Page 1

IntelliVAC™ Contactor

Control Module

USER MANUAL

(Series E)

Bulletin 1503VC

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the Additional Resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Product Description Chapter 1

Table of Contents

Scope ...................................................................................................... 1-1

Description ........................................................................................... 1-1

IntelliVAC Features ..................................................................... 1-2

IntelliVAC Versions .................................................................... 1-3

Specifications ........................................................................................ 1-4

Mount ing a nd Connections ....................................................... 1-4

Configuration ............................................................................... 1-4

Firmware ....................................................................................... 1-4

Electrical Ratings (Table 1.A) ..................................................... 1-5

Mechanical Ratings (Table 1.B) ................................................. 1-6

Altitude Derating (Table 1.C) ................................................... 1-6

Introduction ..........................................................................................1-1

Re ceiving and St orage Chapter 2

Receiving .............................................................................................. 2-1

Storage ................................................................................................... 2-1

Installation and Wiring Chapter 3

General Precautions ............................................................................. 3-1

Safety and Codes .................................................................................. 3-1

Arrangements ....................................................................................... 3-2

Integral to an Allen-Bradley MV Controller ............................ 3-2

OEM .............................................................................................. 3-3

Fuse Protection .................................................................................... 3-5

Gr ou ndi ng ............................................................................................ 3-5

Connections ......................................................................................... 3-6

Control Power .............................................................................. 3-6

Status R elays ................................................................................. 3-6

Interface Connections ................................................................. 3-7

Wiring Guidelines Electrically Held Contactors ............................. 3-8

Control with Solid-Stat e Dev ices ............................................... 3-9

Two-Wire Control ................................................................... 3-10

Three-Wire Control ................................................................. 3-11

Wiring Guidelines Mechanical Latch Contactors ........................ 3-13

Mechanical Latch Contactors ......................................................... 3-14

Capacitor Trip ........................................................................... 3-14

Motor Jogging Control .................................................................... 3-16

Undervoltage Protection ................................................................. 3-17

Time Delay Undervoltage ................................................................ 3-17

1503-UM053B -EN-P – Ju ne 2013

Page 4

ii Table of Conte nts

Setup and Commissioning Chapter 4

IntelliVAC Configuration .................................................................. 4-1

DIP Factory Default Settings (Table 4.A) ........................................ 4-2

IntelliVAC DIP Switch Explanation (Table 4.B) ............................ 4-2

Moni tori ng and Troubleshooting Chapter 5

Introduction ......................................................................................... 5-1

Module Status ...................................................................................... 5-1

Contactor Status .................................................................................. 5-2

IntelliVAC Status Indication, Series C (Table 5.A) ................ 5-3

IntelliVAC Status Indicati on, Seri es D (Ta ble 5.B) ................ 5-4

IntelliVAC Status Indication, Series E (Table 5.C) ................. 5-5

Module Troubleshooting (Table 5.D) ...................................... 5-6

Min. IntelliVAC Operatio nal Su pp ly Vo lta g es (Table 5. E)......... 5-7

Spare Parts Chapter 6

Spare Parts List ..................................................................................... 6-1

Optional Equipment ................................................................... 6-1

Appendix A Typical Contactor Drop-out Time Settings

Typical Contactor Drop-out Tim e Settings (Table A.1) .............. A-1

1503-U M053B -EN-P – Ju ne 2013

Page 5

Chapter 1

Product Description

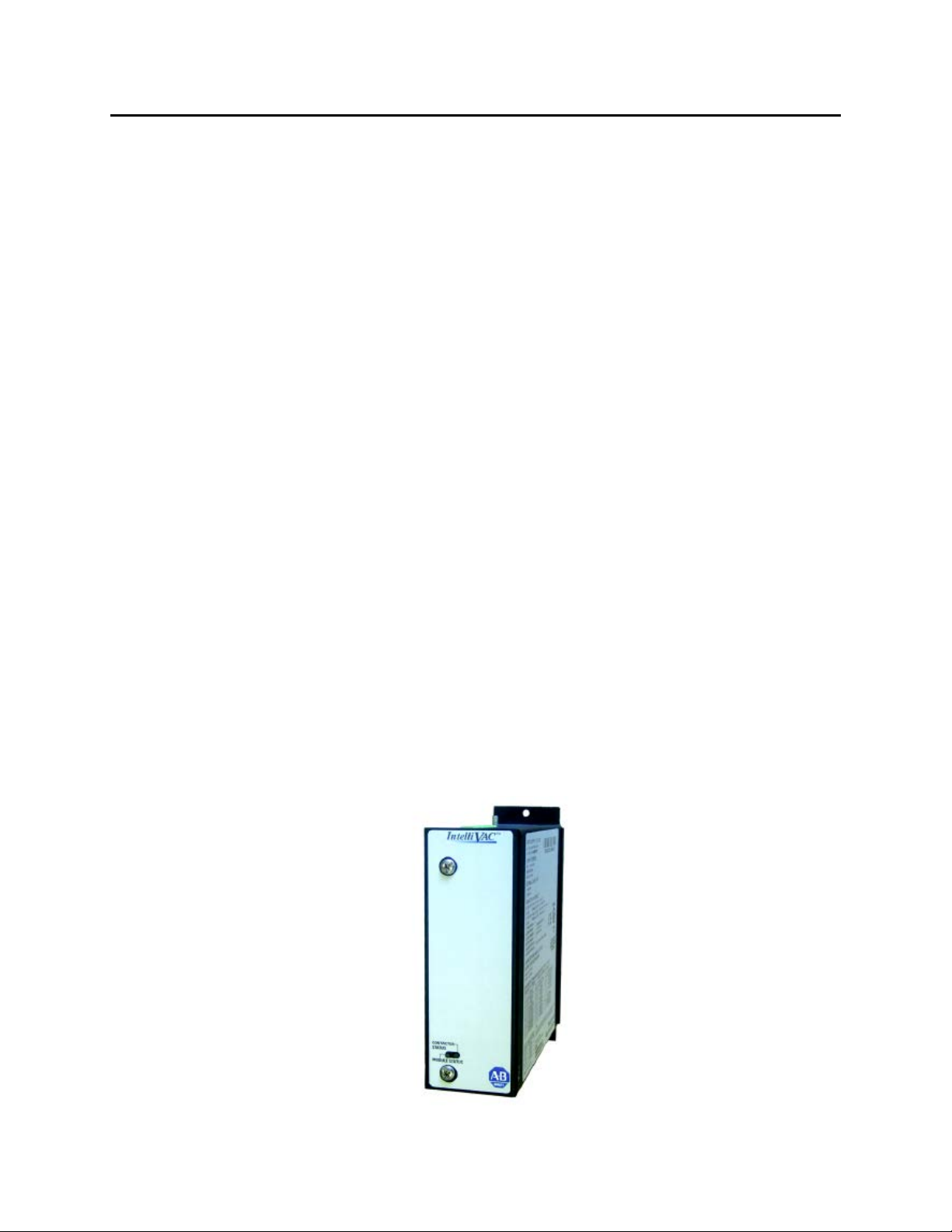

Introduction Thi s docu ment cont ains i nfor ma tion fo r the Allen-Bradley Bulletin

15 03VC I ntelli VAC™ co ntrol module. The Bullet in 15 03VC i s used to

control the Allen-Bra dley Bullet in 150 2 va cuum cont act ors t hat a re a

signifi cant component of the Bulletin 1500/1900 CENTERLINE

Medium Voltage Motor Controllers offered by Rockwell Automation.

An IntelliVAC control modu le may also be pr ovi ded a s a lo ose

component, for application with a Bulletin 1502 contactor by a third

party (OEM).

Scope Thi s docu ment app lies t o the Seri es E v ersion of I ntelli VAC. Refer to

publication 1503-UM051C-EN-P for information related t o the S eries

A and B designs, and 1503-UM052C-EN-P for information related to

Seri es C a nd D desi gns.

Description Intelli VAC i s an effici ent a nd flexible solut io n for cont rolli ng m edium

vo lta ge va cuum cont actors used i n motor st ar ter and f eeder

applications. IntelliVAC may be used to control both 400 and 800

Amp co nta ctors. E lectri cally held a nd mecha nica lly la tched cont actor

types can be controlled with IntelliVAC.

1503-U M053B-EN-P – Ju ne 2013

Page 6

1-2 Product Description

Description (cont.)

Figure 1.1 – IntelliVAC Contactor Control Module

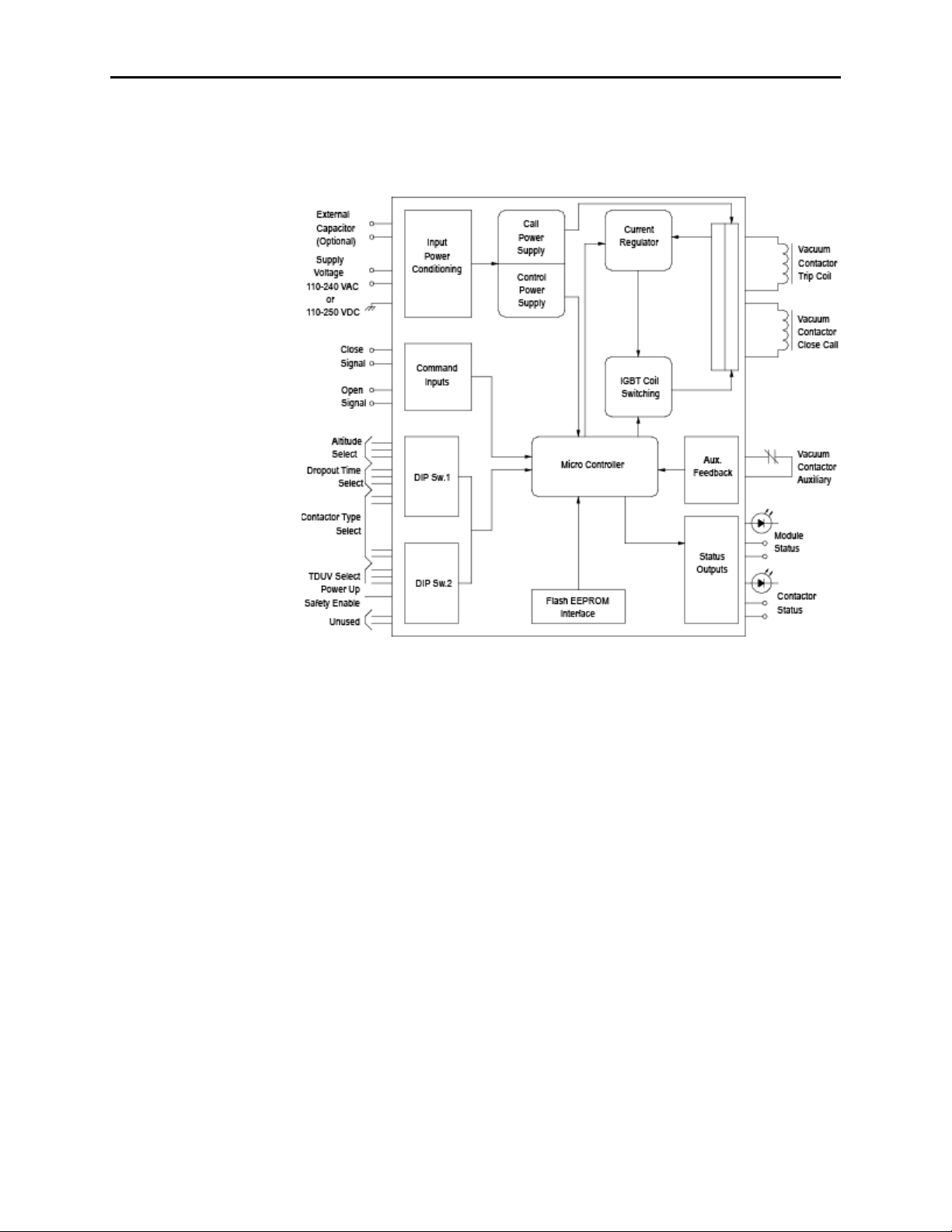

Figure 1.2 – IntelliVAC Block Diagram

IntelliVAC Features

A wi de ra nge of supp ly vo lta ge (11 0 – 240 V AC 50/60 Hz, 110 -

250 V DC) a llows i mplementation i n multiple ap plications

Co nsist ent vacuu m cont actor pi ck-up ti me (a t a g iven sup ply

voltage) ensures repea ta ble per for mance

Selectable vacu um co nta ctor dr op-out time improves coordination

with upst rea m po wer fuses

Elect roni c alt it ude compensati on (40 0 A only) elim ina tes

mechanical com pensa tion requi red for alti tud es abov e 1,0 00

met ers (800 A contactors include a user -fri endly alt itud e

adjustment)

Power loss ride-t hro ugh ( TDU V) a llows t he va cuum cont actor to

rem ai n closed du ring short po wer lo ss (ma y req uir e an o ptional

ext erna l capacit or, dependant on ri de-through ti me)

1503-U M053B- EN-P – Ju ne 2013

Page 7

Product D escri ption 1-3

IntelliVAC Features (cont.)

