MODELLING & ENGRAVING SET PMGS 12 C3

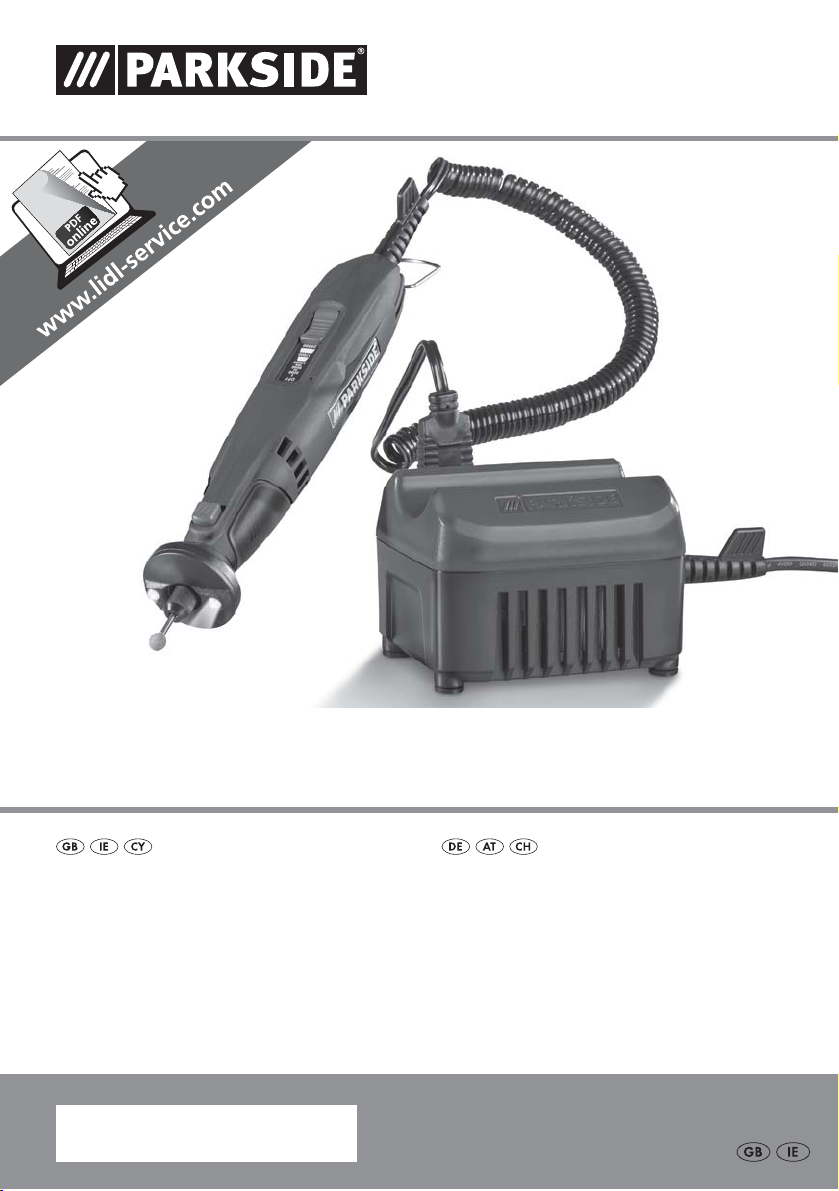

MODELLING & ENGRAVING SET

Translation of the original instructions

IAN 270853

MODELLBAU- UND GRAVIERSET

Originalbetriebsanleitung

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / CY Translation of the original instructions Page 1

DE / AT / CH Originalbetriebsanleitung Seite 15

A

C

B

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Features ................................................................... 2

Package contents ............................................................ 2

Technical details ............................................................. 2

General Power Tool Safety Warnings ................................3

1. Work area safety .......................................................... 3

2. Electrical safety ........................................................... 3

3. Personal safety ............................................................ 4

4. Power tool use and care .................................................... 4

5. Service .................................................................. 4

Safety instructions for all applications ............................................ 5

Additional safety instructions for all applications .................................... 6

Supplementary safety instructions for grinding and abrasive cutting ..................... 7

Supplementary safety instructions for working with wire brushes. . . . . . . . . . . . . . . . . . . . . . . . 7

Safety instructions for drills ..................................................... 7

Safety instructions for LED lights ................................................. 8

Safety instructions for batteries .................................................. 8

Appliance-specific safety instructions for transformers ................................ 8

Operation .......................................................8

Changing the batteries ........................................................ 8

Changing/inserting the tool/collet chuck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Switching on and off/setting speed range ......................................... 9

Using the grip ring with LED light ................................................ 9

Notes on material processing/tools/speed range ................................... 9

Tips and tricks ..............................................................11

Maintenance and cleaning .........................................11

Disposal ........................................................11

Kompernass Handels GmbH warranty ..............................12

Service .........................................................13

Importer .......................................................13

KOMPERNASS HANDELS GMBH ....................................13

Translation of the original Conformity Declaration .....................13

PMGS 12 C3

GB│IE│CY

│

1 ■

MODELLING AND ENGRAVING

SET PMGS 12 C3

Introduction

Congratulations on the purchase of your new appliance. You have selected a high-quality product.

The operating instructions are part of this product.

They contain important information about safety,

usage and disposal. Before using the product, please

familiarise yourself with all operating and safety

instructions. Use the product only as described and

for the range of applications specified. Please also

pass these operating instructions on to any future

owner.

Intended use

This mini-drill is intended for drilling, milling, engraving, polishing, cleaning, grinding, cutting of

wood, metal, plastics, ceramics and stone in dry

rooms. Any other usage of or modification to the

appliance is deemed to be improper and carries

a significant risk of accidents. The manufacturer

accepts no responsibility for damage(s) attributable

to misuse. This appliance is not intended for commercial use.

Features

Modelling and engraving set

ON/OFF switch/control dial

Plug connector for mains adapter

Metal clip

Grip ring

Tensioning nut

Grip ring with LED light

Spindle lock

Mains adapter (see fig. A):

Plugging device for plug connector

Cradle

Mains adapter

Power cable (with mains plug)

Accessories (See fig. B):

6 HSS drill bits

2 mandrels as tool holders

3 polishing discs

4 grinding discs

1 metal brush

16 cutting discs

5 collet chucks

2 synthetic brushes

3 milling bits

2 engraving bits

5 grinding bits

1 combination key

ON/OFF switch LED light

Package contents

1 modelling and engraving set

1 mains adapter

1 plastic case

1 accessories set (50 pieces)

1 LED ring incl. batteries

1 operating instructions

Technical details

Modelling and engraving set PMGS 12 C3:

Rated voltage: 12 V (DC)

Rated power consumption: 22 W

Rated rotational speed: n 5000–20000 rpm

Rated capacity:

Drills:

Discs: max. Ø 25 mm

Mains adapter PMGS 12 C3-1:

INPUT:

Rated supply voltage: 230 V ~, 50 Hz

OUTPUT:

Rated output voltage: 12 V

Rated output current: 1 A

Protection class: II /

Protection rating: IP20

max. Ø 3.2 mm

(alternating current)

(DC)

(double insulation)

■ 2 │ GB

│IE│

CY

PMGS 12 C3

Noise emission value:

Noise measurement value determined in accordance with EN 60745-1. The A-rated noise level of

the power tool is typically as follows:

Sound pressure level: L

Uncertainty: K

Sound power level: L

Uncertainty: K

= 57.3 dB(A)

pA

= 3 dB

pA

= 68.3 dB(A)

WA

= 3 dB

WA

Vibration emission value:

a

= 0.817 m/s

h

Uncertainty K: 1.5 m/s

2

2

■ WARNING!

Always wear safety googles

NOTE

► The vibration level specified in these instruc-

tions has been measured in accordance with

a standardised measuring procedure and can

be used to make equipment comparisons. The

specified vibration emission value can also

be used to make an initial exposure estimate.

WARNING!

► The vibration level varies in accordance with

the use of the power tool and may be higher

than the value specified in these instructions

in some cases. Regular use of the electric tool

in such a way may cause the user to underestimate the vibration. Try to keep the vibration

loads as low as possible. Measures to reduce

the vibration load are, e.g. wearing gloves

and limiting the working time. All states of

operation must be taken into account (e.g.

times when the power tool is switched off and

times where the power tool is switched on but

running without load).

General Power Tool

Safety Warnings

WARNING!

► Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may result

in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future

reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools cre-

ate sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

PMGS 12 C3

GB│IE│CY

│

3 ■

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or

carrying the tool. Carrying power tools with

your finger on the switch or energising power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jew-

ellery or long hair can be caught in moving

parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children. Do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use. Many acci-

dents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

5. Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained.

■ 4 │ GB

│IE│

CY

PMGS 12 C3

Safety instructions for all applications

General safety instructions for grinding, sandpaper sanding, working with wire brushes,

polishing, milling and abrasive cutting:

a) This power tool is intended for use as a grinder,

sandpaper sander, wire brush, polisher, milling

machine and abrasive cutting appliance.

