Page 1

2010

VSX-1020-K

For details, refer to "Important Check Points for good servicing".

AUDIO/VIDEO MULTI-CHANNEL RECEIVER

VSX-1020-K

VSX-1025-K

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

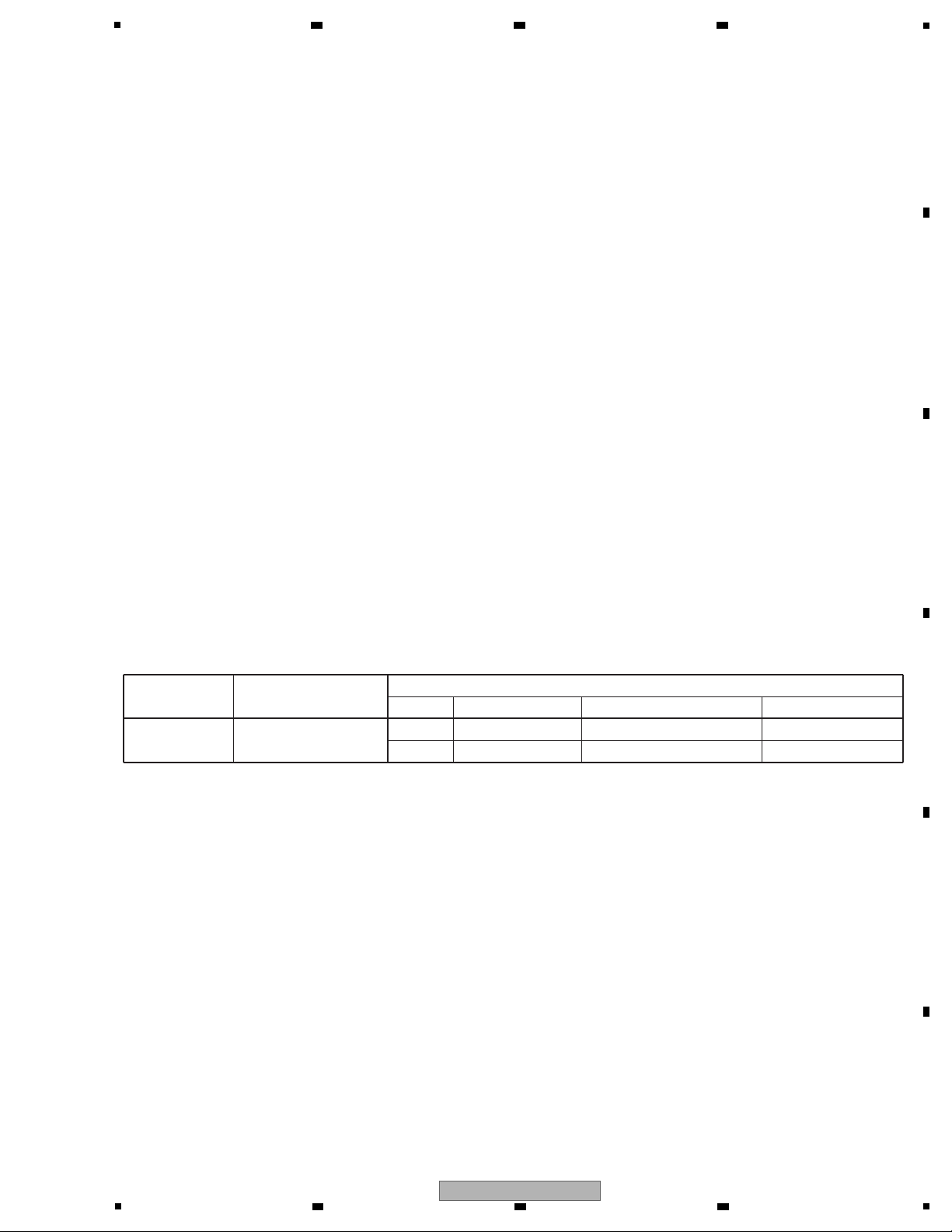

Model Type Power Requirement Remarks

VSX-1020-K UXCNCB AC 120 V

VSX-1025-K CUXCN AC 120 V

ORDER NO.

RRV4045

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-IZK MAR.

2010 Printed in Japan

Page 2

1

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

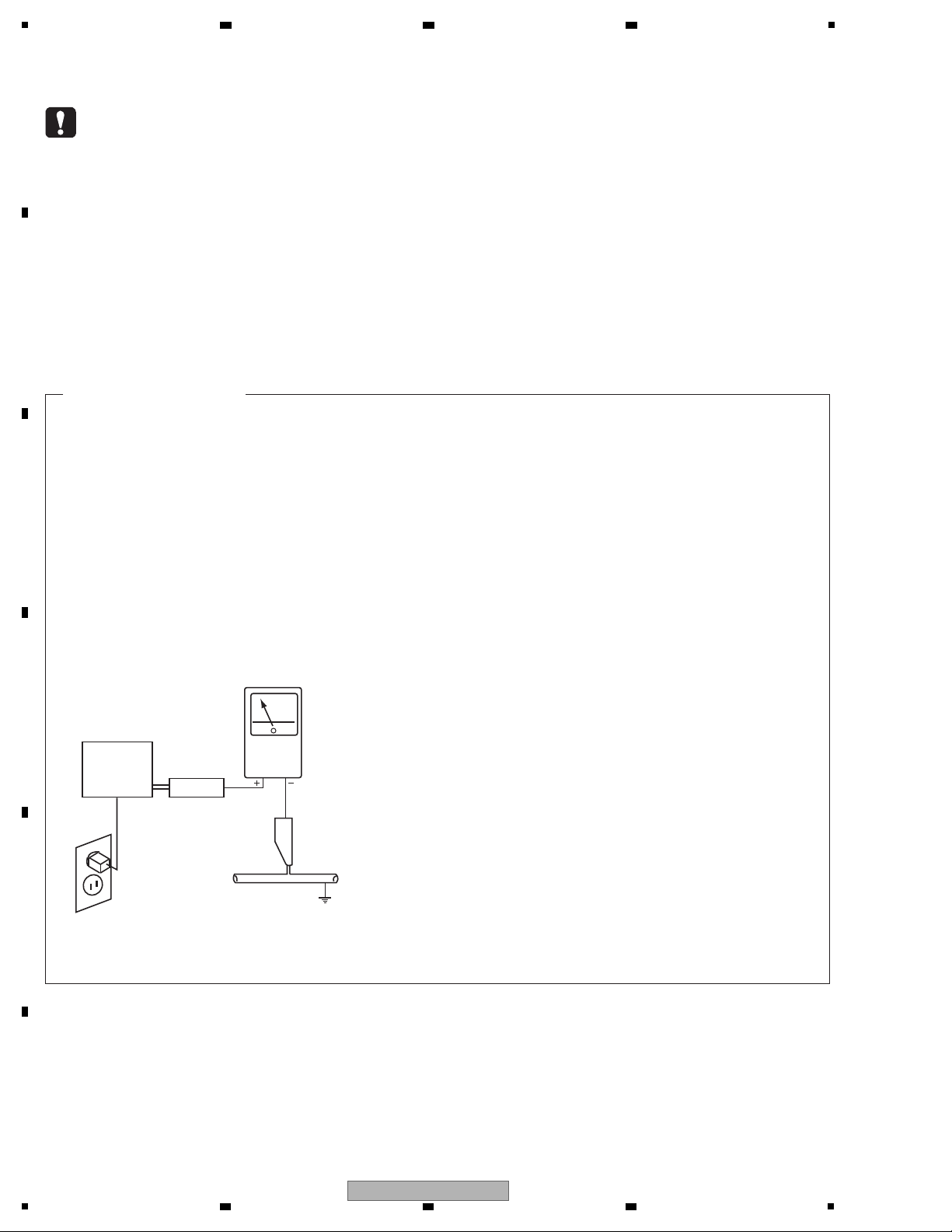

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

(FOR USA MODEL ONLY)

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

VSX-1020-K

Page 3

5

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

6 7 8

A

B

C

D

5

VSX-1020-K

6 7 8

E

F

3

Page 4

1

2 3 4

CONTENTS

SAFETY INFORMATION ..........................................................................................................................................................2

1. SERVICE PRECAUTIONS ....................................................................................................................................................5

A

B

C

D

E

F

1.1 NOTES ON SOLDERING ...............................................................................................................................................5

1.2 NOTES ON REPLACING PARTS ...................................................................................................................................5

1.3 CAUTION ........................................................................................................................................................................5

2. SPECIFICATIONS .................................................................................................................................................................6

2.1 SPECIFICATIONS...........................................................................................................................................................6

2.2 PANEL FACILITIES .........................................................................................................................................................7

3. BASIC ITEMS FOR SERVICE.............................................................................................................................................11

3.1 CHECK POINTS AFTER SERVICING..........................................................................................................................11

3.2 PCB LOCATIONS .........................................................................................................................................................12

3.3 JIGS LIST......................................................................................................................................................................13

4. BLOCK DIAGRAM...............................................................................................................................................................14

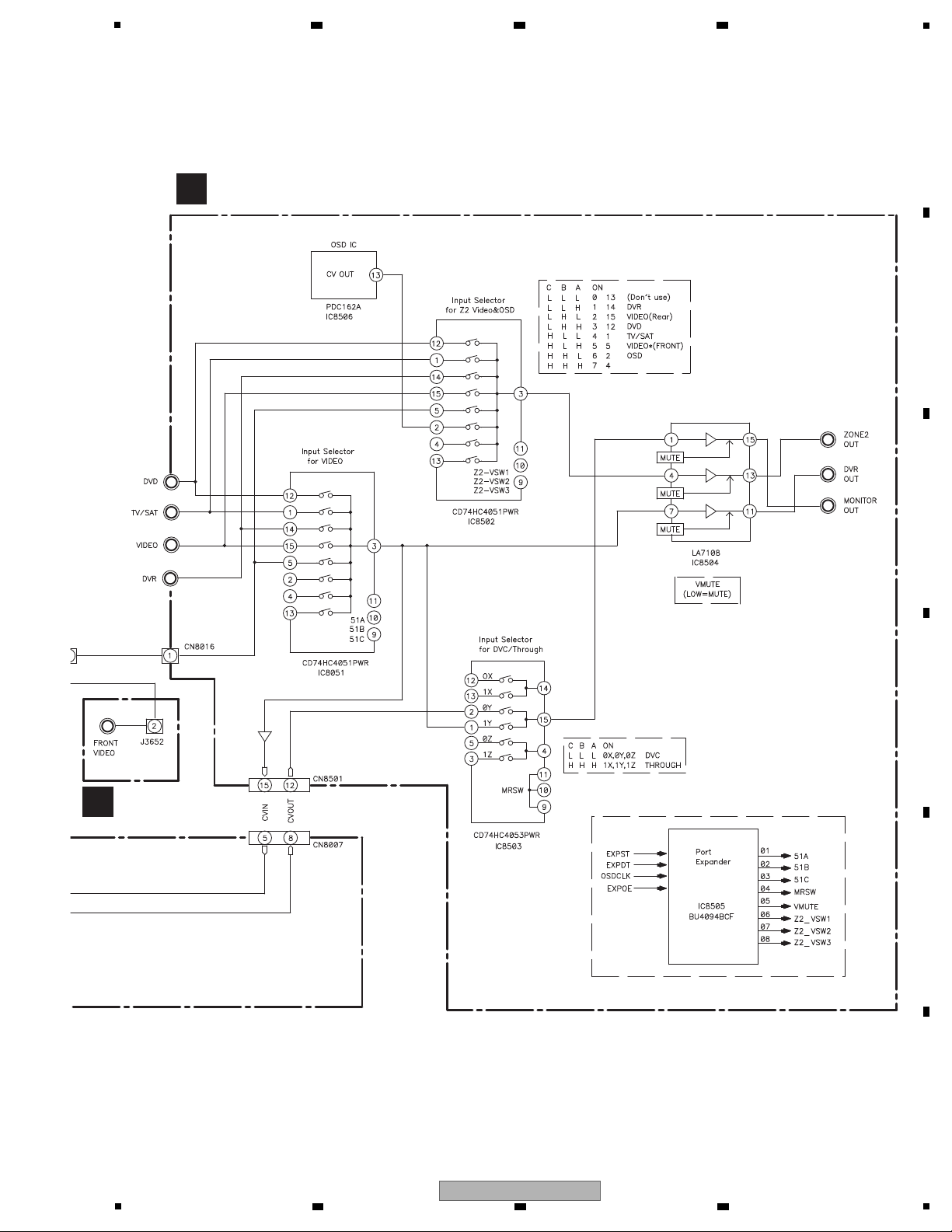

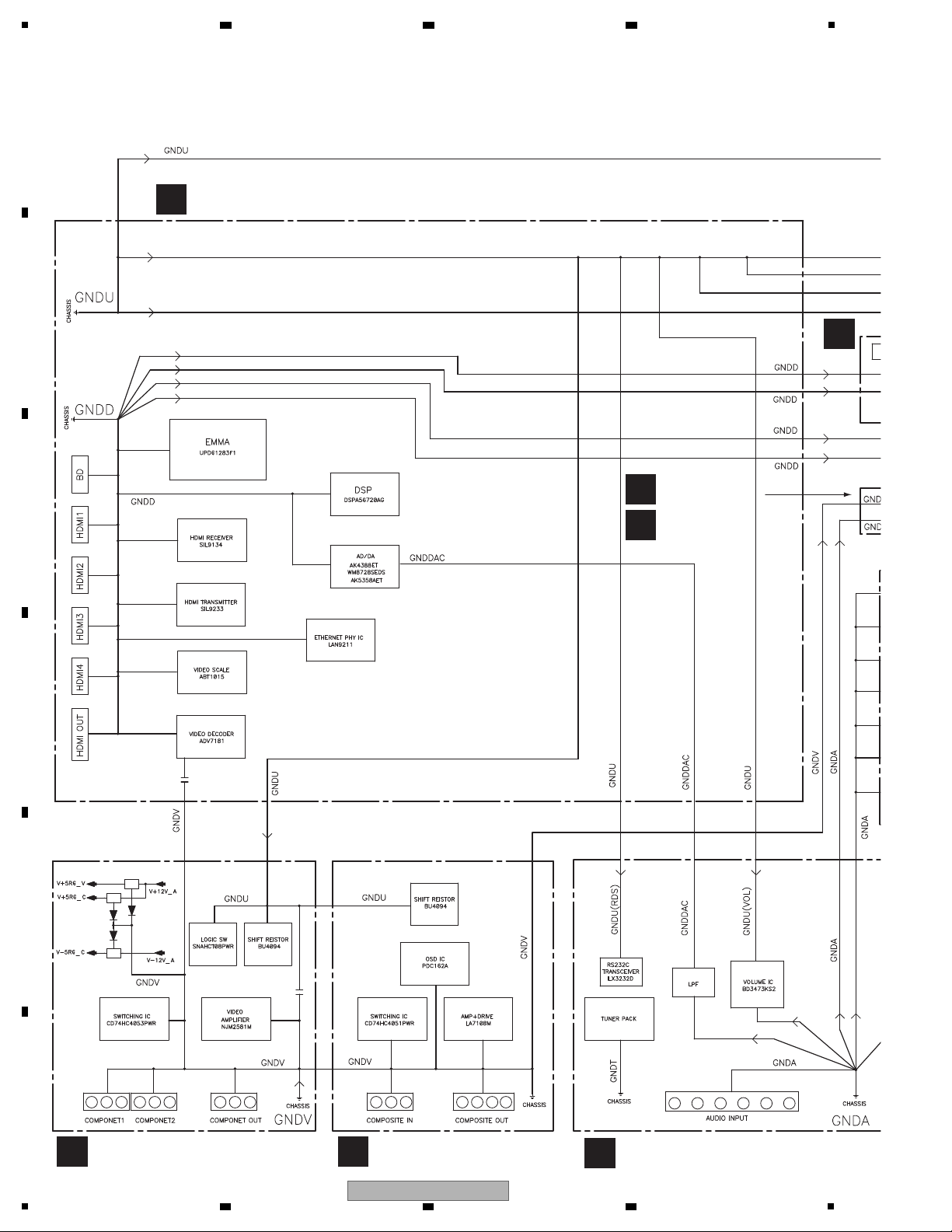

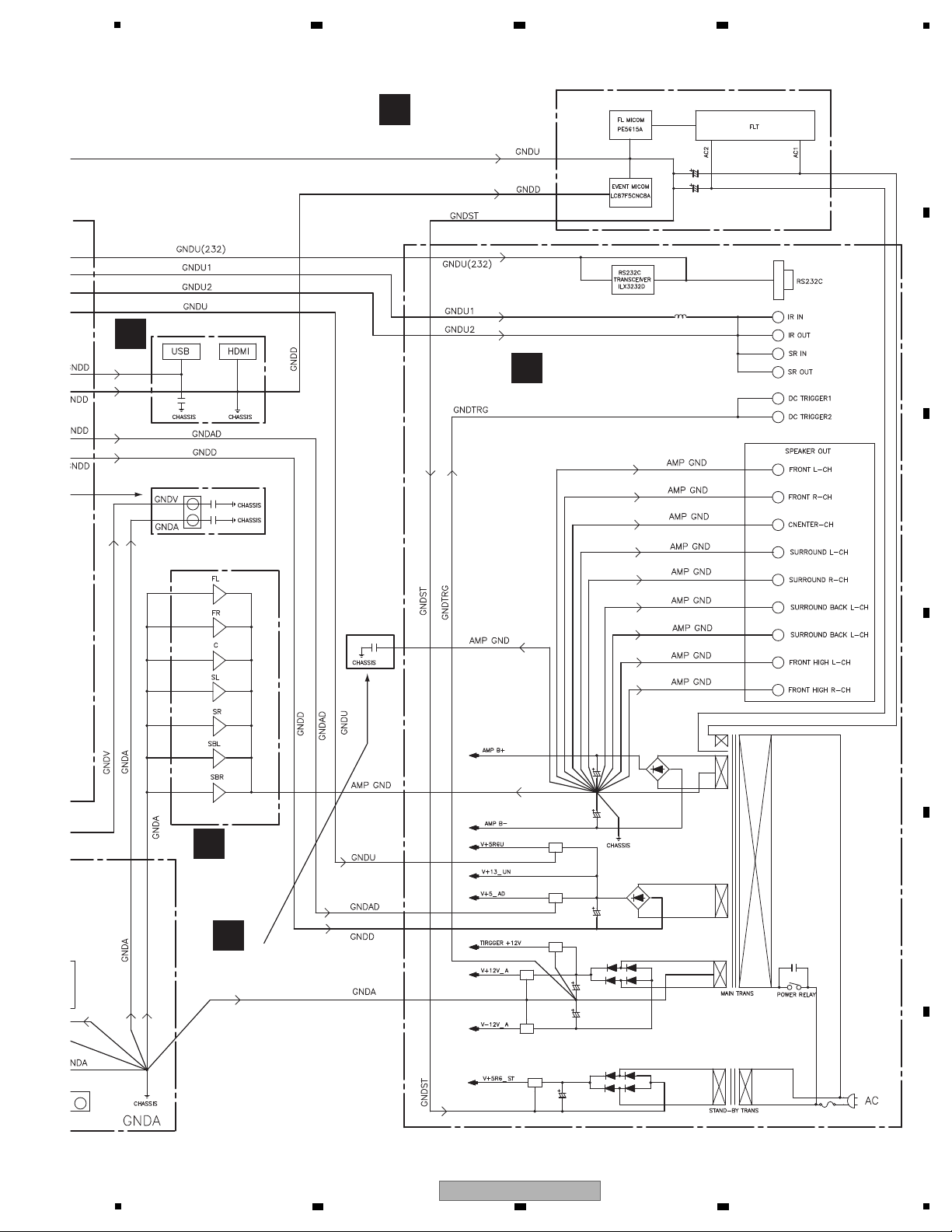

4.1 OVERALL WIRING DIAGRAM......................................................................................................................................14

