Page 1

Allen-Bradley

160 SSC

V ariable Speed

Controller

(Series B)

0.37 – 2.2 kW (0.5 – 3 HP)

FRN 5.xx – 6.xx

User

Manual

Page 2

Important User Information

In no event will the Allen-Bradley Company be

responsible or liable for indirect or consequential

damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are

included solely for illustrative purposes. Because

of the many variables and requirements

associated with any particular installation, the

Allen-Bradley Company cannot assume

responsibility or liability for actual use based on

the examples and diagrams.

The information in this manual is organized in

numbered chapters. Read each chapter in

sequence and perform procedures when you are

instructed to do so. Do not proceed to the next

chapter until you have completed all procedures.

Throughout this manual we use notes to make you

aware of safety considerations:

A TTENTION: Identifies information

about practices or circumstances that

can lead to personal injury or death,

property damage or economic loss.

No patent liability is assumed by Allen-Bradley

Company with respect to use of information,

circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in

whole or in part, without written permission of

the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you

aware of safety considerations.

Attentions help you:

D identify a hazard

D avoid the hazard

D recognize the consequences

Important: Identifies information that is

especially important for successful application

and understanding of the product.

Page 3

This Page Intentionally Left Blank.

Notes

N-1

Page 4

Notes

This Page Intentionally Left Blank.

N-2

Page 5

This Page Intentionally Left Blank.

Notes

N-3

Page 6

Notes

This Page Intentionally Left Blank.

N-4

Page 7

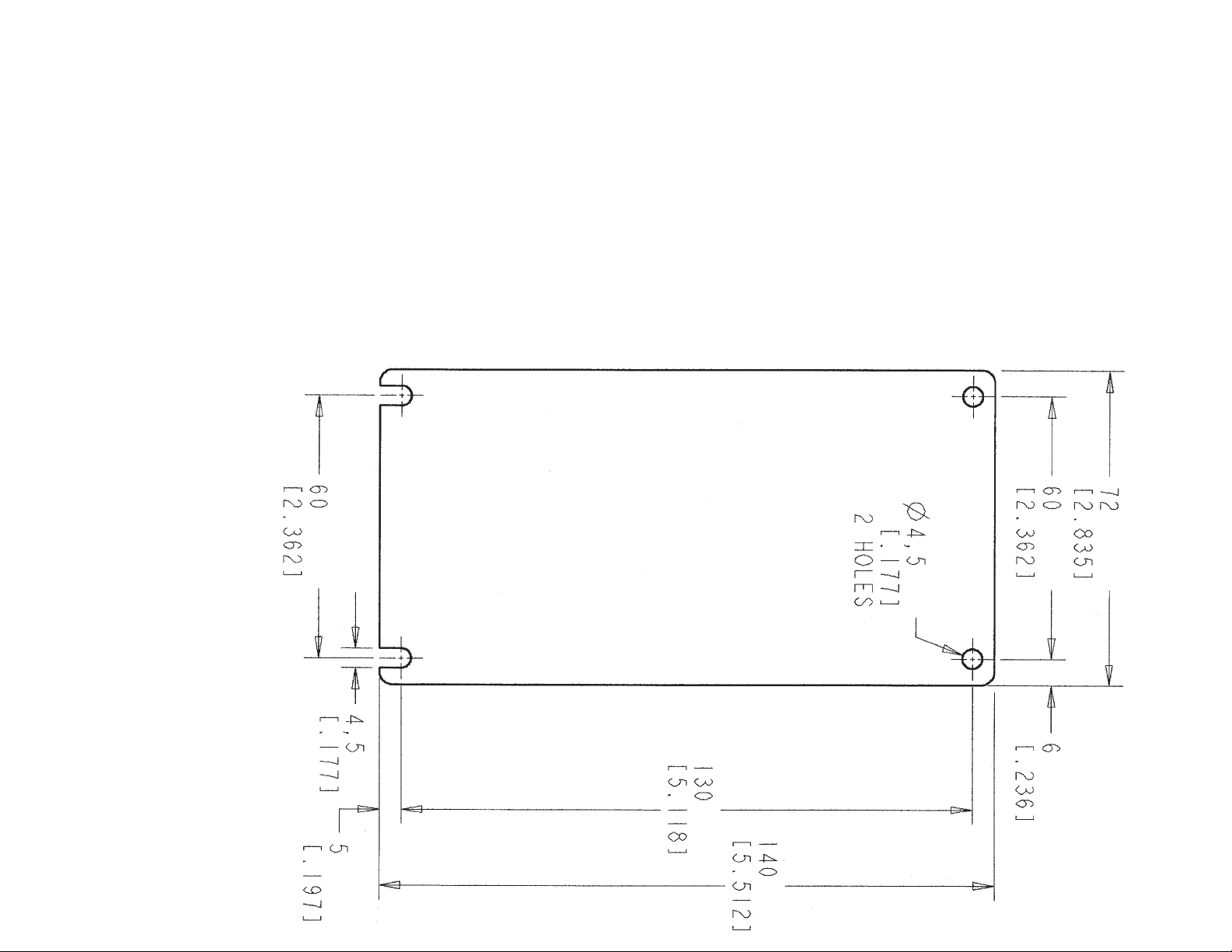

Attach template to mounting surface

and drill four (4) 4.5mm (0.177 inches) diameter holes.

Dimensions are in millimeters [inches].

Page 8

Publication 160-5.9 Summary of Changes

D The Firmware Version of the drive was

changed from FRN5.01 to FRN6.0.

D The parameter P78 – [Compensation] was

added to help eliminate non-sinusoidal motor

currents that are generated by some

motor/drive combinations. See page 5-12.

This information was supplied previously in

the form of a Document Update, Publication

160-5.9DU4, which has been eliminated.

D Firmware version FRN 6.0 includes

enhancements made to the current sensing to

help filter out capacitive current. These

enhancements improve the overall accuracy of

the drive’s displayed output current. Due to

this improvement, the installation of a

“Reactor at Drive” is no longer recommended

because it negatively effects the drive’ s

current sensing accuracy. If an external device

is required to be mounted at the drive for

Reflected Wave purposes, an RWR protective

device is recommended. Cable length

recommendations for an “RWR at Drive” have

Summary of Changes

been added to both T able 2.F and Table 2.G

replacing our previous recommendations of a

“Reactor at Drive”.

D The paragraph titled “Recommended Line

Side Protection” has been updated to provide

added clarity on the use of devices other than

fuses for the purposes of line side protection.

T able 2.C and Table 2.D have also been

updated.

D The paragraph titled “Motor Cable

Recommendations” has been updated.

T able 2.E was added to provide recommended

cable types based on cable distances and

environmental conditions.

D Part numbers and dimensional information for

the new 24V DC interface module and “RF”

series of line filters have been added to

Appendix A.

D Publication 160-5.9DU2 has been

incorporated into the manual. The contents of

the document update can now be found in

Appendix B.

Page 9

Summary of Changes

Summary of Change

This Page Intentionally Blank

Page 10

Table of Contents

Chapter 1 – Information and Precautions 1-1. . . . . . . . . . . . . . . .

General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Precautions 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions Used In This Manual 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 – Installation and Wiring 2-1. . . . . . . . . . . . . . . . . . . .

Installation and Storage 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Compliance 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Features 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Wiring For Preset Speed and Analog Signal Follower Models 2-2. . . . . . . . . . . . .

Input Power Conditioning 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Line Side Protection 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Cable Recommendations 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Wiring Requirements 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Wiring – Analog Signal Follower Model 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Wiring – Preset Speed Model 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Wiring Diagrams 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 – Program Keypad Module 3-1. . . . . . . . . . . . . . . . . . .

Features 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Mode 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Mode 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing Program Keypad Module 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 – Start-Up 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-up Procedure 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 – Parameters and Programming 5-1. . . . . . . . . . . . . . .

Overview of Parameters 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Example 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Group Parameters 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Group Parameters 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 – Troubleshooting and Fault Information 6-1. . . . . . . .

Fault Information 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram of Bulletin 160 Analog Signal Follower 6-4. . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Controller Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog Numbers for Bulletin 160 Accessories A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Dimensions A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessory Dimensions A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 11

Table of Contents

Important Information

Appendix B

CE Compliance B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Essential Requirements for a Conforming EMC Installation B-1. . . . . . . . . . . . . . . . . . . .

General Instructions for an EMC Compliant Installation B-2. . . . . . . . . . . . . . . . . . . . . . .

Low Voltage Directive 73/23/EEC Compliance B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

Index I-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 12

Information and Precautions

General Information1

Receiving –

thoroughly inspect the equipment before

accepting the shipment from the freight company.

Check the item(s) received against the purchase

order. If any items are obviously damaged, do not

accept delivery until the freight agent notes the

damage on the freight bill.

If you find any concealed damage during

unpacking notify the freight agent. Also, leave the

shipping container intact and have the freight

agent make a visual inspection of the equipment

in order to verify damage.

General Precautions

In addition to the precautions listed throughout

this manual, you must read and understand the

following statements which are general to the

system.

It is your responsibility to

Chapter 1

Unpacking – Remove all packing material,

wedges, or braces from within and around the

controller. Remove all packing material from the

heat sink.

Inspection – After unpacking, check the item(s)

nameplate catalog number against the purchase

order. An explanation of the catalog numbering

system for the Bulletin 160 controller is included

as an aid for nameplate interpretation. Refer to

the following page for complete nomenclature.

Important: Before you install and start up the

controller, inspect the mechanical integrity of the

system (e.g., look for loose parts, wires,

connections, etc.).

ATTENTION: The surface

temperatures of the controller may

become hot, which may cause injury.

ATTENTION: This controller

contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static

control precautions are required when

installing, testing, servicing or

repairing this assembly. Component

damage may result if ESD control

procedures are not followed. If you are

not familiar with static control

procedures, reference A-B Publication

8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other

applicable ESD protection handbook.

ATTENTION: Only personnel

familiar with the controller and

associated machinery should plan or

implement the installation, start-up,

and subsequent maintenance of the

system. Failure to comply may result

in personal injury and/or equipment

damage.

SSC is a trademark of Rockwell Automation

ATTENTION: An incorrectly

applied or installed controller can

result in component damage or

reduction in product life. Wiring or

application errors such as undersizing

the motor, supplying an incorrect or

an inadequate AC supply, or

excessive ambient temperatures may

result in system malfunction.

ATTENTION: The controller

contains high voltage capacitors

which take time to discharge after

removal of mains supply. Before

working on controller, ensure

isolation of mains supply from line

inputs [L1, L2, L3 (U, V, W)]. Wait

one minute for capacitors to

discharge to safe voltage levels.

