Page 1

Medium Voltage

Drive Harmonic

Filter and Power

Factor Correction

Units

Bulletin 1519

2300 - 4160 volts

250 - 3500 hp

User Manual

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the Additional Resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Introduction Chapter 1

1519-IN050B-EN-P June 2013

Functional Description................................................................................ 1-1

Theory of Operation ................................................................................... 1-1

Application Considerations......................................................................... 1-2

Protective Features ..................................................................................... 1-3

Reactor Overtemperature.................................................................. 1-3

Reactor/Capacitor Overload ............................................................. 1-3

Short-Circuit Protection for Capacitors ............................................ 1-4

Blown Capacitor Fuse Detection ...................................................... 1-4

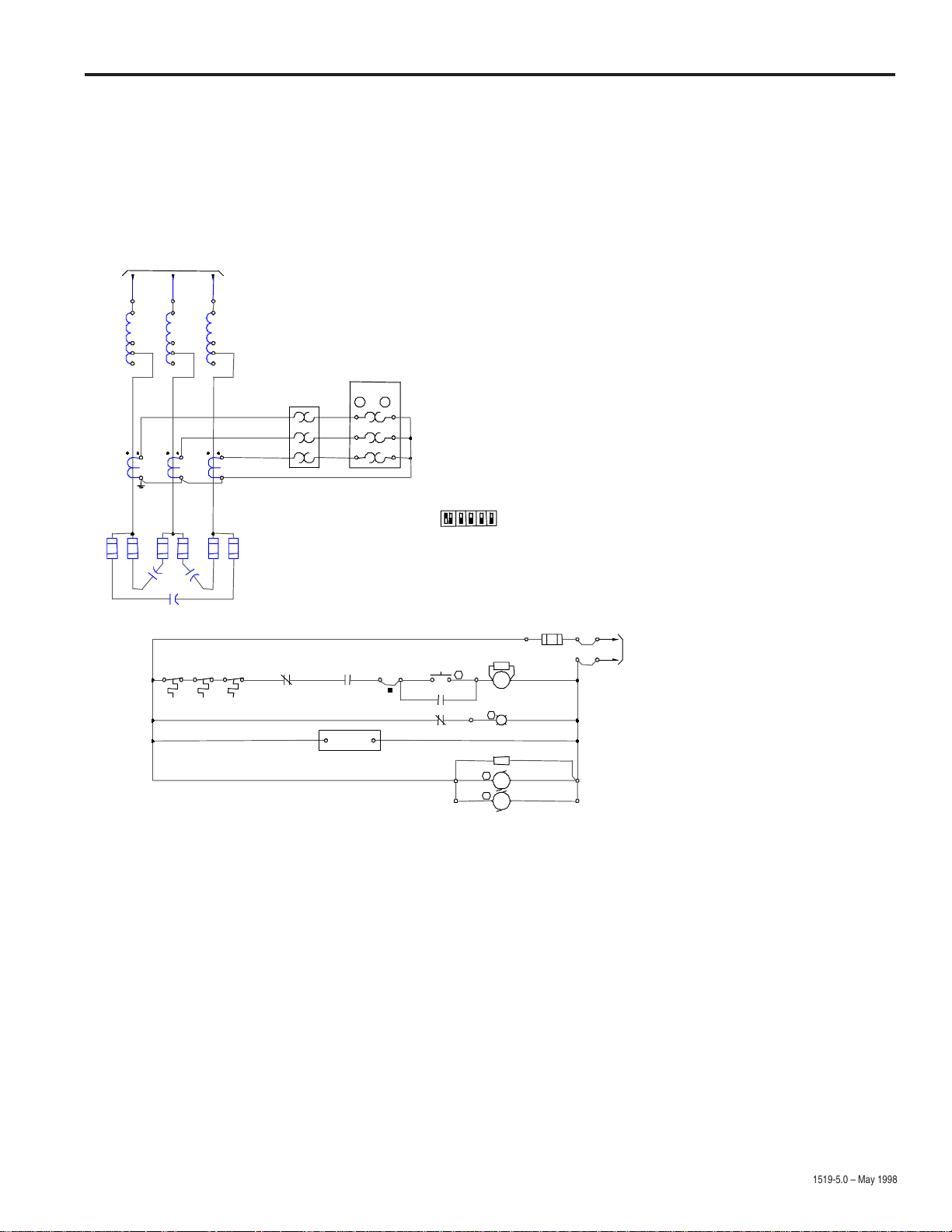

Schematic Diagrams

Typical Schematic • 5th Filter Fed from Drive Input Contactor

(Figure 1.1) .................................................................................. 1-5

Physical Layout and Chapter 2

Component Identification

Component I.D. and Functional Descriptions............................................. 2-1

Filter Reactor ................................................................................... 2-1

Filter Capacitor ................................................................................ 2-1

Current Transformer ........................................................................ 2-1

SMP-3 Overload Relay .................................................................... 2-1

592 Overload Relay ......................................................................... 2-2

Reset Relay/Pushbutton ................................................................... 2-2

Surge Suppressor ............................................................................. 2-2

Cooling Fans .................................................................................... 2-2

Strip Heater and Thermostat ............................................................ 2-2

Component Identification (Figure 2.1)....................................................... 2-3

Control Components (Figure 2.2).............................................................. 2-4

Overall Dimensions (Figure 2.3) ............................................................... 2-5

Table Of Contents

Performance Specifications Chapter 3

and Design Assumptions

Installation Chapter 4

Performance Specifications and Design Assumptions............................... 3-1

Handling .................................................................................................... 4-1

Power and Control Wiring......................................................................... 4-1

Routing ............................................................................................ 4-1

Cable Terminal Access .................................................................... 4-2

Ground Bus ...................................................................................... 4-2

Auxiliary Components ..................................................................... 4-2

Page 4

ii Table of Contents – Medium Voltage Drive Harmonic Filter and Power Factor Correction Units User Manual

Commissioning Chapter 5

Pre-start-up Inspection............................................................................... 5-1

Settings ...................................................................................................... 5-2

Annual Inspection Chapter 6

Physical Inspection .................................................................................... 6-1

Bolts ................................................................................................. 6-1

Structure .......................................................................................... 6-1

Cable ................................................................................................ 6-1

Components ..................................................................................... 6-2

Interlocks ......................................................................................... 6-2

Foreign Material .............................................................................. 6-2

Troubleshooting and Repair Chapter 7

Troubleshooting ......................................................................................... 7-1

