Parkside PGS 500 A1 Translation Of The Original Instructions

DIE GRINDER PGS 500 A1

DIE GRINDER

Translation of the original instructions

GERADSCHLEIFER

Originalbetriebsanleitung

IAN 289715

EYΘYΣ ΛEIANTHPAΣ

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τη σελίδα με τις εικόνες και εξοικειωθείτε με όλες τις λειτουργίες

της συσκευής.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / NI/CY Translation of the original instructions Page 1

GR / CY Μετάφραση των αυθεντικών οδηγιών λειτουργίας Σελίδα 13

DE / AT / CH Originalbetriebsanleitung Seite 25

PGS 500 A1

1

o

-

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Features ................................................................... 2

Package contents ............................................................ 2

Technical data .............................................................. 2

General Power Tool Safety Warnings ................................3

1. Work area safety .......................................................... 3

2. Electrical safety ........................................................... 3

3. Personal safety ............................................................ 4

4. Power tool use and care .................................................... 4

5. Service .................................................................. 5

Safety instructions for all applications ............................................ 5

Additional safety instructions for all applications .................................... 7

Supplementary safety instructions for grinding ...................................... 7

Supplementary safety instructions for working with wire brushes. . . . . . . . . . . . . . . . . . . . . . . . 8

Original accessories/auxiliary equipment ......................................... 8

Use .............................................................8

Changing/inserting the tool/collet chuck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Grinding stone .............................................................. 8

Switching on and off/setting speed range ......................................... 9

Notes on working with materials/tools/speed range ................................ 9

Cleaning, care and storage .........................................9

Kompernass Handels GmbH warranty ..............................10

Service .........................................................11

Importer .......................................................11

Disposal ........................................................11

Translation of the original Conformity Declaration .....................12

PGS 500 A1

GB│IE│NI│CY

│

1 ■

DIE GRINDER PGS 500 A1

Introduction

Congratulations on the purchase of your new appliance. You have chosen a high-quality product. The

operating instructions are part of this product. They

contain important information about safety, usage

and disposal. Before using the product, please familiarise yourself with all operating and safety instructions. Use the product only as described and for the

range of applications specified. Please also pass

these operating instructions on to any future owner.

Intended use

The appliance is intended for grinding and deburring metal with aluminous abrasives and work with

sanding belt bodies. It is furthermore intended for

brushing and polishing metal. Any other use of or

modification of the appliance is deemed contrary

to the intended use and carries the risk of serious

personal injury. Not for commercial use.

