Page 1

Reference Manual

1.

General Description ............................................1

2. Specication Quick Reference .............................1

3. Catalog Numbers .....................................................1

4. Certication Marks

...................................................1

5. Input ............................................................................3

6. Output in Normal Mode

........................................4

7. Output in Buer Mode

............................................5

8. Battery Input

..............................................................6

9. Buer Time ...............................................................7

10. Eciency and Power Losses .................................8

11. Functional Diagram .............................................8

12. Check Wiring and Battery Quality Tests

............9

13. End-of-Charge Voltage

..........................................9

14. Relay Contacts and Inhibit Input .....................10

15. Front Side User Elements ....................................11

16. Terminals and Wiring

...........................................12

17. Reliability .......................................................... 12

18. EMC ...................................................................... 13

19. Environment ................................................... 14

20. Protection Features .................................... 14

21. Safety .................................................................. 15

22. Certications

..................................................... 15

23. Environmental Compliance ......................... 16

24. Physical Dimensions and Weight

.............. 16

25. Installation Notes ......................................... 17

26. Accessories ........................................................ 18

27. Application Notes ......................................... 19

27.1. Battery Replacement Intervals

...... 19

27.2. Parallel and Serial Use

....................... 20

27.3. Using the Inhibit Input ..................... 21

27.4. Troubleshooting

................................. 21

Bulletin 1606 Switched Mode Power Supplies

Catalog Number: 1606-XLS240-UPSE

Index

Terminology and Abbreviations

•DC UPS—Uninterruptible power supply with DC input.

•Normal mode—Describes a condition where the battery is charged, the input voltage is in range and the output is loaded within the

allowed limits..

• Buffer mode—Describes a condition where the input voltage is below the transfer threshold level, the unit is running on battery (buffering)

and the output is loaded within the allowed limits.

• Charging mode—Describes a condition where the battery is being charged, the input voltage is in range and the output is loaded within the

allowed limits.

• Inhibit mode—Describes a condition where buffering is disabled intentionally by using the inhibit input of the DC UPS (e.g. for service

actions or to save battery capacity).

•Buffer time—Equivalent to the term “hold-up time.”

• T.b.d.—To be defined, value or description will follow later.

Page 2

Bulletin 1606 Switched Mode Power Supplies

1. Description

This uninterruptible power supply (UPS) controller

1606-XLS240-UPSE is an addition to standard 24V

power supplies to bridge power failures or

emergency systems which must be kept fully in

operation for e.g. 72 hours.

The DC-UPS includes an internal temperature sensor

and a professional battery management system

which charges and monitors the battery to achieve

the longest battery service life as well as many

diagnostic functions that ensure a reliable operation

of the entire system.

A unique feature of the 1606-XLS240-UPSE is that only

one 12V battery is required to buer the 24V

output. This makes matching batteries unnecessary

and allows a precise battery charging and testing.

1606-XLS240-UPS Series

Related products

1606-XLS240-UPS

battery

included

larger

battery sizes

additional

12V output

1606-XLS240-UPSC

1606-XLS240-UPSE

1606-XLS240-UPSD

DC-UPS Control Unit

■

Requires Only One 12V Battery for a 24V Output

■

Allows Batteries Between 17Ah and 130Ah

■

Battery Charging with Temperature Tracking

■

Stable Output Voltage in Buer Mode

■

Superior Battery Management for Longest Battery Life

■

Comprehensive Diagnostic and Monitoring Functions

■

Replace Battery Signal Included

■

Electronically Overload and Short Circuit Protected

■

50% Power Reserves

■

3 Year Warranty

2. Specication Quick Reference

Input voltage nom. 24Vdc

range 22.5-30Vdc

Output current min.15A Normal mode

min. 10A Buer mode

Output voltage typ. 0.23V lower

22.25V Buer mode, 10A

Allowed batteries 17Ah to 130Ah VRLA lead acid

Temperature range -25 to +50°C

Dimensions 49x124x117mm WxHxD

Buer time (at 10A) typ. 55 minutes 26Ah battery

typ. 4 hours 100Ah battery

Typical setup of a DC-UPS system:

AC

24V

Power

Supply

e.g.:

as input voltage

24V

DC-UPS

12V

Battery

Normal mode

DC

24V

Load

e.g.: PLC

3. Catalog Numbers

DC UPS

Accessories 1606-XLSBAT2 Battery module 12V 26Ah

1606-XLSBATBR23 Mounting kit w/o battery

1606-XLS240-UPSE Controller

1606-XLB Panel/Wall mount bracket

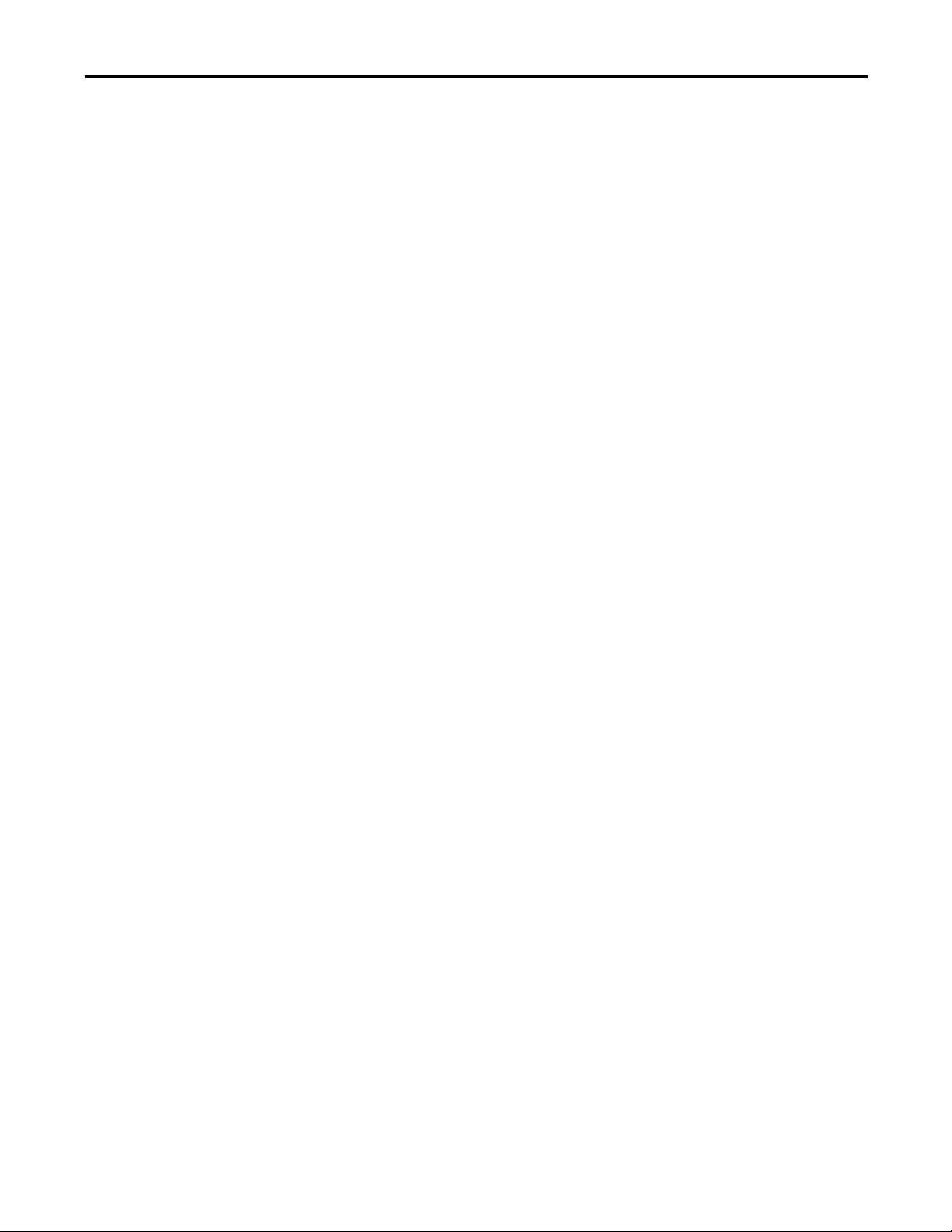

4. Certication Marks

IND. CONT. EQ.

UL 508

C-Tick

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

2 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

UL 60950-1

UL 508

GOST R

EMC, LVD

Marine RINA

Marine

Page 3

Bulletin 1606 Switched Mode Power Supplies

Intended Use

• This device may only be installed and put into operation by qualified personnel.

