Page 1

Perkins 400 Series

Models 403C-11, 403C-15, 404C-22 and 404C-22T

WORKSHOP MANUAL

403C-11 Three cylinder naturally aspirated diesel

engine

403C-15 Three cylinder naturally aspirated diesel

engine

404C-22 Four cylinder naturally aspirated diesel

engine

404C-22T Four cylinder turbo charged diesel engine

Perkins Confidential: Green

Publication TPD 1458E, Issue 3.

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in September 2002 by Technical Publications.

i

Page 2

7KLV SXEOLFDWLR QLV ZULWWHQLQ

3HUNLQ V $SSUR YHG&OHD U (QJOLVK

Chapters

1 General information

2 Specifications

3 Cylinder head assembly

4 Piston and connecting rod assemblies

5 Crankshaft assembly

6 Timing case and drive assembly

7 Cylinder block assembly

8 Engine timing

9 Aspiration system

10 Lubrication system

11 Fuel system

12 Cooling sy stem

13 Flywheel and housing

14 Electrical equipment

15 Auxiliary equipment

16 Special tools

The following pages contain a detailed table of contents

ii

Page 3

400 Series

Contents

1 General information

Introduction .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1

Safety precautions . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2

POWERPART recommended consumable products ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4

Engine views ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6

Engine identification . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 7

Engine lift equipment ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 8

2 Specifications

Basic engine data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 9

Standard torques ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 10

Special torques .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 11

Compression test data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 12

3 Cylinder head assembly

Rocker cover and inlet manifold

Operation 3-1 To remove and to fit

Rocker assembly

Operation 3-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 14

Workshop Manual TPD 1458E, issue 3 - Perkins Confidential: Green iii

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..13

Page 4

400 Series

Operation 3-3 To dismantle and to assemble .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15

Operation 3-4 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16

Exhaust manifold and gasket

Operation 3-5 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 17

Fuel injection pipes / fuel return pipes

Operation 3-6 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 18

Cylinder head setscrews

Operation 3-7 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 19

Cylinder head

Operation 3-8 Tightening sequence 403C-11 and 403C-15

. ... ... ... ... ... ... ... ... ... ... ... ... ... 20

Operation 3-9 Tightening sequence 404C-22 and 404C-22T .. ... ... ... ... ... ... ... ... ... ... ... ... 21

Cylinder head gasket

Operation 3-10 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 22

Operation 3-11 To select the correct thickness of cylinder head gasket .. ... ... ... ... ... ... ... 23

Valve and valve spring

Operation 3-12 To remove and to fit

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 24

Operation 3-13 To inspect - valve spring ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25

Operation 3-14 To inspect - valve stem and thickness of valve head ... ... ... ... ... ... ... ... ... 26

Cylinder head to valve stem clearance

Operation 3-15 To inspect

. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 27

Cylinder head

Operation 3-16 To inspect

. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 28

Valve seat width

Operation 3-17 To inspect and to correct ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29

Valve depth

Operation 3-18 To check . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 30

Operation 3-19 To lap the contact face of the valve seat . ... ... ... ... ... ... ... ... ... ... ... ... ... ... 31

Valve tip clearance

Operation 3-20 To check and to adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 32

iv Workshop Manual TPD 1458E, issue 3 - Perkins Confidential: Green

Page 5

400 Series

4 Piston and connecting rod assemblies

Big end bearing and cap

Operation 4-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 33

Piston and connecting rod

Operation 4-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 34

Operation 4- 3 To dismantle and to assemble . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 35

Piston rings

Operation 4-4 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 36

Operation 4-5 To measure the piston ring clearance ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 37

Operation 4-6 To measure the piston ring gap .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..38

Piston and connecting rod assemblies

Operation 4- 7 To dismantle and to assemble

Piston and piston ring

Operation 4-8 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..40

Connecting rod

Operation 4-9 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..41

Connecting rod bearing clearance

Operation 4-10 To check

Small end bush

Operation 4-11 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 43

.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..42

. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 39

5 Crankshaft assembly

Crankshaft pulley

Operation 5-1 To remove and to fit

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..45

Crankshaft retaining bolts and crankshaft

Operation 5-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 46

Crankshaft

Operation 5-3 To inspect for deflection ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 47

Workshop Manual TPD 1458E, issue 3 - Perkins Confidential: Green v

Page 6

400 Series

Main bearings

Operation 5-4 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 49

Bearing holder ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 50

6 Timing case and drive assembly

Timing cover

Operation 6-1 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 51

Operation 6-2 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 52

Angleich

Operation 6-3 To remove and to fit

.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 53

Slider

Operation 6-4 To remove and to fit

.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 54

Camshaft retaining plate

Operation 6-5 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 55

Camshaft and tappets

Operation 6-6 To remove and to fit

.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 56

Camshaft assembly

Operation 6-7 To inspect

. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 57

Maximum fuel screw and maximum speed screw

Operation 6-8 Location

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 58

Front oil seal and PTO cover

Operation 6-9 To remove and to fit

.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 59

Idler gear and oil pump

Operation 6-10 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 60

Idler hub

Operation 6-11 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 61

Gear teeth backlash

Operation 6-12 To check ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 62

vi Workshop Manual TPD 1458E, issue 3 - Perkins Confidential: Green

Page 7

400 Series

Oil pump end float

Operation 6-13 To check and adjust . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..63

Governor springs

Operation 6-14 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 64

7 Cylinder block assembly

Front crankshaft bush

Operation 7-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 65

Operation 7-2 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..66

Cylinder block top face

Operation 7-3 To inspect

Cylinder bore

Operation 7-4 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..68

. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 67

8 Engine timing

Operation 8-1 Injection timing . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 69

Operation 8-2 To check the timing of the fuel injection pump ... ... ... ... ... ... ... ... ... ... ... ... .. 70

9 Aspiration system

Breather system

Operation 9-1 Closed circuit, naturally aspirated - to clean and to renew .. ... ... ... ... ... ... ..73

Operation 9-2 Closed circuit turbo charged - to clean and to renew ... ... ... ... ... ... ... ... ... .. 74

Turbocharger

Operation 9-3 To remove and to fit

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..75

10 Lubrication system

Lubricating oil canister

Operation 10-1 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..77

Pressure relief valve

Operation 10-2 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 78

Workshop Manual TPD 1458E, issue 3 - Perkins Confidential: Green vii

Page 8

400 Series

Lubricating oil sump

Operation 10-3 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 79

Lubricating oil strainer and suction pipe

Operation 10-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 80

Lubricating oil pump

Operation 10-5 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 81

Rotor tip clearance

Operation 10-6 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 82

Oil pressure switch

Operation 10-7 To remove and to fit

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 83

Lubricating oil pipes

Operation 10-8 To remove and to fit

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 84

11 Fuel system

Atomisers

Operation 11-1 To remove and to fit

Fuel lift pump

Operation 11-2 To remove and to fit

Fuel injection pump

Operation 11-3 To remove and to fit

Operation 11-4 To eliminate air from the fuel system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 89

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 85

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 87

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 88

12 Cooling system

Coolant pump

Operation 12-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 91

Operation 12-2 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 92

Fan and mounting

Operation 12-3 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 93

viii Workshop Manual TPD 1458E, issue 3 - Perkins Confidential: Green

Page 9

400 Series

Thermostat

Operation 12-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 94

Operation 12-5 To drain the cylinder block . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 95

Operation 12-6 To test and to inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..96

13 Flywheel and housing

Flywheel

Operation 13-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 97

Operation 13-2 To check for concentricity and alignment of the flywheel housing . ... ... ..98

Operation 13-3 To check for run-out of the flywheel and alignment of the flywheel face .99

Starter ring gear

Operation 13-4 To remove and to fit

Backplate and rear oil sea l

Operation 13-5 To remove and to fit

. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 100

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 101

14 Electrical equipment

Electrical shut off solenoid

Operation 14-1 To remove and to fit

Bus-bar / glowplugs

Operation 14-2 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 104

Drive belt

Operation 14-3 To inspect an d to adjust .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 105

Alternator

Operation 14-4 To remove and to fit

. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 103

. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 106

Starter motor

Operation 14-5 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 107

Wiring diagram 15 amp alternator - 403C-11 .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 108

Wiring diagram 40 amp alternator - 403C-11 . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 109

Wiring diagram 55 amp alternator 403C-15, 404C-22 and 404C-22T . ... ... ... ... ... ... ... 110

Automatic shutdown connector ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 111

Wiring diagram - automatic shutdown 15 amp alternator - 403C-11 . ... ... ... ... ... ... ... 112

Workshop Manual TPD 1458E, issue 3 - Perkins Confidential: Green ix

Page 10

400 Series

Wiring diagram - automatic shutdown 40 amp alternator - 403C-11 ... ... ... ... ... ... ... ..113

Wiring diagram - automatic shutdown 55 amp alternator 403C-15, 404C-22

and 404C-22T .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..114

15 Auxiliary equipment

Operation 15-1 None fitted . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..115

16 Special tools

Special tools list .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..117

x Workshop Manual TPD 1458E, issue 3 - Perkins Confidential: Green

Page 11

400 Series

1

General information 1

Introduction

This workshop manual has been written to provide assistance for technicians who service and overhaul the

Perkins 403C-11, 403C-15, 404C-22 and the 404C-22T engine. The assumption is made that the engine is

removed from the application.

The engine conforms with USA EPA/CARB and EC emissions legislation for agricultural and industrial

applications.

Where the information applies only to certain engine types, this is indicated in the text.

Special tools are available and listed in chapter 16. POWERPART recommended consumable products are

listed in this chapter. There is a reference to the relevant special tools and consumable products at the

beginning of each operation.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible danger to the person.

Caution: This indicates that there is a possible danger to the engine.

Note: Is used where the information is important, but there is not a danger.

Warning! Read and remember the "Safety precautions". They are given for your protection and must be used

at all times.

Generally, if new joints are to be fitted, it is accepted that the faces for the joint will be cleaned, as this is normal

workshop practice. Also, it is understood that during assembly and inspection, all parts are to be thoroughly

cleaned and lubricated, and where present, burrs and scale are to be removed.

All open ports of high-precision components e.g. fuel injection equipment must be covered until assembly, to

prevent the entry of foreign matter.

When either the "left" or the "right" side of the engine is referred to, it is when viewed from the flywheel end.

When fitting setscrews or studs into holes that enter oil, coolant or air passages, a suitable sealant should be

used to prevent leakage.

Micro encapsulated anaerobic sealant (M.E.A.S.) has been applied to the threads instead of jointing

compounds or other sealants when the fasteners are fitted in through holes into oil or coolant passages. The

identification of these fasteners, as supplied, is by the colour of the sealant.

With M.E.A.S. sealed studs, the sealed end must be fitted into the component. The threaded holes must have

a 1,59 mm (0.0625 in) 45° chamfer to ensure that the M.E.A.S. sealant is not removed when the new fasteners

are fitted. If the fasteners have to be removed and fitted again, the threads must be cleaned and a suitable

sealant used.

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 1

Page 12

1

400 Series

Safety precautions

These safety precautions are important. You must refer also to the local regulations in the country of use.

Some items only refer to specific applications

l Only use these engines in the type of application for which they have been designed.

l Do not change the specification of the engine.

l Do not smoke when you put fuel in the tank.

l Clean away fuel which has been spilt. Material which has been contaminated by fuel must be moved to a

safe place.

l Do not put diesel fuel in the tank during engine operation (unless it is absolutely necessary).

l Do not add lubricating oil, or adjust the engine while it runs (unless you have had the correct training; even

then extreme care must be used to prevent injury).

l Do not make adjustments that you do not understand.

l Ensure that the engine does not run in a location where it can cause a concentration of toxic emissions.

l Other persons must be kept at a safe distance while the engine or auxiliary equipment is in operation.

l Do not permit loose clothing or long hair near moving parts.

l Keep away from moving parts during engine operation. Warning! Some moving parts cannot be seen

clearly while the engine runs.

l Do not operate the engine if a safety guard has been removed.

l Do not remove the filler cap or any component of the cooling system while the engine is hot and while the

coolant is under pressure, because dangerous hot coolant can be discharged.

l Do not allow sparks or fire near the batteries (especially when the batteries are on charge) because the

gases from the electrolyte are highly flammable. The battery fluid is dangerous to the skin and especially

to the eyes.

l Disconnect the battery terminals before a repair is made to the electrical system.

l Only one person must control the engine.

l Ensure that the engine is operated only from the control panel or from the operators position.

l If your skin comes into contact with high-pressure fuel, obtain medical assistance immediately.

l Diesel fuel and lubricating oil (especially used lubricating oil) can damage the skin of certain persons.

Protect your hands with gloves or a special solution to protect the skin.

l Do not wear clothing which is contaminated by lubricating oil. Do not put material which is contaminated

with oil into the pockets of clothing.

l Discard used lubricating oil in accordance with local regulations to prevent contamination.

l Ensure that the control lever of the transmission drive is in the "out-of-drive" position before the engine is

started.

l Use extreme care if emergency repairs must be made in adverse conditions.

l The combustible material of some components of the engine (for example certain seals) can become

extremely dangerous if it is burned. Never allow this burnt material to come into contact with the skin or with

the eyes.

l Always use a safety cage to protect the operator when a component is to be pressure tested in a container

of water. Fit safety wires to secure the plugs which seal the hose connections of a component which is to

be pressure tested.

l Do not allow compressed air to contact your skin. If compressed air enters your skin, obtain medical help

immediately.

l Turbochargers operate at high speed and at high temperatures. Keep fingers, tools and debris away from

the inlet and outlet ports of the turbocharger and prevent contact with hot surfaces.

l Do not clean an engine while it runs or while it is hot. If cold cleaning fluids are applied to a hot engine,

certain components on the engine could be damaged.

l Fit only genuine Perkins parts.

2 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 13

400 Series

Viton seals

Warnings!

l Some seals used in engines and in components fitted to engines are made of Viton. Viton is used by many

manufactures and is a safe material under normal conditions of operation. If Viton is burned, a product of

this burnt material is an acid which is extremely dangerous. Never allow this burnt material to come into

contact with the skin or with the eyes. If it is necessary to come into contact with components which have

been burnt, ensure that the precautions which follow are used:

l Ensure that the components have cooled.

l Use Neoprene gloves and discard the gloves safely after use.

l Wash the area with calcium hydroxide solution and then with clean water.

l Disposal of components and gloves which are contaminated must be in accordance with local regulations.