Harmonic Filter Fault ...................................................................... 7-1

SMP-3 Relay ................................................................................... 7-1

592 Thermal Overload Relay........................................................... 7-2

Component Replacement Instructions........................................................ 7-2

Current Transformers ...................................................................... 7-2

Filter Reactors.................................................................................. 7-3

Cooling Fans .................................................................................... 7-3

Capacitors and Capacitor Fuses ...................................................... 7-3

Renewal Parts Chapter 8

Control Components .................................................................................. 8-1

Power Components .................................................................................... 8-2

Reactors (5th filter only – 6-pulse drives) • Table 8.B ..................... 8-2

Reactors (5th, 7th & 11th filters – 12-pulse drives) • Table 8.C......... 8-2

Current Transformers (5th filter only – 6-pulse drives)

• Table 8.D ................................................................................. 8-3

Current Transformers (5th, 7th & 11th filters – 12-pulse drives)

• Table 8.E .................................................................................. 8-3

Capacitors (5th filter only – 6-pulse drives) • Table 8.F................... 8-4

Capacitors (5th, 7th & 11th filters – 12-pulse drives) • Table 8.G ........ 8-4

Capacitor Fuses (5th filter only – 6-pulse drives) • Table 8.H ............ 8-5

Capacitor Fuses (5th, 7th & 11th filters – 12-pulse drives) • Table 8.J ... 8-5

)."%.0*UNE

Page 5

Chapter 1

1519-IN050B-EN-P June 2013

Introduction

Functional Description A harmonic filter consists of one or more tuned inductor/capacitor circuits. A

three-phase, iron core reactor is wired in series with three single-phase

individually fused capacitors. These harmonic filters are designed for use with

Bulletin 1557 Medium Voltage Drives.

There are two basic types of standard harmonic filters. Filter Type 1 consists

of an inductor/capacitor combination tuned to the 5th harmonic (5 times the

fundamental power system frequency) which is designed to reduce harmonics

and provide power factor correction when used in conjunction with a drive

with a 6-pulse rectifier. These Type 1 filters may also be used in conjunction

with drives that have 12-pulse rectifiers. When a 5th harmonic filter is applied

with a 12-pulse drive it will primarily provide power factor correction and may

provide some degree of harmonic reduction.

Type 2 harmonic filters consist of series inductor/capacitor combinations tuned

for approximately the 5th, 7th, and 11th harmonics and are designed specifically

for use with 12-pulse drives. Drives with 12-pulse rectifiers do not produce

significant amounts of 5th or 7th harmonic current, however, the 5th and 7

filters are designed to prevent a potentially detrimental resonance condition

from occurring. Type 2 filters provide harmonic reduction as well as power

factor correction.

Harmonic filters of Type 1 or Type 2 are designed to correct the power factor

to between 0.95 lagging and 0.95 leading over the 50-60% to 100% speed

range for a typical variable torque load.

A particular harmonic filter may or may not allow compliance with the

harmonic current limits specified in IEEE Std 519-1992 (IEEE Recommended

Practices and Requirements for Harmonic Control in Electrical Power

Systems). Calculations need to be carried out which take into account specific

power system data in order to assess compliance with IEEE 519 harmonic

limits for a particular drive application.

th

Theory of Operation Operating the rectifier of any drive will create harmonic currents that flow

back towards the power source and to other plant loads. These harmonics

result from the non-linearity of the rectifier, which draws a non-sinusoidal

current from a sinusoidal voltage source. The magnitude of the harmonic

currents generated by the rectifier is primarily related to the pulse number of

the rectifier.

1519-5.0 – May 1998

Page 6

1-2 Introduction

Theory of Operation (cont.) These harmonic currents can result in distortion of the voltage waveform. In

rare instances, excessive voltage distortion on the power system can have ill

effects on the system. These effects can include overheating of motors or

transformers, capacitor failure, misoperation of relays, computer system

disruption, and telephone system interference.

The purpose of a harmonic filter is to shunt certain harmonic currents that are

produced by the rectifier away from the power system. The result is a

reduction in distortion of the voltage waveform on the power system and a

reduction in the likelihood of harmonics affecting plant or utility system

components.

Application Considerations Switching with Drive Input Contactor versus Dedicated Harmonic Filter

Contactor

To simplify the system and reduce capital cost, a harmonic filter can be

switched using the same contactor or breaker that feeds the input power to the

associated drive. In this configuration, the harmonic filter is energized as long

as the drive input contactor is closed. The input contactor is usually configured

to close when the Emergency Stop string is completed. The contactor would

then stay closed regardless of whether the drive is running or stopped.

If the system is configured as described above, the user should consider

whether the leading kilovolt-ampere rating (kvar) provided by the filter when

the drive is not running (and thus not drawing any lagging kvar) result in an

acceptable system power factor. In this configuration it is necessary to shut

down the drive in the event of a harmonic filter fault condition since the drive

input contactor is the only means by which the filter can be taken off line. If a

harmonic filter fault were to occur and it was necessary to operate the drive

without the filter it would be necessary to physically disconnect and isolate

power cables from the harmonic filter while the drive system is shut off. It is

necessary to prevent reclosure of the drive input contactor within approximately

five minutes of opening to prevent energizing a harmonic filter capacitor

which may still have a DC charge on it.

Alternatively, a harmonic filter can be switched with a dedicated vacuum

contactor. In general, the vacuum contactor would be configured to energize

the filter when the associated drive receives a start command. The vacuum

contactor would be configured to de-energize the filter when the drive has

stopped. In this way the leading kvar from the filter is only present when the

drive is operating and power factor correction is required.

)."%.0*UNE

NOTE: Re-energization of the harmonic filter should be delayed until the

filter has had adequate time to discharge – typically 5 minutes.

Page 7

Introduction 1-3

1519-IN050B-EN-P June 2013

Application Considerations (cont.) In this scheme, energizing the filter can be a permissive to allow starting the

drive or the drive can be configured to operate independently of the harmonic

filter. Similarly, a harmonic filter fault can be configured to shut down the

drive or it can be configured to create an alarm only and allow the drive to

continue to operate. The isolation switch associated with the harmonic filter

contactor can be opened to allow servicing of the filter without necessarily

affecting operation of the associated drive.

