Philips 21PV385 58, 21PV385 39, 21PV385 07, 21PV385 01 Service Manual

TV-VCR Combination

Service

21PV385

/01/07/39/58

Service

Service

Service Manual

Contents

Chapter

Adjustment Procedure

Sec. 1:

Schematic Diagrams and CBA's

Exploded Views

Mechanical and Electrical Parts Lists

Survey of versions:

/01 PAL-BG, EURO

/07 PAL I, UK/IRELAND

/39 PAL/SECAM-BG+PAL/SECAM-L/L',FRANCE

/58 PAL-BG/DK+SECAM-BG/DK,EAST-EURO

VN: 1A

Sec. 2:

Standard Maintenance

Mechanism Alignment Procedures

Disassembly / Assembly of Mechanism

Deck Exploded Views

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified

be used.

Published by BK 2004 Video Service Department Printed in the Netherlands c

Copyright reserved Subject to modification GB 3103 785 22300

MAIN SECTION

TV-VCR COMBINATION

Sec. 1: Main Section

I Adjustment Procedures

I Schematic Diagrams and CBA’s

I Exploded Views

I Mechanical and Electrical Parts List

TABLE OF CONTENTS

IMPORTANT SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

STANDARD NOTES FOR SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

PREPARATION FOR SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

OPERATING CONTROLS AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

CABINET DISASSEMBLY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

ELECTRICAL ADJUSTMENT INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

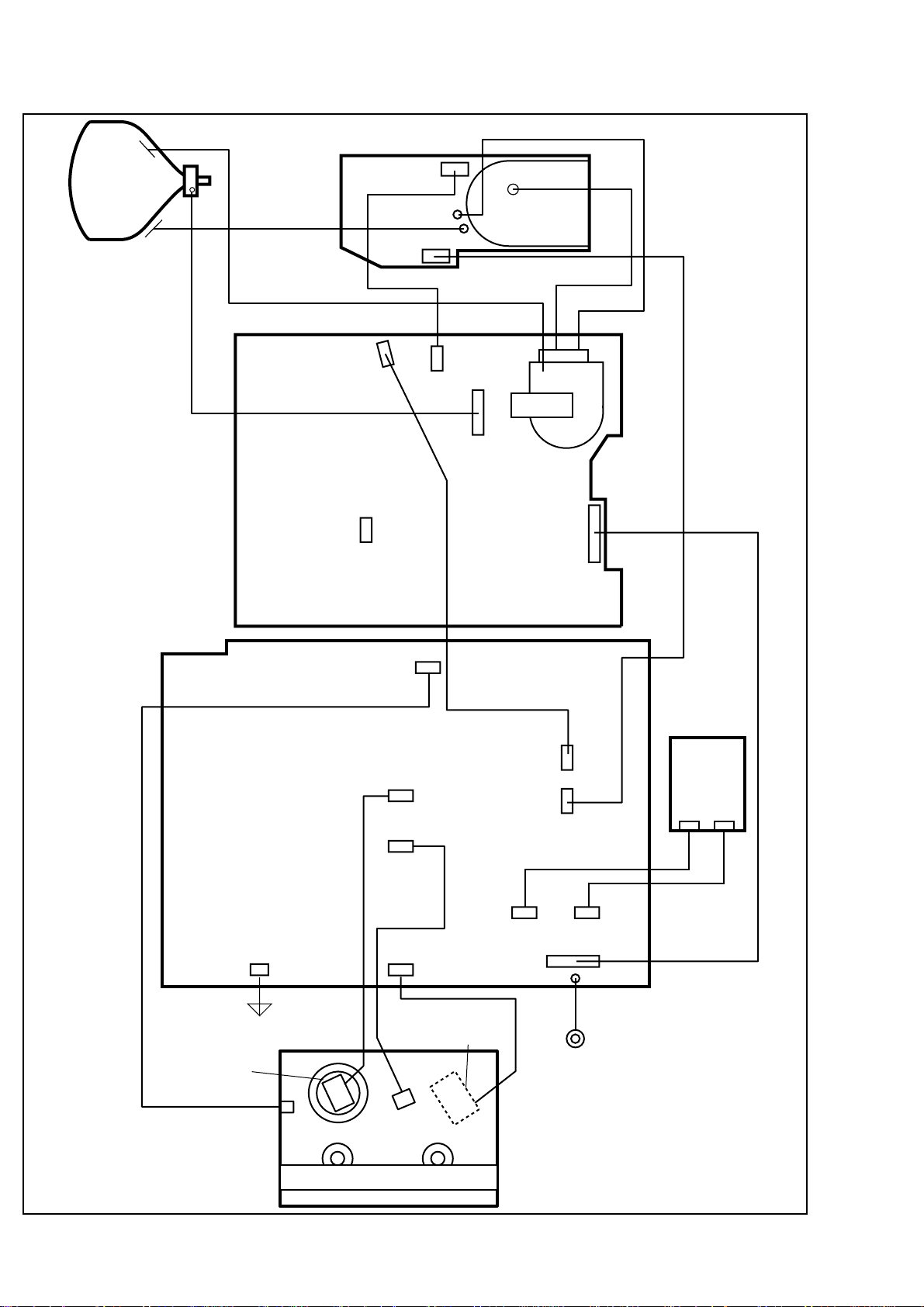

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

SYSTEM CONTROL TIMING CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

IC PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

LEAD IDENTIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13-1

ELECTRICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

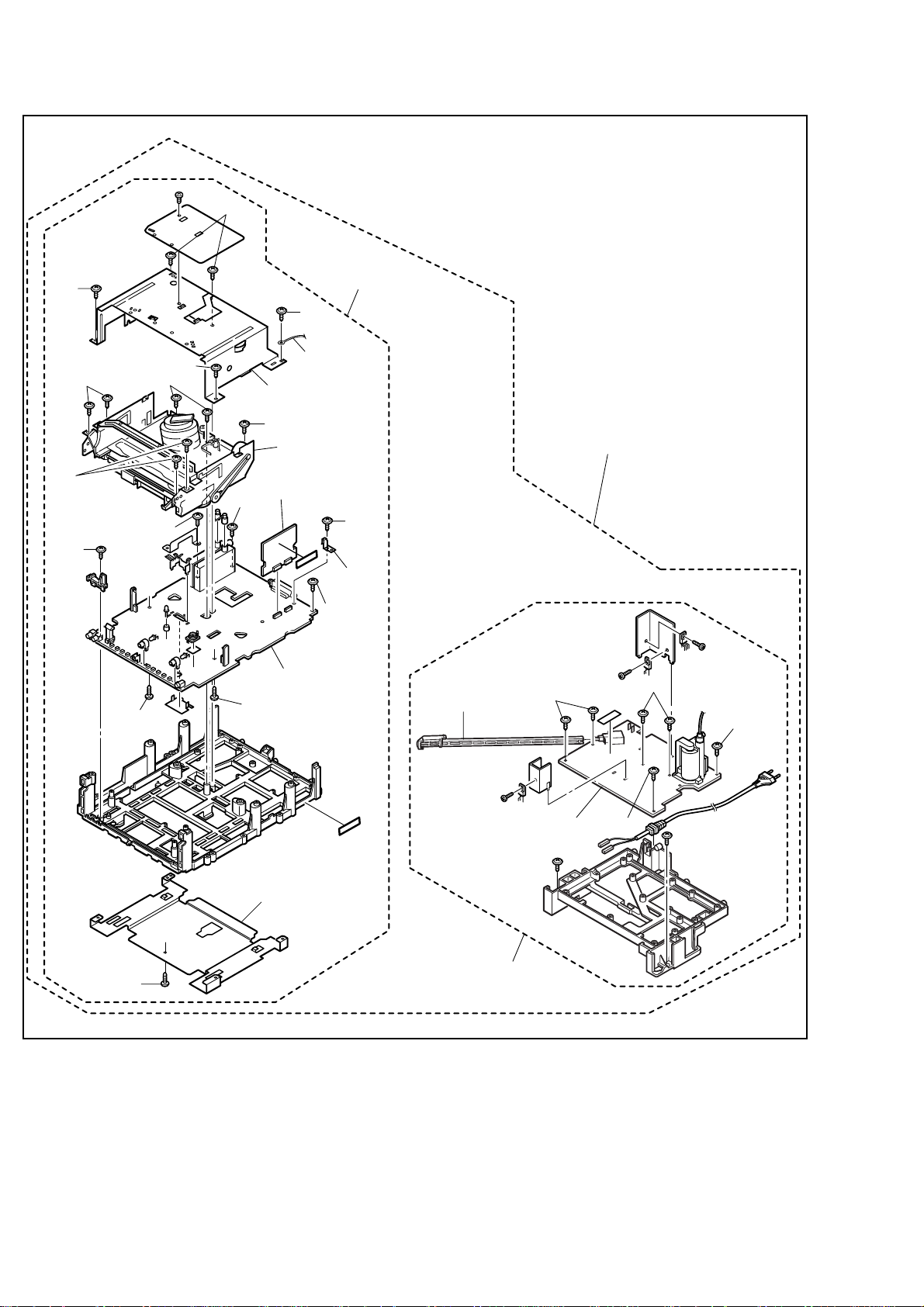

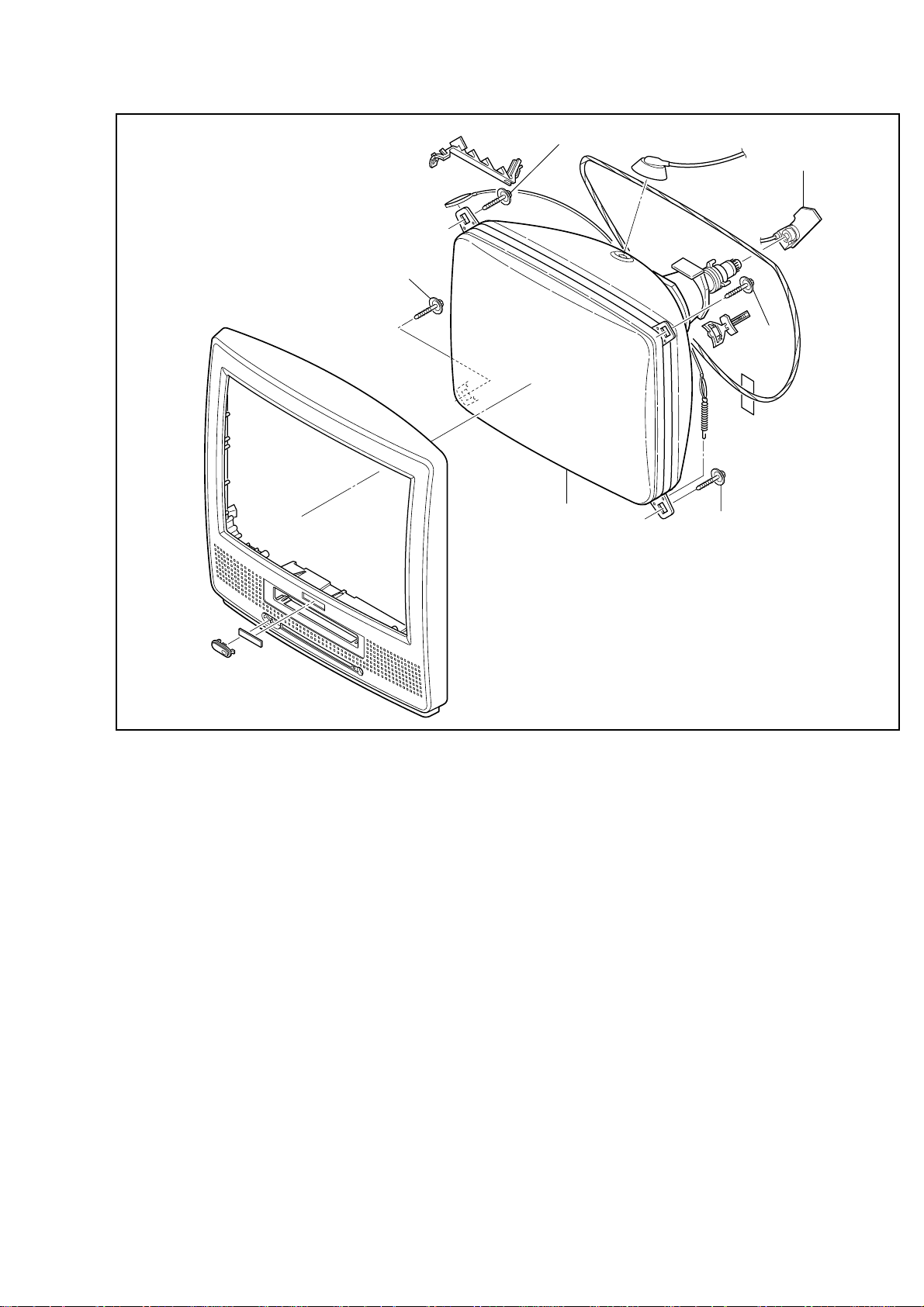

EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15-1

MECHANICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16-1

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for TV Circuit

1. Before returning an instrument to the customer, always make a safety check of the entire instru-

ment, including, but not limited to, the following

items:

a. Be sure that no built-in protective devices are de-

fective and have been defeated during servicing.

(1) Protective shields are provided on this chassis

to protect both the technician and the customer.

Correctly replace all missing protective shields, including any removed for servicing convenience.

(2) When reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place

all protective devices, including but not limited to,

nonmetallic control knobs, insulating fishpapers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not oper-

ate this instrument or permit it to be operated

without all protective devices correctly installed and functioning. Servicers who defeat

safety features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to, (1) spacing between the picture tube and the cabinet

mask, (2) excessively wide cabinet ventilation

slots, and (3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug prongs.

Place the instrument AC switch in the on position.

Connect one lead of an ohmmeter to the AC plug

prongs tied together and touch the other ohmmeter lead in turn to each tuner antenna input exposed terminal screw and, if applicable, to the

coaxial connector. If the measured resistance is

less than 1.0 megohm or greater than 5.2 megohm, an abnormality exists that must be corrected

before the instrument is returned to the customer.

Repeat this test with the instrument AC switch in

the off position.

