Page 1

Installation Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

PHOTOSWITCH® Liquid Level and Resistance Sensing Control

Bulletin 13DJ3-3000

low

Product Data

conductivity such

moisture content as

In

addition

can be wired

a

llowing the

A so

simu

electronic counting, da

computer.

The control

transients,

power up. These features a

in solving

to

for

use

lid-state output signal

ltaneous

ly

has protection against false operation due

line

the more

as antibio

low

as

high sens

voltage dropouts

itiv

electronic control

of

both sets

with

a relay output. This signal

ta

difficult industrial level applications

tics, refrigerants,

5%.

ity,

the control

of

relay contacts

can be obtained

logging,

of

llow

the 13DJ3 Series 3000 Control to

has a fast

latching on certain applications,

from

or feeding information to

1/2 second

or

sand

with

response time and

for external loads.

the control

can be used

or

less,

for

to

line voltage

or

during in

.

a

a

be used

itia

l

Descripti

The

Liquid

or so

Feature

on

PHOTOSWITCH

Level Control

lids with

Bulletin

a moisture content as

13DJ3 Series 3000 is a high sensitivi

designed

to

detect the level

low

as

5%.

s

•Very

high sens

•

Compact, all solid state, plug-in, modular design

with fl

•

DPDT

state logic outputs

•Low

probe voltage isolated

•

Fast response

•

Wide selection

•All

molded parts

(PPO) and polystyrene (PS)

•

Heavy-duty easy

•High

•

Ambient temperature range: -40 to 135°F (-40 to 57°C

itiv

ity—up

to

60 megohms cm

exibili

ty

EM

relay and 12V DC solid state outputs.

from

line voltage

tim

e

of

probe assemblie

of

rugged, im

to wire terminals

voltage connections isolated

s

pact resist

from low voltage

General

The

Bulletin

13DJ3 Series 3000 Conductive

designed

solids.

placed

c

rods

(fiberglass, cemen

probe

cause the output relay

pump, valve,

The controls

MegOhmscm. This permits the sensing

to

provide a reliable level detection

No

moving parts

in the

conductive

onductive material

to

the metal material container.

to

complete the electrical circuit. Completion

or

will

or floats are required. Metal probe rods are

liquid

at the desired levels. The

completes the

t,

etc.), an add

to

motor

operate over a resis

itional

operate. The relay contacts may be used

control;

audible and/or visual level indicatio

Liquid

circuit

between the probe rod

If

the container

probe rod

tivity range

of

liquids or

ty

of

conductive

liquid resis

for re

Optional solid

ant polyphenylene oxide

Level Control is

of

conductive

is

non-conductive

is

used as a grounding

of

of 0 to

solids

liquids

tivity

liability

)

liquids or

liquid or so

the

circuit will

60

with

for

very

or

lid

n.

Resistance Sensing Contro

PHOTOSWITCH

sensing control.

s

witch

mechanisms or

capable

sensitiv

megohms

Bulletin

In

which converts the minute current

extremely

of handling rela

ity

of

the

control

.

