Page 1

ALLEN–BRADLEY

The Getting Started Guide for HHT

(Catalog Number 1747–PTA1E & 1747–PT1)

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC, PLC 2, PLC 3, and PLC 5 are registered trademarks of Allen-Bradley Company, Inc.

SLC, SLC 500, PanelView, RediPANEL, and Dataliner are trademarks of Allen-Bradley Company, Inc.

IBM is a registered trademark of International Business Machines, Incorporated.

Page 3

Preface

Preface

Read this preface to familiarize yourself with the rest of the manual. This

preface covers the following topics:

• who should use this manual

• the purpose of this manual

• how to use this manual

• conventions used in this manual

• Allen–Bradley support

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use Allen–Bradley

small logic controllers.

You should have a basic understanding of SLC 500 products. You should

understand programmable controllers and be able to interpret the ladder logic

instructions required to control your application. If you do not, contact your

local Allen–Bradley representative for information on available training

courses before using this product.

This manual is a learning and reference guide for the HHT. It is an

introductory document, designed to allow you to begin programming in the

shortest time possible. It does this by focusing on a simple controller and a

simple program. Basic concepts are presented, but only with enough detail

to get you started and let you know that there is more to be learned.

P–1

Page 4

Preface

Contents of this Manual

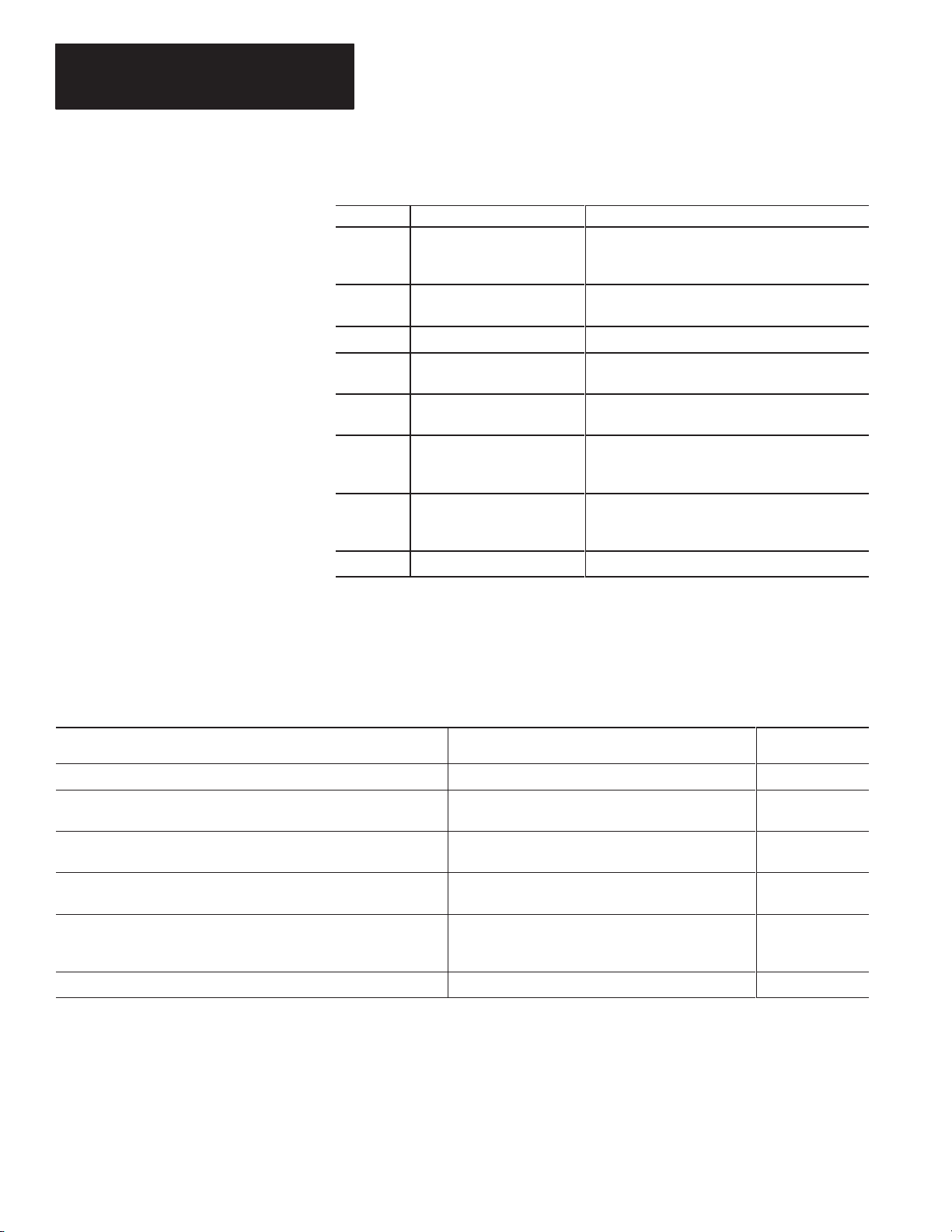

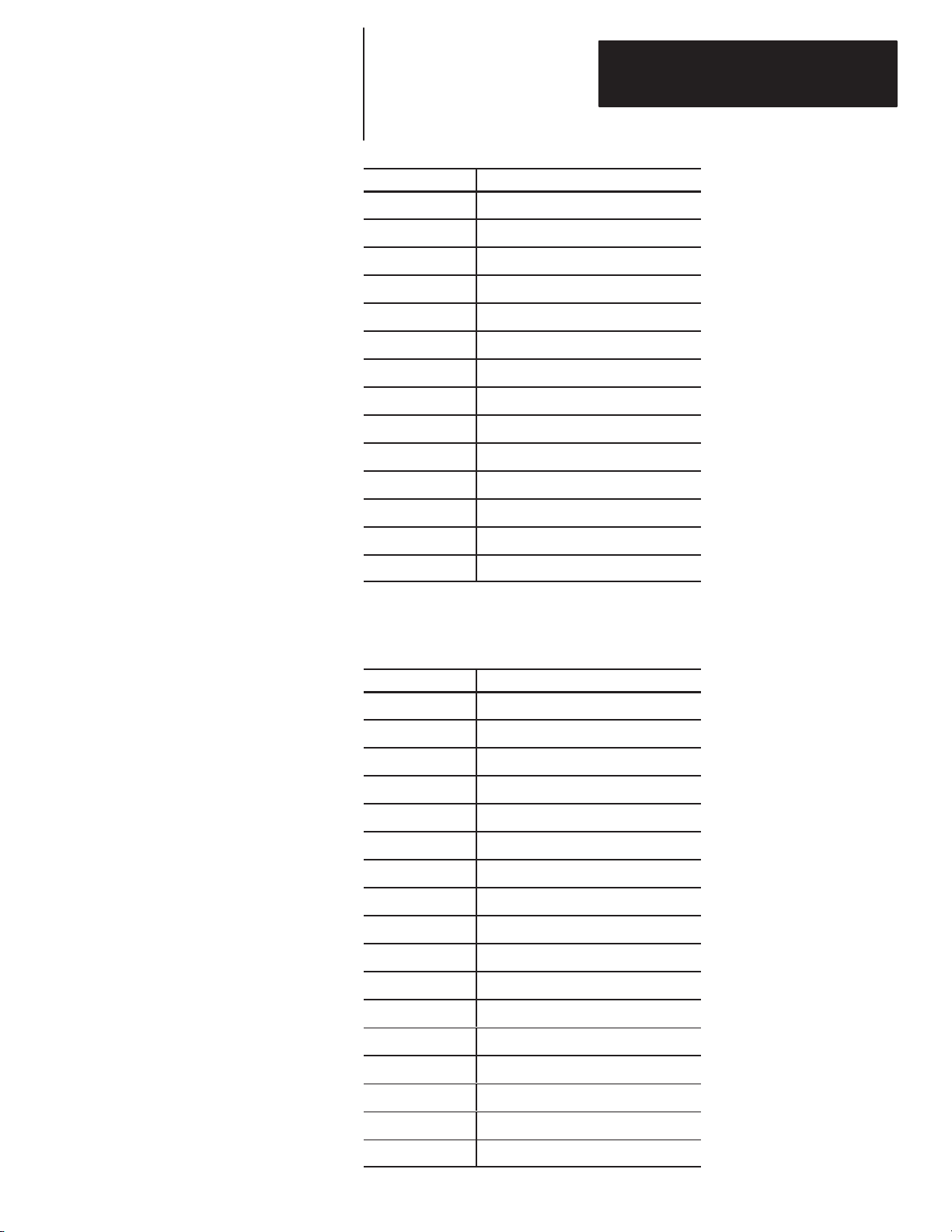

Chapter: Title: Purpose:

Shows you how to set up a controller, install your

1 Setting Up Your Equipment

Memory Pak, Battery, and communication cable,

and connect your HHT to the controller.

2 Control Basics

3 Creating a Program Shows you how to create a program.

4 Online Operations

Appendix

A

Appendix

B

AppendixCIdentifying HHT Function Keys

Glossary Glossary Provides definitions of terms used in this guide.

Additional Ladder Program

Exercises

Troubleshooting Errors

& Instruction Mnemonics

Presents basic information you will need to know

before you can begin programming with the HHT.

Shows you how to download (restore) your program

to the controller, monitor, and test the program.

Introduces you to branching of instructions and the

timer instruction.

Provides a listing of error messages that you may

encounter while working through the guide. Also,

offers possible solutions for these errors.

Provides a listing of HHT function keys and their

meaning. Also provided is a list of instruction

mnemonics.

Related Documentation

The following documents contain additional information concerning

Allen–Bradley SLC and PLC products. To obtain a copy, contact your local

Allen–Bradley office or distributor.

For Read this Document

An overview of the SLC 500 family of products SLC 500 System Overview 1747–2.30

Document

Number

A description on how to install and use your Modular SLC 500

programmable controller

A description on how to install and use your Fixed SLC 500

programmable controller

A procedural and reference manual for technical personnel who use an

HHT to develop control applications

A complete listing of current Automation Group documentation, including

ordering instructions. Also indicates whether the documents are

available on CD–ROM or in multi–languages.

A glossary of industrial automation terms and abbreviations Allen–Bradley Industrial Automation Glossary ICCG–7.1

P–2

Installation & Operation Manual for Modular Hardware

Style Programmable Controllers

Installation & Operation Manual for Fixed Hardware Style

Programmable Controllers

Allen–Bradley Hand–Held Terminal User’s Manual 1747–809

Automation Group Publication Index SD499

1747–804

1747–800

Page 5

Preface

How to Use this Manual

Common Techniques Used in this Manual

Allen–Bradley Support

To use this manual effectively:

• Work through the chapters in sequential order, completing each one

before moving on to the next.

• Perform the exercises in appendix A to apply what you have learned in

the chapters.

• Consult appendix B to correct and identify any errors you encounter while

working through this manual.

• Refer to the glossary for definitions of unfamiliar terms.

• Use the index to locate further information on topics.

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

• Text in this

font

indicates words or phrases you should type.

• Key names match the names shown and appear in bold, capital letters

within brackets (for example,

Allen–Bradley offers support services worldwide, with 78 Sales Support

offices, 494 Authorized Distributors and 242 authorized Systems Integrators

located throughout the United States, plus Allen–Bradley representatives in

every major country in the world.

[ENTER]).

Local Product Support

Contact your local Allen–Bradley representative for:

• Sales and Order Support

• Product Technical Training

• Warranty Support

• Support Service Agreements

Technical Product Assistance

If you need to contact Allen–Bradley for technical assistance, please review

the information in appendix B, Troubleshooting Errors, first. Then call your

local Allen–Bradley representative.

Your Questions or Comments on this Manual

If you have any suggestions for how this manual could be made more useful

to you, please send us your ideas on the enclosed reply card.

If you find a problem with this manual, please notify us of it on the enclosed

Publication Problem Report.

P–3

Page 6

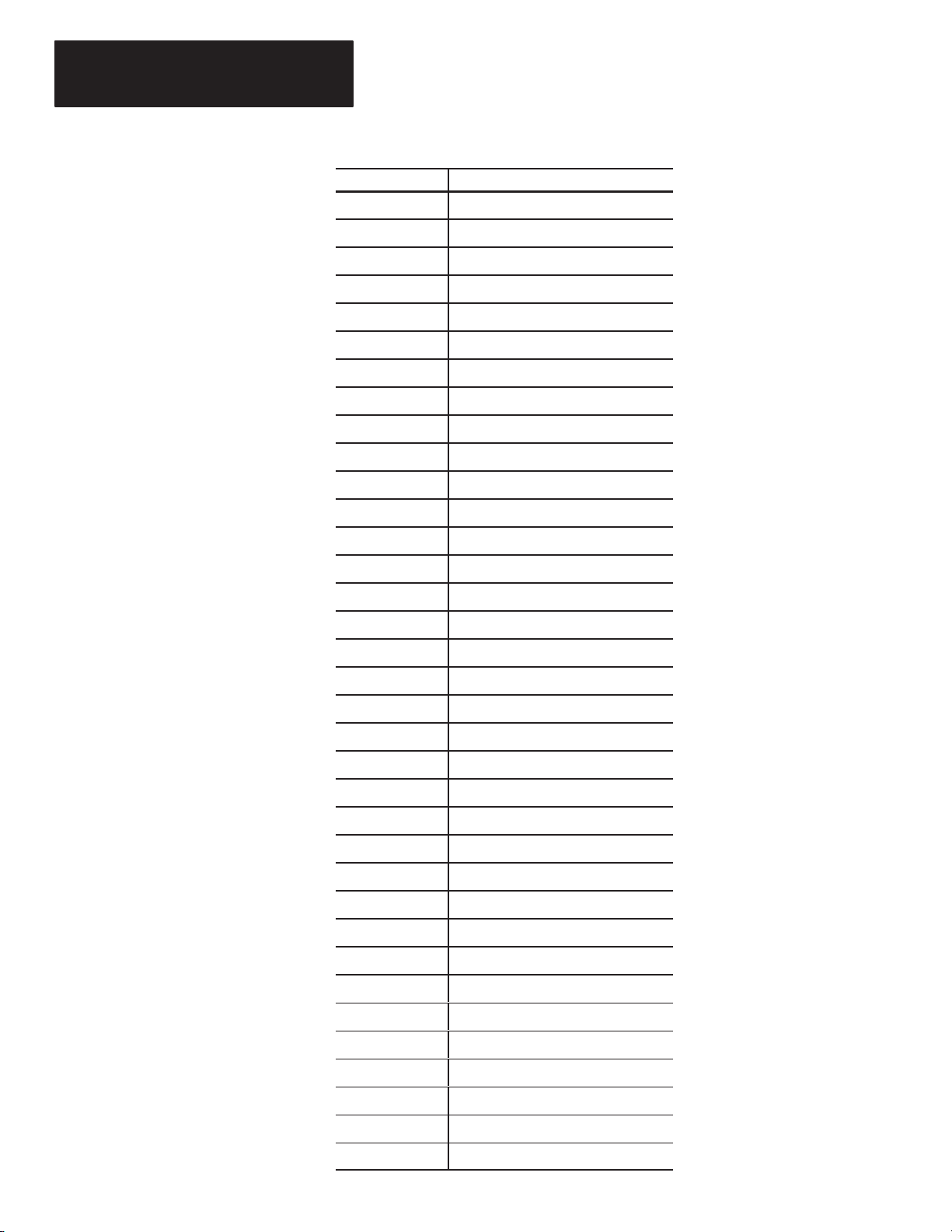

T

able of Contents

The Getting Started Guide for HHT

Setting Up Your Equipment

Control Basics

Chapter 1

Controller Styles 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting

Up a Demo Unit

Setting

Up a Field–Wired Controller

Installing the Memory Pak, Battery

HHT

Features

Powerup

HHT

HHT Display Format 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The

Keyboard

Menu

Function Keys (F1, F2, F3, F4, F5)

Data Entry Keys (A 7, B 8, C 9...) 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto

Shift

Cursor Keys 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ZOOM and RUNG Keys 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

, and Communication Cable

Chapter 2

SLC

500 File Concepts

Program 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program

Data

How External I/O Devices Communicate with the Processor 2–3. . . . . . . . . . . . .

Addressing

External I/O Addressing Formats 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HHT Display of Instructions/Addresses 2–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Ladder

True/False

Logical

Processor Operating Cycle 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Files

Files

External I/O

Logic Concepts

Status

Continuity

1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4. . . . . . . . . . .

1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–9. . . . . . . . . . . . . . . . . . . . . . . . .

1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Program

Chapter 3

Configuration

Controller Styles 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog Numbers 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arbitrary

Creating

Clearing the Memory of the HHT 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Naming

Naming Your Program 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Processor 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Y

Monitoring Y

Programming

Entering

of SLC 500 Controllers

Controller Used in this Guide

a Program

the Program and Configuring the Controller

our I/O

our Data File

a Simple Ladder Rung

a Rung

3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6. . . . . . . . . . . . . . . . .

3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 7

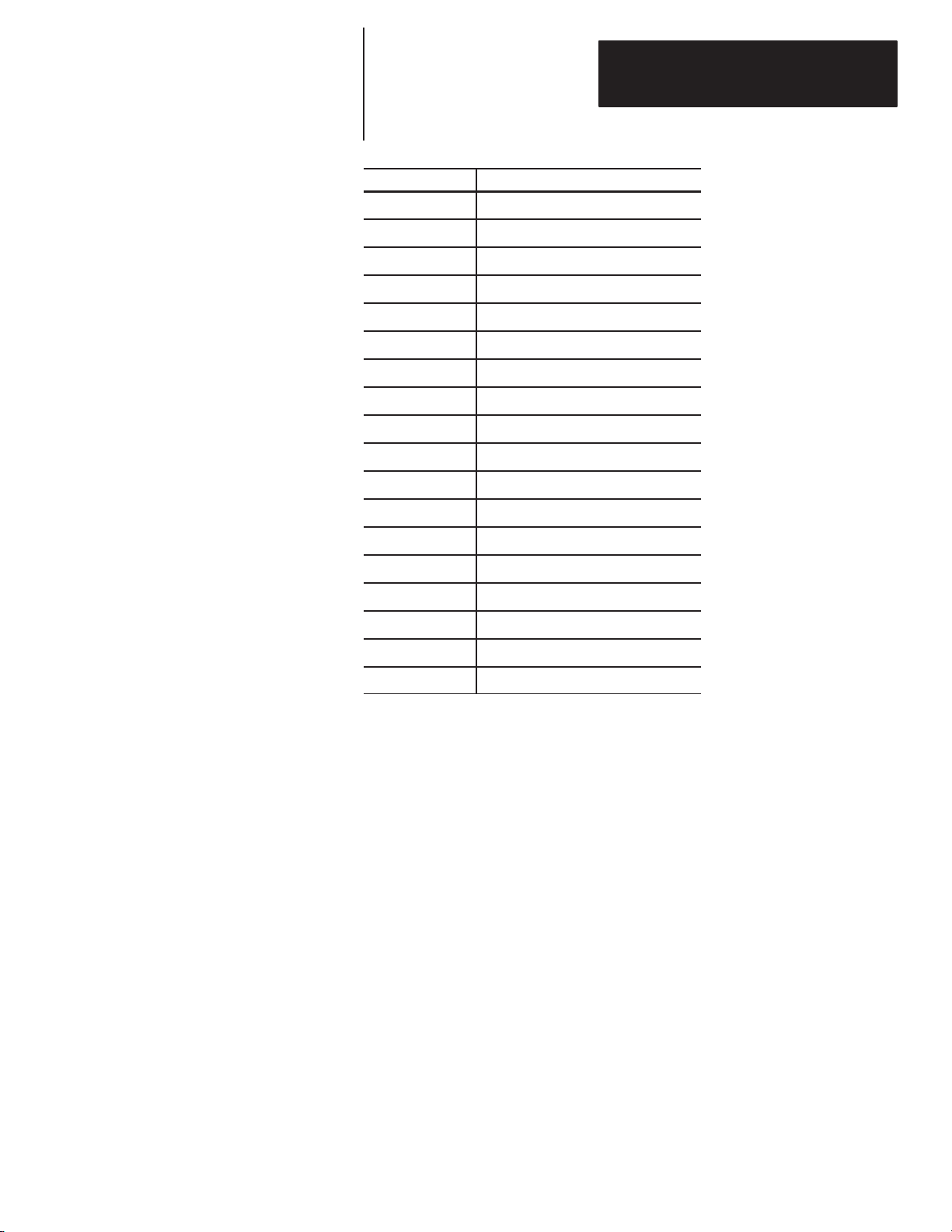

T

able of Contents

The Getting Started Guide for HHT

Online Operations

Additional Ladder Program

Exercises

Entering

Entering

Saving Your Program 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

an “Examine if Closed” Instruction

an “Output Energize” Instruction

Chapter 4

Downloading Your Program 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Going

Online

Downloading Your Program 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing

Monitoring

Testing Y

Monitoring

Program Mode to Run Mode

the Program in Run Mode

our Downloaded Program

Data Files

Appendix A

Entering

Entering

Input and Output Branches

Creating

Adding

Inserting

Adding

Inserting

Saving

Downloading

Testing

Entering

the Program

an Input Branch

an Instruction

an Output Branch

an Instruction

the Program

the Program

the Ladder Program

a T

imer Instruction A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Program

3–12. . . . . . . . . . . . . . . . . . . . .

