Page 1

Installation Instructions

SLC ControlNet Scanner Module

Catalog Number 1747-SCNR

Use this document to help you install the ControlNet™ 1747-SCNR

Scanner module.

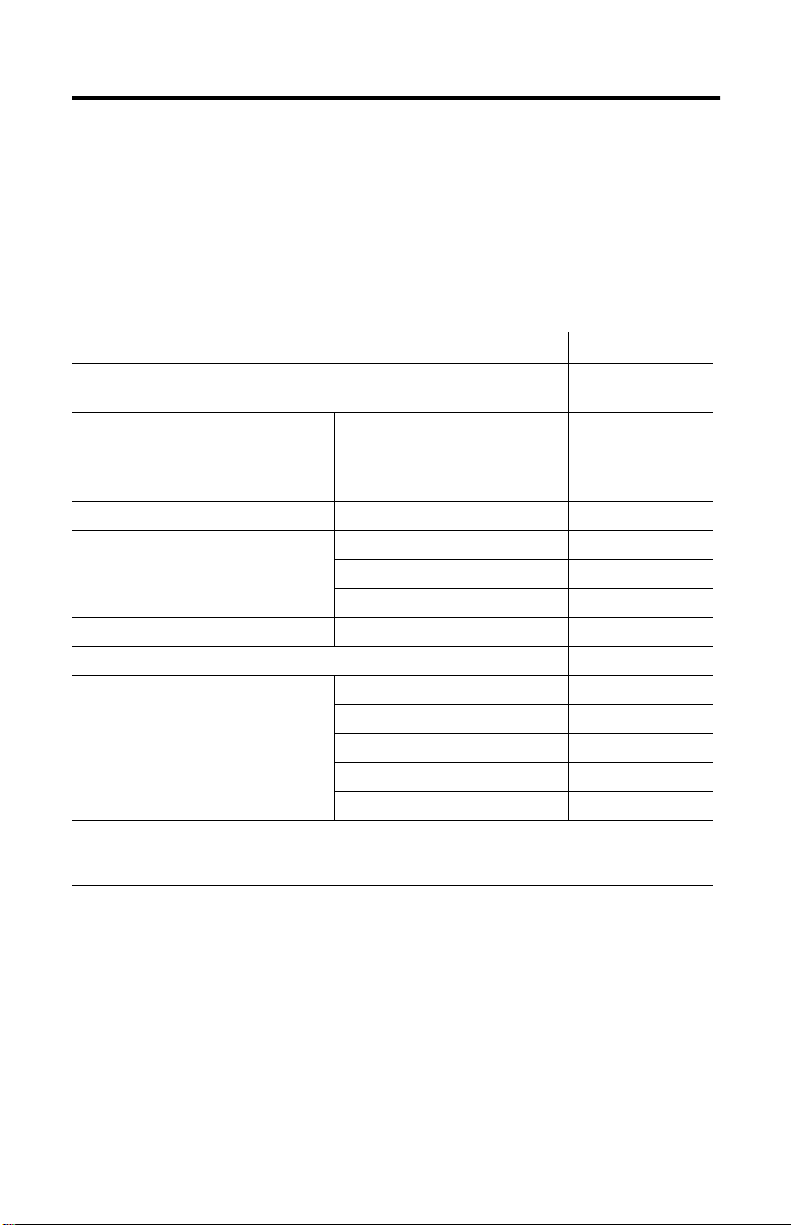

For information about See page

important user information 2

preventing electrostatic discharge 4

compliance to European Union Directives 4

related publications 5

module features 6

preparing the module for installation 7

selecting the ControlNet node address 8

inserting the 1747-SCNR scanner into the chassis 8

connecting to a ControlNet network 9

connecting programming terminal to ControlNet network 11

cables 12

applying chassis power 13

alphanumeric display 13

OK indicator and display mnemonics 14

status indicators 19

specifications 20

hazardous location approval 21

Publication 1747-IN059C-EN-P - September 2001

Page 2

2 SLC ControlNet Scanner Module

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable

laws, regulations, codes and standards. In no event will

Allen-Bradley be responsible or liable for indirect or consequential

damage resulting from the use or application of these products.

Any illustrations, charts, sample programs and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley does not

assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Rockwell Automation,

is prohibited.

Throughout this manual, notes may be used to make you aware of

safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequence of a

potential hazard.

WARNING

Identifies information about practices or circumstances

that can cause an explosion in a hazardous

environment, w hi ch may lead to personal in jury or

death, property damage or economic loss.

ÿ

Publication 1747-IN059C-EN-P - September 2001

Page 3

SLC ControlNet Scanner Module 3

ATTENTION

ÿ

IMPORTANT

ATTENTION

ÿ

Identifies information about practices or circumstances

that can lead to person a l injury or death, property

damage or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Environment and Enclosure

This equipment is inte nded for use in a P ollut ion Degr ee

2 industrial environment, in overvoltage Category II

applications (as defined in IEC publication 60664-1), at

altitudes up to 2000 meter without derating.

