Page 1

WALL CHASER PMNF 1350 A1

WALL CHASER

Operation and Safety Notes

Translation of original operation manual

DRÁŽKOVACÍ FRÉZA DO ZDIVA

Pokyny pro obsluhu a bezpečnostní pokyny

Překlad originálního provozního návodu

MAUERNUTFRÄSE

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

IAN 93548

REZKALNIK ZIDNIH UTOROV

Navodila za upravljanje in varnostna opozorila

Prevod originalnega navodila za uporabo

DRÁŽKOVACIA FRÉZA DO MURIVA

Pokyny pre obsluhu a bezpečnostné pokyny

Preklad originálneho návodu na obsluhu

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Pred branjem odprite stran s slikami in se nato seznanite z vsemi funkcijami naprave.

Před čtením si otevřete stranu s obrázky a potom se seznamte se všemi funkcemi přístroje.

Pred čítaním si odklopte stranu s obrázkami a potom sa oboznámte so všetkými funkciami prístroja.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB Operation and Safety Notes Page 5

SI Navodila za upravljanje in varnostna opozorila Stran 15

CZ Pokyny pro obsluhu a bezpečnostní pokyny Strana 25

SK Pokyny pre obsluhu a bezpečnostné pokyny Strana 35

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 45

Page 3

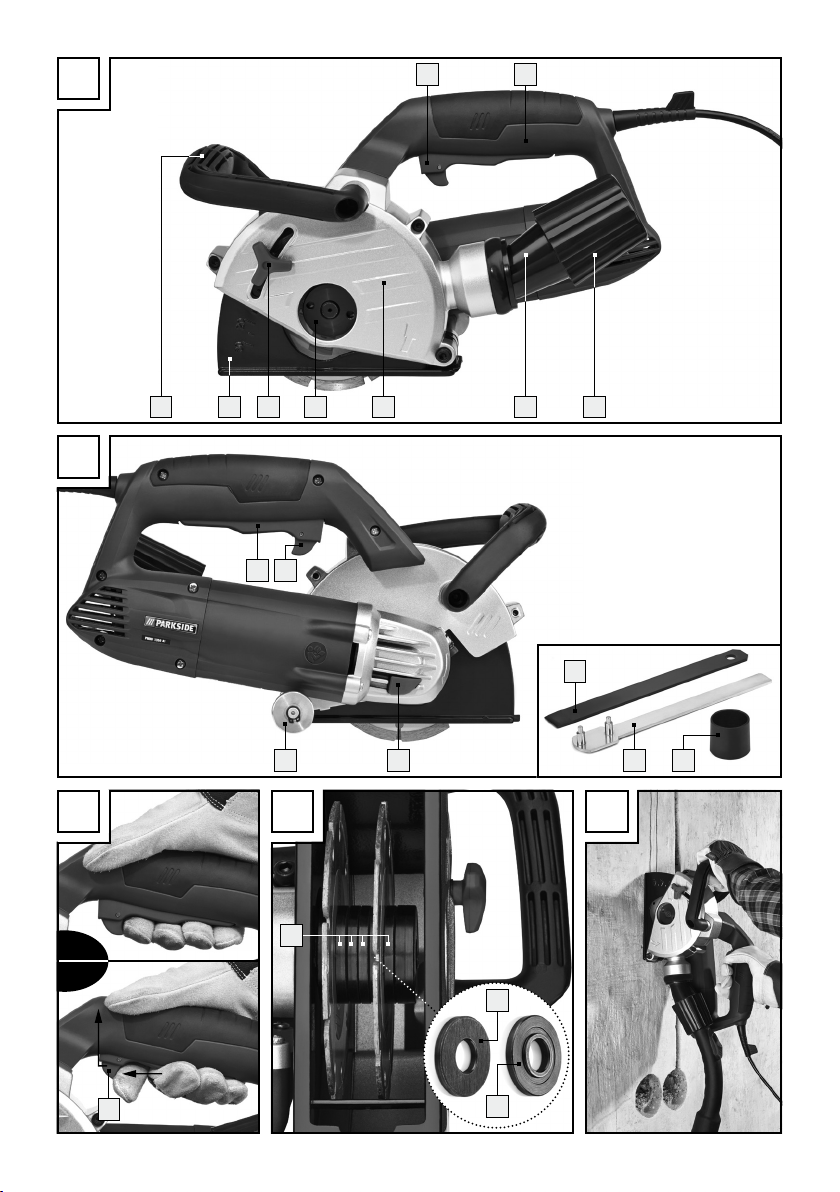

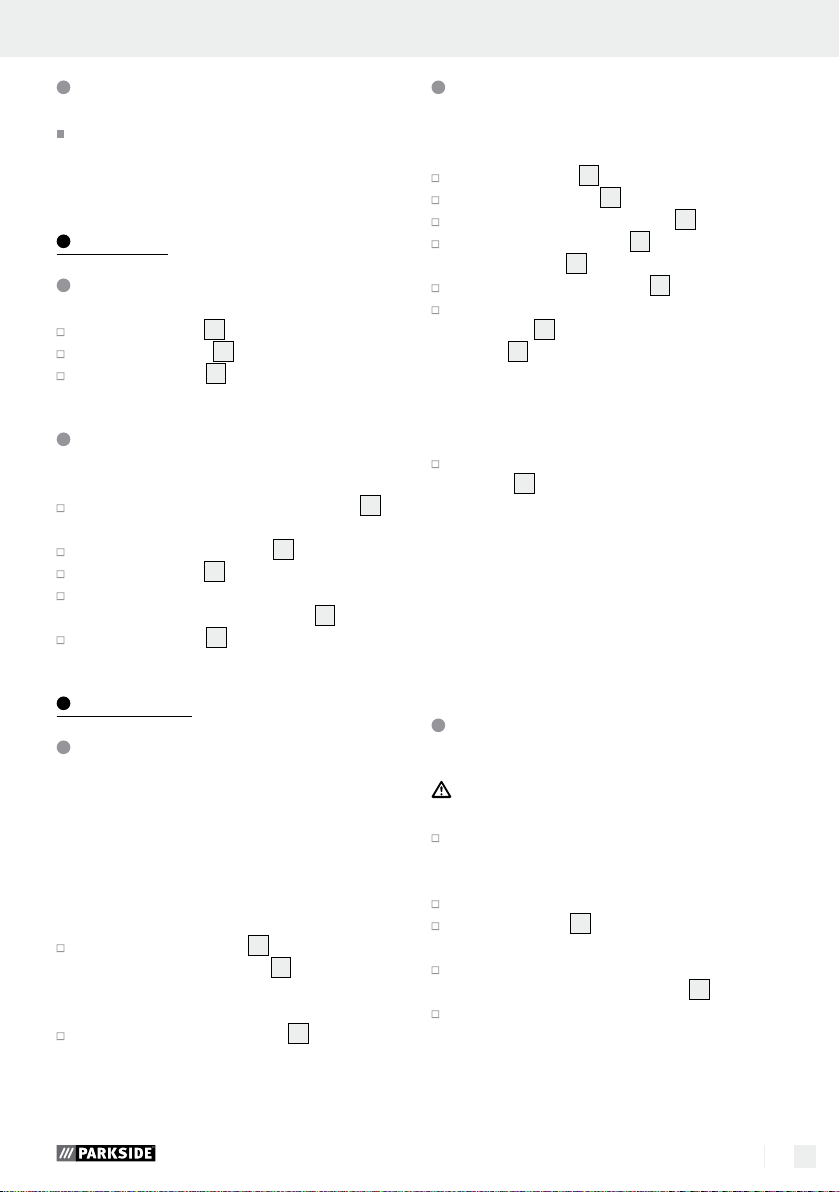

A

0

1

1 2

8

5 3 a

467

3

B

91

16

11 10 1215

C D E

14

9

14

13

Page 4

Page 5

Table of contents

Introduction

Intended use ........................................................................................................................................Page 6

Device description ..............................................................................................................................Page 6

Scope of delivery ............................................................................................................................... Page 6

Technical Data ....................................................................................................................................Page 6

General power tool safety warnings

1. Work area safety ........................................................................................................................... Page 7

2. Electrical safety ..............................................................................................................................Page 7

3. Personal safety ...............................................................................................................................Page 7

4. Power tool use and care ................................................................................................................ Page 8

5. Service ............................................................................................................................................Page 8

Cut-off machine safety warnings ....................................................................................................... Page 8

Further safety instructions for abrasive cutting-off operations ........................................................ Page 10

Supplementary Instructions ................................................................................................................Page 10

Original a ccessories / too ls ...............................................................................................................P a ge 11

Start-up

Setting the groove depth....................................................................................................................P ag e 11

Installing the dust extraction adapter ................................................................................................Pa ge 11

Operation

Switching ON / O FF ...........................................................................................................................P a ge 11

Installing and adjusting the cutting width of the diamond cutting discs ......................................... P ag e 11

Handling the wall chaser ...................................................................................................................Pa ge 11

Maintenance and Cleaning .............................................................................................Page 12

Warranty ........................................................................................................................................Page 12

Disposal ............................................................................................................................................ Page 12

Declaration of conformity / Manufacturer ........................................................Page 13

5 GB

Page 6

Wall chaser PMNF 1350 A1

Introduction

We congratulate you on the purchase of your new

device. You have chosen a high quality product. The

instructions for use are part of the product. They

contain important information concerning safety,

use and disposal. Before using the product, please

familiarise yourself with all of the safety information

and instructions for use. Only use the unit as de

and for the specified applications. If you pass the

product on to anyone else, please ensure that you

also pass on all the documentation with it.

scribed

15

Face pin wrench

16

Chisel

Scope of delivery

1 Wall chaser

2 Cutting discs (preinstalled)

1 Face pin wrench

1 Extraction adapter (preinstalled)

1 Reducer

(for use with the extraction adapter and a size

∅ 32 mm vacuum hose)

1 Chisel

1 Instructions for use

Intended use

The wall chaser (normative cut-off machine), in the

following also referred to as device, in conjunction

with an approved industrial dust extractor, is intended

to cut or slit primarily mineral materials, e.g. concrete

or masonry when firmly applied with the guide sled

without the use of water. Any other uses, and / or

modifications to the appliance, are deemed to be

improper usage and may result in serious physical

injury. Not for commercial applications.