Protective Features There are a number of protective features that are incorporated in each tuned

circuit of the harmonic filter to cover the following functions:

• reactor overtemperature

• reactor/capacitor overload

• short-circuit protection for capacitors

• blown capacitor fuse detection

Reactor Overtemperature

Reactor overtemperature is implemented in the form of a normally closed

thermal switch, one of which is embedded in each of the three windings of a

particular harmonic filter reactor. The thermal switches operate at a temperature

somewhat below the maximum allowable temperature for the reactor

insulation. The three switches are wired out individually to a terminal strip on

the top of the reactor where the switches are then connected in series. These

contacts are typically configured to open a dedicated harmonic filter contactor

and/or shut down an associated drive.

Reactor/Capacitor Overload

An Allen-Bradley Bulletin 592 Thermal Overload relay is driven by windowtype current transformers which are installed on each of the phases feeding

each set of three capacitors. The heater elements are factory selected to

protect the filter reactors and capacitors from an overload condition. If there is

one capacitor per phase in a particular harmonic filter then the heater elements

are selected on the basis of the root-mean-square (rms) current rating of the

reactor in the filter. This heater element sizing also allows protecting the

capacitors against overload. If there are two identical capacitors per phase in

the harmonic filter then the heater elements are chosen based on half of the

rms current rating of the associated reactor. A contact from the 592 overload

relay is wired to either open a dedicated harmonic filter contactor and/or shut

down the associated drive.

1519-5.0 – May 1998

Page 8

1-4 Introduction

Protective Features (cont.) Short-circuit Protection for Capacitors

Short-circuit protection for harmonic filter capacitors is addressed by

individual fusing of each capacitor. The intent of the capacitor fusing is to

clear a short-circuit-type fault condition on a failed capacitor. The fuses are

chosen to prevent a capacitor from rupturing. The fuses are not designed to

prevent the capacitor from failing. These fuses are generally chosen at 175%

to 200% of the capacitor rms current rating. The thermal overload described

above prevents operation of the fuse in the overload region.

Blown Capacitor Fuse Detection

Blown capacitor fuse detection is performed by an Allen-Bradley SMP-3 relay.

This relay is also fed by window-type current transformers which are used on

each phase for every capacitor. The phase loss function of this relay is used to

detect a blown capacitor fuse. If a capacitor fuse has blown then there will be

no current flow in that particular phase. It is undesirable for a harmonic filter

to continue to operate with a blown fuse on one or more capacitors since this

significantly alters the tuned frequency of the filter. A contact from the SMP-3

relay is wired to open a dedicated harmonic filter contactor and/or shut down

the associated drive. Note that the SMP-3 relay is not used as an overload relay

in this application since it is designed for a sinusoidal waveform. It determines

the rms value of a current waveform by repetitively sampling to find the peak

of the waveform. It then assumes that the rms current is the peak value divided

by the square root of two. This relationship between peak and rms current is

not correct when there is significant harmonic content in the waveform. For

this reason the DIP switches for overload protection are set substantially above

the current ratings of the filter components to prevent nuisance tripping due to

overload and allow phase loss detection to reliably take place.

)."%.0*UNE

Page 9

Introduction 1-5

1519-IN050B-EN-P June 2013

Schematic Diagrams Figure 1.1

Typical schematic • 5

FROM VFD INPUT CONTACTOR UNIT

2400V, 3, 60Hz

FT2FT1 FT3

0%

0%

95%

95%

100%

100%

105%

105%

CT1 CT2 CT3

C2 C3

C1

5th HARMONIC FILTER

REACTOR

THERMOSTATS

0%

REACTOR

95%

100%

105%

2

3

4

CAPACITO R FUSES

CAPACITO RS

59 2

OVE RL OA D

15 15A

SOLID STATE

PHASE LOSS RELAY

COMM

1A1

L1

2A

3A

L3L2T3

SMP-3592

(40)

(30)

SMP-3

60

50

SMP-3

REMOTE

RESET

T1

T2

15C15B

th

Filter fed from drive input contactor

SMP-3 SWITCH SETTINGS

AUTO

ON

TRIP

CLASS

FOR FLC SETTING

SEE DIMENSI O N DRAWING

FILTER RESET

5HFPR

5HFPR

13A

13A

OFF

GF

MAN

TESTJAM

SS

D

15D

16

D

SS

D

D

13A

5HFPR

5th FILTER

TRIPPED

FAN

55 0 CFM

FAN

55 0 CFM

13

D122

TO VFD CUSTO MER TERMINAL BLOCKS (DCTB)

14

ON VFD DRAWING SHT.4

D123

(CONTROL POWER FROM VFD INPUT CONTACTOR UNIT)

14

14

1519-5.0 – May 1998

Page 10

1-6 Introduction

1)."%.0*UNE

Page 11

Chapter 2

1519-IN050B-EN-P June 2013

Physical Layout and Component Identification

Component Identification Refer to Figures 2.1 and 2.2 to identify the functional components described in

and Functional Descriptions this section.

Note: For illustrative purposes, a 5

shown. In a 5th, 7th and 11th configuration, there will be two (2) cabinets as

shown with the 7th and 11th filter legs in the right-hand cabinet. Customer load

terminals and low voltage control components are always located in the 5

filter-leg cabinet (left-hand side).

th

harmonic filter with six (6) capacitors is

th

Filter Reactor

A three-phase, iron-core reactor with ±5% taps on the inductance is wired in

series with capacitors to create a specific tuned frequency for the filter. Each

winding has a normally closed thermal switch that opens when the temperature

reaches an excessive level.

Filter Capacitor

Single phase, individually fused capacitors are used in combination with a

reactor to tune the filter to a specific frequency. The capacitors also serve the

purpose of providing leading kvar to correct the power factor of the associated

drive.

Current Transformer

Window-type current transformers are used around the conductors feeding

each capacitor. The 5A CT secondary drives a 592 thermal overload relay and

an SMP-3 relay.

SMP-3 Overload Relay

Only the phase loss function of this relay is used to detect a blown fuse on a

capacitor. A blown fuse on a capacitor generally indicates that the associated

capacitor has failed in a short-circuit condition. The overload setting on this

relay is intentionally set high since the overload function is not used. The

SMP-3 relay is a manually reset device.

1519-5.0 – May 1998

Page 12

2-2 Physical Layout and Component Identification

Component Identification 592 Overload Relay and Functional Descriptions (cont.)