This equipment is s uppl ied as “ope n typ e” eq uipm ent. It

must be mounted within an enclosure that is suitably

designed for t hose speci fic enviro nmental cond itions that

will be present and appropriately designed to prevent

personal injury resulting from accessibility to live parts.

The interior of the enclosure must be accessible only by

the use of a tool. Subsequen t sec tion s of th is public atio n

may contain additional information regarding specific

enclosure type ratings that are required to comply with

certain product safety certifications.

NOTE: See NEMA Standards publication 250 and IEC

publications 60529, as a pplicable, for ex planatio ns of t he

degrees of protection provided by different types of

enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication

1770-4.1 (“Industrial Automation Wiring and Grounding

Guidelines”), for additional installation requirements

pertaining to this equipment.

Publication 1747-IN059C-EN-P - September 2001

Page 4

4 SLC ControlNet Scanner Module

Prevent Electrostatic Discharge

The scanner module is sensitive to electrostatic discharge.

ATTENTION

ÿ

Electrostati c discharge can damag e int eg rated circuits or

semiconductors if you touch backplane connector pins.

Follow these guidelines when you handle the module:

• touch a grounded object to discharge static potential

• wear an approved wrist-strap grounding device

• do not touch the backplane connector or connector

pins

• do not touch circuit components inside the module

• if available, use a static-safe work station

• when not in use, keep the module in its static-shield

bag

Compliance to European Union Directives

If this product has the CE mark, it is approved for installation within

the European and EEA regions. It has be en desi gned and tes ted to

meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Publication 1747-IN059C-EN-P - September 2001

Page 5

SLC ControlNet Scanner Module 5

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage by applying the safety requirements of EN 61131-2

Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriat e

sections in this publication as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

• Automation Systems Catalog, publication B113

This equipment is classified as open equipment and must be

installed (mounted) in an enclosure as a means of providing safety

protection.

Related Publications

For: Refer to the: Publication:

software configuration

information

planning and installation

information

terminating ControlNet

coaxial cables information

1.The publication number listed includes only t he base number. The Automation Bookstore a nd Manuals On line

will list the latest version of the publication. For example, 1747-RM623C-EN-P.

ControlNet 1747-SCNR

Reference Manual

ControlNet Cable System

Planning and Installation Manual

Terminating Your ControlNet

Coaxial Cables

1747-RM623

1786-6.2.1

CNET-DM001

1

1

If you need a copy of these manuals, access the Automation

Bookstore website at http://www.theautomationbookstore.com or

the Manuals On line website at http://www.ab.com/manuals.

