Assembly and operating instructions

REMKO fresh water station EFS 25

Instructions for user and specialist

0039-2013-04 Edition 1, en_GB

Read the instructions prior to performing any task!

Read these operating instructions carefully before commissioning / using this device!

These instructions are an integral part of the system and must

always be kept near or on the device.

Subject to modifications; No liability accepted for errors or misprints!

Installation and operating instructions (translation of the original)

Table of contents

1 Safety and usage instructions............................................................................................................. 4

1.1 General safety notes....................................................................................................................... 4

1.2 Identification of notes...................................................................................................................... 4

1.3 Personnel qualifications.................................................................................................................. 4

1.4 Dangers of failure to observe the safety notes................................................................................ 4

1.5 Safety-conscious working............................................................................................................... 4

1.6 Safety instructions for the operator................................................................................................. 5

1.7 Safety notes for installation and inspection tasks........................................................................... 5

1.8 Unauthorised modification and changes......................................................................................... 5

1.9 Intended use................................................................................................................................... 6

1.10 Safety-conscious working............................................................................................................. 4

1.11 Warranty........................................................................................................................................ 6

1.12 Transportation and packaging....................................................................................................... 6

1.13 Environmental protection and recycling........................................................................................ 6

2 Technical data....................................................................................................................................... 7

2.1 Unit data.......................................................................................................................................... 7

2.2 Pressure loss characteristic curve.................................................................................................. 8

3 Unit description..................................................................................................................................... 9

4

Design and planning........................................................................................................................... 10

4.1 General Information...................................................................................................................... 10

4.2 Design of the storage tank............................................................................................................ 11

5 Circulation operation.......................................................................................................................... 12

6 Assembly and installation (Specialist).............................................................................................. 12

7 Commissioning (specialist)............................................................................................................... 14

7.1 General Information...................................................................................................................... 14

7.2 Filling the primary circuit............................................................................................................... 14

7.3 Commissioning the controller........................................................................................................ 15

7.4 Maximum dispensing medium flow rate........................................................................................ 16

7.5 Setting the Temperature............................................................................................................... 18

7.6 Commissioning report................................................................................................................... 19

8 Maintenance........................................................................................................................................ 19

9 Depiction of spare parts (specialist)................................................................................................. 20

10 Index..................................................................................................................................................... 22

3

REMKO fresh water station

1

1.1

Carefully read the operating manual before commissioning the units for the first time. It contains

useful tips and notes such as hazard warnings to

prevent personal injury and material damage.

Failure to follow the directions in this manual not

only presents a danger to people, the environment

and the system itself, but will void any claims for

liability.

Keep this operating manual and the refrigerant

data sheet near to the units.

1.2

This section provides an overview of all important

safety aspects for proper protection of people and

safe and fault-free operation.The instructions and

safety notes contained within this manual must be

observed in order to prevent accidents, personal

injury and material damage.

Notes attached directly to the units must be

observed in their entirety and be kept in a fully

legible condition.

Safety notes in this manual are indicated by symbols. Safety notes are introduced with signal words

which help to highlight the magnitude of the danger

in question.

Safety and usage instructions

General safety notes

Identification of notes

DANGER!

CAUTION!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause injury or material and environmental damage.

NOTICE!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause material and

environmental damage.

This symbol highlights useful tips and recommendations as well as information for efficient

and fault-free operation.

1.3

Personnel qualifications

Personnel responsible for commissioning, operation, maintenance, inspection and installation must

be able to demonstrate that they hold a qualification which proves their ability to undertake the

work.

Contact with live parts poses an immediate

danger of death due to electric shock. Damage

to the insulation or individual components may

pose a danger of death.

DANGER!

This combination of symbol and signal word

warns of a situation in which there is immediate

danger, which if not avoided may be fatal or

cause serious injury.

WARNING!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may be fatal or cause

serious injury.

Dangers of failure to observe

1.4

the safety notes

Failure to observe the safety notes may pose a risk

to people, the environment and the units. Failure to

observe the safety notes may void any claims for

damages.

In particular, failure to observe the safety notes

may pose the following risks:

n The failure of important unit functions.

n The failure of prescribed methods of mainte-

nance and repair.

n Danger to people on account of electrical and

mechanical effects.

1.5

Safety-conscious working

The safety notes contained in this manual, the

existing national regulations concerning accident

prevention as well as any internal company

working, operating and safety regulations must be

observed.

4

Safety instructions for the oper-

1.6

ator

The operational safety of the units and components is only assured providing they are used as

intended and in a fully assembled state.

n The units and components may only be set up,

installed and maintained by qualified personnel.

n The existing regulations concerning accident

prevention must be adhered to.

n Do not operate units or components with

obvious defects or signs of damage.

n Contact with equipment parts or components

can lead to burns or injury.

n Ensure that electrical energy does not pose a

risk.

n Regulations of the VDE and the local energy

supply company must be adhered to.

NOTICE!

Material damage due to mineral oils!

Mineral oil products permanently damage

EPDM seal elements; the sealing properties

may therefore be lost. We do not take responsibility or provide warranty replacements for

damage caused by seals that are damaged in

this way.

– It is essential that you prevent EPDM from

coming into contact with mineral oil substances.

– Use a lubricant that is free of mineral oil

and has a silicone or polyalkylene basis,

such as Unisilkon L250L and Syntheso

Glep 1 made by Klüber, or a silicon spray.

Safety notes for installation and

1.7

inspection tasks

n The operator must ensure that all inspection

and installation work is carried out by authorised and qualified personnel who have thoroughly read the operating manual.

n Works on the pump/system may only be car-

ried out whilst at a standstill as a matter of principle.

n Appropriate hazard prevention measures must

be taken to prevent risks to people when performing installation, repair, maintenance or

cleaning work on the units.

n The setup, connection and operation of the

units and its components must be undertaken

in accordance with the usage and operating

conditions stipulated in this manual and comply

with all applicable regional regulations.

n Regional regulations and laws as well as the

Water Ecology Act must be observed.

n The power supply should be adapted to the

requirements of the units.

n The units and components must be kept at an

adequate distance from flammable, explosive,

combustible, abrasive and dirty areas or

atmospheres.

n Safety devices may not be modified or

bypassed.

NOTICE!

Malfunction!