Anti-kiss a nd anti -pumpi ng protection ensure tha t t he vacuu m

contactor close – open sequence occurs as expected, avoiding rapid

re-closure due to fau lty cont rol d evices

Delayed r esta rt pr otects t he vacuu m conta ctor b y ensuri ng t hat the

rat ed dut y cycle is not exceeded

Tempo rary jog function (elect rically held cont act ors o nly) allows

the motor to be posi ti oned for p rocess set -up

IntelliVAC Versions

Series A

Series B

Series C

Up dat ed versi on o f the Series B modu le.

Ther e are t wo versi ons o f I ntelli VAC co ntr ol. The

fi rst type i s used to control v acuu m cont actors that are

electrically held, with a single electrical coil that is

economized electronically. The second is used to

control mecha nica lly lat ched va cuum contact ors.

There is a single version of IntelliVAC, to control

bo th elect ri cally held and mechanically latched

va cuum cont act ors.

Series D Minor functionality (firmware) enhancements

(primarily related to definition and handling of Faults

and Wa rning s).

Series E R evised ha rdware to allow co nnecti on t o t he

Int elliVAC Plus or I ntelli VAC MC> Remo val o f the

mi ni Din co nnecto r for fla shing fi rmwa re (firmwa re is

now flashed using the IntelliVAC Plus or IntelliVAC

MC boards) . N ew inpu t circui ts t o redu ce ther mal

ou tpu t, and d ecrease sensi ti vit y t o leakage cur rent .

Refer t o Cha pter 6, for cat alog num bers for each version of Int elliVAC.

Note: A Series C, D or E IntelliVAC m odule can be used t o rep lace

a Seri es A or Series B module. When rep laci ng an o lder ser ies

of Int elliVAC wi th a newer one, not e tha t t he Module and

Co nta ctor Status o utpu ts may functi on di fferent ly. R efer t o

publication 1503-UM051C-EN-P and/or Chapter 5 of this

1503-U M053B-EN-P – Ju ne 2013

Page 8

1-4 Product Description

do cument , a nd make any necessa ry changes to the co ntrol

circuit.

1503-U M053B- EN-P – Ju ne 2013

Page 9

Product D escri ption 1-5

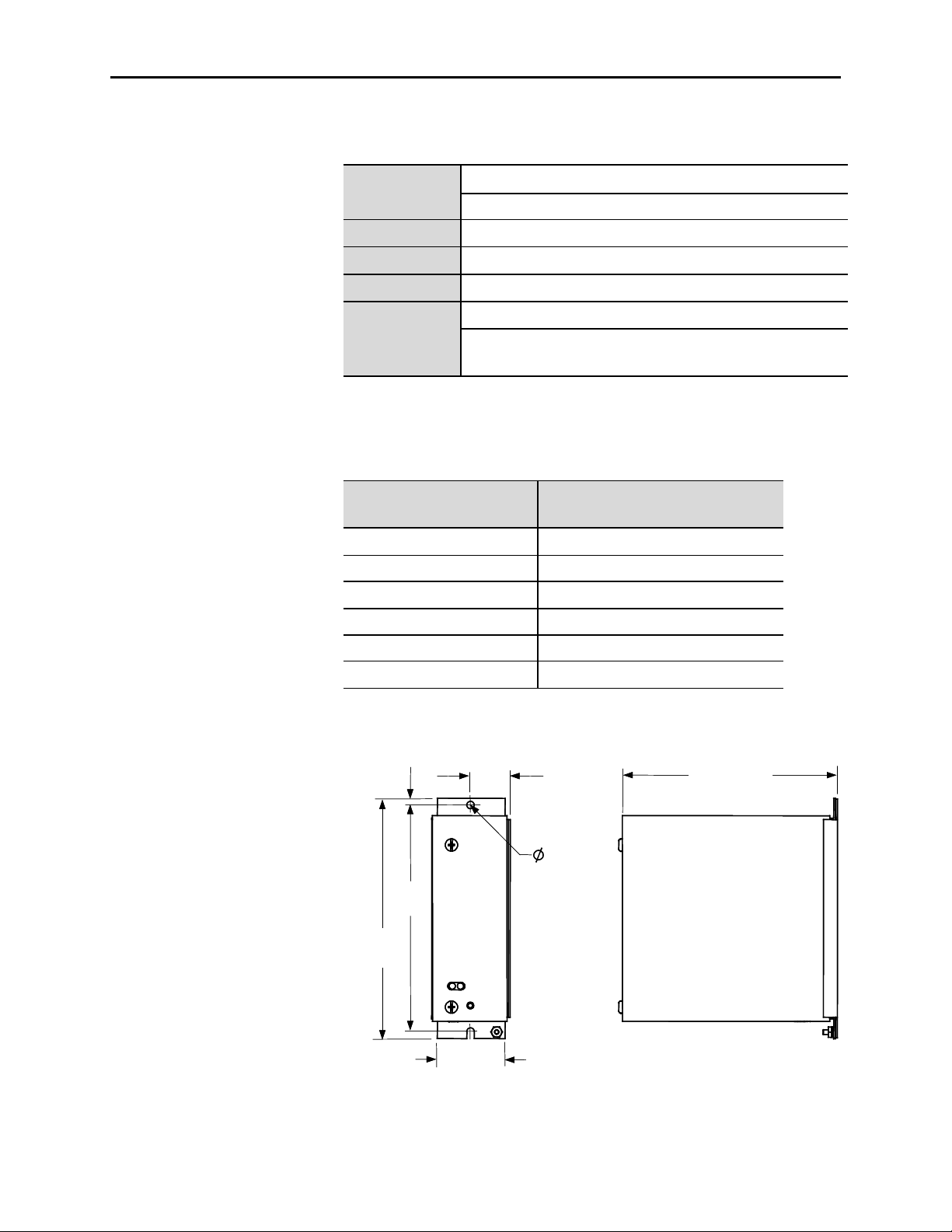

Specifications Mounting and Connections

The IntelliVAC control mod ules a re m ount ed usi ng t wo ( 2) scr ews ( see

Figur e 1.3 ). They are typi cally locat ed in the lo w volt age control pa nel

of the medi um vo lta ge cont roller (Bullet in 1500 /190 0 cont rollers, in

the case of Rockwell Automation).

Intelli VAC i s int erfa ced to the Bulleti n 1502 vacuum cont act ors u sing

a “qui ck” co nnector , locat ed at the mod ule, a wir e ha rness and “qui ck”

connector at the co nta cto r. Control po wer a nd ot her co ntr ol ci rcui t

connect ions are simila rly a chieved wi th “qui ck” co nnecto rs.

Configuration

IntelliVAC is easily confi gur ed for a wi de va riety of m ediu m vo lta ge

mo to r and feeder cont rol app lica ti ons. It is configu red using D IP

swi tches, locat ed withi n the enclosur e (fr ont side) . Plea se refer to

Chapter 4 for information.

Bulletin 1500/1900 controllers are shipped with IntelliVAC preconfi gur ed for t he requ ired a ppli cat io n. Please refer to the docu ment s

provided wit h the ord er.

Firmware

IntelliVAC ha s fir mwa re stored i n flash EEP ROM; t heref ore, thi s ma y

be updated in the field (if necessary). The IntelliVAC

is up dat ed usi ng ei ther the I ntelliVAC Plus, or Int elliVAC MC

supplem enta ry boa rds.

The firmware versi on suppli ed wi th t he mod ule is di splay ed on top o f

the DIP swi tches ( see Fig ure 4 .1) .

Seri es C modules use only ver sion 2.00 3 app lica ti on fi rmwa re. This

fi rmwa re is also compa ti ble wi th t he Seri es A a nd B modu les. Series D

modules use only version 3.001 or 3.002 application firmware. This

fi rmwa re is not com pat ib le wit h any ot her S eri es Letter mod ules.

Seri es E modules use o n 4 .00 4 or newer fi rmwa re. This fi rmwa re is not

com pati ble wi th a ny ot her S eries Let ter modules.

Refer t o Cha pter 6 f or p art number s of t he va rious ser ies of modu les.

The Series Letter of the mo dule i s print ed on t he label on t he cover of

the module, besi de the pa rt num ber.

