Rice Lake 920i User Manual

920i Based Truck In/Out System

Software Application

Version 1.01

Operator’s Manual

78855 Rev A

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction and System Overview.............................................................................................. 1

2.0 Supervisor Mode.......................................................................................................................... 2

2.1 Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Report Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.1 Print Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.2 Set EOL Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.3 Report Printer Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.4 Printer Ticket Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.5 View Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.6 Format Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5.7 Clear Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Transactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.9 Set Date Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.10 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.0 Scale Select............................................................................................................................... 13

4.0 Weighing.................................................................................................................................... 14

4.1 Weigh In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.1 Customer Selection - Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.2 Product Selection - Optional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.3 Project Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.4 Weigh In Canceled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Weigh Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.1 Truck Number or Transaction Lookup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Weigh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.1 Customer Selection - Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.2 Product Selection - Optional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.3 Project Selection - Optional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.0 Appendix .................................................................................................................................... 21

5.1 Serial Port Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.1 Required 920i Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Default Ticket Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EPD Software License Agreement......................................................................................................... 24

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

Version 1.01 May 2, 2014 3:00 pm

Contents i

ii 920i Based Truck In/Out Weigh Program

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

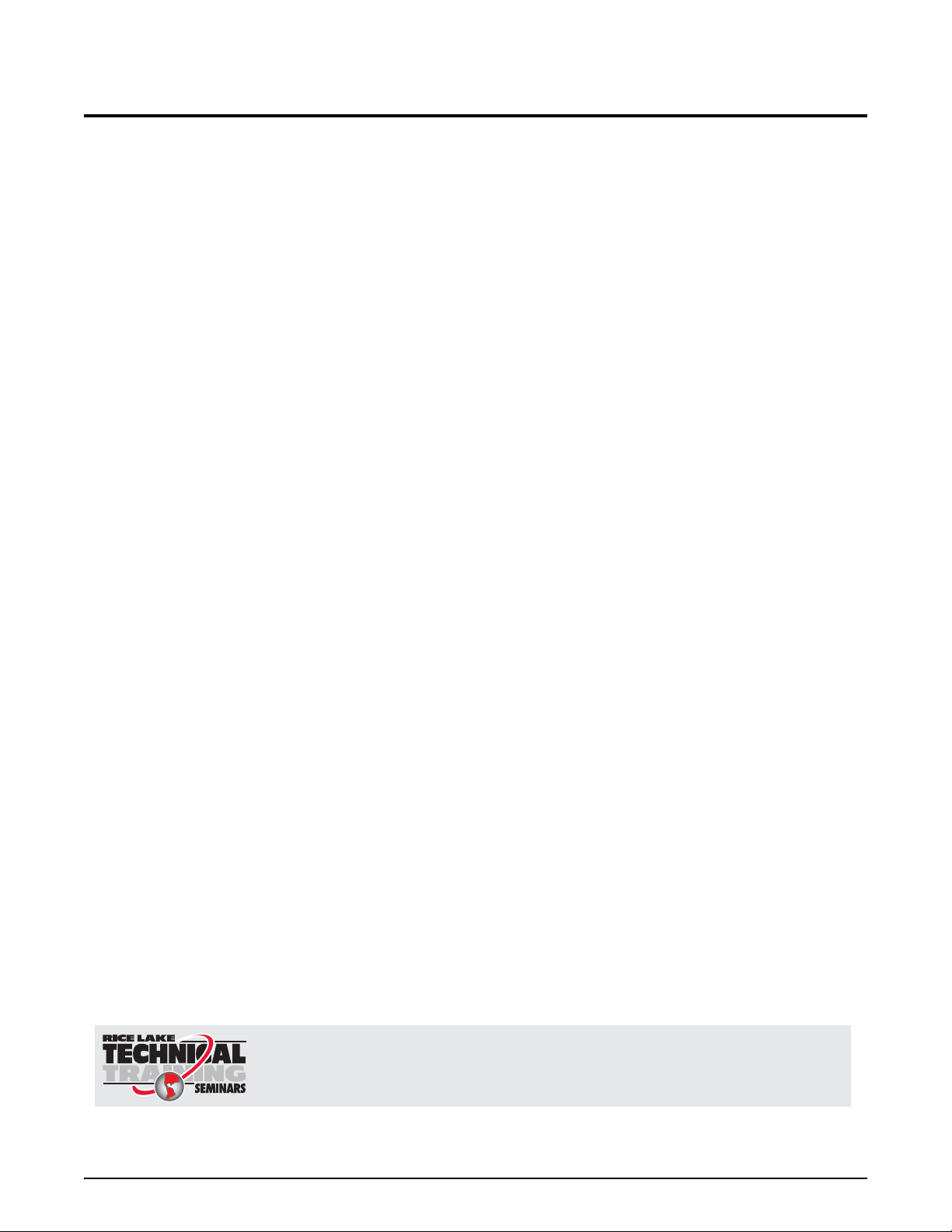

1.0 Introduction and System Overview

Weigh

Weigh Out

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

Supervisor

Mode

Select

=>

Scale

#1

Truck

Ta re

Gross

Customer

Product

Project

Net

Weigh In

Scale

Select

This manual provides information on using a truck in/out weighing program (PN 77297) for manual truck

