Page 1

Installation and Assembly:

A

Lock Down Hardware for Display Base Stands

Model: HL4UN-002, HL4UN-002-Q10

Parts List

Description Qty. Part # Qty. Part #

1/4-20 x 1 3/4" carriage bolt 2 520-1017 20 520-1017

M4 x 16 mm phillips trilobe screw 2 520-2621 20 520-2621

B

M4 x 16 mm socket pin screw 2 520-1087 20 520-1087

C

1/4-20 sloped nut 3 530-0035 23 530-0035

D

M4 x 12 mm socket pin screw

E

#8 flat washer

F

plastic cap

G

4 mm allen wrench 1 560-9646 3 560-9646

H

C

D

2

2

2

HL4UN-002 HL4UN-002-Q10

520-1079

540-1001

590-1294

20

20

20

E F

H

Measure distance between center lines of cut outs in

1

bottom of display base. Use measurement to mark

location of holes at point 1 and point 2, on table.

Drill two holes using a 9/32'' drill bit.

NOTE: Display and base may appear

different than illustrated

2

A B

520-1079

540-1001

590-1294

G

TOOLS NEEDED

• drill

• 9/32" drill bit

• 5/8" open box wrench

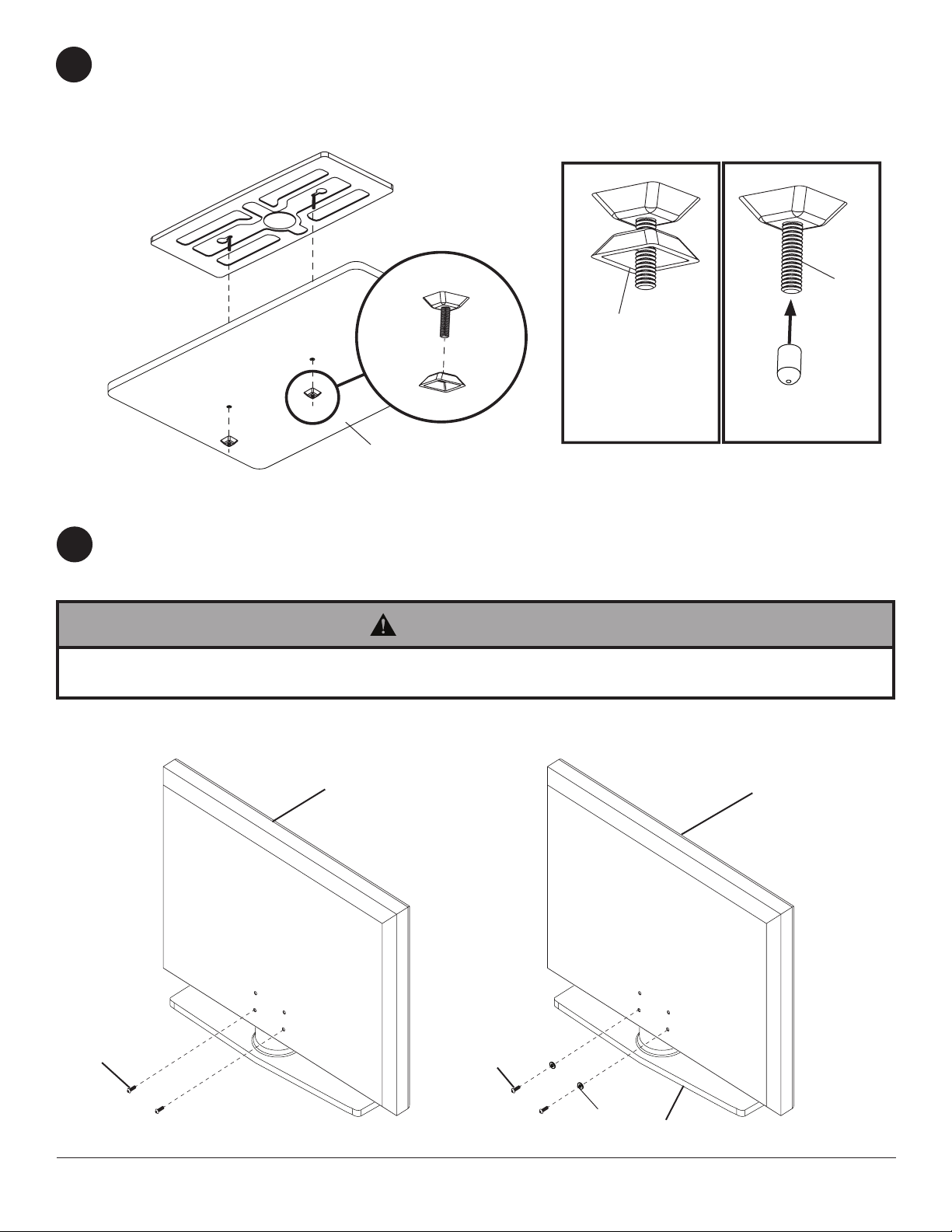

Insert two 1/4-20 x 1-3/4" carriage bolts (A)

into bottom of display base as shown in detail 1.

POINT 1

FRONT

MEASURE

DISTANCE

FRONT

A

POINT 2

BOTTOM OF BASE

1 of 2

DETAIL 1

ISSUED: 06-03-11 SHEET #:120-9110-1

Page 2

Hand tighten slope nut (D) through 1/4-20 x 1-3/4" carriage bolt (A) until snug against bottom of desktop surface.

3

Thread another slope nut (D) upside-down, about two turns from rst slope nut (D). Insert an open box wrench

between both slope nuts (D) and tighten. NOTE: Avoid jamming both slope nuts (D) together, doing so may make

it difcult to remove slope nut used for tightening rst slope nut (D) as shown in gure 3.1. After slope nut is secure

remove bottom slope nut as shown in gure 3.2. Repeat with remaining 1/4-20 x 1 3/4" carriage bolt (A).

Fasten two plastic caps (G).

FRONT

D

A

D

BOTTOM OF DESKTOP

Installation of Security Screws for Base/Screen Assembly

Thread two M4 x 16 phillips pan trilobe screws (B) to bottom display attachment holes as shown in g. 4.1.

4

Remove the two M4 x 16 phillips pan trilobe screws (B) and attach display screen to display base using two M4 x

16 mm socket pin screws (I) or M4 x 12 mm socket pin screws (E) with #8 at washers (F), as shown in gure 4.2.

Tighten with 4 mm security allen wrench (H). Use TV supplied screws for remaining holes.

TIGHTENING

SLOPE NUT

G

FIGURE 3.1 FIGURE 3.2

NOTE: Do not overtighten slope nut (D)

plate may distort

WARNING

• If screws don’t get three complete turns in the screen inserts or if screws bottom out and bracket is still not tightly

secured, damage may occur to screen or product may fail.

NOTE: Screws are installed using bottom

two display mounting locations.

NOTE: Display and base may appear

different than illustrated

A

B

DISPLAY SCREEN

C or E

DISPLAY BASE

g 4.1 g 4.2

2 of 2

All other brand and product names are trademarks or registered trademarks of their respective owners.

F

ISSUED: 06-03-11 SHEET #:120-9110-1

© 2011, Peerless Industries, Inc. All rights reserved.

DISPLAY SCREEN

Loading...

Loading...