Page 1

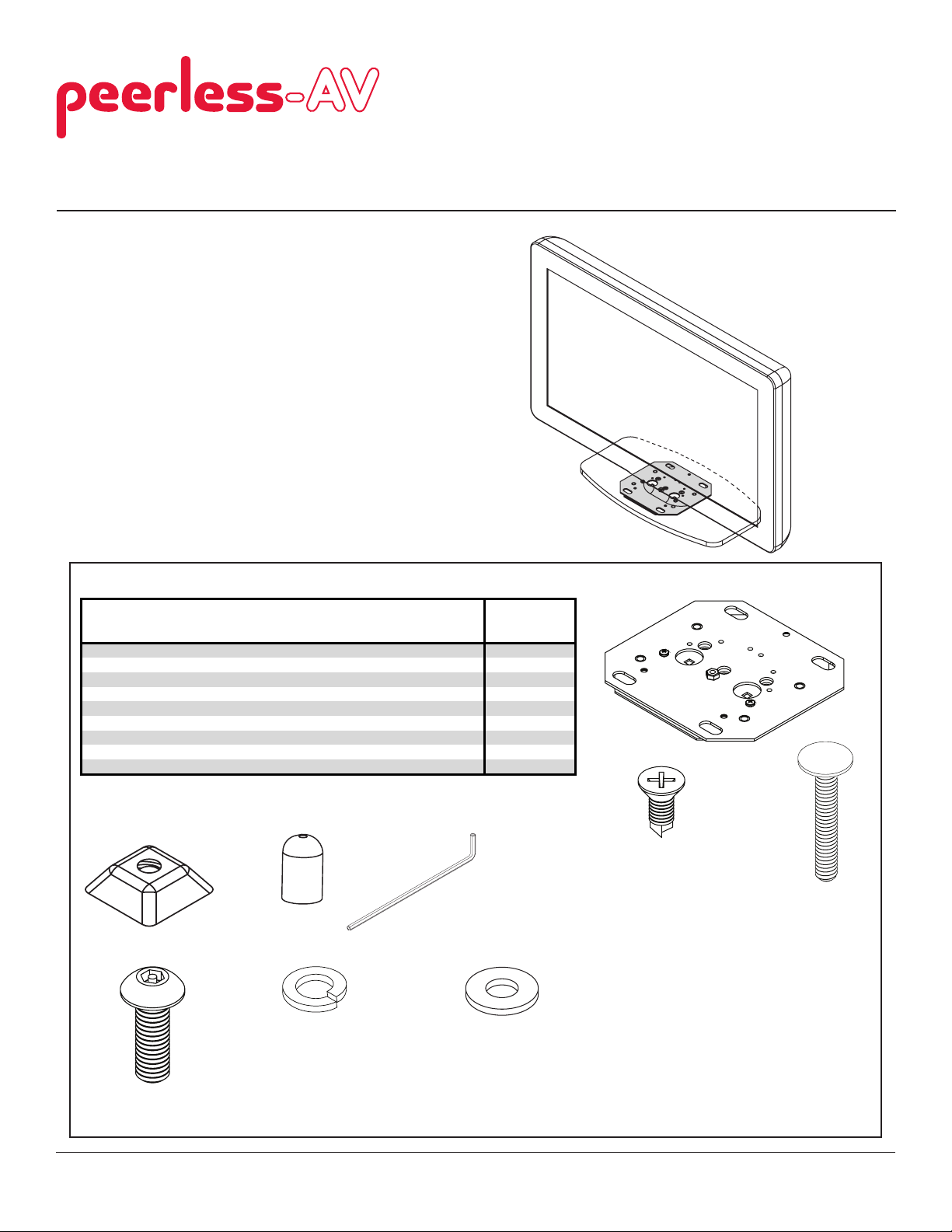

Installation and Assembly:

A

Desktop Swivel Mount for Philips 32HFL2082 and 40HFL2082 Displays

Model: HLG440-PH, HLG440-PH-Q10

Mounting to Desktop Surface

Mounting using Bolt Down Method

NOTE: Read entire instruction sheet before you start installation and assembly.

