Page 1

ControlNet

Scanner

1747-SCNR

Reference Manual

Page 2

Important User Information

SHOCK HAZARD

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com/) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a

hazard, avoid a hazard, and recognize the consequence.

Labels may be located on or inside the equipment (for

example, drive or motor) to alert people that dangerous

voltage may be present.

Labels may be located on or inside the equipment (for

example, drive or motor) to alert people that surfaces may

be dangerous temperatures.

Allen-Bradley, FLEX I/O, RSLinx, RSLogix 500, RSNetWorx, SLC, and SLC 500 are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This publication contains new and revised information not in the last

release.

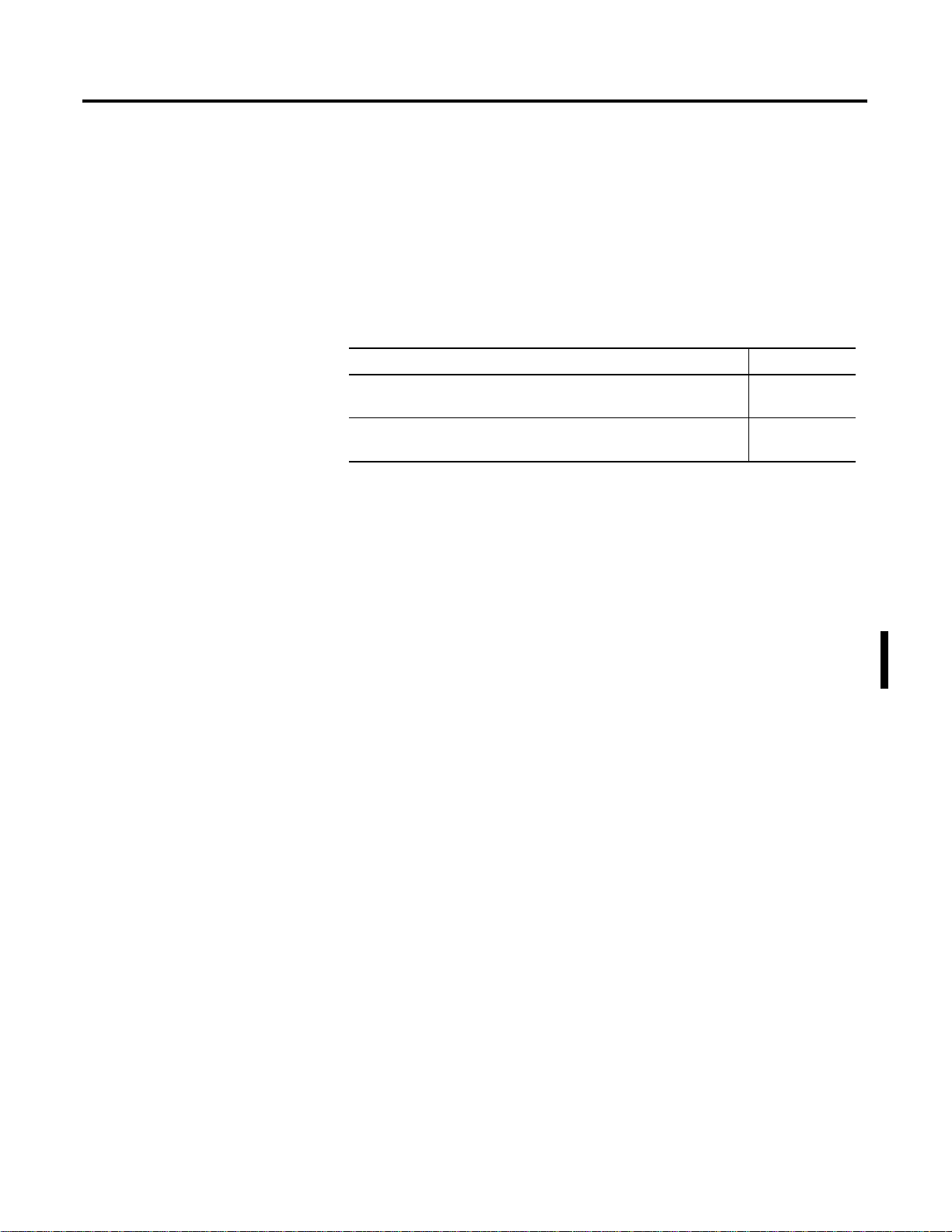

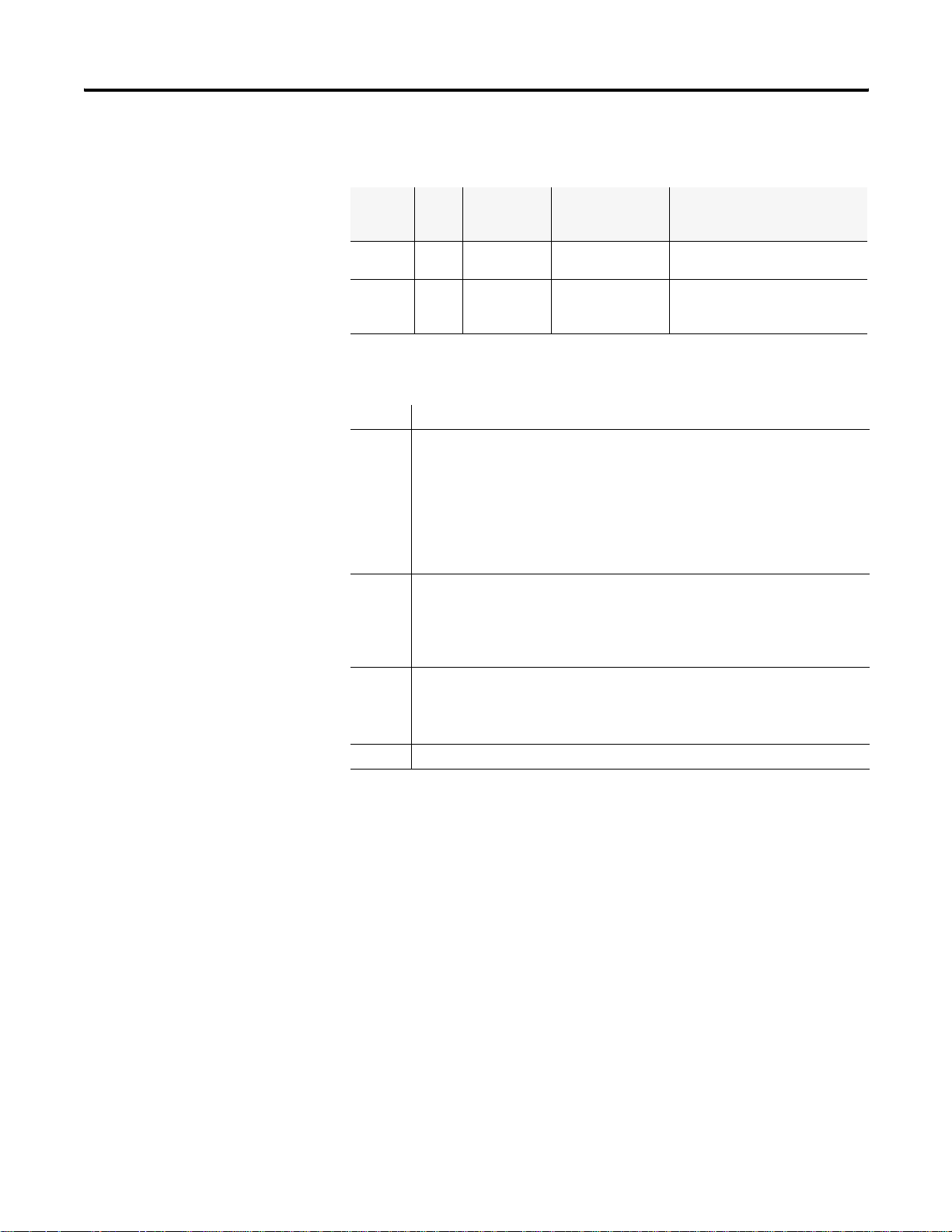

New and Revised Information

See the table for a summary of the major additions in this manual.

For See Page

An explanation of the processor and firmware levels that include the

ControlNet explicit message instruction capability

New information about the ControlNet explicit message instruction

that uses the CIP client management capability of module

Other changes in this manual provide an update or clarification of th e

material.

2-12

4-1

Change Bars

Change bars (as shown with this paragraph) show the areas in this

manual that are different from previous editions and indicate the

addition of new or revised information.

1 Publication 1747-RM623D-EN-P - June 2006

Page 4

2 Summary of Changes

Notes:

Publication 1747-RM623D-EN-P - June 2006

Page 5

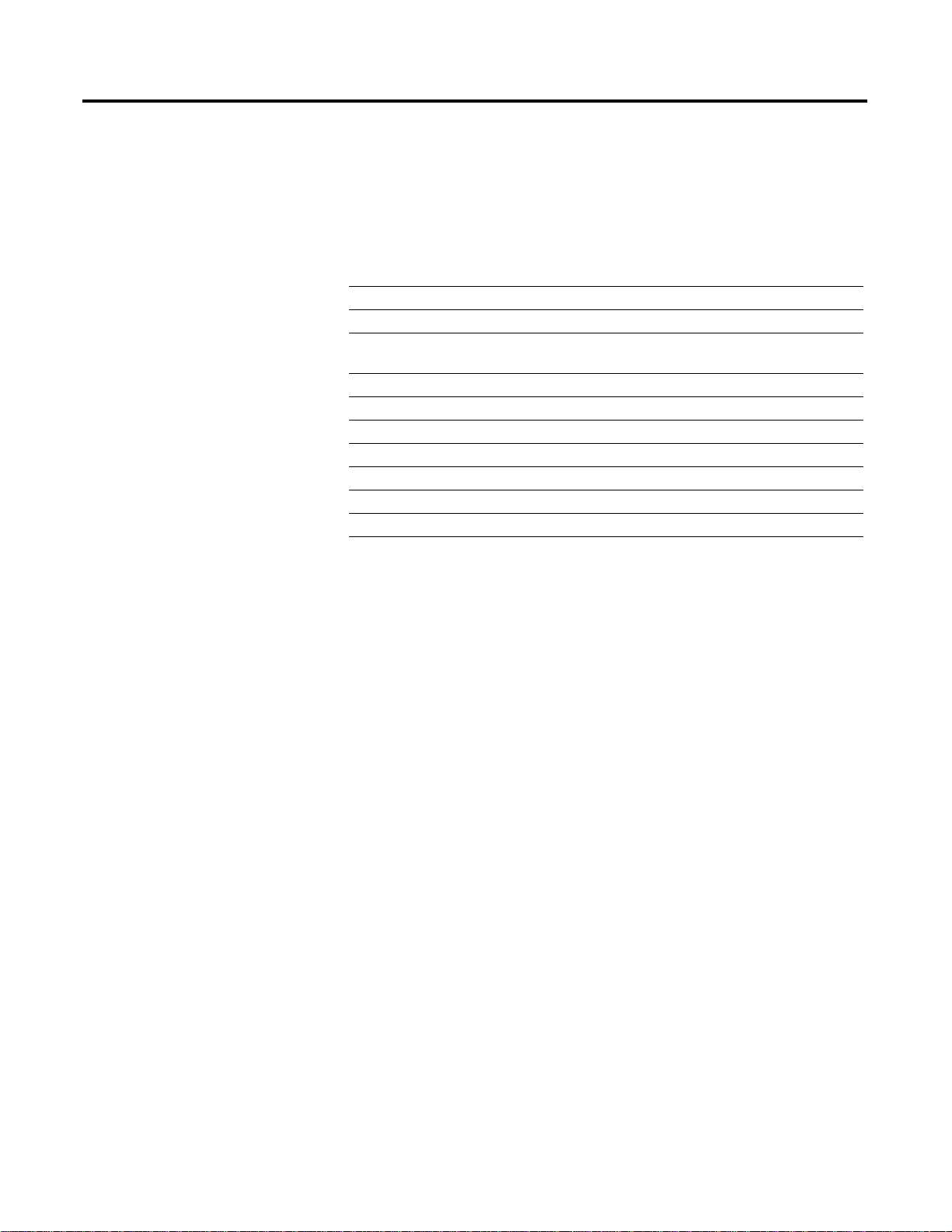

Table of Contents

Preface

Install and Connect the

ControlNet Scanner

Prepare to Use the ControlNet

Scanner

What This Manual Contains. . . . . . . . . . . . . . . . . . . . . . . . P-1

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . P-1

Common Techniques Used in This Manual. . . . . . . . . . . . . P-1

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Chapter 1

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 1-1

Identify Scanner Features . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Prepare for Module Installation . . . . . . . . . . . . . . . . . . . . . 1-2

Select the ControlNet Node Address. . . . . . . . . . . . . . . . . . 1-3

Insert the 1747-SCNR Scanner Into the Chassis . . . . . . . . . . 1-3

Connect to a ControlNet Network . . . . . . . . . . . . . . . . . . . 1-5

Connect Programming Terminal to ControlNet Network 1-6

SLC 500 I/O Configuration for the 1747-SCNR Module . . . . 1-8

Chapter 2

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 2-1

What Your Scanner Does . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Communicate with Your SLC Processor . . . . . . . . . . . . . . . 2-1

Communicating with Your SLC processor Using M1

and M0 Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Understand ControlNet Data transfer . . . . . . . . . . . . . . . . . 2-3

Scheduled Data Transfer Operations on a ControlNet

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Unscheduled Data Transfer Operations on a ControlNet

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Link Layer Services . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Understand 1747-SCNR Mapping . . . . . . . . . . . . . . . . . . . . 2-5

Discrete Input File . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

1747-SCNR M1 File. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Discrete Output File. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

1747-SCNR M0 File. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Communicate with Your Devices. . . . . . . . . . . . . . . . . . . . 2-9

I/O Scheduled Data Transfer . . . . . . . . . . . . . . . . . . . . 2-9

Unscheduled Data Server . . . . . . . . . . . . . . . . . . . . . . . 2-10

CIP Client Request Transfer . . . . . . . . . . . . . . . . . . . . . 2-10

Configure and Map Scheduled

Data Exchange with RSNetWorx

for ControlNet Software

3 Publication 1747-RM623D-EN-P - June 2006

Chapter 3

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 3-1

Begin the Configuration Process . . . . . . . . . . . . . . . . . . . . 3-1

Questions to Ask. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Data Transfer Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Page 6

Table of Contents 4

Work with the ControlNet Explicit

Message Instruction

Chapter 4

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 4-1

Understand the ControlNet Explicit Message Instruction . . 4-1

Work with the Explicit Message Instruction (CEM) . . . . . . . 4-2

CEM Instruction Parameters . . . . . . . . . . . . . . . . . . . . . . 4-2

CEM Instruction Setup Screen Parameters . . . . . . . . . . . . 4-3

Troubleshoot Chapter 5

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 5-1

Troubleshoot with the Status Indicators and

Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Apply Chassis Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Alphanumeric Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

OK Indicator and Display Mnemonics . . . . . . . . . . . . . . . . 5-3

Local Database Access Using

PLC-5 MSG Instructions

Appendix A

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . A-1

What We Assume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Read and Write Access To 1747-SCNR Local Database

Using PLC-5 MSG Instruction. . . . . . . . . . . . . . . . . . . . . . . A-1

Use CIP Messaging to Access

Local Database and ControlNet

Data Files Access

Appendix B

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . B-1

What We Assume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Read and Write Access to 1747-SCNR Data Files Using

