PEUGEOT Ludix 4T Workshop Manual

Sales division

Technical network leadership

WORKSHOP MANUAL

-

TABLE OF CONTENTS

1

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

TABLE OF CONTENTS

TABLE OF CONTENTS . ... .......................................... ... ... .... ... .......................................... ... ... ... .......................1

PRODUCTS DANGER SYMBOLS USED........ .... ... ... ............................................. ... .... ... ... ............................. 3

CHARACTERISTICS......................................................................................................................................... 5

Engine........................................................................................................................................................5

Capacities..................................................................................................................................................5

Chassis......................................................................................................................................................5

Dimensions and weight................ .... ... ... ... .... .......................................... ... ... ... ... .......................................6

Tyres ..........................................................................................................................................................6

Brakes........................................................................................................................................................6

SERVICE SCHEDULE AND COMMISSIONING...............................................................................................7

To be checked at each service...................................................................................................................7

Service operations .....................................................................................................................................8

Time required for maintenance........................................ ... ... .... ... .......................................... ...................8

Battery preparation (Except battery without maintenance)* ......................................................................9

New machine preparation..........................................................................................................................9

SPECIAL IMPORTANT POINTS.....................................................................................................................10

Fuel..........................................................................................................................................................10

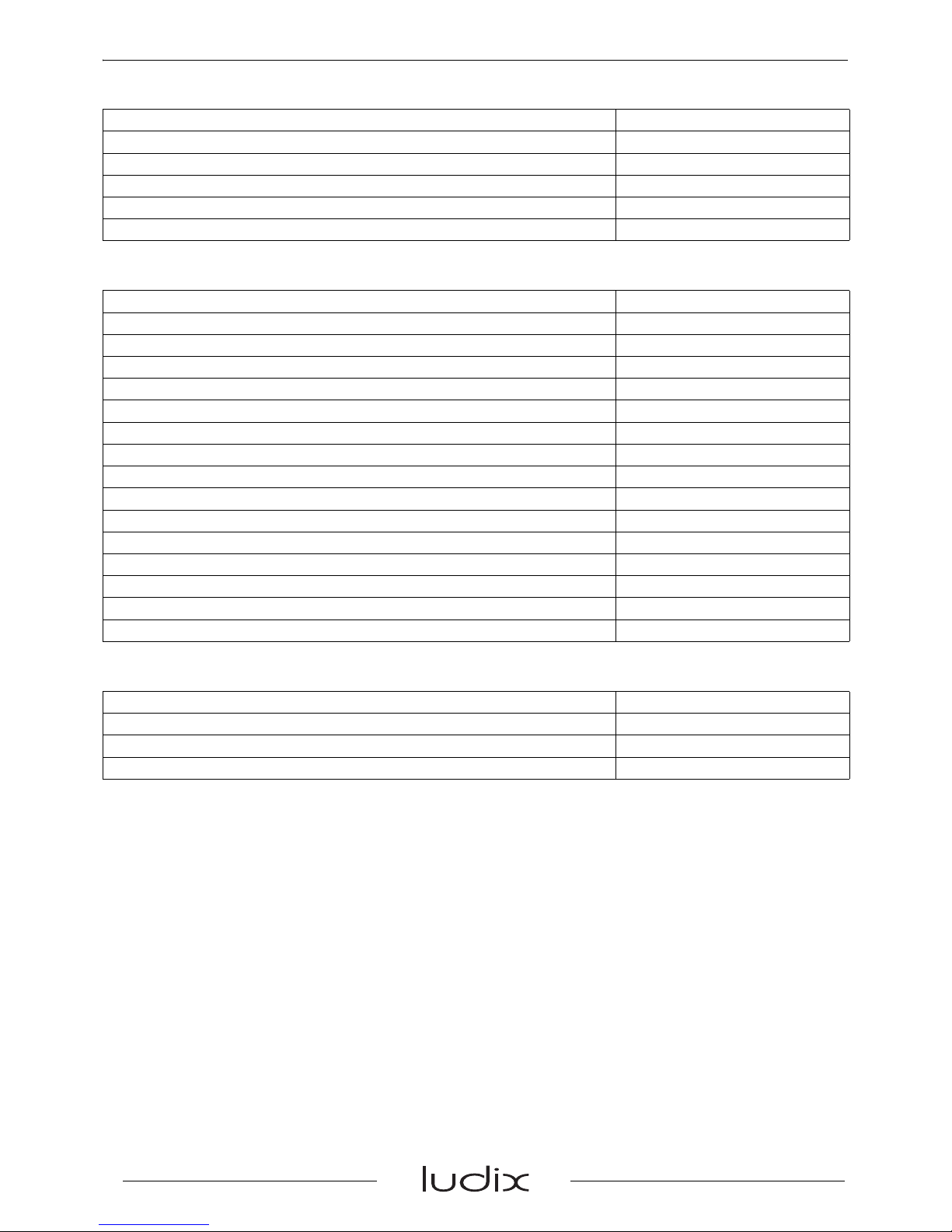

TIGHTENING TORQUES .............................. ... .... ... ... ............................................. ... ..................................... 11

Engine part ..............................................................................................................................................11

Body panels .............................................................................................................................................12

Cycle part.................................................................................................................................................12

Standard ..................................................................................................................................................12