3–13. . . . . . . . . . . . . . . . . . . . . . .

4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3. . . . . . . . . . . . . . . . . . . . . . . . . .

4–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Errors

Identifying HHT Function

Keys & Instruction

Mnemonics

Glossary

ii

Appendix B

HHT Error Messages B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System LED Status B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Processor Error Codes B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

HHT

Function Keys and Their Meaning

Instruction Mnemonics C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

Getting Started Guide

for HHT

Chapter

Chapter 2

A–B

1

Setting Up Your Equipment

This chapter briefly describes SLC 500 controller styles, then shows you how

to set up your equipment in preparation for the exercises in later chapters.

Topics include:

• Controller Styles

• Setting up a Demo Unit

• Setting up a Field–Wired Controller

• Installing the Memory Pak, Battery, and Communication Cable

• HHT Features

• HHT Powerup

• HHT Display Format

• The Keyboard

1–1

Page 9

Chapter 1

Setting Up Your Equipment

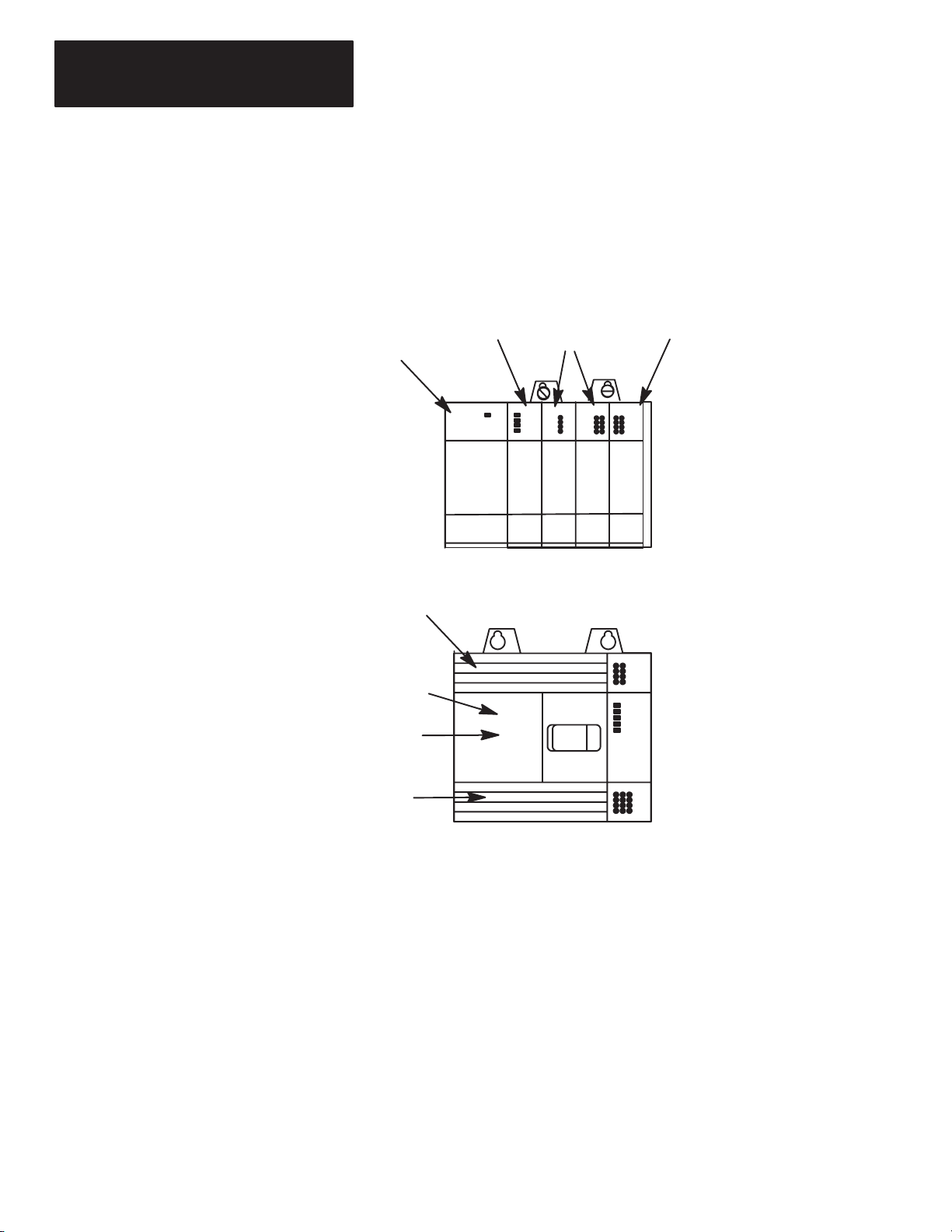

Controller Styles

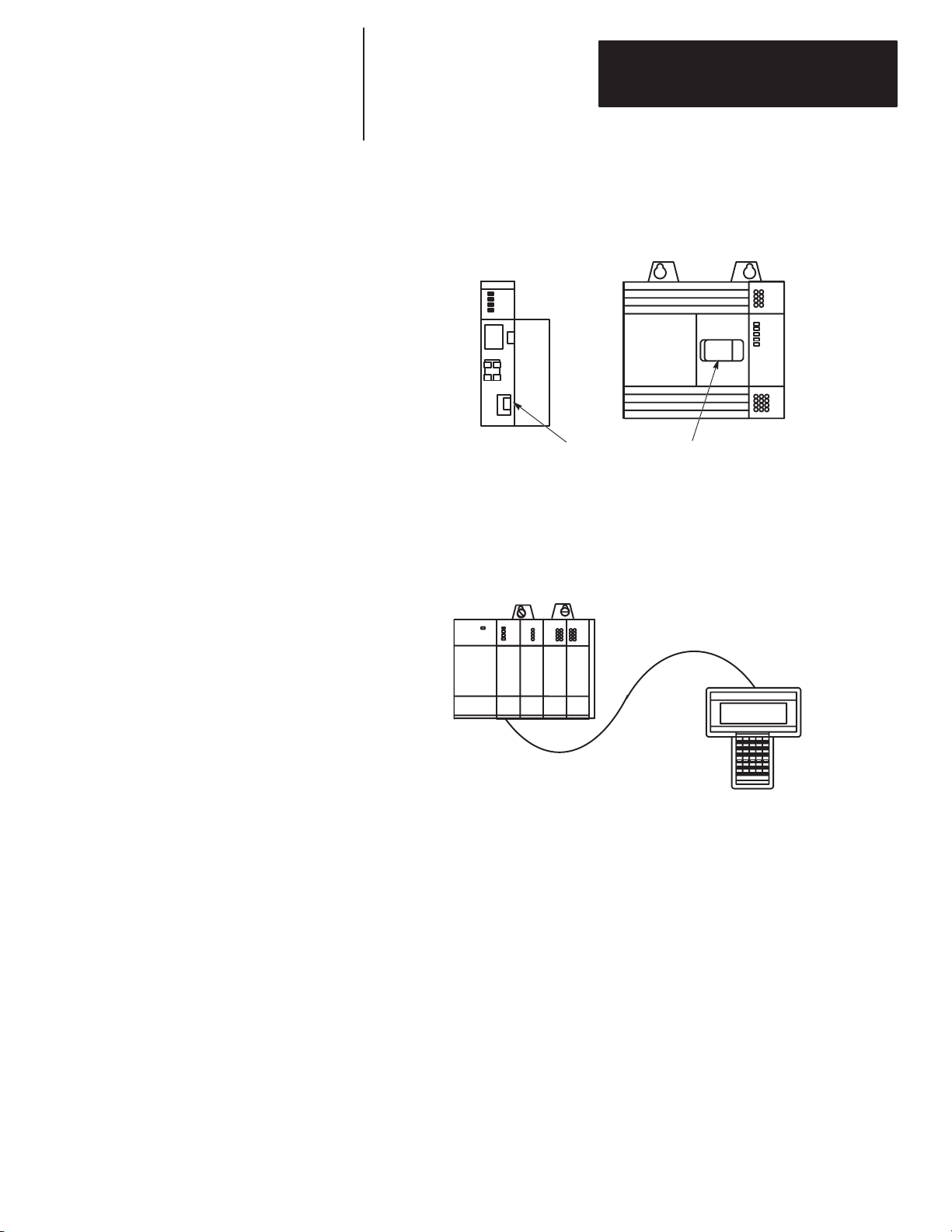

The SLC 500 comes in two different styles: modular and fixed. These styles

are shown below. The modular controller consists of a rack, power supply,

processor (CPU), and Input/Output (I/O) modules. The fixed controller

consists of a power supply, processor (CPU), and a fixed number of I/O

contained in a single unit. You can add an expansion rack to the fixed

controller.

Output Module

SLC 500 Modular Controller

Power Supply

Output Terminals

Processor

Input Modules

Slot 0 1 2

3

Power

Supply

Processor (CPU)

Input

Terminals

Slot 0

SLC 500 Fixed Controller

Further information on hardware is found in the Installation and Operation

Manuals, Publication 1747–800 (fixed controllers) and 1747–804 (modular

controllers).

1–2

Page 10

Getting Started Guide

for HHT

Chapter 1

Setting Up Your Equipment

Setting Up a Demo Unit

SLC 500 Modular Controller

SLC 500 demo units are available with either a fixed controller or modular

controller. This guide assumes you are using a modular controller demo unit

for all the programming exercises. If you use a fixed controller demo unit,

you will need to use different configuration information and I/O addresses in

the exercises. This is explained later.

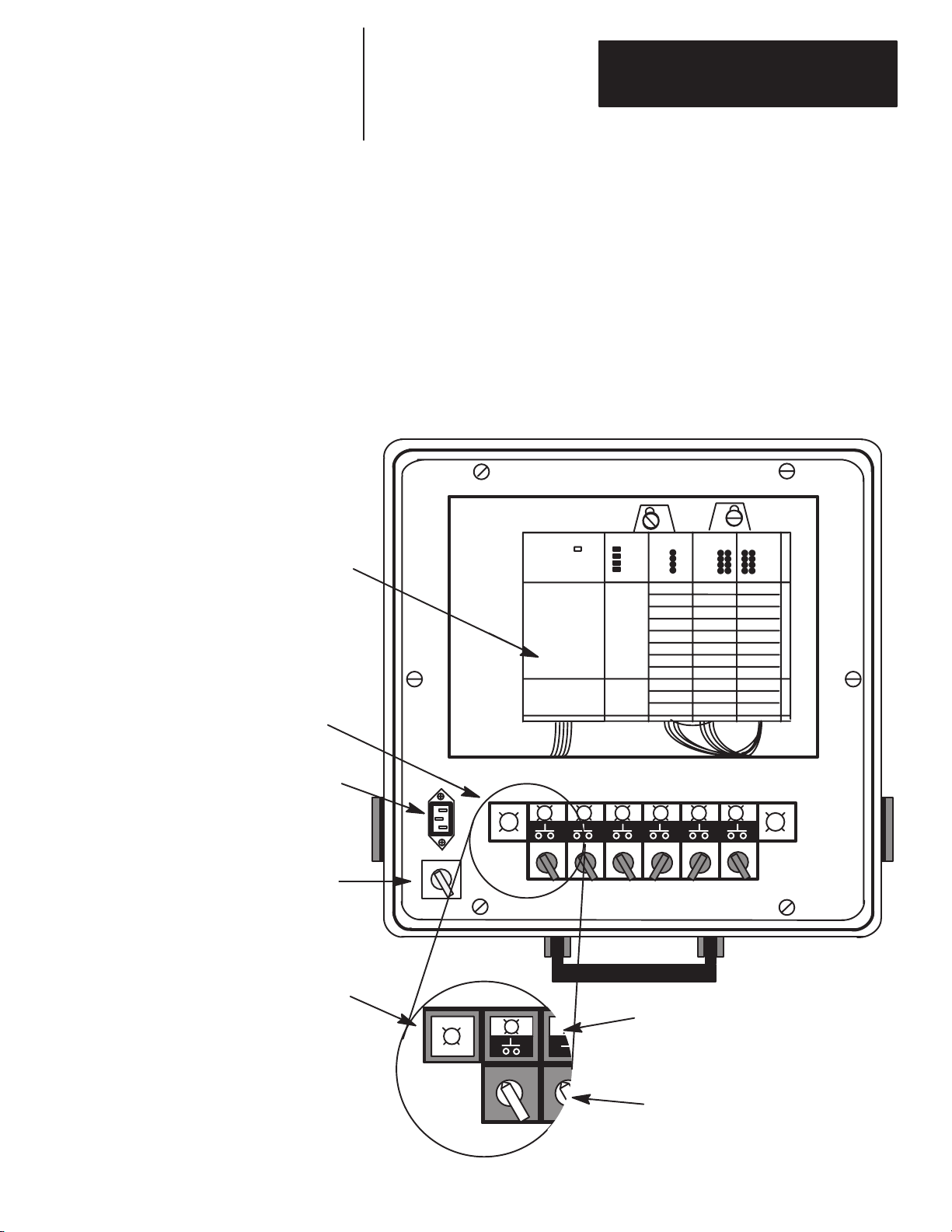

The figure below shows an SLC 500 modular controller demo unit. It is

completely wired, with 12 external inputs (6 push buttons and 6 selector

switches) and 8 external outputs (pilot lights).

Note the On/Off Power Switch and the Power Supply Receptacle on the

demo. Make certain that the power switch is Off, then insert one end of the

power cord into the power supply receptacle and the other end into an

electrical socket.

Input/Output

Panel

Power Supply

Receptacle

On/Off Power

Switch

Pilot Light

102

60

0

6

O

O

F

N

F

O

6

O

N

F

F

Combination

Pilot Light/Pushbuttons

Selector Switches

1–3

Page 11

Chapter 1

Setting Up Your Equipment

Setting Up a Field–Wired

Controller

Installing the Memory Pak, Battery, and Communication Cable

The details of installing and wiring the controller and external input/output

devices are beyond the scope of this guide.

If you are using a field–wired fixed or modular controller, refer to the

Installation and Operation Manuals, Publication 1747–800 (fixed controllers)

and 1747–804 (modular controllers), for information on installation and

wiring of the controller and external input/output devices.

We recommend that your controller have two external input circuits and two

external output circuits to complete the exercises in this guide.

The HHT (with communication cable), the memory pak, and the battery are

supplied separately. Install the memory pak, battery, and communication

cable as follows:

1. Install the memory pak first. The English version is catalog number

1747–PTA1E.

Important: The memory pak contains CMOS devices. Wear a

grounding strap and use proper grounding procedures to

guard against damage to the memory pak from

electrostatic discharge.

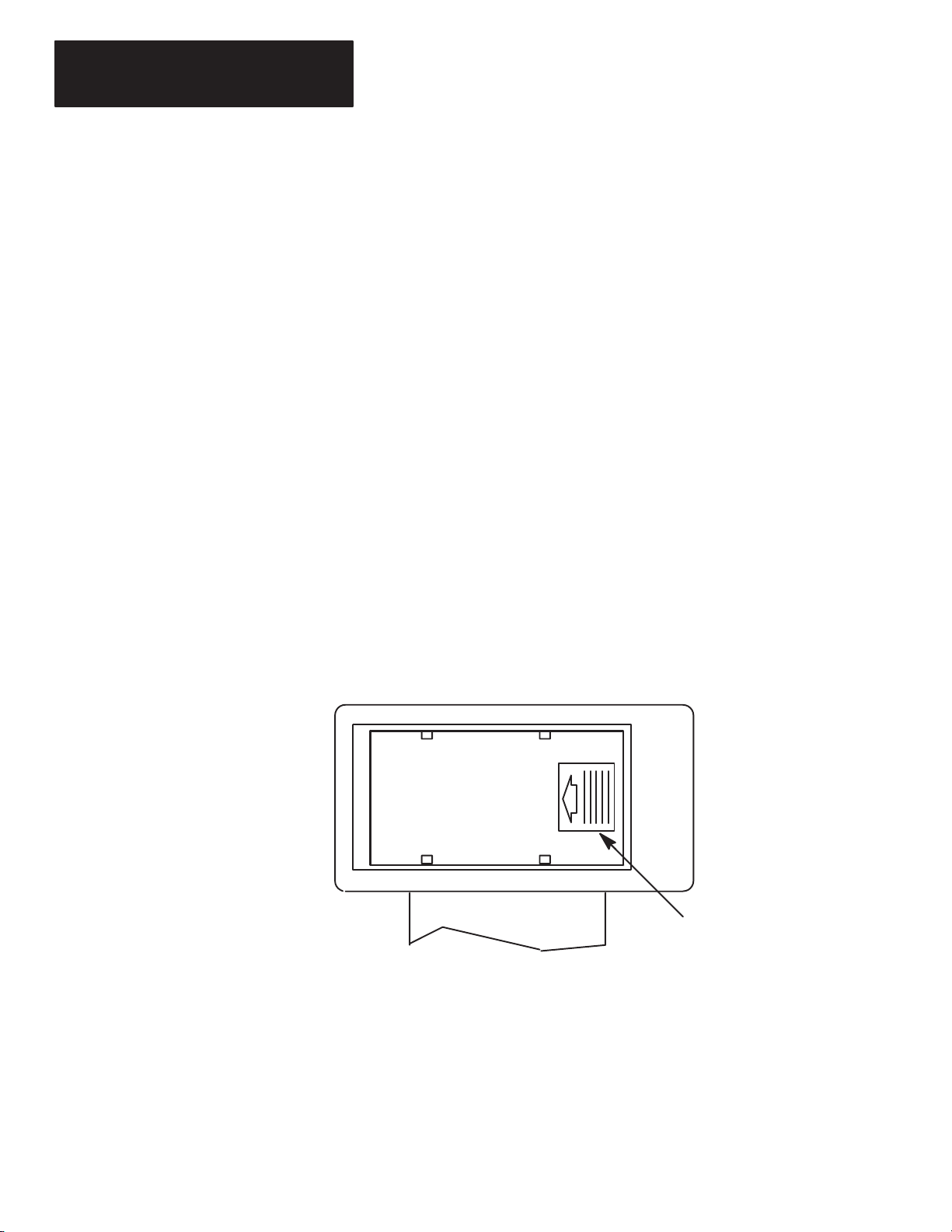

A. To install the memory pak, remove the cover from the back of the

HHT.