Please follow all safety instructions, instructions, diagrams and data that you receive

with the appliance. If you do not observe the

following instructions, this can lead to electrical

shock, fire and/or serious injuries.

b) Do not use any accessories that have not been

provided or recommended by the manufacturer for this power tool. Just because you can

attach the accessories to your power tool, does

not ensure they are safe to use.

c) The permissible speed of the accessory tool

used must be at least as high as the maximum

speed specified for the power tool. Accessories

that rotate faster than the permissible rate can

break and throw pieces into the air.

d) The external diameter and thickness of the

accessory tool used must comply with the

dimensions of the power tool. Incorrectly

dimensioned accessory tools cannot be sufficiently shielded or controlled.

e) Grinding discs, sanding drums or other ac-

cessories must match the grinding spindle

or collet chuck of your power tool exactly.

Accessory tools which do not fit precisely into

the take-up of the power tool will rotate unevenly, vibrate severely and can lead to a loss

of control.

f) Discs, grinding cylinders, cutting tools or other

accessories mounted on a mandrel must be

completely inserted in the collet or chuck.

Any "protrusion" or exposed parts of the

mandrel between the grinding tool and the

collet or chuck must be kept to a minimum.

If the mandrel is not sufficiently tightened or the

grinding tool protrudes too far, the tool could

come loose and been thrown out at high speed.

g) Never use damaged accessory tools. Before

each use, check accessory tools such as grinding discs for chips or cracks, sanding drums

for cracks, wearing or excessive wear and tear

and wire brushes for loose or broken wires.

If the power tool or the accessory tool in use

is dropped, check to see if it is damaged or

use an undamaged accessory tool. When you

have checked and inserted the accessory tool,

ensure that you and any other people in the

vicinity remain outside of the range of the

rotating accessory tool and allow the tool

to rotate at maximum speed for one minute.

Damaged accessory tools usually break during

this test period.

h) Wear personal protective equipment.

Depending on the application, ensure that

you use full face protection, eye protection

or goggles. If required, use a dust mask, ear

protectors, protective gloves or special apron

to protect you from grindings and material

particles. Eyes should be protected from flying

debris that may be generated during certain

applications. Dust or filter masks must filter any

dust created by the application. If you are exposed to loud noise for any length of time, you

may suffer hearing loss.

i) Ensure that other people remain at a safe dis-

tance to your workspace. Anyone who enters

the workspace must wear personal protective

equipment. Fragments of the workpiece or

broken accessory tools can fly off and cause

injury – even outside the immediate working

area.

j) Hold the power tool by the insulated gripping

surfaces, when performing an operation

where the accessory tool may contact hidden

wiring or its own cord. Contact with a live cable

can also make metal parts of the appliance live

and could result in an electric shock.

k) Always hold the power tool firmly. When

running up to full speed, the torque of the

motor can cause the power tool to twist.

PMGS 12 C3

GB│IE│CY

│

5 ■

l) If possible, use clamps to hold the workpiece

in position. Never hold a small workpiece in

one hand and the power tool in the other while

you are using it. By clamping small workpieces,

you keep both hands free for better control of

the power tool. When cutting round workpieces

such as dowels, rods or pipes, be aware that

these can roll away and this can cause the tool

to jam and be thrown towards you.

m) Hold the power cord away from any rotating

accessories. If you lose control of the appliance, the cord may get cut or caught and your

hand or arm could get caught in the rotating

accessory tool.

n) Never put the power tool down until the

accessory tool has come to a complete standstill. The rotating accessory tool can come into

contact with the surface and cause you to lose

control of the power tool.

o) When changing accessory tools or changing

settings, tighten the collet nut, the chuck or

other fixing elements tightly. Loose fixing ele-

ments can shift unexpectedly and lead to loss of

control; unfixed, rotating components will fly off

violently.

p) Do not leave the power tool running whilst

carrying it. Accidental contact between your

clothing and the rotating accessory tool could

lead to physical injury.

q) Clean the ventilation slits of your power tool

regularly. The engine fan draws dust into the

housing and a strong accumulation of metal

dust can cause electrical hazards.

r) Do not use the power tool in the vicinity of

flammable materials. Sparks can ignite such

materials.

s) Do not use any accessory tools which require

liquid coolant. The use of water or other liquid

coolants may lead to electric shock.

Additional safety instructions for all

applications

Kickback and corresponding safety instructions

Kickback is a sudden reaction caused when a

rotating accessory tool, e.g. grinding disc, abrasive

band, wire brush, etc., catches or jams. Catching

or jamming leads to an abrupt stop of the rotating

accessory tool. If this happens, an uncontrolled

power tool will turn rapidly against the direction of

rotation of the accessory tool.

If, for example, a grinding disc catches or jams, the

edge of the grinding disc that is projecting into the

workpiece can get caught and break off the grinding disc or cause a kickback. The grinding disc can

then fly in the direction of the operator or away

from him, depending on the direction of rotation

of the disc at the blockage. This can also break

grinding discs.

A kickback is caused by incorrect use or misuse

of the power tool. This can be avoided by taking

proper precautions as given below.

a) Hold the power tool firmly in both hands and

position your body and arms so they can

absorb the force of a kickback. By taking

adequate precautions, the operator can stay

in control of the kickback forces.

b) Take special care when working around

corners, sharp edges, etc. Avoid allowing the

accessory tool to bounce back from the workpiece or jam in the workpiece. The rotating

accessory tool is more likely to jam in corners or

sharp edges or if it bounces. This can cause a

loss of control or kickback.

e) Do not use toothed saw blades. Such acces-

sories often cause a kickback or loss of control

over the power tool.

d) Always move the accessory tool in the same

direction in the material in which it leaves the

material (in other words, the same direction

in which the dust is thrown out). Guiding the

power tool in the wrong direction will cause the

cutting edge of the accessory tool to jump out of

the workpiece which can lead to the accessory

tool being pulled in this direction.

■ 6 │ GB

│IE│

CY

PMGS 12 C3

e) Always fix the workpiece when using rotary

files, cutting discs, high-speed milling tools or

hard-metal tools. Even a minimal tilting in the

groove can cause these tools to jam and lead

to a kickback. When cutting disc jams, it usually

breaks. When a rotary file, high-speed milling

tool or hard-metal milling tool jams, the accessory tool can jump out of the groove and lead

to loss of control of the power tool.

Supplementary safety instructions

for grinding and abrasive cutting

Special safety instructions for grinding and

abrasive cutting

a) Use only the grinding accessories approved

for your power tool and only for the recommended applications. Example: Never grind

with the side surface of a cutting disc. Cutting

discs are designed to remove material with the

edge of the disc. Any lateral application of force

on these grinding tools can lead to breakage.

b) Use only undamaged mandrels of the correct

size and length and without undercut on

the shoulder for conical and straight pencil

grinders. Using an appropriate mandrel re-

duces the risk of breakages.

c) Avoid cutting disc jams or excessive contact

pressure. Do not make any excessively deep

cuts. Overloading the cutting disc increases the

stress and likelihood of tilting or jamming and

thus the possibility of kickback or breakage of

the grinding tool.

d) Avoid putting your hand in the area in front

of and behind the rotating cutting disc. When

you move the cutting disc away from your hand,

it is possible, in the event of a kickback, that the

power tool along with the rotating disc could be

thrown out directly towards you.

e) If the cutting disc jams or you stop working,

switch the tool off and hold it steady until the

disc has completely stopped turning. Never

attempt to pull a rotating cutting disc out of a

cut. This could lead to kickback. Identify and

remove the cause of the jam.

f) Do not switch the power tool back on as long

as it is in the workpiece. Allow the cutting disc

to reach its full speed before you carefully

continue the cut. Otherwise, the disc may jam,

jump out of the workpiece or cause kickback.

g) Support panels or large workpieces to re-

duce the risk of the cutting disc jamming and

causing a kickback. Large workpieces can

bend under their own weight. The workpiece

must be supported on both sides, namely in the

vicinity of the cut, and also at the edge.

h) Be particularly careful when making "pocket

cuts" into existing walls or other obscured

areas. The inserted cutting disc may cut into

gas or water pipes, electrical wiring or other

objects that can cause kickback.

Supplementary safety instructions

for working with wire brushes

Special safety instructions for working with

wire brushes:

a) Be aware that the brush can lose wire bristles

even during normal operation. Do not overstress the wires by applying excessive pressure to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

b) Allow the brush to run at working speed for

at least one minute before applying it to the

workpiece. Ensure that no one is standing in

front of or in line with the brush during this

time. Loose pieces of wire could fly off during

the run-in period.

c) Aim the rotating steel brush away from your-

self. When working with these brushes, small

particles and minute pieces of wire can fly off

at great speed and pierce skin.

Safety instructions for drills

■ Loss of control can lead to injuries.

