Page 1

DeviceNet™

Communication

Module

Catalog Number 160-DN2

Firmware 3.xxx

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1

available from your local Rockwell Automation Sales Office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc.

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

Shock Hazard labels may be located on or inside the drive to

alert people that dangerous voltage may be present.

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

SSC is a registered trademark of Rockwell Automation, Inc.

Allen-Bradley, ControlLogix, PLC-5, and SLC are trademarks of Rockwell Automation, Inc.

RSLinx, RSLogix, and RSNetWorx for DeviceNet are trademarks of Rockwell Software.

Page 3

Summary of Changes

The information below summarizes the changes made to this manual

since its last release (March, 1999):

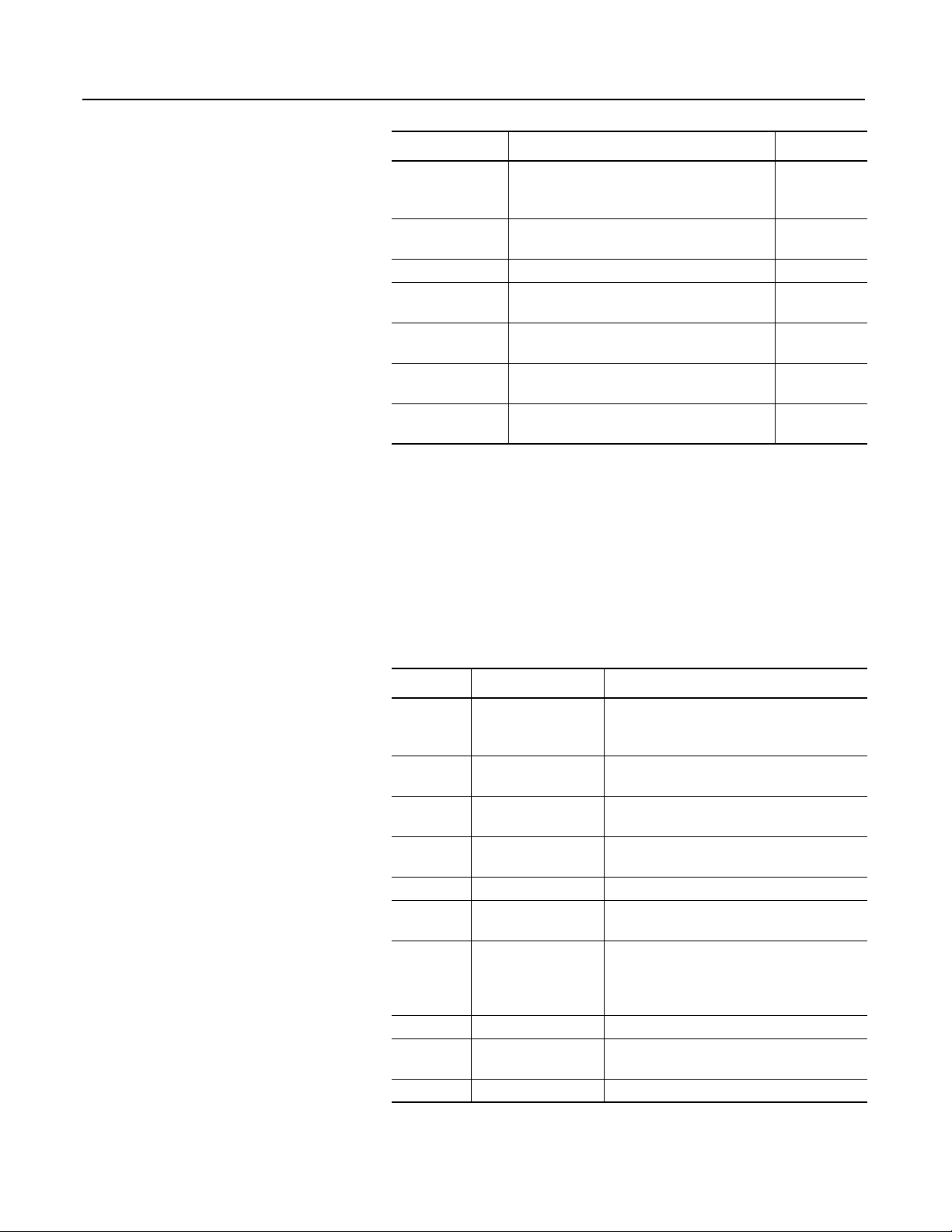

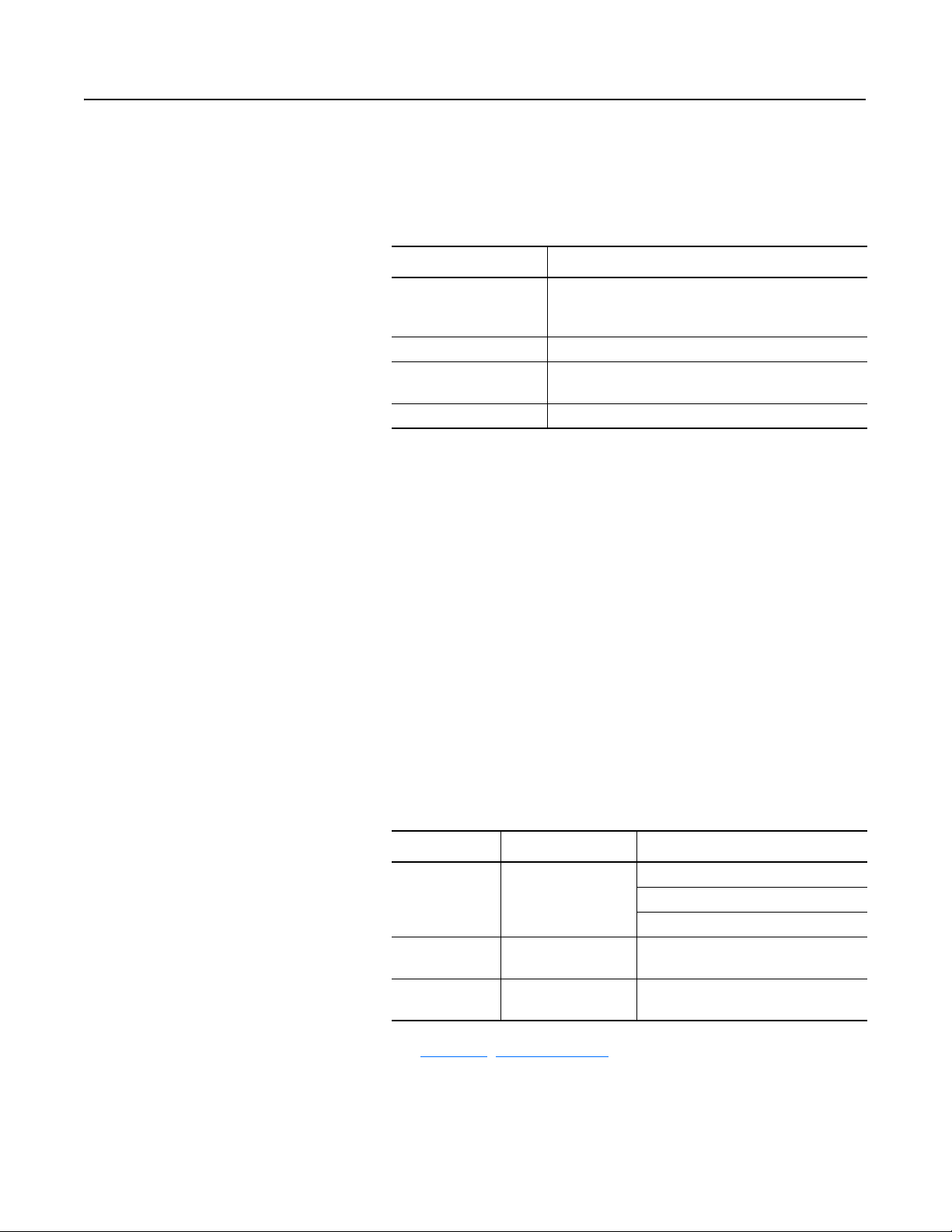

Location Description of Changes

Chapter 3 Added three new sections — Surge-Suppression, Common Mode Noise,

and Output Disconnect — after the Low Voltage Directive 73/23/EEC

Compliance section.

Chapter 5 Added EDS file search screen and removed obsolete Table 6 (EDS files for

Bulletin 160 using a 160-DN2 version 3.000 or later).

Chapter 6 Replaced DeviceNet Manager software references and screens with those

of RSNetWorx for DeviceNet. Added I/O and explicit messaging information

and ladder logic examples for ControlLogix, PLC-5, and SLC controllers.

Chapter 7 In the “Understanding the FAULT LED” section, added Bulletin 160 Fault

Codes 11, 20, 36, and 46 to the table on pages 7-3

Appendix B In section “Class Code 0xB3 — 160 Parameter Table Object” in the

“Instance 1 Attributes” chart on pages B-18

Types for these Attribute IDs:

Attribute ID Parameter Name Data Type

9 Drive Status WORD (was USINT)

10 Drive Type USINT (was UINT)

12 Input Status WORD (was USINT)

15 Preset Status WORD (was USINT)

33 Maximum Freq UINT (was USINT)

35 Base Frequency UINT (was USINT)

39 Skip Frequency UINT (was USINT)

and 7-4.

and B-19, corrected the Data

In section “Class Code 0x04 — Assembly Objects,” subsection “Instance

Data Format: Output Assemblies” on page B-24

Instance 21 in bit 5 and bit 6 columns. Re-arranged numerical order of all

footnotes on this page.

In section “Class Code 0x04 — Assembly Objects,” subsection “Instance

Data Format: Output Assemblies” on page B-25

Instance 101 in bit 0, bit 1, and bit 2 columns. Re-arranged numerical order

of all footnotes on this page.

In section “Class Code 0x04 — Assembly Objects,” subsection

“Configuration Assembly Data Formats,” deleted unnecessary Instance 190

table (pages B-29 through B-34).

, added new footnotes for

, added a new footnote for

Publication 0160-5.18 - June 2003

Page 4

S-2 Summary of Changes

The March 1999 release of the Bulletin 160-DN2 DeviceNet

Communication Module User Manual covers the software

enhancements of Firmware Version 3.xxx and contains new and

updated information.

Bulletin 160-DN2 version 3.xxx

Software Enhancements

Compatibility with Bulletin 160 drives

(Series A, B, and C)

Features and enhancements in the 160-DN2 module that are different

than those in the 160-DN1 module include:

Bulletin 160 (Series A, B, and C) drives can be connected to a

DeviceNet network.

Ability to Create Electronic Data Sheets Configuration tools, such as DeviceNet Manager, can create an

Electronic Data Sheet (EDS file) for the 160 SSC drive and 160-DN2

module.

Added Parameter Object This object describes the parameters in the 160 SSC drive and

160-DN2 module.

Added Parameter Group Object This object describes the parameter groups associated with the

160 SSC drive and 160-DN2 module.

New and Revised Chapters to

this Manual

The bulletin 160-DN2 DeviceNet Communication Module User

Manual, Publication 0160-5.18, is a new manual. It is, however,

similar to the 160 DeviceNet Communication Module User Manual,

Publication 0160-5.5. The main differences can be found in the

following chapters:

Using This Manual Preface

Quick Start for Experienced Users Chapter 2

DeviceNet Parameter Descriptions Chapter 5

Using the 160-DN2 with DeviceNet Scanner Chapter 6

Troubleshooting Chapter 7

DeviceNet Information Appendix B

Summary of Enhancements to

User Manual

Publication 0160-5.18 - June 2003

Refer to the following references in this manual:

Reference Manuals Section P-2

Manual Organization P-3

DeviceNet Compatibility P-4

Replacing a 160-DN1 with a 160-DN2 P-4

Required Tools and Equipment 3-1

DeviceNet Parameter Descriptions Chapter 5

Creating EDS Files replaces Installing EDS Files 6-3

Troubleshooting Updated Chapter 7

Parameter Object B-9

Parameter Group Object B-11

Acknowledge Handler Object B-17

Page 5

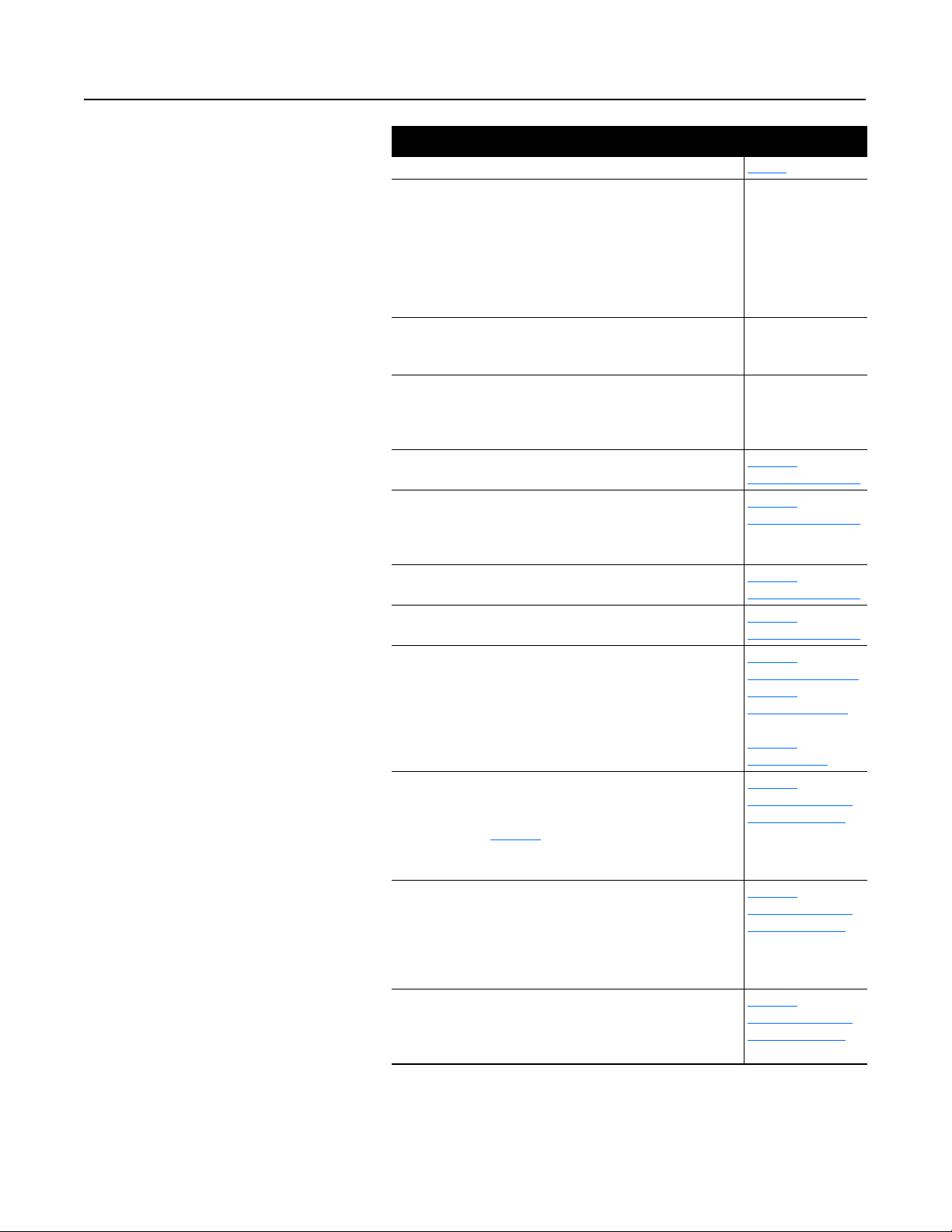

Table of Contents

Preface

Using This Manual Manual Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Who Should Use This Manual?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Product References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Manual Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