Assembly Object Services . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Assembly Object Instance Numbers Supported for Get

and Set Member on Data Attribute . . . . . . . . . . . . . . . . B-2

1747-SCNR Memory Layout . . . . . . . . . . . . . . . . . . . . . . . . B-3

Publication 1747-RM623D-EN-P - June 2006

Page 7

CIP Client Management Appendix C

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . C-1

What We Assume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

CIP Client Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Send a Get Attribute All Request to Node 14 Identity Object C-4

SLC 500 Processor: N7 Data File (hex) . . . . . . . . . . . . . C-5

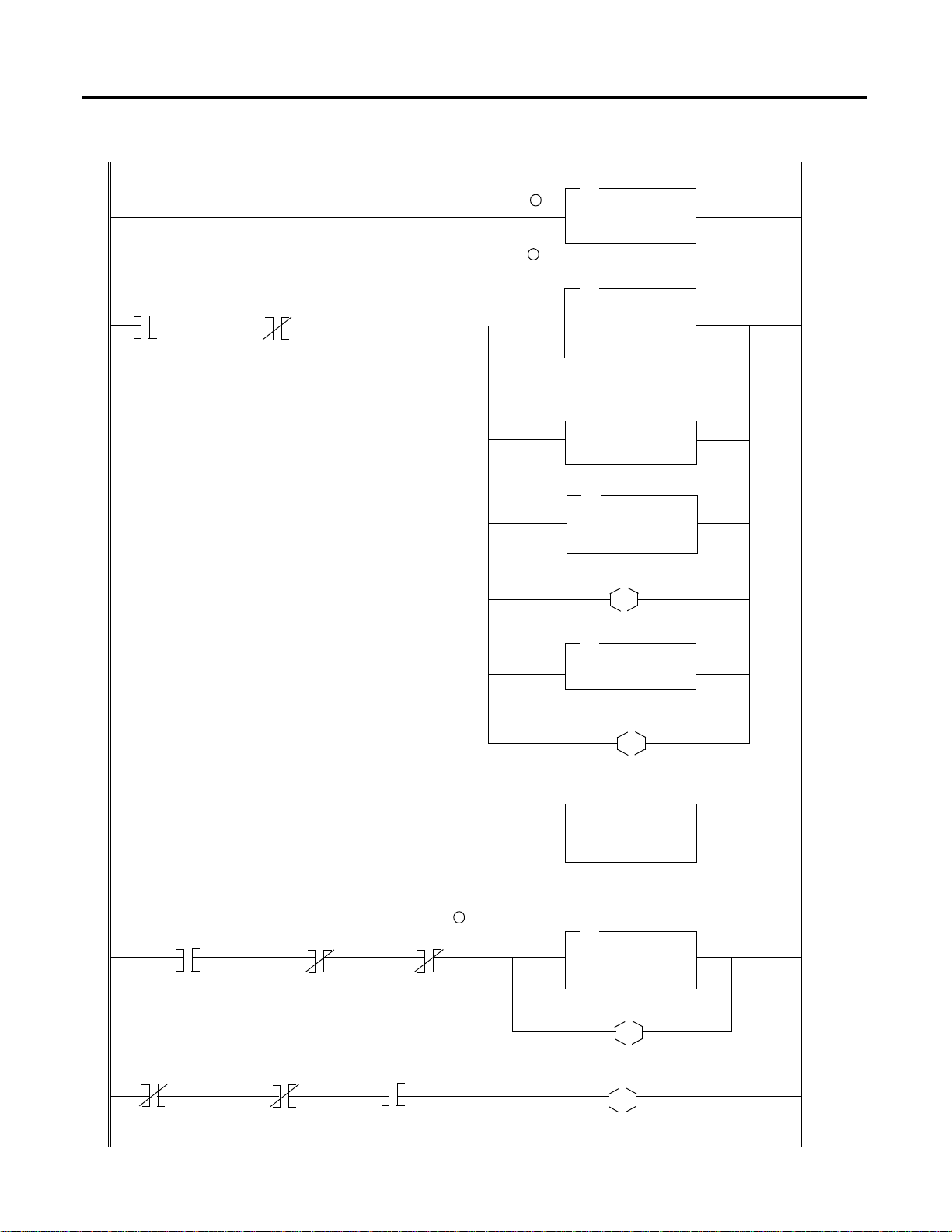

SLC 500 Ladder Program . . . . . . . . . . . . . . . . . . . . . . . C-6

SLC 500 Processor: Data Files (hex) . . . . . . . . . . . . . . . C-7

Send a Set Attribute Single Request . . . . . . . . . . . . . . . . . . C-8

SLC 500 Processor: N7 Data File (hex) . . . . . . . . . . . . . C-9

Example: SLC 500 Ladder Program . . . . . . . . . . . C-10

SLC 500 Processor: Target Input Data File (hex) . C-11

Send a Set Member Request. . . . . . . . . . . . . . . . . . . . . . . C-12

SLC 500 Processor: N7 Data File (hex) . . . . . . . . . . . . C-13

Example: SLC 500 Ladder Program . . . . . . . . . . . C-14

SLC 500 Processor: Target Input Data File (hex) . C-15

Example of Reset Bit Management Appendix D

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . D-1

What We Assume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Table of Contents 5

Publication 1747-RM623D-EN-P - June 2006

Page 8

Table of Contents 6

Application Examples Appendix E

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . E-1

What We Assume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Example 1: Configure the 1747-SCNR Scanner with the

1746-IV16 Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Configure the ControlNet Network with RSNetWorx

for ControlNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Example 2: Configure the 1747-SCNR Scanner with the

1746-NIO4V Analog Input/Output Module. . . . . . . . . . . . . E-9

Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

Configure the ControlNet Network with RSNetWorx

for ControlNe Software. . . . . . . . . . . . . . . . . . . . . . . . . E-9

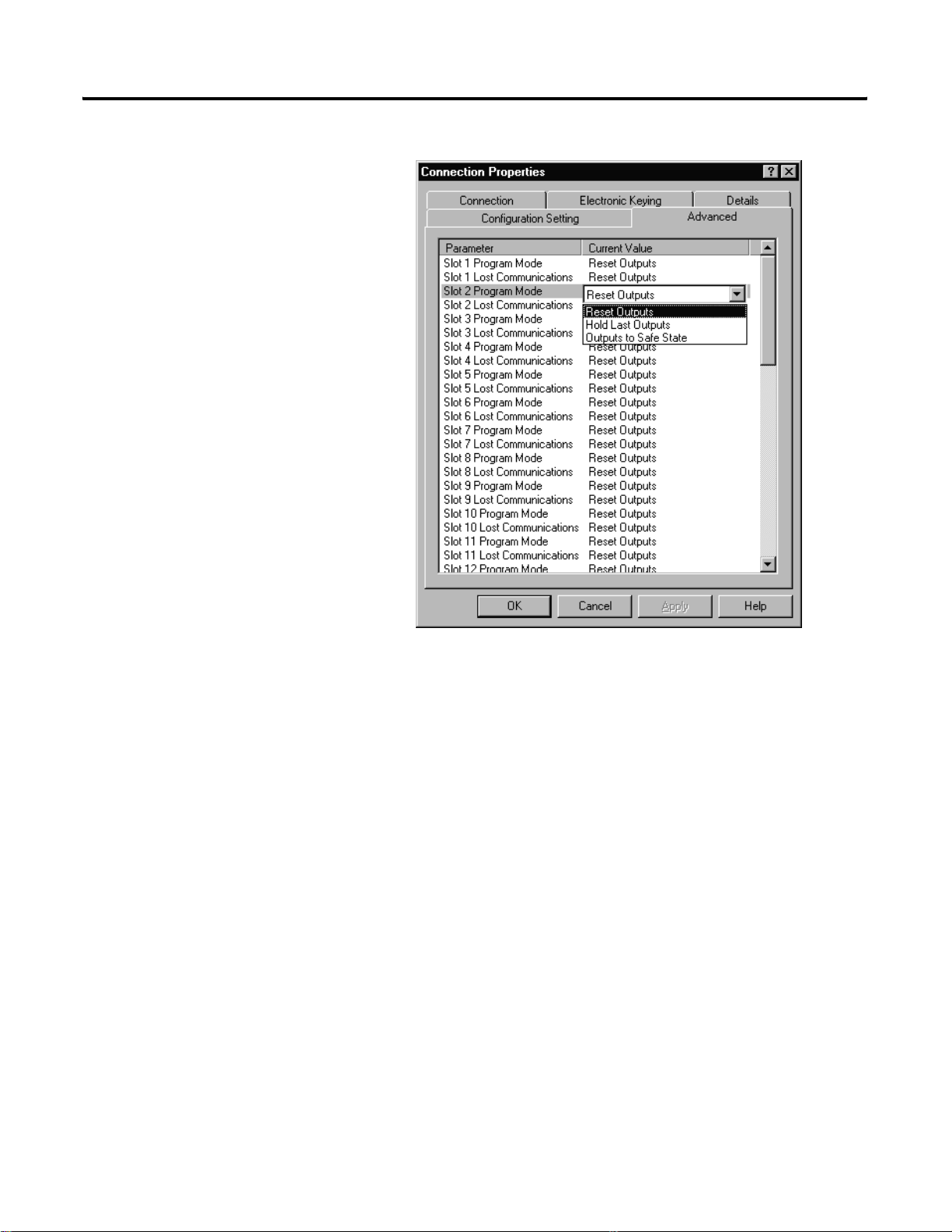

Configure a Module Connection. . . . . . . . . . . . . . . . . E-16

Example 3: Configure the 1747-SCNR Scanner with the

1746-NI8 Analog Input Module . . . . . . . . . . . . . . . . . . . . E-19

Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-19

Configure the ControlNet Network with RSNetWorx

for ControlNet Software . . . . . . . . . . . . . . . . . . . . . . . E-19

Configure a Module Connection. . . . . . . . . . . . . . . . . E-25

Example 4: Configure the 1747-SCNR Scanner with the 1746-BAS

Series B Interface Module . . . . . . . . . . . . . . . . . . . . . . . . E-28

Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-28

Configure the ControlNet Network with RSNetWorx

for ControlNet Software . . . . . . . . . . . . . . . . . . . . . . . E-28

Configure a Module Connection. . . . . . . . . . . . . . . . . E-34

Example 5: Configure the 1747-SCNR Scanner with the

1794-IE4XOE2 Analog Combo Module. . . . . . . . . . . . . . . E-41

Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-42

Configure the ControlNet Network with RSNetWorx

for ControlNet Software . . . . . . . . . . . . . . . . . . . . . . . E-42

Configure a Module Connection. . . . . . . . . . . . . . . . . E-48

Example 6: Creating Peer-to-Peer Scheduled Connections

Between 1747-SCNR ControlNet Scanners . . . . . . . . . . . . E-51

Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-51

Configure the ControlNet Network with RSNetWorx

for ControlNet Software . . . . . . . . . . . . . . . . . . . . . . . E-52

Configure a Scheduled Connection Between

ControlNet Scanners. . . . . . . . . . . . . . . . . . . . . . . . . . E-54

Publication 1747-RM623D-EN-P - June 2006

Page 9

Preface

What This Manual Contains

Who Should Use This Manual

Use this manual to install, configure, and apply the features of the

scanner. See the table for a list of where to find specific information.

For specification and hazardous locations i nformation, refer to SLC

ControlNet Scanner Installation Instructions, publication 1747-IN059.

For Information About See

How to install and connect the module Chapter 1

How to prepare to install the module Chapter 2

How to configure and map scheduled data exchange using RSNetWorx for

ControlNet software

How to use the SLC ControlNet explicit message instruction Chapter 4

How to troubleshoot and read LEDs Chapter 5

Local database access using PLC-5 MSG instructions Appendix A

Local database and ControlNet data files access using CIP messaging Appendix B

CIP client management Appendix C

Reset bit management Appendix D

Application examples Appendix E

We wrote this manual for control engineers and technicians who are

installing, programming, and maintaining a control system that

includes an SLC 500 processor communicating on a ControlNet

network with a ControlNet scanner. Here is what we assume.

Chapter 3

Common Techniques Used in This Manual

• You are developing a ControlNet network using an SLC

processor in conjunction with a ControlNet scanner.

• You know each of your device’s I/O parameters and

requirements.

• You understand SLC processor programming and operation.

• You are familiar with RSNetWorx for ControlNet software.

• You are familiar with the Microsoft Windows environment.

We use the following conventions throughout this manual.

• Numbered lists provide sequential steps.

• Bulleted lists provide information, not procedural steps.

1 Publication 1747-RM623D-EN-P - June 2006

Page 10

Preface P-2

The screen captures shown in this manual are

pictures of the software’s actual screens.

Terminology

See these tables for a list of ControlNet network terms and acronyms

used in this manual.

Term Definition

Actual Packet Interval

(API)

Big-endian A computer architecture in which, within a given multi-byte

Bit A unit of information consisting of a 1 or a 0. This is the smallest

Class A set of objects all of which represent a similar system

Client 1. An object that uses the services of another (server)

Connection A logical binding between two application objects. These

Connection Path The attribute is made up of a byte stream that defines the

Consume The act of receiving data from a producer.

Consumer A node that is receiving data from a producer.

Device A physical hardware connection to the link. A device may

Error A discrepancy between a computed, observed, or measured

Frame Single data transfer on a link.

Instance The actual physical presentation of an object within a class.

Link A collection of nodes with unique MAC IDs. Segments

Little-endian A computer architecture in which, within a given multi-byte

The measure of how frequently a specific connection produces

its data.

numeric representation, the most significant byte has the lowest

address (the word is stored big-end-first - typically Motorola

architecture).

data unit that can be transmitted.

component. A class is a generalization of the object, a template

for defining variables and methods. All objects in a class are

identical in form and behavior, but they may contain different

attribute values.

object to perform a task.

2. An initiator of a message to which a server reacts.

application objects may be in the same or different devices.

application object to which a connection instance applies.

contain more than one node.

value or condition and the specified or theoretically correct value

or condition.

Identifies one of many objects within the same object class.

connected by repeaters make up a link; links connected by

routers make up a network.

numeric representation, the least significant byte has the lowest

address (the word is stored little-end first - typically Intel

architecture).

Publication 1747-RM623D-EN-P - June 2006

Page 11

Preface P-3

Multicast Connection A connection where one node produces data and multiple nodes

consume that exact same data. Connections can be either

point-to-point or multicast.

Network A series of nodes connected by some type of communication

medium. The connection paths between any pair of nodes can

include repeaters, routers, and gateways.

Network Access Port

(NAP)

Physical Layer variant that lets a temporary node to be

connected to the link by connection to the NAP of a permanent

node.

Network Address or

A node’s address on the link (also called MAC ID).

Node Address

Network Status

Indicators

Network Update Interval

(NUI)

Network Update Time

Indicators on a node displaying the status of the Physical and

Data Link Layers.

A single occurrence of the ControlNet Network Update Time

(NUT).

Repetitive time interval in which data can be sent on the link.

(NUT)

Node A connection to a link that requires a single MAC ID.

Object 1. An abstract representation of a computer’s capabilities.

Objects can be composed of any or all of the following

components: data (information which changes with time)

configuration (parameters for behavior) methods (things

that can be done using data and configuration)

2. A collection of related data (in the form of variables) and

methods (procedures) for operating on that data that

have clearly defined interface and behavior.

Originator The client responsible for establishing a connection path to the

target.

Point to Point

Connection

A connection that exists between two nodes only. Connections

can be either point-to-point or multicast.

Produce Act of sending data to a consumer.

Producer A node that is responsible for transmitting data.

Redundant Media A system using more than one medium to help prevent

communication failures.

Requested Packet

Interval (RPI)

Scanner Configuration

Tool (SCT)

The measure of how frequently the originating application

requires the transmission of data from the target application.

Software tool that lets you to configure scheduled connections,

map data for these connections, and monitor the status for the

configured connections.