If there is contamination of the skin or eyes, wash the affected area with a continuous supply of clean water or

with calcium hydroxide solution for 15 - 60 mi nutes. Obtain immediate medical attention.

Safety cautions when an engine is cleaned

Care should be taken, when an engine is cleaned with a high pressure cleaning system.

Cautions:

l Do not wash an engine while it runs or while it is hot. If cold cleaning fluids are applied to a hot engine,

certain components on the engine could be damaged.

l Leave the engine to cool for at least one hour and disconnect the battery connections before cleaning.

l Do not wash any part of the fuel injection pump (FIP), cold start device, electrical shut off solenoid (ESOS)

or electrical connectors.

l Ensure that the alternator, starter motor and any other electrical components are shielded and not directly

cleaned by the high pressure cleaning system.

If these cautions are ignored, the engine or certain components could be damaged, fail to operate and also

make the manufacturer’s warranty invalid.

1

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 3

Page 14

1

400 Series

POWERPART recommended consumable products

Perkins have made available the products recommended below in order to assist in the correct operation,

service and maintenance of your engine and your machine. The instructions for the use of each product are

given on the outside of each container. These products are available from your Perkins distributor.

POWERPART Antifreeze

Protects the cooling system against frost and corrosion.

Part number 21825166.

POWERPART Easy Flush

Cleans the cooling system.

Part number 21825001.

POWERPART Gasket and flange sealant

To seal flat faces of components where no joint is used. Especially suitable for aluminium components.

Part number 21820518.

POWERPART Gasket remover

An aerosol for the removal of sealants and adhesives.

Part number 21820116.

POWERPART Griptite

To improve the grip of worn tools and fasteners.

Part number 21820129.

POWERPART Hydraulic threadseal

To retain and seal pipe connections with fine threads. Especially suitable for hydraulic and pneumatic systems.

Part number 21820121.

POWERPART Industrial grade super glue

Instant adhesive designed for metals, plastics and rubbers.

Part number 21820125.

POWERPART Lay-Up 1

A diesel fuel additive for protection against corrosion.

Part number 1772204.

POWERPART Lay-Up 2

Protects the inside of the engine and of other closed systems.

Part number 1762811.

POWERPART Lay-Up 3

Protects outside metal parts.

Part number 1734115.

POWERPART Metal repair putty

Designed for external repair of metal and plastic.

Part number 21820126.

POWERPART Pipe sealant and sealant primer

To retain and seal pipe connections with coarse threads. Pressure systems can be used immediately.

Part number 21820122.

4 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 15

400 Series

POWERPART Radiator stop leak

For the repair of radiator leaks.

Part number 21820127.

POWERPART Retainer (high strength)

To retain components which have an interference fit. Currently Loctite 638.

Part number 21820638.

POWERPART Safety cleaner

General cleaner in an aerosol container.

Part number 21820128.

POWERPART Silicone adhesive

An RTV silicone adhesive for application where low pressure tests occur before the adhesive sets. Used for

sealing flange where oil resistance is needed and movement of the joint occurs.

Part number 21826038.

POWERPART Silicone RTV sealing and jointing compound

Silicone rubber sealant which prevents leakage through gaps. Currently Hylosil.

Part number 1861108.

1

POWERPART Stud and bearing lock

To provide a heavy duty seal to components that have a light interference fit.

Part number 21820119 or 21820120.

POWERPART Threadlock and nutlock

To retain small fasteners where easy removal is necessary.

Part number 21820117 or 21820118.

POWERPART Universal jointing compound

Universal jointing compound which seals joints. Currently Hylomar.

Part number 1861117.

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 5

Page 16

1

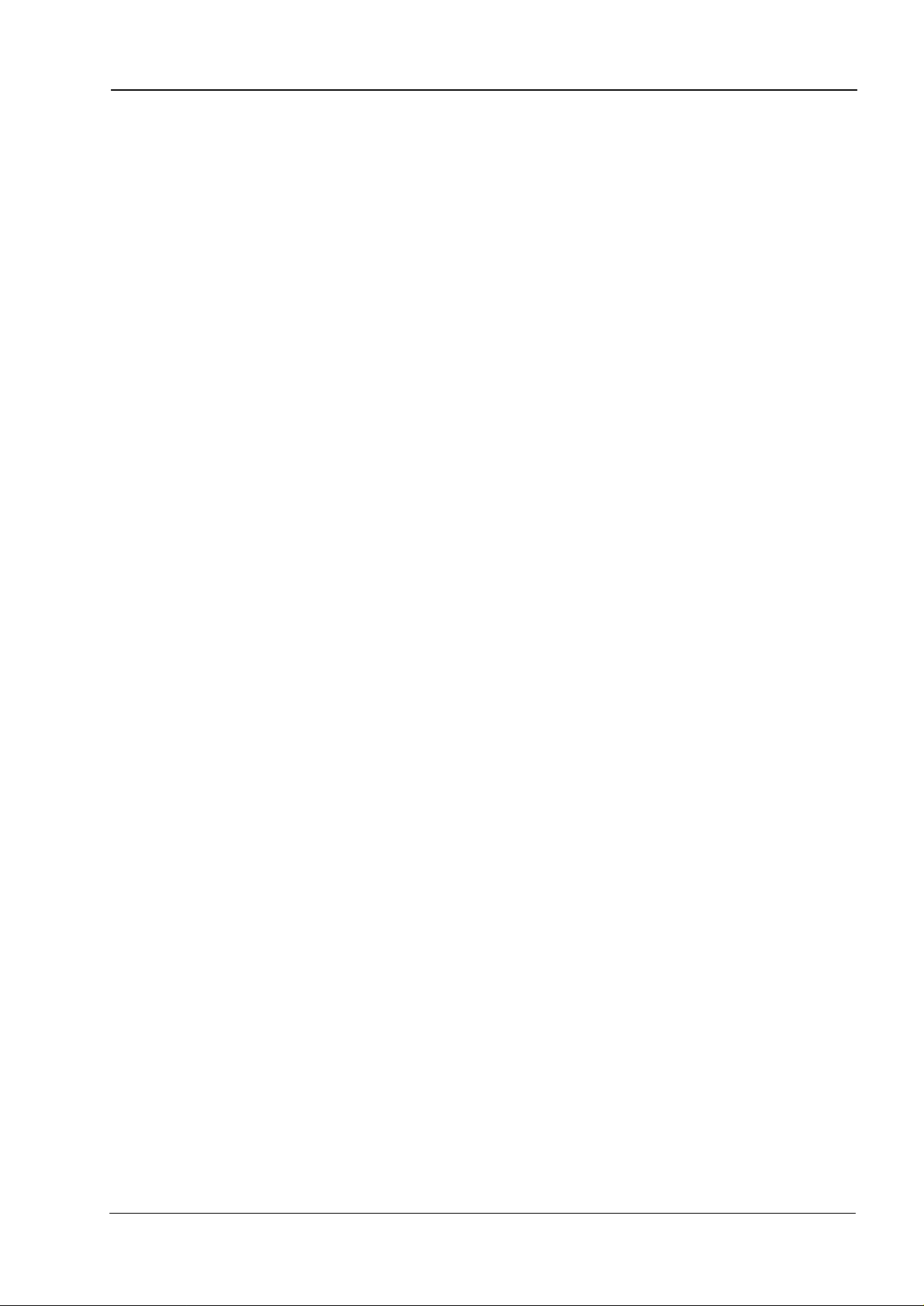

Engine views

400 Series

H1029

H1030

6 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 17

400 Series

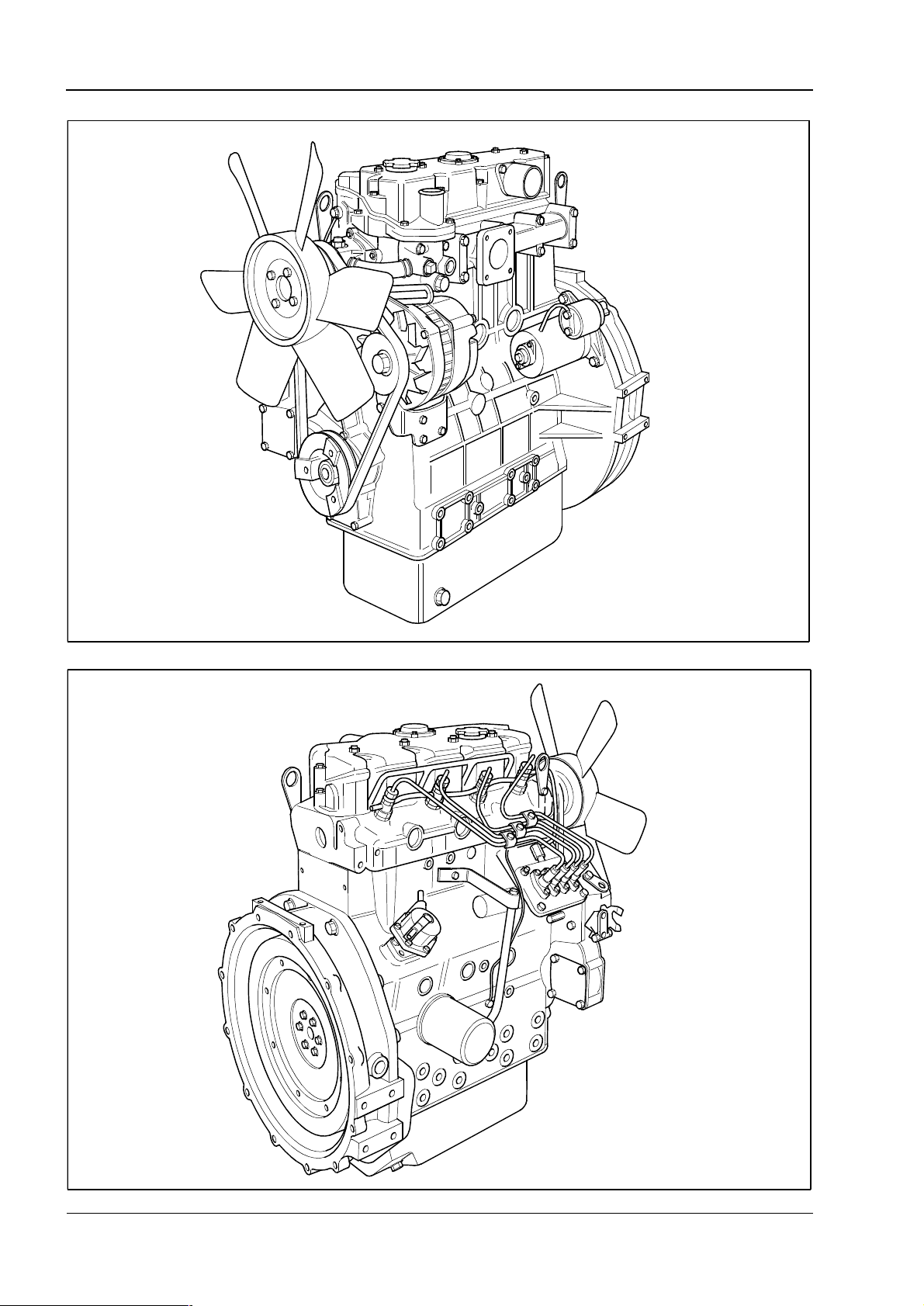

Engine identification

Engine build lists numbering system

The standard engine build list numbering code is defined as follows:

Code I II III IV V

Example HP TBA U 000001 D

Code I Engine build code

Code HH HL HP HR

Engine 403C-11 403C-15 404C-22 404C-22T

Code II engine build list

The build list increases numerically for both OEMS and distributors.

Code III country of manufacture

Code J U

Country of manufacture Made in Japan Made in U.K.

Code IV engine serial number

Individual serial number commencing with 000001 increasing numerically.

1

Code V year of manufacture

Code H J

Year 2001 2002

Perkins

LIST NO SERIAL NO TYPE

TYPE

H1031

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 7

Page 18

1

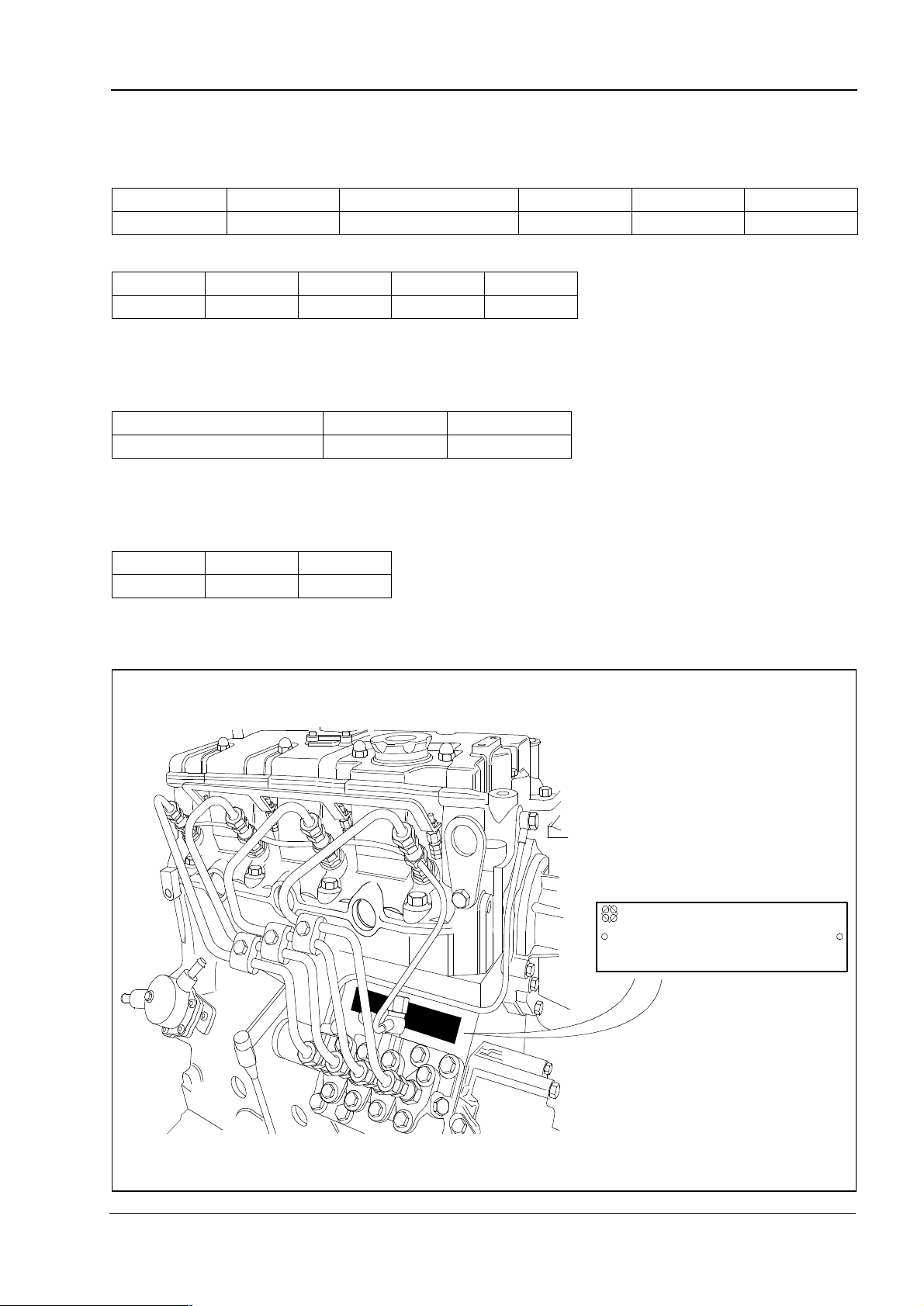

Engine lift equipment

Recomm en d ed torque : l if ting eye bolt s

Engine Nm (lbf ft) kgf m

All models 26 (19) 2,6

Maximum engine weights

400 Series

Engine Engine specification Maximum engine

weights (dry)

Long flywheel housing speci fic at ion 114 kg

403C-11

403C-15

404C-22

404C-22T

(1) Engine may alter with final specification.

