Page 1

• X9 500 cc

SERVICE STATION

MANUAL

Piaggio & C. S.p.A.

Pontedera

After Sales Service

Dis. 594523 - 04/01

Grafica e Stampa:

“© Copyright 2001 - PIAGGIO & C. S.p.A. Pontedera.

All rights reserved. Reproduction, in whole or in part, forbidden.”

Data subject to change without notice.

No responsibility is assumed for the use of non-genuine components and accessories other than those tested

and approved by the Manufacturer.

C.L.D. - Pontedera (PI)

Page 2

SERVICE STATION

MANUAL

X9 500 cc

This manual has been designed by Piaggio for use in authorized dealers' and subdealers' workshops.

It is assumed that those who use this publication for maintaining and repairing Piaggio vehicles are familiar with the

principles of mechanics and with vehicle repairing procedures and techniques. Any significant changes to the

characteristics of the vehicles or to specific repairing procedures will be covered in updates of this manual.

Since satisfactory results cannot be obtained without the necessary equipment and tooling, we recommend referring

to the pages of this manual concerning the specific equipment required and to the catalogue of specific tools.

Pieces of particularly important information are identified as follows:

Note: Provides important information intended to simplify and clarify a procedure.

Warning

Caution

NOTE - For any intervention to the engine, refer to the “Service Station Manual” for 500 cc Engines.

- Denotes specific procedures to be used to avoid damaging the vehicle.

- Identifies specific procedures to be followed to avoid injury to repairing personnel.

Page 3

TABLE OF CONTENTS

VEHICLE SPECIFICATIONS

AND OVERHAUL DATA

SPECIFIC TOOLING

MAINTENANCE AND TROUBLESHOOTING

ELECTRICAL EQUIPMENT

1

2

3

4

ENGINE

FRONT AND REAR SUSPENSIONS

BRAKING SYSTEM

BODYWORK

5

6

7

8

PREDELIVERY OPERATIONS

TABLE OF WORKING TIMES

9

10

Page 4

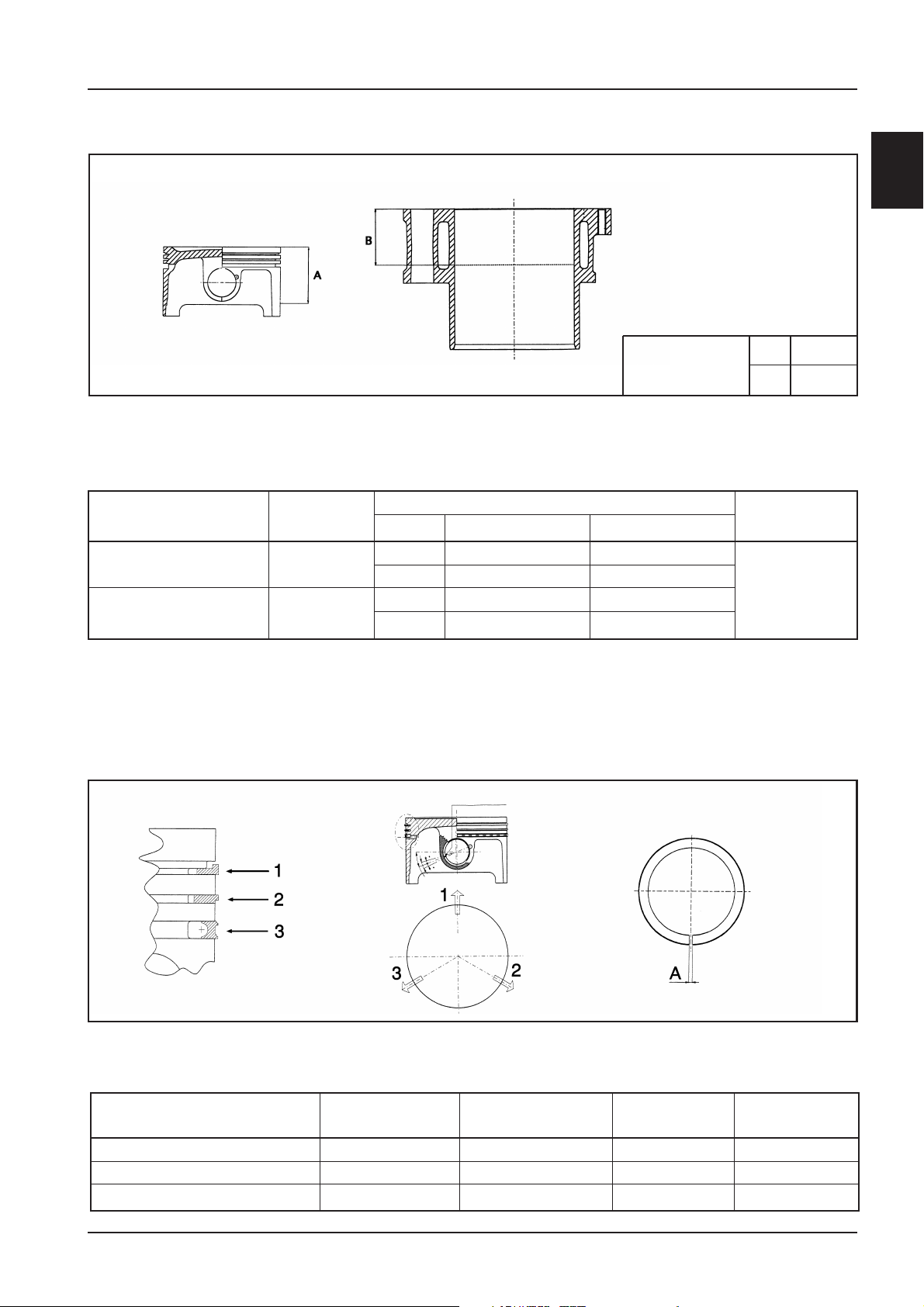

Assembly plays

Vehicle overhaul data

1

(Values in mm)

DIAMETER

MEASURING

HEIGHT

A 43.2

B 43

01_004

Mating between piston and cylinder

(Values in mm)

PART DIMENSIONS MATING CLASSES ASSEMBLY

CODE CYLINDER PISTON CLEARANCE

Cylinder 92

Ø C B 91.997 - 92.004 91.954 - 91.961

Piston 91.961

- 0.010

+ 0.018

+ 0.014

- 0.014

A 91.990 - 91.997 91.947 - 91.954

C 92.004 - 92.011 91.961 - 91.968

0.036

-

0.050

Ø P D 92.011 - 92.018 91.968 - 91.975

The piston must be fitted so that the arrow faces the exhaust side. The piston rings must be fitted so that the marks

face upwards.

Piston rings

Ring opening

Arrange for the

piston rings

opening as shown

Assemble the rings

2 and 3 with the

“Top” writing facing

upwards.

in the figure

“A” value of the ring

inside the cylinder

(Values in mm)

PART DIMENSIONS CLEARANCE SEAT CLEARANCE

CODE CLEARANCE AFTER USE

1st Compression ring 92 x 1.5 A 0.15 - 0.35 0.5

2nd Compression ring 92 x 1.25 A 0.25 - 0.50 0.65

Scraper ring 92 x 2.5 A 0.25 - 0.50 0.65

01_005

1 - 7

Page 5

Vehicle overhaul data

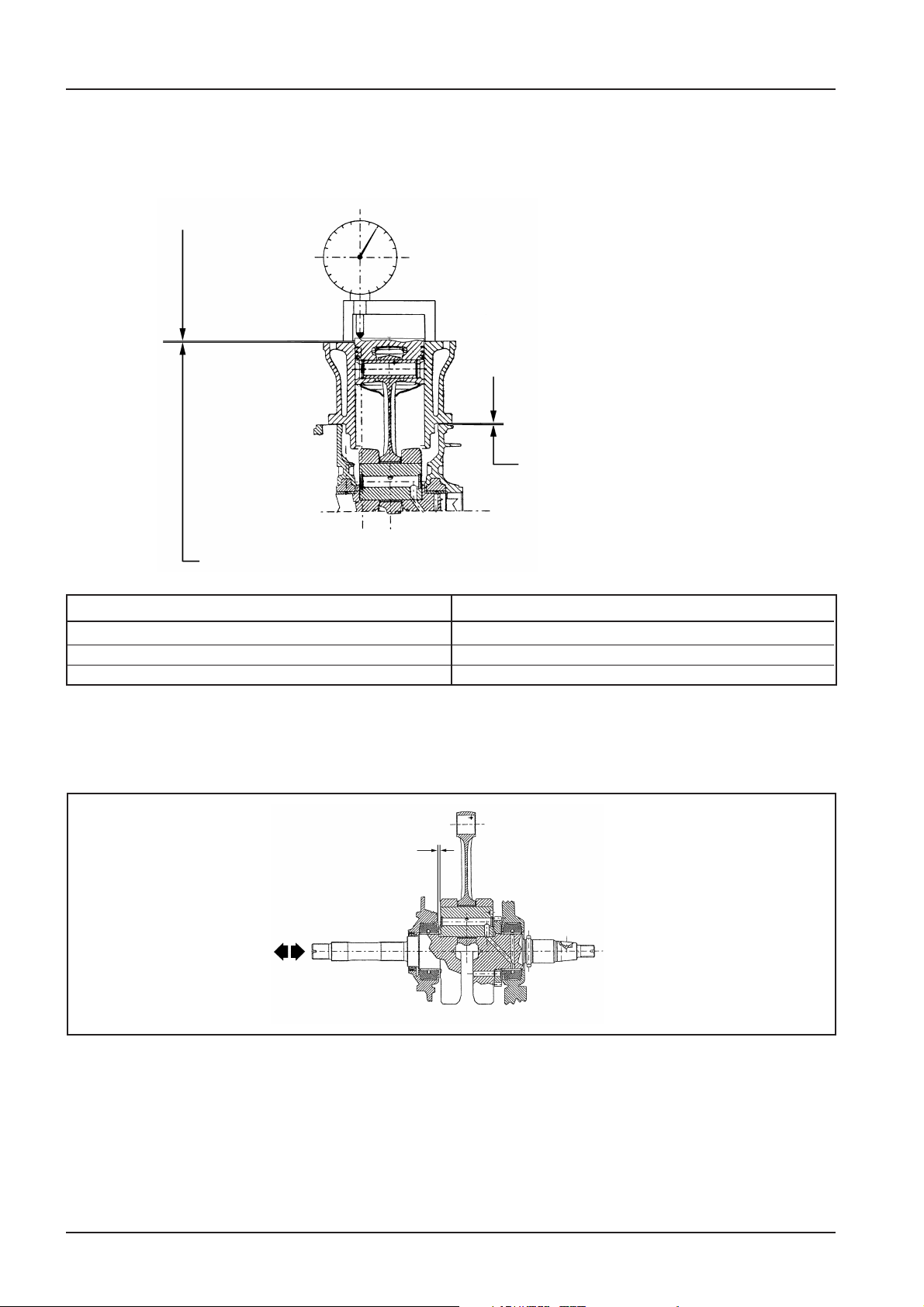

SHIMMING METHOD FOR LIMITING THE COMPRESSION RATIO: CR = 10.5 : 1

+

“A” MEASUREMENT

(WITH PISTON AT TDC)

-

N.B.: The “A” measurement is referred to the piston

projection or recess value; it indicates the type of

gasket to be fitted on the cylinder to restore the

compression ratio. Therefore the more the surface

formed by the piston crown sticks out of the surface

formed by the cylinder top, the thicker the gasket will

be. Vice versa, the more the piston crown is hollow to

the cylinder top, the less thick the gasket will be.

FIT THE GASKETS SHOWN IN THE TABLE

ACCORDING TO THE “A” MEASUREMENT

NOTE: THE “A” MEASUREMENT MUST BE TAKEN WITH NO

GASKET FITTED BETWEEN CRANKCASE AND CYLINDER

“A” MEASUREMENT THICKNESS OF BASE GASKET

- 0.185 - - 0.10 0.4 ± 0.05

- 0.10 - + 0.10 0.6 ± 0.05

+ 0.10 - + 0.185 0.8 ± 0.05

Crankshaft/crankcase axial clearance 0.1 - 0.5 mm (cold engine)

01_006

1 - 8

01_010

Page 6

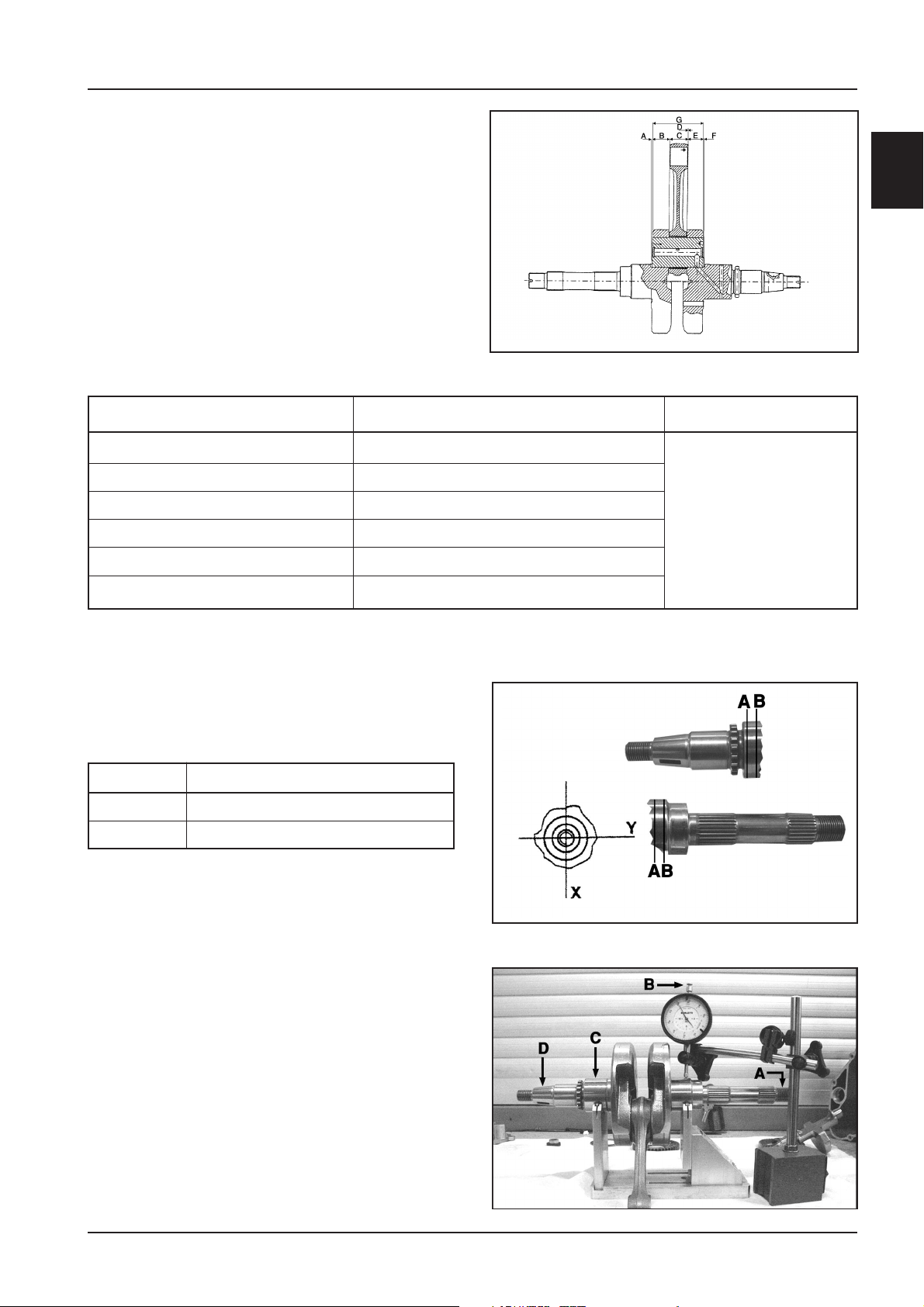

Crankshaft/connecting rod axial clearance

PART DIMENSIONS CLEARANCE

Web, transmission side A =0.8

Shaft section, transmission side B =19.6

Connecting rod C =22

Shaft section, flywheel side E =19.6

Web, flywheel side F =13

Crankshaft assembly G =63.5

± 0.025

+ 0.05

0

- 0.10

- 0.15

+ 0.05

0

± 0.025

+ 0.1

- 0.05

Vehicle overhaul data

1

01_007

D = 0.20 - 0.40

Crankshaft alignment and diameters

- Measure the housings on both axes x and y.