Device description

(see Fig. A–D)

1

ON- / OFF-switch

2

Handle

3

Dust extraction adapter

3 a

Union nut

4

Protective cover

5

Adapter flange (with thread)

6

Depth stop set screw

7

Depth stop

8

Additional handle

9

Switch lock

10

Spindle lock

11

Roller

12

Reducer

13

Centring flange

14

Spacers

6 GB

Technical Data

Mains voltage: 230 V∼ 50 Hz

Power input : 1350 W

Rated no load speed: 9000 min

Disc ø: 125 mm

Mounting hole: 22.2 mm

Groove depth: 0–30 mm

Groove width: 8–26 mm

Thread: M14

Protection class: II /

Weight: approx. 4.05 kg

Noise and vibration

Noise and vibration ratings were determined

according to EN 60745.

Noise level L

Uncertainty K

Sound power level L

Uncertainty K

: 97.6 dB(A)

pA

: 3 dB

pA

: 108.6 dB(A)

WA

: 3 dB

WA

Wear ear protection.

Exposure to noise can cause hearing loss.

The total vibration (vector sum of three directions) is

calculated in accordance with EN 60745.

Declaration of vibration emission value

(Cutting concrete slab):

Main Handle: 6.417 m / s

Auxiliary Handle: 4.258 m / s

Uncertainty K = 1.5 m / s

2

2

-1

2

Page 7

Introduction / General power tool safety warningsIntroduction

The vibration emission value specified was measured

according to a standardised testing method and may

vary depending on the method the power tool is

being used, and in exceptions be higher than the

specified value.

The vibration emission value specified can be used

to compare power tools.

The vibration emission value specified can also serve

as a preliminary assessment of the impact.

Try to keep the vibration loads as low as possible.

Measures to reduce the vibration load are, e.g. wearing gloves and limiting the working time. Wherein

all states of operation must be included (e.g. times

when the power tool is switched off and times where

the power tool is switched on but running without

load).

General power tool

safety warnings

Read all safety warnings

and all instructions. Failure to follow the warn-

ings and instructions may result in electric shock, fire

and / or serious injury.

Save all warnings and instructions for

future reference.

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plug

and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e)

When operating a power tool outdo

use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

ors,

s

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) D

o not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away

while operating a power tool. Distractio

can cause you to lose control.

ns

3. Personal safety

a) Stay alert, watch what you are doing

and use common sense when operating a power tool. Do not use a power

tool while you are tired or under the

influence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

7 GB

Page 8

c) Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and / or

battery pack, picking up or carrying

the tool. Carrying power tools with your fing

o

n the switch or energising power tools that hav

the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper foot-

ing and balance at all times. This enables

better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If devices are provided for the connec-

tion of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of dust collection

can reduce dust-related hazards.

er

4. Power tool use and care

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for mis-

alignment or binding of moving parts,

breakage of parts and any other con-

e

dition that may affect the power tool’s

operation. If damaged, have the power

tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

5. Service

a) Have your power tool serviced by a

qualified repair person using only

tical replacement parts. This will ensure

that the safety of the power tool is maintained.

iden-

a) Do not force the power tool. Use the

correct power tool for your applica

The correct power tool will do the job better

and safer at the rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power

source and / or the battery pack from

the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

8 GB

tion.

Cut-off machine safety warnings

a) The guard provided with the tool must

be securely attached to the power tool

and positioned for maximum safety,

so the least amount of wheel is exposed towards the operator. Position

yourself and bystanders away from

the plane of the rotating wheel. The

guard helps to protect operator from broken

wheel fragments and accidental contact with

wheel.

b) Only use diamond-tip cutting discs with

your power tool. Just because an accessory

can be attached to your power tool, it does not

assure safe operation.

c) The rated speed of the accessory must

be at least equal to the maximum spee

d

Page 9

General power tool safety warningsGeneral power tool safety warnings

marked on the power tool. Accessories

running faster than their rated speed can break

and fly apart.

d) Wheels must be used only for recom-

mended applications. For example:

do not grind with the side of cut-off

wheel. Abrasive cut-off wheels are intended

for peripheral grinding, side forces applied to

these wheels may cause them to shatter.

e) Always use undamaged wheel flanges

that are of correct diameter for your

selected wheel. Proper wheel flanges sup-

port the wheel thus reducing the possibility of

wheel breakage.

f) Do not use worn down reinforced

wheels from larger power tools. Wheels

intended for a larger power tool are not suitable for the higher speed of a smaller tool and

may burst.

g) The outside diameter and the thickness

of your accessory must be within the

capacity rating of your power tool. In-

correctly sized accessories cannot be adequately

guarded or controlled.

h) The arbour size of wheels and flanges

must properly fit the spindle of the

power tool. Wheels and flanges with arbour

holes that do not match the mounting hardware

of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

i) Do not use damaged wheels. Before

each use, inspect the wheels for chips

and cracks. If power tool or wheel is

dropped, inspect for damage or install

an undamaged wheel. After inspecting

and installing the wheel, position yourself and bystanders away from the

plane of the rotating wheel and run

the power tool at maximum no load

speed for one minute. Damaged wheels

will normally break apart during this test time.

j) Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasse

As appropriate, wear dust mask, hearing protectors, gloves and shop apron

capable of stopping small abrasive or

workpiece fragments. The eye protection

s.

must be cap-able of stopping flying debris generated by various operations. The dust mask

or respirator must be capable of filtrating particles generated by your operation. Prolonged

exposure to high intensity noise may cause

hearing loss.

k) Keep bystanders a safe distance away

from work area. Anyone entering the

work area must wear personal protective equipment. Fragments of workpiece or

of a broken wheel may fly away and cause injury beyond immediate area of operation.

l) Hold the power tool by insulated grip-

ping surfaces only, when performing

an operation where the cutting accessory may contact hidden wiring or its

own cord. Cutting accessory contacting a

“live” wire may make exposed metal parts of

the power tool “live” and could give the operator an electric shock.

m) Position the cord clear of the spinning

accessory. If you lose control, the cord may

be cut or snagged and your hand or arm may

be pulled into the spinning wheel.

n) Never lay the power tool down until

the accessory has come to a complete

stop. The spinning wheel may grab the surface

and pull the power tool out of your control.

o) Do not run the power tool while car-

rying it at your side. Accidental contact

with the spinning accessory could snag your

clothing, pulling the accessory into your body.

p) Regularly clean the power tool’s air

vents. The motor’s fan will draw the dust inside

the housing and excessive accumulation of

powdered metal may cause electrical hazards.

q) Do not operate the power tool near

flammable materials. Sparks could ignite

these materials.

r) Do not use accessories that require

liquid coolants. Using water or other liquid

coolants may result in electrocution or shock.

9 GB

Page 10

Further safety instructions for

abrasive cutting-off operations

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel. Pinching or snagging causes rapid

s

talling of the rotating wheel which in turn causes th

uncontrolled power tool to be forced in the direction

opposite of the wheel’s rotation at the point of the

binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the

surface of the material causing the wheel to climb

out or kick out. The wheel may either jump toward

or away from the operator, depending on direction

of the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and / or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

a) Maintain a firm grip on the power tool

and position your body and arm to

allow you to resist kickback forces. Always use auxiliary handle, if provided,

for maximum control over kickback or

torque reaction during start-up. The op-

erator can control torque reactions or kickback

forces, if proper precautions are taken.

b) Never place your hand near the rotat-

ing accessory. Accessory may kickback over

your hand.

c) Do not position your body in line with

the rotating wheel. Kickback will propel

the tool in direction opposite to the wheel’s

movement at the point of snagging.

d) Use special care when working cor-

ners, sharp edges etc. Avoid bouncing

and snagging the accessory. Corners,

sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of

control or kickback.

e) Do not attach a saw chain, woodcarv-

ing blade, segmented diamond wheel

10 GB

with a peripheral gap greater than

10 mm or toothed saw blade. Such blades

create frequent kickback and loss of control.

f) Do not “jam” the wheel or apply ex-

cessive pressure. Do not attempt to

make an excessive depth of cut. Over-

e

stressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel

in the cut and the possibility of kickback or

wheel breakage.

g) When wheel is binding or when inter-

rupting a cut for any reason, switch

off the power tool and hold the power

tool motionless until the wheel comes

to a complete stop. Never attempt to

remove the wheel from the cut while

the wheel is in motion otherwise kickback may occur. Investigate and take cor-

rective action to eliminate the cause of wheel

binding.

h) Do not restart the cutting operation in

the workpiece. Let the wheel reach full

speed and carefully re-enter the cut.

The wheel may bind, walk up or kickback if

the power tool is restarted in the workpiece.

i) Support panels or any oversized work-

piece to minimize the risk of wheel

pinching and kickback. Large workpieces

tend to sag under their own weight. Supports

must be placed under the workpiece near the

line of cut and near the edge of the workpiece

on both sides of the wheel.

j) Use extra caution when making a

“pocket cut” into existing walls or

other blind areas. The protruding wheel

may cut gas or water pipes, electrical wiring

or objects that can cause kickback.

Supplementary Instructions

Approved cutting wheel designs: diamond

set, disc diameter 125 mm, disc thickness max.

2.2 mm

Always wear a dust mask!

Always wear ear protection!