4.2 DIGITAL AUDIO BLOCK DIAGRAM..............................................................................................................................16

4.3 ANALOG AUDIO BLOCK DIAGRAM ............................................................................................................................18

4.4 DIGITAL VIDEO BLOCK DIAGRAM..............................................................................................................................19

4.5 ANALOG VIDEO BLOCK DIAGRAM ............................................................................................................................20

4.6 GND BLOCK DIAGRAM ...............................................................................................................................................22

5. DIAGNOSIS.........................................................................................................................................................................25

5.1 DIAGNOSIS FLOWCHART...........................................................................................................................................25

5.2 ERROR INDICATIONS..................................................................................................................................................40

6. SERVICE MODE .................................................................................................................................................................41

6.1 TEST MODE .................................................................................................................................................................41

7. DISASSEMBLY ....................................................................................................................................................................43

8. EACH SETTING AND ADJUSTMENT ................................................................................................................................50

8.1 HOW TO UPDATE FIRMWARE ....................................................................................................................................50

8.2 IDLE CURRENT ADJUSTMENT ..................................................................................................................................53

9. EXPLODED VIEWS AND P

ARTS LIST...............................................................................................................................54

9.1 PACKING SECTION......................................................................................................................................................54

9.2 EXTERIOR SECTION...................................................................................................................................................56

10. SCHEMATIC DIAGRAM ....................................................................................................................................................60

10.1 AUDIO ASSY ..............................................................................................................................................................60

10.2 COMPONENT ASSY ..................................................................................................................................................62

10.3 COMPOSITE, MIC, F-VIDEO and BRIDGE2 ASSYS.................................................................................................64

10.4 F-HDMI, USB MTG and HDMI MTG ASSYS ..............................................................................................................66

10.5 AMP ASSY..................................................................................................................................................................68

10.6 DISPLAY, HEADPHONE and POWER SW ASSYS....................................................................................................70

10.7 D-MAIN ASSY (1/12) ..................................................................................................................................................72

10.8 D-MAIN ASSY (2/12) ..................................................................................................................................................78

10.9 D-MAIN ASSY (3/12) ..................................................................................................................................................80

10.10 D-MAIN ASSY (4/12) ................................................................................................................................................82

10.11 D-MAIN ASSY

(5/12) ................................................................................................................................................84

10.12 D-MAIN ASSY (6/12) ................................................................................................................................................86

10.13 D-MAIN ASSY (7/12) ................................................................................................................................................88

10.14 D-MAIN ASSY (8/12) ................................................................................................................................................90

10.15 D-MAIN ASSY (9/12) ................................................................................................................................................92

10.16 D-MAIN ASSY (10/12) ..............................................................................................................................................94

10.17 D-MAIN ASSY (11/12) ..............................................................................................................................................96

10.18 D-MAIN ASSY (12/12) ..............................................................................................................................................98

10.19 MAIN and BRIDGE1 ASSYS ..................................................................................................................................100

11. PCB CONNECTION DIAGRAM ......................................................................................................................................102

11.1 AUDIO ASSY ............................................................................................................................................................102

11.2 COMPONENT ASSY

................................................................................................................................................104

11.3 COMPOSITE, MIC, F-VIDEO and BRIDGE2 ASSYS...............................................................................................106

11.4 F-HDMI, USB MTG and HDMI MTG ASSYS ............................................................................................................108

11.5 AMP ASSY................................................................................................................................................................110

11.6 DISPLAY, HEADPHONE and POWER SW ASSYS..................................................................................................114

11.7 D-MAIN ASSY...........................................................................................................................................................118

11.8 MAIN ASSY...............................................................................................................................................................122

11.9 BRIDGE1, GUIDE3 GIUIDE-L and GUIDE-R ASSYS ..............................................................................................126

12. PCB PARTS LIST ............................................................................................................................................................128

4

1

2 3 4

VSX-1020-K

Page 5

5

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

The part listed below is difficult to replace as a discrete component part.

When the part listed in the table is defective, replace whole Assy.

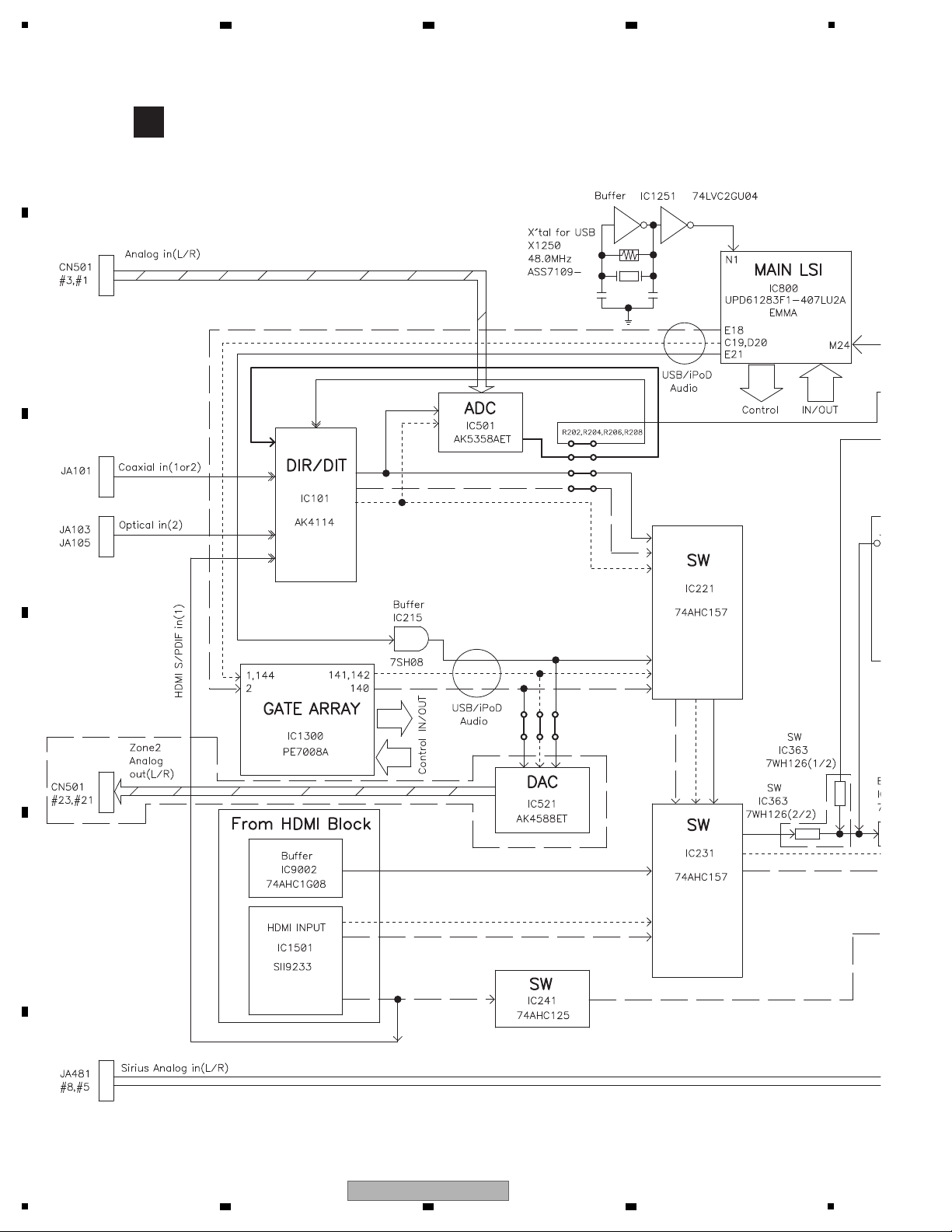

EMMA2RL2 UPD61283F1-407LU2A BGA

IC1501 HDMI Receiver SII9233ACTU IC with heat-pad

Assy Name

D-MAIN Assy

IC800

7028069261010-IL

PCB Assy Part No.

Ref No. Function Part No.

Parts that is Difficult to Replace

Remarks

• Discharging

For more detail, please refer to “7. DISASSEMBLY - 1. Discharging”.

• Notes on Ground Points Connection

For more detail, please refer to “7. DISASSEMBLY - 2. Notes on Ground Points Connection”.

6 7 8

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

1.2 NOTES ON REPLACING PARTS

1.3 CAUTION

C

D

E

F

VSX-1020-K

5

6 7 8

5

Page 6

1

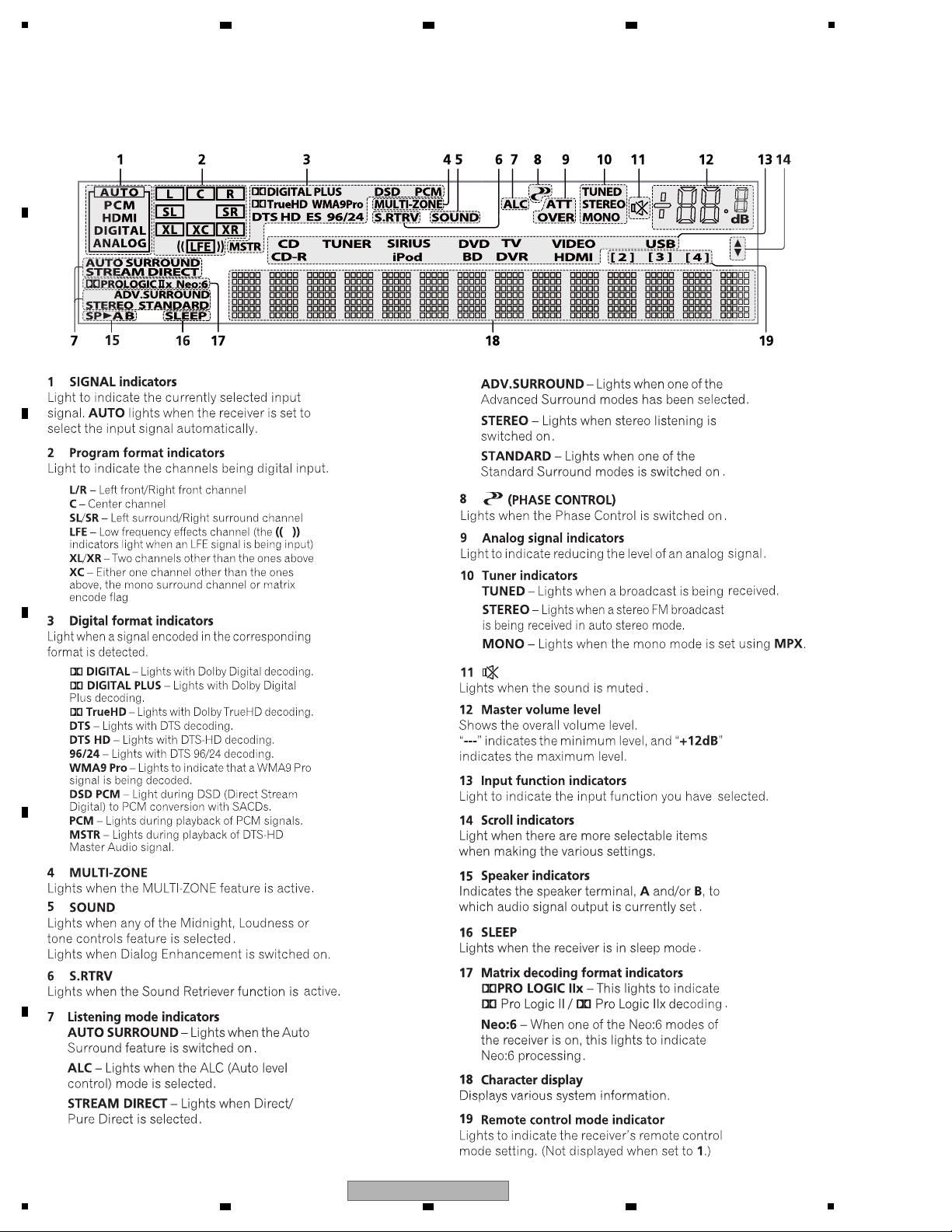

iPod cable

(L308102013010-IL)

Accessories

Remote control

(8300759500010-IL)

AM loop antenna

(ATB7013)

FM wire antenna

(ADH7030)

Dry cell batteries

(AAA size IEC R03) x2

Microphone (for Auto MCACC setup)

(APM7008)

(VSX-1020-K)

(VSX-1025-K)