A Bulletin 592 thermal overload relay is used to prevent an excessive current

condition in the reactor and capacitors. This is a manually reset, eutectic alloytype device. The ratchet stud assembly is heated by current flowing through

the heater element. Relay operation occurs when the temperature of the ratchet

stud reaches the melting point of the eutectic alloy, freeing the ratchet wheel

and opening the normally closed contact.

Reset Relay/Pushbutton

The reset relay is used to latch in a fault that occurs on the harmonic filter.

The reactor thermal switches, 592 overload contact, and SMP-3 relay contact

for a filter leg are wired in series with the reset relay. When one of these

devices operates the reset relay latches open until the individual device(s) are

reset and the reset pushbutton associated with the reset relay is depressed.

Surge Suppressor

Acts to reduce voltage transients associated with de-energization of a reset

relay coil.

Cooling fan

Each cabinet has two continuously running cooling fans each with a 550 CFM

capacity. They are supplied either 110/120 V or 220 V depending on the

control voltage available. The fans are oriented to blow air out of the top,

forward-facing vent.

Strip Heater and Thermostat (Optional)

Strip heaters are located in each cabinet for preventing condensation which

may occur if the cabinet temperature is lower than the ambient temperature.

They are available for either a 110/120 V or 220 V separate source.

)."%.0*UNE

Page 13

Figure 2.1

1519-IN050B-EN-P June 2013

Component Identification

(top, side and bottom door removed)

Physical Layout and Component Identification 2-3

Current Transformers

Thermostat

Cooling Fans

Customer Terminals

Capacitor Fuses

Capacitors

Strip Heater

Assembly

Low Voltage Wire Duct

Reactor

1519-5.0 – May 1998

Page 14

2-4 Physical Layout and Component Identification

Figure 2.2

Control Components

Bul. 592 Overload Relays

Reset Relays

Shorting Blocks (Optional)

SMP-3 Overload Relays

Terminal Blocks

1)."%.0*UNE

Page 15

Note: Dimensions are in inches (mm).

1519-IN050B-EN-P June 2013

4.25 x 9 (108 x 229)

Power Cable Opening

3 x 6 (76 x 152)

Control Wire Opening

Figure 2.3

Overall Dimensions

10.4

(264)

30.1 (765)

Physical Layout and Component Identification 2-5

5.4 (137)

+

+

36 (914)

44 (1118)

Customer Terminals

3 x 3 (76 x 76)

Control Wire Opening

4.25 x 9 (108 x 229)

Power Cable Opening

4.6 (117)

25 (635)

15.5 (394)

2.3

(58)

39.4 (1001)

Anchor Holes

++

6.5

(165)

+

Holes

+

Anchor

23.7 (602)

+

9.3

(236)

4 (102)

5 (127)

6.5

(165)

56 (1422)

91 (2311)

16 (406)

19 (482)

12

(305)

1519-5.0 – May 1998

Page 16

2-6 Physical Layout and Component Identification

)."%.0*UNE

Page 17

Chapter 3

1519-IN050B-EN-P June 2013

Performance Specifications and

Design Assumptions

These harmonic filters are designed to limit rms currents to fall within the

reactor rms current ratings assuming that the associated drive is operated

within its ratings and other harmonic producing loads do not exceed the levels

listed below. In addition, filters are designed to allow the capacitors to operate

within their published voltage and current ratings as follows:

• rms capacitor voltage limit: 125% of nameplate voltage

• peak capacitor voltage limit: 135% of peak nameplate voltage

• rms capacitor current limit: 180% of rated 60 Hz current

For variable torque loads the reactors and capacitors have been selected on the

basis that other harmonic producing loads, up to 50% of the drive rating, may

exist on the user or utility power systems. For constant torque loads it is

assumed that there are no other significant harmonic producing loads.

If power factor correction capacitors are present on the plant or utility power

system, consideration should be given to resonant frequencies and potential

harmonic amplification that could occur.

These harmonic filters are NEMA type 1 construction rated for ambient

temperatures between 0 and 40°C (32 and 104°F). They are available with

110/120 V or 220 V control. Standard units are available to compliment the

following drive power ratings:

Power Factor

Harmonic Filter Correction Controller

• 6-pulse drives (5th filter only)

2400V 60 Hz – 200-1500 hp 2400V – 250-2500 hp

3300V 50 Hz – 200-1500 hp 3300V – 350-3000 hp

4160V 60 Hz – 200-1750 hp 4160V – 250-3500 hp

• 12-pulse drives (5th, 7th and 11th filters)

2400V 60 Hz – 500-2500 hp

3300V 50 Hz – 500-3000 hp

4160V 60 Hz – 500-3500 hp

See Chapter 8 (Renewal Parts) for specific horsepower breakdowns for each

voltage level.

1519-5.0 – May 1998

Page 18

3-2 Performance Specifications and Design Assumptions

1)."%.0*UNE

Page 19

Chapter 4

1519-IN050B-EN-P June 2013

Installation

ATTENTION: Installation of industrial control equipment

must only be performed by qualified personnel. Failure to do so

may result in damage to equipment, injury to personnel and/or

delays in commissioning the equipment.

Handling Please refer to the handling publication received with your shipment for details

regarding receiving, unpacking, initial inspection, handling, storage and

installation site preparation. These units are certified for seismic zone 4

conditions; however, this is only in effect if the unit is properly anchored with

½-in. anchor bolts to a concrete pad at floor level. Any other mounting situation

that requires seismic certification must be analyzed and approved separately.

Power and Control Wiring ATTENTION: Ensure main power has been disconnected and

locked out before starting the power and control wiring procedure.

Verify with a hot stick or meter that all circuits are voltage-free.

Failure to do so may result in electrical shock causing severe

burns, injury or death.

Routing

See Figure 2.3 for locations of access holes in the top and bottom of the cabinet

for incoming power cables and control wiring. Also shown is the location of

the customer power terminals. The customer terminals are always located in

the 5th filter cabinet (i.e. the left cabinet in a 5th, 7th and 11th configuration).

Cabling to the 7th and 11th filter legs is done internal to the cabinets. The

maximum recommended cable size entering the unit is (1) 500 or (2) 250 MCM

per phase at the factory. You must use ½-in. bolts for connecting the lugs to

the terminals. The bolts must be torqued to 48 ft-lb (65 N-m) for proper

contact pressure. Phase 1 is located closest to the front of the cabinet.

ATTENTION: Ensure bolts are tightened to specified torque.

Failure to correctly torque the bolts on the incoming cable lugs

may result in overheating of the connections and damage to the

equipment.