board firmware

1503-U M053B-EN-P – Ju ne 2013

Page 10

1-6 Product Description

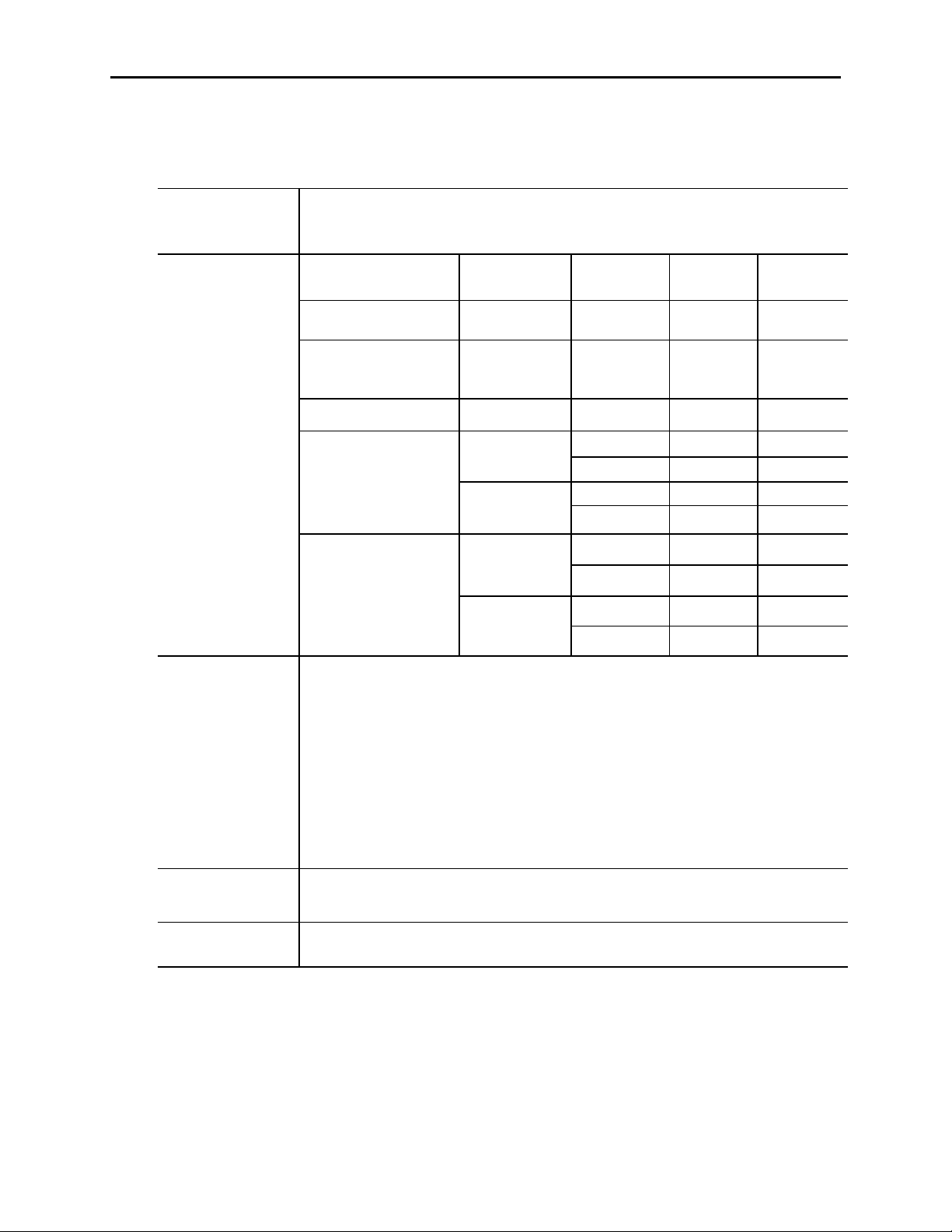

Table 1 .A – El ectri cal Ratings

Main Inpu t Vo ltage

(L1 to L2/N)

AC – 110 to 240 V rms, +10/-15%, 4 7 to 63 Hz

DC – 1 10 to 250 V, +10/-15%

Main Input Current

(L1 to L2/N )

Command Inputs

⊇ ⊂

Des cription

Con tac tor Ratin gs

(A mps)

Control Voltage

(AC o r DC)

Inr ush Current 400/800 120/240

Idle Current

(Maximum without contactor coil

400/800 120/240 125 mA 35 mA

energized)

Hold Current ⊄ (maximum)

400/800 120/240 300 mA 100 mA

120 4.6 A 3.6 A

400

Close Current ⊄

(0.2 sec)

240 3.4 A 3.3 A

120 11.3 A 4.8 A

800

240 8.9 A 4.5 A

120 7.0 A 3.7 A

400

Trip Current (latch) ⊄

(0.2 sec)

240 3.6 A 2.0 A

120 7.0 A 3.3 A

800

240 4.3 A 1.9 A

AC – 70 to 240 V rms

DC – 70 to 250 V

Max imum on state current f or open or close command:

@ 276 V AC, 60Hz, TA = 60°C

11mA

AC

2.4mA

@ 276 V DC, TA = 60°C

DC

Minimum on state curr ent f or open or close command:

@ 70 V AC, 60Hz, TA = 60°C

2.5mA

1.2 m A @ 68 V DC, T

AC

= 60°C

A

Max imum off state current for open or close command:

= 60°C

A

= 60°C

A

1.9 µA @ 60 V AC, 60 Hz, T

900 µA @ 60 V DC, T

AC Rating DC Rating

25 A peak (1/2

cycle )

25 A peak

1503-U M053B- EN-P – Ju ne 2013

Status Outp ut Contacts

Standards and Approvals

⊇ T

Ambient Temperature

A =

⊄ Includes idle current.

⊂ Ensure compatibility of IntelliVAC input ratings with those of circuit components activating these inputs.

Consider means of isolating/loading these signals, as required (using interposing relays or load resist ors.)

Consult factory for assistance, if needed. The Series C and D IntelliVACs a re compatible with most PLC outputs,

and have been verified with Rockwell Automation OA t ype 120V triac outputs. See Chapter 3, Wiring Guidelines.

AC – 250 V rms, 5 A, R load; 2 A (reactive), PF = 0.4

DC – 30 V, 5 A, R load; 2 A (reactive), L/R = 7 ms

CE, cULus, CS A, IEC pending

Page 11

Product D escri ption 1-7

5.1 (0.20)

Dimensions in mm (inches)

29.7

(1.17)

174.8

(6.88)

185.3

(7.29)

59.4

(2.34)

165.9 (6.53)

5.8 (0.228)

2 places

5.1 (0.20)

Dimensions in mm (inches)

29.7

(1.17)

174.8

(6.88)

185.3

(7.29)

59.4

(2.34)

165.9 (6.53)

5.8 (0.228)

2 places

Specifications (cont.)

Table 1 .B – Mechani cal Ratings

Ope rat ing: 0° to 60°C ambient at the control module

Tempe rature

Non-Opera ting: -40° to 85°C

Altitud e

Po llution

Hu midity

Shock and Vibration

(Operational)

Ambient temperature is derated at altitudes above 1,000 meters (3,300 feet).

Please refer to Table 1.C.

-1000 to 5000 meters

Pollution lev el II (as def ined by UL 840 and IEC 60664-1)

95% non-condensi ng

Shock – 15 g peak, 11 milliseconds

Vibra tion – 10 to 57 Hz, 0.015 inch displacement peak t o peak

– 57 to 150 Hz, 2.5 g acceler ation

Table 1 .C – Altitude Derating

Altitude

-1000 to 0 60

1 to 1000 60

1001 to 2000 58

2001 to 3000 56

3001 to 4000 54

4001 to 5000 52

Maximum Operating Ambient

at the control module (°C)

Derate by 2°C / 1000 m for high altitude operation

Figure 1.3 – Mechanical Dimensions

1503-U M053B-EN-P – Ju ne 2013

Page 12

Chapter 2

Receiving and Storage

Receiving Up on receiving the cont roller, r emove t he pa cki ng and check fo r da ma ge

tha t ma y ha ve occurred during shi ppi ng. Report a ny da mage immedi ately

to the cla im s office of the ca rrier.

NOTE: If t he Int elliVAC m odule is a n integra l com ponent of a

com plete MV co ntr oller (Bullet in 150 0/19 00), special receivi ng a nd

ha ndling inst ruct io ns will app ly. For deta ils, refer to the ser vice ma nual

pr ovi ded with t he equipm ent.

Storage It is important to consider the following storage requi rem ents i f yo u ar e

not inst alli ng your cont roller i mm edia tely aft er r eceivi ng i t.

• St ore t he controller i n a clean, dry , dust -free environment.

• St ora ge t emper at ure sho uld b e maint ai ned bet ween -40°C and 85°C (40°F and 185°F).

• Relati ve hum idity must not exceed 9 5%, non-condensing.

1503-UM053B -EN-P – Ju ne 2013

Page 13

2-2 Receiving and Storage

(This page is intentionally left blank)

1503-U M053B -EN-P – Ju ne 2013

Page 14

Chapter 3

A T T E N T I O N

A T T E N T I O N

A T T E N T I O NA T T E N T I O N

A T T E N T I O NA T T E N T I O N

Safety and Codes

Installation and Wiring

General Precautions In add it ion t o the preca ut ions list ed throu ghout t his manual, t he

followi ng st at ement s, whi ch ar e g eneral t o the system, m ust be read a nd

understood.

The cont roller cont ains ESD (electrostat ic

discharge) sensit ive part s and a ssemblies. St ati c

control pr ecaut io ns ar e requi red when

inst alli ng test ing, ser vici ng, o r repa iri ng the

assembly . Co mpo nent da ma ge ma y result if

ES D cont rol pr ocedu res are not followed. I f

you are not familiar with static control

pr ocedures, refer t o app lica ble ES D prot ecti on

handbooks.

An incorrectly app lied o r inst alled controller

can dam age compo nents o r reduce pro duct life.

Wi ri ng or a pplicati on err ors, su ch as i ncorrect

or ina dequ ate AC su pply, or excessive am bient

temper at ures, ma y result in m alfu ncti on of t he

system.

Only personnel fam ili ar wit h the cont roller a nd

associ at ed machi nery sho uld plan or implem ent

the installation, start-up, a nd subseq uent

ma intena nce of t he syst em. Fa ilur e to do t his

ma y r esult i n persona l injury a nd/or equi pment

damage.

1503-U M053B-EN- P – Ju ne 2013

Page 15

3-2 Installation and Wir ing

A T T E N T I O N

A T T E N T I O N

The Canadi an E lectr ical Co de (CEC) ,

Na ti ona l Electrica l Code (N EC) , or other local

cod es out line pr ovi sio ns for safely i nsta lling

electrical equi pment. Inst alla tion MU ST

com ply wi th speci fica ti ons regardi ng wi re t ype,

conduct or si zes, bra nch ci rcui t pro tect io n,

int erlock ing and di sconnect devi ces. Fa ilure t o

do so may resu lt i n personal i njury and/or

equi pment da mage.