Scheduled Data transfers that occur in a deterministic and repeatable

manner on predefined NUTs.

Server An object which provides services to another (client) object.

Service Operation or function that an object performs upon request from

another object.

Target The end-node to which a connection is established.

Unscheduled Data transfers that use the remaining time in the NUT after the

scheduled transfers have been completed.

Publication 1747-RM623D-EN-P - June 2006

Page 12

Preface P-4

Abbreviations and

Meaning

Acronym

API Actual packet interval

BNC A connector for coaxial cable having a bayonet-type shell

with two small knobs on the female connector which

lock into spiral slots in the male connector when it is

twisted

CIP The control and information protocol defined by part 4 of

the ControlNet standard. CIP includes both connected

and unconnected messaging.

LED Light emitting diode

MAC ID The address of a node

NAP Network access port

NUI Network update interval

NUT Network update time

RPI Requested packet interval

SCT Scanner configuration tool

Publication 1747-RM623D-EN-P - June 2006

Page 13

Install and Connect the ControlNet Scanner

Chapter

1

What This Chapter Contains

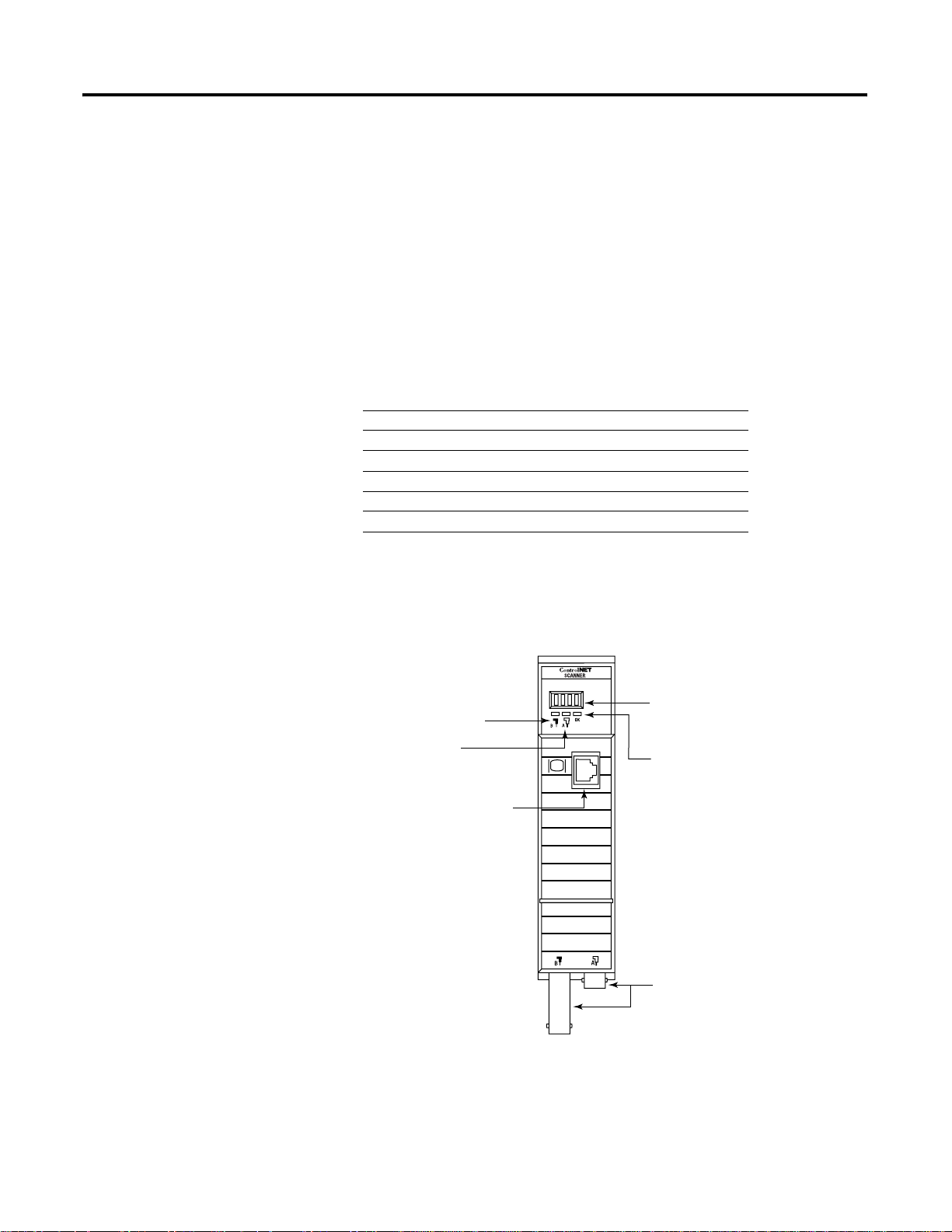

Identify Scanner

This chapter describes how to install and connect your ControlNet

1747-SCNR scanner. See the table that shows where to find specific

information in this chapter.

The following drawing identifies the features of the 1747-SCNR

scanner.

Module Features

For Information About See Page

Identifying scanner features 1-1

Preparing the module for installation 1-2

Selecting the ControlNet node address 1-3

Inserting the 1747-SCNR into an SLC chassis 1-4

Connecting the 1747-SCNR to a ControlNet network 1-5

SLC 500 I/O configuration 1-8

Node Address and Status Display

displays scanner node address and

Channel B

Status Indicator

Channel A

Status Indicator

ControlNet Network

Access Port

NAP RJ45 connector

status.

Module Status Indicator

indicates whether the device is

powered and is functioning properly.

ControlNet Redundant Media Ports

BNC Connectors

(Channels A and B)

1 Publication 1747-RM623D-EN-P - June 2006

30751

Page 14

1-2 Install and Connect the ControlNet Scanner

3

Prepare for Module Installation

Before you install your module, you need the following items:

RSNetWorx for

Personal Computer with

Microsoft Windows

SLC 1746 Chassis with SLC

5/02, 5/03, 5/04, or 5/05 Processor

and Appropriate Programming

Software (RSLogix 500 Software)

ControlNet

software,

Catalog Number

9357-CNETL3

ControlNet 1784-PCC (shown),

or 1784-PCIC, or 1784-KTCX15,

or 1770-KFC15 Module

1747-SCNR Scanner Reference

Manual, Publication 1747-RM62

(this manual)

Before you install the module, you must know how to do this.

41523

• Program and operate an Allen-Bradley SLC 50 0 programmable

controller.

• Install and configure the devices on your ControlNet network.

The 1747-SCNR scanner fits in any slot of the chassis except for the

leftmost slot of the first chassis, which is reserved for the SLC 500

processor.

Publication 1747-RM623D-EN-P - June 2006

Page 15

Install and Connect the ControlNet Scanner 1-3

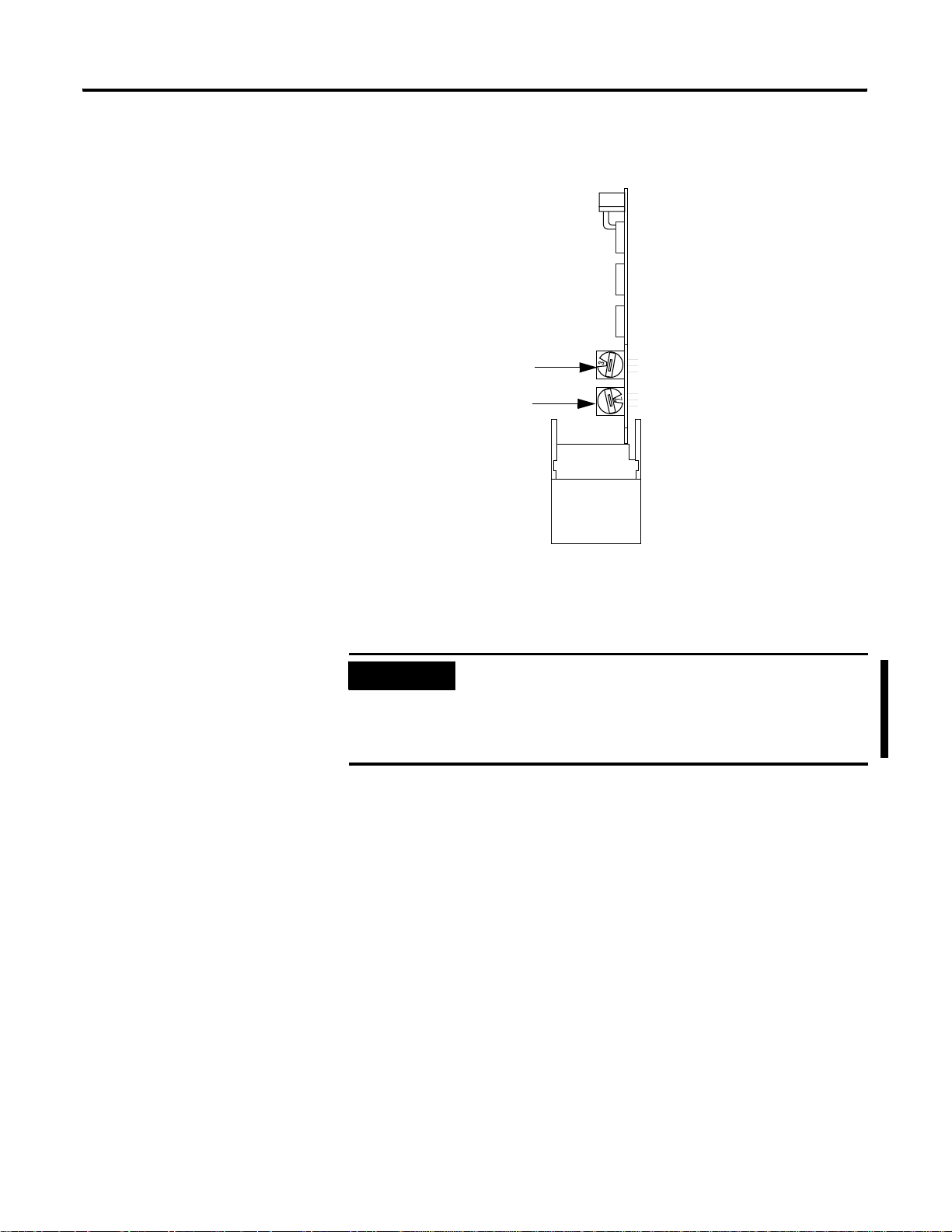

Select the ControlNet Node Address

Select the ControlNet node address of the 1747-SCNR module by

setting the two 10-digit rotary switches on the top of the scanner.

10-digit Rotary Switch: Ones Digit

10-digit Rotary Switch: Tens Digit

Top View of Module

30752

You can select a node address from 01 to 99 for a device on a

ControlNet link. Zero (00) is not a valid node address.

IMPORTANT

Since 00 is the default value from manufacturing, you

must change the node address when using the

scanner for the first time. Turning on the scanner

with the node address set to 00 clears the module

memory back to the factory default.

Publication 1747-RM623D-EN-P - June 2006

Page 16

1-4 Install and Connect the ControlNet Scanner

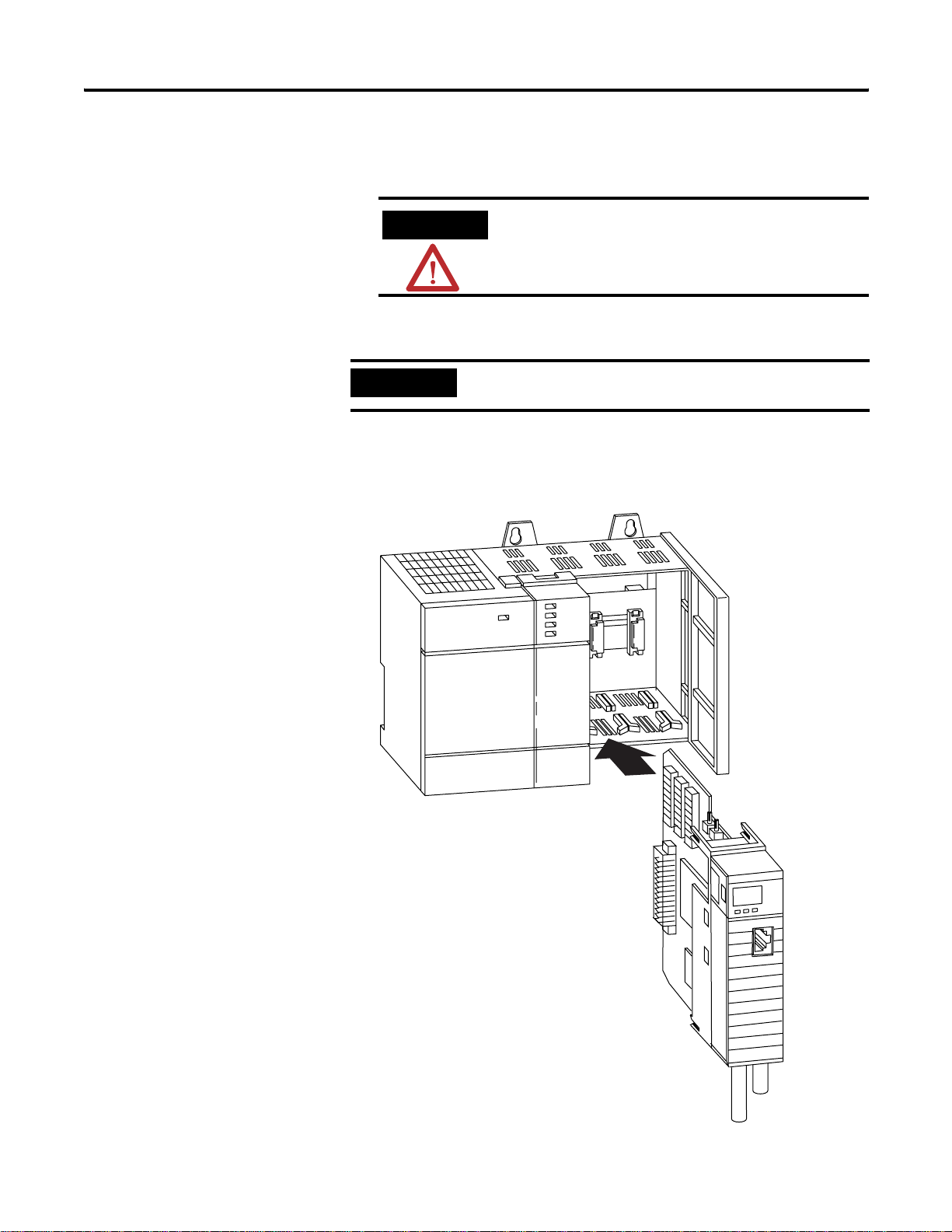

Insert the 1747-SCNR Scanner Into the Chassis

To insert the 1747-SCNR scanner into the SLC chassis complete these

procedures.

ATTENTION

Do not install the 1747-SCNR scanner with the

chassis power supply on. Installing the module

with the chassis power supply on may damage

the module.

1. Turn off the SLC chassis power supply.

IMPORTANT

If you disconnect the ac power, you lose the chassis

ground. Electrostatic damage (ESD) protection is lost.

2. Select a slot for the module in the chassis, choosing any slot

except the left-most slot of the first chassi s, which is reserv ed for

the SLC 500 processor.

Publication 1747-RM623D-EN-P - June 2006

30801-M

Page 17

Install and Connect the ControlNet Scanner 1-5

3. Insert the module into the slot you have selected, noting that we

recommend that you insert the 1747-SCNR scanner as close to

the chassis power supply as possible.

4. Apply firm and even pressure to seat the module in the I/O

chassis backplane connectors.