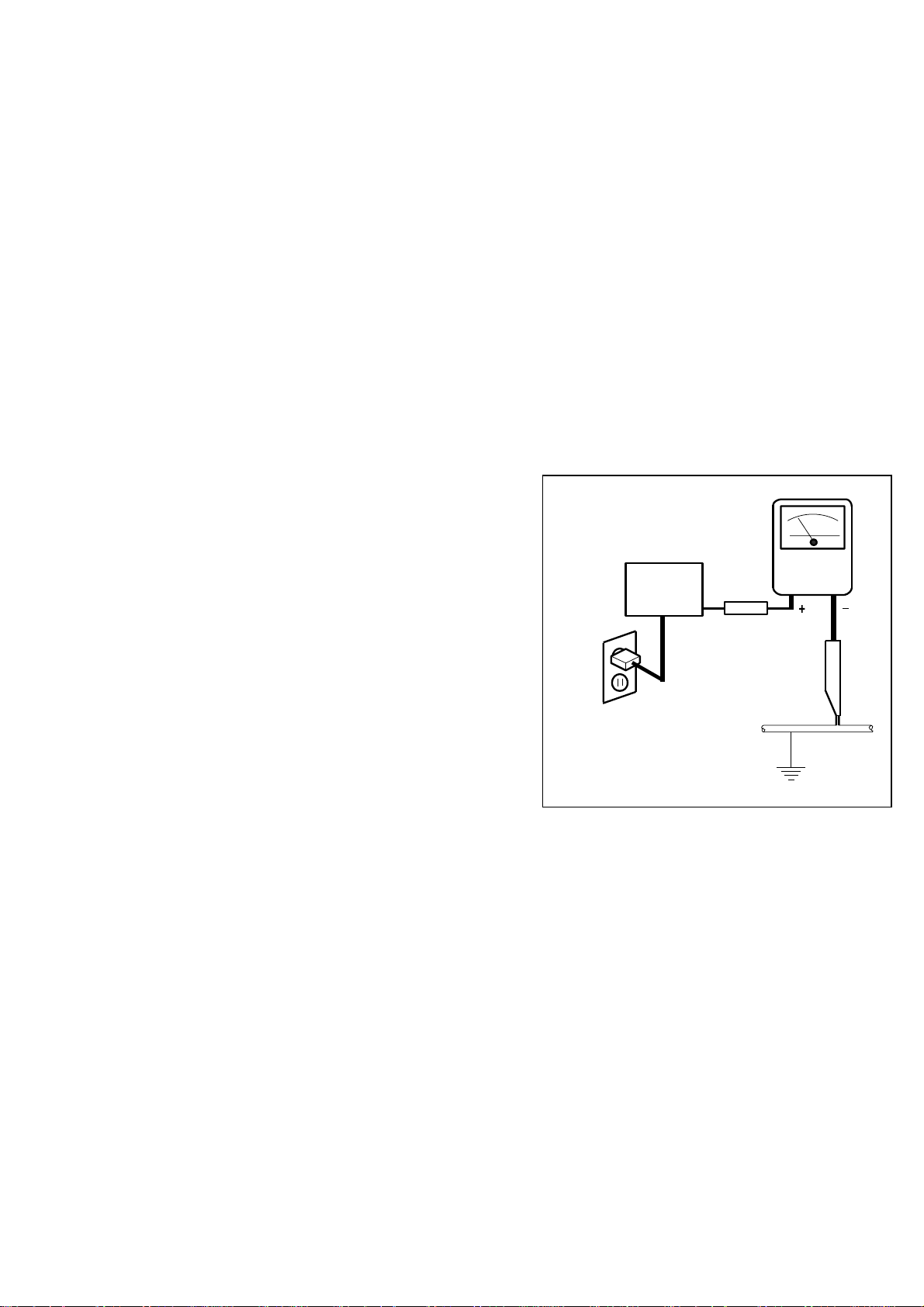

d. Leakage Current Hot Check - With the instru-

ment completely reassembled, plug the AC line

cord directly into a 120V AC outlet. (Do not use an

isolation transformer during this test.) Use a leak-

age current tester or a metering system that complies with American National Standards Institute

(ANSI) C101.1 Leakage Current for Appliances

and Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on position and then in the off position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle brackets, metal cabinet, screw

heads, metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis. Any current

measured must not exceed 0.5 milli-ampere. Reverse the instrument power cord plug in the outlet

and repeat the test.

READING SHOULD

NOT BE ABOVE 0.5 mA

LEAKAGE

DEVICE

BEING

TESTED

TEST ALL EXPOSED

METAL SURFACES

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

CURRENT

TESTER

EARTH

GROUND

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO

THE CUSTOMER OR BEFORE CONNECTING

THE ANTENNA OR ACCESSORIES.

e. X-Radiation and High Voltage Limits - Because

the picture tube is the primary potential source of

X-radiation in solid-state TV receivers, it is specially constructed to prohibit X-radiation emissions.

For continued X-radiation protection, the replacement picture tube must be the same type as the

original. Also, because the picture tube shields

and mounting hardware perform an X-radiation

protection function, they must be correctly in place.

High voltage must be measured each time servic-

1-1-1 T6550SFTY

ing is performed that involves B+, horizontal deflection or high voltage. Correct operation of the

X-radiation protection circuits also must be reconfirmed each time they are serviced. (X-radiation

protection circuits also may be called "horizontal

disable" or "hold down.") Read and apply the high

voltage limits and, if the chassis is so equipped,

the X-radiation protection circuit specifications given on instrument labels and in the Product Safety

& X-Radiation Warning note on the service data

chassis schematic. High voltage is maintained

within specified limits by close tolerance safety-related components/adjustments in the high-voltage

circuit. If high voltage exceeds specified limits,

check each component specified on the chassis

schematic and take corrective action.

2. Read and comply with all caution and safety-related notes on or inside the receiver cabinet, on the

receiver chassis, or on the picture tube.

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this TV receiver. Design alterations and additions, including,

but not limited to circuit modifications and the addition of items such as auxiliary audio and/or video

output connections, might alter the safety characteristics of this receiver and create a hazard to the

user. Any design alterations or additions will void

the manufacturer's warranty and may make you,

the servicer, responsible for personal injury or

property damage resulting therefrom.

4. Picture Tube Implosion Protection Warning -

The picture tube in this receiver employs integral

implosion protection. For continued implosion protection, replace the picture tube only with one of

the same type number. Do not remove, install, or

otherwise handle the picture tube in any manner

without first putting on shatterproof goggles

equipped with side shields. People not so

equipped must be kept safely away while picture

tubes are handled. Keep the picture tube away

from your body. Do not handle the picture tube by

its neck. Some "in-line" picture tubes are equipped

with a permanently attached deflection yoke; because of potential hazard, do not try to remove

such "permanently attached" yokes from the picture tube.

5. Hot Chassis Warning -

a. Some TV receiver chassis are electrically connect-

ed directly to one conductor of the AC power cord

and maybe safety-serviced without an isolation

transformer only if the AC power plug is inserted

so that the chassis is connected to the ground side

of the AC power source. To confirm that the AC

power plug is inserted correctly, with an AC voltmeter, measure between the chassis and a known

earth ground. If a voltage reading in excess of 1.0V

is obtained, remove and reinsert the AC power

plug in the opposite polarity and again measure

the voltage potential between the chassis and a

known earth ground.

b. Some TV receiver chassis normally have 85V

AC(RMS) between chassis and earth ground regardless of the AC plug polarity. This chassis can

be safety-serviced only with an isolation transformer inserted in the power line between the receiver

and the AC power source, for both personnel and

test equipment protection.

c. Some TV receiver chassis have a secondary

ground system in addition to the main chassis

ground. This secondary ground system is not isolated from the AC power line. The two ground systems are electrically separated by insulation

material that must not be defeated or altered.

6. Observe original lead dress. Take extra care to assure correct lead dress in the following areas: a.

near sharp edges, b. near thermally hot parts-be

sure that leads and components do not touch thermally hot parts, c. the AC supply, d. high voltage,

and e. antenna wiring. Always inspect in all areas

for pinched, out of place, or frayed wiring. Check

AC power cord for damage.

7. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or wiring that meet original specifications. Additionally,

determine the cause of overheating and/or damage and, if necessary, take corrective action to remove any potential safety hazard.

8. Product Safety Notice - Some electrical and mechanical parts have special safety-related characteristics which are often not evident from visual

inspection, nor can the protection they give necessarily be obtained by replacing them with components rated for higher voltage, wattage, etc.. Parts

that have special safety characteristics are identified by a ( ! ) on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or

other hazards. The Product's Safety is under review continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are strictly inspected to confirm with the recognized product safety and electrical codes of the countries in which they are to be

sold. However, in order to maintain such compliance, it is equally important to implement the following precautions when a set is being serviced.

1-1-2 T6550SFTY

Precautions during Servicing

A. Parts identified by the ( ! ) symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations applying to spurious radiation. These must also be replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. When a power cord has been replaced, check that

5~6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Use care that foreign objects (screws, solder drop-

lets, etc.) do not remain inside the set.

K. Crimp type wire connector

When replacing the power transformer in sets

where the connections between the power cord

and power transformer primary lead wires are performed using crimp type connectors, in order to

prevent shock hazards, perform carefully and precisely the following steps.

Replacement procedure

1) Remove the old connector by cutting the wires at a

point close to the connector.

Important: Do not re-use a connector (discard it).

2) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3) Align the lengths of the wires to be connected. Insert the wires fully into the connector.

4) Use the crimping tool to crimp the metal sleeve at

the center position. Be sure to crimp fully to the

complete closure of the tool.

L. When connecting or disconnecting the VCR con-

nectors, first, disconnect the AC plug from AC supply socket.

1-1-3 T6550SFTY

Safety Check after Servicing

Examine the area surrounding the repaired location for

damage or deterioration. Observe that screws, parts

and wires have been returned to original positions.

Afterwards, perform the following tests and confirm the

specified values in order to verify compliance with

safety standards.

