Installation Instructions | Installationsanleitung | Notice d’installation

Istruzioni per l’installazione | Instrucciones de instalación

Sartorius

YDO01M-232 (A11)

YDO01M-232CLK (A31)

YDO01M-232CO (A1)

YDO01M-485 (A2 | A3)

YDA01M-20MA (A9)

YDO01M-IO (A5)

YDO01M-EN (B9)

Data Output Port for Midrics® COM1 and UniCOM Interfaces

Datenausgang für Midrics®-Schnittstellen COM1 und UniCOM

Port de sortie pour interfaces Midrics® COM1 et UniCOM

Porta in uscita per interfacce Midrics® COM1 e UniCOM

Puerto de salida para interfaces COM1 y UniCOM de Midrics®

98647-004-16

2

English – page 3

In cases involving questions of interpretation, the German-language version shall prevail.

Deutsch – Seite 20

Im Auslegungsfall ist die deutsche Sprache maßgeblich.

Français – page 37

En cas de questions concernant l’interprétation, la version en langue allemande fera autorité.

Italiano – pagina 54

In caso di interpretazione dubbia, fa testo la versione in lingua tedesca.

Español – página 71

En caso de interpretación, la versión en lengua alemana será determinante.

3

Intended Use

The YD.01M-... data output port is

designed for installation in Midrics®

model MIS... and MW... display and

control units and complete scales as an

optional standard COM1 interface or

UniCOM universal data interface.

For COM1:

– YDO01M-232 (Option A11):

Bidirectional RS-232 data interface.

You can connect the following to the

YDO01M-232 port: Printer (YDP02IS,

YDP03, YDP04IS, YDP12IS, universal

printer) or computer (SBI, XBPI or SMA

operation).

– Alibi memory

– YBT01 external Bluetooth adapter

– YRD02Z second display

– USB adapter cable, for connecting

a computer over USB (part no.

YCC01IS).

– YDO01M-232CLK “Clock" (Option A31):

As standard RS-232, plus date/time

For UniCOM:

– YDO01M-232CO (Option A1):

as for RS-232, plus digital I/O (TTL/5V)

– YDO01M-485 (Options A2 and A3):

Bidirectional data interface, electrically

isolated, for use with the RS-422

(Option A2) or RS-485 (Option A3) protocol.

The YDO01M-485 lets you network up

to 32 Midrics scales/display and control

units in an XBPI-bus.

– YDA01M-20MA (Option A9):

Analog output port for use as a current

interface (0/4 to 20 mA, 0 - 24 mA) or

voltage interface (0 to 24 volts).

The YDA01-20MA module enables connection of a PLC system or a remote

analog display unit.

– YDO01M-IO (Option A5):

Digital input/output module; for connecting Midrics equipment to external

controllers.

– YDO01M-EN (Option B9):

Ethernet interface (e.g. for connecting

to a PLC or PC).

Symbols

The following symbols are used in

these instructions:

§ indicates required steps

$ indicates steps required only under

certain conditions

> describes what happens after you

have performed a particular step

! indicates a hazard

Contents

3 Intended Use

4 Installation in the Display and

Control Unit

4 Installing the COM1 PCB

5 Installing the UniCOM PCB

7 Installing the Interface Cable

8 Configuring the Interface Module:

YDO01M-485, YDA01M-20MA

10 YDO01M-IO: Specifications

10 YDO01M-EN

11 Pin Assignment Charts

11 COM1

11 UniCOM

12 Configuring COM1 and UniCOM

16 Synchronization

17 Data Interfaces

17 Data Input Format (Commands)

18 Data Output Format

19 GMP-compliant Printouts

4

Installation in the Display and Control Unit

Installation

Installation of the interface module in the Midrics display and control unit (and additionally the installation of the cable gland and connection of the connecting cable to the terminal screw strip) is only required if the Midrics display and control unit was not

equipped at the factory with this data output in accordance with the customer's order.

Notes:

§ The interface module should be installed by a certified technician who has received

specialized training from Sartorius.

§ IP65 protection:

Make sure to use the connecting cable with screw-lock hardware designed for the interface module in question (see “Accessories").

!Make sure to disconnect the equipment from power before beginning installation.

!Any installation work that does not conform to the instructions in this manual will result

in forfeiture of all claims under the manufacturer's warranty.

!Installation work that affects the IP65 protection rating must be performed with extreme

care.

The cable gland (IP65 protection) for connection of the interface to the display and control unit is covered by a protective cap. Please use extreme caution when performing any

work on the equipment that affects this cable gland.

§ To open the display and control unit, remove the screws from the front panel.

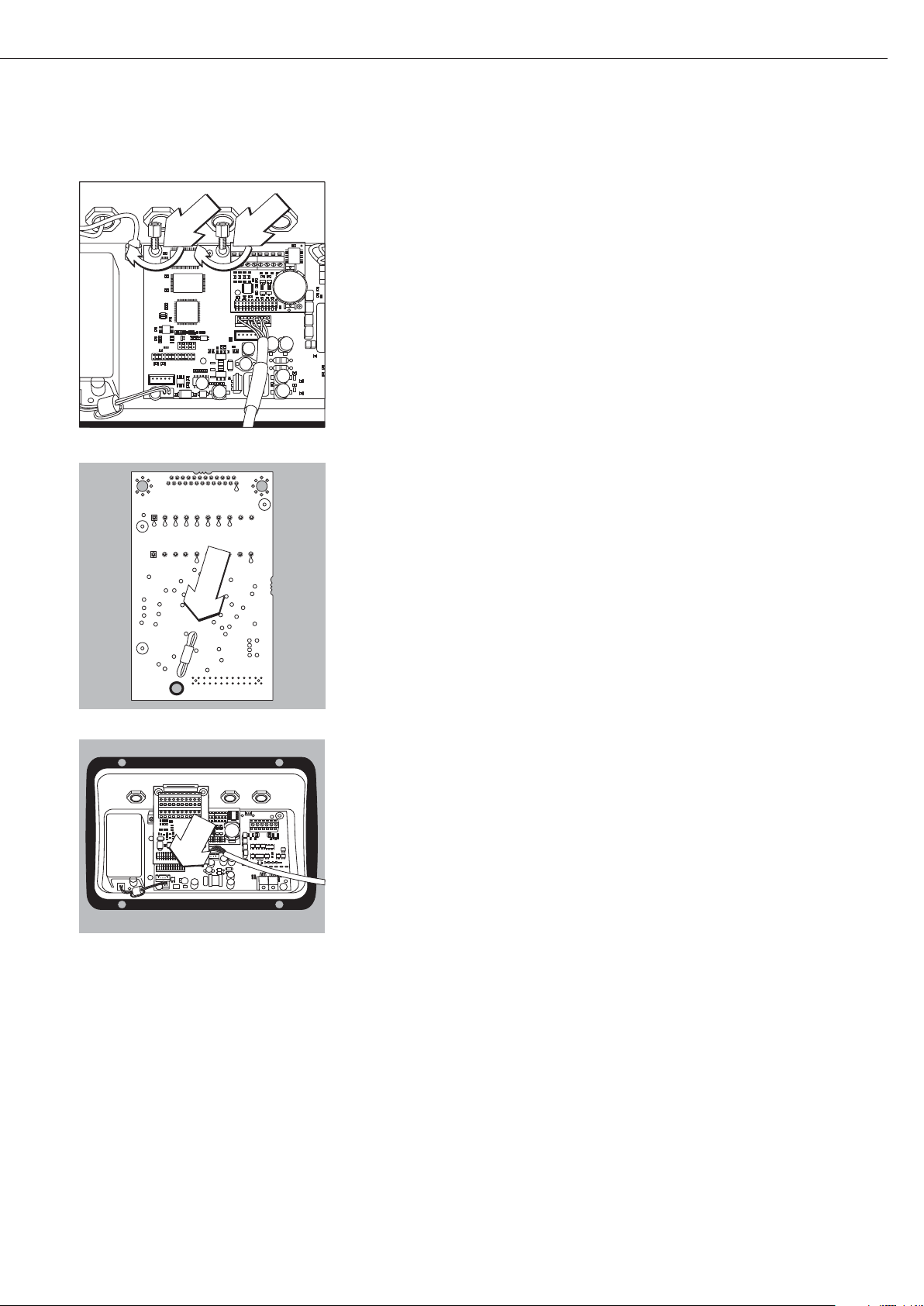

Installing the COM1 PCB:

§ Remove fastening screw.

5

§ Attach spacing bolts.

§ Plug in PCB mounting.

§ Plug the interface module (YDO01M-232 or YDO01M-232CLK) onto the digital PCB

in the Midrics display and control unit. To do this, attach the female terminal strips on

the interface module to the corresponding male terminal strips on the digital PCB.

§ Fasten the interface module with the screw.

The interface modules are equipped with their own terminal screw strips.

Connect the cable to this terminal strip.

Installing the UniCOM PCB:

§ Remove the 2 fastening screws.

6

§ Attach the 2 spacing bolts.

§ Plug in PCB mounting.

§ Plug the interface module (YDO01M-232CO, YDO01M-485, YDA01M-20MA or

YDO01M-IO) onto the digital PCB in the Midrics display and control unit. To do this,

attach the female terminal strips on the interface module to the corresponding male

terminal strips on the digital PCB.

§ Fasten the interface module with the 2 screws.

The interface modules are equipped with their own terminal screw strips.

Connect the cable to this terminal strip.

