Page 1

Medium Voltage

SMC Flex™

Motor Controller

Bulletins 1503E, 1560E

and 1562E

User Manual

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the Additional Resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belong ing to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Page

Preface Service Procedure............................................................................ P-1

Product Overview Chapter 1

Manual Objectives............................................................................ 1-1

Documentation.................................................................................. 1-1

Description........................................................................................ 1-1

1503E – OEM Controller ........................................................... 1-1

1560E – Retrofit Controller ....................................................... 1-2

1562E – Combination Controller ............................................... 1-2

SMC-Flex Control Module ......................................................... 1-2

Starting Modes.................................................................................. 1-3

Soft Start .................................................................................... 1-3

Selectable Kickstart.................................................................... 1-4

Current Limit Start ..................................................................... 1-4

Dual Ramp Start ......................................................................... 1-5

Full Voltage Start ....................................................................... 1-5

Preset Slow Speed ....................................................................... 1-6

Linear Speed Acceleration and Deceleration .............................. 1-7

Soft Stop...................................................................................... 1-8

Protection and Diagnostics ............................................................... 1-9

Overload..................................................................................... 1-9

Underload.................................................................................. 1-11

Undervoltage ............................................................................. 1-11

Overvoltage ............................................................................... 1-11

Unbalance.................................................................................. 1-12

Stall Protection and Jam Detection ........................................... 1-12

Ground Fault ............................................................................. 1-13

Thermistor/PTC Protection ....................................................... 1-14

Open Gate ................................................................................ 1-16

Line Faults................................................................................ 1-16

Excessive Starts/Hour .............................................................. 1-17

Overtemperature....................................................................... 1-17

Metering.......................................................................................... 1-17

Communication............................................................................... 1-18

Programming .................................................................................. 1-18

Status Indication ............................................................................. 1-19

Control Options .............................................................................. 1-19

Pump Control Option ............................................................... 1-19

Application Considerations.................................................. 1-20

Braking Control Option............................................................. 1-21

Hardware Description..................................................................... 1-22

Power Module .......................................................................... 1-22

Self-Powered Silicon-Controlled Rectifier Gate Driver Board .... 1-22

Interface Board......................................................................... 1-23

1560E-UM050B-EN-P - June 2013

Page 4

ii Table of Contents – MV Dialog Plus Medium Voltage Controller User Manual

Product Overview (cont.) Chapter 1 Page

Typical MV SMC-Flex Power System Diagrams

Bulletin 1562E (Without Stop Control).................................... 1-24

Bulletin 1562E (With Stop Control).......................................... 1-25

Bulletin 1562E (Without Stop Control)..................................... 1-26

Bulletin 1562E (With Stop Control).......................................... 1-27

Functional Descriptions .................................................................. 1-28

Bulletin 1562E • Basic Control – Controlled Start Only ......... 1-28

Bulletin 1562E • Basic Control – With Controlled Stop........... 1-29

Bulletin 1562E • DPI Control – Controlled Start Only............. 1-29

Bulletin 1560E • Basic Control – Controlled Start Only ......... 1-30

Bulletin 1560E • Basic Control – With Controlled Stop........... 1-30

Bulletin 1560E • DPI Control – Controlled Start Only............. 1-30

Schematics:

Bul. 1562E IntelliVAC Control Circuit (Without Stop Control) ... 1-31

Bul. 1562E IntelliVAC Control Circuit (With Stop Control) ........ 1-32

Bul. 1562E IntelliVAC Control Circuit (With DeviceNet)........... 1-33

Bul. 1560E IntelliVAC Control Circuit (Without Stop Control) ... 1-34

Bul. 1560E IntelliVAC Control Circuit (With Stop Control) ........ 1-35

Bul. 1560E IntelliVAC Control Circuit (With DeviceNet) .......... 1-36

Installation Chapter 2

Receiving .......................................................................................... 2-1

Safety and Codes .............................................................................. 2-1

Unpacking and Inspection ................................................................ 2-1

General Precautions .......................................................................... 2-2

Transportation and Handling ............................................................ 2-2

Installation Site ................................................................................. 2-3

Mounting ..................................................................................... 2-3

Grounding Practices .................................................................... 2-4

Recommended Torque Values........................................................... 2-4

Power Connections ........................................................................... 2-5

Bulletin 1562E ............................................................................ 2-5

Bulletin 1560E ............................................................................ 2-8

Bulletin 1503E .......................................................................... 2-11

Power Wiring.................................................................................. 2-12

Interlocking..................................................................................... 2-12

Installation ...................................................................................... 2-13

Physical Location ...................................................................... 2-13

Fan............................................................................................. 2-13

Ground Bus Bar......................................................................... 2-13

Power and Control Wiring ........................................................ 2-13

Control Cables........................................................................... 2-13

Fibre-Optic Cables .................................................................... 2-13

Power Factor Correction Capacitors ......................................... 2-14

1560E-UM050B-EN-P - June 2013

Page 5

Table of Contents – MV Dialog Plus Medium Voltage Controller User Manual iii

Installation (cont.) Chapter 2 Page

Surge Arrestor Protection Devices ................................................. 2-16

Motor Overload Protection ............................................................. 2-17

EMC Compliance ............................................................................ 2-18

Control Power.................................................................................. 2-19

Control Terminal Designations ...................................................... 2-20

Commissioning Procedure Chapter 3

Preliminary Set-Up ........................................................................... 3-1

System Characteristics...................................................................... 3-2

Preliminary Check ............................................................................ 3-3

Programming .................................................................................... 3-3

Hi-Pot and Megger Test.................................................................... 3-4

Typical MV SMC-Flex Power System Diagram ............................... 3-5

Connection and Test Information for Interface Board ...................... 3-6

Power Supply Tests .......................................................................... 3-7

Control Function Tests ................................................................... 3-10

Resistance Checks .......................................................................... 3-11

Voltage Sensing Module ................................................................. 3-11

Start-Up .......................................................................................... 3-12

Programming Chapter 4

Overview........................................................................................... 4-1

Keypad Description .......................................................................... 4-1

Programming Menu .......................................................................... 4-1

Menu Structure Hierarchy ................................................................. 4-2

Parameter Linear List ........................................................................ 4-4

Password ........................................................................................... 4-5

Parameter Management ................................................................... 4-6

Parameter Modification .................................................................... 4-8

Soft Start ........................................................................................... 4-9

Current Limit Start............................................................................ 4-9

Dual Ramp Start ............................................................................. 4-10

Full Voltage Start ........................................................................... 4-11

Linear Speed .................................................................................... 4-11

Basic Setup ..................................................................................... 4-11

Motor Protection.............................................................................. 4-13

Example Settings ............................................................................ 4-13

Motor Information ........................................................................... 4-15

1560E-UM050B-EN-P - June 2013

Page 6

iv Table of Contents – MV Dialog Plus Medium Voltage Controller User Manual

Metering Chapter 5 Page

Overview........................................................................................... 5-1

Motor Data Entry.............................................................................. 5-1

Options Chapter 6

Overview........................................................................................... 6-1

Human Interface Module .................................................................. 6-1

Programming Parameters................................................................... 6-3

Control Wiring................................................................................... 6-5

Diagnostics Chapter 7

Overview........................................................................................... 7-1

Fault Display...................................................................................... 7-1

Clear Fault ......................................................................................... 7-2

Fault Buffer........................................................................................ 7-2

Fault Contact...................................................................................... 7-3

Fault Definitions ................................................................................ 7-4

Communications Chapter 8

Overview............................................................................................ 8-1

Communication Ports ........................................................................ 8-1

Human Interface Module ................................................................... 8-1

Keypad Description..................................................................... 8-2

Connecting the Human Interface Module to the Controller........ 8-4

Control Enable ............................................................................ 8-4

Control Enable ................................................................................... 8-6

Loss of Communication and Network Faults .................................... 8-6

SMC-Flex Specific Information ........................................................ 8-6

Default Input/Output Configuration .................................................. 8-7

Variable Input/Output Configuration ................................................ 8-7

SMC-Flex Bit Identification .............................................................. 8-8

Reference/Feedback........................................................................... 8-9

Parameter Information ....................................................................... 8-9

Scale Factors for PLC Communication ............................................. 8-9

Display Text Unit Equivalents .......................................................... 8-9

Configuring DataLinks .................................................................... 8-10

Updating Firmware .......................................................................... 8-10

1560E-UM050B-EN-P - June 2013

Page 7

Table of Contents – MV Dialog Plus Medium Voltage Controller User Manual v

Troubleshooting Chapter 9 Page

General Notes and Warnings ............................................................ 9-1

Fault Display Explanation ................................................................ 9-3

Control Module Removal .................................................................. 9-6

Voltage Feedback Circuit Tests......................................................... 9-7

Voltage-Sensing Board Replacement ................................................ 9-8

IGDPS Boards ................................................................................... 9-9

IGDPS Board LEDs......................................................................... 9-10

Circuit Board Replacement.............................................................. 9-11

Power Circuit Troubleshooting ....................................................... 9-12

Thyristor (SCR) Testing............................................................ 9-12

SCR Replacement Procedure .................................................... 9-13

Snubber and Resistor Circuit Testing.............................................. 9-27

Snubber Resistor Replacement ........................................................ 9-30

Wiring Diagrams ............................................................................. 9-31

Maintenance Chapter 10

Safety and Preventative ................................................................... 10-1

Periodic Inspection .......................................................................... 10-1

Contamination ........................................................................... 10-1

Vacuum Bottles......................................................................... 10-2

Terminals .................................................................................. 10-2

Coils .......................................................................................... 10-2

Solid-State Devices ................................................................... 10-3

Static-Sensitive Items ................................................................ 10-3

Overload Maintenance After a Fault Condition........................ 10-3

Final Check Out ........................................................................ 10-3

"Keep Good Maintenance Records" ......................................... 10-4

Power Components ................................................................... 10-4

Control Components – Electronic ............................................. 10-4

Fans ........................................................................................... 10-4

Interlocks................................................................................... 10-4

Barriers...................................................................................... 10-4

Environmental Considerations......................................................... 10-5

Hazardous Materials ................................................................. 10-5

Disposal..................................................................................... 10-6

1560E-UM050A-EN-P – August 2004

Page 8

vi Table of Contents – MV Dialog Plus Medium Voltage Controller User Manual

Appendix A 1560E/1562E SMC-Flex Specifications Page

Specifications – Table A.1 ............................................................... A-1

Altitude Derating –Table A.2 ........................................................... A-3

Area Available for Cable Entry/Exit – Table A.3 ............................ A-3

Cable Quantity and Size – Table A.4 ............................................... A-4

Shipping Weights and Dimensions – Table A.5............................... A-5

Power Bus and Ground Bus – Table A.6.......................................... A-6

Power Fuses and Losses – Table A.7 ............................................... A-7

Control Wire and Power Wire – Table A.8 ...................................... A-8

Appendix B Parameter Information

Parameter List................................................................................... B-1

Appendix C 1560E and 1562E Relay Control

Functional Description ..................................................................... C-1

Bulletin 1562E • Basic Control – Controlled Start Only .......... C-1

Bulletin 1562E • Basic Control – With Controlled Stop............ C-2

Bulletin 1562E • DPI Control – Controlled Start Only.............. C-2

Bulletin 1560E • Basic Control – Controlled Start Only .......... C-3

Bulletin 1560E • Basic Control – With Controlled Stop............ C-3

Bulletin 1560E • DPI Control – Controlled Start Only.............. C-4

Schematics:

Bul. 1562E Relay Control Circuit (Without Stop Control) ............ C-5

Bul. 1562E Relay Control Circuit (With Stop Control)................. C-6

Bul. 1562E Relay Control Circuit (With DeviceNet) ................... C-7

Bul. 1560E Relay Control Circuit (Without Stop Control) ............ C-8

Bul. 1560E Relay Control Circuit (With Stop Control)................. C-9

Bul. 1560E Relay Control Circuit (With DeviceNet) ................. C-10

Appendix D Spare Parts

Bul. 1503E • 1000-1500V, 180/360A (6-device) ............................. D-1

Bul. 1503E, 1560E, 1562E • 2300V, 180/360A (6-device).............. D-2

Bul. 1503E, 1560E, 1562E • 2300V, 600A (6-device)..................... D-3

Bul. 1503E, 1560E, 1562E • 3300/4160V, 180/360A (12-device)... D-4

Bul. 1503E, 1560E, 1562E • 3300/4160V, 600A (12-device).......... D-5

Bul. 1503E, 1560E, 1562E • 5500/6900V, 180/360A (18-device)... D-6

Bul. 1503E, 1560E, 1562E • 5500/6900V, 600A (18-device).......... D-7

Accessories ....................................................................................... D-8

Appendix E Accessories

Accessories ........................................................................................E-1

1560E-UM050A-EN-P – August 2004

Page 9

Preface

Service Procedure For your convenience, the Rockwell Automation Global Manufacturing

Solutions (GMS), provides an efficient and convenient method of servicing

medium voltage products.

Contact your local area support office to make arrangements to have a

qualified service representative come to your facility.

A complete listing of Area Support Offices may be obtained by calling your

local Rockwell Automation Distributor or Sales Office.

For MV SMC-Flex technical support on start-up or existing installations,

contact your Rockwell Automation representative. You can also call

1-519-740-4790 for assistance Monday through Friday from 9:00 a.m.

to 5:00 p.m. (Eastern time zone).

1560E-UM050B-EN-P - June 2013

Page 10

Preface

1560E-UM050B-EN-P - June 2013

Page 11

Chapter 1

Product Overview

Manual Objectives This manual is intended for use by personnel familiar with Medium Voltage and

solid-state power equipment. The manual contains material which will allow the

user to operate, maintain and troubleshoot the MV SMC-Flex

controllers. The family consists of the following Bulletin numbers: 1503E,

1560E and 1562E.