l

13DJ3

is

also designed

this application the control

flow

light

contacts

into a s

tively heavy electrical

when used

for

resistance sensing

to

be used as a resistance

operates as an electronic

through delicate

witching

loads. The maximum

output

is

15

Page 2

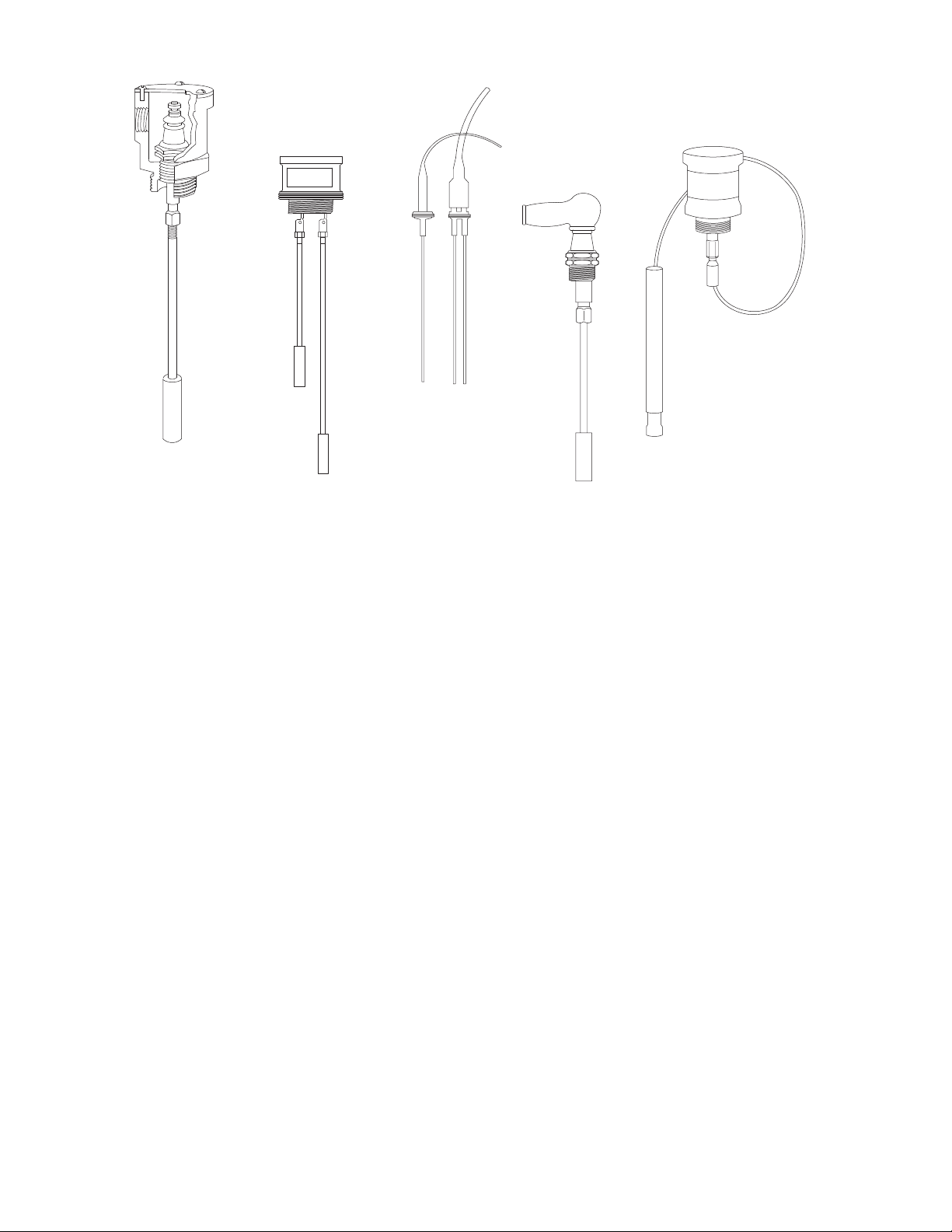

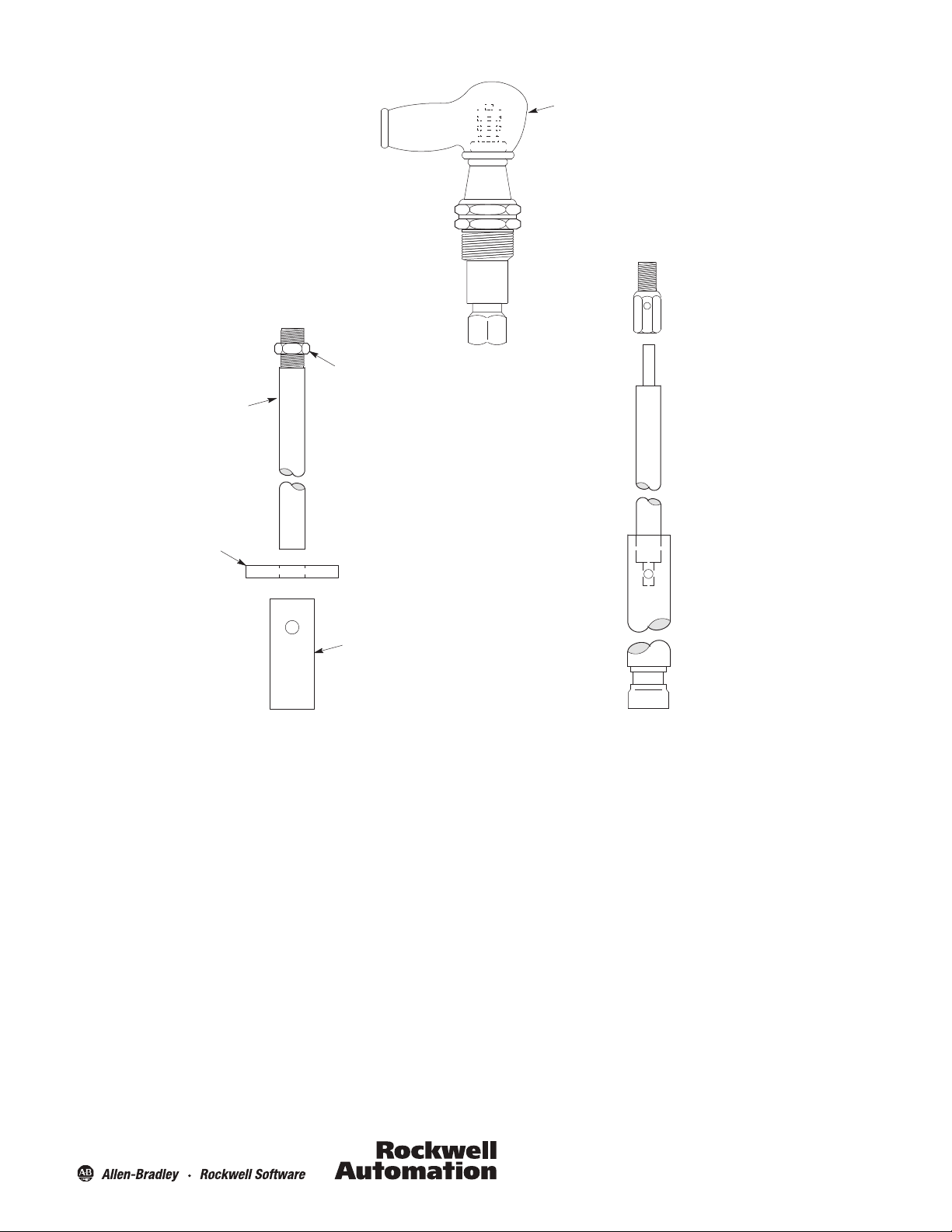

Figure 1: Probes for Level Controls Series 61, 63,

Type 61LF1

probe tting

with Type

64MR1 suspension

wire and tip

Type 61LJ2

probe tting

with

Type 64CR1

probe rods

and tips

Type 63GH1

and 63GH2

sanitary probe

tting and rod

assemblies

Type 61BD1

probe tting

with

Type 64CR1

probe rod

and tip

Type 61LF1

probe tting

with

Type 64CR1

probe rod

and tip

64

Probe Assemblies

A

selection

applications. The probe assembly consists

convenient insta

steel probe rod

desired length

provide the required surface

Figure 1 shows typical probe assemblies.