5. Restore power to the SLC chassis.

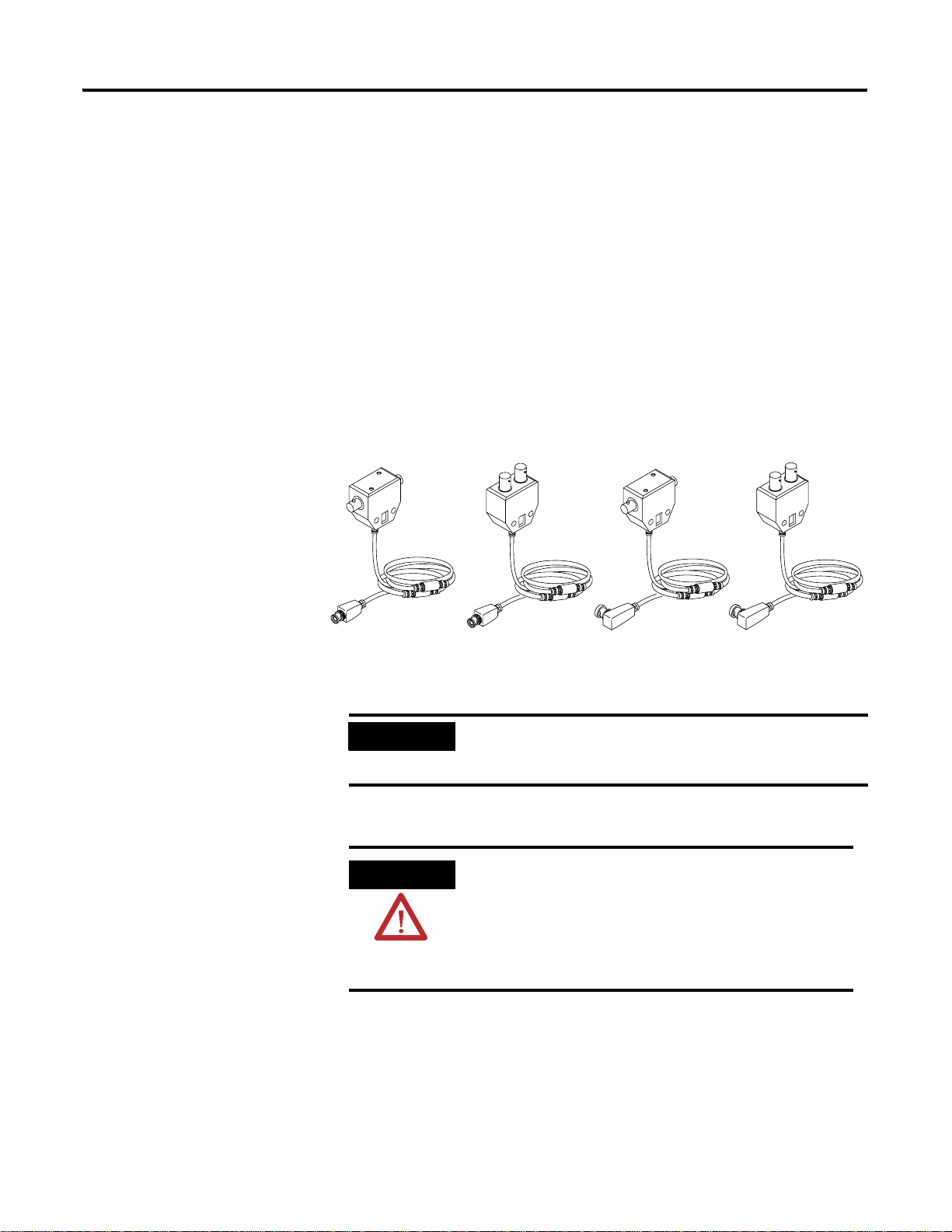

Connect to a ControlNet Network

Connect the 1747-SCNR scanner to a ControlNet network via a tap

with a 1 m (39.4 in.) drop cable. Four taps are available from

Rockwell Automation, Inc., as shown in the figure.

Straight T-tap

1786-TPS 1786-TPYR

IMPORTANT

Straight Y-tap

1786-TPYS

1786-TPR

Right-angle Y-tapRight-angle-Tap

Allen-Bradley ControlNet taps contain passive

20094

electronics and must be purchased from Rockwell

Automation for the network to function properly.

After terminating your segments, connect your node to the network.

WARNING

If you connect or disconnect the ControlNet cable

with power applied to this module or any device

on the network, an electrical arc can occur. This

could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

Publication 1747-RM623D-EN-P - June 2006

Page 18

1-6 Install and Connect the ControlNet Scanner

Nonredundant Media

A

Remove the tap’s dust cap—located on the straight or right-angle connector—and set it aside.

.

Redundant Media

A

B

30802

If Your Network Supports Connect the Tap’s Straight or Right-angle

Connector

Nonredundant media To the channel A connector on the scanner—channel B is

not used.

(1)

Redundant media From the trunk-cable A to channel A on the scanner

andfrom trunk-cable B to channel B on the scanner

(1)

We recommend using channel A for nonredundant media.

For detailed information on planning and installing your ControlNet

system, see the table for a list of related publications.

Publication 1747-RM623D-EN-P - June 2006

Publication Publication Number

ControlNet Coax Tap Installation Instructions 1786-IN007

ControlNet Network Access Cable Installation Instructions 1786-TD006

Industrial Automation Wiring and Grounding Guidelines 1770-IN041

Page 19

Install and Connect the ControlNet Scanner 1-7

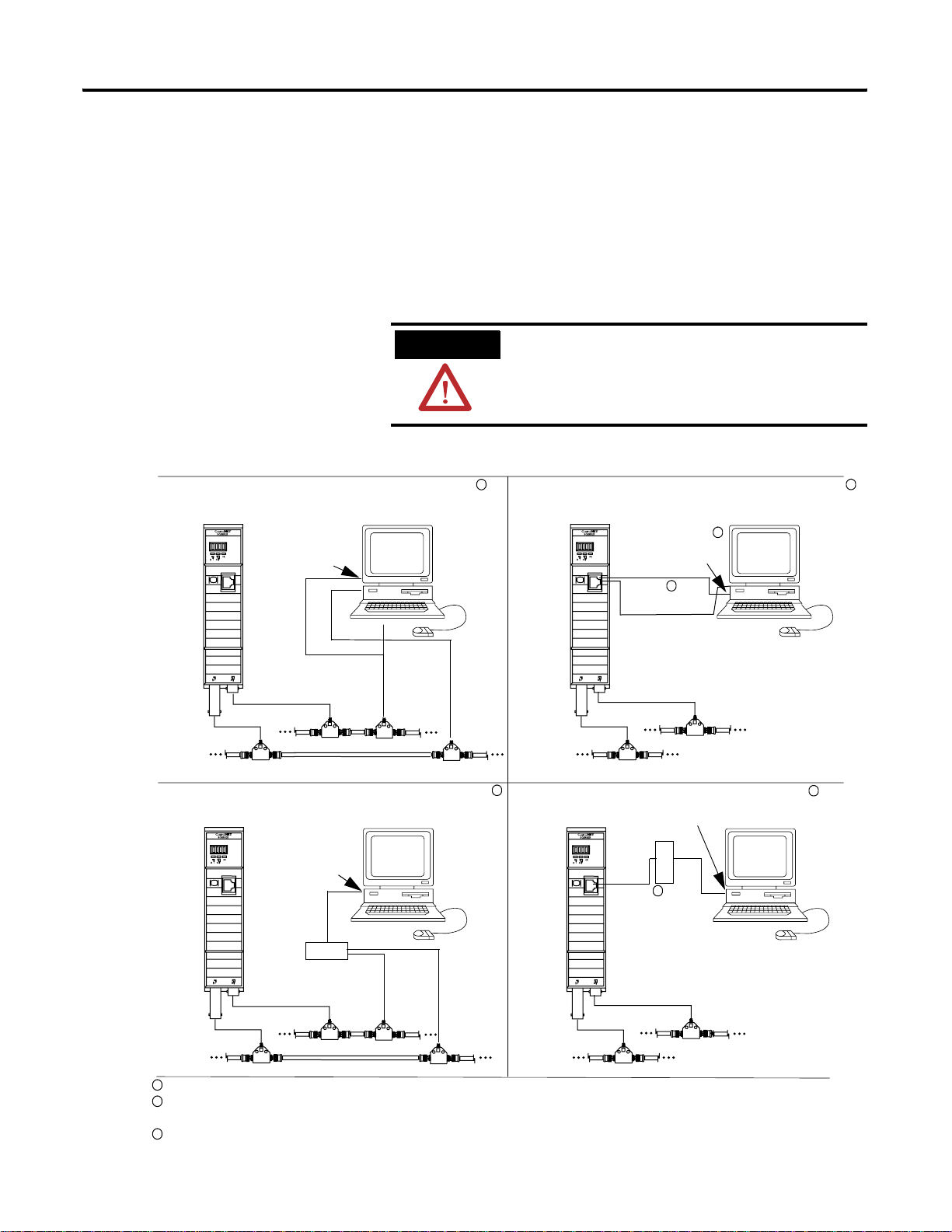

Connect Programming Terminal to a ControlNet Network

You can connect the programming terminal to a ControlNet network

through a:

• ControlNet product NAP using a network access cable

(1786-CP).

• tap on a ControlNet network.

ATTENTION

Do not connect the same communication card

to both the NAP and a tap on the ControlNet

network.

Using 1784-PCIC communication card on coax media

ControlNet 1747-SCNR Scanner

Programming Terminal

1784-KTCx15

A

B

ControlNet Network

Using 1770-KFC15 communication interface on coax media

ControlNet 1747-SCNR Scanner

Programming Terminal

Serial Connection

1

Using 1784-PCC or -PCIC communication card and NAP

ControlNet 1747-SCNR Scanner

1784-PCC

Programming Terminal

3

or -KTCx15

1786-CP

A

2

ControlNet Network

B

1

Using 1770-KFC15 communication interface and NAP

Serial Connection

1770-KFC15

1786-CP

2

1

1

1770-KFC15

A

A

B

B

ControlNet Network

1

Shown with redundant media (redundant media is not required).

2

The network access cable (1786-CP) can be plugged into any ControlNet product’s NAP to provide programming capability on the

ControlNet Network

41521

ControlNet network. A programming terminal connected through this cable is counted as a node and must have a unique address.

3

The 1784-PCC ships with its own ControlNet cable (1784-PCC1).

Publication 1747-RM623D-EN-P - June 2006

Page 20

1-8 Install and Connect the ControlNet Scanner

SLC 500 I/O Configuration for the 1747-SCNR Module

ATTENTION

Select the I/O card. If you do not have an I/O card, complete the

following procedure.

Open RSLogix 500 software and use the following procedure to

configure the 1747-SCNR module.

In the RSLogix 500 project Window:

1. Open the I/O Configuration window.

2. Select the 1747-SCNR slot number.

3. Select the 1747-SCNR module from the current available cards

list. If it is not available, perform the following steps:

a. Choose the other ..Requires I/O card type ID line in the

Current cards available list.

b. In the Other type I/O Card window, type 13628.

c. On the line associated with the scanner slot, the I/O

Configuration window will report the following:

Use the 1786-CP cable when connecting a

scanner to the network through a NAP. Using

a commercially-available RJ-style cable could

result in network failure.

Publication 1747-RM623D-EN-P - June 2006

OTHER I/O Module- ID Code = 13628

d. Double-click the scanner line to open the Advanced I/O

Configuration window.

e. Se t M0 Length to 1651 (decimal) and M1 Length to 608

(decimal).

4. Close the I/O Configuration and Advanced I/O Configuration

windows.

Page 21

Chapter

Prepare to Use the ControlNet Scanner

2

What This Chapter Contains

What Your Scanner Does

Read this chapter to understand how to use your ControlNet

1747-SCNR Scanner. The following table describes what this chapter

contains and where to find specific information.

In a typical configuration, the scanner acts as an interface between

ControlNet devices and an SLC processor. The scanner communicates

with ControlNet devices over the network to do this:

For Information About See Page

What your scanner does 2-1

Communicating with your SLC processor 2-1

Understanding ControlNet data transfer 2-3

Understanding 1747-SCNR mapping 2-5

Communicating with your devices 2-9

• Read inputs from a device.

• Write outpu ts to a device.

• Issue native ControlNet requests to a remote node on the

ControlNet link (CIP client).

• Download configuration data.

Communicating with Your SLC Processor

1 Publication 1747-RM623D-EN-P - June 2006

The scanner communicates with the processor in the form of M1/M0

File Transfers and/or Discrete I/O (DIO). Information exchanged

includes the following.

• Device I/O data

• Status and control information

• CIP client requests and response s

• Local database

An M1/M0 file transfer is a method of moving large amounts of data

between an SLC 500 processor and its scanner.

Discrete input and output (DIO) is the transfer of one to 32 words

between an SLC 500 processor and a scanner. All 32 words of input

data and all 32 words of output data are updated on each SLC

program scan.

Page 22

2-2 Prepare to Use the ControlNet Scanner

t

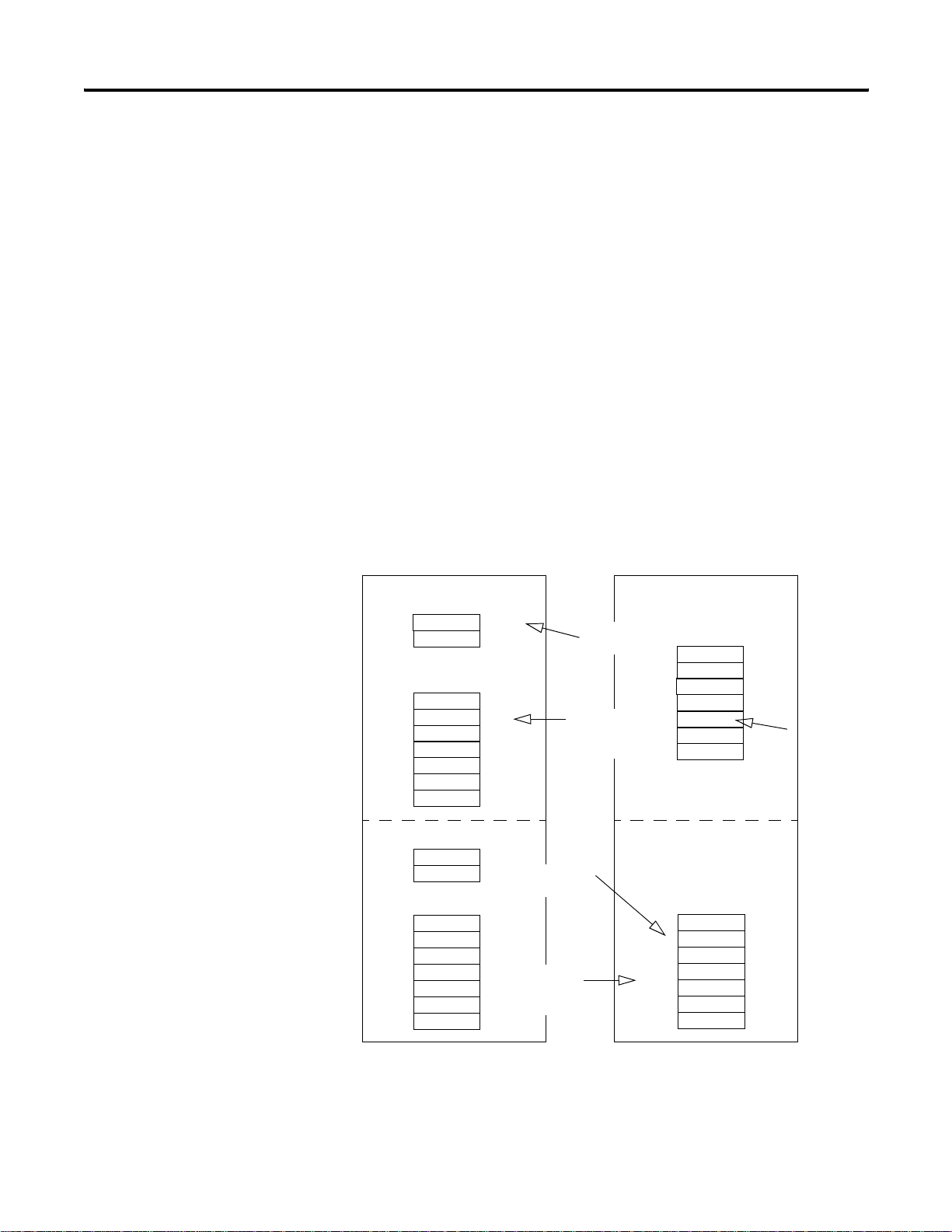

Communicating with Your SLC processor Using M1 and M0 Files

Y our processor can communicate with the scanner via M1 file transfer

reads and M0 file transfer writes.