• This device is designed for installation in an enclosure and is intended for the general professional use such as in industrial control, office,

communication, and instrumentation equipment.

• Do not use this power supply in aircraft, trains, nuclear equipment or similar systems where malfunction may cause severe personal injury or

threaten human life.

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 3

Page 4

Bulletin 1606 Switched Mode Power Supplies

5. Input

Input voltage

nom. DC 24V

Input voltage ranges

nom. 22.5 to 30Vdc Continuous operation, see Fig. 5-1

30 to 35Vdc Temporarily allowed, no damage to the DC-UPS *)

35Vdc Absolute maximum input voltage with no damage to the

DC-UPS

0 to 22.5Vdc The DC-UPS switches into buer mode and delivers

output voltage from the battery if the input was above

the turn-on level before and all other buer conditions

are fullled.

Allowed input voltage ripple

max. 1.5Vpp Bandwidth <400Hz

1Vpp Bandwidth 400Hz to 1kHz

Allowed voltage between input

and earth (ground)

max. 60Vdc or

42.4Vac

Turn-on voltage

typ. 22.8Vdc The output does not switch on if the input voltage does

not exceed this level.

max. 23Vdc

Input current **)

typ. 120mA Internal current consumption for the DC-UPS

typ.

max.

2.0A

2.7A

Current consumption for battery charging ***)

External capacitors on the input

No limitation

*) The DC-UPS shows “Check Wiring” with the red LED and buering is not possible.

**) The total input current is the sum of the output current,

the current which is required to charge the battery during the

charging process and the current which is need

ed to supply the DC-UPS itself. See also

Fig. 5-2 . This calculation does not apply

in overload situations where the DC-UPS limits the output current, therefore see Fig. 5-3.

***) Please note: This is the input current and not the current which ows into the battery during charging. The battery current can

be found in section 8.

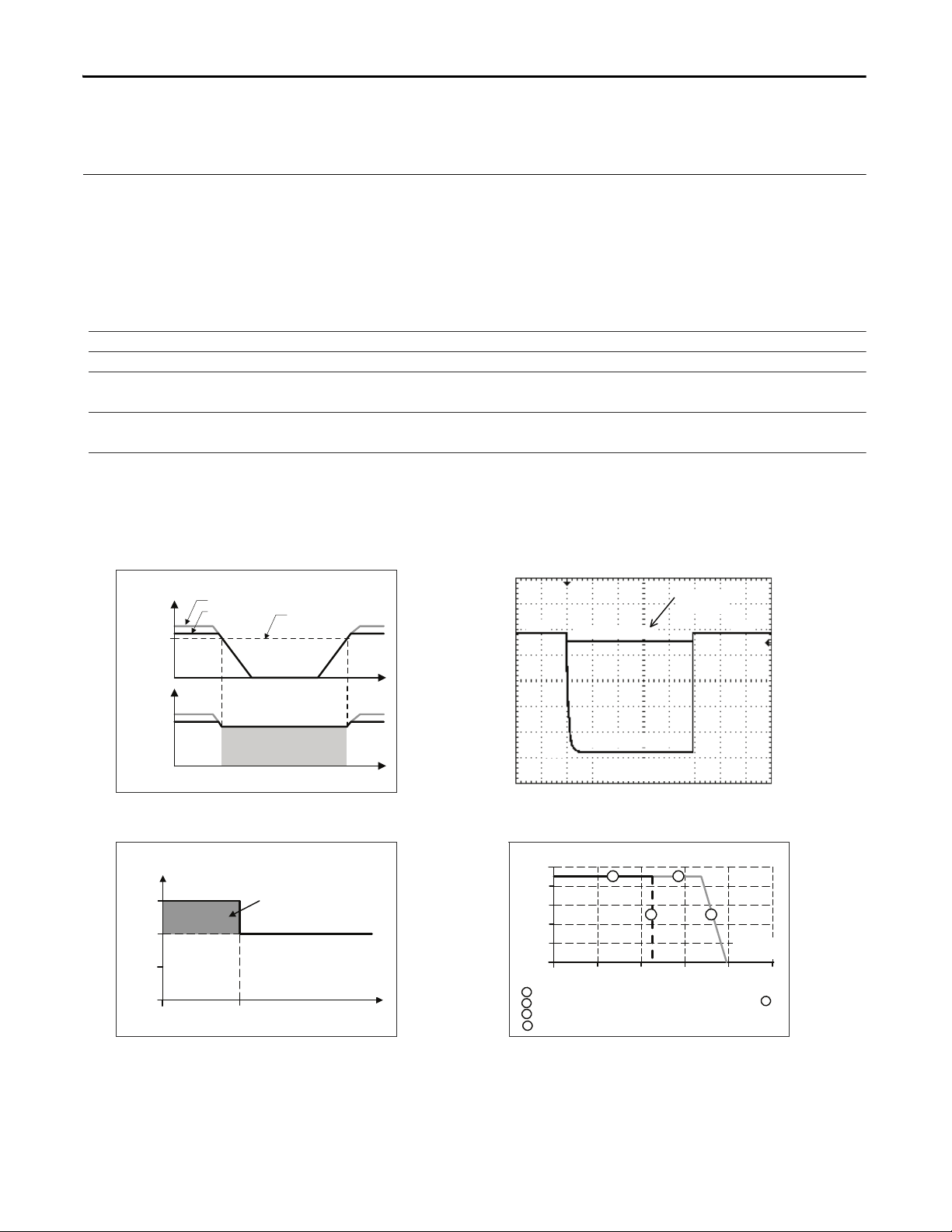

Fig. 5-1 Input voltage range Fig. 5-2 Input current, denitions

A: Rated input voltage range

B: Temp. allowed, no harm to the unit

C: Absolute max. input voltage

D: Buffer mode

V

IN

18 30 35V22.50

AB

C

D

V

OUT

Internal

current

consumption

Current

consumption

for battery

charging

Output

Current

Input

Current

Fig. 5-3 Input current and output voltage vs.

output current, typ. (battery fully charged)

Electric output current limitation

The DC-UPS is equipped with an electronic output

current limitation. This current limitation works

in a switching mode which reduces the power

losses and heat generation to a minimum. As a

result, the output voltage drops since there is not

enough current to support the load. A positive

eect of the current limitation in switching mode

is that the input current goes down despite an

increase in the output current resulting in less

stress for the supplying source.

0

0

5

10

15

20A

O

u

t

p

u

t

C

u

r

r

e

n

t

4812

20A

Output Voltage

15

20V

Overload

I

n

p

u

t

C

u

r

r

e

n

t

10

4 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 5

Bulletin 1606 Switched Mode Power Supplies

6. Output in Normal Mode

Output voltage in normal mode

nom. DC 24V The output voltage follows the input voltage reduced by

the input to output voltage drop.

Voltage drop between input and

output

max. 0.3V At 10A output current, see Fig. 6-1 for typical values

max. 0.45V At 15A output current, see

Fig. 6-1 for typical values

Ripple and noise voltage

max. 20mVpp 20Hz to 20MHz, 50Ohm *)

Output current nom. 15A Continuously allowed

Output power nom. 360W Continuo usly allowed

Short-circuit current

min. 17.9A Load impedance 100mOhm, see Fig. 6-2 for typical values

max. 21A Load impedance 100mOhm, see

Fig. 6-2 for typical values

Capacitive and inductive loads

No limitation

might be higher if the supplying source has a higher ripple and noise voltage.

Fig. 6-1 Input to output voltage drop, typ.

Fig. 6-2

Output voltage vs. output current in

normal mode at 24V input, typ.

Input to Output

Voltage drop

0

02 10

0.1

0.15

0.25

18A

0.05

0.2

0.3

0.35

0.4V

Ou

t

p

u

t

C

u

r

r

e

n

t

468 121416

Output Voltage

0

05101520

4

8

12

28V

16

20

24

25

A

Output Current

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 5

Page 6

Bulletin 1606 Switched Mode Power Supplies

7. Output in Buer Mode

If the input voltage falls below a certain value (transfer threshold level), the DC-UPS starts buering without any

interruption or voltage dips. Buering is possible even if battery not fully charged.