DeviceNet Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Replacing a 160-DN1 with a 160-DN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Rockwell Automation Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Chapter 1

Product Overview Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

LEDs and DeviceNet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

DIP Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2

Quick Start for

Experienced Users

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3

Installation and Wiring Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

EMC Directive 89/336/EEC Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Low Voltage Directive 73/23/EEC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Surge Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Common Mode Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Drive Output Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Removing Program Keypad Module or Ready/Fault Panel . . . . . . . . . . . . . . . . 3-5

Understanding Module Configuration Switches . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Setting the DeviceNet Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting the Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Cable Lengths and Baud Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Installing the Communication Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Wiring the DeviceNet Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting the DeviceNet Drop Line to the Module . . . . . . . . . . . . . . . . . . . . . 3-10

Removing Communication Module From a Drive . . . . . . . . . . . . . . . . . . . . . . 3-10

Publication 0160-5.18 - June 2003

Page 6

ii Table of Contents

Chapter 4

Modes of Operation Powering Up the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Power-up Reset Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Chapter 5

DeviceNet Parameter

Descriptions

DeviceNet Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Electronic Data Sheet (EDS) Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Parameters and EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Bulletin 160 SSC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Locating EDS Files on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Bulletin 160 SSC Interface Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

DeviceNet Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Drive Display Parameters (Read Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Drive Program Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Using 160-DN2 with

DeviceNet Scanner

Chapter 6

Needed Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Setting Device MAC ID’s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Using RSNetWorx for DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Going Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Creating an EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Accessing and Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Selecting Input and Output Assemblies for I/O Messaging . . . . . . . . . . . . . . . . 6-5

Changing the Output Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Changing the Input Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Enabling Network Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Configuring Drive Input Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Modifying Drive Reset Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Configuring the 160 to Accept Speed Commands from the Network . . . . . . . . . 6-9

Configuring the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Example Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Setting Up the Scan List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Mapping the Drive Data in the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Saving the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Using I/O Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Example Ladder Logic Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

ControlLogix Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

PLC-5 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

SLC Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Using Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

About Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Formatting Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Executing Explicit Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Publication 0160-5.18 - June 2003

Page 7

Table of Contents iii

Chapter 7

Troubleshooting Understanding the COMM LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Understanding the FAULT LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Appendix A

Specifications Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B

DeviceNet Information DeviceNet Message Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Object Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Supported Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Class Code 0x01 — Identity Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Class Code 0x03 — DeviceNet Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Class Code 0x05 — Connection Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Class Code 0x0F — Parameter Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Class Code 0x10 — Parameter Group Object . . . . . . . . . . . . . . . . . . . . . . . B-11

Class Code 0x28 — Motor Data Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Class Code 0x29 — Control Supervisor Object . . . . . . . . . . . . . . . . . . . . . . B-13

State Transition Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Run/Stop Event Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Class Code 0x2A — AC Drive Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Class Code 0x2B — Acknowledge Handler Object . . . . . . . . . . . . . . . . . . . B-17

Class Code 0xB3 — 160 Parameter Table Object . . . . . . . . . . . . . . . . . . . . B-18

Class Code 0xB4 — DN Interface Object . . . . . . . . . . . . . . . . . . . . . . . . . . . B-22

Class Code 0x04 — Assembly Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-23

Instance Data Format: Output Assemblies . . . . . . . . . . . . . . . . . . . . . . . . B-24

Instance Data Format: Input Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . B-26

Configuration Assembly Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . B-29

Index

Publication 0160-5.18 - June 2003

Page 8

iv Table of Contents

Publication 0160-5.18 - June 2003

Page 9

Preface

Using This Manual

Manual Objectives The purpose of this manual is to provide you with the necessary

information to apply the Bulletin 160 SSC DeviceNet

Communication Module. This manual describes methods to install,

configure, and troubleshoot the Bulletin 160 SSC DeviceNet

Communication Module.

For information on specific features of the Bulletin 160 SSC drive,

refer to the Bulletin 160 SSC User Manual.

Important: Read this manual in its entirety before installing,

operating, servicing, or initializing the Bulletin 160 DeviceNet

Communication Module.

Who Should Use This Manual? This manual is intended for qualified personnel. To make efficient use

of the Communication Module, you must be able to program and

operate serial communications devices, as well as have an

understanding of the parameter settings and functions of the Bulletin

160 SSC drive.

You should understand DeviceNet network operations, including how

slave devices operate on the network and communicate with a

DeviceNet master.

Product References In this manual we refer to the:

• Bulletin 160-DN2 DeviceNet Communication Module as

Communication Module and Module.

• Bulletin 160 SSC Variable Frequency AC Drive as the Drive.

Conventions Parameter names are shown in the format PXX - [*] where P denotes

parameter, XX represents the parameter number, and * represents the

parameter name. For example, P01 - [Output Frequency].

Firmware Version The firmware release is displayed as FRN X.xxx, where:

FRN = Firmware Release Number

X = Firmware (whole) Number

(.) = Decimal point separator

xxx = Place holders representing minor updates

Places to the right of the decimal do not affect content of this manual.

Publication 0160-5.18 - June 2003

Page 10

P-2 Using This Manual

Related Documentation

For: Refer to: Publication

Bulletin 160 SSC

Drive

RSNetWorx for

DeviceNet Software

ControlLogix ControlLogix User Manual 1756-6.5.13

SLC 500 and

1747-SDN

PLC5

and 1771-SDN

DeviceNet Cables

and Components

DeviceNet Network

Installation

User Manual Series A

User Manual Series B

User Manual Series C

RSNetWorx for DeviceNet Getting Results Guide

Online help (installed with the software)

DeviceNet Scanner Module Installation Instructions

DeviceNet Scanner Module Configuration Manual

DeviceNet Scanner Module Installation Instructions

DeviceNet Scanner Module Configuration Manual

DeviceNet Product Overview DN-2.5

DeviceNet Cable System Planning and Installation

Manual

0160-5.0

0160-5.9

0160-5.15

9398-DNETGR

1747-5.8

1747-6.5.2

1771-5.14

1771-6.5.118

DN-6.7.2

Important: Read the DeviceNet Cable System Planning and

Installation Manual, Publication DN-6.7.2, in its entirety before

planning and installing a DeviceNet system. If the network is not

installed according to this document, unexpected operation and

intermittent failures can occur.

Documentation can be obtained online at http://www.ab.com/manuals.

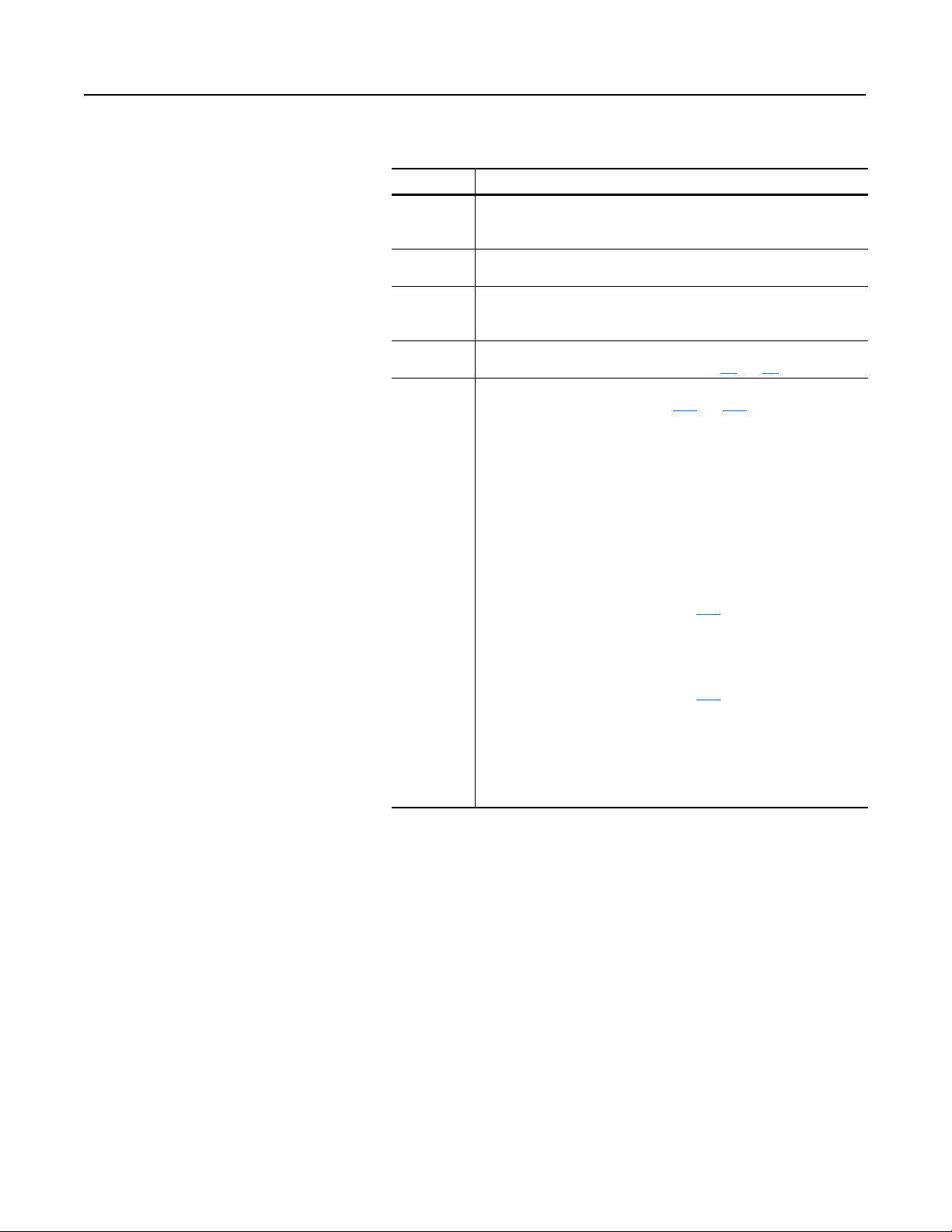

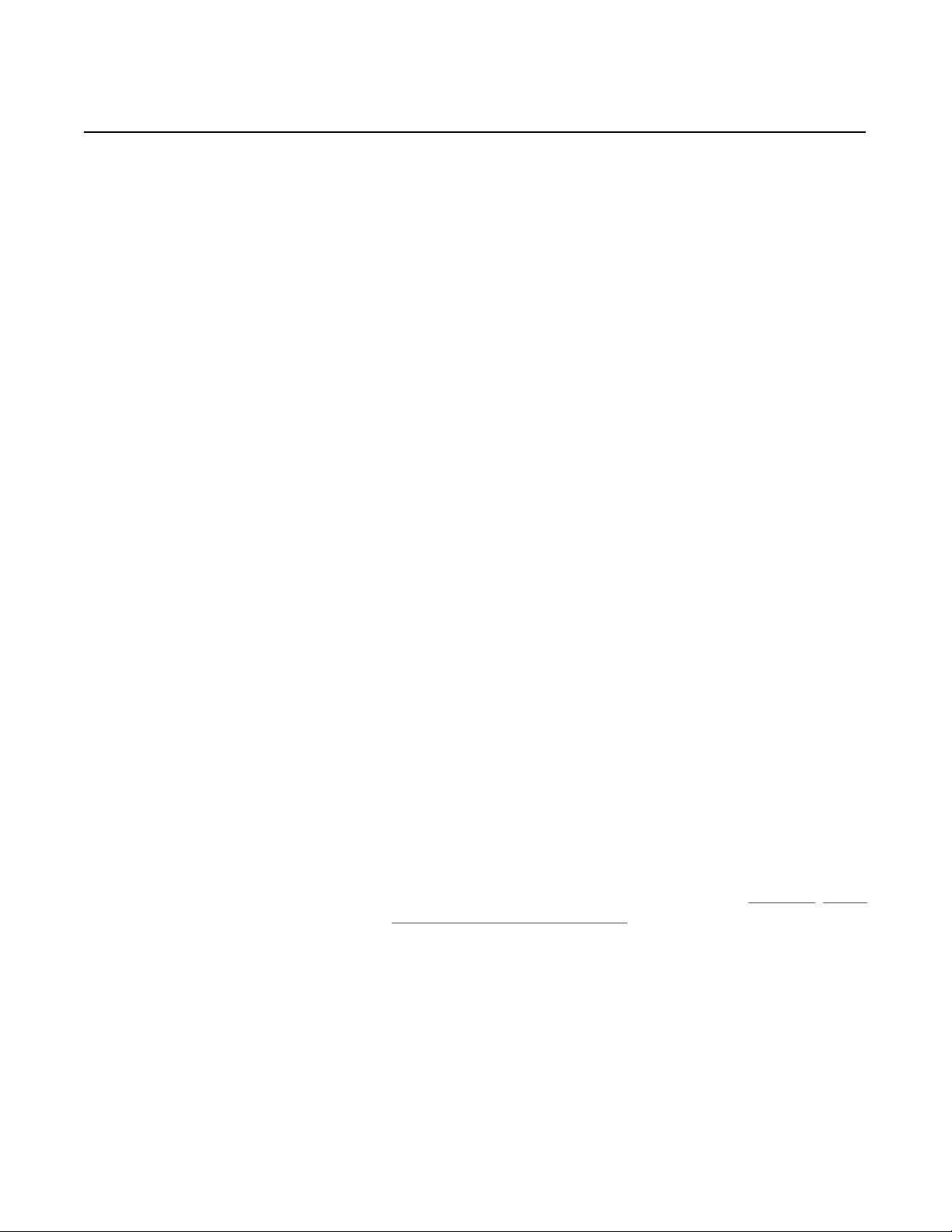

Manual Organization This 160-DN2 Module user manual contains the following sections:

Chapter Title Contents

Preface Using This Manual Manual objectives, audience, vocabulary, manual

conventions and organization, safety precautions,

and DeviceNet compatibility.

1 Product Overview Module description, LEDs, DIP switches, and

DeviceNet compatibility.