The scanner does not send data to your processor. Data transfer

between your scanner and the processor must be initiated by the

processor. For example, data is sent, or written, to the scanner by

your processor by placing the data in the M0 file. This data is

organized in the scanner and then, based on the area you updated,

the appropriate action is initiated to send it on the ControlNet

network.

An M1 file transfer is the transfer of data from the scanner to the

processor. The scanner makes data collected from the network’s

devices available for the processor to read.

An M0 file transfer is the transfer of data from the SLC 500 processor

to the scanner. The processor writes data to the scanner’s memory.

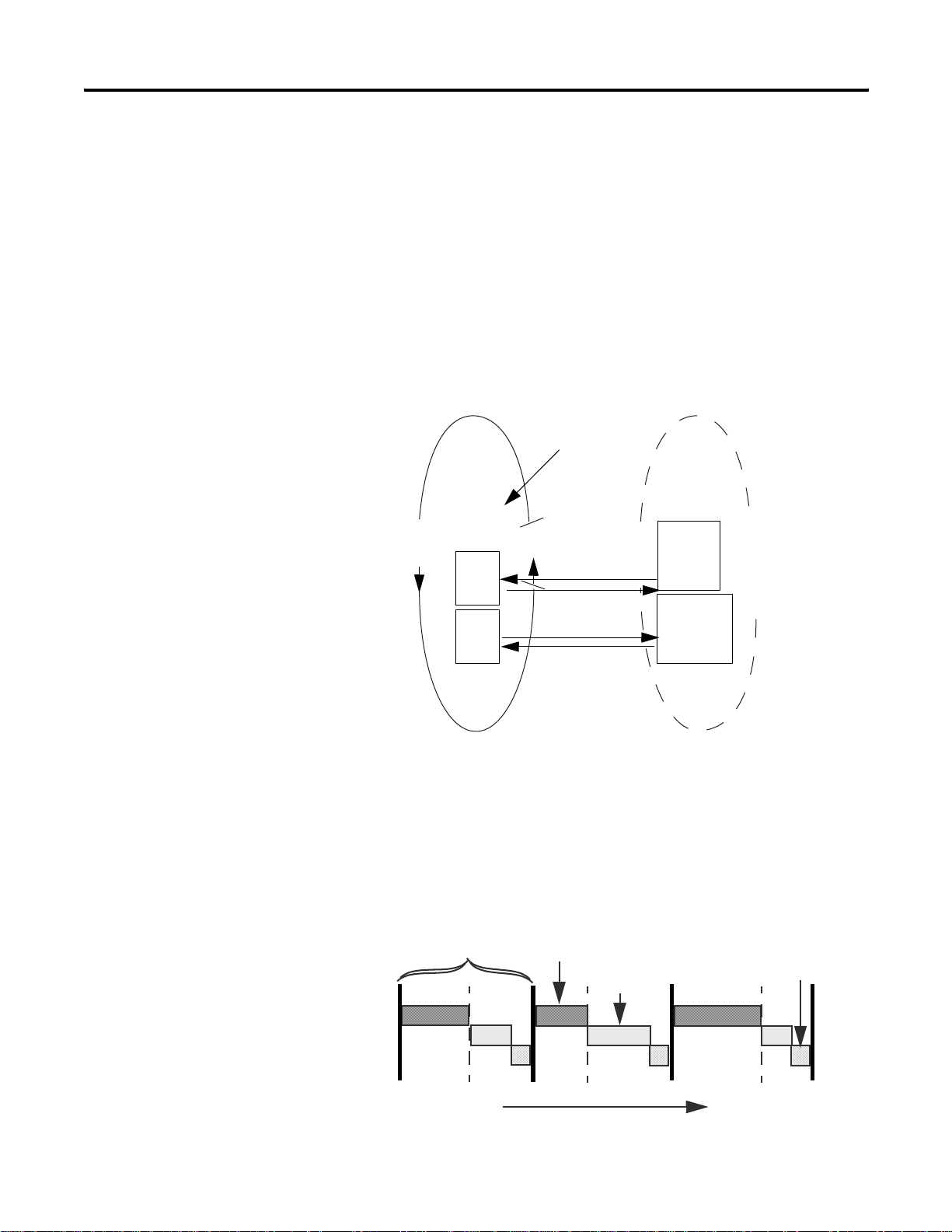

SLC 500 Processor

Discrete Input Image

A1

B

M1 Data File

C

A2

D

E

Discrete Output Image

X

Y

M0 Data File

Z

Discrete Input

Transfer

M1 file

transfer

(read)

Discrete Output

Transfer

I/O Map

M0 file

transfer

(write)

1747-SCNR Scanner

Internal Input

Data Storage

A1

B

C

A2

D

E

ControlNe

network

Internal Output

Data Storage

X

Y

Z

Publication 1747-RM623D-EN-P - June 2006

41553

Page 23

Prepare to Use the ControlNet Scanner 2-3

S

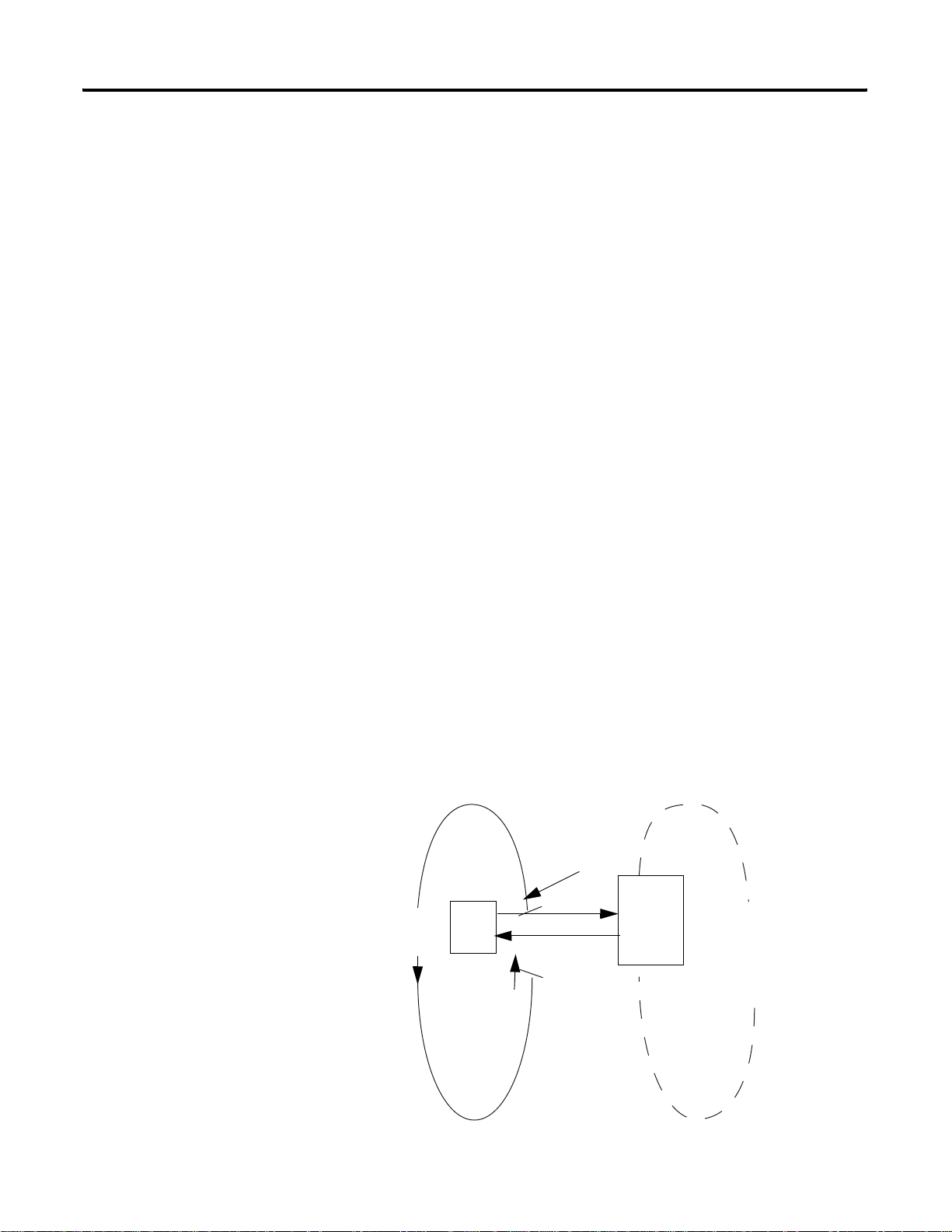

Understand ControlNet Data transfer

The ControlNet system is designed to do this:

• Provide high-speed, repeatable, deterministic I/O transmission.

• Let control and message information co-exist on the same

physical media.

• Make sure that I/O data transfers are not affected by:

• programming-terminal activity.

• inter-scanner message activity on the network.

Scheduled Data Transfer Operations on a ControlNet Network

ControlNet scheduled data transfer on a 1747-SCNR Scanner:

• is continuous.

• transmits on the network asynchronously to the ladder logic

program scan.

• occurs at the actual rate that is determined by RSNetWorx for

ControlNet software.

For discrete I/O data transfer between logic scans (during

housekeeping), the following updates occur.

• The gathered input image is moved from the scanner to the SLC

processor's input image file for use during the next logic scan.

• The 1747-SCNR output data is updated with data from the SLC

processor output image file and is sent during the next

scheduled communication.

M0 and M1 files are data files that reside in the 1747-SCNR scanner

only. Data from these files will be available to the SLC processor using

ladder instructions. Scheduled data update will be triggered by the

Housekeeping period start, which occurs once per scan. This process

is illustrated below.

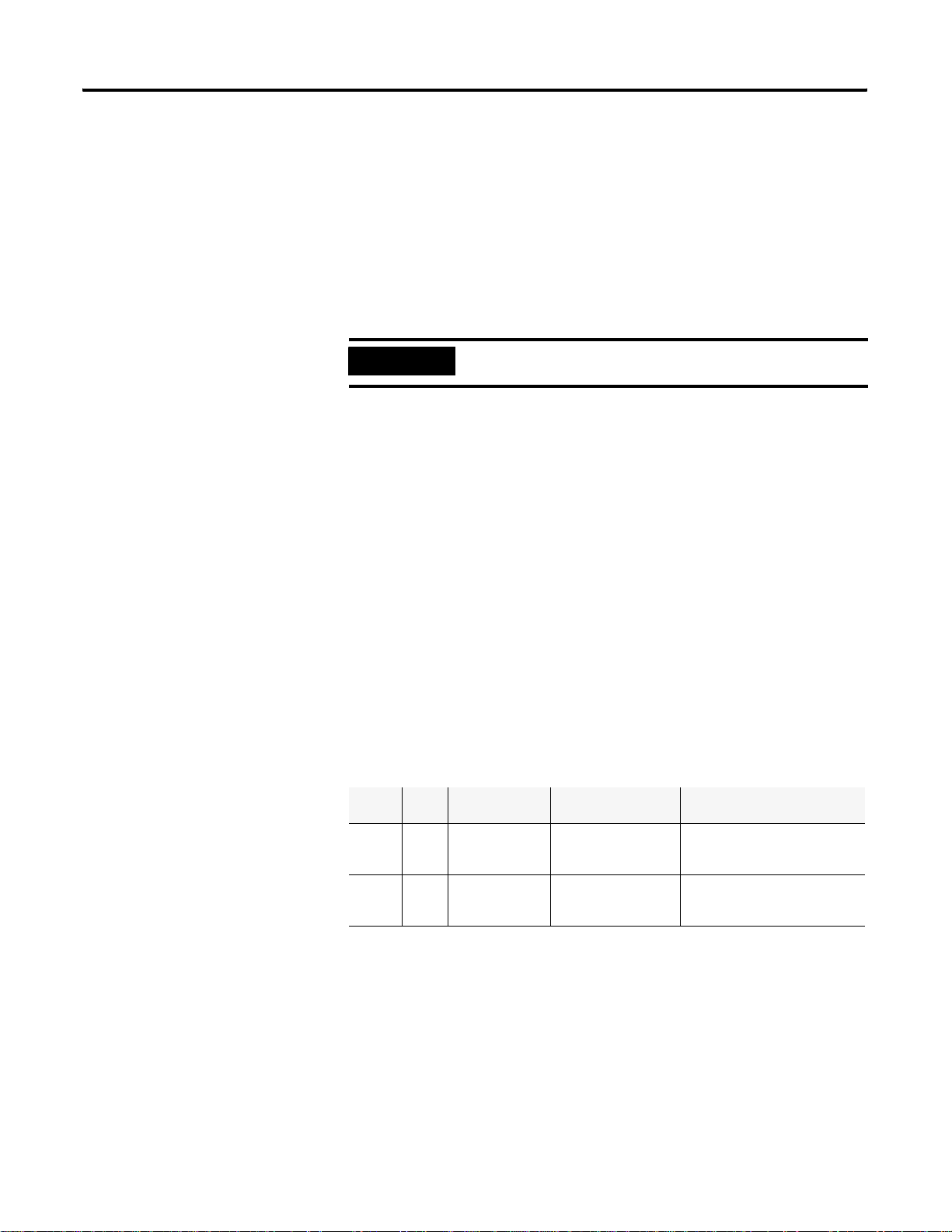

Housekeeping

Scheduled

Data

Table

Files

Logic Scan

LC 500 Program Scan Data Tables Files Housekeeping

Data Update

Data

Private

Memory

Buffers

Scheduled Data Transfers

41554

1747-SCNR Scheduled Data

Publication 1747-RM623D-EN-P - June 2006

Page 24

2-4 Prepare to Use the ControlNet Scanner

6

Unscheduled Data Transfer Operations on a ControlNet Network

The ControlNet network lets you use unscheduled mess agin g in

addition to deterministic delivery.

Unscheduled operations include:

• peer-to-peer messaging.

• messaging from any remote CIP client device.

• messaging from programming devices.

• CIP client message initiated by the SLC processor ladder

program.

This process is illustrated in the figure.

Housekeeping

Logic Scan

Data

Table

Files

Data

M0 file transfer

(SLC processor

read and write)

Table

Files

SLC 500 Program Scan

M0 file transfer

(write request read response)

1747-SCNR Unscheduled Data

Data Tables Files

Housekeeping

Link Layer Services

The figure illustrates link layer services.

