Page 1

PFAFF

246

®

Service

Innovation

Nr.

296-12-1^

552

Manual

mode

by

PFAFF

engl.

9/89

Page 2

Notes

The

machine

If

it

observed.

Service-

Apart

is

not

CONTENTS

on

safety

is

converted

.

and

from

exceptions

permitted.

must

repair

only

to

be

used

another

work

must

according

for

the

version,

only

be

to

DIN

purpose

all

valid

carried

57 105 and

it

out

was

designed

safety

by

qualified

VDE

0105, work on

for.

regulations

personnel.

Page

must

live

be

parts

11

12

10

1

2

3

4

5

6

7

8

Positioning the feed dog

Preliminaryadjustment of feed lifting

Centering the needle in the needle hole

Topand bottom feed advancing motions

Hook

timing,

hook-to-needle clearance and

Needle guard

Final adjustment of feed lifting

Clearance

between

presser

foot

motion

and

needle

motion

needle

plate

bar

height

4

7

8

9

10

12

13

14

(-706/35; -706/47and -706/48)

9

Top-to-bottom-feed timing

Top feed lifting motion

Bobbin

Tension

case opener

release

mechanism

15

16

17

18

13

14

15

Threadcheck

Bobbin

winder

Final worksteps

spring

19

20

21

Page 3

Instructions for adjusting Pfaff

245,

1245

and

1246 machines

Note:

Technical

Needle

Needle

Top

feed lift: 5

data

system:

bar

rise:

All illustrations in this book apply to Pfoff 245 and 1245 single-needle

machines. On Pfaff 246 and 1246 two-needle machines various adjustments

have to be mode

effect;

some

twice.

The respective sections contain a note to this

of the illustrations in these sections apply in reflex.

134-35 on subcl. -706/05, -706/07 and -706/35

134 on subcl. -706/25

190

ModelsAand

Models B/C and C =

Models C/D and D =

7

5

5.5

8.0

• on subcl.-706/47 and-706/48

B

=1.6

mm

2.0

mm

2.2-2.5

mm

on subcl. -706/05

mmonsubcl.

mm

on subcl. -706/25

mm

on subcl. -706/35

mm

on subcl. -706/48

-706/07

and

mm

-706/47

Max.

clearance

between

presser

foot

and

needle

plate:14mm*

Tools, gauges and other items needed for adjustment

Setofscrewdrivers

Set of alien keys ranging

Set of spanners from 7 to 14

C-clomp, No. 08-880 137-00

Gauge,

Metal

Sewing

No.

rule

thread and material for testing

En

machines equipped with knee lifter or subcl. -910/04.

08-880

with

136-14

blades

from

mm

from 2to10 mm

2 to 6

mm

wide

purposes

wide

Page 4

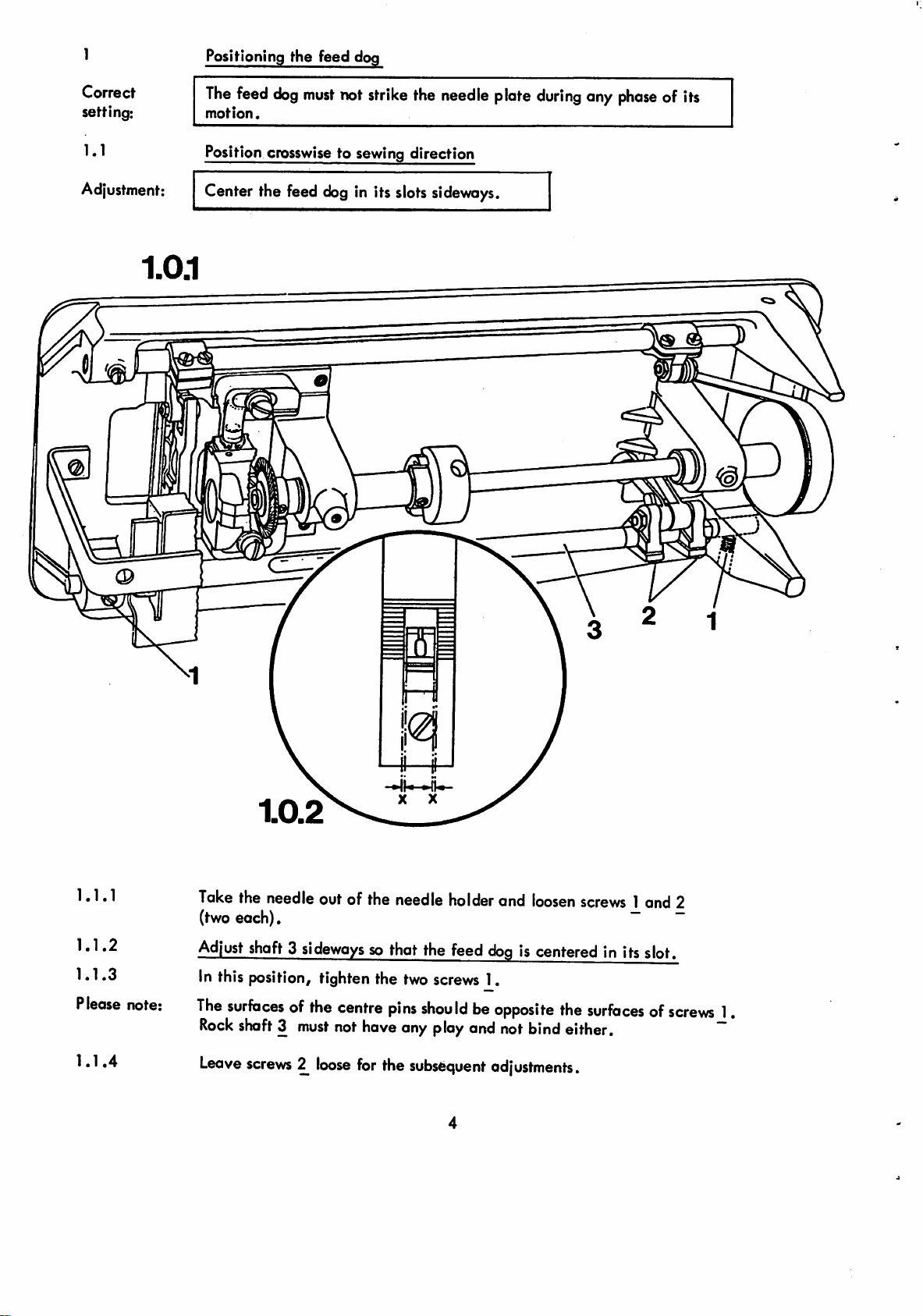

1

Positioning the feed dog

Correct

setting:

1.1

Adjustment:

The

feed

dog

must

not

strike

the

needle

motion.