2 Quick Start for

Experienced Users

3 Installation and Wiring Installation, switch configuration, cabling, and

4 Modes of Operation Power-up and modes of operation.

5 DeviceNet Parameter

Descriptions

6 Using 160-DN2 with

DeviceNet Scanner

7 Troubleshooting LED indications and fault descriptions.

Appendix A Specifications Environmental, electrical, and communication

Appendix B DeviceNet Information DeviceNet message types and object classes.

Communication Module features, configuration,

and diagnostics.

removal.

EDS file parameters, Bulletin 160 SSC interface,

product codes.

Mac IDs, RSNetWorx for DeviceNet, configuration,

input/output assemblies, network control, scan list,

I/O messaging, ladder program examples, explicit

messaging.

specifications.

Publication 0160-5.18 - June 2003

Page 11

Using This Manual P-3

Safety Precautions Please read the following safety precautions carefully:

ATTENTION: Risk of injury or death exists. The

drive contains high voltage capacitors which take time

!

!

to discharge after removal of mains supply. Before

installing or removing the DeviceNet Communication

Module, make sure to isolate the mains supply from line

inputs [L1, L2, L3 (R, S, T)]. Wait three minutes for

capacitors to discharge to safe voltage levels. Failure to

do so may result in injury or death.

ATTENTION: Risk of injury or equipment damage

exists. Only personnel familiar with DeviceNet devices,

Bulletin 160 SSC drives, and associated machinery

should plan or implement the installation, start-up,

configuration, and subsequent maintenance of the

Communication Module. Failure to comply may result

in injury and/or equipment damage.

ATTENTION: Risk of equipment damage exists. This

module contains ESD (Electrostatic Discharge)

!

!

!

sensitive parts that can be damaged if you do not follow

ESD control procedures. Static control precautions are

required when handling this Communication Module.

If you are unfamiliar with static control procedures,

refer to Guarding Against Electrostatic Damage,

Publication 8000-4.5.2.

ATTENTION: Risk of injury or equipment damage

exists. When a system is configured for the first time,

there may be unintended or incorrect machine motion.

Disconnect the motor from the machine or process

during initial system testing.

ATTENTION: Hazard of equipment damage exists. If

explicit messages are programmed to frequently change

parameter data in the drive, the EEPROM will quickly

exceed its life cycle and cause the drive to malfunction.

Do not create a program that frequently uses explicit

messages to change a parameter in the drive.

Publication 0160-5.18 - June 2003

Page 12

P-4 Using This Manual

DeviceNet Compatibility The 160-DN2 Communication Module is intended for use only with

Bulletin 160 SSC Series A, Bulletin 160 SSC Series B, and Bulletin

160 SSC Series C (FRN 7.03 and later) devices. Bulletin 160 SSC

(Series C) devices must use a 160-DN2 Communication Module to

connect to a DeviceNet network. Bulletin 160 SSC (Series A and B)

devices can use either a 160-DN2 or 160-DN1 Communication

Module to connect to a DeviceNet network.

When properly connected, the Communication Module

communicates via the DeviceNet Protocol. The Communication

Module/Bulletin 160 SSC combination comprise a Group 2 Slave

Only device. This device supports DeviceNet slave Polled, Change of

State/Cyclic messaging, and DeviceNet slave Explicit messaging. It

does not support the Explicit Unconnected Message Manager

(UCMM).

Replacing a 160-DN1 with a

160-DN2

You can replace a 160-DN1 Communication Module with a 160-DN2

Communication Module on any 160 SSC (Series A and Series B)

drive. To do so, you will need to create an EDS file for the new 160DN2 Communication Module and map the module to the network.

Chapter 6

, Using 160-DN2 with DeviceNet Scanner, provides

detailed instructions on how to perform these tasks.

Rockwell Automation Support Rockwell Automation, Inc. offers support services worldwide, with

over 75 sales/support offices, over 500 authorized distributors, and

over 250 authorized systems integrators located through the United

States alone. In addition, Rockwell Automation, Inc. representatives

are in every major country in the world.

Local Product Support — Contact your local Rockwell

Automation, Inc. representative for sales and order support, product

technical training, warranty support, and support service agreements.

Technical Product Assistance — If you need to contact Rockwell

Automation, Inc. for technical assistance, please review the

information in Chapter 7

problems, then call your local Rockwell Automation, Inc.

representative.

, Troubleshooting first. If you still have

Publication 0160-5.18 - June 2003

U.S. Allen-Bradley Drives Technical Support:

E-mail: support@drives.ra.rockwell.com

Tel: (1) 262.512.8176

Fax (1) 262.512.2222

Online: www.ab.com/support/abdrives

UK Customer Support Center:

E-mail: esupport2@ra.rockwell.com

Tel: +44 (0) 870 2411802

Fax: +44 (0) 1908 838804

Germany Customer Service Center:

E-mail: ragermany-csc@ra.rockwell.com

Tel: +49 (0) 2104 960-630

Fax: +49 (0) 2104 960-501

Page 13

Chapter 1

Product Overview

This chapter contains the following information:

• physical layout of the module

• location of configuration switches

• DeviceNet overview and components

Module Description The Bulletin 160 SSC DeviceNet Communication Module is an

optional interface device designed to provide a direct, digital link

between DeviceNet devices and the Bulletin 160 SSC drive. The

module connects to the Bulletin 160 SSC through the expansion/

keypad port on the front of the drive.

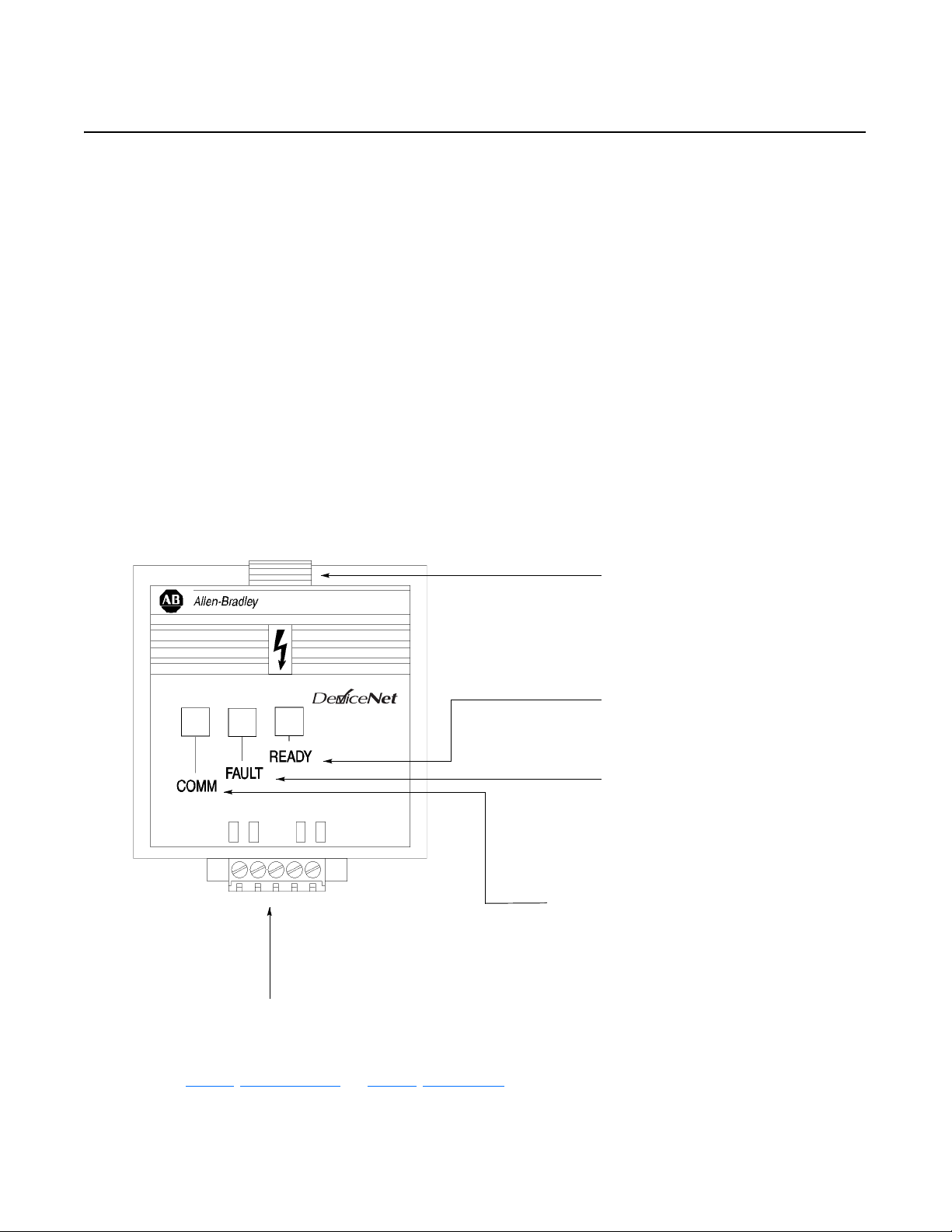

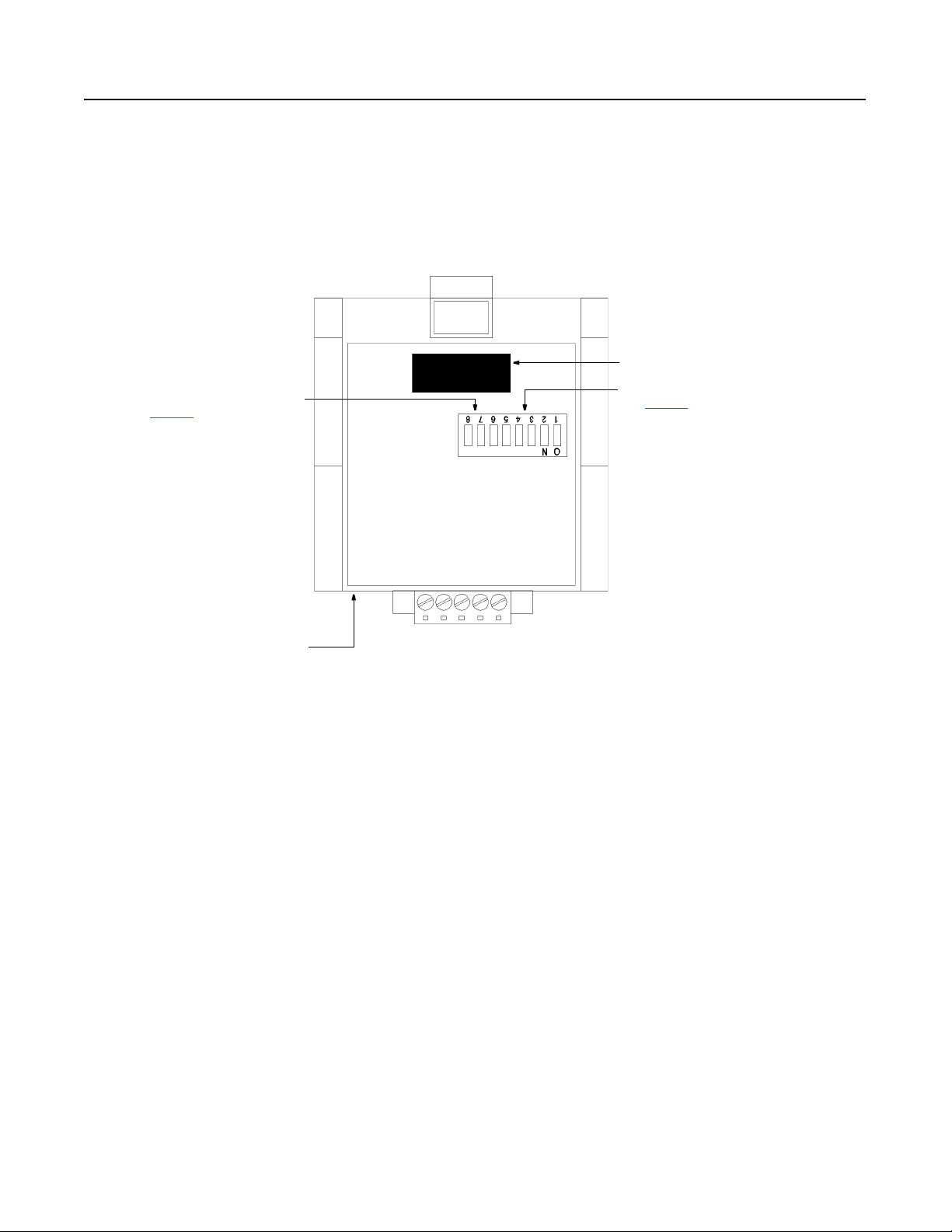

LEDs and DeviceNet Connection Figure 1.1

Module Front View

TM

CONFORMANCE TESTED

DeviceNet Terminal Block Plug - The Communication Module

receives power and communications through this connector.

Module Installation Latch

Ready LED - GREEN when drive is powered up ➀

Fault LED - RED when drive is faulted

OFF when drive not faulted ➀

COMM - This bi-colored LED (red/green) provides status

information on DeviceNet communications ➀

➀ See Chapter 4, Modes of Operation, and Chapter 7, Troubleshooting, for detailed operation.