2. SPECIFICATIONS

2.1 SPECIFICATIONS

A

B

2 3 4

C

D

E

F

6

1

2 3 4

VSX-1020-K

Page 7

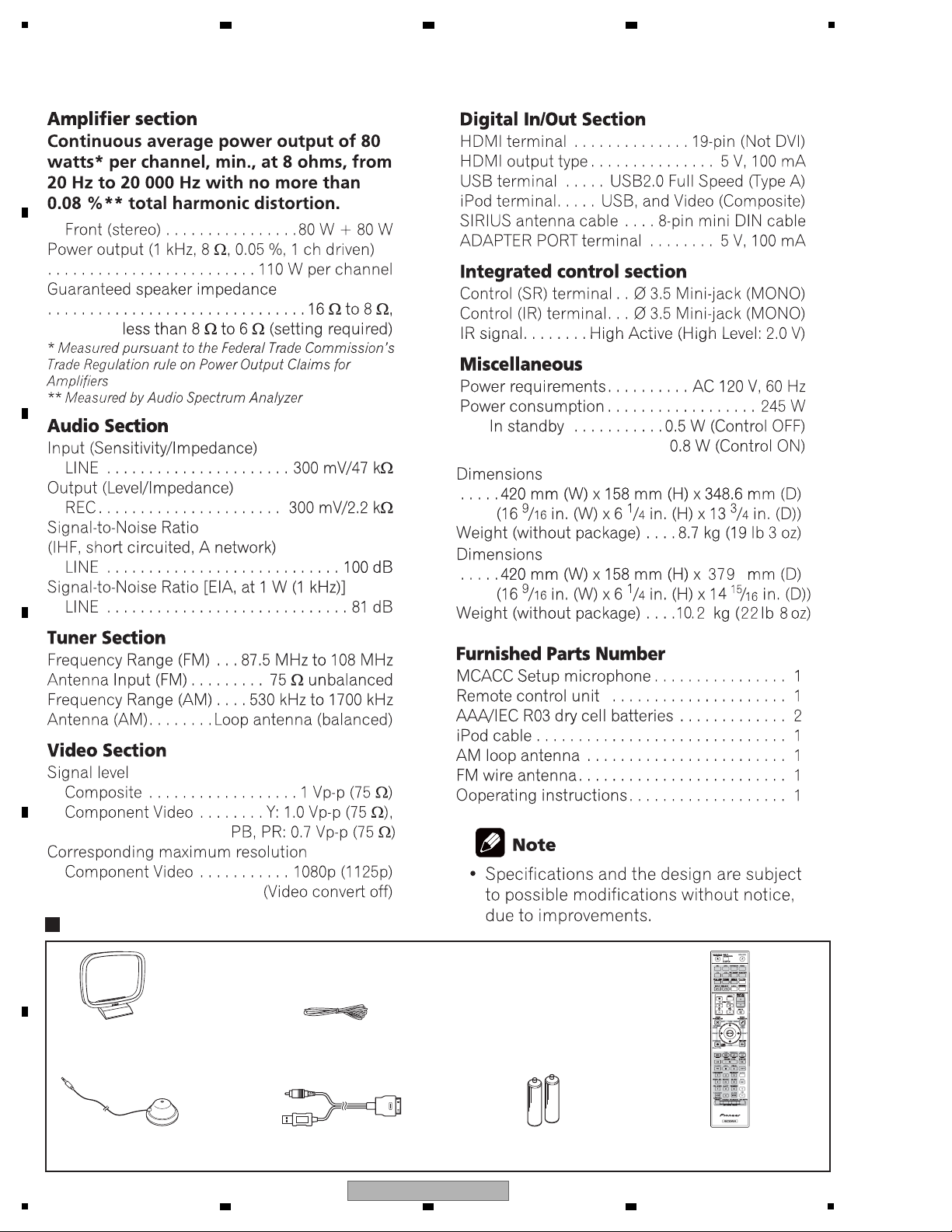

Front panel

5

2.2 PANEL FACILITIES

6 7 8

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

7

Page 8

A

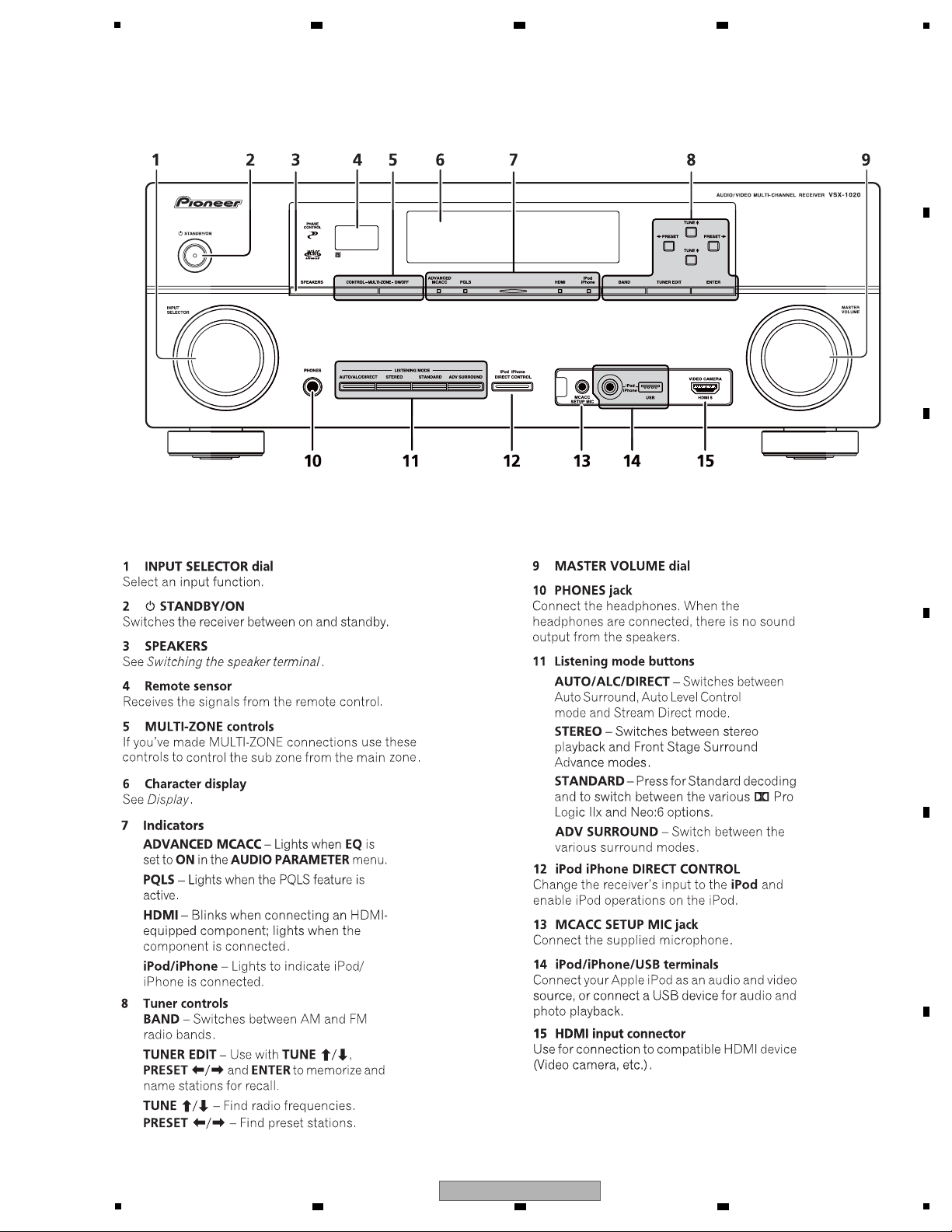

Display

B

1

2 3 4

C

D

E

F

8

1

2 3 4

VSX-1020-K

Page 9

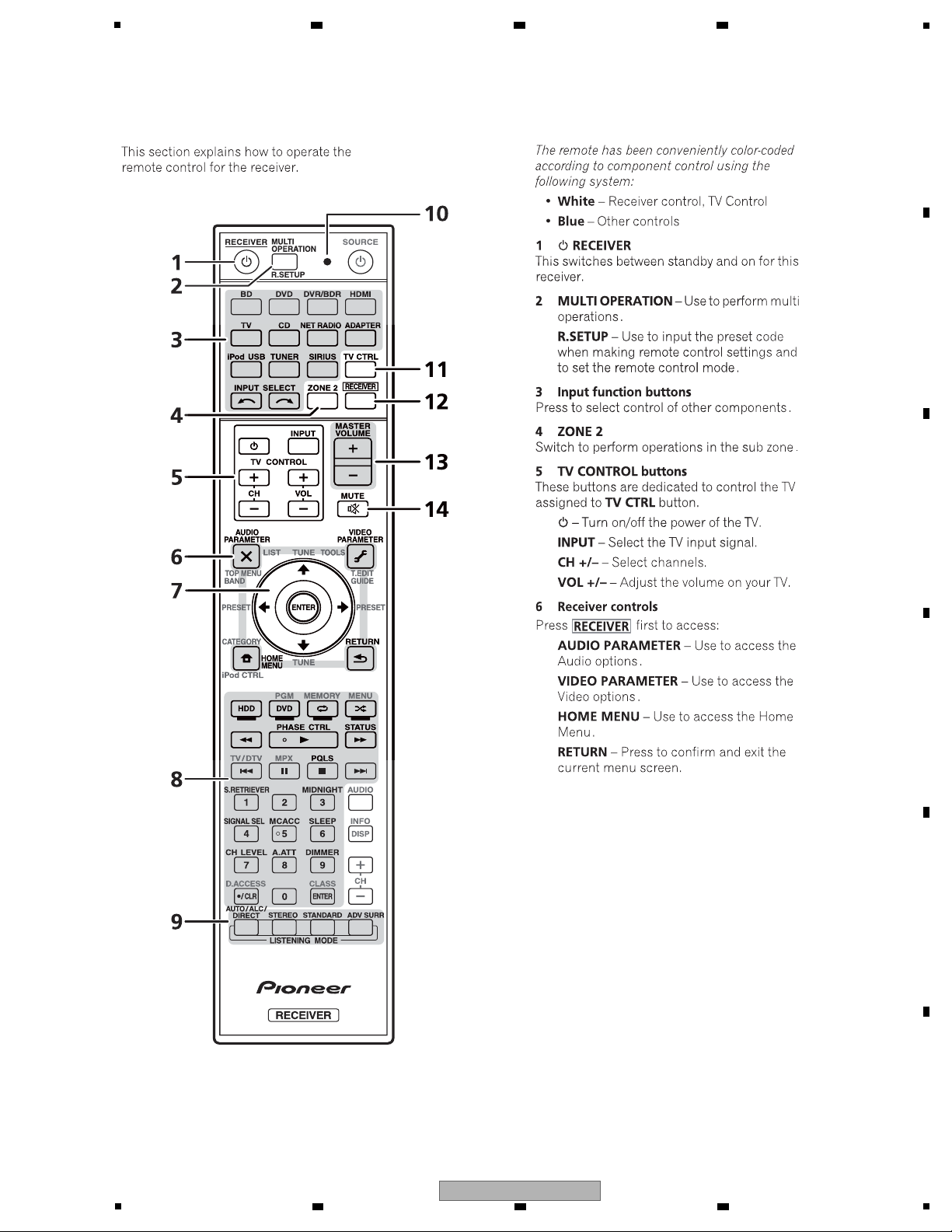

Remote control

5

6 7 8

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

9

Page 10

1

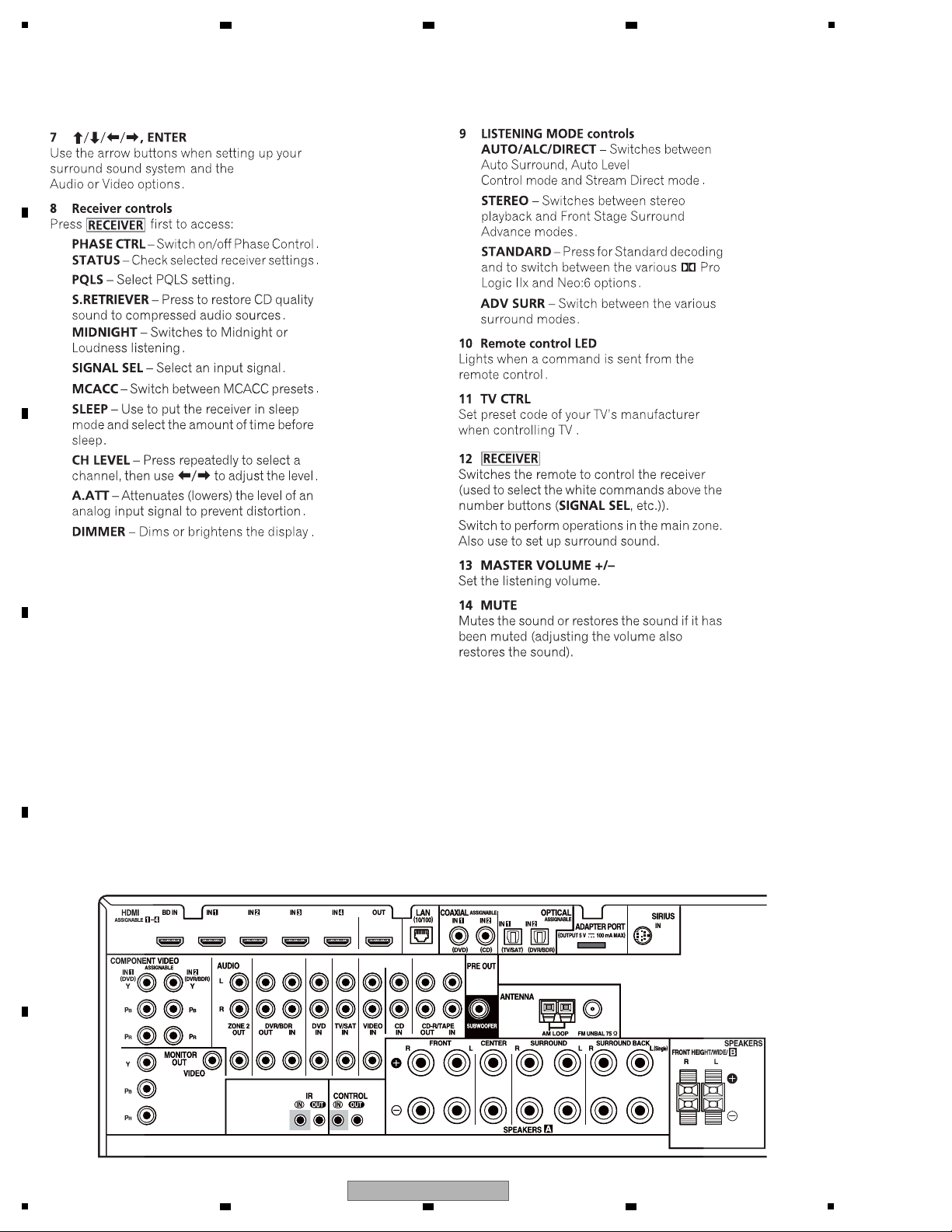

Rear panel

A

B

2 3 4

C

D

E

F

10

1

2 3 4

VSX-1020-K

Page 11

5

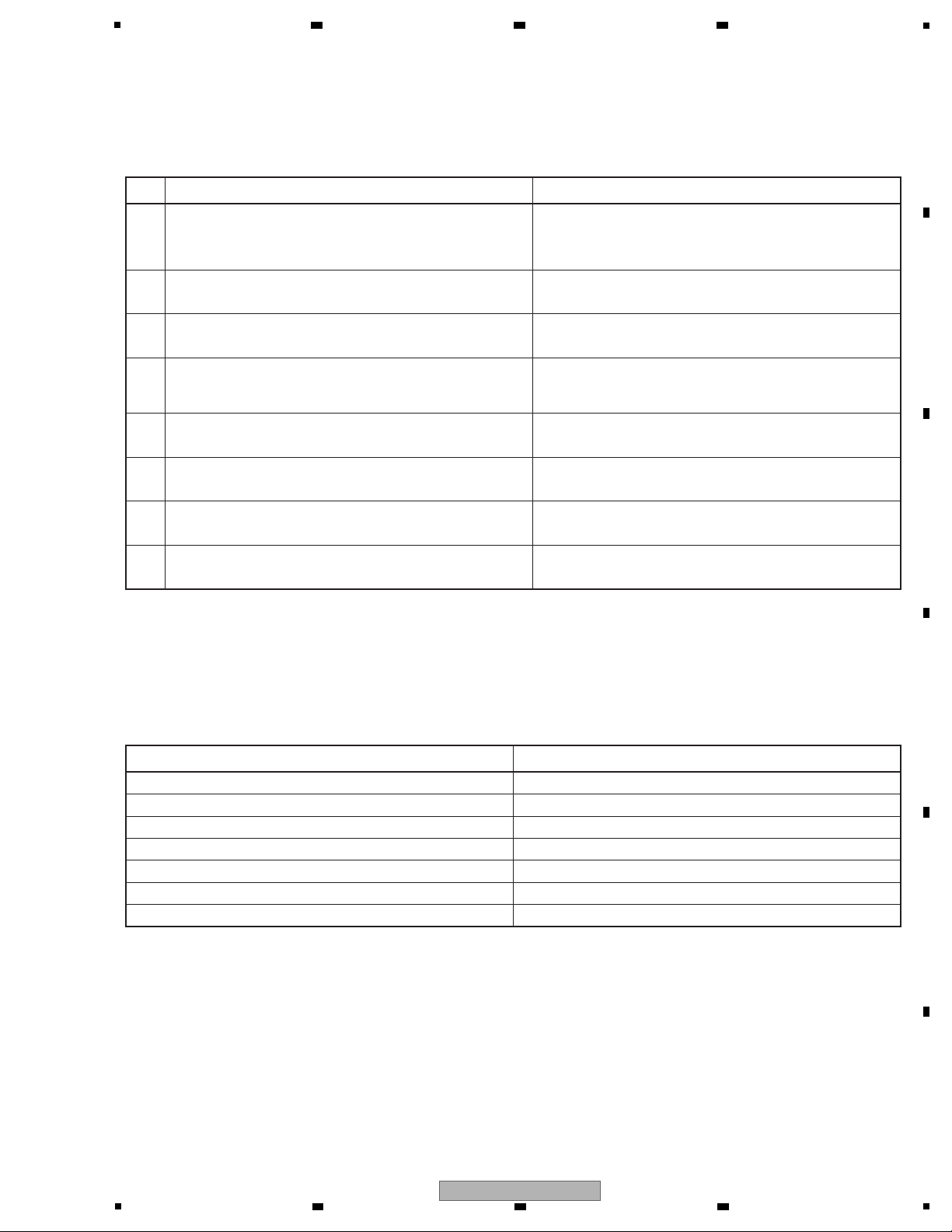

Item to be checked regarding video Item to be checked regarding audio

Block noise Distortion

Horizontal noise Noise

Flicker Volume too low

Disturbed image (video jumpiness) Volume too high

Too dark Volume fluctuating

Too bright Sound interrupted

Mottled color

No. Procedures Check points

1

2

3

4

5

6

7

8

Confirm whether the customer complain has been solved.

If the customer complain occurs with the particular source,

such as Dolby Digital, DTS, AAC, DVD-A and HDMI, input it for

the operation check.

The customer complain must not be reappeared.

Video, Audio and operations must be normal.

Check the analog audio playback.

(Make the analog connections with a DVD player.)

Each channel audio and operations must be normal.

Check the digital audio playback.

(Make the digital connections with a DVD player.)

Each channel audio and operations must be normal.

Check surround playback.

(Select Surround mode and check the multichannel operations

via the DSP circuit.)

Each channel audio and operations must be normal.

Check the tuner (AM and FM) operations. Audio and operations must be normal.

Check the video outputs.

(Connect with a DVD player.)

Video and operations must be normal.

Check the sound from headphone output. Sound must be normal, without noise.

Check the appearance of the product. No scratches or dirt on its appearance after receiving it for

service.

Items to be checked after servicing / VSX, SC

To keep the product quality after servicing, confirm recommended check points shown below.

See the table below for the items to be checked regarding video and audio.