Parts List

Description Qty Part # Qty Part #

swivel plate assembly 1 090-1983 10 090-1983

B 10-32 x 3/8 flat head self drilling screw 3 560-2743 30 560-2743

C 1/4-20 x 1-3/4" thin head carriage bolt 2 560-1764 20 560-1764

D 1/4-20 slope nut 3 530-0035 23 530-0035

E plastic cap 2

F 4 mm allen wrench 1 560-9646 3 560-9646

G M5 x 20 mm socket pin screw 2 520-1065 20 520-1065

H #10 split lock washer 2 540-1035 20 540-1035

#10 flat washer 2 540-9400 20 540-9400

I

HLG440-PH HLG440-PH-Q10

590-1294

20

590-1294

A

B C

Before you start make sure all parts listed are included with your product.

D E

G

H I

F

1 of 4

ISSUED: 10-30-10 SHEET #:125-9164-2 09-14-11

Page 2

Mounting using Bolt Down Method

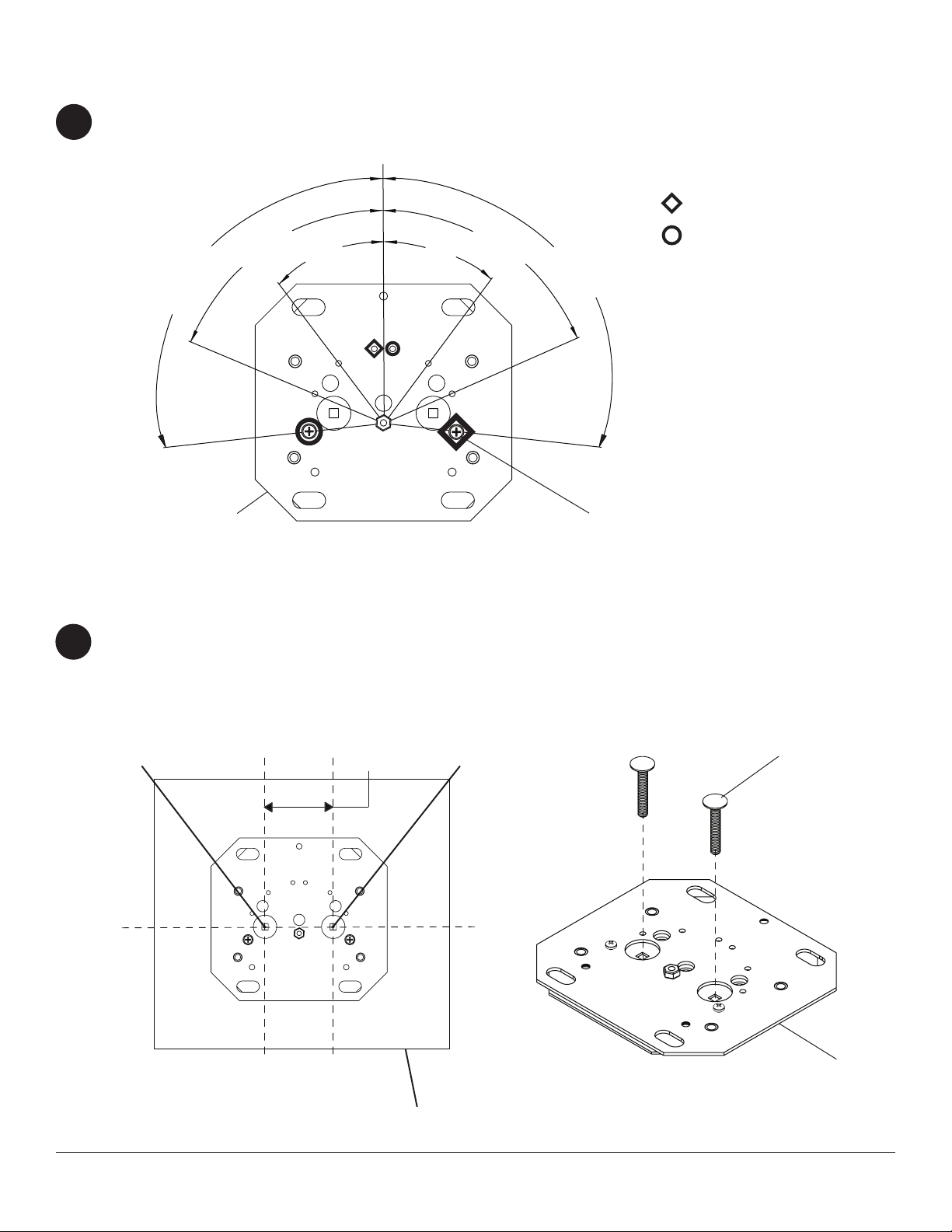

Choose swivel range below and identify swivel range holes of swivel plate assembly (A).

1

FRONT

60°

90°

90°

60°

30° 30°

USE HOLES TO LOCK SWIVEL

PLATE ASSEMBLY 90° FROM

CENTER

RIGHT SIDE

LEFT SIDE

A

Use swivel plate assembly (A) as a template to mark location of holes, point 1 and point 2, approximately 3" apart

2

on table. Drill two holes using a 1/4'' drill bit.

Place two 1/4-20 x 1-3/4" thin head carriage bolts (C) into slots of swivel plate assembly (A).

FRONT

POINT 1

3"

(76 mm)

POINT 2

SWIVEL RANGE HOLE

C

TABLE TOP

2 of 4

A

ISSUED: 10-30-10 SHEET #:125-9164-2 09-14-11

Page 3

Secure swivel plate assembly (A) to bottom of display base using three 10-32 x 3/8" at head self drilling screws (B)

3

in 32" or 42" orientation.

NOTE: Make sure that screws in display base align with slots and holes in swivel plate assembly (A)

as shown below.

DISPLAY

BASE SCREWS

FRONT

B

DISPLAY

BASE SCREWS

32" Display Base Attachment Location

A

ARROW INDICATES FRONT OF SWIVEL