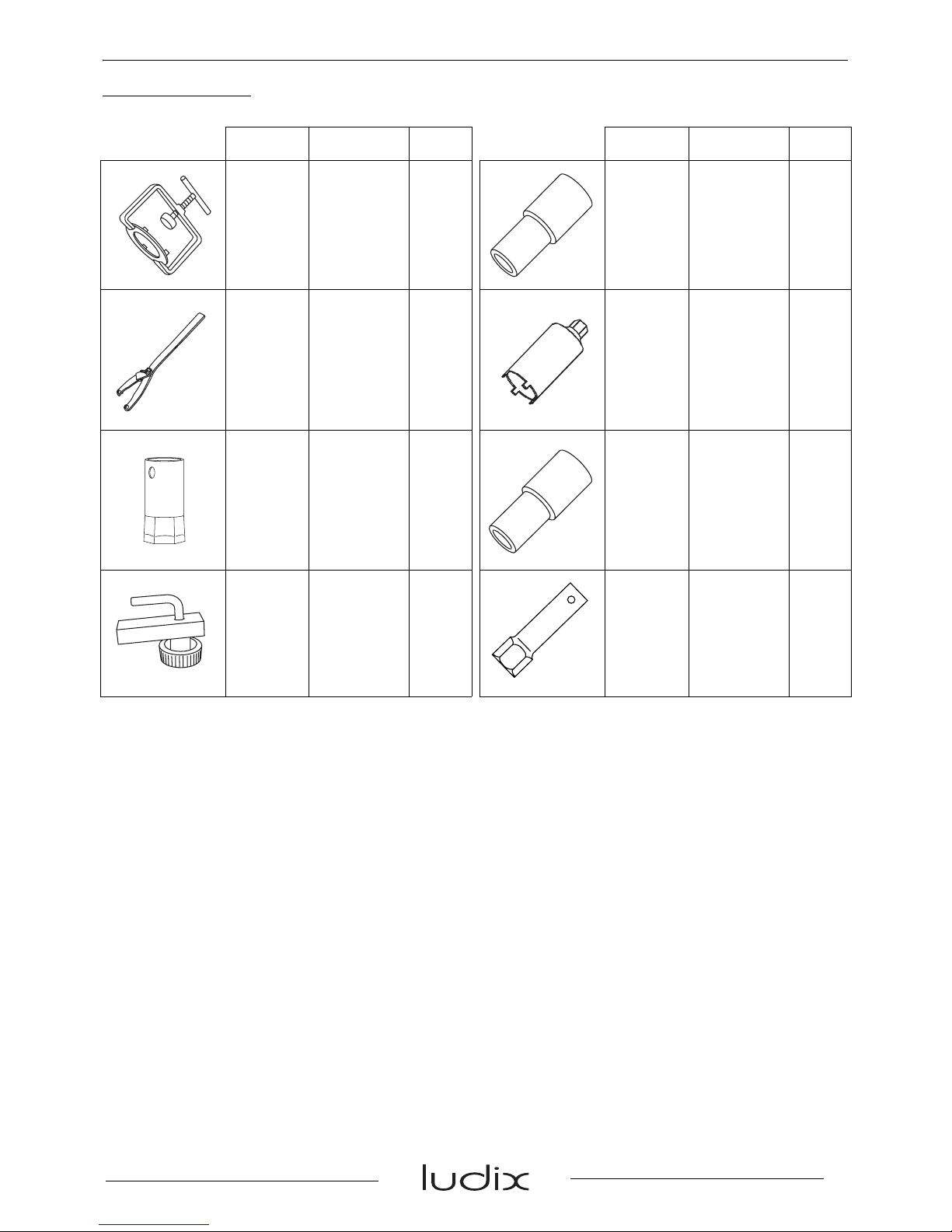

SPECIAL TOOLS............................................................................................................................................13

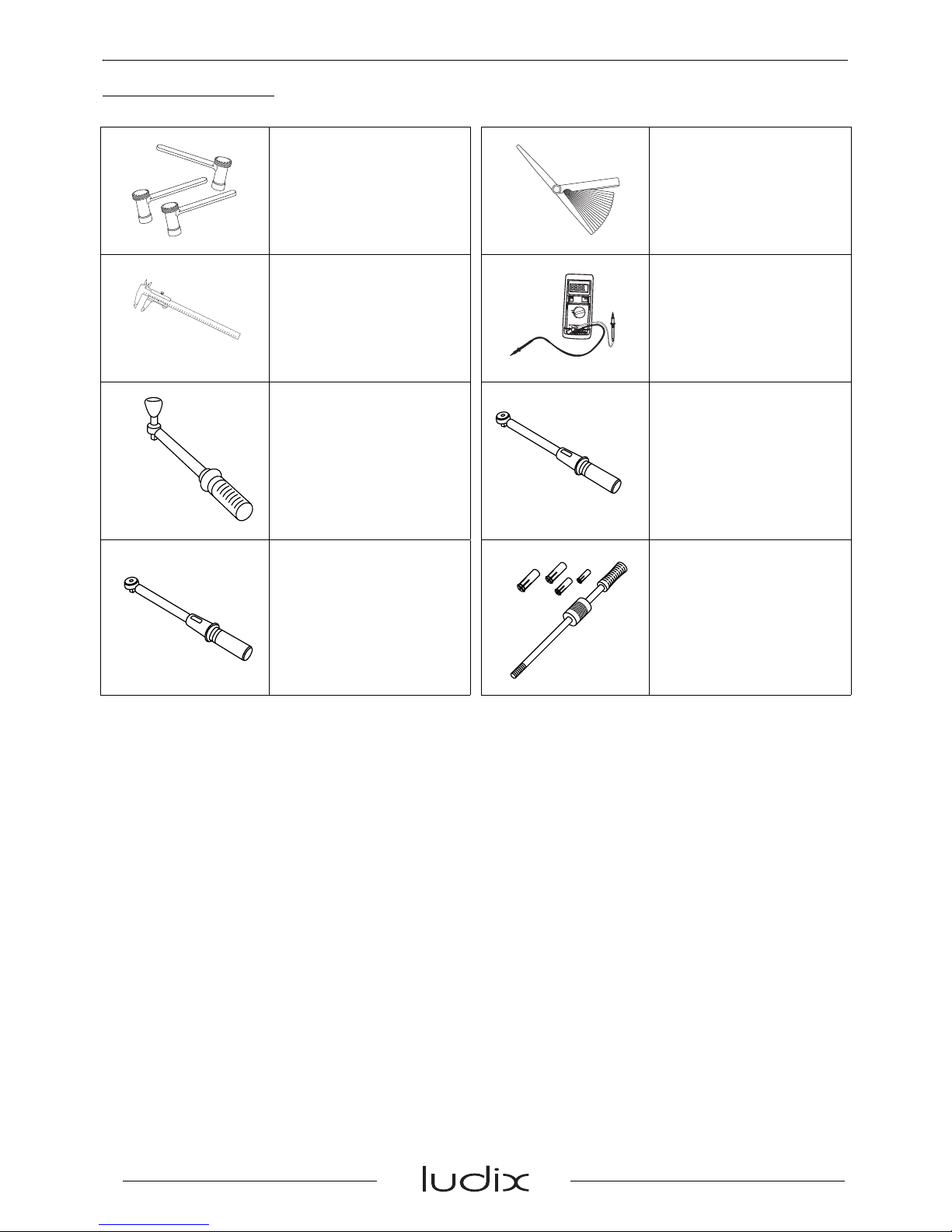

STANDARD TOOLS................... ... .................................................................................................................. 14

