Page 1

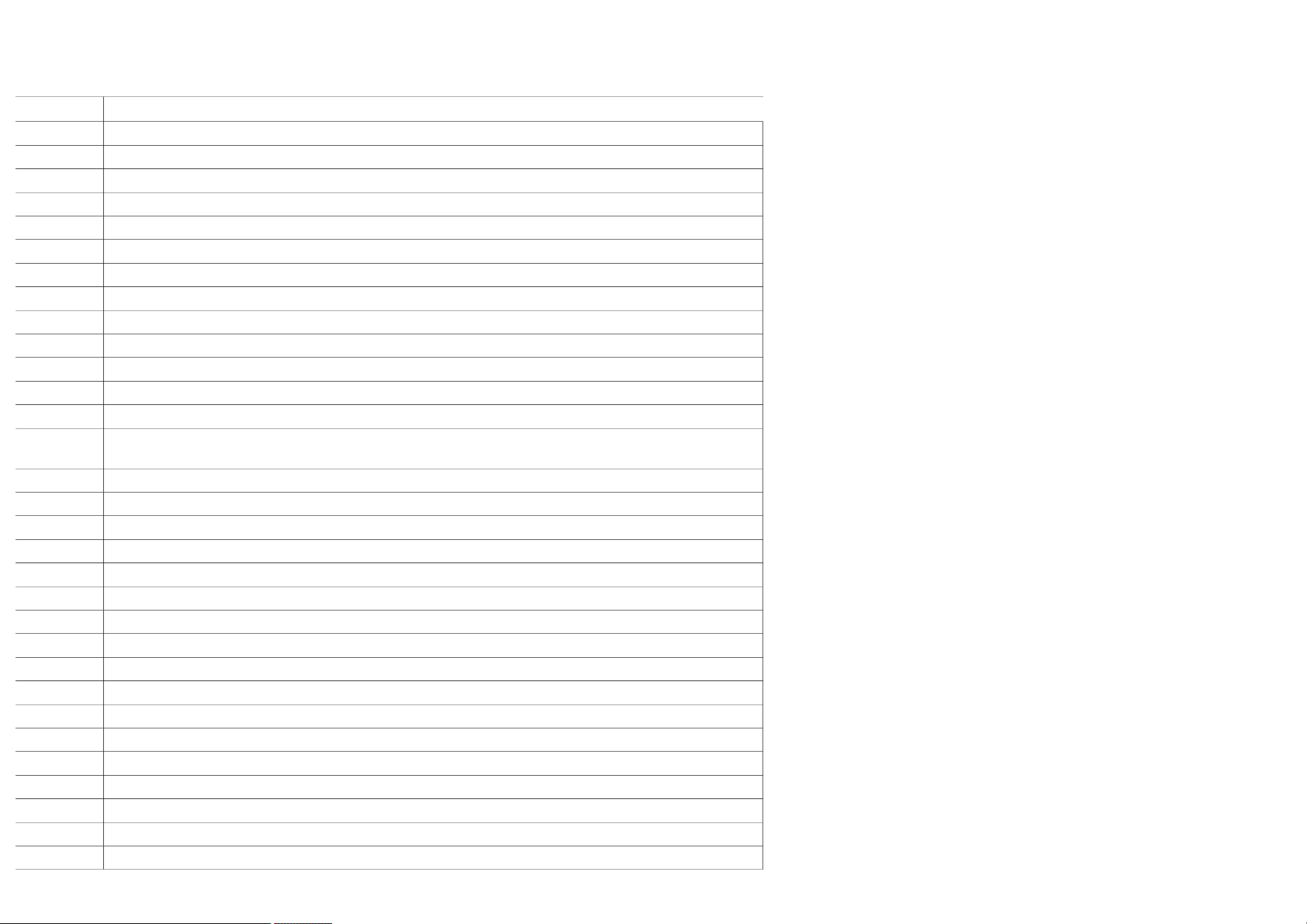

Andrew Burrows Rocker arms / Adjustment 03/02/16

Rocker arms, adjustment

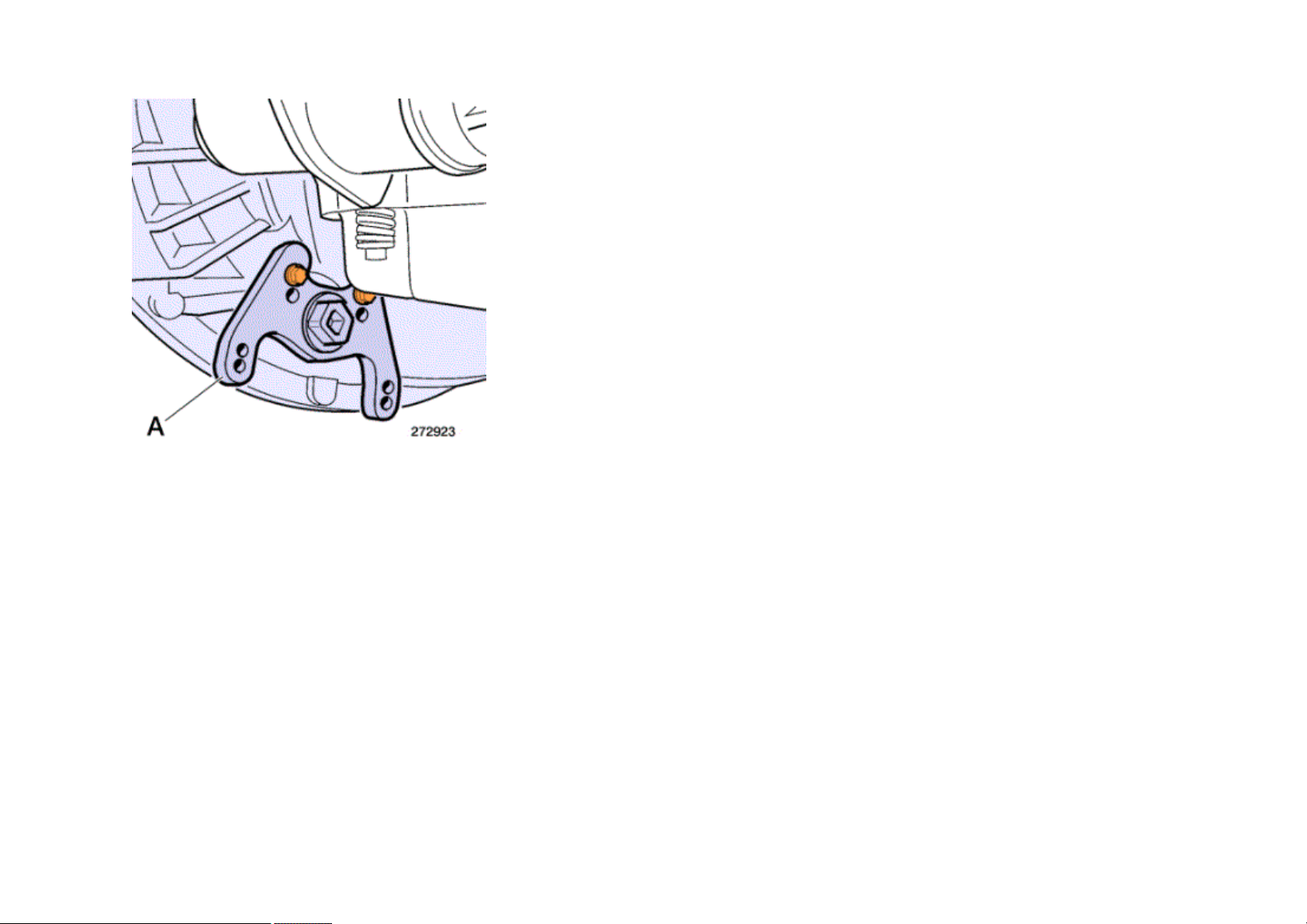

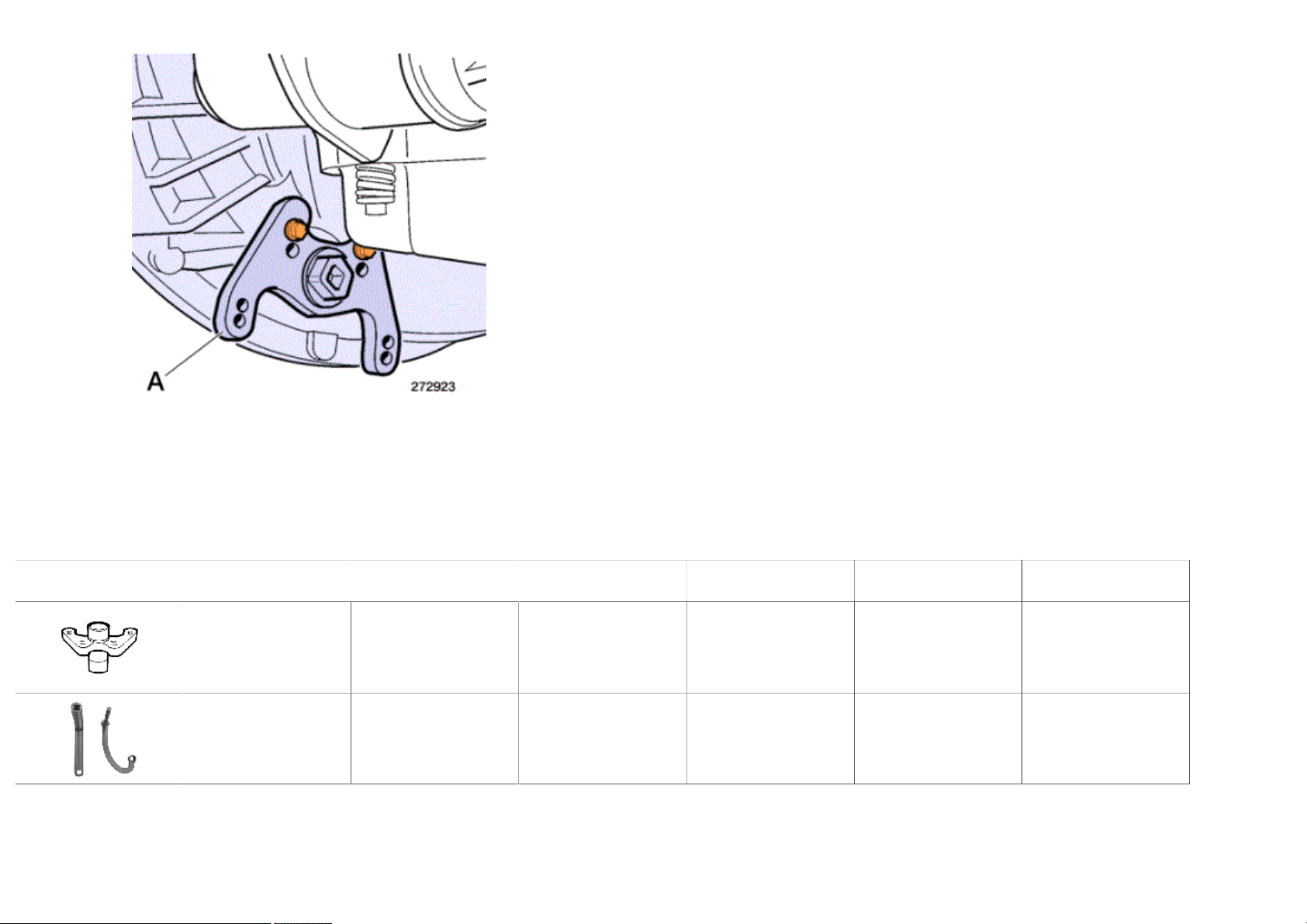

Position the marks on the camshaft which indicate the number of the cylinder to adjust between the marks on the camshaft front bearing cap.

Use tool A.

A = 6956

Direction of rotation of engine: anticlockwise.

See pages .

Camshaft marks

1 / 12

Page 2

Andrew Burrows Rocker arms / Adjustment 03/02/16

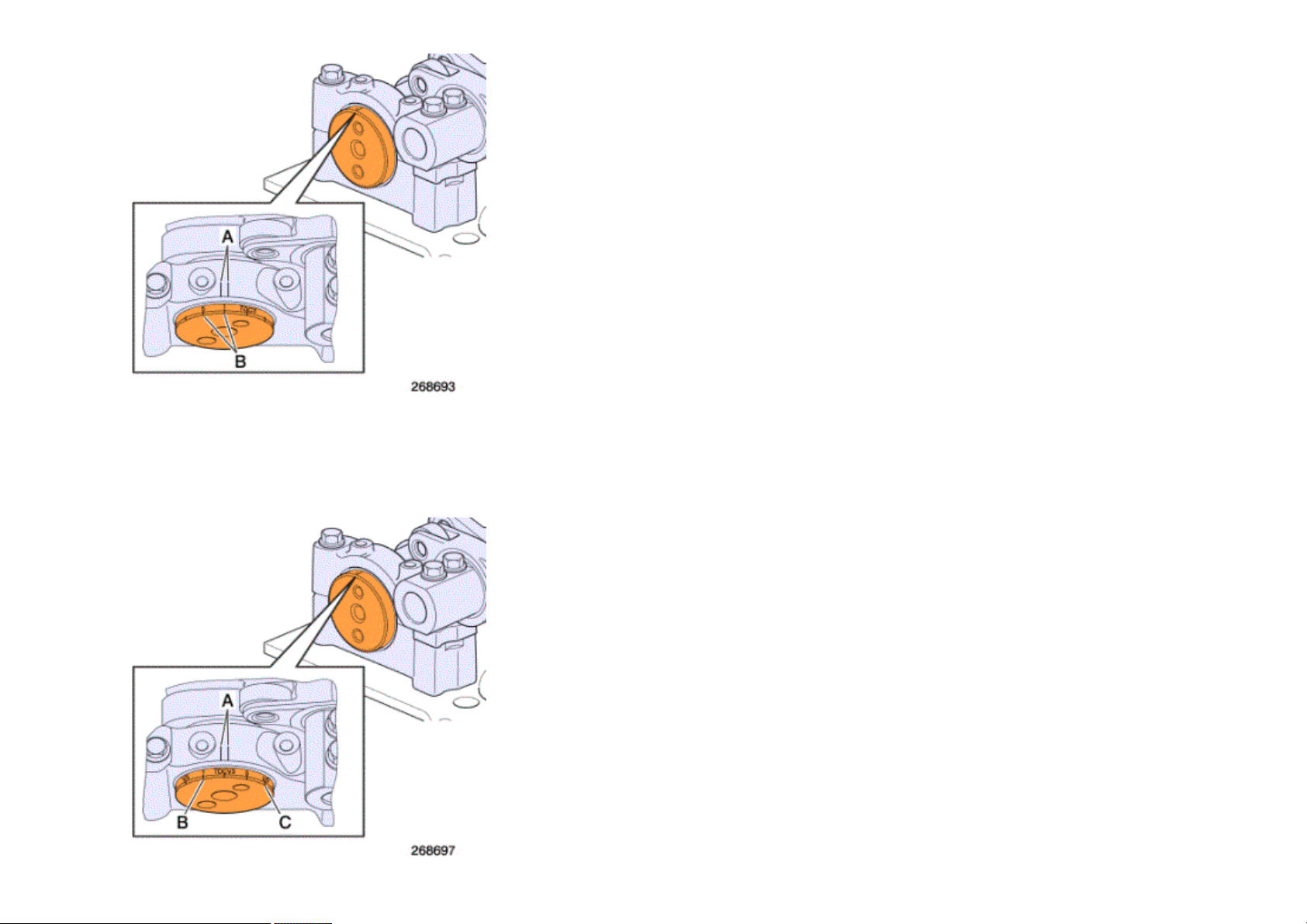

Without "Optibrake" exhaust brake

The marks (B) 1 - 5 - 3 - 6 - 2 - 4 correspond to the recommended inlet valve clearances , to the recommended exhaust valve clearances and to the

recommended pump injector pre-travel distances for each relative cylinder.

Mark (B) must be positioned in the centre of marks (A) when carrying out the adjustment.

2 / 12

Page 3

Andrew Burrows Rocker arms / Adjustment 03/02/16

With "Optibrake" exhaust brake

The marks (B) 1 - 5 - 3 - 6 - 2 - 4 correspond to the recommended inlet valve clearances and to the recommended pump injector pre-travel distances for

each relative cylinder.

The marks (C) V1 - V5 - V3 - V6 - V2 - V4 correspond to the recommended exhaust valve clearances for each relative cylinder.

The marks (B) or (C) must be positioned between the marks (A) to make the correct adjustment.

Adjustment of inlet valves

Measure the valve clearances using feeler gauges.

See pages .