Short flywheel housing specification 96 kg

Backplate specification 87 kg

Long flywheel housing speci fic at ion 176 kg

Short flywheel housing specification 154 kg

Backplate specification 150 kg

Long flywheel housing speci fic at ion 220 kg

Short flywheel housing specification 196 kg

Backplate specification 184 kg

Long flywheel housing speci fic at ion 230 kg

Short flywheel housing specification 206 kg

Backplate specification 194 kg

(1)

H1032

8 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 19

400 Series

2

Specifications 2

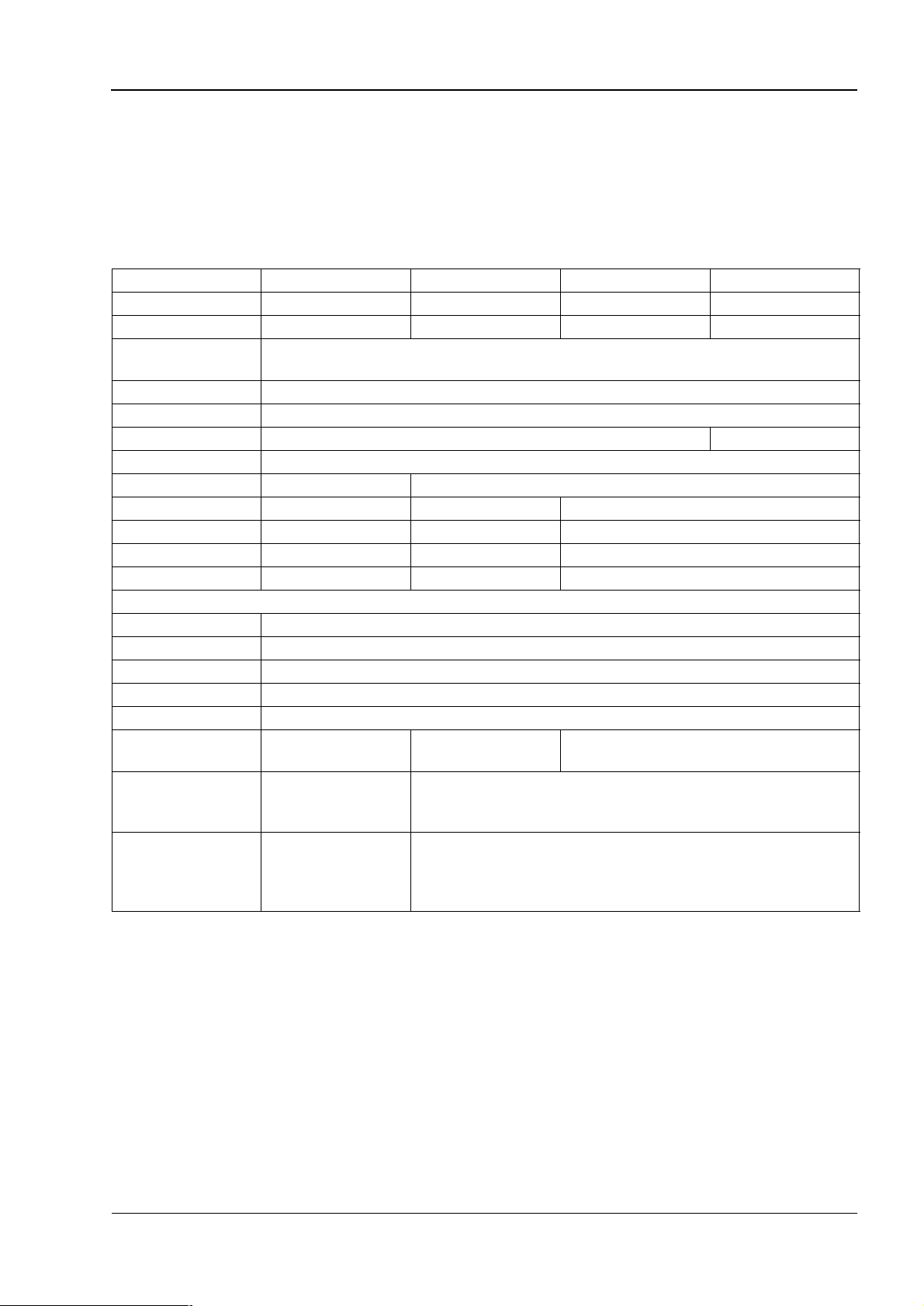

Basic engine data

Engine model 403C-11 403C-15 404C-22 404C-22T

Engine build code HH HL HP HR

Number of cy linde rs 3 3 4 4

Cylinder

arrangement

Cycle Four stroke

Direction of rotation Clockwise from the front

Induction system Naturally aspirated Turbo charged

Combustion system Indirect injection

Nominal bore 77 mm (3.03 in) 84 mm (3.3 in)

Stroke 81 mm (3.19 in) 90 mm (3.5 in) 100 mm (3.9 in)

Compression ratio 23: 1 22.5: 1 23.3: 1

Cubic capacity 1,131 litres (69 in³) 1,496 litres (91 in³) 2,216 litres (135.2 in³)

Firing order 1, 2, 3 1, 2, 3 1, 3, 4, 2

Valve tip clearance (cold)

Inlet 0,2 mm (0.0078 in)

Exhaust 0,2 mm (0.0078 in)

Governor Mechanical all speed

Fuel injection Cassette type fuel injection pump

Electrical system 12 Volt

Lubricating oil

pressure relief valve

Lubricating oil

pressure switch

located on to p cover

Lubricating oil

pressure switch

located on cylinder

block oil rail

304 - 500 kPa 262 - 359 kPa 352 - 448 kPa

49,0 kPa 29,4 kPa

49,0 kPa 98,0 kPa

Vertical in line

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 9

Page 20

2

400 Series

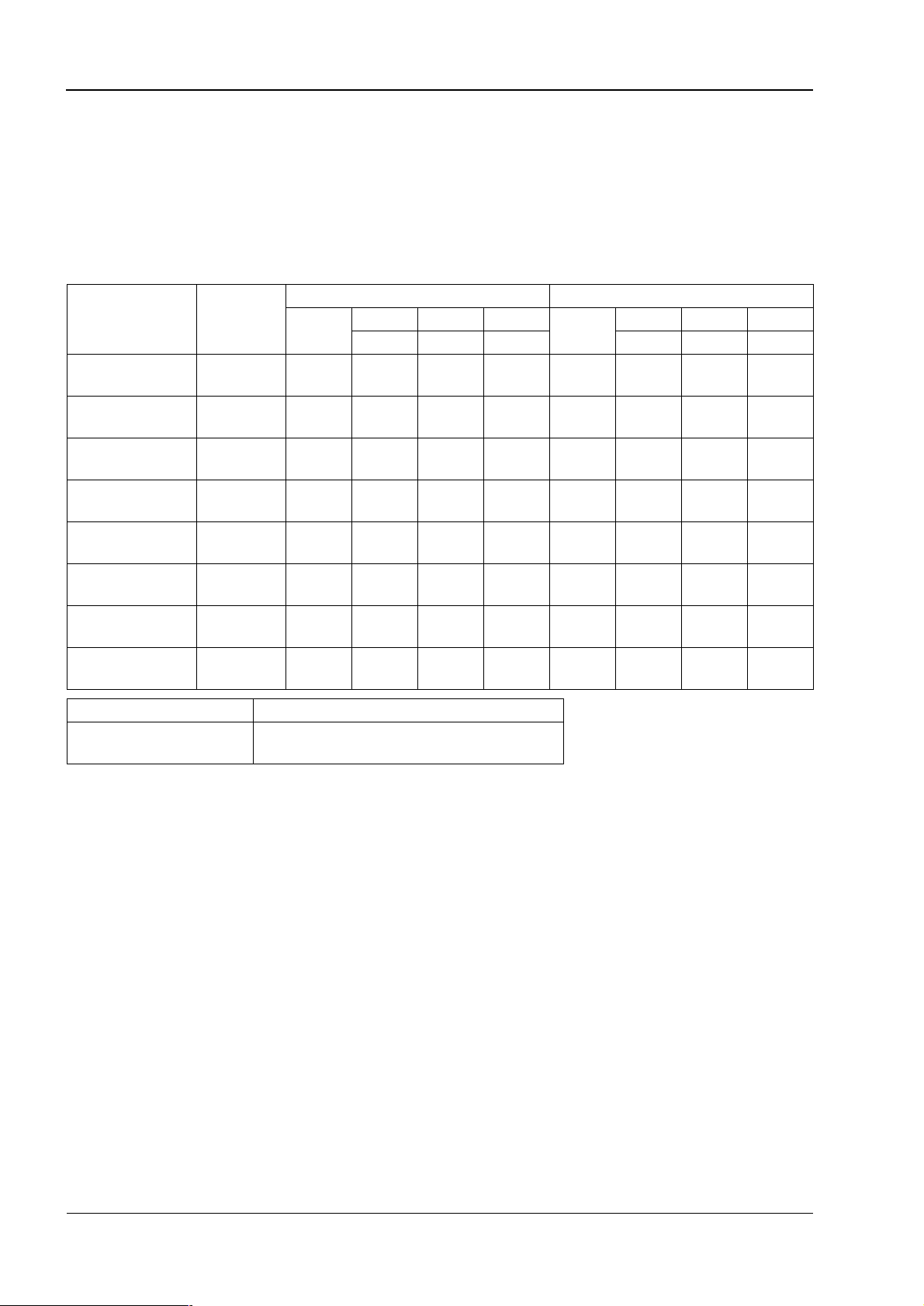

Standard torques

Most of the torque tensions on the engine are standard. Special torque tensions are listed in the separate

specific torque tables. The standard torque tensions listed in the tables below can be used when a specific

torque is not necessary.

The torque tensions below apply to components lubricated lightly with clean engine oil before they are fitted.