Output voltage in buer mode

nom. DC 24V Output voltage is stabilized and independent from

battery voltage

22.45V ±1%, at no load,

22.25V ±1%, at 10A output current

Transfer threshold for buering

typ. 80mV higher than the output voltage in buer mode

Ripple and noise voltage max. 20mVpp 20Hz to 20MHz, 50Ohm

Output current nom. 10A Continuously allowed

15A < 5s with full output voltage *)

Short-circuit current

min. 17.9A Load impedance 100mOhm **)

max. 21A Load impedance 100mOhm **)

*) If the output current is in the range between 10A and 15A for longer than 5s, a hardware controlled reduction of the

maximal output current to 10A occurs. If the 10A are not suci

ent to maintain the 24V, buering stops after another 5s.

Buering will again be possible as soon as the input voltage recovers.

**) If the nominal output voltage cannot be maintained in buer mode, the DC-UPS switches o after 5s to save battery

capacity.

Fig. 7-1 Buering transition, denitions

Buffer mode

Output

voltage

24V

28V

Input

voltage

t

t

Transfer

threshold

5

0

0

m

s

/

D

I

V

0

V

O

u

t

p

u

t

V

o

l

t

a

g

e

I

n

p

u

t

V

o

l

t

a

g

e

2

4

V

2

2

.

2

5

V

a

t

1

0

A

2

4

V

Fig. 7-3 Available output current in

buer mode

Fig. 7-4 Output voltage vs. output current

in buer mode, typ.

Output Current

0

05 Sec.

15A

10A

Time

5A

BonusPower

Output Voltage

A

B

C

Continuously available

Available for 5s then auto switching to curve

Buffering will stop after 5s

D

0

0

5101520

5

10

15

25V

20

25A

Output

Current

A B

CD

D

Buffering will stop after 5s

Fig. 7-2 Transfert behavior, typ.

6 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 7

8. Battery Input

The DC-UPS requires one 12V VRLA battery to buer the 24V output.

Battery voltage

nom. DC 12V Use one maintenance-free 12V VRLA lead acid battery or

one battery module which is listed in the Accessories

section.

Battery voltage range

9.0 – 15.0V Continuously allowed, except deep discharge protection

max. 35Vdc Absolute maximum voltage without any damage to the unit

typ. 7.4V Above this voltage level battery charging is possible

Allowed battery sizes

min. 17Ah

max. 130Ah

Internal battery resistance

max. 100mOhm See individual battry data sheets for this value.

Battery charging method CC-CV Constant current, constant voltage mode

Battery charging current (CC-mode) nom. 3.0A Independent from battery size

max. 3.4A

End-of-charge-voltage (CV-mode)

13.0-14.4V See section 15.

Battery charging time typ. 9h *) For a 26Ah battery

typ. 34h *) For a 100Ah battery

Battery discharging current **)

typ. 21A Buer mode, 10A output

current, 11.5V on the battery

terminal of the DC-UPS, see Fig. 8-1 for other parameters

typ. 0.3A Buer mode, 0A output current

max. 50μA At no input, buering had switched o, all LEDs are o

typ. 270mA At no input, buering had switched o, yellow LED

shows “buer time expired” (max. 15 minutes)

Deep discharge protection ***)

typ. 10.5V At 0A output current

typ. 9.8V At 10A output current

*) The charging time depends on the duration and load current of the last buer event. The numbers in the table represent a

fully discharged battery.

**) The current between the battery and the DC-UPS is more than twice the output current. This is caused by boosting the 12V

battery voltage to a 24V level. This high current requires large wire gauges and short cable length for the longest possible

buer time. The higher the resistance of the connection between the battery and the DC-UPS, the lower the voltage on the

battery terminals which increases the discharging current. See also section 26 for more installation instructions.

***) To ensure longest battery lifetime, the DC-UPS has a battery deep discharge protection feature included. The DC-UPS stops

buering when the voltage on the battery terminals of the DC-UPS falls below a certain value. The yellow LED will show

“buer time expired” for a period of 15 minutes after the unit stopped buering.

Fig. 8-1 Battery discharging current

vs. output current, typ.

Battery Current

0

0

10

20

5

15

25

30A

2.5 7.5 10 5.21A515

O

u

t

p

u

t

C

u

r

r

e

n

t

Voltage on

battery terminal

of the DC-UPS:

A:

10.5V

B:

11V

C:

12V

A B C

Bulletin 1606 Switched Mode Power Supplies

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 7

Page 8

Bulletin 1606 Switched Mode Power Supplies

9. Buer Time

The buer time depends on the capacity and performance of the battery as well as the load current. The diagram

below shows the typical buer times of the standard battery modules.

Buer time with 26Ah battery (1606-XLSBATASSY2) min. 99’30’’ At 5A output current *)

min. 39’ At 10A output current *)

typ. 130’ At 5A output current, see

Fig. 9-1

**)

typ. 55’ At 10A output current, see

Fig. 9-1

**)

Buer time with 100Ah battery min. 62h 20’ At 0.5A output current *)

min. 3h At 10A output current *)

typ. 82h 20’ At 0.5A output current, see Fig. 9-1

**)

typ. 4h At 10A output current, see

Fig. 9-1 **)

*) Minimum value includes 20% aging of the battery and a cable length of 1.5m with a cross section of 2.5mm2 between the

battery and the DC-UPS and requires a fully charged (min. 24h) battery.

**) Typical value includes 10% aging of the battery and a cable length of 0.3m with a cross section of 2.5mm

2

between the battery

and the DC-UPS and requires a fully charged (min. 24h) battery.

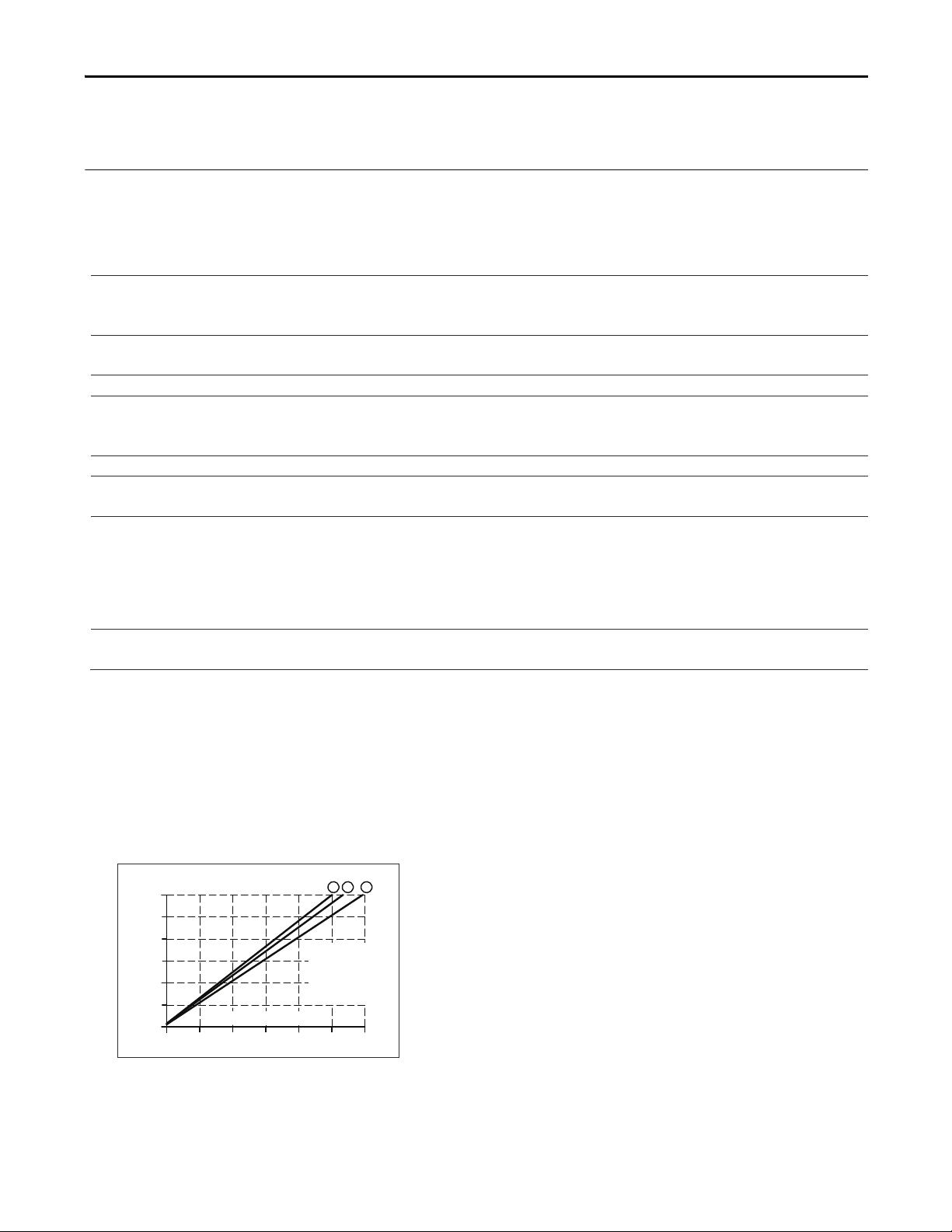

Fig. 9-1 Buer time vs. output current with a 65Ah and a 100Ah battery

Buffer Current

0

40 50

0.5

1.0

1.5

2A

70 8060 90h30

A

B

A:

65Ah Battery

B:

100Ah Battery

Buffer Time (Hours)

30h

Buffer Current

0

5

2

4

6

8

10A

10 15 20 25

Buffer Time (Hours)

A

B

A:

65Ah Battery

B:

100Ah Battery

5

The battery capacity is usually specied in amp-hours (Ah) for a 20h discharging event. The battery discharge is nonlinear (due to the battery chemistry). The higher the discharging current, the lower the appropriate battery capacity.

The magnitude of the reduction depends on the discharging current as well as on the type of battery. High current

battery types can have up to 50% longer buer times compared to regular batteries when batteries are discharged

in less than one hour.

High discharging currents do not necessarily mean high power losses as the appropriate battery capacity is reduced

with such currents. When the battery begins to recharge after a discharging event, the process is completed much

faster since only the energy removed from the battery needs to be “relled.”

For this reason, the buer time cannot be calculated using the Ah capacity value. The equation “I x t” = capacity in

Ah generally leads to incorrect results when the discharging current is higher than C20 (discharging current for 20h).

8 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 9

Bulletin 1606 Switched Mode Power Supplies

10. Eciency and Power Losses

Eciency typ. 97.8% Normal mode, 10A output current, battery fully charged

Power losses typ. 2.9W Normal mode, 0A output current, battery fully charged

typ. 5.5W Normal mode, 10A output current, battery fully charged

typ. 7.2W During battery charging, 0A output current

typ. 18.5W Buer mode, 10A output current

Fig. 10-1 Eciency at 24V, typ.

Fig. 10-2 Losses at 24V, typ.

Efciency vs. output

current in normal mode

94.5

39

95.5

96.0

97.0

15A

95.0

96.5

97.5

98%

O

u

t

p

u

t

C

u

r

r

e

n

t

57 1113

Power losses versus output current

0

07.5

6

12

15A

3

9

15

18W

O

u

t

p

u

t

C

u

r

r

e

n

t

2.5 5 10 12.5

A

B

A:

Buffer Mode

B:

Charging Mode

C:

Normal Mode

C

11. Functional Diagram

Fig. 11-1 Functional diagram

-

+

-

+

DC- UPS

24V

Power

Supply

Step-up

Converter

Battery

Charger

Electronic

Current

Limiter

Battery

Tester

+

-

12V Battery

+

-

Buffered

Load

Cut-off

Relay

Input Output

Battery

Diagnosis LED

(yellow)

Status LED

(green)

Inhibit +

Controller

Check Wiring LED

(red)

Replace Battery

Buffering

Contact

Ready Contact

Battery Temperature

(7)

Inhibit -

(8)

(1)

(2)

(3)

(4)

(5)

(6)

Input Fuse

&

Reverse

Polarity

Protection

*

Temp.

*) Return current protection: this feature uses a Mosfet instead of a diode to minimize the voltage drop and power losses.

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 9

Page 10

Bulletin 1606 Switched Mode Power Supplies

12. Check Wiring and Battery Quality Tests

The DC-UPS is equipped with an automatic “Check Wiring” and “Battery Quality” test.

“Check Wiring” test:

Under normal circumstances, an incorrect or bad connection from the battery to the DC-UPS or a missing (or blown)

battery fuse would not be recognized by the UPS when operating in normal mode. Only when backup is required

would the unit be unable to buer. Therefore, a “Check Wiring” test is included in the DC-UPS. This connection is

tested every 10 seconds by loading the battery and analyzing the response from the battery. If the resistance is too

high, or the battery voltage is not in range, the unit displays “Check Wiring” along with the red LED. At the same time,

the green “Ready” LED will turn o.

“Battery Quality” or “State of Health” (SoH) test:

The battery has a limited service life and needs to be replaced at xed intervals determined by the specied service

life (acc. to the Eurobat guideline), based on the surrounding temperature and the number of charging and

discharging cycles. If the battery is used longer than the specied service life, its capacity will degrade. Section 27-1

contains additional information on the topic. The battery quality test cannot identify a gradual loss in capacity.

However, it is able to detect a battery failure within the specied service life of the battery. Therefore a battery quality

test in included in the DC-UPS.

A battery problem is indicated by the yellow LED (replace battery pattern) and the relay contact “Replace Battery.”

Please note that it can take up to 170 hours (with the largest battery size) until a battery problem is reported. This

should avoid nuisance error messages as any urgent battery problems will be reported by the “Check Wiring” test and

create a warning signal.

When “Replace Battery” is indicated, we recommend replacing the battery as soon as possible.

13. End-of-Charge Voltage

The end-of-charge voltage depends on the temperature of the battery. An excessively high end-of-charge voltage may

damage the battery and shorten its lifetime. Therefore the DC-UPS includes an internal temperature sensor, which

regulates the end-of-charge voltage depending on the battery temperature. To achieve the longest lifetime,

the battery should be placed at the coldest location.

The temperature dierence between the DC-UPS and the battery requires a correction of the end-of-charge voltage.

This can be done with the selector on the front side of the unit. See section 15 for details.

10 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 11

Bulletin 1606 Switched Mode Power Supplies

14. Relay Contacts and Inhibit Input

The DC-UPS is equipped with relay contacts and signal inputs for remote monitoring and controlling of the unit.

Relay contacts:

Ready:

Contact is closed when battery is charged more than 85%, no wiring failure is recognized, input

voltage is sucient and inhibit signal is not active.

Buering: Contact is closed when unit is buering.

Replace Battery: Contact is closed when the unit is powered from the input and the battery quality test (SOH test)

reports a negative result.

Relay contact ratings max 60Vdc 0.3A, 30Vdc 1A, 30Vac 0.5A resistive load

min 1mA at 5Vdc min.

Isolation voltage max 500Vac, signal port to power port

Signal input:

Inhibit: The inhibit input disables buering. In normal mode, a static signal is

required. In buer mode, a pulse with a minimum length of 250ms is

required to stop buering. The inhibit is stored and can be reset by

cycling the input voltage. See also section 27.3 for application hints.

7 +

5.1V

3mA

Inhibit

8

-

Signal voltage max. 35Vdc

Signal current max. 6mA, current limited

Inhibit threshold min. 6Vdc, buering is disabled above this threshold level

max. 10Vdc

Isolation nom. 500Vac, signal port to power port

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 11

Page 12

Bulletin 1606 Switched Mode Power Supplies

15. Front Side User Elements

A

Power Port

Quick-connect spring-clamp terminals, connection for input voltage,

output voltage and battery

B

Signal Port

Plug connector with sc rew terminals, inserted from the bottom.

Connections for the Ready, Buering, Replace Battery contacts and for

the Inhibit input. See details in section 14. .

C

Green Status LED

Ready: Battery is charged > 85%, no wiring failure is recognized, input

voltage is sucient and inhibit signal is not active.

Charging: Battery is charging and the battery capacity is below 85%.

Buering: Unit is in buer mode.

Flashing pattern of the green status LED:

Ready

1

0

1

0

Charging

1

0

Buffering

D

Yellow Diagnosis LED

Overload: Output has switched o due to long overload in buer mode

or due to high temperatures.

Replace battery: Indicates a battery that failed the battery quality test (SoH test).

Battery should be replaced soon.

Inhibit active: Indicates that buering is disabled because of an active inhibit signal.

Flashing pattern of the yellow diagnosis LED:

1

0

Overload

1

0

Replace

Battery

1

0

Inhibit

active

E

Red Check Wiring LED

This LED indicates a failure in the installation (e..g. input voltage excessively low), wiring, battery or battery fuse.

