Page 1

Medium Voltage

AC Drive

Bulletin 1557

User Manual

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the Additional Resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

TABLE OF CONTENTS

Chapter 1 .......................................................... Using This Manual

Chapter 2 ......................................................... Introduction

Chapter 3 .......................................................... Specifications

Chapter 4 .......................................................... Hardware Description

Chapter 5 .......................................................... Description of Operation

Chapter 6 .......................................................... Parameter and Variable

Descriptions

Chapter 7 .......................................................... Operator Interface Terminal

Chapter 8 .......................................................... Installation

Chapter 9 .......................................................... Commissioning

Chapter 10 ........................................................ Troubleshooting

Chapter 11 ........................................................ Spare Parts

1557-UM050F-EN-P – June 2013

Page 4

1557-UM050F-EN-P – June 2013

Page 5

USING THIS MANUAL 1-1

Warnings tell readers where people may be hurt if

procedures are not followed properly.

Cautions tell readers where machinery may be damaged

or economic loss can occur if procedures are not

followed properly.

This symbol alerts the user to a potential electrical shock

hazard which exists on a component or printed circuit

board.

Manual Objectives

This manual is intended for use by personnel familiar with Medium Voltage and variable speed solid-state

drive equipment. The manual contains material which will allow the user to operate, maintain, and

troubleshoot the drive system.

IMPORTANT USER INFORMATION

Because of the variety of uses for this equipment and because of the differences between this solid-state

equipment and electromechanical equipment, the user of and those responsible for applying this

equipment must satisfy themselves as to the acceptability of each application and use of the equipment.

In no event will Rockwell Automation be responsible or liable for indirect or consequential damages

resulting from the use or modification of this equipment.

The illustrations shown in this manual are intended solely to illustrate the text of this manual Because of

the many variables and requirements associated with any particular installation, Rockwell Automation

cannot assume responsibility or liability for actual use based upon the illustrative uses and applications.

No patent liability is assumed by Rockwell Automation with respect to use of information, circuits,

equipment or software described in this text.

Reproduction of the content of this manual, in whole or in part, without written permission of Rockwell

Automation is prohibited.

Both of these:

• Identify a possible trouble spot.

• Tell what causes the trouble.

• Give the result of improper action.

• Tell the reader how to avoid trouble.

1557-UM050F-EN-P – June 2013

Page 6

1-2 USING THIS MANUAL

REPAIR OR REPAIR/EXCHANGE PROCEDURE

For your convenience, Rockwell Automation and Rockwell Automation Global Technical Services(GTS),

provide an efficient and convenient method of returning equipment eligible for repair or repair/exchange.

A Product Service Report (P.S.R.) number is required to return any equipment for repair. This may be

obtained from your area Rockwell Automation Distributor, Sales Office or Area Support Division.

Return any equipment to be repaired to the Area Support Division nearest you. Be sure to reference the

P.S.R. number on the carton and packing slip. Include your company name and address, your repair

purchase order number, and a brief description of the problem. This will facilitate quick return of your

equipment.

A complete listing of Global Technical Services offices may be obtained by calling your area Rockwell

Automation Distributor or Sales Office.

1557-UM050F-EN-P – June 2013

Page 7

INTRODUCTION CHAPTER 2

The Bulletin 1557 drive is a Pulse Width Modulated Current Source Machine side converter (PWM - CSI).

It is designed to supply 3 phase currents to standard induction motor loads. The Bul. 1557 MV (medium

voltage) drive converts 3 phase 50/60 Hz input power to an adjustable AC frequency current source for

speed control of AC squirrel cage motors.

The solid state technology used in the design is of proven reliability. A number of circuit implementation

techniques used are unique to the Allen-Bradley Bulletin 1557 drive.

The basic design philosophy emphasizes the isolation of single component failures, such that multiple

component failures do not occur. This leads to a low MTTR, (Mean Time To Repair), with extensive fault

diagnostic circuits and easy accessibility.

The basic design features of the Allen-Bradley Bulletin 1557 drive are as follows:

The three phase motor currents are sinusoidal with low total harmonic distortion.

The design uses isolated driver circuits, one per gate turn off thyristor (GTO), and

silicon controlled line side converter (SCR).

Two output phases are individually current sensed, ensuring protection and control.

The design is capable of producing smooth low speed torque with low harmonic current

to the motor.

A fuseless electronic protection scheme is used in the power circuit for normal fault

conditions. Power fuses provide back up protection and ensure safety.

Heatsinks are monitored with temperature sensors to detect overtemperatures.

(BUL 1557 Air-cooled units only)

The 1557 Drive uses a North American design base with all components readily

accessible from the front without need to extensively dismantle the unit.

The drive system logic is microcomputer based, thus eliminating numerous trimpots

for system calibration.

Fault and alarm indication is performed using an operator interface panel.

1557-UM050F-EN-P – June 2013

Page 8

2-2 INTRODUCTION

An Input contactor with fused isolating switch is optional on the 1557 drive and is only supplied

when specified or if the customer does not have an existing full voltage starter.

The standard 1557 drive is a tachless design. A tachometer is recommended for applications

requiring an output frequency lower than 6 hertz or applications with a starting torque greater than

30%.

A drive isolation transformer or AC line reactor is required with each drive. An isolation

transformer is mandatory when existing motors are used, 12-Pulse line side converters are used,

or for stepping down the main supply voltage. An AC line reactor may only be used when new

motors are used with the proper level of phase to ground insulation. Consult your Rockwell

Automation representative for more information.

1557-UM050F-EN-P – June 2013

Page 9

SPECIFICATIONS CHAPTER 3

The electrical and environmental specifications of the Bulletin 1557 MV Drive are provided below:

Input Voltages: 2300Vac ± 10%, 3-Phase

3300Vac ± 10%, 3-Phase

4160Vac ± 10%, 3-Phase

6900Vac ± 10%, 3-Phase

Input Frequency: 50/60Hz ± 3Hz

Efficiency: 97% at full load (minimum)

Output Voltage: 0 to 2300Vac, 3-Phase

0 to 3300Vac, 3-Phase

0 to 4160Vac, 3-Phase

0 to 6900Vac, 3-Phase

Output Frequency: 6Hz to 75Hz (Without Tach)

0.2Hz to 75 Hz (With Tach)

Speed Regulation: 0.5% of maximum speed (Without Tach)

0.1% of maximum speed (With Tach)

Speed Reference: 0 to 10V dc or

4 to 20 mA dc

Operating Temperature: Ambient temperature must be within the range of 0° to 40°C

with a relative humidity of up to 95% (non-condensing)

Storage Temperature: Ambient temperature must be within the range of –40° to 70°C