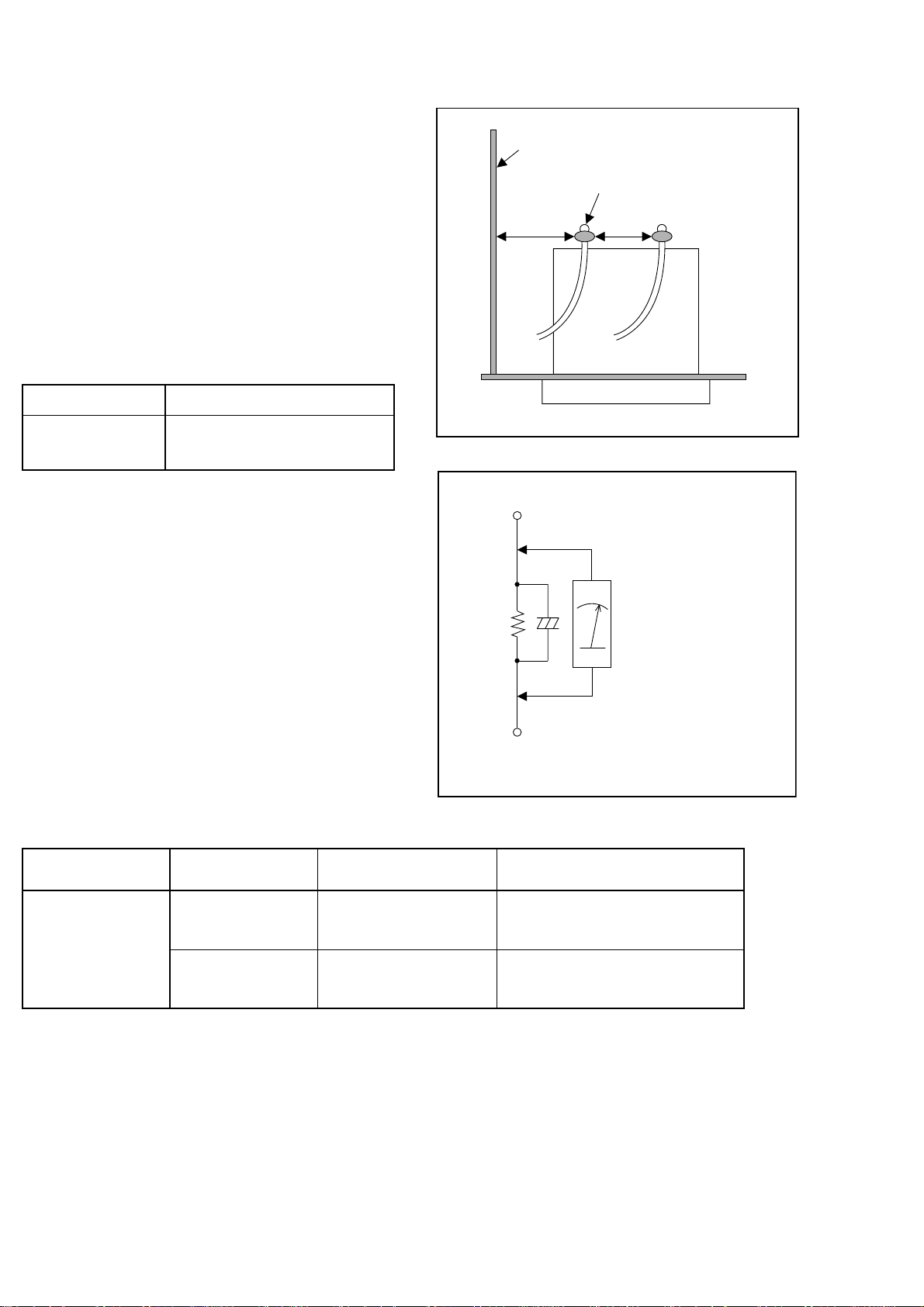

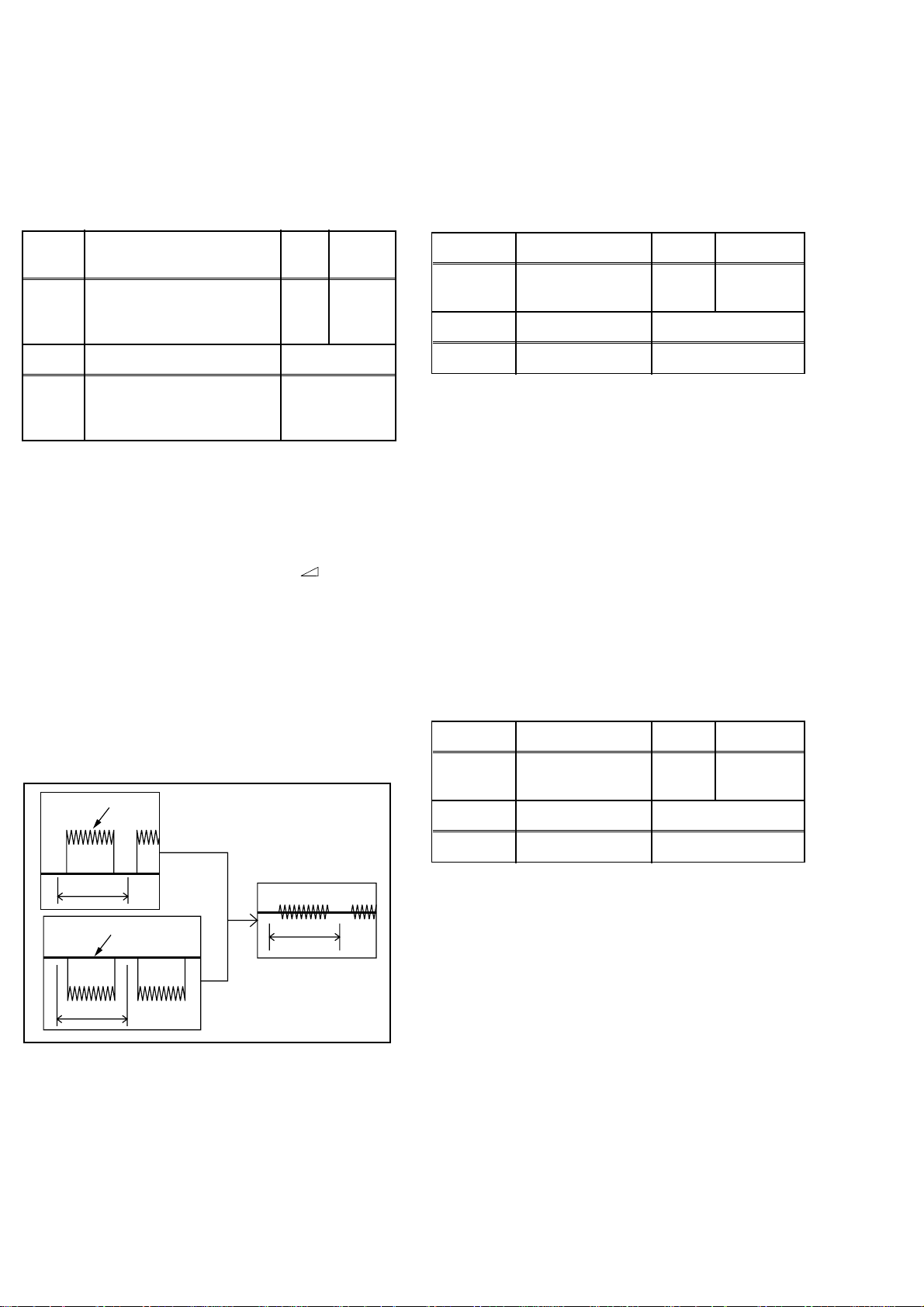

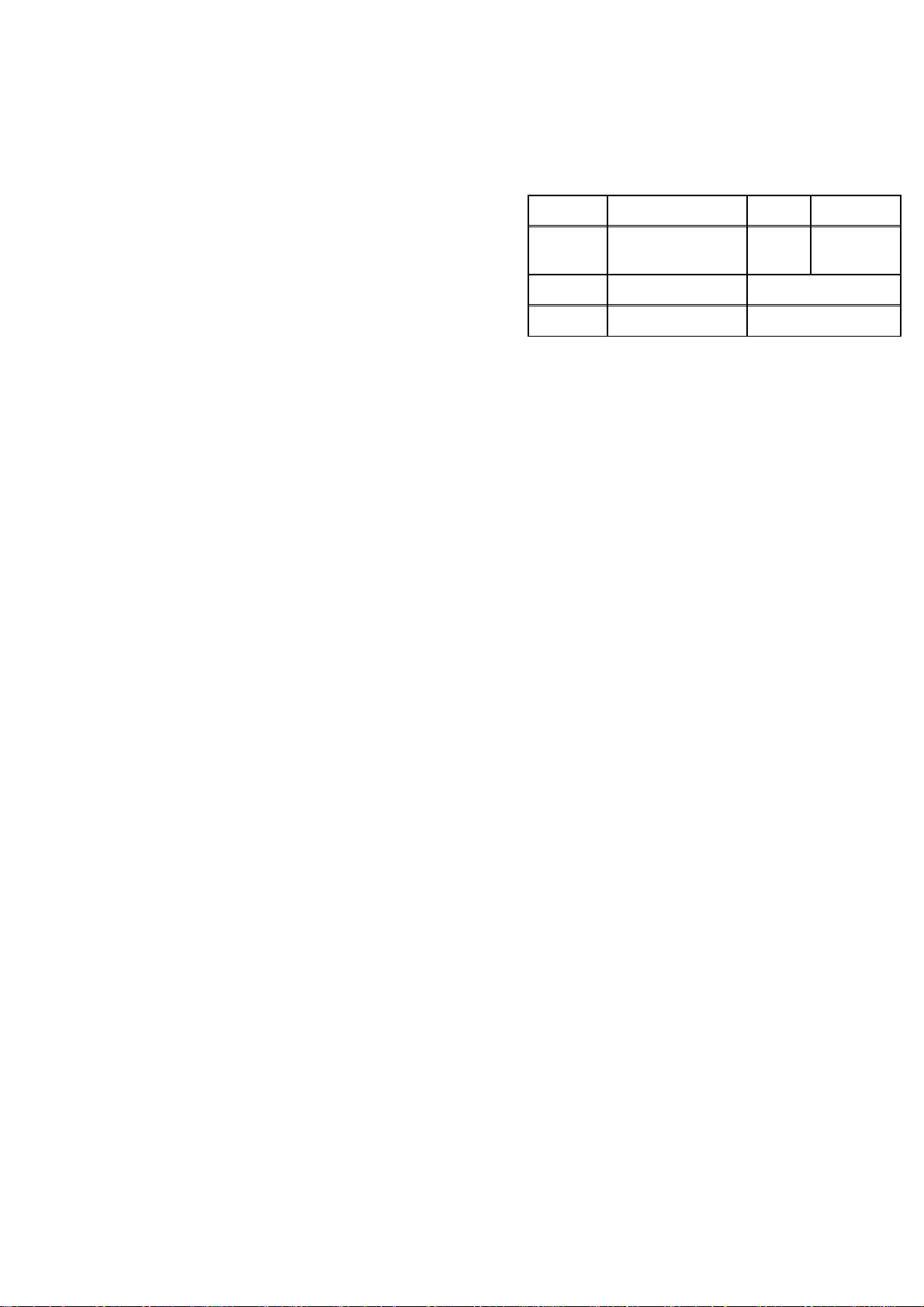

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d) (d’)

220 to 240 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.).

≥ 3mm(d)

≥ 6 mm(d’)

Chassis or Secondary Conductor

Primary Circuit Terminals

dd’

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Fig. 1

Measuring Method : (Power ON)

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across both terminals of load

Z. See Fig. 2 and following table.

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

2kΩ RES.

Connected in

220 to 240 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

parallel

50kΩ RES.

Connected in

parallel

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

One side of

B

Power Cord Plug Prongs

One side of power cord plug

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

Fig. 2

1-1-4 T6550SFTY

STANDARD NOTES FOR SERVICING

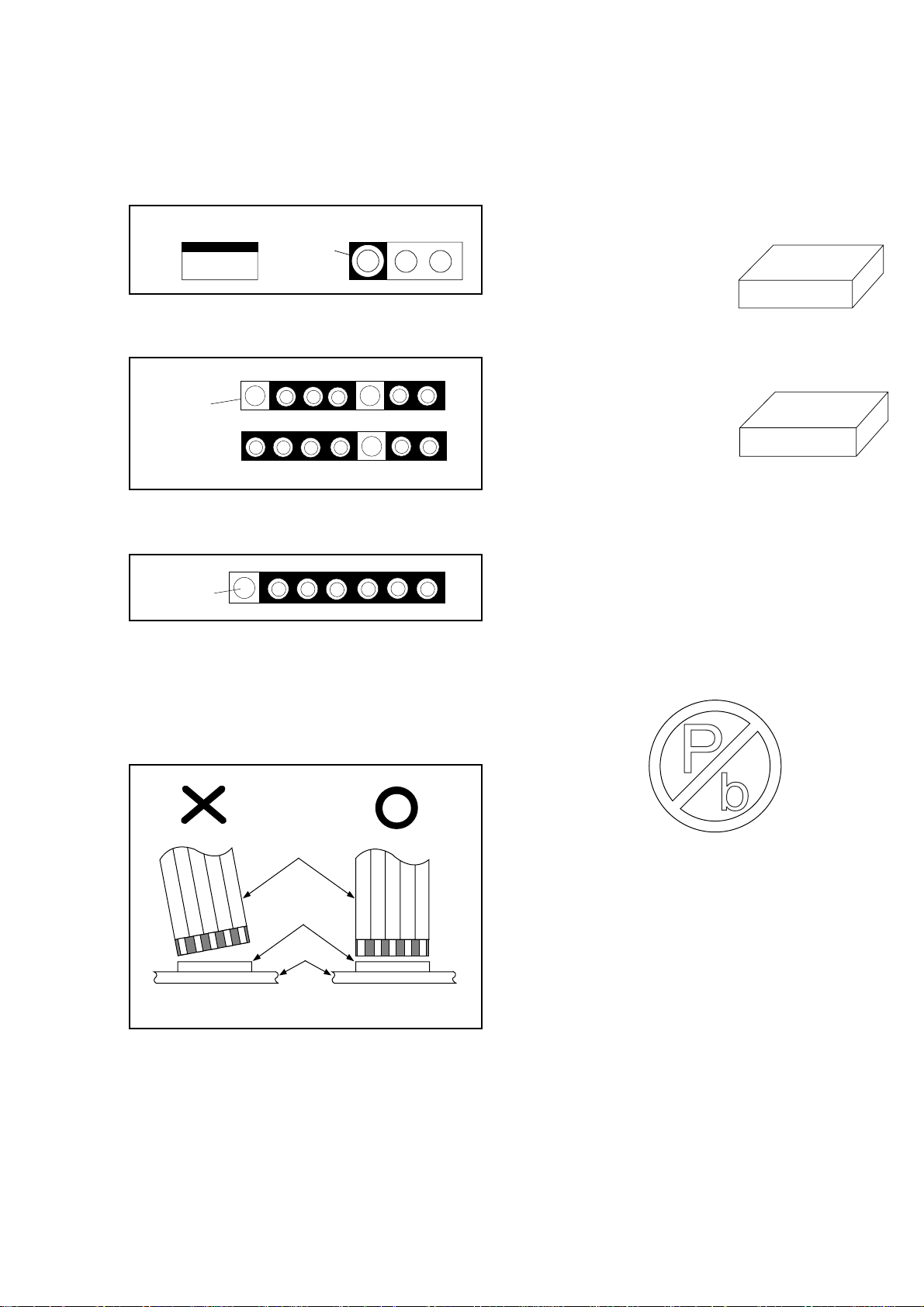

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is indicated as shown:

Top View

Out

2. For other ICs, pin 1 and every 5th pin is indicated

as shown:

Pin 1

3. The 1st pin of every pin connector are indicated as

shown:

Input

In

Bottom View

5

10

How to Read the Values of the Rectangular Type Chip Components

Example:

(a) Resistor

473

= 473 = 47 [kΩ]

(b) Capacitor

= Not Shown

Caution:

Once chip parts (Resistors, Capacitors, Transistors,

etc.) are removed, they must not be reused. Always

use a new part.

(Top View)

(Top View)

Pin 1

Instructions for Connectors

1. When you connect or disconnect FFC cable (connector), be sure to disconnect the AC cord.

2. FFC cable (connector) should be inserted parallel

into the connector, not at an angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

[ CBA= Circuit Board Assembly ]

Pb (Lead) Free Solder

Pb free mark will be found on PCBs used Pb free

solder. (Refer to figure.) For PCBs with Pb free

mark, be sure to use Pb free solder. For PCBs

without Pb free mark, use standard solder.

Pb free mark

Replacement Procedures for

Leadless (Chip) Components

The Following Procedures are Recommended for the Replacement of the Leadless Components Used in this Unit.

1. Preparation for replacement

1.1. Pb free solder

a. Soldering Iron

Use a soldering iron for Pb free solder.

b. Solder

Be sure to use Pb free solder.

c. Soldering time

Do not apply heat for more than 4 seconds.

d. Preheating

Leadless capacitor must be preheated before

installation. (130°C~150°C, for about two minutes.)

1-2-1 SFTY_Z13P

1.2. Standard solder

a. Soldering Iron

Use a pencil-type soldering iron (less than 30

watts).

b. Solder

Eutectic solder (Tin 63%, Lead 37%) is recommended.

c. Soldering time

Do not apply heat for more than 4 seconds.

d. Preheating

Leadless capacitor must be preheated before

installation. (130°C~150°C, for about two minutes.)

Notes:

a. Leadless components must not be reused after

removal.

b. Excessive mechanical stress and rubbing for the

component electrode must be avoided.

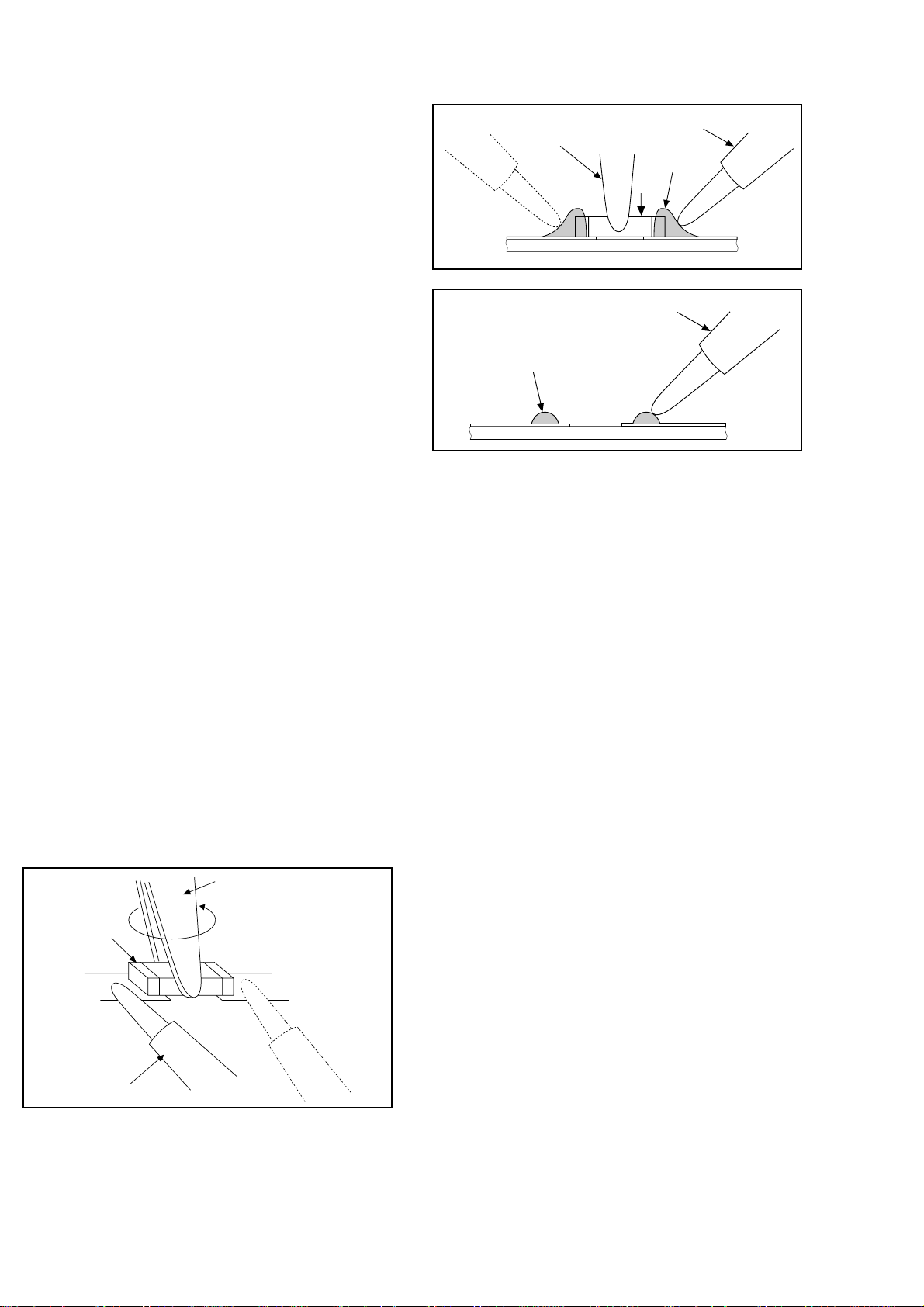

2. Removing the leadless component

Grasp the leadless component body with tweezers

and alternately apply heat to both electrodes. When

the solder on both electrodes has melted, remove

leadless component with a twisting motion.

Notes:

a. Do not attempt to lift the component off the board

until the component is completely disconnected

from the board by the twisting action.

b. Take care not to break the copper foil on the printed

board

3. Installing the leadless component

a. Presolder the contact points of the circuit board.

b. Press the part downward with tweezers and solder

both electrodes as shown below.

Note:

Do not glue the replacement leadless component to

the circuit board.

Tweezers

Chip

Soldering Iron

Tweezers

Soldering Iron

Solder

Soldering Iron

Presolder

How to Remove / Install Flat Pack IC

Caution:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering machine, whose shape matches that of the Flat PackIC.

2. Do not apply the hot air to the chip parts around the

Flat Pack-IC for over 6 seconds as damage may

occur to the chip parts. Put Masking Tape around

the Flat Pack-IC to protect other parts from damage. (Fig. S-1-2)

3. The Flat Pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or solder lands under the IC when removing it.

1. Removal

With Hot - Air Flat Pack - IC Desoldering Machine:

a. Prepare the Hot - Air Flat Pack - IC Desoldering

Machine, then apply hot air to Flat Pack - IC (about

5~6 seconds). (Fig. S-1-1)

b. Remove the Flat Pack- IC with tweezers while

applying the hot air.

With Soldering Iron:

a. Using desoldering braid, remove the solder from all

pins of the Flat Pack - IC. When you use solder flux

which is applied to all pins of the Flat Pack - IC, you

can remove it easily. (Fig. S-1-3)

b. Lift each lead of the Flat Pack - IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air Desoldering

Machine. (Fig. S-1-4)

With Iron Wire:

a. Using desoldering braid, remove the solder from all

pins of the Flat Pack - IC. When you use solder flux

which is applied to all pins of the Flat Pack - IC, you

can remove it easily. (Fig. S-1-3)

1-2-2 SFTY_Z13P

b. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

c. Pull up on the wire as the solder melts so as to lift

the IC leads from the CBA contact pads, while

heating the pins using a fine tip soldering iron or

hot air blower.

Note:

When using a soldering iron, care must be taken

to ensure that the Flat Pack - IC is not being held

by glue, or when it is removed from the CBA, it

may be damaged if force is used.

2. Installation

a. Using desoldering braid, remove the solder from

the foil of each pin of the Flat Pack - IC on the CBA,

so you can install a replacement Flat Pack - IC

more easily.

b. The "I" mark on the Flat Pack - IC indicates pin 1

(See Fig. S-1-6). Make sure this mark matches the

1 on the CBA when positioning for installation.

Then pre - solder the four corners of the Flat PackIC (See Fig. S-1-7).

c. Solder all pins of the Flat Pack - IC. Make sure that

none of the pins have solder bridges.