Documentation The following Rockwell Automation publications provide pertinent

information for the MV SMC-Flex and components:

• MVB-5.0 General Handling Procedures for MV Controllers

• 1500-UM055B-EN-P Medium Voltage Controller Two-High Cabinet

(200A/400A) – User Manual

• 1502-UM050C-EN-P 400A Vacuum Contactor, Series D

– User Manual

• 1502-UM052B-EN-P 400A Vacuum Contactor, Series E

– User Manual

• 1502-UM051C-EN-P 800A Vacuum Contactor, Series D and E

– User Manual

• 1560E-SR022A-EN-P Medium Voltage SMC-Flex Controllers

– General Specifications

TM

family of

Description The MV SMC-Flex is a solid-state, three-phase, AC line controller. It is

designed to provide microprocessor-controlled starting and stopping of

standard three-phase, squirrel-cage induction motors, using the same

control module as the Allen-Bradley Bulletin 150 SMC-Flex.

1503E – OEM Controller

A chassis-mount medium voltage solid-state controller designed to mount in

an OEM or customer supplied structure, and designed to work in conjunction

with an existing or OEM/customer supplied starter. It is comprised of

several modular components, including:

• Frame-mounted or loose power stacks including gate driver boards

• Loose interface and voltage feedback boards

• Fiber optic cables for SCR firing

• Microprocessor based control module

• Bypass vacuum contactor

%5-"%.0*UNE

Page 12

1-2 Product Overview%5-"%.0*UNE%5-"%.0*UNE

Description (cont.) 1560E – Retrofit Controller

A medium voltage solid-state controller designed to work in conjunction

with an existing customer-supplied starter. It includes:

• Tin-plated, copper, horizontal power bus (optional)

• A continuous, bare copper ground bus

• Power electronics

• A bypass vacuum contactor

• Three (3) current transformers

• A low voltage control panel complete with microprocessor-based control module

• Top and bottom plates to accommodate power cables.

Note: See Interlocking, page 2-8.

1562E – Combination Controller

A medium voltage solid-state controller that provides isolation and

protection for new installations. It includes:

• Tin-plated, copper, horizontal power bus (optional)

• A continuous, bare copper ground bus

• Power electronics

• A main non-load-break isolating switch and operating handle

• An isolation vacuum contactor

• A bypass vacuum contactor

• Three (3) current limiting power fuses for NEMA Class E2 operation

• Three (3) current transformers

• A control power transformer (optional)

• A low voltage control panel complete with microprocessor-based control

module

• Space for necessary auxiliary control and metering devices

• Top and bottom plates to accommodate power cables

• Motor overload protection (included in SMC-Flex control module)

%5-"%.0*UNE

SMC-Flex™ Control Module

The MV SMC-Flex controller offers a full range of starting and stopping

modes as standard:

• Soft Start with Selectable Kickstart

• Soft Stop

• Current Limit Start with Selectable Kickstart

• Linear Acceleration with Selectable Kickstart

• Linear Deceleration

• Dual Ramp Start

• Preset Slow Speed

• Full Voltage Start

: This option utilizes gating patterns which result in motor and line currents that produce noise

and vibration in the motor and/or distribution transformer. This must be considered before

applying this option.

:

Page 13

SMC-Flex™ Control Module (cont.)

Other features that offer further user benefit include:

• Extensive protection features

• Metering

• Communication capability

Innovative control option provides enhanced performance:

• Pump Control (Start and Stop Control modes)

These modes, features and options are further described in this chapter.

: This option utilizes gating patterns which result in motor and line currents that produce noise and vibration

in the motor and/or distribution transformer. The factory should be consulted before applying this option.

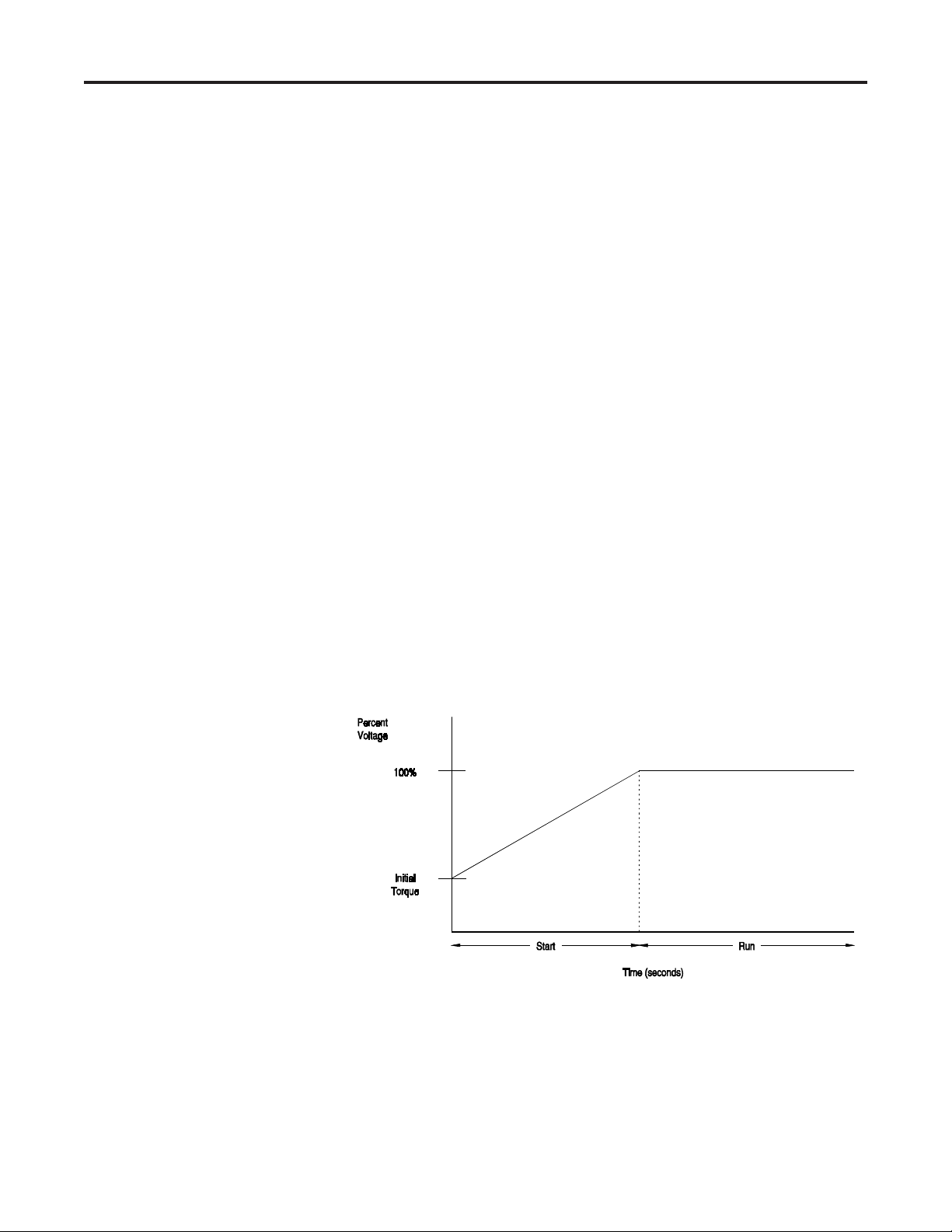

Starting Modes Soft Start

Product Overview 1-3%5-"%.0*UNE

This mode has the most general application. The motor is given an initial

torque setting, which is user-adjustable from 0 to 90% of locked-rotor

torque. From the initial torque level, the output voltage to the motor is

steplessly increased during the acceleration ramp time. The acceleration

ramp time is user-adjustable from 0 to 30 seconds. Once the MV SMC-Flex

controller senses that the motor has reached the up-to-speed condition during

the voltage ramp operation, the output voltage automatically switches to

full voltage, and the bypass contactor is closed.

Figure 1.1– Soft Start

%5-"%.0*UNE

Page 14

1-4 Product Overview

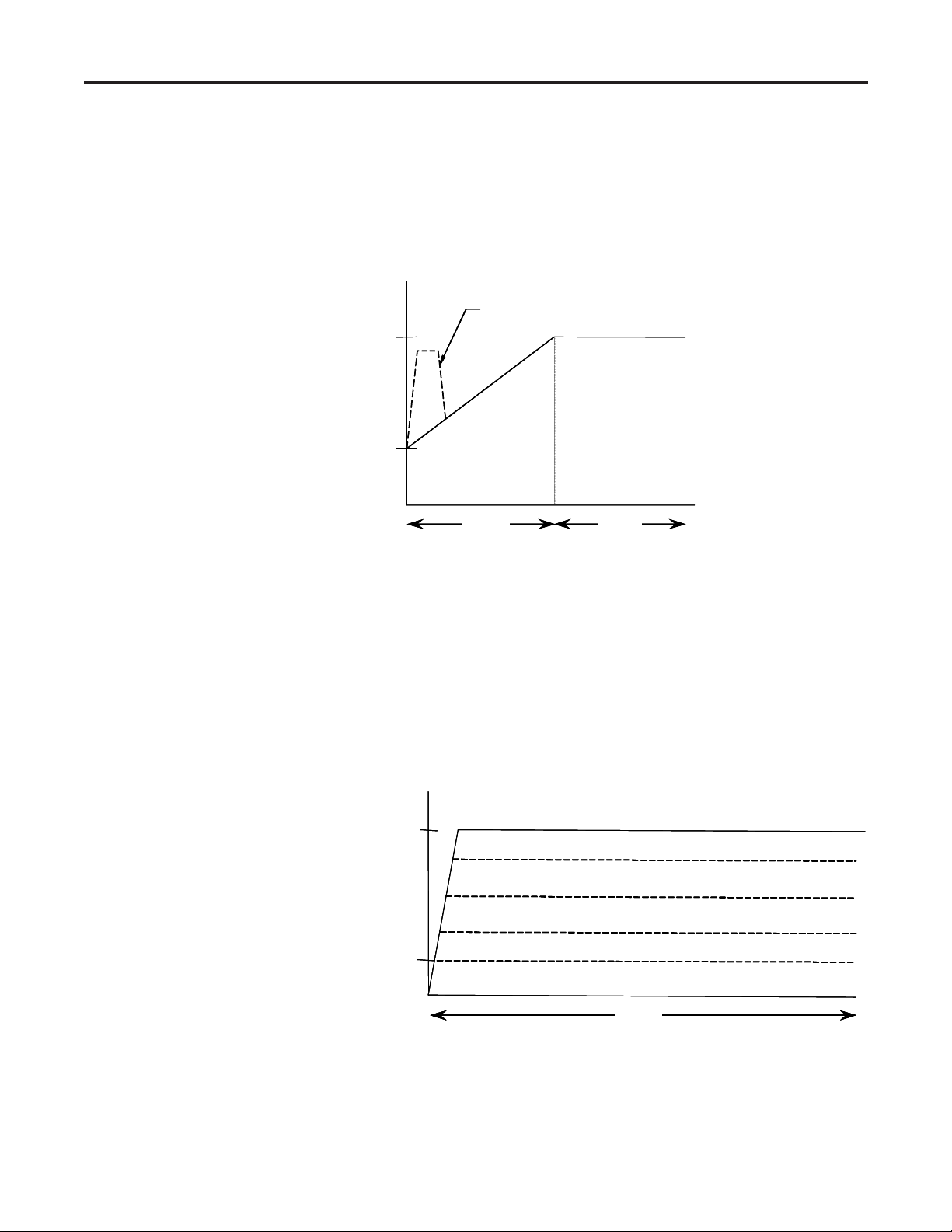

Starting Modes (cont.) Selectable Kickstart :

Selectable kickstart provides a power boost at start-up that is user-adjustable

from 0 to 90% of locked rotor torque. The additional power helps motors

generate higher torque to overcome the resistive mechanical forces of some

applications when they are started. The selectable kickstart time is useradjustable from 0.0 to 2.0 seconds.

Kickstart

Kickstart

100%

100%

Initial

Initial

Torque

Torque

Start

Start

Figure 1.2 – Selectable Kickstart

Run

Run

e (seconds)

e (seconds)

Tim

Tim

Current Limit Start ;

This starting mode provides a true current limit start that is used when

limiting the maximum starting current is necessary. The Current Limit level

is user-adjustable from 50% to 600% of the motor's full-load ampere rating,

and the current limit time is user-adjustable from 0 to 30 seconds. Once the

MV SMC-Flex™ controller senses that the motor has reached the up-tospeed condition during the current limit starting mode, the output voltage

automatically switches to full voltage and the bypass contactor is closed.

600%

600%

Percent Full

Percent Full

Load Current

Load Current

50%

50%

Start

Start

e (seconds)

e (seconds)

Tim

Tim

Figure 1.3 – Current Limit Start

%5-"%.0*UNE

: Kickstart is also available with Current Limit Start, Dual Ramp Start and Linear Acceleration.

; The Current Limit Start mode design is based on a motor with a locked-rotor current rating that is 600% of

the full-load current rating.