Altitude: No derating below 1000 m above sea level

1557-UM050F-EN-P – June 2013

Page 10

3-2 SPECIFICATIONS

1557-UM050F-EN-P – June 2013

Page 11

HARDWARE DESCRIPTION 4-1

Hardware Overview

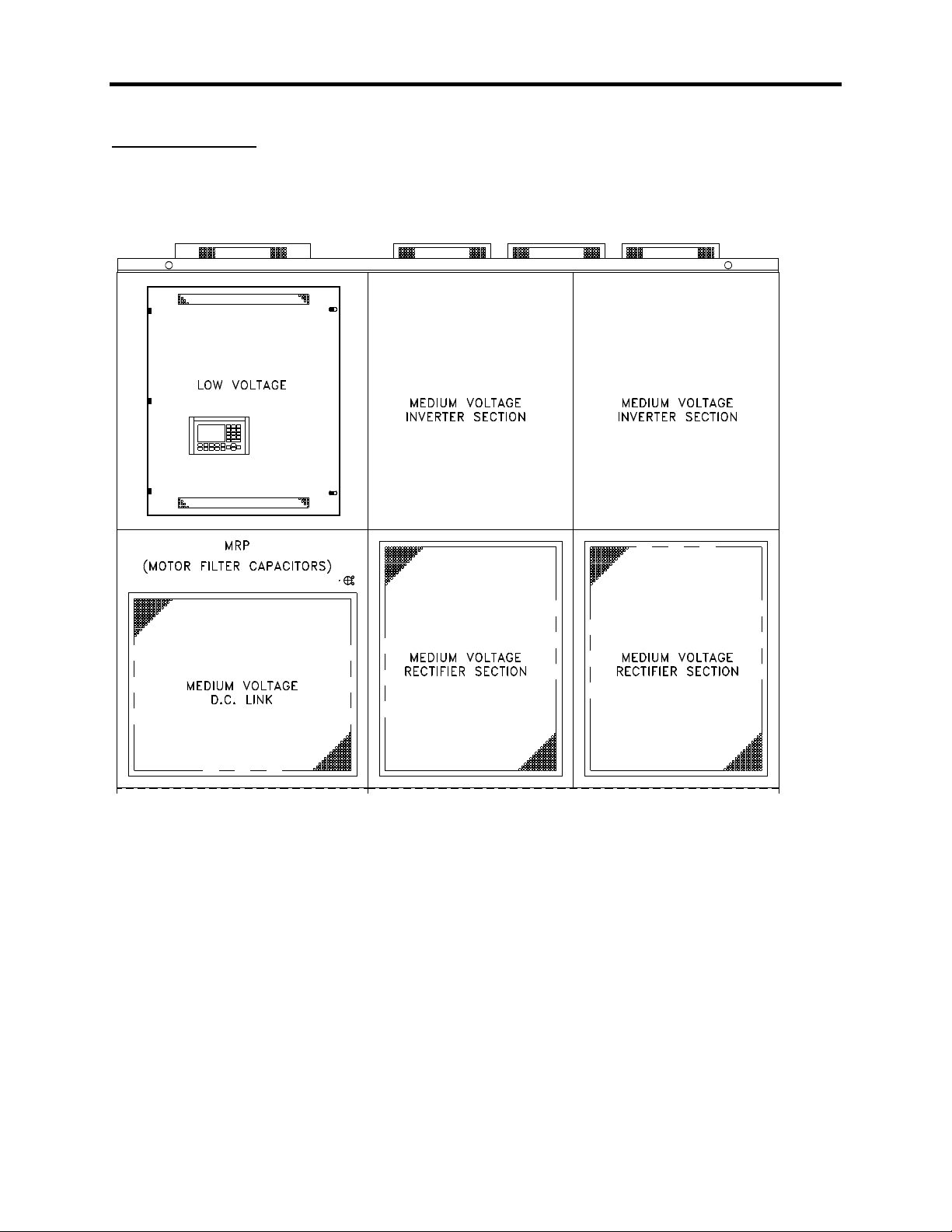

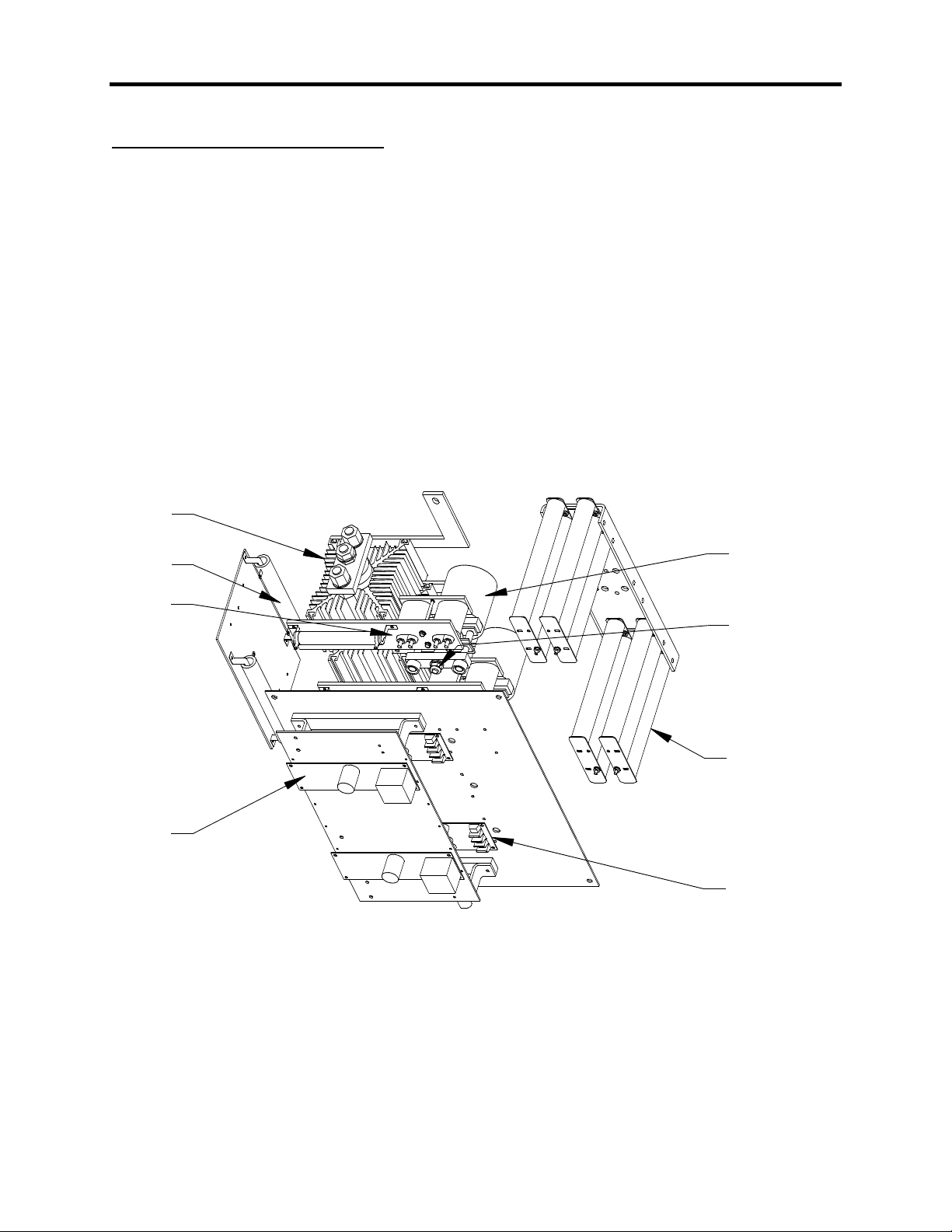

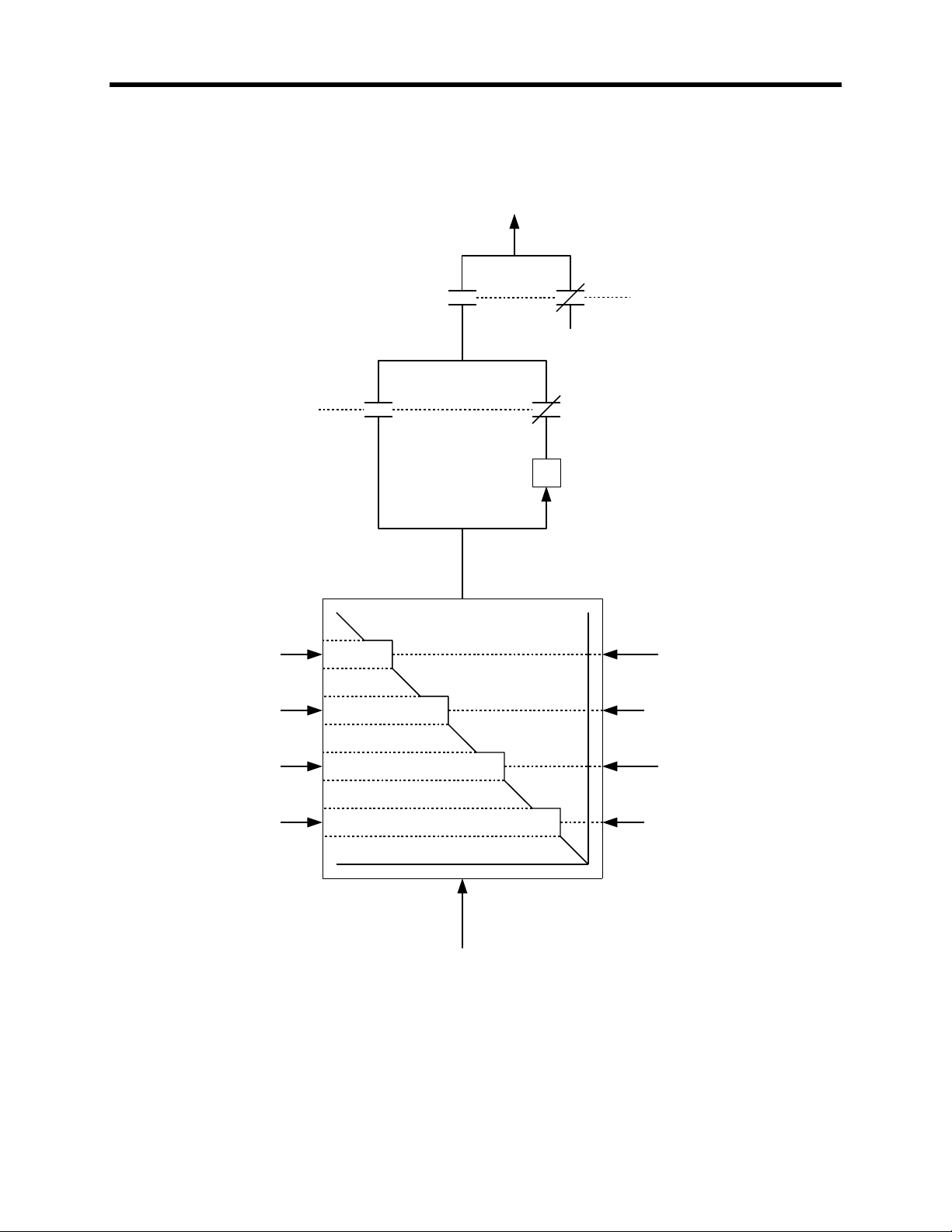

The basic drive consists of two cabinets; the D.C. link/control cabinet and the converter cabinet. An input

contactor cabinet is optional. (See Figure 4.1)

Figure 4.1 – Outline of 1557 Drive

1557-UM050F-EN-P – June 2013

Page 12

4-2 HARDWARE DESCRIPTION

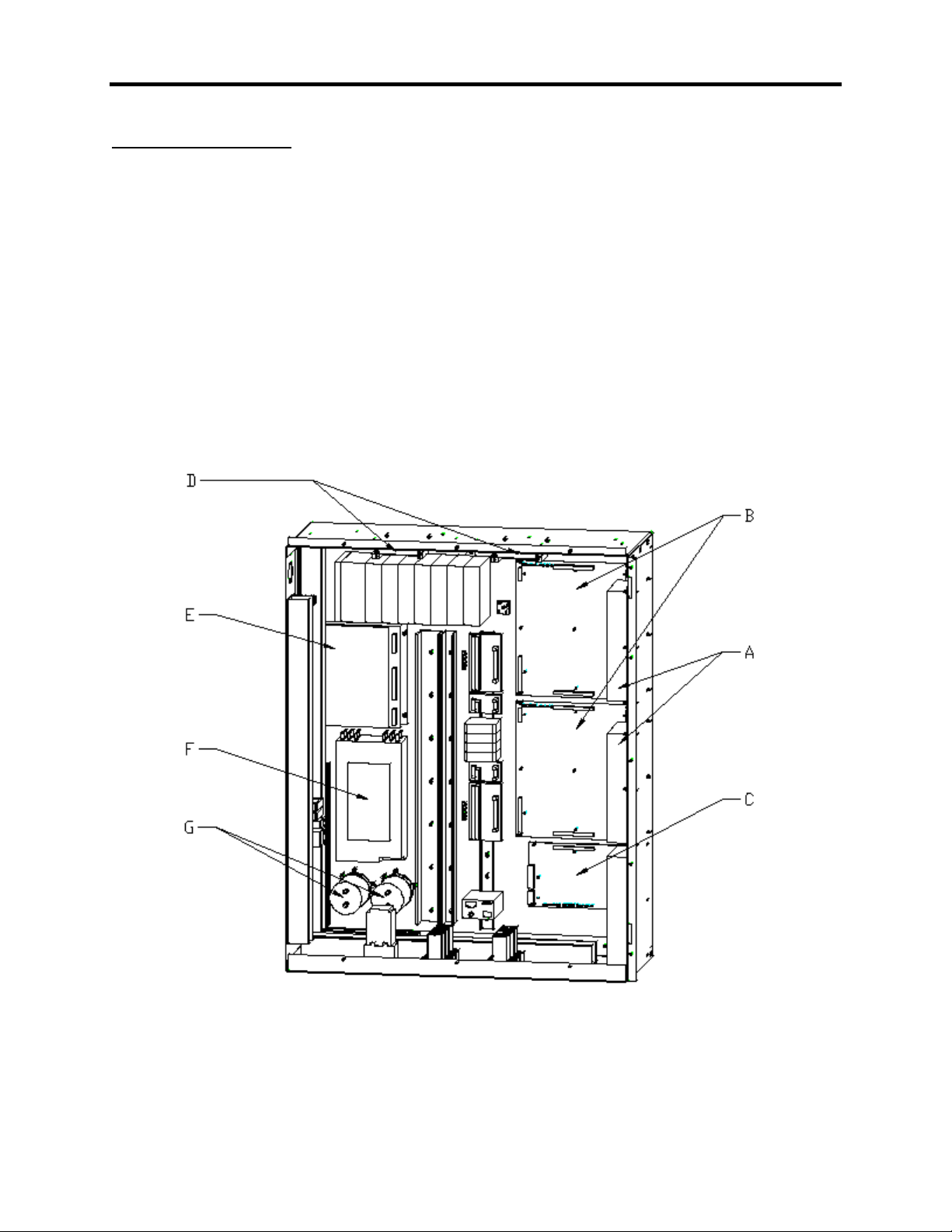

DC Link Control Cabinet

The D.C. link/control cabinet is 44 inches wide. The top section has a panel with operator interface

devices mounted on a door within a door. A fully vented door is in the bottom position.

Access to the low voltage control compartment is gained through the hinged low voltage panel.

All low voltage compartments contain the following elements:

4.2 (A) Fiber optic interface boards ( 2 )

4.2 (B) Drive control boards ( 2 for 6-pulse, 3 for 12-pulse )

4.2 (C) Communication processor board ( 1 )

4.2 (D) Digital I/O boards ( 2 )

4.2 (E) D.C./D.C. converter ( 1 )

4.2 (F) A.C./D.C. power supply ( 1 )

4.2 (G) Capacitors

See Figure 4.2

Figure 4.2 – Typical Low Voltage Compartment

1557-UM050F-EN-P – June 2013

Page 13

HARDWARE DESCRIPTION 4-3

Warning: Allow 5-10 minutes for motor filter capacitors to

safely discharge voltage prior to opening cabinet doors.

D.C. Link Reactor

The D.C. link reactor is floor mounted and may be shipped separately and installed on site in larger drives.

Motor Filter Capacitors

Located behind the low voltage compartment, the motor filter capacitors are accessible when the upper

medium voltage door is opened. There are 3 capacitors for low horsepower drives and 6 for larger drives.

The capacitors are liquid filled and mounted on rails. The metal cases of the capacitors are grounded to

the cabinet.