Network Update Time (NUT)

Scheduled

Service

Unscheduled

Service

M0

Local

Database

area

M0

CIP client

message

area

Unscheduled Data Transfers

41555

Network Maintenance

Publication 1747-RM623D-EN-P - June 2006

Time

4155

Page 25

Prepare to Use the ControlNet Scanner 2-5

The ControlNet system places your scheduled transfers in the first part

of each network update interval (NUI). Time is automatically reserved

for network maintenance, and unscheduled transfers are performed

during the remainder of the interval.

Unscheduled messaging on a ControlNet network is

non-deterministic.Your application and your configuration (for

example, number of nodes, application program, NUT) deter mine

how much time there is for unscheduled messaging.

Understand 1747-SCNR Mapping

IMPORTANT

The ControlNet network reserves time for at least one

unscheduled transfer per NUI.

The 1747-SCNR scanner and the SLC processor exchange the

following information through the backplane:

• Input data

• Output data

• Status data

• Command data

• CIP messages

The 1747-SCNR mapping is described in the following. Bit field

descriptions follow each table.

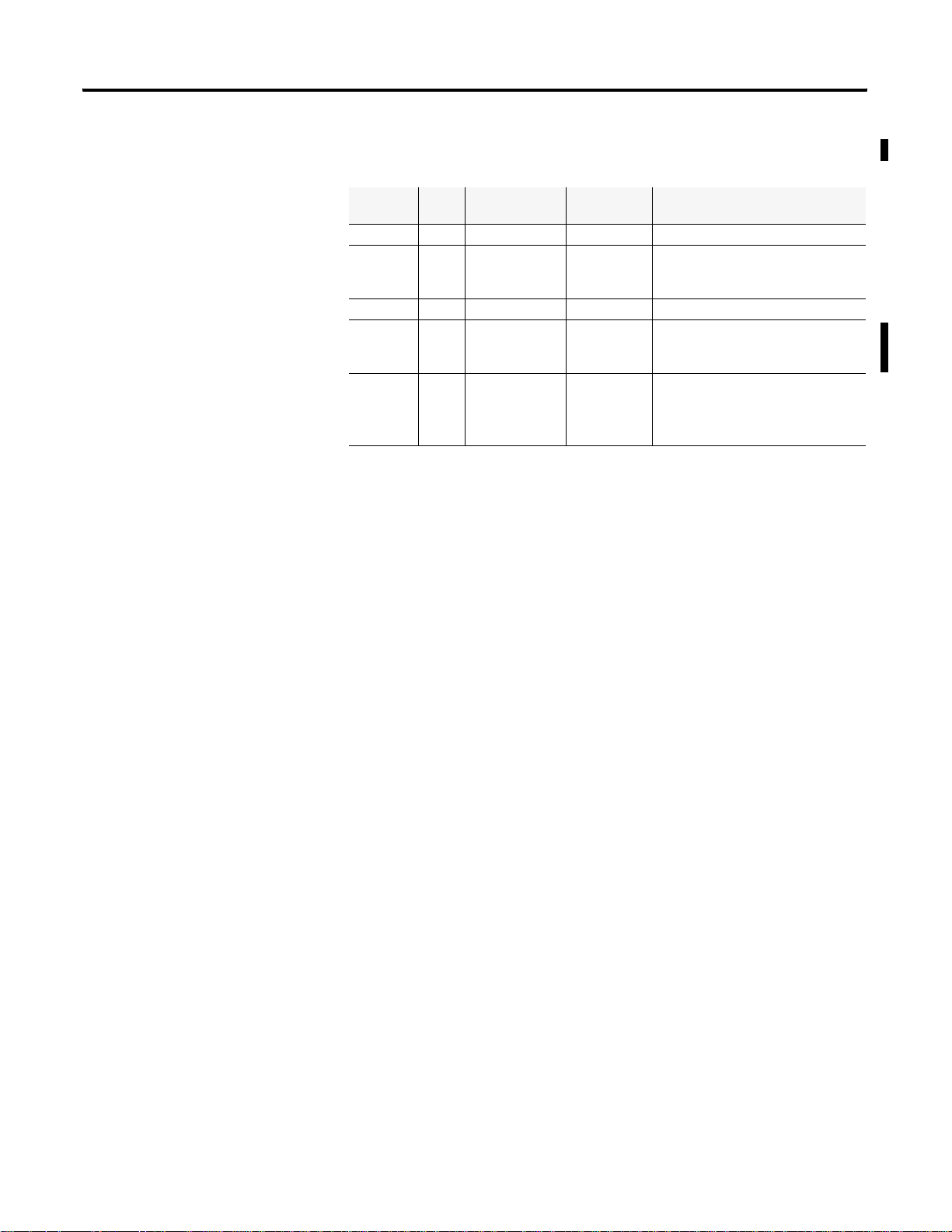

Discrete Input File

Word

Offsets

0 1 N/A Module Status (see

1-31 31 Scheduled ControlNet Input

Word

Size

ControlNet

Transfer Mode

Contents Description

the next section,

“Module Status”)

Data

Bit field reporting general

status information.

You can map up to 31 words of

input data using RSNetWorx

for ControlNet software.

Publication 1747-RM623D-EN-P - June 2006

Page 26

2-6 Prepare to Use the ControlNet Scanner

Module Status (I:e.0)

Bit 0 1747-SCNR Module Faulted.

Bit 1 1747-SCNR Communication Module Fault

The 1747-SCNR scanner is not on line. See M1 word 2 (M1:e2) for the

ControlNet network status.

Bit 2 1747-SCNR Connection Fault

There is a fault in at least one scheduled connection.

Bit 3-7 Reserved.

Bit 8 Reset 1747-SCNR Module Acknowledge

The 1747-SCNR scanner will complement this bit each time the scanner is reset

due to complementing the Reset module command bit (O:e.0/8 where e is the

scanner slot number). See Example of Reset Bit Management.

Bit 9 Disable ControlNet Scheduled Connections Acknowledge

The 1747-SCNR scanner will set this bit when the Disable ControlNet

Scheduled Connections Command bit is set (O:e.0/9) and all scheduled

connections have been closed. The 1747-SCNR scanner will clear this bit when

the Disable ControlNet Scheduled Connections Command bit is cleared.

Bit 10 Scanner Mode

The 1747-SCNR scanner clears this bit when it is in idle mode. The 1747-SCNR

Scanner sets this bit when it is in run mode.

Bit 11-15 Reserved.

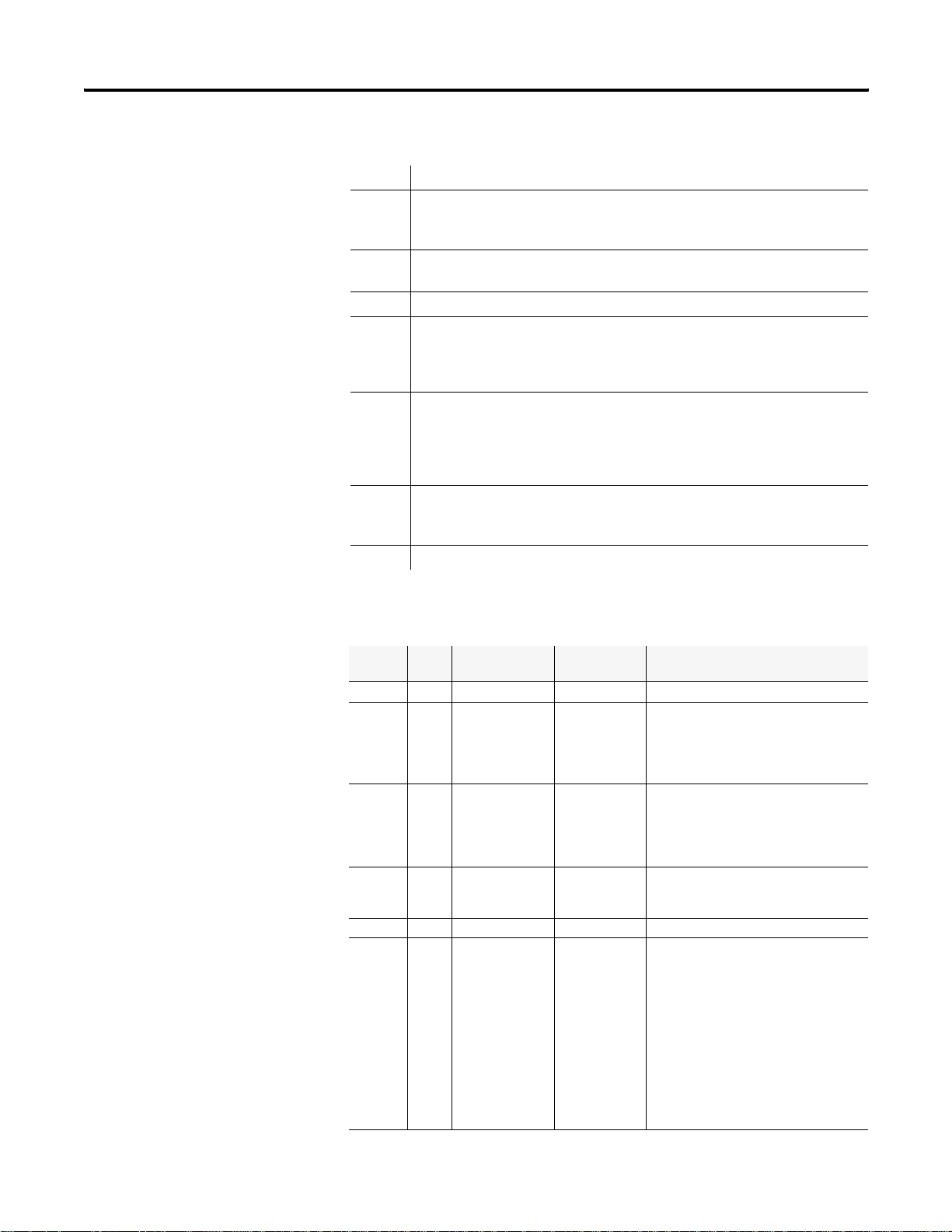

1747-SCNR M1 File

Word

Offsets

0 1 N/A Reserved Reserved for future use.

1 1 N/A Module

2 1 N/A ControlNet

3-255 253 Scheduled ControlNet

256-599 344 N/A Reserved Reserved.

600-607 8 N/A Connection

Word

Size

ControlNet

Transfer Mode

Contents Description

Value indicating the current

Status (See

the next page

“Module

Status”)

Status (See

the next page

“ControlNet

Status”)

Input Data

Status

operational status of the module. See

the Troubleshooting for probable

causes and recommended actions.

Value indicating the current channel

LEDs.

You can map scheduled input data in

this area using RSNetWorx for

ControlNet software.

Bit field reporting scheduled

connections status.

Two consecutive bits per scheduled

connection:

Connection State

(Even bit numbers)

1:connection opened

0:connection closed

Remote Device Mode

(Odd bit numbers)

1:remote device is in run mode

0:remote device is in idle mode

Publication 1747-RM623D-EN-P - June 2006

Page 27

Prepare to Use the ControlNet Scanner 2-7

Module Status (M1:e.1)

See Troubleshooting for probable causes and recommended actions.

Value Description

0x20 The scanner is not configured.

0x21 The current configuration is not valid.

0x22 Connections are configured, but no connections are established.

0x23 Connections are configured, but only 25% are successfully established.

0x24 Connections are configured, but only 50% are successfully established.

0x25 Connections are configured, but only 75% are successfully established.

0x26 All configured connections are established.

0x42 The node address is set to 00. This caused the scanner to erase network and

connection configuration stored in flash.

0x43 The scanner detected a network error due to a ControlNet cable problem or there

are no other nodes on the network.

0x44 The scanner has the same ControlNet address as another device on the network.

ControlNet Status (M1:e.2)

See the table that contains bit numbers and their descriptions.

Bit 0-2 Channel A status

Value LED State

000 Off

001 Green

010 Flashing green/off

011 Flashing red/off

100 Flashing red/green

101 Alternating red/off

110 Alternating red/green

111 Red

Bit 3 Reserved

Bit 4-6 Channel B status

Value LED State

000 Off

001 Green

010 Flashing green/off

011 Flashing red/off

100 Flashing red/green

101 Alternating red/off

110 Alternating red/green

111 Red

Bit 7-15 Reserved

Publication 1747-RM623D-EN-P - June 2006

Page 28

2-8 Prepare to Use the ControlNet Scanner

Discrete Output File

Word

Offsets

0 1 N/A Module Command Bit field used to send commands

1-31 31 Scheduled ControlNet Output

Word

Size

ControlNet

Transfer

Mode

Contents Description

to the 1747-SCNR Scanner.

You can map up to 31 words of

Data

output data using RSNetWorx for

ControlNet software.

Module Command (O:e.0)

Bit 0-7 Reserved

Bit 8 Reset Scanner Command

By complementing this bit, you reset the 1747-SCNR scanner (the reset occurs

when the SLC slot is de-activated).

It is important to note that if you do not disable the slot while the scanner is

resetting, the SLC module will fault with the error code nn57h (specifically, I/O

module in slot nn did not respond to a lock shared memory command in the

requested time limit) where nn is the slot number of the scanner . This is why the

reset bit change is not taken into account until the slot is disabled.

Bit 9 Disable ControlNet Scheduled Connections Command

When the bit value is 1, the 1747-SCNR scanner will close all scheduled

connections.

When the bit value is 0, the 1747-SCNR scanner will enable all scheduled

connections.

Bit 10 Scanner Mode Command

When the bit value is 0, the 1747-SCNR scanner is forced to Idle mode.

When the bit value is 1, the scanner’s mode will be determined by the mode of

the processor in slot 0.

Bit 11-15 Reserved

Publication 1747-RM623D-EN-P - June 2006

Page 29

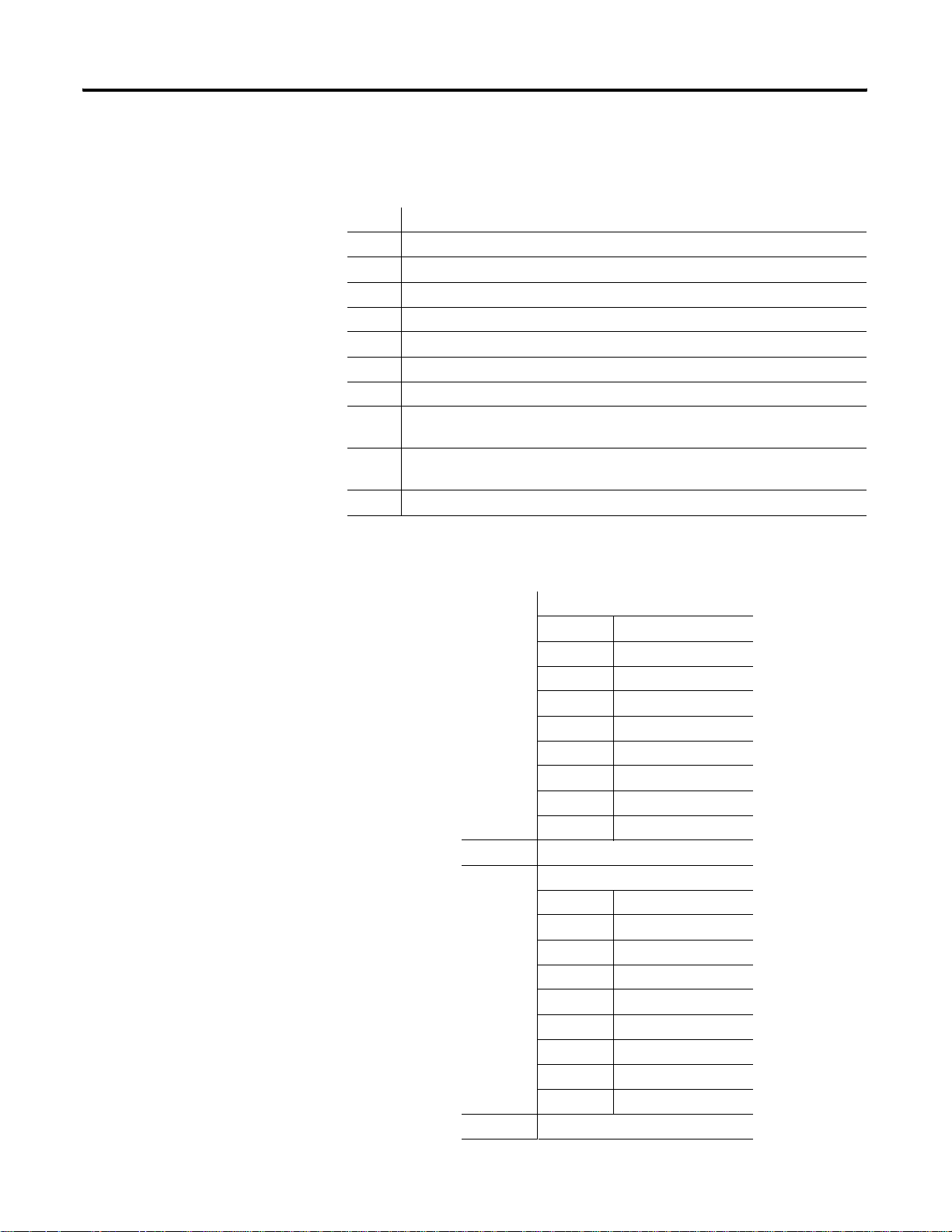

1747-SCNR M0 File

Prepare to Use the ControlNet Scanner 2-9

Word

Offsets

0-2 3 N/A Reserved Reserved.

