Operating and

installation instructions

REMKO remote controls

Easy-Control remote control for heat pumps

EC 1

0242-2019-11 Edition 1, en_GB

Read the instructions prior to performing any task!

Read these operating instructions carefully before commissioning / using this device!

These instructions are an integral part of the system and must

always be kept near or on the device.

Subject to modifications; No liability accepted for errors or misprints!

Translation of the original

Table of contents

1 Safety and usage instructions............................................................................................................. 4

1.1 General safety notes....................................................................................................................... 4

1.2 Identification of notes...................................................................................................................... 4

1.3 Personnel qualifications.................................................................................................................. 4

1.4 Dangers of failure to observe the safety notes................................................................................ 4

1.5 Safety-conscious working............................................................................................................... 4

1.6 Safety notes for the operator........................................................................................................... 5

1.7 Safety notes for installation, maintenance and inspection.............................................................. 5

1.8 Unauthorised modification and changes......................................................................................... 5

1.9 Intended use................................................................................................................................... 5

1.10 Warranty........................................................................................................................................ 5

1.11 Transport and packaging............................................................................................................... 6

1.12 Environmental protection and recycling........................................................................................ 6

2 Technical data........................................................................................................................................ 7

2.1 Unit data.......................................................................................................................................... 7

2.2 Unit dimensions............................................................................................................................... 7

3 Unit description..................................................................................................................................... 8

4

Scope of delivery.................................................................................................................................. 8

5 Operation............................................................................................................................................... 9

6 Electrical wiring................................................................................................................................... 15

7 Installation........................................................................................................................................... 17

8 Addressing the EC1............................................................................................................................ 18

9 Index..................................................................................................................................................... 19

3

REMKO remote controls

1 Safety and

usage instructions

1.1 General safety notes

Carefully read the operating manual before commissioning the units for the first time. It contains

useful tips and notes such as hazard warnings to

prevent personal injury and material damage.

Failure to follow the directions in this manual not

only presents a danger to people, the environment

and the system itself, but will void any claims for

.

liability

Keep this operating manual and the refrigerant

data sheet near to the units.

1.2 Identification of notes

This section provides an overview of all important

safety aspects for proper protection of people and

safe and fault-free operation.The instructions and

safety notes contained within this manual must be

observed in order to prevent accidents, personal

injury and material damage.

Notes attached directly to the units must be

observed in their entirety and be kept in a fully

legible condition.

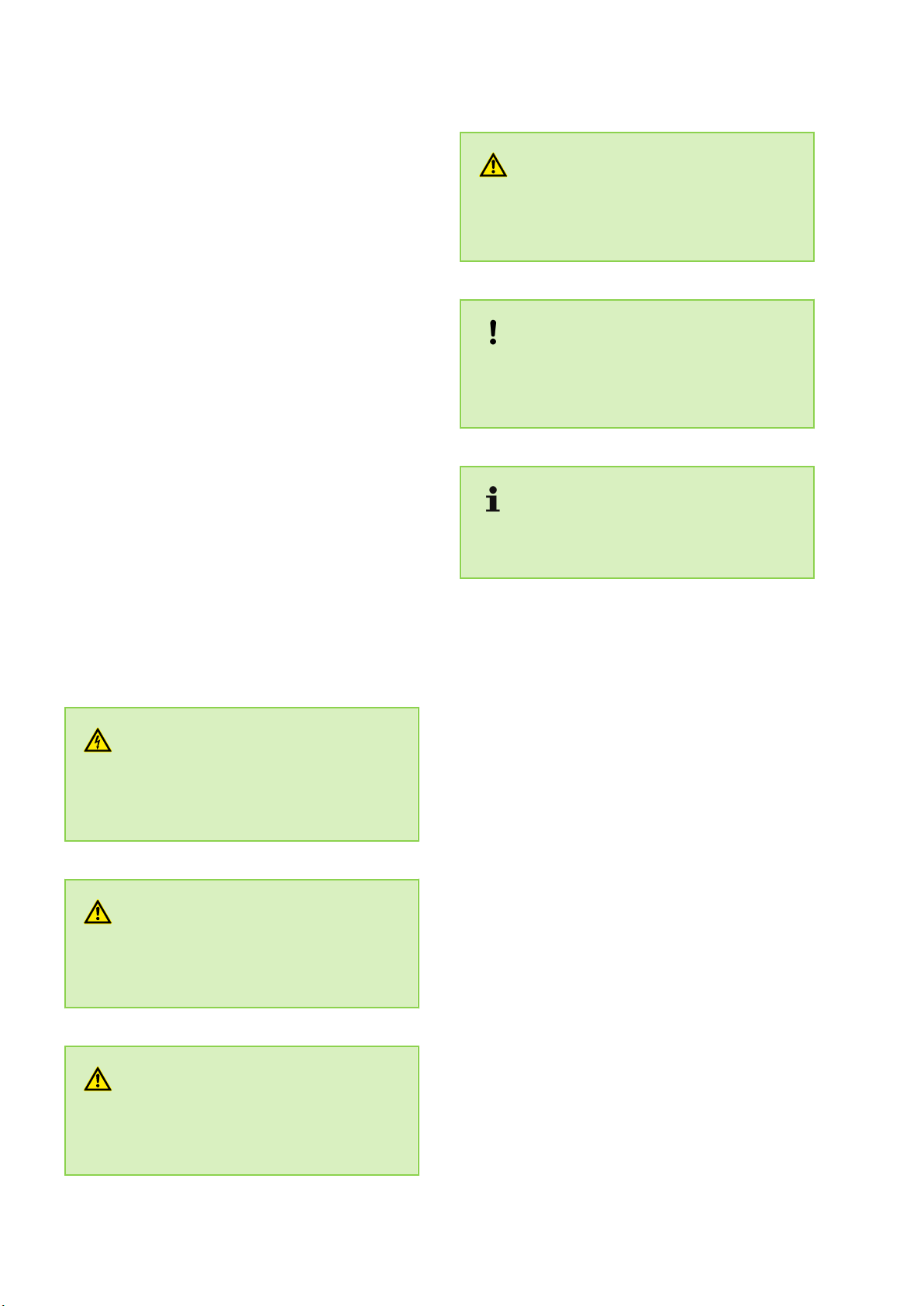

Safety notes in this manual are indicated by symbols. Safety notes are introduced with signal words

which help to highlight the magnitude of the danger

in question.