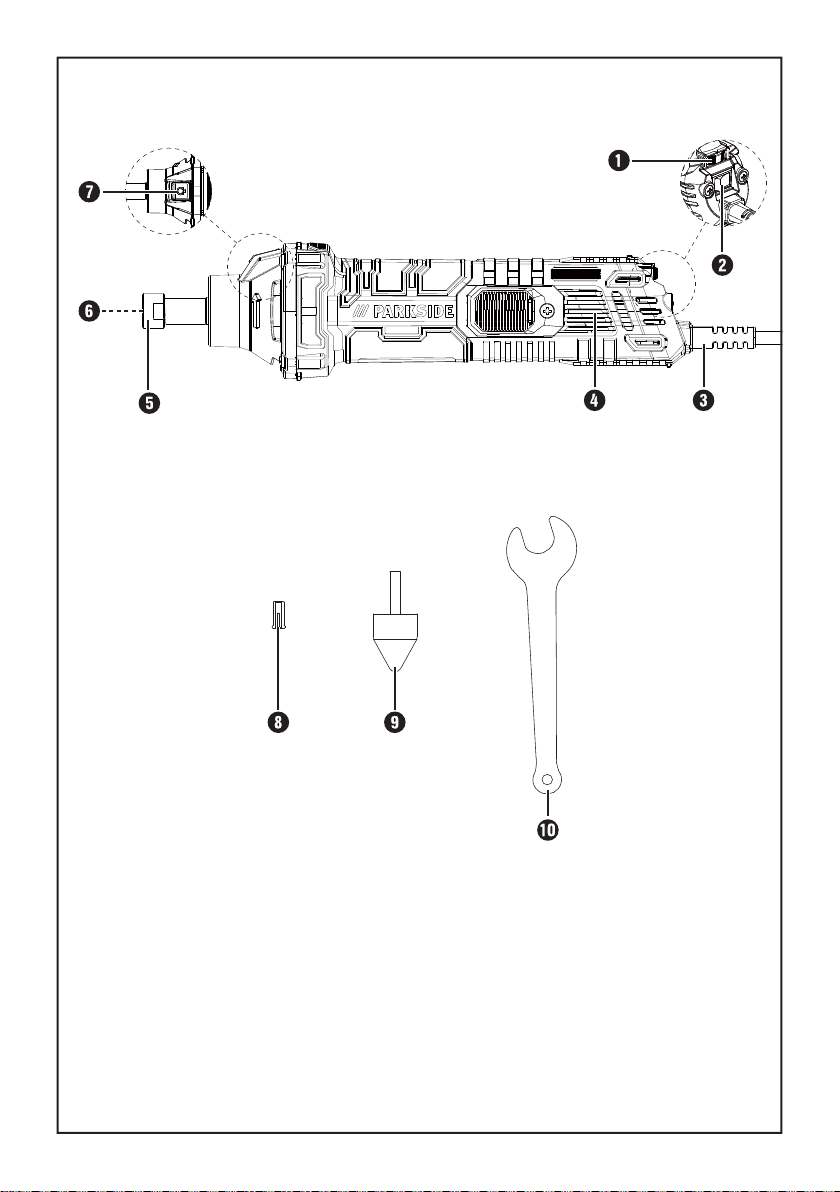

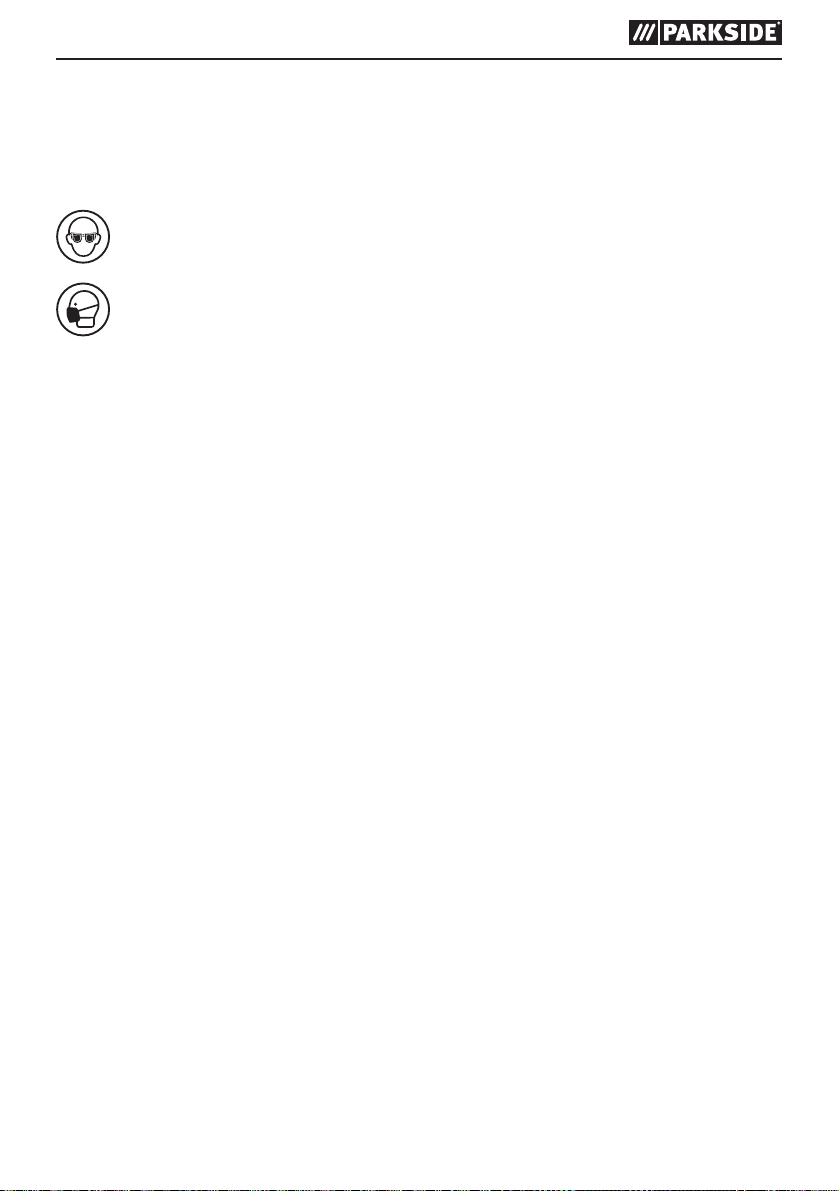

Features

Steplessly adjustable speed control

ON/OFF switch

Power cord

Ventilation slits

Tensioning nut

Collect chuck 6 mm (pre-assembled)

