Andrew Burrows Oil pump / Tightening torques 13/02/16

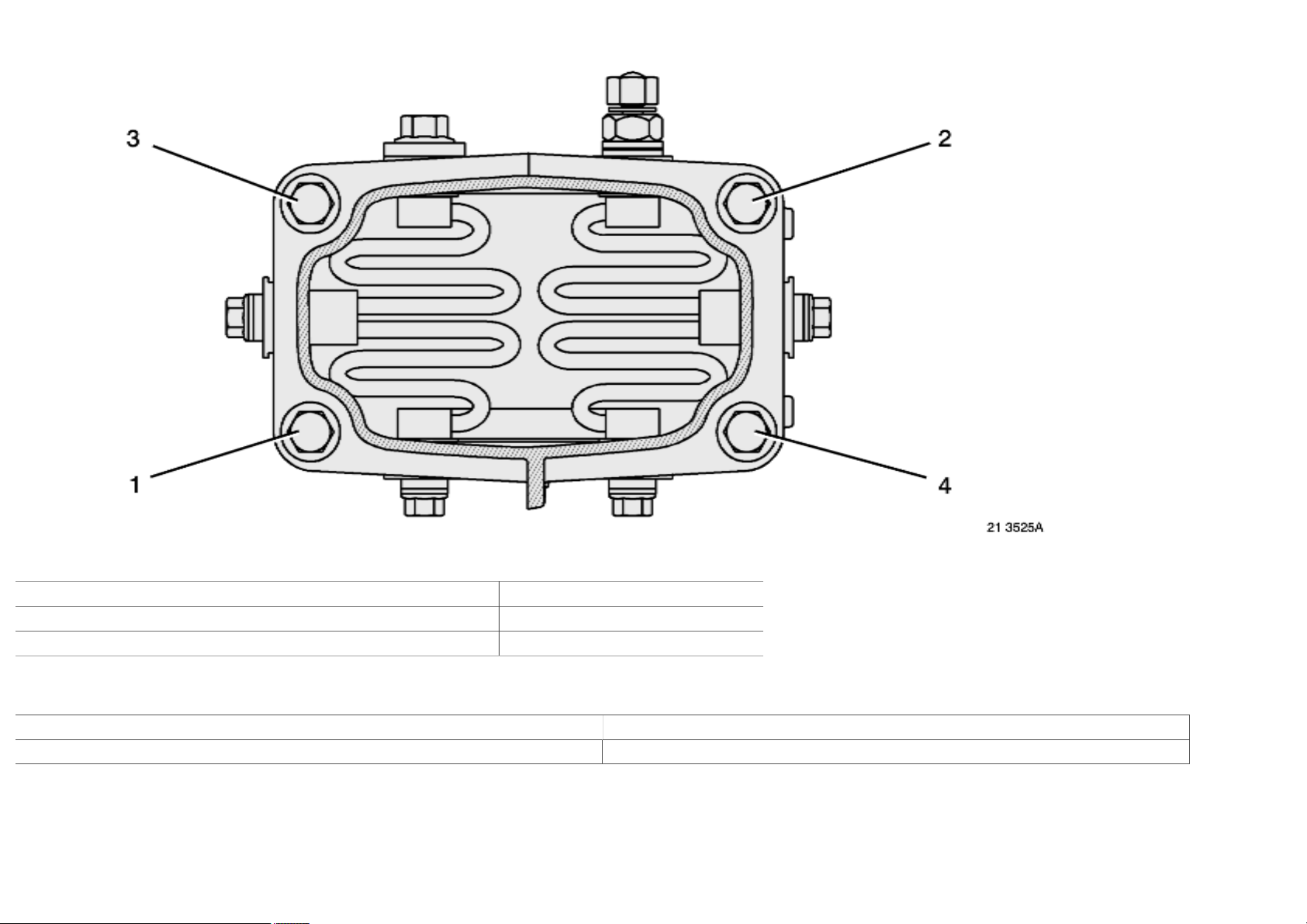

Oil filler pipes, tightening torques

Oil filler pipes

Plastic lock 27±2 Nm

Dipstick guide bolts 20±4 Nm

1 / 1

Andrew Burrows Cylinder head cover / Tightening torques 13/02/16

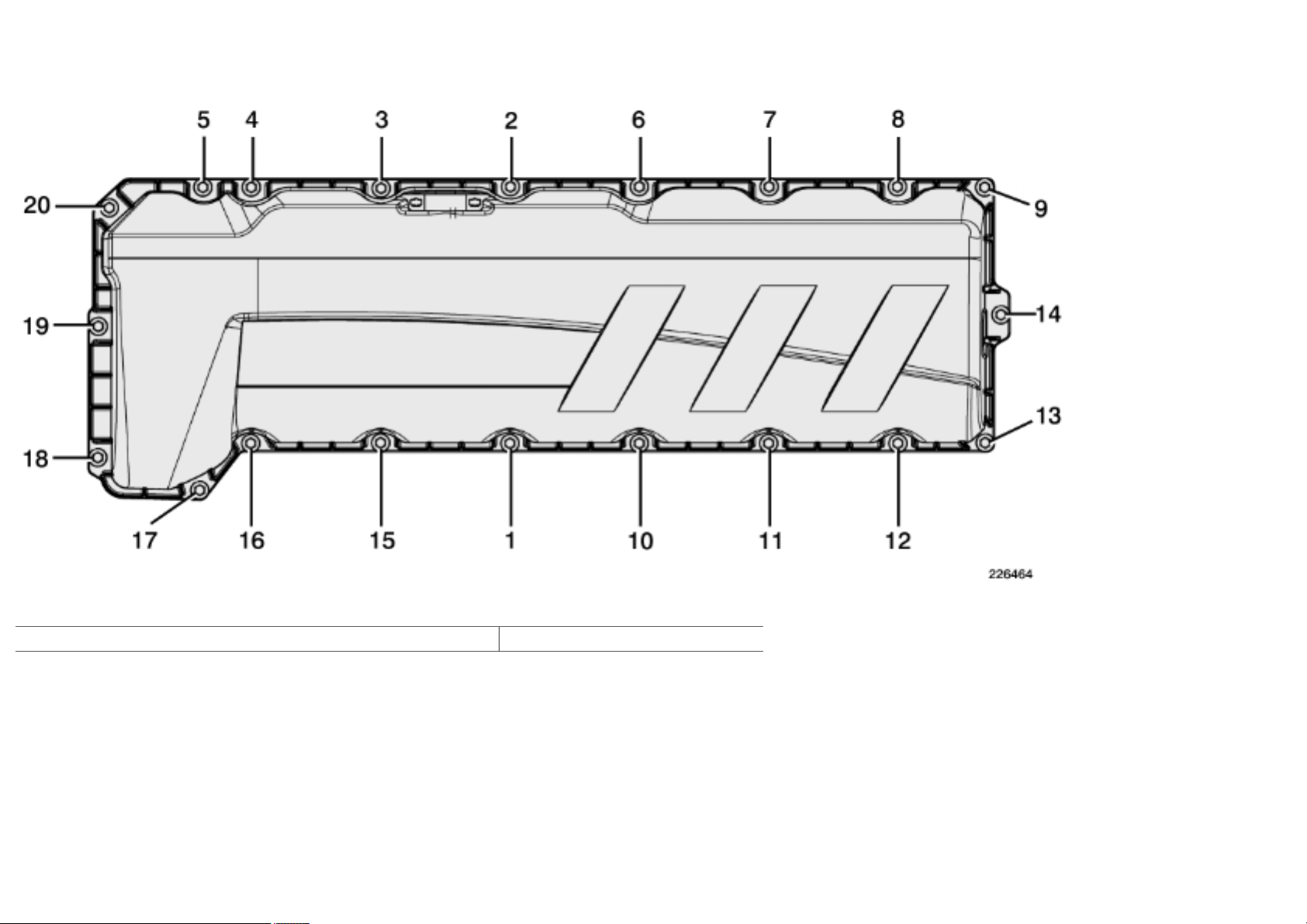

Cylinder head cover, tightening torques

The item numbers indicate the tightening sequence.

