Page 1

160-RS1

Serial

Communication

Module

FRN 1.xx

User Manual

R

S232

Serial C

om

m

READ

Y

FAULT

CO

M

M

CAT

160-RS1

SER

.A.

.S

U

IN

DE

A

M

Page 2

Important User Information

Solid state equipment has operational characteristics differing from

those of electromechanical equipment. “Safety Guidelines for the

Application, Installation and Maintenance of Solid State Controls”

(Publication SGI-1.1) describes some important differences between

solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying

this equipment must satisfy themselves that each intended application

of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable

for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley

Company cannot assume responsibility or liability for actual use

based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with

respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part,

without written permission of the Allen-Bradley Company is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

!

circumstances that can lead to personal injury or death,

property damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important:

Identifies information that is especially important for

successful application and understanding of the product.

Shock Hazard labels may be located on or inside the drive

to alert people that dangerous voltage may be present.

DriveExplorer, DriveTools, DriveTools32, MicroLogix and SLC are trademarks of Rockwell Automation.

PLC and PLC-5 are registered trademarks of Rockwell Automation.

RSLinx and RSLogix 500 are trademarks of Rockwell Software, Inc.

Windows and Windows NT are registered trademarks of Microsoft Corporation

Page 3

Using This Manual

Product Overview

Quick Start for Experienced

Users

Installation and Wiring

Table of Contents

Preface

Who Should Use This Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p–i

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p–i

RS1 Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p–i

Reference Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p–ii

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p–ii

Chapter 1

Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Configuration DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Chapter 2

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Chapter 3

EMC Directive 89/336/EEC Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Low Voltage Directive 73/23/EEC Compliance . . . . . . . . . . . . . . . . . . . . . 3–1

Module Configuration Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Setting the Baud Rate – SW1 & SW2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Setting the Protocol – SW3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Selecting the Checksum Mode – SW4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Module Installation/Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Keypad or Ready/Fault Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Installing the RS1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Removing the RS1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Wiring the Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Connecting the Communication Cable to the Module. . . . . . . . . . . . . . . . 3–8

Modes of Operation

RS1 Data Table Interface

Parameter Descriptions

Chapter 4

Powering Up the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Power-up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Chapter 5

Supported PCCC Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Data Table Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Chapter 6

RS1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Page 4

toc–ii Table of Contents

Using the RS1 Module with

DriveExplorer™ Software

Using the RS1 Module with a

Programmable Controller

Chapter 7

Required Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Example Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Setting Baud Rates and Configuring the Communications Port . . . . . . . 7–2

Monitoring and Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Monitoring Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Uploading Editable Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Downloading Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Chapter 8

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

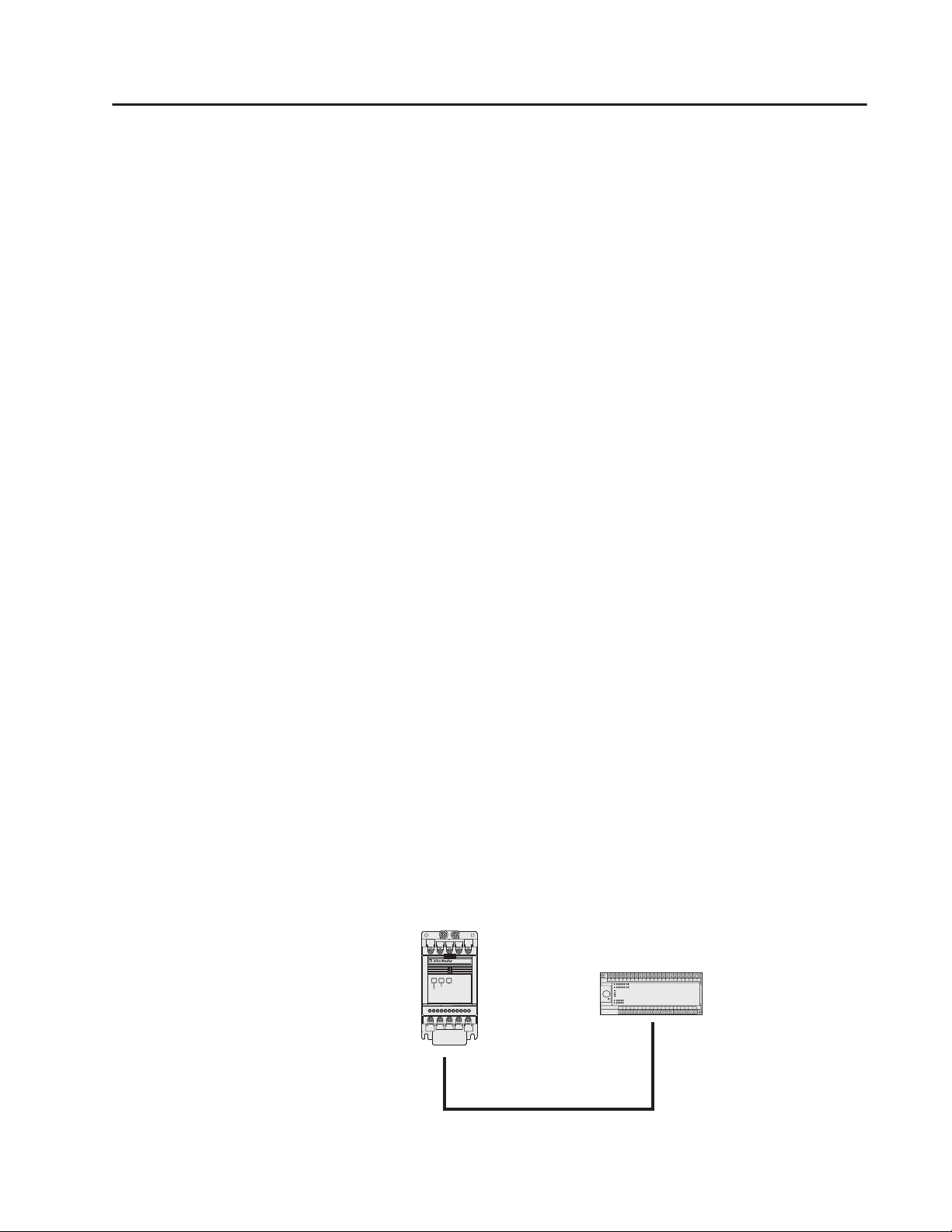

Example Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

Setting the Drive to Enable Network Control . . . . . . . . . . . . . . . . . . . . . . 8–2

Setting the Baud Rate and Checksum Mode . . . . . . . . . . . . . . . . . . . . . . 8–2

Connecting the Drive to the Programmable Controller. . . . . . . . . . . . . . . 8–2

Controlling the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

Program the Ladder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–3

Reading and Writing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

Program the Ladder for Parameter Reads and Writes. . . . . . . . . . . . . . . 8–5

Troubleshooting

Specifications

RS1 Module Compatibility

Chapter 9

LED Indicators and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

READY LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–2

COMM LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–2

FAULT LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–2

RS1/DF1 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–3

Appendix A

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Appendix B

Page 5

Preface

Using This Manual

The purpose of this manual is to provide you with the necessary

information to apply the Bulletin 160-RS1 Communication Module.

Described in this manual are methods for installing, configuring, and

troubleshooting the RS1 Communication Module.

For information on specific drive features, refer to the Bulletin 160

User Manual.

Who Should Use This Manual?

Conventions

Important:

This manual is intended for qualified personnel. To make efficient use

of the Communication Module, you must be able to program and

operate serial communications devices, as well as have an

understanding of the parameter settings and functions of the 160

Drive.

In this manual we refer to the:

• 160 RS1 Communication Module as Communication Module,

RS1 Module or Module.

• 160 SSC Adjustable Frequency AC Drive as the 160 Drive or

drive.

In addition, parameter numbers and names (both 160 Drive and RS1

Module) are shown in bold typeface and follow the format PXX - [*]

where P denotes parameter, XX denotes the two digit parameter

number, and * represents the parameter name.

For example, P01 - [Output Frequency].

Read this manualin its entiretybefore installing, operating,

servicing, or initializing the RS1 Module.

RS1 Compatibility

The RS1 Module is compatible with all series of 160 Drives. When

properly connected, the module communicates via RS-232 using the

Allen-Bradley DF1 protocol.

Page 6

p–ii Preface

Reference Manuals

For Read This Document

Information about the DF1 protocol DF1 Protocol and Command Set Reference Manual 1770-6.5.16

Additional information about networking and the SLC™ 500 SLC 500 Modular Hardware Style Manual 1747-6.2

Information about the AIC+ AIC+ Advanced Interface Converter User Manual 1761-6.4

Instruction set information for the SLC 500 and MicroLogix™

1000

For general MicroLogix 1000 information MicroLogix 1000 User Manual 1761-6.3

For DriveExplorer™ information DriveExplorer User Manual 9306-5.0

For 160 SSC Drive Information: 160 SSC User Manual Series A

A complete listing of current Allen-Bradley documentation,

including ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multi-languages.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Safety Precautions

The following documents contain additional information concerning

Allen-Bradley products. To obtain a copy, contact your local AllenBradley Sales Office or visit the “On-Line Publications” area of the

Allen-Bradley home page on the World Wide Web at:

SLC 500 and MicroLogix 1000 Instruction Set

Reference Manual

160 SSC User Manual Series B

160 SSC User Manual Series C

Allen-Bradley Publication Index SD499

www.ab.com

Publication

Number

1747-6.15

0160-5.0

0160-5.9

0160-5.15

ATTENTION: Only personnel familiar with 160 Drives,

!

Communication Modules andassociated machinery should

plan or implement the installation, start-up, configuration

and subsequent maintenanceof this module.Failure to comply may result in personal injury and/or equipment damage.

.

ATTENTION: This module contains ESD (Electrostatic

!

Discharge) sensitive parts and assemblies. Static control

precautions are required when installing, testing, servicing,

or repairing this assembly. Component damage may result

if ESD control procedures are not followed. If you are not

familiar with static control procedures, reference AllenBradley Publication 8000-4.5.2, Guarding Against Electro-

static Damage or any other applicable ESD protection

handbook.

ATTENTION: The drive contains high voltage capacitors

!

which take time to discharge after removalofACline power.

Before installing or removing the CommunicationModule,

ensure isolation of mains supply from line inputs L1, L2,

L3 (R, S, T). Wait the recommended amount of time for the

capacitors to discharge to safe voltage levels (refer to the

160 User Manual for recommended time). Failure to do so

may result in personal injury or death.

ATTENTION: When a system is configured for the first

!

time, the motor must be disconnected from the machine or

process during initial system testing. Hazard of injury or

equipment damage may occur due to unintended or incorrect machine motion.

Page 7

Product Overview

This chapter contains the following information:

• The physical layout of the module.

• Location of configuration switches.

• Overview and components.

Chapter

1

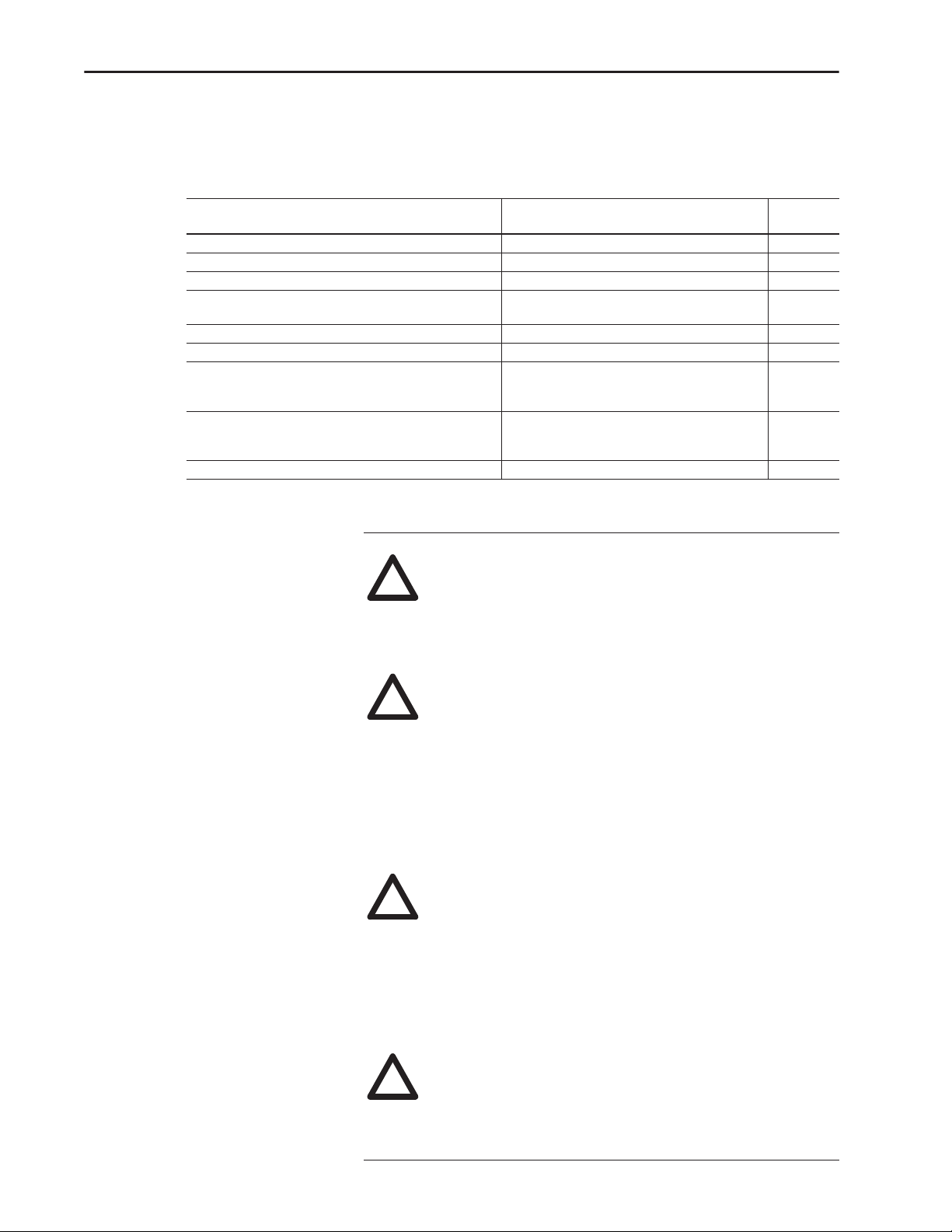

Module Description

The RS1 Module is an optional interface device designed to provide a

direct, digital link between RS-232 devices and the 160 Drive. The

module connects to the drive through the expansion/keypad port on

the front of the drive. Refer to the figures 1.1 and 1.2 for general

layout of the module and Chapters 4 or 9 for details on the LED

indicators.