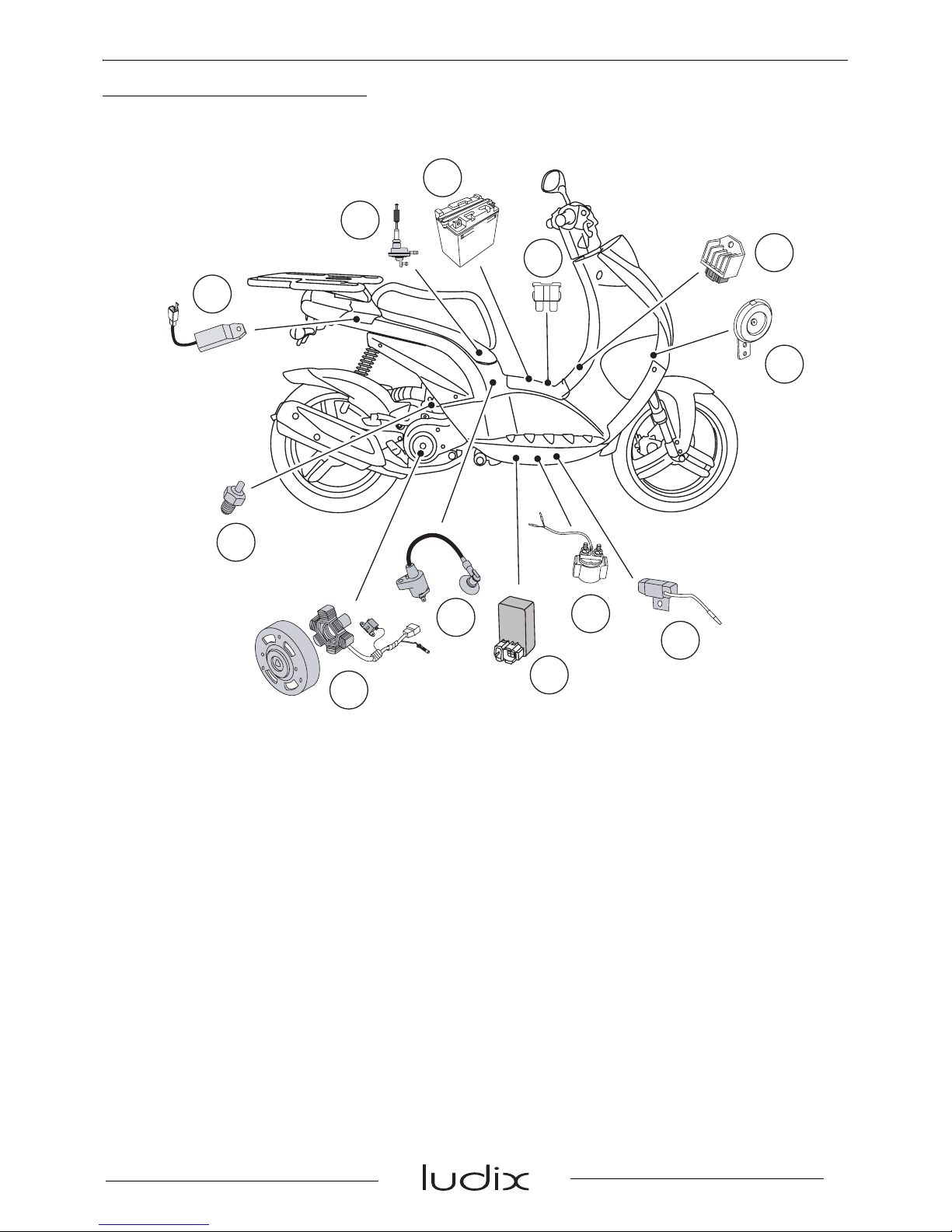

LOCATION OF COMPONENTS...................................................................................................................... 15

BODY PANELS ...............................................................................................................................................16

Removal of the front shield panel.............................................................................................................16

Removal of the rear shield panel .............................................................................................................16

Removal of the footboard.........................................................................................................................17

Removal of the under body panel............................................................................................................17

Removal of the fuel tank ..........................................................................................................................18

Removal of handlebar fairing...................................................................................................................19

TABLE OF CONTENTS

2

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

SERVICE OPERATIONS................................................................................................................................. 20

Changing the engine oil ...........................................................................................................................20

Draining the relay box..............................................................................................................................21

Replacing the air filter ..............................................................................................................................22

Removal of the spark plug .......................................................................................................................23

Transmission............................................................................................................................................23

Installing the valve clearance........................... ... ... ............................................. .... ... ... ...........................27

Idle setting................................................................................................................................................28

Removal of the fuel filter ..........................................................................................................................28

Brake inspection ........................................... ... ........................................................................................28

Replacing the brake pads ........................................................................................................................29

Checking the brake fluid level..................................................................................................................29

Rear brake linings....................................................................................................................................30

MISCELLANEOUS OPERATIONS .................................................................................................................33

Removal of the fork..................................................................................................................................33

Replacing the bearings of the steering system........................................................................................33

Steering system tightening method..........................................................................................................35

Wheel bearing replacement............................................. ... ... .......................................... .... ... .. ...............36

ELECTRICITY.................................................................................................................................................. 37

Ignition principle schematic/Car buretor hea ter ............. ... ... ... .......................................... .... ... ... ... ... ........37

Checking the ignition system ...................................................................................................................38

Checking the carburettor heating circuit...................................................................................................39

Regulator/Starter motor relay/Ignition unit/Starter resistor/HT coil...................................................................40

Checking the starter motor relay..............................................................................................................40

Checking the starter resistance ...............................................................................................................41

Checking the high tension coil .................................................................................................................41

Vacuum-operated cock............................................................................................................................42

FUEL SYSTEM................................................................................................................................................43

Removal of the carburettor.......................................................................................................................43

The carburettor and its components ........................................................................................................49

POWER UNIT.......................................... ... .....................................................................................................50