DANGER!

Contact with live parts poses an immediate

danger of death due to electric shock. Damage

to the insulation or individual components may

pose a danger of death.

DANGER!

This combination of symbol and signal word

warns of a situation in which there is immediate

danger

cause serious injury.

, which if not avoided may be fatal or

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause injury or material and environmental damage.

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause material and

environmental damage.

This symbol highlights useful tips and recommendations as well as information for efficient

and fault-free operation.

1.3 Personnel qualifications

Personnel responsible for commissioning, operation, maintenance, inspection and installation must

be able to demonstrate that they hold a qualification which proves their ability to undertake the

work.

1.4

Failure to observe the safety notes may pose a risk

to people, the environment and the units. Failure to

observe the safety notes may void any claims for

damages.

In particular, failure to observe the safety notes

may pose the following risks:

n The failure of important unit functions.

n The failure of prescribed methods of mainte-

n Danger to people on account of electrical and

CAUTION!

NOTICE!

Dangers of failure to observe the safety notes

nance and repair

mechanical effects.

.

WARNING!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may be fatal or cause

serious injury

.

1.5 Safety-conscious working

The safety notes contained in this manual, the

existing national regulations concerning accident

prevention as well as any internal company

working, operating and safety regulations must be

observed.

4

1.6 Safety notes for the operator

The operational safety of the units and components is only assured providing they are used as

intended and in a fully assembled state.

n The units and components may only be set up,

installed and maintained by qualified personnel.

n Protective covers (grille) over moving parts

must not be removed from units that are in

operation.

n Do not operate units or components with

obvious defects or signs of damage.

n Contact with certain unit parts or components

may lead to burns or injury

n The units and components must not be

exposed to any mechanical load, extreme

levels of humidity or extreme temperature.

n Spaces in which refrigerant can leak sufficient

to load and vent. Otherwise there is danger of

suffocation.

n All housing parts and device openings, e.g. air

inlets and outlets, must be free from foreign

objects, fluids or gases.

n The units must be inspected by a service tech-

nician at least once annually. Visual inspections and cleaning may be performed by the

operator when the units are disconnected from

the mains.

.

1.7 Safety notes for installation, maintenance and inspection

n The units and components must be kept at an

adequate distance from flammable, explosive,

combustible, abrasive and dirty areas or

atmospheres.

n Safety devices must not be altered or

bypassed.

Unauthorised modification

1.8

and changes

Modifications or changes to units and components

are not permitted and may cause malfunctions.

Safety devices may not be modified or bypassed.

Original replacement parts and accessories

authorised by the manufactured ensure safety

use of other parts may invalidate liability for

resulting consequences.

. The

1.9 Intended use

The units are designed depending on the model

and equipment exclusively as a control unit for the

heat pump and the heating system.

Any different or additional use shall be classed as

non-intended use. The manufacturer/supplier

assumes no liability for damages arising from such

use. The user bears the sole risk in such cases.

Intended use also includes working in accordance

with the operating and installation instructions and

complying with the maintenance requirements.

Under no circumstances should the threshold

values specified in the technical data be exceeded.

n Appropriate hazard prevention measures must

be taken to prevent risks to people when performing installation, repair

cleaning work on the units.

n The setup, connection and operation of the

units and its components must be undertaken

in accordance with the usage and operating

conditions stipulated in this manual and comply

with all applicable regional regulations.

n Local regulations and laws such as Water

Ecology Act must be observed.

n The power supply should be adapted to the

requirements of the units.

n Units may only be mounted at the points pro-

vided for this purpose at the factory. The units

may only be secured or mounted on stable

structures, walls or floors.

n Mobile units must be set up securely on suit-

able surfaces and in an upright position. Stationary units must be permanently installed for

operation.

n The units and components should not be oper-

ated in areas where there is a heightened risk

of damage. Observe the minimum clearances.

, maintenance or

1.10 Warranty

For warranty claims to be considered, it is essential

that the ordering party or its representative complete and return the "certificate of warranty" to

REMKO GmbH & Co. KG at the time when the

units are purchased and commissioned.

The warranty conditions are detailed in the "General business and delivery conditions". Furthermore, only the parties to a contract can conclude

special agreements beyond these conditions. In

this case, contact your contractual partner in the

first instance.

5

REMKO remote controls

1.11 Transport and packaging

The devices are supplied in a sturdy shipping container or inside the heat pump casing. Please

check the equipment immediately upon delivery

and note any damage or missing parts on the

delivery and inform the shipper and your contractual partner

anteed.

Plastic films and bags etc. are dangerous

toys for children!

Why:

- Leave packaging material are not around.

- Packaging material may not be accessible to

children!

. For later complaints can not be guar-

WARNING!

1.12 Environmental protection and recycling

Disposal of packaging

All products are packed for transport in environmentally friendly materials. Make a valuable contribution to reducing waste and sustaining raw materials. Only dispose of packaging at approved

collection points.

Disposal of equipment and components

Only recyclable materials are used in the manufacture of the devices and components. Help protect

the environment by ensuring that the devices or

components (for example batteries) are not disposed in household waste, but only in accordance

with local regulations and in an environmentally

safe manner

cling specialists or at collection points.