F

Battery Temperature Selector

A: Same as this unit Temperature compensated end-of-charge voltage.

B: 10°C lower than this unit Temperature compensated end-of-charge voltage with an oset conditional upon tempera

C: 20°C lower than this unit Temperature compensated end-of-charge voltage with an oset conditional upon tempera

D: Battery temperature is 30°C Fixed end of charge voltage for 30°C battery temperature

E: Battery temperature is 20°C Fixed end of charge voltage for 20°C battery temperature

F: Battery temperature is 10°C Fixed end of charge voltage for 10°C battery temperature

C

D

E

12 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 13

16. Terminals and Wiring

Power terminals Signal terminals

Type Bi-stable, quick-connect spring-

clamp terminals. IP20 Fingertouch-proof. Suitable for eldand factory installation. Shipped

in open position.

Plug connector with screw terminal. Finger-touch-proof

construction with captive screws for 3.5mm slotted

screwdriver. Suitable for eld and factory installation.

Shipped in open position. To meet GL requirements,

unused terminal compartments should be closed.

Solid wire 0.5-6mm2 0.2-1.5mm2

Stranded wire 0.5-4mm2 0.2-1.5mm2

AWG 20-10AWG 22-14AWG

Ferrules Allowed, but not required Allowed, but not required

Pull-out force 10AWG:80N, 12AWG:60N,

14AWG:50N, 16AWG:40N

according to UL486E

Not applicable

Tightening torque Not applicable 0.4Nm, 3.5lb.in

Wire stripping length 10mm / 0.4inch 6mm / 0.24inch

Fig. 16-1 Spring-clamp terminals, connecting a wire

Insert wire

Close the lever

To disconnect wire, reverse the procedure.

Instructions:

a) Use appropriate copper cables that are designed

for an operating temperature of 60°C.

b) Follow national installation codes and regulations!

c) Ensure that all strands of a stranded wire are properly inserted in

the terminal connection!

d) Up to two stranded wires with the same cross-section are

permitted in one connection point.

17. Reliability

Lifetime expectancy min. 137 400h At 10A output current, 40°C

min. > 15 years At 5A output current, 40°C

min. > 15 years At 10A output current, 25°C

MTBF SN 29500, IEC 61709 886 000h At 10A output current, 40°C

1 482 000h At 10A output current, 25°C

MTBF MIL HDBK 217F 397 900 At 10A output current , 40°C, ground benign GB40

545 000 At 10A output current , 25°C, ground benign GB25

The Lifetime expectancy shown in the table indicates the operating hours (service life), and is determined by the

lifetime expectancy of the built-in electrolytic capacitors. Lifetime expectancy is specied in operational hours.

Lifetime expectancy is calculated according to the capacitor’s manufacturing specications. The prediction model

allows a calculation of up to 15 years from date of shipment.

MTBF stands for Mean Time Between Failures, which is calculated according to statistical device failures and indicates

reliability of a device. It is the statistical representation of the likelihood of failure of a specic unit and does not

necessarily represent the life of a product.

Bulletin 1606 Switched Mode Power Supplies

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 13

Page 14

Bulletin 1606 Switched Mode Power Supplies

18. EMC

The unit is suitable for applications in industrial environments as well as in residencial, commercial and light industry

environment without any restrictions. The CE Mark indicates conformance with EMC guideline 89/336/EC, 93/68/EC and

2004/108/EC and the low-voltage directive (LVD) 73/23/EC, 93/68/EC and 2006/95/EC.

A detailed EMC report is avalaible upon request.

EMC Immunity

EN 61000-6-1, EN 61000-6-2 Generic standards

Electrostatic discharge EN 61000-4-2 Contact discharge

Air discharge

8kV

15kV

Criterion A*)

Criterion A*)

Electromagnetic RF eld EN 61000-4-3 80MHz-2.7GHz 10V/m Criterion A

Fast transients (Burst) EN 61000-4-4 Out- and Input lines

Signal lines **)

2kV

2kV

Criterion A

Criterion A

Surge voltage

EN 61000-4-5 + -

500V

500V

Criterion A

Criterion A

+ -

housing

500V

Criterion A

Conducted disturbance EN 61000-4-6 0.15-80MHz 10V Criterion A

*) DIN rail earthed

**) Tested with coupling clamp.

EMC Emission

EN 61000-6-3 and EN 61000-6-4 Generic standards

Conducted emission EN 55022 Input lines Class B*)

Class B*)

Radiated emission EN 55011, EN 55022 Class B

This device complies with FCC Part 15 rules.

Operation is subjected to following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

*) Informative measurement with voltage probe

Switching frequency

The DC-UPS has three converters with three different switching frequencies included.

Switching frequency of boost converter 100kHz Constant frequency

Switching frequency of electronic output current limitation 78kHz Constant frequency

Switching frequency of battery charger 19.5kHz Constant frequency

Output

Input

+

-

EN 55022

Output lines

14 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 15

Bulletin 1606 Switched Mode Power Supplies

19. Environment

Operational temperature -25°C to +50°C Full power, for the DC-UPS control unit.

Keep battery in a cooler environment!