Failure to do so may result in

personal injury or death.

1-1

Page 13

Chapter 1 –

Information and Precautions

Figure 1.1 – Catalog Number Code Explanation

160 – A A04 N SF1 P1

First

Position

Bulletin

Number

An “S” in the

Bulletin Number

denotes a single

phase input

voltage.

➀ This manual applies only to the open style (IP20) device. Refer to separate instruction sheets for Chassis Mount

and NEMA 4 (IP66) devices.

Second

Position

Voltage Rating

A 200 – 240V 1∅

200 – 240V 3∅

B 380 – 460V 3∅

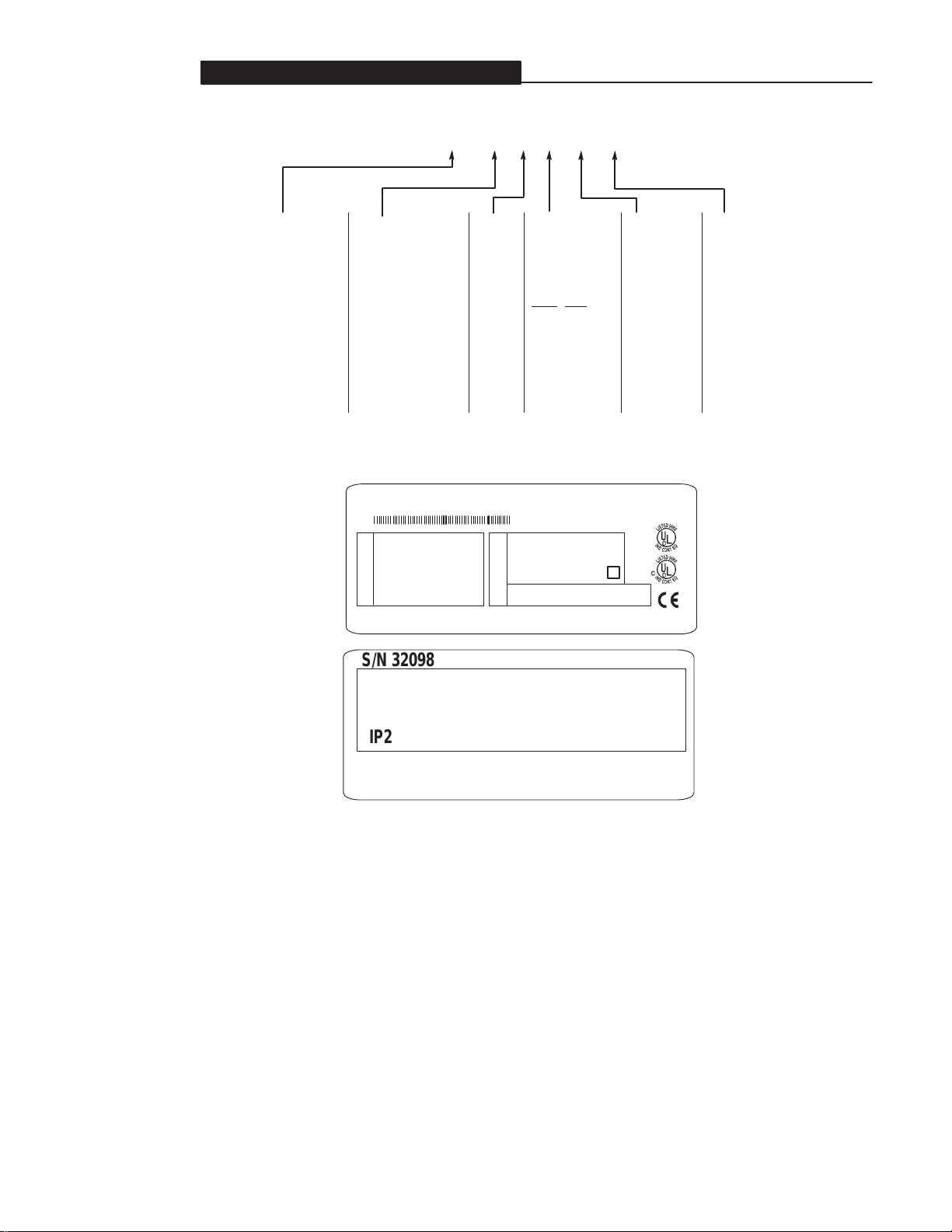

Figure 1.2 – Nameplate Information

CAT160–AA04NSF1P1 SER B

I

V:

N

A:

P

Hz:

U

VA:

T

ALLEN-BRADLEY

S/N 32098

OPERATING AMBIENT TEMP: 0 – 50°C

SHORT CIRCUIT CURRENT: 10KA

POWER TERMINAL WIRE: Use 75°C Cu Wire

IP20

WARNING: ! Allow 1 Minute after power is removed

before servicing. Accessible surfaces may be hot.

Compatible with Type B RCD protection devices only.

200-240

5.4

50/60

2200

Third

Position

Current

Rating

A01

A02

A03

A04

A06

Fourth

Position

Enclosure

Type

Letter Type

N Open (IP20)

P Chassis Mount

(external

heatsink)

A08

A12

O

V:

3∅

U

T

P

U

T

4mm

Torque 1.35 Nm (12 in.-lbs.)

200-230

4.5

A:

Hz:

0-240

Motor

0.75kW/1HP

Rating:

2

– .75mm2 (12 – 18 AWG.)

Fifth

Position

Control

SF1 = Analog

Signal

➀

Follower

PS1 = Preset

Speed

FRN:

6.xx

3∅

MADE IN U.S.A.

Sixth

Position

Programmer

(Optional)

Program

Keypad Module

Nameplate is located on the

side of the unit.

Conventions Used In This Manual

Parameter numbers and names are shown in bold typeface and follow the format PXX – [*] where P

denotes parameter, XX denotes the two digit parameter number, and * represents the parameter name. For

example, P01 – [Output Frequency].

1-2

Page 14

Installation and Wiring

Chapter 2

Installation and Storage

Take these actions to prolong controller life and

performance:

D store within an ambient temperature range of

–40_ to +85_C

D store within a relative humidity range of 0%

to 95%, non-condensing

D protect the cooling fan by avoiding dust or

metallic particles

D avoid storing or operating the controller where

it could be exposed to a corrosive atmosphere

D protect from moisture and direct sunlight

D operate at an ambient temperature range of 0_

to +50_C

T o maintain proper working conditions, install the

controller on a flat, vertical and level surface. Use

mounting screws up to 4.5mm (0.177 inches) in

diameter or mount on 35mm DIN Rail.

CE Compliance

Refer to Appendix B for detailed information.

Mounting Requirements

Controller Features

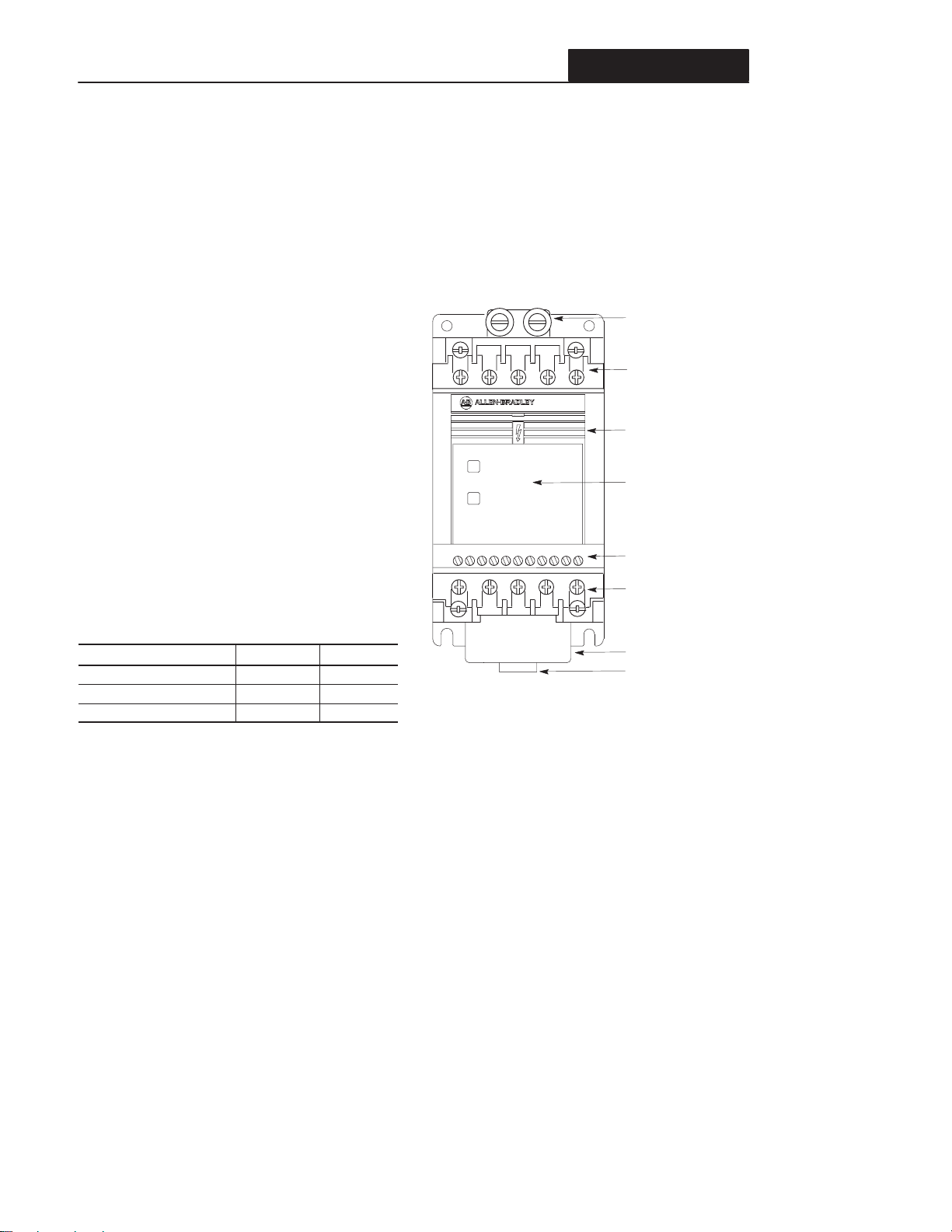

Figure 2.1 below details the features of both the

Analog Signal Follower and Preset Speed models.

Important: The features are the same for single

and three phase units.

Figure 2.1 – Controller Features

Ground Tab/

Protective Earth

BR

L3L2L1

FAUL T ➁

READY ➂

3

T

–

876543219110 1

–

R

ST

2

T1T

VDCDC

UW

BR

+

+

Terminal Block One

(TB1) – For Line

Power. ➀

Ready/Fault

Indicating Panel –

Standard for Bulletin

160 controllers. ➃

LEDs – Indicate

operational status.