Standard torques for setscrews and nuts

Coarse thread Fine thread

Thread size Strength

M 4

M5

M6

M8

M10

M12

M14

M16

8.8

11T

8.8

11T

8.8

11T

8.8

11T

8.8

11T

8.8

11T

8.8

11T

8.8

11T

Pitch

mm

0,7

0,8

1,0

1,25

1,5

1,75

2,0

2,0

Torque Torque Torque

Nm lbf ft kgf m Nm lbf ft kgf m

3

4

6

8

10

14

26

32

50

62

75

104

118

157

167

230

2

3

4

6

7

10

19

24

37

46

55

77

87

116

123

170

0,3

0,4

0,6

0,8

1,0

1,4

2,7

3,3

5,1

6,3

7,6

10,6

12,0

16,0

17,0

23,4

Pitch

mm

1,0

1,25

1,25

1,5

1,5

Torque Torque Torque

----

----

---30

35

56

66

84

113

132

167

175

245

22

26

41

49

62

83

97

123

129

181

3,0

3,6

5,7

6,7

8,6

11,5

13,5

17,0

17,8

25,0

Bolt strength Examples of applicable material

8.8

11T

S45C

SCM435

10 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 21

400 Series

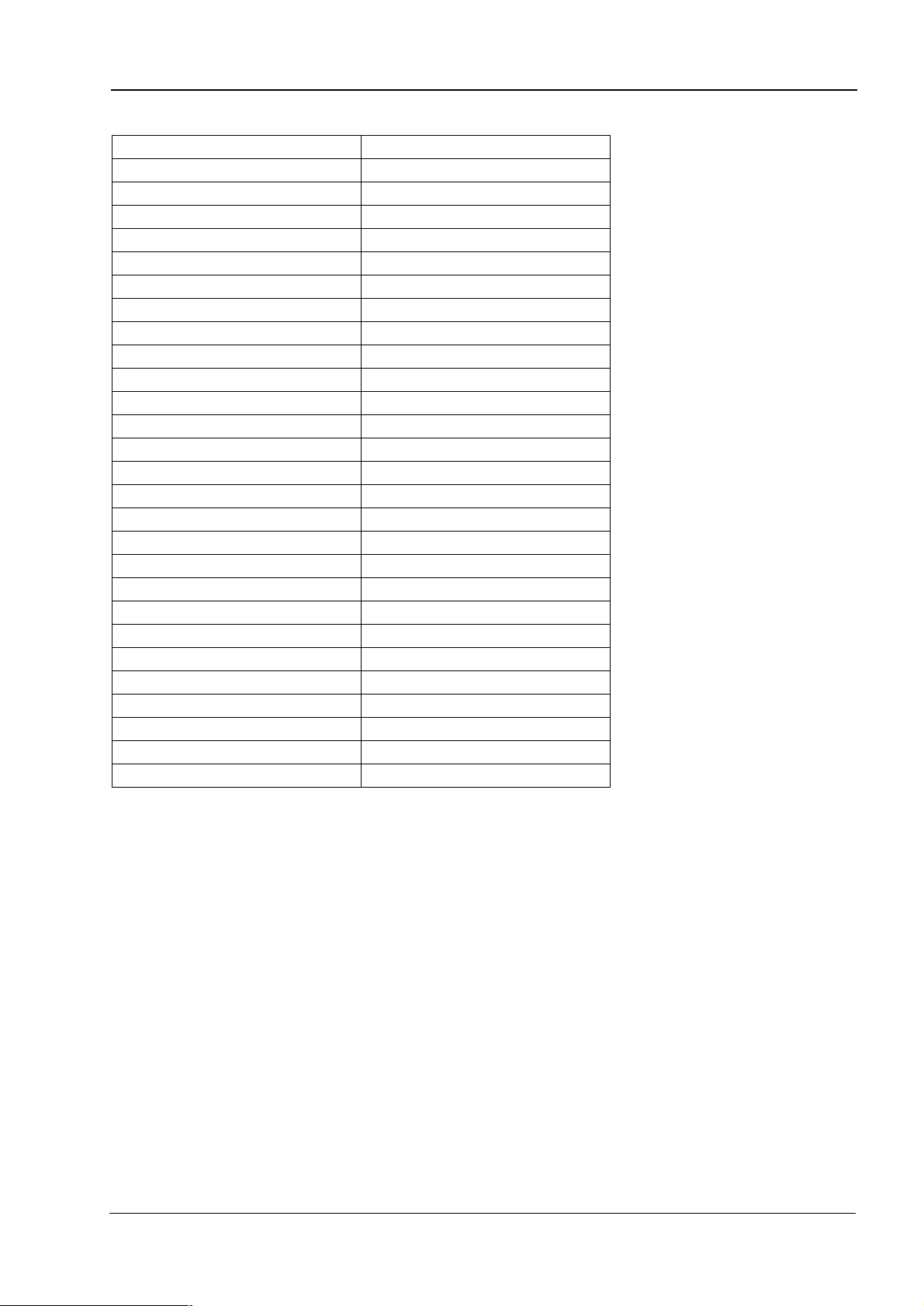

Special torques

Torque Nm (lbf ft) kgf m

Angleich 5 (3.6) 0,5

Atomiser 64 (47.2) 6,4

Atomiser pipes 23 (16.9) 2,3

Blanking plug rear of cylinder block 7 (5.1) 0,7

Crankshaft carrier to block 27 (19.9) 2,7

Connecting rod nuts 52 (38.3) 5,2

Crankshaft nut 303 (223.5) 30,3

Crankshaft sub assembly 52 (38.3) 5,2

Exhaust manifold 25 (18.4) 2,5

Flywheel 74 (54.5) 7,4

Fuel injection pump 15 (11) 1,5

Fuel injection pump leak off rail 7 (5.1) 0,7

Glow plug 18 (13.2) 1,8

Head setscrew 101 (74.5) 10,3

Leak off rail 27 (19.9) 2,7

Lift pump banjo 12 (8.8) 1,2

Lift pump mounting setscrew 6 (4.4) 0,6

Oil pipe 12 (8.8) 1,2

Oil strainer 10 (7.3) 1,0

Relief valve 64 (47.2) 6,4

Timing case 10 ( 7.3) 1,0

Rocker assembly nuts 33 (24.3) 3,3

Rocker cover 14 (10.3) 1,4

Electrical shut off solenoid 18 (13.2) 1,8

Sump drain plug 35 (25.8) 3,5

Temperature switch 27 (19.9) 2,7

Thermostat setscrew 14 (10.3) 1,4

2

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 11

Page 22

2

400 Series

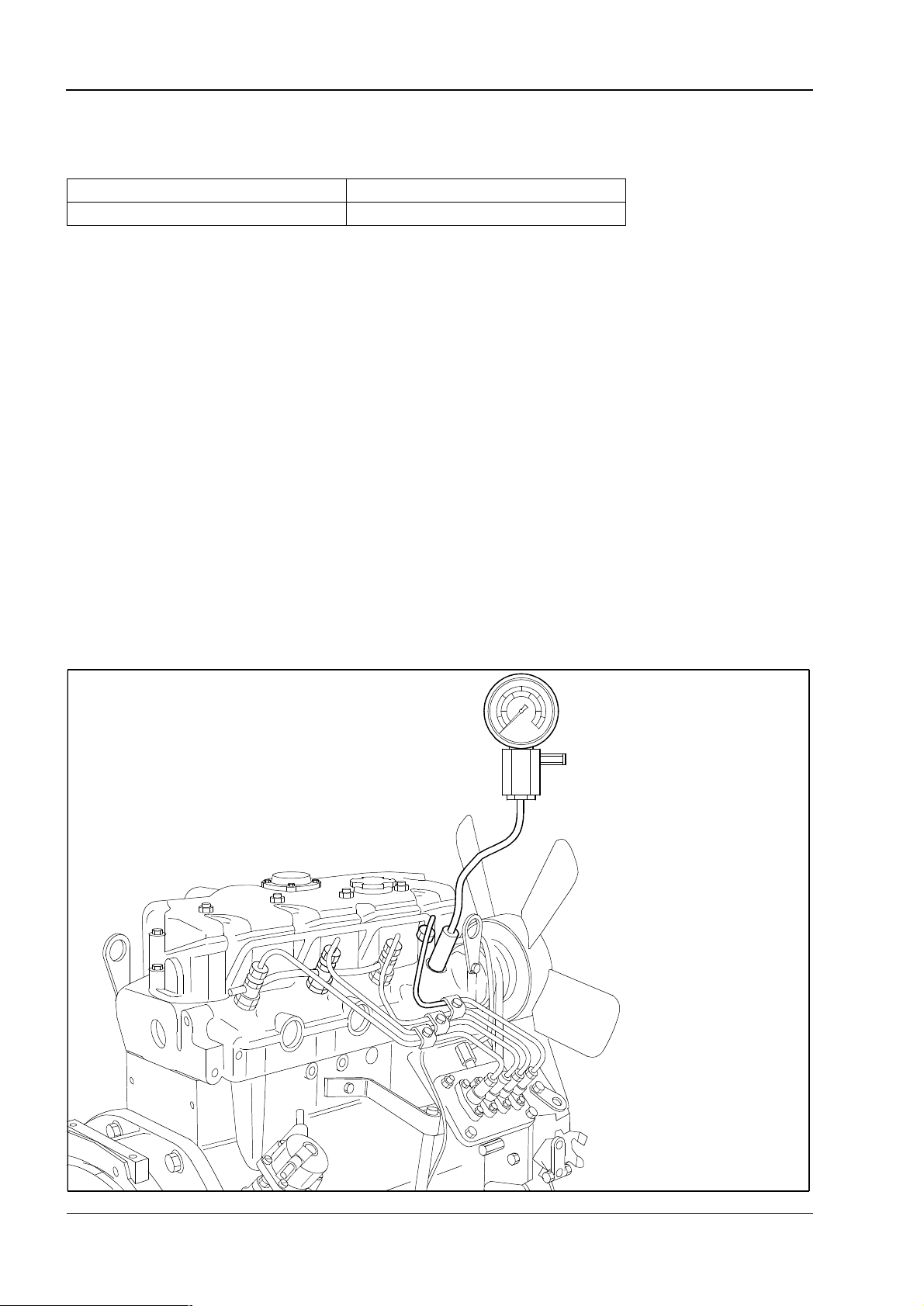

Compression test data

Many factors affect compression pressures, the battery, starter motor condition, ambient conditions and the

type of gauge used can give a wide variation of results for a given engine.

Standard value To be repaired

>2940 kPa (426.6 lbf / in²) @ 250 rpm <2450 kPa (355.5 lbf / in²) @ 250 rpm

Compression tests should only be used to compare between cylinders of an engine. If one or more cylinders

vary by more than 350 kPa (50 lbf / in²) then those cylinders may be faulty.

Compression tests should not be the only method used to show the condition of an engine, but they should be

used together with other symptoms and tests.

How to do a compression test

Note: Before the compression test, ensure that the battery is in good condition and fully charged. Also ensure

the starter motor is in good condition.

1 Ensure that the valve tip clearances are set correctly.

2 Remove the atomisers, see Operation 11-1.

3 Fit a suitable gauge into the atomiser hole of the cylinder to be tested.

4 Disconnect the stop solenoid or put the stop solenoid in the no fuel position. Operate the starter motor and

record the pressure indicated on the gauge.

Caution: Do not remove the stop solenoid as this will allow the engine to start.

5 Repeat for each cylinder.

H1033

12 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 23

400 Series

3

Cylinder head assembly 3

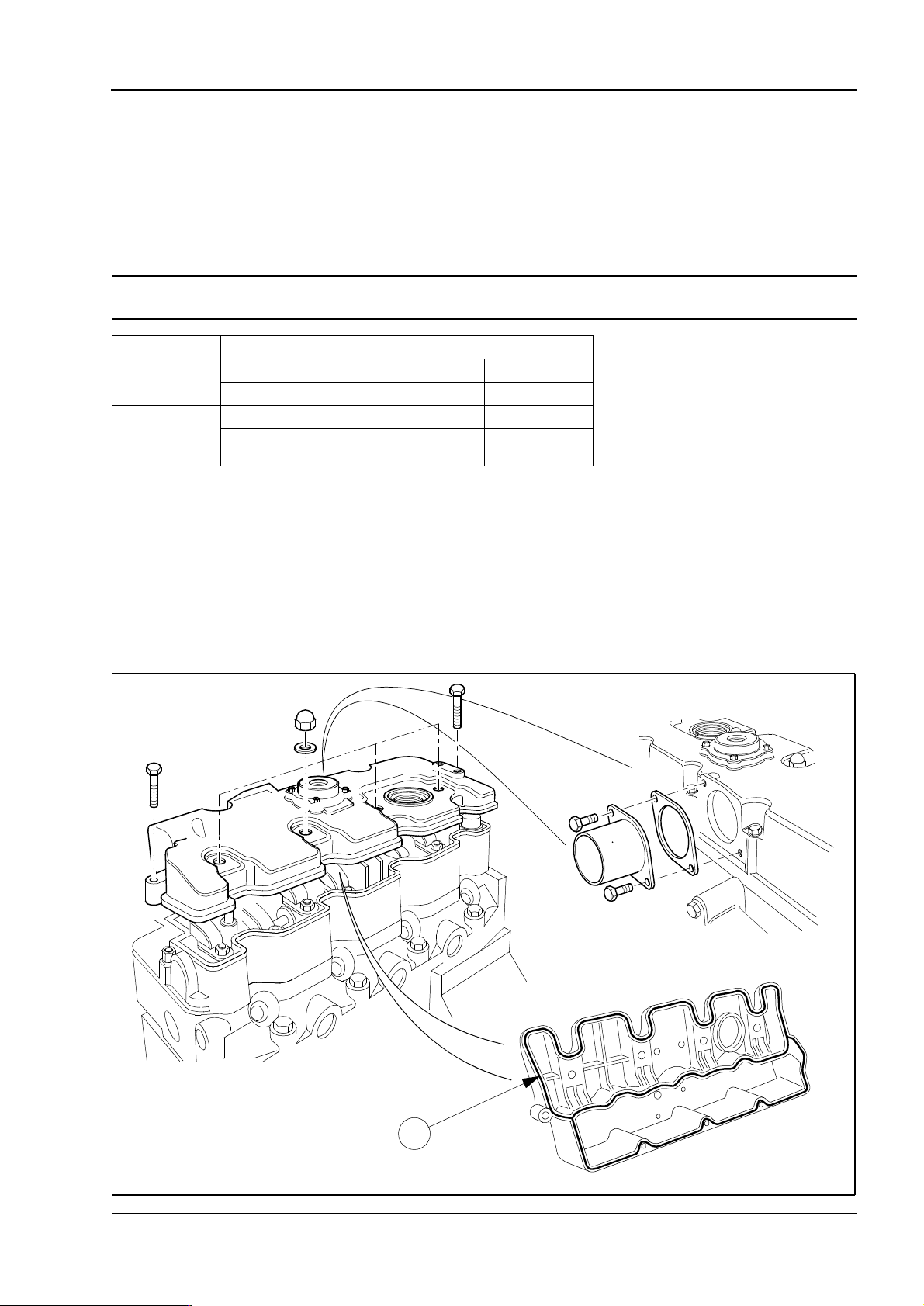

Rocker cover and inlet manifold

To remove and to fit Operation 3-1

Engine Torque Nm (lbf ft) kgf m

403C-11

403C-15

404C-22

404C-22T

Notes:

l An ‘O’ ring (1) is fitted in the groove in the rocker cover.

l Inspect the ‘O’ ring and renew if necessary.