Standard diameter

Class 1 40.010 - 40.016

Class 2 40.016 - 40.022

Max. allowable runout: A = 0.15 mm

B = 0.01 mm

C = 0.010 mm

D = 0.10 mm

01_008

01_009

1 - 9

Page 7

TABLE OF CONTENTS

SPECIFIC TOOLING

2

Page 8

Specific Tooling

Specific tools for Piaggio X9 500 cc 4-stroke 4-valve

RECOMMENDED TOOLS

TOOL NAME PART NO.

Circlip pliers 002465Y

Steering thrust ring removing drift 020004Y

Crankshaft aligning tool 020074Y

Support for “METABO HG 1500/2” air heater 020150Y

“METABO HG 1500/2” air heater 020151Y

Mityvac-type vacuum pump 020329Y

Stroboscopic gun for two- and four-stroke engines 020330Y

Digital multimeter 020331Y

Single battery charger 020333Y

Multiple battery charger 020334Y

Magnetic stand and dial gauge 020335Y

Engine support connection 020482Y

Engine mount base 020527Y

Engine mount revolving base 020604Y11

= New tools

2 - 2

Page 9

Specific Tooling

NECESSARY TOOLS

TOOL NAME PART NO.

STEERING SEAT FITTING TOOL, to be fitted with parts 9 - Lower 001330Y

bearing adaptor, 10 - Upper bearing adaptor

Bell Ø 80 mm 001467Y002

20 mm pliers 001467Y006

Bell Ø 63 mm 001467Y007

18 mm pliers 001467Y008

Bell Ø 45 mm 001467Y017

Bell Ø 60 mm 001467Y031

15 mm pliers 001467Y034

Hub bearing extraction bell 001467Y035

Steering tube ring spanner 020055Y

Oil pressure gauge 020193Y

Valve seal rings assembly tool 020306Y

37x40 mm adaptor 020358Y

42x47 mm adaptor 020359Y

52x55 mm adaptor 020360Y

20 mm guide (Driven pulley bearings) 020363Y

25 mm guide (Driven pulley bearings) 020364Y

Ø 28x30 mm adaptor 020375Y

Adapter sleeve 020376Y

Bushing (valve removing tool) 020382Y012

15 mm guide 020412Y

Valve oil seal extractor 020431Y

Oil pressure gauge unio 020434Y

17 mm guide (countershaft bearings) 020439Y

Driven half pulley spring compressor 020444Y

46-55 mm spanner 020444Y009

Ø 24 mm adaptor 020456Y

Steering tube lower bearing extractor 020458Y

Drift for fitting bearing on steering tube 020459Y

Injection tester kit 020460Y

Flywheel extractor 020467Y

Piston fitting band 020468Y

Injection tester reprogramming kit 020469Y

Piston pin retainer fitting tool 020470Y

Countershaft timing peg 020471Y

Flywheel retaining tool 020472Y

Clutch bell housing retaining tool 020473Y

Drive pulley stop spanner 020474Y

Piston position comparator support 020475Y

Pillar kit 020476Y

Ø 37 mm adaptor 020477Y

Driven pulley needle roller drift 020478Y

Countershaft stop spanner 020479Y

Fuel pressure measuring kit 020480Y

Control unit interface wiring harness 020481Y

30 mm guide 020483Y

Piston stop fork 020512Y

Compass wrench (valve lifter bell stop) 020565Y

Exhaust gas analyser 494929

2

2 - 3

Page 10

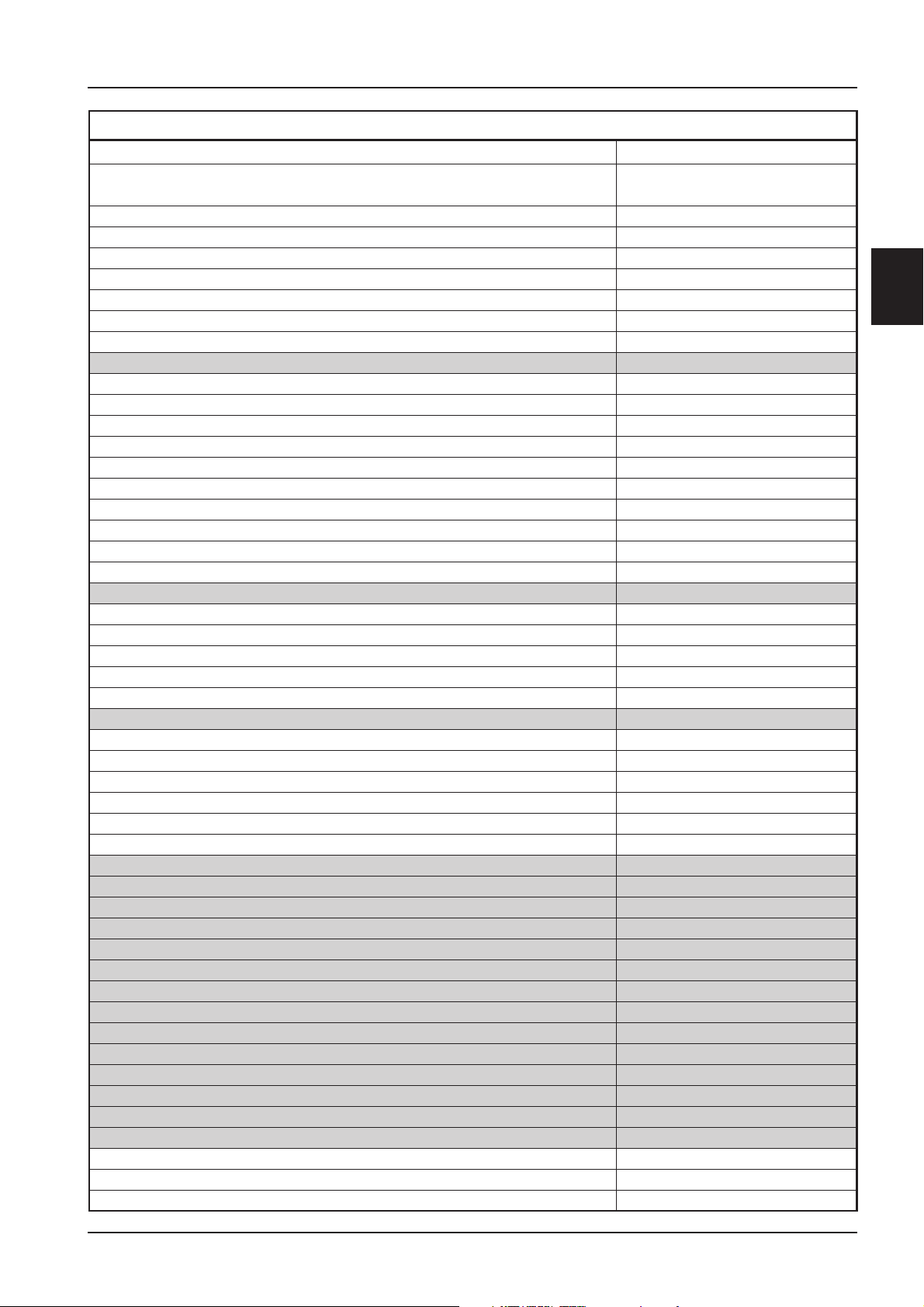

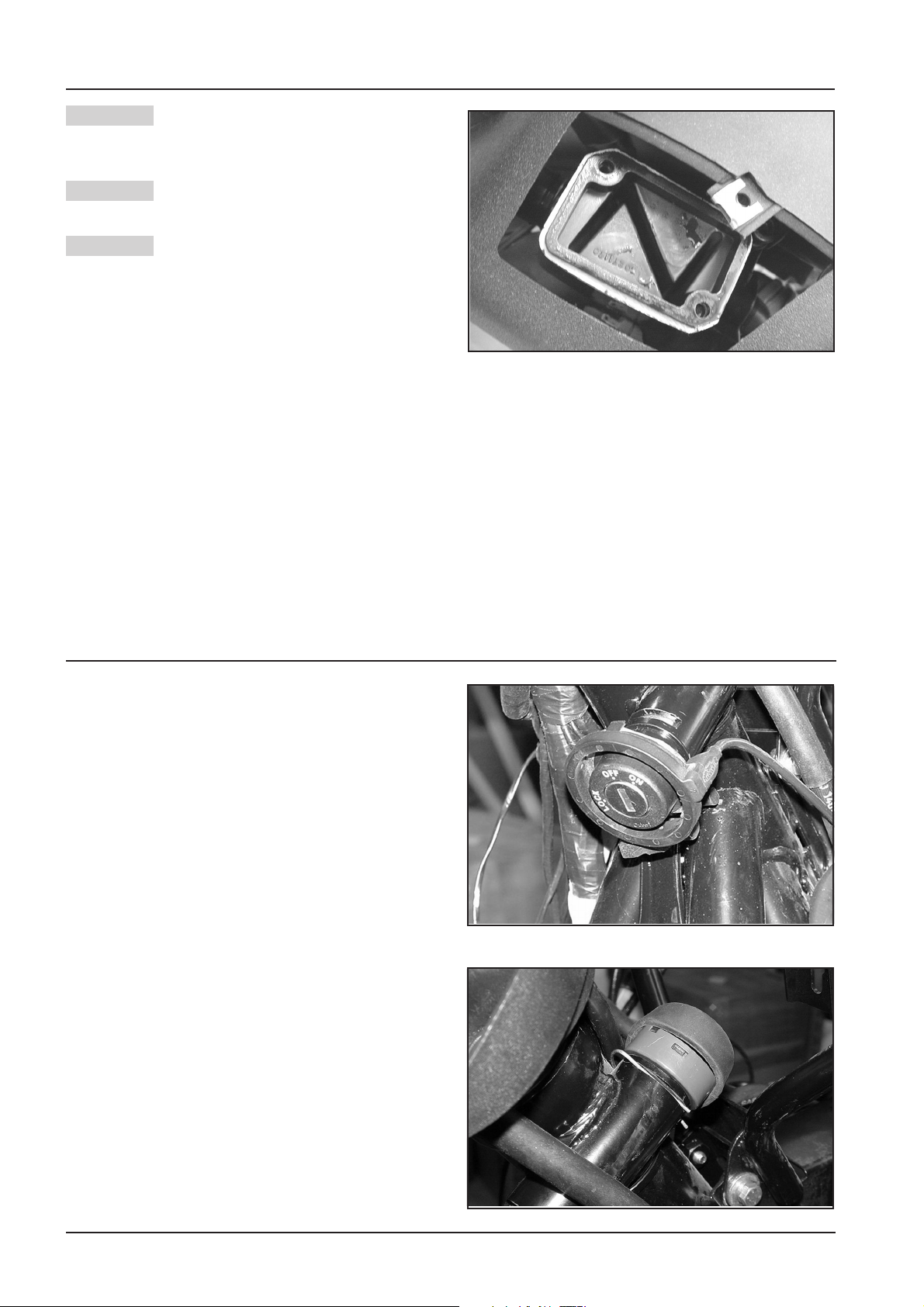

Spark plug

Check and replacement

Maintenance

Warning

is cold. Replace the spark plug every 12,000 km. The

use of unsuitable ignition control units and spark plugs

other than those specified can seriously damage the

engine.

Recommended spark plug: CHAMPION RG 6 YC

- Put the vehicle on the central stand.

- Open the door on the left side of the vehicle by

levering in the recess in the lower part of the door after

removing the screw.

- Disconnect the spark plug HV cable cap.

- Unscrew the spark plug with the spanner provided.

- Check the spark plug to see if the insulator is cracked,

the electrodes are worn out or excessively sooty. Also

check the condition of the seal washer and measure

the spark gap with a suitable thickness gauge.

Spark gap: 0,7 - 0,8 mm

- If necessary adjust the spark gap by carefully bending the side electrode.

If the spark plug has any of the defects mentioned

above, replace it with a plug of the recommended

type.

- Insert the plug into the hole with the proper inclination, screw it in fully by hand and then tighten it with

the specially designed spanner.

Tightening torque: 10 N·m (1 Kg·m)

- Push the spark plug cap all the way down onto the

spark plug and then proceed to the reassembly.