, e.g. using certified firms and recy-

6

2 Technical data

60 (±2)

86

86

50

14

14

24

50

90

50

90

A

B

C

2.1 Unit data

Series Easy-Control EC1

Power supply V/Hz 230 AC, 50

Current load (heating cycle pump) A 3

Probe NTC3950, l0K

Accuracy °C/F ± 0.5/± 1

Set the temperature °C 5-35

Temperature display °C 5-99

Ambient temperature °C 0-45

Humidity (non-condensing) % rel. hum. 5-95

Storage temperature °C 5-45

Current consumption W < 1.5

Timing error % < 1

Housing PC +ABS (fire-resistant)

Suitable flush-mounted socket mm

Wire clips

mm

2

86 x 86 square or European 60 mm

round box

Wire 2 x 1.5 or 1 x 2.5

Enclosure class IP30

Keys Capacitive touch keys

We reserve the right to make technical changes for the purpose of technical advancement.

Unit dimensions

2.2

Fig. 1: Dimensions (all measurements in mm)

A: Front view

B: Side view

7

C: Rear view

REMKO remote controls

3 Unit description

The Easy-Control remote control EC 1 is a touch

display with an integrated room probe. Operation is

intuitive and self-explanatory due to its clear

arrangement. For example, to enter the desired

room temperature it is only necessary to touch the

“up/down” arrow keys. The anti-freeze protection

function or an absence program can also be set.

Using the room probe it is possible to realise room

temperature-guided regulation in the heating and

cooling mode. The installation is suitable for a

standard flush-mounted socket. Communication

with the heat pump takes place via a Modbus protocol.

The controller can be used as a wall-mounted

single-room controller

.

4 Scope of delivery

Description Quantity

Easy-Control EC 1 1

Fastening screws 4

Operating manual 1

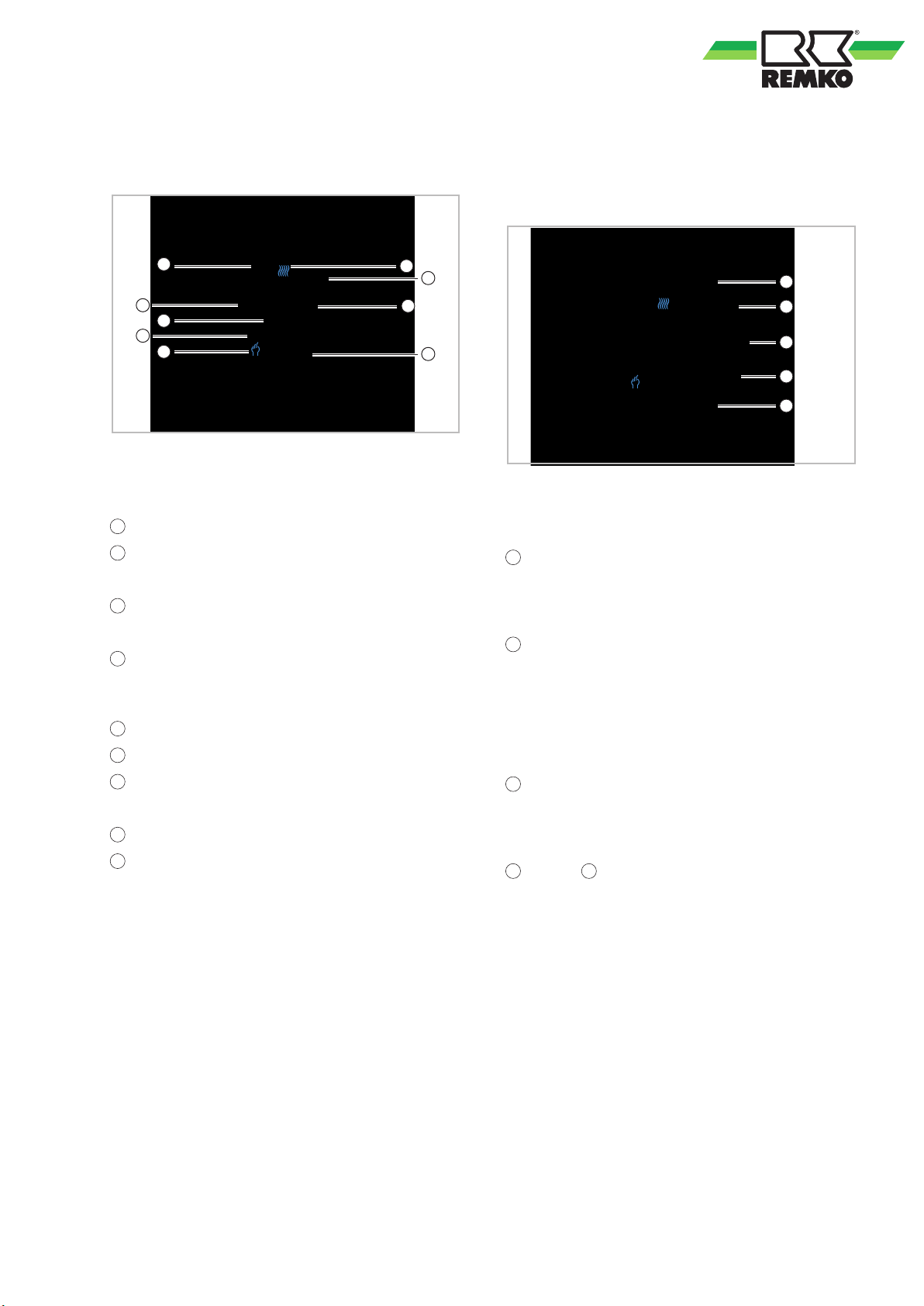

Fig. 2: Controller as wall-mounted single-room controller

8

6

1

2

4

5

8

7

3

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

10

11

12

13

5 Operation

Remote control display

Keys for the remote control settings

Fig. 3: Remote control display

The remote control display is realised through the

corresponding symbols on the touch display

.