Arrangements

Integral to an Allen-Bradley M V Controller

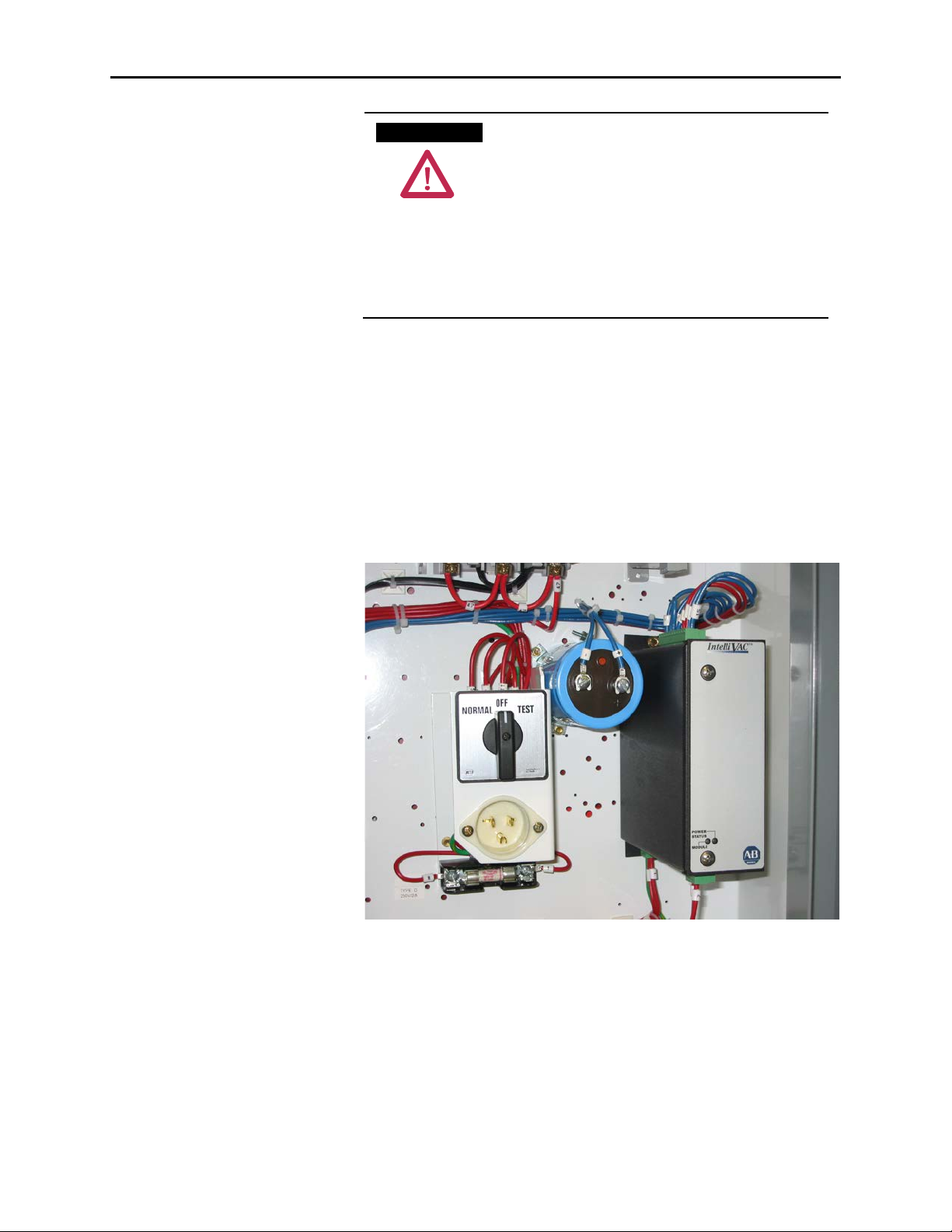

The Int elliVAC i s ava ila ble a s a pri ma ry com ponent of a n Allen-Bradley

The Int elliVAC i s offer ed in two arrangement s, Integr al ( par t of a

Bulletin 1500/ 1900 MV cont ro ller) o r a s an OEM co mpo nent.

Bulletin 1500/1900 MV controller as shown in Figure 3.1.

Figure 3.1 – Typical IntelliVAC Install atio n within a Bul letin 15 00/19 00 MV Controller (Shown

with o ptional external cap acitor)

1503-U M053B -EN-P – Ju ne 2013

Page 16

Installati on a nd Wir ing 3-3

OEM

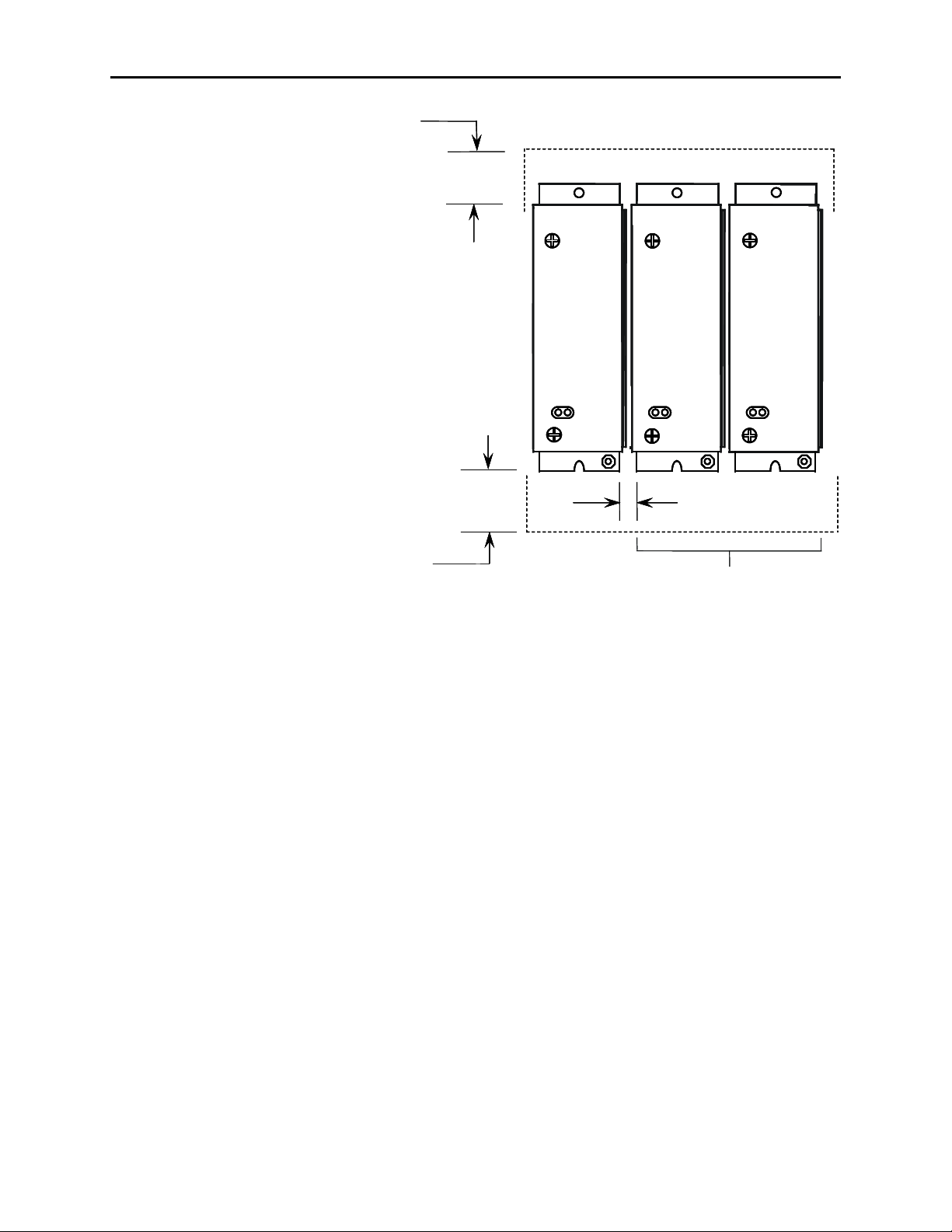

The Int elliVAC may be o rder ed as an OEM compo nent. This a llows the

OEM t o mou nt t he com ponents i n a confi gur at ion m ost sui tab le to the

mo to r controller equi pment lay out . Ca re m ust b e exerci sed t o ensur e t he

Intelli VAC ha s adequ ate venti lat ion pr ovided arou nd it. Refer to Figur e

3.2 fo r mount ing t he Int elliVAC. It i s recom mended that a mini mum o f

1. 5 inches ( 38. 1mm ) of free air spa ce be pr ovi ded b etween t he

Intelli VAC and any solid b arrier abov e or b elow.

The OEM i s responsible for controller fusing, mot or overload pro tection,

control devi ces (eg. Start/Stop push buttons), and wiring between the

Intelli VAC and 15 02 v acuu m contactor (using optio nal wir e harness) .

Wi ri ng and mou nti ng fo r opt ional i tem s, such a s TDU V Capacitor, are

also the OEM’s responsibilit y. R efer t o Figur e 3.3 for basic connect io ns.

1503-U M053B-EN- P – Ju ne 2013

Page 17

3-4 Installation and Wir ing

38.1

(1.50)

38.1

(1.50)

6.4 (0.25)

Additional Modules

(as required)

Minimum bottom clearance

Minimum top clearance

Dimensions in mm (inches)

38.1

(1.50)

38.1

(1.50)

6.4 (0.25)

Additional Modules

(as required)

Minimum bottom clearance

Minimum top clearance

Dimensions in mm (inches)

Arrangements (cont.)

Figure 3.2 – Typical Mounting Configurations

Note: Adja cent Int elliVAC modu les may be mo unted wit h a

minimum separation of 6.4 mm (0.25 inches).

1503-U M053B -EN-P – Ju ne 2013

Page 18

Installati on a nd Wir ing 3-5

MOV

32

1

EC

-

+

4

TCO

12

11

AUX CCO

5

6

L1 L2/NG

+ -

STOP

START

OVERLOAD

CONTROL

POWER

FUSE

*

7 8

OPEN

16

15

CONTACTOR

STATUS

M

M-INTELLIVAC

M

CAPACITOR

(OPTIONAL)

+ -

9 10

CLOSE

14

13

MODULE

STATUS

CONTROL POWER

INPUT POWER

CONFIGURATION

DIP SWITCHES

Figu re 3. 3 – IntelliVAC Typical Schematic (Electrically Held Vacuum Co ntactor)

1503-U M053B-EN- P – Ju ne 2013

Page 19

3-6 Installation and Wir ing

A T T E N T I O N

A T T E N T I O N

Fuse Protection The IntelliVAC module requires external fuse protection to coordinate

wi th t he power supply and conta ctor. The fuse rati ngs shown i n Table

3.A allow the passage of inrush currents expected when the contactor is

closed , or fro m reco mm ended externa l capa cit ors fo r the TD UV o ption.

They will also protect the contact or co ils i n the event of a m odule

malfunction.

The recommended fuses have been test ed to ensure reliable protection of

the module. If t he su pply vo lta ge is DC, the m odule must be used wit h an

ext erna l fuse t hat is a ppr oved fo r and r at ed to interrupt t he DC voltage

supply . The t ypes listed a re Fer raz-Shawmut Mid get Fuses ( 1-1/2" X

13/32"). The TRM is a time-delay type, rat ed 250 VAC. The ATM i s a

fast-a cti ng t ype, rated 5 00 VD C.

Table 3 .A – Intelli VAC Fuse Protection

Rated Supply Voltage Contactor Type

400A EH TRM 2 T RM 3.2

110/120 VAC

220/240 VAC

125 VDC

250 VDC

EH = Electrically Held vacuum contactor

ML = Mechanical Latch vacuum contactor

800A EH

400/800A ML

400A EH TRM 2 TRM 6.25

800A EH

400/800A ML

400A EH/ML

800A EH/ML ATM 5 ATM 6

400A EH/ML

800A EH/ML

Recommended Fuse

(min imum) (ma ximum)

TRM 2

TRM 2

TRM 2

TRM 2

ATM 3

ATM 3

ATM 5

TRM 6.25

TRM 3.2

TRM 6.25

TRM 6.25

ATM 3

ATM 5

ATM 6

Note: If ext erna l ca paci tors a re co nnected, o r more tha n one

Intelli VAC module i s pr ot ected b y a common cont rol fuse, the

ma xi mum recommended fuse should be used to pr event fuse

op ening due to incr eased inr ush curr ent when co ntr ol po wer i s

applied.

Grounding The Intelli VAC modu le must be connect ed to a common ground

termi nal (P E) on t he cont roller pa nel. The gr ound t erm ina l is locat ed on

the bottom of m odule enclo sure (refer t o Figur e 3.4 ).

It is important that IntelliVAC is properly

gr ounded usi ng the gro und co nnection

provided. Fai lure to do so may resu lt i n damage

to equ ipm ent o r per sona l injury.

1503-U M053B -EN-P – Ju ne 2013

Page 20

Installati on a nd Wir ing 3-7

1503-U M053B-EN- P – Ju ne 2013

Page 21

3-8 Installation and Wir ing

L2/NL1

CONTACTOR STATUS OUTPUT (N.O.)

MODULE S TATUS OUTPUT (N.O.)