7

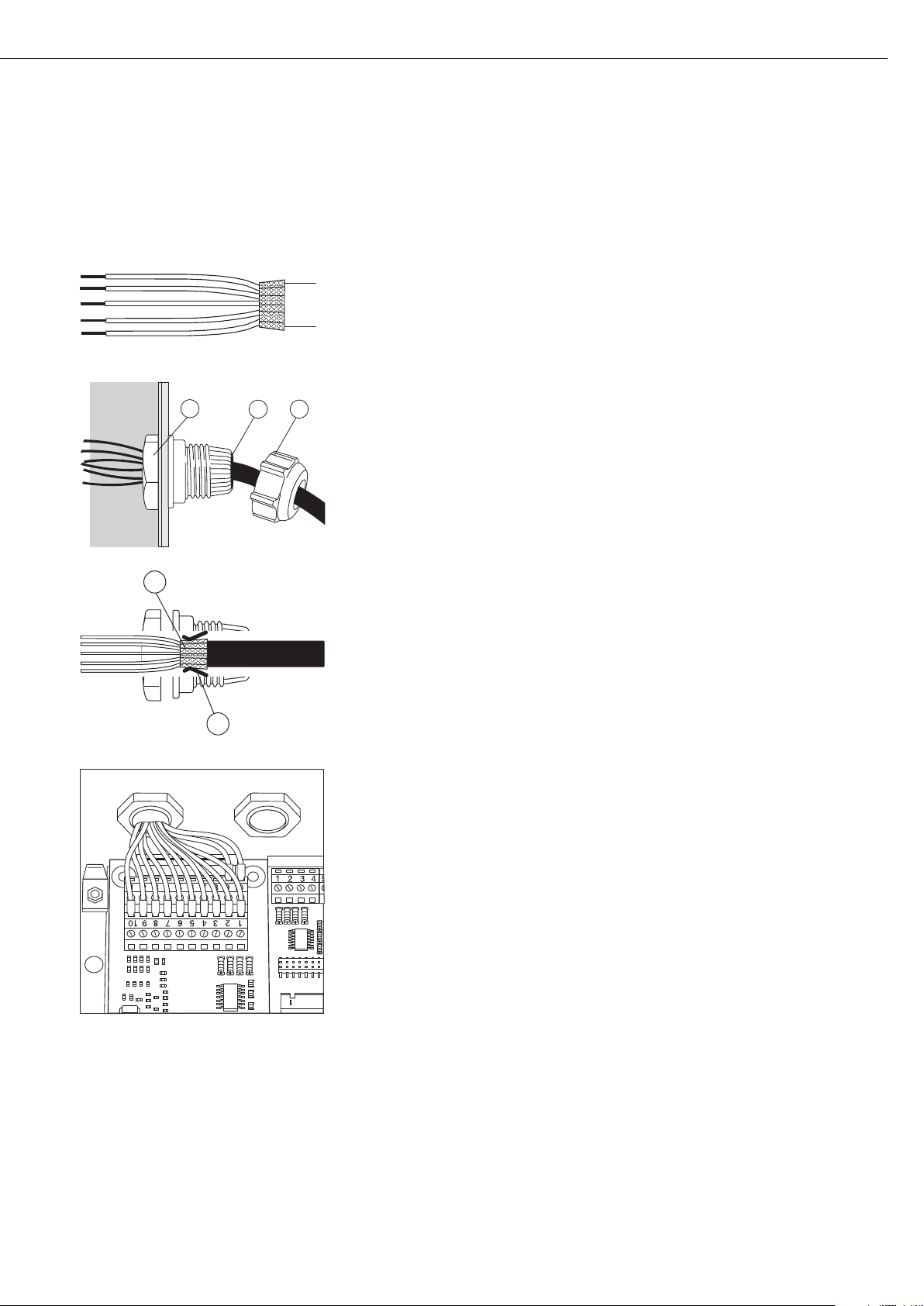

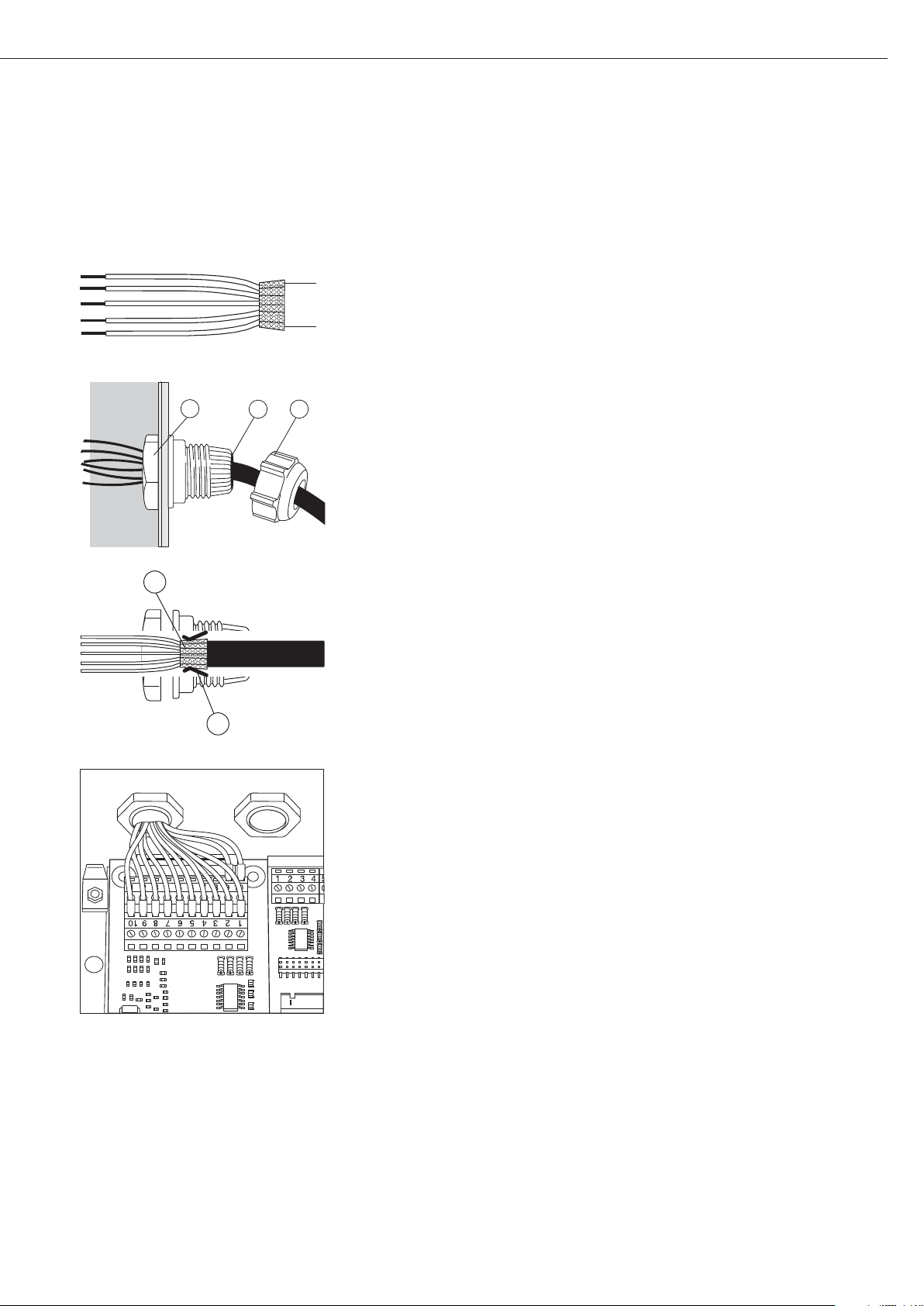

Installing the Interface Cable

§ Pin assignments: please see “Pin Assignment Charts" in this manual.

§ Use the cable gland to connect the peripheral device to the indicator.

§ Prepare the cable as follows:

– Expose approximately 10 cm (4 in) of the cable end for installation

– Remove all but approximately 1 cm (1/2 inch) of the shielding and fold it back over the

casing

– Strip the casing from approximately 1 mm (1/2 inch) of the wires and attach ferrules to

the wire ends.

§ Attach the cable gland:

!Please use extreme caution when performing any work on the equipment that affects this

cable gland. Use a torque wrench and tighten the cable gland to 5 Nm.

– Remove the protective cap from the bore hole on the display and control unit.

– Guide the enclosed cable gland through the bore hole and secure it inside the housing

with the nut (1).

– Slide the cable gland over the cable until the clamps (3) are in contact with the shield (2).

Tighten the nut (4) until the sealing clamp (5) forms a slight ridge between nut and

cable.

– Make sure the shield is in contact with the clamps.

§ Connect the cable:

– Connect the wires securely in accordance with the terminal assignments.

– Please see “Pin Assignment Charts" in this manual for details.

§ Close the display and control unit. Make sure that the rubber seal between the front

panel and the housing is correctly positioned.

§ After you close the housing again, use a pressure gauge to check the integrity of the IP65

protection. For details, contact the Sartorius Service Center.

Setting the Operating Parameters in the COM1 and UniCOM Interfaces

After installing and configuring the interface module in the display and control unit,

select the parameters in the operating menu that correspond to your requirements.

For details, see “Configuring COM1 and UniCOM." For more information, refer to the

installation and operating instructions for the Midrics scale.

4

1

5

2

3

8

Configuring the Interface Module: YDO01M-485, YDA01M-20MA

YDO01M-485 (Options A2 and A3)

Characteristics

The YDO01M-485 module (serial RS-485/RS-422 interface, electrically isolated

1

) can be

operated with your choice of RS-485 or RS-422 protocol.

The module is configured by eight switches.

In addition to defining whether RS-485 or RS-422 is used, certain terminating resistors

(120 O) and/or bias resistors may have to be activated or deactivated, depending on

whether a network or point-to-point connection is used.

The positions of the switches are indicated in the drawing on the left. Close switches 1

through 4 for RS-422 operation.

The following list shows the functions of switches in the closed (“ON") position:

Function (on = closed) Switch

Terminating resistor, transmitting side 120O 1 - 1

Bias resistor, transmitting side (TxD+, pull-up) 680O 1 - 2

Bias resistor, transmitting side (TxD–, pull-down) 680O 1 - 3

ON: RS-422 operation | open: RS-485 mode 1 - 4

Terminating resistor, receiving side 120O 2 - 1

Bias resistor, receiving side (RxD+, pull-up) 680O 2 - 2

Bias resistor, receiving side (RxD–, pull-down) 680O 2 - 3

No function 2 - 4

Note on setting the switches:

Switches must be set pairwise as follows:

– Switches 1–2 and 1–3: both ON or both OFF

– Switches 2–2 and 2–3: both ON or both OFF

Operation as an RS-485 Interface (Option A3):

§ Switches 1 - 4 must be open to operate the module in RS-485 mode (factory setting).

§ If necessary, deactivate the bias resistors for the RS-485 mode. To do this, open the

switch (factory setting).

The bias resistors must occur no more than once per data transmission path (whether

over a network or in a point-to-point connection); otherwise, transmission errors may

occur. Please refer to the specifications or wiring diagram for the remote station or

network node in question for detailed information. Always activate or deactivate bias

resistors in pairs.

§ The terminating resistor (transmitting side, switch 1 – 1) must be activated if the device

is at either end of an RS-1 bus system, or when connected point-to-point with another

device. The remote station must also have a 120-O terminating resistor. If necessary,

activate the terminating resistor (120 O) for RS-485 operation:

close switches 1 - 1 and 2 - 1 (“ON")

Operation as an RS-422 Interface (Option A2):

§ Close switches 1 - 4 for RS-422 operation (“ON")

§ If necessary, deactivate the bias resistors for RS-422-operation. To do this, open the

switches.

§ Activate the terminating resistor on the receiving side (switch 2 – 1), if no external termi-

nating resistor is available. Always deactivate terminating resistors on the transmitting

side (switch 1 – 1).

1

) The shielding in the connecting cable is connected at one end to the housing of the indicator.

The indicator is connected to the protective grounding conductor.

9

YDA01M-20MA (Option A9)

Characteristics

The YDA01M-20MA interface module is an analog output port. This module can be

operated as either a current interface (0/4 - 20 mA, 0 - 20 mA) or a voltage interface

(0 to 10V. The internal power supply is electrically isolated

1)

).

The interface module can be configured for any of the following 4 operating states:

– Voltage interface, 0 to 10 V

– Current interface, 0 to 20 mA

– Current interface, 4 to 20 mA

– Current interface, 0 to 24 mA

Configuring the module for the intended use involves opening and closing certain

switches. The positions of the switches are indicated in the drawing on the left.

The operating state is defined by the configuration of switches 1 and 2 (switches 3 and 4

have no function):

Operating status Switch

Voltage interface, 0 to 10 V SW 1–1: closed = “ON",

SW 1–2: open

Current interface, 0 to 20 mA SW 1–1: open,

software 1–2: closed = “ON"

Current interface, 4 to 20 mA SW 1–1: open, software 1–2: open

(factory setting)

Current interface, 0 to 24 mA SW 1–1: closed = “ON"

SW 1–2: closed = “ON"

1

) The shielding in the connecting cable is connected at one end to the housing of the display and control unit.

The display and control unit is connected to the protective grounding conductor.

– Max. load: 390 ohms

Notes

– The shielding in the current interface connecting cable is connected at one end to the

housing of the display and control unit.

– The display and control unit is connected to the protective grounding conductor.

– If the display and control unit is operated with a rechargeable battery, operation of the

current interface is not possible.

§ The YDA01M-20MA is installed directly on the digital PCB in the Midrics display and

control unit. For details, please see “Installation in the Display and Control Unit."

10

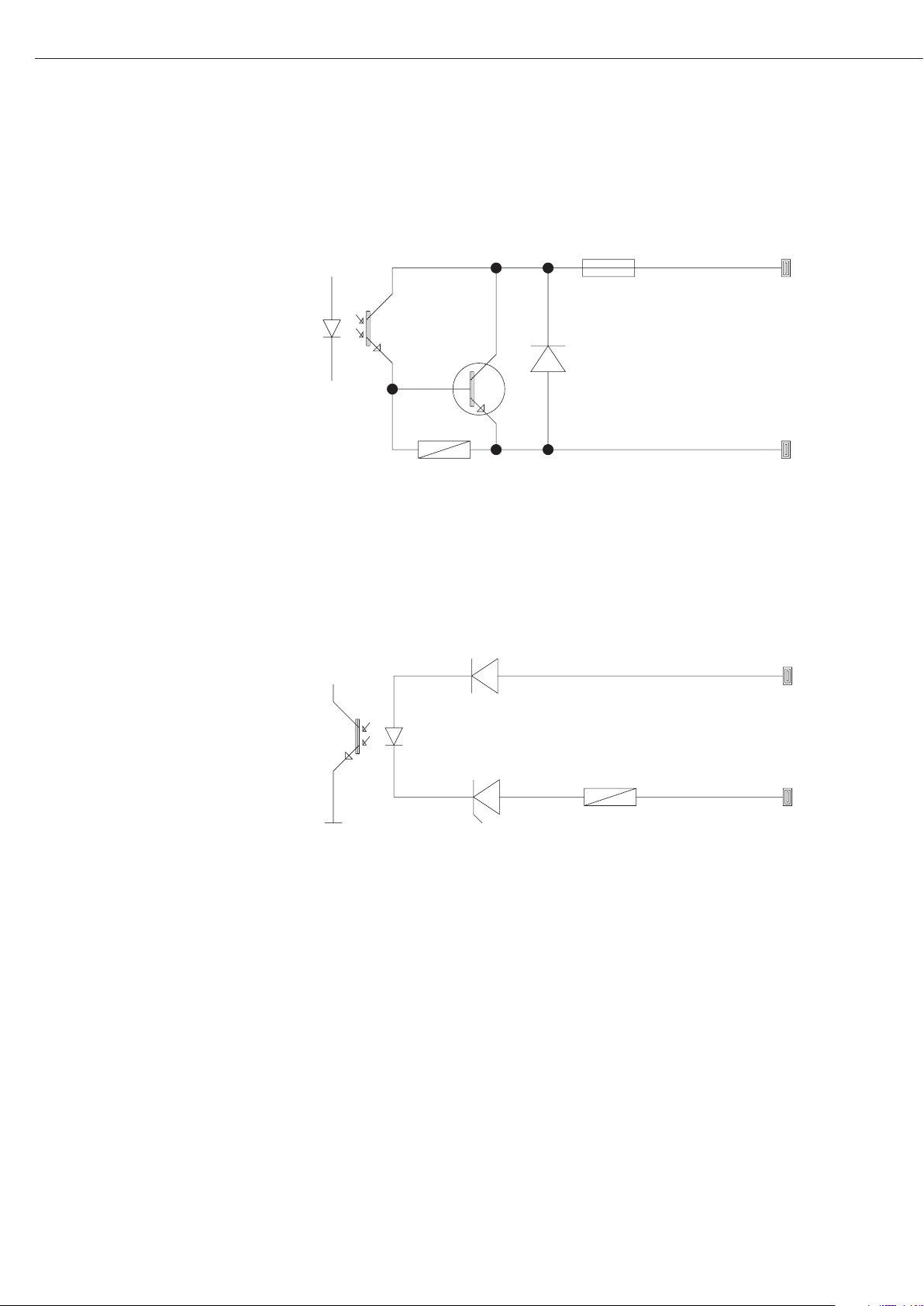

Example: Basic Circuit Diagram

YDO01M-IO, Option A5:

Specifications

Digital inputs

– Quantity: 5

– Low level: –3 V to +5 V

– High level: +11 V to +30 V

– Maximum current

consumption: 2.6 mA at 15 V

– Inputs are activated by applying

the corresponding voltage.