Page 15

Product Overview 1-5

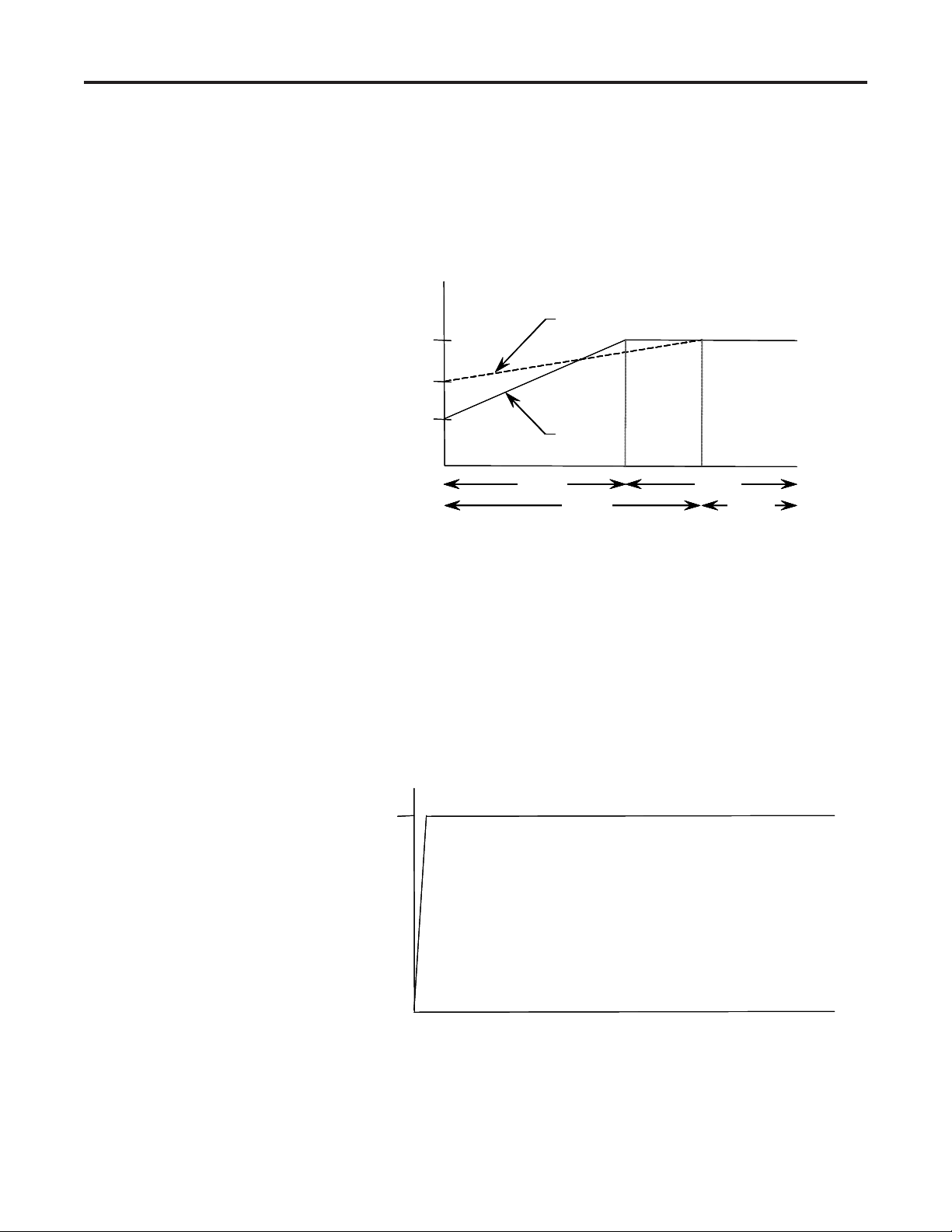

Dual Ramp Start :

This starting mode is useful for applications that have varying loads (and

therefore varying starting torque requirements). Dual Ramp Start allows

the user to select between two separate Soft Start profiles with separately

adjustable ramp times and initial torque settings.

Percent

Percent

Voltage

Voltage

100%

100%

InitialTorque#2

InitialTorque#2

Initial Torque #1

Initial Torque #1

Start#1

Start#1

mp #

Ramp #

Ra

Ramp #1

Ramp #1

2

2

Time (seconds)

Time (seconds)

Run #1

Run #1

Run #2Start#2

Run #2Start#2

Figure 1.4 – Dual Ramp Start

: Dual Ramp Start is available only with the standard controller.

Full Voltage Start

This starting mode is used for applications requiring across-the-line starting.

The output voltage to the motor will reach full voltage within ¼ second.

100%

100%

Percent

Percent

Voltage

Voltage

e (seconds)

e (seconds)

Tim

Tim

Figure 1.5 – Full Voltage Start

%5-"%.0*UNE

Page 16

1-6 Product Overview

Starting Modes (cont.) Preset Slow Speed

This option can be used in applications that require a slow-speed jog for

general purpose positioning. Preset Slow Speed provides either 7% of

base speed (low) or 15% of base speed (high) settings in the forward

direction. Reverse can also be programmed and offers 10% of base speed

(low) and 20% of base speed (high) settings.

Forward

Forward

Forward

15% – High

15% – High

15% – High

7% – Low

7% – Low

7% – Low

Time (seconds)

Time (seconds)

Time (seconds)

Start

Start

Start

Run

RunRun

10% – Low

10% – Low

10% – Low

20% – High

20% – High

20% – High

Reverse

Reverse

Reverse

Figure 1.6 – Preset Slow Speed Option

Important: Slow speed running is not intended for continuous operation due

to reduced motor cooling. The two starts per hour limitation also applies to

slow speed operation. This option employs a cycle-skipping scheme which

produces limited torque. Applications should be checked with the factory.

%5-"%.0*UNE

Page 17

Product Overview 1-7

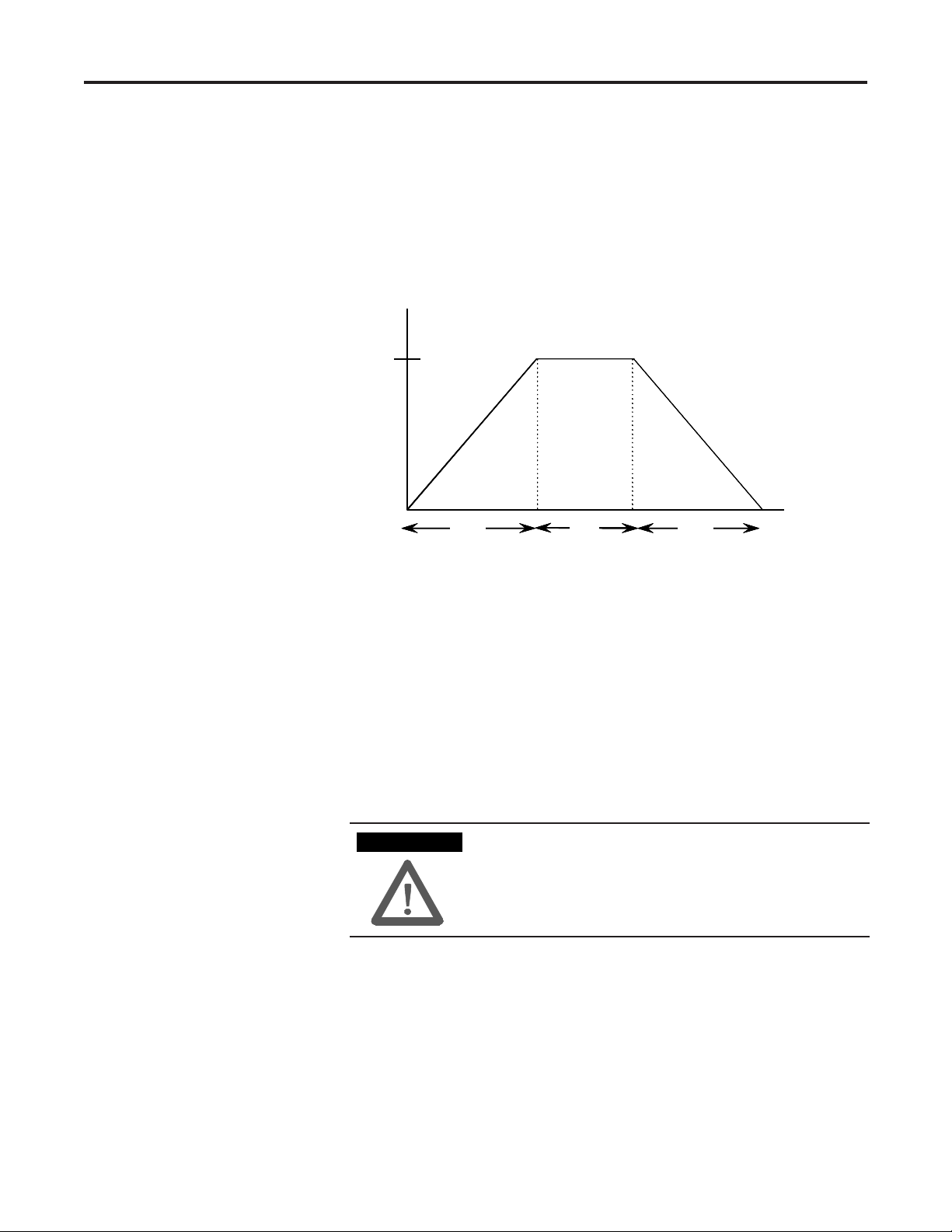

Linear Speed Acceleration and Deceleration

The SMC-Flex has the ability to control the motor speed during starting

and stopping maneuvers. A tachometer signal (0 to 5V DC) is required to

perform this start mode. The start time is selectable from 0 to 30 seconds

and determines the time the motor will ramp from 0 speed to full speed.

Kickstart is available with this option.

100%

100%

Motor

Motor

Speed

Speed

Run Stop

Start

Start

Run Stop

Time (seconds)

Time (seconds)

Figure 1.7 – Linear Speed Acceleration

Linear deceleration does not need to be used, even if linear acceleration is

used. The stop time can be programmed for 0 to 60 seconds. Linear

deceleration cannot brake the motor/load and reduce the stop time.

Note: Consult factory if settings over 30 seconds are required. The base

rating of the MV SMC-Flex is two starts (or one start/stop combination)

per hour, thirty seconds maximum for each operation. A stopping operation

counts as a start for purposes of thermal capacity calculations.

A T T E N T I O NA T T E N T I O N

Linear Deceleration is not intended to be used as an

emergency stop. Such usage may result in severe injury

or death. Refer to the applicable standards for

emergency stop requirements.