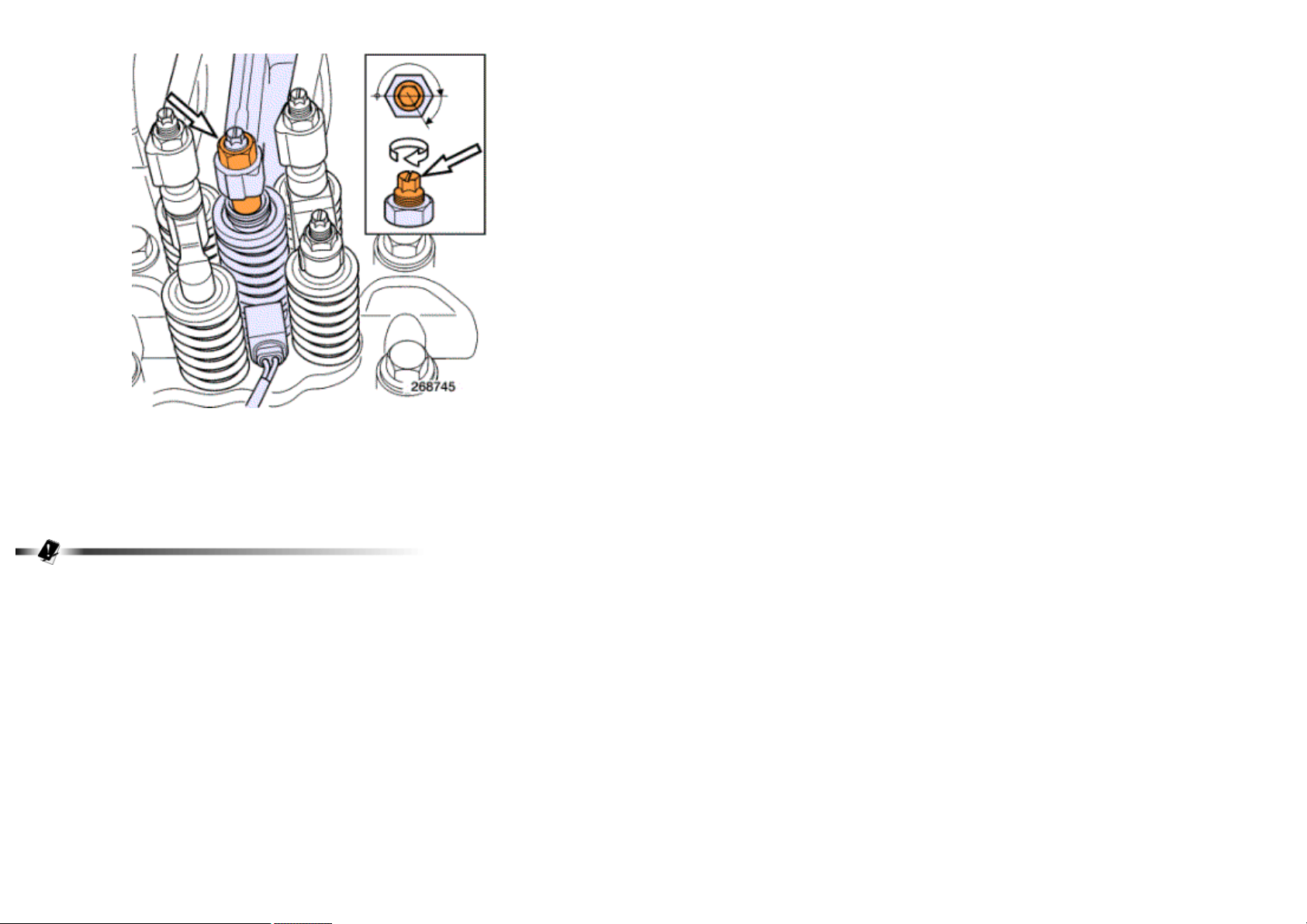

Loosen the locknut and the adjuster.

Adjust the clearance between the rocker arm and the valve yoke by means of screw.

Tighten the locknut to torque while holding the adjuster.

See pages .

Make a mark on the rocker arm when adjustment is finished.

Perform the same operation on all the other cylinders.

3 / 12

Page 4

Andrew Burrows Rocker arms / Adjustment 03/02/16

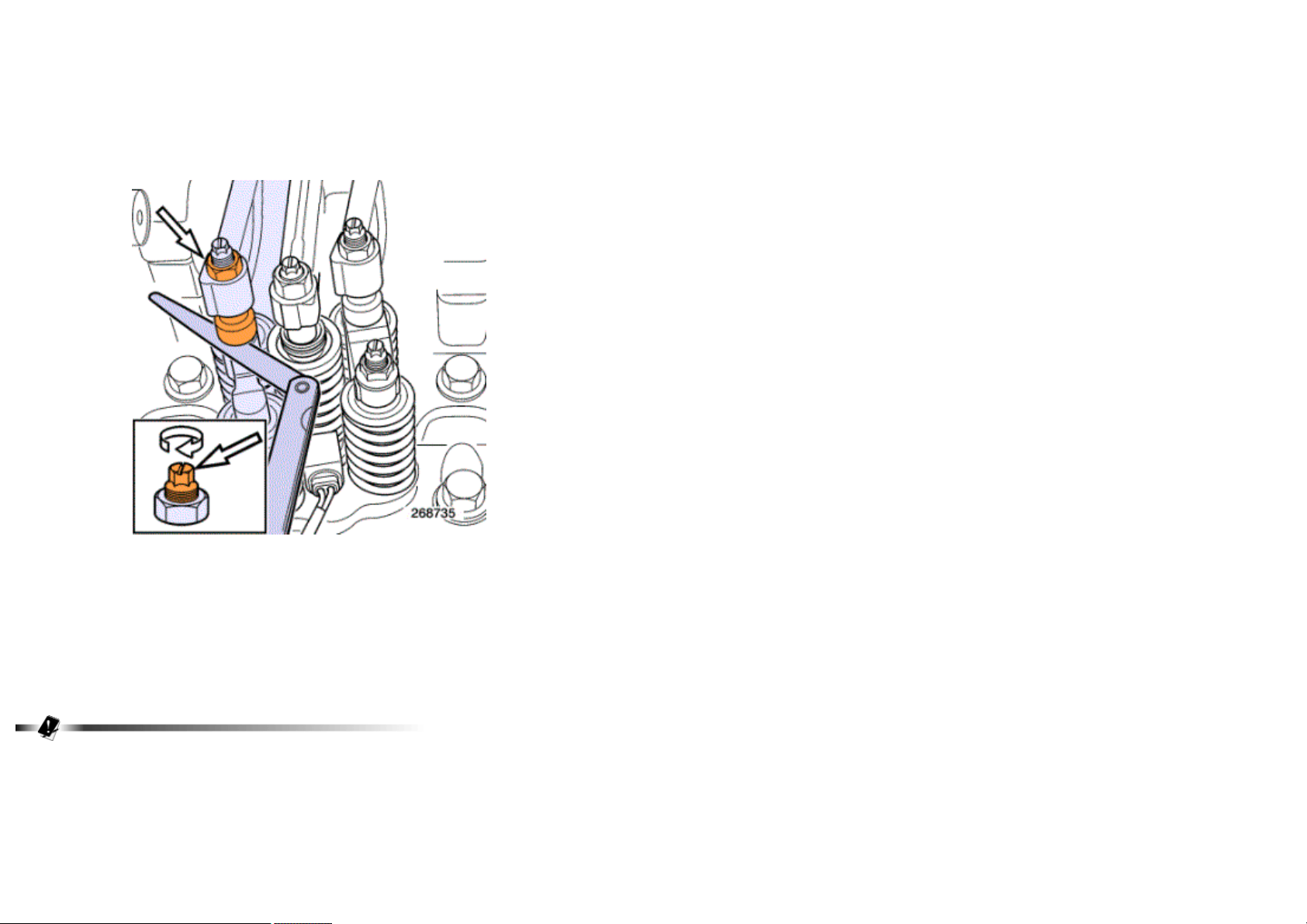

Adjustment of unit pump injectors pre-travel

Check the torque of the injector flange attachment bolts without removing the rocker arm assembly.

Use tool A.

A = 0162

Tighten to torque.

See pages .

This operation is to be performed at each valve adjustment maintenance.

4 / 12

Page 5

Andrew Burrows Rocker arms / Adjustment 03/02/16

Loosen the locknut and the adjuster.

Screw up the adjuster by hand until contact is made with the pump injector.

Tighten the adjuster through 2/3 of a turn to obtain a unit pump injector preload.

Tighten the locknut to torque while holding the adjuster.

See pages .

Make a mark on the rocker arm when adjustment is finished.

Perform the same operation on all the other cylinders.

Exhaust valve adjustment

5 / 12

Page 6

Andrew Burrows Rocker arms / Adjustment 03/02/16

Without "Optibrake" exhaust brake

Measure the valve clearances using feeler gauges.

See pages .

Loosen the locknut and the adjuster.

Adjust the clearance between the rocker arm and the valve yoke by means of screw.

Tighten the locknut to torque while holding the adjuster.

See pages .

Make a mark on the rocker arm when adjustment is finished.

Perform the same operation on all the other cylinders.

6 / 12

Page 7

Andrew Burrows Rocker arms / Adjustment 03/02/16

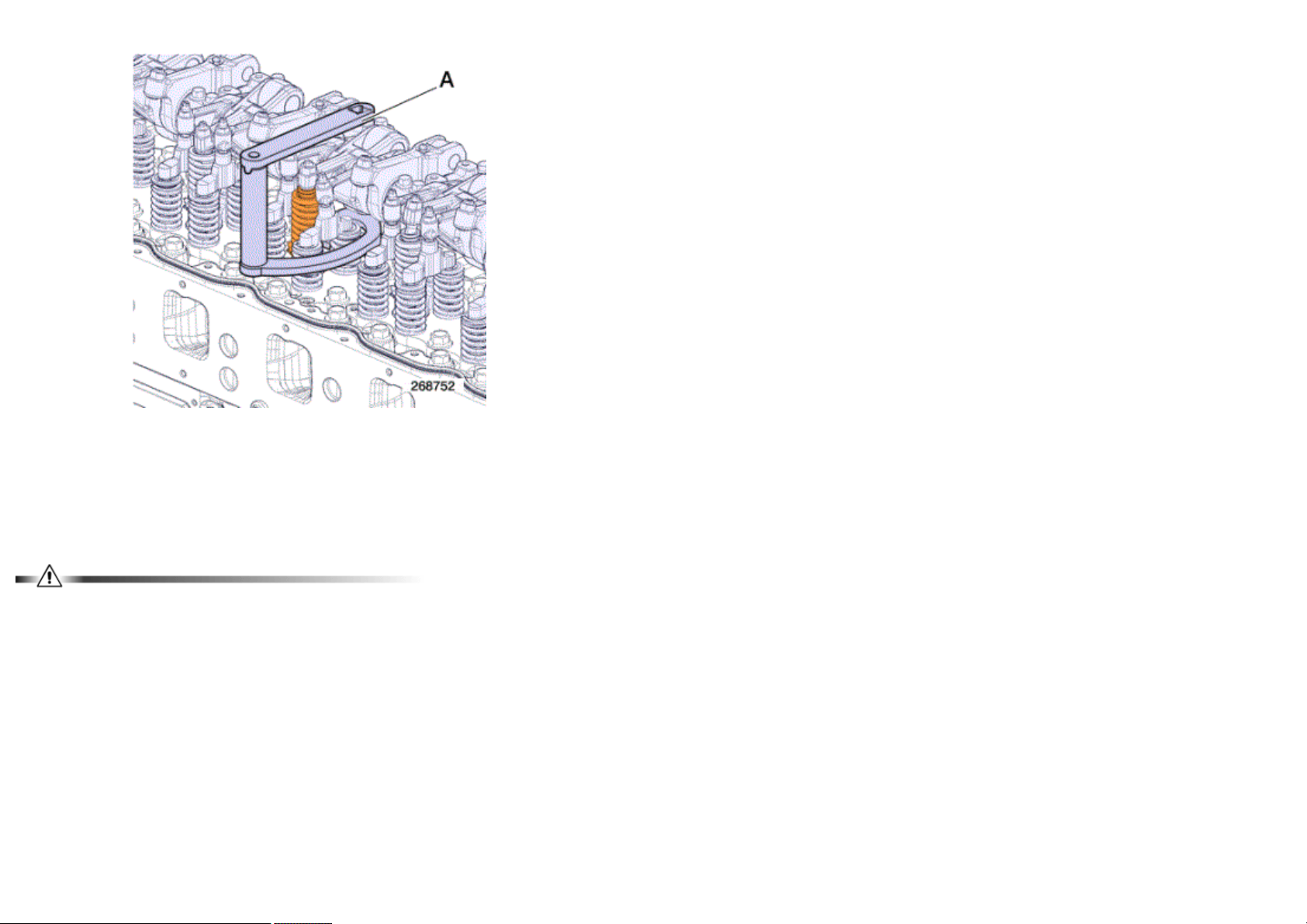

With "Optibrake" exhaust brake

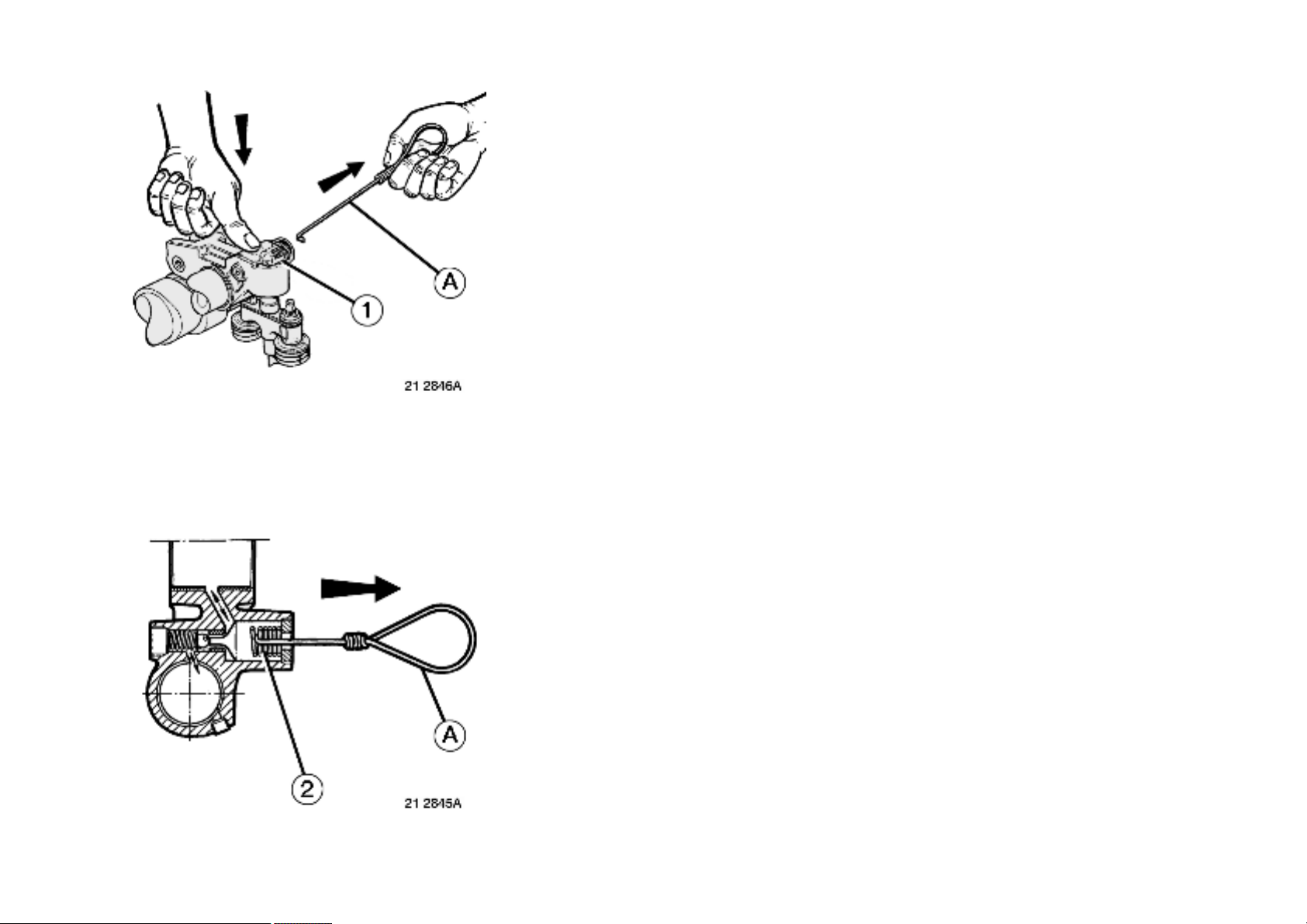

Before making the adjustment, press rocker arm (1).