Days of the week

Setpoint

Is displayed if the room temperature is set.

Room temperature

Is displayed if the room temperature is displayed.

Automatic mode, time program active

In this case, no time programs of the Smart-Control

T

ouch are active.

Manual mode, no time program

Heating/cooling

Present or absent

It is possible to enter up to 6 heating times per day

.

Room set/actual temperature

ime

T

Fig. 4: Keys on the remote control

The remote control is operated using the relevant

keys on the touch display

.

“On / off” key

Activation of the room temperature regulation. If

the display is switched of

f, anti-freeze protection

mode is active

“M” key

Switching from manual mode to present/absent

mode (time program). The following symbols

appear:

- “Manual” = manual mode

- “Clock” = time program

“Clock” key

Using this key it is possible to select and set the

hours, minutes and days of the week (1-7). To confirm and continue, press the “clock” key.

and the 14 "arrow” keys

T

o set the room temperature touch the “Up/down”

arrow keys [13 and 14]. The “Set” symbol is displayed and the set temperature is displayed. After

the setting is implemented, the display jumps from

“Set” back to the home symbol and the current

room temperature is displayed.

Key lock

To prevent accidental adjustment or access by

unauthorised persons, it is possible to lock the display. Press the “Clock” key [12] and the “Up arrow”

[13] at the same time for 5 seconds. If the key lock

is activated a padlock symbol appears on the right

next to the time.

9

REMKO remote controls

Setting the time and the day of the week

- Press the “Clock” key [12]. The minute display

flashes.

- Set the minutes with the “Up/down” arrows [13

and 14]. Press the “Clock” key [12] to confirm. The

hour display flashes.

- Set the hours with the “Up/down” arrows [13 and

14]. Press the “Clock” key [12] to confirm. The day

of the week flashes at the top of the display

- Set the day with the “Up/down” arrows. Monday

1, Tuesday 2, etc. Press the “M” key [11] to confirm.

Programming Unit

Press

Press

Press

1 x

2 x

3 x

Minutes

Hours

1-7 (Monday-Sunday)

.

Setting the time programs

You have the option of storing six different time

programs in the EC1 per day

When doing so you can perform programming for

days 1-5 (Monday to Friday), and day 6 (Saturday),

as well as day 7 (Sunday) respectively.

It is not possible to program the individual days

(from day 1 to day 5). (Only block programming).

Programming takes place with the key “

arrow keys “ ” and “ ”.

The following times and temperatures are programmed in the factory:

Weekday switching times (Monday - Friday)

Time Temperature

06:00 - 08:00 hrs 20 °C

08:00 - 17:00 hrs 15 °C

17:00 - 22:00 hrs 20 °C

22:00 - 06:00 hrs 15 °C

.

” and the

Weekend switching times (Saturday - Sunday)

Time Temperature

06:00 - 22:00 hrs 20 °C

22:00 - 06:00 hrs 15 °C

10

To set or change the switching times and room temperature, proceed as follows:

Programming Parameter Unit

Press

Press

Press

Block programming day 1-5 (Monday-Friday)

Programming Parameter Unit

Press 4 x

Press 5 x

Press

Press

Press 8 x

Press

Press 10 x

Press

Press 12 x

Press

1 x

2 x

3 x

6 x

7 x

9 x

11 x

13 x

Actual time Minutes

Actual time Hours

Actual day of the week 1-7 (Monday-Sunday)

Switching time 1 time Minutes

Switching time 1 time Hours

Switching time 1 temperature Room target temperature

Switching time 2 time Minutes

Switching time 2 time Hours

Switching time 2 temperature Room target temperature

Switching time 3 time Minutes

Switching time 3 time Hours

Switching time 3 temperature Room target temperature

Switching time 4 time Minutes

Press 14 x

Press

Press

Press 17 x

Press

Press 19 x

Press

Press

If the power to the remote control is switched off, the time must be reset.

The parameter settings are retained.

15 x

16 x

18 x

20 x

21 x

Switching time 4 time Hours

Switching time 4 temperature Room target temperature

Switching time 5 time Minutes

Switching time 5 time Hours

Switching time 5 temperature Room target temperature

Switching time 6 time Minutes

Switching time 6 time Hours

Switching time 6 temperature Room target temperature

11

REMKO remote controls

Programming day 6 (Saturday)

Programming Parameter Unit

Press

Press

Press

Press 25 x

Press

Press 27 x

Press

Press 29 x

Press

Press

Press 32 x

Press

Press 34 x

Press

Press 36 x

Press

22 x

23 x

24 x

26 x

28 x

30 x

31 x

33 x

35 x

37 x

Switching time 1 time Minutes

Switching time 1 time Hours

Switching time 1 temperature Room target temperature

Switching time 2 time Minutes

Switching time 2 time Hours

Switching time 2 temperature Room target temperature

Switching time 3 time Minutes

Switching time 3 time Hours

Switching time 3 temperature Room target temperature

Switching time 4 time Minutes

Switching time 4 time Hours

Switching time 4 temperature Room target temperature

Switching time 5 time Minutes

Switching time 5 time Hours

Switching time 5 temperature Room target temperature

Switching time 6 time Minutes

Press

Press 39 x

If the power to the remote control is switched off, the time must be reset.

The parameter settings are retained.