Storage temperature -40 to +85°C Storage and transportation, except battery

Humidity 5 to 95% r.H. IEC 60068-2-30

Do not energize while condensation is present

Vibration sinusoidal 2-17.8Hz: ±1 .6mm; 17.8-500Hz: 2g IEC 60068-2-6

Shock 30g 6ms, 20g 11ms IEC 60068-2-27

Altitude 0 to 6000m Approvals apply only up to 2000m

Over-voltage category III EN 50178

II EN 50178 above 2000m altitude

Degree of pollution 2 EN 50178, not conductive

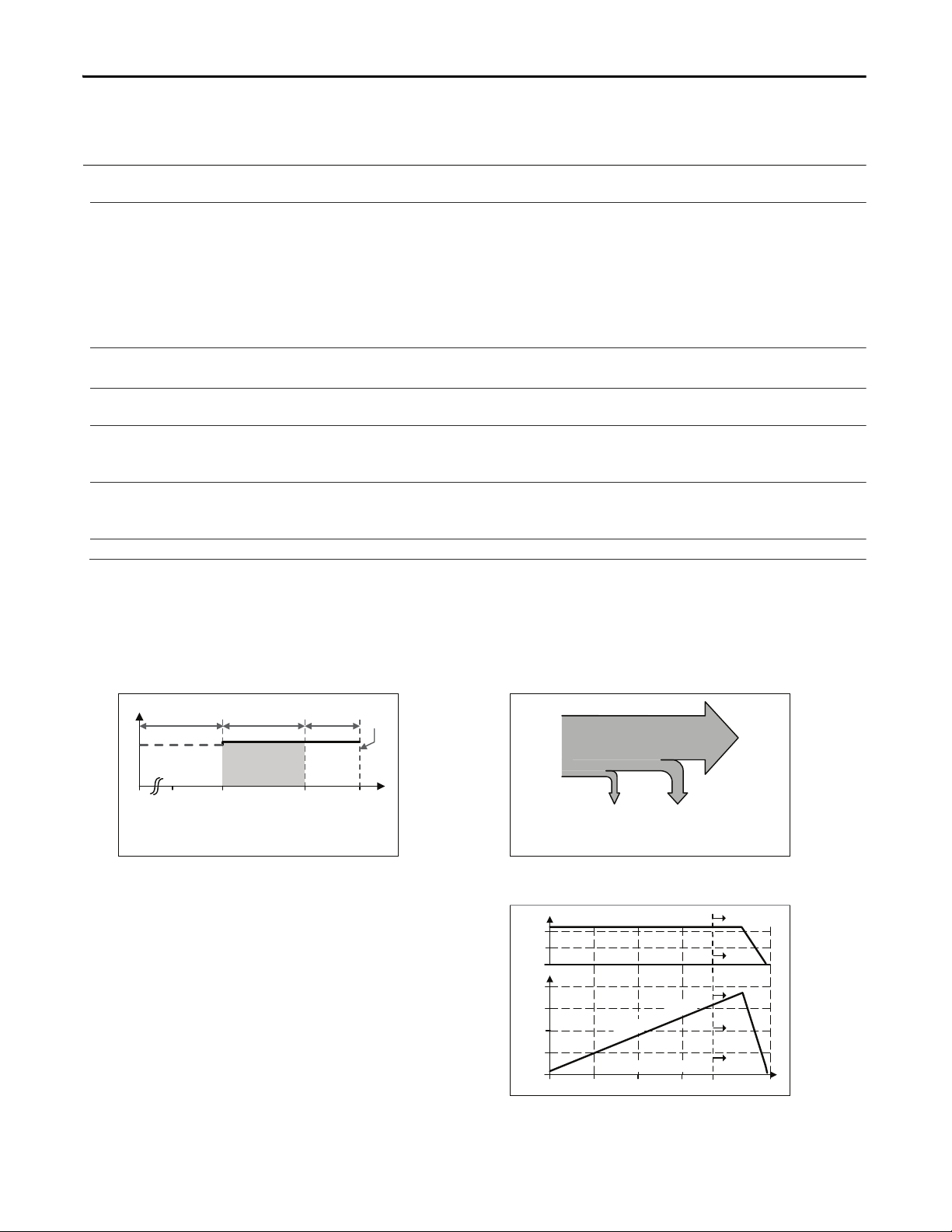

Fig. 19-1 Output current vs. ambient temperature

Fig. 19-2 Output current vs. ambient temperature

Allowable Output Current in Normal Mode

0

-25 0 20 30

50°C

2.5

5

7.5

10

12.5

15A

4010

Ambient Temperature

Allowable Output Current in Buffer Mode

0

-25 0 20 30

50°C

2.5

5

7.5

10

12.5

15A

10 40

Ambient Temperature

c

o

n

t

i

n

u

o

u

s

f

o

r

t

y

p

.

5

s

The ambient temperature is dened 2cm below the unit.

20. Protection Features

Output protection Electronically protected against overload, no-load and short-circuits

Output over-voltage protection

in buer mode

typ. 32Vdc

max. 35Vdc

In case of an internal defect, a redundant circuitry

limits the maximum output voltage. The output

automatically shuts-down and makes restart attempts.

Degree of protection IP20 EN/IEC 60529

Penetration protection > 3.5mm E.g. screws, small parts

Reverse battery polarity protection yes Max. –35Vdc;

Wrong battery voltage protection yes Max. +35Vdc (e.g. 24V battery instead of 12V battery)

Battery deep discharge protection yes The limit is battery current dependent

Over temperature protection yes Out put shut-down with automatic restart

Input over-voltage protection yes Max. 35Vdc, no harm or defect of the unit

Internal input fuse 25A, blade type No user accessible part, no service part

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 15

Page 16

Bulletin 1606 Switched Mode Power Supplies

21. Safety

Output voltage SELV IEC/EN 60950-1

PELV EN 60204-1, EN 50178, IEC 60364-4-41

Max. allowed voltage between any input, output or signal pin and ground:

60Vdc or 42.4Vac

Class of protection III PE (Protective Earth) connection is not required.

Isolation resistance > 5MOhm Power port to housing, 500Vdc

Dielectric strength 500Vac Power port to signal port

500Vac Power port / signal port to housing

Touch current (leakage current) The leakage current which is produced by the DC-UPS itself depends on the input

voltage ripple and need to be investigated in the nal application.

For a smooth DC input voltage, the produced leakage current is less than 100

μA.

22. Certications

EC Declaration of

Conformity

Complies with:

- CE EMC directive

- CE Low-voltage directive

UL 508

LISTED E56639 for the use in the U.S.A. (UL 508) and Canada

(C22.2 No. 14-95). Industrial Control Equipment

ISA 12.12.01, CSA

C22.2 No. 213

RECOGNIZED UNDER FILE NUMBER E244404 for use in the U.S.A.

(ISA 12.12.01) and Canada (C22.2 No. 213)

Hazardous Location Class I, Div. 2 - Groups A, B, C, D

GOST R

GOST R certication is applicable for products intended for sale and

use within Russia. See below for link to Certicate.

C-TICK

C-tick compliance is for products intended for sale and use within

the Australian market. See below for the link to the C-tick Declaration

of Conformity.

Marine GL GL (Germanischer Lloyd) classied for marine and offshore

applications. Environmental category: C, EMC2. See below for link

to Certicate.

Marine Rina

RINA (Registro Italiano Navale) certied. See below for the link to

the certicate.

UL 60950-1

RECOGNIZED E168663 for use in the U.S.A. (UL 60950-1)

and Canada (C22.2 No. 60950)

Information Technology Equipment, Level 3

CSA C22.2 No. 213

ISA 12.12.01

CSA Certied under File Number 240020; CERTIFIED for use in the

U.S.A. (ISA 12.12.01) and Canada (C22.2 No. 213)

Hazardous Location Class I, Div. 2 - Groups A, B, C, D

Product certification information (including Certificates and Declarations of Conformity) can be found at www.ab.com/certifications.

16 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 17

Bulletin 1606 Switched Mode Power Supplies

23. Environmental Compliance

The unit does not release any silicone and is suitable for use in paint shops.

Electrolytic capacitors included in this unit do not use electrolytes such as Quaternary Ammonium Salt Systems.

Plastic housings and other molded plastic materials are free of halogens, wires and cables are not PVC insulated.

The materials used in our production process do not include the following toxic chemicals:

Polychlorinated Biphenyl (PCB), Pentachlorophenol (PCP), Polychlorinated naphthalene (PCN), Polybrominated

Biphenyl (PBB), Polybrominated Biphenyl Oxide (PBO), Polybrominated Diphenyl Ether (PBDE), Polychlorinated

Diphenyl Ether (PCDE), Polybrominated Diphenyl Oxide (PBDO), Cadmium, Asbestos, Mercury, Silica

24. Physical Dimensions and Weight

Width 49mm / 1.93’’

Height 124mm / 4.88’’ Plus height of signal connector plug

Depth 117mm / 4.61’’ Plus depth of DIN rail

Weight 545g / 1.2lb

DIN Rail Use 35mm DIN rails according to EN 60715 or EN 50022 with a height of 7.5 or 15mm.

The DIN rail height must be added to the depth (117mm) to calculate the total required installation

depth.

Fig. 24-1 Side view

Fig. 24-2 Front view

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 17

Page 18

Bulletin 1606 Switched Mode Power Supplies

25. Installation Notes

Mounting:

The power terminal shall be located on top of the unit. An appropriate electrical and re end-product enclosure should

be considered in the end use application.

Cooling:

Convection cooled, no forced air cooling required. Do not obstruct air ow!

Installation clearances:

40mm on top, 20mm on the bottom, 5mm on the left side are recommended when loaded

permanently with more than 5A. Do not place heat sources next to the 1606-XLS240-UPSE

since it can inuence the function of rthe internal temperature sensor. Keep a minimum of

15mm from the adjacent device.

Risk of electrical shock, re, personal injury or death!

Turn power o and disconnect battery fuse before working on the DC-UPS. Protect against inadvertently re-powering.

Make sure the wiring is correct by following all local and national codes. Do not open, modify or repair the unit. Use

caution to prevent any foreign object from penetrating in the housing. Do not use in wet locations or in areas where

moisture and condensation can be expected.

Service parts:

The unit does not contain any service parts. The tripping of an internal fuse is caused by an internal fault. If damage or

malfunctioning should occur during operation, immediately turn power o and send unit to the factory for inspection.

Wiring and installation instructions:

(1) Connect the power supply to the input terminals of the DC-UPS.

(2)

Connect the battery to the battery terminals of the DC-UPS. Do not install the battery in airtight housings or cabinets.

(3) Connect the buered load to the output terminals of the DC-UPS. The output is decoupled from the input allowing load

(4)

Install the fuse upon completion of the wiring.

Fig. 25-1 Typical wiring diagram

24V

Power

Supply

+

-

NLPE

DC-UPS

1606-XLS240

-UPSE

24V

IN

24V

OUT

12V

BAT

+

-+-+-

12V

Battery

Module

+

-

Buffered

Load

+

-

Non-

buffered

Load

+

-

24V

buffered

branches

24V

Non-bufferd

branches

The battery should be installed according to EN50272-2, which includes sucient ventilation. Batteries store energy and

must be protected against energy hazards. Use a 30A battery fuse type ATO® 257 30 (Littelfuse) or similar in the battery path.

The battery fuse protects the wires between the battery and the DC-UPS. It also allows the disconnection of the battery from

the DC-UPS which we recommend when working on the battery or DC-UPS. Disconnect battery fuse before connecting the

battery. Please note: Excessively long or short wires between the DC-UPS and battery may shorten the buer time or result

in a malfunction of the DC-UPS. Do not use wires smaller than 2.5mm² (or 12AWG) and no longer than 2x1.5m (cord length

1.5m). Avoid voltage drops on this connection.

circuits to be easily split into buered and non-buered sections. Noncritical loads can be connected directly to the|

power supply and will not be buered. The energy of the battery can then be used in the circuits that require buering.