Compress valve spring (2) to free the oil in the rocker arm.

Use a piece of rigid iron wire to make a hook (A).

7 / 12

Page 8

Andrew Burrows Rocker arms / Adjustment 03/02/16

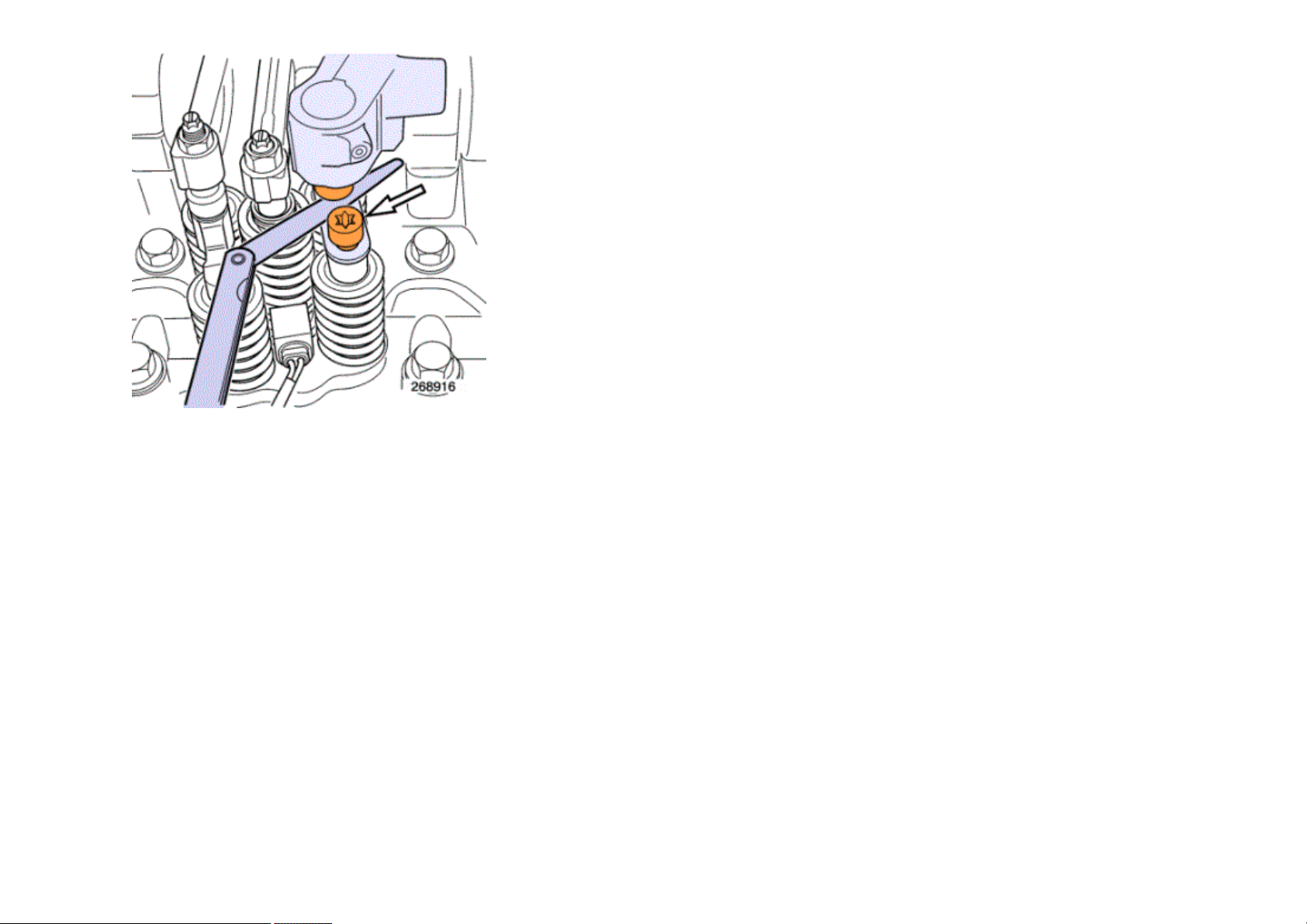

Check the clearance between the valve yoke and the exhaust rocker arm piston. Turn the piston to ensure that it is properly seated in its housing.

Use a feeler gauge corresponding to the recommended clearance.

See pages .

In the event of rocker arm play or sticking, make the check with a thicker or thinner feeler gauge in order to determine the thickness of the new adjusting

shim.

8 / 12

Page 9

Andrew Burrows Rocker arms / Adjustment 03/02/16

In the event of incorrect clearances.

Remove bolt.

Remove adjusting shim .

Hold the caliper in place when unbolting.

9 / 12

Page 10

Andrew Burrows Rocker arms / Adjustment 03/02/16

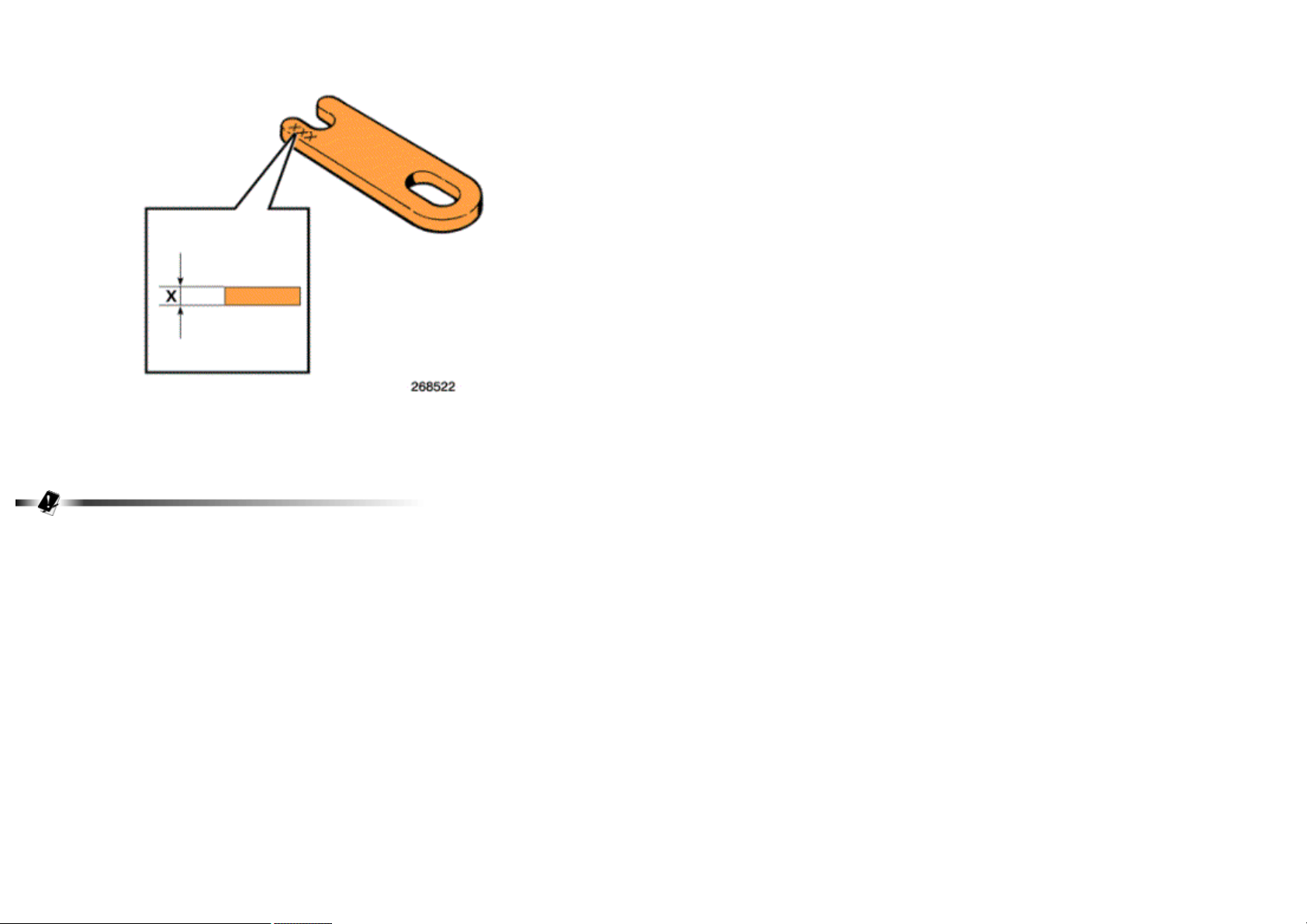

Note down the thickness X engraved on adjusting shim.

Determine the thickness of the new adjustment shim, in order to obtain the recommended clearance.

See pages .

You can superimpose a maximum of 2 adjusting shims, provided that they have the same thickness. Adjusting shims are available with thicknesses of

0.05 by0.05 mm.

10 / 12

Page 11

Andrew Burrows Rocker arms / Adjustment 03/02/16

Fit shim.

Fit bolt.

Tighten to torque.

See pages .

Hold the caliper in place when tightening.

Again check the clearance between the valve yoke and the arm piston.

Make a mark on the rocker arm when adjustment is finished.

Perform the same operation on all the other cylinders.

11 / 12

Page 12

Andrew Burrows Rocker arms / Adjustment 03/02/16

Remove tool A.