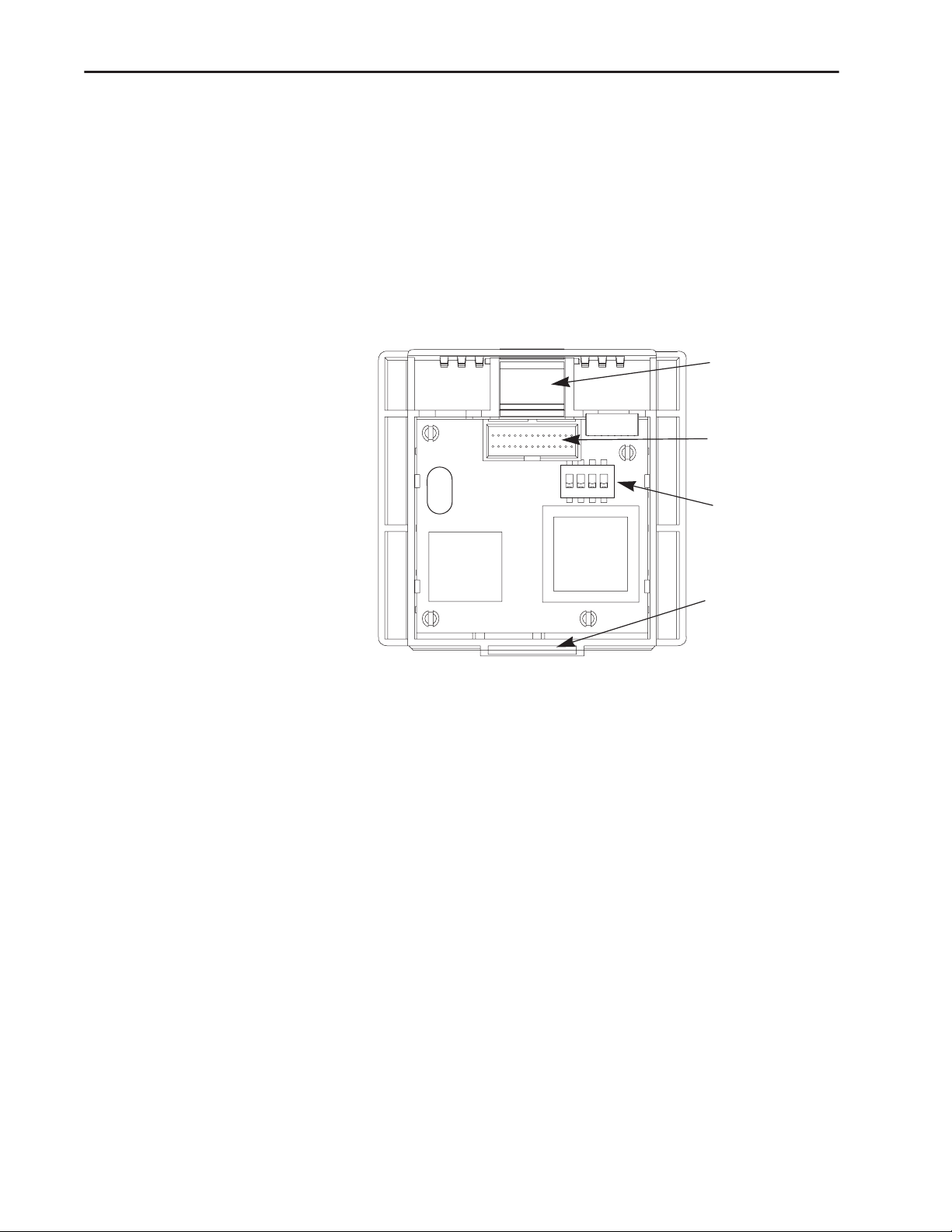

Figure 1.1

Module Front View

Module Installation Latch

Status LEDs

Refer to Chapters 4 & 9

for Further Information

COMM

FAULT

READY

RS232

Serial Comm

SER

MADE IN U.S.A.

9 Pin, Female D-Shell Connector

Refer to Chapter 3 for Details

CAT

160-RS1

Nameplate

Provides Firmware Version

and Series Letter

Page 8

1–2 Product Overview

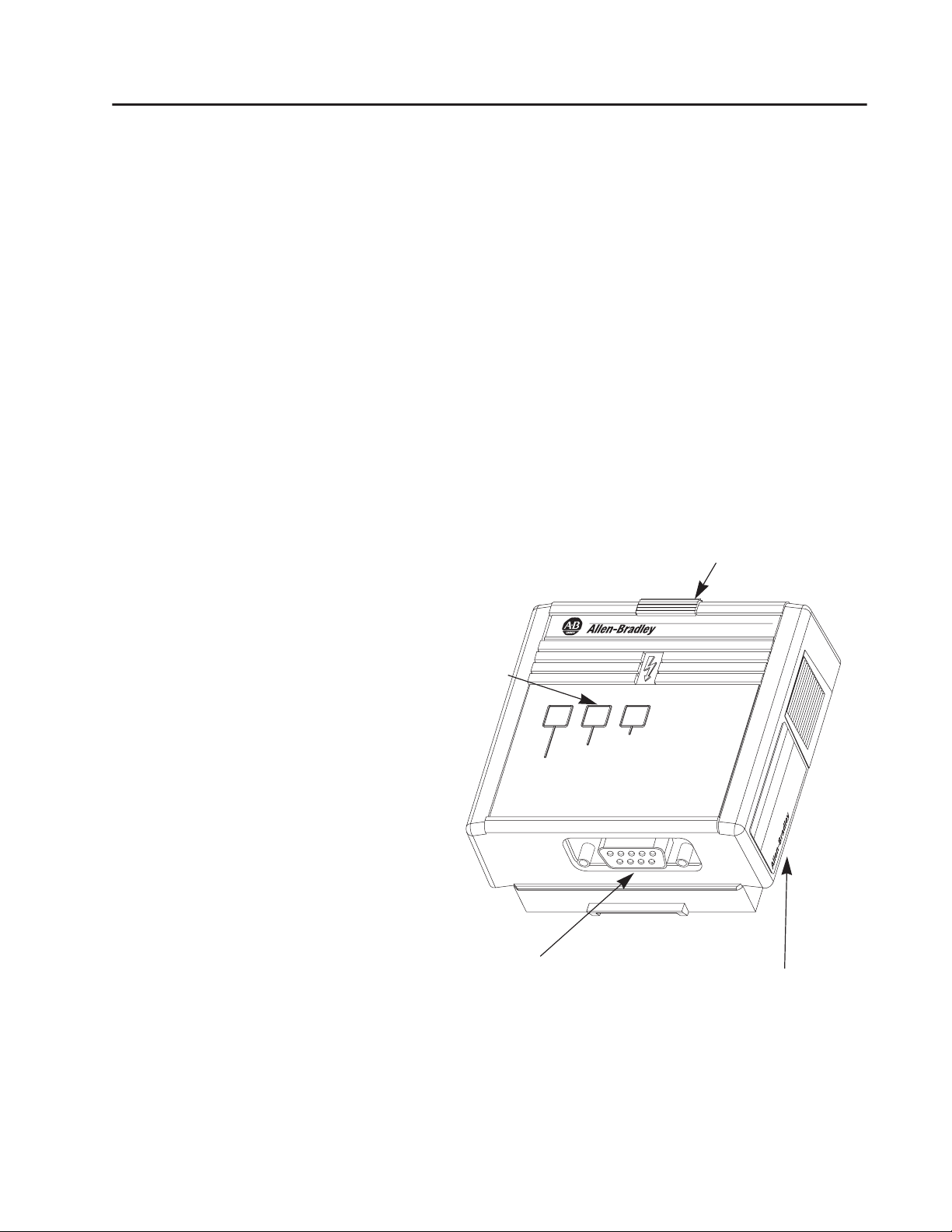

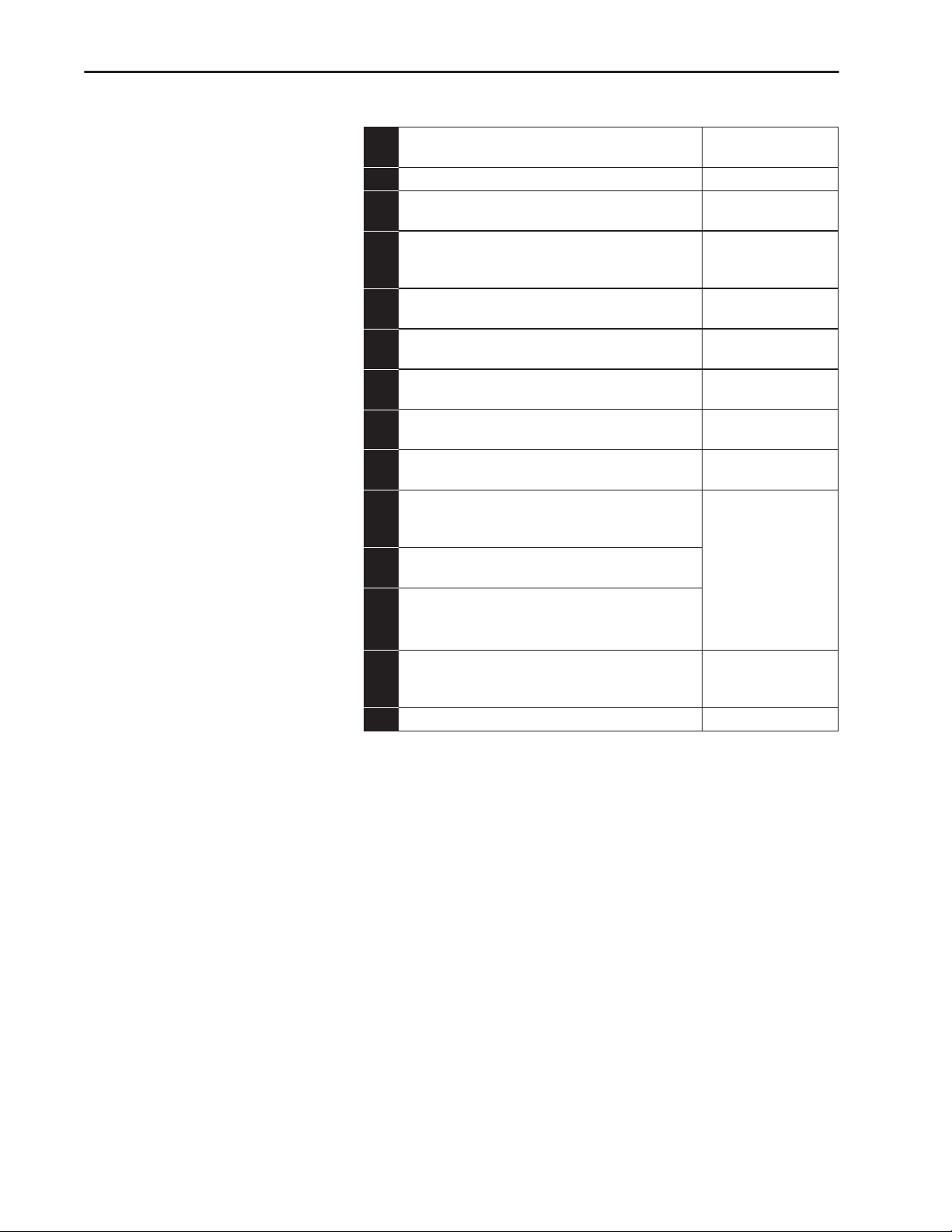

Configuration DIP Switches

The Communication Module has one four position DIP switch for

setting the baud rate, protocol and checksum type. DIP switches are

located on the rear of the module (see below) and are only accessible

when the module is removed from the 160 Drive. Refer to Chapter 3

for switch configuration information.