Publication 0160-5.18 - June 2003

Page 14

1-2 Product Overview

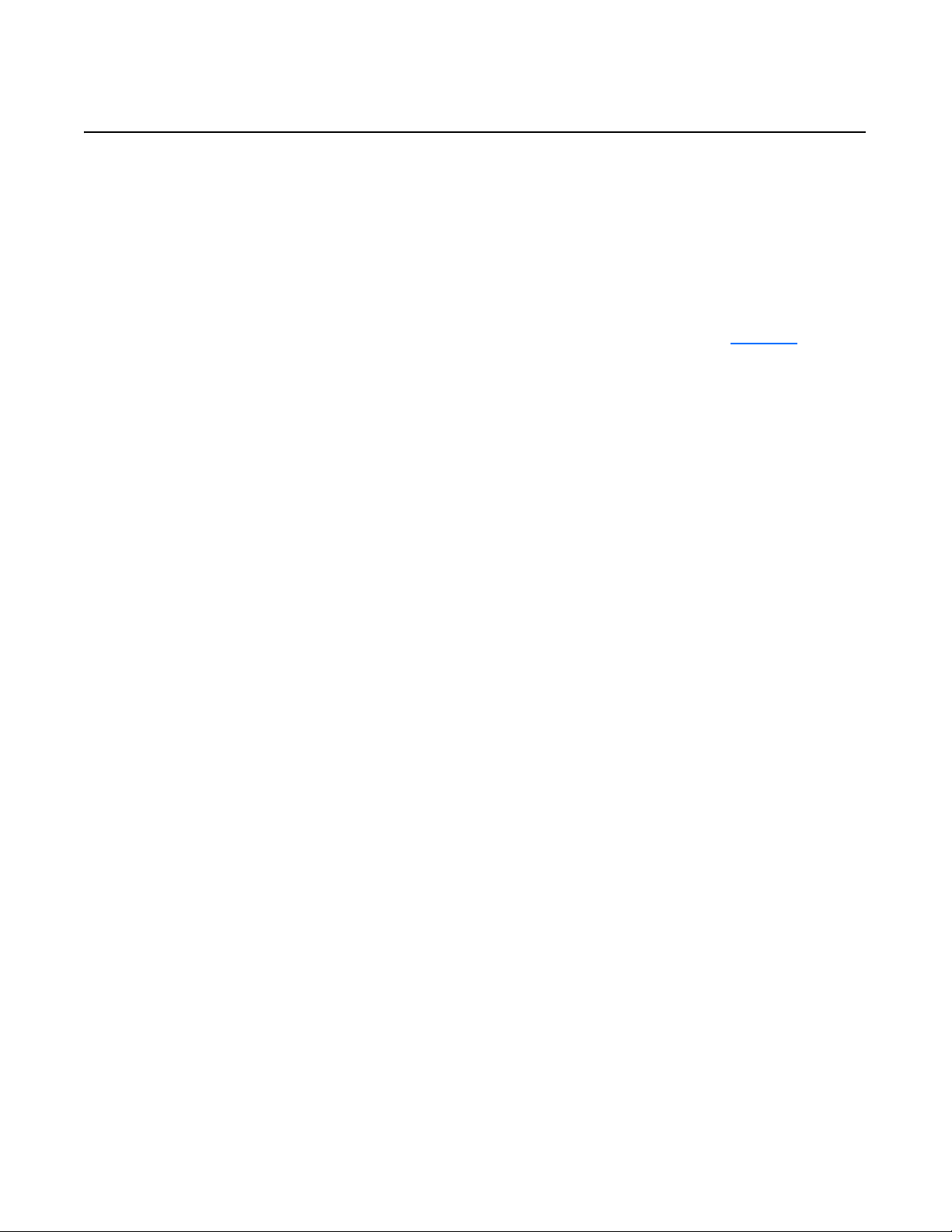

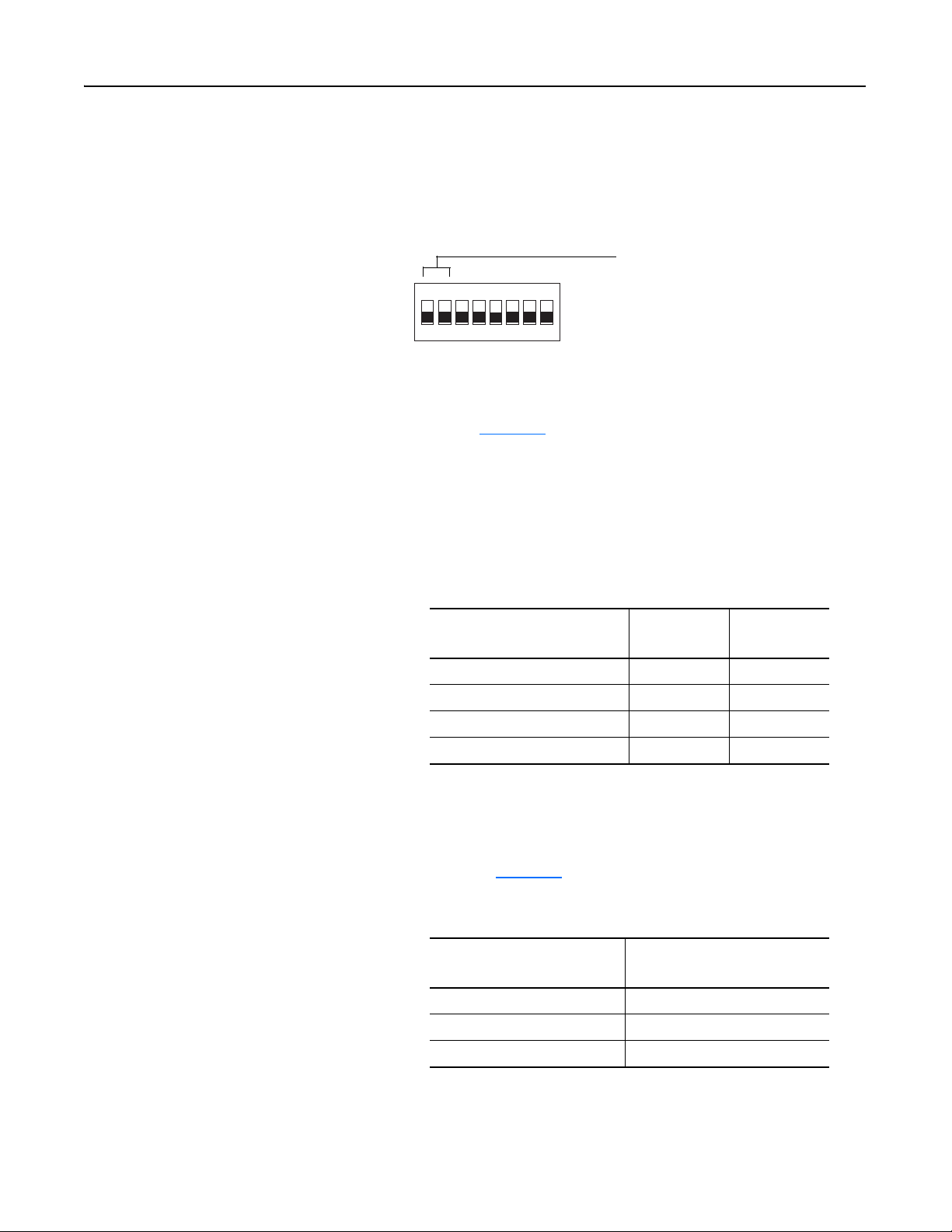

DIP Switches Figure 1.2

Module Rear View

The Communication Module has one eight position DIP switch for setting the

DeviceNet Node Address and Baud Rate. DIP switches are located on the

rear of the module and are only accessible when the module is removed

from the Bulletin 160 SSC drive.

Expansion/Keypad Port Connector

SW.7 - SW.8 = Baud Rate Selection

(see page 3-7

Label with DeviceNet Serial Number

)

SW.1 - SW.6 = Node Address Selection

(see page 3-6

)

Publication 0160-5.18 - June 2003

Page 15

Chapter 2

Quick Start for Experienced Users

Introduction This chapter can help you start using the Bulletin 160 DeviceNet

Communication module. If you have previously installed or

configured a DeviceNet network and are familiar with Rockwell

Automation DeviceNet modules and drives, this information can help

reduce installation and startup time. If you are uncertain, use the full

installation/configuring information beginning in Chapter 3

We base the procedures listed in this chapter on the assumption that

you understand DeviceNet concepts and know how to program the

Bulletin 160 SSC drive. You should also be able to understand

electronic process control and interpret the ladder logic instructions

required to generate the electronic signals that control your

application.

Because it is a start-up guide for experienced users, this chapter does

not contain detailed explanations about the procedures listed. It does,

however, reference other chapters in this book where you can get

more information.

.

If you have any questions or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the

referenced chapters and other recommended documentation before

trying to apply the information.

The information contained in this chapter includes:

• What tools and equipment you will need.

• When to address, configure, and program the module.

• How to install and wire the Communication Module.

• System power-up procedures.

Required Tools and Equipment Have the following tools and equipment ready:

• small blade screwdriver

• DeviceNet configuration software or hardware device

Publication 0160-5.18 - June 2003

Page 16

2-2 Quick Start for Experienced Users

Procedures

Step Refer to . . .

1 Review Attention statements in the Preface. Preface

2 Check the contents of the shipping box.

Unpack the shipping box, making sure that it contains:

• Bulletin 160 DeviceNet module (Catalog Number 160-DN2)

• 10-pin linear plug with probe holes and jack screws

• DeviceNet Communication Module 160-DN2 User Manual

If the contents are incomplete, call your local Allen-Bradley

representative for assistance.

3 Ensure that the drive is correctly installed and wired. (The

Stop Input, TB3-7 and TB3-8, must be jumpered together

to start the drive.)

4 Ensure that the DeviceNet master and network are

installed and functioning by DeviceNet standards.

5 Remove the Program Keypad Module or

Ready/Fault Indicating Panel from the drive.

6 Set the DeviceNet Module’s node address and baud rate.

Set the DIP Switches at the back of the module. Switches 1

through 6 set the node address; switches 7 and 8 set baud

rate.

7 Install the DeviceNet module on the drive. Chapter 3,

8 Wire the DeviceNet connector and plug it into the drive. Chapter 3,

9 Power up the drive and the network.

Important: When power-up occurs, the COMM

(communication status) LED flashes green for 1/4 second, red

for 1/4 second, and then goes blank while the Communication

Module finishes its initialization. If the COMM LED goes red,

there is a problem.

10 Select the appropriate Electronic Data Sheet (EDS) file.

Select the EDS file with the DeviceNet software or hardware

configurator that you are using to configure the Communication

Module (see Chapter 5

11 Configure the Bulletin 160 SSC drive for DeviceNet so that

the drive can accept speed reference and control logic via

the network.

Use configuration software such as RSNetWorx for DeviceNet

or hardware such as DeviceView Hand Held DeviceNet

Configurator.

12 Configure the DeviceNet Scanner to recognize the Bulletin

160 SSC drive.

Use RSNetWorx for DeviceNet to configure the DeviceNet

Scanner’s “Scan List” to recognize the Bulletin 160 SSC drive.

for EDS file descriptions).

—

Publication 160-SSC

User Manual

DeviceNet Cable

System Planning and

Installation Manual

(Publication DN-6.7.2)

Chapter 3

Installation and Wiring

Chapter 3,

Installation and Wiring

Installation and Wiring

Installation and Wiring

Chapter 3

Installation and Wiring,

Chapter 4

Modes of Operation,

and

Chapter 7

Troubleshooting

Chapter 6

Using 160-DN2 with

DeviceNet Scanner,

and DeviceNet

Software or Hardware

Configurator Manual

Chapter 6

Using 160-DN2 with

DeviceNet Scanner

Chapter 6,

Using 160-DN2 with

DeviceNet Scanner

,

,

,

,

,

,

Publication 0160-5.18 - June 2003

Page 17

Chapter 3

Installation and Wiring

This chapter contains information necessary to:

• Meet requirements for CE compliance (EMC / Low Voltage directives).

• Suppress transient EMI from “hard contact” load switching.

• Reduce high frequency common mode noise current.

• Properly connect/disconnect power to the motor.

• Remove a preinstalled Program Keypad Module or Ready/Fault

Indicating Panel.

• Configure and install the Communication Module.

• Wire the DeviceNet communication cables.

• Remove an installed Communication Module from the drive.

Read this chapter completely before you attempt to install or

configure the Communication Module. Before you apply power,

review the Safety Precautions

all connections are secure and all selections are correct.

on Preface page P-3, making sure that

ATTENTION: When you make changes to the

switch settings, use a blunt pointed instrument. Do not

!

!

use a pencil or pen because damage may occur.

ATTENTION: Unpredictable operation may occur if

you fail to check connections and DIP switch settings

for compatibility with your application. Unpredictable

operation may result in personal injury, death, and

equipment damage.

Required Tools and Equipment Before installing and configuring the 160-DN2 Communication

Module, make sure that the contents of the shipping box include:

• Bulletin 160-DN2 module (Catalog Number 160-DN2)

• 10 pin linear Plug (Part Number 1787-PLUG10R)

• this manual

In addition, you will need to supply:

• a small blade screwdriver

• DeviceNet configuration software or hardware device

• DeviceNet thick cable or thin cable. For details and part numbers,

refer to the DeviceNet Product Overview, Publication DN-2.5.

Publication 0160-5.18 - June 2003

Page 18

3-2 Installation and Wiring

EMC Directive 89/336/EEC

Compliance

Low Voltage Directive 73/23/EEC

Compliance

The 160-DN2 Communication Module complies with

Electromagnetic Compatibility (EMC) Directive 89/336/EEC when

conforming to these installation requirements:

• Applying the essential requirements for a conforming EMC

installation for the Bulletin 160 SSC drive. Refer to the Bulletin

160 SSC User Manual.

• Connecting the DeviceNet cable shield to the SSC drive’s

protective earth terminal, PE, with a low impedance connection.

• Installing a clamp-on ferrite cable clamp (see Figure 3.9

DeviceNet communication cable within 10 cm (4 in.) of the SSC

drive. When multiple SSC drives are contained in one control

cabinet, it is sufficient to install one clamp-on ferrite cable clamp

where the DeviceNet communication cable enters the control

cabinet.

The 160-DN2 Communication Module complies with Low Voltage

Directive 73/23/EEC when conforming to these installation

requirements:

• Applying the essential requirements for a conforming Low Voltage

Directive installation for the Bulletin 160 SSC drive. Refer to the

Bulletin 160 SSC User Manual.

) on the

• Observing the Safety Precautions

Attention statements throughout this manual when installing the

module.

on Preface page P-3, and other

Surge Suppression Transient EMI can be generated whenever inductive loads such as

relays, solenoids, electro-mechanical brakes, motor starters, or motors

are operated by “hard contacts.” The wiring guidelines contained

herein are based on the assumption that you safeguard your system

against the effects of transient EMI by using surge suppressors to

suppress transient EMI at its source. Inductive loads switched by only

solid-state output devices do not require surge suppression. However,

inductive loads that are in series or parallel with hard contacts require

surge suppression to protect control circuits as well as to suppress

transient EMI.

Even if regularly cycled inductive loads have no interaction with

the control system, these loads need suppression if their

conductors are:

• Connected to the same separately derived system as that of the

control system.

• Routed in proximity with conductors of the control system (per

routing guidelines).

Publication 0160-5.18 - June 2003

The application (voltage and load of the inductive circuit) dictates the

specific suppressor needed at the source of the inductive load. Testing

has determined that the best overall RC surge suppressor combination

Page 19

Installation and Wiring 3-3

is 220 ohms and 0.50 microfarads. Select the voltage rating for the

normal AC voltages. A typical surge suppressor that can be used for

most transient EMI problems is Electrocube part number RG1676-16

(rated 480V ac).

Surge suppressors are usually most effective when connected at the

inductive loads. However, you can also connect surge suppressors at

the switching devices, but they may be less effective because the

wires connecting the switching devices to the inductive loads act as

antennas that radiate EMI. You can evaluate the effectiveness of a

particular suppressor by using an oscilloscope to observe the voltage

waveform on the line.