Digital outputs

– Quantity: 5

– Maximum current flow per channel:

100 mA

– Voltage range: 0–30 VDC

– Each output is formed

by an opto-electronic coupler.

YDO01M-EN (Option B9)

Equipment Supplied

– YDO01M-EN interface module

– Operating instructions (this document)

– Interface description (fieldbus for

TCP Modbus)

Assembly

Connect interface module YDO01M-EN

(Ethernet interface) directly to the digi-

tal board of the scales without configu-

ration. For more information, please

refer to chapter entitled “Installing Data

Output Ports in the Indicator”.

Insert the YCC02RJ45M7 plug on the

Sartorius Ethernet cable (option M38)

into the port of the interface module.

Note:

!Only use cables and plugs that conform

to the Ethernet specification (CAT5 or

better):

Ethernet cable with Sartorius order no.

YCC02RJ45M7 (Option M38) cable

gland

Use the interface module only with the

following devices:

– Indicator MIS1, MIS2 (IP65)

– Complete scales MW1, MW2 (IP65)

1

23

4

1

0.2A

4

30V

OUTx_high

OUTx_low

Inputx_high

LV1

LV1

LV2

23

Inputx_low

LV2

11

Pin Assignment Charts

COM1

– RS-232 interface: YDO01M-232

(Option A11), YDO01M-232CLK (A31):

Pin assignments in the 8-contact terminal screw strip on the interface module:

Pin 1: +12 V: Supply voltage for

Sartorius printers

Pin 2: Reset_Out

(peripheral device restart)

Pin 3: +5 V Out

Pin 4: Ground (GND)

Pin 5: Clear to send (CTS)

Pin 6: Data terminal ready (DTR)

Pin 7: Data input (R+D)

Pin 8: Data output (T+D)

UniCOM

– Pin assignments in the two 10-contact

terminal screw strips on the interface

module:

RS-232 interface: YDO01M-232CO

(Option A1):

Pin 1: Clear to send (CTS)

Pin 2: Data terminal ready (DTR)

Pin 3: Data input (R+D)

Pin 4: Data output (T+D)

Pin 5: Ground (GND)

Pin 6: Universal IN

Pin 7: Control output: “lighter"

Pin 8: Control output: “equal"

Pin 9: Control output: “heavier"

Pin 10: Control output: “set"

Pin 11: +12 V: Supply voltage for

Sartorius printers

Pin 12: Reset_Out

(peripheral device restart)

Pin 13: Ground (GND)

Pin 14: Ground (GND)

Pin 15: +5 V output

Pin 16: +5 V switched

(e.g., for bar code scanner)

Pin 17: Ground (GND)

Pin 18: Ground (GND)

Pin 19: Not connected

Pin 20: Ext. supply voltage output

+15V to 25V

Digital I/O interface:

YDO01M-IO (Option A5):

Pin 1: External output port 5: low

Pin 2: External output port 5: high

Pin 3: External output port 4: low

Pin 4: External output port 4: high

Pin 5: External output port 3: low

Pin 6: External output port 3: high

Pin 7: External output port 2: low

Pin 8: External output port 2: high

Pin 9: External output port 1: low

Pin 10: External output port 1: high

Pin 11: Input port 5: low

Pin 12: Input port 5: high

Pin 13: Input port 4: low

Pin 14: Input port 4: high

Pin 15: Input port 3: low

Pin 16: Input port 3: high

Pin 17: Input port 2: low

Pin 18: Input port 2: high

Pin 19: Input port 1: low

Pin 20: Input port 1: high

– Pin assignments in the two terminal

screw strips on the interface module:

YDO01M-485: RS-485 mode

(Option A2):

Pin 1: Data + (T+D-R+D+)

Pin 2: Data - (T+D-R+D-)

Pin 3: Not connected

Pin 4: Not connected

Pin 5: Signal ground, electrically

isolated (GND_GALV)

Pin 6: Signal ground, electrically

isolated (GND_GALV)

Pin 11: Ext. supply voltage input

+15V to 25V *

Pin 12: Ext. supply voltage input

+15V to 25V *

Pin 13: Ground (GND) *

Pin 14: Ground (GND) *

1

2

3

4

5

66

YDO01M-485: RS-422 mode

(Option A3):

Pin 1: Data output + (T+D+)

Pin 2: Data output - (T+D-)

Pin 3: Data input + (R+D+)

Pin 4: Data input - (R+D-)

Pin 5: Signal ground, electrically

isolated (GND_GALV)

Pin 6: Signal ground, electrically

isolated (GND_GALV)

Pin 11: Ext. supply voltage input

+15V to 25V *

Pin 12: Ext. supply voltage input

+15V to 25V *

Pin 13: Ground (GND) *

Pin 14: Ground (GND) *

* = Not electrically isolated

YDA01M-20MA

(current/voltage interface):

6-pin terminal screw strip on the interface module

Pin 1: I_out (+)

for current interface

(0/4 to 20/24 mA)

Pin 2: I_in (–)

for current interface

(0/4 to 20/24 mA)

Pin 3: V_out (+)

for voltage interface,

0V to + 10V

Pin 4: V_in (–)

for voltage interface,

0V to + 10V

Pin 5: GND, electrically isolated

(electrically isolated ground)

Pin 6: GND, electrically isolated

(electrically isolated ground)

Pin assignment of the

Ethernet interface (RJ45)

YDO01M-EN (Option B9):

Pin 1: TxD+

Pin 2: TxDPin 3: RxD+

Pin 4: Not in use

Pin 5: Not in use

Pin 6: RxDPin 7: Not in use

Pin 8: Not in use

Chassis: GND

1

2

3

4

5

66

1

2

3

4

5

66

12

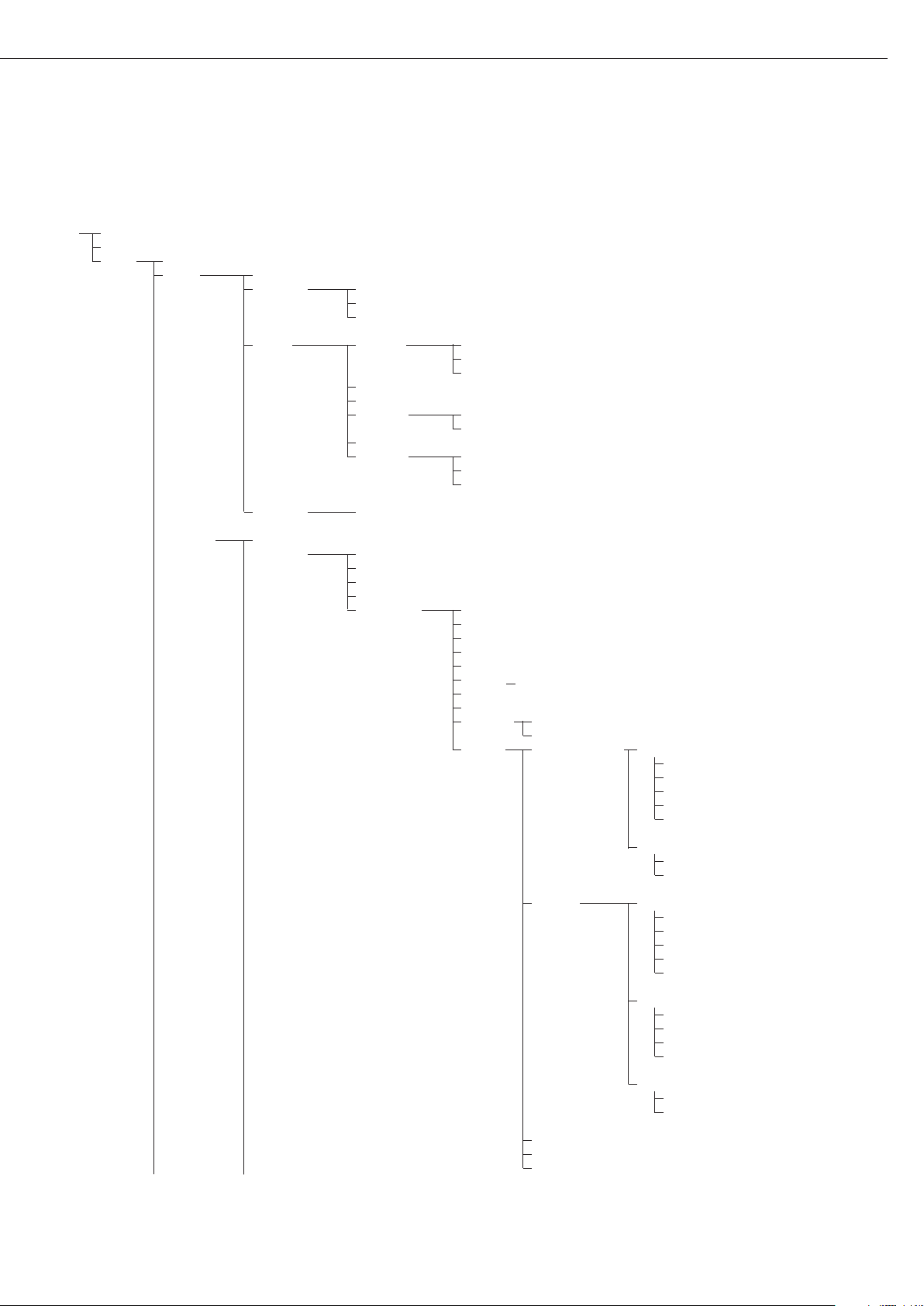

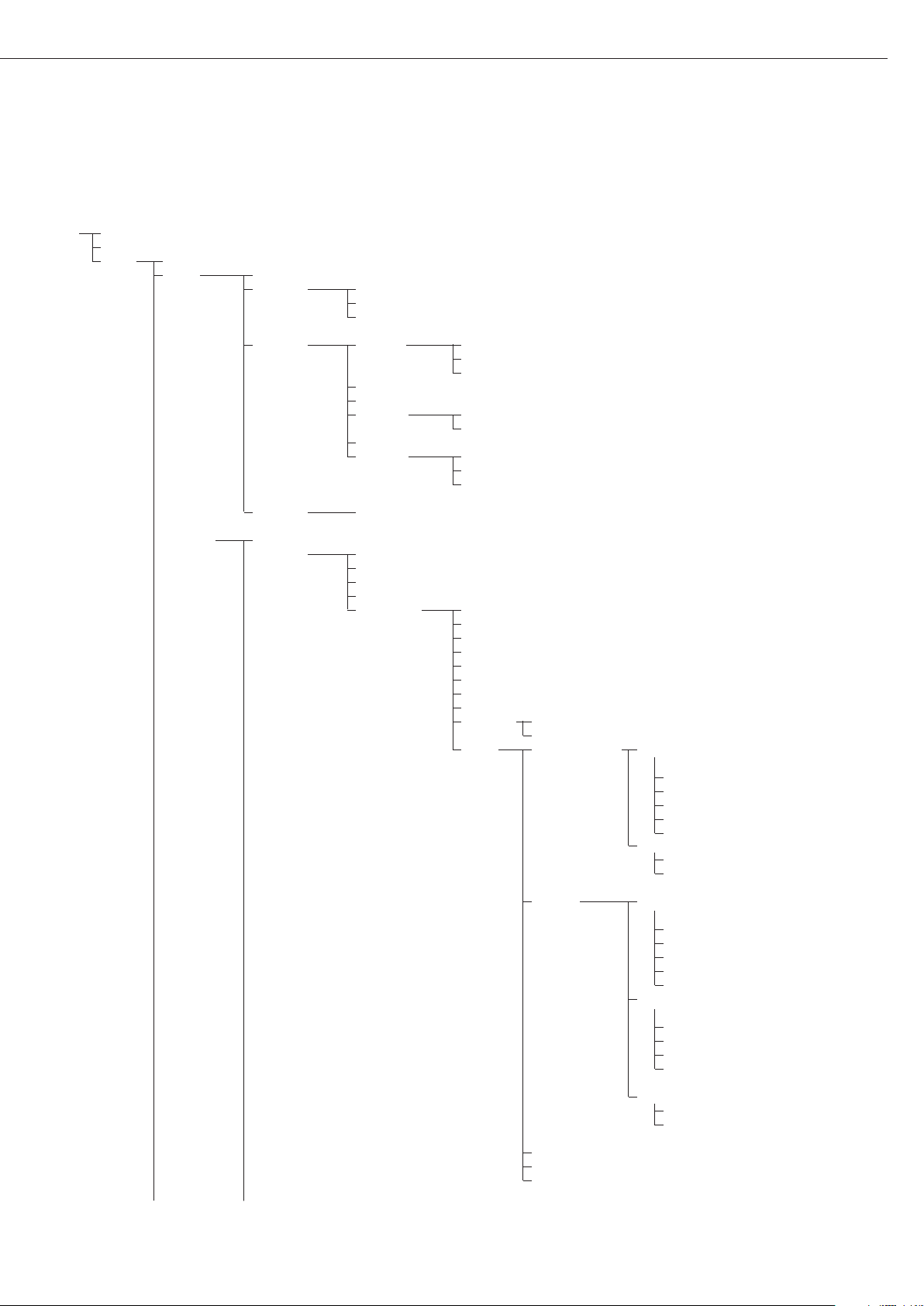

Configuring COM1 and UniCOM

Operating menu overview for the COM1 and UniCOM interfaces

(see also “Operating Menu Overview" in the chapter entitled “Configuration" in the Midrics operating instructions).