1557-UM050F-EN-P – June 2013

Page 14

4-4 HARDWARE DESCRIPTION

4.3(A)

4.3(D)

4.3(F)

4.3(B)

4.3(C)

4.3(E)

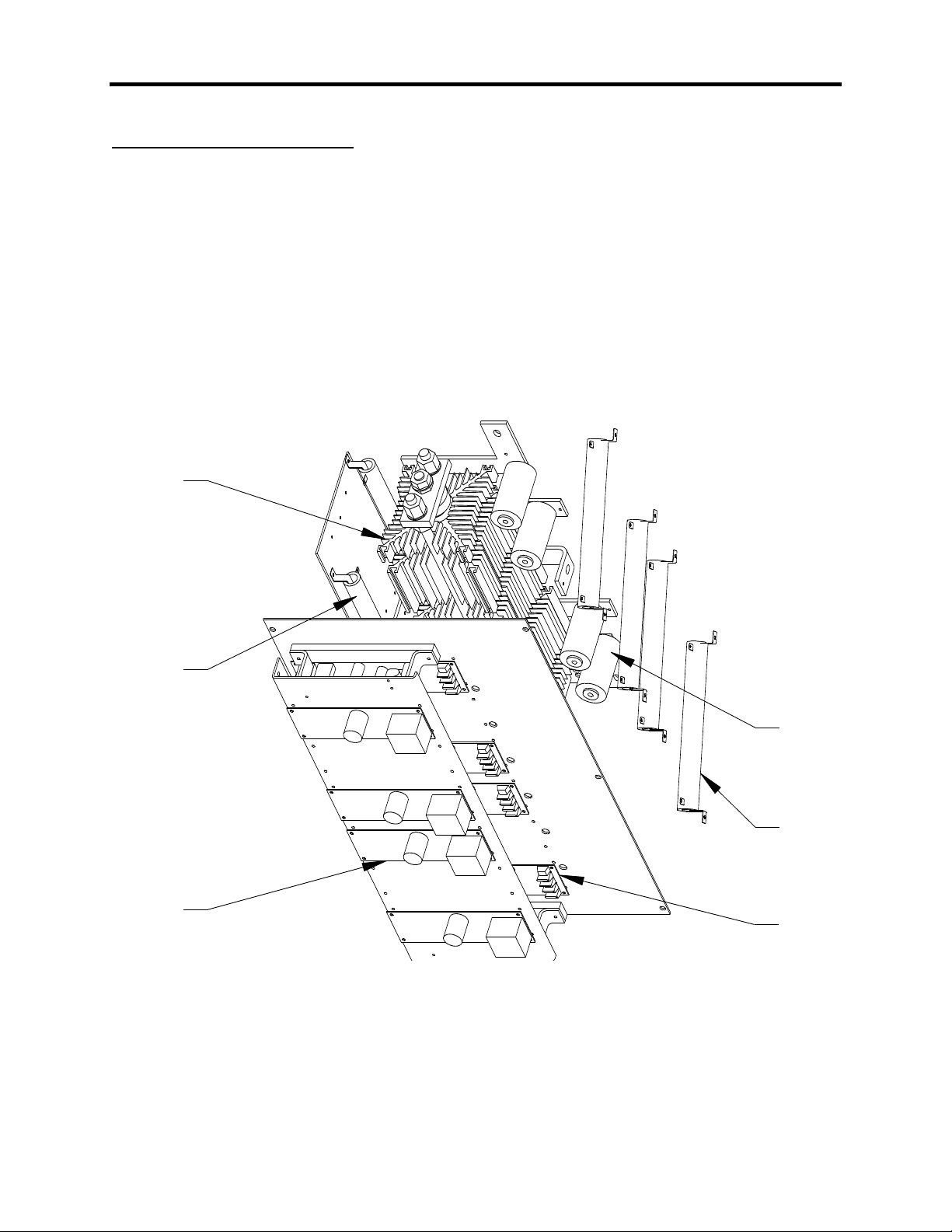

Line side converter Components

The line side converter is located in the lower half of the converter cabinet. The line side converter

consists of three identical cells; each cell consists of the following:

4.3 (A) -line side converter heatsink stack

-Silicon Controlled Line side converter (SCR) thyristors

-heatsinks

-clamp

4.3 (B) -snubber capacitors

4.3 (C) -snubber resistors

4.3 (D) -voltage sharing/diagnostic resistors

4.3 (E) -gate driver circuit boards

4.3 (F) -power supply boards

(See Figure 4.3 )

Figure 4.3 – Line Side Converter Components

(2300 V Line Side Converter shown)

1557-UM050F-EN-P – June 2013

Page 15

HARDWARE DESCRIPTION 4-5

4.4(A)

4.4(E)

4.4(D)

4.4(G)

4.4(C)

4.4(D)

4.4(B)

4.4(F)

Machine side converter Components

The machine side converter is located in the upper half of the converter cabinet. The machine side

converter consists of three identical cells. each cell consists of the following:

4.4 (A) -machine side converter heatsink stack assemblies

-Gate Turn Off (GTO) thyristors

-heatsinks

-clamp

4.4 (B) -snubber resistors

4.4 (C) -snubber capacitors

4.4 (D) -snubber diode assemblies

- Fast recovery diode

- diode clamp

-snubber capacitors for the snubber diodes

-snubber resistors for the snubber diodes

4.4 (E) -voltage sharing/diagnostic resistors

4.4 (F) -gate driver circuit boards

4.4 (G) -power supply boards

(See Figure 4.4 )

Figure 4.4 – Machine Side Converter Components

(2300 V Machine Side Converter shown)

Three of the machine side converter heatsink assemblies (one in each phase) have thermistors mounted

on the heatsinks, each thermistors is wired to a small circuit board (Thermistor Feedback board) which is

located near the gate driver boards. In the event of heatsink overtemperature, a fault signal is sent to the

controller and the drive will shut down.

1557-UM050F-EN-P – June 2013

Page 16

4-6 HARDWARE DESCRIPTION

Voltage Feedback Circuit Boards

Voltage feedback boards are located in the converter cabinet on the far left side mounted on a vertical

glass polyester channel. The boards consist of series connected resistors for sensing input voltage, DC

link voltage, and output voltage.

Cooling Fans

There are several different arrangements of cooling fans. Fans are required to remove heat from the drive

to ensure proper operation of its components. The fans draw air into the drive through the vented lower

doors and exhaust it through vented enclosures at the top of the drive.

1557-UM050F-EN-P – June 2013

Page 17

DESCRIPTION OF OPERATION CHAPTER 5

Introduction ......................................................................................................................... 1

Speed Command ................................................................................................................ 3

Skip Speeds ........................................................................................................................ 5

Speed Ramp ....................................................................................................................... 7

Speed Control ..................................................................................................................... 9

Flux Control ....................................................................................................................... 11

Flux Control for Synchronous Motor .................................................................... 13

Current Control .................................................................................................................. 14

Line Converter Feedback .................................................................................................. 16

Machine Converter Feedback ........................................................................................... 18

Motor Model ...................................................................................................................... 20

Line Converter Protection ................................................................................................. 22

Machine Converter Protection .......................................................................................... 24

Analog Outputs ................................................................................................................. 26

Test Modes ....................................................................................................................... 28

Synchronous Transfer ....................................................................................................... 29

Transfer To Bypass ........................................................................................................... 30

Transfer To Drive .............................................................................................................. 31

Thyristor Diagnostics

Bulletin 1557 Drive ............................................................................................... 33

Bulletin 1557M Mini Drive .................................................................................... 35

Flying Start ................................................................................................................ 36

Tachometer/Encoder Option ............................................................................................. 37

1557-UM050F-EN-P –June 2013

Page 18

1557-UM050F-EN-P – June 2013

Page 19

DESCRIPTION OF OPERATION 5-1

Introduction

The Bulletin 1557 is an adjustable speed ac drive in which motor speed control is achieved through

control of the motor torque. The motor speed is measured and the torque is adjusted as required to make

the measured speed equal to the speed command. The stator frequency is determined by the motor and

load and the drive synchronizes itself to the motor. This is in contrast to the more common volts/hertz ac

drive in which the drive determines the stator frequency and does not attempt to synchronize its output to

the motor.

The method of control used is known as direct vector control. The term vector control indicates that the

position of the stator current vector is controlled relative to the motor flux vector. Direct vector control

means that the motor flux is measured, in contrast to the more common indirect vector control in which

the motor flux is predicted. In both cases, the stator current is resolved into flux producing and torque

producing components which are controlled independently. The intent is to achieve performance similar

to a dc machine, in which the torque can be changed quickly without affecting the flux. The flux cannot

be changed quickly because of the rotor time constant, which is in the range of seconds for large

machines.