1519-5.0 – May 1998

Page 20

4-2 Installation

Power and Control Wiring Cable Terminal Access (cont.)

Cable terminals are accessible from the front of the unit with the medium

voltage doors open. If more working space is required for connecting

incoming cables, swing out the low voltage compartment by removing the top

medium voltage door and then removing the self-tapping screws which

connect the vertical channel to the structure. In order to remove the medium

voltage door, the control wires for the fans must be disconnected and

temporarily removed from the inside surface of the door. Remember to reinstall the self-tapping screws and the fan control wires.

ATTENTION: Replace all components and hardware as

shipped before re-energizing equipment. Failure to do so may

result in electrical shock, causing severe burns, injury or death.

Ground Bus

The ground bus is accessible through openings on either side at the rear of the

cabinet. It is the responsibility of the installer to ensure the filter unit is

properly grounded in accordance with the Canadian Electrical Code (CEC) or

the National Electrical Code (NEC) and any local codes.

ATTENTION: Ensure that the filter unit is properly grounded.

Failure to do so may result in electrical shock, causing severe

burns, injury or death.

Auxiliary Components

A low voltage (115 V or 230 V as specified) power supply is required for

auxiliary components. Terminal blocks are accessible when the low voltage

door is opened. Low voltage wiring may enter the cabinet through the

designated openings in the top or bottom of the cabinet (see Figure 2.3). When

entering through the bottom, use the wire duct provided to route wires into the

low voltage compartment.

)."%.0*UNE

Page 21

Chapter 5

1519-IN050B-EN-P June 2013

Commissioning

Pre-start-up Inspection ATTENTION: Ensure main power has been disconnected and

locked out before commissioning the unit. Verify with a hot

stick or meter that all circuits are voltage-free. Failure to do so

may result in electric shock causing severe burns, injury or death.

• Visually inspect all bolted power connections to ensure they are secure. Do

not apply a wrench to any connection unless it is obvious that the connection

has not been tightened (over torquing will cause damage to bolts as well as

components). If a bolt must be tightened, the following torques must be used:

¼-in. hardware 6 ft-lb (8 N-m)

5/16-in. hardware 12 ft-lb (16 N-m)

3/8-in. hardware 20 ft-lb (27 N-m)

½-in. hardware 48 ft-lb (65 N-m)

Important: If torquing a cable connection to the top of a capacitor fuse or

directly to a capacitor terminal, a reduced torque of 10 ft-lb (13.5 N-m) must

be used to avoid over-stressing the capacitor. In addition, if torquing

connection at the top of a capacitor fuse, hold the lower nut in place while

tightening the upper nut.

• Visually inspect all power wires and lugs for any signs of damage from

assembly or shipping. Contact Rockwell Automation immediately if any

damage is discovered (see page 1 for phone numbers).

• Check for proper functioning of all door interlocks (clip type and key-type).

They must prevent medium voltage doors from being opened if there is

power applied to the filter. Contact Rockwell Automation immediately if

any malfunction is discovered (see inside cover page for phone numbers).

ATTENTION: Ensure the mechanical interlocking

mechanisms are in place and functioning properly before

energizing the equipment. Improper interlocking could expose

personnel to energized components causing severe burns, injury

or death.

1519-5.0 – May 1998

Page 22

5-2 Commissioning

Pre-start-up Inspection (cont.) • For future reference, record component data on the table below:

Table 5.A

Component Specifications

Fifth Filter Seventh Filter Eleventh Filter

Capacitor kVAR (3) @ (3) @ (3) @

(3) @

Capacitor Farads (3) @ (3) @ (3) @

(3) @

Reactor Amps

Reactor mH

Reactor Tap Connection

CT Ratio (3) @ (3) @ (3) @

(3) @

O/L Elements

SMP-3 Setting (FLC)

Settings The SMP-3 relay(s) are factory set to allow detection of a blown capacitor fuse

(phase loss detection). No adjustment should be required on the SMP-3 relay(s).

The overload elements are factory selected and installed to provide proper

overload protection. No adjustment should be required on the heater elements.

The reactor(s) are factory set on the nominal inductance tap. The reactor(s)

have ±5% taps to allow increasing or decreasing the inductance and thus

changing the tuned frequency of the filter.

In general, Rockwell Automation should be consulted when considering a

change to a reactor tap setting, SMP-3 setting or 592 heater elements.

)."%.0*UNE

Page 23

Chapter 6

1519-IN050B-EN-P June 2013

Annual Inspection

ATTENTION: Ensure annual inspections are performed on the

unit. Failure to perform inspections may result in poor equipment

performance, possible damage and/or injury to personnel.

Physical Inspection On an annual basis, harmonic filter units should be physically inspected for

any signs of damage, component breakdown, misadjustment, stress (electrical,

mechanical or thermal) or foreign material. Specifically, check the following:

ATTENTION: Ensure main power has been disconnected and

locked out before starting the inspection. Verify with a hot stick

or meter that all circuits are voltage-free. Failure to do so may

result in electric shock causing severe burns, injury or death.

Bolts

Check tightness of all bolted power connections with a torque wrench. Set the

wrench to the nominal torque as specified on page 5-1 and apply the set torque

to the connection. Do not tighten beyond the set torque. For inspecting

connections to capacitor terminals, a reduced torque of 10 ft-lb (13.5 N-m)

must be used. Visually inspect all component mounting bolts and tighten any

which are obviously loose.

Structure

Check the cabinet and internal structure for any damage (dents, holes, etc.)

which could reduce electrical clearances or allow direct access to live parts

from outside the cabinet. Repair the damage or order replacement parts as

required.

Cable

Check for cut or worn insulation or damaged lugs due to electromechanical

stress or improper routing (cables will move when subjected to high current).

Replace any damaged cables and re-position any cables that may have moved

from their proper position. Make sure cables do not contact any sharp edges.

1519-5.0 – May 1998

Page 24

6-2 Annual Inspection

Physical Inspection (cont.) Components

Check all components for any signs of damage or overheating. Any

components displaying physical damage or severe discoloration should be

replaced (see Chapter 8). In particular, check the capacitors for ruptures and

make sure there is no leaking dielectric fluid.

Interlocks

Check for proper functioning of all door interlocks (clip type and key type).

They must prevent medium voltage doors from being opened if there is power

applied to the filter.

Foreign Material

Check for dust, dirt, iron filings etc. that may have entered the structure and

vacuum clean if necessary. In particular, check the cooling fans and vents to

make sure they are unobstructed.