2

of

probe assemblies

lla

tion into

or

insulated suspension wire

for

the particular insta

a tank, vat,

is

available

or

lla

tion;

area at a point

for

a wide variety

of

a probe

fitting

of

threaded

other container; a stainless

which may be cut

and a probe

of

contact

with

tip

designed

the

to

the

liquid.

for

to

Series 61 probe fittings are ceramic insulated

which

may be used either alone

Sing

le

and double probe fittings are available. Series 63 sanitary probe

f

ittings are

Sanitary probes

Series 64 probe

suspension wire of

available

for

do not require probe tips

tip

assemblies are combinations

the desired length

or in

dairy and other food processing installations.

used with all Series 61 probe fittings

one

of

a variety

for sa

with

a suitable probe

.

with

stainless steel

of metal enclosures.

tisfactory opera

of

a probe rod

tip

trim

tio

n.

or

and are

Page 3

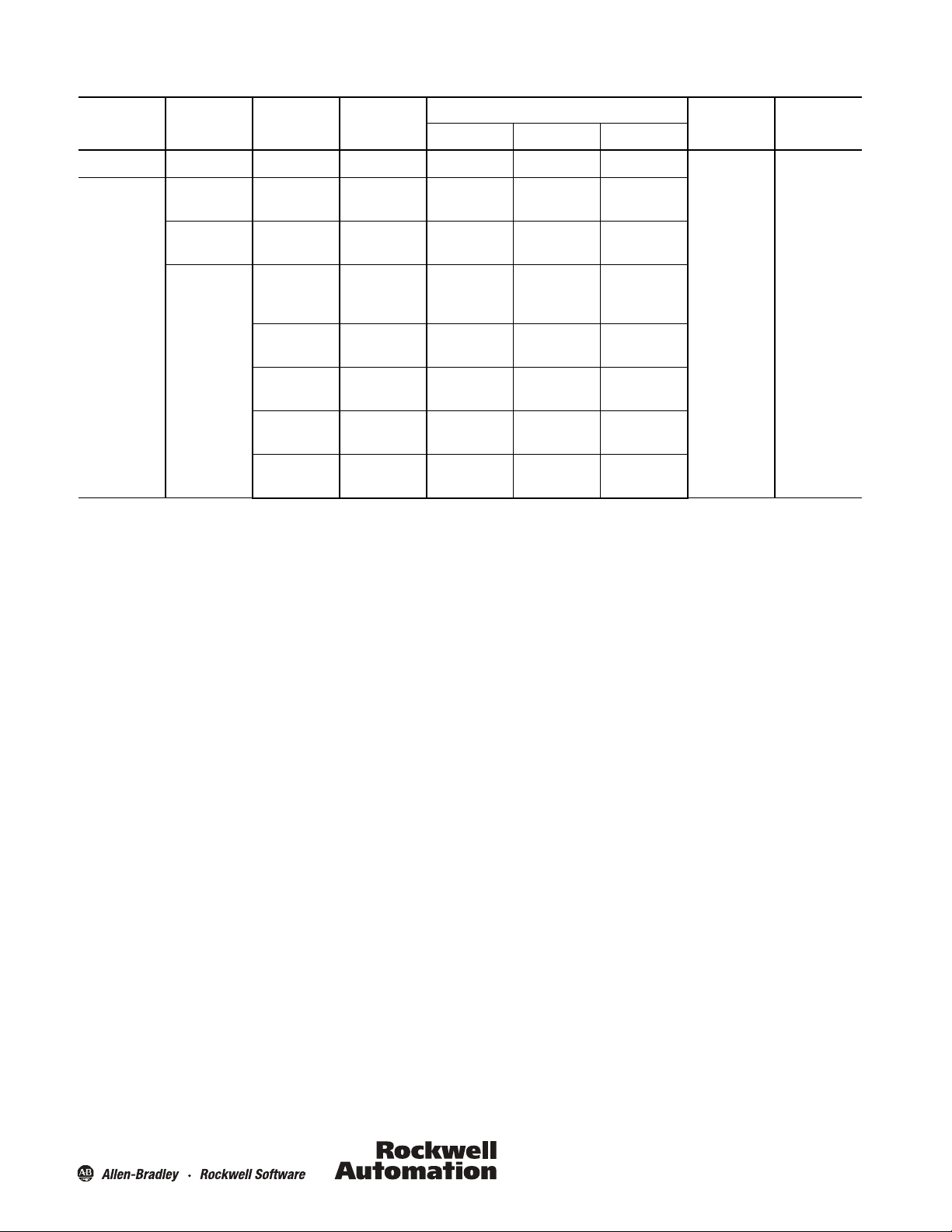

Tab le 1:

Level and Resistance Control

Output Characteristics

Bulletin Number Control Base Output Voltage Supply

13DJ3-3000 — — —

Response Time Resistivity RangeType Rati ng Leak age

60-1600B

60-1601B

8-670

supplied with

control base

8-651

8-652

63-116

63-115

Specifications

Power Consumption:

Resistivity Range:

Resistance Sensing Sensitivity:0--15 MegOhms

Maximum Probe Voltage

Maximum Probe Curren

:

t:

Solid State Output Signal:

Speed

of Response

P

ermissible

Ambient

Temperature

:

Lead Len

gth

:

:

3

watts (includes control base

Typical liquid resis

(See Table

22.5

65

12

0

.003 sec.

Up to

-- 4 0

5)

V A C

(Ranges

mA to 0

.001

V DC

open

circuit limited to

to 0

.20 sec. (See Table

2,000 ft (609.6 m) (See Table

to

135°F (--40

120V AC

50/60 Hz

240V AC

50/60 Hz

———

———

DPDT

EM

Relay

SPNO

TRIAC AC

SPNO

FET AC/DC

Volt age

DC Output

NPN Open

Collec tor

)

tivity 0--60 MegOhms • cen

in six ranges. (See Table

1, 2, &

3), 29

VA C

(Ranges

mA.

(See Table

6)

30mA short

7)

8)

Use #16

to 57°C)

5A, 120V AC

2.5A, 240V AC

1A, 120V DC

1A, 265V AC

20mA min.

30mA,

120V AC/DC

30mA,

24V DC

250mA,

24V DC

timete

r

6,

Consult factory for

4, 5, & 6)

(See Table

circuit.

Terminals #5 and #2 on Control Base

AW G wire minimum

—

1mA

10μA

—

1mA

higher ranges.

6)

Refer to Table 7 Refer to Table 6

)

.