Backside

Slide cover to the left. Lift of

of HHT

f cover

.

1–4

Page 12

Getting Started Guide

for HHT

Chapter 1

Setting Up Your Equipment

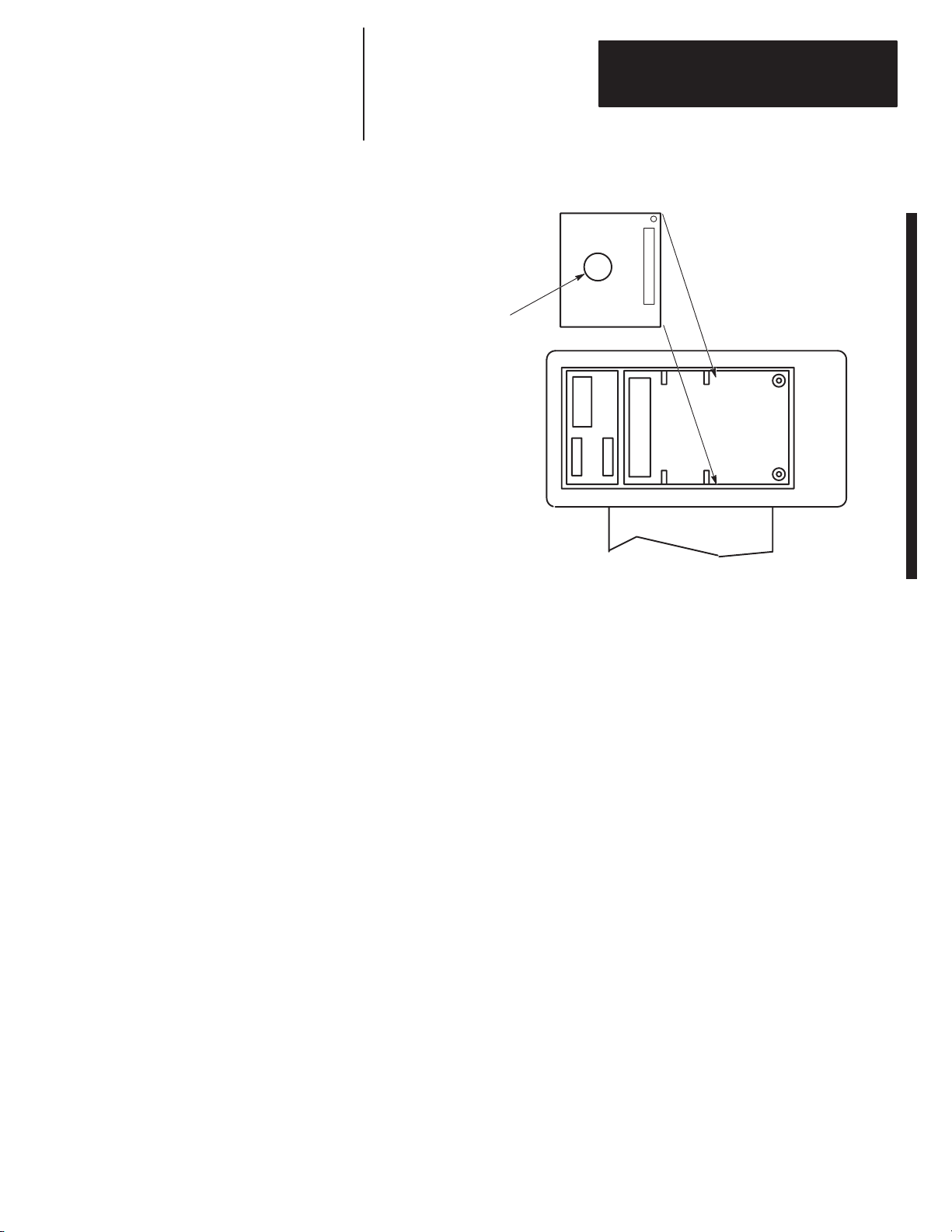

B. Insert the memory pak in its compartment as indicated in the following

figure.

After the memory pak

is in the compartment,

press down on handle

to secure connector in

socket.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Backside of HHT

1–5

Page 13

Chapter 1

Setting Up Your Equipment

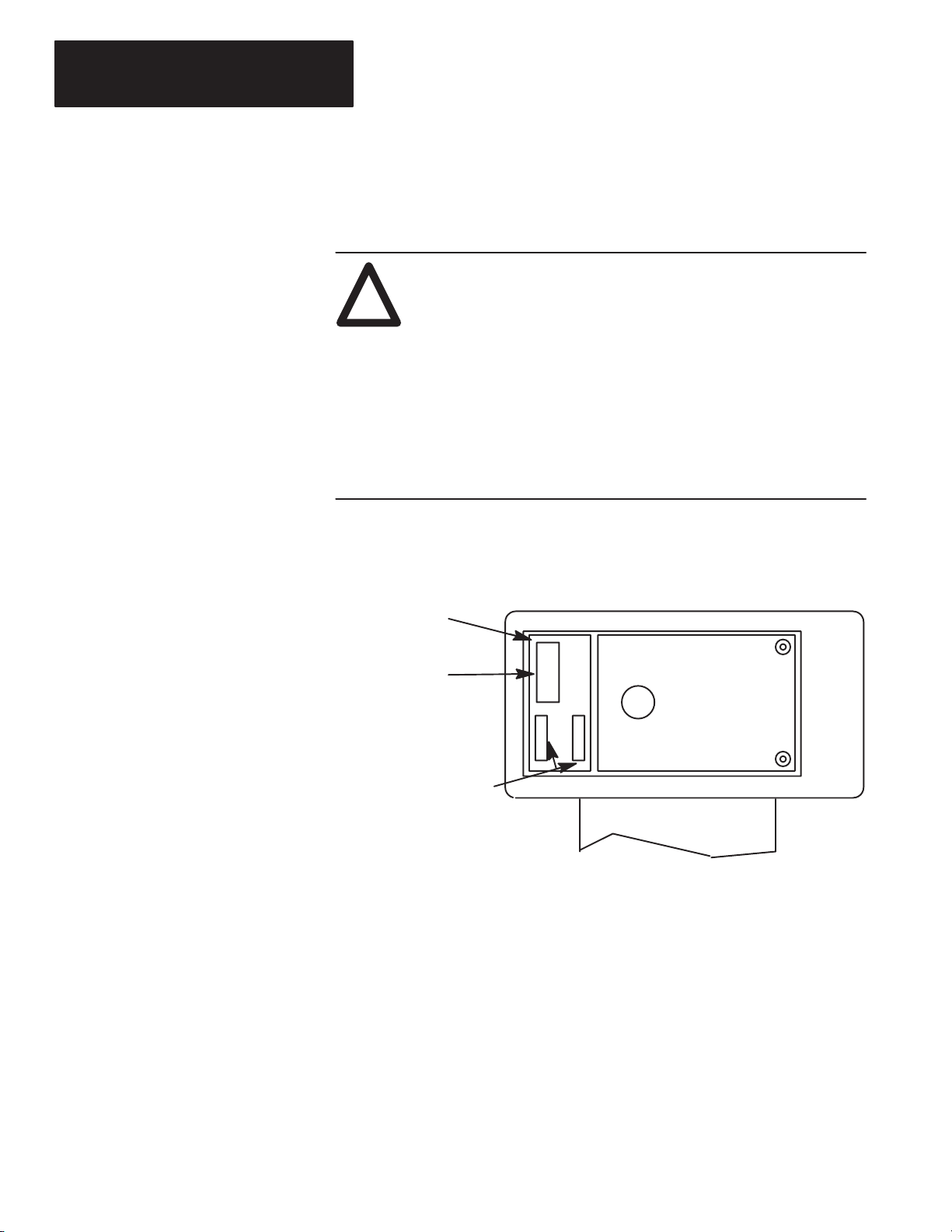

2. Install the battery, catalog number 1747–BA. The battery compartment is

next to the memory pak compartment.

ATTENTION: If you do not install a battery, the letter B

appears flashing on the prompt line of the HHT display to let you

!

know that battery power is low; in addition, each time you power

up, the self–test diagnostic will be interrupted, and the statement

BATTERY

TEST FAILED

will appear.

To prevent this from happening, leave the “battery low defeat

jumper” inserted in the battery socket. The HHT will be

functional, but your user program will be cleared form memory

when you de–energize the HHT. If you do not download the user

program to the processor before you de–energize the HHT, your

program will be lost.

A. Remove the jumper from the battery socket, then plug the battery

connector into the socket (red wire up). Secure the battery between

the clips.

Battery

Compartment

Plug battery connector into

socket (red wire up).

Secure battery between clips.

B. Replace the cover.

.

.

.

Backside of HHT

1–6

Page 14

Getting Started Guide

for HHT

Chapter 1

Setting Up Your Equipment

3. Locate the Communications Port of the controller. The figure below

shows where it is located on modular and fixed controllers.

Processor Module

(Modular Controller)

(cover open)

(Communication Port)

SLC 500 Fixed Controller

Connectors are keyed. Connect one end of the 1747–C10 communication

cable to the top of the HHT. The other connector plugs into the

communication port on the front of the fixed I/O controller, or into the

communication port on the front of the CPU module of modular controllers.

1747–C10 Cable

SLC Controller

(Modular)

HHT

If you are using a 1747–NP1 Wall–Mount power supply or a 1747–NP2

Global Desk Top power supply, plug the communication cable connector into

the socket provided.

1–7

Page 15

Chapter 1

Setting Up Your Equipment

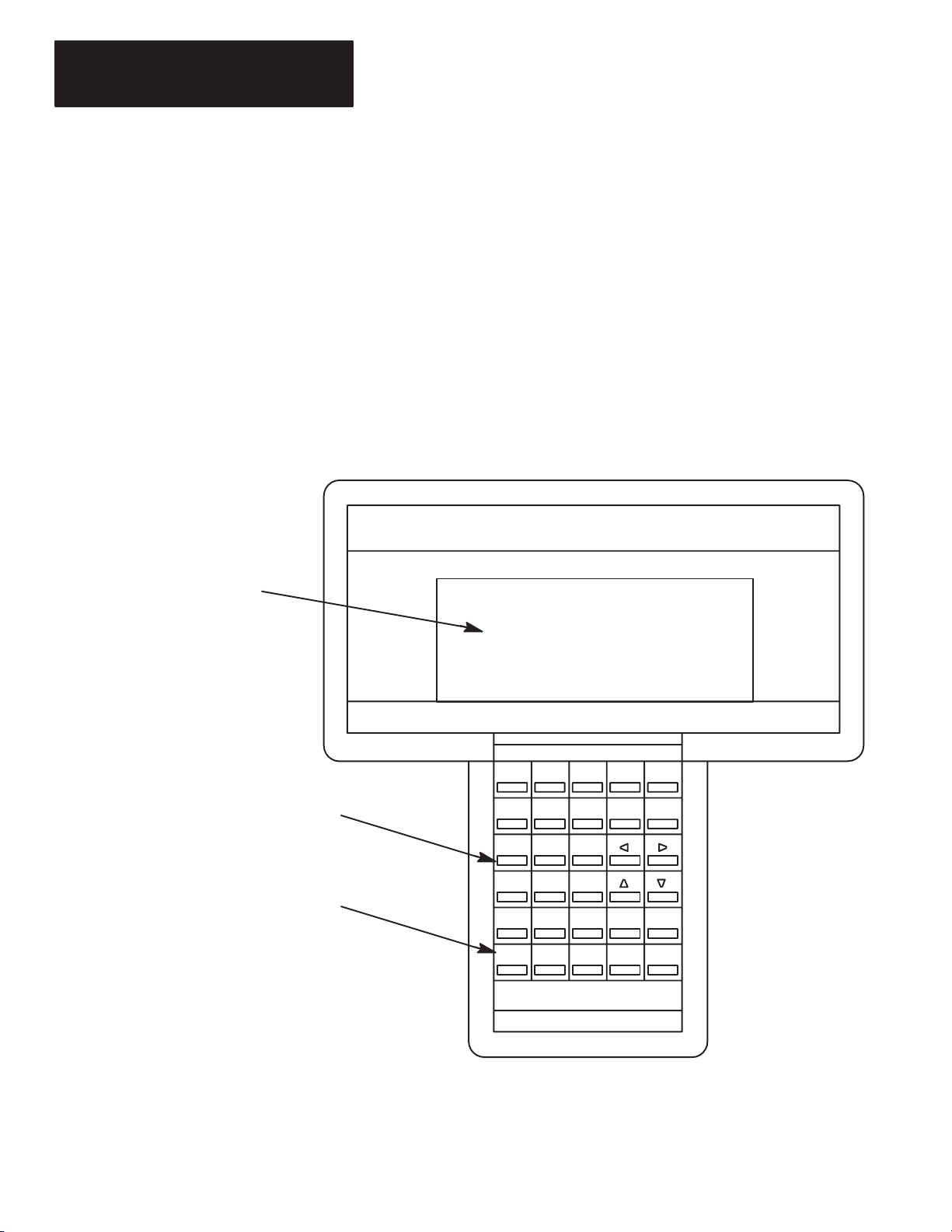

HHT Features

Display Area

Use the Hand–Held Terminal to configure the SLC 500 controller,

enter/modify a user program, download/upload programs, monitor controller

operation, test, and troubleshoot. The HHT has its own memory to store a

program.

You can use the HHT stand alone (for remote programming development

with 1747–NP1 or NP2 power supply), point–to–point (one HHT to one

controller), or on a DH–485 network (communicate with up to 31 nodes over

4,000 feet). When equipped with a battery (1747–BA), the HHT will retain a

user program in memory for storage and later use.

The HHT is menu–driven. The display area accommodates 8 lines x 40

characters. You can display five rungs of a user program. When monitoring

the program in the RUN mode, instructions in a ladder diagram are

intensified to indicate “true” status.

SLC 500 PROGRAMMING SOFTWARE Rel. 2.03

Allen–Bradley Company Copyright 1990

PRESS A FUNCTION KEY

SELFTEST TERM PROGMAINT UTILITY

All Rights Reserved

F1 F2 F3 F4 F5

1747 – PTA1E

OFL

1–8

Calculator–style,

color–coded keyboard

Keys operate with motion and

tactile response.

F1 F2

NO

ACC/POS

PRE/LEN

A

7

D

4

T

1

#0–

F3 F4 F5

S

I

U

B

C

8

9

E

F

5

6

R

M

2

3

.