- Remove the spark plug when the engine

NGK CR 7 EKB

03_001

3

03_002

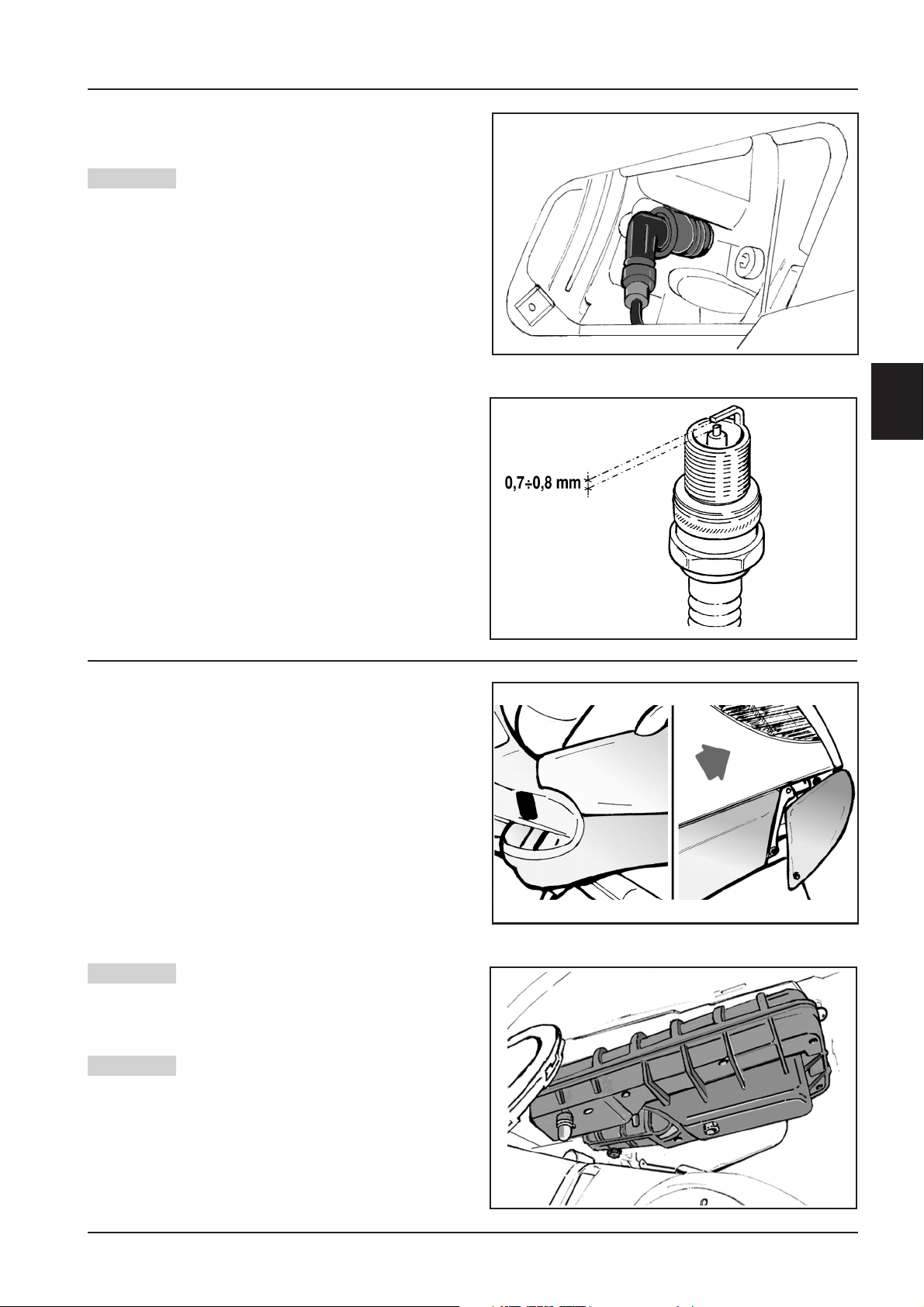

Air filter

- Remove the left-hand lower side panel as described

in Chapter 8-Bodywork.

- Remove the cleaner cap after loosening the eight

fixing screws, including one screw of the knob type.

- Pull out the filter element.

- Replace the air filter with a new one.

Note: Check and if necessary blow the air filter every

6,000 km. Direct the air jet from the inside to the outside

of the filter (i.e. in the opposite direction to the air flow

during normal engine operation).

Warning

roads, the air filter needs to be cleaned and replaced at

shorter intervals than indicated in the Maintenance

Schedule.

Warning

in place as this would result in excessive wear of the

cylinder and piston as well as in damage to the throttle

body.

- If the vehicle is mostly used on dusty

- Do not run the engine if the air filter is not

03_003

03_004

3 - 3

Page 11

Maintenance

Engine oil level

In four-stroke engines oil is used to lubricate the valve

gear components, the crankshaft bearings and the

power plant. A lack of engine oil can cause serious

damage to the engine.

In all four-stroke engines, oil deterioration and consumption are, to some extent, normal, especially during

running-in. Consumption partly depends on the riding

style (for example, constantly riding at full throttle

increases oil consumption).

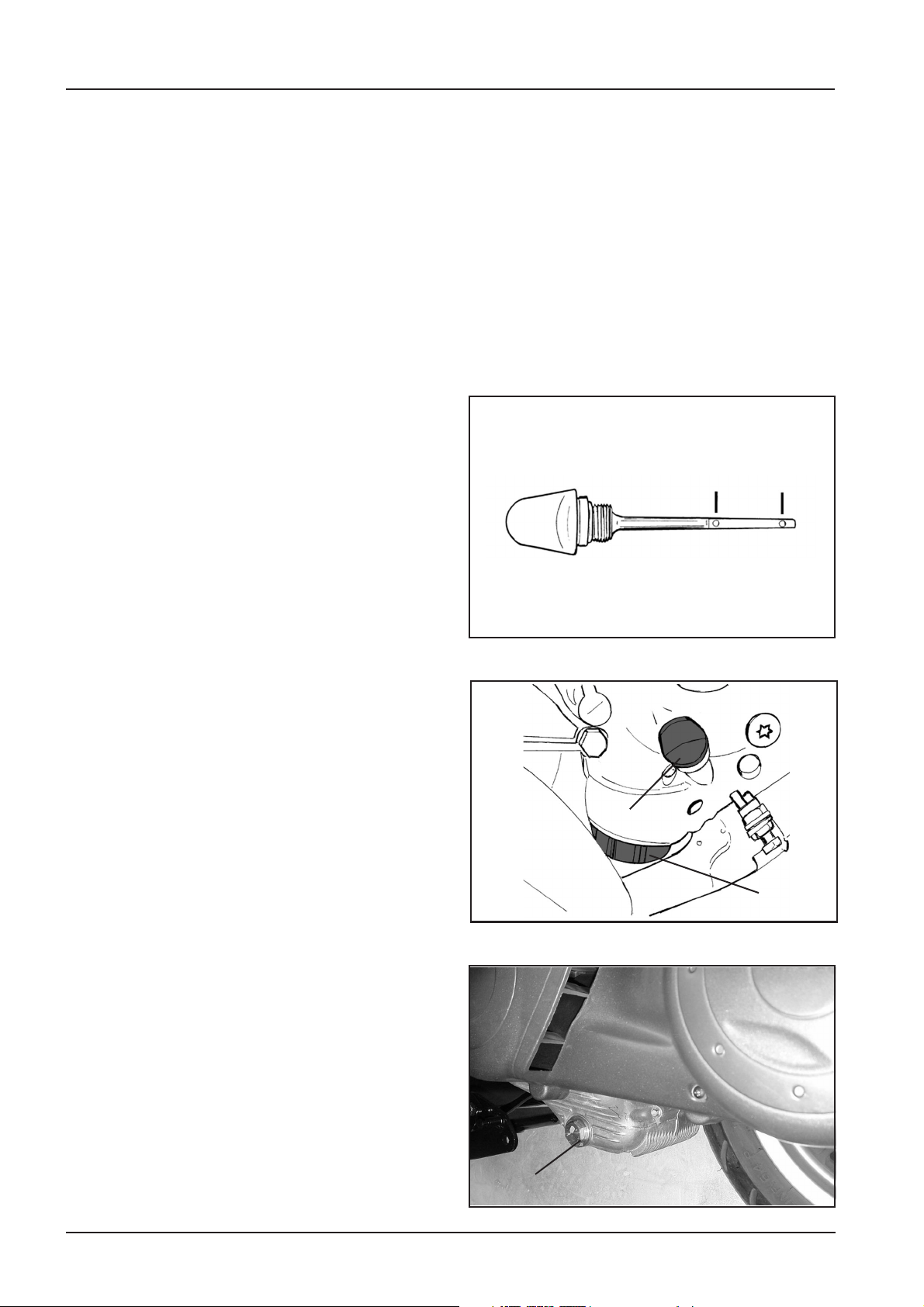

Checking the oil level

Perform this operation when the engine cold, as described below:

1) Put the vehicle on its central stand on a flat surface.

2) Unscrew dipstick «A», dry it with a clean cloth and

refit by screwing it completely.

3) Remove the dipstick again and check that the oil

level is between the MAX and MIN marks on the

dipstick; top up if necessary.

The MAX level mark indicates an amount of about 1700

cc of engine oil.

The level will be lower if checked after using the vehicle

(i.e. when the engine is hot). To obtain a correct

indication of the oil level, wait for at least 10 minutes

after switching off the engine.

Since a certain amount of oil remains in the circuit, the

replenishment must be made by adding approximately

1,500 cc of fresh oil through cap «A». Subsequently

start the engine, let it idle for a few minutes and then

switch it off. After about 5 minutes, check the level and

if necessary top up without exceeding the MAX level.

The filter cartridge must be replaced every time the oil

is changed. For top-ups and renewals use fresh oil of

the Selenia HI Scooter 4 Tech type.

Note: Renew the oil when the engine is hot.

MAX MIN

03_005

Topping up

If the oil level is too low, top up by adding fresh oil

without exceeding the MAX level.

Approximately 400 cc of oil are needed to restore the

level between the MIN and MAX marks.

Oil pressure warning light

A warning light on the instrument panel comes on when

the ignition key is turned to the “ON” position. The light

must go out after the engine has started.

Should the warning light come on while braking,

idling or cornering, check the oil level and the

lubrication system as soon as possible.

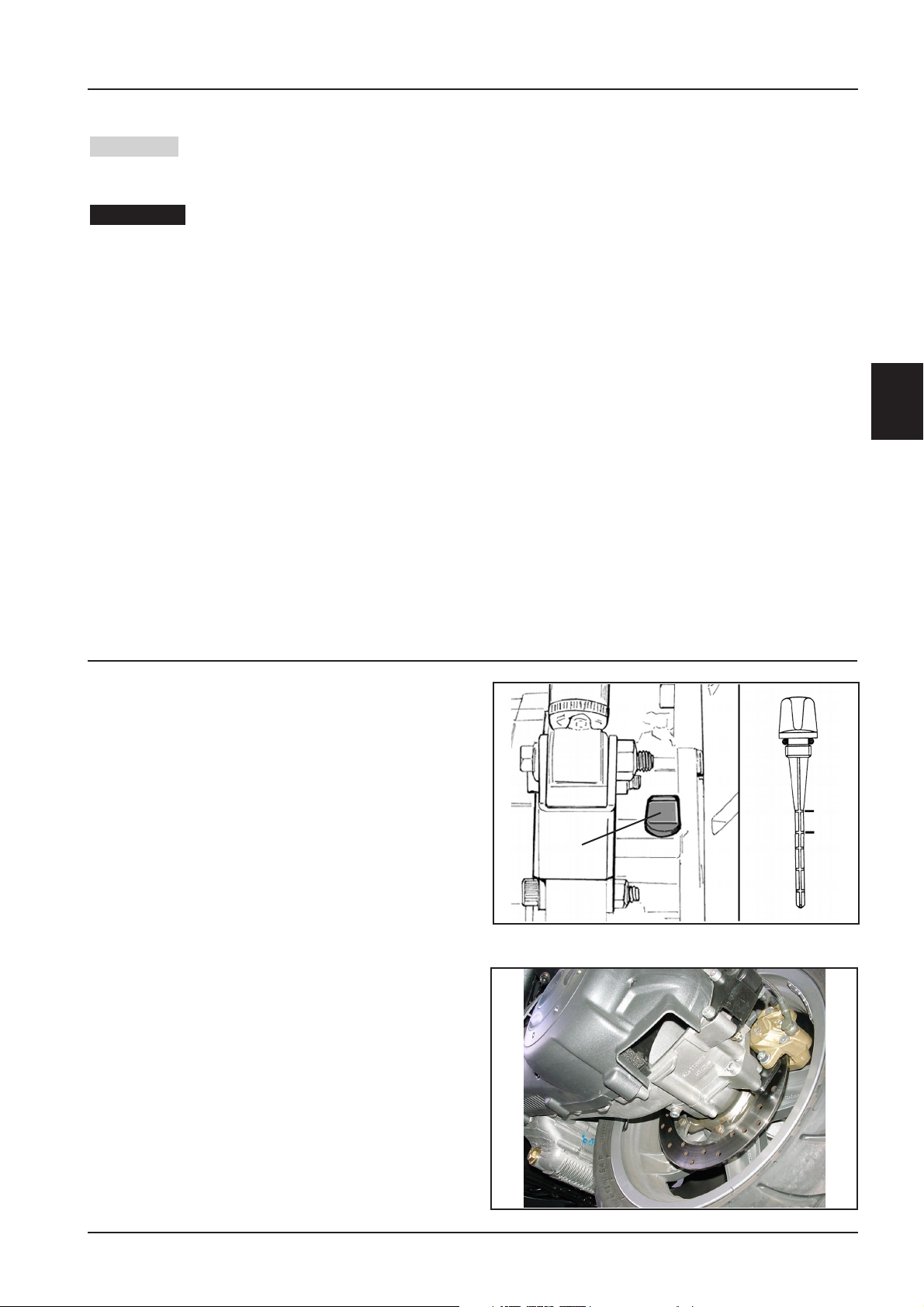

Renewing the oil and the filter

The oil and the filter must be renewed every 6,000 km.

Drain all the oil from the engine by removing gauze

strainer drain plug «B» on the transmission side. To

facilitate the outflow, also remove cap/dipstick «A».

Once the oil has drained completely through the drain

hole, unscrew oil filter cartridge «C» and remove it as

described below.

A

C

03_006

B

03_007

3 - 4

Page 12

Replacing the filter

Maintenance

Warning

ment. Carry out the disposal of the oil, the gasket and

the filter in accordance with the law.

Caution

hot engine parts.

- Remove the silencer.

- Remove filler plug «A».

- Remove and clean the drain plug gauze strainer with

compressed air.

- Using a strap wrench for filters, remove cartridge

filter «C».

- Ensure that the O-rings on the prefilter and the drain

plug are in good condition.

- Lubricate the O-rings and then refit the gauze strainer

and the oil drain plug. Tighten the drain plug with the

prescribed torque.

- Fit a new cartridge filter after lubricating the O-ring.

Turn in until the gasket makes contact and then

tighten it with the prescribed torque.

- Reinstall the silencer.

- Add engine oil as previously described.