Flat Pack-IC

Fine Tip

Soldering Iron

Desoldering Braid

Soldering Iron

Fig. S-1-3

Sharp

Pin

Fig. S-1-4

CBA

Fig. S-1-1

Hot-air

Flat Pack-IC

Desoldering

Machine

Hot Air Blower

or

Iron Wire

Soldering Iron

To Solid

Mounting Point

Fig. S-1-5

Example :

Masking

Tape

Tweezers

Flat Pack-IC

Fig. S-1-2

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

1-2-3 SFTY_Z13P

Fig. S-1-6

Presolder

<Correct>

Grounding Band

1MΩ

CBA

Flat Pack-IC

CBA

Fig. S-1-7

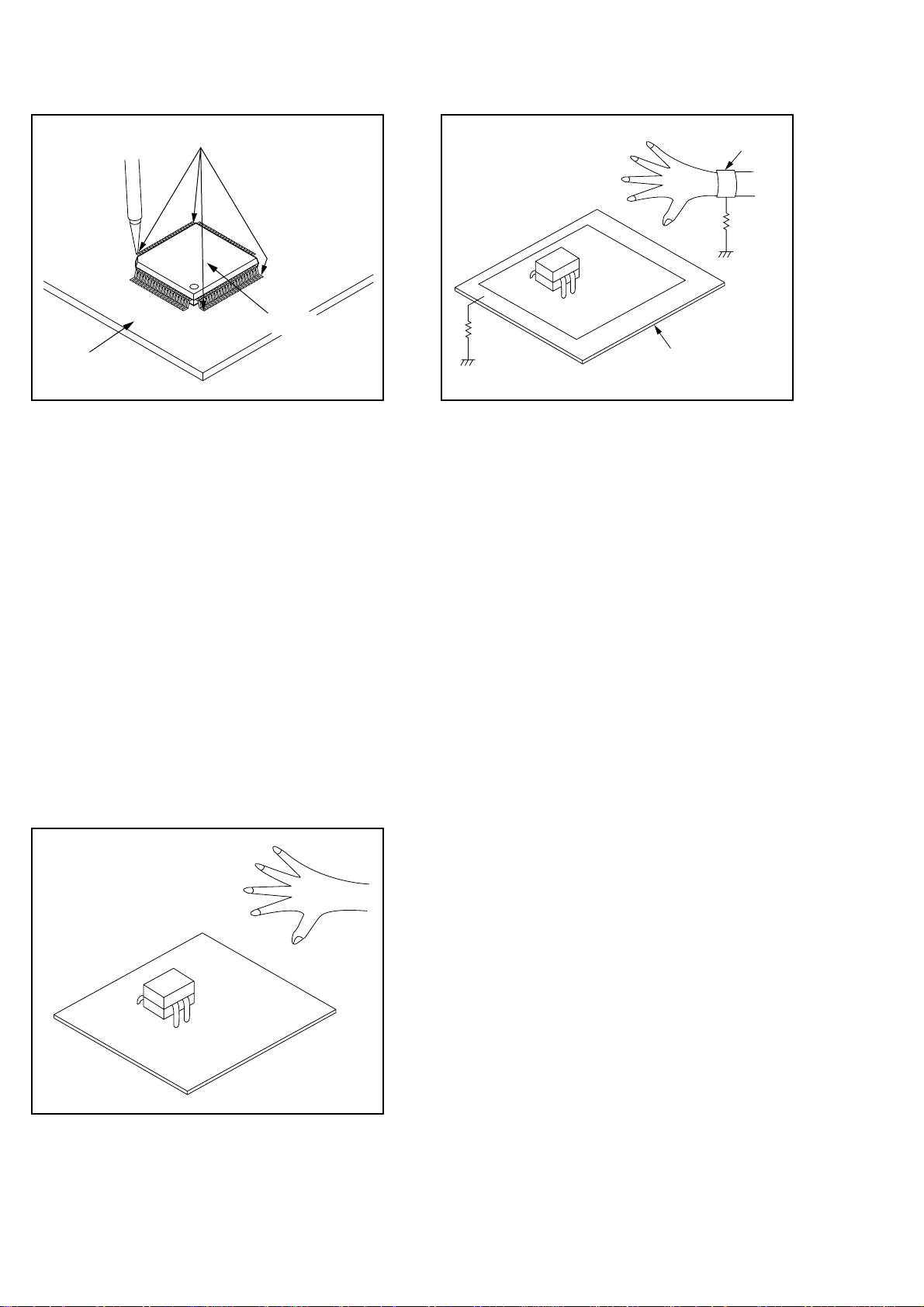

Instructions for Handling

Semiconductors

Electrostatic breakdown of the semiconductors may

occur due to a potential difference caused by electrostatic charge during unpacking or repair work.

Ground for Human Body

Be sure to wear a grounding band (1MΩ) that is properly grounded to remove any static electricity that may

be charged on the body.

Ground for Work Bench

Be sure to place a conductive sheet or copper plate

with proper grounding (1MΩ) on the work bench or

other surface, where the semiconductors are to be

placed. Because the static electricity charge on the

clothing will not escape through the body grounding

band, be careful to avoid contacting semiconductors to

clothing.

1MΩ

Conductive Sheet or

Copper Plate

<Incorrect>

CBA

1-2-4 SFTY_Z13P

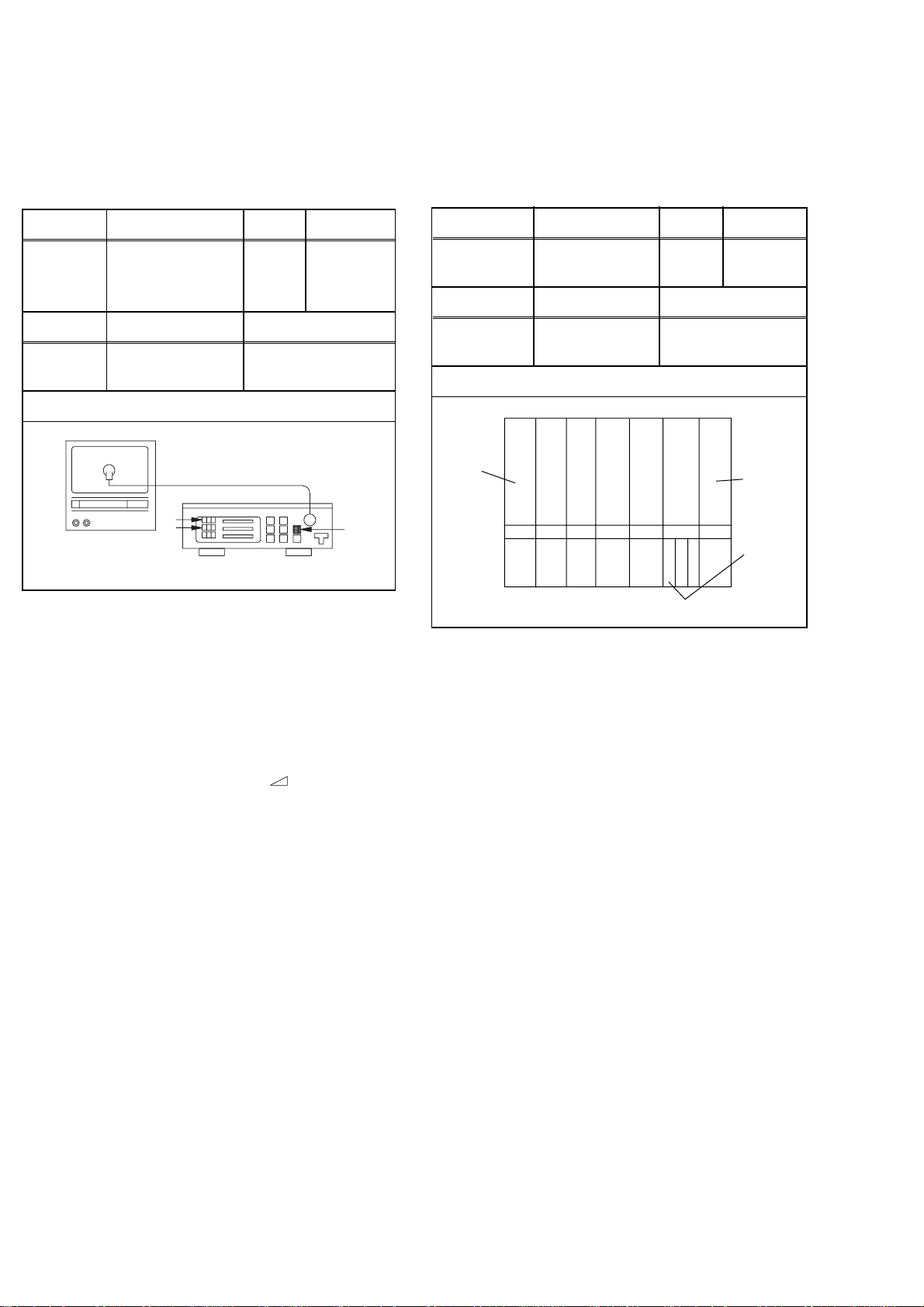

PREPARATION FOR SERVICING

How to Enter the Service Mode

Caution: 1

1. Optical sensors system are used for Tape Start and

End Sensor on this equipment. Read this page

carefully and prepare as described on this page

before starting to service; otherwise, the unit may

operate unexpectedly.

Preparing: 1

1. Cover Q202 (START SENSOR) and Q201 (END

SENSOR) with Insulation Tape or enter the service

mode to activate Sensor Inhibition automatically.

Note: Avoid playing, rewinding or fast forwarding the

tape to its beginning or end, because both Tape End

Sensors are not active.

How to Enter the Service Mode

1. Turn the power on. (Use main power on the TV

unit.)

2. Press [STANDBY/ON], [2], [7], [1], and [MUTE] buttons on the remote control unit in that order within 5

seconds. When entering the service mode, “4” will

display at corners of the screen.

3. During the service mode, electrical adjustment

mode can be selected by remote control key.

Details are as follows.

Key Adjustment Mode

6 No need to use.

7 No need to use.

8

9

Caution: 2

1. The deck mechanism assembly is mounted on the

Main CBA directly, and SW211 (REC-SAFETY

SW) is mounted on the Main CBA. When deck

mechanism assembly is removed from the Main

CBA due to servicing, this switch can not be operated automatically.

H. Shift adjustment mode: See adjustment instructions page 1-6-5.

V.size/V. shift adjustment: See adjustment instructions page 1-6-4.

Preparing: 2

1. To eject the tape, press the STOP/EJECT button

on the unit (or Remote Control).

2. When you want to record during the Service mode,

press the Rec button while depressing SW211

(REC-SAFETY SW) on the Main CBA.

Q201

(END SENSOR)

Q202

(START SENSOR)

Key Adjustment Mode

Picture adjustment mode: Press the

MENU button to change from BRT

(Bright), *CNT (Contrast), *COL

MENU

-

0

1

2

3

4

5

(Color), *TNT(Tint) and SHP(SHARP).

Press P+/P- key to adjust Initial Value.

*Marked items are not necessary to

adjust normally.

SECAM Black Level adjustment mode:

See adjustment instructions page

1-6-4.

Cut-Off adjustment mode: See adjustment instructions page 1-6-5.

White Balance adjustment mode: See

adjustment instructions page 1-6-6.

C-Trap adjustment mode: See adjustment instructions page 1-6-3.

DSPC adjustment mode: See adjustment instructions page 1-6-3.

H adjustment mode: See adjustment

instructions page 1-6-2.

Head switching point adjustment mode

(Auto adjustment): See adjustment

instructions page 1-6-8.

Auto record mode: Perform recording

(15 Sec.)-->Stop-->Rewind (Zero

return) automatically.

Head switching point adjustment mode

(Manual adjustment): See adjustment

instructions page 1-6-8.

SW211

(REC-SAFETY SW)

MAIN CBA

1-3-1 T6550PFS

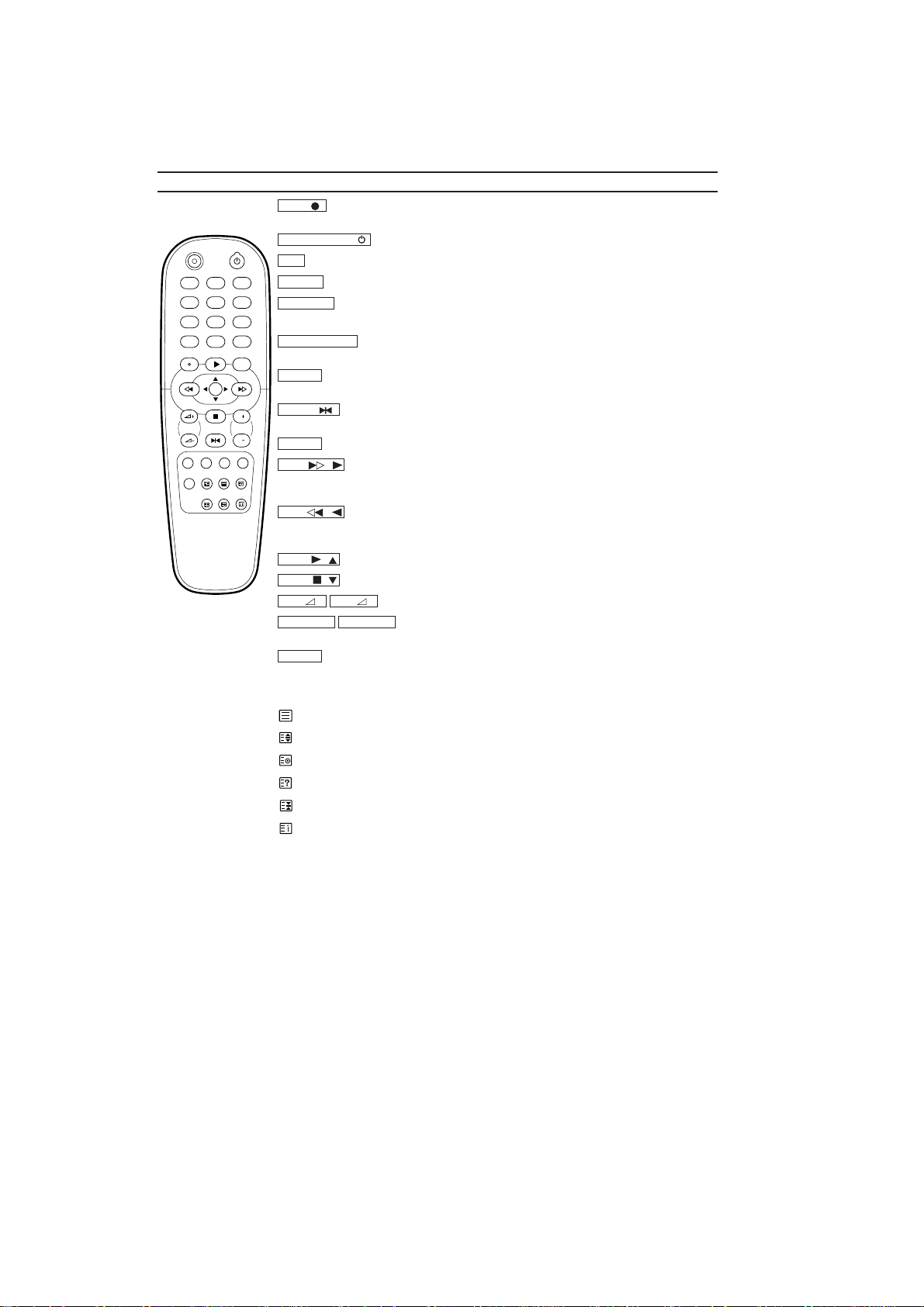

OPERATING CONTROLS AND FUNCTIONS

The remote control

To record the TV channel selected at this moment or press repeatedly to start a

To switch off or on, interrupt menu function.

Press to select channels at TVCR.

To select the switch-off time in 30 minutes intervals.

Doesn’t work on these models. (21PV385/01,07)

To access or remove the TVCR’s on-screen status display. To exit on-

To delete last entry. To clear a programmed recording (TIMER). To reset the

To stop the tape and play back a picture step by step. (except for during fast

To call up main menu of TVCR.

When tape playback is stopped, press to fast forward the tape at high

-

When tape playback is stopped, press to rewind the tape at high speed.