)."%.0*UNE

Page 25

Chapter 7

1519-IN050B-EN-P June 2013

Troubleshooting and Repair

Troubleshooting Annunciation and action in the event of a harmonic filter fault will vary

depending on the particular drive/harmonic filter system. If the drive input

starter is used as the harmonic filter switching device, then a harmonic filter

fault will have the effect of creating an external fault described as “HF FAULT”

(for Harmonic Filter Fault) on the associated drive. Any fault on the drive

results in opening of the associated input starter, which de-energizes the filter.

This Harmonic Filter Fault will be annunciated on the Panelview operator

terminal under “ALARMS”.

Harmonic Filter Fault

The contacts for reactor overtemperature, SMP-3 blown capacitor fuse

detection, and Bulletin 592 thermal overload are generally wired in series and

any one of these conditions can create a Harmonic Filter Fault. If a Harmonic

Filter Fault occurs then the SMP-3 relay(s) and 592 overloads should be

checked to see if they are in the tripped condition. Both the SMP-3 and the

592 are manually reset relays.

SMP-3 Relay

If an SMP-3 relay has tripped this generally indicates that one or more

capacitors in the harmonic filter have failed in a short-circuit condition. Reset

the SMP-3 relay by pressing its reset push button. For your safety, wait five

minutes before accessing the capacitors to allow them to discharge. Verify

with a hot stick and meter that the capacitors are voltage-free.

The fuses mounted on top of each of the capacitors associated with the tripped

SMP-3 relay should be checked with an ohmmeter for continuity. If a very

high resistance is seen on one or more fuses, this indicates that the fuse has

blown. It is also likely that the associated capacitor has failed. To check a

capacitor an ohmmeter can be connected to the capacitor terminals. If a

gradual change in resistance is seen on the meter then the capacitor is good. If

a very low resistance and no gradual change in resistance is seen this indicates

that the capacitor has shorted internally and must be replaced.

1519-5.0 – May 1998

Page 26

7-2 Troubleshooting and Repair

Troubleshooting (cont.) 592 Thermal Overload Relay

If a 592 thermal overload relay has tripped this indicates that an excessive

current has occurred in the harmonic filter. An overload condition means that

the reactor and/or the capacitors in the filter have been subjected to a current

higher than they were designed for. Some investigation should be carried out

to determine why the overload occurred. An overload could occur if excessive

harmonic currents are present due to non-linear loads other than the drive it

was designed for. The heater element sizing should be confirmed with Rockwell

Automation to make sure that it coincides with the reactor current. Nuisance

tripping could result if the heater elements are undersized for the particular filter.

Component Replacement If any damaged components are discovered, check your customized parts list

Instructions or see Chapter 8 (Renewal Parts) to determine the appropriate replacement

part. See page 1 for parts supply contacts. Generally, all components are

easily accessible and simply require removal of cables and mounting hardware.

Make sure to label wire and cable terminations before disconnecting and

properly torque power connections when reassembling per page 5-1. The

following are some specific details to note regarding certain components:

ATTENTION: Damaged components must be replaced with

those bearing the same part number or equivalent. Failure to use

correct replacement parts, or to follow the specified replacement

guidelines, may result in equipment damage or poor equipment

performance.

ATTENTION: Ensure main power has been disconnected and

locked out before replacing any components. Verify with a hot

stick or meter that all circuits are voltage-free. Failure to do so

may result in electric shock causing severe burns, injury or death.

Current Transformers

The orientation is important for proper current sensing. Make sure the

replaced unit is physically oriented the same way as the others in the grouping

as indicated by the position of the control wire terminals. You will need to

disconnect the power cable associated with the particular current transformer at

one end as well as the control wires from the Bul. 592 overload relay in order

to remove the unit being replaced.

)."%.0*UNE

Page 27

Troubleshooting and Repair 7-3

1519-IN050B-EN-P June 2013

Component Replacement

Instructions (cont.)

Filter Reactors

The mounting provision for the reactors is variable in the left-to-right direction.

There are sliding nuts under the mounting slots that may move while the

reactor is being removed. When the new reactor is placed in position, simply

slide the nuts into position with a screwdriver and reinstall the mounting bolts.

Make sure there is a minimum of 3 in. of clearance between reactors and

between any reactor and the cabinet. There are lifting channels on top of each

reactor suitable for forklifts that will accommodate a single fork for smaller

reactors and two forks for larger reactors. Make sure the capacity of the

forklift is sufficient before lifting reactors (the reactor weight is specified on

the nameplate).

Cooling Fans

When replacing cooling fans, make sure they are oriented in the proper

direction. The airflow direction is indicated by an arrow on the outside surface

of the fan housing and should be pointing outward (out through the door).

Also, make sure the leads are not reversed as this will reverse the fan rotation.

Capacitors and Capacitor Fuses

Before beginning any disassembly to replace capacitors, take note of the

jumper configuration and cable termination locations (i.e. wye or delta

configuration). When torquing connections on a capacitor terminal or on the

top of a fuse, remember to use only 10 ft-lb (13.5 N-m).

1519-5.0 – May 1998

Page 28

7-4 Troubleshooting and Repair

1)."%.0*UNE

Page 29

Chapter 8

1519-IN050B-EN-P June 2013

Renewal Parts

Control Components The following control components are common to all variations of Harmonic

Filters regardless of power ratings and options. Select the appropriate part

number based on your control voltage. A customized, detailed parts list was

shipped with your unit and should be used as a primary reference.

Table 8.A

Control Components

Part Number

Description

Cooling Fan 22610-101-02 22610-101-03 2 4

Strip Heater Assy. 80160-695-52 80160-695-53 1 2

Thermostat Assy. 80160-696-51 80160-696-51 1 2

SMP-3 O/L Relay 193-C1F1 193-C1F1 1 or 2

Relay Adapter 193-BPM4 193-BPM4 1 or 2

Bul. 592 O/L Relay 592-BOV16 592-BOV16 1 or 2

Reset Relay 700-F220A1 700-F220A2 1 or 2

Reset Relay Contact

Adder

Surge Suppressor 199-FSMA1 199-FSMA2 1 or 2

Reset Button Assy. 800T-A2D1 800T-A2D1 1 1

Reset Button Contact

Block

1 required for each set of 3 capacitors (some 5

u

115 V 50 Hz or

120 V 60 Hz

Control

195-FA20 195-FA20 1 or 2

800T-XD1 800T-XD1 Not required 2

th

only filters have 6 capacitors)

220 V 50 Hz

Control

Qty. per 5th filter

u

u

u

u

u

u

Qty. per 5

th

& 11th filter

3

3

3

3

3

3

, 7

th

1519-5.0 – May 1998

Page 30

8-2 Renewal Parts

Power Components The following power components must be chosen specifically for the voltage

and horsepower ratings of the unit. A customized, detailed parts list was

shipped with the unit and should be used as a primary reference.