■ Hold the appliance by the insulated handles

when you are carrying out work during which

the deployed tool may come into contact with

concealed power cables or its own power

cable. Contact with a live cable can also make

metal parts of the appliance live and could

result in an electric shock.

PMGS 12 C3

GB│IE│CY

│

7 ■

Safety instructions for LED lights

WARNING! RISK OF INJURY TO THE

EYES!

■ Never aim the light directly at people or ani-

mals and never look directly into the light

beam of the LED light.

Safety instructions for batteries

CAUTION!

■ Do not leave used batteries in the device as

even leak-protected batteries corrode and

chemicals can be released which could damage your health or destroy the appliance. Do

not leave batteries lying around unattended.

They could be swallowed by children or

pets. In case of swallowing, consult a doctor

immediately.

■ If you do not plan to use the appliance for

an extended period, remove the batteries to

prevent leakages.

■ Leaking or damaged batteries can cause skin

irritations if touched. If this occurs, wear suitable gloves.

■ Ensure that batteries cannot be short-circuited.

Do not throw batteries into a fire.

■ Do not attempt to recharge non-rechargeable

batteries. There is a risk of explosion!

Appliance-specific safety instructions

for transformers

Only for indoor use!

WARNING!

■ Dusts from materials such as leaded paint,

some types of wood and metal can be harmful to your health.

■ Contact with or inhalation of these dusts can

represent a health hazard for the person

operating the appliance and other people in

the vicinity.

■ Wear safety goggles and a protective dust

mask!

■

Safety transformer fail-safe

Thermal link

■

Operation

■ Never use the appliance for other purposes

and only original parts/accessories. Using

attachments or accessory tools other than those

recommended in the operating instructions can

lead to a risk of injury.

Changing the batteries

♦ Make sure that the LED light is turned off. Remove

the three screws from the rear of the grip ring

with LED .

♦ Replace the used batteries in the appliance

with new batteries of the same type (button

cell LR41). Note polarity when installing new

batteries.

♦ Close the battery compartment again by replacing

the three screws.

Changing/inserting the tool/collet

chuck

♦ Press the spindle lock and hold it down.

♦ Turn the tensioning nut

into place.

♦ Undo the tensioning nut

using the combination key .

♦ Remove any attached tool.

♦ First push the intended tool through the tensioning

nut

before inserting it into the appropriate

collet chuck for the tool shaft.

♦ Press the spindle lock

♦ Push the collet chuck

and screw the tensioning nut tight with the

combination key .

until the lock clicks

from the thread

and hold it down.

into the thread insert

■ 8 │ GB

│IE│

CY

PMGS 12 C3

Using an accessory tool with a mandrel :

NOTE

► Use the screwdriver side of the combination

key

to undo and tighten the screw on the

mandrel

♦ Insert the mandrel

described.

♦ Use the combination key

on the mandrel .

♦ Insert the desired accessory tool between the

two washers on the screw.

♦ Use the combination key

on the mandrel .

.

into the power tool as

to undo the screw

to tighten the screw

Switching on and off/setting speed

range

Switching on/setting the speed range:

♦ Connect the plug

by plugging it into the plugging device

(see fig. A).

♦ Connect the appliance to the power supply

by inserting the power plug into the socket.

♦ Push the ON/OFF switch

between "5000" and "20000".

to the mains adapter

to a position

♦ Move the ON/OFF switch of the LED light

the position "I" to switch it on.

♦ Move the ON/OFF switch of the LED light

the position "0" to switch it off again.

♦ Proceed in reverse order to replace the grip

ring

.

Notes on material processing/tools/

speed range

■ Use the milling bits for working on steel and

iron at maximum speed.

■ Calculate the rotational speed range for work-

ing on zinc, zinc alloys, aluminium, copper and

lead by trying it out on test pieces.

■ Use a low rotational speed for work on plastics

and materials with a low melting point.

■ Use a high rotational speed for working on

wood.

■ Carry out cleaning, polishing and buffing work

in the middle range.

The following are recommendations only and not

binding. When carrying out practical work, carry

out your own tests to see which tool and which settings are ideal for the material you are working on.

Setting a suitable rotational speed

to

to

Switching off:

♦ Push the ON/OFF switch

position.

to the "OFF"

Using the grip ring with LED light

♦ Hold down the spindle lock and screw the

tensioning nut anticlockwise off the thread.

♦ Release the spindle lock

♦ Then screw the grip ring

the thread.

♦ Screw the grip ring with LED

the screw thread.

♦ Hold down the spindle lock

tensioning nut clockwise onto the thread.

♦ Release the spindle lock

.

anticlockwise off

clockwise onto

and screw the

.

PMGS 12 C3

Number on the

speed control

5000 Plastics and materials

9000 Stone, ceramics

13000 Soft wood, metal

17000 Hardwood

20000 Steel

Material

being worked

with a low melting

point

GB│IE│CY

│

9 ■

Application examples/selecting a suitable tool

Function Accessories Use Protrusion

(min–max) mm

Drilling

Milling

Engraving

Polishing, rust removal

CAUTION!

Exert only a light pressure when applying the

tool to the workpiece.

Cleaning

Grinding

Cutting

■ Note that the maximum diameter of the grinding assembly and of grinding cones and pencil grinders

with a thread insert may not exceed 55mm and the maximum diameter for sandpaper sanding acces-

sories may not exceed 80mm.

NOTE

► The max. permissible length of a mandrel is 33 mm.

■ Store the accessories in the original box or store the accessory components somewhere else to protect

them from damage.

■ Store the accessories somewhere dry and not in the vicinity of aggressive media.

HSS drills

Milling bits

Engraving bits

Metal brush

Polishing discs

Synthetic brushes

Grinding discs

Grinding bits

Cutting discs metal

Working wood 18–25, using the

smallest drill, the

protrusion is 10 mm

Various jobs; e.g.

creating recesses,

hollows, forms,

grooves or slits

Labelling, handicraft 18–25

Rust removal 9–15

Various metals and

plastics, especially

precious metals such

as gold and silver

e.g. cleaning hardto-access plastic

housings or the area

around a door lock

Grinding work on

stone, wood, fine

work on hard materials

such as ceramics or

alloyed steel

Working metal,

plastic and wood

18–25

12–18

9–15

12–18

10

12–18

■ 10 │ GB

│IE│

CY

PMGS 12 C3

Tips and tricks

■ If you exert too much pressure, the fitted tool can

break and/or the workpiece could be damaged.

You will achieve optimum working results by

moving the tool over the workpiece at a steady

speed and while exerting light pressure.

■ When carrying out cutting work, hold the appli-

ance firmly with both hands.

■ Observe the data and the information in the

table to prevent the end of the spindle from

touching the perforated base of the grinding

tool.

Maintenance and cleaning

The appliance is maintenance-free.

■ Remove all dirt from the appliance. Use a dry

cloth to do this.

Disposal

The packaging is made from environmentally friendly material and can

be disposed of at your local recycling

plant.

Do not dispose of power tools in

your normal household waste!

European Directive 2012/19/EU requires that

worn-out power tools be collected separately and

recycled in an environmentally compatible manner.

Please consult your local authorities regarding

suitable disposal of worn out power tools.

Batteries should not be disposed of

with normal household waste.

WARNING!

■ Have the power tool repaired by the Ser-

vice centre or a qualified electrician and

only using genuine replacement parts. This

will ensure that the safety of the appliance is

maintained.

WARNING!

■ Always ensure that the power plug or

the mains cable is replaced only by the

manufacturer of the appliance or by an

approved customer service provider. This

will ensure that the safety of the appliance is

maintained.

NOTE

► Replacement parts not listed (such as carbon

brushes, switches and mains adapter) can be

ordered via our service hotline.

Consumers are legally obliged to dispose of used

batteries at a collection point in their town/district

or at a retail store. This obligation is intended to

ensure that batteries are disposed of in an environmentally responsible manner. Dispose of batteries

only when they are fully discharged.

PMGS 12 C3

GB│IE│CY

│

11 ■

Kompernass Handels GmbH

warranty

Dear Customer,

This appliance has a 3-year warranty valid from

the date of purchase. If this product has any faults,

you, the buyer, have certain statutory rights. Your

statutory rights are not restricted in any way by the

warranty described below.

Warranty conditions

The validity period of the warranty starts from the

date of purchase. Please keep your original receipt

in a safe place. This document will be required as

proof of purchase.

If any material or production fault occurs within

three years of the date of purchase of the product,

we will either repair or replace the product for you

at our discretion. This warranty service is dependent

on you presenting the defective appliance and

the proof of purchase (receipt) and a short written

description of the fault and its time of occurrence.

If the defect is covered by the warranty, your product

will either be repaired or replaced by us. The repair

or replacement of a product does not signify the

beginning of a new warranty period.

