CIRCULAR SAW PHKS 1350 C2

CIRCULAR SAW

Translation of the original instructions

HANDKREISSÄGE

Originalbetriebsanleitung

IAN 285129

ΔΙΣΚΟΠΡΙΟΝΟ ΧΕΙΡΟΣ

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τις δυο σελίδες με τις εικόνες και εξοικειωθείτε με όλες τις

λειτουργίες της συσκευής.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / NI / CY Translation of the original instructions Page 1

GR / CY Μετάφραση των αυθεντικών οδηγιών λειτουργίας Σελίδα 15

DE / AT / CH Originalbetriebsanleitung Seite 29

Contents

Introduction ......................................................2

Proper use .................................................................2

Features ................................................................... 2

Package contents ............................................................ 2

Technical details ............................................................. 2

General Power Tool Safety Warnings ................................3

1. Work area safety .......................................................... 3

2. Electrical safety ........................................................... 3

3. Personal safety ............................................................ 4

4. Power tool use and care .................................................... 4

5. Service .................................................................. 4

Device-specific safety instructions for circular saws .................................. 5

Safety information for circular saw blades ......................................... 6

Original accessories/additional equipment ........................................ 7

Before use .......................................................8

Check that the blade guard is functioning correctly .................................. 8

Initial operation ..................................................8

Fitting/changing the saw blade ................................................. 8

Mounting/setting the guide fence ............................................... 8

Connecting the sawdust extraction appliance ...................................... 9

Operation .......................................................9

Switching on and off .........................................................9

Setting the cutting angle ....................................................... 9

Setting the cutting depth ....................................................... 9

Working with the circular saw .................................................. 9

Switching the laser on and off .................................................. 9

Set rotational speed .......................................................... 9

Tips and tricks .............................................................. 10

Maintenance and Cleaning ........................................10

Disposal ........................................................10

Disposing of the batteries .....................................................10

Kompernass Handels GmbH warranty ..............................11

Service .........................................................12

Importer .......................................................12

Translation of the original Conformity Declaration .....................13

PHKS 1350 C2

GB│IE│NI│CY

│

1 ■

CIRCULAR SAW PHKS 1350 C2

Introduction

Congratulations on the purchase of your

new appliance. You have selected a highquality product. The operating instructions are part

of this product. They contain important information about safety, use and disposal.

Before using the product, familiarise yourself with

all operating and safety instructions. Use this product

only as described and only for the specified areas

of application. Please also pass these operating

instructions on to any future owner(s).

Proper use

This circular saw (hereinafter "appliance") is

designed for longitudinal, cross and mitre cuts in

firmly supported solid wood, chipboard, plastics

and lightweight construction materials. Any other

uses of or modifications to the device are deemed

to be improper usage and may result in serious

physical injury. Not for commercial use.

Features

Safety lock-out

ON/OFF switch

Cutting depth scale

Allen key SW 6

Locking screw

Base plate

Guide fence slot

Wing screw for guide fence slot

Wing screw for cutting angle preselector

Cutting angle scale

Spindle lock

Auxiliary handle

ON/OFF switch laser

Laser discharge opening

Guide fence

Clamping flange

Clamping screw/plain washer

Blade guard

Release lever for the blade guard

Saw blade

Chip ejector

Vacuum adapter for dust extraction

Rotational speed preselector adjusting wheel

Battery compartment cover

Package contents

1 circular saw

1 guide fence

1 vacuum adapter for dust extraction

1 Allen key SW 6

2 saw blades

2 batteries

1 operating instructions

Technical details

Nominal power input: 1350 W

Rated voltage: 230 V ∼ 50 Hz

(Alternating current)

Idle speed: n

Saw blades: 1x Ø 190 mm x 2.5 mm x

190mm

1x Ø 190 mm x 2.5 mm x

Max. cutting depth: at 0°:

max. 56 mm

Protection class: II /

Noise and vibration data:

Noise measurement determined in accordance

with EN 60745. The A-rated noise level of the

tool is typically:

Noise emission value:

Sound pressure level: L

Uncertainty: K

Sound power level: L

Uncertainty: K

2.200–4.700 rpm

0

Ø 20 mm, 24 teeth

Ø 20 mm, 48 teeth

wood/plastic 65 mm

at 45°:

wood/plastic 44 mm

(Double shielded)

= 93 dB(A)

PA

= 3 dB

PA

= 104 dB(A)

WA

= 3 dB

WA

■ 2 │ GB

│IE│NI│

CY

PHKS 1350 C2

Wear ear protection!