Figure 1.2

Module Rear View

Module Latch

Expansion/Keypad Port

Connector

ON

1234

SW1 - SW4

DIP Switches

D-Shell Connector

Page 9

Chapter

2

Quick Start for Experienced Users

This chapter can help you start using the RS1 Communication

Module. If you have installed or configured a network previously and

are familiar with Allen-Bradley communication modules and drives,

this information can help reduce the time of installation. If you are

uncertain, use the full installation/configuration information

beginning in Chapter 3.

We base the procedures here on the assumption that you understand

the basic concepts and know how to program the 160 Drive. In

addition, you should understand electronic process control and be

able to interpret the ladder logic instructions required to generate the

electronic signals that control your application.

Because it is a start-up guide for experienced users, this chapter does

not contain detailed explanations about the procedures listed. It does,

however, reference other chapters in this book where you can get

more information.

Required Tools and Equipment

If you have any questions or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the

referenced chapters and other recommended documentation before

trying to apply the information.

This chapter contains the following information:

• What tools and equipment you need.

• When to address, configure and program the module.

• How to install and wire the Communication Module.

• System power-up procedures.

Have the following tools and equipment ready:

• 1/8 in. (3.2 mm) flat blade screwdriver.

• Blunt, pointed instrument (not pen or pencil) for setting the DIP

switches.

Page 10

2–2 Quick Start for Experienced Users

Procedures

Step Action

10.

11. Check for proper operation.

For Further Information

Refer to . . .

1. Review Attention statements in the Preface.

Ensure that power has been removed to the 160 Drive. 160 Drive

2.

Verify that the 160 Drive is correctly installed and

3.

wired. Stop Input (TB3-7, TB3-8) must be jumpered

together to start drive.

Remove Program Keypad Module or Ready/Fault

4.

Indicating Panel from the drive.

Set the RS1 Module’s baud rate, protocol and check-

5.

sum type DIP switches.

6. Install the RS1 Module.

7. Connect communication cable.

8. Power up the drive and the network.

Configure the 160 Drive for the RS1 Module so the

9.

drive can accept control logic and speed reference via

the network.

Set P46 - [Input Mode] to a value of “2.” This will configure

the drive to accept the logic commands from the network.

Set P59 - [Frequency Select] to “1.” This will configure the

drive to accept speed commands from the network.

Configure the RS1 Module parameters for your

application.

P114 - [Application Timeout], etc.

For Example:

P103 - [Fault Mode],

User Manual

User Manual

(Installation)

(Installation)

(Installation)

(Installation)

(Installation)

(Using the RS1 Module

with a Programmable

Controller)

(Using the RS1 Module

with DriveExplorer

(Parameter Descriptions)

160 Drive

Chapter 3

Chapter 3

Chapter 3

Chapter 3

Chapter 3

Chapter 8

or

Chapter 7

Software)

Chapter 6

Page 11

Chapter

3

Installation and Wiring

This chapter contains information needed to:

• Meet the requirements of the EMC and Low Voltage directives

for CE compliance.

• Remove a pre-installed Program Keypad Module or Ready/Fault

Indicating Panel.

• Configure and install the RS1 Module.

• Wire the communication cables.

• Remove the RS1 Module from the drive.

Read this chapter completely before you attempt to install or

configure your module. Before applying power, review the Attention

statements presented throughout this manual. Verify that all

connections are secure and that all selections are correct.

ATTENTION: Unpredictable operation may occur if you

!

fail to check connections and DIP switch settings for compatibility with your application. Unpredictable operation

may result inpersonal injury, death, and equipment damage.

EMC Directive 89/336/EEC

Compliance

Low Voltage Directive 73/23/

EEC Compliance

This product complies with Electromagnetic Compatibility (EMC)

Directive 89/336/EEC when conforming with the following

installation requirements:

• The essential requirements for a conforming EMC installation for

the Bulletin 160 SSC are employed. Refer to the Bulletin 160 SSC

User Manual.

This product complies with Low Voltage Directive 73/23/EEC when

conforming with the following installation requirements:

• The essential requirements for a conforming Low Voltage

Directive installation for the Bulletin 160 SSC are employed.

Refer to the Bulletin 160 SSC User Manual.

• Review the Attention statements in the Preface, and other areas

throughout this manual prior to installation of the module.

Page 12

3–2 Installation and Wiring

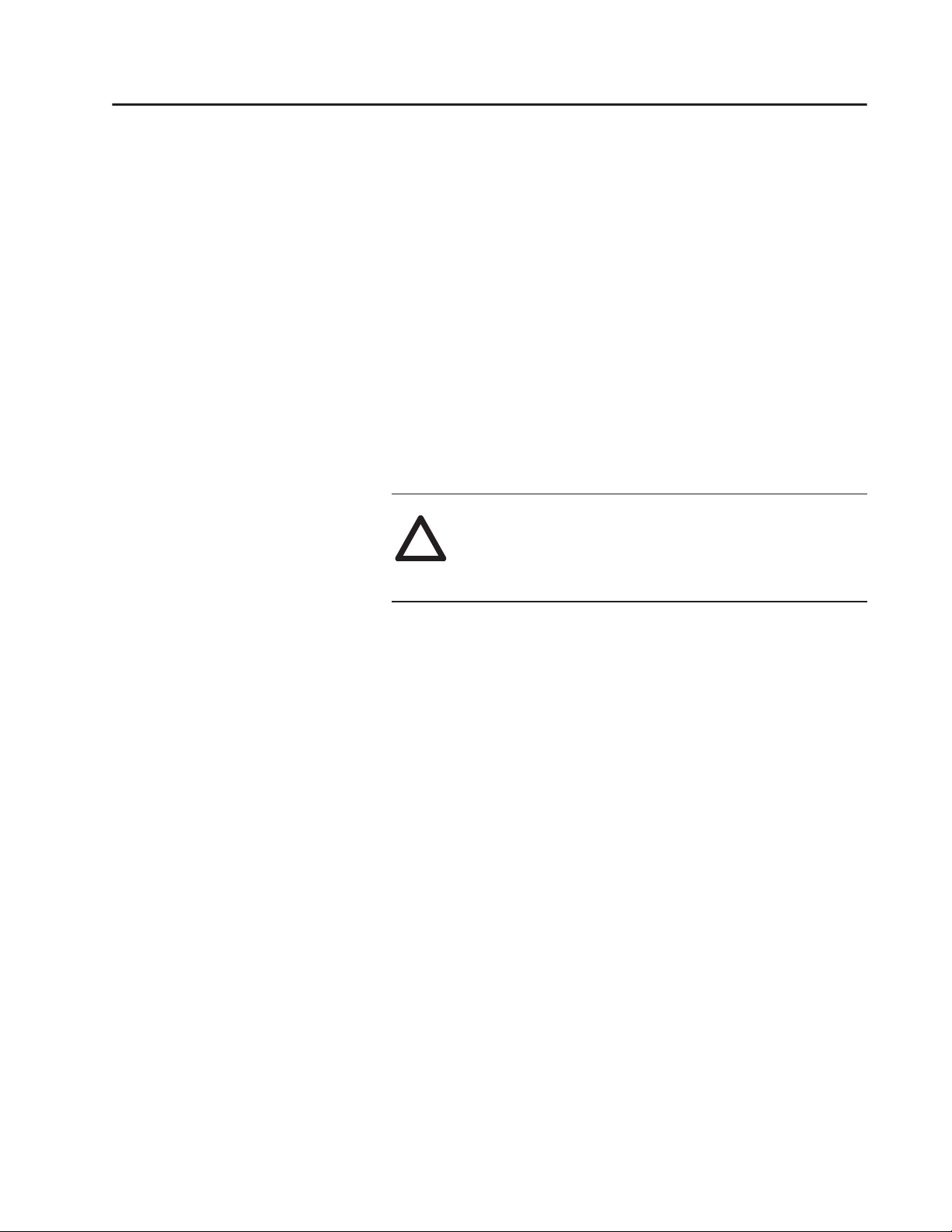

Module Configuration Switches

The RS1 Module utilizes a four position DIP switch (see figure

below) to configure the baud rate, protocol and checksum. These

switches must be set to match the application settings. Refer to the

paragraphs that follow for details.

Important:

When you makechanges to theswitch settings, use a blunt,

pointed instrument (not a pen or pencil).

Figure 3.1

DIP Switch Location (Back of Module)