38 x

Switching time 6 time Hours

Switching time 6 temperature Room target temperature

12

Programming day 7 (Sunday)

Programming Parameter Unit

Press

Press

Press

Press 43 x

Press

Press 45 x

Press

Press 47 x

Press

Press

Press 50 x

Press

Press 52 x

Press

Press 54 x

Press

40 x

41 x

42 x

44 x

46 x

48 x

49 x

51 x

53 x

55 x

Switching time 1 time Minutes

Switching time 1 time Hours

Switching time 1 temperature Room target temperature

Switching time 2 time Minutes

Switching time 2 time Hours

Switching time 2 temperature Room target temperature

Switching time 3 time Minutes

Switching time 3 time Hours

Switching time 3 temperature Room target temperature

Switching time 4 time Minutes

Switching time 4 time Hours

Switching time 4 temperature Room target temperature

Switching time 5 time Minutes

Switching time 5 time Hours

Switching time 5 temperature Room target temperature

Switching time 6 time Minutes

Press

Press 57 x

If the power to the remote control is switched off, the time must be reset.

The parameter settings are retained.

56 x

Switching time 6 time Hours

Switching time 6 temperature Room target temperature

13

REMKO remote controls

Access to the expert level

In order to access the expert level, the Easy-Control remote control must be deactivated with the “

Once the remote control has been deactivated, press the “M" key and “ ” key at the same time for approx.

five seconds.

The expert level is now released and starts with the parameter “1” from the following table.

With the “M” key you can now display the individual parameters in order

Change the parameters using the arrow keys “

Parameter Function Value range Factory setting User settings

1

2 Switching hysteresis "1 °C - 5 °C" "1 °C"

3 Key lock

4 Probe type

Correction of the

room temperature

"-9 °C - + 9 °C "-2 °C"

0: Key lock apart from

1: All keys locked

In: Internal probe of

the remote control

Ex: External probe

AL: Internal and

external probe

” and “ ”.

“on / of

f”

.

1

AL Factory setting

” key.

5 Min. temperature "+5 °C - +15 °C" 5 °C

6 Max. temperature "+15 °C - +45 °C" 35 °C

7 Time 12/24 hrs.

8 Temperature display

9

A

b Display brightness

c BUS address "01 - 99" 1

d Band "01 - 06" 1 Factory setting

After the settings are entered, it is not necessary to save the parameters. The data is accepted automatically.

Max. room set tem-

perature

Min. room set temper-

ature

0: 12 hrs

1: 24 hrs

0: measured room

temperature

1: Room target tem-

perature

"25 °C - 70 °C" 45 °C

"0 °C - 10 °C" 10 °C

Display brightness in

stand-by mode

0 (dark) - 99 (light)

1

0

14

6 Electrical wiring

A 3 / B 3

N EP 42A 52A

Sensor Inputs

DNG 61S

DNG 51S

43A

N EP 22A 3

2A

DNG R

DNG 41S

stuptuO eerF

laitnetoP

33A

3B 3A

DNG 31S

TMS I/O

23A

L N EP

`L N EP

`L N EP

N EP `L 01A

N EP 1A 1 L`

N EP `L 21A

N EP `L 41A

N EP 10A

N

EP 20A

N EP 30A

N EP 40A N EP 02A 1

2

A

rewoP

stuptuO rotautcA

ylppuS rotautcA

stu

ptuO r

ota

utcA

stuptuO rotautcA

DNG V5+ 52S

DNG

V5+ 62S

DNG V5+ 72S

DNG V5+ 82S

DNG V5+ 92S

Akt

u

ator Signa

l

DNG 04A

DNG 14A

DNG 24A

DNG 34A

DNG 44A

DNG 54A

DNG 64A

DNG SSn KLC OM IM

0T1 0T1

0T2 0T2

2B 2A

1B V21+ DNG 1A

14S 04S DNG V5+ 02S

34S 24S DNG V5+ 12S

54S 44S DNG V5+ 2

2S

74S 64S DNG V5+ 32S

94S 84S DNG V5+ 42S

DNG 10S

S

ensor Inputs

DNG 3

0

S

DNG 40S

DNG 5

0S

DNG 60S

DNG 70S

DNG 80S

DNG 90S

DNG 01S

1S DNG 1

DNG 21S

03A 03A

13A

DS

Fuse

54 JR

Sensor

Inputs

Sensor

Inputs

Sensor Inputs

A 3

B 3

230 V / 2~ / 50 Hz

A1

B

1

2

A2

Fasten the remote control to a wall of the reference room.

The remote control must be freely accessible and must not be obstructed, free air circulation must be guaranteed.