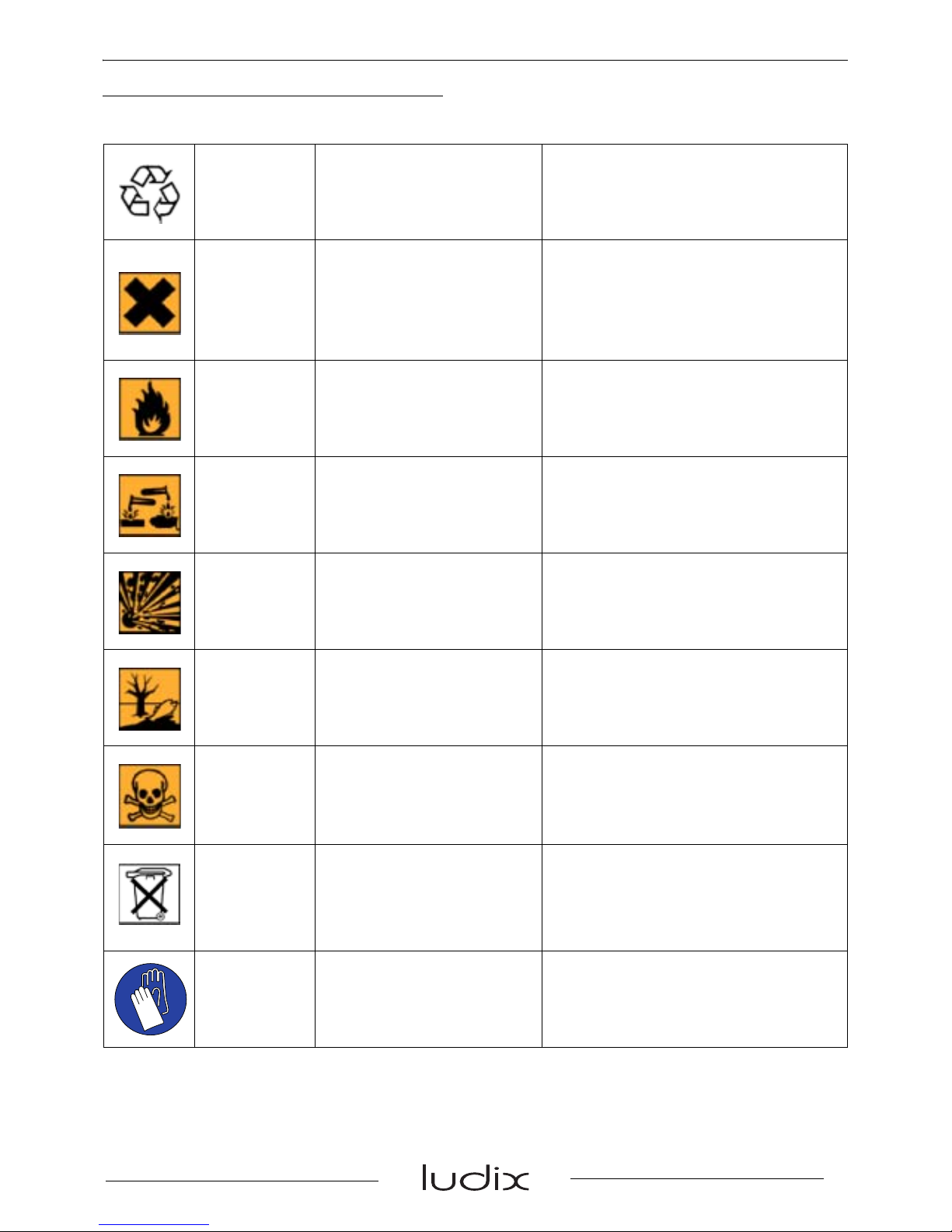

PRODUCTS DANGER SYMBOLS USED

3

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

PRODUCTS DANGER SYMBOLS USED

Protection of individuals and of the environment.

Möbius band

Recyclable.

Means that the product or the package

can be recycled. However, this does not

guarantee that the product will be

recycled.

Irritant

The product can irritate the

skin, eyes and respiratory

organs.

Avoid contact with skin and clothes. Wear

gloves, safety glasses and appropriate

clothing such as a cotton overall. Do not

breath fumes. If in contact, wash

thoroughly with water.

Flammable

The product is flammable.

Keep it away from flames or any heat

source (barbecue, radiator, heating, etc.).

Do not leave the product in the sun.

Corrosive

The product can damage living

tissues or other surfaces.

Avoid contact with skin and clothes. Wear

gloves, safety glasses and appropriate

clothing such as a cotton overall. Do not

breath fumes.

Explosive

The product can explode under

certain circumstances (flame,

heat, impact, friction).

Avoid impacts, friction, sparks and heat.

Hazardous to the

environment

The product affects fauna and

flora. Do not dump it in

dustbins, sinks or in the

environment.

The ideal solution is to bring this product

to your nearest household waste recycling

centre.

Toxic

The product can seriously

affect health if it is inhaled,

ingested or in contact with skin.

Av oid direct contact with the body, even b y

inhalation. If you fee l unwell, seek medical

advice immediately.

Do not throw aw ay

into a garbage can

One of the product's

component is toxic and can be

hazardous to environment.

i.e.:. Used batteries.

This symbol informs the consumer that the

used product shall not be thrown awa y into

a garbage can, but shall be brought back

to the merchant or dropped at a specific

collection point.

Compulsory

gloves

Operation that can be

dangerous for people.

People's saf ety can be seriously aff ected if

the recommendations are not fully

respected.

PRODUCTS DANGER SYMBOLS USED

4

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

People's safety

Operation that can be

dangerous for people.

People's saf ety can be seriously aff ected if

the recommendations are not fully

respected.

Important

Operation that can be

hazardous to the vehicle.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

Good operating

condition of the

vehicle

The operation must be carried

out in strict compliance with the

documents.

Serious damage to the vehicle and in

certain cases a cancellation of the

warranty can be involved if the

recommendations are not fully respected.

Note

Operation that can be difficult.

Indicate a note which gives key

information to make the procedure easier.