Module Latch

Expansion/Keypad

Port Connector

SW1 - SW4 DIP Switches

ON

1234

ON

Off / 0 =

1

3

2

On / 1 =

4

D-Shell Connector

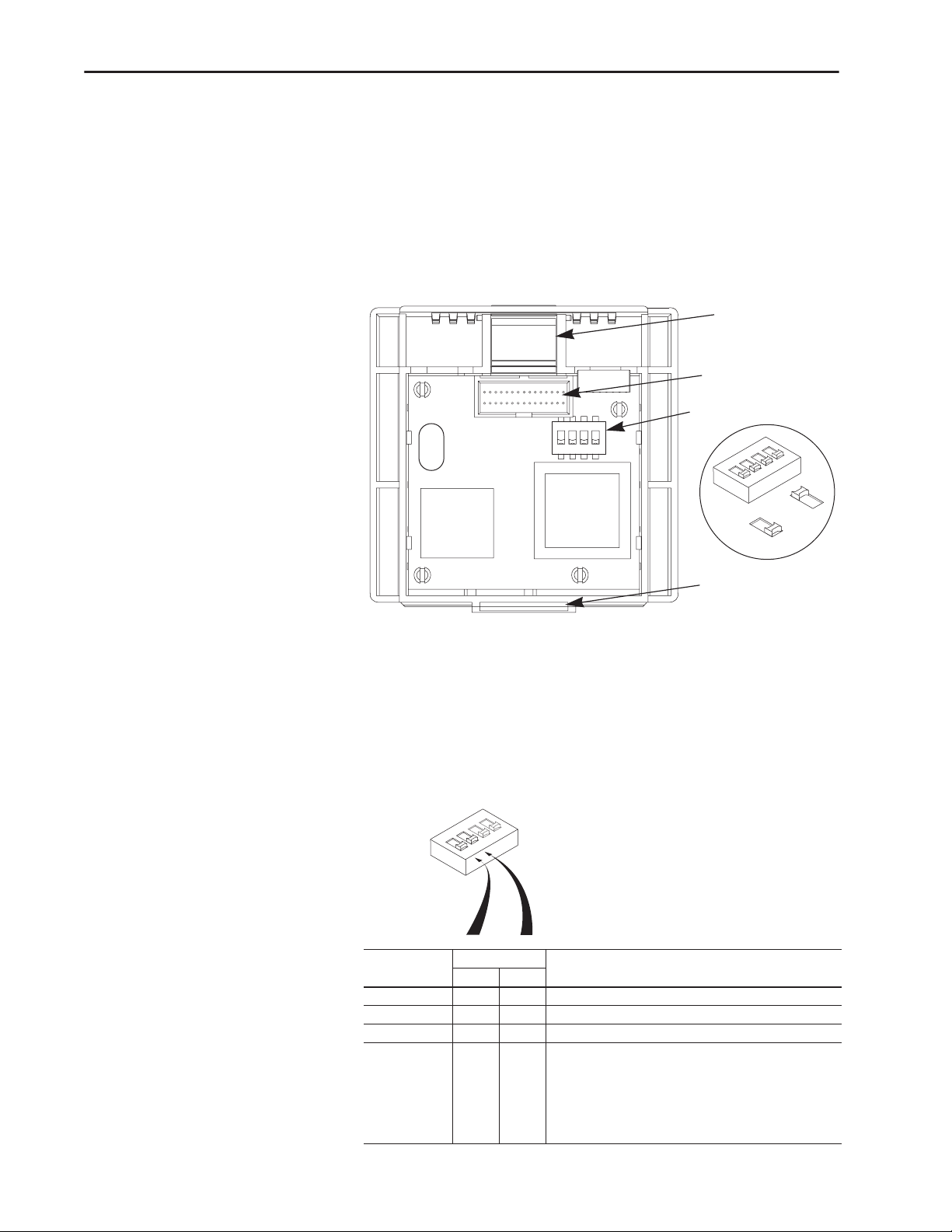

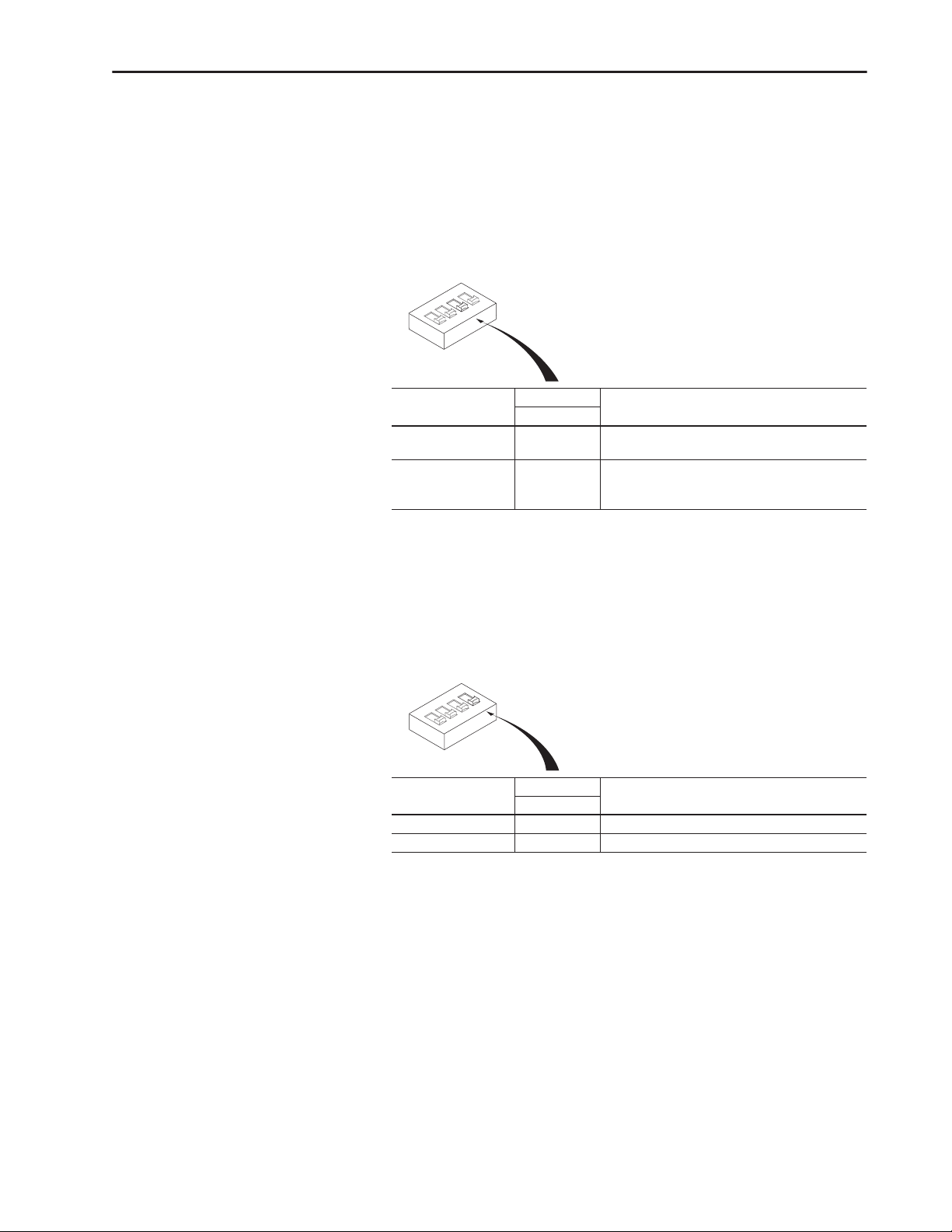

Setting the Baud Rate – SW1 & SW2

DIP switches SW1 and SW2 set the baud rate. Using the table below,

configure the module for your application. Selection of the “EPROM

Mode” (SW1 & SW2 are On) will cause the baud rate, protocol and

checksum settings to be read from the RS1 parameters listed below.

Note that these parameters must be programmed for correct

operation.

ON

Switch Setting

Baud Rate

9600 (Default) Off Off

2400 On Off

1200 Off On

EPROM Mode On On Baud Rate will be read from P110 - [EPROM Baud]

4

3

2

1

Switches SW1 & SW2

Special NotesSW1 SW2

Checksum will be read from P109 - [EPROM Checksum]

Protocol will be read from P108 - [EPROM Protocol]

Important: If an “AIC+” is being used and “EPROM

Mode” is selected, SW3 must be set to “On” to enable

software handshaking.

Page 13

Installation and Wiring 3–3

Setting the Protocol – SW3

As shown in the table below, SW3 sets the protocol being used (pointto-point or multi-drop). If EPROM Mode is active (SW1 & SW2 are

On), the protocol will be read from P108 - [EPROM Protocol].

Important:

If an “AIC+” is being used and “EPROM Mode” is

selected, SW3 must be set to “On.”

4

ON

2

1

Options

DF1 Point-to-Point

(Default)

DF1 Multi-Drop On Used for RS-232 applications between a number of

3

Switch SW3

Switch Setting

Special NotesSW3

Off Typically used for RS-232 applications between two

devices.

devices. Additional module (i.e. AIC+) is required

for RS-485 applications/networking.

Selecting the Checksum Mode – SW4

Switch SW4 sets the checksum mode. Configure this mode to be

consistent with your communications and application. If EPROM

Mode is active (SW1 & SW2 are On), the checksum mode will be

read from P109 - [EPROM Checksum] (SW4 will have no effect).

Switch SW4

ON

Options

BCC (Default) Off Block checksum.

CRC On 16 bit algorithm.

4

3

2

1

Switch Setting

Special NotesSW4

Page 14

3–4 Installation and Wiring

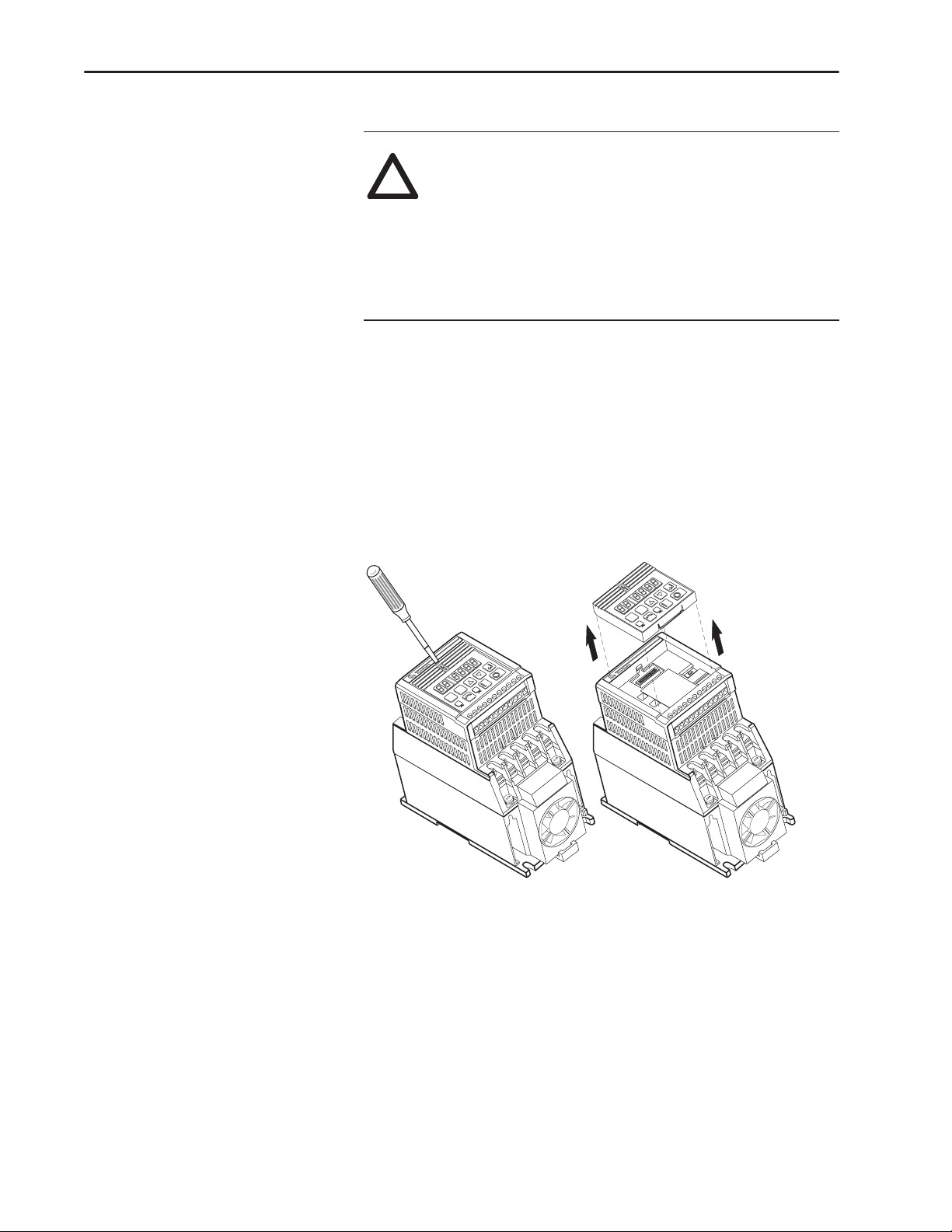

Module Installation/Removal

ATTENTION: The drive contains high voltage capacitors

!

which take time to discharge after removalof mains supply.

Before installing or removing a keypad/module, ensure isolation of mains supply from line inputs L1, L2, L3 (R, S,

T). Waitthe recommended amount of time forthe capacitors

to discharge to safe voltage levels (refer to the 160 User

Manual for recommended time). Failure to do so mayresult

in personal injury or death.

Keypad or Ready/Fault Panel Removal

Before installing the RS1 Module, it may be necessary to remove a

previously installed Program Keypad Module or Ready/Fault panel.

1. Verify that all power to the drive is removed.

2. Insert a small screwdriver into slot, pry back and pivot module

out. Avoid bending or twisting the contact pins located under the

module.

Figure 3.2

Removing Program Keypad Module

Program Keypad Module

(or Ready/Fault Panel)

50 | 60

1 2 3 4 5 6 7 8 9 10 11

+

–

DC

T3

W

T2

V

T1

U

DC

SEL

ESC

1 2 3 4 5 6 7 8 9 10 11

T2

T1

U

SEL

ESC

+

DC

–

DC

T3

W

V

Installing the RS1 Module

After setting the DIP switches, install the RS1 Module in the drive by

following these steps:

1. Verify that all power to the drive is removed.

2. Verify that the latch is up (see Figure 3.3). Insert the module,

ensuring that the pins on the back of the module line up with the

drive connector/expansion port.

3. Press the module down until it is fully seated (sides are flush with

the top surface of the drive).

4. Press the latch down until it snaps into place.

Page 15

Installation and Wiring 3–5

Figure 3.3

Communication Module Installation

RS232

Serial Comm

READY

FAULT

COMM

Latch must be in this position

before installation. Once installed,

push the latch down until it locks

into place.

1 2 3 4 5 6 7 8 9 10 11

+

–

DC

T3

W

T2

V

T1

U

DC

Module should be flush

with top surface of drive

Removing the RS1 Module

If you need to reconfigure the RS1 Module DIP switches, you must

remove the module from the drive.

1. Verify that all power to the drive is removed. Review Attention

statement on page 3–4.

2. Disconnect the cable/connector from the module (if present).

3. Press in on the module’s latch and then push away and up.

4. Grasp the module and pull straight up. Avoid bending or twisting

the contact pins located underneath the center portion of the

module.

Figure 3.4

Removing the Communication Module

RS232

Serial Comm

READY

FAULT

COMM

1 2 3 4 5 6 7 8 9 10 11

T1

+

DC

–

DC

T3

W

T2

V

U

Page 16

3–6 Installation and Wiring

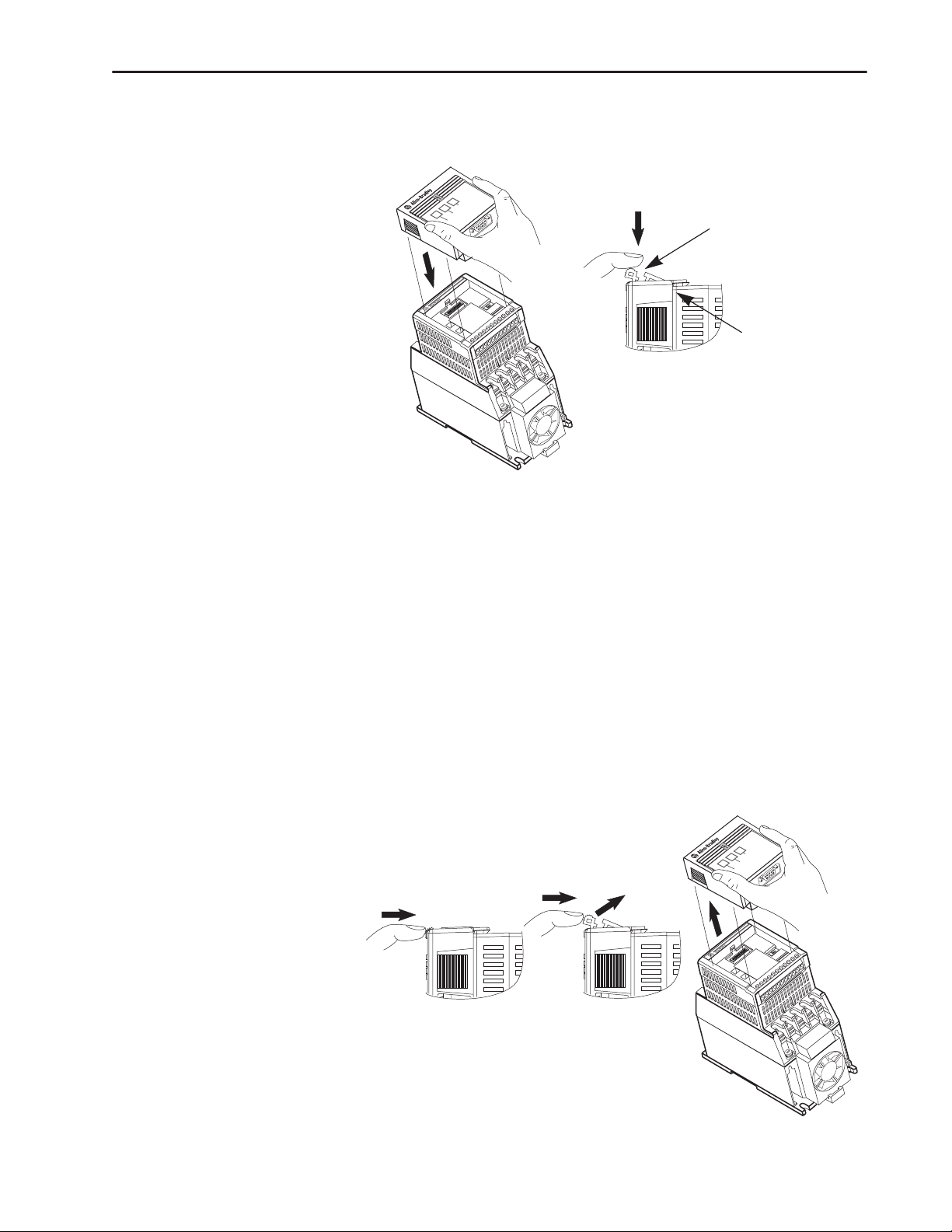

Wiring the Connector

The examples below can be used as a guide when wiring.