)."%.0*UNE

Table 8.B

th

Reactors (5

filter only – 6-pulse drives)

or (Power Factor Correction – 6 or 12-pulse drives

(1 required per unit)

Voltage

2400 V

60 Hz

3300 V

50 Hz

4160 V

60 Hz

Maximum

Horsepower

225 X X 80022-428-01

450 X X 80022-428-02

600 X X 80022-428-03

800 X X 80022-428-04

1250 X X 80022-428-05

1500 X X

1750 X

2250 X 80022-428-07

2500 X 80022-428-08

350 X X 80022-429-01

500 X X 80022-429-02

700 X X 80022-429-03

1000 X X 80022-429-04

1250 X X 80022-429-05

1500 X X

1750 X

2500 X 80022-429-08

3000 X 80022-429-09

225 X X 80022-430-01

450 X X 80022-430-02

600 X X 80022-430-03

900 X X 80022-430-04

1250 X X 80022-430-05

1750 X X 80022-430-06

2250 X 80022-430-07

2750 X 80022-430-08

3500 X 80022-430-10

6-pulse 12-pulse Part Number

Table 8.C

Voltage

2400 V

60 Hz

3300 V

50 Hz

4160 V

60 Hz

th

, 7th & 11th filters – 12-pulse drives)

Maximum

Horsepower

900 80022-431-01 80022-434-01 80022-437-01

1000 80022-431-02 80022-434-01 80022-437-02

1750 80022-431-02 80022-434-02 80022-437-02

2000 80022-431-03 80022-434-02 80022-437-03

2500 80022-431-03 80022-434-03 80022-437-03

900 80022-432-01 80022-435-01 80022-438-01

1750 80022-432-02 80022-435-02 80022-438-02

2500 80022-432-03 80022-435-03 80022-438-03

3000 80022-432-04 80022-435-04 80022-438-04

900 80022-433-01 80022-436-01 80022-439-01

1000 80022-433-02 80022-436-01 80022-439-02

1750 80022-433-02 80022-436-02 80022-439-02

2000 80022-433-03 80022-436-02 80022-439-03

2750 80022-433-03 80022-436-03 80022-439-03

3000 80022-433-04 80022-436-03 80022-439-04

3500 80022-433-04 80022-436-04 80022-439-04

Part Numb e r

th

Filter

5

Reactors (5

(1 of each requi red per unit)

Part Numb e r

7th Filter

80022-428-06

80022-429-06

Part Numb e r

11th Filter

Page 31

Renewal Parts 8-3

1519-IN050B-EN-P June 2013

Power Components (cont.)

Table 8.D

th

Current Transformers (5

filter only – 6-pulse drives)

or (Power Factor Correction – 6 or 12-pulse drives)

(3 required per unit unles s not ed oth erwis e)

Voltage

2400 V

60 Hz

3300 V

50 Hz

4160 V

60 Hz

Maximum

Horsepower

6-pulse 12-pulse Part Number

225 X X 80025-046-01

450 X X 80025-046-01

600 X X 80025-046-01

800 X X 80025-046-02

1250 X X 80025-046-03

1500 X X

1750 X

2250 X

2500 X 80025-046-03 (6)

350 X X 80025-046-01

500 X X 80025-046-01

700 X X 80025-046-01

1000 X X 80025-046-02

1250 X X 80025-046-02

1500 X X

1750 X

2500 X 80025-046-02 (6)

3000 X 80025-046-02 (6)

225 X X 80025-046-01

450 X X 80025-046-01

600 X X 80025-046-01

900 X X 80025-046-01

1250 X X 80025-046-02

1750 X X 80025-046-02

2250 X

2750 X 80025-046-02 (6)

3500 X 80025-046-02 (6)

80025-046-05

80025-046-03 (3)

80025-046-02 (3)

80025-046-02 (3)

80025-046-01 (3)

80025-046-02 (3)

80025-046-01 (3)

Table 8.E

Current Transformers (5

(3 of each requi red per unit)

Voltage

2400 V

60 Hz

3300 V

50 Hz

4160 V

60 Hz

Maximum

Horsepower

1000 80025-046-01 80025-046-01 80025-046-02

1750 80025-046-01 80025-046-01 80025-046-02

2000 80025-046-01 80025-046-01 80025-046-03

2500 80025-046-01 80025-046-01 80025-046-03

1750 80025-046-01 80025-046-01 80025-046-01

2500 80025-046-01 80025-046-01 80025-046-02

3000 80025-046-01 80025-046-01 80025-046-02

1000 80025-046-01 80025-046-01 80025-046-01

1750 80025-046-01 80025-046-01 80025-046-01

2000 80025-046-01 80025-046-01 80025-046-02

2750 80025-046-01 80025-046-01 80025-046-02

3000 80025-046-01 80025-046-01 80025-046-02

3500 80025-046-01 80025-046-01 80025-046-02

th

, 7th & 11th filters – 12-pulse drives)

Part Numb e r

th

Filter

5

Part Numb e r

7th Filter

Part Numb e r

11th Filter

900 80025-046-01 80025-046-01 80025-046-01

900 80025-046-01 80025-046-01 80025-046-01

900 80025-046-01 80025-046-01 80025-046-01

1519-5.0 – May 1998

Page 32

8-4 Renewal Parts

Power Components (cont.)