6 7 8

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

11

Page 12

1

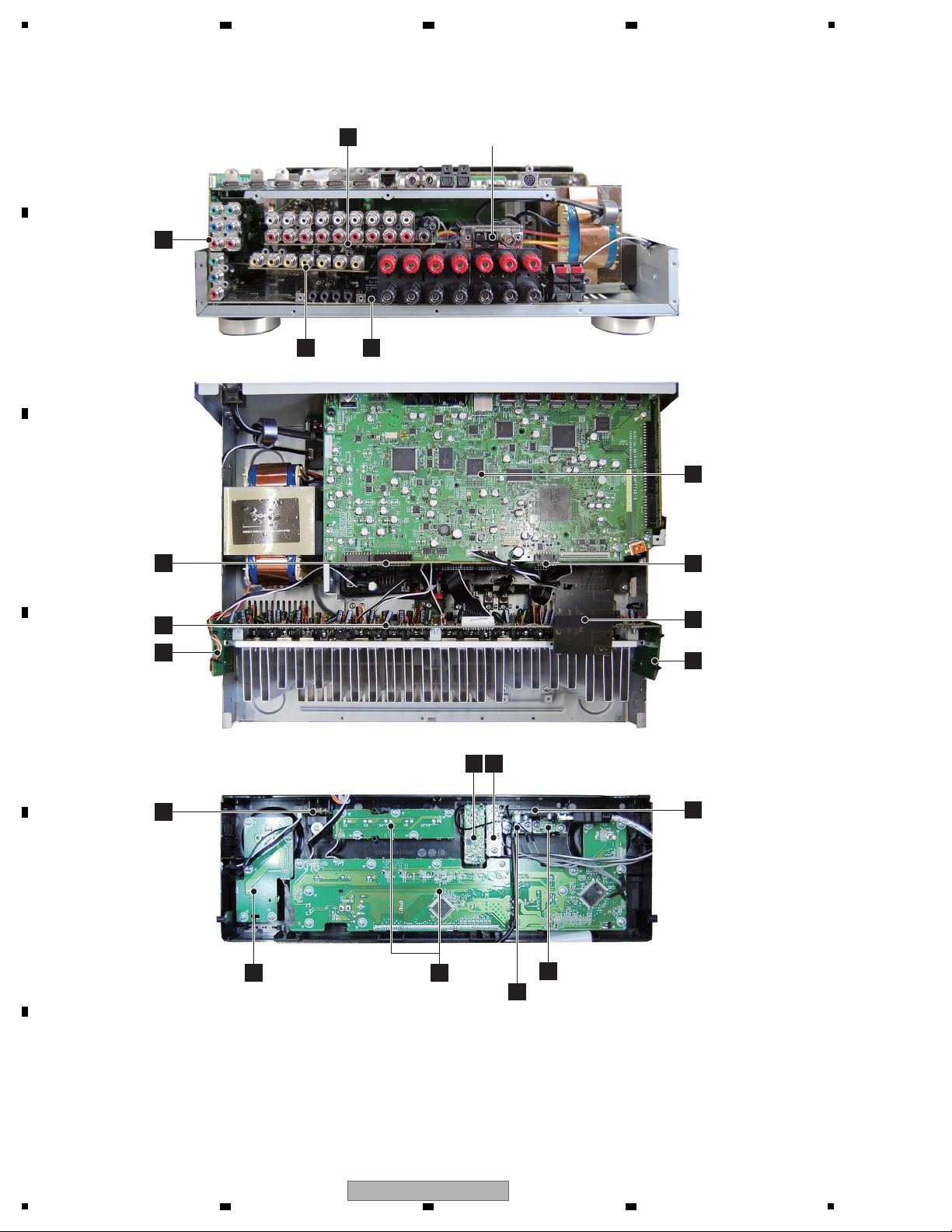

MAIN ASSY

O

DISPLAY ASSY

K

USB MTG ASSY

H

HDMI MTG ASSY

I

POWER SW ASSY

M

COMPOSITE ASSY

C

N

D-MAIN ASSY

P

BRIDGE1 ASSY

G

F-HDMI ASSY

Q

GUIDE3 ASSY

S

GUIDE-R ASSY

B

COMPONENT

ASSY

J

AMP ASSY

F

BRIDGE2 ASSY

L

HEADPHONE

ASSY

R

GUIDE-L ASSY

AUDIO ASSY

A

MIC ASSY F-VIDEO ASSY

D E

FM/AM TUNER UNIT

3.2 PCB LOCATIONS

A

2 3 4

B

C

D

E

F

12

VSX-1020-K

1

2 3 4

Page 13

5

NSP 1..MAIN ASSY 7025HK0918010-IL

2..MAIN ASSY 7028069211010-IL

2..BRIDGE1 ASSY 7028069213010-IL

2..GUIDE-L ASSY 7028069214010-IL

2..GUIDE-R ASSY 7028069215010-IL

2..GUIDE3 ASSY 7028069218010-IL

NSP 1..FRONT ASSY (VSX-1020-K) 7025HK0918011-IL

NSP 1..FRONT ASSY (VSX-1025-K) 7025HK0918051-IL

2..DISPLAY ASSY (VSX-1020-K) 7028069221010-IL

2..DISPLAY ASSY (VSX-1025-K) 70280692210C0-IL

2..POWER SW ASSY 7028069222010-IL

2..USB MTG ASSY 7028069223010-IL

2..HDMI MTG ASSY 7028069224010-IL

2..HEADPHONE ASSY 7028069225010-IL

NSP 1..AMP ASSY 7025HK0918012-IL

2..AMP ASSY 7028069531010-IL

NSP 1..INPUT ASSY 7025HK0918013-IL

2..AUDIO ASSY 7028069241010-IL

2..COMPONENT ASSY 7028069242010-IL

2..COMPOSITE ASSY 7028069243010-IL

2..BRIDGE2 ASSY 7028069244010-IL

2..F-VIDEO ASSY 7028069245010-IL

2..MIC ASSY 7028069246010-IL

NSP 1..F-HDMI ASSY 7025HK0918014-IL

2..F-HDMI ASSY 7028069251010-IL

NSP 1..D-MAIN ASSY 7025HK0918015-IL

2..D-MAIN ASSY 7028069261010-IL

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Jigs List

Jig Name Part No. Remarks

7P extension jig cable GGD1671 Diagnosis (AMP Assy ↔ MAIN Assy)

2P short connector jig GGD1672 Diagnosis (Posistor ↔ MAIN Assy)

13P extension jig cable GGD1669 Diagnosis (AMP Assy ↔ AUDIO Assy)

8P extension jig cable GGD1670 Diagnosis (AMP Assy ↔ MAIN Assy)

Board to board extension jig cable GGD1675 Diagnosis (COMPONENT Assy ↔ MAIN Assy)

Lubricants and Glues List

Name Part No. Remarks

Silicon grease GEM1057 Refer to “9.2 EXTERIOR SECTION”.

Silicon adhesive GYA1011 (KE40RTV-W) Refer to “9.2 EXTERIOR SECTION”.

6 7 8

A

B

3.3 JIGS LIST

C

D

E

VSX-1020-K

5

6 7 8

F

13

Page 14

1

J

AMP

(702

O

MAIN ASSY

(7028069211010-

K

DISPLAY ASSY

(7028069221010-IL: VSX-1020-K)

(70280692210C0-IL: VSX-1025-K)

G

F-HD

(702

L

HEADPHONE ASSY

(7028069225010-IL)

Q

GUIDE3 ASSY

(7028069218010-IL)

M

POWER SW ASSY

(7028069222010-IL)

H

USB MTG ASSY

(7028069223010-IL)

I

H

(

POWER TRANS

FM/AM

TUNER UNIT

R

GUIDE-L ASSY

(7028069214010-IL)

S

GUIDE-R ASSY

(7028069215010-IL)

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

: The power supply is shown with the marked box.

2 3 4

4. BLOCK DIAGRAM

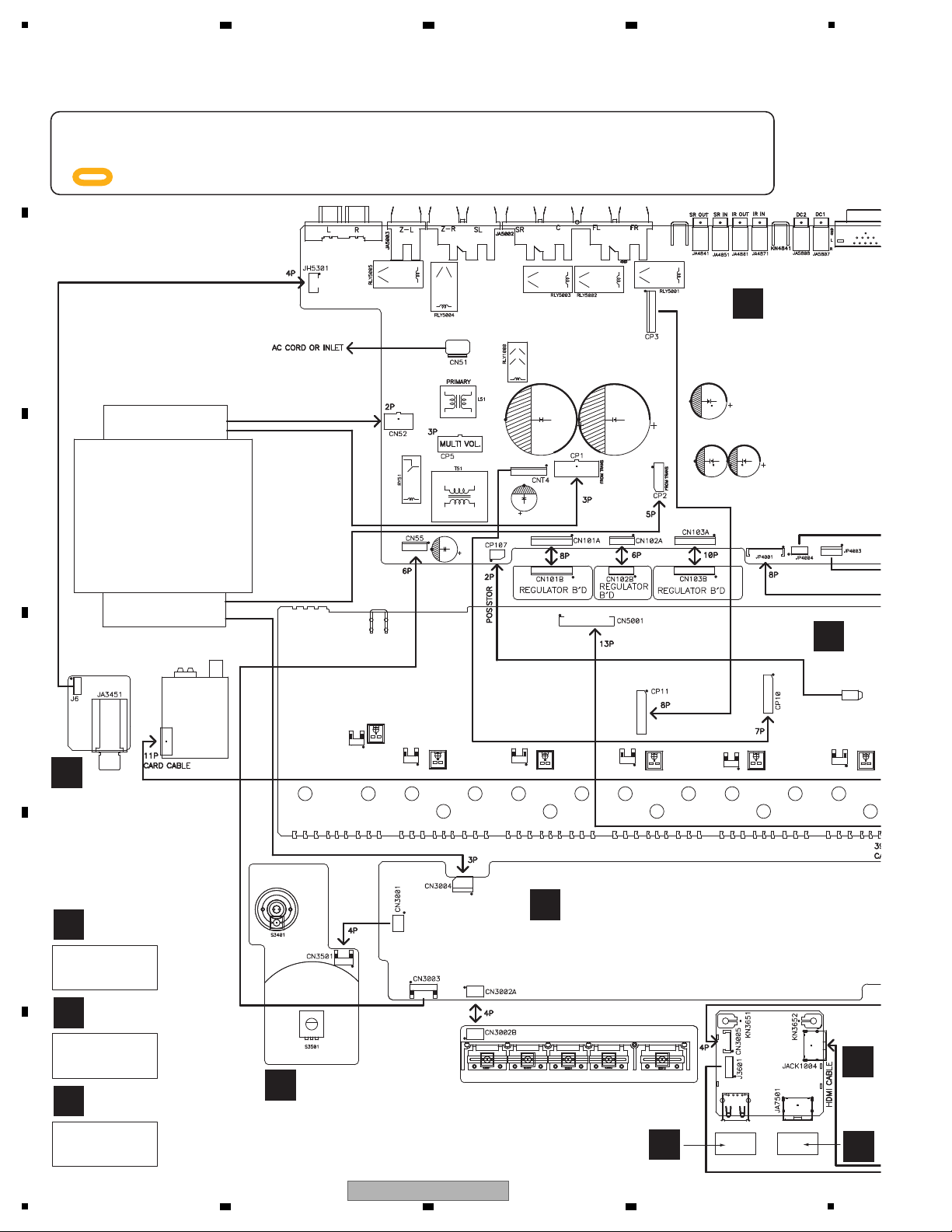

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

14

1

2 3 4

VSX-1020-K

Page 15

5

A

AUDIO ASSY

(7028069241010-IL)

J

AMP ASSY

(7028069531010-IL)

ASSY

B

COMPONENT ASSY

(7028069242010-IL)

D

MIC ASSY

(7028069246010-IL)

F

BRIDGE2 ASSY

(7028069244010-IL)

P

BRIDGE1 ASSY

(7028069213010-IL)

G

F-HDMI ASSY

(7028069251010-IL)

I

HDMI MTG ASSY

(7028069224010-IL)

E

F-VIDEO ASSY

(7028069245010-IL)

C

COMPOSITE ASSY

(7028069243010-IL)

CN7612

CN7601

CN7602

CN7614

CN7615CN7613

D-MAIN ASSY

(7028069261010-IL)