Page 11

General power tool safety warnings / Start-up / OperationGeneral power tool safety warnings

Original accessories / t ools

Use only the accessories and attachments de-

tailed in the operating instructions, or those which

are compatible with the device.

Start-up

Setting the groove depth

Loosen set screw 6.

Set the depth stop 7 to the desired depth.

Tighten set screw 6.

Installing the dust

extraction adapter

Slide the pegs of the extraction adapter 3

into the slots of the dust extraction connection.

Turn the extraction adapter 3 to lock.

Loosen union nut

Insert the tube of the extraction unit far enough

into the opening on the union nut

Tighten union nut

3 a

3 a

.

3 a

.

.

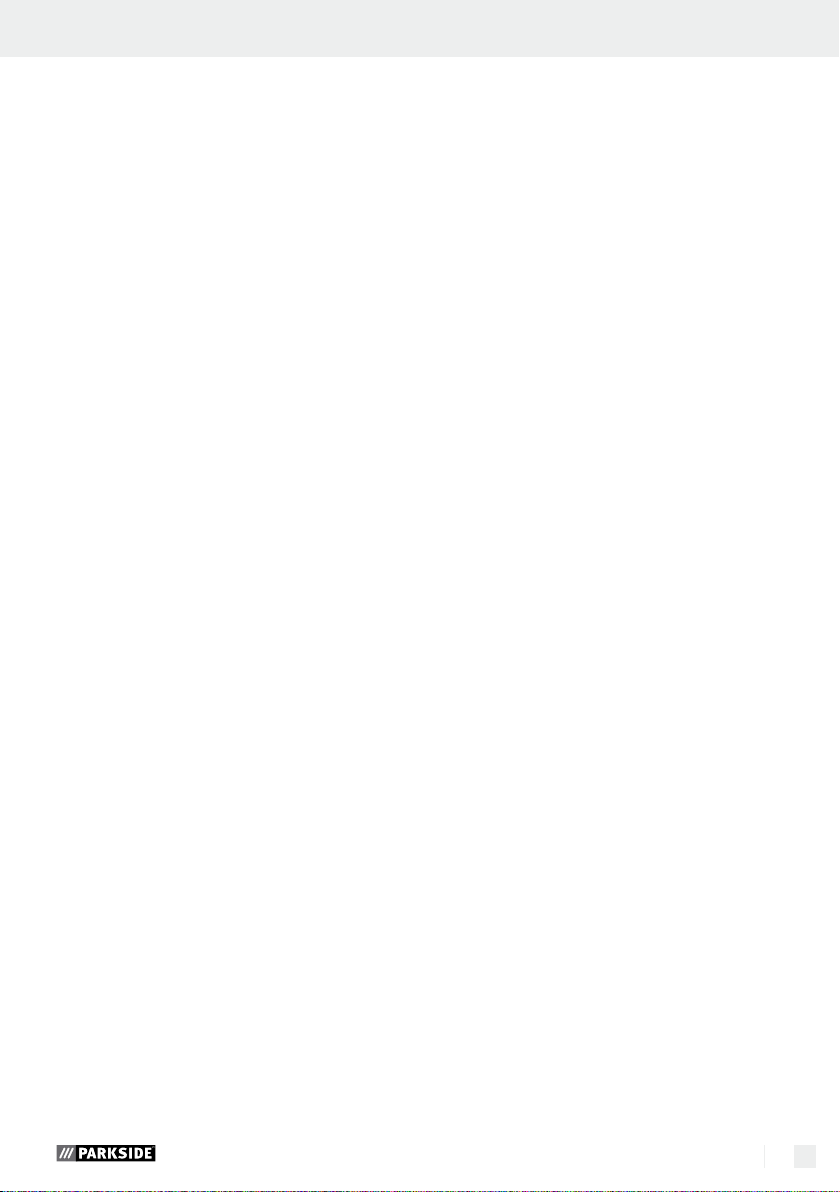

Installing and adjusting

the cutting width of the

diamond cutting discs

Loosen set screw 6.

Slide the depth stop 7 up.

Press and hold the spindle lock 10.

Use the face pin wrench 15 to loosen the

adapter flange

Remove the adapter flange 5.

Set the desired cutting width with the number

of spacers

13

flange

NOTE: You may choose from various spacers.

Please note, the total number of spacers betw

the cutting discs and the thickness of the cutting

discs yield the groove width.

Tighten the adapter flange with the face pin

wrench

lock.

NOTE: When setting a cutting width smaller

than the maximum, you must use the spacers

on the clamping collar side, as the clamping

collar alone cannot secure the discs due to the

thread length on the spindle (see. Fig. D).

NOTE: Always replace diamond cutting discs

in pairs.

5

.

14

. Be sure to use the centring

as the top spacer.

15

. When doing so, hold the spindle

een

Operation

Switching ON / OFF

NOTE: Always switch on the device before bringing

into contact with the material and only then apply

the device to the work piece. The wall grinder features electronic smooth start-up. The motor‘s start-up

is delayed.

Switching the unit on:

Activate the switch lock 9 (see Fig. C). Then

press the ON / OFF switch

Switching the device off:

Release the ON / OFF switch 1.

1

.

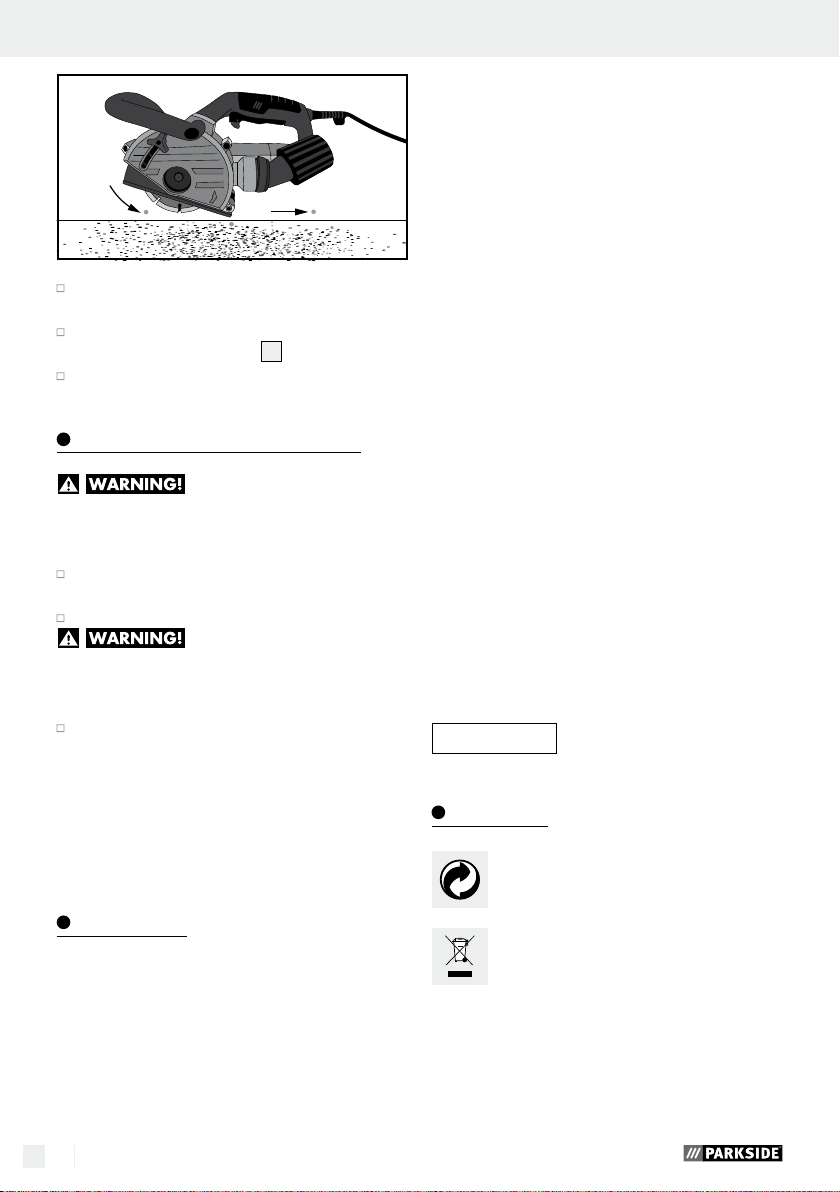

Handling the wall chaser

(see Fig. E)

ATTENTION! This device is only suitable for

dry cuts!

Use a cable detector to check walls for hidden

electrical-, gas- and water lines before using

the wall chaser.

Select the desired groove width.

Apply the roller 11 of the device onto the brick

wall.

Now switch on the device and immerse into

the brick wall until the depth stop

Now cut the groove into the brick wall, noting

the cutting direction. The device must be rotating in the opposite direction. The device can

otherwise erratically be pushed out of the cut.

7

touches.

11 GB

Page 12

Operation / Maintenance and Cleaning / Warranty / Disposal

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

2

1

3

At the end of the groove swing the device out

of the groove and only then switch off the device

Now remove the ridge created between the

two grooves with a chisel

16

.

Do not work on materials containing asbestos!

maufacturing defects, but not for transport damage, f

wearing parts or for damage to fragile components,

e.g. buttons or batteries. This product is for private

use only and is not intended for commercial use.

The warranty is void in the case of abusive and im-

.

proper handling, use of force and internal tampering

not carried out by our authorized service branch. Your

statutory rights are not restricted in any way by this

warranty.

or

Maintenance and Cleaning

RISK OF INJURY! Switch the

device off and pull the plug out of the mains socket

before carrying out any work on the device.

Always keep the device clean, dry and free of

oil or grease.

Use a dry cloth to clean the housing.

If the connection cable

needs to be replaced, this repair must

be performed by the manufacturer or a

representative to prevent safety hazards.

Grinding tools must be handled and transported

with care. Grinding tools have to be stored in su

ch

a way that they are not exposed to mechanical

damage or damaging environmental influences.