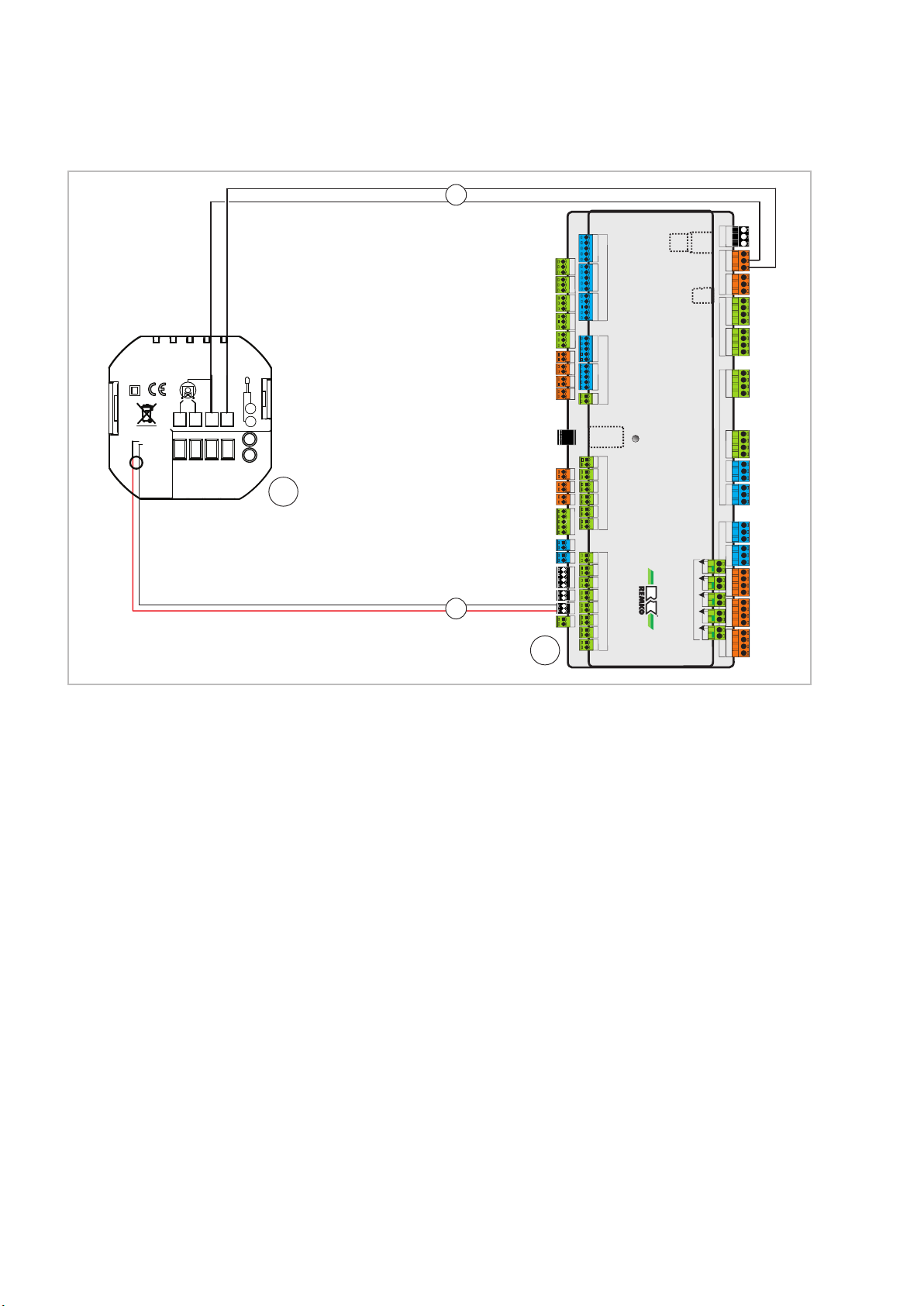

Fig. 5: Installation schematic with two remote controls

A1: Remote control 1 Easy-Control EC1

A2: Remote control 2 Easy-Control EC1

B: I/O module

1: Power supply 230V/2~/50Hz

All electrical installation work must be done by

an electrician.

All electric lines are in accordance VDE regulations to dimension and to lay

15

DANGER!

WARNING!

.

2: Control line Easy-Control A3/B3

(e.g. 2 x 0.75 mm2 screened)

A3 = red

B3 = white

One EC1 remote control is possible per heating

cycle.

B3

A3

N EP 42A 52A

Sensor Inputs

DNG 61S

DNG 51S

43A

N EP 22A 3

2A

DNG R

DNG 41S

stuptuO eerF

laitnetoP

33A

3B

3A

DNG 31S

TMS I/O

23A

L N EP

`L N EP

`L N EP

N EP `L 01A

N EP 1A 1 L`

N EP `L 21A

N EP `L 41A

N EP 10A

N

EP 20A

N EP 30A

N EP 40A

N EP 02A 1

2

A

rewoP

stuptuO rotautcA

ylppuS rotautcA

stu

ptuO r

ota

utcA

stuptuO rotautcA

DNG V5+ 52S

DNG

V5+ 62S

DNG V5+ 72S

DNG V5+ 82S

DNG V5+ 92S

Akt

u

ator Signa

l

DNG 04A

DNG 14A

DNG 24A

DNG 34A

DNG 44A

DNG 54A

DNG 64A

DNG SSn KLC OM IM

0T1 0T1

0T2 0T2

2B 2A

1B V21+ DNG 1A

14S 04S DNG V5+ 02S

34S 24S DNG V5+ 12S

54S 44S DNG V5+ 2

2S

74S 64S DNG V5+ 32S

94S 84S DNG V5+ 42S

DNG 10S

S

ensor Inputs

DNG 3

0

S

DNG 40S

DNG 5

0S

DNG 60S

DNG 70S

DNG 80S

DNG 90S

DNG 01S

1S DNG 1

DNG 21S

03A 03A

13A

DS

Fuse

54 JR

Sensor

Inputs

Sensor

Inputs

Sensor Inputs

A

B

A 3

B 3

2

1

AC 95~240V

IP20

N

L

1

2

3

4

M

Close Open

5

6

NTC

A(RED)

Modbus

B(WHITE)