A = 6956

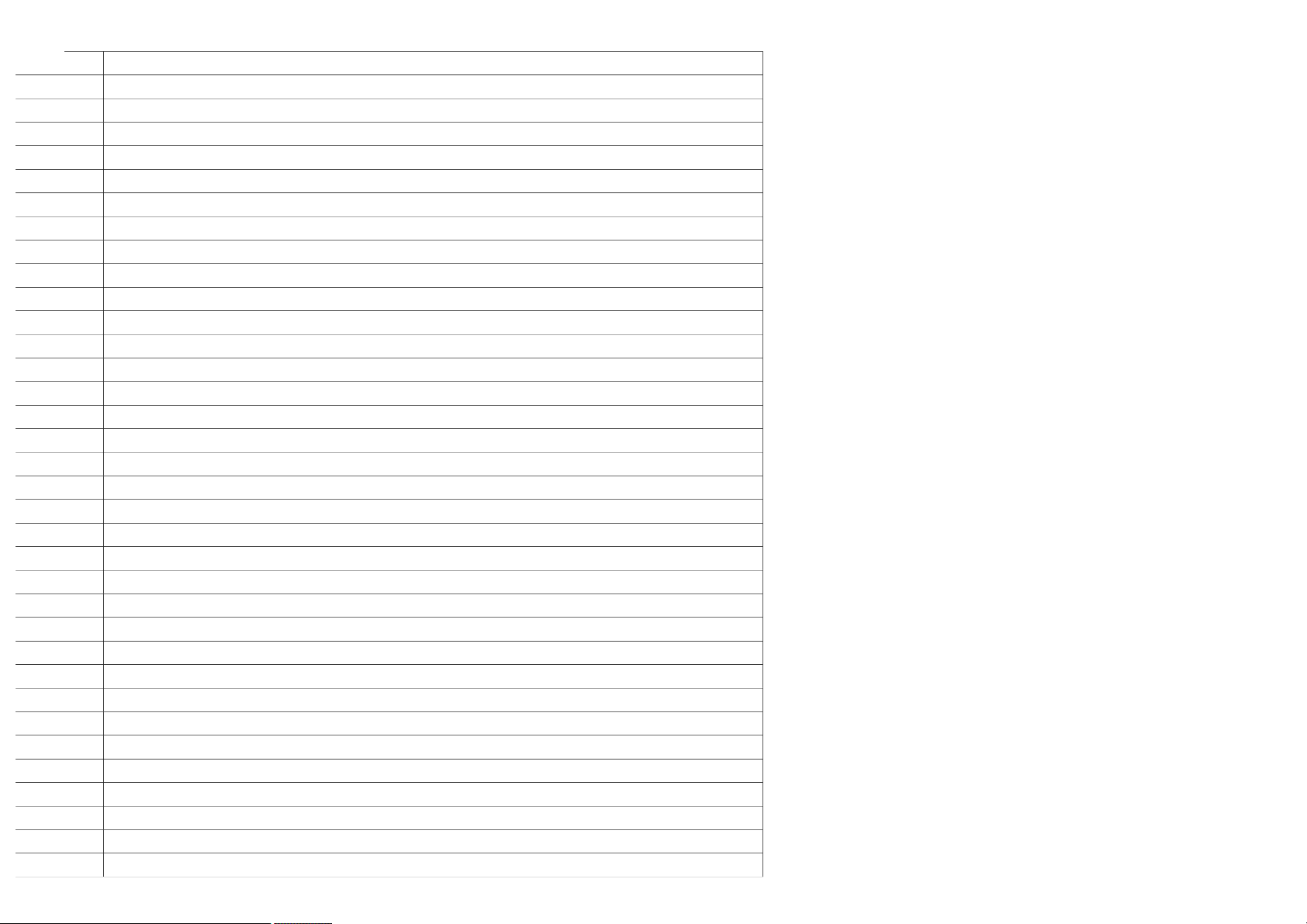

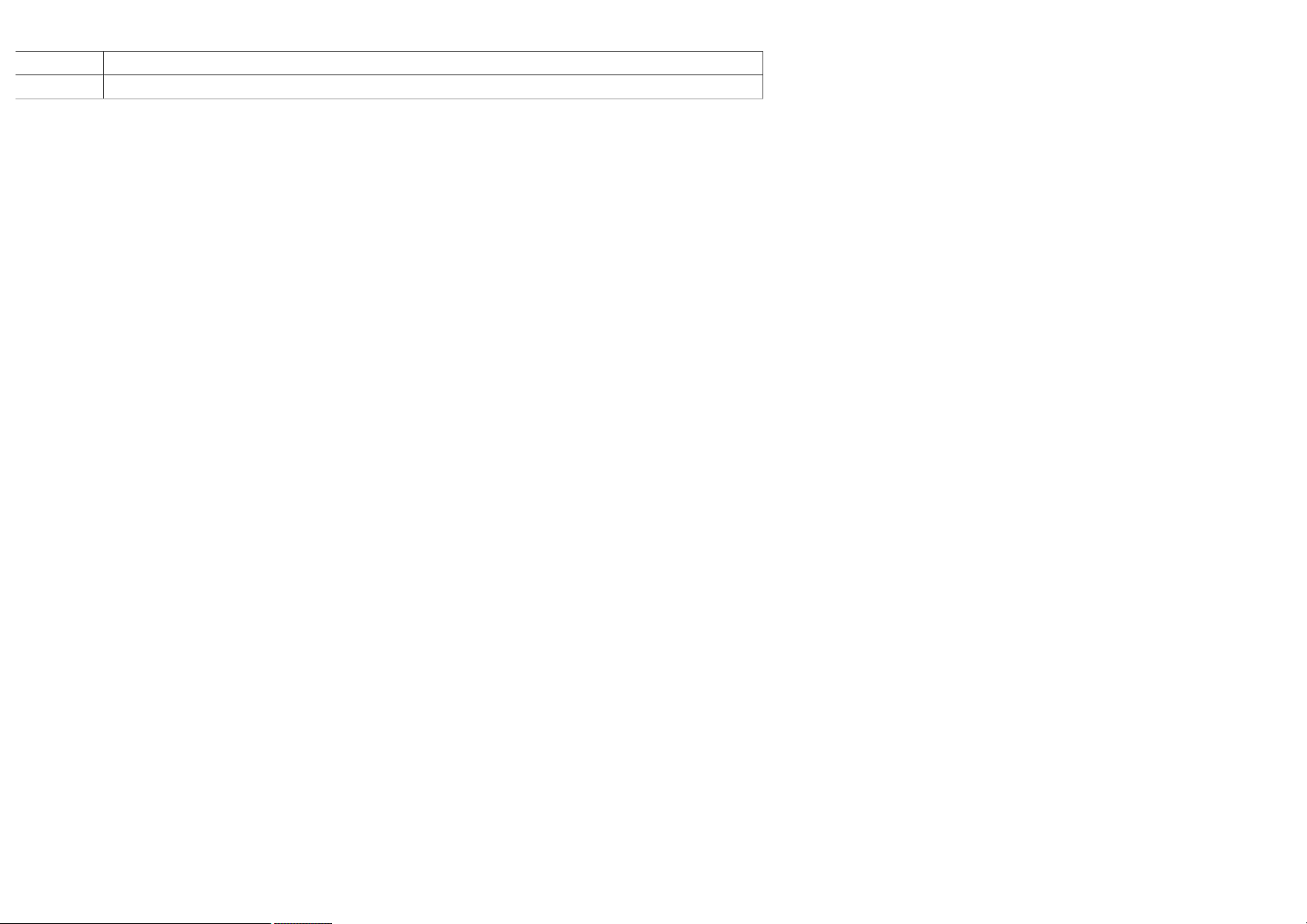

Tools

Specific tools

Illustration RENAULT

Designation Manufacturer's

TRUCKS part N°

7409996956 CONTROL 1 1

7488840162 WRENCH 2 1

reference N°

Manufacturer's code N° Scale Qty

12 / 12

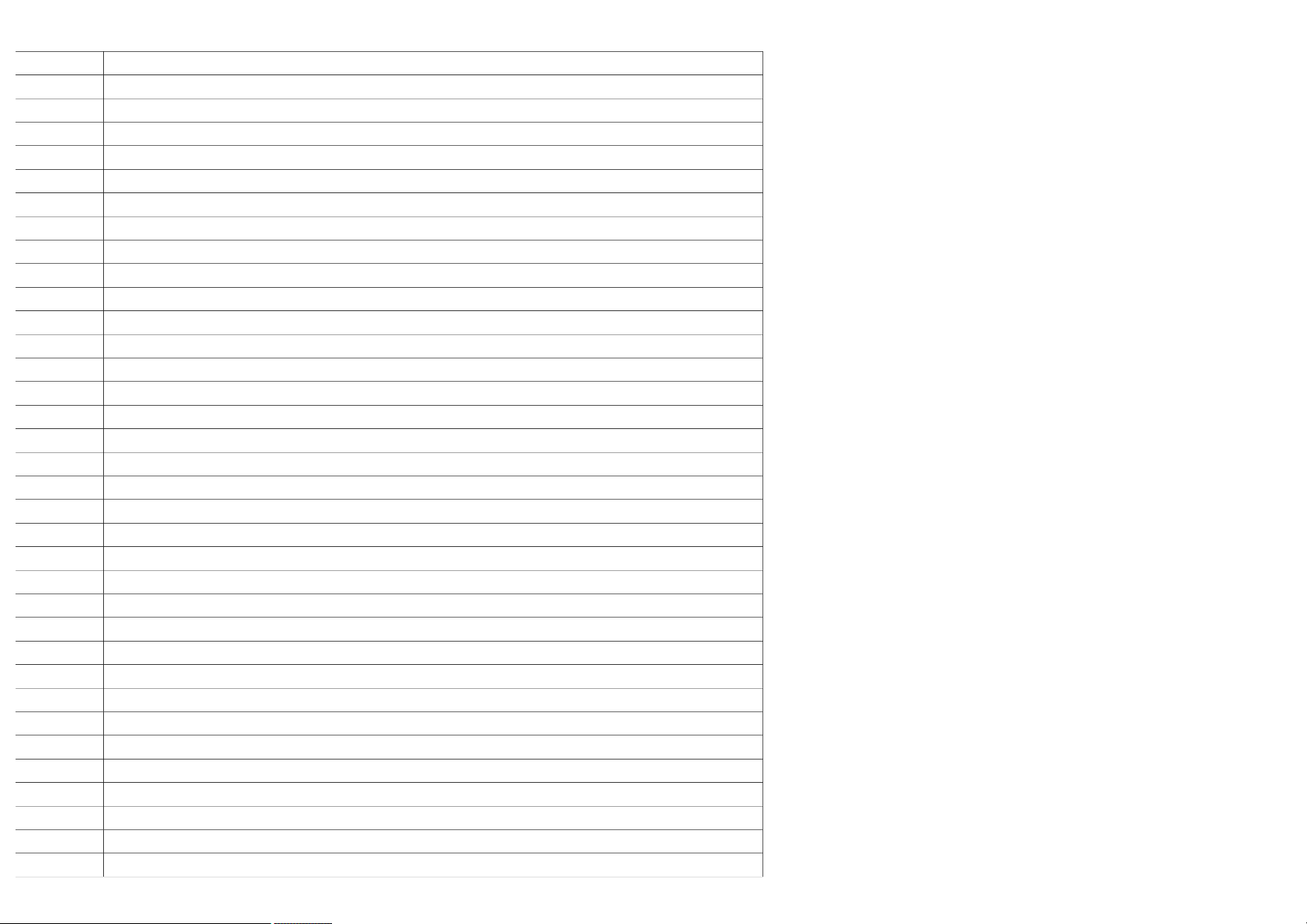

Page 13

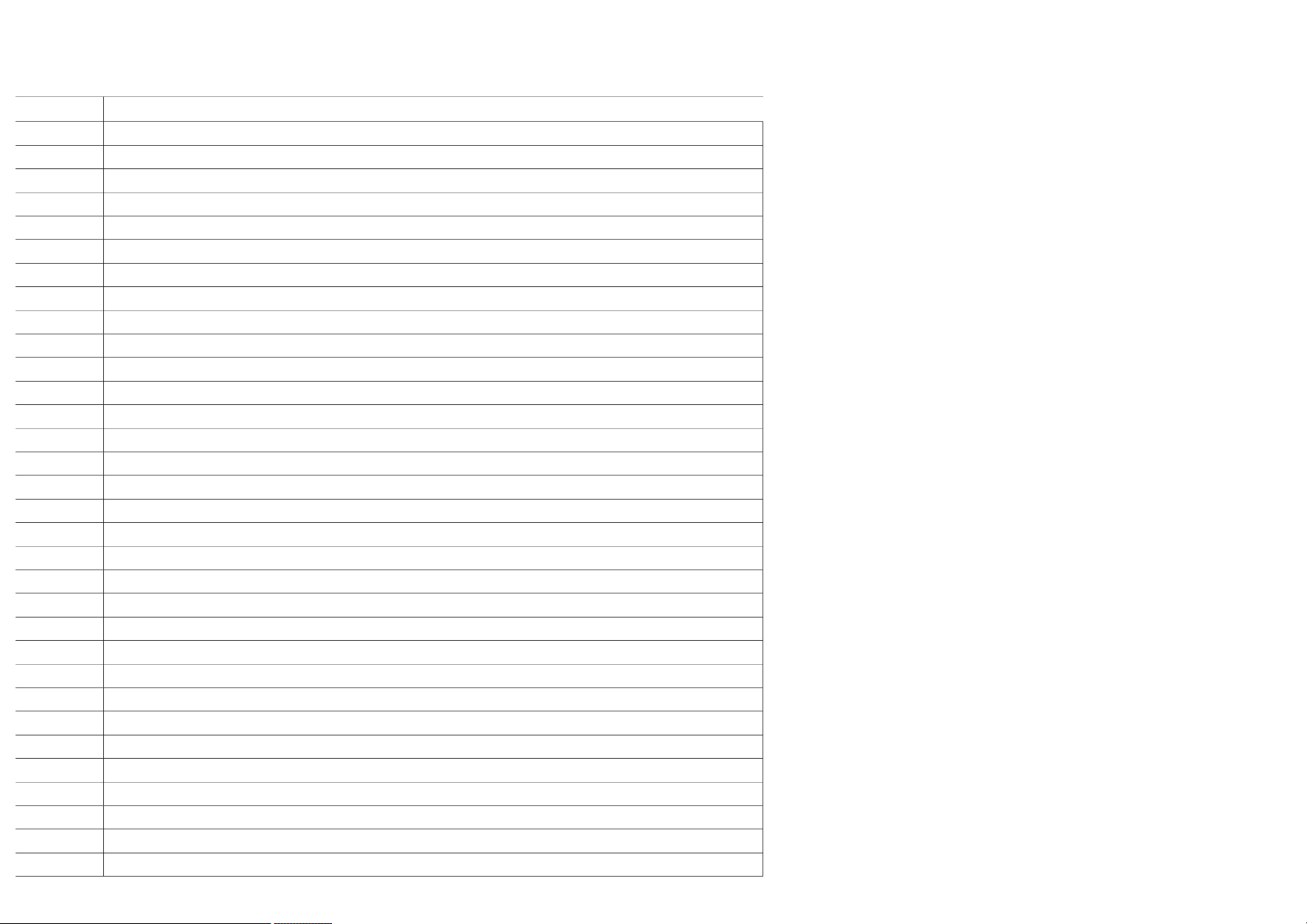

Andrew Burrows Key / Diagram 02/02/16

Group 0 - Electronics

Polarity N° Designation

0010 Communication bus J1587-1 (+ signal)

0011 Communication bus J1587-1 (- signal)

0012 Communication bus J1939-1 (+ signal)

0013 Communication bus J1939-1 (- signal)

0014 Not assigned

0015 Radio remote control

0016 Radio remote control

0017 Radio remote control

0018 Radio remote control

0019 Radio remote control

0020 Radio remote control

0021 “ZF” communication bus (+ signal)

0022 “ZF” communication bus (- signal)