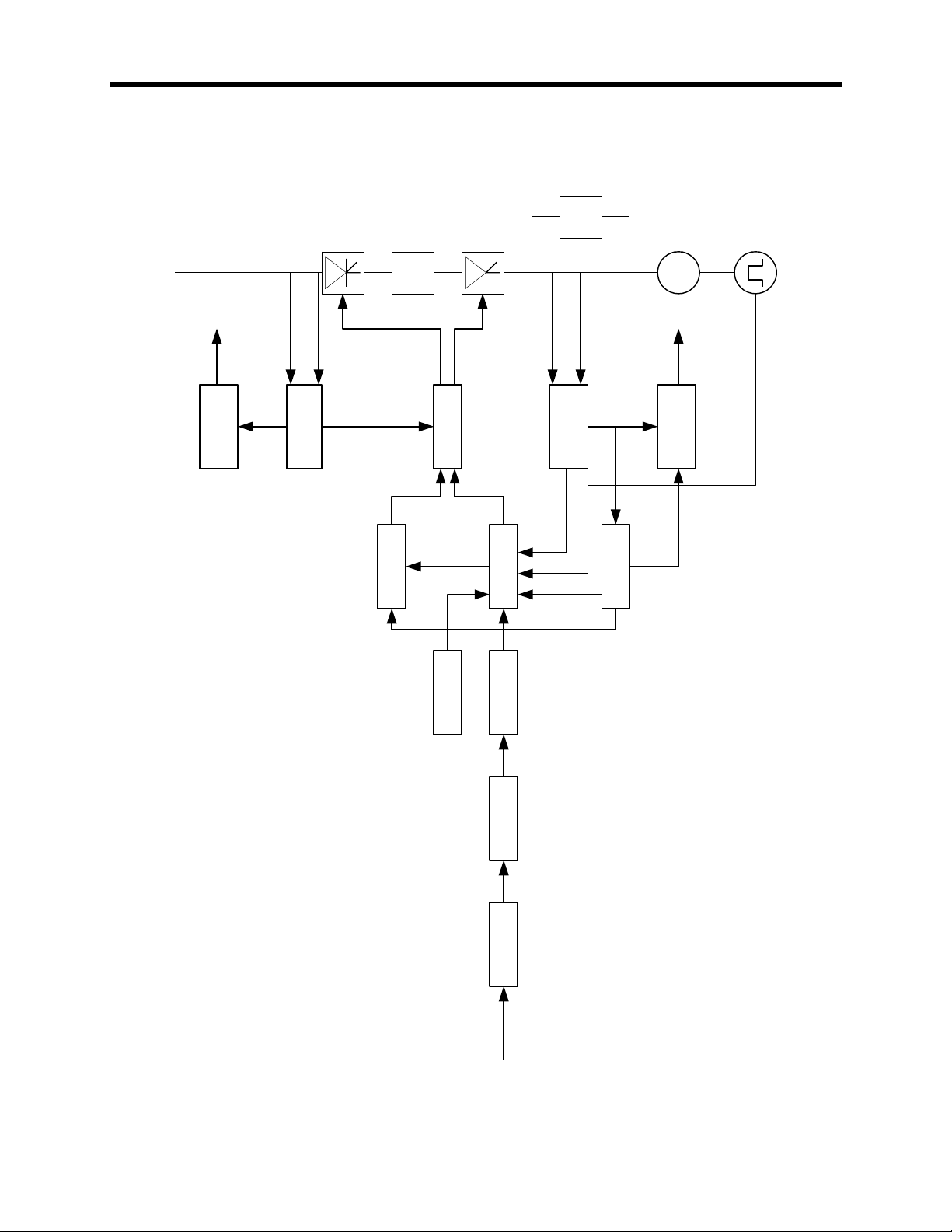

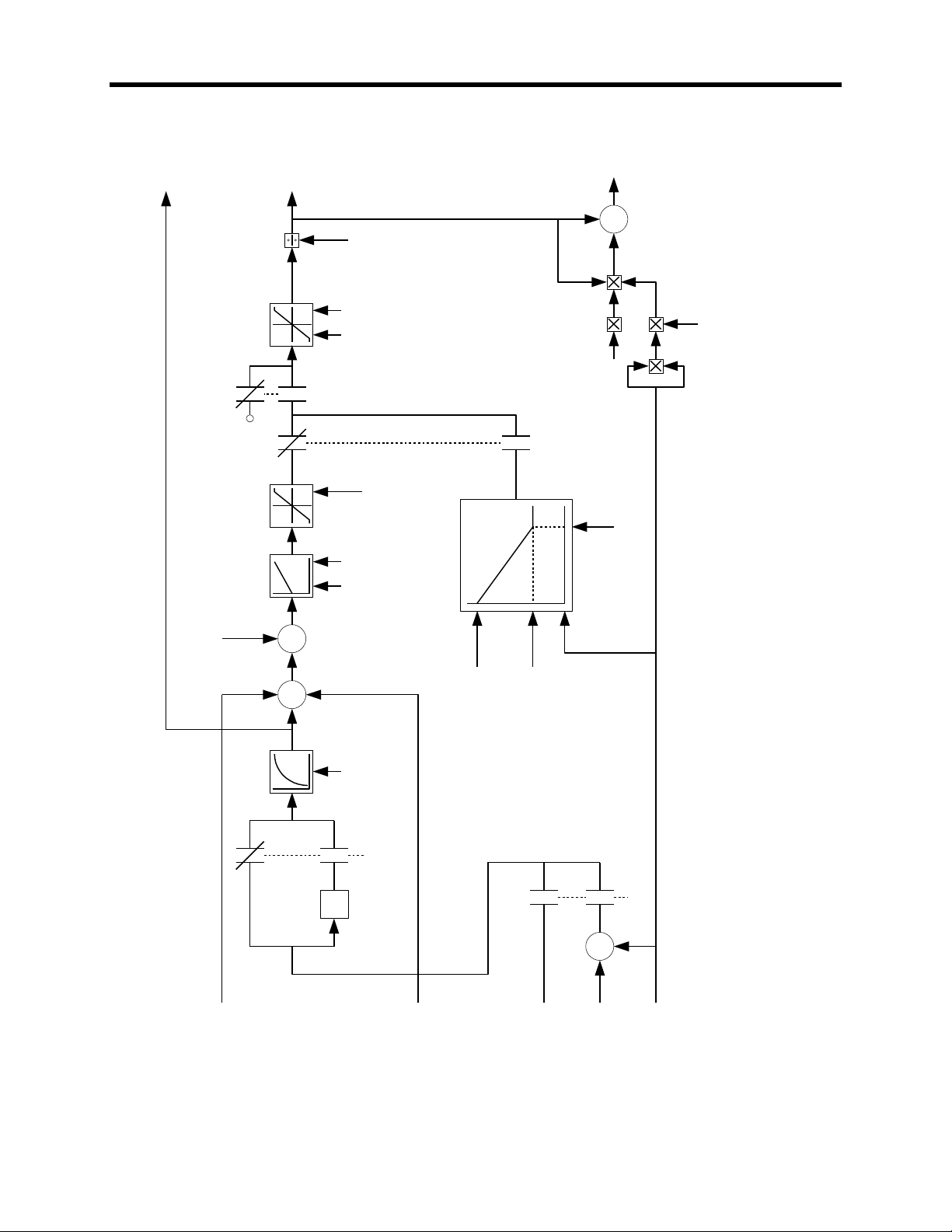

The following description of operation is organized in the same functional blocks as the control block

diagram (Figure 5.1). Most of the functions are the same as those found in any adjustable speed ac or dc

drive. The features which are unique to a direct vector controlled drive are confined to the motor model

and flux control functions.

The Bulletin 1557 drive can be used with either induction (asynchronous) or synchronous motors.

Synchronous motor drives are identical to induction motor drives except for the addition of a current

regulated field supply to the synchronous drive. The features that are unique to a synchronous drive are

confined to the flux control function and the encoder option.

1557-UM050F-EN-P –June 2013

Page 20

5-2 DESCRIPTION OF OPERATION

SPEED

COMMAND

SPEED

RAMP

SPEED

CONTROL

MOTOR

MODEL

LINE

CONVERTER

FEEDBACK

CURRENT

CONTROL

FLUX

CONTROL

SKIP

SPEEDS

LINE

CONVERTER

PROTECTION

MACHINE

CONVERTER

PROTECTION

MACHINE

CONVERTER

FEEDBACK

SYNCHRONOUS

TRANSFER

Flux

Feedback

Slip

Speed

Magnetizin

g Current

Command

Torque

Current

Comand

Stator

Frequency

Tach

Feedback

MOTOR

Faults

Voltage

Feedback

Current

Feedback

DC

Link

Motor Filter

Capacitor

Faults

Voltage

Feedback

Current

Feedback

Line

Converter

Machine

Converter

Line

Converter

Firing Angle

Machine

Converter

Firing Angle

(Pxxx) Indicates a read/write parameter with a linear number of xxx.

(Vxxx) Indicates a read only variable with a linear number of xxx.

Speed

Commands

Figure 5.1

1557-UM050F-EN-P – June 2013

Page 21

DESCRIPTION OF OPERATION 5-3

Speed Command

The function of the speed command block is to select one of 12 possible speed command inputs to serve

as the drive speed command. Bits 12-15 of the Logic Command are used to select the Speed Command

Input from the following list:

2 analog inputs (0-10V)

3 preset speed commands

6 SCANbus ports

1 preset jog speed command

The two analog speed command inputs accept 0-10V signals. The range of each of the analog inputs is

defined by two parameters. These parameters can be adjusted to cause the speed command to either

increase or decrease with an increasing analog input.

The six SCANport ports are multiplexed into a single SCANport input. The range of the digital input is

defined by two parameters in the same way as the analog inputs.

The selected speed command input is clamped to a minimum level set by parameter Speed Command

Minimum and a maximum level set by parameter Speed Command Maximum. (See Parameter and

Variable Description in Chapter 6.)

1557-UM050F-EN-P –June 2013

Page 22

5-4 DESCRIPTION OF OPERATION

0V 10V

A/D

Speed cmd 0 max (P42)

Speed cmd 0 min (P41)

Analog

input 1L

(V353)

Line

AI1

ANALOG SPEED

COMMAND INPUT

0V 10V

A/D

Speed cmd 8 max (P44)

Speed cmd 8 min (P43)

Analog

input 1M

(V355)

Machine

AI1

ANALOG SPEED

COMMAND INPUT

0 32767

Speed cmd 9 max (P46)

Speed cmd 9 min (P45)

DIGITAL SPEED

COMMAND INPUT

SCANport input (V398)

Speed command 0

(V273)

0000 (0)

Preset speed 1

(P33)

0001 (1)

Preset speed 2

(P34)

0010 (2)

Preset speed 3

(P35)

0011 (3)

Speed command 8

(V274)

1000 (8)

1001 (9)

1010 (10)

1011 (11)

1100 (12)

1101 (13)

1110 (14)

Preset jog speed

(P40)

1111 (15)

Speed Command in

(V276)

Speed command 9

(V275)

Speed cmd max

(P48)

Speed cmd min

(P47)

to skip speed

processing

Logic command bits 12 - 15 (spd cmd select)

(V258)

Speed Command

1557-UM050F-EN-P – June 2013

Page 23

DESCRIPTION OF OPERATION 5-5

Skip Speeds

Four skip speeds are provided which may be used to prevent the drive from continuously operating at

certain speeds, usually to avoid exciting mechanical resonance. Each of the four skip speed zones is

defined by two parameters that specify its center point and width. Skip speed zones that overlap are

merged.

After skip speed processing, the speed command input has its sign changed if reverse rotation is

selected, or is set to zero if there is no run request.

1557-UM050F-EN-P –June 2013

Page 24

5-6 DESCRIPTION OF OPERATION

Skip speed 1

(P49)

Skip speed 2

(P50)

Skip speed 4

(P52)

Skip speed 3

(P51)

Skip speed

band 1

(P53)

Skip speed

band 2

(P54)

Skip speed

band 3

(P55)

Skip speed

band 4

(P56)

from speed

command limit

-1

Speed command

(V277)

0

Logic status bit 1 (V258)

(Running)

Logic status bit 2 (V258)

(Forward command)

Skip Speeds

1557-UM050F-EN-P – June 2013

Page 25

DESCRIPTION OF OPERATION 5-7

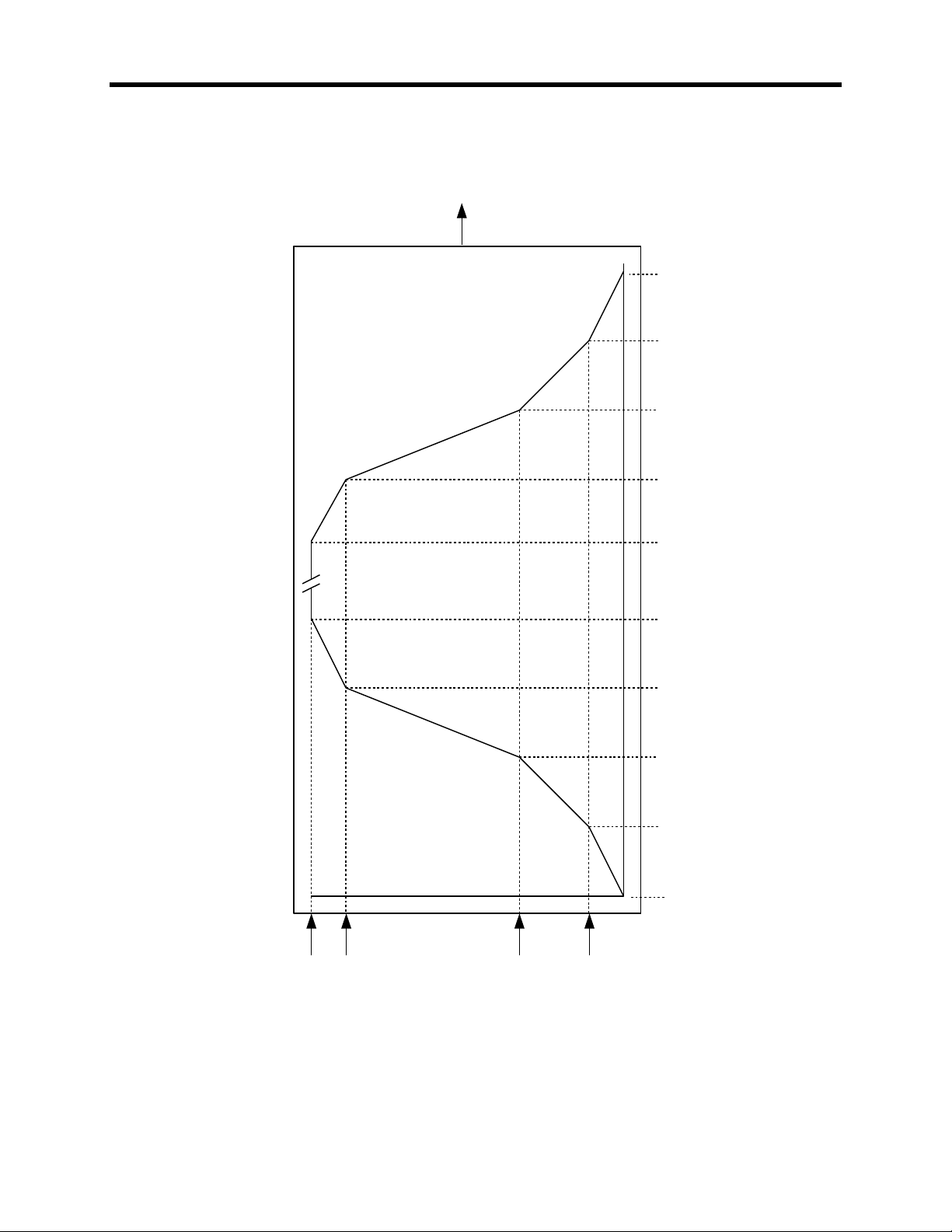

Speed Ramp

The function of the speed ramp is to control the rate of change of the drive speed reference. Independent

four section ramps are provided for acceleration and deceleration. Each ramp is defined by four speed

points which are specified by parameters Ramp Speed 1 to 4 which are the same for both accelerating

and decelerating, and four time intervals which are specified by parameters Acceleration Time 1 to 4 and

Deceleration Time 1 to 4. The input to the speed ramp is the speed command from the skip speed block.