-

To play back a tape, select an item in the menu of TVCR.

-

To stop the tape, select an item in the menu of TVCR.

-

+

VOL

PROG P–PROG P

–

To adjust the volume.

To select the programme number. During playback, press to

+

To eliminate the TV’s sound. Press again to restore the volume.

: To switch Teletext on or off, or transparent mode.

: Enlarge font

: Select Teletext sub-page

: Recall hidden information

:

Stop page changes

: Go back to start page.

REC STANDBY/ON

1 2 3

4 5 6

7 8 9

SLEEP SYSTEM

0

PLAYSTATUS/EXIT CLEAR

REW FWD

MENU

STOP

PROGVOL

STILL

MUTE

REC

One-Touch Recording.

STANDBY/ON

0..9

SLEEP

SYSTEM

To change Video (colour) system. (21PV385/39,58)

STATUS/EXIT

screen menus.

CLEAR

elapsed time counter in the playback, recording or stop mode.

STILL

P

P

forwarding and fast rewinding)

P

MENU

FWD

speed. During playback, press to fast forward the tape while the picture stays on the

screen. To store or confirm entry in the menu. Press to adjust the controls of TVCR menu.

REW

During playback, press to rewind the tape while the picture stays on the screen.To return

the cursor in the menu. Press to adjust the controls of TVCR menu.

PLAY

STOP

VOL

adjust the tracking.

MUTE

Red button/ Green button/ Yellow button/ Blue button/ Doesn’t work on these models.

[21PV385]

1-4-1 T6550IB

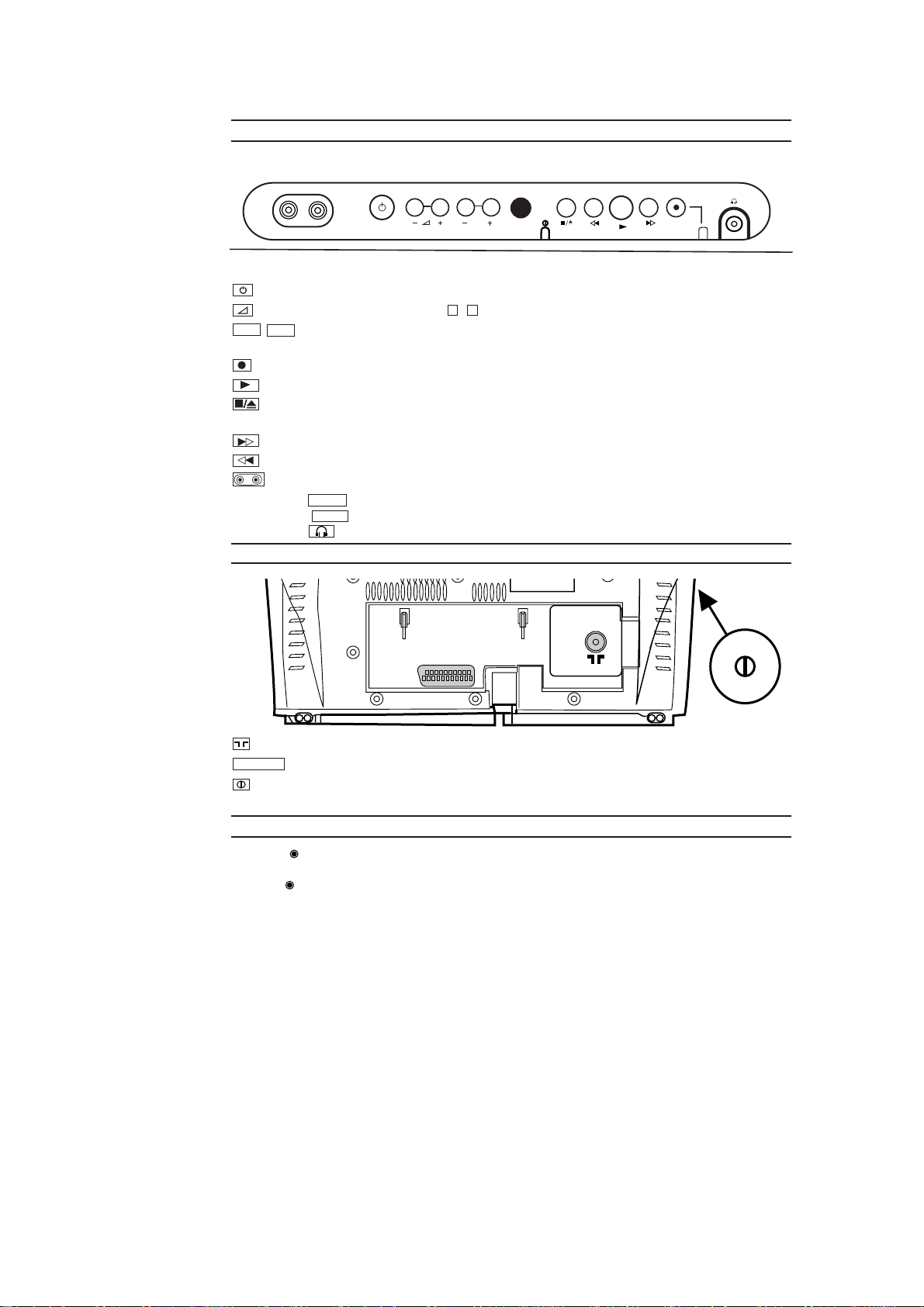

Front of your TVCR

VIDEO AUDIO

STANDBY/ON

P

Standby/on: To switch TVCR on or off, interrupt menu function.

Volume: In connection with the button , to adjust the volume.

P+

Programme number: To select the programme number. During playback, press to adjust the

P-

–+

tracking. To remove vertical jitter in a Still picture.

Record: To record the programme currently selected.

Playback: To play a recorded cassette.

Pause/Stop, eject cassette: To stop the tape; If this key is depressed while in STOP, the cassette is then

ejected from the machine.

When tape playback is stopped, press to fast forward the tape at hight speed.

When tape playback is stoped, press to rewind the tape at hight speed.

Sockets on the front:

White socket / input socket: To connect a camcorder or video game machine (audio).

Yellow socket / input socket: To connect a camcorder or video game machine (video).

AUDIO

VIDEO

Small socket / socket for headphones: To connect headphones.

Back of your TVCR

EXT1/AV1

Aerial input socket: To connect the aerial cable

EXT1/AV

Scart socket :To connect a satellite receiver, decoder, video recorder, etc

Power switch: To switch the TV-Video Combi off.

Caution: If you switch off using the power switch, TIMER-recordings are impossible!

The control lights at the front of machine

STANDBY Standby light: lights up when the TV-Video Combi has been switched on by means of the main

switch.

RECORD Recording light: lights up during recording.

Fast blink: recording pause; timer recording not stand-by.

Slow blink: timer recording is stored in a timer block.

1-4-2 T6550IB

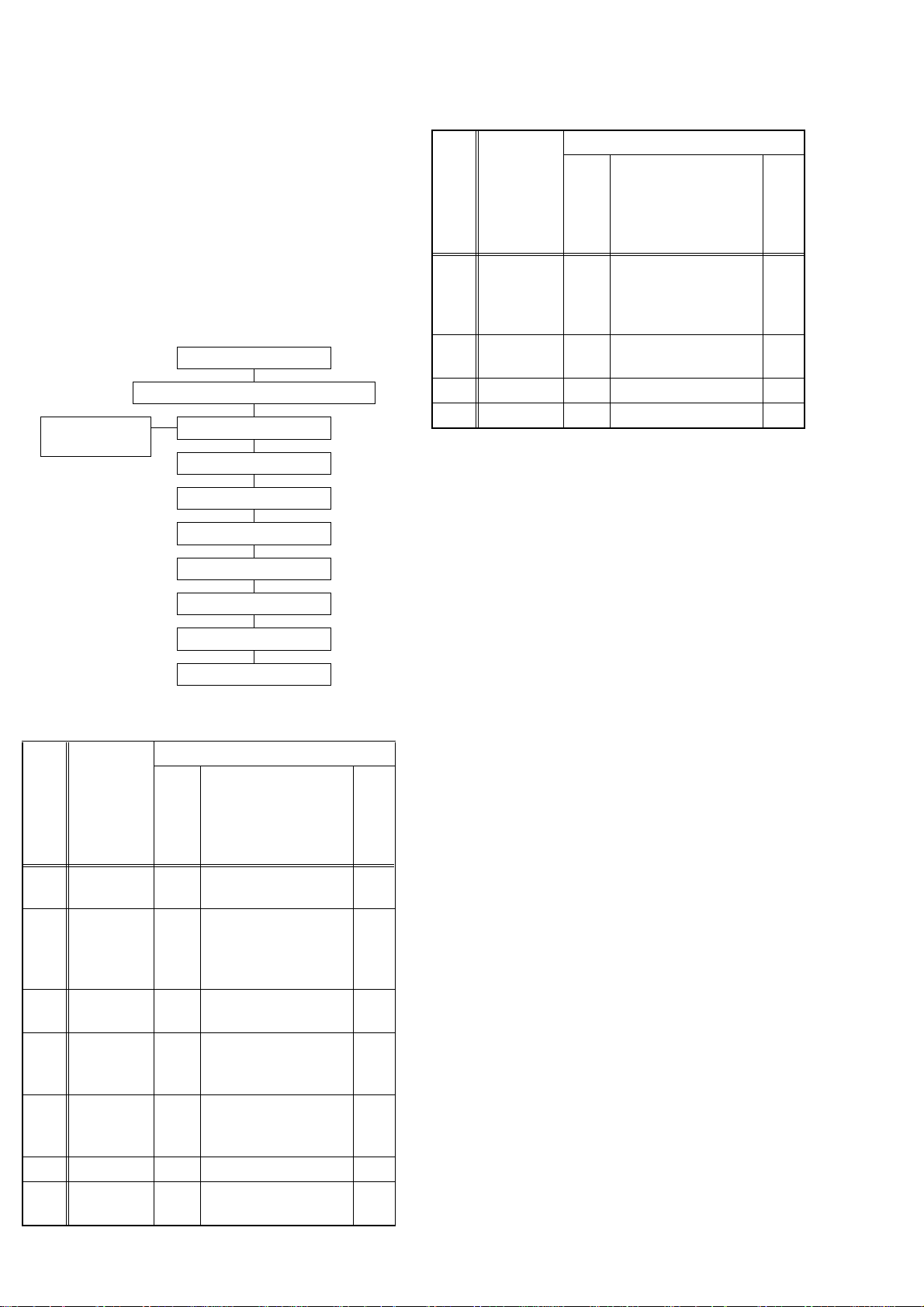

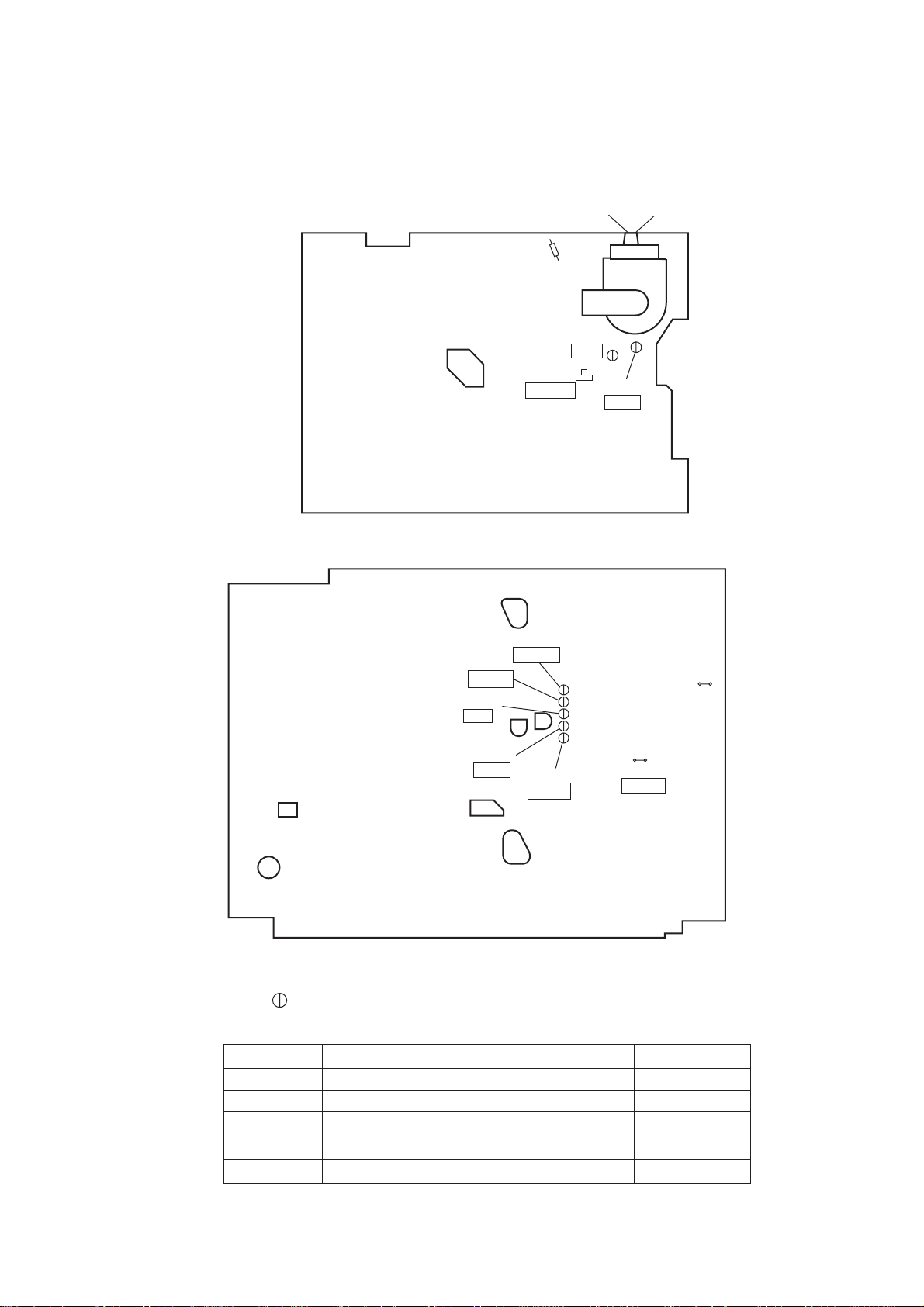

CABINET DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts, and the CBA in order to gain access to

item(s) to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

Caution !!

When removing the CRT, be sure to discharge the

Anode Lead of the CRT with the CRT Ground Wire

before removing the Anode Cap.

[1] Rear Cabinet

[2] Power Unit and Tray Chassis Unit

[3] Power Unit[5] H.V./Power

Supply CBA

[4] Tray Chassis Unit

[6] Top Cover

[7] Bottom Plate

[8] Deck Unit

[9] Text CBA

[10] Main CBA

[11] CRT

2. Disassembly Method

REMOVAL

ID/

LOC.

No.

[1]

[2]

[3] Power Unit 3,5

[4]

[5]

[6] Top Cover 3 5(S-4), CL604 5

[7]

PAR T

Rear

Cabinet

Power Unit

and Tray

Chassis

Unit

Tr ay

Chassis

Unit

H.V./Power

Supply

CBA

Bottom

Plate

REMOVE/

*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/

DESOLDER

1,2,5

3,4,5

3 ---------- -

36(S-3) 4

3(S-5) 6

7(S-1), 2(S-2),

*CN151

Anode Cap, *CN501,

*CN551, *CN601,

CRT CBA, Power

Knob

*CN502, *CN552,

*CN602

Note

1

2

3

REMOVAL

ID/

LOC.

No.

[8] Deck Unit 3, 5

[9] Text CBA 3, 5

[10] Main CBA 3 4(S-10) 9

[11] CRT 4 4(S-11) 10

↓

(1)

(1): Order of steps in Procedure. When reassembling,

(2): Parts to be removed or installed.

(3): Fig. No. showing Procedure of Part Location.

(4): Identification of part to be removed, unhooked,

(5): Refer to the following "Reference Notes in the

PA RT

↓

(2)

follow the steps in reverse order.These numbers

are also used as the identification (location) No. of

parts in Figures.

unlocked, released, unplugged, unclamped, or

desoldered.