Cap nut 11 (8.1) 1,1

Setscrew 11 (8.1) 1,1

Cap nut 14 (10.3) 1,4

Setscrew 14 (10.3) 1,4

1

H1034

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 13

Page 24

3

400 Series

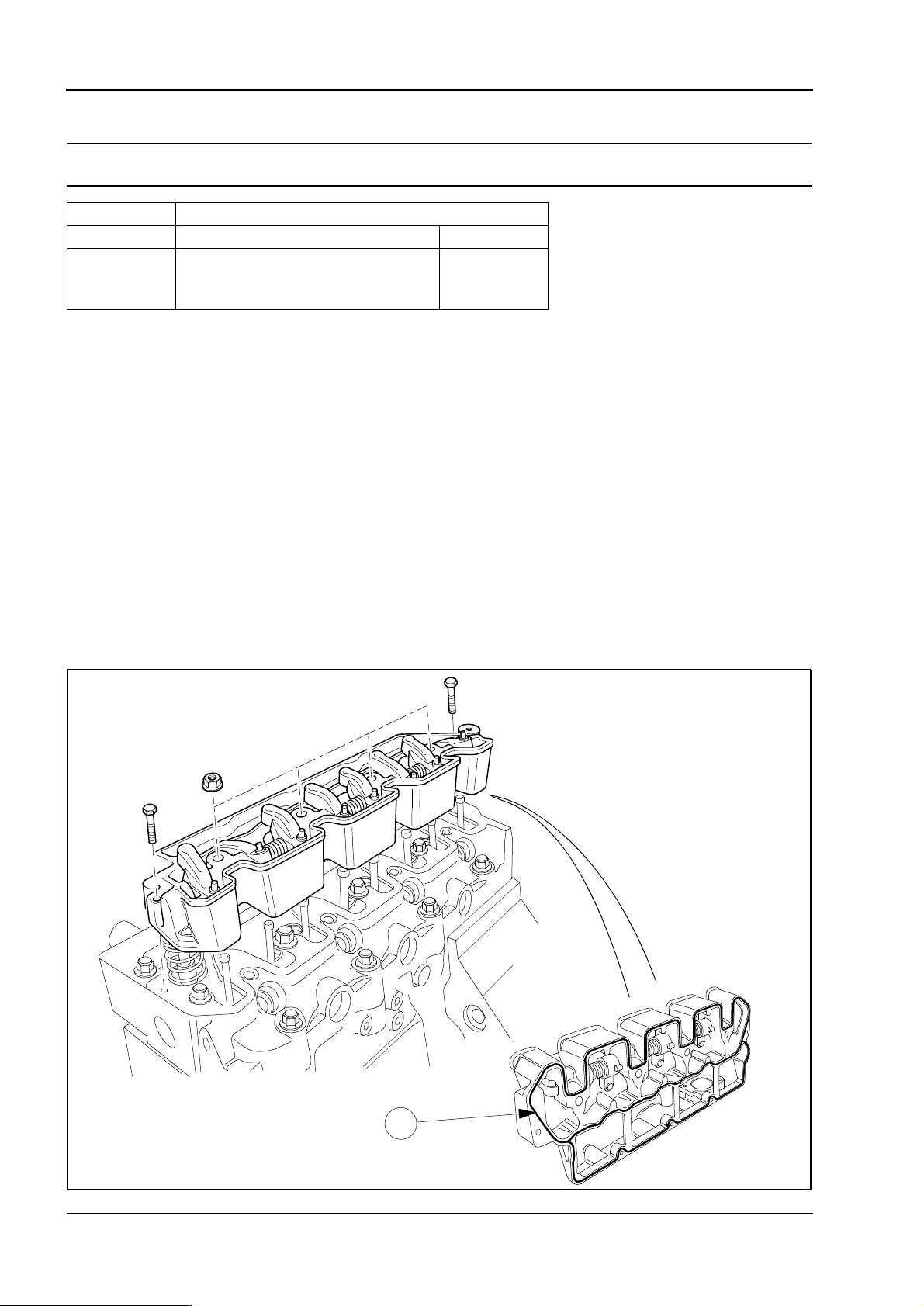

Rocker ass embly

To remove and to fit Operation 3-2

Engine Torque Nm (lbf ft) kgf m

403C-11 Rocker assembly nuts 23 (17.0) 2,3

403C-15

404C-22

404C-22T

Caution: Ensure that the valve stem caps are on the valve stems and the pushrods are located in the rockers

after assembly.

Note: An ‘O’ ring (1) is fitted in the groove in the rocker assembly.

Rocker assembly nuts 33 (24.3) 3,3

1

H1035

14 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 25

400 Series

3

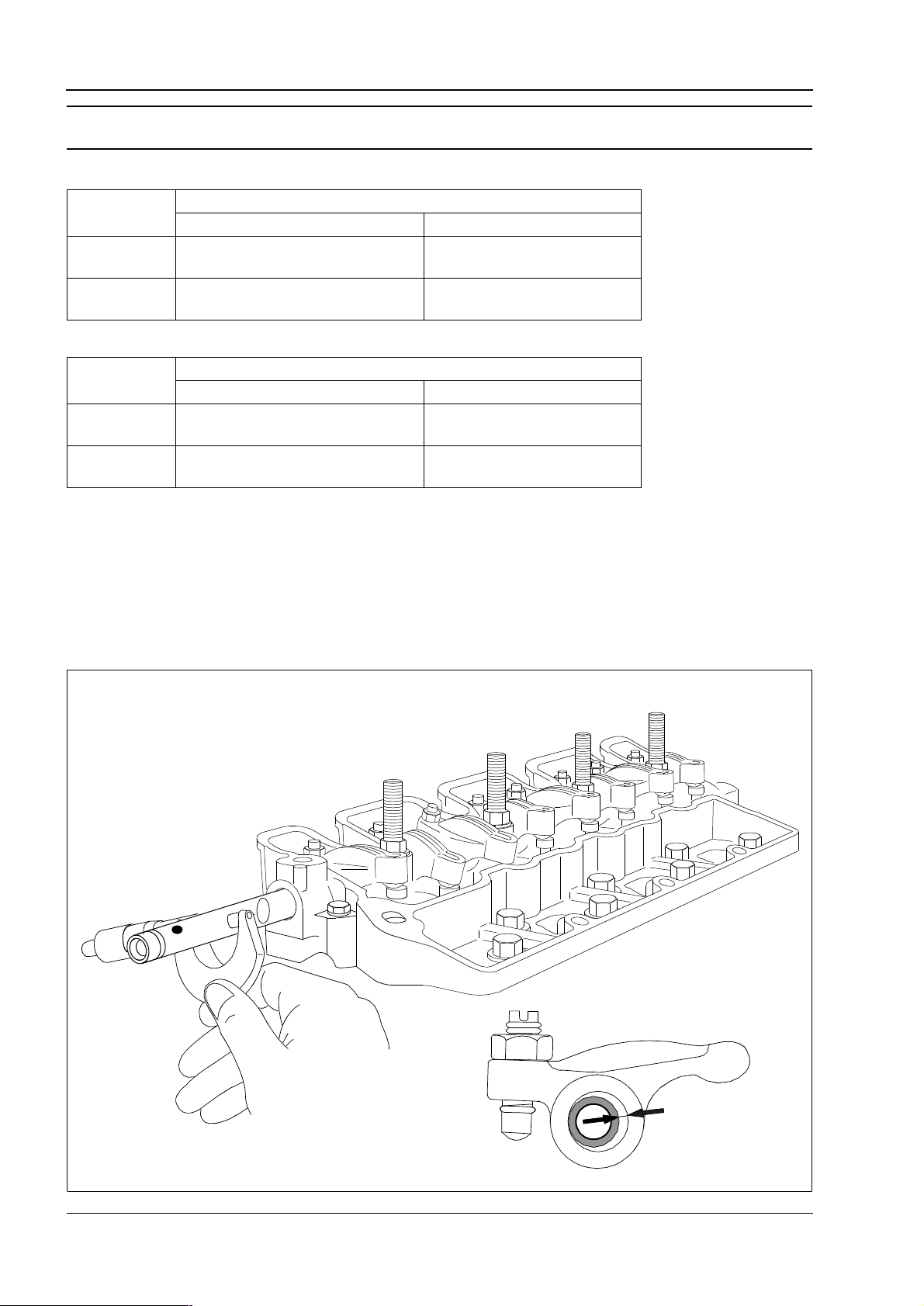

To dismantle and to assemble Operation 3-3

Engine Torque Nm (lbf ft) kgf m

All models Tappet adjustment nut 14 (10.3) 1,4

Use a suitable puller to extract the rocker shaft.

Note: Remember the position of the recess (1) for assembly.

1

H1036

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 15

Page 26

3

s

400 Series

To inspect Operation 3-4

Rockershaft diameter

Engine

403C-11

403C-15

404C-22

404C-22T

Rocker shaft to rocker lever clearance

Engine

403C-11

403C-15

404C-22

404C-22T

11,65 - 11,67 (0.4587 - 0.4595) 11,57 (0.4555)

14,95 - 14,97 (0.5886 - 0.5894) 14,87 (0.5854)

0,032 - 0,068 (0.00126 - 0.00268) 0,2 (0.008)

0,030 - 0,093 (0.00120 - 0.00366) 0,2 (0.008)

Standard Service limit

Standard Service limit

Diameter mm (in)

Clearance mm (in)