0023 Power supply relay control by vehicle management ECU

0024 Injection pump and camshaft speed sensor information (electronic injection / - signal)

0025 Injection pump and camshaft speed sensor information (electronic injection / + signal)

0026 Gear lever communication bus (+ signal)

0027 Hydraulic retarder proportional solenoid valve control

0029 Hydraulic retarder oil boosting solenoid valve control

0031 Hydraulic retarder coolant temperature information

0032 Hydraulic retarder coolant temperature information

0038 Retarder manual control (analogue signal)

0039 Alarm siren activation and/or disabling encoded line

0045 Communication bus for EBS trailer socket (+ signal)

0046 Communication bus for EBS trailer socket (- signal)

0056 Vehicle speed sensor encrypted data line

0057 Information display pull-down menu sequence change signal

0058 Information display pull-down menu sequence change signal

0061 Gearbox input shaft speed information (+ signal)

0062 Gearbox input shaft speed information (- signal)

0063 Automatic gearbox casing oil level sensor power supply

0064 Automatic gearbox identification line

1 / 7

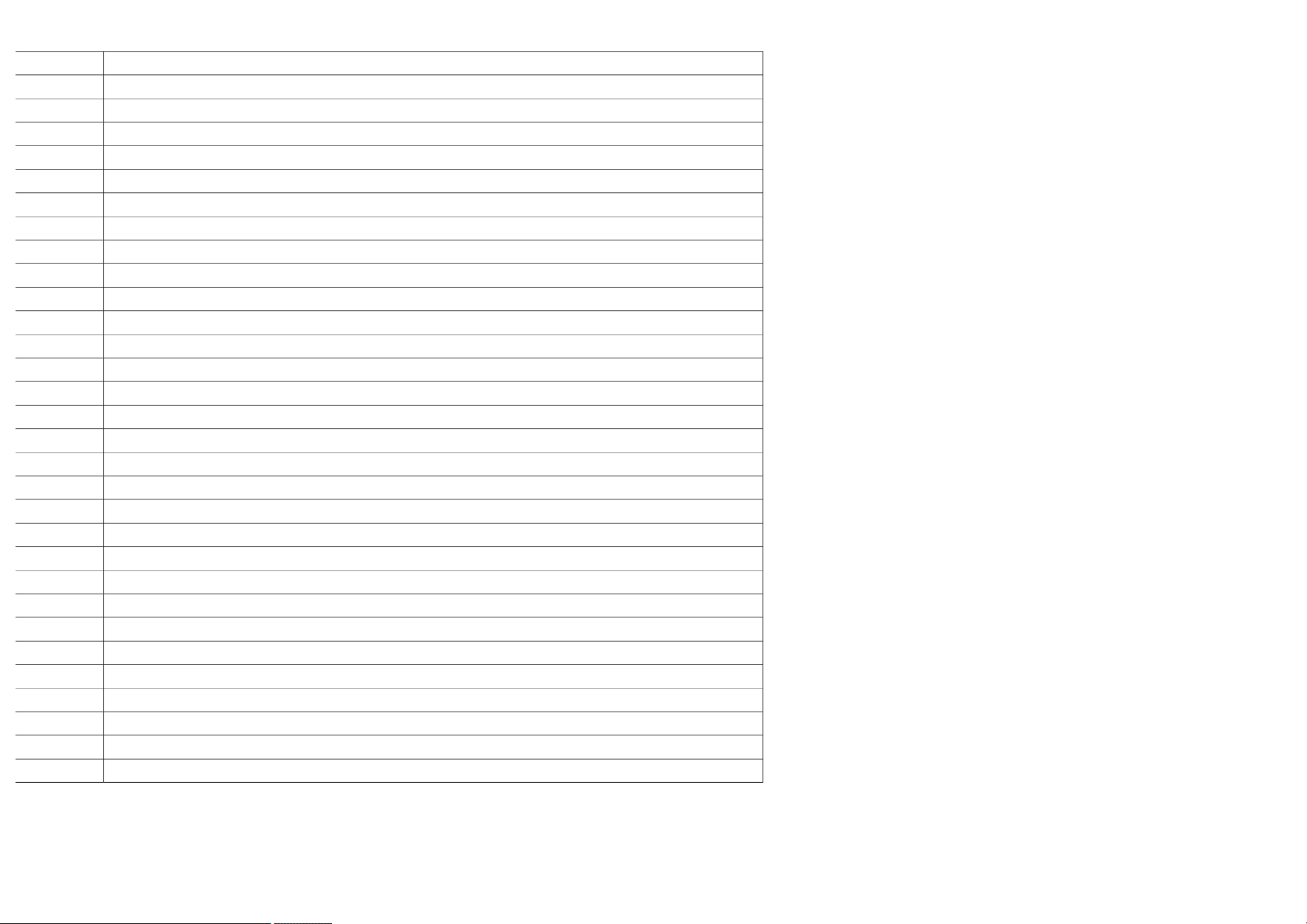

Page 14

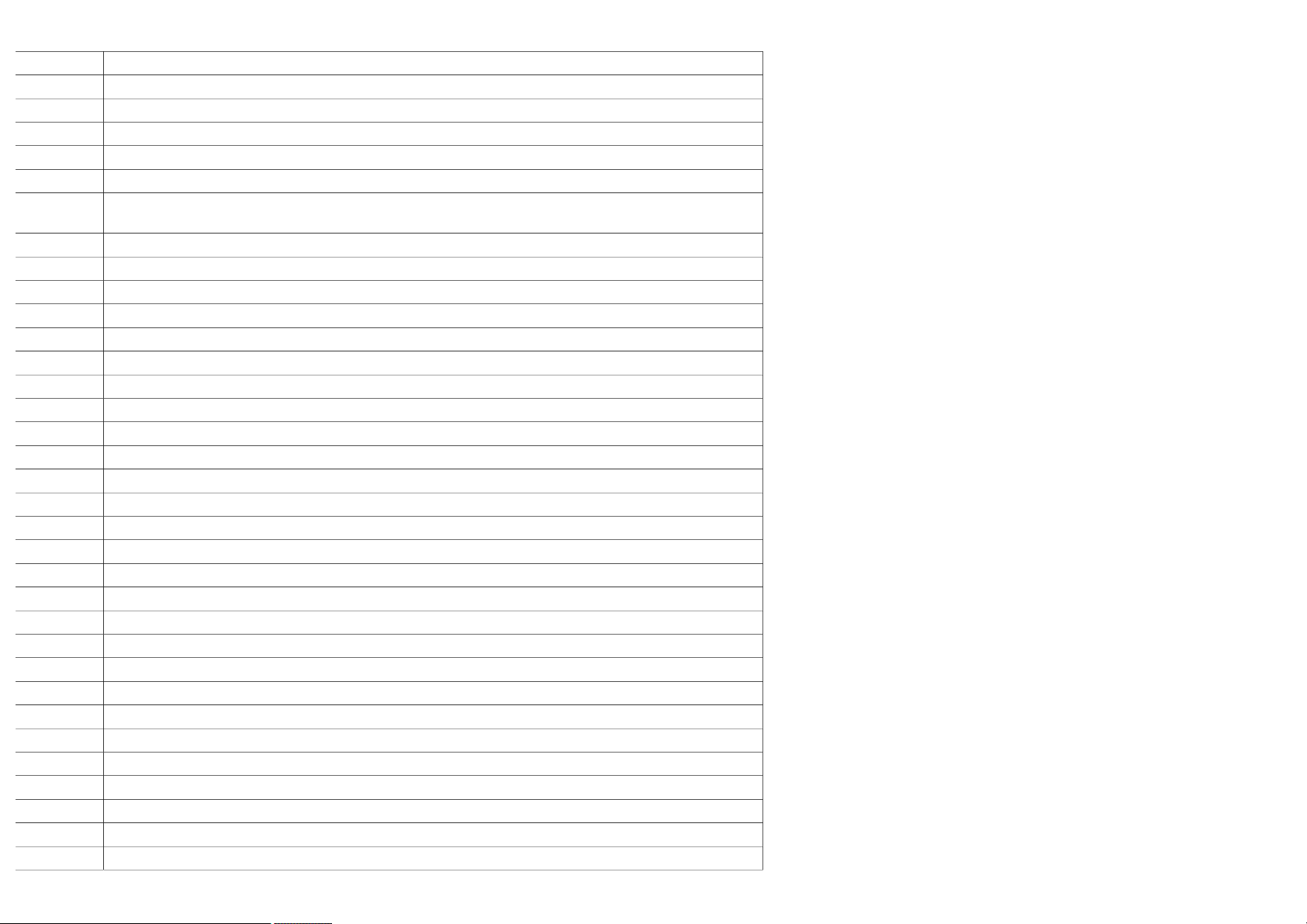

Andrew Burrows Key / Diagram 02/02/16

0065 Automatic gearbox casing oil temperature sensor information

0066 Automatic gearbox casing oil level sensor information

0067 Communication bus J1587 for gearbox diagnostic socket (+ signal)

0068 Communication bus J1587 for gearbox diagnostic socket (- signal)

0069 Gearbox speed selector data bit 1

007 Accelerator pedal potentiometer power supply

0070 Gearbox speed selector data bit 2

0071 Gearbox speed selector data bit 4

0072 Gearbox speed selector data bit 8

0073 Gearbox speed selector data parity bit

0074 Link between gearbox ECU and gear lever display

0075 Automatic gearbox gear lever information in input mode on gearbox ECU

0076 Automatic gearbox hydraulic pressure sensor information

0084 Automatic gearbox output speed sensor information (- signal)

0086 Automatic gearbox temperature sensor information

0087 Automatic gearbox turbine speed sensor information

0088 Automatic gearbox output speed sensor information (+ signal)

0089 Retarder coolant temperature sensor information

0100 Onboard management data transmission bus (+ signal)

0101 Onboard management data transmission bus (- signal)

0102 Onboard management data reception bus (+ signal)

0103 Onboard management data reception bus (- signal)

0104 Communication bus J1587-2 (+ signal)

0105 Communication bus J1587-2 (- signal)

0107 RH front brake pads wear analogue sensor earth

0108 RH front brake pads wear analogue sensor information

0109 RH front brake pads wear analogue sensor power supply (+5V)

011 Humidity sensor information

0114 Temperature sensor analogue signal for adjusting exhaust gases (EGR)

0116 Coolant temperature sensor analogue signal

0117 Pusher or follower rear axle angle sensor minimum voltage

0118 Pusher or follower rear axle angle sensor maximum voltage

0119 Front axle angle sensor minimum voltage

0120 Front axle angle sensor minimum voltage

0123 Red LED indicating that vehicle alarm is set (+) power supply

2 / 7

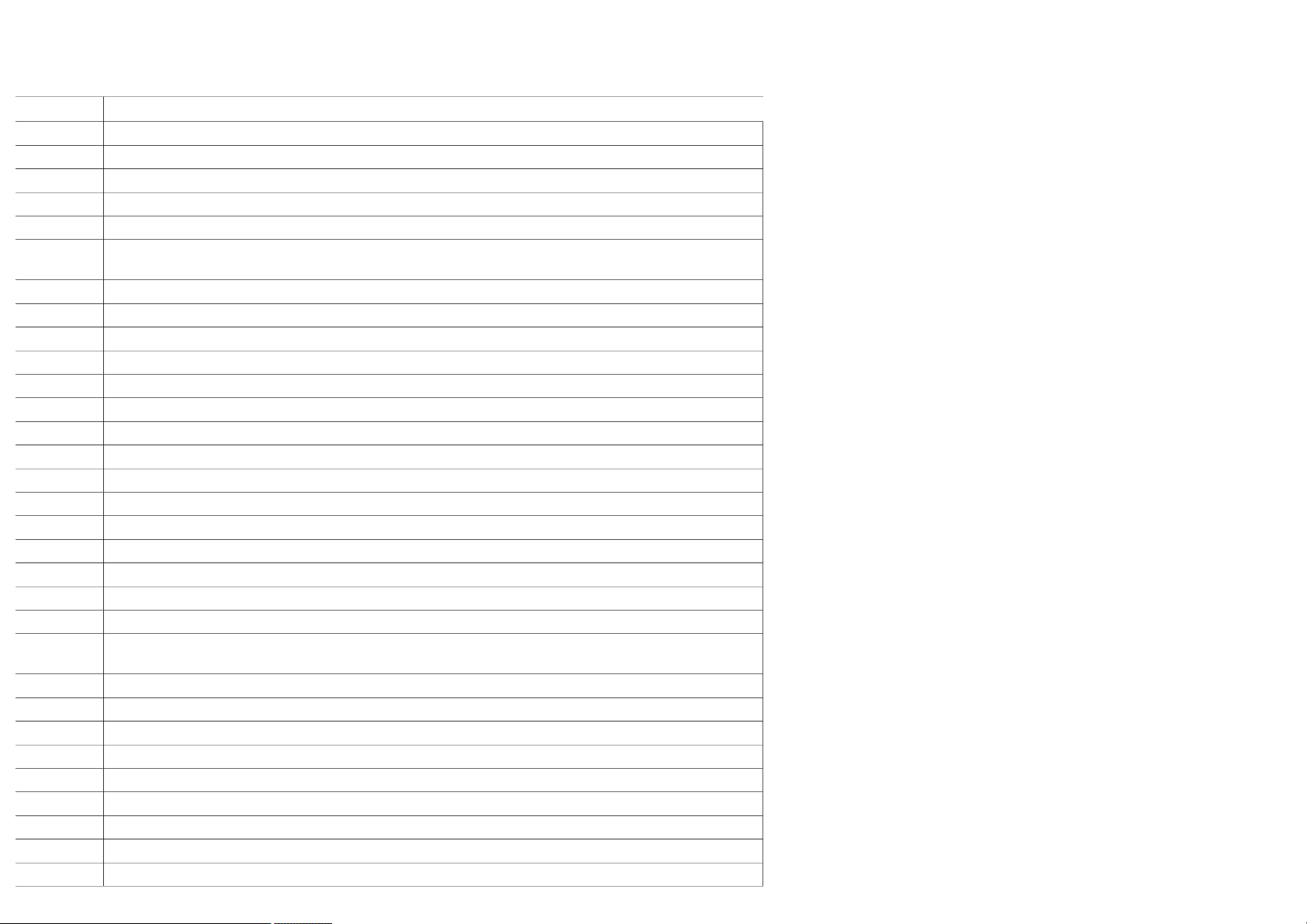

Page 15

Andrew Burrows Key / Diagram 02/02/16

0127 Alarm ultrasonic reception (RX+ signal)

0128 Alarm ultrasonic reception (RX- signal)

0129 Alarm ultrasonic transmission (RX+ signal)

0130 Alarm ultrasonic transmission (RX- signal)

0143 Engine crankcase pressure sensor information

0144 Fuel pressure sensor information

0145 Available power supply (earth delivered by ECU for on-chassis engine stop control)

0146 Available power supply (Information requested by for on-chassis engine stop control)

0147 Communication bus between EBS ECU and front module (- signal)

0148 Communication bus between EBS ECU and front module (+ signal)

0149 Communication bus between EBS ECU and first additional module (- signal)

0150 Communication bus between EBS ECU and first additional module (- signal)

0151 Engine coolant level sensor information

0160 LH front brake pads wear analogue sensor earth

0161 LH front brake pads wear analogue sensor information

0162 LH front brake pads wear analogue sensor power supply (+5V)

0163 First axle RH rear brake pads wear analogue sensor earth

0164 First axle RH rear brake pads wear analogue sensor information

0165 First axle RH rear brake pads wear analogue sensor power supply (+5V)

0166 First axle LH rear brake pads wear analogue sensor earth

0167 First axle LH rear brake pads wear analogue sensor information

0168 First axle LH rear brake pads wear analogue sensor power supply (+5V)

0169 Second axle RH rear brake pads wear analogue sensor earth

017 Accelerator pedal position potentiometer information

0170 Second axle RH rear brake pads wear analogue sensor information

0171 Second axle LH rear brake pads wear analogue sensor power supply (+5V)

0172 Second axle LH rear brake pads wear analogue sensor earth

0173 Second axle LH rear brake pads wear analogue sensor information

0174 Second axle LH rear brake pads wear analogue sensor power supply (+5V)

0175 First rear axle RH speed sensor information

0176 First rear axle RH speed sensor information

0177 First rear axle LH speed sensor information

0178 First rear axle LH speed sensor information

0180 RH rear brake pads wear analogue sensor earth on PUSHER additional module

0181 RH rear brake pads wear analogue sensor information on PUSHER additional module

3 / 7

Page 16

Andrew Burrows Key / Diagram 02/02/16

0182 RH rear brake pads wear analogue sensor power supply (+5V) on PUSHER additional module

0183 LH rear brake pads wear analogue sensor earth on PUSHER additional module

0184 LH rear brake pads wear analogue sensor information on PUSHER additional module

0185 LH rear brake pads wear analogue sensor power supply (+5V) on PUSHER additional module

0186 LH rear brake pads wear analogue sensor earth on PUSHER additional module

0187 RH rear brake pads wear sensor information (follower axle module)

0188 RH rear brake pads wear sensor power supply (+5V) (follower axle module)

0189 LH brake pads wear sensor earth (follower axle module)

0190 LH brake pads wear sensor information (follower axle module)

0191 LH brake pads wear sensor power supply (+5V) (follower axle module)

0192 “Driver’s side hand presence” door sensor information (+ signal)

0193 “Driver’s side hand presence” door sensor power supply

0194 “Driver’s side hand presence” door sensor information (- signal)

0195 “Driver’s side hand presence” door sensor information (+ signal)

0196 “Passenger’s side hand presence” door sensor power supply

0197 “Passenger’s side hand presence” door sensor information (- signal)

0198 Driver’s side door antenna (+ signal)

0199 Driver’s side door antenna (- signal)

0200 Passenger’s side door antenna (+ signal)

0201 Passenger’s side door antenna (- signal)

0202 Cab antenna 1 (+ signal)

0203 Cab antenna 1 (- signal)

0204 Cab antenna 2 (+ signal)

0205 Cab antenna 2 (- signal)

0206 Communication bus J1939-6 (+ signal)

0207 Communication bus J1939-6 (- signal)

0208 Communication bus J1587 (+ signal)

0209 Communication bus J1587 (- signal)

0212 Cruise control analogue sensor power supply

022 Accelerator pedal position potentiometer information

028 Cruise control ON/OFF control

029 Cruise control ON/OFF control

03 Rear stop lights power supply (12N socket)

030 RH rear direction indicator light power supply (12N socket)

0307 Rear fog lights power supply (12N socket)

4 / 7

Page 17

Andrew Burrows Key / Diagram 02/02/16

0308 LH rear direction indicator light power supply (12N socket)

031 Cruise control signal

032 Engine oil temperature information with electronic fuel-injection system

033 Intake air temperature information with electronic fuel-injection system

034 Intake air temperature information (P2) with electronic fuel-injection system

0374 Encoded link between radio frequency receiver and alarm

0375 Hazard lights control by radio frequency receiver and/or alarm

0376 EBS module pressure sensor power supply for trailer control

0377 EBS module pressure sensor information for trailer control

0380 EBS module pressure sensor earth for trailer control

0381 Communication bus between EBS ECU and second additional module (- signal)

0382 Communication bus between EBS ECU and second additional module (+ signal)

0384 "PTO" control signal input for engine speed control (customer’s pre-arrangement)

039 Brake pedal position sensor information with EBS system

040 Brake pedal position sensor information with EBS system

0403 Encoded tractor/trailer link between alarm and freight protection module

0405 Tachograph serial data bus for fleet management

041 Line K information for diagnostic socket

0411 Communication bus J1939-2 (+ signal)

0412 Communication bus J1939-2 (- signal)

0413 Communication bus for bodybuilding or fleet management (- signal)

0414 Communication bus for bodybuilding or fleet management (+ signal)

0415 Communication bus between EBS ECU and on-chassis acceleration sensor (+ signal)

0416 Communication bus between EBS ECU and on-chassis acceleration sensor (- signal)

0424 Communication bus J1939 for docking radar (+ signal)

0425 Communication bus J1939 for docking radar (- signal)

045 Cruise control deceleration control

0460 Switch-operated control (bodybuilder’s pre-arrangement)

0461 Switch-operated control (bodybuilder’s pre-arrangement)

0462 Communication bus for vehicle OBD data socket (+ signal)

0463 Communication bus for vehicle OBD data socket (- signal)

0464 Diesel fuel particulate filter temperature sensor power supply

0465 Diesel fuel particulate filter temperature sensor power supply

047 Cruise control acceleration control

052 Flywheel engine speed sensor information (+ signal)

5 / 7

Page 18

Andrew Burrows Key / Diagram 02/02/16

055 Flywheel engine speed sensor information (- signal)

056 Brake pedal position sensor power supply (+5V)

057 EBS system load sensor information

0608 Reversing lights power supply (12N socket)

0632 Rear marker lights power supply (12N socket)

064 Communication bus between EBS ECU and double rear module (- signal)

066 Communication bus between EBS ECU and double rear module (+ signal)

071 EBS system load sensor earth

072 EBS ECU earth for brake valve

073 EBS system load sensor power supply (+5V)

077 Accelerator pedal position sensor information (rest position)

079 Variable-drive fan power supply

080 Engine oil pressure sensor earth

081 Engine oil pressure sensor power supply

082 Communication bus between gear selector and automatic gearbox ECU (+ signal)

083 Communication bus between gear selector and automatic gearbox ECU (- signal)

084 Shunt between gearbox ECU terminal 66 and 26

0801 Communication bus J1587 for adaptive cruise control system (+ signal)

0802 Communication bus J1587 for adaptive cruise control system (- signal)

0803 Information from cruise control system

0804 Information from cruise control system

0805 Information from cruise control system

0806 Information from cruise control system

0807 Information from cruise control system

0808 Information from cruise control system

0809 Information from cruise control system

0810 Gearbox output speed information (+ signal)

0811 Gearbox output speed information (- signal)

0812 First front axle RH roadwheel speed sensor information (+ signal)

0813 First front axle RH roadwheel speed sensor information (- signal)

0814 Second front axle RH roadwheel speed sensor information (+ signal)

0815 Second front axle RH roadwheel speed sensor information (- signal)

0816 First front axle LH wheel speed sensor information (+ signal)

0817 First front axle LH wheel speed sensor information (- signal)

0818 Second front axle LH wheel speed sensor information (+ signal)

6 / 7

Page 19

Andrew Burrows Key / Diagram 02/02/16

0819 Second front axle LH wheel speed sensor information (- signal)

0820 First front axle RH wheel speed sensor information (+ signal)

0821 First front axle RH wheel speed sensor information (- signal)

0822 First front axle LH wheel speed sensor information (+ signal)

0823 First front axle LH wheel speed sensor information (- signal)

0833 Inclination sensor power supply (+)

0834 Inclination sensor information

0835 Inclination sensor power supply (-)

0836 Clutch position sensor power supply (+)

0837 Clutch position sensor information

0838 Clutch position sensor power supply (-)

0839 Parking brake control power supply (-)

0840 Parking brake control potentiometers N° 1 & 2 power supply

0841 Parking brake wake-up contact power supply

0842 Parking brake control potentiometer N° 1 information

0843 Parking brake control potentiometer N° 2 information

0844 Parking brake unlocking switch N° 1 information

0845 Parking brake unlocking switch N° 2 information

0846 Parking brake module air pressure sensor power supply (+)

0847 Parking brake module air pressure sensor power supply (-)

0848 Parking brake module air pressure sensor information

085 Rail pressure sensor information

087 Engine oil pressure sensor information

088 Retarder torque sensor information

7 / 7

Page 20

Andrew Burrows Key / Diagram 02/02/16

Group 1 - Earths and negative power supplies

Polarity N° Designation

1 Vehicle general earth

11 Microphone (- signal)

12 Gearbox neutral position sensor information

13 Engine water circuit by-pass solenoid valve control

14 AdBlue heating resistor control (in circuit from tank to pump module)

15 AdBlue heating resistor control (in circuit from pump module to dosing solenoid valve)

16 AdBlue heating resistor control (in circuit from dosing solenoid valve to pump module)

17 AdBlue heating resistor control (in circuit from pump module to tank)

18 12 Volts socket earth (multi-pass cab option)

19 AdBlue heating resistor control (in filter, on pump)

101 Humidity sensor power supply (-)

104 Two-tone horn power supply (-)

106 Assistance control information

119 "Front door open" position sensor information for lighting

(overhead light, stepwell light, locker lights, ambient lighting...)