:/

SPACE

SHIFT

ESC

ZOOMRUNG

Enter

Page 16

Getting Started Guide

for HHT

Chapter 1

Setting Up Your Equipment

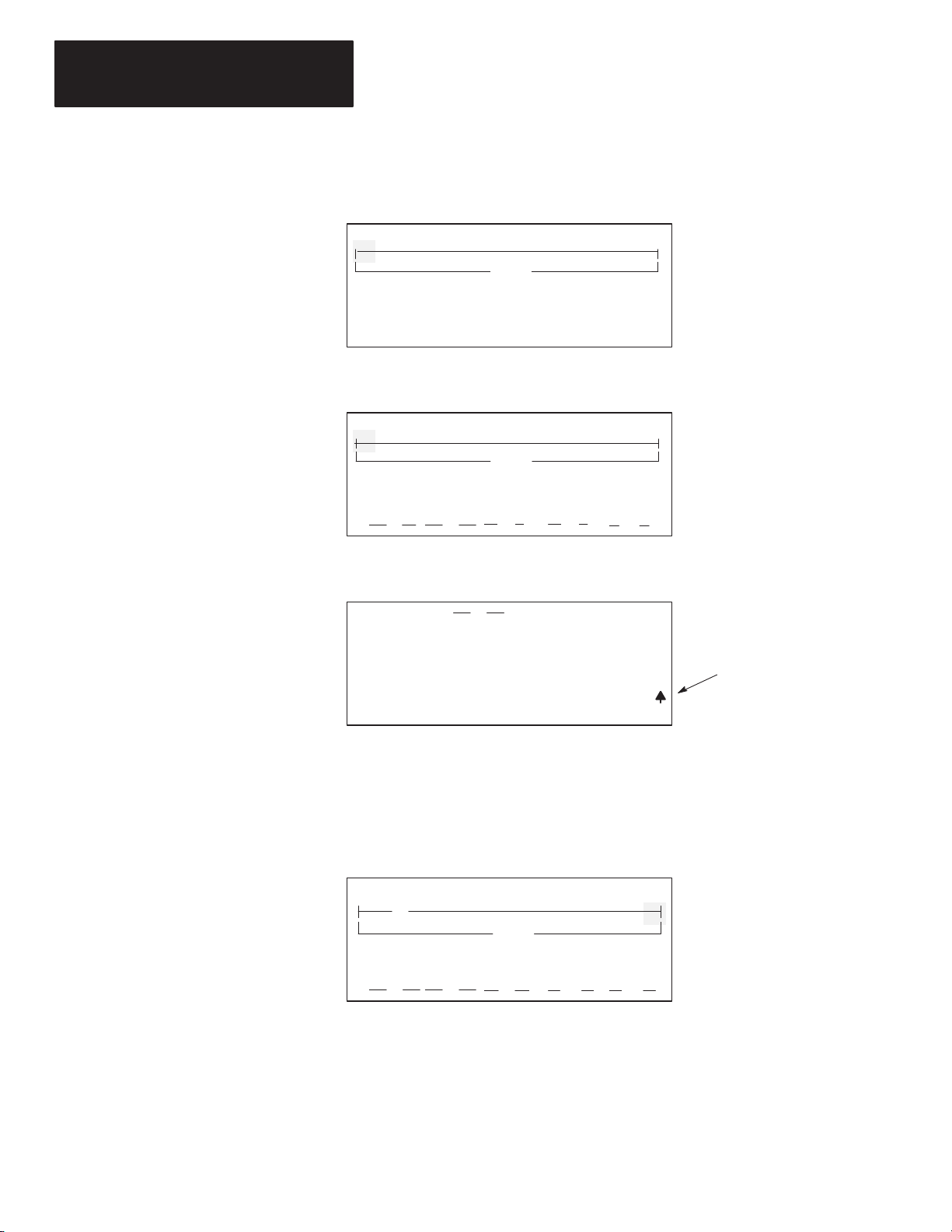

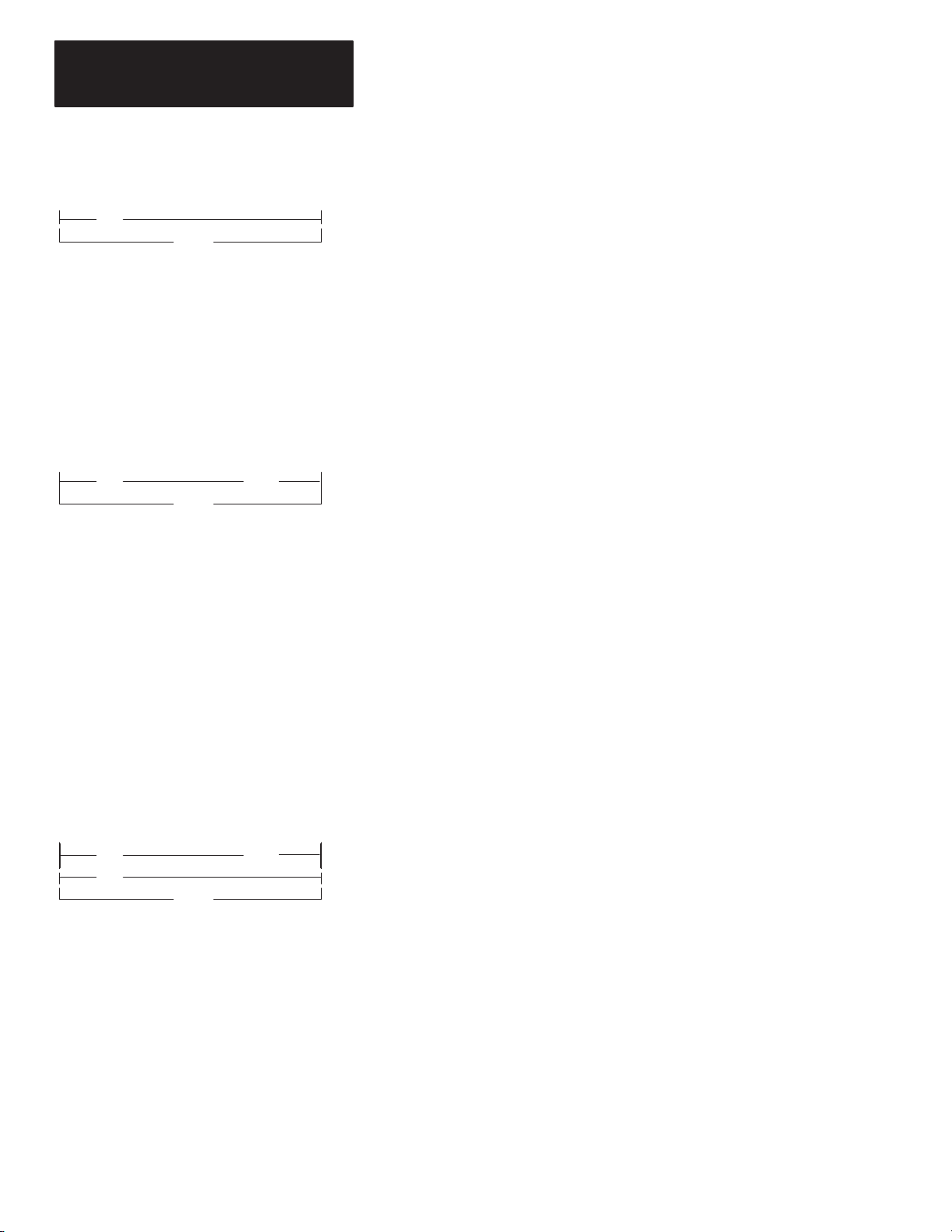

HHT Powerup

HHT Display Format

After you install the memory pak and battery, and plug in the cable, you can

test operation of the HHT by powering up the controller (or plugging in the

Wall–Mount or Global Desk Top power supply).

When the HHT is energized, it will go through a series of diagnostic tests.

Then the following display is shown.

SLC 500 PROGRAMMING SOFTWARE Rel. 2.03

Allen–Bradley Company Copyright 1990

All Rights Reserved

PRESS A FUNCTION KEY

SELFTEST TERM PROGMAINT

F1 F2 F3 F4 F5

1747 – PTA1E

OFL

UTILITY

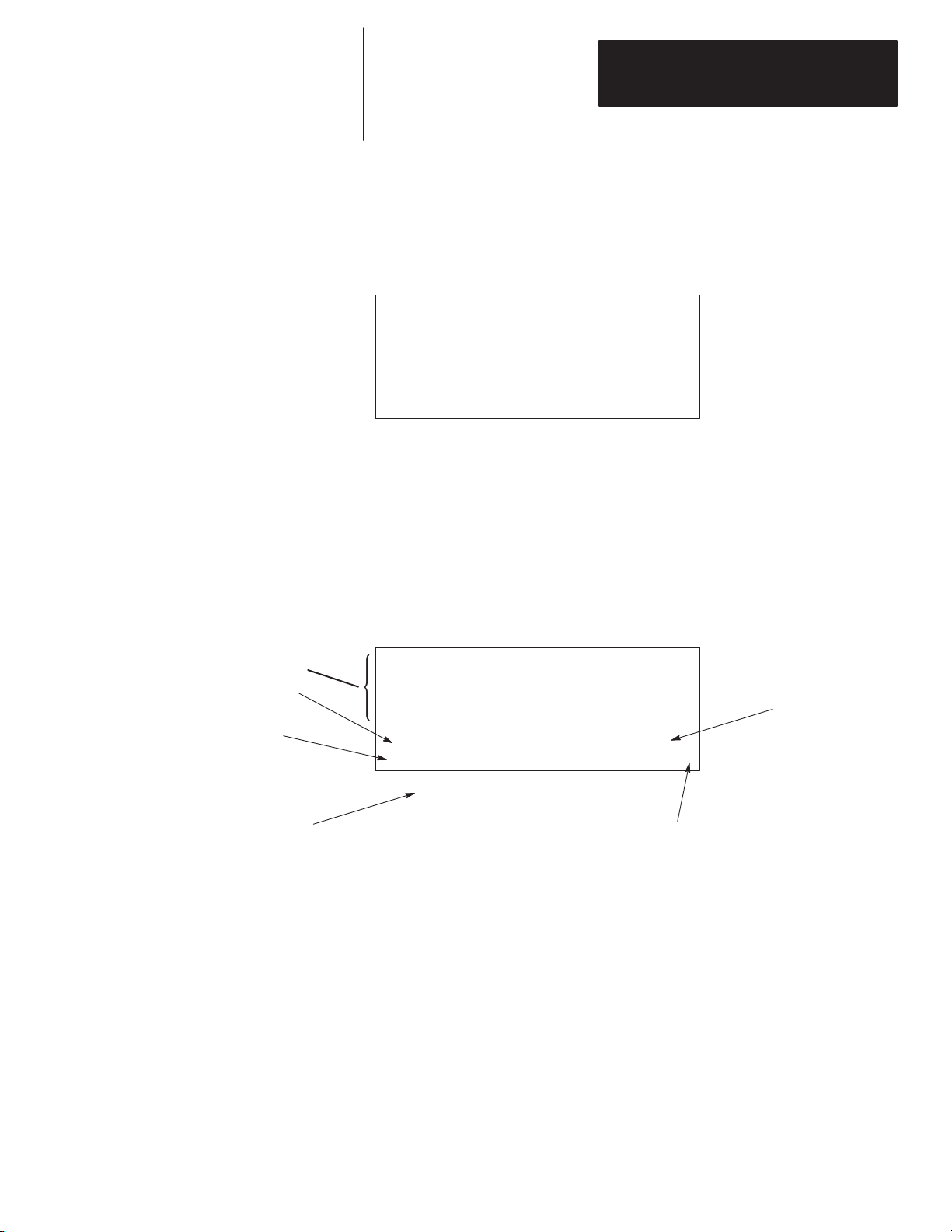

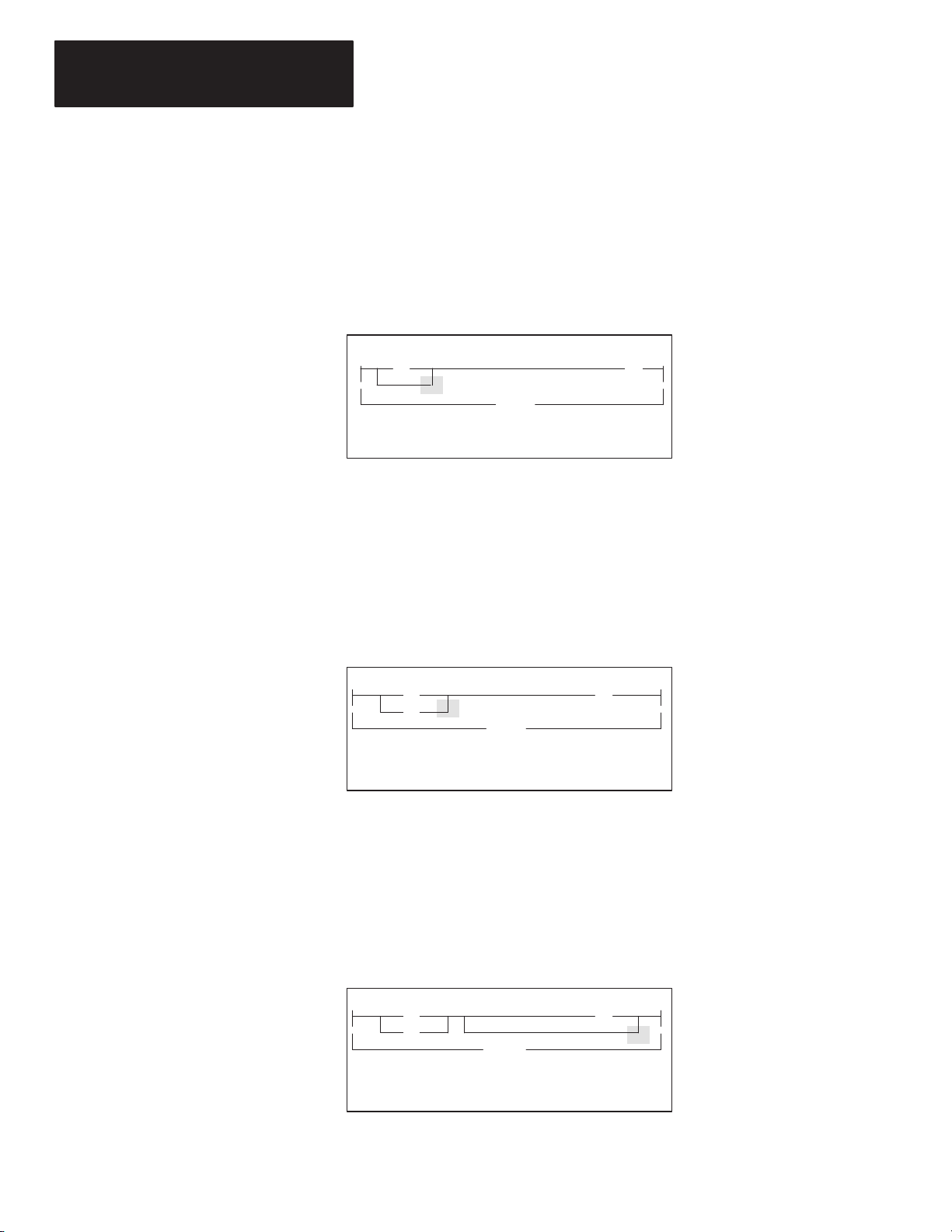

The HHT display format consists of the following:

• Display area

• Prompt/Data Entry/Error Message area

• Menu tree functions

The figure below indicates what appears in these areas. (To access this

[F3]

screen, press

– PROGMAINT

.)

Prompt/Entry/Error Area

Menu tree functions are

directly accessible.

Menu function keys are selected

[F1]

with

The Keyboard

to

[F5] keys.

Display Area

File Name: 101 Prog Name: 1492

File Name Type Size(Instr)

0 System *

1 Reserved *

2 101 Ladder

*

OFL

CHG_NAM CRT_FIL EDT_FIL DEL_FIL MEM_MAP >

F1 F2 F3 F4 F5

When the > symbol is present, pressing

[ENTER] will toggle additional menu functions.

Indicates that the HHT is offline.

This section is intended only as a brief preview of keyboard operation.

Beginning in chapter 3, you will become familiar with the keyboard as you

are guided through various programming procedures.

Menu Function Keys (F1, F2, F3, F4, F5)

The top row of purple keys, F1 through F5, are menu function keys. They

select the menu functions at the bottom of the screen. Note that when the >

symbol is present, the

any) at a particular menu level. The

previous menu level.

[ENTER] key will toggle additional menu functions (if

[ESC] key exits the display to the

1–9

Page 17

Chapter 1

Setting Up Your Equipment

A

B

Data Entry Keys (

C

7,

8,

9...)

These blue keys include numbers, letters, and symbols used for addresses,

password, file numbers, and other data. The data you enter always appears

on the prompt/data entry/error message area of the display.

In general, you obtain the upper character of a key by pressing the

[SHIFT]

key first. You do not have to hold it and press next key. Just press and

release

If you make an error while entering data, press

[SHIFT] and then press the next key.

[ESC]

and re–enter the data,

or use cursor keys and the space key. To complete a data entry, press

[ENTER]. You can also use the [ESC] key to exit the data entry and return to

the next higher (previous) menu level.

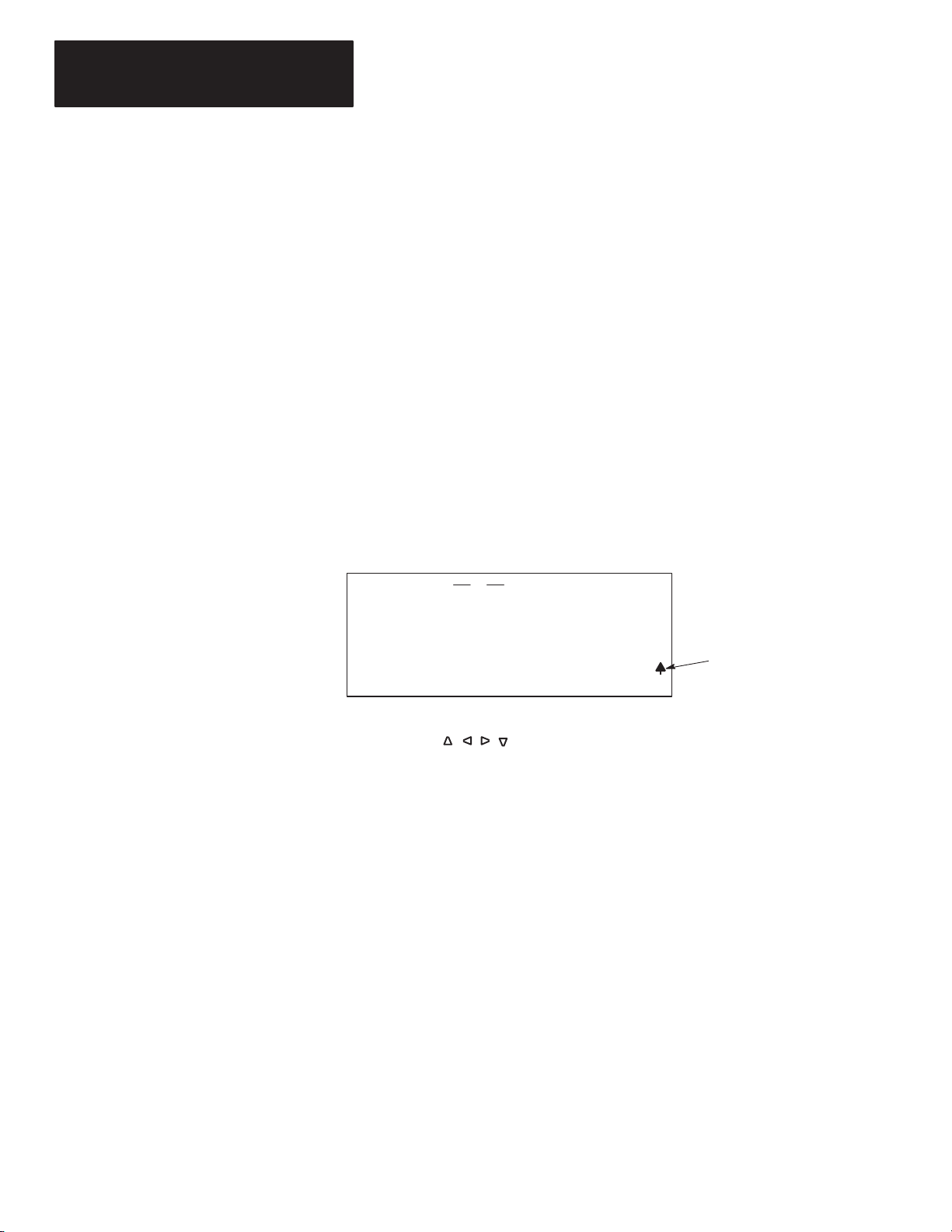

Auto Shift

When you enter an instruction address, the HHT automatically goes to

SHIFT mode. This mode is indicated by a small arrow in the bottom right

hand corner of the display.

ZOOM on XIC

NAME: EXAMINE IF CLOSED

BIT ADDR:

ENTER BIT ADDR:

F1 F2 F3 F4 F5

] [

2.0.0.0.*

Indicates that the HHT is in

SHIFT mode (e.g., to enter

the letter “I” you do not

have to first select SHIFT).

1–10

Cursor Keys

,,,

Use these four green, arrow keys to:

• Correct data entry errors (either type over or use space key).

• Move the cursor left, right, up, and down in a ladder program. Rungs not

shown in the HHT display will automatically scroll into view as you

cursor down (or up) in the program.

• Scroll through controller and I/O configuration selections.

• Scroll through program file directories.

• Scroll through the elements and bits of individual data files.

ZOOM and RUNG Keys

The [ZOOM] key brings up a display that shows the parameters of an

instruction (helpful with timers, counters, sequencers, etc.; also helpful

during editing).

[RUNG] key moves the cursor to a particular rung. Using the [RUNG] key

The

saves time when you have a long ladder diagram. When you press

you are prompted for the rung number that you want to edit or monitor. You

enter the rung number and press

[ENTER], then the cursor moves to the

selected rung and the rung appears at the top of the screen.

[RUNG],

Page 18

Getting Started Guide

for HHT

Chapter

A–B

2

Control Basics

This chapter introduces you to basic concepts essential for understanding

how the SLC 500 controller operates. It covers:

• SLC 500 file concepts

• How external I/O devices communicate with the processor

• Addressing external I/O

• External I/O addressing formats

• Ladder logic concepts

SLC 500 File Concepts

The CPU, or processor, provides control through the use of a program you

create. This program contains files that break down into more manageable

sections. These sections are:

• Program Files — provide storage and control of the main program and

subroutines.

• Data Files — contain the status of inputs, outputs, the processor, timers,

counters, and so on.

