Page 1

Disassembly and

This document has been printed from SPI². Not for Resale

Assembly

KENR6226-01

April 2008

402D-403

GG (Engine)

ngine)

GH

(E

(Engine)

GJ

(Engine)

GK

ngine)

GL (E

GM

(Engine)

(Engine)

GN

Engine)

(

GP

GQ

(Engine)

GS

(Engine)

D-404D Industrial Engine

SAFETY.CAT.COM

Page 2

Important Safety Information

This document has been printed from SPI². Not for Resale

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

Page 3

KENR6226-01 3

This document has been printed from SPI². Not for Resale

Table of Contents

Table of Contents

Disassembly and Assembly Section

Fuel Filter Base - Remove and Install (403D-11,

403D-15, 403D-15T, 403D-17, 404D-15, 404D-22,

404D-22T and 404D-22TA Engines) ..................... 4

Fuel Filter Base - Remove and Install (402D-05 and

403D-07 Engines) ................................................. 5

Fuel Transfer Pump - Remove and Install (Mechanical

Fuel Transfer Pump) ............................................. 7

Fuel Transfer Pump - Remove and Install (Electrical

Fuel Transfer Pump) ............................................. 8

Fuel Injection Lines - Remove and Install .............. 9

Fuel Shutoff Solenoid - Remove and Install ........ 12

Fuel Injection Pump - Remove and Install ........... 13

Fuel Injector - Remove and Install ....................... 15

Turbocharger - Remove and Install ..................... 16

Exhaust Manifold - Remove and Install ............... 18

Inlet and Exhaust Valve Springs - Remove and

Install ........................................... ........................ 19

Inlet and Exhaust Valves - Remove and Install .... 22

Engine Oil Line - Remove and Install ................... 24

Engine Oil Cooler - Remove and Install ............... 26

Engine Oil Relief Valve - Remove and Install ....... 27

Engine Oil Pump - Remove .................................. 28

Engine Oil Pump - Install ...................................... 30

Water Pump - Remove and Install (403D-11,

403D-15, 403D-15T, 403D-17, 404D-15, 404D-22,

404D-22T and 404D-22TA Engines) ................... 32

Water Pump - Remove and Install (402D-05 and

403D-07 Engines) ............................................... 33

Water Temperature Regulator Housing - Remove and

Install .................................................................. 35

Water Temperature Regulator - Remove and Install

(402D-05 and 404D-07 Engines) ........................ 36

Water Temperature Regulator - Remove and Install

(403D-11, 403D-15, 403D-15T, 403D-17, 404D-15,

404D-22, 404D-22T and 404D-22TA Engines) ... 38

Flywheel - Remove ............................................... 39

Flywheel - Install ................................................... 40

Crankshaft Rear Seal - Remove and Install ......... 41

Crankshaft Wear Sleeve (Rear) - Remove and

Install ........................................... ........................ 43

Flywheel Housing - Remove and Install .............. 44

Flywheel Housing - Remove and Install (Engines with

Flywheel Housing and Back Plate) ..................... 45

Crankshaft Pulley - Remove and Install ............... 47

Crankshaft Front Seal - Remove and Install ......... 48

Housing (Front) - Remove .................................... 49

Housing (Front) - Disassemble ............................. 50

Housing (Front) - Assemble .................................. 52

Housing (Front) - Install ........................................ 55

Crankcase Breather - Remove and Install

(Turbocharged Engines) ..................................... 56

Crankcase Breather - Remove and Install (Naturally

Aspirated Engines) .............................................. 58

Valve Mechanism Cover - Remove and Install ..... 60

Rocker Shaft and Pushrod - Remove ................... 62

Rocker Shaft - Disassemble (403D-15, 403D-15T,

403D-17, 404D-

Engines) .............................................................. 62

Rocker Shaft - Disassemble (402D-05, 403D-07,

403D-11 and 40

Rocker Shaft - Assemble (403D-15,

403D-15T,403D-17, 404D-22, 404D-22T and

404D-22TA Eng

Rocker Shaft - Assemble (402D-05, 403D-07,

403D-11 and 404D-15 Engines) ......................... 65

Rocker Shaft a

Cylinder Head - Remove ...................................... 67

Cylinder Head - Install .......................................... 69

Lifter Group - R

Camshaft - Remove .............................................. 72

Camshaft - Disassemble ....................................... 73

Camshaft - Asse

Camshaft - Install .................................................. 74

Engine Oil Pan - Remove and Install ................... 76

Pistons and Conn

Pistons and Connecting Rods - Disassemble ....... 78

Pistons and Connecting Rods - Assemble ........... 80

Pistons and Conn

Connecting Rod Bearings - Remove (Connecting

rods in position) ................................................... 83

Connecting Rod B

in position) ........................................................... 83

Connecting Rod Bearings - Install ........................ 84

Crankshaft Main

Crankshaft Main Bearings - Install ........................ 86

Crankshaft - Remove ............................................ 88

Crankshaft - Inst

Bearing Clearance - Check ................................... 90

Coolant Temperature Switch - Remove and Install

(403D-11, 403D-1

404D-22, 404D-22T and 404D-22TA Engines) ... 91

Coolant Temperature Switch - Remove and Install

(402D-05 and 403

Engine Oil Pressure Switch - Remove and Install

............................................................................. 93

Glow Plugs - Remov

V-Belts - Remove and Install ................................ 96

Fan - Remove and Install ..................................... 96

Alternator-Remo

Alternators) ......................................................... 97

Alternator - Remove and Install (55 Amp

Alternator) ........................................................... 99

Alternator - Remove and Install (40 Amp

Alternator) ........................................................... 99

Alternator-Remo

Alternators) ....................................................... 101

Electric Starting Motor - Remove and Install ..... 102

22, 404D-22T and 404D-22TA

4D-15 Engines) ......................... 63

ines) ........................................... 64

nd Pushrod - Install ....................... 66

emove and Install ......................... 71

mble ........................................... 74

ecting Rods - Remove .............. 77

ecting Rods - Install .................. 81

earings - Install (Connecting rods

Bearings - Remove .................... 85

all ................................................ 89

5, 403D-15T, 403D-17, 404D-15,

D-07 Engines) ........................ 92

e and Install ......................... 95

veandInstall(65Ampand85Amp

veandInstall(14Ampand15Amp

Index Section

Index ............................... .................................... 103

Page 4

4 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Disassembly an

d Assembly

Section

i02959949

Fuel Filter Base - Remove and

Install

(403D-11, 40

403D-17, 404D-15, 404D-22,

404D-22T and 404D-22TA

Engines)

Removal Procedure

Do not allow dirt to enter the fuel system. Thoroughly

clean the are

will be disconnected. Fit a suitable cover over disconnected fuel system component.

