Owner’s Manual

Table of Contents

Placing your machine on the carriage ...........................................................3

Remove the packing attached to your machine ...........................................3

Light Fixture ....................................................................................................4

Your Thread Stand ..........................................................................................5

Belt guard .........................................................................................................6

Attaching your handle bars with controllers .................................................7

Connecting your Mega Quilter 18x8 to your carriage assembly (deck) and

Controls on the handles ..................................................................................8

What is the Tension Release Lever?...............................................................9

How Do I Adjust the Height of the Hopping Foot? ......................................9

Routine Cleaning and Oiling.........................................................................11

Bobbin Winder and Bobbins ........................................................................12

Machine Part Names ......................................................................................15

The Control Unit ............................................................................................16

Threading Overview .....................................................................................17

How Do I Thread the Machine? ...................................................................17

How Do I Change the Needle? ......................................................................20

How Do I Make Adjustments to Make the Perfect Stitch? ........................21

Tension, Tension, Tension..............................................................................22

Trouble Shooting Checklist

Check spring replacement / Tension Knob .................................................24

Timing of your Machine ................................................................................26

2

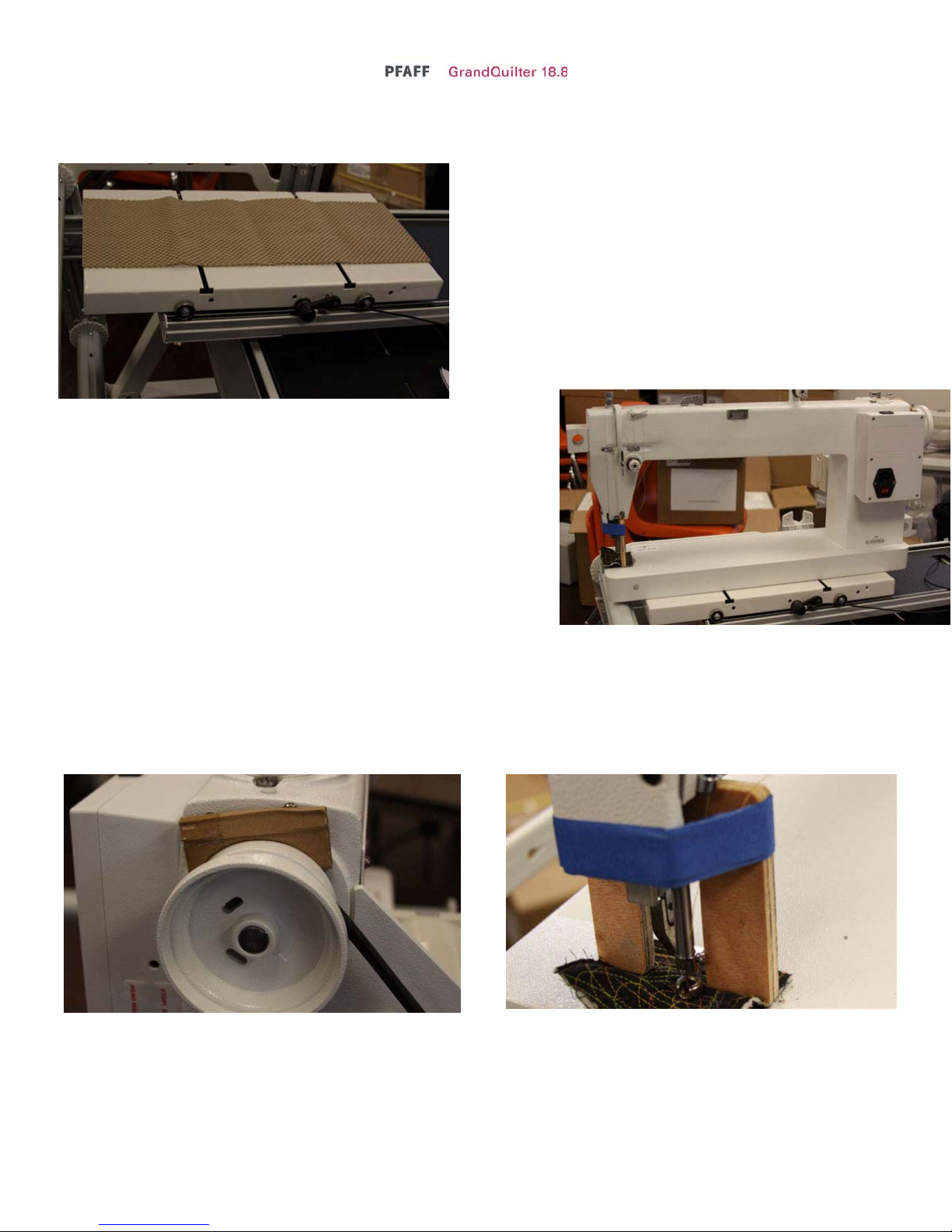

Placing your machine on the carriage.

Prior to placing the machine on the carriage ensure that

you have the encoders attached to the carriage.

You will find a rubber mat shipped with your machine to

help keep the machine from slipping on the metal

surface.

Place the mat on the carriage before placing your

machine on the carriage.

When you place the machine on the carriage you want to ensure

that you center the machine on the carriage.

Carefully place the machine on the carriage. Be ready for it to

roll one way or another as the frame may not be level when you

place the machine on there and you want to control the roll to

prevent the machine from rolling to fast and falling off the

frame.