Lubricate

Lubricate the parts to be

assembled.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

Grease

Grease the parts to be

assembled.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

Glue

Glue the parts to be

assembled.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

New part

Use a new part.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

GLUE

N

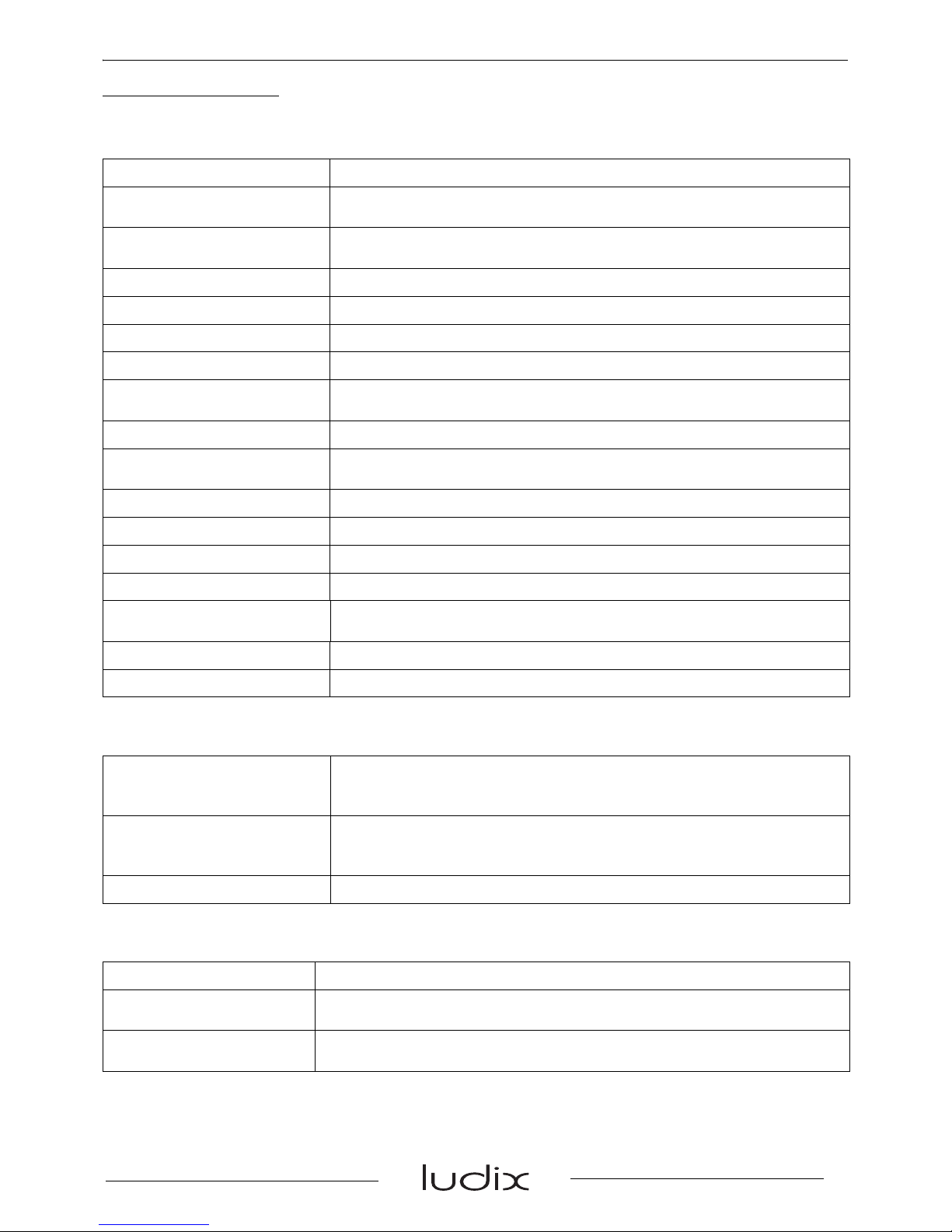

CHARACTERISTICS

5

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

CHARACTERISTICS

Engine

Capacities

Chassis

Engine marking XS1P37QMA-2

Type

4-stroke single-cylinder

2 valves per cylinder with chain driven overhead camshaft

Cooling

By a circulation of forced air by means of a turbine on the flywheel

magneto

Bore x stroke 37 x 46 mm

Cubic capacity 49 cc

Max. power output 3 kW at 8300 rpm

Max. torque rating 3.7 Nm at 6500 rpm

Compression

9.5 bars at 550 rpm

7bars Minimum

Fuel supply Carburettor. KEIHIN NCV

Lubrication

Pressurised wet sump lubrication.

Trochoid pump driven by a chain from the crankshaft

Transmission By 2 variable pulleys and V-type belt

Clutch Centrifugal automatic

Exhaust Catalytic

Starter motor By kick starter or electric starter

Spark plug

NGK CR6HSA

Electrode gap: 0.6 - 0.7 mm

Magneto flywheel 80 W

Standards Euro 2

Relay box

0.1 l SAE 80W90

Minimum grade: API GL4

(0.09 I at oil change)

Crankcase

0.8 l SAE 5W40

Minimum grade: API SL/SJ

(0.65 I at oil change)

Fuel tank 5.3 l

Chassis Tubular chassis

Front suspension

Upside down telescopic front fork

Travel: 73 mm

Rear suspension

Combined spring and hydraulically-damped shock absorber

Travel: 65 mm

CHARACTERISTICS

6

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Dimensions and weight

Tyres

Brakes

Overall length 1750 mm

Width at handlebar 670 mm

Height (without rear-view

mirrors)

1080 mm

Wheelbase 1280 mm

Unladen weight 78 kg

Front wheel rim 14 inch aluminium alloy

Front tyre 80/80 - 14

Front tyre pressure 2.5 bars

Rear wheel rim 14 inch aluminium alloy

Rear tyre 170/70 - 14

Rear tyre pressure 2.8 bars

Front brake

Single disc type, hydraulic control

Fixed calliper with 2 pistons

Disc diameter and

thickness

190 mm - 3 mm

Rear brake Single-cam drum type, controlled by cable

Brake drum diameter 110 mm

Brake lining thickness 4mm

Chassis markings Engine marking

(1) number and manufacturer's plate Engine number (2)

X

X

XXXXXXX

XXXXXXXX

1

XXXXXX

*XXXXXXXXX*

2

SERVICE SCHEDULE AND COMMISSIONING

7

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

SERVICE SCHEDULE AND COMMISSIONING

Heavy duty servicing is for vehicles used under "harsh" conditions: door-to-door deliveries, intensive

urban use (courier), short journeys with engine cold, dusty areas, ambient temperature over 30°C.