The drive control selects the appropriate acceleration or deceleration rate based on the present value of

the ramp output and whether it is increasing or decreasing. The output of the speed ramp is the speed

reference, which is the input to the speed control block. If the motor is coasting and speed feedback is

available, the speed reference is set equal to the motor speed.

1557-UM050F-EN-P –June 2013

Page 26

5-8 DESCRIPTION OF OPERATION

Accel

time 1

(P65)

Accel

time 2

(P66)

Accel

time 3

(P67)

Accel

time 4

(P68)

Decel

time 4

(P65)

Decel

time 3

(P66)

Decel

time 2

(P67)

Decel

time 1

(P68)

Ramp speed 3

(P75)

Ramp speed 2

(P74)

Ramp speed 1

(P73)

Ramp speed 4

(P76)

Speed

Reference

(V278)

Speed Ramp

1557-UM050F-EN-P – June 2013

Page 27

DESCRIPTION OF OPERATION 5-9

Speed Control

The function of the speed control block is to determine the torque current command. The inputs are the

speed reference from the speed ramp, and the stator frequency and slip frequency from the motor model.

Either tach feedback is used, or the slip frequency is subtracted from the stator frequency to determine

the motor speed, which is then made negative if the motor is rotating in reverse. The result is filtered by

an adjustable second order low pass filter to obtain the drive speed feedback.

The speed feedback is subtracted from the speed reference to determine the speed error. Parameter

Speed Reference Step, which is used to demonstrate the step response of the speed loop, is added to

the speed error to form the input to the speed regulator. The response of the speed regulator is

determined by parameters Speed Regulator Bandwidth and Total Inertia. The rate of change of the

speed regulator output is limited to the value specified by parameter Torque Rate Limit. The output of the

speed regulator is clamped to the value specified by parameter Torque Limit Motoring for positive values

and to the value specified by parameter Torque Limit Braking for negative values. The clamped output of

the speed regulator is the torque reference. This is divided by the flux reference to determine Isq

Command, which is the torque component of the stator current command.

Without a tachometer, reliable speed feedback is not available at stator frequencies below about 5 Hz.

The speed regulator is therefore disabled at low speed and the torque reference is determined by open

loop programming. The torque reference changes linearly from the value specified by parameter Torque

Command 0 at zero speed to the value specified by parameter Torque Command 1 at Ramp Speed 1,

and remains constant above this speed if the drive is still in start mode. When tach feedback is enabled

the open loop torque programming is not used.

An estimate of the torque producing current supplied by the motor filter capacitor is calculated from Isq

Command, stator frequency, and parameters Total Leakage Inductance and Filter Capacitor. The

resulting value is called Icq Command and is subtracted from Isq Command to determine Iy Command,

which is the torque component of the dc link current command.

1557-UM050F-EN-P –June 2013

Page 28

5-10 DESCRIPTION OF OPERATION

Tach

feedback

(V348)

Slip

frequency

(V343)

Stator

frequency

(V337)

Speed Feedback Mode

(P89)

-

-1

Logic status bit 3 (V258)

(Forward rotation)

SPEED

FEEDBACK

FILTER

Speed fdbk filter

(P110)

Speed

reference

(V278)

from

sync

transfer

Sync spdref

SPEED

REGULATOR

RATE

LIMIT

TORQUE

LIMITING

Trq command 0

(P86)

Trq command 1

(P87)

Ramp speed 1

(P73)

Speed ref step (P88)

-

Speed

error

(V290)

Spdreg

bandwidth

(P81)

Total

Inertia

(P82)

Trq rate

limit (P83)

Start mode

STARTING TORQUE

PROGRAMMING

1

0

Trq limit

motoring

(P84)

Trq limit

braking

(P85)

Filter capacitor

(P133)

SPEED CONTROL

L Total

leakage

(P130)

Icq

command

(V293)

-

Flux

reference

(V305)

Logic Status Bit (V258)

(Running)

Speed

Feedback

(V289)

ISQ

Command

(V292)

IY

Command

(V294)

Torque

Reference

(V291)

Speed Control

1557-UM050F-EN-P – June 2013

Page 29

DESCRIPTION OF OPERATION 5-11

Flux Control

The function of the flux control block is to determine the magnetizing current command. The inputs are

flux feedback and stator frequency from the motor model, speed feedback from the speed control block,

and line voltage from the current control block.

Below base speed, the flux command varies linearly with Torque Reference from the value specified by

parameter Flux Command No Load at zero torque to the value specified by parameter Flux Command

Base Speed at rated torque. Above base speed, the drive goes into field weakening and the flux

command decreases with increasing speed. The flux command also decreases when the current

regulator approaches advance limit or retard limit.

The flux reference is determined by adding parameter Flux Reference Step, which is used to demonstrate

the step response of the flux regulator, to the flux command. The flux feedback is subtracted from the

flux reference to determine the flux error, which is the input to the flux regulator. The response of the flux

regulator is determined by parameters Flux Regulator Bandwidth, Magnetizing Inductance, and Rotor

Time Constant. The output of the flux regulator is called Isd Command 1. An open loop estimate of the

magnetizing current called Isd Command 0 is determined by dividing the flux reference by parameter

Magnetizing Inductance. Isd Command 0 and Isd Command 1 are added to produce Isd Command,

which is the magnetizing component of the stator current command.

An estimate of the magnetizing current supplied by the motor filter capacitor is calculated from Isd

Command, stator frequency, and parameters Total Leakage Inductance and Filter Capacitor. The

resulting value is called Icd Command and is subtracted from Isd Command to determine Ix Command,

which is the magnetizing component of the dc link current command. Ix Command becomes negative at

high speed because the motor filter capacitor supplies more magnetizing current than the motor requires.

1557-UM050F-EN-P –June 2013

Page 30

5-12 DESCRIPTION OF OPERATION

V line

(V324)

Speed feedback

(V289)

Base Speed

(P98)

Lm

Lm+2Ls'

Flx ref

step

(P102)

L magnetizing

(P131)

Isd command 0 (V308)

Isd

command 1

(V309)

Flux

reference

(V305)

Logic status

bit 1 (V258)

(Running)

Isd

command

(V310)

1.0

-1.0

0

-

Flx cmd

base spd

(P100)

Flx cmd

no load

(P103)

Torque

reference

(V291)

Flux

feedback

(V306)

FLUX COMMAND

PROGRAMMING

FLUX

LIMITING

Flux error

(V307)

FLUX

REGULATOR

Flxreg

bandwidth

(P97)

L magnetizing

(P131)

T rotor

(P132)

EXCITATION

CURRENT

LIMITING

L total

leakage

(P130)

Icd

command

(V311)

-

Ix

Command

(V312)

Filter

capacitor

(P133)

Flux Control

1557-UM050F-EN-P – June 2013

Page 31

DESCRIPTION OF OPERATION 5-13

-

Icd command

gain (P105)

Icd command

(V311)

Isd command

(V310)

If cmd bandwidth

(P104)

LOW PASS

L magnetizing

(p131)

Lmd

(P135)

Ix

command

(V312)

I field

command

(V314)