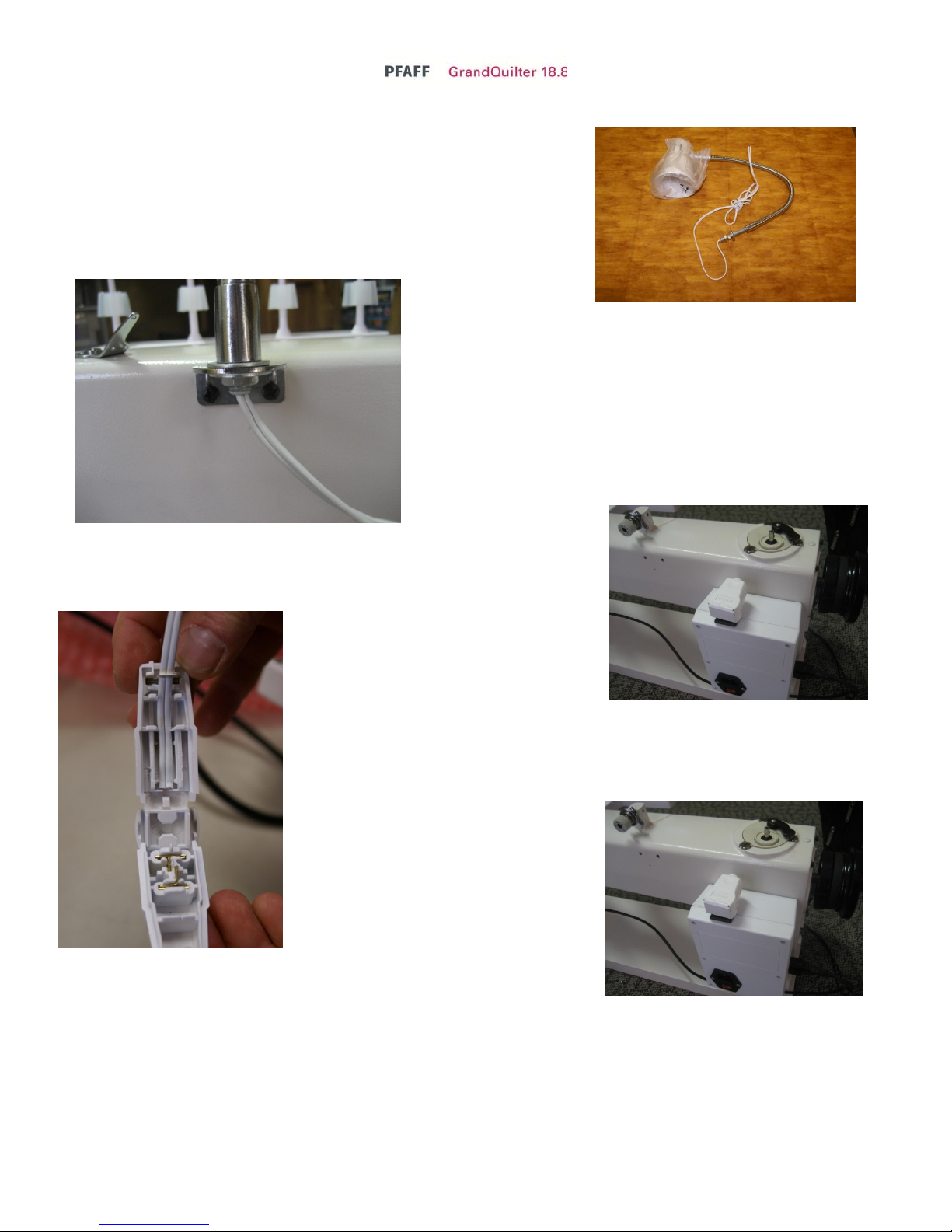

Remove the packing attached to your machine.

Remove the cardboard between the hand wheel and the machine and the piece of wood next to the needle and

save these pieces along with the box in case you should ever need to ship this machine.

3

Light Fixture

To add your light fixture to your machine,

Step 1. Loosen the nuts so that you can slide the lamp fixture into the

space provided on the machine in the lamp support bracket.

Step 2. Tighten the nuts on the base of the lamp to secure the

lamp to the lamp support bracket on the side of your machine.

Step 3. Measure the cord so that you have enough to reach the

outlet on top of the power box on your machine.

Step 4. Trim the cord flush. You don’t need to strip the ends

with the plug we provide.

Step 5. Find the plug which is shipped with your accessories.

Step 6. Open your plug by pulling on

the silver tab and open the plug. Trim

the wires flush with enough to reach the outlet on the top of the power box.

Lay the wires in the space provided in the plug and close the plug. Caution

before you close, make sure that you do not have any wires crossed as this will

create a short.

With the cord in place, plug in your lamp.