Tightening torque:

Tappo scarico olio motore Engine oil drain

plug: 24 - 30 N·m

Oil filter: 12 - 16 N·m

Oil type: Selenia HI Scooter 4 Tech

- Do not dispose of the oil in the environ-

- To avoid burns, take care not to touch

3

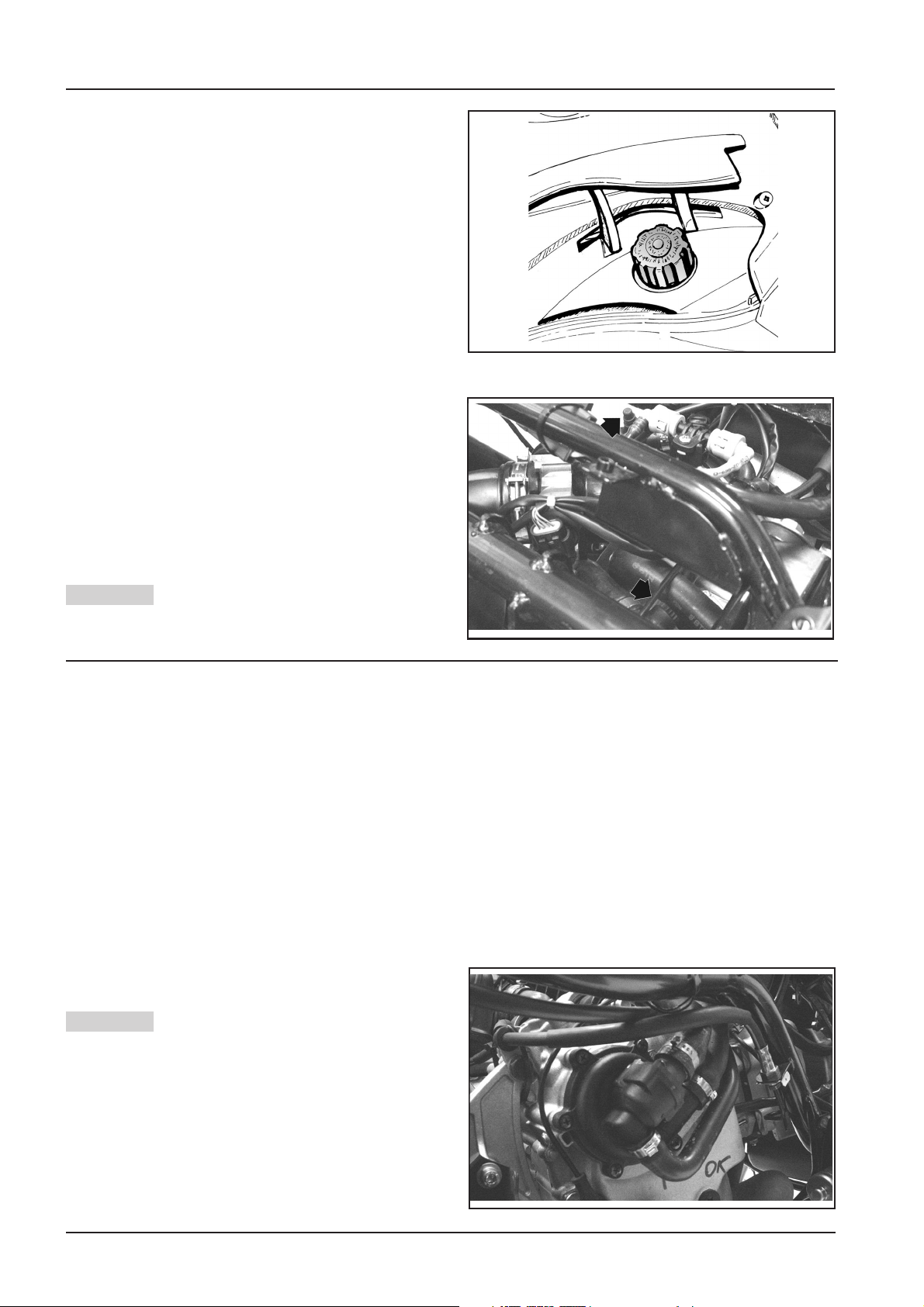

Checking the hub oil level

- Put the vehicle on the central stand on level ground.

- Unscrew oil dipstick «A», wipe it with a clean cloth,

reinsert it and then screw it in fully.

- Pull out the dipstick again and check that the oil level

is between the MIN and MAX marks (see figure); if the

level is below the MIN mark, top up with oil.

- Reinsert the dipstick and screw it tight.

Renewing the hub oil

- Remove oil filler plug «A».

- Unscrew oil drain plug «B» and drain all the oil.

- Retighten the oil drain plug and then fill the hub with

fresh oil.

MAX

MIN

A

03_008

Recommended oil: TUTELA ZC 90

Hub oil capacity: ~ 250 cc

A

B

03_009

3 - 5

Page 13

Maintenance

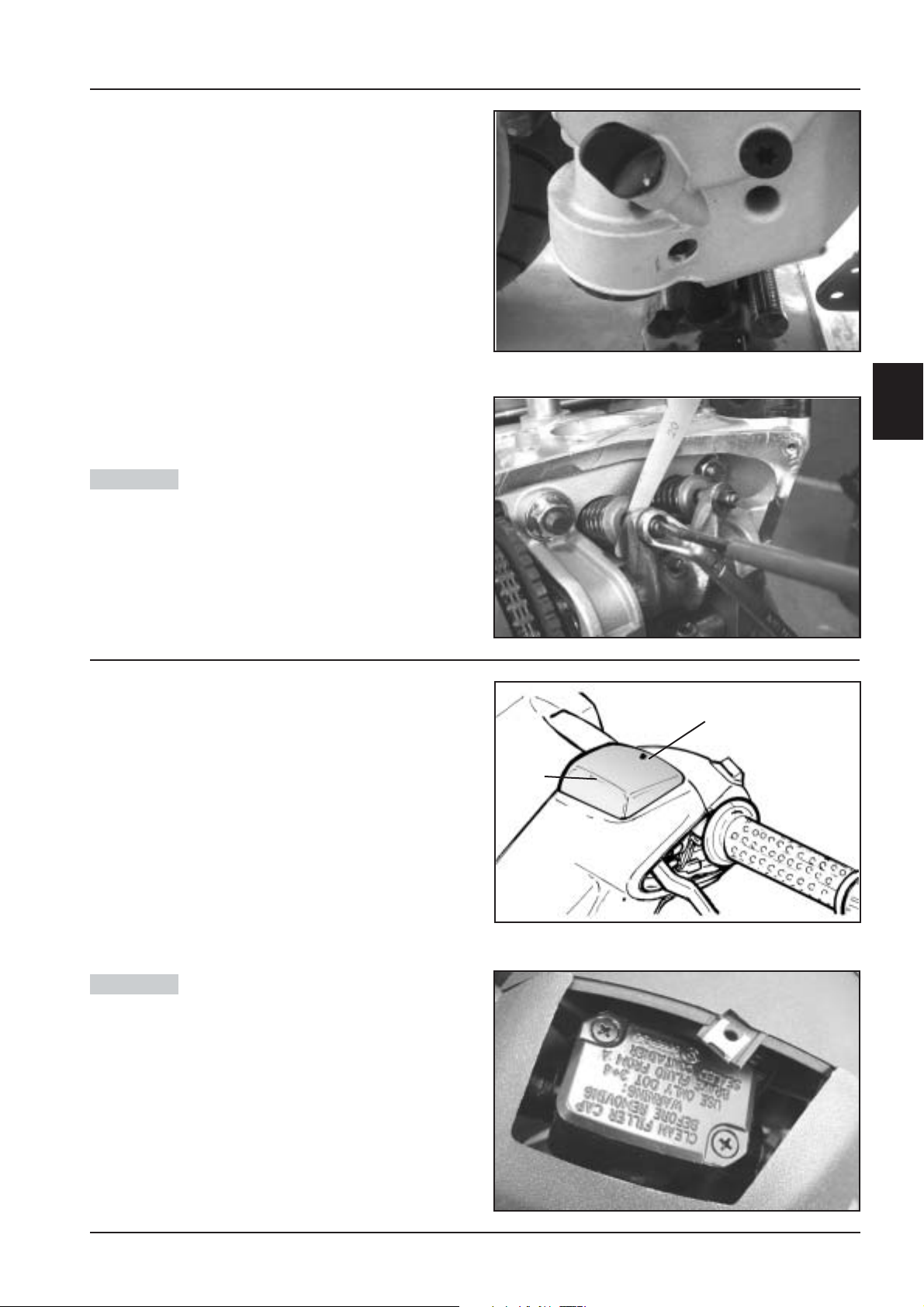

Engine cooling

Adding coolant and bleeding air from the system

The level of the fluid must be checked every 6,000 km

when the engine is cold.

Follow these steps:

- Put the vehicle on the central stand on level ground.

- Remove the expansion tank cap and top up if the

coolant is below or near the MIN level in the expansion

tank. The level of the fluid should always be between

the MIN and MAX marks.

- To have an indication of the coolant level, refer to the

groove in the plastic strip that can be seen through the

coolant filler hole. The upper and lower parts of the

groove correspond to the MAX and MIN levels respectively.

- The coolant consists of a 50 percent mixture of

demineralized water and antifreeze solution with a

base of ethylene glycol and corrosion inhibitors.

Total coolant capacity: ~ 1,8 lt

- To check the presence of air in the circuit follow the

procedure described in Chapter 11-Cooling, in the

manual of Engine 500 cc.

- Switch off the engine and allow it to cool down. After

a few minutes, remove the expansion tank cap and

check the level of the fluid.

- If necessary, top up by pouring fresh coolant into the

expansion tank up to the correct level.

03_010

Warning

- To prevent the coolant from leaking out

of the expansion tank during use, be sure to never

exceed the MAX level when refilling.

Water pump

If the water pump becomes noisy or liquid leaks through

the pump drain hole, check the water pump as described in Chapter 5-Flywheel cover of the manuale

Engine 500 cc. Perform the following preliminary operations:

- Put the vehicle on the central stand on level ground.

- Remove the lower right-hand side panel and the

right-hand footboard as described in Chapter 8Bodywork.

- Remove the silencer to gain access to the flywheel

cover as described in Chapter 5-Engine;

- Remove the sleeves from the water pump cover and

the filler cap from the expansion tank and empty the

cooling circuit.

Warning

- Perform the operation when the engine

is cold.

03_011

- As described in the manual Engine 500cc, partially

drain the system and overhaul the pump.

- After solving the problem and refitting all components,

fill and bleed the cooling circuit again.

N.B.: Change the coolant as described in Chapter 11Cooling of the Manual Engine 500 cc

- Remove the water pump cover shown in the figure

after loosening the six fixing screws.

- Cooling circuit capacity: ~ 1,8 lt.

3 - 6

03_013

Page 14

Adjusting the play of the valves - Checking the valve

gear timing

To adjust the play of the valves and to check the valve

gear timing as described in Chapter 7-Thermal Unit and

Timing system of the Engine manual, follow these

preliminary steps:

- Put the vehicle on the central stand;

- Remove the relevant body sections to gain access to

the pivot fixing the engine to the swingarm (refer to

Chapter 8-Bodywork);

- Support the bottom of the engine, e.g. with a jack;

- Remove the engine from the frame as described in

Chapter 5-Engine;

- Shift the engine backwards to make room for the

removal of the cylinder head cover (until the swingarm

cross member touches the starter motor).

- After adjusting the play of the valves, refit the components by following the reverse procedure to the removal.

Maintenance

03_012

3

Warning

prevent it from touching the stop push button of the

electrohydraulic stand.

Note: The checking areas are shown in the two figures

at the right.

Play of valves:

Intake 0,20 mm cold engine

0.15

Exhaust 0,20 mm cold engine

0.15

Checking the level

To gain access to the front and rear brake fluid reservoirs, remove the covers on the handlebar cover.

Follow these steps:

- Put the vehicle on the central stand and turn the

handlebar to the central position.

- Remove cap «A» after loosening fixing screw «B».

- Check the level of the fluid through the sight.

A certain decrease in the level of the fluid occurs as a

result of pad wear.

Restoring the brake fluid level

- Do not lower the engine too much to

03_012_4

B

A

03_012_1

Warning

Brake fluid type: TUTELA TOP 4

Use the following procedure:

Remove the «A», covers and the tank cap by unscrewing the two screws, remove the gasket and restore the

brake fluid level with liquid of the recommended type,

without exceeding the max. level.

- Only use brake fluid classified as DOT 4.

03_012_2

3 - 7

Page 15

Maintenance

Warning

- Keep the brake fluid away from the skin,

the eyes and clothing. In case of contact, rinse generously with water.

Warning

- The brake fluid is highly corrosive. Take

care not to spill it on the paintwork.

Warning

- The brake fluid is hygroscopic, i.e. it

absorbs humidity from the air. If the humidity contained

in the fluid exceeds a given concentration, the braking

action becomes insufficient.

Never draw the fluid from open or partly empty containers.

Under normal climatic conditions the fluid should be

renewed every 20,000 km, or in any case every two

years.

N.B.: Change the brake fluid and bleed the system as

described in Chapter 7-Braking system.

03_012_3

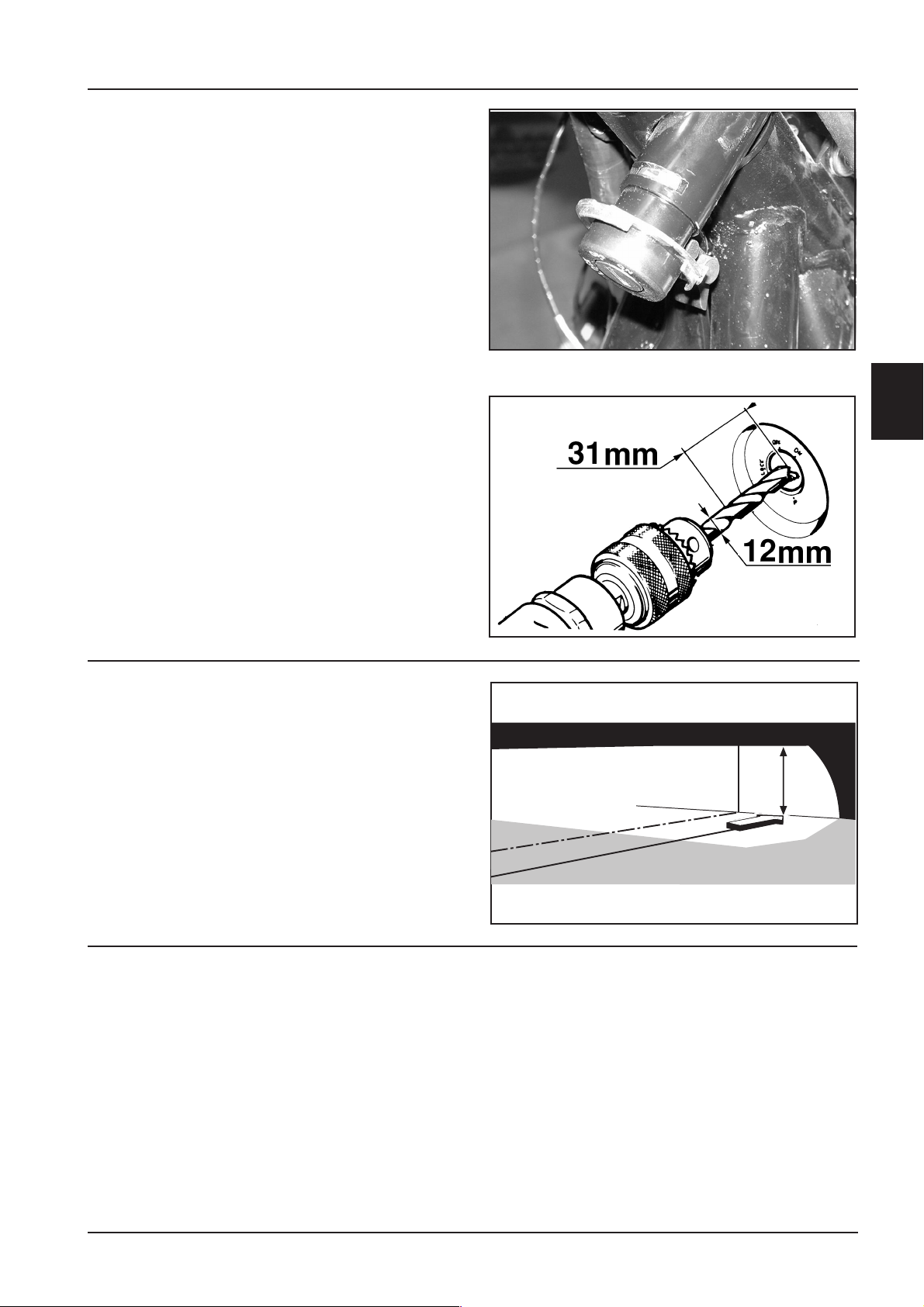

Steering lock

Disassembly with lock turned to “OFF”

- Remove the rear shield as described in Chapter 8-

Bodywork.