Position crosswise to sewing direction

Center the feed

dog

in its

slots

sideways.

plate

during

any

phaseofits

1.1.1

1.1.2

1.1.3

Please

1.1.4

note:

Take

the

needle

(two each). ~ ~

Adjust

In this

The

Rock

Leave

shaft3sidewayssothat the

|X}sition,

surfacesofthe

shaft3must

screws^loose

outof the

tighten the

centre

not

have

for

the

needle

holder

feed

two

screws

pins

shouldbeopposite

any

play

and

subsequent

and

loosen

screws

dogiscentered

1.

the

not

bind

either.

adjustments.

1and 2

in itsslot.

surfacesofscrews

1

""

Page 5

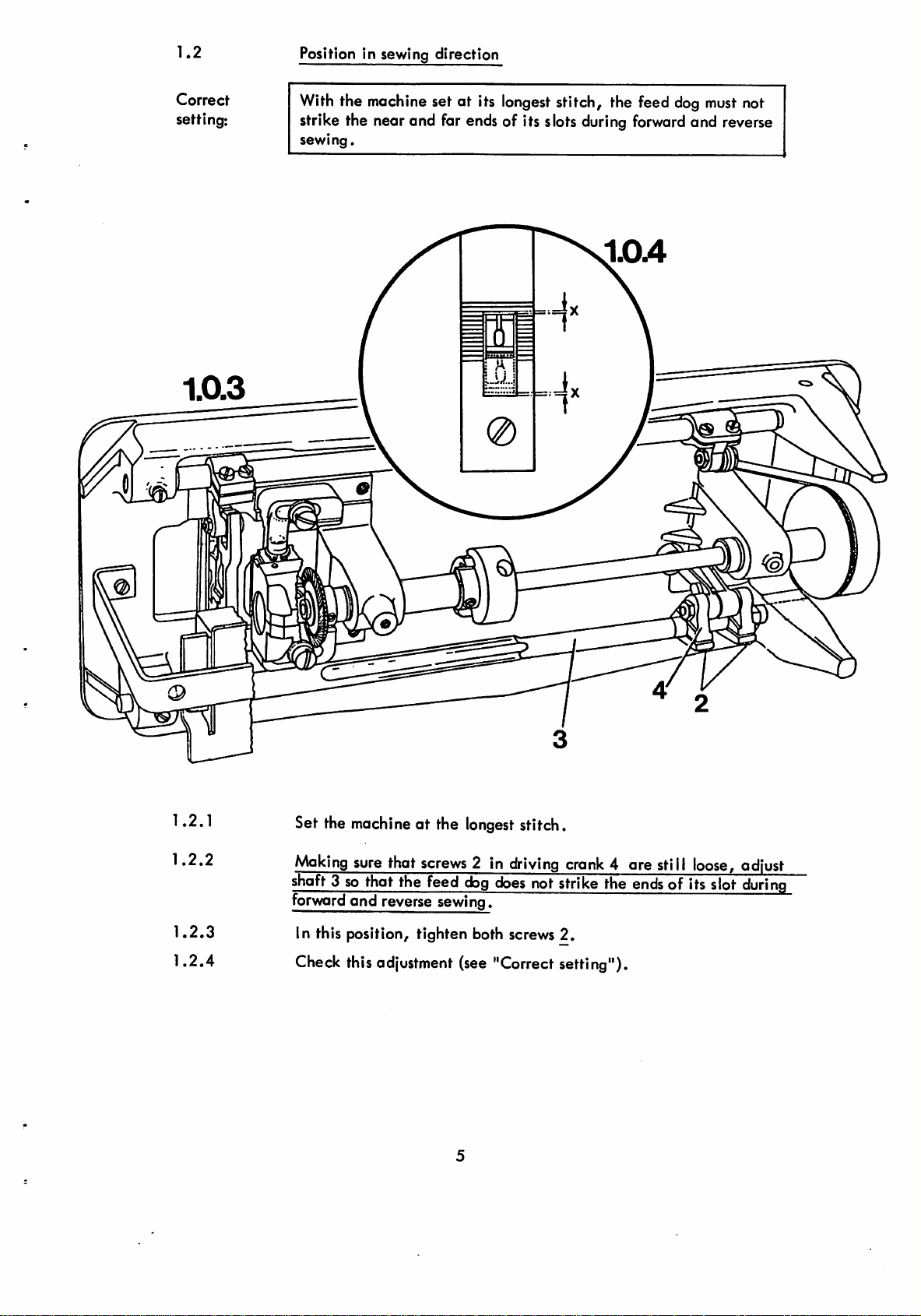

1.2

Position in sewing direction

Correct

setting:

With

the

machine

set at its

longest

stitch, the feed

strike the near and far ends of its slots

sewing.

0

during

forward

dog

must

and reverse

not

1.2.1

1.2.2

1.2.3

1.2.4

Set the machine at the longest stitch.

Making

shaft3 so that the feed

forward

In this position, tighten both screws 2.

sure

that

screws

2 in

dog

and reverse sewing.

driving

does

notstrike the

crank

Check this adjustment (see "Correct setting").