N

N N

1/12- 12/12

A

B

C

A

B

C

6 7 8

A

B

C

D

5

6 7 8

VSX-1020-K

E

F

15

Page 16

1

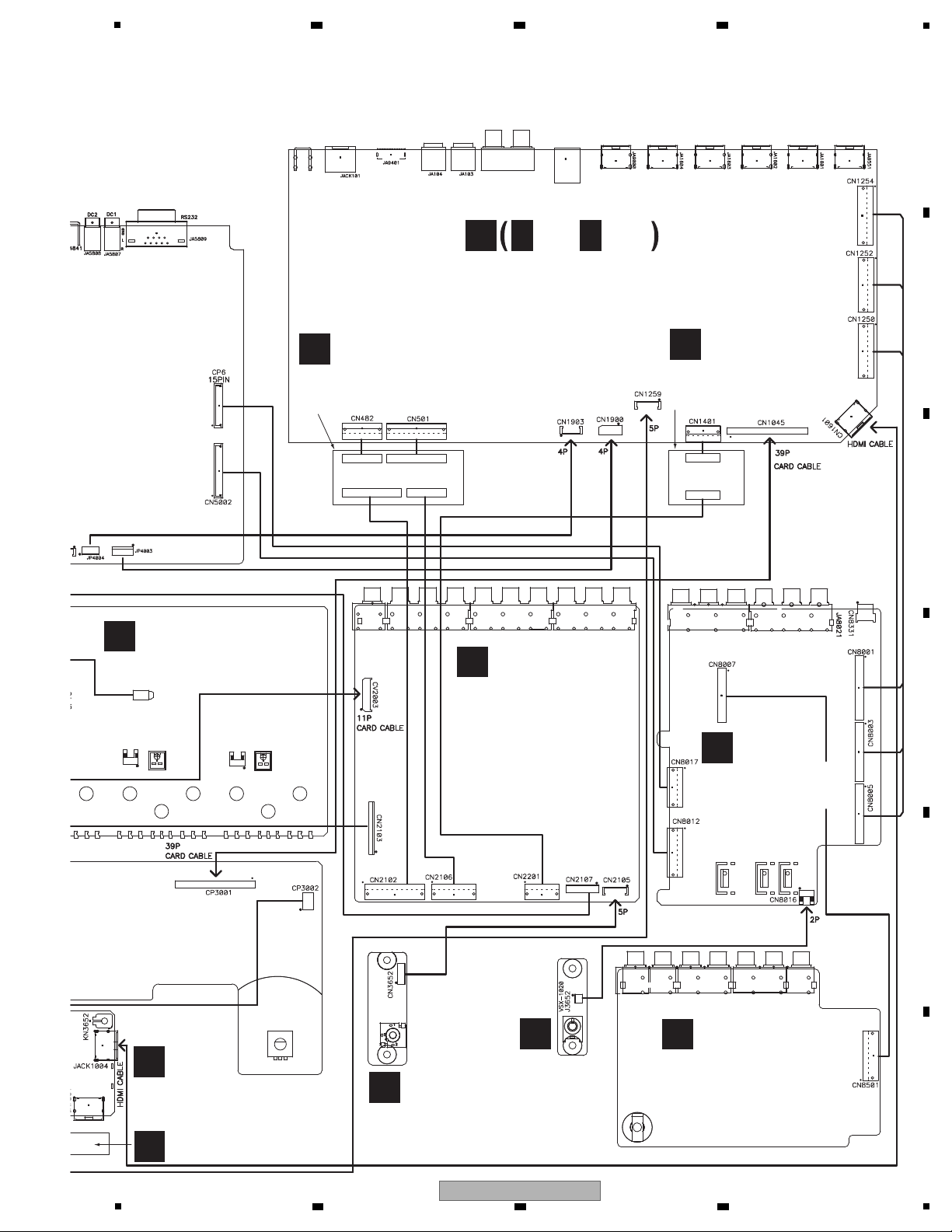

N

D-MAIN ASSY

2 3 4

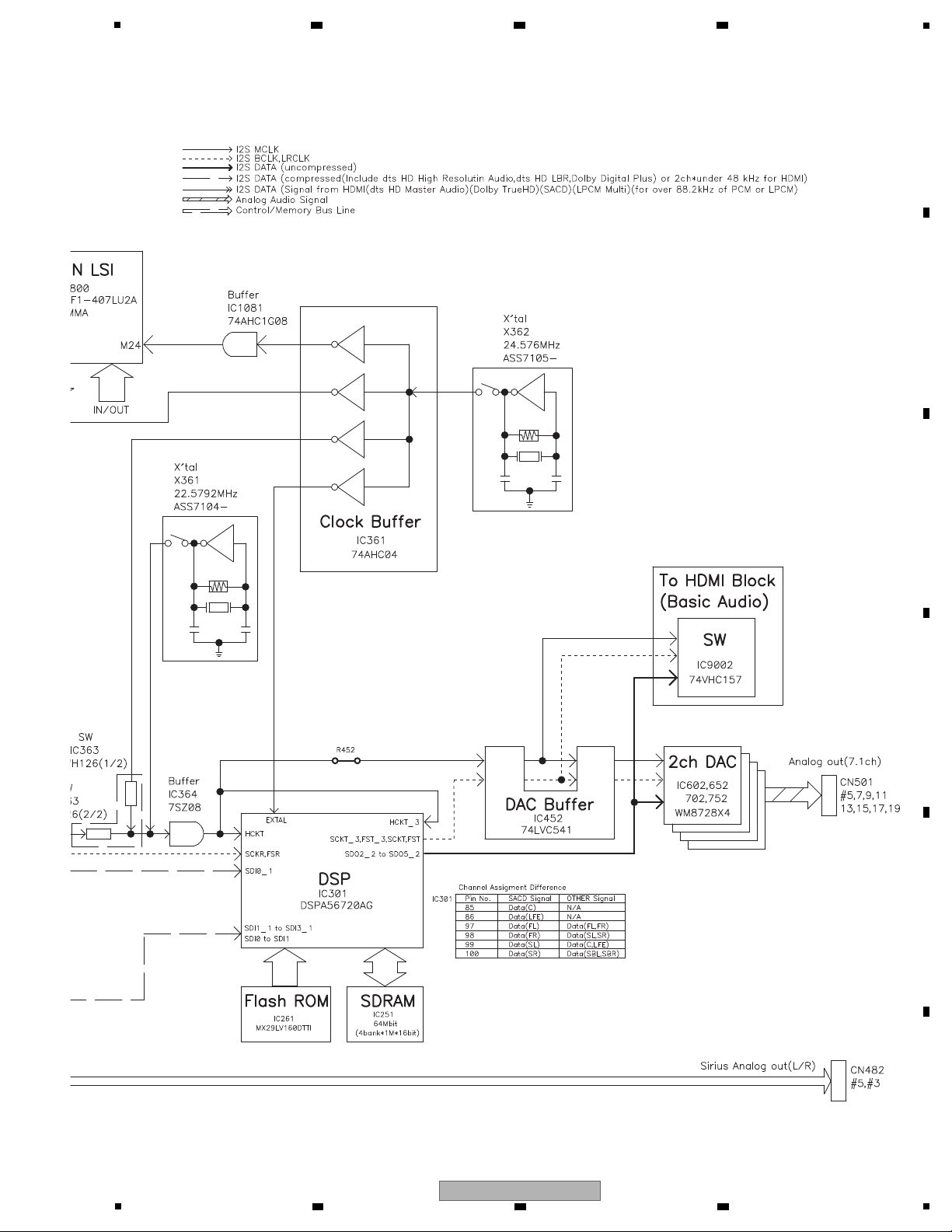

4.2 DIGITAL AUDIO BLOCK DIAGRAM

A

B

C

D

E

F

16

1

2 3 4

VSX-1020-K

Page 17

5

6 7 8

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

17

Page 18

1

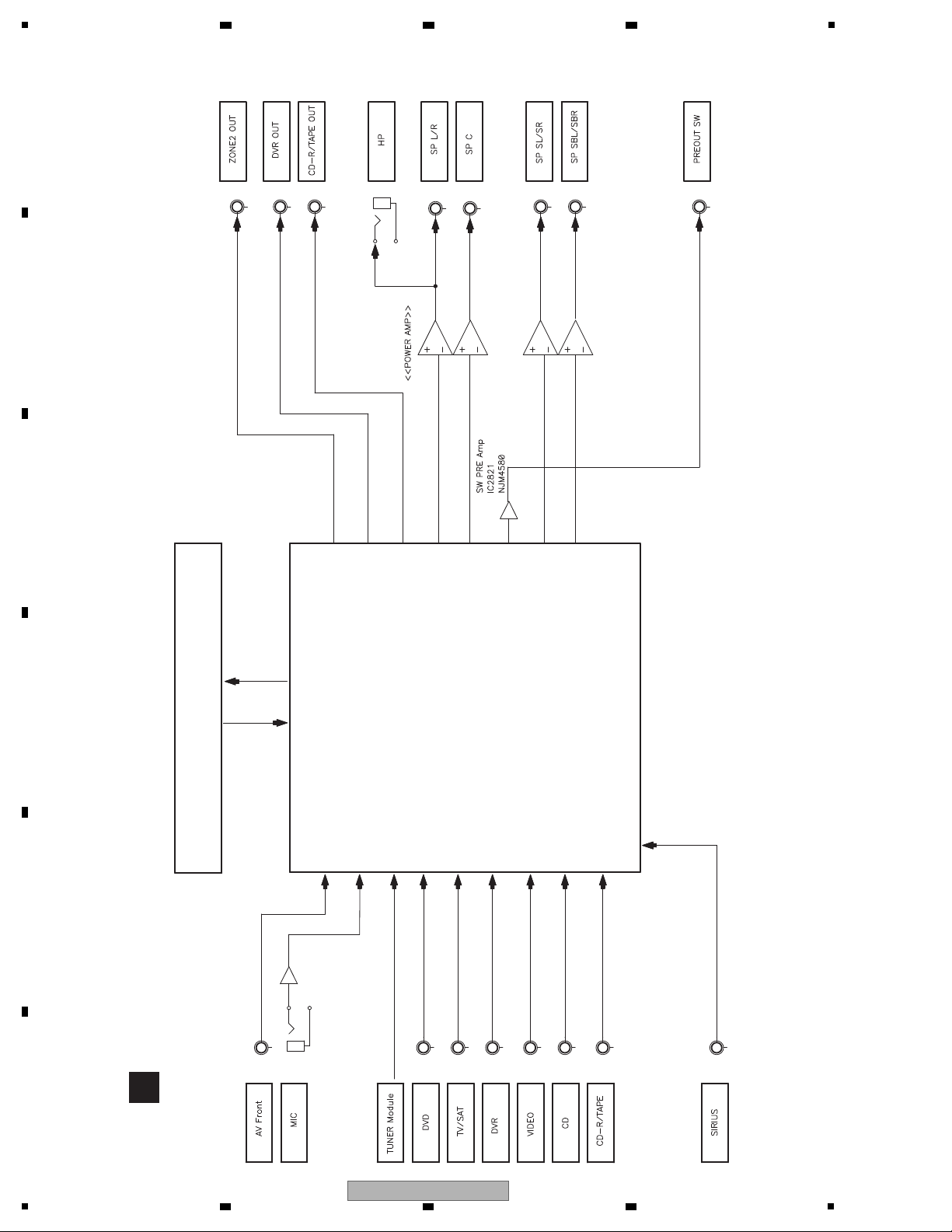

A

AUDIO ASSY

DIGITAL AUDIO BLOCK

Selector / Volume / PRE Amp

IC2501

BD3473KS2

2 3 4

4.3 ANALOG AUDIO BLOCK DIAGRAM

A

B

C

D

E

F

18

1

2 3 4

VSX-1020-K

Page 19

5

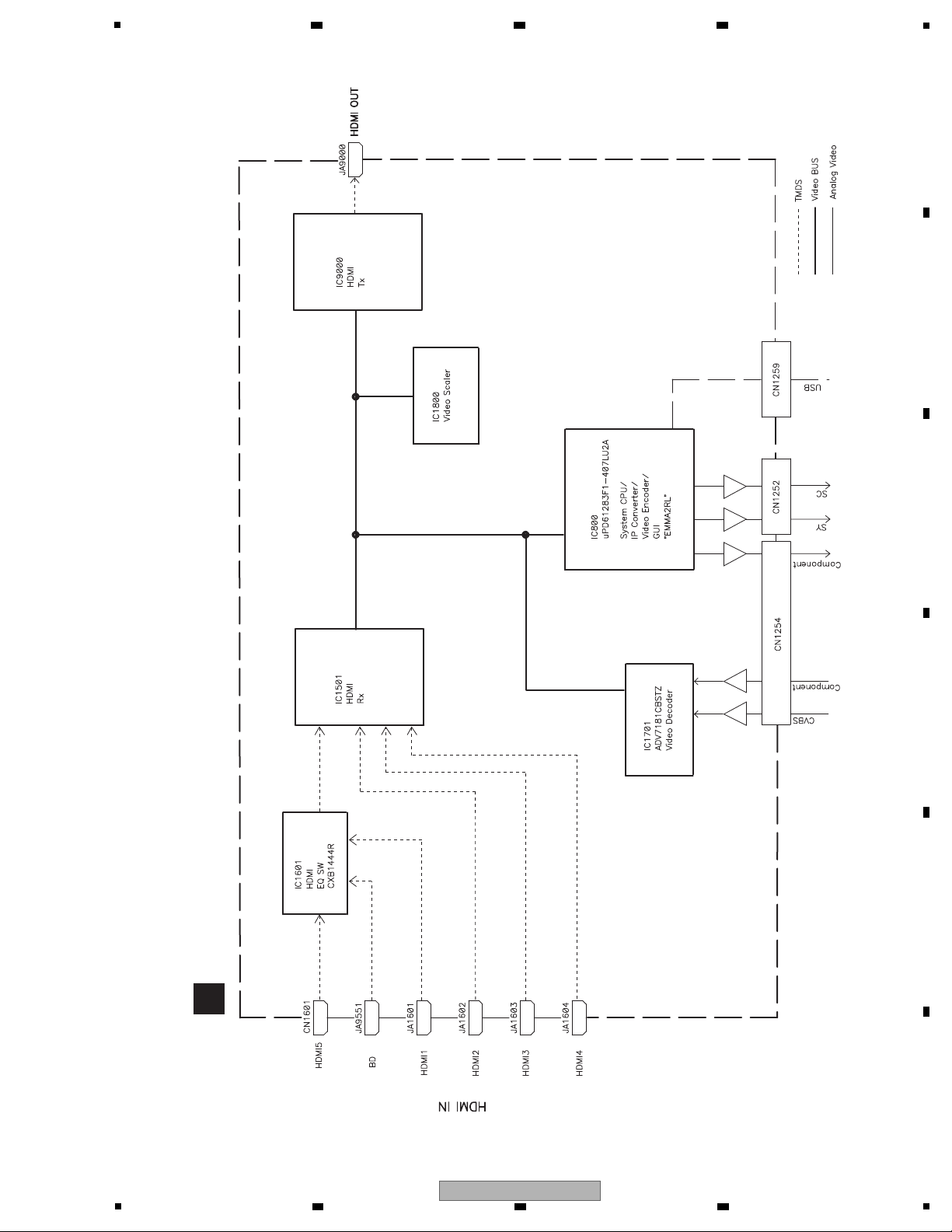

N

D-MAIN ASSY

6 7 8

4.4 DIGITAL VIDEO BLOCK DIAGRAM

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

19

Page 20

1

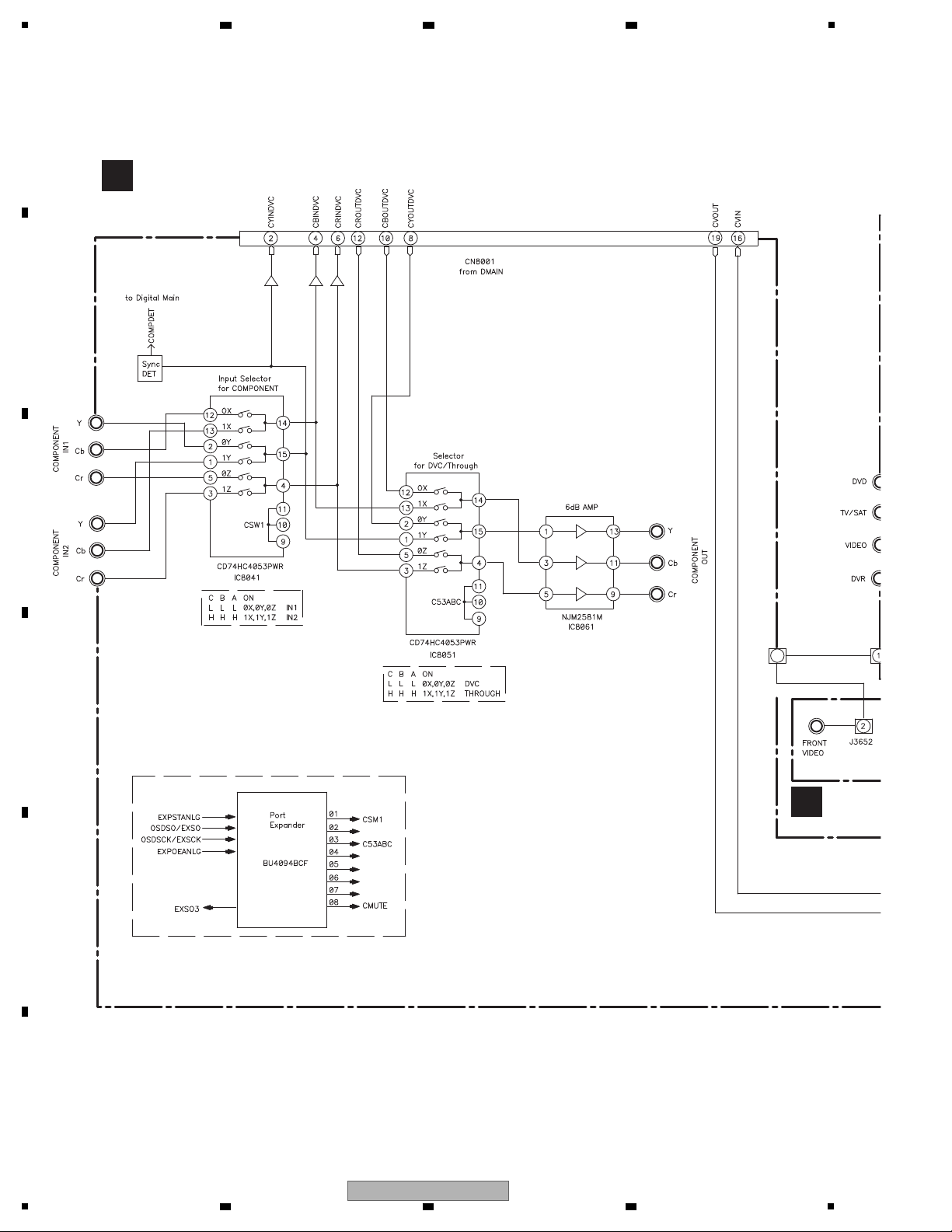

B

COMPONENT ASSY

E

F-VIDE

2 3 4

4.5 ANALOG VIDEO BLOCK DIAGRAM

A

B

C

D

E

F

20

1

2 3 4

VSX-1020-K

Page 21

5

C

COMPOSITE ASSY

E

F-VIDEO ASSY

6 7 8

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

21

Page 22

1

N

D-MAIN ASSY

D

MIC ASSY

E

F-VIDEO

ASSY

B

COMPONENT ASSY

C

COMPOSITE ASSY

A

AUDIO ASSY

G

F-H

4.6 GND BLOCK DIAGRAM

A

B

2 3 4

C

D

E

F

22

1

VSX-1020-K

2 3 4

Page 23

O

MAIN ASSY

J

AMP ASSY

L

HEADPHONE ASSY

G

F-HDMI ASSY

K

DISPLAY ASSY

5

6 7 8

A

B

C

D

E

5

VSX-1020-K

6 7 8

F

23

Page 24

1

A

B

2 3 4

C

D

E

F

24

1

2 3 4

VSX-1020-K

Page 25

5

Step 1: MUTE pin

Replace IC301.

Replace D582.

To Step 2

To Step 3

Step 0: Preliminary confirmation

Confirm the following items before checking

Do

screws of

earth terminal (KN481)

securely tighten

?

Tighten screws securely.

Note:

If this section is not fixed,

the GND for DSP module

may lifted from the chassis

and cause instable potential

and lead to product failures.

No

Ye s

To Step 1

IC301 (Pin 84) (or R324)

Is the

voltage of output

signal 0 V

?

No

No

Ye s

Replace IC582 (side B).

NG

Replace IC581.

NG

DSP1MUTE

V+5_DDD1

Check the Q1900 and

its periphery block.

Check the C121, C114,

C509 and C459.

Check the C333.

IC581 (Pin 1)

Is the

voltage of around

5 V input?

Is the

voltage of 3.3 V

output?

No

Ye s

(to chassis)

V+3R3_D

(to chassis)

D582 (Cathode)

Is the

voltage of around

2.7 V output

?

No

Ye s

IC581 (Pin 3)

No

Ye s

Is the

voltage of 1 V

input?

C333 (+ side)

No

Ye s

V+1_DSPF

NG

Check the C506 and C527.

Check the MAIN Assy.

Is the

voltage of 5 V

input?

C506 (+ side)

No

Ye s

V+5_DAC

NG

Check the C606, C656, C706

and C756.

Replace Q551 (side B).

Is the

voltage of 5 V

input?

C606 (+ side)

No

Ye s

V+5_DACA

NG

Check the C552.

Replace R552.

Is the

voltage of around

5 V input?

C552 (+ side)

No

Ye s

V+5_DACD

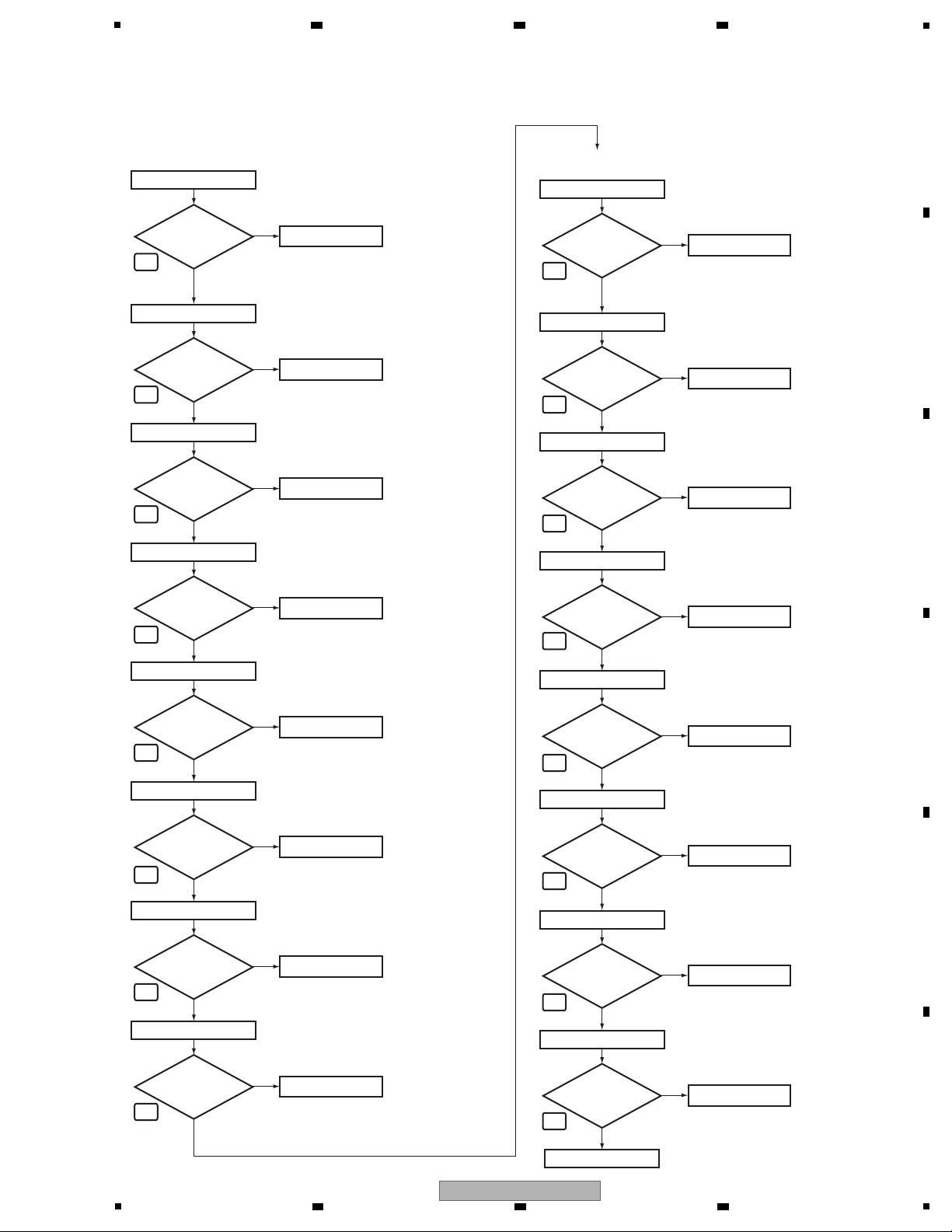

Step 2: Power supply

Simplified diagnosis

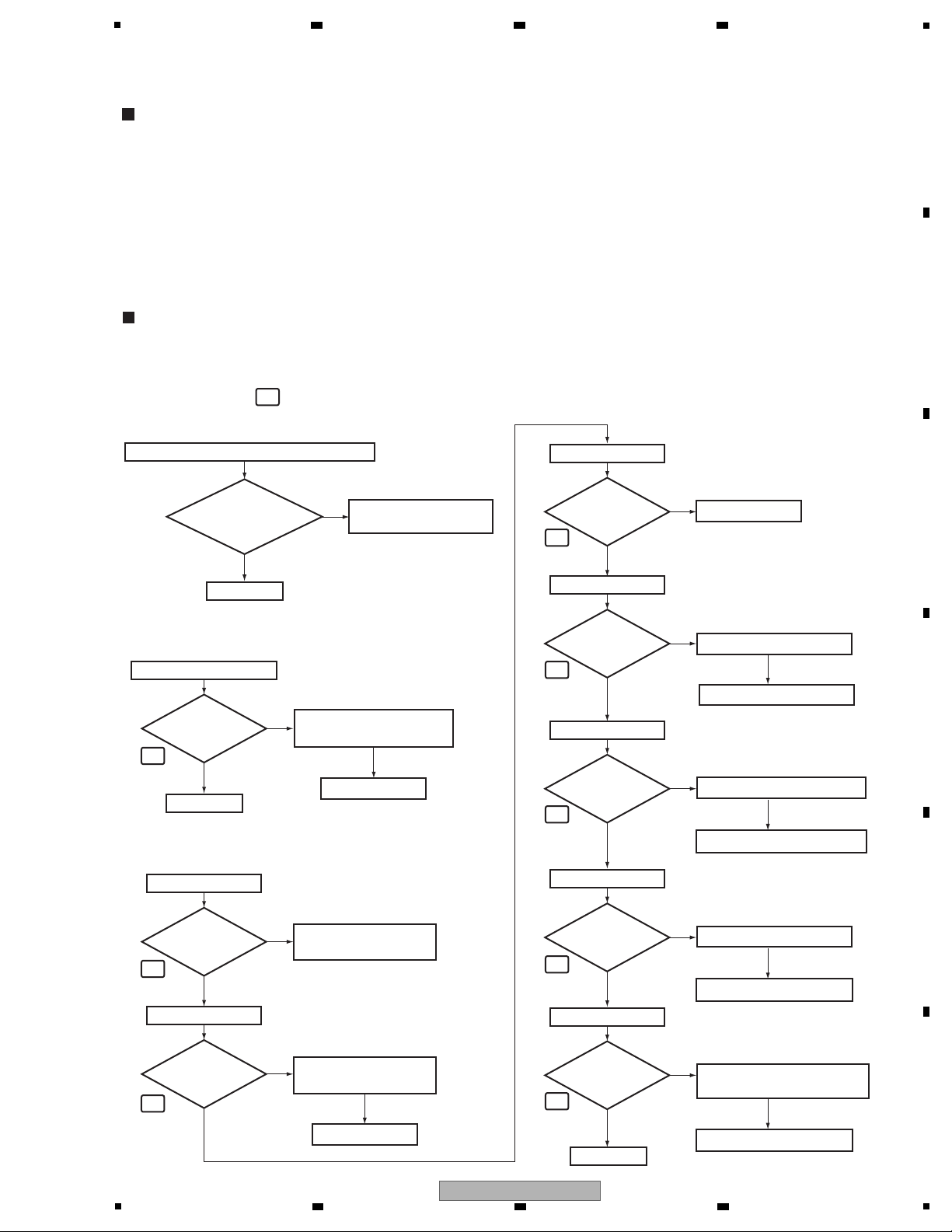

Errors in the Audio Part of the D-MAIN Assy (those simply and roughly predictable by machine operation only)

• Sound abnormality in Delay

If sound abnormality does not occur in the Delay OFF state but occurs in the Delay ON state, it is most likely that a failure

has occurred in SDRAM (IC251) or LATCH (IC281, IC291) in the DSP Part.