- Remove the immobilizer aerial shown in the figure.

- Disconnect the wiring.

- Pull out the retaining spring shown in the figure and

remove the ignition switch.

03_014

3 - 8

03_015

Page 16

- Push the bolt lightly and extract the retainer from the

70÷73 cm

10 m

milled part shown in the figure.

- Extract the bolt assembly from the lock body.

- To refit, follow the reverse procedure.

Maintenance

03_016

Removal with lock in LOCK position

The bolt retaining spring is not accessible in the LOCK

position. It is then necessary to drill the bolt as show in

the figure to eject it.

Note: To refit the bolt from this position, first disengage

the steering lock by putting the lock body (inner and

outer part) in the OFF position.

Proceed as described in the previous paragraph.

Adjusting the headlight

- Place the unloaded vehicle on a level surface, 10

metres from a half-lit white screen, with the tyres

inflated to the prescribed pressure. Ensure that the

axis of the vehicle is perpendicular to the screen.

- Draw a horizontal line on the screen 70-73 cm above

the ground.

- Switch on the headlight, turn on the low beam and

check that the horizontal line that divides the dark

area from the lighted area is not above the line

previously drawn on the screen. To shift the headlight, use the specially designed screw in the front

shield (see figure).

3

03_017

03_018

3 - 9

Page 17

TABLE OF CONTENTS

ELECTRICAL EQUIPMENT

4

Page 18

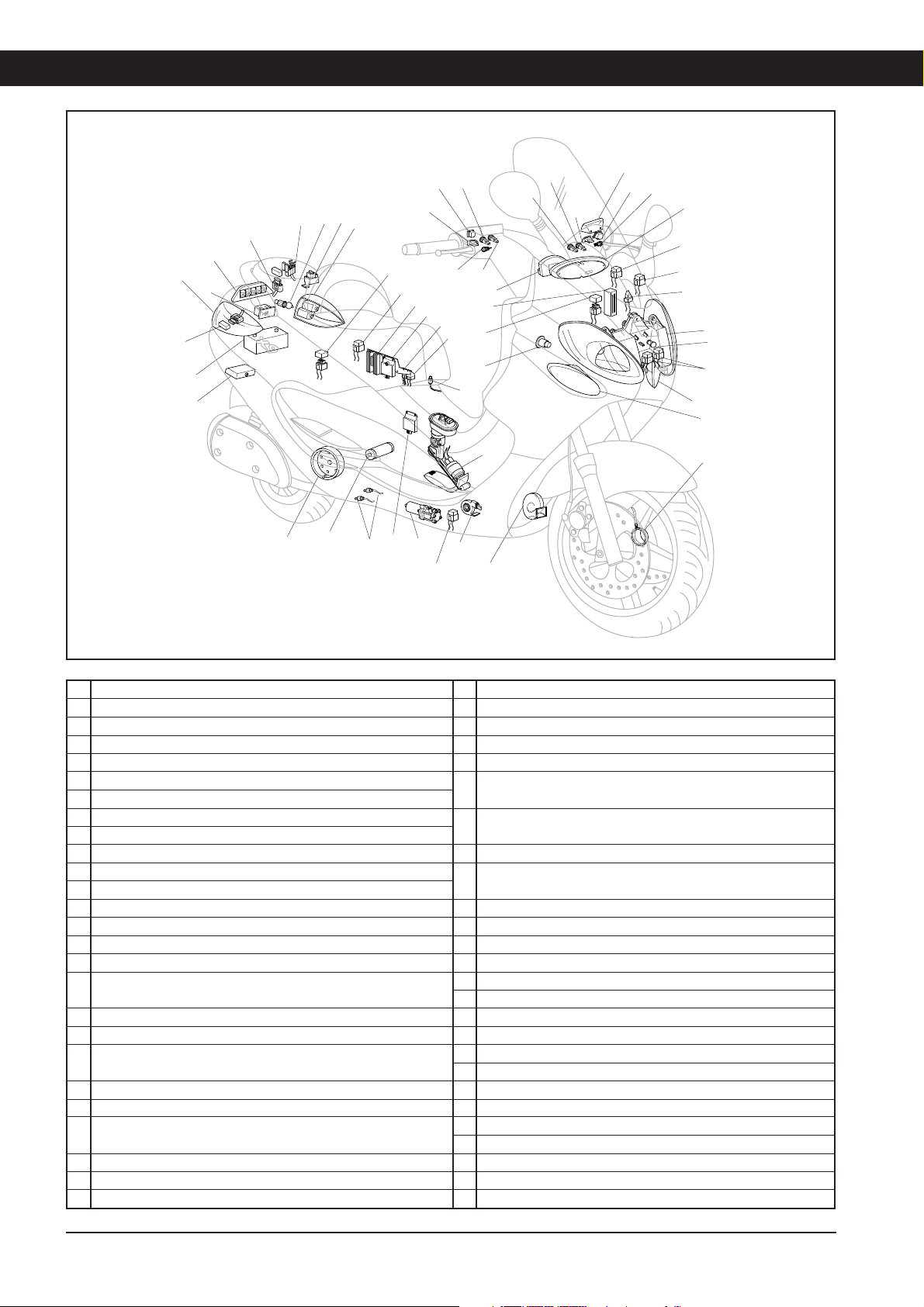

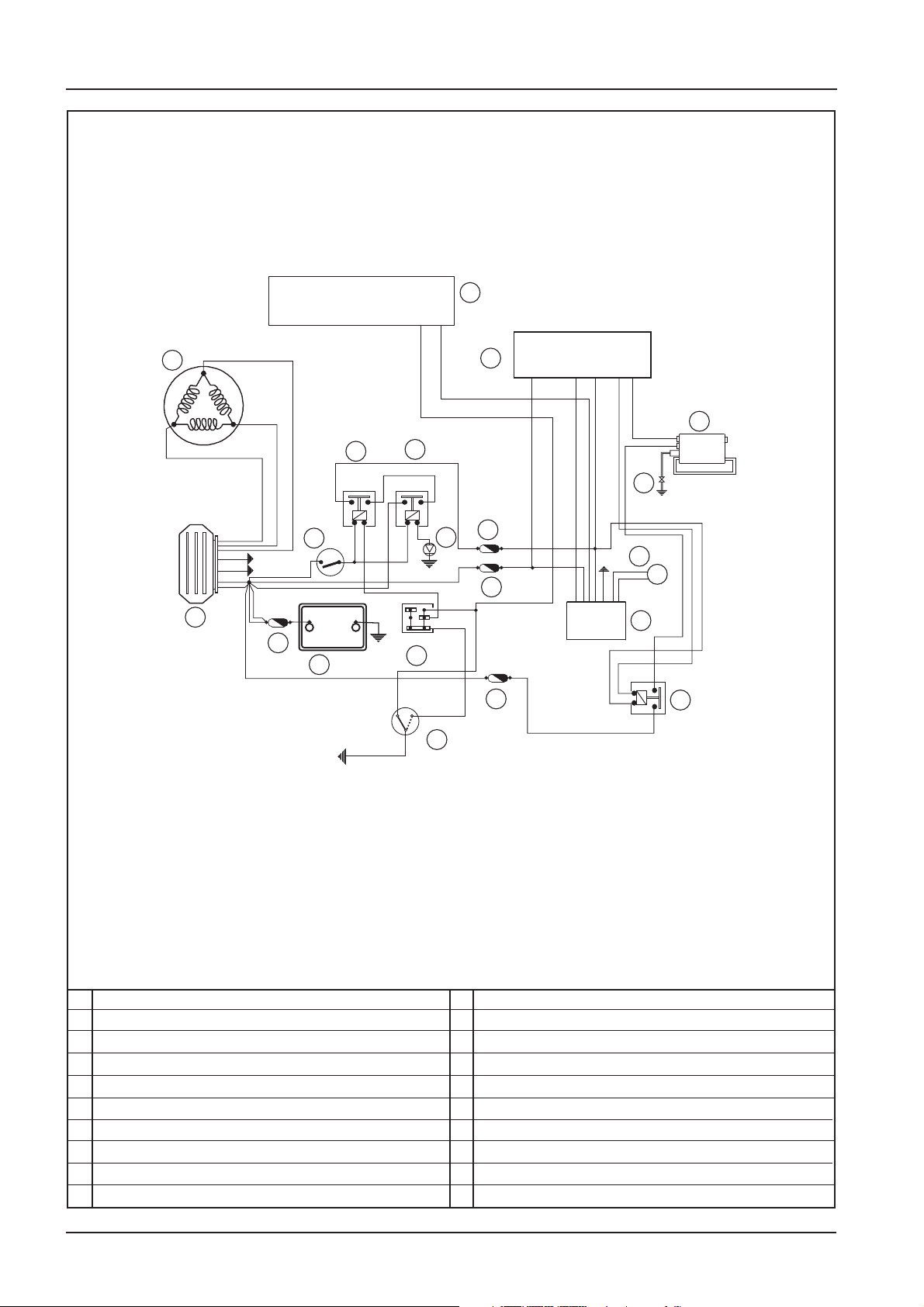

ELECTRICAL EQUIPMENT

3

43

38

8

16

20

33

35

15

48

36

34

17

9

32

13

10

42

19

41

51

37

44

2

3

11

50

21

49

4

5

7

45

14

12

1

31

28

29

27

46

26

25

22

6

47

18

2

30

52

24

40

39

SIDESTAND SWITCH

1

VOLTAGE REGULATOR

2

STAND CONTROL UNIT

3

ELECTRONIC CONTROL UNIT RELAY SWITCH

4

ENGINE STOP RELAY SWITCH

5

SERVICES ELECTROMAGNETIC SWITCH

6

FUSE BOX (3 X 7.5A, 1 X 15A)

7

NO. 2 SOLENOID STARTERS

8

375W FLYWHEEL MAGNETO

9

2 X STAND BUTTON

10

STAND PUMP MOTOR

11

PUMP ASSEMBLY WITH LEVEL INDICATOR

12

STARTER MOTOR

13

HELMET COMPARTMENT LAMP BUTTON

14

HELMET COMPARTMENT LAMP

15

12V SOCKET

16

2 X REAR FUSE BOX FOR CONTROL UNIT (1 X 3A, 1 X 5A,

17

1 X 10A, 1 X 3A)

DIODE BOX (2 X 6 A AND 2 A DIODE)

18

FUSE BOX (2 X 7.5A, 1 X 15A AND 5A)

19

FUSE BOX WITH STRIP FOR STAND PUMP

20

ELECTROMAGNETIC SWITCH (NO. 1 OF 70A)

DIGITAL INSTRUMENT SET (11 WARNING LIGHTS AND LEDS)

21

ANALOG INSTRUMENT SET (5 LAMPS)

22

HEADLIGHT, 2 X PARKING LIGHT BULB, HIGH/LOW BEAM

23

55/55W BULB

LH FRONT TURN INDICATOR WITH 10W BULB

24

REAR BRAKE LIGHT BUTTON

25

LIGHTS SWITCH WITH HEADLIGHT FLASH

26

27

TURN INDICATOR SWITCH

28

HORN BUTTON

29

HAZARD WARNING LIGHT BUTTON

30

RESET BUTTON

31

TRUMPET HORN

32

LH REAR LIGHT WITH 5W PARKING LIGHT BULB AND 10W

TURN INDICATOR BULB

33

REAR BRAKE LIGHT, 5 X 2.3W BULB

34

NUMBER-PLATE LIGHT 12V-5W

35

RH REAR LIGHT WITH 5W PARKING LIGHT BULB AND 10W

TURN INDICATOR BULB

36

12V-14Ah BATTERY

37

FRONT BRAKE LIGHT BUTTON

38

ENGINE STOP SWITCH

39

WHEEL REVOLUTION SENSOR

40

RH FRONT TURN INDICATOR, 10W BULB

41

MAIN RELAY SWITCH

42

LIGHTS SELECTOR SWITCH

43

START BUTTON

44

STAND BUTTON

45

IGNITION SWITCH

46

RADIO DISPLAY

47

ELECTRIC FAN RELAY SWITCH

48

30A FUSE WITH SOLENOID STARTER

49

RADIO CONROL UNIT/INTERCOM/SPEAKERPHONE

50

No. 2 PUMP ELECTROMAGNETIC SWITCHES

51

RELAY SIGNALER GLUED

52

No. 2 HEADLIGHT ELECTROMAGNETIC SWITCHES

4 - 2

Page 19

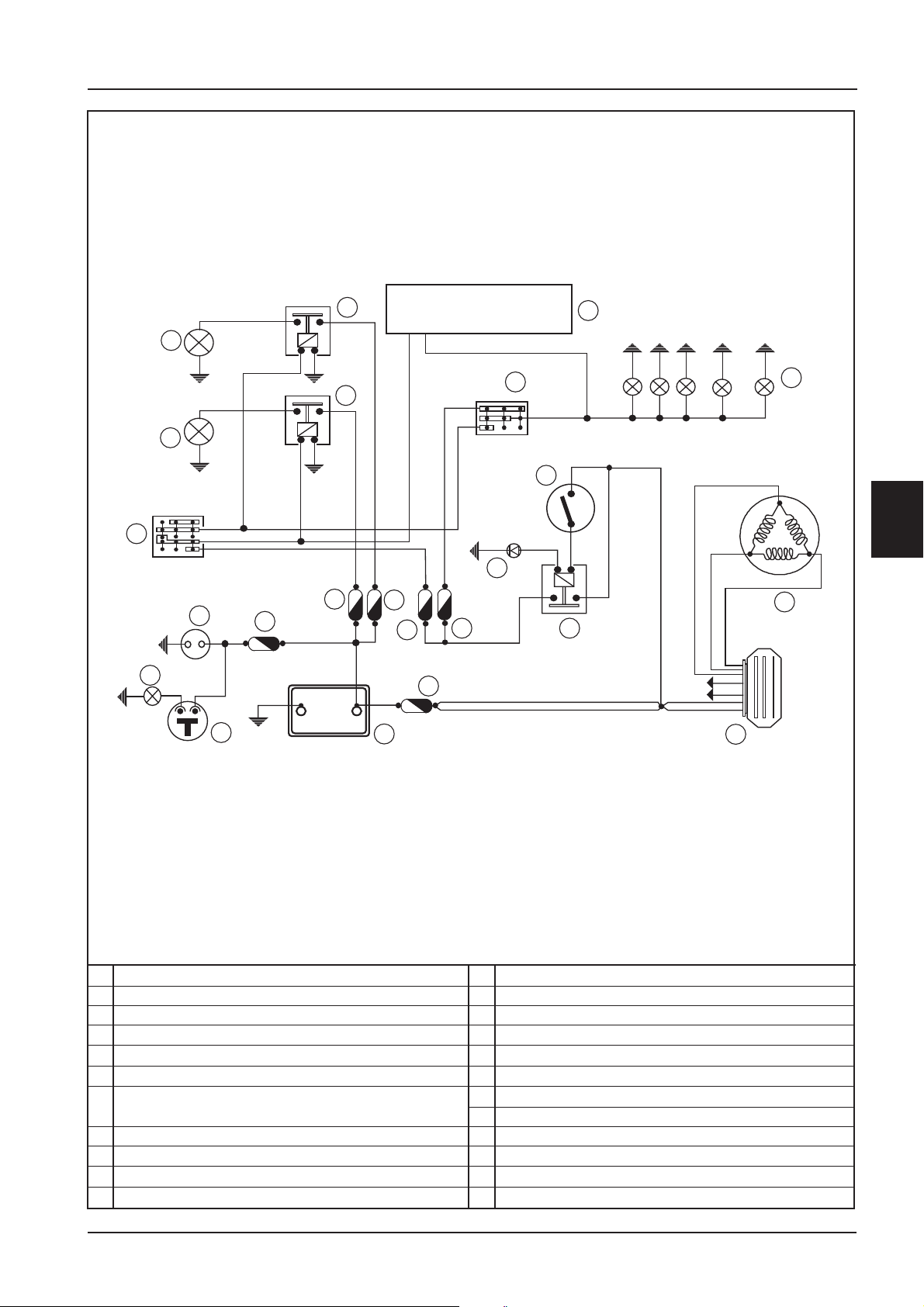

Electrical equipment devices

1. Digital instrument panel (11 LED indicators).

2. Analog instrument panel (5 bulbs).

3. Headlight (2 parking light bulbs, 55/55W low/high

beam bulbs).