Warranty period and statutory

claims for defects

The warranty period is not prolonged by repairs

effected under the warranty. This also applies to

replaced and repaired components. Any damage

and defects present at the time of purchase must

be reported immediately after unpacking. Repairs

carried out after expiry of the warranty period shall

be subject to a fee.

Scope of the warranty

This appliance has been manufactured in accordance with strict quality guidelines and inspected

meticulously prior to delivery.

The warranty covers material faults or production

faults. The warranty does not extend to product

parts subject to normal wear and tear or fragile

parts such as switches, batteries, baking moulds or

parts made of glass.

The warranty does not apply if the product has

been damaged, improperly used or improperly

maintained. The directions in the operating

instructions for the product regarding proper use

of the product are to be strictly followed. Uses

and actions that are discouraged in the operating

instructions or which are warned against must be

avoided.

This product is intended solely for private use and

not for commercial purposes. The warranty shall be

deemed void in cases of misuse or improper handling,

use of force and modifications/repairs which have

not been carried out by one of our authorised

Service centres.

Warranty claim procedure

To ensure quick processing of your case, please

observe the following instructions:

▯ Please have the till receipt and the item number

(e.g. IAN 12345) available as proof of purchase.

▯ You will find the item number on the type plate,

an engraving on the front page of the instructions

(bottom left), or as a sticker on the rear or bottom

of the appliance.

▯ If functional or other defects occur, please

contact the service department listed either by

telephone or by e-mail.

▯ You can return a defective product to us free of

charge to the service address that will be provided

to you. Ensure that you enclose the proof of

purchase (till receipt) and information about

what the defect is and when it occurred.

■ 12 │ GB

│IE│

CY

You can download these instructions

along with many other manuals,

product videos and software on

www.lidl-service.com.

PMGS 12 C3

Service

Service Great Britain

Tel.: 0871 5000 720 (£ 0.10/Min.)

E-Mail: kompernass@lidl.co.uk

Service Ireland

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: kompernass@lidl.ie

CY

Service Cyprus

Tel.: 8009 4409

E-Mail: kompernass@lidl.com.cy

IAN 270853

Importer

Please note that the following address is not the

service address. Please use the service address

provided in the operating instructions.

KOMPERNASS HANDELS GMBH

BURGSTRASSE 21

44867 BOCHUM

GERMANY

www.kompernass.com

Translation of the original

Conformity Declaration

We, KOMPERNASS HANDELS GMBH, documents officer: Mr. Semi Uguzlu, BURGSTR. 21,

44867 BOCHUM, Deutschland, hereby declare that

this product complies with the following standards,

normative documents and the EC directives:

Machinery Directive

(2006/42/EC)

EC Low Voltage Directive

(2014/35/EU)

EMC (Electromagnetic Compatibility)

(2014/30/EU)

RoHS Directive

(2011/65/EU)

Applied harmonised standards:

EN 60745-1:2009/A11:2010

EN 60745-2-1:2010, EN 60745-2-23:2013

EN 55014-1:2006/A2:2011

EN 55014-2:1997/A2:2008

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 61558-1:2006/A1:2009

EN 61558-2-6:2009

Type designation of machine:

Modelling and engraving set PMGS 12 C3:

PMGS 12 C3

Year of manufacture: 07 - 2016

Serial number: IAN 270853

Bochum, 03/02/2016

Semi Uguzlu

- Quality Manager The right to effect technical changes in the context

of further development is reserved.

GB│IE│CY

│

13 ■

■ 14 │ GB

│IE│

CY

PMGS 12 C3

Inhaltsverzeichnis

Einleitung .......................................................16

Bestimmungsgemäßer Gebrauch ...............................................16

Ausstattung ................................................................ 16

Lieferumfang ...............................................................16

Technische Daten ...........................................................16

Allgemeine Sicherheitshinweise für Elektrowerkzeuge ..................17

1. Arbeitsplatz-Sicherheit ..................................................... 17

2. Elektrische Sicherheit ...................................................... 17

3. Sicherheit von Personen ....................................................18

4. Verwendung und Behandlung des Elektrowerkzeugs ............................. 18

5. Service ................................................................. 19

Sicherheitshinweise für alle Anwendungen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Weitere Sicherheitshinweise für alle Anwendungen ................................. 21

Zusätzliche Sicherheitshinweise zum Schleifen und Trennschleifen .....................21

Zusätzliche Sicherheitshinweise zum Arbeiten mit Drahtbürsten ........................ 22

Sicherheitshinweise für Bohrmaschinen .......................................... 22

Sicherheitshinweise für LED-Leuchten ............................................ 22

Sicherheitshinweise zu Batterien ................................................ 23

Gerätespezifische Sicherheitshinweise für Transformatoren ...........................23

Inbetriebnahme .................................................23

Batteriewechsel vornehmen ................................................... 23

Werkzeug / Spannzange einsetzen / wechseln ................................... 23

Ein- und ausschalten /Drehzahlbereich einstellen .................................. 24

Griffring mit LED-Licht verwenden ............................................... 24

Hinweise zu Materialbearbeitung / Werkzeug /Drehzahlbereich .....................24

Tipps und Tricks ............................................................ 26

Wartung und Reinigung ...........................................26

Entsorgung .....................................................26

Garantie der Kompernaß Handels GmbH ............................27

Service .........................................................28

Importeur ......................................................28

KOMPERNASS HANDELS GMBH ....................................28

Original-Konformitätserklärung ....................................28

PMGS 12 C3

DE│AT│CH

│

15 ■

MODELLBAU- UND GRAVIERSET

PMGS 12 C3

Einleitung

Wir beglückwünschen Sie zum Kauf Ihres neuen

Gerätes. Sie haben sich damit für ein hochwertiges

Produkt entschieden. Die Bedienungsanleitung ist

Teil dieses Produkts. Sie enthält wichtige Hinweise

für Sicherheit, Gebrauch und Entsorgung. Machen

Sie sich vor der Benutzung des Produkts mit allen

Bedien- und Sicherheitshinweisen vertraut. Benutzen Sie das Produkt nur wie beschrieben und für

die angegebenen Einsatzbereiche. Händigen Sie

alle Unterlagen bei Weitergabe des Produkts an

Dritte mit aus.

Bestimmungsgemäßer Gebrauch

Die Kleinbohrmaschine ist zum Bohren, Fräsen,

Gravieren, Polieren, Säubern, Schleifen, Trennen

von Holz, Metall, Kunststoff, Keramik oder Gestein

in trockenen Räumen zu verwenden. Jede andere

Verwendung oder Veränderung des Gerätes gilt

als nicht bestimmungsgemäß und birgt erhebliche

Unfallgefahren. Für aus bestimmungswidriger

Verwendung entstandene Schäden übernimmt der

Hersteller keine Haftung. Nicht für gewerblichen

Einsatz bestimmt.

Ausstattung

Modellbau- und Gravierset:

Ein- / Aus -Schalter / Drehzahlregulierung

Stecker für Netzteil

Metallbügel

Griffring

Spannmutter

Griffring mit LED-Licht

Spindelarretierung

Netzteil (siehe Abb. A):

Einsteckvorrichtung für Stecker

Ablage

Netzteil

Netzkabel (mit Netzstecker)

Zubehör (siehe Abb. B):

6 HSS-Bohrer

2 Spanndorne zur Werkzeugaufnahme

3 Polierscheiben

4 Schleifscheiben

1 Metallbürste

16 Trennscheiben

5 Spannzangen

2 Kunststoffbürsten

3 Fräsbits

2 Gravierbits

5 Schleifbits

1 Kombischlüssel

EIN- / AUS-Schalter LED-Leuchte

Lieferumfang

1 Modellbau- und Gravierset

1 Netzteil

1 Kunststoffkoffer

1 Zubehör-Set (50 Teile)

1 Griffring inkl. Batterien

1 Bedienungsanleitung

Technische Daten

Modellbau- und Gravierset PMGS 12 C3:

Bemessungsspannung: 12 V

Bemessungsaufnahme: 22 W

Bemessungsdrehzahl: n 5000 - 20000 min

Bemessungskapazität:

Bohrer: max. ø 3,2 mm

Scheiben: max. ø 25 mm

Netzteil PMGS 12 C3-1:

EINGANG / Input:

BemessungsVersorgungsspannung: 230 V ~, 50 Hz

(Wechselstrom)

AUSGANG / Output:

BemessungsAusgangsspannung:: 12 V

BemessungsAusgangsstrom: 1 A

Schutzklasse: II /

Schutzart: IP20

(Gleichstrom)

(Gleichstrom)

(Doppelisolierung)

-1

■ 16 │ DE

│AT│

CH

PMGS 12 C3

Geräuschemissionswert:

Messwert für Geräusch ermittelt entsprechend EN

60745-1. Der A-bewertete Geräuschpegel des

Elektrowerkzeugs beträgt typischerweise:

Schalldruckpegel: L

Unsicherheit: K

Schallleistungspegel: L

Unsicherheit K: K

= 57,3 dB (A)

pA

= 3 dB

pA

= 68,3 dB (A)

WA

= 3 dB

WA

Schwingungsemissionswert:

a

= 0,817 m/s2

h

Unsicherheit K: 1,5 m/s

2

■ WARNUNG!