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

a around a fuel system component that

3D-15, 403D-15T,

NOTICE

NOTICE

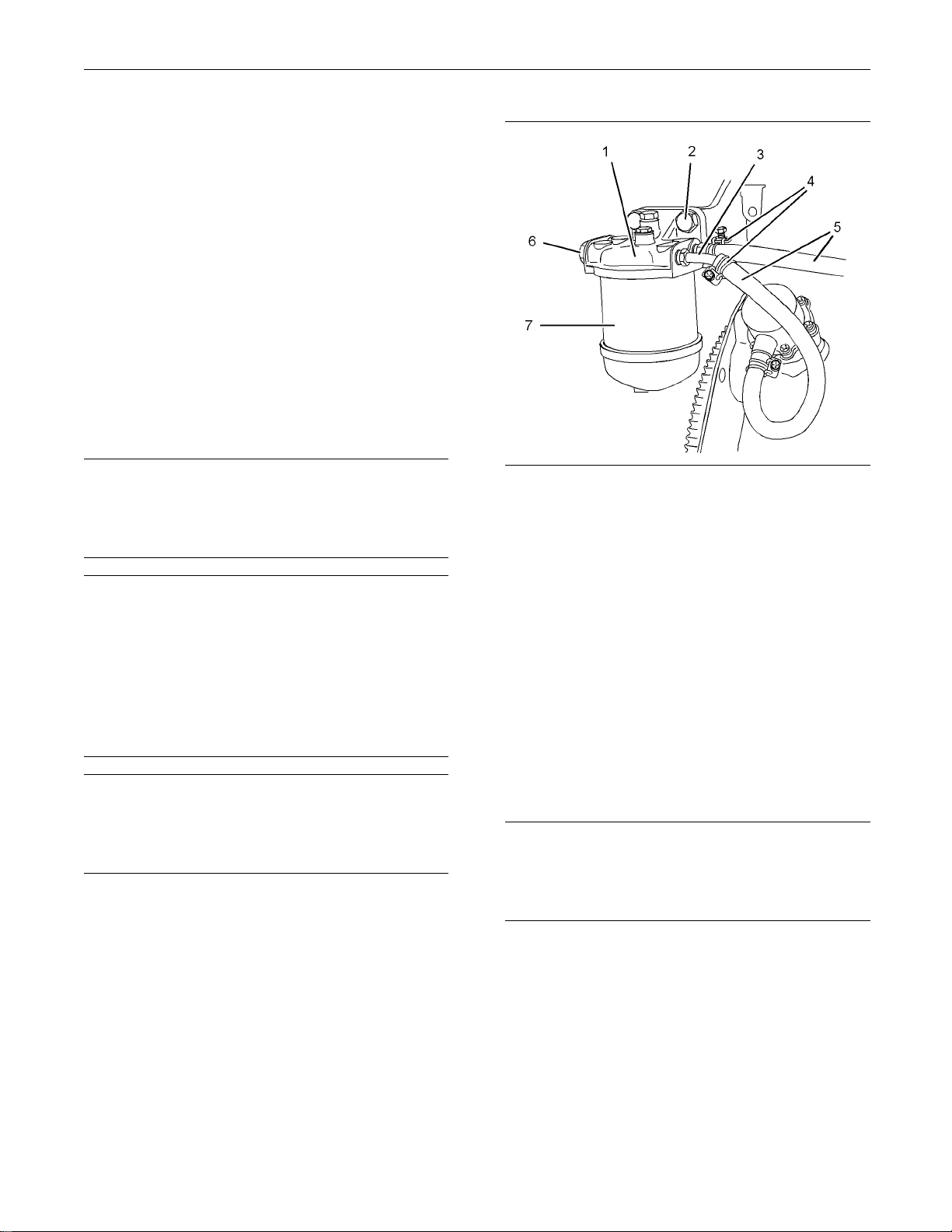

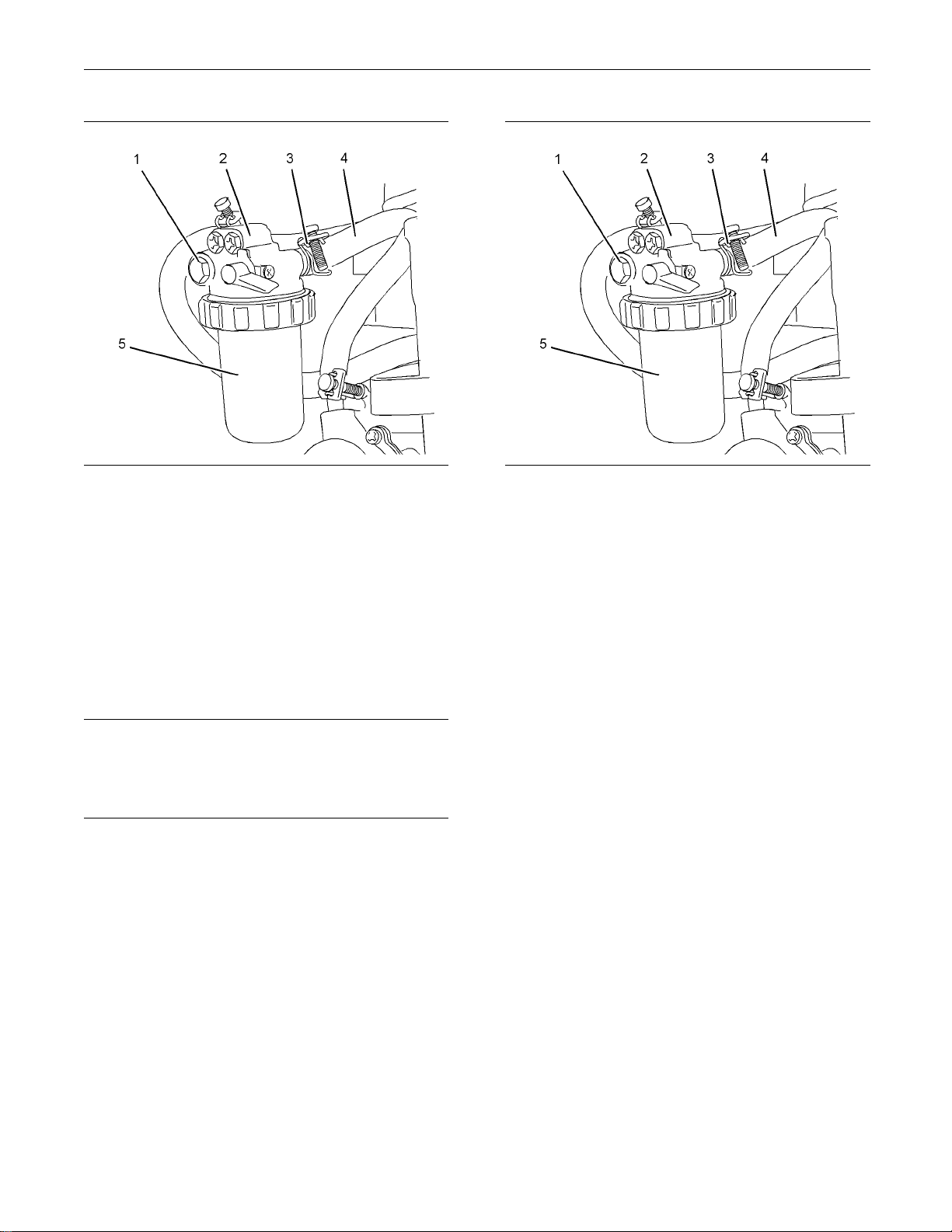

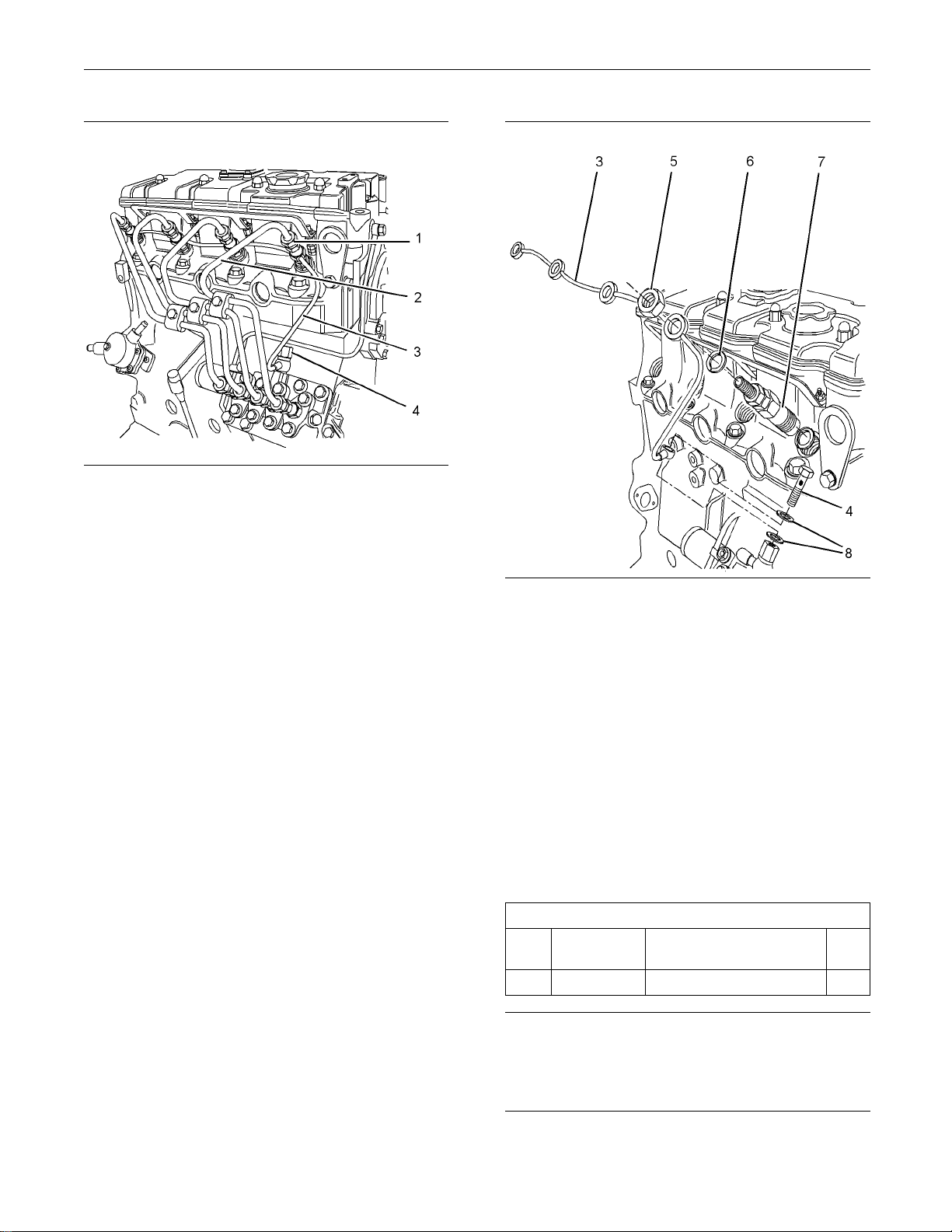

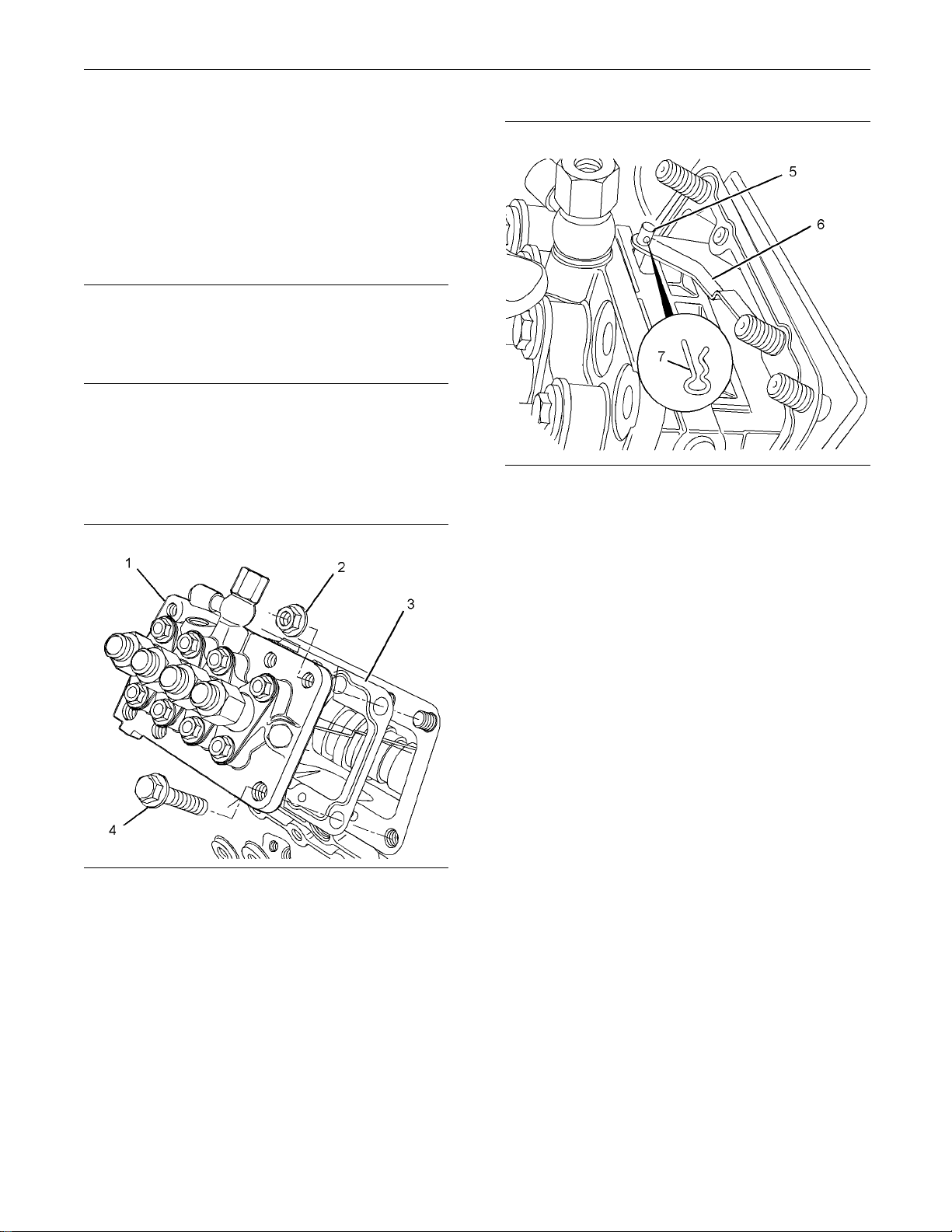

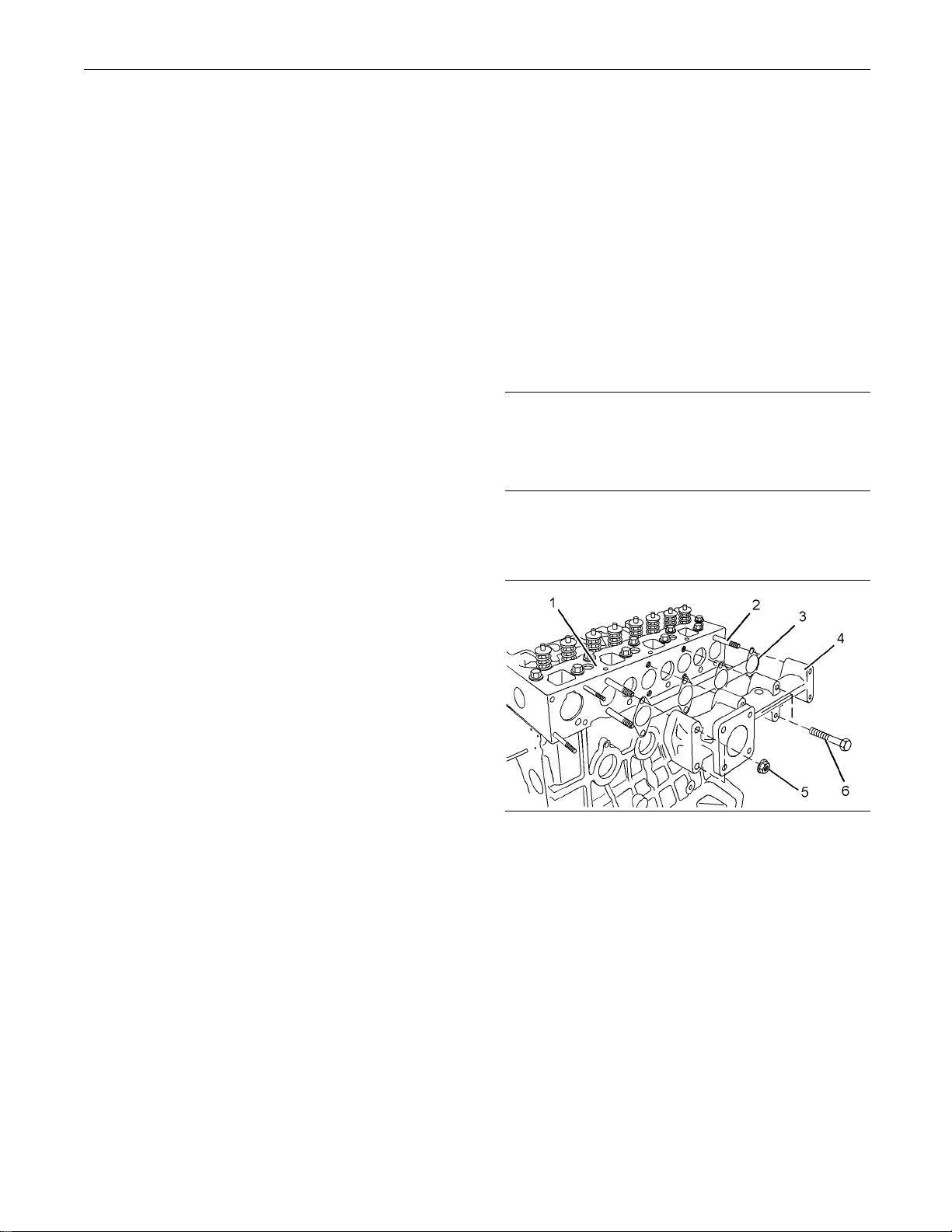

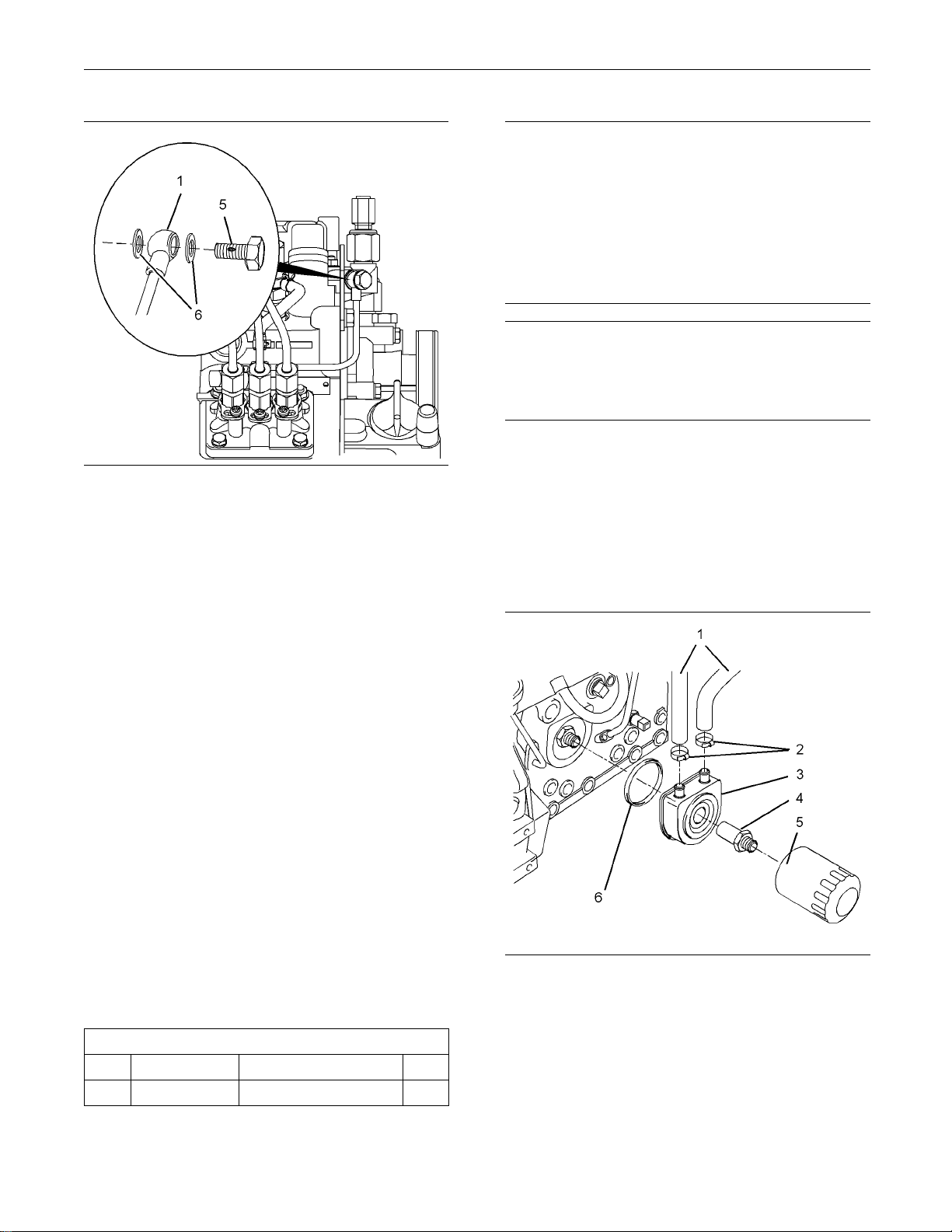

Illustration 1

Typical example

2. Loosen hose clamps (4) and disconnect hoses (5).

3. If necessary, remove fuel filter element (7)

from fuel filter base (1). Refer to Operation

and Maintenance Manual, “Fuel System Filter Replace”.

4. Remove fasteners (2) and remove fuel filter base

(1) from the mounting bracket.

5. If necessary, remove plugs (6) and washers (not

shown) from fuel filter base (1). Remove tube

assemblies (3) and rubber olives (not shown) from

fuel filter base (1).

g01302737

NOTICE

Keep all parts clean from contaminants.

Contaminan

component life.

Note: Place identification marks on all hoses for

installation purposes. Plug all hoses and all the ports

in the fuel filter base. This helps prevent fluid loss,

and this helps to keep contaminants from entering

the system.

1. Turn the fuel supply to the OFF position.

ts may cause rapid wear and shortened

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: If the engine is equipped with a hand priming

pump, the hand priming pump is mounted on the fuel

filter base. The assembly of the fuel filter base and

the hand priming pump is not serviceable.

1. Ensure that the fuel filter base is clean and free

from damage. If necessary, replace the fuel filter

base.

Page 5

KENR6226-01 5

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

i02645711

Fuel Filter B ase - Remove and

Install

3D-07 Engines)