4 ore still

ends

of its slot

loose,

adjust

during

Page 6

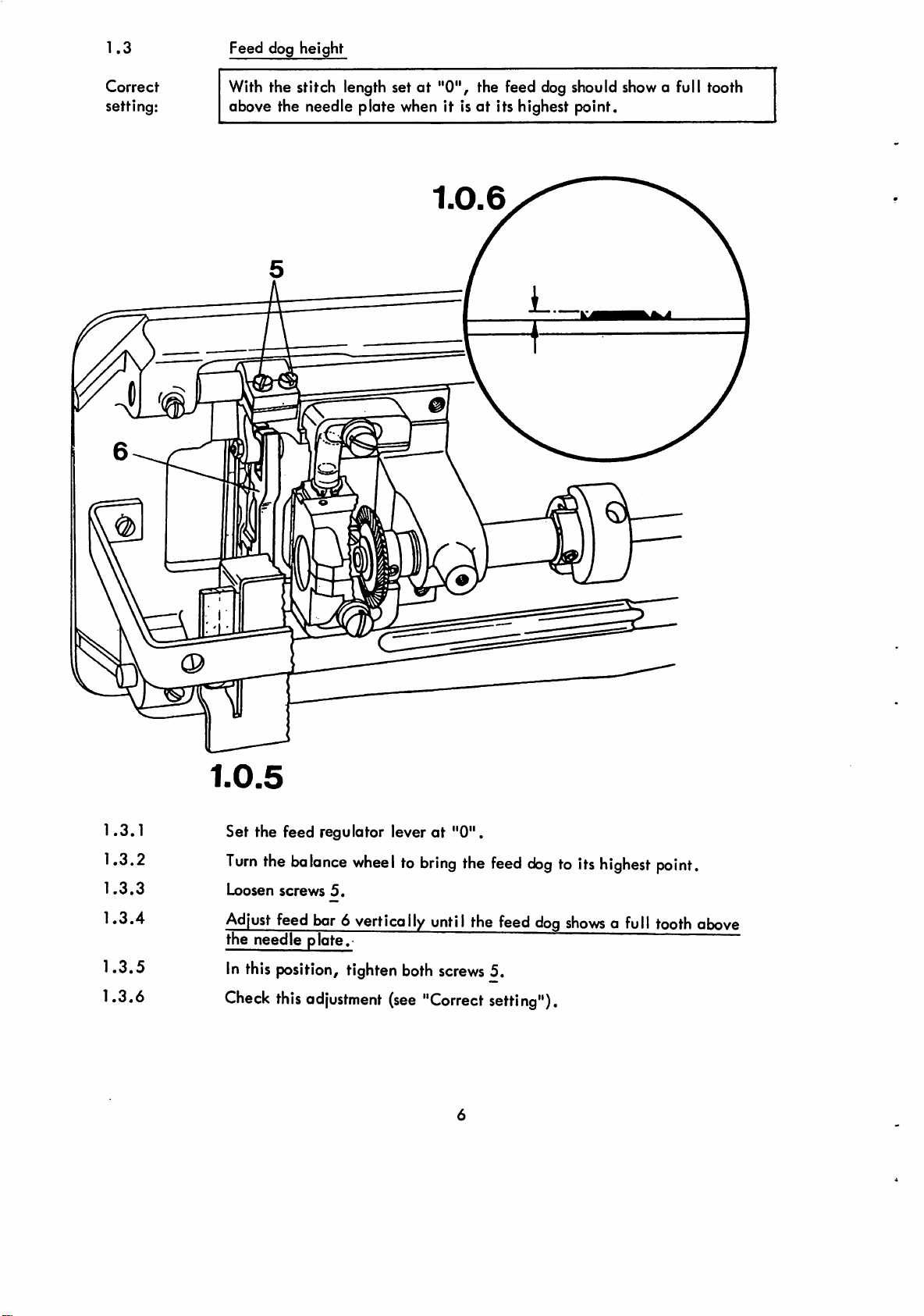

1.3

Feed dog height

Correct

setting:

With the stitch length setat"0",

above the needle plate when it isatits highest point.

the feed dog should show a full tooth

1.3.1

1.3.2

1.3.3

1.3.4

1.3.5

1.3.6

1.0.5

Set

the feed regulator leverat"0".

Turn

the

balance

Loosen

Adjust

the needle plate.

In this position, tighten both

Check

screws

feed bar 6 vertically until the feed

this

wheeltobring

5.

adjustment

(see

the

screws

"Correct

feed

dogtoits

dog

5.

setting").

highest

shows

a full tooth above

point.