The fresh water module must be integrated into

the equipotential bonding system of the electrical installation. If this is not ensured by the

pipe network, set up an approved potential

equalisation connection to the main potential

connection.

Unauthorised modification and

1.8

changes

The operational safety of the fresh water module

that was delivered is guaranteed only with

intended use in accordance with section 1.8 of the

operating instructions. Under no circumstances

should the threshold values specified in the datasheet be exceeded.

Modifications or changes to units and components

are not permitted and may cause malfunctions.

Safety devices may not be modified or bypassed.

Original replacement parts and accessories

authorised by the manufacturer ensure safety. The

use of other parts may invalidate liability for

resulting consequences.

5

REMKO fresh water station

1.9

Intended use

The fresh water module is only permitted to be

installed in heating systems between the buffer

tank and the domestic water circuit. Depending on

the design, it may only be installed and operated

vertically!

Use only REMKO accessories in conjunction with

the fresh water module.

Any different or additional use is a non-intended

use. The manufacturer/supplier assumes no liability for damages arising from a non-intended use.

The user bears the sole risk in such cases.

Intended use also includes working in accordance

with the operating and installation instructions and

complying with the maintenance requirements.

The threshold values specified in the technical

data must not be exceeded.

1.10

The safety notes contained in this manual, the

existing national regulations concerning accident

prevention as well as any internal company

working, operating and safety regulations must be

observed.

Safety-conscious working

WARNING!

Plastic films and bags etc. are dangerous

toys for children!

Why:

- Leave packaging material are not around.

- Packaging material may not be accessible to

children!

1.13

Disposing of packaging

All products are packed for transport in environmentally friendly materials. Make a valuable contribution to reducing waste and sustaining raw materials. Only dispose of packaging at approved

collection points.

Environmental protection and recycling

1.11

For warranty claims to be considered, it is essential

that the ordering party or its representative complete and return the "certificate of warranty" to

REMKO GmbH & Co. KG at the time when the

units are purchased and commissioned.

The warranty conditions are detailed in the "General business and delivery conditions". Furthermore, only the parties to a contract can conclude

special agreements beyond these conditions. In

this case, contact your contractual partner in the

first instance.

1.12

Warranty

Transportation and packaging

The units are shipped in sturdy transport packaging or within the heat pump housing. Immediately check the units on delivery and make a note

of any damage or missing parts on the delivery

note. Inform the forwarding agent and contractual

partner. Claims under guarantee made at a later

date will not be accepted.

Disposing of the units and their components

For the manufacture of the units and components,

only recyclable materials have been used. Help

protect the environment by ensuring that the units

or components (for example batteries) are not disposed of in household waste, but only in accordance with local regulations and in an environmentally safe manner, e.g. using authorised disposal

and recycling specialists or council collection

points.

6

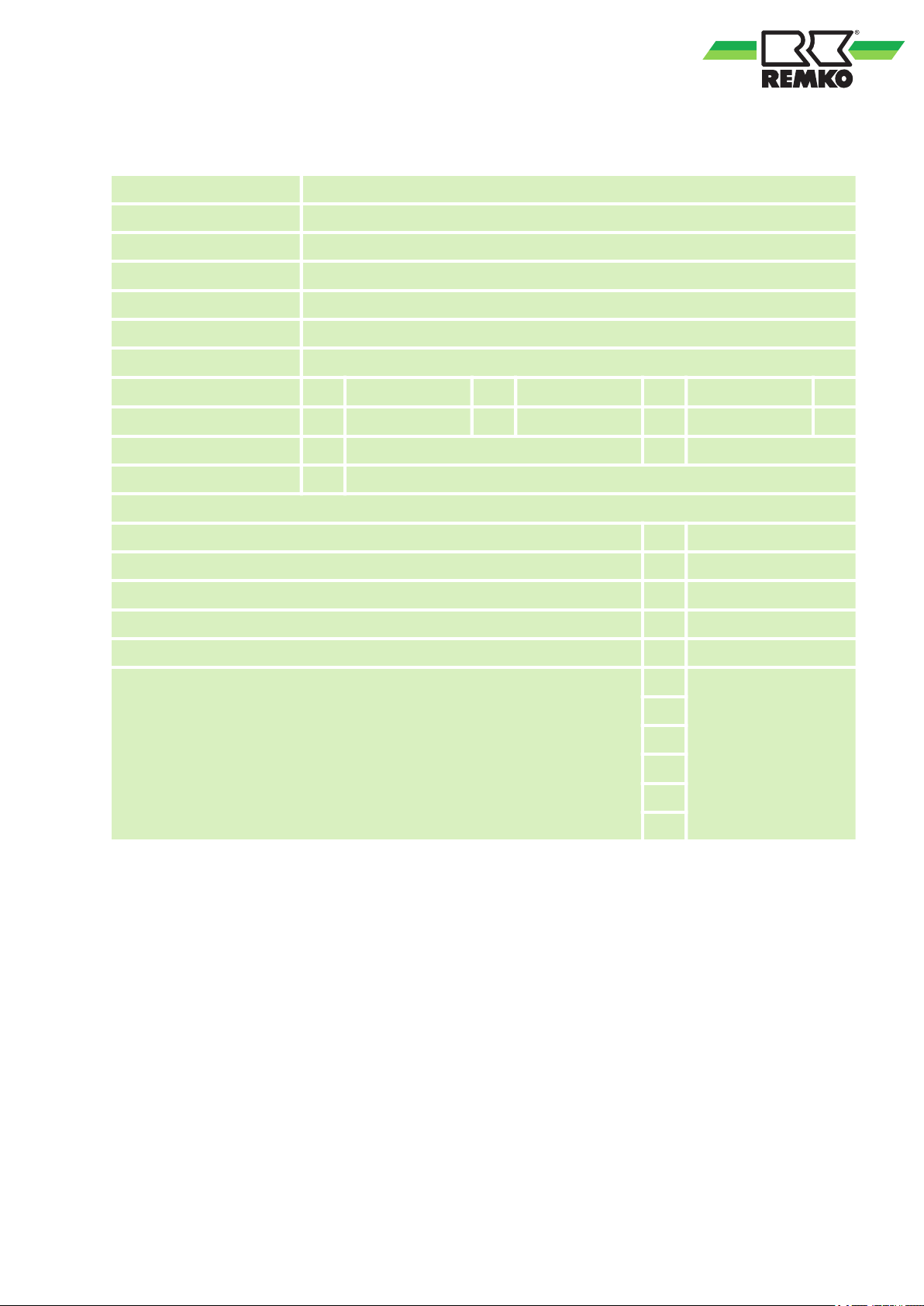

2

2.1

Series EFS 25

Operating data

Maximum permitted pressure, primary bar 3

Maximum permitted pressure, secondary bar 10

Operating temperature °C 2-95

Pipe connections

Primary circuit (tank circuit) Inches 3/4" inside thread

Secondary circuit (domestic water circuit) Inches 3/4" outside thread, flat-sealing