Appl

Fn-Key

Setup WP-1

COM1 OFF *

DATPROT SBI *

(data record) XBPI-232

SMA

Printer YDP01IS Line *

Label

Label, man. form feed

YDP02

YDP03

YDP02IS Line *

Label

UNI-PRI (universal printer)

YDP04IS Line *

Label

Label, man. form feed

MEMORY YAM01IS (Alibi memory)

UniCOM OFF *

DATPROT SBI *

(data record) XBPI-232

XBPI-485

SMA

ETHERNET Source IP: 192.168.0.1 *

Source name

Listen port: 49155 *

Subnet mask: 255.255.255.0 *

Gateway IP: 0.0.0.0 *

DNS IP: 0.0.0.0 *

Target IP: 0.0.0.0 *

Target port: 49155 *

Protocol TCP *

UDP

Mode SBI (server)-SRV* 6.1. Data output manual/automatic

6.1.1 Manual without stability

6.1.2 * Manual after stability

6.1.4 Automatic without stability

6.1.5 Automatic with stability

6.1.7 Print log for PC

7.2. Output: line format

7.2.1 For raw data: 16 characters

7.2.2 * For other apps: 22 characters

SBI-C/S 6.1. Data output manual/automatic

(client) 6.1.1 Manual without stability

6.1.2 * Manual after stability

6.1.4 Automatic without stability

6.1.5 Automatic with stability

6.1.7 Print log for PC

6.3. Time-dependent autom. output

6.3.1 * 1 display cycle

6.3.2 2 display cycles

6.3.4 10 display cycles

6.3.7 100 display cycles

7.2. Output: line format

7.2.1 For raw data: 16 characters

7.2.2 * For other apps: 22 characters

xBPI

SMA

Modbus/TCP

13

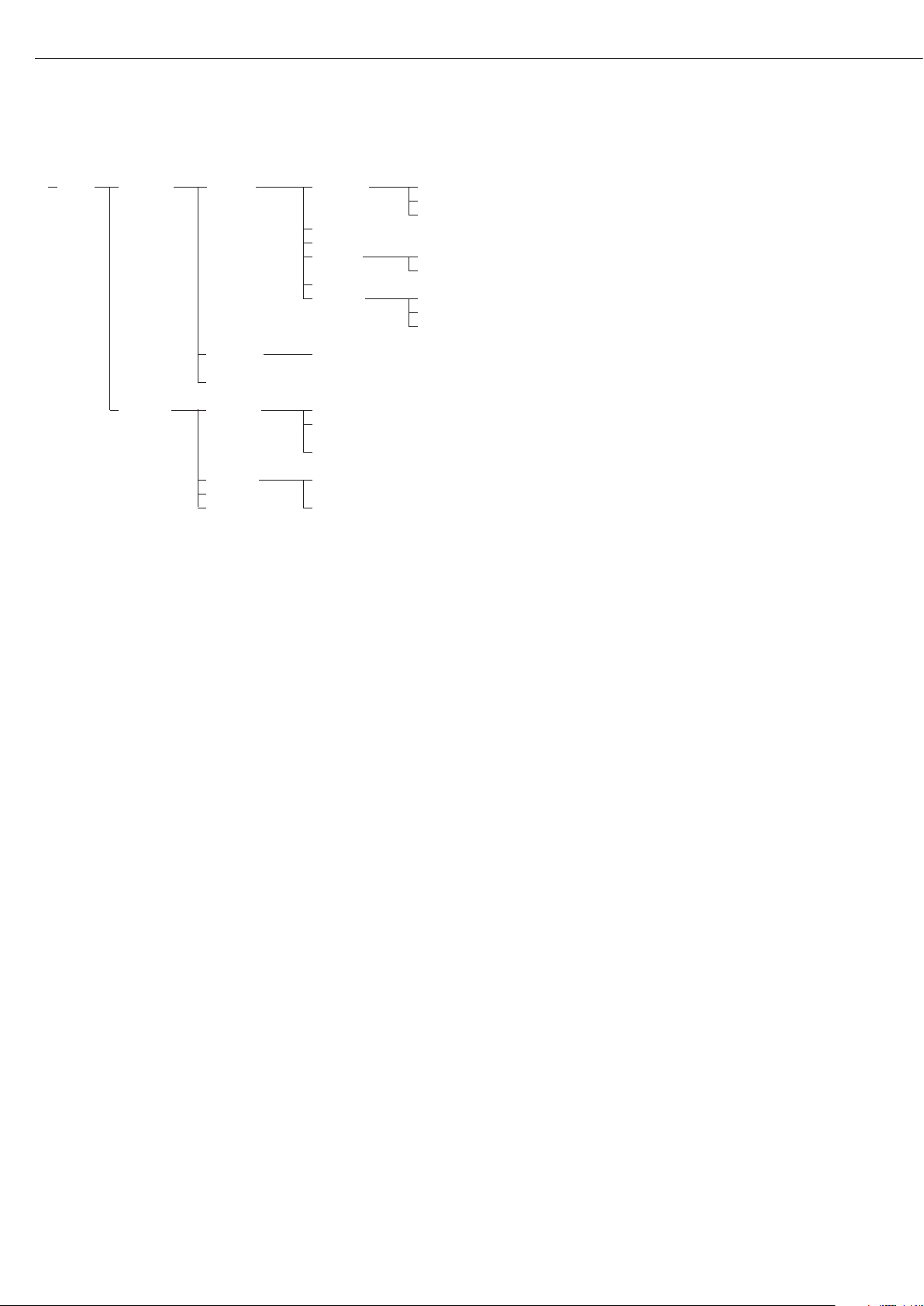

Setup UniCOM Printer YDP01IS Line *

Label

Label, man. form feed

YDP02

YDP03

YDP02IS Line *

Label

UNI-PRI (universal printer)

YDP04IS Line *

Label

Label, man. form feed

MEMORY YAM01IS (Alibi memory)

ANALOG (analog interface)

CTRL IO: CTR INP: 8. 4. x TTL; for YDO01M-232CO, Option A1

Control Control inputs 8. 17. x Electrically isolated; for

inputs/ to YDO01M-IO, Option A5

outputs 8 . 21. x

CTR OUT: 8. 24. x Electrically isolated; for

Control to YDO01M-IO, Option A5

outputs 8. 28. x

* = Factory setting

14

Ethernet interface

In the “UNICOM” menu, select

“ETHERNET” to enter numerical

values under Source IP, ListenPort, etc.

Under Source name, both letters and

numbers can be used. A maximum of

15 characters can be entered. Enter

either a source name or a source IP

address (not both).

Port numbers

Validity range: 0 – 65535

Since many of the ports up to 49150

have already been allocated, we recommend using port numbers above 49150.

This does not apply to Modbus/TCP,

because the following port number

applies here: 502 (see the fieldbus

brochure for details)

Configuring the Interface

You can configure the UniCOM universal data interface for the required operating state (connection of a peripheral

device).

The diagram on the preceding page

shows the relevant section of the

operating menu.

For additional information, see the

chapter entitled “Settings" in the

Midrics operating instructions.

RS-485/RS-422 Interface

If the PCB is configured for use in the

RS-422 operating mode, you can select

the SBI, XBPI-232, or SMA menu item.

YDA01M-20MA Analog Interface

You can configure the following

parameters in the operating menu:

– Output value (menu line 8.12):

8.12.1: Net value

(factory setting)

8.12.2: Gross value

– Error display (menu line 8.13):

8.13.1: High level (20 mA)

(factory setting)

8.13.2: Low level (0/4 mA):

5V on this interface during

operation.

– Output mode (menu line 8.14):

8.14.1: Zero to maximum capacity

(factory setting)

8.14.2: Minimum/maximum values

– Output of minimum/maximum values

(menu line 8.15):

8.15.1: Min. (0/4 mA) input in kg

8.15.2: Max. (20 mA) input in kg

By selecting min./max. values you can

specify the weighing range for output

on the 0/4 to 20mA (0 to 10 V) interface. This selection applies as well to an

SBI scale, but only for the net value.

Input of min. and max. values is always

in kilograms. You can enter negative

values if desired. You can also enter a

min. value that is higher than the max.

value, to effect falling current output.

Examples:

Rising current curve

Min. value, net: -1 kg

Max. value, net: 4 kg

Falling current curve for XBPI scales

Min. value: 5 kg

Max. value: 1 kg

Falling current curve for SBI scales

Min. value: 5 kg

Max. value: 1 kg

15

Ethernet interface: Initialization

Display: Initialization completed

Once initialization of the Ethernet

module has been completed successfully,

the “ ” symbol is displayed.

Network module

initialized

If initialization was not successful,

no symbol is displayed. The symbol

provides no information about the

connection status in relation to the

network.

TCP connections:

In the SBI-C/S operating mode, Midrics

always terminates the connection

independently, after 1 second.

In the other operating modes

(SBI-SRV, SMA, XBPI, ModBus/TCP) the

connection is maintained until it is disconnected by the PC (client). It is only

possible to establish one connection at

a time.

Ethernet interface: Features

Source IP: IP address of the Midrics indicator

If the address 0.0.0.0 is selected, you need to enter a name under

“Source name.” In this case, the IP address should be dynamically allocated

by a DHCP server located within the network.

Source name: This parameter is alternative to the “Source IP” input. A name that is up

to 15 characters in length and serves to identify the Midrics can be entered.

In this case, the address 0.0.0.0 must be selected as the source IP. The name

is announced to the domain name service (DNS) if

– an IP address has been entered under DNS IP

or

– an IP address has been allocated over DHCP.

Device port: Number of the port on which the Midrics listens for server operation.

Subnet mask: IP address mask for the activation of IP addresses in a subnet. If the mask

is to be allocated using a DHCP server, 0.0.0.0 must be entered.

Gateway IP: IP address of a gateway

Address of desired server located in another network using target IP. If the IP

address is to be allocated dynamically using a DHCP server, 0.0.0.0 must be

entered.

Target IP: Address of the server that is to receive the Midrics data.

Important for operation of the Midrics as a client if the SBI mode has been

selected in combination with automatic data output. When using UDP,

an IP address must also be entered here.

Target port: Port number on which a server with the target IP listens in order to receive

data from the Midrics.

Protocol: Select the transport protocol to be used to transmit data over Ethernet.

Please select either:

– TCP, connection-oriented with high data security

or

– UDP, connectionless (does not effect Modbus/TCP)

Mode: Select the data format that contains the user data embedded in TCP or UDP

(e.g. SMA is tunnelled over Ethernet using TCP or UDP).

With the SBI-SRV, XBPI and SMA protocols, the Midrics is always to be seen

as a server. Under SBI-C/S, the Midrics is simultaneously a server and a client.

Client mode is activated when the p [Print] button is pressed or the data

output parameter has been set to “automatic”. For the OPC mode, set the

menu code for “SBI server.” In all other instances, the Midrics is a server.

Under ModBus/TCP, the Midrics is always active as a server (also see the field

bus brochure).

Power-on

response: If the interface module is active, the display of the weight value may be

delayed by up to 20 seconds.

16

Synchronization

Data communication between the display and control unit and a computer

takes the form of messages

(“telegrams") made up of ASCII code.

For error-free data communication, the

settings for baud rate, parity, handshake mode and character format must

be the same at both ends.

You can configure the interface settings

in the Setup menu so that they match

those of the computer. You can also

define parameters in the indicator to

make data output dependent on various

conditions. The conditions that can be

configured are listed in the descriptions

of the application programs (see operating instructions for the Midrics scale).

If you do not connect a peripheral

device to the display and control unit's

interface port, this will not generate an

error message.

Handshake

The weighing instrument interface (Sartorius Balance Interface = SBI) has

transmit and receive buffers. You can

define the handshake parameter in the

display and control unit's Setup menu:

– Hardware handshake (CTS/DTR)

– Software handshake (XON, XOFF)

Hardware Handshake

Hardware handshake with a 4-wire

interface: 1 more character can be

transmitted after CTS (clear-to-send).

Software Handshake

The software handshake is controlled

via XON and XOFF. When a device is

switched on, XON must be transmitted

to enable a connected device to communicate.

The data transmission sequence is as

follows:

Scale ––– byte –––> Computer

(trans- ––– byte –––> (receiving

mitting device)

device)

––– byte –––>

––– byte –––>

<–– XOFF –––

––– byte –––>

––– byte –––>

...

(Pause)

...

<–– XON –––

––– byte –––>

––– byte –––>

––– byte –––>

––– byte –––>

Transmitting Device

Once XOFF has been received, it prevents further transmission of characters.

When XON is received, it re-enables the

transmitting device to send data.

Receiving Device

To prevent too many control commands

from being received at one time, XON is

not transmitted until the buffer is

almost empty.

17

Data Interfaces

Configuring the Data

Interface as a COM Port

(datprot)

Configure the interface as a COM port

in the Setup menu under COM1 or

UniCOM, under the “Data Protocol"

(datprot) menu item.