3-255 253 Scheduled ControlNet

256-699 444 N/A Reserved Reserved.

700-955 256 Unscheduled Local

1000-1650 651 Unscheduled CIP Client

Word

Size

ControlNet

Transfer Mode

Contents Description

Using the RSNetWorx for

Output Data

Database

Message

Area

ControlNet software, you can map

scheduled output data in this area.

Memory area used by remote

devices to read or write data using

CIP messaging or PLC-5 messaging.

Memory used to send CIP client

requests. These messages are then

sent by the 1747-SCNR module as

unscheduled messaging.

Only Input and Output data (from Input file, Output file, M0

ControlNet Output data area, and M1 ControlNet Input data area) are

exchanged during scheduled time.

Data transfer to the M0 Local Database is performed using

Unscheduled messaging. Services available to read or write in this

area are Set Attribute Single, Get Attribute Single, Set Member, and Get

Member.

Communicating with Your Devices

The 1747-SCNR scanner supports up to 64 simultaneous scheduled

connections and up to 50 simultaneous unscheduled connections. The

1747-SCNR scanner also supports up to 32 simultaneous incoming

unconnected requests.

I/O Scheduled Data Transfer

Data received from the devices, or input data, is organized by the

scanner and made available to your processor in the Input file or the

M1 ControlNet data area.

Data received from your SLC processor, or output data, is stored

within the Output file or M0 ControlNet data area. The 1747-SCNR

scanner can then send the data to your remote ControlNet devices.

Publication 1747-RM623D-EN-P - June 2006

Page 30

2-10 Prepare to Use the ControlNet Scanner

All scheduled data transfer to Input, Output, M0 and M1 files must be

mapped on a ControlNet network. You have to specify where I/O

data is to be read from or written to, in other words, mapped. Data

size and location within 1747-SCNR data files have to be configure d

for each connection you want to setup with a remote device. The

configuration is performed using RSNetWorx for ControlNet so ftware.

Unscheduled Data Server

The scanner supports some CIP data server functionality on a specific

local database of 256 words located in the M0 file. Any device on

ControlNet can read or write in this database using the supported

services as described in Local Database Access Using PLC-5 MSG

Instructions and Local Database and ControlNet Data Files Access

Using CIP Messaging.

The SLC processor that has read and write access to this area is then

able to receive or modify data into the database.

Using this Local Database:

• a device can send data to an SLC processor us in g unscheduled

data transfer.

• two devices can exchange unscheduled data by using this

database as a proxy data storage.

• a PLC-5 controller can exchange data with the SLC processor by

reading or writing in this area using MSG instructions.

• an HMI can exchange data with the SLC processor by reading or

writing in this area using PLC-5 type read and write commands.

Publication 1747-RM623D-EN-P - June 2006

Page 31

Prepare to Use the ControlNet Scanner 2-11

CIP Client Request Transfer

The scanner provides some limited CIP client messaging capability.

Using ladder programming, you can manually build a message request

for up to approximately 240 words of in and approximatel y 240 words

of out data, to let configuration and other limited messaging to remote

devices.

The CIP client message management is detailed in CIP Client

Management.

SLC 5/03, 5/04, and 5/05 processors at OS firmware level, series C,

FRN 10, or later, include ControlNet explicit message (CEM)

instruction capability. The CEM instruction uses the CIP client message

capability of the scanner. See Work with the ControlNet Explicit

Message Instruction section for de tails.

Publication 1747-RM623D-EN-P - June 2006

Page 32

2-12 Prepare to Use the ControlNet Scanner

Notes:

Publication 1747-RM623D-EN-P - June 2006

Page 33

Chapter

3

Configure and Map Scheduled Data Exchange with RSNetWorx for ControlNet Software

What This Chapter Contains

Begin the Configuration

This chapter provides information about the mapping of scheduled

connections between 1747-SCNR remote devices. This chapter also

contains questions you should ask before configuring your 1747-SCNR

scanner. The following table describes what this chapter contains and

its location.

For Information About See Page

Beginning the configuration process 3-1

Questions to ask 3-1

Data transfer mapping 3-2

Planning before configuring your scanner helps make sure you can:

Process

• use your memory bandwidth efficiently.

• give attention to device-specific needs and requirements.

• give priority to critical I/O transfers.

• leave room for expansion.

Questions to Ask

1 Publication 1747-RM623D-EN-P - June 2006

Here are some questions you should ask yourself before you begin

configuring the 1747-SCNR scanner:

• What is on your network?

This is a very important question to answer. You should be

familiar with each device's:

• communication requirements.

• I/O importance and size.

• frequency of message delivery.

• How might this network appear in the future?

At this point in your planning, it is advantageous for you to have

some idea of how the network could be expanded. When

mapping your I/O, you have the opportunity to leave room for

future I/O. Answering this question now can save time and

effort in the future.

Page 34

3-2 Configure and Map Scheduled Data Exchange with RSNetWorx for ControlNet Software

Data Transfer Mapping

You can us e the configuration software (RSNetWorx for ControlNet

software) to select either Input or M1 files for input data and either

Output or M0 files for output data. However, it is more appropriate to

use Input and Output files for critical I/O data transfer and M1 and M0

for non-critical I/O data transfer.

Input and Output files contain 31 words each. These files are

appropriate for discrete data. If you have more than 31 words to

transfer, you have to map the remaining connections in M1 and M0

ControlNet data areas.

For input data, you can map your connections anywhere in Input and

M1 ControlNet data areas. It is not possible to overlap the mapping of

two independent input connections.

For output data, you can map your connections anywhere in Output

and M1 ControlNet data areas (refer to chapter 2 for exact memory

mapping.) The overlapping of two output connections is authorized.

IMPORTANT

It is your responsibility to check that no unexpected

overlapping has been configured.

Data exchanged through a single connection cannot be split between

two distinct locations. This means that a 5 word connection cannot

start at location I:29 and continue at another location in the M1 file.

Likewise, you cannot configure this connection with two first words at

address M1:e.4 and M1:e.5 and the rest between M1:10 and M1:12.

You access ControlNet data located in M1 and M0 files using the COP

(copy) instruction in your ladder program. Since the maximum data

length you can transfer with the COP instruction is 128 words, you

need two instructions to copy the whole ControlNet area and control

and status word in processor memory. If you have less than 128

words of data mapped in an M file, we recommend that you pack

them together so that you can use a single copy instruction.

IMPORTANT

When you are building your mapping, we recommend that you save

free space between device connections if the size of these

connections may increase in the future.

To ensure data consistency at the connection level,

be sure that, for all connections configured, data of a

same connection are copied into processor memory

using a single copy instruction.

Publication 1747-RM623D-EN-P - June 2006

Page 35

Chapter

4

Work with the ControlNet Explicit Message Instruction

What This Chapter Contains

Understand the ControlNet Explicit Message (CEM) Instruction

The following table describes what this chapter contains.

The CEM instruction lets generic Common Industrial Protocol (CIP)

commands be initiated to devices, such as drives, communicating on

ControlNet networks. This instruction requires RSLogix 500 software,

version 7.10 or later, for programming.

The CEM instruction uses the explicit message capability built into the

1747-SCNR ControlNet scanner.

While not adding any additional capability over what already exists in

the scanner, the CEM instruction simplifies the programming,

configuration, monitoring, and troubleshooting of explicit messages

on the ControlNet network.

For Information About See Page

ControlNet Explicit Message (CEM) Instruction Overview 4-1

How to Work with the Explicit Message Instruction 4-2

How to Work with the CEM Instruction Parameters 4-2

How to Work with the CEM Instruction Setup Screen Paramter 4-3

Unlike I/O configured in the scanner’s scan list, which is updated on a

continual basis, explicit messages let data be sent and received on an

as-needed basis, minimizing network traffic. For in stan ce, you may

want to write configuration parameters to a drive once at machine

start-up time.

The CEM instruction can be used with any SLC 5/03, 5/04, or 5/05

processor that is at OS firmware level Series C, FRN 10, or later.

1 Publication 1747-RM623D-EN-P - June 2006

Page 36

4-2 Work with the ControlNet Explicit Message Instruction

The CEM instruction uses an integer control block for storing the

instruction parameters and a configuration setup screen, similar to the

MSG instruction. The CIP commands consist of a Service Code; the

object Class, Instance, and Attribute; and Send and Receive Data (if

required for the selected Service Code). The setu p screen provides a

list of standard CIP Services to select from, including:

• Read Assembly.

• Write Assembly.

• Read Parameter.

• Write Parameter.

• Generic Get Attribute Single.

• Generic Set Attribute Single.

In addition, a Custom setting lets you enter any Service Code. Send

data and receive data are stored in separate data table files.

Work with ControlNet Explicit Message (CEM)

Fixed SLC

SLC

5/01

5/02

Output Instruction

SLC

SLC

SLC

5/03

5/04

5/05

•••

This is an output instruction that lets you initiate unconnected CIP

Generic messages via a 1747-SCNR ControlNet scanner installed in the

local chassis.

These messages can be initiated to any nodes on the same ControlNet

network as the 1747-SCNR module, regardless of whe ther the

destination node is in the scanner’s scan list or not, and regardless of

whether the scanner is in Run mode or Idle mode.

Each scanner can process only one CEM instruction at a time. The

instruction is similar in operation to a standar d MSG instruction.

Publication 1747-RM623D-EN-P - June 2006

Page 37

Work with the ControlNet Explicit Message Instruction 4-3

CEM Instruction Parameters

Enter the following parameters when programming this instruction.

• Control Block is an integer file address that you select. It is a

block of words, containing the status bits and other data

associated with the CEM instruction.

• Control Block Length is a display-only field that indicates how

many integer file words are being used by the control block. For

the CEM instruction, the length is always 67 words.

CEM Instruction Setup Screen Parameters

Read these sections for information about the parameters for the CEM

instruction setup screens.

Parameters for this controller on the general tab include the following.

• 1747-SCNR Slot

This drop-down field lists all of the local slots that contain

ControlNet scanner (1747-SCNR) modules within the IO

Configuration. Select the slot number of the particular scanner

that this explicit message will be initiate d through.

• Size in Words (Receive Data)

This field defines the size of the integer data file that will be

used to store the data that is returned by this explicit message

command. For best performance, define this file size to only be

as large as is required. If no receive data is expected, you may

leave this field at 0 and no receive data file will be defined. If

unsure of how much data will be returned, you may select up to

the maximum size of 250 words, and then reduce the size later

based on experience.

• Size in Words (Send Data)

This field defines the size of the integer data file that will be

used to store the data that is sent along with this explicit

message command. For best performance, define this file size to

only be as large as is required. If no send data is required, you

may leave this field at 0 and no send data file will be define d. If

unsure of how much data will be sent, you may select up to the

maximum size of 248 words when defining the instruction, and

then reduce the size later based on experience.

Publication 1747-RM623D-EN-P - June 2006

Page 38

4-4 Work with the ControlNet Explicit Message Instruction

• Data Table Address (Send Data)

• Data Table Address (Receive Data)

If Size in Words (Receive Da ta) is non-zero, then this field requires a

starting integer (N) file address for storing the Receive Data.

Parameters for target device on the general tab include the following.

• Message Timeout (x1 ms)

• ControlNet Addr (dec)

If Size in Words (Send Data) is non-zero, then this field requires

a starting integer (N) file address for storing the Send Data.

The amount of time in milliseconds that the scanner will wait for

a reply to the explicit message command. Range is 2 to 32767.

The target ControlNet node address. Valid range is 1 to 99. If

you enter in the local scanner’s ControlNet node add ress, the

command is executed by the local scanner .

• Service

This pull-down menu lets you select services based on name

rather than Service Code. The Custom service lets you enter any

Service Code in the hexadecimal range of 1 to 7F. These services

are listed in the pull-down selection.

– Read Assembly

– Write Assembly

– Write Output Point

– Read Output Point

– Read Input Point

– Read Parameter

– Write Parameter.

– Read Analog Input

– Write Analog Output

– Generic Get Attribute Single

– Generic Set Attribute Single

– Generic Get Member

– Generic Set Member

– Reset Identity Object

– Custom

Publication 1747-RM623D-EN-P - June 2006

Page 39

Work with the ControlNet Explicit Message Instruction 4-5

• Service Code (hex)

This field is read-only unless the Custom Service is selected.

Possible Service Codes are 1 to 7F (hex). See Volume 1 of the

CIP Common Specification, Appendix A, for the list of valid

explicit messaging Service Codes.

• Class (hex)/(dec)

Possible Classes are 0 to FF (hex). See Volume 1 of the CIP

Common Specification for the list of defined Classes. Yo u may

either enter in a hexadecimal Class value in the (hex) field or a

decimal Class value in the (dec) field.

• Instance (hex)/(dec)

Possible Instances are 0 to FFFF (hex). See Volume 1 of the CIP

Common Specification for the list of valid Instances for each

Class. You may either enter in a hexadecimal Instance value in

the (hex) field or a decimal Instance value in the (dec) field.

• Attribute (hex)/(dec)

Possible Attributes are 0 to FFFF (hex). See Volume 1 of the CIP

Common Specification for the list of valid Attributes for each

Class. You may either enter in a hexadecimal Attribute value in

the (hex) field or a decimal Attribute value in the (dec) field.

• Member (hex)/(dec)

Possible Members are 0 to FFFF (hex). See Volume 1 of the CIP

Common Specification for the list of valid Members for each

Class. You may either enter in a hexadecimal Member value in

the (hex) field or a decimal Member value in the (dec) field.