• No sound at analog signal input

If sound abnormality does not occur with digital signal input (COAX, OPT, etc.) but occurs only with analog signal input,

it is most likely that a failure has occurred in the AD converter (IC501).

• No sound with the PQLS ON (normal sound with the PQLS OFF)

If no sound is output during CD playback with the PQLS ON, it is most likely that a failure has occurred in the crystal

oscillator (X361). (Diagnosis point A)

<If no sound is output in Multi-Channel-Signal Playback or Surround mode with the COAX, OPT, USB, and HDMI inputs>

• Assume that the LCRs are neither in poor connection nor damaged.

• Assume that diagnosis is performed from Side A.

• This shows failure analysis for the DSP Part of the D-MAIN Assy.

DSP Troubleshooting

Check the DSP and down

stream block. Go to step 6.

1

4

5

6

7

8

2

3

1

• The parts marked like in the following chart are located in "Check Points of the D-MAIN Assy."

6 7 8

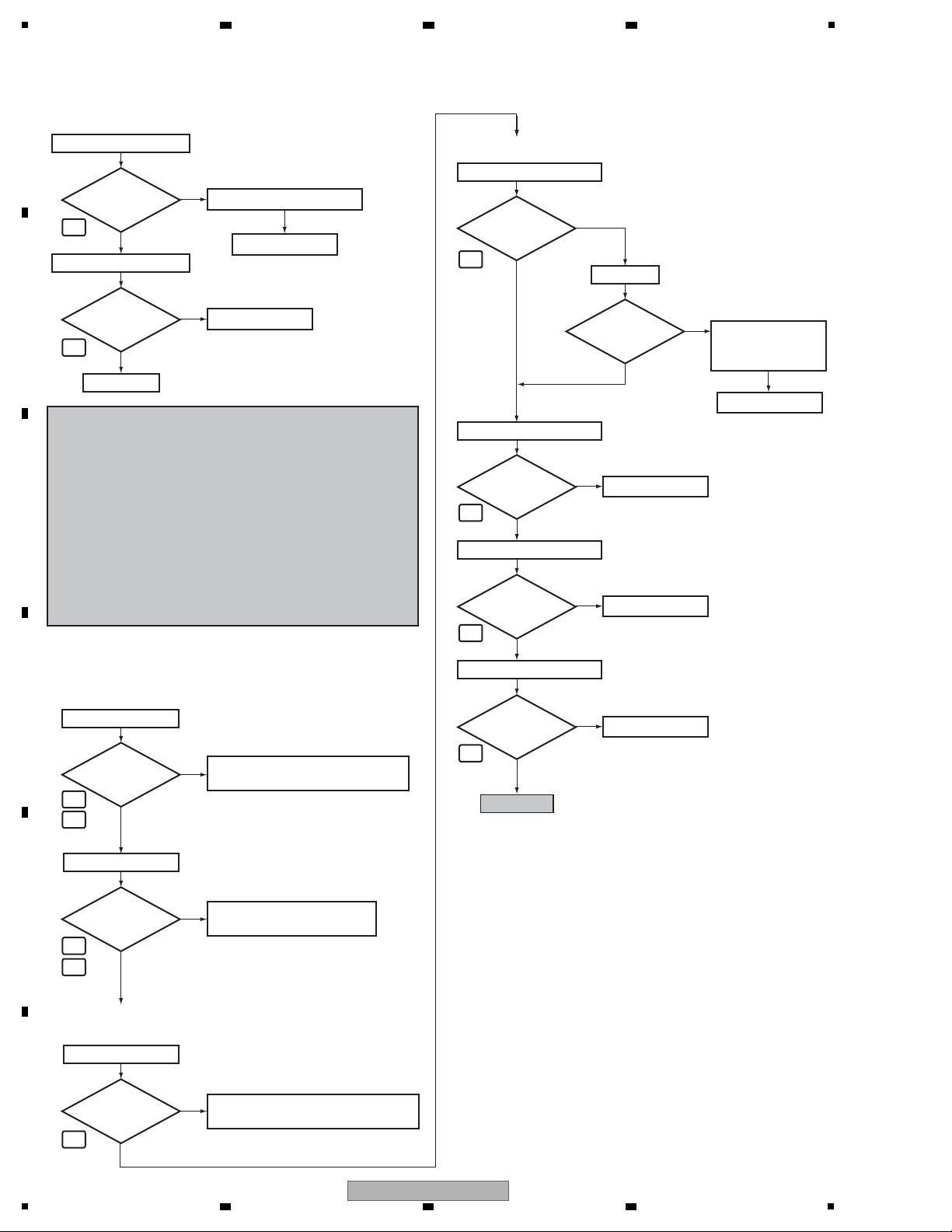

5. DIAGNOSIS

5.1 DIAGNOSIS FLOWCHART

A

B

C

D

E

5

VSX-1020-K

6 7 8

F

25

Page 26

A

Step 4: DIR

Step 4-1

Check the parts and patterns

in the path.

Check the HDMI part, and the parts

and patterns in the path.

Check the OPTICAL IN JACK,

and parts and patterns in the path.

Check the path to

the IC1305

(Port expander).

R101, R102

OPT

Check that the S/PDIF signal is output.

Check that changes by pulling out and inserting the digital

input lines.

Can

observe the

digital signal

?

No

(0 V ⇔ 4 V)

Ye s

R122, R123

COAX

Can

observe the

digital signal

?

No

Ye s

Ye s

Check that it changes in the Playback and Pause modes of

the HDMI.

(0 V ⇔ 3.3 V)

IC101 (Pin 5)

From HDMI part

Can

observe the

digital signal

?

No

(1.65 V center, amplitude more than 0.2 Vp-p)

Step 3: X'tal

To Step 4

Check the X362 (side B).

Replace IC361.

Replace IC361.

Ye s

IC361 (Pins 1, 3, 5, 13)

IC361 (Pins 2, 4, 6, 12)

No

NG

Is there

a 24.576 MHz

input?

No

Is there

a 24.576 MHz

output?

Ye s

Replace IC101.

Ye s

No

Is there

a bit clock

output?

(0 V ⇔ 3.3 V)

To Step 5-3

Replace IC101.

(0 V ⇔ 3.3 V)

Ye s

No

Is there

a LR clock

output?

Replace IC101.

Ye s

R117

XDIRRST

No

NG

Is the

input signal

3.3 V?

Replace IC101.

(0 V ⇔ 3.3 V)

Ye s

No

Is there a

data output?

(0 V ⇔ 3.3 V)

IC101 (Pin 23) (or R110)

DIRMCLK (Master clock)

IC101 (Pin 24) (or R111)

DIRLRCK (LR clock)

IC101 (Pin 25) (or R112)

DIRADAT (Data)

IC101 (Pin 26) (or R113)

DIRBCK (Bit clock)

No

Ye s

Is there a

master clock

output?

Check that the data and clock signals are output.

• When the COAX or OPT is input, go to Step 4.

• When the HDMI (SPDIF path) is input, go to Step 4-1.

Used Source:

[dts HD High Resolution Audio], [dts HD LBR],

[Dolby Digital Plus], [2ch of 48kHz sampling rate or less],

[Other compression stream]

• When the HDMI (SACD) is input, go to Step 5-1.

Used Source: [SACD]

• When the HDMI (I2S path) is input, go to Step 5-2.

Used Source:

[dts HD Master Audio], [Dolby True HD],

[PCM or LPCM of 88.2kHz sampling rate or more],

[LPCM Multi ch]

• When the USB is input, go to Step 5-3.

9

9

10

11

13

14

15

16

17

18

19

B

1

2 3 4

C

D

E

F

26

1

VSX-1020-K

2 3 4

Page 27

5

To Step 6

Step 5: DSP input (digital)

Step 5-1

Step 5-3

Step 5-2

Step 5-4

Digital input of each CH when inputting the digital

signal with audio.

Ye s

IC301 (Pin 86) (or R326)

IC301 (Pin 85) (or R325)

IC301 (Pin 98) (or R332)

IC301 (Pin 99) (or R332)

LFE data (SACD)

No

Is there

a data input?

Ye s

Center data (SACD)

No

Is there

a data input?

Ye s

Surround L/R data

(Front R data (SACD))

No

Is there

a data input?

(0 V ⇔ 3.3 V)

(0 V ⇔ 3.3 V)

(0 V ⇔ 3.3 V)

Ye s

Center/LFE data

(Surround L data (SACD))

No

Is there

a data input?

(0 V ⇔ 3.3 V)

IC301 (Pin 100) (or R332)

Ye s

Surround Back L/R data

(Surround R data (SACD))

No

Is there

a data input?

(0 V ⇔ 3.3 V)

IC301 (Pin 89) (or R327)

IC301 (Pin 134)

Ye s

DSP0MCLK

No

Is there

a data input?

(0 V ⇔ 3.3 V)

Ye s

DSP1MCLK

No

Is there

a data input?

(0 V ⇔ 3.3 V)

IC301 (Pin 93) (or R330)

Ye s

S3BCK

No

Is there

a data input?

(0 V ⇔ 3.3 V)

IC301 (Pin 97) (or R332)

Ye s

Front L/R data

(Front L data (SACD))

No

Is there

a data input?

(0 V ⇔ 3.3 V)

IC301 (Pin 94) (or R331)

S3LRCK

No

Is there

a data input?

(0 V ⇔ 3.3 V)

Check the HDMI part, and the parts

and patterns in the path.

• When the USB is input, check the IC1300

and IC800, and the parts and patterns in

the path.

• When the HDMI I2S or HDMI SACD is input,

check the HDMI part, and the parts and

patterns in the path.

• When the COAX, OPT or HDMI SPDIF is

input, check the parts and patterns in the

path.

When the source is SACD, go to Step 6.

When the source is others, go to Step 5-4.

20

21

22

22

22

23

24

25

22

26

6 7 8

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

27

Page 28

1

Step 6: DSP output (digital)

DAC Buffer

Digital output of each CH when inputting the digital

signal with audio.

Ye s

Center/LFE data

No

Is there

a data output?

Ye s

Surround L/R data

No

Is there

a data output?

Ye s

Front L/R data

No

Is there

a data output?

(0 V ⇔ 3.3 V)

(0 V ⇔ 3.3 V)

(0 V ⇔ 3.3 V)

Ye s

Surround Back L/R data

No

Is there

a data output?

(0 V ⇔ 3.3 V)

IC301 (Pin 123) (or R348)

IC301 (Pin 124) (or R348)

IC301 (Pin 125) (or R348)

IC301 (Pin 122) (or R348)

IC301 (Pin 123) (or R348)

IC301 (Pin 124) (or R348)

IC301 (Pin 125) (or R348)

IC301 (Pin 122) (or R348)

IC452 (Pin 16) (or R459)

IC452 (Pin 13) (or R458)

IC452 (Pin 11) (or R458)

Digital output of each CH when inputting the digital signal

(-∞ dB (no audio)).

Replace IC301.

There is a possibility

of the Boot error.

(Identification of the

defective part near

DSP is extremely

difficult.)

No

Ye s

Is the

voltage of

XDSP1RST at 3.3 V?

(Does it drop to 0V

periodically?)

Ye s

Replace IC301.

Surround L/R data

No

Is the output

0 V fixing?

Replace IC301.

Ye s

Center/LFE data

No

Is the output

0 V fixing?

Surround Back L/R data

Ye s

Replace IC301.

Front L/R data

No

Is the output

0 V fixing?

Ye s

Replace IC301.

No

Is the output

0 V fixing?

DA2MCLK (Master clock)

Ye s

Replace IC452.

No

Is there

a master clock

output?

Check that the clock signal is output.

(0 V ⇔ 3.3 V)

DA2BCK (Bit clock)

Ye s

Replace IC452.

No

Is there

a bit clock

output?

(0 V ⇔ 3.3 V)

(0 V ⇔ 3.3 V)

DA2LRCK (LR clock)

Ye s

Replace IC452.

No

Is there

a LR clock

output?

To Step 7

27

27

27

27

27

27

27

27

28

29

29

A

2 3 4

B

C

D

E

F

28

1

VSX-1020-K

2 3 4

Page 29

5

Replace IC651.

Ye s

CN501 (Pin 9)

Surround R out

No

Replace IC601.

Ye s

CN501 (Pin 7)

Front L out

No

Replace IC601.

Ye s

CN501 (Pin 5)

Front R out

No

Replace IC701.

Ye s

CN501 (Pin 15)

Center out

No

Replace IC701.

Ye s

CN501 (Pin 13)

Sub Woofer out

No

Replace IC751.

Ye s

CN501 (Pin 19)

Surround Back L out

No

Replace IC751.

Ye s

CN501 (Pin 17)

Surround Back R out

No

Replace IC651.

Ye s

CN501 (Pin 11)

Surround L out

No

Analog output of each CH when inputting the digital

signal (-∞ dB (no audio)).

End

Is the output

2.5 V fixing?

Is the output

2.5 V fixing?

Is the output

2.5 V fixing?

Is the output

2.5 V fixing?

Is the output

2.5 V fixing?

Is the output

2.5 V fixing?

Is the output

2.5 V fixing?

Is the output

2.5 V fixing?

Replace IC651.

Ye s

CN501 (Pin 9)

Surround R out

No

Is there

a data output?

Replace IC601.

Ye s

CN501 (Pin 7)

Front L out

No

Is there

a data output?

Replace IC601.

Ye s

CN501 (Pin 5)

Front R out

No

Is there

a data output?

Step 7: DAC output (analog)

Analog output of each CH when inputting the digital signal

with audio.

Replace IC701.

Ye s

CN501 (Pin 15)

Center out

No

Is there

a data output?

Replace IC701.

Ye s

CN501 (Pin 13)

Sub Woofer out

No

Is there

a data output?

Replace IC751.

Ye s

CN501 (Pin 19)

Surround Back L out

No

Is there

a data output?

Replace IC751.

Ye s

CN501 (Pin 17)

Surround Back R out

No

Is there

a data output?

Replace IC651.

Ye s

CN501 (Pin 11)

Surround L out

No

Is there

a data output?

34

34

34

34

34

34

34

34

34

34

34

34

34

34

34

34

6 7 8

A

B

C

D

5

6 7 8

VSX-1020-K

E

F

29

Page 30

1

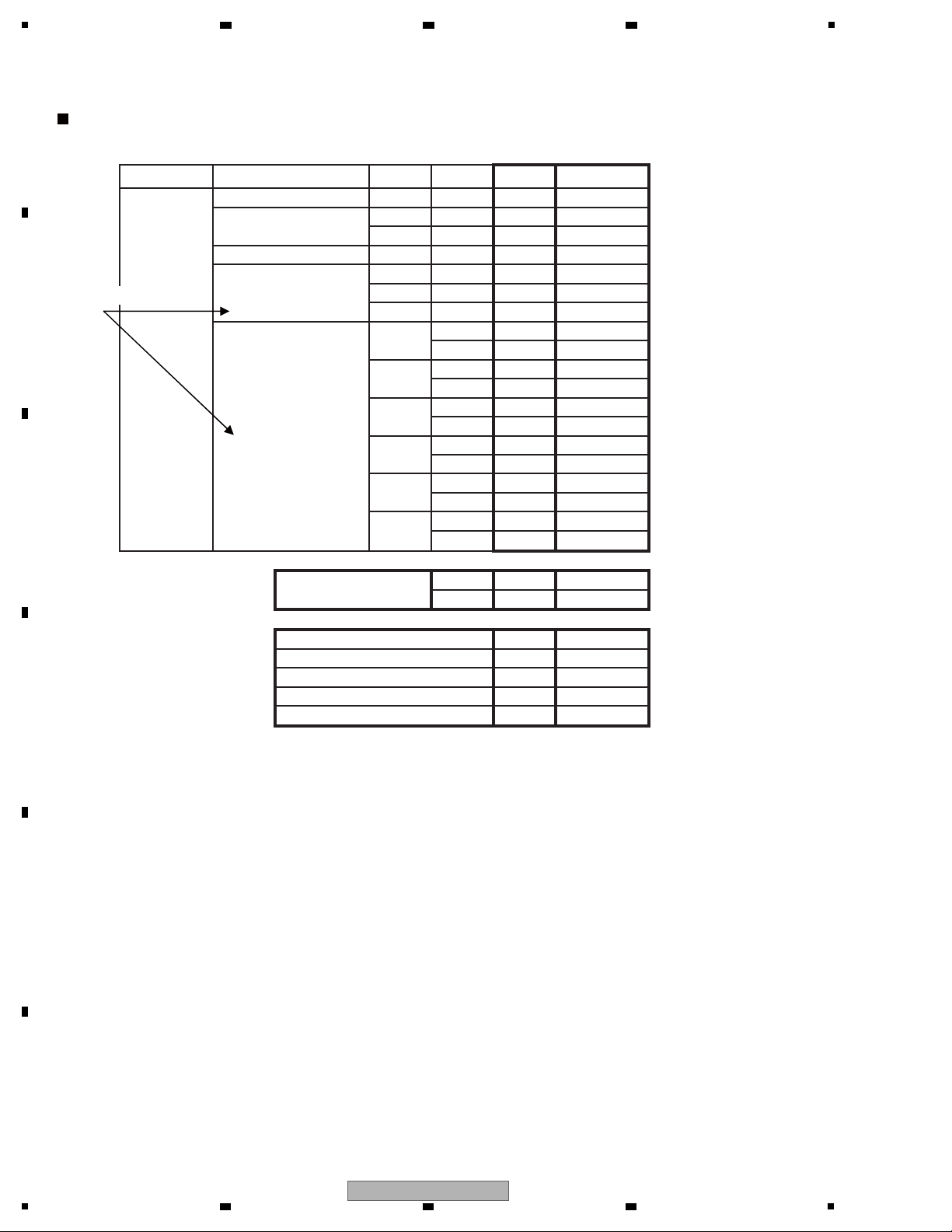

Conditions for selecting SPDIF or I2S output (HDMI transmission)

pcm

fs (kHz) I2S (3 lines)SPDIFLayout

Compression DVD-V 48

Compression *.WAV 44

48

dts-CD 44

PCM 44

48

DVD-V

96 2ch

LPCM 44

Multi

48 2ch

Multi

88 2ch

Multi

DVD-A

96 2ch

Multi

176

Multi

192 2ch No

2ch No

No

No

No

No

No

2ch No

2ch No

2ch No

2ch No

2ch No

2ch No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

2ch

Multi NA NA

NA NA

SACD

2ch (DSD)