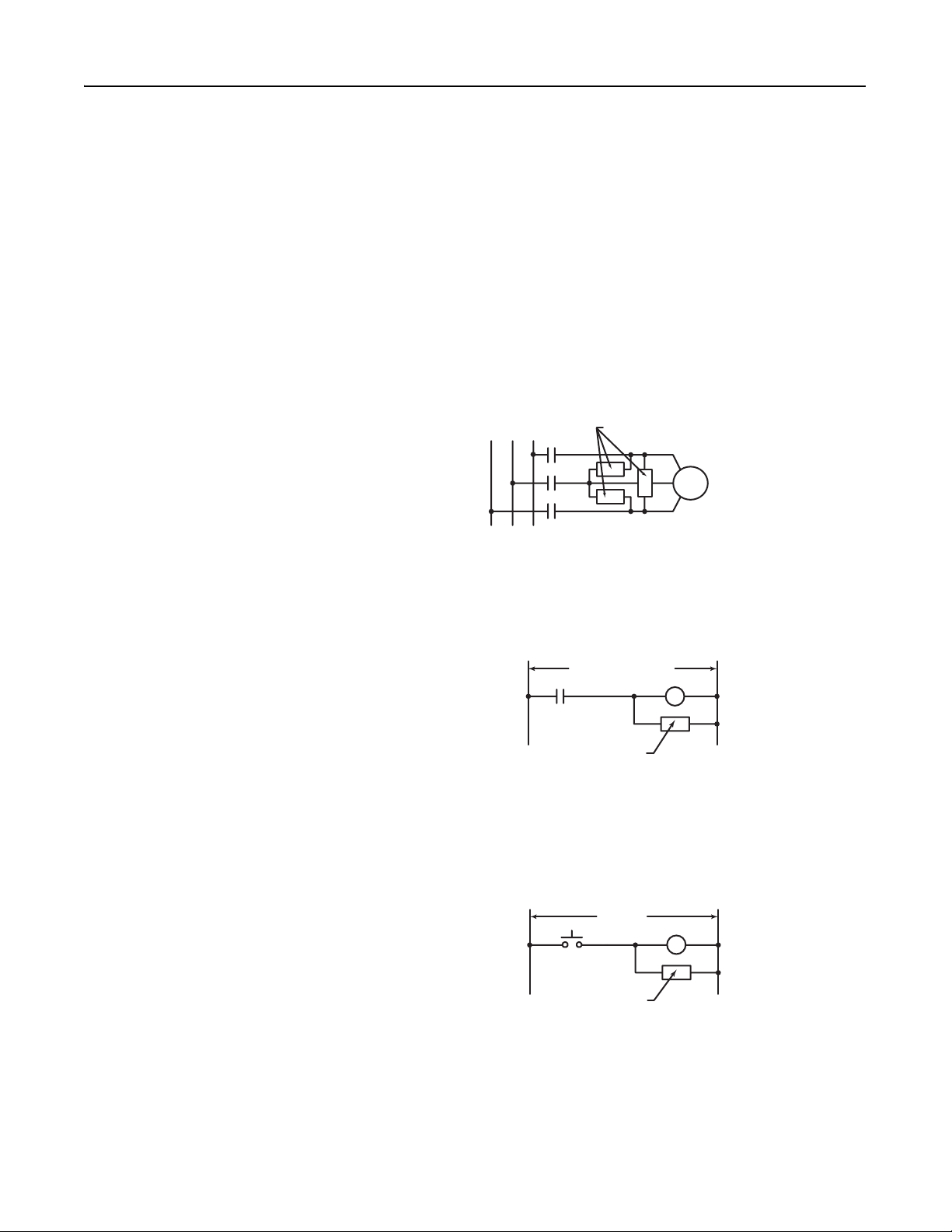

Figure 3.1

Surge Suppressor Connection for 3-Phase Apparatus

230/460VAC

For 3-phase apparatus, a suppressor is needed across each phase

Surge Suppressor

3-Phase

Motor

Figure 3.2

Surge Suppressor Connection for Large Apparatus

115/230/460VAC

Surge Suppressor

For large apparatus (electro-mechanical brakes, contacts up to size 5)

Figure 3.3

Surge Suppressor Connection for Small Apparatus

115VAC

Surge Suppressor

For small apparatus (relays, solenoids, and motor starters up to size 1)

Publication 0160-5.18 - June 2003

Page 20

3-4 Installation and Wiring

Common Mode Noise To greatly reduce high frequency common mode noise current

coupled to ground in high capacitance connections, connect a

common mode choke at the drive end of the motor cable. The

common mode choke reduces the rise time of the high frequency

noise by a factor of 10-20, and the amplitude by a factor of 5. For

multiple 460 volt drive installations with sensitive equipment (e.g.

PLC’s, temperature sensors, sonar detectors, strain gauges, etc.)

sharing a common ground separated by more than 30 feet, you must

install common mode chokes at the outputs of each drive.

In addition to greatly reducing high frequency common mode noise

induced by the drive, a common mode choke also effectively reduces

high frequency common mode noise that is induced by regularly

cycled inductive loads. In installations where inductively-coupled

common mode noise causes system problems, connect a common

mode choke at the source of the inductively-switched load.

For drives on a DeviceNet network, we highly recommend connecting

a common mode choke at the drive end of the motor cable.

Drive Output Disconnect The drive is intended to be commanded by control signals that will

start and stop the motor. Do not use a device that routinely connects

or disconnects output power to the motor with the drive outputting

power (for the purpose of starting and stopping the motor, or for

machine positioning). Connecting or disconnecting power to the

motor with the drive outputting power can produce transient EMI

which can cause network problems to occur.

For emergency stop conditions, make sure that terminal 7 and 8 on

TB2 is broken (opened) using an auxiliary contact of a motor output

contactor. Also, remember to set the Stop Select parameter to “Coast

to Stop.”

Publication 0160-5.18 - June 2003

Page 21

Installation and Wiring 3-5

P

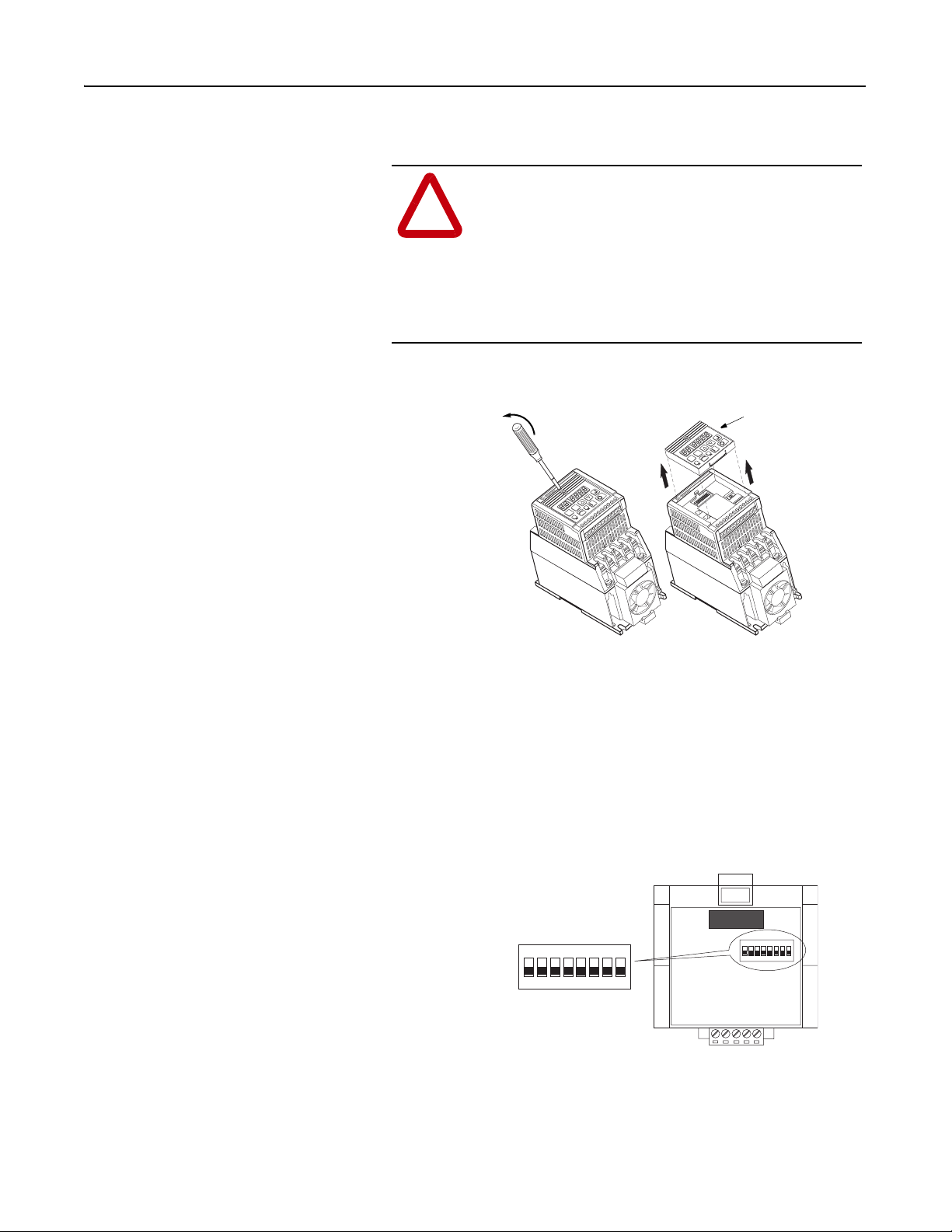

Removing Program Keypad Module

or Ready/Fault Panel

Insert a small screw driver into the slot, pry

back, and pivot module out. Avoid bending

or twisting the contact pins located

underneath the center portion of the

module.

Before installing the Communication Module, it may be necessary to

remove a previously installed module such as a Program Keypad

Module or Ready/Fault Indicating panel.

ATTENTION: Risk of injury or death exists. The

drive contains high voltage capacitors which take time

!

to discharge after removal of mains supply. Before

installing or removing the DeviceNet Communication

Module, make sure to isolate the mains supply from

line inputs [L1, L2, L3 (R, S, T)]. Wait three minutes

for capacitors to discharge to safe voltage levels.

Failure to do this may result in injury or death.

Figure 3.4

Removing Program Keypad Module

rogram Keypad Module

SEL

ESC

SEL

ESC

1 2 3 4 5 6 7 8 9 10 11

T1

+

DC

–

DC

T3

W

T2

V

U

50 | 60

1 2 3 4 5 6 7 8 9 10 11

T3

T2

V

T1

U

+

DC

–

DC

W

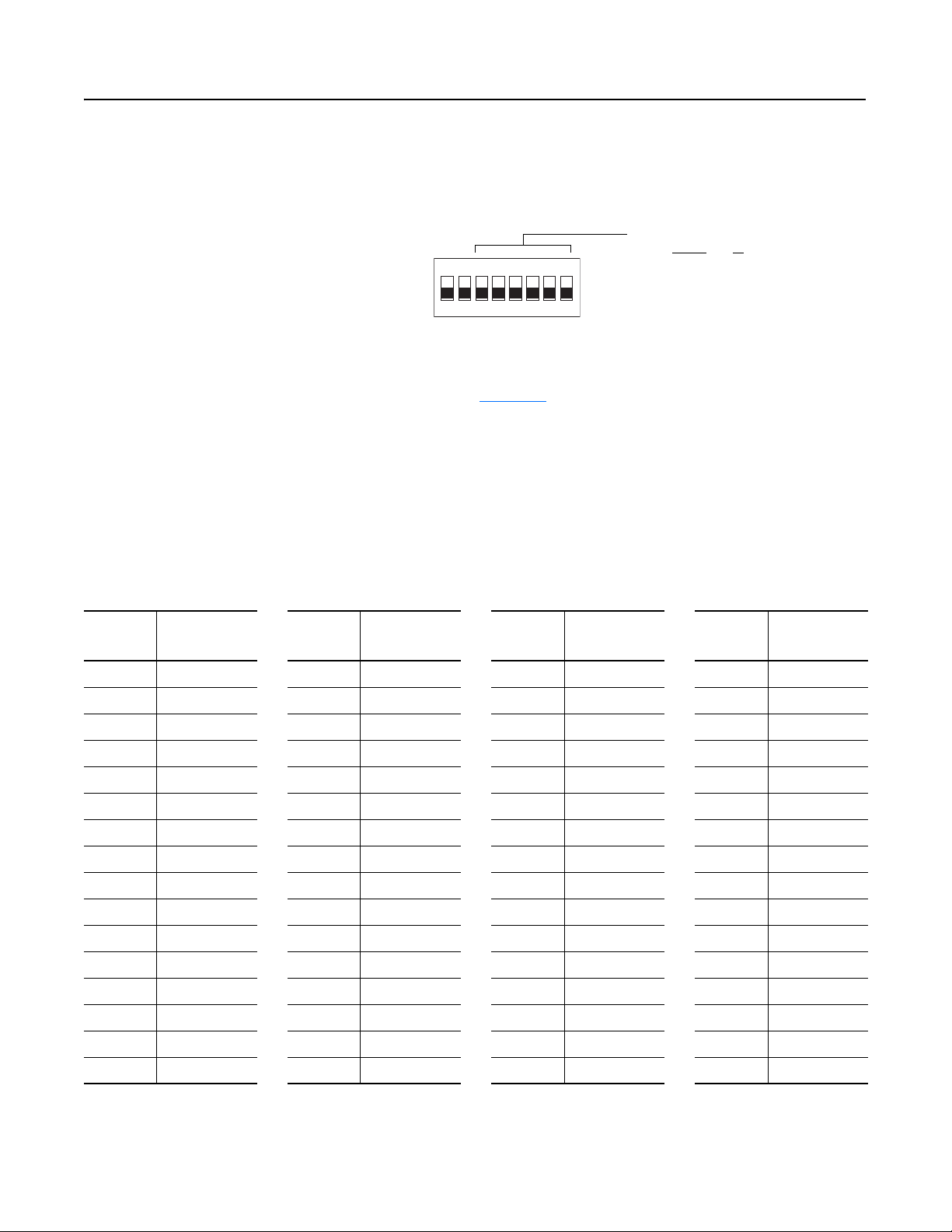

Understanding Module

Configuration Switches

The Communication Module’s DIP switch settings determine:

• DeviceNet node address

• DeviceNet baud rate

The location of the DIP switch and the factory defaults are shown

below.

Figure 3.5

DIP Switches on Rear of Module

DIP Switch

Factory Settings

ON = 1

OFF = 0

123 4567 8

1234 567 8

ON

ON

Important: When setting the Communication Module’s addressing

DIP Switches, make sure that each serial device on the network has a

unique address. Also, all devices connected to the network must be

set at the same baud rate.

Publication 0160-5.18 - June 2003

Page 22

3-6 Installation and Wiring

Setting the DeviceNet Node

Address

DIP switches 6 through 1 set the module’s node address using binary

addressing. The factory default setting is DeviceNet address 63.

Figure 3.6

Setting the Node Address

DeviceNet Address

12345 67 8

ON

000000 - 111111

ON = 1

OFF = 0

(0 to 63)

To set the DeviceNet node address:

1. Refer to Tab le 3. A

below for the switch settings of a specific

address.

2. Using a pointed tool, slide switches 6 through 1 to the appropriate

ON/OFF positions.

Important: When switches 7 and 8 are ON, the DeviceNet address is

set to the value in parameter P103 - [NV MAC ID].