H1037

16 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 27

400 Series

3

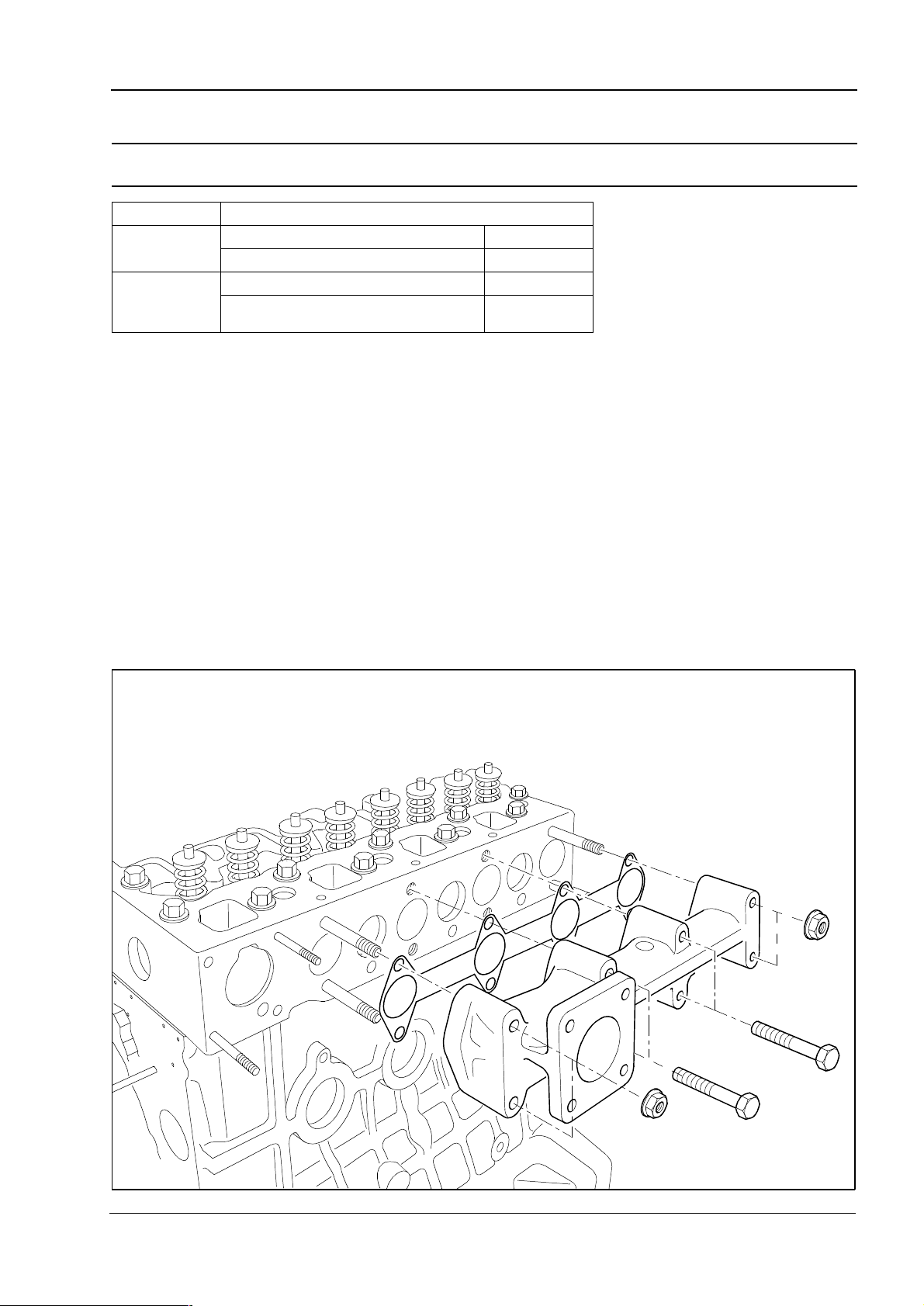

Exhaust manifold and gasket

To remove and to fit Operation 3-5

Engine Torque Nm (lbf ft) kgf m

403C-11

403C-15

404C-22

404C-22T

Setscrew 9,8 (7.2) 0,9

Nuts 9,8 (7.2) 0,9

Setscrew 25 (18.4) 2,5

Nuts 25 (18.4) 2,5

H1038

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 17

Page 28

3

400 Series

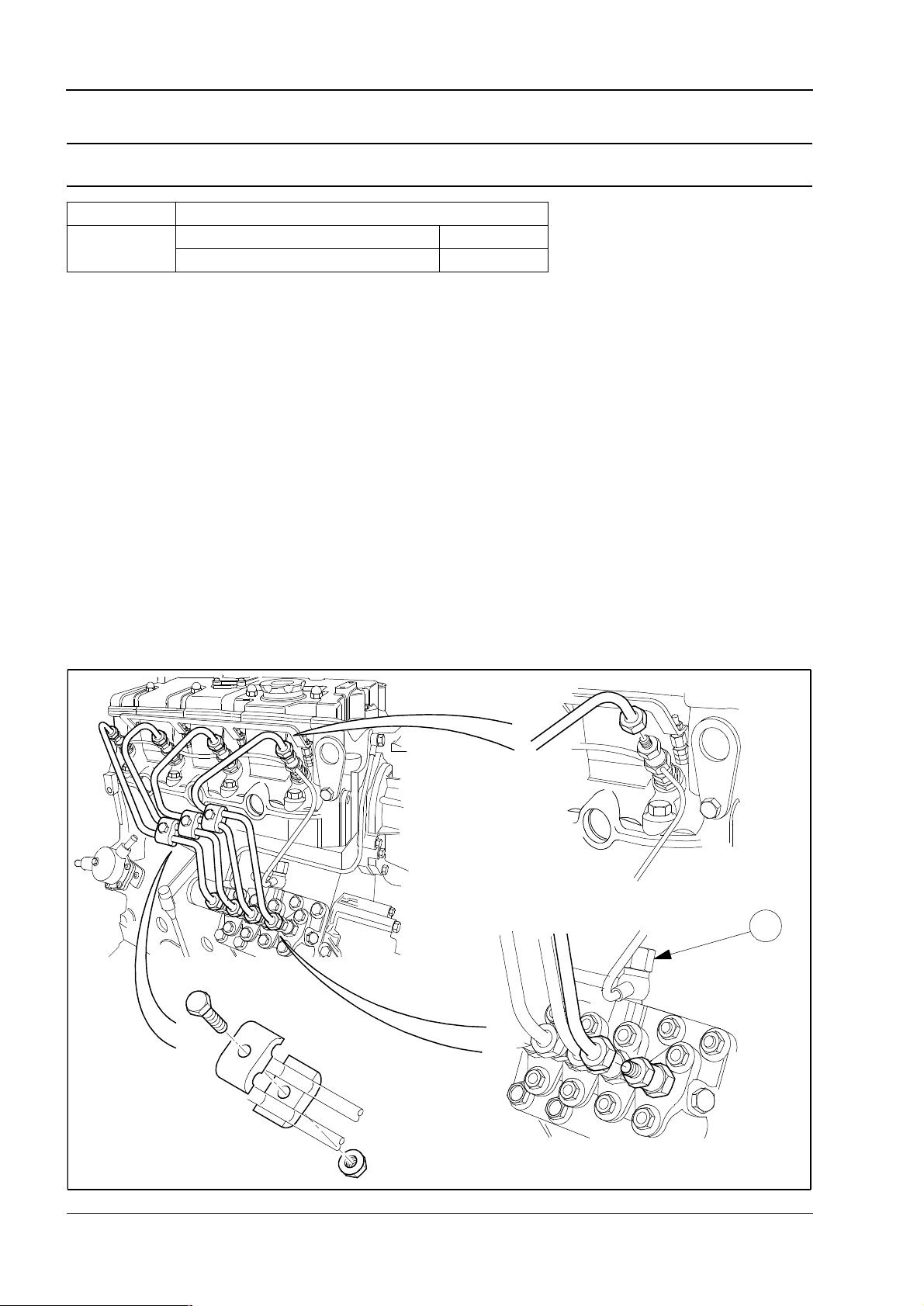

Fuel injection pipes / fuel return pipes

To remove and to fit Operation 3-6

Engine Torque Nm (lbf ft) kgf m

All models

Fuel injection pipe 23 (16.9) 2,3

Banjo bolt (1) 2,5 (3.2) 0,25

1

H1039

18 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 29

400 Series

3

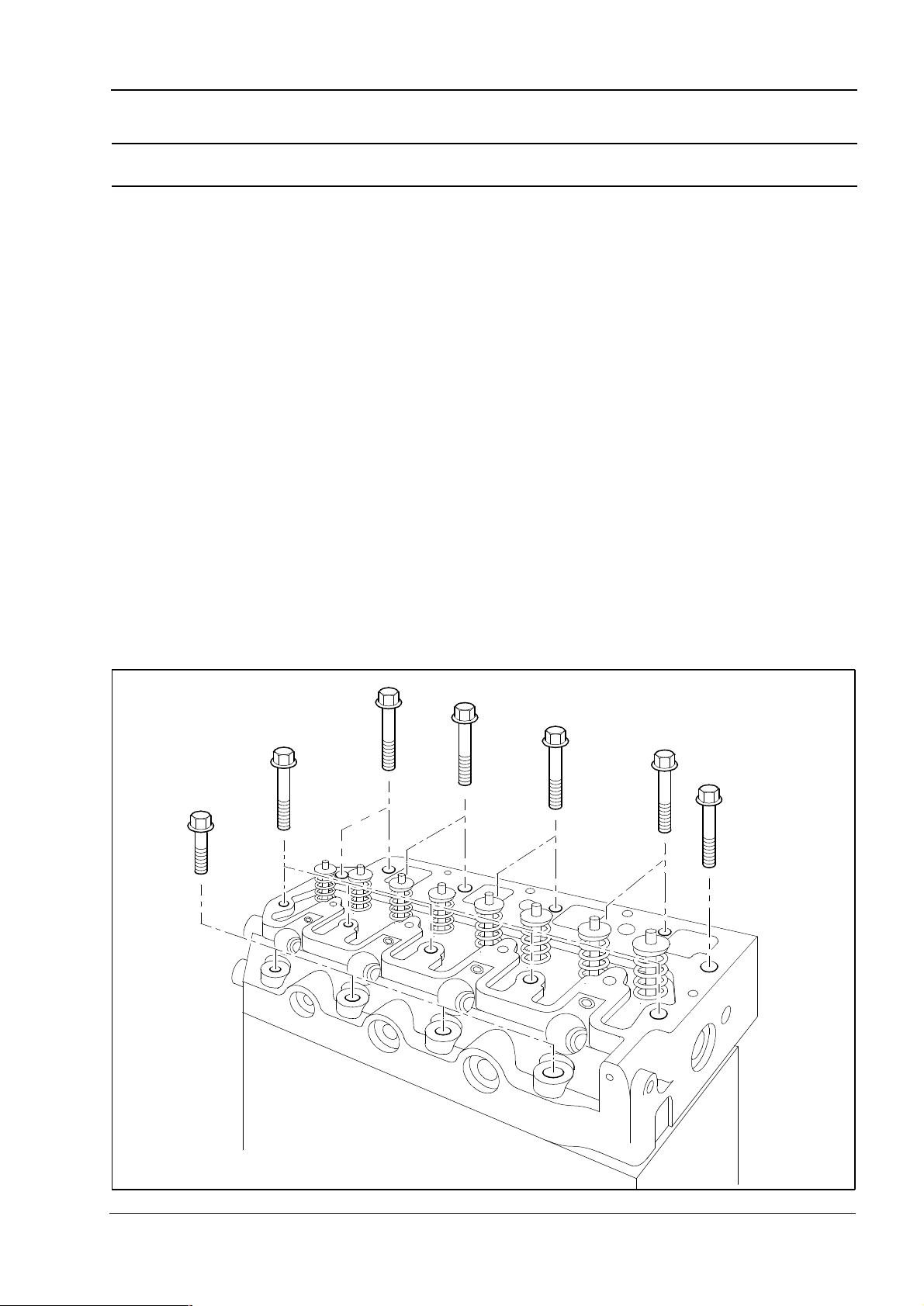

Cylinder head setscrews

To remove and to fit Operation 3-7

Note: If it is necessary to replace the cylinder head the fuel adjustment screw must not be altered from the

original setting. The maximum no load speed must be checked after assembly.

H1040

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 19

Page 30

3

400 Series

Cylinder head

Tightening sequence 403C-11 and 403C-15 Operation 3-8

Engine Torque Nm (lbf ft) kgf m

403C-11 Cylinder head setscrews 51 (37.6) 5,2

403C-15 Cylinder head setscrews 101 (74.5) 10,3

Notes:

l All torques should be checked again after tightening.

l On assembly lubricate cylinder head setscrews with clean oil.

11

5

8

14

20 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

1

4

9

3

2

10

13

7

6

12

H1041

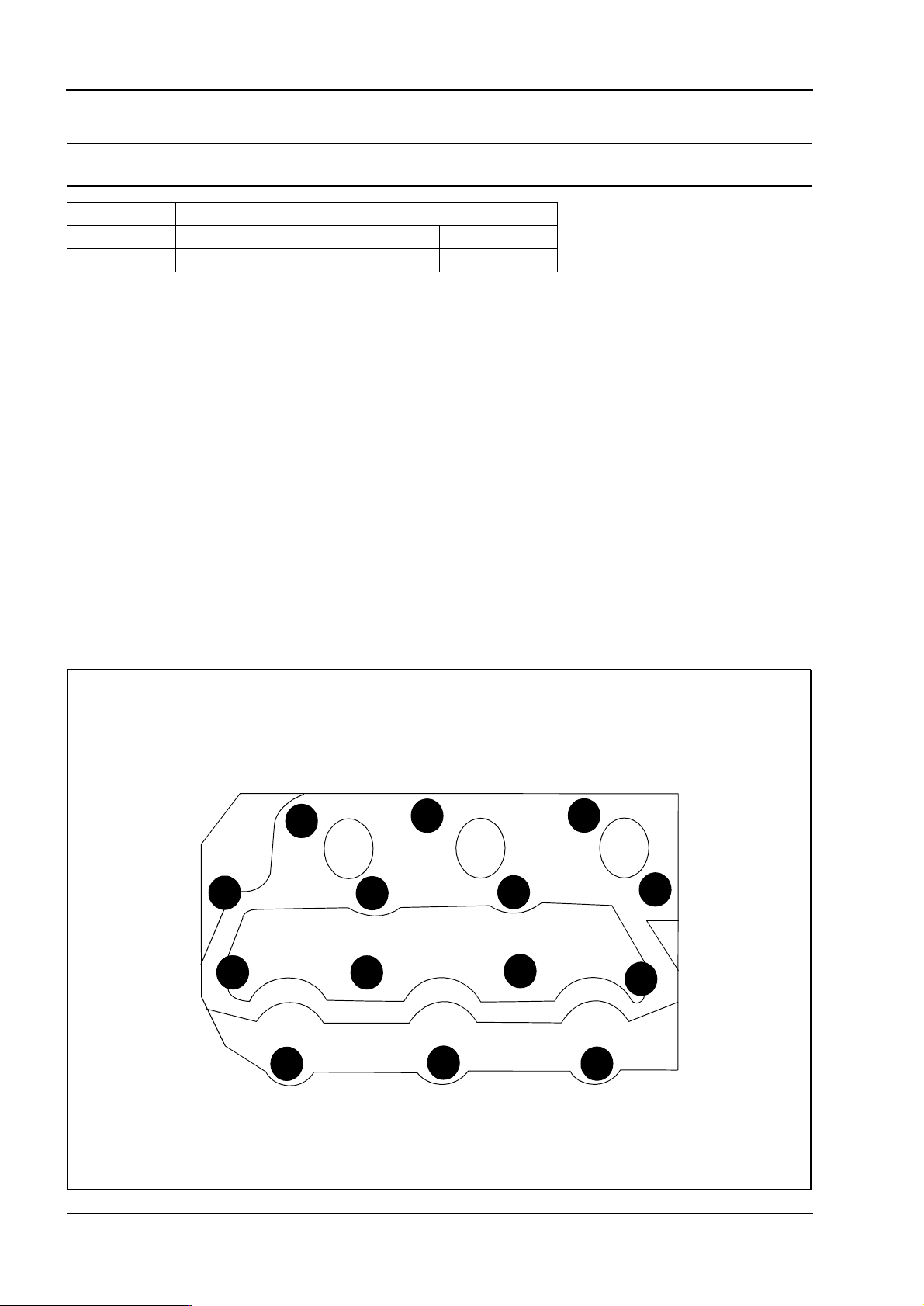

Page 31

400 Series

3

Tightening sequence 404C -22 and 404C-22T Operation 3-9

Engine Torque Nm (lbf ft) kgf m

404C-22

404C-22T

Notes:

l All torques should be checked again after tightening.

l On assembly lubricate cylinder head setscrews with clean oil.

Cylinder head setscrews 101 (74.5) 10,3

12 4

16

15

11

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 21

8

7

3

1

2

513

9

10

6

17

18

14

H1042

Page 32

3

400 Series

Cylinder head gasket

To remove and to fit Operation 3-10

Align the gasket on the dowels in the cylinder block.

Cautions:

l The gasket must only be fitted with the markings (1) facing up.

l When fitting a new gasket it must be replaced with a gasket of the same thickness as originally fitted. The

gasket thickness can be identified by the part number that is stamped on the gasket.

l The correct piston height must be maintained to prevent damage to the pistons and valves and ensure that

the engine conforms to emission legislation.

Note: Always fit dry.

1

n

a

e

l

c

n

U

d

n

A

H1043

22 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 33

400 Series

3

To select the correct thickness of cylinder head gasket Operation 3-11

Caution: If the correct piston height above or below the cylinder block is not obtained, damage to the engine

can occur. The difference between the highest and the lowest piston height must not exceed 0.1 mm.

1 Put the piston height tool (A) on the face of the cylinder block and rotate the gauge dial to the zero position.

2 Rotate the crankshaft until the piston crown is approximately at top dead centre (TDC).

3 Carefully put the tool over the top of the piston with the plunger of the gauge in contact with the piston above

the axis of the gudgeon pin.

4 Rotate the crankshaft to ensure that the piston is at the highest position and make a note of the gauge

indication.

Notes:

l If the cylinder block, crankshaft, connecting rods or pistons are changed the piston height will have to be

checked and the correct thickness gasket used.

l If the original piston is used, ensure that it is assembled to the correct connecting rod and is used in the

original cylinder.

Cylinder head gasket selection

Engine Protrusion above cylinder block top face Gasket thickness

403C-11

403C-15

Engine Protrusion below cylinder block top face Gasket thickness

404C-22

404C-22T

0,55 to 0,64 1,2 mm

0,65 to 0,75 1,3 mm

0,60 to 0,69 1,3 mm

0,70 to 0,79 1,4 mm

-0,45 to -0,30 0,4 mm

-0,29 to -0,20 0,5 mm

H1044

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 23

Page 34

3

400 Series

Valve and valve spring

To remove and to fit Operation 3-12

Special tools

Description Part number

Valve spring remover 21825663

Valve stem seal replacer 21825623

Notes:

l The oil seal for the inlet valve stem is identified by a silver garter spring.

l The oil seal for the exhaust valve stem is identified by a black garter spring (not shown) with the letters “EX”

on the garter.

Warning! Safety glasses must be worn for this operation.

H1045

24 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 35

400 Series

3

To inspect - valve spring Operation 3-13

Visually inspect the valve spring for damage.

Use a spring tester to check spring force and free length. Renew the spring if it is outside the service limit.

Engine

Free length (1) mm (in)

Standard Service limit

All models 35,0 (1.378) 33,5 (1.319)

Spring rate when compressed to 30,4 mm (1.197 in)

Engine

N (lbf) kgf

Standard Service limit

All models 79 (17.8) 8,1 68,6 (15.4) 7,0

1

New

Worn

H1046

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 25

Page 36

3

400 Series

To inspect - valve stem and thickness of valve head Operation 3-14

Use a micrometer to check the valve stem diameters at positions 1, 2 and 3, if less than the service limit, renew.

Check the valve stem for wear or damage, if outside the service limit, renew.

Inlet valve

Engine

Standard Service limit

Diameter mm (in)

All models 6,955 - 6,970 (0.27382 - 0.27441) 6,89 (0.271)

Exhaust valve

Engine

Standard Service limit

Diameter mm (in)

All models 6,940 - 6,950 (0.27323 - 0.27362) 6,84 (0.269)

Valve head thickness

Engine

Thickness mm (in)

Standard Service limit

All models 0,925 - 1,075 (0.03642 - 0.04232) 0,5 (0.020)

If the valve head thickness (4) is less than the service limit, renew the valve.