Equipment

Gravity brake mmWS 200

Primary pump

Secondary pump

Technical data

Unit data

HE pump with

PWM control, 5-63 watts

(optional) HE pump with

PWM control, 5-63 watts

Heat exchanger 30 Plates

Medium flow rate probe 1 x VFS 2.40

Temperature probe Pt 1000, fast

Materials

Valves Brass

Seals: O-rings EPDM

Flat seals AFM 34, asbestos-free

Plate heat exchanger

Insulation EPP

Gravity brake Hostaform

Stainless steel 1.4400/solder:

99.99% Cu

7

A

B

C

[mWS]

[kPa]

]h/l[

0,0

4,9

9,8

14,7

19,6

24,5

29,4

34,3

39,2

44,1

49,0

53,9

58,8

63,7

68,6

73,5

78,4

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

5,0

5,5

6,0

6,5

7,0

7,5

8,0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300

Sekundär

kvs = 2,27

Primär

kvs = 2,65

Grundfos UPM2 15-75 CIL

REMKO fresh water station

Unit data (continued)

Series EFS 25

Dimensions

Height (with insulation) mm 645

Width (with insulation) mm 344

Depth (with insulation) mm 249

Top axis-centre distance mm 86

Bottom axis-centre distance mm 47

Height (with circulation, vertical installation) mm 1115

Height (with circulation, horizontal installation) mm 943

Pressure loss characteristic

2.2

curve

Fig. 1: Pressure loss characteristic curve

A: Pressure [mWS]

B: Medium flow rate [l/h]

C: Pressure [kPa]

8

A

B

C

D

1

2

3

4

7

6

8

9

10

11

5

3

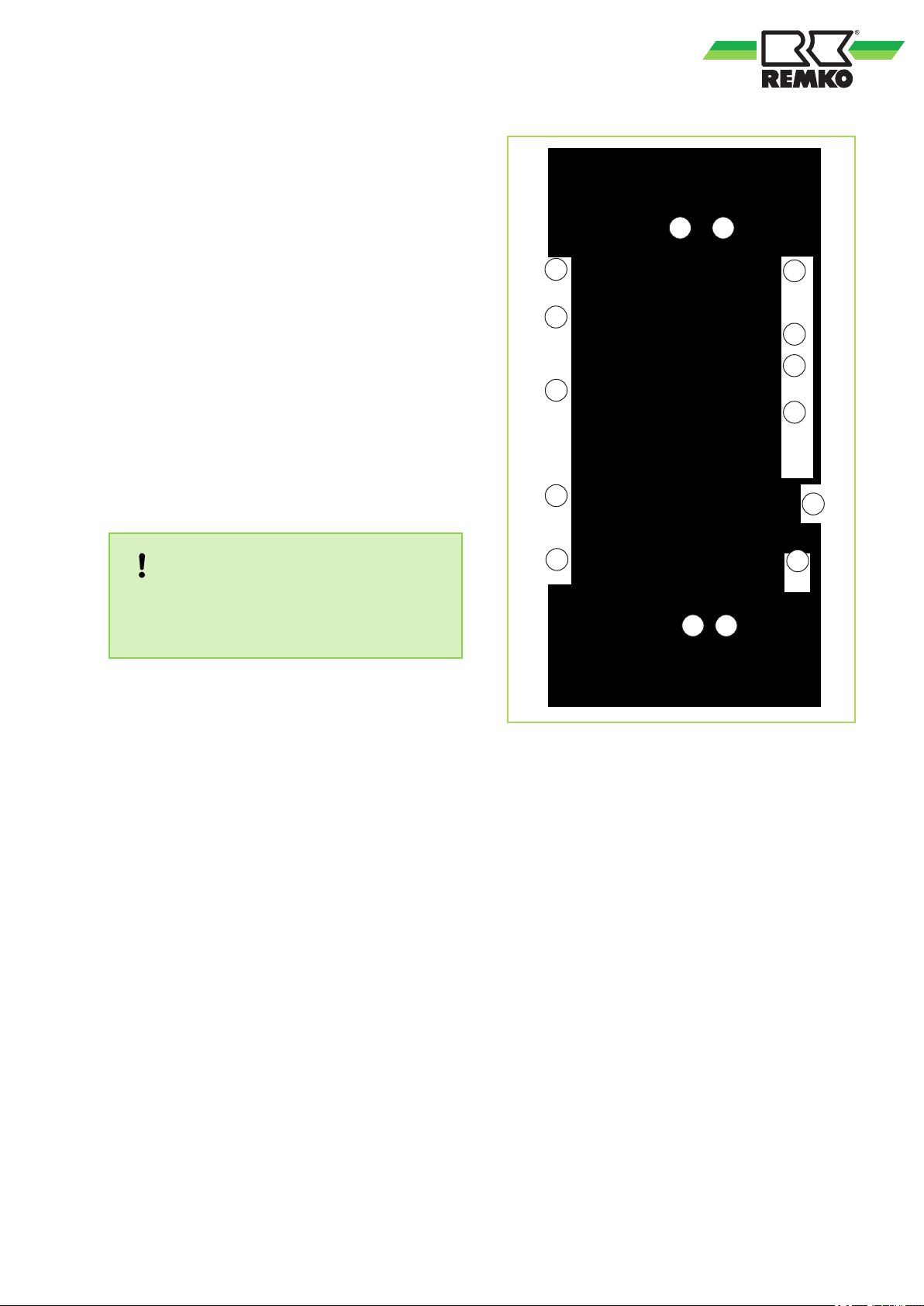

The fresh water station is a pre-installed valve

group that was checked for leak tightness; it is

used to transfer heat between the buffer tank and

the domestic water circuit. It contains a pre-set

controller and important valves for operating the

system:

n Ball valves in the primary circuit

n Piston valves in the secondary circuit

n Safety valve in the secondary circuit

n Pre-installed controller

n Temperature probe on the cold water supply

n Temperature probe on the heating supply

n Ultrasonic flow rate meter on the domestic hot

n Primary pump that can be shut off

n Ball valve for filling/drainage, for bleeding the

Unit description

water outlet

heat exchanger and the pump

NOTICE!