Terminal Block Three

(TB3) – For Control

Wiring.

Terminal Block Two

(TB2) – For Motor

Wiring. ➀

Description Metric English

Min. Panel Thickness (14 GA) 1.9mm 0.0747 in.

Mounting Base Screws m4 x 0.7 # 8–32

Mounting T orque 1.13 to 1.56 Nm. 10–14 lb. in.

D See Appendix A for details on controller

dimensions and weights.

D There must be a minimum of 12.5mm

(0.5 inches) clearance around all sides of the

controller. Use either DIN rail or mounting

holes. (Use the drilling template at the back of

the manual for mounting the controller.)

D Leave debris cover attached during controller

installation to protect from falling debris. T o

ensure proper controller operation, remove

cover before applying power.

Fan

DIN Latch

➀ Refer to Figure 2.2

➁ The FAULT (red) indicator illuminates when a controller fault

condition exists. Refer to Chapter 6 for details on how to clear a fault

and general troubleshooting procedures.

➂ The READY (green) indicator illuminates when the DC bus is

charged and the controller is ready to run.

➃ Bulletin 160 controllers are fully functional when installed with a

Ready/Fault indicating panel. All control functions can be performed

from the control terminal block (TB3). Factory default parameter

settings cannot be changed with the Ready/Fault indicating panel.

A Program Keypad Module can be ordered separately, Catalog

160-P1, or as a factory-installed option by adding “P1” to the end of

the catalog number. Refer to Chapter 3, Program Keypad Module

for a detailed explanation of functionality.

2-1

Page 15

Chapter 2 –

Installation and Wiring

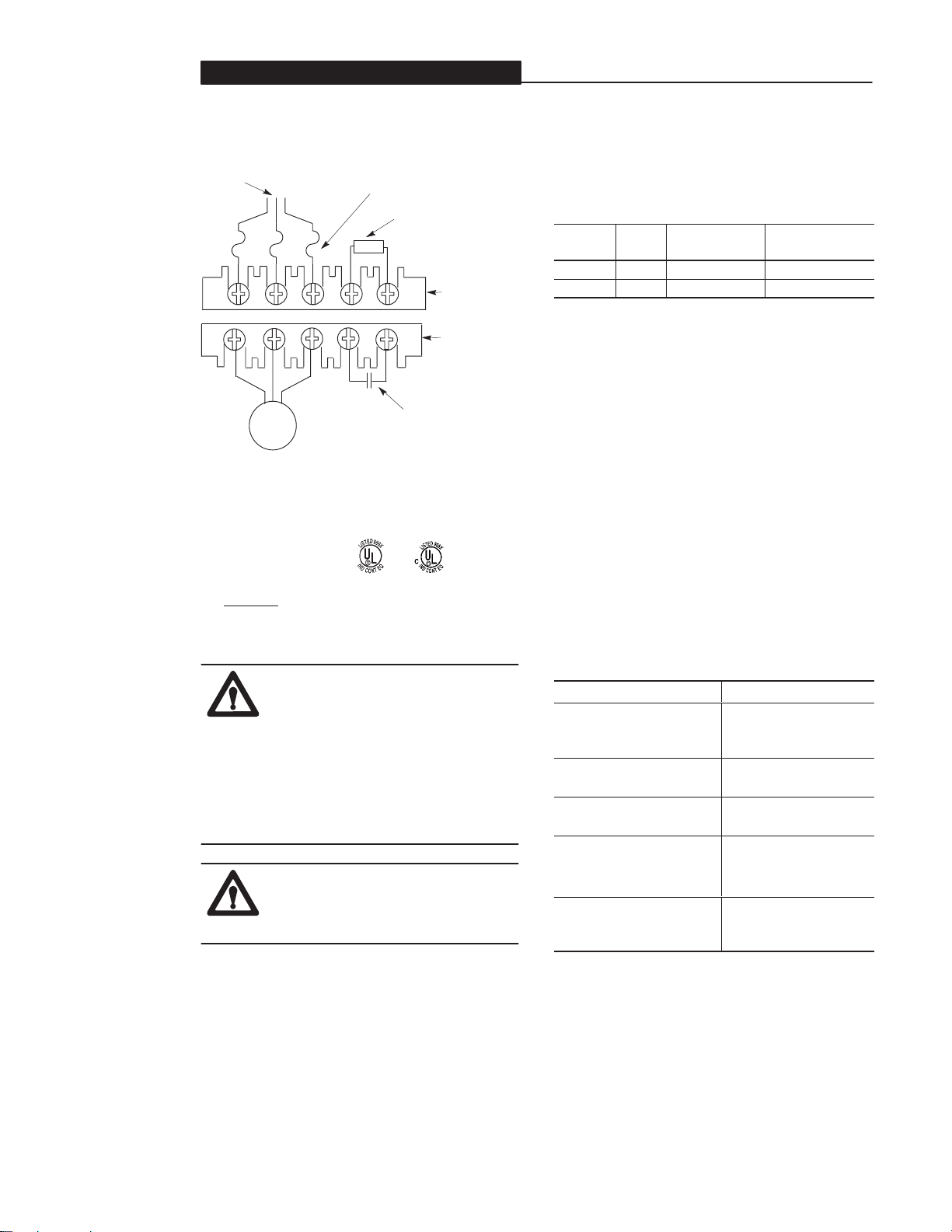

Figure 2.2 – Power Wiring For Analog

Signal Follower and Preset Speed Models

Required Branch

Circuit Disconnect ➀

R

T

1

UW

➀ For single phase input applications, connect the AC input line to

input terminals (L1) R and (L2) S.

➁ Connection for dynamic brake resistors for all models.

Important: P52 – [DB Enable] must be enabled for proper

operation. See Appendix A for part numbers.

➂ Bulletin 160 controllers are

motor overload protective devices. An external overload relay is

not required

➃ Connection for an external capacitor module. Provides extended

ride through capability and improved inherent braking

performance. See Appendix A for part number.

L3L2L1

ST

T

2

T

VDCDC

Motor ➂

for single motor applications.

Input Line Protective Device –

See Table 2.C and Table 2.D.

BR BR

–

+

–

3

+

Capacitor Module

Option ➃

Dynamic Brake

Module Option ➁

Terminal

Block One

(TB1) – For

Line Power and

Brake Resistor.

Terminal Block

Two (TB2) –

For Motor and

Capacitor

Module.

and listed as

Power Wiring For Preset Speed and Analog

Signal Follower Models

Table 2.A – Power Terminal Block Specifications

Terminal

Block

TB1

TB2

➄ The Bulletin 160 SSC is IP20 with wires installed on power

terminal blocks.

Screw

Size

➄

➄

Max/Min Wire

2

Size mm

M4 4 – 0.75 (12 – 18) 1.81 – 1.35 (16 – 12)

M4 4 – 0.75 (12 – 18) 1.81 – 1.35 (16 – 12)

(AWG)

Max/Min Torque

Nm. (lb.in.)

Input Power Conditioning

The controller is suitable for direct connection to

AC power lines within the rated voltage of the

controller (see Appendix A). Listed below are

certain power line conditions which may cause

component damage or reduction in product

life. If any of the conditions exist as described in

the table below, install “one” of the devices listed

under the heading “Corrective Action” on the line

side of the controller. Important: Only one

device per branch circuit is required. It should be

mounted closest to the branch and sized to handle

the total current of the branch circuit.

Table 2.B – Power Line Conditions

2-2

A TTENTION: The controller is

intended to be commanded by control

input signals that will start and stop the

motor. A device that routinely disconnects

then reapplies line power to the controller

for the purpose of starting and stopping the

motor should not be used. If it is necessary

to use this method for starting and stopping

or if frequent cycling of power is

unavoidable, make sure that it does not

occur more than once a minute.

ATTENTION: Do not connect power

factor correction capacitors to controller

output terminals T1, T2, and T3 (U, V, and

W) or component damage could occur.

Power Line Condition Corrective Action

Available short circuit currents

(fault currents) greater than 10,000

Amps

Line has power factor correction

capacitors

Line has frequent power

interruptions

Line has high frequency

(>10 Hz) noise spikes in excess of

900V (Induction heaters, RF

equipment, choppers)

Line has intermittent noise spikes

in excess of 2000V (lightening)

S Check supply voltage.

S Line Reactor (See A-4) or

S Isolation Transformer

S Line Reactor (See A-4) or

S Isolation Transformer

S Line Reactor (See A-4) or

S Isolation Transformer

S MOV option (See A-4) or

S Line Reactor (See A-4) or

S Isolation Transformer

S MOV option (See A-4) or

S Line Reactor (See A-4) or

S Isolation Transformer

Page 16

Chapter 2 –Installation and Wiring

at n

at n

use

)N/A

)

A

)

(

)

****

)

(

)

A

A

***

)

)

)

***

at n

at n

use

)

A

)

)

A

)

****

()

A

AA

A

***

()

A

Recommended Line Side Protection

guidelines must be followed in order to meet the

NEC requirements for branch circuit protection:

The Bulletin 160 Smart Speed Controller has

been UL tested and approved for use with a fuse,

circuit breaker or manual motor starter installed

on the line side of the controller. The maximum

branch circuit protective rating is limited to four

times the rated output current of the drive or

30 amperes, whichever is less.

The ratings in T able 2.C and Table 2.D are the

“minimum” recommended values for use with

each drive rating. It should be noted that the

products listed under the column heading “Other

Protective Devices” must follow the proper

application guidelines stated for those products in

order to meet local or national electrical codes.

When using Bulletin 140 manual motor starters or

Bulletin 1492 circuit breakers the following

Bulletin 140 manual motor starters can be used in

single and group motor applications. In single

motor applications, a fuse or UL489 rated circuit

breaker is required upstream from the Bulletin

140 manual motor starter. In group motor

installations, the Bulletin 140 can be used for

protection of an individual motor within the group

and “one set” of fuses or a UL489 rated circuit

breaker serves as the Short Circuit Protective

Device for the entire “Group Installation”.

Bulletin 1492 circuit breakers are rated as

supplementary protective devices. When using

this device, upstream fuses or UL489 rated circuit

breakers are required for each motor in the branch

circuit regardless if it is a single or group motor

installation.