Cylinder head cover securing bolts 24±4 Nm

1 / 1

Andrew Burrows Rocker arms / Tightening torques 13/02/16

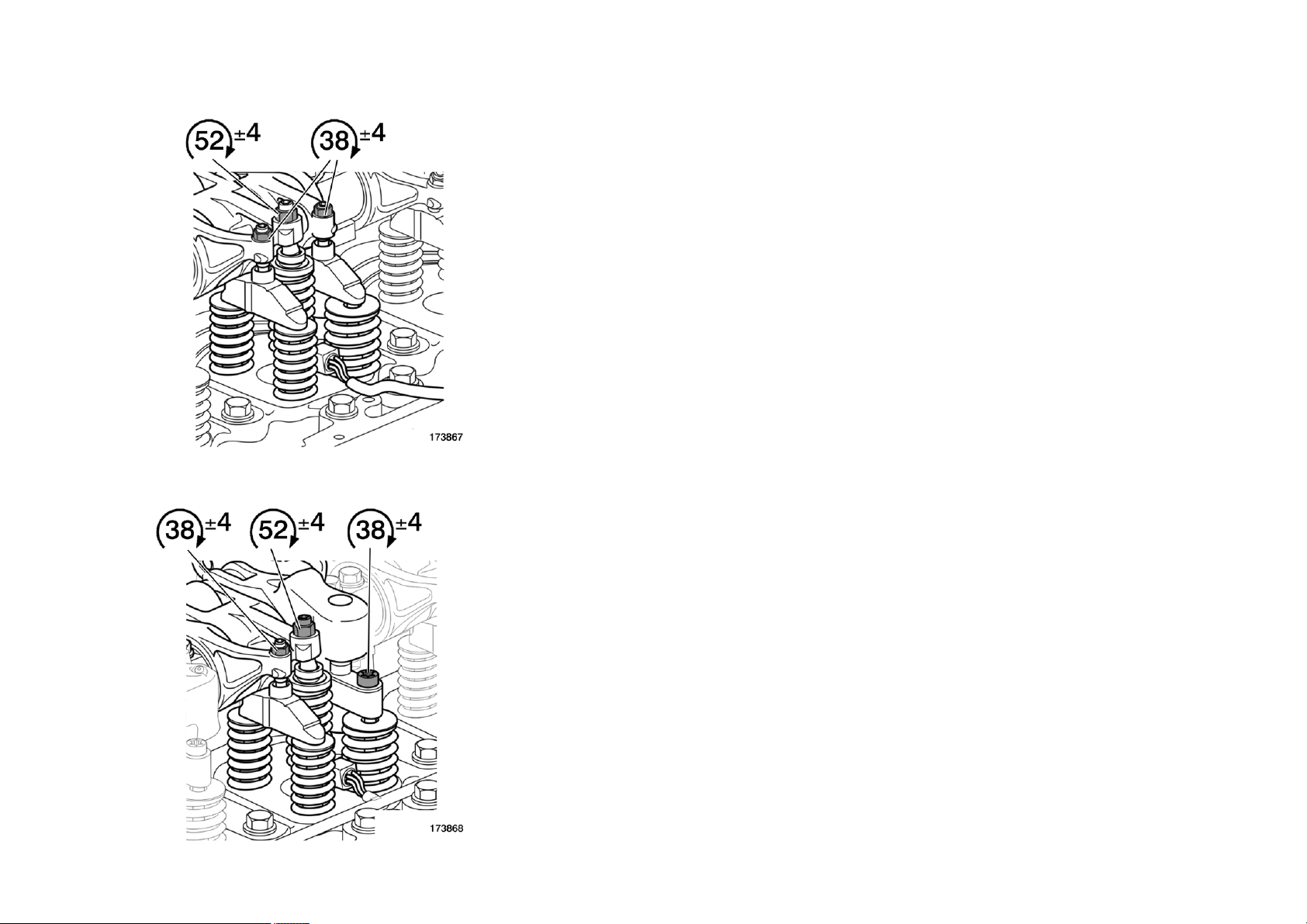

Rocker arms, tightening torques

Without "Optibrake" / "Optibrake +"

With "Optibrake"

1 / 2

Andrew Burrows Rocker arms / Tightening torques 13/02/16

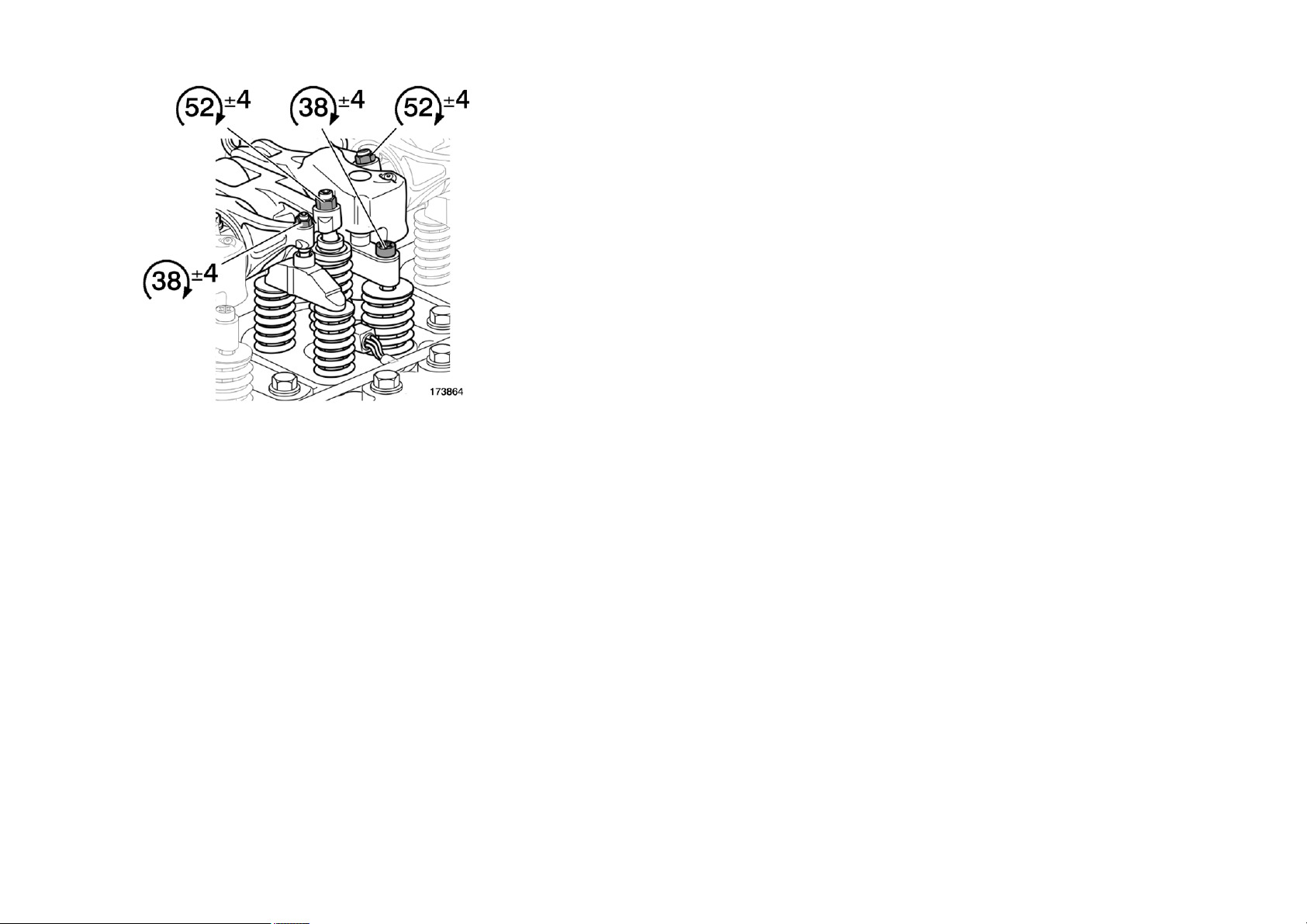

With "Optibrake +"