REMKO remote controls

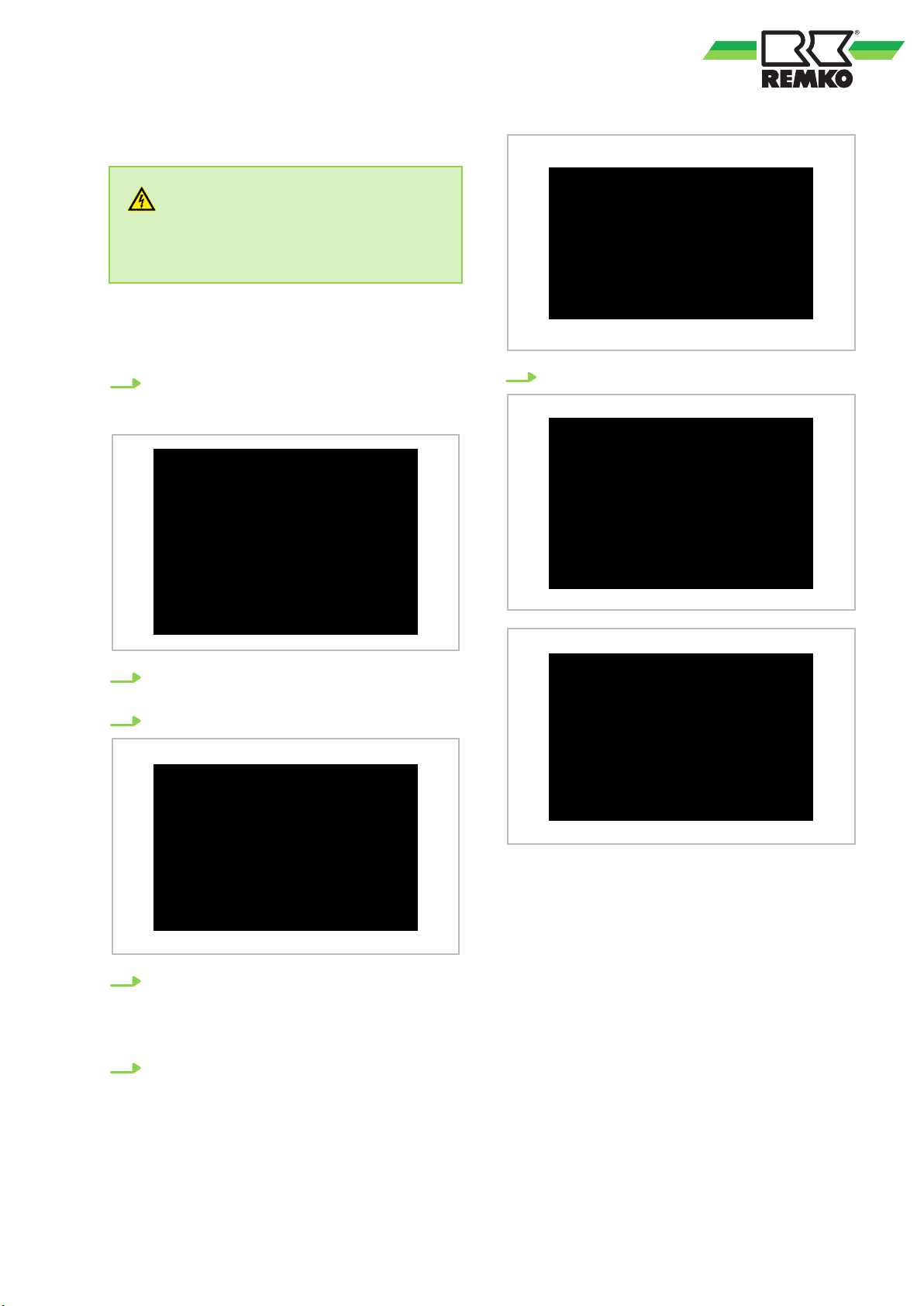

Terminal layout on the Easy-Control

Fig. 6: Terminal layout

A: Remote control Easy-Control EC1

B: I/O module

1: Power supply 230V/2~/50Hz

2: Control line Easy-Control A3/B3

(e.g. 2 x 0.75 mm2 screened)

A3 = red

B3 = white

16

7 Installation

DANGER!

All electrical installation work is to be performed

by specialist companies. Disconnect the power

supply when connecting the electrical terminals.

The thermostat is suitable for a standard flushmounted socket.

Proceed with the installation as follows:

1. For installation, turn the round display clockwise to release the display from the mounting

plate.

6. Mount the display

.

2. Draw the ribbon cable out of the display to

avoid damage.

3. Connect the power supply to terminals 3+4.

4. Connect the 2-core communication cable to

the two cores, white and red.

erminals 1+2 can be used for actuation of a

T

heating cycle pump or valve.

5. Bolt the mounting plate to the flush-mounted

socket with the screws provided.

17

REMKO remote controls

8 Addressing the EC1

A maximum of three probes can be supplied with

mains voltage via the power supply of the REMKO

I/O module. If further remote controls are still to be

installed, they must be supplied with a separate

230 V mains voltage. Each probe, such as a room/

humidity probe or Smart-Control T

control must be assigned its own BUS address.

This address must be stored in the Smart Control

Touch at the corresponding parameter level of the

assigned heating/cooling cycle.