transactions using Rice Lake Weighing System’s 920i digital weight indicator. Stored IDs let you keep a database of

truck IDs, customer product and project information, and weigh-in weights in the indicator’s memory and are

accessed by simply scrolling through the

automatically store up to 100 truck ID’s and tare weig hts, 9 50 customers, 1000 products, an d 1000 projects.

While this manual gives basic information about this program, it only addresses those settings that are important to the

operation of the truck in/out program. For further information on the installation, configuration, and operation of the

920i, consult the 920i Installation Manual, PN 67887.

To install the truck in/out program onto your 920i programmable indicator, it must be in configuration mode before

.cod file can be sent. You can send the .cod file directly from iRev by using the Download Configuration... selection

the

Communications menu and specifying that you want to send the .cod file.

on the

The following main menu screen is shown.

Supervisor main menu using the down arrow on the 920i. The 920i can

The main screen consists of general information that will be added as information is accessed from the database.

Weigh Select this softkey to do a single weighment

Weigh In Allows truck ID entry; generates weigh-in ticket

Weigh Out Allows truck ID entry; generates weigh-out ticket

Scale Select For multi-scale applications, provides a prompt to enter the scale number to be displayed

Supervisor Mode Allows information to be added to the database

All of the softkeys access additional function parameters and are explained in further detail in the following sections.

Figure 1-1. Main Screen

Softkey Description

Table 1-1. Softkey Descriptions

Introduction and System Overview 1

2.0 Supervisor Mode

Exit to

Weigh

Set Date/

Time

10/22/07

08:05AM

SCALE #1

Clear

1

2

3

4

Product

Customer

8

7

6

5

Edit

Edit

Edit

Edit

Go to

Edit

Change

Truck

Project

Report Name

Transactions

Password

System

Diagnostics

Within the supervisors screen you are able to enter/edit customers, products, trucks, projects, and access report

functions.