%5-"%.0*UNE

Page 18

1-8 Product Overview%5-"%.0*UNE%5-"%.0*UNE

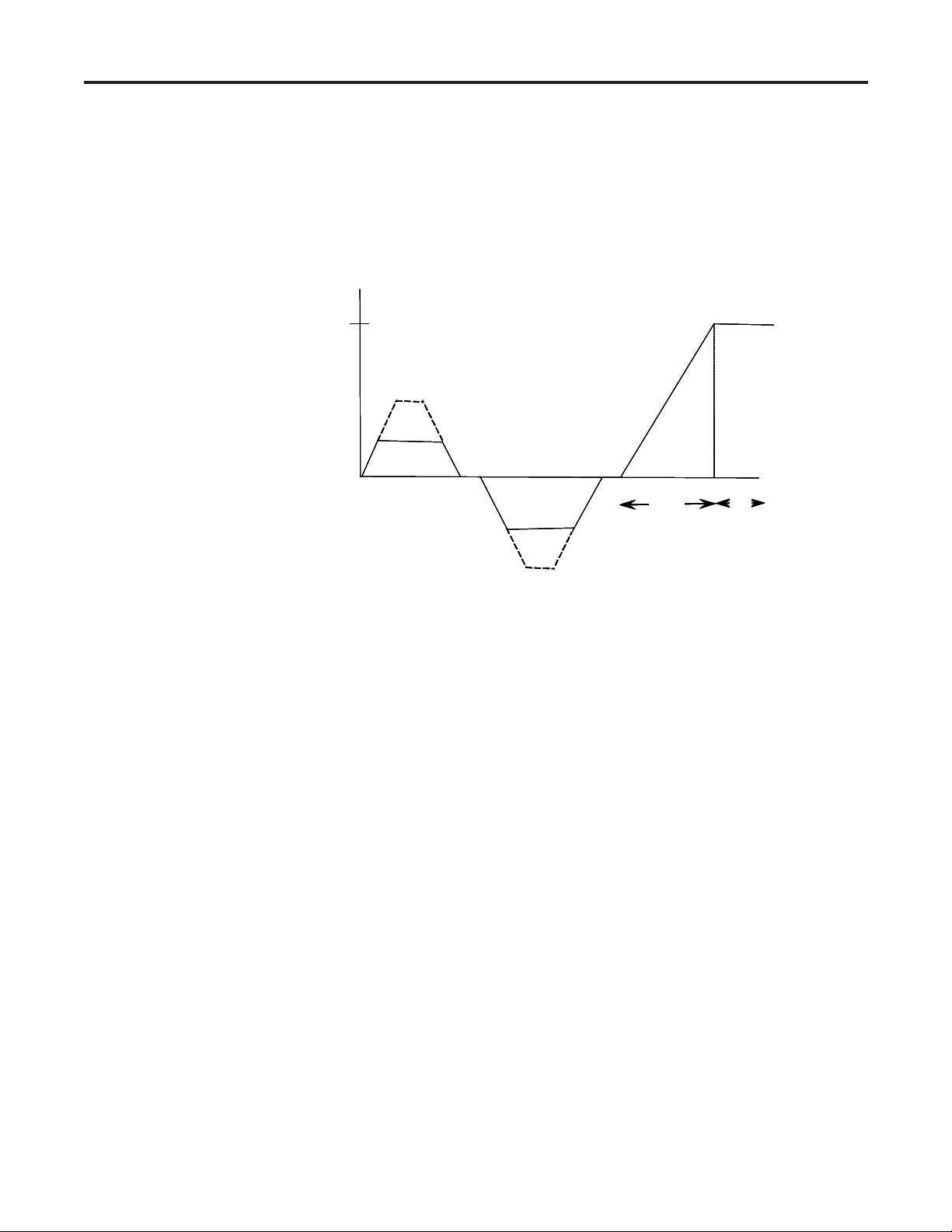

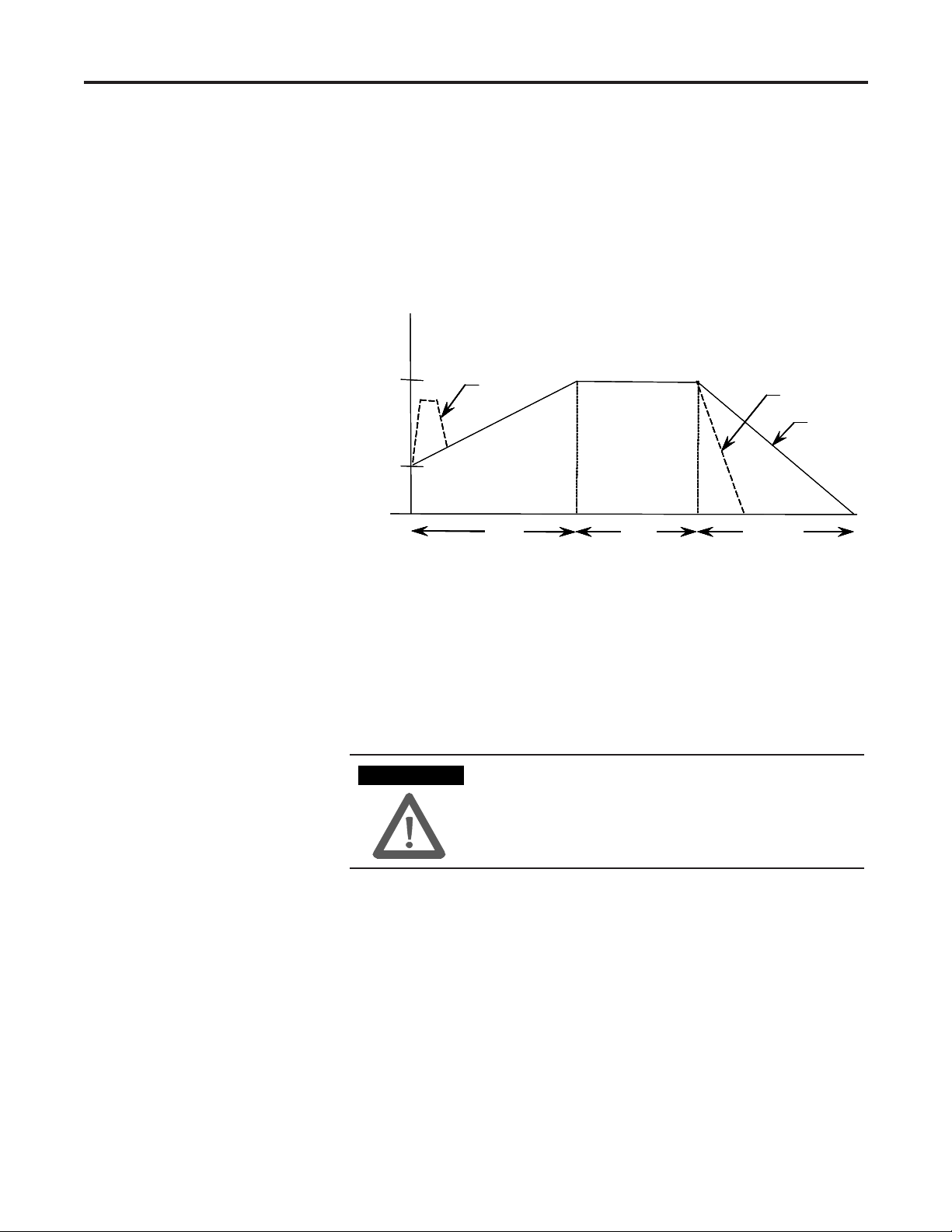

Starting Modes (cont.) Soft Stop

This feature can be used in applications that require an extended coast-torest time. The voltage ramp-down time is user-adjustable from 0 to 60

seconds and is adjusted independently from the starting time. The load

will stop when the output voltage drops to a point where the load torque is

greater than the developed motor torque.

Percent

Percent

Voltage

Voltage

100%

100%

Initia

Initia

Torque

Torque

l

l

Kickstart

Kickstart

Coast-to-rest

Coast-to-rest

Soft Stop

Soft Stop

Start

Start

Time

Time

Run

Run

(seconds)

(seconds)

SoftStop

SoftStop

Figure 1.8 – Soft Stop Option

Note: Consult factory if settings over 30 seconds are required. The base

rating of the MV SMC-Flex is two starts (or one start/stop combination)

per hour, thirty seconds maximum for each operation. A stopping operation

counts as a start for purposes of thermal capacity calculations.

A T T E N T I O NA T T E N T I O N

Soft Stop is not intended to be used as an emergency

stop. Such usage may result in severe injury or death.

Refer to the applicable standards for emergency stop

requirements.

%5-"%.0*UNE

Page 19

Product Overview 1-9

Protection and Diagnostics The MV SMC-Flex™ controller is capable of providing the following

protective and diagnostic features:

Overload

The MV SMC-Flex controller meets applicable requirements as a motor

overload protection device. Thermal memory provides added protection

and is maintained even when control power is removed. The built-in

overload algorithm controls the value stored in Parameter 12, Motor

Thermal Usage (see Chapter 4, Programming). An Overload Fault will

occur when this value reaches 100%. The parameters below provide

application flexibility and easy setup.

Parameter Range

Overload Class Off, 10, 15, 20, 30

Overload Reset Manual – Auto

Motor FLC 1.0 – 1000.0 amps

ServiceFactor 0.01–1.99

Important: During slow speed operations, current waveforms exhibit

non-sinusoidal characteristics. These non-sinusoidal characteristics

inhibit the controller's current-measurement capability. To compensate

for additional motor heating that may result, the controller uses motor

thermal modeling, which increments motor thermal usage. This compensation takes place when the Preset Slow Speed option is used.

Notes:

1. The factory default setting for Overload Class, which is "OFF", disables

overload protection. An overload trip class and the motor's full-load

current rating must be programmed to enable overload protection.

2. If the MV SMC-Flex is used to control a multi-speed motor, or more

than one motor, the Overload Class parameter must be programmed

to "OFF" and separate overload relays must be supplied for each

speed/motor.

3. Automatic reset of an overload fault requires the start input to be

cycled in a 2-wire control scheme.

4. The trip rating is 117% of the programmed FLC.

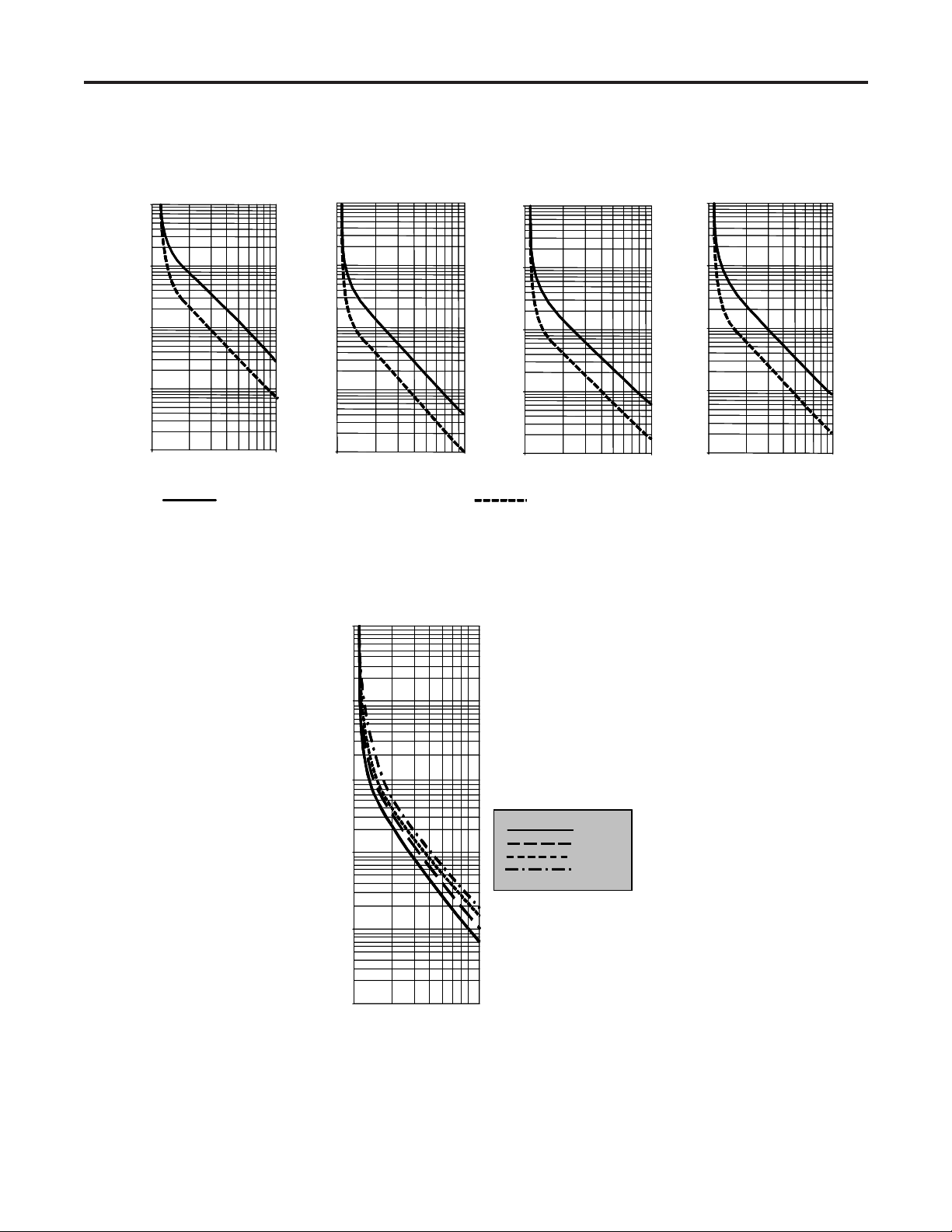

Figures 1.9 and 1.10 provide the overload trip curves for the available trip

classes.

%5-"%.0*UNE

Page 20

1-10 Product Overview

Protection and Diagnostics

(cont.)

Class 10

Class 10

1000.0

1000.0

1000.0

100.0

100.0

100.0

10.0

10.0

10.0

1.0

1.0

1.0

Approximate Trip Time (seconds)

Approximate Trip Time (seconds)

Approximate Trip Time (seconds)

0.1

0.1

0.1

Class 10

11023 987654

11023 987654

11023 987654

Multiples of FLC

Multiples of FLC

Multiples of FLC

10000.0

10000.0

10000.0

1000.0

1000.0

1000.0

100.0

100.0

100.0

10.0

10.0

10.0

Approximate Trip Time (seconds)

Approximate Trip Time (seconds)

Approximate Trip Time (seconds)

1.0

1.0

1.0

11023 987654

11023 987654

11023 987654

Class 15

Class 15

Class 15

Multiplesof FLC

Multiplesof FLC

Multiplesof FLC

10000.0

10000.0

10000.0

1000.0

1000.0

1000.0

100.0

100.0

100.0

10.0

10.0

10.0

ApproximateTripTime (seconds)

ApproximateTripTime (seconds)

ApproximateTripTime (seconds)

1.0

1.0

1.0

11023 987654

11023 987654

11023 987654

Multiples of FLC

Multiples of FLC

Multiples of FLC

Class 20

Class 20

Class 20

10000.0

10000.0

10000.0

1000.0

1000.0

1000.0

100.0

100.0

100.0

10.0

10.0

10.0

Approximate Trip Time (seconds)

Approximate Trip Time (seconds)

Approximate Trip Time (seconds)

1.0

1.0

1.0

11023 987654

11023 987654

11023 987654

Class 30

Class 30

Class 30

Multiples of FLC

Multiples of FLC

Multiples of FLC

Approximate trip time for 3-phase balanced

Approximate trip time for 3-phase balanced

Approximate trip time for 3-phase balanced

condition from cold start.

condition from cold start.

condition from cold start.

100000

100000

1000

1000

100

100

Seconda

Seconda

10

10

1

1

Approximate trip time for 3-phase balanced

Approximate trip time for 3-phase balanced

Approximate trip time for 3-phase balanced

condition from hot start.

condition from hot start.

condition from hot start.

Figure 1.9 – Overload Trip Curves

Auto Reset Times:

Auto Reset Times:

Class 10 = 90 s

Class 10 = 90 s

Class 15 = 135 s

Class 15 = 135 s

Class 20 = 180 s

Class 20 = 180 s

Class 30 = 270 s

Class 30 = 270 s

Class 10

Class 10

Class 10

Class 15

Class 15

Class 15

Class 20

Class 20

Class 20

Class 30

Class 30

Class 30

%5-"%.0*UNE

0

0

100% 1000%

100% 1000%

Percent Full Load Current Setting

Percent Full Load Current Setting

Figure 1.10 – Restart Trip Curves after Auto Reset

Page 21

Product Overview 1-11

Underload :

Utilizing the underload protection of the MV SMC-Flex controller, motor

operation can be halted if a sudden drop in current is sensed.

The MV SMC-Flex controller provides an adjustable underload trip setting

from 0 to 99% of the programmed motor full load current rating. Trip

delay time can be adjusted from 0 to 99 seconds.

: Underload protection is disabled during slow speed and braking operations.