Spindle lock button

Collect chuck 3.2 mm

Grinding stone

Assembly wrench

Package contents

1 die grinder PGS 500 A1

2 collet chucks

1 grinding stone

1 assembly wrench

1 plastic case

1 set of operating instructions

Technical data

Rated power consumption:

Rated voltage: 230 V ~, 50 Hz (AC)

Rated speed: n 4,500–30,000 min

Chuck suspension: max. Ø 6 mm

Protection class:

Noise emission value:

Noise measurement value determined in accordance

with EN 60745. The noise level of the power tool

rated A is typically the following:

Sound pressure level: L

Uncertainty K: K

Sound power level: L

Uncertainty K: KWA = 3 dB

Wear hearing protection!

Vibration emission value:

Total vibration values (vector total of three directions)

determined in accordance with EN 60745:

Vibration emission value: a

Uncertainty K = 1.5 m/s

NOTE

► The vibration level specified in these instruc-

tions has been measured in accordance with

a standardised measuring procedure and

can be used for equipment comparisons. The

specified vibration emission value can also

be used to make an initial exposure estimate.

500 W

II /

(double insulation)

= 78.4 dB (A)

PA

= 3 dB

PA

= 89.4 dB (A)

WA

= 5.301 m/s

h

2

-1

2

■ 2 │ GB

│IE│NI│

CY

PGS 500 A1

WARNING!

► The vibration level varies depending on the

use of the power tool and may be higher

than the value specified in these instructions

in some cases. Regular use of the power tool

in this way may cause the user to underestimate the vibration. Try to keep the vibration

loads as low as possible. Measures to reduce

the vibration load are, e.g. wearing gloves

and limiting the working time. Wherein all

states of operation must be included (e.g.

times when the power tool is switched off and

times where the power tool is switched on but

running without load).

General Power Tool

Safety Warnings

WARNING!

► Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future

reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2. Electrical safety

a) The mains plug of the power tool must fit

into the socket. Never modify the plug in

any way. Do not use any adapter plugs

with earthed (grounded) power tools. Un-

modified plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or ground-

ed surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat,

oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp loca-

tion is unavoidable, use a residual current

device (RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

PGS 500 A1

GB│IE│NI│CY

│

3 ■

3. Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs,

alcohol or medication. A moment of inatten-

tion while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to power source and/or battery pack,

picking up or carrying the tool. Carrying

power tools with your finger on the switch or

energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench be-

fore turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose cloth-

ing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

4. Power tool use and care

a) Do not force the power tool. Use the cor-

rect power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments,

changing accessories or storing power

tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalign-

ment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Prop-

erly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

■ 4 │ GB

│IE│NI│

CY

PGS 500 A1

5. Service

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

WARNING!

Always wear safety googles

Wear a dust mask.

Safety instructions for all

applications

General safety instructions for grinding,

working with wire brushes, polishing and

milling:

a) This power tool is intended for use as a

grinder, sandpaper sander, wire brush, polisher, milling machine and abrasive cutting

appliance. Please follow all safety instructions,

instructions, diagrams and data that you receive with the appliance. If you do not observe

the following instructions, this can lead to an

electrical shock, fire and/or serious injuries.

b) This power tool is not suitable for sandpaper

sanding or abrasive cutting. Using the power

tool for applications for which it is not designed is hazardous and may cause injuries.

c) Do not use any accessories that have not

been provided or recommended for this

power tool by the manufacturer. Just because

you can attach the accessories to your power

tool, does not guarantee safe use.

d) The permissible speed of the attachment part

must be at least as high as the maximum

speed specified for the power tool. Acces-

sories that rotate faster than the permissible rate

can break and throw pieces into the air.

e) The external diameter and thickness of the

attachment part used must comply with the

dimensions of the power tool. Incorrectly

dimensioned attachment parts cannot be sufficiently shielded or controlled.

f) Grinding discs, sanding drums or other ac-

cessories must match exactly the grinding

spindle or collet chuck of your power tool. At-

tachment parts that do not fit precisely into the

take-up of the power tool will rotate unevenly, vibrate severely and can lead to a loss of control.

g) Discs, grinding cylinders, cutting tools or

other accessories mounted on a mandrel must

be inserted completely in the collet or chuck.