4. LH front turn indicators (10W bulb).

5. Rear brake light button.

6. Lights selector switch with headlight flash.

7. Turn indicator switch.

8. Horn button.

9. Hazard warning light button.

10. Reset button.

11. Trumpet horn.

12. Sidestand switch.

13. Voltage regulator.

14. Stand control unit.

15. Engine stop relay switch.

16. Electronic control unit relay switch.

17. Stand pump relay switches.

18. LH rear light (5W parking light bulb, 10W turn

indicator bulb).

19. Rear brake light (5 x 2.3W bulbs).

20. Number-plate light with bulb.

21. RH rear light (5W parking light bulb, 10W turn

indicator bulb).

22. 12V-14Ah battery.

23. Fuse box (3 x 7.5A fuse, 1 x 15A fuse).

24. Starting relay switch.

25. Flywheel magneto (375W).

26. Engine oil pressure sensor.

27. Coolant temperature sensor.

28. Engine rpm sensor.

29. Air temperature sensor.

30. Idle speed adjusting motor.

31. Throttle potentiometer.

32. Petrol injector.

33. 2 stand switches.

34. Stand pump motor.

35. Injection electronic control unit.

36. Decoder.

37. Front brake light button.

38. Engine stop switch.

39. Wheel revolution sensor.

40. RH front turn indicator (10W bulb).

Electrical equipment diagram

41. Relay switch.

42. Lights switch.

43. Start button.

44. Stand button.

45. Immobilizer aerial.

46. Ignition switch.

47. Electric fan.

48. Electric fan relay switch.

49. Main relay switch.

50. HV coil.

51. Fuel gauge with pump.

52. Starter motor.

53. Helmet compartment lamp button.

54. Helmet compartment lamp.

55. 12V socket.

56. 2 rear fuse boxes for control unit (1 x 3A fuse, 1 x 5A

fuse, 1 x 10A fuse, 1 x 3A fuse).

57. Radio display.

58. Relay switch.

59. Outside temperature sensor.

60. Diode box (2 x 6A/2A diodes).

61. Fuse box (2 x 7.5A fuse, 1 x 15A fuse, 1 x 5A fuse).

62. Fuse box with base for stand pump (1 x 70A fuse).

63. Intercom/radio control unit.

64. Intercom connectors.

65. Relay signaler glued.

4

ELECTRICAL CABLES COLOUR: B=White - Bl=Blue

- G=Yellow - Mr=Brown - N=Black - BV=White-Green -

GN=Yellow-Black - Gr=Grey - Rs=Pink - R=Red -

Vi=Violet - V=Green - VN=Green-Black - BN=White-

Black - BBl=White-Blue - GV=Yellow-Green -

Ar=Orange - Az=Azure - GrBl=Grey-Blue - GrN=Grey-

Black.

Warning

ment, take special care to ensure that the leads that link

up to the electronic control device are properly connected by observing the polarity and colour coding of

the connectors.

- When working on the electrical equip-

4 - 5

Page 20

Schematic wiring diagrams

Ignition section

8

4

5

6

12

87

85

2

13

87

30

86

30

85

86

20

9

7

11

10

3

15

+

14

-

DOWN

OFF RUN

16

UP

17

1

87

85

86

18

30

19

1

IMMOBILIZER DECODER

2

IGNITION SWITCH CONTACTS

3

VOLTAGE REGULATOR

4

FLYWHEEL MAGNETO

5

INJECTION ELECTRONIC POWER UNIT

6

HV COIL

7

SPARK PLUG

8

DIGITAL INSTRUMENT SET

9

5A FUSE

10

3A FUSE

4 - 6

11

IMMOBILIZER AERIAL

12

ENGINE STOP RELAY SWITCH

13

MAIN RELAY SWITCH

14

12V-14Ah BATTERY

15

30A FUSE

16

ENGINE STOP SWITCH

17

10A FUSE

18

ELECTRONIC POWER UNIT ELECTROMAGNETIC SWITCH

19

SIDE STAND SWITCH

20

2A DIODE

04_002

Page 21

Lights section

Schematic wiring diagrams

22

19

3

1

2

I

0

P

30

86

30

86

85

85

87

87

6

0

1

4

2

5

7

8

4

86

23

15

20

-

+

21

-

18

14

13

+

17

12

16

30

85

87

9

10

11

1

12V-55W LOW BEAM BULB

2

12V-55W HIGH BEAM BULB

3

LOW BEAM RELAY SWITCH

4

HIGH BEAM RELAY SWITCH

5

DIGITAL INSTRUMENT SET

6

LIGHTS SWITCH

7

2 x 12V-5W FRONT PARKING LIGHT BULB, 2 x 12V-5W REAR

PARKING LIGHT BULB, 1 x 12V-5W NUMBER-PLATE LIGHT BULB

8

IGNITION SWITCH CONTACTS

9

MAIN RELAY SWITCH

10

FLYWHEEL MAGNETO

11

VOLTAGE REGULATOR

7.5 A FUSE

12

15 A FUSE

13

7.5 A FUSE

14

7.5 A FUSE

15

30 A FUSE

16

12V-14Ah BATTERY

17

HELMET COMPARTMENT LAMP BUTTON

18

12V-5W HELMET COMPARTMENT LAMP BULB

19

12V-180W SOCKET

20

15A FUSE

21

LIGHTS SELECTOR SWITCH

22

23

2A DIODE

04_003

4 - 7

Page 22

Schematic wiring diagrams

Battery recharge and starter section

7

-

18

DOWN

10

6

14

M

4

+

11

8

3

15

19

17

UP

OFF RUN

87

86

16

13

9

12

1

30

85

5

20

87

30

85

21

86

2

1

IGNITION SWITCH CONTACTS

2

FLYWHEEL MAGNETO

3

7.5A FUSE

4

STARTER RELAY SWITCH

5

VOLTAGE REGULATOR

6

STARTER MOTOR

7

12V-14Ah BATTERY

8

FRONT BRAKE LIGHT BUTTON AND START INHIBITOR SWITCH

9

REAR BRAKE LIGHT BUTTON AND START INHIBITOR SWITCH

10

DIGITAL INSTRUMENT PANEL

11

START BUTTON

4 - 8

30A FUSE

12

6A DIODE

13

5 X 12V-2.3W BRAKE LIGHT BULB

14

INJECTION POWER UNIT

15

ENGINE STOP RELAY

16

ENGINE STOP SWITCH

17

STAND SWITCH

18

5A FUSE

19

MAIN RELAY SWITCH

20

2A DIODE

21

04_004

Page 23

Consent, electrohydraulic central stand device and level indicators section

Schematic wiring diagrams

13

2

1

4

5

6

7

8

10

3

9

24

12

14

M

85

87 30

25

15

11

16

23

22

+

30

18

21

19

87

30

30

86

85

-

86

87

85

26

M

20

4

86

17

30

28

86

85

87

27

29

1

DIGITAL INSTRUMENT

2

ANALOG INSTRUMENT SET

3

INJECTION ELECTRONIC CONTROL UNIT

4

OUTSIDE TEMPERATURE SENSOR

5

WHEEL REVOLUTION SENSOR

6

FUEL LEVEL THERMISTOR

7

OIL PRESSURE SENSOR

8

RESET BUTTON

9

EMERGENCY BUTTON

10

7.5A FUSE

11

IGNITION SWITCH CONTACTS

12

RADIATOR ELECTRIC FAN MOTOR

13

ENGINE TEMPERATURE SENSOR

14

FLYWHEEL MAGNETO

15

VOLTAGE REGULATOR

16

30A FUSE

17

12V-14Ah BATTERY

18

70A FUSE

19

STAND HYDRAULIC PUMP RELAY SWITCHES

20

STAND HYDRAULIC PUMP MOTOR

21

STAND ELECTRONIC CONTROL UNIT

22

STAND INHIBITOR SWITCH

23

STAND LIMIT SWITCH

24

BUTTON

25

ELECTRIC FAN RELAY SWITCH

26

5A FUSE

27

MAIN ELECTROMAGNETIC SWITCH

28

2A DIODE

29

RELAY SIGNALER GLUED

30

1A DIODE

04_005

4 - 9

Page 24

Schematic wiring diagrams

Turn indicators, horn and accessories prewiring section

6

1

14

13

12

5

10

2

4

9

3

7

15

86

85

8

11

30

87

(+)

8

1

DIGITAL INSTRUMENT PANEL

2

TURN INDICATORS, 2 + 2 X 12V-10W BULB

3

TURN INDICATOR SWITCH

4

ACCESSORIES PREWIRING

5

HORN BUTTON

6

HORN

7

15A FUSE

8

GNITION SWITCH CONTACT

4 - 10

9

7.5A FUSE

10

7.5A FUSE

11

MAIN RELAY SWITCH

12

PRESETTING FOR INTERCOM POWER UNIT INPUT

13

PRESETTING FOR RADIO POWER UNIT SIDE

14

PRESETTING FOR RADIO DISPLAY SIDE

15

2A DIODE

04_006

Page 25

Control panel, warning lights, instruments

Schematic wiring diagrams

18

5

7

6

8

17

20

19

21

22

23

24

31

32

33

34

36

35

4

1

3

2

4

10

9

12

11

13

14

15

16

25

26

27

28

30

29

1

ANALOG CARD GND

2

BATTERY POSITIVE TERMINAL (+30) FOR ANALOG CARD

3

ANALOG CARD SERIAL CLOCK OUTPUT

4

ANTITHEFT DEVICE LED OUTPUT

5

ANALOG CARD SERIAL DATE OUTPUT

6

LIGHTS-ON OUTPUT

7

(NOT CONNECTED)

8

(NOT CONNECTED)

9

INJECTION WARNING LIGHT INPUT

10

RELAY ALARM WARNING LIGHT INPUT GLUED

11

MALFUNCTIONING BRAKE LIGHT OUTPUT

12

RH TURN INDICATOR OUTPUT

13

RH TURN INDICATOR BUTTON INPUT

14

LH TURN INDICATOR BUTTON INPUT

15

HIGH BEAM WARNING LIGHT INPUT

16

AIR TEMPERATURE SENSOR INPUT

17

ENGINE START DISABLED WARNING LIGHT INPUT

18

OIL PRESSURE WARNING LIGHT INPUT

19

MALFUNCTIONING BRAKE LIGHT WARNING LIGHT INPUT

20

LH TURN INDICATOR OUTPUT

21

TURN INDICATOR STOP BUTTON INPUT

22

RESET SERVICE BUTTON INPUT

23

COOLANT TEMPERATURE SENSOR INPUT

24

FUEL LEVEL SENSOR INPUT

25

BATTERY POSITIVE TERMINAL (+30)

26

SENSOR POWER SUPPLY

27

SPEEDOMETER SENSOR EARTH RETURN

28

RPM SENSOR INPUT

29

BATTERY POSITIVE TERMINAL (+30)

30

ANTITHEFT DEVICE LED

31

KEY POSITIVE TERMINAL (+15)

32

SPEEDOMETER SENSOR INPUT

33

GND

34

AIR TEMPERATURE SENSOR EARTH RETURN

35

HAZARD WARNING LIGHT BUTTON INPUT

36

LIGHTS-ON INPUT

04_007

4 - 11

Page 26

Electrical equipment

Battery recharge system

The battery recharge system includes a three-phase

generator with a permanent-magnet flywheel.

The generator is directly connected to the voltage

regulator.

The latter is in turn directly connected to earth and to the

battery positive terminal via the 30A fuse.

Therefore, the system is not connected to the ignition

switch.

The three-phase generator allows considerable recharging power and a fair compromise between supplied power and slow running stability at low rpm.

Recharging system

Searching for leaks

1) Before measuring the output voltage, ensure that no

electrolyte is leaking from the battery.

2) Turn the ignition key to the OFF position and connect

the tester terminals between the battery negative

pole (-) and the black cable.

3) Detach the black cable from the battery negative

pole (-) while keeping the tester terminals connected.

4) With the ignition key still in the OFF position, the

ammeter should read ≤ 0,5 mA.

Checking the charging voltage

Warning

that the battery is in good condition.

1) Put the vehicle on the central stand.

2) With the battery properly connected to the circuit,

position the multimeter prods between the battery

terminals.

3) Start the engine with all lights out and rev up while

measuring the voltage.

- Before performing the check, ensure

VOLTAGE: 14.0-15.0V at 5,000 rpm.

4 - 12

Page 27

Checking the stator winding

Electrical equipment

Warning

stator in place.

1) Remove the undersaddle compartment door

2) Detach the connector between stator and regulator

with the three yellow cables.

3) Measure the resistance between each of the yellow

terminals and the other two.

Resistance: 0.2 - 1 Ω

4) Check that each yellow wire is insulated from earth.

5) If the resistance is not as specified, replace the stator.

Checking the peak current

- With the engine off and swithboard “ON”, turn the

vehicle lights on and let the battery tension set to 12V.

- Connect the amperometric pliers to the 2 outlet re-

charge positive poles of the regulator.

- With lights on, start the engine and read the value on

the pliers with the engine running at high speed.

- The check can be performed with the

4

With efficient battery, the measured value is: > 20A

Voltage regulator/rectifier

Specifications

ITEM STANDARD VALUE

Type Transistorized, non-adjustable, three-phase

Voltage regulator/rectifier

Voltage 14 - 15V at 5000 rpm with lights off

4 - 13

Page 28

Electrical equipment

Instrument panel

The X9 is equipped with a dual instrument panel consisting of an analog section installed in the front fairing

and a digital section mounted on the handlebars.

The analog section includes:

- A dual-scale (km/h-mph) speedometer controlled by

the speed sensor by means of the digital section;

- A tachometer controlled by a signal coming from the

power unit-injection;

- A fuel gauge controlled by a resistive sensor (in the

fuel tank);

- A coolant temperature indicator controlled by a resistive sensor (on the cylinder head).