POWER INPUT

13 14 15 16

Ground Connecti on

Connections There are three green connectors on the IntelliVAC module for

connect ions to the co ntr ol circui tr y. Connect or p lugs a re pr ovi ded wit h

the module. If a ddi ti ona l plugs a re req uir ed, r efer t o Chapt er 6, Spare

parts.

Control Power

Co ntrol po wer i s appli ed to the mo dule wi th a two -pole co nnecto r

The IntelliVAC can accept either AC or DC control po wer. Refer to

Table 1.A for a ccepta ble input power and co ntr ol si gnal rat ings.

located at the bottom rear portion of the module. Refer to Figure 3.4 for

connections. The ‘L1’ connection is i ntend ed to be t he ‘Hot’ o r ‘+ ’ side

of t he co ntr ol po wer, and the ‘L2 /N’ connect ion i s int ended to be the

‘Neutral’, ‘Return’, or ‘-’ si de of the co ntr ol po wer.

St atus Relays

Stat us rela y connect ions a re accessed wit h a fo ur-pole connect or lo cat ed

at the bottom front portion of the mo dule. Refer t o Figu re 3. 4 for

connect ions. There are two sta tus r elay s, each wit h one nor mally-open

contact:

Module Status: Terminals 13 and 14

Contactor Status: Terminals 15 and 16

Refer t o Cha pter 5 Monitoring and Troubleshooting for a descript io n of

op erati on fo r the rela ys.

Refer t o Table 1. A fo r elect rical ratings of t he sta tu s relays.

Figure 3.4 – Bottom side connections

1503-U M053B -EN-P – Ju ne 2013

Page 22

Installati on a nd Wir ing 3-9

1503-U M053B-EN- P – Ju ne 2013

Page 23

3-10 Installation and Wir ing

CONTACTOR INTERFACE

11 128 9 105 6 72 3 41

EX. CAP.

Interface Connections

All other control int erfa ce connect io ns a re made a t a twelve-pole

connect or loca ted on the to p of the modu le. Ref er to Figu re 3. 5 and

Table 3.B fo r connect ions ( and Table 1.A for electrical rat ings).

Refer t o the Wiring Guidelines section i n thi s chapt er fo r gui dance i n

ma ki ng connect io ns to the co ntrol ci rcui t.

Figu re 3. 5 – Top side co nnection s

Table 3 .B – Terminal Assignments for IntelliVAC Interface Connections

Terminal No. Termina l De s igna tio n Des cription

1 External capacitor (negati ve)

2 External capacitor (positive)

3 Lat ch tr ip coil (com mon)

4 Lat ch tr ip coil

5 Close coil (common)

6 Close coil

7 Open / Jog comm and

8 Open / Jog command (common)

9 Close command

10 Close command (common)

11 Contactor auxiliary contact

12 Cont actor auxiliary cont act

Refe r to T able 1.A for ele ctri cal rat ings .

No connection required if option is not used.

Ensure compatibilit y of IntelliVAC input ratings with those of circuit components activating these inputs. C onsider means of

isolati ng/loading these signals, as required (using interposing relays or load resistors). Consult factory for assistance, if needed. The

Series C and D IntelliVACs are compatibl e with most PLC outpu ts, and ha ve been verified with Rockwell Automation OA type 120V

triac outputs. See Wiring Guidelines.

For electrically held contactor, this command will energize the close coil output (CCO).

For mechanically held contact or, this command will energize the trip coil output (TCO).

Power connection for TDUV or capacitor trip options

only

Out put for mechanical lat ch contact or trip coil

Output to close coil of electrically held &

mechanical latch contactor s

Input to open a mecha nical lat ch contactor or jog

an electrically held contactor (mutually exclusive)

Input to initiate the closure of electrically held and

mechanical latch contactor s

Input to indicate the state of the contactor

(typically wired to a normally closed auxiliary

contact )

1503-U M053B -EN-P – Ju ne 2013

Page 24

Installati on a nd Wir ing 3-11

A T T E N T I O NA T T E N T I O N

Wiring Guidelines Electrically

The IntelliVAC can be applied wi th two- or three-wire control circui ts.

Held Contactors

The cont rol syst em utili zed will determ ine t he confi gur at ion of t he input

wiring. Consider the following input and output for the type of control

used:

• Term i nals 9 and 10 – Close Contactor

• Ter mi na ls 15 and 16 – Contactor Status

In eit her ca se, the CLOSE inpu t must recei ve a maint ai ned vo ltage hi gh

to keep t he cont act or closed.

Note:

1. When used with electrically held contactors, the IntelliVAC allows

close co mm ands ever y six seconds. This is to ensure the rated

contactor duty cycle is not exceeded.

2. If IntelliVAC powers up configured for an electrically held contactor,

and t he va cuum cont act or is det ected as being closed, the module wi ll

not respond t o a close command u ntil t he va cuum contactor auxiliary

contact inp ut i s in the correct (closed) sta te a nd m odule power is

rem oved a nd re-applied. (See Cha pter 5)

3. In g enera l, a Clo se command should only be app lied 4 seconds aft er

energi zing I ntelli VAC.

For E mergency St op appli cat ions requiring

rem oval of power, a cont act should be pla ced in

the “L1” co ntrol po wer r ung t o t he I ntelli VAC.

If t he TD UV fea tur e is used, the cont act or wi ll

not open unt il t he progr am med TD UV t ime

has expired.

1503-U M053B-EN- P – Ju ne 2013

Page 25

3-12 Installation and Wir ing

-+

3

2

12

11

AUX

MOV

M

TCO

5

6

-+1

EC

CCO

4

9 10

M

CLOSE

N

G

OVERLOAD

*

CONTROL

POWER

FUSE

CONTROLPOWER

M

M-IV

M-IV

L

CR

CR

SOLID STATE

OUTPUT

INPUT POWER

*

Refer to Table 3.A for recom m ended f use sizing.

Cont rol with Solid-State Devices

When cont rol devi ces t hat employ electr onic or su ppressed outpu t

circu it s are used in the r ung( s) t hat cont rol the i nput s to the I ntelli VAC,

alterna te a rra ngem ents m ay be r equi red. D evices emplo ying transi stor or

triac out put cir cuit s have fini te i mped ance and allow a leak age cur rent to

flo w i n the blocki ng o r of f sta te. Some P LC a nd I/O m odules with r elay

ou tpu ts ha ve R-C snubb er circui ts a cross t he co nta ct t o sup press voltage

transi ents genera ted d uri ng cont act openi ng. The im peda nce of these

snubber circuit s also a llows lea kage cu rrent t o flow when the cont act s ar e

op en. The I ntelli VAC i nput cir cuit s have b een designed such that t ypi cal

ou tpu t lea kage cu rrents sho uld no t creat e unint ended o pera ti on of t he

contact or. The v ast majorit y of cont rol d evices m ay be di rectly connect ed

to the I ntelli VAC wit hout any ina ppr opri ate oper ation occur ring.

Thi s si tuation ca n be pr event ed by consi dera ti on of t he cont ro l devi ces

when desi gni ng t he co ntr ol syst em. With co ntrol dev ices tha t ha ve

excessi ve leakage cur rent (i.e. PLC or si mi lar control devi ces) consider

usi ng rela y ou tpu ts wi th now supp ression across the cont act s. I f thi s

canno t be do ne, consi der the leak age cur rent of the d evice to see if i t i s

com pati ble wi th t he Int elliVAC i nputs (see Ta ble 1.A) . If t he co ntrol

device is not compa ti ble consi der usi ng an i nter posi ng relay connect ed as

shown in Figur e 3.6 .

1503-U M053B -EN-P – Ju ne 2013

Figure 3.6 – Co ntr ol w it h So lid -State Devi ces

Page 26

Installati on a nd Wir ing 3-13

A T T E N T I O N

A T T E N T I O N

A T T E N T I O NA T T E N T I O N

CONTROL

POWER

FUSE

CAPACITOR

(OPTIONAL)

M-IV

EC

TCO

AUX

CCO

L2/N

L1

G

MOV

M

OVERLOAD

RUN

M-IV

CLOSE

* Refer to Table 3.A for recommended f use sizing.

EMERGENCY STOP

(when required)

M

1

2

4

3

11

6

12 5

CONTROL POWER

Two-Wire Control

Wiring Guidelines Electrically

Held Contactors (cont.)

Som e two-wire cont rol schemes ma y be configur ed such that a close

If usi ng two-wire cont rol, the CLOS E contact or i nput i s maint ained high

usi ng a si ngle cont act . Mom enta ri ly op ening thi s inp ut wi ll cause t he

Intelli VAC t o op en the cont act or. Mai ntaini ng the co nta ct wi ll provide a

CLOS E command to Intelli VAC (g iven t hat all permissives are satisfi ed).

If a fa ult occur s, in add iti on to cycling cont rol p ower t o the Int elliVAC

module, the CLOSE command must be removed for a minimum of 4

seconds, before bei ng re-app lied. R efer t o Figur e 3.7 .

com ma nd is pr esent when Int elliVAC is energized. In this case, the

Power-Up S afet y fea ture may be d isabled b y sett ing DIP swi tch 1 2

accordingly. Refer t o Ta ble 4.B.

Only disable the Power-U p safet y fea ture when

abso lutely necessa ry. Doing so can create

unsa fe oper at ing condi ti ons.

For E mergency St op appli cat ions requi ring

rem oval of power, a cont act should be pla ced in

the “L1” co ntrol po wer r ung t o t he I ntelli VAC.

If t he TD UV fea tur e is used, the cont act or wi ll

not open unt il t he progr am med TD UV t ime

ha s exp ired.

1503-U M053B-EN- P – Ju ne 2013

Page 27

3-14 Installation and Wir ing

A T T E N T I O N

A T T E N T I O N

* Refer to Table 3.A for recommended f use sizing.

MOV

32

1

EC

-

+

4

TCO

12

11

AUX CCO

5

6

L1 L2/NG

+ -

STOP

START

OVERLOAD

CONTROL

POWER

FUSE

*

M-IV

9 10

CLOSE

M-IV

15 16

CONTACTOR

STATUS

M

M-IV

M

CAPACITOR

(OPTIONAL)

CONTROL POWER

EMERGENCY STOP

(when required)

Fig ure 3 .7 – Two-Wi re C ont rol

Three-Wire Control

If using three-wi re co ntrol, t he CLOSE co nta cto r inpu t i s maint ained

hi gh usi ng t wo co nta cts. Momenta rily o peni ng thi s inp ut will ca use the

Intelli VAC t o op en the cont act or. Mom enta rily closing the S TART

contact will provi de a CLOSE co mmand to Intelli VAC (gi ven t hat all

per missives are sati sfied).

In thi s confi gura tion, the S TATUS outp ut a cts as a seal-i n cont act. If a

fa ult occu rs, in a ddition t o cycling control power over t o the IntelliVAC

module, the CLOSE command must be removed for a minimum of 4

seconds b efore being re-app lied. Refer to Fi gur e 3.8 .

For E mergency St op appli cat ions requi ring

rem oval of power, a cont act should be pla ced in

the “L1” control power rung to the IntelliVAC.

If t he TD UV fea tur e is used, the cont act or wi ll

not open unt il t he progr am med TD UV t ime

has expired.