NOTICE

NOTICE

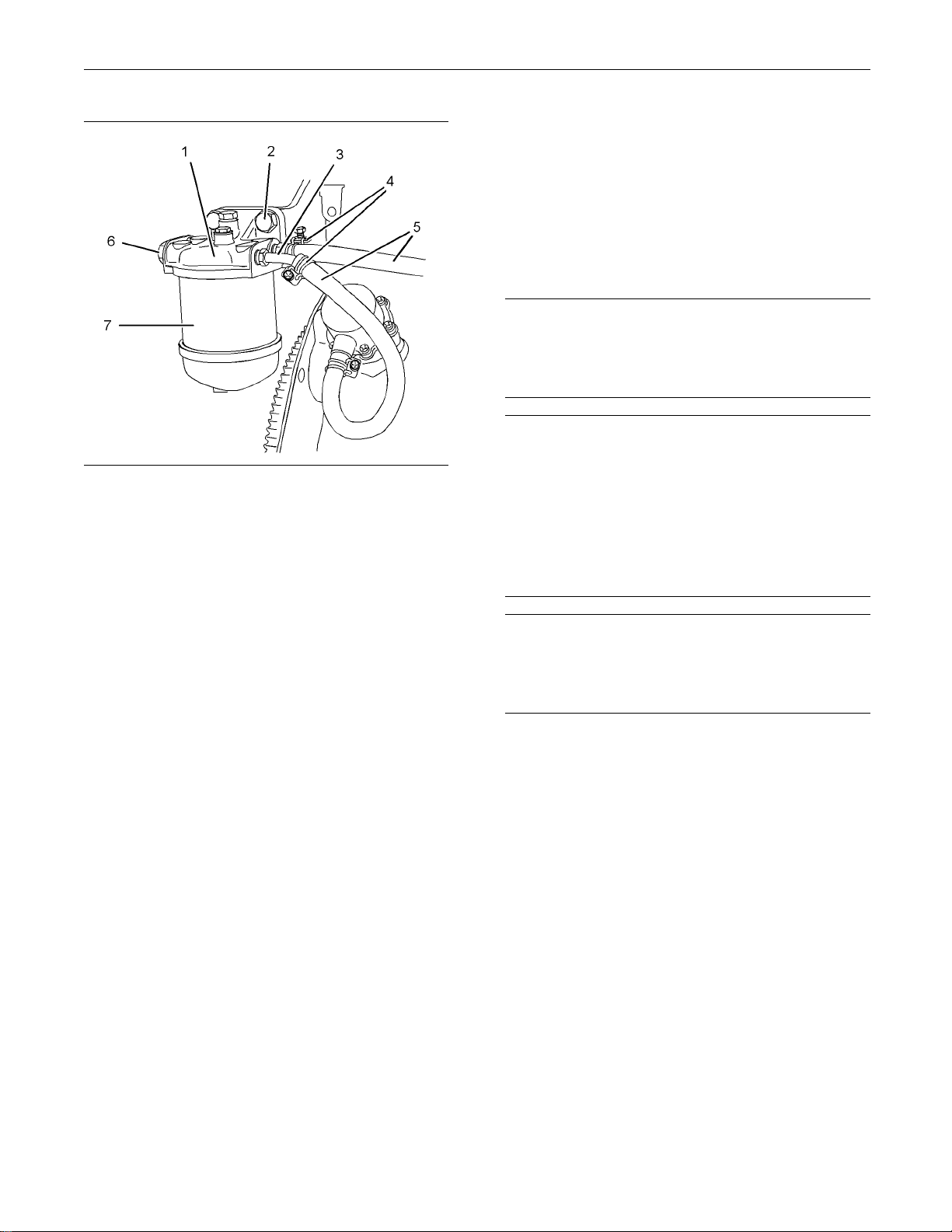

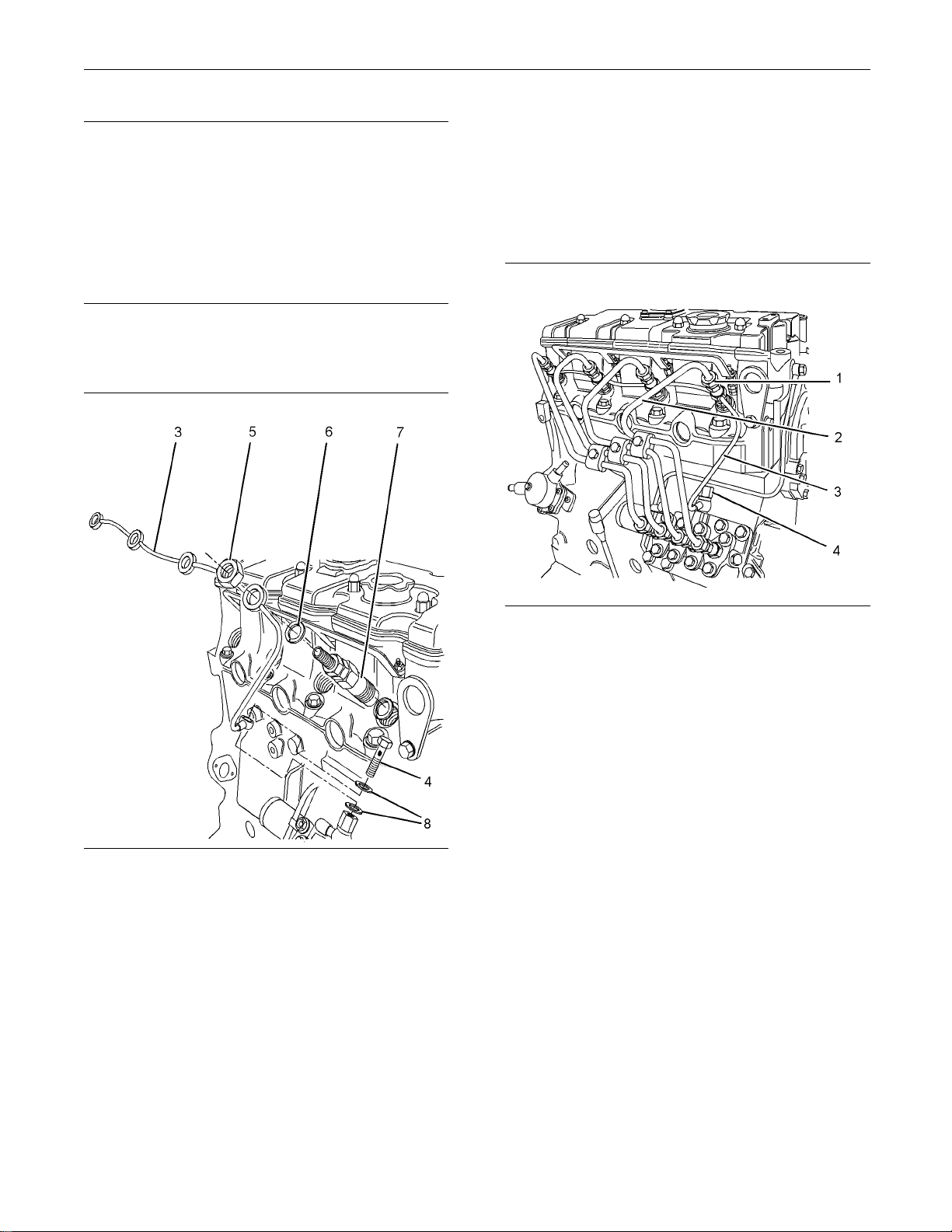

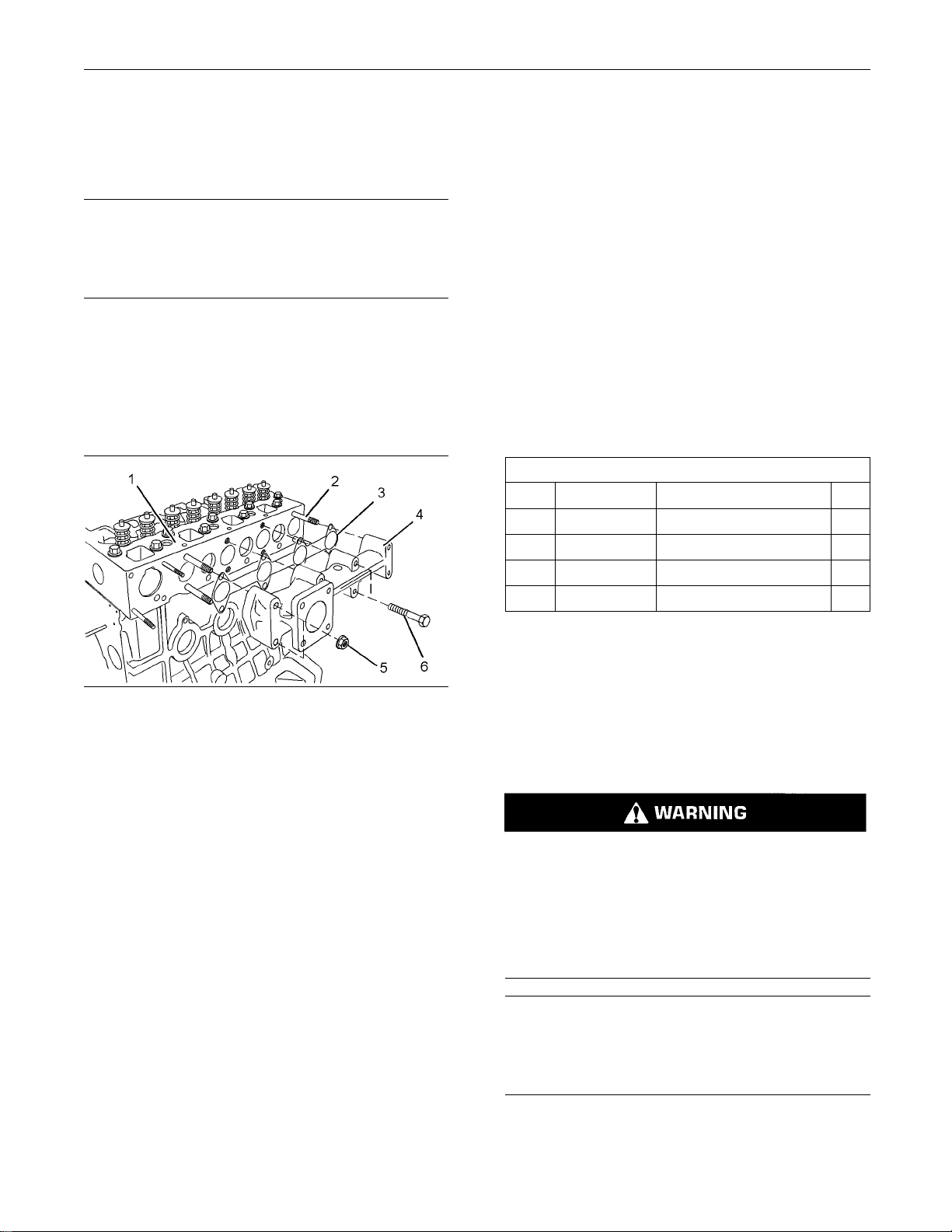

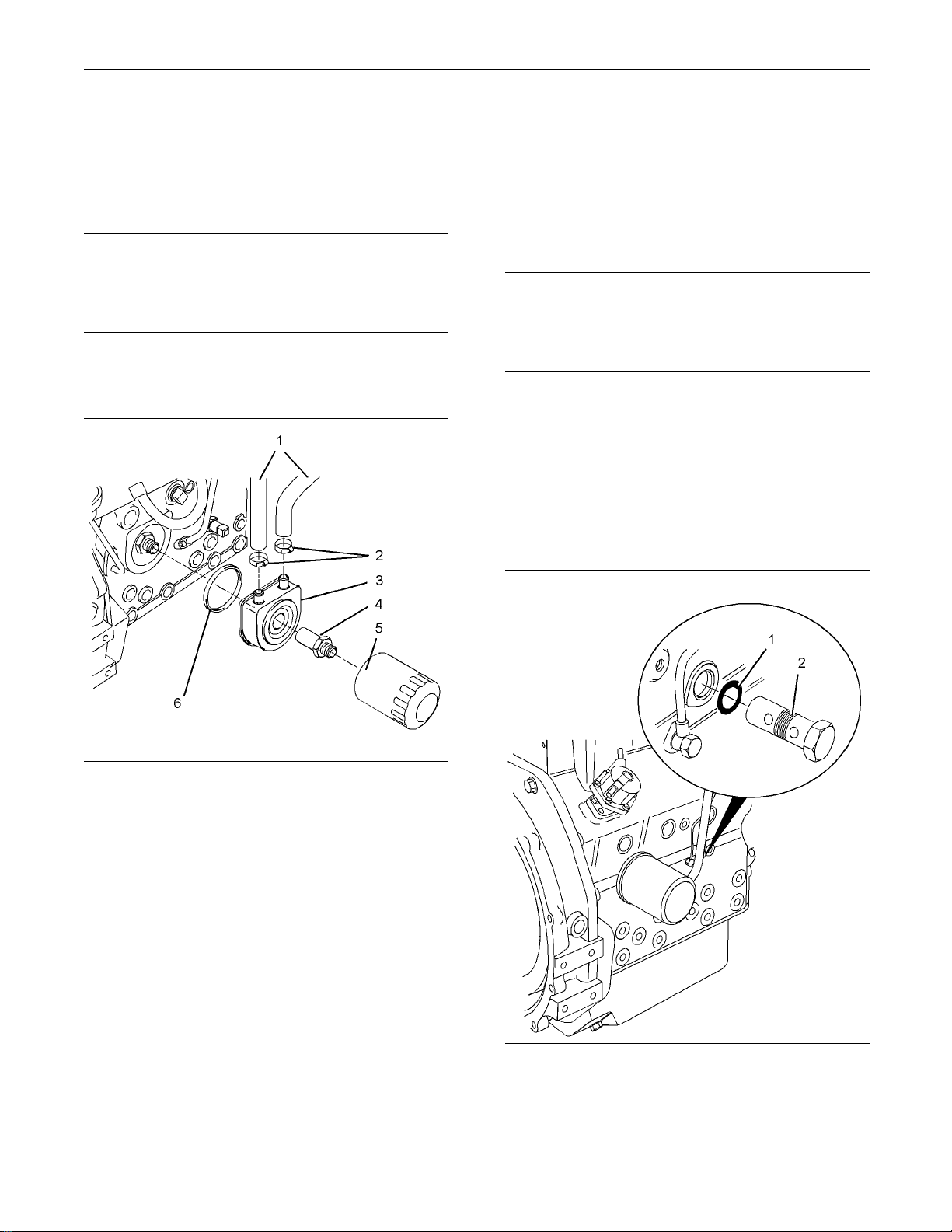

Illustration 2

Typical example

2. If necessary, install new rubber olives (not shown)

onto tube assemblies (3). Install tube assemblies

(3) to fuel filter base (1). Ensure the correct

orientation of the tube assemblies. Tighten the

nuts to a torque of 9 N·m (80 lb in).

g01302737

(402D-05 and 4 0

Removal Procedure

Do not allow dirt to enter the fuel system. Thoroughly

clean the area a

will be disconnected. Fit a suitable cover over disconnected fuel system component.

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

round a fuel system component that

3. Install washers (not shown) onto plugs (6). Install

plugs (6) to fuel filter base (1). Tighten the plugs

to a torque of 23 N·m (17 lb ft).

4. Align fuel filter base (1) with the mounting bracket.

Install fasteners (2). Tighten the fasteners to a

torque of 50 N·m (37 lb ft).

5. If necessary, install a new fuel filter element

(7) to fuel filter base (1). Refer to Operation

and Maintenance Manual, “Fuel System Filter Replace”.

6. Connect hoses (5) and tighten hose clamps (4).

Note: Ensure that the hoses do not contact any other

engine components.

7. Turn the fuel supply to the ON position.

8. Remove the air from the fuel system. Refer to

Operation and Maintenance Manual, “Fuel System

- Prime”.

NOTICE

Keep all parts clean from contaminants.

Contaminants

component life.

Note: Place identification marks on all hoses for

installation purposes. Plug all hoses and all the ports

in the fuel filter base. This helps prevent fluid loss,

and this helps to keep contaminants from entering

the system.

1. Turn the fuel supply to the OFF position.

may cause rapid wear and shortened

Page 6

6 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

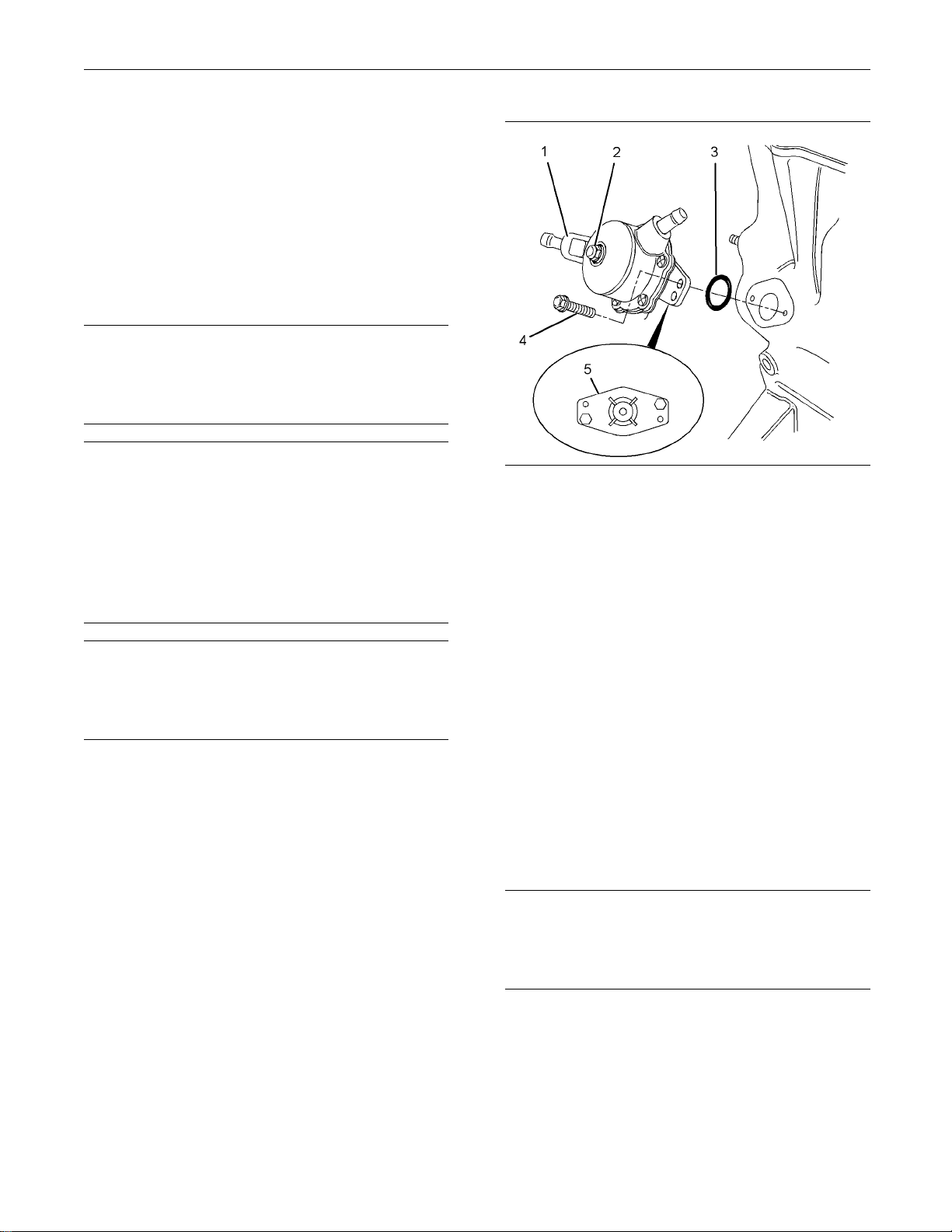

Illustration 3

Typical example

g01303701

2. Loosen hose clamps (3) and disconnect hoses (4).

3. If necessary, remove fuel filter element (5). Refer

to Operations and Maintenance Manual, “Fuel

System Filter - Replace”.

4. Remove bolt (1) and remove fuel filter base (2)

from the mounting bracket.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Ensure that the fuel filter base is clean and free

from damage. If necessary, replace the fuel filter

base.

Illustration 4

Typical example

g01303701

2. Align fuel filter base (2) with the mounting bracket.

Install bolt (1). Tighten the bolt to a torque of

25 N·m (18 lb ft).

3. If necessary, install a new fuel filter element

(6) to fuel filter base (2). Refer to Operation

and Maintenance Manual, “Fuel System Filter Replace”.

4. Connect hoses (4) and tighten hose clamps (3).

Note: Ensure that the hoses do not contact any other

engine components.

5. Turn the fuel supply to the ON position.

6. Remove the air from the fuel system. Refer to

Operation and Maintenance Manual, “Fuel System

- Prime”.

Page 7

KENR6226-01 7

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

i02645722

Fuel Transfer Pump - Remove

and Install

(Mechanical Fu

el Transfer

Pump)

Removal Proce

Do not allow di

clean the area around a fuel system component that

will be disconnected. Fit a suitable cover over disconnected fuel sy

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: Place identification marks on all hoses for

installation purposes. Plug all hoses and all the

ports in the fuel transfer pump. This helps prevent

fluid loss, and this helps to keep contaminants from

entering the system.

rt to enter the fuel system. Thoroughly

stem component.