Note: Spare parts not listed (e.g. carbon brushes,

switches) can be ordered through our call centre.

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP/Min.)

e-mail: kompernass@lidl.co.uk

IAN 93548

Disposal

The packaging is wholly composed of

environmentally-friendly materials that can

be disposed of at a local recycling centre.

Do not dispose of electric tools

in the household waste!

In accordance with European Directive 2002 / 96 / EC

(covering waste electrical and electronic equipment)

and its transposition into national legislation, worn out

electrical power tools must be collected separately

and taken for environmentally compatible recycling.

12 GB

Page 13

Disposal / Declaration of conformity / Manufacturer

Contact your local refuse disposal authority for more

details of how to dispose of your worn out electrical

devices.

Declaration of conformity /

Manufacturer

We, KOMPERNASS HANDELS GMBH, the person

responsible for documents: Mr Semi Uguzlu, BURGSTRASSE 21, 44867 BOCHUM, GERMANY, hereby

declare that this product complies with the following

standards, normative documents and EU directives:

Machinery Directive

(2006 / 42 / EC)

EU Low Voltage Directive

(2006 / 95 / EC)

Electromagnetic Compatibility

(2004 / 108 / EC)

RoHS Directive

(2011 / 65 / EU)

Applicable harmonized standards

EN 60745-1/A11:2010

EN 60745-2-22:2011

EN 55014-1/A2:2011

EN 55014-2/A2:2008

EN 61000-3-2/A2:2009

EN 61000-3-3:2008

Date of manufacture (DOM): 12–2013

Serial number: IAN 93548

Bochum, 31.12.2013

Semi Uguzlu

- Quality Manager -

We reserve the right to make technical modifications in the course of further development.

Reprinting or other duplication of documentation

and documents accompanying the products or excerpts thereof, require the express approval of ISC

GmbH.

Type / Device description:

Wall chaser PMNF 1350 A1

13 GB

Page 14

14

Page 15

Kazalo

Uvod

Predvidena uporaba ......................................................................................................................... Stran 16

Opis naprave ..................................................................................................................................... Stran 16

Obseg dobave .................................................................................................................................. Stran 16

Tehnični podatki .................................................................................................................................Stran 16

Splošna varnostna navodila za električno orodje

1. Varnost na delovnem mestu ......................................................................................................... Stran 17

2. Električna varnost .......................................................................................................................... Stran 17

3. Varnost oseb .................................................................................................................................. Stran 17

4. Skrbno ravnanje in uporaba električnega orodja ..................................................................... S tran 18

5. Servis .............................................................................................................................................. Stran 18

Varnostni napotki za rezalne stroje .................................................................................................. Stran 19

Nadaljnji varnostni napotki za uporabo rezalnega orodja .......................................................... Stran 20

Dopolnilna navodila .......................................................................................................................... Stran 21

Originalni pribor / originalne dodatne naprave ............................................................................. Stran 21

Začetek uporabe

Nastavitev globine utora .................................................................................................................. Stran 21

Montaža adapterja za sesalnik ....................................................................................................... Stran 21

Uporaba

Vklop / Izklop ..................................................................................................................................... Stran 21

Montaža in nastavitev širine reza diamantne rezalne plošče ....................................................... Stran 21

Rokovanje z rezkarjem zidnih utorov ............................................................................................... Stran 22

Vzdrževanje in čiščenje ..................................................................................................... Stran 22

Garancija ....................................................................................................................................... Stran 22

Odstranjevanje ......................................................................................................................... Stran 23

Izjava o sklad nosti / Izdelovalec ............................................................................... Stran 23

Garancijski list ........................................................................................................................... Stran 24

15 SI

Page 16

Uvod

Rezkalnik zidnih utorov

PMNF 1350 A1

Uvod

Iskrene čestitke ob nakupu vaše nove naprave. Odločili

ste se za zelo kakovosten izdelek. To navodilo za

uporabo je sestavni del tega izdelka. Vsebuje pomembna

navodila za varnost, uporabo in odstranitev. Preden začnete izdelek uporabljati, se seznanite z vsemi

navodili za uporabo in varnostnimi napotki. Izdelek

uporabljajte samo tako, kot je opisano, in samo za

navedena področja uporabe. Če izdelek odstopite

novemu lastniku, mu zraven izročite tudi vse dokumente.

Predvidena uporaba

Rezkalnik zidnih utorov (normativno rezalni stroj), v

nadaljevanju imenovan naprava, je namenjen v povezavi z odobrenim industrijskim sesalnikom za rezanje ali zarezovanje s trdnim vodilu v pretežno mineralne obdelovance, npr. beton ali zid brez uporabe

vode. Kakršna koli drugačna uporaba ali sprememba stroja velja kot nepredvidena in predstavlja znatno nevarnost nesreč. Ni za poslovno uporabo.

Opis naprave (glejte sl. A–D)

1

VklopNO-izklopNO stikalo

2

Ročaj

3

Adapter za sesalnik

3 a

Natična matica

4

Zaščitni pokrov

5

Sprejemna prirobnica (z navojem)

6

Nastavljalni vijak za omejevalnik globine

7

Omejevalnik globine

8

Dodatni ročaj

9

Blokada vklopa

10

Gumb za blokado vretena

11

Tekalno kolo

12

Reducirni kos

13

Centrirna prirobnica

14

Vmesni sloji

15

Ključ za čepe

16

Ročno dleto

16 SI

Obseg dobave

1 rezkalnik zidnih utorov

2 rezalni plošči (prednameščeni)

1 ključ za čepe

1 sesalni adapter (prednameščen)

1 reducirni kos

(za uporabo s sesalnim adapterjem in gibka cev

sesalnika za prah premera ∅ 32 mm)

1 ročno dleto

1 navodila za uporabo

Tehnični podatki

Omrežna napetost: 230 V∼ 50 Hz

Vhodna moč: 1350 W

Nazivno število vrtljajev: 9000 min

ø Plošče: 125 mm

Sprejemna izvrtina: 22,2 mm

Globina utora: 0–30 mm

Širina utora: 8–26 mm

Navoj: M14

Razred zaščite: II /

Teža: pribl. 4,05 kg

Hrup in vibracije

Vrednosti hrupa in vibracij so ugotovljene v skladu

z EN 60745.

Raven zvočnega tlaka L

Negotovost K

Raven hrupa L

Negotovost K

: 3 dB

pA

WA

: 3 dB

WA

: 97,6 dB(A)

pA

: 108,6 dB(A)

Nosite opremo za zaščito sluha.

Učinek hrupa lahko vpliva na izgubo sluha.

Skupna vrednost nihanja (vektorska vsota treh smeri)

določena skladno z EN 60745.

Navedba vrednosti o emisijah vibracije (pri rezanju

betonske plošče)

Ročaj: 6,417 m / s

Dodatni ročaj: 4,258 m / s

Negotovost K: 1,5 m / s

2

2

2

Navedena emisijska vrednost nihanja je izmerjena

po standardnem postopku preverjanja in se lahko

-1

Page 17

glede na način, na katerega se električno orodje

uporablja, spremeni in je v izjemnih primerih nad

navedeno vrednostjo.

Navedeno emisijsko vrednost nihanja lahko uporabite za primerjavo električnega orodja z drugimi.

Navedeno vrednost emisije nihanja lahko uporabite

tudi za uvodno ocene vplivanja.

Poskusite ohraniti obremenitev zaradi vibracij čim nižjo.

Najboljši ukrep za zmanjšanje obremenitve zaradi

vibracij je nošnja rokavic med uporabo orodja in omejitev delovnega časa. Pri tem je treba upoštevati vse

dele obratovalnega cikla (npr. čase, med katerimi

je električno orodje izklopljeno, in čase, ko je sicer

orodje vklopljeno, vendar deluje brez obremenitve).

Splošna varnostna navodila

za električno orodje

Preberite varnostna

opozorila in navodila! Neupoštevanje varno-

stnih opozoril in navodil lahko vodi do povzročitve

električnega udara, požara in / ali hudih poškodb.

Vsa varnostna opozorila in navodila shranite za uporabo v prihodnje!

V varnostnih navodilih uporabljeni pojem „električno

orodje” se nanaša na električno orodje na omrežni

pogon (s kablom za priključitev na omrežje) in na

električno orodje na akumulatorski pogon (brez

kabla za priključitev na omrežje).

1. Varnost na delovnem mestu

a) Delovno območje naj bo vedno čisto

in dobro osvetljeno. Nered in neosvetljena

delovna področja so lahko vzrok za nezgode.

b) Z orodjem ne delajte v okolici, kjer

obstaja nevarnost eksplozije in v kateri se nahajajo vnetljive tekočine, plini

ali prah. Električna orodja proizvajajo iskrice,

ki bi lahko povzročile vžig prahu ali pare.

c) Poskrbite, da bodo otroci in druge

osebe med uporabo električnega orodja dovolj oddaljene od mesta uporabe.

Če vaša pozornost ni v celoti usmerjena na

delo, lahko izgubite nadzor nad orodjem.

2. Električna varnost

a)

Priključni vtič mora ustrezati električni

vtičnici. Vtiča v nobenem primeru ne

smete spreminjati. Skupaj z ozemljenimi

stroji ne uporabljajte dodatnih nastav

kov vtiča. Originalen nespremenjen vtič in

ustrezna vtičnica zmanjšata tveganje električnega udara.

b) Preprečite telesni stik z ozemljenimi

površinami, kot so cevi, grelci, štedilniki in hladilniki. Obstaja povečano tveganje

električnega udara, če je vaše telo ozemljeno.

c) Preprečite stik orodja z vodo ali vlago.