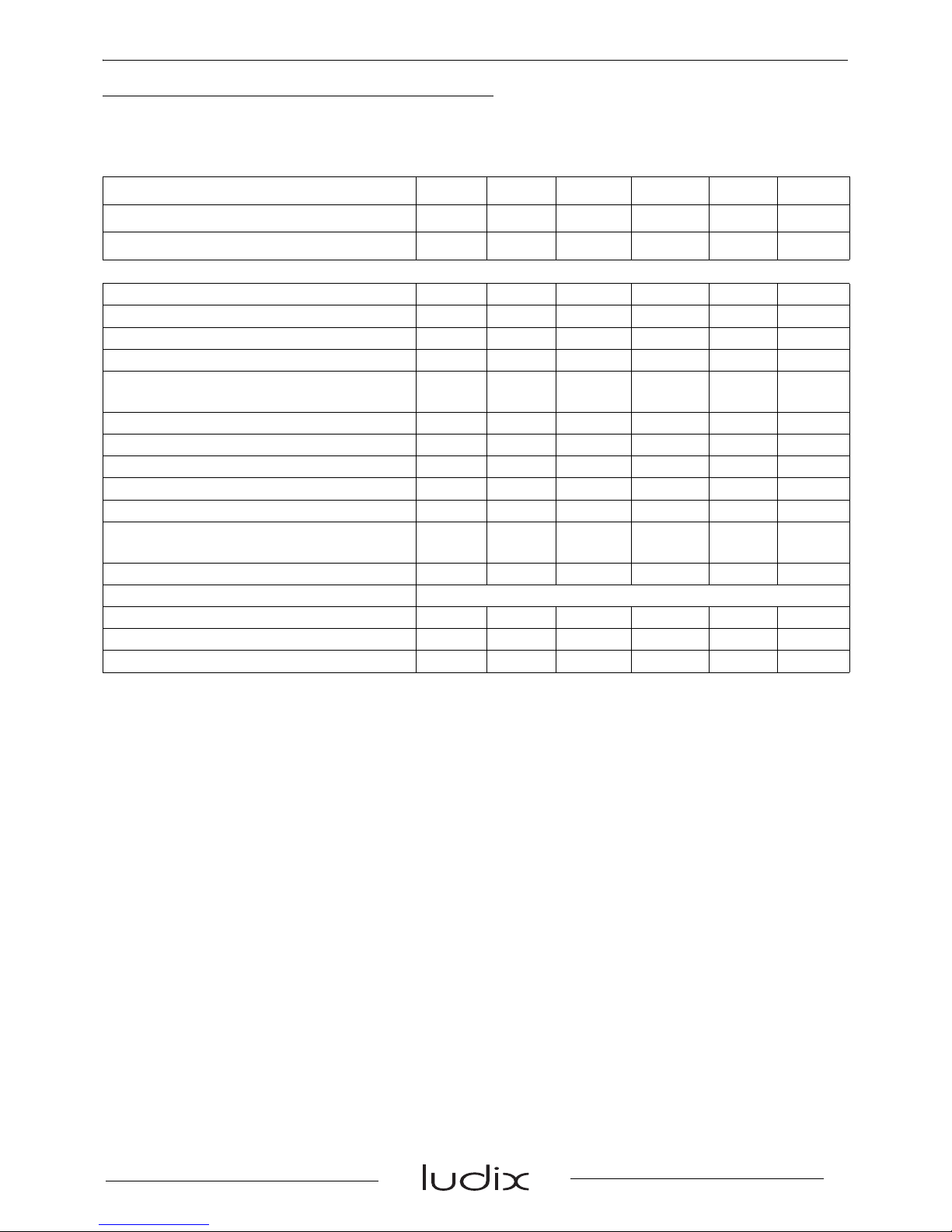

Service operations 500 2000 5000 10000 15000 20000

Heavy duty servicing 500 1000 2500 5000 7500 10000

Minimum servicing

1 months 6 months 12 months 24 months 36 months 48 months

To be checked at each service

Steering column play V V V V V V

Wheel bearing play C C C C C C

Throttle cable play V V V V V V

Operation of electrical equipment V V V V

Condition of the front brake hydraulic

control

VVV V VV

Brake fluid level V V V V V V

Front brake pad wear C C C C C C

Rear brake lining wear C C C C C C

Condition of petrol pipes C C C C C C

Tyre condition, pressure and wear C C C C C C

State of front suspension. State of rear

suspension

VVV V VV

Battery electrolyte level. Battery charge V V V V V V

Engine oil level Every 1000 kms

Headlight height adjustment V V V V V V

Tightness of nuts and bolts V V V V V V

Overall operation. Road test V V V V

V: Check, clean, adjust. N: Clean.

R: Change. C: Inspect and change if necessary.

G: Check, clean, lubricate. * Depending on equipment.

