Page 1

Installation and Assembly - Desktop Mount for

Sharp 32

IMPORTANT! Read entire instruction sheet before you start inst allation and assembly .

", 37" & 42" HT3 models

Models:HG442-HT3,

HG442-HT3-S

Maximum Load Capacity: 75 lb (34 kg)

WARNING

• Do not begin to install your Peerless product until you have read and understood the instructions and warnings contained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, please call

Peerless customer care at 1-800-865-2112.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached hardware and components.

• Never exceed the Maximum Load Capacity .

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screws firmly , but do not overtighten. Overtightening can damage the items, greatly reducing their holding

power.

Tools Needed for Assembly

• 3M rubber and vinyl #80 spray adhesive (can be purchased at www .3mestore.com/62494949258.html)

• phillips screwdriver

1 of 7

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED: 02-28-08 SHEET #: 090-9143-2 04-28-08

Page 2

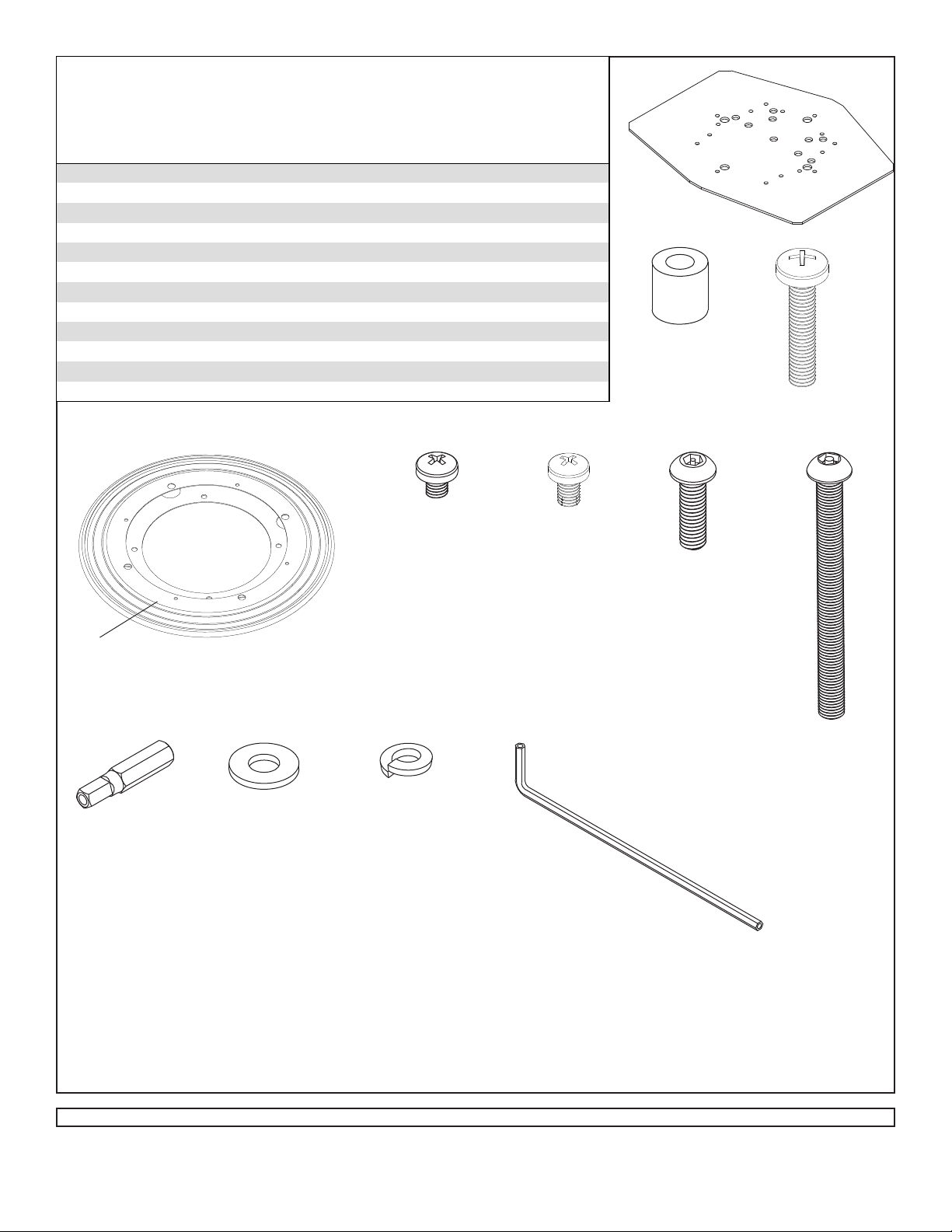

Bef ore you b egin, make s ure all part s shown are included with your product.