Table 3.A Switch Settings for DeviceNet Node Addressing

DeviceNet

Address

0 000000 16 010000 32 100000 48 110000

1 000001 17 010001 33 100001 49 110001

2 000010 18 010010 34 100010 50 110010

3 000011 19 010011 35 100011 51 110011

4 000100 20 010100 36 100100 52 110100

5 000101 21 010101 37 100101 53 110101

6 000110 22 010110 38 100110 54 110110

7 000111 23 010111 39 100111 55 110111

8 001000 24 011000 40 101000 56 111000

9 001001 25 011001 41 101001 57 111001

10 001010 26 011010 42 101010 58 111010

11 001011 27 011011 43 101011 59 111011

12 001100 28 011100 44 101100 60 111100

13 001101 29 011101 45 101101 61 111101

Switch Settings

6 <---- 1

DeviceNet

Address

Switch Settings

6 <---- 1

DeviceNet

Address

Switch Settings

6 <---- 1

DeviceNet

Address

Switch Settings

6 <---- 1

14 001110 30 011110 46 101110 62 111110

15 001111 31 011111 47 101111 63 111111

Publication 0160-5.18 - June 2003

Page 23

Installation and Wiring 3-7

Setting the Baud Rate Dip switches 7 and 8 set the baud rate at which the Communication

Module communicates on the network. The factory default setting for

baud rate is 125 kbps.

Figure 3.7

Setting the Baud Rate

Use DIP Switch 8 and 7 for

12345 67 8

ON

To set the DeviceNet Baud Rate:

setting the DeviceNet Baud

Rate.

ON = 1

OFF = 0

1. Refer to Tab le 3. B

for the switch setting of a specific Baud Rate.

2. Slide switches 7 and 8 to the appropriate positions using a pointed

tool.

Important: When switches 7 and 8 are ON, the DeviceNet Baud

Rate is set to the value in parameter P104 - [NV Baud Rate].

Table 3.B Switch Settings for DeviceNet Module Baud Rate

Baud Rate

125 kbps 0 0

250 kbps 0 1

500 kbps 1 0

Set by module parameter P104 1 1

Switch Setting8 Switch Setting

7

Cable Lengths and Baud Rates

The baud rate determines the maximum length of the DeviceNet

cable. Refer to Tabl e 3.C

to determine cable lengths and baud rates.

Table 3.C Baud Rate vs. Cable Length

Baud Rate

125 kbps 500 meters (1640 feet)

250 kbps 250 meters (820 feet)

500 kbps 100 meters (328 feet)

Maximum Cable Length

(Trunk Line)

Publication 0160-5.18 - June 2003

Page 24

3-8 Installation and Wiring

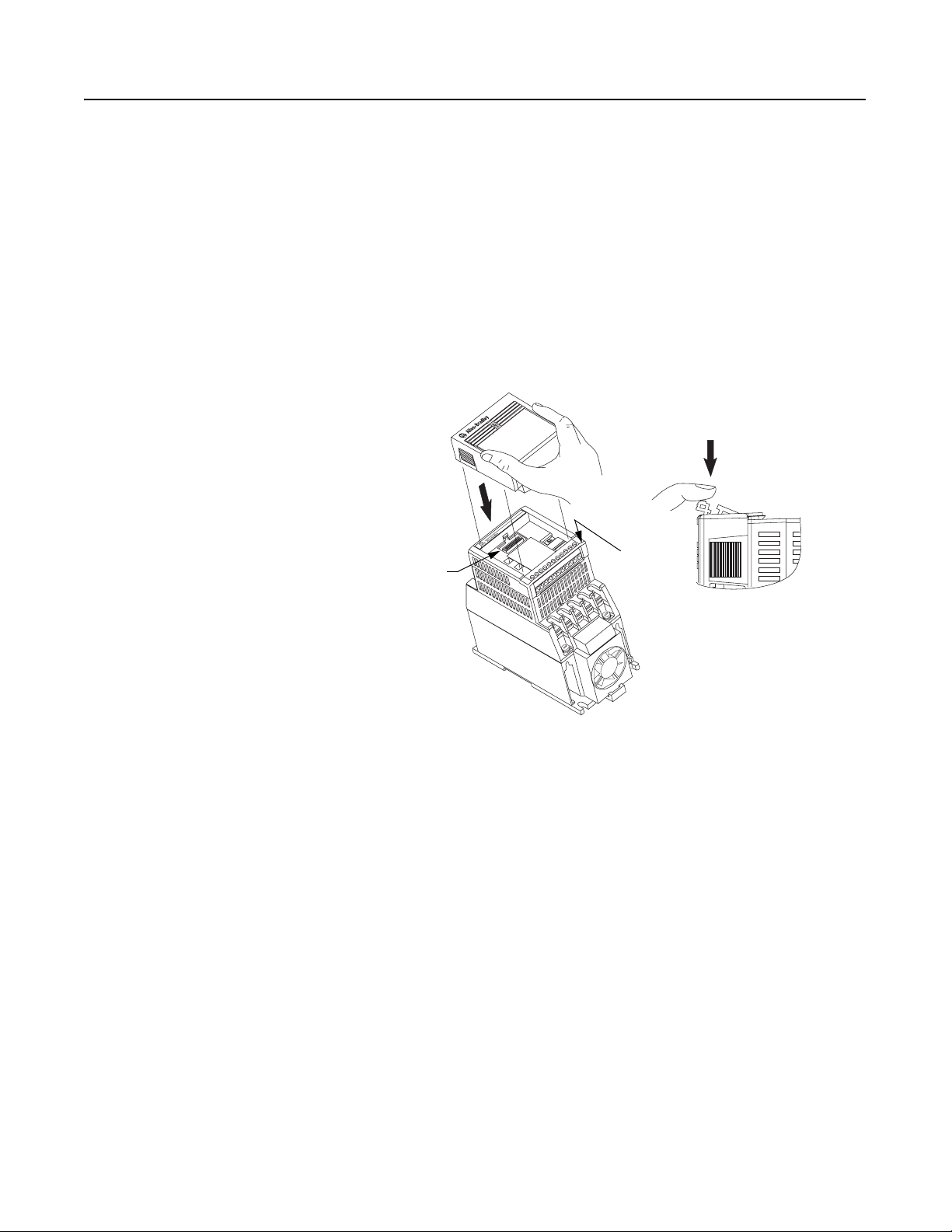

Installing the Communication

Module

After setting the DIP switches, secure the Communication Module to

the drive by following these steps:

1. Insert the module, ensuring that the pins on the back of the

module line up with the drive’s expansion port.

2. Press down on the module until it is fully seated. The module is

fully seated when its sides are resting on the drive’s face.

3. Press down on the latch until it snaps into place.

Figure 3.8

Installing the Communication Module

Expansion

Port

1 2 3 4

5 6 7

1

T

U

8 9 10 11

2

T

–

D

3

T

W

V

Drive’s

Face

+

C

D

C

Publication 0160-5.18 - June 2003

Page 25

Installation and Wiring 3-9

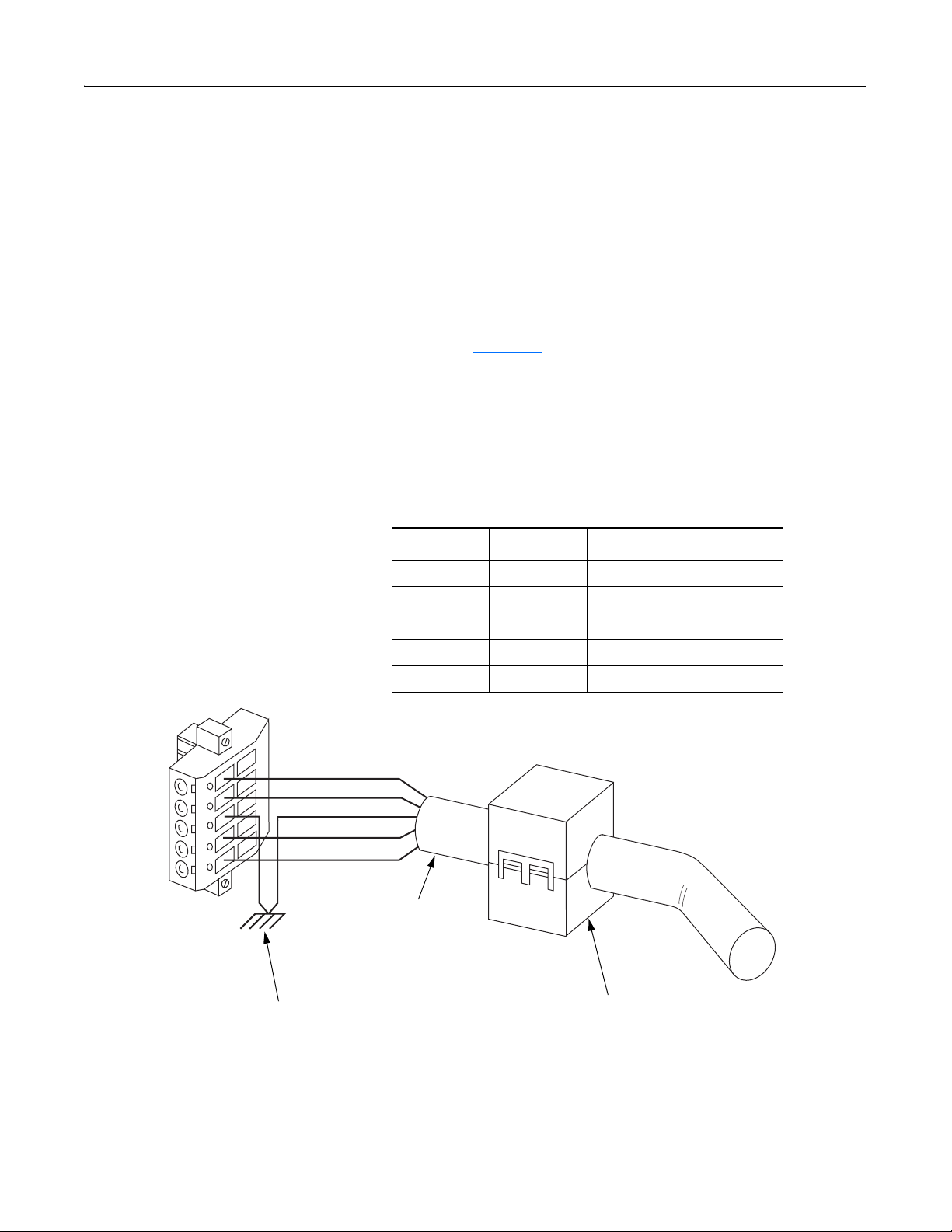

Wiring the DeviceNet Connector Follow these recommendations for communications wiring:

•See DeviceNet Cable System Planning and Installation Manual,

Publication DN-6.7.2, for planning and installing DeviceNet

networks.

• Keep communication wiring away from high noise sources such as

motor cables.

• Increase noise immunity by:

– Using a trunk line in place of a drop line.

– Using a ferrite cable clamp around the communication line

(see Figure 3.9

).

1 2 3 4 5

Red

White

Bare

Blue

Black

– Grounding the cable shield as shown in Figure 3.9

.

Figure 3.9

Wiring the DeviceNet 10-Pin Linear Plug

The Communication Module receives power and communications through the DeviceNet connector.

DeviceNet cable wires connect to the DeviceNet plug as shown below:

Color Terminal Signal Function

Black 1 COMM Common

Blue 2 CAN_L Signal Low

Bare 3 SHIELD Shield

White 4 CAN_H Signal High

Red 5 VDC+ Power Supply

DeviceNet Trunk Line

or Drop Line

Trunk line is recommended for

greatest noise immunity.

Grounding Recommendations

Attach bare wire to earth GND as close to the drive as

possible. For greatest noise immunity, drive should be

single point ground.

Important: For each DeviceNet Network with multiple

devices, only one device must be grounded.

Optional Clamp-On Ferrite Cable Clamp

Install core within 10 cm (4") of Communication

Module. Use Ferrishield (part #HI28B2039) or

Fair-Rite (part #0443164151 – quantity of 2 required).

Publication 0160-5.18 - June 2003

Page 26

3-10 Installation and Wiring

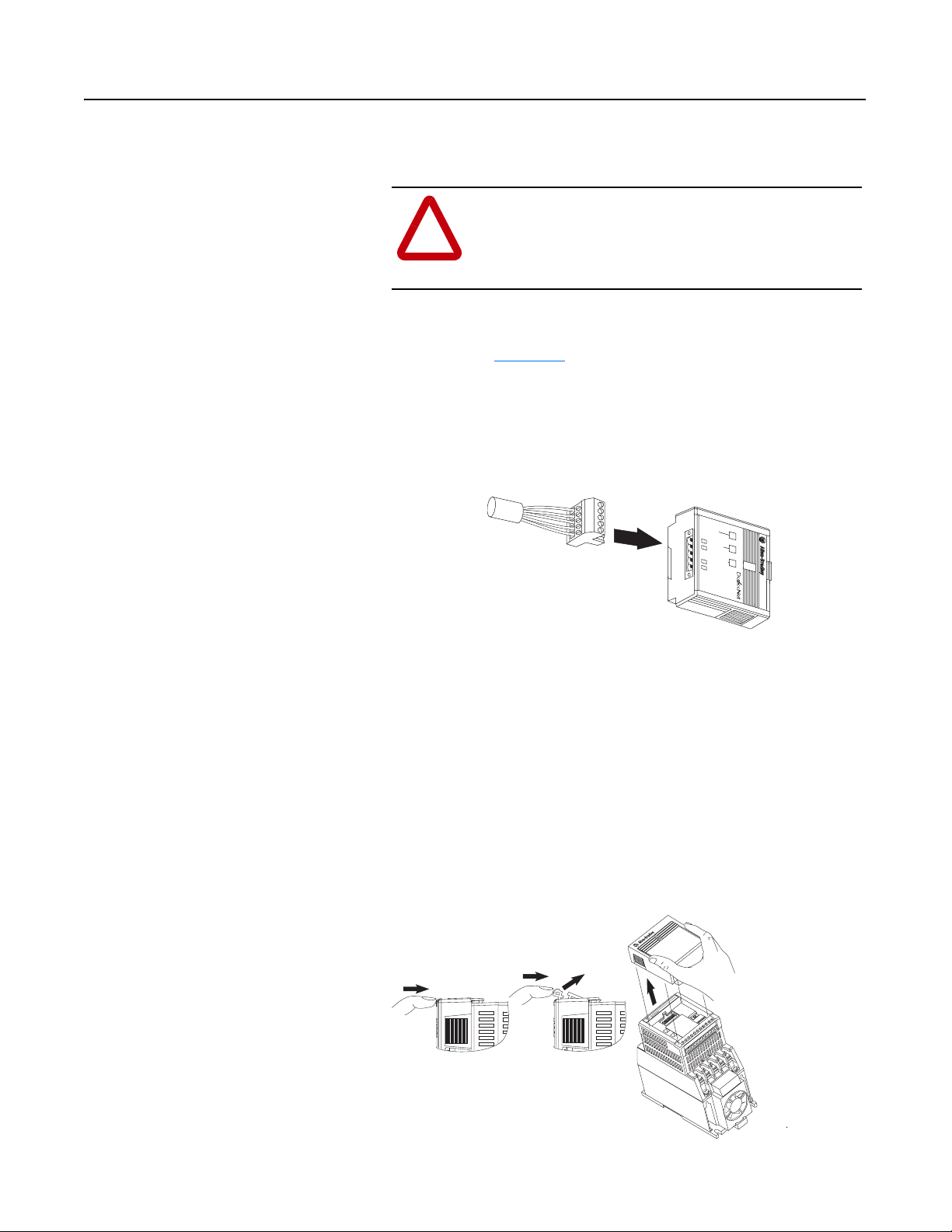

Connecting the DeviceNet Drop

Line to the Module

To connect your module DeviceNet drop line:

1. Turn off the network power supply.

ATTENTION: Do not wire the Communication

Module with the network power supply on. Wiring the

!

module with the network power supply on may short

your network or disrupt communication.