SBI Communication

This is a simple ASCII interface.

Data output is configured under menu

lines 6.1 and 6.3:

– Manual output of displayed value with

or without stability (menu items 6.1.1

and 6.1.2)

– Automatic output of displayed value

with or without stability (menu items

6.1.4 and 6.1.5) at intervals defined by

display updates. The number of display

updates comprising an output interval

is configured under menu item 6.3.

– Output of a configurable printout.

Output is linked to the Printout

(prtprot) settings.

If you do not activate and configure a

user-definable data record, the printout

simply contains the current value displayed on the indicator (weight with

unit, calculated value, alphanumeric

display).

SMA Communication

Standardized communications protocol

of the Scale Manufacturers Association

Data Input Format

(Commands)

You can connect a computer to your

display and control unit to send commands controlling weighing instrument

functions and applications via the interface port.

All commands use the same format

(data input format) starting with the

ESC character (ASCII 27) and ending

with a carriage return (CR; ASCII 13)

and a line feed (LF; ASCII 10). The total

length of a command is anywhere from

4 characters (1 command character

between the start and end described

above) to 7 characters (4 command

characters).

The table below shows the available

command characters; each command

must be flanked by the start and end

characters as described above.

Example: The command character for

output is “P" (“transmit readout

value"). The string “ESC P CR LF"

triggers this command.

Command Meaning

K Weighing mode 1

L Weighing mode 2

M Weighing mode 3

N Weighing mode 4

O Block keys

P Output readout

to data interface

R Unblock keys

T Tare and zero

(combination tare function)

f3_ Zero (see also the

“kZE_" command)

f4_ Tare (without zeroing;

as the “kT_" command)

kF1_ F1: Trigger k key function

kF2_ F2: Trigger c key function

(Midrics 2 only)

kF3_ F3: Trigger r key function

(Midrics 2 only)

kF4_ F4: Trigger O key function

(Midrics 2 only)

kF5_ F5: Trigger w key function

(Midrics 2 only)

Command Meaning

kF6_ F6: Trigger I key function

(Midrics 2 only)

KF7_ d key

kCF_ CF: Trigger c key function

(Midrics 2 only)

kP_ Trigger p key function

Output to printer port

kT_ Trigger T key function

(tare)

kZE_ Trigger ( key function

(zero)

x1_ Output model designation

of active weighing instrument.

Example: “LP6200S-0C"

x2_ Output serial number

of active weighing instrument;

Example: “0012345678"

x3_ Output software version

of active weighing instrument;

Example: “00-20-04"

z1_ Activate input for printout

header 1

z2_ Activate input for printout

header 2

txx...x_ xx...x: Enter letters

Length acc. to input

(Midrics 2 only)

The ASCII code for the “underline"

character is 95.

Format for entering printout header

lines: “ESC z x a ... a _ CR LF" where

x=(header line) 1 or 2, and a ... a: = up

to 20 characters of text, followed by the

“underline" character, carriage return

and line feed.

18

Error Codes:

Pos. 12345678910111213141516

***Err**##****CRLF

or ***Err*###****CR LF

*: Space

#: Error code number (2 or 3 digits)

Example (output of value: +1255.7 g):

Pos. 12345678910111213141516

+** * 1255. 7* g* * CRLF

Position 1: Plus or minus sign or space

Position 2: Space

Positions 3-10: Weight value with decimal point; leading

zeros are output as spaces.

Position 11: Space

Positions 12 - 14: Unit symbol or space

Position 15: Carriage return

Position 16: Line feed

Data Output Format with 22 Characters

(with Data Header)

Normal Operation:

Pos. 12345678910111213141516171819202122

IIIIII+*DDDDDDDD* UUUCRLF

or IIIIII-*DDDDDDDD* UUUCRLF

or ********************CRLF

I: ID code character, right-justified with spaces Space

+-: Plus or minus sign

*: Space

A: Digit or letter (max. 7 characters plus decimal point)

U: Unit symbol (1 to 3 letters, followed by 0 to 2 spaces)

CR: Carriage return

LF: Line feed

Special Codes:

Pos. 12345678910111213141516171819202122

Stat********––******CRLF

or Stat********H*******CRLF

or Stat********HH******CRLF

or Stat********L*******CRLF

or Stat********LL******CRLF

or Stat********C*******CRLF

*: to 2 spaces – –: Final readout mode

H: Overload HH: Overload in Checkweighing

L: Underload LL: Underload in Checkweighing

C: Calibration/adjustment

Data Output Format

Each line in a print job can contain up to 22 characters (up to

20 printable characters plus two control characters). The first

6 characters, called the “data header", identify the subsequent

value. You can suppress the header under menu item 7.2 in

the “Printouts" menu; in this case, the print job has up to

16 characters (up to 14 printable characters plus two control

characters).

Examples:

+ 235 pcs Without data header

Qnt + 235 pcs With data header

Display segments that are not activated are output as spaces.

Values with no decimal point are output without a decimal

point.

Data Output Format with 16 Characters

(without Data Header)

Normal Operation:

Pos. 123456789101112131415 16

+* DDDDDDDD* UUUCR LF

or - * DDDDDDDD* UUUCR LF

or **************CR LF

+-: Plus or minus sign

*: Space

D: Digit or letter (max. 7 characters plus decimal point)

U: Unit symbol (1 to 3 letters, followed by

0 to 2 spaces)

CR: Carriage return

LF: Line feed

Special Codes:

Pos. 12345678910111213141516

******––******CR LF

or ******H*******CR LF

or ******HH******CR LF

or ******L*******CR LF

or ******LL******CR LF

or ******C*******CR LF

*: Space

– –: Final readout mode

H: Overload

HH Overload in Checkweighing

L: Underload

LL Underload in Checkweighing

C: Calibration/adjustment

19

Data Interfaces

GMP-compliant Printouts

When the corresponding menu item is

active, the measured result is bracketed

on the printout by a GMP header and

a GMP footer (GMP: “Good Manufacturing Practice").

The GMP header precedes the first

measured result. The GMP footer is

printed either after each measured

result (“ISO/GLP/GMP: For 1 application

result," menu item 7.11.2), or after the

last result in a series of measurements

(“ISO/GMP/GLP: For several application

results," menu item 7.11.3). To end a

series of measured results, press and

hold the p key (> 2 sec).

In this case, the A symbol is displayed

after the GMP header is printed and

remains in the display until the GMP

footer is printed.

At the end of a calibration procedure,

the GMP printout is generated automatically.

If you use a label printer for GMP-compliant printouts and menu item 7.11.3

is active, the header and footer are

printed on two different labels.

To generate GMP-compliant printouts

on labels, select menu item 7.11.2.

Examples of GMP headers and one example of a GMP footer are shown in the following:

------------------- Dotted line

14.01.2007 09:43 Date and time

1)

Typ MIS2 Midrics model

Ser.no. 12345678 Midrics serial no.

Vers. 1.1007.12.1 Software release for application

BVers. 01-25-01 Software release for basic version

------------------- Dotted line

GMP footer:

------------------- Dotted line

14.01.2007 09:45 Date and time

1)

Name: Field for operator signature

Blank line

------------------- Dotted line

1)

YDO01M-232 (Option A31) required

20

Verwendungszweck

Der Datenausgang YD.01M-...

wird eingesetzt zum Einbau in Auswertegeräte und Komplettwaagen der

Modelle Midrics MIS..., MW... als optionale Standard Schnittstelle COM1 oder

Universal-Datenschnittstelle UniCOM.

Für COM1:

– YDO01M-232 (Option A11):

Bidirektionale RS232-Datenschnittstelle.

Das Modul YDO01M-232 ermöglicht:

Den Anschluss verschiedener Drucker

(YDP02IS, YDP03, YDP04IS, YDP12IS,

Universal-Drucker), den Datenaustausch

mit einem PC (SBI-, xBPI- oder SMABetrieb).

– Anschluss eines Alibispeichers.

– Bluetooth Adapter YBT01.

– Zweitanzeige YRD02Z.

– USB-Adapterkabel zum PC-Anschluss

über USB YCC01IS.

– YDO01M-232CLK »Clock«

(Option A31): wie Standard RS232,

plus Datum/Uhrzeit.

Für UniCOM:

– YDO01M-232CO (Option A1):

wie Standard RS232 zusätzlich mit

Digital In/Out (TTL/5V)

– YDO01M-485 (Optionen A2 und A3):

Bidirektionale Datenschnittstelle, galvalnisch getrennt, wahlweise einsetzbar

im RS422-Betrieb (Option A2) oder im

RS485-Betrieb (Option A3).

Das Modul YDO01M-485 ermöglicht ein

Netzwerk bis zu 32 MidricsWaagen/Indikatoren über XBPI-Bus.

– YDA01M-20MA (Option A9):

Analogausgang, wahlweise einsetzbar

als Stromschnittstelle (0/4 - 20mA, 0 24 mA) oder als Spannungsschnittstelle

(0 bis 10 V).

Das Modul YDA01-20MA ermöglicht

den Anschluss einer SPS oder einer

externen Analoganzeige.

– YDO01M-IO (Option A5):

Digitales Ein-/Ausgabemodul zum

Anschluss von Midrics an externe

Steuerungen.

– YDO01M-EN (Option B9):

Ethernet-Schnittstelle (z.B. Anschluss

an eine SPS oder einen PC).

Zeichenerklärung

Folgende Symbole werden in dieser

Anleitung verwendet:

§ steht vor Handlungsanweisungen

$ steht vor Handlungsanweisungen,

die nur unter bestimmten Voraussetzungen ausgeführt werden sollen

> beschreibt das, was nach einer aus-

geführten Handlung geschieht

! weist auf eine Gefahr hin

Inhalt

20 Verwendungszweck

20 Inhalt

21 Einbau in das Auswertegerät

21 COM1-Platine einsetzen

22 UniCOM-Platine einsetzen

24 Schnittstellenkabel montieren

25 Module konfigurieren:

YDO01M-485, YDA01M-20MA

27 YDO01M-IO: Spezifikationen

27 YDO01M-EN

28 Steckerbelegungsplan

28 COM1

28 UniCOM

29 Voreinstellungen COM1 und

UniCOM

33 Synchronisation

34 Datenschnittstellen

34 Dateneingangsformat (Kommandos)

35 Datenausgangsformat

36 GMP-Protokoll

21

Einbau in das Auswertegerät

Einbau

Der Einbau des Schnittstellenmoduls in das Midrics-Auswertegerät (zusätzlich der Einbau

der Kabelverschraubung und der Anschluss der Verbindungskabel an die Schraubklemmenleiste) ist nur dann erforderlich, wenn das Midrics-Auswertegerät nicht bereits werksseitig auf Kundenbestellung mit dem betreffenden Datenausgang ausgerüstet ist.

Hinweise:

§ Der Einbau des Schnittstellenmoduls sollte nur von einem geschulten und autorisierten

Sartorius-Fachmann ausgeführt werden.

§ IP65-Schutz:

Entsprechendes Anschlusskabel mit Kabelverschraubung für das jeweilige Schnittstellenmodul verwenden (Zubehör).

!Vor Beginn der Arbeiten das Gerät vom Netz trennen.

!Bei unsachgemäßer Installation entfällt die Gewährleistung.

!IP65-Schutzart beeinflussende Arbeiten sind äußerst sorgfältig durchzuführen.

Die Kabeldurchführung (IP65-Schutz) für den Anschluss der Schnittstelle am Auswertegerät ist durch Blindstopfen verschlossen. Alle Arbeiten an der Kabelverschraubung sehr

sorgfältig ausführen.

§ Frontplatte abnehmen: 4 Schrauben der Frontplatte lösen.

COM1-Platine einsetzen:

§ Befestigungsschraube herausdrehen

22

§ Abstandbolzen einschrauben

§ Platinenhalter einstecken

§ Das Schnittstellenmodul (YDO01M-232 und YDO01M-232CLK) auf die Digitalplatine des

Midrics-Auswertegerätes aufstecken. Dazu die Buchsenleisten des Schnittstellenmoduls

in die korrespondierenden Steckerleisten der Digitalplatine stecken.

§ Schnittstellenmodul mit der Schraube befestigen.

Die Schnittstellenmodule sind mit eigenen Schraubklemmenleisten ausgerüstet.

Die Anschlusskabel an diese Klemmenleisten anschließen.

UniCOM-Platine einsetzen:

§ 2 Befestigungsschrauben herausdrehen

23

§ 2 Abstandbolzen einschrauben

§ Platinenhalter einstecken

§ Das Schnittstellenmodul (YDO01M-232CO, YDO01M-485, YDA01M-20MA, YDO01M-EN)

auf die Digitalplatine des Midrics-Auswertegerätes aufstecken. Dazu die Buchsenleisten

des Schnittstellenmoduls in die korrespondierenden Steckerleisten der Digitalplatine stecken.

§ Schnittstellenmodul mit der Schraube befestigen.

Die Schnittstellenmodule sind mit eigenen Schraubklemmenleisten ausgerüstet.

Die Anschlusskabel an diese Klemmenleisten anschließen.

24

Schnittstellenkabel montieren

§ Anschlussbelegung: siehe Abschnitt »Steckerbelegungsplan«.

§ Anschlusskabel des Peripheriegerätes mit der Kabelverschraubung mit dem Auswertegerät

verbinden.