Undervoltage ;

Utilizing the undervoltage protection of the MV SMC-Flex, motor operation

can be halted if a sudden drop in voltage is detected.

The MV SMC-Flex controller provides an adjustable undervoltage trip

setting from 0 to 99% of the programmed motor voltage. Trip delay time

can be adjusted from 0 to 99 seconds.

Note: For medium voltage applications, undervoltage protection should be

set from 80 to 99%.

An alarm (pre-fault) indication level can be programmed to indicate the

unit is getting close to faulting. The alarm modification information is

displayed through the LCD, HIM, Communication (if applicable) and

alarm contact closing.

Overvoltage ;

Utilizing the overvoltage protection of the MV SMC-Flex, motor operation

can be halted if a sudden increase in voltage is detected.

The MV SMC-Flex controller provides an adjustable overvoltage trip

setting from 0 to 199% of the programmed motor voltage. Trip delay time

can be adjusted from 0 to 99 seconds.

Note: For medium voltage applications, overvoltage protection should be

set from 100 to 115%.

An alarm (pre-fault) indication level can be programmed to indicate the

unit is getting close to faulting. The alarm modification information is

displayed through the LCD, HIM, Communication (if applicable) and

alarm contact closing.

;Undervoltage, overvoltage, and voltage unbalance protection are disabled during braking operation.

%5-"%.0*UNE

Page 22

1-12 Product Overview

Protection and Diagnostics

(cont.)

Unbalance :

The MV SMC-Flex is able to detect an unbalance in line voltages. Motor

operation can be halted if the unbalance is greater than the desired range.

The MV SMC-Flex controller provides an adjustable unbalance setting

from 0 to 25% of the line voltages. Trip delay time can be adjusted from 0

to 99 seconds.

An alarm (pre-fault) indication level can be programmed to indicate the

unit is getting close to faulting. The alarm modification information is

displayed through the LCD, HIM, Communication (if applicable) and

alarm contact closing.

:Undervoltage, overvoltage, and voltage unbalance protection are disabled during braking operation.

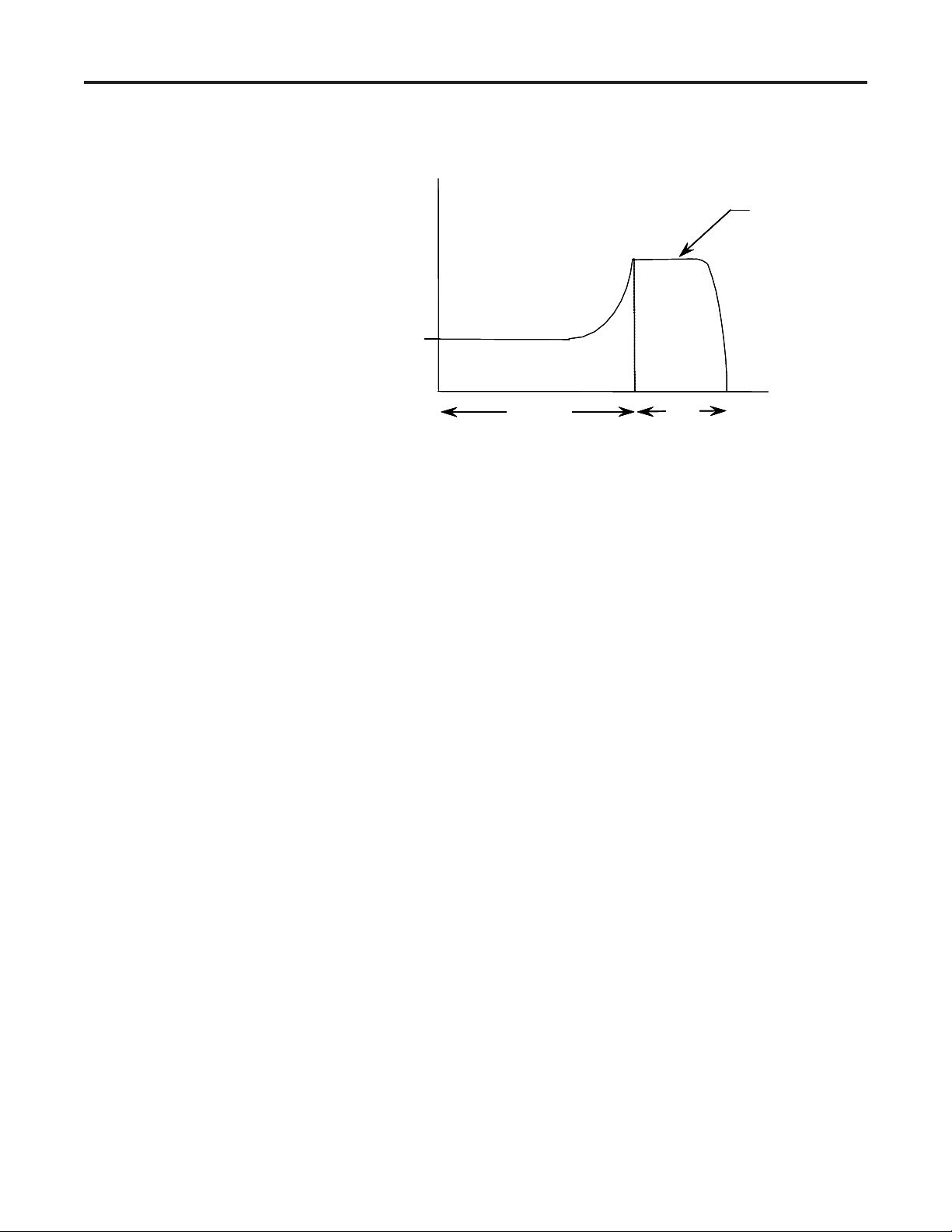

Stall Protection and Jam Detection

The MV SMC-Flex controller provides both stall protection and jam

detection for enhanced motor and system protection.

• Stall protection is user-adjustable from 0.0 to 10.0 seconds (enabled only

after the programmed start time expires).

• An alarm (pre-fault) indication level can be programmed to indicate the

unit is getting close to faulting. The alarm modification information is

displayed through the LCD, HIM, Communication (if applicable) and

alarm contact closing.

• Jam detection allows the user to determine the jam level (up to 1000% of

the motor's full-load current rating) and the delay time (up to 99.0 seconds)

for application flexibility.

600%

600%

Percent

Percent

FullLoad

FullLoad

Current

Current

Programmed StartTime Stall

Programmed StartTime Stall

Time (seconds)

Time (seconds)

Figure 1.11 – Stall Protection

%5-"%.0*UNE

Page 23

Percent

Percent

FullLoad

FullLoad

Current

Current

600%

600%

Running

Running

Time (seconds)

Time (seconds)

Figure 1.12 – Jam Detection :

Jam

Jam

Product Overview 1-1

User Programmed

User Programmed

Trip Level

Trip Level

:

Jam Detection is disabled during slow speed and braking operation.

Ground Fault

In isolated or high impedance-grounded systems, core-balanced current

sensors are typically used to detect low level ground faults caused by

insulation breakdowns or entry of foreign objects. Detection of such

ground faults can be used to interrupt the system to prevent further damage,

or to alert the appropriate personnel to perform timely maintenance.

The MV SMC-Flex’s ground fault detection capabilities consist of using a

core balance current transformer for 1 to 5A core-balanced ground fault

protection with the option of enabling Ground Fault Trip, Ground Fault

Alarm, or both (a core balance CT is provided with 1562E units).

Ground Fault Trip

The MV SMC-Flex will trip with a ground fault indication if:

• No trip currently exists

• Ground fault protection is enabled

• GF Inhibit Time has expired

• GF Current is equal to or greater than the GF Trip Level for a time

period greater than the GF Trip Delay

Parameter 75, Gnd Flt Inh Time, allows the installer to inhibit a ground

fault trip from occurring during the motor starting sequence and is

adjustable from 0 to 250 seconds.

%5-"%.0*UNE

Page 24

1-14 Product Overview

Protection and Diagnostics

(cont.)

Ground Fault Trip (cont.)

Parameter 74, Gnd Flt Delay, allows the installer to define the time period

a ground fault condition must be present before a trip occurs. It is

adjustable from 0.1 to 25 seconds.

Parameter 73, Gnd Flt Level, allows the installer to define the ground

fault current at which the MV SMC-Flex will trip. It is adjustable from

1.0 to 5.0 A.

Important: The ground fault inhibit timer starts after the maximum phase

of load current transitions from 0 A to 30% of the device’s minimum FLA

Setting or the GF Current is greater than or equal to 0.5 A. The MV

SMC-Flex does not begin monitoring for a ground fault condition until the

Gnd Flt Inh Time expires.

Ground Fault Alarm

The MV SMC-Flex will indicate a Ground Fault Alarm if:

• No warning currently exists

• Ground fault alarm is enabled

• GF Inhibit Time has expired

• GF Current is equal to or greater than the Gnd Flt A Lvl

Parameter 77, Gnd Flt A Lvl, allows the installer to define the ground fault

current at which an alarm will be indicated. It is adjustable from 1.0 to 5.0 A.

Parameter 78, Gnd Flt A Dly, allows the installer to define the time period

a ground fault alarm condition must be present before a trip occurs. It is

adjustable from 0.1 to 25 seconds.

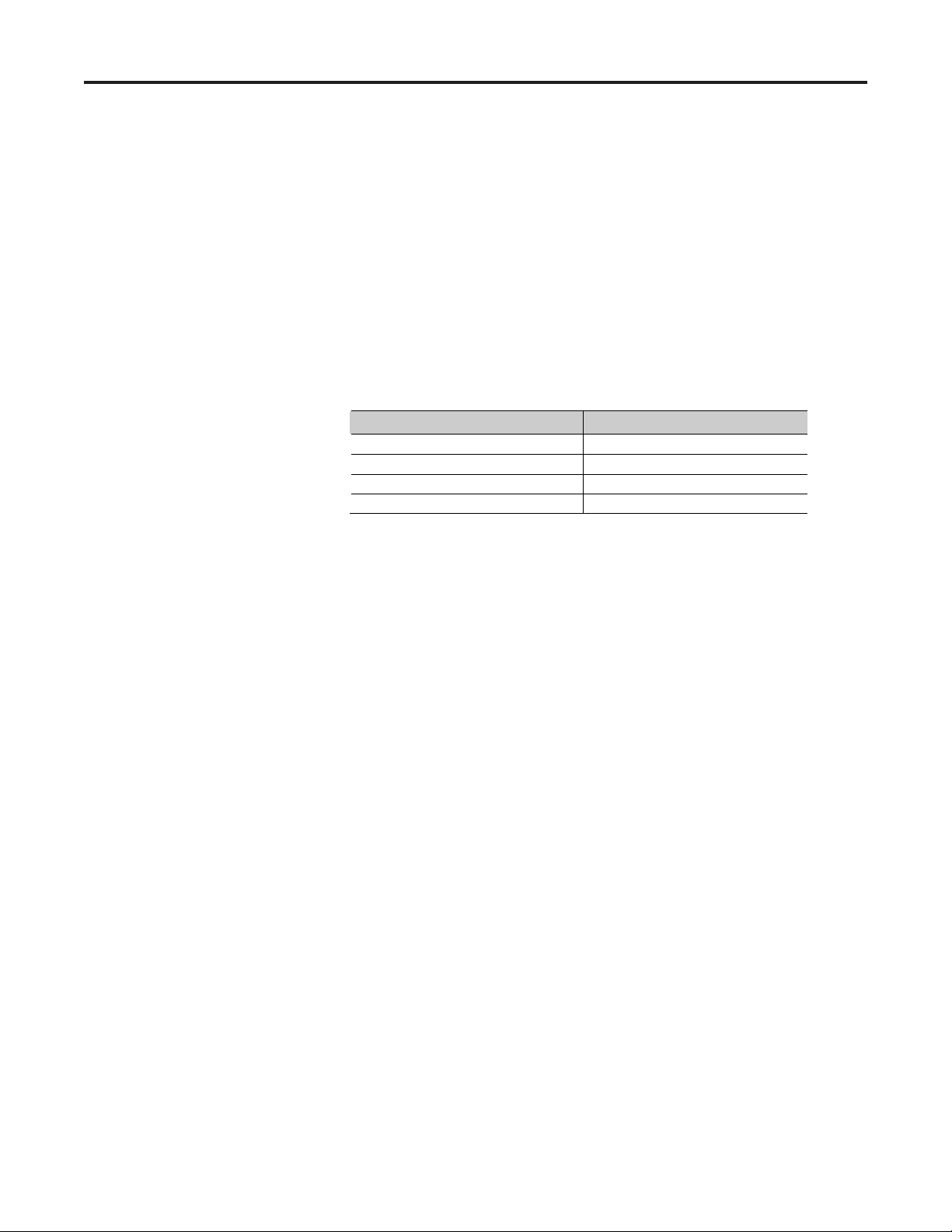

Thermistor/PTC Protection

The MV SMC-Flex provides terminals 23 and 24 for the connection of

positive temperature coefficient (PTC) thermistor sensors. PTC sensors are

commonly embedded in motor stator windings to monitor the motor

winding temperature. When the motor winding temperature reaches the

PTC sensor’s temperature rating, the PTC sensor’s resistance transitions

from a low to high value. Since PTC sensors react to actual temperature,

enhanced motor protection can be provided to address such conditions as

obstructed cooling and high ambient temperatures.