Publication 1747-IN059C-EN-P - September 2001

Page 6

6 SLC ControlNet Scanner Module

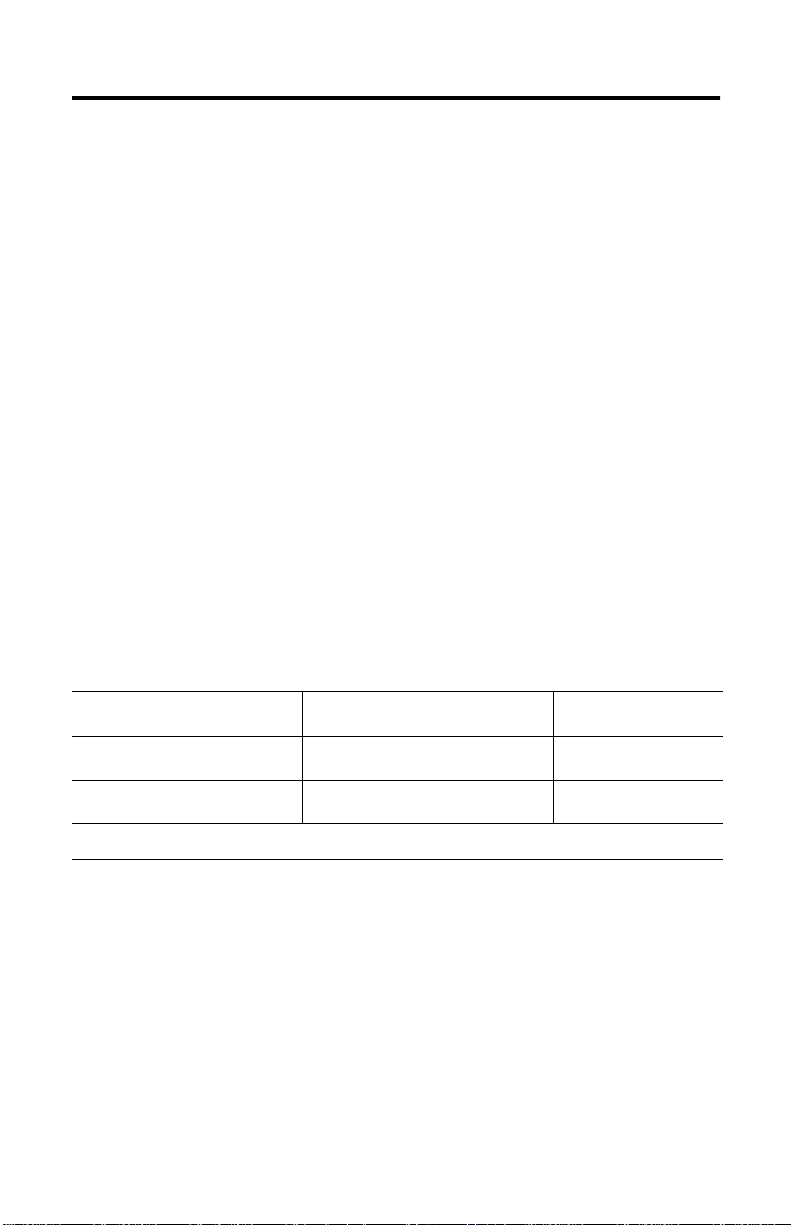

Identify Scanner Module Feat ures

Use this illustration to identify the features of the 1747-SCNR

Scanner module.

Node Address and Status Display

Channel B

Status Indicator

Displays scanner node address and status

Channel A

Status Indicator

ControlNet Network

Access Port

(NAP)-RJ45 connector

Module Status Indicator

Indicates whether the device is powered and is

functioning properly

ControlNet Redundant Media Ports

BNC connectors (Channels A and B)

30751-M

Publication 1747-IN059C-EN-P - September 2001

Page 7

SLC ControlNet Scanner Module 7

Prepare for Module Installation

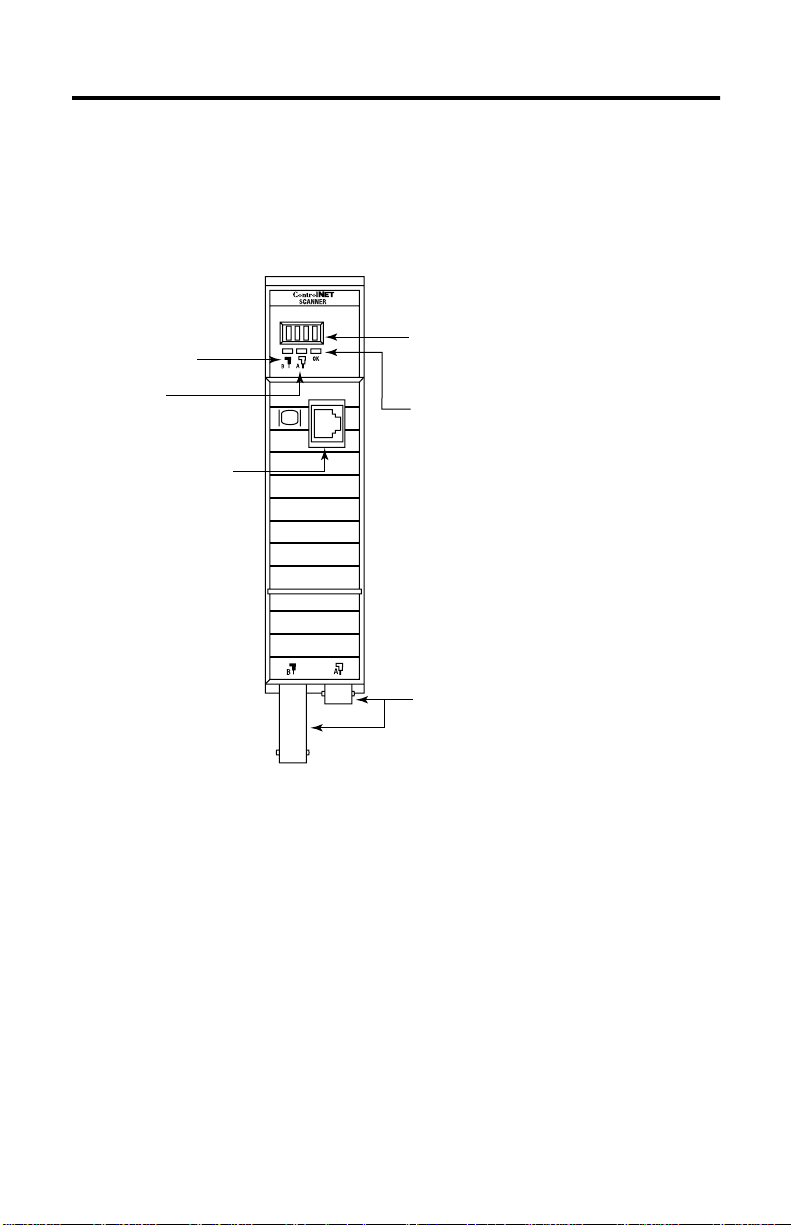

Before you install your module, you need the following items:

RSNetWorx for

Personal Computer with

Windows

Microsoft

1746 chassis with SLC

SLC

5/02, 5/03, 5/04, or 5/05 processor and

the appropriate configuration software

(RSLogix 500

)

ControlNet

catalog number

9357-CNETL3

,

1747-SCNR Scanner Module

Reference Manual, publication

1747-RM623 (The publication

number includes the base number

only. The current versions will be

listed in the Automation

Bookstore and Manuals On line.)

ControlNet 1784-PCC (shown), or

1784-PCIC, or 1784-KTCX15, or

1770-KFC15

41523

Before you install the module, you must know how to:

• program and operate an Allen-Bradley SLC 500 programmable

controller

• install and configure the devices on your ControlNet network

Make Sure That Your Processor and Scanner Are Compatible

The 1747-SCNR Scanner module fits in any sl ot of the ch assis except

for the left-most slot of the first chassis, which is reserved for the

SLC 500 processor.

Publication 1747-IN059C-EN-P - September 2001

Page 8

8 SLC ControlNet Scanner Module

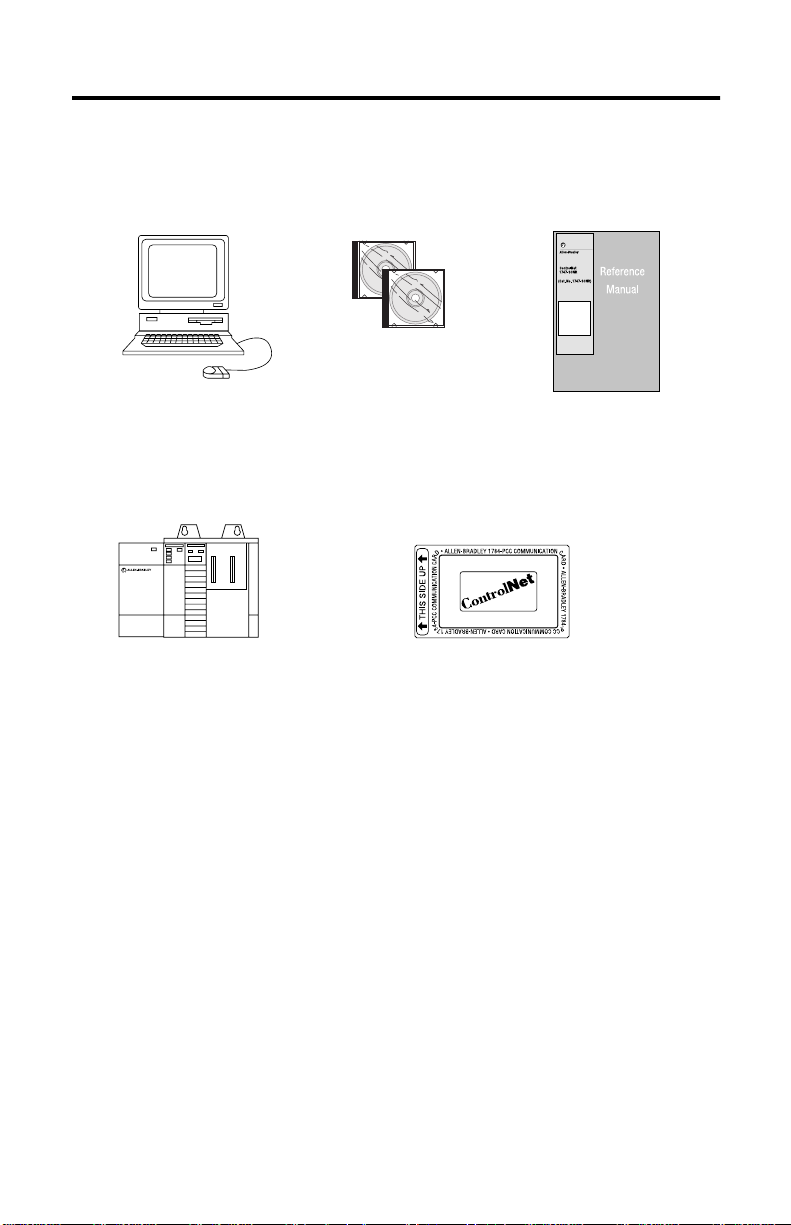

Select the ControlNet Node Address

Select the ControlNet node address of the 1747-SCNR by setting the

two 10-digit rotary switches on the top of the scanner. Valid switch

settings range from 01 through 99. Zero (00) is not a valid node

address.