123 Clutch pedal position sensor information

124 12 volts power socket earth

130 Overhead lights lighting earth (after master switch)

131 Communication bus between gear selector and ECU (- signal)

132 Communication bus between gear selector and ECU (+ signal)

141 Tachograph speed sensor information

142 Tachograph speed sensor information

144 Voltage converter earth for CB power supply

147 Master switch coil control

148 Master switch control

151 Available power supply (rear compartment open warning light)

152 Overhead lights earth

155 Voltage converter earth for radiotelephone power supply

156 Transfer box "low speed" information

157 Front wheels diff lock information

158 Transfer box PTO engaged information

159 Transfer box diff lock information

1 / 3

Page 21

Andrew Burrows Key / Diagram 02/02/16

169 Doors central locking electronic box inhibition earth (presence of key in ignition switch)

173 N° 1/2/3 cylinder injectors earth (line 1)

174 N° 4/5/6 cylinder injectors earth (line 1)

183 Hydraulic retarder proportional solenoid valve earth

184 Hydraulic retarder charge accumulator solenoid valve earth

193 Earth between A/C ECU and fan management ECU

197 Master switch relay earth

198 Battery charging receptacle earth

1001 Front spotlight earth

1006 Exhaust brake solenoid valve N° 2 control earth

1007 Exhaust brake solenoid valve N° 2 control earth

1008 Exhaust brake electrovalve power supply (-)

1010 Fan electric clutch pilot-control earth

1012 EBS system solenoid valve earth

1018 Reversing lights relay control earth

1019 12 volts socket voltage converter earth

1020 Rear, doors opening/closing information

1021 Rear overhead lights power supply (-)

1025 Corrected vehicle speed information

1026 Engine speed regulation control (first selection)

1029 Automatic gearbox solenoid valve earth

1030 Automatic gearbox solenoid valve earth

1031 Automatic gearbox solenoid valve earth

1032 Automatic gearbox solenoid valve earth

1033 Automatic gearbox solenoid valve earth

1034 Automatic gearbox solenoid valve earth

1035 Automatic gearbox solenoid valve earth

1036 Automatic gearbox solenoid valve earth

1037 Automatic gearbox solenoid valve earth

1038 Automatic gearbox solenoid valve earth

1039 Automatic gearbox neutral earth

1043 Automatic gearbox solenoid valve earth

1045 Retarder control selector interface earth

1046 Automatic gearbox solenoid valve earth

1051 Air conditioning cut-out upon engine power loss control

2 / 3

Page 22

Andrew Burrows Key / Diagram 02/02/16

1058 Fuel preheating relay control

1077 Earth delivered by engine management ECU for starting relay control

1081 Piloted axle control sensor earth

1084 Piloted axle control solenoid valve earth

1119 Alarm diode earth

1124 Roadwheels anti-slip sensor earth (ESP)

1140 PTO N° 1 engagement request

1141 Engine speed regulation control (second selection)

1147 Master switch closing control (ADR)

1148 Master switch closing control (ADR)

1149 Master switch warning light earth (ADR)

1150 Alternator earthing relay (-) control (ADR)

1151 N° 1/2/3 cylinder injectors earth (line 2)

1152 Cruise control operating control

1153 N° 4/5/6 cylinder injectors earth (line 2)

1154 Fuel pump control

1155 Air suspension ECU relay control

1156 Water/fuel separator bleeding solenoid valve control

1157 Alarm sound volume reduction control

1159 "Door open" information

1160 Engine retarder VGT2 solenoid valve earth

1161 Information feedback for "difficult terrain" warning light

1162 Turbocharger speed sensor earth

1163 Master switch diode earthing (ADR)

1164 Electrical master switch relay earthing (ADR)

1165 Single "H" solenoid valve N° 1 earthing

1166 Single "H" solenoid valve N° 2 earthing

1167 AdBlue tank level and temperature sensor earth

1168 AdBlue tank level and temperature sensor power supply (+5V)

1180 Driver presence in seat sensor power supply (-)

1200 Gearbox neutral position sensor information (after diode)

3 / 3

Page 23

Andrew Burrows Key / Diagram 02/02/16

Group 2 - Positive power supplies

Polarity N° Designation

2 (+) power supply capable of being cut by master switch

20 Microphone (+ signal)

21 Urea heating resistor N° 1 (+) power supply

22 Key switch relay excitation (after ignition position)

23 Urea heating resistor N° 2 (+) power supply

24 (+) power supply after ignition (air management ECU, information

display, alarm, engine immobilizer, doors central locking)

25 Battery charge, alternator terminal A+, engine running warning light

26 Charging socket (+) power supply

28 Hydraulic pump power supply

200 Radio antenna power supply (+12V)

201 (+) power supply not cut by master switch

202 Full-time (+) power supply (headlights and hazard lights management ECU)

203 (+) power supply not cut by master switch (tachograph)

205 Starter relay control

206 (+) power supply after relay (fan-coil heaters)

208 (+) power supply capable of being cut by master switch (available power supply)

209 Radio antenna coaxial cable signal

210 Radio antenna coaxial cable earth

211 (+) power supply after ignition (ABS/EBS trailer socket)

212 (+) power supply after vehicle management ECU power supply relay

214 Accessories (+) power supply (ignition key position 1)

215 (+) power supply after ignition (rearview mirror

defrosting relay, swivelling rearview mirrors control)

216 GPS antenna coaxial cable signal

217 GPS antenna coaxial cable earth

218 GSM antenna coaxial cable signal

219 GSM antenna coaxial cable earth

220 GSM antenna coaxial cable signal (radiotelephone pre-arrangement)

221 GSM antenna coaxial cable earth (radiotelephone pre-arrangement)

229 (+) power supply after ignition (vehicle management ECU, tachograph)

238 (+) power supply after master switch (heated windscreen)

240 Brake pedal position sensor information

1 / 4

Page 24

Andrew Burrows Key / Diagram 02/02/16

243 (+) power supply after ignition (cab tilt relay)

247 (+) power supply capable of being cut by master switch (cab tilting)

260 (+) power supply after air suspension ECU power supply relay

263 Full-time (+) power supply for central locking of electrical locks and electrical master switch

control or network isolation relay power supply and electronic master switch if FPT type vehicle

268 Intermediate conductor between battery banks

270 (+) power supply capable of being cut by master switch (automatic gearbox)

273 (+) power supply after ignition (hydraulic retarder)

274 (+) power supply after ignition (air suspension management ECU)

275 (+) power supply after ignition (available power supply)

291 Engine management and vehicle management ECUs

electronic fuel-injection function power supply

292 Engine ECU electronic fuel-injection function digital power supply

293 N° 1 cylinder injector control (line 1)

294 N° 3 cylinder injector control (line 1)

295 N° 2 cylinder injector control (line 1)

296 N° 5 cylinder injector control (line 1)

297 N° 6 cylinder injector control (line 1)

298 N° 4 cylinder injector control (line 1)

2000 (+) power supply after heated windscreen resistor fuse

2005 Brake pedal position sensor information

2014 (+) power supply after ignition (air conditioning/heating)

2016 Information between air conditioning control and ventilation control ECU.

2017 Information between air conditioning control and ventilation control ECU.

2018 Information between air conditioning control and ventilation control ECU.

2023 (+) power supply after master switch for retarder

2025 (+) power supply after ignition for ABS and/or EBS system

2050 Auto/manual retarder mode request

2056 (+) power supply capable of being cut by master switch

2057 on-chassis (+) power supply (bodybuilder’s pre-arrangement)

2069 Automatic gearbox solenoid valve (+) power supply

2070 Automatic gearbox solenoid valve (+) power supply

2071 Automatic gearbox solenoid valve (+) power supply

2072 Automatic gearbox solenoid valve (+) power supply

2088 Automatic gearbox solenoid valve (+) power supply

2093 Power supply after master switch

2 / 4

Page 25

Andrew Burrows Key / Diagram 02/02/16

2109 Air suspension ECU remote control electrical socket (+) power supply

2117 (+) power supply after ignition

2119 Master switch opening condition (ADR)

2120 (+) power supply after master switch (available power supply)

2121 (+) power supply after ignition (diff lock control, PTO electrovalves)

2122 (+) power supply after ignition (vehicle management ECU)

2123 (+) power supply after ignition (engine speed regulation adjustment,

water/fuel separator bleed solenoid valve, auto/manual selection)

2124 Accelerator and clutch pedals position sensor power supply

2125 (+) power supply after bodybuilder’s pre-arrangements ECU relay

2126 Alternator earthing relay (+) power supply (ADR)

2127 (+) power supply after automatic gearbox ECU relay

2128 Night lighting power supply (available power supply)

2132 Batteries DC (+) power supply (independent heating)

2220 Winch power supply

2221 (+) power supply after master switch (available for bodybuilding and/or parking socket)

2222 (+) power supply for all power fuses (alternator output B+)

2223 (+) power supply before master switch (flasher unit and power fuses box)

2224 (+) power supply after master switch (air preheating)

2226 Alternator excitation earthing upon opening of master switch

2227 (+) power supply before master switch (engine

immobilizer electronic box, automatic gearbox ECUs)

2229 Alternator-controlled (+) power supply (engine running)

2230 (+) power supply after master switch (air production management ECU)

2231 Accessories (+) power supply (sun-roof and headlamps ride corrector)

2232 Accessories (+) power supply (electrically-operated windows)

2233 (+) power supply after master switch

2234 (+) power supply after ignition (in-cab bodybuilder’s pre-arrangements)

2235 Vehicle management ECU “wake-up” (+) power supply

2302 (+) power supply after master switch (refrigerator and voltage dropper)

2303 Alarm siren and piloted axle ECU power supply

2304 (+) power supply after master switch (independent heating)

2306 (+) power supply after master switch (independent heating)

2307 "Batteries being charged" information (engine running)

2309 (+) power supply after master switch (EBS electronic box ECU)

2310 (+) power supply after ignition (onboard management ECU and doors management ECU)

3 / 4

Page 26

Andrew Burrows Key / Diagram 02/02/16

2311 (+) power supply after ignition (available power supply)

2312 (+) power supply after ignition (onboard management ECU)

2315 Accessories power supply (bodybuilder’s pre-arrangement)

2316 (+) power supply after master switch (lighting and signalling management ECU)

2317 (+) power supply after ignition (reversing lights and bodybuilder’s pre-arrangements relay)

2318 "Panic / alarm" system control

2319 Alarm sound volume reduction information

2320 Automatic gearbox ECU power supply relay control

2323 Engine coolant fan motor power supply

2325 Power supply after ignition (gear selector)

2327 (+) power supply after master switch (onboard management system)

2328 Batteries DC power supply

2328 Alimentation (+) directe batterie après interrupteur général de l'équiment ADR

2329 (+) power supply vehicle management ECU relay

2330 Jake brake relay power supply

2331 24 Volts dashboard socket and 24V/12V voltage converter power supply

2332 Air conditioning electronic management power supply

2334 Driver presence in seat sensor power supply power supply (+)

2930 N° 1 cylinder injector control (line 2)

2940 N° 3 cylinder injector control (line 2)

2950 N° 2 cylinder injector control (line 2)

2960 N° 5 cylinder injector control (line 2)

2970 N° 6 cylinder injector control (line 2)

2980 N° 4 cylinder injector control (line 2)

2981 Optiroll mode request

4 / 4

Page 27

Andrew Burrows Key / Diagram 02/02/16

Group 3 - Signalling

Polarity N° Designation

3 Stop lights power supply

30 Trailer RH side direction change indicator lights power supply

31 Hazard lights control

32 Vehicle RH side direction change indicator lights control

33 Vehicle LH side direction change indicator lights control

34 Day/night function tell-tale light power supply

36 Hazard lights warning light control

37 RH front direction change indicator lights and side repeaters power supply

38 RH rear direction change indicator lights power supply

39 LH front direction change indicator lights and side repeaters power supply

301 LH rear direction change indicator lights power supply

302 LH front direction change indicator lights and side repeaters power supply

303 Parking lights lighting relay control

304 RH side parking lights and marker lights power supply

305 LH side parking lights and marker lights power supply

306 (+) power supply before rear fog lights fuse

307 Rear fog lights power supply

310 (+) power supply after master switch (horn)

311 Horn power supply

312 Horn relay control

313 Parking lights lighting control

320 Day/night function relay control

321 (+) power supply after master switch (illuminated warning)

322 Illuminated warning relay control (revolving beacons, illuminated "D" signs...)

323 Illuminated warning power supply

352 Trailer EBS system state of activation information

370 Rear fog lights lighting relay control

373 (+) power supply after master switch (steering wheel

fingertip controls – main beam headlights lighting)

374 Encoded line between alarm ECU and doors central locking ECU

386 “Heated rearview mirrors" function activation request

388 12 Volts power supply coming from voltage converter for headlamps ride correctors

1 / 2

Page 28

Andrew Burrows Key / Diagram 02/02/16

389 Penetration lights pre-arrangement and front grille identification lights power supply

390 Two-tone horn power supply

2 / 2

Page 29

Andrew Burrows Key / Diagram 02/02/16

Group 4 - Comfort accessories

Polarity N° Designation

4 Heated rearview mirrors resistors and windscreen defrosting controls power supply

41 12V power supply for 12 Volts socket (multi-pass cab option)

43 Air conditioning fan power supply relay control

45 (+) power supply after master switch (overhead lights)

46 12V power supply after 24V/12V converter for radiotelephone

47 Accessories power supply (headlamps ride correctors motor)

402 Driver’s side window winder motor power supply

403 Driver’s side window winder motor power supply

404 Auxiliary audio input, LH side

405 Auxiliary audio input, RH side

406 Auxiliary audio inputs earth

407 Auxiliary audio inputs diagnostic line

413 Independent heating fuel pump motor (-) power supply

414 Independent heating fuel pump motor (+) power supply

428 Swivelling rearview mirrors motors (-) power supply

429 Swivelling rearview mirrors motors (+) power supply

430 RH swivelling rearview mirror vertical movement motor (+) power supply

431 LH swivelling rearview mirror horizontal movement (+) power supply

432 RH swivelling rearview mirror horizontal movement (+) power supply

433 Passenger’s side electrically-operated front curtains motor control

434 Link between passenger’s side switch and driver’s side curtains control switch

435 Link between passenger’s side switch and driver’s side curtains control switch

436 Switch-operated order for locking electric door strikers

437 Headlamps ride adjustment

443 Passenger’s side electrically-operated front curtains motor control

444 LH front loudspeaker earth

445 Rear loudspeaker power supply (+), RH side

446 Rear loudspeaker power supply (-), RH side

447 LH front loudspeaker power supply

448 RH front loudspeaker power supply

449 Rear loudspeaker power supply (+), LH side

450 Rear loudspeaker power supply (-), LH side

1 / 4

Page 30

Andrew Burrows Key / Diagram 02/02/16

451 LH front loudspeaker power supply

452 (+) power supply after master switch (diagnostic and data extraction sockets)

454 Windscreen electrically-operated curtains motor control

455 Windscreen electrically-operated curtains motor control

456 Accessories power supply (electrically-operated curtains)

462 Power supply after air conditioning compressor "pressure sensor" block fuse

463 (+) power supply after air conditioning compressor "pressure sensor"

block fuse (hydraulic retarder, automatic gearbox, horn, fan-coil heater)