Any "protrusion" or exposed parts of the

mandrel between the grinding tool and the

collet or chuck must be kept to a minimum. If

the mandrel is not sufficiently tightened or the

grinding tool protrudes too far, the attachment

part can come loose and be ejected at high

speed.

h) Never use damaged attachment parts. Before

each use, check attachment parts such as

grinding discs for chips or cracks, sanding

drums for cracks, deterioration or excessive

wear and tear, and wire brushes for loose

or broken wires. If the power tool or the attachment part is dropped, check to see if it is

damaged or use an undamaged attachment

part. When you have checked and inserted the

attachment part, ensure that you and any other

people nearby remain outside of the range of

the rotating attachment part and allow the tool

to rotate at maximum speed for one minute.

Damaged attachment parts usually break during

this test period.

i) Wear personal protective equipment. Depend-

ing on the application, ensure that you use

full face protection, eye protection or safety

goggles. If appropriate, use a dust mask, ear

protectors, protective gloves or special apron

to protect you from grindings and material

particles. The eyes should be protected from

flying debris that may be caused during certain

applications. Dust or filter masks must be used to

filter any dust created by the application. If you

are exposed to loud noise for a longer period,

you may suffer hearing loss.

PGS 500 A1

GB│IE│NI│CY

│

5 ■

j) Ensure that other people remain at a safe dis-

tance to your workspace. Anyone who enters

the workspace must wear personal protective

equipment. Fragments of the workpiece or

broken attachment parts can become airborne

and cause injury – even outside the immediate

working area.

k) Hold the power tool only by the insulated

gripping surfaces when performing work

during which the attachment part can contact

hidden wiring or its own cord. Contact with a

live cable may also energise metal parts of the

appliance and result in an electric shock.

l) Always hold the power tool firmly. When

running up to full speed, the torque of the motor

can cause the power tool to twist.

m) If possible, use clamps to hold the workpiece in

position. Never hold a small workpiece in one

hand and the power tool in the other while

you are using it. By clamping small workpieces,

you keep both hands free for better control of the

power tool. When cutting round workpieces such

as dowels, rods or pipes, be aware that these

can roll away, which can cause that the tool jams

and is thrown towards you.

n) Hold the power cord away from any rotating

accessories. If you lose control of the appliance,

the cord may get cut or caught and your hand

or arm could get caught in the rotating attachment part.

o) Never put the power tool down until the at-

tachment part has come to a complete standstill. The rotating attachment part could come

into contact with the surface and cause you to

lose control of the power tool.

p) When changing attachment parts or the set-

tings on the appliance, tighten the collet nut,

the chuck or other fixing elements tightly.

Loose fastening elements can shift unexpectedly

and lead to loss of control; unfastened, rotating

components will be ejected by force.

q) Do not leave the power tool running while

you carry it. Accidental contact of your clothing with the rotating attachment part could lead

to a physical injury.

r) Clean the ventilation slits of your power tool

regularly. The engine fan draws dust into the

housing and a strong accumulation of metal dust

can cause electrical hazards.

s) Do not use the power tool near flammable

materials. Sparks can ignite such materials.

t) Do not use any attachment parts that require

liquid coolant. The use of water or other liquid

coolants may lead to an electric shock.

■ 6 │ GB

│IE│NI│

CY

PGS 500 A1

Additional safety instructions for all

applications

Kickback and corresponding safety instructions

Kickback is a sudden reaction caused when a rotating attachment part, e.g. grinding disc, abrasive

band, wire brush, etc. catches or jams. Catching

or jamming leads to an abrupt stop of the rotating

attachment part. If this happens, an uncontrolled

power tool will turn rapidly against the direction of

rotation of the attachment part.

If, for example, a grinding disc catches or jams, the

edge of the grinding disc that is projecting into the

workpiece can get caught and break off the grinding

disc or cause a kickback. The grinding disc can then

fly in the direction of the operator or away from him,

depending on the direction of rotation of the disc at

the blockage. This can also break grinding discs.