Table 8.F

Capacitors (5

or (Power Factor Correction – 6 or 12-pulse drives)

(3 required per unit unless noted othe rwi s e)

th

filter only – 6-pulse drives)

Volta g e

2400 V

60 Hz

3300 V

50 Hz

4160 V

60 Hz

Maximum

Horsepower

225 X X 80025-927-02

450 X X 80025-957-02

600 X X 80025-926-02

800 X X 80025-958-02

1250 X X 80025-959-02

1500 X X

1750 X

2250 X

2500 X 80025-959-02 (6)

350 X X 80025-957-01

500 X X 80025-926-01

700 X X 80025-958-01

1000 X X 80025-959-01

1250 X X 80025-960-01

1500 X X

1750 X

2500 X

3000 X 80025-960-01 (6)

225 X X 80025-927-02

450 X X 80025-957-02

600 X X 80025-926-02

900 X X 80025-958-02

1250 X X 80025-959-02

1750 X X 80025-960-02

2250 X

2750 X 80025-959-02 (6)

3500 X 80025-960-02 (6)

6-pulse 12-pulse Part Number

80025-960-02

80025-959-02 (3)

80025-958-02 (3)

80025-959-01 (3)

80025-958-01 (3)

80025-960-01 (3)

80025-959-01 (3)

80025-959-02 (3)

80025-958-02 (3)

)."%.0*UNE

Table 8.G

th

Capac itors (5

(3 of each requi red per unit)

Voltage

2400 V

60 Hz

3300 V

50 Hz

4160 V

60 Hz

, 7th & 11th filters – 12-pulse drives)

Maximum

Horsepower

Part Numb e r

th

Filter

5

Part Numb e r

7th Filter

Part Numb e r

11th Filter

900 80025-927-02 80025-927-02 80025-957-02

1000 80025-957-02 80025-927-02 80025-958-02

1750 80025-957-02 80025-957-02 80025-958-02

2000 80025-926-02 80025-957-02 80025-959-02

2500 80025-926-02 80025-926-02 80025-959-02

900 80025-927-01 80025-927-01 80025-957-01

1750 80025-957-01 80025-957-01 80025-958-01

2500 80025-926-01 80025-926-01 80025-959-01

3000 80025-958-01 80025-958-01 80025-960-01

900 80025-927-02 80025-927-02 80025-957-02

1000 80025-957-02 80025-927-02 80025-958-02

1750 80025-957-02 80025-957-02 80025-958-02

2000 80025-926-02 80025-957-02 80025-959-02

2750 80025-926-02 80025-926-02 80025-959-02

3000 80025-958-02 80025-926-02 80025-960-02

3500 80025-958-02 80025-958-02 80025-960-02

Page 33

Renewal Parts 8-5

1519-IN050B-EN-P June 2013

Power Components (cont.)

Table 8.H

th

Capacitor Fuses (5

filter only – 6-pulse drives)

or (Power Factor Correction – 6 or 12-pulse drives)

(Quantities as noted)

Voltage

2400 V

60 Hz

3300 V

50 Hz

4160 V

60 Hz

Maximum

Horsepower

6-pulse 12-pulse Part Number

225 X X 80025-834-01 (6)

450 X X 80025-834-02 (6)

600 X X 80025-834-02 (6)

800 X X 80025-834-03 (6)

1250 X X 80025-834-04 (6)

1500 X X

1750 X

2250 X

2500 x 80025-834-04 (12)

350 X X 80025-834-02 (3)

500 X X 80025-834-03 (3)

700 X X 80025-834-03 (3)

1000 X X 80025-834-05 (3)

1250 X X 80025-834-06 (3)

1500 X X

1750 X

2500 X

3000 X 80025-834-06 (6)

225 X X 80025-834-01 (3)

450 X X 80025-834-02 (3)

600 X X 80025-834-02 (3)

900 X X 80025-834-03 (3)

1250 X X 80025-834-04 (3)

1750 x X 80025-834-06 (3)

2250 X

2750 X 80025-834-04 (6)

3500 X 80025-834-06 (6)

80025-834-06 (6)

80025-834-04 (6)

80025-834-03 (6)

80025-834-05 (3)

80025-834-03 (3)

80025-834-06 (3)

80025-834-05 (3)

80025-834-04 (3)

80025-834-03 (3)

Table 8.J

Capacitor Fuses (5

(Quantities as noted)

Voltage

2400 V

60 Hz

3300 V

50 Hz

4160 V

60 Hz

th

, 7th & 11th filters – 12-pulse drives)

Maximum

Horsepower

Part Numb e r

th

Filter

5

Part Numb e r

7th Filter

Part Numb e r

11th Filter

900 80025-834-01 (6) 80025-834-01 (6) 80025-834-02 (6)

1000 80025-834-02 (6) 80025-834-01 (6) 80025-834-03 (6)

1750 80025-834-02 (6) 80025-834-02 (6) 80025-834-03 (6)

2000 80025-834-02 (6) 80025-834-02 (6) 80025-834-04 (6)

2500 80025-834-02 (6) 80025-834-02 (6) 80025-834-04 (6)

900 80025-834-01 (3) 80025-834-01 (3) 80025-834-02 (3)

1750 80025-834-02 (3) 80025-834-02 (3) 80025-834-03 (3)

2500 80025-834-03 (3) 80025-834-02 (3) 80025-834-05 (3)

3000 80025-834-03 (3) 80025-834-03 (3) 80025-834-06 (3)

900 80025-834-01 (3) 80025-834-01 (3) 80025-834-02 (3)

1000 80025-834-02 (3) 80025-834-01 (3) 80025-834-03 (3)

1750 80025-834-02 (3) 80025-834-02 (3) 80025-834-03 (3)

2000 80025-834-02 (3) 80025-834-02 (3) 80025-834-05 (3)

2750 80025-834-02 (3) 80025-834-02 (3) 80025-834-05 (3)

3000 80025-834-03 (3) 80025-834-02 (3) 80025-834-06 (3)

3500 80025-834-03 (3) 80025-834-03 (3) 80025-834-06 (3)

1519-5.0 – May 1998

Page 34

8-6 Renewal Parts

)."%.0*UNE

Page 35

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

code and links to software service packs, and a MySupport feature that you can customize to make the best use of these

tools. You can also visit our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

information, support chat and forums, software updates, and to sign up for product notification updates.

, you can find technical manuals, technical and application notes, sample

for FAQs, technical

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

SM

Te c hC o n n e c t

representative, or visit http://www.rockwellautomation.com/support/

support programs. For more information, contact your local distributor or Rockwell Automation

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wo rld wide Loca tor at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

Medium Voltage Products, 135 Dundas Street, Cambridge, ON, N1R 5X1 Canada, Tel: (1) 519.740.4100, Fax: (1) 519.623.8930

Online: www.ab.com/mvb

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respec tive companies.

Publication 1519-IN050B-EN-P - June 2013

Supersedes Publication 1519-5.0 - May 1998 Copyright © 2013 Rockwell Automation, Inc . All rights reserved. Printed in Canada.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...