Important:

Keepcommunication wiring awayfrom high noisesources

such as motor cables.

Figure 3.5

Wiring the RS1 Connector

RS232

Serial Comm

CAT

160-RS1

Pin 9

SER

MADE IN U.S.A.

READY

FAULT

COMM

Pin 1

9 Pin, Female D-Shell Connector

Personal Computer Serial Connections

RS232

Serial Comm

READY

FAULT

COMM

N.C.

N.C.

N.C.

N.C.

Adapter Cable to MicroLogix Serial Communications Cable

RS232

Serial Comm

READY

FAULT

COMM

N.C.

N.C.

1761-CBL-PM02

Adapter Cable

N.C.

N.C.

RS1 Module

9 Pin, Male

COM

TX

RX

N.C.

COM

RS1 Module

9 Pin, Male

COM

TX

RX

N.C.

COM

1

, D-Shell Connector

1

6

2

7

33

8

4

9

5

1

, D-Shell Connector

1

6

2

7

33

8

4

9

5

PC RS-232 Port

9 Pin, Female1, D-Shell Connector

5

COM

9

4

8

7

2

6

1

DTR

TX

RX

DCD

RI

CTS

RTS

DSR

to A-B Cable 1761-CBL-PM02

9 Pin, Male1, D-Shell Connector

1

N.C.

6

2

7

8

4

9

5

TX

RX

N.C.

COM

N.C.

N.C.

N.C.

N.C.

1

Gender specified refers to the cable connectors

Refer to the MicroLogix 1000 User Manual,

publication 1761-6.3 for further details

Page 17

Figure 3.5

Wiring the RS1 Connector

SLC 500 Port 1 Serial Communications

Installation and Wiring 3–7

- continued

RS1 Module

9 Pin, Male

RS232

Serial Comm

READY

FAULT

COMM

N.C.

N.C.

N.C.

N.C.

1

, D-Shell Connector

COM

COM

1

2

TX

33

RX

4

N.C.

5

6

7

8

9

SLC RS-232 Port

9 Pin, Female1, D-Shell Connector

5

COM

9

4

8

7

2

6

1

DTR

TX

RX

DCD

N.C.

CTS

RTS

DSR

1761-NET-AIC+ Connections

RS1 Module

1

9 Pin, Male

RS232

Serial Comm

READY

FAULT

COMM

N.C.

N.C.

N.C.

N.C.

, D-Shell Connector

COM

COM

1

2

TX

33

RX

4

N.C.

5

6

7

8

9

AIC+ RS-232 Port 1

9 Pin, Female1, D-Shell Connector

5

COM

9

4

8

7

2

6

1

N.C.

TX

RX

DCD

N.C.

N.C.

N.C.

®

Channel 0 Serial Communications

PLC-5

RS1 Module

9 Pin, Male

RS232

Serial Comm

READY

FAULT

COMM

N.C.

N.C.

N.C.

N.C.

1

, D-Shell Connector

TX

RX

N.C.

1

2

3

4

5

COM

COM

6

7

8

9

to Channel 0

1

Gender specified refers to the cable connectors

PLC RS-232 Port

25 Pin, Male

1

, D-Shell Connector

1

C. GND

14

2

TXD

15

3

RXD

16

4

RTS

17

5

CTS

18

6

DER

19

7

SG. GND

20

8

DCD

21

9

RES

22

10

N.C.

23

11

RES

24

12

RES

25

13

N.C.

N.C.

RES

N.C.

RES

RES

N.C.

DTR

RES

N.C.

N.C.

RES

RES

Page 18

3–8 Installation and Wiring

Connecting the Communication

Cable to the Module

Follow these steps to connect your module.

1. Verify that the cable/connector is correctly wired (See Figure

3.5).

2. Locate the D-shell connector at the base of the RS1 Module.

3. Plug cable/connector into the RS1 D-shell connector and secure.

Page 19

Chapter

Modes of Operation

Chapter 4 contains the following information:

• Powering up the drive with the RS1 Module installed.

• The modes of operation and LED indications.

4

Powering Up the Drive

LED Indicators

After you have installed the RS1 Module, apply power to the drive

and to the connected device. The READY LED should illuminate. If

it does not, refer to Chapter 9, Troubleshooting.

The RS1 Module has three LEDs (see figure below) which provide

module status.

READY LED

FAULT LED

COMM LED

RS232

Serial Comm

READY

FAULT

COMM

The LEDs are defined as follows:

• COMM – The COMM LED has four possible states:

Green (solid) The cable is connected (both ends) and module is ready to

communicate.

Green (flashing) The module is on-line and communicating.

Red (solid) Connection was lost or application timed out.

Red (flashing) Device is transmitting & receiving data but application has timed out.

•FAULT – This LED tracks the fault status of the 160 Drive.

When no faults are present, the LED will be off. The LED will

illuminate (red) if a drive fault occurs.

• READY – The Ready LED will illuminate (green) whenever the

module is connected to the drive and power is applied.

Page 20

4–2 Modes of Operation

Modes of Operation

The RS1 Module has three modes of operation.

• Power-up mode

• Run mode

• Error mode

Power-up Mode

The following sequence of operation occurs:

1. During power-up, the READY LED illuminates.

2. The module reads and stores the DIP switch settings.

If the power-up sequence is successful, the module enters the run

mode and the COMM LED flashes green or turns solid green.

If the power-up sequence fails, the COMM LED will go to solid red

and the module will enter the Error Mode. See the Error Mode

description in this section.

Run Mode

After a successful power-up, the RS1 Module enters the run mode

and operates as a slave device to a master device. In run mode, the

module:

• Accepts and responds to messages from the master on the

network.

• Monitors cable integrity.

If an error is detected, the module enters error mode (see below).

Error Mode

If the module detects an error, the COMM LED flashes red or turns

solid red. Refer to Chapter 9 for details on how to recover from an

error.

Page 21

Chapter

RS1 Data Table Interface

This chapter provides you with the following information:

• Supported PCCC commands of the RS1 Module.

• RS1 Module Data Table Structure.

5

Supported PCCC Command

List

Data Table Structure

The RS1 Module communicates over RS-232 using the

Allen-Bradley DF1 protocol. The DF1 protocol uses PCCC

(Programmable Controller Communication Commands) to determine

the data format. PCCC describes the action of the message (set or get)

and the location of the data involved. For further PCCC information,

refer to DF1 Protocol and Command Set Reference Manual,

publication 1770-6.5.16.

The RS1 Module responds to the PCCC types shown in the following

table.

Table 5.A

PCCC Types

CMD Code FNC Code Command Name

0x06 0x03 Identify Host and some Status

0x0F 0x67 Typed Write (Logical ASCII Addressing only)

0x0F 0x68 Typed Read (Logical ASCII Addressing only)

0x0F 0xA2 Protected Type Logical Read with 3 Address Fields

0x0F 0xAA Protected Type Logical Write with 3 Address Fields

0x0F 0xA1 Protected Type Logical Read with 2 Address Fields

0x0F 0xA9 Protected Type Logical Write with 2 Address Fields

The RS1 Module maintains a data table that allows DF1 devices (such

as an SLC 500 or MicroLogix 1000) to set or request data using

standard PCCC. The data table in the RS1 Module contains:

• Drive parameter information

• RS1 parameter information

• Logic command & status data

• Speed command & status data

• Communication status information.

The data table is formatted as integer files and follows the form

shown on the next page.

Page 22

5–2 RS1 Data Table Interface

Table 5.B

Data Table Format

Parameter Number File Address Description

None N10:0 Total number of drive & RS1 parameters (R/W -

Parameters 1-1xx N10:1 - N10:1xx Drive parameter value read or write. 160 drive

None N13:0 Total number of RS1 parameters (R/W - values only).

RS1 Parameters

1-xx

None N30:0 Total number of drive parameters (Read Only - Full/

Parameters 1-1xx N30:1 - N30:1xx Read Full/All Info for drive parameters. 160 drive

None N33:0 Total number of RS1 parameters (Read Only - Full/

RS1 Parameters

1-xx

None N41:0 Logic Command/Status – Writing sends a logic

None N41:1 Reference/Feedback – Writing sends a speed

111 N42:0 Number of ENQs to transmit before retrying

112 N42:1 Number of NAKs received before message is

113 N42:2 Message timeout

114 N42:3 Application timeout.

N13:1 - N13:xx Read/write value for RS1 parameters 1-xx.

N33:1 - N33:xx Read Full/All Info for RS1 parameters 1-xx.

values only).

parameters 1-99 and RS1 parameters 100-1xx.

All information).

parameters 1-99 and RS1 parameters 100-1xx.

All information).

command to drive. Reading supplies logic status.

command to drive. Reading supplies speed

feedback from drive.

message.

canceled.

The “File Address” section of the data table is divided into eight

areas, each having a different purpose.

1. Parameter Value Read or Write (N10). Reading data from files

in this area will cause the module to read parameter values from

the device and send those values as the response to the read

message. Writing data to files in this area will cause the module

to write that data into device parameters.

2. RS1 Parameter Value Read or Write (N13). Reading data from

files in this area will cause the module to read parameter values

from the RS1 and send those values as the response to the read

message. Writing to N13 will cause changes to RS1 parameters.

3. Parameter Read Full (N30). This area is read-only. When read,

the data returned consists of 20 words of information about each

parameter including scaling, parameter text, units text, minimum,

maximum, and default values. When reading this area, set the

number of elements to twenty times the number of parameters to

be read.

Refer to table on next page.

Page 23

RS1 Data Table Interface 5–3

Parameter Read Full Response Format

Data Word Description Character

1 Parameter Value or Status Word

2 Descriptor

3 Multiply Value

4 Divide Value

5 Base Value

6 Offset Value

7 Parameter Text 2 1

8 Parameter Text 4 3

9 Parameter Text 6 5

10 Parameter Text 8 7

11 Parameter Text 10 9

12 Parameter Text 12 11

13 Parameter Text 14 13

14 Parameter Text 16 15

15 File, Group, Element

16 Minimum Value

17 Maximum Value

18 Default Value

19 Unit Text 2 1

20 Unit Text 4 3

4. Logic Command (N41:0). Writing sends a logic command to the drive. The format is:

Logic Bits

Command Description15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

X Stop 1 = Stop, 0 = Not Stop

X Start 1 = Start, 0 = Not Start

X N/A Reserved

X Clear Faults 1 = Clear Faults, 0 = Not Clear Faults

X X Direction 00 = No Command 10 = Reverse Command

X X N/A Reserved

X X X X N/A Reserved

X X X Reference

X N/A Reserved

1

Presets 0, 1 & 2 are not available when commanding over a network.

Presets 3, 6 & 7 are only available with Preset Speed drives that are commanded over a network.

Presets 4 & 5 are always available when commanding over a network.

Series A & B Analog Signal Follower drives have no presets.

Select

1

01 = Forward Command 11 = Hold Direction Command.

000 = No Command 011 = Preset 3 110 = Preset 6

001 = TB3 Control 100 = Preset 4 111 = Preset 7

010 = Network Control 101 = Preset 5

5. Logic Status (N41:0). Reading supplies logic status. Data is formatted as follows:

Logic Bits

Command Description15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

X Enabled 1 = Enabled, 0 = Not Enabled

X Running 1 = Running, 0 = Not Running

X Command Direction 1 = Forward, 0 = Reverse

X Rotating Direction 1 = Forward, 0 = Reverse

X Accel 1 = Accelerating, 0 = Not Accelerating

X Decel 1 = Decelerating, 0 = Not Decelerating

X N/A Reserved

X Fault 1 = Faulted, 0 = Not Faulted

X At Speed 1 = At Speed, 0 = Not At Speed

X X X Local 000 = TB3 Control, 001 = Network Control

X X X X Frequency Source 0000 = Preset 0 0100 = Preset 4 1000 = TB3

0001 = Preset 1 0101 = Preset 5 1001 = Network

0010 = Preset 2 0110 = Preset 6 1010 = Not Defined

0011 = Preset 3 0111 = Preset 7 1111 = Not Defined

Page 24

5–4 RS1 Data Table Interface

6. Reference Command (N41:1) Writing sends a speed reference

to the 160 drive. This is a scaled speed reference from 0 to 32767,

where 0 = 0 Hz and 32767 = P33 - [Maximum Frequency].