A kickback is caused by improper or incorrect use

of the power tool. This can be avoided by taking

proper precautions as described below.

a) Hold the power tool firmly in both hands

and position your body and arms, so that

they can absorb the kickback forces. By

taking adequate precautions, the operator can

stay in control of the kickback forces.

b) Take special care when working around

corners, sharp edges, etc. Avoid allowing

the attachment part to bounce back from

the workpiece or jam in the workpiece. The

rotating attachment part is more likely to jam

on corners or sharp edges or if it bounces back

from them. This can cause a loss of control or

kickback.

c) Do not use toothed saw blades. Such attach-

ment parts often cause a kickback or loss of

control over the power tool.

d) Always move the attachment part in the

material in the same direction as the direction in which the cutting edge leaves the

material (in other words, the same direction in which the chips are thrown out).

Guiding the power tool in the wrong direction

will cause the cutting edge of the attachment

part to jump out of the workpiece, which can

lead to the attachment part being pulled in this

direction.

e) Always fix the workpiece when using rotary

files, high-speed milling tools or hard-metal

tools. Even a slight tilting in the groove can

cause these attachment parts to jam and lead

to a kickback. When a rotary file, high-speed

milling tool or hard-metal milling tool jams,

the accessory tool can jump out of the groove

and lead to loss of control of the power tool.

Supplementary safety instructions

for grinding

Special safety instructions for grinding:

a) Use only the grinding accessories approved

for your power tool and only for the recommended applications. Example: Never grind

with the side surface of a cutting disc. Cutting

discs are designed to remove material with the

edge of the disc. Any lateral application of

force on these grinding tools can lead to breakage.

b) Use only undamaged mandrels of the correct

size and length and without undercut on the

shoulder for conical and straight pencil grinders. Using an appropriate mandrel reduces the

risk of breakages.

PGS 500 A1

GB│IE│NI│CY

│

7 ■

Supplementary safety instructions

for working with wire brushes

Special safety instructions for working with

wire brushes:

a) Be aware that the wire brush loses wire

bristles even during normal operation. Do

not overstress the wires by applying excessive pressure to the brush. The wire bristles

can easily penetrate thin clothing and/or skin.

b) Allow the brush to run at working speed

for at least one minute before applying

it to the workpiece. Ensure that no one is

standing in front of or in line with the brush

during this time. Loose pieces of wire can

become airborne during the run-in period.

c) Aim the rotating steel brush away from

yourself. When working with these brushes,

small particles and minute pieces of wire can fly

off at great speed and pierce skin.

Original accessories/auxiliary

equipment

■ Use only the accessories and auxiliary equip-

ment that are specified in the operating instructions and are compatible with the appliance.

Use

Changing/inserting the tool/collet

chuck

♦ Press the spindle lock and hold it down.

♦ Loosen the tensioning nut from the thread

using the assembly wrench .

♦ Remove any tool that may be inserted.

♦ First, push the intended tool through the tension-

ing nut

ate collet chuck for the tool shaft.

♦ Press the spindle lock and hold it down.

♦ Push the (6 mm) collet chuck

insert and screw the tensioning nut tight with

the assembly wrench .

♦ To use the (3.2 mm) collet chuck

into the pre-assembled (6 mm) collet chuck .