+++

+ -

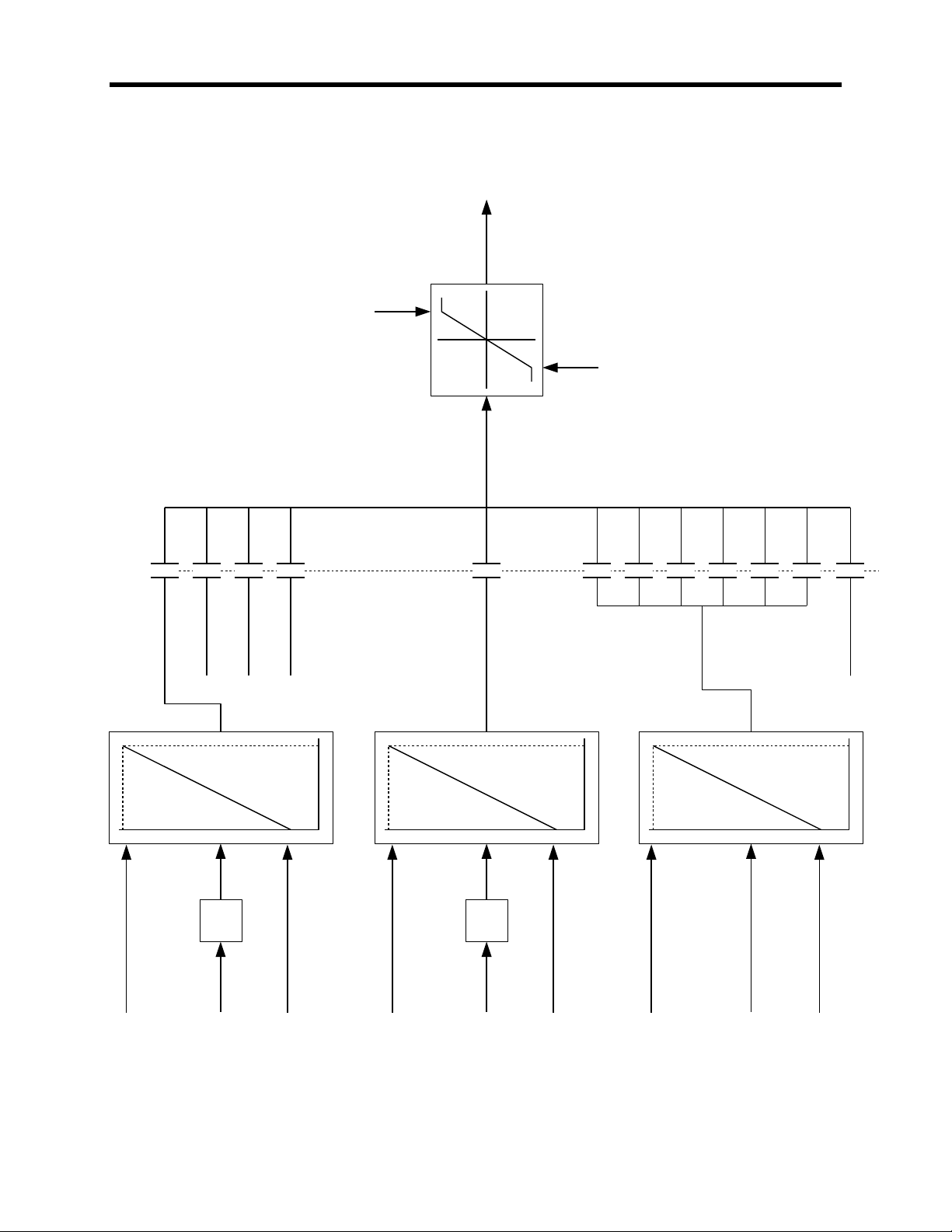

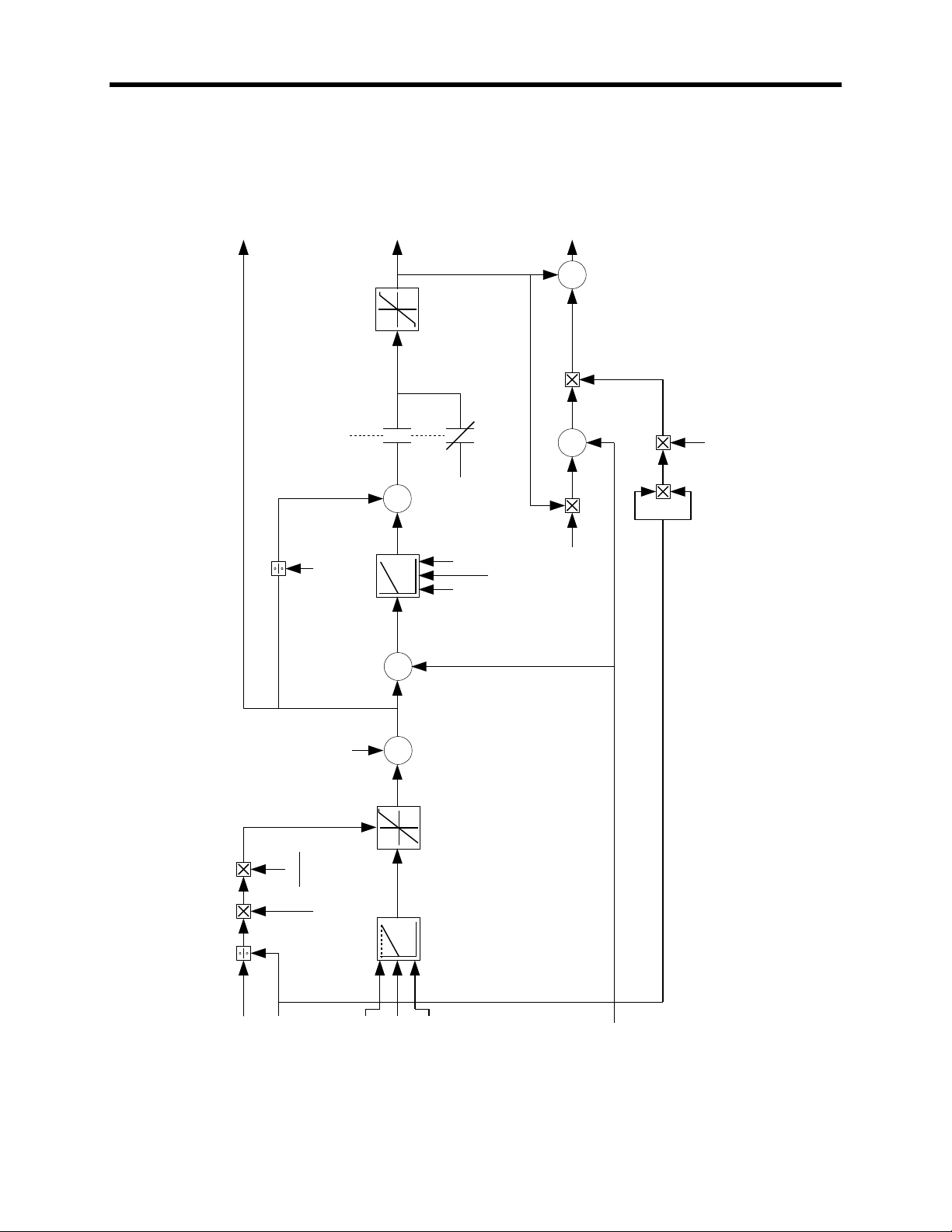

Flux Control for Synchronous Motor

Flux Control for Synchronous Motor

Most of the magnetization for a synchronous motor is supplied by the rotor field winding, unlike an

induction motor where all of the magnetizing current is supplied through the stator. However, control of

the motor flux through the field current is very slow because of the large time constant of the dc field

winding and the current and voltage limitations of the field supply. To obtain sufficiently fast response

from the flux regulator the magnetizing current is split into transient and steady state components, with

the steady state component supplied through the rotor and the transient component through the stator.

The additions to the flux control required for synchronous machines are shown in the block diagram

below. A low pass filter controlled by parameter If Cmd Bandwidth is used to extract the steady state

component of Isd Command which becomes I Field Command, the current reference for the field supply.

The transient component of Isd Command is obtained by subtracting I Field Command from the original

Isd Command and multiplying by the ratio of L magnetizing to Lmd to provide the same gain for the

steady state and transient components. The portion of the motor filter capacitor current supplied by the

drive is then added to determine Ix Command, which is the magnetizing component of the dc link current

command.

Parameter Icd Command Gain determines how the motor filter capacitor current is split between the

motor and the drive. When this parameter is set to its minimum value of 0.0, all the capacitor current is

supplied by the drive. The line current is higher than the motor current and the motor operates at

approximately unity power factor. When this parameter is set to its maximum value of 1.0, all the

capacitor current is supplied by the motor. The line current is less than the motor current and the motor

operates at a lagging power factor with reduced field current. Increasing Icd Command Gain improves

the input power factor of the drive, but also increases the coupling between flux and torque and causes

the stability of the flux control to deteriorate.

1557-UM050F-EN-P –June 2013

Page 32

5-14 DESCRIPTION OF OPERATION

Current Control

The function of the current control block is to determine the firing angles of the line and machine

converters. The inputs are the torque and flux producing components of the dc link current command

from the speed control and flux control blocks respectively, and the dc link current and line voltage from

the line converter feedback.

The square root of the sum of the squares of Ix Command and Iy Command is calculated to determine

the dc link current command. In dc current test mode, parameter DC Current Test Command is used as

the dc link current command. Parameter DC Current Reference Step, which is used to demonstrate the

step response of the current regulator, is added to the current command and the sum is clamped to a

minimum value of zero to produce the dc current reference. The dc current feedback is subtracted from

the dc current reference to determine the dc current error, which is the input to the current regulator. The

response of the current regulator is determined by parameters Current Regulator Bandwidth, DC Link

Inductance, and DC Link Time Constant. The output of the current regulator is clamped to a fixed

positive limit of 0.990 pu, and to a variable negative limit called the retard limit. Retard limit is calculated

from dc current feedback, line voltage feedback, and parameter Commutation Inductance, and its function

is to ensure reliable commutation of the line converter when regenerating. When the drive is not running,

the dc voltage reference is set equal to the retard limit to force the dc link current to zero as quickly as

possible.

The line converter firing angle is the inverse cosine of the dc voltage reference. The machine converter

firing angle is determined by taking the inverse cosine of the ratio of Ix Command to the dc current

command, adding 90 degrees and changing the sign.

1557-UM050F-EN-P – June 2013

Page 33

DESCRIPTION OF OPERATION 5-15

-1

X + Y

2

2

CURRENT

REGULATOR

Ix

(V312)Iy(V294)

Idc

Command

Test (P119)

Idc test mode

COS

-1

90 Degrees

Alpha

Machine

(V328)

Curreg

bandwidth

(P113)

Idc ref

step

(P120)

Idc

reference

(V321)

Idc

error

(V323)

T DC link

(P115)

L DC link

(P114)

I dc

feedback

(V322)

V line

(V324)

0.80 pu

-

L commutation

(P117)

0.99 pu

COS

-1

Alpha

Line

(V328)

V dc Reference

(326)

Logic Status Bit 1 (V255)

(Running)

Current Control

1557-UM050F-EN-P –June 2013

Page 34

5-16 DESCRIPTION OF OPERATION

Line Converter Feedback

The function of the line converter feedback block is to convert the raw voltage and current feedback

signals to the form required by the drive control software. It represents most of the analog portion of the

line side Drive Control Board. Since identical hardware is used for both converters, some functions are

not used on one or the other.

The two line converter voltage feedback boards provide a total of five voltage feedback signals

representing the three ac (V1, V2, V3) and two dc (VP, VN) line to ground voltages. The two dc voltages

are subtracted to determine the line side dc link voltage (VDC), which is used by the hardware dc link

overvoltage protection. The three ac voltages are summed to produce the neutral to ground voltage

(VNG) on the input transformer. This signal is not monitored by the drive control. The three ac line to

ground voltages are subtracted from each other to produce the three ac line to line voltages (V12, V23,

V31).

The first two line to line voltages are integrated and a signal which is the product of the corresponding

(fictitious) "delta" current and the commutating inductance is subtracted from each to compensate for the

commutation notches. The resulting reconstructed line voltages are called "flux" signals because the

corresponding signals on the machine side represent rotor flux. The third flux signal (F31) is produced by

inverting and adding the other two flux signals (F12, F23). The three flux signals are half-wave rectified

and added to produce the flux magnitude feedback (FLX), which is proportional to the volts/Hz of the

supply and is used as the input to an A/D converter which measures the line voltage magnitude. The flux

signals are also converted to three square waves that are combined and used to synchronize the line

converter firing to the line voltage.

Current feedback is provided by current transformers in two of the ac input lines. The current in the

remaining phase (I2) is reproduced by inverting and adding the other two current feedback signals (I1, I3).

The line current feedback signals are subtracted and rescaled to create the two fictitious delta currents

(I12, I23) used in the reconstruction of the input voltages described in the preceding paragraph. The

three line current feedback signals are also half-wave rectified and added to produce the dc link current

feedback (IDC), which is used as the input to an A/D converter and to the hardware overcurrent

protection.

The preceding description applies to 6-pulse and 12-pulse converters using the original Drive Control

Board 80165-018, which has no voltage feedback from the slave bridge. For 12- or 18-pulse converters

using the new 18-Pulse Drive Control Board 80190-118, there is voltage and current feedback from all

bridges, which is combined to create an equivalent 6-pulse feedback.

1557-UM050F-EN-P – June 2013

Page 35

DESCRIPTION OF OPERATION 5-17

V line

(V324)

Line

Frequency

D/AD/A

D/AD/A

A/D

F/D

A/D

-1

3

-1

3

VNG

INTEGRATORS

V12

V23

V31

VDC

V1

V2

V3

phase to

ground

voltages

phase

currents

VP

VN

-

-

-

-

-

I1

I2

I3

-

-

-

-

0

-

-

-

-

F12

F23

F31

FLX

I DC

Feedback

(V322)

I1

I2

I3

I DC

I12

I23

Hardware

Software

L commutation

(P117)

Line Converter Feedback

1557-UM050F-EN-P –June 2013

Page 36

5-18 DESCRIPTION OF OPERATION

Machine Converter Feedback

The function of the machine converter feedback block is to convert the raw voltage and current feedback

signals to the form required by the drive control software. It represents most of the analog portion of the

machine side Drive Control Board. Since identical hardware is used for both converters, some functions

are not used on one or the other.

The two machine converter voltage feedback boards provide a total of five voltage feedback signals

representing the three ac (V1, V2, V3) and two dc (VP, VN) line to ground voltages. The two dc voltages

are subtracted to determine the machine side dc link voltage (VDC), which is used by the hardware dc

link overvoltage protection. The three ac voltages are summed to determine the motor neutral to ground

voltage (VNG), which is used as the input to an A/D converter which measures this voltage for ground

fault protection purposes. The three ac line to ground voltages are subtracted from each other to produce

the three motor line to line voltages (V12, V23, V31).

A signal that is the product of the corresponding (fictitious) “delta” current and the stator resistance is

subtracted from the first two stator voltages to compensate for the stator resistance drop. These two

voltages are then integrated and a signal which is the product of the corresponding "delta" current and the

motor total leakage inductance is subtracted from each to produce the rotor flux signals. The third flux

signal (F31) is produced by inverting and adding the other two flux signals (F12, F23). The three flux

signals are half-wave rectified and added to produce the flux magnitude feedback (FLX), which is used as

the input to an A/D converter which measures the rotor flux magnitude. The flux signals are also

converted to three square waves that are combined and used to determine the stator frequency and to

synchronize the machine converter firing to the motor flux.

Stator current feedback is provided by current transducers (LEM's) in two of the motor phases. The

current in the remaining phase (I2) is reproduced by inverting and adding the other two current feedback

signals (I1, I3). The stator current feedback signals are subtracted and rescaled to create the two

fictitious delta currents (I12, I23) used in the reconstruction of the rotor flux described in the preceding

paragraph. A three phase to two phase conversion of the stator current feedback is performed by

designating phase 1 as the "alpha" phase, and inverting one of the delta current signals to provide the

"beta" phase which is in quadrature with the "alpha" phase. These two signals are used as the inputs to

A/D converters that measure the two components of stator current.