1

1

4

2

2

3

3

H1047

26 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 37

400 Series

3

Cylinder head to valve stem clearance

To inspect Operation 3-15

Check the clearance (3) between the valve stem and the cylinder head. If the clearance is greater than the

service limit, the valves must be checked for wear, see Operation 3-14, If the valves are within service limits,

renew the cylinder head.

1 Put a new valve in the valve guide.

2 Put a dial test indicator with a magnetic base (1) onto the face of the cylinder head.

3 With the valve lifted 15,0 mm (0.6 in) and the gauge (2) in contact with the edge of the valve head, move the

valve radially away from the gauge. With the head in this position, set the gauge to ‘0’.

4 Move the valve radially across the axis of the cylinder head towards the gauge. Make a note of the reading

on the gauge if the reading is greater than the service limit, renew the cylinder head.

Maximum permissible clearances with a valve lift of 15 mm (0.6 in).

Inlet valve

Engine Clearance mm (in) standard Service limit

403C-11 0,025 - 0,052 (0.0010 - 0.0020) 0,2 (0.008)

403C-15, 404C-22 and 404C-22T 0,030 - 0,060 (0.0012 - 0.0024) 0,2 (0.008)

Exhaust valve

Engine Clearance mm (in) standard Service limit

403C-11 0,045 - 0,072 (0.0020 - 0.0030) 0,25 (0.010)

403C-15, 404C-22 and 404C-22T 0,050 - 0,075 (0.0020 - 0.0030) 0,25 (0.010)

1

2

3

H1048

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 27

Page 38

3

400 Series

Cylinder head

To inspect Operation 3-16

Maximum regrind limit mm (in)

Distortion Maximum service limit Maximum regrind

0,05 (0.002) or less 0,12 (0.005) 0,15 (0.006)

Use a straight edge and feeler gauge to check the six positions for distortion.

Caution: Do not grind beyond the maximum limit.

1

3

5

2

28 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

6

4

H1049

Page 39

400 Series

3

Valve seat width

#

To inspect and to co rrect Operation 3-17

Special tools

Description Part number

Valve seat cutter 27610030

Inlet valve Exhaust valve

Engine

403C-11 1,70 - 2,10 (0.0670 - 0.0830) 2,5 (0.098) 1,70 - 2,10 (0.0670 - 0.0830) 2,5 (0.098)

403C-15 1,66 - 1,87 (0.0653 - 0.0736) 2,5 (0.098) 1,66 - 1,73 (0.0653 - 0.0681) 2,5 (0.098)

404C-22

404C-22T

1,50 - 2,00 (0.0591 - 0.0790) 2,5 (0.098) 1,94 - 2,16 (0.0764 - 0.0850) 2,5 (0.098)

If the contact face (1) of the valve seat is more than the service limit, check the valve stem for wear, see

Operation 3-14 and the cylinder head to valve stem clearance, see Operation 3-15. If greater than the service

limit, use a seat cutter of 45° to correct the seat.

If the valve stem clearance exceeds the service limit, renew the valve.

Clearance mm (in) Clearance mm (in)

Standard Service limit Standard Service limit

If the bore in the cylinder head for the valves is worn, replace the cylinder head. If the valve seat in the cylinder

head is damaged or worn, cut a new seat if the valve depth will remain within tolerance.

1

45°

Contact

Width

H1050

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 29

Page 40

3

400 Series

Valve depth

To check Operation 3-18

If the valve depth (1) is greater than the service limit, use a new valve to check the valve depth.

If the depth still exceeds the service limit, renew the cylinder head. If the depth is within the service limit renew

the valves.

Engine

403C-11 0,65 - 0,95 (0.0256 - 0.0374) 0,85 - 1,15 (0.0335 - 0.0453) 1,8 (0.071)

403C-15 0,85 - 1,15 (0.0335 - 0.0453) 0,85 - 1,15 (0.0335 - 0.0453) 1,8 (0.071)

404C-22

404C-22T

0,65 - 0,95 (0.0256 - 0.0374) 0,65 - 0,95 (0.0256 - 0.0374) 1,8 (0.071)

Inlet standard Exhaust standard Service limit

Depth mm (in)

1

H1051

30 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 41

400 Series

3

To lap the contact face of the valve seat Operation 3-19

Use the valve seat cutter to obtain the correct seat contact width and seat recess on a new cylinder head, use

a valve lapping tool and lapping compound to finish.

H1052

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 31

Page 42

3

400 Series

Valve tip clearance

To check and to adjust Operation 3-20

The valve adjustment sequence is viewed from the front of the engine.

Rotate the crankshaft clockwise when viewed from the front.

Caution: Only adjust the valve clearances when the engine is cold.

Engine Valve overlap Adjust valves

403C-11

403C-15

404C-22

404C-22T

No. 1 Cylinder 3 and 6

No. 2 Cylinder 2 and 5

No. 3 Cylinder 1 and 4

No. 4 Cylinder 1 and 2

No. 2 Cylinder 5 and 6

No. 1 Cylinder 7 and 8

No. 3 Cylinder 3 and 4

Valve tip clearance (cold)

Inlet 0,2 mm (0.0078 in)

Exhaust 0,2 mm (0.0078 in)

Torque Nm (lbf ft) kgf m

Tappet adjustment nut 14 (10.3) 1,4

H1053

32 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 43

400 Series

4

Piston and connecting rod assemblies 4

Big end bearing and cap

To remove and to fit Operation 4-1

Engine Torque Nm (lbf ft) kgf m

403C-11 Nut 32 (23.6) 3,3

403C-15, 404C-22 and 404C-22T Nut 52 (38.3) 5,2

Standard clearance Service limit

0,1 - 0,3 mm (0.004 - 0.012 in) 0,7 mm (0.276 in)

Caution: Ensure that the connecting rod bolts (2) do not damage the crankshaft when the connecting rod is

removed or fitted.

Notes:

l The connecting rods and caps are numbered matched pairs and must be kept together when removed from

the engine. The numbers (1) must be aligned when assembled.

l The piston and connecting rods are matched to a cylinder, record the position of each connecting rod and

piston for correct assembly. After the connecting rods are fitted check for axial movement.

l The fuel adjustment screw must not be altered from the original setting. The maximum no load speed must

be checked after assembly.

2

1

H1054

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 33

Page 44

4

400 Series

Piston and connecting rod

To remove and to fit Operation 4-2

The Shibaura name on the inside of the piston must be facing the fuel pump on assembly.

To assemble the connecting rod assembly, see page 35.

1

H1055

34 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 45

400 Series

4

To dismantle and to assemble Operation 4-3

The Shibaura (1) name (inside of the piston) must be aligned with the stamped number on the

connecting rod (1).

The numbers stamped on the connecting rods and caps must be the same and aligned.

C

A

M

A

3

2

1

1

H1056

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 35

Page 46

4

400 Series

Piston rings

To fit Operation 4-4

Any letters or markings on the surface of the ring will always be positioned on the top face (facing upwards).

Use a suitable piston ring expander to fit the piston rings.

1 Fit the spring of the oil control ring (6) in the bottom groove of the piston with the latch pin (1) inside both

ends of the spring. Fit the oil control ring (4) over the spring (6). Ensure that the ring gap is at 180° to the latch

pin.

2 Fit the second ring (3) with the taper face into the second groove, with the word "TOP" towards the top of

the piston.

New second rings have a green identification mark which must be on the left of the ring gap when the ring is

fitted and the piston is upright.

The second ring has a step (5) at the top inside edge of the tapered face.

3 Fit the top ring (2) with the word 'TOP' towards the top of the piston.

New top rings have a red identification mark which must be on the left of the ring gap when the ring is fitted

and the piston is upright.

4 Ensure that the ring gaps are 90° apart.

1

M

A

6

2

90°

3

4

M

A

90°

5

H1057

36 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 47

400 Series

4

To measure the piston ring clearance Operation 4-5

Use a feeler gauge to measure the clearance between the piston ring groove and the piston ring. If the

clearance is greater than the service limit, use a new piston ring and check the clearance again.

If the clearance is within the service limit with a new piston ring, renew the piston rings. If the clearance is

outside the service limit with a new piston ring, renew the piston.

Note: The number 1 piston ring of the 404C-22T is of the ‘keystone’ design, therefore it is difficult to measure

the wear due to it’s position in the piston ring groove. When either number 2 ring or the oil control ring is outside

the service limit renew all rings.

Engine Torque Nm (lbf ft) kgf m Standard Service limit

0,06 - 0,10 mm

(0.0024 - 0.0039 in)

0,05 - 0,09 mm

(0.0020 - 0.0035 in)

0,02 - 0,06 mm

(0.0008 - 0.0024 in)

0,07 - 0,11 mm

(0.0028 - 0.0043 in)

0,04 - 0,08 mm

(0.0016 - 0.0032 in)

0,02 - 0,06 mm

(0.0008 - 0.0024 in)

0,04 - 0,08 mm

(0.0016 - 0.0032 in)

0,02 - 0,06 mm

(0.0008 - 0.0024 in)

0,25 (0.0098 in)

0,25 (0.0098 in)

0,15 (0.0059 in)

0,25 (0.0098 in)

0,25 (0.0098 in)

0,15 (0.0059 in)

0,25 (0.0098 in)

0,15 (0.0059 in)

403C-11

403C-15

404C-22

404C-22T

Number 1 ring

Number 2 ring

Oil control ring

Number 1 ring

Number 2 ring

Oil control ring

Number 2 ring

Oil control ring

H1058

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 37

Page 48

4

To measure the piston ring gap Operation 4-6

If the piston ring is worn or damaged, renew.

Piston ring gap

Clean the carbon from the top of the cylinder bore.

Insert the ring into the cylinder at right angles to the cylinder block and measure the gap with a feeler gauge.

If the gap is greater than the service limit, renew the piston ring.

Engine Ring number Standard Service limit

Number 1 ring 0,15 - 0,27 mm (0.0059 - 0.0106 in) 1,0 mm (0.039 in)

403C11

403C-15

404C-22

404C-22T

Number 2 ring 0,12 - 0,24 mm (0.0047 - 0.0094 in) 1,0 mm (0.039 in)

Oil control ring 0,20 - 0,35 mm (0.0079 - 0.0138 in) 1,0 mm (0.039 in)

Number 1 ring 0,20 - 0,35 mm (0.0079 - 0.0138 in) 1,0 mm (0.039 in)

Number 2 ring 0,20 - 0,40 mm (0.0079 - 0.0158 in) 1,0 mm (0.039 in)

Oil control ring 0,20 - 0,40 mm (0.0079 - 0.0158 in) 1,0 mm (0.039 in)

400 Series

à

38 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

á

H1059

Page 49

400 Series

4

Piston and connecting rod assemblies

To dismantle and to assemble Operation 4-7

Gudgeon pin

Check the outside diameter of the gudgeon pin. If it is less than the service limit, renew the gudgeon pin.

Engine Outside diameter Service limit

403C-11 20,996 - 21,002 mm (0.82660 - 0.82680 in) 20,98 mm (0.8260 in)

403C-15

404C-22

404C-22T

Engine Standard clearance Service limit

403C-11 -0,004 - +0,004 mm (-0.00016 - +0.00016 in) 0,02 mm (0.0008 in)

403C15

404C-22

404C-22T

27,996 - 28,000 mm (1.10220 - 1.10240 in) 27,98 mm (1.1016 in)

-0,001 - +0,007 mm (-0.00040 - +0.00030 in) 0,02 mm (0.0008 in)

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 39

Page 50

4

400 Series

Piston and piston ring

To inspect Operation 4-8

Piston

If the outer surface of the piston is damaged (cracked, scored, burning etc) renew.

Piston skirt

Check the larger diameter of the piston skirt (10 mm from bottom).

Check the inside diameter (thrust direction) of the cylinder. Calculate the clearance between the cylinder and

the piston. If the clearance is more than the service limit, or piston diameter is less than service limit, renew

the piston

Engine Cylinder diameter Service limit

403C-11 76,932 - 76,947 mm (3.02880 - 3.02940 in) 76,7 mm (3.020 in)

403C-15

404C-22

404C-22T

Engine Clearance between piston and cylinder Service limit

403C-11 0,0525 - 0,0865 mm (0.00210 - 0.00340 in) 0,25 mm (0.010 in)

403C-15

404C-22

404C-22T

83,948 - 83,963 mm (3.30503 - 3.30562 in) 83,7 mm (3.295 in)

0,0380 - 0,0720 mm (0.00150 - 0.00283 in) 0,25 mm (0.010 in)

40 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 51

400 Series

4

Connecting rod

To inspect Operation 4-9

Engine Standard Service limit

All models

The large and small end bores must be parallel with each other within the limits of ± 0,31 mm (0.008 in)

measured 100 mm (3.397 in) each side of the connecting rods axis on a test mandrel.

Check the small end bush for wear or for other damage and renew it if necessary.

Check the fit of the gudgeon pin in the small end bush and check the gudgeon pin for wear.

Distortion for 100 mm (3.937 in) < 0,08 mm (0.0031 in) 0,20 mm (0.0079 in)

Parallel for 100 mm (3.937 in) < 0,05 mm (0.0020 in) 0,15 mm (0.0059 in)

± 0,08 mm

(0,0031 in)

100 mm

(3.937 in)

100 mm

(3.937 in)

± 0,08 mm

(0,0031 in)

H1060

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 41

Page 52

4

400 Series

Connecting rod bearing clearance

To check Operation 4-10

To check the clearance between the crankshaft bearing journal and the bearing cap.

1 Clean the bearing surfaces and the exposed half of the crankshaft journal.

2 Fit the bearing caps and tighten the bearing cap to torque.

3 Remove the bearing cap of the clearance to be checked.

4 Place a piece of Plastigauge ® across the full width of the bearing surface on the crankshaft journal, fit the

bearing cap and tighten the bearing cap setscrew to the specified torque.

5 Remove the bearing cap but do not move the Plastigauge ®.

6 Use the Plastigauge ® envelope to measure the widest point of the Plastigauge ®. This reading indicates

the bearing clearance in thousandths of an inch.

7 If the bearing clearance is not within the specifications the crankshaft must be reground and undersize

bearings fitted.