Vibration emission value:

Cutting wood a

= 3.7 m/s

h,W

Uncertainty K = 1.5 m/s

WARNING!

2

2

► The vibration level specified in these instructions

has been measured in accordance with the

standardised measuring procedure specified

in EN 60745 and can be used to make equipment comparisons. The specified vibration

emission value can also be used to make an

initial exposure estimate. The vibration level

varies in accordance with the use of the tool

and may be higher than the value specified

in these instructions in some cases. It is easy

to underestimate the vibration load if the

electrical power tool is used regularly in this

manner.

NOTE

► Try to keep the vibration loads as low as

possible. Measures to reduce the vibration

load are, e.g. wearing gloves and limiting the

working time. Wherein all states of operation

must be included (e.g. times when the power

tool is switched off and times where the

power tool is switched on but running without

load).

General Power Tool

Safety Warnings

WARNING!

► Read all safety warnings and all instructions.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or ground-

ed surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

PHKS 1350 C2

GB│IE│NI│CY

│

3 ■

3. Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier

to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and

the work to be performed. Use of the power

tool for operations different from those intended

could result in a hazardous situation.

■ 4 │ GB

│IE│NI│

CY

5. Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

PHKS 1350 C2

Device-specific safety instructions for

circular saws

Safety instructions for all saws

Cutting procedures

a) DANGER: Keep hands away from

cutting area and the blade. Keep

your second hand on auxiliary

handle, or motor housing. If both hands are

holding the saw, they cannot be cut by the blade.

b) Do not reach underneath the workpiece. The

guard cannot protect you from the blade below

the workpiece.

c) Adjust the cutting depth to the thickness of the

workpiece. Less than a full tooth of the blade

teeth should be visible below the workpiece.

d) Never hold piece being cut in your hands

or across your leg. Secure the workpiece to

a stable platform. It is important to support

the work properly to minimize body exposure,

blade binding, or loss of control.

e) Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live”

wire will also make exposed metal parts of the

power tool “live” and could give the operator an

electric shock.

f) When ripping, always use a rip fence or

straight edge guide. This improves the accuracy of cut and reduces the chance of blade

binding.

g) Always use blades with correct size and

shape (diamond versus round) of arbour

holes. Blades that do not match the mounting

hardware of the saw will run eccentrically, causing loss of control.

h) Never use damaged or incorrect blade

washers or bolt. The blade washers and bolt

were specially designed for your saw, for optimum performance and safety of operation.

Further safety instructions for all saws

Kickback causes and related warnings

▯ kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator;

▯ when the blade is pinched or bound tightly

by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back

toward the operator;

▯ if the blade becomes twisted or misaligned in

the cut, the teeth at the back edge of the blade

can dig into the top surface of the wood causing

the blade to climb out of the kerf and jump back

toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can

be avoided by taking proper precautions as given

below.

a) Maintain a firm grip with both hands on the

saw and position your arms to resist kickback

forces. Position your body to either side of the

blade, but not in line with the blade. Kickback

could cause the saw to jump backwards, but kickback forces can be controlled by the operator, if

proper precautions are taken.

b) When blade is binding, or when interrupting

a cut for any reason, release the trigger and

hold the saw motionless in the material until

the blade comes to a complete stop. Never

attempt to remove the saw from the work or

pull the saw backward while the blade is in

motion or kickback may occur. Investigate and

take corrective actions to eliminate the cause of

blade binding.

c) When restarting a saw in the workpiece,

centre the saw blade in the kerf and check

that saw teeth are not engaged into the

material. If saw blade is binding, it may walk

up or kickback from the workpiece as the saw is

restarted.