2 / 2

Andrew Burrows Camshaft / Tightening torques 13/02/16

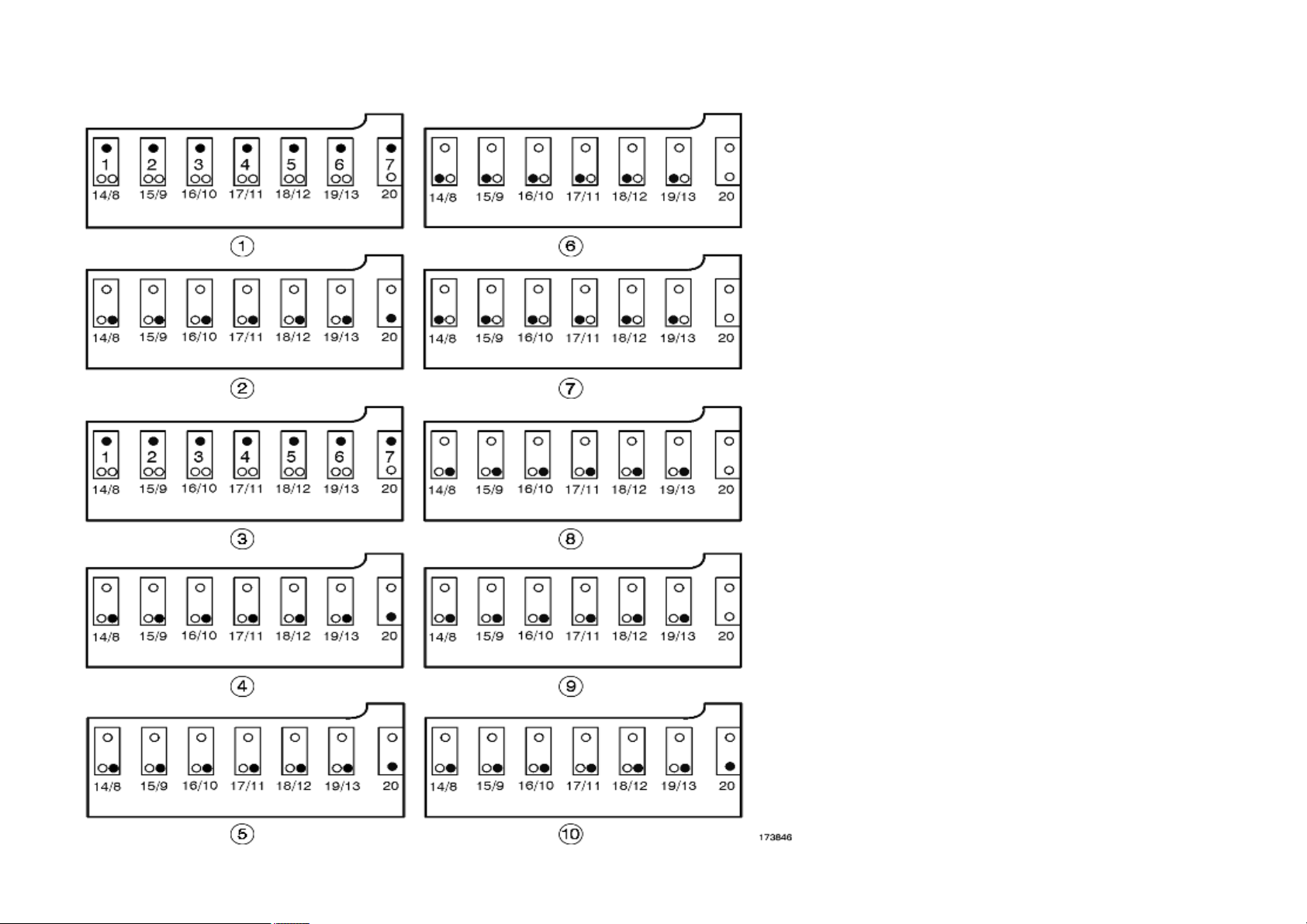

Rocker shaft and camshaft bearing caps, tightening torques

Camshaft

1 / 2

Andrew Burrows Camshaft / Tightening torques 13/02/16

Stage 1: bolts (1 › 7) 40±3 Nm

Stage 2: bolts (8 › 13 - 20) 60±5 Nm

For the 2th stage, tighten bolts gradually in the following order: 11 - 10 - 12 - 9 - 13 - 8 - 20, so that the rocker shaft can be lowered without being

damaged.

Stage 3: bolts (1 › 7) 90±5 °

Stage 4: bolts (8 › 13 - 20) Loosen the bolts

Rocker shaft

Stage 5: bolts (8 › 13 - 20) 60±5 Nm

For the 5th stage, tighten bolts gradually in the following order: 11 - 10 - 12 - 9 - 13 - 8 - 20, so that the rocker shaft can be lowered without being

damaged.

Stage 6: bolts (14 › 19) 40±3 Nm

Stage 7: bolts (14 › 19) 120±5 °

Stage 8: bolts (8 › 13) Loosen the bolts

Stage 9: bolts (8 › 13) 40±3 Nm

Stage 10: bolts (8 › 13 - 20) 120±5 °

2 / 2

Andrew Burrows Retarders / Tightening torques 13/02/16

"Optibrake/Optibrake +" retarder, tightening torques

Control solenoid valve 24±4 Nm

Rocker arms elastic blades securing bolts 25±3 Nm

1 / 1

Andrew Burrows Injectors / Tightening torques 13/02/16

Pump injector mounting flange, tightening torques

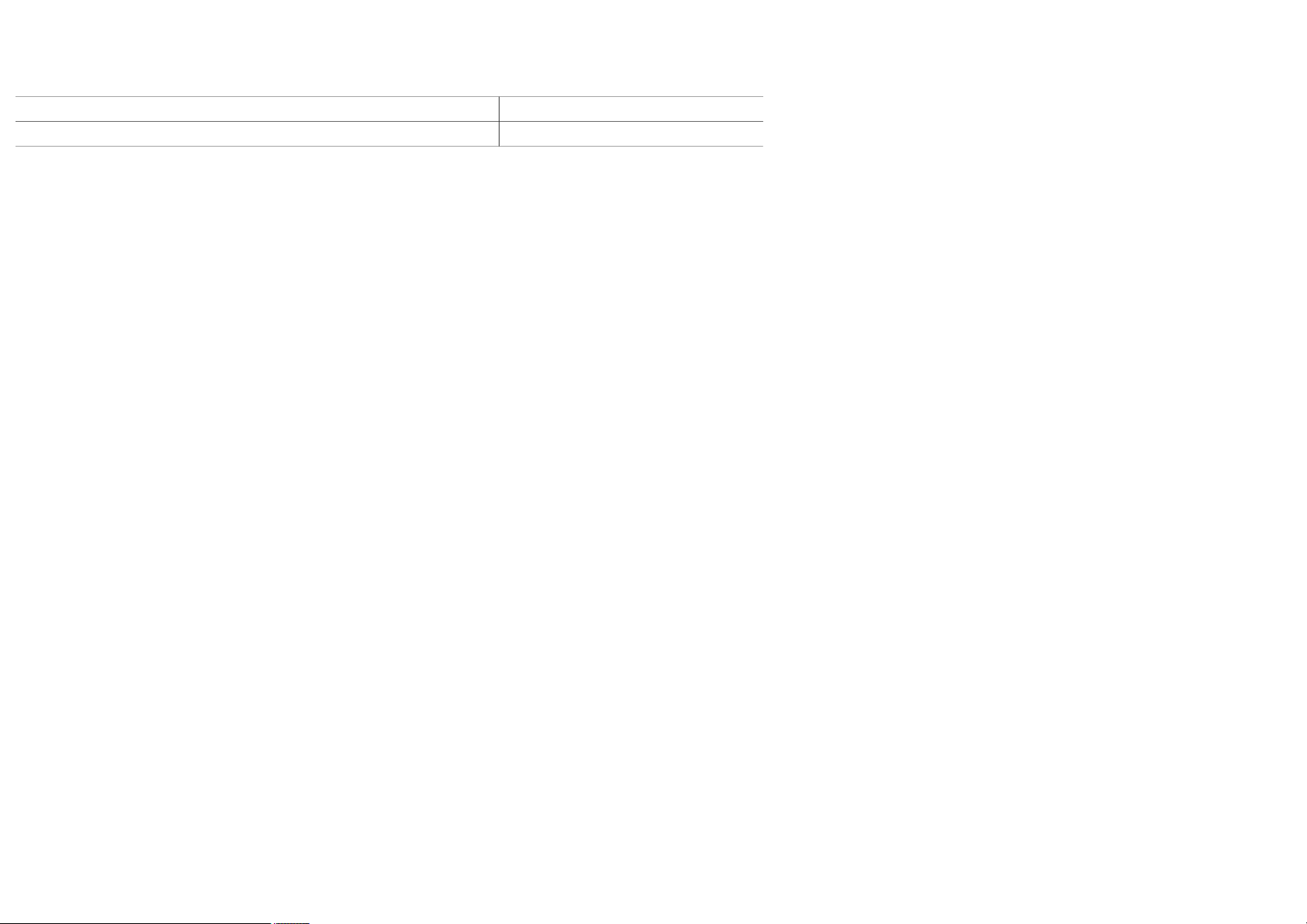

Assembly type A

A = Socket with boss.