S=Screw, P=Spring, L=Locking Tab, CN=Connector, *=Unhook, Unlock, Release, Unplug, or Desolder

2(S-2) = two Screw (S-2)

Ta bl e ."

REMOVE/

*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/

DESOLDER

7(S-6), (S-7), (S-8),

Desolder *(CN201,

CL401, CL402,

CL403)

(S-9), Text Holder,

*CN751, *CN752

↓

(3)

↓

(4)

Note

7

8

↓

(5)

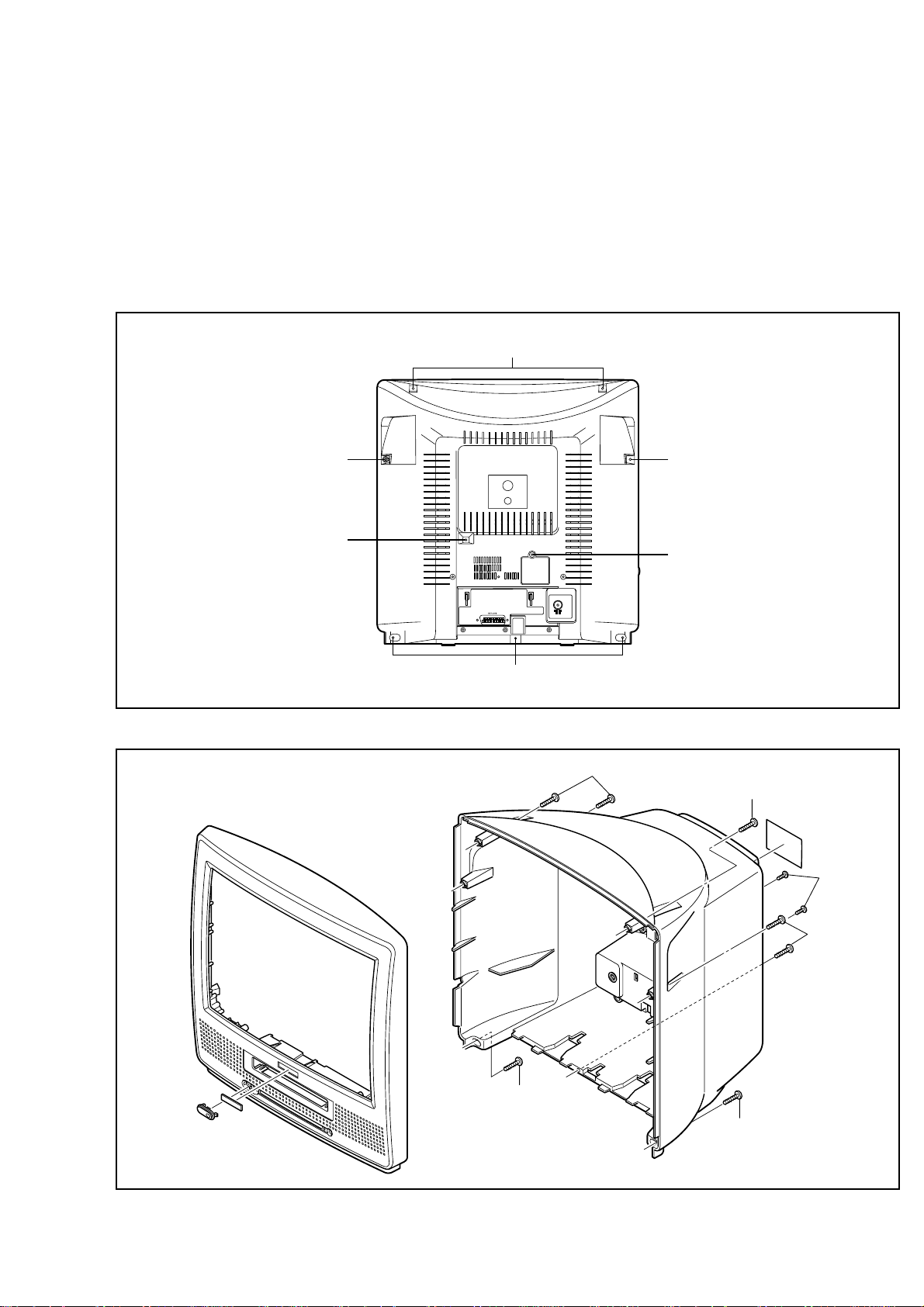

Reference Notes in the Table

1. Removal of the Rear Cabinet.

Remove seven screws (S-1) and two screws (S-2).

Disconnect connector CN151 and remove the Rear

Cabinet.

Caution !!

Discharge the Anode Lead of the CRT with the CRT

Ground Wire before removing the Anode Cap.

2. Removal of the Power Unit and Tray Chassis Unit.

Discharge the Anode Lead of the CRT with the

CRT Ground before removing the Anode Cap.

Disconnect the following: Anode Cap, CN501,

CN551, CN601, CRT CBA, and Power Knob. Then

pull the Power Unit and Tray Chassis Unit out backward.

3. Removal of the Power Unit.

Disconnect connectors CN502, CN552, and

CN602. Then slide the Power Unit out.

4. Removal of the H.V./Power Supply CBA.

Remove six screws (S-3) and pull up the H.V./

Power Supply CBA.

1-5-1 T6550DC

5. Removal of the Top Cover.

Remove five screws (S-4) and CL604, and remove

the Top Shield.

6. Removal of the Bottom Plate.

Remove a screw (S-5). Then slide the Bottom Plate

out front.

7. Removal of the Deck Unit.

Remove seven screws (S-6), screw (S-7) and

screw (S-8). Then, desolder connectors (CN201,

CL401, CL402, CL403) and lift up the Deck Unit.

S-1 S-1

8. Removal of the Text CBA.

Remove a screw (S-9) and Text Holder, and disconnect connectors CN751 and CN752. Then, lift

the Text CBA up.

9. Removal of the Main CBA.

Remove four screws (S-10) and pull up the Main

CBA.

10.Removal of the CRT.

Remove four screws (S-11) and pull the CRT backward.

S-1

[1] REAR CABINET

S-2

S-2

S-1

Fig. 1

S-1

S-1

S-2

S-1

S-1

S-1

[1] REAR CABINET

1-5-2 T6550DC

Fig. 2

S-4

S-4

[4] Tray

Chassis Unit

S-4

S-6

S-6

S-10

S-7

S-6

S-10

S-4

[6] Top Cover

S-6

[8] Deck Unit

[9] Text CBA

S-10

[10] Main CBA

S-8

CL604

Text

Holder

S-10

S-9

Power Knob

[2] Power Unit and

Tray Chassis Unit

S-3

S-3

S-3

S-5

[7] Bottom Plate

[5] H.V./Power

Supply CBA

[3] Power Unit

S-3

Fig. 3

1-5-3 T6550DC

S-11

S-11

Anode Cap

CRT CBA

S-11

[11] CRT

S-11

Fig. 4

1-5-4 T6550DC

ANODE

CRT

GND

CRT CBA

CN501B

SCREEN

CN502

H.V./POWER SUPPLY CBA

CN552

CL501A

FOCUS

CN501

CN551

MAIN CBA

CN151

CN601

TO DEGAUSS

COIL

CL403

CL401

CL402

CN201

CN751

CL603A

CN602

CL302A

CL301A

CN752

TEXT CBA

CN901

CN902

TO SPEAKER

CYLINDER

ASSEMBLY

FE HEAD

CAPSTAN

ACE HEAD

ASSEMBLY

MOTOR

TO TOP COVER

DECK UNIT

CL604

1-5-5 T6550DC

Fig. 5

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note:

"CBA" is abbreviation for "Circuit Board

Assembly."

NOTE:

Electrical adjustments are required after replacing

circuit components and certain mechanical parts.

It is important to perform these adjustments only

after all repairs and replacements have been completed.

Also, do not attempt these adjustments unless the

proper equipment is available.

Test Equipment Required

1. PAL Pattern Generator (Color Bar, Monoscope,

Black Raster, White Raster, Sympte)

2. SECAM Pattern Generator (Gray Scale)

3. AC Milli Voltmeter (RMS)

4. Alignment Tape (9965 000 14514), Blank Tape

(E180)

5. DC Voltmeter

6. Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div,

F-Range: DC~AC-60MHz

7. Frequency Counter

8. Plastic Tip Driver

9. RF input (at each broadcasting system)

Receiving Channel : VHF Low

Input level : 80dBµV

10.Ext.input

FRONT VIDEO-IN JACK or REAR SCART JACK

How to set up the option code

1. Enter the Service mode.

2. Press the [STATUS/EXIT] button on the remote

control unit. The option code appears on the display.

3. If needed, input the option code as shown below

using number buttons on the remote control unit.

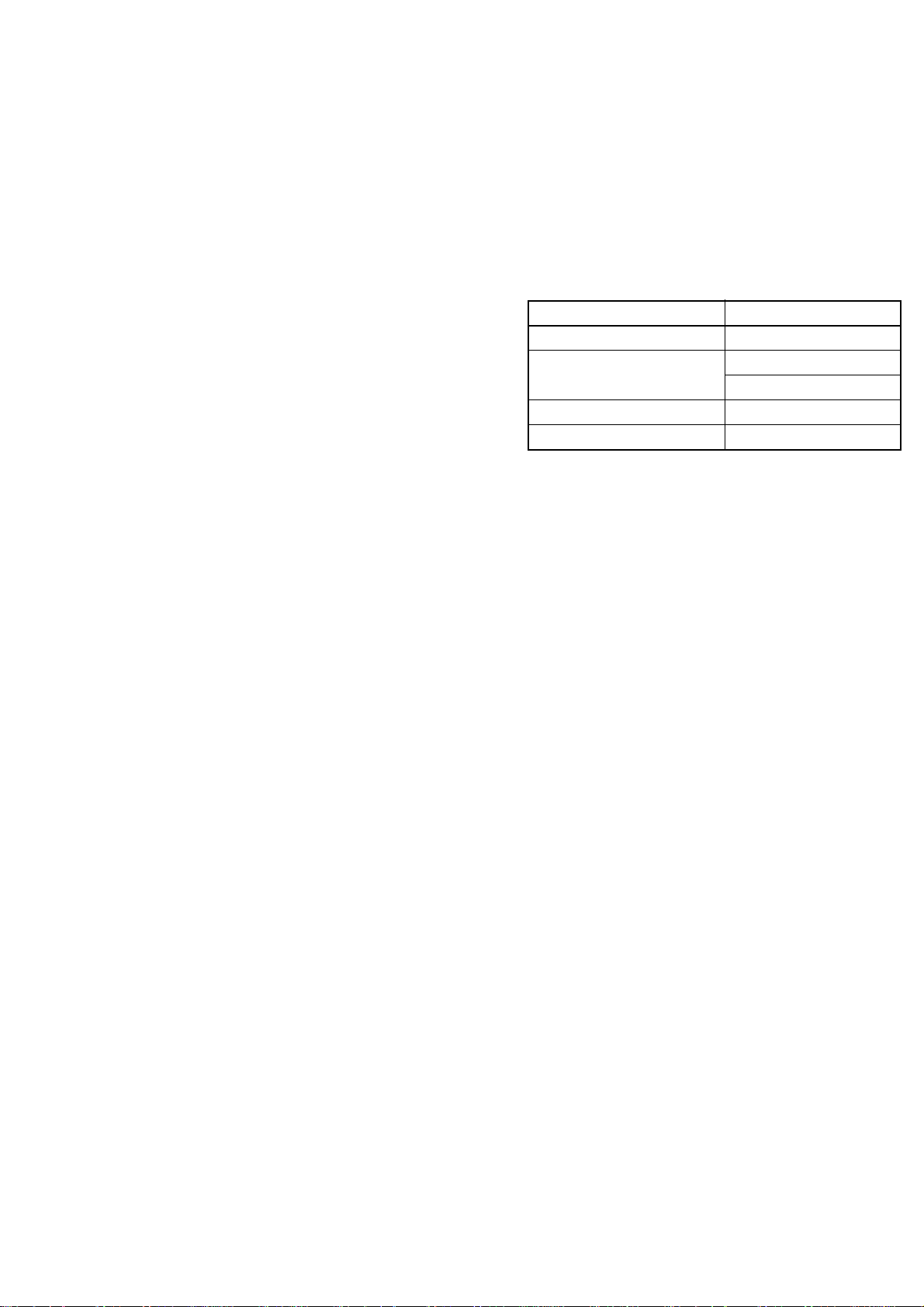

Model Option Code

21PV385/07 0176

0178

21PV385/01

0242

21PV385/58 0179

21PV385/39 0177

4. To reset the software, press [PAUSE] and [5] buttons on the remote control unit.

The option code is changed.

How to Set up the Service mode:

NOTE:

After replacing the IC202 (Memory) or Main CBA,

the set value in IC202 (Memory) will be lost. So it

is necessary to set up or adjust in the Service

mode after its replacement.

Service Mode:

1. Turn the power on. (Use main power on the TV

unit.)

2. Press [STANDBY/ON], [2], [7], [1], and [MUTE] buttons on the remote control unit in that order within 5

seconds.

- To cancel the service mode, press [STANDBY/ON]

button on the remote control.

1-6-1 T6550EA

1. DC114V (+B) Adjustment

2. H Adjustment

Purpose: To obtain correct operation.

Symptom of Misadjustment: The picture is dark and

unit does not operate correctly.

Test point Adj. Point Mode Input

TP503

(+B),

TP504

(GND)

Tape M. EQ . Spec .

---

Note: TP503(+B), TP504(GND), VR601 --- H.V./Power

Supply CBA

1. Connect the unit to AC Power Outlet. (exact

AC230V)

2. Input a color bar signal from RF (or Ext.) input and

leave it for at least 20 minutes.

3. Connect DC Volt Meter to TP503(+B) and

TP504(GND).

4. Adjust VR601 so that the voltage of TP503(+B)

becomes +114±0.5V DC.

VR601

DC Voltmeter,

Plastic Tip Driver

RF

(or Ext.)

+114±0.5V DC

Color

Bar

Purpose: To get correct horizontal position and size of

screen image.

Symptom of Misadjustment: Horizontal position and

size of screen image may not be properly displayed.

Test point Adj. Point Mode Input

R590

Tape M. EQ. Spec.

--- Frequency Counter 15.625kHz±75Hz

Note: R590 --- H.V./Power Supply CBA

1. Connect Frequency Counter to R590.

2. Set the unit to the Ext. mode and no input is necessary. Enter the Service mode.

(See page 1-6-10.)

3. Operate the unit for at least 20 minutes.

4. Press [2] button on the remote control unit and

select H-Adj mode.

5. Press [P+/P-] buttons on the remote control unit so

that the display will change [0] to [7.]

At this moment, choose display [0] to [7] when the

Frequency counter display is closest to

15.625kHz±75Hz.

6. Turn the power off and on again.

P+/P-

buttons

Ext. ---

1-6-2 T6550EA

3. C-Trap Adjustment

Purpose: To get minimum leakage of the color signal

carrier.

Symptom of Misadjustment: If C-Trap Adjustment is

incorrect, stripes will appear on the screen.

Test point Adj. Point Mode Input

4. To enter the DSPC mode, press [1] button on the

remote control unit. Recording starts automatically

and “DSPC” appears on the display.

TVCR

DSPC

J349F3

(B-OUT)

Tape M. EQ. Spec.

---

minimum

Note: J349F3 (B-Out)--- Main CBA

1. Connect Oscilloscope to J349F3.

2. Input a color bar signal from RF (or Ext.) input.

Enter the Service mode. (See page 1-6-10.)

3. Press [0] button on the remote control unit and

select C-TRAP mode.

4. Press [P+/P-] buttons on the remote control unit so

that the carrier leakage B-Out (4.43MHz) value

becomes minimum on the oscilloscope.

5. Turn the power off and on again.

P+/P-

buttons

Oscilloscope,

Pattern Generator

Figure

RF

(or Ext.)

200mVp-p Max.

Color Bar

Fig. 1

VIDEO INPUT JACK (Ext. input)

5. Recording continues for 10 seconds in SP mode.

Note: Since the reference value of LP V-ENV is

computed from the reference value of SP V-ENV,

there is no need to survey it.