dure

NOTICE

NOTICE

NOTICE

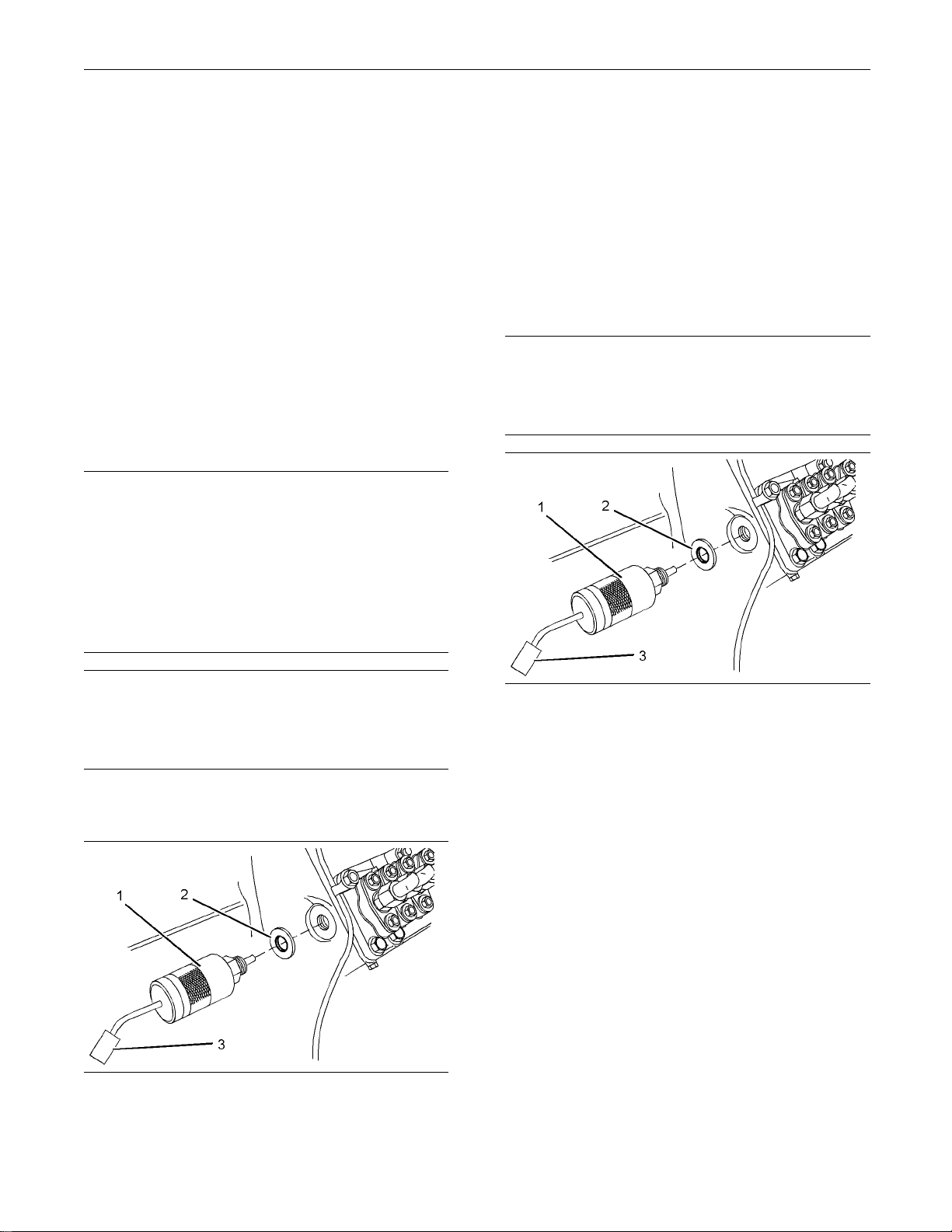

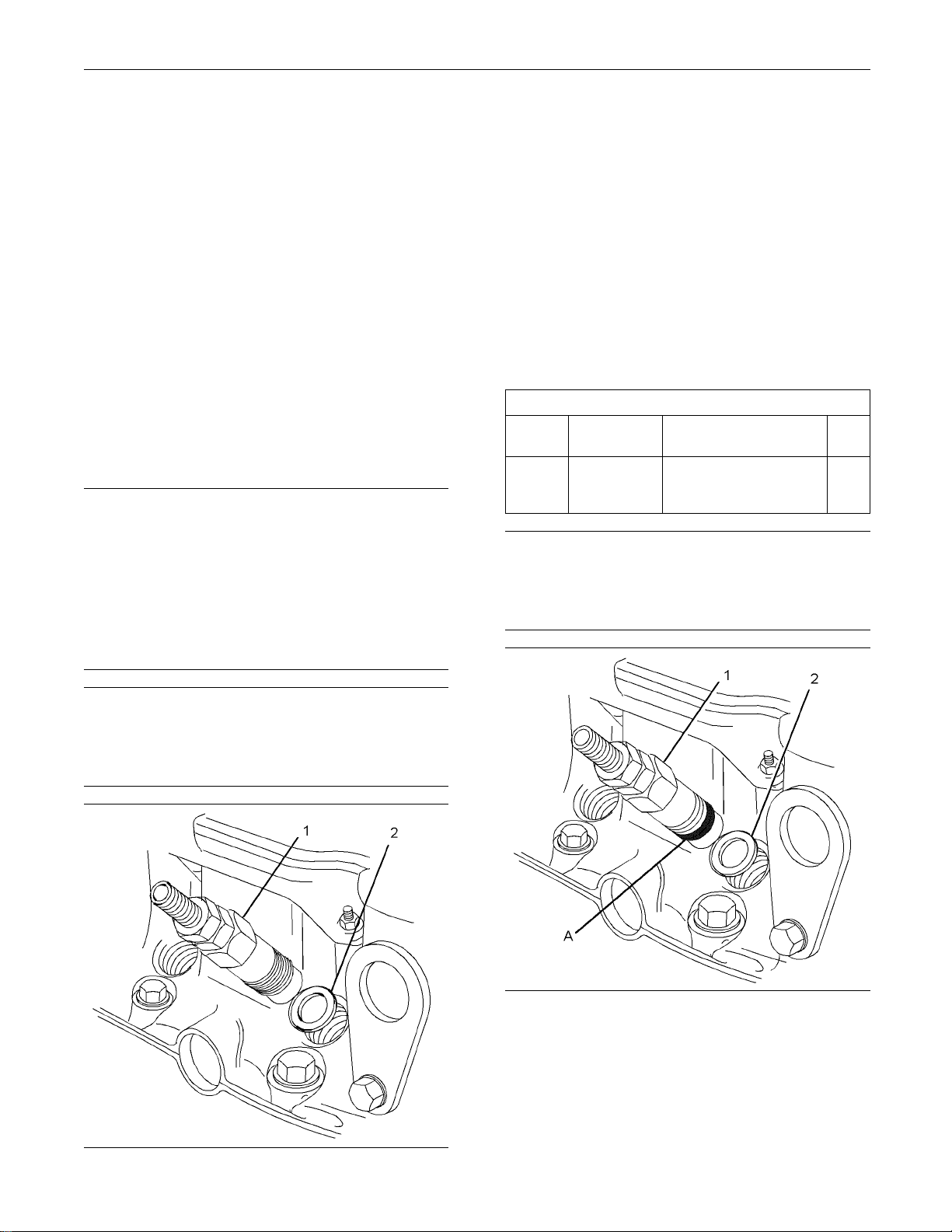

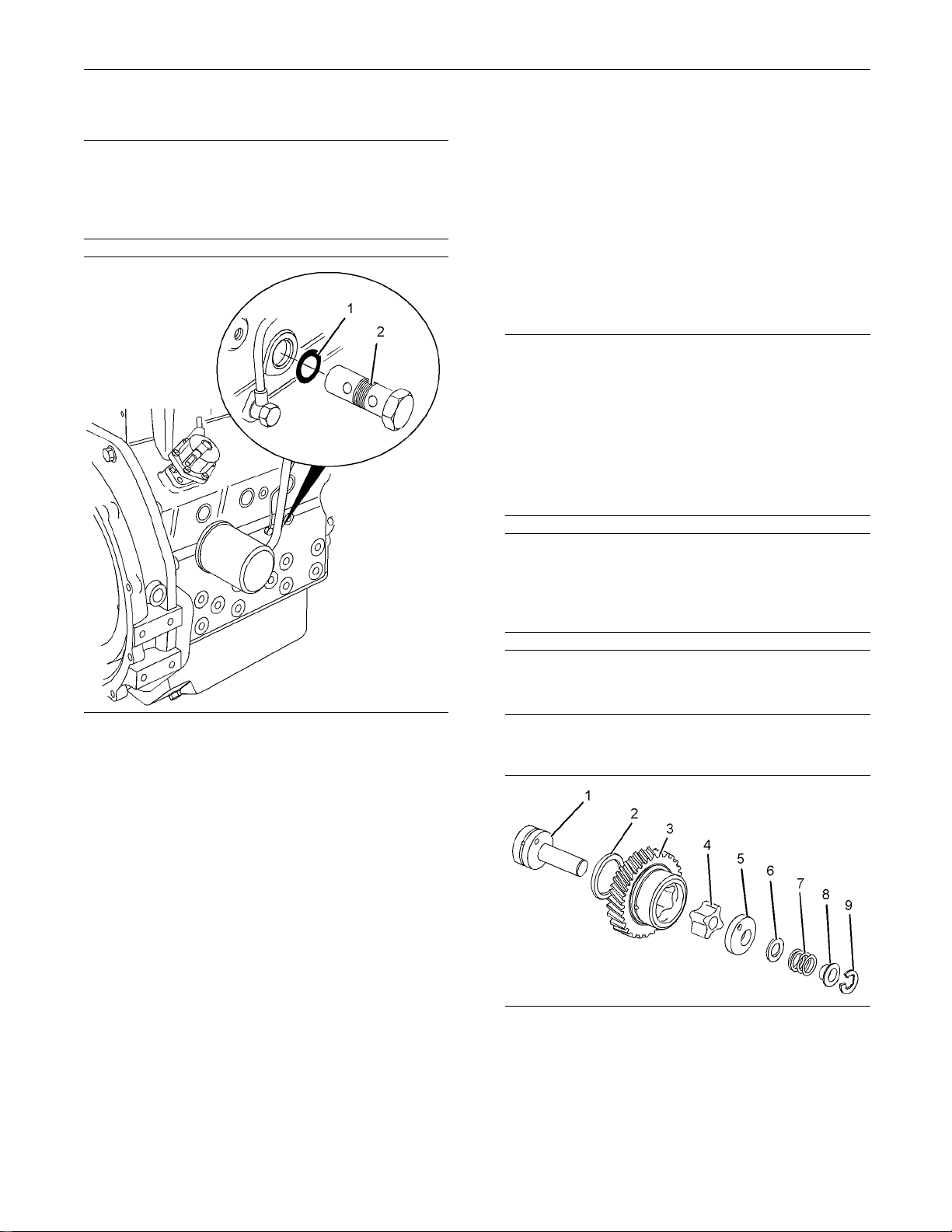

Illustration 5

Typical example

Note: The fuel transfer pump can be oriented in two

positions. Before removing the fuel transfer pump

from the cylinder block, note the orientation of flange

(5) on fuel transfer pump (1) for assembly.

2. Loosen the hose clamps and disconnect the

hoses (not shown) from fuel transfer pump (1).

3. Evenly loosen bolts (4) and remove fuel transfer

pump (1) from the cylinder block.

Note: In order to remove the fuel transfer pump, it

may be necessary to rotate the crankshaft until the

operating plunger of the fuel transfer pump is not

under pressure.

4. Remove O-ring seal (3) from fuel transfer pump

(1).

g01326306

1. Turn the fuel supply to the OFF position.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Page 8

8 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

i02645719

Fuel Transfer Pump - Remove

and Install

(Electrical Fu

Removal Procedure

Care must be taken to ensure that fluids are contained

during perform

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compar

nent containing fluids.

ance of inspection, maintenance, test-

el Transfer Pump)

NOTICE

tment or disassembling any compo-

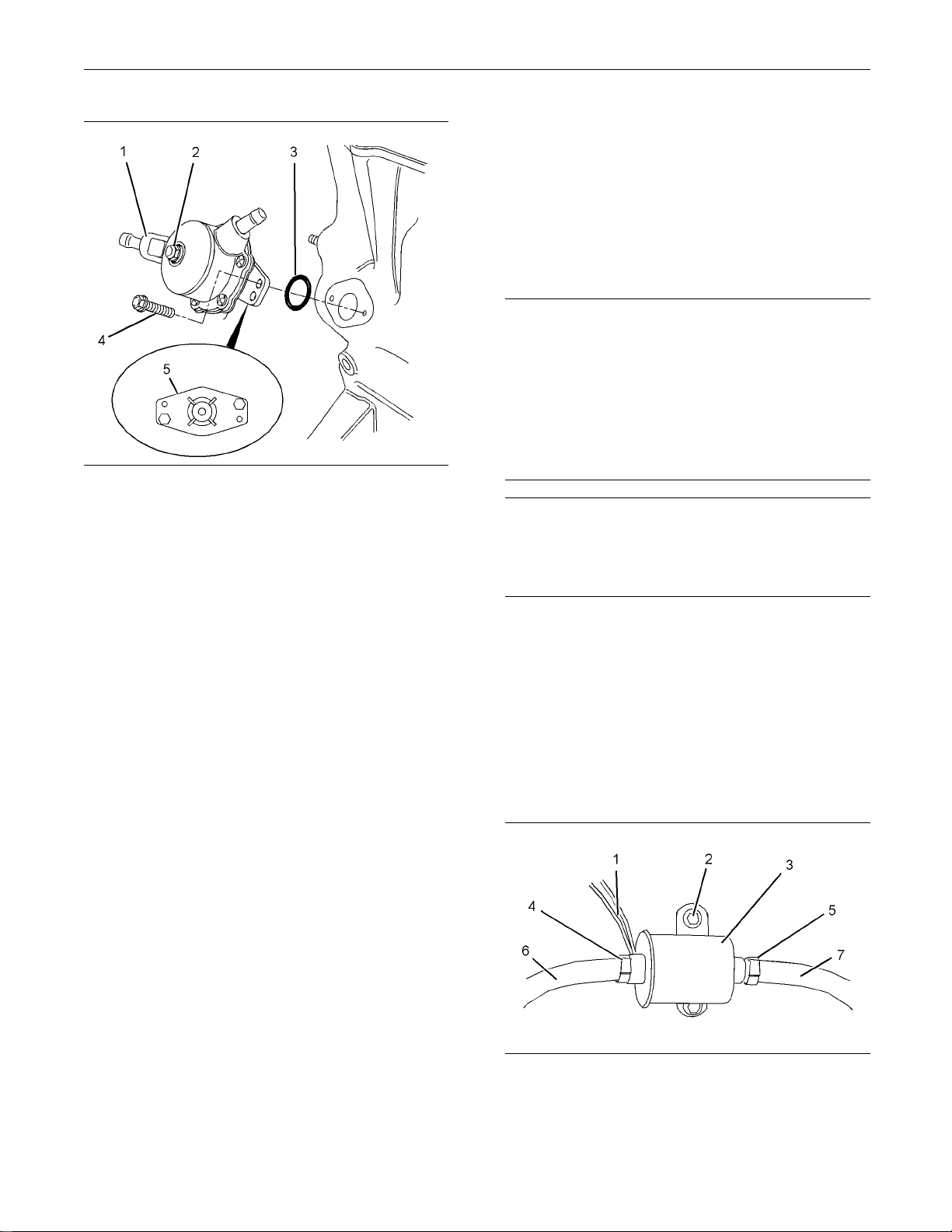

Illustration 6

Typical example

1. Clean the mating surfaces of the cylinder block

and flange (5) on the fuel transfer pump.

Note: Ensure that the camshaft lobe for the fuel

transfer pump is at minimum lift before the fuel

transfer pump is installed. The fuel transfer pump

canbeorientedintwopositions.Ensurethatthefuel

transfer pump is oriented in the correct position.

2. Install a new O-ring seal (3) to fuel transfer pump

(1).

3. Lubricate the operating plunger of fuel transfer

pump (1) with clean engine oil.

4. Position fuel transfer pump (1) on the cylinder

block. Ensure that the operating plunger is

positioned correctly on the camshaft lobe. Install

bolts (4). Tighten the bolts to a torque of 6 N·m

(53lbin).

5. Connect the hoses (not shown) to fuel transfer

pump (1). Tighten the hose clamps.

g01326306

Dispose of all

mandates.

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: Put identification marks on all hoses, on all

hose assembl

for installation purposes. Plug all hose assemblies

and tube assemblies. This helps to prevent fluid loss

and this help

the system.

1. Turn the fue

2. Turn the battery disconnect switch to the OFF

position.

fluids according to local regulations and

NOTICE

ies, on wires and on all tube assemblies

s to keep contaminants from entering

l supply to the OFF position.

Note: The inlet for the fuel transfer pump can be

rotated 360 degrees by loosening bolt (2). The

fuel inlet is adjustable in 15 degree increments. If

adjustment is made to the position of the fuel inlet,

tighten bolt (2) to a torque of 2.5 N·m (22 lb in).

6. Turn the fuel supply to the ON position.

7. Prime the fuel system. Refer to Systems

Operation, Testing and Adjusting, “Fuel System Prime” for additional information.

Illustration 7

Typical ex

3. Disconnect harness assembly (1).

ample

g01304057

Page 9

KENR6226-01 9

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

4. Loosen hose clamps (4) and (5). Disconnect

hoses (6) and (7

5. Remove bolts (2) and remove electric transfer

pump (3).

Installation

1. Ensure that the electric transfer pump is clean

and free from d

electric transfer pump.

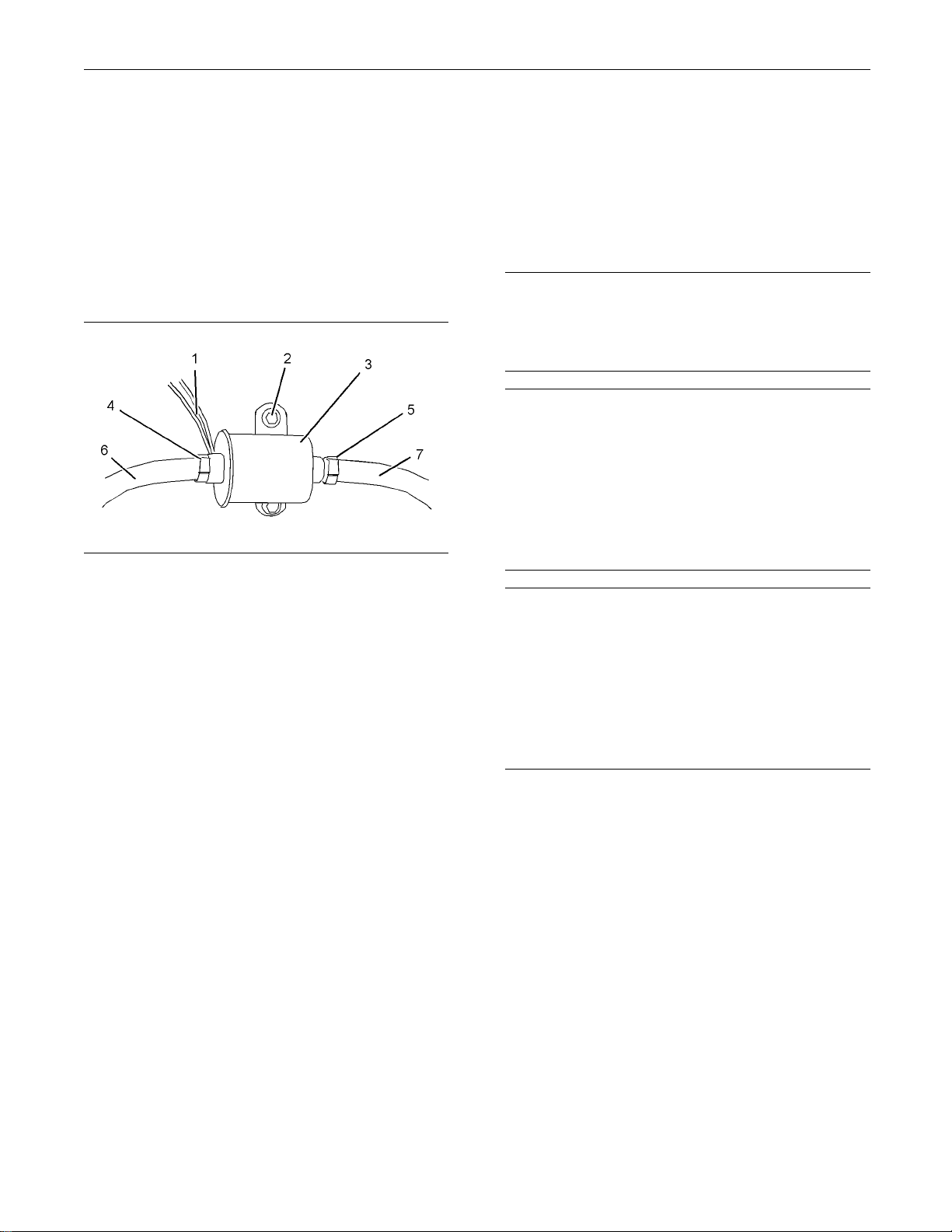

Illustration 8

Typical example

2. Position el

and install bolts (2).

).

Procedure

amage. If necessary, replace the

g01304057

ectric transfer pump (3) on the mounting

i02959953

Fuel Injection Lines - Remove

and Install

Removal Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants m

component life.

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting

collect the fluid with suitable containers before opening any compartment or disassembling any component contain

Dispose of all fluids according to local regulations and

mandates.

Do not let the tops of fuel injectors turn when the fuel

line nuts are loosened or tightened.

ay cause rapid wear and shortened

NOTICE

and repair of the product. Be prepared to

ing fluids.

NOTICE

3. Tighten bol

4. Connect hoses (6) and (7). Tighten hose clamps

(4) and (5)

5. Connect harness assembly (1).

6. Turn the fuel supply to the ON position.

7. Turn the ba

position.

8. Remove the

Operation and Maintenance Manual, “Fuel System

- Prime”.

ts (2) to a torque of 9 N·m (79 lb in).

.

ttery disconnect switch to the ON

air from the fuel system. Refer to

The fuel injectors will be damaged if the top of the

injector turns in the body.

The engine will be damaged if a defective fuel injector

is used because the shape of fuel (spray pattern) that

comes out of the nozzle will not be correct.

Note: Place identification marks on all tube

assemblies for installation. Plug all lines and tube

assemblies in order to prevent contamination.

1. Turn the fuel supply to the OFF position.

Page 10

10 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Illustration 9

Typical example

g01326550

2. Disconnect nuts (1) for fuel injection lines (2) from

the fuel injectors.

3. Disconnect nuts (1) for fuel injection lines (2) from

the fuel injection pump.

4. Remove fuel injection lines (2) from the engine

as a unit.

5. Use suitable caps in order to plug the open ports

of the fuel injection pump immediately.

6. The 403D-15, 403D-15T, 403D-17, 404D-22,

404D-22T and 404D-22TA engines have a rigid

fuel return line.

For engines with a rigid fuel return line, remove

banjo bolt (4) from fuel return line (3). Rem ove

washers (8).

The 402D-05, 403D-07, 403D-11 and 404D-15

engines have a flexible fuel return hose.

For engines with a flexible fuel return hose,

disconnect the hose from the fuel injection pump.

ion 10

Illustrat

Typical example

g01326555

7. Remove nuts (5) from fuel injectors (7).

Note: For e

ngines with a rigid fuel return line, ensure

that the fuel return line is not distorted when the nuts

are loosened.

8. Remove fuel return line (3) and washers (6) from

fuel injectors (7).

9. Use suitable caps in order to plug the fuel injectors

immediately.

Installation Procedure

Table 1

Tools

Part Name Qty

Pipe Nut Tool

1

Tool

A

Part

Number

27610294

Required

Injector

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Page 11

KENR6226-01 11

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

The 402D-05, 403D-07, 403D-11 and 404D-15

NOTICE

engines have a fl

exible fuel return hose.

Do not let the tops of fuel injectors turn when the fuel

line nuts are lo

osened or tightened.

The fuel injectors will be damaged if the top of the

injector turns

in the body.

For engines with a flexible fuel return hose,

connect the fu

el return hose to the fuel injection

pump.

4. Tighten nuts (

5)toatorqueof27N·m(20lbft).

The engine will be damaged if a defective fuel injector

is used becaus

e the shape of fuel (spray pattern) that

comes out of the nozzle will not be correct.

Note: The installation procedure is similar for the

two cylinder,

the three cylinder and the four cylinder

engines.

Illustration 11

Typical e

xample

g01326555

1. Remove the caps from fuel injectors (7). Install

new washe

rs (6) and fuel return line (3) to fuel

injectors (7).

Note: Th

e washers (6) have two small holes.

2. Install nuts (5) to fuel injectors (7).

3. The 403D-15, 403D-15T, 403D-17, 404D-22,

404D-22TA and 404D-22TA engines have a rigid

fuel ret

urn line.

For engines with a rigid fuel return line, install new

washers

(8) to fuel return line (3) and install banjo

bolt (4) to the fuel injection pump. Tighten banjo

bolt (4) to a torque of 7 N·m (62 lb in).

Illustration 12

Typical example

g01326550

5. Remove the caps from the outlet connections of

the fuel injection pump. Install the fuel injection

lines to the engine as a unit.

6. Connect fuel injection lines (2) to fuel injectors (7).

Tighten the union nuts (1) finger tight.

7. Use Tooling (A) to tighten union nuts (1) at the fuel

injection pump.

For 402D-05 and 403D-07 engines, tighten union

nuts (1) to a torque of 20 N·m (15 lb ft).

For 403D-11, 403D-15, 403D-15T, 403D-17,

404D-15, 404D-22, 404D-22T and 404D-22TA

engines, tighten the union nuts (1) to a torque of

23 N·m (17 lb ft).

Note: For the three cylinder and the four cylinder

engines, tighten the center union nuts first.