1557-UM050F-EN-P – June 2013

Page 37

DESCRIPTION OF OPERATION 5-19

D/AD/A

D/AD/A

A/D

F/D

A/D

-1

3

-1

3

VNG

INTEGRATORS

V12

V23

V31

VDC

V1

V2

V3

phase to

ground

voltages

phase

currents

VP

VN

-

-

-

-

-

I1

I2

I3

-

-

-

-

-

R stator (P129)

-

-

L total leakage

(P130)

-

-

F12

F23

F31

FLX

Flux from

voltage (V342)

Is alpha

I12

I23

Hardware

Software

A/D

A/D

Is beta

V neutral

motor

(V347)

- 1

Stator

Frequency

(V337)

Machine Converter Feedback

1557-UM050F-EN-P –June 2013

Page 38

5-20 DESCRIPTION OF OPERATION

Motor Model

The function of the motor model block is to calculate the motor current, voltage, flux, torque, power, and

slip frequency.

After the three phase to two phase conversion described in the machine converter feedback section, the

resulting stator current feedback signals (alpha and beta) are converted from analog to digital form. They

are then transformed from the stationary reference frame to the rotor flux reference frame that rotates at

stator frequency. This transformation produces two components of stator current which, ignoring

harmonics, are dc quantities in the steady state. The two components of stator current are the direct axis

current (Isd) in phase with the rotor flux, and the quadrature axis current (Isq) which is displaced 90

degrees from the rotor flux. The stator current magnitude is calculated by taking the square root of the

sum of the squares of the two components of stator current.

The two components of stator current are used along with parameters Rotor Time Constant and

Magnetizing Inductance to calculate the slip frequency and the rotor flux. Slip frequency is used in the

calculation of the motor speed. The rotor flux calculated from current is used in the low speed range on

drives fitted with a tachometer. The rotor flux determined from voltage and current that is described in the

machine converter feedback section is used in the high speed range and is not usable at very low

speeds. Without a tachometer, the flux feedback selection is permanently set to the flux feedback

derived from voltage and the flux feedback derived from current is not used. Therefore, there is no flux

feedback available below about 5 Hz and open loop control is employed as described in the speed control

and flux control sections.

The flux feedback is used along with the two components of stator current, the stator frequency, and

parameters Stator Resistance and Total Leakage Inductance to calculate the stator voltage. The motor

torque is calculated by multiplying the flux feedback by the q-axis current, which is then multiplied by the

speed to determine the motor power. Motor voltage, torque, and power are therefore all calculated rather

than measured quantities.

1557-UM050F-EN-P – June 2013

Page 39

DESCRIPTION OF OPERATION 5-21

Is alpha

Is beta

VECTOR

ROTATOR

STATOR

VOLTAGE

CALCULATION

Isq

(V339)

Isd

(V338)

Slip

frequency

(V343)

Flx from

current

(V341

T rotor

(P132)

L magnetizing

(P131)

ROTOR

FLUX

CALCULATION

FDBK

SELECT

X + Y

2

2

Stator

frequency

(V337)

Flx from

voltage

(V342

Speed

feedback

(V259)

Flux

feedback

R Stator

(P129)

L total leakage

(P130)

I stator

(V340)

V stator

(V344)

Flux feedback

(V306)

Torque

(V345)

Motor power

(V346)

Motor Model

1557-UM050F-EN-P –June 2013

Page 40

5-22 DESCRIPTION OF OPERATION

Line Converter Protection

Except for the dc link overcurrent and overvoltage detection, the line converter protection is implemented

entirely in software. Adjustable parameters specifying the trip level and time delay are provided for each

fault (see Chapter 6, Parameter and Variables Description). The dc link current and line voltage feedback

are obtained as described in the section on line converter feedback. The current feedback for ground

fault detection is obtained from a zero sequence current transformer installed in the drive input (only on

drives with AC line reactor). The voltage across the CT burden resistor is measured through a differential

analog input (AI2) on the line converter Drive Control Board.

For all faults except line converter overload, if the measured voltage or current exceeds the specified trip

level for the specified time interval, the corresponding fault bit is set in one of the fault words and the

master fault bit is set in Logic Status 1. For the detection of overload faults, the dc link current is first

converted to its ac equivalent by multiplying by 1.10 and then squared. The amount by which the square

of the current exceeds a threshold level is then integrated with time. An overload fault is declared if the

output of the integrator exceeds the trip level calculated from the specified overload trip level and time.

An overload warning is issued when the I2t level reaches half the trip level.

The response to a line converter fault falls into three categories, depending on the type of fault. For class

1 faults, such as line overcurrent, line overvoltage and undervoltage, and dc link overcurrent and

overvoltage, the line converter is immediately phased back to retard limit until the current drops to zero.

The gating is then disabled and the input and output contactors are opened. For class 2 faults, such as

ground fault and overload, the motor is brought to a normal stop before the drive is shut down and the

contactors opened. For class 3 faults (warnings), such as a pending overload, no action is taken.

The dc link overcurrent and overvoltage are special cases in that the fault detection is performed by

hardware but the time delay is performed by software. The detection of these two faults is implemented

in hardware because a very fast response is required. The hardware fault detection responds to

instantaneous values rather than average values as the software fault detection does. The response to

dc link overcurrent faults is different from all other faults because it freezes the GTO gating until the dc

link current has dropped to zero. This action is taken to prevent the GTO's from being destroyed by

attempting to commutate a current above their safe rating. Line converter current feedback is used for

this function instead of motor current feedback because the motor current includes the current supplied

by the filter capacitor, which does not flow through the GTO bridge.

1557-UM050F-EN-P – June 2013

Page 41

DESCRIPTION OF OPERATION 5-23

Line O/C trip

(P161)

Idc feedback

(V322)

TIME

DELAY

Line O/C

delay

(P162)

Line overcurrent

Fault Flags 1L bit 4

(V369)

V Line

(V324)

Line O/V trip

(P165)

TIME

DELAY

Line O/V

delay

(P166)

Line overvoltage

Fault Flags 1L bit 6

(V369)

TIME

DELAY

Line U/V delay

(P168)

Line Uvervoltage

Warning Flags

bit 2 (V373)

Line U/V trip

(P167)

DC O/C trip

(P169)

IDC

TIME

DELAY

DC O/C delay

(P170)

Line h/w o/c

Fault Flags 1L bit 5

(V369)

Line DC O/V trip

(P173)

VDC

TIME

DELAY

Line DC O/V delay

(P174)

Line dc overvoltage

Fault Flags 1L bit 7

(V369)

Gnd flt O/C

trip

(P171)

TIME

DELAY

Gnd flt O/C

delay

(P172)

Ground fault

Fault Flags 1L bit 9

(V371)

A/D

Analog input 2L

(V354)

Line

Converter

A12

TRIP

LEVEL

CALC

Idc feedback

(V322)

1.10

1.04 pu

-

Line O/L trip

(P163)

Line O/L delay

(P164)

0.5

Line overload

Fault flags 2 bit 0

(V371)

Line overload warning

Warning flags bit 0

(V373)

HARDWARE SOFTWARE

INTEGRATOR

Line Converter Protection

1557-UM050F-EN-P –June 2013

Page 42

5-24 DESCRIPTION OF OPERATION

Machine Converter Protection

Except for the hardware overcurrent and dc link overvoltage detection, the machine converter protection

is implemented entirely in software. Adjustable parameters specifying the trip level and time delay are

provided for each fault. The motor current and voltage feedback are obtained as described in the motor

model section. The motor speed feedback is derived by measuring the stator frequency and adding the

calculated slip frequency as described in the section on speed control.

For all faults except motor overload, if the measured voltage, current, or speed exceeds the specified trip

level for the specified time interval, the corresponding fault bit is set in one of the fault words and the

master fault bit is set in Logic Status. For the detection of overload faults, the amount by which the

square of the motor current exceeds a threshold level is integrated with time. An overload fault is

declared if the output of the integrator exceeds the trip level calculated from the specified overload trip

level and time. An overload warning is issued when the I2t level reaches half the trip level.

The response to a machine converter fault is exactly the same as the response to a line converter fault.

The hardware overcurrent and dc link overvoltage are special cases in that the fault detection is

performed by hardware but the time delay is performed by software. The detection of the dc link

overvoltage is implemented in hardware because a very fast response is required. The hardware fault

detection responds to instantaneous values rather than average values as the software fault detection

does. The hardware motor overcurrent detection is provided because it is required for dc link overcurrent

detection on the line converter, and both converters use identical Drive Control Boards.

1557-UM050F-EN-P – June 2013

Page 43

DESCRIPTION OF OPERATION 5-25

Motor O/C trip

(P177)

I stator

(V340)

TIME

DELAY

Motor O/C delay

(P178)

Motor overcurrent

Fault Flags 1M bit 4

(V370)

Motor O/V trip

(P181)

TIME

DELAY

Motor O/V delay

(P182)

Motor overvoltage

Fault Flags 1M bit 6

(V370)

V stator

(V344)

Motor O/C trip

(P177)

I DC

TIME

DELAY

Motor O/C delay

(P178)

Mtr h/w o/c

Fault Flags 1M bit 5

(V370)

DC O/V trip

(P187)

TIME

DELAY

DC O/V delay

(P188)

Mtr dc overvoltage

Fault Flags 1M bit 7

(V370)

V DC

Gnd flt O/V

trip

(P169)

TIME

DELAY

Gnd flt O/V

delay

(P190)

Neutral overvoltage

Fault flags 2 bit 5

(V371)

V neutral

motor

(V347)

Motor O/S

trip

(P165)

TIME

DELAY

Motor O/S

delay

(P156)

Mtr overspeed

Fault flags 2 bit 2

(V371)

Speed

feedback

(V259)

HARDWARE SOFTWARE

TRIP

LEVEL

CALC

1.04 pu

-

Motor O/L trip

(P179)

Motor O/L delay

(P180)

0.5

Motor overload

Fault flage 2 bit 1

(V371)

Motor overload waring

Warning flags bit 1

(V373)

INTEGRATOR

I stator

(V340)

Machine Converter Protection

1557-UM050F-EN-P –June 2013

Page 44

5-26 DESCRIPTION OF OPERATION

Analog Outputs

A total of twelve programmable analog outputs is provided, six on each of the two Drive Control boards.

The analog outputs are 8-bit, non-isolated, with a range of -10V to +10V. The arrangement of analog

outputs is different for the original Drive Control boards 80165-018 and the new 18-Pulse Drive Control

boards 80190-118. For the original boards, four of the six analog outputs on each board are intended for

diagnostic purposes and are available at test points for connection to an oscilloscope or chart recorder.

The remaining two analog outputs on each board are intended for connection to external devices such as

meters or isolation modules, and are available at the analog I/O connector on each board. With the new

18-pulse boards, the analog outputs are split equally between three diagnostic outputs and three external

outputs. The allocation of the analog outputs is shown below:

No. Output Control Board 80165-018 80190-118

1 Analog output 1L Line (lower) Test point AO1 Test point AO1

2 Analog output 2L Line (lower) Test point AO2 Test point AO2

3 Analog output 3L Line (lower) Test point AO3 Test point AO3

4 Analog output 4L Line (lower) Test point AO4 Connector J8

5 Analog output 1M Machine (upper) Test point AO1 Test point AO1

6 Analog output 2M Machine (upper) Test point AO2 Test point AO2

7 Analog output 3M Machine (upper) Test point AO3 Test point AO3

8 Analog output 4M Machine (upper) Test point AO4 Connector J8

9 Analog output 5L Line (lower) Connector J5 Connector J8

10 Analog output 6L Line (lower) Connector J5 Connector J8

11 Analog output 5M Machine (upper) Connector J5 Connector J8

12 Analog output 6M Machine (upper) Connector J5 Connector J8

Any parameter or variable can be assigned to any analog output, but it should be kept in mind that the

analog outputs on the two Drive Control Boards are serviced at different rates. The analog outputs on

each board are updated six times per cycle, which means that the line converter outputs are updated at a

fixed rate while the update rate for the machine converter varies with motor speed. The scaling of the

variables assigned to the analog outputs is given in the variable descriptions and cannot be changed.

However, the four or six external outputs are each provided with an adjustable offset and scale factor

which are applied after the predefined scaling to allow these outputs to be rescaled to suit the external

device they are driving.