3

Page 4

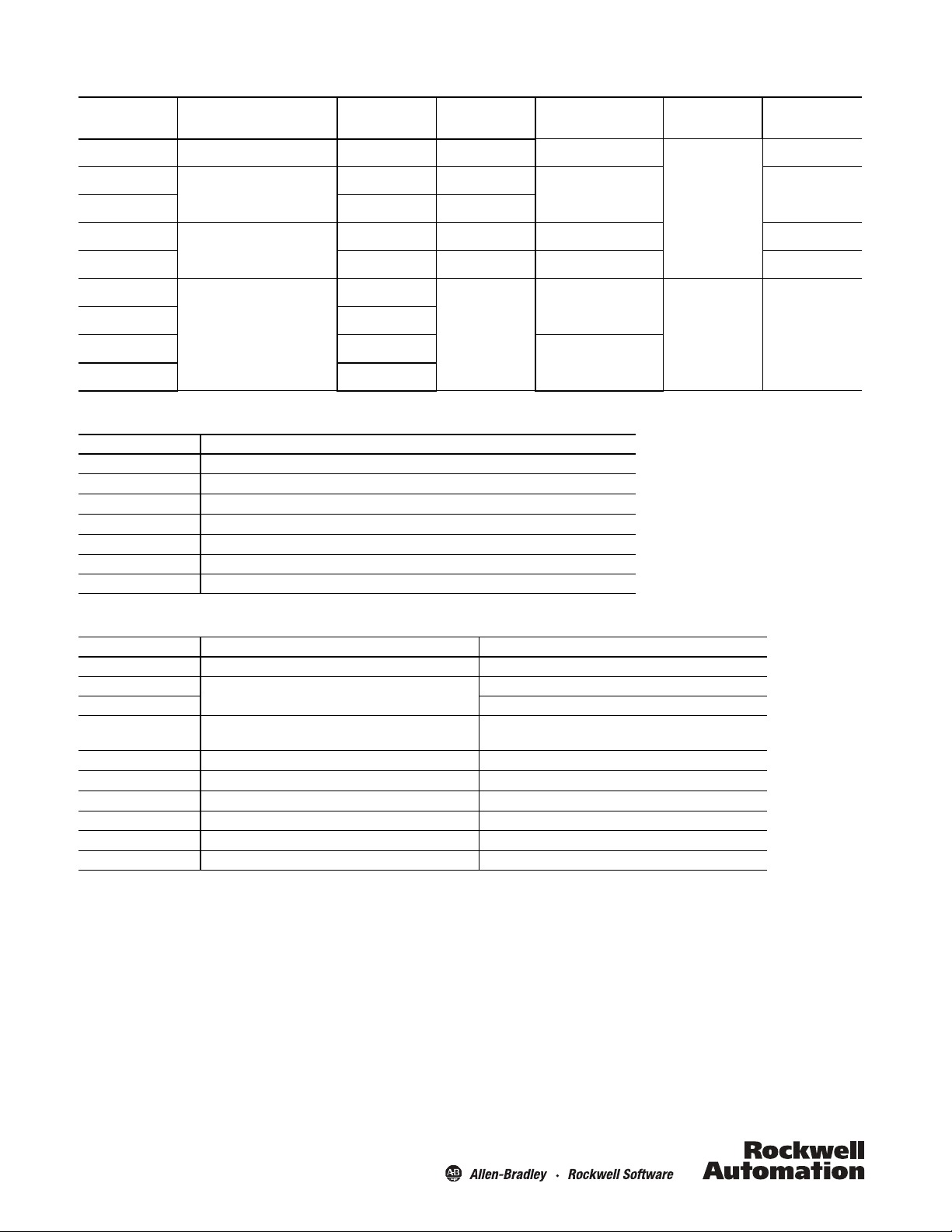

Tab le 2:

Probe Fittings

Bulletin Number Description Rods or Wires Used Housing Material Fitting Pipe Thread

Maximum

Temp era tur e

Maximum Pressure

psi

61BD1-1000 Probe fitting with rubber cap 1 None 1/2 in.

61LF1-1000

61LF1-1000M 316 Stainless Steel

61LJ2-1000

61LJ2-1000 316 Stainless Steel 200 (1,378 kPa)

63GH1-1000

63GH2-1000 2

63GJ1-1000 1

63GJ2-1000 2

Tab le 3:

Probe Rod Assemblies

Bulletin Number Description

64CR164CR164CR164CR164CR164CR164CR1-

Probe fitting in cast enclosure

Two probe fittings in cast enclosure

Special sanitary probe with 3 ft

(0.91m) probe rod(s) supplied with

10ft (3 m) cable and separable

connector

1000

1001

1002

1003

1004

1005

1006

316 Stainless Steel Probe Tip and 1/

316 Stainless Steel Probe Tip and 1/

316 Stainless Steel Probe Tip and 1/

316 Stainless Steel Probe Tip and 1/

316 Stainless Steel Probe Tip and 1/

316 Stainless Steel Probe Tip and 1/

316 Stainless Steel Probe Tip and 1/

4 in.

dia. x

4 in. dia. x

4 in. dia. x

4 in. dia. x

4 in. dia. x

4 in. dia. x

4 in. dia. x

2Bronze

Bronze 2 in. 250 (1,724 kPa)

1

None

12 in. (0.3 m) Probe

24 in. (0.61 m) Probe

36 in. (0.91m) Probe

48 in.

72 in. (1.83 m) Probe

96 in. (2.44 m) Probe

120 in. (3 m) Probe

(1.22 m) Probe

Rod

Rod

Rod

Rod

Rod

Rod

Rod

1 in. 200 (1,378 kPa)

Fits 1 1/2 in. LAMD 13H nut for

#15 Union Ferrule

Fits 2 in. LAMD 13H nut for

#15 Union Ferrule

300°F

149°C

212°F

100°C

250 (1,724 kPa)

—

Tab le 4:

Spare Parts

Part Nu mber Descrip tion Applic ation

3-

170

- 49-

1

21

21

- 50

- 224 1 1/2 in. diameter Teflon

31

33-

287

- 66

58

61-

3284

61-

3285

61

- 3288

61-

3519

Rubber

Cap

Connector and

10 ft (3 m) Cable

1/4-- 20 UNC Hex NutUsed with 64CR1 probe

Insulation Suspension Wir

316 SS 5/8?

diameter Suspension Wire Probe Ti

316 SS

Adap

tor Connects suspension wire to 61 Series pr

316 SS 9/1

6 in. diameter Probe Ti

Resistor

Packa ge

Assembly

Space

r Separates double probes when the long pr

e

p

p

For

61BD1

For 63GH2 -- 63G

For 63GH1 -- 63G

Used when the required probe length exceeds

Used when the required probe length exceeds

Required on all probe rods for rated

For

J2

J1

13DJ3--3000

assemblies

obes

sensitivi

obe

ty

exceeds

10 ft (3 m)

10 ft (3 m)

30 in. (76.2 cm)

4

Page 5

61BD1 Model 1000

also used in

61LF1- 61LJ2

all models

PROBE ROD

*PART NO.