Fig ure 3 .8 – T hree-W ir e Con tro l

1503-U M053B -EN-P – Ju ne 2013

Page 28

Installati on a nd Wir ing 3-15

CLOSE COMMAND

TO MICRO

MICRO OUTPUT

TO CLOSE COIL

CONTACTOR STATUS

RELAY OU T P U T

CONTACTOR

AUXLIARY

INPUT TO MICRO

CLOSE LEVEL OF

CURRENT TO CLOSE

COIL

MODULE STATUS

RELAY OUTPUT

Contact status relay closes on request to close. It will open if the contactor aux i liary contact does not close within 200 millisec onds and

module will fault (opening module status relay).

15mS

200mS

90mS

(@120VAC)

80mS

60mS

5mS

SELECTABLE DROP

OUT TIME

(0 TO 190mS)

CLAMP DELAY

DEBOUNCE

NATURAL

CONTACTOR

DROP OUT

CONTACTOR PICK UP

ACKNOWLEDGE

WINDOW

DEBOUNCE

30mS

For this example, the 130 milli s econd drop-out time has been selected. The base drop-out time is 50 milliseconds . The microcontroller delay i s

130-50=80 milliseconds.

15mS

Wiring Guidelines Electrically

Held Contactors (cont.)

Figu re 3.9 – Ti ming Diag ram 4 00 A (Electrically H eld) Co ntactor

for IntelliVAC Control with three-wire Control

1503-U M053B-EN- P – Ju ne 2013

Page 29

3-16 Installation and Wir ing

MOV

32

1

EC

-

+

4

TCO

12

11

AUX CCO

5

6

L1 L2/NG

+ -

CLOSE

OVERLOAD

CONTROL

POWER

FUSE

*

CONTROL POWER

M-IV

9 10

CLOSE

CC

M-IV

M

MOV

TC

M

+ -

M-IV

7 8

OPEN

OPEN

OVERLOAD

* Refer to Table 3.A for recommended f use sizing.

Intelli VAC cont rol m ay be used fo r mecha nica l la tch co nta cto rs.

Wiring Guidelines Mechanical

Latch Contactors

A momenta ry co ntr ol signal i s needed to close the co nta ctor, a nd a second

mo ment ar y control si gna l is need ed t o o pen the cont act or. The

mo ment ar y op en/close commands m ust be at least 50 m illi seconds in

duration.

Refer t o Figu re 3. 10 for a typi cal m echanical la tch co ntr ol scheme.

Note:

1. A mecha nica l lat ch cont act or m ay already be closed when po wer i s

app lied t o t he Int elliVAC cont rol module.

2. It is permissible to apply an open command t o t he Int elliVAC

mo dule a s power is re-applied.

Figu re 3.10 – Mechan ical Latch Contactor Control

1503-U M053B -EN-P – Ju ne 2013

Page 30

Installati on a nd Wir ing 3-17

Mechanical Latch Contactors

Capacitor Trip

The Int elliVAC can be confi gured to pr ovi de capa cit or trip functionality

wi th m echanical la tch cont act ors. A cap acit or m ust be connect ed t o t he

Intelli VAC (termina ls #1 a nd #2) in o rder to pr ovi de t his ca pabi lity . The

capa cit or pr ovi des cont rol p ower fo r the I ntelli VAC a s well as sto red

energy t o trip t he conta ctor. Ma ximum recom mended ca pacitor size is

1650 µF for 120V control or 330 µF for 240V control. Use of larger

capa cit ors wi ll requi re a current lim it ing circui t t o prev ent o pening the

control fuse on energization.

The Int elliVAC must recei ve an ‘OP EN’ command wi thin a few seconds

of losing AC control power . Thi s ti me li mit depends on voltage and

capa cit or size as sho wn in the t ab le below. If t he elapsed time exceeds thi s

limit , the cont act or ca nnot be t ripp ed by Intelli VAC. In t his case, the

contact or ca n be t ri pped b y pr essing t he relea se but to n on the doo r in

front of the contactor.

A sepa ra te volt age sour ce is need ed to pro vide the ‘OPEN’ command. This

may be taken from the ext ernal capacitor as shown in Figure 3.11.

Table 3 .C – Mechani cal Lat ch Contactor – Capacitor T rip Times

Con tac tor

Rating

400 Amp

No minal Vo lta ge

(Vac)

120

240

Ac tual

V

(Vac )

input

120

110 2.7

100 1.7

240

200 4.7

Note: Minimum capacitor voltage ratings:

Ext. Capa c itor

(µF)

1650

330

Ma x. time

for trip

(sec)

3.5

7.5

• 120V applications – 200V DC (250V DC preferred)

• 240V appli cat io ns – 400V DC (450V DC preferred)

1503-U M053B-EN- P – Ju ne 2013

Page 31

3-18 Installation and Wir ing

MOV

32

1

EC

-

+

4

TCO

12

11

AUX CCO

5

6

L1 L2/NG

+ -

CLOSE

OVERLOAD

CONTROL

POWER

FUSE

*

CONTROL POWER

M-IV

9 10

CLOSE

CC

M-IV

M

MOV

TC

M

+ -

M-IV

7 8

OPEN

OPEN

CAPACITOR

OVERLOAD

*

Refer to Table 3.A for recommended fuse sizing.

Figure 3.11 – Mechan ical L atch Contactor with Capacitor Trip Optio n

1503-U M053B -EN-P – Ju ne 2013

Page 32

Installati on a nd Wir ing 3-19

A T T E N T I O N

A T T E N T I O N

MOV

32

1

EC

-

+

4

TCO

12

11

AUX CCO

5

6

L1 L2/NG

+ -

STOP

START

OVERLOAD

CONTROL

POWER

FUSE

*

CONTROL POWER

M-IV

9 10

CLOSE

M-IV

15 16

CONTACTOR

STATUS

M

M-IV

M

+ -

JOG

M-IV

7 8

OPEN

* Refer to Table 3.A for recommended f use sizing.

EMERGENCY STOP

(when required)

Motor Jogging Control Note: J og funct io nali ty ca n wor k wi th elect ri cally held conta ctor only.

When used with electrically held contactors, the IntelliVAC allows close

com ma nds ever y six seconds. Thi s i s t o ensur e t he r at ed contact or dut y

cycle o f 60 0 op erations per hour is no t exceed ed.

For motor jogg ing oper ations, the seco nd control i nput, or OPEN

command, will clo se the co nta ctor fo r as long as t he i nput is p resent, and

op en t he cont act or when the i nput is r emoved. (Refer to Figure 3.12.)

Thi s m etho d will bypa ss t he sta nda rd six second mo tor r e-sta rt dela y fo r

jogg ing purpo ses only. Operati ons wi ll be limit ed to two sta rt s every

twelve seconds.

If t he TD UV fea tur e is used, the cont act or wi ll

not open unt il t he progr am med TD UV t ime

ha s exp ired. Ther efor e, appli cati ons requ iring

an i mmedi at e remov al of p ower during

emer gency stop co ndit ions are not comp at ible

wi th t he TDUV fea tu re.

Figu re 3. 12 – Motor Joggin g Con tro l

1503-U M053B-EN- P – Ju ne 2013

Page 33

3-20 Installation and Wir ing

A T T E N T I O NA T T E N T I O N

Undervoltage Protection The Int elliVAC cont roller prot ects t he conta ctor f rom cont rol vo lta ge

di ps and loss of p ower. It pro vides u nderv oltage release and pr events

att empt s to close the cont act or when t here is not suffici ent power

ava ila ble t o gu arant ee reliable closing of t he co nta cts. The underv oltage

pr otecti on wi ll be i nit ia ted u nder t he followi ng condit ions, r egardless o f

nominal control voltage:

1. I f the sup ply voltage dr ops b elow 90 V (AC or DC) duri ng the first

20 0 milli seconds after a Clo se co mma nd i s received . Thi s a ppli es to

bo th elect ri cally held and mecha nica l la tch co nta cto rs.

2. If t he supply volt age d rop s below 72 V (AC or DC) aft er t he 200

millisecond close sequence (electrically held contactors only).

Time Delay Undervoltage

The Int elliVAC can be confi gur ed to pr ovide time dela y under voltag e

(TDUV) pr ot ection. The f eatur e is a vailable to keep elect ri cally held

contact ors clo sed du ring a vo lta ge di p or brief power loss. Thi s opt ion

ma y r equi re the a ddi ti on of a capacit or (see below) . R efer to Chapt er 6

for typi cal ca pacit or si zing . The ca paci tor i s connected t o t ermina ls 1(-)

and 2(+) of the IntelliVAC. (Ref er to Figur e 3.1 3.)

If t he TD UV fea tur e is used, the cont act or wi ll

not open unt il t he progr am med TD UV t ime

ha s exp ired. Ther efor e, appli cati ons requ iring

an i mmedi at e remov al of p ower during

emer gency stop co ndit ions are not comp at ible

wi th t he TDUV fea tu re.

Table 4.B of t he “Set up a nd Co mm issioni ng” cha pt er ha s the dip swi tch

setti ngs to pr ovi de TD UV fr om 0. 2 to 2 seco nds. Int elliVAC can

pr ovi de TDUV prot ecti on wit hout t he use o f an ex terna l ca paci to r, a s

shown in Table 3.D.

Table 3 .D – Maximum TDUV Time (without Capacitor)

Control Volta ge

110/120 V

220/240 V

Max. TDUV Time (secs)

400 A 800 A

0.2

1.0

0.2

1.0

If t he underv olta ge cond it ion persi sts b eyond t he set dela y t ime, the

contact or will be op ened and an undervoltage fault or warning condition will

occu r (see Cha pter 5) .

1503-U M053B -EN-P – Ju ne 2013

Page 34

Installati on a nd Wir ing 3-21

1503-U M053B-EN- P – Ju ne 2013

Page 35

3-22 Installation and Wir ing

*

Refer to Table 3.A for recommended fuse sizing.

MOV

32

1

EC

-

+

4

TCO

12

11

AUX CCO

5

6

L1 L2/NG

+ -

STOP

START

OVERLOAD

CONTROL

POWER

FUSE

*

CONTROL POWER

M-IV

9 10

CLOSE

M-IV

15 16

CONTACTOR

STATUS

M

M-IV

M

CAPACITOR

(cont.)

Time Delay Undervoltage

Figure 3.13 – TDUV Control Circuit

1503-U M053B -EN-P – Ju ne 2013

Page 36

Chapter 4

S H O C K H A Z A R DS H O C K H A Z A R D

I M P O R T A N TI M P O R T A N T

Rem ove p ower fr om the modu le before

Ground Stud

Supply Power Input

Status Relay Outputs

LEDs

DIP Switches

Interface C onnections

Setup and Commissioning

IntelliVAC Configuration The I ntelli VAC modu le is confi gur ed for a speci fic a ppli cat ion by set ti ng

DIP switches. They are accessed by loosening the t wo scr ews on the front

of t he uni t, and rem oving the co ver b y slidi ng i t fo rwa rd. The swi tches

are f ound on t he fro nt ed ge of t he Int elliVAC circui t b oard ( see Figur e

4.1) . Ther e a re 16 swi tches, wit h num ber 1 being at the top closest to the

circu it boa rd pa rt numb er label. (Refer t o Table 4. B).

Hazardo us vo ltage is pr esent inside the module

whi ch may ca use per sona l i njury or death.

Rem ove a ll sou rces of po wer from the mo dule

and d ischa rge any connect ed cap aci tors before

rem oving the co ver.

rem oving the co ver a nd before cha nging t he

DIP switch set ti ngs. The new D IP swi tch

setti ngs are reco gni zed o nly on power-up.