Multi

No

No (DSD)

dts HD Master Audio

dts HD High Resolution Audio No

dts HD LBR No

Dolby TrueHD

No

No

Dolby Digital Plus No

Indistinguishable

A

2 3 4

B

C

D

E

F

30

VSX-1020-K

1

2 3 4

Page 31

5

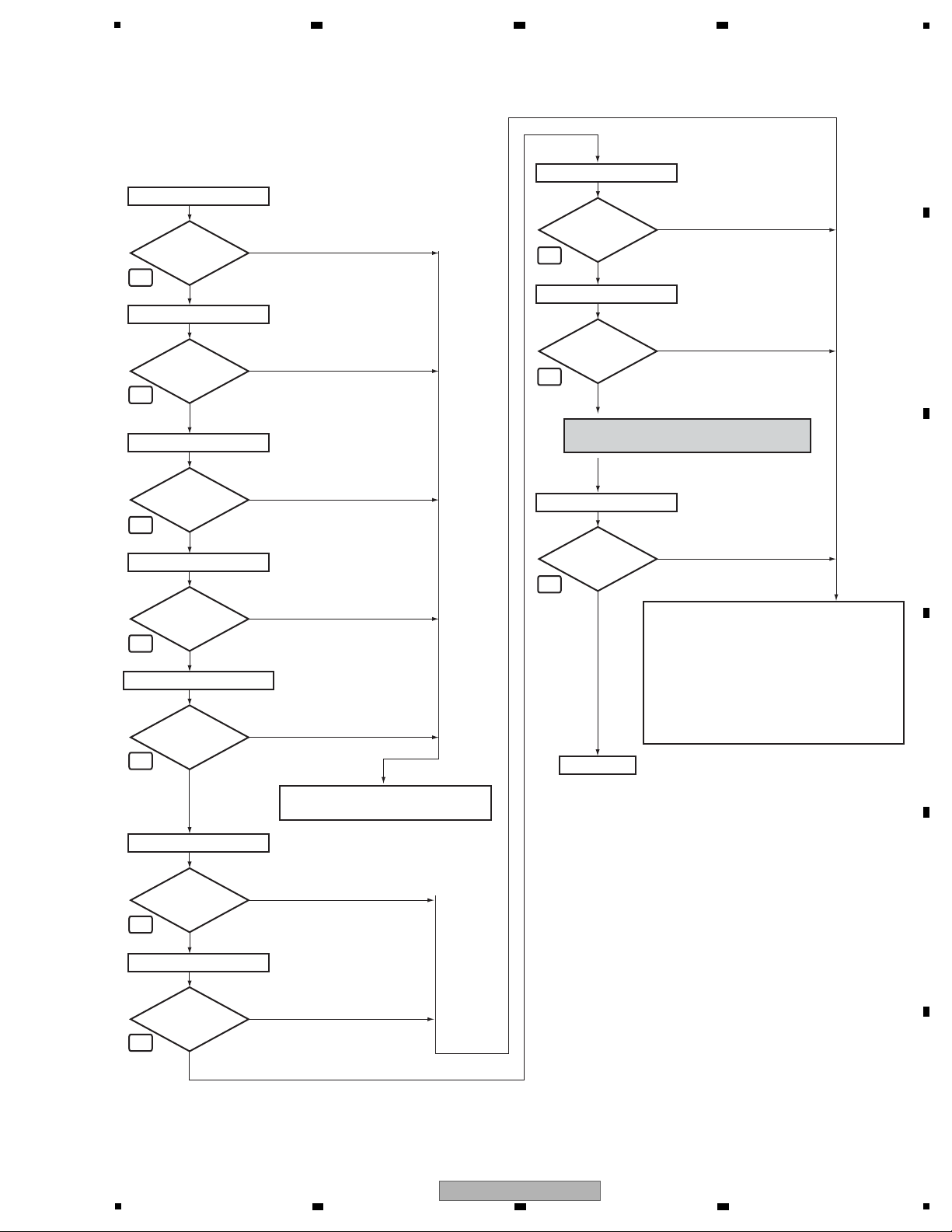

To Step 2

Step 1: Power supply

CN1900 (Pins 1, 2)

Is the

voltage of around

13 V input

?

No

Ye s

V+13_UN

Check IC1900 and its

peripheral circuits.

<When no image is displayed after the unit is turned on, the HDMI LED on the front panel lights, and the HDMI or analog signal is input.>

• If conversion between 480i and 480p is not possible, it is most likely that IC800 is in failure. Check its peripheral circuits.

• Assume that the LCRs are neither in poor connection nor damaged.

• Analog video Convert (Ex.: S → COMPONENT) is satisfied by diagnosing the input and output.

• Although diagnosis is assumed to be performed from Side A, the wiring numbers on Side B are also described in the flowchart.

• This shows failure analysis for the HDMI & DVC Part of the D-MAIN Assy.

• The confirmation of peripheral circuits means mainly a power supply of IC, a sync signal, a existence of the input/output signal,

a conduction check and the appearance check of the bridges.

HDMI & DVC Block Troubleshooting

Check the MAIN Assy.

L1902

Is the

voltage of 5 V

output?

No

NG

Ye s

V+5_DDD

Check Q1900 and its periphery.

(Pins 1,2,5,6: around 9 V

Pin 3: around 6 V Square wave)

A

B

Check IC1900 and its

peripheral circuits.

R1916

Is the

voltage of around

5 V output?

No

NG

Ye s

V+5_HD

Check Q1900 and its periphery.

(Pins 1,2,5,6: around 9 V

Pin 3: around 6 V Square wave)

C

IC1100 (Pin 5) (side B)

Is the

voltage of around

3.3 V output

?

No

Ye s

V+3R3_EM_V

Check IC1100 and its peripheral

circuits.

Check IC1101 and its peripheral

circuits.

Check IC1102 and its peripheral

circuits.

Check IC1104 and its peripheral

circuits.

IC1101 (Pin 5) (side B)

Is the

voltage of around

3.3 V output

?

No

Ye s

V+3R3_EM_D

IC1102 (Pin 5) (side B)

Is the

voltage of around

2.5 V output

?

No

Ye s

V+2R5_EM

IC1104 (Pin 5) (side B)

Is the

voltage of around

1 V output

?

No

Ye s

V+1_EM

Check IC1930 and its

peripheral circuits.

L1931

Is the

voltage of around

3.3 V output

?

No

NG

Ye s

V+3R3_HHH

Check Q1930 and its periphery.

(Pin 1: around 7.5 V Square wave

Pins 5,6: around 16.5 V)

D

Check IC1930 and its

peripheral circuits.

L1932

Is the

voltage of around

1.8 V output

?

No

NG

Ye s

V+1R8_HHH

Check Q1931 and its periphery.

(Pin 1: around 5.5 V Square wave

Pins 7,8: around 16.5 V)

D

A

• The parts marked like in the following chart are located in "Check Points of the D-MAIN Assy."

6 7 8

A

B

C

D

E

5

VSX-1020-K

6 7 8

F

31

Page 32

1

Step 2: X'tal

Step 4: HDMI IN, HDMI OUT

To Step 3

Ye s

IC803 (Pins 5, 7) (side B)

IC1302 (Pin 7)

No

Is there

a 27 MHz

output?

No

Is there

a 36.864 MHz

output?

Ye s

E

To Step 4

CLK27EMMA, CLK27ABT

XHDTX1RST

F

JA1601-JA1604 (Pin 18)

Step 4-1: HDMI IN 1, 2, 3, 4

Is the voltage

around 5 V ?

No

Ye s

+5V

Check the soldering of JA1601JA1604 and the source equipment

connected in JA1601-JA1604.

JA1601-JA1604 (Pin 19)

Is the voltage

around 5 V ?

No

Ye s

Hot plug detect

Check IC1501 and its peripheral

circuits.

Check IC803 and its peripheral

circuits.

Step 3: RESET

Ye s

R931 (side B)

No

Is the

voltage "H"

(around 3.3 V)

?

XEMRST

Check the soldering and parts of

the path.

Ye s

R1851 (side B)

No

Is the

voltage "H"

(around 3.3 V)

?

XVSRST

Check the soldering and parts of

the path.

Ye s

IC1300 (Pin 91)

No

Is the

voltage "H"

(around 3.3 V)

?

XGARST

Check the soldering and parts of

the path.

Ye s

R1509

No

Is the

voltage "H"

(around 3.3 V)

?

Check the soldering and parts of

the path.

G

H

Ye s

R9018

No

Is the

voltage "H"

(around 3.3 V)

?

Check the soldering and parts of

the path.

Check IC1302 and its peripheral

circuits.

X1501 (Pins 1, 3)

No

Is there a

27 MHz input or

output?

Ye s

F

Q

JA1601-JA1604 (Pins 15,16)

Does

a signal output in

constant period

?

No

Ye s

DDC (SDA/SCL)

Check the soldering of JA1601JA1604.

JA1601-JA1604

(Pins 1,3,4,6,7,9,10,12)

Is there

0.5Vp-p in CLK

and DATA?

No

Ye s

TMDS signal

Check the soldering of JA1601JA1604.

Check X1501 and IC1501

and its peripheral circuits.

X1701 (Pins 1, 3)

No

Is there

a 28.63636 MHz

output?

Ye s

Check X1701 and IC1701

and its peripheral circuits.

R1270

No

Is there

a 48 MHz

signal?

Ye s

Check IC1251 and its peripheral

circuits.

A

A

2 3 4

B

C

D

E

F

32

VSX-1020-K

1

2 3 4

Page 33

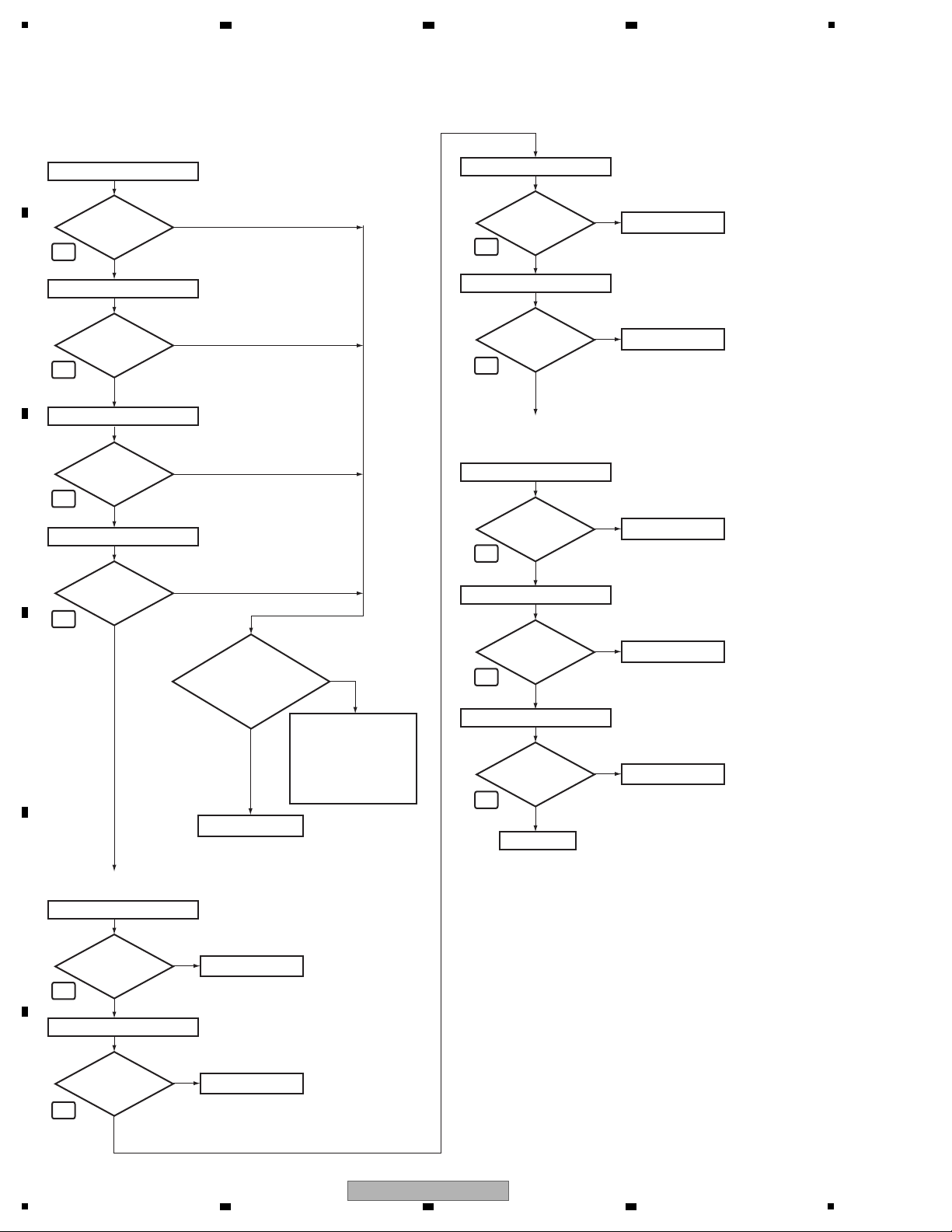

To Step 4-2

JA9000 (Pin 18)

Is the voltage

around 5 V ?

No

Ye s

+5V

Check IC9001 and its peripheral

circuits.

JA9000 (Pin 19)

Is the voltage

around 5 V ?

No

Ye s

Hot plug detect

Check the sync equipment.

IC1800

IC9000

JA9000 (OUT 1)

(Pins 1,3,4,6,7,9,10,12)

Is there

0.5Vp-p in CLK

and DATA?

No

Ye s

TMDS signal

Video Scalar IC

HDMI Tx IC

Check the soldering of JA9000

and IC9000, and its peripheral

circuits.

NG

Check IC1501 and its

peripheral circuits.

J

K

L

M

Step 4-2: BD IN

To Step 4-3

JA9551 (Pin 18)

Is the voltage

around 5 V ?

No

Ye s

+5V

Check the soldering of JA9551.

Check the source equipment

connected in JA9551.

IC1501

Is the voltage

around 5 V ?

No

HDMI Rx IC

Check IC1601 and its peripheral

circuits.

JA9551 (Pins 15,16)

Does

a signal output in

constant period

?

No

Ye s

Ye s

DDC (SDA/SCL)

JA9551 (Pin 19)

Hot plug detect

Check the soldering of JA9551

and the path.

IC1601 (Pins 67,68,

70,71,73,74,76,77)

Is there

0.5Vp-p in CLK

and DATA?

No

Ye s

TMDS signal

JA9551

(Pins 1,3,4,6,7,9,10,12)

TMDS signal

Check IC1601 and its peripheral

circuits.

Is there

0.5Vp-p in CLK

and DATA?

No

Ye s

Check the soldering of JA9551

and the path.

N

I

B

A

A

A

IC1807,IC1808(side B),IC1809,

IC1810(side B),IC1811(side B)

(Pins 11-17)

Are signals

output?

No

Ye s

P** HSYNC VSYNC

PDE, PDCLK

Check IC1807-IC1811 and its

peripheral circuits.

Whole

diagram

HDMI OUT

5

6 7 8

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

33

Page 34

1

Step 5: COMPONENT IN

Step 5-1: HDMI OUT (more than 480p)

CN1254 (Pin 14)

Is the voltage

"H" ?

No

Ye s

COMPDET

Check CN1254 and diagnose

the COMPONENT Assy.

P

CN1254 (Pins 2,4,6)

Is there a

analog video

signal? *

No

Ye s

Y_IN, CB_IN, CR_IN

* Diagnose it from the COMPONENT Assy side.

Check CN1254 and diagnose

the COMPONENT Assy.

Q1151,Q1155,Q1157

(Emitter), (side B)

Are the

signals output at

emitter?

No

Ye s

SG_A, SG_B, SG_C

Check Q1151, Q1155, Q1157 and

its peripheral circuits.

IC1701 (Pins 2,5-8,12-19,

25-28,59-62,64),R1706

(side B)

Are the

signals output?

No

Q** RXHSYNC, RXVSYNC, RXOCLK

Check IC1701 and its peripheral

circuits.

Ye s

IC1807,IC1808(side B),

IC1809,IC1810(side B),

IC1811(side B)

(Pins 11-17)

Are the

signals output?

No

P** HSYNC, VSYNC, PDE, PDCLK

Check IC1807-IC1811 and its

peripheral circuits.

Ye s

To Step 5-2

B

Step 4-3: HDMI IN 4 (Front IN)

To Step 5

CN1601 (Pin 18)

Is the voltage

around 5 V ?

No

NG

NG

Ye s

V+5_F

Check the soldering of CN1601.

Diagnose the F-HDMI Assy.

NG

Diagnose the F-HDMI Assy.

NG

Diagnose the F-HDMI Assy.

NG

Check IC1501 and its peripheral

circuits.

Check the source equipment.

CN1601 (Pins 15,16)

Does

a signal output in

constant period

?

No

Ye s

DDC (SDA/SCL)

Check the soldering of CN1601.

IC1601 (Pins 25,26,

28,29,31,32,34,35)

Is there

0.5Vp-p in CLK

and DATA?

No

Ye s

TMDS signal

IC1601 (Pins 48,49,51,

52,54,55,57,58)

TMDS signal

Check IC1601 and its peripheral

circuits.

Is there

0.5Vp-p in CLK

and DATA?

No

Ye s

Check the soldering between

IC1601 and CN1601.

CN1601

(Pins 1,3,4,6,7,9,10,12)

TMDS signal

Is there

0.5Vp-p in CLK

and DATA?