31-- 224

1/2 in. NPT

PART NO. 33--287

NO. 3--170

RUBBER CAP

Suspension wire

adaptor and probe tip

assembly

SUSPENSION WIRE

ADAPTOR

NO. 61--3285

SUSPENSION WIRE

NO. 58--66

ORDER SEPARATELY

AND SPECIFY

REQUIRED LENGTH

Figure 2

*AVAILABLE AS OPTIONAL EXTRA WITH

DOUBLE PROBE ASSEMBLIES, WHEN

EITHER ROD EXCEEDS 30 INCHES

IN LENGTH.

PROBE TIP

NO. 61--3288

PROBE TIP ASSEMBLY

See Table 4 for further

description.

NO. 61--3284

5

Page 6

Tab le 5:

Typical Control Ranges and Probe Materials

Typic al Liqui d

Acetate Aci

d5

Ammonia6

Ammonium Chlori

Ammonium Iodi

Ammonium Nitrat

Ammonium Sulfate

Antibiotics

Barium Chlori

Barium Nitrat

Bee

Butyric Aci

Cadium Bromi

Cadium Chlori

Cadium Iodi

Cadium Nitrat

Cadium Sulfat

Calci um Chlori

Calci um Nitrat

Copper Chlori

Cupric Nitrat

Cupric Sulfat

Distilled Water

Formic Aci

Hydrobromic Aci

Hydrochloric Aci

Hydrofluoric Aci

Hydroiodic Aci

Lead Nitrat

Lithium Car

Lithium Chlori

Lithium

Lithium Iodi

Lithium Sulfat

Magnesium Chlori

Magnesium Nitrate

Magnesium Sulfate

Mercuric Bromi

Mil

Nitric Aci

Oxalic Aci

Phosphoric

Potassium

Potassium Bromi

Potassium Car

Potassium Chlori

Potassium

Potassium Fluori

Potassium

Potassium Iodi

Potassium Nitrat

Potassium Oxalat

Potassium Sulfat

de 5--25 2--10

de 10--50 2--12

e5

de 10--25 5--15

e4

r

d1

de 5--30 35--100

de 5--50 30--60

de 5--45 30--160

e5

e5

de 5--35 5--15

e6

de 10--35 10--15

e10

e

d5

d5

d5

d5

d

e20

bona

te

de 5--40 5--15

Hydroxide 1.25--7

de 10--25 5--20

e

de 5--28 10--20

de 0.223--0.422 40,000--60,000

k 200--2,000

d5

d3

Acid 10--87 5--20

Acetate10

de 10--36 2--10

bona

te

de 5--20 4--18

Cyanide 3--61

de 5--40 5--15

Hydroxide 5--40 2--5

de 10--55 5--18

e10

e

e

Concentration

(% by weight)

--

50 600--1,300

.4--

15 1,000--2,000

--

50 3--20

5--30 5--20

.2--8.4

--

20 1,000--2,000

--

48 10--20

--

36 20--70

--

50 10--20

--

35 10--15

2.5--17.5

--

60 100--200

--

15 2--5

--

40 1--5

--

30 3--20

58 1 SS

--

30 15--20

0

.2

.5

525 1 SS

10--17 10--12

5--25 20--40

--

60 1--5

.5--

712

--

30 4--18

5--50 5--20

--

20 5--12

10 11 1 SS

10 12 1 M

Resistivity Range

(ohms cm

)

200,000-- 2 M

Ω

30--50

200--2,000

20--100

20,000--200,000

300 1 SS

4--12

--

20

--

20

Control Range

2HC

2SS

1

1SS

1SS

1HC

5SS

1SS

1SS

1 or 2 SS

2SS

1SS

1SS

1SS

1SS

1SS

1SS

1SS

1

1SS

1SS

3SS

1SS

1HB

1HB

1

1SS

1SS

1SS

1SS

1M

1SS

1SS

3SS

1 or 2 SS

1SS

1SS

1HC

1SS

1SS

1SS

1SS

1SS

1SS

1M

1SS

1SS

Suitable Probe

Material

HB,

HC

HB,

HC

M,

HC

6

Page 7

Table 5: Typical Control Ranges and Probe Materials (continued

)

Typic al Liqui d

Potassium Sulfi

Propionic

Re

Silver Nitrat

Sodium

Sodium Car

Sodium Chlori

Sodium

Sodium Iodi

Sodium Nitrat

Sodium Sulfate

Sodium Sulfi

Strontium Chlori

Strontium Nitrat

Sulfuric Aci

Synthetic Late

Ta p w ate

Zinc Chlori

Zinc Sulfate

de 5--50 2--10

Acid 5--30 900--1,200

frigerant

s2

e10

Acetate20

bona

te

de 5--25 5--15

Hydroxide 20--50 5--20

de 10--40 5--20

e10

de 2--18 5--20

de 10--20 5--12

e10

d5

x2

r

de 10--40 10--15

Measured at normal room temperatur

Suitable probe materials

SS = 316 stainless steel (standard)

M = Monel

HB = Hastelloy B2

HC = Hastelloy C

Concentration

(% by weight)

--

60 5--20

--

30 15--18

5--15 10--20

--

30 7--12

10--15 8--12

--

40 10--15

--

50 1--10

5--30 20--100

e

Resistivity Range

(ohms cm

)

MΩ--20M

Ω

MΩ--20M

Ω

2,000--20,000

Control Range

1SS

2M

5 or 6 SS

1SS

1SS

1SS

1SS

1M

1SS

1SS

1SS

1SS

1SS

1SS

1HC

6SS

3SS

1M

1SS

Suitable Probe

Material

Tab le 6:

Level and Resistance Sensing Ranges

Liquid Resistivity

Range

1

2

3

4

5

6

0 --

600

600 -- 6,0

6,000 -- 60,0

60,000 --

.6MΩ -- 6M

6MΩ -- 60M

ohms

00

0.6M

Resistance

/cm

00

Ω

Ω

Ω

Sensing

0 --

150

Ω

150 -- 1,500Ω

1,500 -- 15,000Ω

15,000 --

150,000

150,000 -- 1.5M

1.5 -- 15M

Ω

Ω

Ω

Or

ange

Or

ange

Brown

330

Ω

Red

Viole

Red

2,700

Ω

Red

Viole

Or

ange

,000Ω

27

Red

Viole

Yellow

270

,000Ω

Red

Viole

Gr

een

2

.7M

Ω

Red

Viole

Blue

M

Ω

27

Range

Resistor

t

t

t

t

t

22.5

22.5

22.5

29

29

29

V AC

V AC

V AC

V DC

V DC

V DC

Maximum

Volts

Maximum

Current

65 m

AAc

8.33 m

ABee

0.83 m

A

0.1 mA

0.01 m

A

0.001 m

A

Typic al

Solutions

i

ds Bases Salts

r Milk Wat e r

Water Al

cohols

Wat e r

Alcohols Ammonia

Wat e r

tibioti

cs

An

Re

frigerant

Re

frigerants

Synthetic

Distilled

Distilled

s

Latex

Note:

All range resistors are 1/2 W ±

10% except Range

1, which is

2 W.

7

Page 8

Tab le 7:

Speed of Response (sec

Range

1

2

3

4

5

6

Ordering Instruct

onds)

Solid-State Outputs

O

N

0.0

03

0.0

035

0.0

04

0.0

06

0.0

23

0.1

90

ions

O

FF

0.0

60

0.0

60

0.0

60

0.0

60

0.0

60

0.1

90

1. Select 13DJ3--3000

2. Select Control Base

Bulletin Numbers Voltage Supply Description

60-

1600

B

60

- 1610

B

60

- 1601

B

60

- 1611

B

For NEMA 3, 4, 12, and 13; order open type

3.

Select Probe Fittin

Bulletin Number

61BD1-

1000

61LF1-

1000

LF1- 1000

61

61LJ2-

1000

61LJ2-

1000

Note

: 61 Series probe fittings require suitable Series

63GH1-

1000

63GH2-

1000

63GJ1- 1000

63GJ2- 1000

4.

Select Probe

Bulletin Number

64CR1-

1000

64CR1-

1001

64CR1-

1002

64CR1-

1003

64CR1-

1004

64CR1-

1005

64CR1-

1006

50/60

50/60

M

M

Rod Assemblies

Probe Tip and 1/

Probe Tip and 1/

Probe Tip and 1/

Probe Tip and 1/

Probe Tip and 1/

Probe Tip and 1/

Probe Tip and 1/

120

VA C

230

VA C

g

Probe fitti ng with rubber

Probe fitti ng in

Two probe fittings in cast

Special sanitary pr

probe

cable

Open

Ty p e

Hz

NEMA 1

Enclosure

Open

Ty p e

Hz

NEMA 1

Enclosure

base

and 61--4090

enclosure

.

Description

cap

cast enclosure

enclosure

64

probe tips and probe rod or suspension wires shown below.

obe

with

rod(s) supplied with 10 ft

and

separable

4 in. dia. x

4 in. dia. x

4 in. dia. x

4 in. dia. x

4 in. dia. x

4 in. dia. x

4 in. dia. x

3 ft (0.91 m)

(3 m)

connecto

r

for

61 Series Probe Fittin

Description

12 in. (0.3 m) Probe

24 in. (0.61 m) Probe

36 in. (0.91 m) Probe

48 in. (1.22 m) Probe

72 in. (1.83 m) Probe

96 in. (2.44 m) Probe

120 in. (3 m) Probe

Rod

Rod

Rod

Rod

Rod

Rod

Rod

O

N

0.0

0.0

0.0

0.0

0.0

0.2

Relay Output

12

13

14

18

33

00

Rods or

Wires Used

1

2

1

2

1

2

gs

Installati

The control

O

FF

0.0

70

0.0

70

0.0

70

0.0

70

0.0

70

0.2

00

or

the probe rod. Rods may be ordered

than required and cut

threaded

should be inserted in

For deep well

suspension

613288,

insulating

The probe rod

probe

61 Series fittings have a 1/4--20 female

thread

When the long probe

(0.76m), a Teflon

rod

For

tip to

Series 63 sanitary probes

made for special sanitary fittings.

union ferrule

nut

secured before

f

it

Series

the

on

point

for liquid level

breaks contact

with

the probe

to

for

connection

the probe

and other long probe applications over 10 ft (3 m),

wires and tips should be installed. Standard probe

is

used

with all probe rods. Special probe

sleeve,

is used with s

or

suspension wire

fitting

as fo

llows

:

of

the probe rod

or

of

any multiple probe assembly

insulating

immediately above the probe

suspension wire

prevent

are

supplied

1--1/2 in. ferrule,

63

probe rods are

assemblies, an insulating

it from

touching other surfaces

and

to

be secured

by

the customer and are soldered, brazed,

insertion

of

while

3 ft (0.91 m) long and are

job.

is

the point at which the

tip

and

is

to

size,

the desired length. One end

to

the probe

tip

fitting.

and held

uspension wir

adaptor 61--3285

thread

suspension wire adaptor

spacer 31--224,

tip to

prevent the rods

for

dairy and food

The probe insulator

with

a #13H union nut. The ferrule

the probe assembly. Probes 63GH1 and 63GH2

probes 63GJ1 and 63GJ2

liquid

determined

or

may be supplied longer

by

of

the rod

the length

is

The unthreaded (cut) end

by

means

of

a set screw.

tip

tip

61--3284

with

e.

is

connected

to

receive the 1/4--20 ma

to the

.

is

over

30 in.

is fitted

over the short probe

from

touching.

sleeve

fits

over the probe

.

indus

try

applications are

is

made

to fit

or

otherwise

fit a 2 in. ferrule.

to

be cut

to

length on

makes

of

le

a #15

and

All

Mounting

The 13DJ3 controls may be mounted

par

titio

n, panel board, bracket,

enclosure

place

is

being mounted, the control base should be stored

to avoid

moisture and mechanical damage

The enclosure mounting hole dimensions are shown on

sheet metal, wood

use

d.