PHKS 1350 C2

GB│IE│NI│CY

│

5 ■

d) Support large panels to minimise the risk of

blade pinching and kickback. Large panels

tend to sag under their own weight. Supports

must be placed under the panel on both sides,

near the line of cut and near the edge of the

panel.

e) Do not use dull or damaged blades.

Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade

binding and kickback.

f) Blade depth and bevel adjusting locking

levers must be tight and secure before making

cut. If blade adjustment shifts while cutting, it

may cause binding and kickback.

g) Use extra caution when sawing into existing

walls or other blind areas. The protruding blade

may cut objects that can cause kickback.

Lower guard function

a) Check lower guard for proper closing

before each use. Do not operate the saw if

lower guard does not move freely and close

instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally

dropped, lower guard may be bent. Raise the

lower guard with the retracting handle and

make sure it moves freely and does not touch

the blade or any other part, in all angles and

depths of cut.

b) Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced before use. Lower guard may operate sluggishly

due to damaged parts, gummy deposits, or a

build-up of debris.

c) Lower guard may be retracted manually

only for special cuts such as “plunge cuts”

and “compound cuts”. Raise lower guard by

retracting handle and as soon as blade enters

the material, the lower guard must be released.

For all other sawing, the lower guard should

operate automatically.

d) Always observe that the lower guard is

covering the blade before placing saw down

on bench or floor. An unprotected, coasting

blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the

time it takes for the blade to stop after switch is

released.

Supplementary notes

■ Do not use any grinding discs.

■ Use only saw blade with diameters correspond-

ing to the label on the saw.

■ When sawing wood or other materials which

may create dusts that are hazardous to health,

always connect a suitable, certified vacuum

extractor device.

■ Wear a dust mask when sawing wood.

■ Use only the recommended saw blades.

■ Always wear ear protectors.

■ Do not allow the teeth of the saw blade to overheat.

■ When sawing plastic, avoid melting the plastic.

Safety information for

circular saw blades

Wear protective gloves!

Wear respiratory protection!

Wear protective glasses!

Wear hearing protection!

■ 6 │ GB

│IE│NI│

CY

PHKS 1350 C2

WARNING! Protect yourself from laser

radiation!

This appliance contains a Class 2 laser.

► NEVER direct the laser beam at people or

animals.

► NEVER look directly into the laser beam.

The laser beam can cause serious eye damage.

► Do NOT direct the laser beam at strongly

reflective material. Reflected laser beams are

also dangerous.

► Any adjustment intended to increase the

intensity of the laser beam is forbidden.

There is a risk of personal injury!

► No liability will be accepted for damage

resulting from manipulation of the laser

equipment or from disregarding these safety

instructions.

► Caution if other than the controls or adjust-

ments specified here or other procedures

are carried out, this may lead to dangerous

exposure to radiation.

NOTE

► If the device is not used according to the

manufacturer’s operating instructions, the

protection provided may be impaired.

DANGER

Mishandling the batteries can cause

fires, explosions, leakages or other

hazards!

► Do not throw the batteries into a fire and do

not subject them to high temperatures.

► Do not open, deform or short-circuit batteries,

since this can lead to chemical leakage.

► Do not attempt to recharge batteries. Do not

charge batteries unless they are explicitly

labelled as "rechargeable". There is a risk of

explosion!

DANGER

► Check the condition of the batteries at

regular intervals. Leaking chemicals can

cause permanent damage to the device. Take

particular care when handling damaged or

leaking batteries. Risk of chemical burns!

Wear protective gloves.

► Chemicals which leak from a battery can

cause skin irritation. In the event of contact

with the skin, rinse with copious amounts of

water. If the chemicals come into contact with

your eyes, rinse thoroughly with water, do not

rub and consult a doctor immediately.

► Keep batteries out of the reach of children.

Children might put batteries into their mouth

and swallow them. If a battery has been

swallowed, seek medical assistance IM-

MEDIATELY.

► Do not mix different types of batteries.

► Always insert the batteries the right way

round (observe correct polarity) otherwise

there is a danger that they could explode.

► If you do not intend to use the device for a

long time, remove the batteries.

Changing the batteries:

■ Open the cover of the battery compartment

with a suitable Philips screwdriver.