A check for pressure and leak tightness after

successful installation must always be performed before commissioning

Fig. 2: Product description

A: Secondary side: Hot water outlet

B: Primary side: Inlet from the buffer tank

C: Primary side: Return flow to the buffer tank

D: Secondary side: Cold water inlet

1: Piston valve (hot water outlet)

2: Fill/drain valve

3: Safety valve, 10 bar

4: Temperature probe, fast

5: Primary pump

6: Ball valve

7: Ball valve with gravity brake

8: Analogue medium flow rate temperature probe

VFS 2-40

9: Heat exchanger

10: Temperature probe, fast

11: Piston valve (cold water inlet)

9

D

A B C

EFS HGU

RES

M

AB

A

B

A42

REMKO fresh water station

4

4.1

The fresh water station is a fresh water module

that heats domestic water according to the continuous flow heater principle. In order to ensure faultfree operation of the fresh water station, the

system must fulfil certain prerequisites. Before

installation, take some time for planning.

Installation example

The operating mode can be bivalent alternative.

This hydraulic diagram serves merely to assist in planning activities;

the hydraulic system on site must be planned and laid out by the installer!

Subject to technical changes!

Design and planning

General Information

CAUTION!

Danger of scalding due to hot water!

Due to external circulation in the primary circuit, water with a temperature of up to 90 °C

can leak out at the dispensing connection.

– No external pumps are permitted to be

installed between the fresh water module

and the buffer tank.

– The fresh water module is not permitted to

be connected to a heating cycle distributor.

Fig. 3: Fresh water station with optional circulation set and optional return distribution

A: Cold water

B: Hot water

C: Heater heating cycle

D: Circulation

10

4.2

Design of the storage tank

You can use the following table to calculate the approximate required volume of the buffer tank.

Temperature in buffer tank [°C] HW temperature [°C]

50 45 1.5

60

70

80

Sample calculation for the design of the buffer tank:

Temperature of buffer tank: 60 °C, required dispensing medium flow rate at water valve: 20 l/min

DHW temperature set on the controller: 45 °C

How large must the Storage tank be if a 20-minute dispensing operation is to take place without reheating?

20 l/min x 20 min = 400 l

set in controller

45 0.9

50 1.2

55 1.6

45 0.7

50 0.9

55 1.0

45 0.6

50 0.7

55 0.8

Reqd. Storage tank volume per

litre of HW [Litre]

400 l x 0,9 = 360 l ð The heated part of the buffer tank must be 360 litres in size.

The hot water volume depends on the position of the installed S 08 probe (Smart Control hot water

probe). The higher this is installed on the buffer tank, the lower the hot water volume.

11

REMKO fresh water station

5

The fresh water station is (optionally) equipped

with a circulation pump. Three possible operating

modes are stored in the controller to operate the

circulation pump (also see the operating instructions of the controller).

n Pulse-controlled operation (as necessary /

n Time-dependent operation:

n Temperature-dependent operation:

Any of the operating modes can be combined, e.g.

time-dependent and temperature-dependent operation. In this case, circulation is only active if the

temperature falls below the temperature on the circulation temperature probe and the time window is

active. Outside this time window, the circulation

pump can be activated via a dispensing pulse if

pulse-controlled operation is also activated.

Circulation operation

requirement):

Actuating a hot water dispensing connection

for a short time (dispensing impulse: ~2 seconds) starts the circulation pump. The circulation pump then runs for a few minutes (adjustable).

Operation of the circulation pump can be

adjusted on a weekly timer within a freelyselectable period. In this operating mode, circulation begins at the start of the period that is

set. Circulation is deactivated after the set

period expires.

In this operating mode, circulation is only

started if the temperature falls below the minimum temperature that can be set on the circulation temperature probe within the operation

period. Circulation is deactivated after the

adjustable target temperature is reached or

after the set period expires.

NOTICE!

In the delivered state, circulation is not activated (see the operating instructions of the

controller). If the REMKO circulation pump is

installed, the operating mode must be activated

urgently. The speed of the circulation pump

must be specified via the PWM signal. ( Factory setting: 0 % ).

6

If the fresh water station is not installed directly on

the storage tank, note the following points:

1. Determine the installation location of the

2. Transfer the dimensions for the holes to the

3. Drill the holes and insert the enclosed wall

4. Turn the screws into the wall plugs until

5. Remove the front insulation jacket.

Assembly and installation (Specialist)

DANGER!

Danger due to electric shock!

– Remove the power plug before carrying out

electrical work on the controller!

– Plug the power plug of the controller back

in to a socket only after completing all

installation works. In this way, you can prevent the motors from starting up accidentally.

NOTICE!

To avoid damage to the system, the installation

location must be dry, capable of carrying the

load and frost-free.

fresh water module near to the buffer tank.

On the heating side, the pipes must not

exceed a length of 4 m for DN 20.

wall. A corresponding drilling template is provided on the board under the fresh water

module

plugs.

around 40 mm is sticking out of the wall.