4

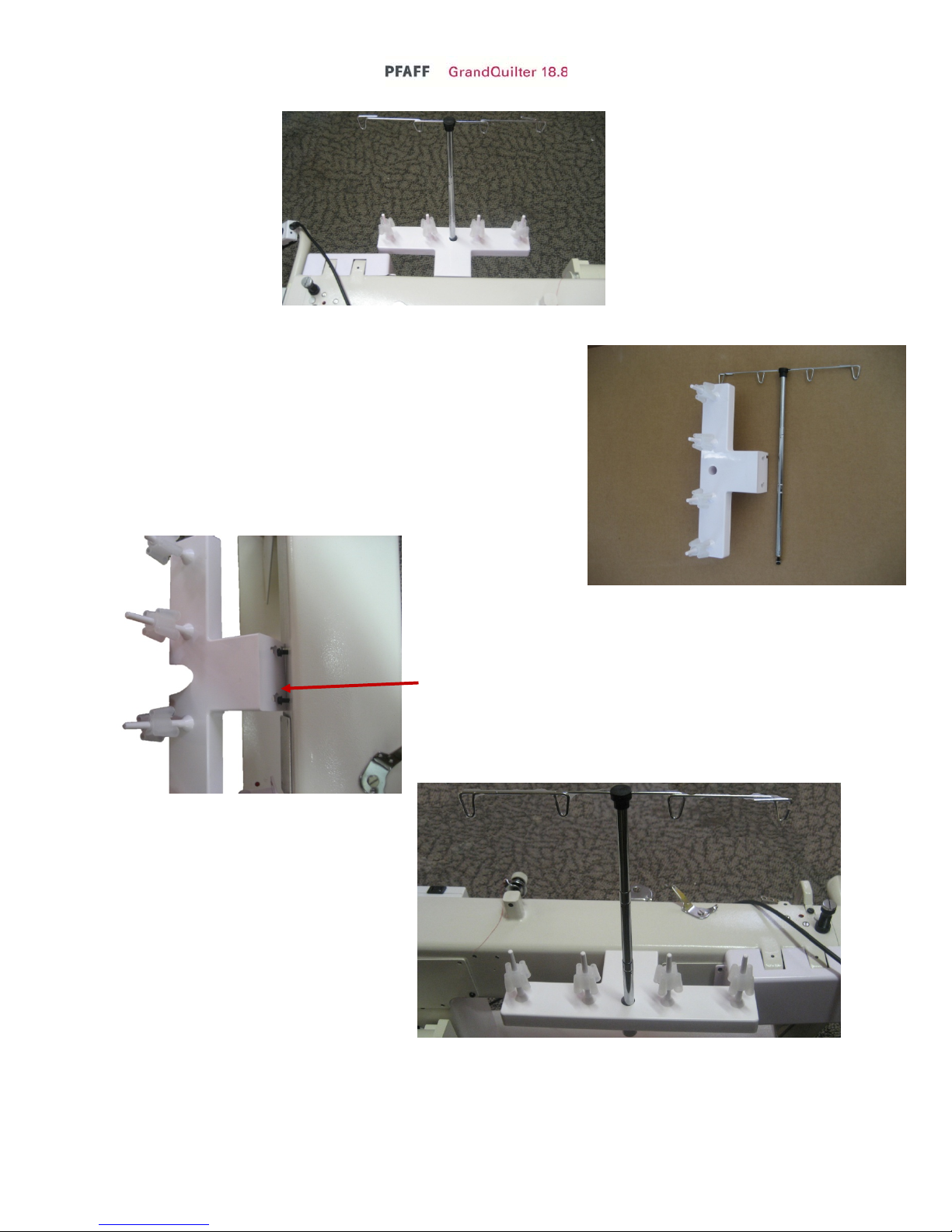

Your Thread Stand

Your Grand Quilter 18.8 comes with a four spool thread stand.

Some assembly required.

You will need to attach your thread stand to the side of your

machine with the two screws provided.

On the side of the machine you will see two screws where you

will place the base of the thread stand.

On the side of the thread stand you will see where to connect.

Now you can insert the thread tree into the

holder on the thread stand.

5

Belt guard

Your machine comes with a belt guard to prevent damage to your motor sensor and protect you from getting

caught in the belt. In the box you will find the plastic cover and attached to the machine are the screws used to

hold the belt guard in place.

Step 1. Locate the screws on the machine there are two

above the hand wheel and one can be found below the

hand wheel.

Step 2. Remove the three screws.

Step 3. Locate the belt guard and position over the hand

wheel and the motor.

Step 4. Replace the three screws so that they hold the belt guard in place.

This photo shows the belt guard in place and how it

protects the motor sensor and the belt.