Vdor vode v električno orodje poveča tveganje

električnega udara.

d) Kabla ne uporabljajte za nošenje orod-

ja, za obešanje orodja ali za vlečenje

vtiča iz vtičnice. Kabel zavarujte pred

vročino, olji, ostrimi robovi ali gibljivim

delom orodja. Poškodovani ali zavozlani

kabli povečajo tveganje električnega udara.

e) Kadar z električnim orodjem delate na

prostem, uporabljajte samo električne

podaljške, ki so primerni in namenjeni

uporabi na prostem. Uporaba električnega

podaljška, ki je izdelan za uporabo na prostem,

zmanjša tveganje električnega udara.

f) Če se uporabi električnega orodja v

vlažnem okolju ne da izogniti, uporabljajte zaščitno stikalo za okvarni tok.

Uporaba zaščitnega stikala za okvarni tok

zmanjša tveganje električnega udara.

3. Varnost oseb

a) Ves čas bodite pozorni, pazite, kaj de-

late in pri delu z električnim orodjem

ravnajte razumno. Orodja ne uporabljajte, če ste utrujeni ali če ste pod

vplivom droge, alkohola ali zdravil.

Trenutek nepozornosti med uporabo orodja

lahko povzroči resne poškodbe.

17 SI

-

Page 18

Splošna varnostna navodila za električno orodje

b) Vedno uporabljajte osebno zaščitno

opremo in vedno zaščitna očala. Upo-

raba osebne zaščitne opreme kot so maska

za prah, delovni čevlji z zaščito proti drsenju,

zaščitna čelada ali zaščita sluha, odvisno od

načina uporabe električnega orodja, zmanjšuje tveganje nastanka poškodb.

c) Preprečite nenameren vklop naprave.

Prepričajte se, da je električno orodje

izklopljeno, preden ga priključite na

oskrbo s tokom, dvignete ali nosite.

Če imate pri nošenju naprave prst na stikalu

za VKLOP / IZKLOP ali je naprava vklopljena,

to lahko vodi do povzročitve nesreč.

d) Pred vklopom orodja odstranite vsa

orodja, ki jih potrebujete za nastavitve in vse vijačne ključe. Orodje ali ključ

v vrtečem se delu orodja bi lahko povzročil

poškodbe.

e) Izogibajte se abnormalni telesni drži.

Skrbite za varno stojišče in pazite na

ravnotežje. Na ta način lahko napravo, še po-

sebno v nepričakovanih situacijah, bolje kontrolirate.

f) Oblečeni bodite v primerna oblačila.

Ne nosite širokih oblačil ali nakita.

Poskrbite, da v bližino vrtečih se delov stroja ne pridejo lasje, oblačila in

rokavice. Ohlapna oblačila, nakit ali dolgi

lasje bi se lahko ujeli v premikajoče se dele.

g) Kadar je vgrajena oprema za odsesa-

vanje ali prestrezanje prahu, se prepričajte, da je oprema priključena in

pravilno uporabljena. Uporaba opreme

zmanjša ogrožanje zaradi prahu.

4. Skrbno ravnanje in uporaba

električnega orodja

a) Naprave ne preobremenjujte. Za vaše

delo uporabljajte za to namenjeno

električno orodje. Z ustreznim električnim

orodjem boste v določenem območju zmogljivosti delali bolje in bolj varno.

b) Ne uporabljajte električnega orodja,

čigar stikalo je defektno. Električno orod

je,

ki se ne da več vklopiti ali izklopiti, je nevarno

in ga je treba dati v popravilo.

c) Preden izvajate nastavitve na napra-

vi, zamenjujete dele opreme ali napravo date iz rok, izvlecite električni

vtič iz vtičnice. Ti previdnosti ukrepi

preprečujejo nenameren zagon električnega orodja. Ti previdnosti ukrepi

preprečujejo nenameren zagon naprave.

d) Neuporabljano električno orodje hra-

nite zunaj dosega otrok. Osebam, ki z

napravo niso seznanjene ali niso prebrale teh navodil, uporabe naprave

ne dovolite. Električno orodje je nevarno, če

ga uporabljajo neizkušene osebe.

e) Napravo skrbno negujte. Kontroliraj-

te, če premikajoči se deli naprave

brezhibno delujejo in se ne zatikajo,

če so deli naprave odlomljeni ali

poškodovani, ter da delovanje naprave ni ovirano. Poškodovane dele dajte pred ponovno uporabo naprave v

popravilo. Vzrok za mnoge nesreče je slabo

vzdrževano električno orodje.

f) Poskrbite, da bodo rezalna orodja

vedno ostra in čista. Skrbno vzdrževana

rezalna orodja z ostrimi rezili se ne zatikajo in

so lažje vodljiva.

g) Električna orodja, dodatno opremo,

nastavke itd. uporabljajte v skladu z

navodili za uporabo in na način, ki je

predpisan posebej za ta specialni tip

stroja. Vedno upoštevajte delovne pogoje in vrsto dela, ki ga želite opraviti.

Uporaba električnih orodij v namene, ki se razlikujejo od namenov, ki jih je predvidel proizvajalec, lahko povzroči nastanek nevarnih situacij.

5. Servis

a) Vaše naprave dajte vpopravilo servi-

sni službi ali strokovnjaku za električne naprave, popravilo pa naj poteka

samo z originalnimi nadomestnimi

Na ta način se zagotovi, da varnost naprave

ostane ohranjena.

deli.

18 SI

Page 19

Varnostni napotki za

rezalne stroje

a) Zaščitni pokrov, ki spada k električne-

mu orodju, mora biti trdno pritrjen in

nastavljen tako, da se doseže najvišja

stopnja varnosti, torej je proti upravljavcu obrnjen najmanjši možen del

rezalnega telesa. Upravljavec in bližnje

osebe se ne smejo zadrževati v bližini

ravni vrtljive rezalne plošče. Zaščitni

pokrov mora ščititi upravljavca pred drobci in

naključnim stikom z rezalnim telesom.

b) Uporabljajte izključno diamantne re-

zalne plošče za vaše električno orodje.

Dejstvo, da lahko pribor namestite na električn

orodje, ne zagotavlja varne uporabe.

c) Dovoljeno število vrtljajev električnega

orodja mora biti najmanj tako visoko,

kot je najvišje število vrtljajev, navedeno na električnem orodju. Pribor, ki

se vrti hitreje, kot je dovoljeno, se lahko razleti

in odleti.

d) Rezalna telesa je dovoljeno uporabljati

le za priporočeno uporabo. Na primer:

Nikoli ne režite s stransko površino

rezalne plošče. Rezalne plošče so namenje-

ne za odstranjevanje materiala z robom plošč

Stransko delovanje sil na ta rezalna telesa lahko povzroči zlom.

e) Za izbrano rezalno ploščo vedno upo-

rabljajte nepoškodovano vpenjalno

prirobnico pravilne velikosti in oblike.

Ustrezna prirobnica podpira rezalno ploščo in

tako zmanjša nevarnost zloma rezalne plošče.

f) Ne uporabljajte obrabljenih rezalnih

plošč večjih električnih orodij. Rezalne

plošče večjih električnih orodij niso zasnovane

za višje število vrtljajev manjših električnih orodij in se lahko zlomijo.

g) Zunanji premer in debelina uporablje-

nega orodja mora ustrezati podatkom

o dimenzijah vašega električnega orodja

. Napačno izmerjenih uporabljenih orodij ni

mogoče dovolj zavarovati ali nadzorovati.

h) Rezalne plošče in prirobnica se morajo

natančno prilegati na vreteno vašega

električnega orodja. Uporabljena orodja,

e.

ki se ne prilegajo natančno na vreteno električnega orodja, se vrtijo neenakomerno, močno

vibrirajo in lahko privedejo do izgube nadzora.

i) Ne uporabljajte poškodovanih rezal-

nih plošč. Pred vsako uporabo preverite rezalne plošče glede krušenja in

razpok. Če električno orodje ali rezalna plošča pade na tla, preverite, ali je

poškodovano / -a ali pa uporabite nepoškodovano rezalno ploščo. Ko je

rezalna plošča preverjena in jo uporabljate, se upravljavec in bližnje osebe

ne smejo zadrževati v bližini ravni

vrtljive rezalne plošče in pustite, da

naprava približno minuto deluje z naj-

o

višjim številom vrtljajev. Poškodovane

rezalne plošče se večinoma med tem preizkusom zlomijo.

j) Nosite osebno zaščitno opremo. Glede

na uporabo uporabljajte popolno zaščito za obraz, zaščito za oči ali zaščit

očala. Če je potrebno, nosite protiprašno masko, zaščito za sluh, zaščitne

rokavice ali poseben predpasnik, ki

bodo preprečili dostop majhnih delcev

in materiala do vas. Oči je treba zaščititi

pred letečimi tujki, ki nastanejo pri različnih

vrstah uporabe. Protiprašna maska ali zaščita

za dihala mora filtrirati prah, ki nastane pri uporabi. Če ste dlje časa izpostavljeni glasnemu

hrupu, lahko pride do poškodb sluha.

k) Zagotovite, da so druge osebe varno

oddaljene od vašega delovnega območja. Vsaka oseba, ki vstopi v delovno

območje, mora nositi osebno zaščitno

opremo. Drobci obdelovanca ali zlomljeni

deli uporabljenega orodja lahko odletijo in

povzročijo telesne poškodbe tudi izven neposrednega delovnega območja.

I) Kadar izvajate delovne operacije, pri

katerih uporabljeno električno orodje

lahko zadene ob skrito električno napeljavo ali lastni priključni kabel, držite napravo le na izoliranih površinah

za prijemanje. Stik z vodnikom, ki je pod

napetostjo, lahko premosti napetost na kovinske

dele naprave in povzroči udar električnega toka.

na

19 SI

Page 20

Splošna varnostna navodila za električno orodje

m) Napajalnega kabla ne približujte vr-

tljivim uporabljenim orodjem. Če izgu-

bite nadzor nad napravo, lahko prerežete ali

zajamete napajalni kabel ali pa se vaša dlan

ali roka ujame v vrtljivo uporabljeno orodje.

n) Nikoli ne odložite električnega orodja,

preden se orodje popolnoma ne ustavi.