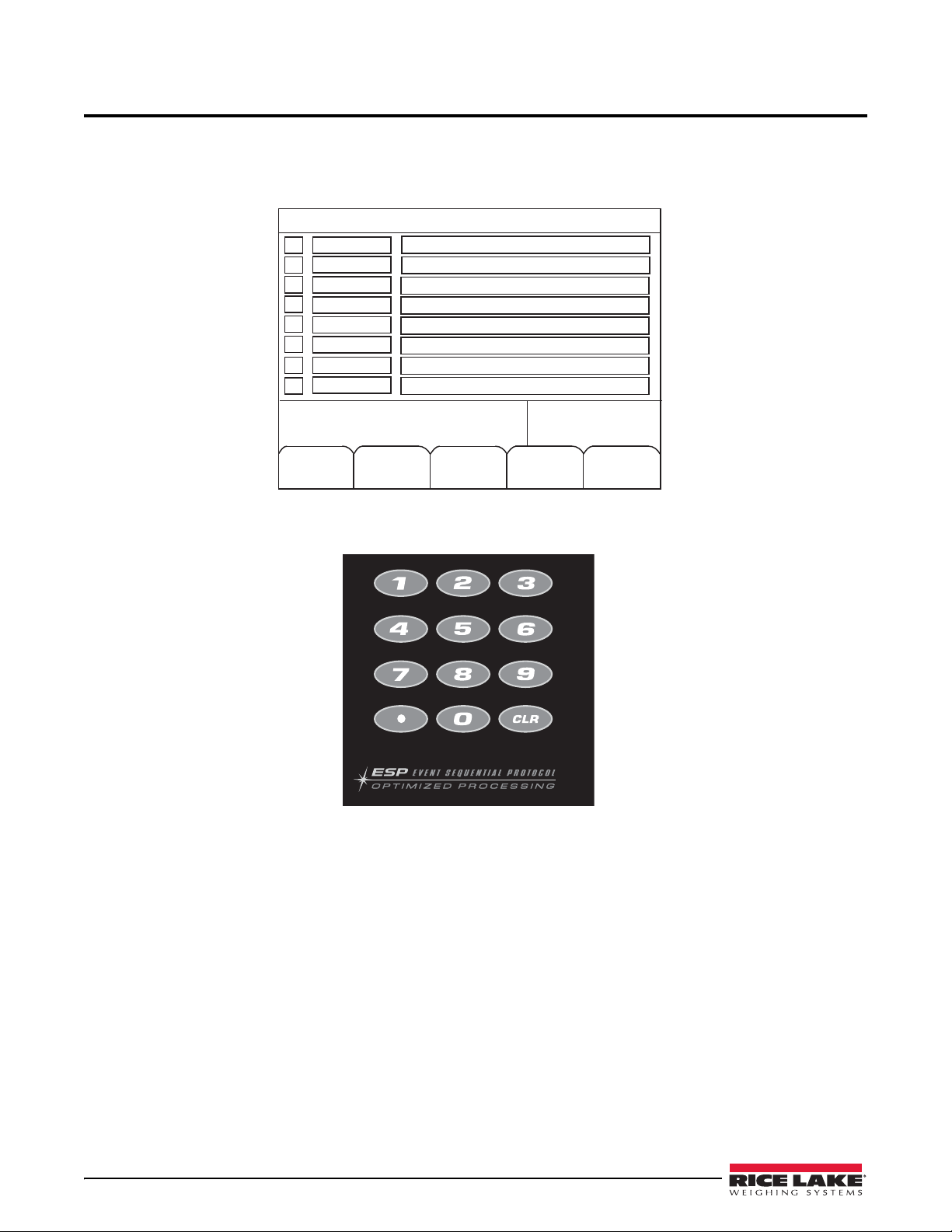

1. Press the

shown in Figure 2-1.

2. Using the numeric keypad on the 920i or the front panel keypad, select the desired field.

Supervisor Mode softkey from the main menu screen to access the supervisor menu main screen,