The following table defines the MV SMC-Flex PTC thermistor input and

response ratings:

%5-"%.0*UNE

Page 25

Product Overview 1-15

Table 1.A – PTC Input R atings

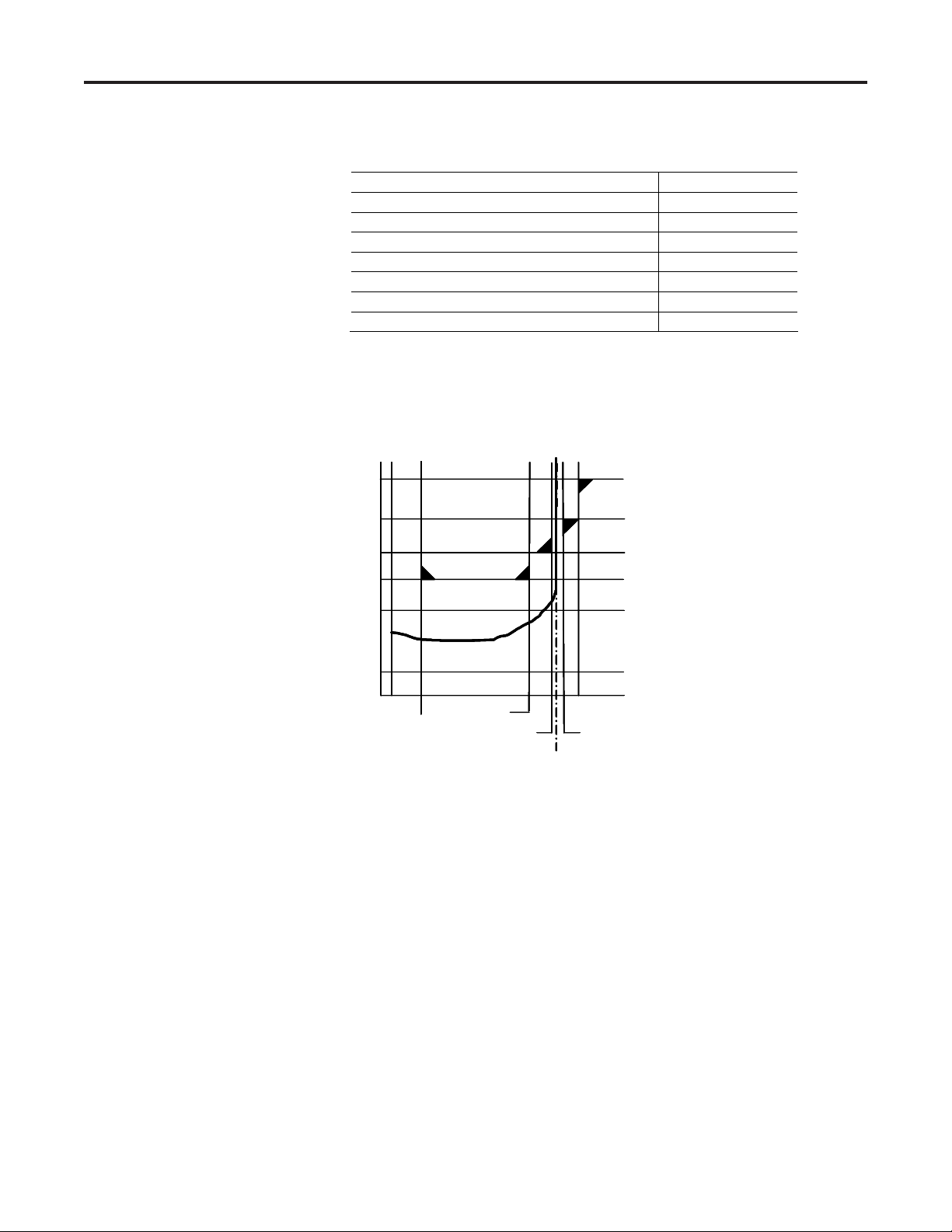

Response Resistance 3400Ω ± 150 Ω

Reset Resistance 1600 Ω ± 100 Ω

Short-circuit Trip Resistance 25 Ω ±10Ω

Maximum Voltage at PTCTerminals (R

Maximum Voltage at PTCTerminals (R

Maximum Number of Sensors 6

Maximum Cold Resistance of PTC Sensor Chain 1500 Ω

Response Time 800 ms

=4kΩ)<7.5V

PTC

= open) 30V

PTC

The following figure illustrates the required PTC sensor characteristics,

per IEC-34-11-2.

4000

4000

4000

4000

1330

1330

1330

1330

550

550

550

550

250

250

250

250

100

100

100

100

20

20

20

20

10

10

10

10

-20°C

-20°C

0°C

0°C

TNF-20K

TNF-20K

TNF- 5K

TNF- 5K

TNF

TNF

TNF+15K

TNF+15K

TNF+ 5K

TNF+ 5K

Figure 1.13 – PTC Sensor Characteristics per IEC-34-11-2

PTC Trip

The MV SMC-Flex will trip with a PTC indication if:

• No other fault currently exists

• PTC protection is enabled

• The resistance across terminals 23 and 24 is either greater than the

relay’s response resistance or less than the short-circuit trip resistance.

%5-"%.0*UNE

Page 26

1-16 Product Overview

Protection and Diagnostics

(cont.)

Open Gate

An open-gate fault indicates that improper SCR firing, typically caused by

an open SCR gate or driver system, has been detected on one of the power

poles. Before the controller shuts down, it will attempt to start the motor a

total of three times (or as programmed in Parameter 82).

An open gate is detected when the module sends a gate signal to the SCRs

but does not detect that they turned on. SCR turn-on is detected when the

voltage across the leg (L-T) collapses.

Line Faults

The MV SMC-Flex™ controller continually monitors line conditions for

abnormal factors. Pre-start protection includes:

• Line Fault (with phase indication)

– Line voltage loss

– Missing load connection

– Shorted SCR

Running protection includes:

• Line Fault (no phase indication)

– Line voltage loss

– Missing load connection

Phase reversal protection

: Phase reversal protection is functional only at pre-start.

: can be toggled either ON or OFF.

%5-"%.0*UNE

Page 27

Product Overview 1-17

Excessive Starts/Hour

The MV SMC-Flex™ module allows the user to program the desired

number of starts per hour (up to 99). This helps eliminate motor stress

caused by repeated starting over a short time period.

Note: The base rating of the MV SMC-Flex is two starts (thirty seconds

each max.) per hour. Applications requiring more frequent starts, or longer

duration starts, should be reviewed with the factory to avoid equipment damage.

Overtemperature

The power module temperature is monitored during starting and stopping

maneuvers by thermistors. The thermistor is connected to the gate driver

board where it is processed, and the status is transmitted by fibre-optic

cable through the interface board to the control module. When an

overtemperature condition exists (>85°C), the control module trips and

indicates a "PTC Power Pole" fault.

An overtemperature condition could indicate high ambient temperature,

overloading or excessive cycling. After the power module temperature is

reduced to allowable levels, the fault can be cleared (see page 9-1 for

instructions).

Metering Power monitoring parameters include:

• Three-phase current

• Three-phase voltage

• Power in MW

• Power usage in MWh

• Power factor

• Motor thermal capacity usage

• Elapsed time

• Motor speed (100%, with use of optional tachometer input)

Notes:

1. Voltage measurement is not available during the braking operation of

the SMB Smart Motor Braking, Accu-Stop, and Slow Speed with

Braking control options.

2. The elapsed time and MWh values are automatically saved to memory

every 12 hours.

3. Motor thermal capacity usage is determined by the built-in electronic

thermal overload. An overload fault occurs when this value reaches

100%.

%5-"%.0*UNE

Page 28

1-18 Product Overview

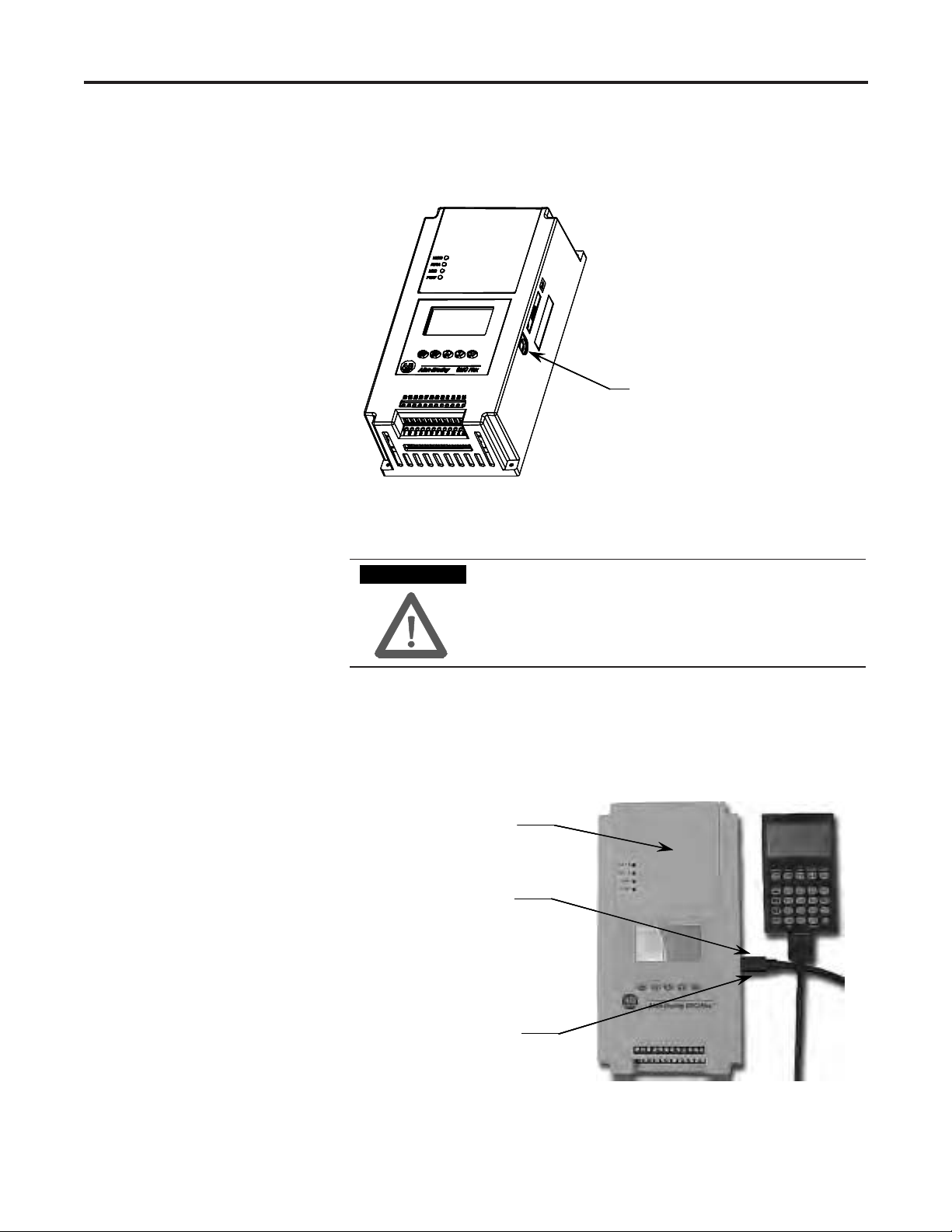

Communication A serial interface port (DPI) is provided as standard, which allows

connection to the Bulletin 20-HIM LCD human interface modules.

DPIDPI

Figure 1.14 – DPI Location

A T T E N T I O NA T T E N T I O N

Two peripheral devices can be connected to the DPI.

The maximum output current through the DPI is 280 mA.

Programming Setup is easy with the built-in keypad and three-line, sixteen-character

backlit LCD. Parameters are organized in a three-level menu structure,

using a text format for straightforward programming.

Port 5 –DPI Communications

Port 5 –DPI Communications

Port 2

Port 2

%5-"%.0*UNE

Ports 2 and 3 when two HIMs

Ports 2 and 3 when two HIMs

are connected with a splitter

are connected with a splitter

Figure 1.15 – Built-in Keypad and LCD

Page 29

Product Overview 1-19

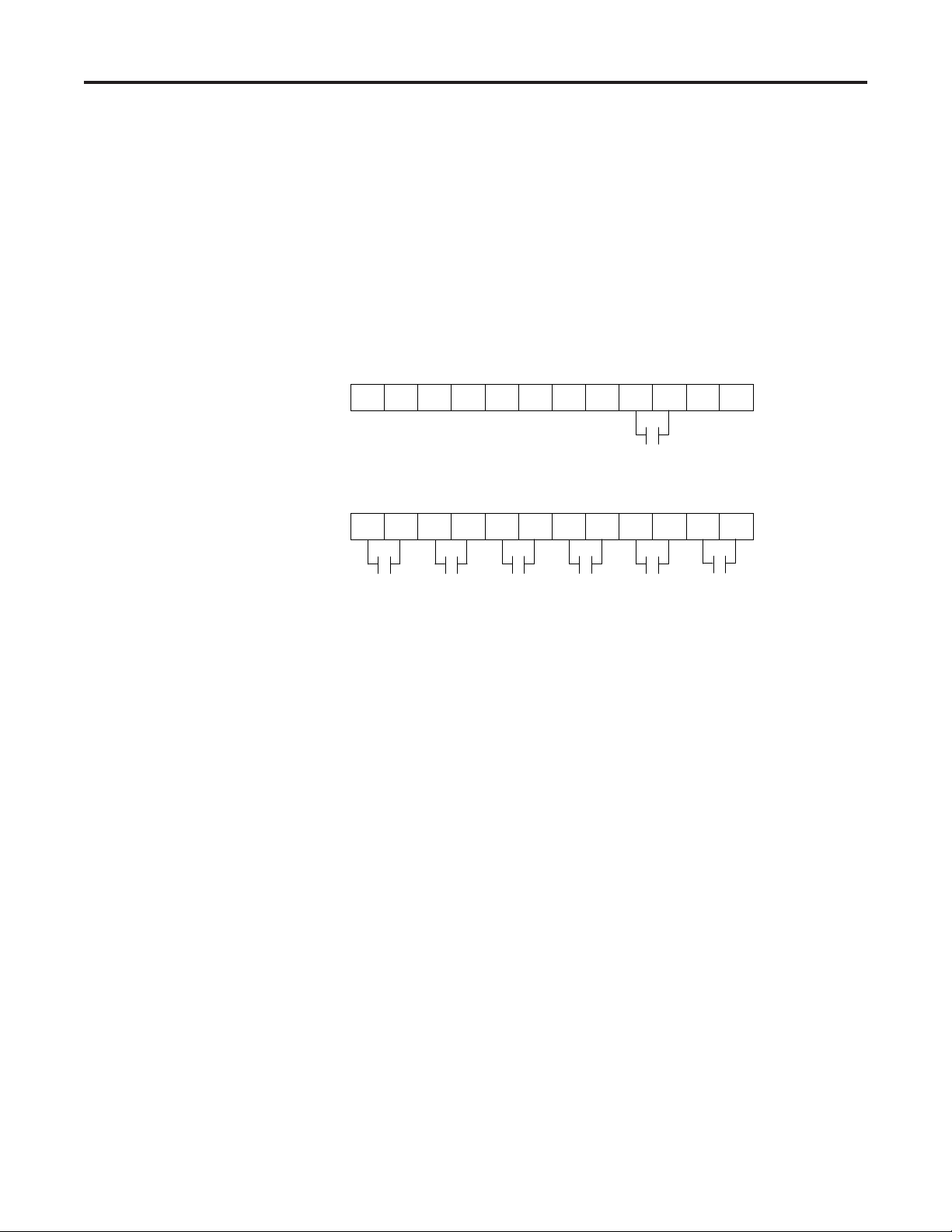

Status Indication Four programmable hard contact outputs are provided as standard:

• The Auxiliary #1 Contact is N.O. It is always programmed for

Up-to-speed to control the bypass contactor in MV applications.

• The fault Contact is for fault indication and is programmable for N.O./N.C.

• The alarm Contact is for alarm indication and is programmable for N.O./N.C.

• The Auxiliary #2 Contact is for normal indication and is programmable

for N.O./N.C. For MV applications, it is configured as N.O. to control

the line contactor.

11 12 13 14 15 16 17 18 19 20 21 22

11 12 13 14 15 16 17 18 19 20 21 22

SMC-Flex

SMC-Flex

Control Terminals

Control Terminals

23 24 25 26 27 28 29 30 31 32 33 34

23 24 25 26 27 28 29 30 31 32 33 34

PTC

PTC

Input

Input

TACH

TACH

Input

Input

Ground

Ground

Fault

Fault

Fault

Fault

Contact

Contact

Aux#1

Aux#1

Up-to-Speed

Up-to-Speed

Alarm

Alarm

Contact

Contact

Aux #2

Aux #2

Normal

Normal

Figure 1.16 – Control Terminals

Control Options The MV SMC-Flex™ controller offers the control options described below.

Important: The options listed in this section are mutually exclusive and

must be specified when ordering. An existing controller may be upgraded

to another control option by replacing the control module and possibly other

components. Consult your nearest Rockwell Automation sales office.

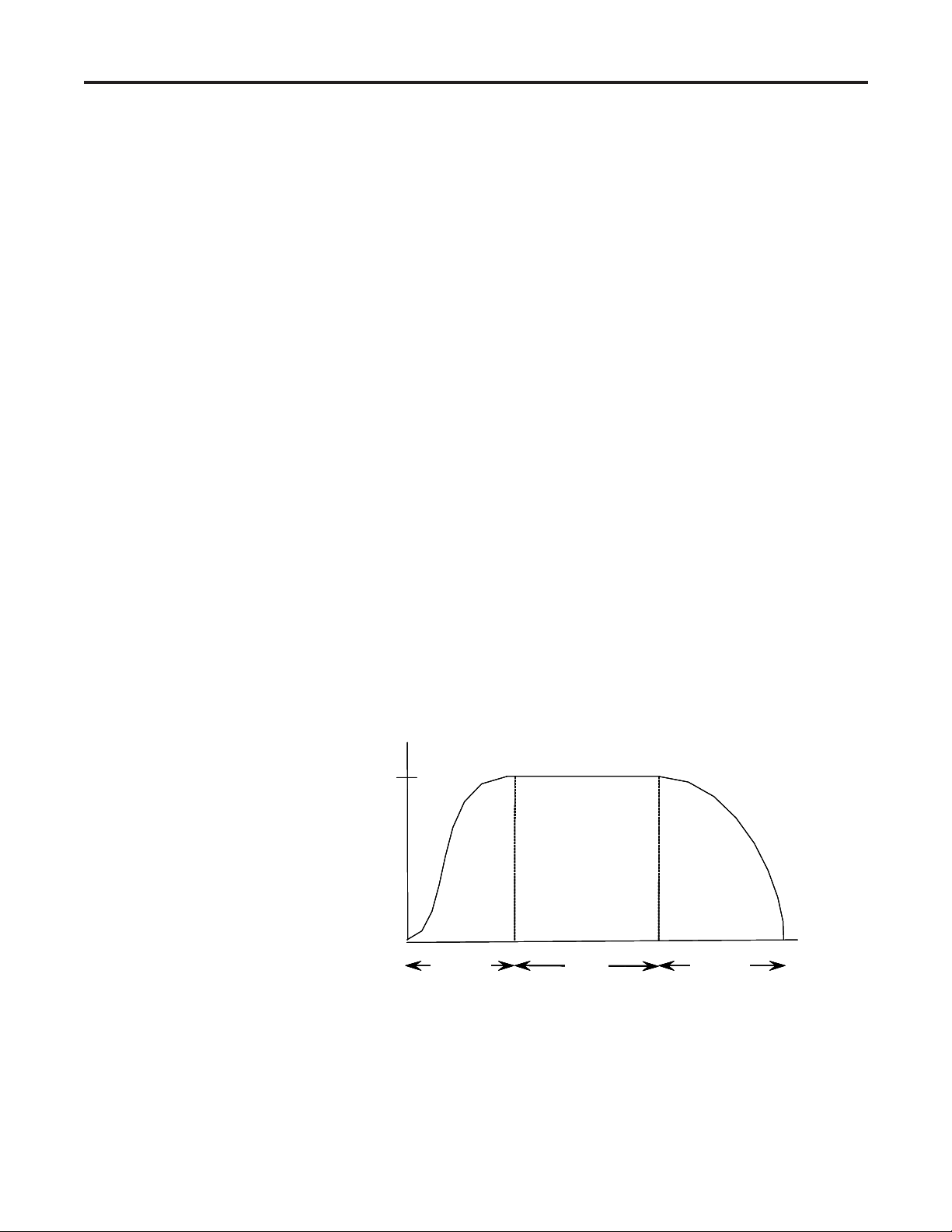

Pump Control Option

This option reduces surges during the starting and stopping of a centrifugal

pump by smoothly accelerating and decelerating the motor. The microprocessor analyzes the motor variables and generates commands that control

the motor and reduce the possibility of surges occurring in the system.

The motor current will vary during the acceleration period, and may be

near the motor rated starting current. The pump algorithm does not limit

starting current since full voltage is needed to reach full speed with a

loaded motor.

The starting time is programmable from 0-30 seconds, and the stopping

time is programmable from 0-120 seconds.

%5-"%.0*UNE

Page 30

1-20 Product Overview

Control Options (cont.) Pump Application Considerations

1. Consult factory if start time settings over 30 seconds are required.

The base rating of the MV SMC-Flex is two starts (or one start/stop

combination) per hour, thirty seconds maximum for each operation.

A st o pping operation counts as a start for purposes of thermal capacity

calculations.

2. The Pump Control option functions only for centrifugal pumps. It is

not suited for positive displacement, piston, or other types of pumps.

3. The Pump Stop option functions only for a centrifugal pump running

at greater than approximately 2/3 of the motor rated horsepower.

4. Pump applications with input and/or output valves that are closed during

starting and/or stopping may not benefit from the Pump Control option.

Consult the factory for applications with valves.

5. For starting or stopping times longer than 15 seconds, power fuse

selection should be reviewed to ensure no element damage occurs.

The fuse minimum melting time-current characteristic curve should

be consulted to ensure that, at 1.1 times the full voltage locked rotor

current of the motor, the actual starting or stopping time does not

exceed 75% of the fuse melting time.

6. Motor overload and/or upstream breaker settings may have to be

adjusted to allow the starting or stopping current to flow for extended

periods.

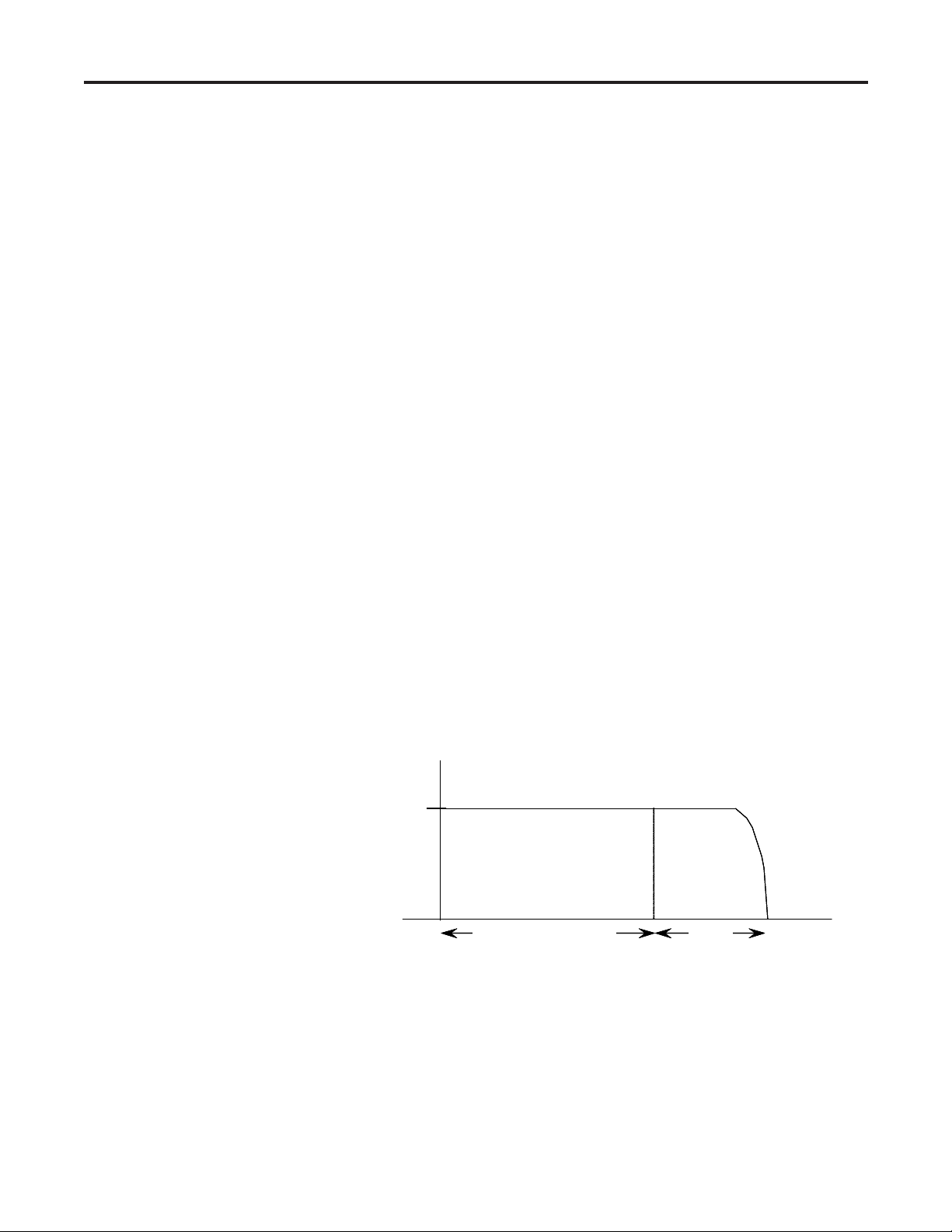

100%

100%

Motor

Motor

Speed

Speed

Pump Start Run Pump Stop

Pump Start Run Pump Stop

Ti

me (seconds)

me (seconds)

Ti

Figure 1.17 – Pump Control Option

%5-"%.0*UNE

Page 31

A T T E N T I O NA T T E N T I O N

Product Overview 1-21

Pump stopping is not intended to be used as an

emergency stop. Refer to the applicable standard for

emergency stop requirements.

A T T E N T I O NA T T E N T I O N

Pump stopping may cause motor heating depending on

the mechanical dynamics of the pumping system.

Therefore, select the lowest stopping time setting that

will satisfactorily stop the pump.

Braking Control Option

The Braking Control option (Smart Motor Braking, Accu-Stop and Slow

Speed with Braking) are not offered for standard use in MV applications.

Please consult factory for further assistance.

%5-"%.0*UNE

Page 32

1-22 Product Overview

Hardware Description The following sections contain descriptions of system components and

system operation. Each section will be described to give the user an

understanding of the MV SMC-Flex to facilitate operation and maintenance

of the system. Refer to Figures 1.18 through 1.21, Typical MV SMC-Flex

Power System.