Figure 4.1 – DIP Switch and Connector Locations

1503-U M053B-EN- P – Ju ne 2013

Page 37

4-2 Setup and Commissioning

Table 4 .A – DIP Switch Factory Default Settings

Altitude: 0 – 1000m

Ext. cap TDUV time: 0.2 sec

Power -Up Saf ety : Enable

An Intelli VAC unit shipped separ at ely fr om t he fa ctory wi ll hav e a

default configur at ion per Tab le 4.A.

Des cription

Drop-out tim e: 130 msec

Contactor config.: 400A EH

TDUV config.: No TDUV

DIP switch SW1

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

0 0 1

0 1 1

0 0 0 1

DIP switch SW2

0

0 0

0

IntelliVAC u nit s shipped i n a complete MV cont roller (Bulletin

15 00/ 1900 ) wi ll be confi gured to sui t t he insta lled ap plicati on (i.e.

contact or t ype). The user sho uld veri fy t he sett ings before energi zing the

equi pment . Tab le 4.B d efines t he sett ings fo r each swit ch.

Table 4 .B – IntelliVAC DIP Switch Explanation

1503-U M053B -EN-P – Ju ne 2013

Page 38

Setup and Commissio ning 4-3

The altit ude compensation by DIP switch settings applies to Series E 400 amp vacuum contactors onl y. Al l 800 amp cont act ors are ada pted

for altitude by altering the return springs. 800 amp contactors are to be set for 1 t o 1000m (001 DIP setting).

By-pass contactors in MV SMC applications must be set for 50 millisecond drop-out ti me.

Refer to Appendix A for typical drop-out time settings used when power fuses are provided by Rockwell Automation.

1503-U M053A-EN- P – Sep temb er 2008

Page 39

Monitoring and Troubleshooting

Introduction

The I ntelli VAC modu le has two lig ht em it ti ng di odes ( LED s) a nd rela y

ou tpu ts t o indi cat e the stat us of the co nta ctor and the m odule. The LED s

are v isi ble on t he fro nt o f the module and the rela y ou tpu ts a re accessed

on the bottom front of the module.

Chapter 5

Figure 5.1 – Int elli VAC LEDs

Note: Thi s u ser manua l cont ai ns info rma tio n for both Series C a nd

Seri es D Int elliVAC versions. Refer t o the correct info rma tion

belo w f or t he Intelli VAC series in use.

Module Status The Modu le St atus i s indi cat ed wi th a Green L ED if t he m odu le is

funct ioni ng pr oper ly and ha s a va lid confi gur at ion. If t he mo dule powers

up with an invalid configur at ion t he LED will be Red (fla shing once),

indicating a Fault condition which will not allow t he cont act or t o clo se. If

the m odule po wers up p rop erly and ex peri ences an undervolt age condition

when at tempt ing to close the co nta ctor or while t he co nta ctor is closed:

• Series C – the LED will be Red (Fa ult). If t he cont act or does not

close p rop erly, a Fault is generat ed, t he L ED t urns Red, and input s

are i nhi bited unt il t he mo dule power is remov ed and r eapp lied.

• Series D/E – the LED will be yellow (flashing once). If the

und ervo lta ge condi ti on i s corr ected during t he selected TDUV

int erva l (a s set via DIP swi tch) , then no rmal oper at ion resum es.

1503-U M053B-EN- P – Ju ne 2013

Page 40

5-2 Monit oring a nd Troubleshoot ing

I M P O R T A N T

I M P O R T A N T

Module Status (cont.) I f the pro cessor has an int erna l fau lt, the L ED will be Red, the o utp uts

will be cleared, and the processor must be reset ( input power must be

cycled). If the reset is successful, t he LED will be Green and t he modu le

wi ll respo nd to t he cont rol i nput s. The i nput comma nd m ust b e to ggled

before the module wi ll r espond to a new com mand (r isi ng edg e tr igg ered).

For S eri es D /E, t he Module St at us LE D is also used t o indi cat e various

“Warni ng” condit ions relat ed to the co nta cto r per formance (see Table

5.B).

Mod ule Stat us outpu t rela y has a norma lly o pen conta ct. The cont act is

op en dur ing a Fault condi ti on ( LED red) , and clo sed during a hea lthy

condi tion (LED green). The rela y i s open for some wa rning conditi ons,

but closed for less severe issues.

The module stat es ar e summ ar ized i n Tables 5.A a nd 5. B.

Contactor Status

Co nta ctor Status o utpu t relay has a normally op en cont act . The co nta ct

The cont act or st at es ar e summ ari zed in Tables 5.A a nd 5.B.

The Contactor Status is indicated with a yellow LED that is off until a

CLOSE command is r eceived. The yellow L ED will sta y on if t he

contact or clo ses proper ly, unt il t he cont act or i s opened . If the pro cessor

ha s a n int erna l fau lt, the LED wi ll b e red.

is open when the cont act or is op en ( LED off), and closed when the

contact or has received a close com ma nd (for 20 0 milli seconds) or if i t i s

closed (LE D on).

The LED s ar e red/ green t ypes wit h bo th

sections ON to pr oduce yellow. If viewed from

a sha rp a ngle, you may see only green or r ed.

Please view fro m di rect ly in fr ont of t he mo dule

to ensur e a ccura te co lor reco gnit ion.

1503-U M053B -EN-P – Ju ne 2013

Page 41

Monitorin g and Troubles hooti ng 5-3

Table 5 .A – IntelliVAC Status Indication (Series C only)

Con dition s

Des cription

Norm al Healthy Module and Contactor OPEN Green Closed Off Open

Norm al Healthy Module and Contactor CLOSED Green Closed Yellow Closed

War ning Invalid Comm and Present Yellow Closed Off Open

War ning Mechanical Latch Fail to Trip Yellow Open Yellow Closed

Fa ult Power Up with Contactor CLOSED Red – F lash 2 O pen Yellow Closed

Fa ult Contactor Fails to Pick Up Green Open Re d – Flash 1 O pen

Fa ult Contactor Drop Out During Hold Green Open Re d – Flash 2 O pen

Fa ult Long Contactor Drop Out Time Green O pen Red – Flash 3 Open

Fa ult Microcontroller M alf unction Red Open Re d Open

Fa ult Power Up with Invalid Dip Switch Configuration

Red – Flash 1 ⊂

Fa ult Undervoltage with a CLOSE Command Pr esent Red Open Off Ope n

Warning = Recoverable Condit ion – Remove and retry offending signal

Fa ult = No n-recoverable condition – Module power must be removed and re-applied.

Flash 1 = 1 Flash Red LED followed by a pause.

Fl as h 2 = 2 Consecutive Red LED flashes followed by a pause.

Flash 3 = 3 Consecutive Red LED flashes followed by a pause.

Only for Electrically Held Contactor

Invalid Command Types:

1. Close, Jog or Trip commands present during power up sequence.

2. Close or Jog command re-applied t oo quickly (be fore contactor opening sequence is verified).

Allow at least 60 msec, plus drop out delay time, before re-a pplying these signals.

NOTE : Contactor will only respond to a close command re-applications after th e re-start delay timer has expired.

3. Close and T rip commands present simultaneously (valid with Mechanical Latch contactors only).

U ndervoltage conditions are defined on page 3-17.

Modu le Statu s Contactor Status

LED Color Re lay LED Color Relay

Open Off Ope n

1503-U M053B-EN- P – Ju ne 2013

Page 42

5-4 Monit oring a nd Troubleshoot ing

11

11

12

12

Contactor Status (cont.)

Table 5 .B – IntelliVAC Status Indication (Series D only)

Con dition s

Norm al Healthy Module and Contactor OPE N Green Closed Off Open

Norm al Healthy Module and Contactor CLOSED Green Closed Yellow Closed

War ning Inv alid Command Present Yellow Closed Off Open

War ning Mechanical Latch Fail to Trip Yellow Closed Yellow Closed

Fa ult Power Up with Contactor CLOSED Re d – F lash 2 O pen Yellow Closed

War ning Contactor Fails to Pick Up Yellow – R1 Closed Off / Yellow Ope n/Close d

War ning Contactor Drop Out During Hold Yellow – R2 Closed Off / Yellow Open/ Closed

War ning Long Contactor Drop Out Time Yellow – R3 Closed Off / Yellow Ope n/Close d

Fa ult M icrocontroller Malfunction Red Ope n Red Open

Fa ult Power Up with Invalid Dip Switch Configuration

War ning Underv oltage wit h a CLO SE Command Pr esent Yellow – Fla shing Open/Closed Off / Yellow Open/Clos ed

Warnings will be cleared when a change of input state occurs, and the condition has been resolved.

Faults require control power to be removed until the unit resets

Flash 1 = 1 Flash Red LED followed by a pause

Flash 2 = 2 Consecutive Red LED flashes followed by a pause

Ye llow – R1 = Yellow with 1 Red flash followed by a pause

Ye llow – R2 = Yellow with 2 consecutive Red flashes followed by a pause

Ye llow – R3 = Yellow with 3 consecutive Red flashes followed by a pause

Invalid Command Types:

1. Close, Jog or Trip commands pre sent du ring p ower up seq ue nce

2. Close or Jog command re-applied to o quickly (be fore contactor o pening sequence is verified).

Allow at least 60 msec, plus drop out delay time, before re-a pplying these signals.

NOTE : Contactor will only respond to a close command re-a pplications after the re-start delay timer has expired.

3. Close and T rip commands present simultaneously (valid with Mechanical Latch contactors only).

Open during undervoltage, Closed if voltage restored

W ill reflect actual status of the contactor

Only for Electrically Held Contactor

Undervoltage condit ions are defined on page 3-17.

Des cription

Red – Flash 1 ⊂

Modu le Statu s Contactor Status

LED Color Re lay LED Color R ela y

Open Off Open

1503-U M053B -EN-P – Ju ne 2013

Page 43

Monitorin g and Troubles hooti ng 5-5

11

11

Table 5 .C - IntelliVAC Status Indication (S er i e s E on l y )

Con dition s

Des cription

Norm al Healthy Module and Contactor OPEN Green Closed Off O pen

Norm al Healthy Module and Contactor CLOSED Green Closed Yellow Closed

War ning Invalid Comm and Present Yellow Closed Of f Open

War ning Mechanical Latch Fail to Trip Yellow Closed Yellow Closed

Fa ult Power Up with Contactor CLOSED Red – Flash 2 Open Yellow Closed

War ning Contactor Fails to Pick Up Yellow – R1 Closed Off / Yellow Open/Clos ed

War ning Contactor Drop Out During Hold Yellow – R2 Closed Off / Yellow Open/Closed

War ning Long Contactor Drop Out Time Yellow – R3 Closed Of f / Yellow O pen/Clos ed

Fa ult Microcontroller M alf unction Red Open Red Open

Fa ult Power Up with Invalid Dip Switch Configuration

Fa ult Contactor Fails to Drop Out

Red – Flash 1 ⊂

Red – Flash 3

War ning Under volt age with a CLOSE Com mand Present Yellow – Fla shing O pen/Closed Of f / Yellow O pen/Clos ed

W arnings will be cleared when a change of input state occurs, and the condition has been resolve d.

Faults require control power to be removed until the unit resets

Flash 1 = 1 Flash Red LED followed by a pause

Flash 2 = 2 Consecutive Red LED flashes followed by a pause

Flash 3 = 3 Consecutive Red LED flashes followed by a pause

Ye llow – R1 = Y el low wit h 1 Red flash followed by a pause

Ye llow – R2 = Yellow with 2 consecutive Red flashes followed by a pause

Yellow – R3 = Yellow with 3 consecutive Red flashes followed by a pause

Invalid Command Types:

1. Close, Jog or Trip commands present during power up sequence

2. Close or Jog command re-applied to o quickly (be fore contactor o pening sequence is verified).

Allow at least 60 msec, plus drop out delay time, before re-a pplying these signals.