Vrteče uporabljeno orodje lahko pride v stik z

odlagalno površino, zaradi česar lahko izgubite nadzor nad električnim orodjem.

o) Električno orodje med prenašanjem ne

sme delovati. Vaša oblačila se lahko ob ne-

namernem stiku z vrtljivim uporabljenim orodj

zataknejo in orodje lahko zareže v vaše telo.

p) Redno čistite prezračevalne reže elek-

tričnega orodja. Ventilator motorja vleče

prah v ohišje, akumulacija kovinskega prahu

pa lahko povzroči nevarnosti zaradi elektrike.

q) Električnega orodja ne uporabljajte v

bližini vnetljivih materialov. Iskre lahko

povzročijo vnetje teh materialov.

r) Ne uporabljajte orodja, ki zahteva

tekoča hladilna sredstva. Uporaba vode

ali drugih hladilnih sredstev lahko povzroči

električni udar.

em

Nadaljnji varnostni napotki za

uporabo rezalnega orodja

Povratni udarec in ustrezni varnostni

napotki

Povratni udarec je nenadna reakcija zaradi zataknjene ali zablokirane rezalne plošče. Zataknitev

ali blokada vodi do takojšnje ustavitve vrtečega

uporabljenega orodja. S tem se nenadzorovano

električno orodje pospešeno zavrti v nasprotni

smeri delovanja na mestu blokade.

Če se npr. rezalna plošča zatakne ali zablokira v

obdelovancu, se lahko rob rezalne plošče, ki je

pogreznjena v obdelovanca, zatakne in odlomi ali

povzroči povratni udarec. Rezalna plošča se nato

premakne proti upravljavcu ali stran od njega, odvisno od smeri delovanja plošče v točki blokade. S

tem se lahko rezalne plošče tudi zlomijo. Povratni

udarec je posledica napačne ali pomanjkljive uporabe električnega orodja. Preprečite ga lahko z

20 SI

ustreznimi previdnostnimi ukrepi, kot je opisano v

nadaljevanju.

a) Električno orodje trdno držite in posta-

vite vaše telo in roke v takšen položaj,

v katerem lahko nadzorujete sile povratnega udarca. Vedno uporabljajte

dodatni ročaj, če je nameščen, da boste

imeli čim večji nadzor nad silami povratnega udarca ali čim hitreje reagirali

pri visokih vrtljajih. Upravljavec lahko z

ustreznimi previdnostnimi ukrepi obvlada povratni udarec in nastale sile.

b) Nikoli ne približujte rok vrtečim upo-

rabljenim orodjem. Orodje se lahko pri

povratnem udarcu premakne prek vaše dlani.

c) Izogibajte se območju pred in za vrte-

č

o rezalno ploščo. Povratni udarec premakne

električno orodje v nasprotno smer vrtenja rezalne plošče v točki blokade.

d) V kotih, pri ostrih robovih itd. delajte

posebej previdno. Preprečite, da bi

orodje odskočilo ali se zataknilo v obdelovanca. Vrteče uporabljeno orodje se

lahko v kotih, na ostrih robovih ali ob odboju

zatakne. To povzroči izgubo nadzora ali povratni udarec.

e) Ne uporabljajte verižnega ali nazobča-

nega rezila in ne segmentirane diam

tne plošče z več kot 10 mm širokimi

režami. Takšna orodja povzročijo povratni

udarec ali izgubo nadzora nad električnim

orodjem.

f) Preprečite blokado rezalne plošče ali

premočno pritiskanje. Ne izvajajte preglobokih rezov. Preobremenitev rezalne

plošče poveča njeno obremenitev in dovzetnost

za zataknitev ali blokado, s tem pa tudi mož

povratnega udarca ali zloma rezalnega telesa.

g) Če se rezalna plošča zatakne ali če

prekinete z delom, napravo izklopite

in jo držite pri miru, dokler se plošče

ne zaustavi. Nikoli ne poskušajte iz

reza izvleči rezalne plošče, ki se še vrti,

saj lahko pride do povratnega udarca.

Ugotovite in odpravite vzrok zataknitve.

h)

Ne vklopite električnega orodja, dokle

se nahaja v obdelovancu. Najprej naj

an-

nost

r

Page 21

rezalna plošča doseže polno število

vrtljajev, preden previdno nadaljujete

z rezanjem. Sicer se lahko plošča zatakne,

odskoči iz obdelovanca ali povzroči povratni

udarec.

i) Plošče ali velike obdelovance podprite,

da boste zmanjšali tveganje povratnega udarca zaradi zataknjene rezalne

plošče. Veliki obdelovanci se lahko zaradi la-

stne teže zvijejo. Obdelovanca je treba podpr

na obeh straneh reza, tako v bližini odreza

kot tudi na robu.

j) Bodite posebej previdni pri „rezanju

žepov“ v obstoječe stene ali drugih območjih, v katere ne morete videti. Rezal-

na plošča, ki se pogrezne, lahko pri rezanju v

plinske ali vodne napeljave, električne napeljave ali druge predmete povzroči povratni udarec.

eti

Montaža adapterja za sesalnik

Potisnite čep adapterja za sesalnik 3 v vdol-

bino na priključku sesalnika.

Z vrtenjem zapahnite adapter za sesalnik 3.

Odvijte natično matico

Cev naprave za odsesavanje vstavite dovolj

globoko v odprtino v natični matici

Trdno zategnite natično matico

3 a

.

3 a

.

3 a

.

Uporaba

Vklop / Izklop

NAPOTEK: Napravo vedno vključite pred stikom z

materialom in jo šele nato približajte obdelovancu.

Rezkalnik zidnih utorov je opremljen z elektronskim mehkim zaganjalnikom. Motor se zažene z zakasnitvijo.

Dopolnilna navodila

Dovoljene zgradbe rezalnih plošč: opre-

mljene z diamantom,

na plošče največ 2,2 mm

Vedno nosite masko za zaščito pred

prahom.

Vedno nosite opremo za zaščito sluha.

premer plošče 125 mm

, debeli-

Originalni pribor / originalne

dodatne naprave

Uporabljajte samo pribor in dodatne naprave,

ki so navedeni v navodilih za uporabo oziroma

ki imajo sprejemne nastavke, skladne z napravo.

Začetek uporabe

Nastavitev globine utora

Odvijte pritrdilni vijak 6.

Nastavite omejevalnik globine 7 na želeno

globino.

Zategnite pritrdilni vijak 6.

Vklop naprave:

Pritisnite blokado vklopa 9 (glejte sl. C). Nato

pritisnite vklopno-izklopno stikalo

Izklop naprave:

Izpustite vklopno-izklopno stikalo 1.

1

.

Montaža in nastavitev širine

reza diamantne rezalne plošče

Odvijte pritrdilni vijak 6.

Potisnite omejevalnik globine 7 navzgor.

Pritisnite gumb za blokado vretena 10 in ga

zadržite.

S ključem za čepe 15 odvijte sprejemno pri-

robnico

Snemite sprejemno prirobnico 5.

Nastavite želeno širino reza s številom vmesnih

slojev

sloj namestite centrirno prirobnico

N

Upoštevajte, da dobite širino utora iz vsote dis-

tančnih plošč med diamantnima rezalnima plo-

ščama in debeline rezalnih plošč.

S ključem za čepe 15 zategnite sprejemno

prirobnico. Pri tem pritisnite gumb za blokado

vretena.

5

.

14

. Pri tem pazite, da kot zgornji vmesni

13

.

APOTEK: Na voljo imate več distančnih plo

šč.

21 SI

Page 22

Uporaba / Vzdrževanje in čiščenje / Garancija

NAPOTEK: Pri nastavljanju manjše širine reza

morate uporabiti vmesne sloje na strani pritrdilne

prirobnice za pritrjevanje rezalnih plošč, saj

pritrdilna prirobnica plošč zaradi dolžine navoja na vretenu ne more sama pritrjevati (gl. sl. D).

NAPOTEK: Diamantne rezalne plošče zamenjujte v paru.

Rokovanje z rezkarjem zidnih

utorov (glejte sl. E)

POZOR! Naprava je primerna le za suho re-

zanje!

Preden začnete uporabljati rezkalnik zidnih

utorov, z napravo za iskanje napeljav preverite

stene in zidovje glede skritih električnih, plinskih

in vodnih napeljav.

Izberite želeno širino utora.

Nastavite napravo s tekalnim kolesom 11 na zid

Zdaj vklopite napravo in ga pogreznite v zid

16.

7

.

2

1

3

do omejila

Zdaj izrežite utor v zid; pri tem pa upoštevajte

smer rezkanja.

Naprava mora vedno delovati v nasprotni smeri. Sicer lahko naprava nenadzorovano zdrsne

iz reza.

Na koncu utora najprej odstranite napravo iz

utora in jo šele nato izklopite.

Zdaj izbijte nastali rob med obema utoroma z

dletom

Materialov, ki vsebujejo azbest, ni dovoljeno

obdelovati!

Vzdrževanje in čiščenje

NEVARNOST NESREČE!

Pred vsemi deli na napravi napravo izklopite in izvlecite električni vtič iz vtičnice.

Orodje mora biti ves čas čisto, suho in na njem

ne sme biti olj ali masti za mazanje.

Za čiščenje ohišja uporabljajte suho krpo.

Če je potrebna zamen-

java priključne napeljave, to mora iz-

vesti proizvajalec ali njegov zastopnik,

da ne pride do nevarnosti.

Z rezalnimi orodji je treba ravnati in jih transpor-

tirati previdno. Rezalna orodja je treba skladiščiti

tako, da niso izpostavljena mehanskim poškodba

in škodljivim vplivom okolja.