■ Remove the spent batteries.

■ Insert two new 1.5 V alkaline button cells (type

AG 13/LR 44, e.g. GPA 76) observing the

correct polarity and screw the battery compartment cover firmly closed.

CAUTION!

If operating and adjustment equipment is used or

procedures other than those specified here are

carried out, this may result in hazardous radiation

exposure.

Original accessories/additional

equipment

■ Only use the accessories and additional equip-

ment that are specified in the operating instructions and are compatible with the appliance.

PHKS 1350 C2

GB│IE│NI│CY

│

7 ■

Before use

Check that the blade guard is

functioning correctly

WARNING! RISK OF INJURY!

■ Switch off the appliance and pull out the

power plug before starting any work on

the appliance.

■ Make sure that all moving parts of the blade

guard

devices designed to cover the saw blade are

working correctly.

■ Activate the blade guard only using the

release lever for the blade guard .

♦ Pull the release lever for the blade guard

all the way back.

When you let go of the release lever for the

blade guard , the blade guard must

move freely back to its starting position.

move freely without jamming and all

Initial operation

The PHKS 1350 C2 circular saw has Intelligent

Power Control. This automatic power delivery

system ensures that for a particular speed range

the power output remains constant when working

on harder and more resistant materials.

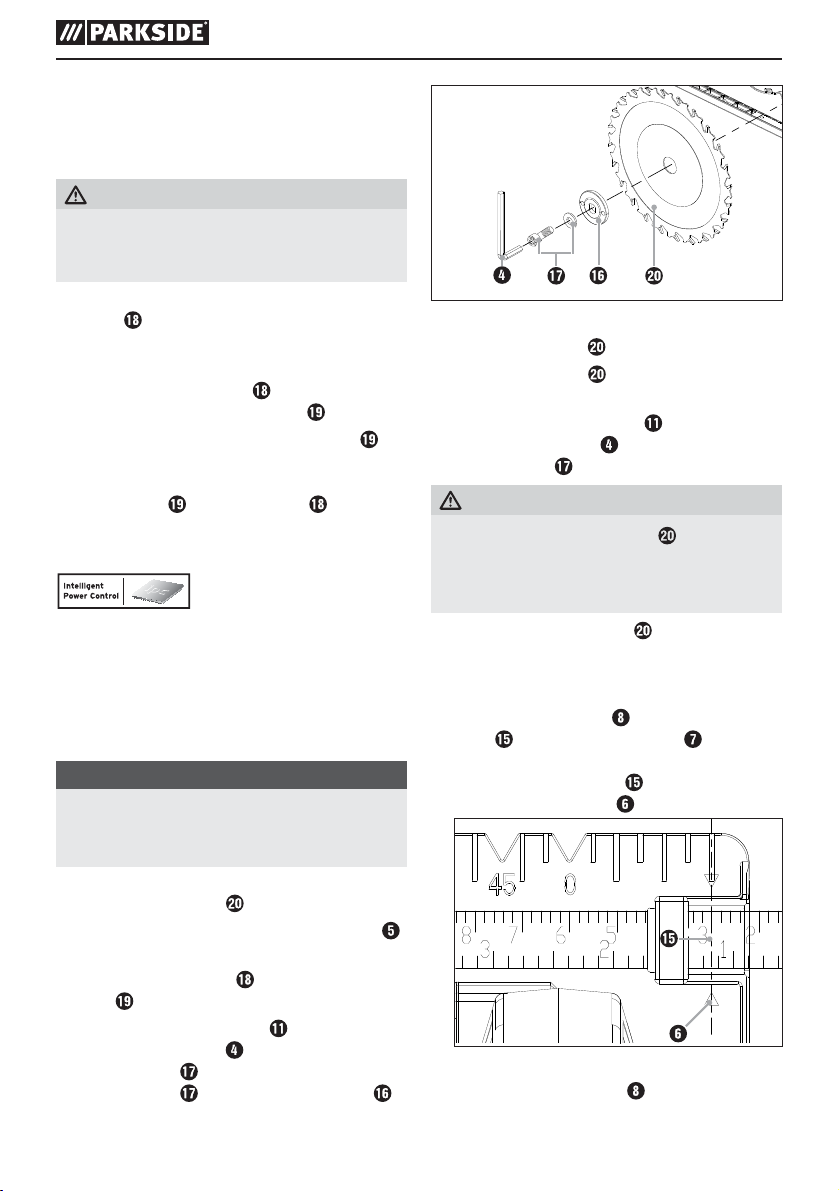

Fitting/changing the saw blade

NOTE

► All blades used should conform to EN 847-1.