6

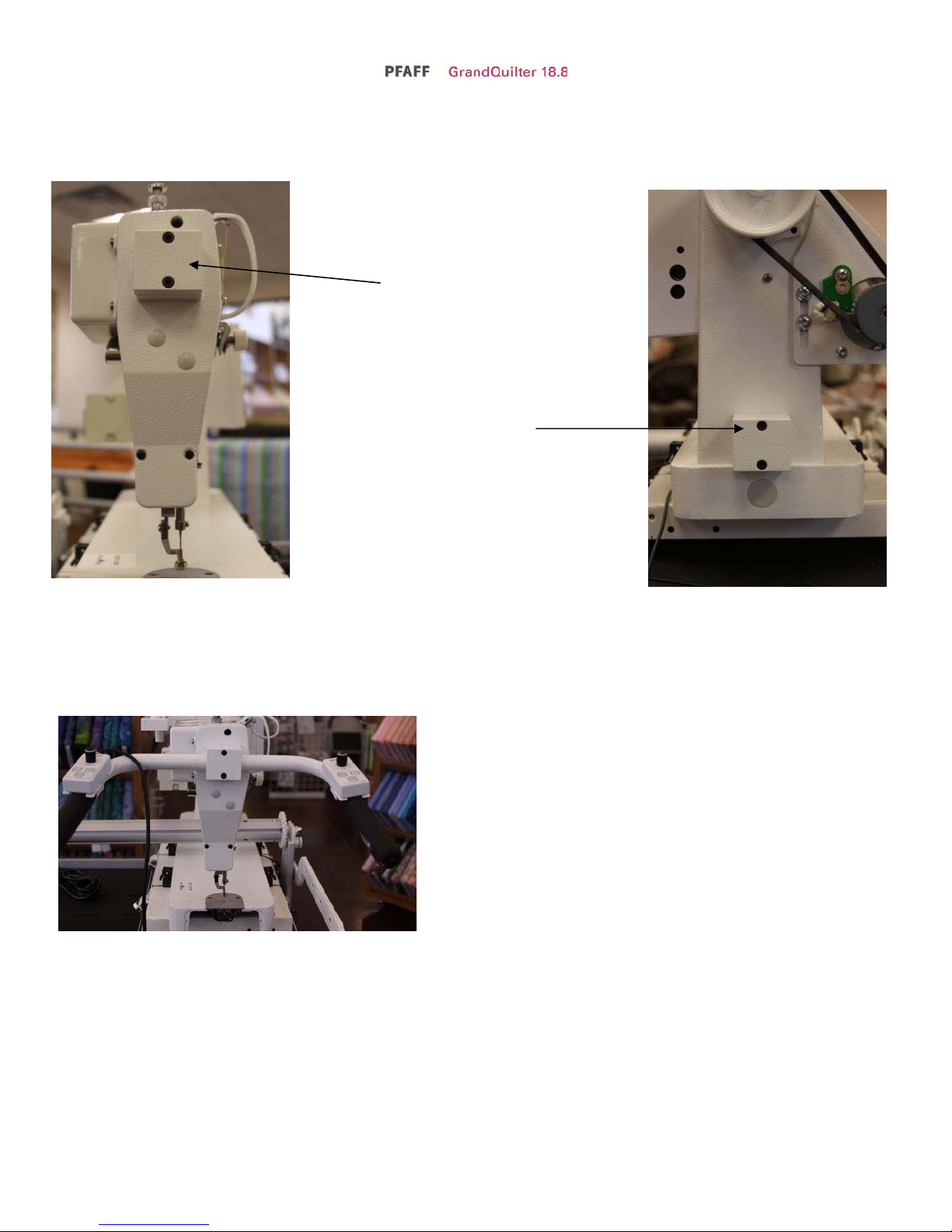

Attaching your handle bars with controllers

There are two locations where you can connect your handle bars with controllers to your Mega Quilter 18x8.

These photos show the block that will hold

the handle bars in place on your Mega

Quilter 18x8.

This block is on the front of

the machine or the needle side of the

machine and is used for free motion

quilting.

This block is on the back of the

Machine or the motor side of the machine

and is used when following a pantograph

with the laser light.

Step 1. Remove the two hex screws from the block using the allen wrench provided in your accessory bag.

As you remove the screws the front of the block will come off.

Step 2. Locate your handles which have the controllers attached and also have a 9 pin cable attached to the left

controller.

Step 3. Center the handles on the block and place the front

part of the block back in place and put the screws in. As you

get to the point of the screws being tight ensure that they are

angled good for you.

If you need to adjust the angle of the handles you can loosen

the screws and move the handles up and down to help with

your comfort.

7

Connecting your Grand Quilter 18.8 to your Carriage Assembly (Deck) and

Controls on the Handles

For one year after the purchase of the Pfaff GrandQuilter 18.8 longarm sewing machine, we will

repair or replace (at our option), without any cost to you for either parts or labor, any machine

or part that proves to be defective in materials or workmanship.

Any cables that the Purchaser needs to connect must be connected with care. Careless

connection or disconnection may result in damage to the cables and/or components that the

cables are connected to. Such damage is not covered under warranty.

Your Carriage Assembly (Deck) comes without the encoders and cables connected. You will have a sheet with

your machine to show how to attach these encoders so that the stitch regulations will work. This cable is routed

to the power box of your machine and plugged into the receptacle on the back of the power box.