Tragen Sie immer eine Schutzbrille

HINWEIS

► Der in diesen Anweisungen angegebene

Schwingungspegel ist entsprechend einem

genormten Messverfahren gemessen worden

und kann für den Gerätevergleich verwendet

werden. Der angegebene Schwingungsemissionswert kann auch zu einer einleitenden Einschätzung der Aussetzung verwendet werden.

WARNUNG!

► Der Schwingungspegel wird sich entspre-

chend dem Einsatz des Elektrowerkzeugs

verändern und kann in manchen Fällen über

dem in diesen Anweisungen angegebenen

Wert liegen. Die Schwingungsbelastung

könnte unterschätzt werden, wenn das

Elektrowerkzeug regelmäßig in solcher Weise

verwendet wird. Versuchen Sie, die Belastung

durch Vibrationen so gering wie möglich zu

halten. Beispielhafte Maßnahmen zur Verringerung der Vibrationsbelastung sind das Tragen von Handschuhen beim Gebrauch des

Werkzeugs und die Begrenzung der Arbeitszeit. Dabei sind alle Anteile des Betriebszyklus zu berücksichtigen (beispielweise Zeiten,

in denen das Elektrowerkzeug abgeschaltet

ist, und solche, in denen es zwar eingeschaltet ist, aber ohne Belastung läuft).

Allgemeine

Sicherheitshinweise

für Elektrowerkzeuge

WARNUNG!

► Lesen Sie alle Sicherheitshinweise

und Anweisungen. Versäumnisse

bei der Einhaltung der Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und/oder

schwere Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise und

Anweisungen für die Zukunft auf.

Der in den Sicherheitshinweisen verwendete Begriff

„Elektrowerkzeug“ bezieht sich auf netzbetriebene

Elektrowerkzeuge (mit Netzkabel) und auf akkubetriebene Elektrowerkzeuge (ohne Netzkabel).

1. Arbeitsplatz-Sicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und

gut beleuchtet. Unordnung und unbeleuchtete

Arbeitsbereiche können zu Unfällen führen.

b) Arbeiten Sie mit dem Elektrowerkzeug nicht in

explosionsgefährdeter Umgebung, in der sich

brennbare Flüssigkeiten, Gase oder Stäube

befinden. Elektrowerkzeuge erzeugen Funken, die

den Staub oder die Dämpfe entzünden können.

c) Halten Sie Kinder und andere Personen wäh-

rend der Benutzung des Elektrowerkzeugs fern.

Bei Ablenkung können Sie die Kontrolle über

das Gerät verlieren.

2. Elektrische Sicherheit

a) Der Anschlussstecker des Elektrowerkzeuges

muss in die Steckdose passen. Der Stecker

darf in keiner Weise verändert werden.

Verwenden Sie keine Adapterstecker gemeinsam mit schutzgeerdeten Elektrowerkzeugen.

Unveränderte Stecker und passende Steckdosen verringern das Risiko eines elektrischen

Schlages.

b) Vermeiden Sie Körperkontakt mit geerdeten

Oberflächen, wie von Rohren, Heizungen,

Herden und Kühlschränken. Es besteht ein

erhöhtes Risiko durch elektrischen Schlag, wenn

Ihr Körper geerdet ist.

PMGS 12 C3

DE│AT│CH

│

17 ■

c) Halten Sie Elektrowerkzeuge von Regen oder

Nässe fern. Das Eindringen von Wasser in ein Elekt-

rogerät erhöht das Risiko eines elektrischen Schlages.

d) Zweckentfremden Sie das Kabel nicht, um

das Elektrowerkzeug zu tragen, aufzuhängen

oder um den Stecker aus der Steckdose zu

ziehen. Halten Sie das Kabel fern von Hitze,

Öl, scharfen Kanten oder sich bewegenden

Geräteteilen. Beschädigte oder verwickelte Kabel

erhöhen das Risiko eines elektrischen Schlages.

e) Wenn Sie mit einem Elektrowerkzeug im

Freien arbeiten, verwenden Sie nur Verlängerungskabel, die auch für den Außenbereich

zugelassen sind. Die Anwendung eines für den

Außenbereich geeigneten Verlängerungskabels

verringert das Risiko eines elektrischen Schlages.

f) Wenn der Betrieb des Elektrowerkzeuges in

feuchter Umgebung nicht vermeidbar ist, verwenden Sie einen Fehlerstromschutzschalter.

Der Einsatz eines Fehlerstromschutzschalters vermindert das Risiko eines elektrischen Schlages.

3. Sicherheit von Personen

a) Seien Sie stets aufmerksam, achten Sie darauf,

was Sie tun und gehen Sie mit Vernunft an die

Arbeit mit einem Elektrowerkzeug. Benutzen

Sie kein Elektrowerkzeug, wenn Sie müde sind

oder unter dem Einfluss von Drogen, Alkohol

oder Medikamenten stehen. Ein Moment der

Unachtsamkeit beim Gebrauch des Elektrowerkzeuges kann zu ernsthaften Verletzungen führen.

b) Tragen Sie persönliche Schutzausrüstung und

immer eine Schutzbrille. Das Tragen persönlicher

Schutzausrüstung wie Staubmaske, rutschfeste

Sicherheitsschuhe, Schutzhelm oder Gehörschutz,

je nach Art und Einsatz des Elektrowerkzeuges,

verringert das Risiko von Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte Inbetrieb-

nahme. Vergewissern Sie sich, dass das

Elektrowerkzeug ausgeschaltet ist, bevor Sie es

an die Stromversorgung und / oder den Akku

anschließen, es aufnehmen oder tragen. Wenn

Sie beim Tragen des Elektrowerkzeuges den Finger

am Schalter haben oder das Gerät bereits eingeschaltet an die Stromversorgung anschließen, kann

dies zu Unfällen führen.

d) Entfernen Sie Einstellwerkzeuge oder Schrau-

benschlüssel, bevor Sie das Elektrowerkzeug

einschalten. Ein Werkzeug oder Schlüssel, der

sich in einem drehenden Geräteteil befindet,

kann zu Verletzungen führen.

e) Vermeiden Sie eine abnormale Körperhaltung.

Sorgen Sie für einen sicheren Stand und halten

Sie jederzeit das Gleichgewicht. Dadurch kön-

nen Sie das Elektrowerkzeug in unerwarteten

Situationen besser kontrollieren.

f) Tragen Sie geeignete Kleidung. Tragen Sie

keine weite Kleidung oder Schmuck. Halten

Sie Haare, Kleidung und Handschuhe fern

von sich bewegenden Teilen. Lockere Kleidung,

Schmuck oder lange Haare können von sich

bewegenden Teilen erfasst werden.

g) Wenn Staubabsaug- und -auffangeinrichtun-

gen montiert werden können, vergewissern

Sie sich, dass diese angeschlossen sind und

richtig verwendet werden. Die Verwendung

einer Staubabsaugung kann Gefährdungen

durch Staub verringern.

4. Verwendung und Behandlung des

Elektrowerkzeugs

a) Überlasten Sie das Gerät nicht. Verwenden

Sie für Ihre Arbeit das dafür bestimmte

Elektrowerkzeug. Mit dem passenden Elektro-

werkzeug arbeiten Sie besser und sicherer im

angegebenen Leistungsbereich.

b) Benutzen Sie kein Elektrowerkzeug, dessen

Schalter defekt ist. Ein Elektrowerkzeug, das

sich nicht mehr ein- oder ausschalten lässt, ist

gefährlich und muss repariert werden.

c) Ziehen Sie den Stecker aus der Steckdose

und/oder entfernen Sie den Akku, bevor Sie

Geräteeinstellungen vornehmen, Zubehörteile wechseln oder das Gerät weglegen. Diese

Vorsichtsmaßnahme verhindert den unbeabsichtigten Start des Elektrowerkzeuges.

d) Bewahren Sie unbenutzte Elektrowerkzeuge

außerhalb der Reichweite von Kindern auf.

Lassen Sie Personen das Gerät nicht benutzen,

die mit diesem nicht vertraut sind oder diese

Anweisungen nicht gelesen haben. Elektro-

werkzeuge sind gefährlich, wenn sie von

unerfahrenen Personen benutzt werden.

■ 18 │ DE

│AT│

CH

PMGS 12 C3

e) Pflegen Sie Elektrowerkzeuge mit Sorgfalt.