8. Use Tooling (A) to tighten union nuts (1) at the fuel

injections.

For 402D-05 and 403D-07 engines, tighten union

nuts (1) to a torque of 20 N·m (15 lb ft).

Page 12

12 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

For 403D-11, 403D-15, 403D-15T, 403D-17,

404D-15, 404Dengines, tighten the union nuts (1) to a torque of

23 N·m (17 lb ft).

9. Turn the fuel supply to the ON position.

10. Prime the fuel

Maintenance Manual, “Fuel System - Prime” for

more information.

22, 404D-22T and 404D-22TA

system. Refer to Operation and

i02645718

Fuel Shutof f Solenoid Remove an d In

Removal Procedure

Care must be taken to ensure that fluids are contained

during perfo

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compa

nent containing fluids.

rmance of inspection, maintenance, test-

rtment or disassembling any compo-

stall

NOTICE

2. Disconnect electrical connection (3) from

the harness ass

connections for installation.

3. Remove fuel sh

injection pump housing by rotating the fuel shutoff

solenoid in a counterclockwise direction.

4. Remove sealing washer (2) from fuel shutoff

solenoid (1).

embly (not shown). Mark all

utoff solenoid (1) from the fuel

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Dispose of a

mandates.

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Turn the battery disconnect switch to the OFF

position.

ll fluids according to local regulations and

NOTICE

Illustration 14

Typical example

1. Install sealing washer (2) to fuel shutoff solenoid

(1).

2. Install fuel shutoff solenoid (1) into the fuel

injection pump housing by rotating the fuel shutoff

solenoid in a clockwise direction. Tighten the fuel

shutoff solenoid to a torque of 17 N·m (12 lb ft).

3. Connect electrical connection (3) to the harness

assembly (not shown).

4. Turn the battery disconnect switch to the ON

position.

g01326564

Illustration 13

Typical e

xample

g01326564

Page 13

KENR6226-01 13

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

i02959957

Fuel Injection Pump - Remove

and Install

Removal Procedure

Start By:

a. Remove the fuel shutoff solenoid. Refer to

Disassembly a

Solenoid - Remove and Install”.

Care must be taken to ensure that fluids are contained

during perfor

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compa

nent containing fluids.

Dispose of al

mandates.

nd Assembly, “Fuel Shutoff

NOTICE

mance of inspection, maintenance, test-

rtment or disassembling any compo-

l fluids according to local regulations and

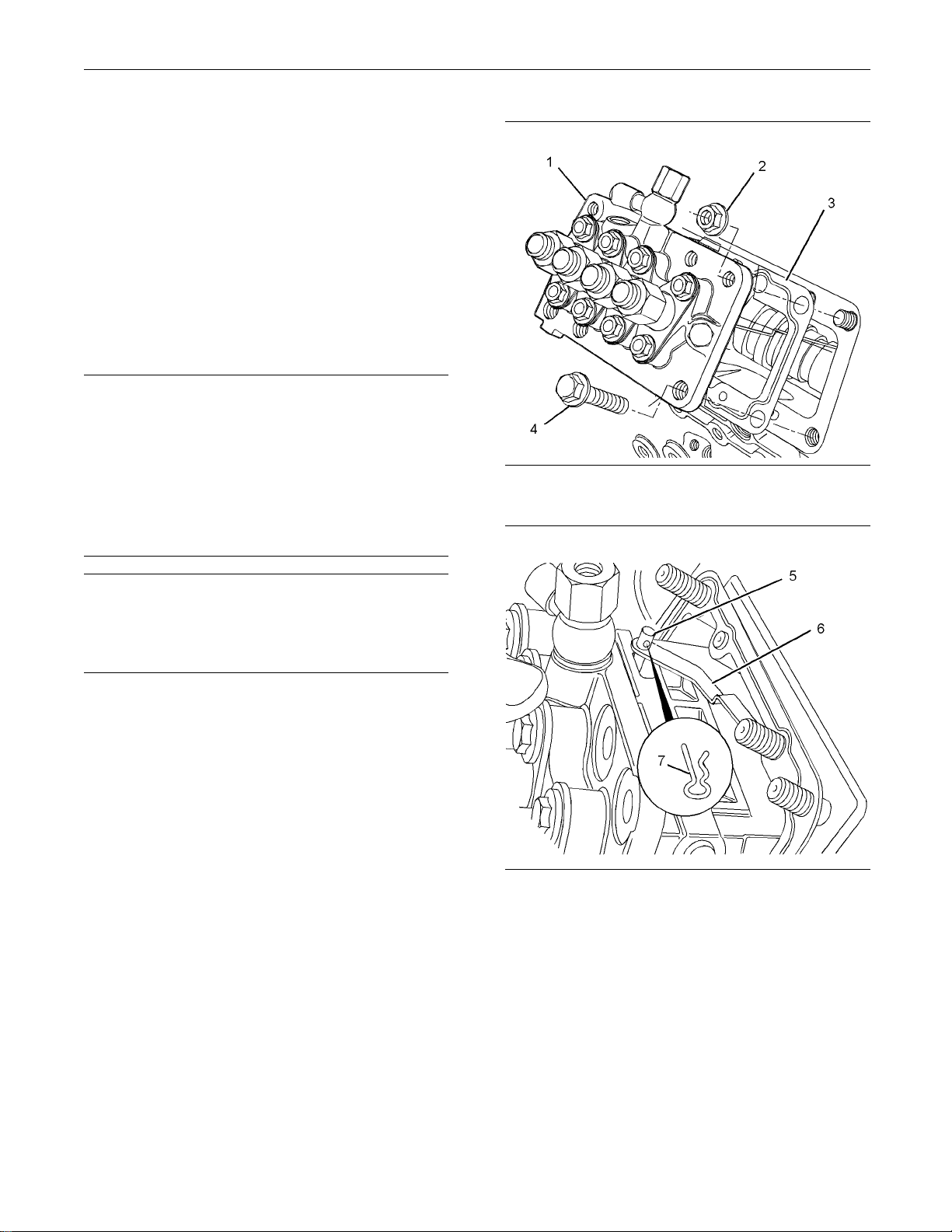

Illustration 15

Typical example

g01327005

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The removal procedure is similar for the two

cylinder, t

engines. The Illustrations show a four cylinder engine.

1. Remove the f

he three cylinder and the four cylinder

uel injection lines. Refer to

Disassembly and Assembly, “Fuel Injection Lines

- Remove and Install” for more information.

The 402D-05, 403D-07, 403D-11 and 404D-15

engines have a flexible fuel return hose.

For engines with a flexible fuel return hose,

disconnect the fuel hose from the inlet connection

of the fuel

injection pump.

Illustration 16

Typical example

2. Gradual

the fuel injection pump to the cylinder block.

3. Careful

cylinder block and remove clip (7) that connects

link (6) to fuel rack control (5).

ly loosen bolts (4) and nuts (2) that fasten

ly raise fuel injection pump (1) from the

g013270

06

4. Remove fuel injection pump (1) from the cylinder

block.

5. Remove shims (3) from the mounting face of the

cylinder block.

Page 14

14 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Note: Record the thickness of each shim and the

number of shims

for reassembly. The fuel injection

timing is determined by the thickness of the shim

pack that is between the fuel injection pump and

the mounting f

ace on the cylinder block. Refer

to Specifications, “Fuel Injection Pump” for more

information.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The installation procedure is similar for the

two cylinder, the three cylinder and the four cylinder

engines. The Illustrations show a four cylinder engine.

1. Clean the mating surfaces of the cylinder block

and the fuel injection pump.

Illustration 17

Typical example

g01327005

2. New shims (3) must be used during assembly.

Install the correct thickness and the correct

number of shims on the mounting face of the

cylinder block. Refer to Specifications, “Fuel

Injection Pump” for more information.

Illustration 18

Typical example

g01327006

3. Positionfuelinjectionpump(1)closetothe

mounting face of the cylinder block, and connect

link (6) and fuel rack control (5) with clip (7).

4. Align fuel injection pump (1) with the studs on the

cylinder block. Install the fuel injection pump to

the cylinder block.

5. Install bolts (4) and nuts (2). Ensure that the

tube clip for the engine oil line is secured by the

appropriate fastener.

For 402D-05, 403D-07, 403D-11 and 404D-15

engines, evenly tighten bolts (4) and nuts (2) to a

torqueof6N·m(53lbin).

For 403D-15, 403D-15T, 403D-17, 404D-22,

404D-22T and 404D-22TA engines, evenly tighten

bolts (4) and nuts (2) to a torque of 15 N·m

(11 lb ft).

6. Install the fuel injection lines. Refer to Disassembly

and Assembly, “Fuel Injection Lines - Remove

and Install”.

The 402D-05, 403D-07, 403D-11 and 404D-15

engines have a flexible fuel return hose.

For engines with a flexible fuel return hose,

connect the fuel hose to the inlet connection of

the fuel injection pump.

Page 15

KENR6226-01 15

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

End By:

a. Install the fuel shutoff solenoid. Refer to

Disassembly and Assembly, “Fuel Shutoff

Solenoid - Rem

Fuel Injector

ove and Install”.

i02959963

- Remove and

Install

Removal Proce

Start By:

a. Remove the fuel injection lines. Refer to

Disassembly and Assembly, “Fuel Injection Lines

- Remove and I

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusti

collect the fluid with suitable containers before opening any compartment or disassembling any component contai

Dispose of all fluids according to local regulations and

mandates.

ng and repair of the product. Be prepared to

ning fluids.

dure

nstall”.

NOTICE

1. Use a deep socket to remove fuel injector (1) from

the cylinder he

2. Remove seat washers (2) from the cylinder head.

Note: 402D-05 and 403D-07 engines have two seat

washers. The seat washers are different diameters.

The 403D-11, 4

404D-15, 404D-22, 404D-22T and 404D-22TA

engines have one seat washer.

3. Cap all openings or plug all openings immediately.

ad.

03D-15, 403D-15T, 403D-17,

Installation Procedure

Table 2

Required Tools

Too l

A

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Part

Number

1861117

Part Description Qty

POWERPART

Universal Jointing

Compound

NOTICE

1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Illustration 19

Typical example

g01320610

Illustration 20

Typical ex

1. Clean the bore for the fuel injector in the cylinder

2. Install n

ample

head. Ensu

Clean the threads on the body of the fuel injector.

fuel injector in the cylinder head.

re that no debris enters the cylinder.

ew seat washers (2) into the bore for the

g01304054

Page 16

16 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Note: 402D-05 and 403D-07 engines have two seat

washers. The se

The 403D-11, 403D-15, 403D-15T, 403D-17,

404D-15, 404D-22, 404D-22T and 404D-22TA

engines have o

3. Apply a bead of Tooling (A) to the first two threads

of the fuel in

head. The bead should have a diameter of 2 mm

(0.08inch)andalengthof6mm(0.25inch).

Note: Ensure that Tooling (A) does not cover the

body of the fuel injector below the threads.

4. Install fuel injector (1) into the cylinder head. Use a

deep socket to tighten the fuel injector to a torque

of 64 N·m (47 l

End By:

a. Install the fuel injection lines. Refer to Disassembly

and Assembly, “Fuel Injection Lines - Remove

and Install

at washers are different diameters.

ne seat washer.

jector that engage into the cylinder

b ft).

”.

i02645771

Turbocharg

er - Remove and

Install

Removal pro

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Keep all parts clean from contaminants.

Contamina

component life.

nts may cause rapid wear and shortened

cedure

NOTICE

NOTICE

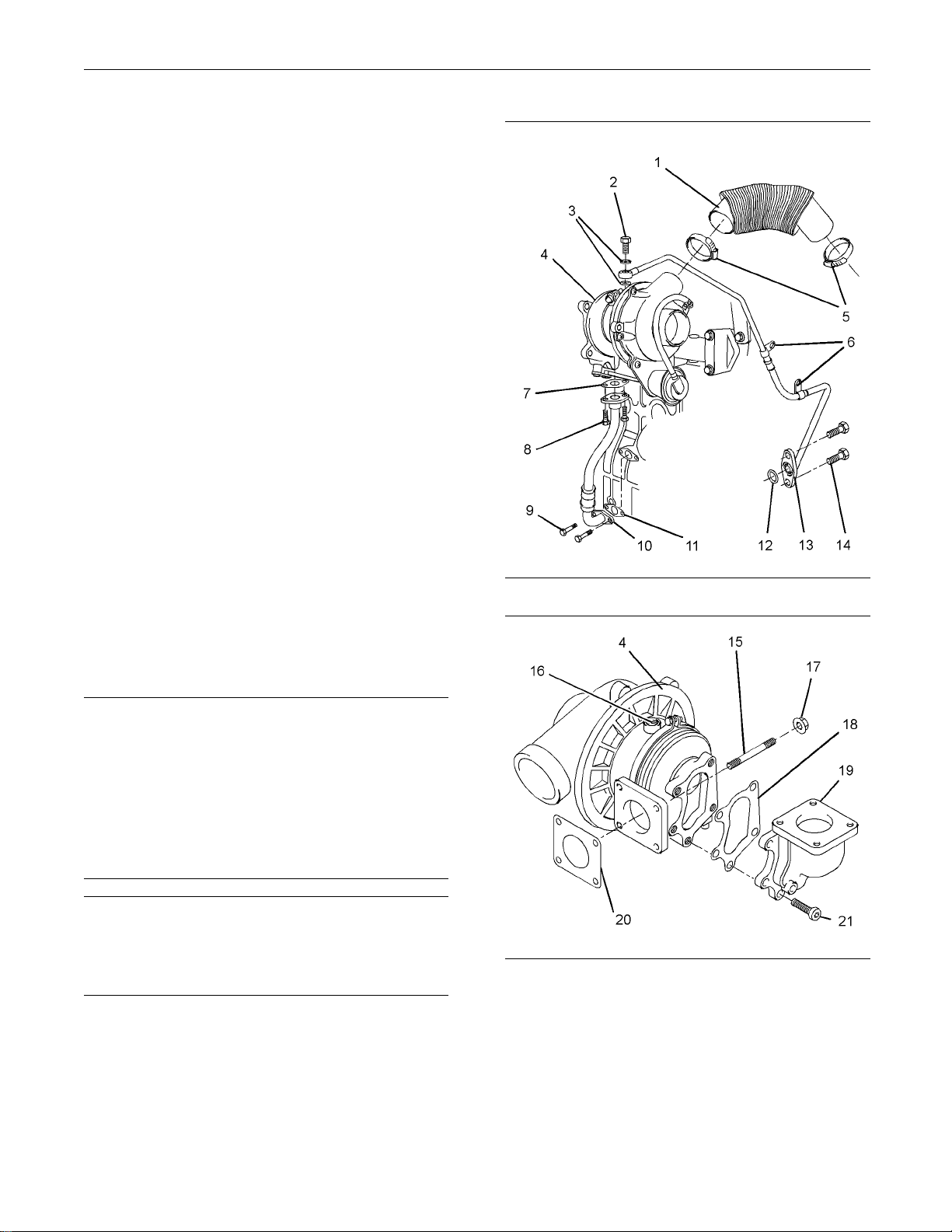

ion 21

Illustrat

Illustration 22

g01304121

g01304528

1. Loosen hose clamps (5) and remove air inlet hose

Note: Plug and cap all open ports and tube

assemblies.

(1).

2. Remove allen head screws (21) and remove

exhaust elbow (19) from turbocharger (4). Remove

gasket (18) from the turbocharger.

Page 17

KENR6226-01 17

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

3. Remove banjo bolt (2) and washers (3). Remove

the fasteners a

tube clips (6). Remove bolts (14) and remove tube

assembly (13) from the cylinder block. Remove

O-ring seal (1

4. Remove bolts (8) and disconnect tube assembly

(10) from the

If necessary, remove bolts (9) and remove tube

assembly (10

joint (11).

nd the spacers (not shown) for

2).

turbocharger. Remove joint (7).

) from the cylinder block. Remove

5. Remove nuts (

from the exhaust manifold. Remove gasket (20)

from the exhaust manifold. If necessary, remove

studs (15) fr

Note: Do not use the actuator rod of the wastegate

to lift the t

urbocharger.

Installati

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Ensure that the turbocharger is clean and free

from damage. Inspect the turbocharger for

wear.Ifthe

turbocharger must be replaced.

2. Te st t he a c

to Systems Operation, Testing and Adjusting,

“Wastegate - Test” for more information. If the

actuator i

operate within the specified limits, the complete

turbocharger must be replaced.

17) and remove turbocharger (4)

om the exhaust manifold.

on procedure

NOTICE

turbocharger is worn, the complete

tuator for correct operation. Refer

s damaged or the actuator does not

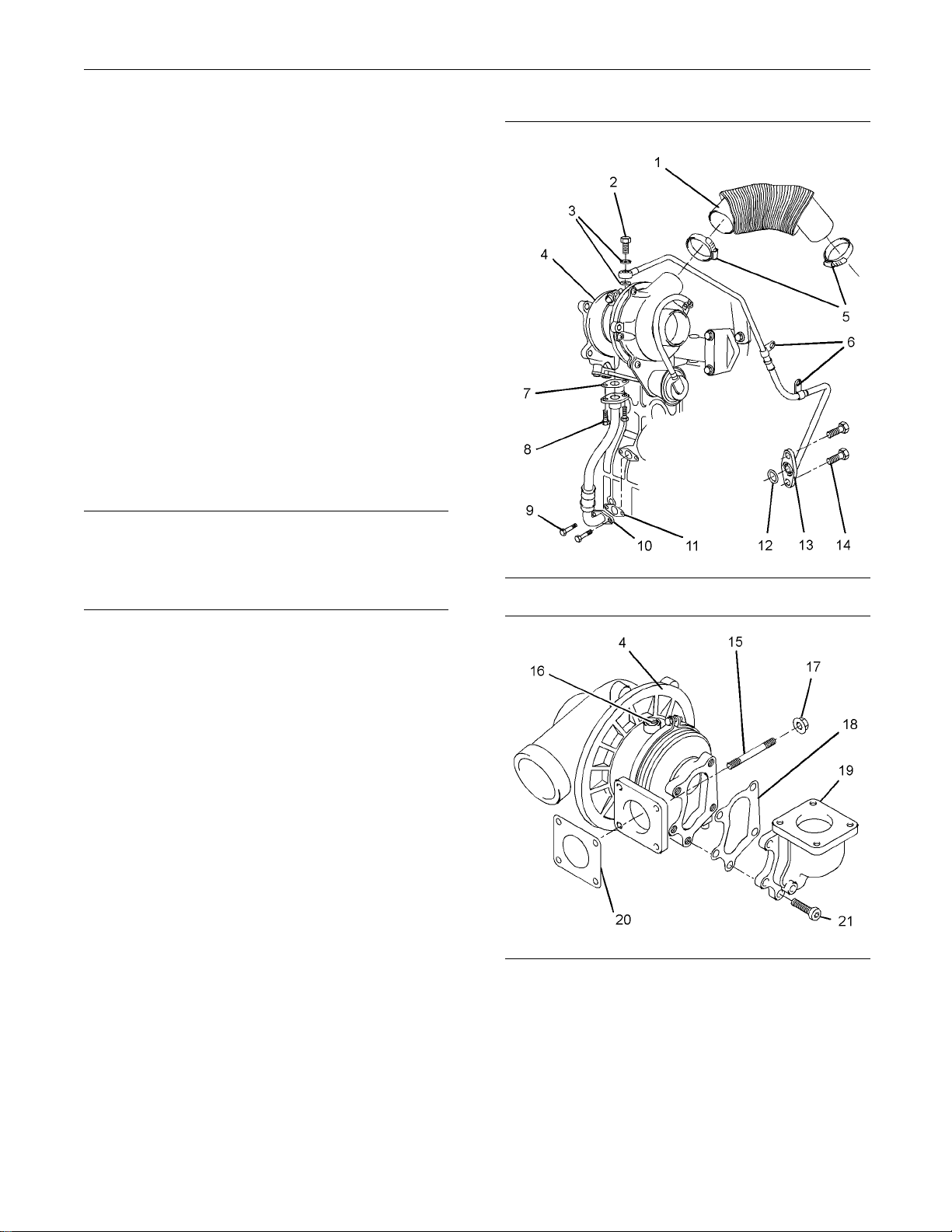

Illustrat

ion 23

g01304121

Illustration 24

3. Clean the mating surfaces of the exhaust manifold.

If necessary, install studs (15) to the exhaust

manifold. Tighten the studs to a torque of 18 N·m

(13 lb ft). Install a new gasket (20) over the studs.