No

Ye s

Check the soldering of CN1601.

N

N

O

A

Whole

diagram

Analog IN, HDMI OUT

A

2 3 4

B

C

D

E

F

34

1

2 3 4

VSX-1020-K

Page 35

5

Step 5-2: Component IN, HDMI OUT (at 480i)

Q

P

Step 6: HDMI OUT

CN1254 (Pin 16)

Is there a

luminance

signal?

No

Ye s

A_VVYIN

Check CN1254 and diagnose

the COMPONENT Assy.

IC1701 (Pin 36) (side B)

Are there

color and luminance

signals?

No

Ye s

A_VVYIN

Check the soldering between

IC1701 and CN1254 and its

peripheral circuits.

IC1701 (Pins 2,5-8,59-62,

64),R1706 (side B)

Are the

signals output?

No

Ye s

Q** RXHSYNC, RXVSYNC,

RXOCLK

Check IC1701 and its peripheral

circuits.

IC1805 (Pins 3-9),

IC1806 (Pin 4) (side B)

Perform the same check items up to those

for IC1805 and IC1806 of Step 7.

Are the

signals output?

No

Ye s

Q16-23

VICLK

Check IC1805, IC1806 and its

peripheral circuits.

C

To Step 7

C

IC1801 (Pins 11-13),

IC1802, IC1803 (Pins 11-18),

IC1804 (Pin 4) (side B)

Are the

signals output?

No

Ye s

PHSYNC, PVSYNC, PDE

P**

PCLK

Check IC1801 to IC1804 and its

peripheral circuits.

IC800 (through hole)

(Pins E13,D13,E12,D12,E11,

D11,E10,D10,D15) (side B)

Are there

signals?

No

Ye s

VID0-7, VICLK

Check IC1805 and IC1806 and its

peripheral circuits.

Check the soldering.

Check IC800 and its peripheral

circuits. Check the soldering.

R872-R875,R878,R879,

R884-R887

Is there a

signal?

No

Ye s

VOD,VOCLK

Replace the D-MAIN Assy.

To Step 6

B

6 7 8

A

B

C

D

5

6 7 8

VSX-1020-K

E

F

35

Page 36

1

Step 7: COMPOSITE IN, HDMI OUT

CN1254 (Pin 16)

Is there a

signal?

No

Ye s

A_VVYIN

Check CN1254 and diagnose

the COMPONENT Assy.

P

IC1701 (Pin 36) (side B)

Is there a

signal?

No

Ye s

A_VVYIN

Check the soldering between

IC1701 and CN1254 and its

peripheral circuits.

IC1701 (Pins 2,5-8,59-62,

64),R1706 (side B)

Are the

signals output?

No

Ye s

Q** RXHSYNC, RXVSYNC,

RXOCLK

Check IC1701 and its peripheral

circuits.

IC1805 (Pins 3-9),

IC1806 (Pin 4) (side B)

Are the

signals output?

No

Q16-23

VICLK

Check IC1805, IC1806 and its

peripheral circuits.

Ye s

To Step 8

C

Step 8: COMPONENT IN

COMPONENT OUT

Perform the same check items up to

those for IC1701 and R1706 of Step 5-1.

R1214

Are there

signals?

No

NG

Ye s

A_VCYOUT_EM

R1219

A_VCBOUT_EM

R1224

A_VCROUT_EM

Replace the D-MAIN Assy.

P

Q

Q

IC1805 (Pins 3-9),

IC1806 (Pin 4) (side B)

Are the

signals output?

No

Ye s

Q16-23

VICLK

Note: When the connection is Composite S OUT, refer to the

diagnose of IC800 and later in steps 9 and 10.

Check the soldering between

IC1701 and IC1805, IC1806.

CN1254 (Pin 8)

Are there

signals?

No

Ye s

A_VCYOUT

CN1254 (Pin 10)

A_VCBOUT

CN1254 (Pin 12)

Diagnose the COMPONENT Assy.

A_VCROUT

Check the soldering and

connection of the CN1254.

Check Q1202 and its peripheral circuits.

Check Q1203 and its peripheral circuits.

Check Q1204 and its peripheral circuits.

Are there

signals?

No

Ye s

A_VCYOUT

A_VCBOUT

A_VCROUT

Replace Q1202, Q1203, Q1204

and its peripheral parts.

IC800 (through hole)

(Pins E13,D13,E12,D12,E11,

D11,E10,D10,D15) (side B)

Are there

signals?

No

Ye s

VID0-7, VICLK

Check IC1805, IC1806 and its

peripheral circuits.

Check IC800 and its peripheral

circuits.

DVC ON, Analog IN, OUT

A

2 3 4

B

C

D

E

F

36

1

2 3 4

VSX-1020-K

Page 37

5

Step 9: S IN, S OUT

To Step 10

Perform the same check items up to

those for IC1805 and IC1806 of Step 6.

R1203

Are there

signals?

No

NG

Ye s

A_VSYOUT_EM

R1209

A_VSCOUT_EM

Diagnose the IC800 (through hole) of Composite/S/

Component OUT and later.

Replace the D-MAIN Assy.

S

Q

Q

Q

Q

Note: When the connection is Composite OUT and Component OUT,

refer to the diagnose of IC800 and later in steps 8 and 10.

Note: When the connection is S Component OUT,

refer to the diagnose of IC800 and later in steps 8 and 9.

CN1254 (Pin 19)

Are there

signals?

No

Ye s

A_VSYOUT

CN1254 (Pin 21)

A_VSCOUT

Check the soldering and

connection of the CN1254.

P

Is there a

signal?

No

Ye s

CN1254 (Pin 8)

Diagnose the COMPONENT Assy.

A_VCYOUT

Check the soldering and

connection of the CN1254.

Check Q1202 and its peripheral circuits.

Q1200 Emitter

Q1201 Emitter

Are there

signals?

No

Ye s

Check Q1200, Q1201 and

its peripheral parts.

Is there a

signal?

No

Ye s

Replace Q1202 and its peripheral

parts.

IC800 (through hole)

(Pins E13,D13,E12,D12,E11,

D11,E10,D10,D15) (side B)

Are there

signals?

No

Ye s

VID0-7, VICLK

Check IC1805, IC1806 and its

peripheral circuits.

IC800 (through hole)

(Pins E13,D13,E12,D12,E11,

D11,E10,D10,D15) (side B)

Are there

signals?

No

Ye s

VID0-7, VICLK

Check IC1805, IC1806 and its

peripheral circuits.

Check IC800 and its peripheral

circuits. Check the soldering.

Step 10: COMPOSITE IN, COMPOSITE OUT

(at DVC ON)

Step 11: GUI/JPEG (USB)

Composite/S/Component OUT

Go to .

C

Step 12: GUI/JPEG (USB)

HDMI OUT

Perform the same check items up to

those for IC1805 and IC1806 of Step 7.

Is there a

signal?

No

Ye s

R1214

Replace the D-MAIN Assy.

A_VCYOUT_EM

A_VCYOUT

Check IC800 and its peripheral

circuits. Check the soldering.

NG

6 7 8

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

37

Page 38

1

A

A

MC

BC

F

LR

S

C

SB

4

11

1

231

1

1

7

1

7

(121)

(118)

19

RR

A

B

1

4

L,L,L,L,L,L,L,

GNDCH3

GNDCH6

GNDCH4

R402

R403

L452

L453

D561

D562

C9401

C9403

C9404

L651

L652

C1900

D9000

C1901

C1903

C1904

Q1900

7

14

IC361

CN401

IC363

C1908

IC364

C1909

IC365

50

75

IC9000

IC1301

IC1302

IC1303

C1910

8

16

IC1304

D581

L281

C1911

8

16

IC1305

IC561

C1912

D582

D583

C1915

R621

C1917

R623

C1918

R1318

R434

L481

L482

L483

L291

C1345

R1320

D1900

IC9401

JA9401

C1930

8

16

IC1900

C1354

C1931

IC581

C1355

C1932

C1933

C603

C1934

Q1930

IC584

C1935

Q1931

7

14

IC391

C1936

C1937

C1938

C608

C1939

R1915

C419

R1916

R457

R458

C1941

C1942

C1943

C614

C9451

R467

C1952

C1953

C1954

C9460

C1956

D1932

C1957

C1958

R1930

D1934

L1815

R1931

L1816

R1932

L1817

R1933

R475

R476

R283

R477

R284

C1960

R478

R479

R671

R673

R480

D9451

D9452

C9477

R1368

R1369

R293

R294

R1949

R9455

IC9451

C9481

R1372

R1373

1950

1954

R494

C653

L101

L103

L104

C658

L105

L106

R9475

L302

R9476

L303

R9477

C664

L304

R9478

L501

L502

R9482

IC211

L701

L702

C487

C488

F9451

F9452

F9453

F9454

L521

CN1403 CN1404

4

7

14

IC241

X1300

R119

L551

R312

R120

L361

R316

R317

L363

R318

L364

L365

2

R126

L366

10

20

IC452

R127

L367

IC453

24

48

IC261

L751

CN301

L752

R320

R321

L561

L562

R132

D1403

D481

Q9701

D482

D483

D484

C101

R332

C102

R721

R723

R530

10

20

IC281

R1800

R1801

R1803

C114

R1804

L1300

C115

R1805

L1301

R1806

L1302

R1807

L1303

R1808

L1304

L9004

32

64

96

128

IC1800

R348

R1809

10

20

IC291

C505

R1810

C121

R1811

C122

R1812

JH1900

R1817

C703

R1818

R1819

C708

L9401

R552

L9402

L9403

R1823

R1824

R1825

R1828

L1900

C714

R1829

L1901

X9451

L1902

C522

L1903

C523

L1904

C330

C331

C527

R1830

C334

R1831

C335

R1832

R1833

R1834

R1835

R1836

R1837

R575

C539

F1800

R1845

F1801

R1846

F1802

C540

R1849

R771

R9357

R773

C543

R581

R582

R1850

L1930

L1931

L1932

L1933

C363

C753

D501

D502

C758

X361

C567

C568

71

12

24

36

48

IC101

72

L402

L403

L404

C764

L211

36

72

108

144

IC301

C579

L601

L602

C580

C581

C582

Q241

L241

C1301

Q1300

Q9000

Q9001

C1306

IC9402

L9404

R1952

R1953

CN1900

CN1903

C9407

C9408

C1902

C1913

C1343

C606

C1940

C612

C1944

C420

C618

C9472

C261

JA9451

C459

C656

CN482

JA481

C662

C668

JA101

JA102

JA103

JA104

CN501

C103

C1823

C1825

C506

C509

C706C712

C524

C718

C332

C552

C756

C762

C768

C577

C1307

KN481

C333

PC

1

1

1

5

15

10

15

1

5

1

5

1

5

50

55 60 65 70 75

80

15

10

15

20

1

5

1

15

10

5

1

15

10

5

1

1

1

1

1

5

1 5 10 15

15

1015

1

1

5

1

1

5

15

10

1

1

1

1

1

11 11

1

15

15 20

30 35 40

45 50 55

25

10

1 1

1 1

1

1

5

1

1

1

1

1 1

15

1

1

1

1 1 1

15 10

1520

5

1

1

5

101520

25

30

35

40

45

15

1 1

1

E

1

1

1

5

10

15

20

1

1 1

1 1 1

1 1

1 5 10 15 20 25 30

35 40 45 50 55 60

65 70 75 80

85 90 95

100 105 110 115 120 125

1

1

1

5

10

15

20

1 1

1

1

111

111

1

1

1

111

11111

1

1

1

1

1

1

1

1

15 10

15

20

25 30 35

40 45

1 5 10 15 20 25 30 35

40 45 50 55 60 65 70

75 80 85 90 95 100 105

110 115 120 125 130 135 140

E

E

1

E

1

1

1

15

15 15

10

1 5

1

11

15 15

20

10

N

D-MAIN ASSY

8: V+5_DACA

6: V+5_DAC

7: V+5_DACD

4

24

22

26

202325

21 1

2: V+5_DDD1

3: V+3R3_D

Check Points of the D-MAIN Assy

DSP Part HDMI Part

10

15

13

14

16

11

29

28

9

27

18

19

17

Whole

diagram

E

D

D

K

IC1800

IC1301

G

I

A: V+13_U

C: V+5_HD

B: V+5_DDD

5: V+1_DSPF

A

B

C

D

E

F

2 3 4

38

VSX-1020-K

1

2 3 4

Page 39

5

A

1

23

1

1

1

39

1

2191

41

1

14

30

30

DIGITAL MAIN

ASSY

ANP7740-6

5

C

D

RED

ASSY

DIGITAL MAIN

21

1

21

13

2200uF/6.3V

7020-06926-000-1S

GNDCH2

GNDCH1

GNDCH5

GNDCH7

D9000

C1901

R802

R803

R804

25

50

75

100

IC9000

C1718

JA9000

R813

R814

C1721

36

72

108

144

IC1501

CN800

R820

L1200

R821

L1201

R822

L1202

L1203

L1204

X1250

L1400

L1401

R834

R1525

R9225

R1526

R9226

R1527

R1528

R1529

C800

L1605

L1606

L1607

R1530

L1608

R1532

R1533

R1534

R1535

R1536

R1150

R1539

L1611

L1806

L1808

C814

C9460

R855

R857

R1930

L1815

R1931

L1816

R1932

L1817

R1933

C1576

C823

R1555

R1556

L1250

C834

L1251

R1949

R875

R1950

R879

R1954

C846

C849

C855

R94

R9477

R9478

C871

C874

F9451

F9452

F9453

IC800

IC801

C888

C1203

Q1200

Q1201

Q1202

Q1203

C1014

Q1204

CN1601

Q1400

Q1401

Q1402

Q1403

Q1405

Q1408

R1007

C1030

R1008

D1200

D1201

33

66

IC1001

C1032

R1202

R1010

R1011

D1400

R1015

D1401

R1016

D1402

Q9702

Q9703

R1406

R1020

R1021

14

7

IC1401

7

14

IC1406

7

14

IC1407

7

14

IC1408

20

40

60

80

IC1601

CN1259

JA1601 JA1602 JA1603 JA1604

C1252

R1807

R1808

L9004

96

128

IC

R1809

L9005

L9006

L9007

L9008

10

20

IC1807

R1810

R1811

10

20

IC1809

L1501

R1812

L1502

L9010

R1045

R

L1701

L1702

L1706

R1829

R1830

R1831

R1832

IC1250

IC1251

C9752

C917

C9753

C9754

R1263

F800

F801

F802

R1268

F1800

F1801

F1802

R1849

R1850

R1469

R1858

L1931

L1932

JA9551

R1862

R1865

R1866

R1867

R1868

R1871

R1872

Q801

L800

L802

L803

L804

L805

L807

L809

Q9000

Q9001

C1115

X1501

C1501

C1503

CN1900

C1705

C1716

C9033

C1720

C1150

C9049

C1745

C1940

C805

C1944

C809

C818

C820

C1577

C831

CN1400

CN1401

C1202

C1411

C1800

C1611

CN1250CN1252

C1823

CN1254

C1825

C1251

CN1405

LF

A30C5

[[ G ]]

15

10 15 20 25

30 35 40 45 50

55 60 65 70 75

80 85 90 95 100

1 5 10 15 20 25 30 35

40 45 50 55 60 65 70

75

80 85 90 95 100 105

110 115 120 125 130 135 140

15

10

1

1

1

1

1

1

1111

11111

1

1

1

111

1

1 1

11

1

1

30 35 40

1

1 1

1

1

1

A

1

1

5

E

E

E

E

E

E

E

EE

E

1

1 1

1

1 5 10 15 20 25 30

35404550556065

1

1

1

1

1

1

1

E

1

1

1

5

10

15

10

15

10

15

10

1 5 10 15 20

25 30 35 40

45 50 55 60

65 70 75 80

51

1 1

1 1

1

1510

90 95

100 105 110 115 120 125

1

111

15 10

1520

1 1

15 10

1520

1

1

1

1

1111

1

1

5

1

5

1

1

1

1

1

1

1

1

1

1 1

11

11

E

11

1

1

1

1

E

1

1

15

15 15

10

15

10

15 15

20

10

15 15

20

10

15 15

20

10

151015

20

25

30

35

SIDE A

IC800

L

H

F

F

M

IC9000

IC1809

J

IC1501

N

O

I

O

Q

P

IC1601

IC1807

A: V+13_UN

BD ININ 1IN 2IN 3IN 4

R1270

R884

R886

R875

R874

R887

R872

R885

R879

R873

R1214

R1209

R1203

Q1200

Q1201

Q1204

Q1202

Q1203

6 7 8

A

B

C

D

E

F

VSX-1020-K

5

6 7 8

39

Page 40

1

Item

[Error Indications]

[Purpose]

Error Indications When an Abnormality in The Amplifier System is Detected

[How to Enter Release Mode]

FL Display

LED

Flashes

NG

Count.

Detection

Method

Process After Detection Description / Remarks

“AMP DC”

(“DC output from

SP term”)

detection

Flashing

"AMP ERR"

for 3 seconds

MCACC

LED

DC

XDCERR

(Pin 80 of IC3004)

Detect "L"

1) Muting on, speaker relay off.

2) "AMP ERR" flashing

3) Shutdown after 3 seconds.

4) "MCACC" LED flashing

5) Power on is not acceptable.

To detect high DC output from amplifier damage

(defect status).

A process to protect speakers (for protection of

connected external devices).

For checking, refer to "How to enter release

mode" below.

If the DC detection port become “H” for

3 seconds, the unit will returns to normal

condition automatically.

“AMP overload”

detection.

N/A

iPod

LED

OL

XOLERR

(Pin 71 of IC3004)

Detect "L"

1) Muting on, speaker relay off.

2) Shutdown immediately.

3) "iPod" LED flashing

4) Power on is acceptable.

To detect overloading (abnormal status) with

low-load driving or a short circuit of the speaker

terminals (for protection of the amplifier).

“Over Heat”

detection.

Flashing

"AMP

OVERHEAT"

for 3 seconds

Center

Blue

LED

STMP

TEMPERR5

(Pin 72 of IC3004)

Detect "H"

1) Muting on, speaker relay off,

2) "OVERHEAT" flashing

3) Shutdown after 3 seconds.

4) "Center Blue" LED flashing

5) Power on is acceptable after

1 minute.

To detect overheat of inner tempareture.

"Abnormality DC

voltage of the

Digital power

supply" detection

N/A PQLS DERR

XVDDERR

(Pin 70 of IC3004)

Detect "L"

1) Muting on, speaker relay off.

2) Shutdown immediately.

3) "PQLS" LED flashing