2. Make sure that the DeviceNet 10-pin Linear Plug is correctly

wired (see Figure 3.9

).

3. Locate the DeviceNet connector on the bottom of the module.

4. Insert the plug into the DeviceNet connector.

Figure 3.10

Installing the Drop Line

COMM

FAULT

READY

Removing Communication Module

From a Drive

CONFORMANCE TESTED

TM

If you need to reconfigure the Communication Module DIP switches,

you must remove the Communication Module from the drive.

1. Remove the DeviceNet plug from the Communication Module.

2. Press in on the module’s latch and then push away and up.

3. Grasp the module and pull straight up. Avoid bending or twisting

the contact pins located underneath the center portion of the

module.

Figure 3.11

Removing the Communication Module

Publication 0160-5.18 - June 2003

1 2 3 4 5 6 7 8 9 10 11

T2

T1

U

+

DC

–

DC

T3

W

V

Page 27

Chapter 4

Modes of Operation

This chapter contains information about:

• Powering up the drive with an installed 160-DN2 DeviceNet

communication module.

• Understanding the module’s modes of operation.

Before you apply power, review the Safety Precautions

page P-3

.

on Preface

Powering Up the Drive After you have installed the 160-DN2 module, apply power to the

drive and to the Network. The COMM LED should flash green or turn

solid green. If it does not, refer to Chapter 7

, Troubleshooting.

Modes of Operation The 160-DN2 module operating modes are:

• Power-up reset mode

• Run mode

• Error mode

Power-up Reset Mode

During power-up or reset, the COMM LED is off.

The 160-DN2 module follows this sequence of operation:

1. When power-up occurs, the COMM LED flashes green for 1/4

second, red for 1/4 second, and then goes blank while the 160DN2 module finishes its initialization.

2. Performs power-up initialization.

3. Reads and stores the DIP switch settings.

4. Performs a duplicate node address check to verify that another

node is not assigned the same DeviceNet address as the 160-DN2

module.

If the power-up or reset is successful, the 160-DN2 module enters the

Run mode and the COMM LED flashes green or turns solid green.

Publication 0160-5.18 - June 2003

Page 28

4-2 Modes of Operation

Modes of Operation (Continued) Power-up Reset Mode (Continued)

If the power up or reset sequence fails, the COMM LED will turn

solid red and the 160-DN2 module will enter the Error mode (see

heading below for more information).

Table 4.A COMM LED State During Power-up Reset Mode

COMM LED State Description

Flashes Green 1/4 second,

Red 1/4 second,

then goes blank

Blank Power-up initialization is taking place.

Solid Red 160-DN2 module is in Error mode. Indicates failed

Solid Green 160-DN2 module is in the Run mode.

Occurs when power is applied to module.

initialization, duplicate node address or incorrect baud rate.

Run Mode

After a successful power-up or reset, the 160-DN2 module enters the

run mode and operates as a slave device to a master device. In run

mode, the module:

• Accepts messages from the master on the DeviceNet network.

• Monitors DeviceNet incoming power.

If an error is detected, the 160-DN2 module will enter the Error mode

(see heading below for more information).

Error Mode

Publication 0160-5.18 - June 2003

If the 160-DN2 module detects an error, the COMM LED is affected.

Errors are critical or noncritical, and are summarized below.

Table 4.B COMM LED State During Error Mode

COMM LED State Error Type Description

Power-up initialization failure.

Solid Red

Flashing Red

Off

See Chapter 7

, Troubleshooting for details in the troubleshooting

Critical

(not recoverable)

Non-Critical

(recoverable)

Non-Critical

(recoverable)

Duplicate node address detected.

Incorrect baud rate.

I/O connection timed out.

DeviceNet power lost.

chart on how to recover from an error.

Page 29

Chapter 5

DeviceNet Parameter Descriptions

This chapter contains:

• a description of DeviceNet parameters

• the definition of Electronic Data Sheet (EDS) files

• Bulletin 160 SSC Interface parameters

• brief description of Bulletin 160 parameters

Important: This chapter describes the parameter set for a Series C

Bulletin 160. If you are using a Series A or Series B Bulletin 160, not

all the parameters listed in this manual may apply to that drive. When

using a Series A Bulletin 160, please refer to the Bulletin 160 SSC

User Manual, Publication 0160-5.0. When using a Series B Bulletin

160, please refer to the Bulletin 160 SSC User Manual, Publication

0160-5.9.

DeviceNet Parameters The 160-DN2 communication module contains a set of parameters

that define how the module will interact with the Bulletin 160 SSC

drive and the DeviceNet network. These parameters may be used to

set the module’s address, baud rate, and I/O data format. Parameters

may also be read to attain status from the module.

Electronic Data Sheet (EDS) Files EDS files are specially formatted ASCII files that provide all of the

information necessary for a configuration tool such as RSNetWorx

for DeviceNet to access and alter the parameters of a device. The EDS

file contains information on the number of parameters in a device and

how those parameters are grouped. Additionally, the EDS file

contains information about each parameter such as parameter min,

max, and default values, parameter data format and scaling, and the

parameter name and units.

Parameters and EDS File You select an EDS file for the Bulletin 160 drive using a software

application such as RSNetWorx for DeviceNet. (See Chapter 6

160-DN2 with DeviceNet Scanner, for instructions to select an

appropriate EDS file.) An EDS file defines all the parameters in the

Bulletin 160 drive and the 160-DN2 module, and creates a public

interface to the drive on the DeviceNet network. Configuration tools

such as RSNetWorx for DeviceNet use EDS files to present you with

parameters that enable you to configure the 160 SSC drive via

DeviceNet by changing values associated with individual parameters.

, Using

Publication 0160-5.18 - June 2003

Page 30

5-2 DeviceNet Parameter Descriptions

Parameters and EDS File

(Continued)

Parameter values may be read or written via DeviceNet. Writing a

value to a parameter may configure drive operations such as

acceleration or deceleration rates. Writing a value to a parameter may

also configure DeviceNet operations such as which input or output

assemblies are to be used for polled I/O communications with a

master. Reading a parameter value gives you status information.

Bulletin 160 SSC Interface This parameter set contains all of the parameters described in the

Bulletin 160 SSC User Manual, plus a few extra parameters to configure

the operation of the 160-DN2 module on the DeviceNet network.

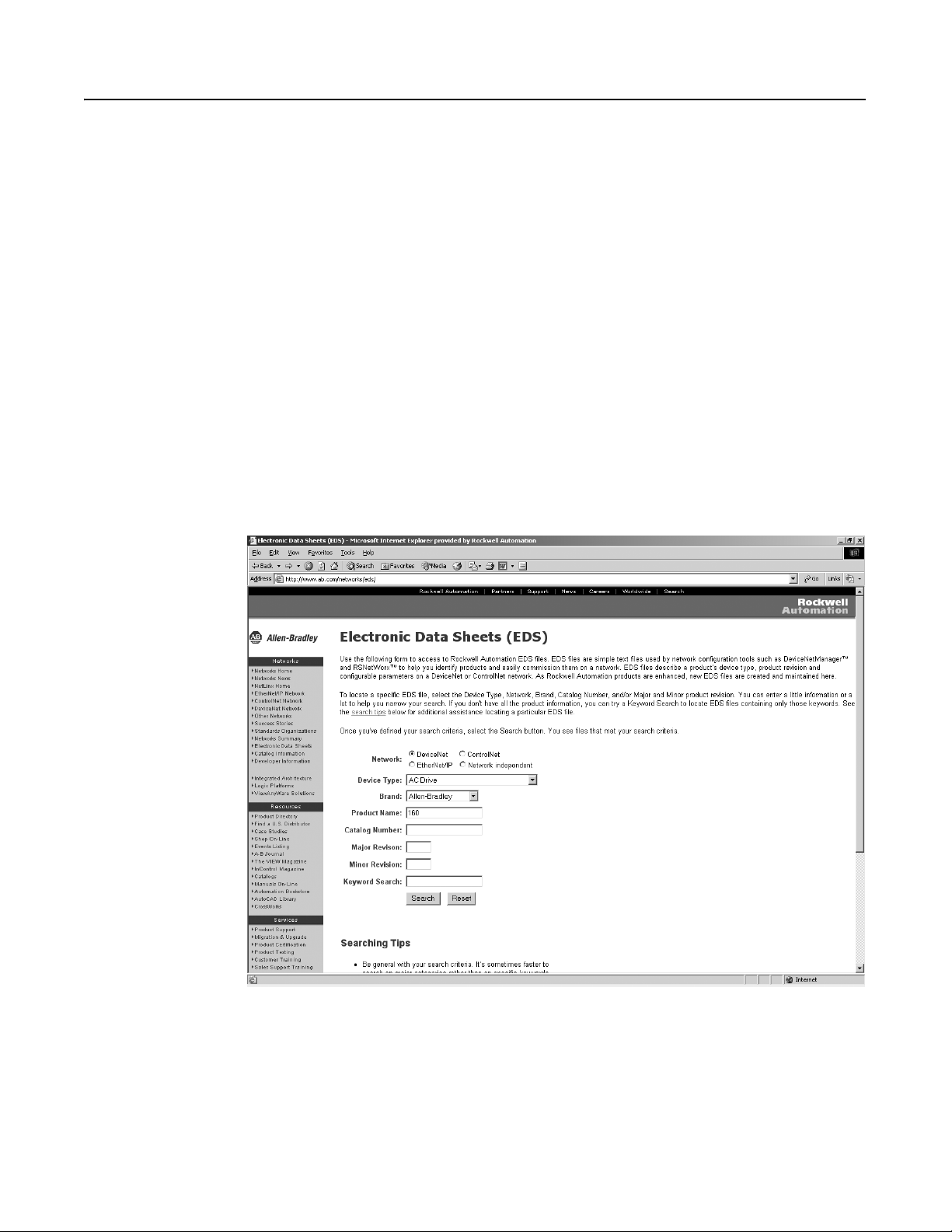

Locating EDS Files on the Internet Bulletin 160 SSC drives are available in Analog Signal Follower and

Preset Speed models. Each model supports a slightly different set of

parameters. (In general, the Preset Speed model contains extra

parameters for setting up preset speeds.) Accordingly, each drive

model uses an EDS file specific to that model.

You can find the EDS file for your drive at http://www.ab.com/

networks/eds. Select the search criteria for the EDS file to be the

same as that shown in the screen below.

Publication 0160-5.18 - June 2003

After the EDS file list appears, find your specific drive in the Product

Name column. Then, in the Brand column of that row click on the

Allen-Bradley Company link to access the EDS file for downloading.

Important: Use the correct EDS file for your specific drive model,

horsepower, and voltage. If an incorrect EDS file is used, you may not

be able to set up the drive with the configuration tool.

Page 31

DeviceNet Parameter Descriptions 5-3

Bulletin 160 SSC Interface

Parameters

The Bulletin 160 SSC Interface parameters are grouped together

logically. The following sections provide information about the

Bulletin 160 SSC Interface parameter groups:

• DeviceNet Parameters

• Drive Display Parameters

• Drive Program Parameters

The following parameter lists summarize the Bulletin 160 SSC

Interface. For more detailed information on the Display Group and

Program Group parameters, see the Bulletin 160 SSC User Manual.

Important: The following information contains object mapping data,

which is needed when using Explicit Messaging. Refer to Chapter 6,

Page 6-23

, for more information.

DeviceNet Parameters Use the following parameters to configure and monitor the DeviceNet

Network Interface. These parameters are unique to drives equipped

with the 160-DN2 DeviceNet Communication Module.

Parameter

Number

Name and Description

Object Mapping

(Class-Instance-

Attribute)

Min./Max.

Range

Factory

Default

101 [Switches MAC ID]

This read only parameter displays the state of the Node Address DIP switches.

This address may not be the current address of the module if the Baud Rate DIP

switches are set to 3. In this case P103 - [NV MAC ID] is used.

102 [Switches Baud]

This read only parameter displays the state of the Baud Rate DIP switches. A

value of 3 means that the actual baud rate used by this module is given in the

value of P104 - [NV Baud Rate].

0 = 125 kbps

1 = 250 kbps

2 = 500 kbps

3 = Use nonvolatile parameters for Address and Baud.

103 [NV MAC ID]

This read/write parameter enables you to program the Node Address of the

module independent of the DIP switch settings. To use this feature, set the baud

rate DIP switches (7 and 8) to ON before power-up. Changing this parameter

does not change the actual node address until power is cycled.

104 [NV Baud Rate]

This read/write parameter enables you to set the baud rate of the module without

having to set the DIP switches. To use this feature, set the baud rate switches (7

and 8) to ON before power up. Changing this parameter does not change the

actual data rate until power is cycled.

0 = 125 kbps

1 = 250 kbps

2 = 500 kbps

105 [Bus Off Error]

This read/write parameter determines how the Communication Module

processes a CAN Bus Off condition.

0 = Hold CAN chip in its bus off (reset) state when bus off is detected.

1 = If possible, fully reset the CAN chip and continue communicating

when a bus off condition is detected.

0xB4-1-3 0 to 63 63

0xB4-1-4 0 to 3 0

0xB4-1-5 0 to 63 63

0xB4-1-6 0 to 2 0

0x03-1-3 0 to 1 0

Publication 0160-5.18 - June 2003

Page 32

5-4 DeviceNet Parameter Descriptions

DeviceNet Parameters (Continued)

Parameter

Number

106 [Bus Off Count]

This read/write parameter counts the number of times the CAN chip went to the

bus off state. This counter stops counting when the count reaches 255. Any write

to this parameter will reset the counter to 0.