18 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 19

Bulletin 1606 Switched Mode Power Supplies

26. Accessories

Battery Modules

One pre-assembled battery module with a single 12V battery is available. As an option, the mounting bracket is also

available without battery. This option oers more exibility in selecting an approriate battery or can save shipping and

logistics costs. See individual datasheets for detailed information.

1606-XLSBATASSY2

Battery type High current version12V, 26Ah VRLA lead-acid maintenance free battery

Service life 10 to 12years According to EUROBAT guideline

Dimensions 214x179x158mm Width x height x depth

Weight 9.9kg

DIN Rail mountable no

Order number 1606-XLSBATASSY2 Battery module

1606-XLSBATBR2 Mounting bracket without battery

1606-XLSBAT2 Replacement battery only

Fig. 27-1

1606-XLSBATASSY2

1606-XLB Wall / Panel mounting bracket

Use this bracket to mount the DC UPS units onto a at surface without using a DIN rail. Both the aluminium brackets and the

black plastic slider of the DC UPS must be removed so that the two surface brackets may be mounted.

Fig. 26-2 1606-XLB Wall / Panel Mounting Bracket

Fig 26-3 Assembled Wall / Panel Mounting Bracket

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 19

Page 20

Bulletin 1606 Switched Mode Power Supplies

27. Application Notes

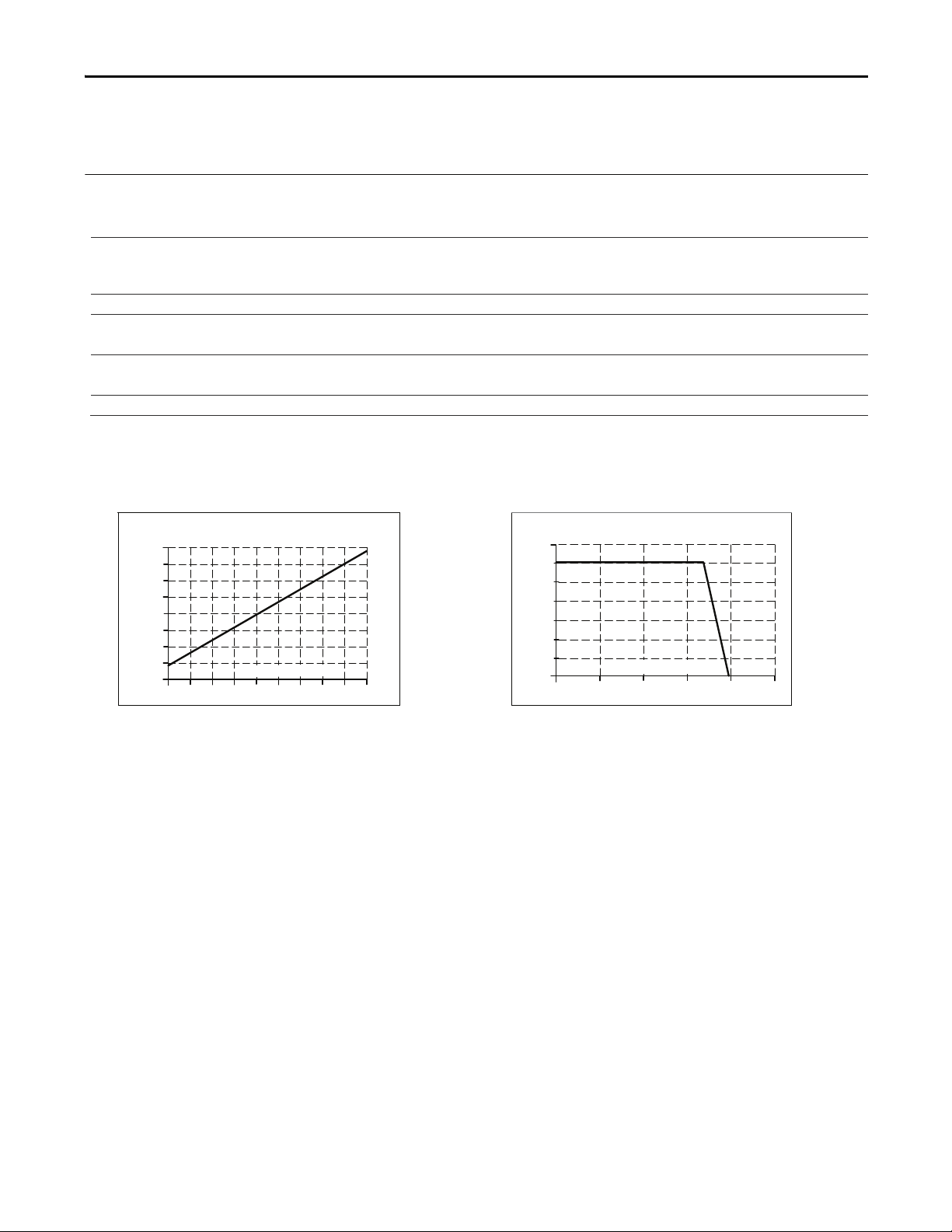

27.1. Battery Replacement Intervals

Batteries have a limited lifetime. They degrade slowly beginning from the production and need to be replaced

periodically, The design life gures can be found in the indidividual battery datasheets and are usually specied according

to the Eurobat guideline or according to the manufacturer’s specications.

The design life is the estimated life based on laboratory condition, and is quoted at 20°C using the manufacturer’s

recommended oat voltage condition. According to the Eurobat guideline, design lives have been structured into the

following distinct groups:

3 - 5 years:

This group of batteries is very popular in stand-by applications and in small emergency equipment.

This represents a 4 years design life with a production tolerance of ±1 year.

6 - 9 years:

This group of batteries is generally used when an improved life is required.

This represents a 7.5 years design life with a production tolerance of ±1.5 years.

10 - 12 years:

This group of batteries is used in applications for which longest life and highest safety level are

required. This represents a 11 years design life with a production tolerance of ±1 year.

A battery failure within the specied design life of the battery usually results in complete loss of battery

function (broken cell, faulty connection, …) and will be detected and reported by the periodical battery tests

included in the 1606-XLS240-UPSE DC-UPS control unit.

If the operational parameters dier from those specied for the design life, earlier replacement of the battery may prove

necessary. The “real life” is called service life and is dened as the point at which the cell’s actual capacity has reached

80% of its nominal capacity. At the end of the service life, capacity degrades much more rapidly, so that further use of

the battery is not recommended.