469 Link between passenger’s side and driver’s side window winder motor control switch

470 Link between passenger’s side and driver’s side window winder motor control switch

476 Independent heating control

484 Switch-controlled doors electric strikers unlocking order

485 Cab tilt pump motor power supply

489 Fan-coil heater pressure sensor power supply

491 Air/water independent heater water distribution solenoid valve control

496 Passenger’s side front window winder motor power supply

497 Passenger’s side front window winder motor power supply

4000 Passenger’s side front window winder motor 12V power supply output for CB radio

4002 Independent heating rheostat adjustment (level 1)

4003 Independent heating timer diagnostic information

4004 Independent heating rheostat adjustment (level 2)

4005 Driver’s side electrically-operated curtains motor control

4006 Driver’s side electrically-operated curtains motor control

4010 24 Volts dashboard socket power supply

4014 Sun-roof motor control

4015 Sun-roof motor control

4016 Air conditioning compressor clutch relay control

4017 Air conditioning compressor clutch earth

4019 Air conditioning fresh air recycling control (position 3)

4020 Air conditioning fresh air recycling control (position 2)

4021 Air conditioning fresh air recycling control (position 1)

4022 Air conditioning air recycling control position transcription

4023 Information between air conditioning control and fan control ECU

4024 Information between air conditioning control and fan control ECU

4025 Information between air conditioning control and fan control ECU

2 / 4

Page 31

Andrew Burrows Key / Diagram 02/02/16

4026 Air conditioner air outlet setting control

4028 Ventilation unit fresh air recycling control (speed 1)

4029 Link between engine heating switch and engine heating electrovalve pilot-control relay contact

4030 Ventilation unit fresh air recycling control (speed 2)

4050 Ventilation unit fresh air recycling control (speed 3)

4051 12V socket power supply after le 24V/12V voltage converter

4052 Air conditioning pressure sensor information (intermediate level)

4053 Overhead lamps lighting earth (before switch)

4055 Passenger’s side electrically-operated curtains motor control

4056 Passenger’s side electrically-operated curtains motor control

4057 Cab rear electrically-operated curtains motor control

4058 Cab rear electrically-operated curtains motor control

4060 Rearview mirrors defrosting relay control by vehicle management ECU

4065 External loudspeaker power supply (+) (available power supply)

4066 External loudspeaker power supply (-) (available power supply)

4067 External loudspeaker earth braid (available power supply)

4068 Radio "mute" mode control by hands free telephone

4069 Hands free telephone kit input (+ signal)

4070 Hands free telephone kit input (- signal)

4306 Alternator-controlled power supply (engine running)

4308 Cigar lighter power supply

4309 24V/12V voltage converter and onboard radio power supply

4310 Accessories power supply (electrically-operated seats)

4311 Rear doors electric striker locking / unlocking control

4312 Rear doors electric striker locking / unlocking control

4313 Passenger’s side front door electric striker locking/unlocking control

4314 Passenger’s side front door electric striker locking/unlocking control

4315 Passenger’s side front door unlocked information

4316 Driver’s side front door electric striker locking/unlocking control

4317 Driver’s side front door electric striker locking/unlocking control

4318 Driver’s side front door unlocked information

4320 Air conditioning compressor information feedback

4321 Interior lighting control

4322 Stepwells lighting control

4323 CD player control ("CD in" information)

3 / 4

Page 32

Andrew Burrows Key / Diagram 02/02/16

4324 CD player control ("CD out" information)

4325 CD player control ("CD on" information)

4326 CD player control (“CD AF GND" information)

4327 CD player control (“CD AF IN left" information)

4328 CD player control ("CD AF IN right" information)

4440 Interior lighting control two-way switch line

4441 Interior lighting control two-way switch line

4442 Link between dashboard and cab rear switches for sun-roof control

4443 Link between dashboard and cab rear switches for sun-roof control

4460 12V radiotelephone power supply

4461 12V accessories power supply

4462 Independent heating control (ADR)

4463 Air conditioning compressor control

4466 Ambient lighting lamps power supply

4467 Independent heating switch-operated control

4469 Independent heating switch-on

4470 Independent heating control from information display (air/water)

4 / 4

Page 33

Andrew Burrows Key / Diagram 02/02/16

Group 5 - Safety accessories

Polarity N° Designation

54 Electromagnetic retarder power supply (level 1)

55 Electromagnetic retarder power supply (level 2)

56 Electromagnetic retarder power supply (level 3)

57 Electromagnetic retarder power supply (level 4)

59 Corrected speed information given by tachograph

500 Electronically pilot-controlled electromagnetic retarder switches box relay N° 1 control

501 (+) power supply after fuse (windscreen wiper)

502 Windscreen wiper motor power supply (high speed) after fuse (windscreen wiper)

503 Relay control time-delayed via vehicle management ECU

504 Windscreen wiper motor power supply (low speed)

506 Windscreen wash pump motor power supply

507 Windscreen wiper motor fixed stop power supply

508 Windscreen wiper speed controller power supply

509 Windscreen wiper motor fixed return power supply

510 Headlamps wash pump time-delayed power supply

522 (+) power supply after ignition for trailer socket

539 ABS system LH front inlet electrovalve control

540 ABS system LH front outlet electrovalve control

556 ABS system RH front inlet electrovalve control

557 ABS system RH front outlet electrovalve control

566 Speed limitation system intermediate speed memorization line

588 Electronically pilot-controlled electromagnetic retarder switches box relay N° 2 control

589 Electronically pilot-controlled electromagnetic retarder switches box relay N° 3 control

5021 Gearbox sensor information for superimposition of speeds

5024 Electronically pilot-controlled electromagnetic retarder switches box relay N° 4 control

5025 Electronically pilot-controlled electromagnetic retarder terminal V control

5028 Stop lights relay control by vehicle management ECU

5031 Automatic gearbox ECU power supply (after power relay)

5048 Acceleration module and lockover angle sensor power supply

5050 Trailer EBS module power supply (+24V)

5064 Water in fuel bleeding request

5065 Airbag triggered warning light information

1 / 3

Page 34

Andrew Burrows Key / Diagram 02/02/16

5066 Key presence in ignition switch information (ADR)

5067 Emergency stop switch (ADR)

5068 Emergency stop switch (ADR)

5069 On-chassis emergency stop switch

5070 On-chassis emergency stop switch

5071 Key presence in ignition switch information (ADR)

5072 IVS information

5073 Changeover to difficult terrain mode request

5074 Vehicle immobilization request

5075 Accelerator pedal second rest position sensor information

5077 Brake pedal position sensor information (EBS)

5079 EBS front module power supply (battery voltage)

5080 EBS front module power supply (earth)

5081 EBS rear module power supply (battery voltage)

5082 EBS rear module power supply (earth)

5083 EBS first additional module power supply (battery voltage)

5084 EBS second additional module power supply (earth)

5085 Brake holding authorization control

5086 Brake holding authorization information

5087 EBS second additional module power supply (battery voltage)

5088 EBS second additional module power supply (battery voltage)

5089 Trailer brake EBS information

5091 Air inlet electrovalve control for trailer EBS

5092 Air outlet electrovalve control for trailer EBS

5093 EBS load solenoid valve control for trailer

5094 Headlamps wash pump power supply

5095 Headlamps wash pump relay power supply

5096 High pressure pump power supply

5097 High pressure pump power supply

5098 Fuel heating resistors power supply

5099 Power supply after master switch (battery voltage)

5100 (+) power supply after master switch for airbag ECU

5101 Engine starting relay power supply

5102 Engine starting relay earthing

5108 Road speed information

2 / 3

Page 35

Andrew Burrows Key / Diagram 02/02/16

5109 Link between gear selector and automatic gearbox ECU (information redundancy)

3 / 3

Page 36

Andrew Burrows Key / Diagram 02/02/16

Group 6 - Lighting

Polarity N° Designation

6 Instrument panel and customer extra lighting fuses (+) power supply

60 (+) power supply after RH and LH side fog driving lights fuse

and multi-function information display in service warning light

62 Main beam headlights power supply relay control

64 Switches night lighting and other vehicle controls power supply

65 (+) power supply after fog driving lights fuse

68 Fog driving lights control

69 Fog driving lights control

602 RH main beam headlight (+) power supply after fuse

603 LH main beam headlight (+) power supply after fuse and

multi-function information display in service warning light

604 RH dipped beam headlight (+) power supply after fuse

605 LH dipped beam headlight (+) power supply after fuse and

multi-function information display in service warning light

606 Working spotlight, valves lighting, trailer sockets lighting... power supply

607 Multi-function information display working spotlight in service warning light

608 Reversing lights power supply

609 Long range driving lights power supply relay control and/or automatic gearbox ECU power supply

610 Main beam headlights relay power supply control

611 RH and LH side long range driving lights (+) power supply

after fuse and/or automatic gearbox ECU power supply

612 Long range headlights power supply

613 RH and LH side long range driving lights (+) power supply before fuse

615 Front searchlight (+) power supply after fuse

618 24-way ADR socket power supply for authorization of use of

power circuit, valves lighting or van interior lighting power supply

621 (+) power supply after Main beam headlights and van interior lighting relay

623 (+) power supply after fuse (power supply for fire vehicle pre-arrangement)

632 Lighting power supply (+24V) available for customer

634 Trailer sockets power supply (terminal 2 and 6 on 24N socket or 5 and 6 on 15-way socket)

635 Reversing buzzer power supply

640 (+) power supply after rear searchlight fuse

641 Front searchlight 12 Volts power supply

643 Rear searchlight control

1 / 2

Page 37

Andrew Burrows Key / Diagram 02/02/16

644 Rear searchlight 12 Volts power supply

646 Extra lighting control

647 Extra lighting power supply

651 Bodybuilding system in work position information

655 Door open warning light power supply (-)

659 Day/night warning light power supply (+)

661 Reverse gear engaged position sensor information

662 Rear fog lights cut-off

663 Main beam headlights and fog driving lights common power supply

665 Dipped beam headlights power supply relay control

666 (+) power supply after fuse (working spotlight)

2 / 2

Page 38

Andrew Burrows Key / Diagram 02/02/16

Group 7 - Onboard instruments

Polarity N° Designation

7 Engine speed information (alternator, terminal W information)

71 Pull-down menu 'Raise' request

72 Pull-down menu 'Extend' request

73 Pull-down menu 'Selection' request

74 Pull-down menu 'Lower' request

76 Fuel level sensor information (+ signal)

709 External temperature sensor information (+ signal)

710 External temperature sensor information (- signal)

711 Cab internal temperature sensor information (- signal)

712 Cab internal temperature sensor information (+ signal)

718 Fuel level sensor information (- signal)

719 Power supply after master switch (multi-function information display)

720 Air filter clogging information

766 Fifth wheel position N° 1 sensor digital output

767 Fifth wheel position N° 2 sensor digital output

768 Fifth wheel position N° 3 sensor digital output

775 Driver’s seat belt locking information

778 Bit 1 between fleet management ECU and information display information

779 Bit 2 between fleet management ECU and information display information

780 Bit 3 between fleet management ECU and information display information

781 Bit 4 between fleet management ECU and information display information

1 / 1

Page 39

Andrew Burrows Key / Diagram 02/02/16

Group 8 - Auxiliary equipment and monitoring

Polarity N° Designation

81 Coolant level probe power supply

82 Coolant level probe information

83 Parking brake engaged relay control

84 Construction site mode switch power supply

85 Construction site mode switch information

86 Inter-wheel diff lock control

87 Rear inter-wheel diff lock information

88 Gearbox-driven PTO in service information

89 Independent heating auxiliary pump

803 Air preheating resistors and/or preheating in service power supply

808 Fuel heating resistors power supply

813 Air suspension rear solenoid valve and 6x2 lift-up axle electrovalve control

814 Air suspension RH rear electrovalve control

815 Air suspension LH rear electrovalve control

816 Air suspension front electrovalve control

823 Exhaust brake solenoid valve power supply

824 Charge air pressure limitation control electrovalve power supply

825 (+) power supply for tachograph pulse generator sensors (Euro 2) or

(-) power supply for tachograph encryption sensor (as from Euro 3)

829 Servo steering sensors information

846 ASR system control

851 Diagnostic socket information (line K)

867 Brake pads wear sensor information

868 Brake pads wear sensor, RH/LH link on first front axle

869 Oil level probe information (+ signal)

870 Oil level probe information (- signal)

879 Vehicle front suspension level sensor information

880 Vehicle rear suspension level sensor information

881 Vehicle RH rear suspension level sensor information

899 Common point between air suspension RH and LH level and pressure sensors

8020 30 km/h speed limitation control

8040 Brake pads wear sensor, first/second front axle link

1 / 5

Page 40

Andrew Burrows Key / Diagram 02/02/16

8041 Brake pads wear sensor, RH/LH link on first rear axle

8044 Variable-drive fan motor speed sensor earth

8046 Variable-drive fan motor speed sensor power supply

8067 Chassis-mounted engine speed control

8077 Air suspension pressure sensors power supply

8079 Hub-piloted axle oil level sensor information

8080 Control solenoid valve control for LH cornering

8081 Control solenoid valve control for RH cornering

8082 Safety solenoid valve control

8083 Live equipment warning light power supply

8084 Alarm stop control

8085 Gearbox PTO activation information

8093 PTO N° 1 electrovalve control

8098 Rear inter-wheel diff lock information

8100 Available power supply (engine starting request)

8104 Available power supply (engine alert)

8108 Available power supply (engine starting information)

8109 Cab tilt relay control authorization

8110 On-chassis engine stop request

8111 Cab tilt relay control

8112 PTO N° 3 engagement request

8113 PTO N° 2 engagement request

8114 Transfer box neutral selection electrovalve control

8115 PTO N° 3 engagement electrovalve control

8116 Equipment in dangerous position information warning light power supply

8118 Parking brake engaged information

8119 On-chassis engine speed deceleration request

8120 On-chassis engine speed acceleration request

8121 Automatic return to rated engine speed request

8122 Available power supply (PLC min. output N° 1)

8123 Available power supply (PLC min. output N° 2)

8124 Transfer box changeover to low speed request

8125 Transfer box changeover to low speed control

8126 PTO electrovalves diff lock control

8127 Transfer box diff lock engagement request

2 / 5

Page 41

Andrew Burrows Key / Diagram 02/02/16

8128 Rear inter-wheel diff lock control

8129 Rear inter-wheel diff lock solenoid valve control

8131 Available power supply (analogue) or PTO N° 2 solenoid valve control

8132 Available power supply (PLC analogue input N° 2)

8133 CAN bus disabling control

8134 PTO N° 2 engaged information

8136 Engine speed setting control

8137 Suspension level control activation

8138 Suspension level control

8140 Air suspension rear drive axle level sensor earth

8142 Air suspension rear drive axle level sensor power supply

8143 Air suspension remote control (memory position)

8144 Air suspension remote control (lifting position)

8145 Air suspension remote control (lowering position)

8146 Air suspension remote control (memory 2 position)

8147 Air suspension remote control (return to normal position)

8148 Rear axle suspension air spring electrovalve control

8149 Rear axle lift-up air spring electrovalve control

8150 Rear drive axle air inlet/outlet electrovalve control

8151 Second rear axle lifting control

8152 Second rear axle raising control

8153 Load-shedding lift-up axle control

8154 Air suspension remote control (front axle control)

8155 Air suspension remote control (front axle control)

8156 Front axle air suspension pressure sensor information

8157 Lift-up rear axle air suspension pressure sensor information

8158 Rear axle LH side air suspension pressure sensor information

8159 Rear axle RH side air suspension pressure sensor information

8160 Rear axle LH side air suspension pressure sensor information

8161 Available power supply (PTO N° 2 solenoid valve pilot-control)

8165 PTOs N° 1 & 2 engagement electrovalve earth

8166 PTO N° 1 engagement electrovalve control

8167 PTO N° 2 engagement electrovalve control

8169 PTO N° 1 in service information

8170 Available power supply (parameter programmable frequency-related output)

3 / 5

Page 42

Andrew Burrows Key / Diagram 02/02/16

8172 Transfer box neutral position activation control

8173 Double H position sensor information

8174 Fogging pre-arrangement (+ signal)

8175 Fogging pre-arrangement (- signal)

8176 Tank low level pre-arrangement (- signal)

8177 Tank low level pre-arrangement (+ signal)

8178 Difficult terrain idling request

8179 Front axle inter-wheel diff lock solenoid valve control

8180 Brake pads wear sensor, RH/LH link on second front axle

8181 Brake pads wear sensor, first rear axle/second front axle link

8182 Brake pads wear sensor, first/second rear axle link

8183 Brake pads wear sensor, RH/LH rear link on second axle

8185 Automatic gearbox gear selector position information (position 1)

8186 Automatic gearbox gear selector position information (position 2)

8187 Automatic gearbox gear selector position information (position 3)

8188 Automatic gearbox gear selector position information (position 4)

8189 Automatic gearbox gear selector position information (position 5)

8190 Automatic gearbox gear selector position information (position 6)

8191 Retarder ON control

8192 Axle N° 4 brake air pressure switch

8207 AdBlue dosing solenoid valve control

8208 AdBlue dosing solenoid valve earth

8209 Exhaust gases temperature sensor earth

8210 Exhaust gases temperature sensor power supply

8211 AdBlue tank temperature sensor signal

8212 Exhaust gases temperature after catalytic converter sensor power supply

8213 AdBlue tank level sensor signal

8214 Exhaust gases temperature after catalytic converter sensor earth

8215 Engine cooling circuit by-pass solenoid valve power supply (+)

8216 Engine cooling circuit by-pass solenoid valve power supply (-)

8217 Diagnostic pressure sensor N° 1 information

8218 Diagnostic pressure sensor N° 2 information

8219 Diagnostic pressure sensor N° 3 information

8220 Diagnostic pressure sensor N° 4 information

8221 Gear selector position sensor information

4 / 5

Page 43

Andrew Burrows Key / Diagram 02/02/16

8222 Gear selector position sensor information

8223 Gear selector position sensor information

8224 Gear selector position sensor information

8225 Gear selector position sensor information

8226 60 tonnes safety electrovalve power supply

8227 Forbidden reversing inhibition control

8228 Electric winch winding electrovalve power supply (+)

8229 Electric winch winding electrovalve power supply (+)

8240 Electric parking brake 2-function electrovalve terminal N° 1 power supply

8241 Electric parking brake 2-function electrovalve terminal N° 2 power supply

8242 Trailer test electrovalve power supply (-)

8243 Trailer test electrovalve power supply (+)

8244 Parking brake holding electrovalve power supply (+)

8245 Parking brake holding electrovalve power supply (-)

5 / 5

Page 44

Andrew Burrows Key / Diagram 02/02/16

Group 9 - Free

Polarity N° Designation

971 Available wire N° 1 - From cab to chassis

972 Available wire N° 2 - From cab to chassis

973 Available wire N° 3 - From cab to chassis

974 Available wire N° 4 - From cab to chassis

975 Available wire N° 5 - From cab to chassis

977 Available wire N° 1 - From dashboard to ledge

978 Available wire N° 2 - From dashboard to ledge

979 Available wire N° 3 - From dashboard to ledge

980 Available wire N° 4 - From dashboard to ledge

981 Available wire N° 5 - From dashboard to ledge

982 Available wire N° 6 - From dashboard to ledge

983 Available wire N° 7 - From dashboard to ledge

1 / 1

Page 45

Andrew Burrows Oil pump / Tightening torques 03/02/16

Lubrication components, tightening torques

Oil pump

The item numbers indicate the tightening sequence.