6. The tape is rewinded to the recording start point.

7. The unit enters the play mode automatically and

the V-ENV levels of each the reference value of SP

mode and the computing value of LP mode are

memorized into the EEPROM.

8. "OK" or "NG" appears on upper left corner of the

screen with blueback.

In case of "OK": "OK" (green) is indicated without

ejecting tape.

In case of "NG": "NG" (red) is indicated with ejecting tape.

l

TVCR TVCR

OK

NG

Fig. 2

4. How to measure the standard

V-ENV value of Digital Studio

Picture Control

Purpose: To set the recording condition appropriate

for the recording tape.

Symptom of Misadjustment: Recording or playing

back picture quality may fall. The picture will be tinted.

1. Insert a new tape (type: E180) for the DSPC alignment into the TV/VCR.

2. Input the black raster signal from the video input

jack (VIDEO-IN).

3. Enter the service mode. (See page 1-6-10.)

Normal

Abnormal

Fig. 3

1-6-3 T6550EA

5. SECAM Black Level Adjustment

6. V. Size Adjustment

Purpose: To set Black Level of the SECAM signal R-

Y/B-Y to Ref. level.

Symptom of Misadjustment: If Black Level of the

SECAM signal R-Y/B-Y is incorrect, the picture is bluish or reddish in grayscale compared with PAL signal.

Tes t

point

J361G4

Tape M. EQ. Spec.

---

Analog Oscilloscope (unus-

able Digital Oscilloscope)

1. Degauss the CRT and allow CRT to operate for 20

minutes before starting the alignment.

2. Input the SECAM Gray Scale signal from Ext.

input.

3. Enter the service mode. (See page 1-6-10.)

4. To enter the C/D/S mode, press [ -] on the

remote control unit.

5. To select SBR (SECAM Black Level R-Y), press [6]

button on the remote control unit.

6. Press [P+/P-] buttons to adjust Y signal to the black

ref. level.

7. To select SBB (SECAM Black Level B-Y), press [7]

button on the remote control unit.

8. Press [P+/P-] buttons to adjust Y signal to the black

ref. level.

Y Signal

Adj. Point Mode Input

P+/P-

buttons

Pattern Generator,

Ext.

SECAM

Gray

Scale

---

Purpose: To obtain correct vertical height of screen

image.

Symptom of Misadjustment: If V. Size is incorrect,

vertical height of image on the screen may not be

properly displayed.

Test point Adj. Point Mode Input

Screen

Tape M. EQ. Spec.

--- Pattern Generator 90±5%

1. Enter the Service mode. (See page 1-6-10.)

Press [9] button on the remote control unit and

select V-S mode. (Press [9] button then display will

change to V-P and V-S).

2. Input monoscope pattern and leave it for at least 20

minutes.

3. Press [P+/P-] buttons on the remote control unit so

that the monoscope pattern is 90±5% of display

size and the circle is round.

P+/P-

buttons

RF

(or Ext.)

Monoscope

7. V. Shift Adjustment

Purpose: To obtain correct vertical position of screen

image.

Symptom of Misadjustment: If V. position is incorrect, vertical position of image on the screen may not

be properly displayed.

Test point Adj. Point Mode Input

Screen

Tape M. EQ. Spec.

P+/P-

buttons

RF

(or Ext.)

Monoscope

1H

Black REF. Level

1H

1H

5mV/Div (10:1 Prove)

Fig. 4

--- Pattern Generator 90±5%

1. Enter the Service mode. (See page 1-6-10.)

Press [9] button on the remote control unit and

select V-P mode. (Press [9] button then display will

change to V-P and V-S).

2. Input monoscope pattern and leave it for at least 20

minutes.

3. Press [P+/P-] buttons on the remote control unit so

that the top and bottom of the monoscope pattern

are equal to each other.

1-6-4 T6550EA

8. H. Shift Adjustment

Purpose: To obtain correct horizontal position and

size of screen image.

Symptom of Misadjustment: Horizontal position and

size of screen image may not be properly displayed.

Test point Adj. Point Mode Input

Screen

Tape M. EQ. Spec.

--- Pattern Generator 90±5%

1. Enter the Service mode. (See page 1-6-10.)

Press [8] button on the remote control unit and

select H-P mode.

2. Input monoscope pattern and leave it for at least 20

minutes.

3. Press [P+/P-] buttons on the remote control unit so

that the left and right side of the monoscope pattern are equal to each other.

4. Turn the power off and on again.

P+/P-

buttons

RF

(or Ext.)

Monoscope

8. To enter the CUT OFF (G) mode, press [2] button

on the remote control unit.

9. Press the [P+/P-] buttons until the horizontal line

becomes white.

10.To enter the CUT OFF (B) mode, press [3] button

on the remote control unit.

11.Press the [P+/P-] buttons until the horizontal line

becomes white.

12.Turn the screen control so that the horizontal line

adjusted white looks lightly.

13.Turn the power off and on again.

9. Cut-off Adjustment

Purpose: To adjust the beam current of R, G, B, and

screen voltage.

Symptom of Misadjustment: White color may be

reddish, greenish or bluish.

Test point Adj. Point Mode Input

Screen

Tape M. EQ. Spec.

--- Pattern Generator

Notes:

Screen Control (FBT) --- H.V./Power Supply CBA

FBT= Fly Back Transformer

Use the Remote Control Unit

1. Degauss the CRT and allow CRT to operate for 20

minutes before starting the alignment.

2. Set the screen control to minimum position. Input

the Black raster signal from RF (or Ext.) input.

3. Enter the service mode. (See page 1-6-10.)

Dimmed horizontal line appears on the CRT.

4. To enter the C/D/S mode, press the [ -] button

on the remote control unit.

5. To enter the CUT OFF (R) mode, press [1] button

on the remote control unit.

6. Turn the screen control up until dimmed horizontal

line appears.

7. Press the [P+/P-] buttons until the horizontal line

becomes white.

Screen-Control,

P+/P- buttonsRF(or Ext.)

Black Ras-

ter

See Reference

Notes below

1-6-5 T6550EA

10. White Balance Adjustment

11. Sub-Brightness Adjustment

Purpose: To mix red, green and blue beams correctly

for pure white.

Symptom of Misadjustment: White becomes bluish

or reddish.

Test point Adj. Point Mode Input

Screen

Tape M. EQ. Spec.

---

Screen-Control,

P+/P- buttonsRF(or Ext.)

Pattern Generator,

Color analyzer

Figure

Color Ajalyzer

See below

White

Raster

(APL 100%)

Fig. 5

Purpose: To get proper brightness.

Symptom of Misadjustment: If Sub-Brightness is

incorrect, proper brightness cannot be obtained by

adjusting the Brightness Control.

Test point Adj. Point Mode Input

Screen

Tape M. EQ. Spec.

---

White

P+/P-

buttons

Pattern

Generator

Figure

RF

(or Ext.)

See below

ABC

SYMPTE

Black

This bar

(A) just

visible

Note: Use remote control unit

1. Operate the unit more than 20 minutes.

2. Face the unit to east. Degauss the CRT using Degaussing Coil.

3. Input the White Raster (APL 100%).

4. Set the color analyzer to the CHROMA mode and

after zero point calibration, bring the optical receptor to the center on the tube surface (CRT).

5. Enter the Service mode. Press [ -] button on the

remote control.

6. Press [4] button on the remote control unit for Red

adjustment. Press [5] button on the remote control

unit for Blue adjustment.

7. In each color mode, Press [P+/P-] buttons to adjust

the values of color.

8. Adjusting Red and Blue color so that the temperature becomes 8500K (x : 290 / y : 300) ±3%.

9. At this time, Re-check that Horizontal line is white.

If not, Re-adjust Cut-off Adjustment until the Horizontal Line becomes pure white.

10. Turn off and on again to return to normal mode. Receive APL 100% white signal and Check Chroma

temperatures become 8500K (x : 290 / y : 300) ±3%.

Note: Confirm that Cut Off Adj. is correct after this

adjustment, and attempt Cut Off Adj. if needed.

Fig. 6

Note: Bar (A) in Fig. 7 --- 0 IRE

1. Enter the service mode. (See page 1-6-10.)

Then input SYMPTE signal from RF (or Ext.) input

and leave it for at least 20 minutes.

2. Press [MENU] button. (Each time [MENU] button is

pressed, display will change BRT, CNT, COL, TNT,

and SHP in that order.) Select BRT and press [P+/

P-] buttons so that the bar (A) in Fig. 6 is just visible.

3. Turn the power off and on again.

1-6-6 T6550EA

12. Setting for CONTRAST,

COLOR, TINT and SHARP

Data Values

General

1. Enter the Service mode. (See page 1-6-10)

2. Press [MENU] button. (Each time [MENU] button is

pressed, display will change BRT, CNT, COL, TNT,

and SHP in that order.)

CONTRAST (CNT)

1. Press [MENU] button on the remote control unit.

Then select CNT display.

2. Press [P+/P-] buttons on the remote control unit so

that the value of "CONTRAST" (CNT) becomes 83.

COLOR (COL)

1. Press [MENU] button on the remote control unit.

Then select "COLOR" (COL) display.

2. Press [P+/P-] buttons on the remote control unit so

that the value of "COLOR" (COL) becomes 65.

TINT (TNT)

1. Press [MENU] button on the remote control unit.

Then select "TINT" (TNT) display.

2. Press [P+/P-] buttons on the remote control unit so

that the value of "TINT" (TNT) becomes 68.

13. Focus Adjustment

Purpose: Set the optimum Focus.

Symptom of Misadjustment: If Focus Adjustment is

incorrect, blurred images are shown on the display.

Test point Adj. Point Mode Input

Screen Focus Control

Ta p e M. EQ . Sp ec .

--- Pattern Generator See below.

Note: Focus VR (FBT) --- H.V./Power Supply CBA

FBT= Fly Back Transformer

1. Operate the unit more than 30 minutes.

2. Face the unit to the East and degauss the CRT

using a Degaussing Coil.

3. Input the monoscope pattern.

4. Adjust the Focus Control on the FBT to obtain clear

picture.

RF

(or Ext.)

Monoscope

SHARP (SHP)

1. Press [MENU] button on the remote control unit.

Then select "SHARP" (SHP) display.

2. Press [P+/P-] buttons on the remote control unit

and select "0."

1-6-7 T6550EA

14. Head Switching Position Adjustment

Purpose: Determine the Head Switching Point during

Playback.

Symptom of Misadjustment: May cause Head

Switching Noise or Vertical Jitter in the picture.

Note: Unit reads Head Switching Position automatically and displays it on the screen (Upper Left Corner).

Manual Adjustment

1. Enter the service mode. (See page 1-6-10.)

2. Playback the test tape (9965 000 14514).

3. Press the number [5] button on the remote control

unit.

4. The Head Switching position will display on the

screen; if adjustment is necessary follow step 4.

7.0H (448µs) is preferable.

5. Press [P+/P-] buttons on the remote control unit if

necessary. The value will be changed in 0.5H steps

up or down. Adjustable range is up to 9.5H. If the

value is beyond adjustable range, the display will

change as:

Lower out of range: 0.0H

Upper out of range: -.-H

6. Turn the power off and on again.

Auto Adjustment

1. Load the test tape (9965 000 14514) that have

been recorded the Head Switching Position Value.

2. Enter the service mode.

3. Press [3] button on the remote control unit in the

tape stop mode. The unit playback and adjust the

Head Switching Position automatically.

4. The adjusting report appears on upper left corner

of the screen with blueback.

In case of adjusting correctly: the Head Switching

Position Value recorded in the test tape (9965 000

14514) is indicated with green.

In case of adjusting incorrectly: "NG" (red) is indicated with ejecting tape.

l

TVCR TVCR

7.0H

NG

Correct

Incorrect

Fig. 7

1-6-8 T6550EA

Adjustment Points and Test Points

H.V./Power Supply CBA Top View

Focus-control (Upper side)

R590

(H Adjustment)

VR601

+B ADJ

Main CBA Top View

TP007

N-A-PB

TP002

RF-SW

TP001

CTL

Screen-control (Lower side)

TP503

+B

TP504

GND

J361G4

(SECAM

Black Level

Adjustment)

TP008

IC202

C-PB

TP003

V-OUT

J349F3

B-OUT

TEST POINT INFORMATION

: Indicates a test point with a jumper wire across a hole in the PCB.

TEST POINTS NOT USED IN ELECTRICAL ADJUSTMENTS

Test Point

TP001

TP002

TP008

TP503

TP504

Mechanical Alignment Procedures

Mechanical Alignment Procedures

Mechanical Alignment Procedures

Electrical Adjustment Instructions

Electrical Adjustment Instructions

Used in: Page No.