Napotek: Nadomestne dele, ki tukaj niso navedeni (npr. oglene krtačke, stikala) lahko naročite prek

.

našega klicnega centra.

Garancija

Ta naprava ima 3 leta garancije od datuma

nakupa. Naprava je bila skrbno izdelana

in pred dobavo natančno preverjena.

Prosimo, da blagajniški račun shranite

kot dokazilo o nakupu. V primeru uveljavljanja garancije se po telefonu obrnite

na svojo servisno službo. Samo tako je

zagotovljeno brezplačno pošiljanje vašega izdelka.

Garancija velja le za napake pri materialu ali izdelavi, ne pa tudi za poškodbe pri transportu, potrošne

dele ali za poškodbe lomljivih delov, npr. stikal ali

akumulatorjev. Izdelek je namenjen izključno za

zasebno in ne za poslovno uporabo.

V primeru zlorabe ali nepravilnega ravnanja, pri

uporabi sile ter pri posegih, ki jih ni izvedla naša

pooblaščena servisna poslovalnica, garancija preneha veljati. Vaših zakonskih pravic ta garancija ne

omejuje.

m

22 SI

Page 23

Jamstvo ne podaljša garancijske dobe. To velja tudi

za zamenjane in popravljene dele. Morebitne po

škodbe in pomanjkljivosti, ki obstajajo že pri nakupu, je

treba javiti takoj po razpakiranju, najpozneje pa

dva dni po datumu nakupa.Popravila po preteku

garancijske dobe je treba plačati.

SI

Servis Slovenija

Phone: 080080917

e-mail: kompernass@lidl.si

IAN 93548

Odstranjevanje

Elektromagnetna kompatibilnost

(2004 / 108 / EC)

RoHS Direktiva

(2011 / 65 / EU)

Uporabljeni harmonizirani standardi

EN 60745-1/A11:2010

EN 60745-2-22:2011

EN 55014-1/A2:2011

EN 55014-2/A2:2008

EN 61000-3-2/A2:2009

EN 61000-3-3:2008

Oznaka tipa / Naprave:

Rezkalnik zidnih utorov PMNF 1350 A1

Embalaža sestoji iz naravi prijaznih materialov, ki jih lahko odvržete v lokalne

zbiralnike za recikliranje odpadkov.

Električnega orodja ne

mečite med hišne odpadke!

V skladu z evropsko direktivo 2002 / 96 / EC o

starih električnih napravah in njenim izvajanjem v

narodnem pravu je treba električno orodje zbirati

ločeno in vrniti v naravi primerno ponovno predelavo.

Vse o možnostih za odstranjevanje odsluženih naprav boste izvedeli pri vaši občinski ali mestni upravi.

Izjava o skladnosti /

Izdelovalec

Mi, podjetje KOMPERNASS HANDELS GMBH, za

dokumente odgovorna oseba: gospod Semi Uguz

BURGSTRASSE 21, 44867 BOCHUM, GERMANY,

izjavljamo, da je ta izdelek skladen z naslednjimi

normativi, normativnimi dokumenti in direktivami ES:

Direktiva o strojih

(2006 / 42 / EC)

lu,

Date of manufacture (DOM): 12–2013

Serijska številka: IAN 93548

Bochum, 31.12.2013

Semi Uguzlu

- Vodja kakovosti -

Pridržujemo si pravico do tehničnih sprememb.

Ponatis ali drugačno razmnoževanje dokumentacije

in spremnih dokumentov izdelkov, tudi po delih, je

dovoljeno le z izrecno odobritvijo podjetja ISC

GmbH.

Direktiva ES o nizkonapetostni električni

opremi (2006 / 95 / EC)

23 SI

Page 24

Garancijski list

KOMPERNASS HANDELS GMBH

BURGSTRASSE 21

44867 BOCHUM

GERMANY

080080917

Garancijski list

1. S tem garancijskim listom jamčimo Kompernaß

Handels GmbH, da bo izdelek v garancijskem

roku ob normalni in pravilni uporabi brezhibno

deloval in se zavezujemo, da bomo ob izpolnjenih spodaj navedenih pogojih odpravili morebitne pomanjkljivosti in okvare zaradi napak

v materialu ali izdelavi oz. po svoji presoji izdelek zamenjali ali vrnili kupnino.

2. Garancija je veljavna na ozemlju Republike

Slovenije.

3. Garancijski rok za proizvod je 3 leta od dneva

izročitve balga. Dan izročitve blaga je enak

dnevom prodaje, ki je razviden iz računa.

4. Kupec je dolžan okvaro javiti pooblaščenemu

servisu oz. se informirati o nadaljnjih postopkih

na zgoraj navedeni telefonski številki. Svetujem

vam, da pred tem natančno preberete navodila

o sestavi in uporabi izdelka.

5. Kupec je dolžan pooblaščenemu servisu pre-

dložiti garancijski list in račun, kot potrdilo in

dokazilo o nakupu.

6. V primeru, da proizvod popravlja nepooblaščeni servis ali oseba, kupec ne more uveljavljati

zahtevkov iz te garancije.

7. Vzroki za okvaro oz. nedelovanje izdelka morajo biti lastnosti stvari same, in ne vzroki, ki so

zunaj proizvajalčeve oz. prodajalčeve sfere. Kupe

c ne more uveljavljati zahtevkov iz te garancije

če se ni držal priloženih navodil za sestavo in

uporabo izdelka ali, če je izdelek kakorkoli

spremenjen ali nepravilno vzdrževan.

8. Jamčimo servisiranje in rezervne dele za minimalno dobo, ki je zahtevana s strani zakonodaje.

9. Obrabni deli oz. potrošni material so izvzeti iz

garancije.

10. Vsi potrebni podatki za uveljavljanje garancije

o

se nahajajo na dveh ločenih dokumentih (gar

cijski list, račun).

11. Ta garancija proizvajalca ne izključuje pravic

potrošnika, ki izhajajo iz odgovornosti prodajalca za napake na blagu.

,

an-

Prodajalec:

Lidl d.o.o.k.d., Pod lipami 1, SI-1218 Komenda

24 SI

Page 25

Úvod

Použití ke stanovenému účelu ......................................................................................................... Strana 26

Popis přístroje ...................................................................................................................................Strana 26

Obsah dodávky ...............................................................................................................................Strana 26

Technická data ................................................................................................................................. Strana 26

Všeobecné bezpečnostní pokyny pro elektrické nástroje

1. Bezpečnost na pracovišti ............................................................................................................ Strana 27

2. Elektrická bezpečnost ................................................................................................................. Strana 27

3. Bezpečnost osob ......................................................................................................................... Strana 28

4. Pečlivé zacházení selektrickými nástroji a jejich použití ........................................................ Strana 28

5. Servis ............................................................................................................................................Strana 29

Bezpečnostní pokyny pro dělící a brousící stroje ......................................................................... Strana 29

Další bezpečnostní pokyny pro používání dělících a brusných kotoučů .................................... Strana 30

Doplňující pokyny ............................................................................................................................ S trana 31

Originální příslušenství / originální přídavné přístroje .................................................................. Strana 31

Uvedení do provozu

Nastavení hloubky drážky ............................................................................................................. St rana 31

Montáž adaptéru pro vysavač ...................................................................................................... Stran a 31

Obsluha

Zapínání a vypínání ........................................................................................................................ St r a na 31

Montáž a nastavení šířky řezu diamantových dělících kotoučů ................................................. Strana 31

Zacházení s frézou do zdiva .......................................................................................................... Strana 32

Údržba a čištění .....................................................................................................................Strana 32

Záruka ............................................................................................................................................Strana 32

Zlikvidování ..............................................................................................................................Strana 33

Prohláše ní o shodnosti / Výrobce ........................................................................... Strana 33

25 CZ

Page 26

Úvod

Drážkovací fréza do zdiva

PMNF 1350 A1

Úvod

Blahopřejeme vám ke koupi nového výrobku. Rozhodli jste se pro kvalitní produkt. Návod kobsluze

je součástí tohoto výrobku. Obsahuje důležité pokyny pro bezpečnost, použití a likvidaci. Před použitím výrobku se seznamte se všemi pokyny k obsluze a bezpečnostními pokyny. Používejte výrobek

jen popsaným způsobem a na uvedených místech.

Při předání výrobku třetí osobě předejte i všechny

podklady.

Použití ke stanovenému účelu

Drážkovací fréza do zdiva (podle normy dělící a

brousící stroj), v následujícím textu také jmenovaná

jako přístroj, je určená pro dělení a drážkování převážně minerálních materiálů jako např. betonu nebo

zdiva za použití připuštěného průmyslového vysavače na pevném podkladu s vodícími kolečky a bez

chlazení vodou. Jakékoli jiné použití nebo úprava

přístroje je v rozporu s použitím ke stanovenému

účeliu a skrývá značná nebezpečí zranění. Výrobek

není určen ke komerčnímu používání.

15

Klíč

16

Ruční sekáč

Obsah dodávky

1 drážkovací fréza do zdiva

2 dělící kotouče (předmontované)

1 klíč

1 adaptér pro vysavač (předmontovaný)

1 redukce

(k použití s adaptérem pro vysavač a hadicí

vysavače o ∅ 32 mm)

1 ruční sekáč

1 návod kobsluze

Technická data

Síťové napětí: 230 V∼ 50 Hz

Příkon: 1350W

Vyměřovací počet otáček: 9000 min

Kotoučový ø: 125 mm

Otvor uchycení: 22,2 mm

Hloubka drážky: 0–30 mm

Šířka drážky: 8–26 mm

Závit: M14

Třída ochrany: II /

Hmotnost: cca. 4,05kg

-1

Popis přístroje (viz obr. A–D)

1

VYpínaČ

2

Rukojeť

3

Adaptér pro vysavač

3 a

Převlečná matice

4

Ochranný kryt

5

Příruba (se závitem)

6

Šroub zarážky pro nastavení hloubky

7

Zarážka hloubky

8

Přídavná rukojeť

9

Blokování spuštění

10

Aretace hřídele

11

Vodící kolečko

12

Redukční tvarovka

13

Centrovací příruba

14

Distance

26 CZ

Hluk a vibrace

Hodnoty hluku a vibrací byly zjištěny podle normy

EN 60745.