When the housing has been securely fastened,

conduits

to

or

machine screws, bolts,

the housing

in

the knock out holes provided and replace the

control base.

The

wiring

between the control

lengths listed below.

Tab le 8:

Maximum Recommended Cable Lengt

Range

1

2

3

4

5

6

Cable Length

2000 ft (

1000 ft (

500 ft (

2000 ft (

2000 ft (

150 ft (45.7 m)

in

any position

or similar support.

on a sturdy wa

While

the

NEMA

in a safe

.

page 12

or similar fasteners

may be

connect the cables

and the probes should not exceed the

h

609

.6 m)

304

.8 m)

152

.4 m)

609

.6 m)

609

.6 m)

and

ll,

or

8

Page 9

Resistor Selecti

ATTENTION

Do not

run probe

or

reset leads

in

same

conduit with

power lines

or high

current

carrying c

onductors.

.188

(4.8)

NEMA 1 #61- 3322- 3

3.938

(100)

.875 (22.2)

5.25

(133.4)

5.938

(150.8)

7.25

(184.1)

4.875

(123.8)

.375

(9.5)

.688

(17.5)

5.938

(150.8)

.812

(20.6)

3.875

(98.4)

.375

(9.5)

.875 DIA. ( 22.2)

8 K.0.’S TOTAL

*

*

*

*

TYP.

1.188

(30.2)

1.063

(27)

*

*

NEMA 3, 4, 5, 12 & 13

#61- 4090

4

(101.6)

8.75

(222.2)

9.5

(241.3)

.375

(9.5)

6.25

(158.7)

4.875

(123.8)

.625 (15.9)

.312 (7.9)

HOLE (4)

8.25

(209.5)

When the resis

select

the range resistor that corresponds

tivity

on

of

the

liquid is

known, convert

to

the resis

5.

When the resis

probe

For operation

connect

s

hou

ld

until the relay energizes.

tivity

of

the

tip

1/16 in. (1.5 mm)

with

the relay energized

the

Range 1 resistor (330 ohms)

energize.

If it

does not, use successively higher range resistors

If

liquid is

not known, immerse the high level

into

the

liquid.

relay action

with

the probe immersed,

to

Ter m i n a l s 1 and

is

sluggish, use the next higher

range resistor.

For operation

c

onnect the Range 1 resistor (330 ohms)

s

hou

ld

until the

range res

Note:

with

the relay de-energized

de-energize.

If it

relay de-energizes.

does not, use successively higher range resistors

If

relay action

with

to

Ter m i n a l s 1 and

is

sluggish, use the next higher

istor.

For resistance sensing applications, use the values of

resistance sensing sensitivity listed in Table

probe circuit resistivity for selection

resistor.

Note:

Wiring for

Ranges 1--2--3 differs from

wiring instructions in Wiring Diagrams

to

ohms • cm and

tivity range

2.

The relay

in

the probe immersed,

3.

The relay

6 in place of

of

the proper r

Ranges

ange

4--5--6. Follow

in Figures 6--11.

Ta b l e

Outline and Mounting Dimension

Unless otherwise indicated, dimensions shown are

parentheses are

in millimeters

.

s

in

inches. Those

in

Wiring

All external wiring

applicable local

Wire

no smaller than 16

Since the 13DJ3 control operates

resistance, the insulation

the probe must be extremely high.

to

plas

tic

insulated wire to

moisture

with

probes are furnished

cable assembly

or crack and permit leakage paths

paper,

should conform

codes. See

wiring

AWG is recommende

resistance

to

diagrams

with

liquids

of

the

It is

the Na

tional

for external

d.

having high electrica

wiring

important, therefore,

insure that the insulation will

to

develop. Wires insulated

cotton,

asbestos, etc. must not be used. Series 63 sanitary

with

a molded separable connector and

.

Electric Code and

connections.

l

connecting the control

to

use

not absorb

10 ft (3 m)

Figure 3

Figure 4

9

Page 10

Figure 5

Open Type

5.25

(133.3)

4.781

(121.4)

.25

.031

(.8)

1.25

(31.7)

2.5

(63.4)

3.125

(79.4)

.531

(13.5)

EITHER MAY BE USED FOR

THIRD MOUNTING HOLE

#8 SCREW

TERMINALS

(16)

4 MTG. HOLES

.185 DIA.

(2.54)

2.375

(60.3)

2.25

(57.1)

3.625

(92.1)

WITH INSTALLED PLUG-IN MODULE

.375

(9.5)

Low Level Alarm

INC

IN0

IC

L1

2NC

2N0

2C

L2

13DJ3-- MODEL 3000

PLUG-IN

CONTROL MODULE

1

2

3

4

8

7

0

5

LINE VOLTAGE

ALARM

RANGE

RESISTOR

Single probe low level alarm. The relay is de-energized with

probe immersed and energized with probe out of liquid.

Connections are shown for operation on ranges 1, 2 & 3.

For operation on ranges 4, 5 & 6, connect range resistor to

terminal “4” instead of terminal “3.”

Tank must be grounded

Low Level Alarm

Self-Latching with Push Button Reset

Tank must be grounded

INC

IN0

IC

L1

2NC

2N0

2C

L2

13DJ3-- MODEL 3000

PLUG-IN

CONTROL MODULE

1

2

3

4

8

7

0

5

LINE VOLTAGE

ALARM

RANGE

RESISTOR

Single probe low level alarm with electronic latching & push

button reset. The relay is de-energized with probe immersed

and energized with probe out of liquid. Connections are shown

for ranges 1, 2 & 3. For operaion on ranges 4, 5 & 6, connect

range resistor to terminal “4” instead of terminal “3.”