Notes on terminology: The term program used in Hand–Held Terminal

(HHT) displays and documentation is equivalent to the term processor file

used in APS software displays and documentation. Both terms mean the

collective program files and data files created under a particular program or

processor file name.

Program

The HHT and each CPU can hold one program at a time. The program is

made up of program files (up to 256 per controller) and data files (up to 256

per controller).

Program

Program Files

Data Files

A program is created in the offline mode using your HHT. It is then

downloaded to the processor for online operation.

2–1

Page 19

Chapter 2

Control Basics

Program Files

Program files contain controller information, the main control program, and

any subroutine programs. The first three program files are required for each

program. These are:

• File

0

This file stores the controller configuration and other system information.

• File

1

This file is reserved for internal controller use.

• File

2

This file stores the main control program.

• Files

Most of your work with program files will be in file 2, the main program file.

This file contains your ladder logic program that you create to control your

application.

3 – 255

These files are optional and used for subroutine programs.

Data Files

Data files contain the data associated with the program files. Each program

can contain up to 256 data files. These files are organized by the type of data

they contain. Each piece of data in each of these files has an address

associated with it that identifies it for use in the program file. For example,

an input point has an address that represents its location in the input data file.

Likewise, a timer in the timer data file has an address associated with it that

allows you to represent it in the program file.

The first 9 data files (0 – 8) have default types. You designate the remainder

of the files (9 – 255) . The default types are:

• File 0 – Output Data

This file stores the state of the output terminals for the controller.

• File

1 – Input Data

This file stores the status of the input terminals for the controller.

• File

2 – Status Data

This file stores controller operation information.

• Files

• File

• Files

3 – 7

These files are pre–defined as Bit, Timers, Counters, Control, and Integer

data storage, respectively.

8

This file is reserved for internal use.

9 – 255

These files are user–defined as Bit, Timer, Counters, Control, and Integer

data storage.

2–2

Most of your work with data files will be in files 0 and 1, the output and

input files. Refer to appendix A for an example of the Timer data file.

Page 20

Getting Started Guide

for HHT

Chapter 2

Control Basics

How External I/O Devices Communicate with the Processor

Input Module

in slot 1

F8

0

Pushbutton 0 is wired to terminal 0.

Pressing pushbutton 0 will cause

the corresponding status bit in the

input data file to go from 0 to 1.

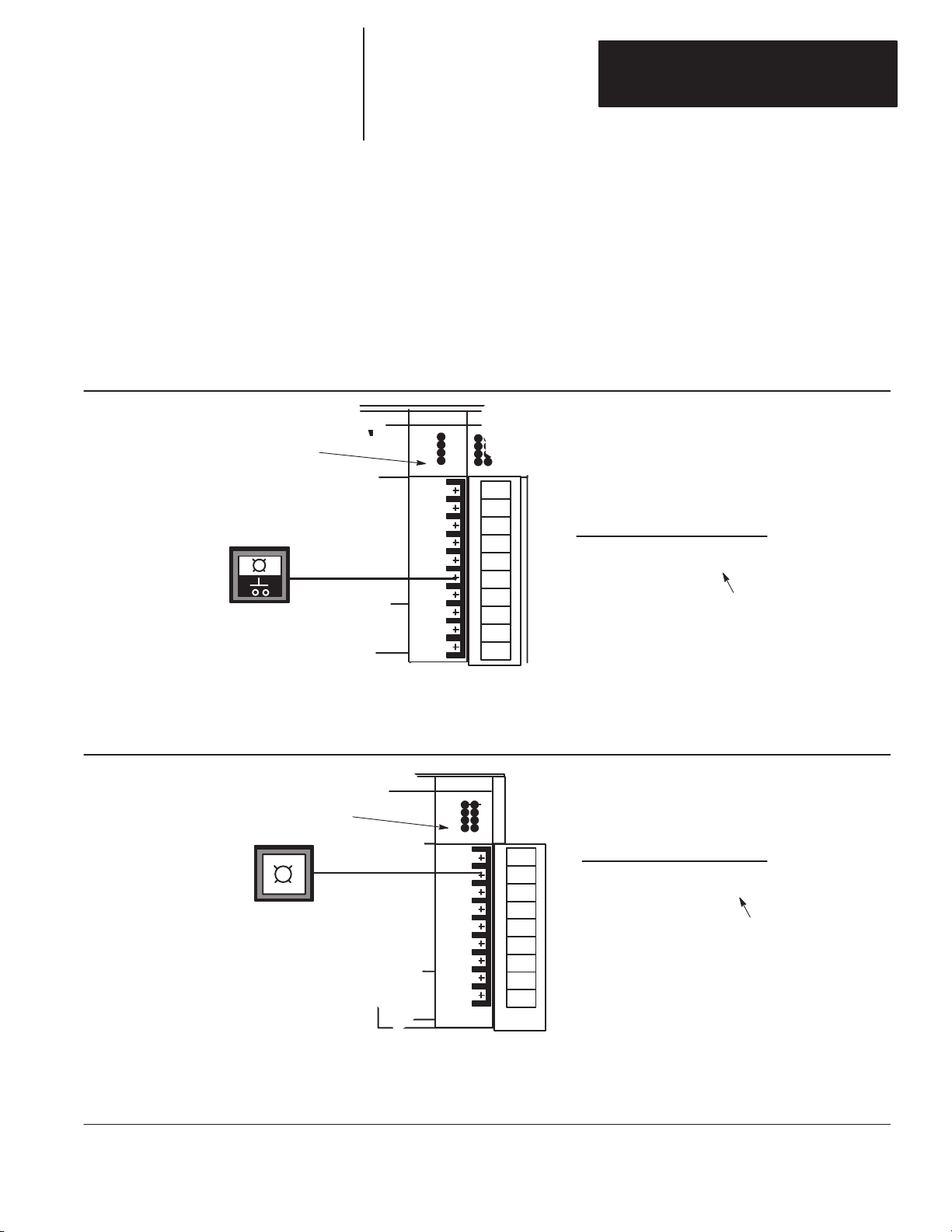

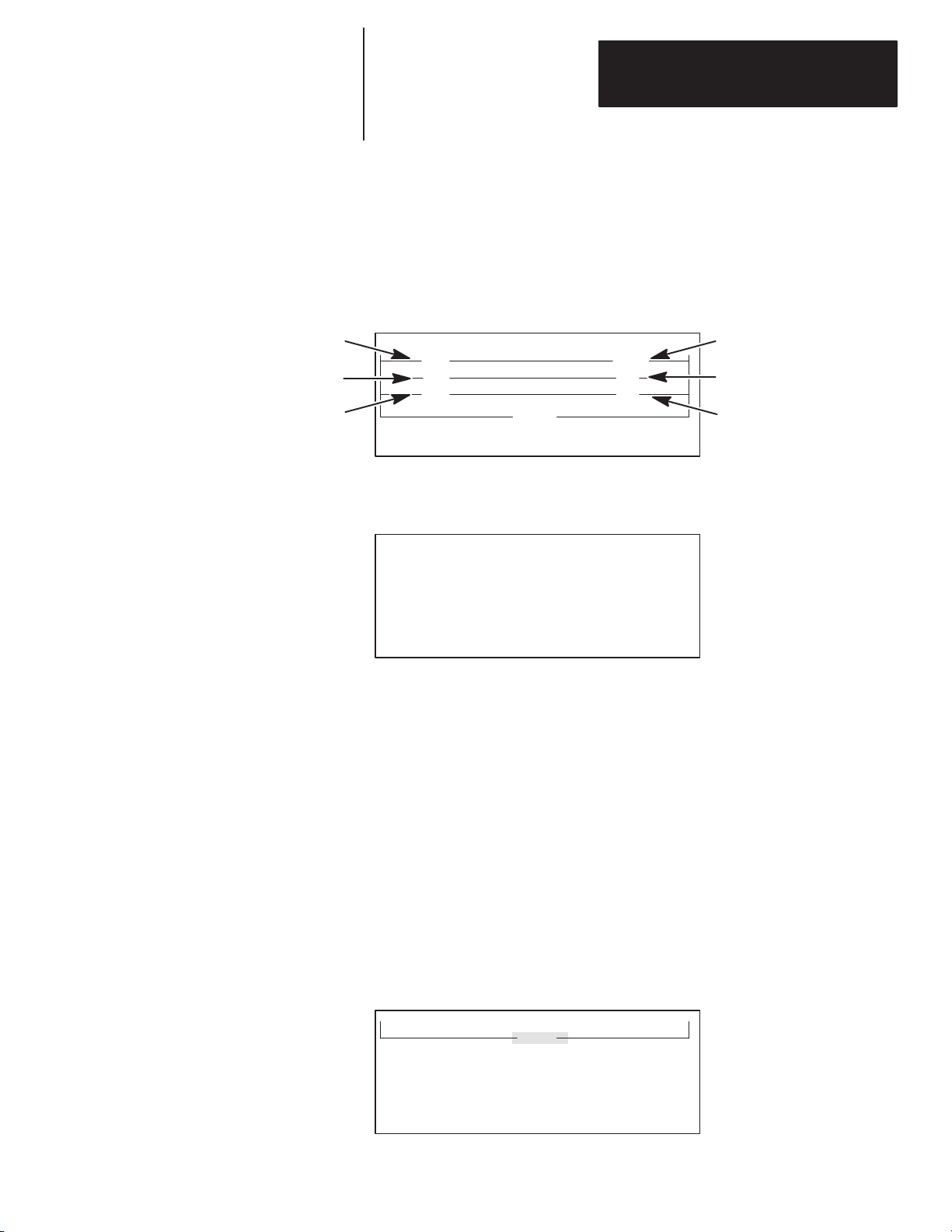

The figure below applies to a modular controller demo unit having an input

module in slot 1 and an output module in slot 3. See page 1–2 for a diagram

of the slot location. To simplify the illustration, only pushbutton 0 and pilot

light 0 of the external I/O are shown.

Each of the external input circuits is represented by a status bit in the input

data file of the program. Each of the external output circuits is represented

by a status bit in the output data file of the program. During controller

operation, the processor applies the input data to the program, solves the

program based on the instruction you enter, and energizes and de–energizes

external outputs.

SLC 5/01 CPU

INPUT

INPUT

INPUT

IN 0

IN 1

IN 2

IN 3

Input Data File

address data

I:1 0000

Status bit 0

corresponds to

terminal 0 of the

input module in

slot 1.

Closing an external input circuit changes the corresponding status bit from 0 to 1.

Opening an external input circuit changes the corresponding status bit from 1 to 0.

Output Module

in slot 3

0

Pilot light 0 is wired to terminal 0.

The pilot light will be energized

when the processor has completed

evaluation of the program and

transfers the ON/OFF status to

the outputs.

When an output data file status bit has been solved as a 1, the corresponding external output circuit will

be energized (ON).

When an output data file status bit has been solved as a 0, the corresponding external output circuit is

de–energized (OFF).

OUTPUT

OUT

OUT 1

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

OUT 7

Output Data File

address data

0

O:3 0000 0000

Status bit 0

corresponds to

terminal 0 of the

output module in

slot 3.

2–3

Page 21

Chapter 2

Control Basics

Addressing External I/O

As pointed out in the last section, external inputs and outputs are linked to

the input data file and output data file of the program. Each status bit in

these files has an address. You specify the appropriate address when you

enter an instruction in your ladder program.

For our purposes, input addresses have the form I:e/b

where

= Input data file

I

:

= Element or slot delimiter

= Slot number of the input module

e

= Bit or terminal delimiter

/

b

= Terminal number used with input device

Similarly, output addresses have the form

O:e/b

where

O

= Output data file

:

= Element or slot delimiter

= Slot number of the output module

e

/

= Bit or terminal delimiter

= Terminal number used with output device

b

Examples:

I:1/0

= Input, slot 1, terminal 0

I:2/0 = Input, slot 2, terminal 0

O:3/0 = Output, slot 3, terminal 0

O:3/7 = Output, slot 3, terminal 7

O:0/7 = Output, slot 0, terminal 7 (fixed controllers only because of slot 0)

I:0/4 = Input, slot 0, terminal 4 (fixed controllers only because of slot 0)

Eventually, you will be addressing other data files, such as Status, Bit, Timer,

Counter, Integer, and Control. Addressing of these files is discussed in the

HHT User Manual.

2–4

Page 22

Getting Started Guide

for HHT

Chapter 2

Control Basics

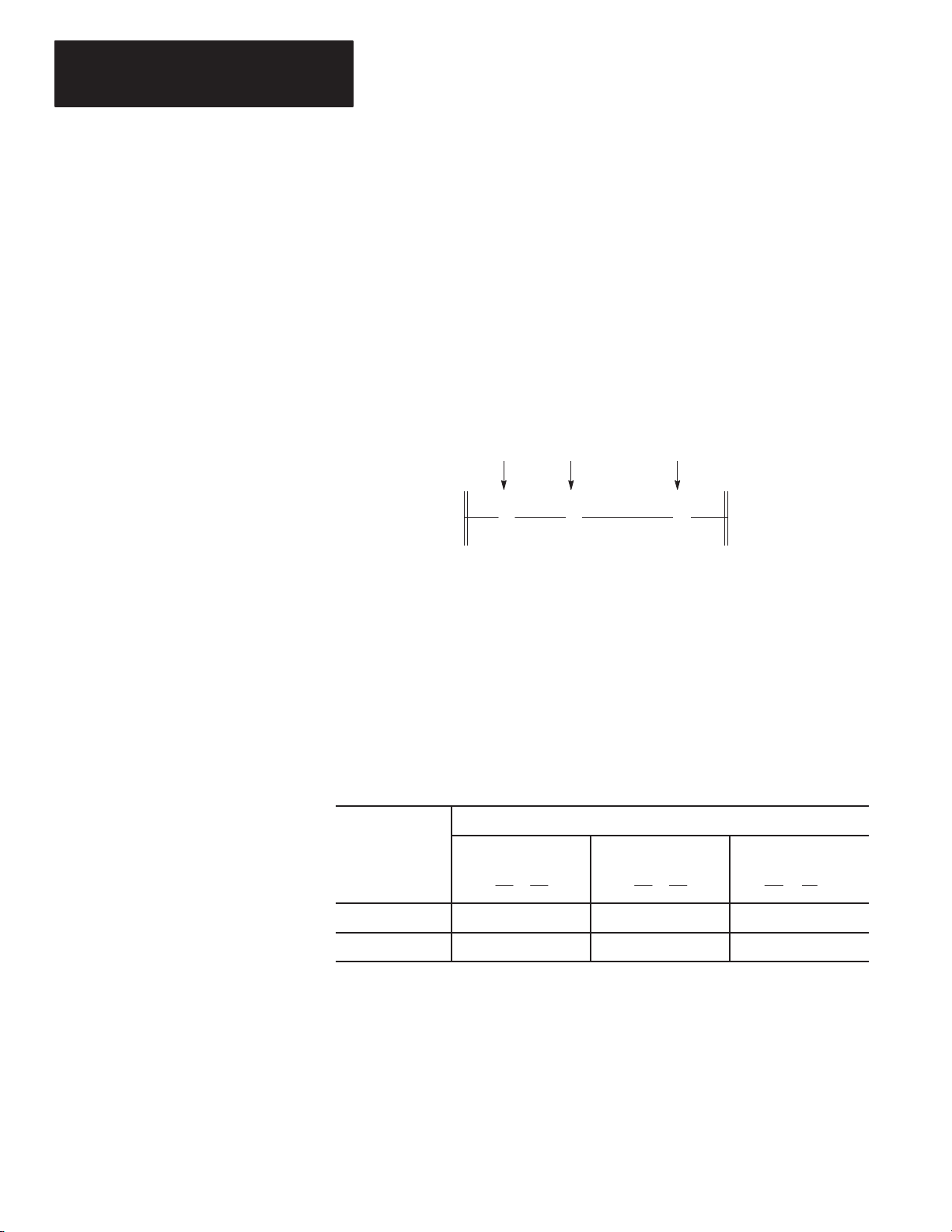

External I/O Addressing Formats

There are three ways in which an external I/O address appears in this guide:

• The five keyboard entries you make to enter the address in the HHT:

Delimiter Delimiter

O:2/7

Output Data File Slot 2 Terminal 7

• The full address, as it appears in the HHT displays:

Word 0Data File 0

O0:2.0/7

Output Data File Slot 2 Terminal 7

• The convention we use to show the address in the ladder diagrams:

Word 0Slot 2Output Data File

Your programming device displays the full address.

For example, when you assign the address O:3/0,

the programming device will show it as O0:3.0/0

(output file, file 0, slot 3, word 0, terminal 0).

O:2.0

( )

7

Terminal 7

HHT Display of Instructions/Addresses

The HHT displays I/O addresses as shown below.

When you locate the cursor on an instruction (as

shown below), the HHT displays the instruction

address in the upper left corner of the display.

NO FORCEOTE:O0:3.0/0

] [

<END>

INS_RNG MOD_RNG SEARCH DEL_RNG UND_RNG

F1 F2 F3 F4 F5

These numbers provide you with the following ladder program information:

2.0.0.0.2

( )

OFL

file number

rung number

nest level

branch level

instruction number (An asterisk

(*) means the cursor is not on

an instruction.)

>

2–5

Page 23

Chapter 2

Control Basics

Ladder Logic Concepts

As we mentioned earlier, the program files you create contain the program

used for your controlling application. The programs are written in a

programming language called Ladder Logic. This name is derived from its

ladder–like appearance.

A ladder logic program consists of a number of rungs, on which you place

instructions. Instructions each have a data address associated with them and

based on the status of these instructions the rung is solved.