Kontrollieren Sie, ob bewegliche Teile einwandfrei funktionieren und nicht klemmen, ob Teile

gebrochen oder so beschädigt sind, dass die

Funktion des Elektrowerkzeuges beeinträchtigt ist. Lassen Sie beschädigte Teile vor dem

Einsatz des Gerätes reparieren. Viele Unfälle

haben ihre Ursache in schlecht gewarteten

Elektrowerkzeugen.

f) Halten Sie Schneidwerkzeuge scharf und

sauber. Sorgfältig gepflegte Schneidwerkzeuge

mit scharfen Schneidkanten verklemmen sich

weniger und sind leichter zu führen.

g) Verwenden Sie Elektrowerkzeug, Zubehör,

Einsatzwerkzeuge usw. entsprechend diesen

Anweisungen. Berücksichtigen Sie dabei die

Arbeitsbedingungen und die auszuführende

Tätigkeit. Der Gebrauch von Elektrowerkzeugen

für andere als die vorgesehenen Anwendungen

kann zu gefährlichen Situationen führen.

5. Service

a) Lassen Sie Ihr Elektrowerkzeug nur von quali-

fiziertem Fachpersonal und nur mit OriginalErsatzteilen reparieren. Damit wird sicherge-

stellt, dass die Sicherheit des Elektrowerkzeugs

erhalten bleibt.

Sicherheitshinweise für alle

Anwendungen

Gemeinsame Sicherheitshinweise zum Schleifen, Sandpapierschleifen, Arbeiten mit Drahtbürsten, Polieren, Fräsen oder Trennschleifen:

a) Dieses Elektrowerkzeug ist zu verwenden als

Schleifer, Sandpapierschleifer, Drahtbürste,

Polierer, zum Fräsen und als Trennschleifmaschine. Beachten Sie alle Sicherheitshinweise,

Anweisungen, Darstellungen und Daten, die

Sie mit dem Gerät erhalten. Wenn Sie die

folgenden Anweisungen nicht beachten, kann

es zu elektrischem Schlag, Feuer und / oder

schweren Verletzungen kommen.

b) Verwenden Sie kein Zubehör, das vom Her-

steller nicht speziell für dieses Elektrowerkzeug vorgesehen und empfohlen wird. Nur

weil Sie das Zubehör an Ihrem Elektrowerkzeug

befestigen können, garantiert das keine sichere

Verwendung.

c) Die zulässige Drehzahl des Einsatzwerkzeugs

muss mindestens so hoch sein wie die auf

dem Elektrowerkzeug angegebene Höchstdrehzahl. Zubehör, das sich schneller als zuläs-

sig dreht, kann zerbrechen und umherfliegen.

d) Außendurchmesser und Dicke des Einsatz-

werkzeugs müssen den Maßangaben Ihres

Elektrowerkzeugs entsprechen. Falsch bemes-

sene Einsatzwerkzeuge können nicht ausreichend abgeschirmt oder kontrolliert werden.

e) Schleifscheiben, Schleifwalzen oder anderes

Zubehör müssen genau auf die Schleifspindel

oder Spannzange Ihres Elektrowerkzeugs

passen. Einsatzwerkzeuge, die nicht genau in

die Aufnahme des Elektrowerkzeugs passen,

drehen sich ungleichmäßig, vibrieren sehr stark

und können zum Verlust der Kontrolle führen.

f) Auf einem Dorn montierte Scheiben, Schleif-

zylinder, Schneidwerkzeuge oder anderes

Zubehör müssen vollständig in die Spannzange oder das Spannfutter eingesetzt werden.

Der „Überstand“ bzw. der frei liegende

Teil des Dorns zwischen Schleifkörper und

Spannzange oder Spannfutter muss minimal

sein. Wird der Dorn nicht ausreichend gespannt

oder steht der Schleifkörper zu weit vor, kann

sich das Einsatzwerkzeug lösen und mit hoher

Geschwindigkeit ausgeworfen werden.

g) Verwenden Sie keine beschädigten Ein-

satzwerkzeuge. Kontrollieren Sie vor jeder

Verwendung Einsatzwerkzeuge wie Schleifscheiben auf Absplitterungen und Risse,

Schleifwalzen auf Risse, Verschleiß oder

starke Abnutzung, Drahtbürsten auf lose oder

gebrochene Drähte. Wenn das Elektrowerkzeug oder das Einsatzwerkzeug herunterfällt,

überprüfen Sie, ob es beschädigt ist, oder

verwenden Sie ein unbeschädigtes Einsatzwerkzeug. Wenn Sie das Einsatzwerkzeug

kontrolliert und eingesetzt haben, halten Sie

und in der Nähe befindliche Personen sich

außerhalb der Ebene des rotierenden Ein-

PMGS 12 C3

DE│AT│CH

│

19 ■

satzwerkzeugs auf und lassen Sie das Gerät

eine Minute lang mit Höchstdrehzahl laufen.

Beschädigte Einsatzwerkzeuge brechen meist in

dieser Testzeit.

h) Tragen Sie persönliche Schutzausrüstung.

Verwenden Sie je nach Anwendung Vollgesichtsschutz, Augenschutz oder Schutzbrille.

Soweit angemessen, tragen Sie Staubmaske,

Gehörschutz, Schutzhandschuhe oder Spezialschürze, die kleine Schleif- und Materialpartikel von Ihnen fernhält. Die Augen sollen

vor herumfliegenden Fremdkörpern geschützt

werden, die bei verschiedenen Anwendungen

entstehen. Staub- oder Atemschutzmaske

müssen den bei der Anwendung entstehenden

Staub filtern. Wenn Sie lange lautem Lärm

ausgesetzt sind, können Sie einen Hörverlust

erleiden.

i) Achten Sie bei anderen Personen auf siche-

ren Abstand zu Ihrem Arbeitsbereich. Jeder,

der den Arbeitsbereich betritt, muss persönliche Schutzausrüstung tragen. Bruchstücke

des Werkstücks oder gebrochener Einsatzwerkzeuge können wegfliegen und Verletzungen

auch außerhalb des direkten Arbeitsbereichs

verursachen.

j) Halten Sie das Gerät nur an den isolierten

Griffflächen, wenn Sie Arbeiten ausführen,

bei denen das Einsatzwerkzeug verborgene

Stromleitungen oder das eigene Netzkabel

treffen kann. Der Kontakt mit einer spannungs-

führenden Leitung kann auch metallene Geräteteile unter Spannung setzen und zu einem

elektrischen Schlag führen.

k) Halten Sie das Elektrowerkzeug beim Starten

stets gut fest. Beim Hochlaufen auf die volle

Drehzahl kann das Reaktionsmoment des Motors dazu führen, dass sich das Elektrowerkzeug

verdreht.

l) Wenn möglich, verwenden Sie Zwingen, um

das Werkstück zu fixieren. Halten Sie niemals

ein kleines Werkstück in der einen Hand und

das Elektrowerkzeug in der anderen, während Sie es benutzen. Durch das Festspannen

kleiner Werkstücke haben Sie beide Hände zur

besseren Kontrolle des Elektrowerkzeugs frei.

Beim Trennen runder Werkstücke wie Holzdübel, Stangenmaterial oder Rohre neigen diese

zum Wegrollen, wodurch das Einsatzwerkzeug

klemmen und auf Sie zu geschleudert werden

kann.

m) Halten Sie das Anschlusskabel von sich

drehenden Einsatzwerkzeugen fern. Wenn

Sie die Kontrolle über das Gerät verlieren, kann

das Kabel durchtrennt oder erfasst werden und

Ihre Hand oder Ihr Arm in das sich drehende

Einsatzwerkzeug geraten.

n) Legen Sie das Elektrowerkzeug niemals

ab, bevor das Einsatzwerkzeug völlig zum

Stillstand gekommen ist. Das sich drehende

Einsatzwerkzeug kann in Kontakt mit der Ablagefläche geraten, wodurch Sie die Kontrolle

über das Elektrowerkzeug verlieren können.

o) Ziehen Sie nach dem Wechseln von Einsatz-

werkzeugen oder Einstellungen am Gerät die

Spannzangenmutter, das Spannfutter oder

sonstige Befestigungselemente fest an. Lose

Befestigungselemente können sich unerwartet

verstellen und zum Verlust der Kontrolle führen;

unbefestigte, rotierende Komponenten werden

gewaltsam herausgeschleudert.

p) Lassen Sie das Elektrowerkzeug nicht laufen,

während Sie es tragen. Ihre Kleidung kann

durch zufälligen Kontakt mit dem sich drehenden Einsatzwerkzeug erfasst werden und das

Einsatzwerkzeug sich in Ihren Körper bohren.

q) Reinigen Sie regelmäßig die Lüftungsschlitze

Ihres Elektrowerkzeugs. Das Motorgebläse

zieht Staub in das Gehäuse, und eine starke

Ansammlung von Metallstaub kann elektrische

Gefahren verursachen.

r) Verwenden Sie das Elektrowerkzeug nicht

in der Nähe brennbarer Materialien. Funken

können diese Materialien entzünden.

s) Verwenden Sie keine Einsatzwerkzeuge, die

flüssige Kühlmittel erfordern. Die Verwendung

von Wasser oder anderen flüssigen Kühlmitteln

kann zu einem elektrischen Schlag führen.