10-digit rotary switches: ones digit

10-digit rotary switches: tens digit

30752

Important: Since 00 is the default value from man ufacturing, you

must change the default value when using the

scanner for the fir s t tim e .

Top View of Module

Insert the 1747-SCNR Scanner Into the Chassis

To insert the 1747-SCNR Scanner into the SLC chassis:

1. Turn off the SLC chassis power supply.

ATTENTION

ÿ

Important: If you disconnect the ac power, you lose the chassis

Publication 1747-IN059C-EN-P - September 2001

Do not install the 1747-SCNR Scanner module with

the chassis power supply on. Installing the module

with the chassis power supply on may damage the

module.

ground. Electrostatic damage (ESD) protection is lost.

Page 9

SLC ControlNet Scanner Module 9

2. Select a slot for the module in the chassis. Choose any slot

except the left-most slot of the first chassis, which is reserved

for the SLC 500 processor.

3. Insert the module into the slot you have selected. We

recommend that you insert the 1747 -SC NR Scanner as close to

the chassis power supply as possible.

30801-M

4. Apply firm, even pressure to seat the module in the I/O

chassis backplane connectors.

5. Restore power to the SLC chassis.

Connect to a ControlNet Network

Connect the 1747-SCNR Scanner module to a ControlNet network

via a tap with a 1m (39.4 in.) drop cable.

Publication 1747-IN059C-EN-P - September 2001

Page 10

10 SLC ControlNet Scanner Module

Four Allen-Bradley ControlNet taps are available from Rockwell

Automation as shown below.

Straight T-tap

Straight Y-tap

Right-angle T-tap

Right-angle Y-tap

1786-TPS

1786-TPYS

1786-TPR

1786-TPYR

20094-M

Important: Allen-Bradley ControlNet taps contain passive

electronics and must be purchased from Rockwell

Automation for the network to function properly.

After terminating your network segments, connect your node to the

network.

Nonredundant media

A

Redundant media

A

B

30802-M

WARNING

If you connect or disconnect the ControlNet cable with

power applied to this module or any device on the

network, an electric al arc can occur . Thi s could cause an

explosion in hazardous location installations. Be sure

ÿ

that power is removed or the area is nonhazardous

before proceeding.

Publication 1747-IN059C-EN-P - September 2001

Page 11

SLC ControlNet Scanner Module 11

Remove the tap’s dust cap—located on the straight or righ t-angle

connector—and set it aside.

If your network supports Connect the tap’s straight or right-angle connector

nonredundant media to the channel A connector on the scanner— channel

B is not used.

redundant media from trunk-cable A to channel A on th e scan ner and

from trunk-cable B to channel B on the scanner.

1. Rockwell Automation recommends using channel A for nonredundant media.

1

For detailed information about planning and installing your

ControlNet system, see the following information sources.

Source Source Number

ControlNet Coax Cable System Planning and Installation Manual 1786-6.2.1

ControlNet Media System Component List AG-2.2

ControlNet Coax Tap Installation Instructions 1786-5.7

ControlNet Network Access Cable Installation Instructions 1786-2.6

Industrial Automation Wiring and Grounding Guidelines 1770-4.1

Terminating Your ControlNet Coaxial Cables

1.The publication number listed includes only the base number. The Automation Bookstore and Manuals On

line will list the latest version of the publication. For example, CNET-DM001A-EN-P.

CNET-DM001

1

Connect Programming Terminal to ControlNet Network

Y ou can connect the programming terminal to a ControlNet network

through a:

• ControlNet product’s NAP using a network access cable

(1786-CP)

• tap on a ControlNet network

ATTENTION

ÿ

Use the 1786-CP c able when connec ting a scanner to

the network through a NAP. Using a commercially

available RJ-style cable could result in network

failure.

Publication 1747-IN059C-EN-P - September 2001

Page 12

12 SLC ControlNet Scanner Module

Cables

Several types of RG-6 quad-shield cables may be appropriate for

your ControlNet installation—depending on the environment factors

associated with your application and installation site.

The following Allen-Bradley ControlNet cable system components

are available from Rockwell Automation:

1

Item

ControlNet Coax Tool Kit - ControlNet Coax Tool (enables you to

make successful coaxial cables)

Coax Tap Kit Right-angle T-tap

Repeaters Dual channel coaxial repeater 1786-RPCD

Fiber Optic Repeaters

RG-6 Quad Shield Cable Standard-PVC CM-CL2 1786-RG6

ControlNet Network Access Cable–3.05 m (10 ft) 1786-CP

BNC Connectors Barrel (plug to plug) 1786-BNCP

1. For a complete list of Allen-Bradley ControlNet cable syste m component s th at a re availa ble f ro m Rockwell

Automation and cable system components available from other suppliers, see the ControlNet Media

System Component List, publication AG-2.2.