N.C. RESET

SWITCH

Typical Series 13DJ3 Wiring Diagrams

Figure 6

10

Figure 7

Page 11

Figure 8

High Level Alarm

INC

IN0

IC

L1

2NC

2N0

2C

L2

13DJ3-- MODEL 3000

PLUG-IN

CONTROL MODULE

1

2

3

4

8

7

0

5

LINE VOLTAGE

ALARM

RANGE

RESISTOR

Single probe high level alarm. The relay is de-energized with

probe immersed and energized with probe out of liquid.

Connections are shown for operation on ranges 1, 2 & 3.

For operation on ranges 4, 5 & 6, connect range resistor to

terminal “4” instead of terminal “3.”

Tank must be grounded

+

--

SOLID

STATE

OUTPUT

12 V MIN

High Level Alarm

Self-Latching with Push Button Reset

Tank must be grounded

INC

IN0

IC

L1

2NC

2N0

2C

L2

13DJ3-- MODEL 3000

PLUG-IN

CONTROL MODULE

1

2

3

4

8

7

0

5

LINE VOLTAGE

ALARM

RANGE

RESISTOR

Single probe high level alarm with electronic latching & push

and energized with probe out of liquid. Connections are shown

for ranges 1, 2 & 3. For operation on ranges 4, 5 & 6 connect

range resistor to terminal “4” instead of terminal “3.”

N.C. RESET

SWITCH

Pump Up Constant Level Control

INC

IN0

IC

L1

2NC

2N0

2C

L2

13DJ3-- MODEL 3000

PLUG-IN

CONTROL MODULE

1

2

3

4

8

7

0

5

LINE VOLTAGE

PUMP

RANGE

RESISTOR

A double probe installation, used for pump-up constant level

control. The relay is de-energized when the upper probe is

immersed and does not energize until the liquid drops below

the lower proble. Connections are shown for ranges 1, 2 & 3.

For operation on ranges 4, 5 & 6 connect range resistor to

terminal “4” instead of terminal “3.”

Tank must be grounded

+

--

SOLID

STAT E

OUTPUT

12 V MIN

Figure 10

Pump Down Constant Level Control

LINE VOLTAGE

Figure 9

PUMP

INC

IN0

IC

L1

2NC

2N0

2C

L2

13DJ3-- MODEL 3000

PLUG-IN

CONTROL MODULE

RANGE

RESISTOR

1

2

3

4

8

7

0

5

A double probe installation, used for pump-down constant

level control. The relay is energized when the upper probe is

immersed and de-energized when the liquid drops below the

lower proble. Connections are shown for ranges 1, 2 & 3. For

operation on ranges 4, 5 & 6, connect ground to terminal “4”

instead of terminal “3.”

For insulated tanks, a grounded third probe must

must be added as shown. If an additional wire is

run between the control ground and the third probe,

it should be grounded at the control.

Figure 11

11

Page 12

61 Series Probe Assemblies

Pump Down Constant Level Control

INC

IN0

IC

L1

2NC

2N0

2C

L2

13DJ3-- MODEL 3000

PLUG-IN

CONTROL MODULE

1

2

3

4

8

7

0

5

LINE VOLTAGE

PUMP

RANGE

RESISTOR

A double probe installation, used for pump-down constant

level control. The relay is energized when the upper probe is

immersed and de-energized when the liquid drops below the

lower probe. Connections are shown for ranges 1, 2 & 3. For

operation on ranges 4, 5 & 6, connect range resistor to terminal

“4” instead of terminal “3.”

For insulated tanks, a grounded third probe

must be added as shown. If an additional wire

is run between the control ground and the

third probe, it should be grounded at the

control.

1.812 (46)

3.5

(88.9)

.5 (12.7)

1

(25.4)

1/2--14 NPT

1/4--20 NC2

.375 (9.5)

1/2--14

NPSC

WEEP HOLES

(3)

VIEW WITH

COVER REMOVED

2.125 DIA.

(54)

1.812

(46)

2.437

(61.9)

2.438

(61.9)

LH

VIEW WITH

COVER REMOVED

3.125 DIA.

(76.2)

1/2--14

NPSC

2.875 DIA.

(73)

.812 (20.6)

61BD1

Figure 12

Figure 11

A

12

1--11 1/2

NPT

.625 (15.9)

61LF1

63 Series Probe Assemblies

#13--H UNIONNUT

(SUPPLIED BY CUSTOMER)

POLARIZED

CONNECTOR

(TO PREVENT

INTERCHANGING

OF PROBE WIRES)

PROBE

INSULATOR

#15 UNION FERRULE

(SUPPLIED BY CUSTOMER)

SOLDER FERRULE

TO TANK FOR

MOUNTING

FITTING

INSULATOR

(TO PREVENT

PROBE RODS

FROM TOUCHING)

Type 63GJ1

63GH1

Figure 13

.625 (15.9)

Type 63GJ2

63GH2

61LJ2

PROBE WIRE

TO CONTROL

*NOTE:

FOR TYPES 63GJ1

AND 63GJ2

USE 2 FITTINGS

FOR TYPES 63GH1

AND 63GH2

USE 1 1/2 FITTINGS

PROBE

(CUT TO LENGTH

ON INSTALLATION)

2--11 1/2

NPT

Page 13

Figure 14

2

(50.8)

1.125

(28.6)

.562 DIA.

(14.3)

.25 DIA.

(6.35)

1/4--20 UNC

.75

(19)

“A” DIM.

6

(152.4)

61--3284

.875 DIA. (22.2)

PROBE TIP

NO. 316 S.S.

INSULATED

1.25

(31.8)

.312 (7.9)

61--3285

ADAPTER

NO. 316 S.S.

7/16 HEX (11.1)

58--66

.281 DIA. (7.1)

NO. 16 S.S. WIRE,

INSULATED

WITH GEON

LENGTH TO BE

SPECIFIED BY

CUSTOMER

64CR1

1/4-- 20 NC2

HEX NUT,

NO. 316 S.S.

64 Series Probe Assemblies

13

Page 14

14

Page 15

15

Page 16

13DJ-2.0 Ver 02

February 2013

Printed in USA

Loading...

Loading...