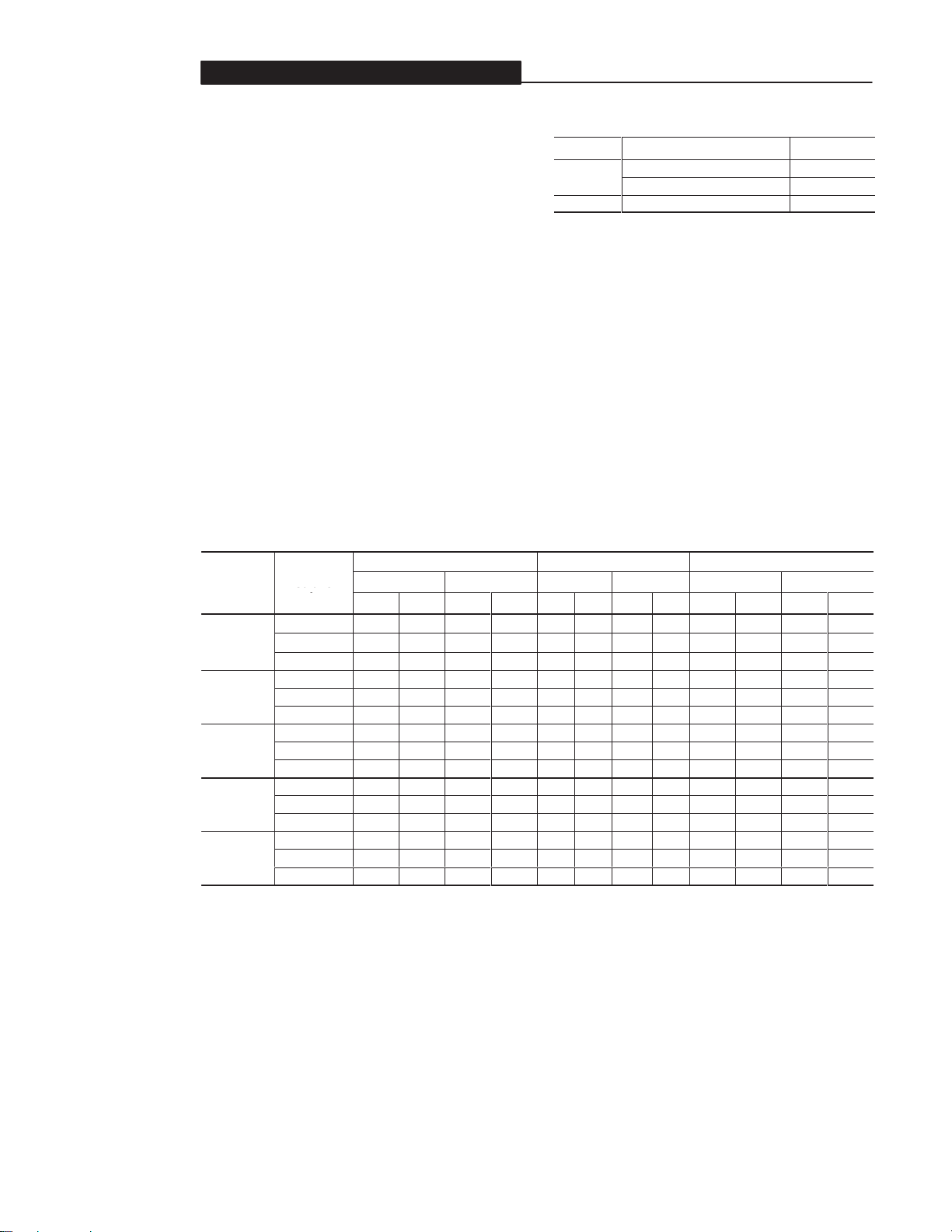

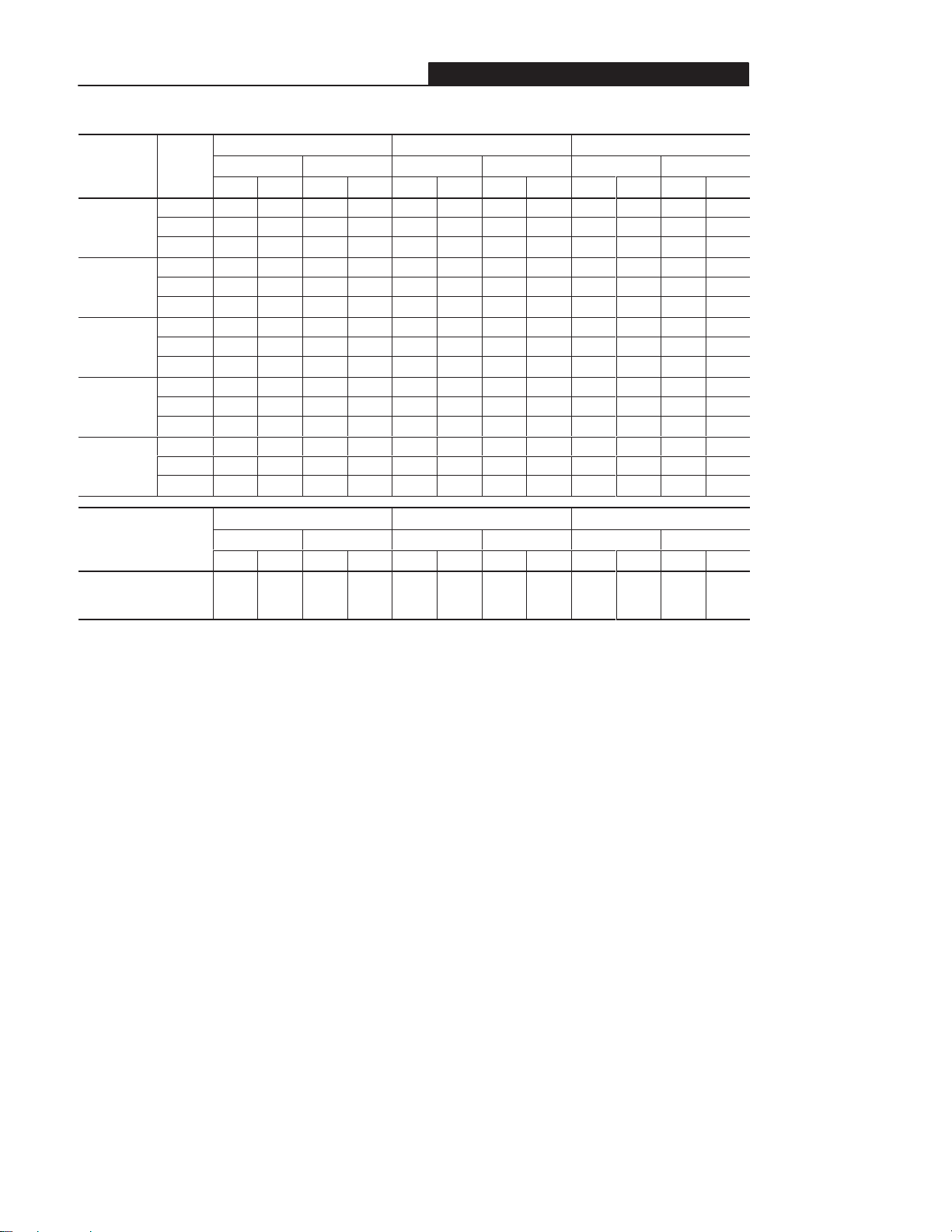

Table 2.C – Minimum Recommended Line Side Protective Devices for 200 – 240V rated units

3 ∅ Rating

kW (HP)

.37 (1/2

.55 (3/4)

.55 (3/4

.75 (1)

.75 (1

1.5 (2)

1.5 (2

2.2 (3)

1 ∅ Rating

kW (HP)

N/

.37

.37 (1/2)

1/2

.55

.55 (3/4)

3/4

.75 (1)

.75 (1

1.5 (2)

Fuse

Rating

6 16.37 (1/2

6

6

6

10

10

15 (16

15 (16)

25

Fuse Types

Class CC Class J Rating Type

KLDR/CCMR

KLDR/CCMR

➁

➂

TMR

ATMR

➃

FNQR LPJ 16

FNQR

➇

➁

JDT

JDT

➂

JT

AJT

➃

LPJ

Other Protective Devices

16

16

16

16

16

16

20

140-MN-****

140-MN-

1492-CB3-H***

1492-CB3-H

HFD ***L

HFD

➆

L

➄

➅

Table 2.D – Minimum Recommended Line Side Protective Devices for 380 – 460V rated units

3 ∅ Rating

kW (HP)

.37 (1/2) N/A 3 (4)

.37 (1/2

.55 (3/4)

.55 (3/4

.75 (1)

1.5 (2)

2.2 (3)

➀ Must be dual element time delay.

➁ Littlefuse

➂ Gould Shawmut

➃ Bussman

➄ Allen-Bradley Bulletin 140 manual motor starter. Not recommended

for repetitive application of power to the input of the drive.

Fuse ratings in ( ) denote European size.

1 ∅ Rating

kW (HP)

N/

N/A

N/

N/A

N/A

N/A 15 (16) 16

Fuse

Rating

3 (4

3 (4)

3 (4

➀

6

10

➀

➀

KLDR/CCMR

ATDR/ATQR

Fuse Types

Class CC Class J Rating Type

➁

➂

➃

FNQR

➅ Allen-Bradley Bulletin1492 circuit breaker. Not recommended for

➆ Westinghouse type HFD circuit breaker

➇ Controller is also compatible with RK1, RK5, and BS88

➇

➁

JDT

➂

AJT

➃

LPJ

repetitive application of power to the input of the drive.

fuse types.

Other Protective Devices

6.3

6.3

6.3

6.3

6.3

16

140-MN-****

1492-CB3-H***

HFD ***L

➆

➄

➅

2-3

Page 17

Chapter 2 –

Dry

Motor

Ratings

Insulat on

(3 HP)

(

)

(

)

(

)

(

)

Installation and Wiring

Motor Cable Recommendations

A variety of cable types are acceptable for

variable speed controller installations. For many

installations, unshielded cable is adequate,

provided it can be separated from sensitive

circuits. As an approximate guide, allow a

spacing of 1 meter (3.3 feet) for every 10 meters

(33 feet) of unshielded length. If you cannot

Table 2.E – Recommended Cable Type(s)

Condition Insulation Type(s) Example(s)

Dry

Wet XLPE XHHW-2

➀ For AC line voltages in excess of 264V AC, or motor cable

distances greater than 50 ft (15m), wire with XLPE insulation is

recommended.

PVC① THHN

XLPE XHHW-2

separate motor cables from sensitive circuits, or if

you must run motor cables from multiple

controllers (more than three) in a common

conduit or cable trays, shielded motor cable is

recommended to reduce system noise.

Motor cables should be four-conductor with the

ground lead and shield (if using shielded cable)

connected to the controller ground terminal and

the motor frame ground terminal.