Straight T-tap

Right-angle Y-tap

Straight Y-tap

Low-voltage dc coax adapter 1786-RPA

Short-range fiber module 1786-RPFS

Medium-range fiber module 1786-RPFM

BNC/RG-6 plug 1786-BNC

Bullet (jack to jack) 1786-BNCJ

Isolated-bulkhead (jack to jack)1786-BNCJI

Terminators (BNC-75Ω) 1786-XT

Cat. No.

1786-CTK

1786-TPR

1786-TPS

1786-TPYR

1786-TPYS

Important: Install all wiring for your ControlNet system in

accordance with the regulations contained in NFP A 70

the National Electronic Code (or applicable count ry

codes), state codes, and applicable municipal codes.

For detailed information about ControlNet cabling, see the

ControlNet System Overview, publication CNET-SO001A-EN-P and

the publications listed in the table on the previous page.

Publication 1747-IN059C-EN-P - September 2001

Page 13

SLC ControlNet Scanner Module 13

Apply Chassis Power

Node Address and

Status Display

30750-M

When you apply chassis power, the module address and status

display cycles through the follow ing displays:

1. POST - The 1747-SCNR runs Power On Self Test.

2. 1111, 2222, etc. - The 1747-SCNR is executing its startup

sequence.

3. The 1747-SCNR firmware version is displayed temporarily after

startup.

4. A#nn (where nn = ControlNet node address) then I/O or

I/OX (based on the number of connections configured and

established) then IDLE or RUN (based on the scanner mode).

Alphanumeric Display

The four character alphanumeric display provides you with

additional visual information about the current operating status of

the module.

The following tables describes problems that may occur while using

your 1747-SCNR, the probable cau ses, and t he recommended actio n.

Publication 1747-IN059C-EN-P - September 2001

Page 14

14 SLC ControlNet Scanner Module

OK Indicator and Display Mnemonics

The OK indicator is handled consistently with the ControlNet

specifications for the Identity object.

Sequence OK

Indicator

Startup Alternately

red/ green

Run time Green A#XX N/A ControlNet

Alpanumeric

Display

POST N/A The

FIRM

WARE

I/O

IDLE N/A The scanner is

RUN N/A The scanner is

Module Status

Word (M1 file)

N/A 1747-SCNR

0x26 All configured

Description Probable

1747-SCNR

module is

running Power

On Self Test.

firmware

revision. This is

a temporary

display after

startup.

node address

connections

are

established.

in idle mode.

in run mode.

Cause

Power was

applied to the

module.

Power was

applied to the

module.

None No action

None No action

The SLC

processor or

adapter in

slot 0 is in

program

mode or the

Scanner

Mode

Command bit

of the Module

Command

word is clear

(O:x.0/10

where x is the

scanner slot

number).

The SLC

processor in

slot 0 is in run

mode and the

Scanner

mode

Command bit

of the Module

Command

word is set

(O:x.0/10).

Recommended

Action

No action

required.

No action

required.

required.

required.

If you want to

put the scanner

into run mode,

put the SLC

processor in

slot 0 into run

mode and set

the Scanner

Mode

Command bit of

the Module

Command word

(O:x.0/10) using

an

unconditional

OTE instruction.

If you want to

put the scanner

into program

mode, either

put the SLC

processor in

slot 0 into

program mode

or clear the

Scanner Mode

Command bit of

the Module

Command word

(O:x.0/10).

Publication 1747-IN059C-EN-P - September 2001

Page 15

SLC ControlNet Scanner Module 15

Sequence OK

Run time Green EDIT N/A The scanlist in

Indicator

Flashing

Green

Alpanumeric

Display

I/OX 0x20 The scanner is

Module Status

Word (M1 file)

0x21 The current

Description Probable

the

1747-SCNR is

being modified.

not configured.

configuration is

not valid.

The scanner is

not able to start

any scheduled

communication

to remote

devices. Only

unscheduled

communication

is possible.

Cause

Edits have

been enabled

with

RSNetWorx

for

ControlNet.

Note:

Previously

configured

connections

will be

reestablished

if lost. Newly

configured or

changed

connections

will not be

established

until edits are

accepted.

Module not

configured.

Module not

configured

properly.

Recommended

Action

Finish

modifying the

scanlist with

RSNetWorx for

ControlNet and

then accept

edits.

Cancel edits

with

RSNetWorx for

ControlNet.

Use RSNetWorx

for ControlNet

to download a

new

configuration.

Use RSNetWorx

for ControlNet

to schedule the

existing

configuration.

Use RSNetWorx

for ControlNet

to download a

new

configuration.