Figure 2-1. Supervisor Menu Main Screen

Figure 2-2. 920i Numeric Keypad

2 920i Based Truck In/Out Weigh Program

2.1 Customer

Exit to

Weigh

06/08/13

08:05AM

SCALE #1

Phone

1

2

3

4

7

6

5

ID

Name

Address 1

Address 2

Address 3

Accum

Enter Selection Number

Menu/

Cancel

Customer

Home

Cancel

10/22/13

08:05AM

SCALE #1

End

Customer

Enter ID

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

a b c d e f g h i j k l m n o p q r s t u v w x y z

! # $ & ? ( ) < > + * % = / \ “ . , : ; ‘ | ~[ ] { }

1

4

3

2

5

6

ID

Name

Address 1

Address 2

Address 3

Phone

Note

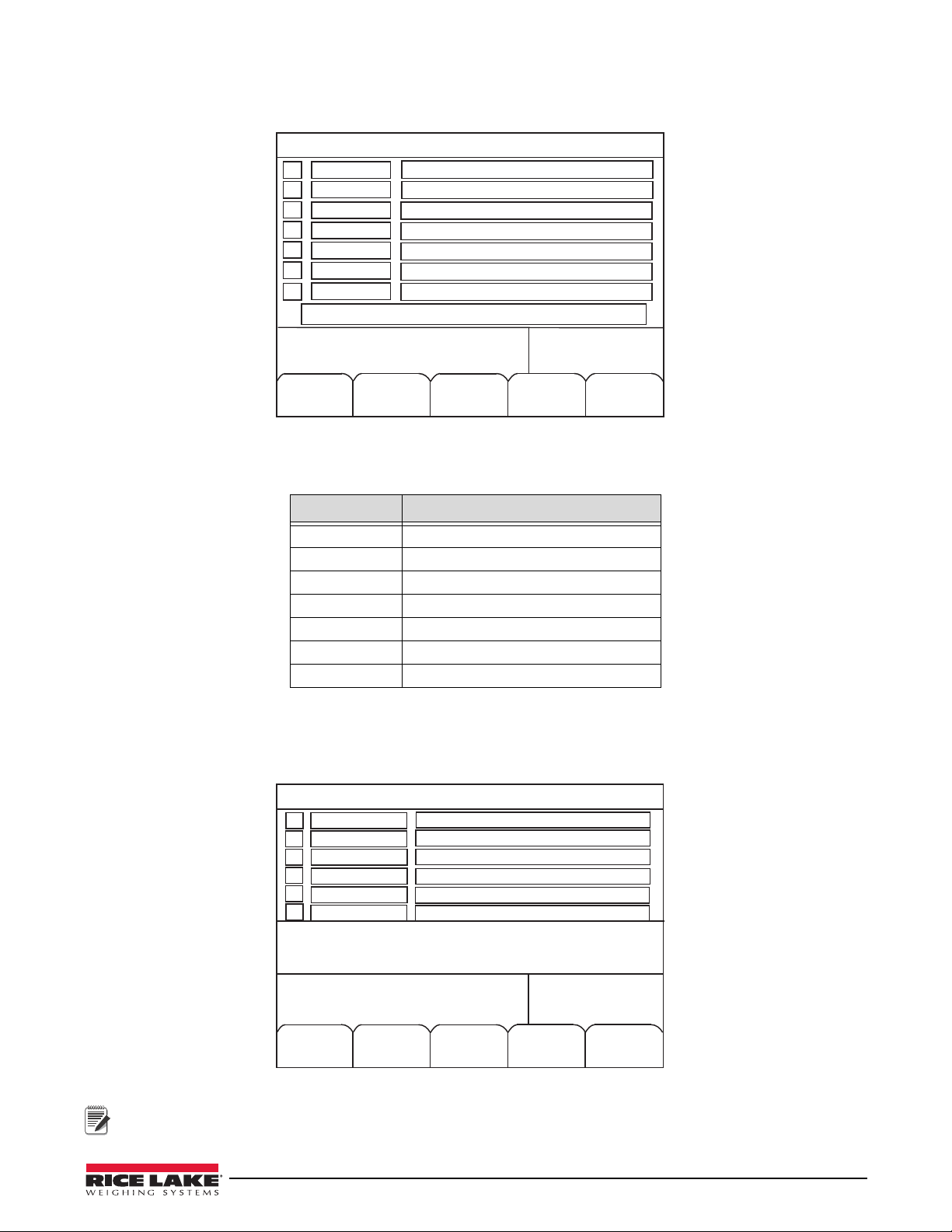

1. Select 1 - Customer, to access the customer entry screen, shown in Figure 2-3.

Figure 2-3. Customer Entry Screen

2. Enter the field number to be edited using the numeric keypad. The following table lists the amount of

characters allowed for each field.

Field Characters Allowed

ID 16 character alphanumeric

Name 20 character alphanumeric

Address 1 20 character alphanumeric

Address 2 20 character alphanumeric

Address 3 20 character alphanumeric

Phone 20 character alphanumeric

Accum Can’t edit, view only

Table 2-1. Customer Entry Character Parameters

3. Enter customer information using the

menu.

4. Move the cursor back down to the

When entering the customer ID, if it is not currently found in the program, the on-screen prompt tells you that it’s

not found, but adding that entered customer ID number. Press the Save softkey to save the new customer ID.

up/down, right/left navigation keys, to scroll through the alpha-numeric

Enter line and press enter to save.

Figure 2-4. Customer Entry ID Screen

Supervisor Mode 3

You can use the up/down arrows on the navigation pad on the 920i to scroll through and view customer

Note

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

ID

Name

Rate

Accum

Total

Enter Selection Number

Menu/

Cancel

Products

information already entered into the database.

5. Enter other customer parameters, using the same steps.

6. When complete, press the

Exit to Weigh softkey to access the weigh screen or the Menu/Cancel softkey to go to

the Supervisor main menu.

2.2 Product

1. Select 2 - Product, from the Supervisor’s main menu to access the product parameter screens.

Figure 2-5. Product Entry Screen

2. Enter the field number to be edited on the numeric keypad. The following table lists the amount of characters

allowed for each field.

Field Characters Allowed

ID 16 character alphanumeric

Name 20 character alphanumeric

Rate Numeric

Accum Can’t edit/view only

Total Can’t edit/view only

Table 2-2. Product Entry Character Parameters

3. Use the

up/down navigation keys, to scroll through the alpha-numeric menu to edit or enter the product

information.

4. Press

enter to save the values. Additional entries can be made by using the navigation keys to add additional

products.

5. When complete, use the

Menu/Cancel softkey to go to the Supervisor Main Menu screen.

4 920i Based Truck In/Out Weigh Program

2.3 Truck

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

ID

Ta re

Descrip

Accum

Enter Selection Number

Menu/

Cancel

Trucks

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

ID

Name

Descrip 1

Descrip 2

Enter Selection Number

Menu/

Cancel

Projects

Accum

1. Select 3 - Truck , from the Supervisor’s main menu to access the truck parameter screen.

Figure 2-6. Truck Entry Screen

2. Enter the field number to be edited on the numeric keypad. The following table lists the amount of characters

allowed for each field.

Field Characters Allowed

ID 16 character alphanumeric

Tare Numeric (keyed or from scale)

Descrip 20 character alphanumeric

Accum Can’t edit/view only

Table 2-3. Truck Entry Character Parameters

3. Using the

4. Press

up/down navigation keys, to scroll through the alpha-numeric to edit or enter the truck information.

Save softkey to save the values. Additional entries can be made by using the navigation keys to add

additional truck numbers.

5. To store a tare value taken from the scale, press the

2 key after selecting an ID and press enter with nothing

entered. This stores the the current weight on the scale as the tare.

6. When complete, use the

Menu/Cancel softkey to go to the Supervisor Main Menu screen.

2.4 Project

1. Select 4 - Project from the Supervisor’s main menu to access the project parameters screen.

Figure 2-7. Project Entry Screen

Supervisor Mode 5

Loading...

Loading...