Tightening procedure for already used copper injector sleeves

Stage1 20+5 Nm

Stage2 60±5 °

1 / 3

Andrew Burrows Injectors / Tightening torques 13/02/16

Assembly type B

A = Double groove flat socket with washer.

Tightening procedure for new copper injector sleeves

Stage1 20+5 Nm

Stage2 180±5 °

Fully loosen the yoke securing bolt before proceeding with stage 3.

Stage3 20+5 Nm

Stage4 90±5 °

At each disassembly operation, change the washer.

Tightening procedure for a used injector socket or removing an injector.

Stage1 20+5 Nm

Stage2 180±5 °

Fully loosen the yoke securing bolt before proceeding with stage 3.

Stage3 20+5 Nm

Stage4 90±5 °

At each disassembly operation, change the washer.

2 / 3

Andrew Burrows Injectors / Tightening torques 13/02/16

Retightening at valve maintenance

Injector flange attachment bolts 45+5 Nm

3 / 3

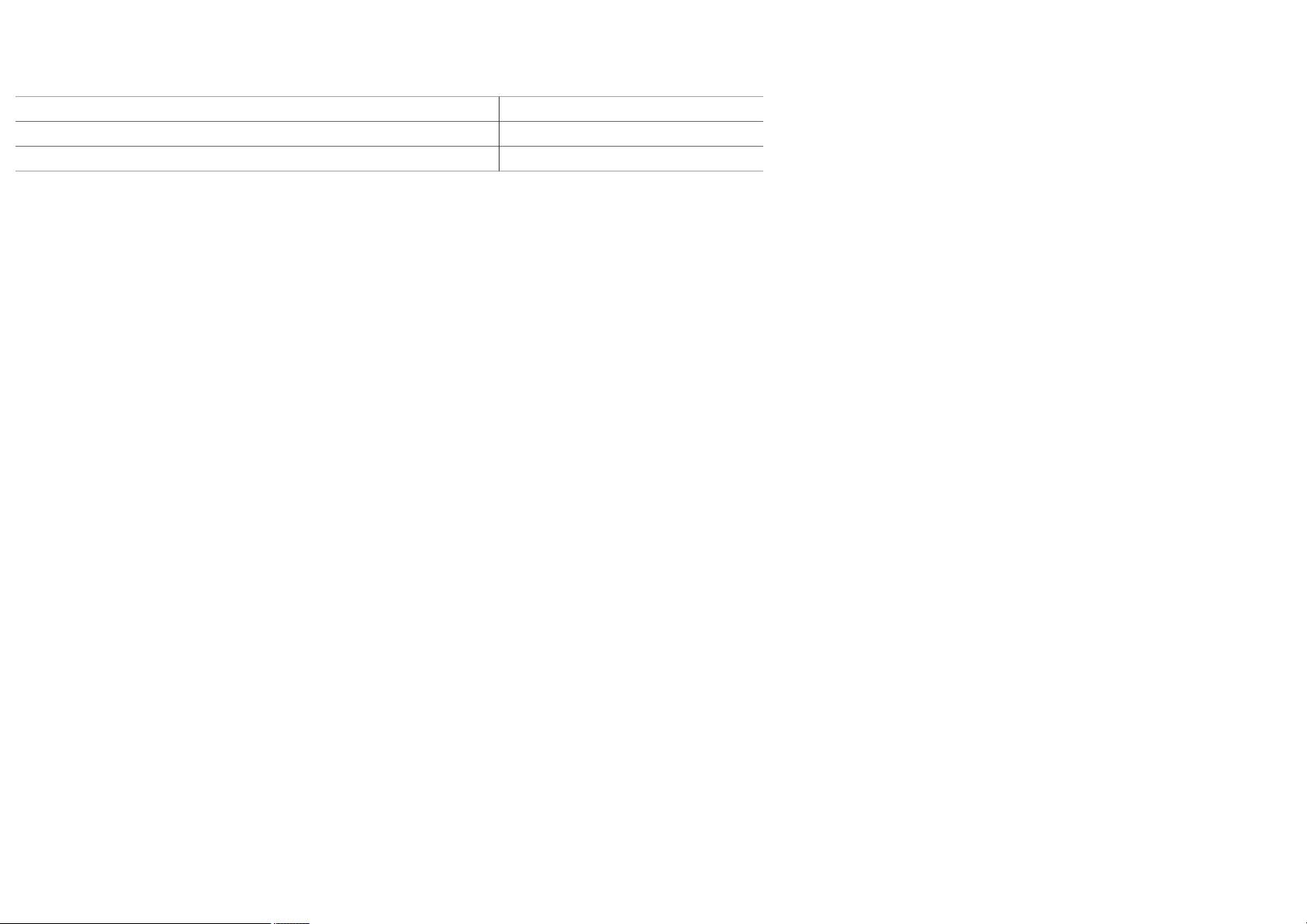

Andrew Burrows Cylinder head / Tightening torques 13/02/16

Cylinder head, tightening torques

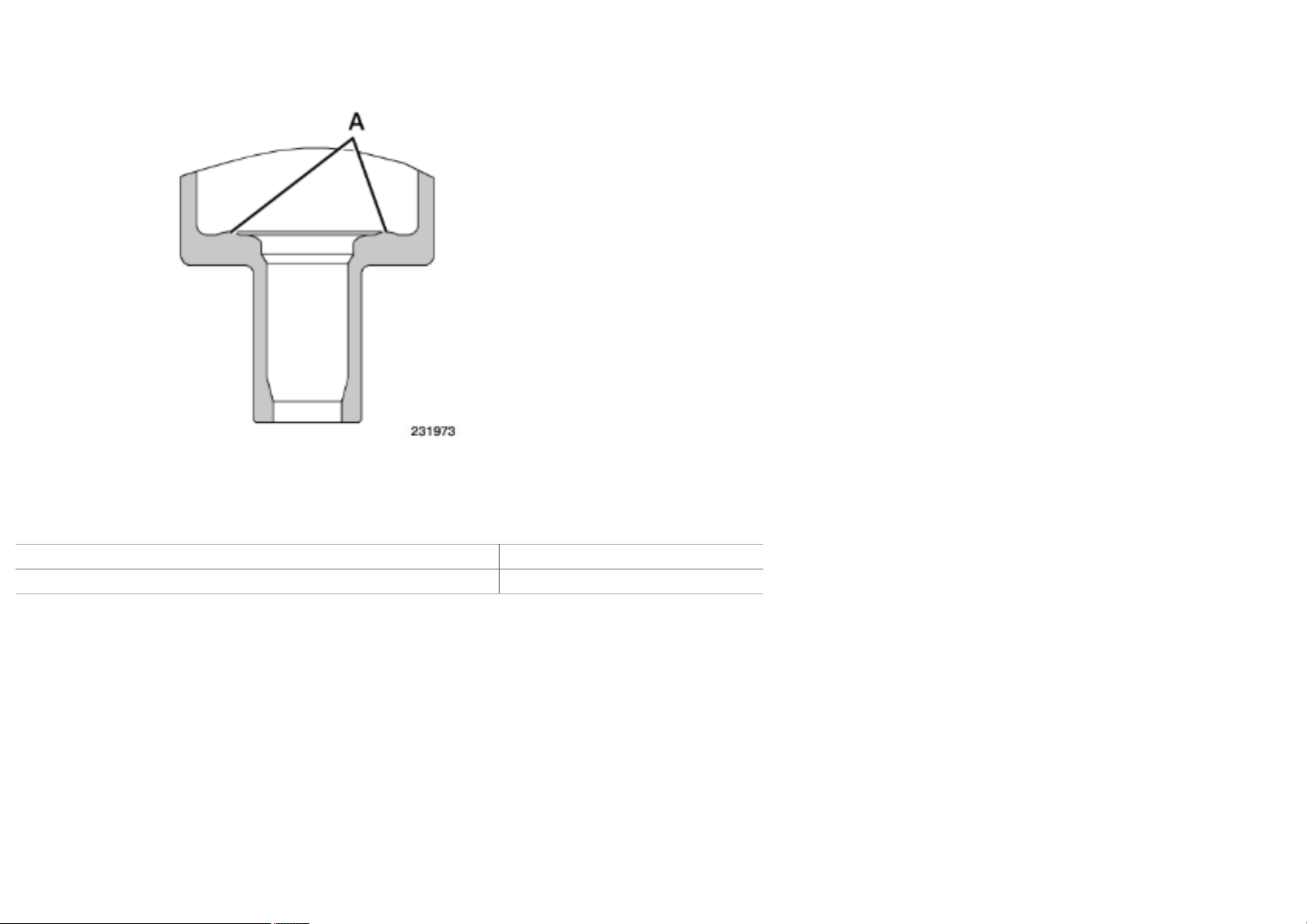

The bolts can be re-used no more than 5 times maximum. Mark the bolt head with an indentation (A) after tightening each time using a centre punch. In

this case, apply engine oil to the screw-threads and under the bolt heads.Do not apply engine oil to new bolts, which are already pre-lubricated.