Page 7

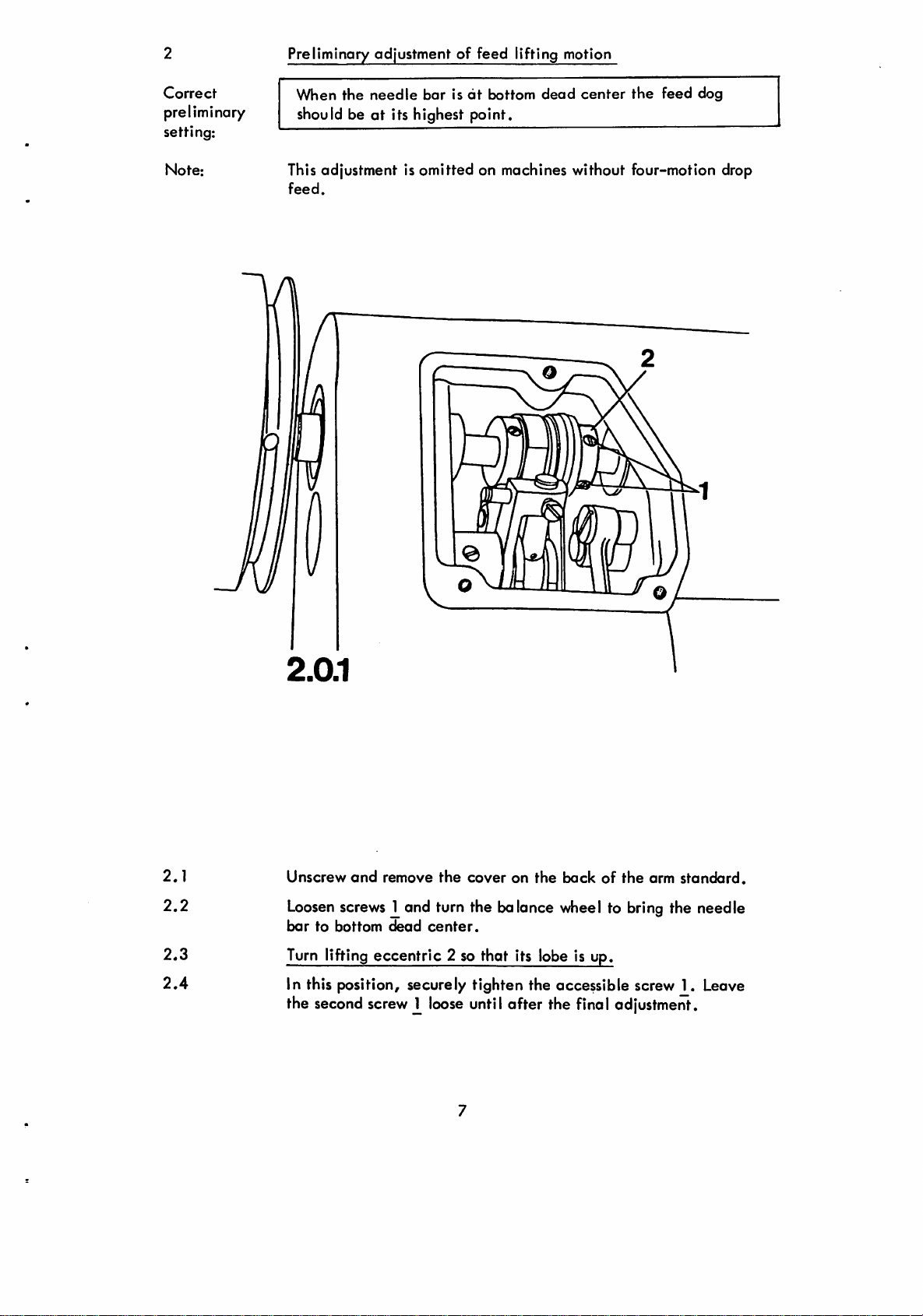

Preliminary adjustment of feed lifting motion

Correct

preliminary

setting:

Note:

When

the

needle

barisdt

bottom

dead

center

the

feed

dog

should beatits highest point.

This adjustment is omitted on machines without four-motion drop

feed.

2.1

2.2

2.3

2.4

©

Unscrew

Loosen

bartobottom

Turn lifting

and

screws

remove

the

coveronthe

bockofthe

arm

and turn the balance wheel to bring the needle

dead

center.

eccentric

2 so that its lobe is up.

standard.

In this position, securely tighten the accessible screw 1. Leave

the

second

screw^loose

until

after the

final

adjustment.

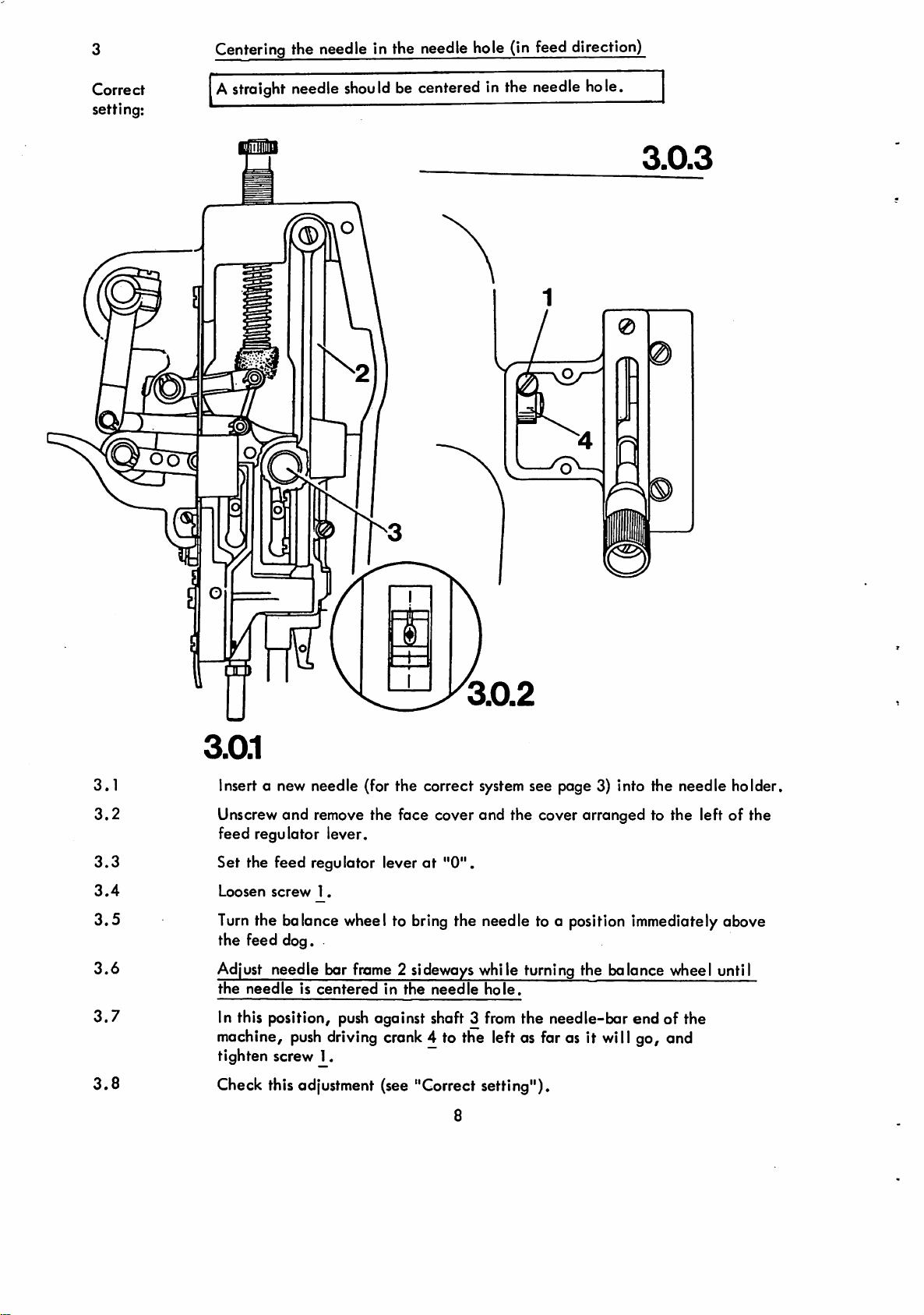

Page 8

Centering the needle in the needle hole (in feed direction)

Correct

setting:

OOT(

Astraight needle

should

be centered in the needle hole.

3.0.3

0

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.0.1

Insert a new needle (for the correct

Unscrew

and

remove the face cover and the cover arranged to the left of the

feed regulator lever.