107 [Output Assembly]

This read/write parameter sets the output assembly instance that is to be used

for polled messaging with the master. The output assembly defines the data

format that the drive receives from the master. The name (output assembly) is

somewhat misleading in that this parameter determines the format of data being

sent to the drive by the master. It is named output assembly because the

DeviceNet specification refers to all assemblies as they relate to the master. The

following assembly instances are valid for this parameter:

0 = No Data

1 = Basic Contactor Output

2 = Two Command Contactor Output

3 = Basic Overload Output

4 = Basic Motor Control Output

5 = 2 Command Motor Control

20 = Basic Speed Control

21 = Extended Speed Control

100 = Speed Control in Hz

101 = Preset Control (for Preset Speed units only)

103 = Allen-Bradley Drive Assembly

Important: See Appendix B, pages B-24

assembly.

Name and Description

to B-25 for the formats of the output

Object Mapping

(Class-Instance-

Attribute)

0x03-1-4 0 to 255 0

0x29-1-100 0 to 103 20

Min./Max.

Range

Factory

Default

108 [Input Assembly]

This read/write parameter sets the input assembly instance that is to be used for

polled messaging with the master. The input assembly defines the data format that

the drive sends to the master in response to a polled message from the master.

The name (input assembly) is somewhat misleading in that this parameter

determines the format of data being sent to the master. It is named input assembly

because the DeviceNet specification refers to all assemblies as they relate to the

master. The following assembly instances are valid for this parameter:

0 = No Data

50 = Basic Overload Input

51 = Extended Overload Input

52 = Basic Motor Control Input

53 = Extended Motor Control Input

54 = Extended Motor Control 2

70 = Basic Speed Control Input

71 = Extended Speed Control Input

102 = Custom Parameter Based Assembly

104 = Allen-Bradley Drive Assembly

105 = Allen-Bradley Drive Assembly with Parameters

Important: See Appendix B, pages B-26

assembly.

109 [Assembly Word 0]

This read/write parameter is used when P108 - [Input Assembly] is set to 102

Custom Parameter Based Assembly. It defines the first word in an assembly built

from Bulletin 160 parameters. A 0 value defines the end of the assembly. For

more information, see Appendix B, page B-27

0x29-1-101 0 to 105 70

to B-28 for the formats of the input

0xB4-1-7 0 to 88 9

.

Publication 0160-5.18 - June 2003

Page 33

DeviceNet Parameters (Continued)

DeviceNet Parameter Descriptions 5-5

Parameter

Number

110 [Assembly Word 1]

This read/write parameter is used when P108 - [Input Assembly] is set to 102

Custom Parameter Based Assembly. It defines the second word in an assembly

built from Bulletin 160 parameters. A 0 value defines the end of the assembly. For

more information, see Appendix B, page B-27

111 [Assembly Word 2]

This read/write parameter is used when P108 - [Input Assembly] is set to 102

Custom Parameter Based Assembly, or 105 Allen-Bradley Drive Assembly with

Parameters. It defines the third word in an assembly built from Bulletin 160

parameters. A 0 value defines the end of the assembly. For more information, see

Appendix B, page B-27 or B-28.

112 [Assembly Word 3]

This read/write parameter is used when P108 - [Input Assembly] is set to 102

Custom Parameter Based Assembly, or 105 Allen-Bradley Drive Assembly with

Parameters. It defines the fourth word in an assembly built from Bulletin 160

parameters. A 0 value defines the end of the assembly. For more information, see

Appendix B, page B-27 or B-28.

113 [DN Fault Mode]

This read/write parameter determines the drive’s behavior when a

communication fault such as loss of DeviceNet power occurs. The behavior

choices are:

0 = Fault the drive and issue a stop command

1 = Ignore the communication fault

Name and Description

.

Object Mapping

(Class-Instance-

Attribute)

0xB4-1-8 0 to 88 0

0xB4-1-9 0 to 88 0

0xB4-1-10 0 to 88 0

0x29-1-16 0 to 1 0

Min./Max.

Range

Factory

Default

!

114 [Motor Base RPM]

This read/write parameter is set to the motor’s rated nameplate speed in RPM.

115 [DNet Idle Mode]

This Parameter controls the action of the drive when the Scanner is in Idle Mode.

0 = Stop if Idle Mode (default)

1 = Hold last state if Idle Mode

116 [DNet SW Version]

This read only parameter indicates the software version of the DeviceNet option.

The number is shown in the format xx.yy where xx denotes the major revision

level and yy denotes the minor revision level.

117 [COS Mask]

This parameter is a 16-bit mask used to enable automatic change of state

messages. A 0 disables the indicated status from causing an automatic

message. A 1 enables the status. The mask is applied to the defined input status

assembly. The default value is 0xFFFF.

118 [Local Return Md]

This parameter sets the input mode the drive will use when transitioning from

network to local control. This is only used with input mode 2. Available values are

0, 1, 3, 4, and 5.

ATTENTION: Ignoring communication faults may result in

equipment damage, personal injury, or death. Make sure you

understand how ignoring a communication fault affects the

operation of your system.

0x28-1-15 200 to 32000 1800 RPM

0xB4-1-11 0 to 1 0

0xB4-1-12 0.00 to 10.00 3.01

0xB4-1-13 0 to 0xFFFF 0xFFFF

0xB4-1-14 0 to 9 0

Publication 0160-5.18 - June 2003

Page 34

5-6 DeviceNet Parameter Descriptions

Drive Display Parameters

(Read Only)

Parameter

Number

Parameter Name

Object Mapping

(Class-Instance-

Attribute)

Below is a brief description of the Bulletin 160 SSC Interface Display

Group parameters. Refer to the Bulletin 160 SSC User Manual for

more detailed information on these parameters

Description Units

.

01 [Output Frequency] 0xB3-1-1 Frequency at TB2 terminals T1, T2, T3. 0.1 Hz

02 [Output Voltage] 0xB3-1-2 Voltage at TB2 terminals T1, T2, T3. 1 Volt

03 [Output Current] 0xB3-1-3 Current at TB2 terminals T1, T2, T3. 0.01 Amperes

04 [Output Power] 0xB3-1-4 Power at TB2 terminals T1, T2, T3. 0.01 kW

05 [Bus Voltage] 0xB3-1-5 DC Bus voltage level. 1 Volt

06 [Cmd Frequency] 0xB3-1-6 Commanded Frequency. 0.1 Hz

07 [Present Fault] 0xB3-1-7 Coded last fault number. Numeric Value

08 [Heatsink Temp] 0xB3-1-8 Temperature of the drive heatsink. 1 degree C

09 [Drive Status] 0xB3-1-9 Status of drive in binary coded format. Important: Parameter 9

Binary Number

shown below does not match what is published in the Bulletin 160

SSC User Manual. The DeviceNet binary code for Parameter 9 is:

Bit 6 Bit 5 Bit 4

Bit 3 Bit 2 Bit 1 Bit 0

Running

Forwa rd

Accel

Decel

Drive

Fau lted

Reverse

Latched

A-B Internal

Use Only

At

Frequency

Reference

10 [Drive Type] 0xB3-1-10 Used by Allen-Bradley field ser vice personnel. Numeric Value

11 [Firmware Version] 0xB3-1-11 Version of drive firmware used. Numeric Value

12 [Input Status]

➀ 0xB3-1-12 Open (0) Closed (1) state of Drive’s discrete inputs.

Binary Number

Important: Parameter 12 shown below does not match what is

published in the Bulletin 160 SSC User Manual. The DeviceNet

binary code for Parameter 12 is:

Bit 6 Bit 5 Bit 4Bit 7

Bit 3 Bit 2 Bit 1 Bit 0

Preset 1

Input

Preset 2

Input

Preset 3

Input

Unused

Reverse

Stop

Start

Not Used

13 [Power Factor Ang] 0xB3-1-13 Angle (electrical degrees) between V and I. 0.1 degree C

14 [Memory Probe] 0xB3-1-14 Used by Allen-Bradley service personnel. Numeric Value

➀ For preset speed model, this parameter contains the data from parameter 15 in the SSC drive due to conflicting parameter numbers with DeviceNet

specific parameters.

Publication 0160-5.18 - June 2003

Page 35

DeviceNet Parameter Descriptions 5-7

Drive Display Parameters

(Read Only) (Continued)

Parameter

Number

Parameter Name

15 [Preset Status] 0xB3-1-15 Open (0) and closed (1) state of TB3 inputs SW1, SW2, and SW3. Binary Number

16 [Analog Input] 0xB3-1-16 The analog input as a percent of full scale. 0.1%

17 [Fault Buffer 0] 0xB3-1-17 Most recent fault. Numeric Value

18 [Fault Buffer 1] 0xB3-1-18 Second most recent fault. Numeric Value

19 [Fault Buffer 2] 0xB3-1-19 Third most recent fault. Numeric Value

This parameter applies only to the Analog Signal Follower model.

This parameter applies only to the Preset Speed model.

Object Mapping

(Class-Instance-

Attribute)

Description Units

Bit 3 Bit 2 Bit 1 Bit 0

SW1

SW2

SW3

Unused

Publication 0160-5.18 - June 2003

Page 36

5-8 DeviceNet Parameter Descriptions

Drive Program Parameters Below is a brief description of the Bulletin 160 SSC Interface

Program Group parameters. Refer to the Bulletin 160 SSC User

Manual for more detailed information on these parameters.

Parameter

Number

30 [Accel Time 1] 0xB3-1-30 Time to ramp from 0 Hz to maximum frequency. 0.1 Seconds

31 [Decel Time 1] 0xB3-1-31 Time to ramp from maximum frequency to 0 Hz. 0.1 Seconds

32 [Minimum Frequency] 0xB3-1-32 Lowest continuous output frequency. 1 Hz

33 [Maximum Frequency] 0xB3-1-33 Highest continuous output frequency. 1 Hz

34 [Stop Mode Select] 0xB3-1-34 Determines stop mode used. Numeric Value

35 [Base Frequency] 0xB3-1-35 Set to motor’s nameplate frequency. 1 Hz

36 [Base Voltage] 0xB3-1-36 Set to motor’s nameplate voltage. 1 Volt

37 [Maximum Voltage] 0xB3-1-37 Highest voltage the drive will output. 1 Volt

38 [Boost Select] 0xB3-1-38 Sets the volts/Hz relationship. Numeric Value

39 [Skip Frequency] 0xB3-1-39 Frequency at which drive will not run continuously. 1 Hz

40 [Skip Freq Band] 0xB3-1-40 Used with P39 - [Skip Frequency] to create skip band. 1 Hz

41 [Overload Select] 0xB3-1-41 Selects derating factor for motor overload. Numeric Value

42 [Motor Overload] 0xB3-1-42 Set to motor nameplate full load amperes. 0.01 Amperes

43 [Current Limit] 0xB3-1-43 Max output current allowed before limiting. % I rating

44 [DC Hold Time] 0xB3-1-44 DC Injection Braking duration. 0.1 Seconds

45 [DC Hold Voltage] 0xB3-1-45 Voltage level for DC Injection Braking. 1 Volt

46 [Input Mode] 0xB3-1-46 Type of START, STOP, REV, commands. Numeric Value

Parameter Name

Object Mapping

(Class-Instance-

Attribute)

Description Units

ATTENTION: Changing this parameter

value may cause unpredictable network

!

conditions, resulting in equipment damage,

personal injury, or death. Make sure that

you understand how changing this

parameter affects your application.

ATTENTION: Changing this parameter

value may cause unpredictable network

!

47 [Output Configure] 0xB3-1-47 Configures TB3 output relay functionality. Numeric Value

48 [Output Threshold] 0xB3-1-48 Used in conjunction with P47 - [Output Configure]. Numeric Value

49 [PWM Frequency] 0xB3-1-49 Carrier frequency for PWM output waveform. 0.1 kHz

50 [Restart Tries] 0xB3-1-50 Times drive will attempt to reset a fault. Numeric Value

51 [Restart Time] 0xB3-1-51 Time between restart attempts. 0.1 Seconds

52 [DB Enable] 0xB3-1-52 Enables/disables dynamic braking. Numeric Value

53 [S-Curve] 0xB3-1-53 Enables a fixed shape S-curve. Numeric Value

Publication 0160-5.18 - June 2003

conditions, resulting in equipment damage,

personal injury, or death. Make sure that

you understand how changing this

parameter affects your application.

Page 37

DeviceNet Parameter Descriptions 5-9

Drive Program Parameters

(Continued)

Parameter

Number

54 [Clear Fault] 0xB3-1-54 Setting to 1 performs a fault reset. Numeric Value

55 [Probe Address] 0xB3-1-55 Used by Allen-Bradley service personnel. Numeric Value

56 [Reset Functions] 0xB3-1-56 Sets all parameters to their factory default. Numeric Value

57 [Program Lock] 0xB3-1-57 Locks all program group parameters. Numeric Value

58 [Internal Freq] 0xB3-1-58 Digital frequency setpoint. 0.1 Hz

59 [Freq Select] 0xB3-1-59 Selects source of Frequency command. Numeric Value

60 [Zero Offset] 0xB3-1-60 Add or subtracts an offset to the analog input. Numeric Value

60 [DN Preset Cmd] 0xB3-1-92 Network preset command. Numeric Value

61 [Preset Freq 0] 0xB3-1-61 Sets command frequency when selected. 0.1 Hz

62 [Preset Freq 1] 0xB3-1-62 Sets command frequency when selected. 0.1 Hz

63 [Preset Freq 2] 0xB3-1-63 Sets command frequency when selected. 0.1 Hz

64 [Preset Freq 3] 0xB3-1-64 Sets command frequency when selected. 0.1 Hz

65 [Preset Freq 4] 0xB3-1-65 Sets command frequency when selected. 0.1 Hz

66 [Preset Freq 5] 0xB3-1-66 Sets command frequency when selected. 0.1 Hz

67 [Preset Freq 6] 0xB3-1-67 Sets command frequency when selected. 0.1 Hz

68 [Preset Freq 7] 0xB3-1-68 Sets command frequency when selected. 0.1 Hz

69 [Accel Time 2] 0xB3-1-69 Sets second acceleration rate. 0.1 Seconds

70 [Decel Time 2] 0xB3-1-70 Sets second deceleration rate. 0.1 Seconds

71 [IR Compensation] 0xB3-1-71 Adds a voltage to the output based on the torque current. 1%

72 [Slip Comp] 0xB3-1-72 Compensates for the inherent slip of the motor. 0.1 Hz

73 [Reverse Disable] 0xB3-1-73 Setting to 1 disables the reverse. Numeric Value

74 [Analog Select] 0xB3-1-74 Selects between unipolar and bipolar analog input. Numeric Value

75 [Analog Minimum] 0xB3-1-75 Sets the percent of the analog input used to represent

76 [Analog Maximum] 0xB3-1-76 Sets the percent of the analog input used to represent

78 [Compensation] 0xB3-1-78 Some drive/motor combinations have inherent instabilities

79 [Curent Trip] 0xB3-1-79 Percent above P43 - [Current Limit] at which the drive trips

Parameter Name

Object Mapping

(Class-Instance-

Attribute)

Description Units

0.1%

P32 - [Minimum Frequency].

0.1%

P33 - [Maximum Frequency].