T able 2.E provides the recommended wire type

for both wet and dry installations as defined by

NEC 1996 (70-31). These recommendations are

based upon a variety of factors such as insulation

thickness, susceptibility to moisture and

Long Motor Cable Effects

The controller should be installed as close to the

motor whenever possible. Installation with long

motor cables may require the addition of external

devices to limit voltage reflections at the motor

(reflected wave phenomona). See T able 2.F for

recommendations.

Important: The use of an external device to limit

reflected wave issues may effect the accuracy of

the Bulletin 160 current sensing. T able 2.G

provides recommended cable length due to

Capacitive Current considerations.

susceptibility to nicks and cuts during installation.

Table 2.F – Cable Length Recommendations — Reflected Wave

380 – 460V

Insulation

Rating

2.2 kW

1.5kW

2 HP

0.75 kW

1 HP

0.55 kW

0.75 HP

0.37 kW

0.5 HP

➁ The reflected wave data applies to all PWM frequencies 2 to 8 kHz. For 230V ratings see Table 2.G.

➂ Cable lengths listed are for PWM frequencies of 2 kHz. Refer to publication 1204-5.1 for cable length recommendations at other PWM frequencies.

➃ The maximum peak-to-peak voltage of the controller is 1400V due to the minimum on/off time software. Reflective Wave Testing has been

done on cable lengths up to 500 feet. See Table 2.G for Capacitive Current Considerations.

1000 Vp-p

1200 Vp-p

1600 Vp-p 500➃152➃500➃152➃360 110 600 183 500➃152➃500➃152

1000 Vp-p 40 12 40 12 300 92 300 92 250 76 250 76

1200 Vp-p 60 18 60 18 300 92 540 165 340 104 340 104

1600 Vp-p 500➃152➃500➃152➃300 92 540 165 500➃152➃500➃152

1000 Vp-p 55 17 40 12 300 92 300 92 325 99 325 99

1200 Vp-p 125 43 60 18 300 92 375 114 500 152 325 99

1600 Vp-p 500➃152➃500➃152➃300 92 375 114 500➃152➃500➃152

1000 Vp-p 45 14 40 12 300 92 300 92 300 92 300 92

1200 Vp-p 125 38 60 18 300 92 375 114 500 152 500 152

1600 Vp-p 500➃152➃500➃152➃300 92 375 114 500➃152➃500➃152

1000 Vp-p 45 14 40 12 300 92 300 92 300 92 300 92

1200 Vp-p 125 38 50 15 300 92 375 114 500 152 500 152

1600 Vp-p 500➃152➃500➃152➃300 92 375 114 500➃152➃500➃152

Motor Cable Only RWR at Drive

Shielded Unshielded Shielded Unshielded Shielded Unshielded

ft. m. ft. m. ft. m. ft. m. ft. m. ft. m.

40

60 18 60 18 360 110 600 183 260 79 260 79

12 40 12 360 110 300 92 210 64 210 64

➁

③

Reactor at Motor

➃

➃

➃

➃

➃

2-4

Page 18

Chapter 2 –Installation and Wiring

Ratings

kz

(3 HP

(2 HP

(1 HP)

(0.75 HP)

(0.5 HP)

Ratings

Table 2.G – Cable Length Recommendations — Capacitive Current

380 – 460V

2.2 kW

1.5 kW

0.75 kW

0.55 kW

0.37 kW

kHz

2 360 110 750 229 280 85 600 183 410 125 525 160

4 335 102 600 183 260 79 600 183 370 113 475 145

8 300 91 410 125

2 300 91 540 165 430 131 540 165 310 94 425 130

4 300 91 425 130 410 125 425 130 300 91 400 122

8 300 91 300 91

2 300 91 375 114 250 76 375 114 300 91 300 91

4 300 91 300 91 225 69 375 114 300 91 300 91

8 300 91 300 91

2 300 91 375 114 250 76 375 114 300 91 300 91

4 300 91 310 94 225 69 375 114 300 91 300 91

8 300 91 300 91

2 300 91 375 114 250 76 375 114 300 91 300 91

4 300 91 325 99 225 69 375 114 300 91 300 91

8 300 91 300 91

Motor Cable Only RWR at Drive

Shielded

②

Unshielded Shielded

②

ft. m. ft. m. ft. m. ft. m. ft. m. ft. m.

➀ ➀ ➀ ➀

➀ ➀ ➀ ➀

➀ ➀ ➀ ➀

➀ ➀ ➀ ➀

➀ ➀ ➀ ➀

①

Reactor at Motor

Unshielded Shielded

310 94 420 128

300 91 350 107

300 91 300 91

300 91 300 91

300 91 300 91

②

Unshielded

200 – 240V

Shielded Unshielded Shielded Unshielded Shielded Unshielded

ft. m. ft. m. ft. m. ft. m. ft. m. ft. m.

0.37 to 2.2 kW

Motor Cable Only RWR at Drive Reactor at Motor

(0.5 to 3 HP)

2 thru 8 kHz

➀ Not recommended for use above 4 kHz PWM frequency.

➁ When using shielded cable at lightly loaded conditions, the 0.75 Kw (1 Hp) and below cable length recommendations are 61m (200 ft.)

➂ Not recommended for 230V applications.

500 152 800 244 ③ ③ ③ ③ 500 152 800 244

2-5

Page 19

Chapter 2 –

Installation and Wiring

Control Wiring Requirements

D run all signal wiring in either a shielded cable,

or a separate metal conduit.

D only connect shield wire at control terminal

block common terminals TB3-3 and TB3-7.

D do not exceed control wiring length of 15

meters (50 feet). Control signal cable length is

highly dependent on electrical environment

and installation practices. T o improve noise

immunity the control terminal block common

must be connected to earth ground.

D use Belden 8760 (or equivalent) — 18AWG

(0.750mm

conductor.

Table 2.H – Control Terminal Block Specifications

Terminal

Block

2

), twisted pair, shielded or 3

Max/Min

Wire Size

2

(AWG)

mm

TB3 2.5 – 0.5

(14 – 22)

ATTENTION: The controller is

supplied with an internal 12V supply.

Dry contacts or open collectors are

required for discrete control inputs. If

an external voltage is applied,

component damage could occur.

Max/Min

Torque

Nm. (lb.in.)

0.8 – 0.4

(8 – 4)

Control Wiring – Analog Signal Follower

Model

You can control the output frequency of the

controller via the Control T erminal Block (TB3)

using a remote potentiometer, a –10 to +10V DC

analog input, a 4 – 20mA analog input, or use

P58 – [Internal Frequency]. Important: Only

one frequency source may be connected at a time.

If the frequency reference potentiometer and the

4 – 20mA reference are connected at the same

time, an undetermined frequency reference will

result.

Control Wiring – Preset Speed Model

You can control the output frequency of the

controller via the Control T erminal Block (TB3)

using dry contacts or open collector inputs to

SW1, SW2, and SW3 or use P58 – [Internal

Frequency]. A program keypad module is

required to change the factory default settings.

Refer to Chapter 5, parameters 61 – 68 for the

eight preset frequency factory default settings and

switch configurations.

Wiring Diagrams

Important: Refer to the diagrams on the

following pages for control wiring information.

2-6

A TTENTION: The drive start/stop

control circuitry includes solid-state

components. If hazards due to

accidental contact with moving

machinery or unintentional flow of

liquid, gas or solids exist, an

additional hardwired stop circuit is

required to remove AC line power to

the drive. When AC input power is

removed, there will be a loss of

inherent regenerative braking effect

and the motor will coast to a stop. An

auxiliary braking method may be

required.

Page 20

Chapter 2 –Installation and Wiring

Control Wiring

Figure 2.3 – TB3 Control Wiring for Analog Signal Follower Model

Shielded Wire

Signal Specification

+ 10V Pot

1

Pot Wiper or

2

+10/–10V DC Input

Common

3

4–20mA Input

4

Reverse

5

Start

6

Common

7

Stop

8

Normally Closed

9

FAULT

READY

Terminal

TB3

➂

Relay Common

Normally Open

1101

= N.O. Momentary Contact

= N.C. Momentary Contact

Figure 2.4 – TB3 Control Wiring for Preset Speed Model

Shielded Wire

Signal Specification

SW1

1

SW2

2

3

Common

4

SW3

5

Reverse

6

Start

Common

7

Stop

8

9

Normally Closed

Relay Common

Normally Open

1101

FAULT

READY

TerminalTB3

➂

= N.O. Momentary Contact

= N.C. Momentary Contact

10 kΩ Potentiometer, 2 Watts

Controller Input Impedance = 100 kΩ

➁

Common

Controller Input Impedance = 250 Ω

Contact closure input

Contact closure input

➁

Common

➀

➀

Contact closure input required to operate controller

Customer-programmable relay outputs.

Resistive load 0.4A at 125V AC 2A at 30V DC.

Inductive load 0.2 A at 125V AC 1A at 30V DC.

= N.O. Maintained Contact

Contact closure input

Contact closure input

➁

Common

Contact closure input

Contact closure input

Contact closure input

➁

Common

Contact closure input required to operate controller

Customer-programmable relay outputs.

Resistive load 0.4A at 125V AC 2A at 30V DC.

Inductive load 0.2 A at 125V AC 1A at 30V DC.

➀

➀

➀

➀

➀

= N.O. Maintained Contact

➀

➀

➀ Internal 12V supply.

➁ Do not exceed control wiring length of 15 meters (50 feet). Control signal cable length is highly dependent on

electrical environment and installation practices. To improve noise immunity the control terminal block common

must be connected to earth ground.

➂ This diagram shows “three wire” control. Refer to the following page for diagrams of other control wiring methods.

2-7

Page 21

Chapter 2 –

Shielded Wire

Installation and Wiring

Control Wiring (continued)

Use P46 – [Input Mode] to select the control

method for start, stop, and direction control.

Important: Settings 4 through 6 provide

additional flexibility of TB3 control input

terminal 8.

D Setting 0 — Three Wire Control. (This is the

factory default setting). Refer to Figure 2.5.

D Setting 1 — T wo Wire “Run Forward/Run

Reverse” Control. Refer to Figure 2.6.

D Setting 2 — Program Keypad Module control.

See Page 3-1.

D Setting 3 — Momentary “Run Forward/Run

Reverse” control. Refer to Figure 2.7.

D Setting 4 — T wo Wire “Accel/Decel” control.

Refer to Figure 2.8.

D Setting 5 — T wo Wire “Enable” control.

Refer to Figure 2.9.

D Setting 6 — T wo Wire “Local/Remote”

control. Refer to Figure 2.10.

Explanation of Symbols:

= N.O. Momentary Contact

= N.C. Momentary Contact

= N.O. Maintained Contact

= N.C. Maintained Contact

➀ Internal 12V supply.