Set the feed regulator lever

Loosen

Turn

screw

1.

the balance wheel to

at

bring

the feed dog.

Adjust needle bar

the

needleiscentered

In this position,

machine,

push

frome

2 sideways while turning the balance wheel until

in

the

needle

push

against shaft 3

driving crank 4 to the left as far as it will go, and

tighten screw 1.

Check this adjustment (see "Correct setting").

system

"0".

the needle to a position immediately above

hole.

from

8

see page 3) into the needle holder.

the needle-bar end of the

Page 9

Top and bottom feed advancing motions

Correct

setting:

With the machine set for its longest stitch and the needle bar

positionedatbottom dead center the top and bottom feeds should

remain

motionless

when

the feed regulator lever is operated.

4.1

4.2

4.3

4.4

4.5

4.6

4.0.1

Set the machine for its longest stitch.

Loosen

to be turned on its shaft against resistance. ~

Bring the needle bar to bottom dead

Position

(without disturbing the above setting) and turn

direction until the top and bottom feeds remain completely

when the feed regulatior lever is operated.

In this position, tighten screws 1.

Check this adjustment (see "Correctsetting").

screws2just

the

eccentric

sufficiently toallow

center.

lobeoffeed

advancing

feed

advancing

eccentric

just

2 "down"

lightly in feeding

eccentric 2

motion

less

Page 10

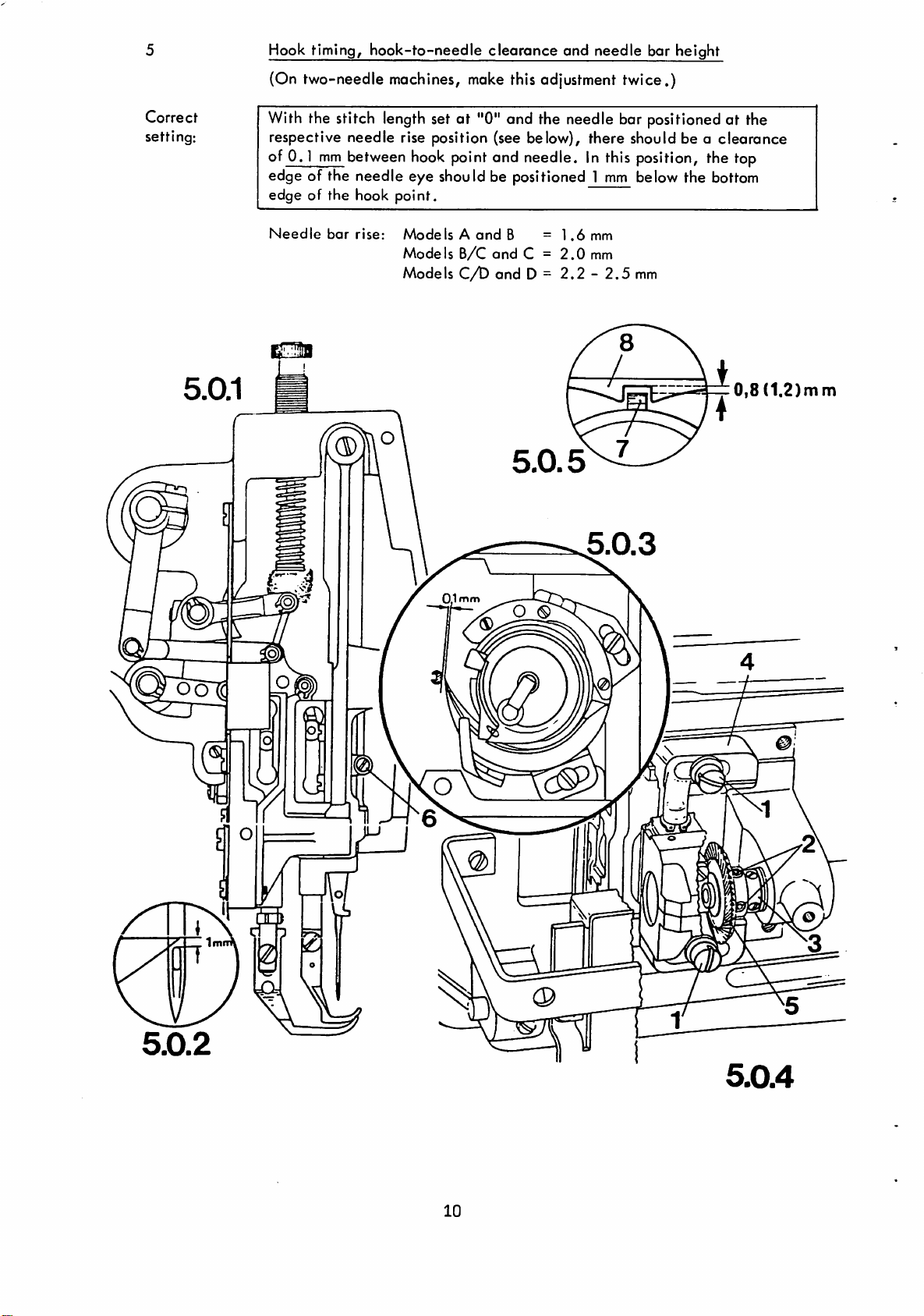

Hook timing, hook-to-needle clearance and needle bar height

Correct

setting:

(On two-needle machines,

With

the stitch

length

moke

this adjustment twice.)

set at "0" and the needle bar positioned at the

respective needle rise position (see below), there should be a clearance

of 0.1

edge of the needle eye should be positioned 1

edge of the hook

Needle

mm

bar

between

rise:

hook

point and needle. In this position, the top

point.

ModelsAand

Models

Models

B/C

C/D

B

and

C =

and D =

=1.6

2.0

2.2-2.5

mm

below the bottom

mm

mm

mm

0,8

(1.2)nim

m

10

Page 11

5.1

Make sure o new

length at

"0".

needle

has been inserted, then set

the

stitch

5.2

5.3

5.4

Unscrew

Loosen

and

remove needle

screws^cmd

2 as

well

plate

as the

and

screws

feed dog.

of collar3.

Turn the balance wheel and bevel gear 5 until the hook point is

positioned in the middle of the needle scarf.