12

A

B

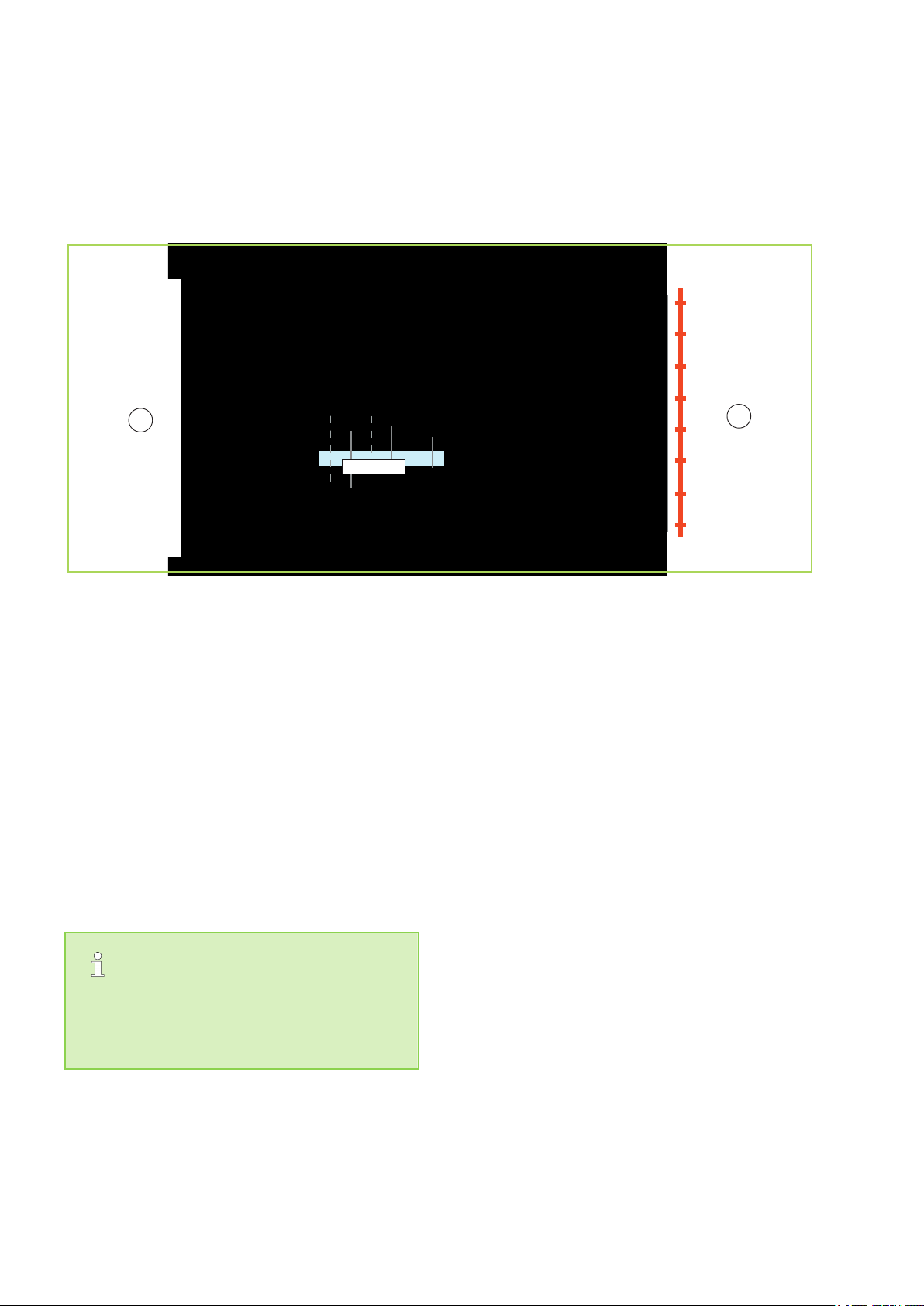

Fig. 4: Distance between the holes

6. Hang the fresh water module onto the

screws. Tighten the screws so that the insulation on the sides is flush to the wall.

7. Connect the pipes of the fresh water module

to the system in accordance with Fig. 5.

1. Secondary side:

Hot water outlet,

Connection ¾" AG, flat-sealing

2. Primary side:

Inlet from buffer tank, ¾" IG,

Piping at least DN 20 22 x 1 mm,

recommended DN 25 28 x 1.5 mm

3. Primary side:

Return flow to buffer tank, ¾" IG,

Piping at least DN 20 22 x 1 mm,

recommended DN 25 28 x 1.5 mm

4. Secondary side:

Cold water inlet,

Connection ¾" AG, flat-sealing

Fig. 5: Piping of the fresh water station

A: Pipe distance from the wall

(secondary) = 107 mm

B: Pipe distance from the wall (primary) = 67 mm

13

B

A

C

0°

45°

90°

14

REMKO fresh water station

7

7.1

NOTE:

Open the valves in the pipes and the fresh water

station slowly, in order to prevent pressure

shocks.

Function of the gravity brake

The primary circuit is equipped with a gravity brake

in the ball valve, in order to prevent undesired

gravity circulation.

The gravity brake must be opened to bleed and

clean the system. To do this, turn the ball valve to

the 45° position. The gravity brake is out of operation.

All ball valves and valves must be opened com-

pletely (0°) in order to operate the system.

Commissioning (specialist)

General Information

7.2

Filling the primary circuit

If the storage tank is (partially) filled

CAUTION!

Danger of scalding due to hot water!

The system is under pressure. By opening the

ball valve for filling/drainage, water of up to 90

°C can leak out of the ball valve for filling/

drainage, which may cause bodily injury.

– Open the ball valve for filling/drainage

slowly and from a safe distance.

1. Open the ball valve (F) by turning it to the 0°

position.

2. Fill the storage tank using the filling valves

provided by the customer until you reach an

operating pressure of 1.5 bar*. Use the

heating water in accordance with VDI 2035 /

ÖNorm H5195-1.

3. Connect a hose to the ball valve for filling/

drainage (B). Carefully actuate the ball valve

for filling/drainage (B) and allow the air to

bleed out.

4. Connect the ball valve for filling/drainage (B).

5. Close the ball valve (F) by turning it to the

90° position.

6. Open the ball valve (G) slowly by turning it to

the 45° position.

7. Carefully actuate the ball valve for filling/

drainage (B) and allow the air to bleed out.

8. Connect the ball valve for filling/drainage (B).

9. After bleeding, check the operating pressure

of the storage tank and increase it if necessary.

10. Open the ball valves (F) and (G) completely

by turning them to the 0° position.

Fig. 6: Setting the gravity brake

A: 0° position - Gravity brake in Operation, only

flowing in flow direction.

B: 45° position - Gravity brake out of Operation,

flowing in both directions.

C: 90° position - Ball valve closed, no flow.

1.5 bar in the primary circuit = recommended

minimum value.