Hladina akustického

tlaku L

: 97,6 dB(A)

pA

Nepřesnost K

: 3 dB

pA

Hladina akustického

výkonu L

Nepřesnost K

: 108,6 dB(A)

WA

: 3 dB

WA

Noste ochranu sluchu.

Hluk může způsobit ztrátu sluchu.

Celkové hodnoty vibrací (vektorový součet třech

směrů) byly zjištěny podle EN 60745.

Údaje emisních hodnot chvění (při řezání betonové

desky)

Rukojeť: 6,417 m / s

2

Page 27

Přídavná rukojeť: 4,258 m / s

Nepřesnost K: 1,5 m / s

2

2

Udaná hodnota emise kmitů byla změřena při testu

podle normy a může se měnit v závislosti na druhu

a způsobu použití elektrického nástroje, ve výjimečných případech může být i vyšší.

Udaná hodnota emise kmitů se může použít ke

srovnání elektrických nástrojů.

Udaná hodnota emise kmitů se může také použít k

počátečnímu odhadu negativního vlivu.

Snažte se minimalizovat zatížení vibracemi. Příkladná opatření pro minimalizování zatížení vibracemi

jsou nošení rukavic při používání nástroje a zkrácení pracovní doby. Přitom je třeba do posouzení zahrnout všechny druhy pracovních cyklů (např. i doby,

kdy je nástroj vypnutý a doby, kdy je nástroj v provozu ale nezatížený).

Všeobecné bezpečnostní

pokyny pro elektrické nástroje

Přečtěte si všechny bez-

pečnostní pokyny a návody! Zanedbání při

dodržování bezpečnostních pokynů a návodů mohou způsobit úraz elektrickým proudem, požár a /

nebo těžká poranění.

Uschovejte všechny bezpečnostní pokyny

a návody pro budoucnost!

Pojem „elek

trický nástroj“ uvedený v bezpečnost

ních

pokynech se vztahuje na elektrické nástroje napájené

ze sítě (se sˇiťovým ka

napájené

akumulátorem (bez síťového kabelu).

belem) a na elektrické nástroje

1. Bezpečnost na pracovišti

a) Svou pracovní oblast udržujte tak, aby

byla čistá a dobře osvětlená. Nepořádek a

neosvětlené pracovní oblasti mohou vést kúrazům.

b) Nepracujte se zařízením v okolí ohro-

ženém výbuchem, v němž se nacházejí

kapaliny, plyny nebo prachy. Elektrické

nástroje vyrábějí jiskry, které mohou zapálit

prach nebo páry.

c) Elektrické nástroje během používání

chraňte před dětmi a jinými osobami.

Při rozptýlení byste mohli ztratit kontrolu nad

zařízením.

2. Elektrická bezpečnost

a) Síťová zástrčka zařízení se musí hodit

do zásuvky. Zástrčka se nesmí žádným způsobem změnit. Nepoužívejte

zástrčky s adaptérem společně a se

zařízeními sochranným uzemněním.

Nezměněné zástrčky a lícující zásuvky snižují

riziko úrazu elektrickým proudem.

b) Vyhněte se tělesnému kontaktu s

uzemněnými povrchy, jako jsou potrubí, topení, sporáky a chladničky. Existuje

zvýšené riziko úrazu elektrickým proudem, je-li

vaše tělo uzemněno.

c) Zařízení chraňte před deštěm nebo

vlhkem. Vniknutí vody do elektrického zaří-

zení zvyšuje riziko úrazu elektrickým proudem.

d) Kabel nepoužívejte knestano venému

účelu jako je nošení zařízení, pověšení

nebo vytáhnutí zástrčky ze zásuvky.

Chraňte kabel před horkem, olejem,

ostrými hranami nebo se pohybujícími

díly zařízení. Poškozené nebo zapletené

kabely zvyšují riziko úrazu elektrickým prou

e) Při práci selektrickým nástrojem ven-

ku použijte jen prodlužovací kabely,

které jsou povoleny pro vnější oblast.

Použití prodlužovacího kabelu povoleného

pro vnější oblast snižuje riziko úrazu elektrickým proudem.

f)

Nelze-li se vyhnout provozu elektrického

nástroje ve vlhkém okolí, použijte ochranný

spínač proti chybnému proudu. Pou-

žití ochranného spínače proti chybnému proudu snižujte riziko úrazu elektrickým proudem.

dem.

27 CZ

Page 28

Všeobecné bezpečnostní pokyny pro elektrické nástroje

3. Bezpečnost osob

a) Buďte neustále pozorní, dbejte na to,

co činíte a dejte se s rozumem do práce s elektrickým nástrojem. Nikdy

nepoužívejte zařízení, jste-li unaveni

nebo pod vlivem drog, alkoholu a

léků. Už okamžik nepozornosti při použití

zařízení může vést kzávažným poraněním.

b) Noste osobní ochranné vybavení a

vždy ochranné brýle. Nošení osobního

ochranného vybavení, jako je maska proti prachu, protiskluzná bezpečnostní obuv, ochranná

přilba nebo ochrana proti sluchu, vzávislosti

na druhu a použití elektrického nástroje, zmenšuje riziko poranění.

c) Zabraňte nechtěnému uvedení do

provozu. Před připojením k napájecímu napětí, před upnutím a nošením

elektrického nástroje se ujistěte, že je

vypnut. Máte-li při nošení zařízení prst na

spínači ZAP / VYP nebo je zařízení zapnuto,

může dojít k úrazům.

d) Před zapnutím zařízení odstraňte na-

stavovací nářadí nebo šroubováky.

Nástroj nebo šroubovák, který se nachází v

rotujícím dílu zařízení může způsobit poranění.

e)

Vyhněte se neobvyklému držení hlavy.

Pečujte vždy o bezpečnou stabilní polohu a udržujte neustále rovnováhu. Tím

můžete zařízení zejména vneočekávaných situacích lépe kontrolovat.

f) Noste vhodný oděv. Nenoste volný

oděv nebo šperky. Chraňte vlasy, oděv

a rukavice před pohyblivými díly. Volný

oděv, šperk nebo vlasy mohou být zachyceny

samopohyblivými díly.

g) Jsou-li namontována zařízení k vysá-

vání a zachycování prachu, ujistěte se,

že jsou tato připojena a správně použita. Správné použití těchto zařízení snižuje

ohrožení prachem.

4. Pečlivé zacházení selektrickými

nástroji a jejich použití

a) Zařízení nepřetěžujte. Pro práci pou-

žijte ktomu určených elektrických

nástrojů. S vhodným elektrickým nástrojem

pracujete lépe a bezpečněji v udaném výkonnostním rozsahu.

b) Nepoužívejte elektrický nástroj,

jehož vypínač je defektní. Elektrický

nástroj, který nelze zapínat a vypínat, je

nebezpečný a musí se opravit.

c) Před nastavením zařízení, výměně dílů

příslušenství nebo odstavením zařízení

vytáhněte zástrčku ze zásuvky. Toto

preventivní opatření brání nechtěnému spuštění zařízení.

d) Nepoužité elektrické nástroje skladuj-

te tak, aby byly z dosahu dětí. Zařízení nenechejte používat osobami, které

s ním nejsou seznámeny nebo které si

nepřečetly tyto návody. Elektrické nástro-

je jsou nebezpečné, používají- li je nezkušené

osoby.

e) Ošetřujte zařízení s pečlivostí. Zkont-

rolujte, fungují-li pohyblivé díly zařízení a neuvázly-li, jsou-li díly zlomené

nebo poškozené, takže je funkce zařízení ohrožena. Před použitím zařízení

nechejte poškozené díly opravit. Příčina

mnohých úrazů tkví ve špatně udržovaných

elektrických nástrojích.

f) Udržujte řezací nástroje ostré a čisté.

Pečlivě ošetřované řezací nástroje s ostrými

řeznými hranami neuvíznou tak často a lze je

snadněji vést.

g) Použijte elektrické nástroje, příslušen-

ství, náhradní nástroje atd. podle těchto návodů a tak, jak je pro tento speciální typ nástroje předepsáno.Přitom

přihlédněte k pracovním podmínkám

a prováděné činnosti. Použití elektrických

nástrojů pro jiná než určená použití může vést

k nebezpečným situacím.

28 CZ

Page 29

5. Servis

a) Zařízení nechejte opravit jen místem

servisu nebo odbornou elektrickou

dílnou a jen s originálními náhradními

díly. Tím se zajistí, že bezpečnost zařízení zů-

stane zachována.

Bezpečnostní pokyny pro dělící

a brousící stroje

a) Ochranný kryt, patřící k elektrickému

nástroji, musí být bezpečně připevněný a nastavený tak, aby zajišťoval

nejvyšší bezpečnost, to znamená, že

smí být odkrytý jen nejmenší díl brusného kotouče směřující k obsluze.

Zdržujte se spolu s osobami stojícími v

blízkosti mimo rovinu rotujícího brusného kotouče. Ochranný kryt má chránit

obsluhu před odletujícími úlomky materiálu a

náhodným kontaktem s brusným kotoučem.

b) Používejte pro Váš elektrický nástroj

j

en diamantové dělící kotouče. Skutečn

že můžete použít některé jiné příslušenství pro

Váš elektrický nástroj nezaručuje bezpečný

provoz.