Publication 1747-IN059C-EN-P - September 2001

Page 16

16 SLC ControlNet Scanner Module

Sequence OK

Indicator

Run time Flashing

Green

Alpanumeric

Display

I/O

I/O

I/O

I/O

Module Status

Word (M1 file)

0x22

0x23

0x24

0x25

Description Probable

Connections

are configured

but no

connections

are

established.

Connections

are configured

but only

25% are

successfully

established.

50%

75%

Cause

View the

Connection

Status screen

in RSNetWorx

for ControlNet

to see why

the

connections

are not

established.

Module

bandwidth is

exceeded.

Recommended

Action

Check to see if

the 1747-SCNR

and the remote

devices are

correctly

connected to

the ControlNet

network.

Reduce the

number of

scheduled

connections by:

- using a

discrete rack

connection

instead of

multiple

discrete module

connections

- combining

multiple I/O

racks into a

single I/O rack

- combining

multiple

peer-to-peer

messages into

one message.

Increase your

Network Update

Time and/or

increase the

Requested

Packet Intervals

for scheduled

data transfers.

Increase your

SLC 500 ladder

program scan

by adding more

logic.

Publication 1747-IN059C-EN-P - September 2001

Page 17

SLC ControlNet Scanner Module 17

Sequence OK

Indicator

Run time Flashing

Green

Alpanumeric

Display

EDIT N/A The scanlist in

SIGM N/A A scanner

Module Status

Word (M1 file)

Description Probable

the 1747-SCNR

is being

modified.

signature

mismatch has

been detected.

The

1747-SCNR

scanner

signature does

not match the

signature

stored in the

active keeper.

The scanner is

not able to start

any scheduled

communication

to remote

devices. Only

unscheduled

communication

is possible.

Cause

Edits have

been enabled

with

RSNetWorx

for

ControlNet.

Note:

Previously

configured

connections

will be

reestablished

if lost. Newly

configured or

changed

connections

will not be

established

until edits are

accepted.

Module is not

configured

properly.

Recommended

Action

Finish

modifying the

scanlist with

RSNetWorx for

ControlNet and

then accept

edits.

Cancel edits

with

RSNetWorx for

ControlNet.

Use RSNetWo rx

for ControlNet

to schedule the

existing

configuration.

Use RSNetWorx

for ControlNet

to download a

new

configuration.

Publication 1747-IN059C-EN-P - September 2001

Page 18

18 SLC ControlNet Scanner Module

Sequence OK

Errors Off None N/A Module is not

Indicator

Flashing

Green

Red (Scrolling

Flashing

Red

Alpanumeric

Display

N/A 0x43 Network error Cable error or

display

showing fault

details)

A#00

FLSH

CFG

ERAS

DUPL

A#XX

Module Status

Word (M1 file)

N/A Module faulted Internal error

0x42 Module erased

0x44 Duplicate node

Description Probable

communicating

network and

connection

configuration

stored in flash

address

Cause

Power supply

fault.

no other

nodes on the

network.

detected.

Network node

address set

to 00.

Another

device with

the same

ControlNet

address is on

the link.

Recommended

Action

Check power

supply, cable

connectors, and

seat module

firmly in

chassis.

Verify network

cabling.

Record fault

details and

contact

Rockwell

Automation

representative

or distributor.

Power down

the module and

change the

address

switches.

Power down

the 1747-SCNR

module and

change the

network

address

switches to a

correct node.

Publication 1747-IN059C-EN-P - September 2001

Page 19

SLC ControlNet Scanner Module 19

Status Indicators

The ControlNet status indicators inform you of the operational state

of the ControlNet network.

Indicator

Color

1

Probable Cause Recommended Action

Off No power No action required or apply power.

A

and

B

Steady Red Faulty unit Cycle power or reset unit. If fault

persists, contact your Rockwell

Automation representative or

distributor.

Alternating

Self-test No action required.

Red/Green

Alternating

Red/Off

Incorrect node

configuration or

Check network address and other

ControlNet configuration parameters.

duplicate

ControlNet node

address

Off Channel disabled Program network for

A

or

B

Steady

Normal operation No action required.

redundant media, if required.

Green

Flashing

Green/Off

Temporary network

errors

• Check media for broken cables, loose

connectors, missing terminators, etc.

• If condition persists, refer to ContolNet

Cable Planning and Installation

Manual, publication 1786-6.2.1.

Flashing

Red/Off

Media fault • Check media for broken cables, loose

connectors, missing terminators, etc.

• If condition persists, refer to ContolNet

Cable Planning and Installation

Manual, publication 1786-6.2.1.

No other nodes

Add other nodes to the network.

present on network

Flashing

Red/Green

Incorrect node

address

Incorrect network

configuration

Change 1747-SCNR node address so that

it is less than or equal to SMAX

Reconfigure ControlNet network so that

2

is greater than or equal to

SMAX

1747-SCNR node address.