NOTE : Contactor will only respond to a close command re-applications after the re-start delay timer has expired.

3. Close and T rip commands present simultaneously (valid with Mechanical Latch contactors only).

Open during undervoltage, Closed if voltage restored

Will reflect actual status of th e co ntac tor

Modu le Statu s Contactor Status

LED Color Re lay LED Color Re lay

Open Off O pen

Open Re d Open

1503-U M053B-EN- P – Ju ne 2013

Page 44

5-6 Monit oring a nd Troubleshoot ing

1503-U M053B -EN-P – Ju ne 2013

Page 45

Monitorin g and Troubles hooti ng 5-7

Module status LED ‘Green’ and Contactor Status LED

Contactor Status (cont.)

Table 5 .D – Module Tr oubleshoo ting

Problem or Trip Indicated Indication of the following conditions Possible Solutions

Contactor does not energize • Motor Protection activated

Contactor closes momentar ily and will not

reclose.

Contactor fails to close. •

Refer t o Table 5. A (Series C) or Ta ble 5. B ( Series D) for definition of Module

• Investigate and reset

• Both Status LEDs ‘Off’

• Module Status LED ‘ Red’ upon power up • IntelliVAC faulted. Cycle control power to reset.

• Module Status ‘Red Flash 1’ upon power up • Impr oper setting of dip switches. Check settings and

• Loose connection in control circuit. • Verify contactor auxiliary set up. Reference Publication

• Module status LED ‘Red’ (Series C) and Contactor

Status LED ‘Off’

or

• Module status LED ‘Yellow – Flashing’ and Contact or

Status LED ‘Off’ (Series D)

‘Red Flash 1’ (Series C)

or

• Module status LED ‘Yellow-R1’ (Series D) and

Contactor Status LED ‘Off’

• Both status LEDs ‘Off ’ • Check internal control fuse. Verify IntelliVAC oper ation

• Check Control Power

• Loose connections in control circuit

• V erify IntelliVAC power input plug is in pla ce and

properly seated

• Verify internal control fuse has not opened (Refer to

Figure 4.1 for locat ion)

Replace IntelliVAC if unsuccessful.

cycle contr ol power.

1502-UM052_ -EN-P (400A) or 1502-UM051_ -EN-P

(800A ) – Auxiliary Contact Set-up Procedur e.

• Verify circuit continuity (is contactor plug connected

proper ly?)

• Under voltage f ault (no T DUV), contr ol volta ge dipped

below tr ip point. Verif y voltage lev els are 110 to 240

VAC, 110 to 250VDC

• Coil damaged or connect ions ar e loose. Repair and

cycle control power (Series C).

• Auxiliary Contact Assembly improperly adjusted.

Reference Publication 1502-UM052_ -EN-P (400A) or

1502-UM051_ -EN-P (800A) – Auxiliary Contact Set-up

Procedure. Cycle cont rol power to reset (Series C).

• A rmature Plate obstructed from closing to coil face.

Verify no foreign material behind the armature plate.

Cycle contr ol power to reset.

in test m ode before applying M edium V oltage. (Refer to

Fig. 4.1 for location.)

LE D sta tes.

1503-U M053B-EN- P – Ju ne 2013

Page 46

5-8 Monit oring a nd Troubleshoot ing

Module Status LED ‘Green’ and Contactor Status LED

R2’ and Contactor Status

Module Status LED ‘Yellow’ and Contactor Status LED

Table 5 .E – Minimum IntelliVAC Operational Supply Voltages

Table 5 .D – Module Tr oubleshoo ting (cont. )

Problem or Trip Indicated Indication of the following conditions Possible Solutions

Contactor opens during operation • Motor Protection activated • Investigate and reset.

• Stop command initiated • Verify circuit

• Module Status LE D ‘Red’ (Series C)

or ‘Yellow – Flashing’ (Series D)

•

‘Red Flash 2’ (Series C)

or

• Module Status LED ‘Yellow –

LED ‘Off’

• Both status LEDs ‘Off ’ • Check control v oltage and inter nal cont rol fuse. ( Refer

Contactor does not open (mechanical latch) •

‘Yellow’

• Under voltage f ault (no T DUV), contr ol volta ge dipped

below trip point. Verify voltage levels ar e 110 to 240

VAC, 110 to 250 VDC.

• With external capacitor and TDUV feature activated,

undervoltage condition for longer than program med

TDUV time. Undervoltage fault activated.

• Contactor Status feedback between Terminals 11 and

12 on the IntelliV AC has closed. The IntelliVAC will deenergize the coil, thinking t he contact or has opened

for other reasons.

to Figure 4.1 for location.)

• T rip me chanism is dam aged. Inspect and replace if

needed.

• Check for loose connections in the control circuit .

Contactor does not open

(electrically held)

• Series C – M odule Status LED ‘Green’ and Contactor

Status ‘Red Flash 3’

• Series D – M odule Status LED ‘Yellow – R3’ a nd

Contactor Status LED ‘Yellow’

• Contactor welded or mecha nisms binding. Inspect and

repair if needed.

Refer t o Table 5.A (Series C) or Table 5. B ( Series D) for definition of Module

LE D sta tes.

Voltage Level

Pick -Up 400/800 95

Drop-O ut 400/800 75

Tr ip (M echanical Latch)

Contactor Rating

(A mps)

400 70

800 80

Minimum Voltage

(VAC, 47 to 63 Hz)

1503-U M053B -EN-P – Ju ne 2013

Page 47

Monitorin g and Troubles hooti ng 5-9

1503-U M053B-EN- P – Ju ne 2013

Page 48

Chapter 6

Spare Parts

Spare Parts List IntelliVAC (electrically held) Series A 1503VC-BMC1

Intelli VAC (mecha nica l lat ch) S eries A 1503VC-BMC2

IntelliVAC (electrically held and

mecha nica l lat ch) S eries B 1503VC-BMC3

IntelliVAC (electrically held and

mechanical la tch) Series C and D

IntelliVAC (electrically held and 1503VC-BMC5

mecha nica l lat ch) S eries E

Internal Fuse: 6.3 A, 250 V (Littlefuse 21506.3) 80174-902-14-R

1503VC-BMC4

Multi-pole connect ors:

2 pole (module po wer) 80174-014-01-R

4 pole (status outputs) 80174-014-03-R

1 2 po le (coil a nd I/ O connect ions) 80174-014-11-R

Optional Equipment

TDUV Capacitor

For 110/120V AC control (1650 µF) 80158-779-51-R

For 220/240V AC control (330 µF) 80158-779-52-R

The Series Letter is printed on the large label on the right-hand side of the enclosure, beside the part

Includes m ounting bracket and ter minal guar ds

numbe r.

1503-U M053B-EN- P – Ju ne 2013

Page 49

6-2 Spar e Parts

(This page is intentionally left blank)

1503-U M053B -EN-P – Ju ne 2013

Page 50

Appendix A

Table A .1 – Typical Contactor Dr op-Out Ti me Settings

4R 6R 9R

18R

19R

2 x 24R ⊇ 100

2 x 32R

⊇

240 *

2 x 38R

⊇

2 x 48X

⊇

⊇

Typical Contactor Drop-out Time Settings

The cont act or d rop -out time settings shown i n the fo llowi ng t able are

typical minimum v alues u sed when the po wer fuses a re pr ovided a s par t of

a com plet e MV cont roller fr om R ockwell Automati on. The

recommenda ti ons are based o n Ferraz-Sha wmut po wer fuses. Ot her f use

types ma y req uir e alt erna te dr op-out ti me sett ings.

The Int elliVAC module D IP swi tches ar e set up to pr ovi de the m ini mum

drop-out ti mes shown (refer to Chapt er 4).

Fus e Ra ting Contactor Drop-out Time Setting (ms ec )

Vo ltag e De sign ation 400A 800A

2R

3R

50

12R

< 5000

⊇ Fus e not suitable for use with contactor.

24R

32R

38R ⊇

48X

57X ⊇ 200

2 x 57X

100

240

⊇

⊇

⊇

⊇

50

75

Note: The drop-o ut t im e is cho sen t o be equa l t o or gr eat er tha n

the int ersect ion of t he ra ted cont actor int erru pting cu rrent and

the fuse melt time curve (except where no ted * ).

1503-U M053B-EN-P – Ju ne 2013

Page 51

A-2 Typical Contactor Drop-out Times

Table A .1 – Typical Contactor Drop-o ut T im e Settings (c ont .)

50E

65E

150E

175E

75

450E

130

75

2 x 250E ⊇ 50

2 x 350E

75

2 x 400E

100

⊇

⊇

⊇

Fus e Ra ting Contactor Drop-out Time Settin g (mse c)

Vo ltag e Des igna tion 400A 800A

20E

30E

40E

80E

50

100

< 5000

100E

125E

200E

250E

300E

350E

400E

50

500E

600E

750E

900E

2 x 300E

2 x 450E

2 x 500E

2 x 600E

2 x 750E

2 x 900E ⊇ ⊇

⊇ Fuse not suitable for use with contactor.

240

240 *

⊇

⊇

⊇

⊇

⊇

⊇

⊇

200

240 *

75

130

240

240 *

Note: The drop-o ut t im e is cho sen t o be equ al to or g reat er tha n the

int ersection of t he ra ted cont act or i nterr upti ng cur rent and t he

fuse melt time curve (except where noted * ).

1503-UM 053B- EN-P – Ju ne 2013

Page 52

Typical Contactor Drop-o ut Times A-3

Table A .1 – Typical Contactor Drop-o ut T im e Settings (c ont .)

4R

6R

9R

75

32R

240 *

⊇ 75

48X

150

⊇

⊇

⊇

⊇

10E

15E

65E

150E

175E

Fus e Ra ting Contactor Drop-out Time Se tting (ms ec )

Vo ltag e Des igna tion 400A 800A

2R

3R

50

50

12R

18R

24R

150

7200

8250

⊇ Fuse not suit able for use with cont actor.

38R

57X

2 x 18R

2 x 24R

2 x 32R

2 x 38R

2 x 48X

2 x 57X

20E

25E

30E

40E

50E

80E

100E

125E

200E

⊇

200

⊇

⊇

⊇

⊇

⊇ ⊇

50 50

240 *

50

130

Note: The drop-out ti me i s chosen to be equ al t o or greater tha n the

intersection of the rat ed cont act or i nterrup ting cur rent and the

fuse melt time curve (except where noted *)

1503-U M053B-EN-P – Ju ne 2013

Page 53

A-4 Typical Contactor Drop-out Times

1503-UM 053B- EN-P – Ju ne 2013

Page 54

Page 55

Me dium Volt age Products,

Pu blication 1503-UM053B-EN-P – June 2013 Copy righ t © 2013 Rockw ell Aut oma ti on, I nc . A ll ri gh ts re s erv ed. Pri nted in Cana da.

Supers edes 1503-UM053A-EN-P – O ct ober 2007

135 Dundas Street, Cambridge, ON, N1R 5X1 Canada, Tel: (1) 519.740.4100, Fax: (1) 519.623.8930, www.ab.com/mvb

Loading...

Loading...