These instruments are of the electrical type, and are

operated by step-by-step motors.

The digital section includes the following indicators:

- Reserve fuel warning light: amber.

- Lights-on and low beam warning light: green.

- High beam warning light: blue.

- Left-hand turn indicator warning light: green.

- Right-hand turn indicator warning light: green.

- Hazard warning lights (four turn indicators): red

- Engine disabled: red.

- Brake light bulb burnt-out warning light: red.

- Oil pressure warning light: red;

- Injection warning light: amber;

- ALARM warning light (electrohydraulic cable): red.

04_009

04_010

The reserve fuel, turn indicator and hazard warning lights are activated by the electronics of the instrument. For

example, the fuel reserve warning light comes on only when the reserve fuel indication from the fuel tank lasts a

minimum of 13.5 seconds. This prevents the warning light from blinking when the engine begins to run on reserve

fuel.

- The flashing function is built in the electronics of the instrument, which allows the hazard warning lights to work

when the ignition switch is in the “OFF” position and the control switch is disabled. The control switch is active only

when the instrument panel is on.

For greater riding safety, the “turn indicator control” function is connected to the mileometer. If the turn indicators are

inadvertently left on, they are automatically switched off after 1 kilometre.

- The “engine start disabled” warning light is activated by the sidestand switch and the emergency switch on the right

side of the handlebar.

- The indication “brake light bulb burnt-out” is activated when at least two of the five bulbs fail to operate.

- The warning light is controlled by a circuit that measures the absorption of the brake light bulb.

- The liquid crystal display shows a 5-digit total mileage count in either kilometres or miles. Naturally, this counter

can never be reset. To select the unit, with key turned to “OFF”, press the “Trip” and “M” buttons at the same

time and turn the ignition switch to the “ON” position. If the two buttons are depressed for longer than three

seconds, the word “SET” is displayed and then the unit toggles between kilometres and miles.

4 - 14

Page 29

3 Four fuses «C» in the glove compartment, on the left

side.

Fuse Protected circuits

1 x 15 A Flash, horn, accessories

1 x 7.5 A Brake light buttons, start button, starter

relay switch

1 x 7.5 A Lights switch, parking lights,

number-plate light

1 x 7.5 A Digital instrument panel, PICS control

unit power supply

4 One fuse «D» of 30A (main fuse) located next to the

battery on the solenoid starter. A spare fuse is also

provided underneath.

Electrical equipment

C

04_016

D

List of bulbs

Function Type Power

Low beam bulb halogen 12V-55W

High beam bulb halogen 12V-55W

Front parking light bulb all-glass 12V-5W x 2

Front turn indicator bulb spherical 12V-10W x 2

Rear parking light bulb spherical 12V-5W x 2

Brake light bulbs spherical 12V-2.3W x 5

Rear turn indicator bulb spherical 12V-10W x 2

Instrument panel lighting bulb all-glass 12V-2W x 5

Glove compartment lamp bulb cylindrical 12V-5W

Number-plate light bulb cylindrical 12V-5W

4

04_017

4 - 23

Page 30

Electrical equipment

Battery (12V - 14Ah)

Caution

- The battery electrolyte causes severe

burns as it contains sulphuric acid. Avoid contact with

the eyes, the skin and clothing.

In case of contact with the eyes or the skin, rinse

generously with water for about 15 minutes and immediately seek medical attention.

In case of ingestion, immediately drink large quantities

of water or milk. Subsequently administer milk of magnesia, beaten eggs or vegetable oil. Immediately seek

medical attention.

Batteries produce explosive gases. Keep them away

from open flames, sparks and cigarettes. If the battery

is charged in a closed place, ensure adequate ventilation.

Always protect the eyes when working close to batteries.

Keep out of reach of children.

Installing charged-dry batteries:

1) - Remove the short closed tube and the plugs. Fill

the cells to the upper level with accumulator sulphuric acid, specific weight 1.26, corresponding to

30° Bé at a temperature of at least 15°C.

2) - Leave at rest for at least two hours and then restore

the level by adding sulphuric acid.

3) - Recharge within 24 hours by means of the specific

charger 020333Y (single station) or 020334Y (multiple station) with intensity equal to about 1/10 of

the battery rated power, until the acid density

reaches the value of about 1,27, corresponding to

31 Bé, and until such values have stabilized.

4) - When the charging is over, level off the acid (by

adding distilled water), put the plugs back into

place and clean thoroughly.

5) - Proceed to install the battery on the vehicle, taking

care to observe the connections described at item

3) of the paragraph Recharging the battery.

Removing and installing the battery

1

Hold tube upright

2

Check visually

3

Float must be disengaged

04_026

- Lift the saddle;

- Remove the rear optical unit and the covering ele-

ment;

- Disconnect the battery by detaching the negative (-)

cable first and then the positive (+) cable.

- Remove the battery strap and then the battery itself.

- To install the battery, follow these steps:

- Fit the lower support shown in the figure on the

battery compartment bottom.

4 - 24

04_018

Page 31

- Fit the front element.

- At last, fit the left side element.

Electrical equipment

04_019

- Cut the breather pipe supplied as shown in the figure.

- Fit the pipe until it contacts the battery and in the

direction shown in the figure.

4

04_020

NOTCHING

NOTCHING

04_021

In contact

The notching

must be in the

lower half of

the pipe

04_022

4 - 25

Page 32

Electrical equipment

- Lock the pipe with a tear-clamp and cut the end that

sticks out of the clamp.

- Insert the battery in the compartment taking care to fit

the breather pipe in the bottom hole.

04_023

- Insert the battery in the compartment taking care to fit

the breather pipe in the bottom hole.

04_024

04_025

4 - 26

Page 33

Electrical equipment

Checking the electrolyte level

Frequently check that the electrolyte reaches the upper

level. To top up, only use distilled water.

If you need to top up the battery too frequently, check

the vehicle electrical equipment as the battery is certainly working in overload conditions, which will lead to

rapid deterioration.

Checking the battery charge

After restoring the electrolyte level, check its density

with the special hydrometer (see figure).

When the battery is charged, electrolyte density must

be between 30 and 32 Bé, corresponding to specific

gravity of 1.26-1.28 at a temperature not lower than

15°C. If density has fallen below 20° Bé, the battery is

completely discharged and needs recharging.

If the vehicle is not used for some time (1 month or more)

the battery must be periodically recharged. In three

months the battery runs down completely.

When refitting the battery take care not to invert the

connections: the ground lead (black) is to be connected

to the negative (-) terminal and the other lead (red)

must be connected to the positive (+) terminal.

Battery recharge

Caution

cell plugs. Keep free flames or sparks away from the

battery during recharge. When the battery has to be

removed from the vehicle, disconnect the negative

terminal first.

Charge the battery using the specific charger 020333Y

(single station) or 020334 (multiple station), by putting

the charger selector on the type of battery to be recharged (use current at 1/10 of the battery rated power).

Connection to the power supply must be made by means

of the corresponding poles (+ with + and – with -).

4) Cleaning the battery

Keep the battery clean, especially the top; coat the

terminals with Vaseline.

Warning

pacity than the one recommended. The use of a fuse of

unsuitable capacity may result in serious damage to the

whole vehicle or even cause a fire.

- Before charging the battery remove all

- Never use fuses having a greater ca-

Warning

that are harmful for batteries. Use only distilled water.

Warning

battery must be charged before using the vehicle.

Failure to properly charge the battery before starting the

vehicle will cause the battery premature breakdown.

Sealed battery

Putting a sealed battery into service

If the vehicle is equipped with a sealed battery, servicing

is limited to checking the charge level and, if necessary,

recharging the battery.

These operations must be performed during predelivery,

and every six months of open-circuit storage.

Therefore, in addition to checking and, if necessary,

charging the battery before delivery, it is necessary to

carry out these operations before storing the vehicle,

and subsequently every six months.

RECHARGING THE BATTERY FOLLOWING OPENCIRCUIT STORAGE

1) Checking the voltage

Before installing the battery on the vehicle, measure the

open-circuit voltage with an ordinary multimeter.

- If the voltage exceeds 12.60 V, the battery can be

installed without recharging.

- If the voltage is less than 12.60 V, recharge the battery

as described at item 2).

2) Constant-voltage charging method

- Constant voltage: 14.40-14.70 V

- Initial charging current: 0.3-0.5 x rating

- Charging time: Recommended 10-12 hrs

3) Constant-current charging method

- Initial charging current: 1/10 of rating

- Charging time: Maximum 5 hrs

Caution

(far below 12.6V), 5 hours’ recharging may not be

enough to obtain optimum performance.

In these conditions, however, to avoid damaging the

battery beyond repair, it is essential not to recharge it for

more than 8 consecutive hours.

- Normal drinking water contains salts

- To ensure maximum performance the

Minimum 6 hrs

Maximum 24 hrs

- When the battery is deeply discharged

4

4 - 27

Page 34

TABLE OF CONTENTS

ENGINE

5

Page 35

Engine

Engine disassembly from frame

Caution

- Perform these operation with the en-

gine cold.

- Disconnect the battery.

- Remove the saddle, and the upper and lower body

sides (Chapter 8 - Bodywork)

- Drain the coolant (Chapter 3 - Maintenance)

- Disassemble the muffler assembly and relevant support, as described below.

- Remove the rear wheel (Chapter 6 - Front/Rear

Suspension)

- Remove the accelerator control transmissions and

mark their position on the throttle body control.

- Disconnect the air filter sleeve and the engine oil

values collecting pipe.

- Disconnect the earth cable from the engine.

- Disconnect the electrical devices from the throttle

body, head, and starter feed cable.

- Detach the fuel delivery and return pipes to the

injector and the coolant system pipes (head outlet

and thermostat input)

- Close the injector Tee Joint with rubber plugs to

prevent dirt from entering.

- Detach the H.V. cable from the spark plug.

- Detach the generator harness from the vehicle electrical system.

Caution

Warning

- Take care when handling the petrol.

- When installing the battery, first fix the

positive cable and then the negative cable.

Muffler assembly disassembly

- Unloose the two fixings of the exhaust manifold on

the head.

- Unloose the 3 screws fixing the muffler to the supporting arm.

- Remove the muffler assembly.

05_001

5 - 2

05_002

Page 36

Supporting arm disassembly

- Unscrew and remove the r.h. shock absorber to

supporting arm lower fixing bolt

- Unloose the arm to engine 2 fixing screws.

- Remove the split pin and unscrew the wheel axle nut;

avoid the wheel turning by means of the integral

brake.

- Remove the supporting arm.

Disassembly of l.h. shock absorber lower pin

- Remove the bolt shown in the figure.

N.B.: To be able to remove the shock absorber support,

remove the two nuts on the brake caliper side and the

screws.

Engine

05_003

Engine pin/swing arm disassembly

- Adequately support the engine.

- Remove the nut shown in the figure.

- Remove the pin.

- Now the engine is free.

Engine assembly to vehicle

- Perform the assembly in the reverse order observing the tightening torques indicated in Chapter 1.

Warning

a slight play with the valve in contact with the register.

- Take care not to invert the position of the two accelerator control transmissions. Check that both show

05_004

5

05_005

N.B.: Carefully clean the injector Tee Joint before reassembling the quick-connections. Direct the injector in such

a way as to avoid any interferences of the electrical cables with the coolant and fuel pipes.

- Check the engine oil level, top up if necessary with oil of the recommended type.

- Fill the cooling system (Chapter 11-Cooling).

- Check the accelerator and electrical devices function.

5 - 3

Page 37

Handlebar

Removal

- Begin by removing the radio-interphone and then

disconnect the feeder cable.

- Remove the digital panel support and the front and

rear sections of the handlebar cover as described in

Chapter 8-Bodywork.

- Disengage the handlebar from the components installed on it.

- Remove the two counterpoises after loosening the

side screws.

- Remove the pumps after loosening the screws on the

clevises shown in the figure.

- Slide the throttle control off the handlebar after loosening the fixing screws.

- Remove the left handgrip.

- Loosen the bolt fastening the handlebar to the steering tube shown in the figure and then remove it.

Remove the handlebar and the plastic support.

Note: If the handlebar is removed to proceed to the

removal of the front fork, simply overturn the handlebar

onto the front of the vehicle without removing the parts

fitted on it. Take care not to damage the flexible transmissions, the pipes or the bodywork.

Fitting

Perform the removing procedure in reverse order. To

align the handlebar with the steering tube, align the

notch on the handlebar with the notch on the sterring

tube. Tighten the fasteners with the torques specified in

Chapter 1.

Tightening torques:

Handlebar fastening bolt: 43 - 47 N·m

Front and rear suspensions

06_001

06_002

Removing the front wheel

- Remove the two brake calipers as described in

Chapter 7-Braking system.

- Unscrew the axle locknut.

- Disengage the axle by loosening the two screws on

the right-hand fork sheath (see figure).

- While supporting the wheel, remove the axle on the

right side of the vehicle.

Caution

not to damage the speed sensor.

Overhauling the front wheel

Check the bearings for any excessive play or stickiness

causing noise and uneven rotation of the wheel.

Should the wheel bearings need to be replaced, follow

these steps:

- Using a suitable extractor on the inner race, remove

the two bearings on the left side of the wheel (speed

sensor side).

- When removing the wheel, take care

6

06_003

06_004

6 - 3

Page 38

Front and rear suspensions

- Support the wheel to allow the removal of the internal

parts.

- Using a mallet and a drift of suitable diameter, simultaneously drive out the inner spacer, the right-hand

bearing and the outer spacer complete with the dust

ring on the same side.

- Refit the two bearings on the left side of the wheel rim.

- Using a tube of suitable diameter on the outer race of

the bearings, push them home into their seats.

- Fit the spacer in the right side of the wheel as shown

in the figure.

- Fit the right-hand bearing by following the same

procedure as the other bearings.

06_005

- Refit the two front brake discs as described in Chapter 7-Braking system.

- Fit the outer spacer and the related ring taking care

not to compress it excessively against the wheel

bearing.

- Check the condition of the speed sensor seal ring and

of the related groove in the wheel rim.

- Insert the pin from the r.h. side by aligning the spacers.

- Take care not to damage the phonic wheel.

- Offset the drives beforehand by about 90°.

- Tighten the wheel axle nut.

- Tighten the two screws of the clamp on the pin

housing, on the r.h. sheath.

06_006

06_007

Tightening torques:

Axle nut: 45 - 50 N·m

Right-hand sheath lower screws: 6 - 7 N·m

6 - 4

06_008

Page 39

Removing the front fork

- Remove the mudguard as described in Chapter 8Bodywork.

- Remove the handlebar and the front wheel as previously described.

- Loosen the two screws fastening the brake line supports (see figure).

Note: It is also possible to remove one of the two fork

rods after loosening the two related screws on the fork

upper plate.

- Remove the two rings, the middle washer shown in

the figure and the spacer below.

Front and rear suspensions

06_009

Caution

allow the steering tube to come out of the head tube.

Warning

the fork assembly so as to prevent it from falling.

- Pull out the fork assembly.

Specific tool:

Steering tube ring spanner: 020055Y

Replacing the steering bearings

- Using the specially designed tool shown in the figure

and a mallet, remove the upper ball bearing.

N.B.:Act at different times between the two points at

180°. Failure to observe this instruction may damage

the housing.