The system pressures that depend on the design

and the components of the heating system are

also crucial for the pressure

14

B

AL

F

G

7.3

Commissioning the controller

DANGER!

Danger due to electric shock!

Check whether the probes and pumps to the

controller are connected and whether the controller housing is closed. Only then should you

insert the power plug into the socket.

1. Remove the controller's front panel (see the

controller instructions).

2. In the selection menu of the controller, select

manual operation ("H1"). Switch the PWM

signal of the pump on ("100 %").

3. Allow the pump to run for a few minutes in

order to bleed the FriwaMini.

4. If you continue to hear air noises after this,

connect a hose to the ball valve for filling/

drainage (B). Carefully actuate the ball valve

for filling/drainage (B) while the pump is still

running and allow the air to bleed out.

5. If you no longer hear any air noises, switch

the pump off. To do this, select manual operation ("H1") in the selection menu of the controller.

6. Set the pump to automatic operation ("A").

7. Slowly open the piston valves on the secon-

dary side (A and L).

8. Open a domestic hot water dispensing connection (e.g. water valve) with a flow of at

least 10 l per minute and allow the water to

run for around 2 minutes, in order to bleed

the secondary circuit. Then close all dispensing connections in the secondary circuit.

9. Use the pre-assembled power supply cable

to connect the fresh water station to the

mains (230 V, 50 Hz).

10. Ensure that the fresh water station is correctly included in the equipotential bonding of

the system.

11. Set the required domestic hot water temperature on the controller (see the following

page).

12. The fresh water station is now ready for operation.

Fig. 7: Commissioning the controller

15

B

[kW]

Friwa EFS 25

0

10

20

30

40

50

60

A

[l/min]

0

20

40

60

80

100

120

140

REMKO fresh water station

7.4

Maximum dispensing medium flow rate

The following diagram shows the maximum dispensing medium flow rate depending on the storage tank

temperature; this assumes a pre-set hot water temperature of 45 °C at the dispensing connection. The integrated controller prevents the temperature from decreasing as long as the maximum medium flow rate is not

exceeded.

Fig. 8: Maximum dispensing medium flow rate

A: Dispensing medium flow rate [l/min]

B: Power [kW]

Boundary conditions:

Cold water temperature: 10 °C,

Maximum pressure loss on the domestic water

side of the fresh water station: 1000 mbar

The following examples explain the relationships

between the individual variables of the hot water

temperature, the dispensing medium flow rate and

the buffer tank temperature, and show how these

affect the transmission capacity of the fresh water

station.

The hot water temperature that is set in the

Smart Control controller (S 08 probe) is the reference temperature for the buffer tank. Factory

setting: 45 °C.

Example 1

Hot water temperature at the dispensing connection: 45 °C

Temperature in the buffer tank: 50 °C

ð Maximum dispensing medium flow rate: 18 l/

min, transmission capacity: 44 kW

Example 2

Hot water temperature at the dispensing connection: 45 °C

Maximum dispensing medium flow rate: 25 l/min

ð Temperature in the buffer tank: 60 °C, transmis-

sion capacity: 62 kW

16

The following diagram shows the maximum dispensing medium flow rate if the hot water temperature is 45

A

B

[l/min]

[kW]

Friwa EFS 25

°C at the dispensing connection, after being mixed with cold water with a temperature of 10 °C. The hot

water temperature set on the controller is 60 °C.

Fig. 9: Maximum dispensing medium flow rate

A: Dispensing medium flow rate [l/min]

B: Power [kW]

Boundary conditions:

Cold water temperature: 10 °C,

Example 1

Hot water temperature on the controller: 60 °C

Temperature in the buffer tank: 70 °C

ð Maximum dispensing medium flow rate: 31 l/

min, transmission capacity: 74 kW

Example 2

Hot water temperature on the controller: 60 °C

Maximum dispensing medium flow rate: 25 l/min

ð Temperature in the buffer tank: ~65 °C, trans-

mission capacity: 60 kW

17

REMKO fresh water station

7.5

Setting the Temperature

Set the required (maximum) domestic hot water temperature on the controller under "Para".

To ensure that scalding cannot occur at the water valve, the maximum hot water temperature must not

exceed 60 °C.

Primary side

The temperature required in the buffer tank on the primary side depends on the desired hot water temperature and the required dispensing quantity. The temperature in the buffer tank must be at least 5 K above the

required hot water temperature.

Secondary side

The possible dispensing medium flow rate [l/min] on the water valve depends on the hot water temperature

that is set in the controller and the temperature that is available in the storage tank.

The recommended maximum domestic water medium flow rate through the fresh water module is 25 l/min.

The following table shows the relationship between the storage tank temperature and the maximum dis-

pensing medium flow rate that is connected when the temperature on the valve is 45°C (e.g. single-lever

mixer). If the hot water temperature that is set on the Controller is higher than 45 °C, the dispensing medium

flow rate consists of a mixture of hot and cold water.

The transmission capacity that is specified for this is required to warm the water quantity of the dispensing

medium flow rate [l/min] from 10 °C to 45 °C.

Temperature in

buffer tank probe

S08

[°C]

HW temperature

set on the con-

troller

[°C]

Maximum medium

flow rate from the

fresh water sta-

tion with the set

HW temperature

[l/min]

Maximum dis-

pensing medium

flow rate at the

water valve for an

HW Temperature

of 45 °C

[l/min]

Transmission

capacity of the

fresh water sta-

tion

[kW]

50 45 18 18 44

45 30 30 73

60

70

80

Reheating is not considered if the cold water temperature is 10 °C

50 23 27 64

55 17 22 52

45 38* 38 92

50 33 37 91

55 27 34 84

60 22 31 74

45 38* 38 92

50 38* 43 105

55 35 45 109

60 30 42 102

* maximum medium flow rate: 25 l/min, pressure

loss of the fresh water station is 1000 mbar in this

case (higher values are possible in a limited way

hydraulically).

18

7.6

Commissioning report

System operator

System location

Serial numbers

REMKO EFS25

- Medium flow rate probes

- Controller

- Software version

Primary piping Ø = mm l = m

Secondary piping Ø = mm l = m

Other installations

Are both circuits cleaned and bled properly? (no air noises in the pump)

Are all shut-off valves in the cold water supply opened?