■ 20 │ DE

│AT│

CH

PMGS 12 C3

Weitere Sicherheitshinweise

für alle Anwendungen

Rückschlag und entsprechende Sicherheitshinweise

Rückschlag ist die plötzliche Reaktion infolge eines

hakenden oder blockierten drehenden Einsatzwerkzeugs, wie Schleifscheibe, Schleifband, Drahtbürste

usw. Verhaken oder Blockieren führt zu einem

abrupten Stopp des rotierenden Einsatzwerkzeugs.

Dadurch wird ein unkontrolliertes Elektrowerkzeug

gegen die Drehrichtung des Einsatzwerkzeugs

beschleunigt.

Wenn z. B. eine Schleifscheibe im Werkstück hakt

oder blockiert, kann sich die Kante der Schleifscheibe, die in das Werkstück eintaucht, verfangen

und dadurch die Schleifscheibe ausbrechen oder

einen Rückschlag verursachen. Die Schleifscheibe

bewegt sich dann auf die Bedienperson zu oder

von ihr weg, je nach Drehrichtung der Scheibe an

der Blockierstelle. Hierbei können Schleifscheiben

auch brechen.

Ein Rückschlag ist die Folge eines falschen oder

fehlerhaften Gebrauchs des Elektrowerkzeugs. Er

kann durch geeignete Vorsichtsmaßnahmen, wie

nachfolgend beschrieben, verhindert werden.

a) Halten Sie das Elektrowerkzeug gut fest und

bringen Sie Ihren Körper und Ihre Arme in

eine Position, in der Sie die Rückschlagkräfte

abfangen können. Die Bedienperson kann

durch geeignete Vorsichtsmaßnahmen die

Rückschlagkräfte beherrschen.

b) Arbeiten Sie besonders vorsichtig im Bereich

von Ecken, scharfen Kanten usw. Verhindern

Sie, dass Einsatzwerkzeuge vom Werkstück

zurückprallen und verklemmen. Das rotieren-

de Einsatzwerkzeug neigt bei Ecken, scharfen

Kanten oder wenn es abprallt dazu, sich zu

verklemmen. Dies verursacht einen Kontrollverlust oder Rückschlag.

c) Verwenden Sie kein gezähntes Sägeblatt. Sol-

che Einsatzwerkzeuge verursachen häufig einen

Rückschlag oder den Verlust der Kontrolle über

das Elektrowerkzeug.

d) Führen Sie das Einsatzwerkzeug stets in der

gleichen Richtung in das Material, in der die

Schneidkante das Material verlässt (entspricht

der gleichen Richtung, in der die Späne ausgeworfen werden). Führen des Elektrowerkzeugs

in die falsche Richtung bewirkt ein Ausbrechen

der Schneidkante des Einsatzwerkzeuges aus

dem Werkstück, wodurch das Elektrowerkzeug in

diese Vorschubrichtung gezogen wird.

e) Spannen Sie das Werkstück bei der Verwen-

dung von Drehfeilen, Trennscheiben, Hochgeschwindigkeitsfräswerkzeugen oder Hartmetall-Fräswerkzeugen stets fest. Bereits bei

geringer Verkantung in der Nut verhaken diese

Einsatzwerkzeuge und können einen Rückschlag

verursachen. Bei Verhaken einer Trennscheibe

bricht diese gewöhnlich. Bei Verhaken von

Drehfeilen, Hochgeschwindigkeitsfräswerkzeugen oder Hartmetall-Fräswerkzeugen, kann der

Werkzeugeinsatz aus der Nut springen und zum

Verlust der Kontrolle über das Elektrowerkzeug

führen.

Zusätzliche Sicherheitshinweise zum

Schleifen und Trennschleifen

Besondere Sicherheitshinweise zum Schleifen

und Trennschleifen:

a) Verwenden Sie ausschließlich die für Ihr

Elektrowerkzeug zugelassenen Schleifkörper

und nur für die empfohlenen Einsatzmöglichkeiten. Beispiel: Schleifen Sie nie mit der

Seitenfläche einer Trennscheibe. Trennschei-

ben sind zum Materialabtrag mit der Kante der

Scheibe bestimmt. Seitliche Krafteinwirkung auf

diese Schleifkörper kann sie zerbrechen.

b) Verwenden Sie für konische und gerade

Schleifstifte mit Gewinde nur unbeschädigte

Dorne der richtigen Größe und Länge, ohne

Hinterschneidung an der Schulter. Geeignete

Dorne verhindern die Möglichkeit eines Bruchs.

c) Vermeiden Sie ein Blockieren der Trennschei-

be oder zu hohen Anpressdruck. Führen Sie

keine übermäßig tiefen Schnitte aus. Eine

Überlastung der Trennscheibe erhöht deren Beanspruchung und die Anfälligkeit zum Verkanten oder Blockieren und damit die Möglichkeit

eines Rückschlags oder Schleifkörperbruchs.

PMGS 12 C3

DE│AT│CH

│

21 ■

d) Meiden Sie mit Ihrer Hand den Bereich vor

und hinter der rotierenden Trennscheibe.

Wenn Sie die Trennscheibe im Werkstück von

Ihrer Hand wegbewegen, kann im Falle eines

Rückschlags das Elektrowerkzeug mit der sich

drehenden Scheibe direkt auf Sie zugeschleudert werden.

e) Falls die Trennscheibe verklemmt oder Sie die

Arbeit unterbrechen, schalten Sie das Gerät

aus und halten Sie es ruhig, bis die Scheibe

zum Stillstand gekommen ist. Versuchen Sie

nie, die noch laufende Trennscheibe aus dem

Schnitt zu ziehen, sonst kann ein Rückschlag

erfolgen. Ermitteln und beheben Sie die Ursa-

che für das Verklemmen.

f) Schalten Sie das Elektrowerkzeug nicht

wieder ein, solange es sich im Werkstück

befindet. Lassen Sie die Trennscheibe erst

ihre volle Drehzahl erreichen, bevor Sie den

Schnitt vorsichtig fortsetzen. Anderenfalls

kann die Scheibe verhaken, aus dem Werkstück

springen oder einen Rückschlag verursachen.

g) Stützen Sie Platten oder große Werkstücke

ab, um das Risiko eines Rückschlags durch

eine eingeklemmte Trennscheibe zu vermindern. Große Werkstücke können sich unter

ihrem eigenen Gewicht durchbiegen. Das

Werkstück muss auf beiden Seiten der Scheibe

abgestützt werden, und zwar sowohl in der

Nähe des Trennschnitts als auch an der Kante.

h) Seien Sie besonders vorsichtig bei Tauch-

schnitten in bestehende Wände oder andere

nicht einsehbare Bereiche. Die eintauchende

Trennscheibe kann beim Schneiden in Gas- oder

Wasserleitungen, elektrische Leitungen oder

andere Objekte einen Rückschlag verursachen.

Zusätzliche Sicherheitshinweise

zum Arbeiten mit Drahtbürsten

b) Lassen Sie Bürsten vor dem Einsatz mindes-

tens eine Minute mit Arbeitsgeschwindigkeit

laufen. Achten Sie darauf, dass in dieser Zeit

keine andere Person vor oder in gleicher Linie

mit der Bürste steht. Während der Einlaufzeit

können lose Drahtstücke wegfliegen.

c) Richten Sie die rotierende Drahtbürste von

sich weg. Beim Arbeiten mit diesen Bürsten können kleine Partikel und winzige Drahtstücke mit

hoher Geschwindigkeit wegfliegen und durch

die Haut dringen.

Sicherheitshinweise für

Bohrmaschinen

■ Der Verlust der Kontrolle kann zu Verletzungen

führen.

■ Halten Sie das Gerät an den isolierten Griffflä-

chen, wenn Sie Arbeiten ausführen, bei denen

das Einsatzwerkzeug verborgene Stromleitungen oder das eigene Netzkabel treffen kann.

Der Kontakt mit einer spannungsführenden

Leitung kann auch metallene Geräteteile unter

Spannung setzen und zu einem elektrischen

Schlag führen.

Sicherheitshinweise für LED-Leuchten

ACHTUNG! VERLETZUNGSGEFAHR

FÜR DIE AUGEN!

■ Richten Sie den Lichtstrahl niemals direkt auf

Menschen oder Tiere und blicken Sie selbst

niemals direkt in den Lichtstrahl der LEDLeuchten.

Besondere Sicherheitshinweise zum Arbeiten

mit Drahtbürsten:

a) Beachten Sie, dass die Drahtbürste auch

während des üblichen Gebrauchs Drahtstücke verliert. Überlasten Sie die Drähte nicht

durch zu hohen Anpressdruck. Wegfliegende

Drahtstücke können sehr leicht durch dünne

Kleidung und / oder die Haut dringen.

■ 22 │ DE

│AT│

CH

PMGS 12 C3

Sicherheitshinweise zu Batterien

ACHTUNG!