Specific tool:

Steering thrust ring removing drift: 020004Y

- Adequately support the vehicle so as to

- Before unscrewing both rings, support

06_010

6

06_011

- Use the same method to extract the seat of the lower

roller bearing.

N.B.: Act at different times between the two points at

180°. Failure to observe this instruction may damage

the housing.

Specific tool:

Steering thrust ring removing drift: 020004Y

06_012

6 - 5

Page 40

Front and rear suspensions

- Remove the lower roller bearing and the dust cover

ring from the fork by means of the specific tool.

- Use the larger half ring pair and the shorter steering

tube protection.

Specific tool:

Steering tube lower bearing extractor: 020458Y

Fitting the steering bearing

- Check the condition of the bearing races and rollers.

- Fit the upper bearing and the lower bearing housing

by inserting the specific tool in the steering sleeve,

provided with 2 adapters.

- Fit the dust cover ring and the roller bearing on the

steering tube by means of a piece of tube having a

suitable diameter, and by resting against the inner

race of the roller bearing.

Specific tool:

Steering seats assembly tool: 001330Y

Upper bearing adapter: 001330Y010

Lower bearing adapater: 001330Y009

06_013

06_014

- Lubricate the steering bearing housing with grease of

the TUTELA Z2 type.

- Fit the steering tube into the sleeve.

- Fit the spacer.

- Tighten the lower collar with a torque of 20-25 Nm

- Fit the lower ring, tighten it with the prescribed torque

(2-2.5 Kgm) and then loosen it completely.

so the entire assembly can settle.

- Tighten it again with a torque of 10-13 Nm

- Turn anticlockwise by 80°-90° of a turn.

(1-1.3 Kgm), then loosen it by 90 degrees.

- Fit the intermediate washer and the upper ring nut,

- Insert the spacer.

then tighten with the prescribed torque.

- Lock the upper collar with a torque of 30-36Nm

(3-3.6 Kgm).

Specific tool:

Specific tool:

Wrench for steering tube ring nut: 020055Y

Wrench for Steering Tube Collar - 020055Y

Tightening torque:

Steering upper ring nut: 30 - 36 N·m

N.B.

Steering lower ring nut: 10 - 13 N·m, then unloose by

This procedure is also valid for the previous UPPER COLLAR

90°

versions with upper ball bearing. SPACER

LOWER COLLAR

06_010

6 - 6

Page 41

Replacing the seal ring and removing the fork rod

- Remove lower screw (1).

- Drain the oil from the suspension.

- Remove the fork rod.

- Replace seal rings (3), (4) and (5) with new ones.

- Fit the new rings after lubricating their seats.

- Reinsert the fork rod;

- Unscrew plug (2);

- Fit from the top a suitable wrench of 12mm in order to

block the pumping element. Refit the lower screw (1).

- Pour in 90 cc of “Fork PG” SAE 20W oil;

- Reassemble by following the reverse procedure.

Front and rear suspensions

Rear shock absorbers

Removal

Follow these steps:

- Put the vehicle on the central stand.

- Using a jack, slightly lift the engine so as to free both

shock absorbers.

- Remove the silencer.

- Unloose the shock absorber spring assembly fixing

screw from the support fixed to the engine, on one

side, and from the one fixed to the muffler support, on

the other side;

- Unscrew the two upper nuts (one on each side) fixing

the shock absorber spring assemblies to the frame

and then remove the assemblies themselves.

Fitting

Perform the removing procedure in reverse order taking

care to observe the prescribed tightening torques.

06_015

6

06_016

Tightening torques:

Shock absorbers lower fixing screw: 33 - 41 N·m

Shock absorbers upper fixing screw: 33 - 41 N·m

6 - 7

Page 42

Front and rear suspensions

Rear wheel

Removal

- Remove the shock absorber as previously described.

- Remove the silencer and the bracket as described in

Chapter 5-Engine.

- Remove the 5 screws fixing the rear wheel to the hub.

- Take down the wheel.

Fitting

Fit the wheel using the reverse procedure to the removal. Tighten the rear wheel fixing screws and the

axle locknut with the prescribed torques.

Tightening torque:

Rear wheel rim screws: 20 - 25 N·m

Central stand (Basic model)

Removal

- Release the springs.

- Unloose the r.h. and l.h. nut.

- Remove the screws.

06_017

Fitting

Perform the above procedure in reverse order and then

move the seal rings into their seats.

Warning

- Lubricate the following parts with TUTELA Z2 grease: spring connection pins, bushes on

stand clamps.

Tightening torques:

Central stand bolt: 25 - 30 N·m

6 - 8

06_018

06_019

Page 43

TABLE OF CONTENTS

BRAKING SYSTEM

7

Page 44

BRAKING SYSTEM

LUBRICATE WITH OIL

LUBRICATE WITH GREASE

APPLY PRODUCT

CLEAN CAREFULLY

WARNING - HANDLE WITH CARE

ALWAYS REPLACE

CALLOUT A B C D E F G H I L M N O

QUANTITY 6 4 3 1112 2105

TORQUE N·m

20-25 42-62 15-20 20-25 20-25 16-20 16-20 20-25 5-6,5 14-17

7 - 2

Page 45

Checking and replacing the brake pads

Removing the front brake pads:

Follow these steps:

- Loosen the two screws shown in the figure and

disengage the calipers from their supports.

- Remove the retaining ring and the pin. During the

operation pay special attention to the pin retaining

spring as it may spring off abruptly.

- Remove the two pads by pulling them downwards.

- Check the thickness of the pads.

Wear limit: 1.5 mm

- Repeat the operations on the brake caliper on the

opposite side.

To fit the pads, follow these steps:

- Insert the two pads into the caliper.

- Fit the pin retaining spring.

- Press down the spring to allow the insertion of the pin

(see figure).

- Insert the pin.

- Fit the retainer.

- Fit the caliper on its support and then tighten the two

screws with the prescribed torque.

Tightening torques:

Screws fixing caliper to support: 20 - 25 N·m

N.B.: If during the assembly it is not possible to fit the

caliper on the disc, refit the pistons in the caliper

carefully.

Braking system

07_001

07_002

Removing and replacing the rear brake pads

Follow these steps:

- Remove the left-hand rear shock absorber support

with the shock absorber itself and the rear wheel as

described in Chapter 6-Front and rear suspensions.

- Unloose the two screws fixing the brake caliper support to the engine.

- Remove the caliper from its support.

- Remove the retaining ring and the pin.

- Remove the two pads by pulling them downwards.

- Check the thickness of the pads.

Wear limit: 1.5 mm

- If the thickness of the pads is less than the prescribed

limit, replace them.

- Refit the parts by following the same procedure used

for the front brake pads.

- Tighten the two screws fixing the caliper support to the

engine with the prescribed torque.

7

07_003

Tightening torques:

Screws fixing caliper to support: 20 - 25 N·m

Screws fixing caliper support to engine: 20 - 25 N·m

7 - 3

Page 46

Braking system

Brake discs

Checking disc thickness

It is important to check the brake discs. The discs

should always be perfectly clean and free from rust,

grease and dirt and shown no deep scoring.

Thickness of front discs when new .............. 4.0 mm

Thickness of rear disc when new .................5.0 mm

Wear limit (front discs) ................................. 3.5 mm

Wear limit (rear) ........................................... 4.5 mm

Checking disc distortion

Take down the wheel and, using suitable equipment,

check that the axial runout of the braking surface does

not exceed the specified limit.

Max. axial runout: 0.1 mm

If the runout exceeds the specified limit, replace the disc

as described below and repeat the measurement.

If the problem persists, check and if necessary replace

the wheel hub.

07_004

Note: When refitting, thoroughly clean the disc and its

seat on the hub.

Replacing the front brake discs

Follow these steps:

- Remove the front wheel as described in Chapter 6Front and rear suspensions.

- For each disc, loosen the five screws shown.

- Carefully clean the seats on the front wheel hub and

the discs.

- When fitting the disc, take care to position it properly

by referring to the arrow stamped on it.

- Tighten the screws with the prescribed torque and

smear them with LOCTITE Threadlocker medium 242.

Note: The disc side bearing the arrow indicating the

direction of rotation must face the outside of the vehicle.

Tightening torques:

Brake disc fixing screws: 5 - 6 N·m

Replacing the rear brake disc

- Remove the rear wheel as described in Chapter 6Front and rear suspensions.

- Remove the hub with the brake disc.

- Follow the same procedure used for the front brake

discs.

07_005

07_006

Note: The disc side bearing the arrow indicating the

direction of rotation must face the outside of the vehicle.

Tightening torques:

Brake disc fixing screw: 14 - 17 N·m

7 - 4

07_007

Page 47

Braking system

General guidelines for servicing the hydraulic braking system

Caution

wear protective gloves when working on the hydraulic

system. In case of contact with the eyes, rinse generously with water.

The used brake fluid is harmful to the environment.

Collect and dispose of used oil according to the regulations in force.

Under normal climatic and riding conditions the brake

fluid should be renewed every two years. However, if

the brakes are subjected to heavy stress the fluid

should be renewed at shorter intervals.

When reassembling, reused parts should be perfectly

clean and free from oil, diesel fuel and grease. It is

therefore necessary to thoroughly clean them with

denatured alcohol. Braking system.

- The brake fluid is corrosive. Always

Note: When topping up or renewing the brake fluid, only

use DOT4 - NHTSA 116 fluid.

Always ensure that all parts are perfectly clean.

The brake fluid is highly corrosive. Take care not to spill

it on painted surfaces.

The brake fluid is hygroscopic, i.e. it absorbs humidity

from the air. If the humidity contained in the fluid

exceeds a given concentration, the braking action becomes insufficient owing to a reduction in the boiling

point of the liquid.

Note: Always take the brake fluid from sealed containers.

Note: Rubber parts must not be left immersed in alcohol

for longer than 20 seconds. After the washing, dry the

parts with a compressed air jet and wipe them with a

clean cloth.

Seal rings must be immersed in the liquid of use. The

use of the PRF1 protective agent is permitted.

Caution

fluid is present on the brake discs or pads. Should the

discs and the pads become contaminated with brake

fluid, replace the pads and clean the disc with a goodquality solvent.

- The braking action is decreased if brake

Renewing the brake fluid and bleeding air from

the brake circuit

Front brake

Follow these steps:

1) Put the vehicle on the stand on level ground.

2) Remove the brake fluid pump reservoir cap as

described in Chapter 8-Bodywork.

3) Remove the two screws shown in the figure and

open the front brake fluid reservoir.

4) Using the bleeder screw on the brake caliper,

empty the brake circuit through a pipe of suitable

diameter.

5) Collect the used fluid in a suitable container.

6) Operate the brake pump until all the fluid has come

out.

7) Close the bleeder valve.

8) Fill the circuit reservoir to the maximum level with

fluid of the prescribed type.

9) Attach the pipe of the specific tool (Mityvac-type

manual pump) to the bleeding connection.

10) While acting on the bleeder with the specific tool,

constantly pour fresh fluid into the reservoir so as to

avoid sucking in air. Stop pumping as soon as the

fluid flows out of the bleeder with no air bubbles.

11) Tighten the bleeder screw with the prescribed

torque.

7

07_008

Tightening torque:

Drain screw: 12 - 16 N·m

7 - 5

Page 48

Braking system

Note: If air keeps coming out during the bleeding,

check all connections. If these are tight, check the

different pump seals and the caliper pistons.

During the operation oil may trickle from the bleeder

screw onto the caliper and the disc. In that case,

carefully dry the caliper and degrease the disc.

Specific tool:

Vacuum pump MITIVAC type: 020329Y

Combined brake

A control system allows the left brake lever to

simultaneously operate the left-hand front caliper and

the rear caliper.

To empty the circuit, follow the procedure given for the

right-hand front brake, using the bleeder of both brake

calipers, front and rear.

07_009

To bleed the system, follow these steps:

1) Attach the specific Mityvac tool to the bleeder fitted

on the pressure divider valve shown in the figure.

2) Fill the left brake fluid reservoir to the maximum

level.

3) Slowly operate the left brake lever while pouring

fresh fluid into the reservoir until all the air has come

out, thus obtaining the bleeding of the first section

of the combined brake line. Tighten the bleeder

valve with the prescribed torque.

4) Proceed to bleed each caliper - the front caliper first

and then the rear caliper - following the same

procedure used for the front brake.

Specific tool:

Vacuum pump MITIVAC type: 020329Y

Tightening torque:

Oil drain screw: 12 - 16 N·m

07_010

7 - 6

Page 49

Removing the brake calipers

Check the condition of the brake lines, the gaskets and

the related connections. Should any fluid leak onto the

calipers, replace them by following these steps:

- Empty the circuit as previously described for the

brake fluid renewal.

- Remove the caliper pipe connection shown in the

figure.

- Collect any fluid residues left in the pipe.

- Remove the two screws fixing the caliper to the

support.

- Remove the caliper.

- Remove the brake pads from the caliper as previously described.

- Replace the caliper with a new one and then follow

the reverse procedure to the removal.

Note: Fit new copper gaskets on the connection.

- Tighten the two fixing screws with the prescribed

torque.

- Complete the operation by filling and bleeding the

circuit.

- Use the same procedure for the three calipers, the

only difference being that the rear brake caliper must

be removed from the vehicle together with its support.

This is obtained by loosening the two screws shown

in the figure after removing the rear wheel as described in Chapter 6-Front and rear suspensions.

Braking system

07_011

07_012

Tightening torque:

Screws fixing caliper to support: 20 - 25 N·m

Removing the brake pumps

To remove and replace the brake pumps, follow these

steps:

- Empty the related braking circuit as described in the

previous paragraphs.

- Remove the connection shown in the figure taking

care to prevent any fluid residues from coming out.

- Remove the two screws fastening the clevis to the

handlebar.

- Replace the broken pump.

- Reassemble taking care to replace the copper gaskets. Fasten the connection and tighten the two

screws fixing the pump to the handlebar.

7

07_013

07_014

7 - 7

Page 50

Braking system

Note: Take care to properly insert the specially designed

projection on the pump clevis in the related hole in the

handlebar (see figure).

- Complete the overhaul by filling and bleeding the

circuit.

- The removing procedure is the same for both brake

pumps (see figure).

Replacing the pressure divider valve

Removal

Should the braking action between the front left and

rear calipers by unevenly distributed (e.g. with the

same surface and adhesive force on both wheels the

rear brake jams while the front brake is not applied or

vice versa, or the brakes work in a completely different

manner, or the divider valve does not work properly),

follow these steps:

07_015

2

1

- Empty the combined brake circuit as previously described.

- Remove the front countershield as described in Chapter 8-Bodywork.

- Unscrew rear caliper connection 1 (see figure).

Note: Place a rag under the divider valve to prevent

brake fluid from soiling the brake pads or other components.

- Remove front brake caliper connection 2.

- Remove connection 3, conveying the fluid from the

pump to the valve.

- Remove the two cheese-headed socket screws fixing

the valve to the frame in the two holes shown in the

figure.

- Remove the valve and replace it with a new one.

Fitting

Follow the reverse procedure to the removal.

3

07_016

07_017

Note: Fit new copper gaskets on the connections.

- Tighten the screws fixing the valve to the frame and,