7. Feedback Command (N41:1) Reading supplies speed feedback

from the drive. This is the actual drive speed scaled from 0 to

32767, where 0 = 0 Hz and 32767 = P33 - [Maximum

Frequency].

8. RS1 Module Parameters (N42). This area contains information

about the communication configuration.

• Number of ENQ's (N42:0). The number of ENQ's sent by

the module before giving up on receiving ACK or NAK.

• Number of NAK's (N42:1). The number of times the module

will resend a message if the response is always NAK.

• Message Timeout (N42:2). The number of milliseconds the

module will wait before sending an ENQ.

• Application Timeout (N42:3). The number of seconds the

module will wait between messages before faulting the 160

drive.

Page 25

Chapter

6

Parameter Descriptions

This chapter provides a listing and description of the RS1 Parameters.

Important:

RS1 Parameters

The RS1 Module contains a set of parameters that are used to define

how the module will interact with the network. These parameters may

be used to set the module’s baud rate, protocol, etc. Parameters may

also be read to attain status from the module.

Parameter Number

Drive

(N10:, N30:)

101 1 Read/Write [Node Address]

102 2 Read Only [DF1 Adapter Ver]

103 3 Read/Write [Fault Mode]

104 4 Read Only [Active Protocol]

105 5 Read Only [DIP BAUD Rate]

106 6 Read Only [DIP Checksum]

107 7 Read Only [DIP Protocol]

108 8 Read/Write [EPROM Protocol]

109 9 Read/Write [EPROM Checksum]

RS1

(N13:, N33:)

Access [Parameter Name] and Description

Address that the RS1 Module will respond to.

Drive power must be cycled before changes will take affect.

Firmware Version of the RS1 Module.

Enables forcing a drive fault for communication errors.

0 = Fault Drive Enabled

1 = Fault Drive Disabled

The current communication protocol that the RS1 is using.

0 = DF1 Point-to-Point

1 = DF1 Multi-drop

2 = Used by Rockwell Automation Field Service Personnel

Selected baud rate from DIP switches SW1-SW2.

0 = 9600 Baud

1 = 2400 Baud

2 = 1200 Baud

3 = EPROM Mode

Current checksum switch setting (selected by SW4).

BCC = 0 (OFF)

CRC = 1 (ON)

Current protocol selected by SW3.

0 = DF1 Point-to-Point

1 = DF1 Multi-drop

The communications protocol used when SW1 & SW2 are set to “On”

(EPROM Mode).

0 = DF1 Point-to-Point

1 = DF1 Multi-drop

Drive power must be cycled before changes will take affect.

The checksum mode used when SW1 & SW2 are set to “On” (EPROM

Mode).

0 = BCC

1 = CRC

Drive power must be cycled before changes will take affect.

Refer to your 160 User Manual for drive parameter

descriptions.

Min./Max.

Values Default

0 to 254 1

– None

0 to 1 0

0 to 2 0

0 to 3 0

0 to 1 0

0 to 1 0

0 to 1 0

0 to 1 0

Page 26

6–2 Parameter Descriptions

Parameter Number

Drive

(N10:, N30:)

RS1

(N13:, N33:)

Access [Parameter Name] and Description

110 10 Read/Write [EPROM BAUD]

The baud rate used when SW1 & SW2 are set to “On” (EPROM Mode).

1 = 1200 Baud

2 = 2400 Baud

3 = 4800 Baud

4 = 9600 Baud

Drive power must be cycled before changes will take affect.

111 11 Read/Write [Max ENQs]

The number of ENQs sent while waiting for a ACK or NAK.

112 12 Read/Write [Max NAKs]

Number of times module resends a message if response is NAK.

113 13 Read/Write [Message Timeout]

Amount of time (milliseconds) RS1 Module waits before sending an ENQ.

114 14 Read/Write [Comm App Timeout]

When logic command/status and reference/feedback messaging is active,

length of time in seconds from last DF1 message before faulting the drive.

115 15 Read [Packets Sent]

Number of DF1 packets sent.

116 16 Read [Packets Received]

Number of DF1 packets received.

117 17 Read [Undelivered Msgs]

Number of undelivered messages.

118 18 Read [ENQs Sent]

Number of ENQs sent.

119 19 Read [ENQs Received]

Number of ENQs received.

120 20 Read [NAKs Received]

Number of NAKs received.

121 21 Read [Bad Packets Rcvd]

Number of bad packets received (NAKed).

122 22 Read [Duplicate Packet]

Number of duplicate packets received.

123 23 Read [Out Memory NAKs]

Number of out of memory NAKs (messages coming faster than they can

be processed).

124 24 Read [AppTimeout Cnt]

Number of application timeouts.

125 25 Read/Write [Overrun Errors]

Action of the RS1 Module on a data rx overrun.

0 = Ignore

1 = Clear UART buffer

126 26 Read Only [Overrun Err Cnt]

Data Overrun Count.

127 27 Read/Write [Force Fault]

Setting this parameter will fault the drive.

0 = No Action

1 = Fault the Drive

128 28 Read/Write [Reset RS1]

Setting this parameter to 1 will only reset the RS1 Module parameters to

factory settings.

Important: Drive parameters can be reset using P56 - [Reset Functions].

0 = No Action

1 = Resets RS1 parameters to defaults

129 29 Read/Write [Clr Comm Stats]

Setting this parameter to 1 will clear all diagnostic counters.

0 = No Action

1 = Clear all DF1 diagnostic counters (P115-124, 126)

Min./Max.

Values Default

1 to 4 9600 Baud

0 to 255 3

0 to 255 3

100 to 65535 100 Milliseconds

0 to 65535 5 Seconds

0 to 65535 0

0 to 65535 0

0 to 65535 0

0 to 65535 0

0 to 65535 0

0 to 65535 0

0 to 65535 0

0 to 65535 0

0 to 65535 0

0 to 65535 0

0 to 1 0

0 to 65535 0

0 to 1 0

0 to 1 0

0 to 1 0

Page 27

Parameter Number

Drive

(N10:, N30:)

RS1

(N13:, N33:)

Access [Parameter Name] and Description

130 30 Read [DIP Switches]

Displays the current DIP switch settings.

Bit

0 0 9600 (Default) SW1,

0 1 2400

1 0 1200

1 1 EPROM Mode

0 DF1 Point-to-Point (Default) SW3

1 DF1 Multi-Drop

0

1

131 31 Read [Actual Speed]

Returns speed feedback from the drive. This is the actual drive speed

scaled from 0 to 32767, where 0 = 0 Hz and 32767 = P33 - [Maximum

Frequency].

132 32 Read [Logic Status]

Returns logic status (N41:0). Refer to page 5–3 for data format.

133 33 Read/Write [Logic Mask]

This parameter determines the source of the drive control logic.

A value of “1” corresponds to terminal block control, and any drive input

mode (P46 - [Input Mode]) value

A value of “2” corresponds to RS1 Module logic control. The input mode

value is “2” or “6.”

If the Logic Mask value is changed from “1” to “2,” the terminal block logic

control is masked out by the RS1 Module. The module does this by

changing the Input Mode to the last previously active network mode, “2” or

“6” (if a network mode has not been active since drive power was applied,

it is set to “2”).

If the Logic Mask value is changed from “2” to “1,” the RS1 logic control is

masked out by the RS1 Module. The module does this by changing the

Input Mode to the last previously active non-network mode (if a nonnetwork mode has not been active since drive power was applied, it is set

to “0”).

IMPORTANT: Power must be cycled or P56-[Reset Functions] must be

set to “2” for this change to take affect.

Description Switch3210

SW2

BCC (Default) SW4

CRC

except “2” or “6.”

Parameter Descriptions 6–3

Min./Max.

Values Default

0 to 0xF

0000

0 to 15

0 to 32767 0

0 to 65535 0

1 to 2 1

Page 28

6–4 Parameter Descriptions

End of Chapter 6

Page 29

Chapter

7

Using the RS1 Module with

DriveExplorer™ Software

The purpose of this chapter is to provide an overview of the steps

needed to use the Bulletin 9306 DriveExplorer software program with

the RS1 Module and 160 Drive. DriveExplorer is a Windows® 95/

Windows NT®/Windows® CE based software program that allows

you to upload/download parameter sets from a computer to the 160

Drive using the RS1 Module as an interface. For detailed

DriveExplorer information, refer to the DriveExplorer User Manual,

publication 9306-5.0.

This chapter will guide through . . .

• Configuring the communication port of the computer and

connection to the RS1 Module.

• Downloading a parameter set to the 160 Drive.

• Uploading the 160 parameter set.

• Saving and retrieving parameter sets.

Required Items

Example Network

Before continuing with this chapter, you should have read the

DriveExplorer User Manual. Understanding the concepts in this

manual will be important in completing this chapter.

The following items will be required:

• A personal computer with the DriveExplorer software installed.

• A 160 SSC Drive and RS1 Communication Module.

• A standard straight-thru serial cable

The following setup is used in this chapter. Refer to Chapter 3 for

connection details.

RS232

Serial Comm

READY

FAULT

COMM

Page 30

7–2 Using the RS1 Module with DriveExplorer™ Software

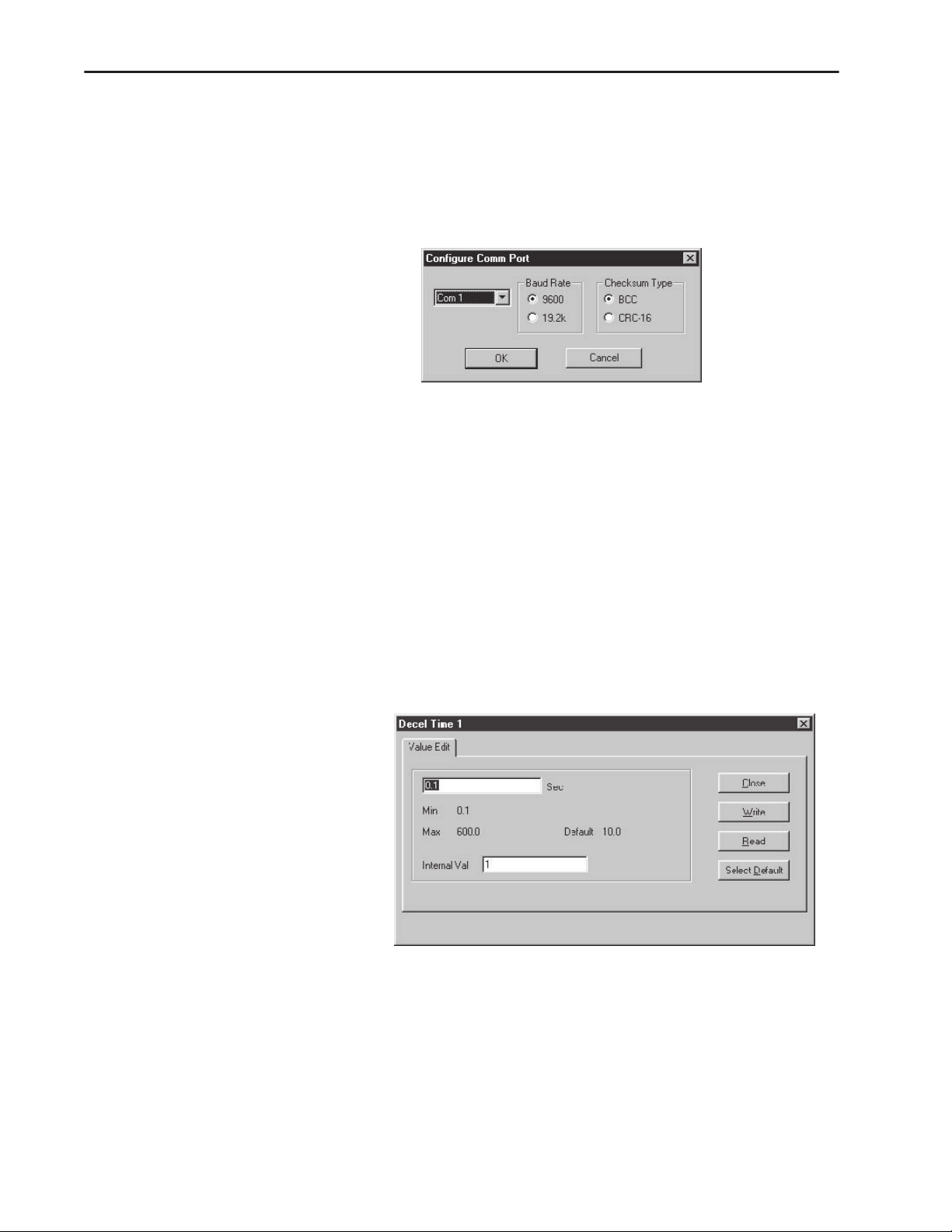

Setting Baud Rates and

Configuring the

Communications Port

Monitoring and Editing

Parameters

1. Before proceeding, the RS1 Module baud rate should be set as

desired and the module installed as explained in Chapter 3.