Circulation set

q

Miscellaneous:

q

Return distribution set

q

Bled

q

Opened

q

Is pressure of at least 1.5 bar present on the primary side?

Is pressure of at least 2.5 bar present on the secondary side?

Is an error message shown on the display?

Installation operation

8

After each retroactive structural modification to the

primary side (e.g. installing a dirt separator, a dirt

trap or a mixing valve), you must start a new commissioning procedure in the controller to ensure

optimum regulation.

You should also carry out commissioning again

after adjusting the mixing valve temperature.

A specialist must check that the safety valve is

functioning correctly when commissioning and at

least once per year.

Maintenance

Checked

q

Checked

q

No message

q

Date, Signature

19

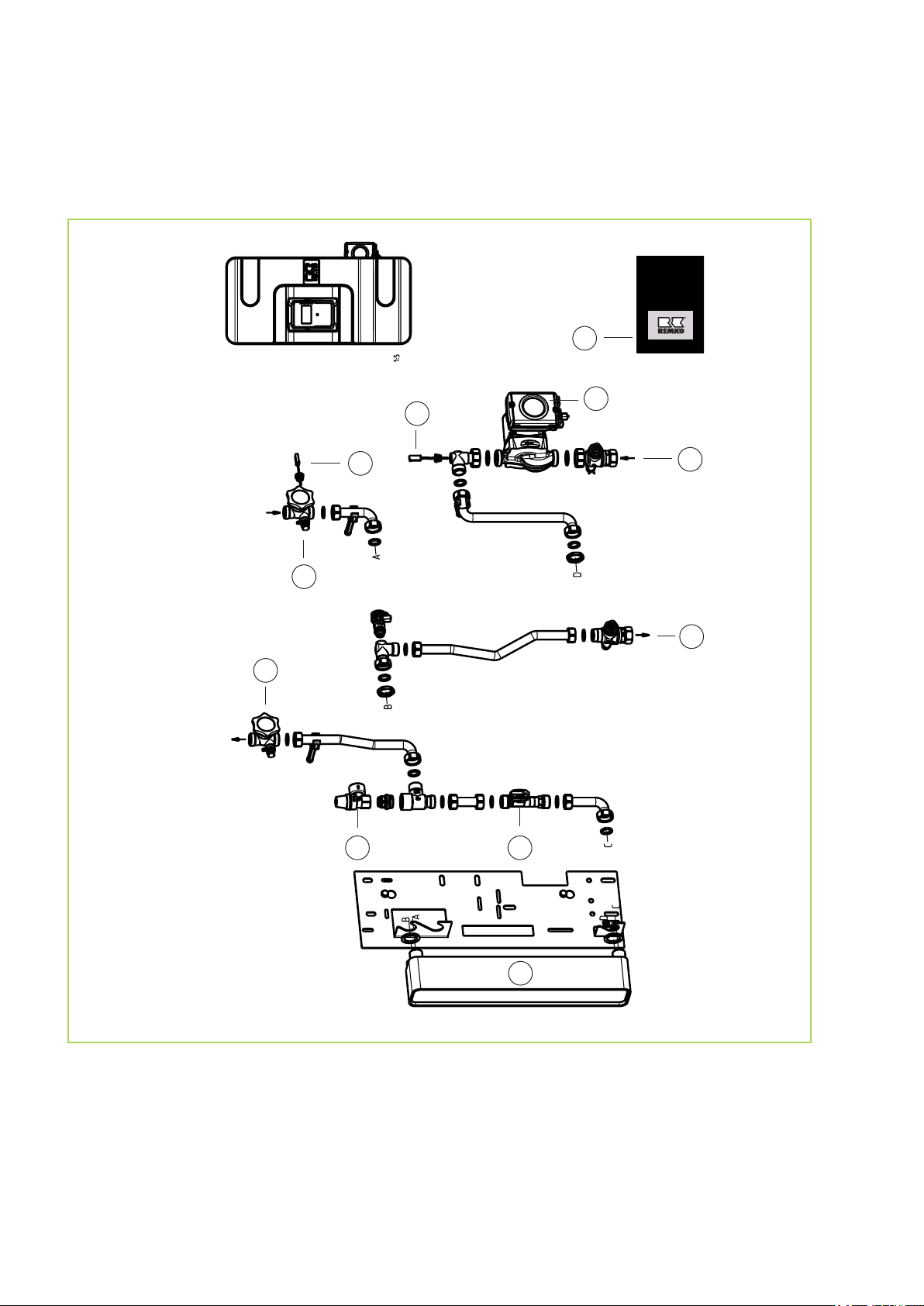

2

3

7

1

3

4

7

4

5

6

8

REMKO fresh water station

9

Depiction of spare parts EFS 25

Depiction of spare parts (specialist)

Fig. 10: Spare parts EFS 25

We reserve the right to modify the dimensions and design as part of the ongoing

technical development process

When ordering spare parts, please always state the EDP no., unit number and unit type (see name plate)!

20

Spare parts list EFS 25

2

1

A

No. Description EFS 25

1 Controller 260156-9

2 Grundfoss circulation pump UPM 2-15/75 CIL 2 260155-2

3 Screw-in probe 15 mm G 1/4 260155-3

4 Piston valve DN 15 260155-6

5 Safety valve (1/2" x 3/4") 10 bar 260155-5

6 Medium flow rate probe (analogue) 260155-1

7 Thermo ball valve DN 20 (3/4") 260155-4

8 Plate heat exchanger 260155-8

When ordering spare parts, please always state the EDP number, unit number and unit type

(see name plate)!