■ Lassen Sie keine verbrauchten Batterien im

Gerät, da selbst auslaufgeschützte Batterien

korrodieren und dadurch Chemikalien freigesetzt werden können, welche Ihrer Gesundheit schaden bzw. das Gerät zerstören. Lassen Sie keine Batterien achtlos herumliegen.

Diese könnten von Kindern oder Haustieren

verschluckt werden. Suchen Sie im Falle eines

Verschluckens sofort einen Arzt auf.

■ Entfernen Sie die Batterien bei längerer Nicht-

benutzung aus dem Gerät, um ein Auslaufen

zu verhindern.

■ Ausgelaufene oder beschädigte Batterien

können bei Berührung mit der Haut Verätzungen verursachen. Benutzen Sie deshalb in

diesem Fall geeignete Schutzhandschuhe.

■ Achten Sie darauf, dass Batterien nicht

kurzgeschlossen werden. Werfen Sie keine

Batterien ins Feuer.

■ Batterien dürfen nicht aufgeladen werden. Es

besteht Explosionsgefahr!

Gerätespezifische Sicherheitshinweise

für Transformatoren

Nur zur Verwendung in Innenräumen!

WARNUNG!

■ Stäube von Materialien wie bleihaltigem An-

strich, einigen Holzarten und Metall können

gesundheitsschädlich sein.

■ Die Berühung oder das Einatmen dieser Stäu-

be kann eine Gefährdung für die Bedienperson oder in der Nähe befindliche Personen

darstellen.

■ Tragen Sie Schutzbrille und Staubschutzmaske!

■

Sicherheitstransformator Fail-Safe

Inbetriebnahme

■ Verwenden Sie das Gerät niemals zweckent-

fremdet und nur mit Originalteilen / -zubehör.

Der Gebrauch anderer als in der Bedienungsanleitung empfohlener Teile oder anderen

Zubehörs kann eine Verletzungsgefahr für Sie

bedeuten.

Batteriewechsel vornehmen

♦ Achten Sie darauf, dass das LED-Licht ausge-

schaltet ist. Entfernen Sie auf der Rückseite des

Griffrings mit LED die drei Schrauben des

Batteriedeckels.

♦ Entnehmen Sie die verbrauchte Batterie und

ersetzen Sie diese durch eine neue (Knopfzelle

LR41). Achten Sie beim Einsetzen auf die richtige Polung der Batterien.

♦ Schließen Sie das Batteriefach wieder, indem

Sie die drei Schrauben wieder eindrehen.

Werkzeug / Spannzange

einsetzen / wechseln

♦ Betätigen Sie die Spindelarretierung und

halten Sie diese gedrückt.

♦ Drehen Sie die Spannmutter

Arretierung einrastet.

♦ Lösen Sie die Spannmutter

schlüssel vom Gewinde.

♦ Entnehmen Sie ggf. ein eingesetztes Werkzeug.

♦ Schieben Sie zuerst das vorgesehene Werk-

zeug durch die Spannmutter

die zum Werkzeugschaft passende Spannzange stecken.

♦ Betätigen Sie die Spindelarretierung

halten Sie diese gedrückt.

♦ Stecken Sie die Spannzange

Gewindeeinsatz und schrauben Sie dann die

Spannmutter

Gewinde fest.

mit dem Kombischlüssel am

bis die

mit dem Kombi-

bevor Sie es in

und

in den

Sicherung Schmelzeinsatz

■

PMGS 12 C3

DE│AT│CH

│

23 ■

Einsatzwerkzeug mit Spanndorn

verwenden:

HINWEIS

► Verwenden Sie die Schraubendreherseite des

Kombischlüssels

der Schraube der Spanndornen .

♦ Setzen Sie den Spanndorn

in das Elektrowerkzeug ein.

♦ Lösen Sie mit Hilfe des Kombischlüssels

Schraube vom Spanndorn .

♦ Stecken Sie das gewünschte Einsatzwerkzeug

zwischen die beiden Unterlegscheiben auf die

Schraube auf.

♦ Ziehen Sie mit Hilfe des Kombischlüssels

Schraube am Spanndorn fest.

zum Lösen und Festziehen

wie beschrieben

Ein- und ausschalten /

Drehzahlbereich einstellen

Einschalten / Drehzahlbereich einstellen:

♦ Schließen Sie den Stecker

an, indem Sie ihn in die dafür vorgesehene

Einsteckvorrichtung stecken (siehe Abb. A).

♦ Schließen Sie das Gerät an die Stromversor-

gung an, indem Sie den Netzstecker in die

Steckdose stecken.

♦ Schieben Sie den EIN- / AUS-Schalter

eine Position zwischen „5000“ und „20000“.

Ausschalten:

♦ Schieben Sie den EIN- / AUS-Schalter

die Position „OFF“.

an das Netzteil

die

die

auf

auf

♦ Halten Sie die Spindelarretierung

und schrauben Sie die Spannmutter

Uhrzeigersinn auf das Gewinde.

♦ Lassen Sie die Spindelarretierung

♦ Bringen Sie den EIN- / AUS-Schalter des LED-

Lichts

in Position „I“, um es einzuschalten.

♦ Bringen Sie den EIN- / AUS-Schalter des

LED-Lichts

auszuschalten.

♦ Gehen Sie zur Wiederanbringung des Griffrin-

ges

in Position „0“, um es wieder

in umgekehrter Reihenfolge vor.

gedrückt

im

los.

Hinweise zu Materialbearbeitung /

Werkzeug /Drehzahlbereich

■ Verwenden Sie die Fräsbits zur Bearbeitung

von Stahl und Eisen unter Höchstdrehzahl.

■ Ermitteln Sie den Drehzahlbereich zur Bearbei-

tung von Zink, Zinklegierungen, Aluminium, Kupfer und Blei durch Versuche an Probestücken.

■ Bearbeiten Sie Kunststoffe und Materialien mit

niedrigem Schmelzpunkt im niedrigen Drehzahlbereich.

■ Bearbeiten Sie Holz mit hohen Drehzahlen.

■ Führen Sie Reinigungs-, Polier- und Schwabbel-

arbeiten im mittleren Drehzahlbereich durch.

Die nachfolgenden Angaben sind unverbindliche

Empfehlungen. Testen Sie beim praktischen Arbeiten auch selbst, welches Werkzeug und welche

Einstellung für das zu bearbeitende Material

optimal geeignet sind.

Geeignete Drehzahl einstellen:

Griffring mit LED-Licht verwenden

♦ Halten Sie die Spindelarretierung gedrückt

und schrauben Sie die Spannmutter

den Uhrzeigersinn vom Gewinde ab.

♦ Lassen Sie die Spindelarretierung

♦ Schrauben Sie anschließend den Griffring

gegen den Uhrzeigersinn vom Gewinde ab.

♦ Schrauben Sie den Griffring mit LED-Licht

Uhrzeigersinn auf das Gewinde.

■ 24 │ DE

│AT│

CH

gegen

los.

im

Ziffer an der

Drehzahlregulierung

5000 Kunststoff und Werk-

9000 Gestein, Keramik

13000 Weichholz, Metall

17000 Hartholz

zu bearbeitendes

Material

stoffe mit niedrigem

Schmelzpunkt

PMGS 12 C3

20000 Stahl

Anwendungsbeispiele / geeignetes Werkzeug auswählen:

Funktion Zubehör Verwendung Überstand

(min–max) mm

Bohren

Fräsen

Gravieren

Polieren,

Entrosten

VORSICHT!

Üben Sie nur leichten

Druck mit dem Werkzeug auf das Werkstück

aus.

Säubern

Schleifen

Trennen

■ Beachten Sie, dass der maximale Durchmesser von zusammengesetzten Schleifkörpern und von Schleif-

konen und Schleifstiften mit Gewindeeinsatz 55 mm und der maximale Durchmesser für Sandpapier-

Schleifzubehör 80 mm nicht überschreiten dürfen.

HINWEIS

► Die max. zulässige Länge eines Spanndorns beträgt 33 mm.

■ Zubehör in der Original-Box lagern oder die Zubehörteile anderweitig gegen Beschädigung schützen.

■ Das Zubehör trocken und nicht im Bereich aggressiver Medien lagern.

HSS-Bohrer

Fräsbits

Gravierbits

Metallbürste

Polierscheiben

Kunststoffbürsten

Schleifscheiben

Schleifbits

Trennscheiben

Metall

Holz bearbeiten 18–25 beim kleinsten

Bohrer ist der Überstand 10 mm

Vielseitige Arbeiten;

z.B. Ausbuchten, Aushöhlen, Formen, Nuten

oder Schlitze erstellen

Kennzeichnung anfertigen, Bastelarbeiten

Entrosten 9–15

Verschiedene Metalle

und Kunststoffe, insbesondere Edelmetalle

wie Gold oder Silber

bearbeiten