1. Definition of terms:

steady - indicator is on continuously in the defined state.

alternating - the two indicators alterna te between the two define d states at the same time (applies to

both indicators

flashing - the indicator alternates between the two defined states (applies to each indicator

independent

2. SMAX is the highest node address on a ControlNet network that can transmit scheduled data.

viewed together

of the other); if both indicators are flashing, they flash together, in phase.

); the two indicators are always in opposite states, out of phase.

viewed

2

.

Publication 1747-IN059C-EN-P - September 2001

Page 20

20 SLC ControlNet Scanner Module

Specifications

SLC ControlNet Scanner Module - 1747-SCNR

Module Location Slot 1 or above

Module Defaults Node Address -00

Maximum Backplane Current 900 mA @ 5V dc

Isolation Voltage O ptical Isolation between backplane and ControlNet

Environmental Conditions:

Operational Temperature

Storage Temperature

Relative Humidity

Shock unpackaged 30g operational

Vibration Unpackaged 5g from 10-150Hz

Immunity Radiated Fields 10 V/m

Agency Certification

(when product or packaging

is marked)

channel 1 Megohm resistor from ControlNet channel

to chassis

0-60°C (32-140°F)

-40 to 85°C (-40 to 185°F)

5-95% without condensation

50g non-operational

27 mHz-1000 mHz

c us

Listed Industrial Control Equipment for use in Class I

Division 2, groups A, B, C, D, Hazardous Locations. Suitable for

use in U.S. and Canada.

marked for all applicable directives

Reference Manual 1747-RM623

Publication 1747-IN059C-EN-P - September 2001

Page 21

SLC ControlNet Scanner Module 21

Hazardous Location Approval

The following information applies only to products marked

with Hazardous Location Approval, when operating in

hazardous locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable for use in

Class I Division 2 Groups A, B, C, D, Hazardous Locations and

nonhazardous locations only. Each product is supplied with

markings on the rating nameplate indicating the hazardous location

temperature code. When combining products within a system, the

most adverse temperature code (lowest “T” number) may be used to

help determine the overall temperature code of the system.

Combinations of equipment in your system are subject to

investigation by the local Authority Having Jurisdicti on at the time of

installation

.

WARNING

ÿ

EXPLOSION HAZARD -

• Do not disconnect equipm ent unl ess p ower ha s been

removed or the area is known to be nonhazardous.

• Do not disconnect connections to this equipment

unless power has been remov ed or the ar ea is known

to be nonhazardous. Secure any external connect ions

that mate to this equipment by using screws, sliding

latches, threaded connectors, or other means

provided with this product.

• Substitution of components may impair suitability for

Class I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Publication 1747-IN059C-EN-P - September 2001

Page 22

22 SLC ControlNet Scanner Module

Les informations suivantes ne concernent que les produits

marqués pour une utilisation en environnements dangereux :

Les produits marqués « CL I, DIV 2, GP A, B, C, D » ne conviennent

qu’à une utilisation en environnements de Classe I Division 2

Groupes A, B, C, D dangereux et non dangereux. Chaque produit

est livré avec des marquages sur sa plaque d’identific ation qui

indiquent le code de température pour les environnements

dangereux. Lorsque plusieurs produits sont combinés dans un

système, le code de température le plus défavorable (code de

température le plus faible) peut être utilisé pour déterminer le code

de température global du système. Les combinaisons d’équipements

dans le système sont sujettes à inspection par les autorités locales

qualifiées au moment de l’installation.

AVERTISSEMENT

ÿ

RISQUE D’EXPLOSION -

• Couper le courant ou s’assurer que l’environnement

est classé non dangereux avan t de débrancher

l’équipement.

• Couper le courant ou s’assurer que l’environnement

est classé non dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs externes

reliés à cet équipement à l’aide de vis, loquets

coulissants, connecteurs filetés ou autres moyens

fournis avec ce prod ui t.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S’assurer que l’environnement est classé non

dangereux avant de changer les piles.

Publication 1747-IN059C-EN-P - September 2001

Page 23

Notes:

SLC ControlNet Scanner Module 23

Publication 1747-IN059C-EN-P - September 2001

Page 24

Allen-Bradley is a registered trademark of Rockwell Automation.

SLC is a trademark of Rockwell Automation.

ControlNet is a trademark of ControlNet International.

Microsoft Windows is a registered trademark of Microsoft Corporation.

RSNetWorx for ControlNet and RSLogix 500 are trademarks of Rockwell Software, Inc.

CSA logo is a registered trademark of the Canadian Standards Association.

Le sigle CSA est la marque déposée de l'Association des Standards pour le Canada.

Publication 1747-IN059C-EN-P - September 2001 PN 957603-68

Supersedes Publication 1747-IN059B-EN-P - February 2001 © 2001 Rockwell Automation. Printed in the U.S.A.

Loading...

Loading...