Power Module

The controller consists of three power modules, one for each phase. Each

power module consists of incoming and outgoing terminals for cables, SCRs,

heatsink and clamp assembly. The SCRs are connected in inverse parallel

(and in series for 12- or 18-SCR assemblies) to form a three-phase, AC

line controller configuration.

Each power module includes a snubber circuit to limit the rate of rise in

voltage across each SCR pair. The module also includes patented gate

driver circuits which derive their power from the snubber circuit.

Voltage sharing resistors are connected across each SCR pair to provide

static voltage balance for series-connected SCRs. These resistors are

tapped to provide a reference for overvoltage protection circuitry on the

gate driver board.

A voltage sensing board is used to reduce the line-side and load-side voltages

to lower levels that can be measured by the SMC-Flex control module.

Self-Powered Silicon-Controlled Rectifier Gate Driver Board

This board provides the turn-on capability for SCR devices. The board

also provides optical fibre isolation between itself and the gating source

logic. It is powered by recovering energy from the snubber circuit, so it is

fully isolated from the control and logic circuits; it is self-economizing

when the unit is not running, or is in bypass mode.

Note: If pump control or stop control are used, the gate driver boards are

powered continuously using separate power supply boards. (Refer to

Chapter 8 for additional details.)

The MV SMC-Flex has three heatsinks fitted with a thermistor to monitor

temperature rise. The circuitry on the gate driver board accepts the

thermistor, and drives a fibre-optic cable if the temperature is below the

setpoint (85°C). If the temperature rises above the setpoint, the driver is

turned off, and the MV SMC-Flex is signalled to stop gating and initiate a

temperature fault.

Due to the self-powered nature of the circuits, this function is active only

while the SMC is active. While the starter is off, or in bypass, no power is

dissipated in the SCRs and the temperature of the SCRs can only decrease.

%5-"%.0*UNE

Page 33

Product Overview 1-23

Interface Board

This circuit board takes current transformer signals plus line-side and loadside voltage feedback signals from the voltage sensing board and passes

them to the SMC-Flex for processing. The control module produces gating

signals for the SCRs, which are received on the interface board, and used

to drive fibre-optic transmitters. The gating signals are sent to the gate-driver

circuit board via fibre-optic cables. The interface board also receives

temperature feedback from the gate-driver board via fibre-optic cable(s).

If the heatsink temperature rises above a set value, a signal is sent to the

SMC-Flex to stop gating the SCRs and initiate a temperature fault.

For a detailed layout of this circuit board, refer to Figure 3.2 on page 3-6.

%5-"%.0*UNE

Page 34

1-24 Product Overview

*

Figure 1.18 – Typical MV SMC-Flex Power System • Bulletin 1562E (Without Stop Control)

%5-"%.0*UNE

Page 35

Product Overview 1-25

Figure 1.19 – Typical MV SMC-Flex Power System • Bulletin 1562E (With Stop Control)

%5-"%.0*UNE

Page 36

1-26 Product Overview

Figure 1.20 – Typical MV SMC-Flex Power System • Bulletin 1560E (Without Stop Control)

%5-"%.0*UNE

Page 37

Product Overview 1-27

Figure 1.21– Typical MV SMC-Flex Power System • Bulletin 1560E (With Stop Control)

%5-"%.0*UNE

Page 38

1-28 Product Overview

Functional Description The following functional descriptions and associated control circuits are

for units using IntelliVAC contactor control modules. For units with

electromechanical (relay) control, refer to Appendix C.

Bulletin 1562E • Basic Control – Controlled Start only

When wired as shown in Figure 1.22, the controller operates as follows:

Pressing the "Start" button initiates the start sequence. Relay "CR" closes

and applies control power to terminal 17 of the SMC-Flex module. The

auxiliary contact #2 ("Normal") closes, energizing "M-IV" and "MC",

which completes the hold-in circuit on the start button, and closes the main

contactor.

The SMC-Flex module examines the line voltage, looks for fault

conditions, checks phase rotation, calculates zero crossing information, and

begins gating the SCRs to start the motor.

When the motor approaches rated speed, the SMC-Flex module closes the

"AUX1" (up-to-speed) auxiliary contacts, energizing "B-IV", which closes

the bypass contactor. The motor then runs at full line voltage.

When the "Stop" button is pressed, the "CR" relay opens terminal 17 on

the SMC-Flex module. The "Normal" contact opens, dropping out the

main contactor, allowing the motor to stop. The "AUX1" contact is held

closed for a short time by the control module. This holds the bypass

contactor closed for about 10 seconds to protect the power electronics from

any voltage transients due to opening the motor circuits.

%5-"%.0*UNE

Page 39

Product Overview 1-29

Bulletin 1562E • Basic Control – With Controlled Stop

When wired as shown in Figure 1.23, the controller operates in much the

same manner as in Figure 1.22.

Terminal 16 on the SMC-Flex module now controls the start and stop

maneuvers. Terminal 16 must remain energized for the module to run.

When the “Stop” button is pressed, and “CR” opens, the

SMC-Flex module

will initiate the option stop. An uncontrolled, or coast stop, is achieved by

opening the connection to terminal 17. This contact should remain open to

ensure all hold-in contacts clear, to prevent a re-start.

If the motor has started, the unit is in the bypass mode, and a trip occurs

within the SMC-Flex module or from an external protection relay; "AUX2"

will open the line contactor immediately, and "AUX1" will remain closed

for 10 seconds. A trip due to an overload or fault condition will result in a

“coast” stop.

Bulletin 1562E • DPI Control – Controlled Start only

The control scheme shown in Figure 1.24 allows the MV SMC-Flex to be

controlled using DPI (Drive Programming Interface). This special usage of

DPI includes provisions for a "Hand" mode of control as well.

With the Hand-Auto selector switch in the "Auto" position, terminal 18 of

the SMC-Flex module is energized, allowing a start command to be

executed via DPI. The "AUX2" contact closes, energizing both "M-IV"

and "MC".

When the motor approaches rated speed, the SMC-Flex module closes

"AUX1", energizing "B-IV", which closes the bypass contactor.

To run in "Hand" mode, the "CR" contact is used to initiate a start

sequence (similar to Figure 1.22).

A stop command can be generated via DPI or by opening "CR", depending

on the control mode.

%5-"%.0*UNE

Page 40

1-30 Product Overview

Functional Description (cont.) Bulletin 1560E • Basic Control – Controlled Start Only

The Bulletin 1560E is intended for addition to an existing motor

controller, which provides circuit isolation, motor switching, and

overload and overcurrent protection. When wired as shown in Figure

1.25, the controller operates as follows:

When a start is initiated in the existing motor controller and the contactor

(or breaker) closes, a contact must be supplied to tell the 1560E to start

also. A "CR" contact will apply control voltage to terminal 17 of the

SMC-Flex module.

When stopping the motor, the contactor in the existing controller will

open, removing power from the motor, and then the “CR” relay. The

bypass hold-in rung will keep the bypass contactor closed for a short time.

The “Fault” contact on the SMC-Flex module should be wired into the

existing controller to trip the main contactor (or breaker) in the event of a

fault condition sensed by the SMC-Flex module.

If possible, it is better to have the SMC-Flex module control the main

contactor directly. In this case, the control circuit would look like, and

function like, the descriptions above for the Bulletin 1562E.

Bulletin 1560E • Basic control – With Controlled Stop

When wired as shown in Figure 1.26, the controller operates much the

same as described above for the Standard module. The control signal uses

terminal 16 instead of 17, and a “coast” stop can be achieved by opening

the connection to terminal 17.

It is more important in this configuration to integrate the control circuit of

the 1560E with the existing controller, for better control of the Stop

option. The “start signal” for this scheme cannot be a slave of the main

contactor, since it must remain closed to accomplish the option stop

maneuver. The SMC-Flex module can be used to control the main

contactor such that it will close when a start is initiated, and remain closed

until it has sensed the motor has stopped following an option stop

maneuver.

%5-"%.0*UNE

Page 41

Product Overview 1-31

Bulletin 1560E • DPI Control – Controlled Start only

The control scheme shown in Figure 1.27 allows the MV SMC-Flex to be

controlled using DPI. This special usage of DPI includes provisions for a

"Hand" mode of control as well.

With the Hand-Auto selector switch in the "Auto" position, and closure of

the existing starter main contactor, terminal 18 is energized, allowing a

start command to be executed via DPI. "AUX2" serves as an interlock

with the main contactor (or breaker) in the existing starter.

As with the other control schemes, the SMC-Flex module closes "AUX1",

energizing "B-IV", as the motor approaches rated speed.

Hand control is enabled with the selector switch in the "Hand" position.

Closure of the "Start" relay, from the existing starter, allows the unit to

initiate motor soft starting.

%5-"%.0*UNE

Page 42

1-32 Product Overview

%5-"%.0*UNE

Figure 1.22 – Bulletin 1562E IntelliVAC Control Circuit • Without Stop Control

Page 43

Product Overview 1-33

Figure 1.23 – Bulletin 1562E IntelliVAC Control Circuit • With Stop Control

%5-"%.0*UNE

Page 44

1-34 Product Overview%5-"%.0*UNE

• With DeviceNet (or DPI) Communication and optional Hand/Auto

%5-"%.0*UNE

Figure 1.24 – Bulletin 1562E IntelliVAC Control Circuit

Page 45

Product Overview 1-35

Figure 1.25 – Bulletin 1560E IntelliVAC Control Circuit • Without Stop Control

%5-"%.0*UNE

Page 46

1-36 Product Overview

%5-"%.0*UNE

Figure 1.26 – Bulletin 1560E IntelliVAC Control Circuit • With Stop Control

Page 47

Product Overview 1-37

Figure 1.27 – Bulletin 1560E IntelliVAC Control Circuit

• DeviceNet (or DPI) Communication and optional Hand/Auto

%5-"%.0*UNE

Page 48

1-38 Product Overview

%5-"%.0*UNE

Page 49

Chapter 2

Installation

A T T E N T I O NA T T E N T I O N

Perform the installation duties correctly. Errors may

cause commissioning delays, equipment damage or

personal injury.

Important: For the 1503E, refer to applicable documentation from OEM

installation, grounding, interlocking and wiring. This manual should be

utilized in conjunction with the OEM supplied documentation, and is

suitable for commissioning, programming, calibration, metering, serial

communications, diagnostics, troubleshooting, and maintenance of a

standard solid-state controller.

Receiving It is the responsibility of the user to thoroughly inspect the equipment

before accepting the shipment from the freight company. Check the item(s)

received against the purchase order. If any items are damaged, it is the

responsibility of the user not to accept delivery until the freight agent has

noted the damage on the freight bill. Should any concealed damage be

found during unpacking, it is again the responsibility of the user to notify

the freight agent. The shipping container must be left intact and the freight

agent should be requested to make a visual inspection of the equipment.

Safety and Codes The Canadian Electrical Code (CEC), National Electrical

A T T E N T I O NA T T E N T I O N

Code (NEC), or other local codes outline provisions for

safely installing electrical equipment. Installation

MUST comply with specifications regarding wire type,

conductor sizes, branch circuit protection, interlocking

and disconnect devices. Failure to do so may result in

personal injury and/or equipment damage.

Unpacking and Inspection After unpacking the material, check the item(s) received against the bill of

lading to ensure that the nameplate description of each item agrees with

the material ordered. Inspect the equipment for physical damage, as stated

in the Rockwell Automation Conditions of Sale.

Remove all packing material, wedges, or braces from within the controller.

Operate the contactors and relays manually to ensure that they operate freely.

Store the equipment in a clean, dry place if it will not be installed immediately

after unpacking. The storage temperature must be between -20°C and 75°C

(-4°F and 167°F) with a maximum humidity of 95%, non-condensing, to

guard against damage to temperature sensitive components in the controller.

%5-"%.0*UNE

Page 50

2-2 Installation

General Precautions In addition to the precautions listed throughout this manual, the following

statements, which are general to the system, must be read and understood.

A T T E N T I O NA T T E N T I O N

A T T E N T I O NA T T E N T I O N

A T T E N T I O NA T T E N T I O N

The controller contains ESD (electrostatic discharge)

sensitive parts and assemblies. Static control

precautions are required when installing testing,

servicing, or repairing the assembly. Component

damage may result if ESD control procedures are not

followed. If you are not familiar with static control

procedures, refer to applicable ESD protection handbooks.

An incorrectly applied or installed controller can

damage components or reduce product life. Wiring or

application errors, such as undersizing the motor,

incorrect or inadequate AC supply, or excessive ambient

temperatures, may result in malfunction of the system.

Only personnel familiar with the controller and associated

machinery should plan or implement the installation,

start-up, and subsequent maintenance of the system.

Failure to do this may result in personal injury and/or

equipment damage.

Transportation and Handling The controller must be transported on a pallet or via use of the lifting

angles supplied as part of all 90-inch (2.3 m) high cabinets or frame units.

A T T E N T I O NA T T E N T I O N

Round rollers can be used to assist in moving the controller to the installation site. Once at the final site, the pipe rolling technique can be used to

place the cabinet in the desired position.

A T T E N T I O NA T T E N T I O N

Ensure that the load rating of the lifting device is

sufficient to safely raise the controller sections. Failure

to do so may result in severe injury and/or equipment

damage. Refer to the packing slip enclosed with shipment

for shipping weights.

Care must be exercised when using either a forklift, or

the pipe rolling technique, for positioning purposes to

ensure that the equipment is not scratched, dented or

damaged in any manner. Always exercise care to

stabilize the controller during handling to guard against

tipping and injury to personnel.

%5-"%.0*UNE

Page 51

Installation 2-3

Installation Site Consider the following when selecting the installation site:

A. The operating ambient temperature should be between 0°C and 40°C

(32°F and 104°F) for NEMA Type 1 or 12 enclosures. For higher