1557-UM050F-EN-P – June 2013

Page 45

DESCRIPTION OF OPERATION 5-27

9.92V

-10.00V

analog

variable

1L

D/A

Line

Converter

AO1

9.92V

-10.00V

analog

variable

2L

D/A

Line

Converter

AO2

9.92V

-10.00V

D/A

Line

Converter

AO3

analog

variable

3L

9.92V

-10.00V

D/A

Line

Converter

AO4

analog

variable

4L

9.92V

-10.00V

analog

variable

1M

D/A

Machine

Converter

AO1

9.92V

-10.00V

analog

variable

2M

D/A

Machine

Converter

AO2

9.92V

-10.00V

D/A

Machine

Converter

AO3

analog

variable

3M

9.92V

-10.00V

D/A

Machine

Converter

AO4

analog

variable

4M

-10.00V

D/A

Line

Converter

AO5

analog

variable

5L

Analog

output

5L

(V357)

9.92V

Analog

offset 5L

(P193)

Analog

scale 5L

(P198)

-10.00V

D/A

Line

Converter

AO6

analog

variable

6L

Analog

output

6L

(V357)

9.92V

Analog

offset 6L

(P193)

Analog

scale 6L

(P198)

-10.00V

D/A

Line

Converter

AO5

analog

variable

5L

Analog

output

5L

(V357)

9.92V

Analog

offset 5L

(P193)

Analog

scale 5L

(P198)

-10.00V

D/A

Line

Converter

AO6

analog

variable

6L

Analog

output

6L

(V357)

9.92V

Analog

offset 6L

(P193)

Analog

scale 6L

(P198)

Analog Outputs

1557-UM050F-EN-P –June 2013

Page 46

5-28 DESCRIPTION OF OPERATION

CAUTION: Application of medium voltage to the drive input or output

when it is operating in gate test mode may cause severe damage to

the drive.

CAUTION: It is the responsibility of the operator to ensure that the

drive and motor are isolated from medium voltage when the drive is

operating in system test mode with the input, output, and bypass

contactors closed.

CAUTION: Open circuit test mode should not be used when the

drive is connected to a load unless an output contactor is provided.

Test Modes

The Bulletin 1557 drive is provided with five test modes that are selected by parameter Test Mode in the

Feature Select group. When Test Mode is set to the default value of zero, the drive is in the normal

operating mode. If the value of this parameter is changed when the drive is running, the change will not

take affect until the drive is stopped.

Setting Test Mode to 1 selects the gate test mode. This mode is used to check the thyristor gating with

the medium voltage off. The line converter gating is at the rated line frequency but is not synchronized

with the line voltage and has positive phase rotation only. The machine converter gating is the same as

in normal operation. The output frequency is determined by the speed reference. Both the input and

output contactors must be open and medium voltage must not be applied to the drive.

Setting Test Mode to 2 selects the dc current test mode. This mode is used to test the line converter and

to tune the current regulator and the line commutating impedance. In the dc current test mode, the line

converter operates normally but the machine converter gating is modified to gate both the positive and

negative legs in the same phase in order to short-circuit the dc link current through the machine

converter. The short circuit current is slowly rotated among the three phases with overlap between

phases to ensure that an open circuit does not occur during commutation. There is no current in the

motor and the output contactor must be open. The dc current command is set equal to the value

specified by parameter DC Current Test Command in the Current Control Parameters group.

Setting Test Mode to 3 selects the system test mode. This mode is used to test the drive as a system,

including interfaces with external devices such as programmable controllers, without applying power to

the drive or motor. The drive behaves as if it was running normally but all thyristor gating is inhibited.

Since the input, output, and bypass contactors operate normally in this mode, the drive cannot prevent

medium voltage being applied to the drive or motor and other measures must be taken to ensure that this

does not occur.

Setting Test Mode to 4 selects the open circuit test mode. This mode is used to test the drives at rated

output voltage and frequency without connecting it to a motor. In open circuit test mode, ac current

sufficient to produce rated voltage at the drive output is forced through the output filter capacitors. When the

drive is started in this mode, it ramps up to rated frequency and synchronizes its output voltage with the line

voltage. The current reference is set to a value that will produce approximately rated voltage at the drive

output. The output voltage can be changed by adjusting parameter Flux Command Base Speed.

1557-UM050F-EN-P – June 2013

Page 47

DESCRIPTION OF OPERATION 5-29

CAUTION: Since the programmable controller and not the drive

controls the output and bypass contactors, the transfer command

must always go via the PLC and never directly to the drive from

another controlling device (e.g. a Remote I/O adapter).

CAUTION: If the phase rotation and phase angle of the bypass

voltage compared to the drive input voltage are not correct, severe

damage may occur to the drive, motor, couplings, and driven

equipment if a transfer to bypass is attempted.

Synchronous Transfer

Synchronous transfer is an optional feature of the Bulletin 1557 ac drive which allows a motor to be

transferred between the drive and a fixed frequency supply in either direction without stopping and with a

very short interruption of power to the motor. Compared to a simple non-synchronous transfer in which

power to the motor is interrupted for a significant length of time, the transient drop in motor speed is much

less with synchronous transfer.

In order to perform a synchronous or non-synchronous transfer both a drive output contactor and a

bypass contactor are required. The name "bypass" indicates that the function of this contactor is to

connect the motor directly to the fixed frequency supply, bypassing the drive.

Synchronous transfer also requires the optional second discrete I/O board to produce the three inputs

and one output used for this function. The three inputs are the "bypass contactor closed" status input,

and the "transfer to bypass" and "transfer to drive" command inputs. The one output is "close bypass

contactor".

In most single motor and all multiple motor applications, a programmable controller is used for overall

control of the synchronous transfer operation. Because of the risk of damage to the motor and drive if the

bypass contactor is closed at the wrong time, close co-ordination is required between the drive and the

programmable controller for the successful execution of a synchronous transfer. In particular, when

transferring from drive to bypass, the time interval between the drive shutting off and the bypass contactor

closing must be accurately controlled. Typically, the PLC gives control of the bypass contactor to the

drive before performing the transfer, and takes back control after the transfer is completed.

Since the drive does not have any means of measuring the input voltage of the bypass contactor, the

drive input voltage is used as the phase reference for synchronization. Independent verification of the

phase rotation and phase angle of the bypass voltage relative to the drive input voltage is therefore

absolutely essential.

As a precaution, a synchronous transfer will not be performed if the phase sequence of the line voltage is

not positive.

1557-UM050F-EN-P –June 2013

Page 48

5-30 DESCRIPTION OF OPERATION

CAUTION: If parameter Synchronous Transfer Off Delay is set

incorrectly, damage may occur to the drive, motor, couplings, and

driven load if a transfer to bypass is attempted.

Transfer to Bypass

When the motor is running on the drive and a synchronous transfer to bypass is required, the transfer

takes place as described below:

1. Before a transfer to bypass is requested, the drive must be given control of the open bypass

contactor. Since the drive is running, it will already have control of the output contactor. The "transfer

to bypass", "transfer to drive", and "bypass contactor closed" inputs and the "close bypass contactor"

output must all be off at this time.

2. The drive is given a "transfer to bypass" command, which must remain active until the synchronous

transfer is complete. If the transfer command is removed before the bypass contactor is requested to

close, the drive will abort the transfer and return to normal running. When the drive receives the

transfer command, it accelerates the motor up to line frequency. If the drive is unable to achieve

synchronous speed, it may be necessary to increase parameter Torque Limit Motoring.

3. When the motor reaches synchronous speed, the synchronizing regulator is activated. The

synchronizing regulator adjusts the drive speed reference as required, to synchronize the motor to the

line with the motor voltage leading the line voltage by an angle specified by parameter Synchronous

Transfer Lead Angle. This parameter can be used to compensate for any phase difference between

the bypass voltage and the drive input voltage. The response of the synchronizing regulator is

controlled by parameter Synchronizing Regulator Gain. If the phase error tends to oscillate, it may be

necessary to adjust parameters Synchronizing Regulator Gain or Speed Regulator Bandwidth.

4. When the phase error between the motor voltage and line voltage has remained less than the value

specified by parameter Synchronizing Error Maximum for the time interval specified by parameter

Synchronizing Time, the drive activates its "close bypass contactor" output. If the drive is unable to

synchronize within the time specified by parameter Sync Transfer Time, the synchronous transfer is

aborted.

5. After a time delay specified by parameter Synchronous Transfer Off Delay, the drive shuts off. It is

very important that parameter Synchronous Transfer Off Delay is set to the correct value. This

should be slightly less than the contactor closing time. If this time delay is set too short the motor

voltage could drift out of phase with the bypass voltage during the time the motor is not under power,

producing a large current and torque transient when the bypass contactor closes, and possibly

causing protective equipment to operate. If the time delay is set too long, a drive overcurrent fault

may occur because the drive is unable to control its output voltage and frequency once the bypass

contactor has closed.

6. When the "bypass contactor closed" input indicates that the bypass contactor has closed, the drive

deactivates the "close output contactor" output. When the output contactor opens, the drive is

disconnected from the motor, leaving the output filter capacitors charged to line voltage. It may take

several minutes for the capacitors to discharge.

7. Control of the closed bypass contactor is taken away from the drive.

8. The "transfer to bypass" command is removed, causing the drive to deactivate its "close bypass

contactor" output. The synchronous transfer is now complete and the motor is running on bypass.

1557-UM050F-EN-P – June 2013

Page 49

DESCRIPTION OF OPERATION 5-31

Transfer to Drive

The drive must synchronize itself with the motor voltage while the motor is still running on bypass, in order

to perform the transfer to drive before the motor flux decays. The output contactor must therefore be

closed with the motor still connected to the line in order to pre-charge the output filter capacitors.

When the motor is running on bypass and a transfer to drive is required, the transfer takes place as

described below:

1. The drive is given a "transfer to drive" command. Initially, both the "close output contactor" and

"close bypass contactor" outputs will be off. When the drive receives the transfer command, it

activates its "close bypass contactor" output and runs its output frequency up to rated line frequency.

The programmable controller must wait for at least 2 seconds to allow the drive to ramp up to rated

frequency.

2. The drive is given control of the closed bypass and open output contactors.

3. The drive is given a normal start command, which causes it to activate its "close output contactor"

output.

4. After the "output contactor closed" input indicates that the output contactor has closed, there is a

short delay to allow the output filter capacitors to charge. The drive then deactivates its "close bypass

contactor" output.

5. When the "bypass contactor closed" input indicates that the bypass contactor has opened, the drive

goes to run mode. As the drive brings the motor torque up to the level required by the load, the motor

speed will drop slightly before returning to line frequency. A drop in speed is unavoidable because

the drive cannot know in advance what torque will be required.

6. The "transfer to drive" command is removed. The synchronous transfer is now complete and the

motor is running on the drive. The drive retains control of the output contactor for protection

purposes.

1557-UM050F-EN-P –June 2013

Page 50

5-32 DESCRIPTION OF OPERATION

TIME

DELAY

Slip

frequency

(V343)

Sync lead angle

(P226)

-

TIME

DELAY

Line flux

angle

Sync reg gain

(P225)

-3 Hz

3 Hz

SYNCXFER

REGULATOR

0

Syncxfer enabled

Sync spdref

to speed control

Shut off drive

close bypass

contactor

Sync off delay

(P227)

Sync time

(P229)

Sync error max

(P228)

Transfer to Drive

1557-UM050F-EN-P – June 2013

Page 51

DESCRIPTION OF OPERATION 5-33

Thyristor Diagnostics Bulletin 1557 Drive

The Bulletin 1557 ac drive tests for open or shorted thyristors both when it is started and continuously

while running. The method used to detect failed thyristors is different for starting and for running, but the

same hardware is used in both situations. The drive control receives a feedback signal via a fibre optic

cable from each thyristor gate driver that indicates whether the anode-cathode voltage of the thyristor is

high or low. A high voltage across a thyristor indicates that it is almost certainly not conducting. A low