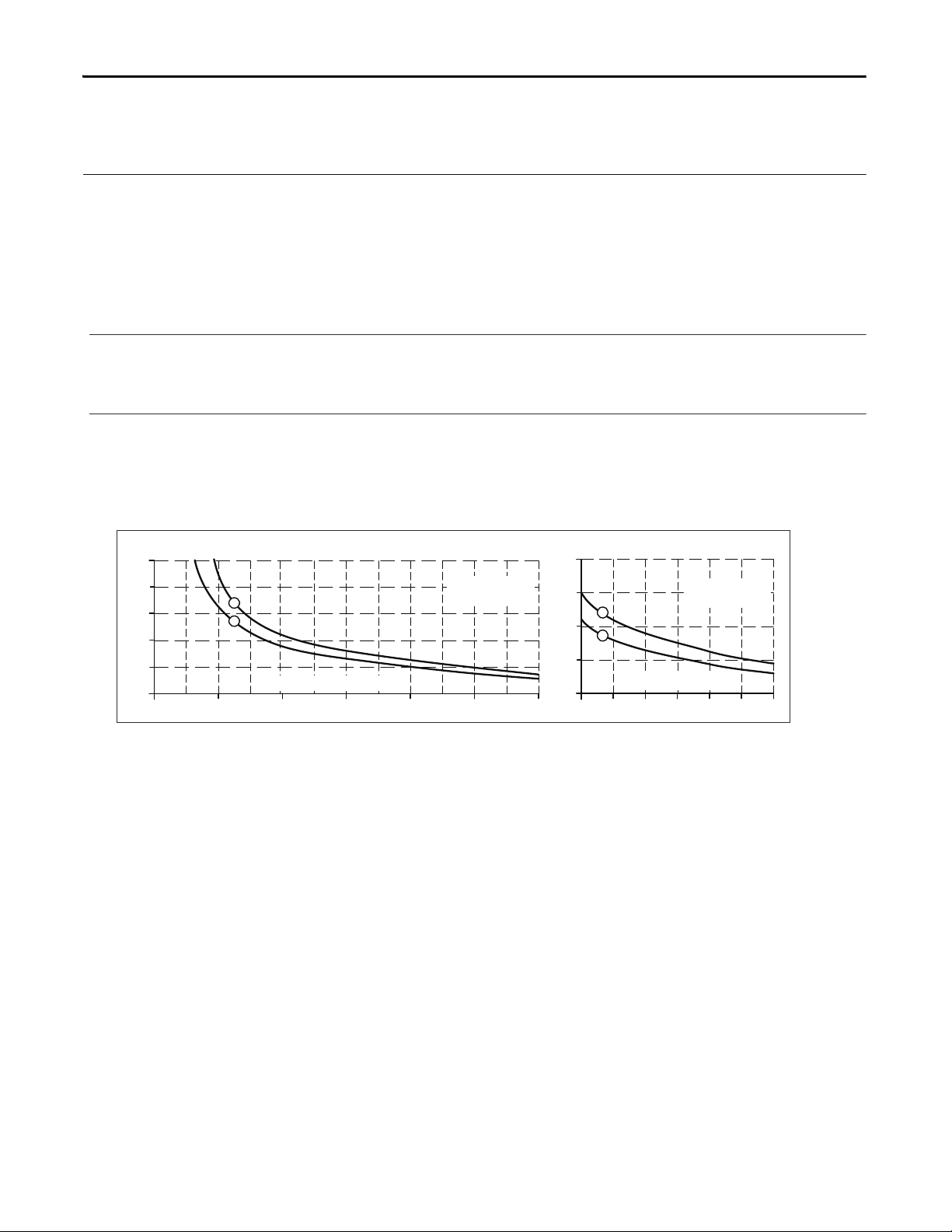

Temperature eect

Temperature has the greatest impact on service life of a battery. The hotter the temperature, the earlier the wear-out phase of the

battery begins. The wear-out results in a degradation of battery capacity. See Fig 27-1 for details.

Eect of discharging cycles

The number as well as the depth of discharging cycles is limited. Replacing the battery may prove necessary earlier than the

calculated service life if the battery exceeds the numbers and values in Fig. 27-2.

Other factors shortening service life

Overcharging and deep discharging shortens the service life and should be avoided. Thanks to the single battery

concept of the 1606-XLS240-UPSE, the end-of-charge-voltage can be set very precisely to the required value, thereby

preventing unnecessary aging eects.

Charge retention is important to achieve the longest battery life. Stored batteries not fully charged age faster than

fully charged batteries. Batteries which are not in use should be recharged at least once a year.

Excessive oat charge ripple across the battery has the ect of reducing life and performance. The 1606-XLS240-UPSE

does not produce such a ripple voltage. This eect may therefore safely be ignored if you’re charging a battery with

your 1606-XLS240-UPSE.

Guidelines for long battery service life

Place the battery in a cool location, for instance near the bottom of the control cabinet.

Do not place the battery near heat generating devices.

Do not store discharged batteries.

Do not discharge the battery more than necessary. Set buer time limiter to the required buer time.

When choosing the battery capacity, always try to get the next higher capacity than the one you require.

The depth of discharge reduces the battery service life and limits the number of cycles. See Fig. 27-2.

20 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 21

Bulletin 1606 Switched Mode Power Supplies

Example for calculating the service life and the required replacement cycle:

Parameters for the example:

A 26Ah battery with a design life of 10-12 years is used.

The average ambient temperature is 30°C.

One buer event consumes approx. 25% of the achievable buer time.

One buer event every two days

Calculation:

Ambient temperature inuence:

According to Fig. 27-1 curve C, a 5 years service life can be expected for an ambient temperature of 30°C.

Number of discharging cycles: 5 years * 182 cycles = 910cycles in 5 years.

According to Fig. 27-2, curve C has to be used (only 25% of battery capacity is required). 910 cycles have only a

negligible inuence in a battery degradation and can be ignored.

Result:

The battery shall be replaced after 5 years.

Please note that the battery degrading begins from the production date (check date code on the battery) which may

shorten the replacement intervals.

Fig. 27-1 Service life versus ambient

temperatures, typ. *)

Fig. 27-2 Cell capacity degradation vs. discharging

cycles *)

20°C

10

30°C 35°C

40°C

45°C

8

6

4

2

Ambient Temperature

25°C

1

3

5

7

9

Service Life in Years

Design Life

of Battery

A:

3-5 Years

B:

6-9 Years

C:

10-12 Years

A

B

C

0

120%

100%

40%

20%

Number of Discharging Cycles

200

60%

80%

Cell Capacity

Depth of

discharge

A:

100%

B:

50%

C:

30%

400 600 800 1000 1200

A

B

C

*) datasheet gures from battery manufacturer

27.2. Parallel and Serial Use

Do not use the DC-UPS in parallel to increase the output power. However, two units of the DC UPS can be paralleled

for 1+1 redundancy to gain higher system reliability.

Do not use batteries in parallel, since the battery quality test might create an error message.

Do not connect two or more units in series for higher output voltages.

Do not connect two or more units in a row to get longer hold-up times.

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Rockwell Automation Publication 1606-RM013A-EN-P — March 2014 21

Page 22

Bulletin 1606 Switched Mode Power Supplies

27.3. Using the Inhibit Input

The inhibit input disables buering. In normal mode, a static signal is required. In buer mode, a pulse with a

minimum length of 250ms is required to stop buering. The inhibit is stored and can be reset by cycling the input

voltage.

As long as the inhibit signal is active in normal mode, an internal relay contact will be opened and the battery will

no longer be charged.

For service purposes, the inhibit input can also be used to connect a service switch. Therefore, the inhibit signal can

be supplied from the output of the DC UPS.

Fig. 28-3 Wiring example for inhibit input

24V

Power

Supply

+

-

DC-UPS

1606XLS240-UPSE

24V

IN

24V

OUT

12V

BAT

+-+-+

-

Signal Port

Inhibit

+

-

12V

Battery

Module

+

-

Buffered

Load

+

-

Service

Switch

27.4. Troubleshooting

The LEDs on the front of the unit and relay contacts indicate about the actual or elapsed status of the DC-UPS. Please

see also section 15

.

The following guidelines provide instructions for xing the most common failures and problems. Always start with

the most likely and easiest-to-check condition. Some of the suggestions may require special safety precautions. See

notes in section

25

rst.

“Check wiring” LED is on Check correct wiring between the battery and the DC-UPS.

Check battery fuse. Is the battery fuse inserted or blown?

Check battery voltage (must be typically between 7.4V and 15.1V).

Check input voltage (must be typically between 22.8V and 30V).

Check battery polarity.

DC-UPS did not buer

Inhibit input was set.

Battery did not have enough time to be charged and is still below the deep discharge

protection limit.

DC-UPS stopped buering Deep discharge protection stopped buering

use a larger battery, or allow

sucient time for ch

arging the battery.

Output was overloaded or short circuit reduce load.

Output has shut down

Cycle the input power to reset the DC UPS.

Let DC UPS cool down, over-temperature protection may have triggered.

DC-UPS constantly switches between normal mode and buer mode

The supplying source on the input is too small and can not deliver sucient current.

Use a larger power supply or reduce the output load.

22 Rockwell Automation Publication 1606-RM013A-EN-P — March 2014

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time unless noted otherwise.

It is assumed that the input power source can deliver a sufficient output current.

Page 23

Page 24

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

notes, sample code and links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools. You can also visit our Knowledgebase at http://

www.rockwellautomation.com/knowledgebase for FAQs, technical information, support chat and forums,

software updates, and to sign up for product notification updates.

, you can find technical manuals, technical and application

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

TechConne ct

representative, or visit http://www.rockwellautomation.com/support/

SM

support programs. For more information, contact your local distributor or Rockwell Automation

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in

this manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldw ide Loc ator at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from

the manufacturing facility. However, if your product is not functioning and needs to be returned, follow these

procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to

improve this document, complete this form, publication RA-DU002

literature.rockwellautomation.com/idc/groups/literature/documents/du/ra-du002_-en-e.pdf.

Publication 1606-RM013A-EN-P — March 2014

, available at http://

Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...