1 / 3

Andrew Burrows Cylinder head / Tightening torques 13/02/16

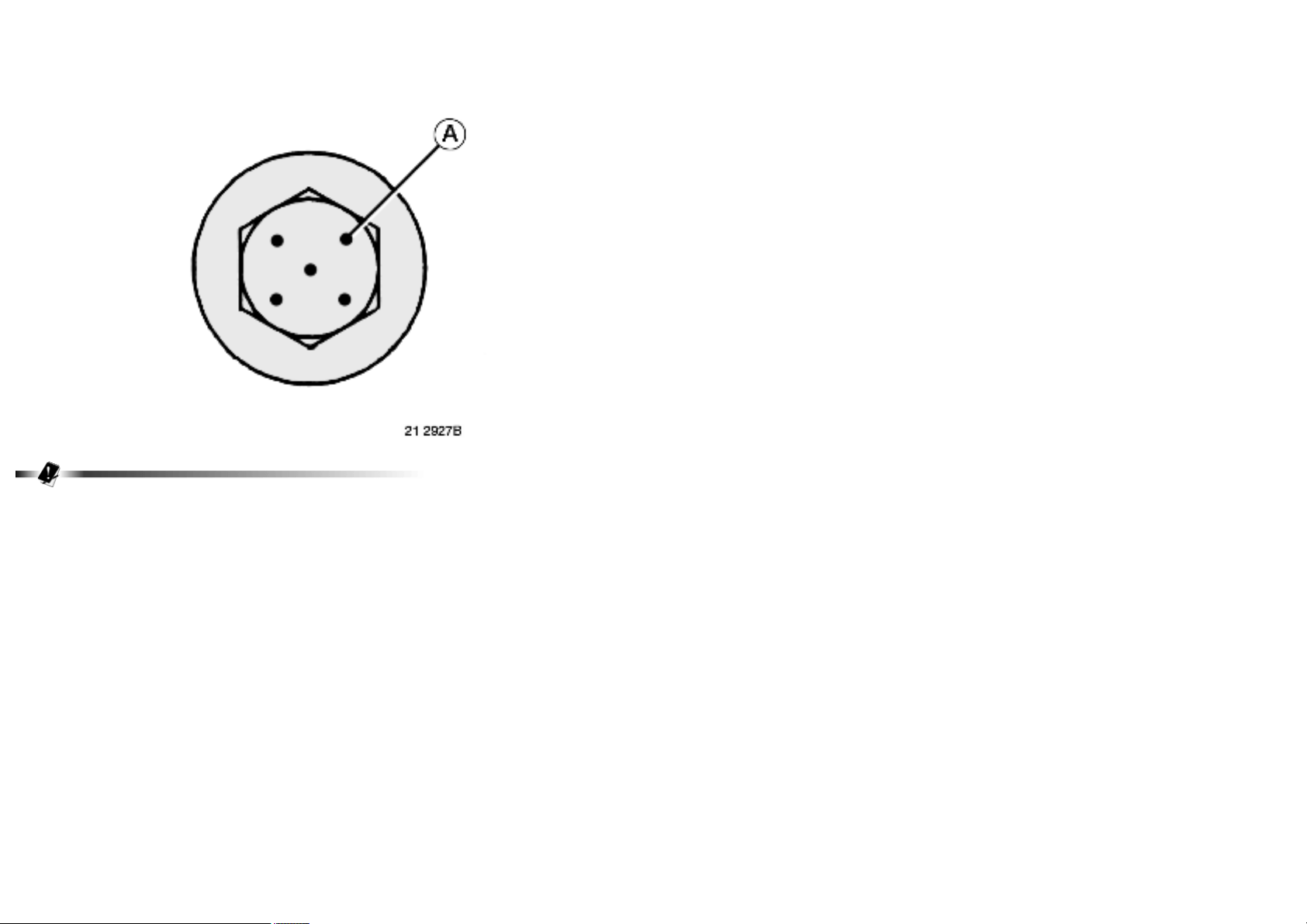

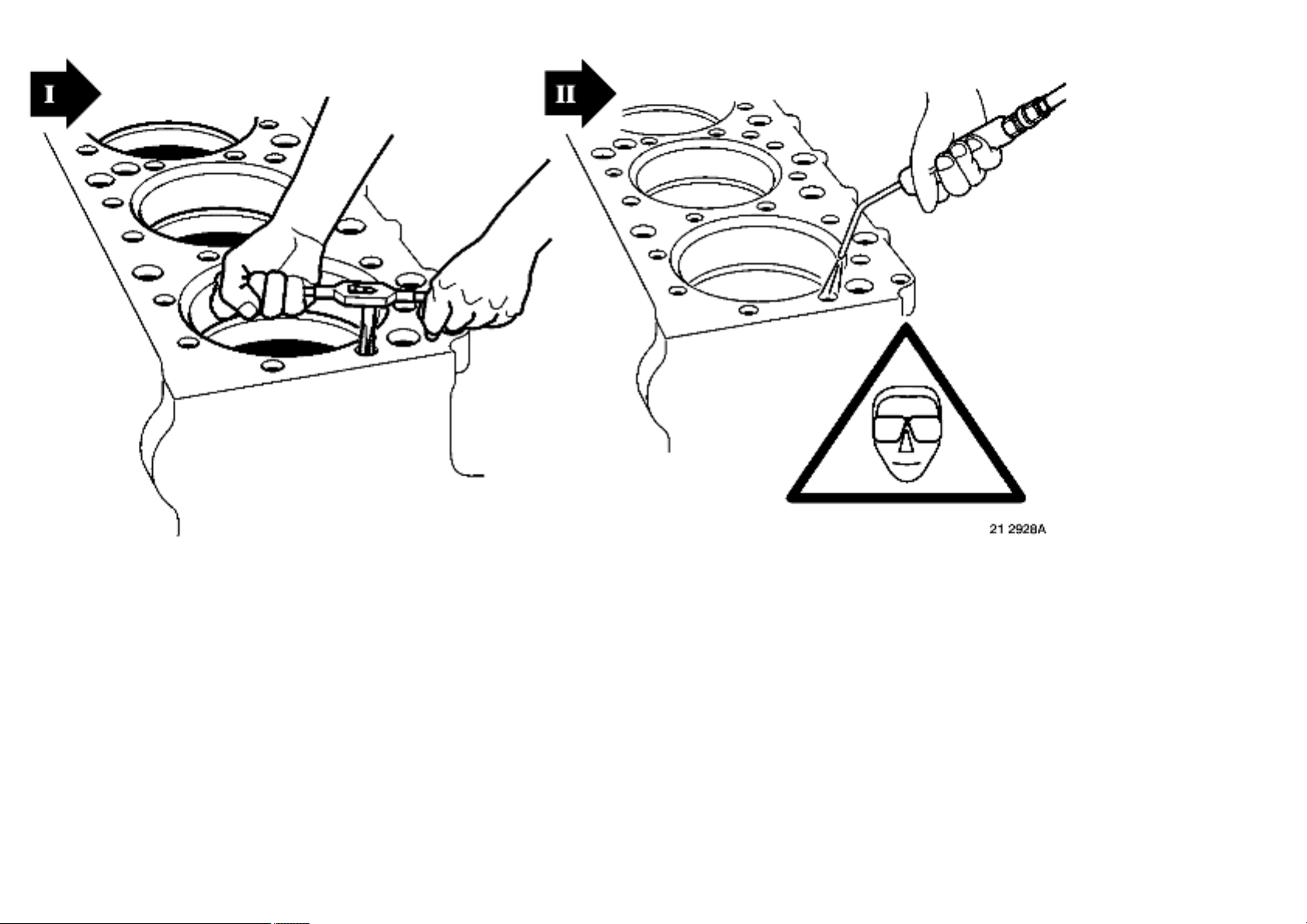

Tap the screw-threads in the cylinder block then blow through with compressed air.