5.5

5.6

5.7

5.8

5.9

5.10

5.11

Adjust hook bracket 4 sideways until there is a clearance of 0.1

between hook point

In this position, tighten screws

Turn bevel

those on the large bevel gear.

Push

gear

bevel gear 5 up against the small bevel gear so that both gears are

neither set too close nor hove too

and

needle.

5 to set the marks of the small bevel gear between

much

play.

mm

In this position, move collar 3 up against bevel gear 5 and tighten the

screwsinthe

Turn the balance wheel to bring the needle bar to bottom dead

Push

the appropriate blade of the needle rise gouge (see needle rise data)

onto the needle bar immediately below its lower bearing, push the

collar.

center.

C-clamp up against the blade and tighten its screw.

5.12 Pull out the gauge blade and turn the balance wheel until the C-clamp

contacts the needle bar bearing.

5.13

5.14

5.15

5.16

5.17

5.18

5.19

Note:

Turn bevel gear 5 until the hook point is opposite the center line of the

needle.

In this position, tighten the accessible screw 2.

Remove

Making sure that the hook point is still positioned opposite the center

line of the

until the bottom

top edge of the needle

In this position, tighten screw6,making sure that the needle scarf

faces the hook point.

Turn the

tighten

the

C-clamp

needle,

balance

it.

from the needle bar.

loosen screw 6

edgeofthe

eye.

wheel until the second screw 2 is accessible, then

and

adjust the needle bar

hook point is positioned

1.0

vertically

mm

above

Check this adjustment (see "Correct setting").

When

exchangingahook

and the cutoutof needle plate 8 the

Models A andB:roughly

Models C and D: roughly 1/2mm

bracket

0,8

mm

make

sure

following

(see Fig.

that

between

clearancesare

5.0.5.)

position

kept:

lug

If necessary, correct hook height by inserting respective washers.

the

7

On NIO machines, make this adjustment with the machine set

at

its longest

stitch.

11

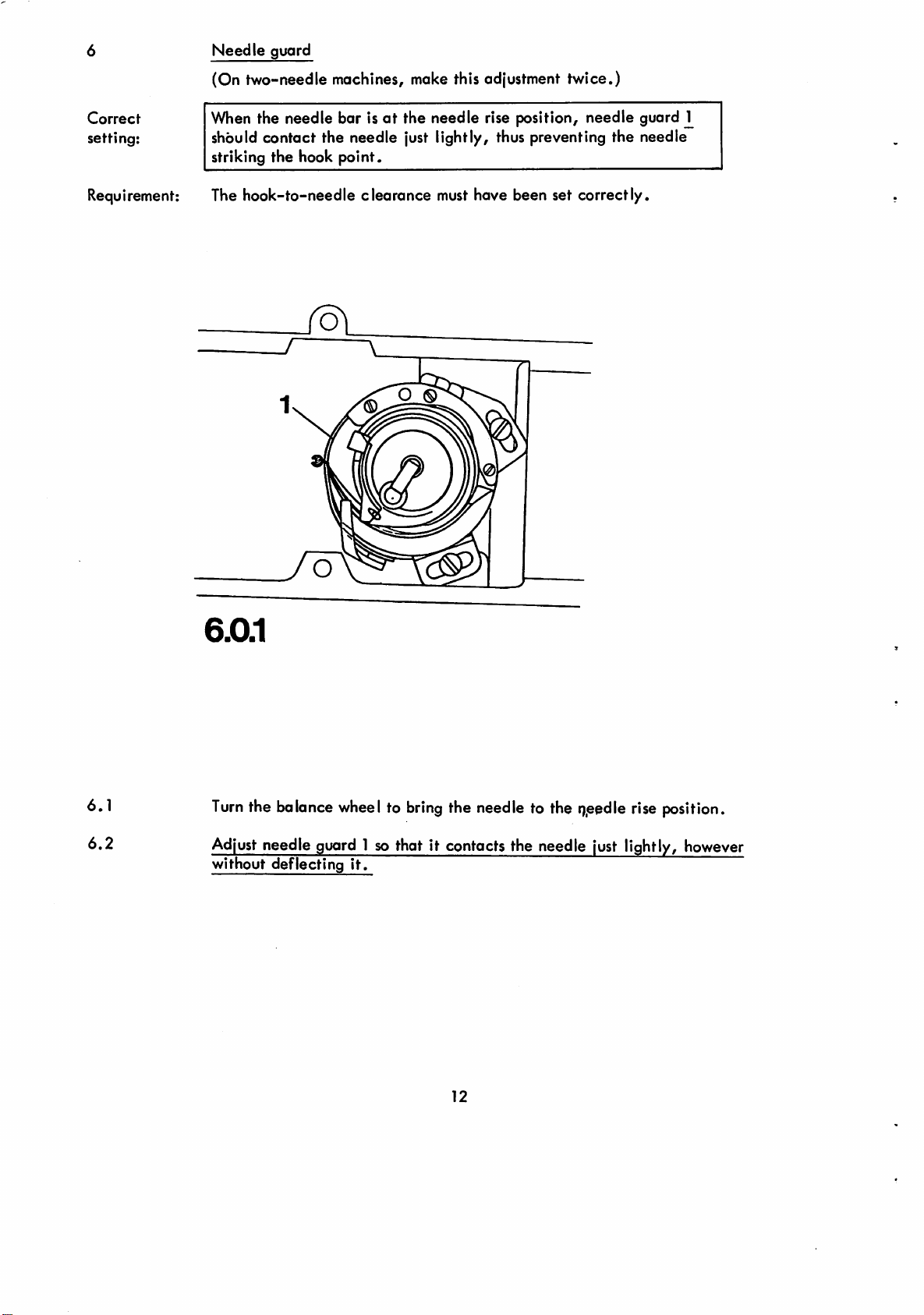

Page 12

Needle

(On two-needle machines, make this adjustment twice.)

guard

Correct

setting:

Requirement: The hook-to-needle clearance

When

the

needle

should contact the needle just lightly, thus preventing the needle

striking the hook point.

bar is at the needle

rise

position, needle

must

have been set correctly.

guard

^

6.1

6.2

6.0.1

Turn

the balance

Adjust needle guard 1 so that it contacts the needle just lightly, however

without

deflecting

wheeltobring

it.

the needle to the

q.eedle

rise position.