4. Position turbocharger (4) onto the exhaust

manifold. Install nuts (17) and tighten to a torque

of 25 N·m (18 lb ft).

Note: Do not use the actuator rod of the wastegate

to lift the turbocharger .

g01304528

Page 18

18 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

5. Ensure that tube assemblies (10) and (13) are

clean and free f

the tube assemblies.

6. If necessary,

assembly (10) onto the cylinder block. Install bolts

(9). Tighten the bolts finger tight.

Position a new joint (7) on tube assembly (10).

Align tube assembly (10) to the bottom of the

turbocharge

finger tight.

Tighten bolt

(89lbin).

7. Lubricate th

clean engine oil through oil inlet port (16). Rotate

the shaft of the turbocharger in order to distribute

the lubrica

8. Install a new O-ring seal (12) to tube assembly

(13). Posit

cylinder block. Install bolts (14). Tighten the bolts

toatorqueof10N·m(89lbin).

9. Install new washers (3) and banjo bolt (2) to tube

assembly (13). Position tube assembly (13) onto

turbochar

tight.

rom damage. If necessary, replace

position a new joint (11) and tube

r. Install bolts (8). Tighten the bolts

s (8) and (9) to a torque of 10 N·m

e bearings of turbocharger (4) with

nt.

ion tube assembly (13) against the

ger (4). Tighten the banjo bolt finger

i02959965

Exhaust Manifold - Remove

and Install

Removal Procedure

Start By:

a. If the engine is equipped with a turbocharger,

remove the tur

and Assembly, “ Turbocharger, Remove and

Install”.

Keep all parts

Contaminants may cause rapid wear and shortened

component li

Note: The two cylinder, the three cylinder and the four

cylinder engines have different exhaust manifolds.

The removal procedure is similar for all models.

bocharger. Refer to Disassembly

NOTICE

clean from contaminants.

fe.

10. If necessa

fasteners (not shown) to tube clips (6). Torque the

fasteners to 10 N·m (89 lb in).

11. Tighten banjo bolt (2) to a torque of 18 N·m

(13 lb ft).

Note: Ensure that the tube assembly does not come

into contact with any other components.

12. Clean the mating surfaces of exhaust elbow (19).

Position a new gasket (18) and exhaust elbow (19)

on turboc

Tighten the bolts to a torque of 32 N·m (24 lb ft).

13. Ensure th

defects or restrictions. Loosely install hose clamps

(5) to air inlet hose (1). Install the air inlet hose to

the conn

and to the turbocharger. Tighten the hose clamps.

ry, install the spacer and install the

harger (4). Install allen head screws (21).

at inlet hose (1) is clean and free from

ection of the inlet manifold (not shown)

Illustration 25

Typical example

1. Loosen nuts (5) and bolts (6).

Note: In order to prevent distortion of the exhaust

manifold, loosen the outer fasteners first.

2. Remove nuts (5) and bolts (6).

Note: Identify bolts of different lengths so that the

bolts can be installed in the correct positions.

3. Remove exhaust manifold (4) from cylinder head

(1). Note the orientation of the exhaust manifold

for installation.

g01326567

4. Remove gasket (3) from cylinder head (1).

Page 19

KENR6226-01 19

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

5. If necessary, remove exhaust manifold studs (2)

from cylinder h

Installation P

ead (1).

rocedure

NOTICE

Keep all parts c

lean from contaminants.

Contaminants may cause rapid wear and shortened

component lif

e.

Note: The two cylinder, the three cylinder and the four

cylinder engines have different exhaust manifolds.

The installation procedure is similar for all models.

1. Ensure that the mating surfaces of the cylinder

head and the exhaust manifold are clean and free

from damage.

Note: On three cylinder engines and four cylinder

engines, tight

en the inner bolts first.

End By:

a. If the engine is equipped with a turbocharger,

install the turbocharger. Refer to Disassembly and

Assembly, “ Tu

rbocharger, Remove and Install”.

i02959972

Inlet and Exhaust Valve

Springs - Remove an d Install

Removal Procedure

Table 3

Required Tools

Tool Part Number Part Description Qty

21825739

A

(1)

B

(2)

B

(3)

B

(1)

402D-05 and 4

(2)

403D-11 and 404D-15 engines

(3)

403D-15, 403 D-15T, 403D-17, 404D-22, 404D-22T and

404D-22TA engines

-

27610235

21825934

03D-07 engines

Val ve Sp r ing

Adapter 1

Adapter 1

Adapter 1

Compressor 1

on 26

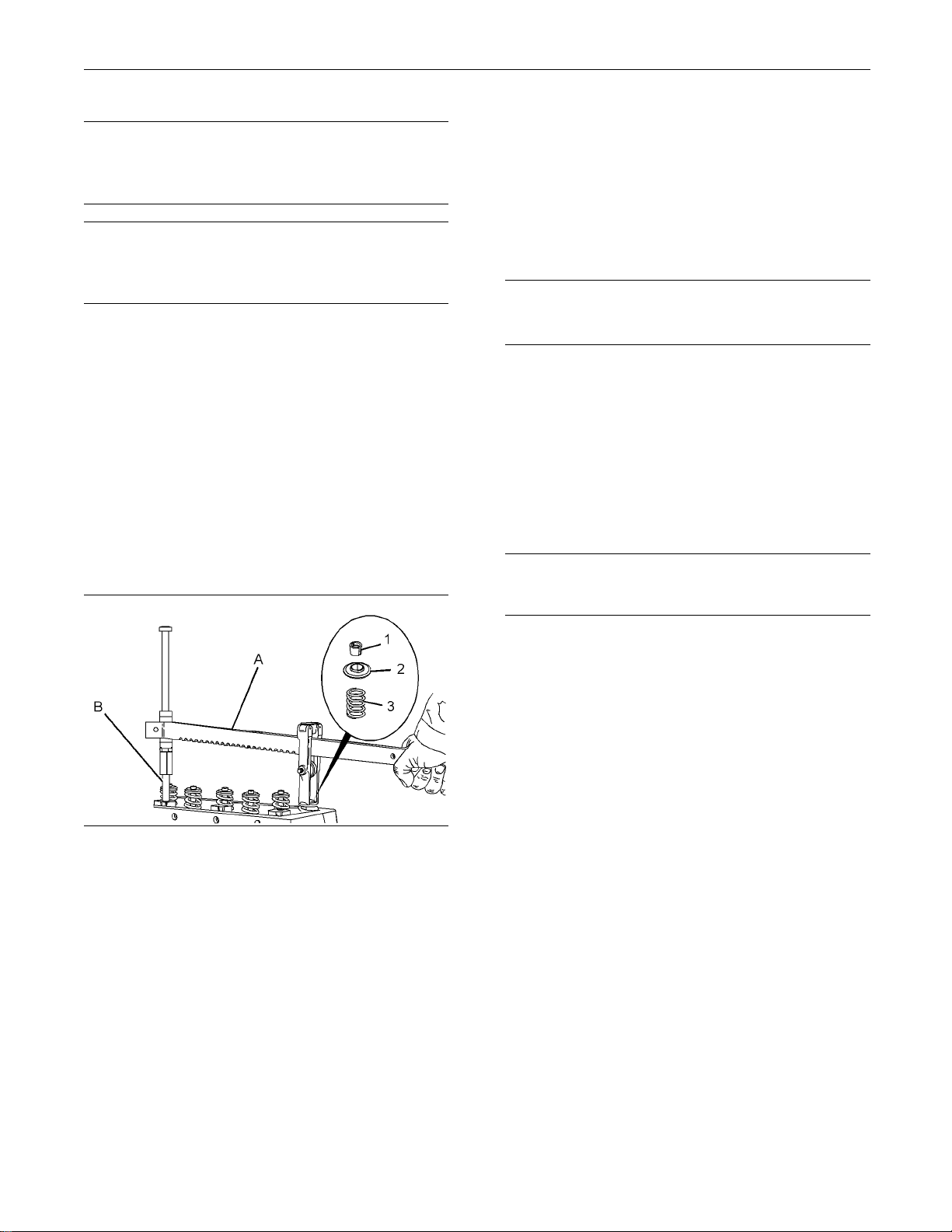

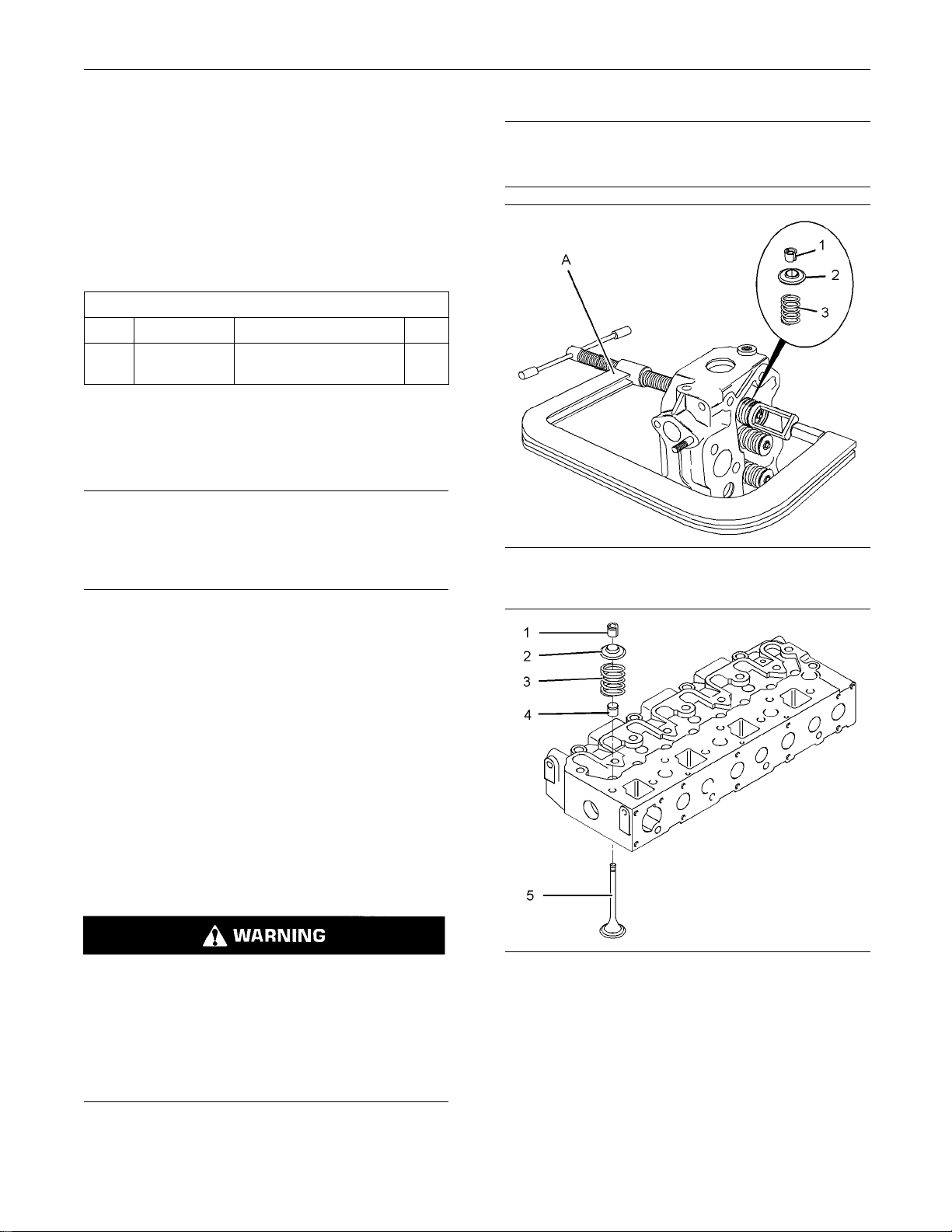

Illustrati

Typical example

g01326567

2. If necessary, install exhaust manifold studs (2) to

cylinder head (1).

3. Install a new exhaust manifold gasket (3) to

cylinder head (1).

4. Align exhaust manifold (4) with studs (2) and

install the exhaust manifold to cylinder head (1).

Note: Ensure that the exhaust manifold is installed

in the correct orientation.

5. Install nuts (5) and bolts (6) finger tight.

Note: Ensu

re that bolts of different lengths are

installed in the correct positions.

6. For 402D-0

5, 403D-07, 403D-11, 403D-15,

403D-15T, 403D-17, and 404D-15 engines,

tighten nuts (5) and bolts (6) to a torque of 10 N·m

(89lbin)

.

For 404D-22, 404D-22T and 404D-22TA engines,

tighten n

uts (5) and bolts (6) to a torque of 25 N·m

(18 lb ft).

Start By:

a. Remove the rocker shaft assembly. Refer to

Disassembly

and Assembly, “Rocker Shaft and

Pushrod - Remove”.

Personal injury can result from being struck by

parts propelled by a released spring force.

Make sure to wear all necessary protective equipment.

Follow t he recommended procedure and use all

recommended tooling to release the spring force.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Page 20

20 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Note: Do not use excessive force to turn the

NOTICE

Install suitable plugs to the inlet ports of the cylinder

head in order to

prevent the entry of loose parts into

the engine.

crankshaft. Th

stems.

d. Continue to ro

e use of force can result in bent valve

tate the crankshaft and gradually

release the pressure on Tooling (A) until the

piston is at the top center position. The valve

NOTICE

Plug the apertures for the push rods in the cylinder

is now held in

spring to be safely removed.

a position that allows the valve

head in order to prevent the entry of loose parts into

the engine.

Note: The removal procedure is similar for the two

Ensure that th

e valve spring is compressed squarely

or damage to the valve stem may occur.

NOTICE

cylinder, the three cylinder and the four cylinder

engines. The following procedure should be adopted

in order to remove the valve springs when the

cylinder head is installed to the engine. Refer to

Disassembly and Assembly, “Inlet and Exhaust

Valves - Remove and Install” for the procedure to

remove the valve springs from a cylinder head that

has been removed from the engine.

Note: Ensure that the appropriate piston is at the top

center position before the valve spring is removed.

Failure to ensure that the piston is at the top center

2. Use tool (A) i

Remove valve keepers (1).

Note: For fou

require replacement the procedure can be carried

out on two cylinders at the same time. The procedure

canbecarri

1with4and2with3.Ensurethatallofthevalve

springs are installed before changing from one pair

of cylinder

n order to compress valve spring (3).

r cylinder engines, if all valve springs

ed out on the following pairs of cylinders.

s to another pair of cylinders.

position may allow the valve to drop into the cylinder

bore.

NOTICE

Do not turn the crankshaft while the valve springs are

removed.

Illustration 27

Typical example

1. Follow Ste

ps 1.a through 1.d in order to position

g0130458

the appropriate piston at top center.

a. Install To

oling (A) and (B) in position on the

cylinder head in order to compress a valve

spring for the appropriate piston.

b. Use Tooling (A) in order to compress valve

spring (3) and open the valve slightly.

Note: Do not compress the spring so that the valve

spring retainer (2) touches the valve stem seal.

3. Apply sufficient pressure to Tooling (A) in order to

allow removal of the valve keepers (1).

Note: Do not compress the spring so that the valve

spring retainer (2) touches the valve stem seal.

Remove valve keepers (1).

4. Slowly rel

easethepressureonTooling(A).

5. Remove valve spring retainer (2) and remove

3

valve spri

ng (3).

6. RemoveTooling(A)and(B).

c. Carefully rotate the crankshaft until the piston

touches the valve.

Page 21

KENR6226-01 21

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

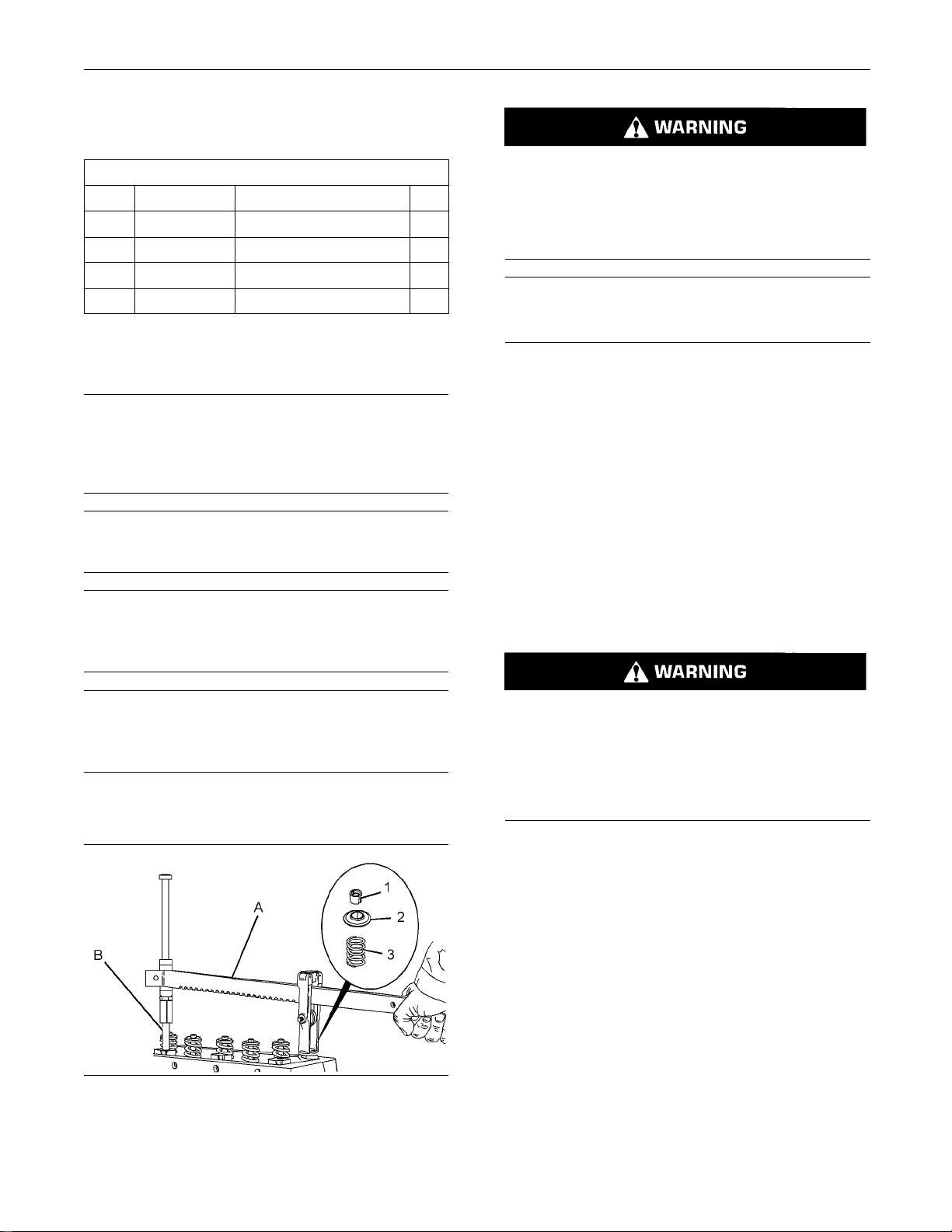

Installation P

Table 4

Tool Part Number Part Description Qty

21825739

A

(1)

B

(2)

B

B

(1)

(2)

(3)

404D-22TA engines

27610235

(3)

21825934 Adapter 1

402D-05 and 403D-07 engines

403D-11 and 404D-15 engines

403D-15, 403D-15T, 403D-17, 404D-22, 404D-22T and

rocedure

Required Tools

-

Valve Spring Compressor 1

Adapter 1

Adapter 1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Do not turn the crankshaft while the valve springs are

removed.