Oil pump securing bolts 24±4 Nm

Oil filler pipes

Plastic lock 27±2 Nm

Dipstick guide bolts 20±4 Nm

Valve body

Valve body mounting bolts 48±8 Nm

Clamp screw 24±4 Nm

Oil strainer

1 / 2

Page 46

Andrew Burrows Oil pump / Tightening torques 03/02/16

Oil strainer securing bolts 24±4 Nm

2 / 2

Page 47

Andrew Burrows Engine block stiffener / Tightening torques 03/02/16

Cylinder block reinforcement, tightening torques

The item numbers indicate the tightening sequence.

Cylinder block stiffener securing bolts 48±8 Nm

1 / 1

Page 48

Andrew Burrows Cylinder head / Tightening torques 03/02/16

Cylinder head, tightening torques

The bolts can be re-used no more than 5 times maximum. Mark the bolt head with an indentation (A) after tightening each time using a centre punch. In

this case, apply engine oil to the screw-threads and under the bolt heads.Do not apply engine oil to new bolts, which are already pre-lubricated.

1 / 4

Page 49

Andrew Burrows Cylinder head / Tightening torques 03/02/16

Tap the screw-threads in the cylinder block then blow through with compressed air.

2 / 4

Page 50

Andrew Burrows Cylinder head / Tightening torques 03/02/16

The cylinder head must be positioned and tightened in accordance with the instructions given in the method (see page ).

The item numbers indicate the tightening sequence.

Stage1 65±5 Nm

Stage2 (check tightening) 65±5 Nm

Stage3 120±5 °

Stage4 90±5 °

Bolts M8 securing the unit pump injectors wiring harness bracket 24±4 Nm

3 / 4

Page 51

Andrew Burrows Cylinder head / Tightening torques 03/02/16

The bolts M8 can be re-used 5 times. If they are, do not apply any product to the screw-threads.Do not apply any product to new bolts, which

are already pre-coated.

4 / 4

Page 52

Andrew Burrows Blanking plug / cap / Tightening torques 03/02/16

Cylinder head plugs, tightening torques

Plug M10 x 1.00 20±4 Nm

Pre-coated plug M14 x 1.50 30±3 Nm

Pre-coated plug M10 x 1.00 10±2 Nm

Pre-coated straight union 10 Nm

1 / 1

Page 53

Andrew Burrows Camshaft / Tightening torques 03/02/16

Rocker shaft and camshaft bearing caps, tightening torques

The bolts can be re-used no more than 5 times maximum. Mark the bolt head with an indentation (A) after tightening each time using a centre punch. In

this case, apply engine oil to the screw-threads and under the bolt heads.Do not apply engine oil to new bolts, which are already pre-lubricated.

1 / 3

Page 54

Andrew Burrows Camshaft / Tightening torques 03/02/16

Stage 1: bolts (1 › 7) 25±3 Nm

Stage 2: bolts (9 - 11 - 13) 90±5 Nm

2 / 3

Page 55

Andrew Burrows Camshaft / Tightening torques 03/02/16

For the 2nd stage, tighten the bolts gradually, starting with bolt (11), so the rocker shaft descends without distorting.

Stage 3: bolts (8 - 10 - 12 - 14) 60±5 Nm

Stage 4: bolts (9 - 11 - 13) Loosen the bolts

Stage 5: bolts (9 - 11 - 13) 60±5 Nm

Stage 6: bolts (1 › 7) 90±5 °

Stage 7: bolts (8 › 14) 100±5 °

3 / 3

Page 56

Andrew Burrows Rocker arms / Tightening torques 03/02/16

Rocker arms, tightening torques

Valve play adjusting screw locknut 38±4 Nm

Exhaust valves play adjusting shim securing bolts (Optibrake retarder) 38±4 Nm

Unit pump injector pre-travel adjusting screw locknut 52±4 Nm

1 / 1

Page 57

Andrew Burrows Cylinder head cover / Tightening torques 03/02/16

Cylinder head cover, tightening torques

The item numbers indicate the tightening sequence.

Cylinder head cover securing bolts 24±4 Nm

1 / 1

Page 58

Andrew Burrows Exhaust manifold / Tightening torques 03/02/16

Exhaust manifold, tightening torques

Stage 1: bolts (1 - 8 - 3 - 10 - 5 - 12) 10±2 Nm

Stage 2: bolts (2 - 7 - 4 - 9 - 6 - 11 - 1 - 8 - 3 - 10 - 5 - 12) 48±8 Nm

1 / 1

Page 59

Andrew Burrows Intake manifold / Tightening torques 03/02/16

Intake manifold, tightening torques

Apply a bead of silicone dia. 2 mm (A) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

Apply "

SILICONE 7091

".

1 / 2

Page 60

Andrew Burrows Intake manifold / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Intake manifold securing bolts 24±4 Nm

Plug M10 20±3 Nm

Boost air pressure / temperature sensor 3.3 Nm

Consumables

Automotive part N° Industrial reference N°

56 89 501 292 Silicon adhesive 7091

2 / 2

Page 61

Andrew Burrows Heater / Tightening torques 03/02/16

Heater, tightening torques

The item numbers indicate the tightening sequence.

Stage1 10±2 Nm

Stage2 24±3 Nm

Intake air heater supply cable securing nut 10±1.5 Nm

1 / 1

Page 62

Andrew Burrows Engine flywheel / Tightening torques 03/02/16

Engine flywheel, tightening torques

The bolts can be re-used no more than 5 times maximum. Mark the bolt head with an indentation (A) after tightening each time using a centre punch. In

this case, apply engine oil to the screw-threads and under the bolt heads.Do not apply engine oil to new bolts, which are already pre-lubricated.

1 / 2

Page 63

Andrew Burrows Engine flywheel / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Stage1 60±5 Nm

Stage2 135±10 °

2 / 2

Page 64

Andrew Burrows Damper / Tightening torques 03/02/16

Damper, tightening torques

The item numbers indicate the tightening sequence.

Stage1 40±4 Nm

Stage2 90±10 Nm

1 / 1

Page 65

Andrew Burrows Damper / Tightening torques 03/02/16

Damper, tightening torques

The item numbers indicate the tightening sequence.

Stage1 40±4 Nm

Stage2 90±10 Nm

1 / 1

Page 66

Andrew Burrows Water pump / Tightening torques 03/02/16

Cooling system, tightening torques

Water pump

The item numbers indicate the tightening sequence.

Water pump securing bolts 24±4 Nm

1 / 3

Page 67

Andrew Burrows Water pump / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Casing securing bolts M10 48±8 Nm

Water pump pulley securing bolts 24±4 Nm

2 / 3

Page 68

Andrew Burrows Water pump / Tightening torques 03/02/16

Water pump drive belt tensioner bracket securing bolts M16 275±45 Nm

Water pump drive belt tensioner bracket securing bolts M10 48±8 Nm

Free pulley securing bolts M10 48±8 Nm

Tensioner roller securing bolts M10 48±8 Nm

Viscous coupling

Viscous coupling fan to hub securing nuts 24±4 Nm

Viscous coupling hub to water pump casing securing nut 48±8 Nm

3 / 3

Page 69

Andrew Burrows Crankshaft / Tightening torques 03/02/16

Crankshaft bearing caps, tightening torques

The bolts can be re-used no more than 5 times maximum. Mark the bolt head with an indentation (A) after tightening each time using a centre punch. In

this case, apply engine oil to the screw-threads and under the bolt heads.Do not apply engine oil to new bolts, which are already pre-lubricated.

Stage1 150±20 Nm

Stage2 120±5 °

1 / 1

Page 70

Andrew Burrows Connecting rods / pistons / Tightening torques 03/02/16

Big end caps, tightening torques

The bolts can be re-used no more than 5 times maximum. Mark the bolt head with an indentation (A) after tightening each time using a centre punch. In

this case, apply

Molycote

grease to the screw-threads and under the bolt heads.Do not apply engine oil to new bolts, which are already pre-lubricated.

Tighten in diagonally opposed sequence.

Use a hexagon socket.

Stage1 30±3 Nm

Stage2 180±6 °

Consumables

Automotive part N° Industrial reference N°

50 00 336 962 Molykote lubricant

1 / 2

Page 71

Andrew Burrows Connecting rods / pistons / Tightening torques 03/02/16

2 / 2

Page 72

Andrew Burrows Engine block stiffener / Tightening torques 03/02/16

Cylinder block reinforcement, tightening torques

The item numbers indicate the tightening sequence.

Cylinder block stiffener securing bolts 48±8 Nm

1 / 1

Page 73

Andrew Burrows Casing / Tightening torques 03/02/16

Engine flywheel housing, tightening torques

Apply a bead of silicone dia. 2 mm (A) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

Apply "

SILICONE 7091

".

1 / 3

Page 74

Andrew Burrows Casing / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Stage 1: bolts M8 - M12 - M14 24±4 Nm

Stage 2: bolts M12 85±15 Nm

2 / 3

Page 75

Andrew Burrows Casing / Tightening torques 03/02/16

Stage 3: bolts M14 140±15 Nm

Consumables

Automotive part N° Industrial reference N°

56 89 501 292 Silicon adhesive 7091

3 / 3

Page 76

Andrew Burrows Casing / Tightening torques 03/02/16

Crankshaft sealed casing, tightening torques

Apply a bead of silicone dia. 2 mm (A) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

Apply "

SILICONE 7091

".

1 / 2

Page 77

Andrew Burrows Casing / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Sump attachment bolts

Stage 1: bolts (2 - 7) 24±4 Nm

Stage 2: bolts (1 › 8) 24±4 Nm

Consumables

Automotive part N° Industrial reference N°

56 89 501 292 Silicon adhesive 7091

2 / 2

Page 78

Andrew Burrows Distribution / Tightening torques 03/02/16

Timing system, tightening torques

Apply a bead of silicone dia. 2 mm (E) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

1 / 6

Page 79

Andrew Burrows Distribution / Tightening torques 03/02/16

Apply "

".

SILICONE 7091

The item numbers indicate the tightening sequence.

2 / 6

Page 80

Andrew Burrows Distribution / Tightening torques 03/02/16

The bolts can be re-used 5 times. If they are, do not apply any product to the screw-threads.Do not apply any product to new bolts, which are

already pre-coated.

Timing plate securing bolts 28±4 Nm

3 / 6

Page 81

Andrew Burrows Distribution / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Crankshaft pinion securing bolt (A) 24±4 Nm

Intermediate pinion hub securing bolts(B)Stage1Stage2 25±3 Nm110±5 °

4 / 6

Page 82

Andrew Burrows Distribution / Tightening torques 03/02/16

Adjustable intermediate pinion hub securing bolts(C)Stage1Stage2 35±4 Nm120±5 °

Camshaft pinion securing bolts(D)Stage1Stage2 45±5 Nm90±5 °

Apply a bead of silicone dia. 2 mm (F) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

Apply "

SILICONE 7091

".

5 / 6

Page 83

Andrew Burrows Distribution / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Timing case bolts

Stage 1 12±2 Nm

Stage 2 24±4 Nm

Consumables

Automotive part N° Industrial reference N°

56 89 501 292 Silicon adhesive 7091

6 / 6

Page 84

Andrew Burrows Casing / Tightening torques 03/02/16

Oil pan, tightening torques

The item numbers indicate the tightening sequence.

Oil sump securing bolts 24±4 Nm

Oil sump drain plug 60±5 Nm

Oil dipstick securing bolt 10±1 Nm

1 / 1

Page 85

Andrew Burrows Oil pump / Tightening torques 03/02/16

Lubrication components, tightening torques

Oil pump

The item numbers indicate the tightening sequence.

Oil pump securing bolts 24±4 Nm

Valve body

1 / 8

Page 86

Andrew Burrows Oil pump / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Oil strainer bracket securing bolts 48±8 Nm

Oil strainer securing bolts 24±4 Nm

2 / 8

Page 87

Andrew Burrows Oil pump / Tightening torques 03/02/16

Oil pressure safety valve cover securing bolts 10±2 Nm

Oil jets

Oil jet securing bolts 24±4 Nm

The bolts can be re-used 5 times. If they are, do not apply any product to the screw-threads.Do not apply any product to new bolts, which are

already pre-coated.

Oil cooler

Oil cooler securing bolts 27±4 Nm

3 / 8

Page 88

Andrew Burrows Oil pump / Tightening torques 03/02/16

Begin by tightening bolts (11 - 14 - 3) to a torque of 24±4 Nm, then tighten all the bolts in the specified sequence.

Oil cooler casing securing bolts 24±4 Nm

Oil cooler casing plug 30±3 Nm

Oil cooler casing water circuit drainage union 40±4 Nm

Oil filter bracket

Euro 3 / 4

Oil filter 25±5 Nm

4 / 8

Page 89

Andrew Burrows Oil pump / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Oil filter bracket unit securing bolts 25±5 Nm

5 / 8

Page 90

Andrew Burrows Oil pump / Tightening torques 03/02/16

Plugs (1) 55±5 Nm

Plug (2) 40±4 Nm

Plug (3) 50±5 Nm

6 / 8

Page 91

Andrew Burrows Oil pump / Tightening torques 03/02/16

Plug (4) 55±5 Nm

Plugs (5) 55±5 Nm

Bolt (6) dia. M6 10±2 Nm

Euro 5

7 / 8

Page 92

Andrew Burrows Oil pump / Tightening torques 03/02/16

The item numbers indicate the tightening sequence.

Oil filter bracket unit securing bolts 25±5 Nm

8 / 8

Page 93

Andrew Burrows / Tightening torques 03/02/16

Oil filter nipple, tightening torque

Assembly A.

Assembly B.

Union 48 Nm

1 / 2

Page 94

Andrew Burrows / Tightening torques 03/02/16

Union 60 Nm

2 / 2

Page 95

Andrew Burrows Turbocharger / Tightening torques 03/02/16

Turbocharger, tightening torques

Turbocharger to exhaust manifold securing bolts 48±8 Nm

Turbocharger oil supply pipe union 25±5 Nm

Turbocharger oil supply tube union (on oil filter bracket) 40±5 Nm

Turbine casing exhaust pressure regulator 24±2 Nm

Stage 1: bolts (1 - 3) 12 Nm

Stage 2: bolts (2 - 4 - 1 - 3) 24±2 Nm

1 / 1

Page 96

Andrew Burrows Air compressor / Tightening torques 03/02/16

Air compressor, tightening torques

Air compressor 636 cm³ drive pinion securing nut 200+50 Nm

Air compressor 636 cm³ securing nut 85±15 Nm

Union(s) 25±3 Nm

1 / 1

Page 97

Andrew Burrows Low pressure pump / Tightening torques 03/02/16

Fuel supply pump, tightening torques

Fuel feed pump securing bolt 8+2 Nm

Fuel feed pump banjo unions 40±5 Nm

1 / 1

Page 98

Andrew Burrows Steering pump / Tightening torques 03/02/16

Steering pump, tightening torques

Steering pump drive pinion securing nut 100±10 Nm

Steering pump securing bolts 24±4 Nm

1 / 1

Page 99

Andrew Burrows Exhaust brake solenoid valve / Tightening torques 03/02/16

"Optibrake" retarder, tightening torques

Control solenoid valve 24±4 Nm

Power supply wires securing nut 1.8±0.3 Nm

1 / 1

Page 100

Andrew Burrows Injectors / Tightening torques 03/02/16

Pump injector mounting stirrup, tightening torques

Assembly type A

A = Socket with boss.

Tightening procedure for already used copper injector sleeves

Stage1 20+5 Nm

Stage2 60±5 °

1 / 3