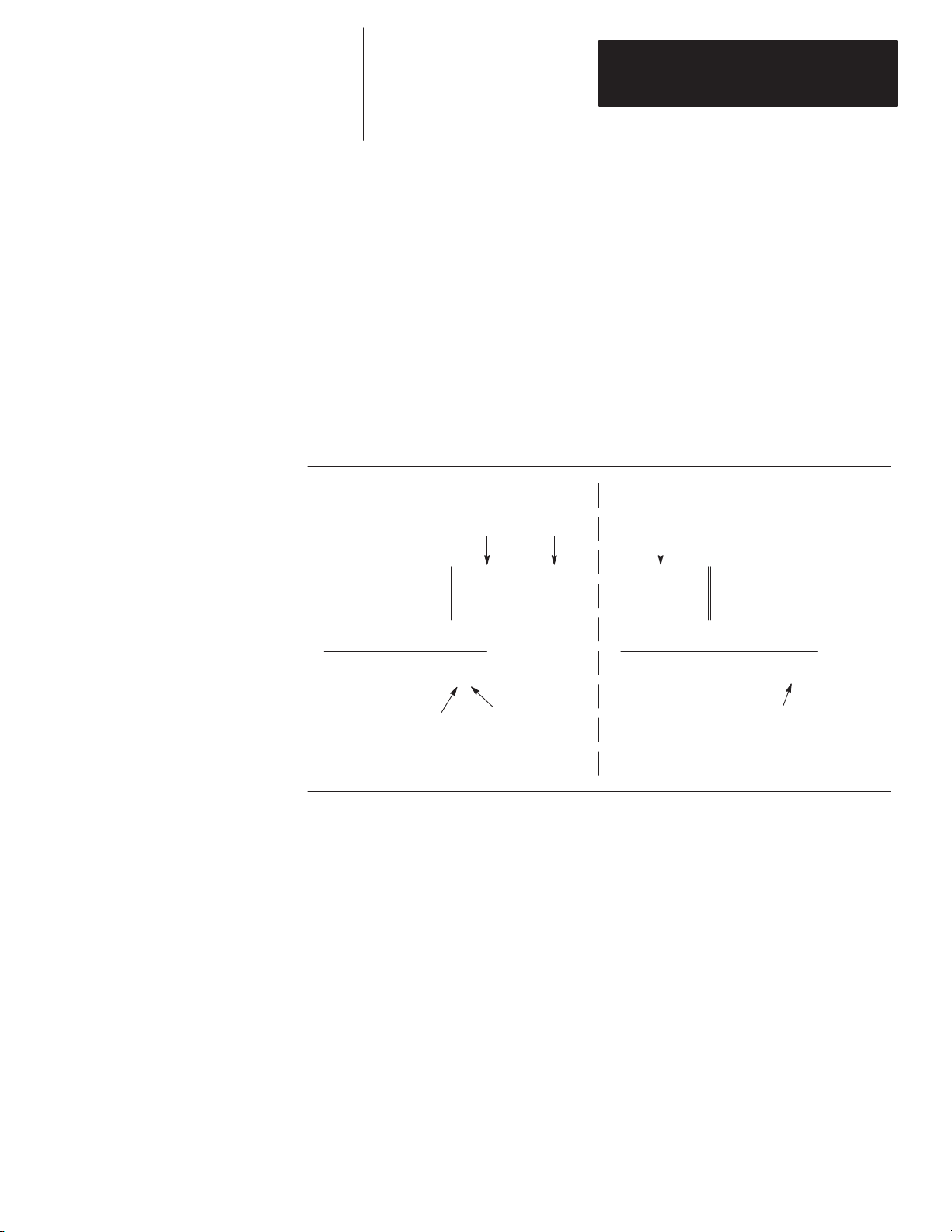

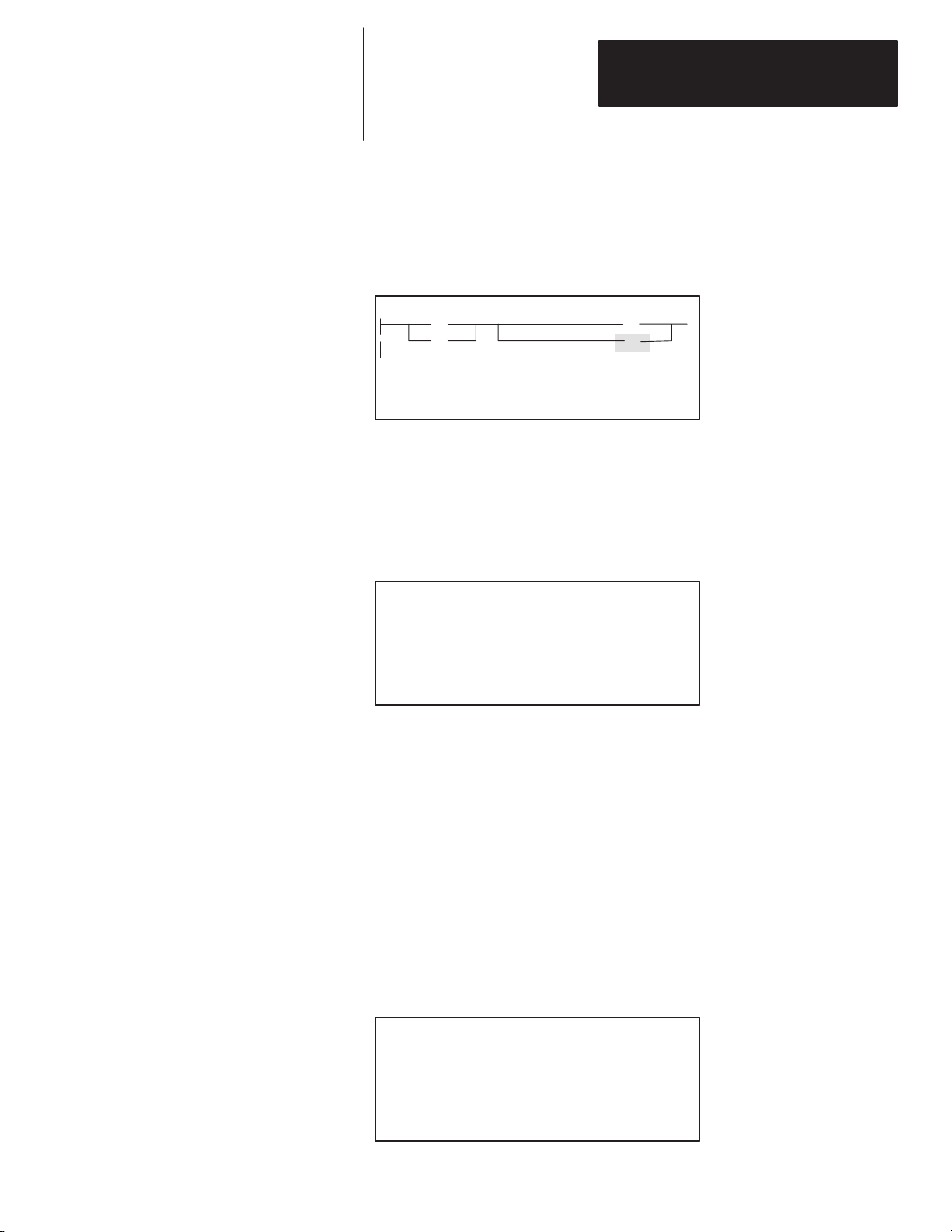

The figure below shows a simple 1–rung ladder program. The rung includes

two input instructions and an output instruction. Note, in the example below

each instruction has a name (Examine if Closed), a mnemonic (XIC), and an

address (I:1/0).

Input Instructions Output Instruction

XIC

I:1.0

] [

0

XIC = Examine if Closed

XIO = Examine if Open

OTE = Output Energize

A simple rung, using bit instructions.

XIO OTE

I:1.0

]/[

1

O:3.0

Address I:1/0

Address I:1/1

Address O:3/0

( )

0

True/False Status

The data file bits that these instructions are addressed to will be either a logic

0 (OFF) or a logic 1 (ON). This determines whether the instruction is

regarded as “true” or “false”:

The status of the instruction is

If the data file

bit is

Logic 0 False True False

Logic 1 True False True

XIC

Examine if Closed

] [

XIO

Examine if Open

]/[

OTE

Output Energize

( )

2–6

Page 24

Getting Started Guide

for HHT

Chapter 2

Control Basics

Logical Continuity

During controller operation, the processor evaluates each rung, changing the

status of instructions according to the logical continuity of rungs. More

specifically, input instructions set up the conditions under which the

processor will make an output instruction true or false. These conditions are:

• When the processor finds a continuous path of true input instructions in a

rung, the OTE output instruction will become (or remain) true. We then

say that “rung conditions are true.”

• When the processor does not find a continuous path of true input

instructions in a rung, the OTE output instruction will become (or remain)

false. We then say that “rung conditions are false.”

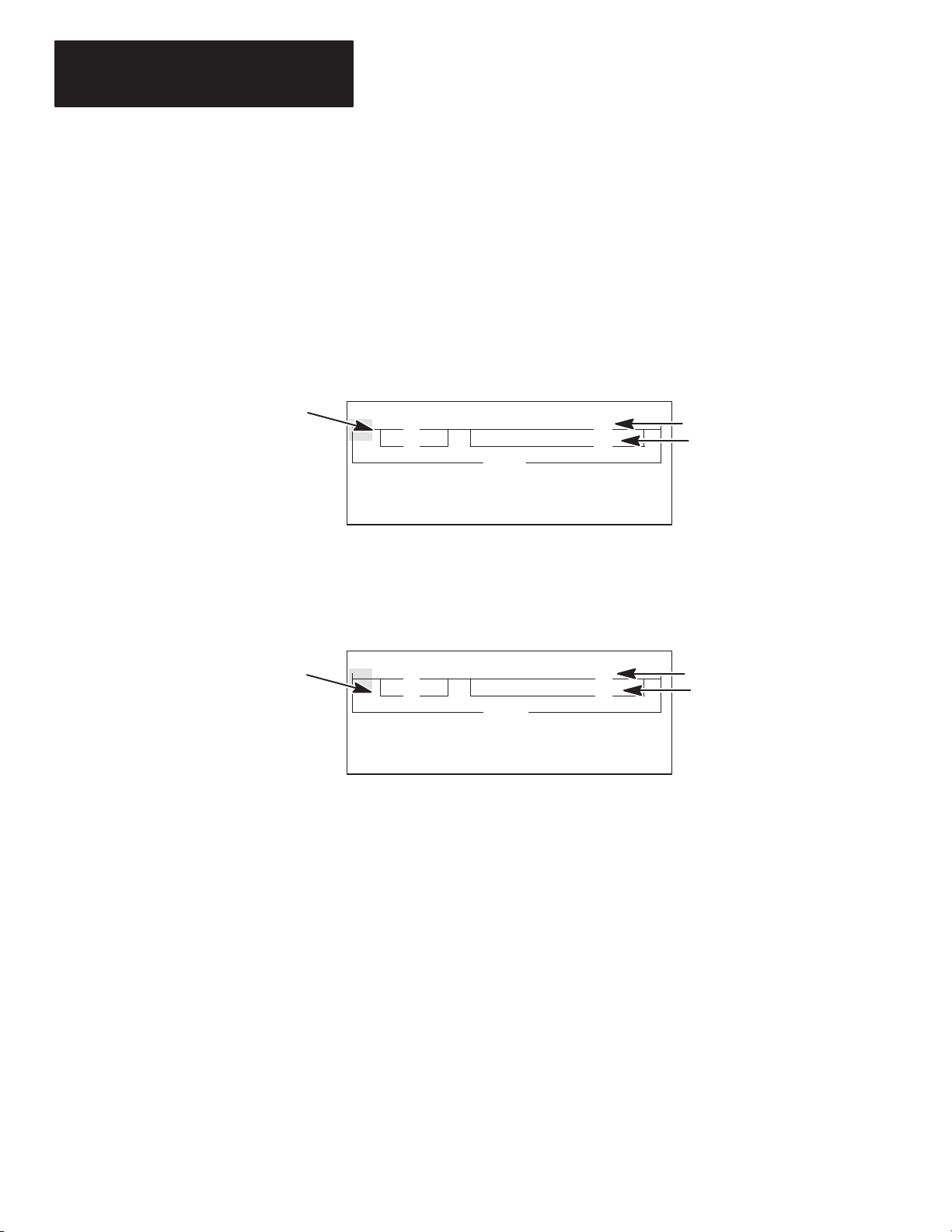

The figure below indicates the data file conditions under which the rung is

true:

Input Instructions Output Instruction

XIC

I:1.0

] [

0

Input Data File

address data

I:1 0001

Status bit I:1/1 is a

logic 0, making the

XIO instruction true.

Status bit I:1/0 is a

logic 1, making the

XIC instruction true.

In the above example, if the input data file was 0000, then the rung would be

false and the output data file would read as 0000 0000.

XIO OTE

I:1.0

]/[

1

O:3.0

address data

O:3 0000 0001

The processor changes status bit O:3/0 to

a logic 1, because a continuous path of

true input instructions exist in the rung.

( )