PLATE ASSEMBLY

(note orientation of plate to base)

FRONT

.88"

42" Display Base Attachment Location

(note orientation of plate to base)

Hand tighten slope nut (D) through 1/4-20 x 1-3/4" thin head carriage bolt (C) until snug against bottom of desktop

4

surface. Thread another slope nut (D) upside-down, about two turns from rst slope nut (D). Insert an open box

wrench between both slope nuts (D) and tighten. NOTE: Avoid jamming both slope nuts (D) together, doing so

may make it difcult to remove slope nut used for tightening rst slope nut (D) as shown in g 4.1. After slope nut is

secure remove bottom slope nut and add plastic cap (E) as shown in gure 4.2. Repeat with remaining

1/4-20 x 1-3/4" thin head carriage bolt (C).

C

C

D

D

Detail 1

C

TIGHTENING

SLOPE NUT

E

BOTTOM OF DESKTOP

3 of 4

FIG 4.1 FIG 4.2

NOTE: Do not overtighten slope nut (D)

plate may distort

ISSUED: 10-30-10 SHEET #:125-9164-2 09-14-11

Page 4

Installation of Security Screws for Base to Display Attachment

32" Display Base (No Screws Required)

5

Attach display to base using hardware provided with display using the manufactures installation manual.

42" Display Base

Attach display to base using two M5 x 20 mm socket pin screws (G), two #10 split lock washers (H), and two

#10 at washers (I) into bottom holes as shown below. Tighten with 4 mm security allen wrench (F).

Use screws supplied with display for remaining holes.

42" Display Base Attachment Location

(note orientation of screws)

DISPLAY

G

I

H

DISPLAY BASE

NOTE: Display and base may appear

different than illustrated

4 of 4

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 10-30-10 SHEET #:125-9164-2 09-14-11

© 2010, Peerless Industries, Inc. All rights reserved.

Loading...

Loading...