Publication 1747-RM623D-EN-P - June 2006

Page 40

4-6 Work with the ControlNet Explicit Message Instruction

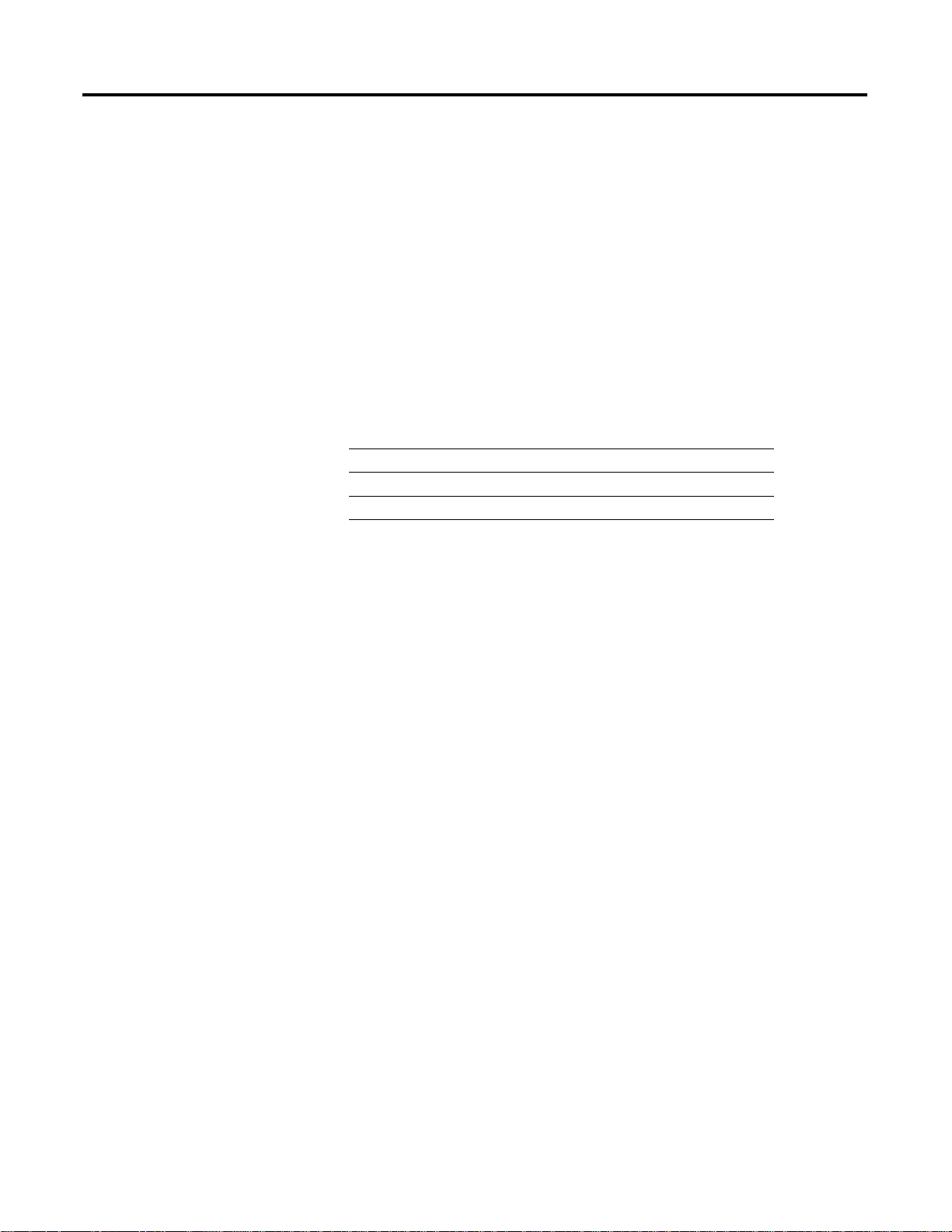

Definitions for Message Status Bits on the General Tab

See the table that lists the various status bits associated with the CEM

instruction as displayed in the CEM instr uction setup screen.

CEM Instruction Setup Screen Status Bit

Bit Definition Bit Mnemonic Bit Address

Timeout TO 08

Error ER 12

Done DN 13

Enabled EN 15

Waiting for slot WS 10

• Timeout bit TO (word 0, bit 8) is set when the scanner times out

• Error bit ER (word 0, bit 12) is set when the message has failed

• Done bit DN (word 0, bit 13) is set when the message has

• Enabled bit EN (word 0, bit 15) is set after the message rung

• Waitin g for Slot bi t WS (word 0 , bit 10) is set when the message

the message either due to no response from the target device or

due to no reply being returned within the configured timeout

period. The ER bit will be set at the same time the TO bit is set.

This bit is reset the next time the message rung goes from false

to true. Do not set or reset this bit. It is informational only.

to complete successfully. This bit is reset the next time the

message rung goes from false to true. Do not set or reset this bit.

It is informational only.

completed successfully. This bit is reset the next time the

message rung goes from false to true. Do not set or reset this bit.

It is informational only.

goes from false to true and the scanner accepts this message

because it is not currently processing any other explicit

messages. (The scanner can process only one CEM instruction at

a time.) If the message rung goes false before the scanner

accepts this message, then the enable bit will remain off and the

message will not be executed. This bit is reset when the

message has completed with either the Done bit set or the error

bit set and the message rung goes false. If the message rung

conditions remain true, you may retrigger the message

instruction by resetting this bit after either the ER or DN bit has

been set, indicating that the previous execution has completed.

rung goes from false to true, but the scanner is still processing

another CEM instruction. To ensure that this message gets

processed, you must leave the message rung conditions true

until the WS bit is reset and the EN bit is set, indicating that the

scanner has accepted this message for processing. Do not set or

reset this bit. It is informational only.

Publication 1747-RM623D-EN-P - June 2006

Page 41

Work with the ControlNet Explicit Message Instruction 4-7

Scanner Status, Error, and Error Description on the General Tab

The Scanner Code displays the explicit message status returned by the

scanner. A scanner code of 0 means no errors. See the CEM

Instruction Scanner Codes table for a list of other valid scanner codes.

CEM Instruction Scanner Codes

Scanner Code Description of Scanner Status

201H Invalid command data size

202H Internal fault detected

204H Invalid service code

205H Invalid IOI size

206H Invalid CIP request block contents

207H CIP message request timeout

208H CIP timeout value too small

Publication 1747-RM623D-EN-P - June 2006

Page 42

4-8 Work with the ControlNet Explicit Message Instruction

A scanner code of 0x207 results in an error code of 1. All other

scanner codes listed result in an error code of 2. The Valid CEM

Instruction error codes table lists all valid CEM instruction error codes.

Valid CEM Instruction Error Codes

Error Code Description of Error Condition

0 No error.

1 Timeout error. ControlNet explicit message timed out by scanner.

2 Scanner error. See Scanner Status.

3 Configuration error. Send file length > 248 or invalid IOI size.

5 Processor error. Invalid response.

6 Processor error. Unsolicited response received.

7 Configuration error. Size of response data > receive data size.

For error code 4, the error de scription displays the CIP response error

code and description as documented in the CIP Common

Specification, Appendix B.

Any time the Error code is non-zero, th e CEM error (ER) bit is set.

Publication 1747-RM623D-EN-P - June 2006

Page 43

Work with the ControlNet Explicit Message Instruction 4-9

Send Data Tab

The Send Data Tab provides a convenient way of viewing and

entering in data to be sent along with the explicit message command.

The data is shown in byte format with a selectable radix of either

Decimal or Hex/BCD. The display only shows the number of words

that are defined in the Size in Words (Send Data) field, starting with

the low byte of the first word as defined in the Data Table Address

(Send Data) field. If the Size in Words is zero, then no data is

displayed. You can also change the data being viewed, but on ly when

offline or during an online edit. Click on the data and enter in a byte

value based on the current radix (0 to 255 for Decimal and 0 to FF for

Hex/BCD). The changed data gets copied to the Send Data data table

file when the rung is accepted. To upda te the Send Data display with

the current values stored in the Send Data data table file, click on the

Refresh button.

Receive Data Tab

The Receive Data Tab provides a con veni ent wa y of vie wing th e data

that is returned by the target device in response to the explicit

message command sent. The data is shown in byte format with a

selectable radix of either Decimal or Hex/BCD. The display only

shows the number of words that are defined in the Size in Words

(Receive Data) field, starting with the low byte of the first word as

defined in the Data Table Address (Receive Data) field. If the Size in

Words is zero, then no data is displayed. To update the Receive Data

display with the current values stored in the Receive Data data table

file, click on the Refresh button.

Publication 1747-RM623D-EN-P - June 2006

Page 44

4-10 Work with the ControlNet Explicit Message Instruction

Control Block Layout

See this table for the control block layout.

SLC 5/0x ControlNet Explicit Message (CEM) Control Block Structu re

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 0

Word 0 EN DN ER WS TO Reserved by the 1747-SCNR module

Word 1 Target MAC ID

Word 2 Message Timeout Preset (x1 ms)

Word 3 Complex I0I Size

Word 4 Reserved Service Code

Word 5 Reserved Class

Word 6 Instance

Word 7 Attribute

Word 8 Member

Word 9 Size of Command Data (Words)

Word 10 Request Status - Scanner Status (Scanner Code)

Word 11 Response Status

Word 12 Extended Status Size (Words)

Word 13 Size of response and status (Words)

Word 14 Complex IOI Buffer

- - - - - - Word 63

Word 64 Error Code Transaction ID

Word 65 Extended Status Debug Word 1

Word 66 Extended Status Debug Word 2

(Lets you to manually set IOI)

Publication 1747-RM623D-EN-P - June 2006

Page 45

Troubleshoot

M

Chapter

5

What This Chapter Contains

Troubleshoot with the

The following table describes what this chapter contains and its

location.

The 1747-SCNR module has indicators on the front plate, as shown in

the figure.

Status Indicators and

Status Display

For Information About See Page

Troubleshooting 4-1

Apply chassis power 4-2

Alphanumeric display 4-2

OK indicator and display mnemonics 4-3

Status Display and

Node Address

OK indicator

ControlNet

Status Indicators

30750-

These indicators are the following.

• An alphanumeric display (of status and node address)

• A and B status indicators

• OK

Use these indicators to troubleshoot the scanner.

1 Publication 1747-RM623D-EN-P - June 2006

Page 46

5-2 Troubleshoot

Apply Chassis Power

Alphanumeric Display

When you apply chassis power , the module addre ss and status display

cycles through the following mnemonics:

1. POST - The 1747-SCNR runs Power On Self Test.

2. 1111, 2222, etc. - The 1747-SCNR is executing its startup

sequence.

3. The 1747-SCNR firmware version is displayed temporarily after

startup.

4. A#nn (where nn = ControlNet node address) then I/O or I/OX

(based on the number of connections configured and

established) then IDLE or RUN (based on the scanner mode).

The four character alphanumeric display provides you with additional

visual information about the current operational status of the module.

See the tables that describe problems that may occur while using your

1747-SCNR module, the probable causes, and the recommended

action.

Publication 1747-RM623D-EN-P - June 2006

Page 47

T roubleshoot 5-3

OK Indicator and Display

The OK indicator is handled consistently with the Con t ro lNet

specifications for the Identity object.

Mnemonics

Sequence OK

Indicator

Startup Alternating

red/green

Run time Green A#XX N/A ControlNet node

Alpanumeric

Display

POST N/A The 1747-SCNR module

FIRM

WARE

I/O

IDLE N/A The scanner is in idle

RUN N/A The scanner is in run

EDIT N/A The scanlist in the

Module Status

Word (M1 file)

N/A 1747-SCNR firmware

0x26 All configured

Description Probable Cause Recommended Action

is running Power On Self

Test.

revision. This is a

temporary display after

start up.

address

connections are

established.

mode.

mode.

1747-SCNR is being

modified.

Power was applied to

the module.

Power was applied to

the module.

None No action required.

None No action required.

The SLC processor in

slot 0 is in program

mode or the Scanner

Mode Command bit of

the Module Command

word is clear (O:e.0/

10 where e is the

scanner slot number).

The SLC processor in

slot 0 is in run mode

and the Scanner

Mode Command bit of

the Module Command

word is set (O:e.0/10).

Edits have been

enabled with

RSNetWorx for

ControlNet software.

Note that previously

configured

connections will be

reestablished if lost.

Newly configured or

changed connections

will not be

established until edits

are accepted.

No action required.

No action required.

If you want to put the

scanner into run mode,

put the SLC processor in

slot 0 into run mode and

set the Scanner Mode

Command bit of the

Module Command word

(O:e.0/10) using an

unconditional OTE

instruction.

If you want to put the

scanner into program

mode, either put the SLC

processor in slot 0 into

program mode or clear

the Scanner Mode

Command bit of the

Module Command word

(O:e.0/10).

Finish modifying the

scanlist with RSNetWorx

for ControlNet software

and then accept edits.

Cancel edits with

RSNetWorx for

ControlNet software.

Publication 1747-RM623D-EN-P - June 2006

Page 48

5-4 Troubleshoot

Sequence OK

Indicator

Run time Flashing

Green

Alpanumeric

Display

I/OX

Module Status

Description Probable Cause Recommended Action

Word (M1 file)

0x20 The scanner is not

configured.

0x21 The current

configuration is not

valid.

The scanner is not able

to start any scheduled

communication to

remote devices. Only

unscheduled

communication is

possible.

I/O

0x22

Connections are

configured but no

connections are

established.

I/O

0x23

Connections are

configured but only 25%

are successfully

established.

I/O

I/O

0x24

0x25

50%

75%

EDIT N/A The scanlist in the

1747-SCNR module is

being modified.

Module is not

configured.

Module is not

configured properly.

View the Connection

Status screen in

RSNetWorx for

ControlNet software

to see why the

connections are not

established.

Module bandwidth is

exceeded.

Edits have been

enabled with

RSNetWorx for

ControlNet software.

Note that previously

configured

connections will be

reestablished if lost.

Newly configured or

changed connections

will not be

established until edits

are accepted.

Use RSNetWorx for

ControlNet software to

download a new

configuration.

Use RSNetWorx for

ControlNet software to

schedule the existing

configuration.

Use RSNetWorx for

ControlNet software to

download a new

configuration.

Check to see if the

1747-SCNR and the

remote devices are

correctly connected to

the ControlNet network.

Reduce the number of

scheduled connections

by:

- using a discrete rack

connection instead of

multiple discrete module

connections

- combining multiple I/O

racks into a single I/O

rack

- combining multiple

peer-to-peer messages

into one message.

Increase your Network

Update Time and/or

increase the Requested

Packet Intervals for

scheduled data transfers.

Increase your SLC 500

ladder program scan by

adding more logic.

Finish modifying the

scanlist with RSNetWorx

for ControlNet software

and then accept edits.

Cancel edits with

RSNetWorx for

ControlNet software

Publication 1747-RM623D-EN-P - June 2006

Page 49

T roubleshoot 5-5

Sequence OK

Indicator

Run time Flashing

Green

Errors Off None N/A Module is not

Flashing

Green

Red (Scrolling

Flashing

Red

Alpanumeric

Display

SIGM N/A A scanner signature

N/A 0x43 Network error. Cable error or no other

display

showing fault

details)

A#00

FLSH

CFG

ERAS

DUPL

A#XX

Module Status

Word (M1 file)

N/A Module faulted. Internal error

0x42 Module erased network

0x44 Duplicate node address. Another device with

Description Probable Cause Recommended Action

mismatch has been

detected. The

1747-SCNR scanner

signature does not

match the signature

stored in the active

keeper.

The scanner is not able

to start any scheduled

communication to

remote devices. Only

unscheduled

communication is

possible.

communicating.

and connection

configuration stored in

flash.

Module is not

configured properly.

Power supply fault. Check power supply,

nodes on the network.

detected.

Network node

address is set to 00.

the same ControlNet

address is on the link.

Use RSNetWorx for

ControlNet software to

schedule the existing

configuration.

Use RSNetWorx for

ControlNet software to

download a new

configuration.