SERVICE SCHEDULE AND COMMISSIONING

8

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

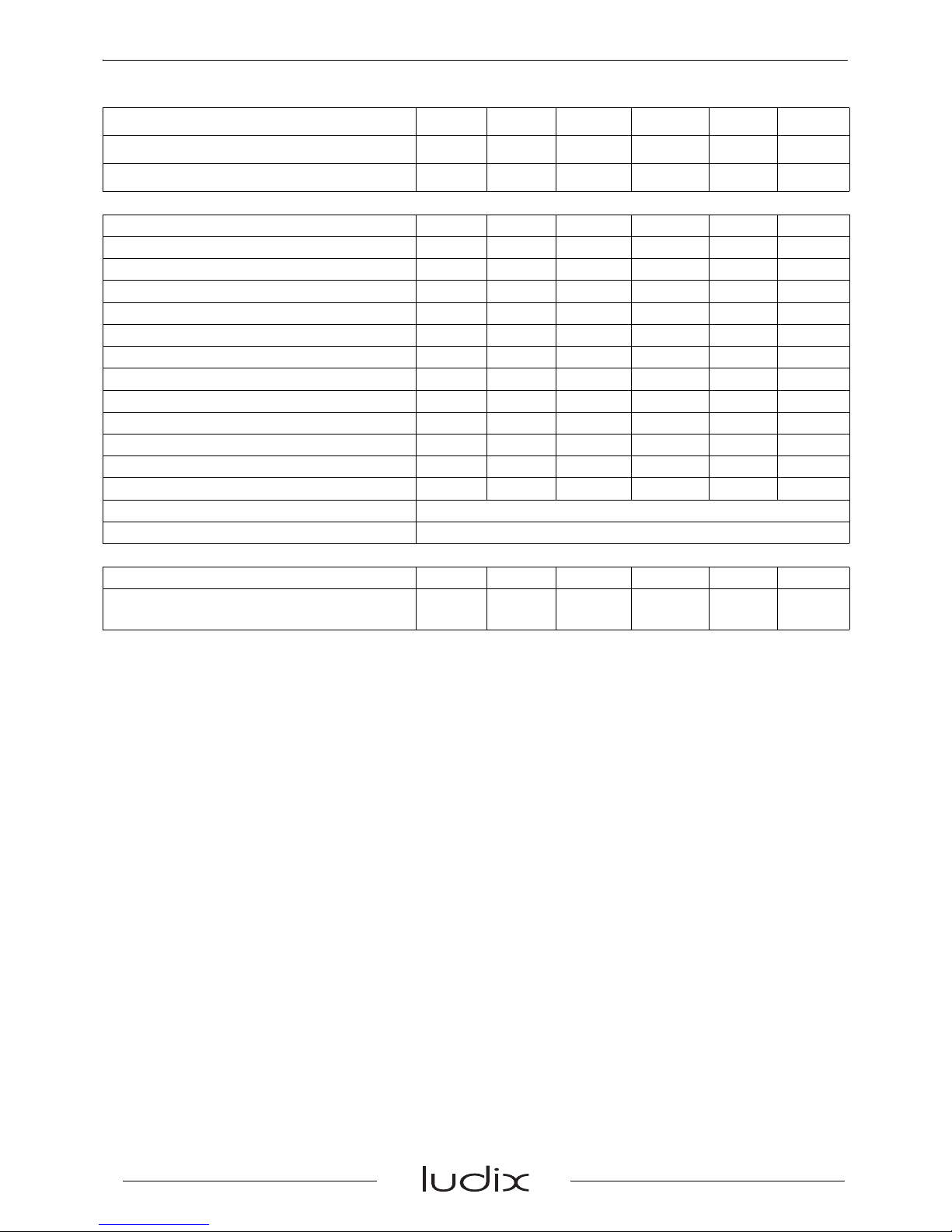

Service operations 500 2000 5000 10000 15000 20000

Heavy duty servicing 500 1000 2500 5000 7500 10000

Minimum servicing

1 months 6 months 12 months 24 months 36 months 48 months

Service operations

Spark plug V R R R R

Air filter R R

Intake silencer drain N N N N

Drive pulley bearings and guides V C V C

Transmission belt R R R R

Driven pulley caged needle bearing G G G G

Kick starter mechanism G G

Valve clearances V V V V V

Setting the carburettor V V

Joints. (Central stand, Brake levers) G G G G

Petrol filter R

Engine oil (+ clean strainer) R R R R R R

Relay box oil R R R R R

Petrol pipe Once every 5 years

Brake fluid Once every 2 years

Time required for maintenance

Code 9100 9150 9300 9400 9500 9600

Servicing time in tenths of an hour

(0.5 h = 30 mn)

1.3 2.2 3.3 4.0 3.3 4.2

V: Check, clean, adjust. N: Clean.

R: Change. C: Inspect and change if necessary.

G: Check, clean, lubricate. * Depending on equipment.

SERVICE SCHEDULE AND COMMISSIONING

9

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Battery preparation (Except battery without maintenance)*

Remove the battery.

Remove the 6 filler caps and the vent plug.

Fill all the battery cells with electrolyte to the upper level shown on the battery " UPPER LEVEL ".

Electrolyte: (35% sulfuric acid = 1.28g/cm3). 0.5 litre can P/N 739733.

Leave the battery to stand for around half an hour.

Top up if necessary.

Charge the battery for at least 2 hours with a current of 0.4 A.

Refit the battery and connect the vapour vent pipe.

Connect the red wire lug to the battery's + terminal, and the green wire lug to the battery's - terminal.

Then, the battery level should be topped up if necessary, after fully charging, using distilled water only.

* Depending on equipment.

New machine preparation

Check the tightness of the carburettor float chamber drain screw.

Check the wheel nuts are tight.

Check nuts and bolts are tight.

Check brake adjustment and efficiency.

Check the tyre pressures cold.

Check operation of the lights, flashers, horn, and brake light.

Check the different warning lights work.

Carry out a road test.

SPECIAL IMPORTANT POINTS

10

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

SPECIAL IMPORTANT POINTS

Fuel

This engine is designed to run on 95 or 98 unleaded fuel only.

Fuel pipes must absolutely be changed if there are any signs of wear, cracks, etc...

The air pipe between the air pump and the exhaust is specific owing to its heat resistance

properties.

Should it be changed, replace it with a genuine pipe.

Petrol is highly inflammable, do not smoke in the working area and avoid pr oximity to flames or

sparks.

Before carrying out any work, leave the engine to cool for at least 2 hours.

