp Heat):

Vibration IEC60068-2-6 (Test Fc, Operating):

Shock IEC60068-2-27:1987, Test Ea (Unpackaged shock, ES#002)

Baud Rate – 125 Kbps

5V DC, 500 mA

24V DC, 90 mA Class 2

Tested at 500V AC for 60 s, DeviceNet to backplane

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

o

0…60

C (32…140 oF)

IEC 60068-2-2 (Test Bc, Unpackaged Nonoperating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Nonoperating Thermal Shock):

o

-40…85

C (-40…185 oF)

5…95% non-condensing

2 g @10…500 Hz

Operating — 30 g

Non-operating — 50 g

Publication 1747-IN058F-EN-P - December 2010

Page 17

1747-SDN DeviceNet Scanner Module 17

SLC DeviceNet Scanner — 1747-SDN

Attribute Value

Emissions CISPR 11:

Group 1, Class A (with appropriate enclosure)

ESD immunity IEC 61000-4-2:

Radiated RF immunity IEC 61000-4-3:

EFT/B immunity IEC 61000-4-4:

Surge transient immunity IEC 61000-4-5:

Conducted RF immunity IEC 61000-4-6:

Magnetic field immunity IEC 61000-4-8

Enclosure type rating None (open style)

Wiring

- Size

- Category

(1)

10-pin Linear plug

- Torque

- Catalog number

North American temperature code T5

(1)

Use this Conductor Category information for planning conductor routing. Refer to Industrial Automation Wiring and

Grounding Guidelines, publication 1770-4.1

6 kV contact discharges

8 kV air discharges

10 V/m with 1 kHz sine-wave 80% AM from 80…2000 Mhz

+2 kV at 5 kHz on communication ports

±2 kV line-earth(CM) on communications ports

10 Vrms with 1 kHz sine-wave 80% AM from 150 kHz…80 MHz

30A/m long duration at 50 Hz

Refer to DeviceNet Media Design Installation Guide, publication

DNET-UM072

2 — on communication ports

0.6…0.8 Nm (5…7 lb-in)

1787-PLUG10R

.

Publication 1747-IN058F-EN-P - December 2010

Page 18

18 1747-SDN DeviceNet Scanner Module

Certifications - 1747-SDN

Certification (when product is

(1)

marked)

c-UL-us UL Listed Industrial Control Equipment, certified for US and Canada. See

CE European Union 89/336/EEC EMC Directive, compliant with:

C-Tick Australian Radiocommunications Act, compliant with:

ODVA ODVA conformance tested to ODVA DeviceNet specifications

(1)

See the Product Certification link at http://www.ab.com for Declaration of Conformity, Certificates, and other certification

details.

Value

UL File E113724.

UL Listed for Class I, Division 2 Group A, B, C, D Hazardous Locations,

certified for US and Canada. See UL File E10314.

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

AS/NZS CISPR 11; Industrial Emissions

Additional Resources

Resource Description

SLC 500 DeviceNet Scanner Module User Manual, publication

1747-UM655

ControlFlash Firmware Upgrade Kit User Manual, publication

1756-QS105

Getting Results with RSLogix 500, publication LG500-GR002

Getting Results with RSLinx, publication LINX-GR001

DeviceNet Media Design and Installation Guide, DNET-UM072

Getting Results with RSNetWorx for DeviceNet, publication

DNET-GR001

Provides application examples for the

DeviceNet scanner module.

Provides instructions on using ControlFlash

to upgrade the firmware.

Provides information on RSLogix 500

software.

Provides information on RSLinx software.

Provides information on using DeviceNet

communication network.

Provides information on using RSNetWorx

for DeviceNet software.

You can view or download publications at http://literature.rockwellautomation.com. To

order paper copies of technical documentation, contact your local Rockwell Automation

distributor or sales representative.

Publication 1747-IN058F-EN-P - December 2010

Page 19

1747-SDN DeviceNet Scanner Module 19

WARNING

AVERTISSEMENT

North American Hazardous Location Approval

The following information applies when

operating this equipment in hazardous

locations:

Products marked "CL I, DIV 2, GP A, B, C, D" are

suitable for use in Class I Division 2 Groups A, B, C,

D, Hazardous Locations and nonhazardous locations

only. Each product is supplied with markings on the

rating nameplate indicating the hazardous location

temperature code. When combining products within

a system, the most adverse temperature code

(lowest "T" number) may be used to help determine

the overall temperature code of the system.

Combinations of equipment in your system are

subject to investigation by the local Authority Having

Jurisdiction at the time of installation.

EXPLOSION HAZARD

• Do not disconnect equipment

unless power has been

removed or the area is known

to be nonhazardous.

• Do not disconnect connections

to this equipment unless power

has been removed or the area

is known to be nonhazardous.

Secure any external

connections that mate to this

equipment by using screws,

sliding latches, threaded

connectors, or other means

provided with this product.

• Substitution of any component

may impair suitability for Class

I, Division 2.

• If this product contains

batteries, they must only be

changed in an area known to

be nonhazardous.

Informations sur l’utilisation de cet

équipement en environnements

dangereux:

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne

conviennent qu'à une utilisation en environnements

de Classe I Division 2 Groupes A, B, C, D dangereux et

non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent

le code de température pour les environnements

dangereux. Lorsque plusieurs produits sont combinés

dans un système, le code de température le plus

défavorable (code de température le plus faible) peut

être utilisé pour déterminer le code de température

global du système. Les combinaisons d'équipements

dans le système sont sujettes à inspection par les

autorités locales qualifiées au moment de

l'installation.

RISQUE D’EXPLOSION

• Couper le courant ou s'assurer

que l'environnement est classé

non dangereux avant de

débrancher l'équipement.

• Couper le courant ou s'assurer

que l'environnement est classé

non dangereux avant de

débrancher les connecteurs.

Fixer tous les connecteurs

externes reliés à cet

équipement à l'aide de vis,

loquets coulissants,

connecteurs filetés ou autres

moyens fournis avec ce produit.

• La substitution de tout

composant peut rendre cet

équipement inadapté à une

utilisation en environnement de

Classe I, Division 2.

• S'assurer que l'environnement

est classé non dangereux avant

de changer les piles.

Publication 1747-IN058F-EN-P - December 2010

Page 20

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its

products. At http://support.rockwellautomation.com

.

knowledge base of FAQs, technical and application notes, sample code and links to software

service packs, and a MySupport feature that you can customize to make the best use of these

tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect support programs. For more information, contact

your local distributor or Rockwell Automation representative, or visit

ttp://support.rockwellautomation.com.

h

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the

information that's contained in this manual. You can also contact a special Customer Support

number for initial help in getting your product up and running.

United States 1.440.646.3434

Monday – Friday, 8 a.m. – 5 p.m. EST

Outside United States Please contact your local Rockwell Automation representative for any technical

support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not functioning and

needs to be returned, follow these procedures.

, you can find technical manuals, a

United States Contact your distributor. You must provide a Customer Support case number (call the

Outside United States Please contact your local Rockwell Automation representative for the return

Rockwell Auotmation, Allen-Bradley, TechConnect, SLC, SLC 500, SLC 5/02, SLC 5/03, SLC 5/04, SLC 5/05, RSLinx, RSLogix 500, and

RSNetWorx are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

phone number above to obtain one) to your distributor in order to complete the return

process.

procedure.

Publication 1747-IN058F-EN-P - December 2010 PN-93987

Supersedes Publication 1747-IN058E-EN-P - February 2007 Copyright © 2010 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...