Improper assembly of parts that are spring loaded

can cause bodily injury.

T o prevent possible injury, follow the established

assembly procedure and wear protective equipment.

NOTICE

Ensure that the valve spring is compressed squarely

or damage to the valve stem may occur.

3. Install Tooling (A) and (B) in the appropriate

position on the cylinder head in order to compress

the valve spri

ng.

4. Apply sufficient pressure to Tooling (A) in order to

install valve

keepers (1).

Note: Do not compress the spring so that valve

spring retai

ner (2) touches the valve stem seal.

Install the valve spring keepers.

5. Carefully release the pressure on Tooling (A).

NOTICE

Plug the apertures for the push rods in the cylinder

head in order to prevent the entry of loose parts into

the engine.

NOTICE

Install suitable plugs to the inlet ports of the cylinder

head in order to

prevent the entry of loose parts into

the engine.

1. Inspect the val

ve springs for the correct length.

Refer to Specifications, “Cylinder Head Valves ”.

Note: Ensure

that the valve keepers are correctly

seated.

The valve spring keepers can be thrown from

the valve when the valve spring compressor is

released. E

nsure that the valve spring keepers

are properly installed on the valve s tem. To help

prevent personal injury, keep away from the front

of the valve

spring keepers and valve springs

during the installation of the valves.

6. Remove Tool

ing (A). Ensure that all of the valves

are secured in place by a valve spring and valve

keepers. Rotate the crankshaft through about

45 degrees

inordertoclearthepistonfromthe

valve. Lightly strike the top of the valve with a soft

hammer in order to ensure that the valve keepers

are proper

ly installed.

End By:

a. Install the rocker shaft assembly. Refer to

Disassembly and Assembly, “Rocker Shaft and

Pushrod -

Install”.

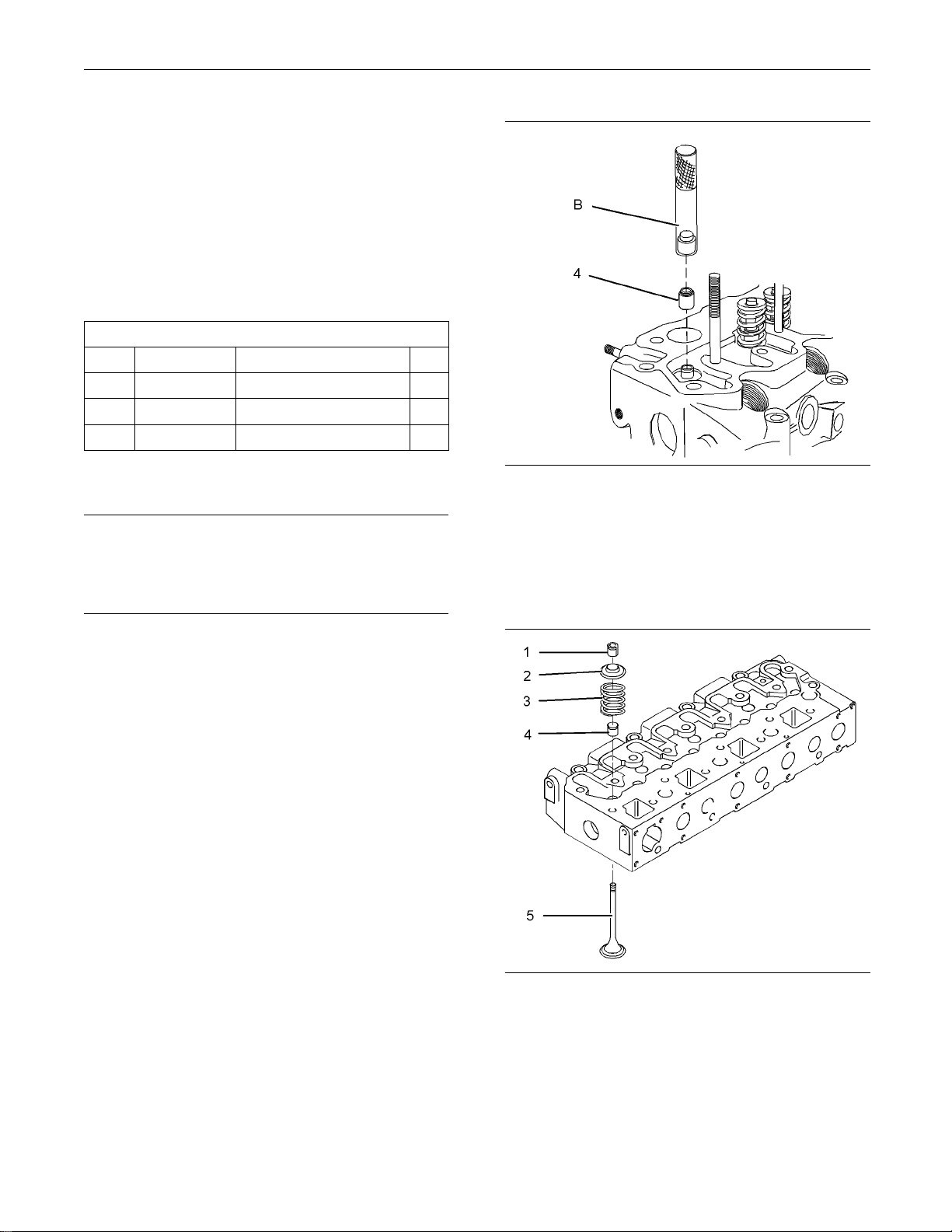

Illustration 28

Typical example

g01304583

2. Install valve spring (3) onto the cylinder head.

Position valve spring retainer (2) onto valve spring

(3).

Page 22

22 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

i02959973

Inlet and Exhaust Valves Remove an d Install

Ensure that the valve spring is compressed squarely

or damage to the

NOTICE

valve stem may occur.

Removal Procedure

Table 5

Required Tools

Tool Part Number Part Description Qty

A 21825663

Start By:

a. Remove the cylinder head. Refer to Disassembly

and Assembly, “Cylinder Head - Remove”.

Valve Spring

Compressor

1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The removal procedure is identical for the

two cylinder, the three cylinder and the four cylinder

engines. The

Illustrations show a four cylinder engine.

1. Clean the bottom face of the cylinder head.

Check the dep

th of the valves below the face of

the cylinder h ead before the valve springs are

removed. Refer to Specifications, “Cylinder Head

Val v e s ” for

the correct dimensions.

2. Place a temporary identification mark on the

heads of the

valves in order to identify the correct

position.

Note: Do not

stamp the heads of the valves.

Stamping or punching the heads of the valves could

cause the valves to fracture.

Illustration 29

Typical example

g01315963

Personal injury can result from being struck by

parts prop

elled by a released spring force.

Make sure to wear all necessary protective equipment.

Illustration 30

Typical example

3. Use Tooling (A) in order to compress the

appropriate valve spring (3). Remove valve

keepers (1).

Follow the recommended procedure and use all

recommen

ded tooling to release the spring force.

Note: Do not compress the valve spring so that valve

spring retainer (2) touches valve stem seal (4).

4. Remove Tooling (A).

g01325840

Page 23

KENR6226-01 23

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

5. Remove valve spring retainer (2). Remove valve

spring (3).

6. Remove valve (5).

7. Remove valve stem seal (4).

8. Repeat Steps 3

Installation

Table 6

Tool Part Number Part Description Qty

21825663

A

(1)

B

B

(1)

(2)

404D-22T and 404D-22TA engines

21825622

(2)

21825623

402D-05 and 40

403D-11, 403D-15, 403D-15T, 403D-17, 404D-15, 404D -22,

to 7 for the remaining valves.

Procedure

Required Tools

Valve Spring Compressor 1

Valve Stem Seal Replacer 1

Val v e St e m Se a

3D-07 engines

l Replacer 1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The installation procedure is identical for the

two cylinder, the three cylinder and the four cylinder

engines. The I

llustrations show a four cylinder engine.

Illustration 31

Typical example

g01315893

2. Use Tooling (B) to install new valve stem seals (4)

onto each of the valve guides.

Note: The outer face of the valve guides must be

clean and dry before installing the valve stem seals.

1. Clean all components of the cylinder head

assembly. En

sure that all ports, all coolant

passages and all lubrication passages in the

cylinder head are free from debris. Follow Steps

1.a through

1.e in order to inspect the components

of the cylinder head assembly. Replace any

components that are worn or damaged.

a. Inspect the cylinder head for wear and for

damage. Refer to Systems Operation, Testing

and Adjusti

ng, “Cylinder Head Inspect”.

b. Inspect the valve seats for wear and for

damage. Ref

er to Specifications, “Cylinder

Head Valves” for further information.

c. Inspect th

e valve guides for wear and for

damage. Refer to Specifications, “Cylinder

Head Valves” and Systems Operation, Testing

and Adjust

ing, “Valve Guide - Inspect” for

further information.

d. Inspect th

e valves for wear and for damage.

Refer to Specifications, “Cylinder Head Valves”.

e. Inspect th

e valve springs for the correct length.

Refer to Specifications, “Cylinder Head Valves”.

Illustration 32

Typical example

g01325840

3. Lubricate the stem of valve (5) with clean engine

oil. Install valve (5) in the appropriate position in

the cylinder head. Check the depth of the valve

below the face of the cylinder head. Refer to

Systems Operation, Testing and Adjusting, “Valve

Depth - Inspect” for more information.

Page 24

24 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

4. Install valve spring (3) to the cylinder head.

Position valve

(3).

Personal injury can result from being struck by

parts propel

Make sure to wear all necessary protective equipment.

Follow the recommended procedure and use all

recommended

Ensure that the valve spring is compressed squarely

or damage to the valve stem may occur.

spring retainer (2) onto valve spring

led by a released spring force.

tooling to release the spring force.

NOTICE

6. Remove Tooling (A).

7. Repeat Steps 4 to 6 for the remaining valves.

8. Place the cylin

Ensure that the heads of the valves are not

obstructed. Gently strike the top of the valves

with a soft ham

keepers (1) are properly installed.

End By:

a. Install the cylinder head. Refer to Disassembly

and Assembly

der head on a suitable support.

mer in order to ensure that valve

, “Cylinder Head - Install”.

i02959976

Engine Oil Line - Remove and

Install

Removal Procedure

NOTICE

Keep all parts clean from contaminants.

Illustration 33

Typical example

5. Use Tooling (A) in order to compress valve spring

(3). Install valve keepers (1).

Note: Donotcompressthespringsothatvalve

spring retainer (2) touches valve stem seal (4).

The valve spring keepers can be thrown from

the valve when the valve spring compressor is

released. Ensure that the valve spring keepers

are properly installed on the valve stem. To help

prevent personal injury, keep away from the front

of the valve spring keepers and valve springs

during the installation of the valves.

g01315963

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Page 25

KENR6226-01 25

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

4. Remove oil line (1) from the engine.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

ion 34

Illustrat

Typical example

g01304820

1. Loosen nut (2) that attaches the clip on oil line (1)

to the fuel injection pump.

2. Remove banjo bolt (3) and remove washers (4)

from the cylinder block.

ion 36

Illustrat

Typical example

g01304820

1. Place oil line (1) on the engine. Ensure that the

clip on the oil line is located below nut (2).

2. Position banjo bolt (3) and new washers (4) onto

oil line (1). Install the banjo bolt and oil line to the

cylinder

block finger tight.

Illustration 35

Typical example

g01307372

3. Remove banjo bolt (5) and remove washers (6)

from the cylinder head.

Page 26

26 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

NOTICE

Care must be taken to ensure that fluids are contained

during perform

ance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before opening any compar

tment or disassembling any compo-

nent containing fluids.

Illustration 37

Typical example

g01307372

3. Position banjo bolt (5) and new washers (6) onto

oil line (1). Install the banjo bolt and the oil line to

the cylinder head finger tight.

4. Tighten nut (2) that attaches the clip on oil line (1)

to the fuel injection pump.

For 402D-05, 403D-07, 403D-11 and 404D-15

engines, tighten nut (2) to a torque of 6 N·m

(53lbin).

For 403D-15, 403D-15T, 403D-17, 404D-22,

404D-22T and 404D-22TA engines, tighten nut (2)

toatorqueof15N·m(133lbin).

Dispose of all

fluids according to local regulations and

mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Drain the coolant from the cooling system into

a suitable con

tainer. Refer to Operation and

Maintenance Manual, “Cooling System Coolant Drain” for the correct procedure.

2. Drain the engine lubricating oil into a suitable

container. Refer to Operation and Maintenance

Manual, “Eng

ine Oil and Filter - Change” for the

correct procedure.

5. Tighten banjo bolts (3) and (5) to a torque of

12N·m(106lbin).

i02645673

Engine Oil Cooler - Remo ve

and Install

Illustration 38

Removal Procedure

Table 7

Required Tools

Tool Part Number Part Description

A

-

Strap Wrench

Qty

1

Typical example

3. Use Tooling (A) to remove oil filter element (5).

4. Loosen hose clamps (2) and disconnect hoses

(1). Note the positions of the coolant inlet and the

coolant outlet for installation.

5. Remove adapter (4) and remove oil cooler (3)

from the cylinder block.

g01304837

Page 27

KENR6226-01 27

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Note: Make a temporary mark in order to show the

orientation of

6. Remove O-ring seal (6) from oil cooler (3).

the oil cooler for installation.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Ensure that the oil cooler is clean and free from

damage. Clean the mating surfaces of the cylinder

block.

i02645679

Engine Oil Relief Valve Remove and Install

Removal Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants m

component life.

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjusting

collect the fluid with suitable containers before opening any compartment or disassembling any component contain

Dispose of all fluids according to local regulations and

mandates.

ay cause rapid wear and shortened

NOTICE

and repair of the product. Be prepared to

ing fluids.

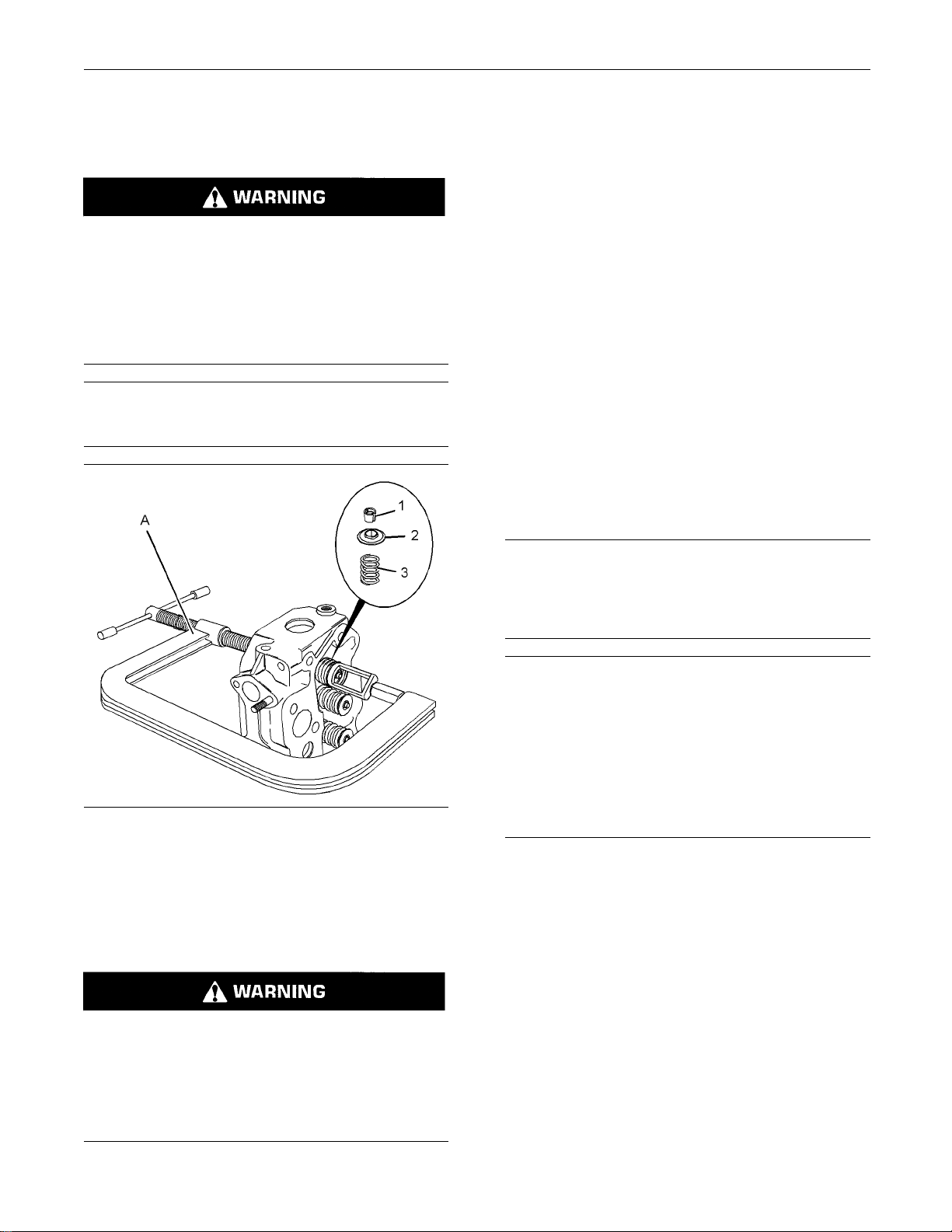

Illustration 39

Typical example

2. Install a new O-ring seal (6) to oil cooler (3).

Position oil cooler (3) on the cylinder block and

install adapter (4). Tighten adapter (4) to a torque

of 34 N·m (25 lb ft).

Note: Ensure that the oil cooler is correctly oriented.

3. Connect hoses (1) to the coolant inlet and the

coolant outlet on oil cooler (3). Tighten hose

clamps (2).

4. Install a new oil filter element (5).

5. Fill the cooling system to the correct level. Refer

to Operation and Maintenance Manual, “Cooling

System Coolant - Fill” for the correct procedure.