➁ If both Run Forward and Run Reverse inputs are closed at

the same time an undetermined state could occur.

➂ Do not exceed control wiring length of 15 meters (50 feet).

Control signal cable length is highly dependent on

electrical environment and installation practices. To

improve noise immunity the control terminal block

common must be connected to earth ground.

Figure 2.5 – TB3 Three Wire control (Setting 0)

( Factory Default Setting)

Shielded Wire

Signal

TerminalTB3

5

Reverse

6

Start

7

Common

8

Stop

Specification

Contact closure input

Contact closure input

➂

Common

Contact closure input required to

operate controller

➀

➀

➀

Important: After a Stop input, the Start input

must be toggled to Run again.

Figure 2.6 – TB3 Two Wire “Run Forward/Run

Reverse” control (Setting 1)

➁

Signal Specification

TerminalTB3

Run Reverse

5

Run Forward

6

Common

7

Stop

8

Contact closure input

Contact closure input

➂

Common

Contact closure input required to

operate controller

➀

➀

➀

Important: The “Run” inputs must be

maintained. After a Stop input, either a Run

Forward or a Run Reverse input must be toggled

to run again.

Figure 2.7 – TB3 Momentary “Run Forward/Run

Reverse” control (Setting 3)

Shielded Wire

➁

Signal Specification

TerminalTB3

Run Reverse

5

Run Forward

6

Common

7

8

Stop

Contact closure input

Contact closure input

➂

Common

Contact closure input required to

operate controller

➀

➀

➀

Important: The “Run” inputs do not need to be

maintained. After a stop input, either a Run

Forward or a Run Reverse input does not need to

be toggled to run again.

ATTENTION: Hazard of injury

exists due to unintended operation.

When P46 – [Input Mode] is set to

“3” and the “Run” input is

maintained, a stop function is

provided only when the stop input is

active (open).

2-8

Page 22

Chapter 2 –Installation and Wiring

Control Wiring (continued)

Figure 2.8 – TB3 Two Wire “Accel/Decel” control

Shielded Wire

➁

③

Refer to Figure 2.11.

Figure 2.9 – TB3 Two Wire “Enable” control

Shielded Wire

➁

③

Refer to Figure 2.11.

Figure 2.10 – TB3 Two Wire “Local/Remote” control

Shielded Wire

➁

③

Refer to Figure 2.11.

(Setting 4)

Signal

TerminalTB3

5

Run Reverse

6

Run Forward

7

Common

③

8

Accel/decel

select

(Setting 5)

TerminalTB3

5

6

7

③

8

(Setting 6)

Signal

TerminalTB3

5

Run Reverse

6

Run Forward

7

Common

③

8

Local/

Remote

Signal

Run Reverse

Run Forward

Common

Enable

Specification

Contact Closure Input

Contact Closure Input

③

Common

Contact Closure Input

Used to select Accel/Decel.

Specification

Contact Closure Input

Contact Closure Input

Common

Contact Closure Input required

to operate controller

Specification

Contact Closure Input

Contact Closure Input

③

Common

Contact Closure Input

Used to select local (TB3)

Control.

①

①

①

①

①

③

①

①

①

①

Figure 2.11

Input Mode

Setting

➃

4

➃

5

➃

6

➃ The “Run” input must be a maintained input. After a stop

command, either a “Run Forward” or “Run Reverse” input must

be toggled to start the controller.

➄ When this input is in an open state, P69 – [Accel Time 2] and

P70 – [Decel Time 2] are active.

➅ When this input in in an open state, all power is removed from

the motor and it will “coast to rest”.

➆ When this input is in an open state the Frequency source is

always from the terminal block regardless of the setting of

P59 – [Frequency Select].

TB3-8

Open

Accel 2

Decel 2

Controller

Disabled

Local (TB3)

Control

TB3-8

Closed

➄

➅

➆

Accel 1

Decel 1

Controller

Enabled

Remote

Control

Important: In modes 4 through 6, Terminal

TB3-8 is also used to clear faults. See Figure 2.12

for details.

Important: The system programmer is

responsible for returning terminal TB3-8 to its

original state if necessary.

Figure 2.12

TB3-8

CLOSED

TB3-8

OPEN

Fault

occurs

Fault

clears

Fault

occurs

Fault

clears

2-9

Page 23

Chapter 2 –

Installation and Wiring

This Page Intentionally Blank

2-10

Page 24

Program Keypad Module

Chapter 3

Features

The program keypad module is located on the

front panel of the controller. It features the

following:

D five keys on the module for display or

programming controller parameters

D three keys for control inputs to the controller

D directional LEDs

D a 6 digit, seven segment LED display

Figure 3.1 – Program Keypad Module Features

These two digits display the active

parameter number for both display and

program parameters, which are

designated as P## throughout this

SELect

The

program mode. It enables the editing of

a parameter value. When you press this

key the program mode indicator flashes.

disables the editing of a parameter

The

motor rotates in reverse direction.

key is only used while in

The

ESCape

toggle between the display mode

and program mode. When in

program mode, this key also

key allows you to

counter clockwise LED

illuminates constantly when the

manual.

value.

➀

When the

indicator

parameter value. When in display

mode, the program indicator does not

display.

Display Mode

The controller always powers up in the display

mode. While in this mode you may view all read

only controller parameters, but not modify them.

Program Mode

You enter the program mode by pressing the ESC

key. While in program mode, you can edit any

programmable controller parameters. Refer to

Chapter 5 for programming steps.

program mode

flashes, you can edit the

These four digits

display the parameter

value or fault code

number.

up/down

Use the

arrow keys to scroll

through a list of

parameters, or increase

and decrease parameter

values. Press and hold

either key to increase

scrolling speed.

Pressing the

while in programming

mode causes the current

value displayed to be

entered into memory. When

you press this key the

program mode indicator

remains on, but stops

flashing.

enter

➂

key

Pressing the

motor to ramp down to 0 Hz and then

ramp up to its set speed in the opposite

➀

Indicates commanded direction. Actual motor rotation could be

different if motor leads are not connected properly. See

Chapter 4, Start-up for details on how to verify motor rotation.

➁

When the motor is running, pressing this key causes the

(currently illuminated) LED to flash indicating motor rotation while

reverse

key causes the

direction.

The

illuminates constantly when

➁

the motor rotates in forward

clockwise LED

direction.

➂

stop

The

start

key initiates a

start command when the

controller is programmed

➀

for local start/stop control

(when P46 – [Input Mode]

is set to “2”).

decelerating to zero. The opposite LED will illuminate indicating

the commanded direction.

Real time frequency adjustment can be achieved when using

P58 – [Internal Frequency].

The

motor to “Coast”, “Ramp” or

“DC Brake” to stop

depending on the setting of

P34 – [Stop Mode].

key initiates the

3-1

Page 25

Chapter 3 –Program Keypad Module

Removing Program Keypad Module

ATTENTION: Ensure that you

disconnect line power and wait

one minute before installing or

removing the program keypad

module. Failure to do so may

result in personal injury or death.

Figure 3.2 – Removing Program Keypad Module

Insert a small screw driver into

slot, pry back, and pivot module

out. Avoid bending or twisting the

contact pins located underneath

the center portion of the module.

ATTENTION: This controller contains

ESD (Electrostatic Discharge) sensitive

parts and assemblies. Static control

precautions are required when installing,

testing, servicing or repairing this

assembly. Component damage may

result if ESD control procedures are not

followed. If you are not familiar with

static control procedures, reference A-B

Publication 8000-4.5.2, “Guarding

Against Electrostatic Damage” or any

other applicable ESD protection

handbook.

Program Keypad

Module

Dipswitch that changes P35 – [Base

Frequency] from 50 to 60 Hertz

when program keypad module is not

installed.

Installing Program Keypad Module

Insert the module bottom end first and then press on the symbol at the top

of the module until the module is fully seated. The module is fully seated

when its face is flush with the edges of its surrounding case.

3-2

Important: When a program keypad

module is installed, P35 – [Base

Frequency] overrides this switch

setting. Once P35 – [Base Frequency]

is changed from its factory default

setting, the switch remains overridden

until all parameters are reset to their

factory default settings using

P56 – [Reset Defaults]

Page 26

Start-Up

Chapter 4

Chapter 5 provides a comprehensive

description of all controller parameters.

Review the factory default settings. If

your controller is equipped with a

Program Keypad Module these

parameters can be changed to meet

your specific application requirements.

An example of how to program a

parameter is shown at the beginning of

Chapter 5.

Start Here

ATTENTION: Power must be applied to the controller to perform the following start-up procedure. Some of the

voltages present are at incoming line potential. To avoid electric shock hazard or damage to equipment, only

qualified service personnel should perform the following procedure. Thoroughly read and understand the

procedure before beginning. If an event does not occur while performing this procedure, Do Not Proceed.

Remove Power by opening the branch circuit disconnect device and correct the malfunction before continuing.

Verify the controller is installed per instructions outlined in Chapter 2 including:

D Minimum clearance distance between controller and other equipment.

D Proper grounding practices have been followed.

D Proper power and control wiring has been used.

Commonly Changed Parameters

Parameter

P30 – [Accel Time 1]

P31 – [Decel Time 1]

P33 – [Maximum Frequency]

P34 – [Stop Mode Select]

P35 – [Base Frequency]

P36 – [Base Voltage]

P42 – [Motor Overload Current]

P46 – [Input Mode]

P47 – [Output Configure]

Preset Speed Model Only

P61 – P68 – [Preset Frequency 0–7]

Start-Up Checklist

Set to...

desired accel time.

desired decel time.

maximum frequency required.

desired stopping mode.

motors rated nameplate frequency.

motors rated nameplate voltage.

motor nameplate Full Load Amps [FLA].

desired control method.

desired output functionality.

desired preset frequencies.

Verify that AC line power at the

disconnect device is within the rated

value of the controller.

Disconnect and lock out all incoming power to

the controller including incoming AC power to

terminals L1, L2 and L3 (R, S and T) of power

terminal block TB1.

Verify that the motor leads are connected to the

power terminal block TB2, terminals T1, T2, T3 (U,

V, W).

Verify that the STOP input is present at the TB3 control terminal block.

See page 2-9 for details on TB3-8 functionality when using P46 – [Input

Mode] settings 4 through 6.

Confirm that all other control inputs are connected to

the correct terminals and are secure. GO TO THE

NEXT PAGE.

A

ATTENTION: A DC Bus

voltage may be present at the

power terminal blocks (TB1)

and (TB2) for approximately

one minute after power is

removed from the controller.

4-1

Page 27

Chapter 4 –Start-Up

A

If you have a blank display panel.