12

Page 13

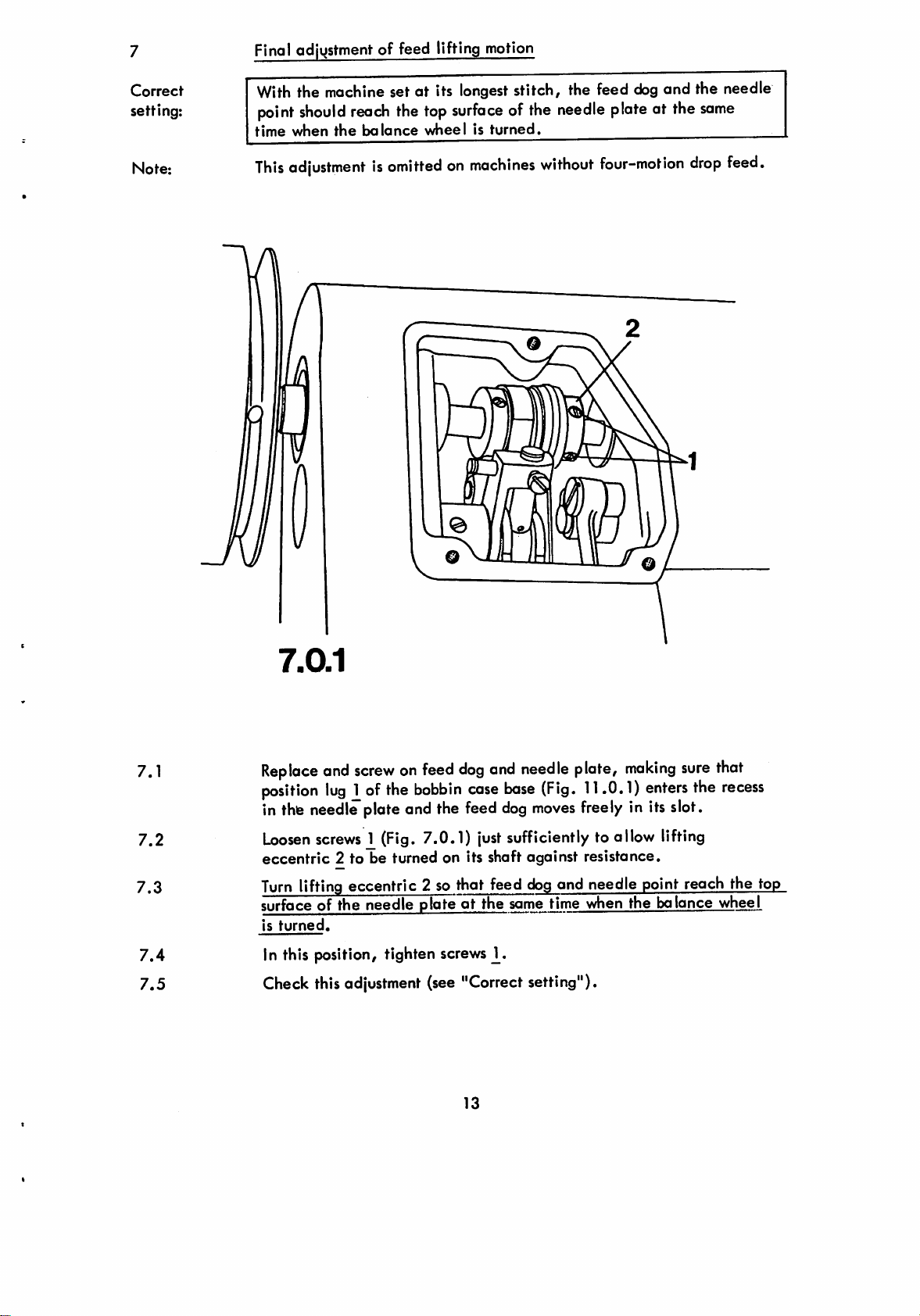

Final adjvjstment of feed lifting motion

Correct

setting:

Note:

With

the machine set at its

point

should

time when

This

adjustmentisomittedonmachines

the

reach

balance

the

longest

top

surfaceofthe

wheelisturned.

stitch, the feed

needle

without

plate

four-motion

dog

and the needle

at the

drop

same

feed.

7.1

7.2

7.3

7.4

7.5

7.0.1

Replace

position

in

Loosen

eccentric

Turn

surface of

is

In this position, tighten screws2•

Check this

and

screwonfeed

lug

1of

the

thiB

needle

screws

lifting eccentric 2 so that feed

turned.

plateand the

1 (Fig. 7.0.1)

2 to be turned on its shaft against resistance.

the

needle

adjustment

dog

bobbin

feed

plateatthe

(see "Correctsetting").

13

and

case

just

needle

base

dog

(Fig.

moves

plate,

11.0.1)

freely

making

enters

in its slot.

sufficiently to allow lifting

dog

and needle point reach the top

same time when the

balance

sure

the

that

recess

wheel

Page 14

Correct

setting;

Note:

Cleoronce

(On

subcl.

When

on

subcl.

it and the needle plate.

The

clearanceonsubcl.

determinedbythe

between

"706/35;

the

presser

-706/35orabout14mmonsubcl.-706/47

presser

footisraised,

machine

0

D

foot

-706/47

-706/05,

design.

and

end

there

needle

-706/48

shouldbea

-706/07

plate

machines

and

only)

clearanceofabout11mm

and

-706/48

-706/25

machines

between

is

8.1

8.2

8.3

8.4

8.5

8.6

Note:

Operate

Reduce

Loosen

Adjust

or

14.0

In

this

to

the

Check

Regulate

a

sewing

the

the

screws

the

mm

|:»sition,

edgeofthe

this

the

test.

presser

bar

pressureonthe

2of

lifting

presser

bar

vertically

respectively

tighten

needle

adjustment

presser

(see

foot

8.0.2

liftertoraise

presser

collar

between

screws2,making

plater ^orisser

"Correct

pressurebyturninginscrew1while

the

presser

barbyturning

3.

untfl

thereisa

presser

foot

sure

setting").