6. Fill the engine oil pan to the correct level. Refer to

Operation and Maintenance Manual, “Engine Oil

Filter - Change” for the correct procedure.

g01304837

Illustration 40

Typical example

1. Remove engine oil relief valve (2) from the cylinder

block.

2. Remove O-ring seal (1) from engine oil relief valve

(2).

g01316066

Page 28

28 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Installation P

Keep all parts c

Contaminants may cause rapid wear and shortened

component life

rocedure

NOTICE

lean from contaminants.

.

i02645678

Engine Oil Pump - Remove

Removal Proced

Start By:

a. Remove the front housing. Refer to Disassembly

and Assembly, “Housing (Front) - Remove”.

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing, adjustin

collect the fluid with suitable containers before opening any compartment or disassembling any component containi

Dispose of all fluids according to local regulations and

mandates.

Keep all parts clean from contaminants.

g and repair of the p roduct. Be prepared to

ng fluids.

ure

NOTICE

NOTICE

Illustration 41

Typical ex

1. Install a new O-ring seal (1) to engine oil relief

2. Lubricate engine oil relief valve (2) with clean

3. Install engine oil relief valve (2) into the cylinder

ample

valve (2).

engine oil

block. Ti

torque of 64 N·m (47 lb ft).

.

ghten the engine oil relief valve to a

g01316066

Contaminants may cause rapid wear and shortened

component life.

NOTICE

If the front housing is not installed, do not turn the

crankshaft. Damage to the engine may occur.

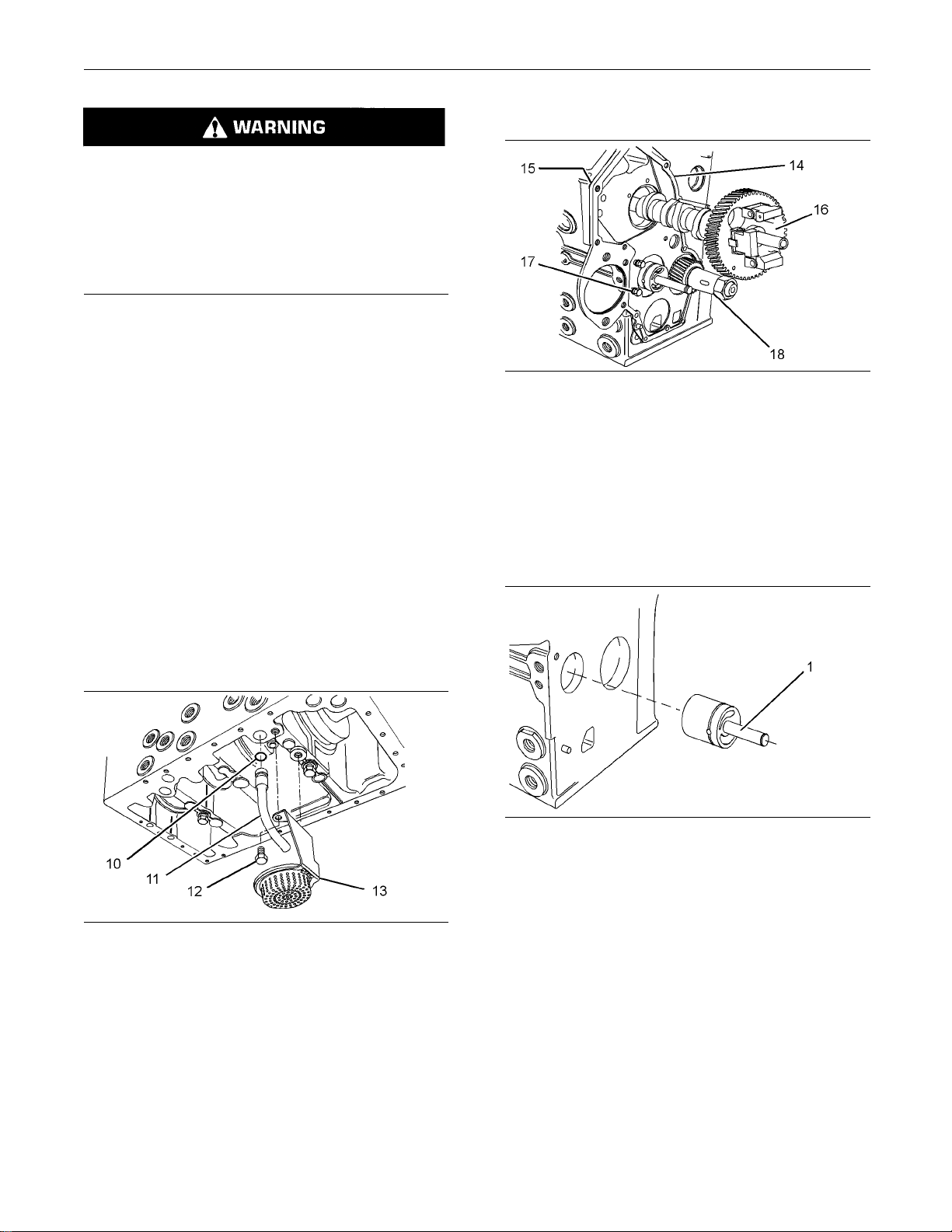

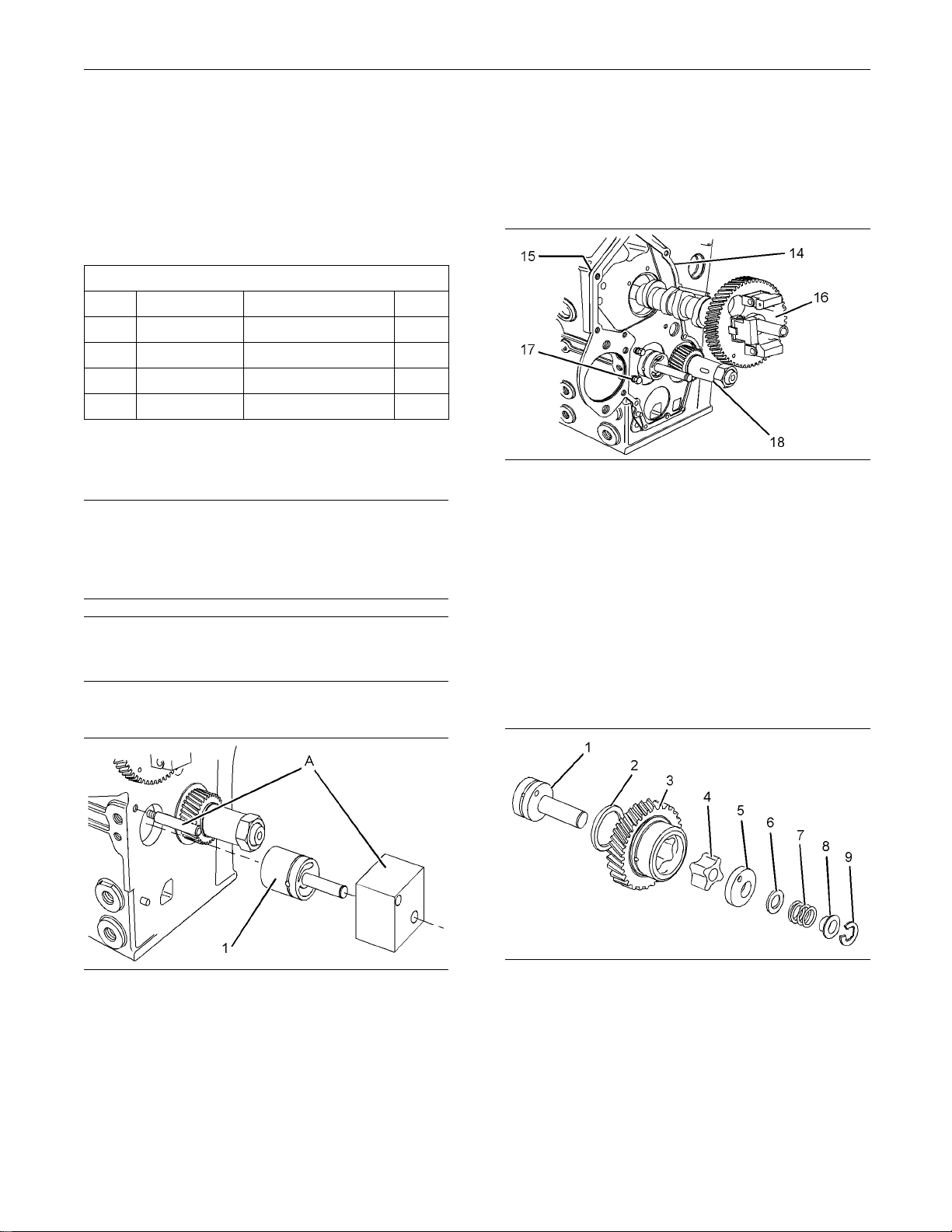

Engine Oil Pump

Illustration 42

g01304840

Page 29

KENR6226-01 29

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Idler Hub

Personal injury can result from being struck by

parts propelled by a released spring force.

Make sure to wear all necessary protective equipment.

Follow the recommended procedure and use all

recommended tooling to release the spring force.

1. Remove C-clip (9) that retains idler gear (3) on

idler hub (1).

2. Remove the following items from idler hub (1):

Collar (8 )

•

Spring (7)

•

Shim (6)

•

Oil pump cover (5)

•

3. Remove idler gear (3) from idler hub (1).

4. Remove inner rotor (4) from idler hub (1).

5. Remove thrust washer (2) from idler hub (1).

6. In order to remove the suction pipe, follow Steps

6.a through 6.d .

Illustration 44

Typical example

1. Remove camsh

aft (16). Refer to Disassembly and

Assembly, “Camshaft - Remove”.

2. Remove bolts

(17) and plate (14) from the cylinder

block. Remove joint (15).

3. Remove crank

shaft (18). Refer to Disassembly

and Assembly, “Crankshaft - Remove”.

g01320621

Illustration 45

Typical example

4. Use a hammer and use a suitable drift to remove

idler hub (1) from the cylinder block. Align the drift

to the rear face of the hub and drive the hub from

the inside of the cylinder block outward.

Illustration 43

g01327023

a. Removetheengineoilpan.Referto

Disassembly and Assembly, “Engine Oil Pan Remove and

Install”.

b. Remove bolts (12) and oil strainer (13) from

the cylind

er block. Inspect the oil strainer for

damage. If the oil strainer is damaged, use a

new part for replacement.

c. Remove suction pipe (11) from the cylinder

block.

d. Remove O-ring seal (10) from the suction pipe.

g01311490

Page 30

30 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

i02960005

Engine Oil Pump - Install

Installation P

Table 8

Tool Part Number Part Description Qty

(1)

A

(2)

A

(3)

A

B

(1)

402D-05 and 403D-07 engines

(2)

403D-11 and 404D-15 engines

(3)

403D-15, 403D-15T, 403D-17, 404D-22, 404D-22T and

404D-22TA engines

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

If the front housing is not installed, do not turn the

crankshaft. Da

21825624

21825625

27610324 Alignment Tool 1

rocedure

Required Tools

Alignment Tool 1

Alignment Tool 1

-

mage to the engine may occur.

Multipurpose Grease 1

NOTICE

NOTICE

3. Use a hammer in order to strike the guide plate of

To o li ng ( A) . D r

ive idler hub (1) into the cylinder

block until the guide plate contacts the front of the

cylinder block.

4. Remove Tooling (A).

Illustration 47

g01320621

5. Install crankshaft (18). Refer to Disassembly and

Assembly, “Crankshaft - Install”.

6. Position a new joint (15) on the cylinder block.

Align plate (14) with the dowels in the cylinder

block and install the plate. Install bolts (17) and

tightentoatorqueof10N·m(89lbin).

7. Install camshaft (18). Refer to Disassembly and

Assembly, “Camshaft - Install”.

Idler Hub

Illustration 46

Typical example

1. Install the p

in of Tooling (A) to the cylinder block.

2. Install idler hub (1) into the guide plate of Tooling

(A). Align th

e guide plate of Tooling (A) with pin

of Tooling (A).

g01305803

Engine Oil Pump

Illustration 48

Typical example

1. Install thrust washer (2). Lubricate the thrust

washer with clean engine oil.

g01304840

Page 31

KENR6226-01 31

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Collar (8)

•

Refer to Illustration 48.

Illustration 49

Typical example

g01305805

Improper assembly of parts that a re spring loaded

can cause bodily injury.

To prevent possible injury, follow the established

assembly procedure and wear protective equipment.

6. Install retain

Illustration 50

Checking end play by using a feeler gauge

ing ring (9) on idler hub (1).

g01320625

7. Use a feeler gauge in order to measure the

end play of the engine oil pump. Refer to

Specifications, “Engine Oil Pump”.

8. If the oil strainer was removed, follow Steps 8.a

through 8.c in order to install the oil strainer.

2. Apply Tooling (B) to the faces of inner rotor (4)

and to the vanes of idler gear (3).

3. Align timing marks (X) on idler gear (3) with the

respective timing marks on gears (19) and (20).

Install idler gear (3) onto idler hub (1).

4. Install inner rotor (4) to idler gear (3).

Personal injury can result from the release of the

spring force.

The drive shaft, the piston, and the drive gear are

under spring force.

Use a press to slowly release the spring force before the components are removed.

5. Install the following items to idler hub (1):

Oil pump cover (5)

•

Shim (6)

•

Spring (7)

•

Illustrat

ion 51

g01327023

a. Install a new O-ring seal (10) on oil tube

assembly (

11).

b. Install oil suction pipe (11) in the cylinder block.

c. Install oil strainer (13) to the cylinder block

and tighten bolts (12) to a torque of 11 N·m

(97lbin)

.

End By:

a. Install the front housing. Refer to Disassembly and

Assembly, “Housing (Front) - Install”.

b. Install the engine oil pan. Refer to Disassembly

and Assembly, “Engine Oil Pan - Remove and

.

Install”

Page 32

32 KENR6226-01

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

i02960013

Water Pump - Remove and

Install

(403D-11, 403D

-15, 403D-15T,

403D-17, 404D-15, 404D-22,

404D-22T and 404D-22TA

Engines)

Removal Procedure

Start By:

a. Remove the fa

Assembly, “Fan - Remove and Install”.

b. Remove the al

Assembly, “Alternator - Remove and Install”.

Keep all part

Contaminants may cause rapid wear and shortened

component li

Care must be t

during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to

collect the

ing any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

1. Drain the co

suitable container for storage or disposal. Refer

to Operation and Maintenance Manual, “Cooling

System Coo

fluid with suitable containers before open-

n. Refer to Disassembly and

ternator. Refer to Disassembly and

NOTICE

s clean from contaminants.

fe.

NOTICE

aken to ensure that fl uids are contained

olant from the cooling system into a

lant - Drain” for more information.

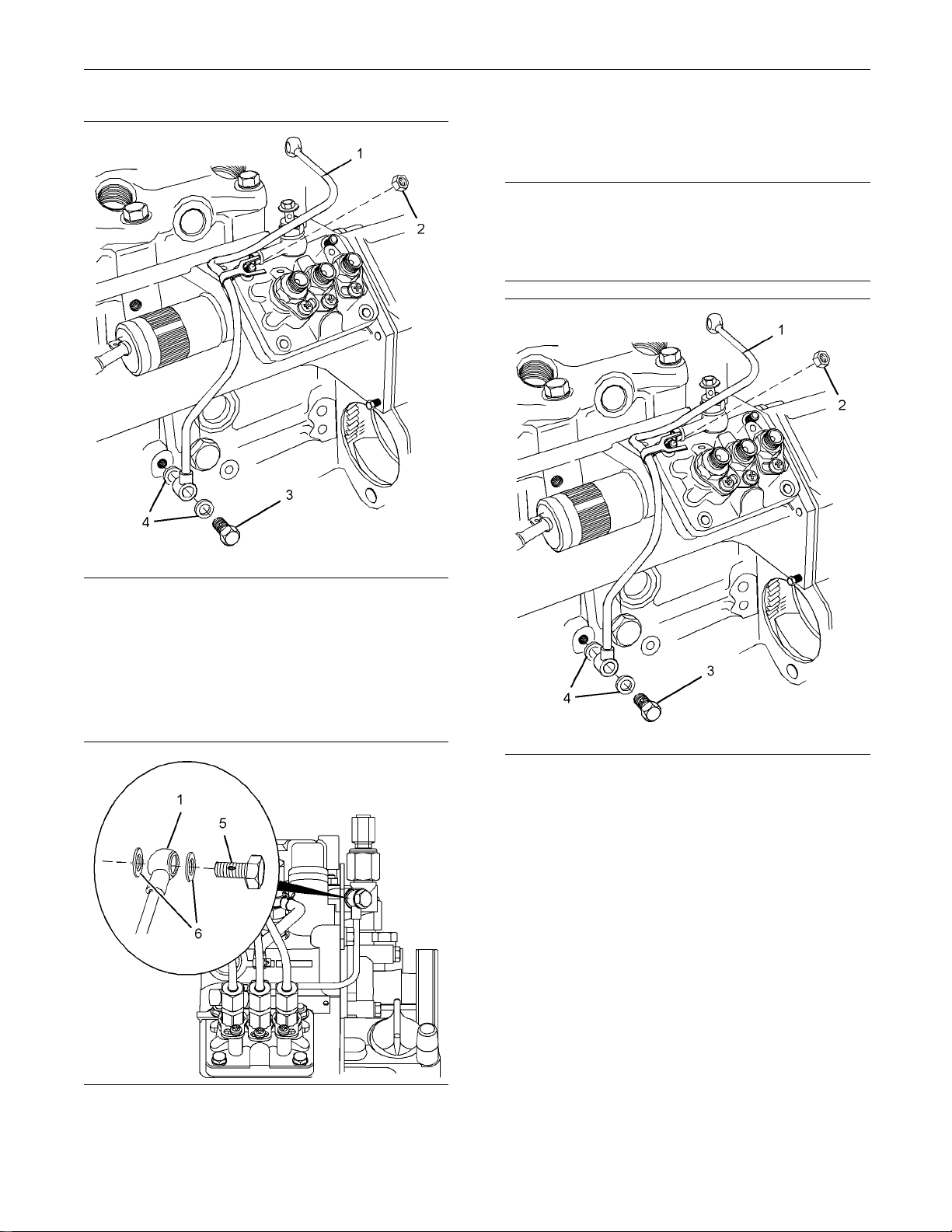

Illustration 52

Typical example

Illustration 53

Typical example

3. Loosen hose clamps (5) and remove hose (6)

from water pump (1).

4. Remove bolt (3) and alternator bracket (2) from

water pump (1).

g01304930

g01305206

2. Loosen the hose clamp and disconnect the hose

(not shown

)fromthewaterpumpinlet.

Note: The alternator bracket on some engines is

secured by two bolts.

5. Remove fasteners (7) and remove water pump (1).

Note: If necessary, gently tap the water pump with a

soft faced hammer in order to loosen the water pump.

6. Remove joint (4) from the cylinder block.

Page 33

KENR6226-01 33

This document has been printed from SPI². Not for Resale

Disassembly and Assembly Section

Installation P

Keep all parts c

Contaminants may cause rapid wear and shortened

component life

1. Ensure that the mating surfaces of the water pump

and the cylinder block are clean and free from

damage.

Illustration 54

Typical example

rocedure

NOTICE

lean from contaminants.