2. The PC serial port must now be configured using DriveExplorer.

A. Start DriveExplorer.

B. The Configure Comm Port window appears.

C. Select the communications port that your computer is using.

Next select the correct Baud Rate and Checksum Type – then

choose OK.

D. From the Explore menu, select

appear in the left pane of the main DriveExplorer window

under “Devices.”

Connect -> Local

. A node will

Monitoring Parameters

To monitor parameters, double-click the drive in the left pane of the

main DriveExplorer window – drive parameters appear on the right.

Editing Parameters

1. Double-click the parameter name to display the edit dialog box.

Important:

2. Edit the parameter as necessary. To retrieve the current parameter

value, select Read. To retrieve the factory default parameter value

choose Select Default.

3. Selecting Write updates the parameter value. Choose Close.

Important:

The edit dialogbox will varybased on the type of value

that you are editing.

In some cases the drive must be reset or power cycled

before changes take effect. Refer to your user manual.

Page 31

Using the RS1 Module with DriveExplorer™ Software 7–3

Uploading Editable Parameters

Downloading Parameters

It is possible to upload editable parameters and their values (in

internal units) from the drive and store them in a file. There are three

upload options: upload all parameters, upload selected parameters,

and upload links.

1. If you want to upload selected parameters, you must select them

in the right pane of DriveExplorer.

2. Select

3. Select All Parameters or Selected Parameters. Choose OK to

4. In the Save in box, navigate to where you want to save the

5. In the File Name box, type a name.

6. In the Save As type box, select DE Parameter Data Files (*.dep)

7. Choose Save to save the file.

To transfer values saved in a parameters (*.dep) file to the drive, you

must download the file.

Actions -> Upload and Save

dialog box.

upload the parameters and display the Save As dialog box.

parameter file.

for parameters.

to display the Save Parameters

Important:

1. To download the file – select

A prompt appears to warn you that setup values may change.

2. Select Ye s to display the Open dialog box.

3. Select the desired file with a .dep extension.

4. Choose Open to download the values in the file.

Do not download a fileuploaded from onedrive(or device)

to a different drive or device.

Actions -> Download -> Archive File

.

Page 32

7–4 Using the RS1 Module with DriveExplorer™ Software

End of Chapter 7

Page 33

Chapter

8

Using the RS1 Module with a

Programmable Controller

This chapter provides an overview of the steps needed to use the RS1

Module with a MicroLogix 1000 (or other Allen-Bradley

programmable controllers). The programmable controller can send

control messages to the RS1 Module and receive status messages

back. The device also allows a ladder logic program to configure and

read parameters from the 160 Drive.

This chapter contains the following information:

• How to setup the RS1 Module with a programmable controller.

• A sample ladder logic program to control the 160 Drive.

• A description of reading parameters using the Message (MSG)

Command.

• A sample ladder logic program to read parameters.

The MicroLogix 1000 Programmable Controller was used with

RSLogix 500™ software for the examples shown in this chapter – the

concepts demonstrated apply to other programmable controllers as

well, including the SLC 500 and PLC-5.

Required Tools

Example Network

Before continuing, the user should have read and understood:

• MicroLogic 1000 Programmable Controller User Manual,

Publication 1761-6.3 (or appropriate controller User Manual).

• SLC 500 and MicroLogix 1000 Instruction Set Reference Manual,

publication 1747-6.15.

The following tools will be needed to complete this chapter:

• 160 Drive equipped with an RS1 Communication Module.

• MicroLogix 1000 Programmable Controller.

160 Drive with RS1

MicroLogix 1000

RS232

Serial Comm

READY

FAULT

COMM

Page 34

8–2 Using the RS1 Module with a Programmable Controller

Setting the Drive to Enable

Network Control

Setting the Baud Rate and

Checksum Mode

The 160 drive must be configured to accept logic and speed

commands from the network. This can be done by configuring two of

the 160 parameters:

1. Set P46 - [Input Mode] to a value of “2.” This will configure the

drive to accept the logic commands from the network.

2. Set P59 - [Frequency Select] to “1.” This will configure the drive

to accept speed commands from the network.

Changing the above parameters can be done with the 160 Keypad

Module or configuration software such as the DriveExplorer.

Important:

The baud rate and checksum mode on the RS1 Module should be

configured to the desired setting for the network (and other devices).

After configuration, install the RS1 Module into the 160 Drive as

explained in Chapter 3. Note that the MicroLogix uses CRC as the

checksum mode.

For a new Input Mode to take affect, drive power must be

cycled.

Connecting the Drive to the

Programmable Controller

Controlling the Drive

The RS1 Module is connected to the programmable controller

through the 9-pin D-shell connector. Since each programmable

controller may have different wiring requirements, Figure 3.5 should

be referenced as a guide.

Important:

Controlling the 160 Drive from a programmable controller is

accomplished using Message Commands to communicate through the

RS1 Module to the drive. To send a Start or Stop command to the

drive, the Message Command (MSG) is set up to write to N41:0. To

read the drive status, the Message Command is set up to read from

N41:0. Refer to Chapter 6 for the logic command and status format.

Drive speed can be controlled or read in the same manner by

accessing N41:1.

The communication port of the programmable controller

may also be used to program the controller, thus the user

may haveto disconnect the cable going to the RS1 Module

before programming the controller.

Page 35

Using the RS1 Module with a Programmable Controller 8–3

Program the Ladder

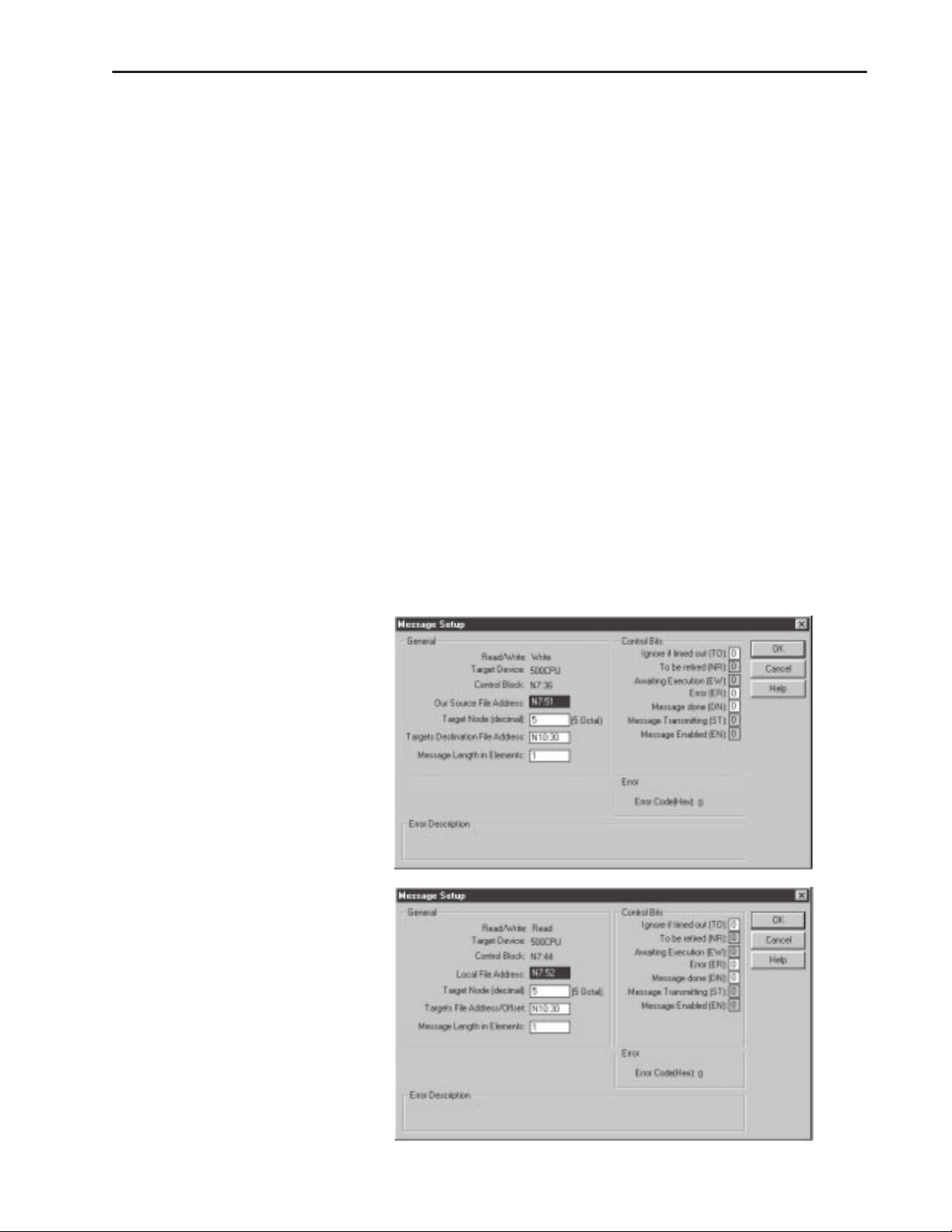

The example ladder program in Figure 8.2 demonstrates writing a

Logic Command to the drive and reading the Logic Status from the

drive.

In the following example ladder program, B3:0/0 is set every 2

seconds. This enables a Logic Command write to be done followed

by the Logic Status read. The data for the Logic Command is stored

in N7:8 of the MicroLogix and is written to location N41:0 of the RS1

Module. For the Logic Status, data from the RS1 Module at location

N41:0 is read by the MicroLogix and stored in N7:9. This ladder

program could be modified to read and write speed commands for the

160 Drive by changing the read and write location in the RS1 Module

from N41:0 to N41:1.

Figure 8.1

MSG Commands Setup – Logic Command/Status

Page 36

8–4 Using the RS1 Module with a Programmable Controller

Figure 8.2

Writing Logic Command and Reading Logic Status

LAD 3 - DF 1 LOGIC --- Total Rungs in File = 5

This rung writes the Logic Command - Data in N7:8 is written to the Drive at N41:0

Enable for the Logic

command Write

B3:0

0000

0

MSG

Read/Write Message

Read/Write Write

Target Device 500CPU

Control Block N7:0

Control Block Length 7

Setup Screen

EN

DN

ER

0001

0002

0003

Enable for the Logic

command Write

B3:0

0

This rung reads the Logic Status from the drive - Data from N41:0 is read and placed in N7:9

Enable for Logic

Command Read

B3:0

1

Enable for Logic

Command Read

B3:0

1

Done Bit - Logic

Command Write

N7:0

13

Error Bit - Logic

Command Write

N7:0

12

MSG

Read/Write Message

Read/Write Read

Target Device 500CPU

Control Block N7:10

Control Block Length 7

Done Bit - Logic

Command Read

N7:10

13

Error Bit - Logic

Command Read

N7:10

12

Enable for the Logic

command Write

B3:0

U

0

Enable for Logic

Command Read

B3:0

L

1

EN

DN

ER

Setup Screen

Enable for Logic

Command Read

B3:0

U

1

0004

Reading and Writing

Parameters

END

Reading or writing parameters can be accomplished using message

commands to communicate through the RS1 Module to the drive. The

drive parameters are accessed at location N10:XX, with the XX being

the parameter number to read or write (i.e. N10:30 accesses

parameter P30 - [Accel Time]).

Page 37

Using the RS1 Module with a Programmable Controller 8–5

You can read or write RS1 Module parameters through location N10

or N13. For location N10, the RS1 parameters start at N10:101, thus

accessing location N10:101 reads or writes RS1 parameter P1 -

[Node Address]. For location N13, the RS1 parameters start at N13:1

(N13:1 also accesses RS1 parameter P1 - [Node Address]).

Program the Ladder for

Parameter Reads and Writes

The example ladder program in Figure 8.4 accomplishes reading and

writing drive parameters.

In the following ladder program, B3:1/4 is set when requesting a

parameter write. When no other Message Commands are enabled,

B3:0/4 will be set, starting the parameter write. For the parameter

write, data from N7:51 is written by the MicroLogix to location

N10:30 (P30 - [Accel Time]) of the RS1 Module. Bits B3:0/4 and

B3:1/4 are cleared when the Message Command is completed.

B3:1/5 is set when requesting a read of a parameter. When no other

Message Commands are enabled, B3:0/5 will be set, starting the

parameter read. For the parameter read, location N10:30 (P30 -

[Accel Time]) of the RS1 Module is read by the MicroLogix and the

data is placed in N7:52. Bits B3:0/5 and B3:1/5 are cleared when the

Message Command is completed.

Figure 8.3

MSG Commands Setup – Parameter Read/Write

Page 38

8–6 Using the RS1 Module with a Programmable Controller

Figure 8.4

Reading and Writing Drive Parameters

LAD 5 - PARAMETER --- Total Rungs in File = 5

Parameter Write - when it's time to perform a parameter write B3:0.4 and B3:1.4 will be set. Data from N7:51 will written out Channel 0

to the 160 - RS1 module at location N10:30 (parameter 30). To write to a different parameter, change word 5 of the control word (N7:41)

to the new parameter number.