TIGHTENING TORQUES

11

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

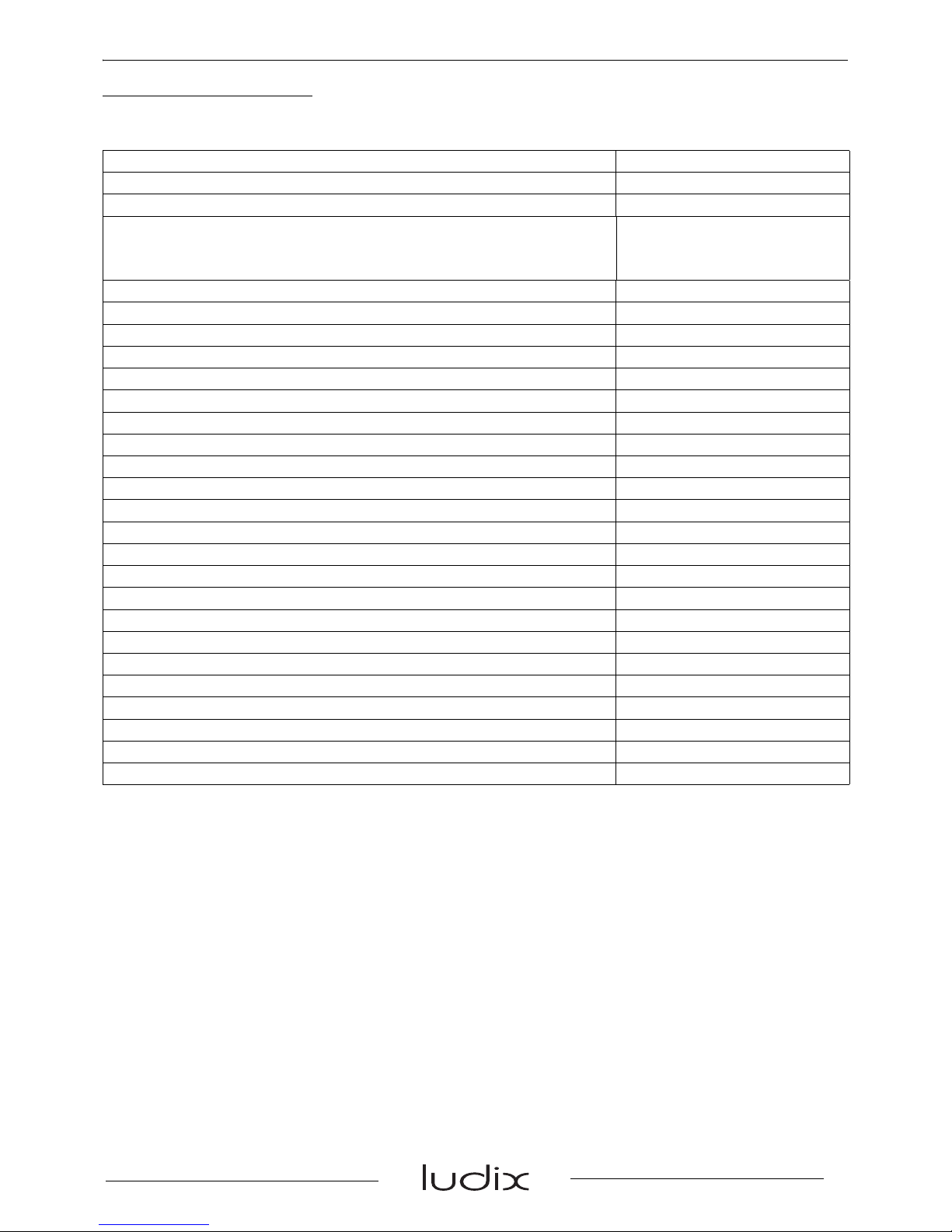

TIGHTENING TORQUES

Engine part

Spark plug 12 Nm

Engine drain plug 20 Nm

Screen 15 Nm

Cylinder head

•Nut

•Screw

20 Nm

12 Nm

Camshaft gear cover 10 Nm

Camshaft gear 20 Nm

Valve clearance covers 15 Nm

Automatic tensioner 10 Nm

Automatic tensioner plug 8 Nm

Chain tensioner 10 Nm

Inlet manifold 10 Nm

Crankcase 12 Nm

RH casing cover 12 Nm

Freewheel 90 Nm

Oil pump 10 Nm

Transmission cover 10 Nm

Relay box cover 22 Nm

Relay box drain plug 10 Nm

Relay box filler cap 10 Nm

Starter motor 10 Nm

Rotor 50 Nm

Turbine 10 Nm

Stator 10 Nm

Engine speed sensor 10 Nm

Drive pulley 55 Nm

Driven pulley 55 Nm

Clutch plate and shoes 55 Nm

TIGHTENING TORQUES

12

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Body panels

Cycle part

Standard

Floor panel 4 Nm

Handlebar cover 1 Nm

Front shield panel 1 Nm

Rear shield 1 Nm

Side panels 1 Nm

Front mudguard 8 Nm

Front wheel spindle 65 Nm

Rear wheel spindle nut 110 Nm

Linkrod to engine pivot 50 Nm

Linkrod to frame pivot 50 Nm

Shock absorber top mount 45 Nm

Shock absorber bottom mount 22 Nm

Exhaust to cylinder head mounting nut 15 Nm

Exhaust to casing mounting bolt 20 Nm

Upper cone (in 2 operations) 40/23 Nm

Upper cone locknut Hand tightened

Steering locknut 70 Nm

Front brake caliper 30 Nm

Front brake disc 22 Nm

Handle bar 40 Nm

Fuel tank 22 Nm

Luggage carrier 25 Nm

Nut and bolt 5 mm diameter 6 Nm

Nut and bolt 6 mm diameter 10 Nm

Nut and bolt 8 mm diameter 22 Nm

Nut and bolt 10 mm diameter 35 Nm

SPECIAL TOOLS

13

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

SPECIAL TOOLS

Tool N° Designation Used with Tool N° Designation Used with

752127

Clutch

compression

tool

756607

Steeing head

cup push tool

752237

Adjustable pin

wrench

757860

Steering tool

752361

39 mm pipe

wrench

759788

Steeing head

cup push tool

755996 766062

Spark plug

spanner

STANDARD TOOLS

14

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

STANDARD TOOLS

Wrenches with

interchangeable end fittings f or

valve clearance adjustment.

Type: Marolotest P/N 500140

Set of shims

Slide calipers Multimeter

Automatic resetting type

torque wrench

5 to 25 Nm

Type:

Facom R.306A25

Automatic resetting type

torque wrench

40 to 200 Nm

Type:

Facom S.208A200

Automatic resetting type

torque wrench

10 to 50 Nm

Type:

Facom J.208A50

Inertia extraction tool and

sockets with internal grip

OFF

OFF

V

DC

DC

V

AC

AC

Ω

20 m

20 m

200 m

200 m

DC

DC

10A

10A

V

Ω

COM

COM

mA

mA

Ω

LOCATION OF COMPONENTS

15

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

LOCATION OF COMPONENTS

1. CDI unit

2. Battery

3. Magneto flywheel

4. Fuse

5. HT coil

6. Regulator

7. Starter motor relay

8. Switch "Reserve"

9. Horn

10.Starter resistor

11.Resistor warming carburator

12.Temperature control unit

-

U

P

P

E

R

L

E

V

E

L

L

O

W

E

R

L

E

V

E

L

5

11

1

2

9

8

6

7

3

4

12

10

Loading...

Loading...