■ Use only saw blade with diameters corre-

sponding to the label on the saw.

Always pull out the plug from the mains before

changing the saw blade

1. Set the cutting depth (using the locking screw

to the minimum position, 0 mm.

2. Swing the blade guard back using the release

lever and put the device down.

3. Press the spindle lock button (until it engages)

and use the Allen key to release the clamping

screw/washer . Now remover the clamping

screw/washer

(see also Fig. A).

!

and the clamping flange

Fig. A: Changing the saw blade

4. Remove saw blade

5. Fitting a saw blade is carried out in the

reverse order.

6. Press the spindle lock button (until it engages)

and use the Allen key to tighten the clamping

screw/washer .

WARNING!

► The arrow on the saw blade

spond to the arrow showing the direction of

rotation (running direction shown on the

device).

■ Ensure that the saw blade

rotational speed of the tool.

.

must corre-

is suitable for the

Mounting/setting the guide fence

♦ Loosen the wing screw and insert the guide

fence into the guide fence slot .

♦ Set the desired cut width with the help of the

scale on the guide fence and the marking

arrow in the base plate (see also Fig. B).

)

♦ Fig. B: Cutting width 3 cm

♦ Retighten the wing screw

.

■ 8 │ GB

│IE│NI│

CY

PHKS 1350 C2

Connecting the sawdust extraction

appliance

♦ Attach the adapter for dust extraction to the

chip ejector .

♦ Connect an approved dust and chip extraction

device.

Operation

Switching on and off

Switching on:

♦ Push the safety lock-out to the left or right

and keep it pressed.

♦ Press the ON/OFF switch . Once the saw is

running you can release the safety lock-out .

Switching off:

♦ Release the ON/OFF switch

Setting the cutting angle

You can select the cutting angle with the help of the

cutting angle scale .

■ Release the wing screw on the cutting angle

preselector , set the desired angle on the

cutting angle scale and then re-tighten the

wing screw.

.

Setting the cutting depth

NOTE

► We generally recommend setting the cutting

depth to approx. 3 mm more than the thickness

of the material. This ensures that you achieve

a clean cut.

♦ Release the locking screw

cutting depth on the cutting depth scale and

then re-tighten the locking screw .

, set the desired

Working with the circular saw

1. Switch on the device – as described in "Switching

on and off" – and then place it with the front

edge of the base plate on the material.

2. Align the machine using the guide fence or

by using a marked line.

3. Hold the machine in both hands using the

handles and saw by exerting an even pressure.

Switching the laser on and off

Switching on:

♦ Press the ON/OFF switch laser

Switching off:

♦ Press the ON/OFF switch laser

NOTE

► If the batteries are spent, replace them with

two new 1.5 V alkaline button cells (type

AG 13/LR 44, e.g. GPA 76) .

.

.

PHKS 1350 C2

Set rotational speed

■ Turn the adjusting wheel to the desired

rotational speed (arrow marking ▲)

(1 = lowest rotational speed/6 = highest rotational speed):

Use the following suggested settings or set the rotational speed on the adjusting wheel

GB│IE│NI│CY

as required.

│

9 ■

Material Rotational

speed

setting

Cross cuts & longitudinal cuts in

hard and soft wood (solid wood)

Chipboard, fibre board 6

Core board, plywood 6

Coated and veneered boards 6

PVC sheets 3–5

Acrylic glass sheets, perspex 2-4

Aluminium plate 4-6

Aluminium profile 4-6

Plaster board 1-2

Stone wool board 1-2

Cement-bonded particle board 1-2

6

Tips and tricks

■ Avoid damaging the cutting edge of sensitive

materials, e.g. coated chipboards or doors, by

sticking masking tape along the cutting line.