Enable Bit Parameter write

control

B3:0

0000

4

Parameter Write

Request Bit

B3:1

4

Parameter WriteData N7:51 is wrote

to RS1 module N10:30

MSG

Read/Write Message

Read/Write Write

Target Device 500CPU

Control Block N7:36

Control Block Length 7

Setup Screen

EN

DN

ER

0001

0002

0003

Enable Bit Parameter write

control

B3:0

4

Parameter Read - when it's time to perform a parameter read B3:0.5 and B3:1.5 will be set. Data from the RS1 module

N10:30 (parameter 30) will be read through Channel 0 back to the controller and placed in N7:52 . To read a different parameter,

change word 5 of the control word (N7:49) to the new parameter number.

Enable Bit Parameter Read

control

B3:0

5

Enable Bit Parameter Read

control

B3:0

5

Done Bit Parameter Write

N7:36

Error Bit Parameter Write

N7:36

Parameter Read

Request Bit

B3:1

5

Done Bit Parameter Read

N7:44

13

Error Bit Parameter Read

N7:44

12

13

12

MSG

Read/Write Message

Read/Write Read

Target Device 500CPU

Control Block N7:44

Control Block Length 7

Setup Screen

Enable Bit Parameter write

control

B3:0

U

4

Parameter Write

Request Bit

B3:1

U

4

Enable Bit Parameter Read

control

B3:0

U

5

Parameter Read

Request Bit

B3:1

U

5

EN

DN

ER

0004

END

Page 39

Chapter

Troubleshooting

The purpose of this chapter is to help you troubleshoot your RS1

Module.

ATTENTION: Servicing energized industrial control

!

!

equipment can be hazardous. Electrical shock, burns, or unintentional actuation of controlled industrial equipment

may cause death or serious injury. Follow the safety-related

practices of NPFA 70E, Electrical Safety for Employee

Workplaces, when working on or near energizedequipment.

Do not work alone on energized equipment.

ATTENTION: Do not attempt to defeat or override fault

circuits. The cause of a fault indication must be determined

and corrected before attempting operation. Failure to

correct a drive or systemmalfunction may resultin personal

injury and/or equipment damage due to uncontrolled

machine system operation.

9

LED Indicators and

Troubleshooting

The RS1 Status LEDs can help you troubleshoot the module in the

event that problems occur. Refer to the paragraphs that follow for

details.

Status LEDs

Refer to Chapter 4 for

detailed LED descriptions

RS232

Serial Comm

READY

FAULT

COMM

Page 40

9–2 Troubleshooting

READY LED

The green READY LED will illuminate whenever the RS1 Module is

connected to the drive and power is applied.

COMM LED

The COMM LED provides status information on module operations.

Table 9.A shows how to use the LED to detect and correct common

operating problems.

Table 9.A

COMM LED Indications

Color State What It Means: What To Do:

Red Solid Cable disconnected or bad connection. Connect cable/check connections.

Application timed out. Application did not access N41:0

before parameter 114 expired –

verify parameter 114 setting.

Green Solid Cable is connected and module is ready. No action required.

Flashing Device is on-line and communicating. No action required.

FAULT LED

When the FAULT LED is Red, a drive fault is present. Drive fault

codes can be read by accessing drive parameter P07 - [Last Fault].

Refer to Tables 9.B and 9.C for fault descriptions/actions.

Table 9.B

1

160 Drive

Fault Code Fault Indication Description Corrective Action

00 No Fault The drive is currently not faulted. No action required.

03 Power Loss Fault DC Bus voltage remains below 85% nominal on

04 Undervoltage Fault DC Bus voltage fell below the minimum value

05 Overvoltage Fault DC Bus maximum voltage exceeded. Bus overvoltage caused by motor regeneration.

06 Motor Stall Fault Motor has stalled. Motor load is excessive. Longer accel time or reduced load required.

07 Motor Overload Fault Internal electronic overload trip. Excessive

08 Overtemperature Fault Excessive heat detected. Clear blocked or dirty heat sink fins. Check ambient

12 Overcurrent Fault Overcurrent detected in hardware trip circuit. Check short circuit at the drive output or excessive

20 Drive Overload Fault An internal electronic overload trip has

22 Drive Reset Stop input not present. Check stop input at TB3 terminal 8.

32 EPROM Fault EPROM has invalid data. Reset EPROM using P56 - [Reset RS1].

33 Max Retries Fault Drive did not reset fault within the max retries

38 Phase U Fault Phase to ground fault detected between drive

39 Phase V Fault Phase to ground fault detected between drive

power up for longer than 5 seconds.

while the motor was running.

motor load exists.

occurred. The drive is overheating.

specified.

and motor phase U.

and motor phase V.

1

Refer to the

Fault Codes

160 User Manual

Monitor incoming AC line for low voltage or line power

interruption.

Monitor incoming AC line for low voltage or line power

interruption.

Extend the decel time, or install dynamic brake option

or external capacitor module.

Reduce motor load.

temperature. Check for blocked or non-operating fan.

load conditions at the motor.

Clear blocked or dirty heat sink fins. Check ambient

temperature. Check for blocked or non-operating fan.

Repair system fault.

Check wiring between drive and motor. Check motor

for grounded phase.

Check wiring between drive and motor. Check motor

for grounded phase.

for the most current fault code information.

Page 41

Troubleshooting 9–3

Table 9.B (continued)

160 Drive1 Fault Codes

Fault Code Fault Indication Description Corrective Action

40 Phase W Fault Phase to ground fault detected between drive

41 UV Short Fault Excessive current has been detected between

42 UW Short Fault Excessive current has been detected between

43 VW Short Fault Excessive current has been detected between

48 Reprogramming Fault Occurs when reset defaults is performed. Clear fault.

49 Zero Overload Fault Occurs when load requires excessive current at

and motor phase W.

these two drive output terminals.

these two drive output terminals.

these two drive output terminals.

zero hertz.

1

Refer to the

160 User Manual

for the most current fault code information.

Check wiring between drive and motor. Check motor

for grounded phase.

Check the motor and external wiring to the drive

output terminals for a shorted condition.

Check the motor and external wiring to the drive

output terminals for a shorted condition.

Check the motor and external wiring to the drive

output terminals for a shorted condition.

Reduce motor load and/or motor dwell time at zero

hertz.

Table 9.C

RS1 Fault Codes

Fault Code Fault Indication Description Corrective Action

51 RS1 Module EPROM Fault Module EPROM has invalid data. Reset to factory defaults P128 - [Reset RS1].

52 RS1 Lost I/O Connection Application timed out. Check master for correct operation (i.e., powered up,

55 Force Fault P127 - [Force Fault] was set to “1.” Clear fault.

run mode, etc.).

RS1/DF1 Error Codes

The following error codes could be returned over DF1 (with the

Message Command) when accessing the RS1 Module.

Table 9.D

Error Codes

Message STS EXT STS Problem Problem

All Messages 10h N/A Illegal command or format. The RS1 does not support this command.

F0h 06h Address does not point to anything usable. The address does not exist, or does not point to anything usable

F0h 0Ah Transaction size plus word address is too large. Trying to read/write multiple parameters with one command.

F0h 12h Invalid parameter or data. Data out of range.

F0h 1Eh Data table element protection violation. Write to Read Only parameter.

F0h 1Fh Temporary internal problem. Unable to execute due to temporary internal conditions –

by this command.

Writing one parameter at a time or reading past end of last

parameter is only supported.

Parameter Read Only when drive is running.

Page 42

9–4 Troubleshooting

End of Chapter 9

Page 43

Appendix

Specifications

Electrical

Supply Voltage Supplied by Drive

Power Consumption 1.25 Watts maximum

Environmental

Ambient Temperature

Operating 0 to 50

Storage –40 to 85

Relative Humidity 0 to 95% non-condensing

Vibration 1.0 G Operational

Shock 15.0 G Operational

Altitude 1,000 m (3,300 ft.) without derating

Communications

Baud Rates 1200, 2400, 4800, 9600 BPS

Checksum BCC or CRC

Protocol DF1 Point-to-Point

°

C (32 to 122° F)

°

C (–40 to 185° F)

2.5 G Non-operational

30.0 G Non-operational

DF1 Multi-Drop

A

Mechanical

Dimensions are in Millimeters and (inches)

70.0

(2.76)

RS232

Serial Comm

READY

FAULT

COMM

1

Required for module removal.

2

Module adds this dimension to the overall drive depth.

67.5

(2.68)

17.34

(0.68)

1

21.4

(0.85)

SER

CAT

160-RS1

2

MADE IN U.S.A.

Page 44

A–2 Specifications

End of Appendix A

Page 45

Appendix

RS1 Module Compatibility

The 160-RS1 Module has been tested and found to be compatible

with the following Allen-Bradley products:

• MicroLogix 1000

Protocol Point-to-Point

PCCC Command 0xA1 Protected Type Logical Read with 2 Address Fields

0xA9 Protected Type Logical Write with 2 Address Fields

Hand Shaking None

Cable

Versions Series D, FRN 1.0 or later

• SLC 500

Protocol Point-to-Point/Multi-Drop Master

PCCC Command 0xA2 Protected Type Logical Read with 3 Address Fields

Hand Shaking None

Cable 9 Pin - 9 Pin (

Versions Series B, FRN 7 (OS 4.01) or later

• 1761-NET-AIC+

Protocol Multi-Drop

PCCC Command All

Hand Shaking None

Cable 9 Pin - 9 Pin

Versions Series A

• PLC-5 Enhanced

Protocol Point-to-Point/Multi-Drop Master

PCCC Command 0x67 Typed Write (Logical ASCII Addressing only)

Hand Shaking None

Cable 9 Pin - 25 Pin (

Versions Series C, FRN E or later

• RSLinx™

Protocol Point-to-Point/Multi-Drop

PCCC Command 0xA1 Protected Type Logical Read with 2 Address Fields

Hand Shaking None

Cable PC Cable (

Versions 1.7.62.00 or later

• DriveExplorer

Protocol Point-to-Point

PCCC Command 0x67 Typed Write (Logical ASCII Addressing only)

Hand Shaking None

Cable PC Cable (

Versions 1.01.10 or later

• DriveTools32™

Protocol Point-to-Point

PCCC Command 0x67 Typed Write (Logical ASCII Addressing only)

Hand Shaking None

Cable PC Cable (

Versions 2.01 or later

See Chapter 3 for details

0xAA Protected Type Logical Write with 3 Address Fields

see Chapter 3 for details)

(see Chapter 5 for details)

0x68 Typed Read (Logical ASCII Addressing only)

see Chapter 3 for details)

0xA9 Protected Type Logical Write with 2 Address Fields

see Chapter 3 for details)

0x68 Typed Read (Logical ASCII Addressing only)

see Chapter 3 for details)

0x68 Typed Read (Logical ASCII Addressing only)

see Chapter 3 for details)

B

Page 46

B–2 RS1 Module Compatibility

End of Appendix B

Page 47

Index

B

Baud Rate, Setting, 3–2

BCC Checksum, 3–3

C

Cabling, 3–6

CE Compliance, 3–1

Checksum Mode

Setting, 3–3

CRC Checksum, 3–3

D

Data Table Interface, 5–1

Data Table Structure, 5–1

Defaults, Factory, 6–2

DF1 Error Codes, 9–3

Dimensions, A–1

DIP Switch

Configuration, 3–2

Location, 1–2, 3–2

Downloading Parameters, 7–3

DriveExplorer, 7–1

E

EPROM Mode, 3–2

Error Codes

RS1/DF1, 9–3

Error Mode, 4–2

Logic Command/Status, 5–3

M

Modes of Operation

Error Mode, 4–2

Power-up Reset, 4–2

Run Mode, 4–2

Module Installation, 3–4

P

Parameter Descriptions, 6–1

Parameters

Downloading, 7–3

Monitoring, 7–2

Saving to a file, 7–3

Uploading, 7–3

PCCC Command List, 5–1

Power-up Mode, 4–2

Protocol, Setting, 3–3

Publications

Related, p–ii

Q

Quick Start, 2–1

R

Removal, Module, 3–5

Reset Defaults, 6–2

Run Mode, 4–2

F

Factory Defaults, Resetting, 6–2

Fault Codes

Drive, 9–2

RS1 Module, 9–3

RS1/DF1, 9–3

Fault LEDs, 9–1

I

Installation, 3–1

K

Keypad Removal, 3–4

L

LEDs

Comm, 9–2

Fault, 9–2

Ready, 9–2

S

Saving parameters to a file, 7–3

Specifications

Communications, A–1

Electrical, A–1

Environmental, A–1

Mechanical, A–1

T

Troubleshooting, 9–1

LEDs, 9–1

U

Uploading Parameters, 7–3

Page 48

I–2 Index

Notes

Page 49

Page 50

Publication 0160-5.14 – March, 1999 P/N 189177 (02)

Supersedes October, 1998 Copyright 1999 Rockwell International Corporation. All rights reserved. Printed in USA

Loading...

Loading...