The READY [green] indicator

will illuminate. Use remote

inputs to TB3 control terminal

block to operate the controller.

Check for proper motor rotation by setting the frequency

source to its minimum setting.

If you are using a program keypad module, verify that the

CLOCKWISE LED is illuminated. If you are using a blank

display panel, verify that the REVERSE input to TB3 is in

the OPEN position.

Issue a START command from either the program keypad

module or TB3 control terminal block.

Reconnect the power to the

controller.

Do you have a Analog Signal

Follower controller or a Preset Speed

controller?

Analog Signal Follower controller Preset Speed controller

If you have a program keypad module.

P01– [Output Frequency] will display. If the

controller has been previously powered up, a

different parameter number may display .

Important: To enable the start and reverse

keys from the program keypad module, set

P46 – [Input Mode] to a “2” and cycle power

or set P56 – [Reset Function] to 2. Refer to

the programming example in Chapter 5.

Check for proper motor rotation by selecting P61 –

[Preset Frequency 0]. This requires removing all inputs

to SW1, SW2, and SW3 on TB3 [see Figure 2.5 in

Chapter 2]. The factory default setting for P61 – [Preset

Frequency 0] is 3 Hz.

If you are using a program keypad module, verify that the

CLOCKWISE LED is illuminated. If you are using a blank

display panel, verify that the REVERSE input to TB3 is in

the OPEN position.

Slowly increase the speed until the motor begins to turn.

Check the direction of the motor.

Issue a STOP command from either the program

keypad module or TB3 control block terminal.

Start-Up is complete.

Disconnect and lock out all incoming power to TB1 terminals L1, L2, and L3 [R, S and T].

Switch any two of the three motor leads connected to TB2, terminals T1, T2 and T3 [U, V and W].

Yes No

4-2

Issue a START command from either the program

keypad module or TB3 control terminal block. Check the

direction of motor rotation.

Issue a STOP command from either the program

keypad module or TB3 control block terminal.

Is the direction of motor

rotation correct?

ATTENTION: A DC Bus voltage may be present at the

power terminal blocks (TB1) and (TB2) for approximately

one minute after power is removed from the controller.

Page 28

Parameters and Programming

Chapter 5

Overview of Parameters

This chapter covers both display and program parameters. Display parameters are read only (they cannot

be programmed), while program parameters can be changed to fit your motor control requirements. You

must have a Program Keypad Module to view/change display and program parameters. The table below

describes which parameters apply to the Preset Speed and Analog Signal Follower models. Refer to the

programming example below for programming instructions.

Parameter Type Parameter Numbers

Analog Signal Follower Model Preset Speed Model

Display 1 through 14 and 16 1 through 15

Program 30 through 60 and 69 through 76, 78 30 through 59 and 61 through 73, 78

The following pages contain descriptions of both display and program

parameters. Any parameter description that is shaded pertains only

to the Preset Speed or Analog Signal Follower model. Refer to the

legend to the right.

Programming Example

The following is an example of the programming steps required to change a program group parameter setting. In this example,

parameter 31 – [Decel Time] is changed from its factory default setting of 10.0 seconds to 2.2 seconds. Refer to Chapter 3,

Figure 3.1 on page 3-1 for an explanation of Program Keypad Module display and programming keys.

Important: To reset ALL values to original factory default settings, refer to P56 – [Reset Defaults].

Action Description Keypad Display

1. To program the value of a program group parameter, enter the

program group by pressing the ESCape key. The “program mode

indicator” will illuminate.

2. Press up/down keys until the desired parameter displays. In this case,

press the up key until parameter 31 – [Decel Time] displays.

= Parameter applies only to the Analog Signal Follower model

= Parameter applies only to the Preset Speed model

300.

Program Mode Indicator

3

1.

1

0.

1

0

0.

3. Press the SELect key. The program mode indicator flashes indicating

that you can use the up/down keys to change the parameter

value.

4. Change the decel time value from the factory default of 10 seconds to

2.2 seconds by pressing the down key until 2.2 displays.

Important: Continuously holding the up or down key will cause the value

to increase or decrease as long as the key is pressed.

5. When the desired value displays, press the ENTER key. This writes

the new value to memory. The program mode indicator will stop

flashing and the display will flash once indicating that the new value

has been accepted.

Important:

the editing process, press the ESCape key. The original value of the

parameter will remain unchanged and you will be exited from the program

mode.

If at any time (while in the program mode) you wish to abort

3

1.

Program Mode Indicator Flashes

3

3

Program Mode Indicator

Stops Flashing

3

Program Mode Indicator

Stops Flashing

1

1. 2.

1.

1. 1 0.

0.

2.

0

2

2

0

5-1

Page 29

Chapter 5 –Parameters and Programming

Display Group Parameters

This group of parameters consists of commonly viewed controller operating conditions such as controller

output frequency , output voltage, output current and frequency command. All parameters in this group

are read only.

Important: The last user selected Display Group parameter will be saved on power down.

Display Group

P#

[Output Frequency] Displays the output frequency at TB2 terminals T1, T2 and

01

T3 (U, V and W).

[Output Voltage] Displays the output voltage present at TB2 terminals T1, T2 and

02

T3 (U, V and W).

[Output Current] Displays the output current present at TB2 terminals T1, T2 and

03

T3 (U, V and W).

[Output Power] Displays the output power present at TB2 terminals T1, T2 and T3

04

(U, V and W).

Parameter Description

05 [Bus Voltage] Displays the DC Bus Voltage level.

[Frequency Command] Displays the frequency that the controller is

06

commanded to output. This command may come from any of the frequency sources

selected by P59 – [Frequency Select] or from a currently selected preset frequency.

[Last Fault] Displays the coded last fault number. If a fault is currently active (has not

07

been cleared) the display will flash. See Chapter 6 for fault code descriptions.

08 [Heatsink Temperature] Displays the temperature of the controller heatsink.

[Controller Status] Displays the status of the controller in a binary

09

coded format.

Important: A “0” = inactive

and a “1” = active.

Bit 3 Bit 2 Bit 1 Bit 0

Running

Forward

Accel

Decel

Min/Max

Range

0 to 240 0.1 Hz

0 to [Max Voltage] 1 V olt

0 to 2 Times

Controller Rated

Output Current

0 to 2 Times Rated

Controller Output

Power

0 to 400 – [230V]

0 to 800 – [460V]

0 to 240 0.1 Hz

0 to 49 Numeric Value

0 to 150 1 Degree C

0000 to 1011 Binary Number

Units

0.01Amps

0.01 kW

1 Volt

5-2

[Controller Type] Used by Rockwell Automation field service personnel.

10

[Control Version] Displays version of controller firmware. Used by Rockwell

11

Automation field service personnel.

Numeric Value Numeric Value

Fixed Value Numeric Value

Page 30

Display Group

Á

Á

ÁÁÁÁ

Á

Á

É

É

É

É

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

P#

[Input Status] Displays the open (0) and closed (1) state of the

12

inputs to TB3 in binary coded format as follows:

Parameter Description

Chapter 5 – Parameters and Programming

Min/Max

Range

Bit 3 Bit 2 Bit 1 Bit 0

Units

Input

Mode 2

(Keypad)

N/A

Input Mode 3

(Momentary

Run FWD/

Run REV)

Run

Reverse

Input

Mode 4

(Accel/

Decel)

Reverse

Bit 0

TB3-5

Input

Mode 0

(3-Wire)

Reverse

Input

Mode 1

(2-Wire)

Run

Reverse

0=Accel 2/

Bit 1

TB3-8

Bit 2

TB3-6

Bit 3

Polarity

[Power Factor Angle] Displays the angle in electrical degrees between motor

13

Stop

Start

Forward

0 = Positive Analog Input

1 = Negative Analog Input

Stop

Run

Stop

N/A

Stop

Run

Forward

Decel 2

1=Accel 1/

Decel 1

Forward

Input

Mode 5

(Enable)

Run

Reverse

0=Drive

1=Drive

Run

Forward

Input Mode 6

(Local/

Remote)

Run

0=Local (TB3)

Disable

1=Remote

Enable

Run

voltage and motor current.

14 [Memory Probe Display] Used by Rockwell Automation field service

personnel.

Á

[Preset Status] Displays the open (0) and closed (1) state of Terminal Block Three

15

(TB3) inputs SW1, SW2, and SW3 in binary coded format. This parameter applies to the

Preset Speed model only.

Bit 3 Bit 2 Bit 1 Bit 0

SW1

SW2

SW3

Not Used

[Analog Input] Displays the analog input as a percent of full scale. Used in setting

16

P60 – [Zero Offset], P75 – [Analog Input Minimum], and P76 – [Analog Input

É

É

É

É

БББББББББББББББББ

Maximum].

Important: On initial set up of the controller, apply a 0V or 4mA analog command to the

БББББББББББББББББ

controller. Once applied, if the value of this parameter displays something other than zero,

БББББББББББББББББ

program that value into P60 – [Zero Offset]. Important: The value of the [Zero Offset] will

БББББББББББББББББ

be subtracted from the value of this parameter.

= This parameter applies only to the Preset Speed model.

Run

Reverse

Control

Control

Run

Forward

0000 to 1111 Binary Number

0.0 to 180.0 0.1 degrees

Numeric Value

ÁÁÁÁ

Numeric Value

ÁÁ

0000 to 0111 Binary Number

–150 to +150.0

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

0.1%

ÁÁ

ÁÁ

ÁÁ

ÁÁ

= This parameter applies only to the Analog Signal Follower model.

5-3

Page 31

Chapter 5 –Parameters and Programming

Program Group Parameters

This group contains parameters whose values can be programmed. Refer to the “Programming Example”

outlined earlier in this chapter. Unless otherwise stated, parameters that are programmed while the

controller is running take immediate effect.

Program Group

P# Parameter Description

[Accel Time 1] Time for the controller to ramp from 0.0 Hz. to P33

30

– [Maximum Frequency]. The rate is linear for any increase in command

frequency unless P53 – [S-Curve] is set to a value other than “0”. Setting

this to 0.0 sec. gives

0.1 sec acceleration

with the initial current

limit turned off. This allows

quicker acceleration times

for low inertia systems. For

medium to high inertia

systems, the minimum value

should be 0.1 sec.

[Decel Time 1] Time for the controller to ramp from P33 – [Maximum

31

Frequency] to 0.0 Hz. The rate is linear for any decrease in command frequency

unless P53 – [S-Curve] is set to a value other than “0”. See P30 – [Accel Time 1]

figure above.

➀

[Minimum Frequency] Lowest frequency that controller will output

32

continuously.

➀

[Maximum Frequency] Highest frequency the controller will output.