Another benefit of this is that it is easier to mark

a line on the tape than on a shiny surface. An

even more effective method of protecting the

cutting edges is to clamp a thin piece of wood

along the cutting line (this wood is also sawn).

Maintenance and Cleaning

WARNING! RISK OF INJURY!

Switch the appliance off and remove

the power plug before starting any

work.

■ The appliance must always be kept clean, dry

and free from oil or grease.

■ To clean the casing, use a soft dry cloth.

WARNING!

■ If the connecting cable needs to be replaced,

this must be carried out by the manufacturer

or his representative in order to avoid safety

hazards.

Disposal

The packaging consists of environmentally

friendly material. It can be disposed of in

the local recycling containers.

Do not dispose of power tools in

your normal domestic waste!

European Directive 2012/19/EU requires that wornout power tools are collected separately and fed

into an environmentally compatible recycling

process.

Your local community or municipal authorities can

provide information on how to dispose of the wornout appliance.

■ 10 │ GB

│IE│NI│

CY

Disposing of the batteries

Batteries must be recycled in accordance

with Directive 2006/66/EC and must not

be disposed of with household refuse.

Battery users are obliged by law to take all

rechargeable and single-use batteries to a collection

point operated by a public authority or a retailer.

The purpose of this obligation is to ensure that

batteries are disposed of in an environmentally

congruent manner. Only dispose of batteries when

they are fully discharged. Batteries must be removed

from the device prior to disposal.

PHKS 1350 C2

Kompernass Handels GmbH

warranty

Dear Customer,

This appliance has a 3-year warranty valid from

the date of purchase. If this product has any faults,

you, the buyer, have certain statutory rights. Your

statutory rights are not restricted in any way by the

warranty described below.

Warranty conditions

The validity period of the warranty starts from the

date of purchase. Please keep your original receipt

in a safe place. This document will be required as

proof of purchase.

If any material or production fault occurs within

three years of the date of purchase of the product,

we will either repair or replace the product for you

at our discretion. This warranty service is dependent on you presenting the defective appliance and

the proof of purchase (receipt) and a short written

description of the fault and its time of occurrence.

If the defect is covered by the warranty, your product

will either be repaired or replaced by us. The repair

or replacement of a product does not signify the

beginning of a new warranty period.

Warranty period and statutory claims for

defects

The warranty period is not prolonged by repairs

effected under the warranty. This also applies to

replaced and repaired components. Any damage

and defects present at the time of purchase must

be reported immediately after unpacking. Repairs

carried out after expiry of the warranty period shall

be subject to a fee.

Scope of the warranty

This appliance has been manufactured in accordance

with strict quality guidelines and inspected meticulously prior to delivery.

The warranty covers material faults or production

faults. The warranty does not extend to product parts

subject to normal wear and tear or fragile parts such

as switches, batteries, baking moulds or parts made

of glass.

The warranty does not apply if the product has been

damaged, improperly used or improperly maintained.

The directions in the operating instructions for the

product regarding proper use of the product are

to be strictly followed. Uses and actions that are

discouraged in the operating instructions or which

are warned against must be avoided.

This product is intended solely for private use and

not for commercial purposes. The warranty shall be

deemed void in cases of misuse or improper handling,

use of force and modifications/repairs which have

not been carried out by one of our authorised

Service centres.

Warranty claim procedure

To ensure quick processing of your case, please

observe the following instructions:

■ Please have the till receipt and the item number

(e.g. IAN 12345) available as proof of purchase.

■ You will find the item number on the type plate,

an engraving on the front page of the instructions

(bottom left), or as a sticker on the rear or bottom of the appliance.

■ If functional or other defects occur, please

contact the service department listed either by

telephone or by e-mail.

■ You can return a defective product to us free of

charge to the service address that will be provided

to you. Ensure that you enclose the proof of

purchase (till receipt) and information about

what the defect is and when it occurred.

PHKS 1350 C2

You can download these instructions

along with many other manuals,

product videos and software on

www.lidl-service.com.

GB│IE│NI│CY

│

11 ■

Loading...

Loading...