ouch remote

Expert level

¯

Settings

¯

Select heating cycle

¯

For example: unmixed cycle

Parameters in the selected cycle

Operating mode

Heating cycle mode

Fixed value

Heating curve adjustment

Cooling cycle mode

Fixed value

Cooling curve adjustment

Time program A

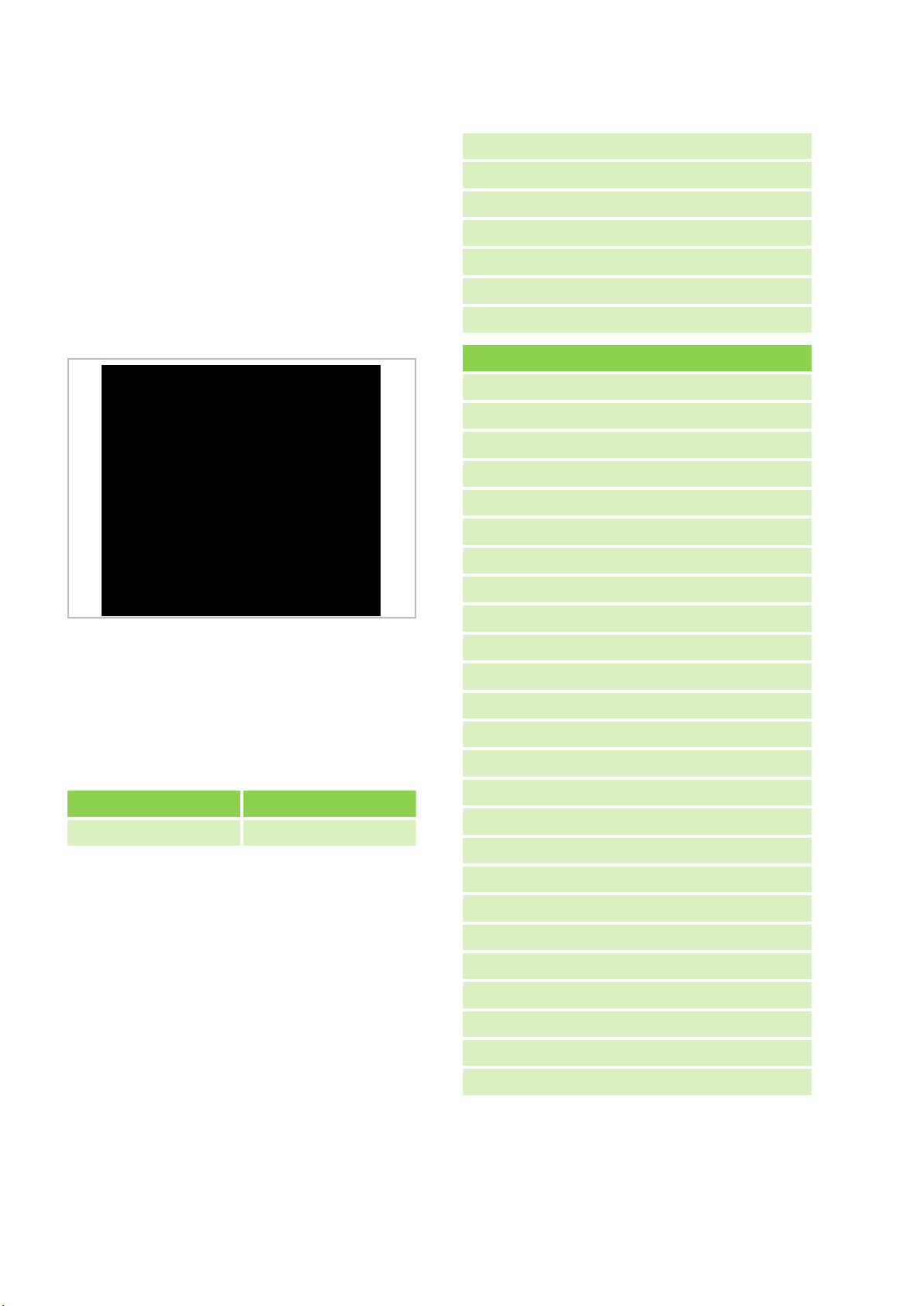

Fig. 7: Setting the BUS address

The BUS address for the Easy-Control room thermostat can be found in the expert level as param-

Ä

eter “c” in chapter

on page 14.

BUS address for room temperature/humidity

probe

Parameter BUS address

c "01 - 99"

For addressing the BUS address of the Easy-Control room thermostat, open the expert level as

described in chapter

on page 14. Under point “c” you can assign a BUS

address for your room thermostats. Make sure that

all components to which you assign an address

are assigned different addresses. If a room/

humidity probe and Easy-Control room thermostat

for example are assigned the same address, this

will result in malfunctions.

After the setting is entered, it is not necessary to

save the parameter. The data is accepted automatically.

‘Access to the expert level’

Ä

‘Access to the expert level’

Time program B

Time program C

Time program function

Room temperature reduction

Room temperature increase

☛ Room unit (OFF) ☚

for example: Easy-Control EC1

BUS address: Easy-Control EC1

Room temperature influence

Dew point monitoring

Dew point distance

Pump type

Min. pump speed A42 (%)

Max. pump speed A42 (%)

Min. pump speed A42 (rpm)

Max. pump speed A42 (rpm)

Pump during cooling

18

9 Index

A

Addressing of the probe .................. 18

Assembly ............................. 15

D

Dimensions ............................. 7

Disposal of equipment .....................6

E

Electrical wiring ......................... 16

Environmental protection ...................6

Expert level ............................ 14

I

Installation ..........................15

Intended use ............................ 5

, 17

O

Operation .............................. 9

R

Remote control display .................... 9

S

Safety

Dangers of failure to observe the safety

notes ............................... 4

General ............................. 4

Identification of notes ................... 4

Notes for inspection .................... 5

Notes for installation ....................5

Notes for maintenance .................. 5

Personnel qualifications ................. 4

Safety notes for the operator ............. 5

Safety-conscious working ................4

Unauthorised modification ...............5

Unauthorised replacement part manufacture

Scope of delivery ........................ 8

Set time programs .......................10

Setting the time programs ................. 10

Settings ................................9

. 5

T

Technical data ........................... 7

Terminal layout ......................... 16

U

Unit data ............................... 7

Unit description .......................... 8

Unit dimensions ......................... 7

W

Warranty ............................... 5

19

REMKO QUALITY WITH SYSTEMS

Air-Conditioning | Heating | New Energies

Telephone +49 (0) 5232 606-0

Telefax +49 (0) 5232 606-260

E-mail info@remko.de

URL www.remko.de

REMKO GmbH & Co. KG

Klima- und Wärmetechnik

Im Seelenkamp 12

32791 Lage

Hotline within Germany

+49 (0) 5232 6 06-0

Hotline International

+49 (0) 5232 606-130

We reserve the right to make technical changes, and provide no guarantee as to the accuracy of this data!

Loading...

Loading...