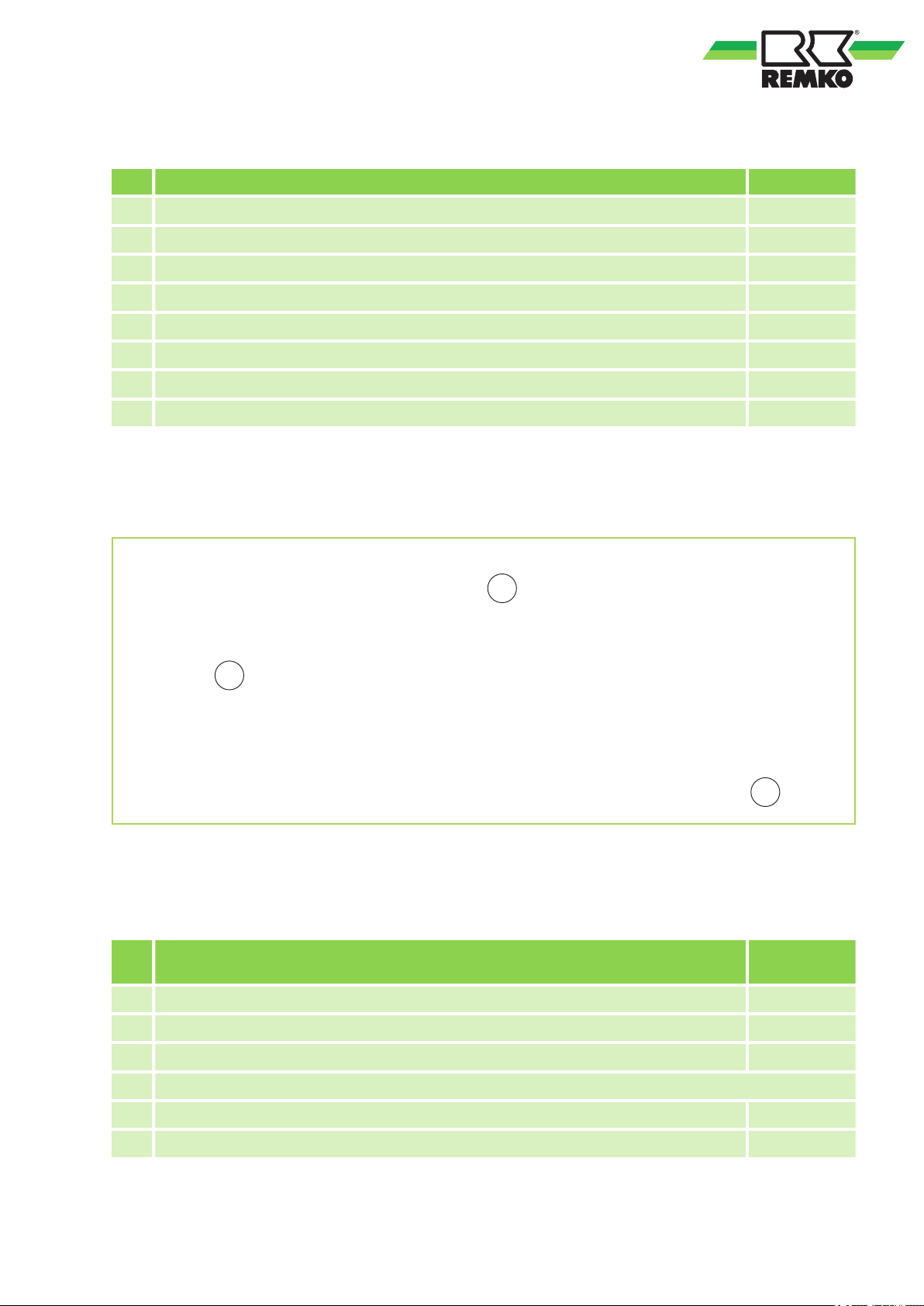

Depiction of circulation pump spare parts

Fig. 11: Circulation pump spare parts

Circulation pump spare parts list

No. Description Circulation

pump

A Circulation pump (complete with pipe assembly) 259052

1 Circulation pump 260155-9

2 Piston valve 260155-6

Spare parts not illustrated

Control cable 260155-10

Powerline cable 260155-11

When ordering spare parts, please always state the EDP number, unit number and unit type

(see name plate)!

21

REMKO fresh water station

10

C

Circulation operation.......................................... 12

Commissioning the controller............................. 15

Controller, commissioning ................................. 15

D

Design of the storage tank................................. 11

Dimensions.......................................................... 8

Dispensing medium flow rate, maximum .......... 16

E

Environmental protection..................................... 6

Equipment............................................................ 8

F

Filling the primary circuit.................................... 14

Function of the gravity brake.............................. 14

G

Gravity brake, function ...................................... 14

I

Intended use........................................................ 6

M

Maintenance...................................................... 19

Materials.............................................................. 8

Maximum dispensing medium flow rate............. 16

O

Operating data..................................................... 8

Ordering spare parts.......................................... 21

P

Packaging, disposal............................................. 6

Pipe connections.................................................. 8

Index

Pressure loss characteristic curve....................... 8

R

Recycling............................................................. 6

S

Safety

Dangers of failure to observe the safety

notes............................................................... 4

General........................................................... 4

Identification of notes...................................... 4

Instructions for the operator............................ 5

Note for inspection work................................. 5

Note for installation work

Personnel qualifications.................................. 4

Safety-conscious working........................... 4, 6

Unauthorised modification ............................. 5

Unauthorised replacement part manufacture.. 5

Set the temperature .......................................... 18

Setting the Temperature.................................... 18

Spare parts........................................................ 20

Storage tank, design.......................................... 11

U

Unit disposal........................................................ 6

W

Warranty.............................................................. 6

................................. 5

22

Consulting

Thanks to intensive training,

our consultants are always

completely up-to-date in terms

of technical knowledge. This has

given us the reputation of being

more than just an excellent,

reliable supplier:

REMKO, a partner

helping you find solutions to

your problems.

Distribution

REMKO offers not just a well

established sales network both

nationally and internationally, but

also has exceptionally highlyqualified sales specialists.

REMKO field staff are more than

just sales representatives: above

all, they must act as advisers to

our customers in air conditioning

and heating technology.

SFlbCustomer Service

Our equipment operates

precisely and reliably. However,

in the event of a fault, REMKO

customer service is quickly at

the scene. Our comprehensive

network of experienced dealers

always guarantees quick and

reliable service.

REMKO INTERNATIONAL

… and also right in your neighbourhood!

Make use of our experience and advice

We reserve the right to make technical changes, and provide no guarantee as to the accuracy of this data!

REMKO GmbH & Co. KG

Air conditioning and heating technology

Im Seelenkamp 12 D-32791 Lage

Postfach 1827 D-32777 Lage

Telephone +49 5232 606-0

Telefax +49 52 32 606-2 60

E-mail info@remko.de

Website www.remko.de

Loading...

Loading...