§ Schnittstellenkabel vorbereiten:

– Kabelende ca. 10 cm abisolieren

– Schirmung auf ca. 1cm kürzen und nach hinten über die Isolierung ziehen

– Adern des Verbindungskabels ca. 1cm abisolieren und mit Aderendhülsen versehen

§ Kabeldurchführung montieren:

!Alle Arbeiten an der Verschraubung vorsichtig durchführen. Einen Drehmomentschlüssel

verwenden. Drehmoment dieser Kabelverschraubung: 5 Nm.

– Blindstopfen an der vorgesehenen Bohrung des Auswertegerätes entfernen

– Beiliegende Kabelverschraubung durch Bohrung stecken und mit Gegenmutter (1) von

innen sichern.

– Kabel durch die Kabelverschraubung stecken bis die Schirmung (2) Kontakt zu den Klem-

men (3) hat. Druckmutter (4) anziehen bis der Dichteinsatz (5) zwischen Druckmutter und

Kabel einen kleinen Wulst bildet.

– Kontakt der Schirmung mit den Klemmen kontrollieren.

§ Verbindungskabel anschließen:

– Adern entsprechend den Klemmenbelegungsplänen fest an den Klemmen verschrauben.

– Belegungspläne siehe Seite 28.

§ Auswertegerät wieder verschließen. Darauf achten, dass der Dichtring zwischen Gehäuse

und Frontplatte richtig aufliegt.

§ Nach Beendigung der Montagearbeiten den IP65-Schutz überprüfen. Dazu Druckmano-

meter verwenden. Weitere Informationen dazu sind beim Sartorius Service zu erfragen.

Schnittstelle COM1 und UniCOM für Betrieb einstellen

Nach Einbau und Konfiguration des Schnittstellenmoduls in das Auswertegerät die

Schnittstelle UniCOM mit Hilfe des Bedienmenüs für die vorgesehene Funktion einstellen.

Siehe dazu das Kapitel »Voreinstellungen COM1 und UniCOM«. Weitere Erläuterungen

dazu enthält das Kapitel »Voreinstellungen« der Midrics-Betriebsanleitung.

4

1

5

2

3

25

Module konfigurieren: YDO01M-485, YDO01M-20MA

YDO01M-485 (Optionen A2 und A3)

Merkmale

Das Schnittstellenmodul YDO01M-485 (serielle RS485/RS422-Schnittstelle, galvanisch

getrennt

1

) kann entweder im RS485- oder im RS422-Betrieb eingesetzt werden.

Die Konfiguration für die vorgesehene Verwendung erfolgt mit acht Schaltern.

Zusätzlich zur Einstellung für den vorgesehenen Betrieb als eine RS485- oder RS422Schnittstelle müssen je nach Einsatzbereich (Netzwerk oder Punkt-zu-Punkt-Verbindung)

die auf der Platine vorhandenen Abschlusswiderstände (120 O) und die Bias-Widerstände

aktiviert oder deaktiviert werden.

Die Anordnung der Schalter ist aus der nebenstehenden Strichzeichnung ersichtlich. Bei

geschlossenem Schalter 1-4 ist die Schnittstelle für RS422-Betrieb konfiguriert.

Folgende Funktionen stehen zur Verfügung, wenn der jeweilige Schalter geschlossen ist

(Stellung: »ON«):

Funktion (ON = geschlossen) Schalter

Abschlusswiderstand, TX-Seite 120O 1 - 1

BIAS-Widerstand, TX-Seite (TXD+, Pull-Up) 680O 1 - 2

BIAS-Widerstand, TX-Seite (TXD–, Pull-Down) 680O 1 - 3

ON: RS422-Betrieb | offen: RS485-Betrieb 1 - 4

Abschlusswiderstand, RX-Seite 120O 2 - 1

BIAS-Widerstand, RX-Seite (RXD+, Pull-Up) 680O 2 - 2

BIAS-Widerstand, RX-Seite (RXD–, Pull-Down) 680O 2 - 3

Ohne Funktion 2 - 4

Hinweis zur Schalterstellung

Immer gleiche Schalterstellung:

– beide Schalter 1–2/1–3 auf ON oder OFF

– beide Schalter 2–2/2–3 auf ON oder OFF

Betrieb als RS485-Schnittstelle (Option A3):

§ Der Schalter 1-4 für die Umschaltung zum RS485-Betrieb muss geöffnet sein (Werksvor-

einstellung).

§ Ggf. Biaswiderstände für den RS485-Betrieb deaktivieren. Dazu die Schalter öffnen

(Werkvoreinstellung).

Die Biaswiderstände dürfen in einer Übertragungsstrecke (Netzwerk oder Punkt-zuPunkt-Verbindung) nur einmal vorkommen, sonst besteht die Gefahr von Übertragungsfehlern. Dazu ggf. Datenblätter oder Schaltungsunterlagen der Gegenstelle oder der Netzwerkknotenpunkte einsehen. Biaswiderstände immer paarweise aktivieren oder

deaktivieren.

§ Der Abschlusswiderstand (TX-Seite, Schalter 1 – 1) muss aktiviert sein, wenn sich das

Gerät an einem der beiden Enden eines RS485-Bussystems befindet oder wenn es mit

einem anderen Gerät mit einer Punkt-zu-Punkt-Leitung verbunden ist. In der Gegenstelle

muss sich ebenfalls ein Abschlusswiderstand von 120 O befinden. Ggf. Abschlusswiderstand (120 O) für den RS485-Betrieb aktivieren:

Schalter 1 - 1 und 2 - 1 schließen (Stellung »ON«)

Betrieb als RS422-Schnittstelle (Option A2):

§ Den Schalter 1 - 4 für die Umschaltung zum RS422-Betrieb schließen (Stellung »ON«)

§ Ggf. Biaswiderstände für den RS422-Betrieb deaktivieren. Dazu die Schalter öffnen.

§ Den Abschlusswiderstand der RX-Seite aktivieren (Schalter 2 – 1), sofern kein externer

Abschlusswiderstand vorhanden ist. TX-Abschlusswiderstände immer deaktivieren

(Schalter 1 – 1).

1

) Der Schirm des Anschlusskabels ist einseitig mit dem Gehäuse des Auswertegerätes verbunden.

Das Auswertegerät ist mit dem Schutzleiter verbunden.

26

YDA01M-20MA (Option A9)

Merkmale

Das Schnittstellenmodul YDA01M-20MA ist ein Analogausgang. Es kann entweder als

Stromschnittstelle (0/4 - 20mA, 0 - 24 mA) oder als Spannungsschnittstelle (0 bis 10 V)

betrieben werden. Die Spannungsversorgung erfolgt intern galvanisch getrennt

1)

).

Das Schnittstellenmodul kann auf einen der vier folgenden Betriebszustände eingestellt

werden:

– Spannungsschnittstelle, 0 bis 10 V

– Stromschnittstelle, 0 bis 20 mA

– Stromschnittstelle, 4 bis 20 mA

– Stromschnittstelle, 0 bis 24 mA

Die Konfiguration für die vorgesehene Verwendung erfolgt durch das Schließen und Öff-

nen von Schaltern. Die Anordnung der Schalter ist aus der nebenstehenden Strichzeich-

nung ersichtlich.

Die Einstellung auf den jeweiligen Betriebszustand erfolgt durch die Einstellung der

Schalter 1 und 2 (Schalter 3 und 4 ohne Funktion):

Betriebszustand Schalter

Spannungsschnittstelle, 0 bis 10 V SW 1–1: geschlossen = Stellung »ON«,

SW 1–2: offen

Stromschnittstelle, 0 bis 20 mA SW 1–1: offen,

SW 1–2: geschlossen = Stellung »ON«

Stromschnittstelle, 4 bis 20 mA SW 1–1: offen, SW 1–2: offen

(Werkvoreinstellung)

Stromschnittstelle, 0 bis 24 mA SW 1–1: geschlossen = Stellung »ON«,

SW 1–2: geschlossen = Stellung »ON«

1

) Der Schirm des Anschlusskabels ist einseitig mit dem Gehäuse des Auswertegerätes verbunden.

Das Auswertegerät ist mit dem Schutzleiter verbunden.

– Max. Bürde: 390 Ohm

Hinweise

– Der Schirm des Anschlusskabels der Stromschnittstelle ist einseitig mit dem Gehäuse des

Auswertegerätes verbunden.

– Das Auswertegerät ist mit dem Schutzleiter verbunden.

– Wird das Auswertegerät mit einem internen oder externen Akku versorgt, ist ein Betrieb

der Stromschnittstelle nicht möglich.

§ Das Schnittstellenmodul YDA01M-20MA wird direkt auf die Digitalplatine der Midrics

Auswertegeräte (MIS..., MW...) aufgesteckt. Siehe dazu das Kapitel »Einbau in das

Auswertegerät«.

27

Beispiel: Prinzipschaltbild

YDO01M-IO, Option A5:

Spezifikationen

Digitale Eingänge

– Anzahl: 5

– Low-Pegel: –3 V bis +5 V

– High-Pegel: +11 V bis +30 V

– Max. Stromaufnahme: 2,6 mA bei 15 V

– Schalten der Eingänge durch Anlegen

der entsprechenden Spannung.

Digitale Ausgänge

– Anzahl: 5

– Maximaler Stromfluss je Kanal:

100 mA

– Spannungsbereich 0–30 Vdc

– Jeder Ausgang wird durch einen

Optokoppler gebildet.

YDO01M-EN (Option B9)

Lieferumfang

– Schnittstellenmodul YDO01M-EN

– Betriebsanleitung (dieses Dokument)

– Software-Schnittstellenbeschreibung

»Feldbus« für Modbus TCP

Montage

Das Schnittstellenmodul YDO01M-EN

(Ethernet-Schnittstelle) wird ohne

Konfiguration direkt mit der Digitalpla-

tine der Waage verbunden. Siehe dazu

das Kapitel »Einbau in Auswertegerät«.

Stecker des Sartorius Ethernet-Kabels

YCC02RJ45M7 (Option M38) in die

Buchse des Schnittstellenmoduls

stecken.

Hinweis:

!Nur Kabel und Stecker gemäß der

Ethernet-Spezifikation verwenden

(CAT5 oder höher):

Ethernet-Kabel mit Kabelverschraubung

Sartorius Bestell-Nr. YCC02RJ45M7

(Option M38)

Schnittstellenmodul nur in folgenden

Geräten einsetzbar:

– Indikator MIS1, MIS2 (IP65)

– Komplettwaage MW1, MW2 (IP65)

1

23

4

1

0.2A

4

30V

OUTx_high

OUTx_low

Inputx_high

LV1

LV1

LV2

23

Inputx_low

LV2

28

Steckerbelegungsplan

COM1

– RS232-Schnittstelle: YDO01M-232

(Option A11), YDO01M-232CLK (A31):

Pinbelegung der 8-pol. Schraubklemmenleiste auf dem Schnittstellenmodul:

Pin 1: +12 V: Betriebsspannung für

Sartorius Drucker

Pin 2: Reset_Out

(Peripherie-Neustart)

Pin 3: +5 V Out

Pin 4: Masse (GND)

Pin 5: Clear to Send (CTS)

Pin 6: Data Terminal Ready (DTR)

Pin 7: Dateneingang (R+D)

Pin 8: Datenausgang (T+D)

UniCOM

– Pinbelegung der zwei 10-pol. Schraub-

klemmenleisten auf dem Schnittstellenmodul:

RS232-Schnittstelle: YDO01M-232CO

(Option A1):

Pin 1: Clear to Send (CTS)

Pin 2: Data Terminal Ready (DTR)

Pin 3: Dateneingang (R+D)

Pin 4: Datenausgang (T+D)

Pin 5: Masse (GND)

Pin 6: Universal In

Pin 7: Steuerausgang »kleiner«

Pin 8: Steuerausgang »gleich«

Pin 9: Steuerausgang »größer«

Pin 10: Steuerausgang »set«

Pin 11: +12 V: Betriebsspannung für

Sartorius Drucker

Pin 12: Reset_Out

(Peripherie-Neustart)

Pin 13: Masse (GND)

Pin 14: Masse (GND)

Pin 15: +5 V Ausgang

Pin 16: +5 V geschaltet

(z.B. für Barcodeleser)

Pin 17: Masse (GND)

Pin 18: Masse (GND)

Pin 19: nicht belegt

Pin 20: Ext. Vers.-Spannungsausgang

+15 ... 25 V

Digital IO-Schnittstelle:

YDO01M-IO (Option A5):

Pin 1: External Output Port 5: low

Pin 2: External Output Port 5: high

Pin 3: External Output Port 4: low

Pin 4: External Output Port 4: high

Pin 5: External Output Port 3: low

Pin 6: External Output Port 3: high

Pin 7: External Output Port 2: low

Pin 8: External Output Port 2: high

Pin 9: External Output Port 1: low

Pin 10: External Output Port 1: high

Pin 11: Input Port 5: low

Pin 12: Input Port 5: high

Pin 13: Input Port 4: low

Pin 14: Input Port 4: high

Pin 15: Input Port 3: low

Pin 16: Input Port 3: high

Pin 17: Input Port 2: low

Pin 18: Input Port 2: high

Pin 19: Input Port 1: low

Pin 20: Input Port 1: high

– Pinbelegung der zwei Schraubklemmen-

leisten auf dem Schnittstellenmodul:

YDO01M-485: RS485-Betrieb

(Option A2):

Pin 1: Daten + (T+D-R+D+)

Pin 2: Daten - (T+D-R+D-)

Pin 3: nicht belegt

Pin 4: nicht belegt

Pin 5: Signal Masse, galvanisch

getrennt (GND_GALV)

Pin 6: Signal Masse, galvanisch

getrennt (GND_GALV)

Pin 11: Ext. Vers.-Spanunngseingang

+15 ... 25 V *

Pin 12: Ext. Vers.-Spanunngseingang

+15 ... 25 V *

Pin 13: Masse (GND) *

Pin 14: Masse (GND) *

1

2

3

4

5

66

YDO01M-485: RS422-Betrieb

(Option A3):

Pin 1: Datenausgang + (T+D+)

Pin 2: Datenausgang - (T+D-)

Pin 3: Dateneingang + (R+D+)

Pin 4: Dateneingang - (R+D-)

Pin 5: Signal Masse, galvanisch

getrennt (GND_GALV)

Pin 6: Signal Masse, galvanisch

getrennt (GND_GALV)

Pin 11: Ext. Vers.-Spanunngseingang

+15 ... 25 V *

Pin 12: Ext. Vers.-Spanunngseingang

+15 ... 25 V *

Pin 13: Masse (GND) *

Pin 14: Masse (GND) *

* = nicht galvanisch getrennt

YDA01M-20MA (Strom-/Spannungsschnittstelle):

6-pol. Schraubklemmenleiste auf dem

Schnittstellenmodul

Pin 1: I_out (+)

für Stromschnittstelle

(0/4 bis 20/24 mA)

Pin 2: I_in (–)

für Stromschnittstelle

(0/4 bis 20/24 mA)

Pin 3: V_out (+)

für Spannungsschnittstelle,

0 bis 10 V

Pin 4: V_in (–)

für Spannungschnittstelle,

0 bis 10 V

Pin 5: GND, galvanisch getrennt

(galvanisch getrennte Masse)

Pin 6: GND, galvanisch getrennt

(galvanisch getrennte Masse)

Pinbelegung der EthernetSchnittstelle (RJ45)

YDO01M-EN (Option B9):

Pin 1: TxD+

Pin 2: TxD–

Pin 3: RxD+

Pin 4: nicht verwendet

Pin 5: nicht verwendet

Pin 6: RxD–

Pin 7: nicht verwendet

Pin 8: nicht verwendet

Chassis: GND

1

2

3

4

5

66

1

2

3

4

5

66

29

Voreinstellungen COM1 und UniCOM

Bedienmenü-Übersicht für die Schnittstelle »COM1« und »UniCOM«

(siehe dazu auch die Bedienmenü-Übersicht im Kapitel »Voreinstellungen« der Midrics-Betriebsanleitung)

Appl

Fn-Key

Setup WP-1

COM1 OFF *

DATPROT SBI *

(Datenprotokoll)

XBPI-232

SMA

Printer YDP01IS Line *

Label

Label, man. Form-Feed

YDP02

YDP03

YDP02IS Line *

Label

UNI-PRI (Universaldrucker)

YDP04IS Line *

Label

Label, man. Form-Feed

MEMORY YAM01IS (Alibispeicher)

UniCOM OFF *

DATPROT SBI *

(Datenprotokoll)

XBPI-232

XBPI-485

SMA

ETHERNET Source IP: 192.168.0.1 *

Source Name

Listen Port: 49155 *

Subnet Mask: 255.255.255.0 *

Gate-IP: 0.0.0.0 *

DNS-IP: 0.0.0.0 *

Ziel IP: 0.0.0.0 *

Ziel-Port: 49155 *

Protokoll TCP *

UDP

Modus SBI (Server)-SRV * 6.1. Datenausgabe manuell/automatisch

6.1.1 Manuell ohne Stillstand

6.1.2 * Manuell nach Stillstand

6.1.4 Automatisch ohne Stillstand

6.1.5 Automatisch mit Stillstand

6.1.7 Protokollprint für PC

7.2. Ausgabe: Zeilenformat

7.2.1 Für Rohdaten: 16 Zeichen

7.2.2 * Für sonstige Anw.: 22 Zeichen

SBI-C/S 6.1. Data output manual/automatic

(Client) 6.1.1 Manuell ohne Stillstand

6.1.2 * Manuell nach Stillstand

6.1.4 Automatisch ohne Stillstand

6.1.5 Automatisch mit Stillstand

6.1.7 Protokollprint für PC

6.3. Zeitabhän. autom. Ausgabe

6.3.1 * 1 Anzeigezyklus

6.3.2 2 Anzeigezyklen

6.3.4 10 Anzeigezyklen

6.3.7 100 Anzeigezyklen

7.2. Ausgabe: Zeilenformat

7.2.1 Für Rohdaten: 16 Zeichen

7.2.2 * Für sonstige Anw.: 22 Zeichen

xBPI

SMA

Modbus/TCP

30

Setup UniCOM Printer YDP01IS Line *

Label

Label, man. Form-Feed

YDP02

YDP03

YDP02IS Line *

Label

UNI-PRI (Universaldrucker)

YDP04IS Line *

Label

Label, man. Form-Feed

MEMORY YAM01IS (Alibispeicher)

ANALOG (Analogschnittstelle)

CTRL IO: CTR INP: 8. 4. x TTL; für YDO01M-232CO, Option A1

Steuerein/ Steuereingänge 8. 17. x Galvanisch getrennt; für

-ausgänge bis YDO01M-IO, Option A5

8 . 21. x

CTR OUT 8. 24. x Galvanisch getrennt; für

(Steuer- bis YDO01M-IO, Option A5

ausgänge) 8. 28. x

* = Werksvoreinstellung

31

31

Schnittstelle konfigurieren

Die universale Datenschnittstelle

UniCOM im Betriebsmenü des Auswertegerätes für den vorgesehenen

Betriebszustand einstellen (Anschluss

eines Peripheriegerätes). Der zugehörige

Ausschnitt des Menübaums ist im Bild

links dargestellt.

Weitere Erläuterungen dazu enthält das

Kapitel »Voreinstellungen« der MidricsBetriebsanleitung.

RS485- / RS422-Schnittstelle

Ist die Platine für RS422-Betrieb konfiguriert, so können die Einstellungen

»SBI«, »XBPI-232« und SMA im Menü

verwendet werden.

Analogschnittstelle YDA01M-20MA

Im Menü ist konfigurierbar:

– Ausgabewert (Menüpunkt 8-12):

8-12-1: Nettowert

(Werksvoreinstellung)

8-12-2: Bruttowert

– Fehlerdarstellung (Menüpunkt 8-13):

8-13-1: High-Pegel (20 mA)

(Werksvoreinstellung)

8-13-2: Low-Pegel (0/4 mA):

Während des Betriebs liegt eine

Spannung von 5 V auf dieser

Schnittstelle

– Ausgabe-Modus (Menüpunkt 8-14):

8-14-1: Null bis Maximallast

(Werksvoreinstellung)

8-14-2: Min./Max.-Werte

– Ausgabe Min./Max.-Werte

(Menüpunkt 8-15):

8-15-1: Min. (0/4 mA) Eingabe in kg

8-15-2: Max. (20 mA) Eingabe in kg

Über die Wahl: Min./Max.-Werte kann

der Wägebereich für die Ausgabe der

0/4 bis 20 mA (0–10 V) frei gewählt

werden. Diese Wahl gilt auch für eine

SBI-Waage, aber nur für den NettoWert.

Die Eingabe der Min.-, Max-Werte

erfolgt immer in der Einheit ‚Kilogramm’. Die Eingabe von negativen

Gewichtswerten ist möglich. Auch kann

der Min.-Wert größer dem Max.-Wert

sein, wenn man eine fallende Stromausgabe haben möchte.

Beispiele:

Steigende Stromkurve

Min.Wert Netto: -1 kg

Max.-Wert Netto: 4 kg

Fallende Stromkurve für XBPI-Waage

Min.-Wert: 5 kg

Max.-Wert: 1 kg

Fallende Stromkurve für SBI-Waage

Min.-Wert: 5 kg

Max.-Wert: 1 kg

Ethernet-Schnittstelle

Im Menü »UNICOM« über »ETHERNET«

unter Source-IP, ListenPort, usw. Zahleneingaben vornehmen. Bei SourceName können Buchstaben und Zahlen

verwendet werden. Es können maximal

15 Zeichen eingegeben werden. Den

Source-Namen alternativ zur Source-IP

eingeben.

Portnummern

Gültigkeitsbereich: 0 – 65535

Da viele der Ports bis 49150 bereits

vergeben sind, empfehlen wir PortNummern oberhalb von 49150 zu verwenden. Gilt nicht für ModBus/TCP,

denn hier gilt die Portnummer: 502

(siehe Broschüre: Feldbus)

32

Ethernet-Schnittstelle:

Initialisierung

Anzeige: Initialisierung beendet

Wenn die Initialisierung des EthernetModuls erfolgreich beendet wurde, wird

das Symbol » « angezeigt.

Netzwerkmodul

initialisiert

War die Initialisierung nicht erfolgreich,

wird kein Symbol angezeigt.

Das Symbol sagt nichts über einen Verbindungszustand zum Netzwerk aus!

TCP-Verbindungen:

Bei Betriebsart SBI-C/S trennt Midrics

die Verbindung immer selbstständig

nach 1 Sekunde.

Bei den anderen Betriebsarten:

SBI-SRV, SMA, XBPI, ModBus/TCP

bleibt die Verbindung bestehen bis sie

der PC (Client) trennt. Es kann nur eine

Verbindung gleichzeitig aufgebaut

werden.

Ethernet-Schnittstelle: Merkmale

Source IP: IP-Adresse des Midrics-Indikator

Wird die Adresse 0.0.0.0 gewählt, soll über einen im Netzwerk vorhandenen

DHCP-Server eine IP-Adresse dynamisch vergeben werden. Dann muss in

Source-Name etwas eingetragen sein.

Source Name: Dieser Parameter ist alternativ zu Source-IP. Es kann ein Name eingetragen

werden, der 15 Zeichen lang ist und zur Benennung des Midrics dient.

Dann muss unter Source-IP die Adresse 0.0.0.0 eingestellt sein!

Der Name wird dem Domain-Name-Server (DNS) bekanntgegeben, wenn

- unter DNS-IP eine IP-Adresse eingegeben wurde

oder

- über DHCP eine IP-Adresse vergeben wurde.

Geräte-Port: Port-Nummer an der das Midrics für den Server-Betrieb lauscht.

Subnet-Mask: IP-Adress-Maske zur Aktivierung von IP-Adressen in einem Unternetz.

Soll die Maske über einen DHCP-Server vergeben werden, muss 0.0.0.0

eingetragen werden.

Gateway-IP: IP-Adresse eines Gateways

Über Ziel-IP gewünschten Server ansprechen, der in einem anderen Netz

liegt. Soll die IP-Adresse dynamisch über einen DHCP-Server vergeben

werden, muss 0.0.0.0 eingetragen werden.

Ziel-IP: Adresse des Servers, der die Daten des Midrics empfangen soll.

Wichtig für den Client-Betrieb des Midrics, wenn Modus SBI mit Datenausgabe »automatisch« gewählt wurde. Bei Verwendung von UDP muss hier

auch eine IP-Adresse eingetragen werden.

Ziel-Port: Portnummer an der ein Server mit der »Ziel-IP« lauscht, um Daten vom

Midrics zu empfangen.

Protokoll: Das Transport-Protokoll auswählen, mit dem die Daten über das Ethernet

verschickt werden.

Bitte wählen zwischen:

- TCP, verbindungsorientiert mit hoher Datensicherheit

oder

- UDP, verbindungslos (für Modbus/TCP wirkungslos)

Modus: Das Datenformat wählen, welches die Nutzdaten enthält, die in TCP oder

UDP eingebettet werden (z.B. SMA wird mit TCP oder UDP über Ethernet

getunnelt).

Bei den Protokollen SBI-SRV, XBPI und SMA ist das Midrics immer als

Server zu sehen. Bei SBI-C/S ist das Midrics Server und Client zugleich.

Client-Betrieb liegt vor, wenn die Taste p [Print] betätigt wird oder der

Parameter »Datenausgabe« auf »Automatisch« gestellt wurde. Für den

OPC-Betrieb den Modus »SBI-Server« einstellen. Für die anderen Fälle ist das

Midrics ein Server. Bei ModBus/TCP ist das Midrics immer als Server aktiv

(siehe auch Broschüre Feldbus).

Einschaltverhalten: Bei aktiviertem Schnittstellen-Modul kann die Anzeige des Gewichtswertes

bis 20 Sekunden verzögert werden.

33

Synchronisation

Zum Datenaustausch zwischen Rechner

und Auswertegerät werden über die

Datenschnittstelle Telegramme aus

ASCII-Zeichen übertragen. Zum fehlerfreien Datenaustausch müssen die Parameter für Baudrate, Parität und Handshake und das Zeichenformat

übereinstimmen.

Eine Anpassung des Auswertegerätes

geschieht über die entprechenden Einstellungen im Setup (Menü). Zusätzlich

zu diesen Einstellungen kann die

Datenausgabe des Auswertegerätes von

verschiedenen Bedingungen abhängig

gemacht werden. Diese Bedingungen

sind bei den jeweiligen Anwendungsprogrammen beschrieben.