2 / 3

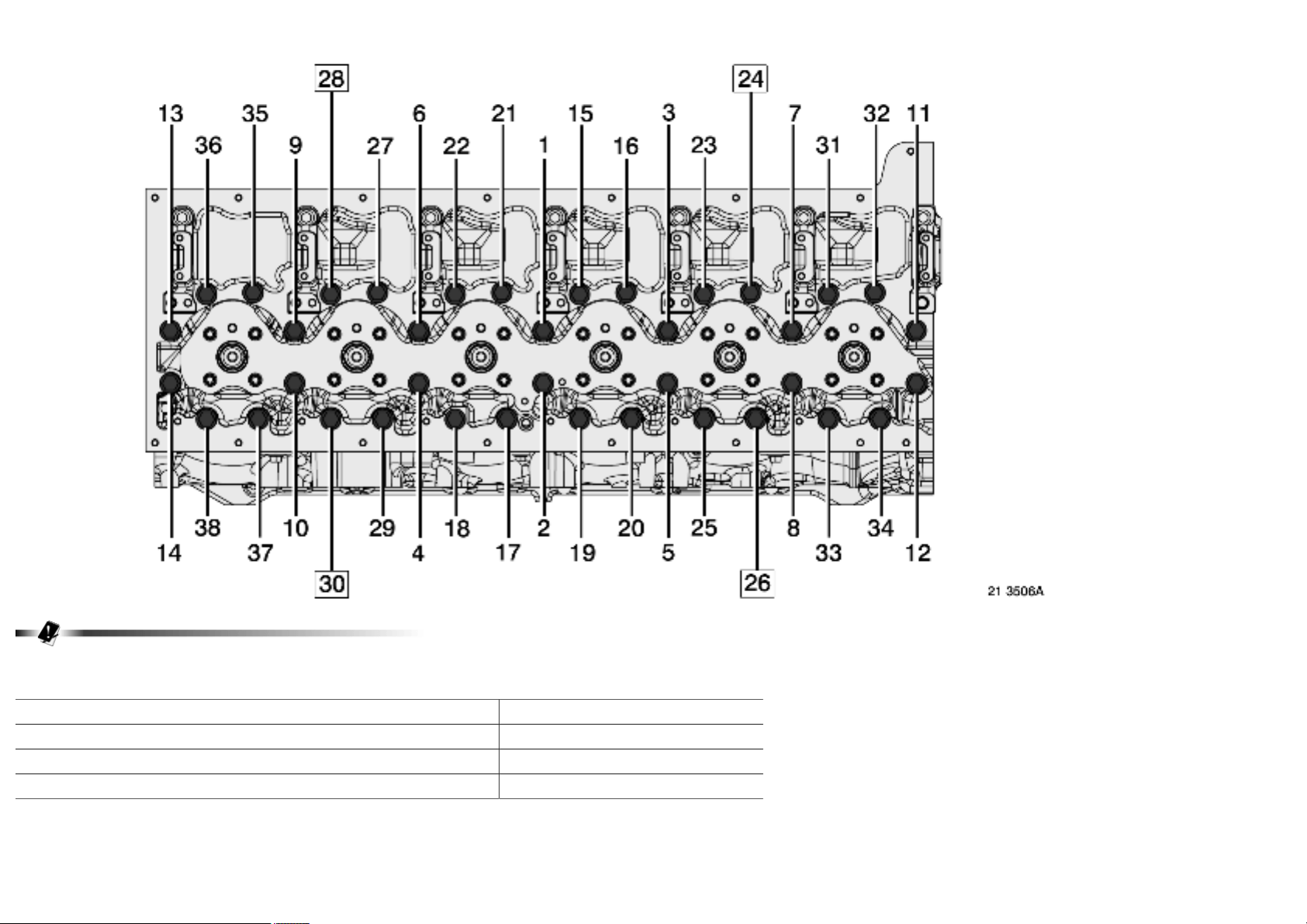

Andrew Burrows Cylinder head / Tightening torques 13/02/16

The cylinder head must be positioned and tightened in accordance with the instructions given in the method (see page ).

The item numbers indicate the tightening sequence.