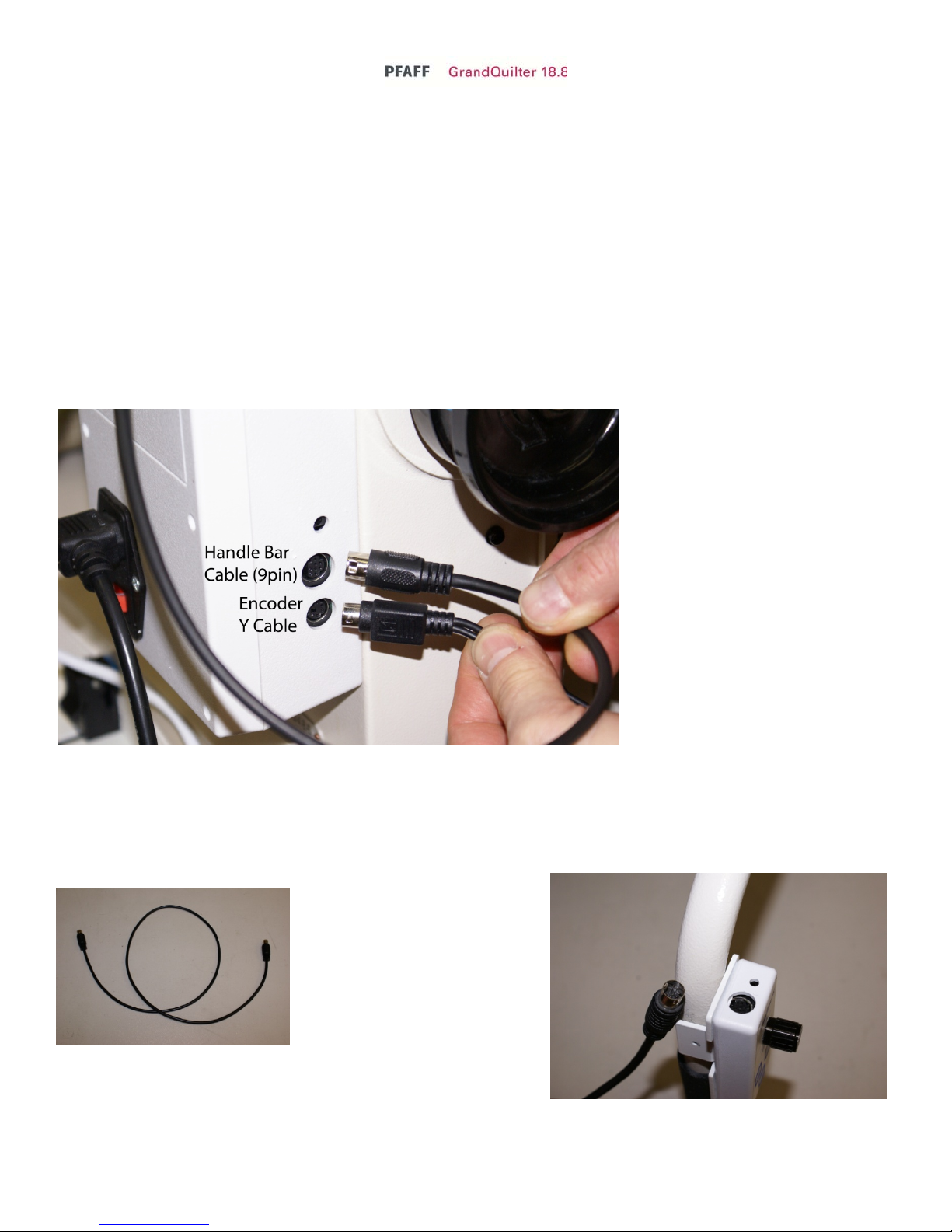

This is looking at the back of your

machine. You can see the three

connecting receptacles in the back

of the machine. The bottom one is

for your Carriage Assembly

(deck). The next one up is for

your controls from the handle bars.

The top one is not used at this

time.

Your left and right controls on your handle bar have a cable that runs through the handle bar to connect the two

controllers. You will need to use the supplied Handle Bar Cable (9 pin) to connect your left handle controller to

connector on the back of the power box.

The Handle Bar Cable (9 pin)

Your Handle Bar Cable (9

pin) Cable connects to the

Controller on the Left handle.

Note this Handle Bar (9 pin) only connects to this left

controller.

8

What is the Tension Release Lever?

The tension release lever raises the hopping foot and releases the

tension on the thread.

You can watch the tension disc plates open as you lift the lever.

NEVER start sewing with the lever up.

Because there is no tension on the thread the bottom stitches will

be huge loops.

How Do I Adjust the Height of the Hopping Foot for Thicker or Thinner

Batting

This is where you adjust the hopping foot for thicker or thinner batting.

Simply loosen the screw and adjust the foot to the level that clears the

fabric when moving the machine around. You need to have about 1

thin dimes worth of space between the bottom of the foot and the fabric

or base of the machine.

You also have the ability to adjust the walking of the machine. The walking of the machine is how much

movement is in the foot.

?

First remove this cover from the side of your machine.

9

Loading...

Loading...