Engine Torque Nm (lbf ft) kgf m

403C-11 Bearing carrier setscrew 23 (16.9) 2,3

403C-15, 404C-22 and 404C-22T Bearing carrier setscrew 52 (38.3) 5,2

Engine Journals Standard clearance Service limit

403C-11

403C-15, 404C-22 and 404C-22T All 0,035 - 0,085 mm (0.00138 - 0.00335 in) 0,20 mm (0.0079 in)

1.0

2.0

2.5

3.0

4.0

PLASTIGAUGE

5.0

6.0

7.0

1 and 2 0,039 - 0,092 mm (0.00150 - 0.00360 in) 0,20 mm (0.0079 in)

3 0,029 - 0,082 mm (0.00110 - 0.00320 in) 0,20 mm (0.0079 in)

INCH

H1066

42 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 53

400 Series

4

Small end bush

To remove and to fit Operation 4-11

Calculate the clearance between the small end bush and the gudgeon pin. if the clearance is greater than the

service limit, renew the bush.

Engine Clearance mm (in) Service limit mm (in)

403C-11 0,010 - 0,025 (0.00040 - 0.00099) 0.08 (0.0031)

403C-15

404C-22

404C-22T

0,010 - 0,025 (0.00040 - 0.00099) 0,10 (0.0040)

H1061

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 43

Page 54

This page is intentionally blank

Page 55

400 Series

5

Crankshaft assembly 5

Crankshaft pulley

To remove and to fit Operation 5-1

Engine Torque Nm (lbf ft) kgf m Special tools Part number

403C-11 Crankshaft nut 123 (90.7) 12,5

403C-15

404C-22

404C-22T

Note: Store the key (1) in a safe place until assembly.

Crankshaft nut 304 (224.2) 30,9

Crankshaft pulley remover 21825619

1

H1062

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 45

Page 56

5

400 Series

Crankshaft retaining bolts and crankshaft

To remove and to fit Operation 5-2

Engine Torque Nm (lbf ft) kgf m

403C-11

403C-15

404C-22

404C-22T

Cautions:

l Ensure that the lubricating oil pressure relief valve has been removed before the crankshaft is removed or

fitted.

l Ensure that the oil ways in the bearings align with the oil ways in the cylinder block.

Remove the bearing holder setscrews (1) and lift the crankshaft assembly out vertically.

Note: If the crankshaft or crankshaft bearings are replaced the fuel adjustment screw must not be altered from

the original setting. The maximum no load speed must be checked after assembly.

Crankshaft bearing holder setscrew 27 (19.9) 2,7

Crankshaft bearing holder to block (allen screws) 27 (19.9) 2,7

Crankshaft bearing holder setscrew 52 (38.3) 5,2

Crankshaft bearing holder to block (allen screws) 27 (19.9) 2,7

1

H1063

46 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 57

400 Series

556

5

Crankshaft

To inspect for deflection Operation 5-3

1 Support the crankshaft on V-blocks.

2 Position a dial gauge on the crankshaft centre journal, and turn the crankshaft gradually by one full turn.

3 If the gauge reading is more than the service limit, renew or regrind the crankshaft.

Engine Deflection mm (in)

Standard Service limit

All models 0,03 or less (0.011) 0,06 (0.0023)

4 When the measured diameter is less than the service limit, regrind and use undersized bearings and bushes.

Crankshaft inspection

1 Check the oil seal contact face for damage or wear.

2 Check oil holes for clogging.

3 Check crankshaft journal (A4) and crank pin (A3) for stepped wear. Take measurements of diameters (A5-

A5) and (A6-A6) at positions (A1) and (A2). If the maximum difference between the measurements (stepped

wear) is more than the service limit of 0,05 mm (0.0019 in) then correction is required.

Grinding specification

When grinding the crankshaft, work with the following specifications:

Radius at pin / journal (B1) 3 mm (0.118 in) ± 0,2 mm (± 0.0078 in)

Finish precision (B2) 1.6Z (∇ ∇ ▼)

Radius around oil hole (B3) 2 mm (0.787 in) maximum / 5 mm (0.196 in) minimum

Note: Use No. 400 emery cloth for final polishing.

2

2

1

3

1

6

4

A

1

2 3

B

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 47

H1064

Page 58

5

400 Series

Crankshaft journal diameter

Engine Size Standard diameter Service limit

Standard 47,964 - 47,975 mm (1.88830 - 1.88880 in) 47,90 mm (1.8860 in)

403C-11

403C-15

404C-22

404C-22T

Undersize 0,25 mm (0.01 in) 47,714 - 47,725 mm (1.87850 - 1.87890 in) 47,65 mm (1.8750 in)

Undersize 0,50 mm (0.02 in) 47,464 - 47,475 mm (1.86870 - 1.86910 in) 47,40 mm (1.8660 in)

Standard 67,957 - 67,970 mm (2.67550 - 2.67597 in) 67,90 mm (2.6732 in)

Undersize 0,25 mm (0.01 in) 67,707 - 67,720 mm (2.66563 - 2.66614 in) 67,65 mm (2.6634 in)

Undersize 0,50 mm (0.02 in) 67,457 - 67,470 mm (2.65579 - 2.65630 in) 67,40 mm (2.6535 in) *

Crankshaft pin diameter

Engine Size Standard diameter Service limit

Standard 40,964 - 40,975 mm (1.61280 - 1.61320 in) 40,90 mm (1.6102 in)

403C-11

403C-15

404C-22

404C-22T

Undersize 0,25 mm (0.01 in) 40,714 - 40,725 mm (1.60290 - 1.60330 in) 40,65 mm (1.6003 in)

Undersize 0,50 mm (0.02 in) 40,464 - 40,475 mm (1.59310 - 1.59350 in) 40,40 mm (1.5905 in)

Standard 51,964 - 51,975 mm (2.04582 - 2.04626 in) 51,90 mm (2.0433 in)

Undersize 0,25 mm (0.01 in) 51,714 - 51,725 mm (2.03598 - 2.03641 in) 51,65 mm (2.0335 in)

Undersize 0,50 mm (0.02 in) 51,464 - 51,475 mm (2.02614 - 2.02660 in) 51,40 mm (2.0236 in) *

Note: If the diameter is less than the maximum undersize service limit (*), the crankshaft must be renewed.

48 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 59

400 Series

5

Main bearings

To dismantle and to assemble Operation 5-4

Engine Torque Nm (lbf ft) kgf m

403C-11 Bearing holder setscrew 23 (16.9) 2,3

403C-15, 404C-22 and 404C-22T Bearing holder setscrew 52 (38.3) 5,2

End float

If the end float is greater than the service limit check the thrust washers for wear.

Note: Item (1) only used on 404C-22 and 404C-22T.

Engine Standard clearance Service limit

403C-11 0,10 - 0,30 mm (0.0040 - 0.0120 in) 0,50 mm (0.0197 in)

403C-15, 404C-22 and 404C-22T 0,10 - 0,40 mm (0.0040 - 0.0160 in) 0,50 mm (0.0197 in)

Engine Thrust washer thickness Service limit

403C-11

403C-15, 404C-22 and 404C-22T 2,95 - 3,00 mm (0.1161 - 0.1181 in) 2,80 mm (0.1102 in)

21,85 - 21,95 mm (0.8602 - 0.8641 in)

21,6 mm (0.8503 in)

1 Identify the location of bearing carriers on the crankshaft and mark before removal.

2 Install bearing carriers on the crankshaft, ensure that the lubricating oil holes align with the feed holes in the

cylinder block.

3 Check end float clearance.

Note: Ensure that the thrust washers are aligned correctly, fitted with their oil grooves towards the crankshaft.

4 Check the thrust washers for wear, poor contact or damage, if damaged renew.

1

H1067

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 49

Page 60

5

400 Series

Bearing holder

Centre bearing

1 Remove the bearing holder and inspect for peeling, melting, stepped wear and damage. if it is damaged

renew.

2 Use Plastigauge ® to measure the oil clearance (see Operation 4-10) between the crankshaft centre

journal and the bearing. If the oil clearance is greater than the service limit, renew the bearings or regrind

the centre journal and use undersize bearings.

Engine Standard oil clearance Service limit

403C-11 0,039 - 0,106 mm (0.00153 - 0.00401 in) 0,20 mm (0.0078 in)

403C-15

404C-22

404C-22T

Engine / Bearing size mm (in) Journal Centre crankshaft diameter mm (in)

403C-11

Standard

Undersize 0,25 (0.01)

Undersize 0,50 (0.02)

403C-15

Standard 1, 2, 3 67,957 - 67,970 (2.67550 - 2.67597)

Undersize 0,25 (0.01) 1, 2, 3 67,707 - 67,720 (2.66563 - 2.66614)

Undersize 0,50 (0.02) 1, 2, 3 67,457 - 67,470 (2.65579 - 2.65630)

404C-22 and 404C-22T

Standard 1, 2, 3, 4 67,957 - 67,970 (2.67550 - 2.67597)

Undersize 0,25 (0.01) 1, 2, 3, 4 67,707 - 67,720 (2.66563 - 2.66614)

Undersize 0,50 (0.02) 1, 2, 3, 4 67,457 - 67,470 (2.65579 - 2.65630)

0,044 - 0,102 mm (0.00150 - 0.00420 in) 0,20 mm (0.0078 in)

1, 2 47,965 - 47,975 (1.88830 - 1.88880)

3 47,954 - 47,965 (1.88800 - 1.88840)

1, 2 47,714 - 47,725 (1.87850 - 1.87890)

3 47,704 - 47,715 (1.87810 - 1.87850)

1, 2 47,464 - 47,475 (1.86870 - 1.86910)

3 47,454 - 47,465 (1.86250 - 1.86870)

50 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 61

400 Series

6

Timing case and drive assembly 6

Timing cover

To remove Operation 6-1

Engine Special tools

Description Part number

403C-11 Front oil seal protector 21825620

403C-15, 404C-22 and 404C-22T Front oil seal protector 21825621

Cautions:

l If the timing case assembly or internal governor components are replaced the fuel adjustment screw should

not be adjusted. The maximum no load speed should be checked after assembly.

l The fuel injection pump, see Operation 11-3 and the keyway in the crankshaft must be removed before the

timing case is removed.

l Ensure that the stop lever arm (1) is held clockwise in tension for removal and assembly.

Note: If the timing case is renewed, a new emission label must be fitted as shown (2).

1 To remove the PTO cover, see Operation 6-9.

2 To remove and to fit the crankshaft pulley, see Operation 5-1.

1

2

3

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 51

H1068

Page 62

6

400 Series

To fit Operation 6-2

Engine Special tools

Description Part number

403C-11 Front oil seal protector 21825620

403C-15

404C-22

404C-22T

To fit

1 The fuel injection pump, see Operation 11-3 and the keyway in the crankshaft must be removed before the

timing case is fitted. Fit the front oil seal protector.

2 To fit the PTO cover, see Operation 6-9.

3 Ensure the oil pin (3) locates in the hole in the idler gear and that the stop lever arm (1) is held clockwise in

tension for removal and assembly.

4 Remove the oil seal protector (4) after fitting the timing cover. Fit the key into the key way in the crankshaft

nose.

5 To fit the crankshaft pulley, see Operation 5-1.

Note: If the timing case is renewed, a new emission label must be fitted as shown (2).

Front oil seal protector 21825621

Caution: If the timing case assembly or internal governor components are replaced the fuel adjustment screw

should not be adjusted. The maximum no load speed should be checked after assembly.

1

2

3

4

52 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

H1069

Page 63

400 Series

6

Angleich

To remove and to fit Operation 6-3

Engine Torque Nm (lbf ft) kgf m

403C-15,

404C-22

404C-22T

Notes:

l The internal setting for the Angleich must not be altered.

l Apply a little Loctite 275 to threads (2) before assembly.

l The Angleich is not fitted to the 403C-11 engine.

Angleich (1) 5 (3.6) 0,5

1

2

H1070

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 53

Page 64

6

400 Series

Slider

To remove and to fit Operation 6-4

The slider (2) must be fitted with the slot (4) held captive by the pin (3).

When fitting the timing case care must be taken to ensure correct alignment of the slider contact (1) with the

governor lever.

Caution: Incorrect alignment of the slider (2) on the pin (3) may result in the loss of engine speed control.

1

2

4

3

H1071

54 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 65

400 Series

6

Camshaft retaining plate

To remove and to fit Operation 6-5

Engine Torque Nm (lbf ft) kgf m

All models Camshaft retainer plate setscrews 11 (8) 1,1

The camshaft retainer plate is fitted between the cylinder block and the camshaft gear. The camshaft retainer

plate is fastened by either two setscrews or a setscrew and an allen screw.

Note: If the camshaft assembly is replaced the fuel adjustment screw must not be altered from the original

setting. The maximum no load speed must be checked after assembly.

H1072

Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green 55

Page 66

6

400 Series

Camshaft and tappets

To remove and to fit Operation 6-6

Caution: Remove the lift pump see Operation 11-2 and the fuel injection pump see Operation 11-3 before

removing the camshaft.

Note: If the camshaft assembly is replaced the fuel adjustment screw must not be altered from the original

setting. The maximum no load speed must be checked after assembly.

Lubricate the tappets with clean lubricating oil before assembly.

1

H1073

56 Workshop Manual, TPD 1458E, issue 3 - Perkins Confidential: Green

Page 67

400 Series

6

Camshaft assembly

To inspect Operation 6-7

Height of cam for inlet and exhaust valves (1).

Engine Height mm (in)

Standard Service limit

403C-11 26,955 - 27,010 (1.06120 - 1.06340) 26,5 (1.0276)

403C-15, 404C-22 and 404C-22T 34,065 - 34,120 (1.34114 - 1.34330) 33,7 (1.3270)

Height of cam for fuel feed pump (2).

Engine Height mm (in)

Standard Service limit

403C-11 27.900 - 28,000 (1.09842 - 1.10240) 27,0 (1.0630)

403C-15, 404C-22 and 404C-22T 31,900 - 32,000 (1.25590 - 1.25984) 30,0 (1.1810)

Height of cam for fuel injection pump (3).

Engine Height mm (in)

Standard Service limit

403C-11 39,900 - 40,100 (1.57090 - 1.57870) 39,8 (1.5669)

403C-15, 404C-22 and 404C-22T 41,940 - 42,060 (1.65120 - 1.65590) 41,8 (1.6450)

1

3

2

H1074