33

Important: This parameter can’t be changed while running.

[Stop Mode Select] Determines stopping mode used by the controller

34

when a stop is initiated. Refer to the P44 – [DC Hold Time] and P45 – [DC Hold

Voltage] diagrams. Settings: 0 = Ramp to Stop 1 = Coast to Stop

2 = DC Injection Braking 3 = DC Injection Braking (w/Auto Shutoff)

Max. Frequency

Speed

'

0

Accel

0

Time

'a a

Time

Decel

Time

Min/Max

Range

0.0 to 600 0.1 Seconds

'

0.1 to 600 0.1 Seconds 10.0

0 to 240 1 Hz 0 Hz

0 to 240 1 Hz 60 Hz

0 to 3 Numeric

Units Factory

Value

Default

10.0

Seconds

Seconds

0

Important: DC Injection braking with auto shutoff: works the same as standard

DC injection braking except that it may shut off before the P44 – [DC Hold Time].

This occurs if the controller is out of current limit before the P44 – [DC Hold

Time] expires.

35 [Base Frequency] Set value to motor’s rated nameplate frequency.

36 [Base Voltage] Set value to motor’s rated nameplate voltage.

➀ The analog inputs to the controller (i.e., 4–20mA, 0 to +10V, or remote potentiometer) can be scaled to P32 – [Minimum Frequency] and

P33 – [Maximum Frequency] by programming P75 – [Analog Input Minimum] and P76 – [Analog Input Maximum].

➁ For controllers without a program keypad module, you can change P35 – [Base Frequency] to 50 Hz via a dipswitch located under the blank

front panel. See the Removing Program Keypad Module section in Chapter 3.

10 to 240 1 Hz 60 Hz

20 to 460 for

460V units and

20 to 230 for

230V units

1 Volt 460 Volts for

460V units

and 230 for

230V units

➁

5-4

Page 32

Boost Select

Chapter 5 – Parameters and Programming

Program Group

P# Parameter Description

37 [Maximum Voltage] Sets the highest voltage that the controller will

output.

P37 – [Maximum Voltage] must be greater than or equal to P36 – [Base Voltage].

38

[

curve.

See Settings 1

through 8 below

39

[Skip Frequency] Works in conjunction with P40 – [Skip

Frequency Band] creating a range of frequencies at which the controller will

not operate continuously.

Frequency

Command

Frequency

Skip

Frequency

Setting

40 [Skip Frequency Band] Determines the band around the P39 –

[Skip Frequency] parameter. The actual band width will be 2 times [Skip

Frequency Band] – 1/2 the band above and 1/2 the band below. A value of zero

will disable the skip frequency.

] Sets the boost voltage and redefines the Volts per Hz

100

1/2

50

Base

Volts

[Base Voltage], %

8

y

b

1

0

[Base Frequency], %

Setting Boost Voltage % of [Base Voltage]

0

0

1

2.5

2

5.0

3

7.5

4

10.0

5

12.5

6

15.0

7

17.5

8

20.0

Controller Output

Frequency

a

'

'

9

10

11

12

Freq.

1/2 Base

50 100

Setting Fan/Pump Curves

9

45.0

10

40.0

11

35.0

12

30.0

Time

➀

➀

Break Point Voltages

in % of

[Base Voltage]

Two times

y

P40–[Skip Freq Band]

b

Setting

.

Min/Max

Range

20 to 510 for

460V units and

20 to 255 for

230V units

0 to 12 Numeric

0 to 240 1 Hz 240 Hz

0 to 30 1 Hz 0 Hz

Units Factory

1 Volt 460 Volts for

Value

Default

460V units

and 230 for

230V units

2

5-5

Page 33

Chapter 5 –Parameters and Programming

DC Injection Braking Mode

amp to Stop Mode

Program Group

P# Parameter Description

41 [Motor Overload Select] Selects the derating factor for the I

load function.

2

t over-

Min/Max

Range

Units Factory

Default

100

[Overload Current]% of Setting

100

80

60

40

20

[Overload Current]% of Setting

No Derating

80

60

40

20

0 25 50 75100 125150

Max Derating

0 25 50 75100125 150

% Base Speed

% Base Speed

175 200

175 200

100

[Overload Current]% of Setting

Min Derating

80

60

40

20

0 25 50 75100 125 150

% Base Speed

Settings:

0 = No Derating

1 = Minimum Derating

2 = Maximum Derating

175 200

42 [Motor Overload Current] Set to motor nameplate full load Amps

(FLA).

43 [Current Limit] Maximum output current allowed before current limiting

occurs. Value set in percent of controller rated output current.

44 [DC Hold Time] Time that P45 – [DC Hold Voltage] will be applied to the

motor when P34 – [Stop Mode Select] is set to either “DC Injection Braking” or

“Ramp to Stop” mode.

45 [DC Hold Voltage] DC Voltage level applied to the motor during braking

when P34 – [Stop Mode Select] is set to either “DC Injection Braking” or “Ramp

to Stop” mode.

0 to 2 Numeric

0.1 to 200%

of controller

rating

1 to 180%

of controller

rating

0 to 25 0.1 Second 0 Seconds

0 to 115 1 Volt 0 Volts

Value

.01 Amperes 115% of

1 % 150%

Controller

Rating

0

Volts and Speed

5-6

Important: If the current exceeds P43 – [Current Limit] the voltage applied to

the motor will be less than this setting.

R

Speed

y

Stop Command

Voltage

[DC Hold Time]

[DC Hold Voltage]

Time

Volts and Speed

Voltage

Speed

y

Stop Command

[DC Hold Time]

[DC Hold Voltage]

Time

Page 34

Chapter 5 – Parameters and Programming

Program Group

P# Parameter Description

46 [Input Mode] Configures the TB3 control inputs for various “3 wire” or “2

wire run-fwd/run-rev control” schemes. Also enables/disables the program keypad

module input control.

the controller is running. Also, power must be cycled or P56 – [Reset Func-

tion] must be set to “2” for the change to take effect.

Settings: 0 = “3 wire” control

See Chapter 2 for wiring diagrams and description of settings.

47 [Output Configure] Configures the TB3 relay output functionality.

Important: This parameter cannot be programmed while

1 = “2 wire” control

2 = Program Keypad Module control

3 = Momentary ‘‘Run Forward/ Run Reverse” control

4 = 2 wire “Accel/Decel” control

5 = 2 wire “Enable” control

6 = 2 wire “Local/Remote” control

Min/Max

Range

0 to 6 Numeric

Units Factory

Value

Default

0

Settings

0 = Controller

Ready/Faulted

1 = At Frequency

2 = Controller Running

3 = Reverse

4 = Motor Overload

5 = Ramp Regulated

6 = Above Frequency

7= Above Current

8 = Above DC Bus

Voltage

9 = Retries Exhausted the number of retries for P50 – [Restart Tries] is

Output changes state when...

energized and returns to shelf state when

power is removed or when a fault occurs.

the controller reaches commanded frequency.

the controller is running.

the controller is commanded to run in the reverse

direction.

when a motor overload condition exists.

the ramp regulator is modifying the

programmed accel/decel times to avoid an

overcurrent or overvoltage fault from occurring.

the controller exceeds the frequency value

set in P48 – [Output Threshold].

the controller exceeds the value set in P48 –

[Output Threshold]. Important: Value for

P48 – [Output Threshold] must be entered in

% of controller rated output current.

the controller exceeds the DC bus voltage value set

in P48 – [Output Threshold].

exceeded.

0 to 9

Numeric

Value

0

5-7

Page 35

Chapter 5 –Parameters and Programming

Program Group

P# Parameter Description

48 [Output Threshold] Determines the on/off point for the TB3

output relay when [P47 – Output Configure] is set to 6, 7, and 8.

49 [PWM Frequency] Carrier frequency for the PWM output waveform.

The chart below provides derating guidelines based on the PWM freq. setting.

100

98

96

94

92

90

88

% Output Current (A)

86

84

Important: Ignoring derating guidelines can cause reduced controller perfor-

mance.

50 [Restart Tries] Maximum number of times the controller will attempt to

reset a fault.

51 [Restart Time] Time between restart attempts.

52 [DB Enable] Enables/disables external dynamic braking.

Setting “0” = Disable. Settings 1 through 100 = % duty cycle braking.

Important: The Rockwell Automation Bulletin 160 DB Resister package is rated

for 5% duty cycle. Use of this package above 5% should not be used and voids

the UL rating of this device. When setting this parameter to a value above 5%

duty cycle the resister must be sized to avoid overheating of the resister package.

Important: This parameter cannot be programmed while the controller is

running.

Settings

12345678

Ranges

0 to 240 Hz

6

0 to 180 %

7

0 to 815 Volts

8

Carrier Frequency, kHz

Min/Max

Range

0 to 815 Numeric

2.0 to 8.0 0.1 kHz 4.0 kHz

0 to 9 Numeric

0.5 to 300 0.1 Seconds 10.0

0 to 100 Numeric

Units Factory

Value

Value

Value

Default

0

0

Seconds

0

5-8

Page 36

Program Group

P# Parameter Description

53 [S-Curve] Enables a fixed shape S-Curve. See formula below:

Formula:

S-Curve Time = Accel or Decel Time x “S-Curve” setting

1/2 S-Curve

Time

a'

1/2 S-Curve

Time

a'a'

(in percent)

Example:

Accel Time = 10 seconds

S-Curve Setting = 3

S-Curve Time = 10 x .3

a'

Enabled

Important: Maximum

S-Curve time is 60

seconds.

Disabled

Chapter 5 – Parameters and Programming

➀

= 3 Seconds

Min/Max

Range

S-Curve

Setting

0 = 0%

1 = 10%

2 = 20%

3 = 30%

4 = 40%

5 = 50%

6 = 60%

7 = 70%

8 = 80%

9 = 90%

10 = 100%

Units Factory

Numeric

Value

Default

0

a'

Accel Time Decel Time

a'

➀ See values in the Min/Max Range column

54 [Clear Fault] Setting this parameter to a “1” performs a fault reset. When

the fault reset function is complete, the value is automatically set back to “0”.

Important: This parameter cannot be programmed while the controller is

running.

55 [Memory Probe Address] Used by Rockwell Automation field

service personnel.

0 to 1 Numeric

Numeric Value Numeric

Value

Value

0

Numeric

Value

5-9

Page 37

Chapter 5 –Parameters and Programming

É

Program Group

P# Parameter Description

56 [Reset Functions] When using this parameter, the controller’s

parameters and their associated defaults are reset according to the descriptions

below:

0 = Idle State

1 = Reset defaults (restores all controller parameter settings to factory defaults).

2 = Update input mode (restores the controller to most recent programmed P46 –