2-3-3

2-3-3, 2-3-4

2-3-3, 2-3-4

1-6-1

1-6-1

1-6-9 T6550EA

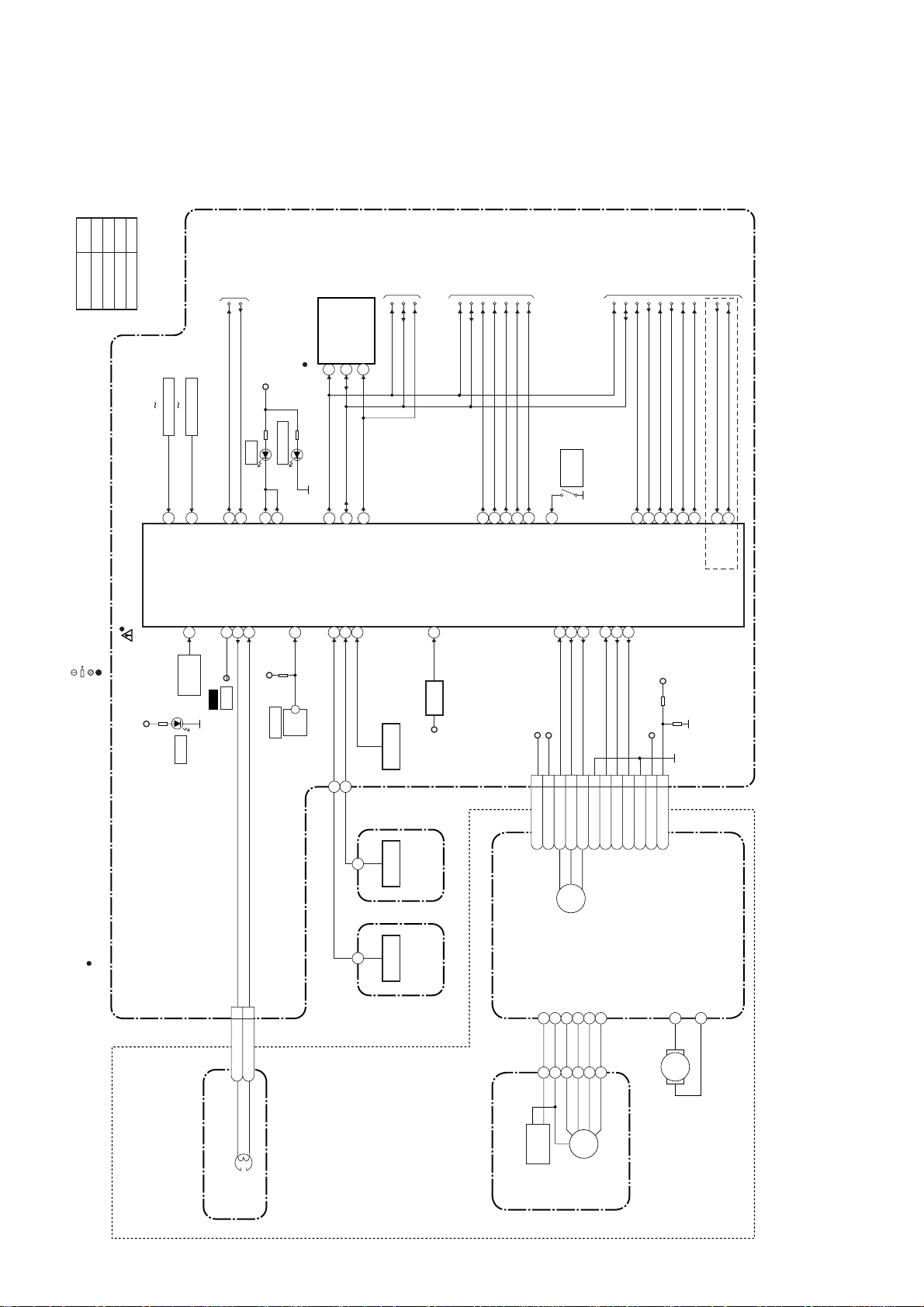

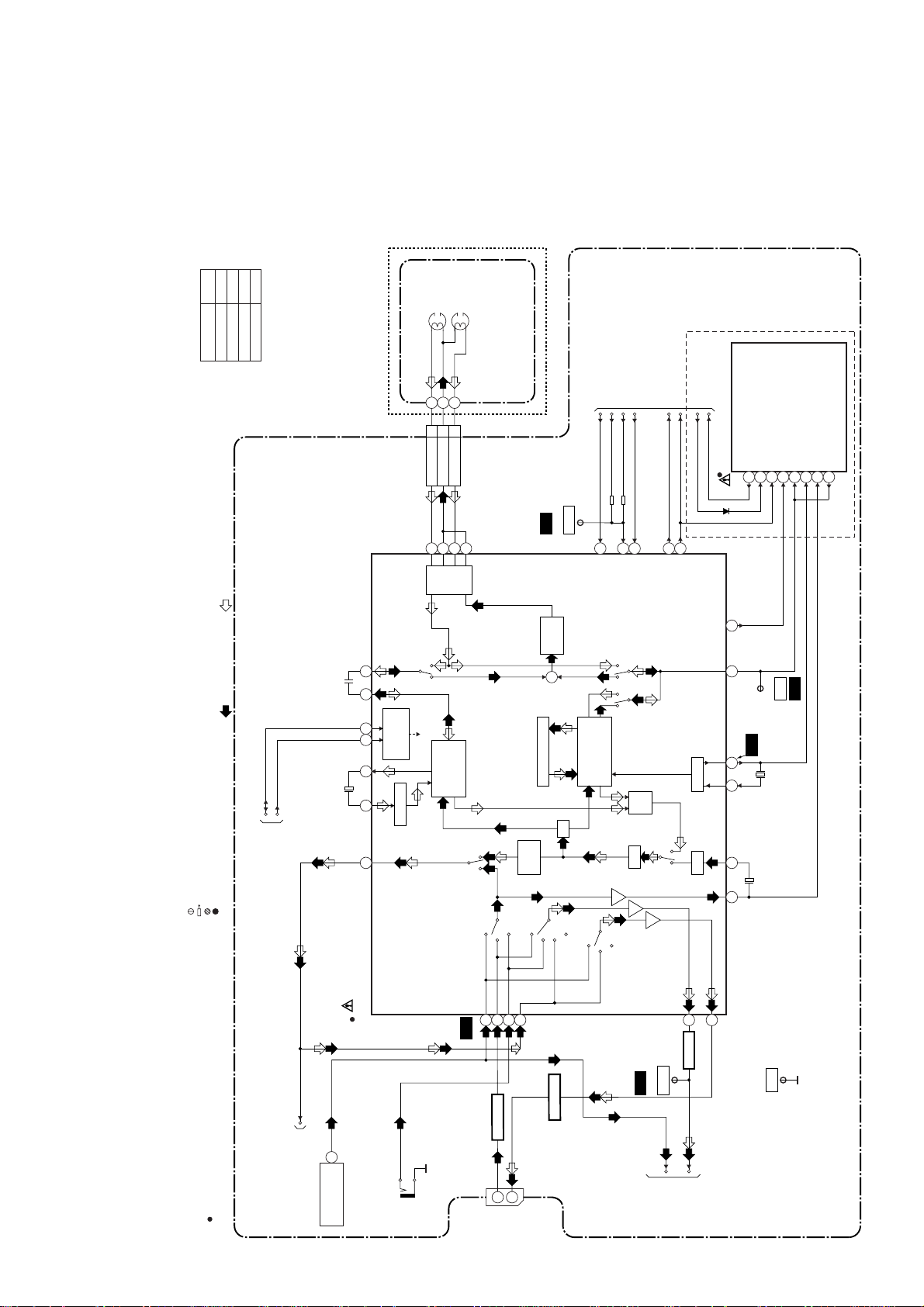

BLOCK DIAGRAMS

Servo/System Control Block Diagram

A

B

C

D

TO POWER

Model Mark

21PV385/07

Comparison Chart of

Models & Marks

21PV385/01

21PV385/58

21PV385/39

SUPPLY BLOCK

P-ON-H

P-DOWN-L

AL+5V

(MEMORY)

SCL

IC202

6

SDA

5

CS

7

TO CHROMA

SCL

SDA

BLOCK

C-OPEN

2

I

SCL

SDA

SP-MUTE

TO AUDIO

BLOCK

EXT-L

SCART-H

A-MUTE-H

SCART-MUTE

SCL

SDA

C-SYNC

D-REC-H

TO VIDEO

BLOCK

V-ENV

C-ROTA

DV-SYNC

RF-SW

TRICK-H

SECAM-H

THE PCB.

WITH A COMPONENT LEAD ON FOIL SIDE.

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN

:USED TO INDICATE A TEST POINT

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

TEST POINT INFORMATION

OR.

.)

KEY SWITCH

SW201 SW205

7

KEY-1

IC201

(SERVO/SYSTEM CONTROL)

RS201

AL+5V

D201

KEY SWITCH

SW206 SW210

8

KEY-2

P-ON-H

CTL AMP-OUT

REMOTE

14

97

TP001

REMOTE

SENSOR

CTL

WF3

S-LED

85

67

P-DOWN-L

CTL(+)

95

D202 REC

CTL(-)

94

D204 STANDBY

24

23

REC-LED

REC-LED

AL+5V

LD-SW

SW212

LD-SW

9

72

71

SCL

SDA

ST-SENS.

END-SENS.

10480

45

C-OPEN

2

I

T-REEL

Q205Q201

T-REEL

RESET

34

Q204

RESET

TIMER+5V

424829

20

44

EXT-L

SP-MUTE

A-MUTE-H

SCART-H

SCART-MUTE

CM+12V

1CM+12V

CN201

REC

SAFETY

SW211

31

REC-SAFETY

C-CONT

C-F/R

C-FG

76

78

87

P-ON+5V(3)

4C-F/R

2P-ON+5V(3)

3C-FG

5

C-CONT

LD-CONT81D-CONT

6FG-GND

7LD-CONT

D-PFG

77

90

8D-CONT

9

D-PFG

74

47

C-SYNC

D-REC-H

AL+12V(1)

10M-GND

11AL+12V(1)

6

15

13

V-ENV

C-ROTA

DV-SYNC

+33V

12VG

18

RF-SW

D

32

33

TRICK-H

SECAM-H

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECT

(CAN DISCONNECT AND RECONNECT

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

MAIN CBA

" " = SMD

)

ASSEMBLY

(DECK

CL402

1CTL(-)

2CTL(+)

AC HEAD ASSEMBLY

CONTROL

HEAD

END-SENS.

ST-SENS.

Q202

1-7-1

SENSOR CBA

(END-SENSOR)

SENSOR CBA

(ST-SENSOR)

M

CAPSTAN

PG

SENSOR

MOTOR

M

DRUM

MOTOR

CAPSTAN MOTOR

CYLINDER ASSEMBLY

M

LOADING

MOTOR

T6550BLS

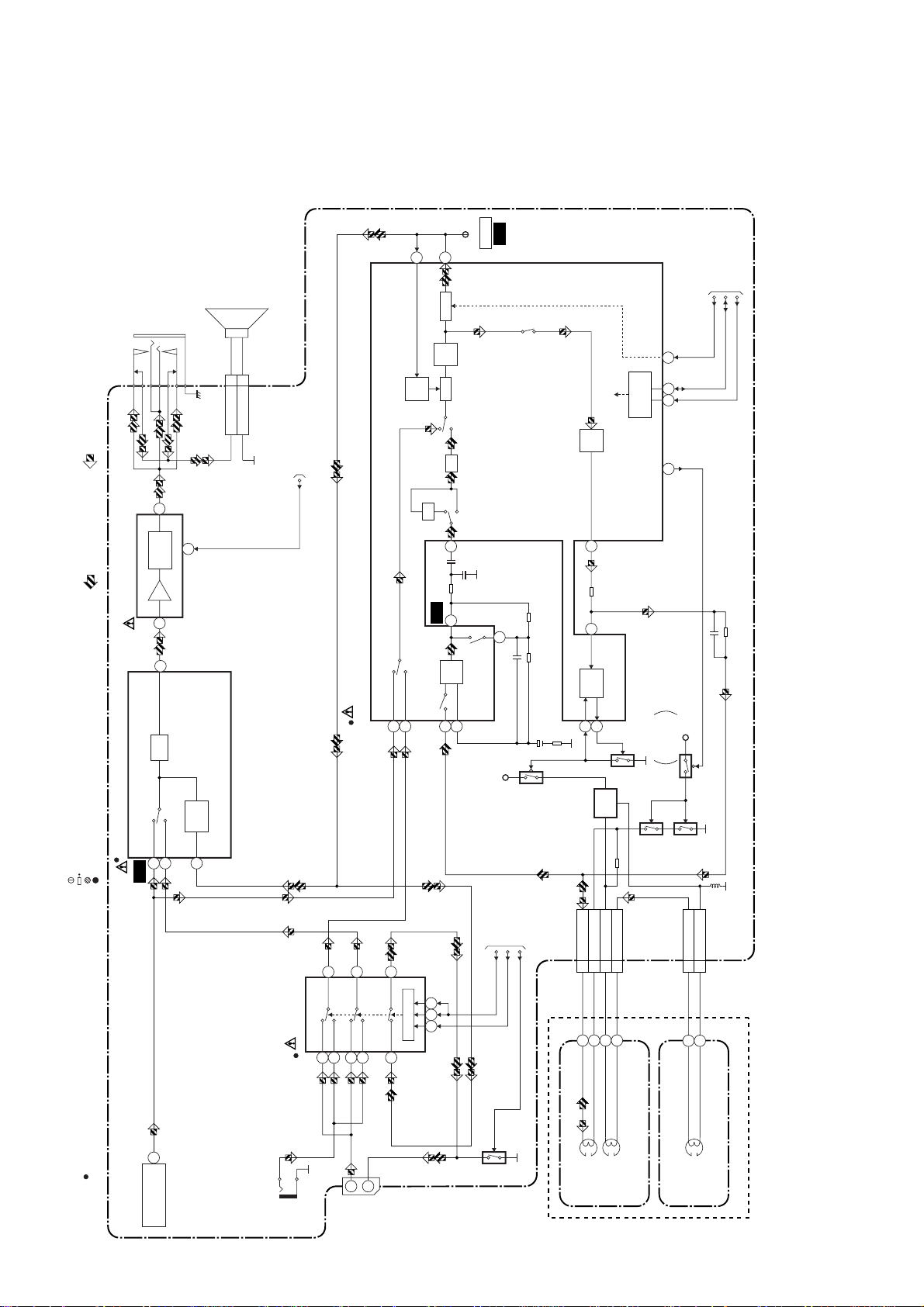

Video Block Diagram

A

B

D

C

VIDEO (L)

VIDEO (R)

HEAD

HEAD

Model Mark

21PV385/07

21PV385/01

21PV385/58

Comparison Chart of

Models & Marks

21PV385/39

(DECK ASSEMBLY)

THE PCB.

REC-VIDEO SIGNAL PB-VIDEO SIGNAL MODE: SP/REC

WITH A COMPONENT LEAD ON FOIL SIDE.

WITH A TEST PIN.

SDA

SCL

TO

SERVO/SYSTEM

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN

:USED TO INDICATE A TEST POINT

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT

CONTROL BLOCK

7978

69684643

65

CYLINDER ASSEMBLY

123

V(L)

V(R)

CL401

V-COM

969593

SP

HEAD

AMP

P

R

SERIAL

DECORDER

LUMINANCE

SIGNAL

PROCESS

Y. DELAY

94

AGC

BYPASS

WF1

REC FM

+

Y

CCD 1H DELAY

CHARA.

INS.

TP002

AGC

C

1/2

RF-SW

RF-SW

C-ROTA

D-REC-H

DV-SYNC

70

80

D-REC-H

RF-SW/C-ROTA

RPRP

CHROMINANCE

SIGNAL

PROCESS

D

TO SERVO/SYSTEM

CONTROL BLOCK

V-ENV

C-SYNC

67

84

62

V-ENV

C-SYNC

DV-SYNC

Y/C

MIX

PR

FBC

TRICK-H

SECAM-H

IC471 (PAL/SECAM DECTECOTR)

28

PB-H OUT

21

2928 44

AGC VXO

58 59

WF2

1

29

C-PB

TP008

X401

4.43MHz

PAL/SECAM

DETECTOR

17

12216

14

WF6

TEST POINT INFORMATION

OR.

.)

WIRE-SOLDER

C-VIDEO

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECT

(CAN DISCONNECT AND RECONNECT

2. PREFIX SYMBOL "CL" MEANS

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TO

CHROMA

MAIN CBA

" " = SMD

BLOCK

TU001

IC401

(VIDEO/AUDIO SIGNAL PROCESS)

24

VIDEO OUT

JK701

V-IN

WF4

TUNER

SCART

485254

Q705

JK703

LINE

BUFFER

20

19

V-IN

V-OUT

1-7-2

SCART

56

LINE

PB/EE

BUFFER

Q703

MUTE

TUNER

PB/EE

MUTE

WF5

V-OUT

TP003

TU-VIDEO

61

BUFFER

Q401

VIDEO

TO CHROMA

BLOCK

63

GND

TP010

T6550BLV

Audio Block Diagram

SP151

JK151

Mode : SP/REC

PB-AUDIO SIGNAL REC-AUDIO SIGNAL

HEADPHONE JACK

1

AMP

OUTPUT

MUTE

CL801

CN151

SP1SP-GND 2

5

SPEAKER

TO

SERVO/SYSTEM

CONTROL BLOCK

SP-MUTE

ALC

WF8

N-A-PB

TP007

11

12

TO

SERVO/SYSTEM

CONTROL BLOCK

DET

INV

LINE

R

MUTE

AMP

ALC

ATT

98

SERIAL

DECODER

AUDIO HD-SW

CONTROL

71

68 69

16

REC-ON

P

REC

AMP

100

SCL

SDA

A-MUTE-H

IC151 (AMP)

7

MAIN CBA

THE PCB.

50

WITH A COMPONENT LEAD ON FOIL SIDE.

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN

:USED TO INDICATE A TEST POINT

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

TEST POINT INFORMATION

OR.

.)

WIRE-SOLDER

ATT

(VIDEO/AUDIO/CHROMA/DEFLECTION/IF)

LINE

TUNER

IC301

52

53

WF7

AUDIO

54

MUTE

IC701 (SW)

WF9

7

EQ

AMP

SP/LP-ON

PB-ON

TUNER

LINE

IC401

(AUDIO SIGNAL PROCESS)

13

4

14

SCART

LINE

SCART

LINE

1

2155

3

12

17

SW CTL

5

6

+5V

Q854

TO SERVO

/SYSTEM

CONTROL

BLOCK

EXT-L

SCART-H

1011 9

SCART-MUTE

CL402

3 A-PB/REC

3

AUTO

1

Q855

BIAS

2

BIAS

OSC

4 A-COM

6 AE-H/FE-H

Q856

Q853(PB=ON)

5 FE-H

+5V

SWITCHING

D-REC-OFF

Q851

CL403

1 FE-H

Q852(PB=ON)

2 FE-H-GND

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECT

(CAN DISCONNECT AND RECONNECT

2. PREFIX SYMBOL "CL" MEANS

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

21

" " = SMD

AUDIO OUT

TU001

JK702

A-IN

JK703

2

A-IN

1

A-OUT

1-7-3

Q701

AUDIO

HEAD

AUDIO

ERASE

HEAD

(DECK ASSEMBLY)

FE HEAD

ACE HEAD ASSEMBLY

FULL

ERASE

HEAD

T6550BLA

Loading...

Loading...