Stage1 100±5 Nm

Stage2 (check tightening) 100±5 Nm

Stage3 120±5 °

Stage4 90±5 °

3 / 3

Andrew Burrows Blanking plug / cap / Tightening torques 13/02/16

Cylinder head plugs, tightening torques

Plug M10 x 1.00 25±3 Nm

Plug M16 x 1.50 50±3 Nm

1 / 1

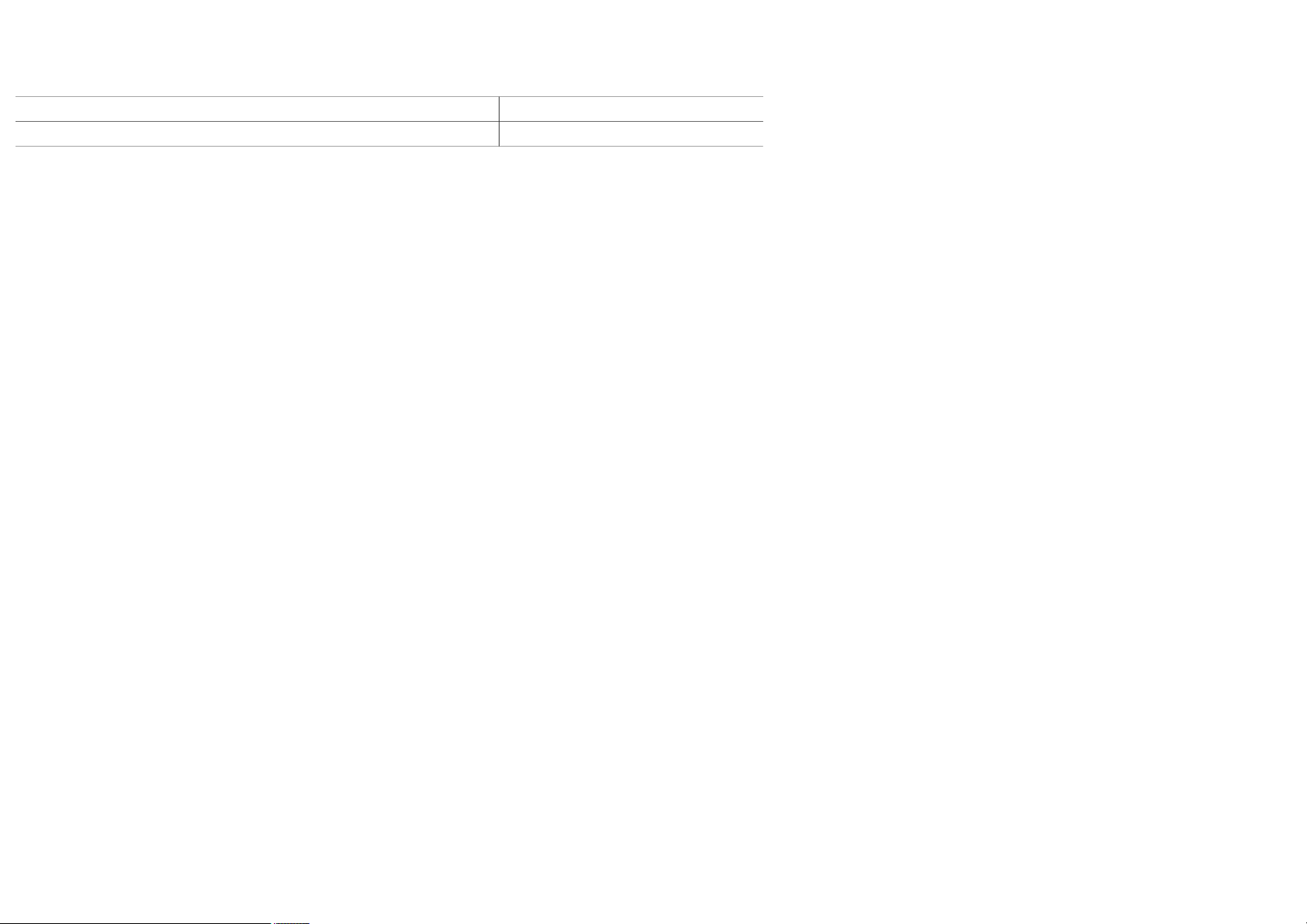

Andrew Burrows Exhaust manifold / Tightening torques 13/02/16

Exhaust manifold, tightening torques

Stage 1: bolts (1 › 12) 5±1.5 Nm

Stage 2: bolts (1 - 4 - 5 - 8 - 9 - 12) 10±1.5 Nm

Stage 3: bolts (3 - 2 - 7 - 6 - 11 - 10 - 1 - 4 - 5 - 8 - 9 - 12) 48±8 Nm

1 / 1

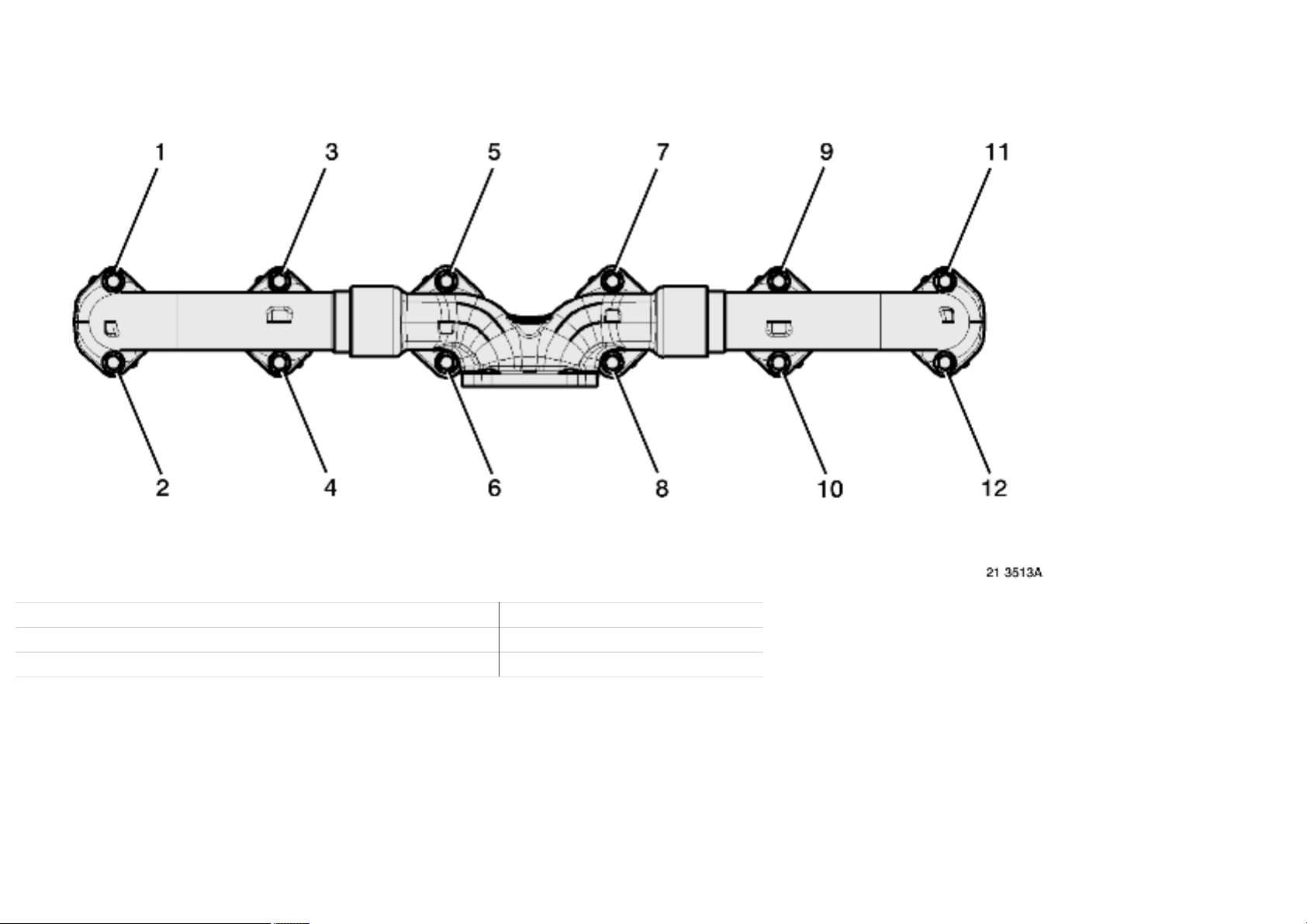

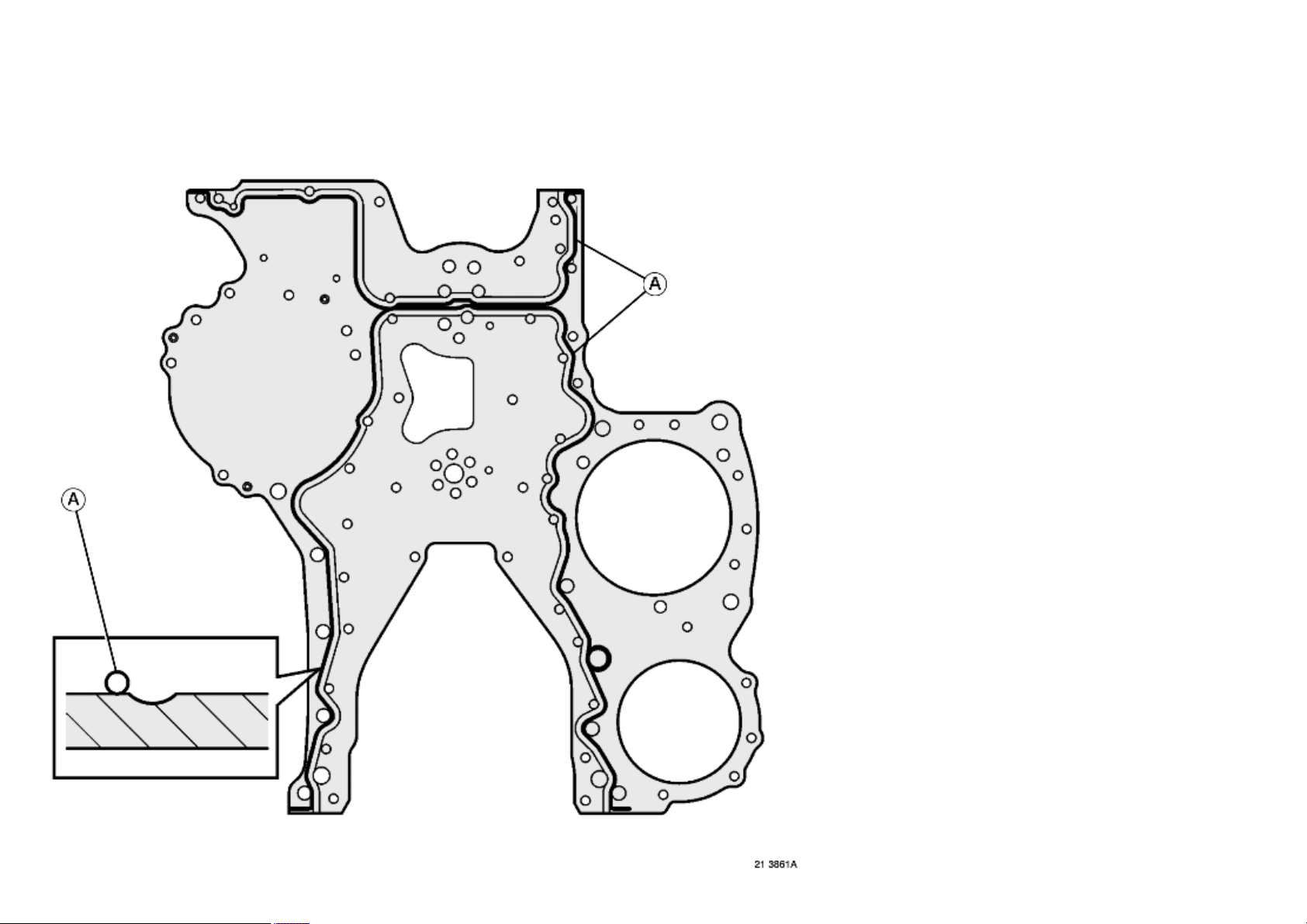

Andrew Burrows Intake manifold / Tightening torques 13/02/16

Intake manifold, tightening torques

Apply a fine coat of sealing compound in the gasket housing (A).

Apply "

ADHESIF SILICONE 7091

".

Install seal.

Carry out the assembly work within 20 minutes following application of the sealing compound.

1 / 3

Andrew Burrows Intake manifold / Tightening torques 13/02/16

The item numbers indicate the tightening sequence.