Eine offene Datenschnittstelle (kein

Peripheriegeät angeschlossen) verursacht keine Fehlermeldungen.

Handshake

Die Datenschnittstelle der Waage ist

aus-gestattet mit Sende- und Empfangspuffer. Im Setup des Auswertegerätes können unterschiedliche Arten des

Handshakes eingestellt werden:

– Hardware-Handshake (CTS/DTR)

– Software-Handshake (XON, XOFF)

Hardware-Handshake

Beim Hardware-Handshake mit

4-Draht-Schnittstelle kann nach CTS

noch 1 Zeichen gesendet werden.

Software-Handshake

Das Software-Handshake wird über

XON und XOFF gesteuert. Beim Einschalten eines Gerätes muss ein XON

gesendet werden, um ein evtl. angeschlossenes Gerät freizugeben.

Der Ablauf der Datenübertragung sieht

folgendermaßen aus:

Waage ––– byte –––> Rechner

(Sender) ––– byte –––> (Empfänger)

––– byte –––>

––– byte –––>

<–– XOFF –––

––– byte –––>

––– byte –––>

...

(Pause)

...

<–– XON –––

––– byte –––>

––– byte –––>

––– byte –––>

––– byte –––>

Sender

Ein empfangenes XOFF verhindert

das weitere Aussenden von Zeichen.

Ein empfangenes XON gibt das Senden

wieder frei.

Empfänger

Um eine Übertragung nicht zu stark

mit Steuerzeichen zu belasten, erfolgt

die Freigabe durch XON erst, nachdem

der Puffer fast geleert ist.

34

Datenschnittstellen

Datenschnittstelle als

Kommunikationsschnittstelle

konfigurieren (datprot)

Im Setupmenü wird unter COM1 oder

UniCOM, «Datenprotokolle» (datprot)

die Schnittstelle als Kommunikationsschnittstelle eingerichtet.

SBI-Kommunikation

Es handelt sich um eine einfache ASCIISchnittstelle.

Unter Menüpunkt 6-1 und 6-3 wird

eingestellt, wie die Daten ausgegeben

werden:

– Manuelle Ausgabe eines Anzeigewertes

mit oder ohne Stillstand (Menüpunkt

6-1-1 und 6-1-2)

– Automatische Ausgabe eines Anzeige-

wertes mit oder ohne Stillstand (Menüpunkt 6-1-4 und 6-1-5) in Abhängigkeit von einer Anzahl von

Anzeigezyklen. Unter Menüpunkt 6-3

wird die Anzahl der Anzeigeintervalle

für die Ausgabe eingestellt.

– Ausgabe eines konfigurierbaren Druck-

protokolls. Ausgabe ist gekoppelt an

den Menüpunkt «Druckprotokolle»

(prtprot).

Mit Ausnahme der Ausgabe eines konfigurierbaren Druckprotokolls wird der

aktuelle Anzeigewert (Wägewert mit

Einheit, berechneter Wert, Zahlen- und

Buchstabenanzeige) ausgegeben.

SMA-Kommunikation

Standardisiertes Kommunikationsprotokoll der Scale Manufacturers Association

Dateneingangsformat

(Kommandos)

Ein über die Datenschnittstelle angeschlossene Rechner (SBI-Kommunikation) kann Befehle zum Auswertegerät

senden um Funktionen Waagen- oder

Applikationsfunktionen zu steuern.

Alle Befehle haben ein gemeinsames

Rahmenformat (Dateneingangsformat).

Sie beginnen mit dem Zeichen ESC

(ASCII: 27) und enden mit der Zeichenfolge CR (ASCII: 13) und LF (ASCII: 10).

Ihre Länge variiert von min. 4 Zeichen

(1 Befehlzeichen) bis max. 7 Zeichen

(4 Befehlszeichen).

Die in der folgenden Tabelle dargestellten Befehle müssen jeweils um das Rahmenformat ESC ... CR LF ergänzt werden.

Beispiel: Es soll der Ausgabebefehl »P«

(„sende Anzeigewert“) an das Aus-wertegerät gesendet werden. Dazu wird die

Zeichenfolge »ESC P CR LF« gesendet.

Befehl Bedeutung

K Wägemodus 1

L Wägemodus 2

M Wägemodus 3

N Wägemodus 4

O Tastatur sperren

P Sende Anzeigewert

zur Datenschnittstelle

R Tastatur freigeben

T Tarieren und Nullstellen

(Tara-Kombifunktion)

f3_ Nullstellen (Zero),

wie Befehl »kZE_«

f4_ Tarieren (ohne Nullstellen),

wie Befehl »kT_«

kF1_ F1: Taste k auslösen

kF2_ F2: Taste c auslösen

(nur Modell Midrics 2)

kF3_ F3: Taste r auslösen

(nur Modell Midrics 2)

kF4_ F4: Taste O auslösen

(nur Modell Midrics 2)

kF5_ F5: Taste w auslösen

(nur Modell Midrics 2)

Befehl Bedeutung

kF6_ F6: Taste I auslösen

(nur Modell Midrics 2)

KF7_ Taste d

kCF_ CF: Taste c auslösen

(nur Modell Midrics 2)

kP_ Taste p auslösen

Drucken auf Druckerschnittstelle

kT_ Taste ) auslösen

(Tarieren)

kZE_ Taste ( auslösen

(Nullstellen)

x1_ Ausgabe Typ aktuelle

Wägeplattform,

Beispiel: »LP6200S-0C «

x2_ Ausgabe Seriennummer

aktuelle Wägeplattform,

Beispiel: »0012345678 «

x3_ Ausgabe Softwareversion

aktuelle Wägeplattform,

Beispiel: » 00-20-04 «

z1_ Eingabe: Protokollkopfzeile 1

z2_ Eingabe: Protokollkopfzeile 2

txx...x_ xx...x: Eingabe Buchstaben

Länge entsprechend

Eingabe (nur Modell Midrics 2)

Das Zeichen »_« (Underline) ist das

ASCII-Zeichen 95 dezimal.

Format für die Eingabe der Protokollkopfzeilen: »ESC z x a ... a _ CR LF« mit

x=1 oder 2 und a ... a: 1 bis 20 Zeichen

für die Kopfzeile x, gefolgt von den Zeichen Underline, CR und LF.

35

Fehlermeldung:

Pos. 12345678910111213141516

***Err**##****CRLF

oder ***Err*###****CRLF

*: Leerzeichen

#: Ziffer (2- oder 3-stellige Fehlernummer)

Beispiel (Ausgabe des Wägewertes +1255,7 g):

Pos. 12345678910111213141516

+** * 1255. 7* g* * CRLF

Position 1: Vorzeichen +, - oder Leerzeichen

Position 2: Leerzeichen

Position 3-10: Gewichtswert mit Dezimalpunkt. Führende

Nullen werden als Leerzeichen ausgegeben.

Position 11: Leerzeichen

Position 12-14: Zeichen für Messeinheit oder Leerzeichen

Position 15: Carriage Return

Position 16: Line Feed

Ausgabeformat mit 22 Zeichen (mit Header)

Normaler Betrieb:

Pos. 12345678910111213141516171819202122

KKKKKK+* AAAAAAAA* E E E CRLF

oder KKKKKK- * AAAAAAAA* E E E CRLF

oder ********************CRLF

K: Zeichen für Kennzeichnung, rechtsbündig aufgefüllt mit

Leerzeichen

+-: Vorzeichen

*: Leerzeichen

A: Zeichen der Anzeige (max. 7 Ziffern und Dezimalpunkt)

E: Zeichen für Messeinheit (1-3 Buchstaben, gefolgt von

2-0 Leerzeichen)

CR: Carriage Return

LF: Line Feed

Sonderbetrieb:

Pos. 12345678910111213141516171819202122

Stat********––******CRLF

oder S t a t ********H*******CRLF

oder S t a t ********HH******CRLF

oder S t a t ********L*******CRLF

oder S t a t ********LL******CRLF

oder S t a t ********C*******CRLF

*: Leerzeichen – –: Auswaage

H: Überlast HH: Überlast Kontrollwaage

L: Unterlast LL: Unterlast Kontrollwaage

C: Justieren

Datenausgangsformat

Eine Druckzeile besteht aus maximal 22 Zeichen (20 druckbare

Zeichen plus zwei Steuerzeichen). Die ersten 6 Zeichen, der

sogenannte Header, kennzeichnen den nachfolgenden Wert.

Die Kennzeichnung (Header) kann unter Menüpunkt 7-2 abgeschaltet werden, so dass die Druckzeile aus 16 Zeichen (14

druckbare Zeichen plus zwei Steuerzeichen) besteht.

Beispiele:

+ 235 pcs ohne Header

Qnt + 235 pcs mit Header

Zeichen, die in der Anzeige nicht sichtbar sind, werden als Leerzeichen ausgegeben. Bei Zahlen ohne Dezimalpunkt wird kein

Dezimalpunkt ausgegeben.

Ausgabeformat mit 16 Zeichen (ohne Header)

Normaler Betrieb:

Pos. 123456789101112131415 16

+* AAAAAAAA* E E E CR LF

oder - * AAAAAAAA* E E E CR LF

oder **************CR LF

+-: Vorzeichen

*: Leerzeichen

A: Zeichen der Anzeige (max. 7 Ziffern und Dezimalpunkt)

E: Zeichen für Messeinheit (1-3 Buchstaben, gefolgt von

2-0 Leerzeichen)

CR: Carriage Return

LF: Line Feed

Sonderbetrieb:

Pos. 12345678910111213141516

******––******CR LF

oder ******H*******CR LF

oder ******HH******CR LF

oder ******L*******CR LF

oder ******LL******CR LF

oder ******C*******CR LF

*: Leerzeichen

– –: Auswaage

H: Überlast

HH: Überlast Kontrollwaage

L: Unterlast

LL: Unterlast Kontrollwaage

C: Justieren

36

Datenschnittstellen

GMP-Protokoll

Bei aktivem Menüpunkt, wird das

Druckprotokoll um den Ausdruck eines

GMP-Kopfes und -Fußes um das Messergebnis ergänzt (GMP: Good Manufacturing Practice).

Der GMP-Kopf wird vor dem ersten

Messergebnis gedruckt. Der GMP-Fuß

wird entweder nach jedem einzelnen

Messergebnis gedruckt (GMP-Protokoll

immer für 1 Messergebnis, 7-11-2) oder

nach dem letzten Messergebnis einer

Serie von Messergebnissen (GMP-Protokoll immer für mehrere Messergebnisse,

7-11-3). Eine Serie von Messergebnissen wird abgeschlossen indem die Taste

p-lang gedrückt wird. Das Symbol A

ist in diesem Fall nach dem Abdruck des

GMP-Kopfes bis zum Druck des GMPFußes in der Anzeige sichtbar.

Nach Beendigung eines Justiervorgangs

wird automatisch immer ein GMP-Ausdruck erzeugt.

Beim Drucken GMP-konformer Ausdrücke auf einem Etikettendrucker

unter Menüeinstellung 7-11-3 geht der

Zusammenhang zwischen GMP-Kopf

und -Fuß verloren (Abdruck auf unterschiedlichen Etiketten). GMP-Ausdrücke

auf Etikettendruckern sollten daher

sinnvollerweise nur unter Menüeinstellung 7-11-2 erfolgen.

Nachfolgend werden Beispiele für einen GMP-Protokollkopf und einen GMP-Protokollfuß

dargestellt:

------------------- Strichzeile

14.01.2007 09:43 Datum/Uhrzeit

1

)

Typ MIS2 Midrics Typ

Ser.no. 12345678 Midrics Serien-Nr.

Vers. 1.1007.12.1 Softw.-Vers. Applikation

BVers. 01-25-01 Softw.-Vers. Basis-Sw.

------------------- Strichzeile

GMP-Fuß:

------------------- Strichzeile

14.01.2007 09:45 Datum/Uhrzeit

1)

Name: Feld für Unterschrift

Leerzeile

------------------- Strichzeile

1

) YDO01M-232, Option A31 notwendig

37

Description générale

L’interface de données YD.01M-... est

destinée à être intégrée dans des indicateurs et des balances complètes des

modèles Midrics® MIS..., MW... comme

interface de données standard COM1

optionnelle ou comme interface de

données universelle UniCOM optionnelle.

Pour COM1 :

– YDO01M-232 (option A11) :

Interface de données RS232 bidirectionnelle.

Le module YDO01M-232 permet de

raccorder différentes imprimantes

(YDP02IS, YDP03, YDP04IS, YDP12IS,

imprimante universelle), d’échanger les

données avec un ordinateur (mode

d’exploitation SBI, xBPI ou SMA).

– Connexion d’une mémoire alibi

– Adaptateur Bluetooth YBT01

– Afficheur supplémentaire YRD02Z

– Câble adaptateur USB pour connecter

un PC via USB YCC01IS

– YDO01M-232CLK « Horloge »

(option A31) :

comme RS232 standard, mais avec

horloge pour date/heure

Pour UniCOM :

– YDO01M-232CO (option A1) :

comme RS232 standard avec en plus

entrée/sortie numérique (TTL/5V)

– YDO01M-485 (options A2 et A3) :

Interface de données bidirectionnelle,

isolée électriquement, utilisable au

choix dans le mode d’exploitation

RS422 (option A2) ou dans le mode

d’exploitation RS485 (option A3).