Parts List

HG442-HT3 HG442-HT3-S

Des cription

mounti ng plate 1 201-1553 201-1553

A

race as sembly 1 201-1555 201-1555

B

spacer

C

M6 x 30 mm screw

D

M5 x 6 mm type F phi l l i ps screw

E

M5 x 8 mm type F phi l l i ps screw

F

M6 x 20 mm socket pin screw 4 N/A 520-9554

G

M6 x 65 mm pent a-pi n s crew 4 N/A 520-1338

H

penta-driv er 1 N/A 520-9249

I

washer 4 N/A 540-9440

J

spl it washer 4 N/A 540-9402

K

4 mm security all en wrenc h 1 N/A 560-9646

L

Parts may appear slightly different than illustrated.

Qty. Part Number Part Number

5 540-1058 540-1058

5 510-9109 510-9109

4 520-9504 520-9504

2 520-1167 520-1167

A

C

D

B

TOP OF RACE

ASSEMBLY

I

E

F

GH

KLJ

2 of 7

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED: 02-28-08 SHEET #: 090-9143-2 04-28-08

Page 3

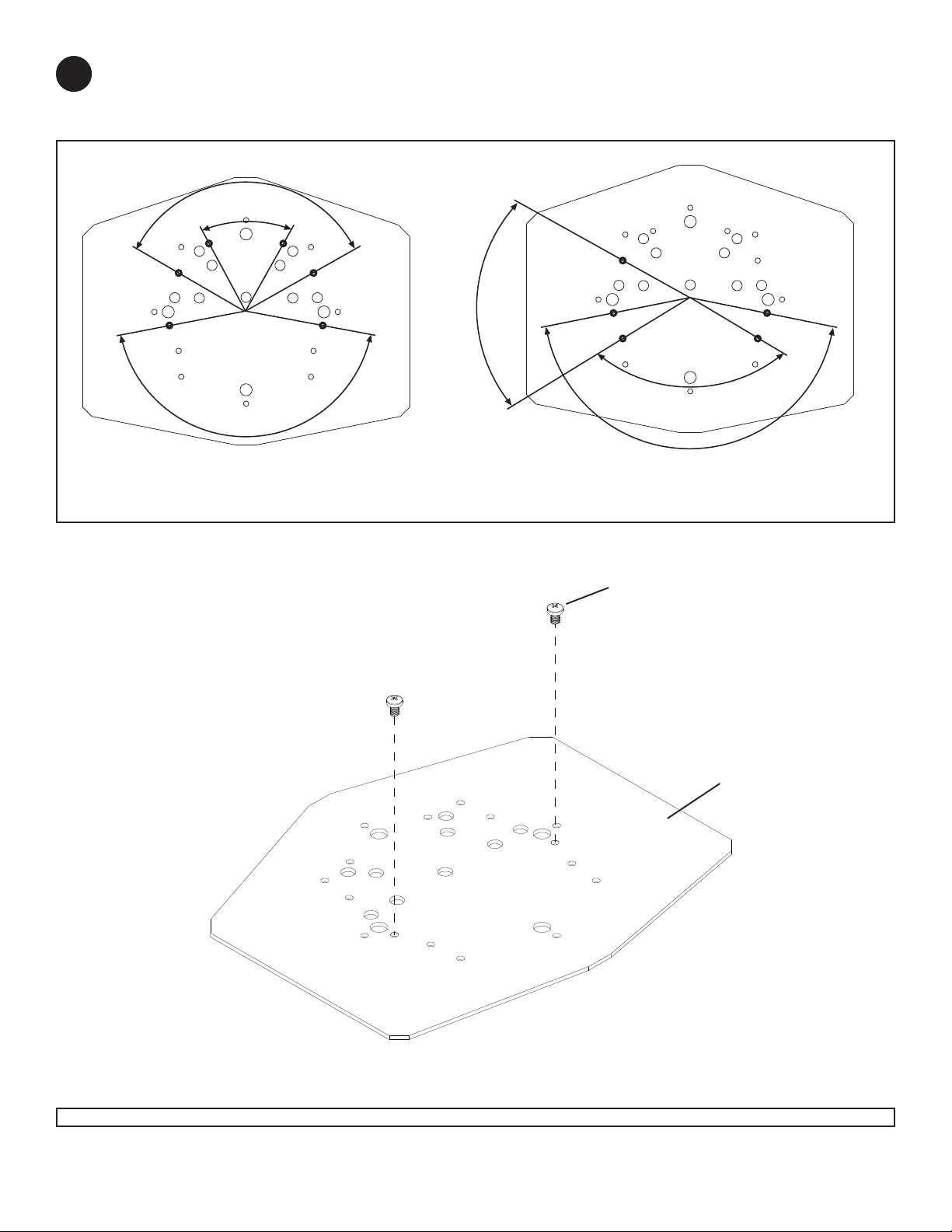

Swivel Restriction Option

Mounting plate (A) can be restricted to 60, 120 or 180 degrees of swivel. Locate the swivel hole patterns according

1

to screen model as shown in fig. 1.1. Insert two M5 x 8 mm screws (F) into holes on left and right side for desired

degree of swivel restriction as shown in fig. 1.2.