Intake manifold securing bolts 24±4 Nm

Plug M10 20±3 Nm

Boost air pressure / temperature sensor 12±2 Nm

2 / 3

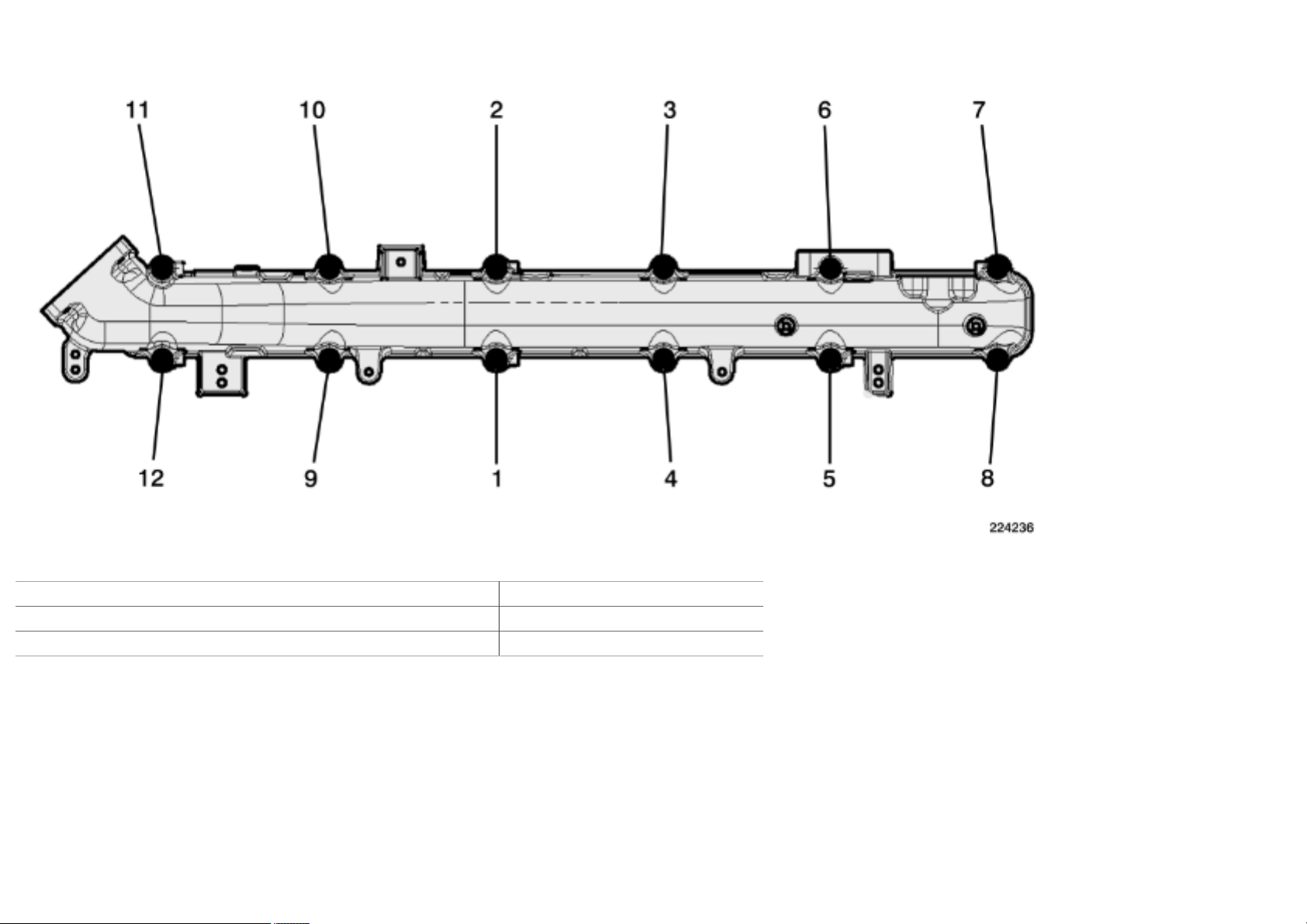

Andrew Burrows Intake manifold / Tightening torques 13/02/16

The item numbers indicate the tightening sequence.

Stage1 10±2 Nm

Stage2 24±4 Nm

Intake air heater supply cable securing nut 10±1.5 Nm

Consumables

Automotive part N° Industrial reference N°

56 89 501 292 Silicon adhesive 7091

3 / 3

Andrew Burrows Air compressor / Tightening torques 13/02/16

Air compressor, tightening torques

Air compressor 636 cm³ drive pinion securing nut 200+ 50 Nm

Air compressor 636 cm³ securing nut 85±15 Nm

Lubrication union 25±4 Nm

1 / 1

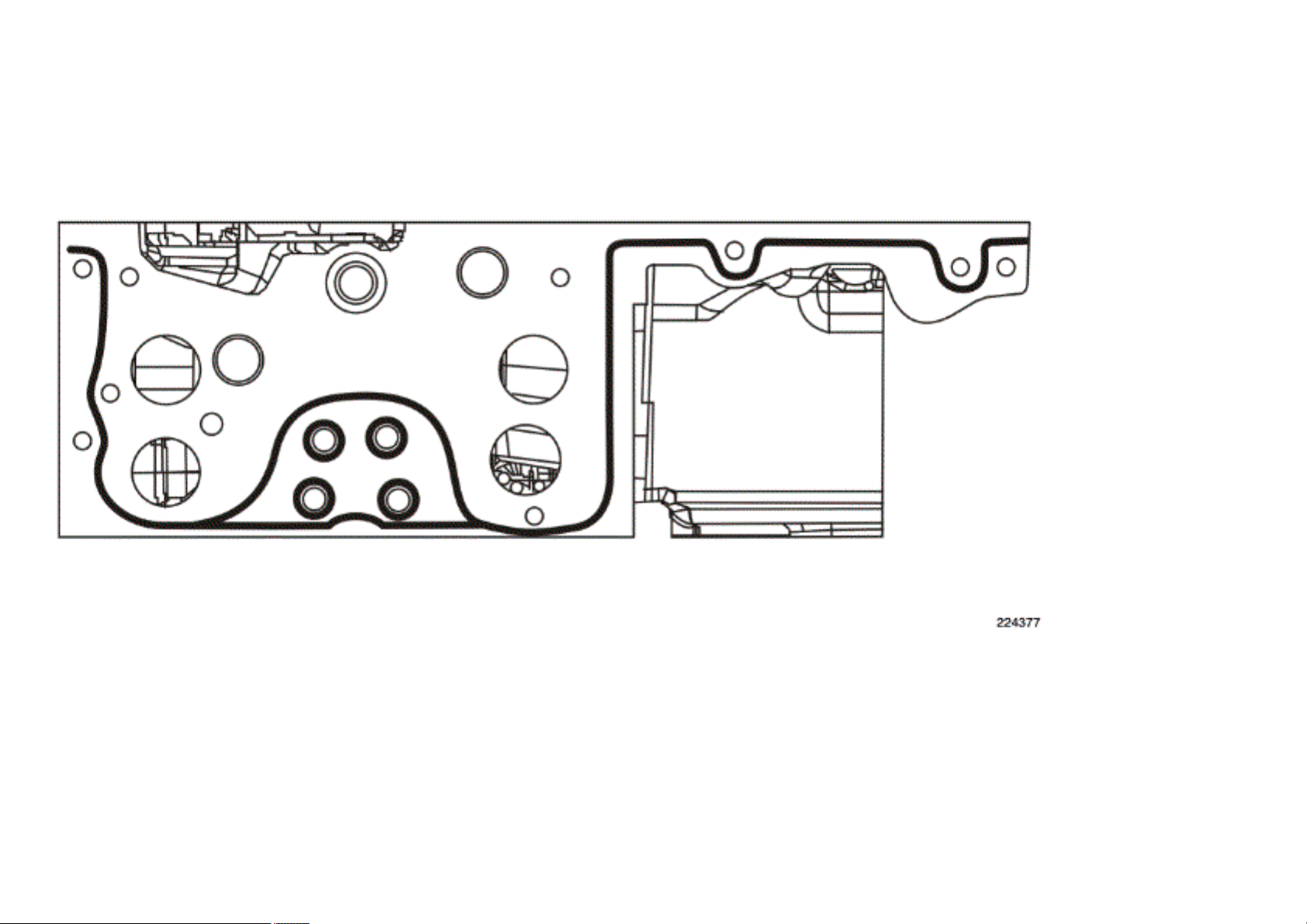

Andrew Burrows Distribution / Tightening torques 13/02/16

Timing system, tightening torques

Assembly type A

1 / 10

Andrew Burrows Distribution / Tightening torques 13/02/16

Apply a bead of silicone dia. 2 mm (A) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

Use a silicone sealant "

ADHESIF SILICONE 7091

".

Apply a bead of silicone dia. 2 mm (A) as shown in the drawing. Perform assembly within 20 minutes of application of the silicone.

Use a silicone sealant "

ADHESIF SILICONE 7091

".

2 / 10

Loading...

Loading...