14

foot.

out

screw

1.

clearanceofabout11mm

and

needle

the

plate.

presser

footisset

making

— ®

parallel

parallel

Page 15

Top-to-boftom-feed timing

Correct

setting:

With

stud1centeredinits

needle

and

the

plote,

other

the

half

vibroting

below

the

slot

and

presser

presser

the

should

foot

presser

moke

sole.

foot

half

lowered

its

motion

onto

above

the

9.1

9.2

9.3

9.4

n

9.0.2

Make

sure

the

presser

1 is centered in its slot, then

allow

lever 3 to be

Adjust

above and the other half

balance

In this position, tighten both

Check this

lever3so

wheelisturned.

adjustment

footislowered

turned

that the

vibrating

below

'

(see "Correct setting").

ontothe

loosen

on drive shaft 4

screws 2 just sufficiently to

presser

the

presser

screws

2.

needle

against

makes

foot sole

half its

plate and

resistance.

motion

when

the

stud

15

Page 16

10

Top feed lifting motion

Correct

setting;

With

and

the

the

presser

needle

foot

point

should

restingonthe

reach

needle

the

needle

plate,tevibrating

plateatthe

same

presser

time.

10.1

10.2

10.3

10.4

10.5

10.0.2

Operate

Loosen

on Its shaft

Turn

lifting

reach

the

In

this

position,

Check

this

presser

bar

screws2|ust

against

eccentric3until

needle

plateatthe

tighten

adjustment

lifter^to

lower

the

sufficientlytoallow

resistance.

the

vibrating

same

time

screws

(see

2.

"Correct

16

setting").

presser

lifting

presser

when

the

foot

onto

the

needle

plate,

eccentric3tobeturned

~

and

the

balance

needle

wheelisturned.

point

Page 17

11

Bobbin cose

(On

two-needle

opener

machines,

moke

this

adjustment

twice.)

Correct

setting;

The

and

of

the

needle

bobbin

thread

cose

recessinthe

mustbetrapped

base5nor

needle

between

plate

neither

position

(see

arrowsinFig.

between

lug

and

opener

the

11.0.2).

finger

walls

11.0.2

4

11.1

11.2

11.3

11.4

11.5

Thread

and

Loosen

against

Turn

vMeel

finger4and

wallsofthe

from

up through the needle holeT

In this position, tighten

Check

the

machine,

lower

the

screws2just

resistance.

collar3on

the

needle

bobbin

recessinthe

the

time

the

this

adjustment

placeapieceoffabric

latter.

sufficientlytoallow

the

hook

thread

loopispickedupby

willbetrapped

cose

base5nor

screws

(see

bracketsothat

between

needle

plate

the

2.

"Correct

17

setting").

under

collar

when

neither

position

(see

arrowsinFig.

hook

the

3 to be

you

turn

between

lug1and

point

untilitis

presser

turned

the

balance

opener

11.0.2)

foot

the

pulled

Page 18

12

Correct

setting:

Note:'

Tension

(On

When

0.5

The

a clearance of more than

release

two-needle

the

presser

mm

apart.

clearance of

mechanism

machines,

footisraised,

0.5

mm

moke

is the

1.0

this

adjustment

both

tension

minimum

mm

may be required.

twice).

discs

shouldbeat

clearance; for thicker threads

least

12.1

12.2

12.3

j

iJT

12.0.1

Operate the presser bar lifter to raise the presser foot.

Adjust

ofatleast

With effective tension pin 3 must,not be under stress.

Check this adjustment (see "Correct setting").

thrust plate 1 behind tension base plate 2 so that there is oclearance

0.5

mm

between

both

tension

discs.

12.0.2

18

Page 19

13

Threod check spring

Correct

setting:

Note:

The

strokeofthe

needle

thickness

Special

spring for a shorter or longer stroke.

point

(which

sewing

thread

has

reached

equalsastroke

operations

check

the

may

spring

surface

of obt. 7

makeitnecessary

shouldbecompleted

ofa pieceof

mm).

fabricofmedium

to setthe

O

when

check

the

13.1

13.2

13.3

13.4

13.5

Make

sure

the

fabric

Loosen

Turn

lever

Continue

thread

stroke.

In

tighten screw 1.

the

to its

this

under

the

screw

balance

highest

turning

check

spring

position,

©

machine

presser

1.

has

foot

been

wheeltosewafew

point.

the

balance

has

recededtothe

push

stop2up

threaded,

and

lower

stitches,

wheelinits

against

then

the latter.

then

normal

starting

the

thread

placeapiece

bring

direction

the

until

of

take-up

the

positionofits7mm

check

spring

and

13.6

Check

this

adjustment

(see

19

"Correct

setting").

Page 20

14

Correct

setting:

Bobbin

When

reliably;

wheel 3

winder

the

must

bobbin

when

outomoTically

about

1.0

mm

winderisengaged

the

bobbin

winderisdisengaged,

the

winder

spindle

however,

shouldbedriven

friction

not contact drive wheel 2. The bobbin winder should stop

when

the

below

its

thread

rim.

woundonthe

bobbin

has

reachedapoint

14.1

14.2

14.3

14.4

14.5

14.6

14.7

14.0.1

Engage the bobbin winder.

Loosen

Adjust the position of the arm shaft to set drWe wheel 2 so close to

friction wheel 3 that the latter will be driven reliably when the

balance

winderisdisengaged.

In this position, tighten

Loosen

If the bobbin is too full, push stud 5 toward the

enough, push the stud toward

Check this adjustment (see "Correct setting").

screws

wheel is

screws

J_,

4.

turned,

but

both

will

not be driven when

screws

the

20

left

J_.

and

right,

tighten screw

the

bobbin

if it is not full

4.

14.0.2

Page 21

15 Final worksteps

15.1 Replace and screw on the face

15.2

15.3 Make a sewing test and

Replace

both of them)below bedplate.

bar pressure by turning screw 1 in or out (Fig.

proper feeding is ensured evenattop speed.

and

screw on bevel gear housing (on 2-needle machines

at

the same time regulate the presser

and

all

other covers.

8.0.1)

until

21

Page 22

PFAFF

Innovation

Pfaff,

D-6750

Kaisersbutern,

Postfach

Telefax

mode

3020/3040,Telefon (0631) 200<D,

(0631)17202

by

PFAFF

Telex45753

Loading...

Loading...