120°

60°

60°

°

120

180°

180°

Models: LC-32HT3U, LC-37HT3U Models: LC-42HT3U

fig 1.1

EXAMPLE: INSTALLED IN

F

HOLES FOR 180° SWIVEL

RESTRICTION

fig 1.2

A

3 of 7

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED: 02-28-08 SHEET #: 090-9143-2 04-28-08

Page 4

NOTE FOR LC-32HT3U: Remove rubber pads from bottom of LCD

stand that come in contact with mounting plate to ensure a flush

fit.

LCD STAND MAY APPEAR

DIFFERENT THAN ILLUSTRATED

2

Choose the correct mounting hole pattern shown in figure 2.1 for

attaching mounting plate (A) to LCD stand. Attach mounting plate

(A) to LCD stand using the appropriate number of M6 x 30 mm

phillips screws (D) and spacers (C) as shown in figure 2.2.

NOTE: Heads of M5 x 8 mm screws (F) must be between

mounting plate (A) and bottom of LCD stand as shown in detail 1.

Models: LC-32HT3U, LC-37HT3U

A

Models: LC-42HT3U

BACK OF

LCD STAND

C

A

fig. 2.2

D

LCD STAND

Rotate the swivel base so large holes in

3

race plate align with mounting holes in

swivel base.

fig. 2.1

A

MOUNTING HOLE

LARGE HOLE

A

F

C

D

DETAIL 1

B

4 of 7

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED: 02-28-08 SHEET #: 090-9143-2 04-28-08

Page 5

NOTE: Race assembly (B) and rivet must be in the correct orientation when installing. Rotate bottom of race

3- 1

assembly (B) until rivet is in the correct position for screen and desired swivel restriction as shown in as shown in

fig. 3.1 and 3.2. Place race assembly (B) onto mounting plate (A) while keeping it in the correct orientation. Att ach

race assembly (B) to mounting plate (A) using M5 x 6 mm type F phillips screws (E) as shown in fig. 3.3.

Rivet Location for Swivel Restriction

Models: LC-32HT3U, LC-37HT3U Models: LC-42HT3U

STAND MOUNTING

HOLES

B

A

RIVET

RIVET

RIVET

RIVET

180° 60° and120°

120° and 60°

fig. 3.1

A

180°

STAND MOUNTING

HOLES

B

fig. 3.2

E

NOTE: BOTTOM OF

B

EXAMPLE: RIVET IN

POSITION FOR 180°

SWIVEL RESTRICTION

RACE ASSEMBL Y

A

fig. 3.3

5 of 7

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED: 02-28-08 SHEET #: 090-9143-2 04-28-08

Page 6

WARNING

• Once race assembly (B) is attached to desk surface, swivel restriction/ orientation of screen cannot be adjusted.

Before applying vinyl #80 spray adhesive to desk surface,

3

place LCD stand right side up in desired location. Rivet

location on race assembly (B) must be in the middle of

swivel restriction range, refer to fig. 1.1 on page 3. Rotate

stand and verify that swivel restriction is correct.

NOTE: Once tape backing is removed be careful not to touch

the sticky surface of the tape with fingers, as this can cause

the tape to lose some of its holding power .

Clean desk surface with rubbing alcohol. Use 3M rubber and

vinyl #80 spray adhesive (not supplied) on the

surface area only. NOTE: S pray adhesive will not remove

easily. W ait at least 4 minutes to dry before removing t ape

backing from race assembly (B) and placing firmly on

surface. While placing the LCD stand/ desktop mount on

desk surface, bottom of race assembly must be held to

prevent the rivet from rotating out of place.

NOTE: Af ter application of tape on race assembly (B), the

bond strength will increase as the adhesive flows onto the

surface. At room tempurature, approximately 50% of the

ultimate strength will be achieved after 20 minutes, 90% after

24 hours, and 100% after 72 hours. In some cases, bond

strength can be achieved more quickly by exposure to

elevated tempuratures (e.g. 150°F [66°C] for 1 hour).

mounting

DRIED 3M RUBBER AND

VINYL #80 SPRA Y

ADHESIVE (not supplied)

LCD ST AND

DESK

SURFACE

6 of 7

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED: 02-28-08 SHEET #: 090-9143-2 04-28-08

Page 7

NOTE: Carefully place screen on LCD stand to reduce the change of displacing it before fully cured.

4

Slide screen onto LCD stand until screen mounting holes and LCD stand mounting holes align as shown in fig. 5.1.

Attach screen to LCD stand using fasteners that come with your screen.

Security Option: Attach screen to LCD st and using four M6 x 20 mm socket pin screws (G), used for the 32" and

37" screens or M6 x 65 mm penta-pin™ screws (H), used for the 42" screen with four split washers (K) and four flat

washers (J) as shown in figure 5.2. Tighten with 4 mm security allen wrench (L) or penta-pin™ driver (I).

Screen may appear

slightly different

than illustrated

J

K

LCD

ST AND

fig 5.1

G or H

MOUNTING SURFACE NOT

SHOWN FOR CLARITY

fig 5.2

7 of 7

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 02-28-08 SHEET #: 090-9143-2 04-28-08

© 2008, Peerless Industries, Inc. All rights reserved.

Loading...

Loading...