0

Output Data File

2–7

Page 25

Chapter 2

Control Basics

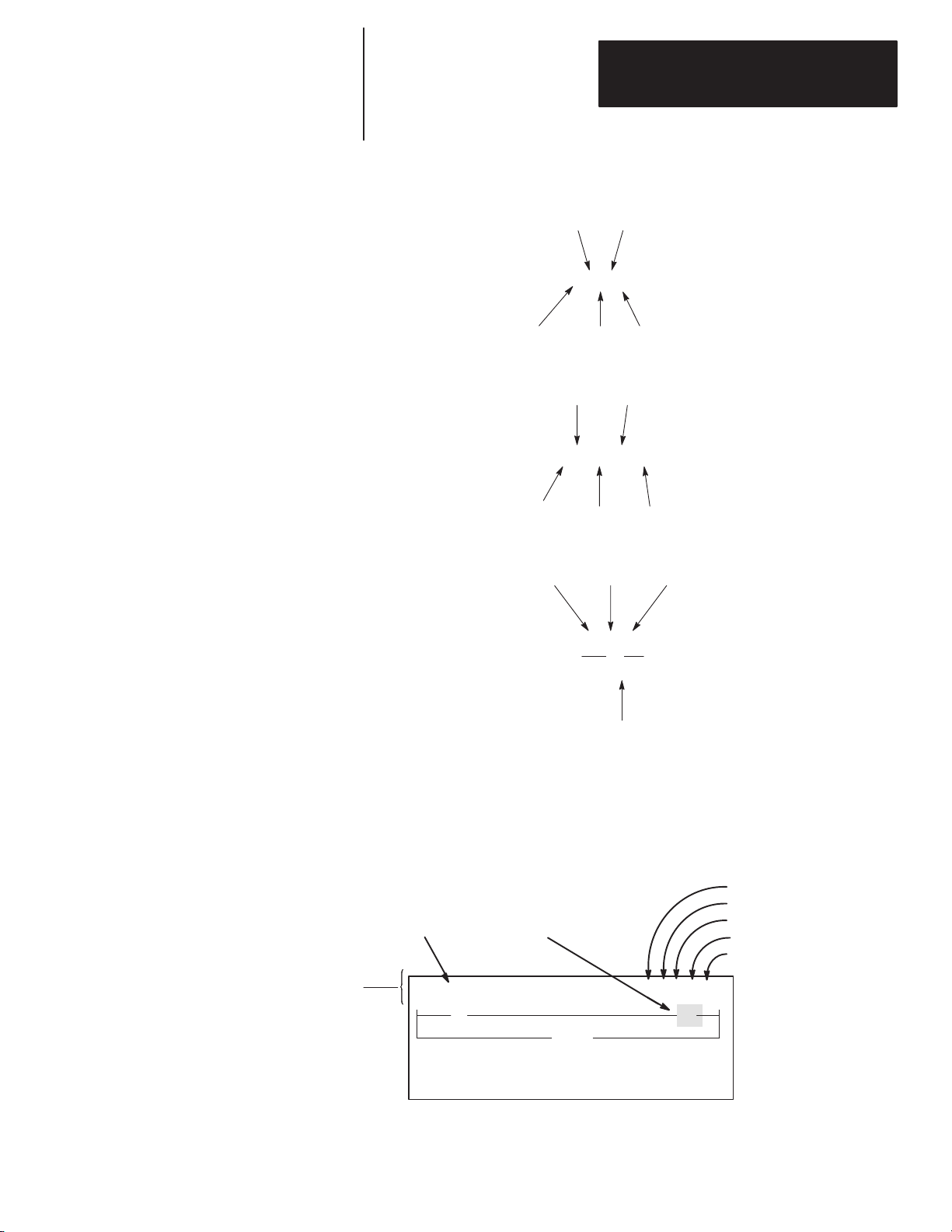

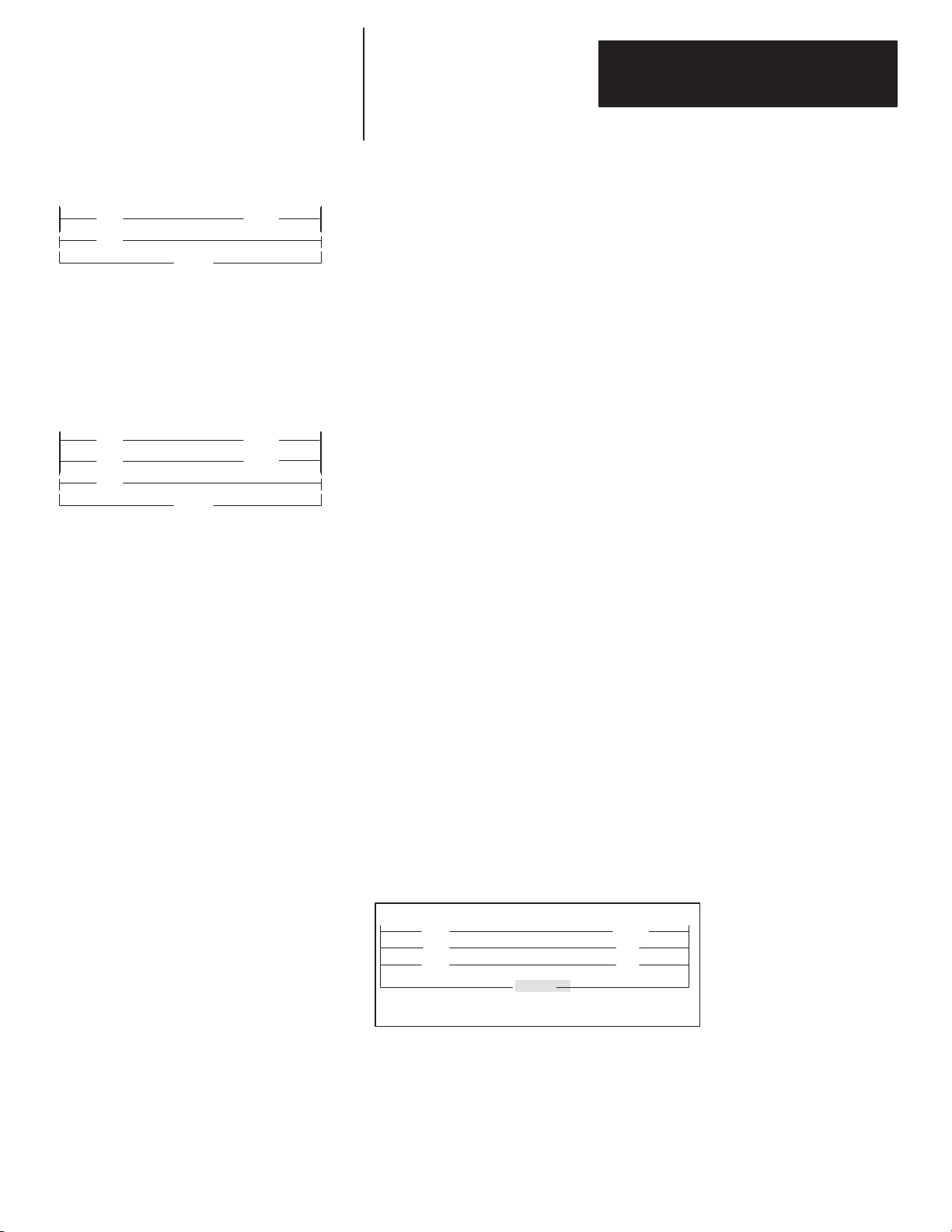

Processor Operating Cycle

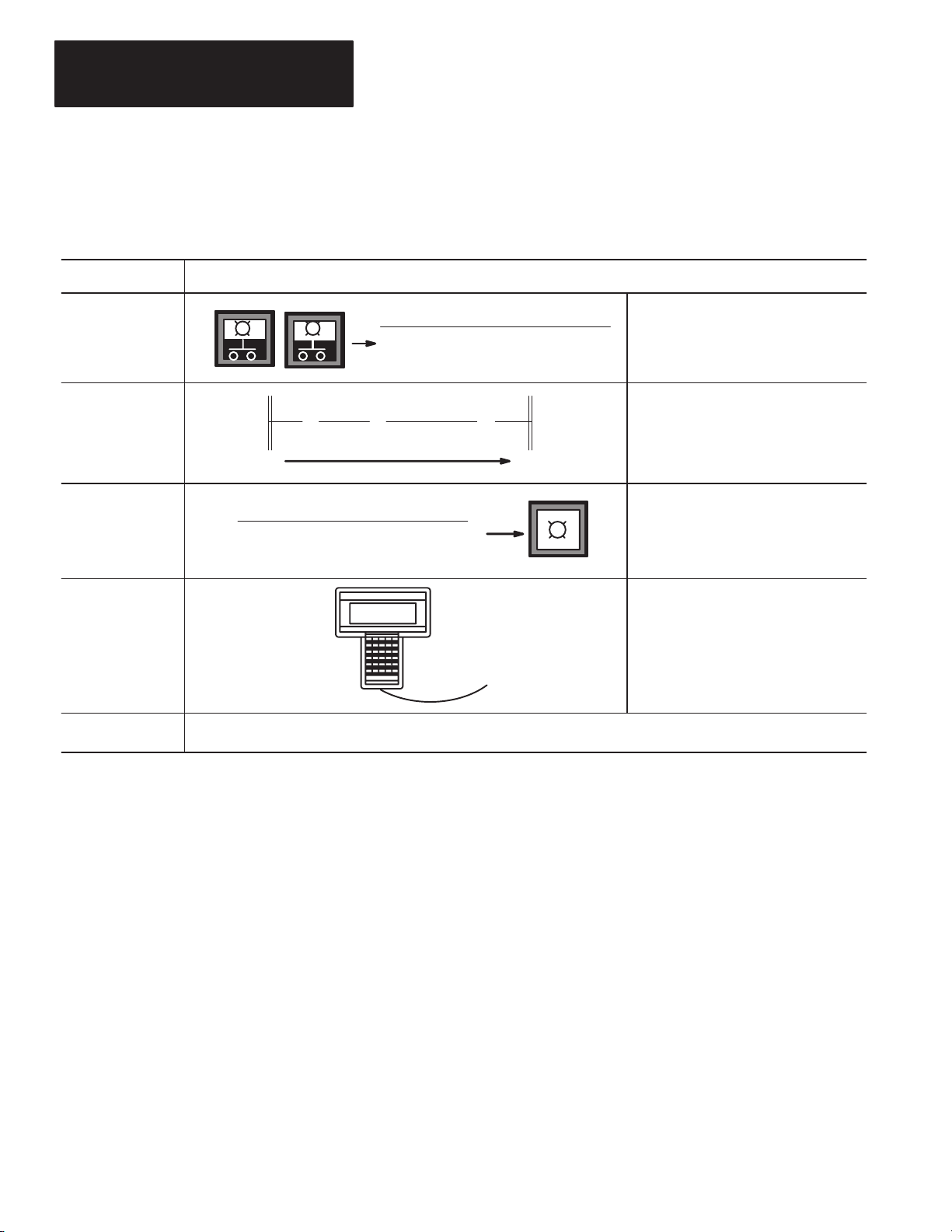

The diagram below indicates the events that occur during the processor

operating cycle. This sequence is repeated many times each second.

Event Description

Input

Scan

Program Scan

Output Scan

Communications

Housekeeping

F8

0

activated

address data

O:3 0000 0001

1

I:1.0

] [

0

Output Data File

address data

I:1 0001

I:1.0

]/[

1

Input Data File

O:3.0

( )

0

0

Illuminated

Processor internal housekeeping takes place.

The status of external input circuits is

read. The input data file is updated with

this information.

The ladder program is executed. The

input data file is evaluated, the ladder

rung is solved, and the output data file

is updated.

The output data file information is

transferred to the external output circuit,

thus energizing or de–energizing it.

Communications with the HHT and other

network devices takes place.

2–8

Page 26

Getting Started Guide

for HHT

Chapter

A–B

3

Creating a Program

In this chapter you create a program. The tasks you will perform:

• For modular controllers: Make a record of the processor module catalog

number, the rack catalog number(s), the I/O module catalog numbers, and

the slot locations of I/O modules.

For fixed controllers: Make a record of the controller catalog number

(and I/O module catalog numbers and slot locations if you are using the

1746–A2 expansion rack).

• Use the HHT to create a program.

• Clear the HHT memory.

• Name the program “1000.”

• Enter the controller configuration.

• Enter a 1–rung ladder program.

• Save the program.

Configuration of SLC 500 Controllers

To make the best use of this guide, you should have access to an SLC 500

Demonstration Unit, which includes completely wired external inputs and

outputs. For the exercises in this guide, we assume that you are using a

Demo unit using a modular controller with the components listed on page

3–4.

3–1

Page 27

Chapter 3

Creating a Program

Controller Styles

As previously mentioned, SLC 500 controllers are available in two styles —

the fixed controller and the modular controller. Examples are shown in the

figure below.

Processor & Power Supply

Expansion Rack

Power Supply

SLC 500 Modular ControllerSLC 500 Fixed Controller

Processor

7–slot rack

12Slot 0

Slot 0 1 2 3 4 5 6

The fixed controller combines a power supply, processor (CPU), and a fixed

number of I/O points in a single unit. You have the option of adding a 2–slot

expansion rack if you want to add I/O points.

The modular controller consists of a power supply, 1–3 I/O racks, a processor

module that you insert in slot 0 of the first rack, and various I/O modules that

you insert in the remaining slots of the racks.

Slot Numbers: Note that slot numbers are indicated in the figure above. In

fixed controllers, slot 0 applies to the processor and fixed I/O points; slots 1

and 2 apply to I/O modules located in the expansion rack. In modular

controllers, slot 0 is always reserved for your processor module; the

remaining slots apply to the various I/O modules you have inserted.

Catalog Numbers

When you configure your controller, you must specify the processor catalog

number, rack catalog numbers, and I/O module catalog numbers as required.

The location of the catalog number on the various components is shown in

the following figures.

3–2

Make a record of controller components: We recommend that you make a

list of the processor, rack, and I/O catalog numbers, and also the rack

numbers assigned to the racks and the slot locations of all I/O modules. You

can then refer to this list as you configure your controller.

Page 28

Getting Started Guide

for HHT

Chapter 3

Creating a Program

Catalog Number Location – SLC 500 Fixed Controllers

Label for Processor Catalog

and Serial Number

SLC

500

CAT

1747–L _ _ _

Processor

Catalog Number

The catalog number for the

expansion rack is 1746–A2. It

appears on side of the rack.

Side View

Catalog Number Location – SLC 500 Modular Controllers

Processor (CPU) Modules

Label for Processor Catalog

and Serial Number

Side View

Racks

SLC

500

CAT

1747–L _ _ _

Processor

Catalog Number

Label for Rack Catalog

and Serial Number

SLC

500

CAT

1746–_ _ _

Rack Catalog Number

I/O Modules

Catalog Number

1746–_ _ _

The catalog number and

serial number for I/O

modules also appears on

the side of the module.

Side View

3–3

Page 29

Chapter 3

Creating a Program

Arbitrary Controller Used in this Guide

In the following procedures, we have assumed that the controller you are

configuring in your program is a modular demo unit including the following

components:

• Rack 1746–A4, 4–slot rack

• Processor 1747–L511 in slot 0

• Input module 1746–IA4 in slot 1

• Input module 1746–IA8 in slot 2

• Output module 1746–OA8 in slot 3

The ladder program shown on page 3–11 contains I/O addresses that are

consistent with the configuration indicated above. If you are using some

other controller configuration, keep in mind that these addresses may not be

valid for your controller.

Creating a Program

A program is always created offline. In creating the program, you will:

• Clear the memory of the HHT.

• Name the program and configure the controller.

• Enter a ladder program.

• Save the program in the HHT.

The abbreviated function keys that you will be encountering, both in this

Guide and on the HHT display, are explained in appendix C.

3–4

Page 30

Getting Started Guide

for HHT

Chapter 3

Creating a Program

Clearing the Memory of the HHT

To create a new program, you must clear the HHT memory (DEFAULT

program).

1. Energize your HHT. After the HHT goes through self–diagnostic tests,

the following display appears

SLC 500 PROGRAMMING SOFTWARE Rel. 2.03

:

Allen–Bradley Company Copyright 1990

All Rights Reserved

PRESS A FUNCTION KEY

SELFTEST TERM PROGMAINT

F1 F2 F3 F4 F5

2. Press [F3]

1747 – PTA1E

– PROGMAINT

OFL

UTILITY

. Either the following display appears (if a

program is in the HHT), or. . .

File Name: Prog Name:2345

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 5

CHG_NAM CRT_FIL EDT_FIL

F1 F2 F3 F4 F5

DEL_FIL

OFL

>

MEM_MAP

this display appears (if a program is not in the HHT).

File Name: Prog Name:DEFAULT

File Name Type Size(Instr)

0 System *

1 Reserved *

2 Ladder *

2345 (or anything other

than DEFAULT) indicates

that a program is in the HHT.

DEFAULT indicates that a

program is not in the HHT.

CHG_NAM CRT_FIL EDT_FIL

F1 F2 F3 F4 F5

DEL_FIL

OFL

>

MEM_MAP

Clear the memory as follows, even if the DEFAULT program is present.

3. Press

4. Press

5. Press [F2]

[ENTER]. More menu options appear.

[F4]

– CLR_MEM

File Name: Prog Name:2345

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 5

ARE YOU SURE?

YES

F1 F2 F3 F4 F5

– YES

. The following display appears

NO

OFL

. This clears the HHT memory. Now you are ready to

create a program.

3–5

Page 31

Chapter 3

Creating a Program

Naming the Program and Configuring the Controller

The following indicates how to name your program and configure your

controller using the HHT.

Naming Your Program

1. Press

2. Press

3. Press

[ENTER] to view more options.

[F1]

– CHG_NAM

[F2]

– PROGRAM

––––––– Change Program/File Name–––––––

File Name:

Program Name: DEFAULT

ENTER NAME: DEFAULT

F1 F2 F3 F4 F5

.

. The following display appears:

OFL

4. Name your program “1000.” (Press [1][0][0][0][SPACE][ENTER].)

The program name is entered.

5. Exit this menu level by pressing

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System *

1 Reserved *

2 Ladder *

CHG_NAM CRT_FIl EDT_FIL

F1 F2 F3 F4 F5

[ESC]. The following display appears:

Program Name

OFL

DEL_FIL >MEM_MAP

3–6

The program directory now shows the name of the program, which is 1000.

Page 32

Getting Started Guide

for HHT

Chapter 3

Creating a Program

Configuring the Processor

1. Press

[ENTER] to view the additional menu functions (as indicated by the

> symbol in the lower right corner). The following display appears:

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System *

1 Reserve *

2 Ladder *

EDT_DAT SEL_PRO EDT_I/O

F1 F2 F3 F4 F5

2. Press [F2]

Type = 1747–L511 CPU–1K USER MEMORY

Series =

Memory Size = 1 K INSTRUCTIONS

TYPE SERIES

F1 F2 F3 F4 F5

3. Press

Type = 1747–L511 CPU–1K USER MEMORY

Series =

Memory Size = 1 K INSTRUCTIONS

– SEL_PRO

[F1] – TYPE

. The following display appears:

CLR_MEM >

. The following display appears:

OFL

Type = 1747–L511 CPU–1K USER MEMORY

OTHER

F1 F2 F3 F4 F5

4. Use the cursor keys ([ ↑ ] or [ ↓ ]) and press [ENTER] to select the the right

processor type. (For our example, we want the

therefore, we just press

[ENTER]

). Processor module 1747–L511 is

1747–L511 type;

entered into memory.

5. Press

[ESC] to return to the following display:

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System *

1 Reserved *

2 Ladder *

EDT_DAT SEL_PRO EDT_I/O

F1 F2 F3 F4 F5

CLR_MEM >

OFL

3–7

Page 33

Chapter 3

Creating a Program

Configuring Your I/O

[F3]

1. Press

Rack 1 = 1746–A4 4–SLOT RACK

Rack 2 = NONE

Rack 3 = NONE

Slot 0 = 1747–L511 CPU–1K USER MEMORY

Slot 1 = NONE

MOD_RCK MOD_SLT DEL_SLT UND_SLT

F1 F2 F3 F4 F5

– EDT I/O

. The following display appears:

The display shows that the processor module we just entered is assigned to

slot 0. It also shows the default rack selection

1746–A4. For our example we

do not have to change the rack selection. If you are using a different rack,

press

[F1] – MOD_RCK

using the up and down cursor keys, then press

, then [F1]

– RACK 1

. Select the appropriate rack,

[ENTER]. If you are using

more than one rack, follow the same procedure for racks 2 and 3.

The next task is to assign the I/O module slots. For our example, we use

slots 1, 2 and 3.

2. Press

Slot

3. Assign input module

[F2] – MOD_SLT

Rack 1 = 1746–A4 4–SLOT RACK

Rack 2 = NONE

Rack 3 = NONE

Slot 0 = 1747–L511 CPU–1K USER MEMORY

Slot 1 = NONE

Slot 1 = NONE

F1 F2 F3 F4 F5

1 = NONE

[↓ ] key. (For our example, we press the [ ↓ ] key once.) The following

appears on the prompt line.

. The following display appears:

OTHER

1746–IA4 to slot 1 by scrolling or jogging with the

screen appears:

Rack 1 = 1746–A4 4–SLOT RACK

Rack 2 = NONE

Rack 3 = NONE

Slot 0 = 1747–L511 CPU–1K USER MEMORY

Slot 1 = NONE

Slot 1 = 1746–IA4 4–INPUT 100/120 VAC

OTHER

F1 F2 F3 F4 F5

3–8

4. Press [ENTER]. 1746–IA4 is entered for slot 1.

5. Call up another slot number using the

[ ↓ ] and [ ↑ ] keys. Press the [ ↓ ]

key once.

Slot

2 = NONE

appears on the prompt line.

Page 34

Getting Started Guide

for HHT

Chapter 3

Creating a Program

6. Press [F2]

– MOD_SLT.

7. Assign 1746–IA8 in slot 2: press the [ ↓ ] key twice, then [ENTER]. The

following display appears:

Rack 1 = 1746–A4 4–SLOT RACK

Rack 2 = NONE

Rack 3 = NONE

Slot 0 = 1747–L511 CPU–1K USER MEMORY

Slot 2 = 1746–IA8 8–INPUT 100/120 VAC

MOD_RCK MOD_SLT DEL_SLT UND_SLT

F1 F2 F3 F4 F5

8. Call up slot 3 using the cursor key. Press the [ ↓ ] key once.

9. Press

10.Assign

[F2]

– MOD_SLT

Slot 3 = NONE

appears on the prompt line.

.

1746–OA8 in slot 3: press the [ ↓ ] seven times. Then press

[ENTER]. The following display appears:

Rack 1 = 1746–A4 4–SLOT RACK

Rack 2 = NONE

Rack 3 = NONE

Slot 0 = 1747–L511 CPU–1K USER MEMORY

Slot 3 = 1746–OA8 8–OUT(TRI) 100/240 VAC

MOD_RCK MOD_SLT DEL_SLT UND_SLT

F1 F2 F3 F4 F5

Your controller is now fully configured.

11. Press

[ESC]. This returns you to the display shown below.

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System *

1 Reserved *

2 Ladder *

EDT_DAT SEL_PRO EDT_I/O

F1 F2 F3 F4 F5

CLR_MEM >

OFL

3–9

Page 35

Chapter 3

Creating a Program

Monitoring Your Data File

To verify that the output and input data files for the I/O modules have been

created, you can call up data files for the I/O.

1. Press

[F1]

– EDT_DAT

Address 15 data 0

O0:3.0 0000 0000

O0:3.0/0 = 0

ADDRESS NEXT_FL PREV_FL NEXT_PG PREV_PG

F1 F2 F3 F4 F5

. The following display appears:

OFL

8 bits

This is file 0, the output data file. It indicates that slot 3 of the controller has

8 bits assigned (representing outputs

O:3/0

through

O:3/7

). (For more

information, see the section concerning “Addressing External I/O” in

chapter 2.)

[F2]

2. Press

Address 15 data 0

I1:1.0 0000

I1:2.0 0000 0000

I1:1.0/0 = 0

ADDRESS NEXT_FL PREV_FL NEXT_PG PREV_PG

F1 F2 F3 F4 F5

– NEXT_FL

. The following display appears:

4 bits

8 bits

OFL

3–10

This is file 1, the input data file. It indicates that slot 1 of the controller has 4

bits assigned (representing inputs

bits assigned (representing inputs

3. Now press

[ESC]

, then [ENTER]. The following display appears. You

I:1/0 through I:1/3), and that slot 2 has 8

I:2/0

through I:2/7).

are now ready for the next section.

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System *

1 Reserved *

2 Ladder *

CHG_NAM CRT_FIL EDT_FIL DEL_FIL MEM_MAP

F1 F2 F3 F4 F5

OFL

>

Page 36

Getting Started Guide

for HHT

Chapter 3

Creating a Program

Programming a Simple Ladder Rung

The following rung consists of an XIC input instruction and an OTE output

instruction. The addresses conform to the controller configuration indicated

in the “Arbitrary Controller” section of this chapter. If you have entered a

different controller configuration, make certain that the addr

esses ar

consistent with your configuration. It is also important that you have an

external input, such as a pushbutton, and an external output, such as a pilot

light, at the terminal addresses used. You will be using these external

devices in later chapters of this guide.

e

I:1.0

] [

0

O:3.0

( )

0

Entering a Rung

To enter the rung, do the following:

1. Begin where we ended on the previous page, at the program directory

display.

2. Press [F3]

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System *

1 Reserved *

2 Ladder *

ENTER FILE NUMBER:

F1 F2 F3 F4 F5

– EDT_FIL

. The following display appears.

OFL

We want to edit file number 2, our main program file.

[2]

3. Press

[ENTER]

other rungs exist at this time. The numbers

. The display shows the END rung of a program. No

2.0.0.0.* appear in the

upper right corner of the display. This indicates that we are in File 2, and

the cursor is located on rung 0, branch 0.

2.0.0.0.*

<END>

INS_RNG MOD_RNG SEARCH DEL_RNG UND_RNG

F1 F2 F3 F4 F5

4. Press [F1]

INS_INST BRANCH MOD_INST ACP_RNG

F1 F2 F3 F4 F5

– INS_RNG

<END>

. The following display appears:

2.0.0.0.*

OFL

>

OFL

>

3–11

Page 37

Chapter 3

Creating a Program

Entering an “Examine if Closed” Instruction

[F1]

1. Press

BIT TMR/CNT I/O_MSG CPT/MTH

F1 F2 F3 F4 F5

– INS_INST

. The following display appears:

2.0.0.0.*

<END>

OFL

COMPARE

>

2. Press [F1]

] [

F1 F2 F3 F4 F5

3. Press [F1]

ZOOM on XIC

NAME: EXAMINE IF CLOSED

BIT ADDR:

ENTER BIT ADDR:

F1 F2 F3 F4 F5

4. At the ENTER

– BIT

—] [—

. The following display appears:

]/[

] [

BIT ADDR:

2.0.0.0.*

<END>

( )

( )

L

OFL

( )

U

>

. The following display appears:

2.0.0.0.*

prompt, type the address I:1/0, then [ENTER].