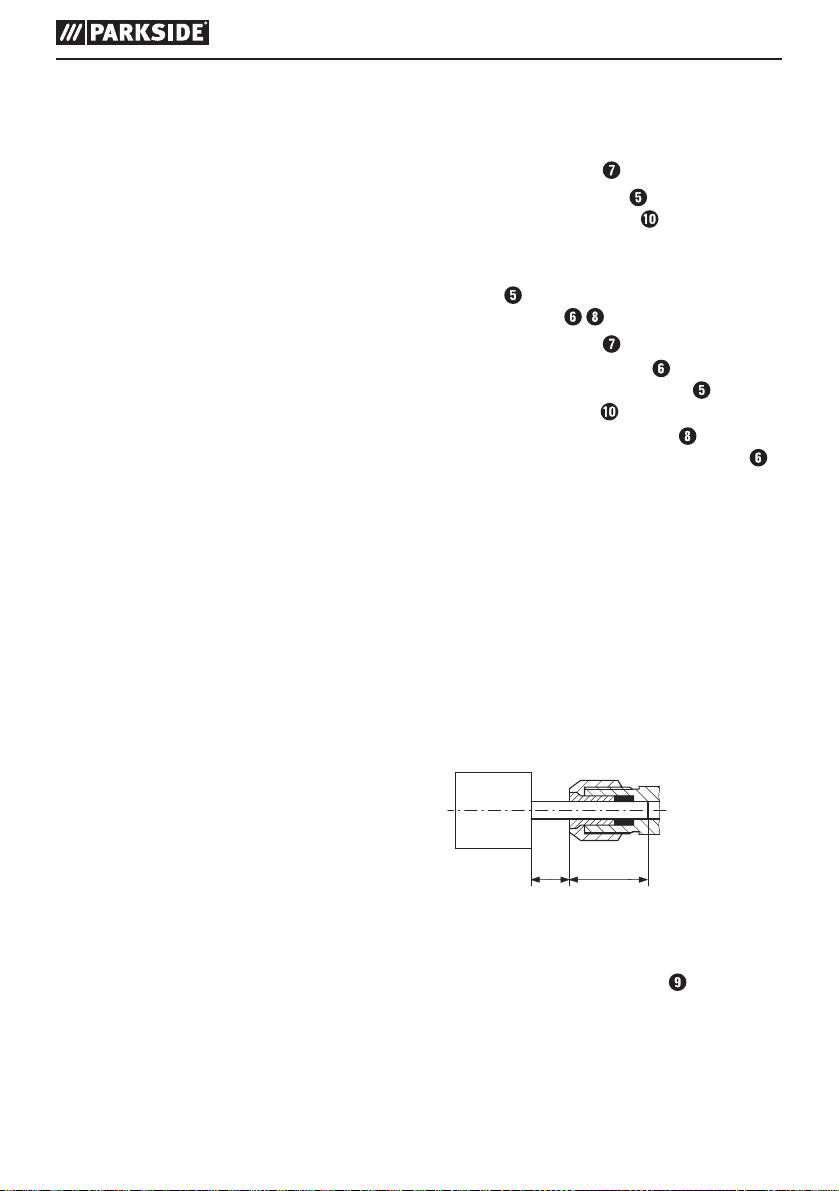

■ Observe the manufacturer‘s recommendation

for small grinding tools. The maximum permissi-

ble protrusion (L0 = length of the shaft between

the collet chuck end and the small grinding

tool) specified by the manufacturer must not be

exceeded when using small grinding tools! If

the protrusion (L0) is increased, the permissible

rotation speed must be lowered. Wherever pos-

sible, insert the complete length of the shaft of

the accessory tool into the collet chuck. Ensure

that the clamping length (Lg) is at least 10 mm.

Only use attachment parts with a maximum

mandrel length of 40 mm.

before inserting it into the appropri-

into the thread

, insert it

■ 8 │ GB

│IE│NI│

CY

L

L

g

o

Grinding stone

♦ Grinding work can be performed on various

metals using the grinding stone

.

PGS 500 A1

Switching on and off/setting speed

range

CAUTION!

■ The rotating direction of the grinding spindle

can be read off the arrow engraved on the

front of the appliance (anticlockwise symbol).

Switching on/setting the speed range:

♦ Set the ON/OFF switch

♦ Set the steplessly adjustable speed control

a position between "1" and “6".

Switching off:

♦ Move the ON/OFF switch

to the "I" position.

to the position "O".

Notes on working with materials/

tools/speed range

■ Determine the rotational speed range for work-

ing on zinc, zinc alloys, aluminium and copper

by trying it out on test pieces.

Cleaning, care and storage

WARNING! RISK OF INJURY!

■ Switch off the appliance and pull out the

power plug before starting any work on

the appliance.

The appliance is maintenance-free.

■ Remove all dirt from the appliance. Use a dry

cloth to do this.

to

WARNING!

■ If the power cord requires replacement, this

should be carried out by the manufacturer or

an approved representative to avoid safety

hazards.

■ Store the appliance and all the individual

pieces carefully in the provided plastic case to

ensure you do not lose any part.

NOTE

► Replacement parts not listed (such as carbon

brushes, switches) can be ordered via our

service hotline.

WARNING!

■ Always ensure that the power plug or

the mains cable is replaced only by the

manufacturer of the appliance or its

customer service. This will ensure that the

safety of the appliance is maintained.

PGS 500 A1

GB│IE│NI│CY

│

9 ■

Loading...

Loading...