(If you entered the wrong instruction by mistake, just press

again.)

5. Press

[F5]

– ACCEPT

. This accepts the address. The following display

appears:

Note that the HHT

“shifts” for you.

[ESC] and try

3–12

] [

<END>

] [

F1 F2 F3 F4 F5

]/[

( )

2.0.0.0.*

OFL

( ) ( )

>L

U

Page 38

Getting Started Guide

for HHT

Chapter 3

Creating a Program

Entering an “Output Energize” Instruction

1. Press

[F3], for the output energize instruction. The following display

appears:

ZOOM on OTE

NAME: OUTPUT ENERGIZE

BIT ADDR:

ENTER BIT ADDR:

F1 F2 F3 F4 F5

( )

2.0.0.0.*

2. Type bit address O:3/0, then [ENTER]. (If you entered the wrong

instruction by mistake, just press

[F5]

3. Press

[F5]

] [

INS_RNG MOD_RNG SEARCH DEL_RNG UND_RNG

F1 F2 F3 F4 F5

– ACCEPT

– ACP_ RNG

, then press [ESC] twice. Then press

. The following display appears:

<END>

[ESC]

2.1.0.0.*

and try again.)

( )

OFL

>

At this point the rung is entered and accepted.

4. Press

[ENTER] to display more menu options.

3–13

Page 39

Chapter 3

Creating a Program

Saving Your Program

Save your program at the end of a program edit. First your program is

compiled, transforming it into a more efficient package. Then the program is

saved from the work area into another part of memory. In addition, the

contents of program files and data files are updated. Also, a summary of data

words used, instructions used, and available memory is updated.

1. Start with the screen below, where we left off in the last section.

2.1.0.0.*

] [

<END>

EDT_DAT SAVE_CT SAVE_EX

F1 F2 F3 F4 F5

( )

OFL

>

2. Press [F5]

Future Access: Yes

MODIFY OPTIONS, ACCEPT TO COMPILE

FUTACC ACCEPT

F1 F2 F3 F4 F5

– SAVE_EX

Compiler Options

. The following display appears:

OFL

FUTACC (Future Access): This option lets you protect proprietary

program data and algorithms. The protection becomes operational only

after the program is downloaded to the controller. The “Future Access:

No” selection disallows online access to the processor unless a matching

copy of the online program is resident in the HHT.

Important: Do not select “Future Access: No” for this exercise.

3. Press [F5]

– ACCEPT

. This compiles and saves the program. After short

time, the following display appears:

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

3–14

CHG_NAM CRT_FIL EDT_FIL

F1 F2 F3 F4 F5

DEL_FIL >MEM_MAP

4. Return to the main display by pressing

OFL

[ESC]

.

Page 40

Getting Started Guide

for HHT

Chapter

A–B

4

Online Operations

In this chapter, you will complete the following tasks:

• Download program 1000, created in chapter 3.

• Test the program.

• Monitor the input and output data files.

4–1

Page 41

Chapter 4

Online Operations

Downloading Your Program

This chapter shows you how to download a program from the HHT to the

processor, then monitor the program. It assumes that you have performed the

tasks in chapter 3, and that the HHT shows the following display.

SLC 500 PROGRAMMING SOFTWARE Rel. 2.03

Allen–Bradley Company Copyright 1990

PRESS A FUNCTION KEY

SELFTEST TERM PROGMAINT

F1 F2 F3 F4 F5

1747 – PTA1E

All Rights Reserved

OFL

UTILITY

Going Online

1. Press [F5]

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

ONLINE WHO PASSWRD

F1 F2 F3 F4 F5

– UTILITY

. The following display appears:

OFL

CLR_MEM

2. Press

3. Press

[F2] – WHO

[F3]

– ATTACH

.

.

Either the following display appears (if a program is not in processor

memory), or. . .

Programmer Processor

Prog: 1000 Prog: DEFAULT

File: File:

Exec Files: 3 Exec Files: 3

Data Files: 9 Data Files: 3

DEFAULT FILE IN PROCESSOR

F1 F2 F3 F4 F5

Program Directory

DWNLOADOFFLINE CLR_PRC

MEM_PRC

PRG

this display appears (if a program is in processor memory).

Programmer Processor

Prog: 1000 Prog: 2345

File: File:

Exec Files: 3 Exec Files: 3

Data Files: 9 Data Files: 9

PROGRAM FILES DIFFER

F1 F2 F3 F4 F5

Program Directory

DWNLOADOFFLINE MODEUPLOAD

PRG

CLR_PRC

Important: If the above display appears and the processor is not

in program mode, then you must change the processor

[F4]

mode. To do this, press

[F5]

– PROGRAM

, then [F2]

– MODE

– YES

, then

, and then [ESC].

4–2

Page 42

Getting Started Guide

for HHT

Chapter 4

Online Operations

Downloading Your Program

1. Press DWNLOAD. The following display appears:

Programmer Processor

Prog: 1000 Prog: DEFAULT

File: File:

Exec Files: 3 Exec Files: 3

Data Files: 9 Data Files: 3

DOWNLOAD TO PROCESSOR?

F1 F2 F3 F4 F5

2. Press [F2]

Program Directory

YES

– YES

. This verifies that you want to download the file to the

NO

PRG

processor. For a brief moment, the following message should appear

DOWNLOADING

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

F1 F2 F3 F4 F5

FILE.

The following display appears:

PRG

MODEDWNLOADUPLOADOFFLINE

CLR_PRC

>

Changing Program Mode to Run Mode

1. Press [F4]

– MODE

. The following display appears:

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

PRG

TESTRUN

F1 F2 F3 F4 F5

2. Press [F1]

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

ARE YOU SURE?

F1 F2 F3 F4 F5

– RUN

. The following display appears:

PROGRAM

NOYES

PRG

4–3

Page 43

Chapter 4

Online Operations

3. Press [F2]

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

F1 F2 F3 F4 F5

– YES

. The following display appears again:

RUN

TESTRUN

PROGRAM

Monitoring the Program in Run Mode

1. Press [ESC], then [ENTER]. The following display appears:

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

RUN

EDT_DATXFERMEMPASSWRD

F1 F2 F3 F4 F5

MONITOR

>

2. Press [F5]

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

ENTER FILE NUMBER: RUN

F1 F2 F3 F4 F5

– MONITOR

. The following display appears:

3 . Press 2, then [ENTER]. The following display appears:

2.0.0.0.*

] [

<END>

MODE EDT_DAT SEARCH

F1 F2 F3 F4 F5

FORCE

( )

RUN

4–4

Page 44

Getting Started Guide

for HHT

Chapter 4

Online Operations

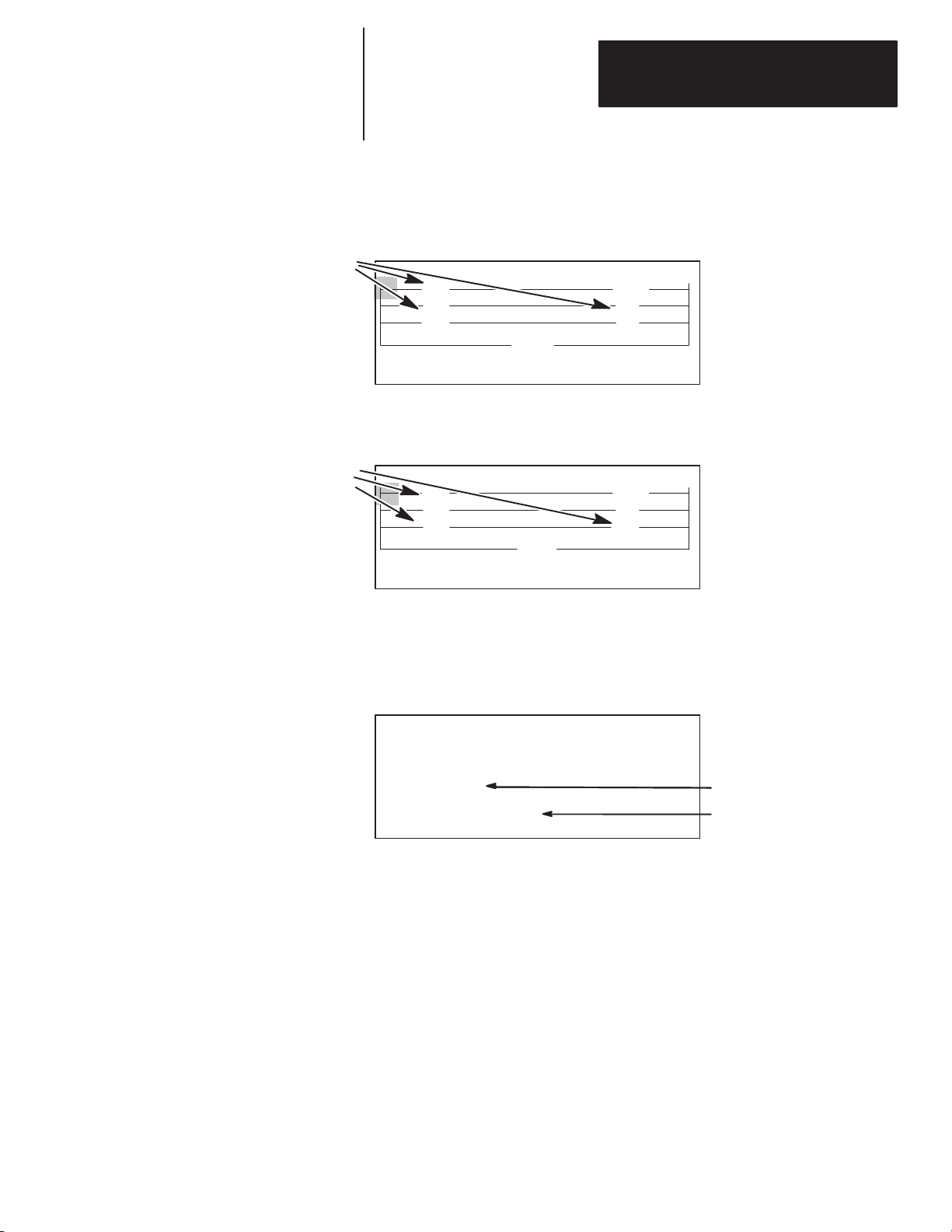

Testing Your Downloaded Program

The following diagram shows the rung you entered if you are using the

modular controller demo unit discussed in chapter 3. If you are using some

other controller configuration, make certain that your external input device

and output device are wired to the controller input and output that you

addressed in your ladder program.

1

F8

0

Address I:1.0/0 corresponds

to pushbutton 0 of the demo

unit.

I:1.0

] [

0

END

<>

Address O:3.0/0

corresponds to pilot light 0

of the demo unit.

0

O:3.0

( )

0

To test the program, press pushbutton 0. Pilot light 0 should go on. The

display should show both the XIC and OTE instructions highlighted to

indicate that they are true.

Processor operation: When you pressed pushbutton 0, the input instruction

went from false to true. This resulted in a path of true input instructions in

the rung, causing the output instruction to go from false to true.

Monitoring Data Files

Now, release the pushbutton. Pilot light 0 should go off. Neither instruction

in the rung should be highlighted. When you released pushbutton 0, the

input instruction went from true to false; this broke the path of true input

instructions, causing the output instruction to go from true to false.

In this procedure, you will monitor the input data file and the output data file.

These files include a status bit for each of the configured I/O terminals of the

controller. You will monitor data file changes as you operate pushbutton 0.

To end the exercise, you will go offline.

1. Beginning with the display shown on the previous page, press

[F3]

– EDT_DAT

Address 15 data 0

O0:3.0 0000 0000

O0:3.0/0 = 0

ADDRESS NEXT_FL PREV_FL NEXT_PG PREV_PG

F1 F2 F3 F4 F5

. The following display appears:

RUN

4–5

Page 45

Chapter 4

Online Operations

2. Monitor output data changes resulting from input device operation. Press

pushbutton 0. Note that the status bit corresponding with output

O:3/0

goes from 0 to 1, as the instruction goes from false to true.

Address 15 data 0

O0:3.0 0000 0001

O0:3.0/0 = 0

ADDRESS NEXT_FL PREV_FL NEXT_PG PREV_PG

F1 F2 F3 F4 F5

3. Press [F2]

Address 15 data 0

I1:1.0 0000

I1:2.0 0000 0000

I1:1.0/0 = 0

ADDRESS NEXT_FL PREV_FL NEXT_PG PREV_PG

F1 F2 F3 F4 F5

– NEXT_FL

. The following display appears:

RUN

RUN

Bit changes from 0 to 1.

4. Monitor input data changes resulting from input device operation. Press

pushbutton 0. Note that the status bit corresponding to input

I:1/0 goes

from 0 to 1, as the instruction goes from false to true.

Address 15 data 0

I1:1.0 0001

I1:2.0 0000 0000

Bit changes from 0 to 1.

4–6

I1:1.0/0 = 0

ADDRESS NEXT_FL PREV_FL NEXT_PG PREV_PG

F1 F2 F3 F4 F5

RUN

5. Return to the main display. Press [ESC] twice. The following display

appears:

2.0.0.0.*

] [

EXIT MONITOR MODE?

YES

F1 F2 F3 F4 F5

6. Press [F2]

– YES

<END>

, then press

( )

NO

[ESC]

RUN

once. The following display

appears:

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

CONTINUE AND GO OFFLINE?

YES

F1 F2 F3 F4 F5

NO

RUN

Page 46

Getting Started Guide

for HHT

Chapter 4

Online Operations

7. Press [F2]

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 3

F1 F2 F3 F4 F5

8. Press

[ESC]

– YES

. The following screen appears:

WHO PASSWRDONLINE

. This brings up the main display.

OFL

CLR_MEM

4–7

Page 47

Chapter 4

Online Operations

4–8

Page 48

Getting Started Guide

for HHT

Appendix

A–B

A

Additional Ladder Program Exercises

This appendix lets you apply what you have learned in the previous chapters.

It covers:

• Entering a program with input and output branches

• Entering a program with a timer instruction

Entering Input and Output Branches

I:1/0

I:1/1

The important feature of this program is the output and input branch. The

input branch is based on what is called OR or parallel logic. This means that

if either input #0 OR input #1 is true, then output #0 and #1 turn on. If the

rung is true, all outputs will be energized. If the rung is false, all outputs will

be de–energized.

We will be editing the program created in chapter 3 to look like the one

shown in the display below. It will consist of one input branch and one

output branch.

O:3/0

] [

] [ ( )

<END>

F1 F2 F3 F4 F5

( )

O:3/1

Creating the Program

1. Start from the main display, which you ended with in chapter 4, Online

Operations.

SLC 500 PROGRAMMING SOFTWARE Rel. 2.03

Allen–Bradley Company Copyright 1990

1747 – PTA1E

All Rights Reserved

PRESS A FUNCTION KEY

SELFTEST TERM PROGMAINT

F1 F2 F3 F4 F5

OFL

UTILITY

2. Press the following function keys (in order): [F3]

[F3]

– EDT_FIL

3. Enter the file number, which is

.

2. Then press [ENTER]. The program

entered in chapter 3 is displayed.

2.0.0.0.*

] [

<END>

INS_RNG MOD_RNG SEARCH DEL_RNG UND_RNG

F1 F2 F3 F4 F5

( )

OFL

>

– PROGMAINT

, then

A–1

Page 49

Appendix

A

Additional Ladder Program Exercises

4. Press [F2]

– MOD_RNG

, then [F2]

– BRANCH

Adding an Input Branch

5. Press [F4]

[ENTER]. Your new display should look like this:

EXT_UP EXT_DWN APP_BR INS_BR DEL_BR

F1 F2 F3 F4 F5

] [

– INS_BR

. Then press the [→] cursor key once, then press

2.0.1.1.*

( )

<END>

OFL

Inserting an Instruction

6. Press [ESC], then [F1]

[F1]

—] [—

.

7. Type the bit address

– INS_INST

I:1/1, then [ENTER].

, then [F1]

.

– BIT

, then

8. Then press

—]

[—

F1 F2 F3 F4 F5

] [

] [

[F5]

—]/[—

– ACCEPT

<END>

—( )—

. The following display appears:

2.0.1.1.*

( )

OFL

—(L)—

—(U)—

>

Adding an Output Branch

9. Press [ESC] twice. Then press the [→ ] cursor key once. Then press

[F2]

– BRANCH

10.Press

[F4]

The following display appears:

] [

] [

EXT_UP EXT_DWN APP_BR INS_BR

F1 F2 F3 F4 F5

.

– INS_BR

<END>

. Then press the [→] cursor key once, then [ENTER].

2.0.1.1.*

( )

OFL

DEL_BR

A–2

Page 50

Getting Started Guide

for HHT

Inserting an Instruction

Appendix

A

Additional Ladder Program Exercises

11. Press [ESC] once, then [F1]

[F3]

—( )—

12.Type the bit address

.

O:3/1, then [ENTER]. Then press [F5]

– INS_INST

The following display appears:

OTE:O0:3.0/1

] [

] [

—]

[—

F1 F2 F3 F4 F5

—]/[—

NO FORCE

<END>

—( )—

2.0.1.1.4

( )

( )

—(L)— —(U)—

Saving the Program

13.Press [ESC] twice. Then press [F5]

[F5]

14.Press

– SAVE_EX

appears:

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 4

, then [F5]

– ACCEPT

, then [F1]

OFL

>

– ACP_RNG

. The following display

– BIT

, then

– ACCEPT

. Then press [ENTER].

.

CHG_NAM CRT_FIL EDT_FIL

F1 F2 F3 F4 F5

DEL_FIL >MEM_MAP

OFL

15.Press [ESC] once.

Downloading the Program

Start with the main display.

1. Press [F5]

2. Press

3. Press

4. Put processor into PROGRAM mode: press

[F5]

5. Press

File Name: Prog Name:1000

File Name Type Size(Instr)

0 System 76

1 Reserved 0

2 Ladder 4

OFFLINE UPLOAD DWNLOAD

F1 F2 F3 F4 F5

– UTILITY

[F2] – WHO

[F3]

– ATTACH

–PROGRAM

[F3]

, then [F2]

– DWNLOAD

.

.

.

, then [F2]

– YES

. Then press

– YES

MODE >CLR_PRC

. The following display appears:

PRG

[F4]

[ESC]

– MODE

.

, then

A–3

Page 51

Appendix

A

Additional Ladder Program Exercises

6. Monitor the ladder program and put the processor into the RUN mode.

To do this, press

[ENTER].

7. Press

[F1]

[ENTER], then [F5]

– MODE

, then [F1]

– RUN

– MONITOR

, then [F2]

, then press 2, then

– YES

, then [ESC].

Testing the Ladder Program

1. Press pushbutton #0. Outputs #0 and #1 turn ON. The following display

appears.

This input instruction becomes bold.

This input instruction becomes bold.

] [

] [ ( )

MODE FORCE SEARCH

F1 F2 F3 F4 F5

<END>

EDT_DAT

2.0.0.0.*

( )

RUN

These

output instructions become bold.